Patents

Literature

498 results about "Macromolecule synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthesis of Macromolecules. In general, each cell synthesizes its own macromolecules and does not receive them previously formed from other cells. For example, muscle cells make their own glycogen, rather than receiving it intact from the:

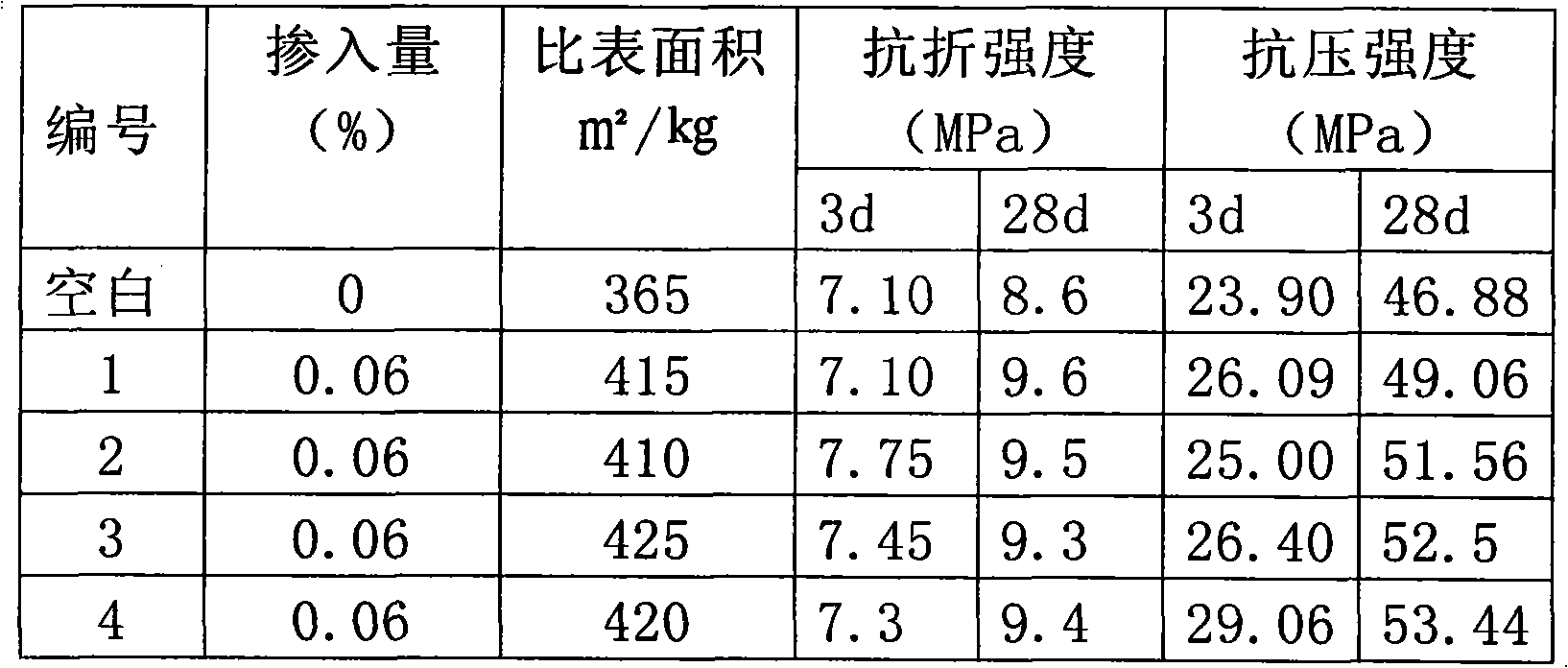

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

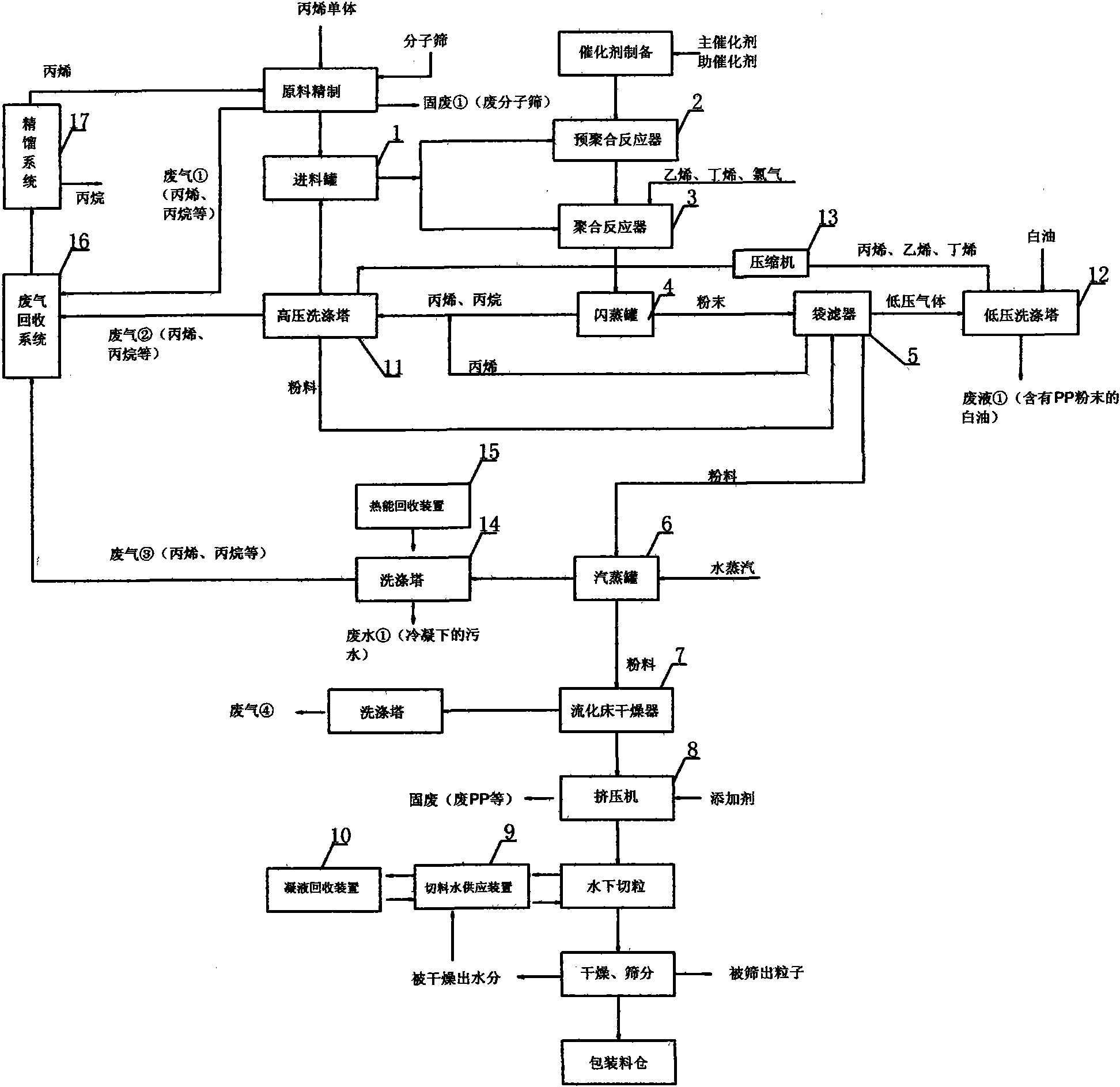

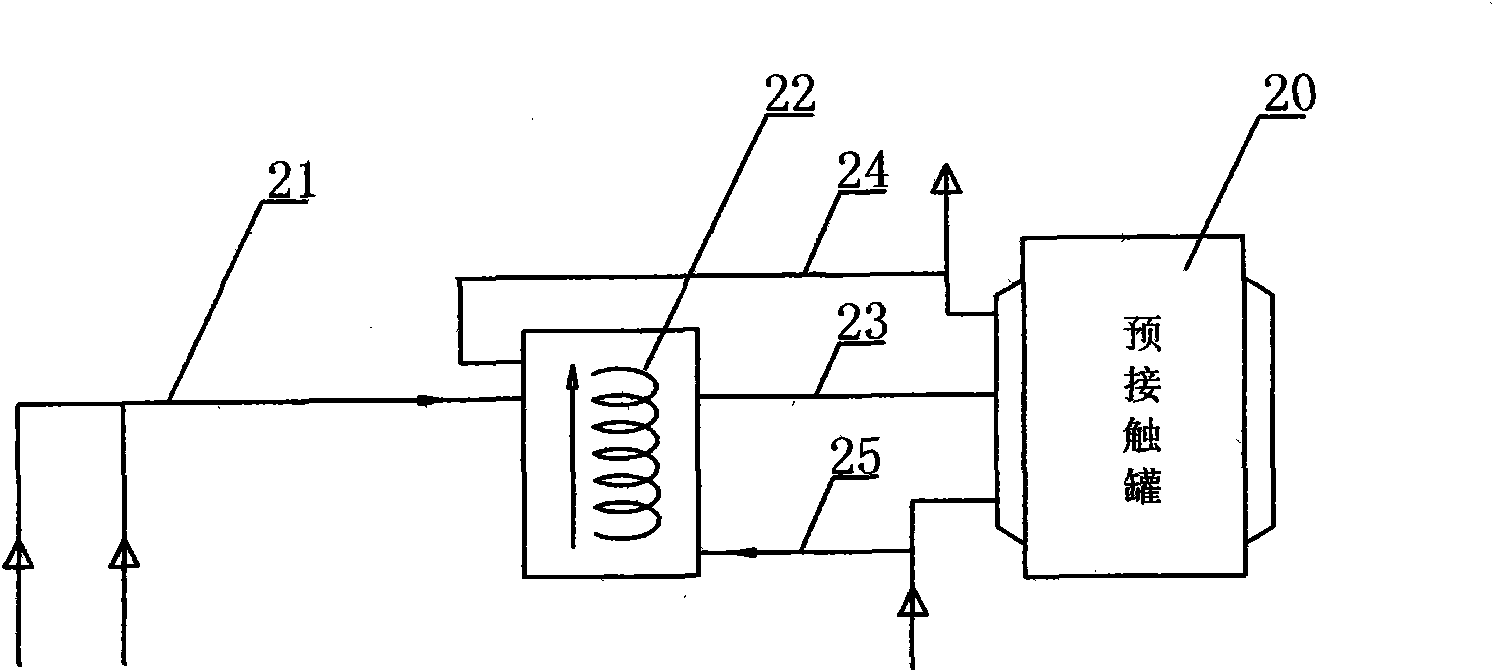

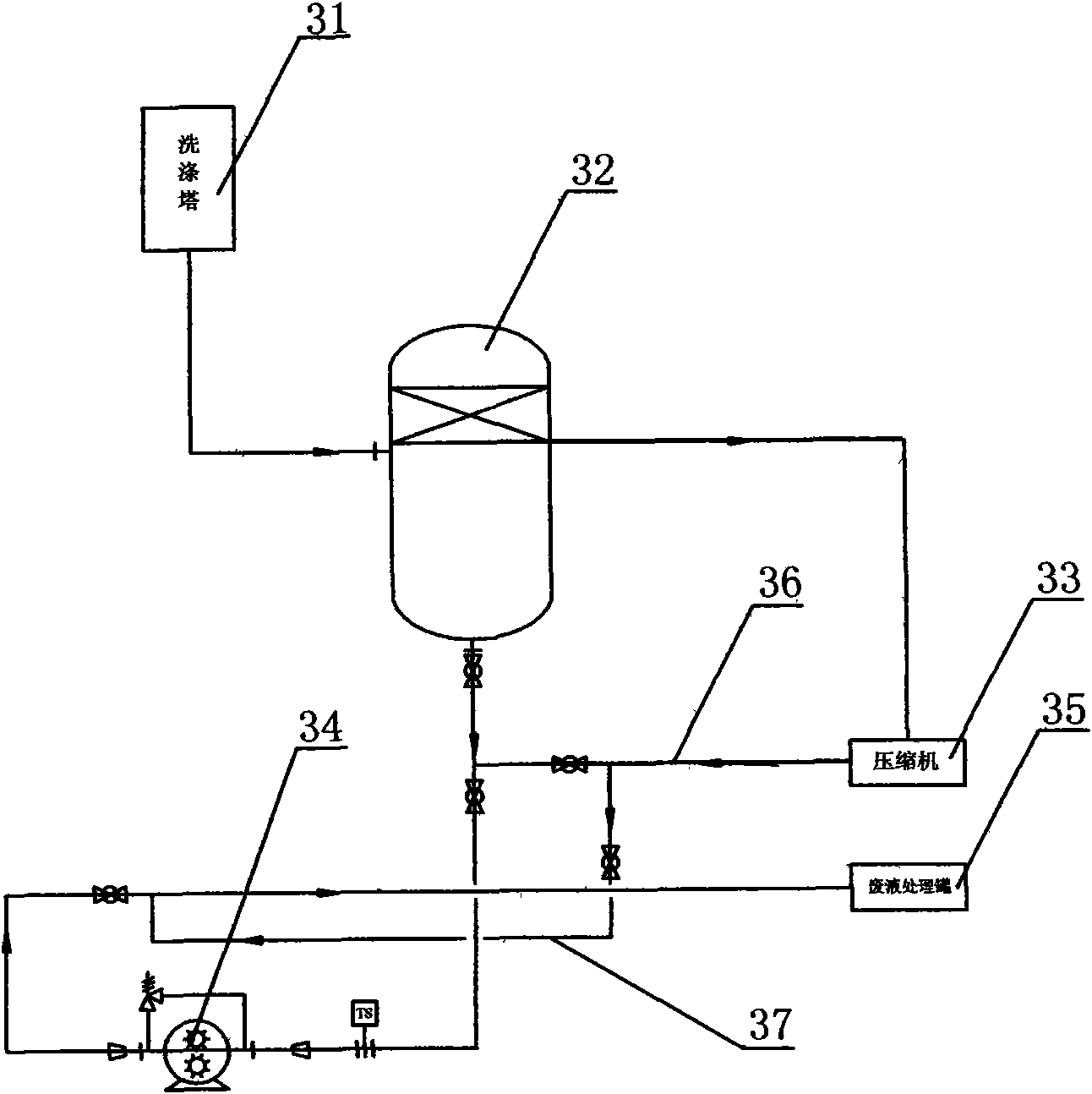

Production method of polypropylene and device thereof

The invention discloses a production method of polypropylene with an English name of Polypropylene (short for PP) and a device thereof, belonging to the technical field of polymer synthesis. The production method comprises the steps of: prepolymerization, polymerization-flash vaporization, degasification-steaming, drying-extruding, granulating-product package and the like. By optimizing the technique steps and parameters of prepolymerization, polymerization, flash vaporization, degasification, steaming, drying, extruding, granulating and the like, the invention improves the utilization ratio of raw materials, simultaneously adds a waste gas and waste liquor recovery system creatively, adds a heat recovery system of a washing tower, uses recovered heat for heating grease, and improves heat utilization ratio; the setting of powder and condensate recovery device improves production efficiency and reduces production cost; a standby water tank is added for granulating and water supply, thus preventing machine stopping caused by fault of the water tank and improving production efficiency; and the improvement of gas-exiting pipelines and exhaust pipelines eliminates potential safety hazard, saves cost and has good environment protection.

Owner:ZHEJIANG SHAOXING SANJIN PETROCHEM

Fluorine-silicon modified self-crosslinking acrylic ester emulsion and preparation thereof

InactiveCN101348595ASimple preparation processReaction conditions are easy to controlCoatingsPolymeric surfacePolymer science

The invention provides a fluorine-silicon modified self-crosslinking acrylic ester emulsion and a preparation method thereof, belonging to the technical field of polymer synthesis. The emulsion is a product formed by organosilicon monomers, fluoride-containing acrylic monomers, (methyl) acrylic monomers and self-crosslinking monomers through core-shell emulsion polymerization. The preparation method adopts a core-shell emulsion polymerization method, thereby ensuring that the fluoride-containing acrylic monomers tend to surface polymerization, and fluorine atoms tend to polymer surface in emulsion film forming process; moreover, the monomers capable of self-crosslinking is added to a shell layer, so as to utilize the crosslinking of the monomers to fixedly limit the migration of the fluorine atoms towards the inside of latex particles, as well as the swing of chains, thereby ensuring that the performances of the fluoride-containing emulsion are completely embodied. The preparation method improves the water resistance, stain resistance, solvent resistance, weather resistance and other comprehensive performances of the emulsion. The fluorine-silicon modified self-crosslinking acrylic ester emulsion prepared through the preparation method can be widely applied to high-grade building paint, industrial paint and wooden ware varnish. Moreover, the preparation method has the characteristics of simple manufacturing process, easy reaction condition control, good emulsion stability and environment-friendly property.

