Patents

Literature

53results about How to "Avoid Repeated Fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

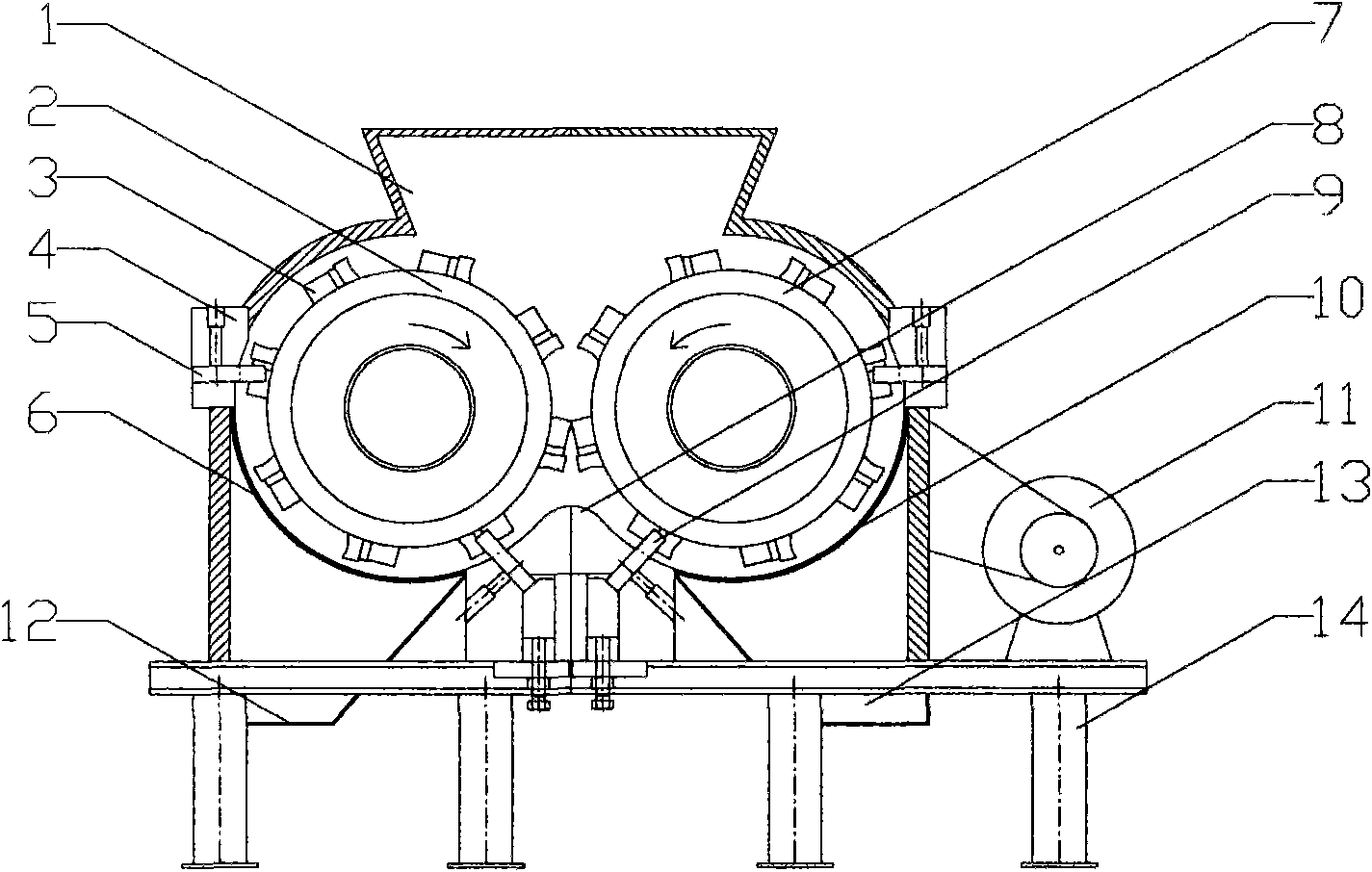

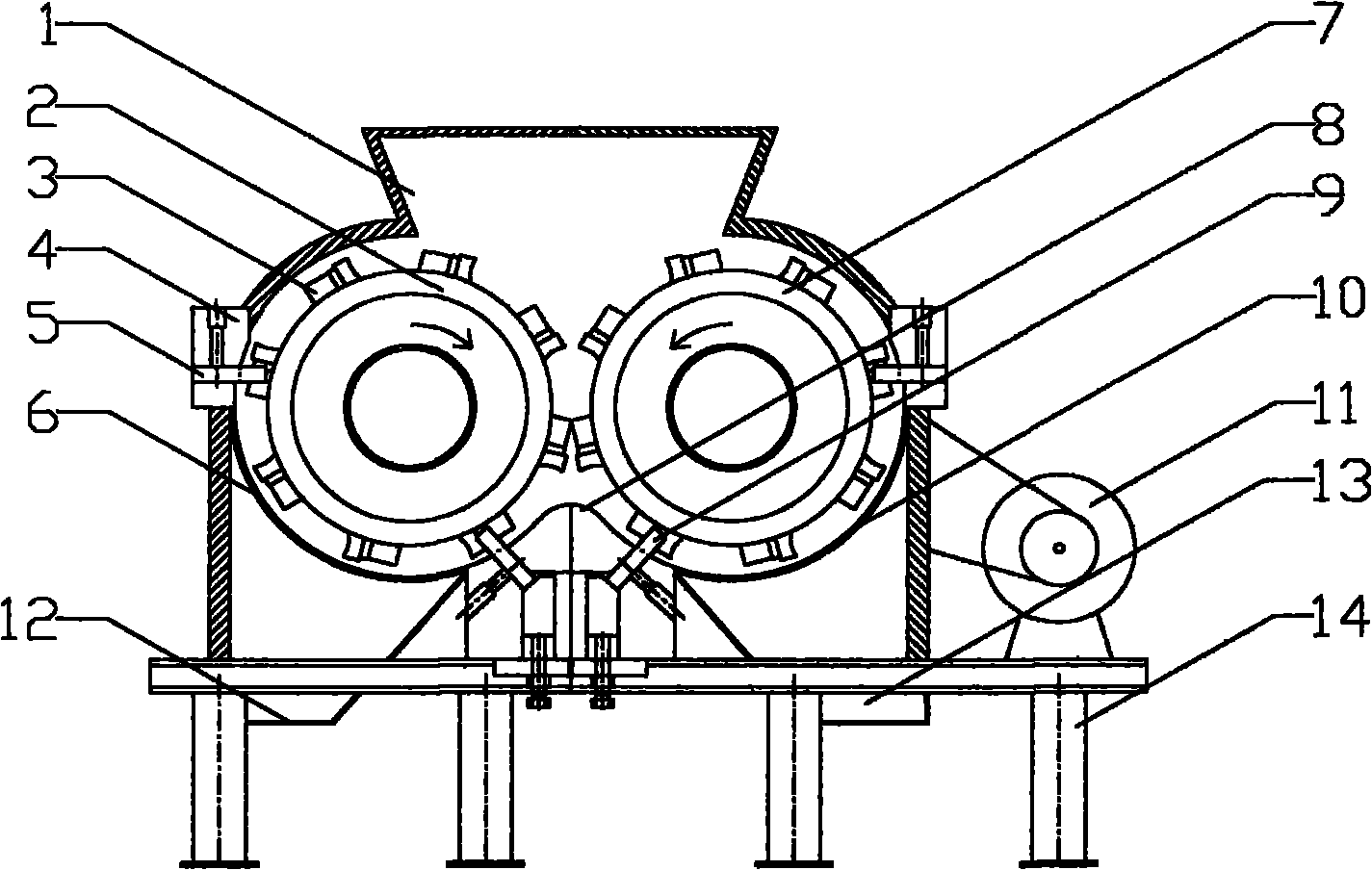

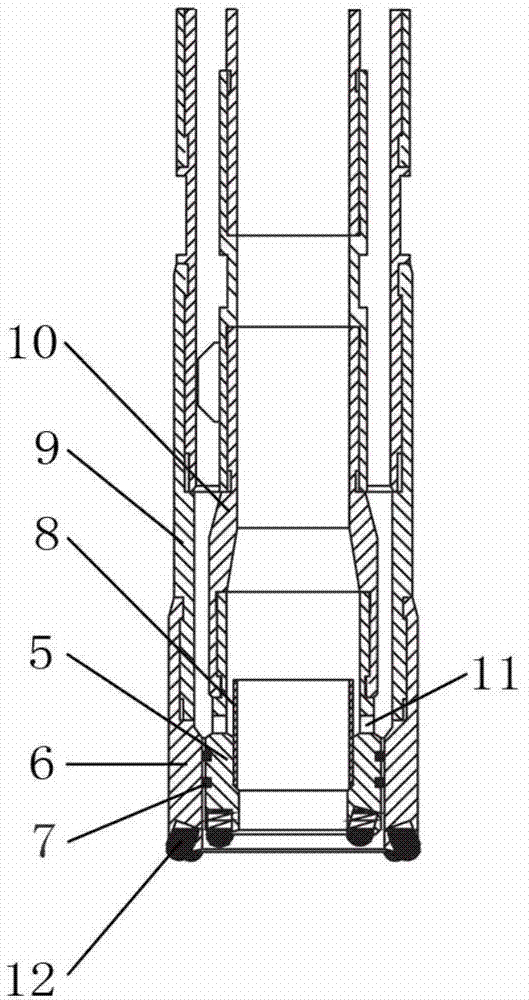

High-efficiency combined type domestic garbage crusher

The invention relates to a high-efficiency combined type domestic garbage crusher, which belongs to the technical field of domestic garbage crushing and comprises a feed hole, a crushing system, a discharge system and a transmission system, wherein the crushing system comprises dual knife rolls, a moving knife group, a static knife group and a knife adjusting device; the discharge system comprises a left screen, a right screen and two discharge holes; and the transmission system comprises a motor and a synchronous gear group, and the synchronous gear group ensures the synchronous running of the dual knife rolls. The left knife roll and the right knife roll are arranged side by side in parallel, a certain gap is reserved between the two knife rolls, and the two knife rolls are connected by the synchronous gear group and run in opposite directions; and the knife rolls are provided with rotating moving knives, the bottoms of the knife rolls are provided with bottom blocks, the bottom blocks are provided with bottom static knives, and simultaneously a frame is provided with a side static knife. Firstly, domestic garbage is crushed in the gap between the two knife rolls, is crushed at the position of the bottom knives after being compressed, then passes through the left screen and the right screen and is respectively discharged from the left discharge hole and the right discharge hole; and the side static knife can crush the garbage with bigger size again. The invention has the advantages of large treatment capacity, high crushing efficiency and low energy consumption.

Owner:SHOUGANG CORPORATION

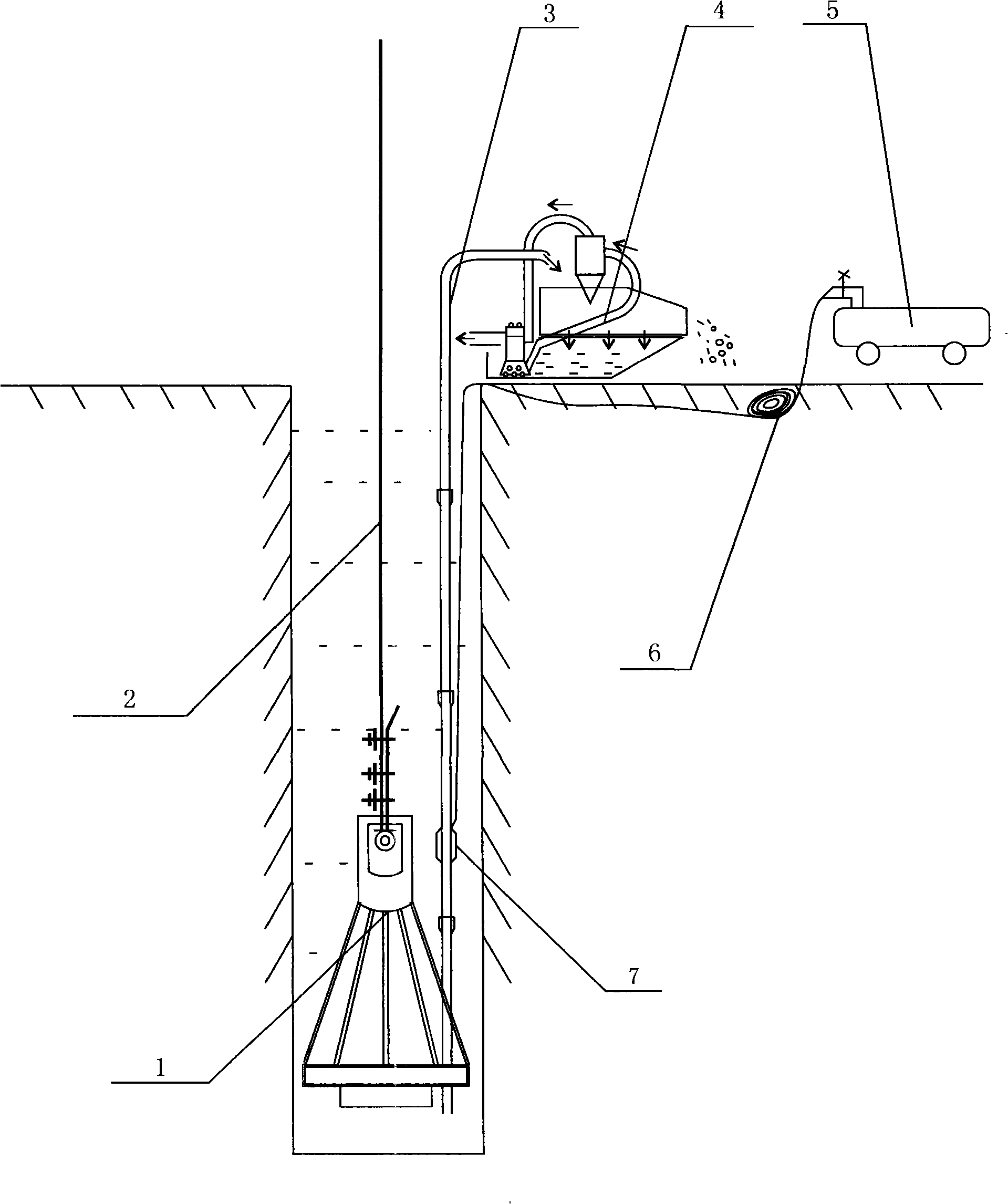

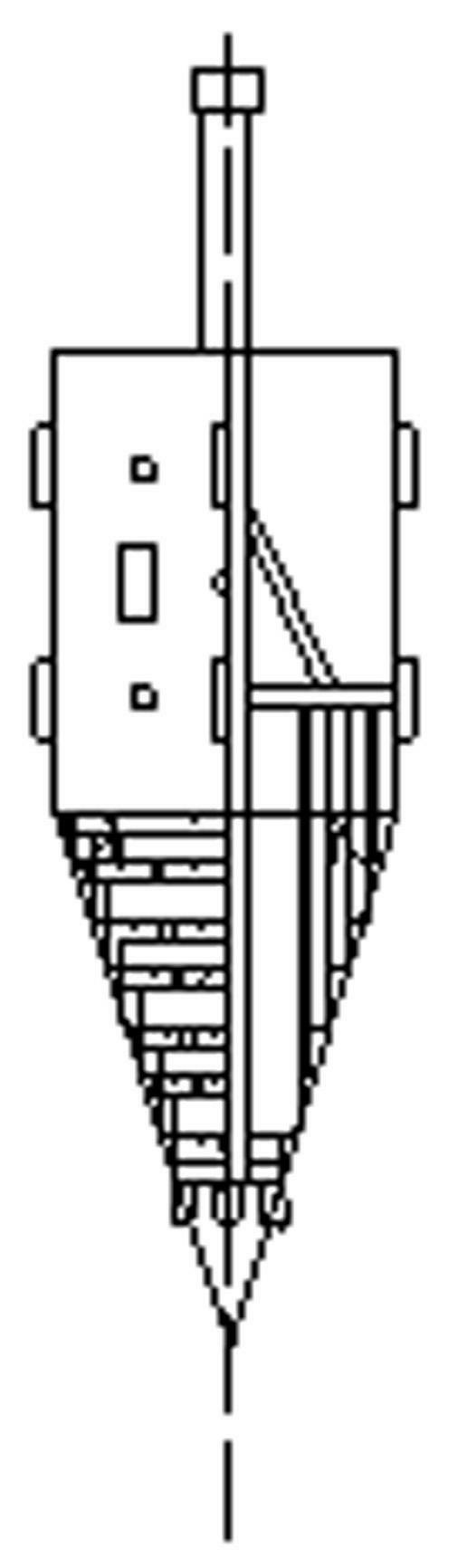

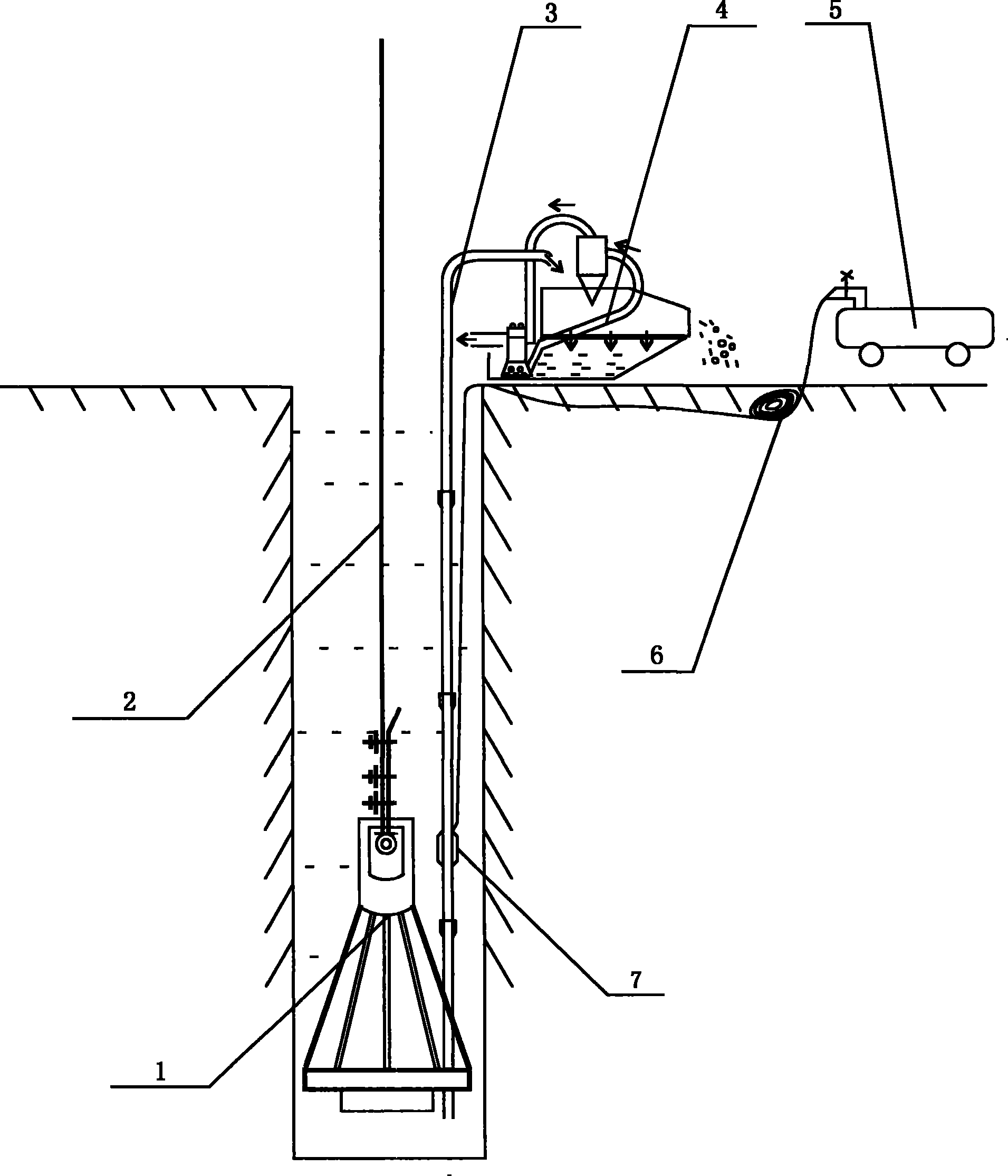

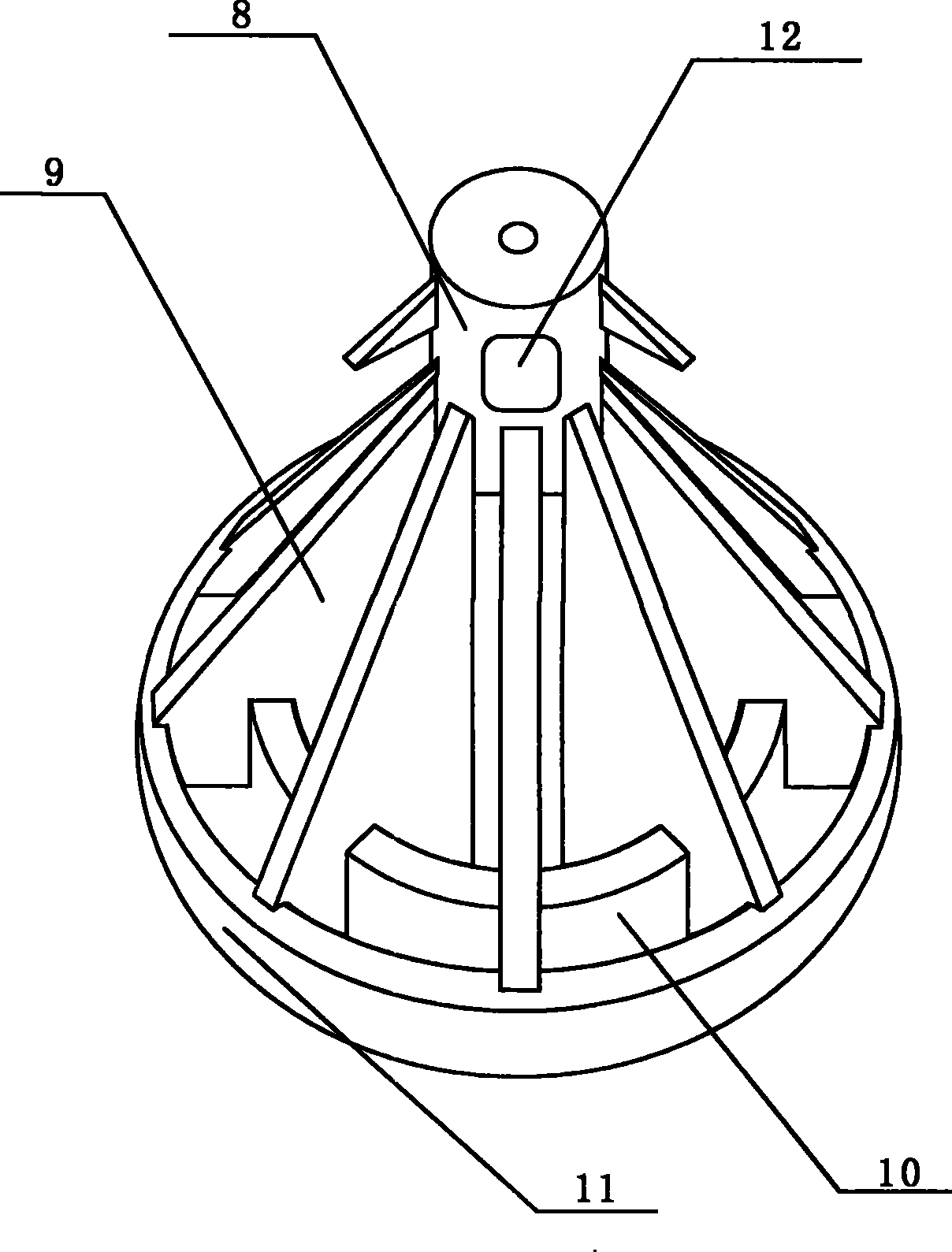

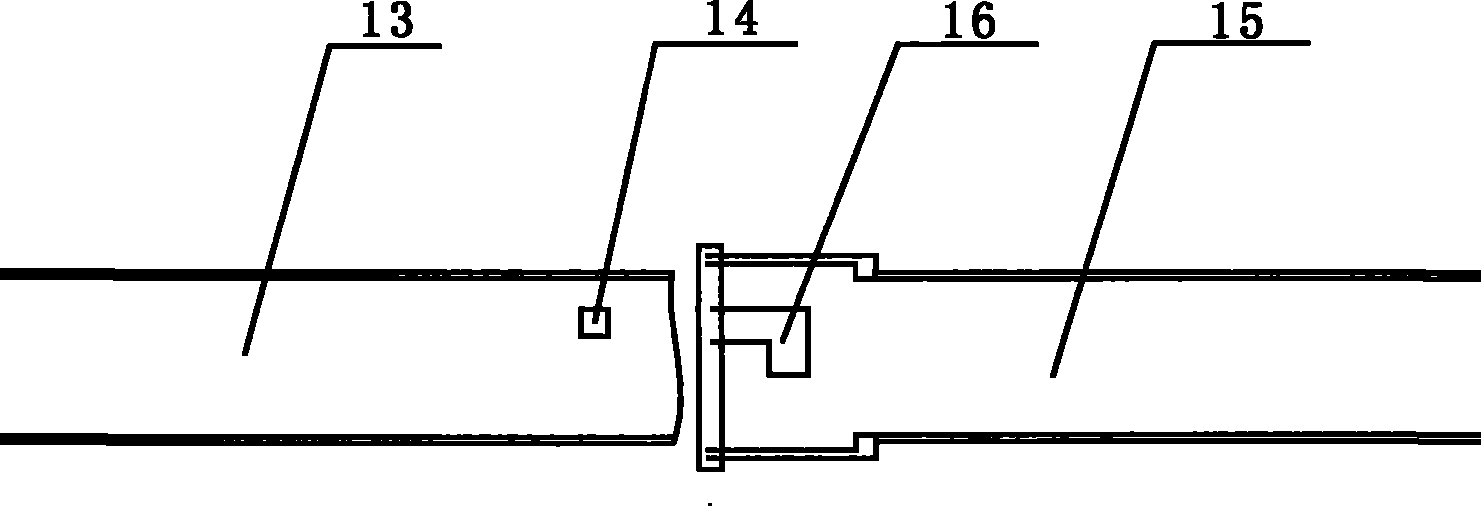

Reverse circulation construction technique and apparatus of single rope impact drill

InactiveCN101275458ARotation does not generateAvoid entanglementConstructionsReciprocating drilling machinesSlagEngineering

