Patents

Literature

583 results about "Cleaning room" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

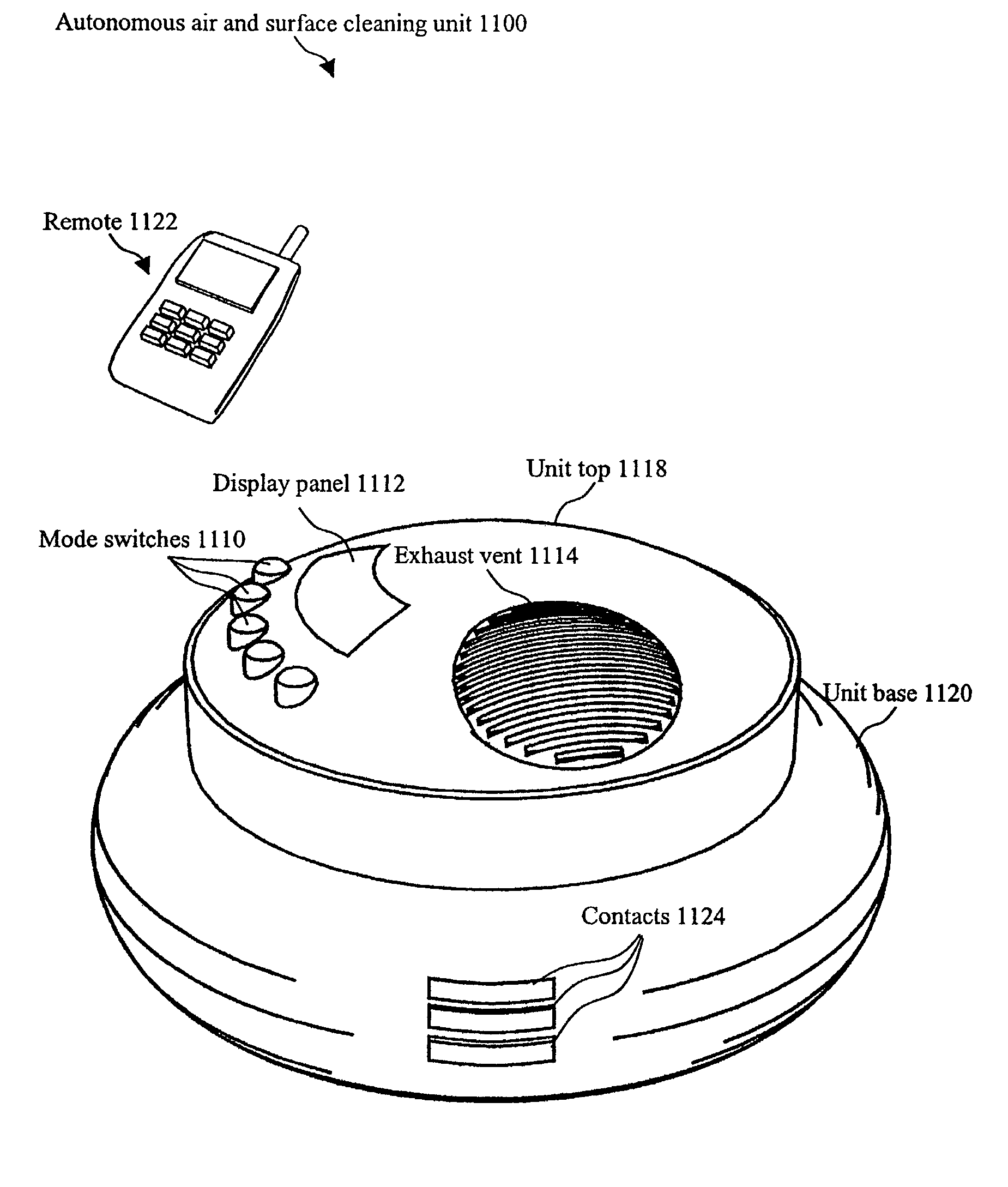

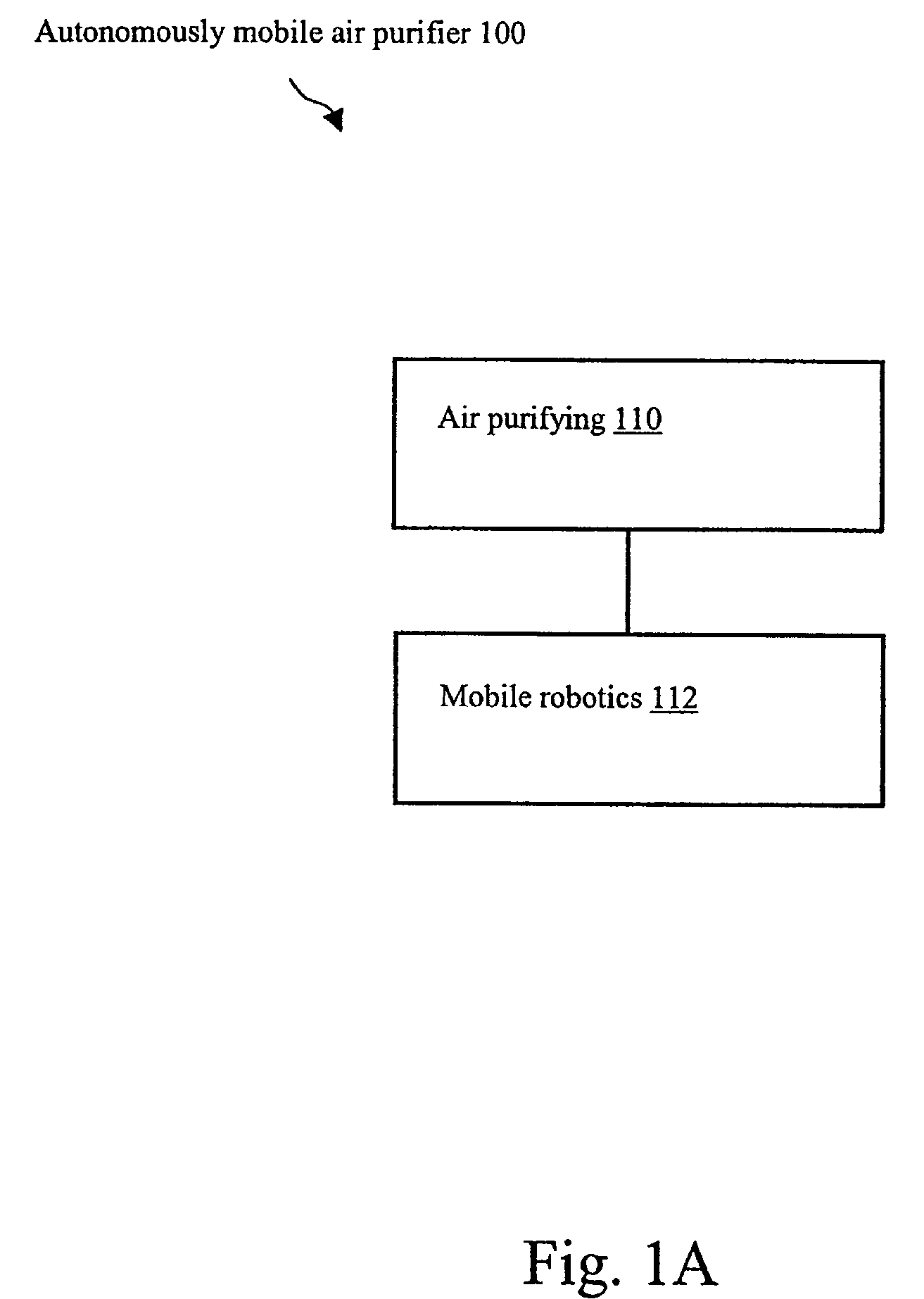

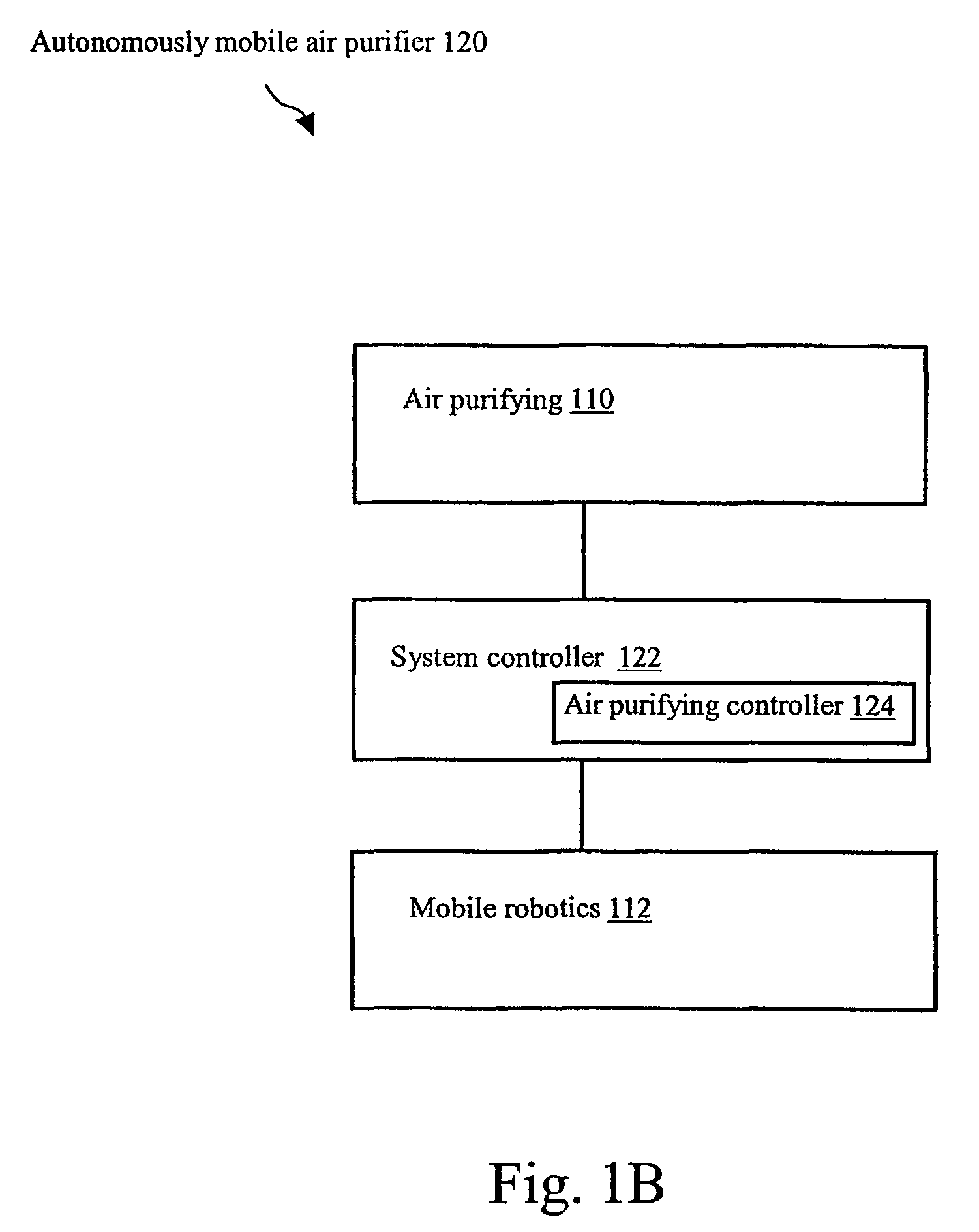

Device and methods of providing air purification in combination with superficial floor cleaning

InactiveUS7837958B2Reduce installationLighting and heating apparatusExhaust apparatusRoboticsAir purifiers

The present invention is a system for and method of providing an autonomously mobile air purifier and surface cleaner in combination with a source of air fragrance in a single device for home or office use. The autonomously mobile air and surface cleaner and fragrancing system includes an air purifier, a fragrancer, a floor cleaner, an input means, a power system, operational and auxiliary sensors, robotics that drive and steer the device, and a central controller operatively connected to each of the aforementioned items to control the operation of the device. The present invention also provides a method for the operation of the device using the air purifier, fragrancer, floor cleaner and robotics to clean a room, and for modifying the operation of the device in response to signals sent from the sensors or from the input means.