Owner:PEKING UNIV +1

Self-crosslinking acrylic ester composition emulsion for plastic printing ink and preparation thereof

A self-crosslink acrylic ester compound emulsion for plastic ink and a preparation method thereof belong to the technical field of macromolecular synthesis. In order to solve the problems of the'ink shrinking' of the plastic ink on the surface of plastics and the adhesion force, the invention provides the self-crosslink acrylic ester compound emulsion for the plastic ink. The latex is a product obtained through emulsion polymerization which is carried out by a functional monomer with low polymerization shrinkage, low surface tension and higher permeability and other vinyl monomers. The invention also discloses the preparation method for the emulsion. The preparation method which is carried out through the pre-emulsification nucleocapsid emulsion technology mainly comprises the following two steps: 1. preparing a seed nucleus emulsion; and 2. preparing the nucleocapsid emulsion based on the seed nucleus emulsion to finally obtain the self-crosslink acrylic ester compound emulsion for the plastic ink. The emulsion which is bright and transparent after film forming has good adhesion force to a plastic base material, and the adhesion force to PP, PE films is particularly excellent.

Owner:PEKING UNIV +1

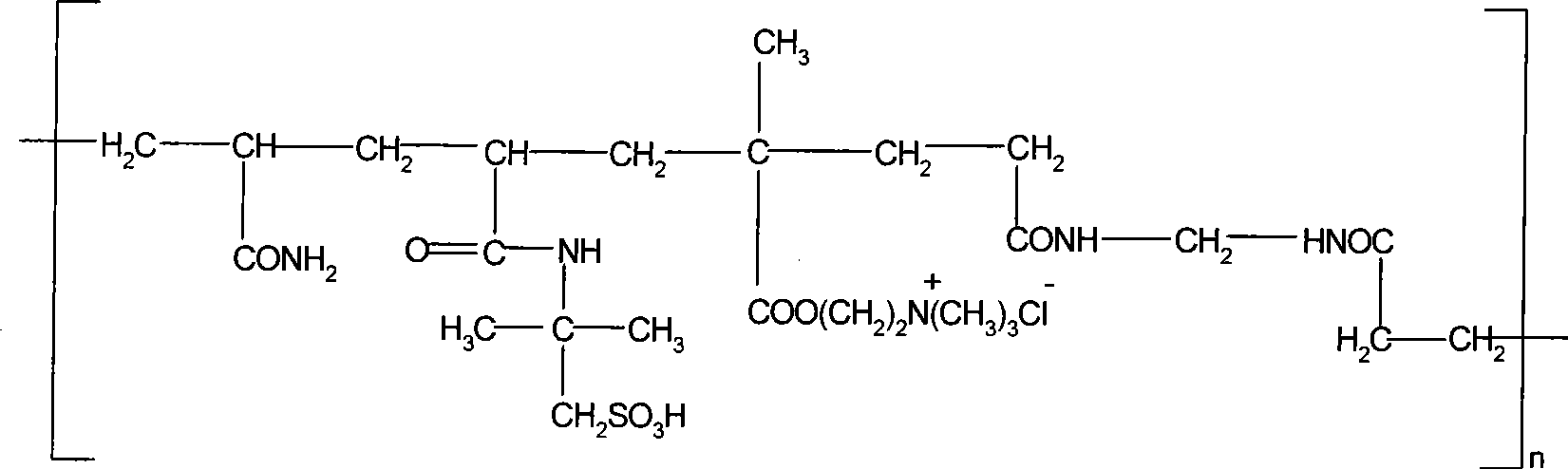

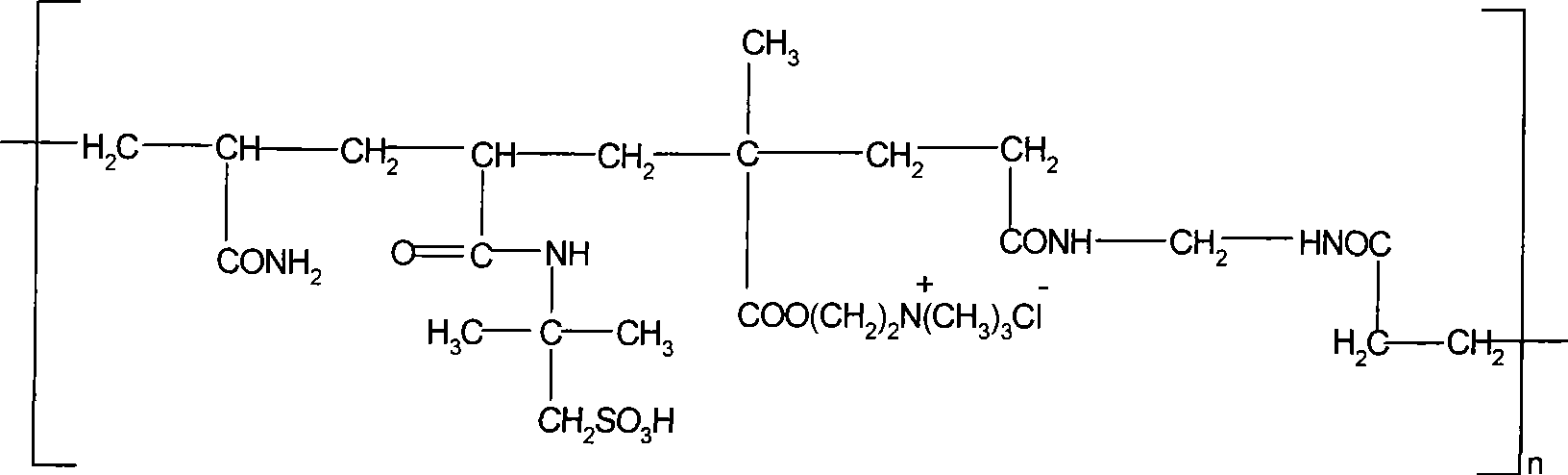

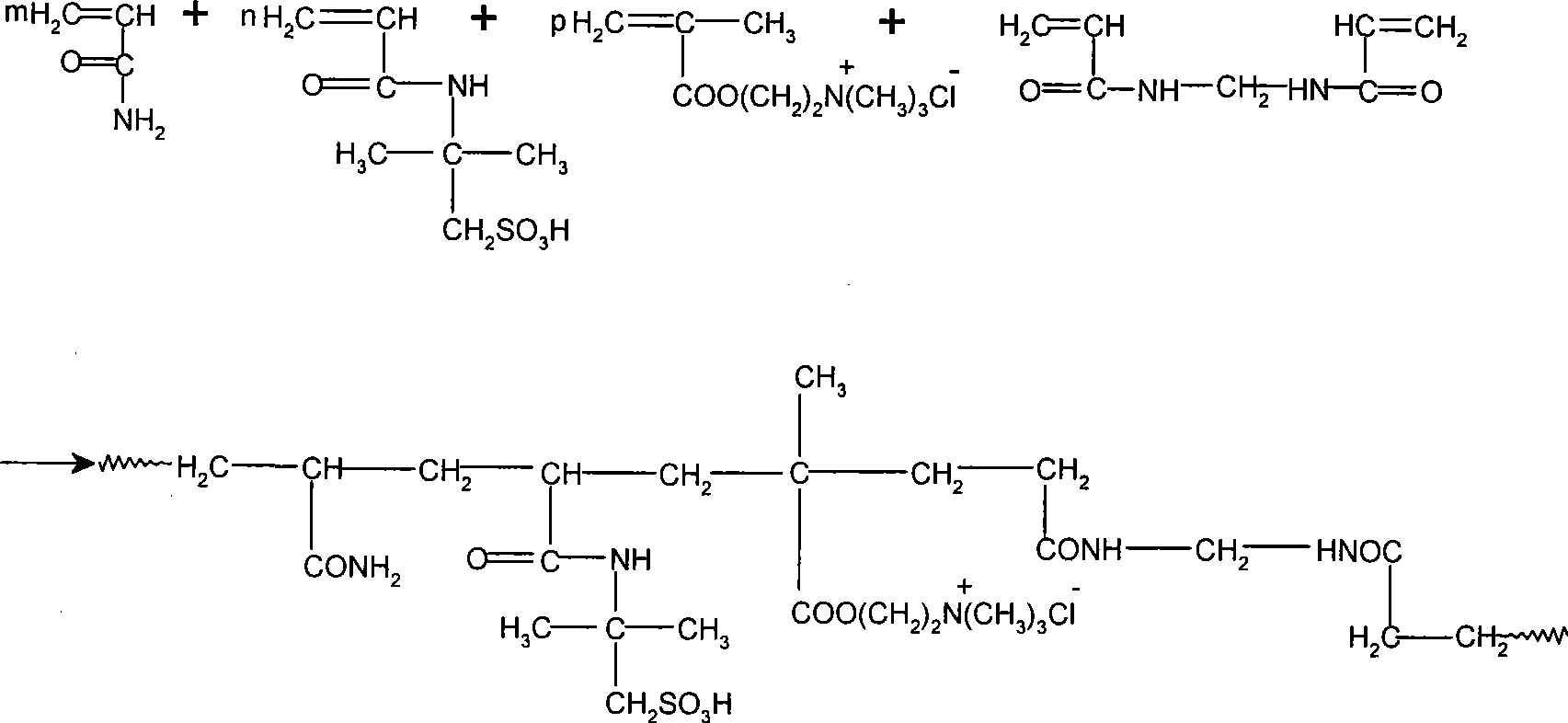

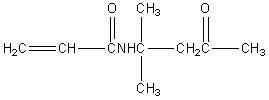

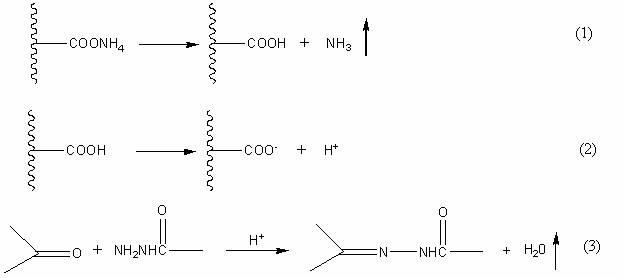

Acid fracturing thickening agent and preparation thereof

InactiveCN101412906AHigh viscosityImprove high temperature resistanceDrilling compositionTemperature resistancePetroleum

The invention discloses a novel acidified fractured thickening agent and a preparation method thereof, and belongs to the field of macromolecular synthesis. The thickening agent is prepared by the method comprising the following steps: adopting a water solution polymerizing method, oxidizing and reducing an evocating agent, adding proper amount of chain extender into a sealed system, and copolymerizing the mixture by the reaction of methacryloyloxy trimethyl-ammonium chloride (DMC), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The thickening agent has the advantages of acid resistance and high temperature resistance, has favorable thickening effect, and is applied to the fields of acidified fracturing construction, strengthening oil extraction work and the like in petroleum extraction.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

