Patents

Literature

250results about How to "Easy to move and control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

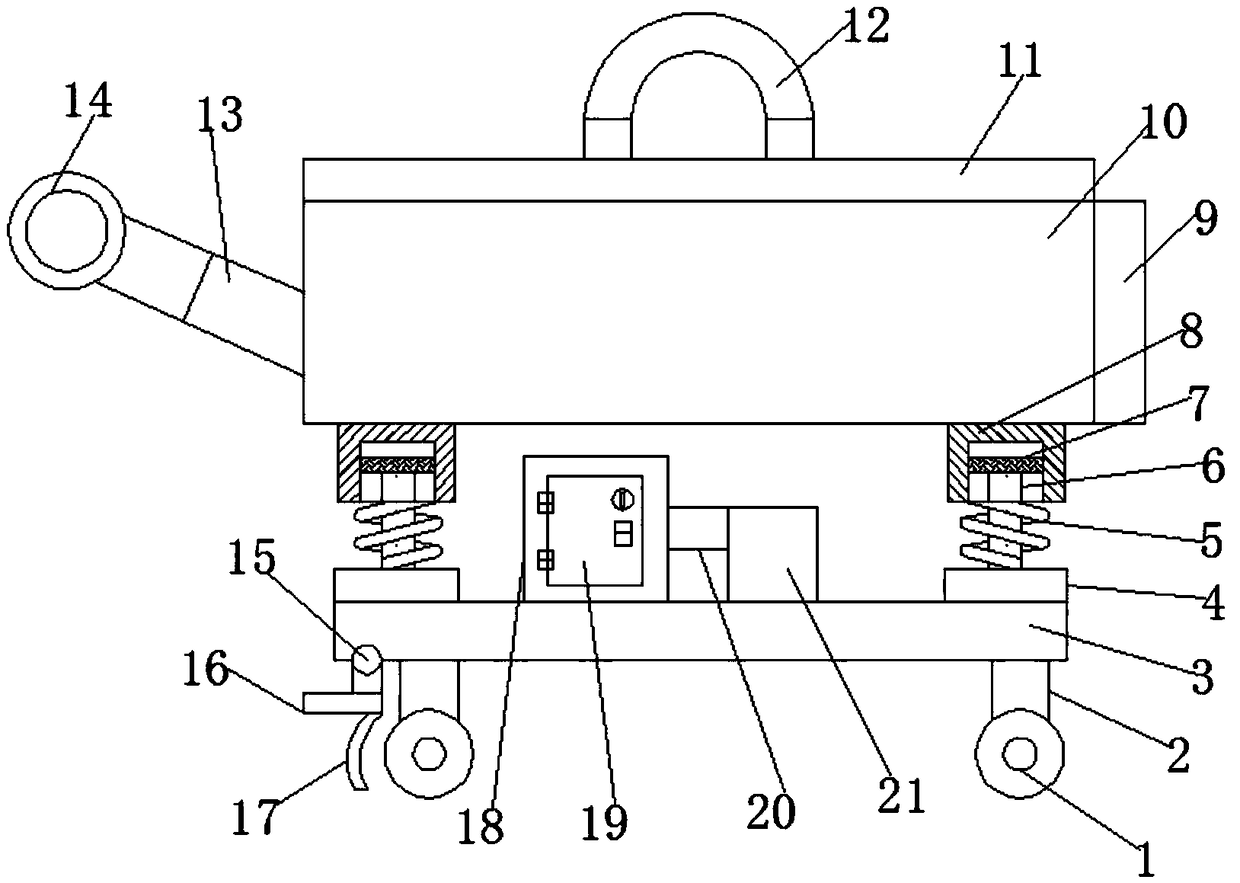

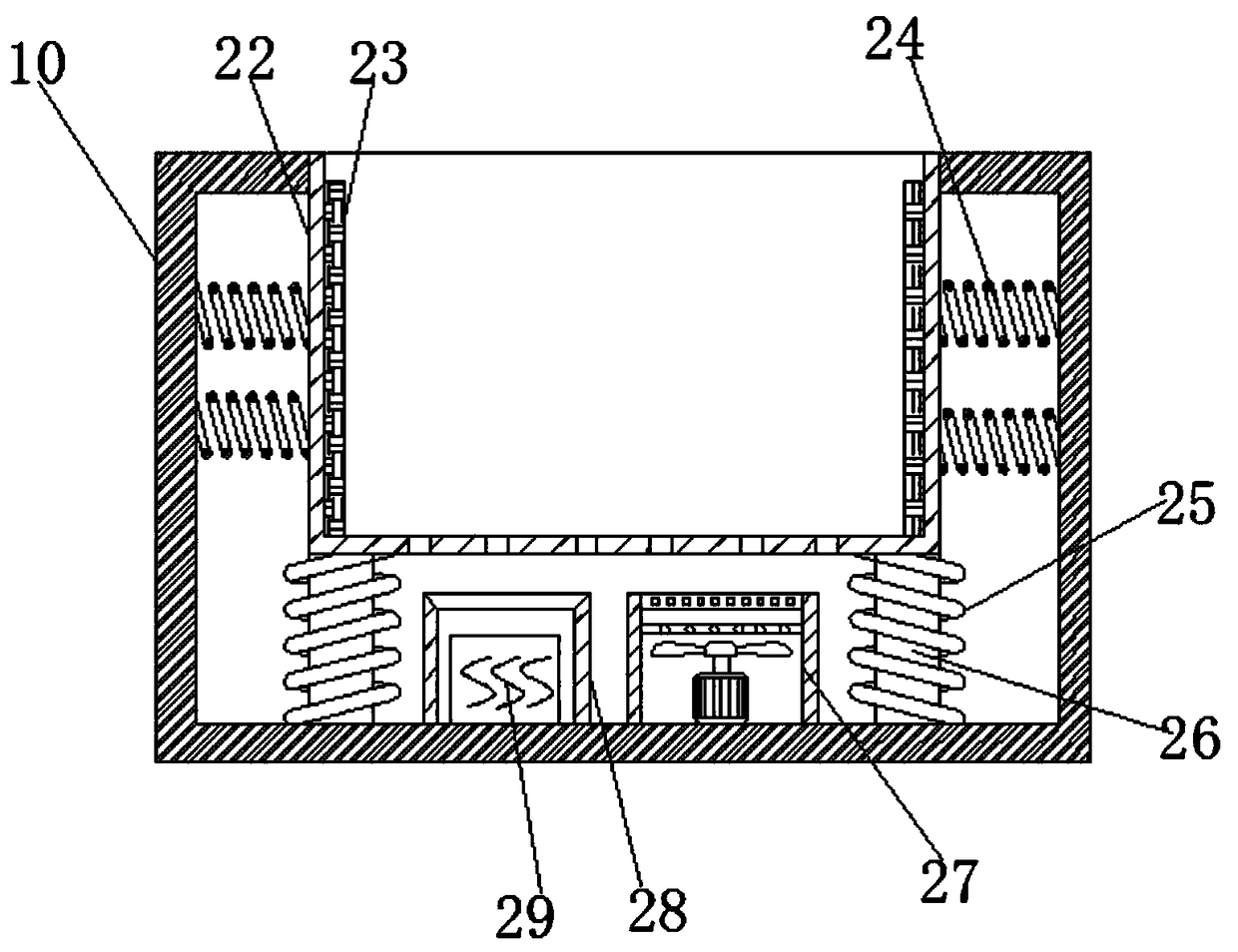

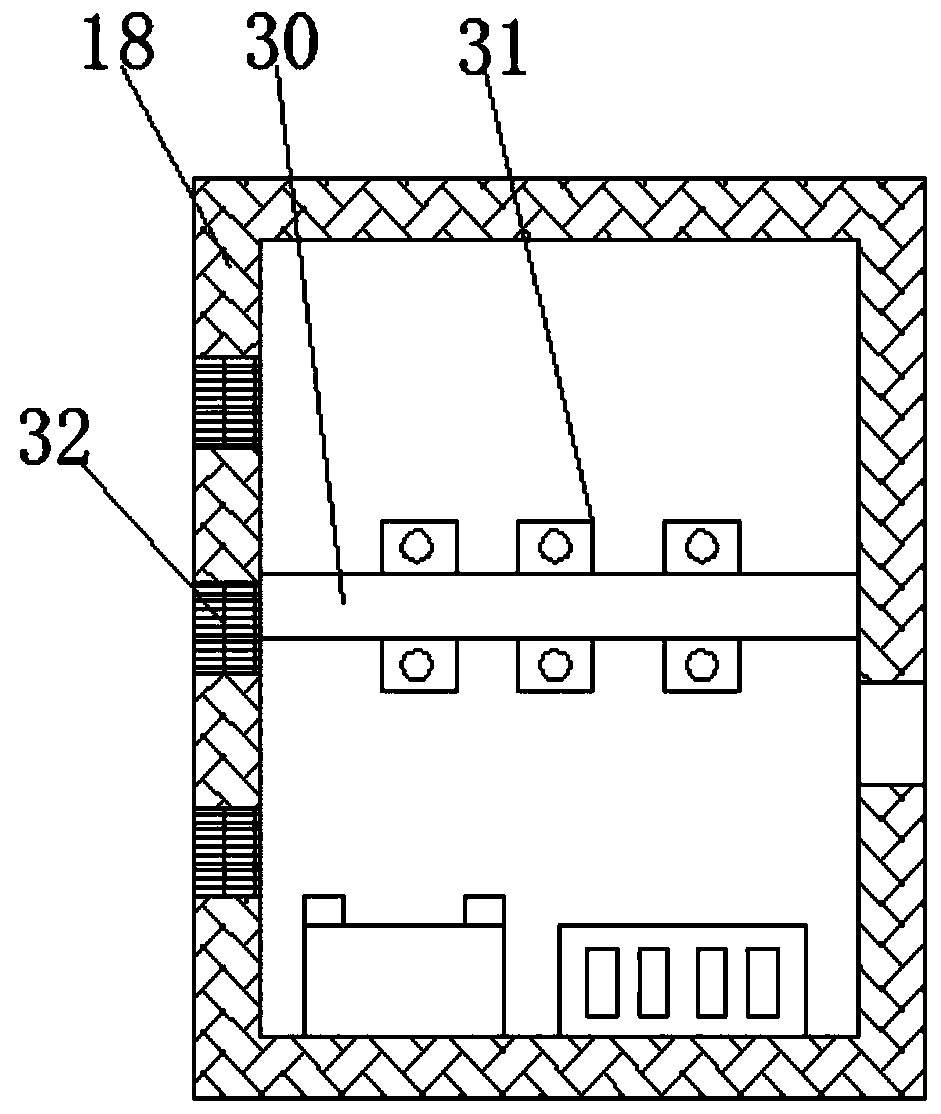