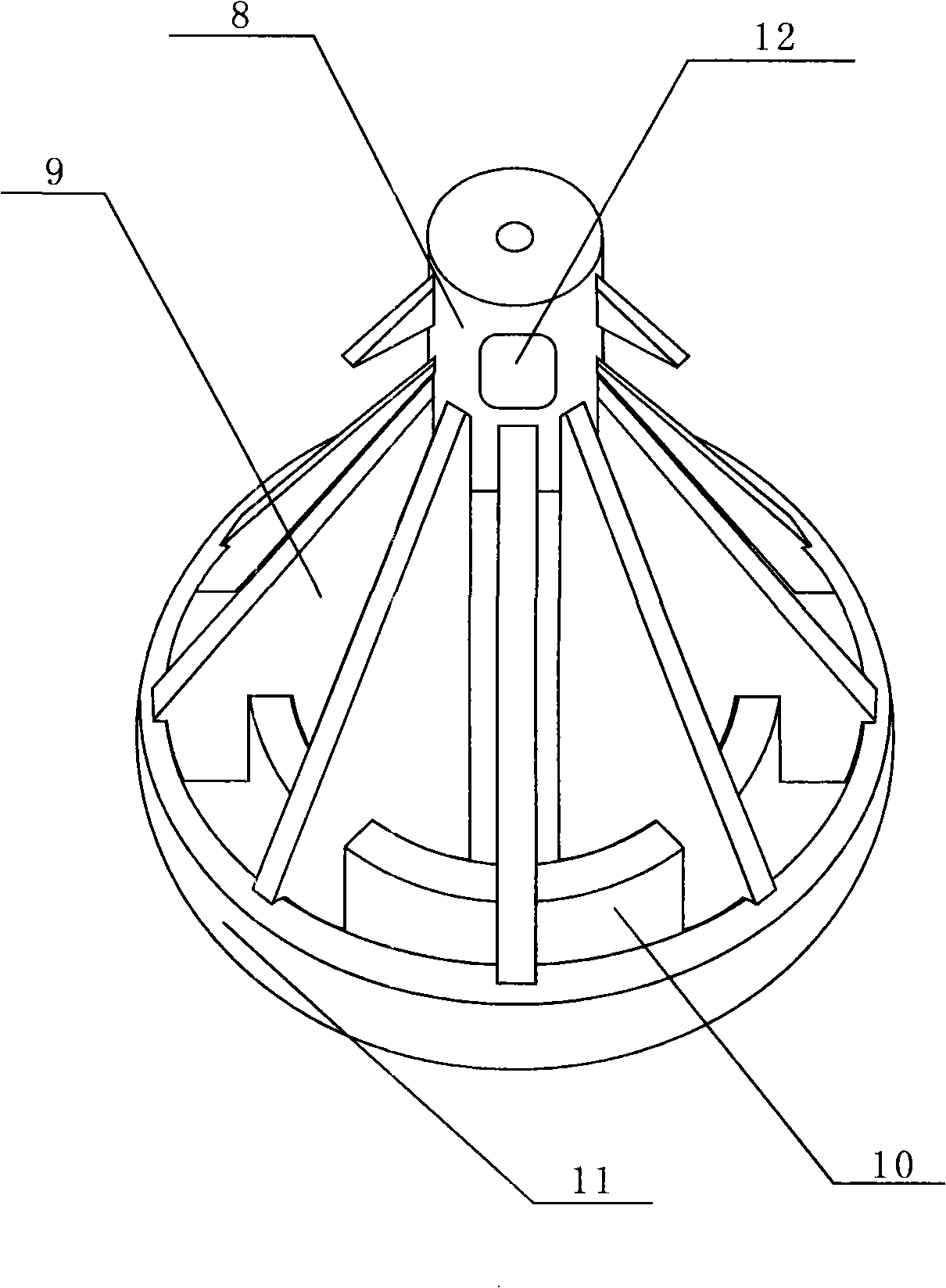

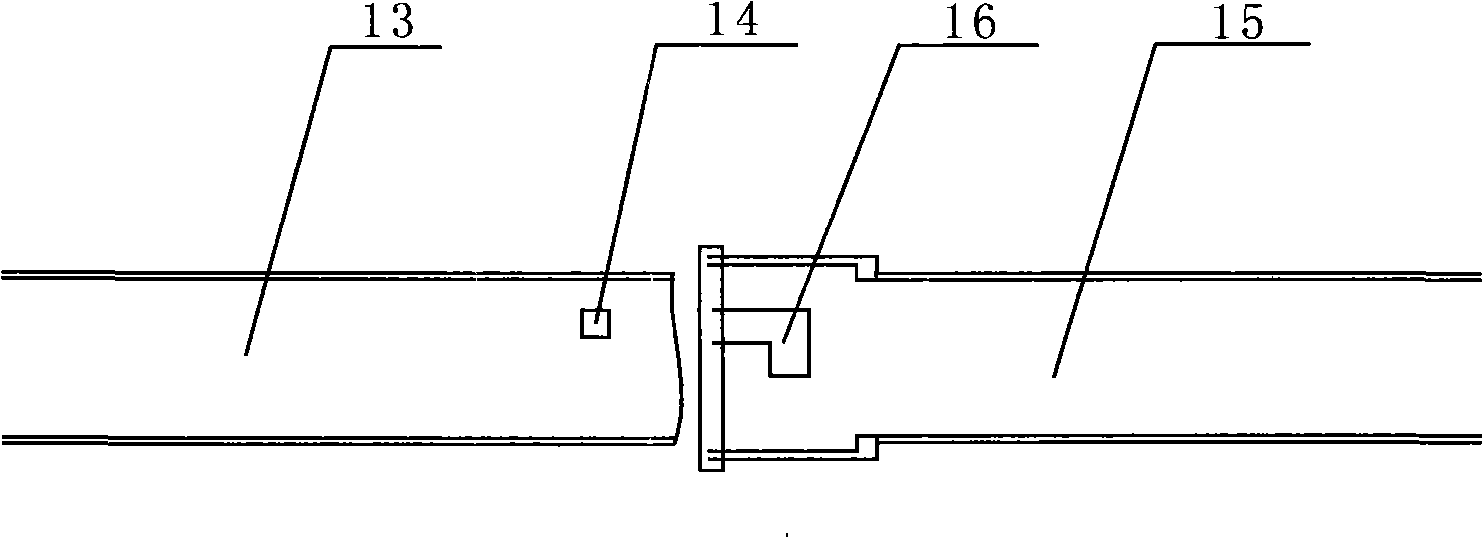

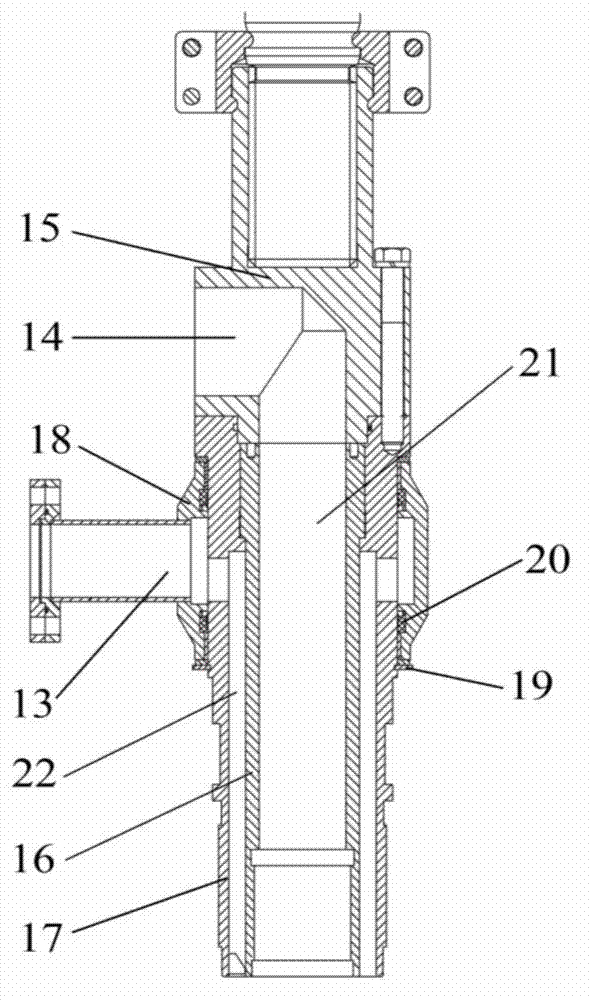

The invention discloses a process and a device for the reverse circulation execution of a single rope impact drill, the reverse circulation execution device comprises a percussion drill, a slurry pumping pipe at the hole bottom and a slurry purifier at the hole mouth, the drill bit is composed of a drill bit body and a cutting blade, the drill bit body is composed of a hammer body, corner boards and a base, the upper end of the hammer body is provided with a connecting hold connected with a non-rotating rope, the corner boards are distributed in the same angle axially on the cylindrical or circular-tube-shaped hammer body, the base is composed of coaxial inner base and outer base, which are tube-shaped, the upper surfaces of the two base are in the same plane, the inner base is higher than the outer base, the lower ends of the corner boards are connected with the two bases, the hammer body, the corner plate and the base are integrated by welding, casting or riveting, the lower end of the base is evenly equipped with multiple cutting blades; pile types of various section shapes can be dilled by the drill bit, the reverse circulation process of hole bottom slag pumping is used when drilling, the execution process is fastened, the energy consumption is reduced, the slag is cleaned completely and clearly, the time for cleaning the hole is shortened.

Owner:张安禄

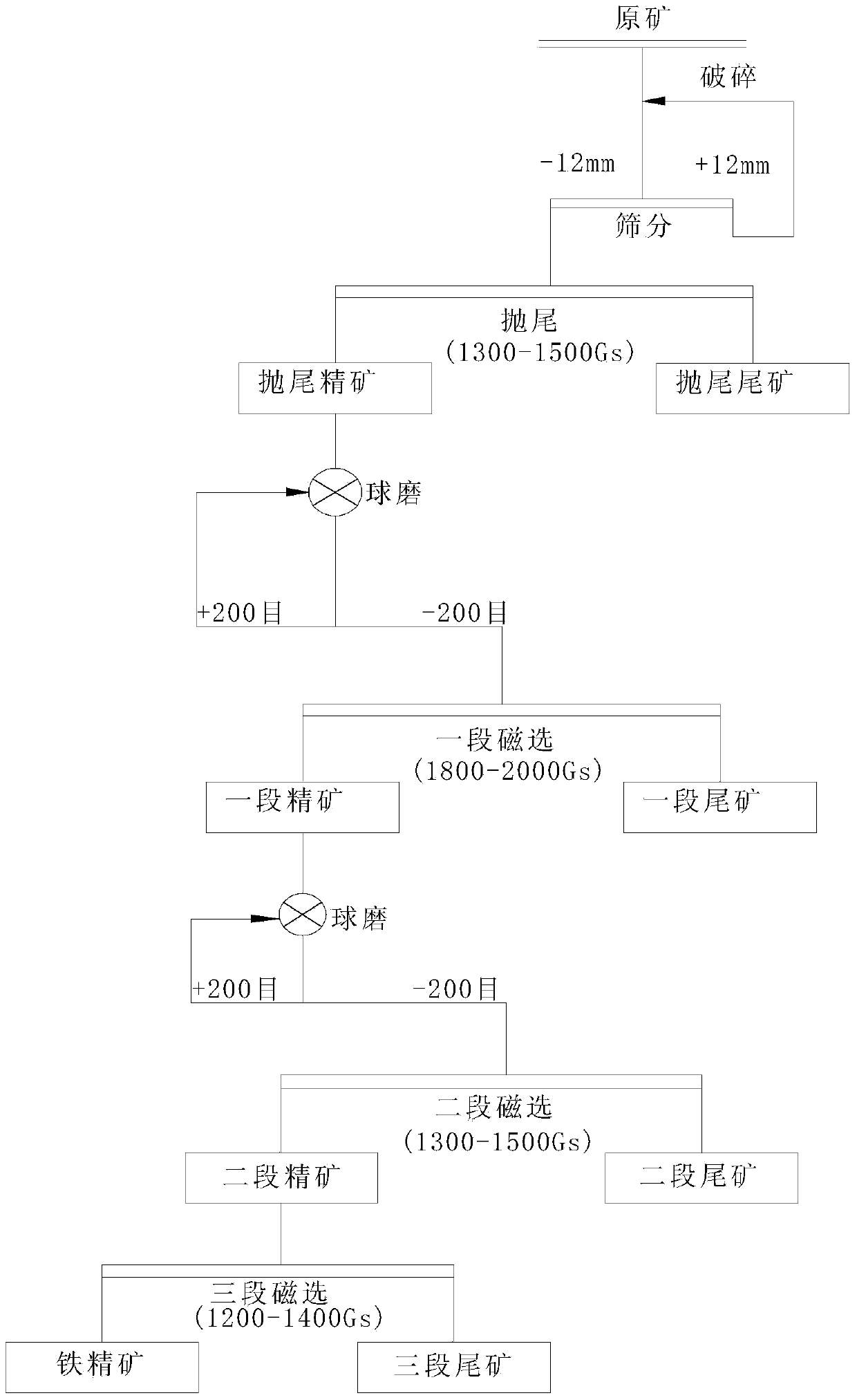

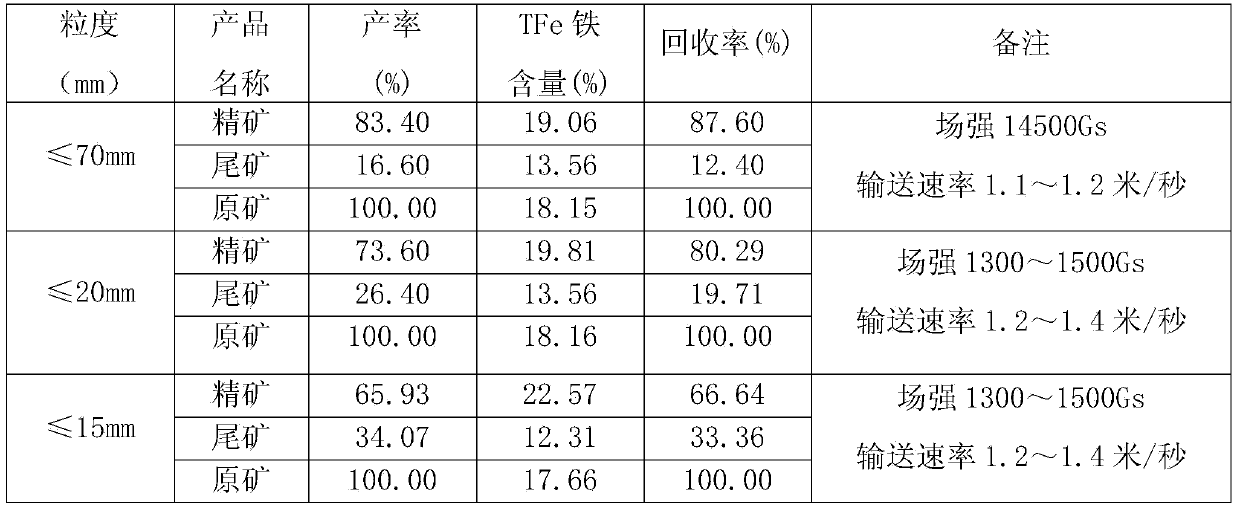

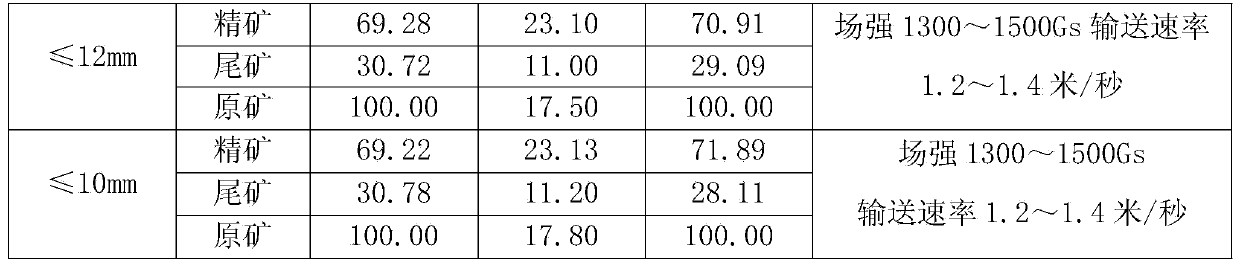

Vanadium titano-magnetite screening method

ActiveCN103736574ALow costImprove qualityMagnetic separationGrain treatmentsMagnetiteScreening method

The invention relates to a vanadium titano-magnetite screening method and belongs to the field of ore screening. The technical problem to be solved in the invention is to provide a vanadium titano-magnetite screening method. The vanadium titano-magnetite screening method comprises the following steps: a, tail-escaping, namely performing tail-escaping on vanadium titano-magnetite with the granularity of less than or equal to 12mm so as to obtain tail-escaping concentrate; b, performing primary grinding and magnetic separation, namely grading the tail-escaping concentrate to prepare 40-45 percent ore pulp of which the granularity is -200 meshes, and performing magnetic separation to obtain primary concentrate; c, performing secondary grinding and magnetic separation, namely demagnetizing the primary concentrate obtained in the step b and performing secondary grinding, grading to prepare 75-80 percent ore pulp with the granularity of -200 meshes, and performing magnetic separation to obtain secondary concentrate; and d, performing third-stage magnetic separation, namely performing magnetic separation on the secondary concentrate obtained in the step c so as to obtain iron ore concentrate. According to the vanadium titano-magnetite screening method, the TFe content of iron ore concentrate obtained by utilizing low-grade vanadium titano-magnetite is 55-57 percent, the quality is stable, and the method has the advantages of low cost, environment friendliness and energy conservation.

