Patents

Literature

528results about How to "Solve construction problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

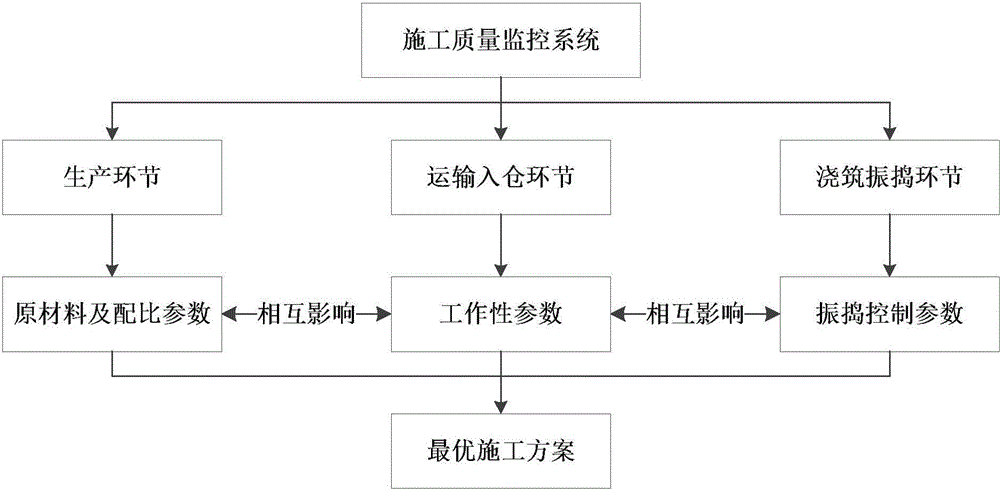

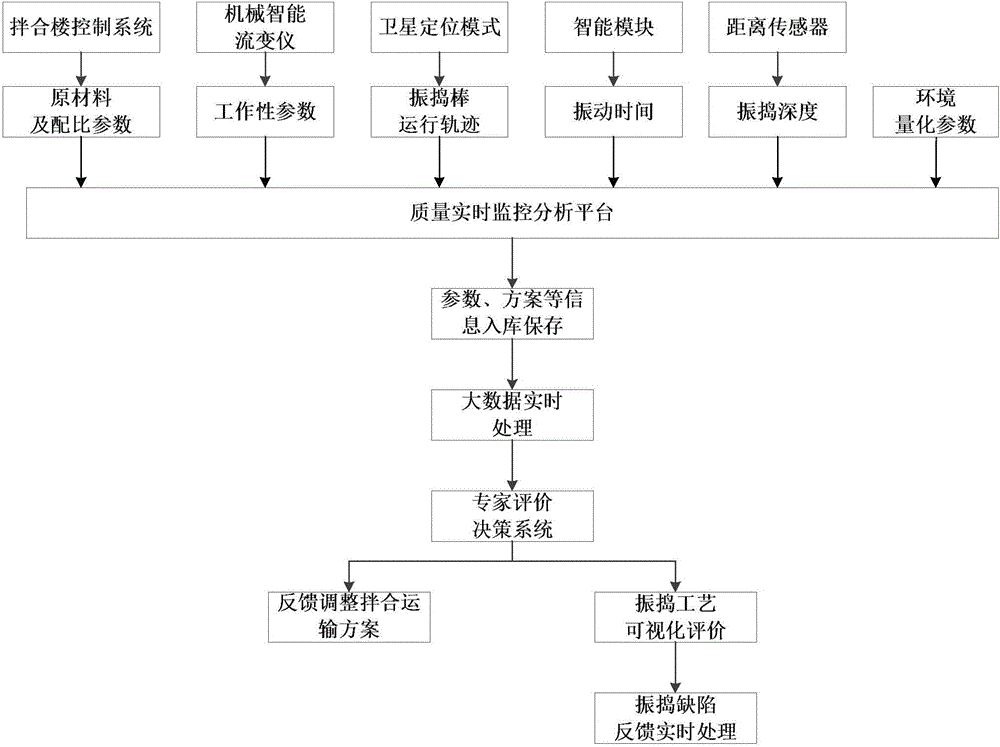

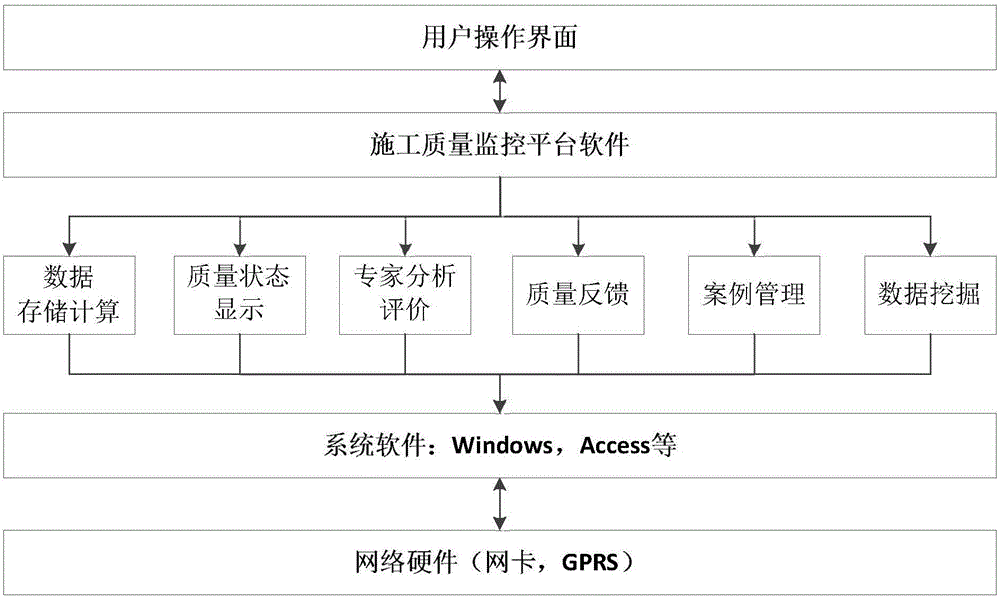

Concrete construction quality intelligent visualized monitoring system based on cloud technology platform

ActiveCN104898622AAutomatic and efficient storage and calculationImprove real-time performanceTotal factory controlProgramme total factory controlData informationMonitoring system

The invention discloses a concrete construction quality intelligent visualized monitoring system based on a cloud technology platform. Quality information parameters of each process of concrete construction production, transportation and pouring are acquired by the system via corresponding equipment and wirelessly transmitted to a quality real-time monitoring platform in a cloud-end server, the construction quality state of each technological link is analyzed through cloud storage, computing and display, and feedback regulation scheme information is timely transmitted to the related operators. The cloud technology is applied in the system so that a problem of insufficient local storage capability of wireless terminal equipment is solved and infinite data information can be processed within a few seconds. Besides, construction quality state information can be accessed, inquired and uploaded by all project participants so that interaction and sharing of the construction quality information can be realized and thus high-efficiency management and control of construction quality can be enhanced.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

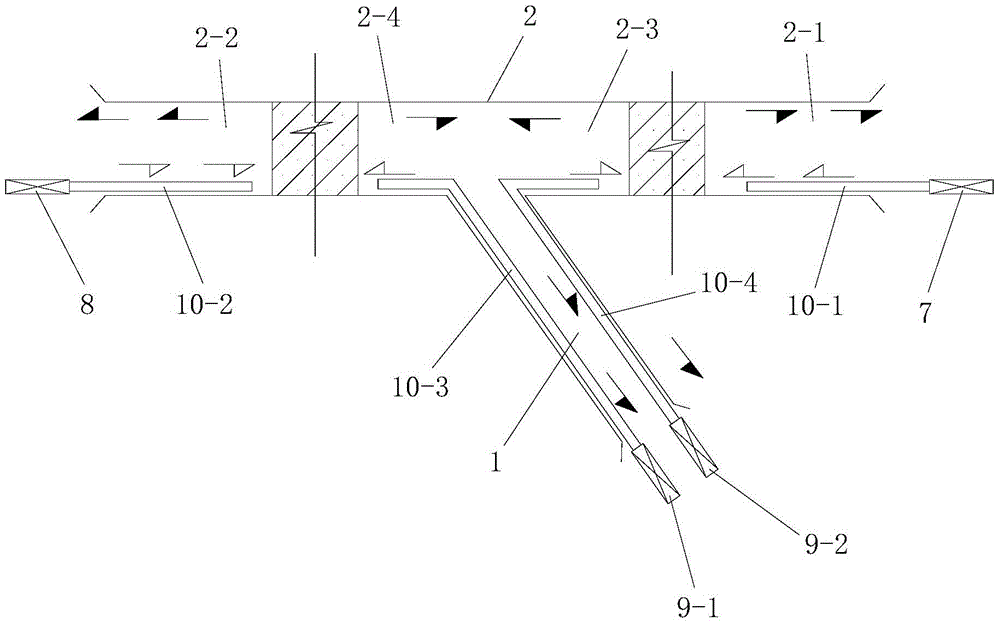

Method for constructing from inclined shaft to main tunnel in weak surrounding rock

ActiveCN101775988ASolve construction problemsThe schedule is smoothUnderground chambersTunnel liningContour lineSafety risk

The invention discloses a method for constructing from an inclined shaft to a main tunnel in weak surrounding rock, which is performed according to the following construction steps: 1) climbing at a gradient of 20 to 25 percent and expanding and excavating the inclined shaft at a position 8 to 12 meters away from a construction edge of the main tunnel, and expanding and excavating a curved roadway at a position 1 to 3m higher than a contour line of a main tunnel cross section wherein the climbing height from a starting point to an ending point is 1 to 3m; 2) installing a large arch supporting frame on the main tunnel cross section, cutting off side wall supporting legs of a small arch supporting frame, and overlapping the two supporting legs of the small arch supporting frame on the large arch supporting frame; 3) inserting a plurality of advanced small pipes into a rock strata transversely along the top of the large arch supporting frame and vertically excavating to three steps of preserved core soil of the main tunnel; and 4) excavating an upward arch at the bottom of the main tunnel because the other side of an intersection of the inclined shaft and the main tunnel is an end wall. The method solves the problem of difficult construction from the inclined shaft to the main tunnel in the weak surrounding rock or sites with complex geological condition changes, greatly reduces safety risks, and has obvious effects.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Full house decoration personalized customization method

ActiveCN103255884AAddressing Incompleteness RegretsScientific and efficient house decorationCovering/liningsThree-dimensional spaceDisplay device

The invention provides a full house decoration personalized customization method and relates to a decoration management method. At present, more and more conditions that home decoration is repeated and family resources are wasted appear. The full house decoration personalized customization method includes the following steps that 1) setting up a general database of decorating elements, 2) obtaining positions and areas of all functional areas, 3) setting up a plurality of sub-modules, 4) setting up a corresponding three-dimensional space model, and pending a database, 5) displaying the three-dimensional space model though a display, and automatically generating a new three-dimensional space model when a user selects elements of a replaceable module to replace elements of each standard module in the three-dimensional space model, 6) according to the three-dimensional model selected by the user, generating an implementation database and a price sheet, and enabling the construction side to conduct standard decoration construction according to the implementation database and the price sheet. According to the technical scheme, the full house decoration personalized customization method effectively improves design efficiency and prevents repeated labor. The design effect and the price are clear at a glance. The full house decoration personalized customization method improves decoration transparency and is convenient to supervise.

Owner:BEIJING JUST EASY BEST RESIDENTIAL FULL DECORATION

Steel trussed beam and flexible arch bridge construction method with vault pushing

ActiveCN102373671AEnsure driving safetySolve construction problemsBridge erection/assemblyControl systemConstruction engineering

The invention discloses a steel trussed beam and flexible arch construction method with vault pushing, which comprises the following steps of: building an assembly support in the side span of a steel trussed beam, assembling a guide beam and the steel trussed beam into an integral space on the assembly support, arranging a horizontal continuous jack and a mechanical, electrical and hydraulic control system on the assembly support, pushing the steel trussed beam forward by using the horizontal jack, and continuing next round of assembly work on the rear assembly support whenever one round is pushed forward. By using the steel trussed beam and flexible arch construction method with vault pushing provided by the invention, the steel trussed beam and the flexible arch are erected outside the operating limit of a highway, and the construction difficult across the highway is solved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