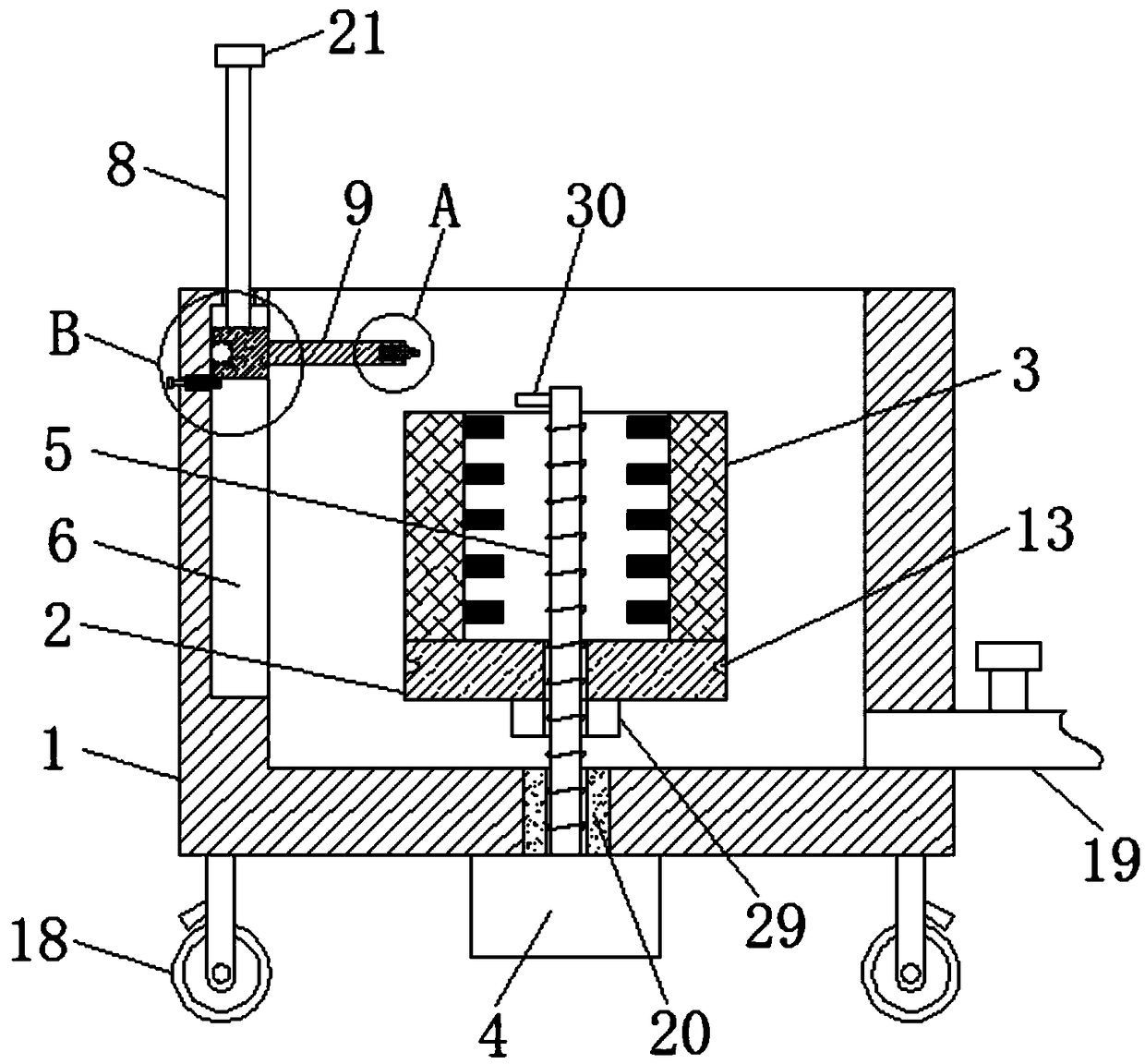

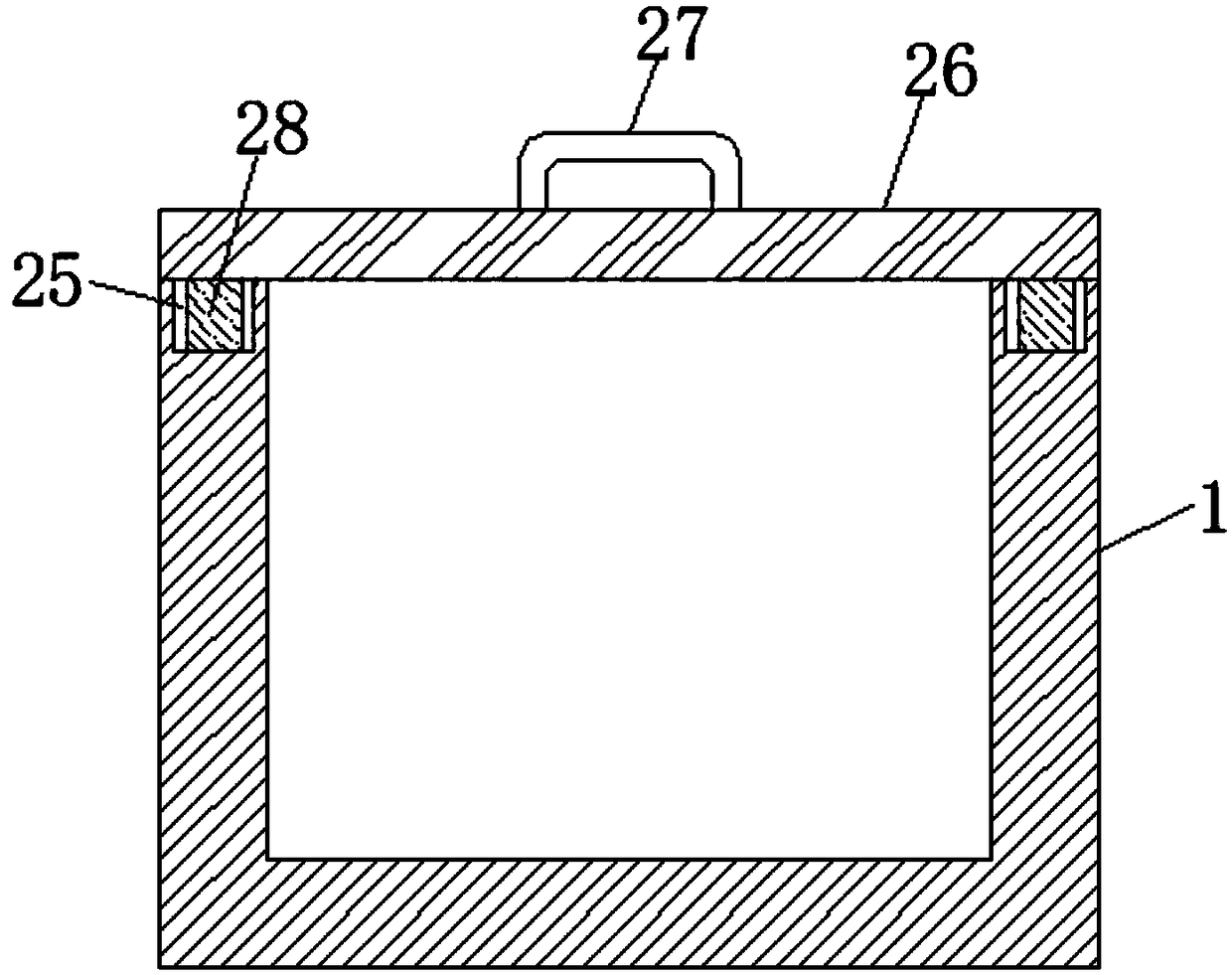

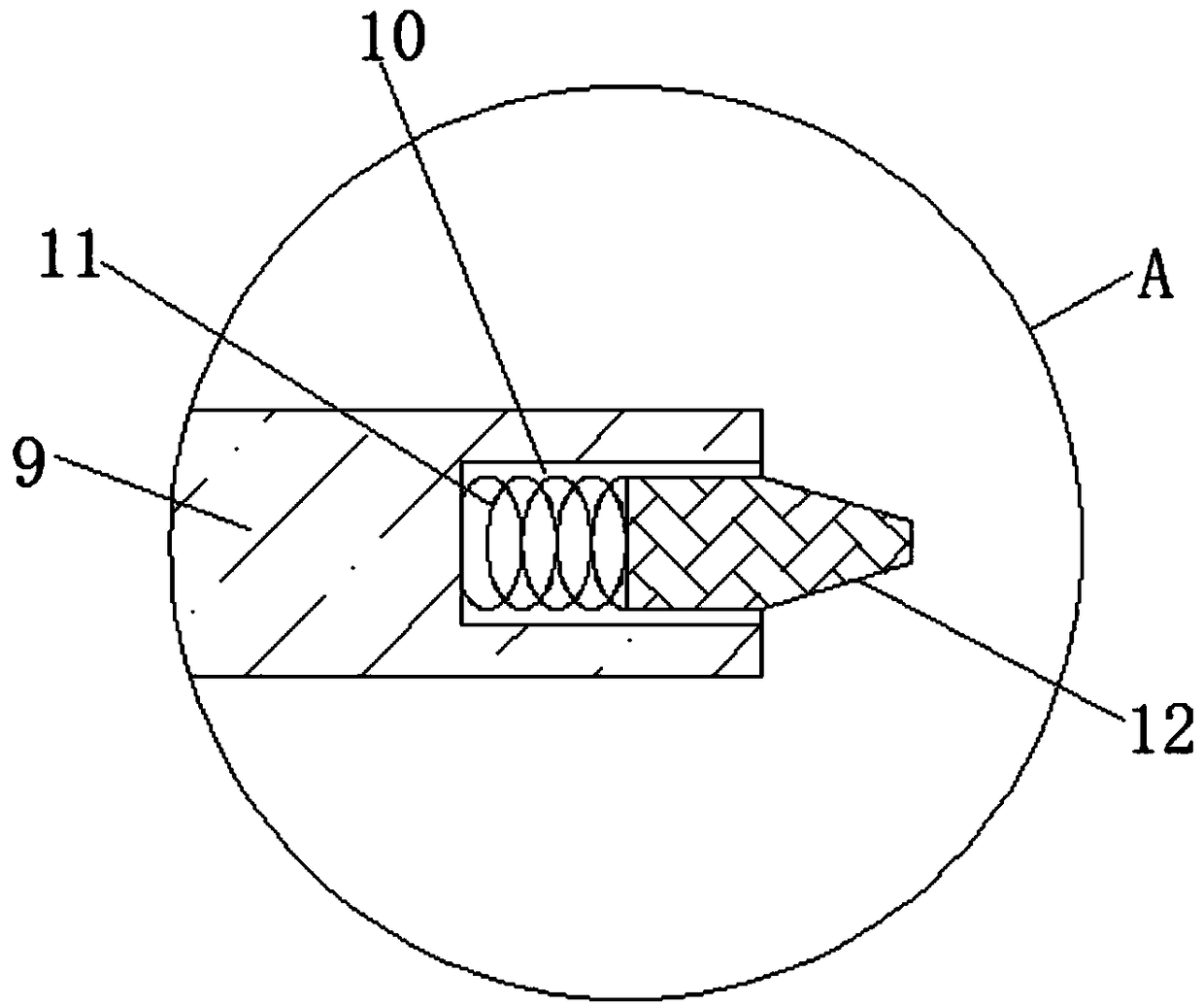

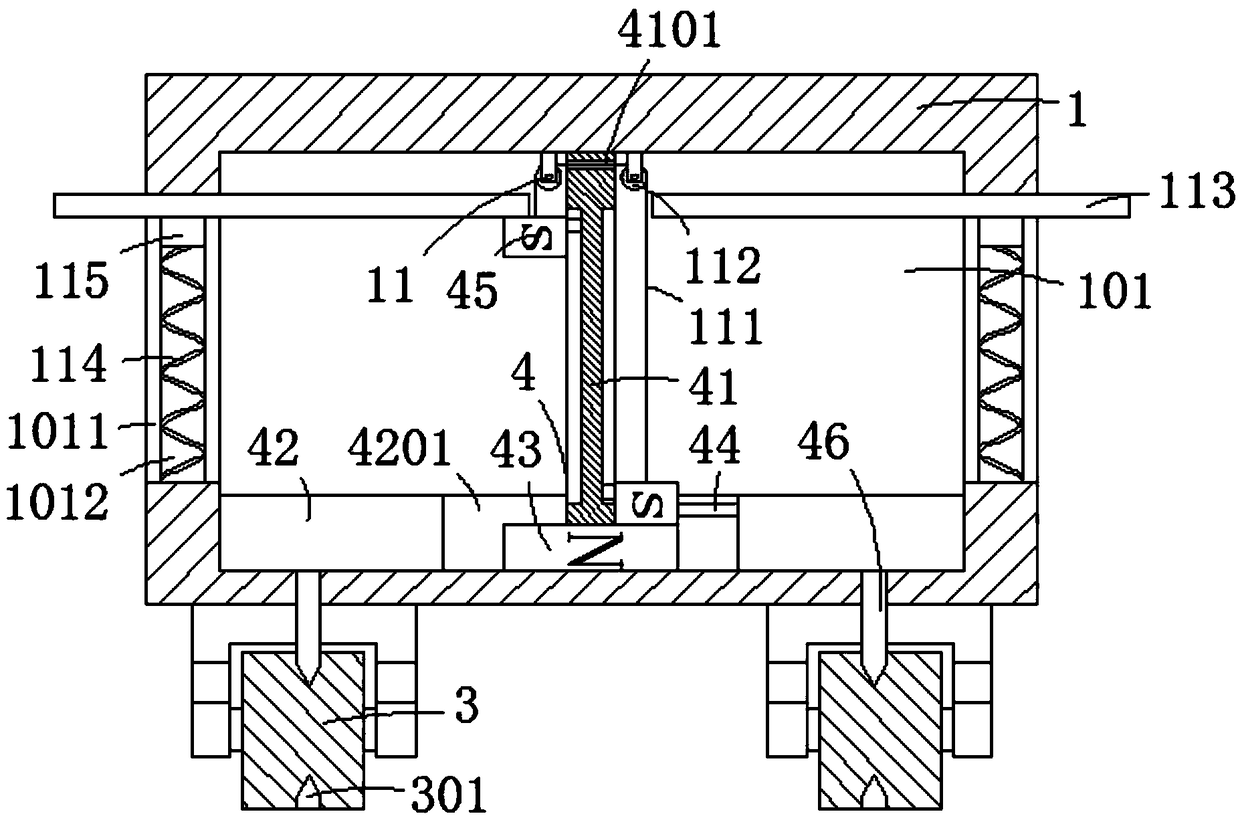

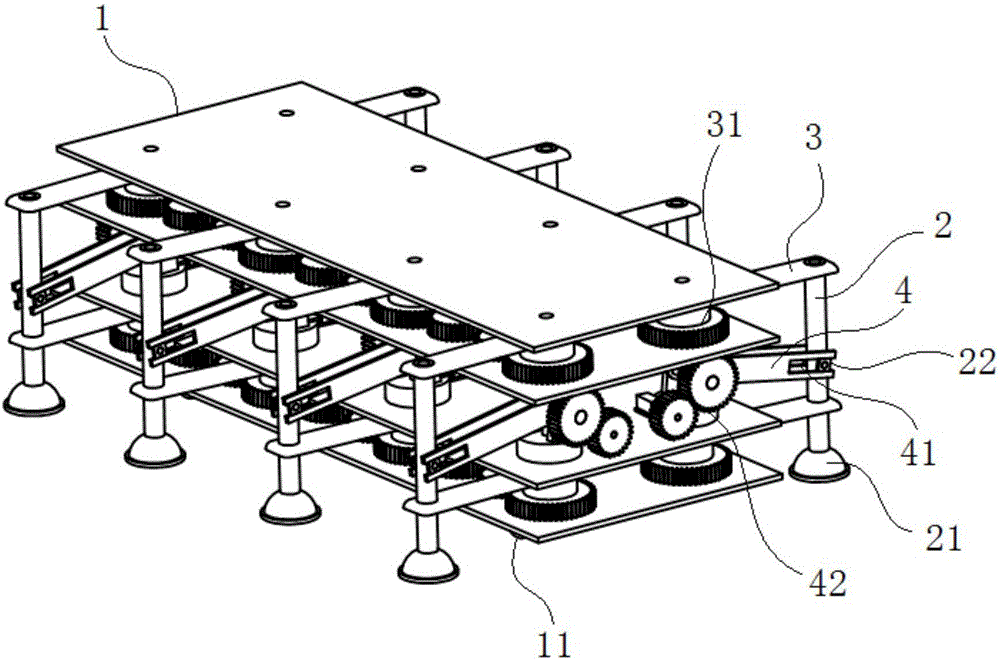

New material technological development superconducting material transporting device with good stability

ActiveCN108928370AAvoid damageImprove shock absorptionShock-sensitive articlesHand carts with multiple axesMechanical engineeringNew materials