Owner:MIYI YUANTONG FERROTITANIUM

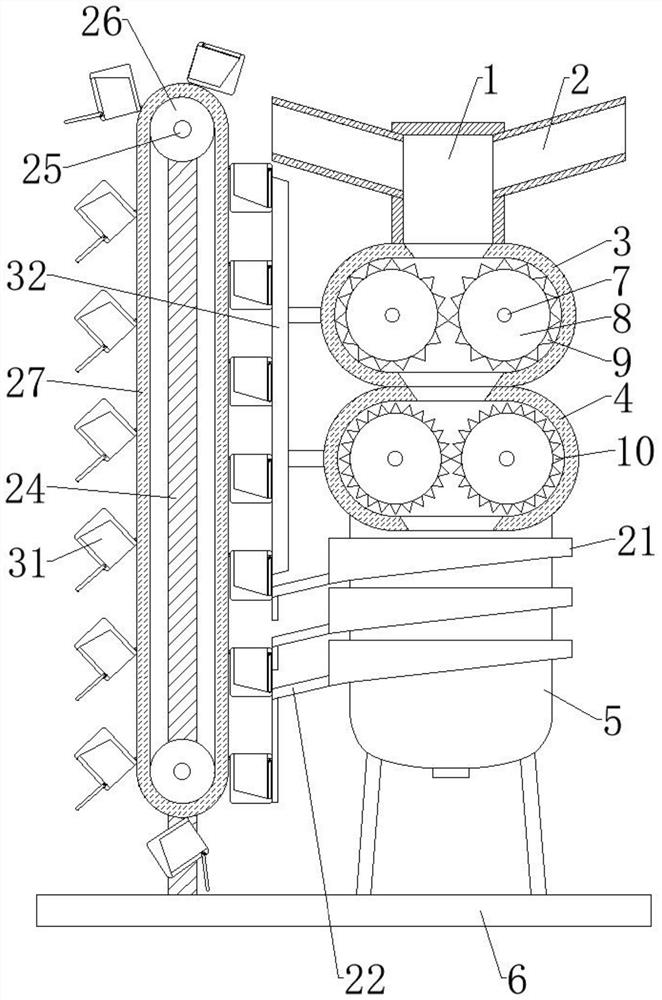

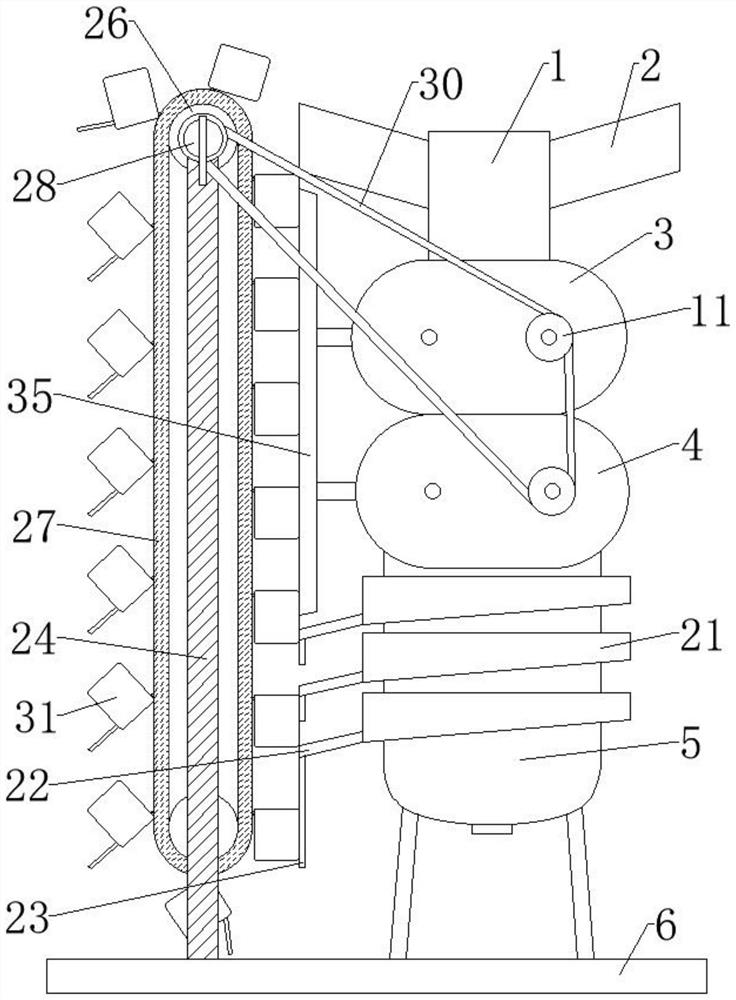

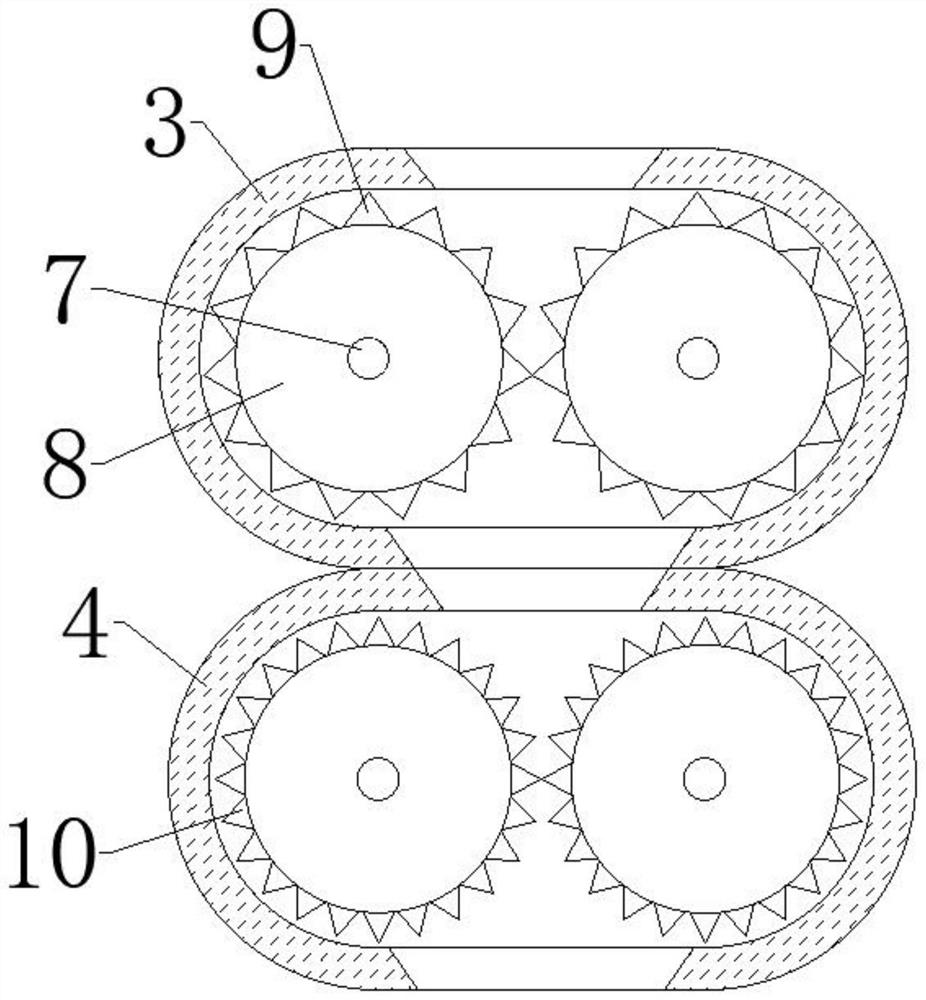

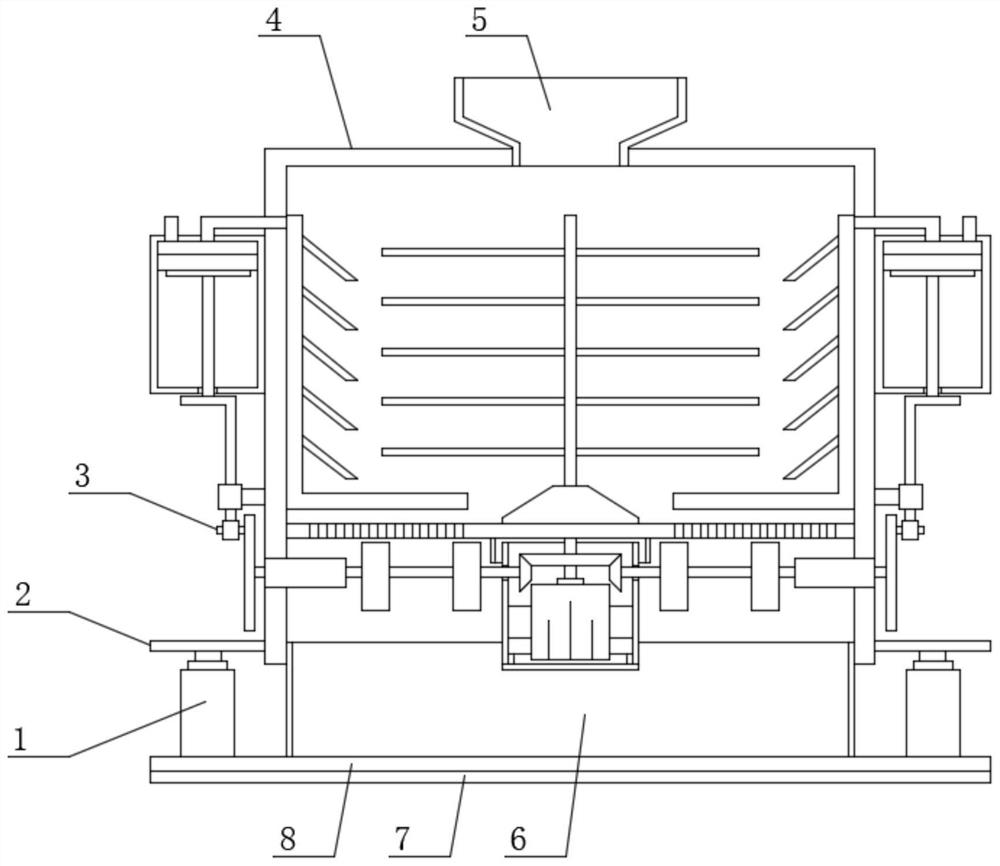

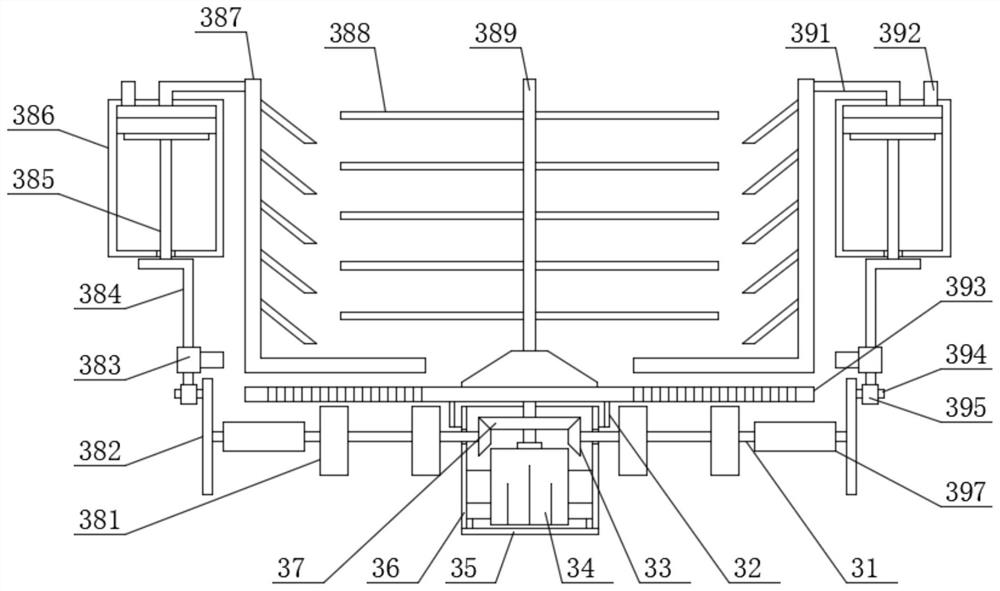

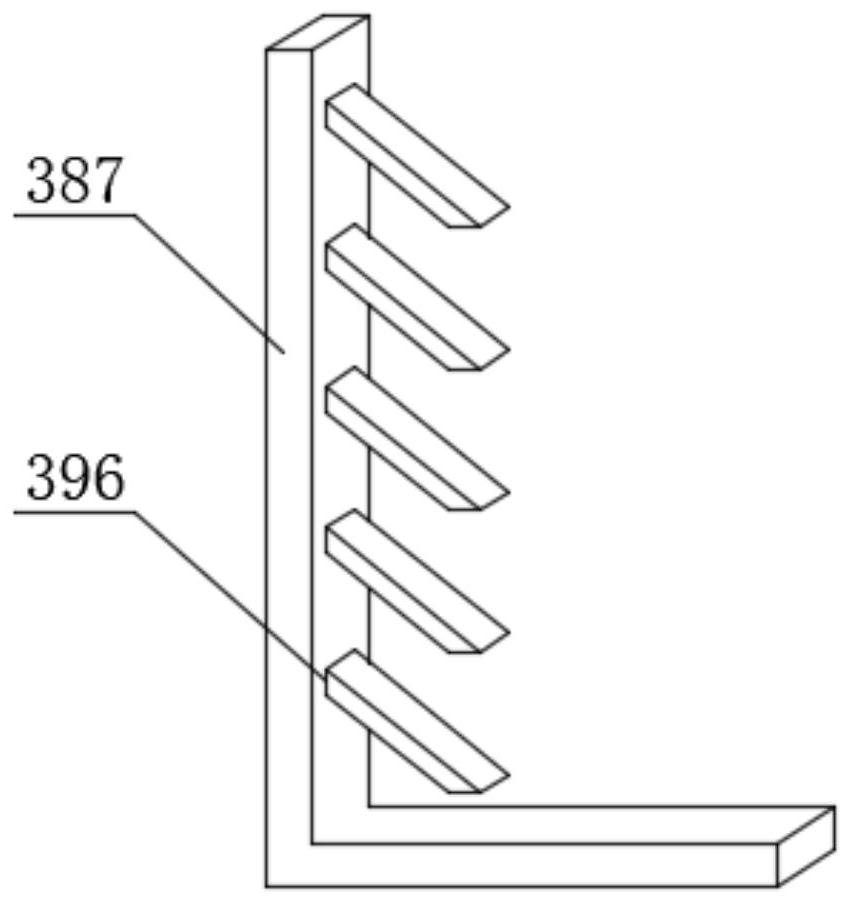

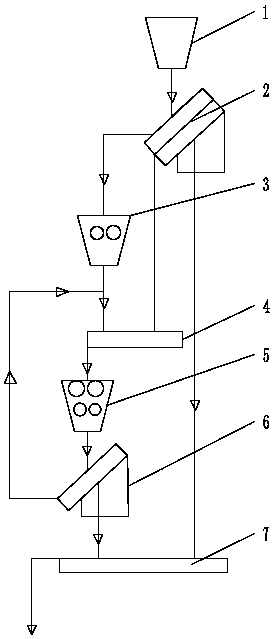

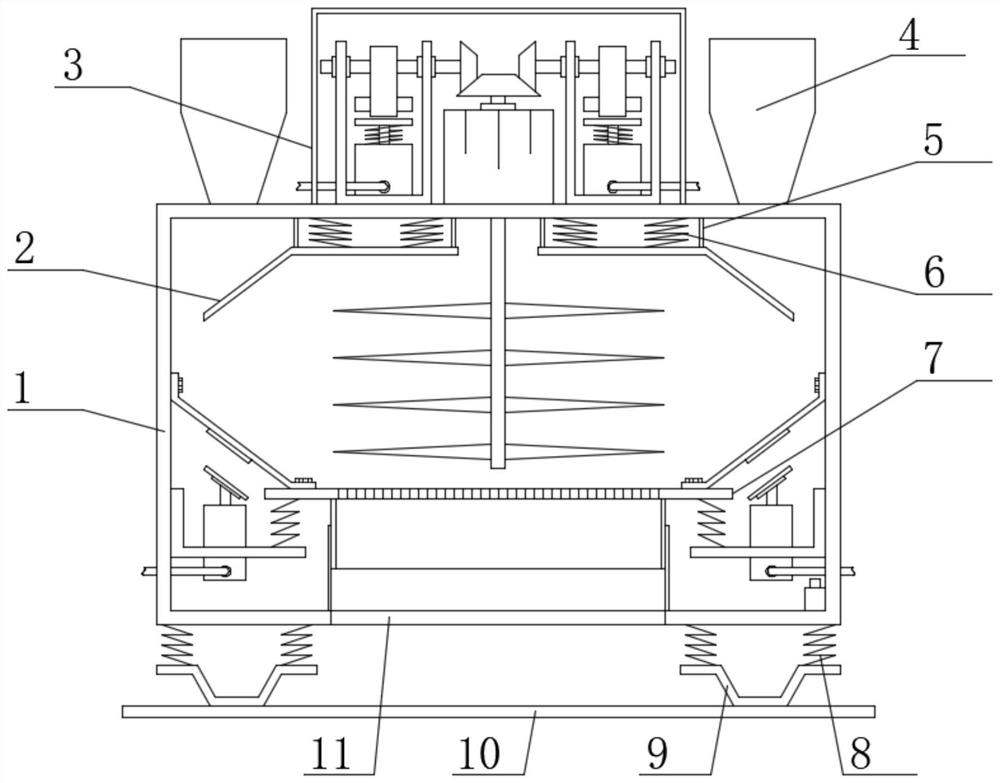

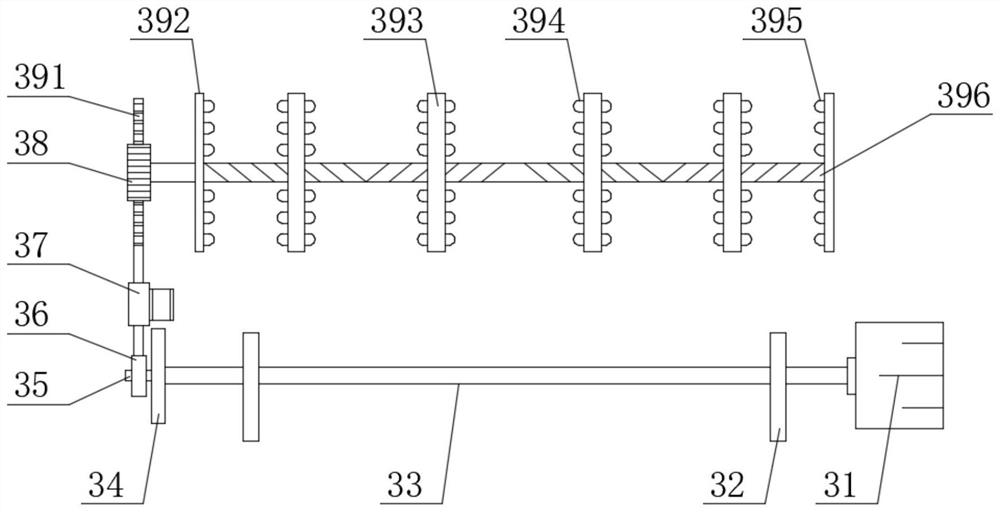

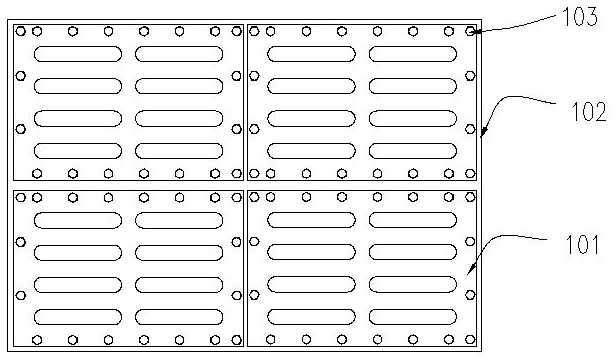

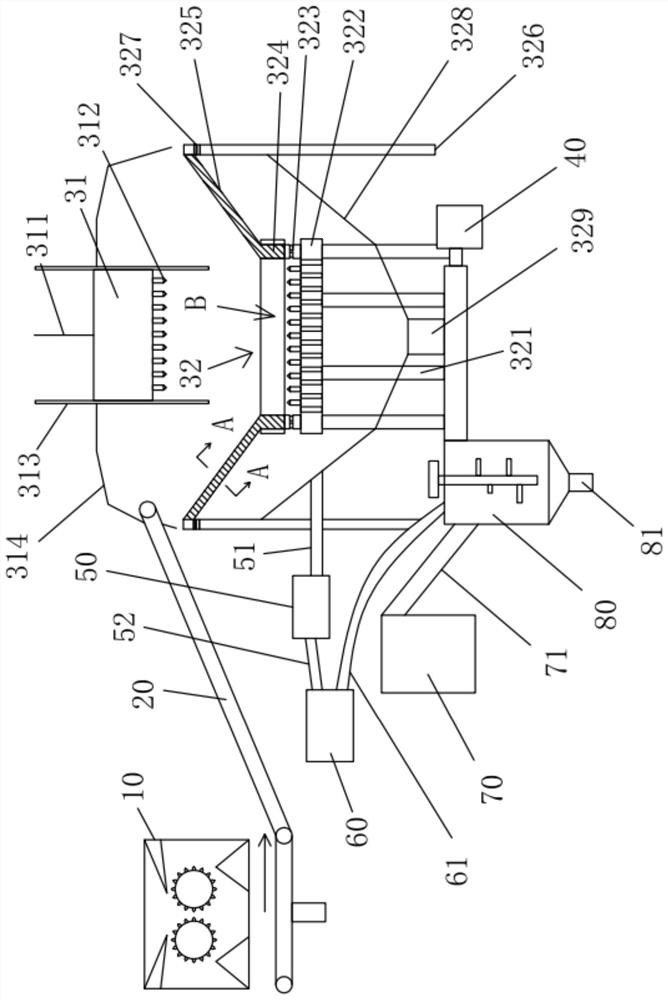

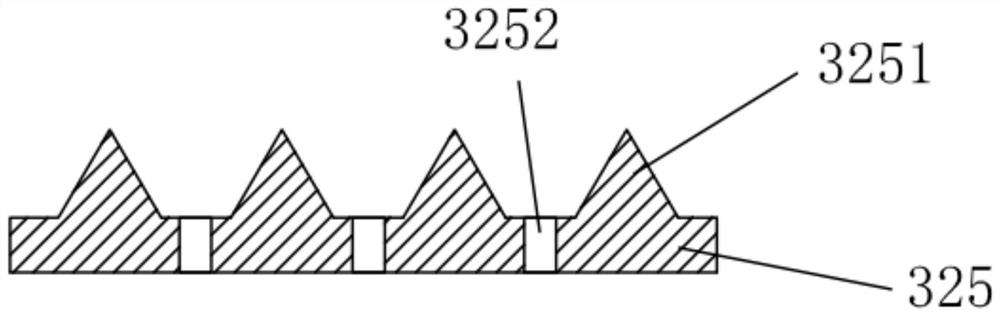

Machine-made sand preparation system with screening function

InactiveCN112691734AAvoid Repeated FragmentationReduce operating costsGrain treatmentsElectric machineStructural engineering

The invention discloses a machine-made sand preparation system with a screening function, and relates to the technical field of machine-made sand preparation. The machine-made sand preparation system comprises a material storage box, feeding boxes are arranged at the top ends of the left and right sides of the material storage box, and the bottom side of the material storage box is fixedly connected with the top end of a first crushing box. According to the machine-made sand preparation system with the screening function, through the arrangement of the first crushing box and a second crushing box, large sand raw materials can be crushed in sequence, and the sand raw materials can be crushed into small particles to enter a screening barrel; and then through mutual cooperation of a supporting net plate, a first driving motor, a rotating shaft, a first screening net, a second screening net, a third screening net, a blocking ring, a discharging groove and an annular collecting box, crushed sand can be screened out in sequence, large sand blocks can be screened out and discharged through the annular collecting box to be separated from fine sand, and then the fine sand is screened out and discharged through a screening box, and repeated crushing of the sand is avoided.

Owner:罗源县洪洋乡人民政府

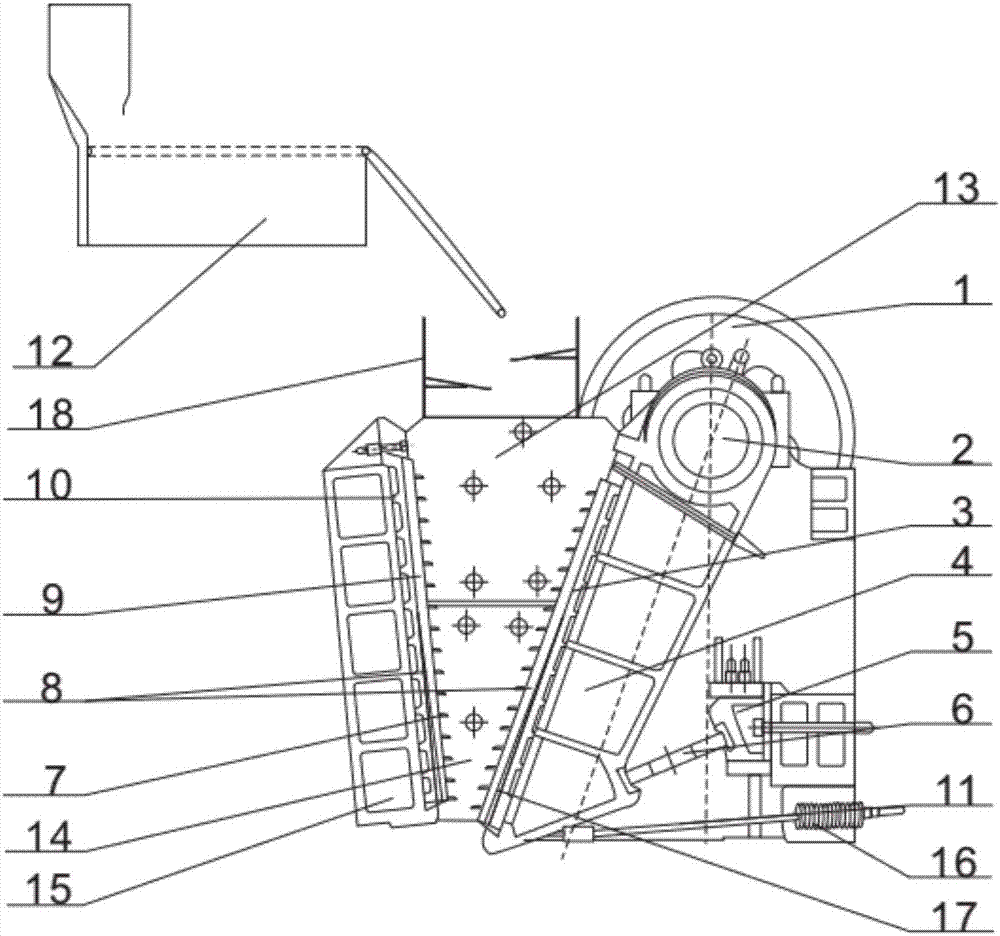

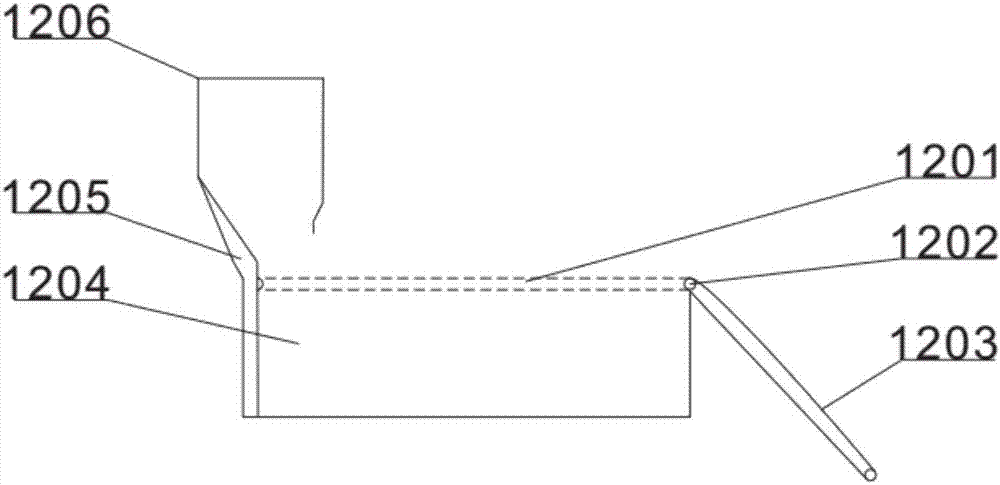

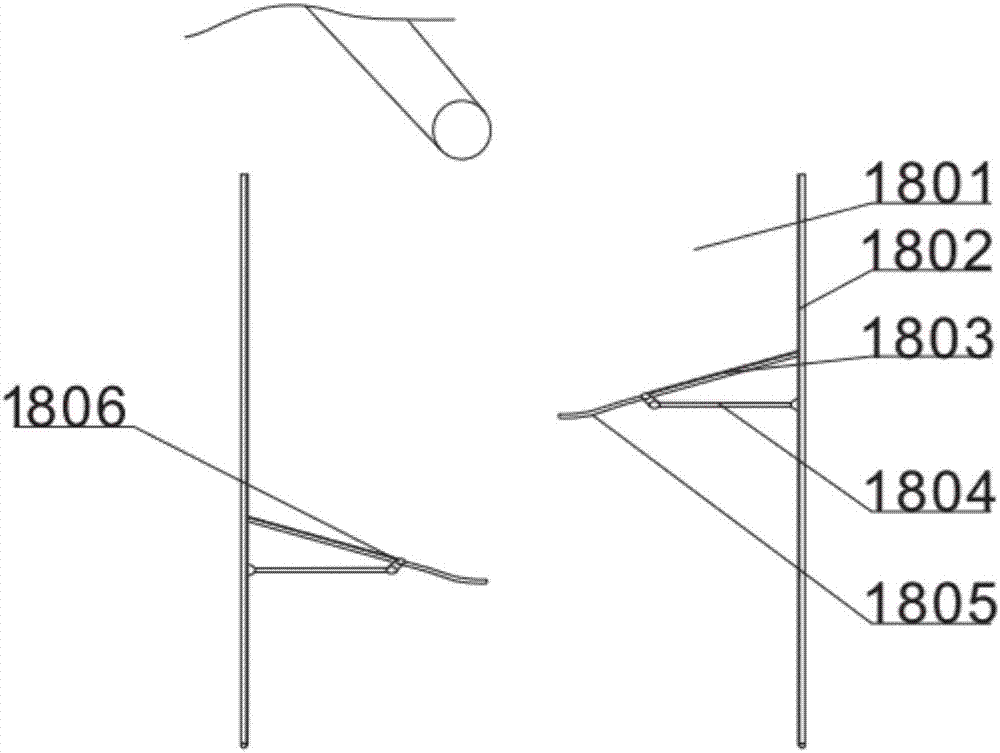

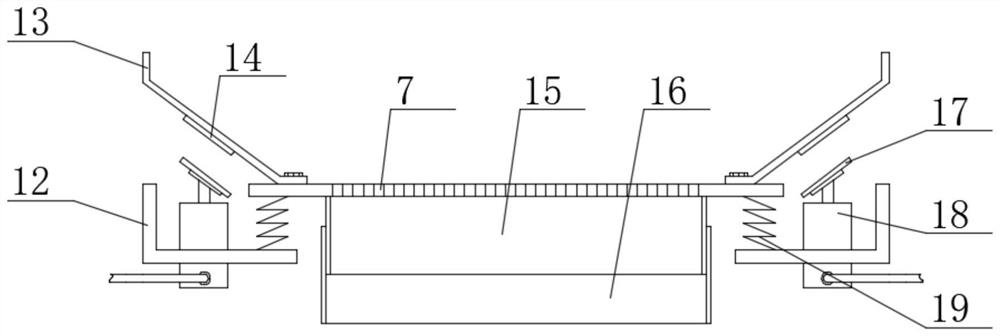

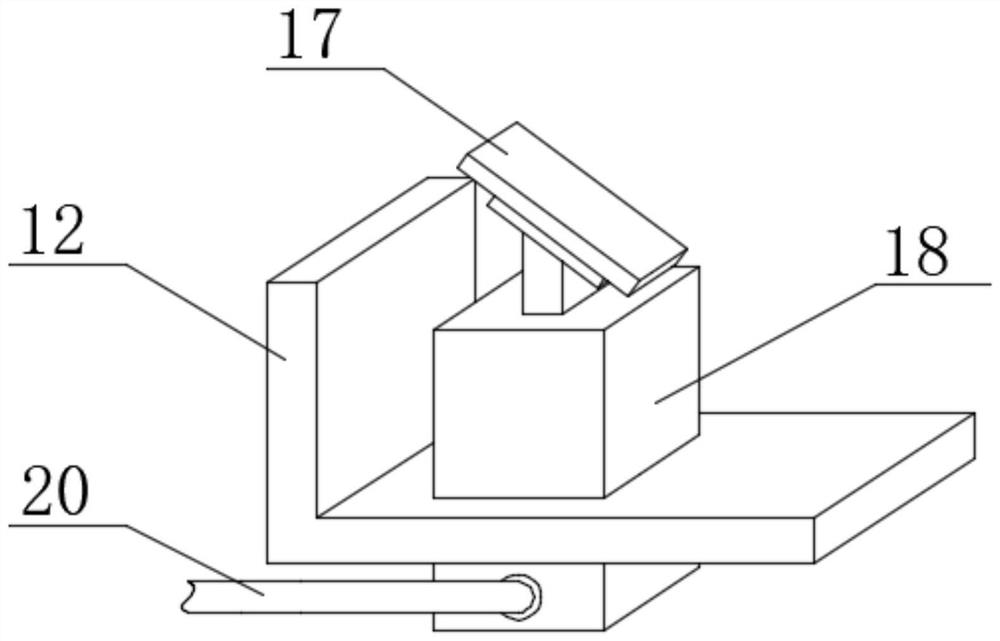

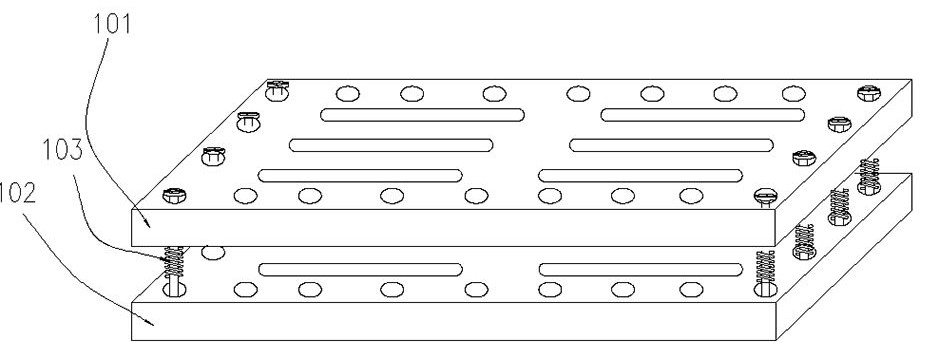

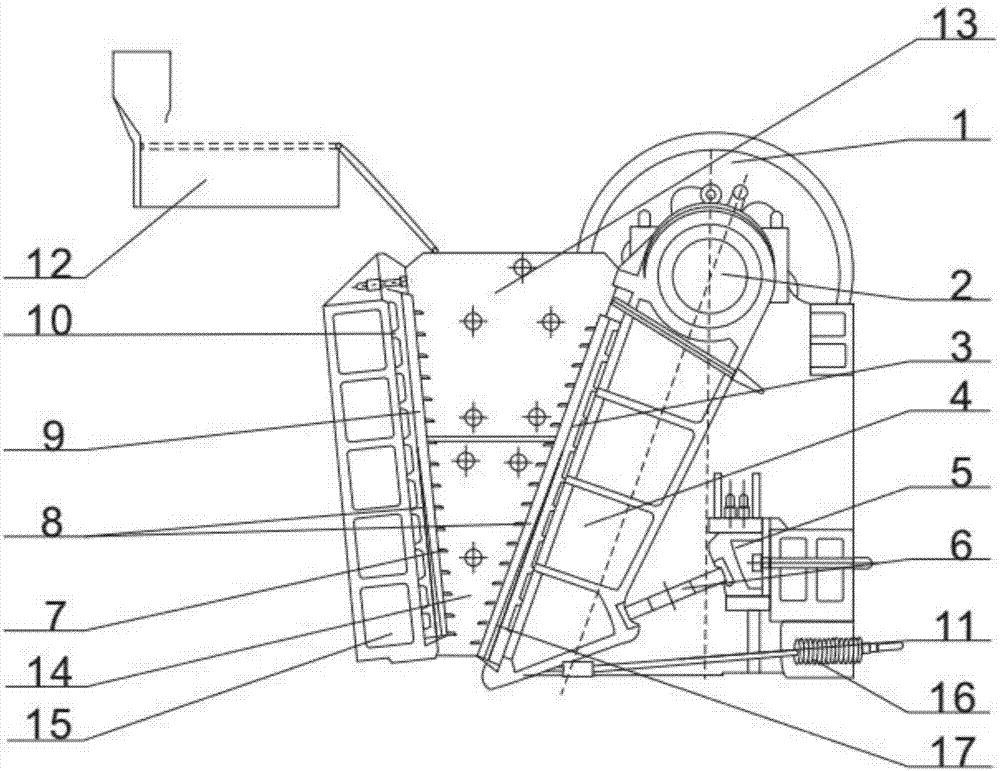

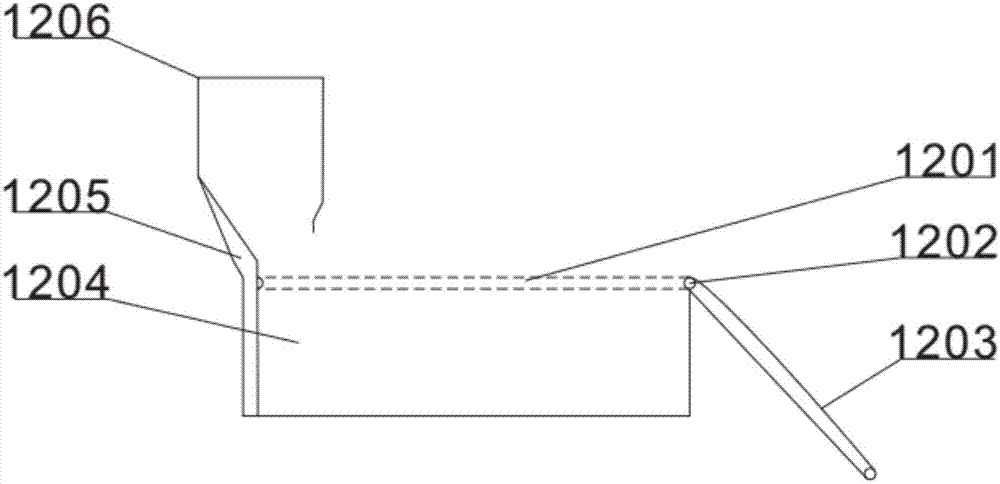

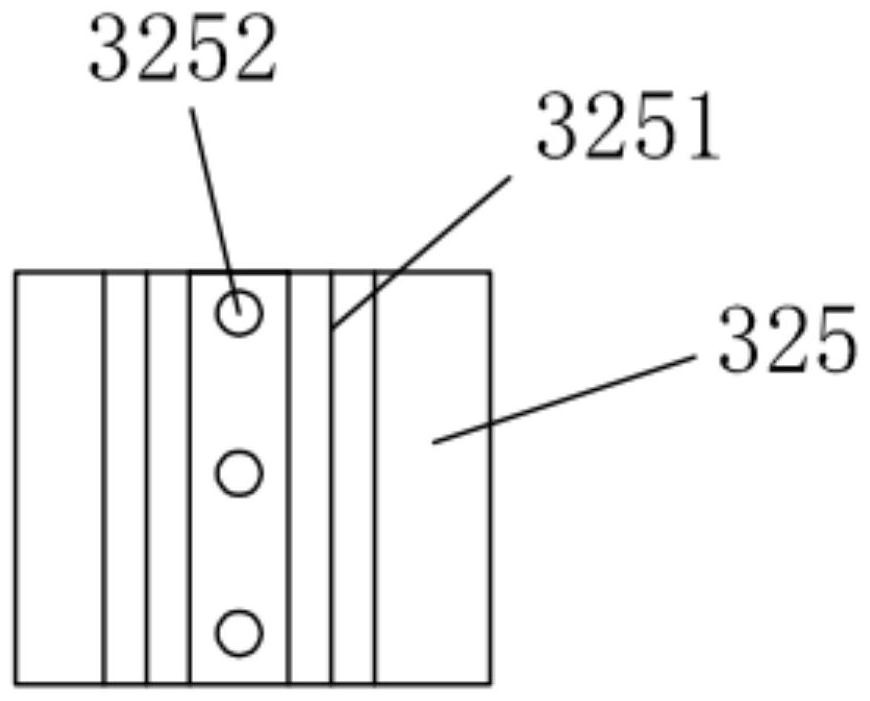

Feeding buffer device of jaw crusher

The invention provides a jaw crusher feeding buffer device, which includes a frame, an upper guard plate, a lower guard plate, a fixed jaw assembly, a movable jaw assembly, an eccentric wheel, a toggle plate, an adjustment seat and a spring rod, and the movable jaw There is a buffer structure between the plate and the movable jaw assembly, teeth are arranged in parallel on the fixed jaw plate and the movable jaw plate, and a screening device is installed above the movable jaw assembly and the fixed jaw assembly. The screening device includes material Box, material receiving box, transmission screen and conveyor belt, the material box and transmission screen are all set above the material receiving box, the lower part of the conveyor belt near the end of the upper guard plate is equipped with a feeding buffer device, the feeding buffer device and the upper guard plate Fixedly connected, the feeding buffer device includes a buffer bucket body, a wear-resistant plate and two buffer components. The buffer components are respectively fixed on the two inner plates of the buffer bucket body. The buffer component includes a sloping plate, a wear-resistant plate, a rubber body and a support plate. The inclined plate is connected with the rubber body through a connecting shaft, and the rubber body is arranged on the side away from the inner plate of the buffer bucket; the invention has low cost and long life.

Owner:张家港明惠金属制品有限公司

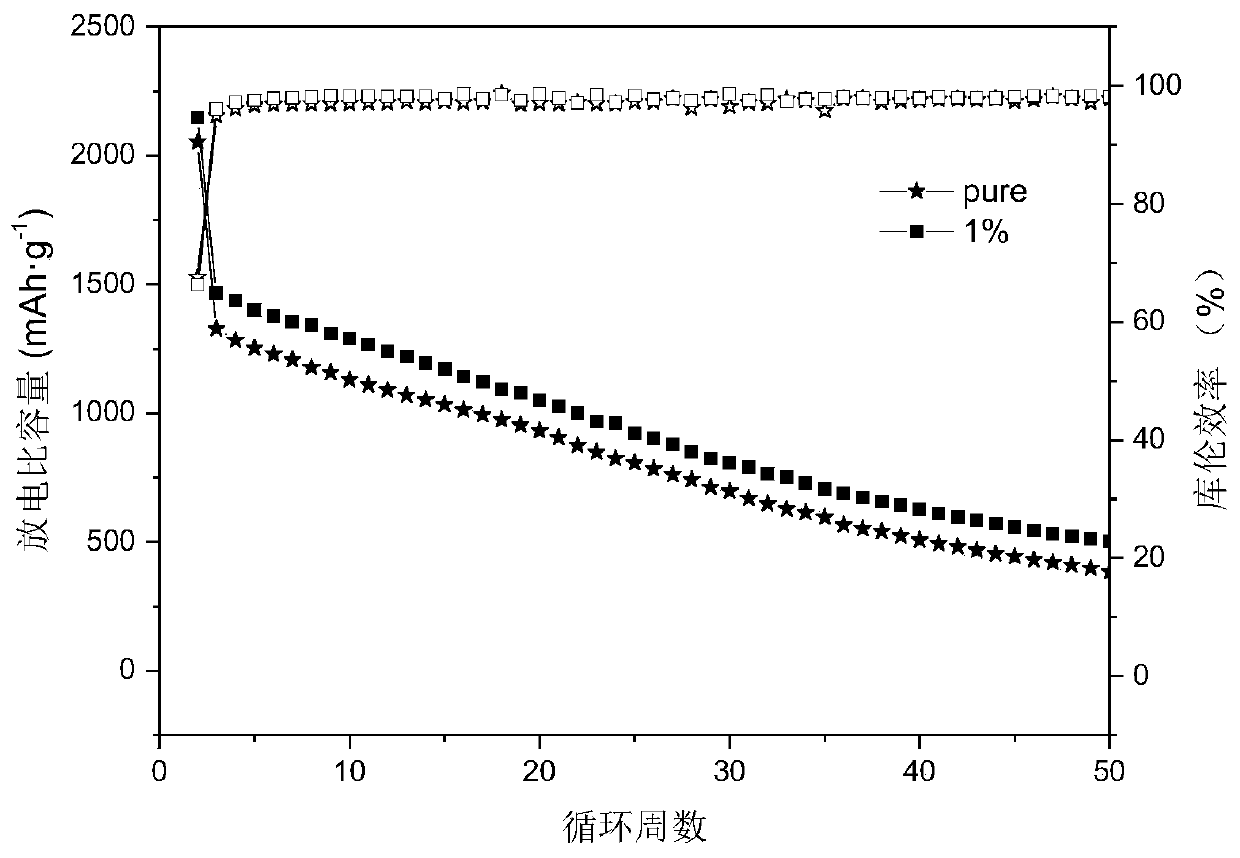

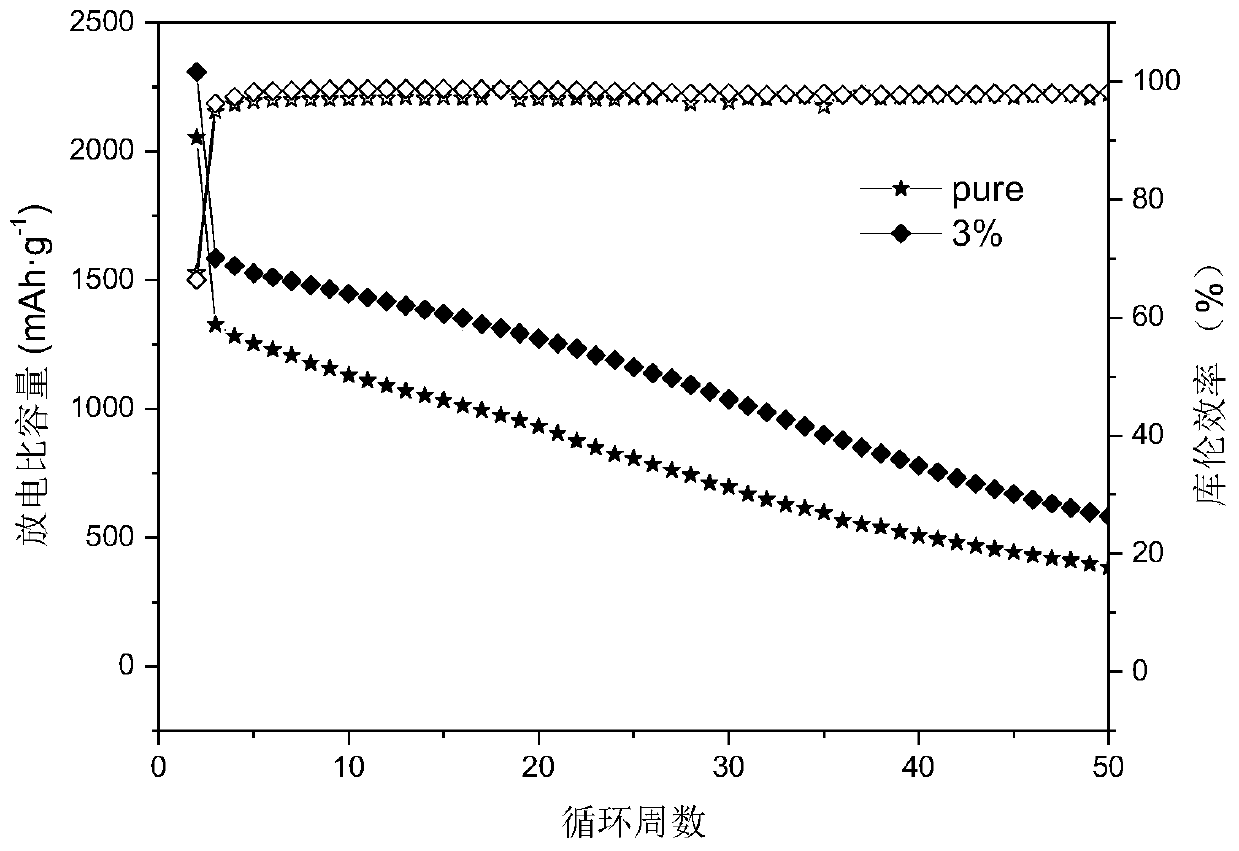

Fluorine-containing silicon monoxide negative electrode material and preparation method and application thereof

InactiveCN110890540AIncrease transfer rateImprove structural stabilityNegative electrodesSecondary cellsSilicon monoxideElectrical conductor

The invention discloses a fluorine-containing silicon monoxide negative electrode material and a preparation method and application thereof. The mass content of fluorine in the fluorine-containing silicon monoxide material is 1-20%, and the fluorine elements are uniformly distributed on the surface of silicon monoxide; the average particle size of the fluorine-containing silicon monoxide materialis 10-70 [mu] m. The preparation method comprises the following steps: mixing and grinding silicon monoxide powder and ammonium fluoride powder to obtain silicon monoxide-ammonium fluoride composite powder; and sintering the silicon monoxide-ammonium fluoride composite powder under the protection of inert gas to obtain the fluorine-containing silicon monoxide negative electrode material. The negative electrode material obtained by the method can form a LiF fast ion conductor layer to coat the surfaces of silicon monoxide particles in the charging and discharging process, formation of a more stable SEI film is promoted, and the electrochemical performance of a battery is improved. The raw materials adopted by the invention are low in cost, the preparation process is simple, a toxic fluorine-containing additive or a fluorine-containing additive with harsh use condition requirements is not adopted, the safety is high, and the method is suitable for large-scale production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Convenient-to-use traditional Chinese medicinal material crushing device for medicine processing

InactiveCN111940076AAvoid Repeated FragmentationUniform sizeSievingScreeningMedicinal herbsCircular disc

The invention discloses a convenient-to-use traditional Chinese medicinal material crushing device for medicine processing, and belongs to the technical field of medicine processing. The device comprises a crushing box, a feeding hopper is arranged in the middle of the upper surface of the crushing box, a crushing mechanism is arranged at the bottom end of the crushing box, the crushing mechanismcomprises a driving motor, and a transmission square shaft is arranged at the output end of the driving motor. Crushing cutters are arranged at the two sides of the transmission square shaft, a screening disc is slidably connected to the bottom end of the transmission square shaft, a driving gear is fixedly connected to the bottom end of the transmission square shaft, transmission shafts are arranged at the two sides of the driving gear, and driven gears in meshed connection with the driving gear are arranged at one ends of the transmission shafts. The convenient-to-use traditional Chinese medicinal material crushing device is simple in structure and convenient to use, has a good crushing function, can prevent crushed medicinal materials from being repeatedly crushed, accordingly reduces the workload of the crushing device, can screen the crushed medicinal materials, and enables the sizes of the medicinal materials to be more uniform.