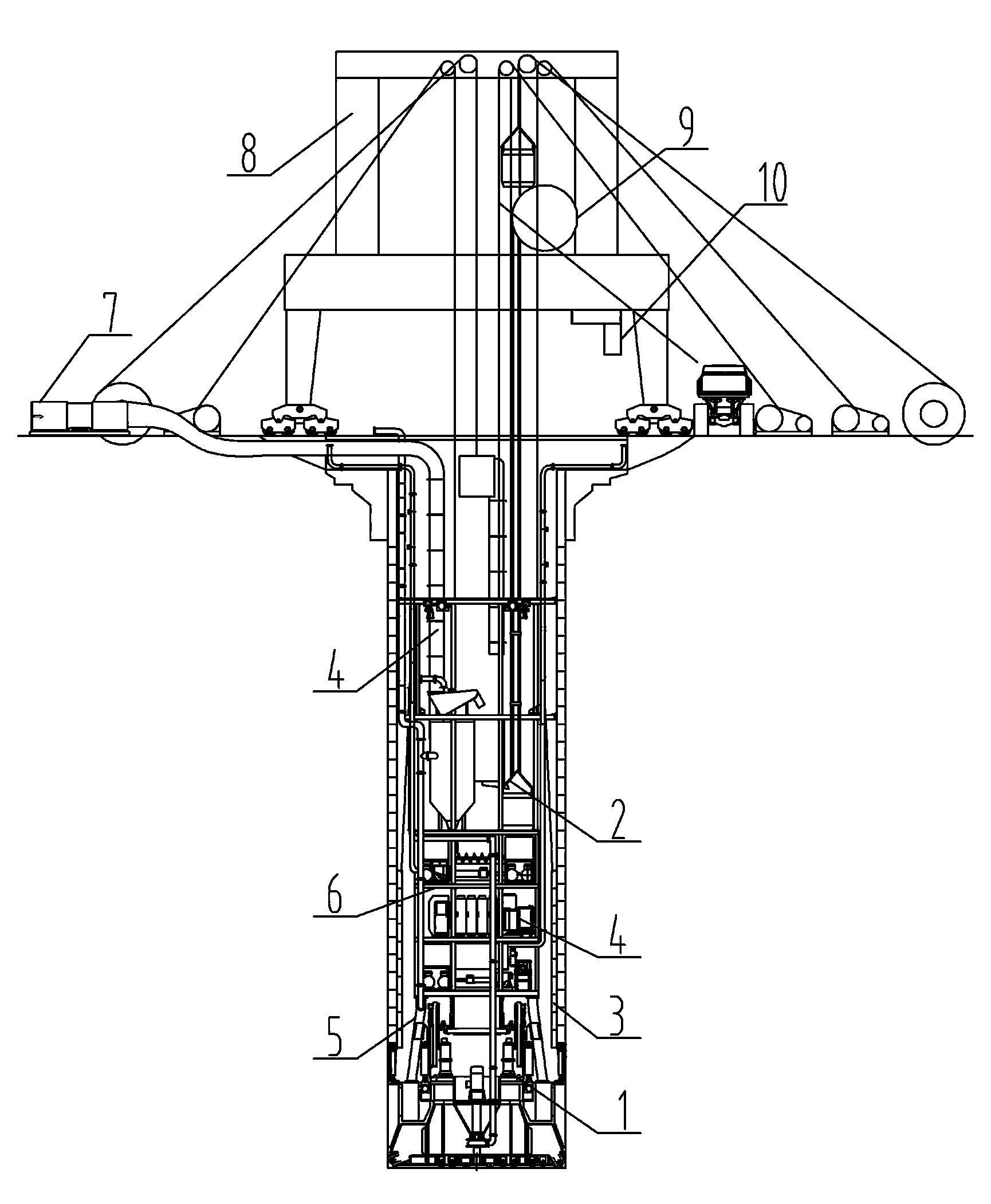

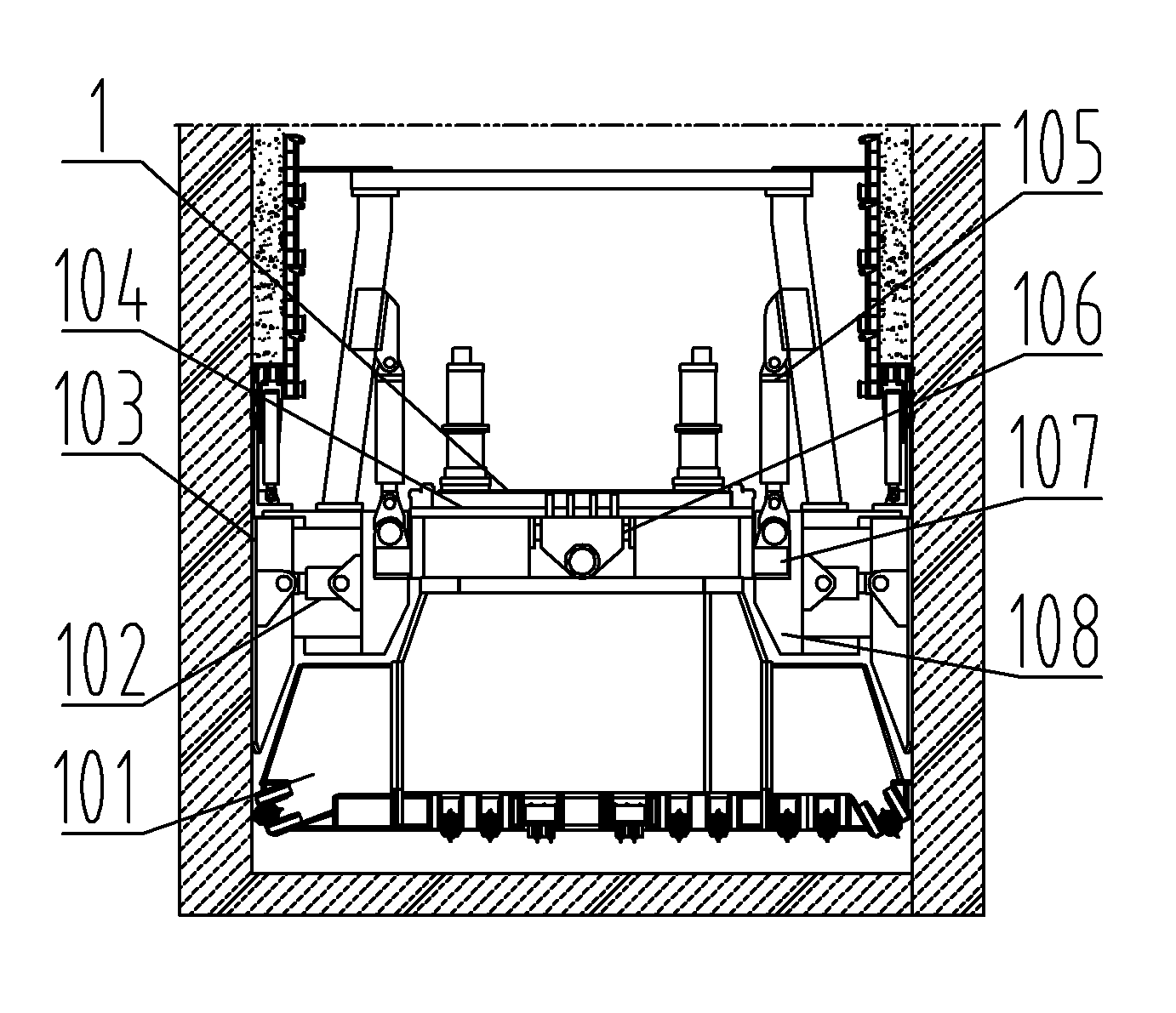

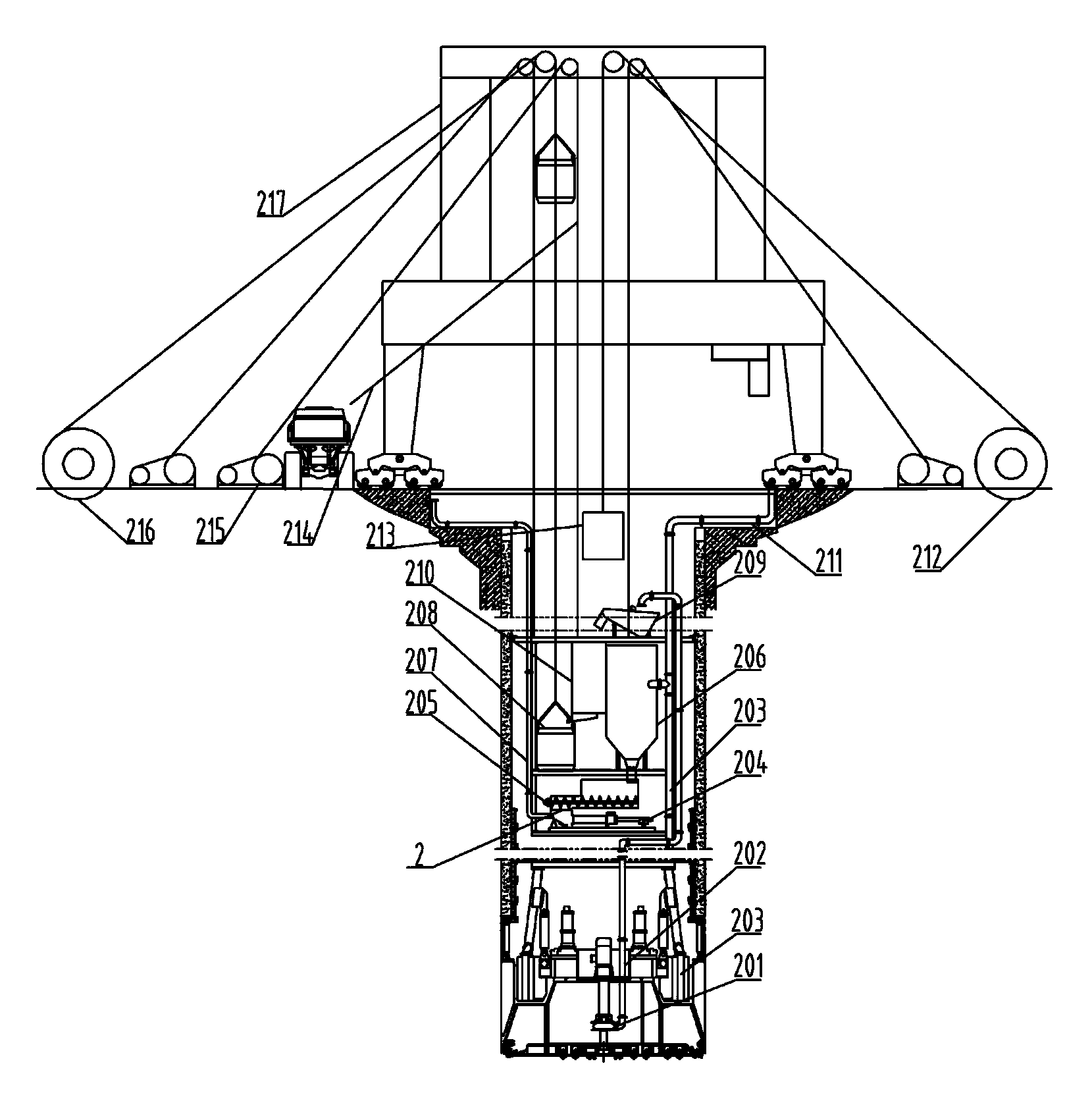

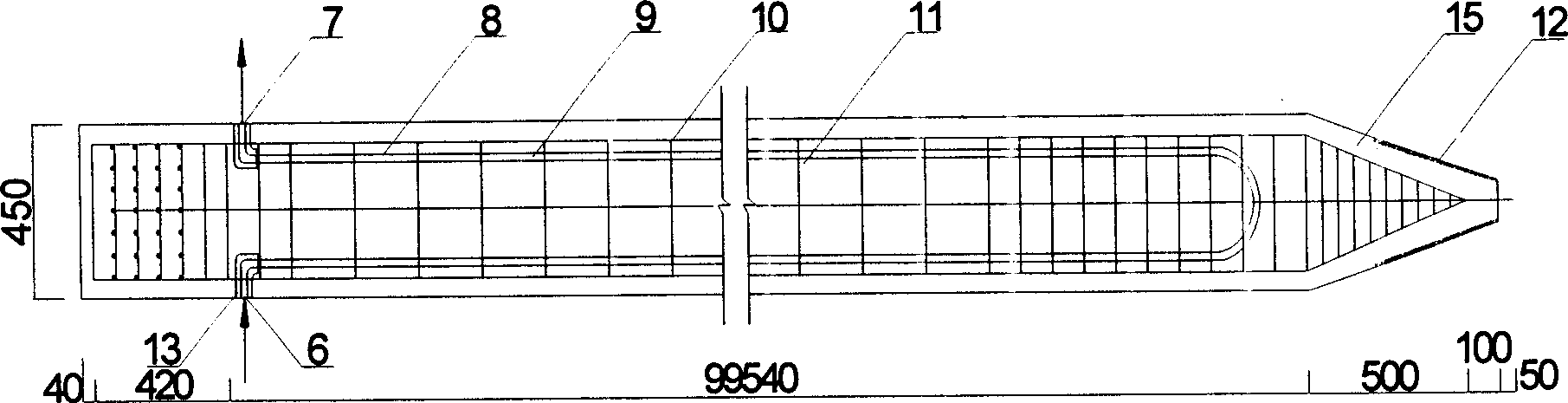

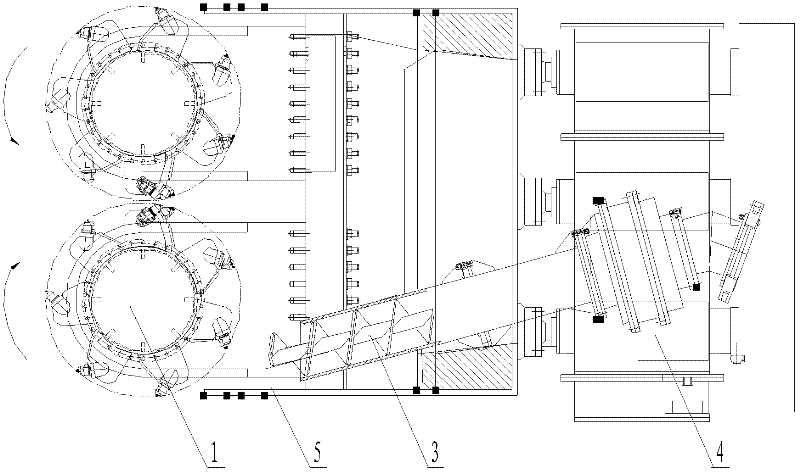

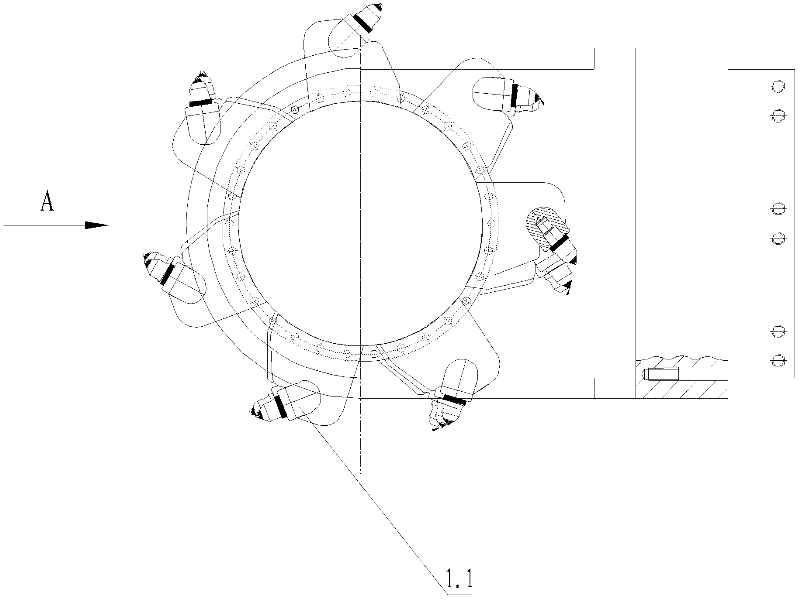

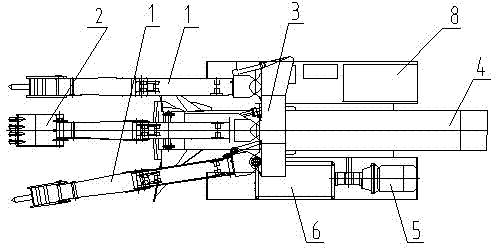

Full-fracture-surface vertical shaft drilling machine

ActiveCN103670420AEfficient constructionImprove construction efficiencyShaft sinkingShaft liningSlagControl engineering

The invention belongs to the technical field of mineral product machinery and discloses a full-fracture-surface vertical shaft drilling machine which comprises a device main girder, device platforms, a head frame, a tunneling system, a personnel and material conveying system, a shaft wall supporting and protecting system, a guaranteeing system and a manipulating chamber. The tunneling system is installed at the front end of the device main girder, the device platforms are installed at the rear end of the device main girder, the head frame is arranged on a shaft mouth, the manipulating chamber is arranged on the head frame, the personnel and material conveying system and the guaranteeing system are installed on the rear portion of the tunneling system, the shaft wall supporting and protecting system is arranged on the rear portion of the tunneling system and the periphery of the tunneling system, the personnel and material conveying system comprises a hoister, a first-level separation station, a slag storage cabin, a second-level separation station, a feeding mechanism and a conveying pump, the shaft wall supporting and protecting system comprises an auxiliary crane, a hoister, an underground concrete mixing tank, a concrete pump and an anchoring system, and the auxiliary crane, the hoister, the underground concrete mixing tank, the concrete pump and the anchoring system are installed on the device platforms respectively. The full-fracture-surface vertical shaft drilling machine solves the construction problems of large-scale vertical shafts such as coal mines, complete equipment of automation, mechanization and integration of the functions of shaft tunneling, slag tapping, supporting, protection, water discharging, ventilation and the like, the construction efficiency is improved, the construction cost is reduced, the construction safety is improved, and the application range is wide.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

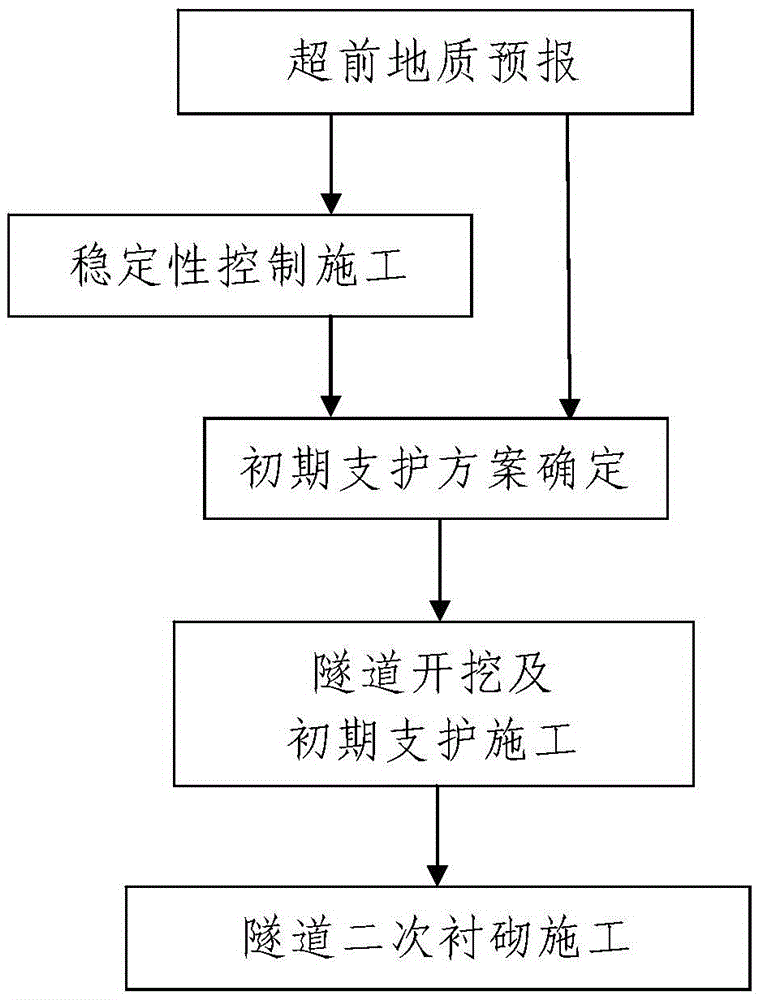

Water-rich weak surrounding rock long-and-big tunnel construction method

The invention discloses a water-rich weak surrounding rock long-and-big tunnel construction method. The method includes that a tunnel inclined shaft is arranged on one side of a main tunnel of a tunnel to be constructed, the main tunnel is divided into a tunnel entry section, a tunnel exit section and a middle connecting section connected between the tunnel entry section and the tunnel exit section, the middle connecting section is divided into an inclined shaft assisting construction entry section and an inclined shaft assisting construction exit section, and each of the tunnel entry section, the tunnel exit section, the inclined shaft assisting construction entry section and the inclined shaft assisting construction exit section is divided into multiple sections for construction. A construction method of each section includes: step 1, performing geological forecasting in advance, and when a debris flow formation exists ahead, entering a step 2, or else, entering a step 3; step 2, performing stability control construction; step 3, determining a primary supporting scheme; step 4, excavating the tunnel, and performing primary supporting construction; step 5, performing secondary lining construction on the tunnel. The water-rich weak surrounding rock long-big tunnel construction method is simple in step, reasonable in design, simple and convenient to construct, good in using effect, capable of meeting construction requirements of water-rich weak surrounding rock long-and-big tunnels, short in construction period and safe in construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

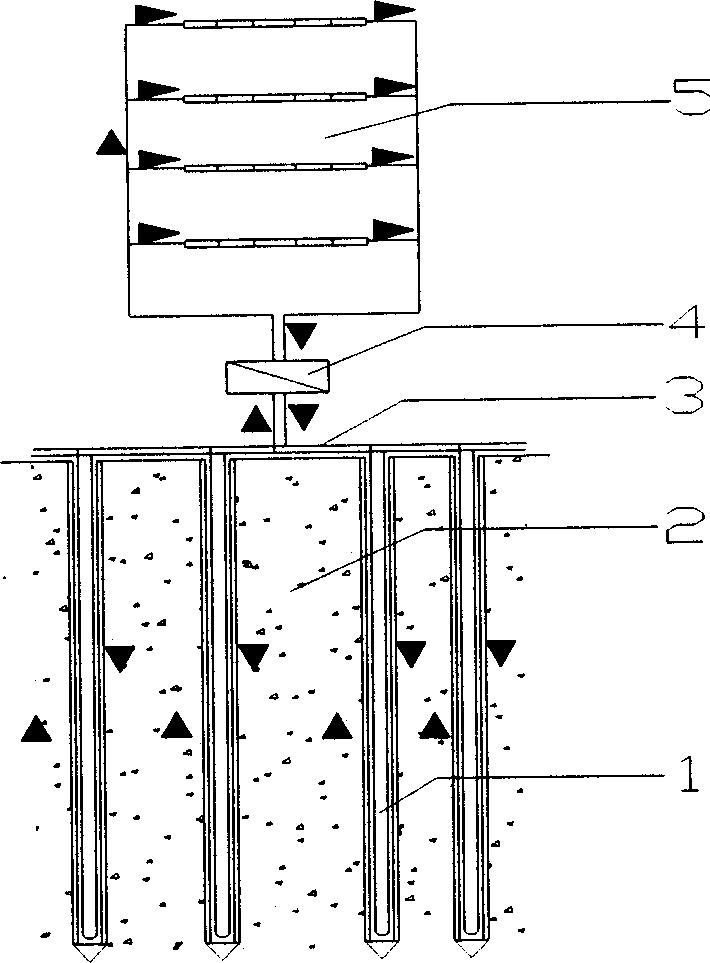

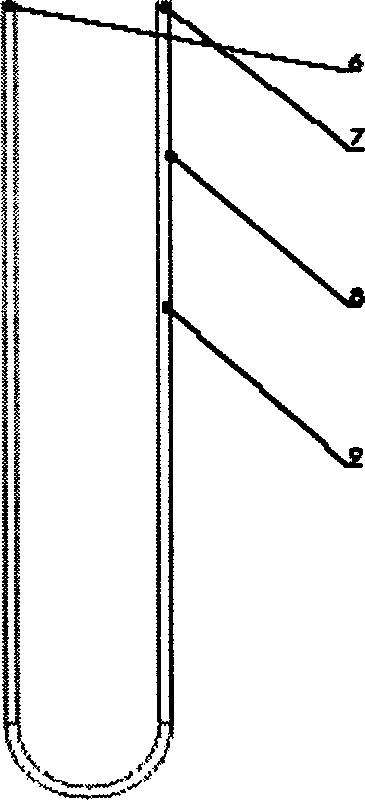

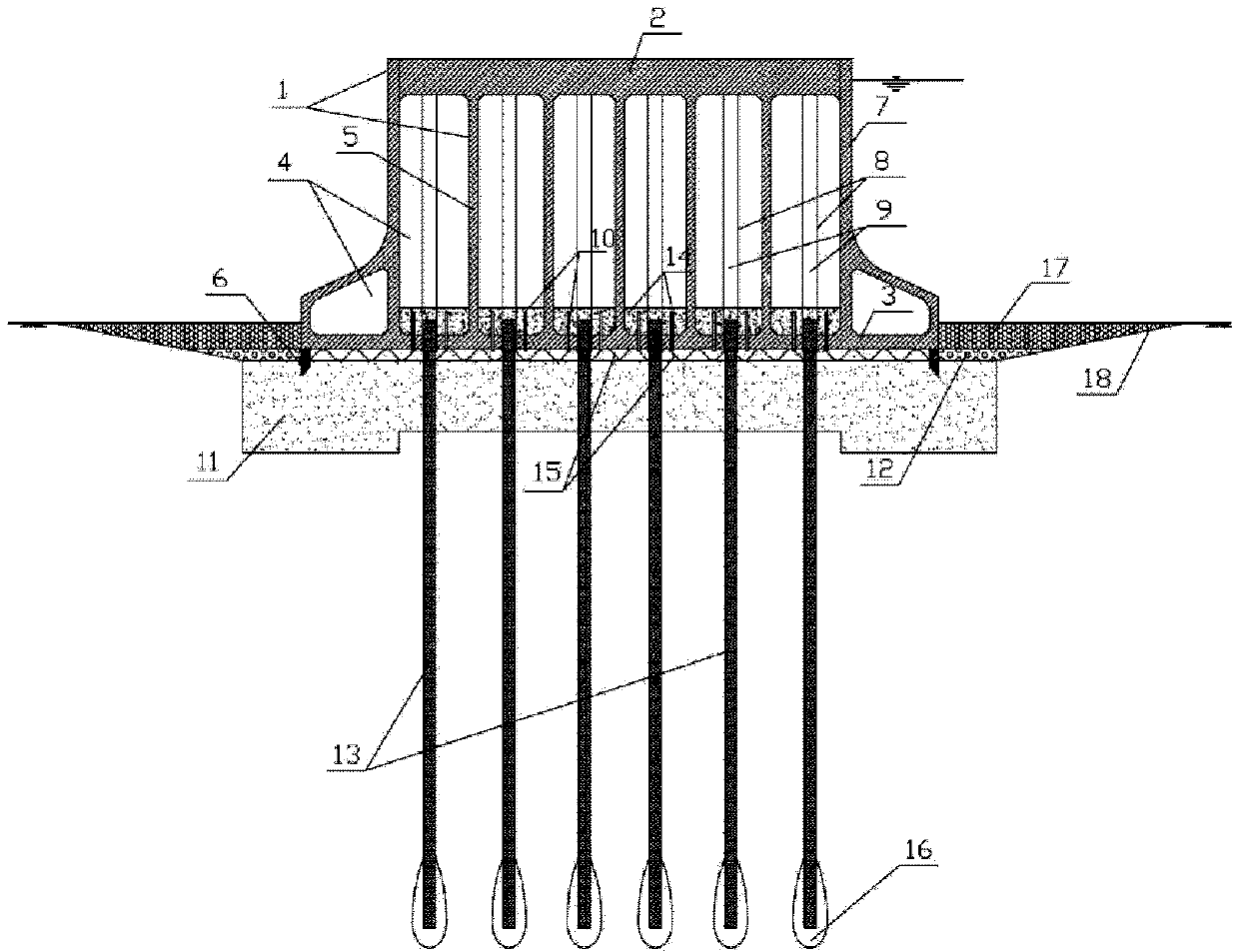

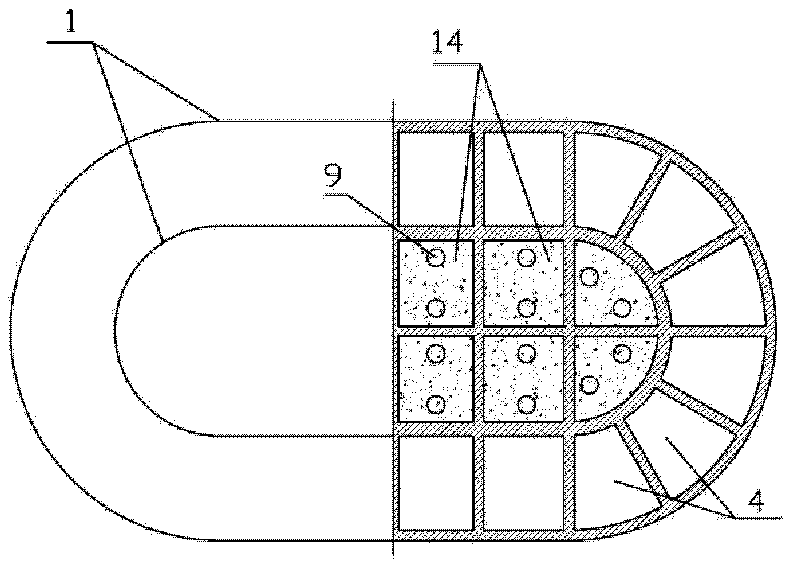

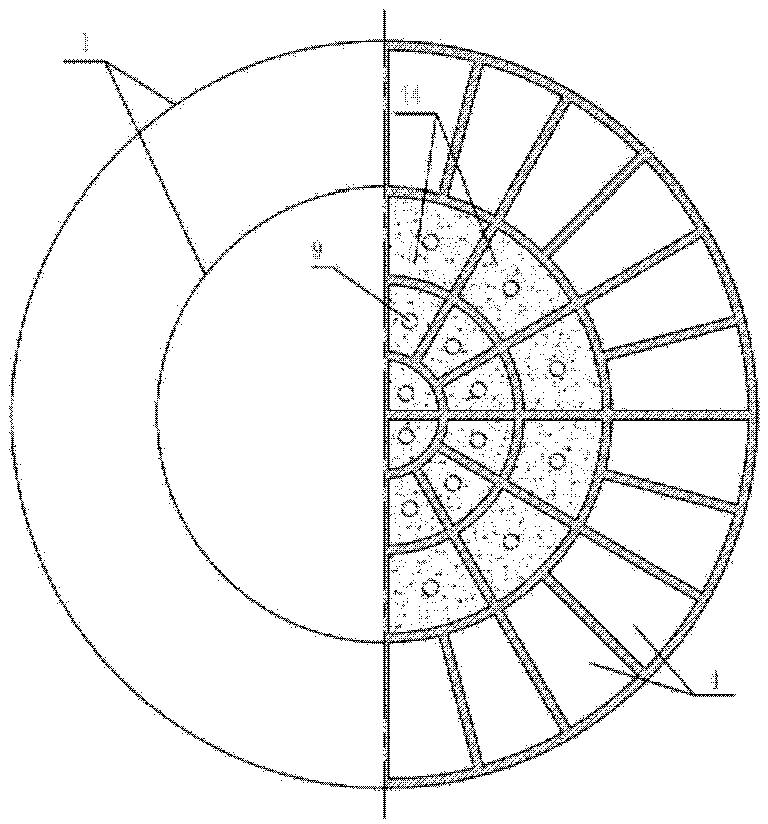

Prefabricated reinforced concrete pile with low temperature geothermal energy conversion function

InactiveCN1804229AConvenient closed loop conversionTraditional mechanics have no effectOther heat production devicesGeothermal energy generationReinforced concreteEngineering

The invention relates to a reinforced concrete square post prefabricated by low temperature and terrestrial heat. It embeds post heat exchangers in variable shapes into the prefabricated reinforced concrete square post to support, baffle sand and reinforce the groundsill; processes the lower-layer lower temperature terrestrial heat exchanger to directly embed the post heat exchanger with pile and heat pump. It binds U-shape pipe heat exchanger, screw coiler heat exchanger or the pipe heat exchanger in other shape on the inner edge of prefabricated reinforced concrete square post with welding method or flange method to be embedded into sand; the pipe heat exchangers inside the prefabricated reinforced concrete square post are connected to the ground pipeline while the pipeline of heat exchanger is filled by fluid via which the heat exchange between steel cage, post concrete and around sand-water system can be processed to form a closed underground low-temperature terrestrial heat exchange.