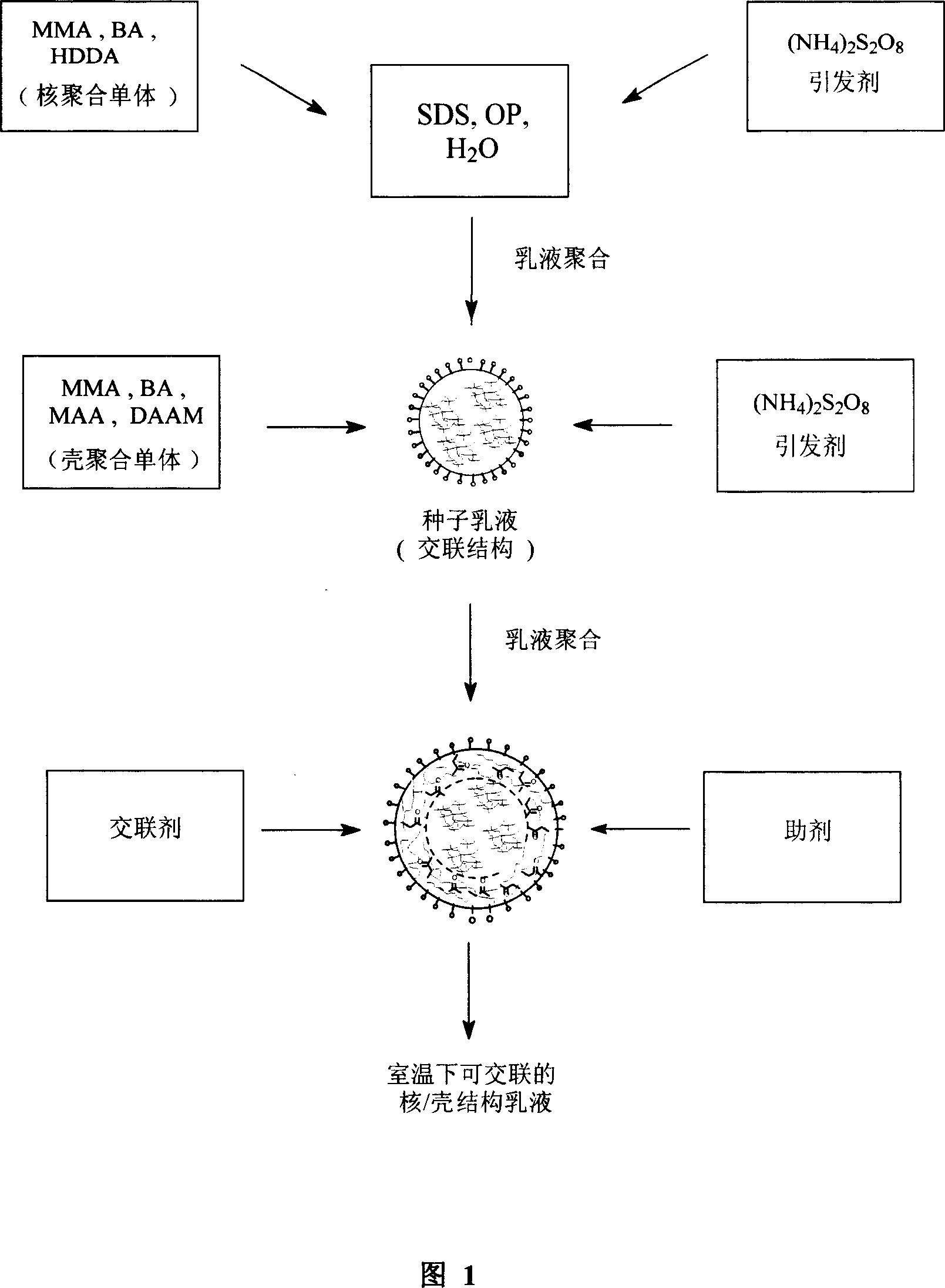

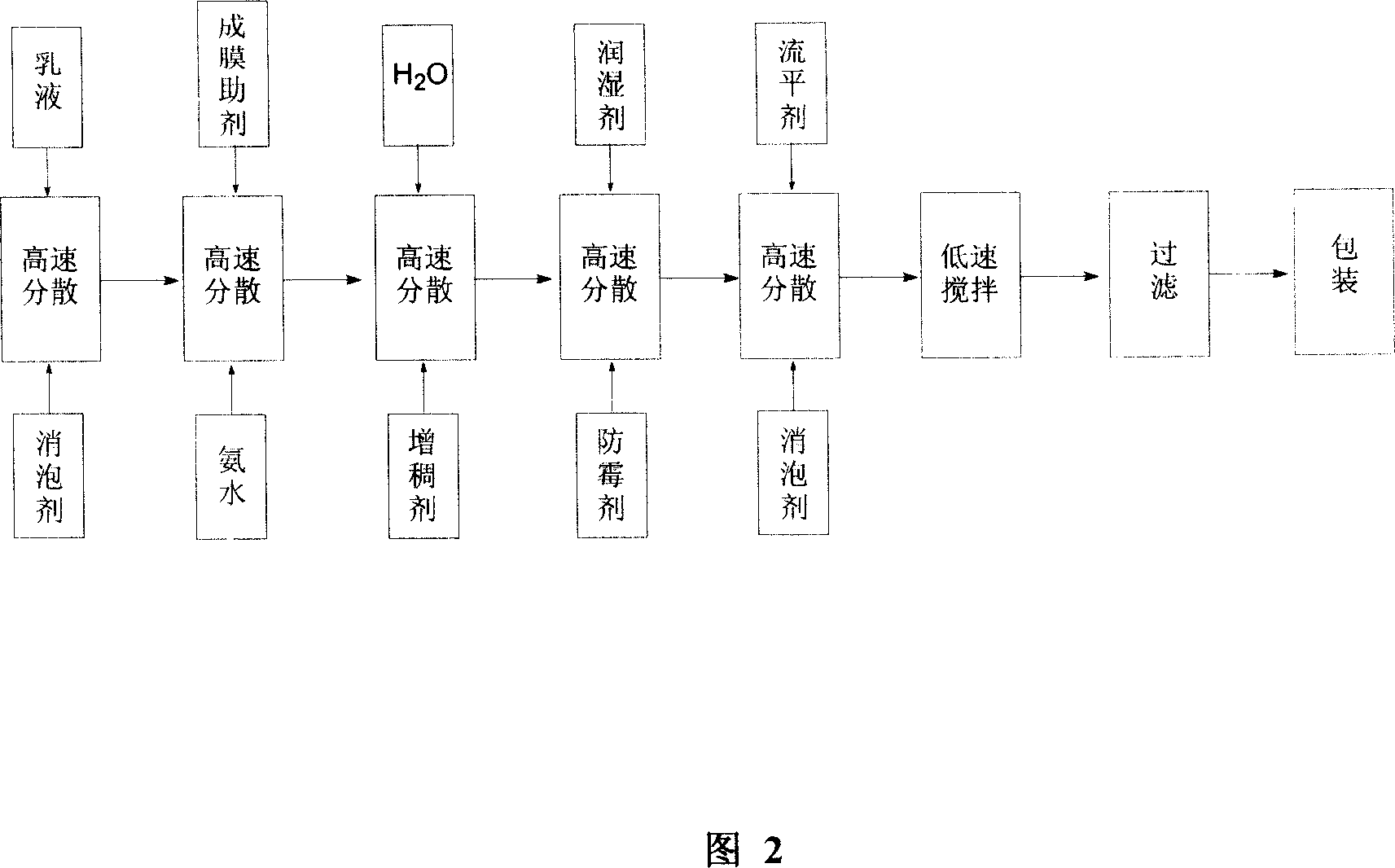

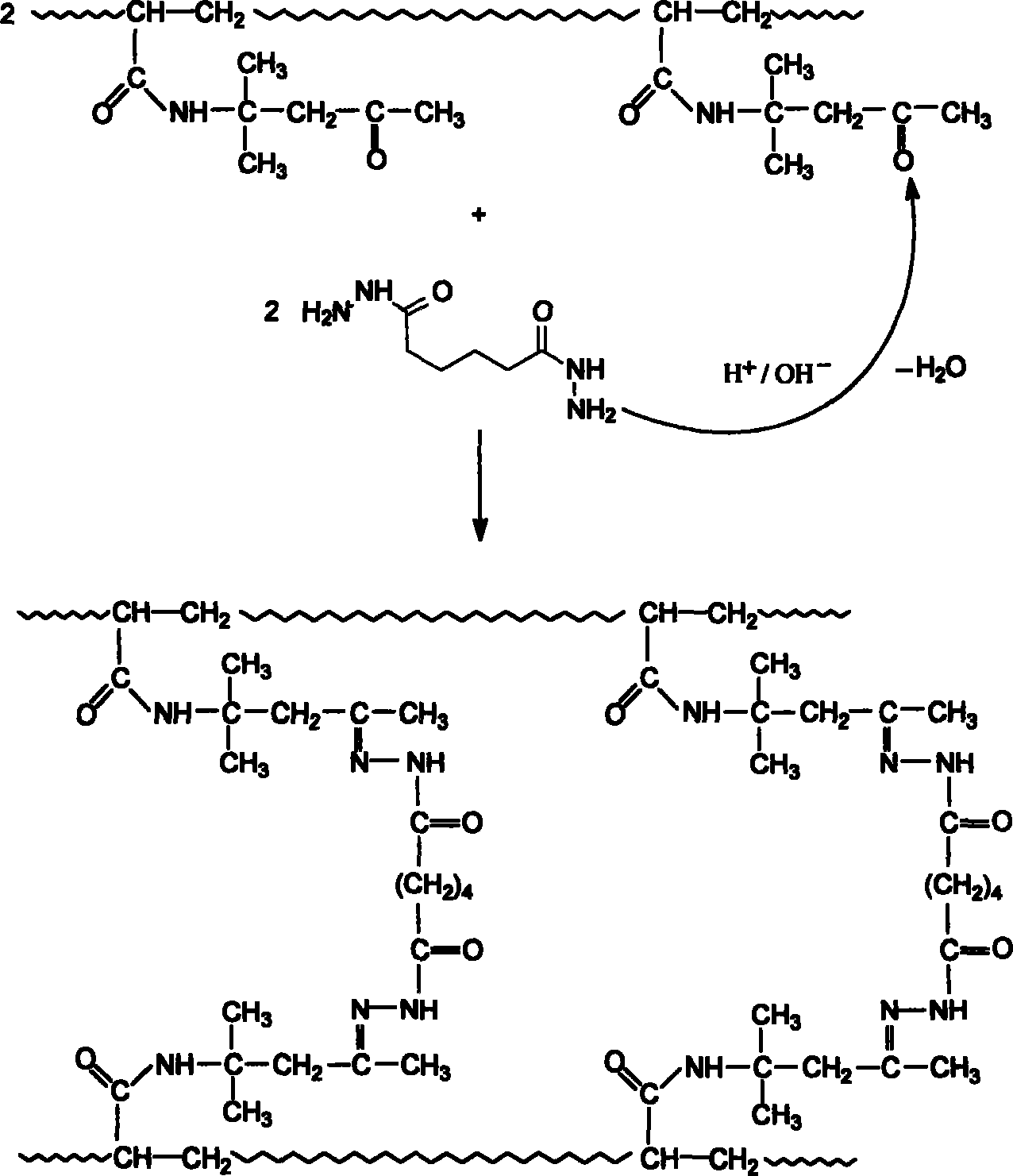

Acrylic ester elastic emulsion of room temperature self-crosslinking core-shell structure and preparing method thereof

InactiveCN102321326AImprove scratch resistanceImprove stain resistanceCoatingsCross-linkPolymer science

The invention relates to an acrylic ester elastic emulsion of a room temperature self-crosslinking core-shell structure and a preparing method thereof, and belongs to the field of macromolecular polymer. The purpose of the invention is to improve the application requirements of elastic coating, such as low-temperature elasticity and anti-contamination, tensile strength and flexibility and the like. The technical scheme adopted in the invention is as follows: using a core-shell polymerization process, introducing cross-linking monomer to shell layer, designing core layer glass state temperature (Tg) to be minus 40 to minus 15 DEG C and shell layer glass state temperature Tg to be 5 to 40 DEG C, and after polymerization of the emulsion and regulating pH to be 8 to 9, adding a certain amount of cross-linking agent, and obtaining the room temperature self-crosslinking elastic emulsion of core-shell structure. The elastic emulsion prepared by the invention can be self-crosslinked at room temperature, and has excellent low-temperature elasticity, scratch resistance, anti-contamination and surface finish, and can meet the requirements of actual application.

Owner:SKSHU PAINT

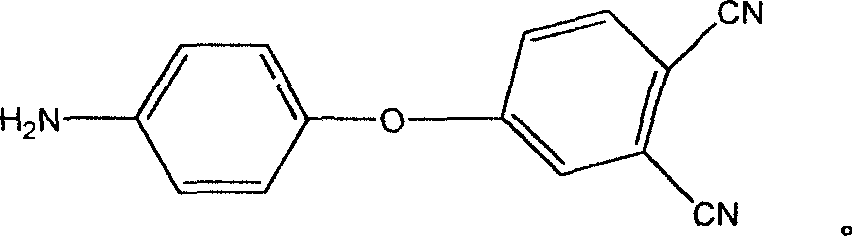

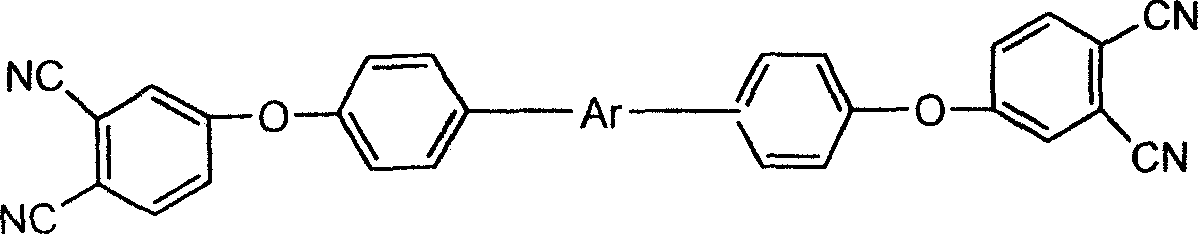

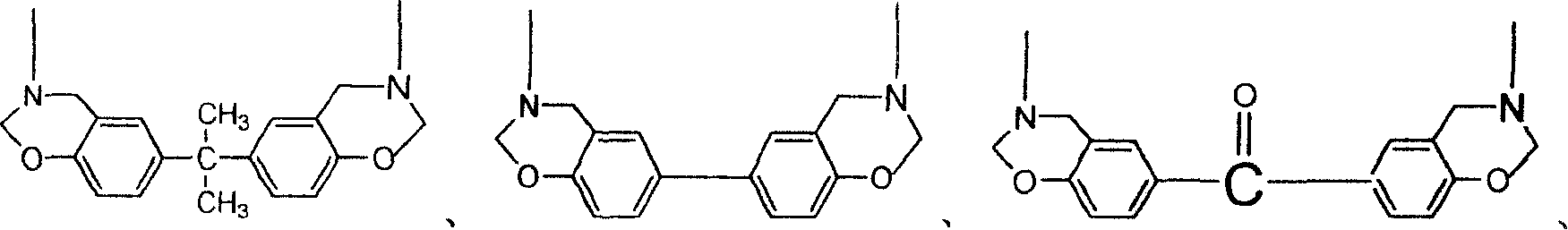

Double end group ortho-benzene dimethyl nitrile-benzo oxazine resin, solidified substance and its preparing method and use

InactiveCN1944400ARegulating and Controlling Control StructuresRegulating and Controlling Control PerformanceCarboxylic acid nitrile preparationOrganic compound preparationBenzeneHeat resistance

The present invention belongs to the field of high molecular synthetic material, and is especially one kind of double end group o-phthalonitrile-benzo oxazine resin, and its solidified substance and preparation process. The present invention provides one kind of 4-aminophenoxyl-o-phthalonitrile monomer and the double end group o-phthalonitrile-benzo oxazine resin therewith. The double end group o-phthalonitrile-benzo oxazine resin has excellent curing reaction activity, low temperature curing performance similar to that of benzo oxazine resin, heat resistance similar to that of o-phthalonitrile resin, greatly lowered curing temperature and capacity of use in high temperature condition. The preparation process is simple and controllable, and the product has excellent application foreground.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Aqueous graphene oxide modified poly(urethane-acrylate) composite material preparation method

The invention belongs to the technical field of polymer synthesis, and relates to aqueous poly(urethane-acrylate) emulsion modification, particularly to an aqueous graphene oxide modified poly(urethane-acrylate) composite material preparation method. According to the preparation method, an improved Hummers method is adopted to prepare graphene oxide, the graphene oxide is dissolved in N,N'-dimethylformamide, ultrasonic peeling is performed to prepare a graphene oxide dispersion solution, and the graphene oxide dispersion solution and n-butylacrylate are adopted to co-modify polyurethane. With the preparation method, the prepared composite material emulsion is uniform and stable, and the curing film has good mechanical property, and can be used in the fields of printing, packaging, furniture, electrical equipment, small metal parts, instrument panels, flooring, wood, paper coating, leathers, plastics, home appliances, electronics, telecommunications, aerospace, aviation and the like.

Owner:JIANGSU UNIV

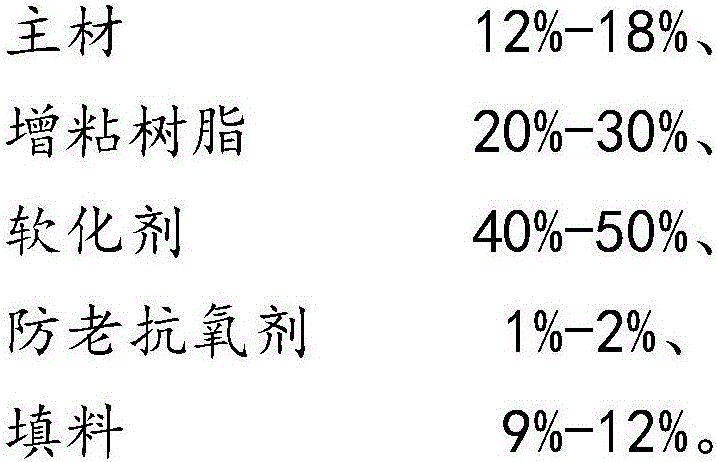

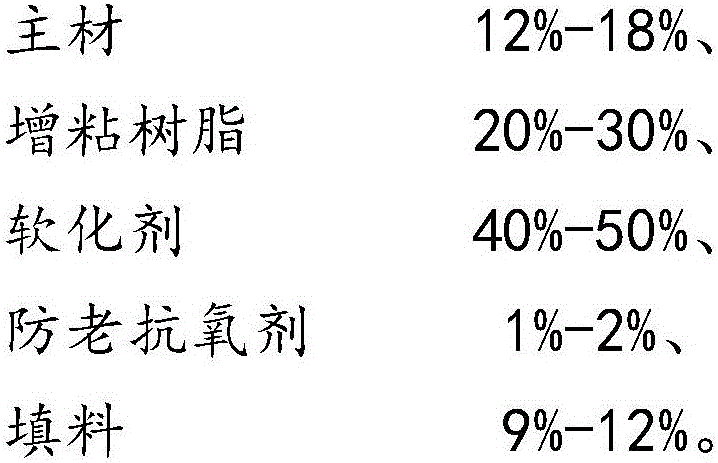

Macromolecular synthesized memory sizing material

The invention discloses a macromolecular synthesized memory sizing material which comprises the following raw materials by weight percentage: 41-48% of elastomer, 38-41% of tackifier, 4-6% of softener, 1.5-3.2% of anti-aging agent and 4.5-9% of filler. A pricked part of a tyre sprayed with the macromolecular synthesized memory sizing material under various daily environments can heal automatically; accidents such as air leakage or tyre burst caused by prick of a sharp object can be effectively avoided; especially, the driving safety in a high speed driving state can be ensured to the greatest extent; the service life of the tyre is prolonged under the condition that the original performance of the tyre is not influenced; and various unnecessary troubles such as tyre repairing are reduced.

