Patents

Literature

1314results about How to "Improve drying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

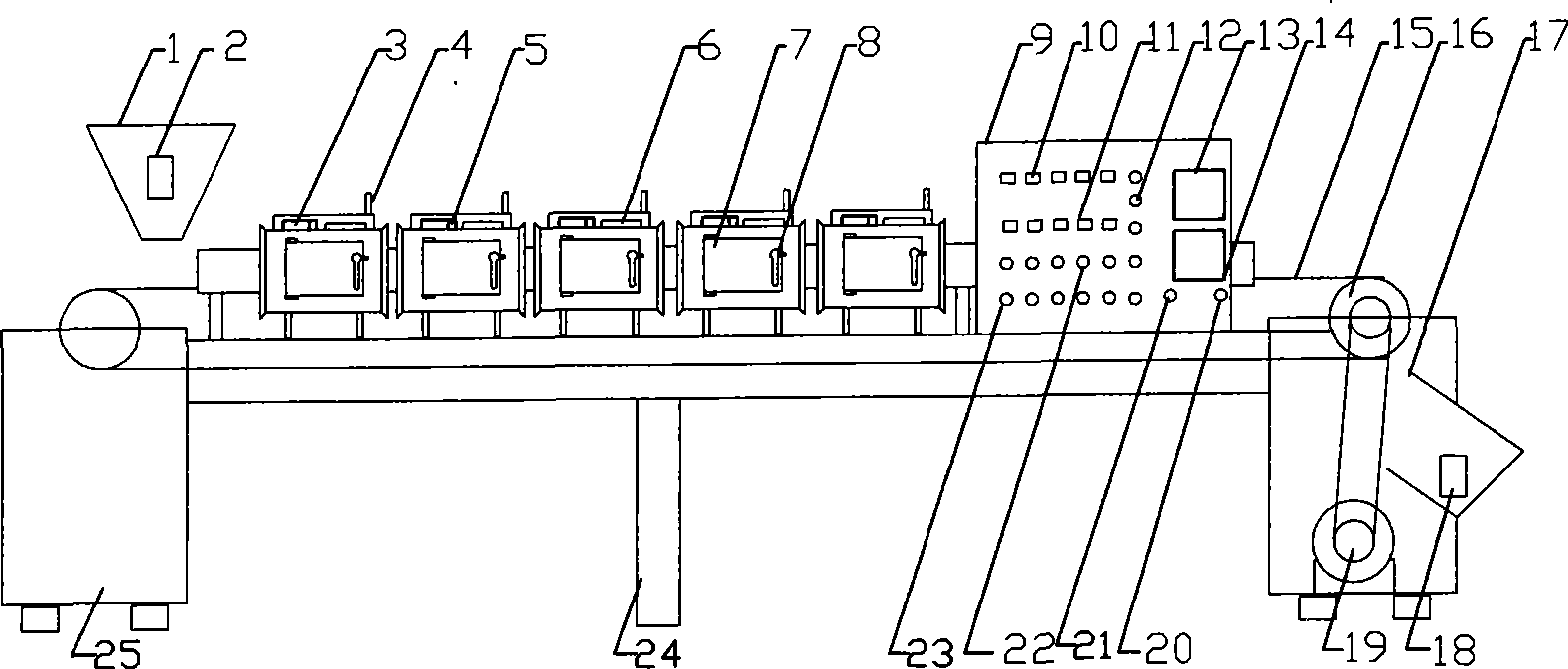

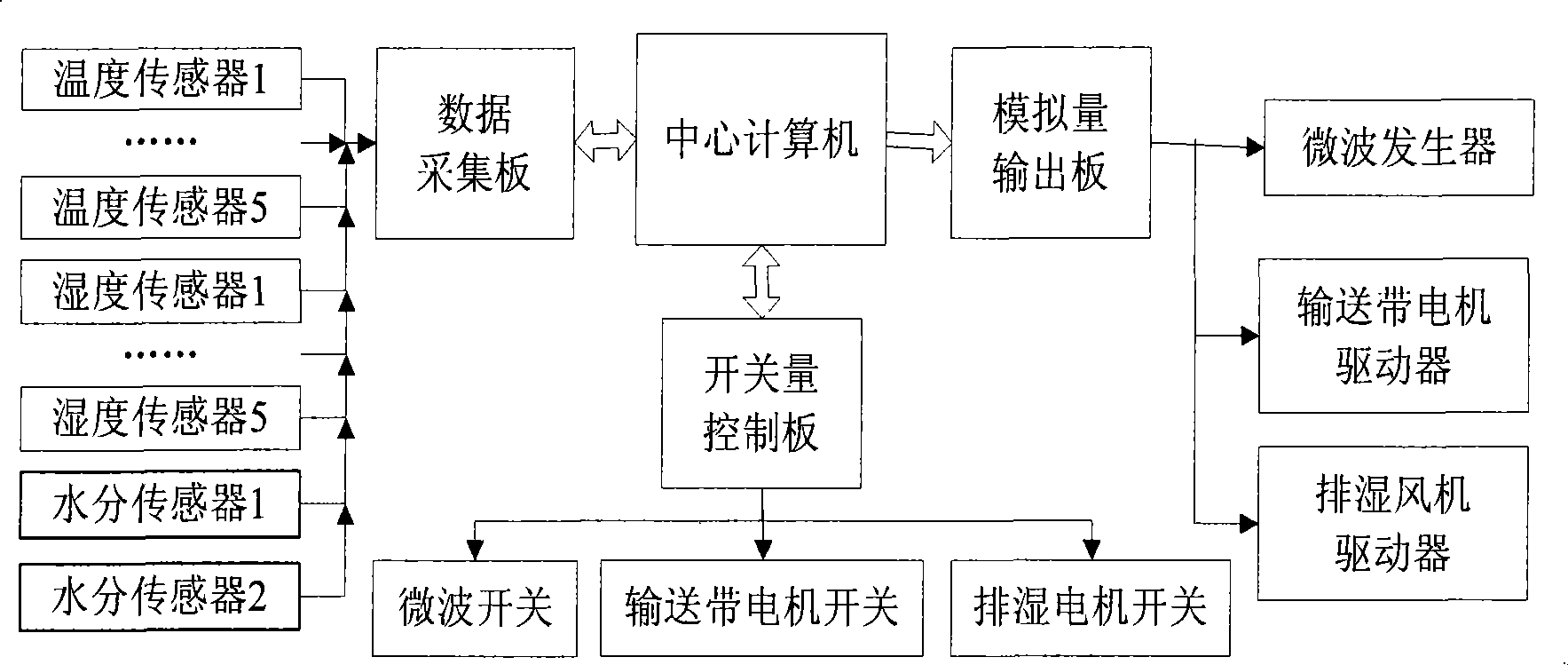

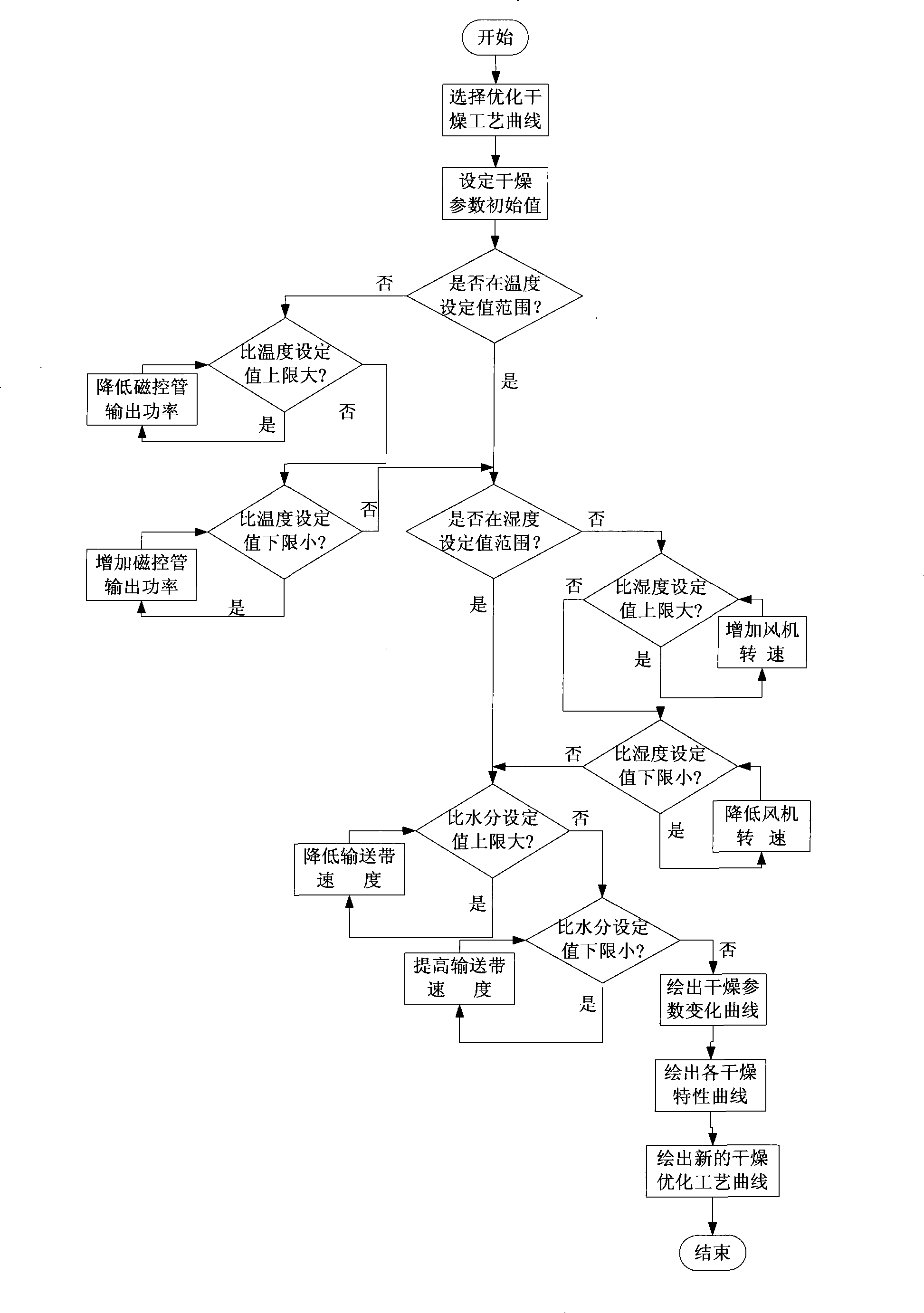

Intelligent microwave continuous drier and control method thereof

InactiveCN101382379AImprove drying qualityEasy to operateDrying solid materials with heatDrying machines with progressive movementsFrequency changerDrive motor

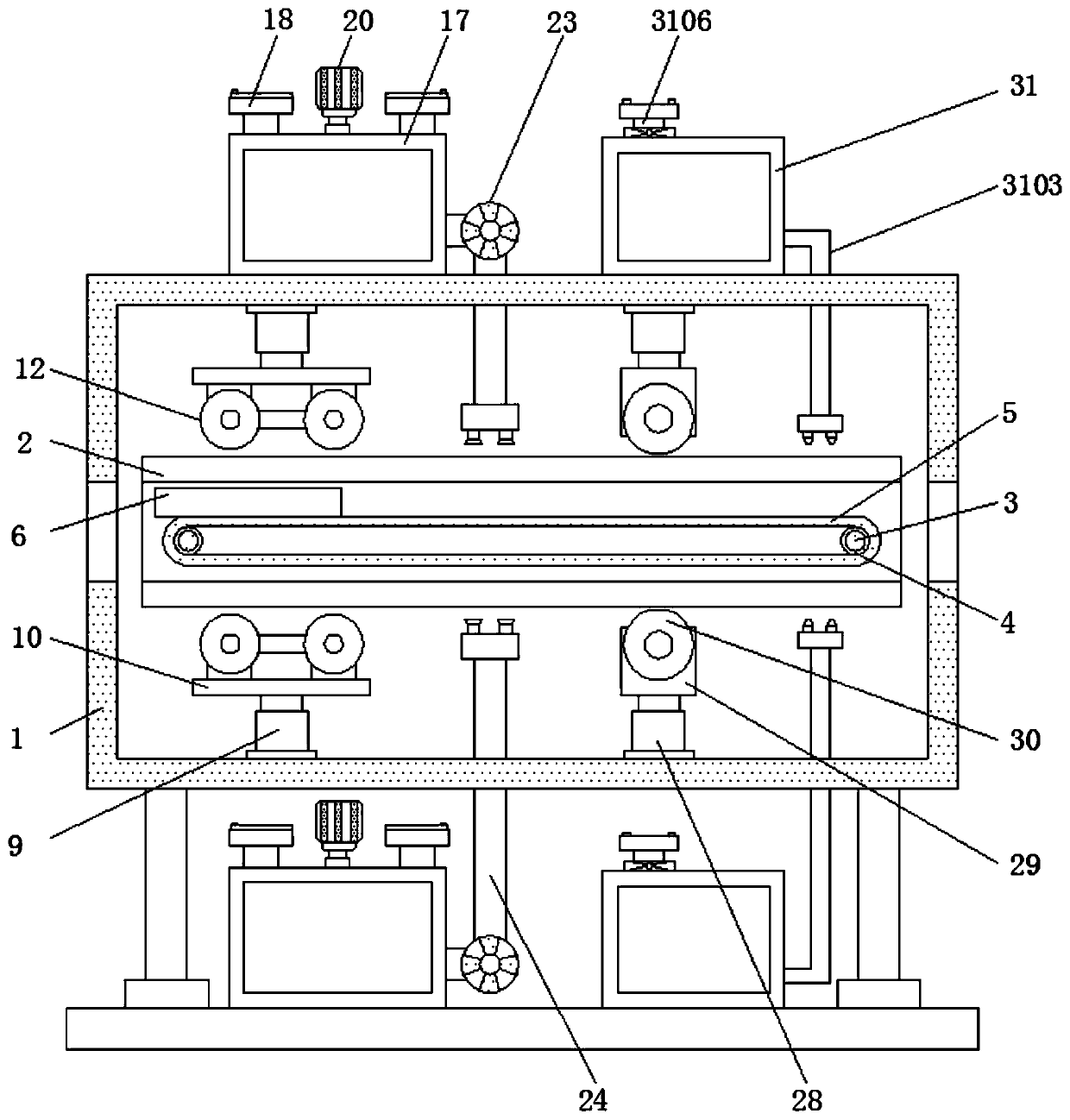

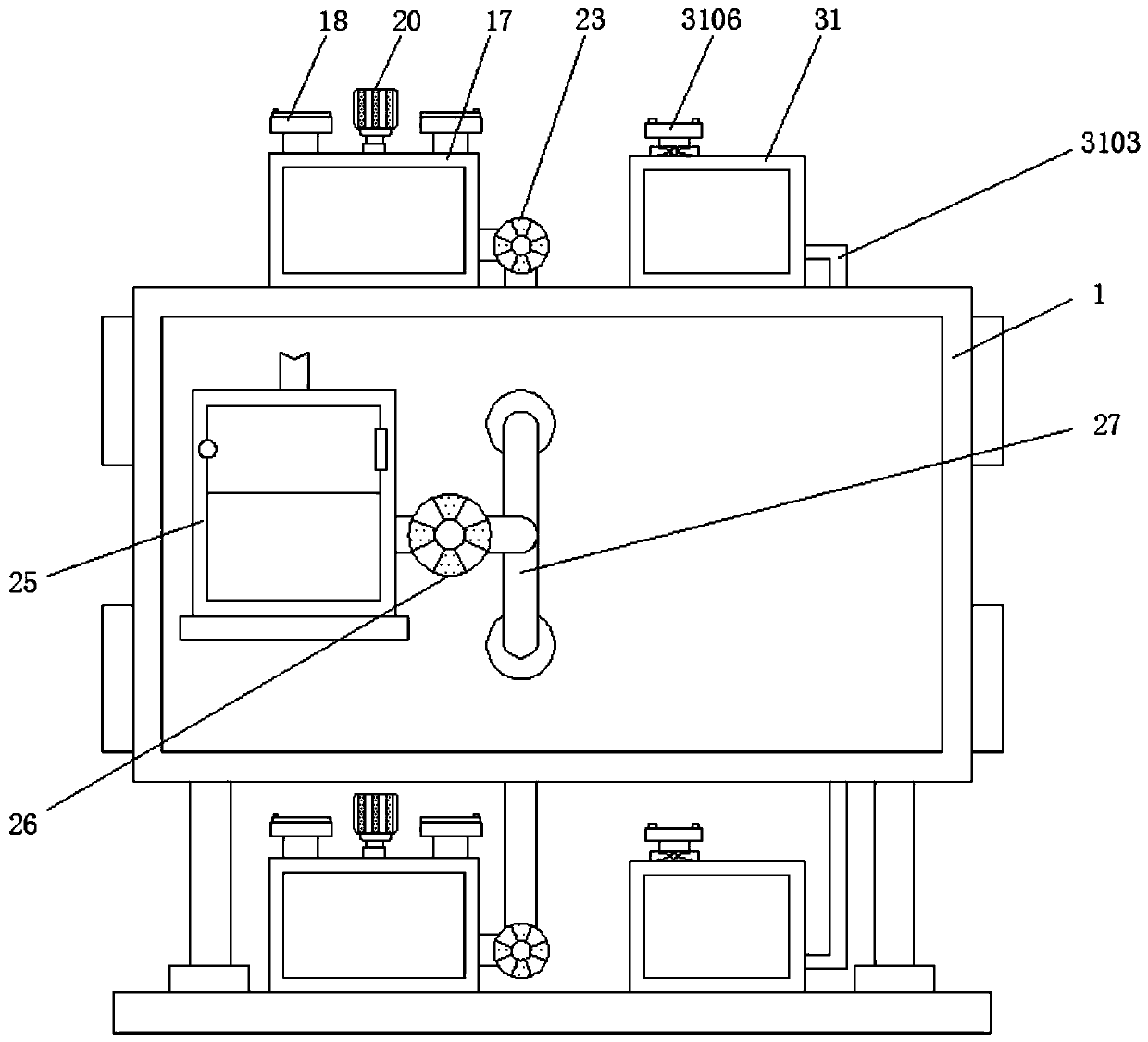

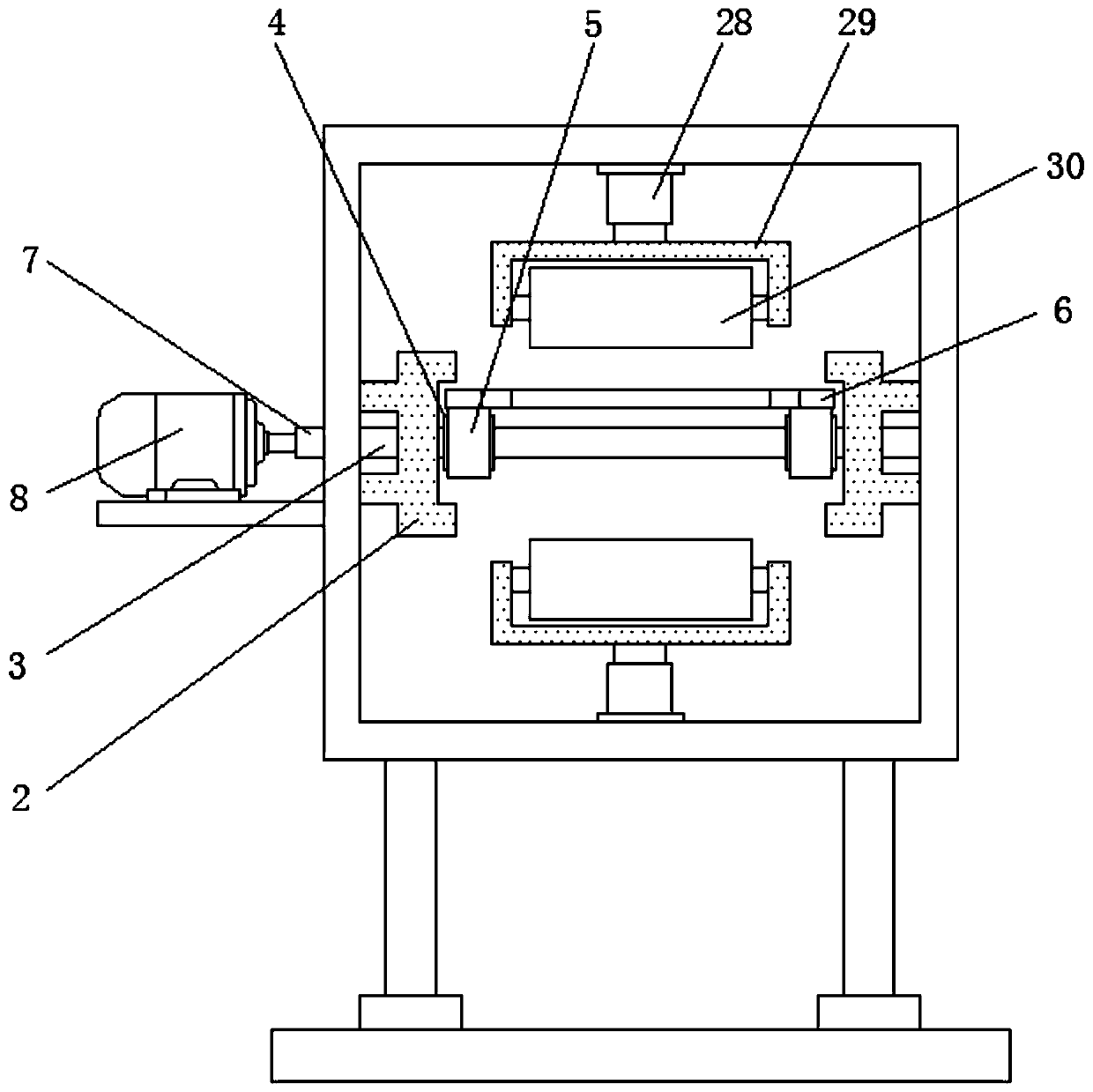

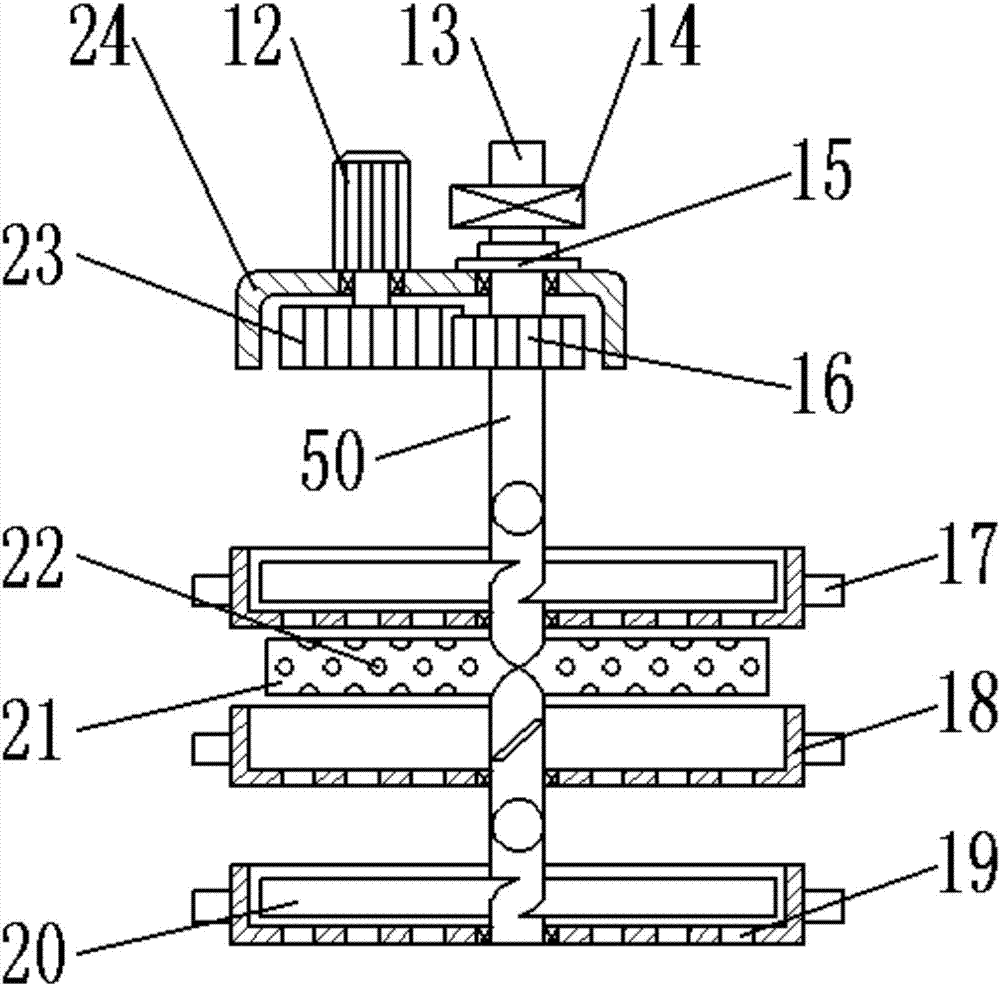

The invention discloses an intellectualized microwave continuous drier and a control method thereof; the drier comprises a rack, a conveying belt, a conveying belt wheel, a driving motor, an instrument control box and a computer; two ends of the conveying belt are respectively provided with a feed hopper and a discharge hopper and the conveying belt runs through a plurality of microwave drying cavities with doors; each microwave drying cavity is internally provided with a microwave magnetron, a temperature sensor, a humidity sensor and a speed-regulating fan; the feed hopper and the discharge hopper are respectively provided with a moisture sensor, and the conveying belt is driven by a speed-regulating motor controlled by a frequency converter. A control system can automatically draw variation curves of the temperature and the humidity of the materials in each drying cavity and the water content ratio of the discharged materials in the drying process of the materials in shorter time according to the collected data of the temperature, the humidity and the water content ratio of the materials in the drying process of the materials, can optimize control parameters continuously according to the change of the temperature, the humidity and the water content ratio in the drying process of the materials, and can regulate the system parameters automatically and realize the dynamic optimization of the drying technique parameters.