Owner:SC JOHNSON & SON INC

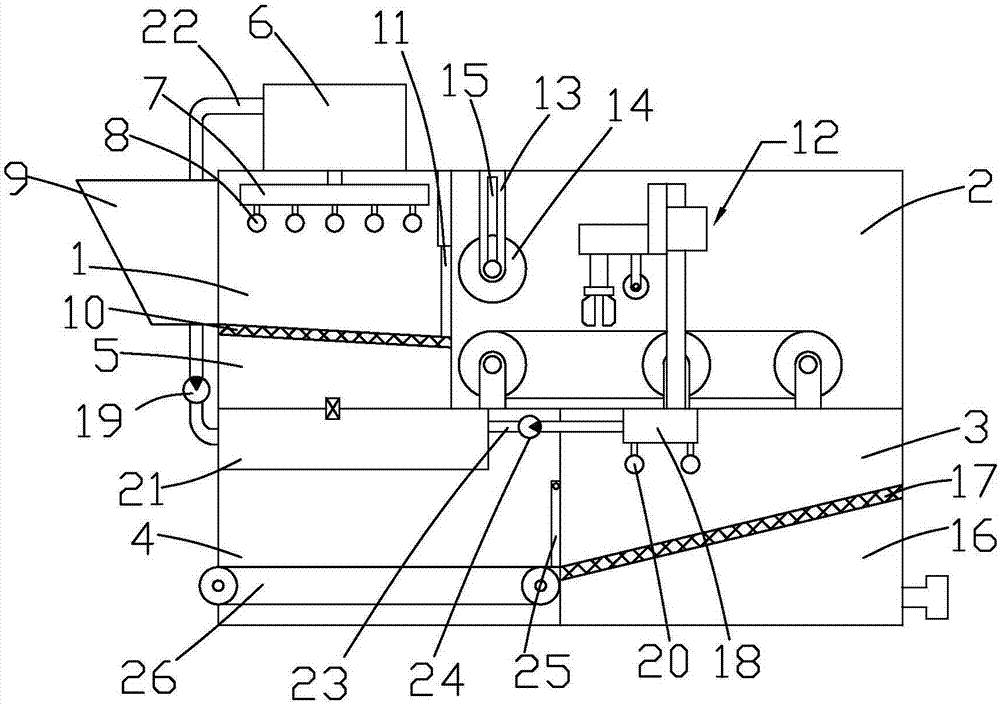

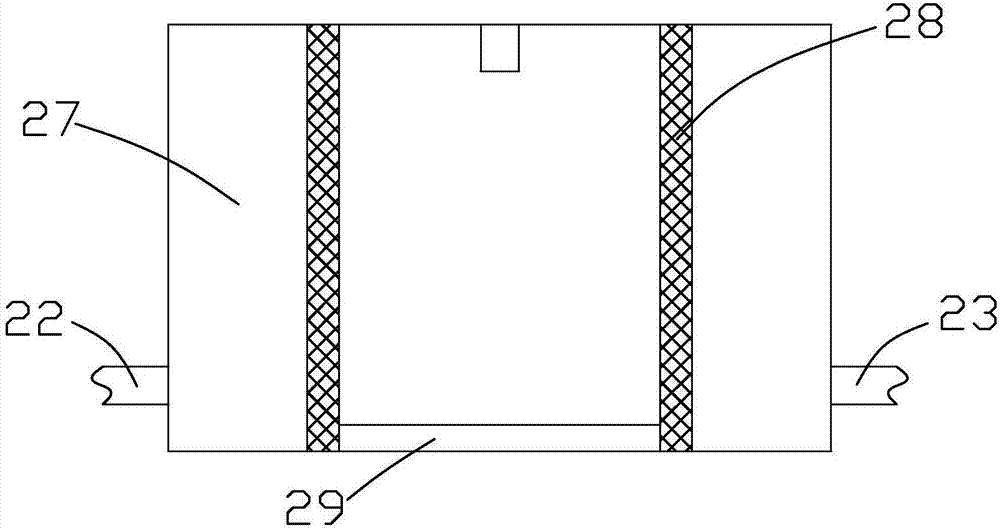

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

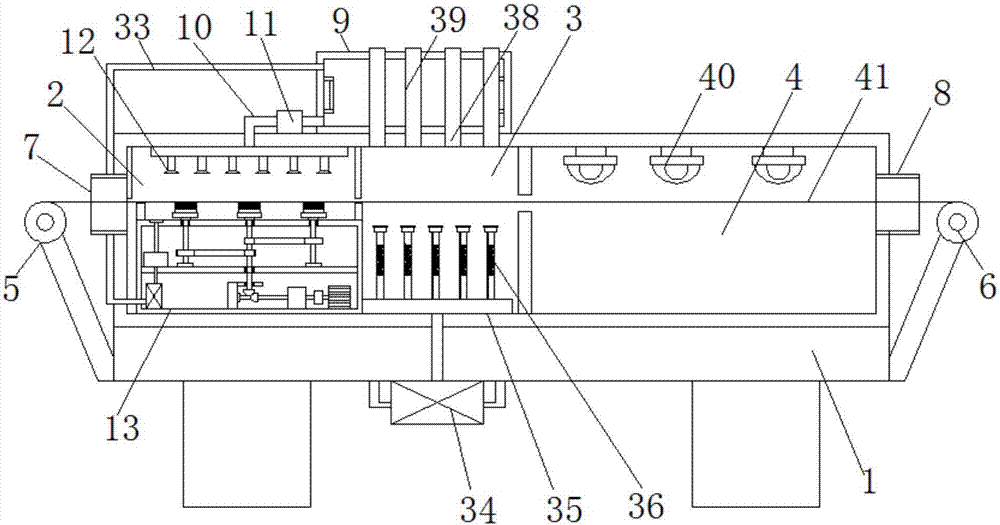

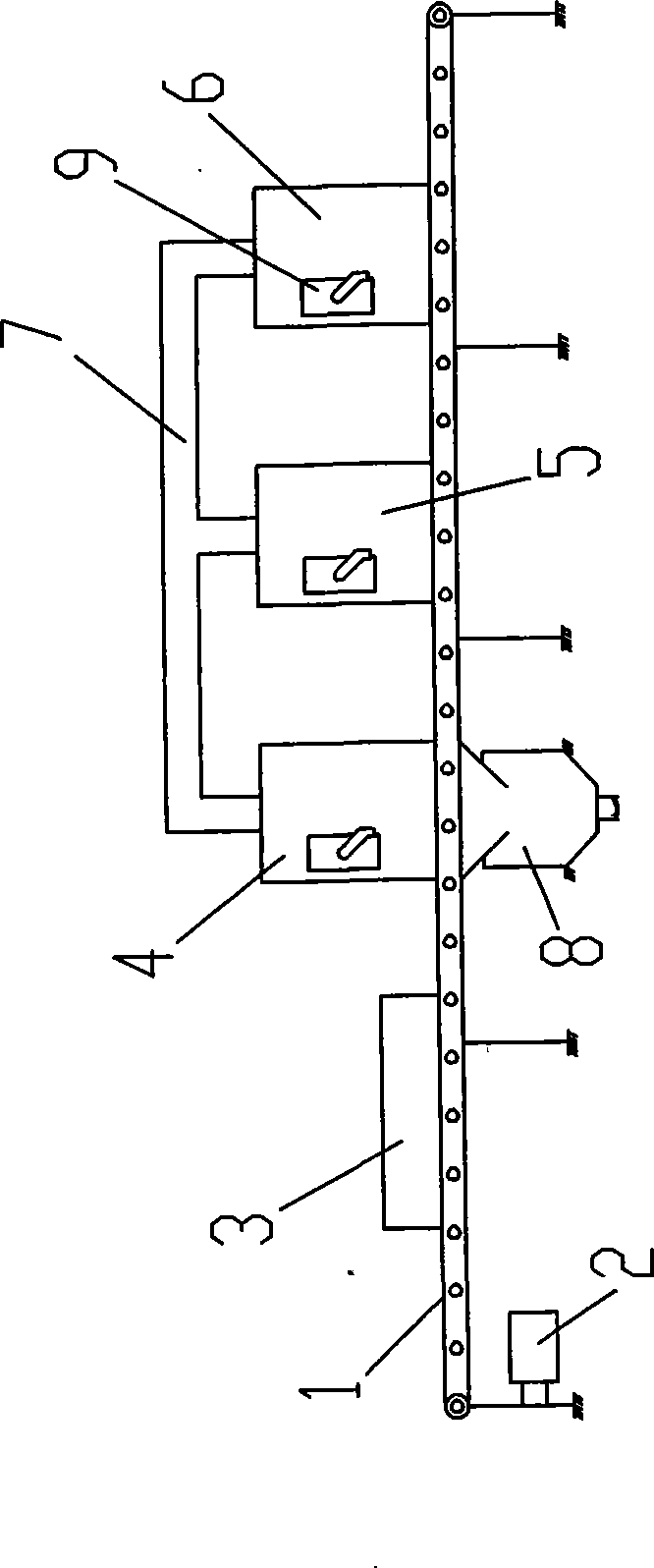

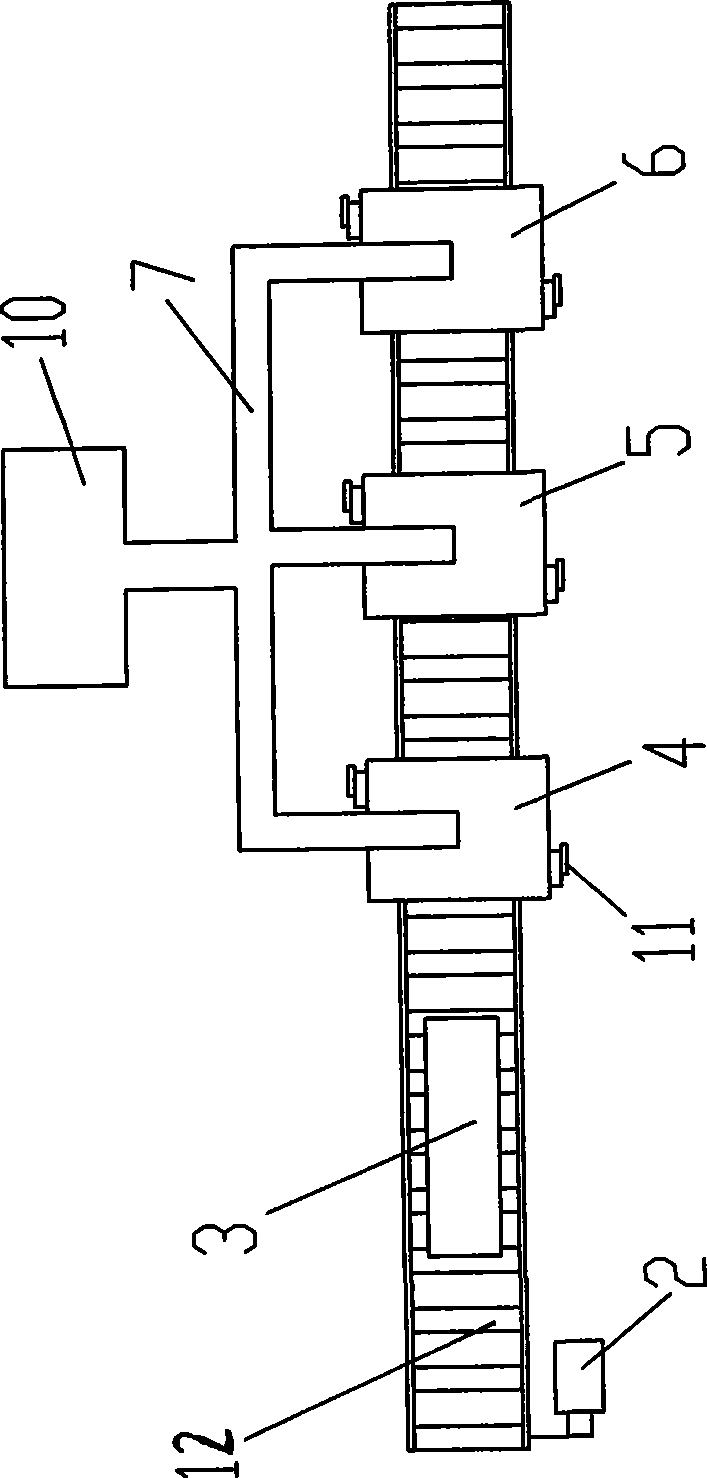

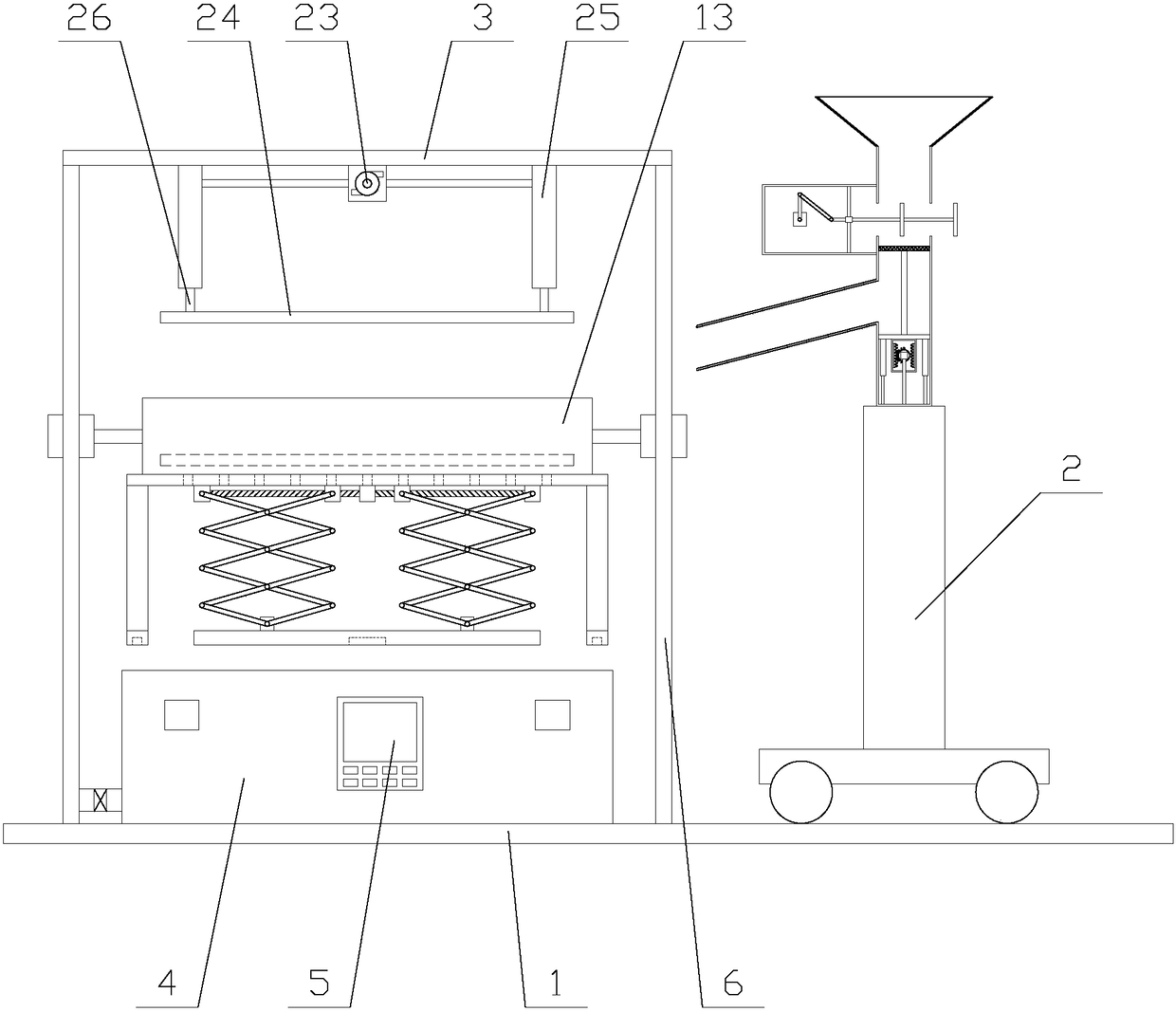

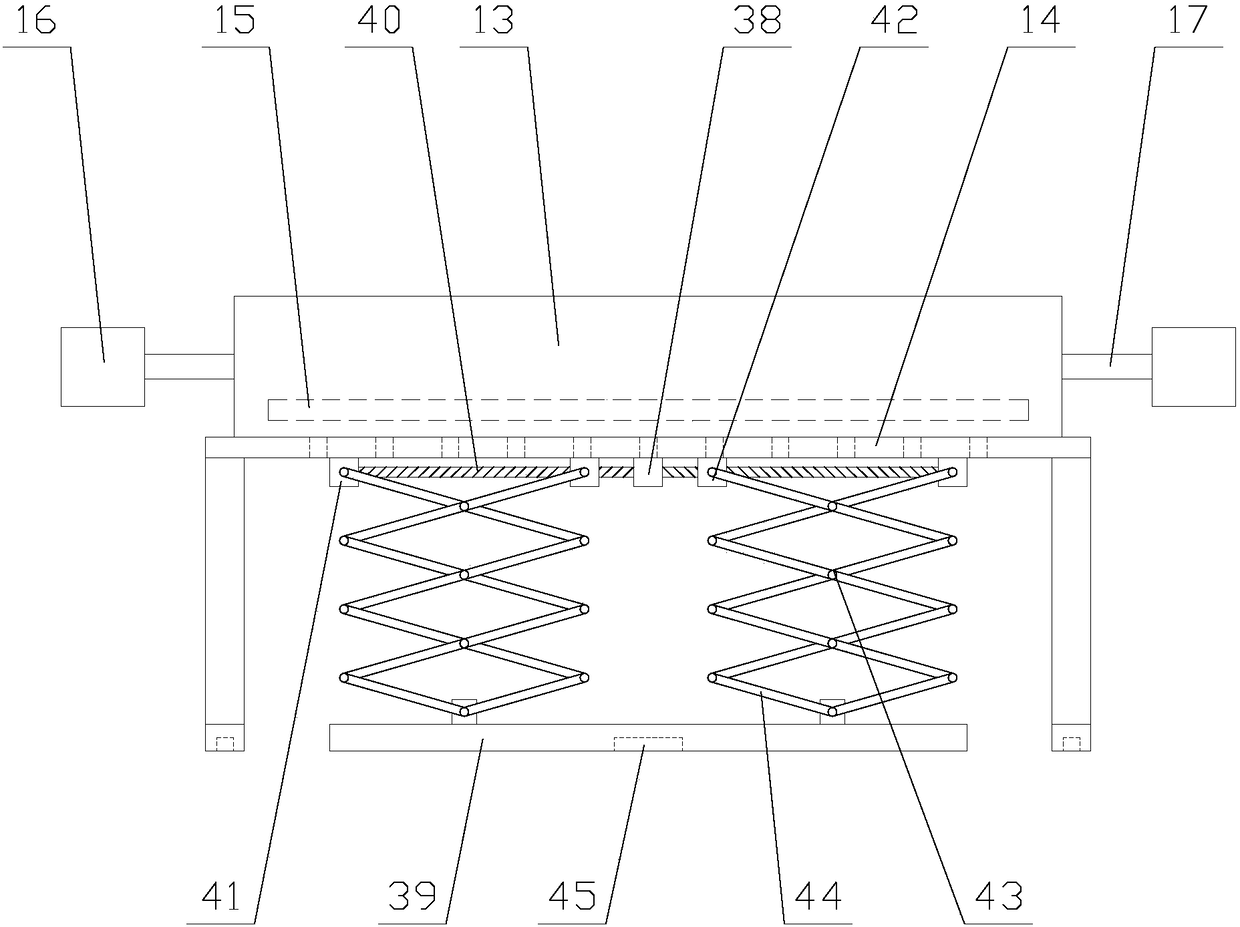

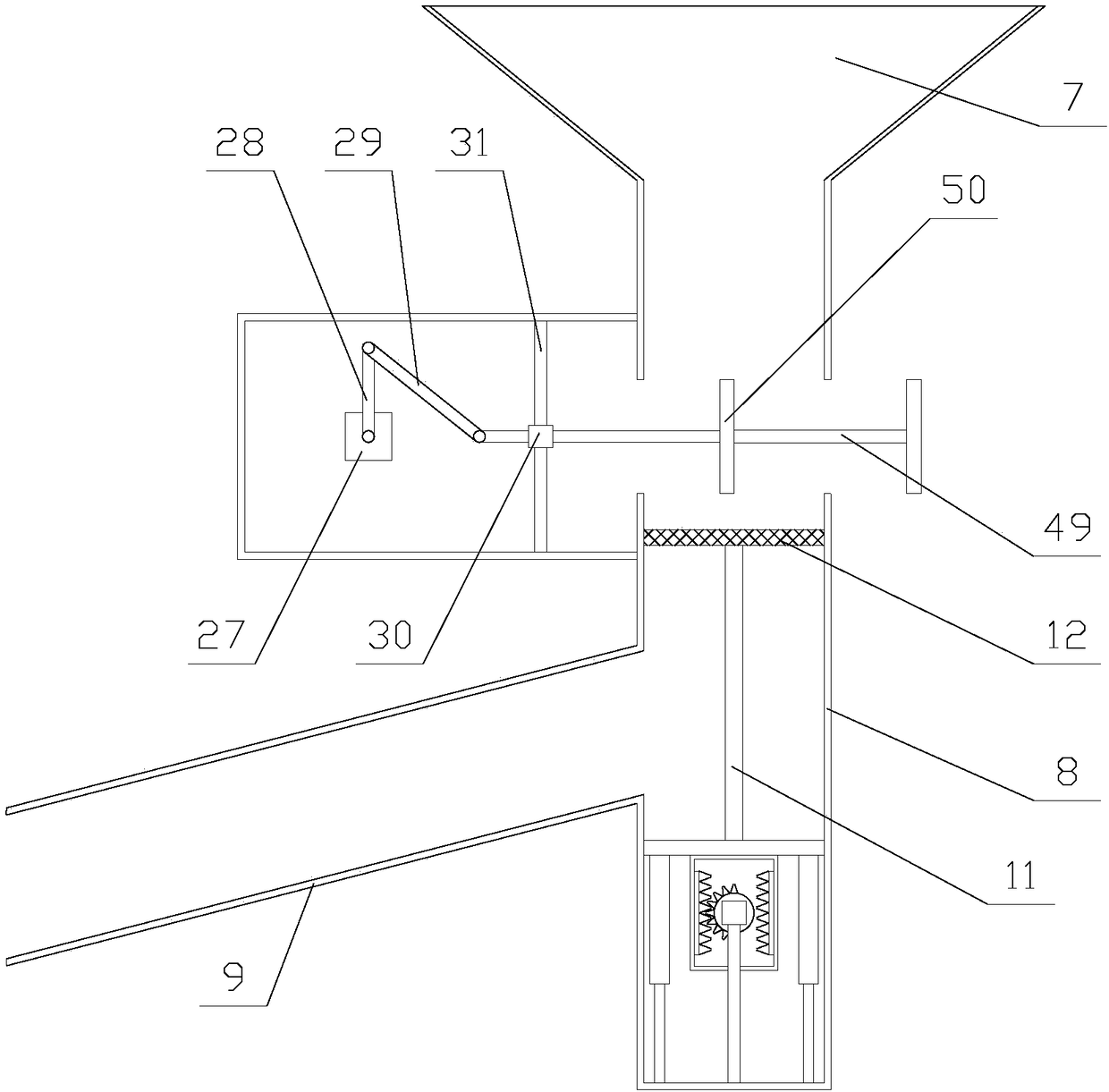

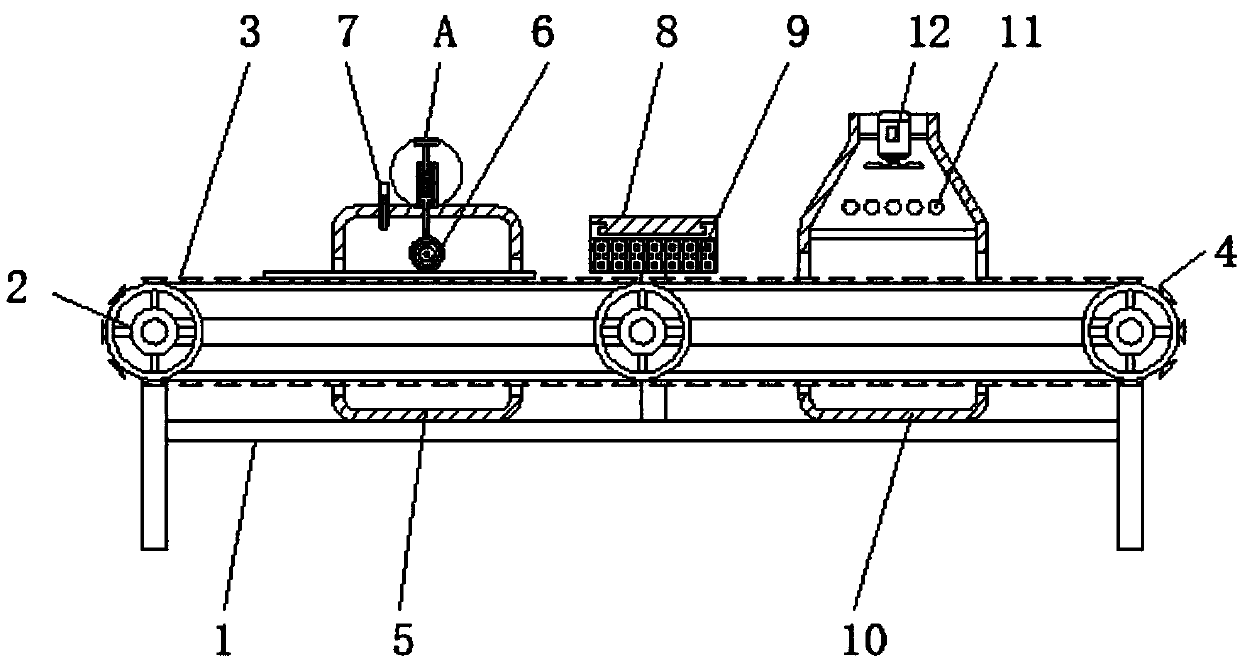

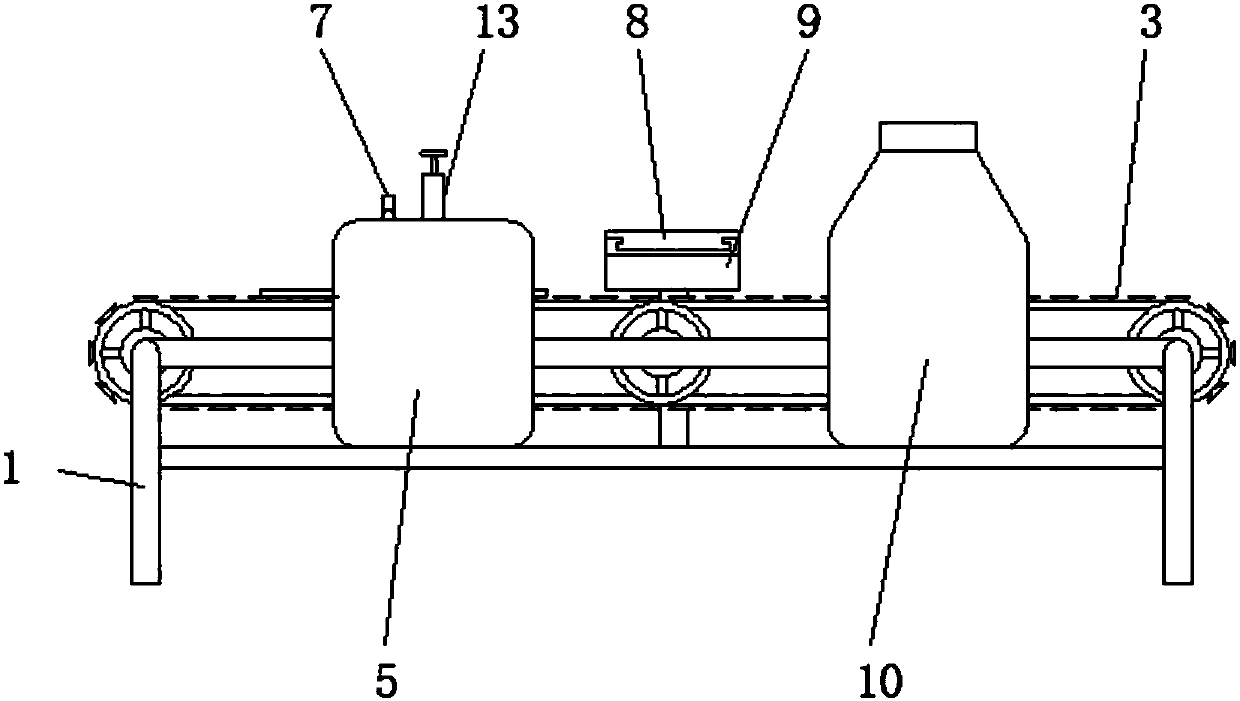

Cleaning machine for rack parts of automobile steering devices

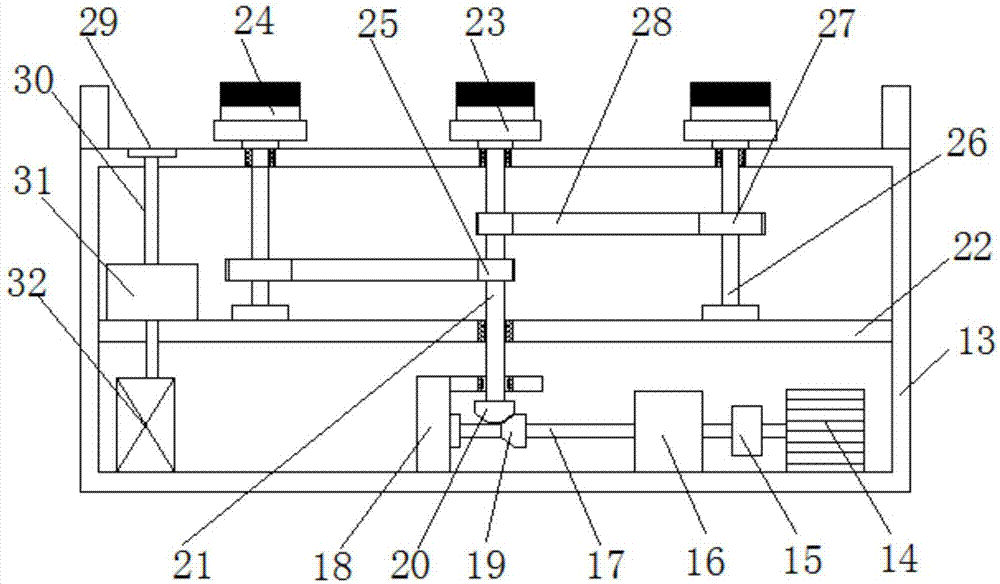

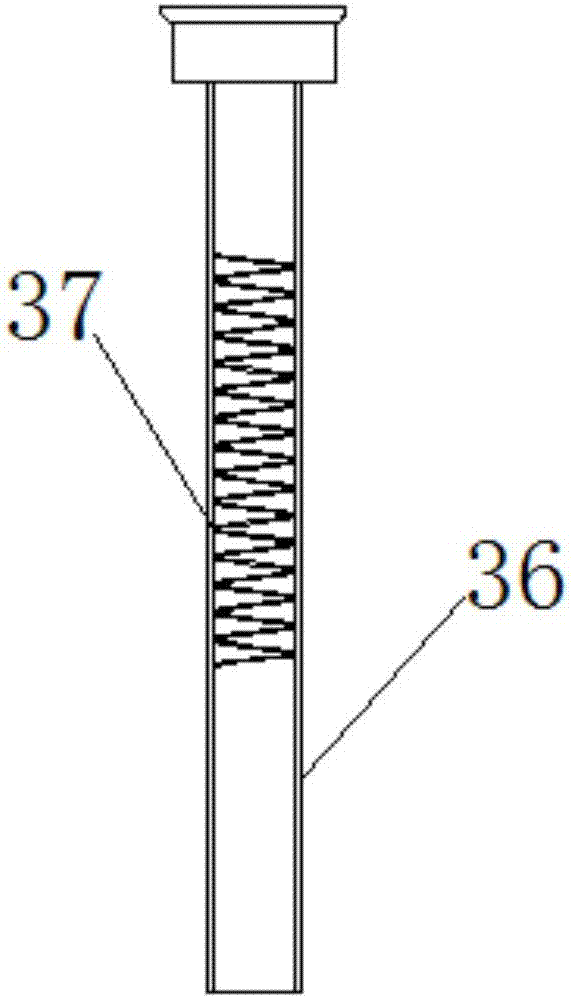

ActiveCN105436111AImprove processing timeImprove labor efficiencyDrying gas arrangementsCleaning using toolsMegasonic cleaningSmall footprint

The invention relates to a cleaning machine for rack parts of automobile steering devices and belongs to the field of cleaning equipment for racks of the automobile steering devices. The cleaning machine is composed of a machine frame, a conveying chain, a spraying and scrubbing tank, an ultrasonic cleaning tank, a high-pressure spraying and cleaning tank, a drying room and an electric appliance control box. The spraying and scrubbing tank is arranged below one end of the conveying chain in a cleaning room. The ultrasonic cleaning tank is arranged at the portion, on one side of the spraying and scrubbing tank, of the machine frame. An ultrasonic vibration plate is arranged on the portion, corresponding to the conveying chain, of the ultrasonic cleaning tank and connected with an ultrasonic generator. The cleaning machine is small in occupied area and convenient to operate. Working efficiency is improved and is high, the cleanliness and cleanliness quality of rack workpieces are guaranteed, and the problems that a manual one-by-one scrubbing manner is adopted for existing steering device rack products, so that working efficiency is low, it is difficult to keep the same cleanliness quality, the labor intensity of workers is larger, and the industrial production requirements cannot be met are avoided. The cleaning machine is especially suitable for cleaning and use of rack products of the steering devices.

Owner:荆州恒隆汽车零部件制造有限公司

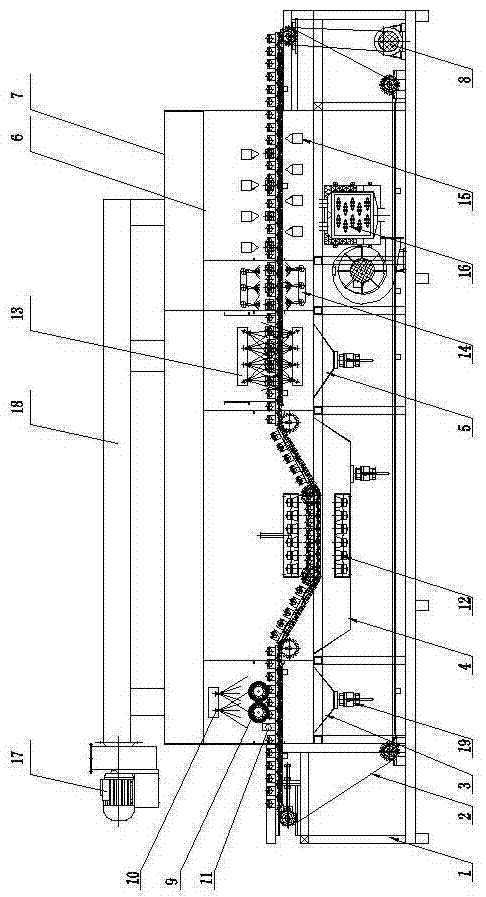

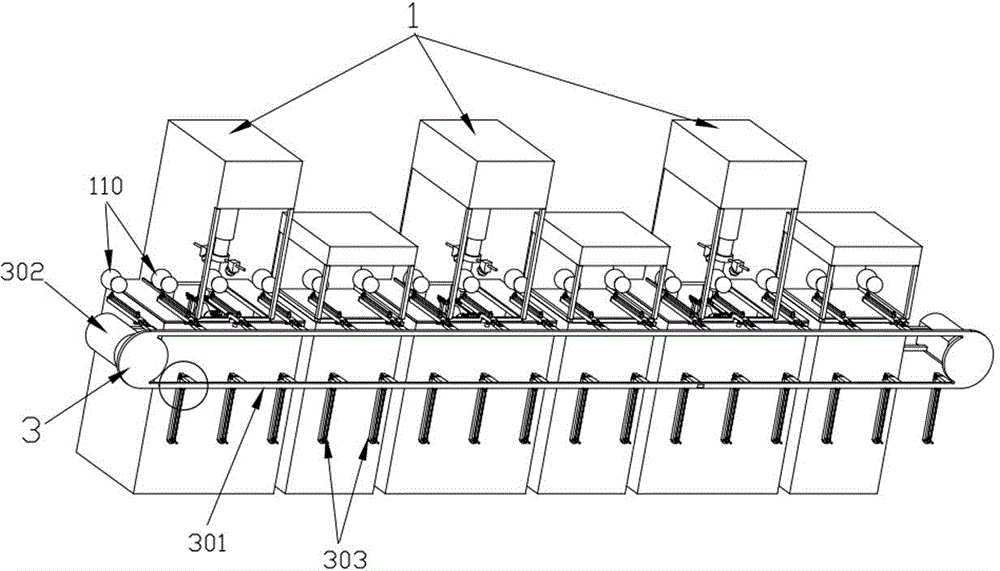

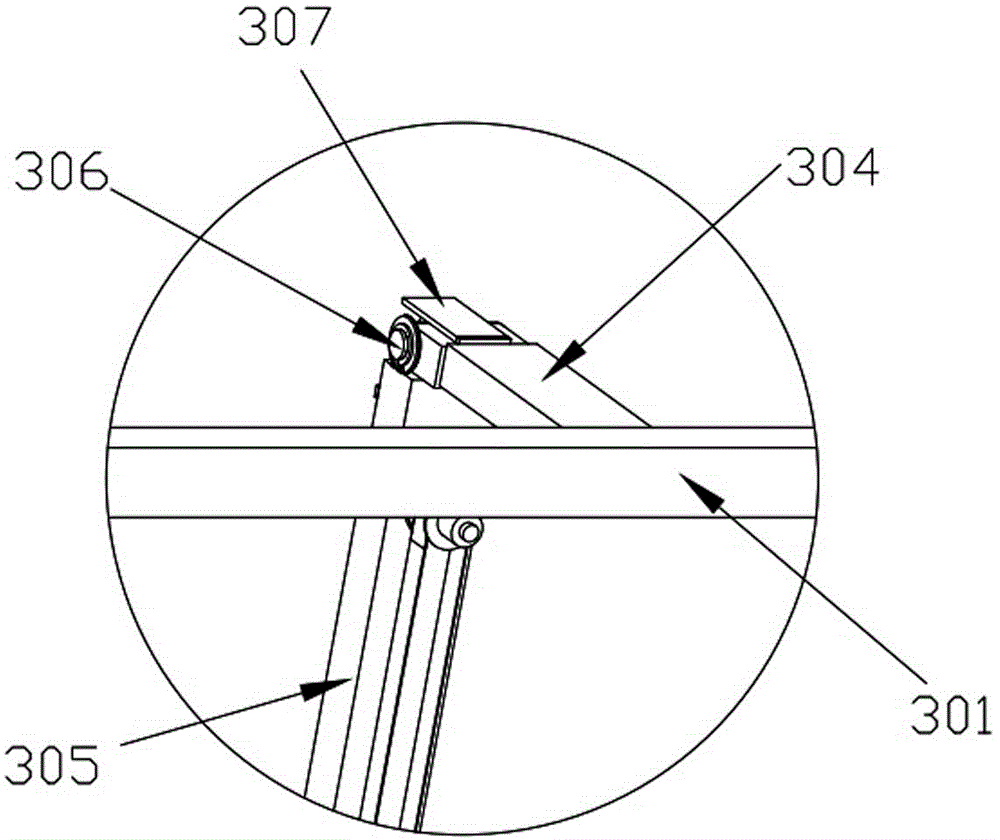

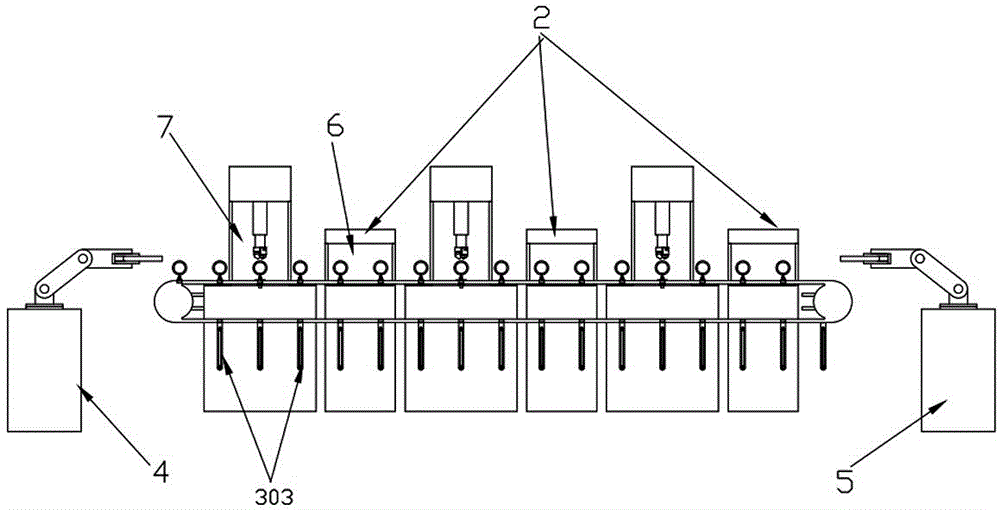

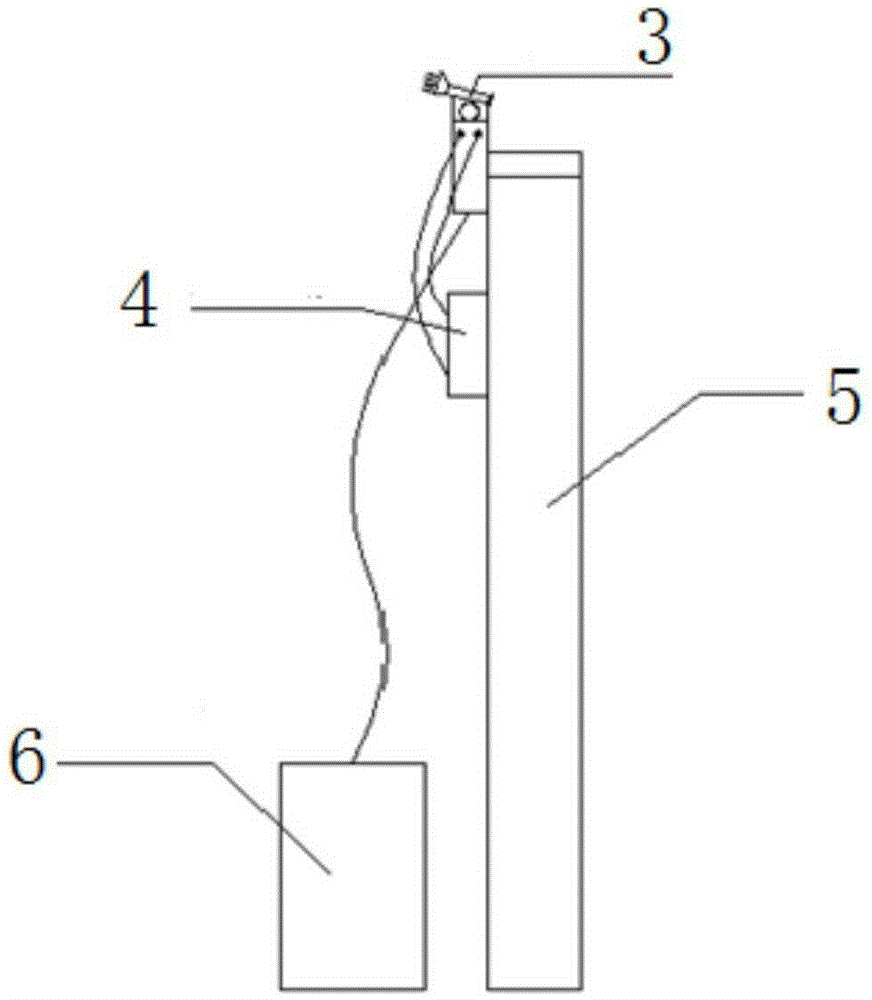

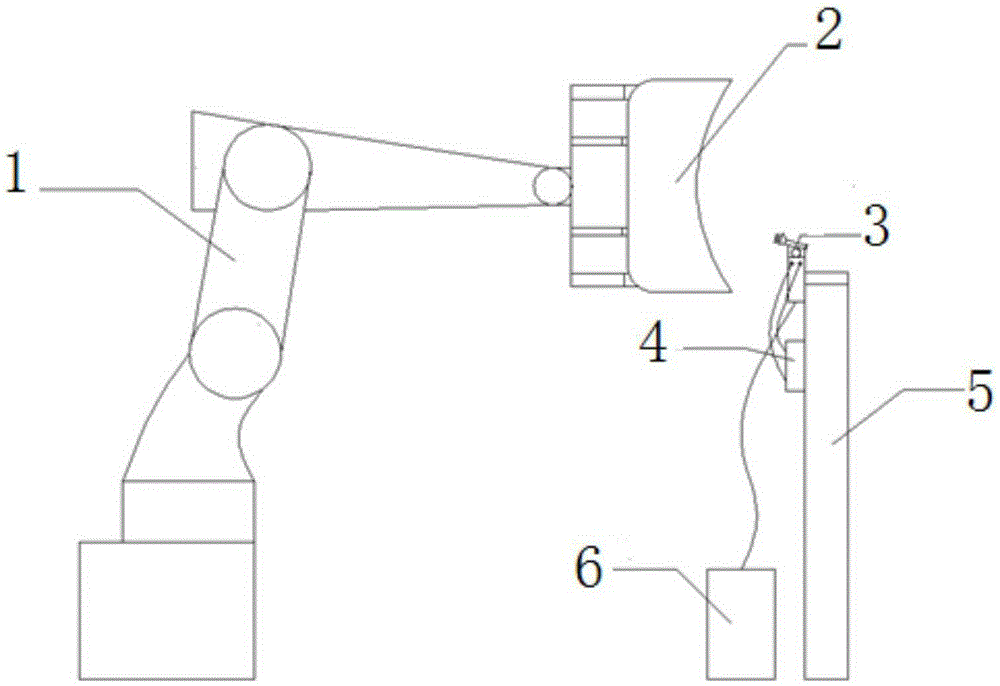

Full-automatic paint spraying assembly line

InactiveCN104056749AHigh degree of intelligenceReduce labor costsLiquid surface applicatorsCoatingsEngineeringAssembly line

The invention discloses a full-automatic paint spraying assembly line of the technical field of automatic machinery. The full-automatic paint spraying assembly line comprises automatic sprayers, automatic dryers, an automatic assembly line, a feeding mechanical hand, an unloading mechanical hand and a touch screen control platform, wherein more than two automatic sprayers are arranged, and a die cleaning mechanism, a spray operating room and a spray mechanism capable of moving triaxially are respectively mounted at the bottom, at the middle and at the top of each automatic sprayer; a die cleaning room used for storing die cleaning water is arranged at the bottom of each die cleaning mechanism; each die cleaning mechanism is composed of two die assembly components which have the same structure and are respectively arranged at the top and at the bottom of each die cleaning mechanism, more than two telescopic air cylinders used for connecting the two die assembly components, and an overturn component used for overturning the two die assembly components, so as to switch positions of the two die assembly components. The assembly line type paint spraying is highly efficient in that various paint spraying procedures can be implemented simultaneously along with synchronous paint drying, the paint with various colors can be sprayed at the same time, and various areas can be simultaneously coated, so that space and cost can be saved, the efficiency is improved, and time consumed for cleaning dies is shortened.