Owner:张延军 +1

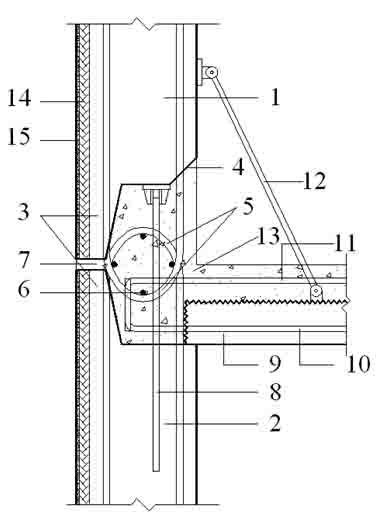

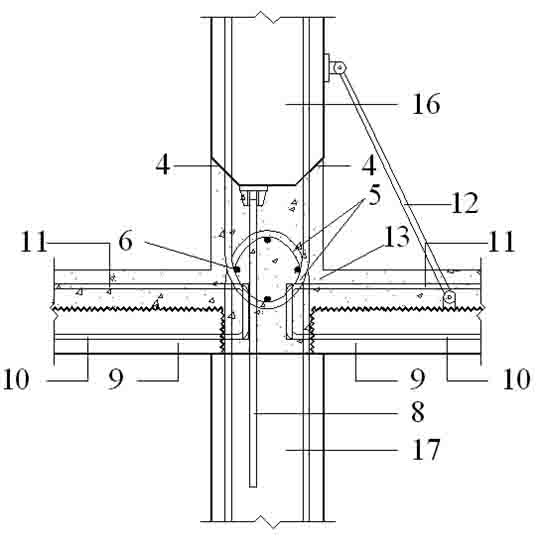

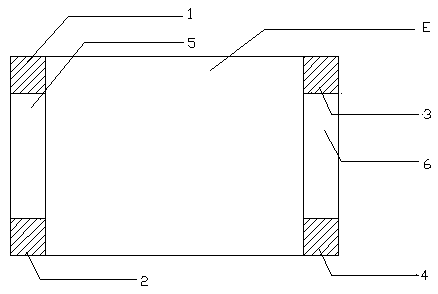

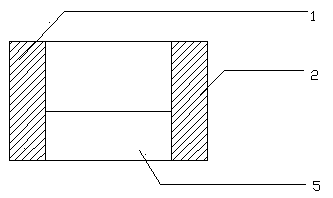

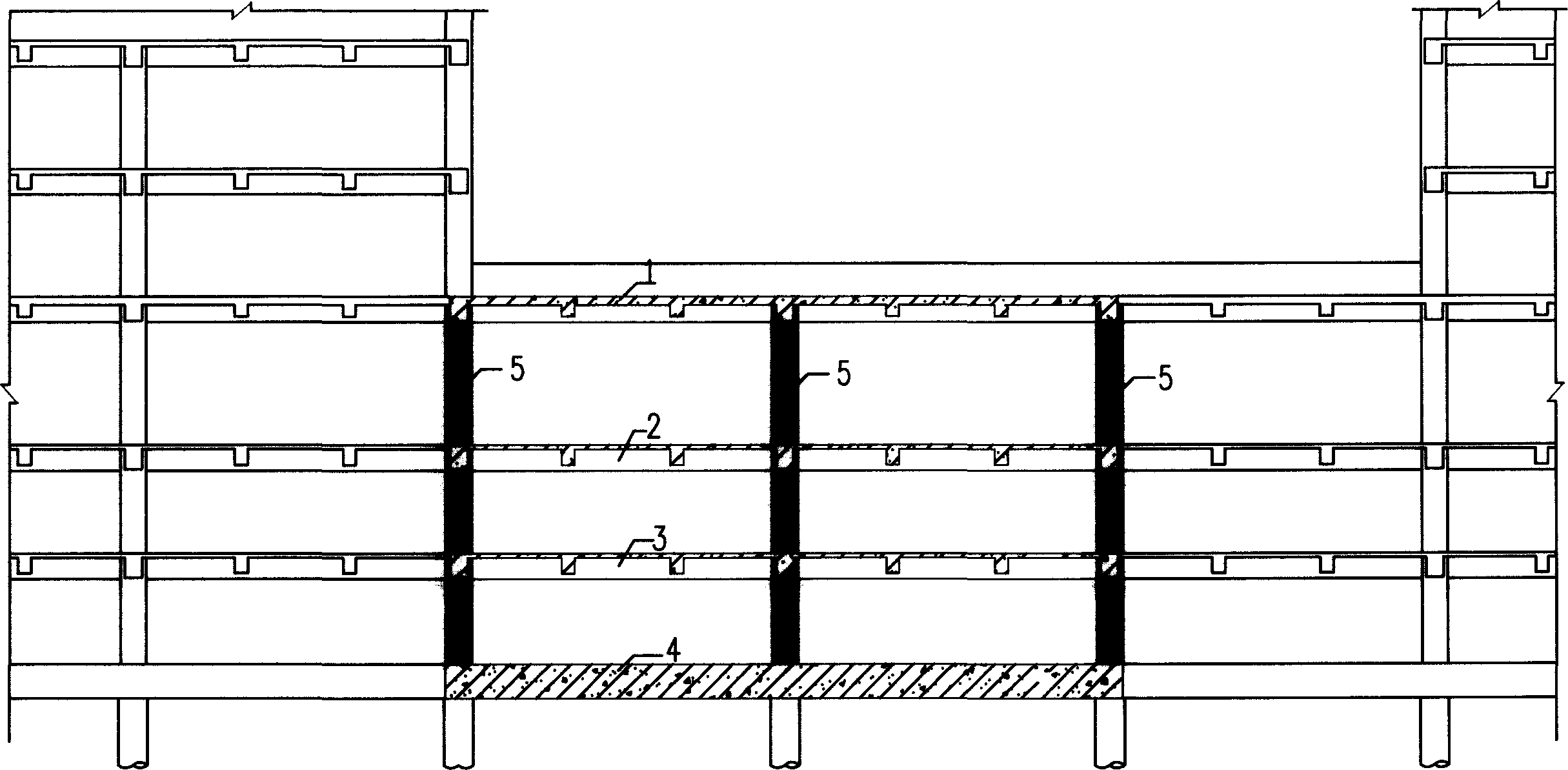

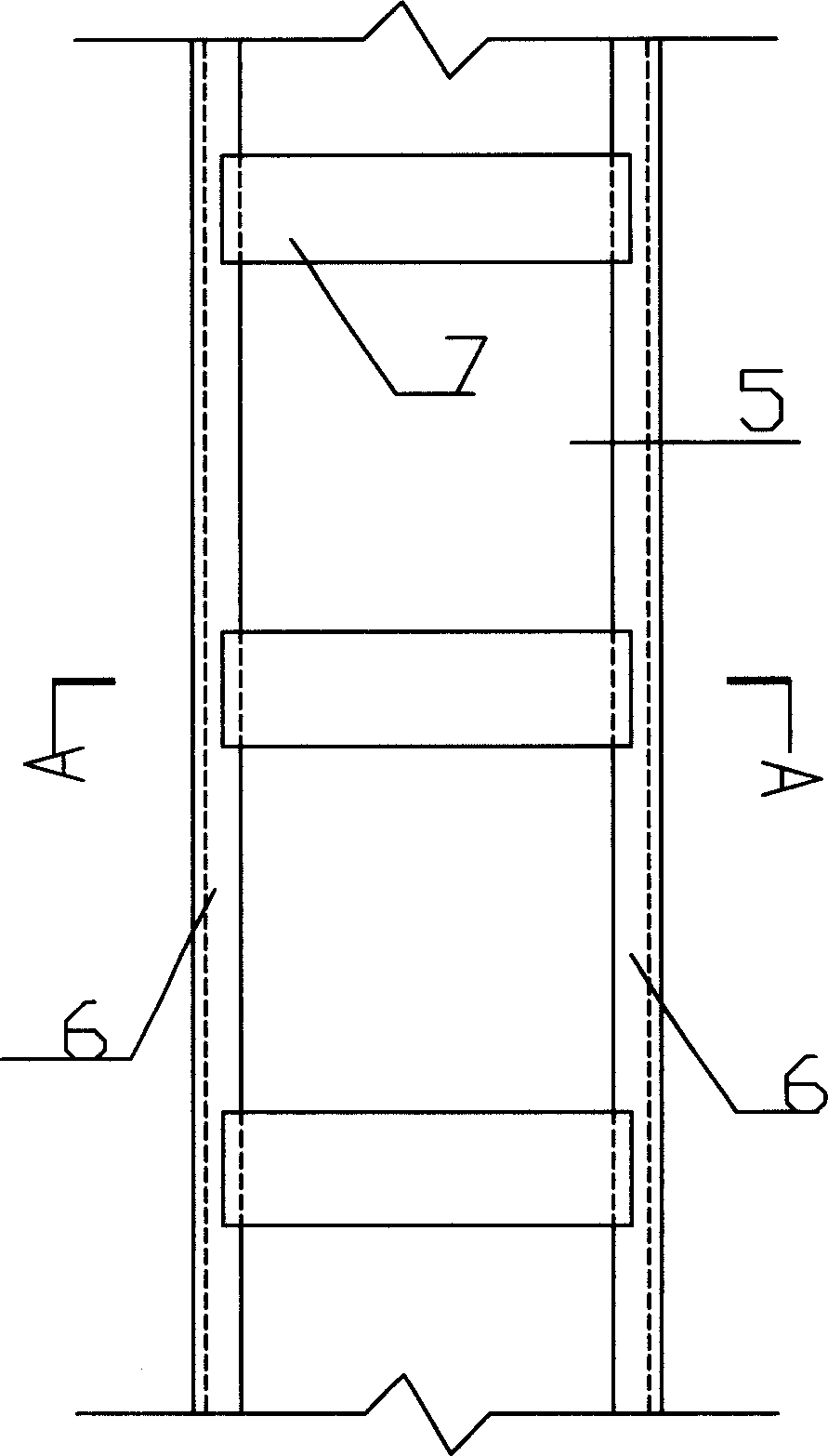

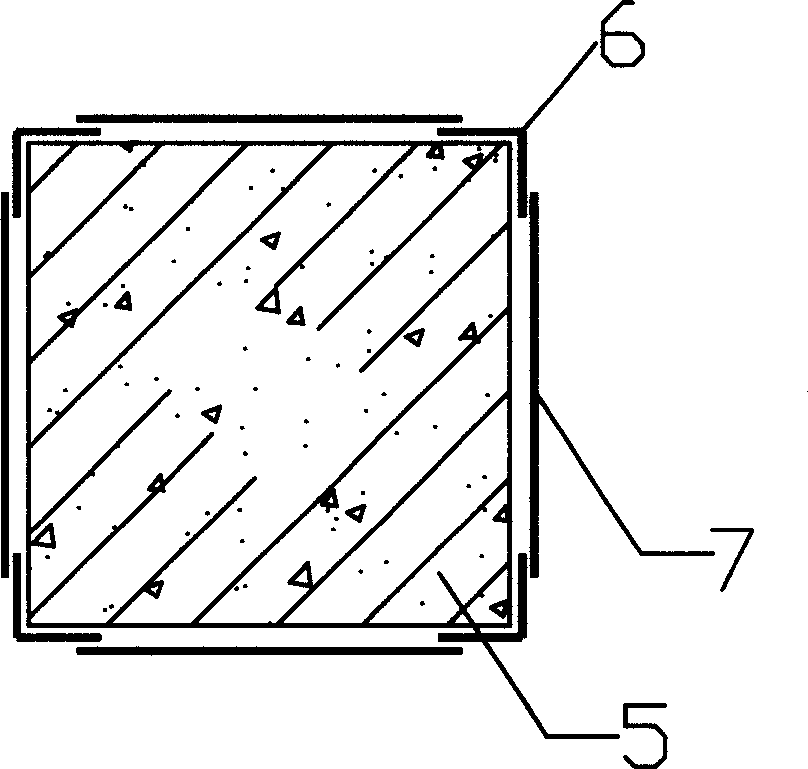

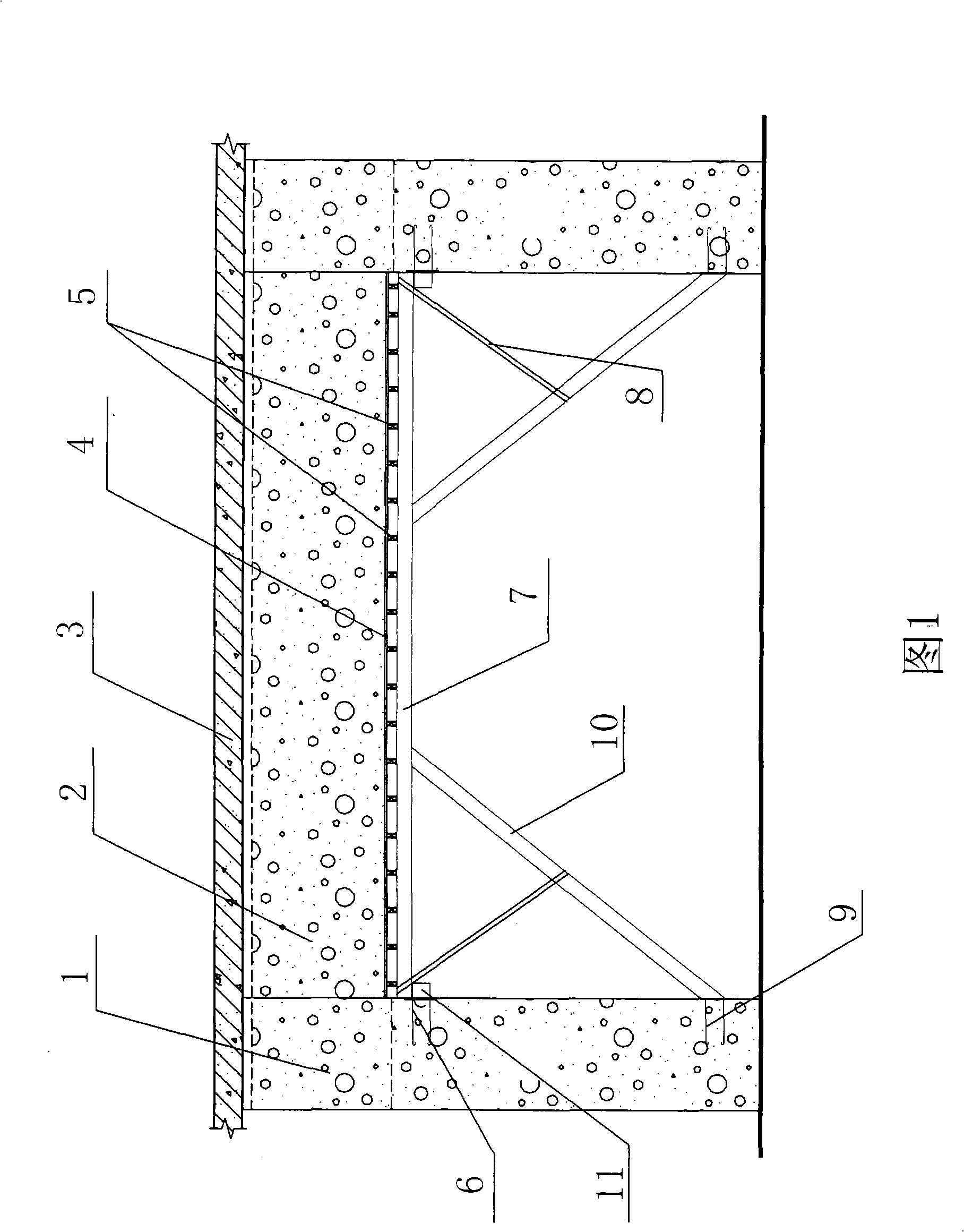

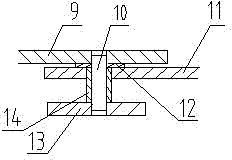

Horizontal seam U-shaped closed rib junction structure of assembled shear wall structure

The invention discloses a horizontal seam U-shaped closed rib junction structure of an assembled shear wall structure, comprising an upper-layer outer wall prefabricated shear wallboard (1), a lower-layer outer wall prefabricated shear wallboard (2), an upper-layer inner wall prefabricated shear wallboard (16), a lower-layer inner wall prefabricated shear wallboard (17), U-shaped closed ribs (5), a horizontal reinforcing rib (6) and filled cast-in-place concrete (13), wherein the U-shaped closed ribs adopting the upper-layer outer wall prefabricated shear wallboard, the lower-layer outer wall prefabricated shear wallboard, the upper-layer inner wall prefabricated shear wallboard and the lower-layer inner wall prefabricated shear wallboard are staggered and are in lap joint to form an annular ring; the horizontal reinforcing rib is arranged in the annular ring to reliably connect the vertical reinforcing steel bars of the assembled shear wall; and the filled cast-in-place concrete of a horizontal seam (7) realizes the purpose that the resistance to shear of the horizontal seam is equivalent to the cast-in-place concrete shear wall. The whole prefabricated assembled shear wall can be reliably connected with the shear wall and a floorslab, the whole prefabricated assembled shear wall performance can be ensured, and the horizontal seam U-shaped closed rib junction structure has the advantages of simple form and material conservation and is convenient to construct.

Owner:SOUTHEAST UNIV

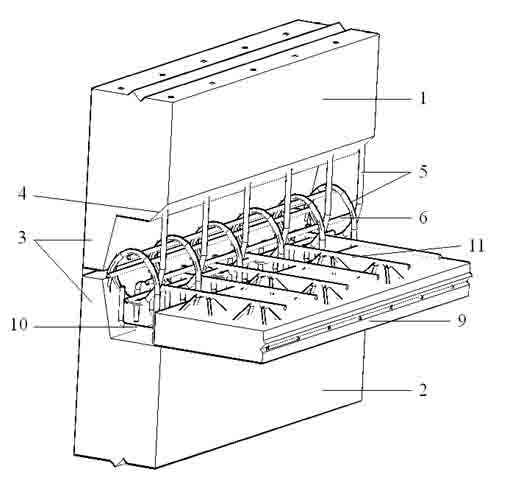

Roller type cutter rectangular pipe jacking machine

The invention relates to a roller type cutter rectangular pipe jacking machine, which comprises a cutter, a cutter driving system, a spiral mechanical unearthing system, a hydraulic propulsion system and a rectangular shell. The cutter adopts a composite formation roller type cutter, is sleeved on the cutter driving system and is driven by the cutter driving system to rotate, the composite formation roller type cutter comprises a plurality of ordinary tools, a swinging tool and an over-excavation tool, a cutter shell adopts a round tubular component, the inner wall of the cutter shell is provided with a separating wall vertical to the axial line of the cutter shell, the ordinary tools are uniformly and fixedly arranged on the outer wall of the cutter shell, the swinging tool is hinged on the inner side of the outer wall of the cutter shell through a pin shaft and can rotate around the pin shaft, and the over-excavation tool is fixedly arranged on the outer side of the outer wall of the cutter shell. The invention has the advantages of high adaptability to formations and high tunneling efficiency. Meanwhile, construction risks can be reduced greatly, construction safety can be ensured, and the machine can adapt to construction of slightly weathered rock formations, composite formations, backfilled formations, continuous walls through the ground, pile foundations and other complex formations and working conditions.

Owner:上海盾构设计试验研究中心有限公司 +1

Mechanical underground excavation construction method for large underground parking lot

ActiveCN105370287ASolve construction problemsReduce construction riskUnderground chambersTunnel liningEnvironment effectReinforced concrete

The invention discloses a mechanical underground excavation construction method for a large underground parking lot, comprising the following steps: constructing two parallel construction tunnels at two ends of the position of the proposed space of the parking lot according to the design condition of the parking lot, marking the rectangular section of the space of the parking lot on the side wall of the construction tunnel, and dividing the rectangular section of the whole space of the parking lot into a plurality of small rectangular sections with same size; and then carrying out segmental jacking construction sequentially on the small rectangular sections, namely the linear distance between the two construction tunnels, by adopting a rectangular tube push bench, and synchronously arranging the rectangular tube push bench inside, then removing profile steel parts between two adjacent rectangular pipe jacking rooms, and constructing reinforced concrete stand columns, beams and bottom plates, thus completing construction of the underground parking lot. The method can be used for solving the difficulty of constructing an underground parking lot without disturbing the ground environment conditions of urban areas; is high in construction speed, small in environmental influence and high in economic benefits; and is high in mechanization degree and small in construction risks.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Construction method of reconstrating existant underground space into subway station

ActiveCN1693591ASolve construction problemsArtificial islandsUnderground chambersFloor slabSubway station

A construction method of renovate underground three-storey garage into double-storey subway station. The garage includes top board storey, the first underground floor slab, the second underground floor slab, bottom floor, column and external wall. The procedures are that 1) reconstruction area is set in the garage. 2) The top board storey is reserved as station top board storey, the first underground floor slab is reserved as station central board; the bottom floor is reserved as station bottom floor. 3) The second underground floor slab is eliminated, and is connected to the column said above. The pipe line and traffic structure is not changed, and the reconstruction is local construction is low to change existing underground three storey garage into underground double storey subway station.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

Caisson and pile combined foundation of consolidated subsoil and construction method of caisson and pile combined foundation

The invention discloses a caisson and pile combined foundation of consolidated subsoil and a construction method of the caisson and pile combined foundation. The caisson and pile combined foundation of the consolidated subsoil comprises the consolidated subsoil, a sand-gravel cushion, a caisson, bored piles, pile bottom grout, top seal concrete and scour protection. The main construction method comprises the following steps: consolidating the foundation with an underwater compaction sand pile or a deep-layer cement mixing pile; laying the sand-gravel cushion on the consolidated subsoil; sinking the caisson with a skirt, pile sinking guide holes and grouting reserved pipes on the sand-gravel cushion; after the caisson is located, constructing bored piles through the pile sinking guide holes; after construction of the bored piles, casting the top seal concrete at the bottom in the caisson; grouting the bottom of the caisson through the grouting reserved pipes at the bottom of the caisson, carrying out pile bottom grouting through grouting pipes in the pile, and at last casting the top plate of the caisson. In the construction process, the scour protection shall be performed around the caisson according to requirements. The caisson and pile combined foundation of the consolidated subsoil and the construction method of the caisson and pile combined foundation, disclosed by the invention, can effectively improve vertical and horizontal bearing capacity of the caisson, and control sedimentation and horizontal displacement of the caisson.