Owner:ANHUI AGRICULTURAL UNIVERSITY

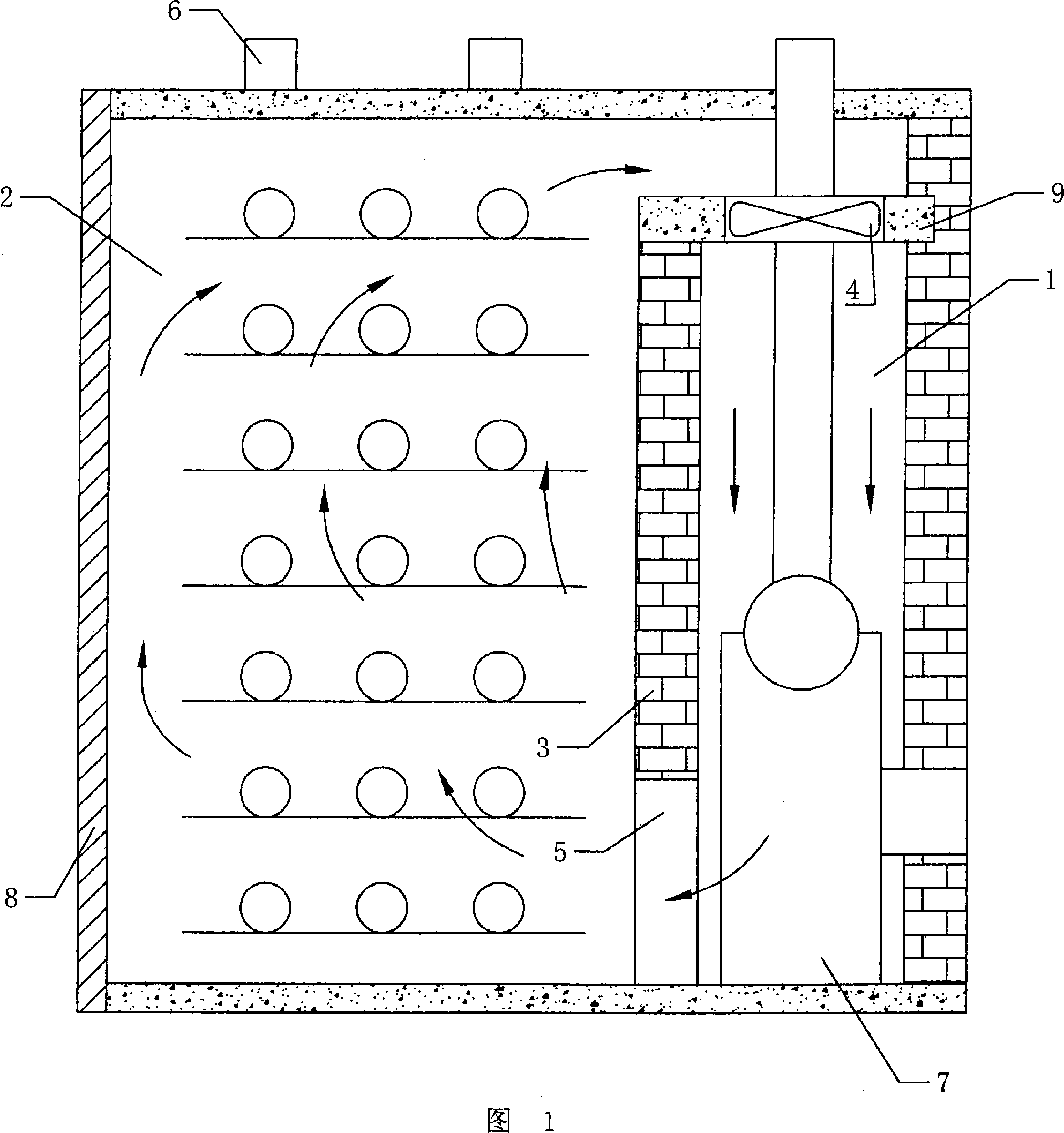

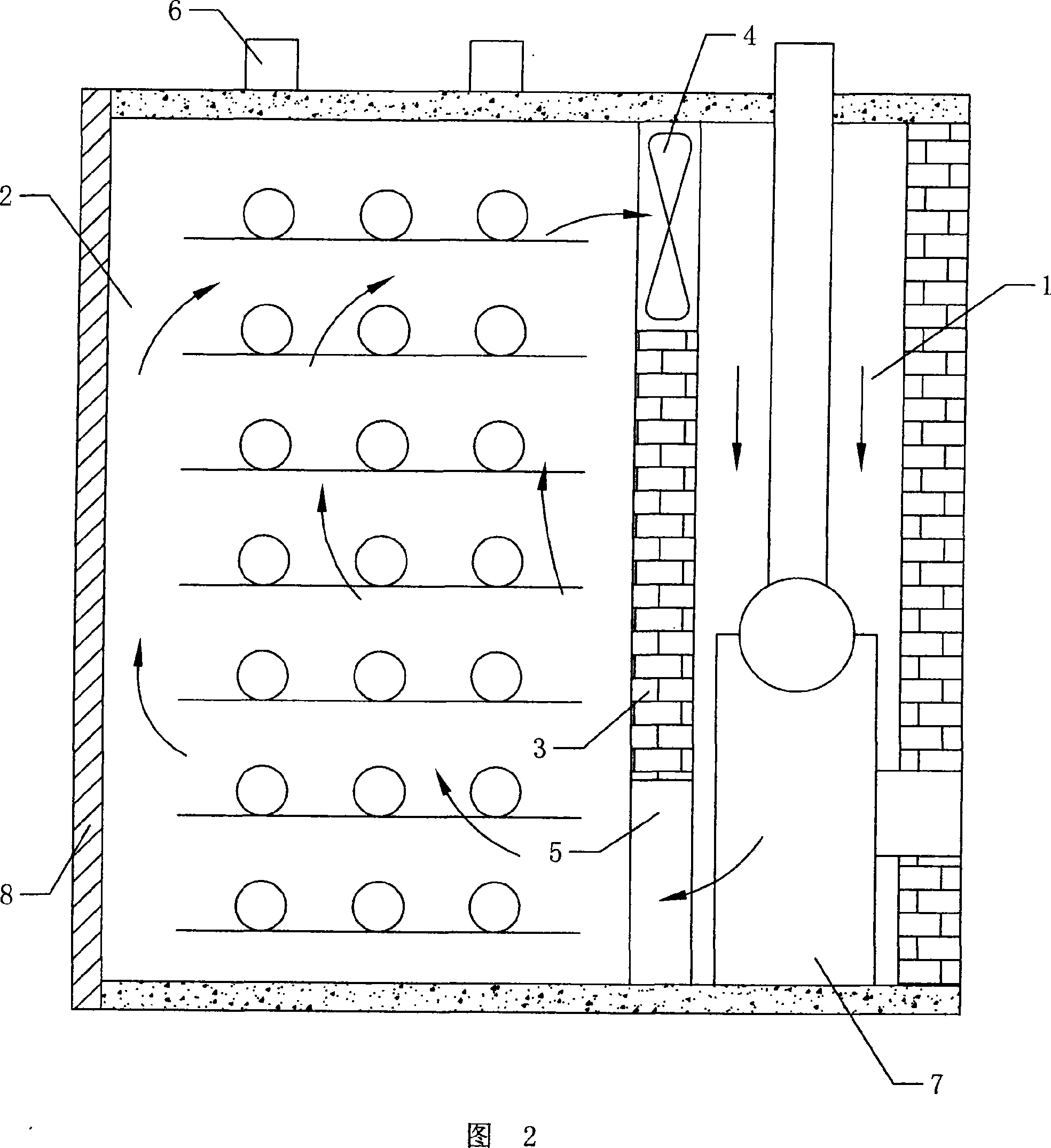

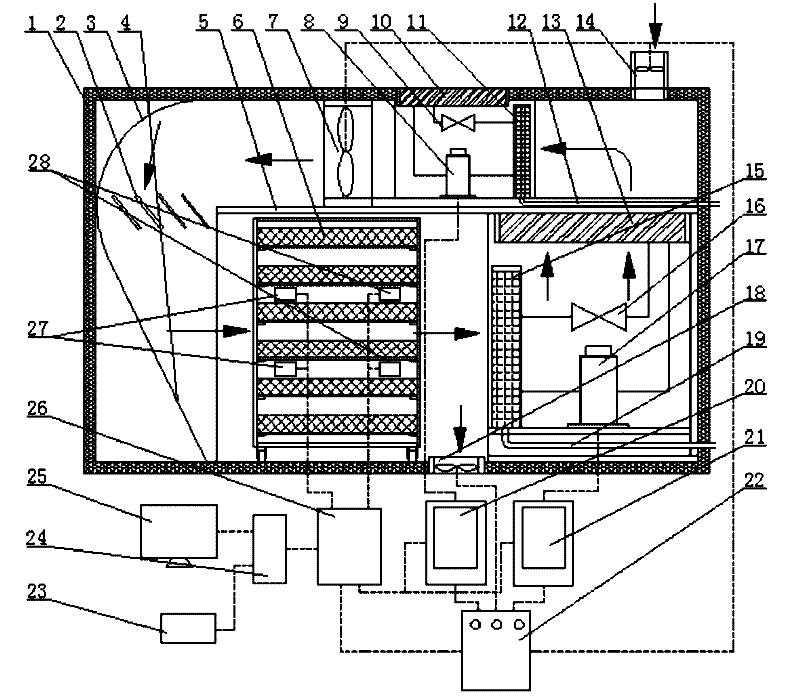

Lumber drying kiln

InactiveCN101144681AHigh thermal efficiencySmooth and even circulationDrying solid materials with heatDrying gas arrangementsEngineeringCombustion

The invention discloses a lumber drying kiln. An isolation wall is arranged between the bottom part and the top part in the drying kiln, the isolation wall divides the space in the kiln into an air heating room used for installing a drying furnace, and a lumber drying room; wherein, an upper ventilation opening is arranged at the upper part of the isolation wall, a lower ventilation opening is arranged at the lower part of the isolation wall, a fan used for blowing air to the air heating room from the lumber drying room is arranged between the air heating room and the lumber drying room; an air exhaust passage is arranged at the top part corresponding to the lumber drying room; because the fan is arranged at the position of the upper ventilation opening, the fan sucks the hot air from the lumber drying room to blow into a lumber heating room, the back flow does not happen, thereby leading the heated air circulation to be smoother, therefore the drying quality to be improved. Because the isolation wall is arranged between the air heating room and the lumber drying room, the charring of the lumber close to a combustion furnace because of over high temperature is avoided, the lumber far away the combustion furnace does not have the drying phenomenon, to lead the drying to be evener.

Owner:李祥文

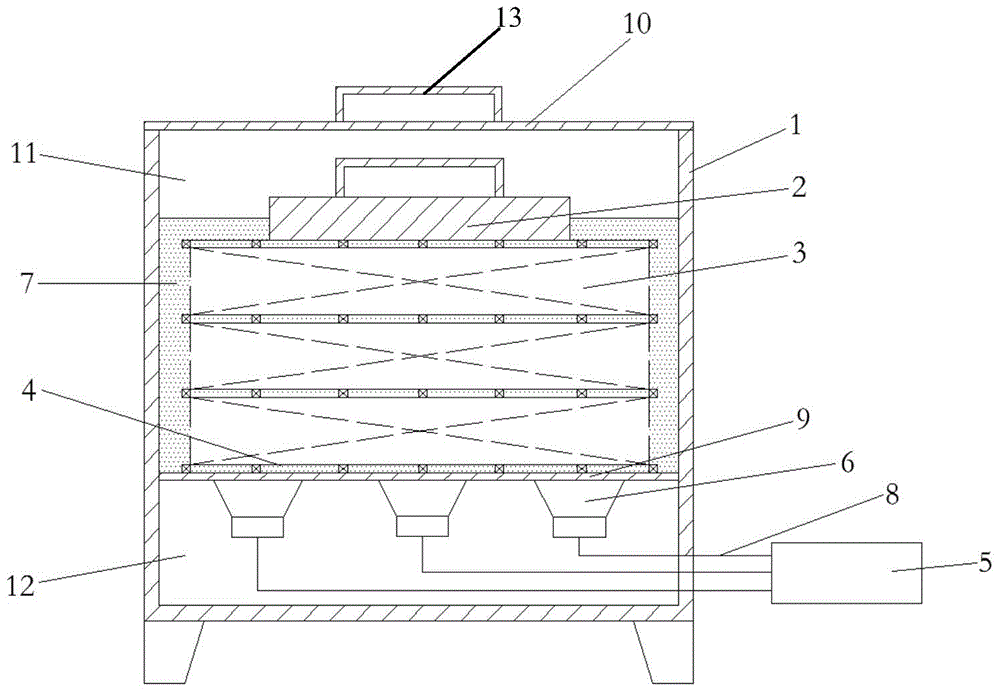

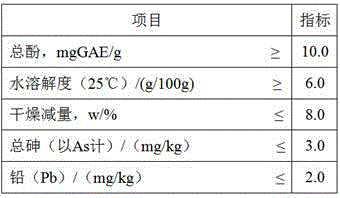

High-voltage electric field and hot air combined drying device

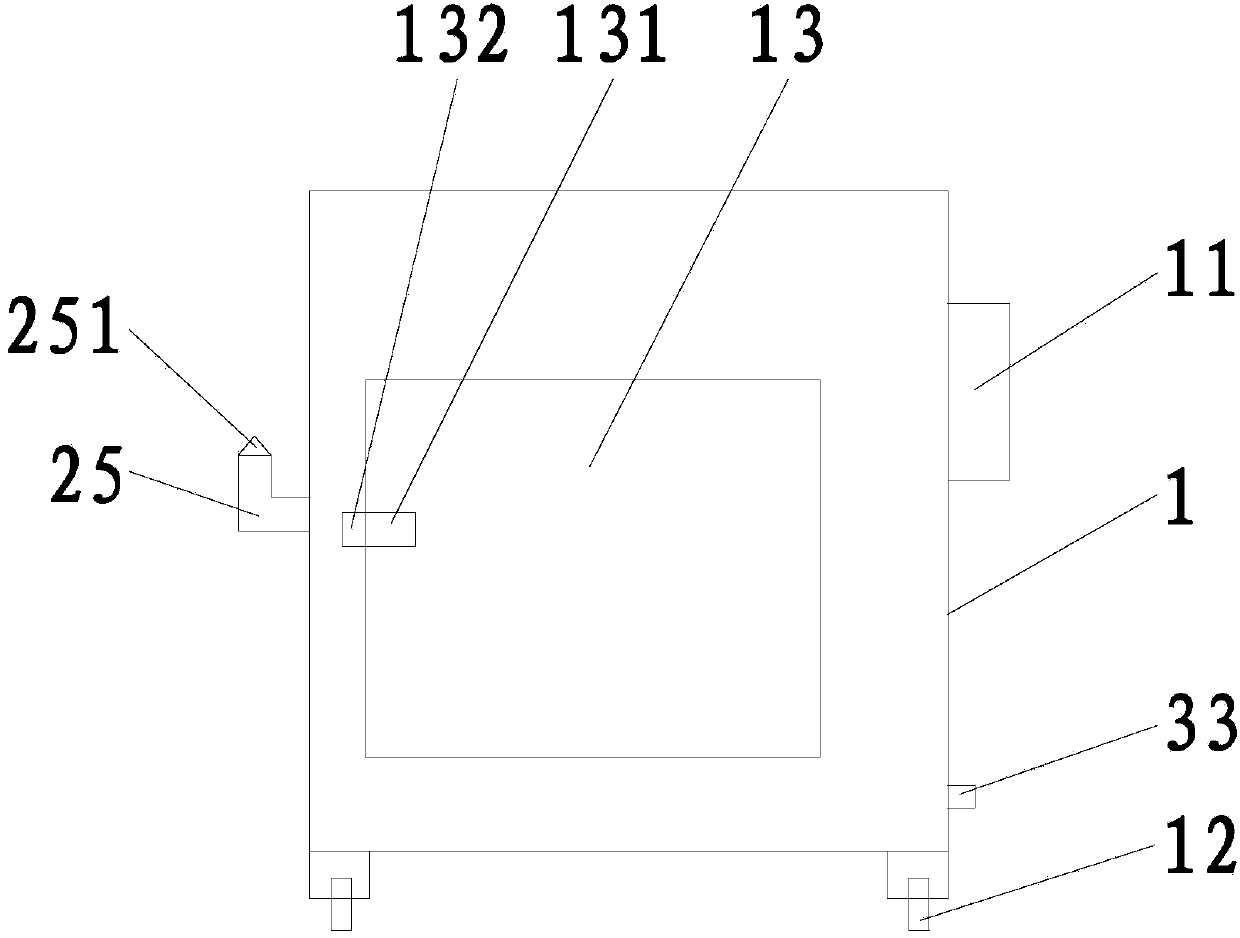

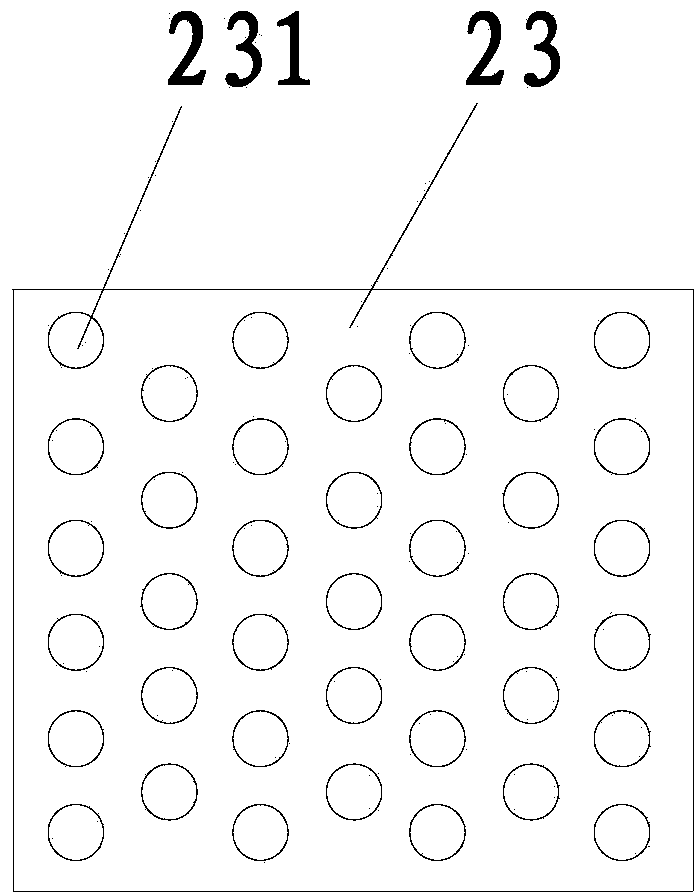

ActiveCN103983091AImprove retentionGood appearanceDrying gas arrangementsDrying chambers/containersThermal instabilityOperability

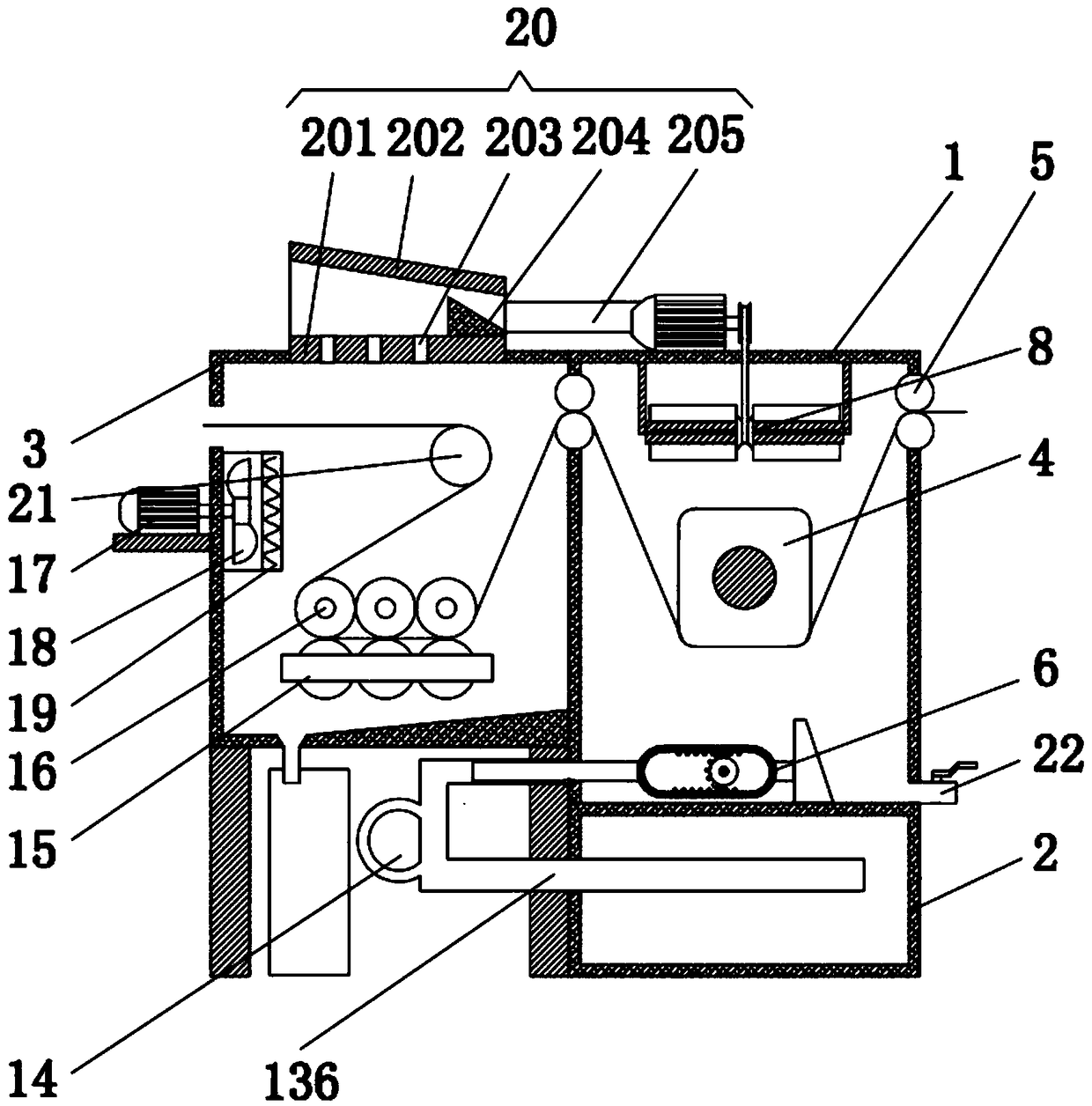

The invention discloses a high-voltage electric field and hot air combined drying device. The high-voltage electric field and hot air combined drying device comprises a box body, a high-voltage electric field drying system, a hot air circulation drying system and a monitoring control system, wherein the high-voltage electric field drying system, the hot air circulation drying system and the monitoring control system are arranged on the box body. According to the high-voltage electric field and hot air combined drying device provided by the invention, the structural design is reasonable, the operability is strong, and the use is convenient; compared with traditional hot air drying, the drying efficiency is high, the drying temperature is low, the drying time can be shortened by 50% than the drying time of drying by pure hot air under the same temperature, the drying energy consumption can be reduced by 51.9%, the high-voltage electric field and hot air combined drying device is particularly suitable for drying materials containing thermal-instability active components, for example, drying the materials of traditional Chinese medicine, medicinal slices, drug, agricultural products, food, biological products and the like, the appearance quality after the drying is good, the reservation degree of the active components is high, and the application range is very wide.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

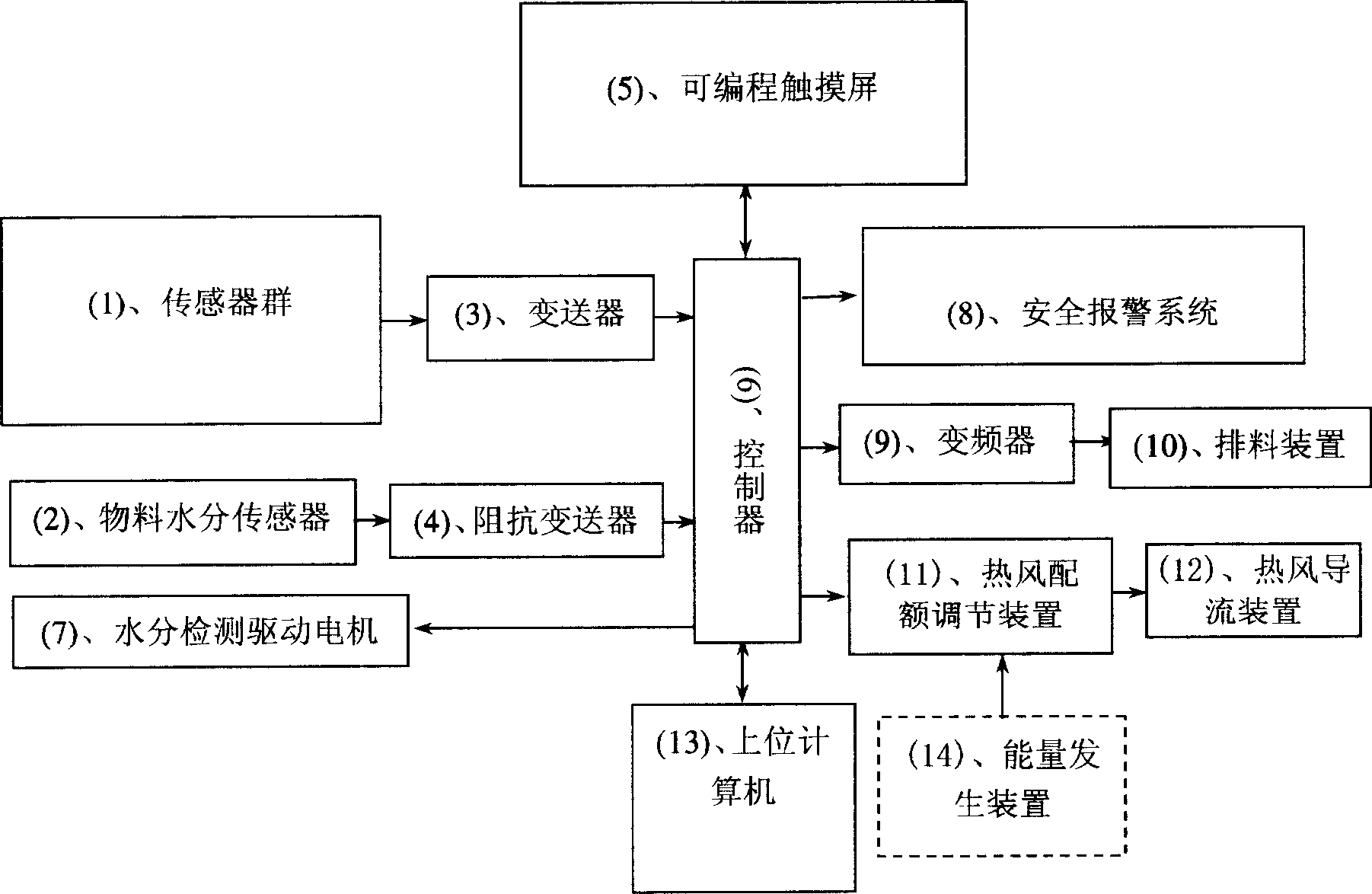

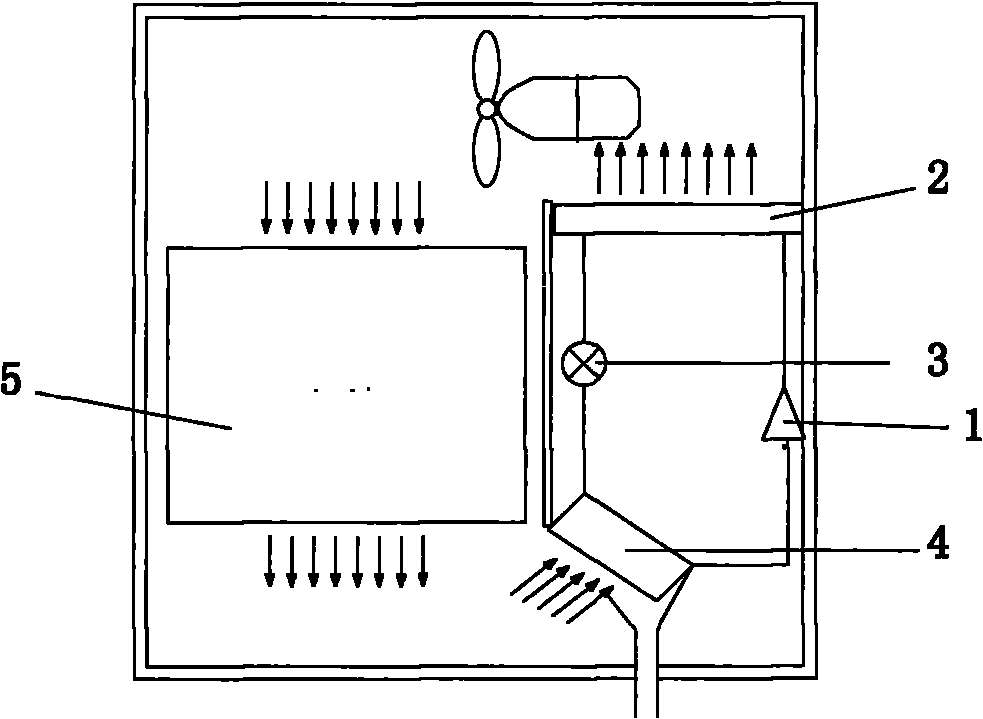

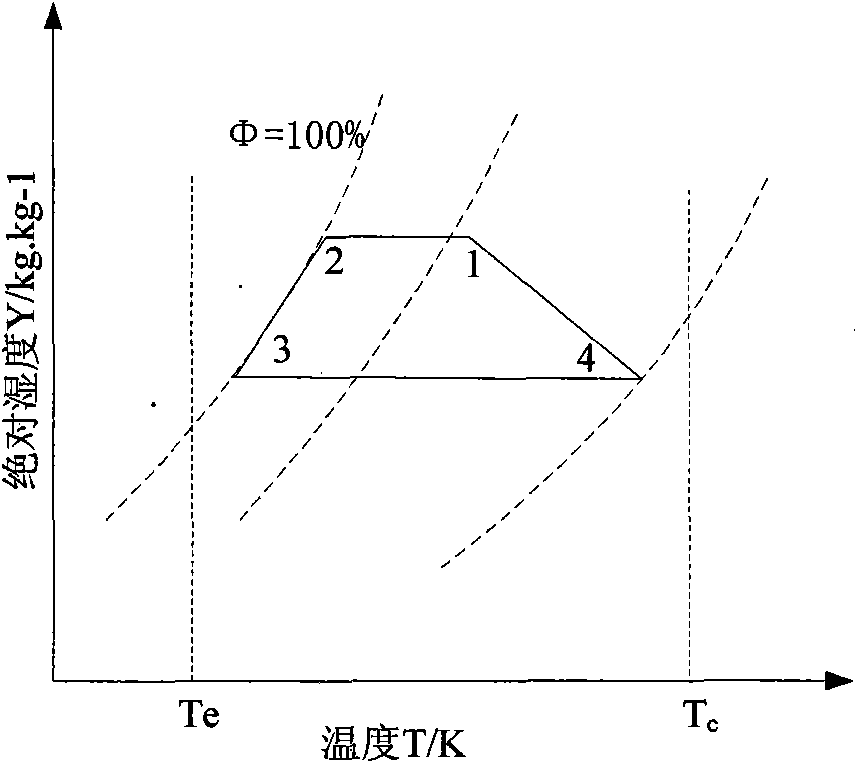

Adaptive control system of hot air drying

InactiveCN1904533AReduce consumptionHigh control precisionDrying solid materialsCommunication interfaceFrequency changer

The invention relates to a kind of hot-wind desiccation controlling system. It includes a sensor group(1), a water sensor of the material(2), a transducer(3), a impedance transducer(4), a controller(6),a converter(9),a blowdown device(10) and a superior computer(13). The output signal of the sensor group(1) and the water sensor of the material(2) connect with the input end of the controller(6) individually through the transducer(3) and the impedance transducer(4). The input and the output interface of the controller (6) and the output and the input interface of the superior computer (13) realize the two-direction communication through the communication interface. The output interface of the controller (6) connects with the blowdown device (10) of the hot-wind desiccation chamber through the converter (9). The input quantity and the change rule of the system is not predefined but determined real time by the superior computer according to the online measuring value. It can save the energy loss, increase the desiccation efficiency and security and improve the hot-wind desiccation quality farthest as the character of the material in desiccation.