Owner:东莞市贾氏机械制造有限公司

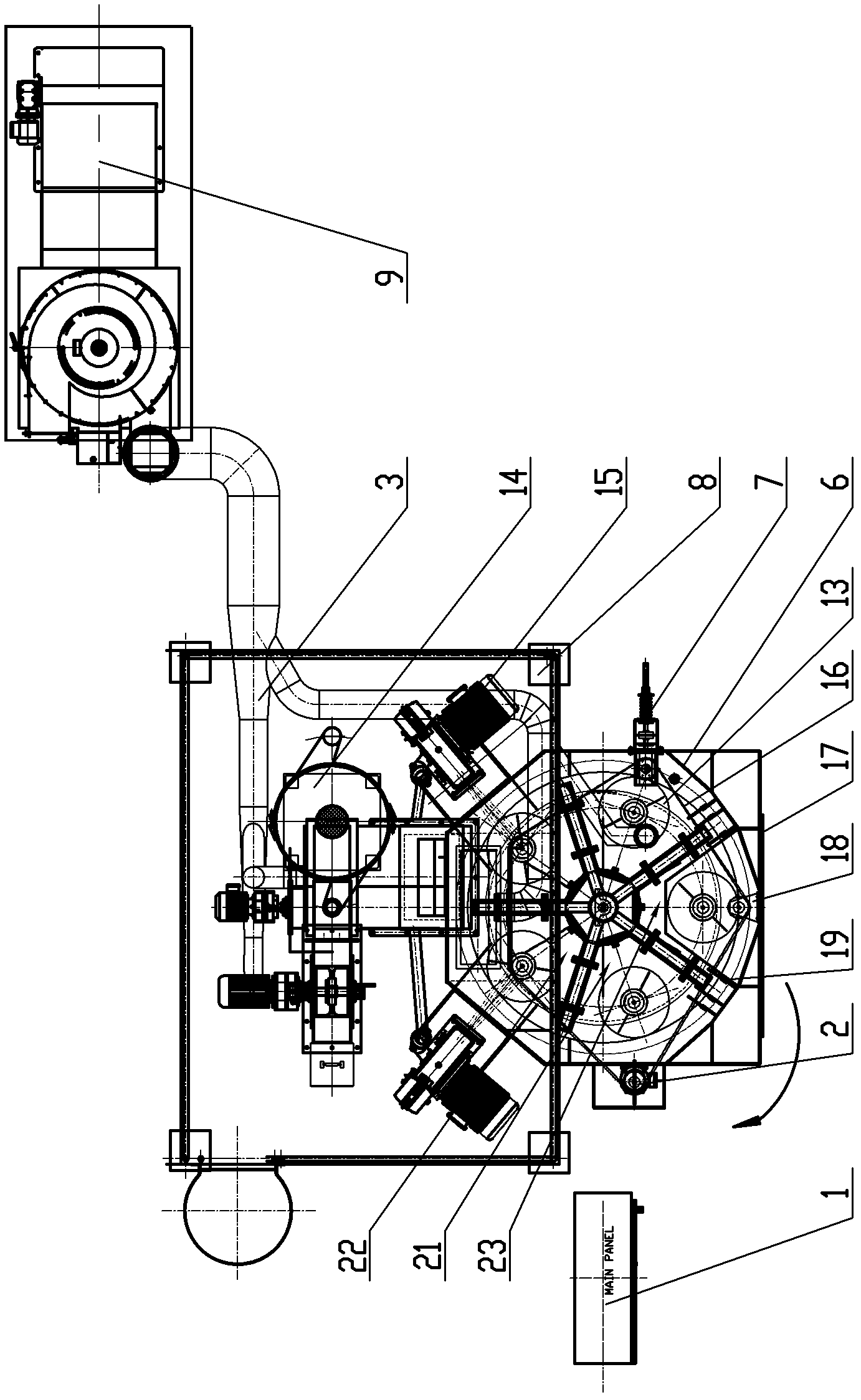

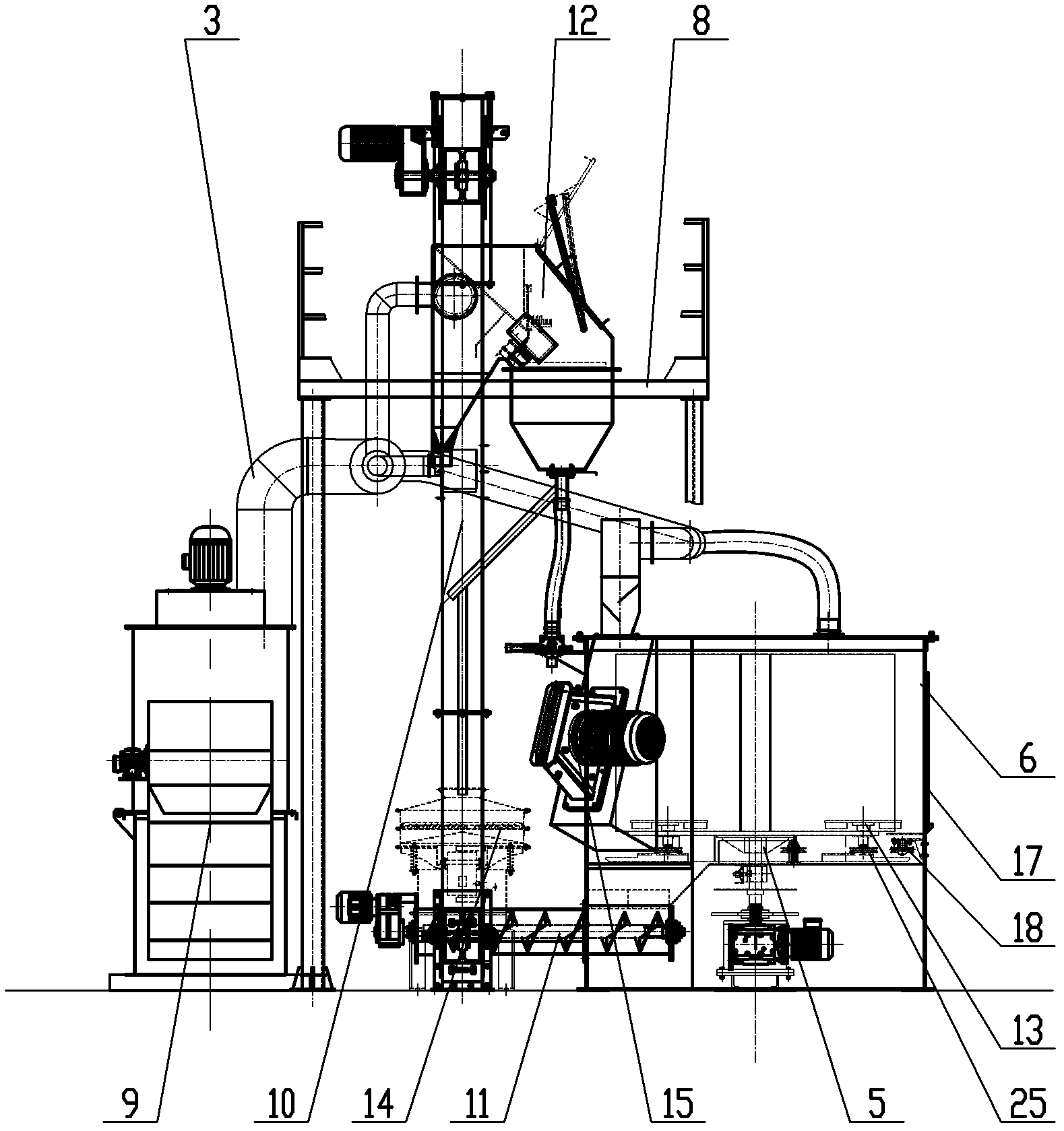

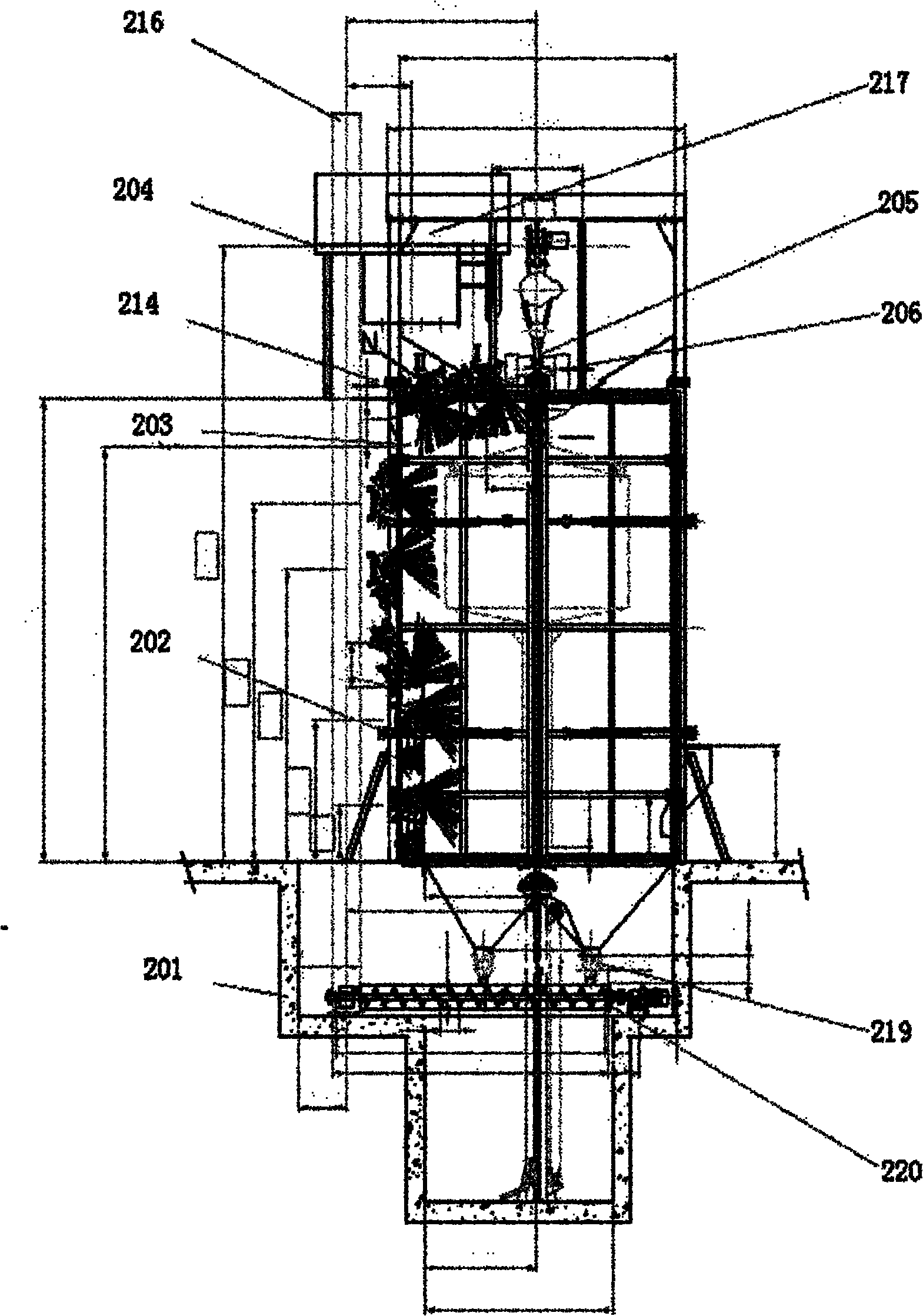

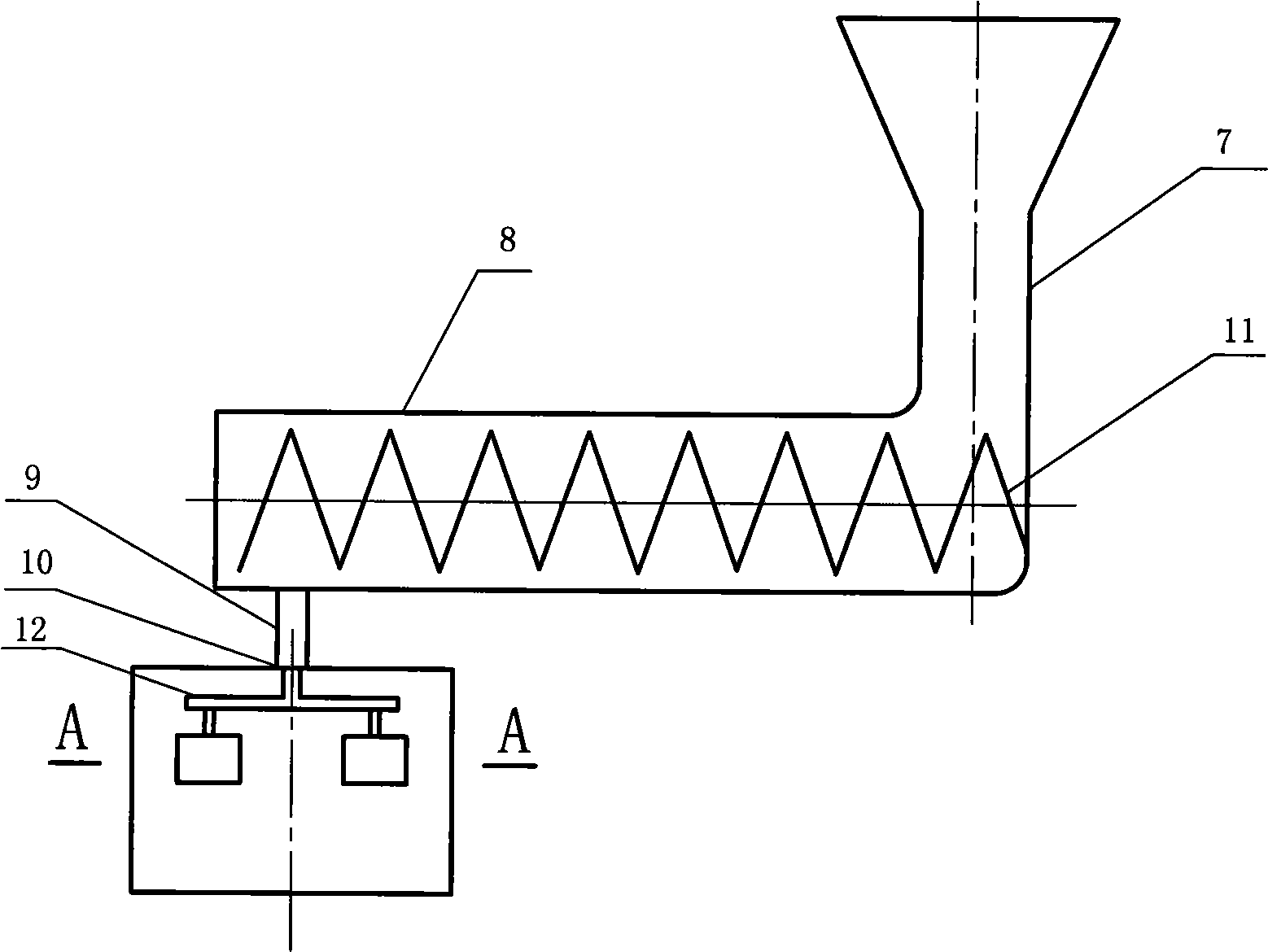

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

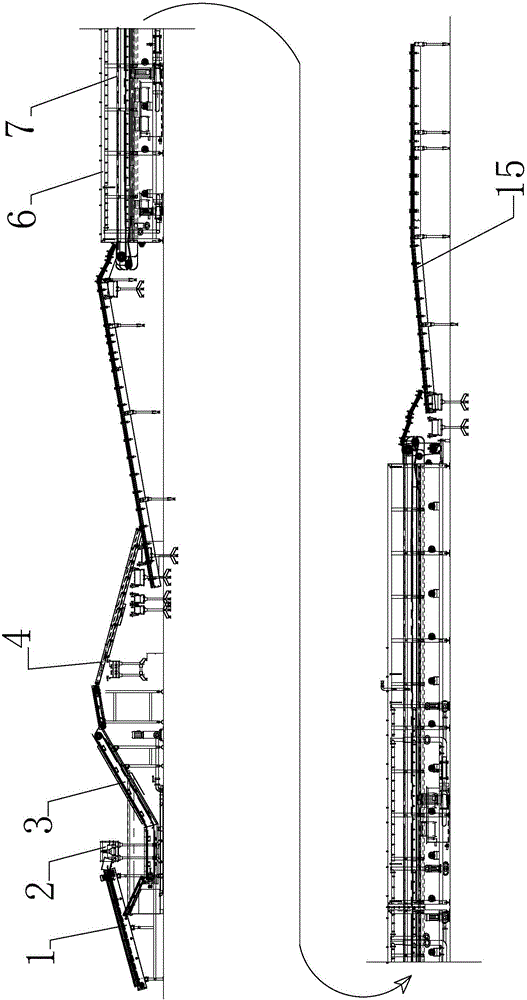

Tableware cleaning line

PendingCN106725183APrevent overturningAvoid wastingTableware washing/rinsing machine detailsCleaning equipmentSlagEngineering

The invention discloses a tableware cleaning line which comprises a top box elevator, an automatic turnover machine, a coarse washing machine, a box body conveyor, a tableware sorting device, tableware conveyor belts, a can turnover device, a cleaning tunnel, a packaging and conveying belt and a tableware assembly device, wherein the discharge end of the top box elevator is close to the feeding end of the automatic turnover machine; an inclined slag remover and a coarse washing machine elevator are arranged in a pond of the coarse washing machine separately; the discharge end of the coarse washing machine elevator is connected with the feeding end of an anti-patterning machine; the out-box end of the automatic turnover machine is provided with the box body conveyor which passes through a box body cleaning room of the cleaning tunnel; the discharge end of the anti-patterning machine is connected with the feeding end of the tableware sorting device; each tableware outlet of the tableware sorting device is correspondingly provided with one tableware conveyor belt separately; and spoons and chopsticks are directly conveyed through the tableware conveyor belts and enter the feeding end of a spoon and chopstick conveyor mesh belt. According to the tableware cleaning line, classifying and cleaning of the tableware are achieved, cleaning is more thorough, and the cleaning efficiency of a table set is greatly improved.

Owner:SHANDONG DINGTAISHENG FOOD IND EQUIP

Automatic cleaning type multifunctional dining-table

InactiveCN101112271AReduce labor intensityImprove satisfactionServing tablesKitchen tablesEngineeringRefrigerated temperature

The invention relates to a self-cleaning multifunctional table which is suitable for families or commerce, characterized in that the invention comprises a table support bracket and a movable table face, wherein the movable table face is supported on a group of driving roller, the driving roller is connected with a propulsion plant, a collection box is arranged at one end of the table support bracket, a cleaning pool is arranged under the movable table face, a cleaning equipment is arranged in the cleaning pool, the movable table face passes through the cleaning pool and the cleaning equipment, a water supply system is arranged at one side of the cleaning pool, and an electric appliance control device is arranged on the table support bracket. The device such as the lift bracket, the freezing refrigerator, the disinfection cupboard and so on can be added on the self-cleaning multifunctional table of the invention. As the function of automatically cleaning and wiping the table is added on the table, people do not spend time and labor on cleaning and wiping the table, thus largely reducing the labor strength, saving the service time and improving the satisfaction of the users.

Owner:王志洪

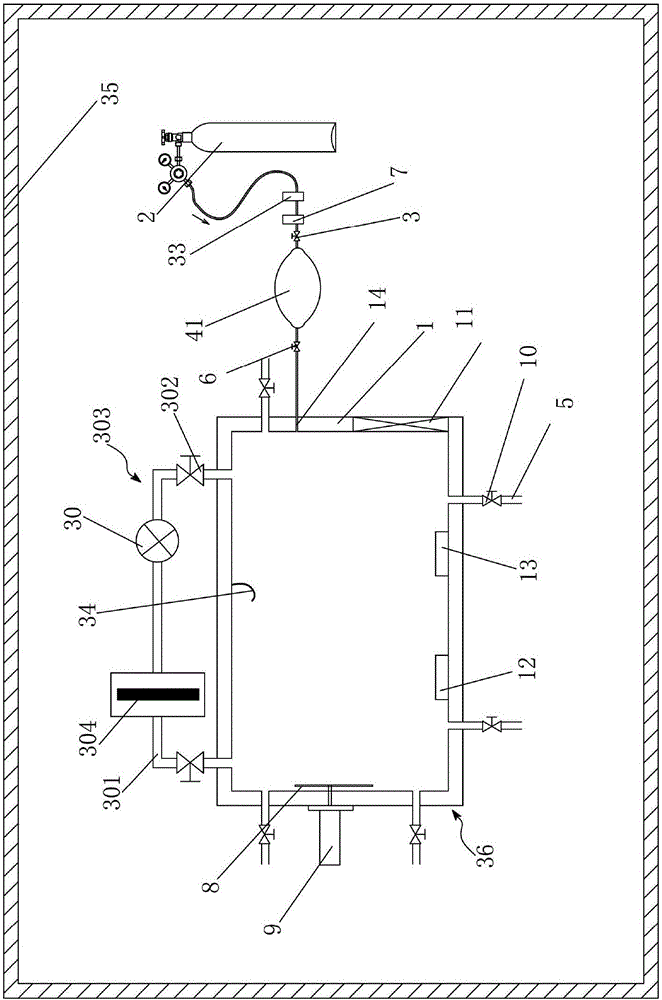

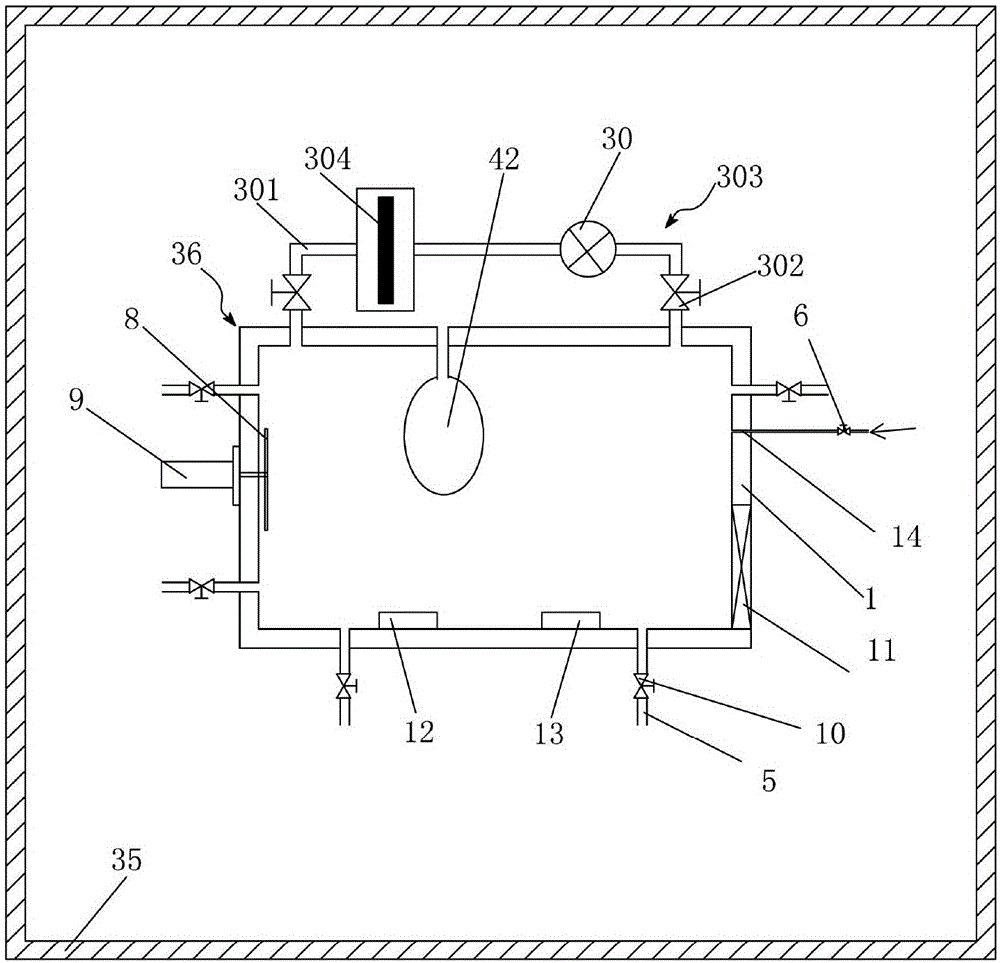

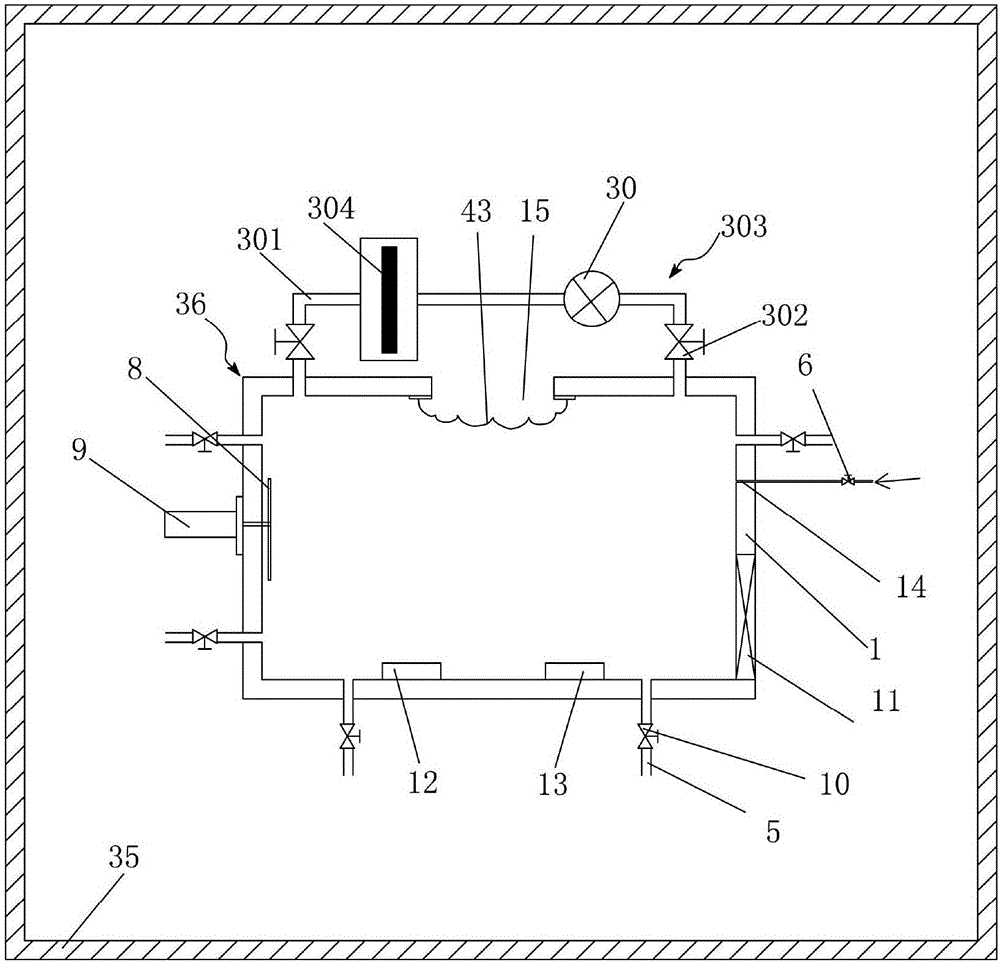

Method and device for controllable foam cleaning for washing, disinfection and sterilization

ActiveCN103191880AImprove efficiencyControl penetrationWashing processesOther washing machinesMode of actionInternal pressure

The invention relates to a method and a device for controllable foam cleaning for washing, disinfection and sterilization. A heating component is used for heating a working solution to generate foams, and a lot of foams are directly formed in a cleaning room or introduced to the cleaning room from the outside; through the effective control of foam cleaning, the dirt, harmful substances and microorganisms which are attached to cleaning objects in the cleaning room are in sufficient contact with effective ingredients on the foam surface in the cleaning room, separated, destroyed or killed by various modes of action, separated from the surface of a cleaned object together with foams along with the decrease of internal pressure and temperature of the cleaning room, and then discharged out from the cleaning room. Compared with the traditional product, the cleaning device designed according to the technology is higher in efficiency, shorter in washing time, lower in energy consumption, less in water consumption and lower in noise and product cost. The method and the device are suitable for cleaning, disinfection or sterilization of various cleaning objects such as tableware, medical appliances, clothes, industrial parts, antiques and antiquities, pets, animals and human skin.

Owner:河北合盛科技有限公司

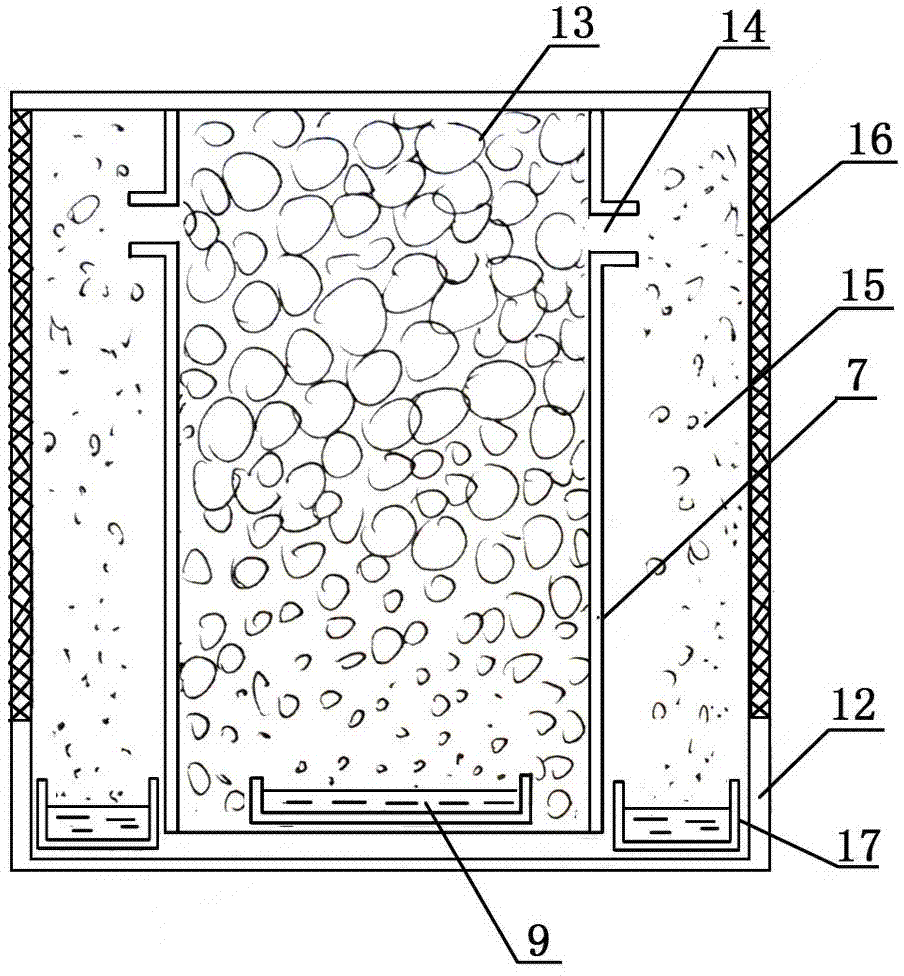

Water bamboo cleaning and peeling integrated equipment and processing method thereof

ActiveCN107259604AImprove removal efficiencyFast peelingClimate change adaptationVegetable peelingSludgeSewage

The invention discloses water bamboo cleaning and peeling integrated equipment and a processing method thereof. The water bamboo cleaning and peeling integrated equipment comprises a first cleaning room, a peeling room, a second cleaning room and a discharging room, wherein a first filter plate is obliquely arranged in the first cleaning room, and a first water collecting basin is arranged below the first filter plate; a first cleaning mechanism is arranged in the first cleaning room; a water bamboo positioning assisting mechanism and a peeling device are arranged in the peeling room; a second filter plate is obliquely arranged in the second cleaning room, and a second water collecting basin is arranged below the second filter plate; a second cleaning mechanism is arranged in the second cleaning room; and a waste water purifying box is arranged on the top surface of the discharging room. The method comprises the steps of cleaning water bamboos for the first time, peeling the cleaned water bamboos, cleaning the peeled water bamboos for the second time, outputting the cleaned water bamboos, loading the output water bamboos into boxes, and cleaning and maintaining the equipment. The processing method disclosed by the invention is simple in steps, the removing speed of sludge on the surfaces of the water bamboos is increased, the surface damage of the water bamboos in the peeling process is reduced, automated cleaning and automated peeling are realized, and the labor intensity of manual operation is reduced.