Owner:白桦

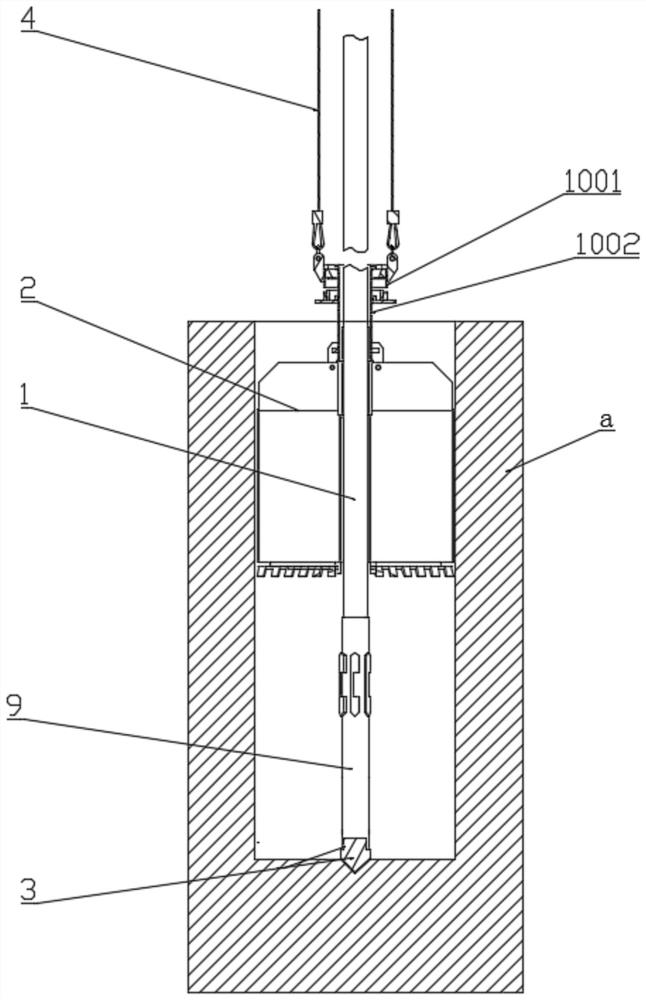

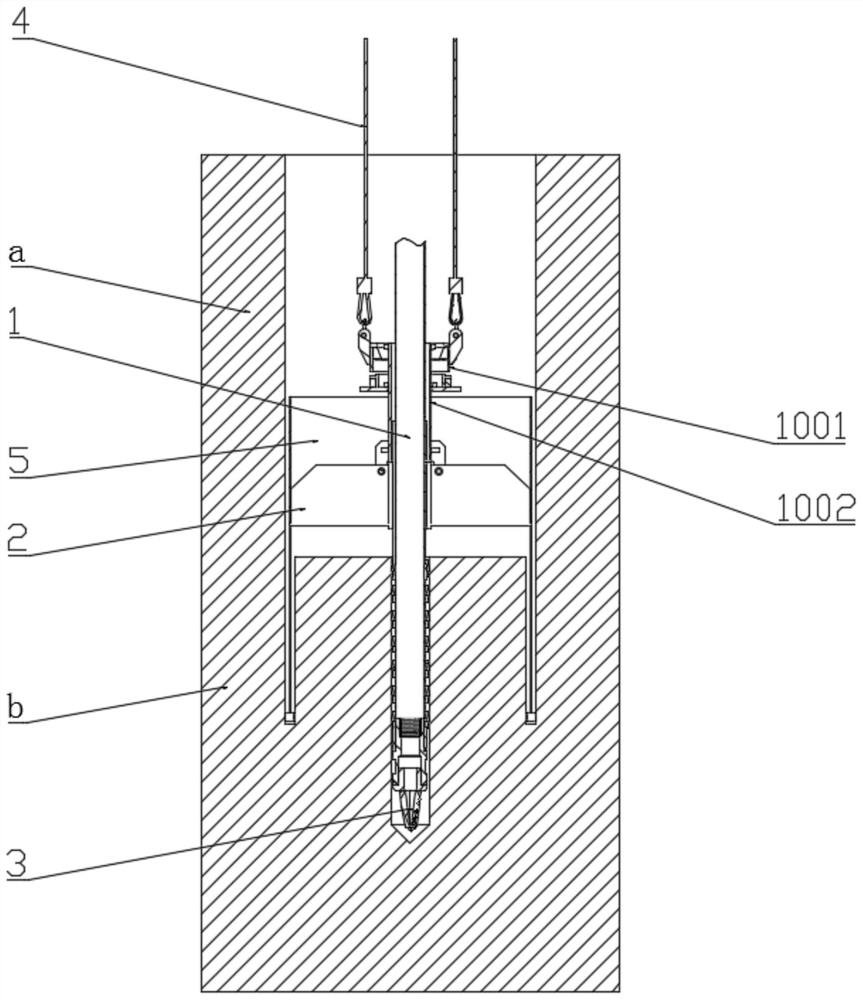

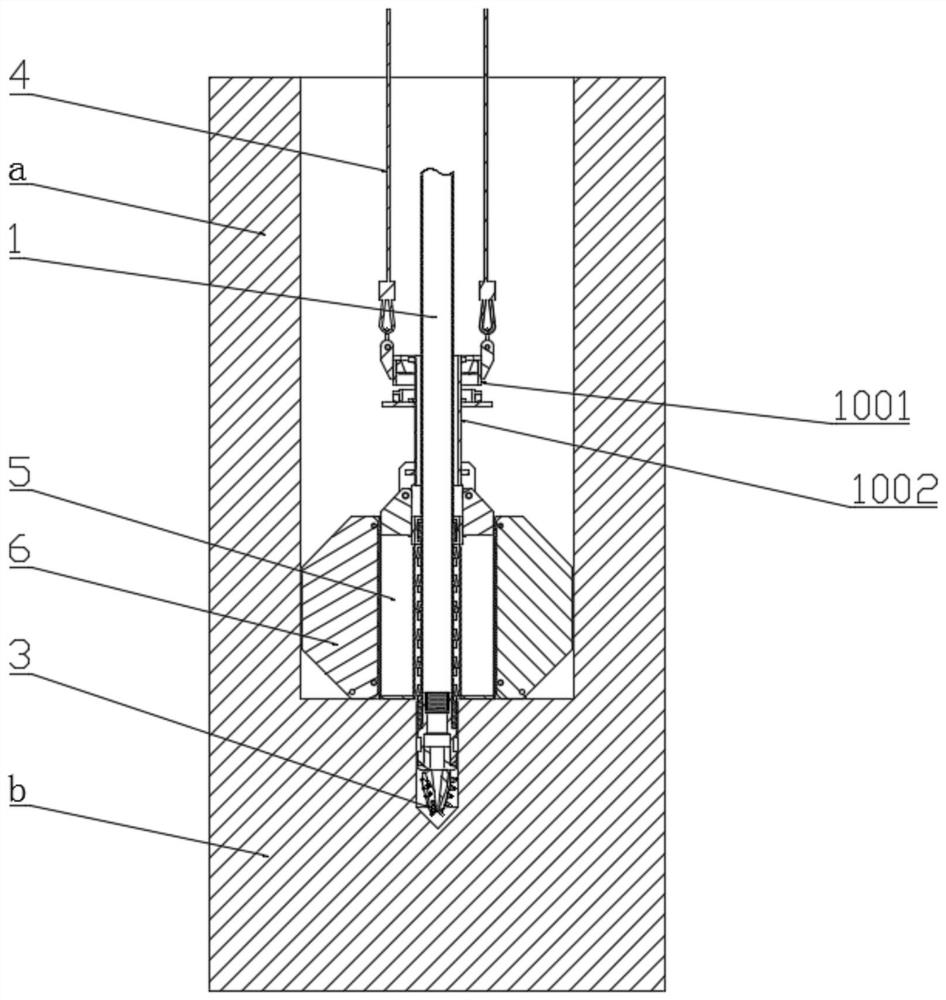

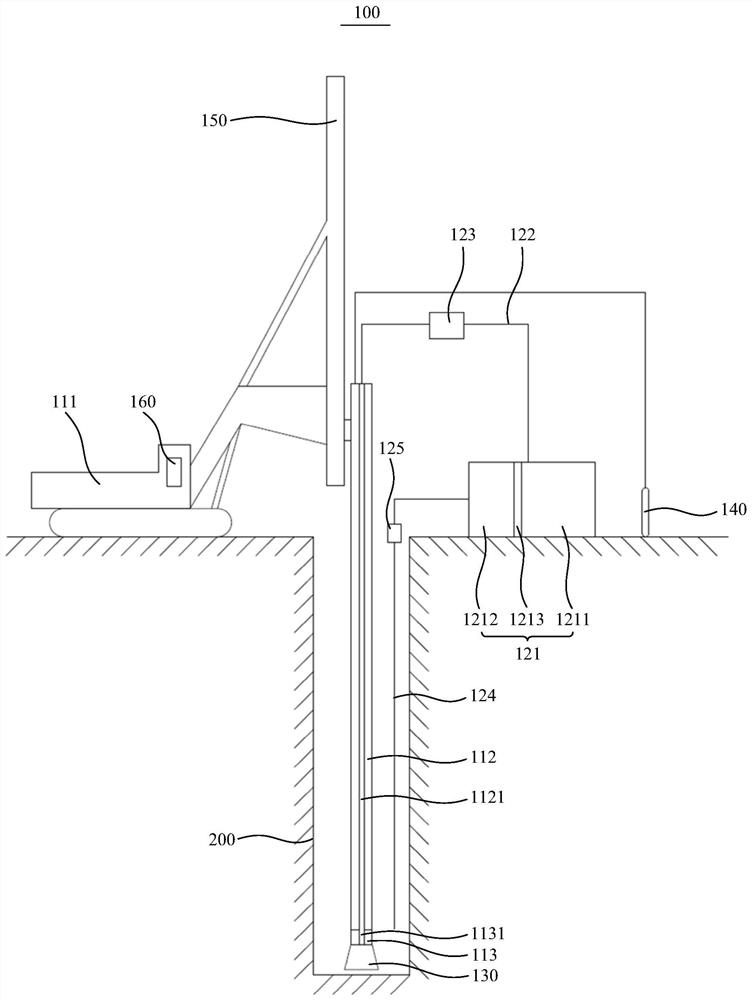

Drilling process of large-diameter geological drilled hole

ActiveCN111734299AEasy to assemble and disassembleIncrease profitDrill bitsDrilling rodsRock coreTorque transmission

The invention discloses a drilling process of a large-diameter geological drilled hole and relates to the technical field of drilling processes. A multi-segment connecting type combined drill rod is adopted as a drill rod. A torque transmission drill rod is mounted at the bottommost end of the combined drill rod. A small drill bit is mounted at the bottom of the torque transmission drill rod, wherein the small drill bit is used for drilling a core. A large drill bit is mounted on the lower portion of the torque transmission drill rod in a sleeving manner, wherein the large drill bit is used for drilling or coring. The large drill bit is connected with the torque transmission drill rod through a torque transmission mechanism. After primary residue collection or coring is completed through the large drill bit, the combined drill rod is reserved in the hole all the time, and the large drill bit is only lifted out of the hole. After residue is unloaded or a rock core is picked out, the large drill bit is dropped to the bottom of the hole along the combined drill rod once again. Synchronous rotation of the combined drill rod and the large drill bit is achieved through the torque transmission mechanism, and secondary drilling is conducted. By means of the drilling process, the drilling efficiency is greatly improved.

Owner:天明(南京)智能装备科技有限公司

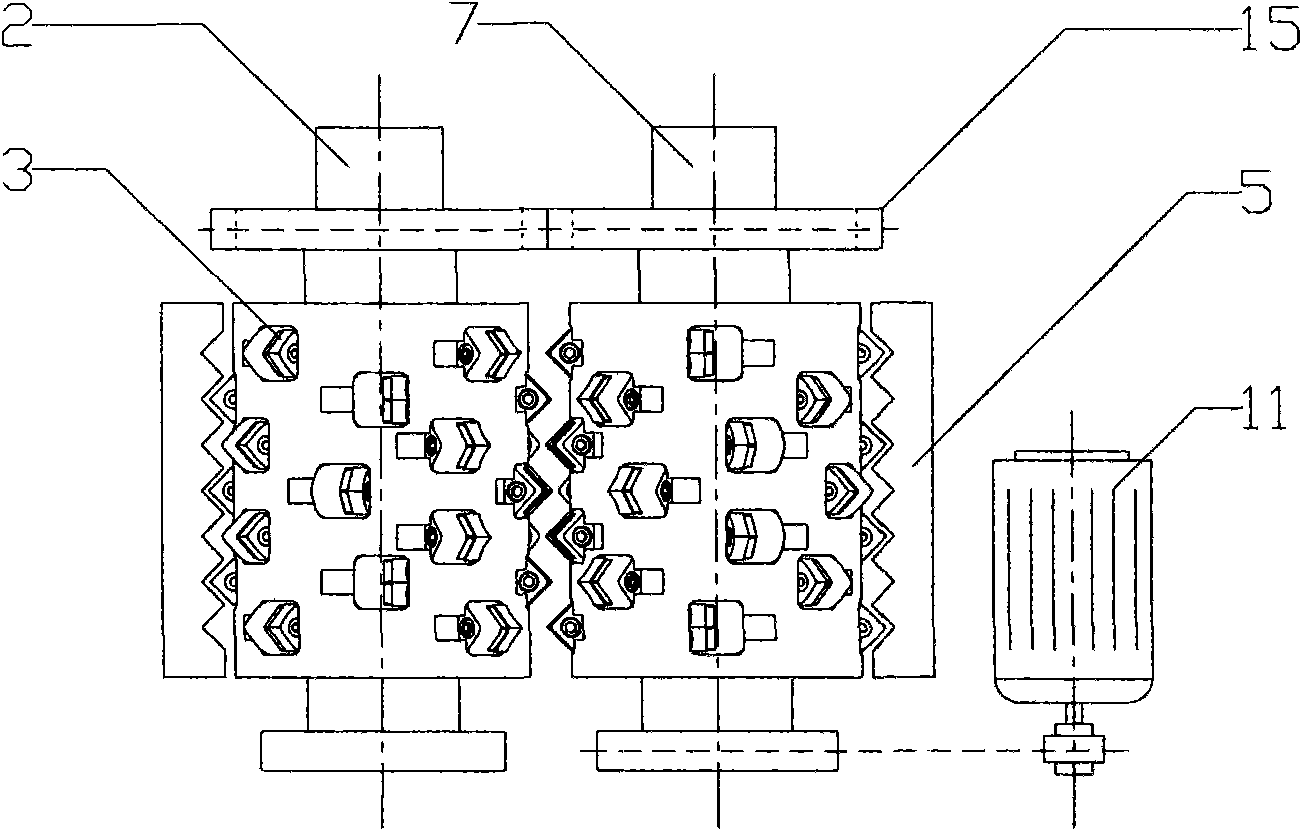

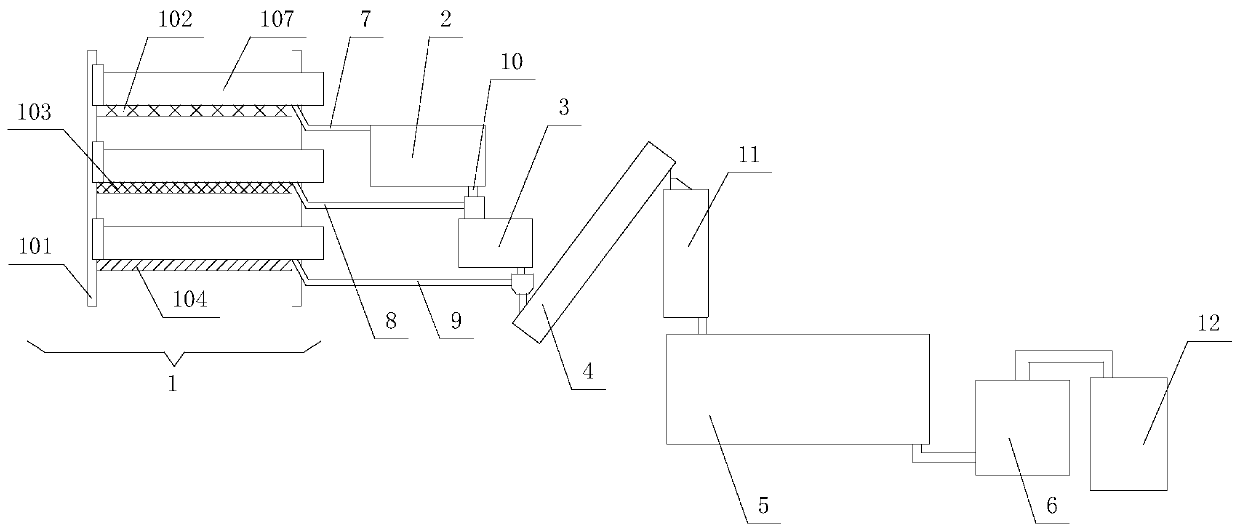

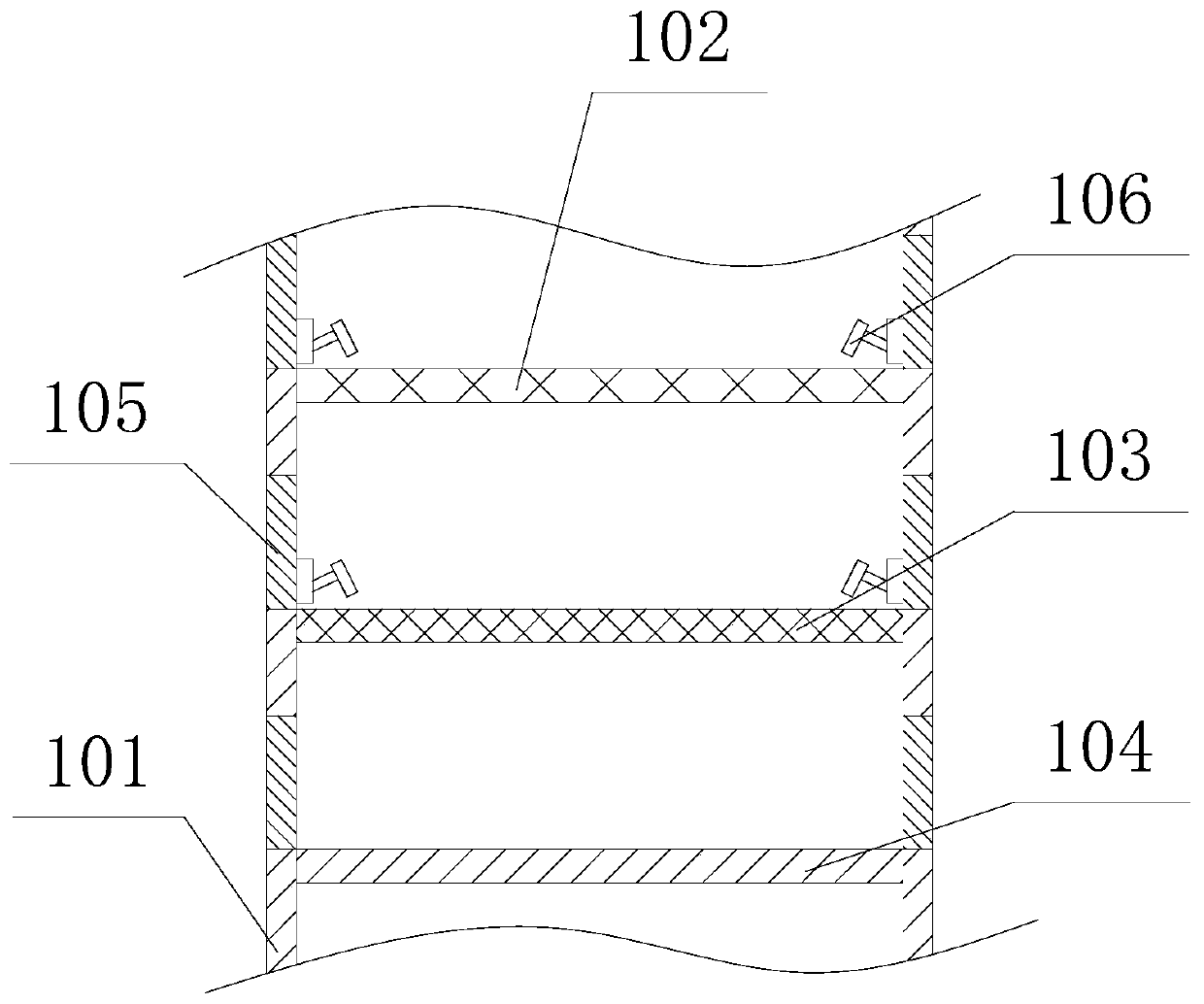

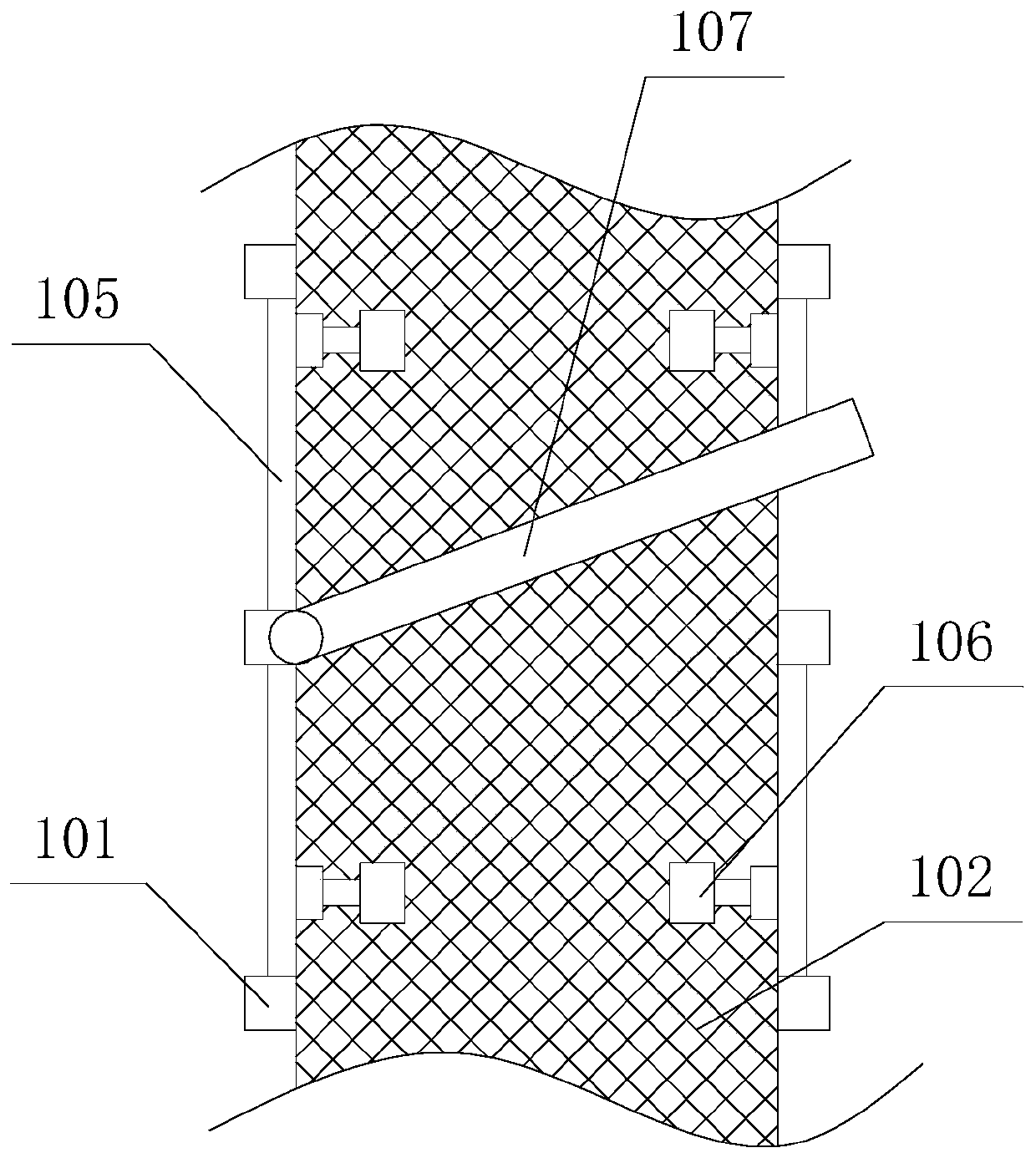

Closed-loop control crushing system and closed-loop control method for sintered fuel

InactiveCN109482315AAvoid influenceAvoid Repeated FragmentationGrain treatmentsFuel treatmentClosed loop

The invention provides a closed-loop control crushing system and a closed-loop control method for sintered fuel. The closed-loop control crushing system comprises a double-layer vibrating screen arranged below a fuel bin, wherein the hole diameter of an upper-layer screen plate of the double-layer vibrating screen is greater than that a lower-layer screen plate of the double-layer vibrating screen; and a screen upper-layer discharging outlet of the double-layer vibrating screen is connected with a double-roller crusher, a discharging outlet of the double-roller crusher and a middle-layer discharging outlet of the double-layer vibrating screen are connected with a four-roller crusher through a first belt conveyor, a discharging outlet of the four-roller crusher is connected with a single-layer vibrating screen, a screen lower-layer discharging outlet of the double-layer vibrating screen and a screen lower-layer discharging outlet of the single-layer vibrating screen are connected with auser end through a second belt conveyor, and a screen upper-layer discharging outlet of the single-layer vibrating screen is connected with the four-roller crusher through the first belt conveyor toform a closed-loop system. According to the closed-loop control crushing system and the closed-loop control method for the sintered fuel, the crushing efficiency can be improved, the fuel treatment capability is improved, and a fuel particle size control technology is effectively achieved in a closed loop mode.

Owner:NANJING MEISHAN METALLURGY DEV +1

Gypsum powder preparation process and system

InactiveCN110423026AAvoid Repeated FragmentationReduce crushing energy consumptionGrain treatmentsEngineeringCrusher

The invention discloses a gypsum powder preparation process and system. The system comprises a conveying device, a jaw crusher, a hammer crusher, a feeding device, a rotary kiln calcining pot and a centrifugal pulverizer which are arranged in sequence, wherein the conveying device comprises a primary conveyer belt, a secondary conveyer belt and a third conveyer belt; discharge baffle plates are correspondingly mounted on the primary conveyer belt, the second conveyer belt and the third conveyer belt; a primary collecting plate which communicates with the jaw crusher, a secondary collecting plate which communicates with the hammer crusher and a third collecting plate which communicates with the feeding device are additionally arranged on a rack; a waste heat channel is formed between the feeding device and the rotary kiln calcining pot; and the centrifugal pulverizer is connected with a storage tank. As ores are graded in a conveying process, energy consumption for continuously crushingthe ores can be reduced, and the ore crushing efficiency can be improved; and in addition, due to adoption of the waste heat channel and a novel centrifugal pulverizing component, the product qualitycan be further improved, and the energy consumption cost for production can be lowered.