Owner:CCCC HIGHWAY CONSULTANTS +1

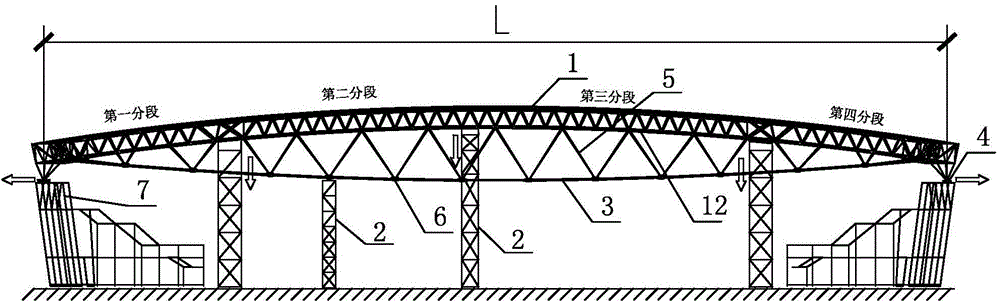

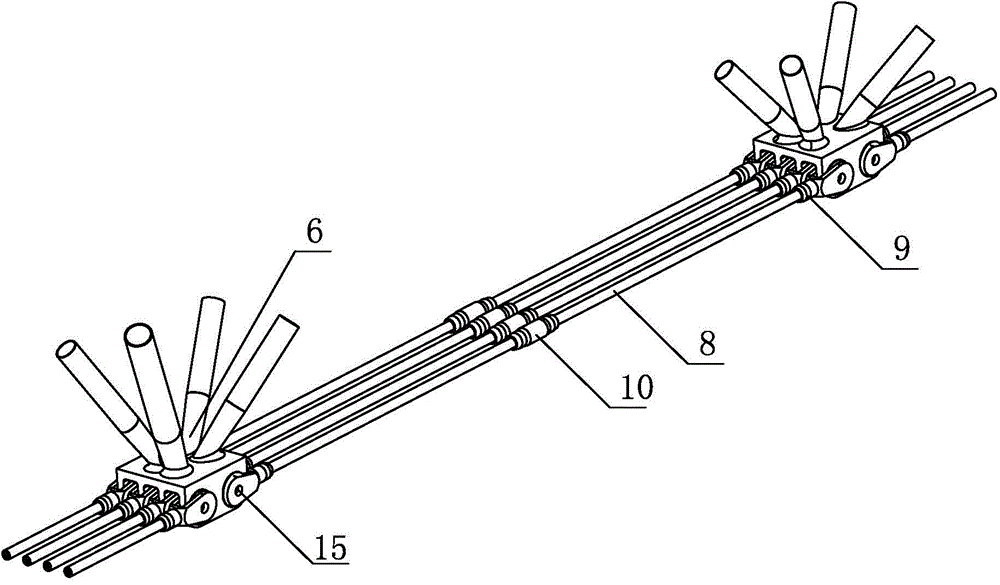

Construction method of large-scale parallel flexible lower-cord combined trusses

The invention belongs to the field of construction of steel structure trusses, and particularly relate to a construction method of large-scale parallel flexible lower-cord combined trusses. The construction method comprises the following steps: (1) assembling upper-cord layers of trusses by sections, and abutting overhead, wherein the trusses need to be arched in advance according to the deformation design in the process of assembling; (2) installing lower-cord web members and lower-cord panel points independently after finishing assembling the trusses of the upper layer; (3) measuring the actual installation spacial distances among the lower-cord panel points, and determining the initial installation geometrical lengths of flexible lower cords; (4) installing all flexible steel pull rods connected in parallel among all spans of the lower cords, and then pretightening the steel pull rods of the lower cords uniformly; and (5) grading synchronously and unloading equally proportionally by using a support frame. By adopting the construction method provided by the invention, the construction difficulty of tensioning the internal force of the lower cords of the ultralarge-scale parallel flexible trusses initiatively can be solved. The construction method has the advantages of high construction efficiency and good economic benefit.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP +1

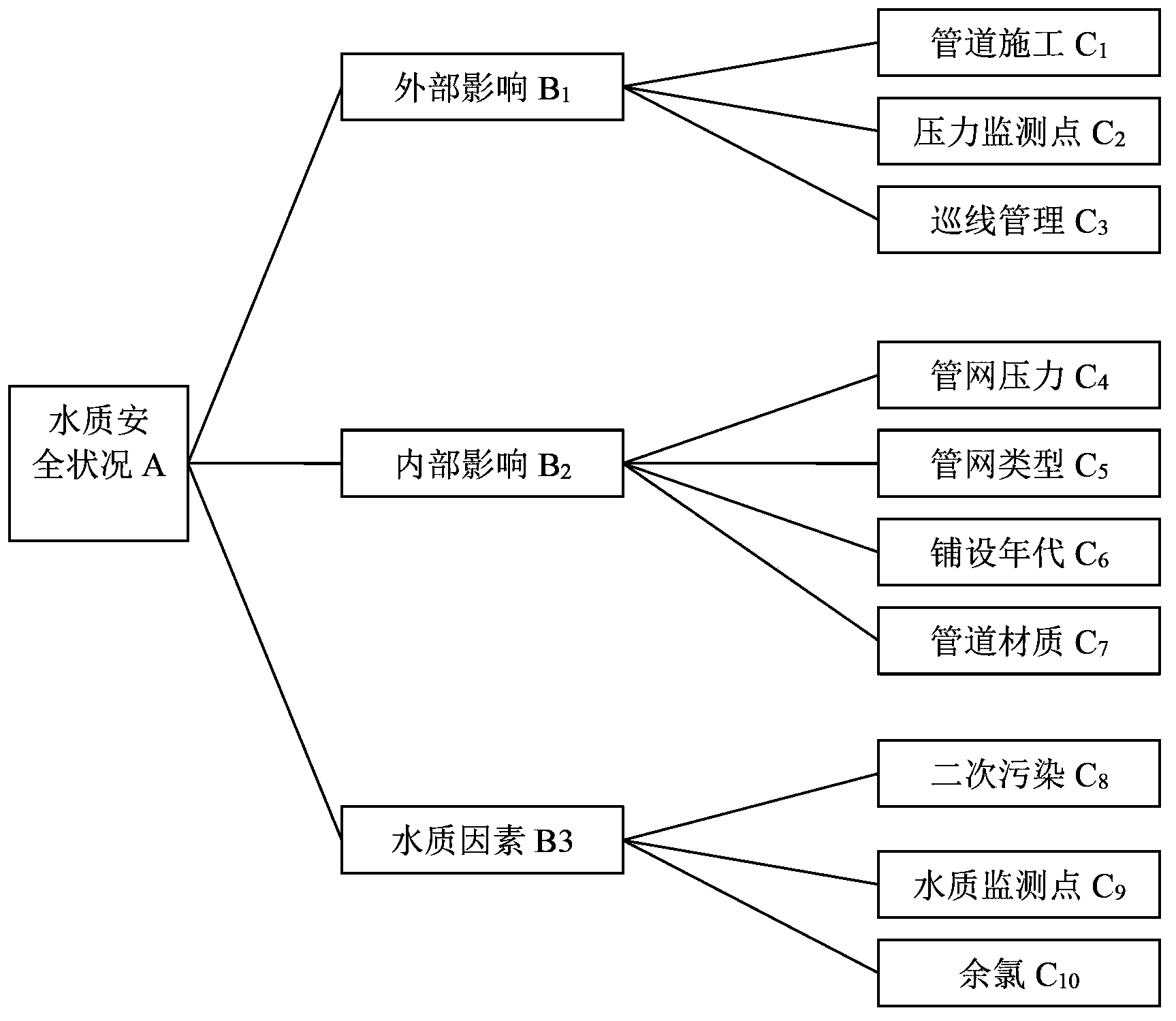

Improved water environment safety evaluation analysis method

ActiveCN103400044AReduce mistakesSolve construction problemsData processing applicationsGeneral water supply conservationWater qualityEngineering

The invention belongs to the evaluation technical field, and particularly relates to an improved water environment safety evaluation analysis method. The improved water environment safety evaluation analysis method includes the steps of based on the relation of interaction between influence factors, based on the combination of the improved network analysis method and fuzzy mathematics, mainly on the basis of building system network analysis, carrying out pairwise comparison on the influence factors under different criterions, obtaining weight vectors comprising the interaction, combining fuzzy vectors obtained through the fuzzy evaluation method to carry out calculation and analysis, and finally obtaining the safety evaluation results. The improved water environment safety evaluation analysis method is accurate in evaluation result, improves the pre-alarm accuracy, achieves the aim of building a water quality safety evaluation model, increases the time correction value and ensures that the weight vectors can accurately and always reflect the relative importance degrees between the influence factors at different moments.

Owner:光大理工环境技术研究院(青岛)有限公司

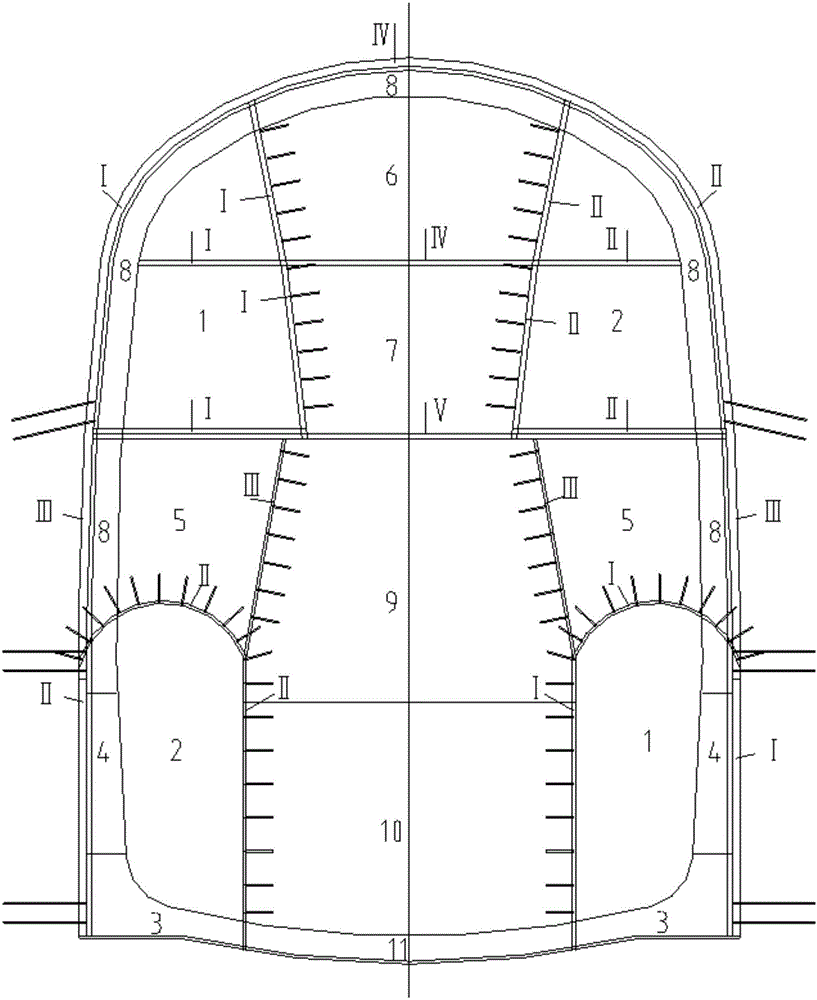

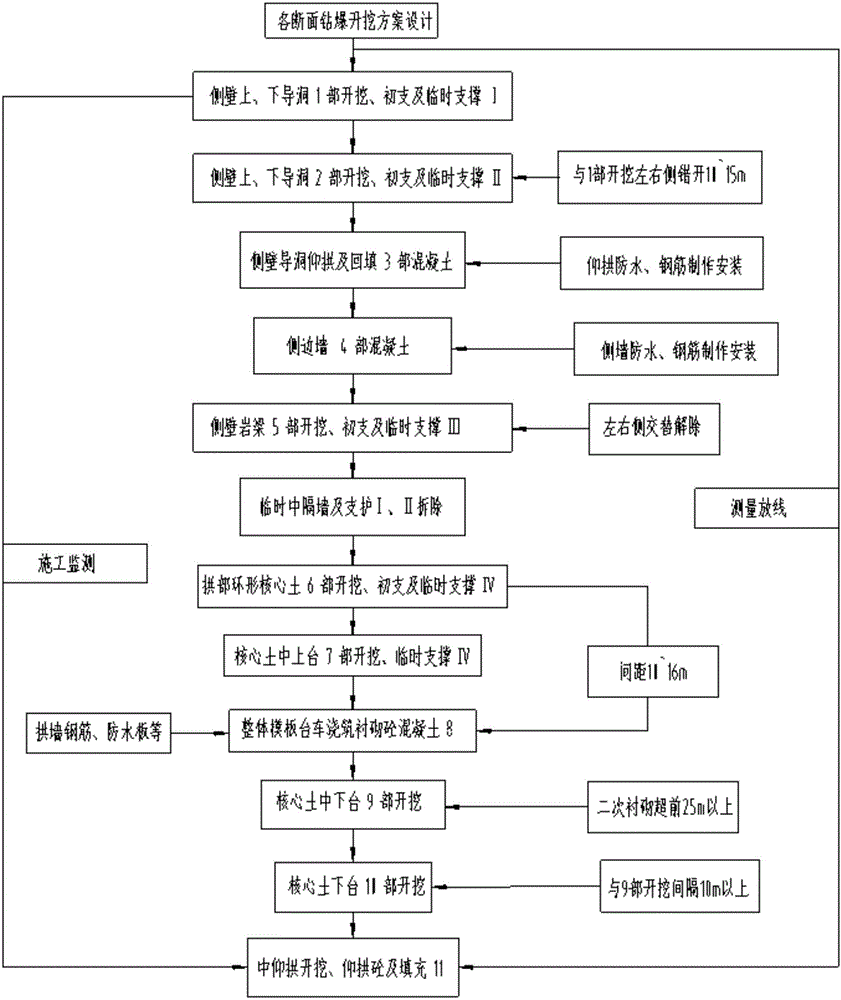

Construction method for excavating upper drift heading and lower drift heading in two side walls of ultra-large subsurface tunnel

InactiveCN106643361AReduce unit consumptionReduce the impactBlastingDrilling and blastingBuilding construction

The invention provides a construction method for excavating an upper drift heading and a lower drift heading in the two side walls of an ultra-large subsurface tunnel and belongs to the technical field of construction engineering. The method comprises the steps of drilling and blasting scheme design; construction requirements meeting of drilling and blasting design; blasting parameter selection; surveying and setting out; excavation of the upper pilot tunnel portion and the lower pilot tunnel portion of the two side walls; removal of reserved rock beam portions; excavation of an annular core soil portion of an arch portion; and excavation of core soil middle-upper steps, middle-lower steps and lower steps. Compared with a traditional two-side-wall drift heading method, according to the method, the way of excavating the upper drift heading and the lower drift heading at the same time is adopted, and the characteristics of the large-section tunnel can be fully utilized; a working face which can be excavated is increased; tunnel excavation conducted at the early stage is accelerated; and the construction period is effectively shortened. According to the method, reserved rock beams are utilized, so that horizontal support strength and global stability are effectively enhanced; horizontal convergence deformation and arch top settlement of the tunnel are decreased; and safety of buildings on the upper portion of the tunnel is guaranteed. According to the construction method, after the high side walls are constructed by means of the bottom of a lower pilot tunnel of the tunnel, backfilling is conducted, the height of a second lining construction section of the tunnel is reduced, and the construction problem of an ultra-large-section formwork trolley is solved.

Owner:CHINA CONSTR EIGHTH ENG DIV

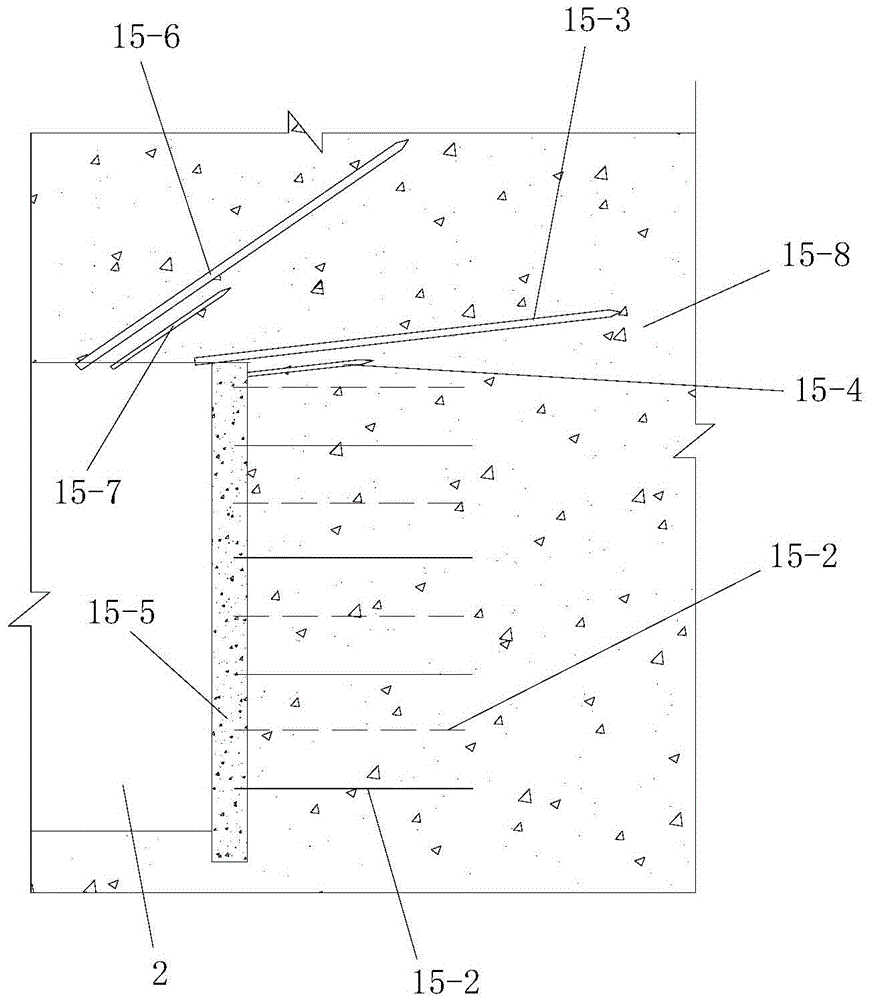

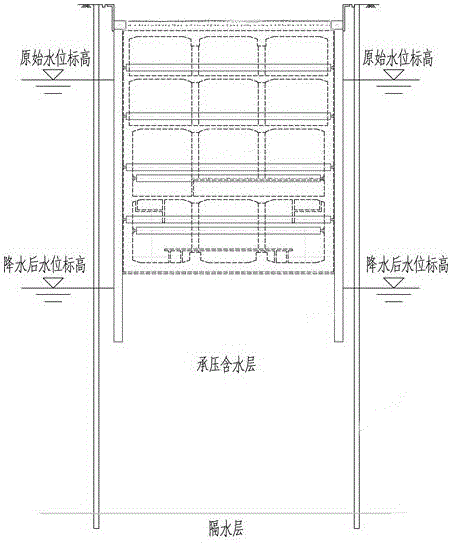

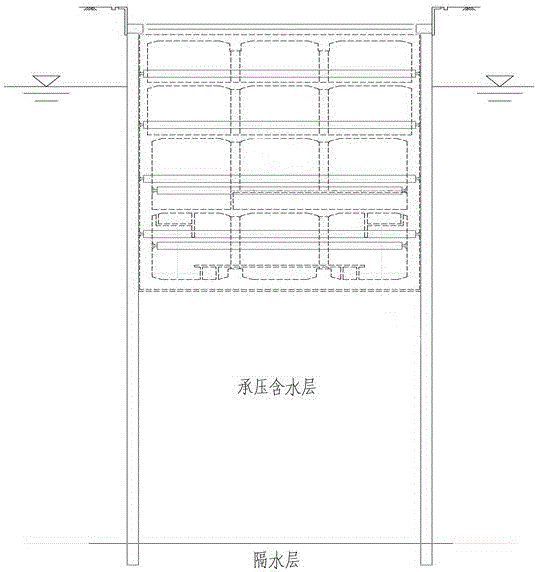

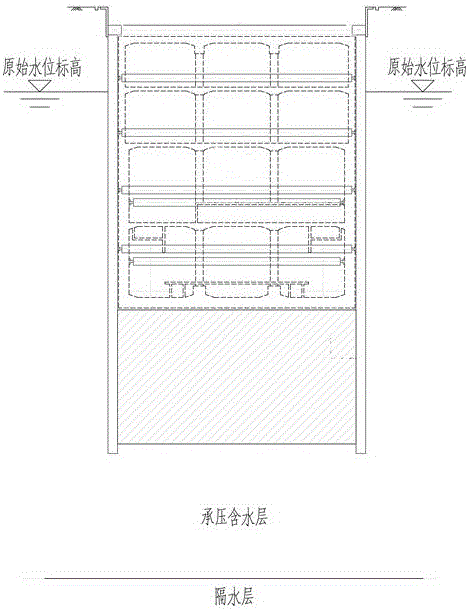

Strongly-permeable stratum deep foundation pit bottom sealing water stopping structure and construction method thereof

ActiveCN105002913AImprove reliabilityImprove waterproof performanceProtective foundationExcavationsSlurry wallReinforced concrete

The invention discloses a strongly-permeable stratum deep foundation pit bottom sealing water stopping structure, which comprises diaphragm walls, underwater plain concrete boards, reinforced concrete partition walls, uplift piles and inner supports, wherein the diaphragm walls are arranged around the foundation pit througgh casting; the inner supports support the diaphragm walls; the reinforced concrete partition walls are formed on the foundation pit below the diaphragm walls through casting; the reinforced concrete partition walls and the diaphragm walls of each two faces form a casting block in a surrounding mode on the foundation base; the uplift piles are casted on the foundation base inside the block; each underwater plain concrete board is formed through casting at each block opening formed by the reinforced concrete partition walls and the diaphragm walls in a surrounding mode; and the uplift piles are firmly embedded in the underwater plain concrete boards. The underwater plain concrete boards enhance overall strength and ridigity of the foundation pit bottom, dual effects of reinforced pit bottom and permeation prevention are provided, influences on stability of the pit bottom by high pressure water and raised pit bottom caused by excavation of the foundation pit can be effectively solved, and lateral displacement of the pit wall and settlement deformation of the surrounding enviornment can be well reduced.