Owner:南通江涌投资开发有限公司

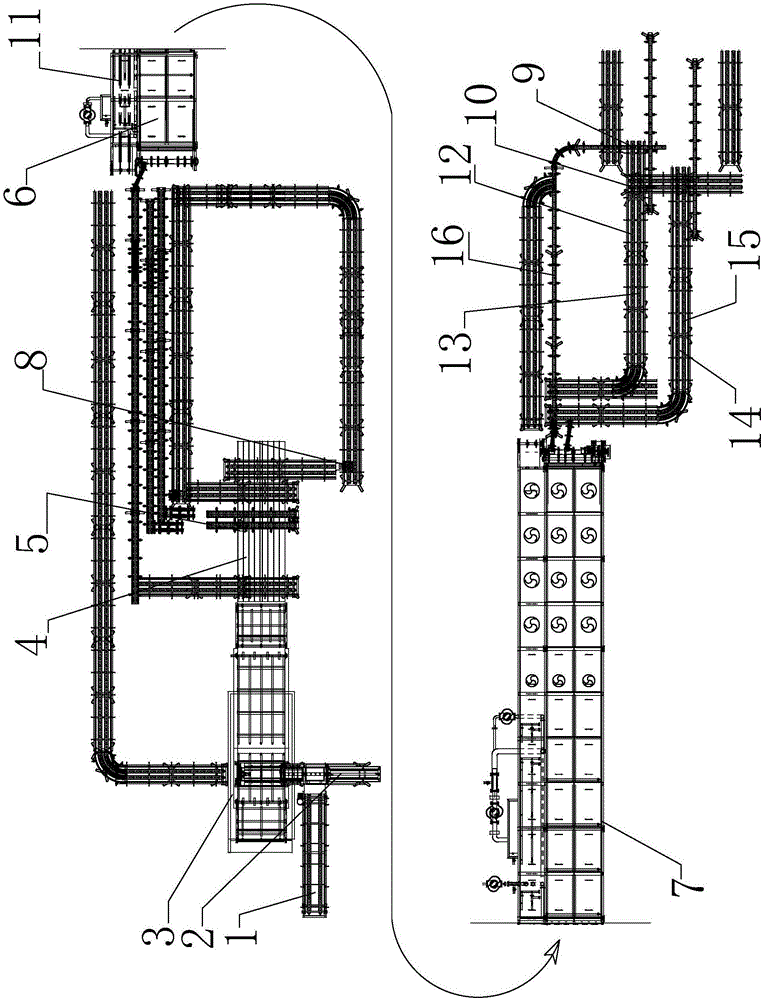

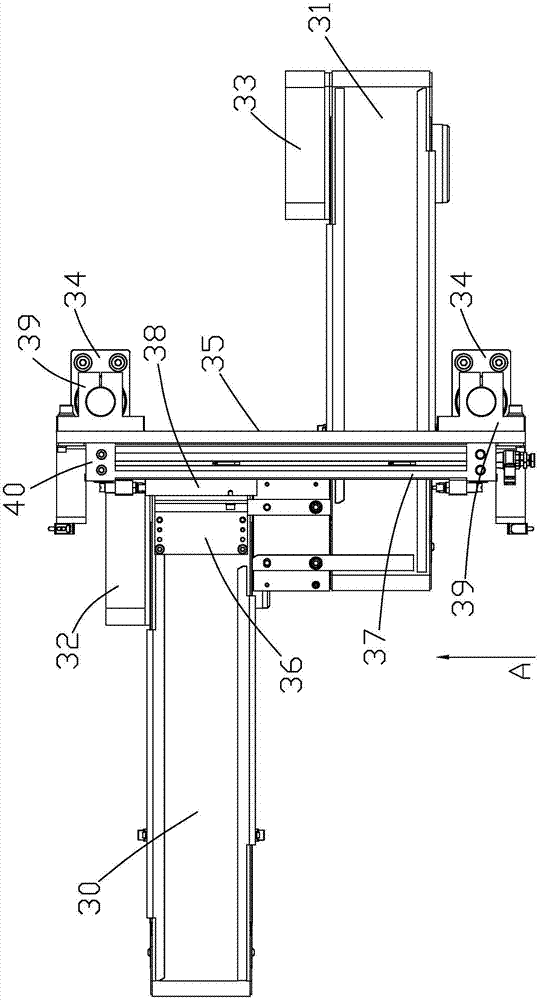

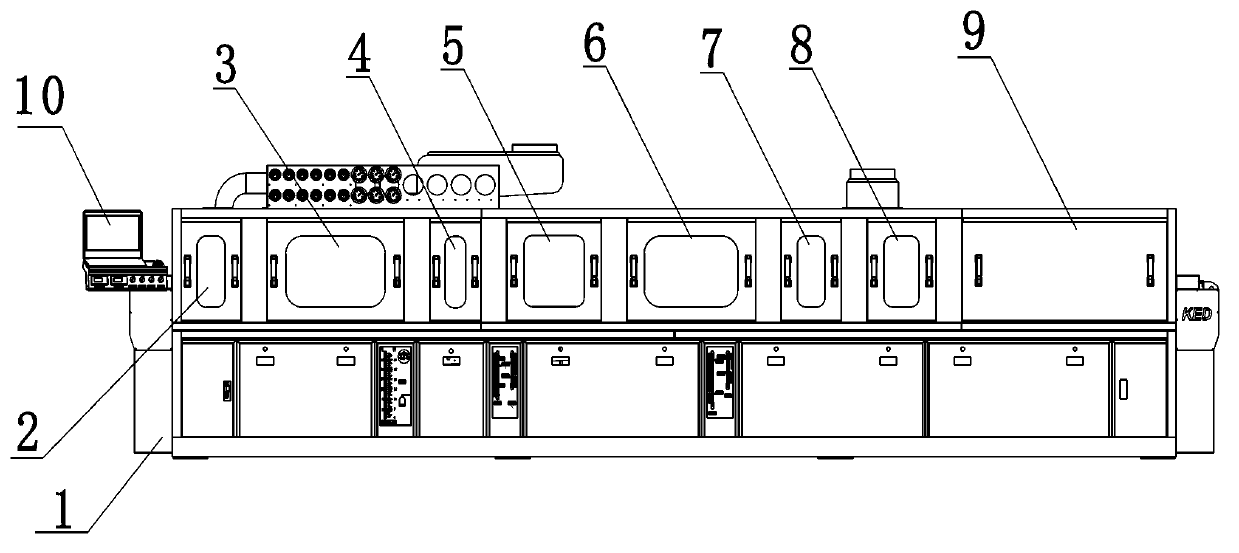

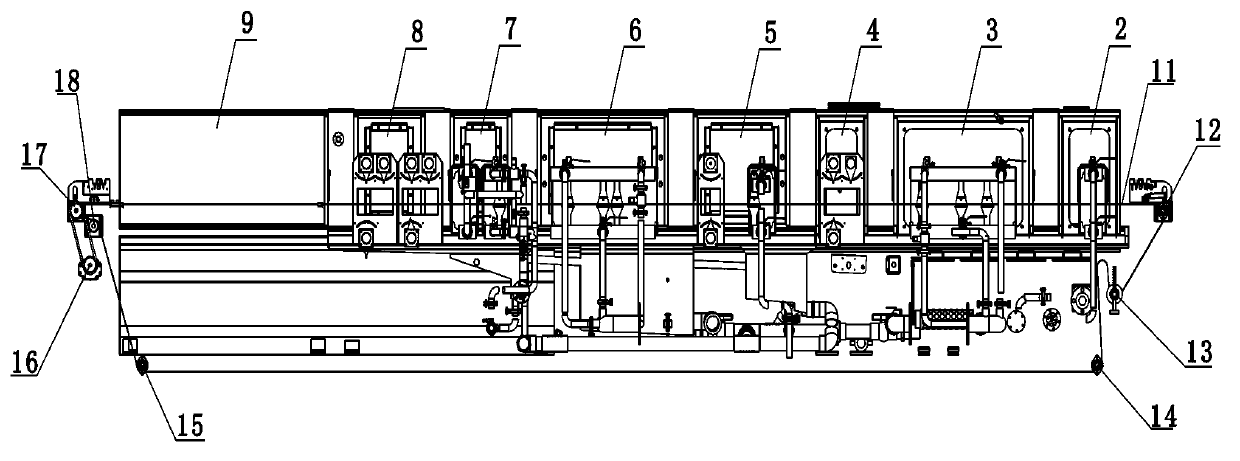

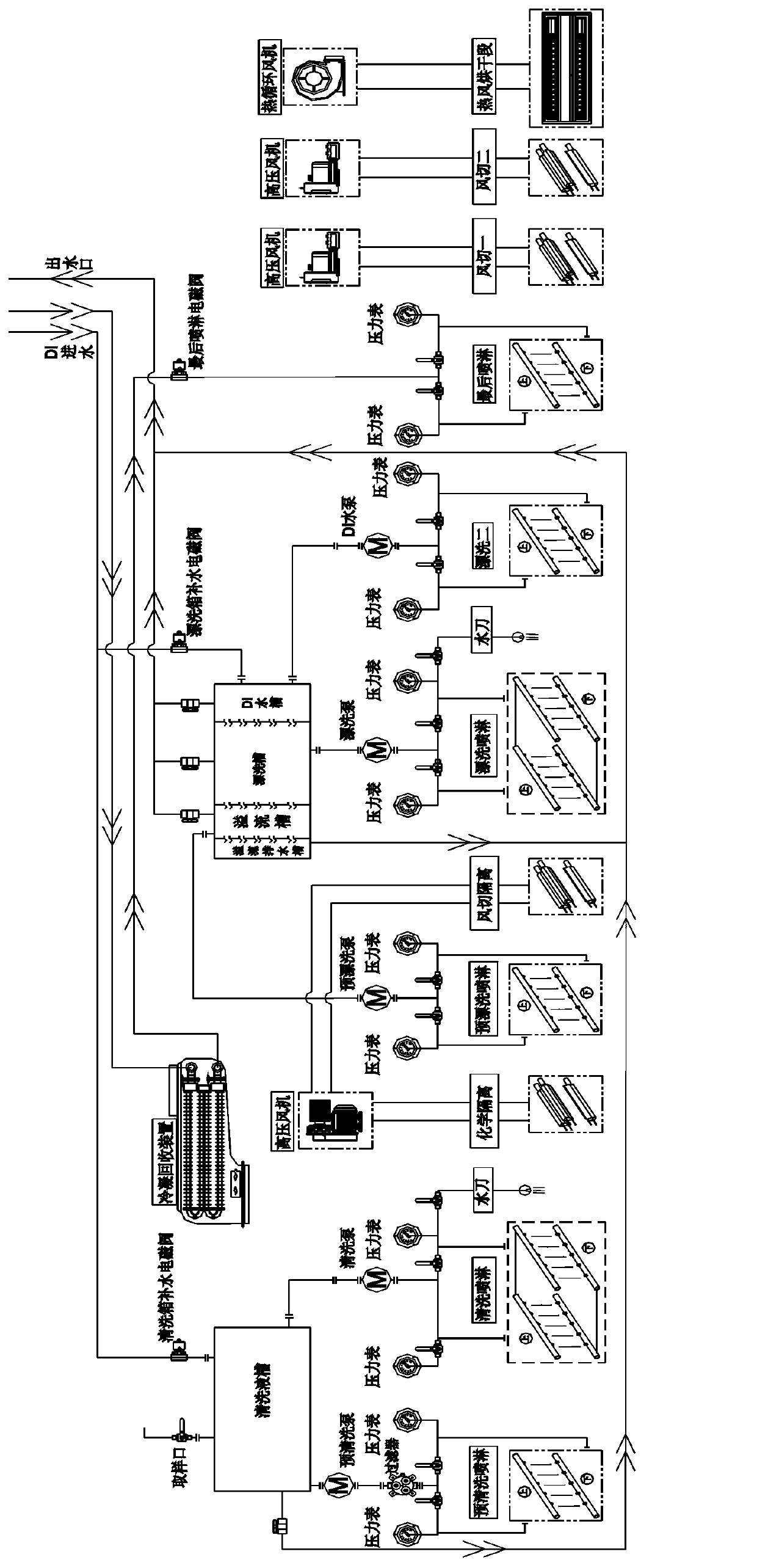

Printed circuit board assembly (PCBA) on-line cleaning machine

InactiveCN102989709ARealize fully automatic online cleaningComprehensive cleaningCleaning using liquidsWater rinsingWind shear

The invention discloses a printed circuit board assembly (PCBA) on-line cleaning machine which comprises a machine body. A mesh belt for transmitting a PCBA board is arranged in the machine body, and a chemical pre-cleaning room, a chemical cleaning chamber, a chemical diaphragm chamber, a digitally integrated (DI) water pre-cleaning chamber, a DI water rinsing chamber, a spraying chamber, a wind shear drying chamber and a hot air drying chamber are arranged above the mesh belt and sequentially arranged along the operation direction of the mesh belt. The PCBA on-line cleaning machine drives the PCBA board through the mesh belt to sequentially perform chemical pre-cleaning, chemical cleaning, chemical isolation, DI water pre-rinsing, DI water rinsing, spraying, wind shear drying, hot air drying and the like from left to right, achieves full-automatic on-line cleaning of the PCBA board, enables the PCBA board to be comprehensively cleaned and rinsed and improves the cleaning and rinsing quality.

Owner:深圳市凯尔迪光电科技有限公司

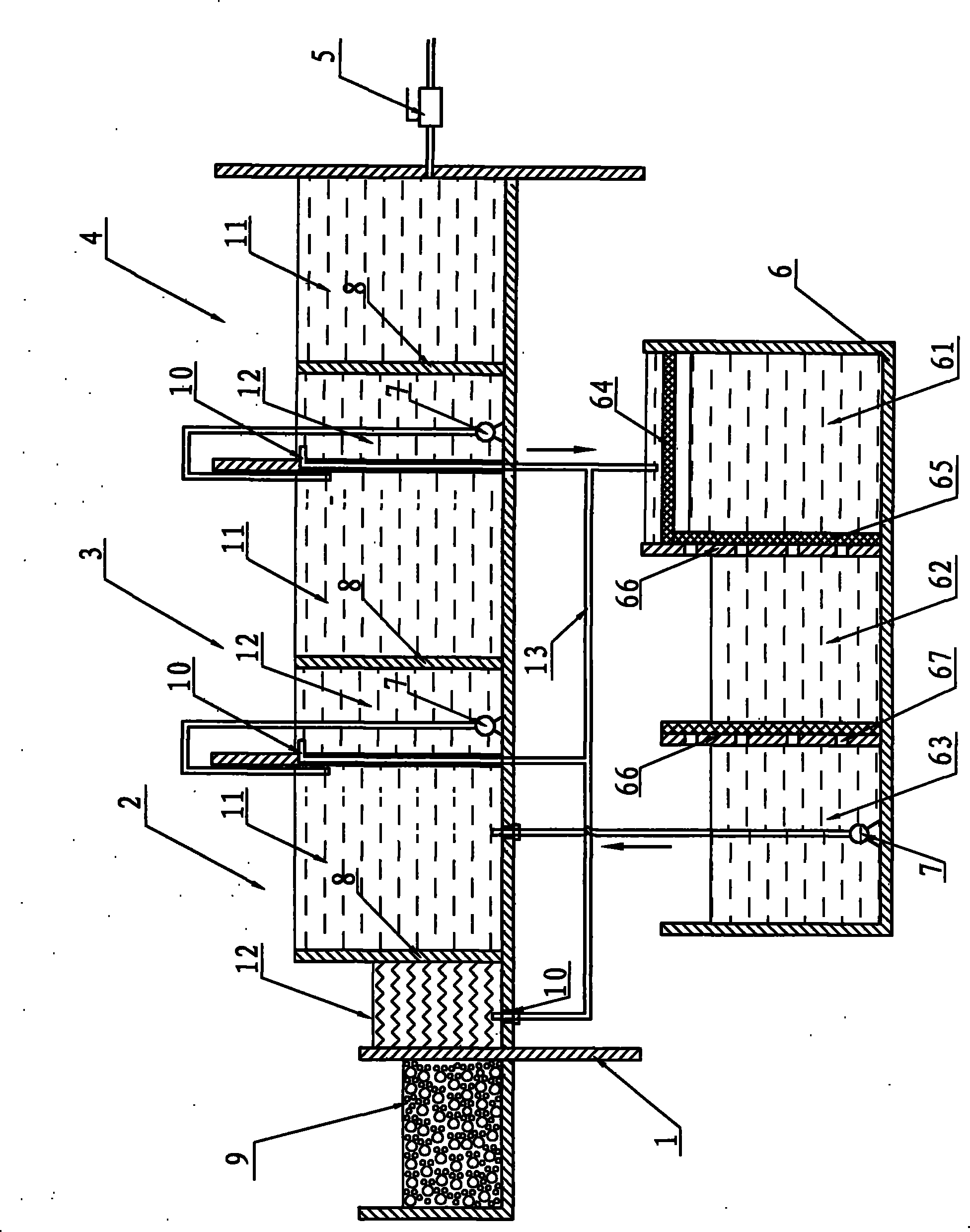

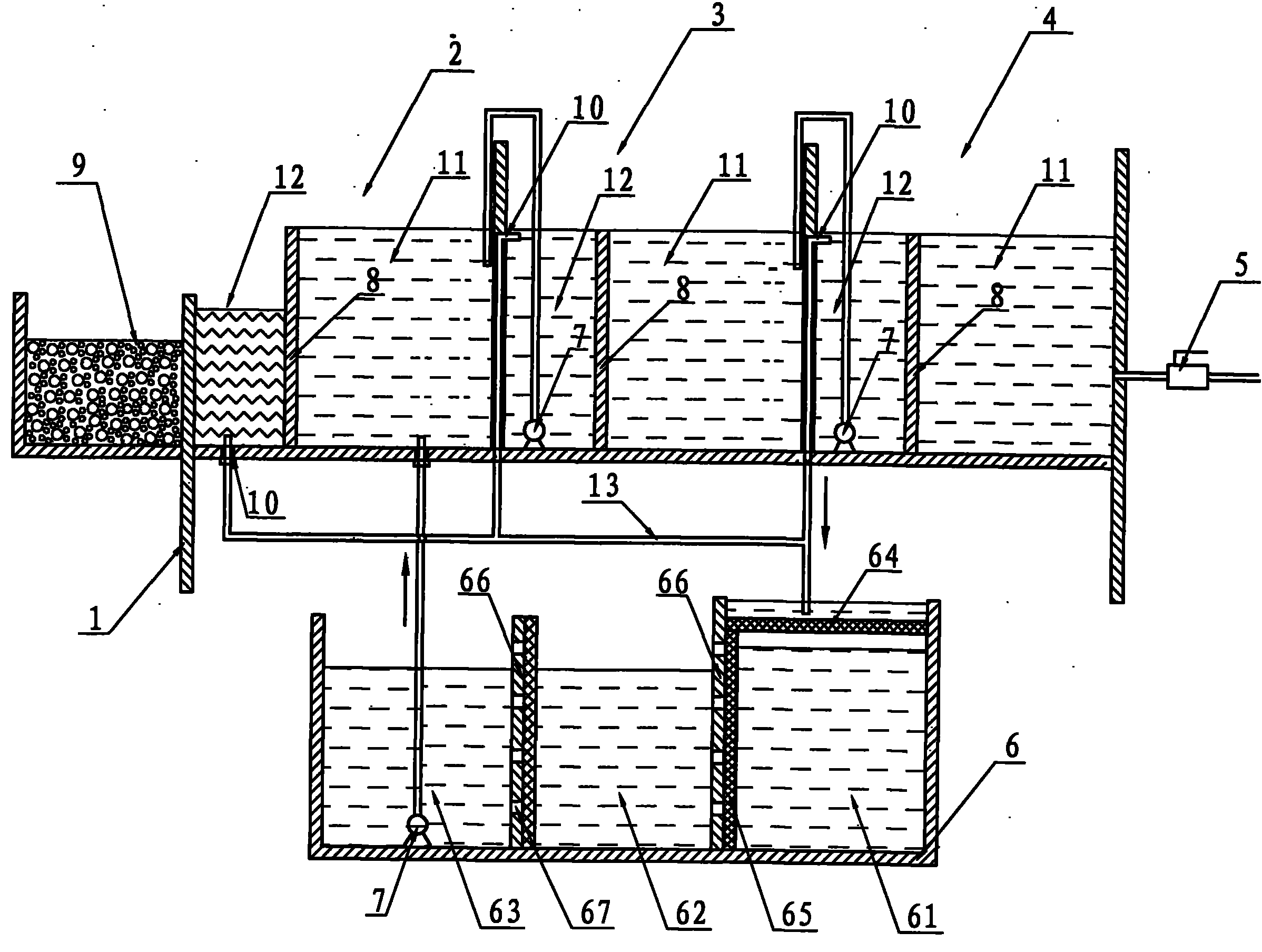

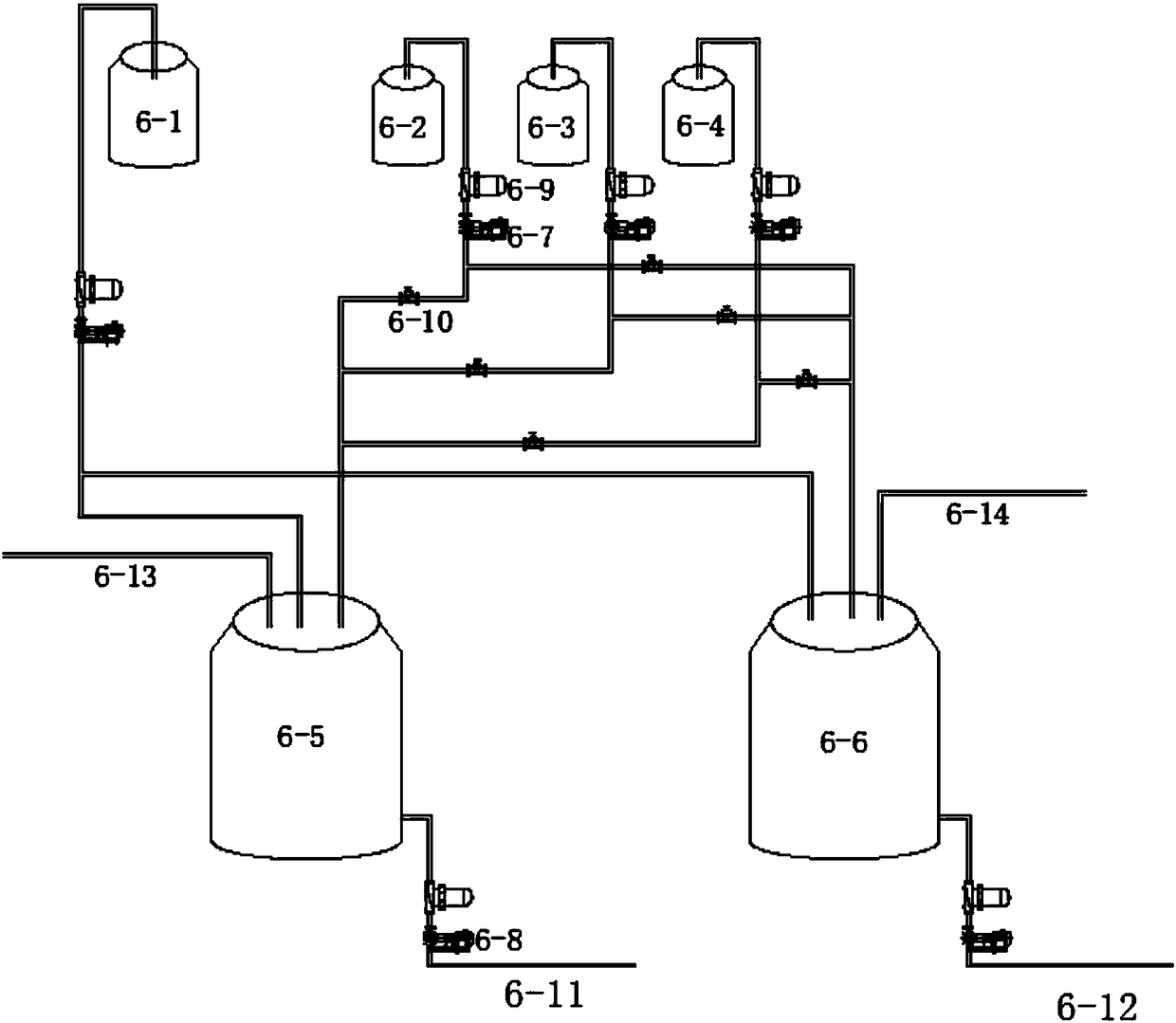

Multilevel circulating cleaning equipment for solar cell silicon wafers

The invention relates to multilevel circulating cleaning equipment for solar cell silicon wafers, which comprises a first rinse tank, a transition rinse tank, a final rinse tank, a water inlet valve, a filter treating pond, a circulating pump, partition embankments and a sewage sump. The partition embankment is arranged in each rinse tank; each rinse tank is divided into a cleaning room and a sewage overflowing room; cleanout fluid overflowed from a rear-way rinse tank is pumped by the circulating pump and is used as cleanout fluid of a front-way rinse tank; sewage overflowed from the outside of the upper surface of each rinse tank flows into the filter treating pond through a flexible pipe for secondary treatment; and the treated cleanout fluid is conveyed to the first rinse tank through the circulating pump and is used as cleanout fluid of the first rinse tank. The actual use of an applicant proves that by the adoption of the multilevel circulating cleaning equipment for the solar cell silicon wafers, the water consumption of cleaning the silicon wafers per ton is only 3 tons, and compared with the conventional cleaning machine, the multilevel circulating cleaning equipment saves water by over 5 tons; and thus the multilevel circulating cleaning equipment has obvious water-saving effect and avoids water resource waste caused by independent water service of the rinse tanks.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

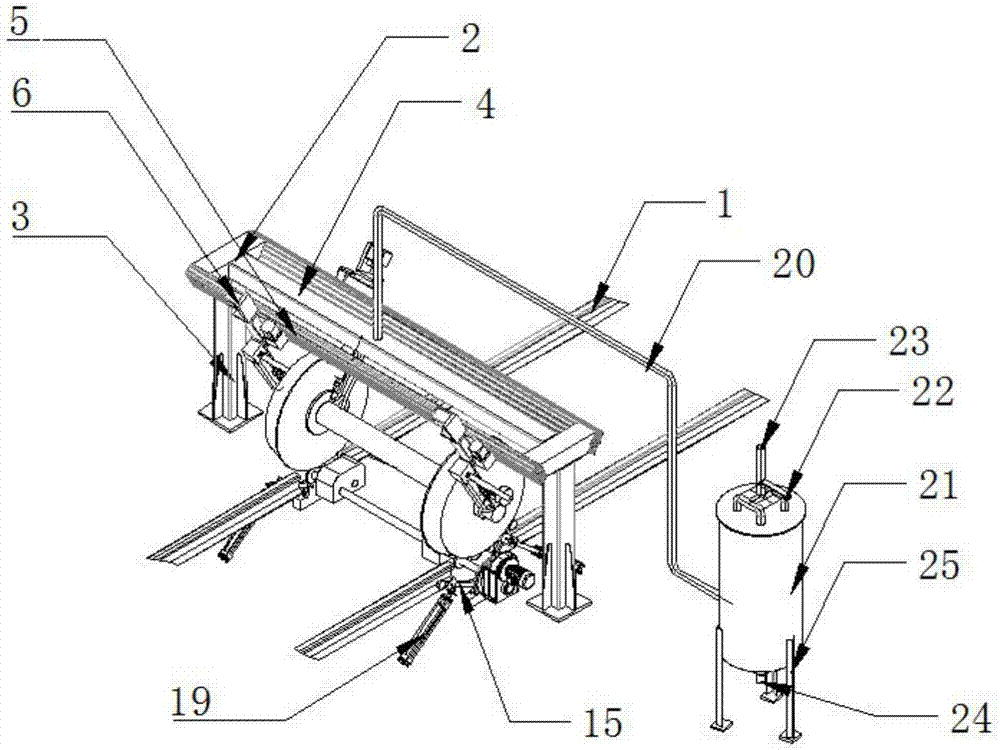

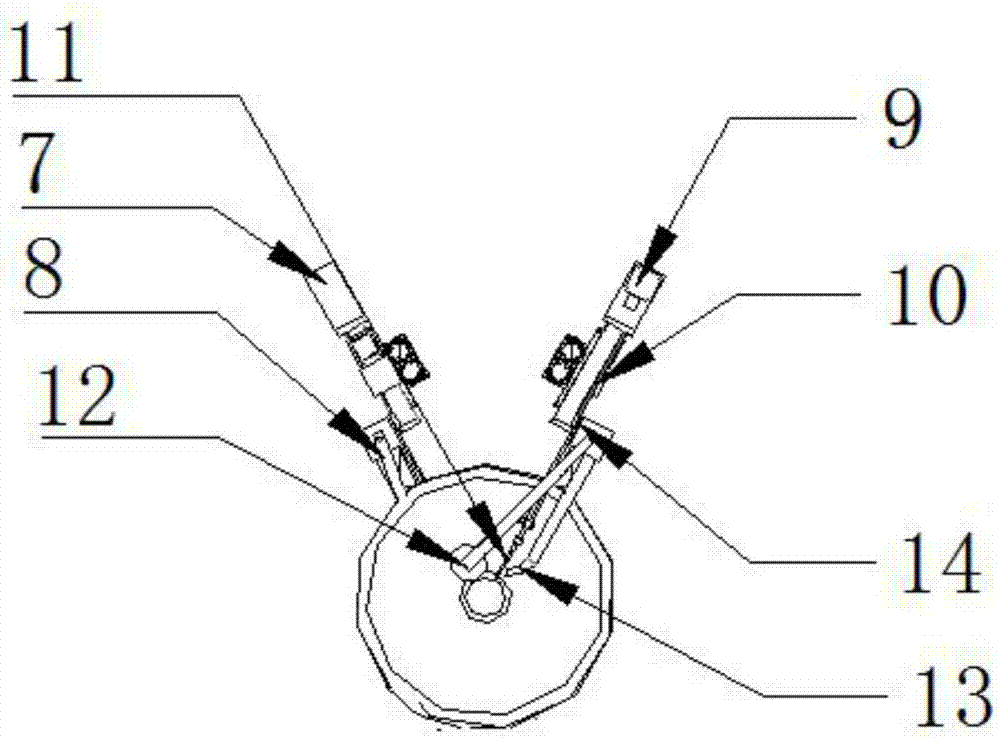

Train wheel set laser cleaning machine and train wheel set cleaning method

InactiveCN107030040ANo pollutionImprove cleaning efficiencyDirt cleaningCleaning using toolsEngineeringManipulator

The invention provides a train wheel set laser cleaning machine. A train wheel set laser cleaning device is arranged in a cleaning room; the cleaning room is provided with a left lifting door and a right lifting door for achieving the effects of safety protection and smoke closing; and the cleaning device comprises a truss, a wheel set limiting driving unit, a waste discharge unit and a wheel set cleaning unit slidingly connected with the truss. The train wheel set laser cleaning machine adopts laser cleaning as a main cleaning mode to achieve high cleaning efficiency; through no grinding and no contact in the laser cleaning, the surfaces of wheel sets cannot be damaged, and the secondary pollution cannot be generated; the laser cleaning is matched with a manipulator to achieve high automation degree and to reduce the labor cost; any chemical reagent and cleaning liquid have no need to use; wastes generated by cleaning are powder; and the powder is small in size and capable of recovering, so that the environmental pollution problem cannot be generated.