Owner:WUXI I REACH TECH

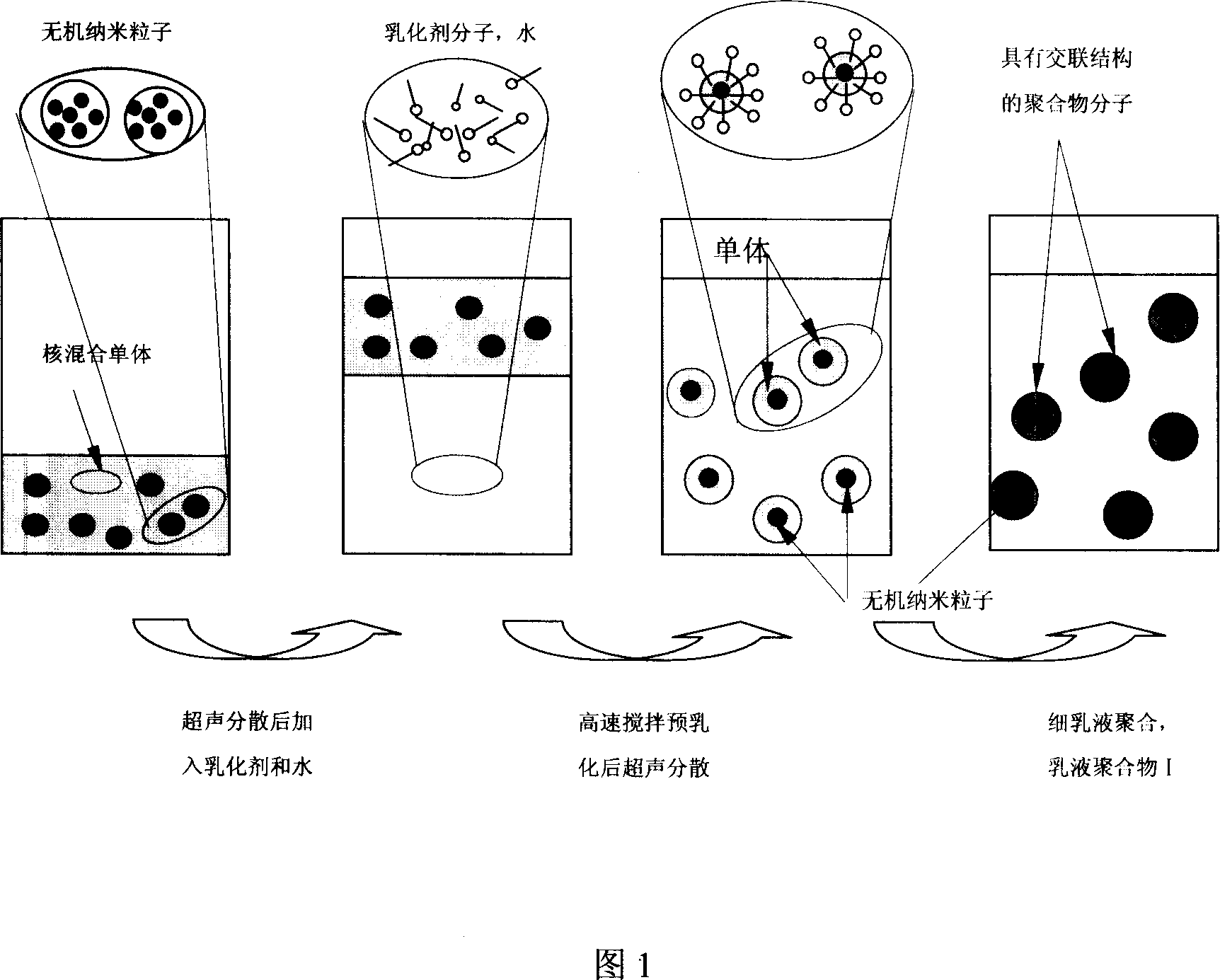

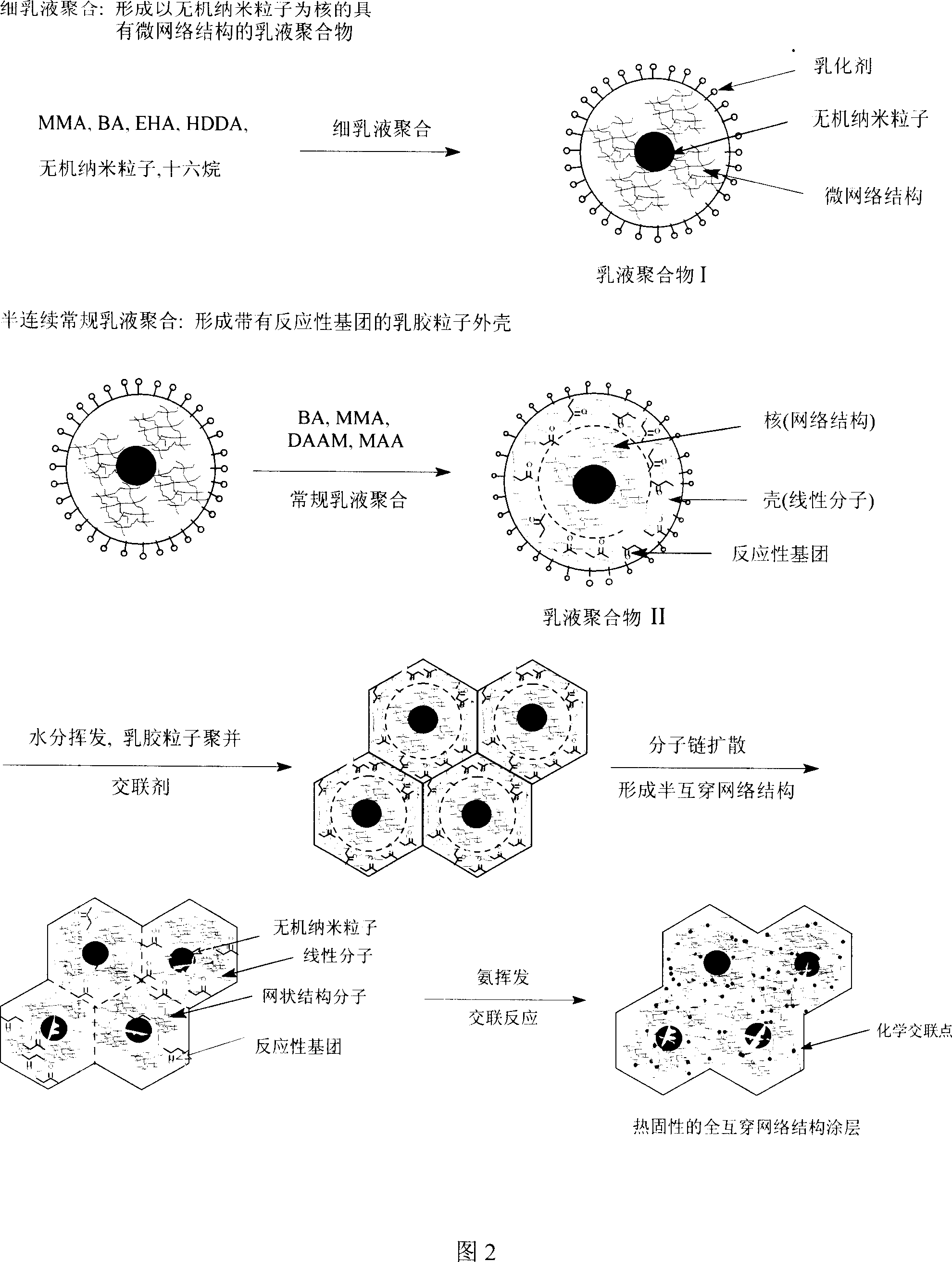

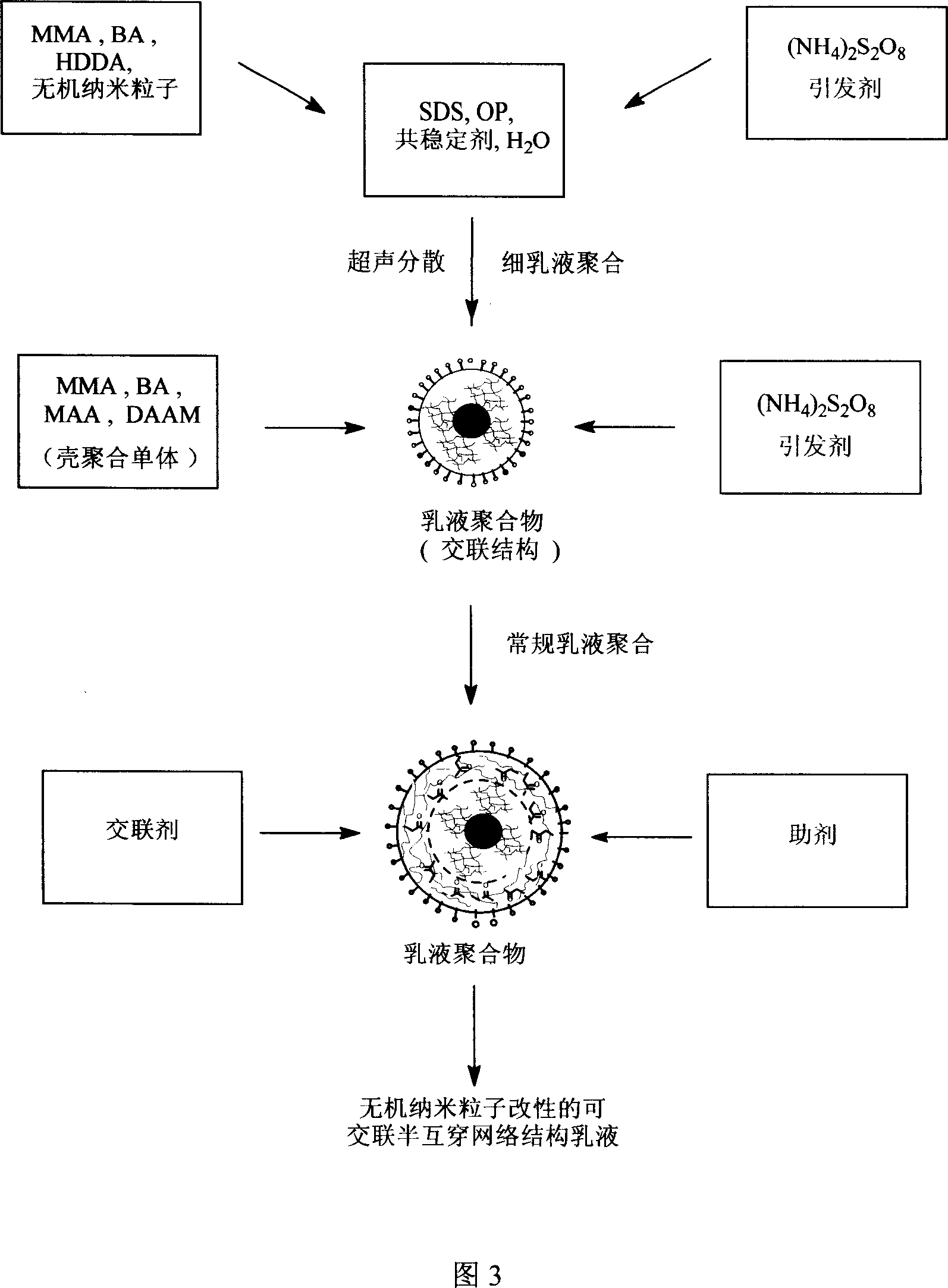

Method of preparing organic/inorganic hybridization reactivity semi-interpenetrating network structure emulsion

The invention discloses a new method for manufacturing Interpenetrating Polymer Network of organic or inorganic reaction latex, which belongs to macromolecule manufacturing polymer synthesis. The emulsion has excellent storage stability. Its coating with a high pencil hardness, excellent scratch resistance, water-resistance, stain resistance, chemical resistance and aging resistance, can be used for wood, metal and surface decoration and construction exterior paint, The water emulsion polymer can be made through the following steps: (a) At least two unsaturated compounds, allyl monomer and inorganic nano particle are polymerized to the cross-linked structure seed emulsion. (b) The unsaturated compounds with reaction and allyl monomer are polymerized to core / shell structure emulsion on the basis of the seed emulsion. (c) In the core / shell structure emulsion, organic / inorganic hybrid with cross-linked structure semi-IPN emulsion can be got for adding cross-linker.

Owner:HUNAN UNIV OF TECH

Polymer material for seismic physical model and its prepn

InactiveCN1772809ASatisfy the wave speed requirementsWave speed control range is largeEducational modelsEpoxyLongitudinal wave

The present invention belongs to the field of high molecular material technology, and is especially one kind of polymer material for seismic physical model and its preparation process. The polymer material consists of epoxy resin mixture comprising epoxy resin and assistant and silicone rubber mixture comprising silicone rubber and assistant in the weight ratio of 0-100. The polymer material is prepared through preparing epoxy resin mixture and silicone rubber mixture separately, mixing these two components in certain weight ratio inside some container via stirring to obtain model material, setting the container inside sealed box to vacuum pump for eliminating bubble, molding, curing inside the mold at 15-25 deg.c for 5-9 days, and demolding to obtain the seismic physical model. The model material has longitudinal wave speed regulating range of 1000-2850 m / s.

Owner:TONGJI UNIV

Environmental protection weeping plastic track

InactiveCN1552999AOvercome disadvantagesPolyureas/polyurethane adhesivesGround pavingsPolyurethane adhesiveWaste rubber

An environment protective and water penetrative plastic trick involves a polymer material, consisting of adhesive, pigment for spraying adhesive, catalyst for carboxylic salt, black waste rubber granules, and color EPDM granules. It is constructed by: making mono-component polyurethane as primary agent to bind recovered rubber granules; mixing with catalyst and stirring uniformly; mechanically spreading; curing at atmosphere - 70 deg.C to form a plastic layer with thickness of 4 - 10mm; and then spreading well-mixed polyurethane adhesive, color EPMD granules and catalyst to form a top plastic layer, finally curing to form the said trick with a plastic layer and a cement substrate. The construction are not only available for tricks, but also for other pavements with low cost, high strength, large extension rate, and good penetration. It can be constructed mechanically and effectively with good flatness.

