Cleaning machine for rack parts of automobile steering devices

A technology for automobile steering gear and washing machine, which is applied in the directions of dryers, chemical instruments and methods, cleaning methods and utensils, etc. Cleaning mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

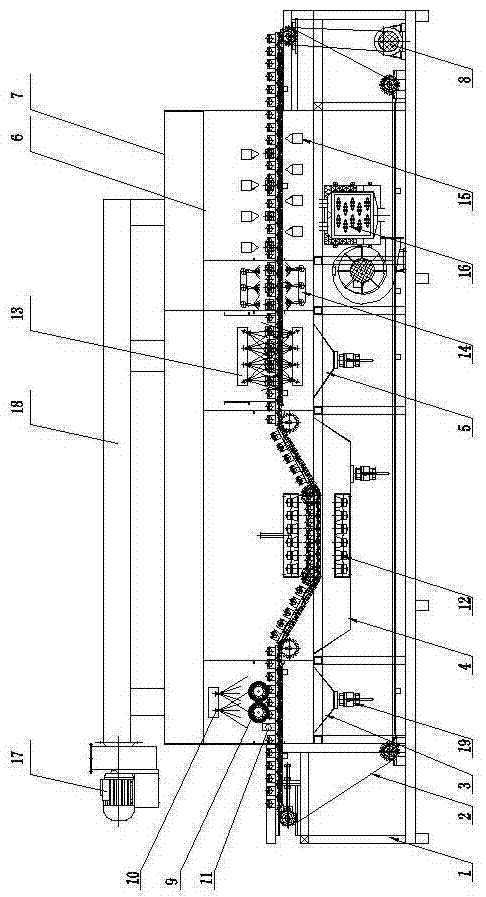

[0016] The automotive steering gear rack parts cleaning machine is composed of a frame 1, a conveyor chain 2, a spray scrub tank 3, an ultrasonic cleaning tank 4, a high-pressure spray cleaning tank 5, a drying room 6 and an electrical control box. A cleaning chamber 7 is installed across the frame 1; a conveyor chain 2 is installed on the top of the frame 1 through a drive shaft and a motor 8. One end of the rack 1 is provided with an electrical control box (not shown in the figure). The conveyor chain 2 one end in the cleaning chamber 7 is equipped with a spray scrub tank 3 by the frame 1 below, and the spray scrub tank 3 top is equipped with a rolling brush 9 by the frame 1. Spray cleaning head 10 is housed by frame 1 above the rolling brush 9 . One side of rolling brush 9 ends is equipped with high-pressure nozzle 11 by frame 1. The high-pressure nozzle 11 is used for cleaning the elongated deep holes of the rack parts.

[0017] An ultrasonic cleaning tank 4 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com