Microspherical SiO2 aerogel compound heat-insulating/warm-keeping external wall paint and preparation method thereof

A heat insulation and exterior wall coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, silica, etc., can solve the problems of affecting thermal insulation performance, low thermal conductivity, and inability to achieve external wall heat insulation, etc., to achieve Effect of improving thermal insulation performance, reducing thermal conductivity, and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

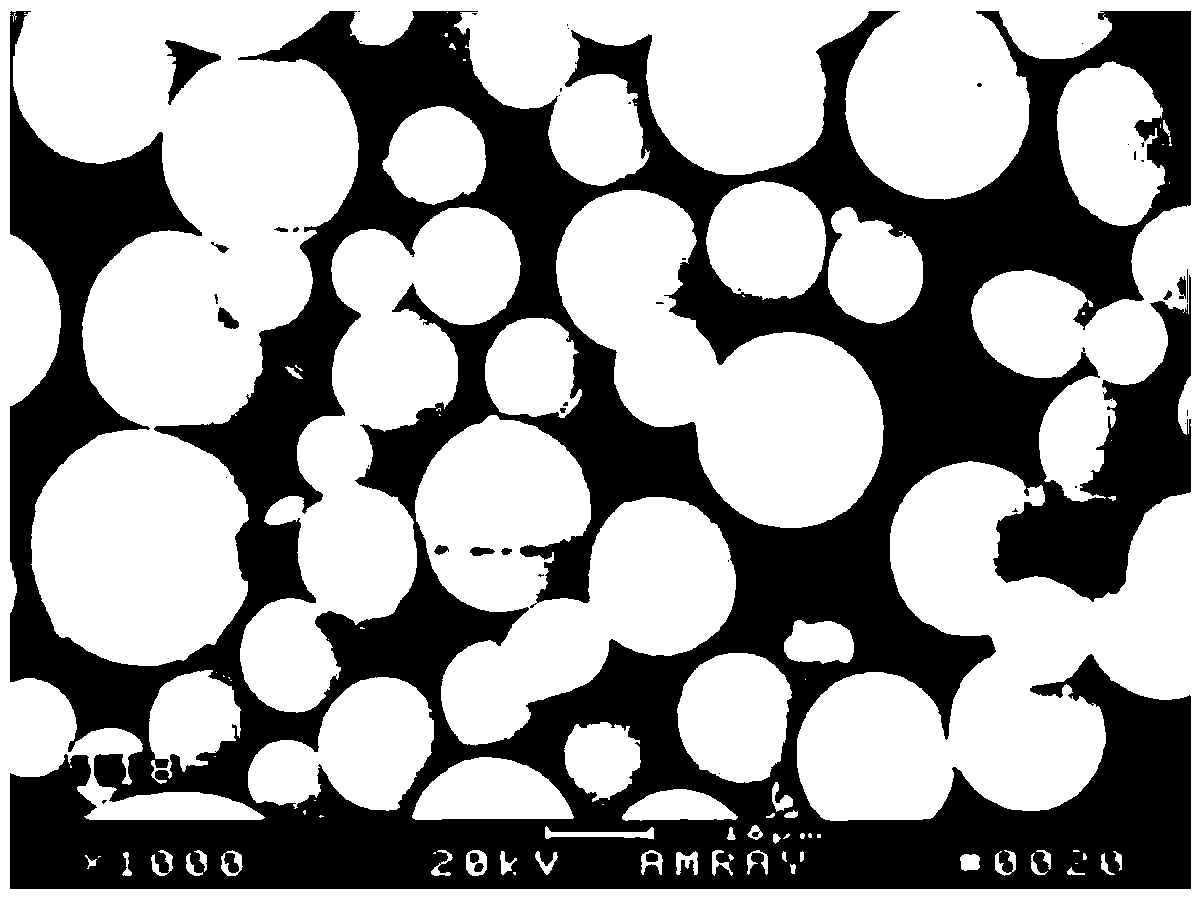

[0060] Microspherical SiO 2 The preparation process steps of airgel powder:

[0061] At room temperature, 25% silica sol was stirred and diluted with 10 volumes of deionized water, and the pH value of the silica sol was adjusted to 2 with 10% hydrochloric acid.

[0062] Measure the volume ratio of n-heptane: Span 80: Tween 85: n-butanol = 1000: 1: 0.1: 25, and prepare the oil phase. At a stirring speed of 500r·min -1 Add the previously prepared silica sol dropwise to the oil phase liquid in an amount of oil phase / silica sol 2.5:1 volume ratio to form a uniform water-in-oil emulsion, and adjust the silica sol in the oil phase by ultrasonic oscillation The size of the microspheres.

[0063] In the state of stirring, add concentrated ammonia water to raise the pH value of the whole emulsion to within the range of 8, and the fine particles of the sol dispersed in the oil phase will quickly precipitate due to the increase of the pH value, so reduce the stirring speed by 50...

Embodiment 2

[0066] Microspherical SiO 2 The preparation process steps of airgel powder:

[0067] At room temperature, 25% silica sol was stirred and diluted with 8 volumes of deionized water, and the pH value of the silica sol was adjusted to 1 with 10% hydrochloric acid.

[0068] Measure n-heptane: Span 80: Tween 85: n-butanol = 1000: 5: 0.5: 50 volume ratio, and prepare the oil phase. When the stirring speed is 1000r·min -1 Add the previously prepared silica sol dropwise to the oil phase liquid in an amount of oil phase / silica sol 5:1 volume ratio to form a uniform water-in-oil emulsion, and adjust the silica sol in the oil phase by ultrasonic oscillation The size of the microspheres.

[0069] In the state of stirring, add concentrated ammonia water to increase the pH value of the whole emulsion to within the range of 7. The fine particles of the sol dispersed in the oil phase will quickly precipitate due to the increase in the pH value, so reduce the stirring speed by 500r. m...

Embodiment 3

[0072] Microspherical SiO 2 The preparation process steps of airgel powder:

[0073] At room temperature, 25% silica sol was stirred and diluted with 10 volumes of deionized water, and the pH value of the silica sol was adjusted to 2 with 10% hydrochloric acid.

[0074] Measure n-heptane: Span 80: Tween 85: n-butanol = 1000: 10: 1: 100 volume ratio, and prepare the oil phase. At a stirring speed of 1500r·min -1 Add the previously prepared silica sol dropwise to the oil phase liquid in an amount of oil phase / silica sol at a volume ratio of 10:1 to form a uniform water-in-oil emulsion.

[0075] In the state of stirring, add concentrated ammonia water to increase the pH value of the whole emulsion to within 8 range, and the fine particles of sol dispersed in the oil phase will quickly precipitate due to the increase of pH value, so reduce the stirring speed by 500~ 700r·min -1 , and then stirred for 15 to 60 minutes, stopped stirring, and separated solid and liquid to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com