Owner:上海康达新材料科技有限公司

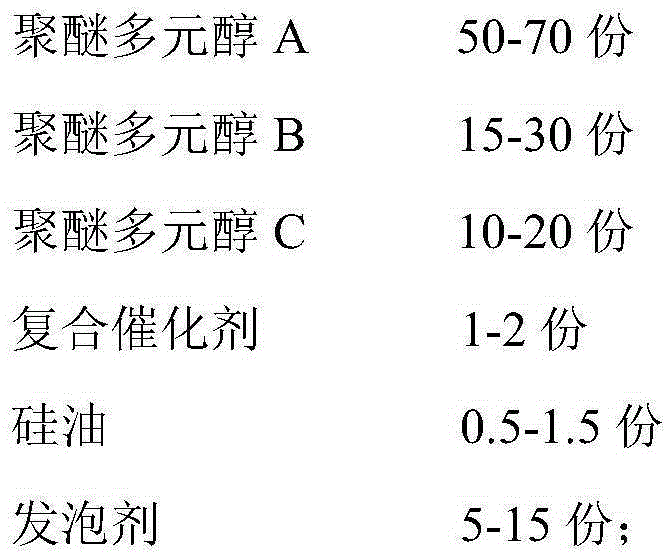

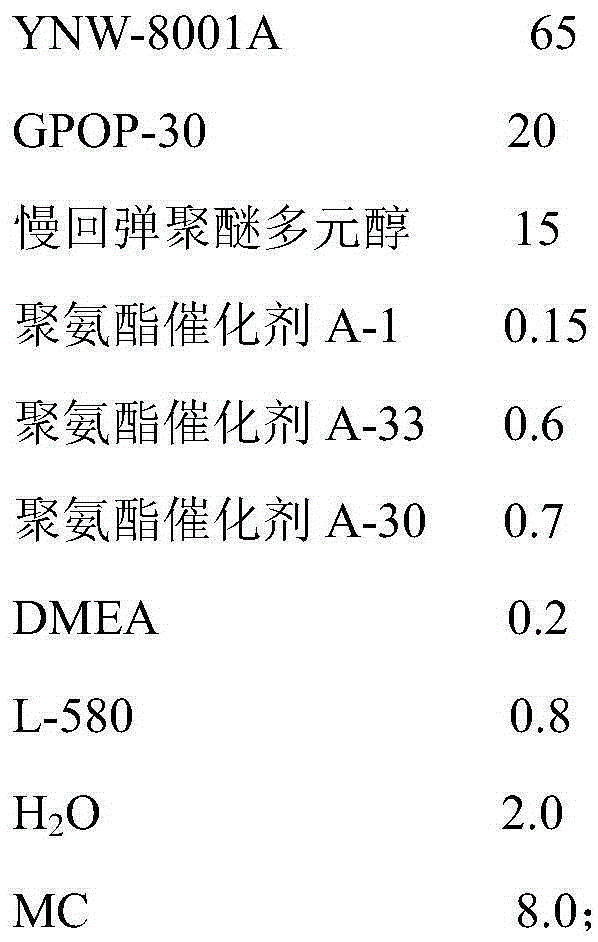

Slow-recovery polyether polyol and preparation method thereof and slow-recovery foam and preparation method thereof

The invention relates slow-recovery polyether polyol and a preparation method thereof and slow-recovery foam and a preparation method thereof, and belongs to the technical field of organic polymer synthesis. The slow-recovery polyether polyol is a copolymer of propylene epoxide and ethylene oxide, and the copolymer takes a composite small-molecular-weight polyhydric alcohol compound as initiator. The preparation method of the slow-recovery polyether polyol comprises the steps that the composite small-molecular-weight polyhydric alcohol compound and a catalyst are reacted in a pressure-proof reaction kettle, a polymeric monomer, water, phosphoric acid and magnesium silicate are sequentially added for reaction, and the slow-recovery polyether polyol is obtained; the slow-recovery foam is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol, a composite catalyst, silicone oil and a foaming agent, and the component B adopts modified DMI; the preparation method of the slow-recovery foam comprises the steps that the component A and the component B are evenly mixed and poured into a mold for curing, and the slow-recovery foam is obtained. The slow-recovery foam material has the advantages of being extremely low in depression residue, good in tensile property and capable of reducing the usage amount of an opening agent.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

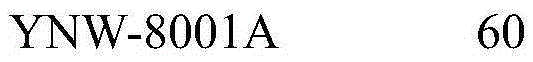

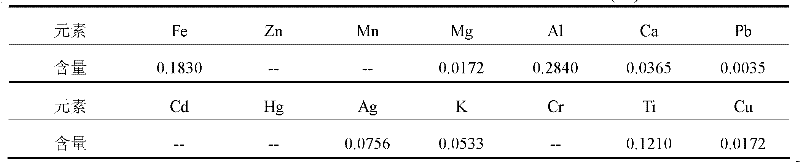

Method for extracting high-purity humic acid from low-rank coal

ActiveCN102558573ALow removal efficiencyImprove removal efficiencyOrganic chemistryFreeze-dryingBasic research

The invention discloses a method for extracting high-purity humic acid from low-rank coal. In the invention, abundant low-quality peat, lignite, weathered coal and the like in china are used as raw materials; and processes such as repeated base-dissolving acidification, centrifugal separation, mixed acid treatment, semi-permeable membrane dialysis, freeze drying and the like are carried out to separate and obtain a high-purity humic acid product with a humic acid content not lower than 97%. Compared with the traditional base-dissolving acidification method and the existing high-purity humic acid preparation method, the method has the advantages of low processing cost, simplicity and convenience in technological operation, high product purity, low impurity element content and the like. The high-purity humic acid prepared by the method can be applied to cathode plate expanding agents of lead storage batteries, medical products and the like, and can be used as a chemical reagent for related basic researches of humic acid substances and an important raw material for synthesis of organic polymers.

Owner:CENT SOUTH UNIV

Method for preparing thermosetting acrylic ester emulsion coating under room temperature

The invention discloses a new making method of thermosetting acrylate emulsion paint under indoor temperature in the macromolecular synthesizing making industry, which comprises the following steps: (1). copolymerizing compound with at least two insaturated groups and olefinic monomer to form seed emulsion with crosslinking structure; (2) polymerizing emulsion to obtain core-case structural emulsion; (3) adding crosslinking agent in the emulsion to obtain the product under indoor temperature.

Owner:HUNAN UNIV OF TECH +1

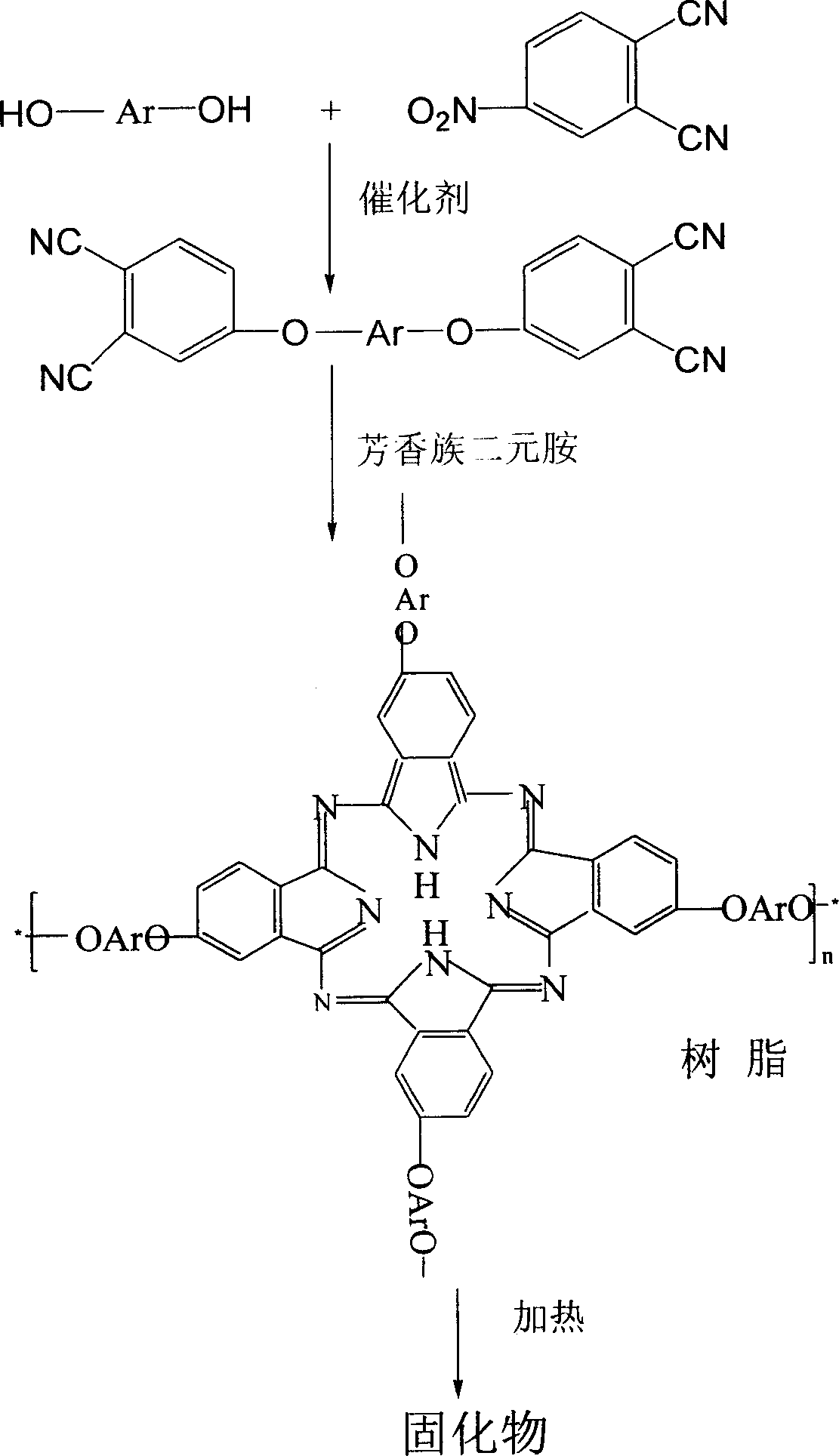

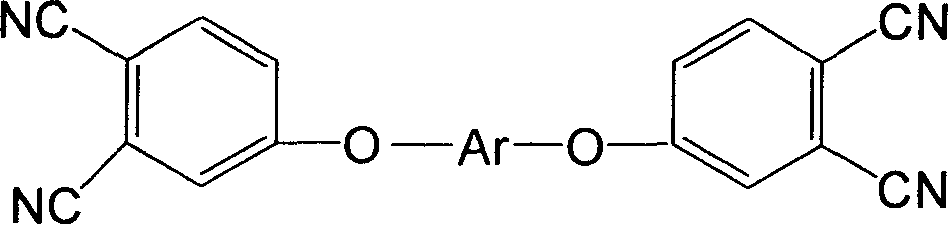

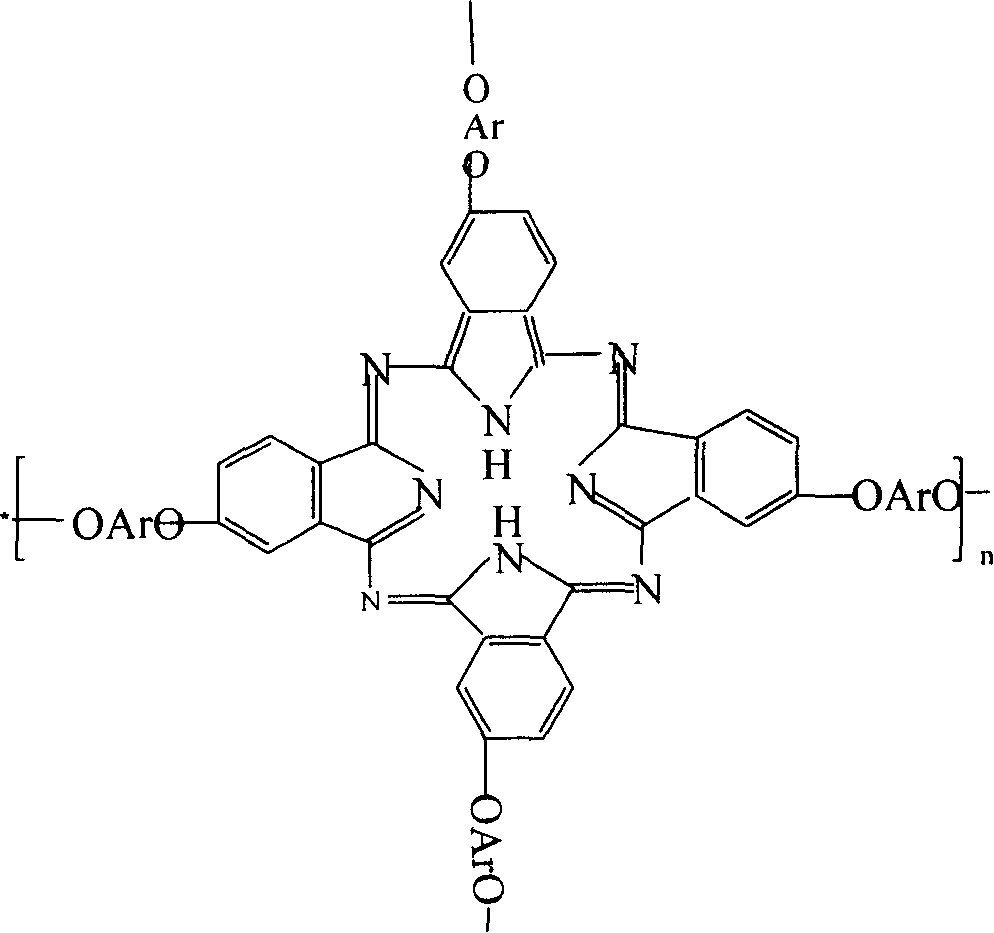

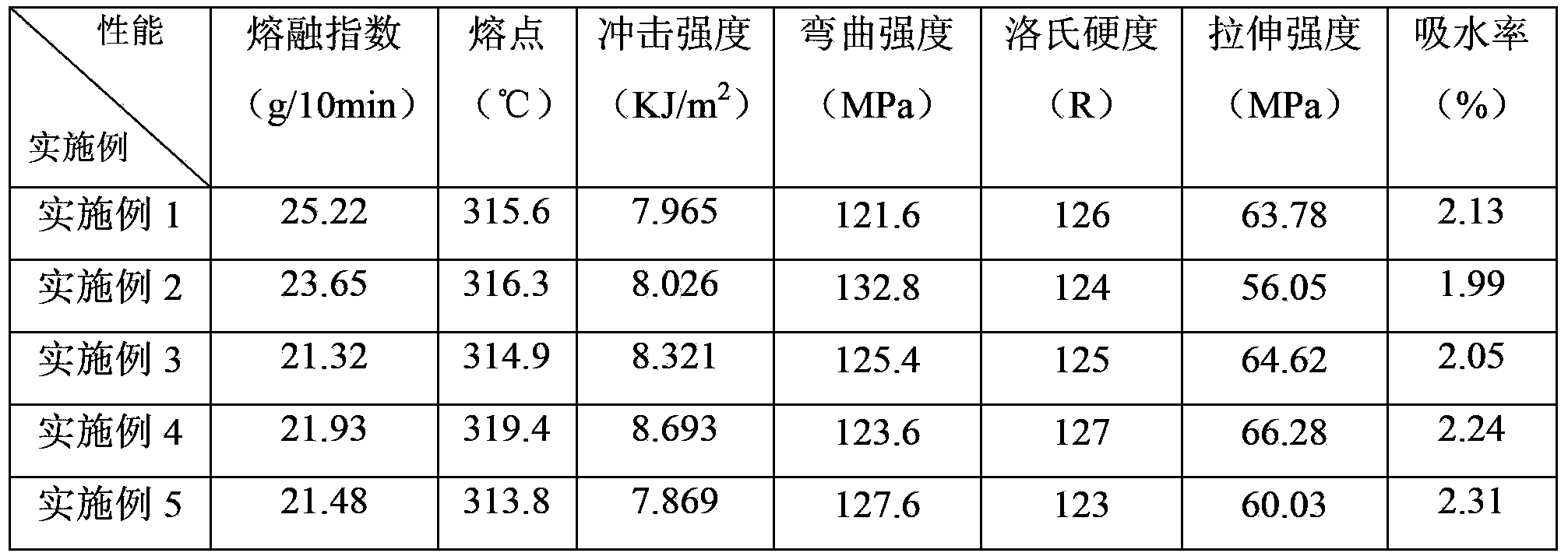

Double end-group phthalonitrile, resin, condensate and its preparation method and uses

ActiveCN1876615ARegulatory and Control StructuresTuning and Controlling PerformanceOrganic chemistryPolymer scienceEnd-group

The invention belongs to the high molecular synthetic material field. The invention relates the double-end phthalonitrile, resin, condensate, which are made by phthalonitrile, and preparing method. The invention uses 4-nitro-o-phthalonitrile and dihydric phenol as reaction integral to get double-end phthalonitrile. The double-end phthalonitrile and diamine are used to react in aromatic amine solution at 140-200Deg.C to get phthalonitrile resin which possesses phthalocyanine ring structure. The resin is cured at 220-280Deg.C, then carried out heat treatment at 320-370Deg.C to get phthalocyanine condensate which possesses high heat stability. The invention has the advantages of good heat stability and fire-retardancy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High-temperature-resistant nylon PA66T material and preparation method thereof

The invention belongs to the field of polymer synthesis, and relates to a high-temperature-resistant nylon PA66T material and a preparation method thereof. The nylon PA66T material is prepared from the following components in mole number: 11.00-12.32 moles of aromatic binary acid, 9.00-9.90 moles of hexane diacid, 19.20-21.34 moles of hexamethylenediamine, 0.035-0.05 mole of a nucleating agent, 0.015-0.03 mole of a catalyst and 250-300 mole of deionized water. The high-temperature-resistant nylon PA66T material provided by the invention has the advantages of light weight, high temperature resistance, high mechanical strength, superior size stability and the like, and is suitable to be applied in a high-temperature environment; and meanwhile, the high-temperature-resistant nylon PA66T material is simple in the synthesis process, is moderate in viscosity, and is suitable for industrial popularization and subsequent machine shaping.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Fluoride alkoxycyclotriphosphazene derivative, preparation and use thereof

InactiveCN101407527AExcellent flame retardant finishing effectImprove flame retardant performanceGroup 5/15 element organic compoundsFibre treatmentAlcoholEmulsion

The invention discloses a fluorine-containing alkoxy ring triphosphonitrile derivative and a preparing method thereof, belonging to the technical field of macromolecule synthesis and textile finishing, and the derivative is used for a multifunctional finishing agent of textile. The method takes fluorine-containing alcohol as a material for reacting with hexachlor ring triphosphonitrile for substitution to synthesize the fluorine-containing alkoxy ring triphosphonitrile derivative; and the fluorine-containing alkoxy ring triphosphonitrile derivative is emulsified by choosing a suitable emulsifier and optimizing emulsion formula, thus obtaining the multifunctional finishing agent of textile with good stability. By adopting the finishing process of rolling-baking-toasting, the textile after finishing has not only good flame-retardant finishing effect but also certain water proof and oil proof effect owning to the introduction of fluoride in the phosphonitrile flame retardant.

