Asphalt self-adhesive and high-polymer self-adhesion rubber waterproof coiled material prepared from asphalt self-adhesive

A technology of waterproof roll material and polymer sheet, which is applied in the direction of non-polymer adhesive additives, other rubber adhesives, asphalt material adhesives, etc. Pollution and overlapping problems, to achieve the effect of reducing deformation, reliable bonding firmness, and avoiding damage

Inactive Publication Date: 2012-07-11

SHENZHEN ZHUOBAO TECH

View PDF7 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of manufacturing process makes the self-adhesive adhesive and the subject material layer bond firmly, and it cannot be peeled off by artificial methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

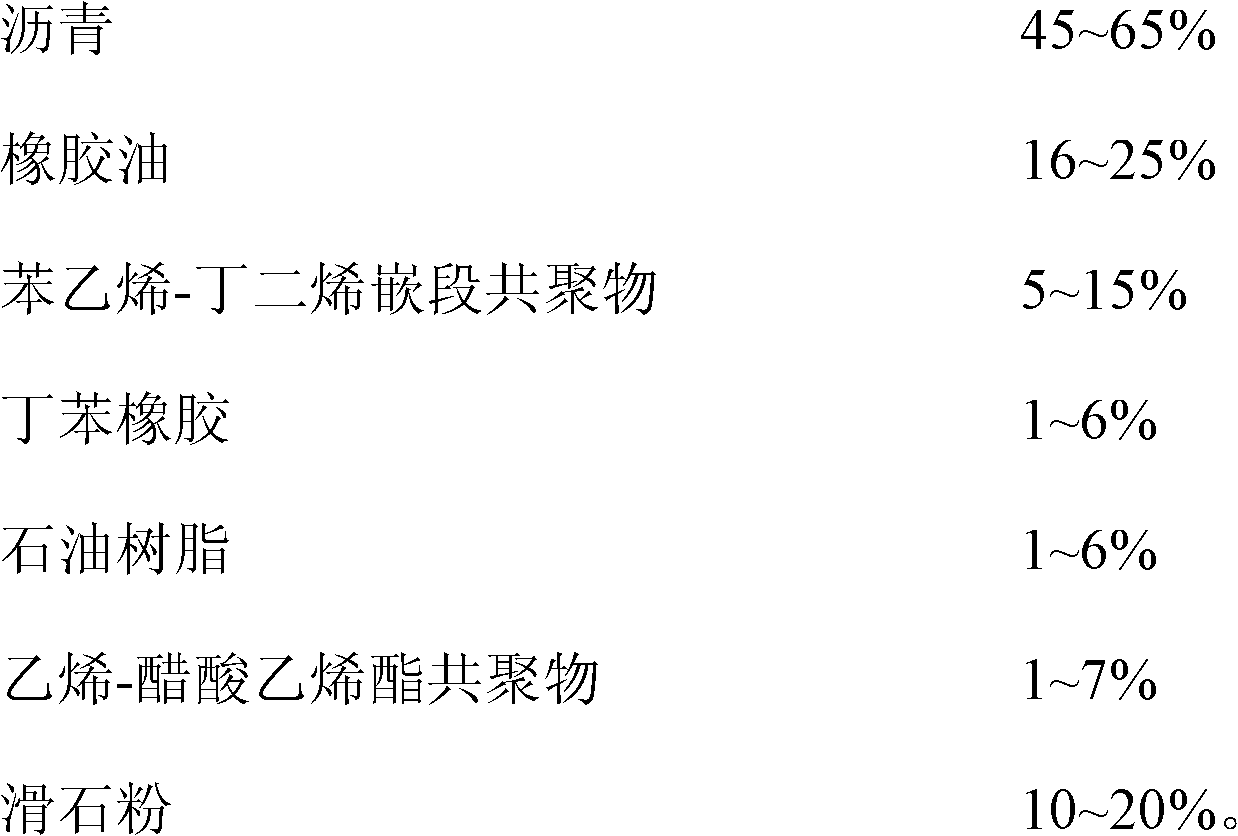

[0046] A kind of asphalt self-adhesive, which comprises by weight percentage:

[0047]