Owner:康定龙源穗城石膏有限责任公司

Chemical raw material crushing device

PendingCN112756074AFully brokenPlay a driving roleSievingScreeningElectric machineryStructural engineering

The invention discloses a chemical raw material crushing device, and belongs to the technical field of crushing devices. The chemical raw material crushing device comprises a crushing box, discharging hoppers are fixedly connected to the two ends of the upper surface of the crushing box, a discharging through hole is formed in the middle of the lower surface of the crushing box, a supporting bottom plate is arranged below the crushing box, and limiting supporting plates are fixedly connected to the two ends of the upper surface of the supporting bottom plate; and the top ends of the limiting supporting plates are fixedly connected with second limiting springs corresponding to the crushing box, a metal screening plate is arranged in the crushing box, the lower surface of the metal screening plate is fixedly connected with a first flow guide pipe, and the bottom end of the first flow guide pipe is slidably connected with a second flow guide pipe fixedly connected with the crushing box. The crushing device is simple in structure and convenient to use, raw materials at the bottom end of the crushing box are thrown up through operation of a driving motor during use, the crushing device can fully crush the raw materials, crushing dead angles are avoided, and the machining quality of the crushing device is remarkably improved.

Owner:梁淑平

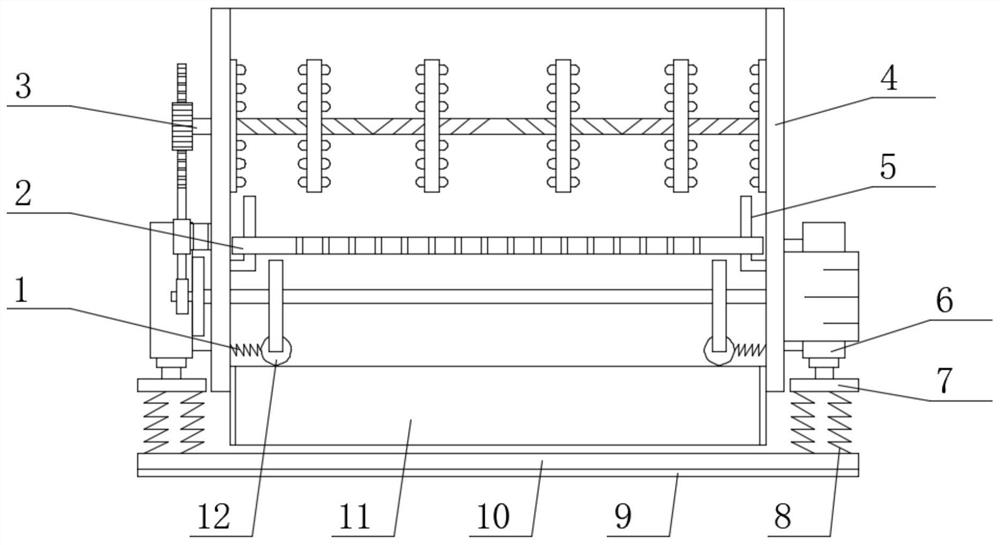

Crushing device for sweet potato starch processing

InactiveCN111822111AAvoid Repeated FragmentationIncrease productivityGrain treatmentsVibration suppression adjustmentsCircular discHydraulic cylinder

The invention discloses a crushing device for sweet potato starch processing, and belongs to the technical field of agricultural products processing. The crushing device comprises a box body, a support base plate is arranged below the box body, the two ends of the box body are provided with hydraulic cylinders, second limiting plates are arranged at the bottom ends of the hydraulic cylinders, theconnection between the second limiting plates and the support base plate is provided with a shock-absorbing spring, a crushing mechanism is arranged in the box body, the crushing mechanism comprises adrive motor, an output end of the drive motor is provided with a drive shaft, one end of the drive shaft is provided with a drive disc, one side of the drive disc is provided with a drive part, one end of the drive disc is provided with a drive cylinder corresponding to the drive part, a limiting screw rod is arranged above the drive shaft, and a driven gear is arranged at one end of the limitingscrew rod; and the crushing device has a simple structure, convenient use, better crushing function, can crush starch blocks quickly, saves time and effort, and improves the production efficiency ofusers.

Owner:高侠

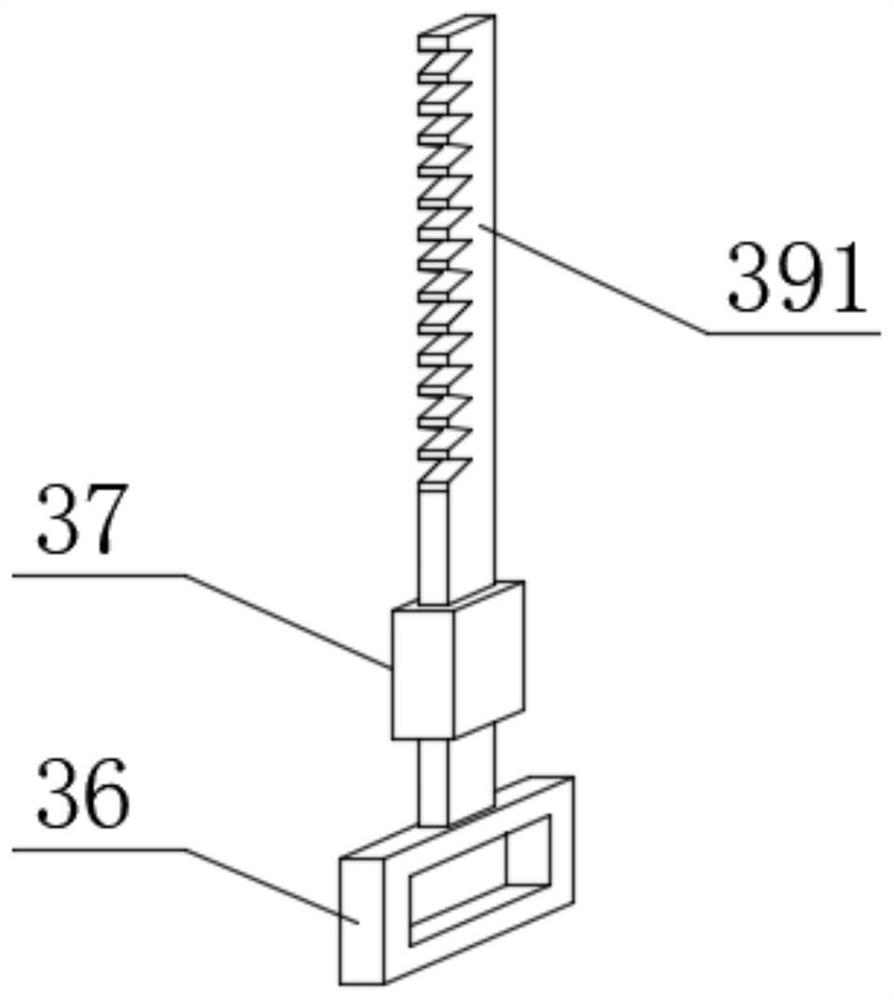

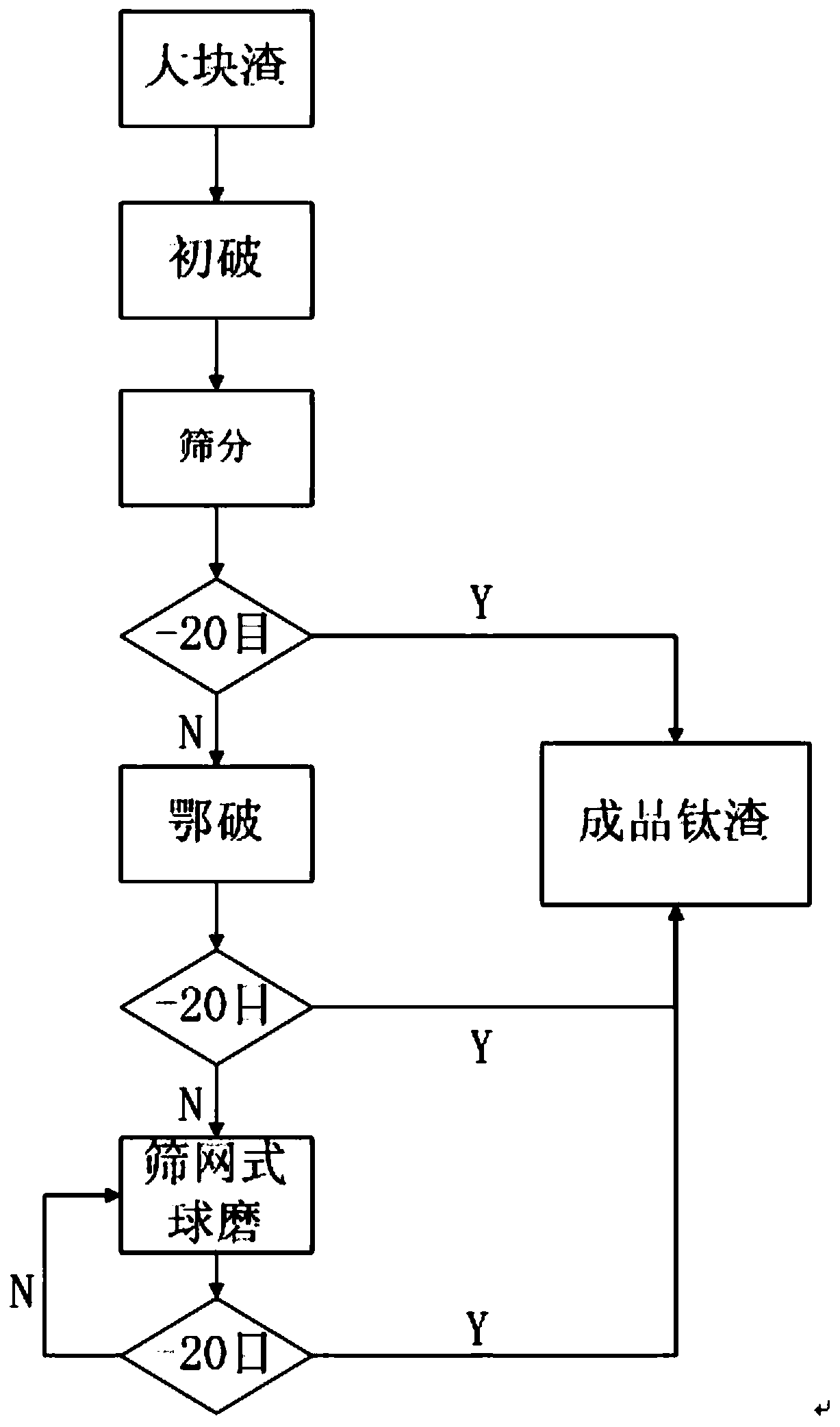

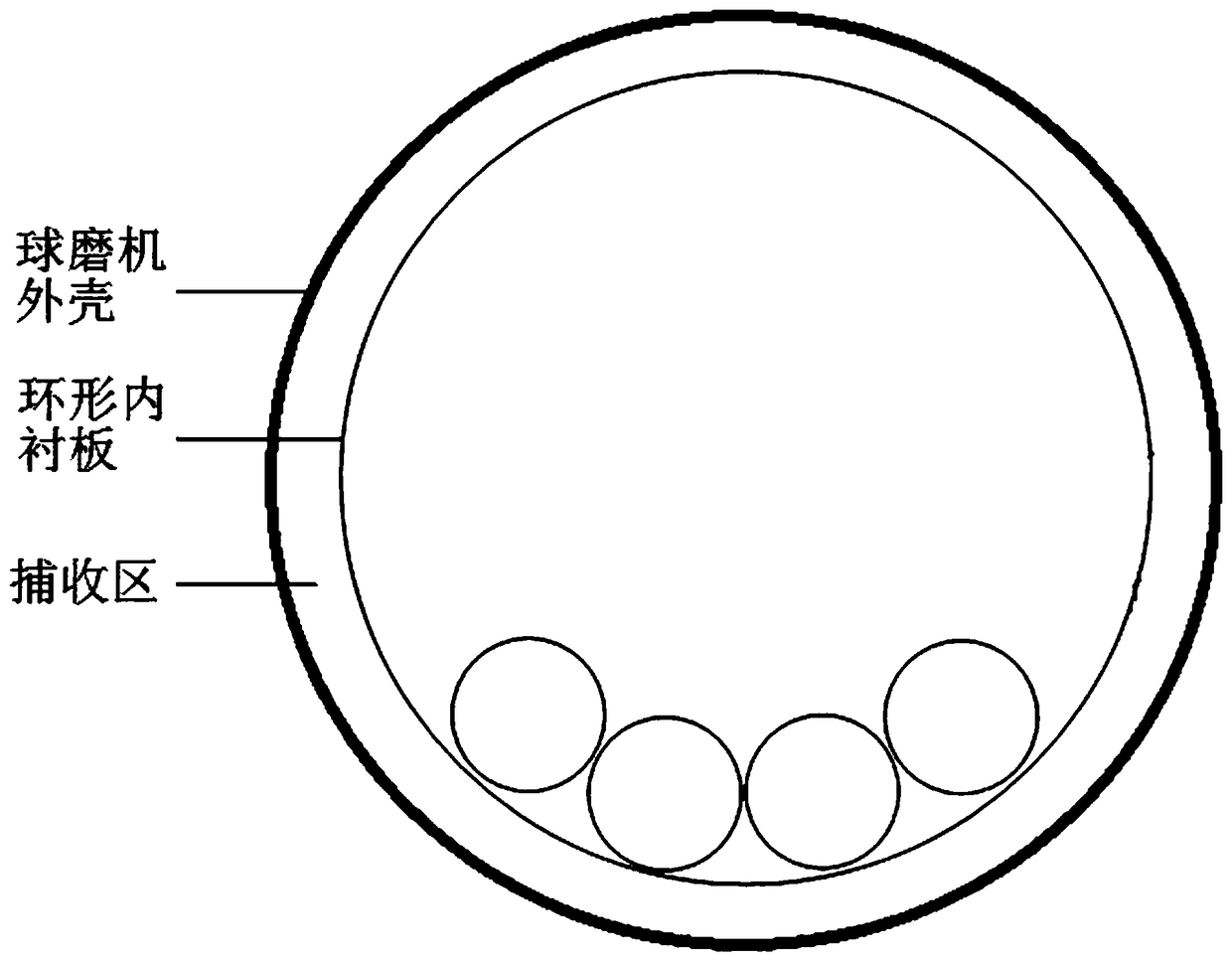

Method for reducing fine powder rate of titanium residue breaking

InactiveCN109248772AAvoid Repeated FragmentationSatisfy Granularity RequirementsGrain treatmentsTitaniumBall mill

The invention discloses a method for reducing the fine powder rate of titanium residue breaking, and belongs to the field of titanium residue breaking treatment. The method comprises three steps of primary breaking sieving, jaw brushing sieving and ball milling sieving, wherein finished titanium residue and small-block titanium residue are obtained by the primary breaking sieving, the small-blocktitanium residue is broken into finished titanium residue and large-particle titanium residue by the jaw brushing sieving, and finally the large-particle titanium residue is subjected to grinding sieving by a double-layer sieve mesh type ball mill to obtain more than 95% of the finished titanium residue. According to the present invention, through the comprehensive utilization of the multi-stage fine-breaking sieving and the double-layer sieve mesh type ball mill, the repeated breaking of the fine-particle titanium residue is avoided, the 200 mesh titanium residue content is effectively reduced, the requirements of the subsequent processing on the particle size of the titanium residue are met, the yield of the titanium residue is improved, and the waste of resources is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

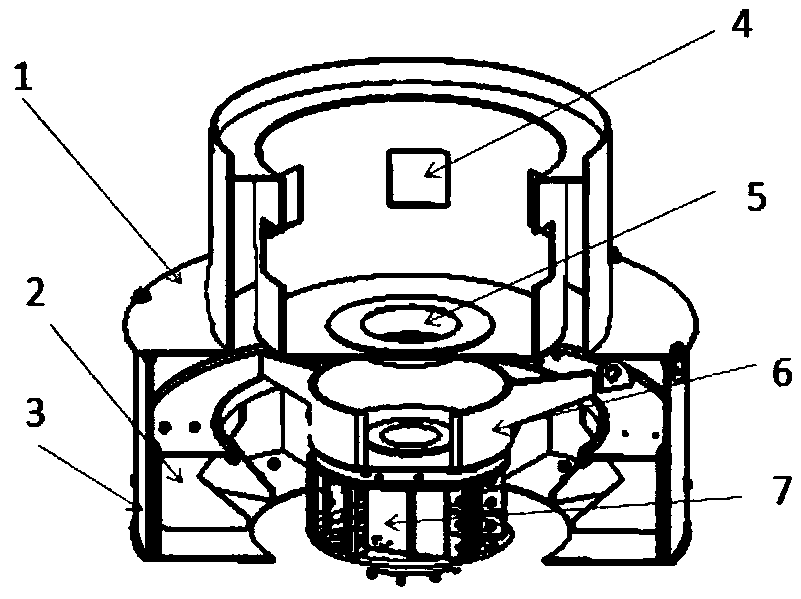

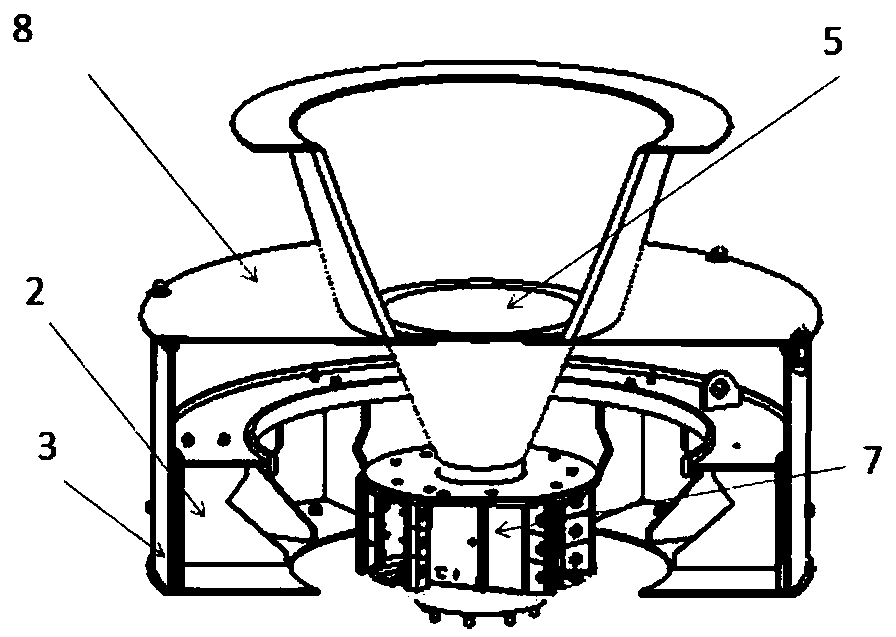

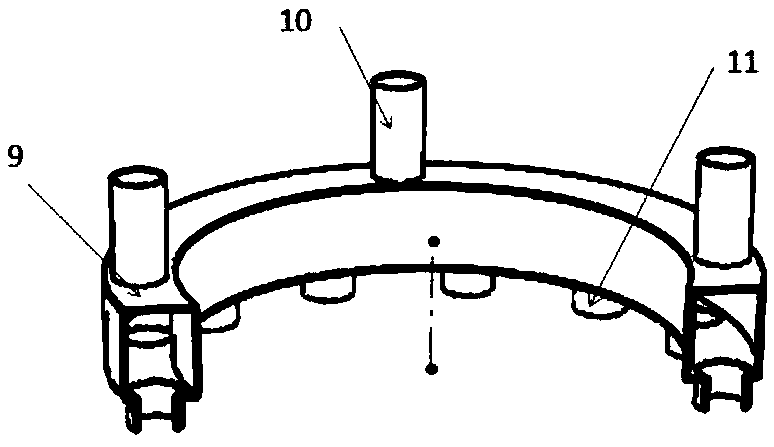

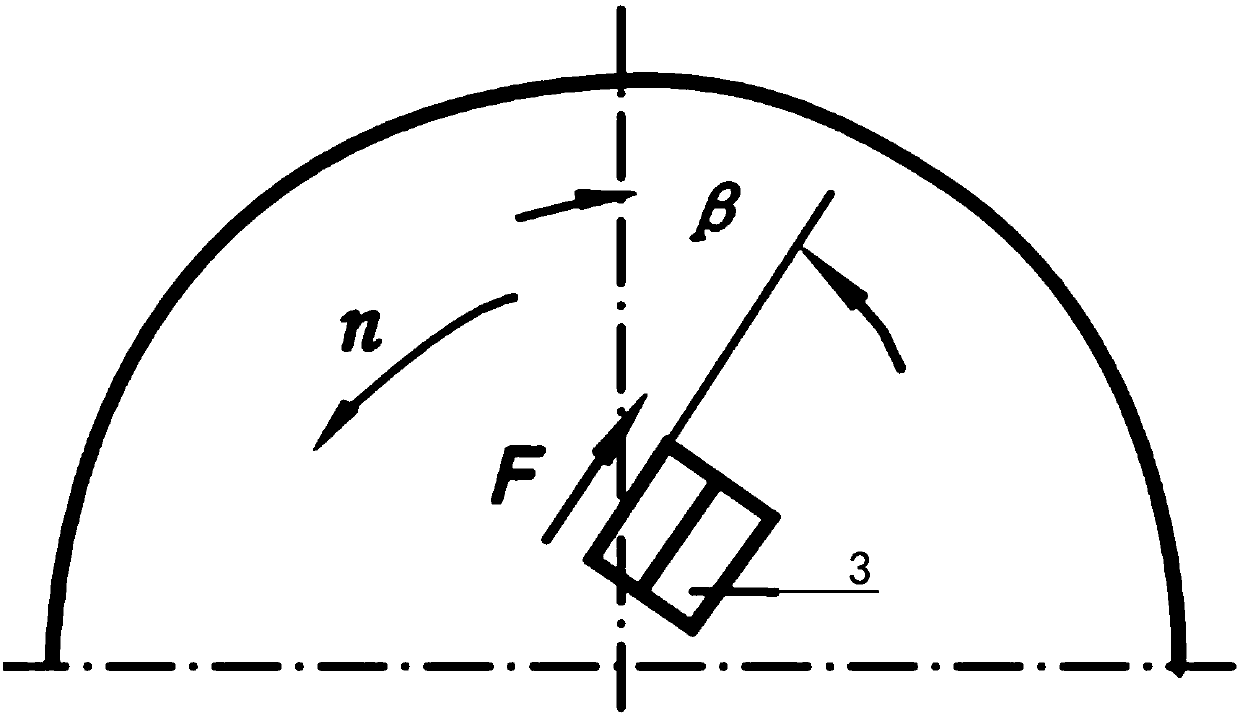

Vertical shaft type impact crusher with powder and dust removal function and powder and dust removal method

PendingCN109012979AAvoid mutual interferenceAvoid Repeated FragmentationDirt cleaningGrain treatmentsAirflowEngineering

The invention relates to a vertical shaft type impact crusher with a powder and dust removal function. The vertical shaft type impact crusher with the powder and dust removal function is characterizedin that upper air suction pipes are arranged, directly communicate with the positive-pressure air space on the periphery of a rotor and do not directly communicate with other normal-pressure and negative-pressure air spaces, and the upper air suction pipes and other normal-pressure and negative-pressure air spaces are in an indirect communication relationship only through rotor channels; and theupper air suction pipes communicate with an air exhaust pipeline of a powder and dust removal system, and an exhaust fan of the powder and dust removal system sucks the positive-pressure powder air onthe periphery of the rotor through the air exhaust pipeline and the upper air suction pipes. By the adoption of the vertical shaft type impact crusher with the powder and dust removal function, mutual interference of the air flow is avoided, the phenomenon that powder and dust is circularly and repeatedly crushed in the machine is avoided, the amount of powder and dust is reduced, the negative pressure is formed in an inlet and an outlet of the machine, and no powder air overflows.