Owner:RANKEN RAILWAY CONSTR GROUP +1

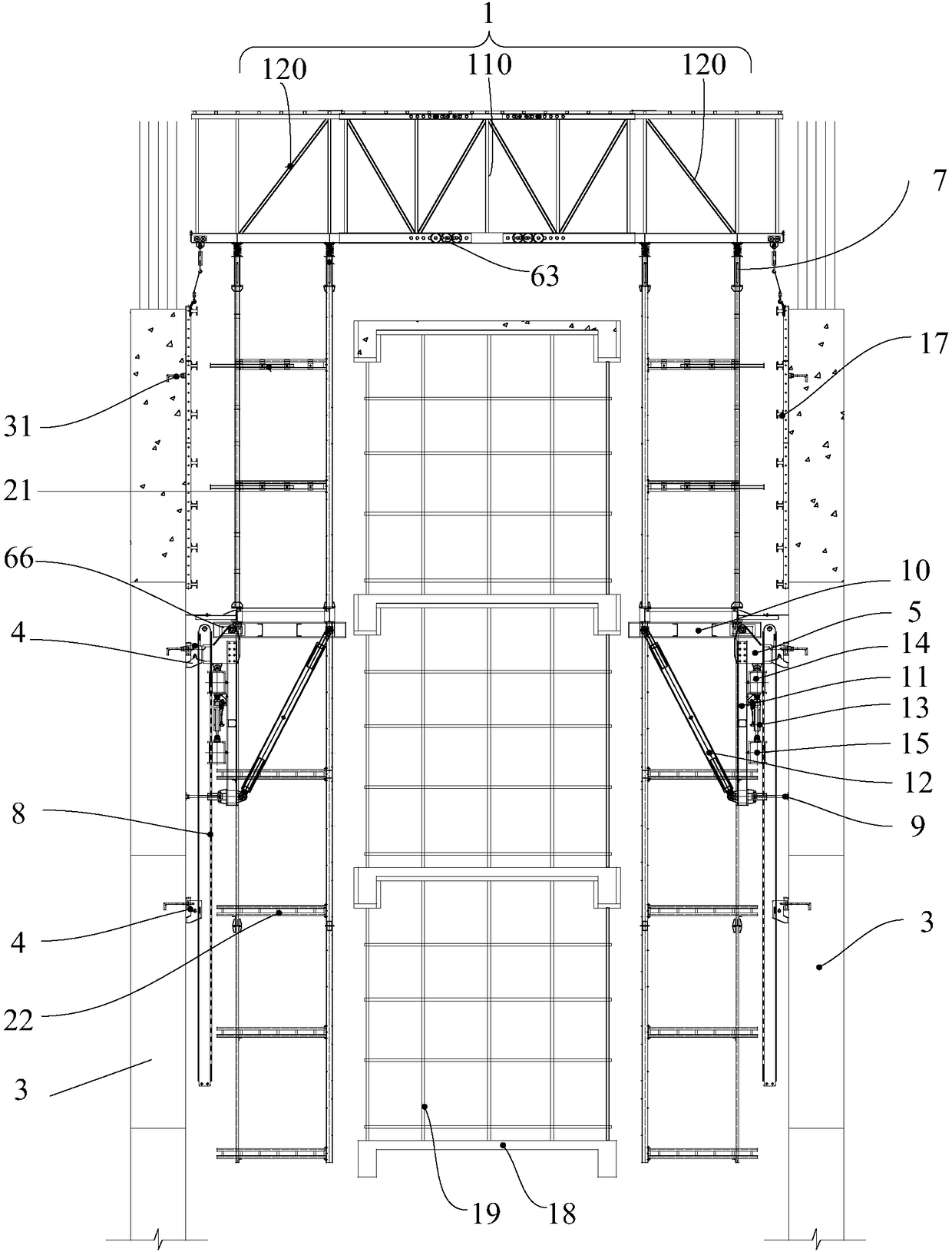

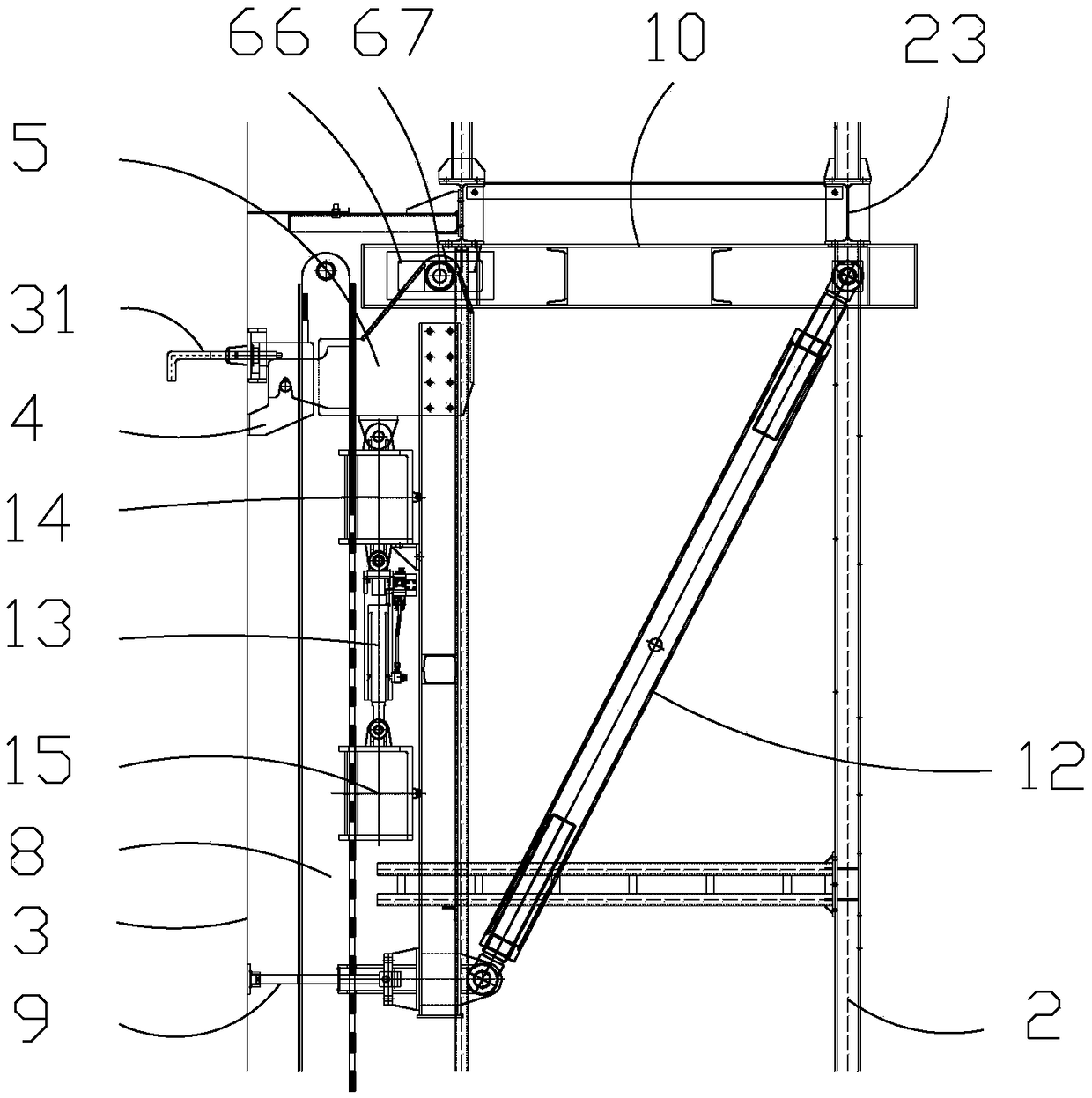

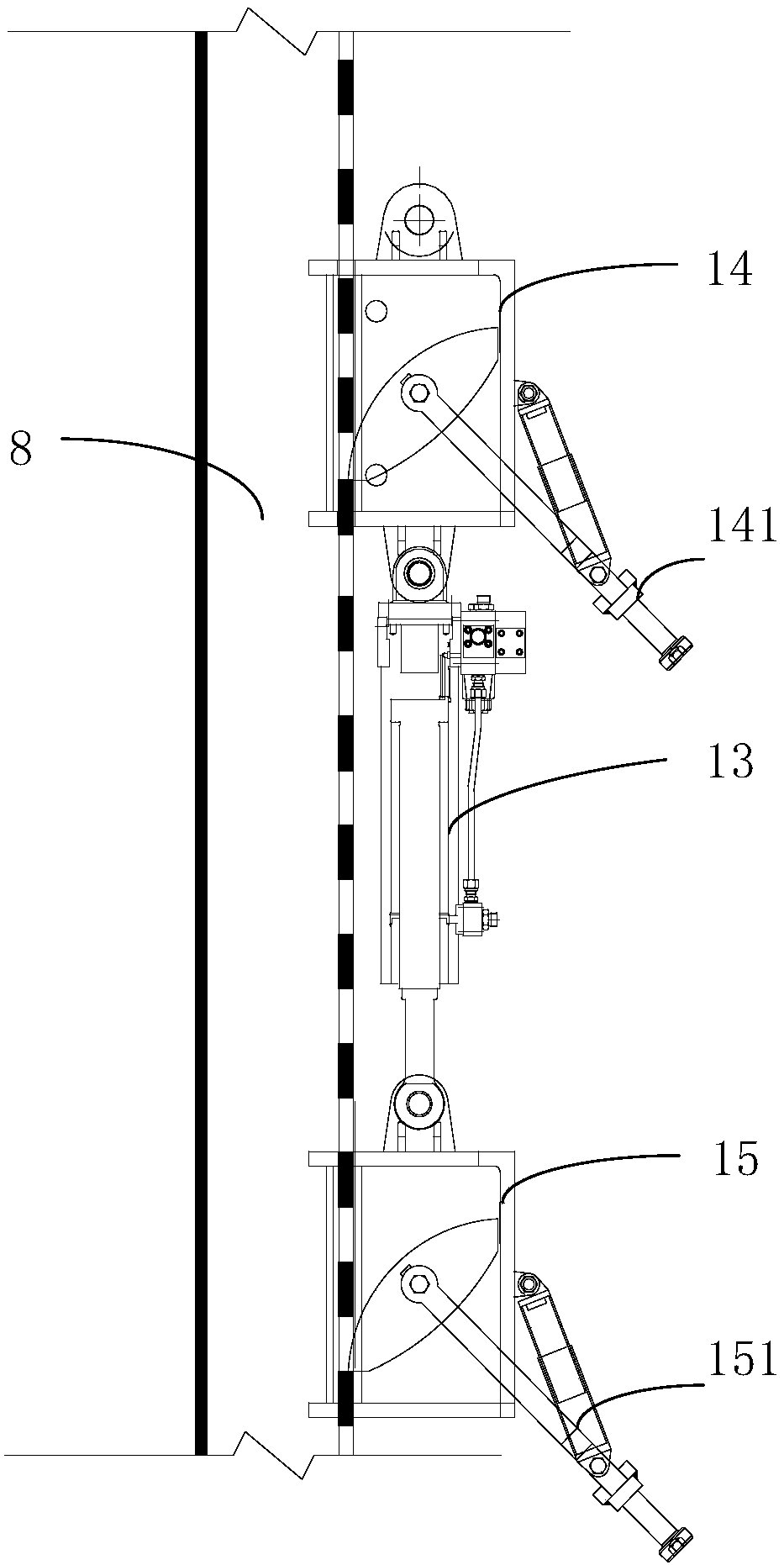

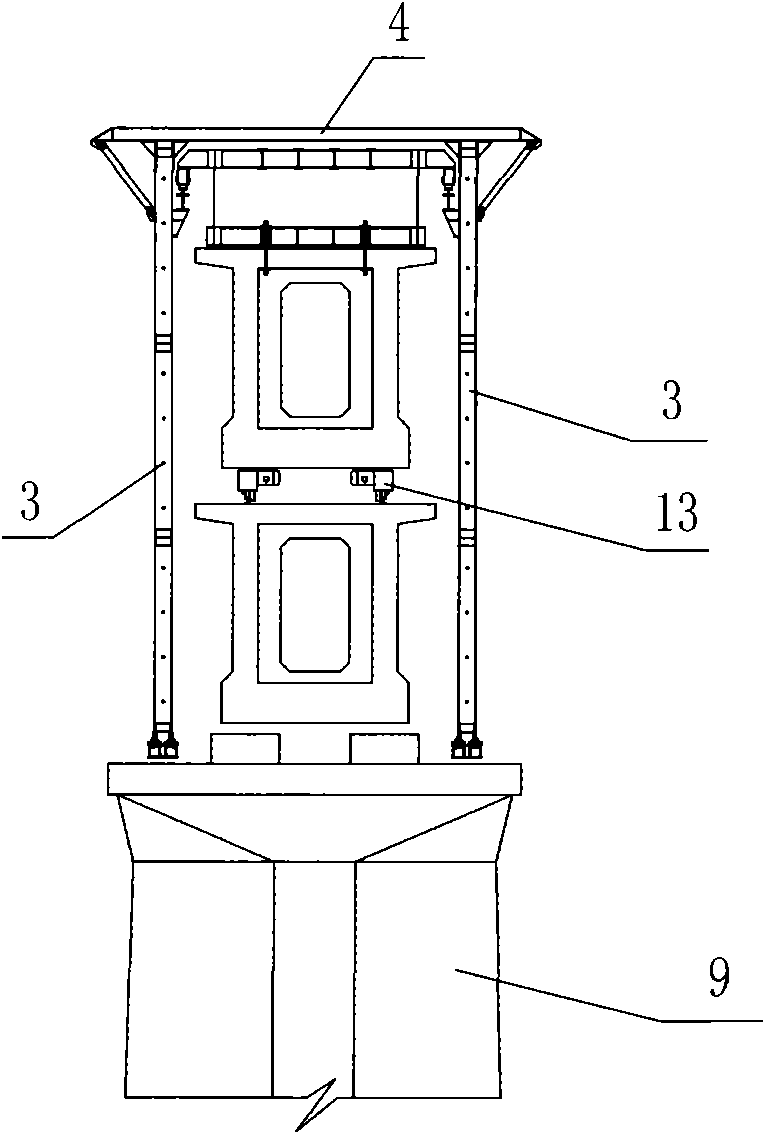

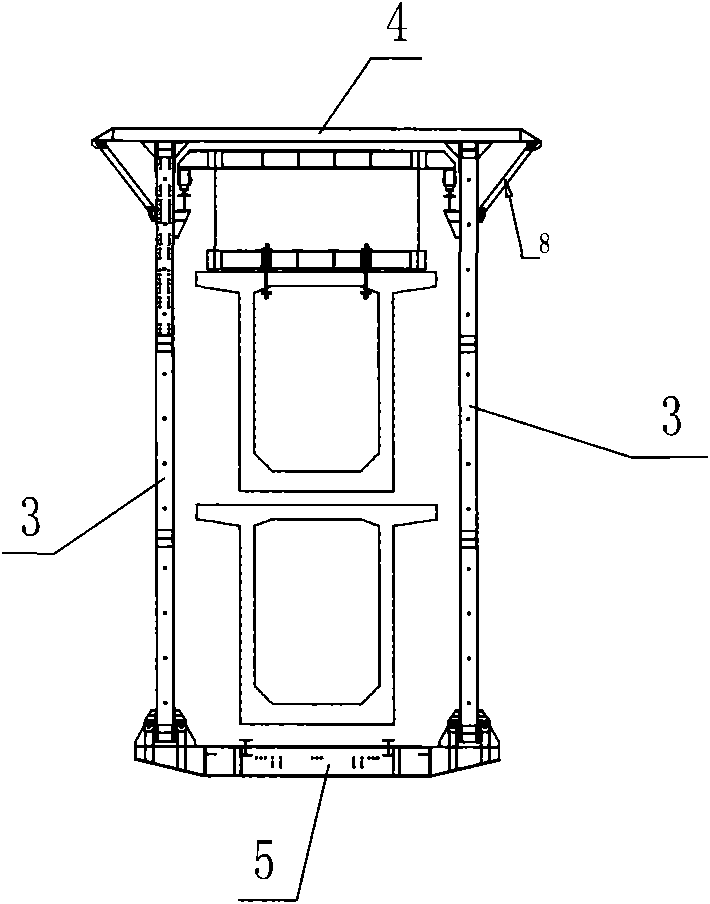

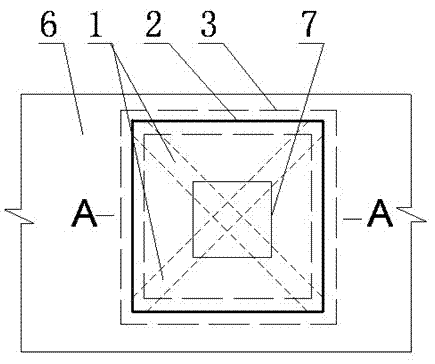

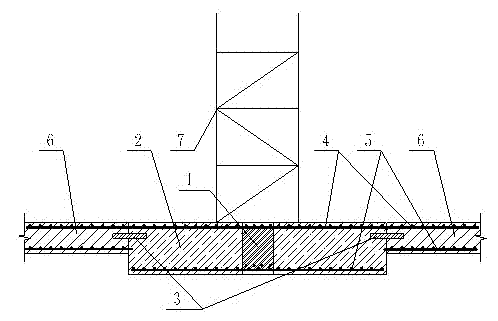

Door-type self-adaptive telescopic hydraulic climbing platform system and climbing method thereof

ActiveCN108222482ASolve construction problemsClimb achievedBuilding support scaffoldsSelf adaptiveMechanical system

The invention discloses a door-type self-adaptive telescopic hydraulic climbing platform system and a climbing method thereof. The platform system comprises a top frame platform, two vertical frame bodies and a plurality of climbing mechanical systems; the two vertical frame bodies are oppositely arranged on the inner wall of a wall body of a core cylinder through the at least two climbing mechanical systems correspondingly; the upper ends of the two vertical frame bodies are connected with the two ends of the top frame platform correspondingly to form a door-type frame body; each climbing mechanical system comprises a plurality of wall-attached devices, load-bearing hooks and mechanical climbing devices; the load-bearing hooks are connected with the vertical frame bodies and the mechanical climbing devices correspondingly; and the door-type self-adaptive telescopic hydraulic climbing platform system further comprises an adjusting mechanism which can make the climbing mechanical systems to be capable of climbing at the position where spaces of the inner wall of the wall body of the core cylinder are changed by adjusting the horizontal position of the load-bearing hooks. According to the door-type self-adaptive telescopic hydraulic climbing platform system and the climbing method thereof, the concrete core cylinder inner construction problem that an existing hydraulic climbing platform cannot be used for contraction of the wall body to which a machine position is attached can be solved.