Embodiment 2

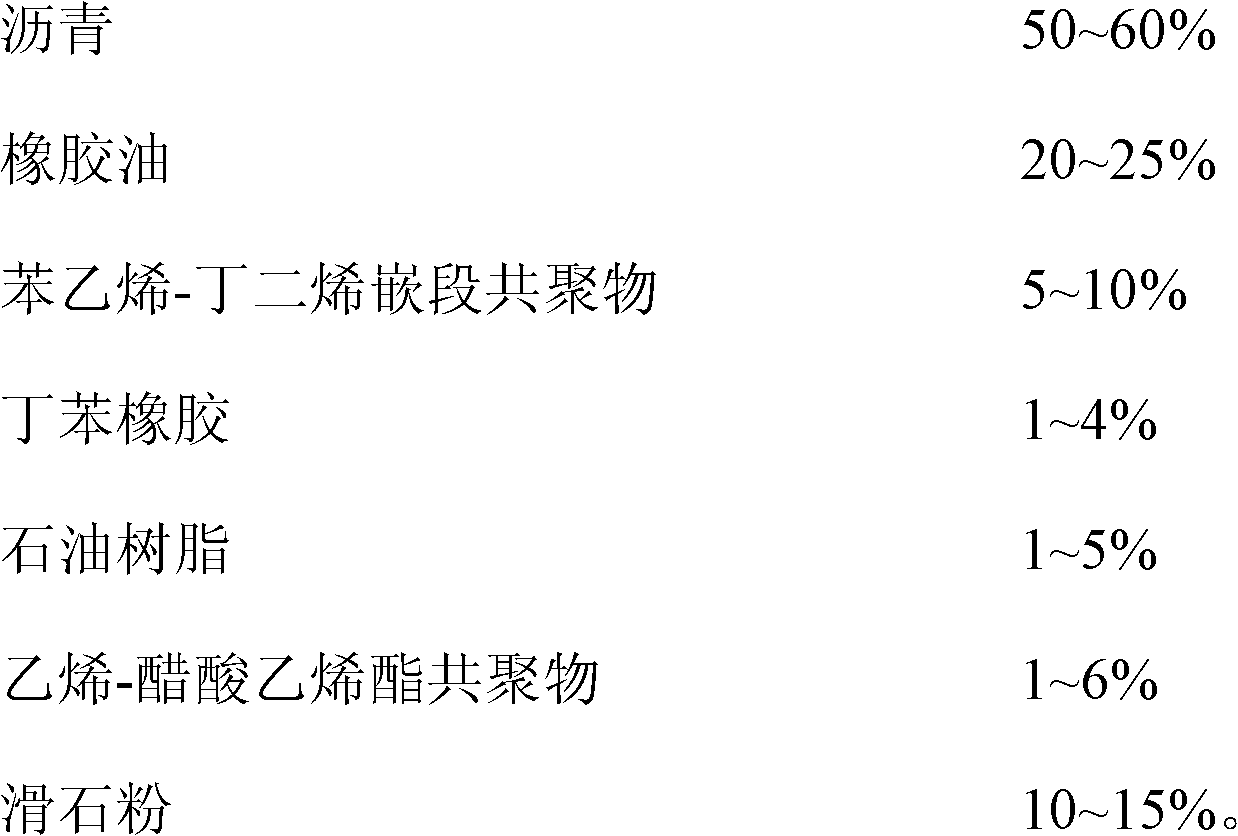

[0049] A kind of asphalt self-adhesive, which comprises by weight percentage:

[0050]

Embodiment 3

[0052] A kind of asphalt self-adhesive, which comprises by weight percentage:

[0053]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses asphalt self-adhesive. The asphalt self-adhesive comprises the following components in percentage by weight: 45 to 65 percent of asphalt, 16 to 25 percent of rubber oil, 5 to 15 percent of styrene butadiene styrene (SBS), 1 to 6 percent of styrene butadiene rubber (SBR), 1 to 6 percent of petroleum resin, 1 to 7 percent of ethylene vinyl acetate (EVA), and 10 to 20 percent of talcpowder. The invention also provides a high-polymer self-adhesion rubber waterproof coiled material which comprises a non-woven fabric coating, a high-polymer sheet coating, and an asphalt self-adhesive coating which consists of the asphalt self-adhesive from bottom to top. Two ends of the waterproof coiled material are provided with joint sides. The asphalt self-adhesive contains EVA, so the compatibility of the self-adhesive and a high-polymer sheet is improved, and compounding intensity of the high-polymer sheet coating is improved. The problem that the high-polymer sheets cannot be jointed reliably in a self-adhesion joint process is solved, so the coiled materials are jointed by the adhesive; and the coiled materials can be adhered firmly and reliably, and adjusted freely and flexibly.