Owner:SOUTH CHINA AGRI UNIV

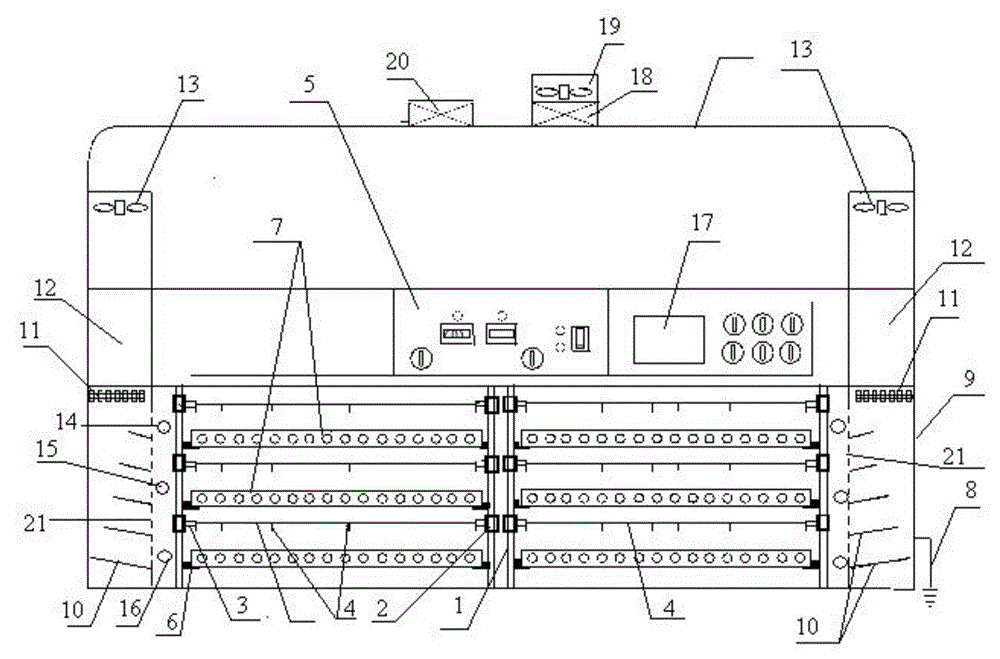

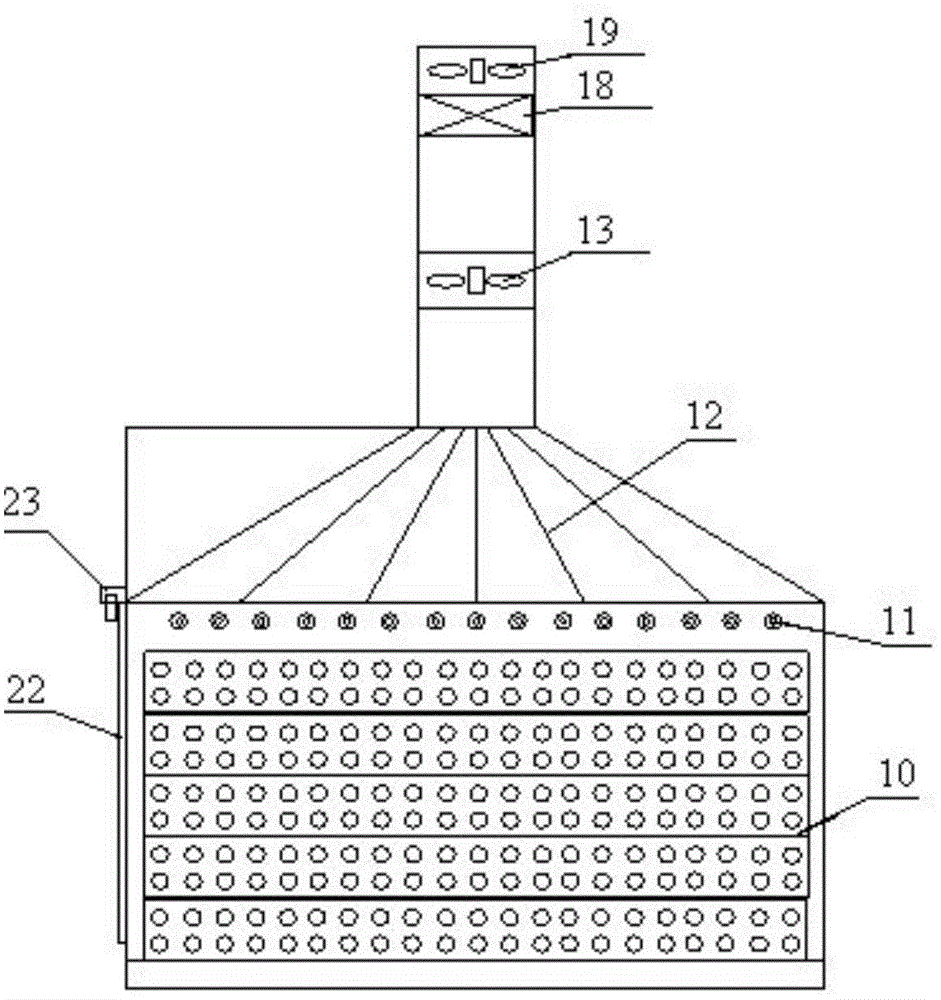

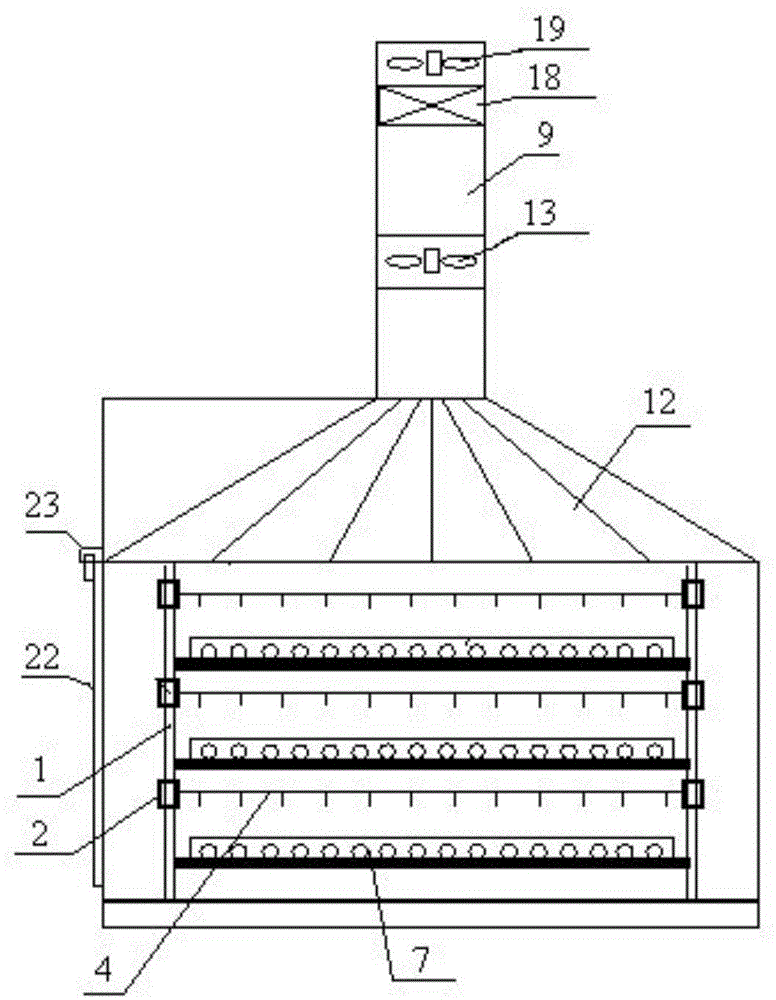

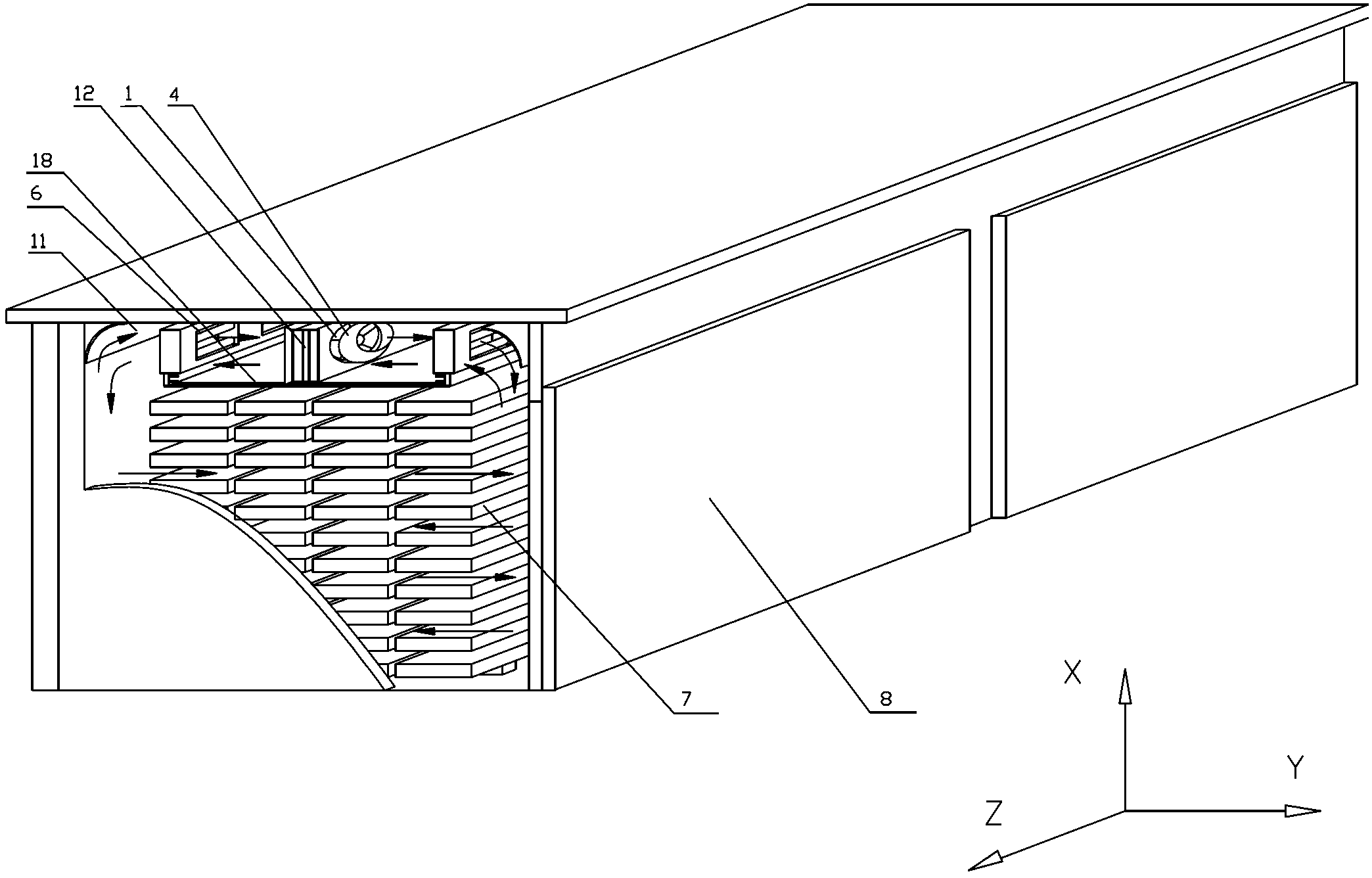

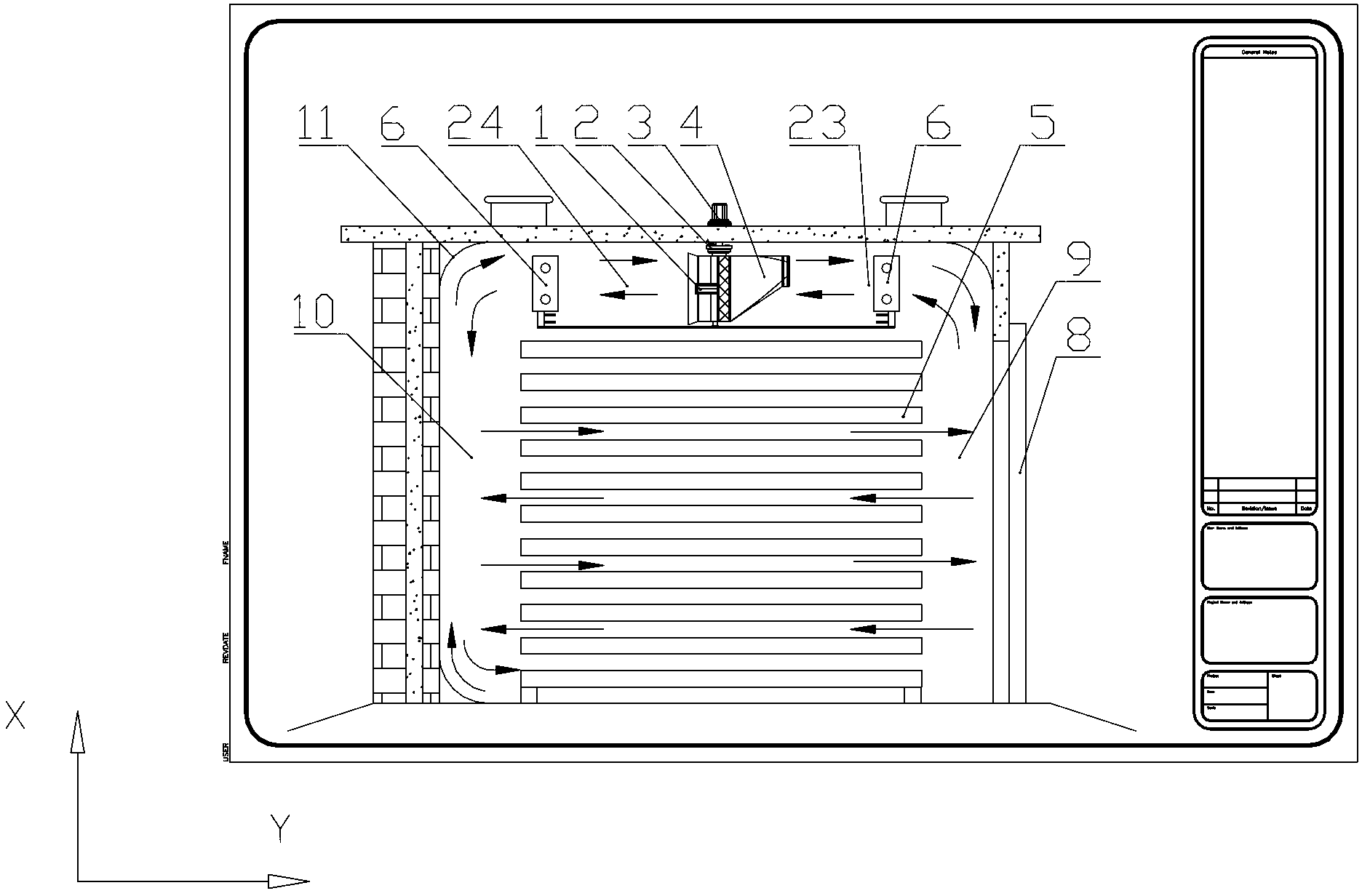

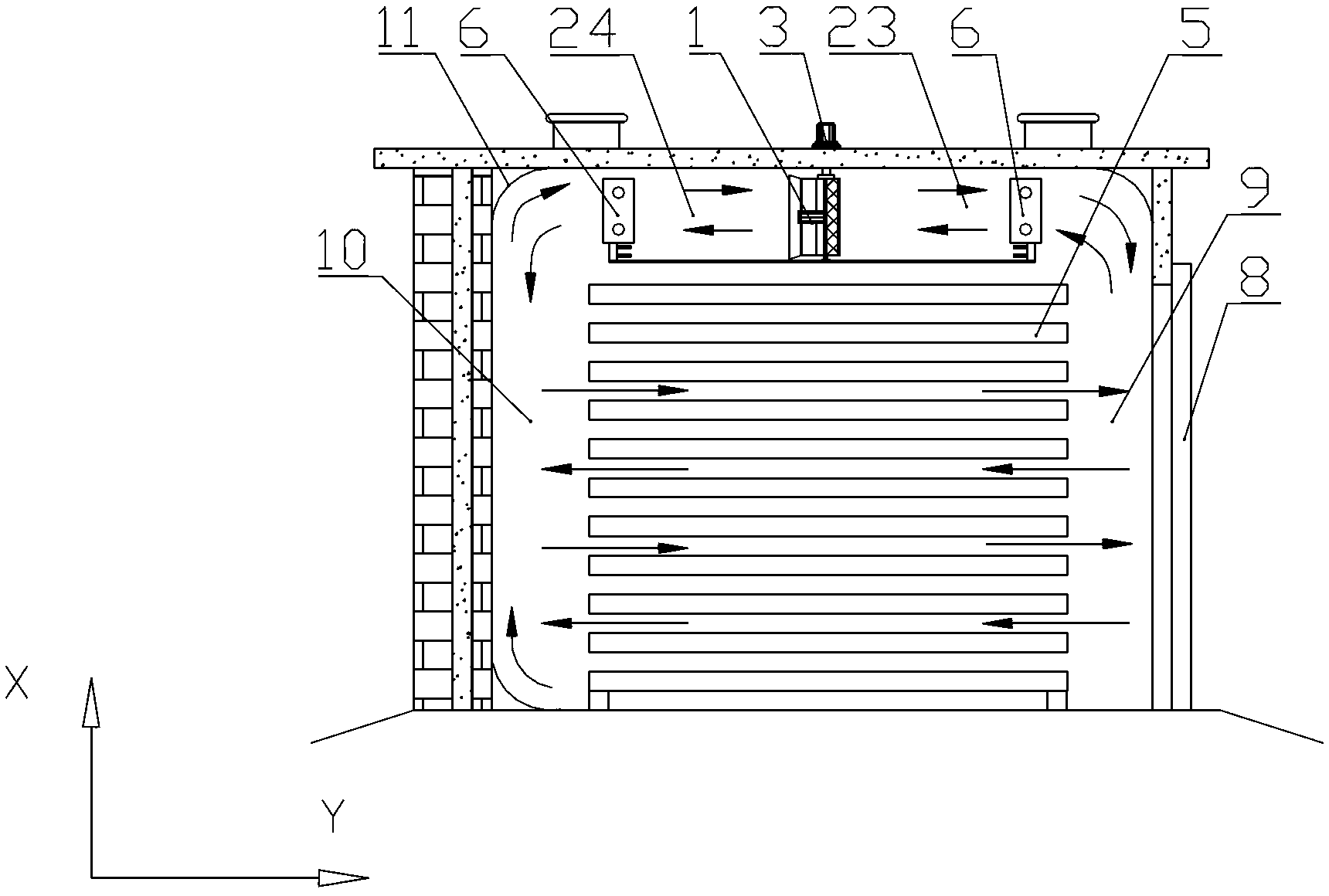

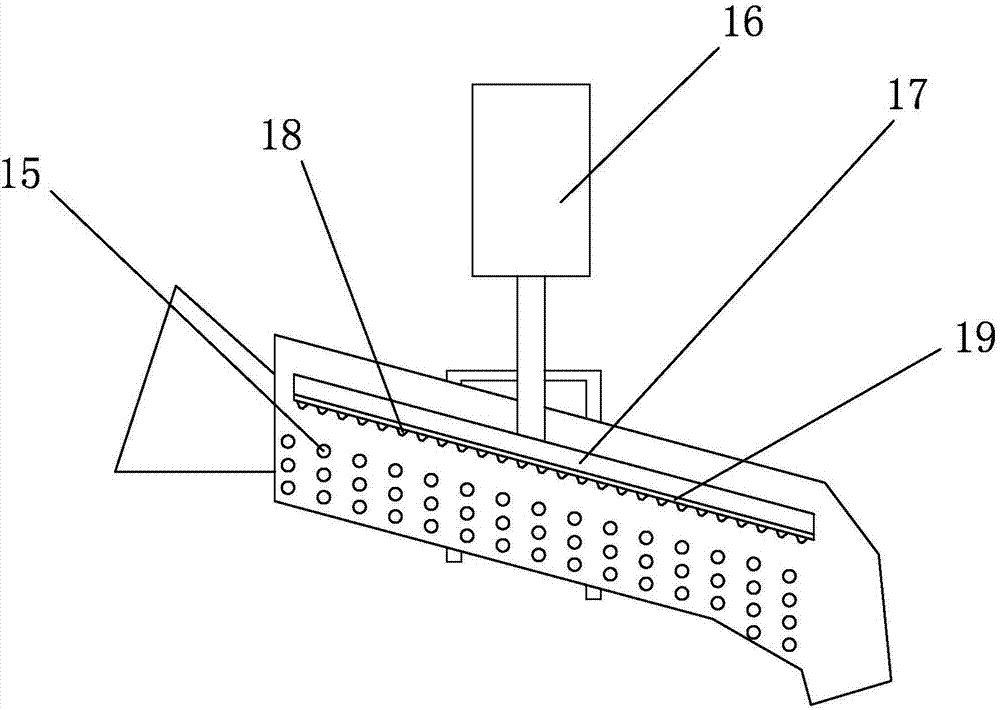

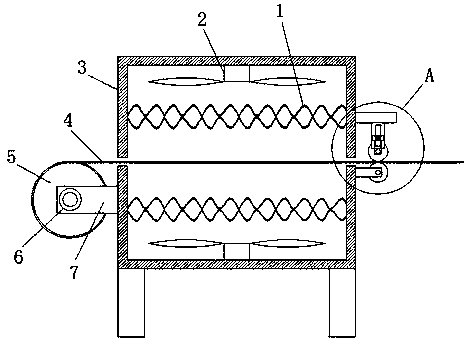

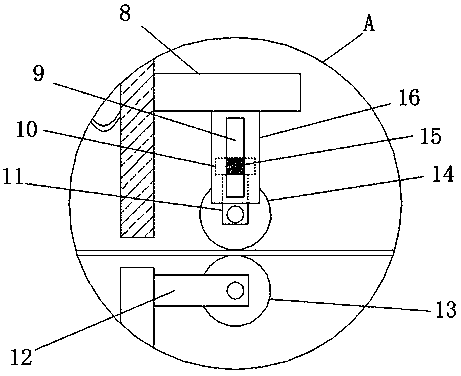

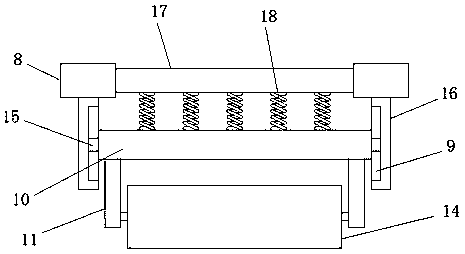

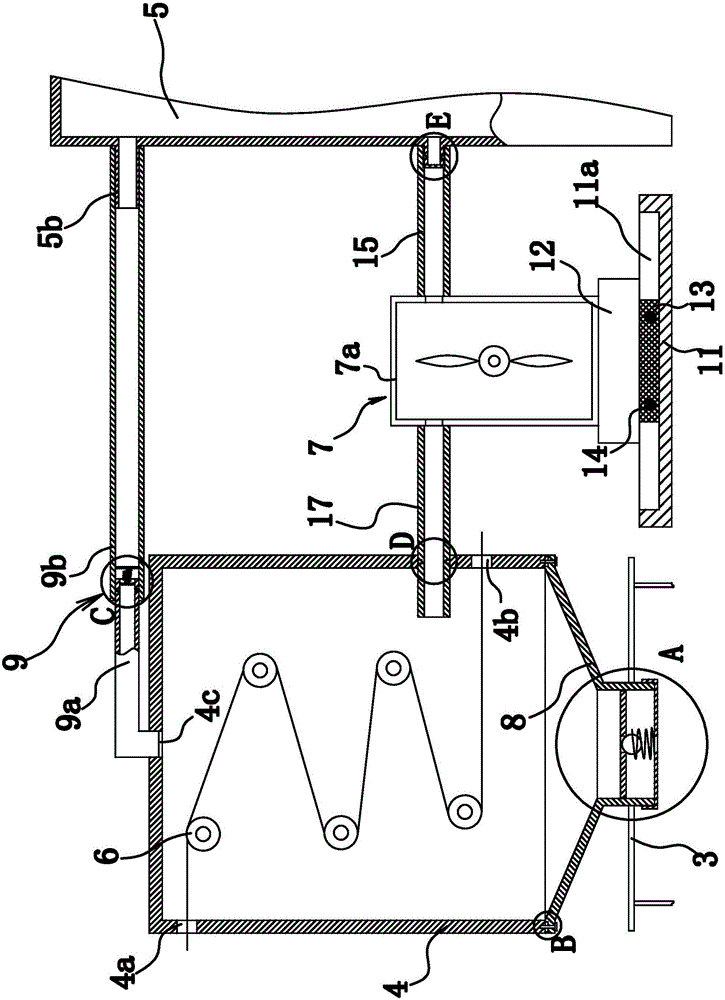

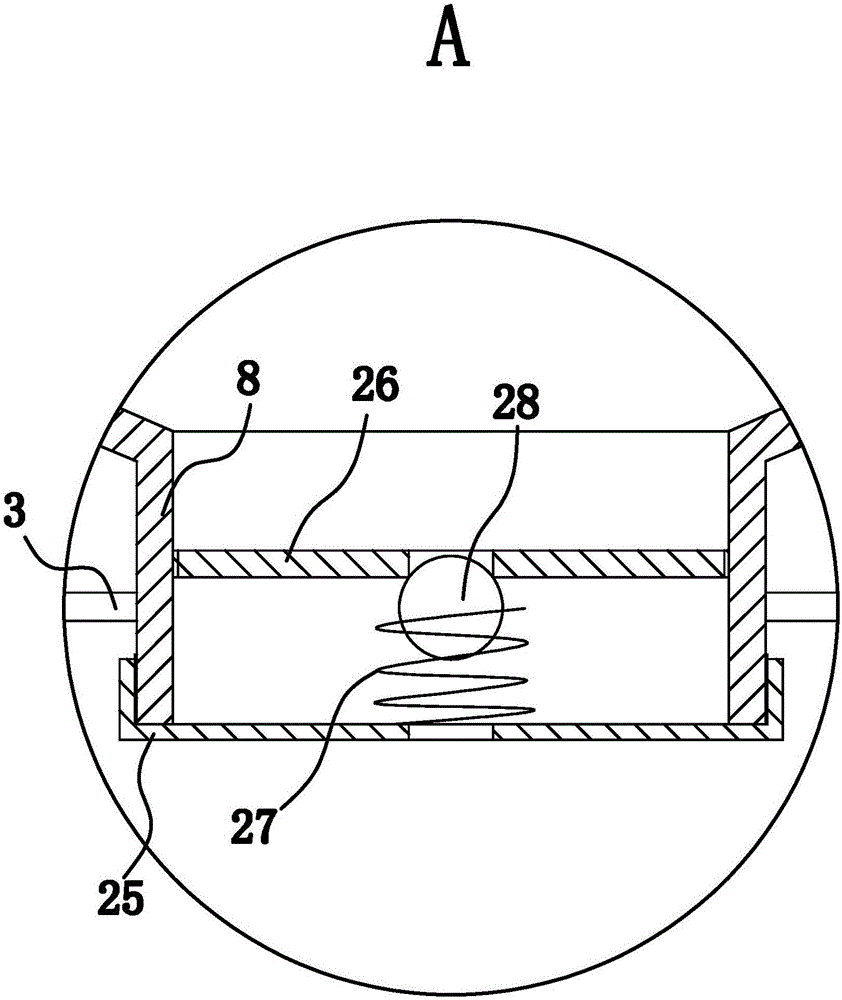

Heating and blowing device for large hot air drying room

InactiveCN103292590AStable forward and reverse air supplyThe same wind pressure and air volumeDrying gas arrangementsChemical productsEngineering