Owner:SHANGHAI CONSTRUCTION GROUP

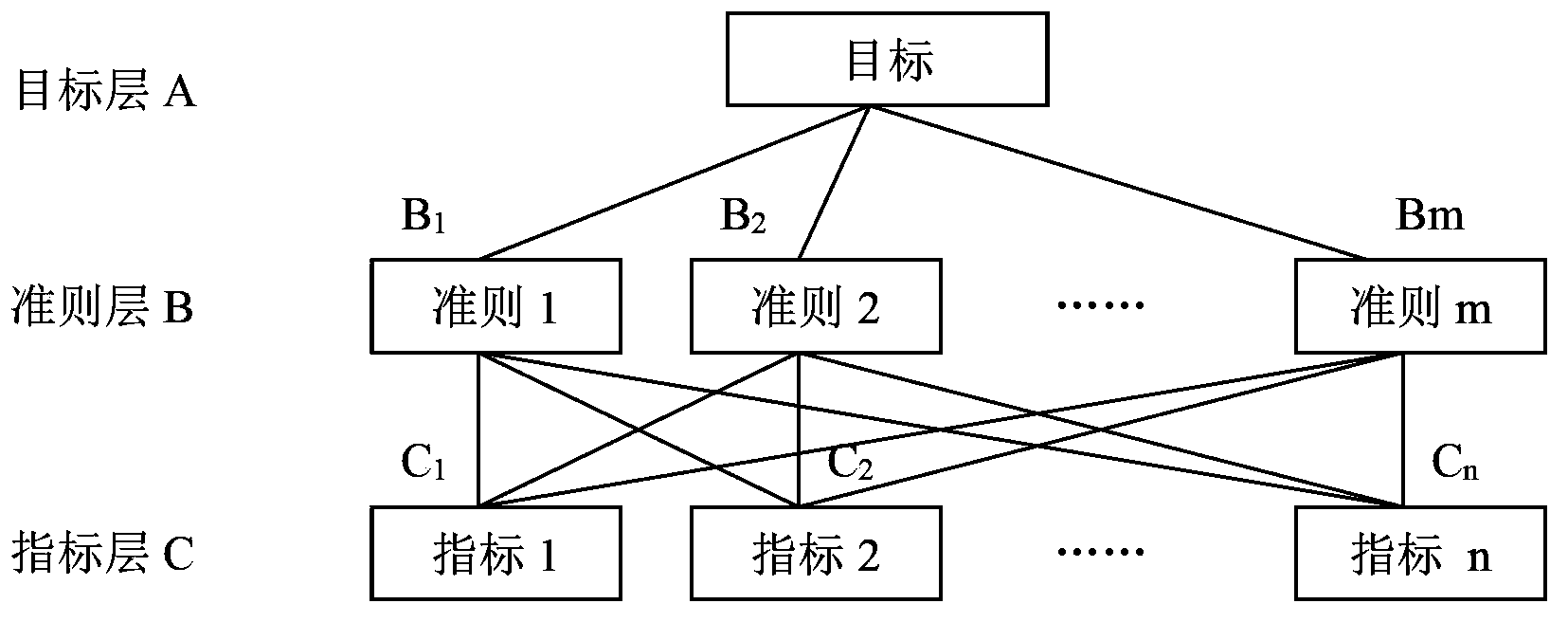

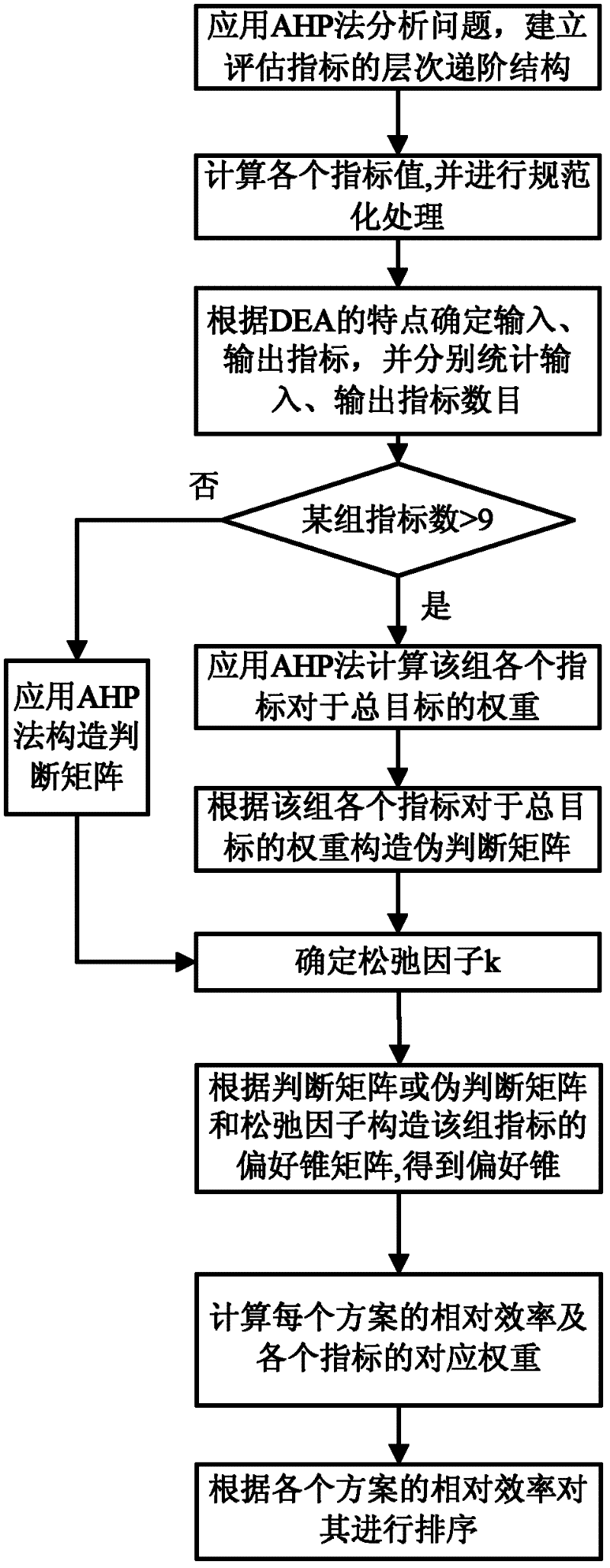

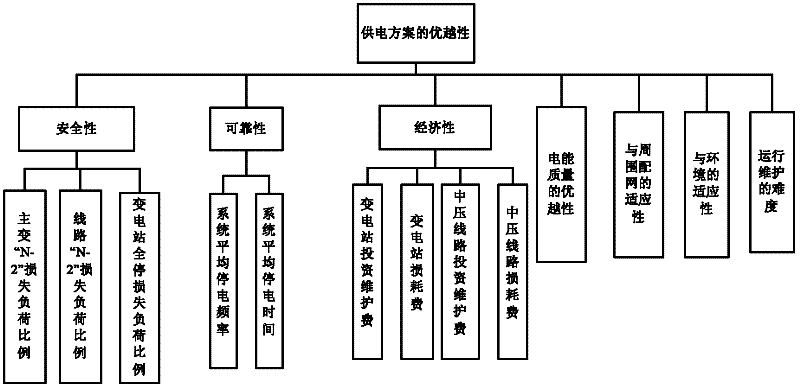

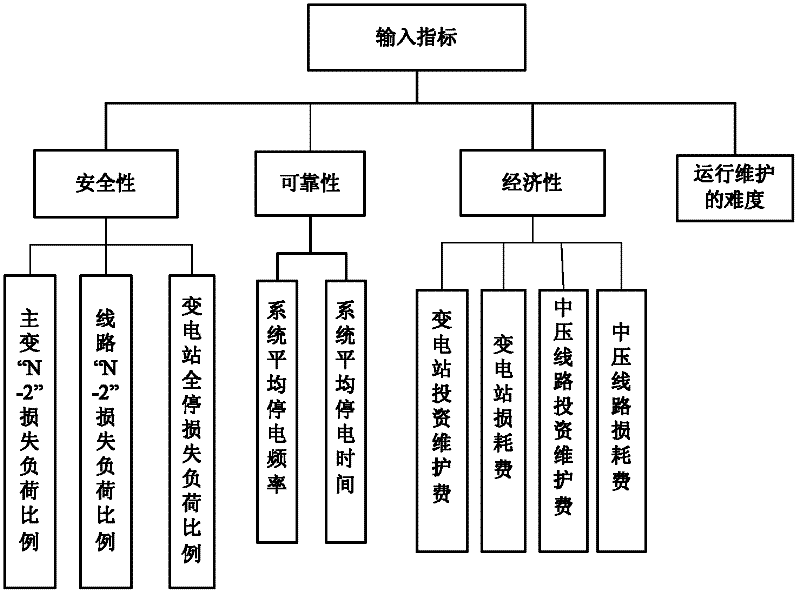

Method for estimating 20-kilovolt medium-voltage distribution scheme

InactiveCN102254091AFully reflect the needsSimplified statistical indicatorsSpecial data processing applicationsRelaxation factorIndex system

The invention discloses a method for estimating a 20-kilovolt medium-voltage distribution scheme, which belongs to the technical field of the application of electric industry. In the method, an estimation index system of the 20-kilovolt distribution scheme is established by an analytic hierarchy process (AHP), and a data envelopment analysis (DEA) estimation model with an AHP preference cone is improved, wherein the provided AHP / DEA model is used for solving the weight of an index. By the method, the problem that 9 comparison objects cannot be exceeded in the conventional method is solved and the problem of combining subjectivity and objectivity reasonably in estimation by introducing a relaxation factor is also solved properly.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Bridge erection method

ActiveCN101457513ASolve construction problemsReduce difficultyBridge erection/assemblyEngineeringPrefabrication

The invention discloses a bridge building method. After piers are built at the designed positions, beam segment prefabrication brackets are arranged between two piers having adjacent side holes and then the beam segments are prefabricated; guide beams are built between each other two adjacent piers; and the prefabricated beam segments are respectively built at the transverse and longitudinal designed positions by the coordination of pulleys and slide rails as well as the traction of jacks and traction cables. The invention breaks the limit of the construction site, and solves the prefabricated beam segment construction problem that the large-scale equipment can not be used in places with narrow site and inconvenient transport.

Owner:THE SECOND OF CHINA RAILWAY PORT CHANNEL ENG GROUP +1

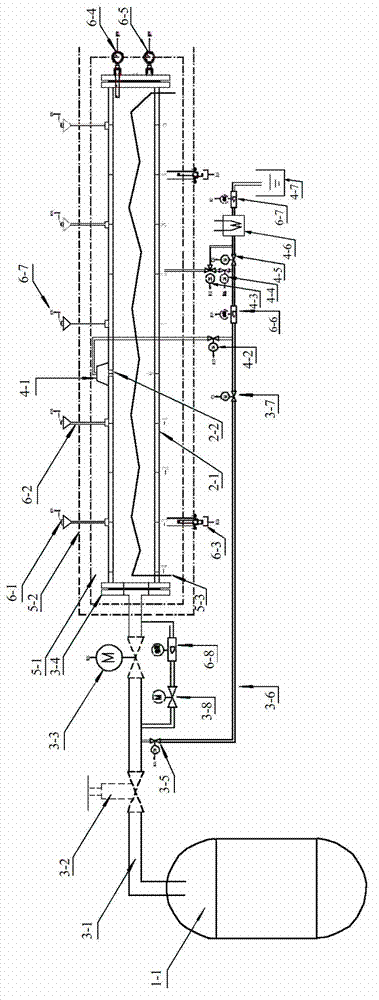

High-energy pipeline local leakage monitoring test bed for nuclear power station

ActiveCN103247358ASolve construction problemsNuclear energy generationNuclear monitoringHigh energyAcoustic emission

The invention belongs to the technical field of measurement in nuke industry, and in particular relates to a high-energy pipeline local leakage monitoring test bed for a nuclear power station. A structure of the high-energy pipeline local leakage monitoring test bed comprises a high-energy medium generation device, wherein the high-energy medium generation device is connected with a testing pipeline through a technological pipeline, the testing pipeline is connected with a leakage rate measurement pipeline, the testing pipeline comprises a testing straight pipeline and a crack simulation test piece, the technological pipeline comprises a main technological pipeline and a temperature and humidity steam testing pipeline as a branch pipeline, the testing straight pipeline is connected with the main technological pipeline, the temperature and humidity steam testing pipeline respectively extends to the crack simulation test piece and the leakage rate measurement pipeline respectively, a plurality of waveguide rods are arranged on the testing straight pipeline, acoustic emission sensors are arranged on the waveguide rods and are connected with signal acquisition cards through cables. The test bed provided by the invention can be used for finishing leakage simulation tests of high-energy pipelines, as well as research and development, demarcating and overhaul of acoustic emission leakage monitoring systems and temperature and humidity leakage monitoring systems.

Owner:CHINA NUCLEAR POWER ENG CO LTD

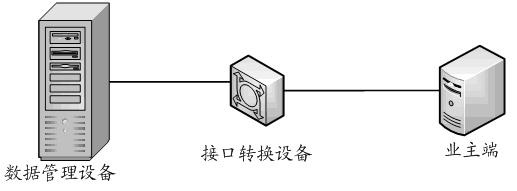

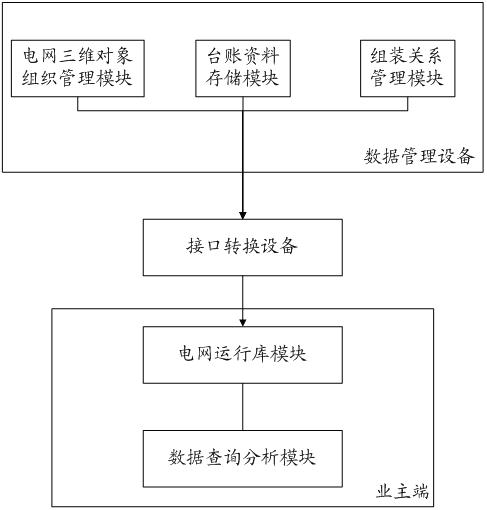

Power grid three-dimensional design result data management system and digital management method thereof

InactiveCN102254251AResolve design outcomesSolve construction problemsData processing applicationsPower gridData management

The invention discloses a power grid three-dimensional design result data management system and a digital management method thereof. The system comprises a three-dimensional design result data management device, an interface conversion device connected with the data management device, and an owner terminal connected with the interface conversion device. The data management device is used for recording the power grid three-dimensional design result; the interface conversion device is used for establishing a conversion relation, and is further used for handing over the conversion relation and the power grid three-dimensional design result to the owner terminal in a digital seamless way; and the owner terminal reads and stores the three-dimensional design result in a local disk file according to the conversion relation. The power grid three-dimensional design result data management system and the digital management method thereof are provided in the invention, the whole set of technical scheme fills the technology gap in the field of power grid three-dimensional design result data management, the actual state that the power grid three-dimensional design result is disjointed with construction, operation, management and monitoring is radically solved, and technical merit and work efficiency in design, building and management of the power grid are both improved.

Owner:GUANGDONG ELECTRIC POWER DESIGN INST

Construction method of structure conversion layer concrete girder steel bracket formwork support

The invention relates to a support construction method of a steel bracket template of a concrete crossbeam in a structure transition layer, which pertains to the technical filed of building construction methods. The method comprises the following steps: an embedded part of a joist supporting bracket is embedded; concrete of a column in the transition layer is poured; after the strength of the concrete of the column in the transition layer reaches more than C20, a column die in the transition layer is disassembled; a steel corbel, a shaped steel joist, a diagonal bracing shaped steel and a connecting shaped steel are arranged; a beam bottom formwork of the transition layer is laid; a preloading test is carried out to a steel joist of the beam of the transition layer; steel bars of the beam of the transition layer are bonded, and the erection of a template of a side beam form of the transition layer and a floor formwork is carried out; and concrete is poured onto the beam of the transition layer and a floor. A shaped steel-combined steel frame is adopted in the method, and the reinforced concrete column after pouring is used for supporting and bearing to form a combined bearing frame of the steel frame and the concrete column, thereby solving the construction difficulties of the formwork body with relatively high risk of the ultra high and overloaded crossbeam, ensuring the safe production of the construction process, solving the load bearing problem of the support frame by utilizing the frame column and guaranteeing construction quality. The method has the advantages of convenient construction and short construction period.

Owner:WENZHOU CONSTR GROUP

Prestressed concrete variable cross-section fish-bellied type continuous box girder construction method

ActiveCN105714684APrevent movementReduce usageBridge erection/assemblyBridge materialsPre stressEngineering

The invention discloses a prestressed concrete variable cross-section fish-bellied type continuous box girder construction method. According to the method, a formwork assembly part, steel bar binding and preserved hole setting part and box girder bottom plate and web plate concrete casting part in the existing prestressed concrete variable cross-section fish-bellied type continuous box girder construction method are improved. The construction difficulty is reduced, so that the construction of a prestressed concrete variable cross-section fish-bellied type continuous box girder becomes simple; the operation is simple.

Owner:CHINA FIRST METALLURGICAL GROUP

Method for intersection angle high-speed railway underpassing low-clearance girder erection

The invention relates to a method for intersection angle high-speed railway underpassing low-clearance girder erection, and solves the problems that in the interchange engineering, when the clearance to the bottom of the girder of the high-speed railway is small, a bridge girder erection machine cannot use the normal construction method to perform the girder erection. In the method, the bridge girder erection machine, carrying pole cross beams, girder transfer tracks, and a girder transfer trolley are effectively combined, the on-site owned conditions are completely utilized, so that the low clearance limit is avoided; and auxiliary facilities are arranged, so that beams are orderly fed in sections and steps. For the box girder erection at the crossings of the highway and railway, the bridge girder erection machine overhead crane is adopted on one end, a construction scheme of hanging chain blocks on the special carrying pole cross beams are adopted on the other end, so that the construction problem of low-clearance small box girder erection can be well solved.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