Owner:HUBEI HANTAI INTELLIGENT EQUIP

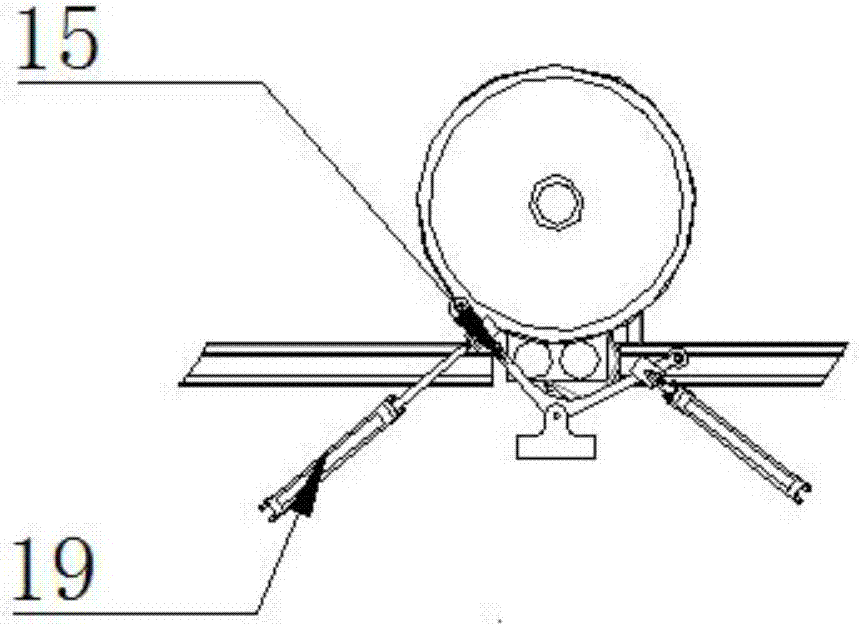

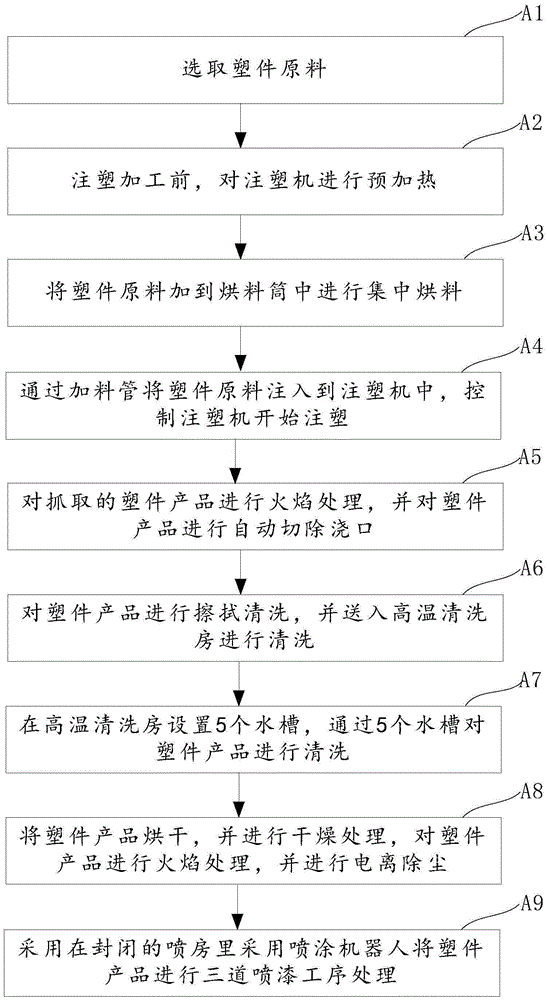

Method for producing colored bumpers

InactiveCN105413979AImprove impact resistanceAvoid defectsPretreated surfacesCoatingsFlame treatmentEngineering

The invention discloses a method for producing colored bumpers. The method includes the steps that A1, plastic part raw materials are selected; A2, an injection molding machine is preheated; A3, the plastic part raw materials are fed into a drying barrel to be dried in a concentrated mode; A4, the injection molding machine is controlled to start injection molding; A5, flame treatment is conducted on a grabbed plastic part product, so that flash and burrs on the surface of the product are removed, and a pouring gate is automatically cut off; A6, the plastic part product is wiped and cleaned and fed into a high-temperature cleaning room to be cleaned; A7, the plastic part product is cleaned; A8, the cleaned plastic part product is dried and fed into a drying room to be dried, then flame treatment is conducted on the plastic part product, and the plastic part product subjected to flame treatment is fed into an ionization dust removal chamber to be subjected to ionization dust removal; and A9, a spraying robot is used for conducting three paint spraying procedures on the plastic part product in a sealed spraying booth. According to the method, the production efficiency is high, the production safety is high, and the percent of pass of products is increased.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

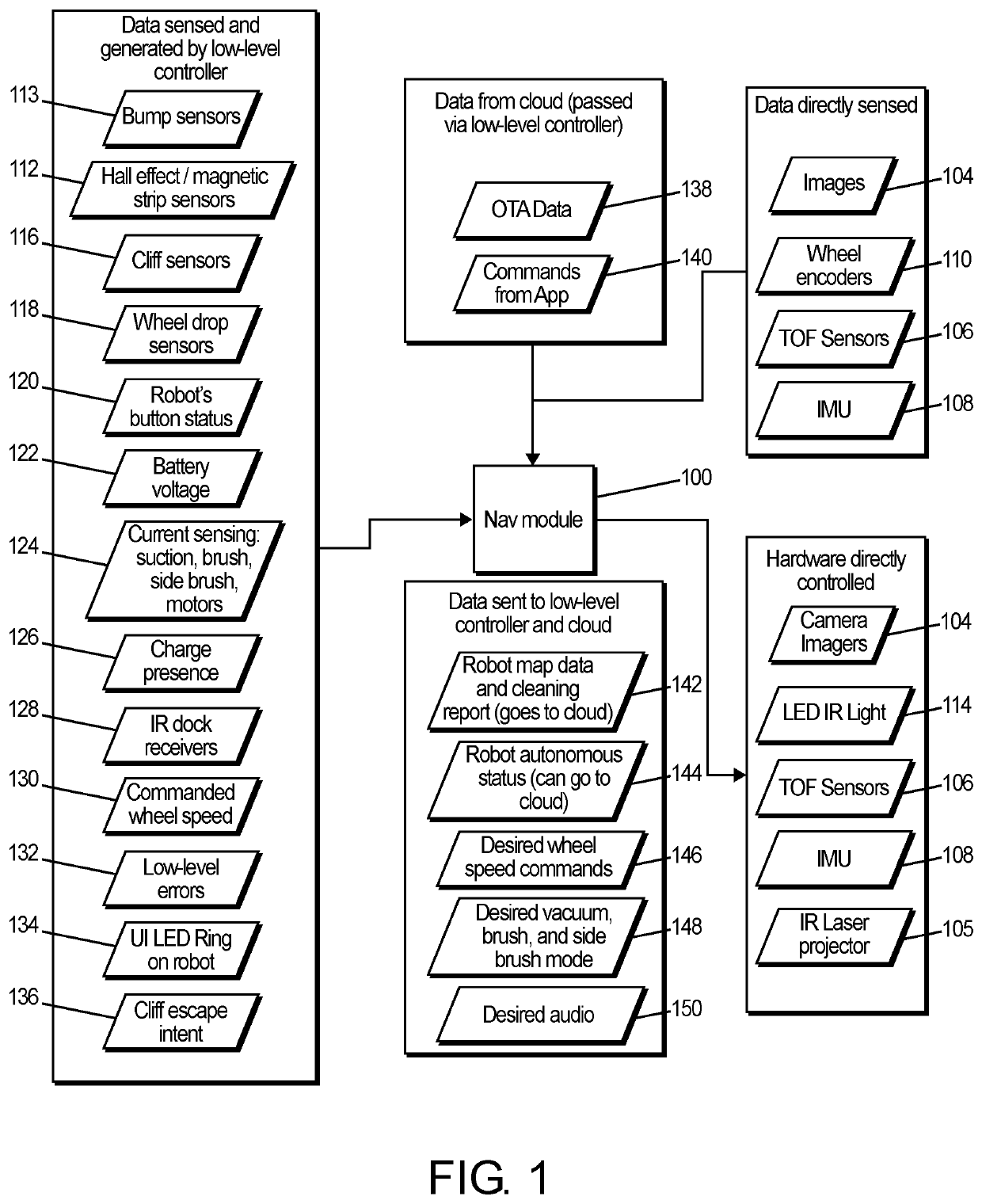

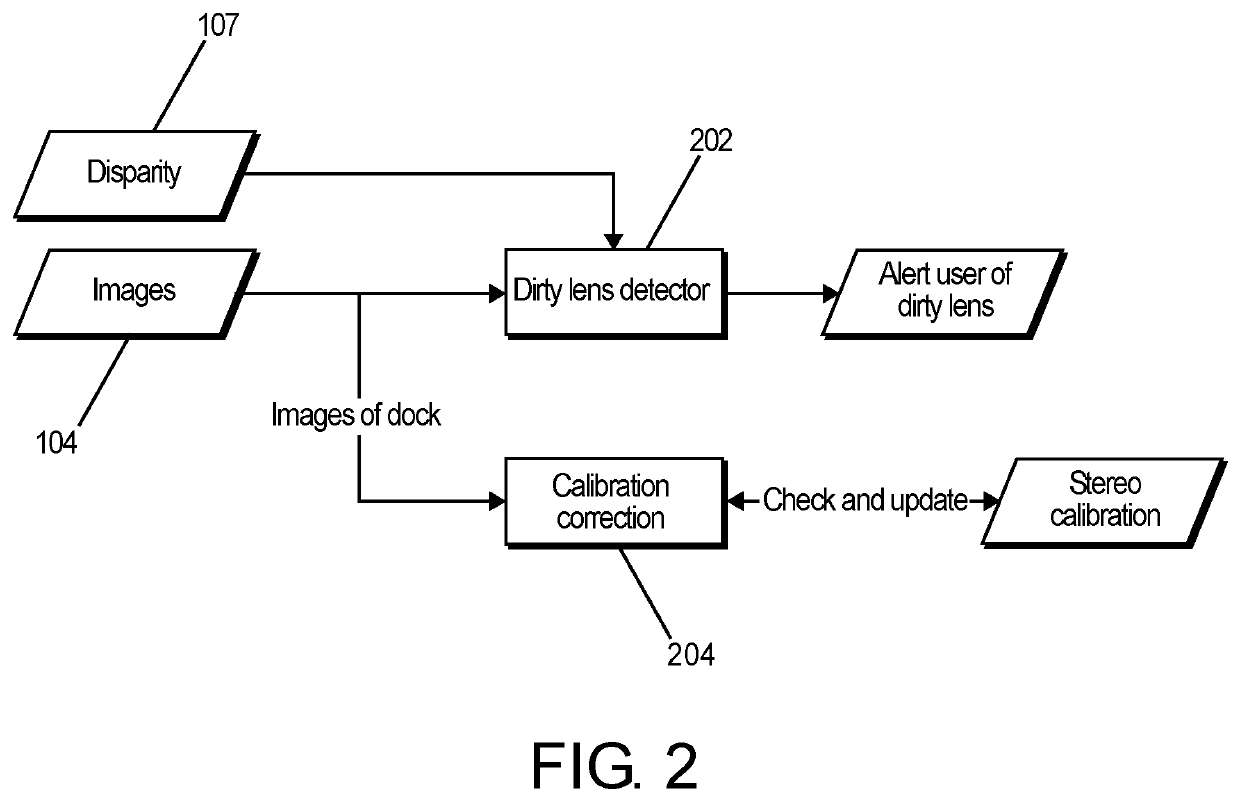

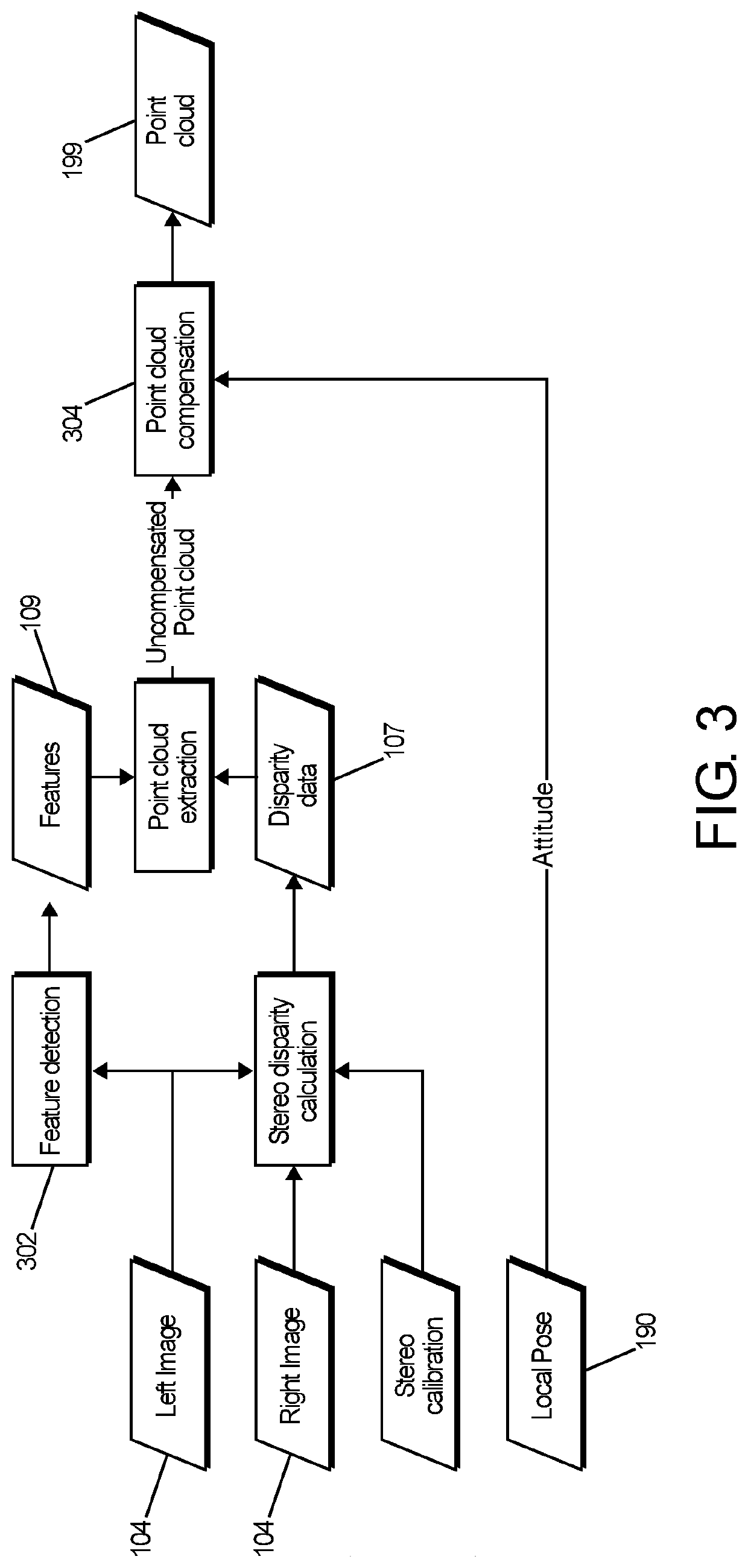

Intelligent cleaning robot

An intelligent, autonomous interior cleaning robot capable of autonomously mapping and cleaning multiple rooms in a house in an intelligent manner is described. Various combinations of passive and active sensors may be used to perform mapping, localization, and obstacle avoidance. In particular, the robot uses stereo cameras with a static projected light pattern to generate 3D data. In addition, the robot may use optical sensors in various locations, laser ToF sensors, inertial measurement units and visual odometry to enhance the localization and mapping capabilities.

Owner:CARNEGIE MELLON UNIV

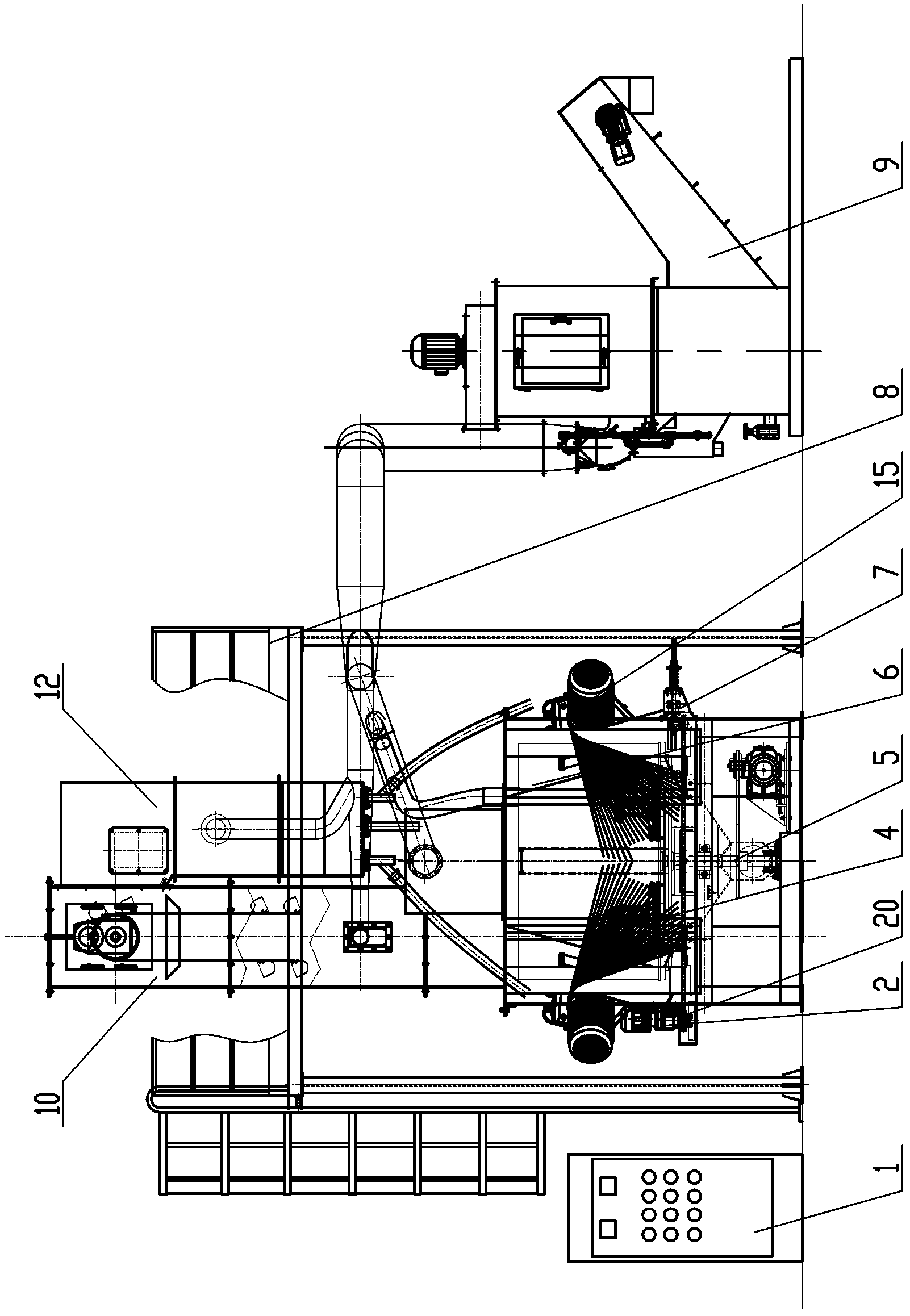

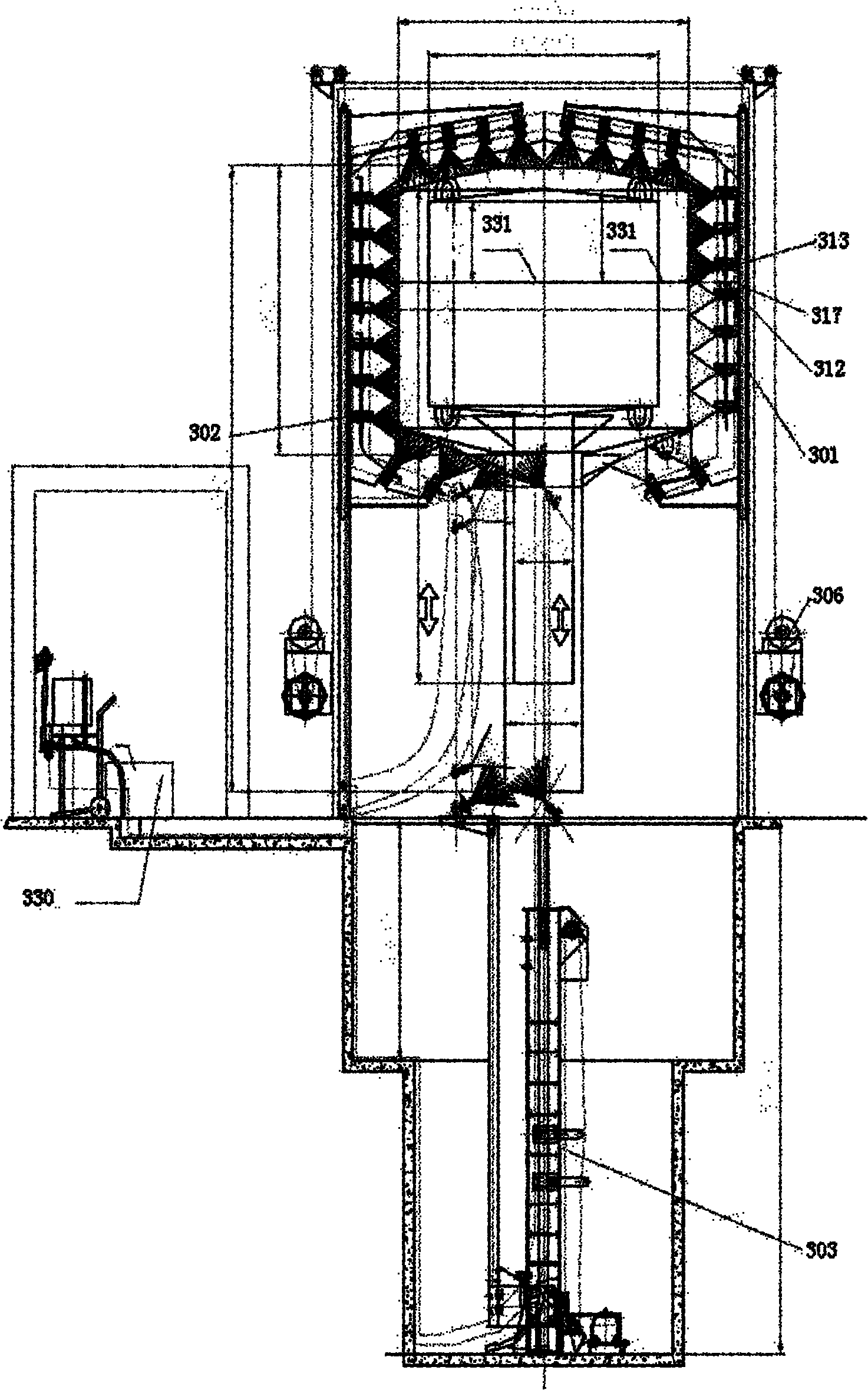

Automatic production line system for coating and maintaining buoys and application method thereof

InactiveCN102173309AAdvanced technologyCompact structureWaterborne vesselsSpraying apparatusProduction lineEngineering

The invention discloses an automatic production line system for coating and maintaining buoys and an application method thereof. The system comprises a hanging and conveying device, a blasting cleaning plant, a shot blasting cleaning plant and a drying unit; all the devices are provided with hanging type loading workpieces; the hanging type loading workpieces are used for realizing ascending and descending, walking and autorotation of the buoys in the process of cleaning the blasting and shot blasting, spraying painting and drying.The application method comprises: a. a trolley is moved to a ring-shaped rail to hoist buoys; b. the buoys enter a cleaning room to carry out blasting and shot blasting; c. the buoys enter a spray room to be painted; d. the buoys enter a drying room to be dried; e. the buoys once again enter the spray room to be painted once again; f. the buoys are dried once again. In the invention, the workpieces are loaded in a hanging manner, the lifting appliances can ascend and descend, walk and automatically rotate. Blasting and shot blasting cleaning, paint spraying, three-station drying are completed respectively to form an automatic coating processing production line; and in addition, program control is realized and a high degree of automation is enjoyed.