Owner:南昌矿机集团股份有限公司

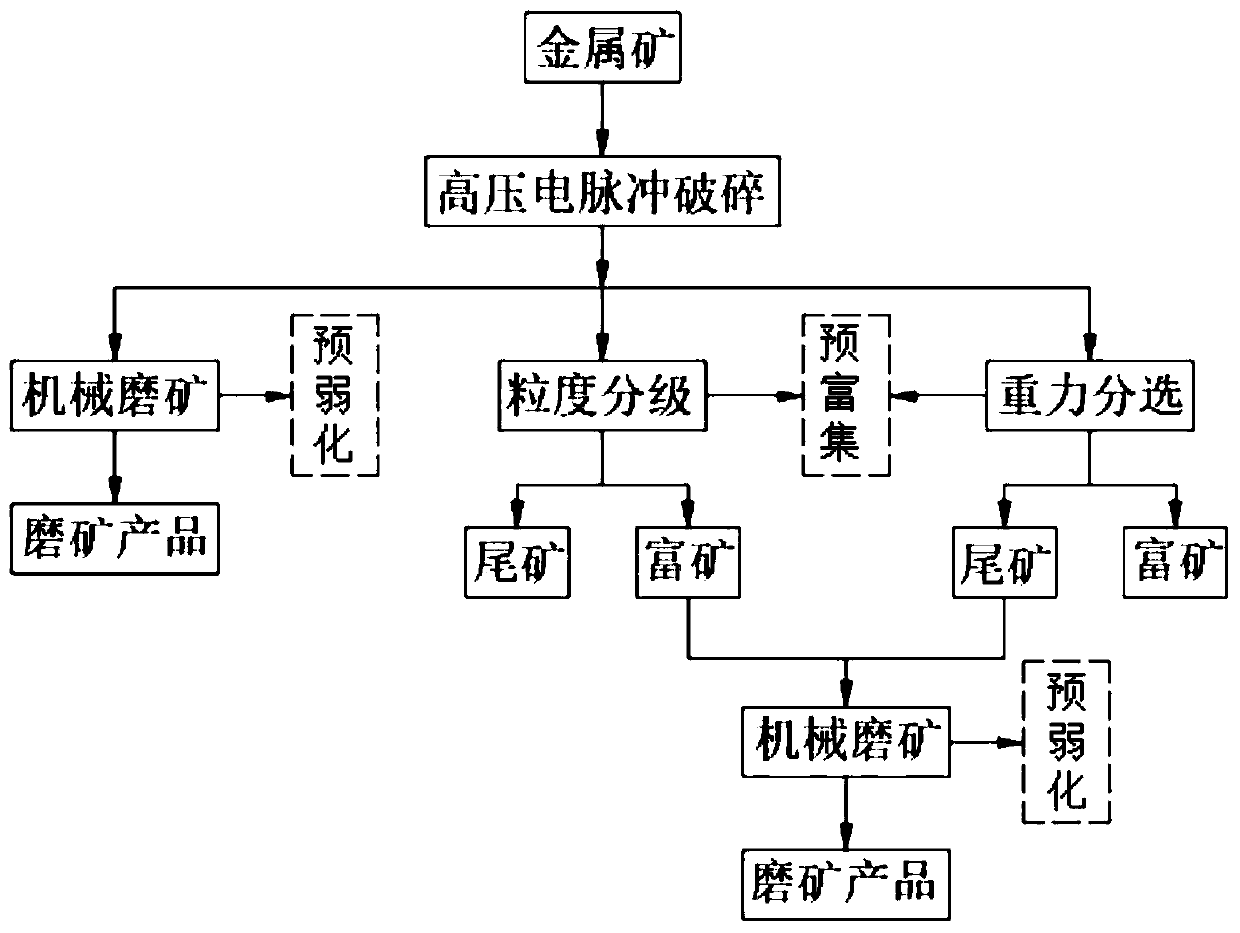

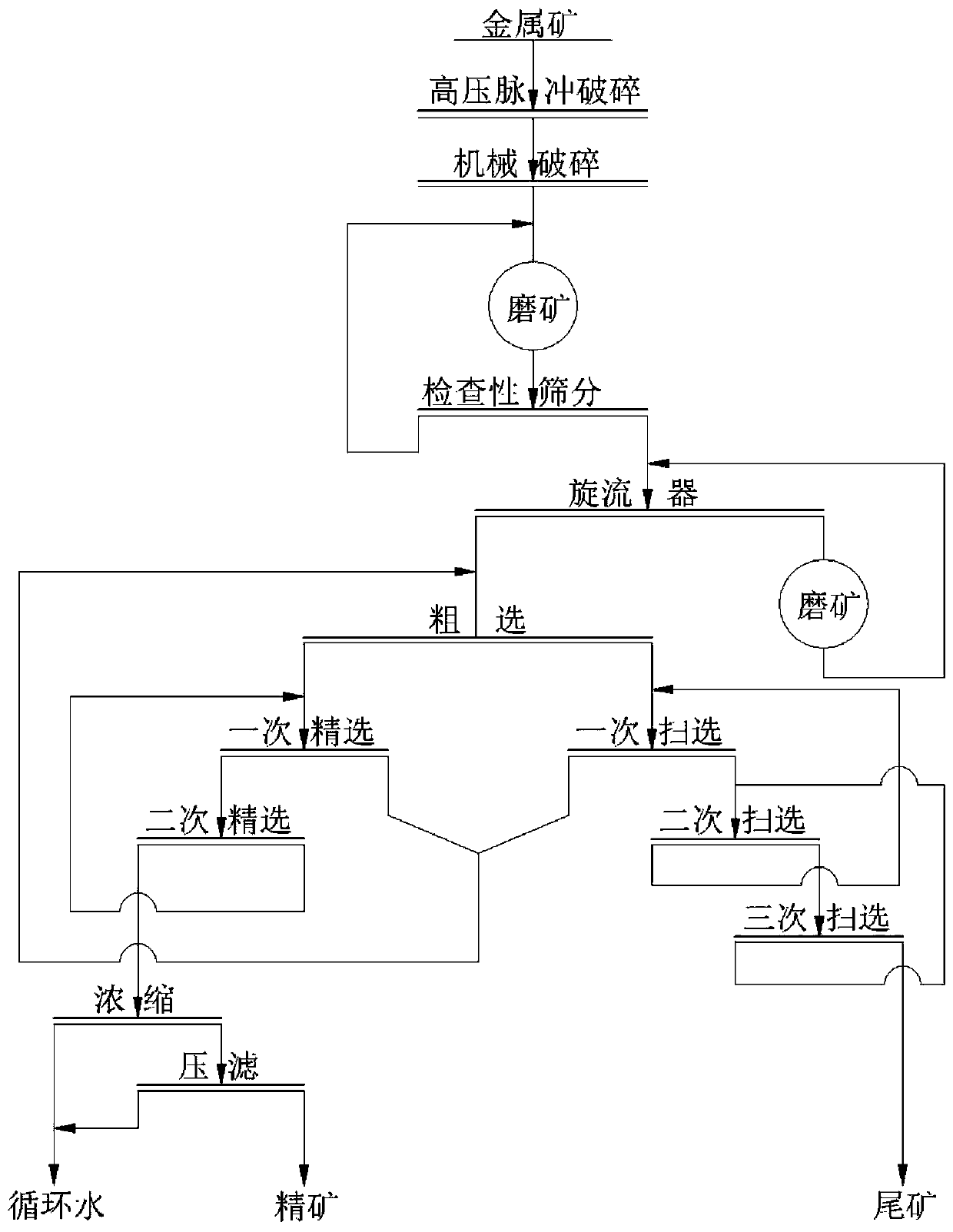

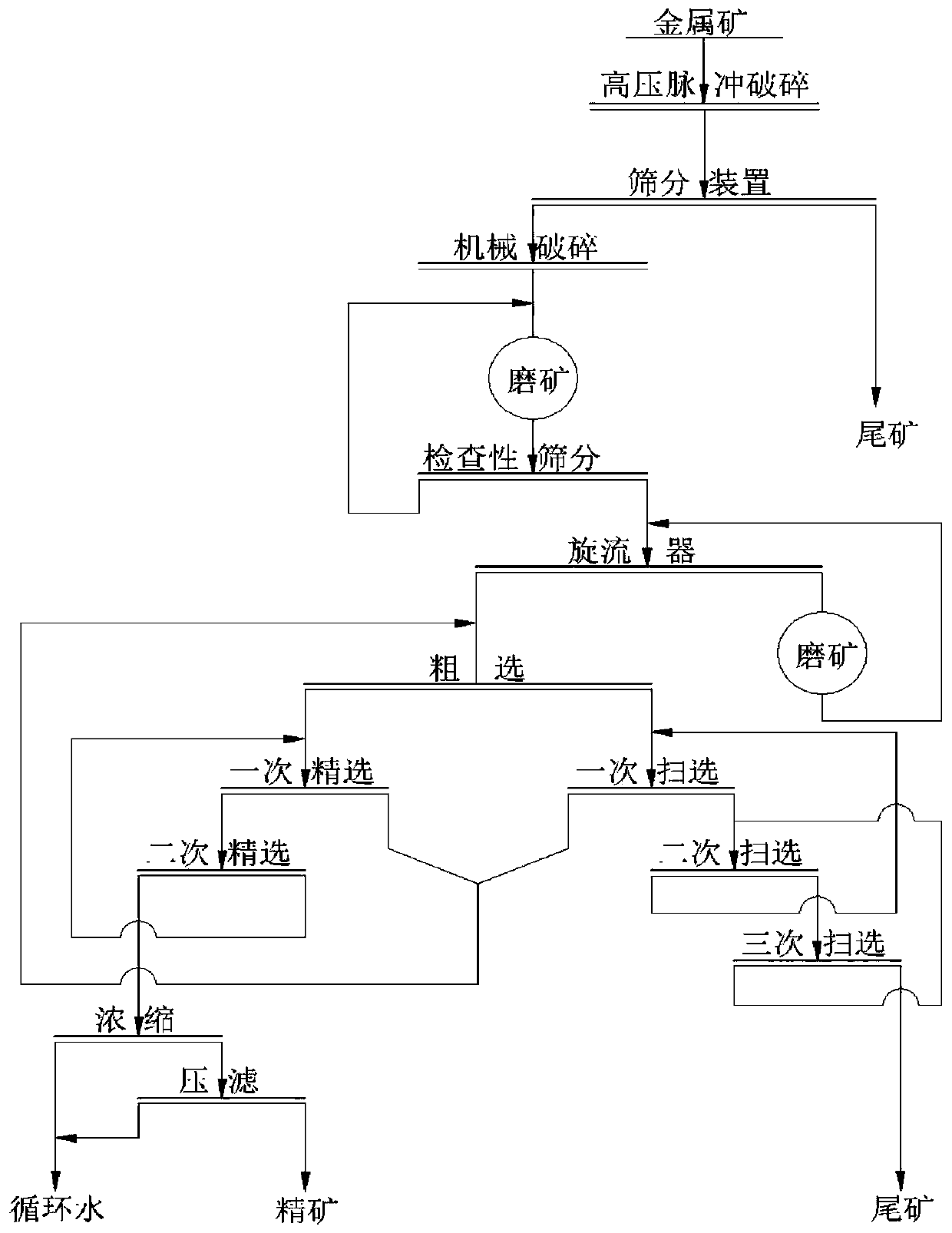

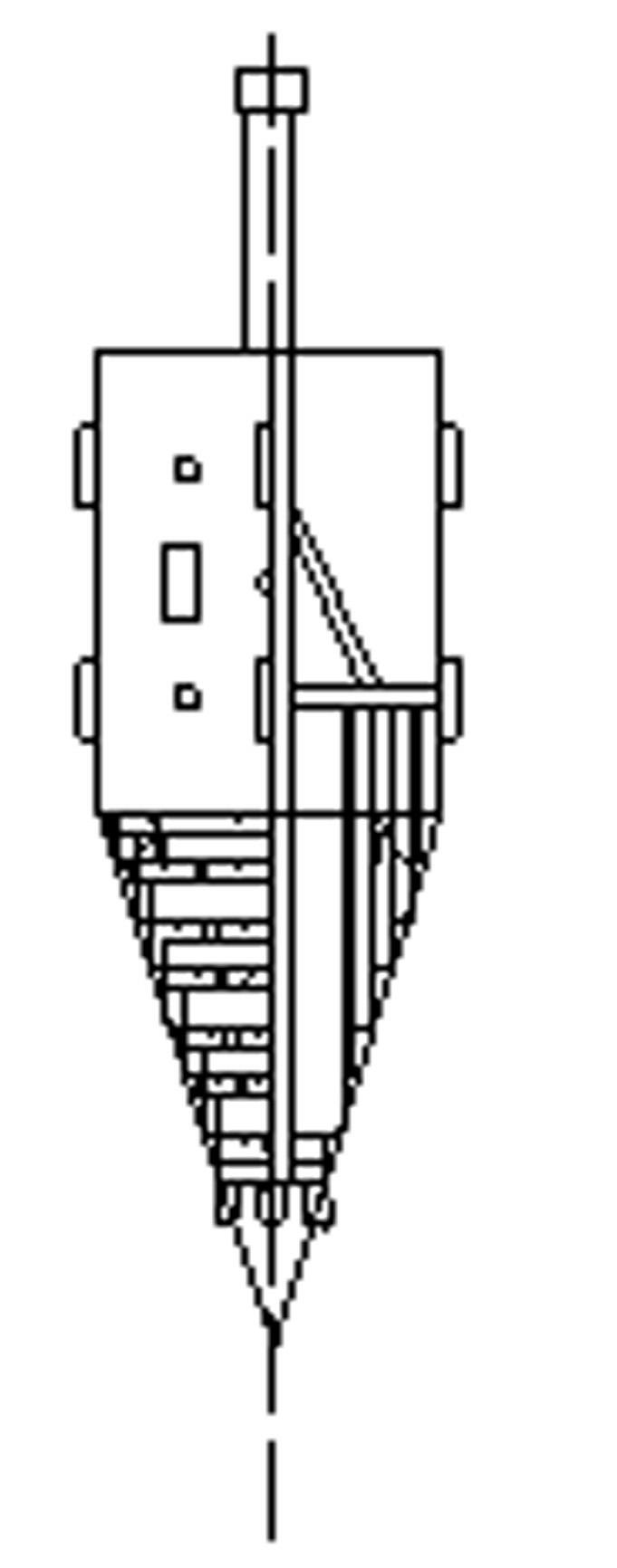

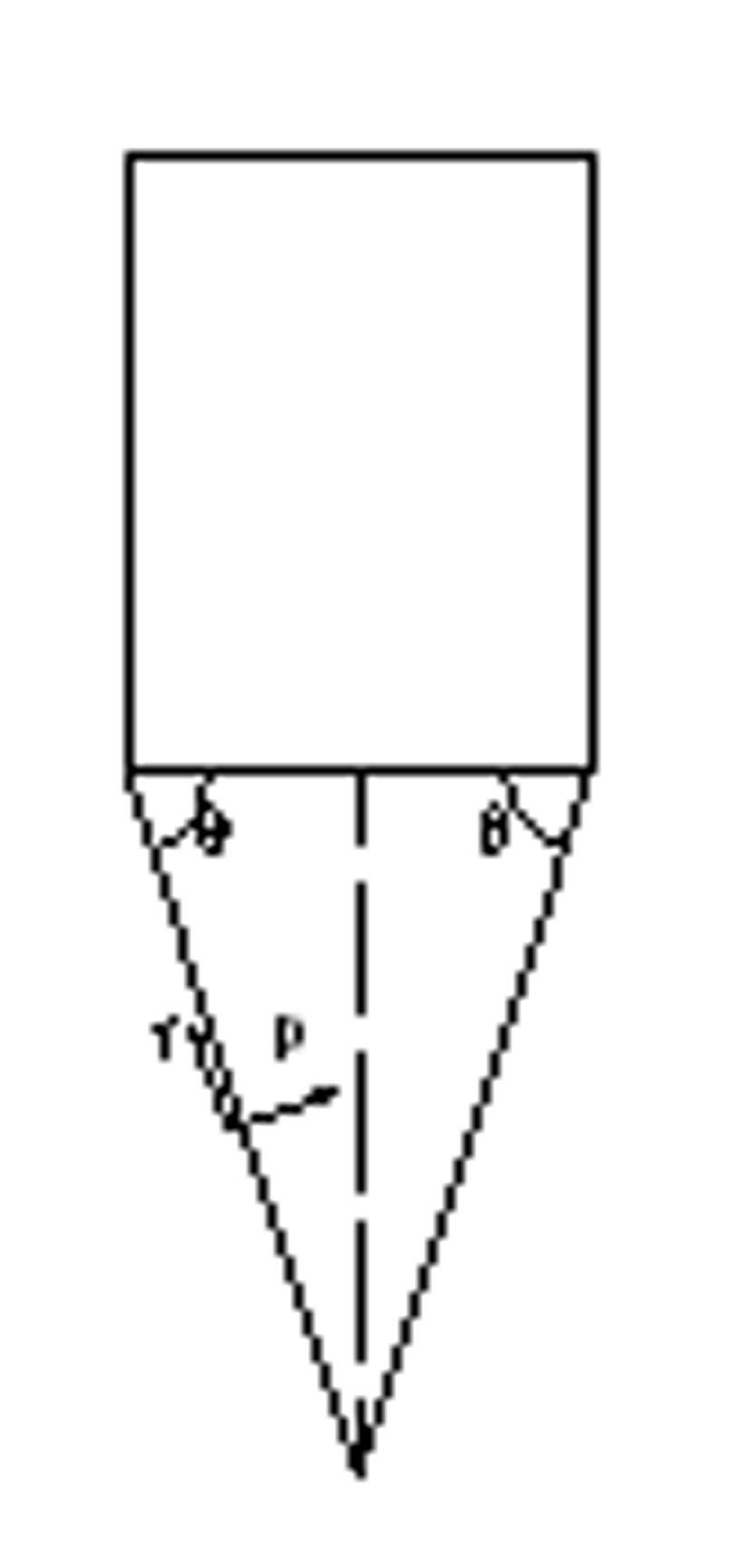

High-voltage electric pulse crushing pre-weakening and enriching process for metal ores

ActiveCN111203312AReduce hardnessReduce the amount of feedSievingScreeningGravity separationHigh voltage

The invention discloses a high-voltage electric pulse crushing pre-weakening and enriching process for metal ores. The process comprises the steps that firstly, raw ore is pretreated through a high-voltage electric pulse crushing device, and the ore subjected to high-voltage electric pulse crushing is divided into three treatment modes according to needs; for the metal ores with high ore hardness,the crushed materials directly enter a mechanical ore grinding device to be crushed and ground; for the metal ores with concentrated useful mineral distribution, the crushed materials enter a particle size grading device to be divided into tailings and rich ores, tailings are discharged in advance, and rich ores enter the mechanical ore grinding device to be crushed and ground; and for the metalores with uniformly distributed useful minerals, the crushed materials enter a gravity separation device to separate materials into tailings and rich ores, tailings are discharged in advance, and richores enter the mechanical ore grinding device to be crushed and ground. According to the process, the advantages of pre-weakening and pre-enrichment of high-voltage electric pulse crushing are utilized at the same time, so that the hardness of ores entering the mechanical ore grinding device is reduced, meanwhile, the mechanical ore grinding feeding amount is reduced, the ore crushing efficiencyis greatly improved, and the separation energy consumption is reduced; and the device is stable and reliable in operation, good in crushing effect, low in energy consumption, simple in process and wide in practicability.

Owner:CHINA UNIV OF MINING & TECH

Rotary drilling hole forming method by using multi-stage alloy pilot roller bit in complex stratum cast-in-place pile construction

ActiveCN102409978AEasy to processEasy landing and drillingDirectional drillingLow speedSoil mechanics

The invention discloses a strong karst area cast-in-place pile construction method based on a rotary drilling hole forming manner. The cast-in-place pile construction method is characterized by comprising the steps of: (1) drilling into the surfaces of a karst layer and a gravel soil layer by adopting a conventional bit; (2) in combination with the basic theory of rock-soil mechanics, finding out a mathematic relation between an optimized value of inclination of a multi-stage alloy pilot roller bit and a coefficient of sliding friction between a rock-soil material and the interface of the bit; (3) after adopting the conventional bit to dill into the surfaces of the karst layer and the gravel soil layer, changing the conventional bit into the multi-stage alloy pilot roller bit, firstly drilling at high pressure and low speed, and then, after the bit is dilled into the rock for more than 50 cm, drilling at low pressure and high speed until the drilling depth or hole depth satisfies design requirements; (4) optimizing the design of mud specific weight in stages for preventing pile holes from collapsing and improving the bearing capacity of pile foundations; and (5) handling sudden accidents, such as fracture of drilling rods, bit falling, bit burying, fracture of cone palms in holes, accidental falling of cone palms and other small operation tools and the like, in the drilling process by adopting a drill tool overshot and a falling object salvage skip.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

