A hydraulic impact rotary reverse circulation drilling device

A hydraulic impact and drilling device technology, which is applied to the driving device of rotary combined drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of small impact frequency adjustment range, low drilling efficiency, and low drilling efficiency. Achieve the effect of high utilization rate of impact energy, avoid repeated crushing, and solve construction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

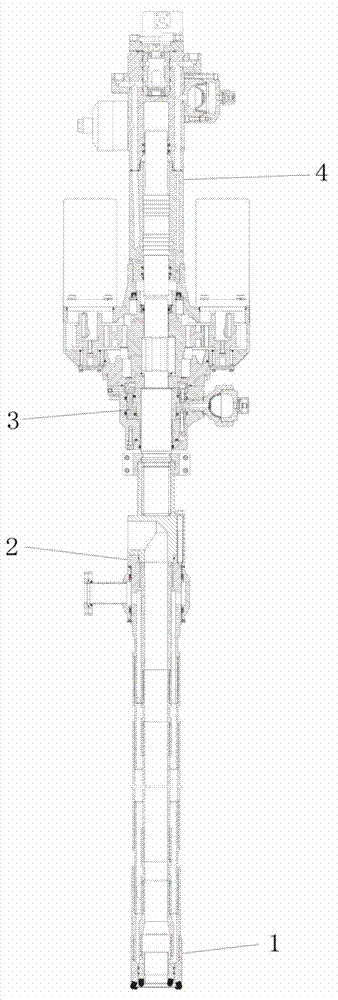

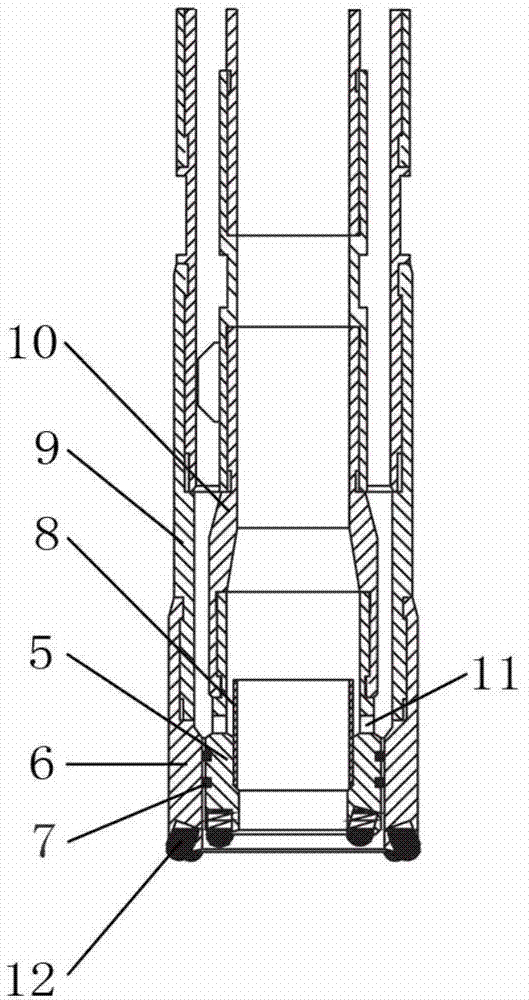

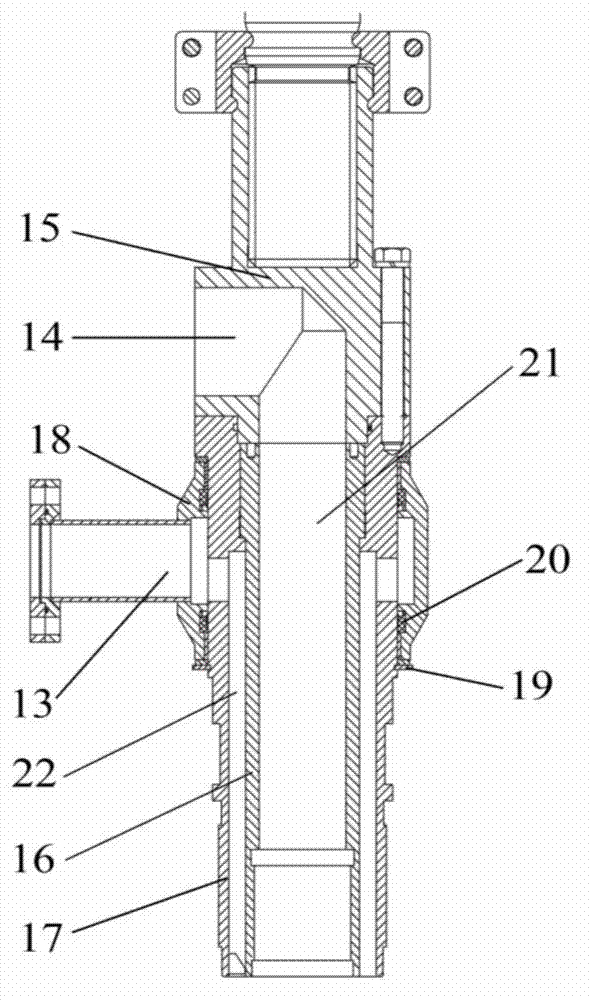

[0015] In the figure: 1-reverse circulation drill bit, 2-reverse circulation faucet, 3-power head, 4-hydraulic impactor, 5-drill bit body, 6-casing boot, 7-sealing ring, 8-guiding sleeve, 9 -transition joint, 10-flow diversion joint, 11-through hole, 12-ball finger alloy, 13-water inlet, 14-slag discharge port, 15-impact swivel joint, 16-drill pipe joint, 17-casing joint, 18-water jacket, 19-circlip, 20-sealing ring, 21-magma upward return center channel, 22-high pressure circulating water channel, 23-front shell, 24-rear shell, 25-impact piston, 26-storage Energy device, 27-oil pipe joint, 28-reversing valve core, 29-reversing valve sleeve, 30-hydraulic motor, 31-mounting seat.

[0016] Embodiment: The reverse circulation drill bit 1 is connected to the lower end of the reverse circulation faucet 2, the upper end of the reverse circulation faucet 2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com