Polycarboxylic acid series high molecular synthetic cement grinding additive and preparation method thereof

A cement grinding aid and polycarboxylic acid-based technology, which is applied in the field of cement grinding aids, can solve the problems of inability to satisfy cement grinding aids, difficult to control the cost, and depend on the price of raw materials, and achieve easy cost control, easy industrial production, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

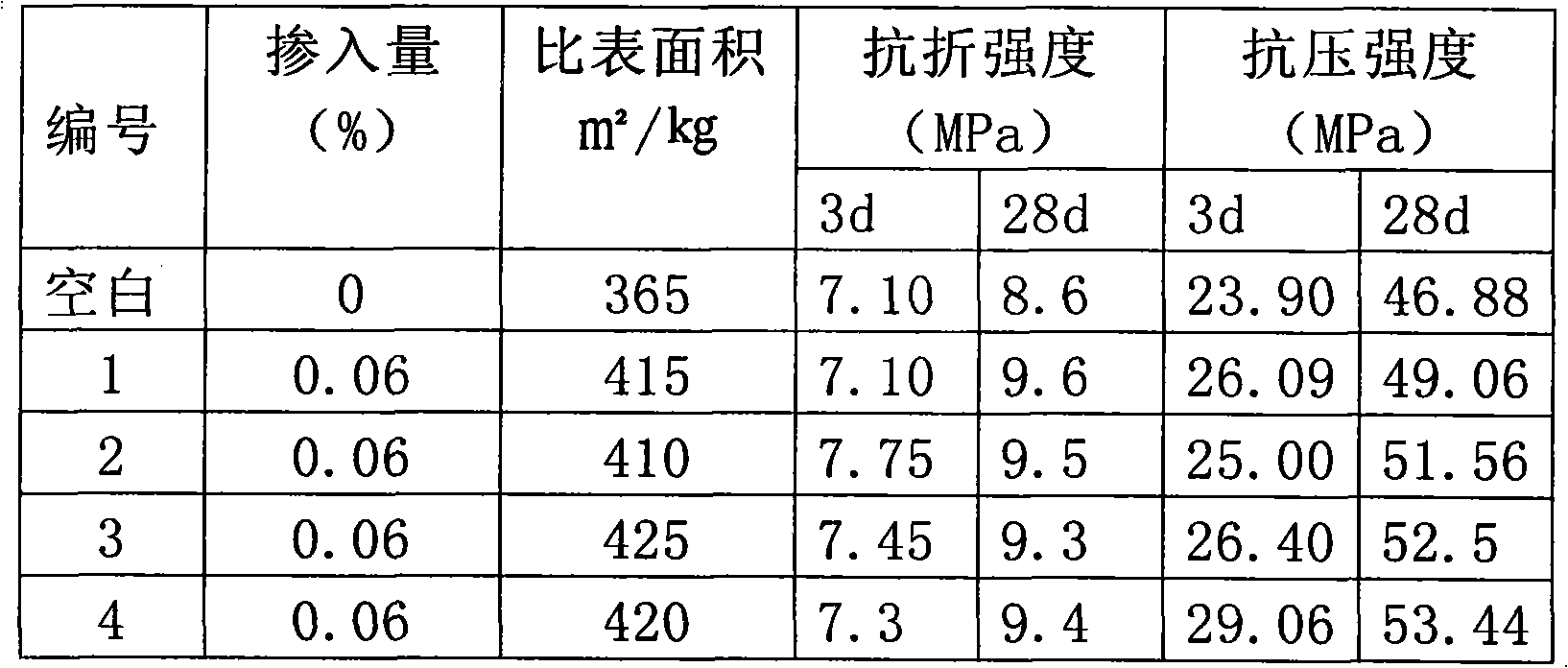

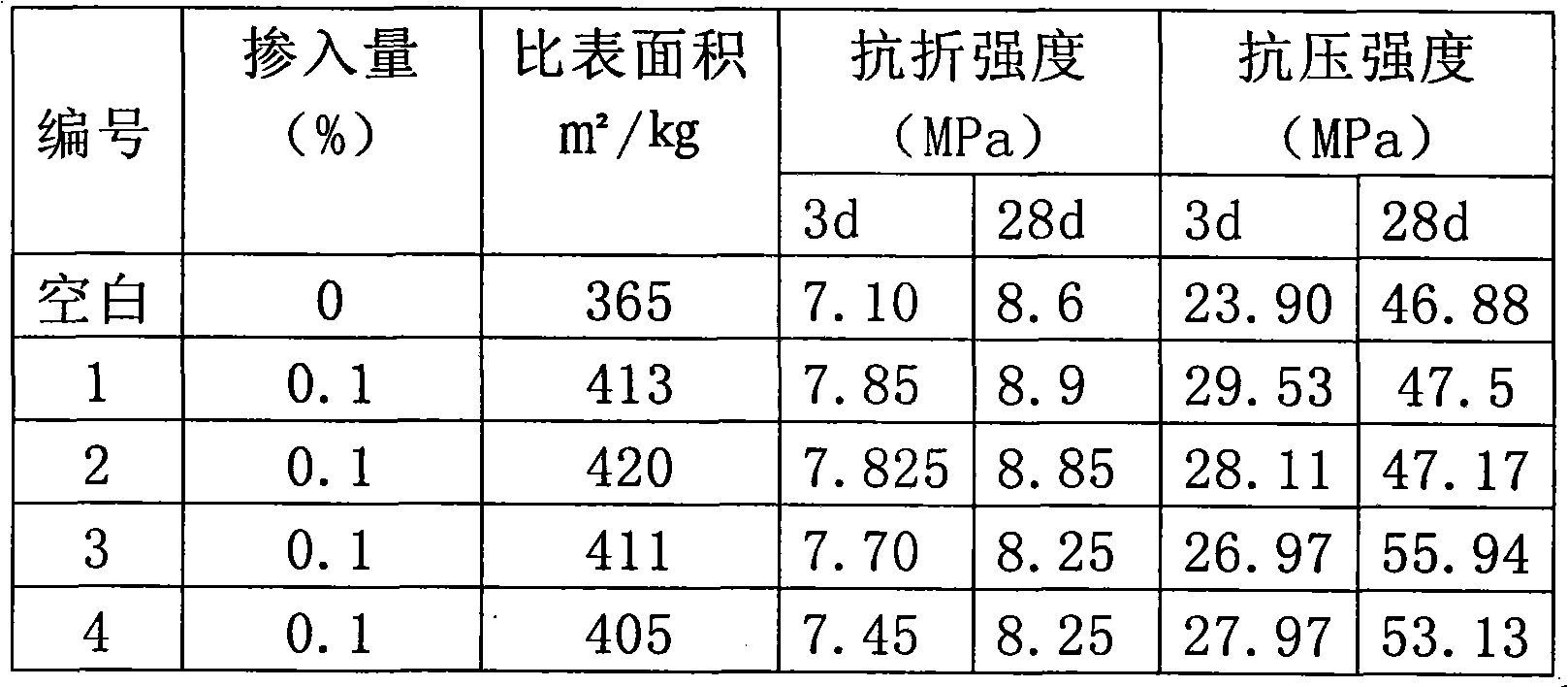

example 1

[0021] Put 50 parts of diethanolamine (it can also be replaced by one of monoethanolamine and triisopropanolamine) and 1000 parts of water into the reaction kettle equipped with a stirring device and a temperature display device in turn, and then put 20 parts of horses into the reaction kettle. Maleic anhydride (can also be replaced by one of maleic acid and methacrylic acid), when adding maleic anhydride, turn on the stirring device to stir and heat, and stabilize the temperature at 70°C to ensure that the reaction temperature is 70°C Under the condition of carrying out, after reacting for 1 hour, obtain maleic acid amide. Then 200 parts of allyl polyethylene glycol with a molecular weight of 1000 (it can also be replaced by one of allyl polyoxyethylene or polyoxypropylene ether with an average relative molecular weight of 500-3000) and 7 parts of ammonium persulfate (It can also be replaced by one of potassium persulfate or sodium persulfate) successively drop into the malei...

example 2