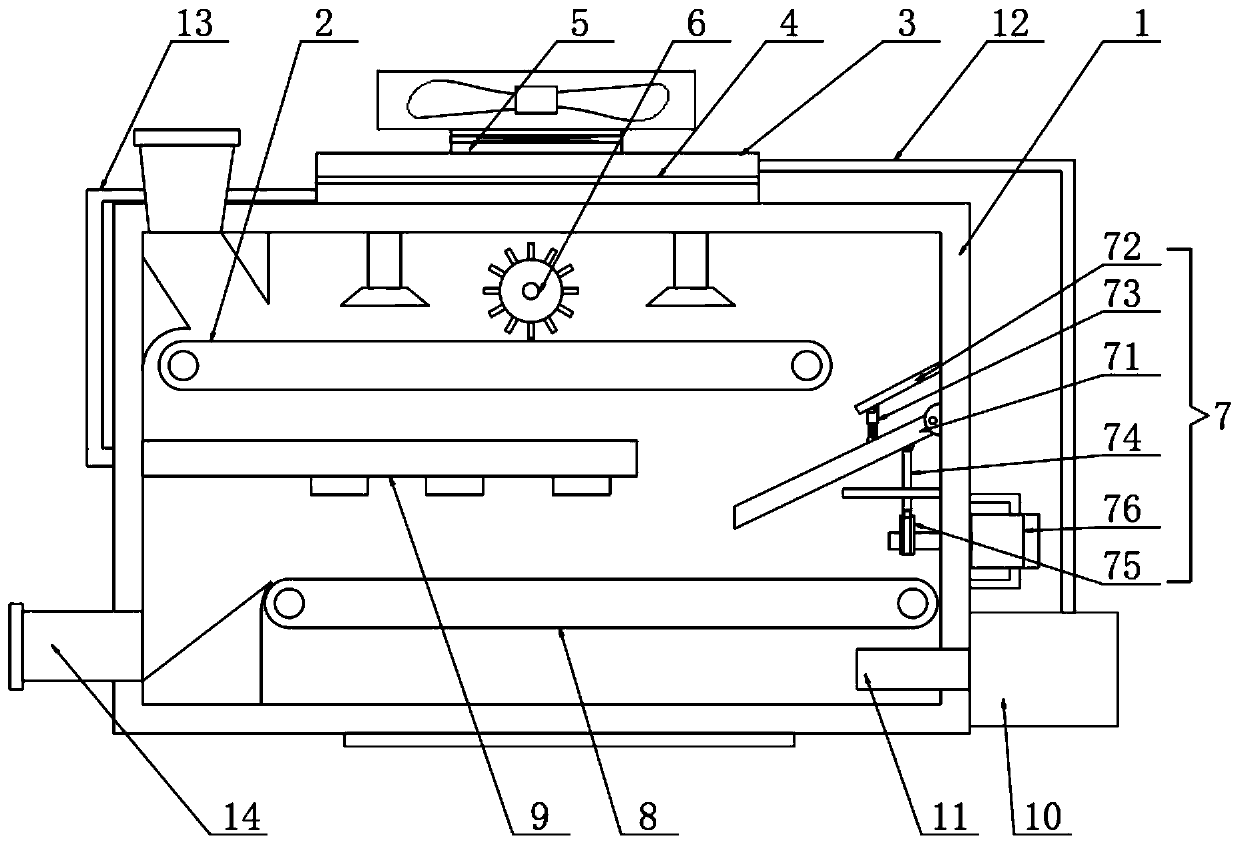

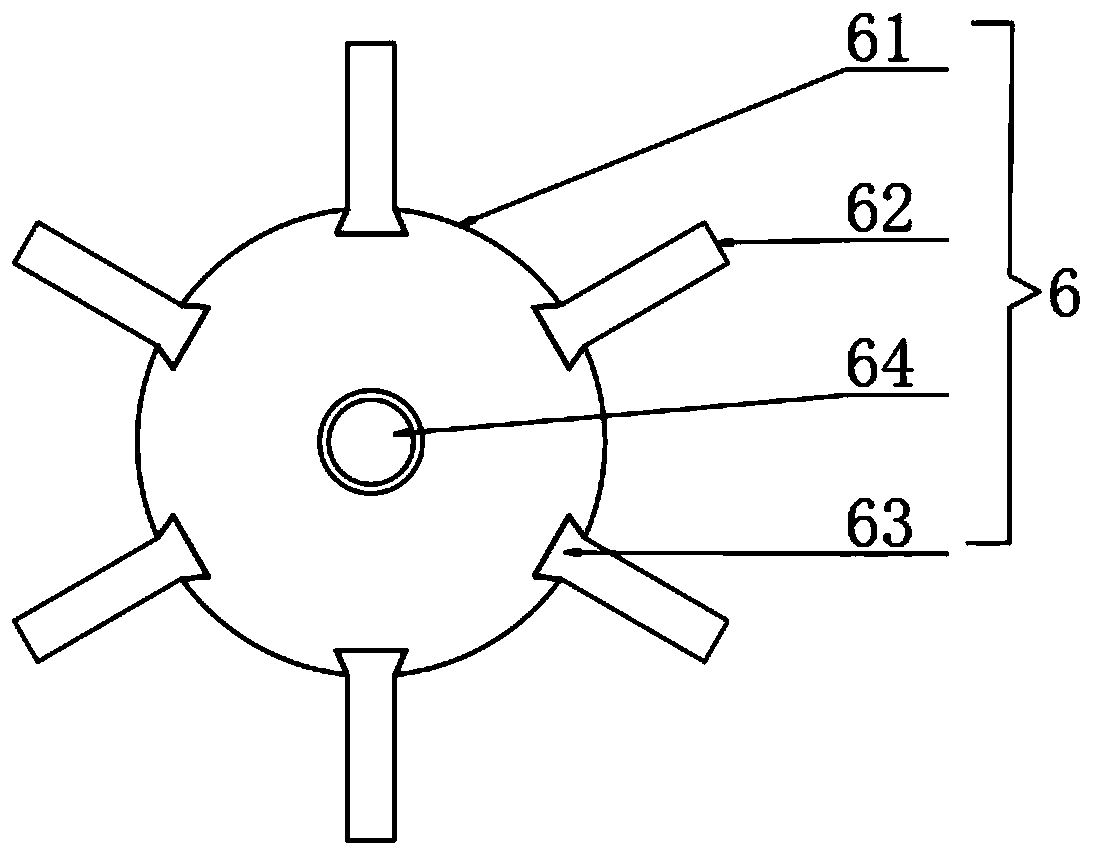

The invention relates to timbers, pharmaceuticals, foods and chemical products, in particular to a heating and blowing device for a large hot air drying room. A plurality of fans (1) are disposed in a rectangular fan support frame (12). Gaps among the fans (1) are blocked by air blocking plates (13). The fans are linked by a synchronization rotation linkage mechanism (2) for synchronous horizontal rotation. The fan support frame (12) is fixed on a rectangular movable frame (17). Rollers (19) embedded into guide rails (18) on two sides are disposed on two sides of the fan support frame (12). An air guide component (4) is disposed on a blowing side of each fan (1). A plurality of radiators (6) corresponding to the fans (1) are disposed at two ends of the guide rails. Three arc flow deflectors (11) are disposed at three inner included angles of the drying room. By the heating and blowing device, power consumption is lowered greatly, operation cost and drying cost are lowered, the drying room is enabled to be efficient, energy-saving and widely applicable, timbers of two or more different kinds or of different thicknesses can be evenly dried simultaneously, production efficiency is increased, and drying operations are highly flexible.

Owner:SHANGHAI UNIV OF ENG SCI

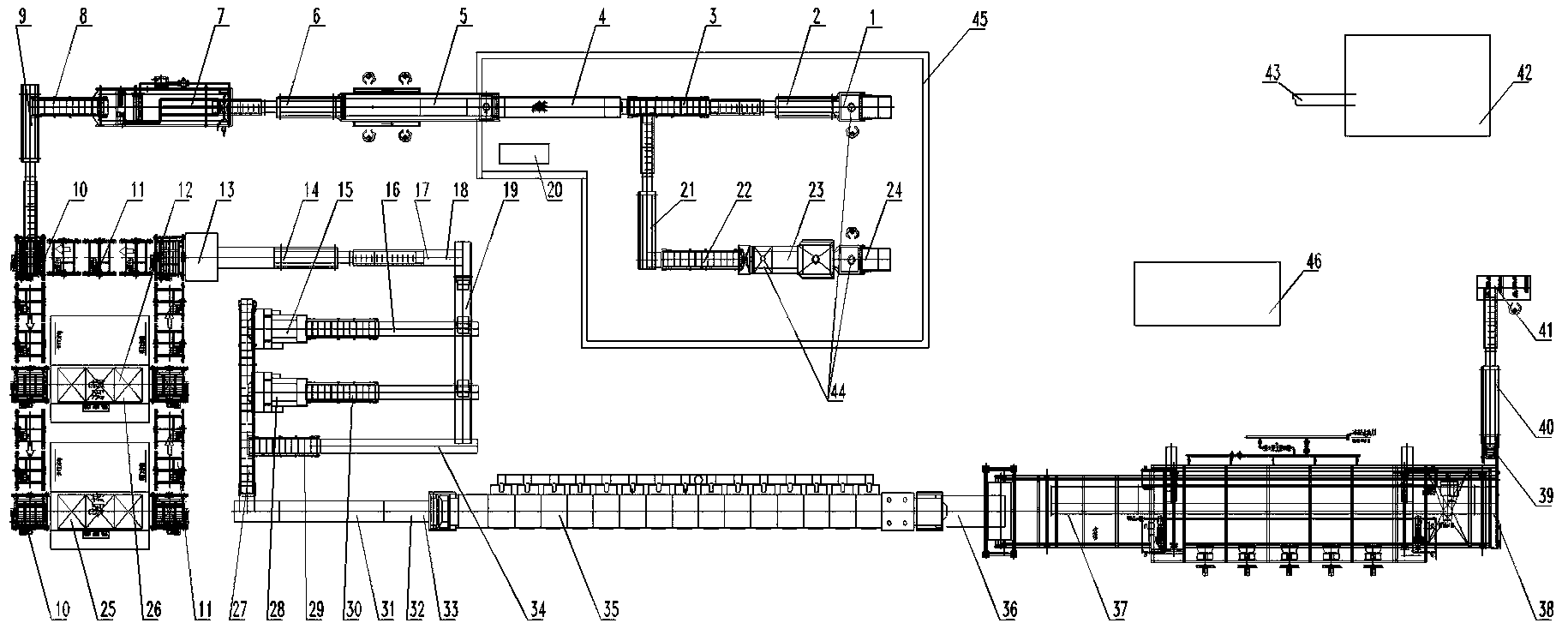

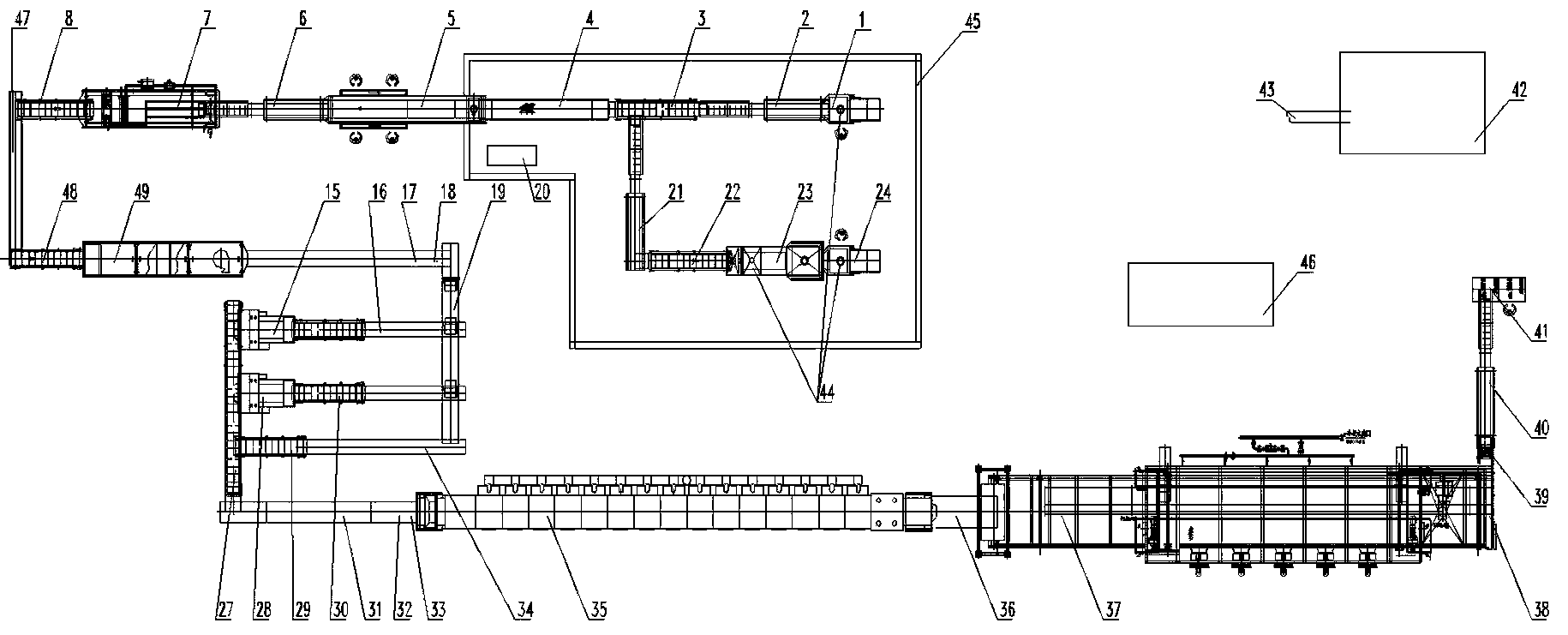

Automatic processing technology and system for traditional Chinese medicinal material pre-processing

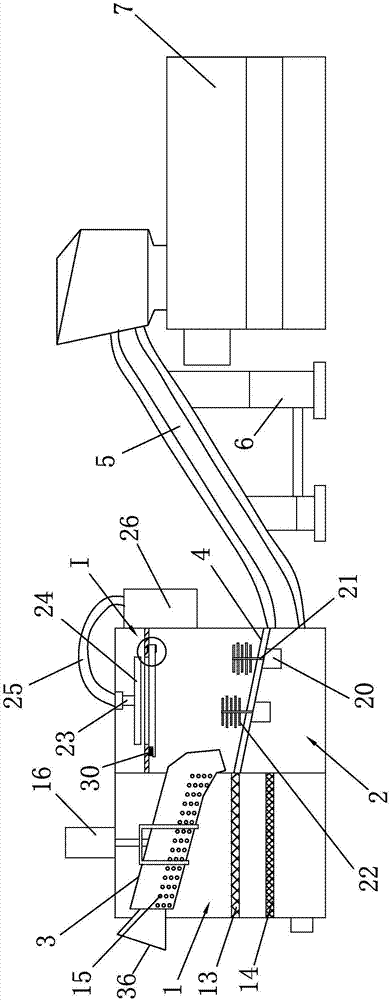

ActiveCN103637911AUniform flowUniform and stable feedingPharmaceutical product form changeAutomatic controlControl system

Disclosed is an automatic processing technology and system for traditional Chinese medical material pre-processing. The processing technology sequentially comprises the procedures of unpacking, clean selecting, washing, medicine infiltrating, cutting, drying and box packaging or bagging. All the procedures are connected through a belt conveyor or a feeding machine or a vibration conveyor or material separating equipment. An automatic control system is used for controlling processing equipment in all links of the processing technology and automatic continuous production is realized. According to the automatic processing technology and system, an assembly line production mode is adopted, all main procedures in the current traditional Chinese medicine pre-processing process are connected organically through conveying equipment, caching conveying equipment and the material separating equipment, an automatic detecting technology and an automatic control technology are adopted to conduct real-time detection and control on the production process, the degree of automation of traditional Chinese medicine pre-processing is greatly improved, the labor intensity of workers can be lowered, the processing environment can be improved and the stability of the product quality can be maintained.

Owner:云南昆船电子设备有限公司

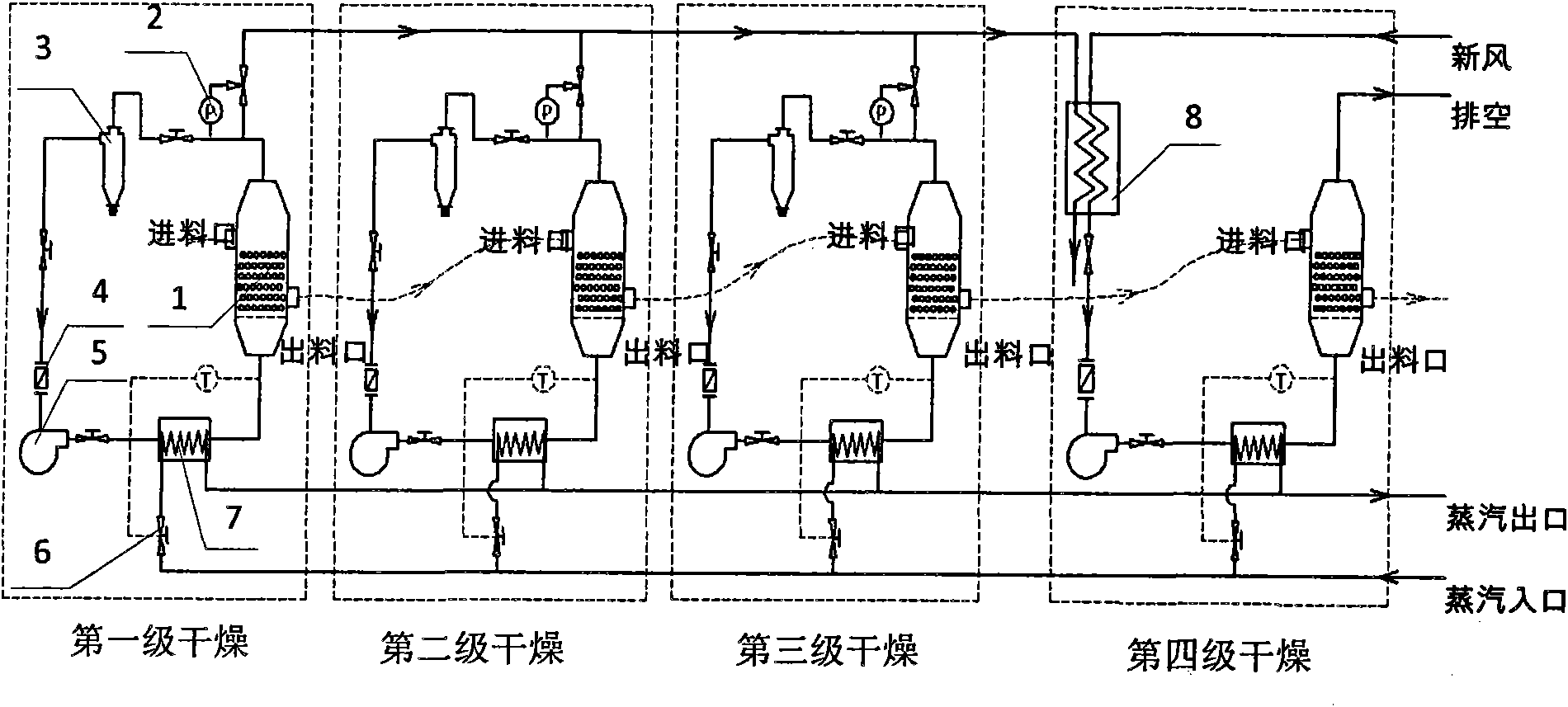

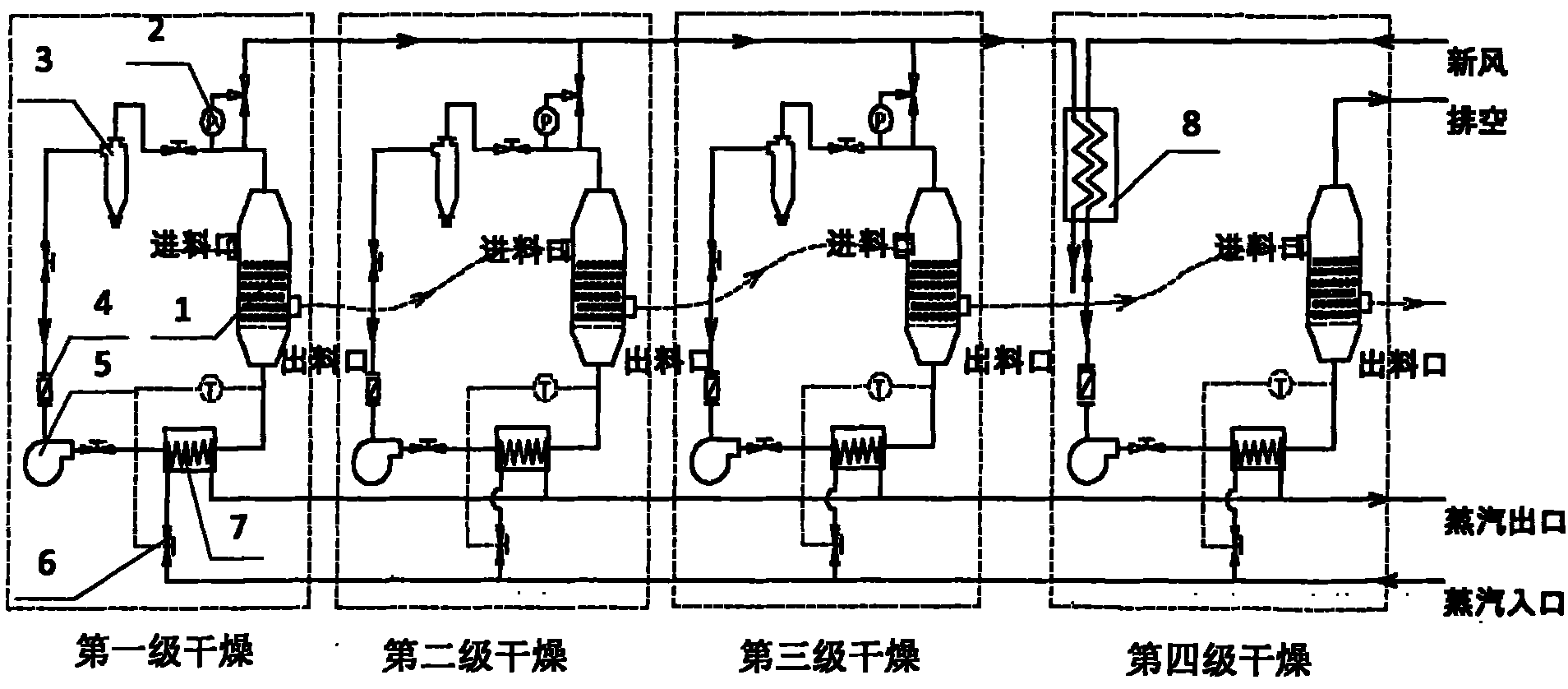

Novel silica gel energy-saving drying device and process thereof

ActiveCN101788221AImprove drying qualityImprove qualityDrying solid materials with heatDrying gas arrangementsThree stageProcess engineering

The invention discloses a novel energy-saving silica gel drying device and a process thereof, which can dry silica gel rapidly and efficiently with the drying thermal efficiency improved to 50 percent from 35 percent of the prior art. The device comprises at least one superheated steam drying unit and at least one hot air drying unit. A required material can be obtained through speed-raising drying and constant-speed drying of the superheated steam drying unit and drying of the hot air drying unit. The process is a superheated steam-hot air combined multi-stage silica gel drying process, the first three stages adopt superheated steam drying, the first-stage steam drying is mainly a speed-raising drying stage, the second stage and the third stage are respectively a stage of constant-speed drying at the corresponding temperature, wherein the silica gel drying speed is high, no breakage or cracking can be easily caused, good properties of the porous structure can be maintained, the drying quality is high, and the fourth-stage hot air drying can maintain a relatively high drying speed. The superheated steam-hot air combined multi-stage silica gel drying process has the advantages of good quality of the dried silica gel and high speed, and the closed drying circulation system has significant effect on energy conservation and emission reduction.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Spraying device for building material machining

ActiveCN110653110AAvoid occlusionPlay a limiting effectPretreated surfacesCleaning using toolsConstruction engineeringStructural engineering

The invention discloses a spraying device for building material machining. The spraying device for building material machining comprises a device body, material supplying boxes and treating boxes; connecting plates are arranged at the inner ends of first hydraulic telescopic rods; cleaning rolls are rotatably connected to the inner side walls of first U-shaped frames, second rotation shafts penetrate through the back side walls of the first U-shaped frames, and the second rotation shafts on the left sides are connected with second motors; the treating boxes are arranged on the front side faceand the back side face of the device body and arranged on the left sides of first motors; first fans are arranged on the right sides of the treating boxes and connected with suction pipes; and secondhydraulic telescopic rods are arranged on the upper side wall and the lower side wall of the device body, second U-shaped frames are arranged at the inner ends of the second hydraulic telescopic rods,and flattening rolls are rotatably connected to the inner side walls of the second U-shaped frames. According to the spraying device for building material machining, a coating in the material supplying boxes is sprayed to building plates through spraying pipes at the upper end and the lower end, and the two faces of the building plates can be simultaneously sprayed.