Owner:SUZHOU UNIV

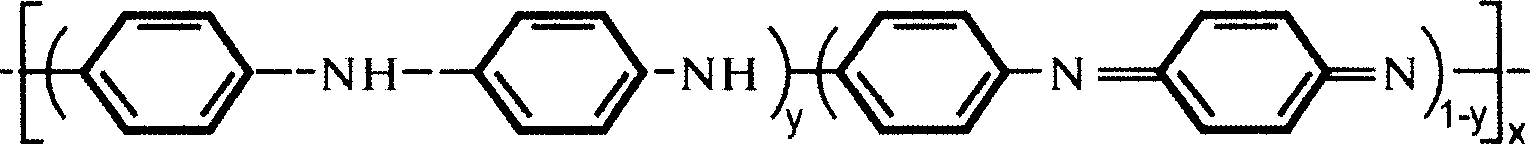

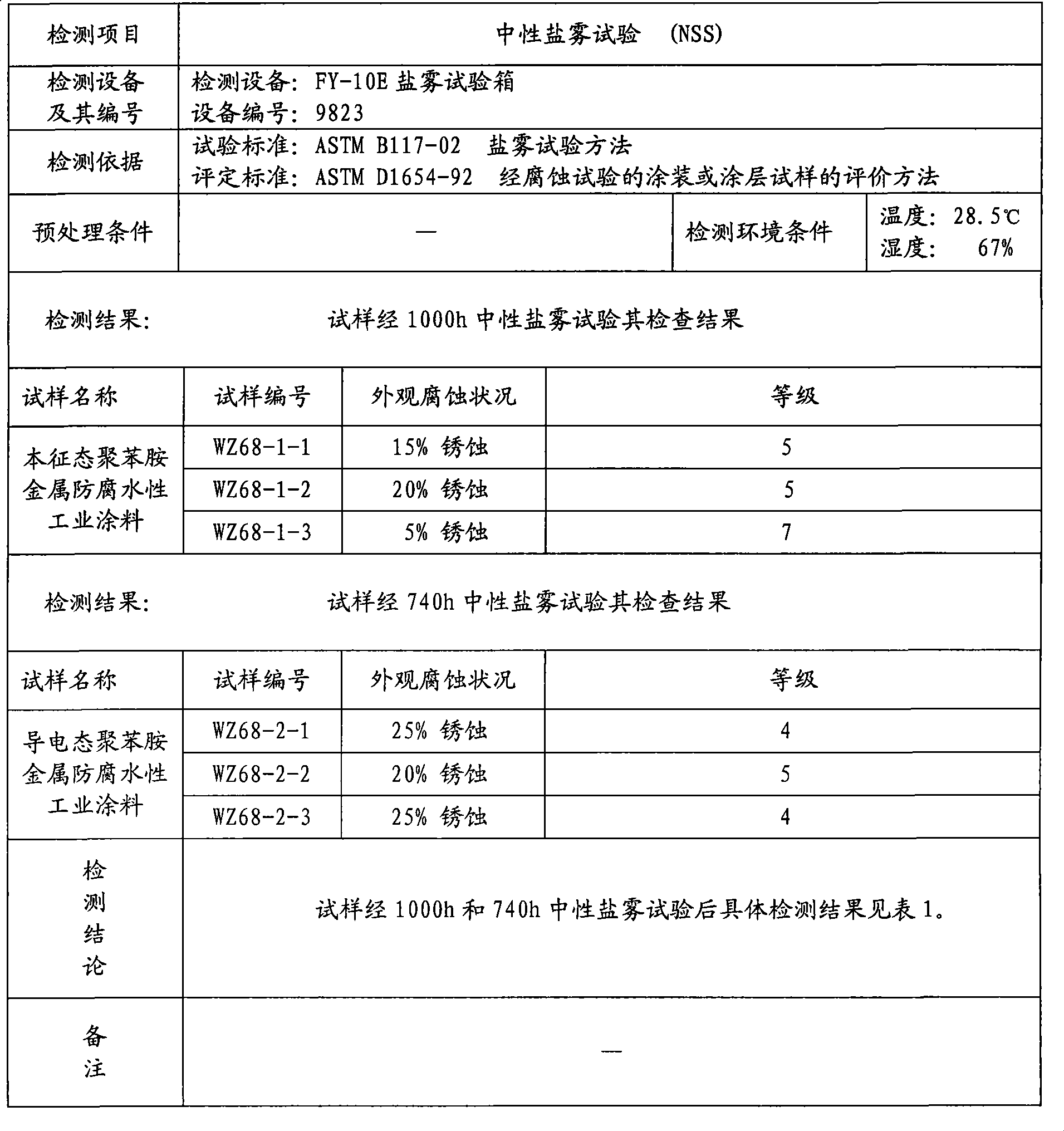

Polyaniline metal anticorrosion water-soluble industrial coatings

The invention relates to an industrial coating which uses polymer synthesis material of Eigenstae polyaniline and conducting state polyaniline so as to be respectively used for preparing industrial coating which can be matched as series of metal antisepsis waterborne basecoat and surface coating. As solvent is not used, the prepared metal antisepsis waterborne basecoat and the surface coating are non-solvent typed metal antisepsis industrial coatings which have extremely low VOC content and are friendly to the environment and used for the metal substrate surface. Being different from the cathode protection function of normally used sacrifice-typed antisepsis coating on the metal surface, the eigenstae polyaniline metal antisepsis waterborne industrial coating is an anode protective coating used for the metal material.

Owner:傅晓平 +2

Method for synthesizing high-viscosity polyphenylene terephthalamide

The invention relates to a method for synthesizing high-viscosity polyphenylene terephthalamide, and belongs to the technical field of polymer synthesis. The method comprises the following steps of: adding dissolution-helping salt into N-methyl pyrrolidone first, adding p-phenylenediamine for dissolution, adding paraphthaloyl chloride for polymerization, and washing and drying an obtained reaction product to obtain the polyphenylene terephthalamide. An acid absorbent used by the synthesis method is calcium hydride, the calcium hydride can react with hydrogen chloride produced in a polymerization reaction, and generated calcium chloride is a cosolvent in a solvent system and is favorable for the stability of a reaction system; and the calcium hydride can remove trace water in the reaction system, so that the influence of water on polyphenylene terephthalamide (PPTA) polymerization is eliminated. Moreover, the unreacted calcium hydride can be easily removed in the subsequent washing step after the PPTA polymerization is finished.

Owner:TSINGHUA UNIV

Process for preparing anti-static polyacrylonitrile fibre

InactiveCN1377995AImprove mechanical propertiesImprove antistatic performanceElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentAntistatic agentPolymer science

The present invention belongs to the field of polymer synthetic fiber, and provides the preparation of a kind of antistatic polyacrylonitrile fiber. During the preparation, zinc oxide crystal whiskerand antistatic agent are added, and this results in product with relatively higher mechanical performance and antistatic performance. The said preparation process is suitable for use in industrial production.

Owner:DONGHUA UNIV

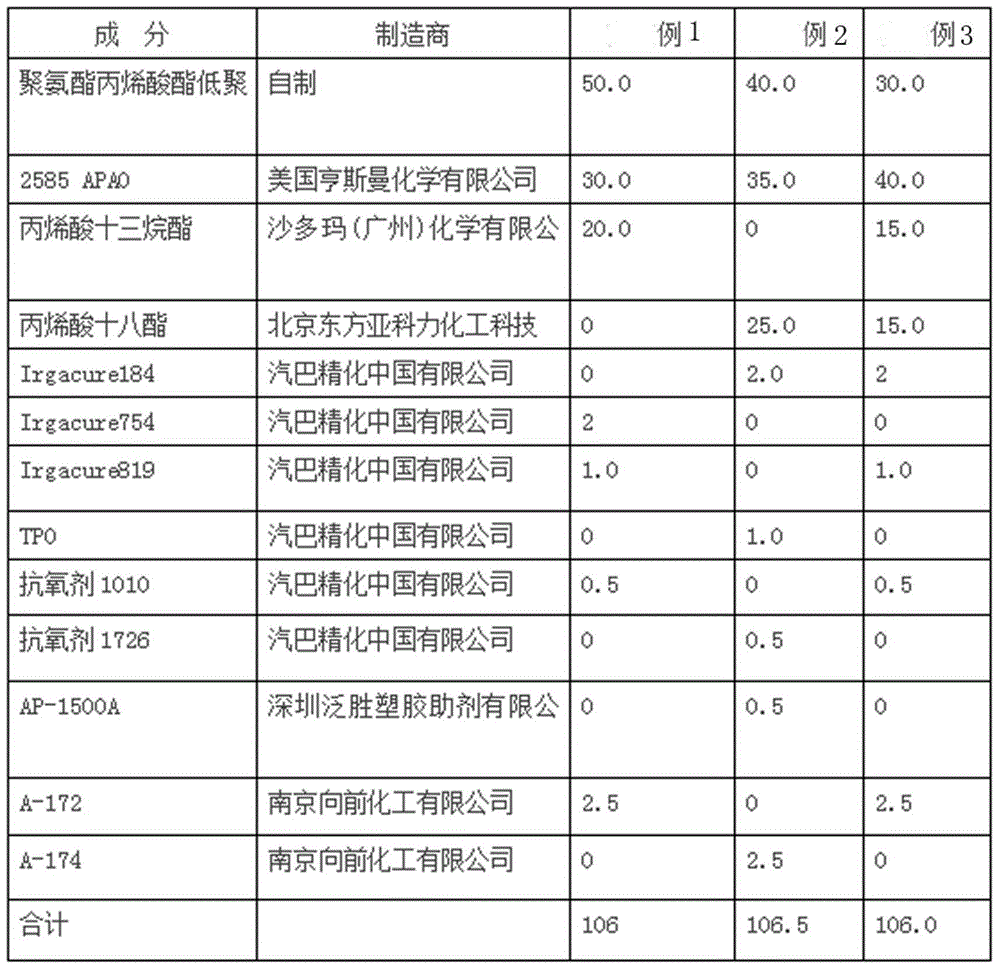

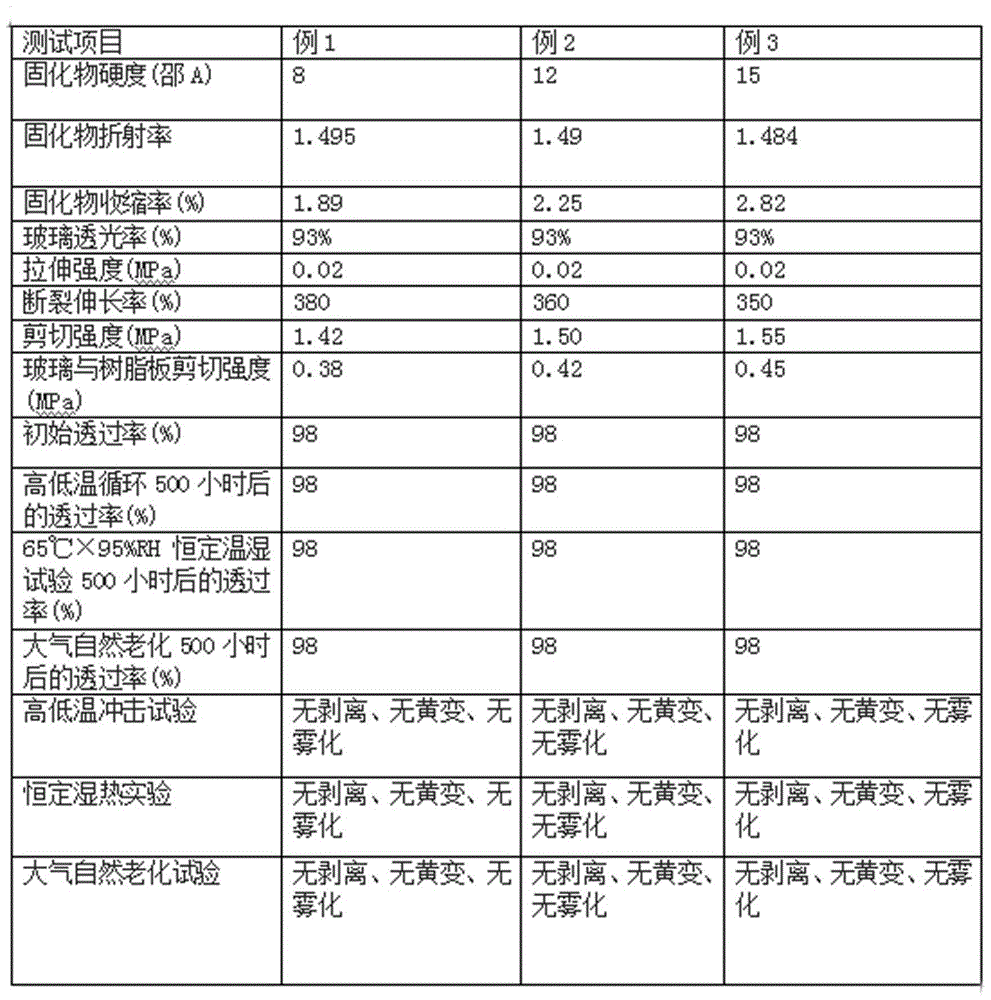

Ultra-flexible polyurethane acrylate resin and liquid-state optical adhesive composition thereof

InactiveCN104892890AImprove performanceFulfil requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveRefractive index

The invention discloses ultra-flexible polyurethane acrylate resin and a liquid-state optical adhesive composition thereof, and belongs to the technical field of polymer synthesis. The ultra-flexible polyurethane acrylate resin has a refractive index of 1.51, resin chromaticity APHA of 30, viscosity of 0.25 million of mPa.s, Tg lower than minus 40 DEG C and molecular weight of 10000-100000. The ultra-flexible polyurethane acrylate resin is prepared from the raw materials comprising liquid-state hydroxyl-terminated polybutadiene, aliphatic and / or alicyclic diisocyanate, a polymerization inhibitor, a catalyst, a solvent and hydroxyalkyl acrylate. A preparation method for the ultra-flexible polyurethane acrylate resin comprises the following steps: uniformly mixing the liquid-state hydroxyl-terminated polybutadiene, the aliphatic and / or alicyclic diisocyanate, the polymerization inhibitor, the catalyst and the solvent to obtain a mixture; then, adding the hydroxyalkyl acrylate into the mixture to react, thereby obtaining the ultra-flexible polyurethane acrylate resin. The ultra-flexible polyurethane acrylate resin has Tg lower than minus 40 DEG C, good flexibility and resin chromaticity APHA of 30. The liquid-state optical adhesive prepared by taking the resin disclosed by the invention as a main component has the advantages of high bonding strength and low shrinkage ratio.

