Cross-flow type layered drying machine

A dryer, cross-flow technology, applied in the direction of dryers, drying chambers/containers, drying gas arrangement, etc., can solve problems such as poor sanitary conditions, cumbersome procedures, skin damage, etc., to improve drying quality and penetration effect , the effect of preventing collusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

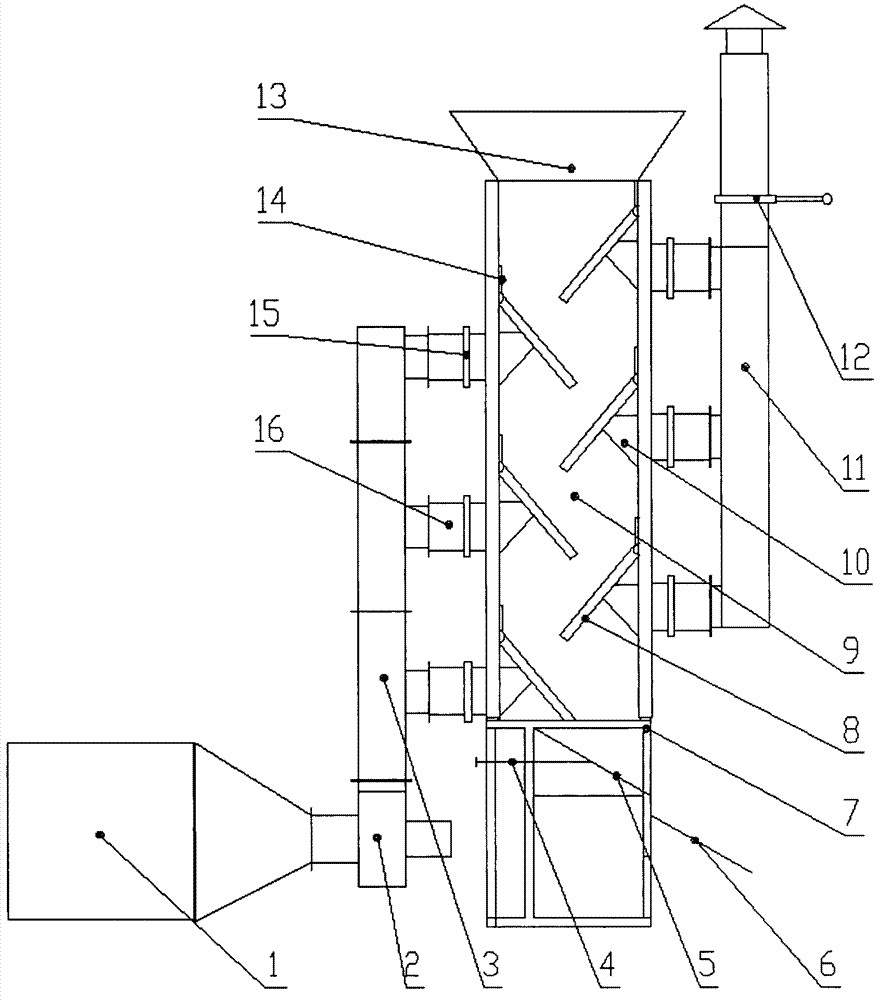

[0011] In the embodiment shown in the figure, the cross-flow layered dryer consists of a heater 1, an induced draft fan 2, a main air duct 3, a discharge adjustment rod 4, a valve 5, a discharge plate 6, a base 7, and a perforated baffle 8 , body 9, angle adjuster 10, dehumidification channel 11, dehumidification adjustment plate 12, feed hopper 13, hinge 14, air intake adjustment plate 15 and secondary air duct 16 constitute. When the cross-flow jujube layered dryer is working, the opening size of the valve 5 can be changed by adjusting the position of the discharge adjustment rod 4 relative to the valve 5, so as to control the speed at which the red dates flow out of the body 9 and the drying time of the material in the body 9. The material flows to the discharge plate 6 through the control of the valve 5 . The hot air generated by the heater 1 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com