Owner:徐州思达新技术开发有限公司

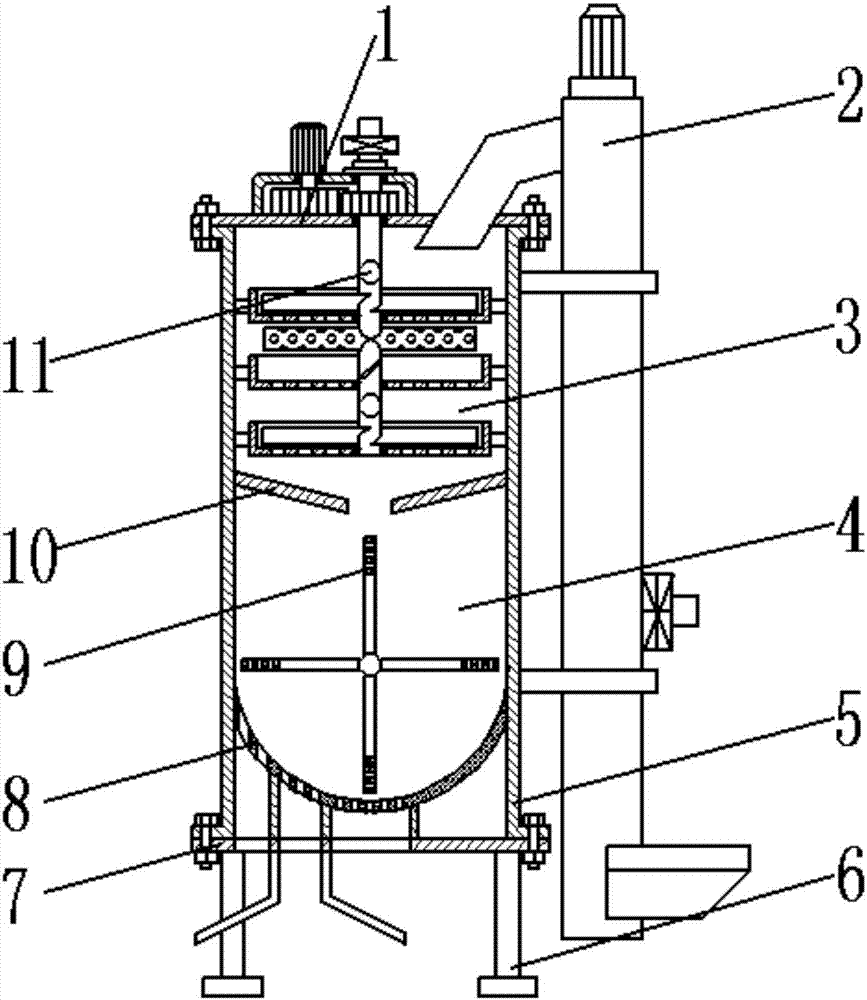

Sludge heating and drying system and method thereof

ActiveCN107216012AEasy to dryReduce work stressSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeWater resources

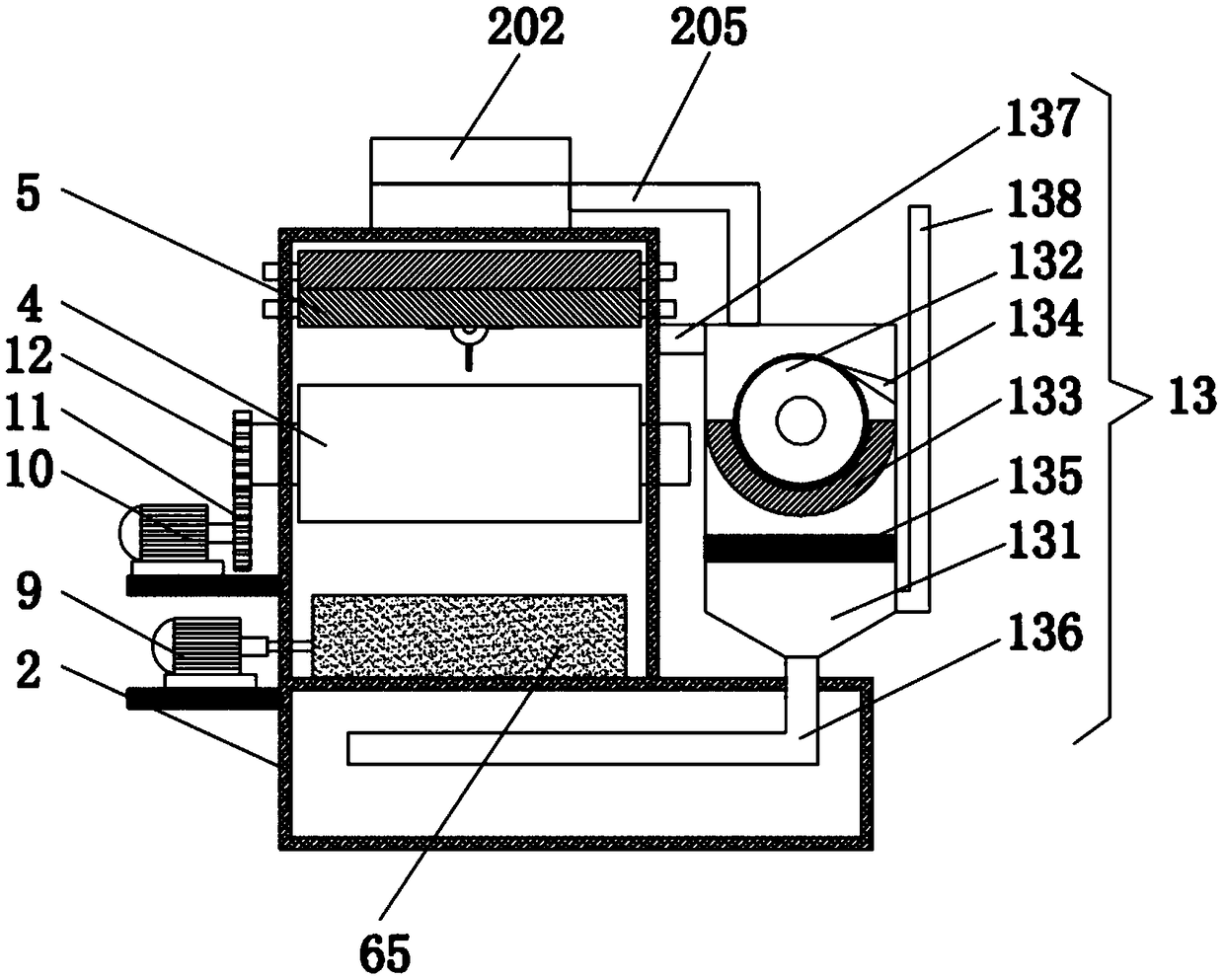

The invention discloses a sludge heating and drying system. The sludge heating and drying system comprises a pretreatment mechanism, a transmission mechanism and a drying mechanism, wherein the pretreatment mechanism comprises a dehydrating cavity and a dispersing cavity, a dehydrating drum and an extrusion device are arranged in the dehydrating cavity, a tilting table and a dispersing device are arranged in the dispersing cavity, and the drying mechanism comprises a drying box body and a heating device. The drying method comprises the following steps: (1) carrying out primary dehydration treatment on sludge; (2) carrying out dispersion treatment on the sludge; (3) carrying out drying treatment on the sludge; and (4) cleaning, checking and repairing. The sludge heating and drying system disclosed by the invention is simple in structure and strong in practicability, most of sewage in the sludge is removed by virtue of the dehydrating cavity, then the dispersion treatment is carried out on the sludge extruded into blocks by virtue of the dispersing cavity, working pressure of the drying box body is reduced, sludge drying effect and sludge drying quality are improved, water resource is saved, and comprehensive utilization rate is improved.

Owner:浙江寰龙环境科技有限公司

Pretreatment device for improving wood impregnation efficiency and wood impregnation treatment method

InactiveCN104416635AExpand the effective channel areaIncrease drug intakeWood treatment detailsWood impregnation detailsCavitationPre treatment

The invention discloses a pretreatment device for improving wood impregnation efficiency and a method for impregnating woods by utilizing the device. The device comprises a wood pretreatment chamber in which a cavity is formed, an ultrasonic treatment system and pretreatment liquid, wherein to-be-treated woods are subjected to ultrasonic pretreatment. The method disclosed by the invention comprises the following steps: pretreating to-be-impregnated woods by using ultrasonic waves under normal pressure, and getting through a liquid moving channel in the woods by utilizing a cavitation effect of the ultrasonic waves, so that the liquid permeability of the to-be-impregnated woods is enhanced, and the effective channel area inside the woods is enlarged; impregnating the woods, and impregnating a wood impregnation modifier into the woods, so that the absorption dose of the impregnated woods is improved, the agent penetration depth is increased, the impregnation period is shortened, and the impregnation effect is improved. The treatment device disclosed by the invention is simple, convenient to operate and is suitable for treating various woods, and process treatment conditions are controllable.

Owner:BEIJING FORESTRY UNIVERSITY

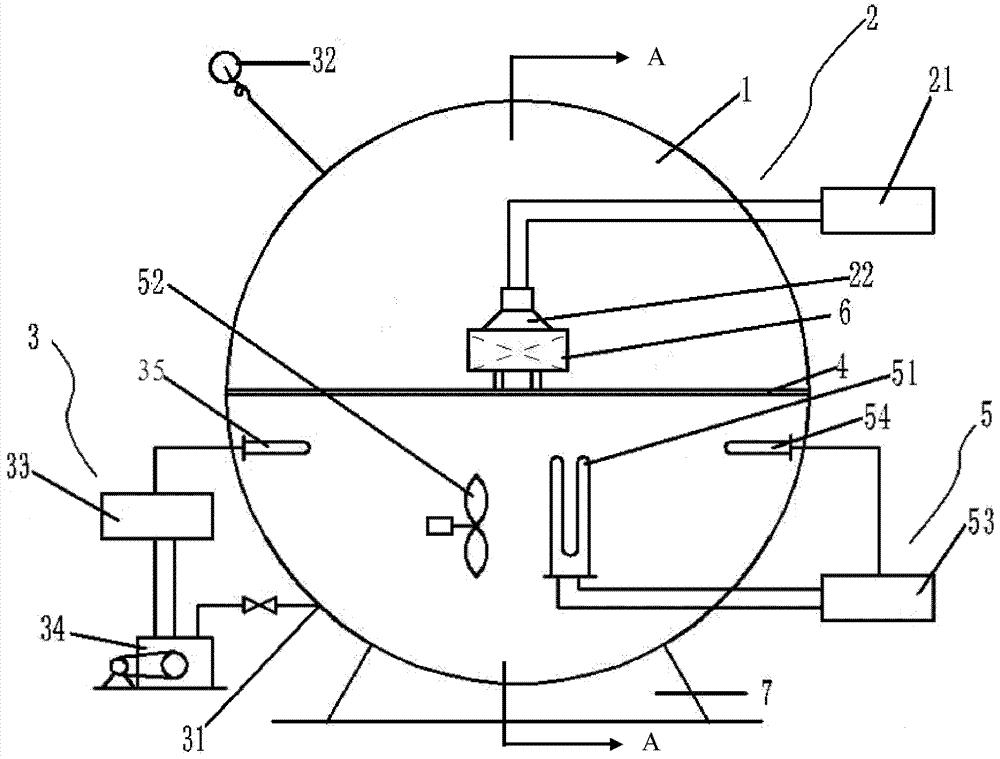

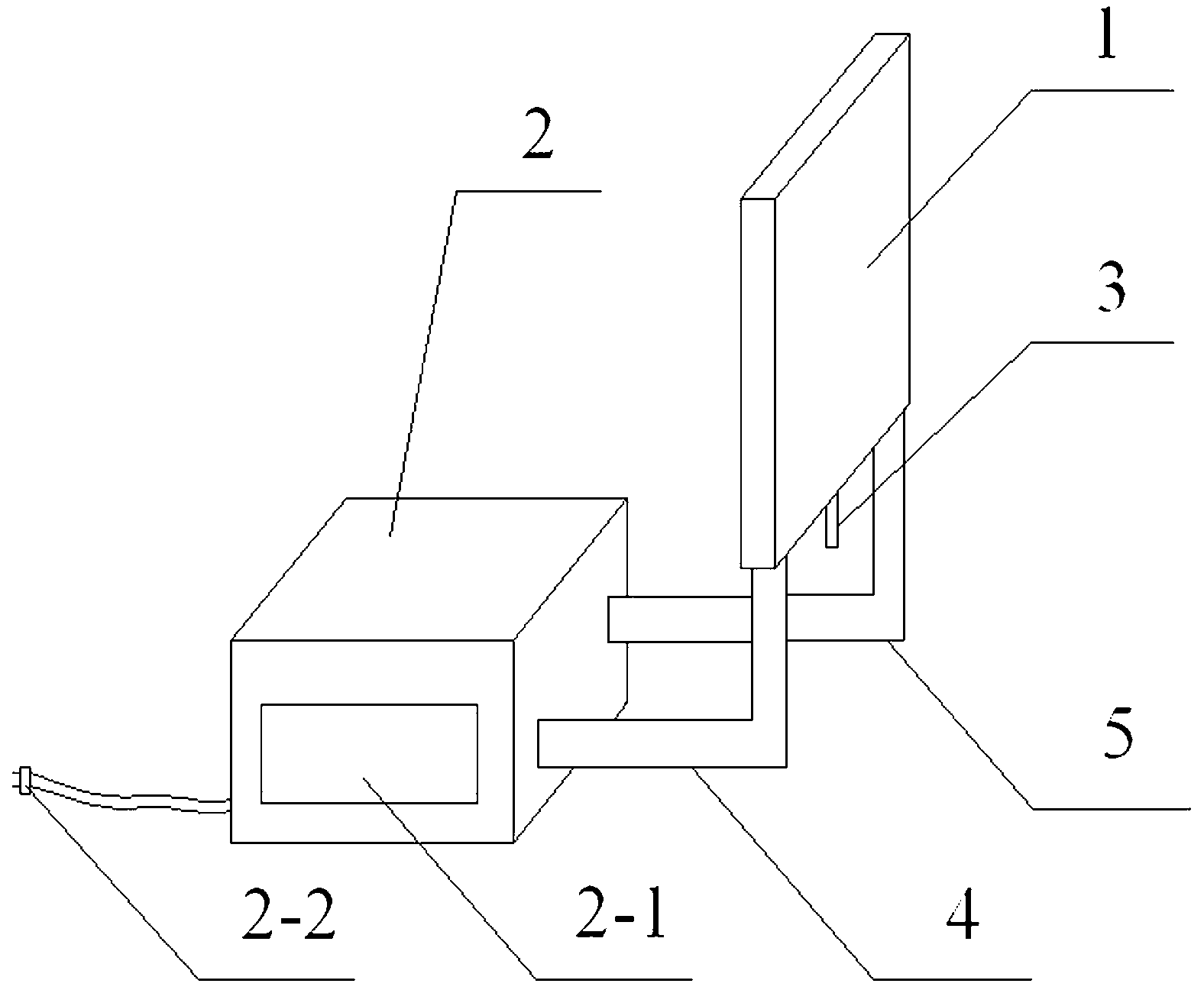

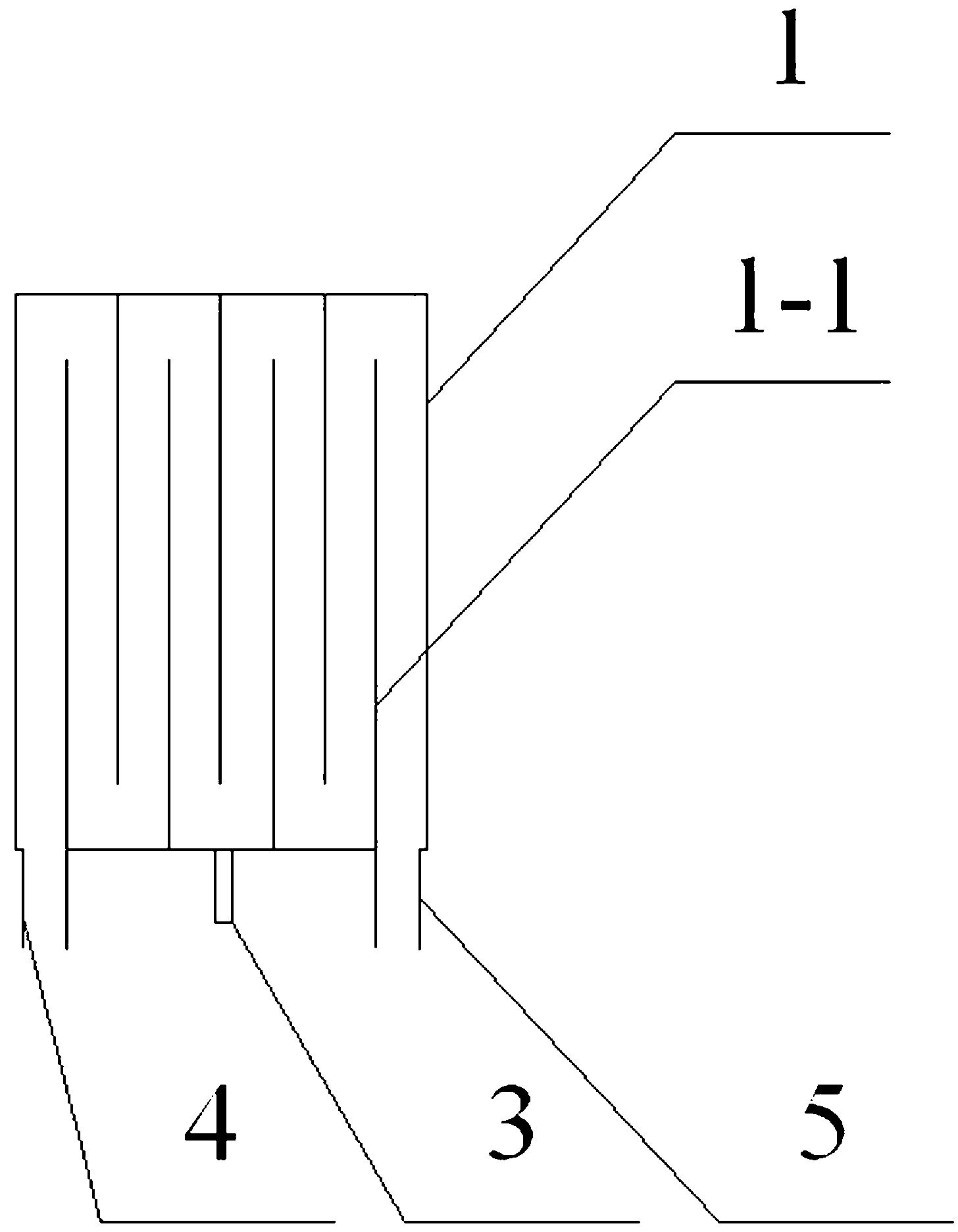

Lumber drying equipment and method of drying lumber by using equipment

ActiveCN103115481AUniform treatmentImprove ultrasonic drying efficiencyDrying using combination processesDrying machines with local agitationProcess engineeringVacuum drying

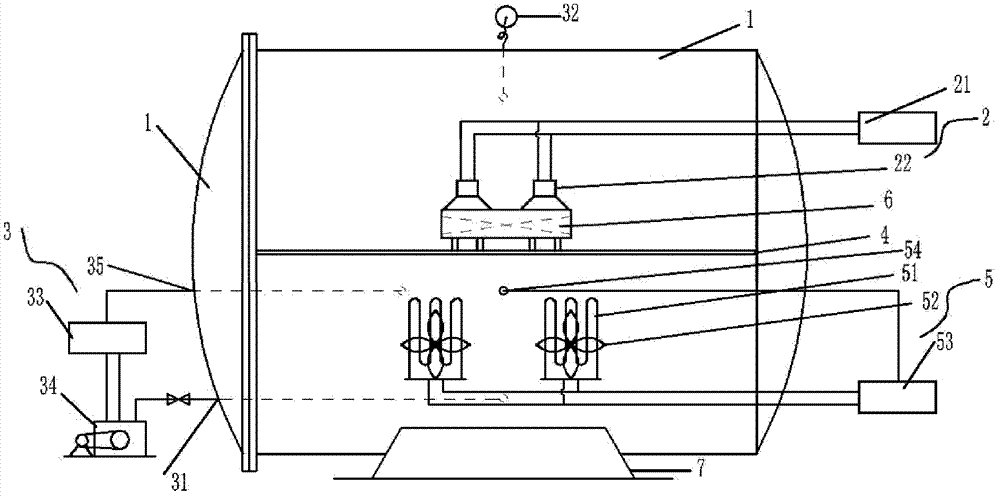

The invention discloses lumber drying equipment and a method of drying lumber by using equipment. The device comprises a lumber drying room (1) with a hollow cavity in the inner portion, an ultrasonic wave processing device (2), a vacuum supply device (3) carrying out the vacuum supply processing to the hollow cavity of the lumber drying room (1), an installing material assembly (4) placing to-be processed lumbers and a heating device (5) carrying out heating processing to the to-be processed lumbers. An ultrasonic wave energy converter is directly contacted with the lumbers in the drying process. The lumbers are dried under the vacuum condition. An ultrasonic wave with certain frequency and power is added in the lumber vacuum drying process. The lumbers are dried under the low drying temperature. Drying rate is high and drying quality is good. Produced drying defects under the high temperature condition of the vacuum drying can be avoided. The drying equipment is simple. The drying method is convenient to operate.

Owner:简木(广东)定制家居有限公司

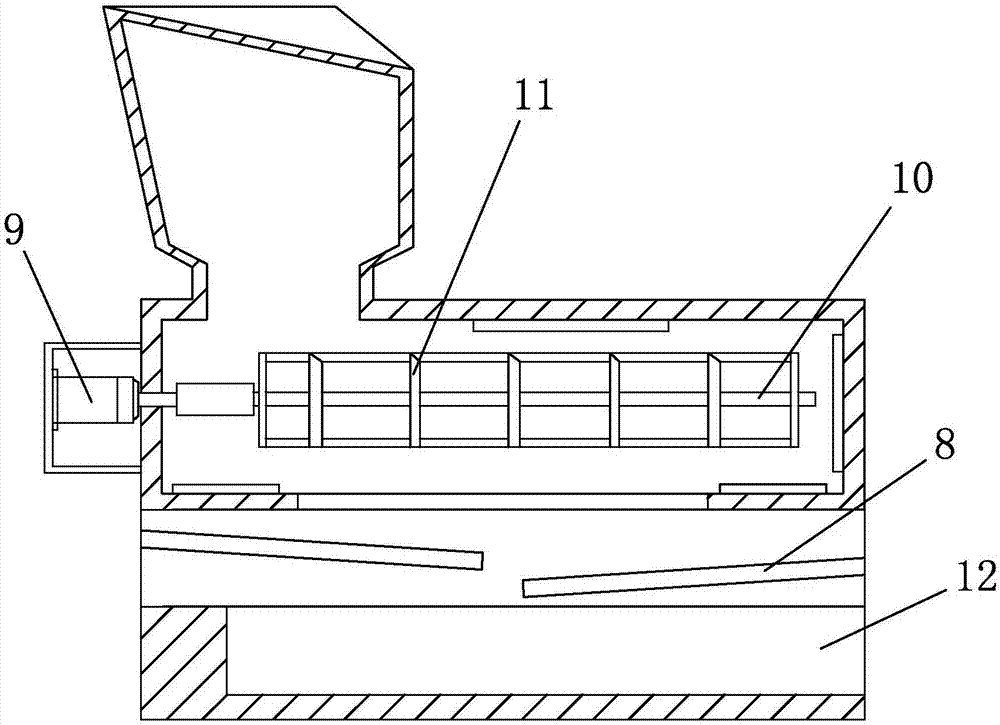

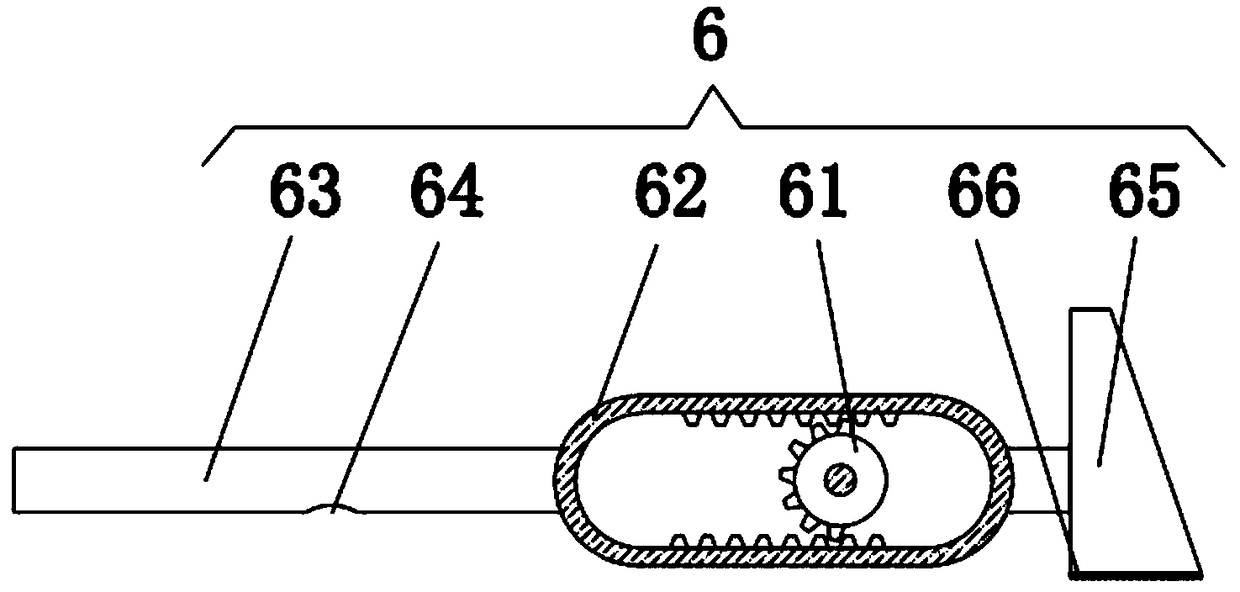

Chemical industry production drying equipment with poking device

InactiveCN109724391AImprove primary drying qualityImprove drying qualityDrying gas arrangementsDrying solid materialsChemical industrySprayer

The invention discloses chemical industry production drying equipment with a poking device in the technical field of chemical industry production. The chemical industry production drying equipment with the poking device comprises a drying box, a first horizontal conveyer belt and a second horizontal conveyer belt; a feeding hopper corresponding to the first horizontal conveyer belt is arranged onthe left side of the top of the drying box; the left side and the right side of the bottom of a heating shell are each provided with an air outlet pipe, and a material poking device is arranged between the two groups of air outlet pipes; and a material shaking and scattering device is obliquely arranged in the middle of the inner wall of the right side of the drying box. According to the chemicalindustry production drying equipment with the poking device, the material poking device is arranged, after materials pass through the first air outlet pipe, the materials are poked by turning claws tobe turned over, and then preliminary drying work is completed through the second air outlet pipe; meanwhile, the material shaking and scattering device is arranged, the materials are shaken and scattered, therefore, the subsequent material drying quality can be greatly improved, and the condition that part of the materials are adhered together is avoided; and secondary drying is conducted throughhot air sprayed by sprayer heads arranged at the bottom of an air distribution pipe, therefore, the drying quality is greatly improved, the drying time is shortened, and the working efficiency is improved.

