A rotary stamping die

A technology for stamping dies and templates, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of rotation angle fixed mold and movable mold matching errors, high precision requirements and manufacturing costs, and increase the labor intensity of operators. Achieve the effect of extending processing time, increasing processing time and reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] The above, upper end, lower end, and lower end described below all refer to the positional relationship in the direction of gravity.

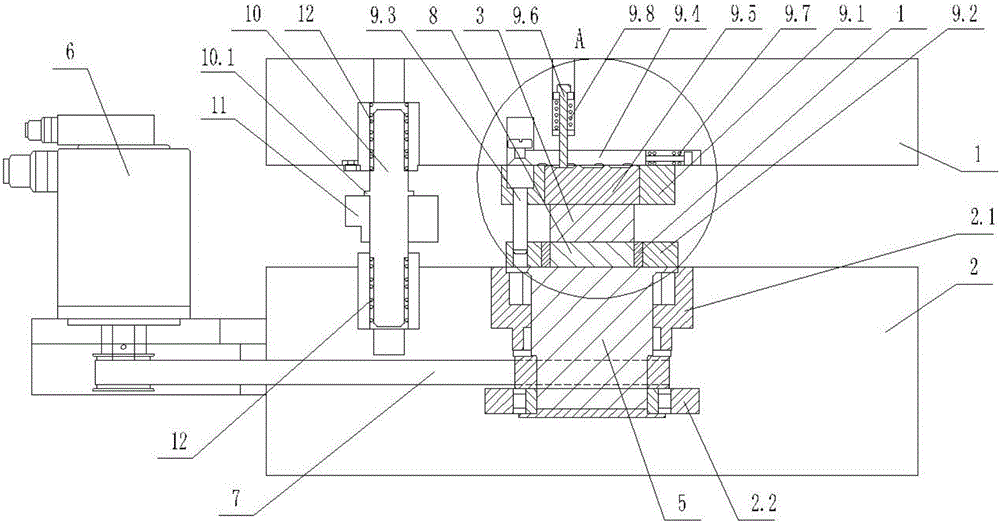

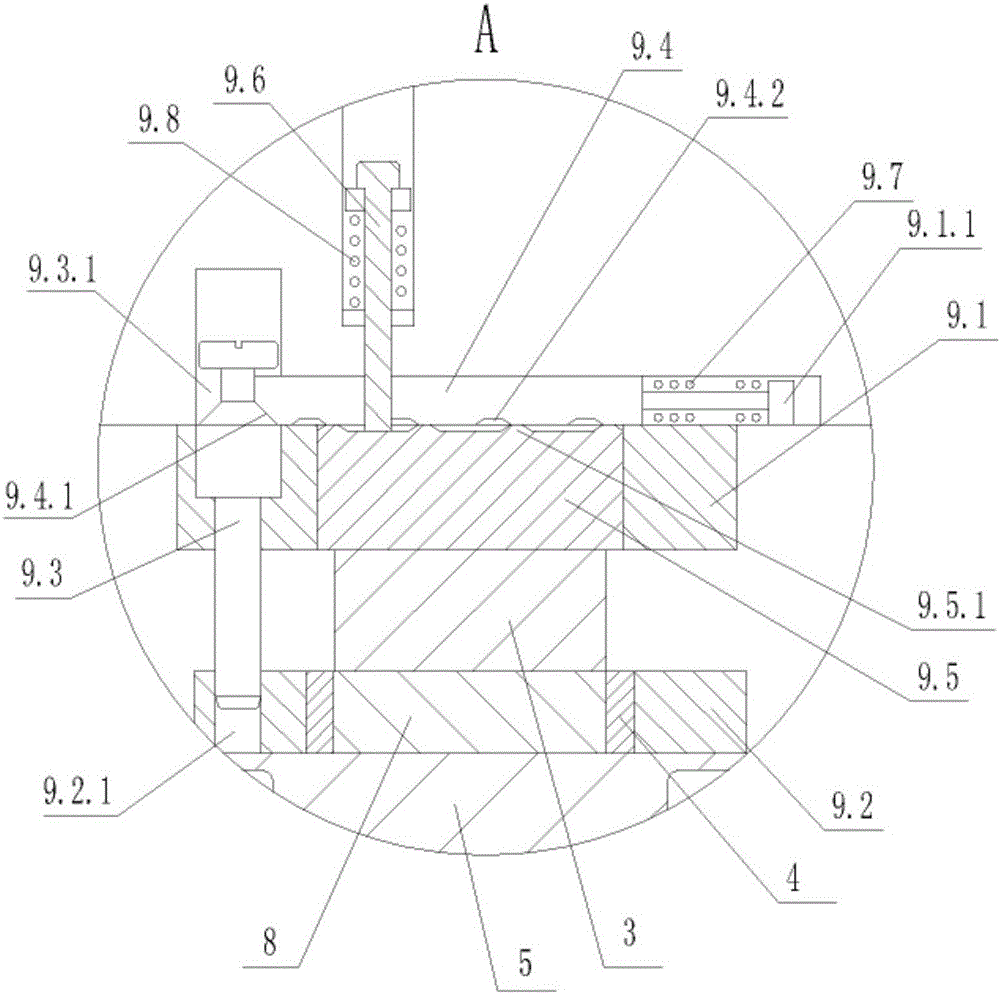

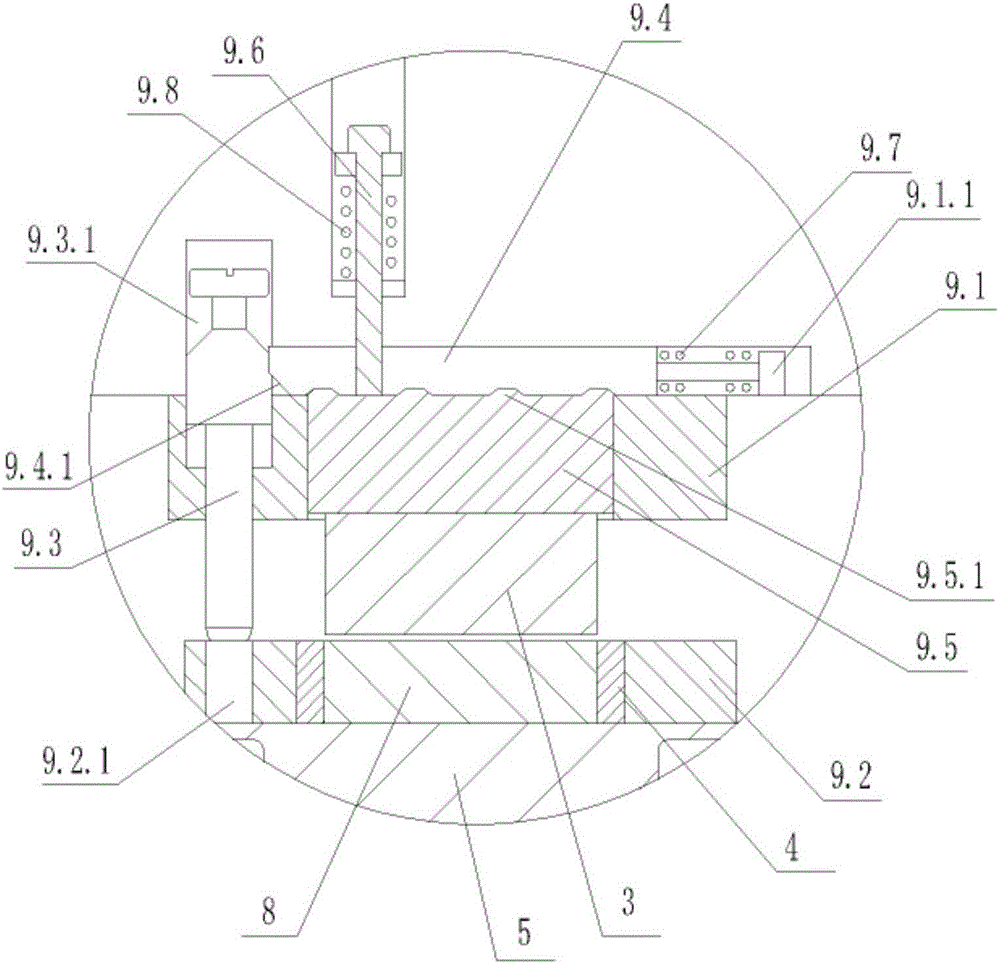

[0018] As shown in the figure, the present invention provides a rotary stamping die, which includes an upper template 1, a lower template 2, an upper module 3 and a lower module 4 for stamping products 8 between the upper template 1 and the lower template 2, and Set on the lower template 2 to drive the rotating shaft 5 of the lower module 4 to rotate, the product 8 is arranged in the mold cavity in the lower module 4, the upper module 3 is fixed to the lower end surface of the upper template 1, and the lower module 4 and One end of the rotating shaft 5 near the upper module 3 is fixed, that is to say, the lower module 4 is fixed to the upper end of the rotating shaft 5 . The rotating shaft 5 is rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com