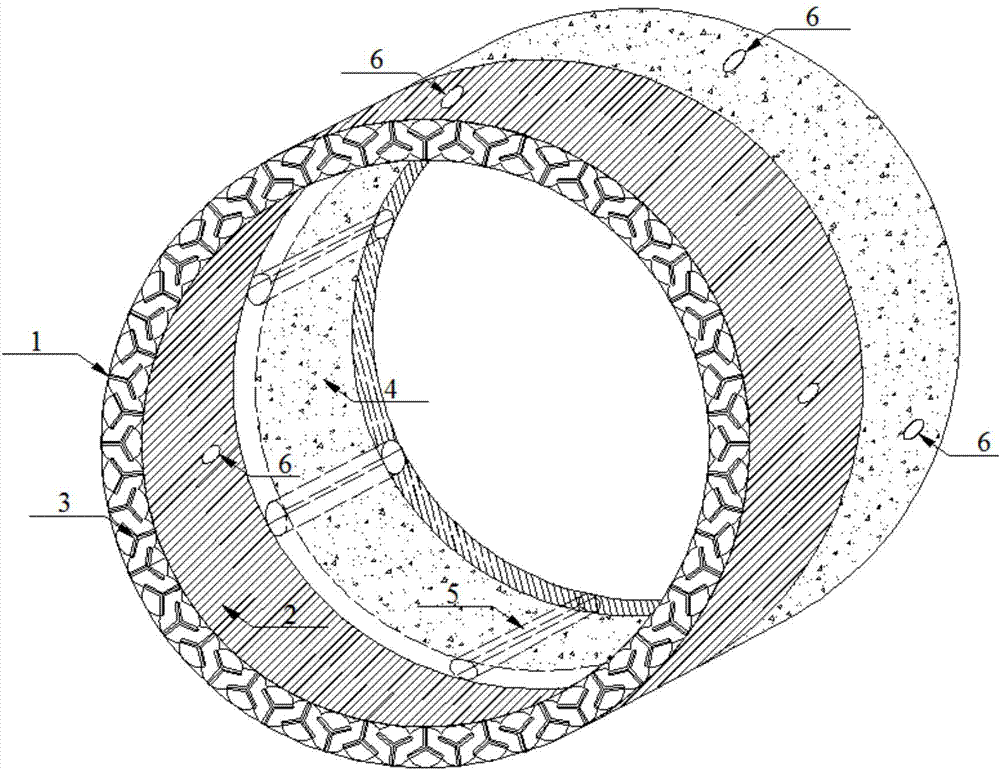

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

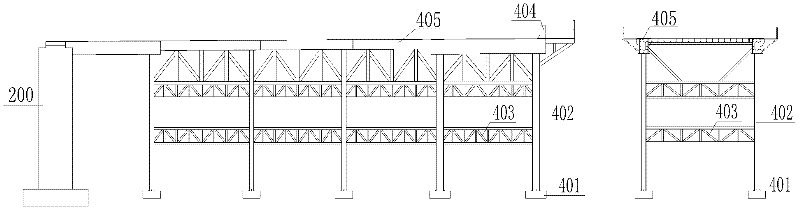

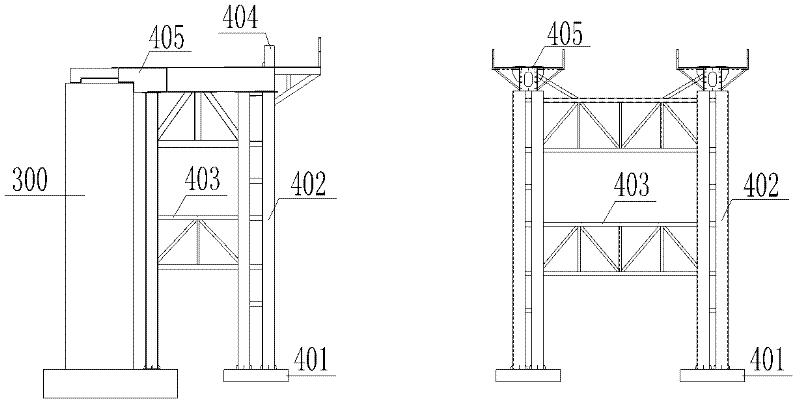

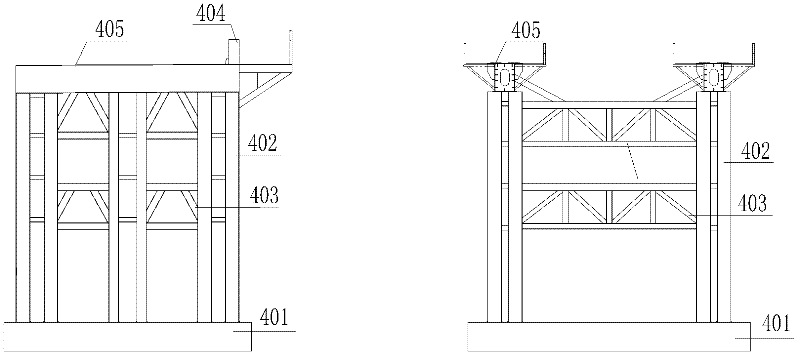

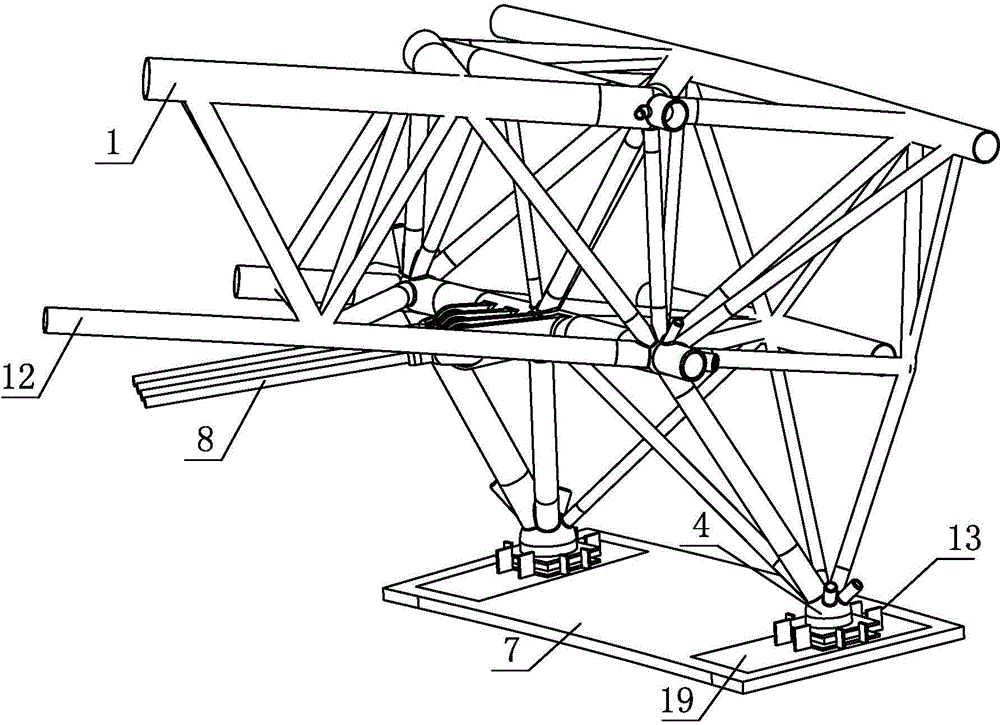

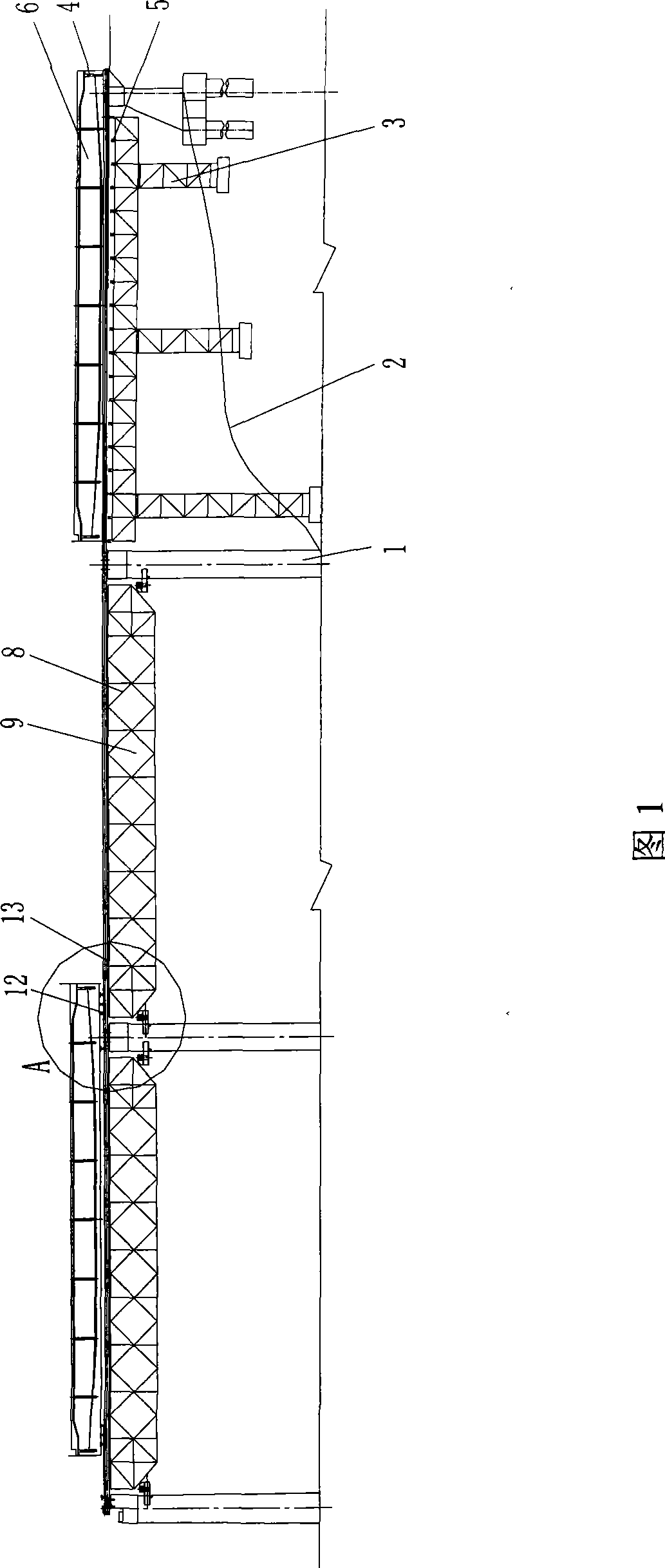

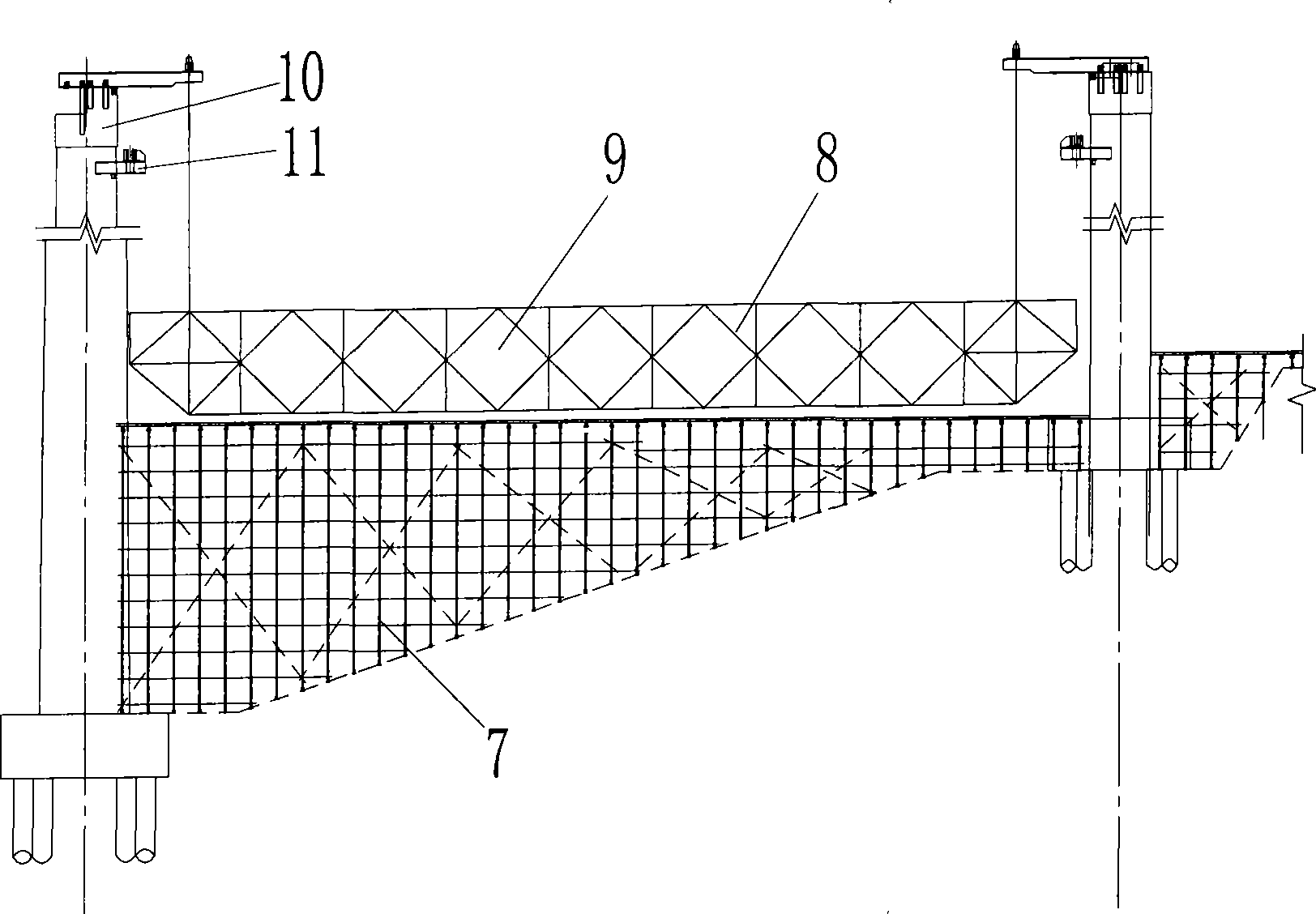

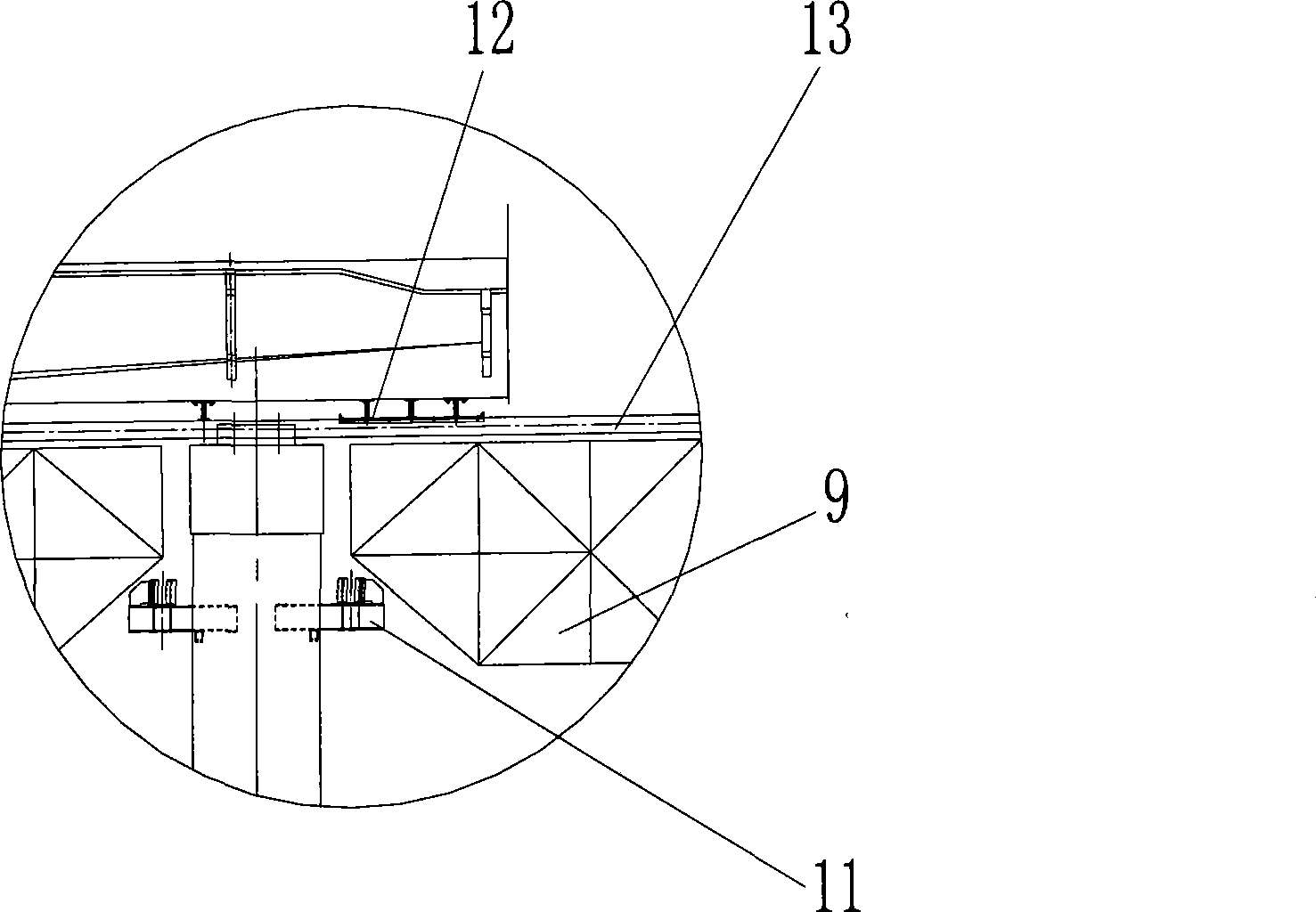

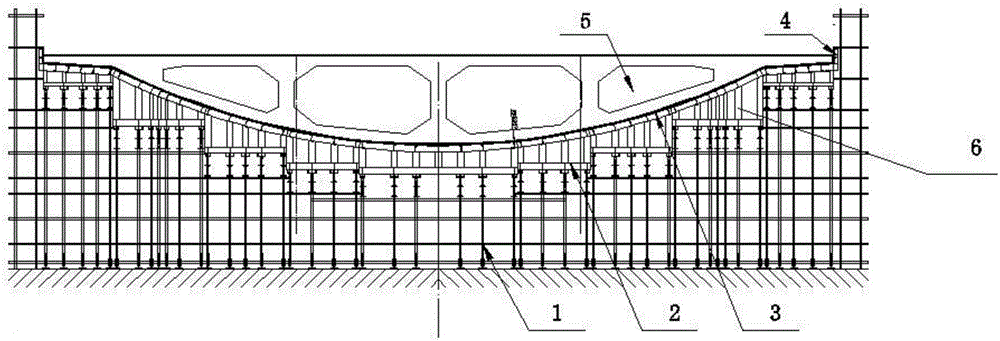

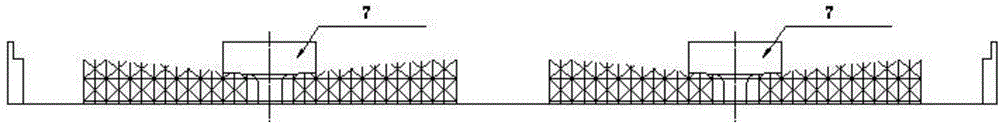

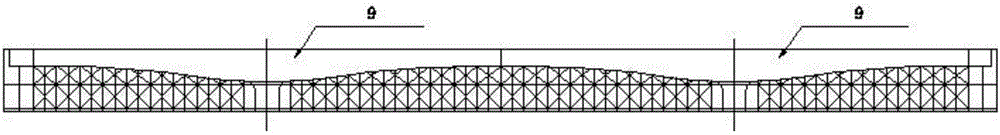

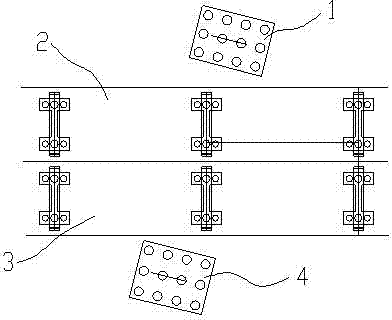

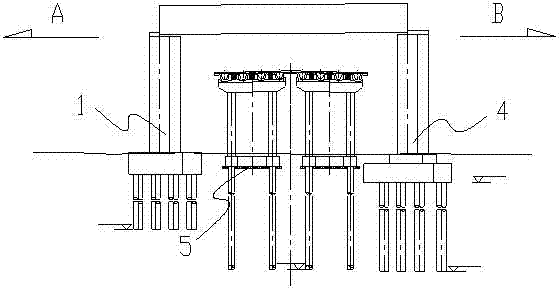

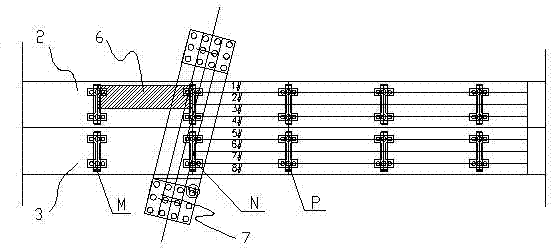

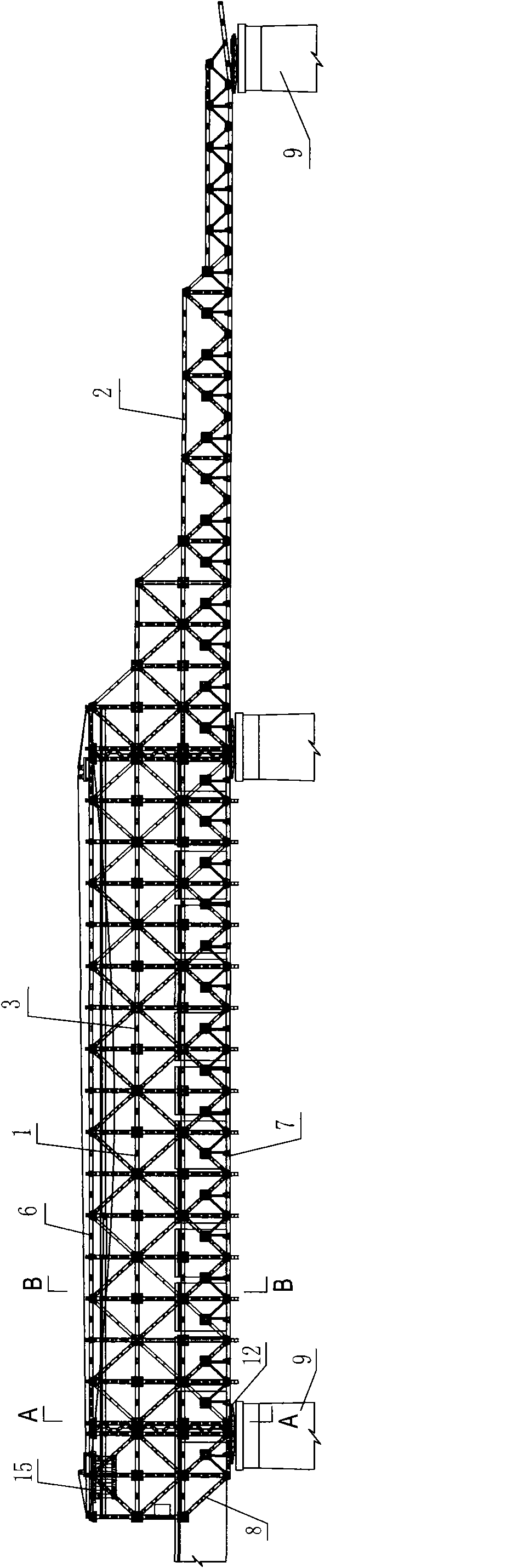

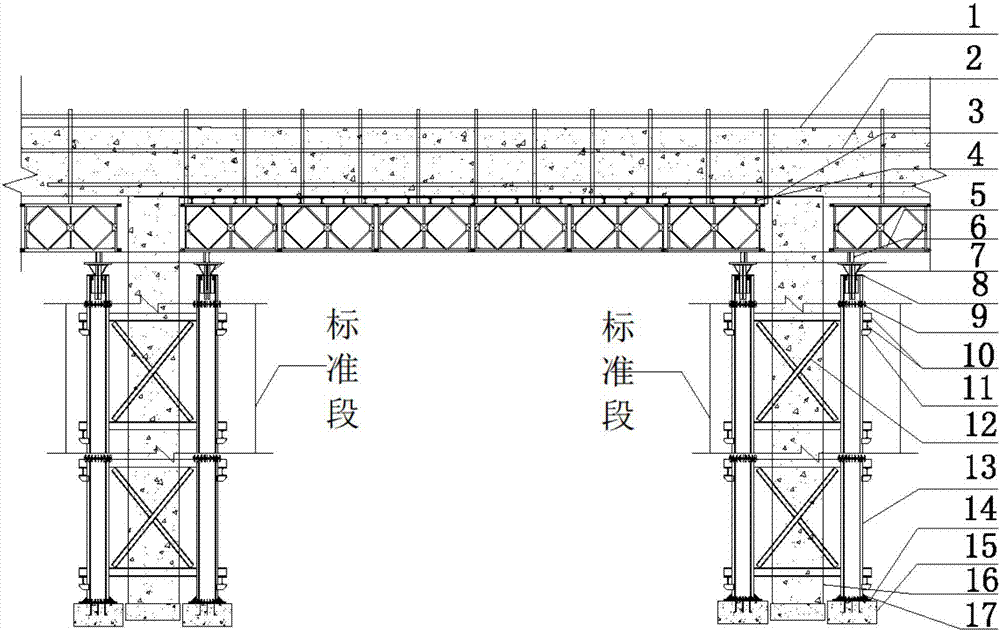

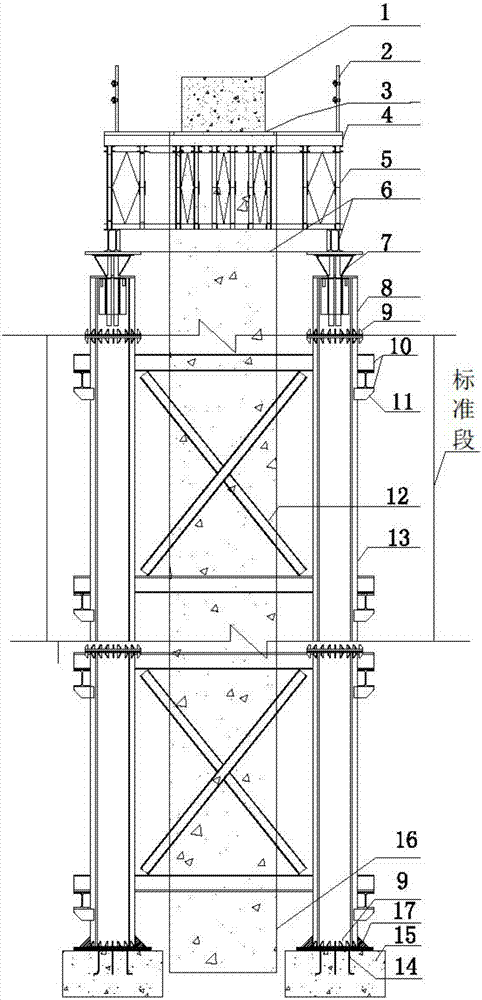

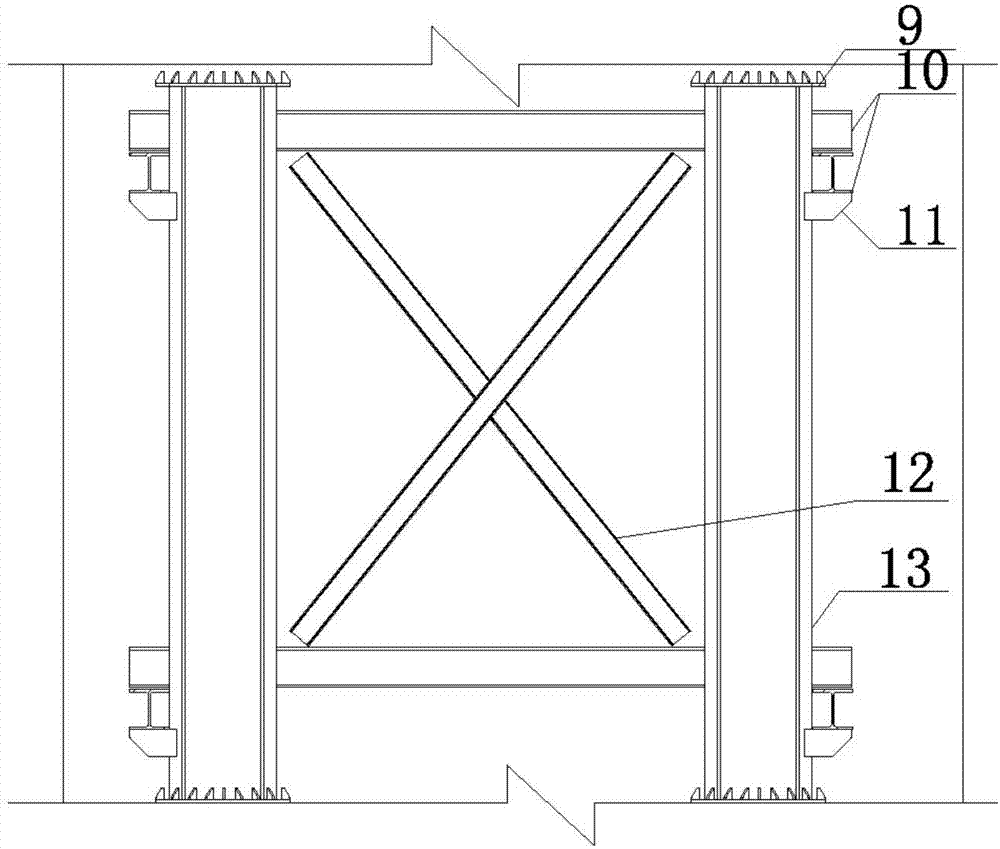

Large-span section assembling bridge manufacturing machine and assembling construction process thereof

