Adaptive control system of hot air drying

A self-adaptive control and hot air drying technology, which is applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problem of not overcoming the influence of changes in the working conditions of the dryer, the inability to evaluate the control accuracy of the drying process, and the lack of drying process control, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

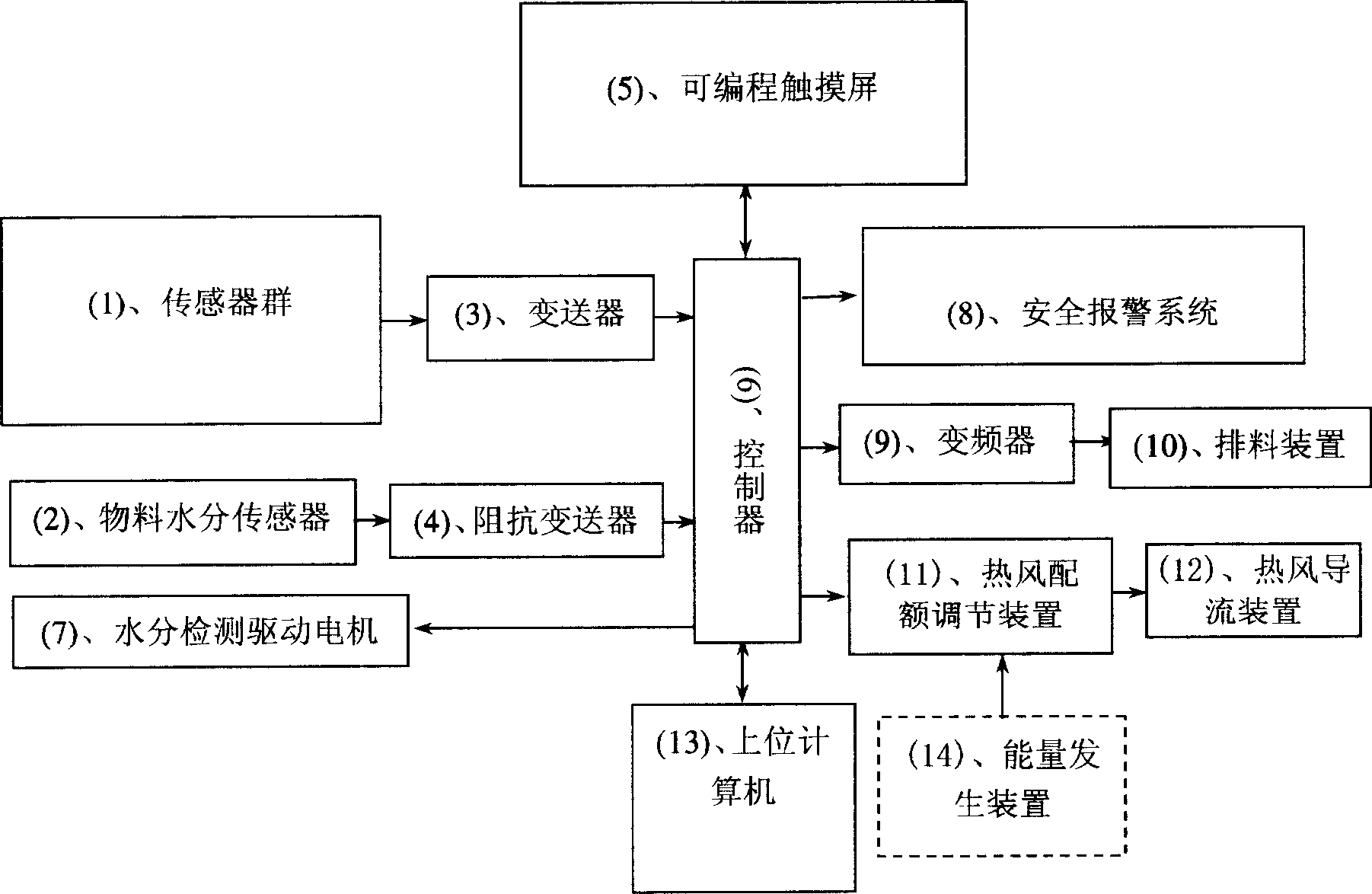

[0015] Principle frame of the present invention is as figure 1 As shown, it includes a sensor group 1, a material moisture sensor 2, a transmitter 3, an impedance transmitter 4, a controller 6, a frequency converter 9, a discharge device 10, and a host computer 13, among which the sensor group 1 and the material moisture sensor The output signal of 2 is connected with the input terminal of controller 6 through transmitter 3 and impedance transmitter 4 respectively, and the input and output interface of controller 6 and the output and input interface of host computer 13 realize two-way communication through communication interface, control The output interface of the device 6 is connected with the discharge device 10 in the hot air drying heat exchange chamber through the frequency converter 9 . In this embodiment, the sensor group 1 includes a drying temperature detection sensor, an ambient temperature detection sensor, a humidity detection sensor, a wind pressure detection se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com