Polycarboxylic acid cement activation reinforced grinding aid and preparation method thereof

A technology of grinding aid enhancer and polyethylene glycol is applied in the field of cement grinding aid, which can solve the problems of unstable performance and narrow application range, and achieve the effect of good grinding aid effect, good enhancement effect and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

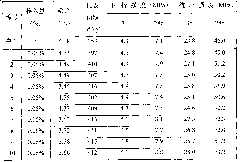

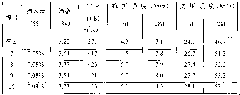

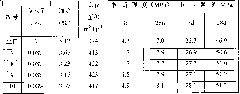

Examples

Embodiment 1

[0019] (1) Preparation of polyethylene glycol maleate

[0020] Add 60 parts of polyethylene glycol with a molecular weight of 600 and 20 parts of maleic anhydride into a reactor equipped with mechanical stirring, raise the temperature to 60°C, and after the two are compatible, add 2 parts of p-toluenesulfonic acid, 70°C After 4h, the polyethylene glycol maleate was obtained, and the esterification rate was 91.4%.

[0021] (2) Preparation of polycarboxylate cement activated grinding aid enhancer

[0022] 70 parts of allyl polyethylene glycol with a molecular weight of 700, 30 parts of (meth) allyl sodium sulfonate, 80 parts of ethylene glycol, and 600 parts of water were respectively added to the esterification product in sequence, heated and continuously stirred, Add 4 parts of ammonium persulfate dropwise, raise the temperature to 90°C after dropping, finish the reaction after 7 hours of reaction, adjust the pH to neutral with sodium hydroxide solution, control the solid con...

Embodiment 2

[0024] (1) Preparation of polyethylene glycol maleate

[0025] Add 80 parts of polyethylene glycol 800 and 20 parts of maleic anhydride into a reactor equipped with mechanical stirring, raise the temperature to 60°C, after the two are compatible, add 3 parts of p-toluenesulfonic acid, and esterify at 70°C for 4h , to obtain polyethylene glycol monomethyl ether maleate with an esterification rate of 89.4%.

[0026] (2) Preparation of polycarboxylate cement activated grinding aid enhancer

[0027] 100 parts of allyl polyethylene glycol with a molecular weight of 1000, 30 parts of (meth) allyl sodium sulfonate, 200 parts of ethylene glycol, and 1000 parts of water were respectively added to the esterification product in sequence, heated and continuously stirred, Add 5 parts of ammonium persulfate dropwise, raise the temperature to 90°C after dropping, finish the reaction after 7 hours of reaction, adjust the pH to neutral with sodium hydroxide solution, control the solid content...

Embodiment 3

[0029] (1) Preparation of polyethylene glycol maleate

[0030] Add 100 parts of polyethylene glycol 1000 and 20 parts of maleic anhydride into a reactor equipped with mechanical stirring, raise the temperature to 60°C, stir mechanically, after the two are compatible, add 4 parts of p-toluenesulfonic acid, After esterification for 5 hours, polyethylene glycol maleate was obtained, and the esterification rate was 83.2%.

[0031] (2) Preparation of polycarboxylate cement activated grinding aid enhancer

[0032] Add 200 parts of allyl polyethylene glycol with a molecular weight of 2000, 30 parts of (meth) allyl sodium sulfonate, 350 parts of ethylene glycol, and 1400 parts of water into the esterification product in sequence, mix and stir evenly, and heat Stir continuously, add 8 parts of ammonium persulfate dropwise, heat up to 95°C after dropping, finish the reaction after 8 hours of reaction, adjust the pH to neutral with sodium hydroxide solution, and control the solid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com