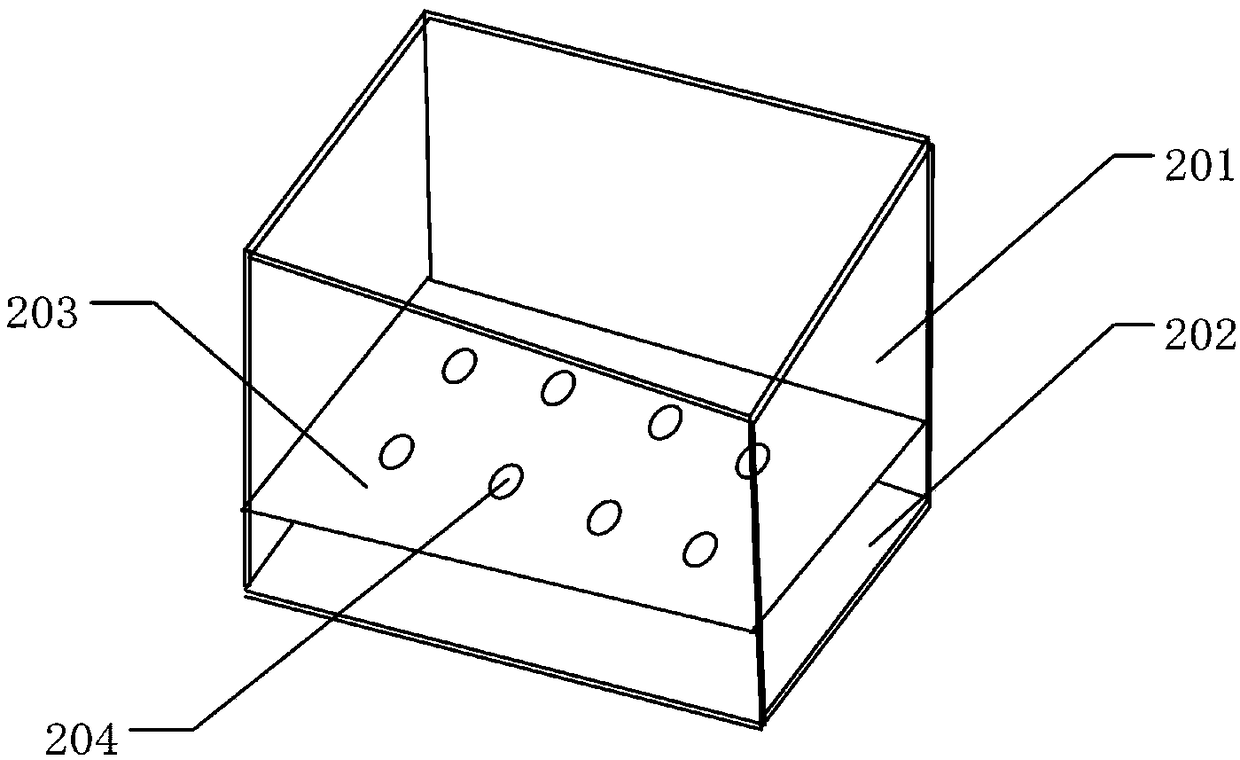

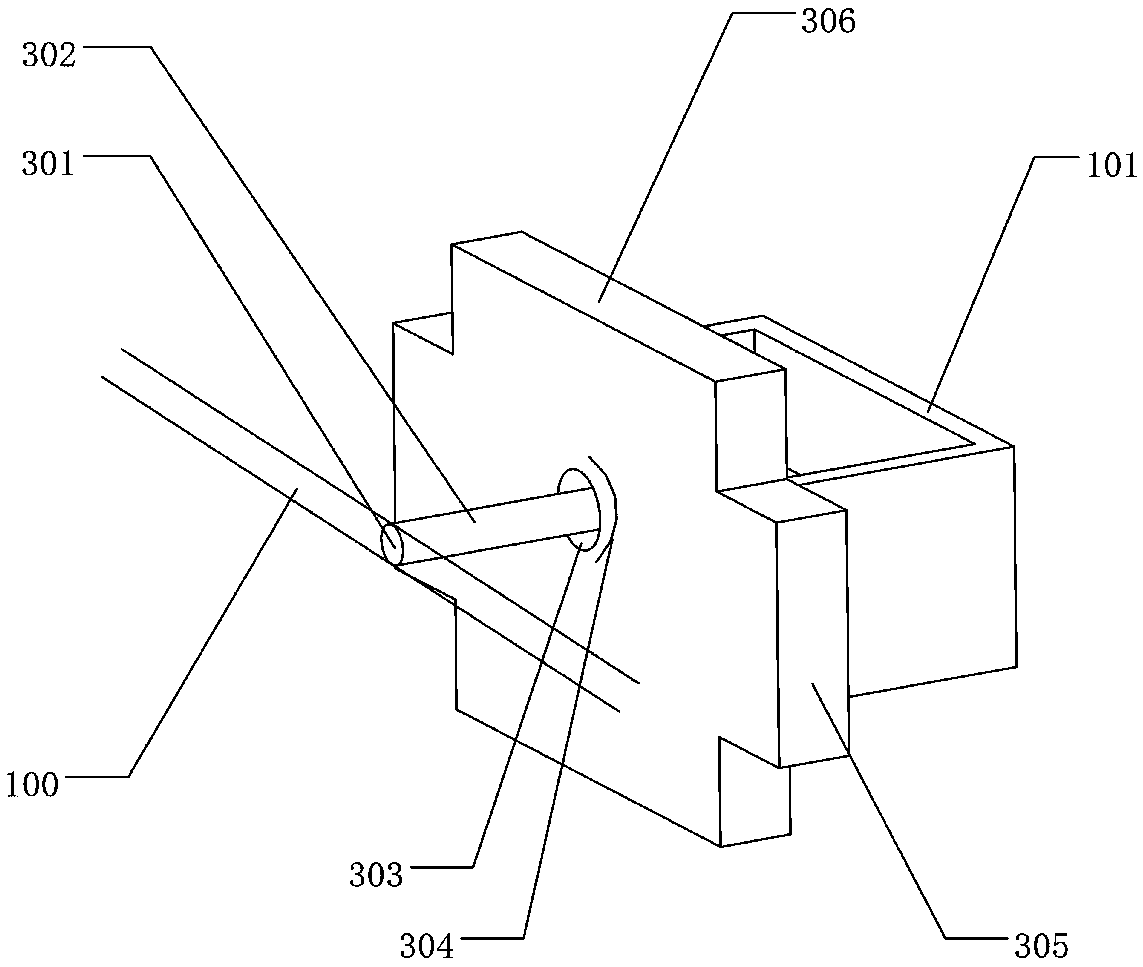

The invention belongs to the technical field of transporting devices and in particular relates to a new material technological development superconducting material transporting device with good stability. In order to solve the technical problem that a superconducting material is easy to vibrate and collide during transportation to be damaged, the following scheme is provided. The new material technological development superconducting material transporting device with the good stability comprises a bottom plate, an internal box body and a transporting box body; a placing opening is formed in the external wall of the top of the transporting box body; a box cover is hinged to the internal wall of the placing opening through a hinge; two fixing blocks are welded on the external wall of the topof the box cover; the same pull handle is fixed on the external walls of the tops of the two fixing blocks through bolts; an internal box body is arranged in the transporting box body; and vent holeswhich are distributed in an equally spaced manner are formed in the external wall of the bottom of the internal box body. According to the new material technological development superconducting material transporting device with the good stability, as a second shock absorbing spring, a third shock absorbing spring and a shock absorbing rubber pad, a very good shock absorbing effect is realized toprevent the superconducting material from being damaged due to bumping and shaking during transportation; and a dehumidifier has a very good dehumidifying effect to prevent the superconducting material from being affected with damp to affect the quality of the superconducting material.