Owner:南通市金宏电化设备有限公司

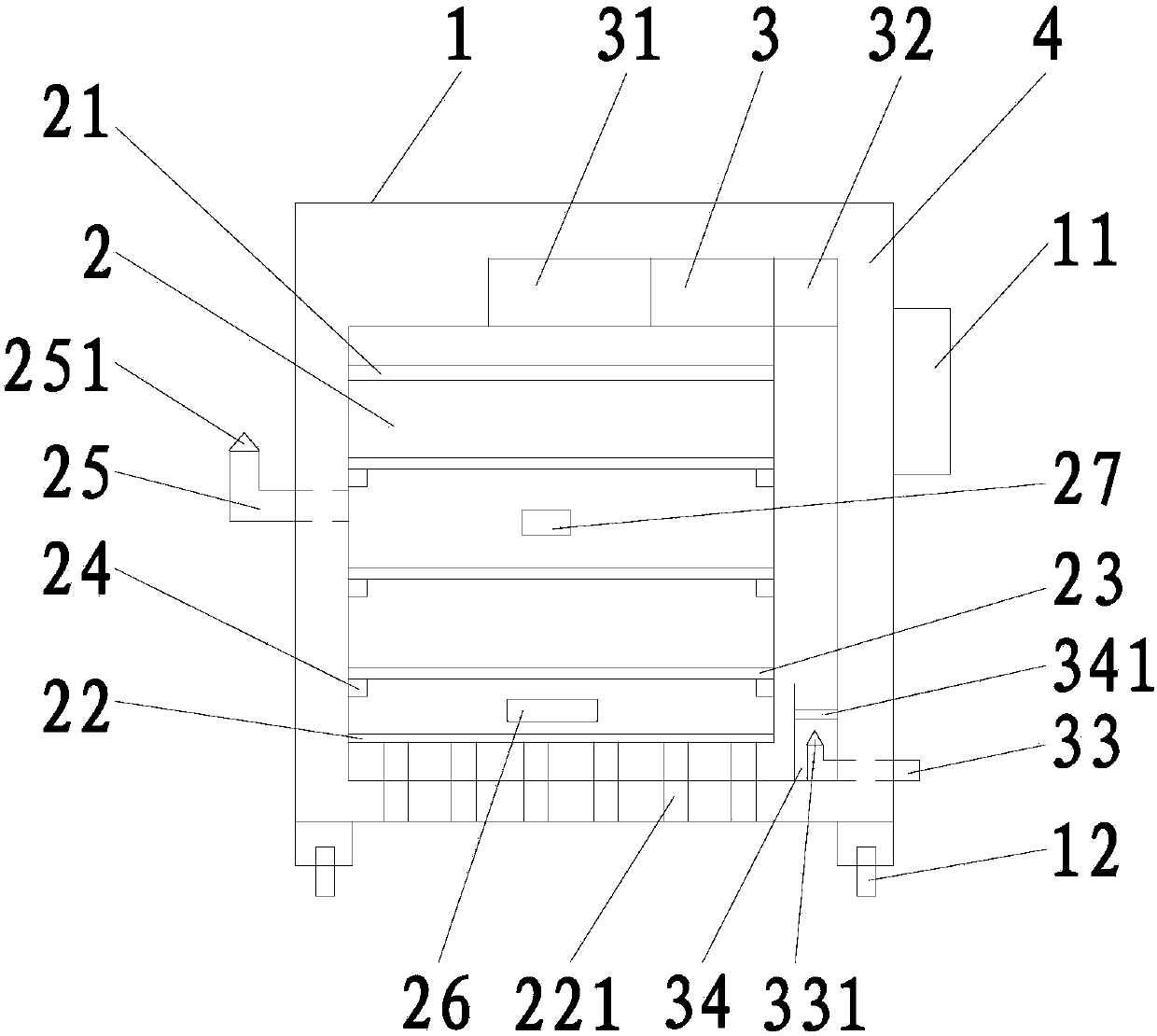

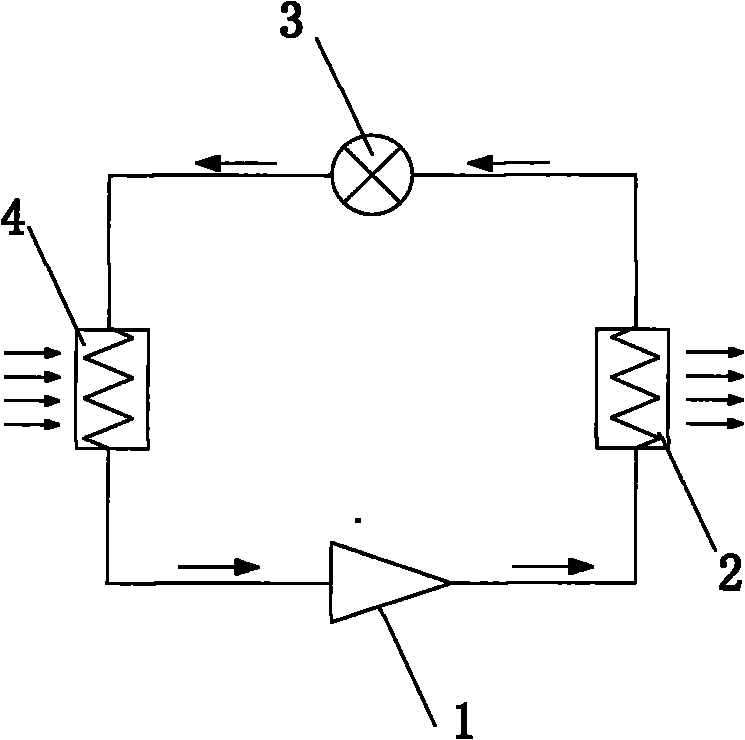

Heat pump drying device

InactiveCN102410709AFast high temperature dryingHigh quality low temperature dryingDrying gas arrangementsDrying solid materialsControl systemProcess engineering

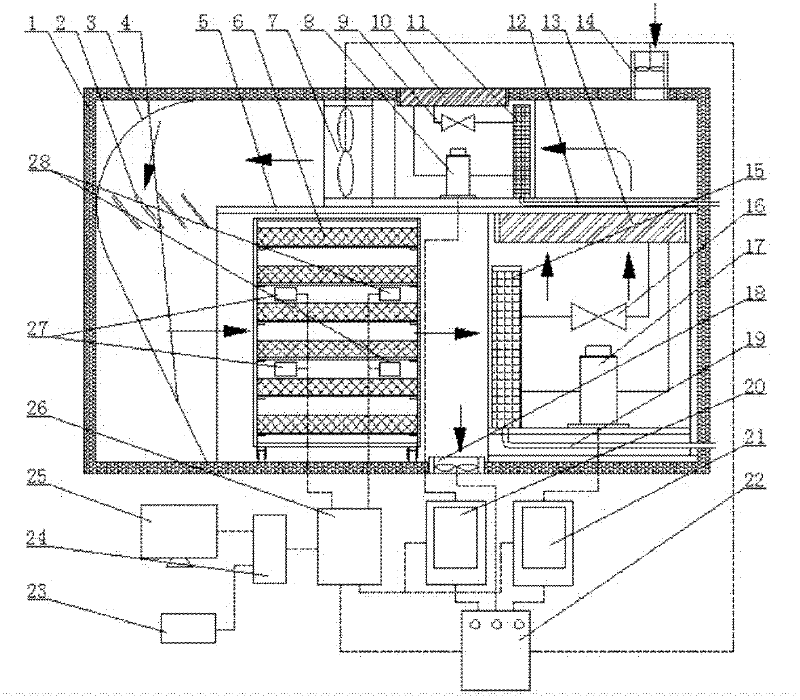

The invention discloses a heat pump drying device, which comprises a drying box and a control system, wherein the drying box comprises a shell and an air inlet fan, a dehumidifying heat pump, a main fan, a material shelf, an air outlet fan and a heating heat pump which are arranged in the shell; when an air inlet and an air outlet are closed, the dehumidifying heat pump, the main fan, the material shelf, the heating heat pump and the dehumidifying pump are communicated in sequence, and a circulating path of a drying medium is formed in the shell; when the air inlet and the air outlet are opened, the air outlet, the dehumidifying heat pump, the main fan, the material shelf and the air outlet are communicated in sequence to form a one-way circulating path of the drying medium; and an air path between the main fan and the material shelf is arc-shaped, and an inclined air deflector is arranged in the air path. The heat pump drying device can not only realize high-temperature drying but also realize low-temperature drying and can meet temperature and humidify requirements of the same product at different drying stages; and the air path for communicating the main fan with the material shelf and the air deflector is improved, therefore airflow vortex is reduced, and drying quality and speed are increased.

Owner:SOUTH CHINA UNIV OF TECH

Split-range drying method for paddy

InactiveCN101878813AIncrease productionFast precipitationSeed preservation by dryingSocial benefitsEconomic benefits

The invention discloses a split-range drying method for paddy. The method has the technical points: performing preliminary cleaning and hot air drying on harvested high-moisture paddy, tempering, redrying and retempering the paddy, and keeping the ratio of the drying time to the tampering time within the range from 1 to 6 until the moisture content is reduced to 18.5 to 18 percent; conveying the paddy into a paddy temporary storage warehouse for slow cooling, ventilation and temporary storage; performing the hot air drying on the paddy of the temporary storage warehouse with a dryer after the paddy harvest season, retempering, drying and retempering the paddy, keeping the ratio of the drying time to the tampering time within the range from 1 to 8 until the moisture of the paddy is reduced to be below 14.5 percent; and conveying the paddy to a warehouse for storage. The method has the advantages of improving the moisture reducing rate and the utilization efficiency of the paddy dryer, reducing the loss after the paddy production caused by high moisture during the concentrated paddy harvest season, ensuring the safety for dry storage of the foodstuffs and having obvious economic benefit and social benefit on the premise of ensuring the drying quality of the paddy.

Owner:WUHAN POLYTECHNIC UNIVERSITY

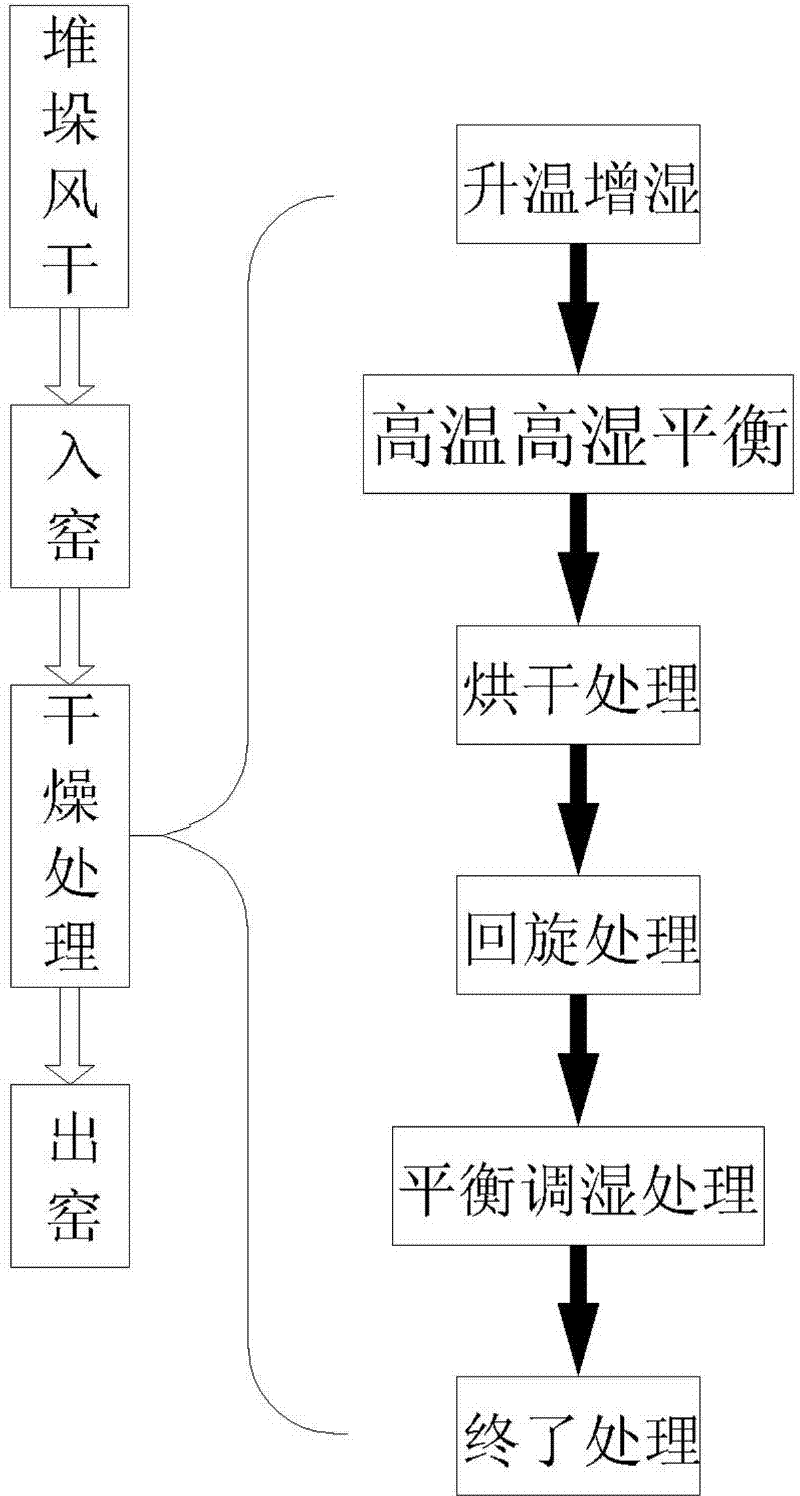

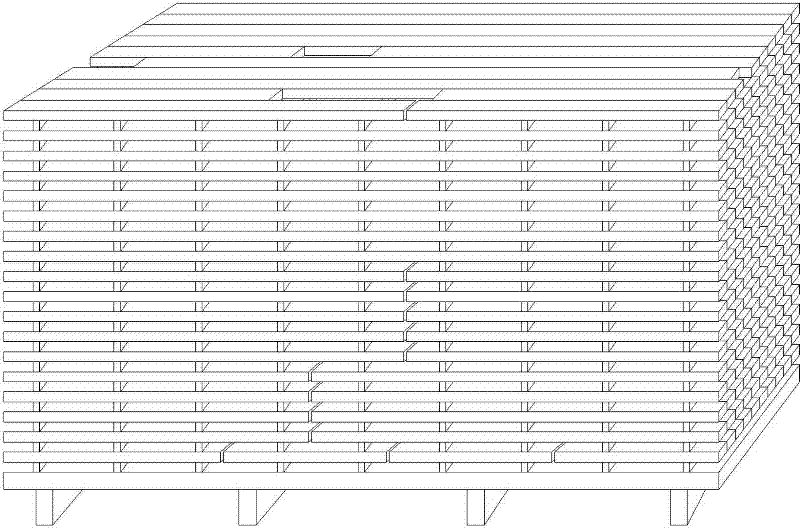

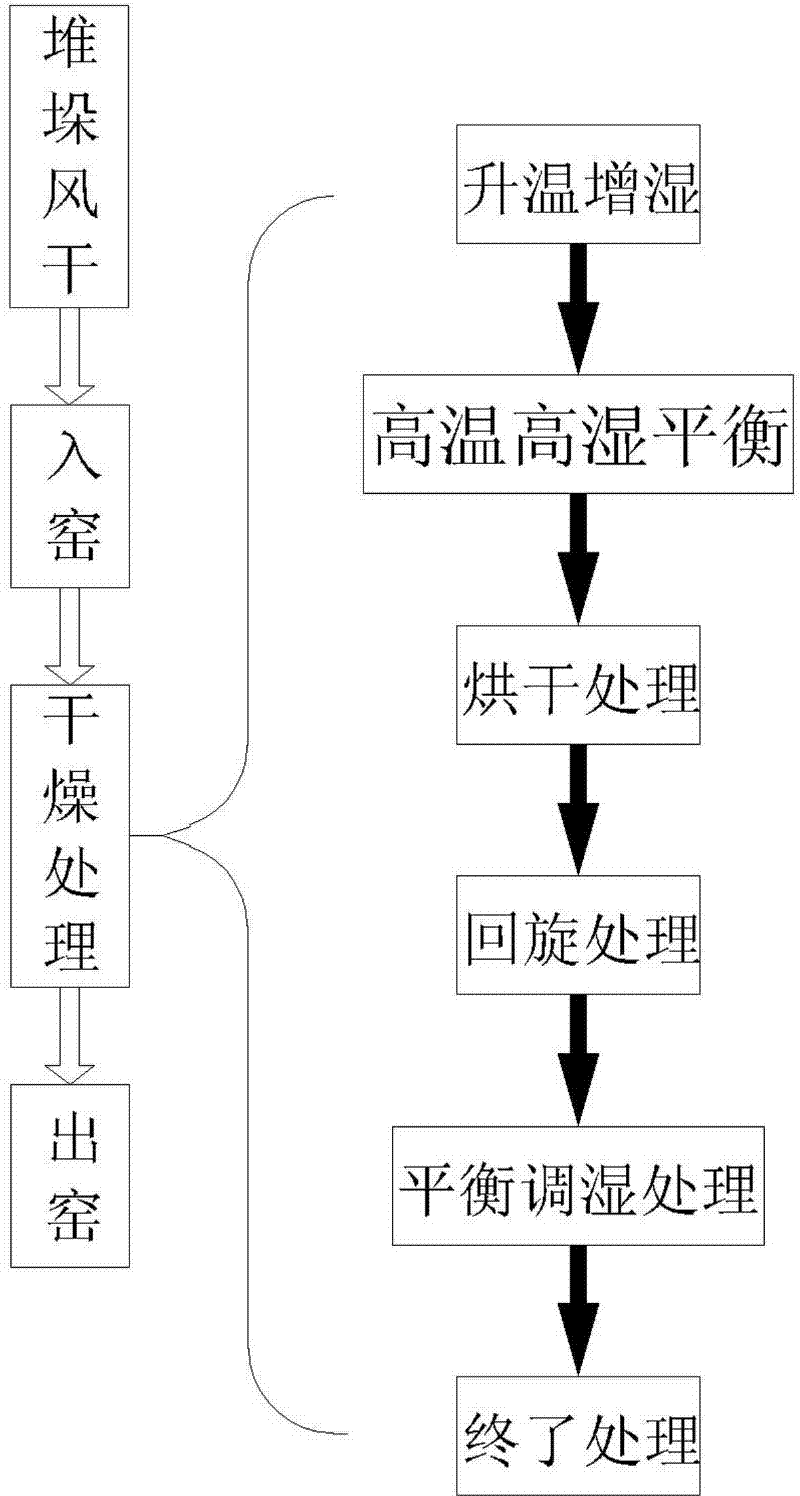

Rotary drying method for timbers

The invention provides a rotary drying method for timbers. The method comprises the following steps of: stacking the timbers and airing the timbers till the water content is about 30 percent; stacking the aired timbers, putting the timbers in a timber drying kiln, preheating, raising the temperature, humidifying, preserving heat and moisture, drying and dehydrating, finally treating and carrying out balanced humidification and rotary treatment many times. The method has the keys that a drying medium in a kiln is kept to form rotary vortex, and the water content of the timbers is not reduced in one step and is kept in rotary decline; by the rotary method, the internal stress of the timbers is dispelled in time, drying stress and surface hardening are eliminated, plasticizing deformation is prevented in the drying stage of the timbers, the defects of air shrinking, bending, deforming, cracking and the like are not caused, the degradation loss of the timbers is reduced to be below 6 percent, the drying period is shortened by about 20 percent, energy can be saved by about 15 percent, and limited timber resources are utilized more effectively; and the method has strong universality, is suitable for various different timbers, and can be widely applied to drying kilns with high automation degree.

Owner:GUANGDONG YIHUA TIMBER IND

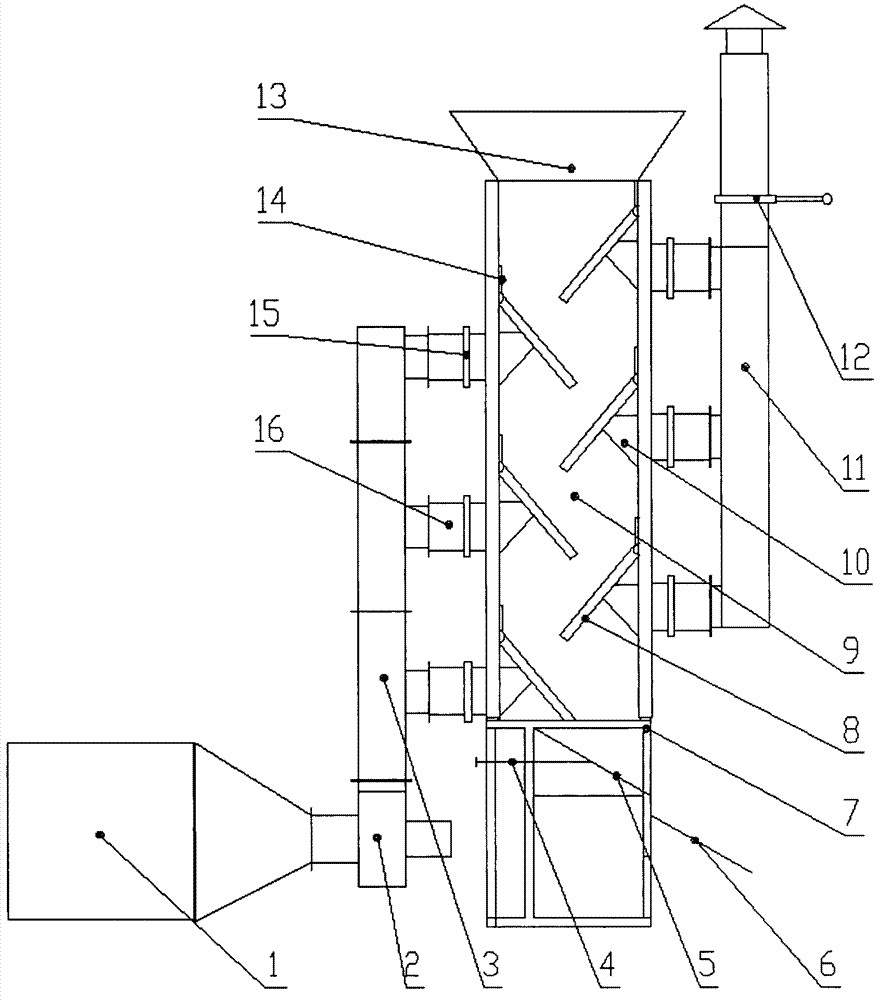

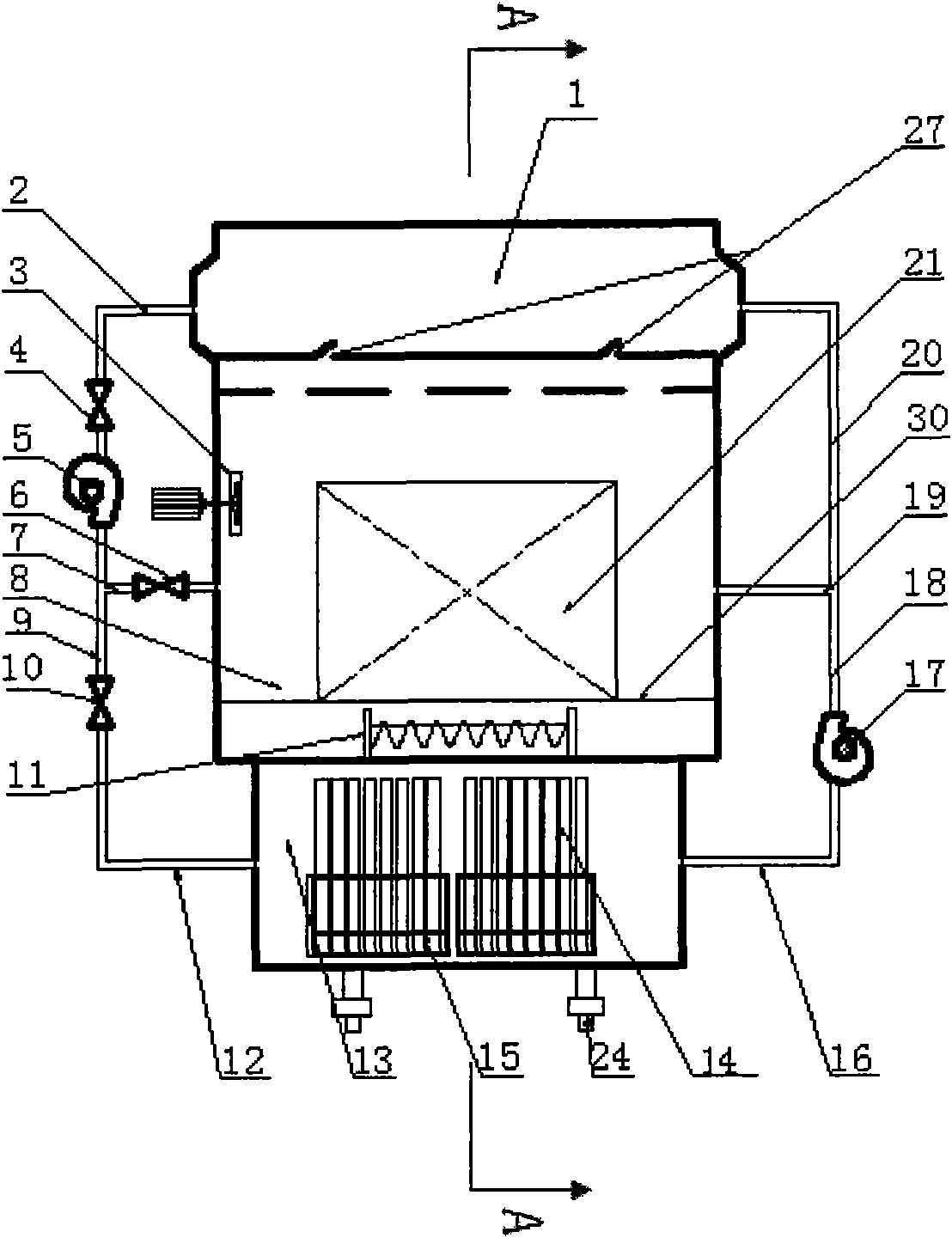

Cross-flow type layered drying machine

InactiveCN103115484AAvoid collusionStrong penetrating powerDrying gas arrangementsDrying chambers/containersWalnut NutCuticle

The invention discloses a cross-flow type layered drying machine, relates to an agricultural product processing machine and belongs to the technical field of agricultural product processing. The cross-flow type layered drying machine aims at solving the problems that when a drying machine is used for drying materials, uneven drying and damage of the cuticles of the materials are easy to occur, the cuticles of the materials are burst when drying temperature is high and the like. The materials enter into the drying machine are separated into material layers with the same thickness due to the fact that baffles with holes are mounted in an intersect-arrayed mode and an inclined mode, self-flow and slow rolling of the materials are achieved by using the self-weight of the materials when hot wind crosses the layered material layer transversely, the cross section position of a moisture-exhaust adjusting plate relative to a moisture-exhaust channel is controlled, drying speed of the materials is controlled, the burst of the material when in a drying process can be avoided. The cross-flow type layered drying machine is simple in structure, high in work efficiency and good in evenness of material drying and can achieve continuous drying operation of the materials. The cross-flow type layered drying machine is suitable for drying operation of granular agricultural products such as dates and walnuts.