[0023] Put 70 parts of diethanolamine (which can also be replaced by one of monoethanolamine and triisopropanolamine) and 1100 parts of water into the reaction kettle equipped with a stirring device and a temperature display device in sequence, and then put 30 parts of horses into the reaction kettle. Maleic anhydride (can also be replaced by one of maleic acid and methacrylic acid), when adding maleic anhydride, turn on the stirring device to stir and heat, and stabilize the temperature at 70°C to ensure that the reaction temperature is 70°C Under the condition of carrying out, after reacting for 1 hour, obtain maleic acid amide. Then 300 parts of allyl polyethylene glycol with a molecular weight of 1000 (it can also be replaced by one of allyl polyoxyethylene or polyoxypropylene ether with an average relative molecular weight of 500-3000) and 10 parts of ammonium persulfate (It can also be replaced by one of potassium persulfate or sodium persulfate) successively drop into t...

example 3

[0025] Put 80 parts of diethanolamine (which can also be replaced by one of monoethanolamine and triisopropanolamine) and 1200 parts of water into the reaction kettle equipped with stirring device and temperature display device in sequence, and then put 40 parts of horses into the reaction kettle. Maleic anhydride (can also be replaced by one of maleic acid and methacrylic acid), when adding maleic anhydride, turn on the stirring device to stir and heat, and stabilize the temperature at 70°C to ensure that the reaction temperature is 70°C Under the condition of carrying out, after reacting for 1 hour, obtain maleic acid amide. Then 400 parts of allyl polyethylene glycol with a molecular weight of 1000 (it can also be replaced by one of allyl polyoxyethylene or polyoxypropylene ether with an average relative molecular weight of 500-3000) and 7 parts of ammonium persulfate (It can also be replaced by one of potassium persulfate or sodium persulfate) successively drop into the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com