Owner:阜阳佰恩得新材料技术有限公司

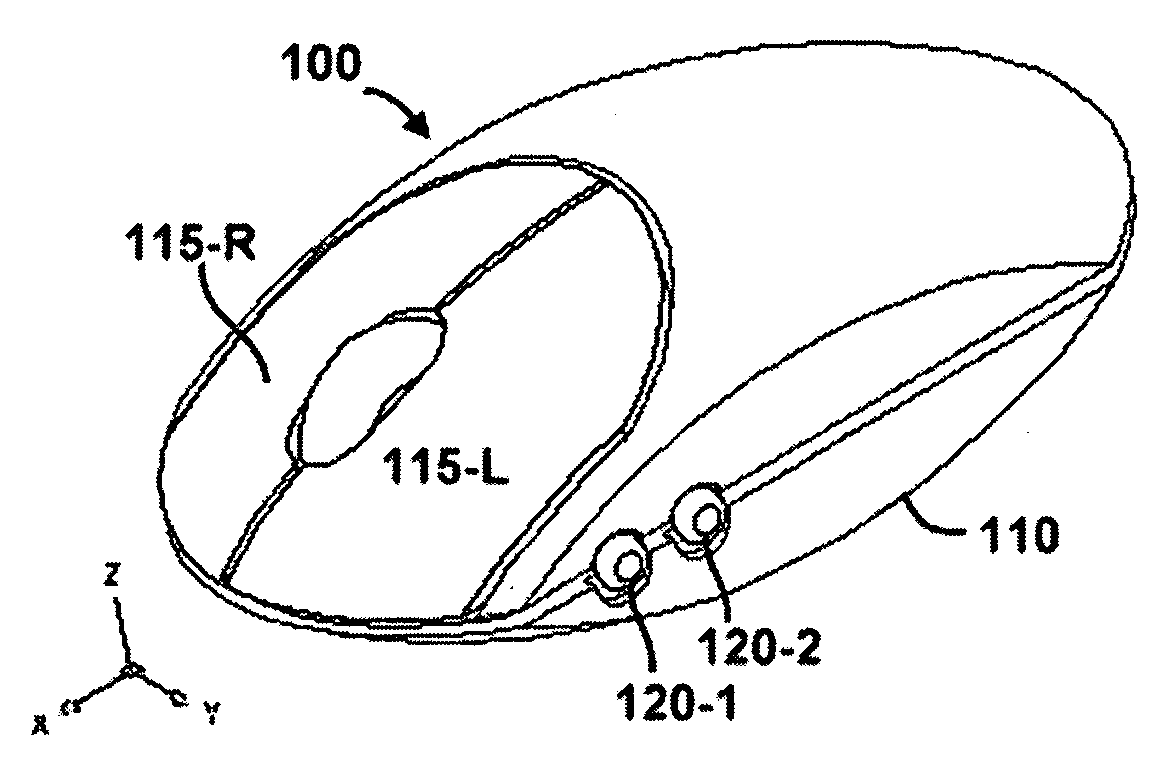

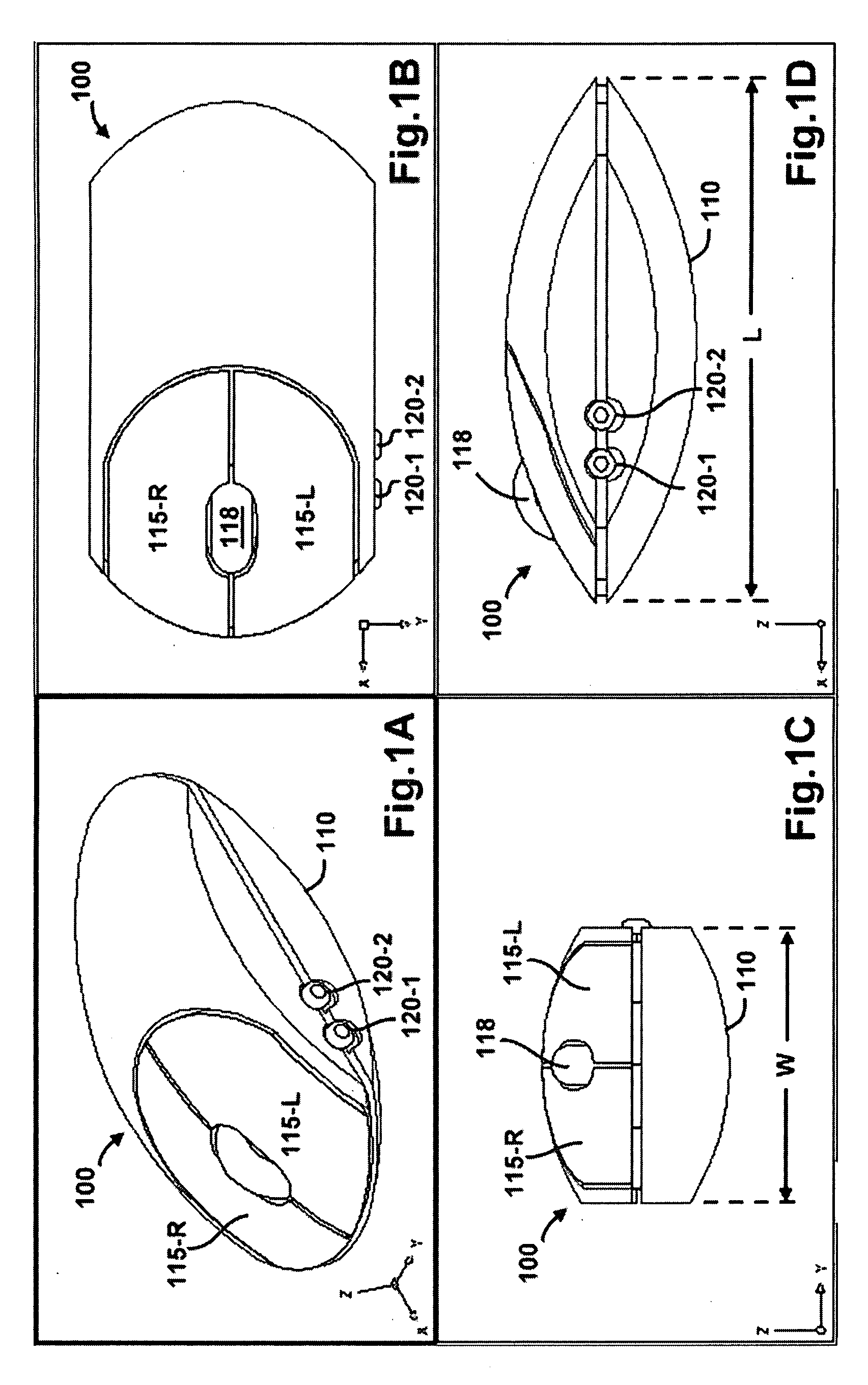

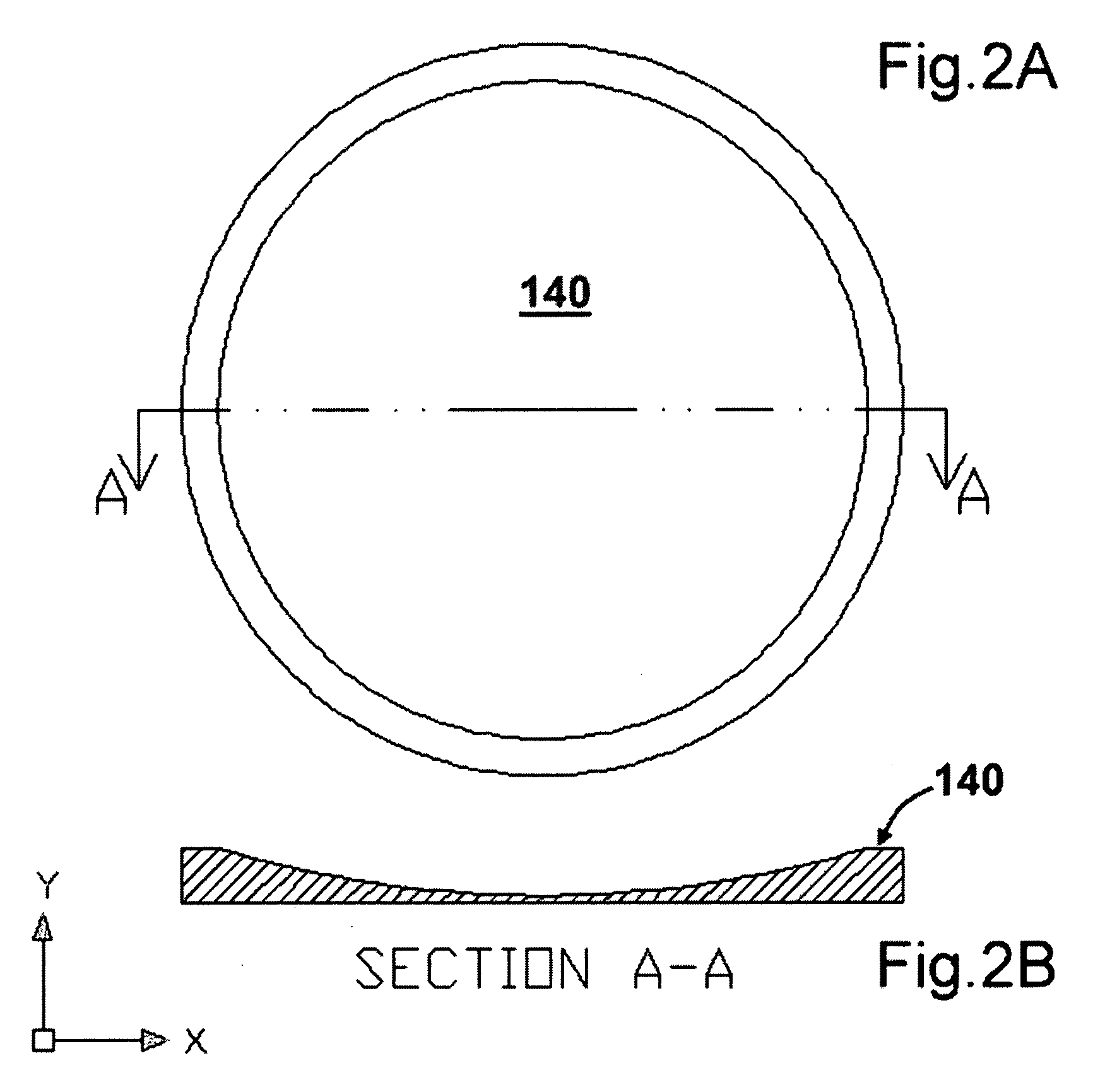

Display cursor control device with enhanced multiple dimensional tilt angle operation

InactiveUS20080100574A1Flexible operationImprove convenienceCathode-ray tube indicatorsInput/output processes for data processingAccelerometerDisplay device

A data-handling and processing system includes an image-display cursor-control device for controlling an image display cursor of an image display. The system is further operated a pad for placing and moving the image-display cursor-control device and the pad has a curved surface. The image-display cursor-control device further includes an accelerometer for sensing a tilt angle in moving along the curved surface of the pad. The image-display cursor-control device further includes a container housing for containing the accelerometer therein. The container housing has a curved bottom surface for conveniently tilting the display-cursor control device to change an elevation level of the accelerometer