Owner:XINJIANG AGRI UNIV

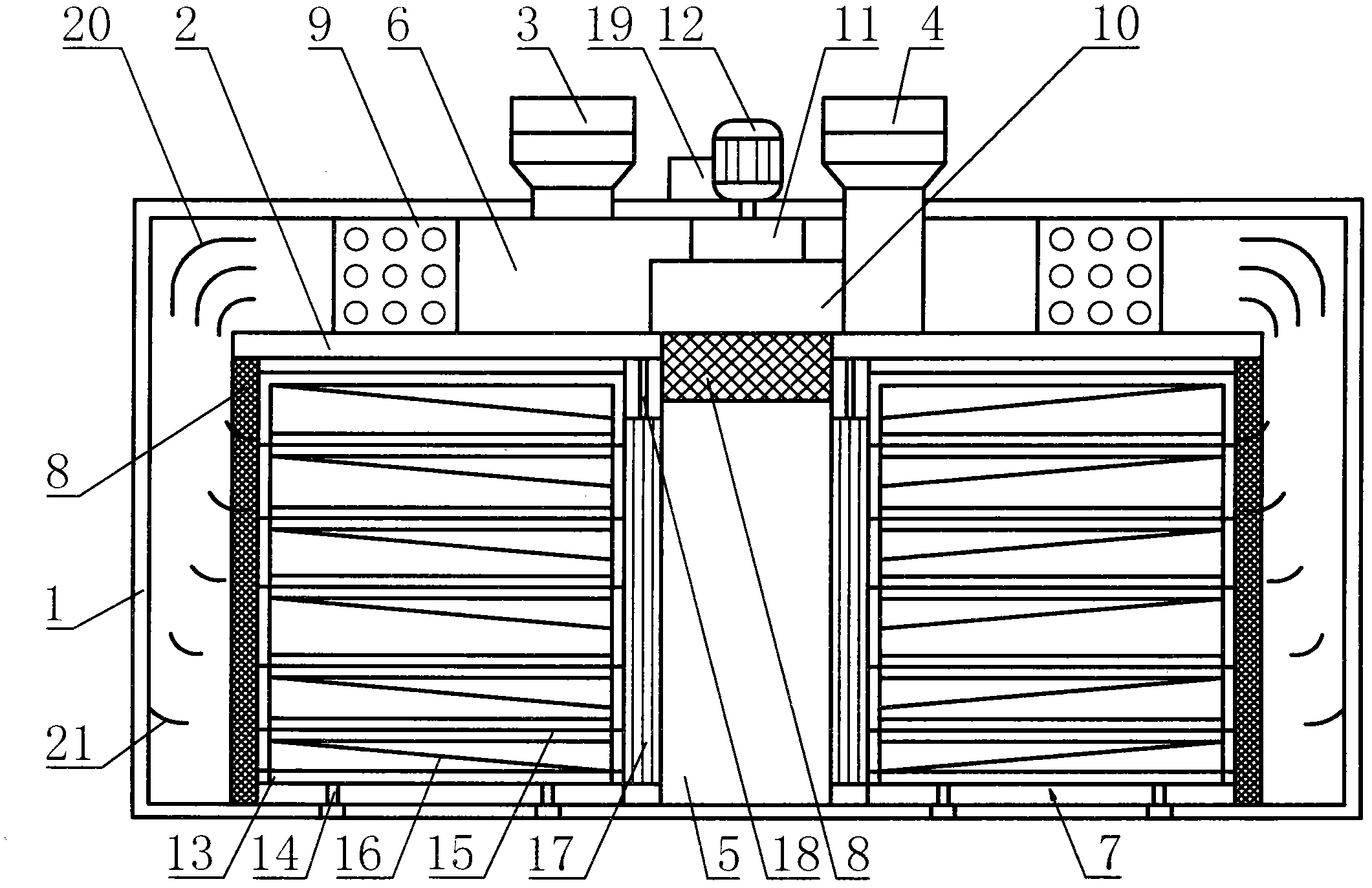

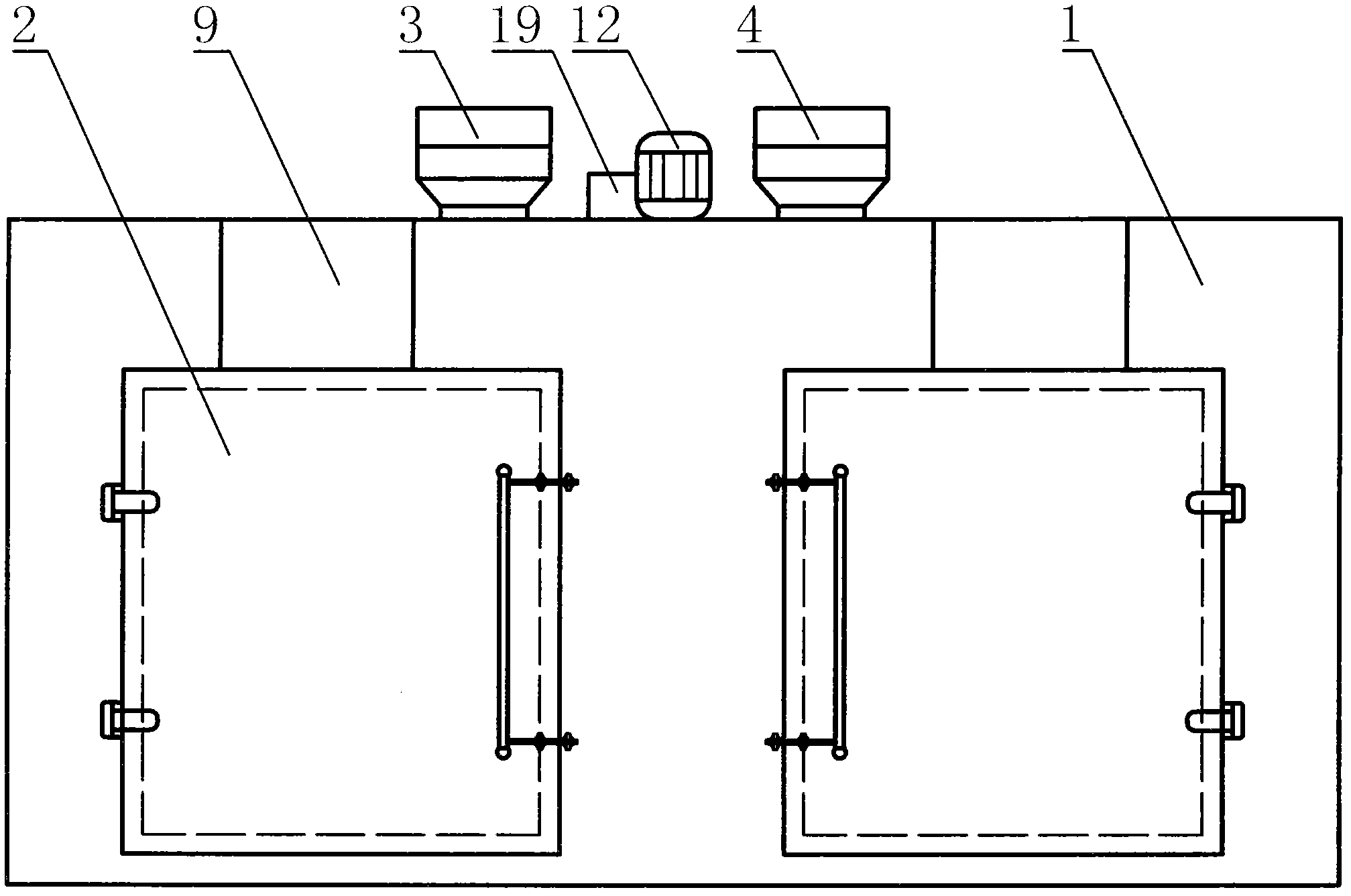

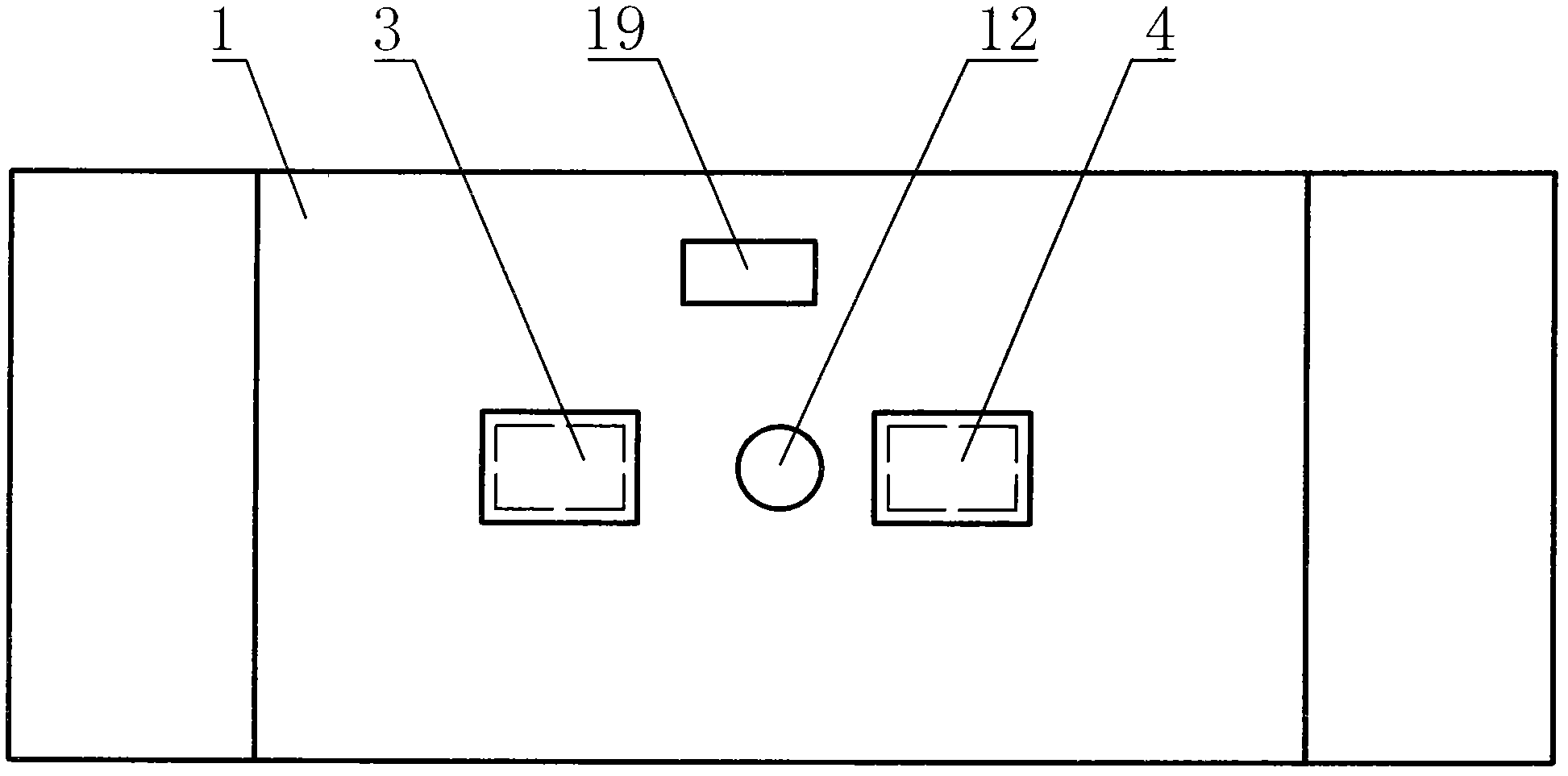

Inflatable-seal-type cross-flow drying oven with dual drying cars

InactiveCN102620533AIncrease throughputReduce drying costsDrying gas arrangementsDrying solid materialsFresh airMoisture

The invention relates to the field of drying equipment, in particular to an inflatable-seal-type cross-flow drying oven with dual drying cars, which has the advantages of even drying, large processing capacity, good sealing property and high heat utilization rate. The drying oven comprises a oven body (1); two drying chambers (2) are arranged in the oven body (1) symmetrically; a fresh air inlet (3), a moisture outlet (4) and an air draft device are arranged at the top of the oven box (1) respectively; an air-out chamber (5) is arranged between the drying chambers (2); an air-in chamber (6) is formed among the top of the drying chamber (2), the side of the drying chambers (2) close to the oven body (1) and the oven body (1); drying cars (7) are arranged in the drying chambers (2); a filter (8) is arranged at the side, close to the air-in chamber (6), of the drying chambers (2) and the other side is communicated with the air-out chamber (5) by an inflatable-seal device; the filter (8) is arranged at the part corresponding to the air draft device, above the air-out chamber (5); the fresh air inlet (3) is communicated with the drying chambers (2) by a heater (9) arranged in the air-in chamber (6); and the moisture outlet (4) is connected with the air draft device.

Owner:马文

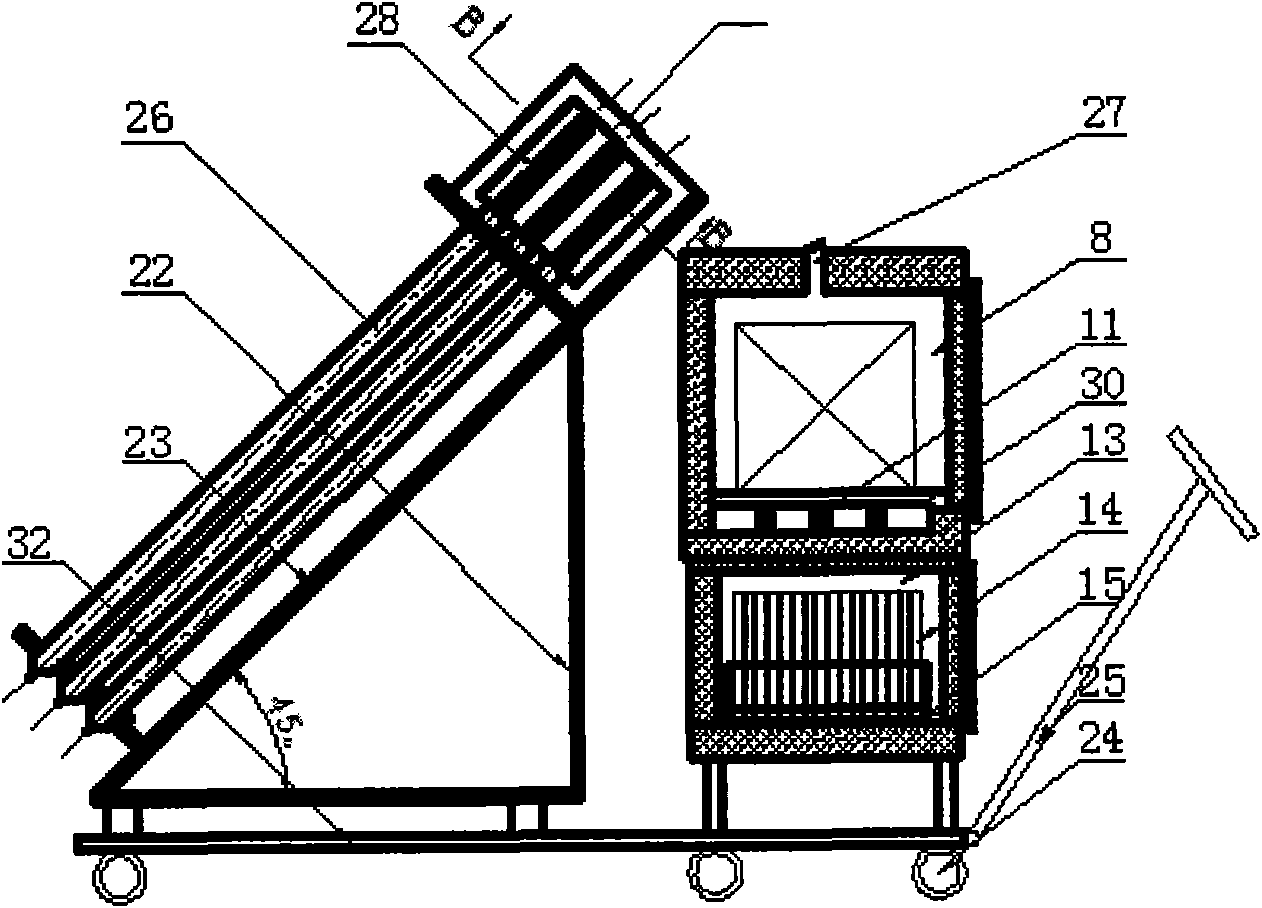

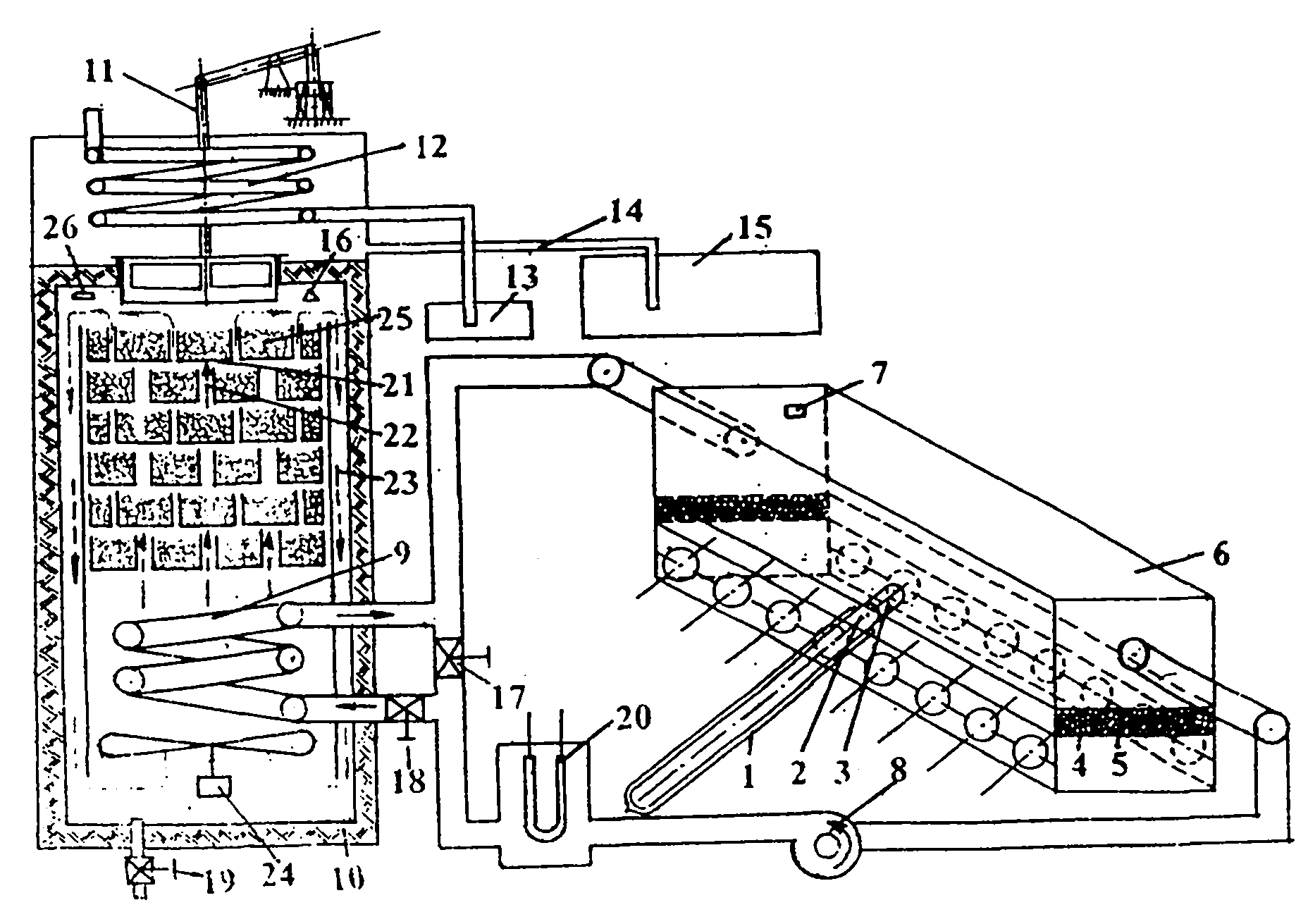

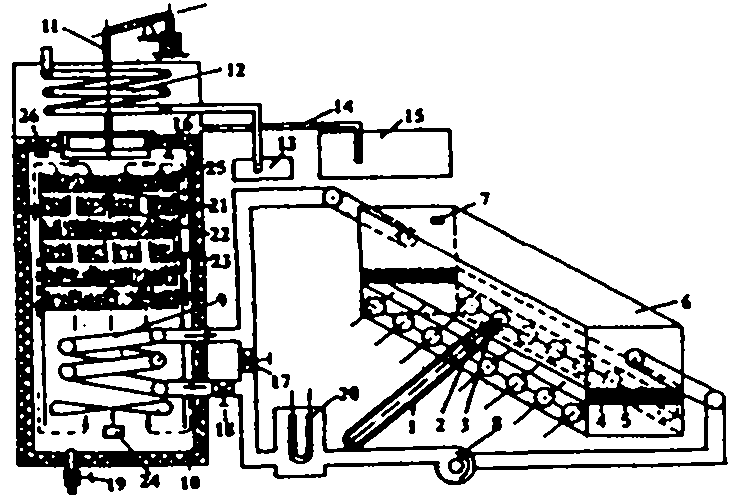

Drying method by using solar energy and device thereof

ActiveCN101776377AImprove drying efficiencyQuality improvementDrying solid materials with heatSolar heat devicesSolar dryingSolar energy conversion efficiency

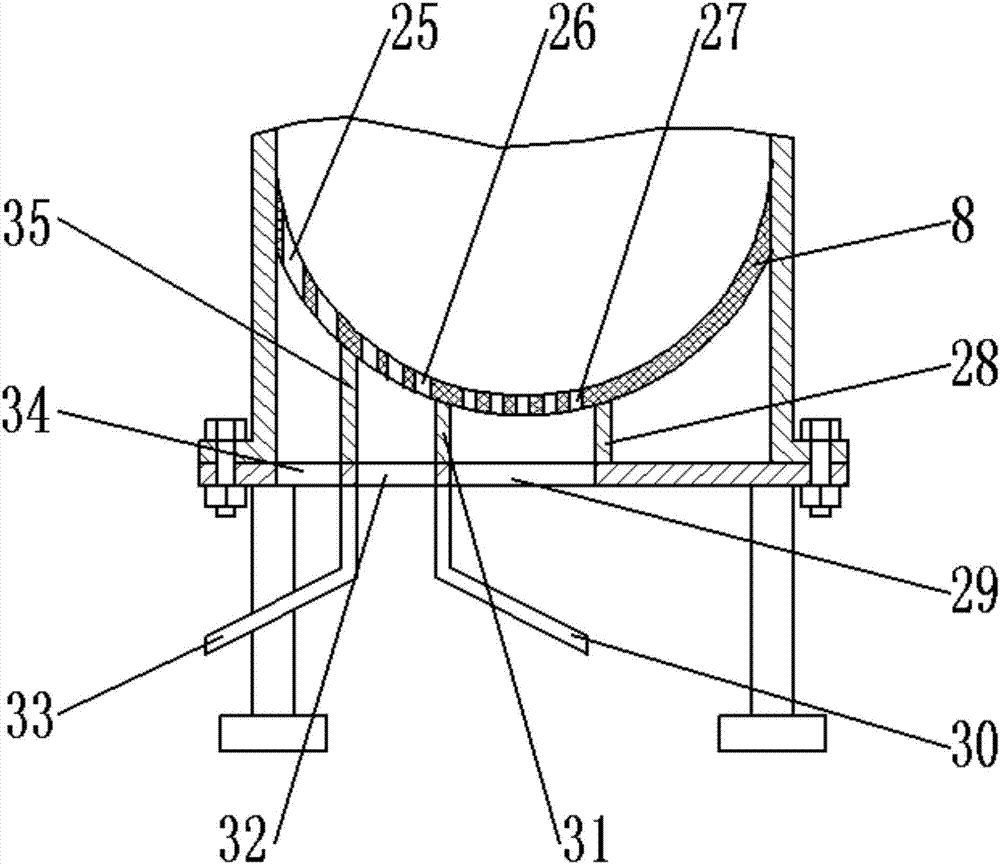

The present invention discloses a wood drying method by using solar energy, comprising the steps of: putting the wood to be dried in a drying cabinet (8); supplying heat to the drying cabinet; and stopping the supply of heat when the temperature T2 of the drying cabinet (8) is higher than the setting drying temperature of the wood to dry the wood under the setting drying temperature. The movable drying device by using solar energy has stable running, constant drying temperature and continuous drying function with lower power consumption, higher solar energy conversion efficiency and good drying quality, thereby reducing the drying cost.

Owner:潍坊恒远新材料科技有限公司

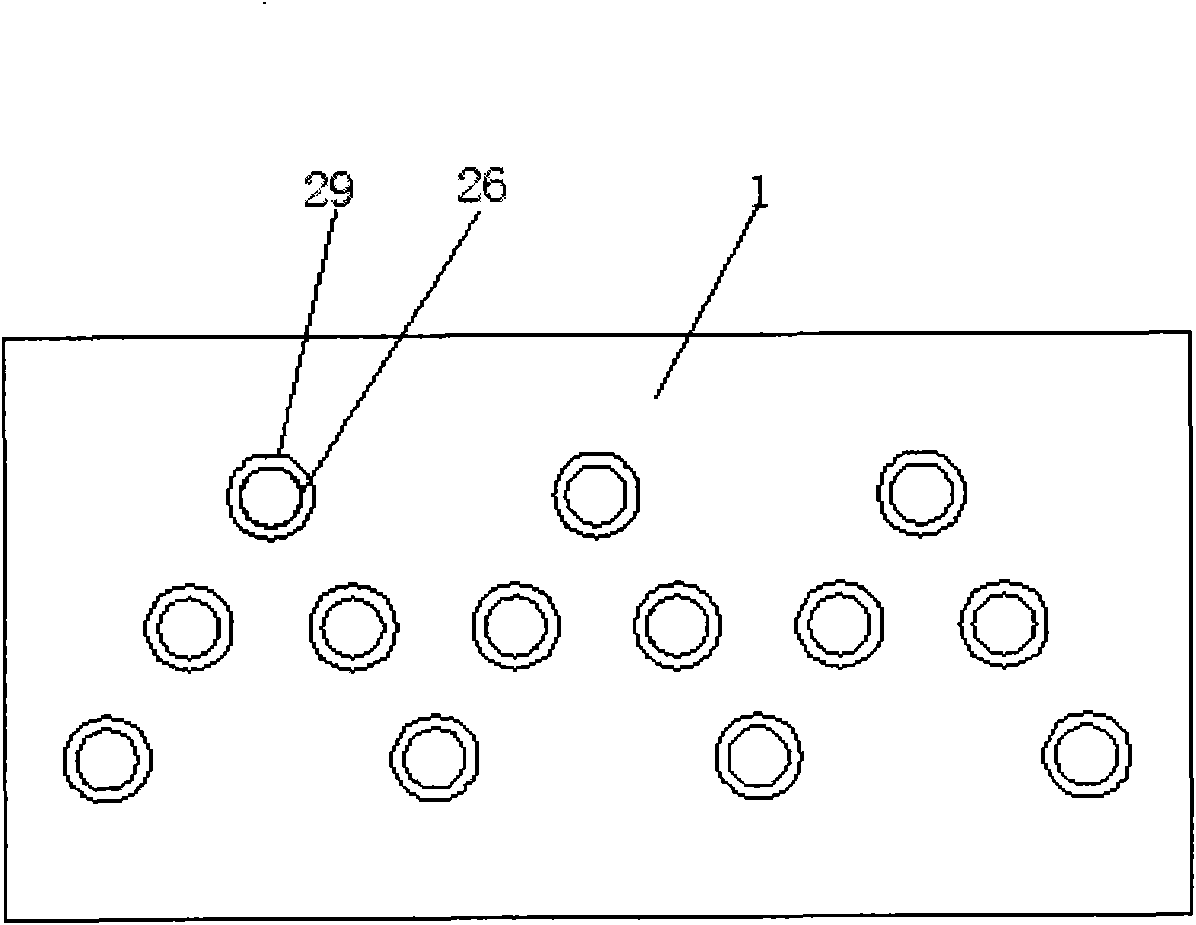

Moisture absorption hot air circular drying oven

ActiveCN104215041AEffective absorptionControl and understand healthDrying gas arrangementsDrying machines with local agitationInsulation layerAtmospheric air

The invention discloses a moisture absorption hot air circular drying oven. The moisture absorption hot air circular drying oven comprises a box body, a drying chamber and a hot air circulating pipeline, wherein the drying chamber and the hot air pipeline are arranged in the box body; a gap among the box body, the drying chamber and the hot air pipeline is taken as a thermal insulation layer; the hot air circulating pipeline is connected with a top plate of the drying chamber and a bottom plate of the drying chamber; a plurality of ventilation holes are distributed in the top plate of the drying chamber and the bottom plate of the drying chamber; the lower part of the bottom plate of the drying chamber is provided with support columns which are connected with the box body; a circulating fan is arranged in the hot air circulating pipeline; a moisture absorption device is arranged in the hot air circulating pipeline; the hot air circulating pipeline is connected with an air supplementing pipe; a plurality of partition plates are arranged in the drying chamber; the inner wall of the drying chamber is provided with a heating pipe, a temperature measuring device and a safety pipe; the other end of the safety pipe is communicated with the atmospheric air; a safety valve is arranged at one end where the safety pipe is communicated with the atmospheric air; a control processing device is arranged outside the box body; the bottom of the box body is provided with pulleys. By adopting the moisture absorption hot air circular drying oven, hot air can be used circularly to the maximum extent, and the drying efficiency is increased.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

Recovery type solar drying device

InactiveCN101839616AIncrease the heat collecting areaIncrease profitSolar heating energyDrying solid materials with heatElectricitySolar drying

The invention relates to a recovery type solar drying device, comprising: 1. a hot air flow heat-collecting and heat-storing circulating system implemented by components such as an all-glass vacuum heat-collecting tube, a heat tube (2), a heat-dissipating piece (3), a metal net layer (4), a pebble heat-storing device (5), a heat exchange device (9), a variable-frequency speed-regulating fan (8) and the like; 2. a material drying system implemented by components such as a material drying insulating box (10), a netty material drying box (21), a fan (24), a material (25) to be dried and the like; 3. a dried material water recovery system implemented by components such as a dried material steam discharge device (11), a condensing device (12), a dried material water recovery pipeline (14) and the like; and 4. components including a valve, an electric auxiliary heating device, a sensor and the like. The recovery type solar drying device has wide application range, can dry different types of materials and form series of products of the solar drying device.

Owner:沈晓莉

Drying device for textile use

InactiveCN108217258AEfficient dryingAvoid creasesDrying gas arrangementsDrying machines with progressive movementsEngineeringCotton material

The invention discloses a drying device for textile use. The drying device for textile use comprises a drying box which is of a hollow cuboid structure, wherein air blowers which are symmetrically arranged are arranged on the inner wall of the top end and the inner wall of the bottom end of the drying box; symmetrically arranged electric heating wires are arranged in the drying box; the two electric heating wires are located between the two air blowers; two symmetrically arranged first connecting plates are connected to one side of the drying box; a rotating motor is mounted on one side of oneof the first connecting plates through screws, and a winding roller is rotatably connected between the first connecting plates; and the output shaft of the rotating motor is connected to one end of the winding roller through the first connecting plates. The drying device for textile use disclosed by the invention is novel in structure, can dry textile cloth effectively, can roll the dried textilecloth and can prevent the textile cloth from being wrinkled, so that the attractive degree of the textile cloth is guaranteed while the drying quality is improved.

Owner:江苏爱纺纺织有限公司

Sludge dewatering method and special oven thereof

InactiveCN101955310ASave energyReduce pollutionSludge treatment by de-watering/drying/thickeningSolar heat devicesVertical projectionFiltration

The invention discloses a sludge dewatering method and a special oven thereof, and the sludge dewatering method comprises the following process steps: 1) pressure filtration: carrying out the pressure filtration on sludge which is not carried out dewatering treatment and has the water content of above 98% by using a plate-frame machine till the water content is below 70%; 2) crushing: shattering the sludge by using a wet soil crushing machine; and 3) drying by a heat pump: leading the sludge to pass through the heat pump drying device to reduce the water content of the sludge to below 30%. The special oven for the sludge dewatering method comprises a box body, a hot air circulation pipeline, a heat pump heating device and a heat insulation device, the oven is provided with a plurality of layers of conveyor belts from top to bottom, the driving directions of the adjacent layer of the conveyor belts are reverse, and a vertical projection point of a terminal point of each layer of the conveyor belt falls on the lower layer of the conveyor belt. The special oven has the advantages of low energy consumption cost, no environmental pollution and good drying quality.