ActiveCN101787678AReasonable structural designLarge spanBridge erection/assemblyStructural engineeringInvestment cost

The invention discloses a large-span section assembling bridge manufacturing machine and an assembling construction process thereof. The bridge manufacturing machine comprises a bridge manufacturing machine main body structure, a crown block system and a forward moving system, wherein the bridge manufacturing machine main body structure comprises a left main truss, a right main truss, an upper lateral brace and a lower lateral brace; the two main trusses comprise a main beam and a guide beam, and the guide beam has a three-layer step type truss structure; and a plurality of connecting rods comprise 87 type military beams and heterogenic rods. The assembling construction process comprises the following steps of: 1. assembling and constructing a first hole beam of a single-hole beam or a porous beam; forwards shifting the bridge manufacturing machine main body structure to construct the next hole beam across the hole; and repeatedly constructing till the integral construction of a constructed bridge is finished and the bridge manufacturing machine main body structure is disassembled. The bridge manufacturing machine has reasonable structural design, large span, convenient processing, manufacture, assembly and installation, strong weight capacity and low investment cost; and the used assembling construction process is simple, is convenient for realization and can be effectively suitable for the assembling construction process of bridge sections with the span of 64m and below 64m.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

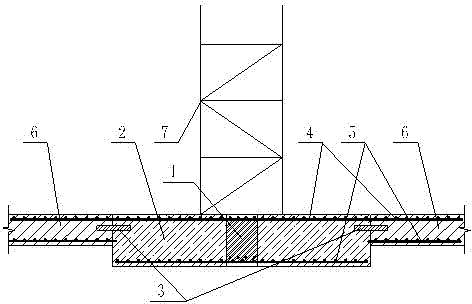

Tower crane foundation in building basement and manufacturing method of tower crane foundation

ActiveCN102677675AImprove stabilityGuaranteed safe operationProtective foundationBasementReinforced concrete

The invention discloses a tower crane foundation in a building basement and a manufacturing method of the tower crane foundation. The tower crane foundation is manufactured into an orthogonal beam slab type reinforced concrete tower crane foundation composed of an orthogonal beam and a slab. During manufacture, a pit of the tower crane foundation is dug in the building basement, and then the orthogonal beam is poured in a traditional mode of pouring reinforced concrete and the slab is poured on the orthogonal beam, and meanwhile, at least one circle of water retaining boards is fixedly inlaid around the slab; base plate surface ribs of basement base plates are embedded according to a traditional mode of pouring the basement base plates, and then the basement base plates are poured; and after the basement base plates are poured, the water retaining boards are inserted into the basement base plates around the slab, so that the orthogonal beam slab type reinforced concrete tower crane foundation is connected with the basement base plates into one. The tower crane foundation has the advantages of fastness, convenience and high efficiency in construction, low construction and operation cost, reliability in performance, safety in operation, convenience in operation and the like.

Owner:CHINA CONSTR FOURTH ENG DIV

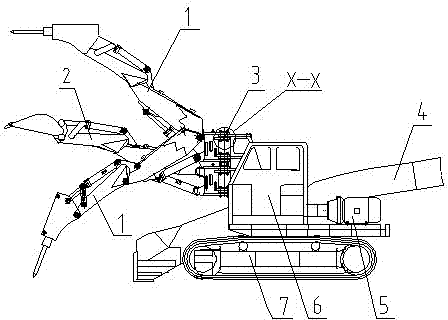

Multi-arm breaking excavation-type heading machine

InactiveCN102926750ASolve construction problemsImprove reliabilitySlitting machinesEngineeringUltimate tensile strength

The invention discloses a multi-arm breaking excavation-type heading machine which comprises a rack, a walking mechanism (7), a transporting mechanism (4), a hydraulic system (8), an electrical system (5), an operating drive mechanism (6) and an excavating mechanism (2), wherein the excavating mechanism is connected with the rack through a connecting device (3); upper parts at two sides of the excavating mechanism are respectively provided with breaking mechanisms (1) which are connected with the rack through the connecting device; and the breaking mechanisms comprise breaking hammers, breaking hammer oil cylinders, chain frames, small arms, small arm oil cylinders, large arm oil cylinders, large arm seats, large arms and rotary oil cylinders. According to the multi-arm breaking excavation-type heading machine, the time spent on breaking large stone materials and treating protruded dangerous stones on roadways manually is shortened greatly; not only is the labor intensity relived, but also the manual working time is shortened, the roadway heading construction progress is improved, the heading construction cost is lowered, and the safety operation coefficient is improved; and the multi-arm breaking excavation-type heading machine provided by the invention is high in use reliability, good in durability, convenient to operate, and high in adaptability, and has long service life.

Owner:李凯

Ultrahigh large-span concrete cast-in-place beam bailey truss framework construction method

ActiveCN107090975AIncrease stiffnessImprove integrityForms/shuttering/falseworksSupporting systemFalsework

Disclosed is an ultrahigh large-span concrete cast-in-place beam bailey truss framework construction method. The measures such as erecting lattice columns and bailey trusses are adopted. The method comprises the steps of arranging a lattice column foundation, erecting the lattice columns, mounting cross bridgings among the columns, installing a top movable head, erecting cover beams, erecting the bailey trusses, installing distributive beams, mounting a side protective barrier, laying a keel, laying templates and the like. A simple framework supporting system which is small in occupied site, solid and reliable and convenient to install and disassemble is formed, a great deal of conventional steel tube floor scaffold material input is avoided, and at the same time, the labor intensity of workers is also reduced. The ultrahigh large-span concrete cast-in-place bailey truss framework construction method can adapt to ultrahigh large-span concrete cast-in-place beam projects in various building constructions.

Owner:中建五局第三建设有限公司

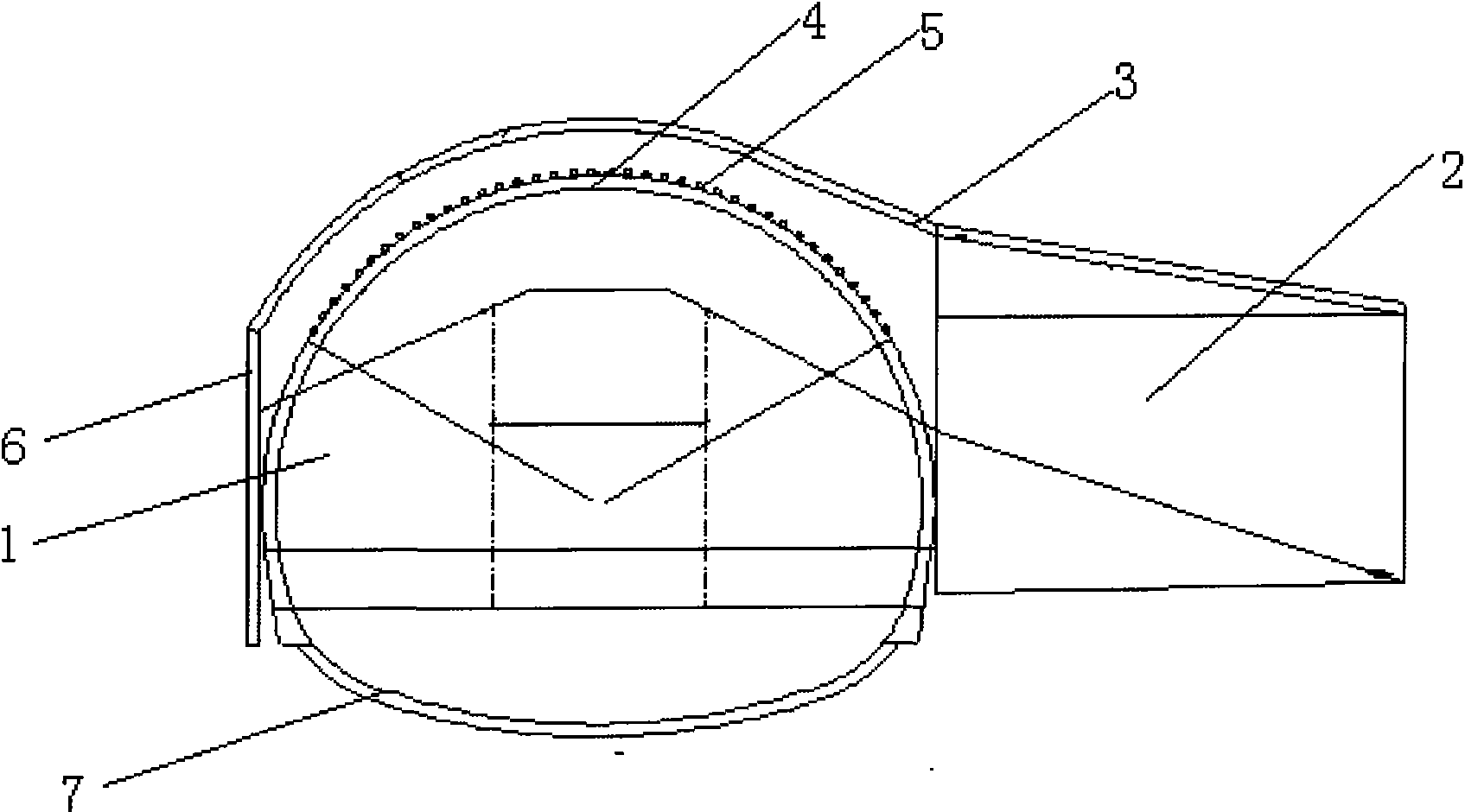

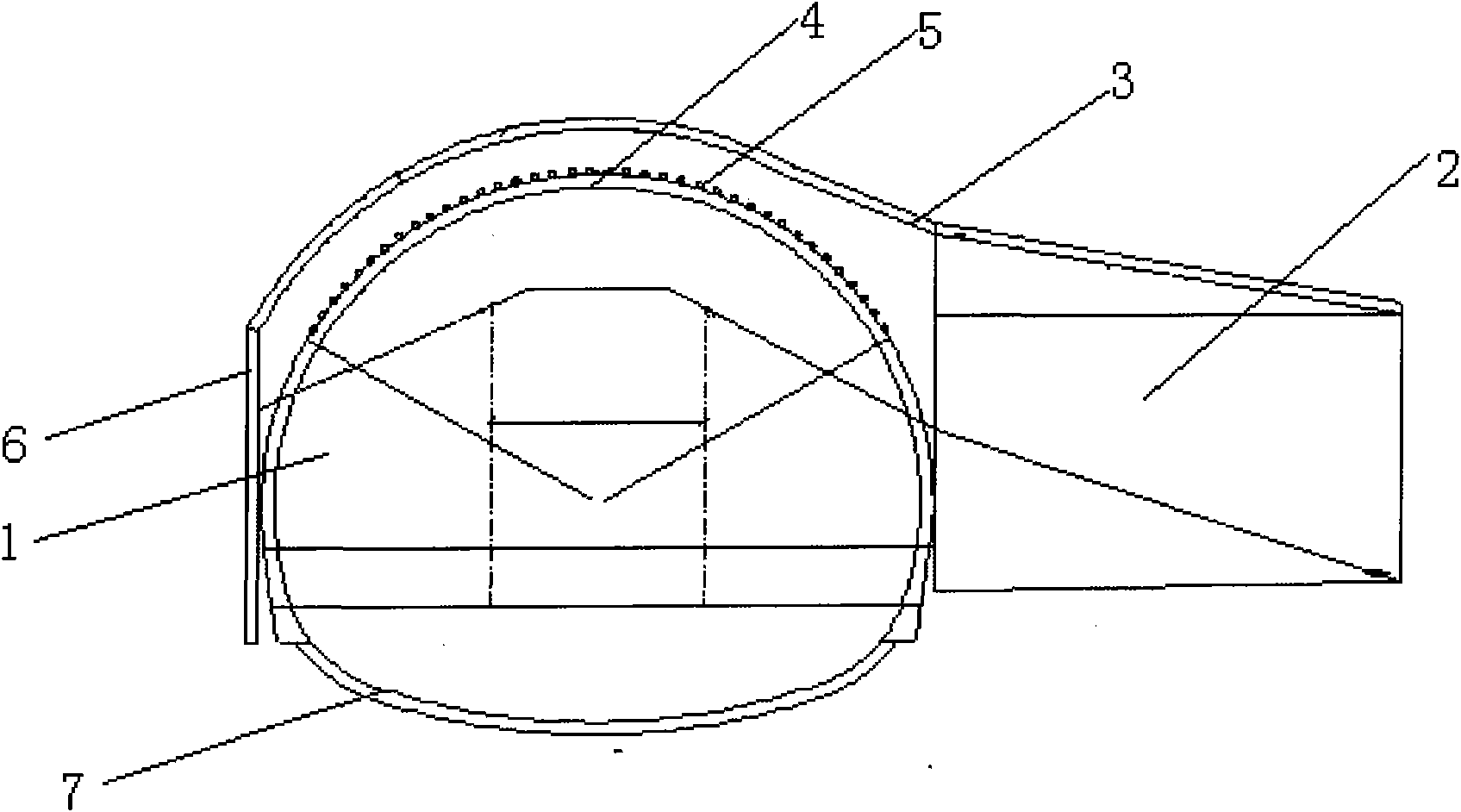

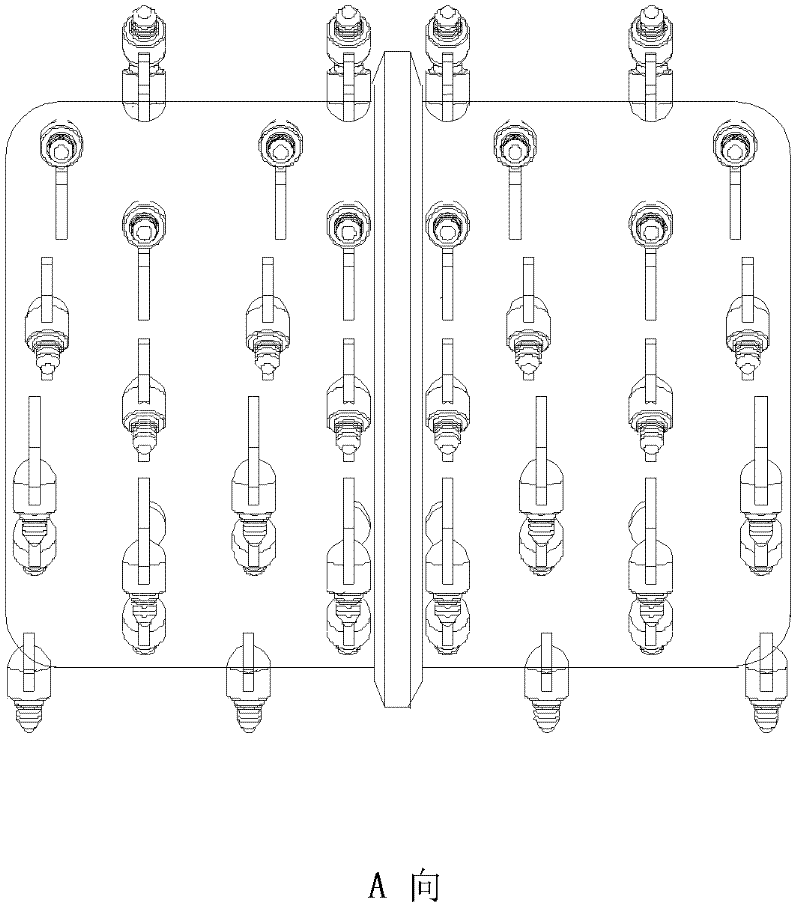

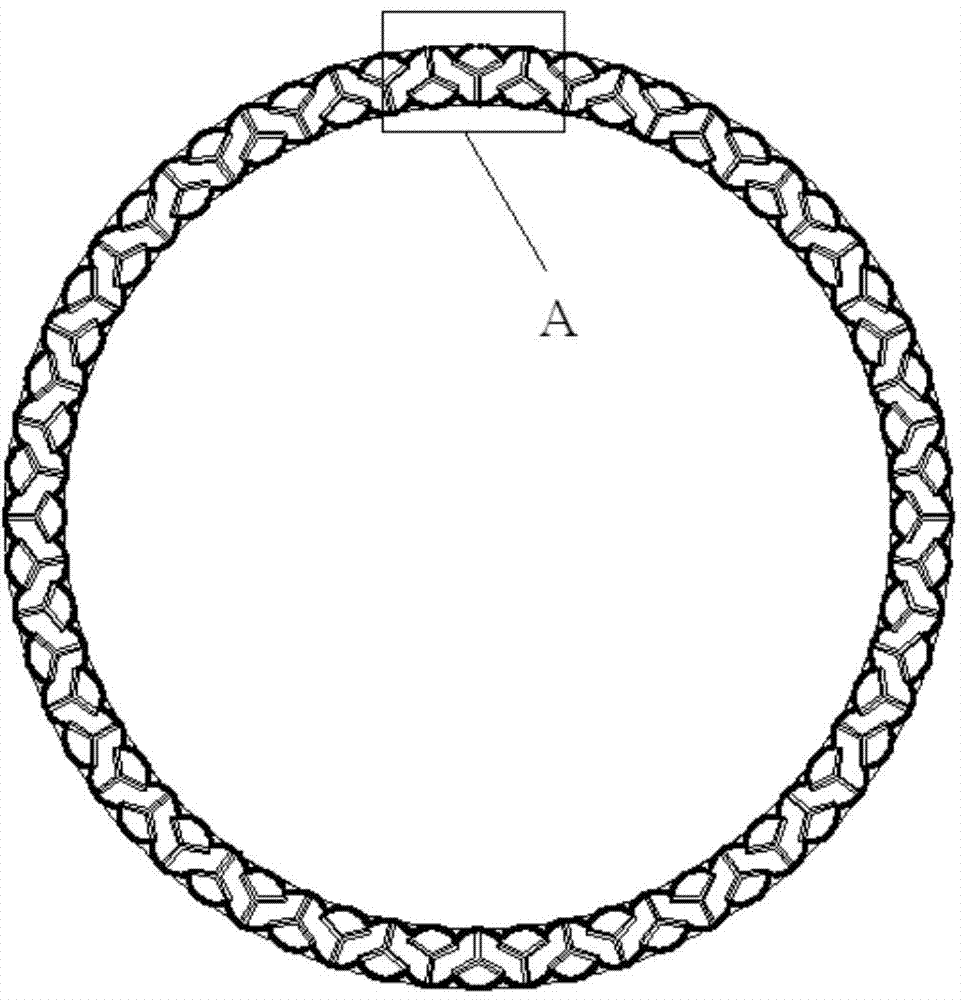

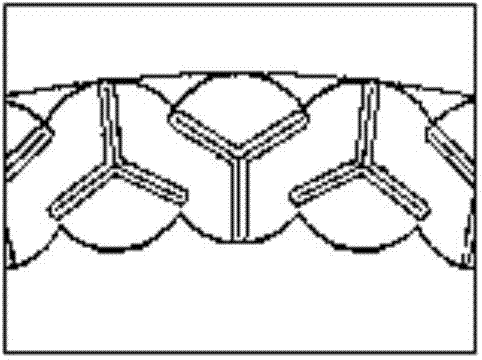

Annular pipe jacking machine

InactiveCN104712339ASolve construction problemsFlexible section shapeUnderground chambersTunnel liningGyroscopeControl system

The invention relates to an annular pipe jacking machine which comprises an annular shell, a cutter head, a muddy water system, a synchronous grouting system, a jacking mechanism, a guide system and a control system. The annular shell comprises an outer-layer shell body and an inner-layer shell body, the cutter head is arranged in the annular shell, the muddy water system comprises a mud inlet and outlet pipeline and a mud and water separation treatment device, the mud and water separation treatment device is arranged on the ground, grouting pipes of the synchronous grouting system are arranged in the annular shell and sections of a jacking pipe respectively, thixotropic slurry is injected through a grouting hole, the jacking mechanism is arranged in a jacking pipe work well and used for jacking the sections of the jacking pipe, the guide system comprises a gyroscope, a tilt meter and a height gauge which are used for determining the posture of the annular pipe jacking machine and tunneling precision, and the control system is arranged on the ground and used for performing cooperative control on the cutter head, the muddy water system, the synchronous grouting system, the jacking mechanism and the guide system. Compared with the prior art, an excavated section is small, the shape of the section is flexible, and the annular pipe jacking machine is suitable for building tunnels with large sections and extra-large sections.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com