Owner:青岛铸造机械集团公司 +1

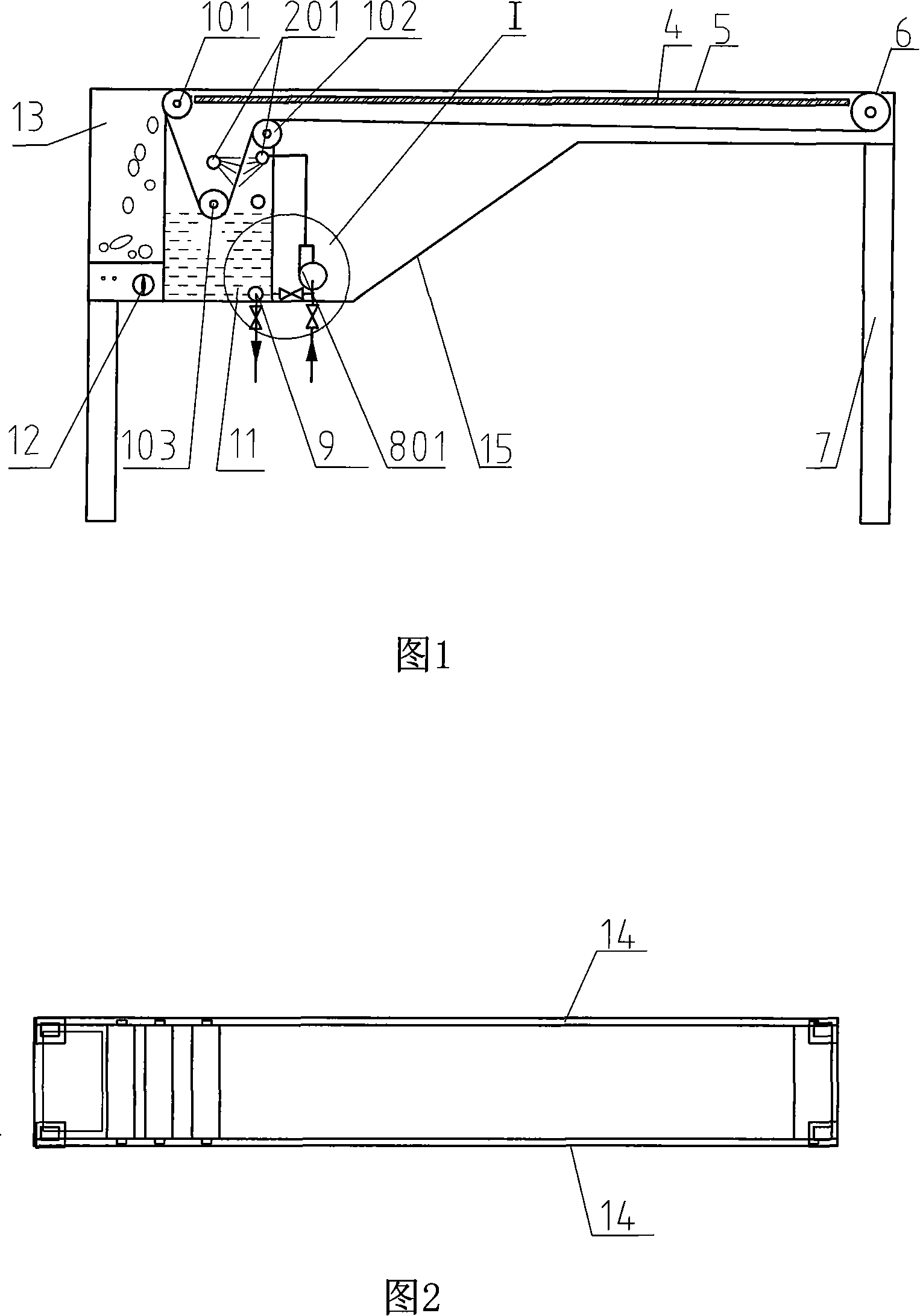

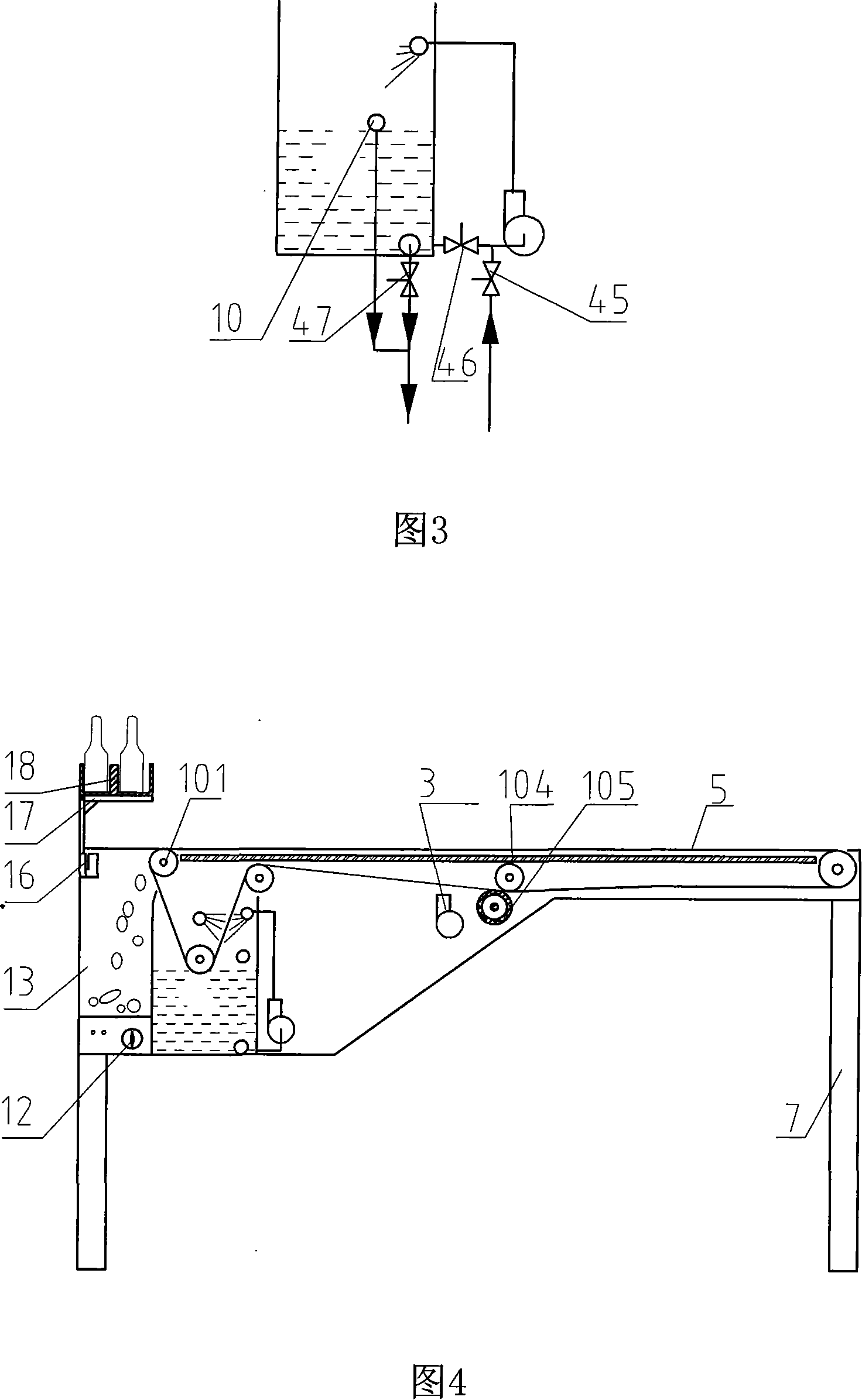

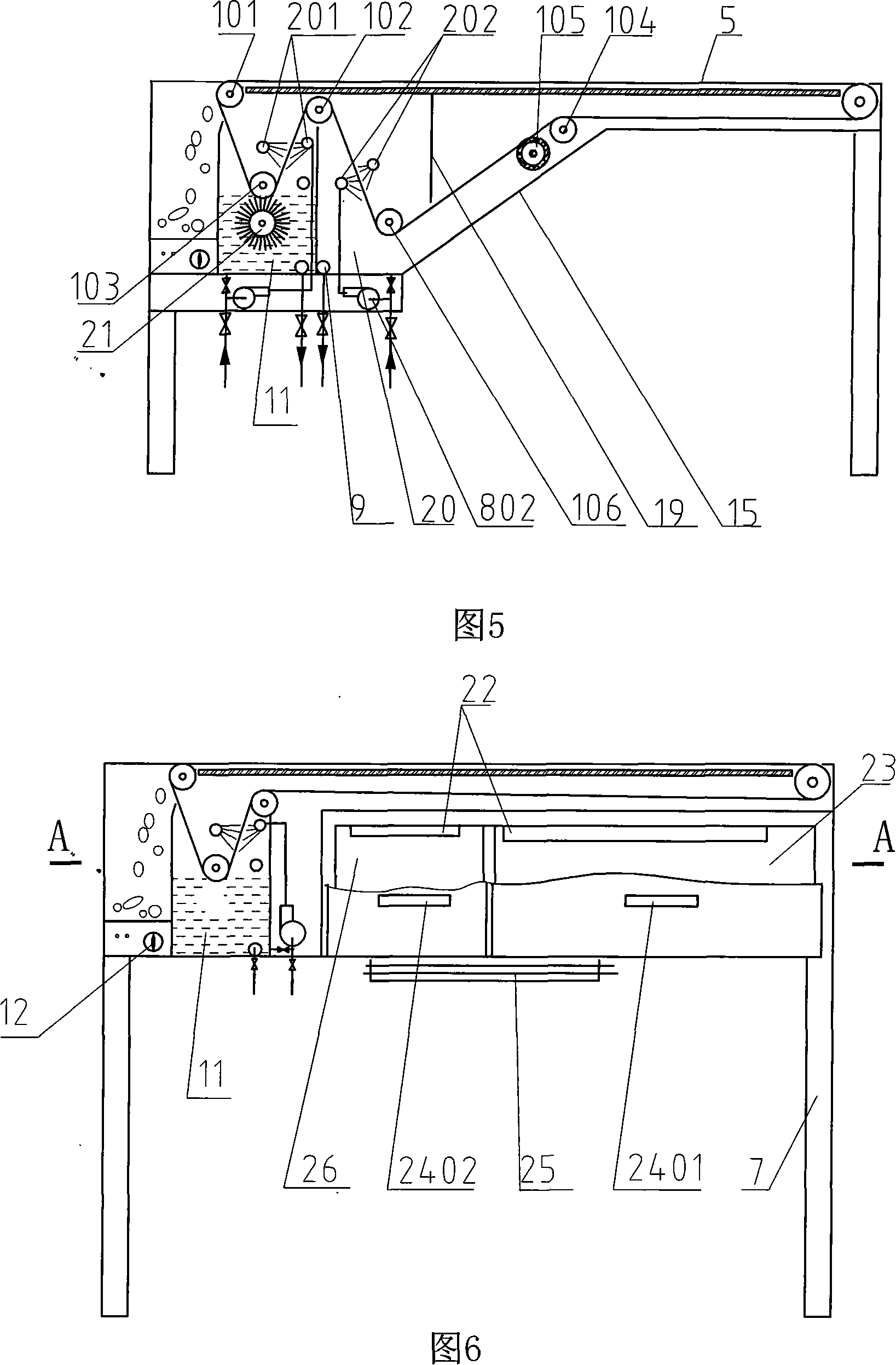

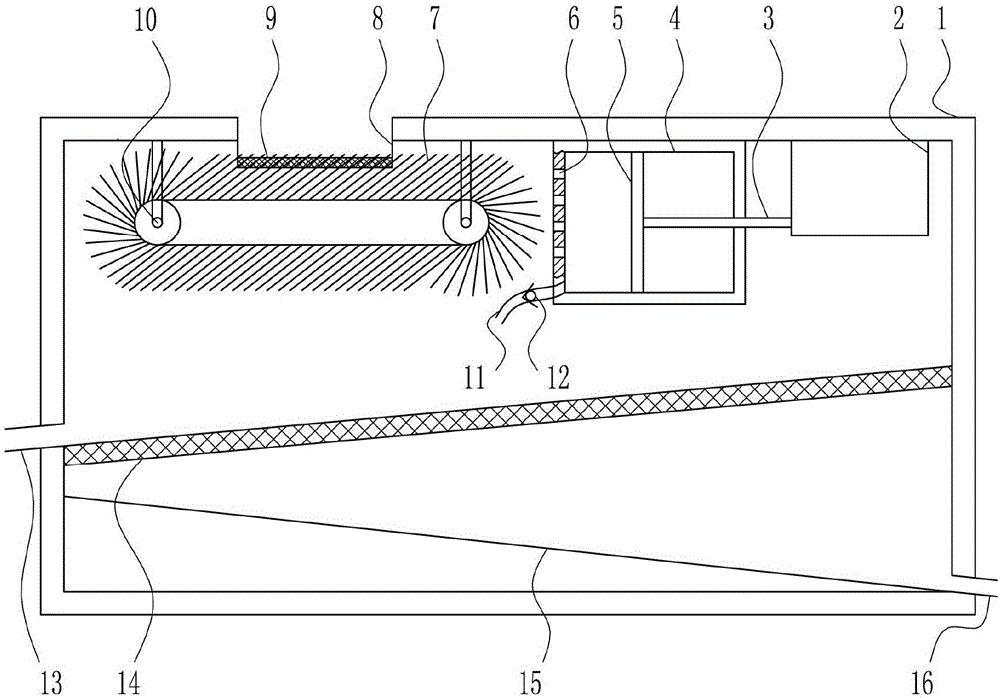

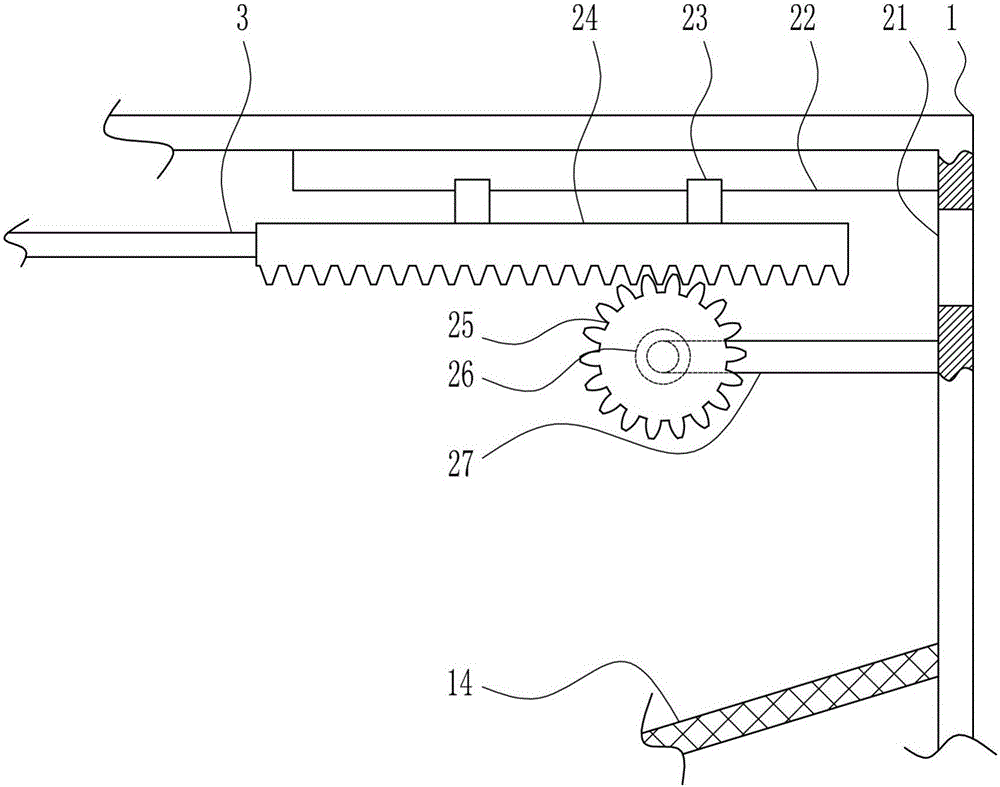

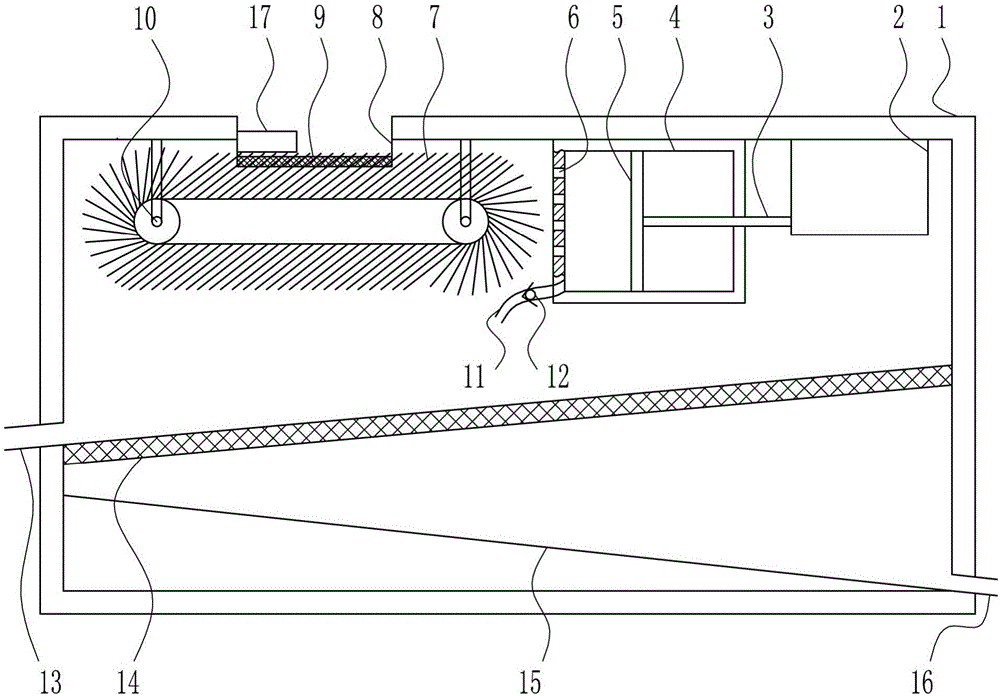

Sole cleaning device for public places

The invention relates to a sole cleaning device and more particularly relates to a sole cleaning device for public places. The invention aims at providing a sole cleaning device for public places. In order to solve the technical problem, the invention provides the sole cleaning device for public places. The sole cleaning device comprises a cleaning box, a pushing device, a pushing rod, a water tank, a piston, a hair brush, a groove body, a net plate, a belt conveying device, a hose, a one-way valve, an impurity removing pipe, a net sieve and the like, wherein the pushing device is arranged at the right side of the inner top part of the cleaning box; the pushing rod is connected at the lower part of the left side of the pushing device; the water tank is arranged at the inner top part of the cleaning box and is positioned at the left side of the pushing device; the piston is arranged in the water tank; and the pushing rod penetrates through the water tank to be connected with the piston. The sole cleaning device has the advantages that the effect of high-efficiency sole cleaning is achieved, the shoe fixing operation is convenient, dirt on a sole is conveniently cleaned, the sewage discharging speed is increased, the structure is simple, the reliability is high, and the generalizability is strong.

Owner:湖州黛丝娅鞋业有限公司

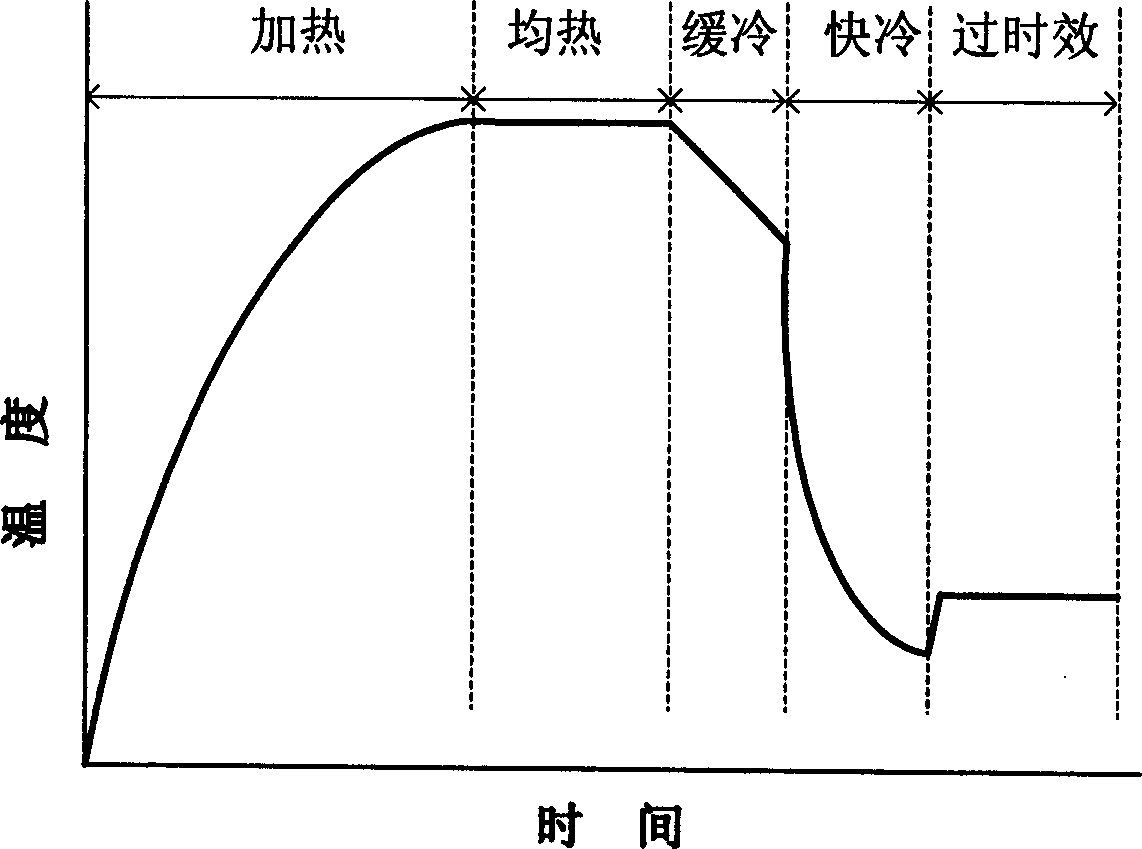

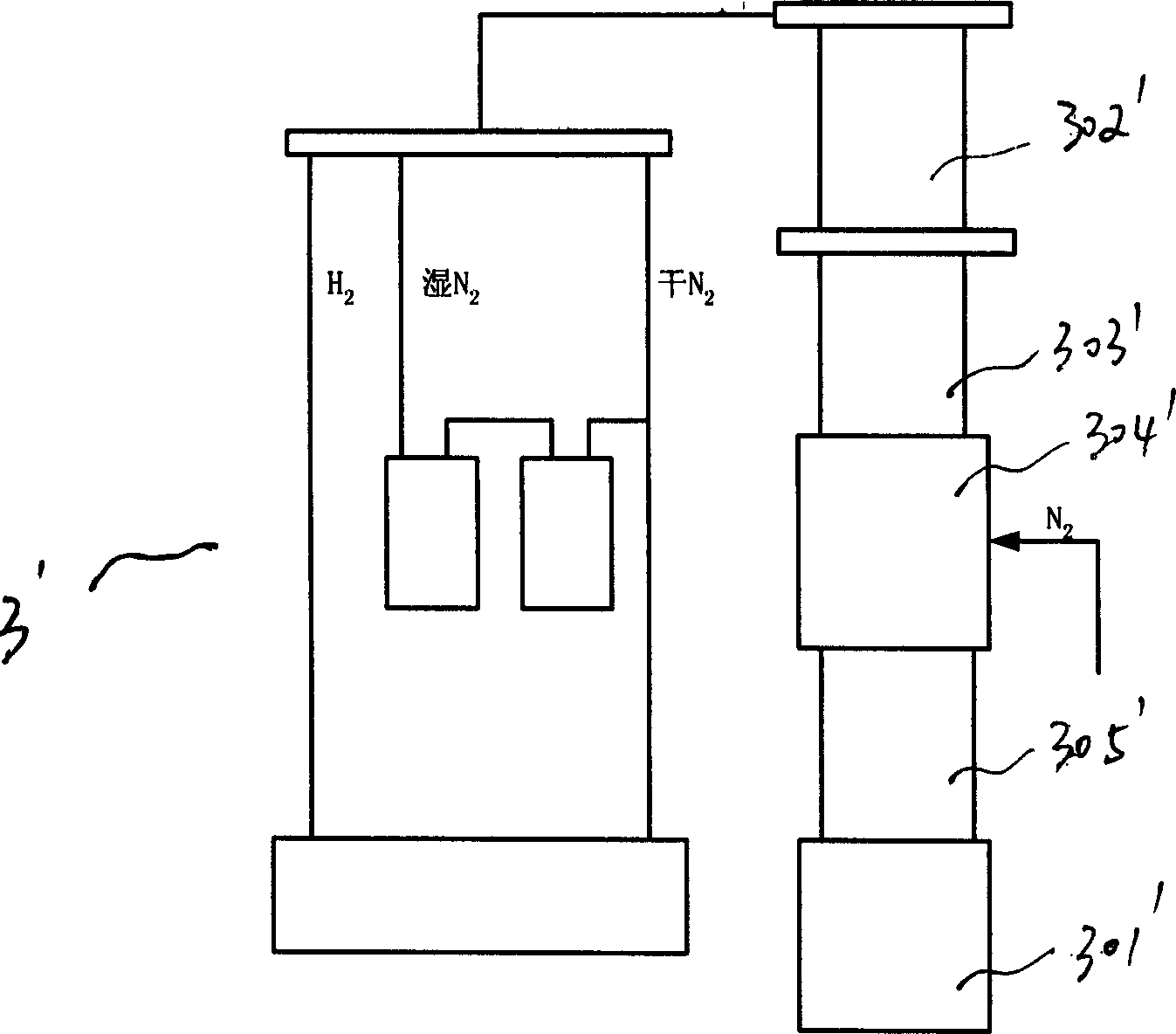

Simulating device for strip steel continuous annealing process

InactiveCN1804621AReduce the impact of cooling effectsUniform temperatureTesting metalsStrip steelContinuous annealing

The invention relates to a strip annealing craft simulating device which comprises a heating room, a soaking room, an over time-effect room, a cooling room and an operated sampling room, it also comprises a sampling gear, wherein the heating room, the soaking room and the over time-effect room are as an integer from up to down; the cooling room is positioned on the lower end of the over time-effect room; the cooling room arranges a cooling medium port, a cooling medium jet case and a jet case distance adjuster; the sampling gear comprises a sampling material frame, a cable and a gear motor.

Owner:BAOSHAN IRON & STEEL CO LTD

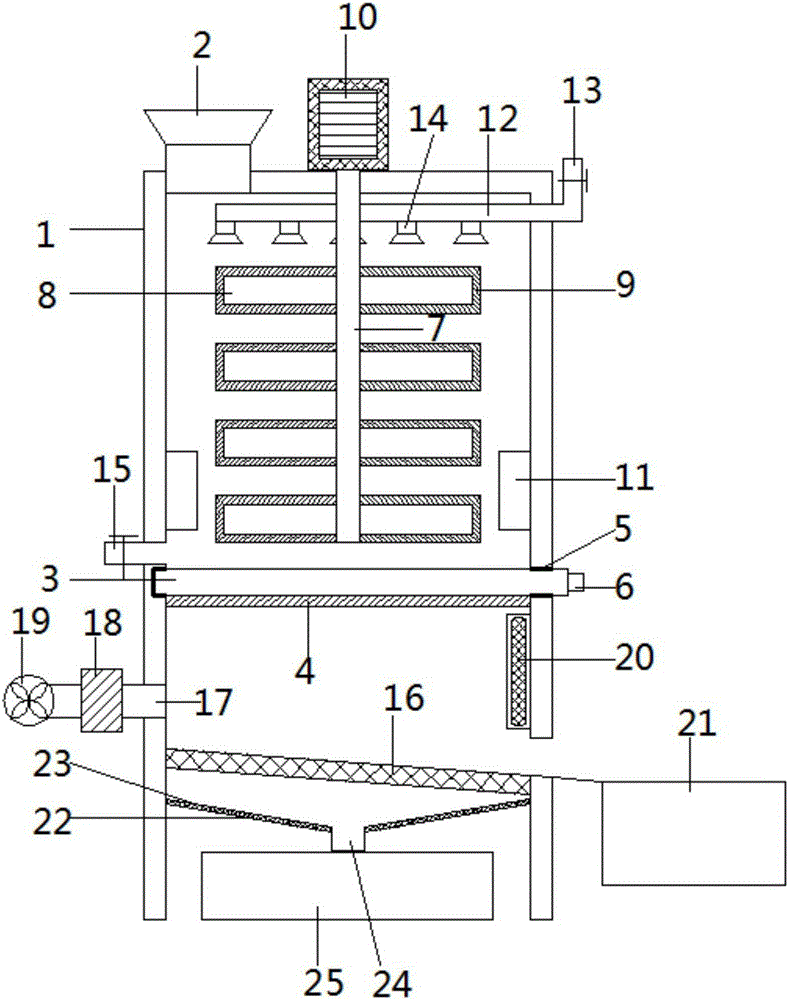

High-efficiency cleaning machine for processing nectarines

InactiveCN105212242AImprove processing efficiencyUse full cleaningFood treatmentUv disinfectionMegasonic cleaning

The invention discloses a high-efficiency cleaning machine for processing nectarines. The high-efficiency cleaning machine comprises a body and a material inlet bucket. The material inlet bucket is arranged at the upper left end of the body. The middle segment in the body is provided with a drawing-pulling separator plate in a horizontal direction. The drawing-pulling separator plate divides the body into an upper chamber and a lower chamber, namely a cleaning chamber and a screening chamber. After cleaning, just through drawing out the drawing-pulling separator, screening can be performed, thereby realizing simple operation and high convenience in use. A nectarine cleaning function and a nectarine screening function are integrated. A processing efficiency of the nectarine is effectively improved. Three cleaning modes of ultrasonic cleaning, brushing by a cleaning rod and clear water flushing are combined, thereby effectively improving cleaning efficiency and ensuring high cleaning effect. In screening, hot-air drying and ultraviolet sterilization can be performed on the nectarines. Furthermore later storage and transportation are facilitated.

