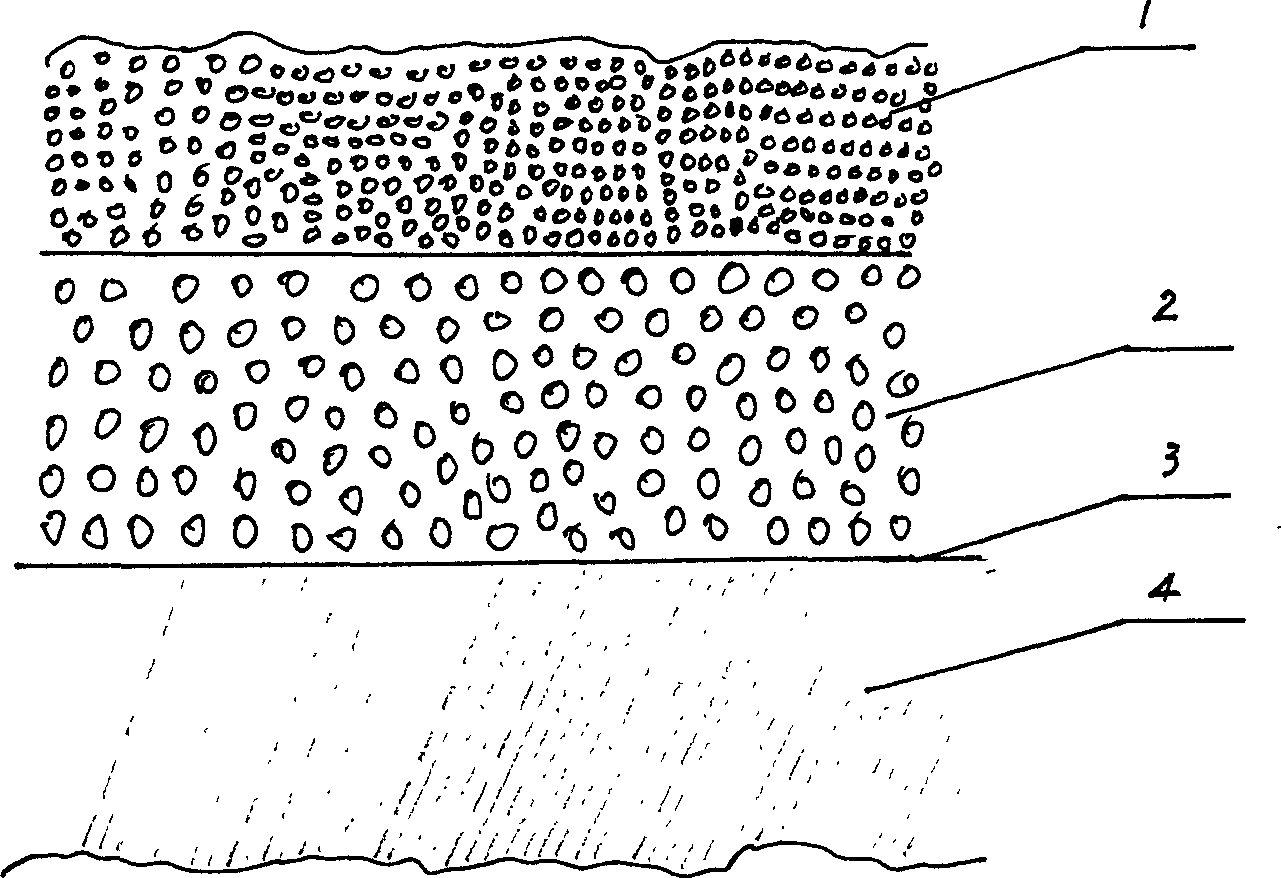

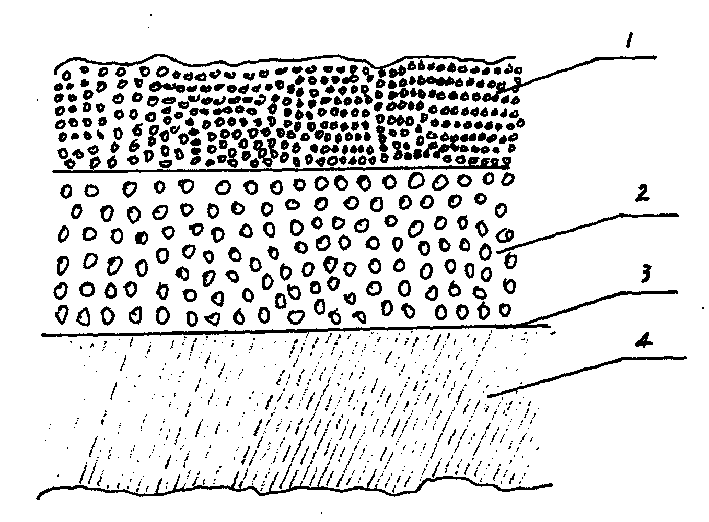

Environmental protection weeping plastic track

A plastic track, environmentally friendly technology, applied in the direction of roads, roads, adhesives, etc., can solve the problems of unreachable tensile strength and elongation, exceeding the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] One-component PU binder preparation

[0032] React 61 parts of polypropylene glycol ethers with molecular weights of 1000 and 2000, 37 parts of TDI and other mixed polyisocyanates and 1.2 parts of butanediol at 85°C for 4 hours, add an appropriate amount of additives after the reaction, and cool to room temperature for later use. The detected NCO content is 9%, and the free TDI content is 0.2%.

Embodiment 2

[0034] red paste preparation

[0035] Grind 12.5 parts of plasticizer and 28.2 parts of iron red into color paste, add 38.6 parts of dehydrated polypropylene glycol ether (molecular weight is 400 and 2000), 19 parts of low molecular polyols, 125 parts of solvent gasoline, 6.3 parts of rheological additives, Stir an appropriate amount of additives at high speed for 1 hour until dipped with a glass rod and does not flow.

Embodiment 3

[0037] Preparation of red PU spray paste

[0038] 200 parts of the PU binder of Example 1, 100 parts of the red paste of Example 2, 300 parts of φ1.5mm red EPDM colloids, and 3 parts of catalyst, and stir evenly to form the water-permeable runway surface layer spray colloids. Make it into a 4-5mm thick rubber block and cure it at 70°C for 24 hours. The test results are shown in Table 1:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com