Acrylic ester elastic emulsion of room temperature self-crosslinking core-shell structure and preparing method thereof

An acrylate and elastic emulsion technology, applied in the field of polymer synthesis, can solve the problems of not much improvement of emulsion flexibility and low-temperature crack resistance, slow curing speed of coatings, uneven ultraviolet irradiation, etc., and achieve excellent mechanical properties, good stain resistance Stainability and the effect of increasing cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below according to example the present invention is further described:

[0042] Accurately weigh 82.1g of deionized water, 6.2g of anionic emulsifier ARICO2518, 48.6g of methyl methacrylate, 134.5g of butyl acrylate, and 3.7g of methacrylic acid, place them in a three-necked flask, stir and pre-emulsify at a high speed, and obtain Core layer monomer pre-emulsion.

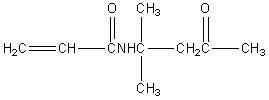

[0043] Accurately weigh 14.1g of deionized water, 1.1g of anionic emulsifier ARICO2518, 15.2g of methyl methacrylate, 15.8g of butyl acrylate, 0.3g of methacrylic acid, and 1.7g of diacetone acrylamide, and place them in a three-necked flask. Stirring at high speed for pre-emulsification to obtain a shell monomer pre-emulsion.

[0044]In a four-necked flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, add 87.9 g of deionized water and 5.7 g of anionic emulsifier ARICO2518, and stir the water bath to raise the temperature to 82±2°C; the system in the four-necked flask to be reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com