Owner:徐州市贾汪区滨农农业科技发展有限公司

Rapid cleaning equipment for medical devices

InactiveCN107597708AImprove cleaning efficiencySave waterCleaning using liquidsWater sourceMedical device

Owner:深圳万研科技研发有限公司

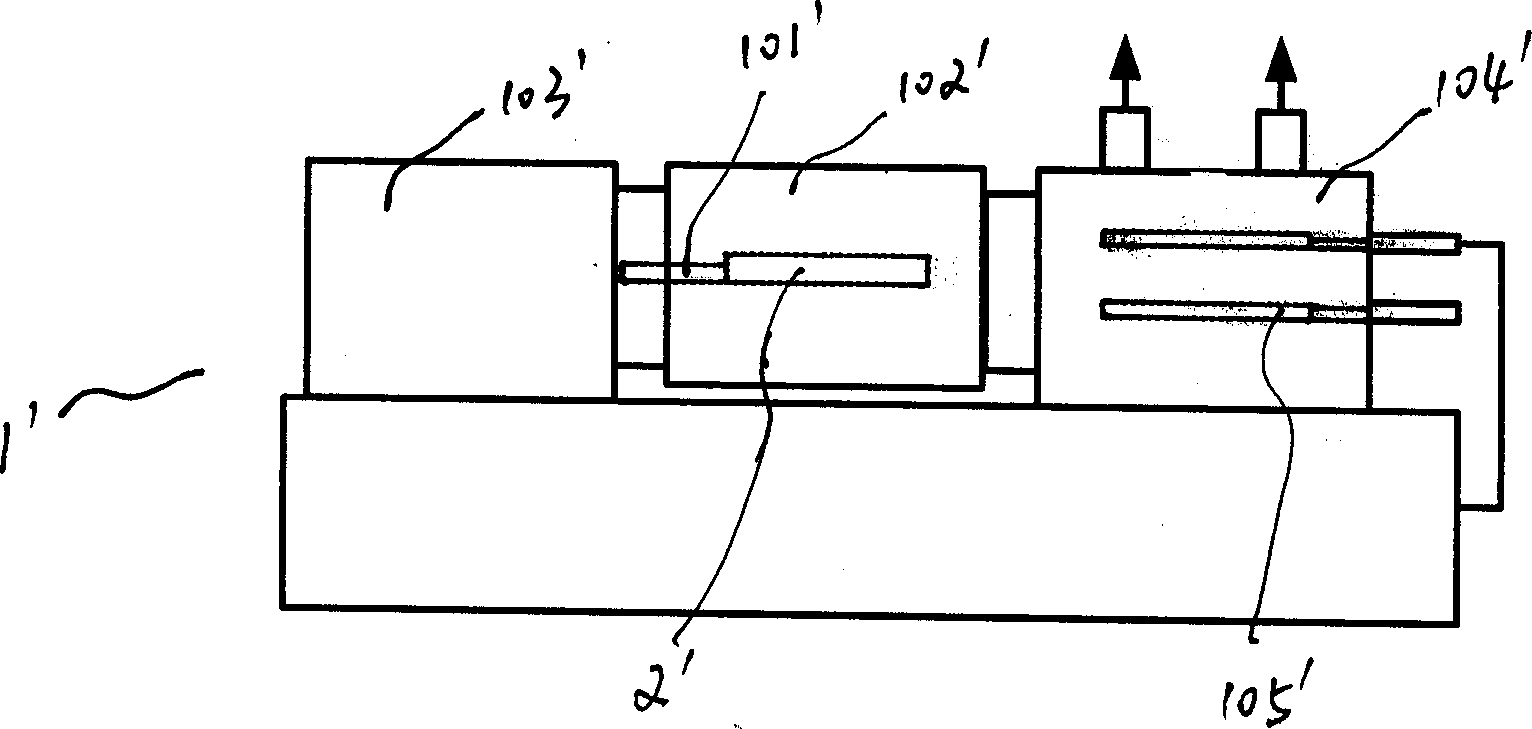

Metal thermal spraying production line

InactiveCN101469397AConcise and efficient designEasy to operateMolten spray coatingProduction lineThermal spraying

The invention discloses a metal hot spray production line and belongs to coating equipment. The metal hot spray production line comprises a platform, a rolling type roll table for operating the workpiece mounted on the platform, a driving motor for driving the operation of the roll table, and a blast room, a cleaning room and a hot spray room straddled on the roll table in sequence from front to back, wherein a sand tank communicated with the blast room is arranged below or at one side of the blast room; and the upper parts of the blast room, the cleaning room and the hot spray room are communicated with a dedusting device through a dust collecting pipeline. The metal hot spray production line has the advantages that the metal hot spray production line not only can rapidly and conveniently performs the hot spray operation but also achieves, the pollution-free and zero emission effects on the environment in the spray operating process, and is not only suitable for the fixing operation in an enterprise but also suitable for the field construction operation.

Owner:XUZHOU ZENITH COATING

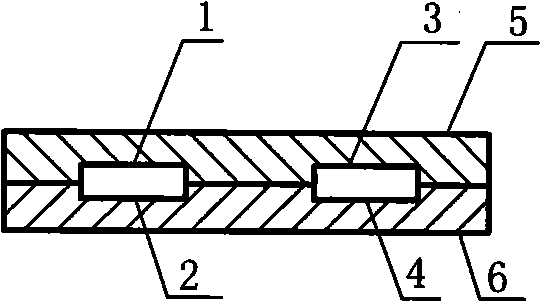

Bulk production method of micro-fluidic chip

The invention relates to a batch production method for a micro-flow control chip. The method comprises: a mould core made of a hard alloy material is selected; the temperature of a left movable mould core part, a left static mould core part, a right movable mould core part, a right static mould core part, a movable mould and a static mould is kept at a temperature of between 85 and 115 DEG C; a superpolymer material is evenly spread according to the thickness of between 1 and 5 centimeters and is dried for 6 to 8 hours at a temperature of between 70 and 75 DEG C; in a cleaning room with 10 thousand level to 100 thousand level at ambient temperature of between 20 and 25 DEG C, a material in a molten state is injected into the middle parts between the left movable mould core part and the left static mould core part and between the right movable mould core part and the right static mould core part; under the conditions at a speed of between 80 and 100 mm / s and pressure of between 40 and 60 MPa, the superpolymer material is injected; the whole injection time is between 27 and 33 seconds; the chip is taken out and is disinfected and sterilized; and finally, a left micro-flow control chip and a right micro-flow control chip are bonded. The method can manufacture the micro-flow control chip in large batch and promote application of micro-flow control chip technology and industrialized development.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Plate-frame type anti-blocking sludge dewatering machine with long service life

InactiveCN108479182AAvoid cloggingAvoid damageSludge treatment by de-watering/drying/thickeningFiltration circuitsCause blockageEngineering

The invention relates to a plate-frame type anti-blocking sludge dewatering machine with long service life. The dewatering machine comprises a conveying mechanism, a pressing mechanism, a water tank,a controller, a cleaning mechanism and a dewatering mechanism; the conveying mechanism comprises a hopper, a material pipe, an oblique tube and a cleaning room, the dewatering mechanism comprises a frame, a stencil, filter cloth, two rotating assemblies and four supporting assemblies, and the cleaning mechanism comprises a water pump, a moving tube, a second filter screen, two translation assemblies and a plurality of nozzles. According to the dewatering machine, sludge is transported through the conveying mechanism, large debris is isolated by a first filter screen to prevent the filter clothfrom being scratched and damaged when the sludge is squeezed, the service life of the filter cloth is ensured, the sludge flows smoothly, the debris on the first filter screen is removed in time through a cleaning assembly, the filter cloth is turned over under the driving of a first motor, the filter cloth is washed and cleaned by the cleaning mechanism to prevent the sludge from adhering to thefilter cloth to cause blockage, and the smooth progress of subsequent sludge dewatering is ensured.

Owner:晋江市意翔环保科技有限公司

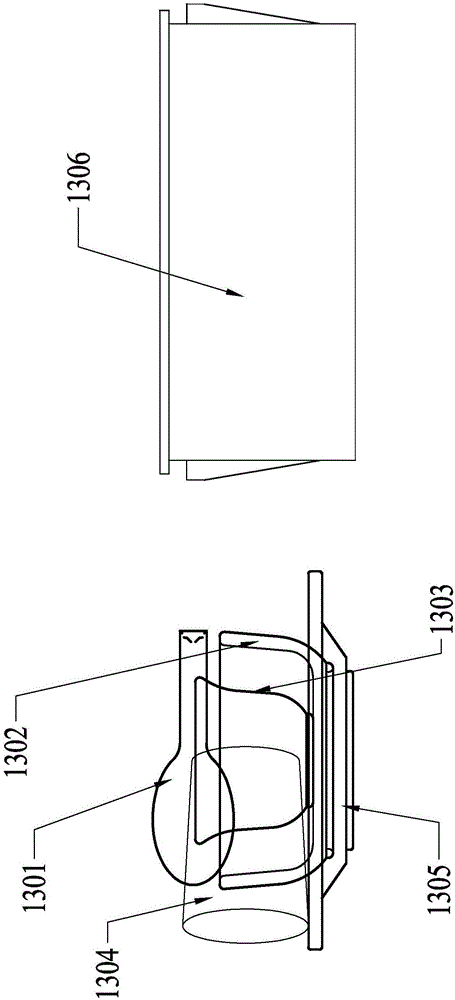

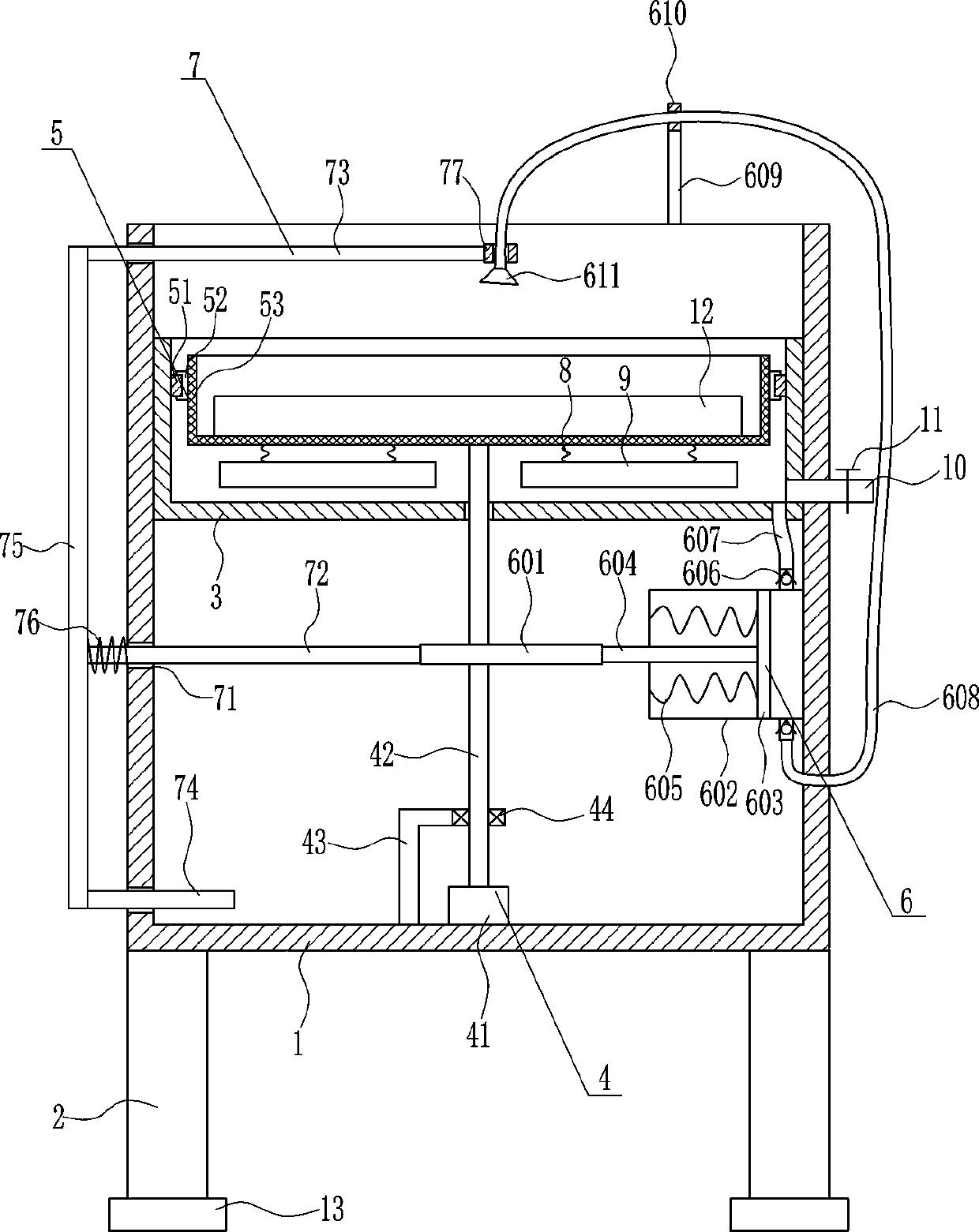

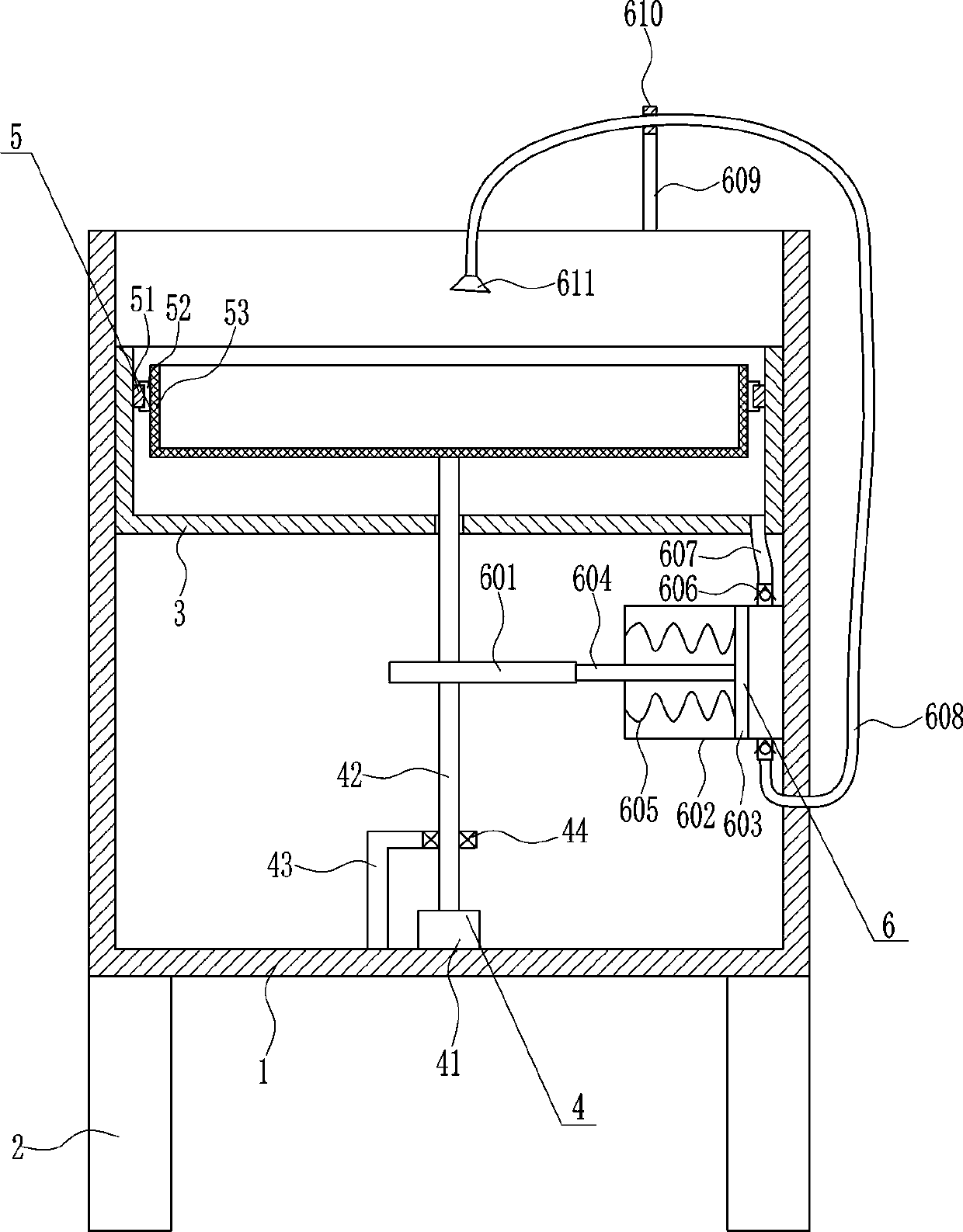

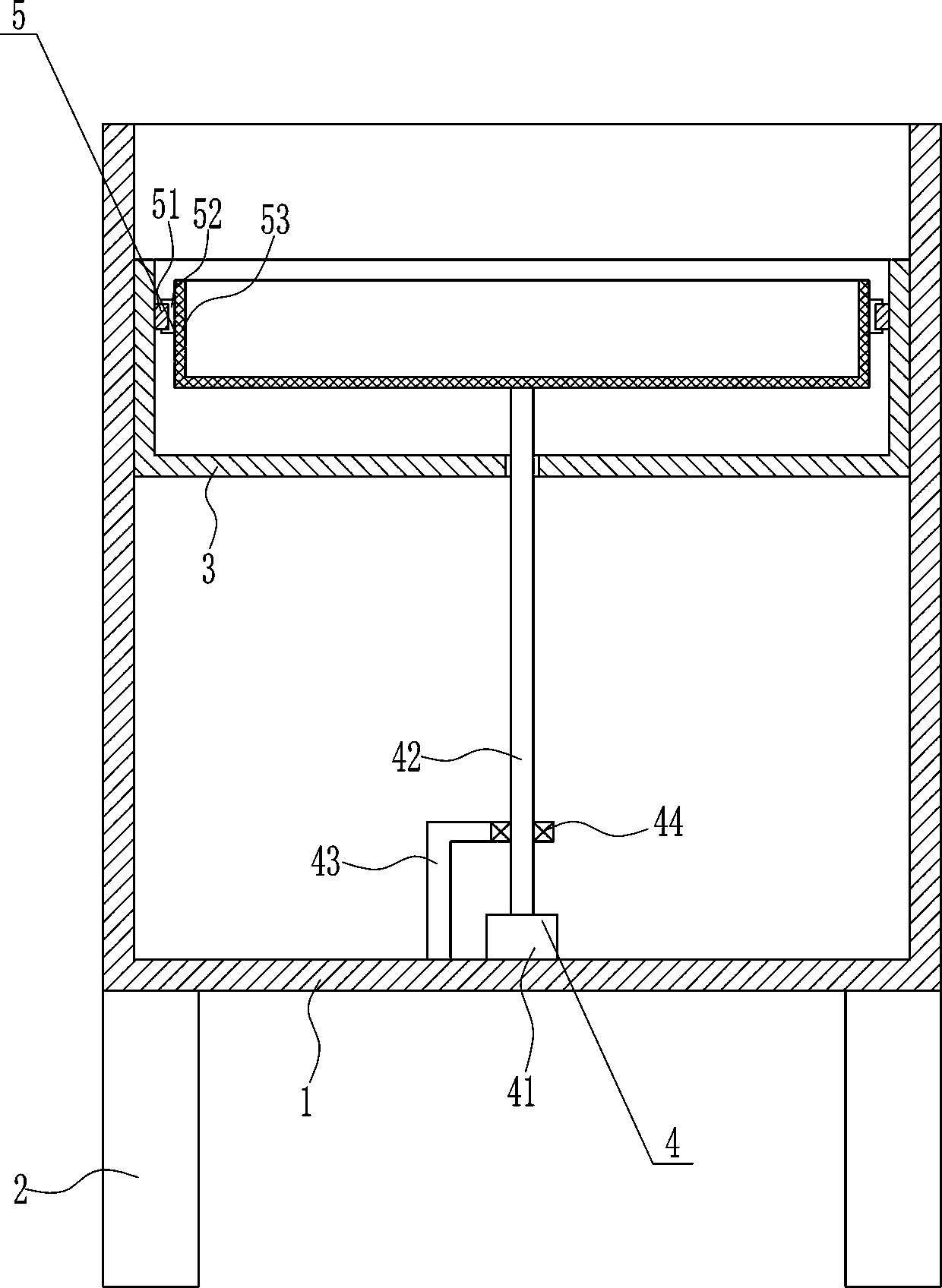

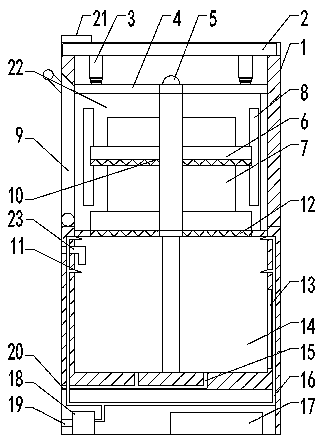

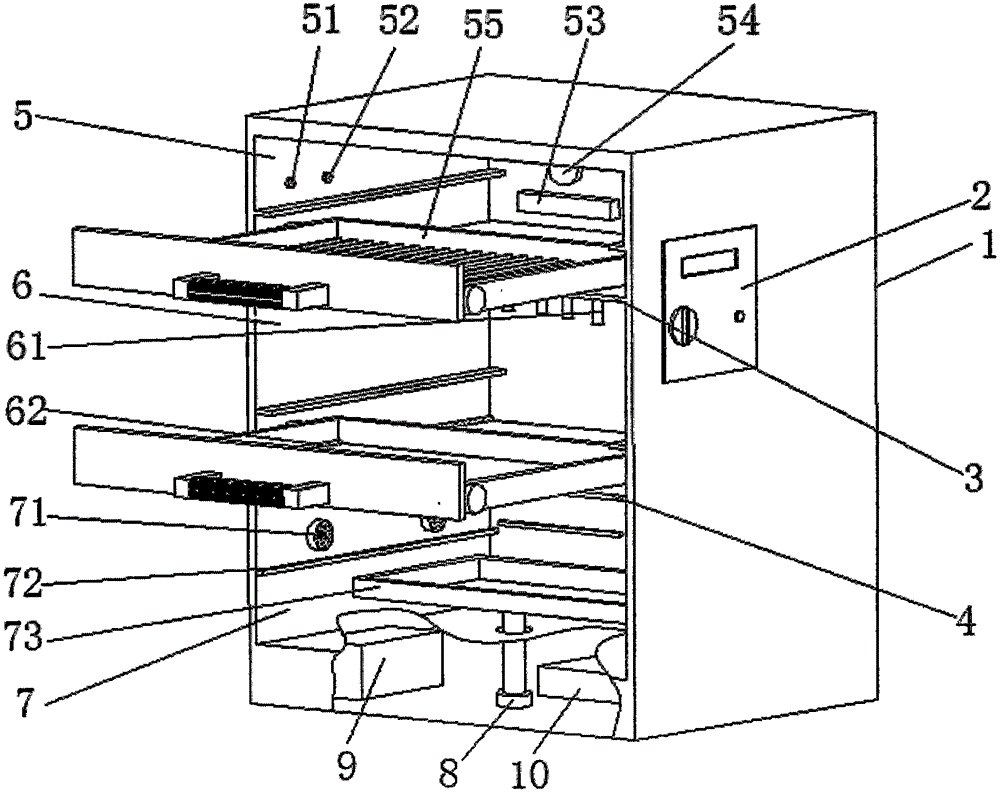

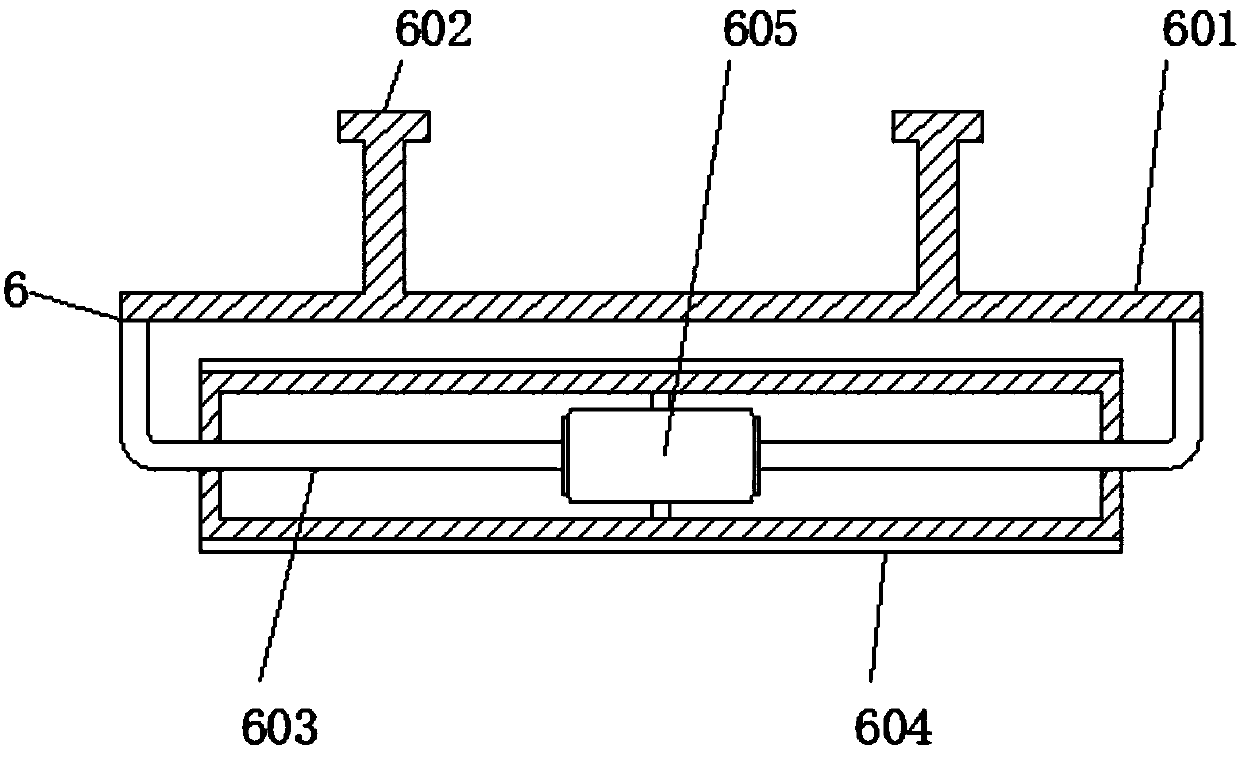

Dish-washing machine

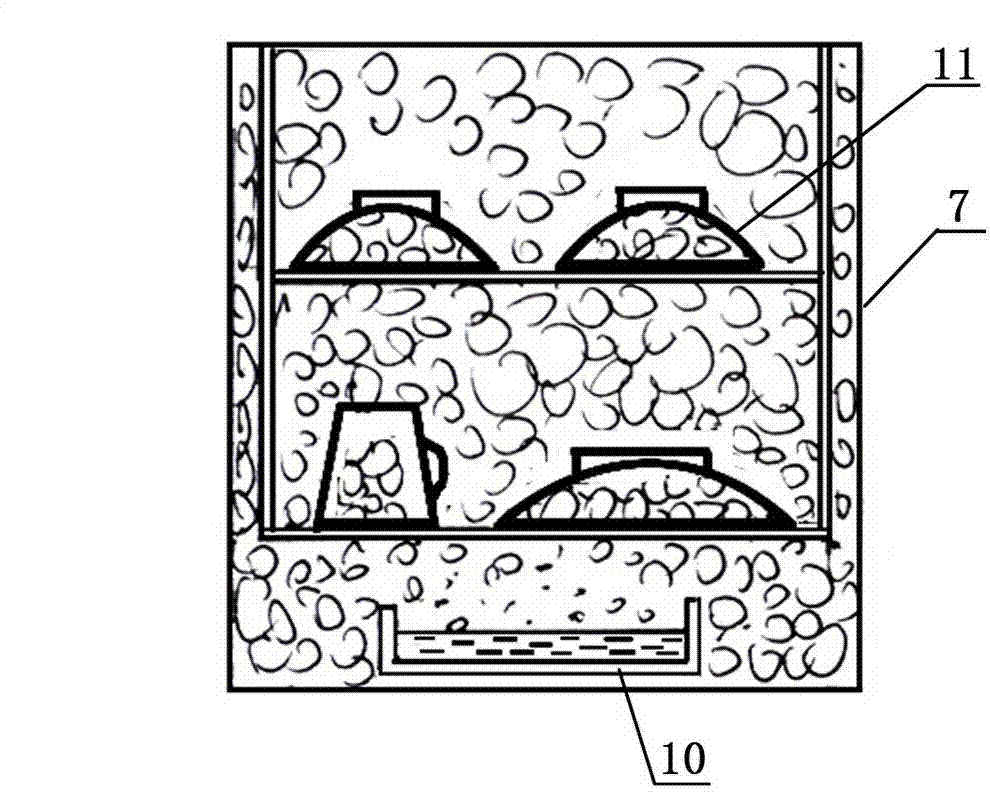

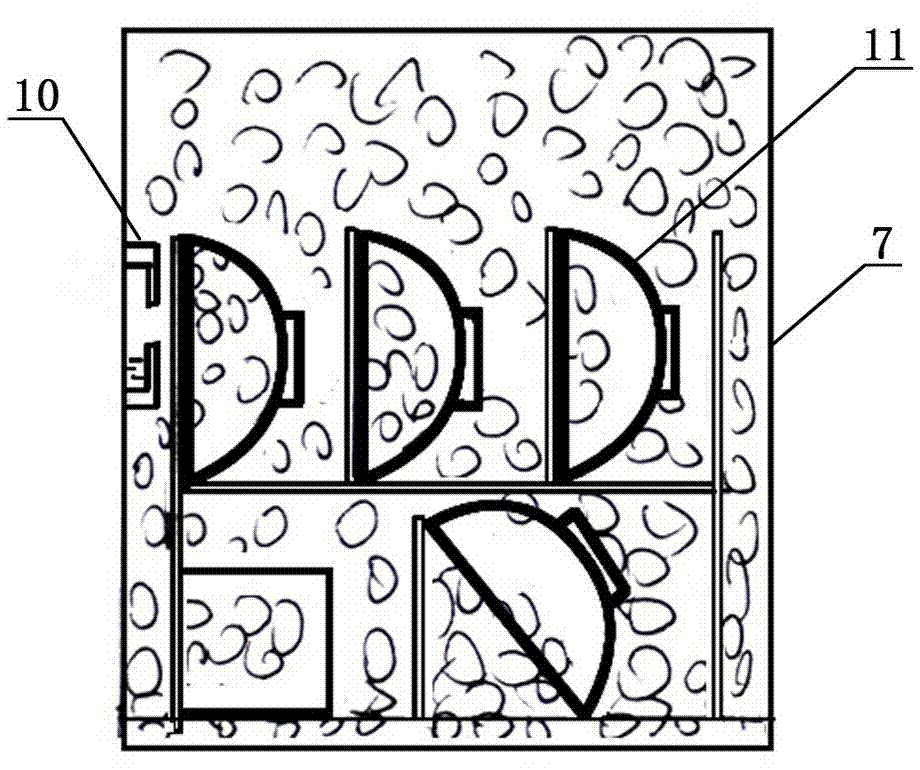

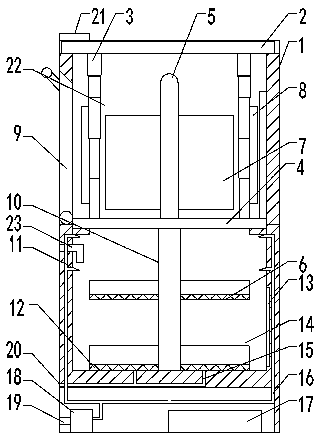

InactiveCN107625505ALow costReduce sizeTableware washing/rinsing machine detailsEngineeringUltrasonic generator

The invention discloses a dish-washing machine, which comprises a machine body; a drying disinfecting room and a cleaning room are arranged in the machine body; the cleaning room is provided with a cleaning device for cleaning dishes; a drying disinfecting device for drying and disinfecting the cleaned dishes and a lifting device for holding dishes are arranged in the drying disinfecting room; to-be-cleaned dishes are placed on the lifting device, and declined to clean by the cleaning device and then raised to dry and disinfect by the drying disinfecting device. By adopting the lifting method,the size of the dish-washing machine is greatly reduced, thus workers can conveniently take out the dish-washing machine without adding special detergent for the dish-washing machine, and the dishescan be cleaned by ordinary detergent, thus the dish washing cost is reduced; through the ultrasound wave generated by an ultrasound wave generator, the washing effect is significant, and the dishes are cleaned by clean water through nozzle during the lifting process; the dish washing speed is quick, and the working efficiency is high; furthermore, the dishes are dried and disinfected through the drying and disinfecting device, the use safety of dishes and chopsticks is guaranteed, and the bacterial breeding is avoided.