Owner:IMU SOLUTIONS

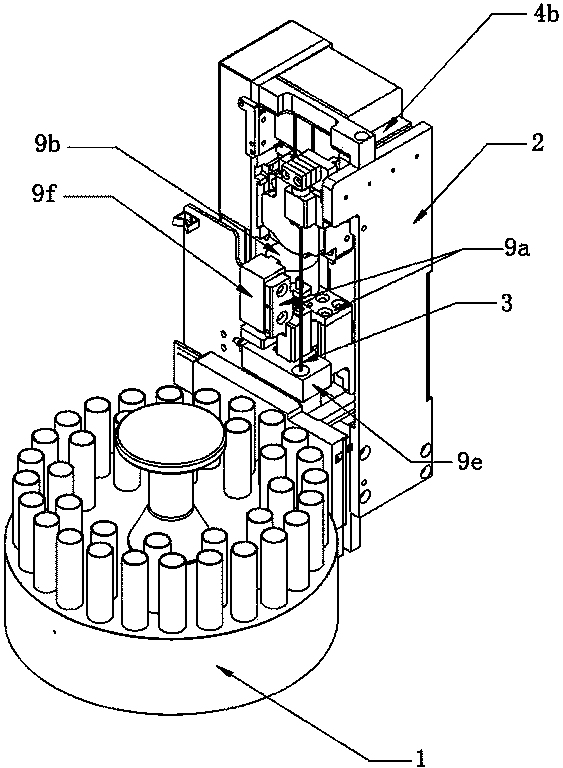

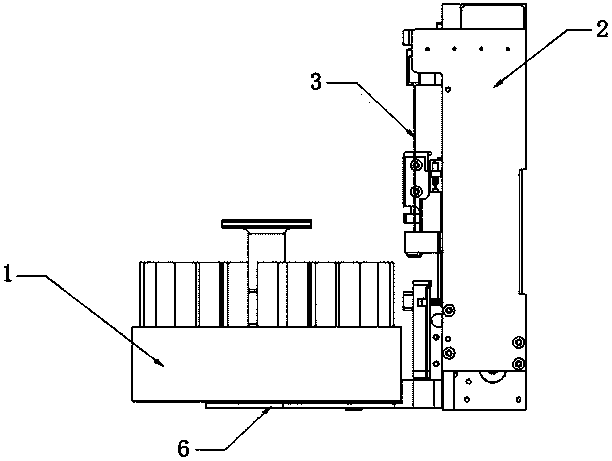

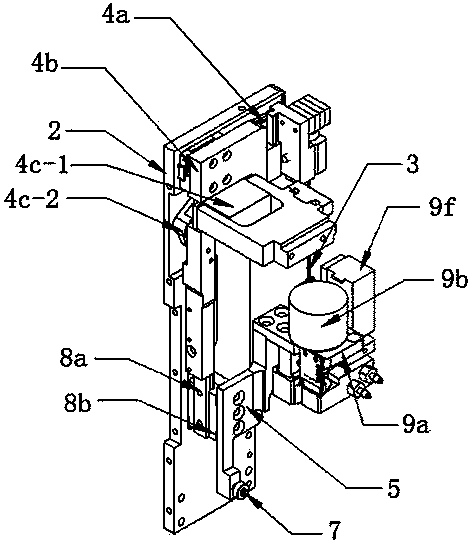

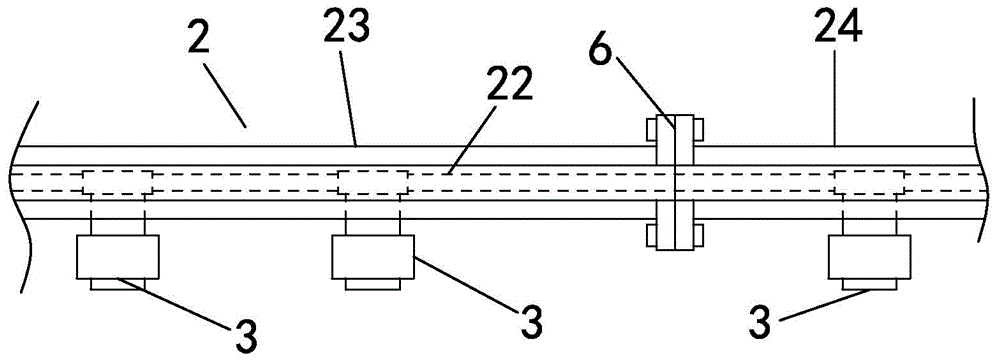

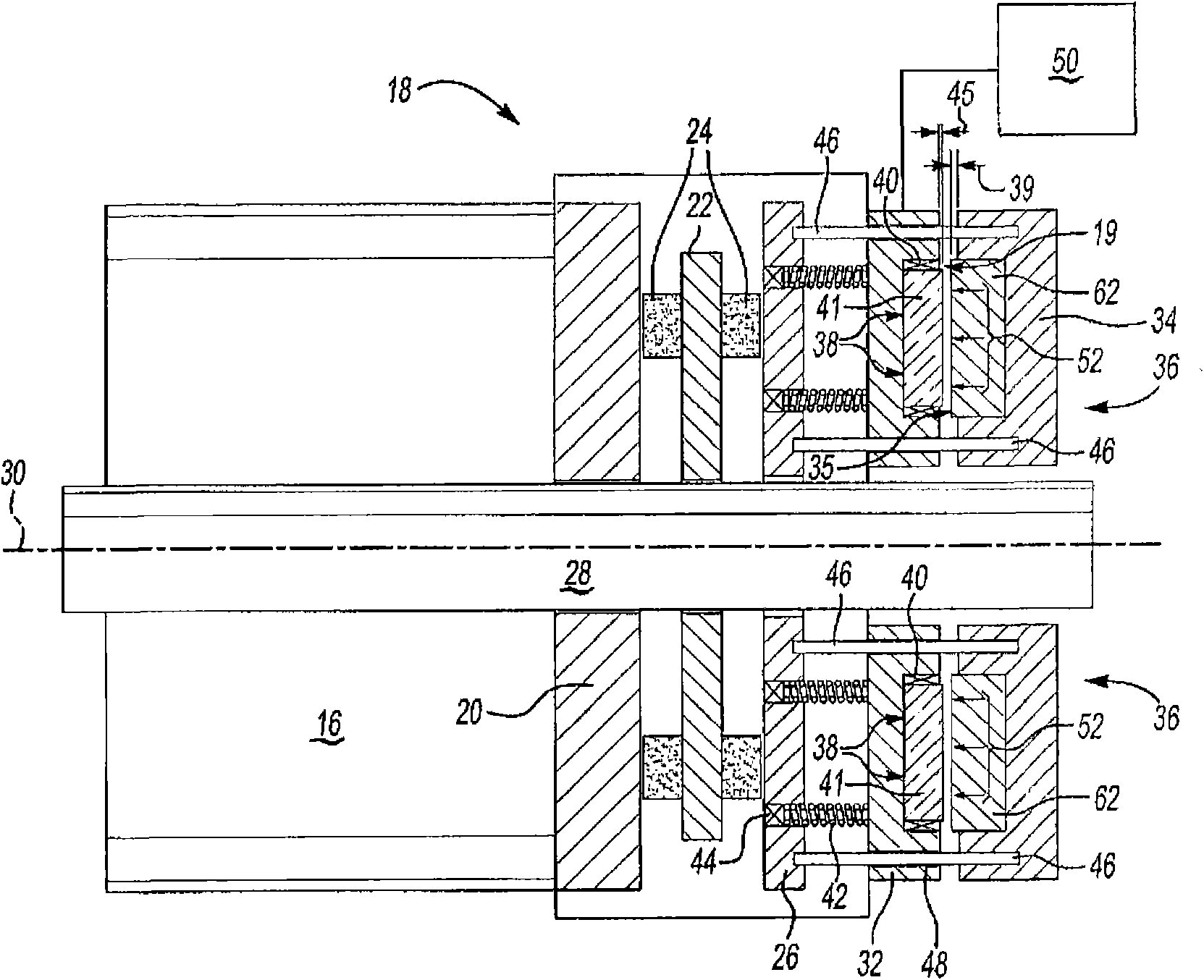

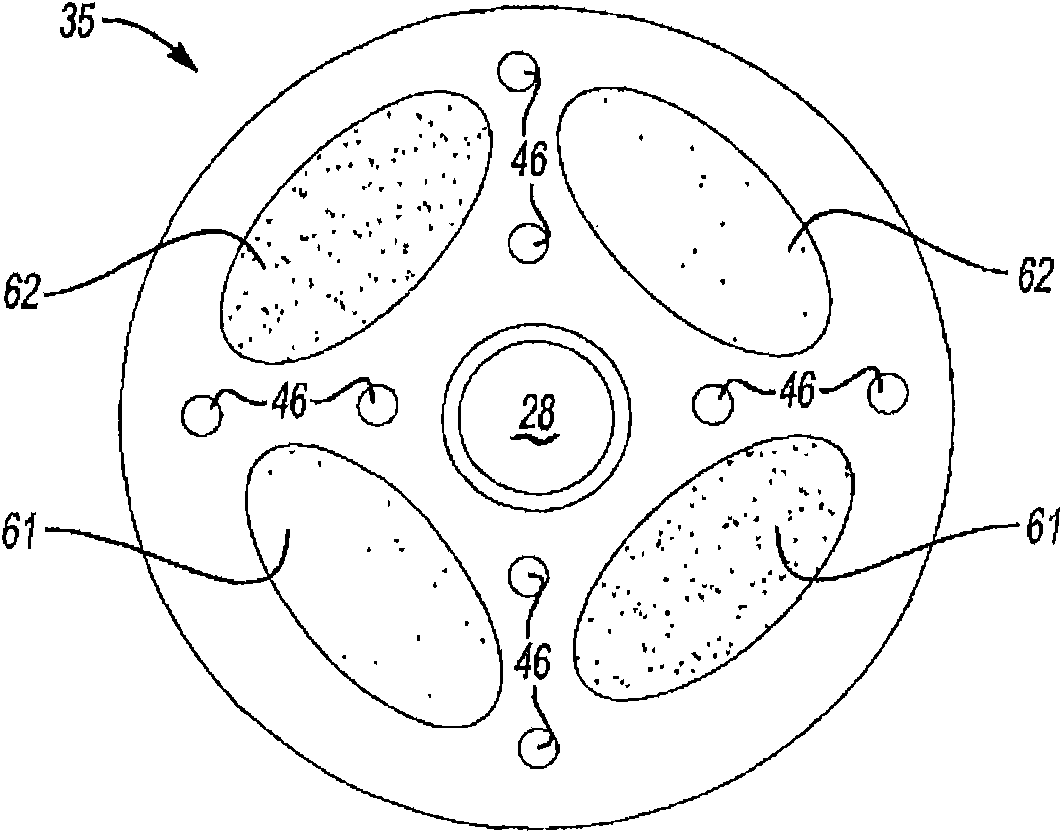