Owner:深圳市浩力新材料技术有限公司

Method for fabricating a window member of the display device of a portable terminal

ActiveUS20130000822A1Improve surface qualitySolve the lack of hardnessFilm/foil adhesivesLaminationDisplay deviceHardness

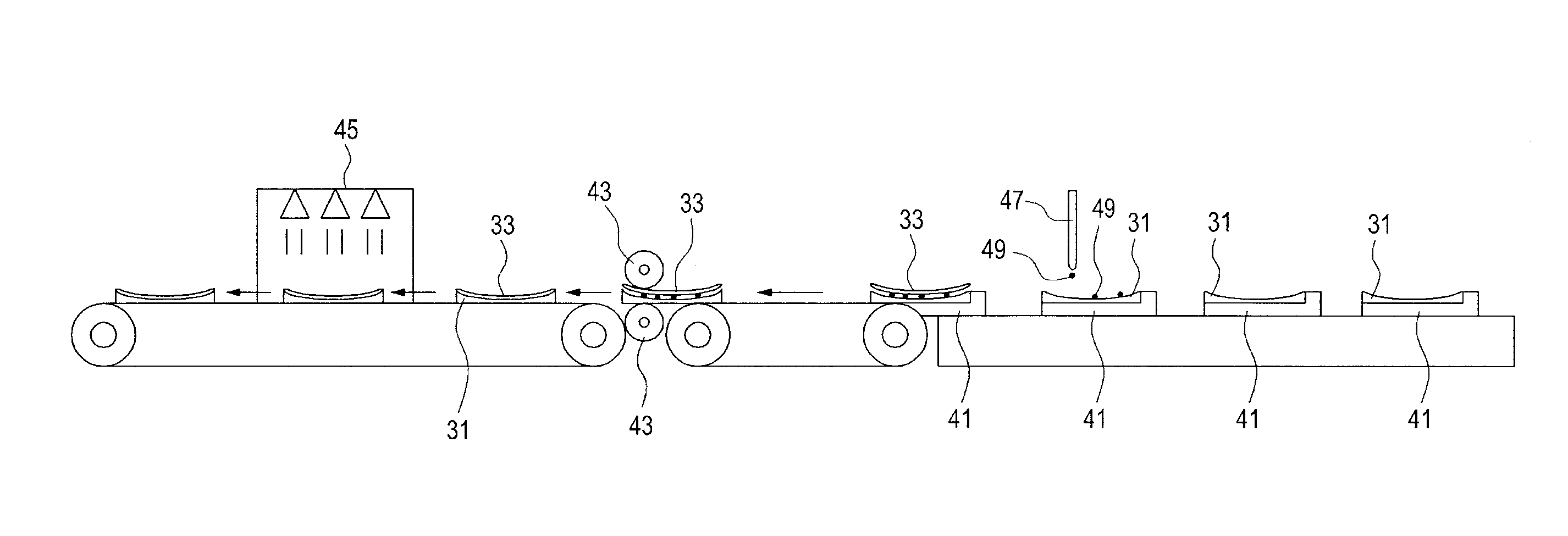

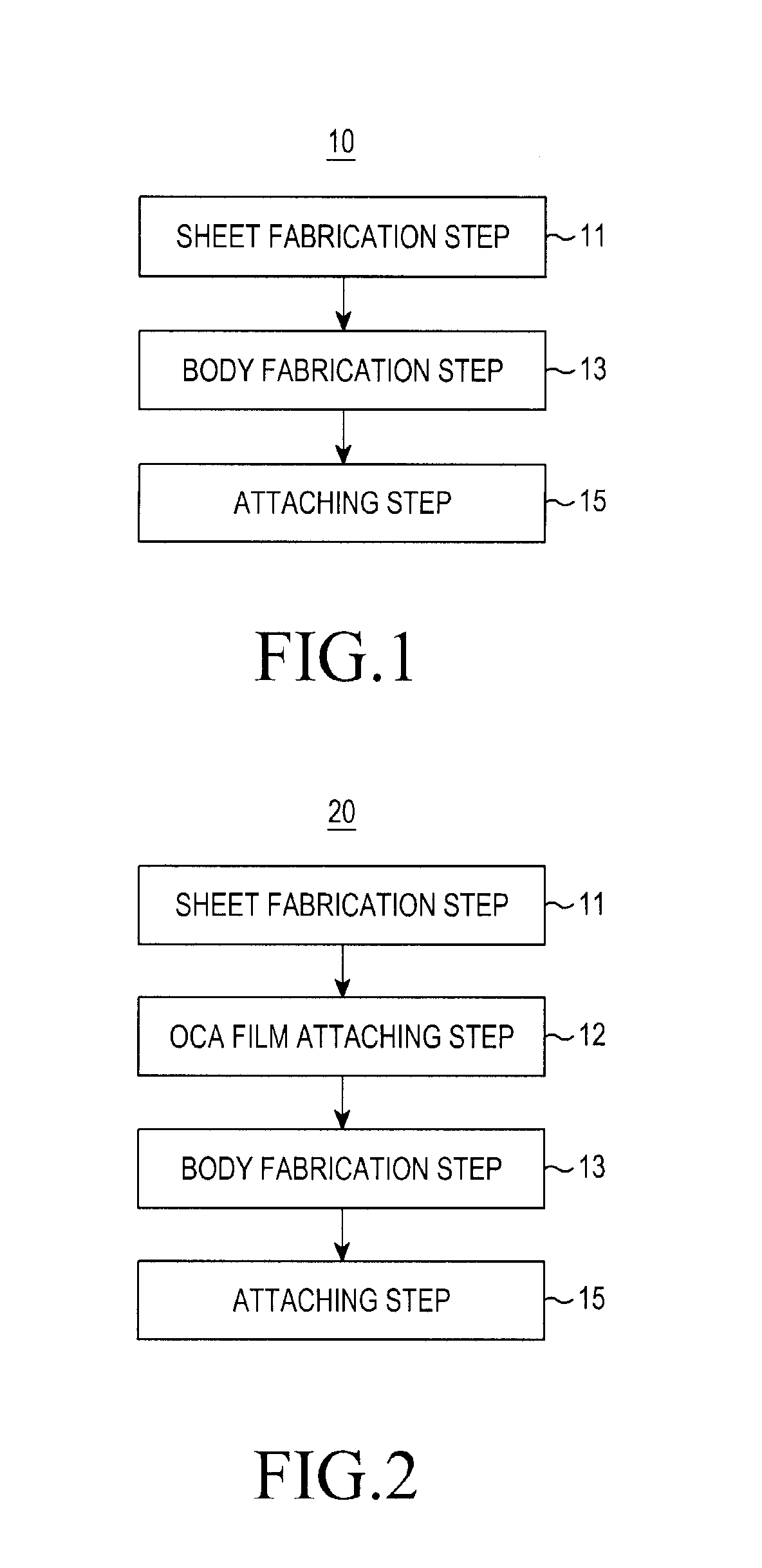

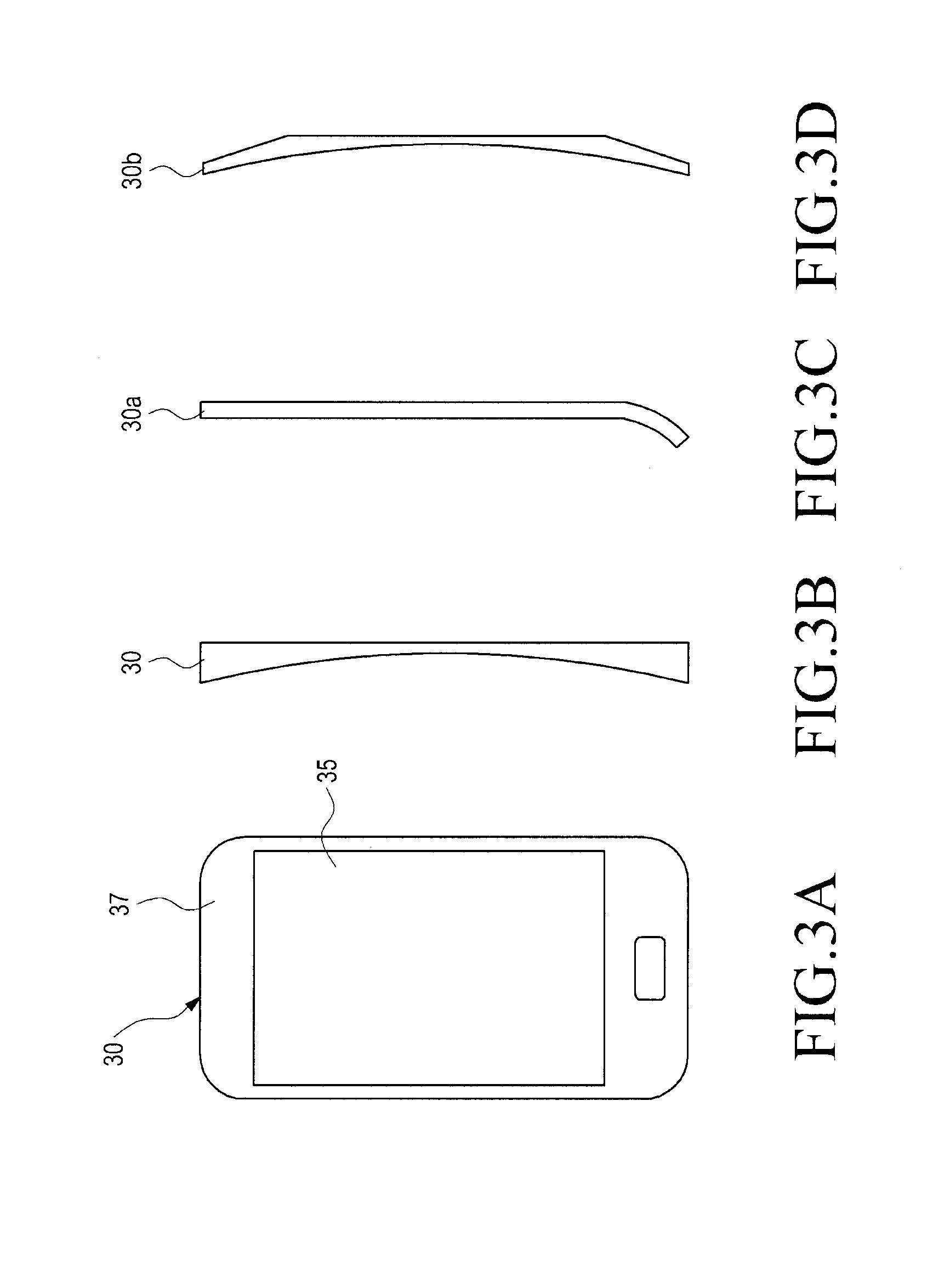

A method for fabricating a window member for a display device of a portable terminal includes: fabricating a high-hardness sheet to be attached to a surface of the window member (‘sheet fabrication step’), fabricating a body of the window member with a high-polymer synthetic resin (‘body fabrication step’), and attaching the high-hardness sheet to an outer surface of the body (‘attaching step’), in which the outer surface of the body is formed to have a curved surface in the body fabrication step.

Owner:SAMSUNG ELECTRONICS CO LTD

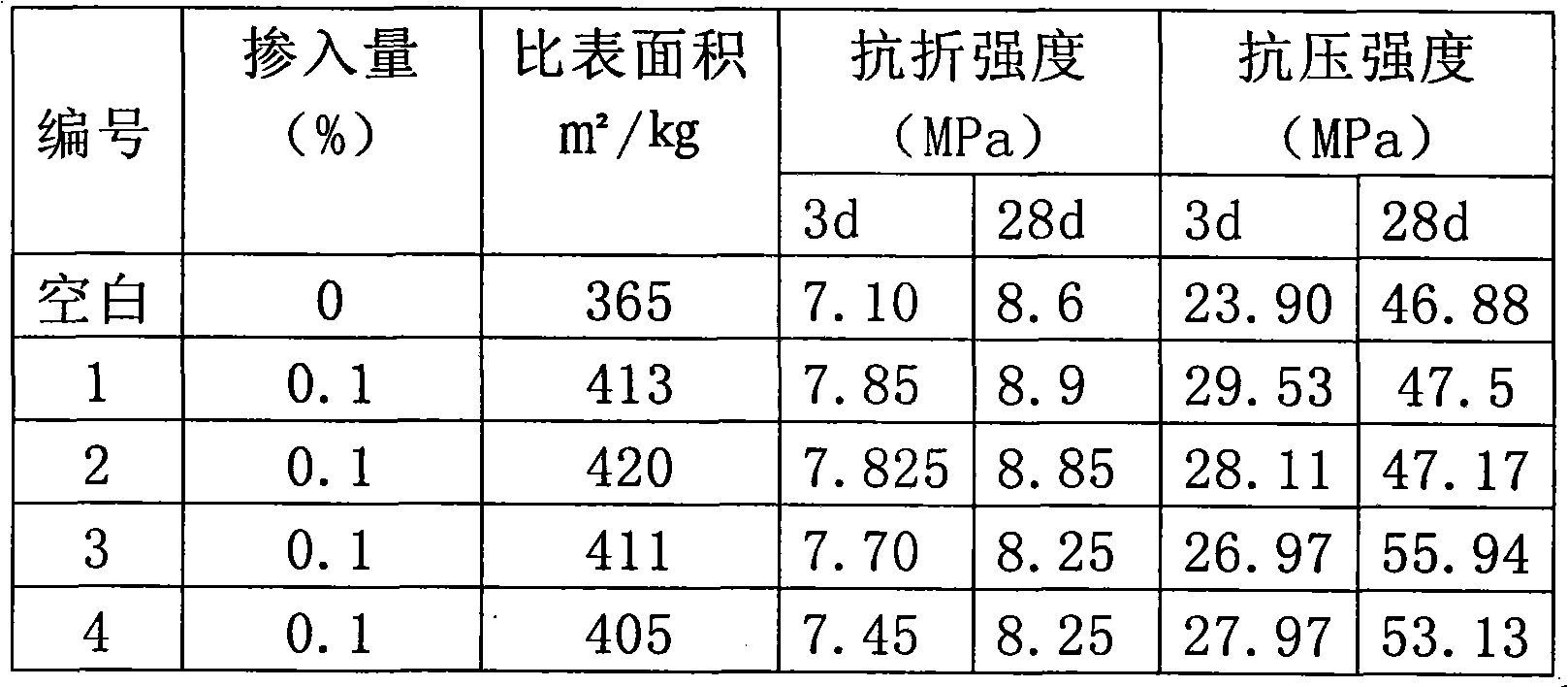

Polycarboxylic acid cement activation reinforced grinding aid and preparation method thereof

ActiveCN101798198AImprove performanceSignificant effect of grinding aid enhancementCement productionPolyethylene glycolEconomic benefits

The invention belongs to the cement grinding aid technical field, in particular relates to a polycarboxylic acid cement activation reinforced grinding aid and preparation method thereof. The grinding aid adopts polyoxyethylene ether and unsaturated carboxylic acid for carrying out esterification, then polyoxyethylene ether ester, alkyl polyethylene glycol, (methyl) sodium alkyl sulphate, polyalcohol and water are polymerized to prepare a polycarboxylic acid cement activation reinforced grinding aid. Compared with the existing polycarboxylic acid compound cement grinding aid, the invention adopts high polymer to synthesize and prepare polycarboxylic acid cement activation reinforced grinding aid, a high polymer synthesized cement grinding aid in real meaning; the polycarboxylic acid cement activation reinforced grinding aid has no chloride, stable performance and obvious grinding reinforcing effect. When dosage is 0.01-0.1% of cement weight, grinding machine hourly output is improved by 10-20%, strength of cement for three days can be increased by 2-6MPa, strength for 28 days can be increased by 4-8MPa, thus having better market prospect and economic benefit.

Owner:安徽海螺材料科技股份有限公司

Polypropylene/extra high molecular weight polyethylene in-situ fibre-formed cocrystallized composite material

InactiveCN1394907AImprove mechanical propertiesSimple processMonocomponent polyolefin artificial filamentFiberHeat resistance

The polypropylene (PP) / ultrahigh molecular weight polyethylene (UHMWPE) in-situ fiber-forming cocrystallized composite material is amde up by uisng PP and UHMWPE through the processes of comixing, in-situ fiber-forming and cocrystillzation. The mass ratio of PP and UHMWPE Is 100 / 5-100 / 20. When the relative molecualr weight of UHMWPE is 100-300X10 to the minus fourth, its effect is better, when PP is one of PPB (block copolymer polypropylene) or PPR (radom copolymer polyropylene, its effect is better, and when PP is PPB, its effect is best, and when the mass ratio of PP and UHMWPE is 100 / 10, its effect is best. The strength and toughness of said invented product are greatly raised, and its bending strength, heat resistance and weatherability can be obviously improved.