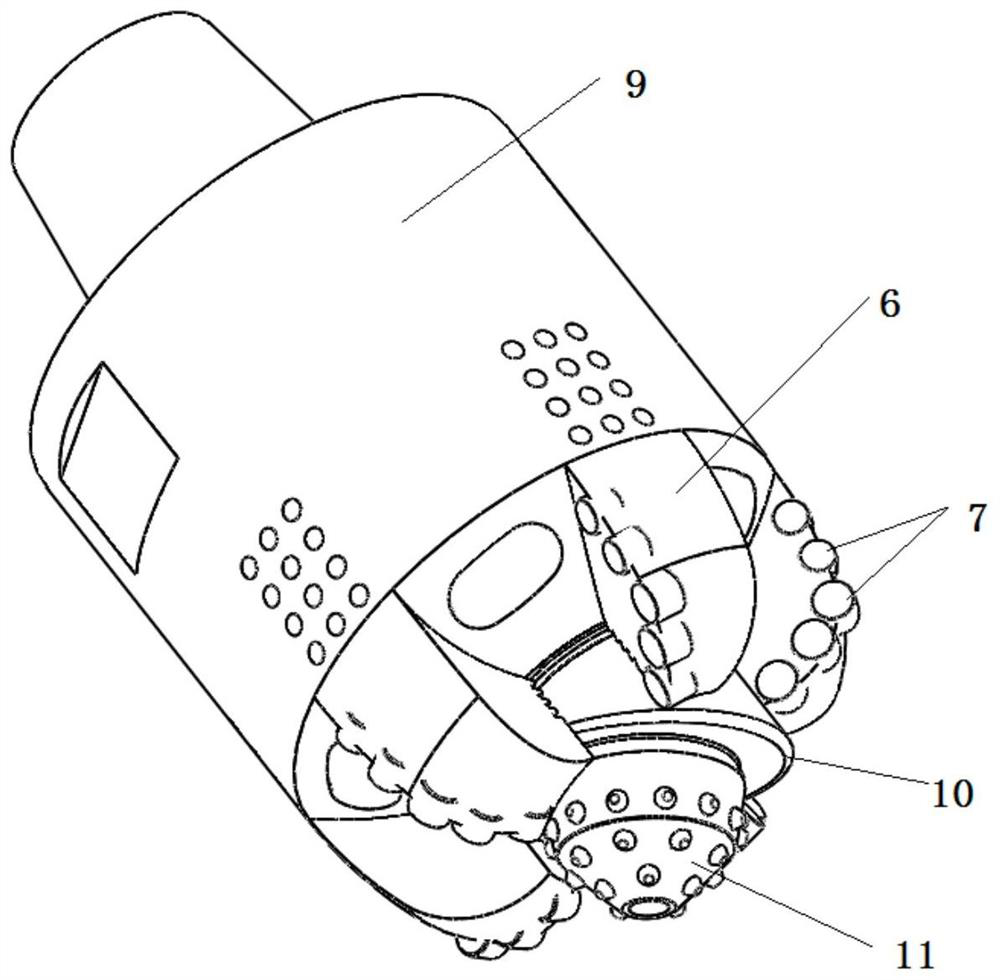

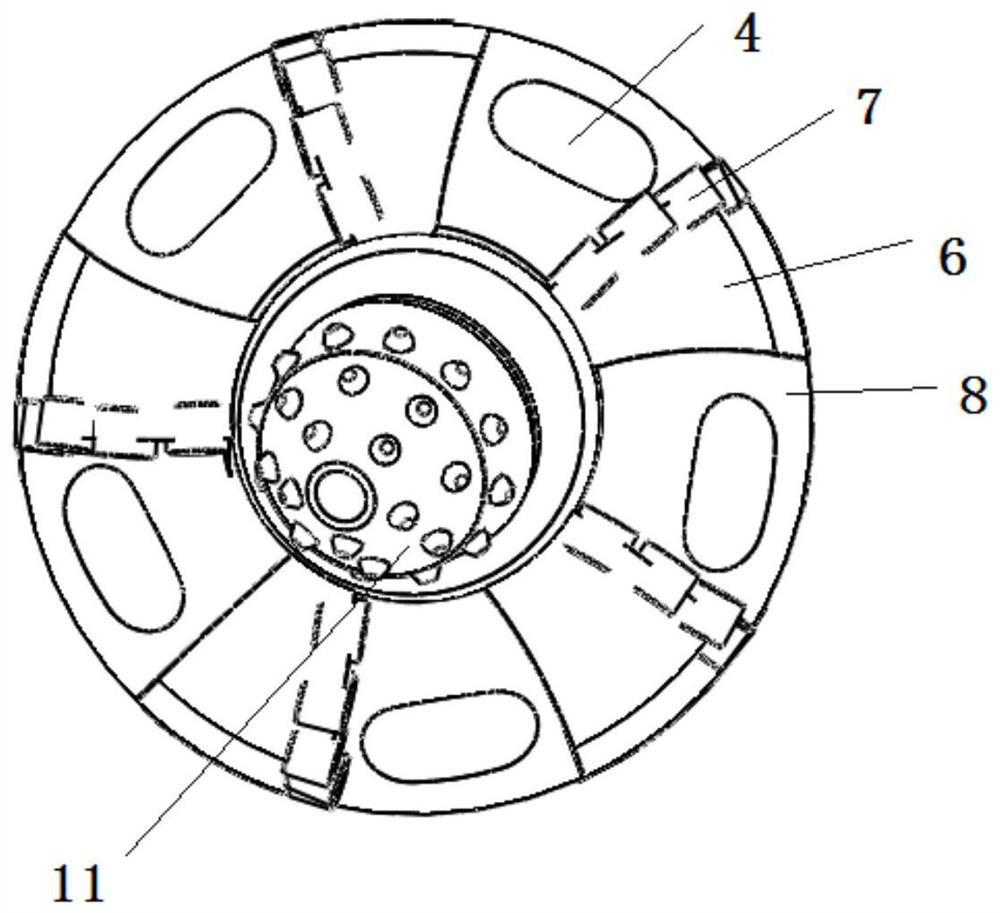

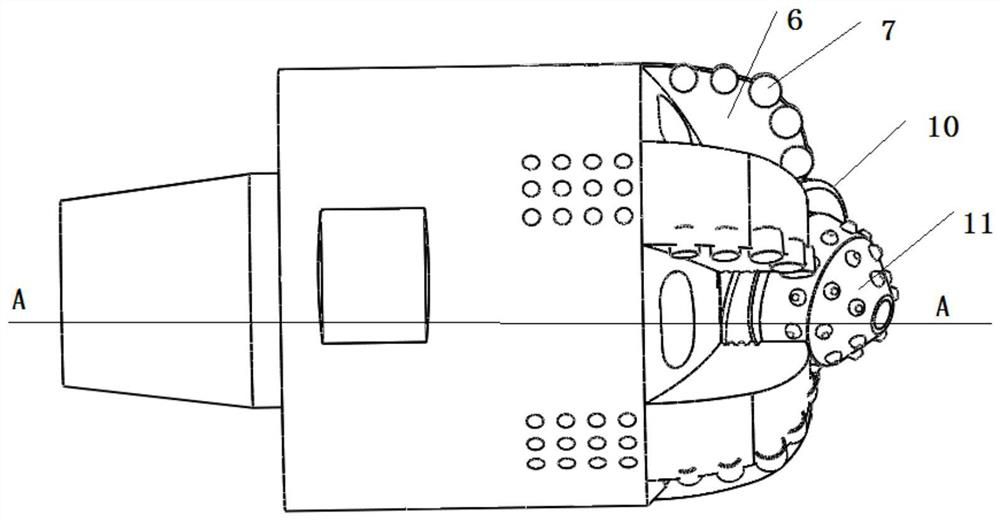

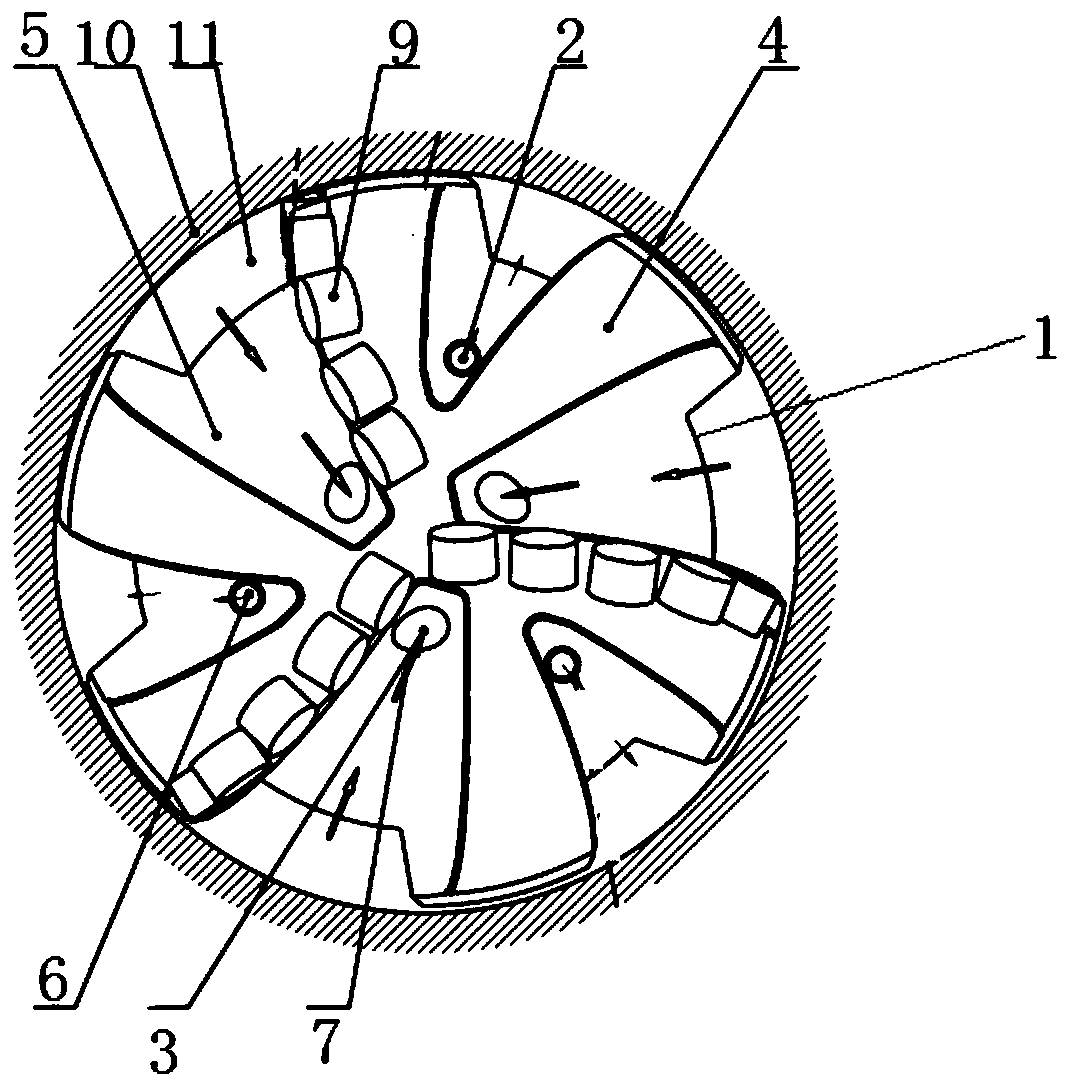

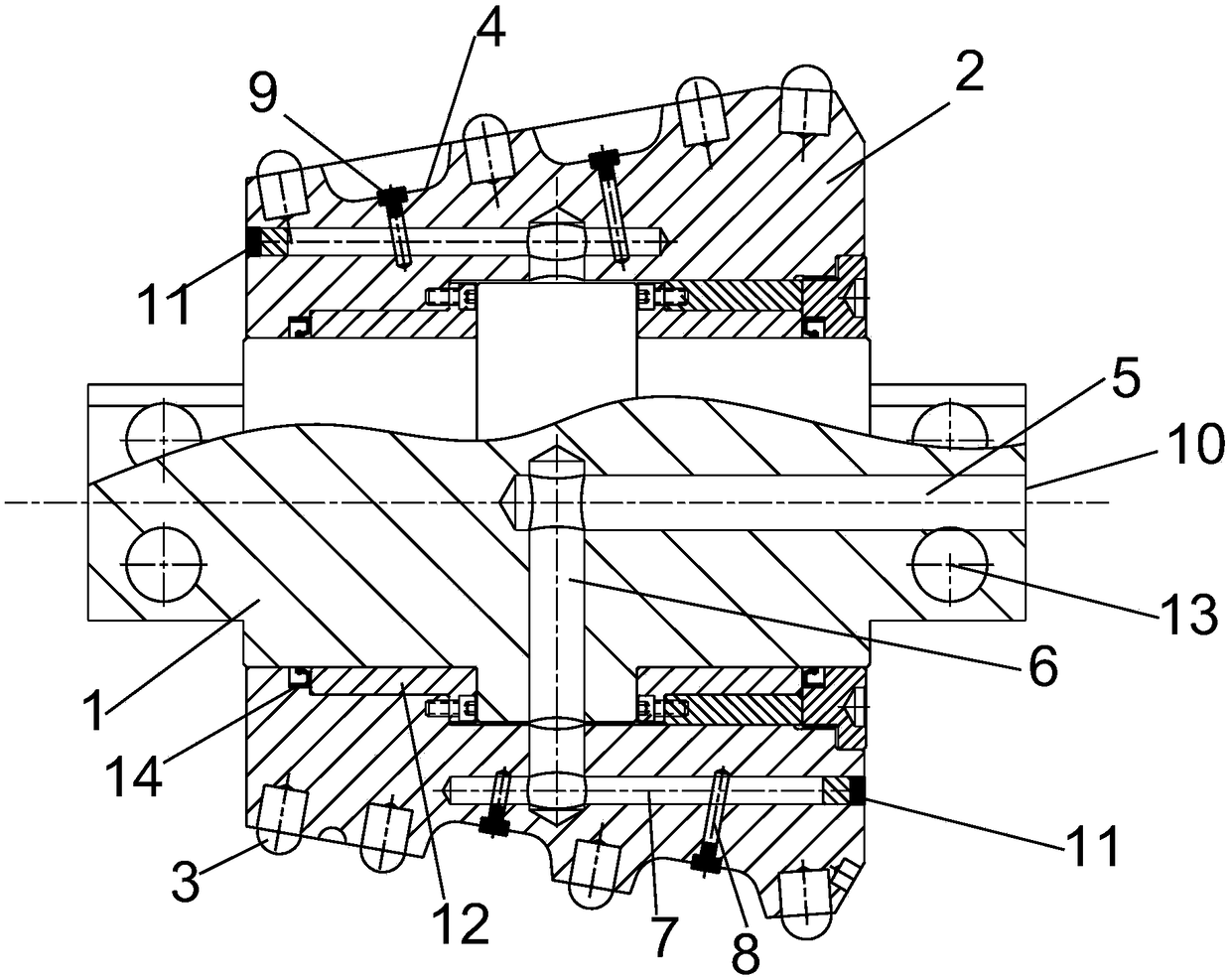

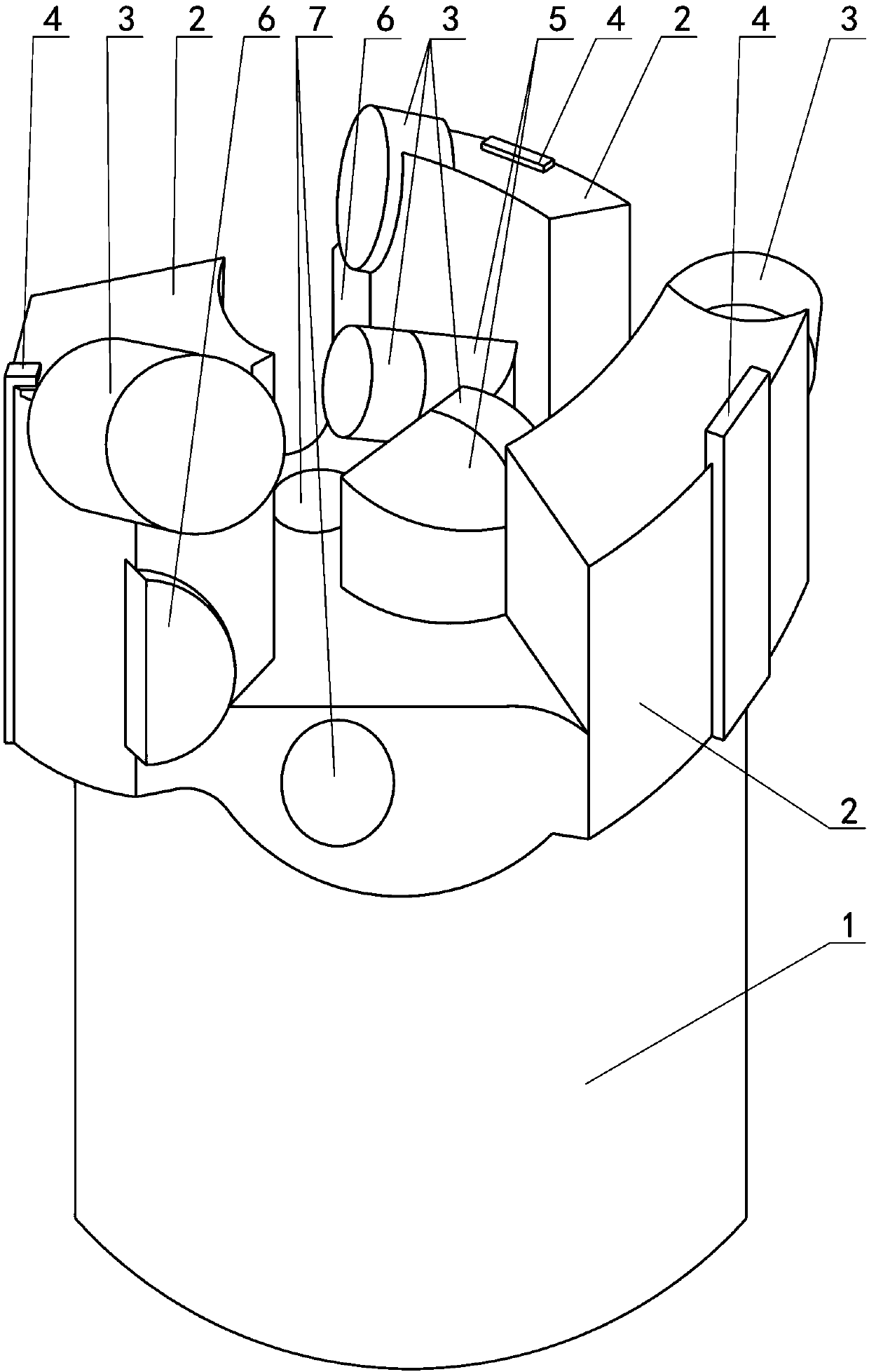

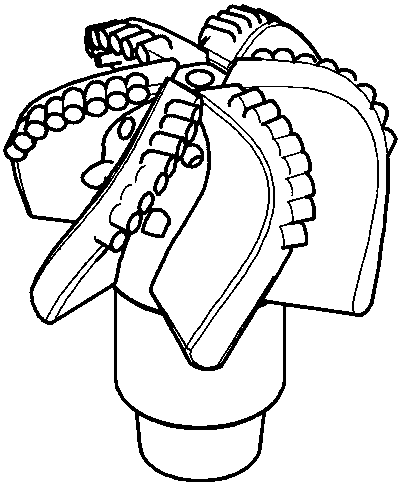

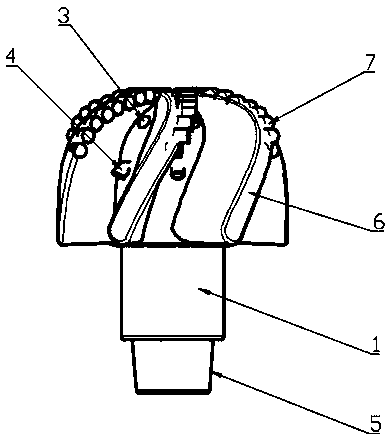

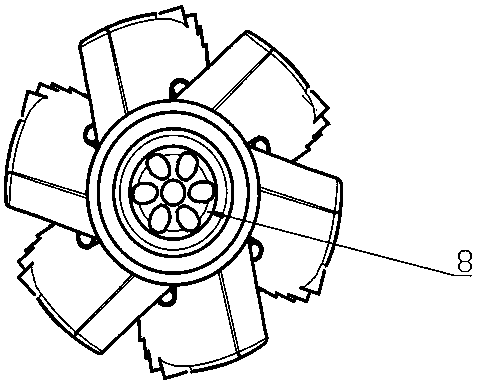

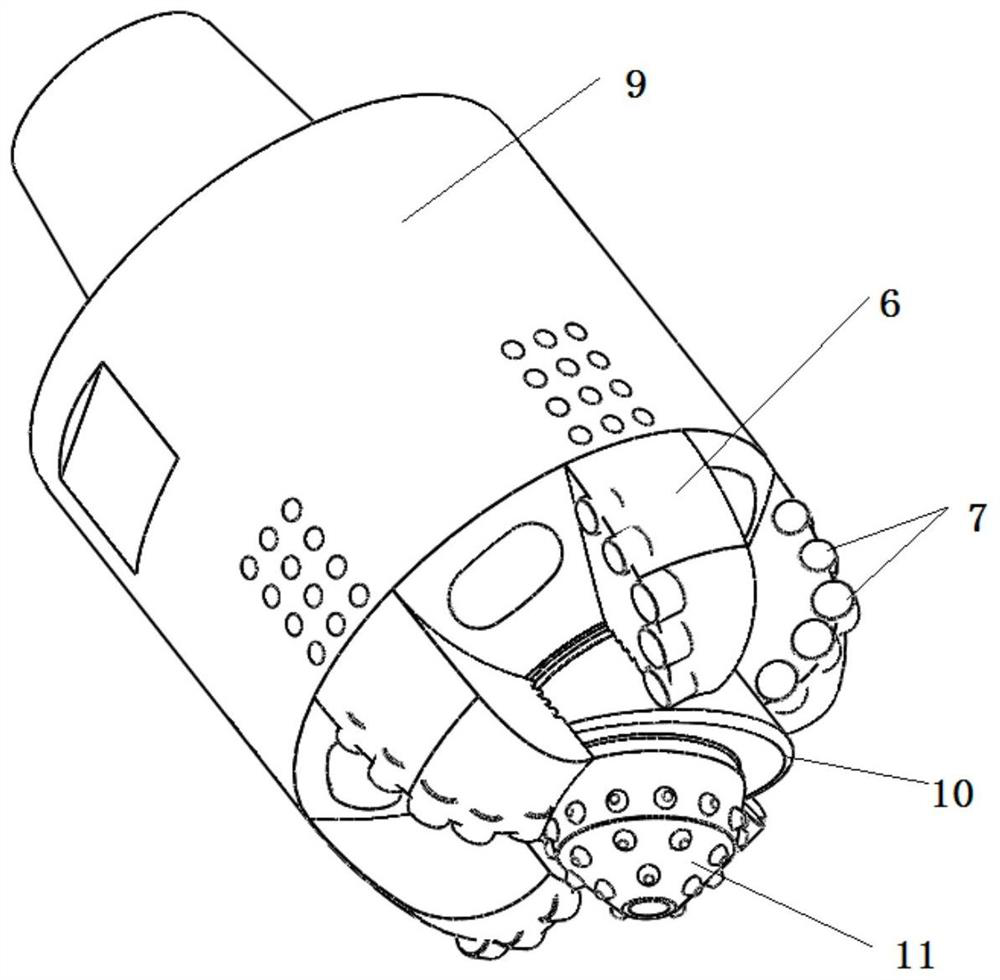

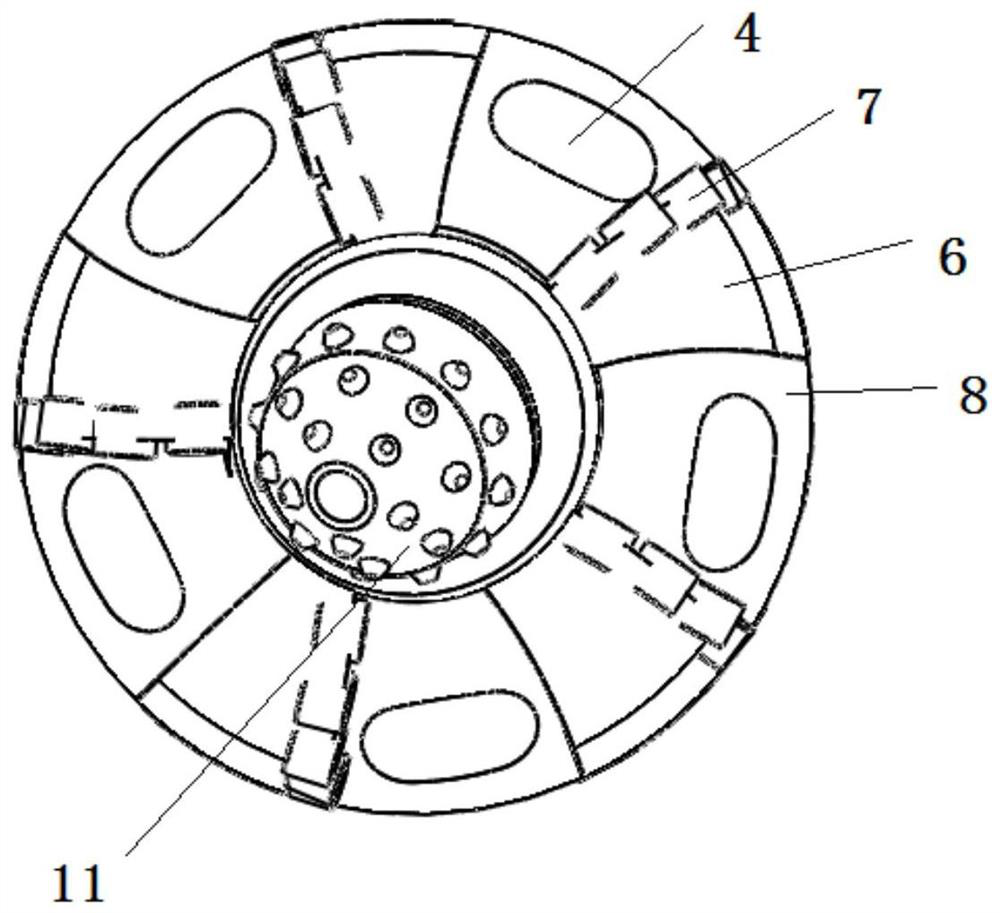

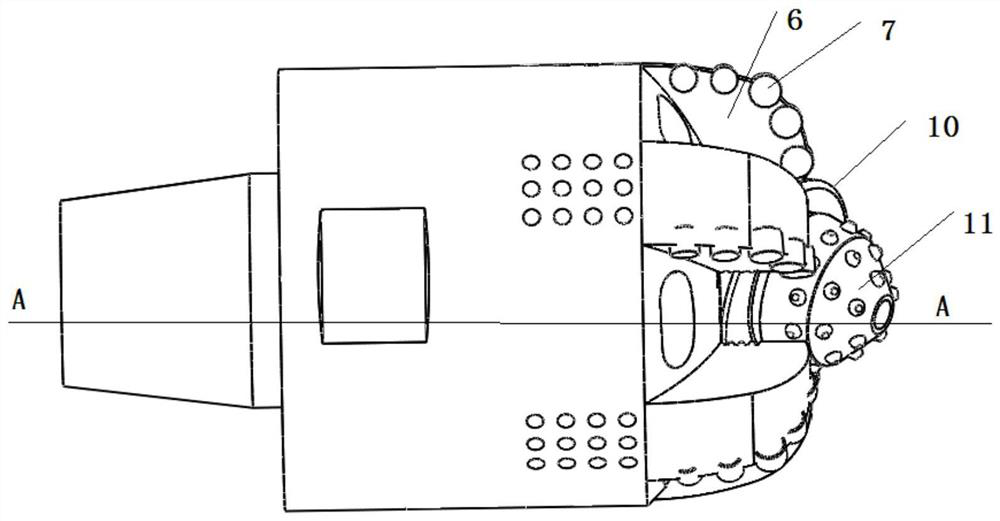

PDC and mono-cone composite inner chip removal drill bit

ActiveCN111894464AIncrease drilling speedOvercome the defect of low rock breaking efficiencyDrill bitsConstructionsWell drillingMechanical engineering

The invention relates to the technical field of drilling tools, in particular to a PDC and mono-cone composite inner chip removal drill bit. The inner chip removal drill bit comprises a mono-cone bitand a PDC drill bit with a main body, a main flow channel and an inner chip removal channel are formed in the height direction of the main body, the inner chip removal channel comprises a first flow channel body, a second flow channel body and an upper flow channel body extending downwards from the top face of the main body, the first flow channel body extends downwards to the main flow channel from the upper flow channel body and is arranged to be capable of reversely discharging initial drilling fluid of the main flow channel to form reverse pressure difference, the second flow channel bodyextends downwards to the bottom face of the main body from the upper flow channel body and is arranged to be capable of extracting chip-carrying drilling fluid on the bottom face of the main body under the pressure difference effect of the first flow channel body, and the mono-cone drill bit is mounted at the bottom of the main flow channel and is arranged to be capable of breaking rocks togetherwith the PDC drill bit. The PDC and mono-cone composite inner chip removal drill bit is jointly formed by the mono-cone bit and the PDC drill bit, so that the PDC drill bit and the mono-cone bit conduct rock breaking operation at the same time, and the operation efficiency of well drilling is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Laser drill bit with negative pressure suction function

InactiveCN111535748AImprove rock breaking efficiencyExtended service lifeDrill bitsConstructionsRock cuttingEngineering

The invention discloses a laser drill bit with a negative pressure suction function. The laser drill bit comprises a drill bit body, wherein a laser system and a fluid circulation system are arrangedin the drill bit body; the drill bit body is provided with a plurality of blades; each cutting removal groove is formed between the corresponding two adjacent blades; the cutting removal grooves are provided with laser outlets, water holes and water draining openings; the laser outlets communicate with the laser system; the water holes and the water draining openings communicate with the fluid circulation system; each of the laser outlets and the corresponding water hole are separately positioned on the corresponding two adjacent cutting removal grooves; and the water draining openings are positioned on the blades. Lasers carried by the drill bit are utilized to irradiate rock and weaken the strength of the rock so as to generate micro cracks on the rock, so that rock breaking by mechanical rotation of cutting teeth of the drill bit is easier and quicker. The laser drill bit has the negative pressure suction function, thereby facilitating the timely transport of broken rock cuttings atthe bottom of a well, avoiding repeated breaking, providing a clean bottom-hole environment for laser irradiation, and achieving the effects of improving the rock breaking efficiency of the drill bitand prolonging the service life of the drill bit.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

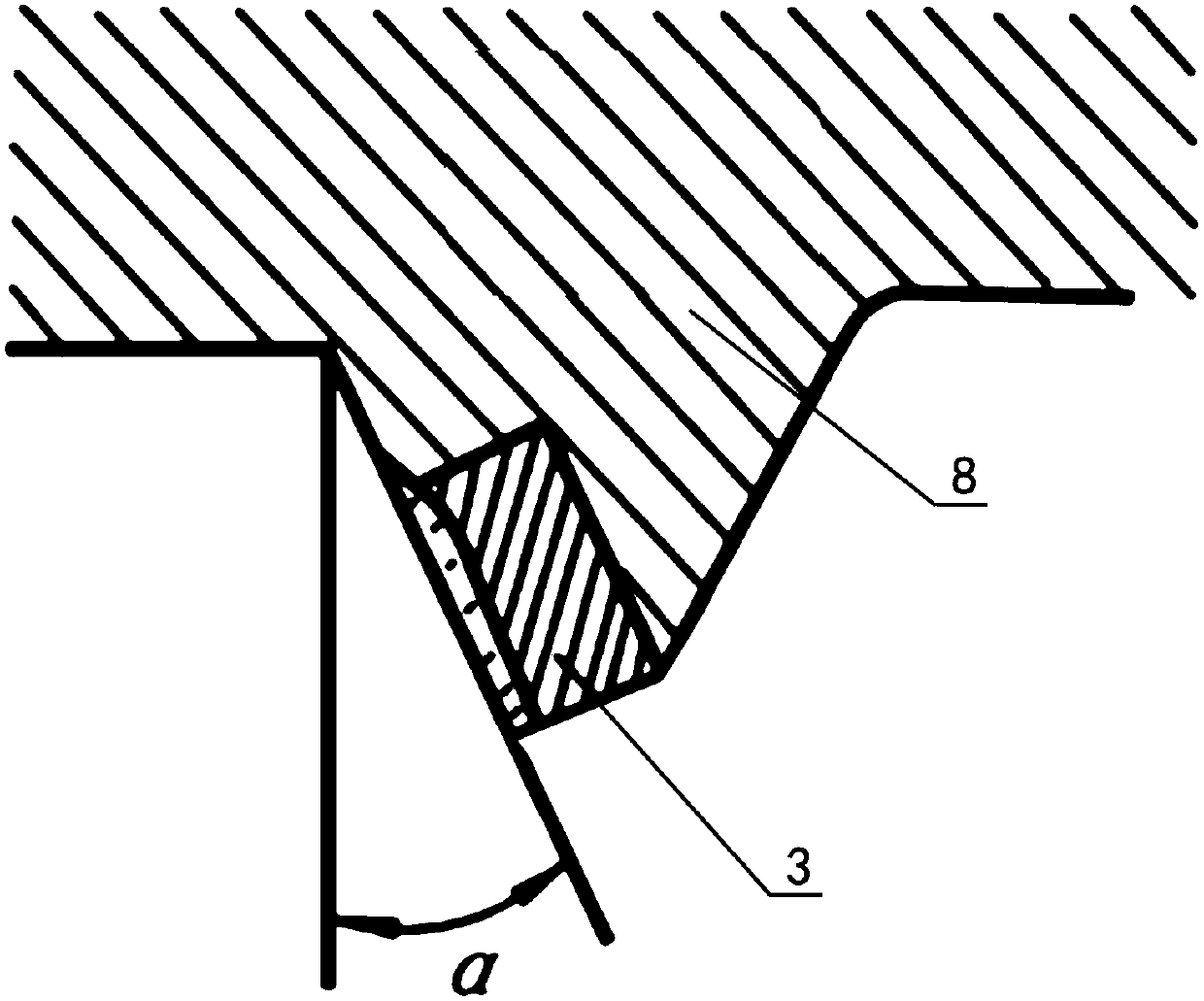

Raise boring machine inserted tooth hob with hydraulic rock breaking function

ActiveCN109488211AAccurate locationExtended service lifeDrill bitsConstructionsSpray nozzleStructural engineering

The invention discloses a raise boring machine inserted tooth hob with a hydraulic rock breaking function, which comprises a hob shaft, a hob shell, rock breaking inserted teeth, a waterway system anda bearing. The hob shell is fixedly connected with the hob shaft through the bearing; the rock breaking inserted teeth are arranged on the outer side wall of the hob shell; and the waterway system isarranged inner parts of the hob shaft and hob shell. An A hob shell structure form and a B hob shell structure form are designed in the hob, nozzle grooves of the A hob shell structure form and B hobshell structure form and the rock breaking inserted teeth are arranged in a staggered mode and are matched with each other, after the A hob (or the B hob) rock breaking inserted teeth are used for rolling and breaking a rock, the nozzle of the B hob (or the A hob) is used for performing hydraulic rock breaking to play a role in expanding initial cracks, and help rock blocks fall off and prevent the rock fragments from being repeatedly broken by the rock breaking inserted teeth; sprayed water can also accurately cool the rock breaking inserted teeth, and the service life of the rock breaking inserted teeth can be prolonged by more than 35%.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

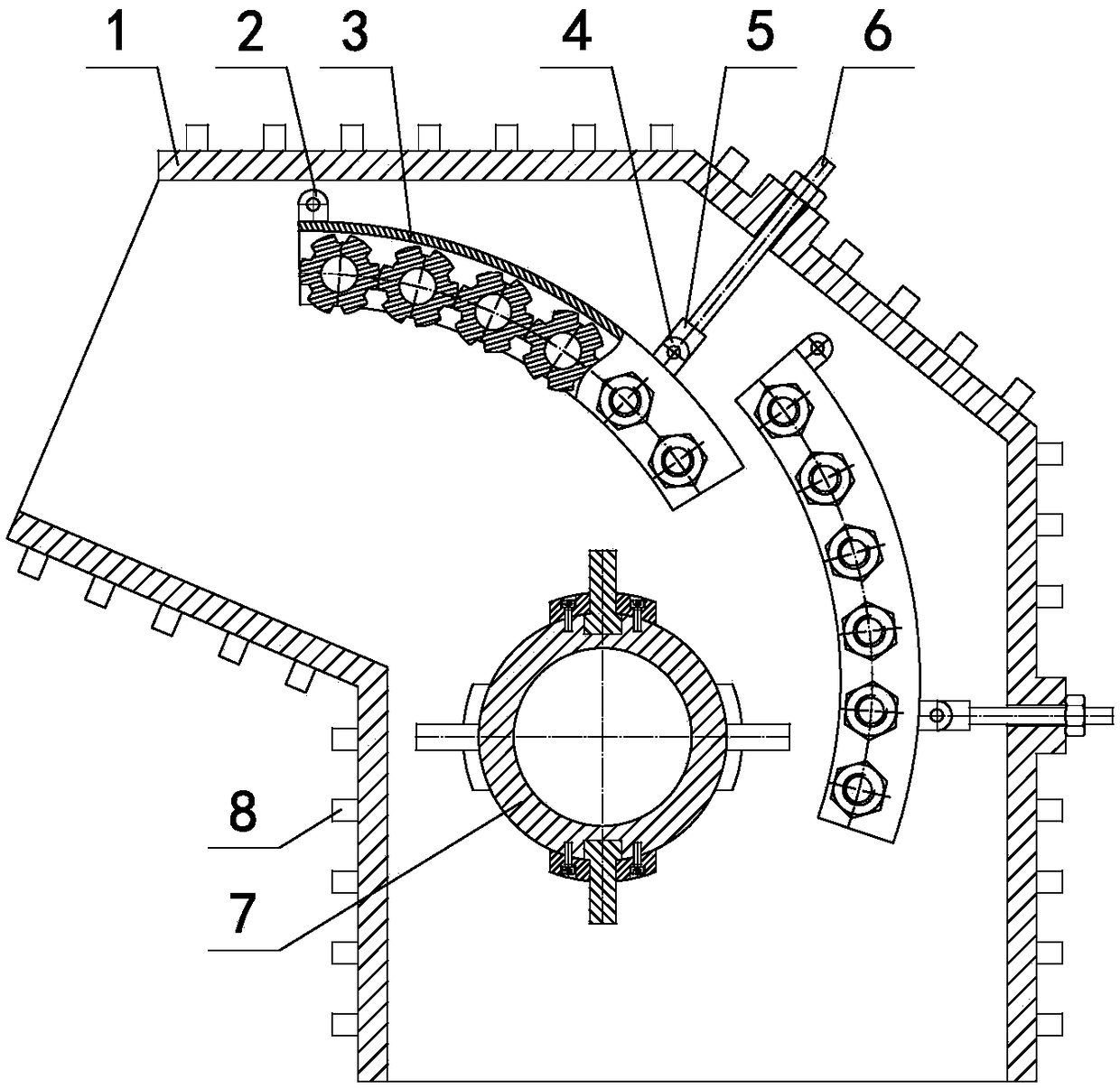

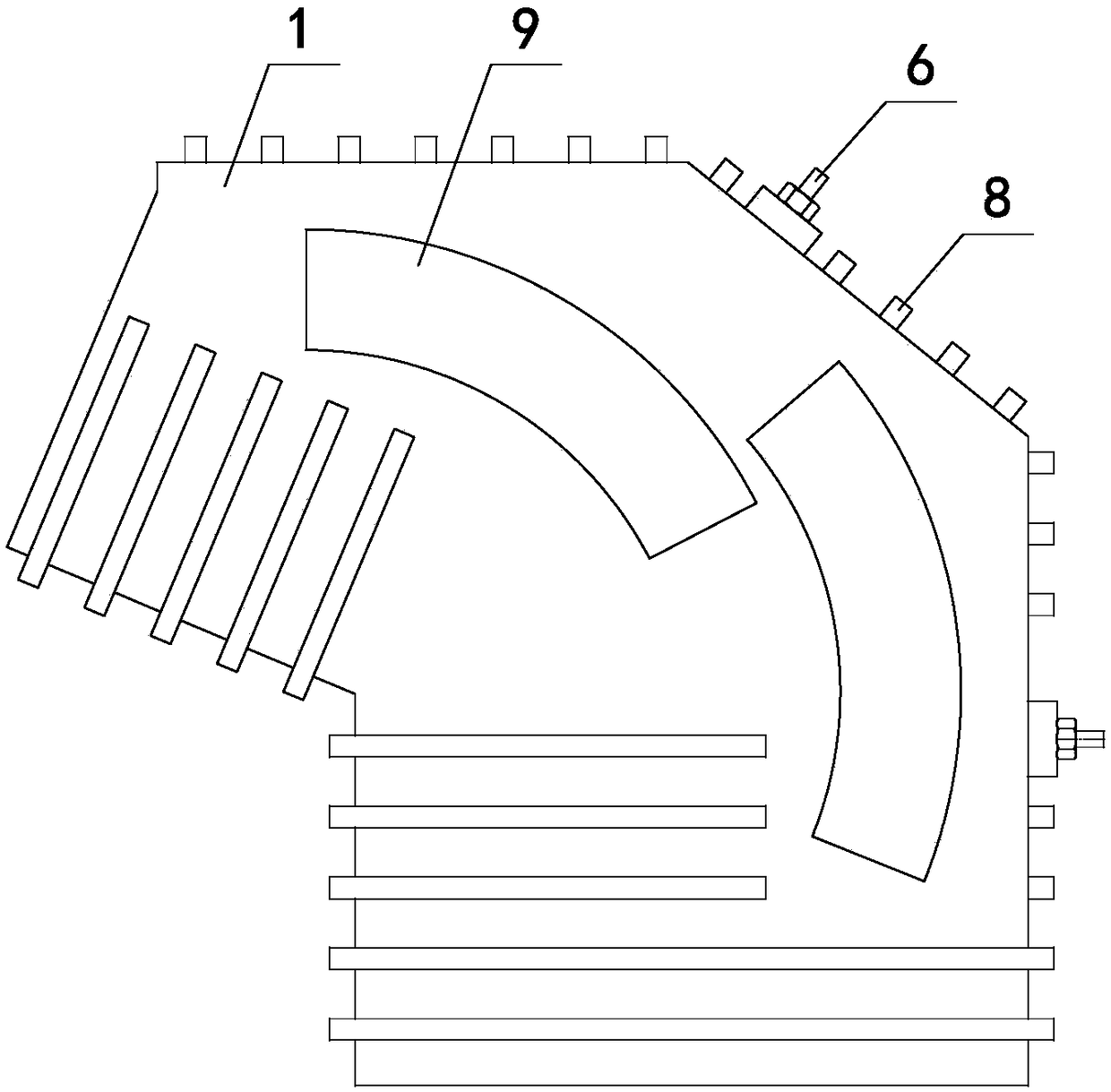

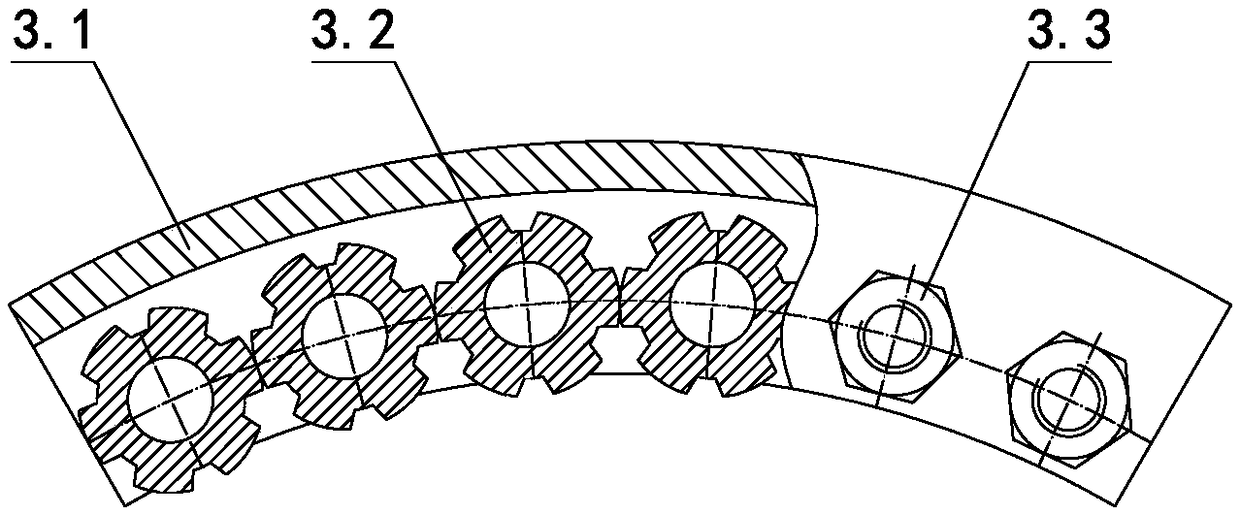

Efficient and durable impact crusher

InactiveCN109225461AAvoid Repeated FragmentationImprove crushing efficiencyGrain treatmentsEngineeringCrusher

The invention relates to an efficient and durable impact crusher. The efficient and durable impact crusher comprises a box, wherein impact frames are arranged in the box; the impact frames comprise arc-shaped cover plates; impact wheels are arranged in the arc-shaped cover plates; the impact wheels are arranged in the arc-shaped cover plates; the back sides of the arc-shaped cover plates are provided with first lug handles; the upper ends of the arc-shaped cover plates are hinged to the first lug handles; the back sides of the arc-shaped cover plates are provided with second lug handles; the second lug handles are hinged with mounting sleeves; lead screws are arranged on the box in an inserting manner corresponding to the mounting sleeves; the lead screws are arranged in the mounting sleeves; a crusher rotor is arranged in the box; the crusher rotor comprises a rotor barrel; the rotor barrel is provided with sinking grooves; plate hammers are arranged in the sinking grooves; the rotorbarrel on both sides of the plate hammers is provided with pressing plates; the plate hammers are fixed on the rotor barrel through the pressing plates; the left side and the right side of the rotor barrel are provided with connection plates; the outer sides of the connection plates are provided with rotating shafts; the rotating shafts are arranged on a front panel and a back panel of the box through bearings. By adopting the efficient and durable impact crusher, the crushing efficiency is improved.