Owner:冯浩

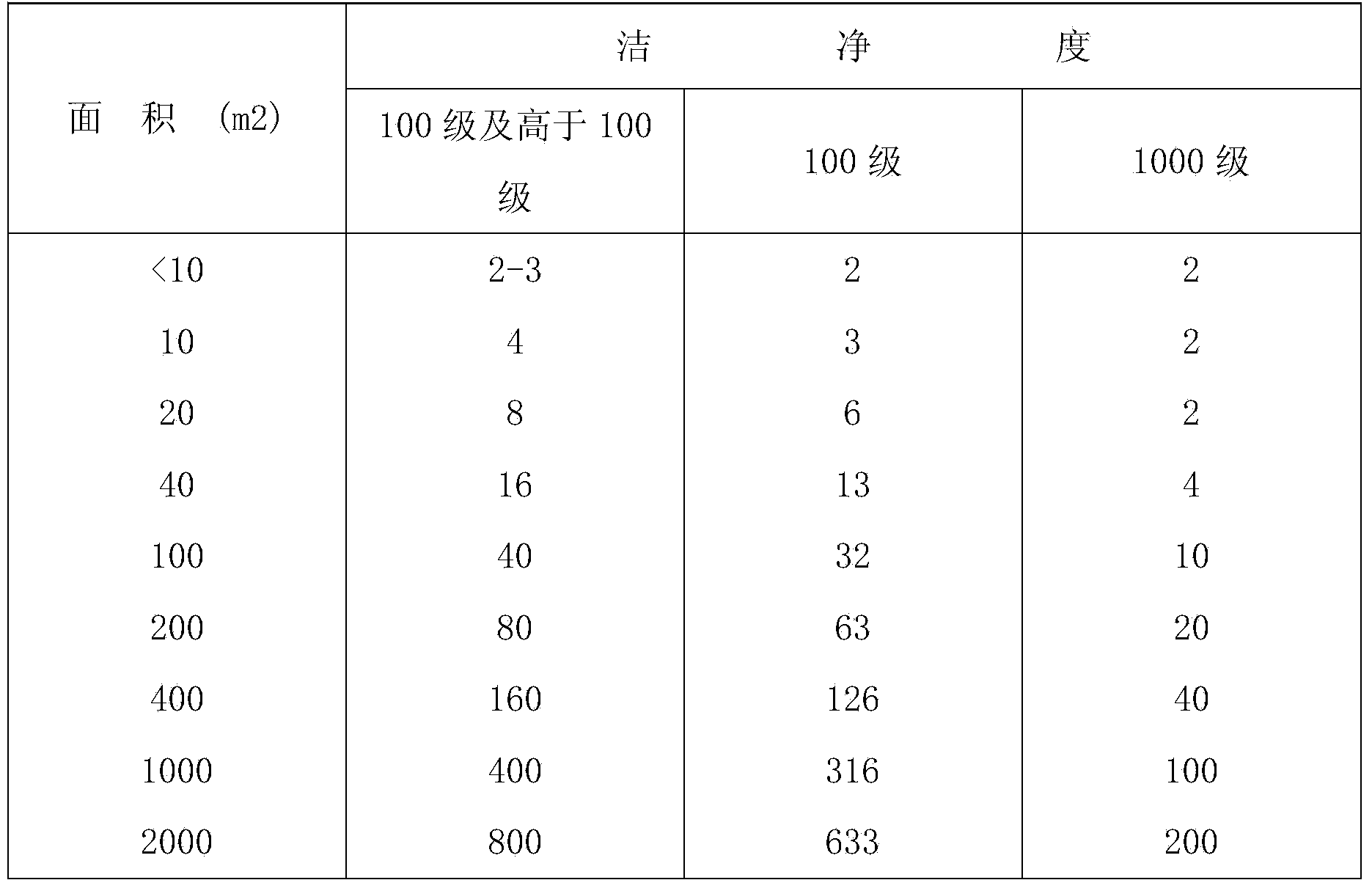

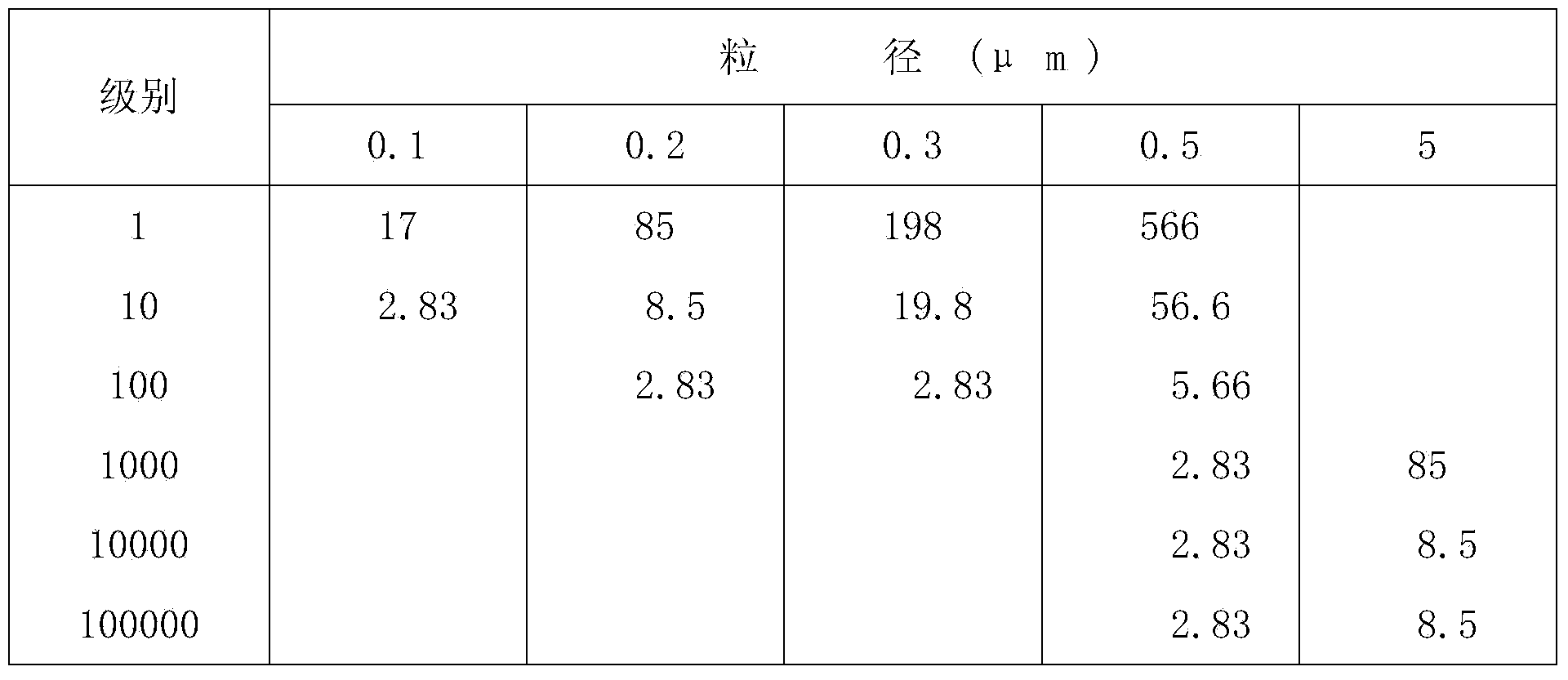

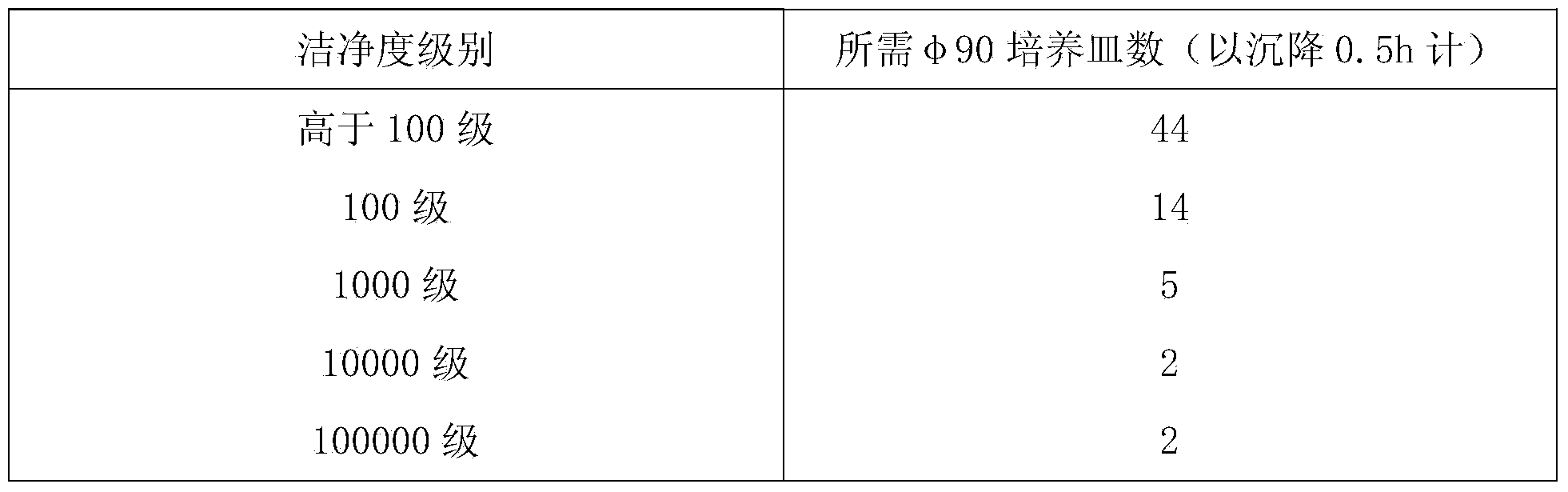

Method for constructing electronic workshop cleaning system

ActiveCN103510704AGuarantee the construction qualityReduce construction difficultyBuilding material handlingTime limitEngineering

The invention discloses a method for constructing an electronic workshop cleaning system. The method includes the steps of purification air conditioning system construction, cleaning room construction, electrical facility installation, device installation, piping engineering, cleaning room comprehensive performance debugging and detecting and the like. According to the method for constructing the electronic workshop cleaning system, the construction quality of the cleaning room can be guaranteed, the construction difficulty is reduced, the project time limit is shortened, and the method has the obvious social and economical benefits.

Owner:江苏金禾建设工程有限公司

Testing device for odors, VOC and floating harmful substances

ActiveCN106093311AAvoid influenceImprove test accuracyMaterial analysisHazardous substanceEngineering

The invention discloses a testing device for odors, VOC and floating harmful substances. The testing device comprises a constant temperature and / or constant humidity cleaning room, and at least one odor and VOC testing bin installed in the constant temperature and / or constant humidity cleaning room. Each odor and VOC testing bin comprises a bin body provided with at least one odor sampling port, wherein the bin body is connected with a gas compensation device which is used for carrying out gas volume compensation on the interior of the bin body in the gas sampling process to prevent pollution gas outside the bin body from entering the bin body due to a gas pressure difference, the gas compensation device is installed inside or outside the bin body, or is provided with a large opening to be fixed to the wall of the bin body in a sealed mode, and each odor and VOC testing bin further comprises an external circulation and filtering device arranged outside the bin body. The bin bodies can sample gas under gas exchange / sealing conditions, the release amount of formaldehyde, VOC and other volatile harmful gas volatilized in a tested object can be detected, and the interference influence on a testing result by the environment factor or other uncertain factors can be avoided, so that stability and testing precision are high.

Owner:北京市产品质量监督检验院 +2

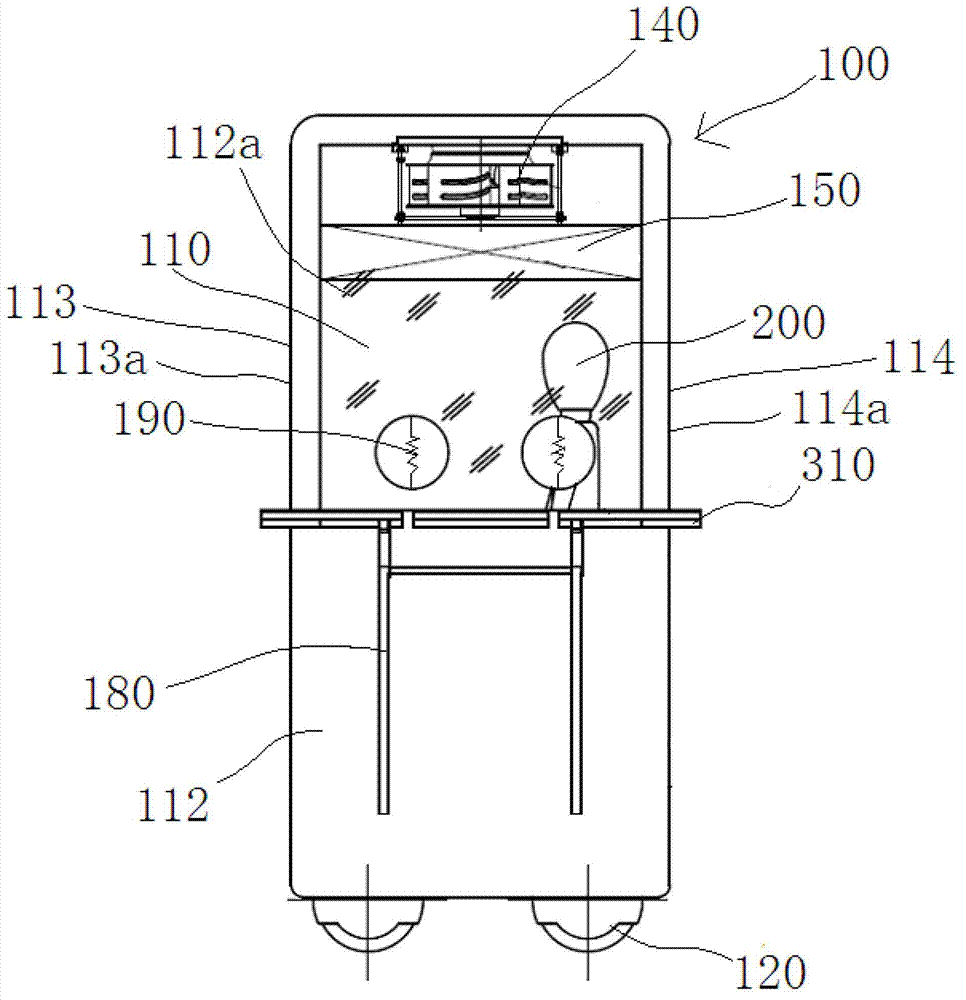

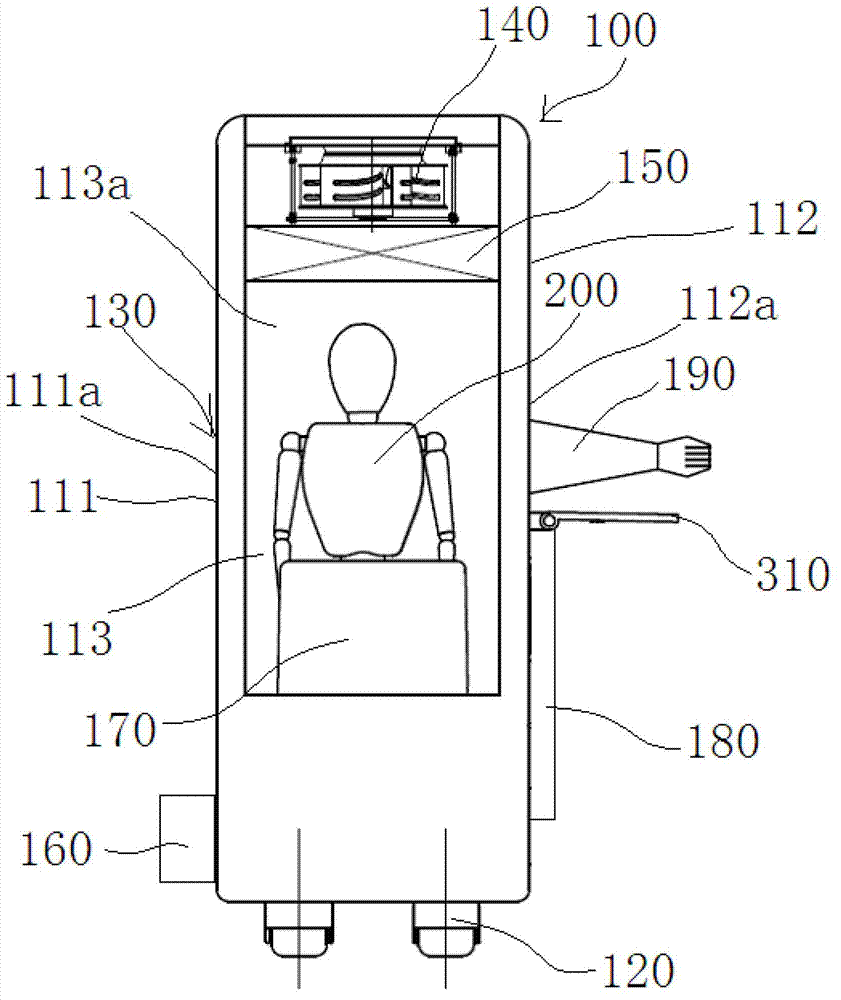

Charging type manned cleaning movable small car used in special environments

InactiveCN103395074AEasy to move and controlSimple and clean shapeManipulatorVariable air volumePharmacy

The invention discloses a charging type manned cleaning movable small car used in special environments. The charging type manned cleaning movable small car comprises a movable small car body, an openable seal door and a power box, wherein a sealed space is reserved in a compartment of the movable small car, the openable seal door is arranged on the first box face of the movable small car, and the power box provides power for the movable small car. An operation system, a variable air volume fan assembly and an efficient air filter are further arranged in the compartment, wherein the operation system drives the small car to move through an instruction, and the variable air volume fan assembly can provide the positive pressure state for the inside of the compartment. A sterilize glove extending outwards is arranged on the second lateral face of the movable small car, and a glove opening of the sterilize glove faces to the inside of the compartment. The charging type manned cleaning movable small car is applied to the special environments in the industries of pharmacy, electronics, precise instruments, meters, bioengineering and the like, wherein human cannot make contact with articles in the special environments, the articles are moved to the required position under the condition that operation personnel in the small car are isolated from the outer environment and are not in direct contact with the articles, and production equipment in a cleaning room can be further controlled or maintained with the aid of auxiliary tools.

Owner:上海千山远东制药机械有限公司

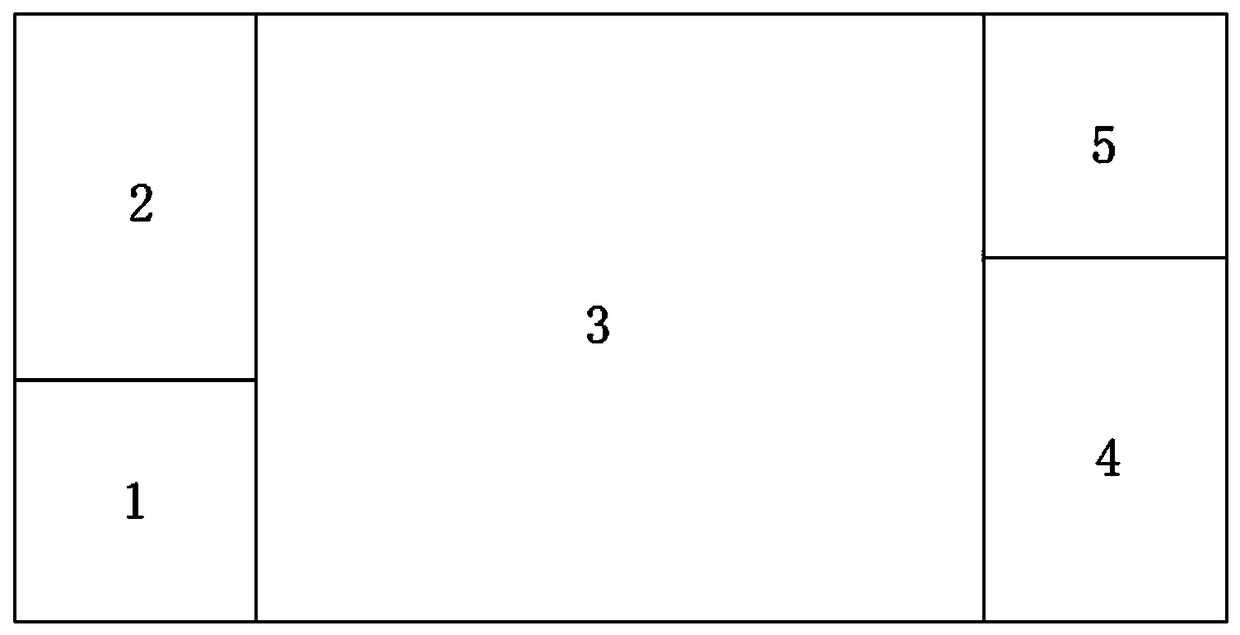

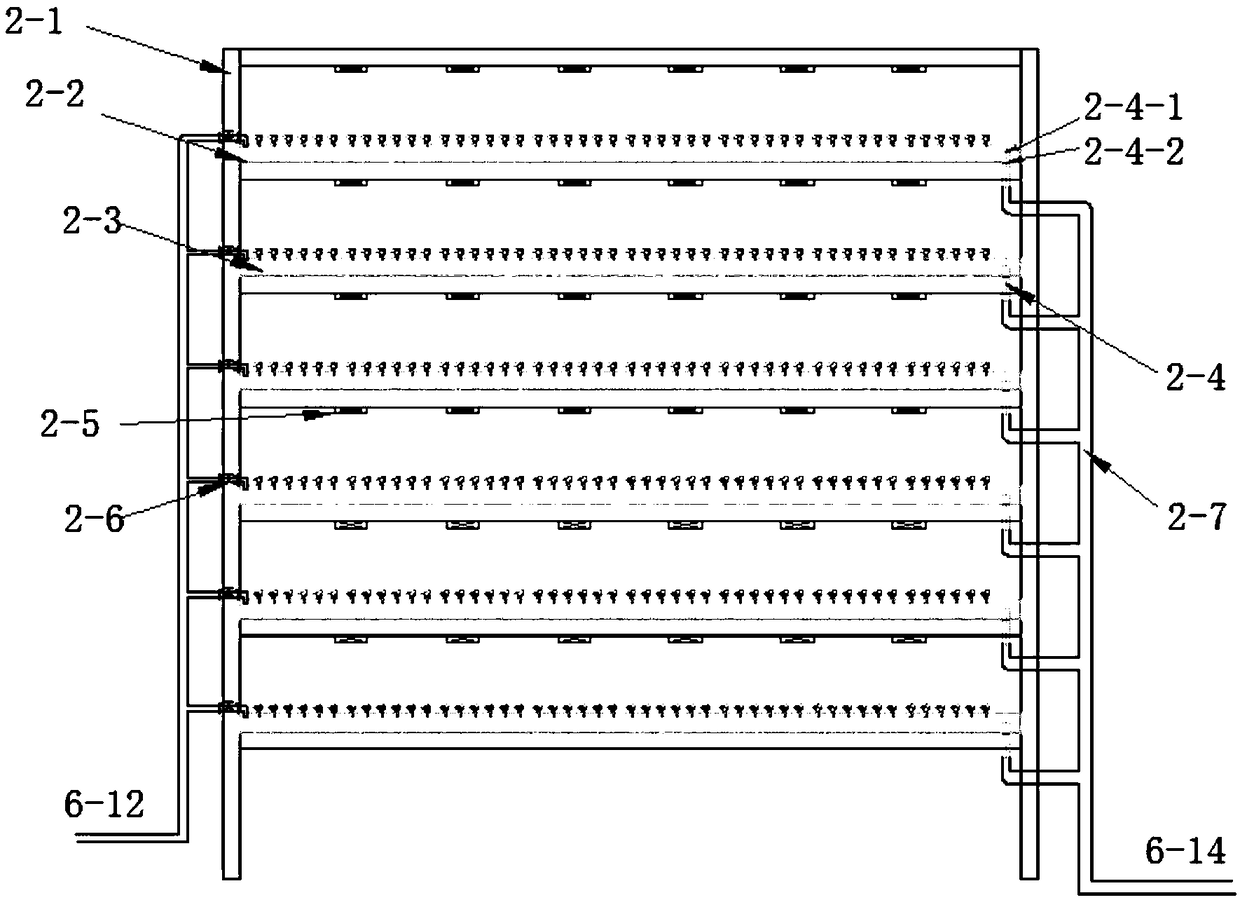

Indoor plant factory system

ActiveCN108575725AHigh degree of automationSave human effortAgriculture gas emission reductionCultivating equipmentsNutrient solutionHouse plants

The invention provides an indoor plant factory system. The system comprises a planting room, a nutrient solution room and a control system, wherein the planting room comprises a seeding room, a seedling room, a cultivation room, a harvesting room, a cleaning room, and is a planting place of plants; the nutrient solution chamber is provided with a mother liquid tank, a nutrient liquid tank and an assorted water supply and drainage system, and is a preparation and control place for a nutrient solution; the control system comprises an HVAC control system, a nutrient solution control system and anLED growth lamp illumination system, and is used for monitoring, adjusting and controlling environmental parameters in a plant factory and a nutrient solution system. The indoor plant factory systemhas the advantages that the degree of automation is high; an assorted loading and unloading device and cultivation groove transport equipment are arranged, so that the manpower is reduced; the nutrient solution, the environmental temperature and humidity, the LED fill-in light, the CO2 gas fertilizer and the like are highly automatically controlled, so that the manpower is reduced, errors caused by human operation are avoided, the space utilization is high, the planting row spacing can be adjusted along with the growth of vegetables, and compared with a conventional planting method, planting amount can be increased by 50% per unit area.

Owner:LIUHEFENG TIANJIN TECH CO LTD

Endoscopic disinfection device for otolaryngological department

InactiveCN105343907ANeat and orderly dischargeEnsure hygiene and safetyLavatory sanitoryHeatWater leakageDisinfectant

The invention discloses an endoscopic disinfection device for the otolaryngological department. The endoscopic disinfection device comprises a shell, a sealing door is hinged to the side face of the shell, the middle of the sealing door is provided with a transparent observation window, the side face of the shell is provided with a control panel, an inner cavity of the shell is divided into a sterilizing room, a cleaning room and a storage room from top to bottom through a first partition plate and a second partition plate, the surface of the second partition plate and the surface of a sliding plate located in the cleaning room are high in the middle and low on the two sides, the bottom of the shell is provided with an equipment mounting cavity, the equipment mounting cavity is provided with a drive motor, a warm air machine and a liquid storage tank, and the liquid storage tank is internally provided with a booster pump; a control panel is electrically connected with the drive motor, the warm air machine and the booster pump. By means of the endoscopic disinfection device, heating sterilization or ultrasonic sterilization can be selected for endoscopes which are difficult to sterilize thoroughly according to requirements, or heating sterilization and ultrasonic sterilization are combined to conduct sterilization, and sterilization is made to be more thorough; sterilization waste water can be drained through water leakage tanks and cleaning spray heads, meanwhile disinfectant can be cleaned away, and subsequent use cannot be affected.

Owner:徐建华

Cleaning and drying device for glass production

InactiveCN107900053AEasy to fixPrevent slidingDrying solid materials without heatDrying gas arrangementsEngineeringConveyor belt

The invention discloses a cleaning and drying device for glass production. The cleaning and drying device comprises a rack, a cleaning room, a sprinkler head and a pressure regulator; support shafts are arranged on two sides above the rack, and electric conveyor belts are arranged around the support shafts; the surface of the electric conveyor belts are provided with suction plates; the cleaning room is arranged on one side of the electric conveyor belts, and a cleaning roller is arranged in the cleaning room; installation frames are arranged at the middle of the electric conveyor belts, and awater absorption sponge is arranged under the installation frames; one side of the installation frames is provided with a drying chamber, and heating wires are arranged in the drying chamber; and a fan is arranged above the heating wires. The glass slide on the device can be avoided by the cleaning and drying device for glass production, and the glass can be cleaned continuously. The pressure regulator can be used to adjust the pressure of the roller to the surface of the glass, so that the cleaning and drying device is suitable for various thickness of glass. In addition, the cleaning and drying device can dry the glass continuously.

Owner:王济龙

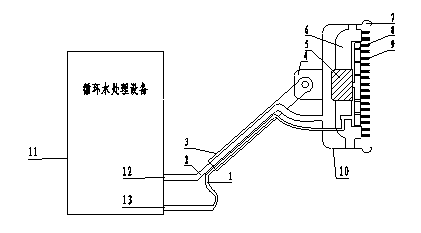

Water circulation device for vehicle cleaning

InactiveCN103419759AEfficient recyclingPrevent splashCleaning apparatus for vehicle exteriorsElectric machineryWater resources

The invention relates to a water circulation device for vehicle cleaning. A cleaning motor is fixed on a motor base, a rubber apron is fixed onto the side of the motor base, a universal connector connected with a handle is fixed at the top end of the motor base, a cleaning pipe and a negative-pressure sewage pipe are disposed in the middle of the handle, the cleaning pipe is communicated with a high-pressure spray pipe, the cleaning motor rotates to drive a revolving brush, water is sprayed from the high-pressure spray pipe to have the surface of a vehicle cleaned, sewage is let out from the negative-pressure sewage pipe to circulating water treatment equipment, the rubber apron is fixed onto the side of the motor base to prevent the water and the sewage from splashing all around, the handle connected with the universal connector can rotate freely to adapt to different angles of cleaning, the sewage can be effectively recycled to the circulating water treatment equipment, and accordingly the purpose of recycling water resources can be achieved.

Owner:陈达平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com