Owner:QINGDAO CHEM COLLEGE

Polycarboxylic acid series high molecular synthetic cement grinding additive and preparation method thereof

The invention discloses a polycarboxylic acid series high molecular synthetic cement grinding additive. The polycarboxylic acid series high molecular synthetic cement grinding additive is prepared from the following raw materials in parts by weight: 50-100 parts of alkylol amine substance, 20-50 parts of unsaturated acid, 1,000-1,500 parts of water, 100-400 parts of unsaturated monomer and 5-10 parts of initiator. According to the invention, a process flow for preparing the conventional grinding additive is simplified to be one-step synthesis from the process flow of esterification, polymerization and compounding, the process is simple and industrial production is easy to realize.

Owner:唐山市龙亿科技开发有限公司

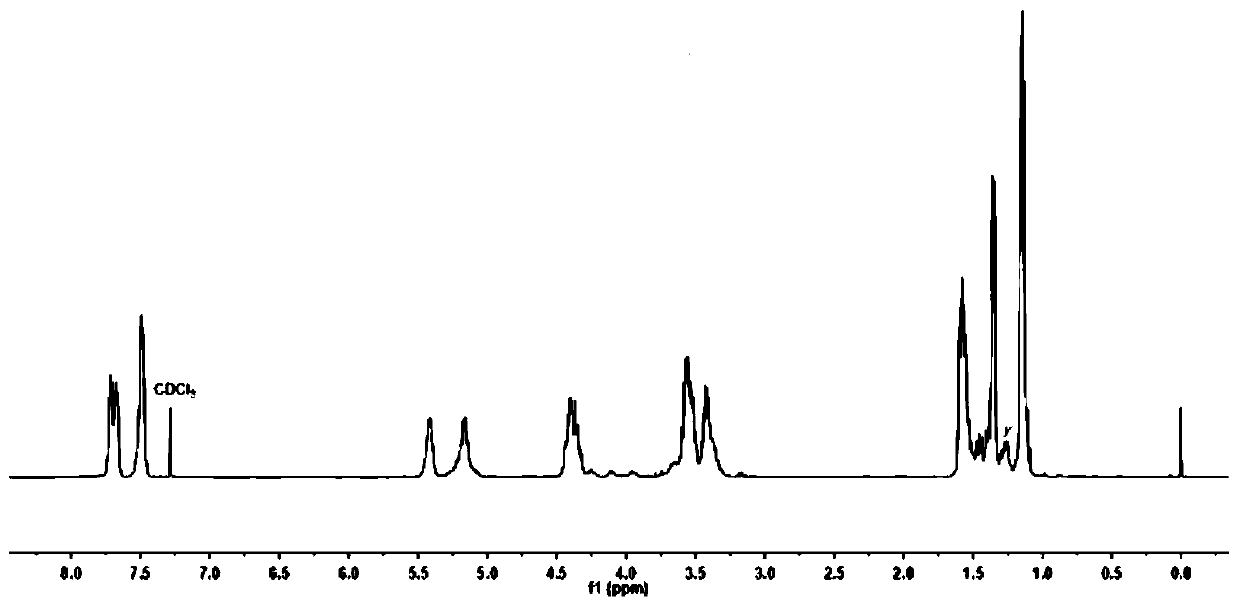

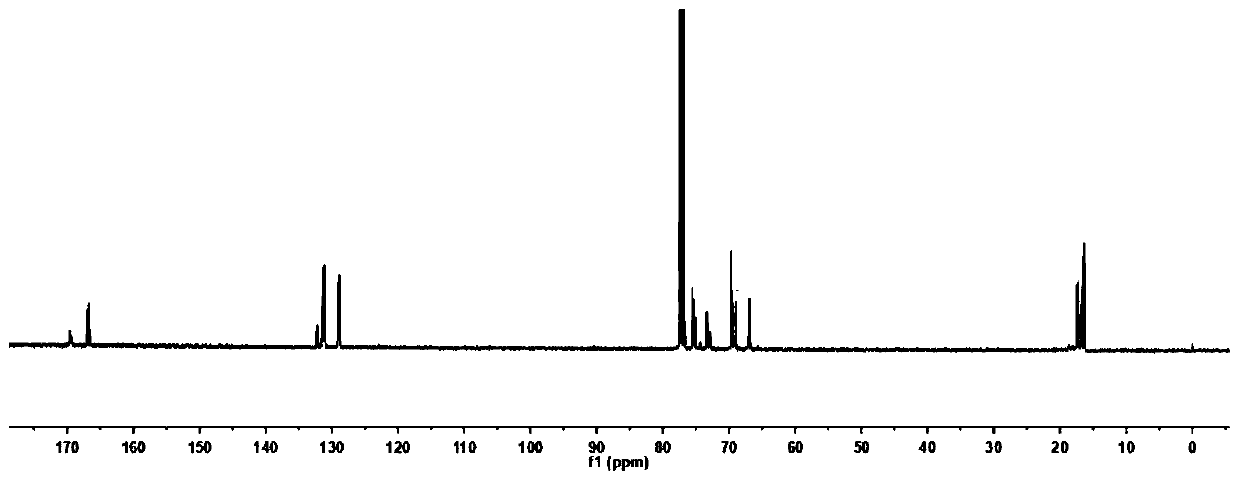

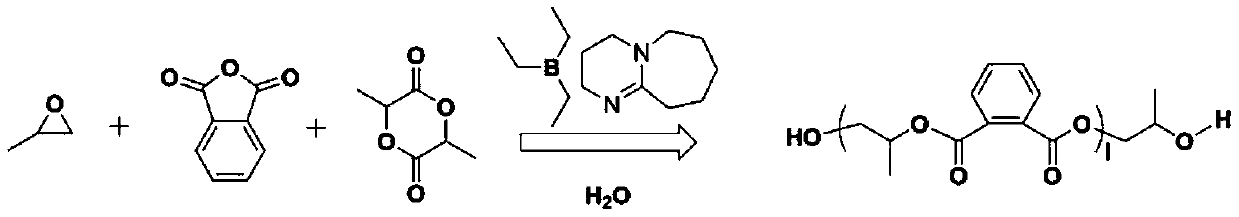

Preparation method of biodegradable block copolymer

The invention belongs to the technical field of macromolecular synthesis and particularly relates to a preparation method of a biodegradable block copolymer. The biodegradable block copolymer is prepared by taking a hydroxyl terminal compound as an initiator and performing synergistic catalysis on an epoxy monomer, an anhydride monomer and a lactone monomer by using nonmetallic lewis acid and lewis base catalysts through one-step polymerization. The preparation method of the biodegradable block copolymer has the following beneficial effects: due to use of the nonmetallic lewis acid and lewis base catalysts, the problem of medal residues of the block copolymer can be solved; furthermore, triblock copolymers and pentablock copolymers containing polyether blocks and with rich structure typescan be prepared. The purification problem that the fractional step method needs to charge for many times and wastes time and energy can be solved by a one-step method, the production efficiency can beimproved and the production cost can be reduced. The biodegradable block copolymer prepared by the method is controllable in relative molecular weight and block length.

Owner:HUAZHONG UNIV OF SCI & TECH

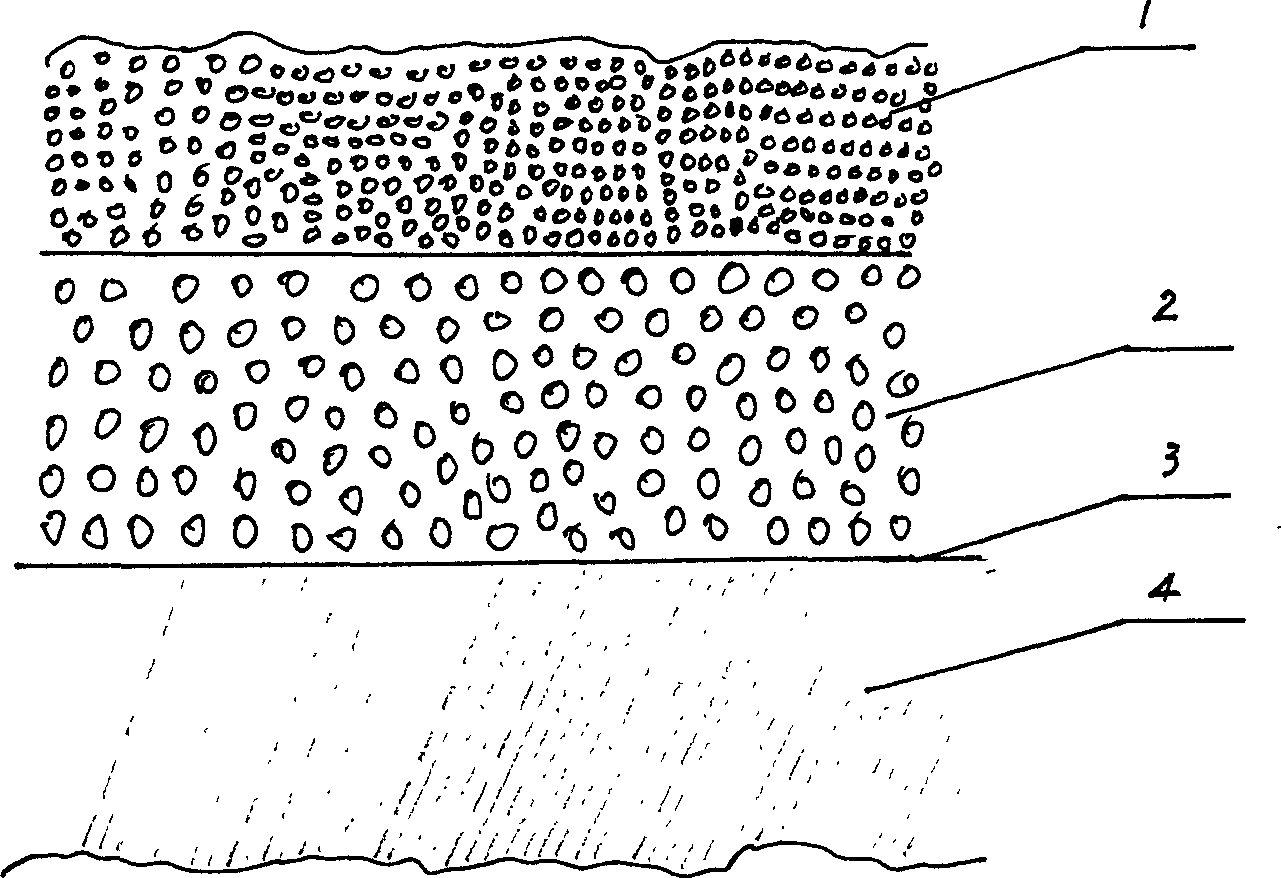

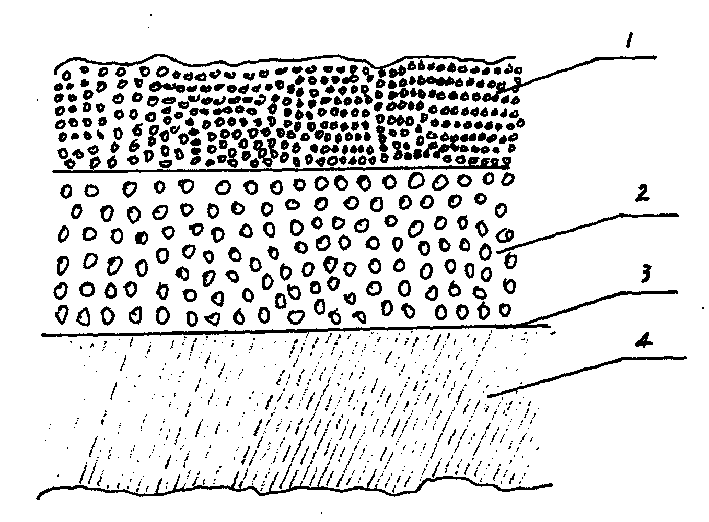

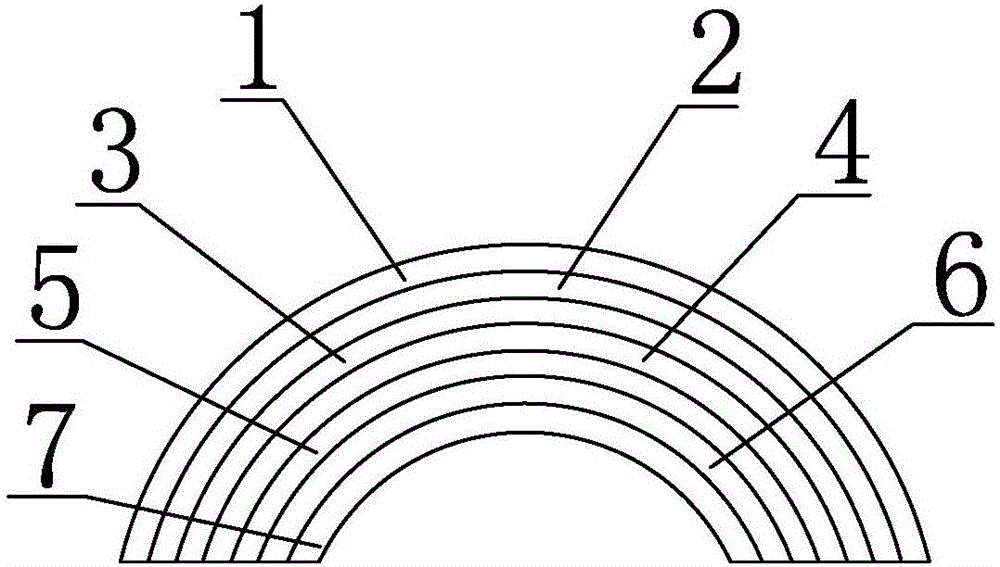

Anti-pricking and anti-busting scientific and technical safety tire and machining method thereof

InactiveCN106080051AImprove tensile propertiesGood adhesionNon-macromolecular adhesive additivesLaminationForeign matterDynamic balance

The invention provides an anti-pricking and anti-busting scientific and technical safety tire and a machining method thereof. The tire structurally comprises a tread rubber layer (1), a buffering layer (2), a steel wire band bundle layer (3), a curtain cloth layer (4), an airtight layer (5) and a polymer synthesis memory sizing material layer (6) in sequence from outside to inside. The thickness of the polymer synthesis memory sizing material layer (6) ranges from 1.5 mm to 20 mm. The tire has the beneficial effects that the polymer synthesis memory sizing material layer is sprayed to the inner surface of the tire, so that the tire is high in strength, stretchability and adhesion, the softening point of the sizing material layer is higher than 150 degrees, the glass transition temperature point of the sizing material layer is lower than -35 degrees, it can be guaranteed that no air leaks from the tire and the tire does not burst when the tire is pricked by foreign matter; spraying is conducted in a free follow-up mode, the evenness of the sizing material spraying effect is guaranteed, and the dynamic balance of the tire is not affected; and the tire can be prevented from being oxidized and polluted by air through an anti-adhesive and anti-pricking sealing protection layer, meanwhile, the anti-pricking and sizing layer shaping capacity is extremely high, ultraviolent rays can be prevented, and the reliability of the product is improved.

Owner:WUXI I REACH TECH

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

Composite red-mud high-molecular synthetic material for building decoration and preparation method thereof

The invention relates to a composite red-mud high-molecular synthetic material for building decoration and a preparation method thereof. The composite red-mud high-molecular synthetic material for building decoration disclosed by the invention is composed of the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 30-200 parts of red mud, 3-6 parts of stabilizer, 3-8 parts of impact modifier, 2-6 parts of impact inhibitor, 1.5-3 parts of coupling agent, 0.8-1.7 parts of paraffin, 0.4-1 part of stearic acid, 0-0.8 part of foaming agent, 0-10 parts of foam regulator, and 0-2 parts of ultraviolet light absorber. According to the invention, red mud used as a raw material is utilized for producing various building decoration materials; therefore, resources are saved; more importantly, the worldwide problem of environmental pollution caused by red mud is solved; and thus, the invention is a good thing having dual purposes.

Owner:杨兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com