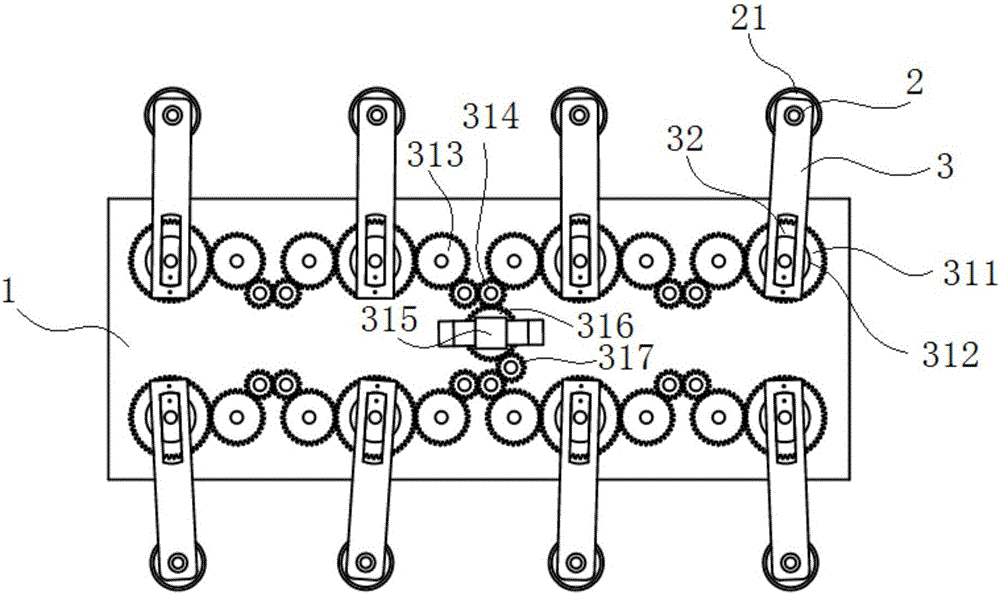

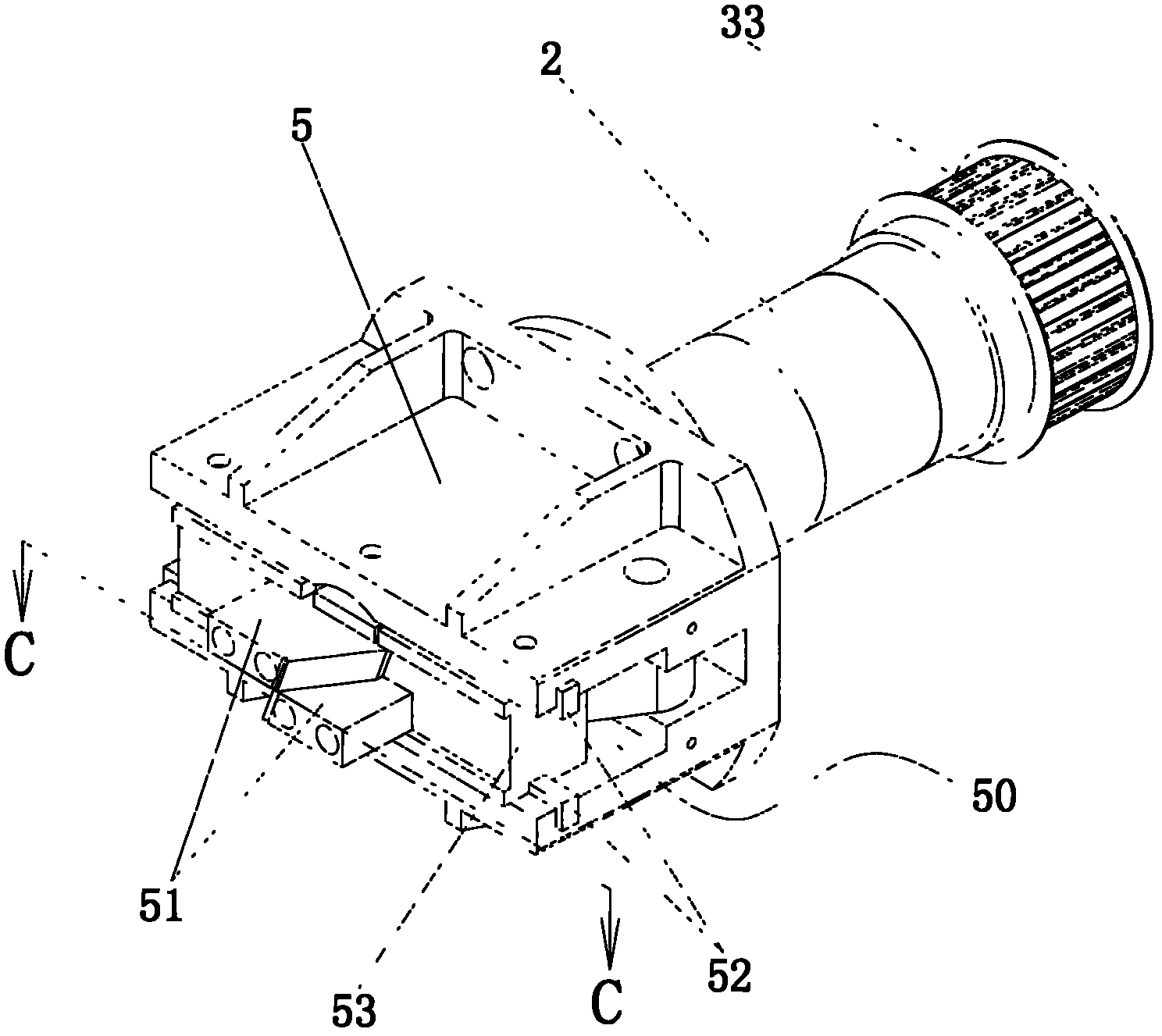

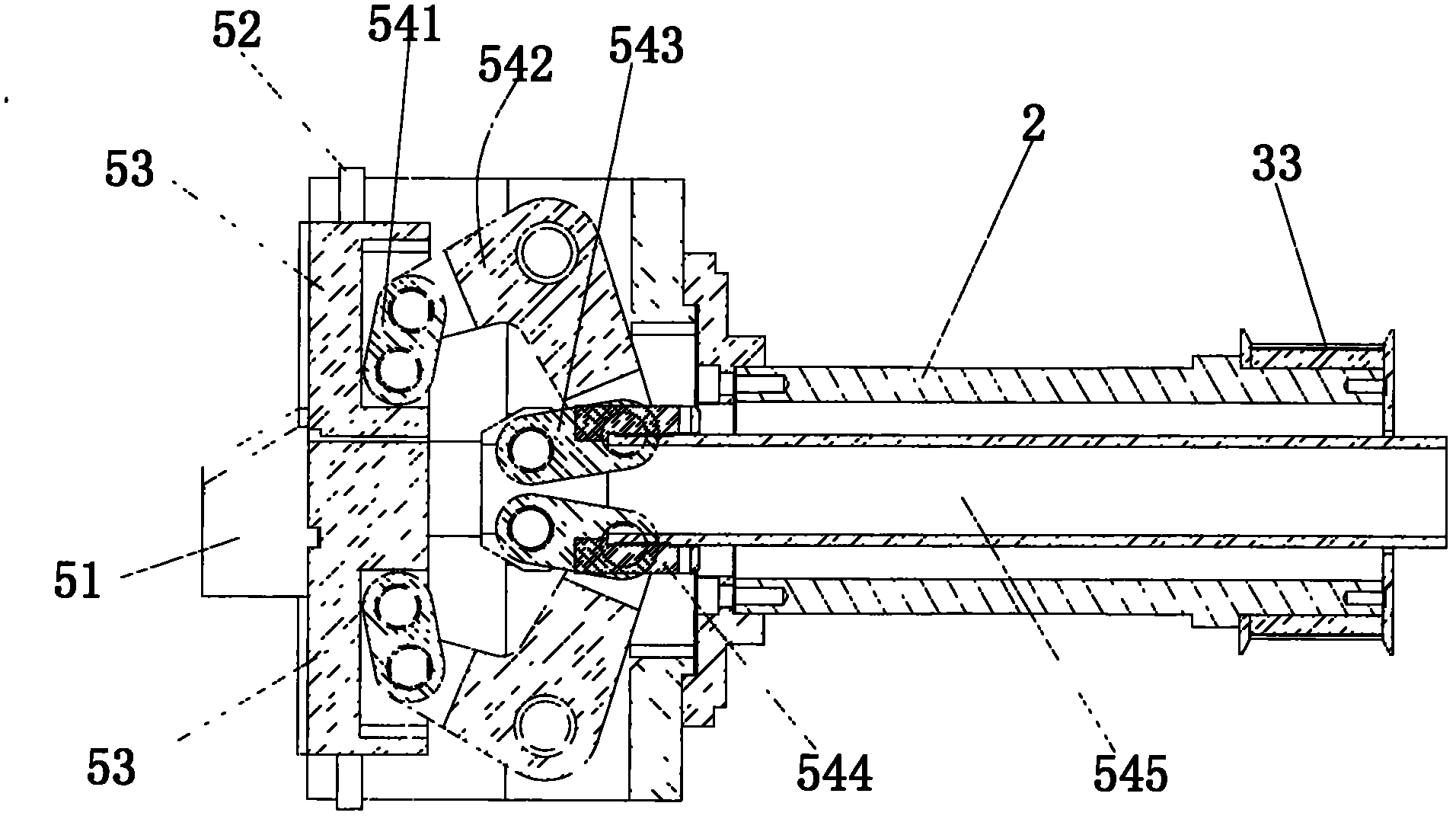

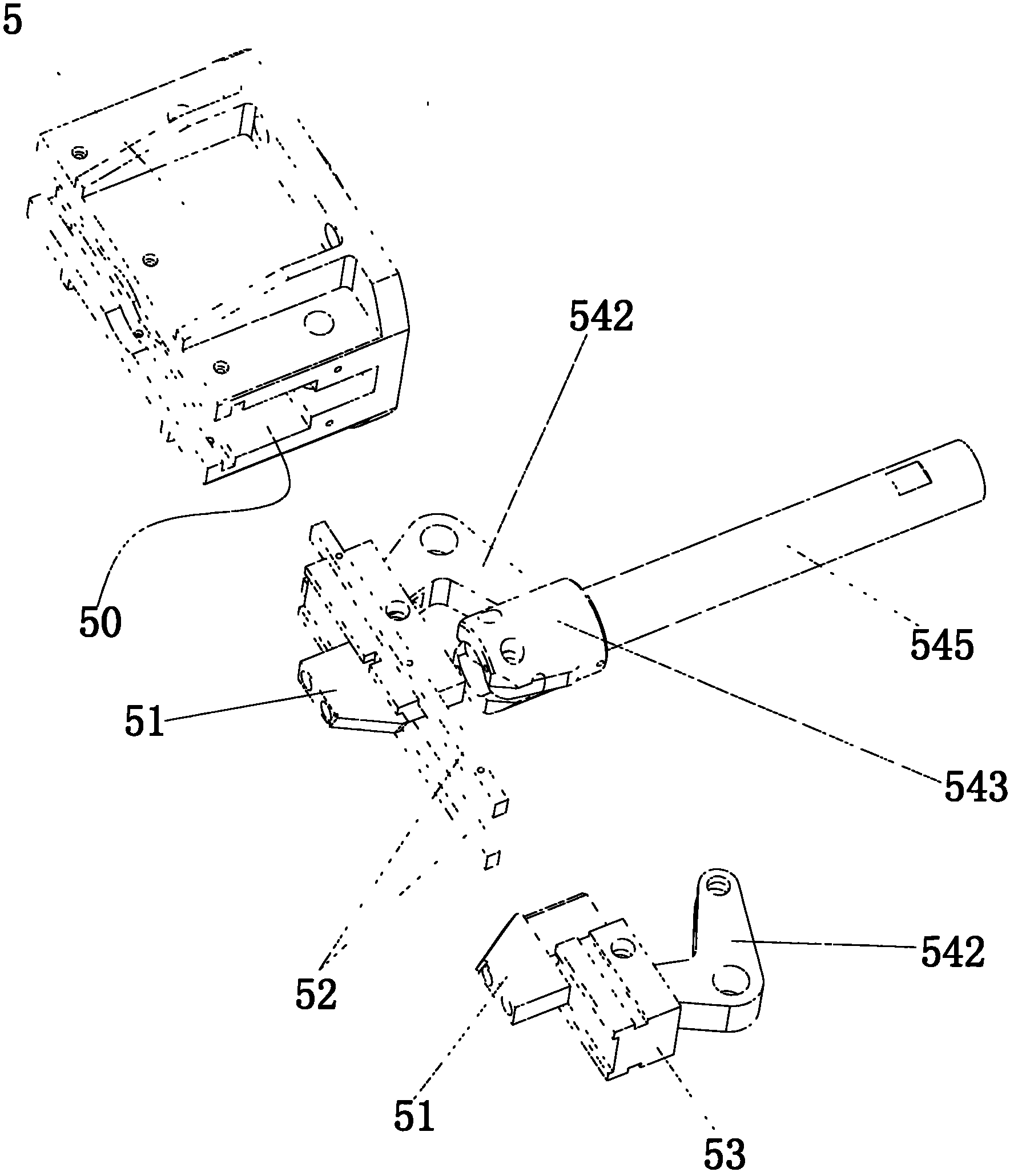

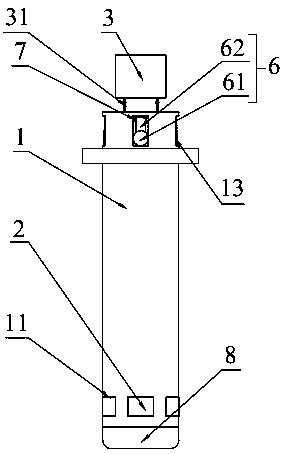

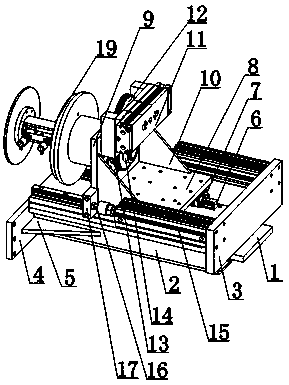