Owner:浙江绿治环保技术有限公司

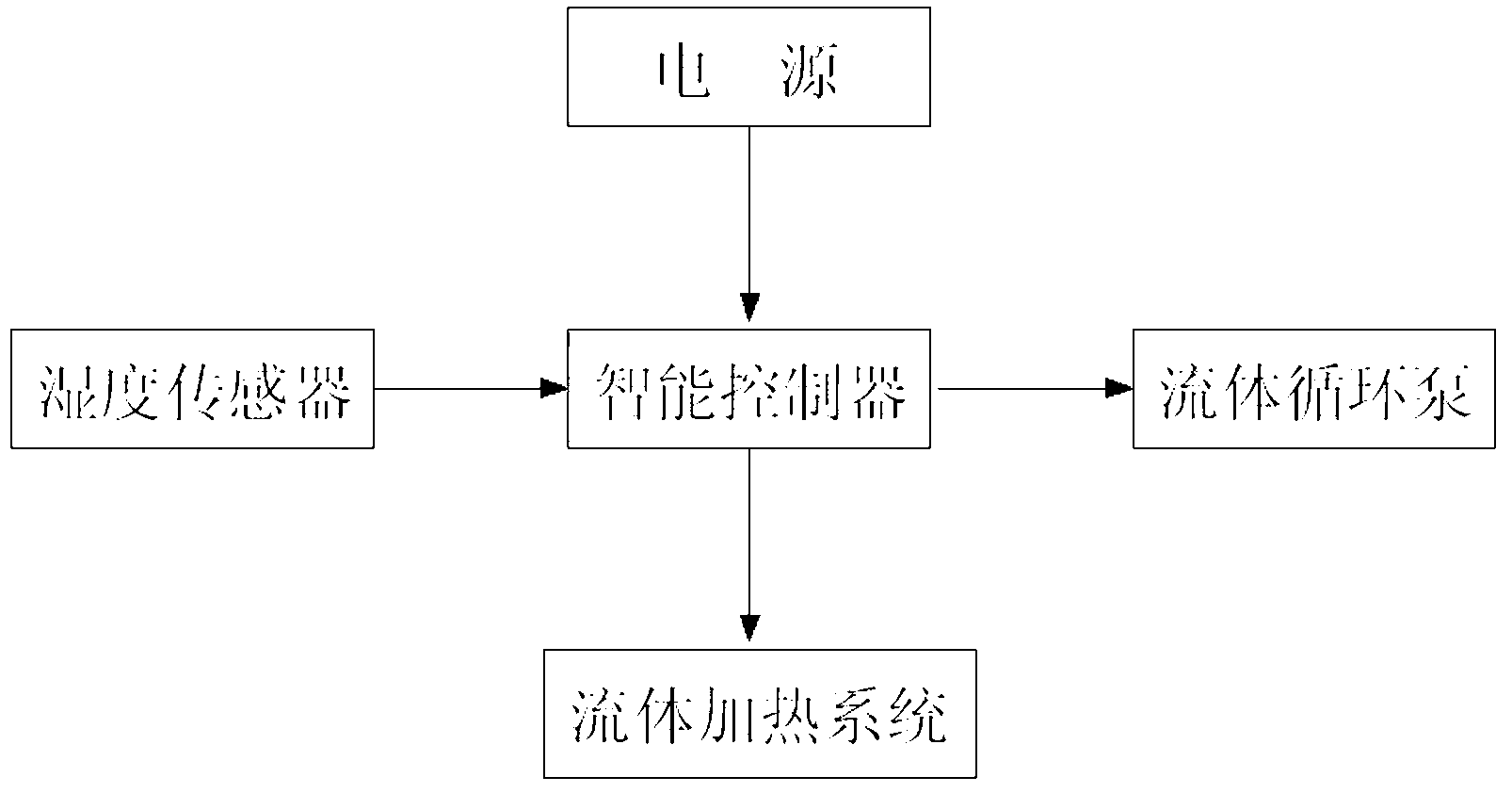

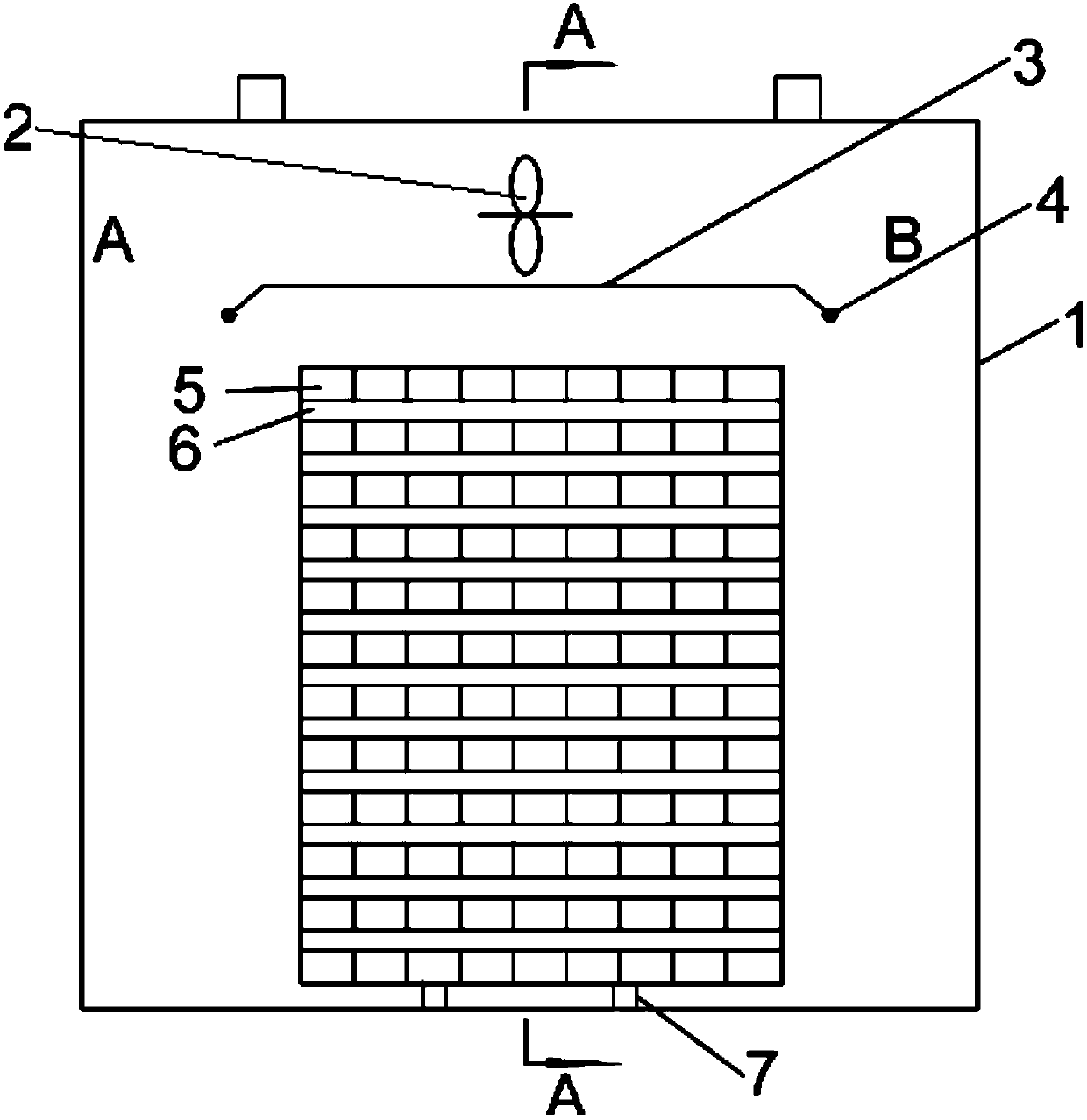

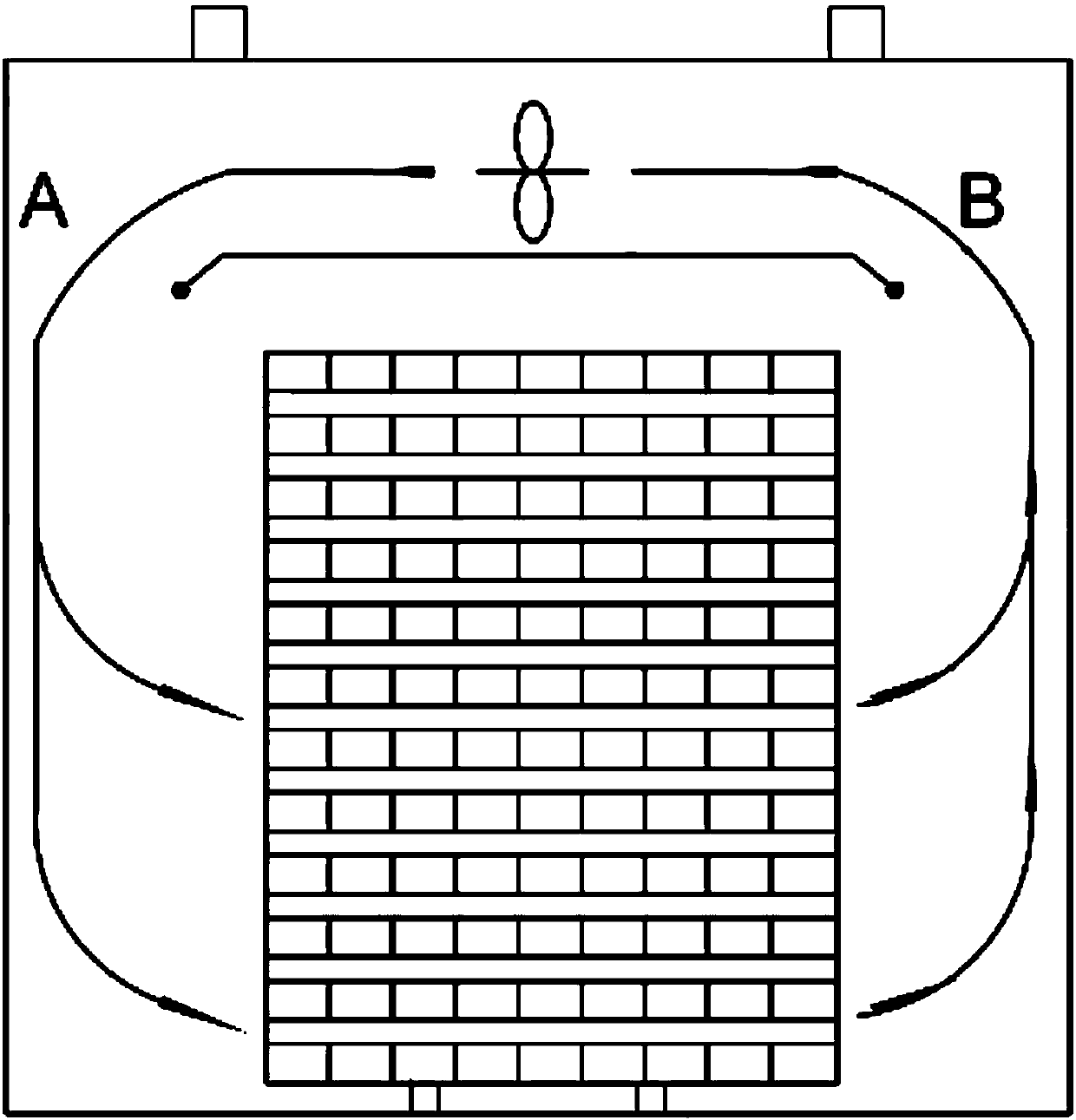

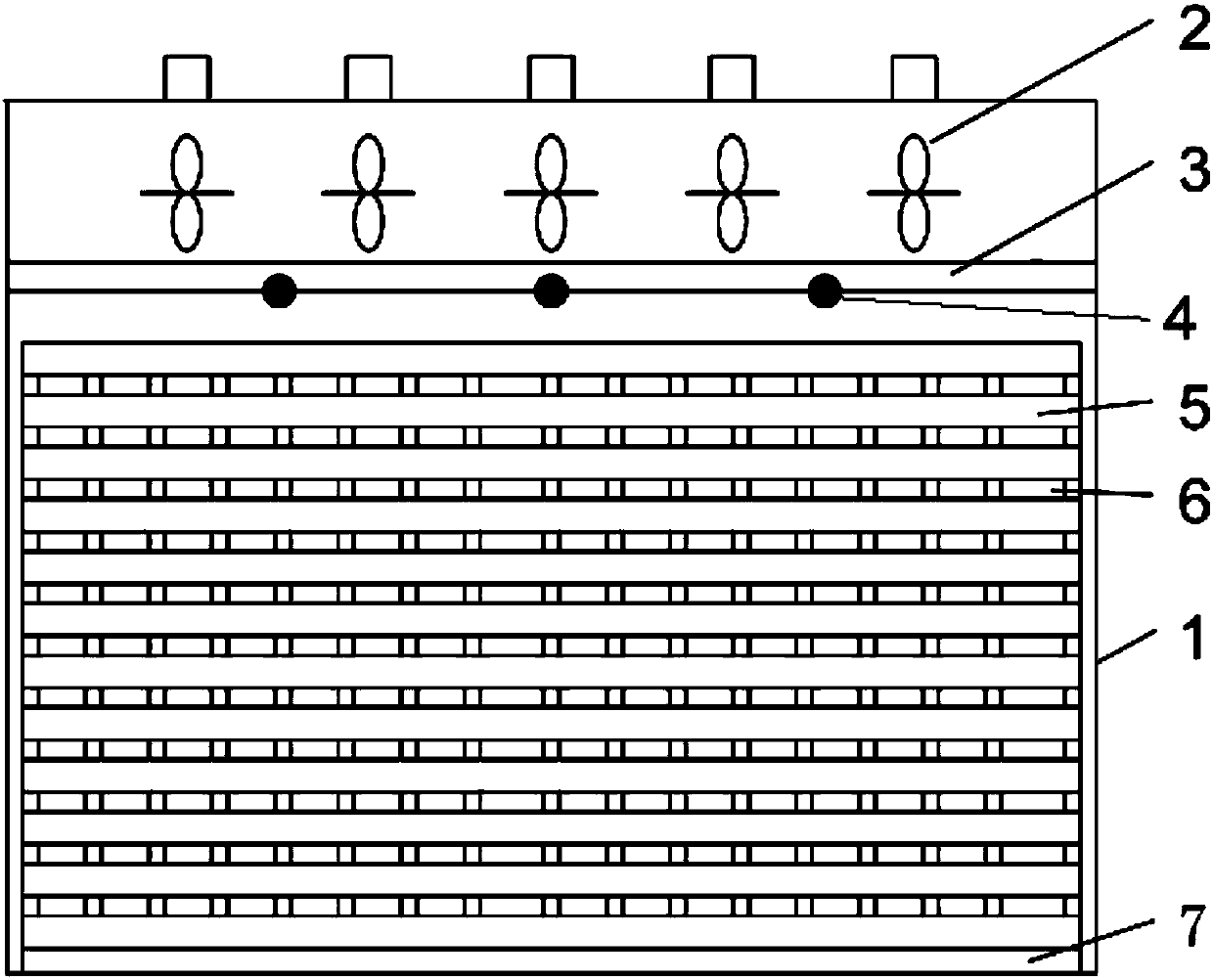

Intelligent towel drier and drying method

InactiveCN103263233AKeep dryImprove drying rateDomestic applicationsHeating arrangementProcess engineeringCirculating pump

The invention relates to the field of towel drying devices, in particular to an intelligent towel drier and a drying method. The intelligent towel drier comprises a drying frame, a control box and a humidity sensor, wherein the drying frame is used for hanging towels. The drying frame is in a box shape with a cavity inside. The cavity is communicated with a liquid inlet pipe and a liquid outlet pipe, wherein the liquid inlet pipe and the liquid outlet pipe are formed in the drying frame. The humidity sensor is arranged at the bottom of the drying frame. A fluid heating system, a fluid circulating pump and an intelligent controller are arranged inside the control box. A liquid outlet and a return port are formed in the control box. The liquid outlet is communicated with the liquid inlet pipe. The return port is communicated with the liquid outlet pipe. A control panel is arranged on the surface of the control box. The humidity sensor feeds signals back to the intelligent controller. The intelligent controller controls the fluid heating system to conduct temperature adjustment and controls output power of the fluid circulating pump to conduct flow speed adjustment. A user can adjust procedure parameters according to personal requirements so as to achieve completely dry effects on different towels after the intelligent drier is used. The intelligent towel drier is simple in operation, convenient to use and practical.

Owner:LUOYANG INST OF SCI & TECH

Moisture content measuring method for wood drying process and wood drying method

ActiveCN108802352AAccurate moisture contentReduce drying defectsWeighing by removing componentWood testingNarrow rangeSolid wood

The invention discloses a moisture content measuring method for a wood drying process and a wood drying method. The moisture content measuring method for the wood drying process and the wood drying method include: measuring an initial moisture content and initial weight of to-be-dried wood, and stacking the to-be-dried wood in a drying kiln; measuring temperature and wind speed of media flowing through two sides of the stacked to-be-dried wood, acquiring saturated vapor pressure of moist air according to dry-bulb temperature, acquiring relative humidity of the moist air according to temperatures of wet and dry bulbs, and finally acquiring density and moisture content of the moist air so as to obtain moisture contents of the to-be-dried wood at different times; according to the moisture contents of the to-be-dried wood, drying the to-be-dried word according to wood drying standards so as to obtain high-quality dry wood. The moisture content measuring method is precise, simple, low in input, applicable to any wood moisture content measurement, less in measuring parameters, simple in calculation, systematically stable, capable of overcoming the defects of large measuring error and narrow range of an electric measuring method and improving quality of solid wood plates, high in efficiency and low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

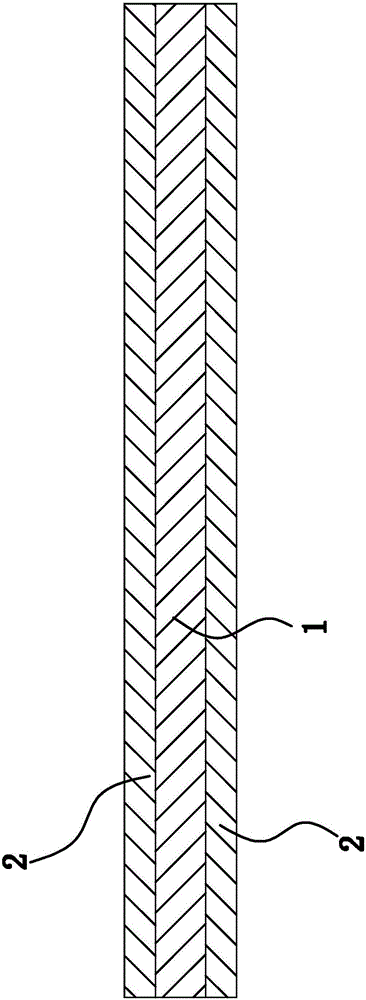

Anti-aging PVC (Polyvinyl Chloride) coating canopy plus material and manufacturing process thereof

ActiveCN106739354ASimple structureImprove job stabilityLamination ancillary operationsSynthetic resin layered productsPolyesterPolyvinyl chloride

The invention provides an anti-aging PVC (Polyvinyl Chloride) coating canopy plus material and a manufacturing process thereof. By using the anti-aging PVC coating canopy plus material and the manufacturing process thereof, the problem that a peculiar smell cannot be removed from an existing canopy plus material is solved. In the anti-aging PVC coating canopy plus material and the manufacturing process thereof, the plus material comprises a basic fabric and two PVC films, wherein the two PVC films are located on the upper side and the lower side of the basic fabric respectively; the PVC films and the basic fabric are laminated together at a high temperature of 190 to 200 DEG C; two side surfaces which are back to back on the two PVC films are subjected to matting treatment; the basic fabric is a 20*20 biaxial basic fabric which is formed by adopting 1,000D*1,000D polyester filaments through warping and weaving; each PVC film is prepared from the following raw materials in parts by weight: 100 parts of PCV resin powder, 3 to 4 parts of antimonous oxide, 50 to 60 parts of dioctyl phthalate, 3 to 4 parts of dimethyl adipate, 3 to 5 parts of titanium pigment, 3 to 6 parts of stabilizer, 2 to 4 parts of soybean oil, 20 parts of calcium carbonate and 3 to 5 parts of activated carbon powder. The manufacturing process comprises the production procedure of the basic fabric, the calendering process of the PVC films and the processing process of a product. The anti-aging PVC coating canopy plus material has the advantage that the peculiar smell can be absorbed.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

Grading sand screening device for building construction

InactiveCN107252765AKeep dryEasy to move with each otherSievingSand dryingSquare cross sectionEngineering

The invention provides a kind of grading and sand screening equipment for building construction, which comprises a tank body; the tank body is set as a hollow cuboid with a square cross section, an upper cover is set at the top opening of the tank body, and a bottom opening is set at the bottom opening of the tank body. cover; the middle part of the tank body is divided into a drying chamber and a screening chamber by a partition; a drying device is provided in the drying chamber; a screening plate and a screening device are provided in the screening chamber; feeding device; the present invention adds the sand added by the feeding hopper into the tank body at a uniform speed through the feeding device, which is also beneficial to reduce the labor intensity of the workers; through the setting of the drying device, the three-layer rotating material guide plate is used to control the sand falling on the guide The sand in the material tray is turned over, and the hot air blown by the hot air blower is used to evenly distribute the hot air blown in by the three-layer rotating air distribution pipe, so as to facilitate the full drying of the sand; The sand is graded and screened to improve the screening quality.

Owner:合肥多智科技开发有限公司

Cleaning and drying device for gauze production

ActiveCN109023772AClean upStable cleaningLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater pipeEngineering

The invention provides a cleaning and drying device for gauze production and relates to the technical field of gauze cleaning and drying. The cleaning and drying device for gauze production includes acleaning tank. A water pipe box is arranged at the bottom of the cleaning box. A drying box is arranged on the left side of the cleaning box. A square rotary roller is fixedly mounted inside the cleaning box. A water injecting and pushing device is arranged at the bottom of the inner wall of the cleaning box. The top of the cleaning box is provided with a water diverting device. A water filteringdevice is arranged at the rear side of the cleaning box. The water filtering device comprises a water filtering box. A pressure roller and a conveying roller are arranged inside the drying box. A swinging water pressing device is arranged at the bottom of the pressure roller, and a ventilation and condensation device is arranged at the top of the drying box. The cleaning and drying device for gauze production has the advantages of high automation, good cleaning and drying effect, certain improvement of gauze production quality and efficiency, convenient cleaning, and reduction of labor intensity and labor cost.

Owner:陈剑璋

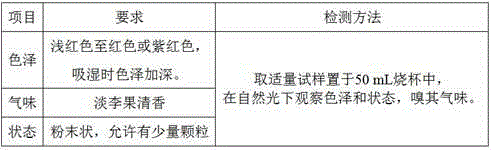

Preparation method of prunus fruit polyphenol

ActiveCN104886577AReduce lossesImprove drying qualityFood ingredientsFood preparationPhenolsBiotechnology

The invention discloses a preparation method of prunus fruit polyphenol, which integrates a plurality of techniques of microwave vacuum drying, ultrasonic-assisted ethanol extraction, macroporous resin absorption purification, spraying drying, microencapsulation, and the like to prepare a fine powder product of prunus fruit polyphenol. With the adoption of the method disclosed in the invention, the loss of polyphenol during production can be reduced, energy loss is reduced, the production efficiency of extraction is improved, the sensibility of the prunus fruit polyphenol product to the environment is reduced, the storing stability of the prunus fruit polyphenol is enhanced, the water solubility of the prunus fruit polyphenol is improved, the processing adaptability of the prunus fruit polyphenol is increased, and the application range of the prunus fruit polyphenol is widened. The fine powder of prunus fruit polyphenol prepared in the invention can be used as a natural pigment and a natural antioxidant to be applied to the food industry.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Strip steel drying device

ActiveCN103836898AReduce efflux lossReduce in quantityDrying gas arrangementsDrying machines with progressive movementsStructural engineeringStrip steel

The invention discloses a strip steel drying device, and belongs to the technical field of drying devices. The strip steel drying device comprises a box, a heating structure, a strip steel outlet and a strip steel inlet. The heating structure comprises a first flow guiding box, a second flow guiding box, a first circulating fan, a second circulating fan, a first air channel, a second air channel and a heater, wherein the first flow guiding box is arranged over strip steel, the second flow guiding box is arranged under the strip steel, the heater is arranged in the first flow guiding box, an air inlet of the first flow guiding box is communicated with the air outlet end of the first circulating fan through the first air channel, a first purging structure is arranged on the side, close to the strip steel, of the first flow guiding box, the air draft end of the first circulating fan is communicated with the box (1), an air inlet of the second flow guiding box is communicated with the air outlet end of the second circulating fan through the second air channel, a second purging structure is arranged on the side, close to the strip steel, of the second flow guiding box, the air draft end of the second circulating fan is communicated with the box, the second purging structure carries out forward air outlet, and the included angle between the air outlet direction of the second purging structure and the strip steel ranges from 30 degrees to 45 degrees.

Owner:湖北大帆金属制品有限公司

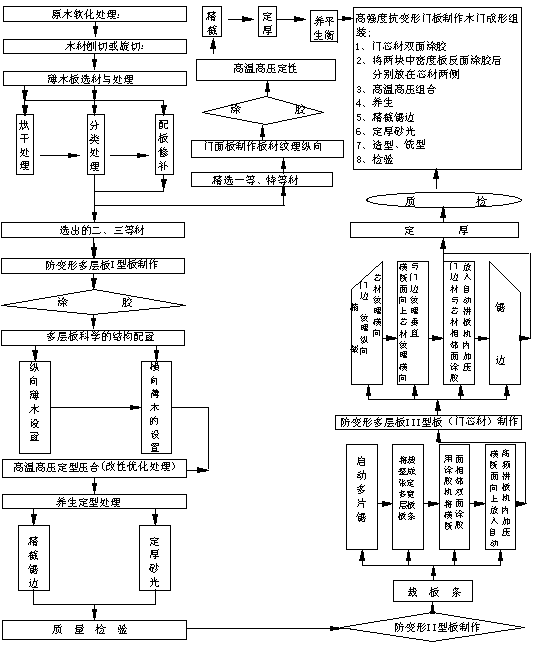

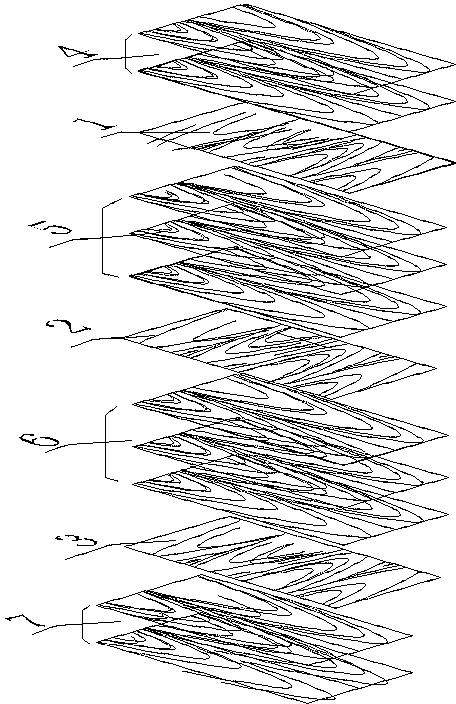

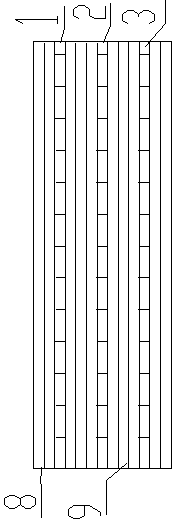

Method for manufacturing environment-friendly high-strength anti-deformation solid wood composite door

InactiveCN103128823AReduce moisture contentOvercoming high moisture content and poor flatnessWood veneer joiningAdhesive application devicesSanderSolid wood

The invention discloses a method for manufacturing an environment-friendly high-strength anti-deformation solid wood composite door. The method includes steps of softening and miniaturizing log to obtain wood sheets; classifying the wood sheets into a panel and core materials and drying the panel and core materials; splicing the thin sheets into integral plates, classifying the integral plates into a panel and core materials, selecting integral plates with transverse textures in the core materials to be used as balance tension plates, arranging the balance tension plates into multiple layers and gluing the multiple layers of balance tension plates; performing press fit for the multiple layers of glued balance tension plates into a multilayer plate by the aid of a hot press, preserving the multilayer plate, cutting off four edges of the multilayer plate and sanding the multilayer plate by a sander so as to set the thickness of the multilayer plate; cutting the multilayer plate into fixed-width battens, manufacturing an anti-deformation core material, and setting the thickness of the anti-deformation core material; and manufacturing a medium-density plate and the anti-deformation core material into a structural plate, preserving the structural plate, cutting four edges of the structural plate, sanding the structural plate to set the thickness of the structural plate, carving the structural plate, milling the profile of the structural plate, milling lines of the structural plate and finishing the structural plate to obtain the high-strength anti-deformation solid wood composite door. The method has the advantages that common wood resources are sufficiently utilized to replace valuable wood resources, accordingly, materials are saved, waste materials are recycled, forest resources are powerfully protected, the cost is lowered, composite materials are replaced, and the method has an excellent application prospect.

Owner:HARBIN SHENGSHI HUALIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com