Owner:重庆市江津区鼎涛汇丰矿山机械有限公司

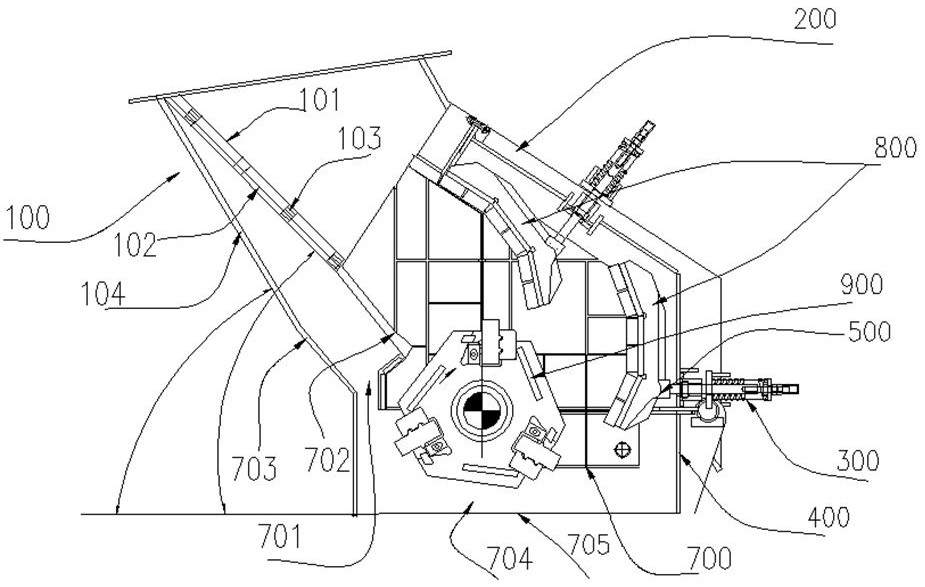

Impact crusher

PendingCN112808388AAvoid Repeated FragmentationIncrease average rateGrain treatmentsStructural engineeringCrusher

The invention discloses an impact crusher. The impact crusher comprises a lower shell, a rack, a transmission device, a rotor, an upper shell, an impact plate, an adjusting device and the like, wherein a pre-screening channel is formed in the lower shell, a pre-screening device is arranged at a feeding port formed by the upper shell and the lower shell and used for pre-screening materials at the feeding port, fine materials subjected to pre-screening enter the pre-screening channel and then are output through a discharging port. After the materials are sorted by the pre-screening device, fine materials enter the pre-screening channel and then are discharged out of the crusher, unqualified coarse materials fall into the rotor working area, the transmission device drives the rotor to rotate to hit the materials onto the impact plate to be subjected to impact crushing, and therefore the materials with qualified particle sizes are obtained. The particle size difference rate of output materials is reduced, the fine powder amount of finished product granules is reduced, the uniformity rate of the materials with the finished product particle size is improved, the beating frequency is reduced, and the efficiency is improved.

Owner:山东博研粉体技术装备有限公司

PDC drill bit capable of achieving fast drilling in soft and hard interbedded rock

The invention discloses a PDC drill bit capable of achieving fast drilling in soft and hard interbedded rock. The PDC drill bit comprises a drill bit body and a connector rigid body and is characterized in that three outer blades are evenly arranged on the outer periphery of the drill bit body, two central blades are arranged in the middle of the drill bit body, a cylindrical PDC is arranged on the upper portion of one side of each outer blade, a cylindrical PDC is arranged on the upper portion of one side of each central blade, the negative rake of each cylindrical PDC is 13-18 degrees, the bypass angle of each cylindrical PDC is 3-5 degrees, and the exposure height of each cylindrical PDC is 10.9-11.2mm. The PDC drill bit has the advantages that by designing the three high outer blades and the two low central blades, mounting the cylindrical PDC on each blade and optimally designing the negative rake, the bypass angle and the exposure height of each cylindrical PDC, the tooth breakage problem of the drill bit during cutting can be prevented, rock powder after cutting can be fast discharged out of the drill bit body, optimal drilling rate and optimal chip removing rate are achieved, the overall drilling speed of the PDC drill bit is increased evidently, and the service life of the drill bit is prolonged.

Owner:SINOHYDRO BEREAU 10 CO LTD

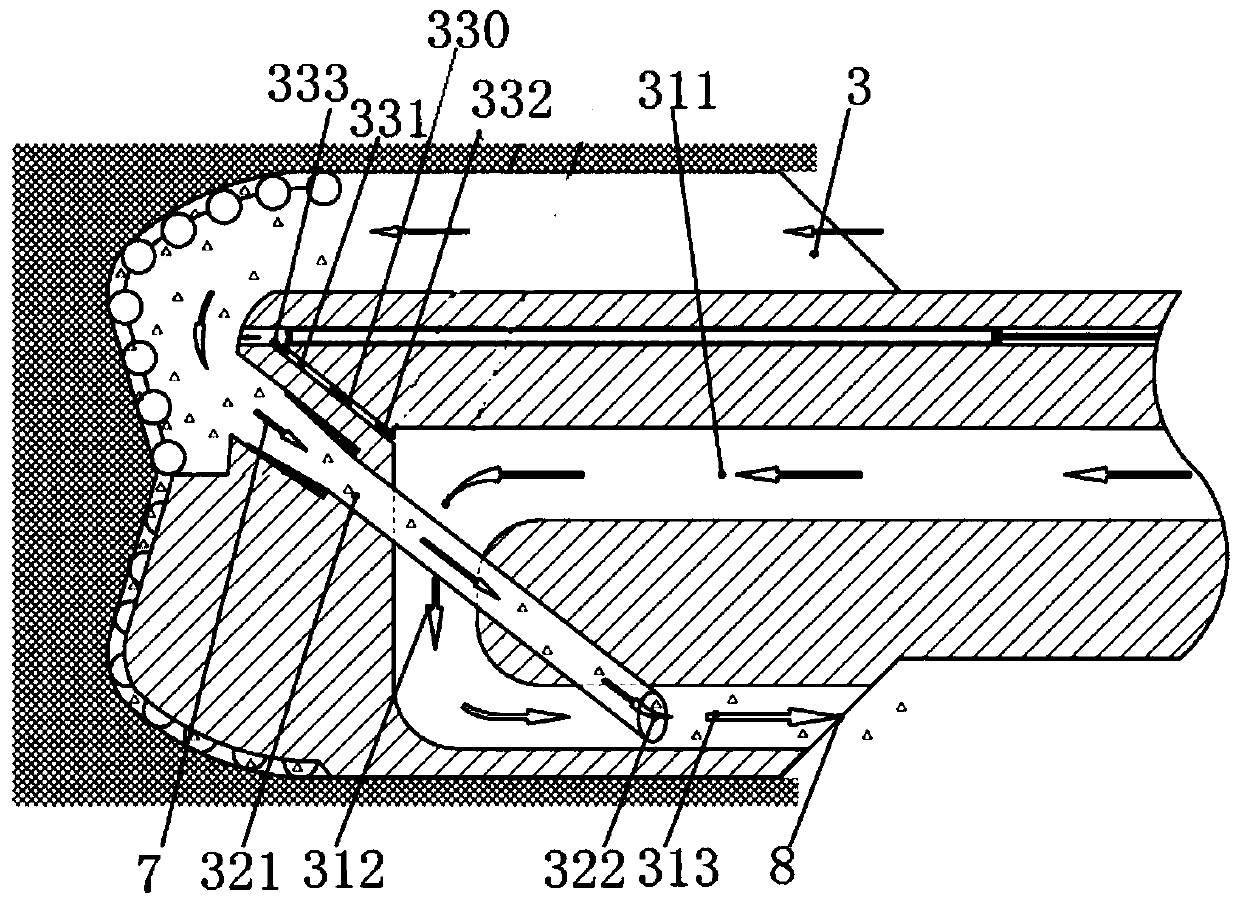

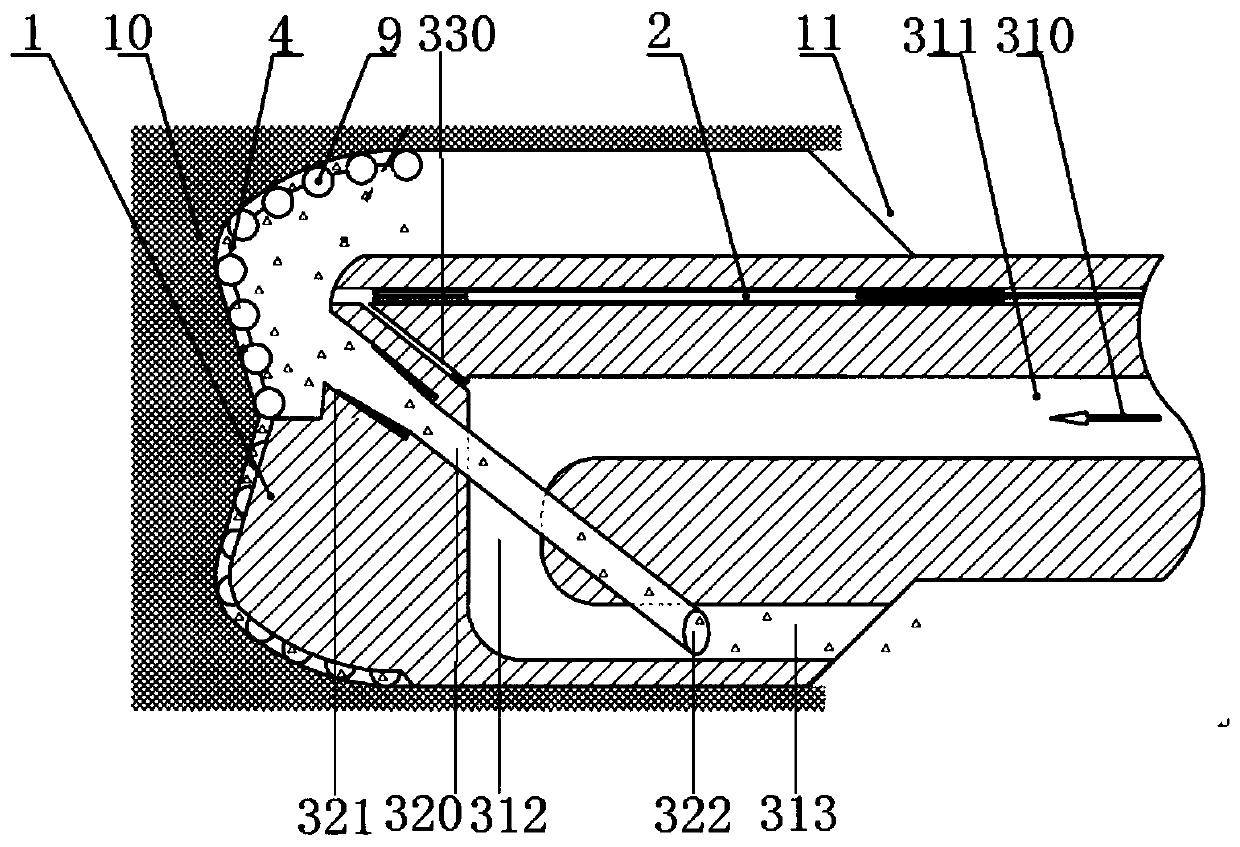

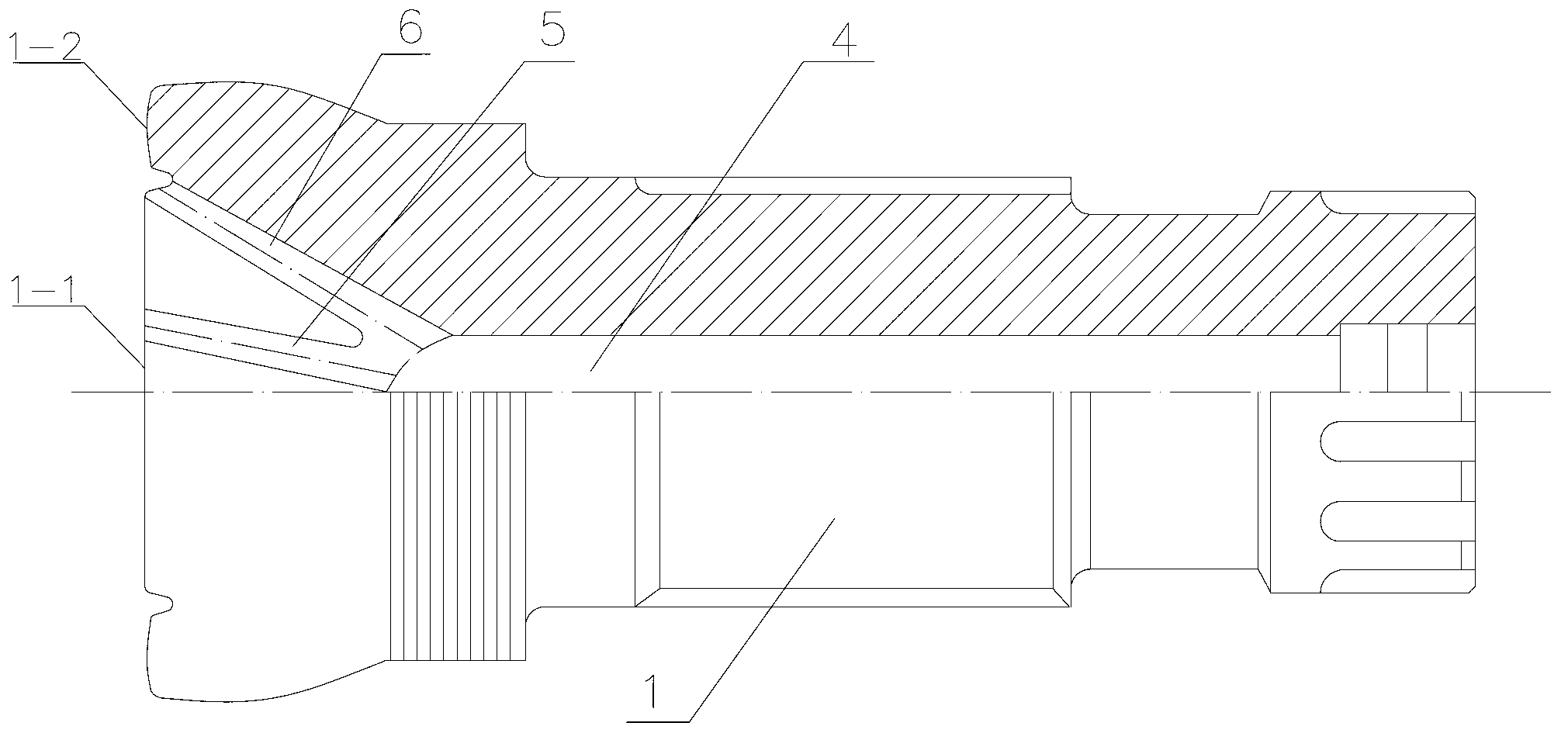

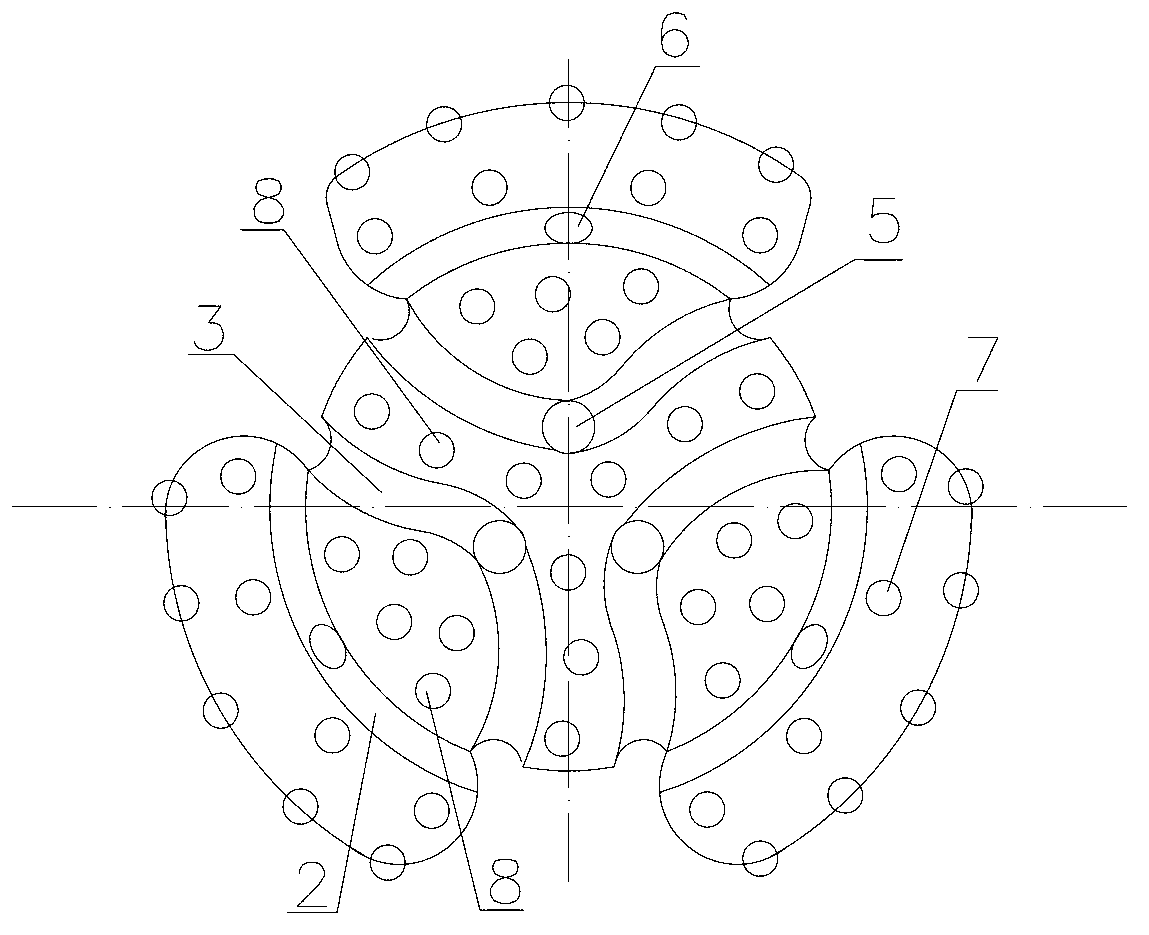

Hydraulic drive percussion primary-secondary drilling bit

ActiveCN103266854AAvoid Repeated FragmentationReduce swirl size and intensityDrill bitsPower toolEngineering

The invention relates to the technical field of underground power tools, particularly to a hydraulic drive percussion primary-secondary drilling bit. The hydraulic drive percussion primary-secondary drilling bit comprises a drilling bit body and teeth which are arranged on the end face of the drilling bit body; the end face of the drilling bit body is in a ladder separation type; an orthographic projection is in a three-plate fan blade type; the end face comprises the end face of a central circle which is in an integral structure and fan-blade-shaped three end faces; the fan-blade-shaped three end faces are uniformly distributed on an external ring of the end face of the central circle; an arc-shaped chip removal groove is formed in the root portion of every fan-blade-shaped end face; the three arc-shaped chip removal grooves are closely attached to the external ring of the end face of the central ring; three bidirectional arc chip removal grooves which are in mutual non-intersection are uniformly formed inside the end face of the central circle; the three bidirectional arc chip removal grooves are corresponding to the three arc-shaped chip removal grooves one to one; and arc-shaped openings of the bidirectional arc chip removal grooves are opposite to arc-shaped openings of the arc chip removal grooves. The hydraulic drive percussion primary-secondary drilling bit has the advantages of enabling rock debris to be convenient to enter into flow channels, enabling repeat crush to be avoided, reducing rate of the rock debris returning to the bottom of a well, preventing fall off of edge teeth and improving rock cleaning efficiency and service life.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

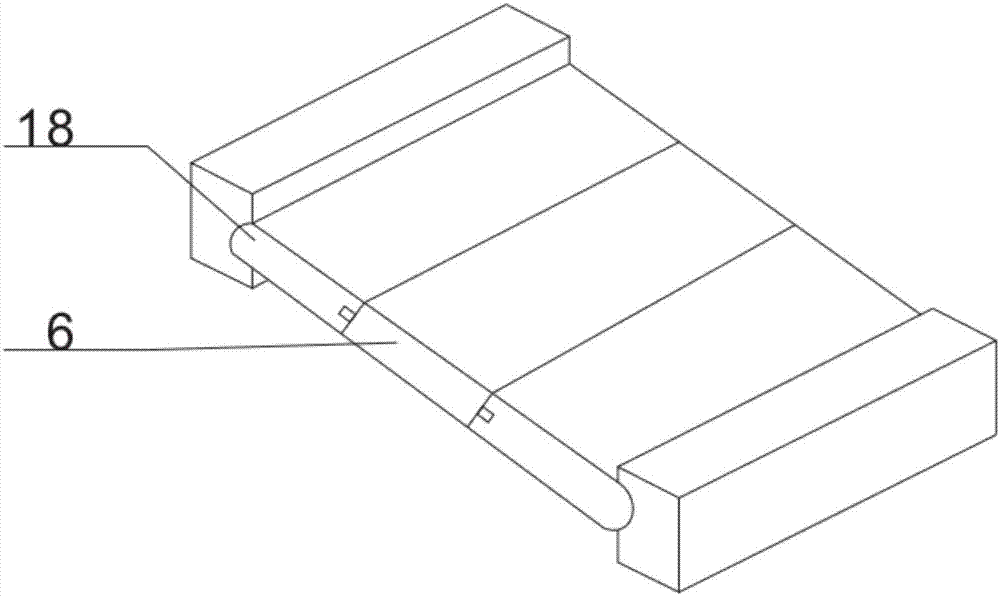

Knee plate of jaw crusher

The invention provides a knee plate of a jaw crusher. The jaw crusher comprises a rack, an upper protecting plate, a lower protecting plate, a fixed jaw assembly, a movable jaw assembly, an eccentricwheel, the knee plate, an adjusting seat and a spring pull rod. The lower end of the fixed jaw assembly is connected with the spring pull rod; the spring pull rod is backwards connected to the rack through a spring; a fixed jaw plate is arranged on the fixed jaw assembly, and a movable jaw plate is arranged on the movable jaw assembly; a buffer structure is arranged between the fixed jaw plate andthe fixed jaw assembly, and a buffer structure is arranged between the movable jaw plate and the movable jaw assembly; a plurality of teeth are parallelly arranged on the fixed jaw plate and the movable jaw plate correspondingly; a screening device is further arranged above the movable jaw assembly and the fixed jaw assembly; the lower end of the movable jaw assembly is connected with the front end of the knee plate, and the rear end of the knee plate is connected with the adjusting seat; the adjusting seat is connected to a rack; abrasion resistant bodies are arranged at the two ends of theknee plate; and the knee plate and the abrasion resistant bodies are fixedly connected, and the ends, away from the knee plate, of the abrasion resistant bodies are in circular arc shapes. The knee plate of the jaw crusher is convenient to use, easy to machine, uniform in crushing, high in crushing efficiency, low in cost, resistant to abrasion and long in service life.

Owner:张家港明惠金属制品有限公司

Plasma pulse rock breaking pile machine

PendingCN112240164ARealize the positive cycleImprove drilling efficiencyEarth drilling toolsThermal drillingClassical mechanicsHigh voltage pulse

The invention discloses a plasma pulse rock breaking pile machine, and relates to the technical field of pile foundation construction. The plasma pulse rock breaking pile machine comprises a pulse discharging mechanism, a circulating mechanism and a drill bit connected with the pulse discharging mechanism, wherein the pulse discharging mechanism outputs high-voltage pulses to the drill bit to enable the drill bit to generate high-voltage arcs, and the circulating mechanism is used for conveying electrolyte to the drill bit and pumping mud generated by drilling out of a pile foundation. The plasma pulse rock breaking pile machine is based on a plasma rock breaking technology, rock breaking is achieved through arc energy through cooperation of the pulse discharging mechanism and the drill bit, and compared with mechanical rock breaking in the prior art, the plasma pulse rock breaking pile machine is simple in structure, capable of achieving the purpose of rapid pile driving and hole forming, and has the advantages of being small in mechanical abrasion, high in working efficiency, and adaptive to rock strata with different hardness.

Owner:BEIJING SANY INTELLIGENT MFG TECH CO LTD

Speed-increasing drilling bit for downhole local pressure reducing

PendingCN107842316ARelieve pressureImprove cutting efficiencyDrill bitsConstructionsDiamond cuttingThermodynamics

The invention belongs to the technical field of drilling tool equipment, and specifically discloses a speed-increasing drilling bit for downhole local pressure reducing. The speed-increasing drillingbit comprises an alloy steel core, and a plurality of cutter blades are evenly distributed on the alloy steel core; the cutter blades are each in a turbine blade shape, and the top ends of the cutterblades are converged in the center line of the alloy steel core; the cutter blades are provided with diamond cutting teeth; and the number of the cutter blades is 5-9, and the cutter blades and the alloy steel core are of an integrated structure. The speed-increasing drilling bit for downhole local pressure reducing can effectively improve the drilling speed and has good stability.

Owner:邓立宇

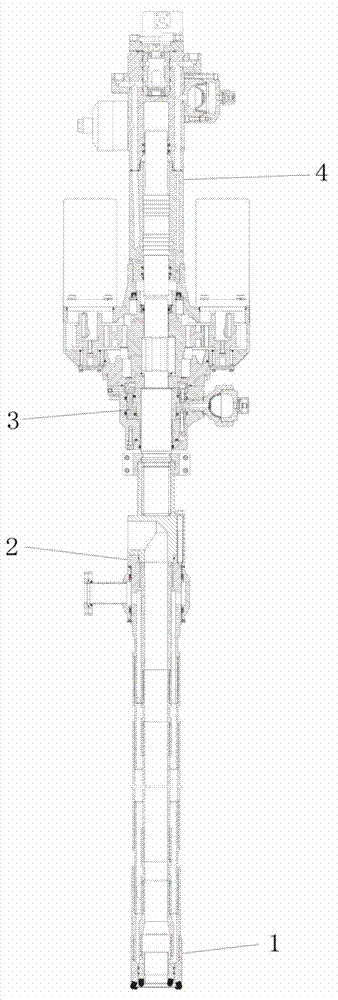

A hydraulic impact rotary reverse circulation drilling device

The invention belongs to the field of drilling equipment and particularly relates to a hydraulic percussion rotary reverse circulation drilling device. The hydraulic percussion rotary reverse circulation drilling device comprises a reverse circulation drill bit, a reverse circulation faucet, a power head and a hydro-percussive hammer and is characterized in that the lower end of a drill bit body in the reverse circulation drill bit and the lower end of a casing shoe are sealed through a seal ring, a flow guide sleeve is fixedly connected onto the inside of the lower end of the drill bit body, the upper surface of the flow guide sleeve is higher than a through hole, the water inlet in the reverse circulation faucet is formed in one side of a water jacket and penetrates a sleeve joint to be communicated with a high-pressure circulating water channel, the water jacket is sleeved outside the sleeve joint and is fixed through a snap spring, a seal ring is arranged between the sleeve joint and the water jacket, a deslagging opening is formed in one side of a percussion rotary joint and is communicated with a magma reverse central channel, a hydraulic motor of the hydro-percussive hammer is fixed on a mounting base and is connected with a reversing valve core, the mounting base is fixed on a rear shell and the upper end of a reversing valve sleeve, and the reversing valve sleeve is arranged inside the rear shell and sleeved outside the reversing valve core. The hydraulic percussion rotary reverse circulation drilling device can be used for performing efficient construction in water-free gravel-cobble stratums.

Owner:卓尔天成工程机械有限公司

Treatment device and treatment method for civil engineering construction waste

ActiveCN114210707AIncrease the number ofImprove centralized processing efficiencyCombination devicesConstruction waste recoveryConstruction engineeringMetal impurities

The invention belongs to the field of environment-friendly machinery, and relates to a civil engineering construction waste treatment device which is characterized in that the output end of a universal pulverizer is used for putting construction waste, the output end of the universal pulverizer is in butt joint with the input end of a magnetic separation conveyor, and the magnetic separation conveyor is used for removing metal impurities in construction materials subjected to primary crushing; and the output end of the magnetic separation conveyor is arranged to the input end of the crushing and filtering device, and the crushing and filtering device is used for filtering the building materials subjected to primary crushing and re-crushing the large building materials. The device can be used for treating the building waste on a large scale, and is particularly suitable for factory use. The invention further provides a civil engineering construction waste treatment method.

Owner:BAICHENG NORMAL COLLEGE

Reverse circulation construction technique and apparatus of single rope impact drill

InactiveCN101275458BRotation does not generateAvoid entanglementConstructionsReciprocating drilling machinesSlag (welding)Pipe

The invention discloses a process and a device for the reverse circulation execution of a single rope impact drill, the reverse circulation execution device comprises a percussion drill, a slurry pumping pipe at the hole bottom and a slurry purifier at the hole mouth, the drill bit is composed of a drill bit body and a cutting blade, the drill bit body is composed of a hammer body, corner boardsand a base, the upper end of the hammer body is provided with a connecting hold connected with a non-rotating rope, the corner boards are distributed in the same angle axially on the cylindrical or circular-tube-shaped hammer body, the base is composed of coaxial inner base and outer base, which are tube-shaped, the upper surfaces of the two base are in the same plane, the inner base is higher than the outer base, the lower ends of the corner boards are connected with the two bases, the hammer body, the corner plate and the base are integrated by welding, casting or riveting, the lower end ofthe base is evenly equipped with multiple cutting blades; pile types of various section shapes can be dilled by the drill bit, the reverse circulation process of hole bottom slag pumping is used whendrilling, the execution process is fastened, the energy consumption is reduced, the slag is cleaned completely and clearly, the time for cleaning the hole is shortened.

Owner:张安禄

Internal chip removal drill combined with pdc and single cone

ActiveCN111894464BIncrease drilling speedOvercome the defect of low rock breaking efficiencyDrill bitsConstructionsEngineeringHydrology

The invention relates to the technical field of drilling tools, in particular to an internal chip removal drill bit combined with a PDC and a single cone. The internal chip removal drill bit includes a single cone bit and a PDC drill bit with a main body. The height direction of the main body has a main flow channel and an inner chip removal channel. The inner chip removal channel includes a first flow channel, a second flow channel and a top of the main body. Facing the downwardly extending upper flow channel, the first flow channel extends downward from the upper flow channel to the main channel and is set to reversely discharge the initial drilling fluid in the main channel to form a reverse pressure difference, and the second flow channel extends from the upper flow channel to the main channel. Extending down to the bottom surface of the main body and set to be able to extract the cuttings-carrying drilling fluid at the bottom surface of the main body under the pressure difference of the first flow channel, the single-cone bit is installed at the bottom of the main flow channel and is set to be able to break rock together with the PDC bit . The PDC and single-cone composite internal chip removal bit is jointly formed by the single-cone bit and the PDC bit, so that the PDC bit and the single-cone bit simultaneously break rocks and improve drilling efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com