Description

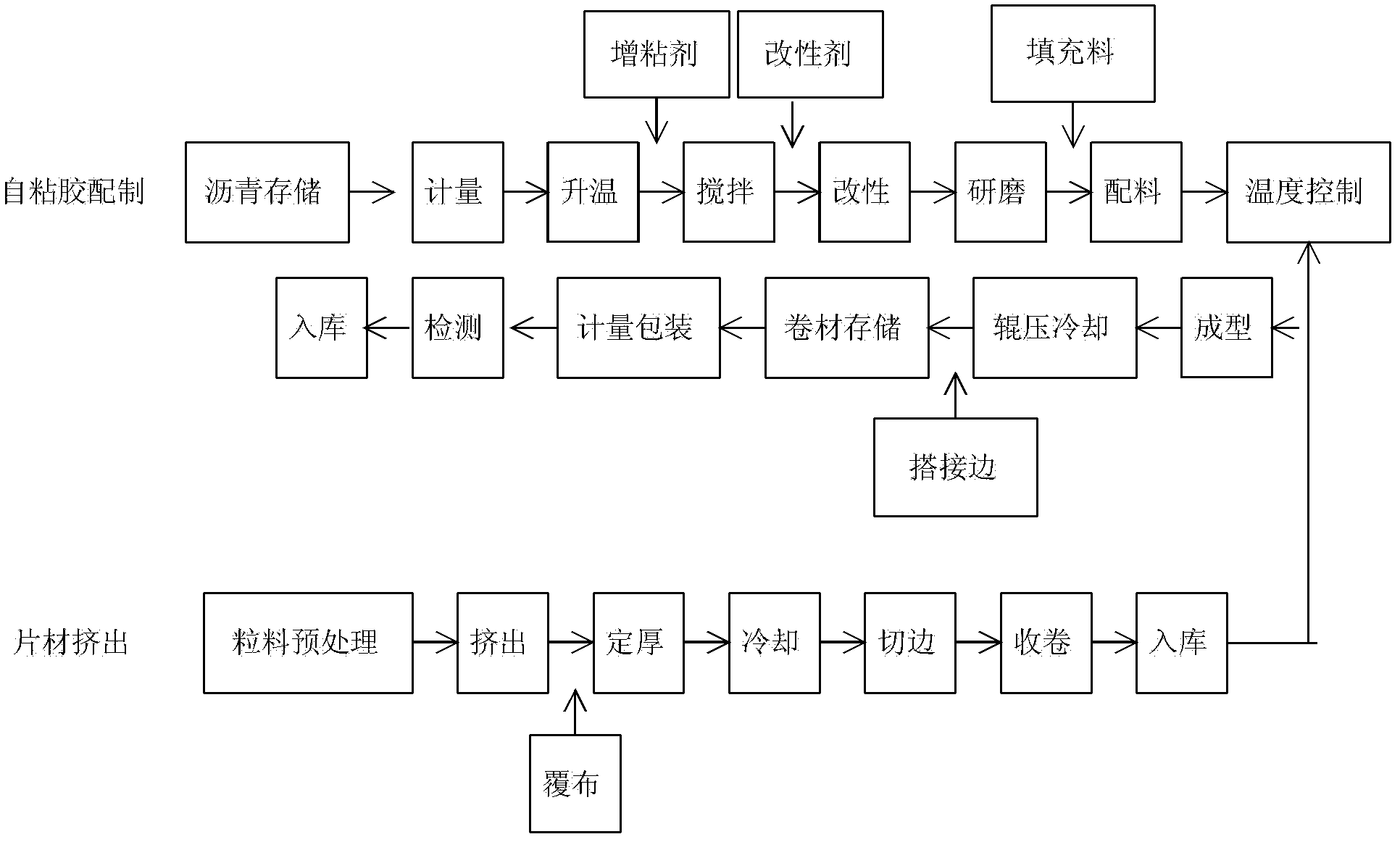

technical field [0001] The invention relates to a self-adhesive glue, and also relates to a polymer self-adhesive rubber waterproof roll material made of the self-adhesive glue, which can realize the adhesive glue overlapping mode. Background technique [0002] At present, my country's waterproof membranes include asphalt-based membranes and polymer membranes. The construction methods of asphalt-based membranes include: wet laying, pre-laying, self-adhesive, hot-melt and empty laying, and the construction methods of polymer membranes include: empty laying, mechanical fixing and gluing. The overlapping methods of asphalt-based coils include: self-adhesive, hot-melt, and the overlapping methods of polymer coils include: hot-melt welding and adhesive bonding. [0003] The hot-melt construction method is more common; the use of empty paving is relatively rare, and it is mainly suitable for engineering projects with a relatively low waterproof level; the self-adhesive constructi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J195/00C09J121/00C09J153/02C09J109/06C09J157/02C09J123/08C09J11/04C09J7/04E04B1/66E04D5/10

Inventor 李明扬蒋继恒杨继海林旭涛

Owner SHENZHEN ZHUOBAO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com