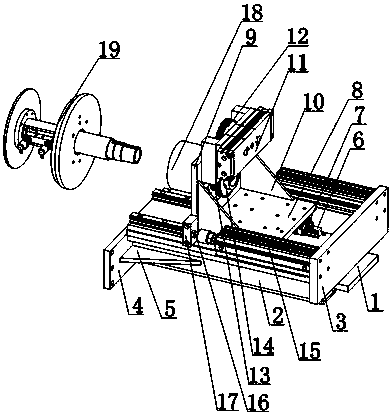

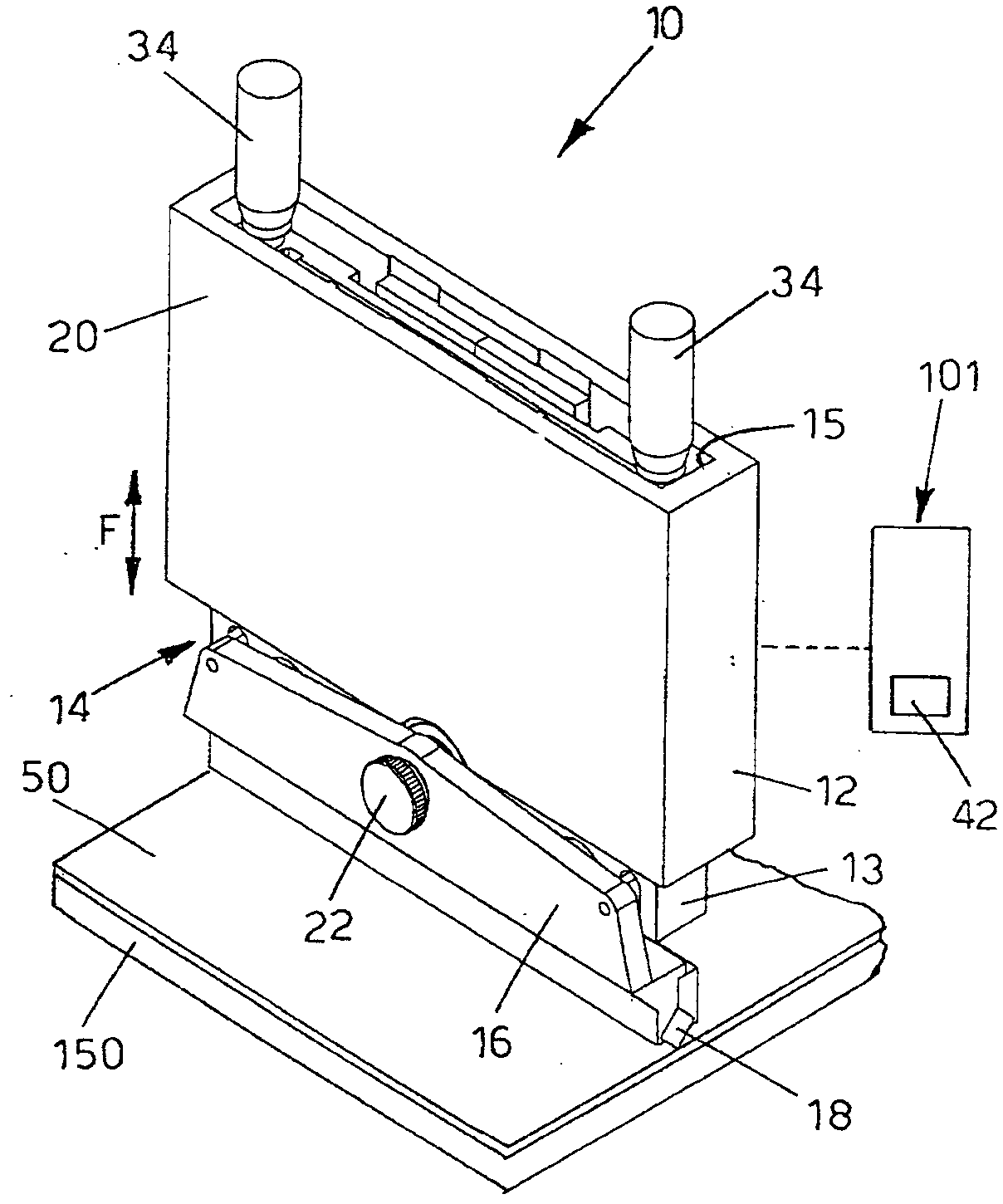

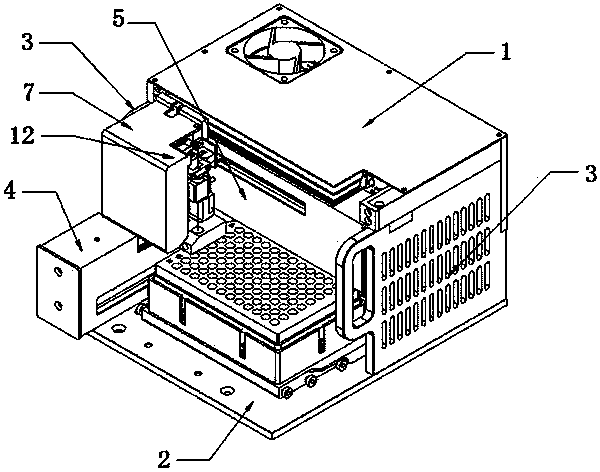

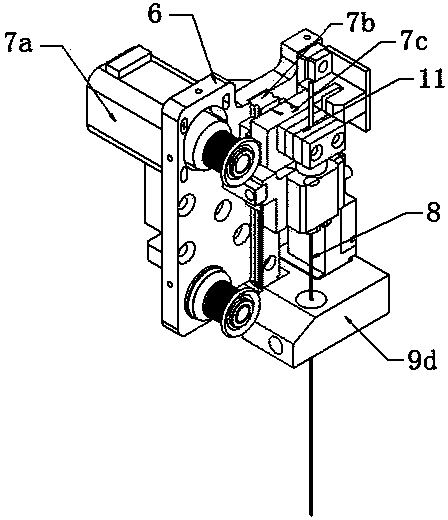

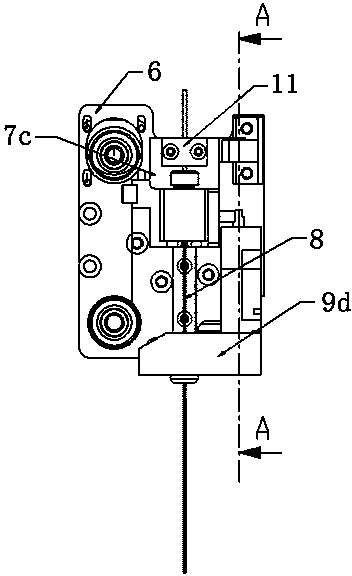

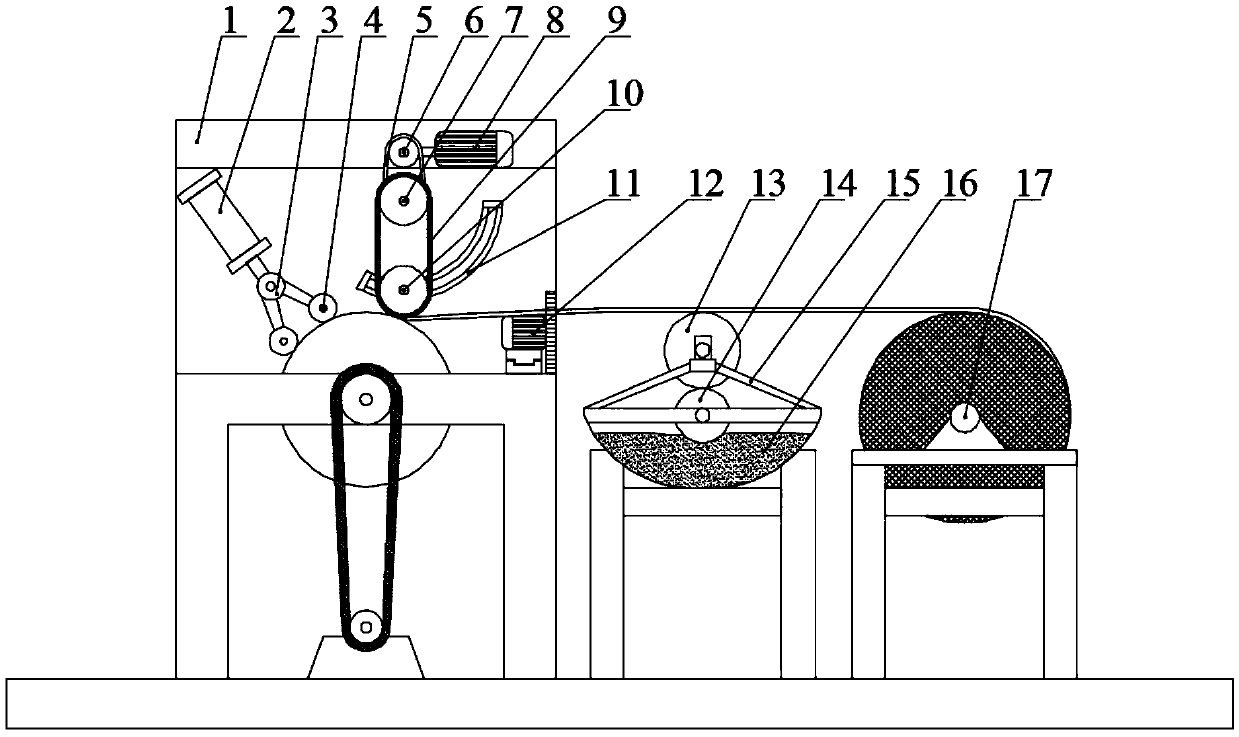

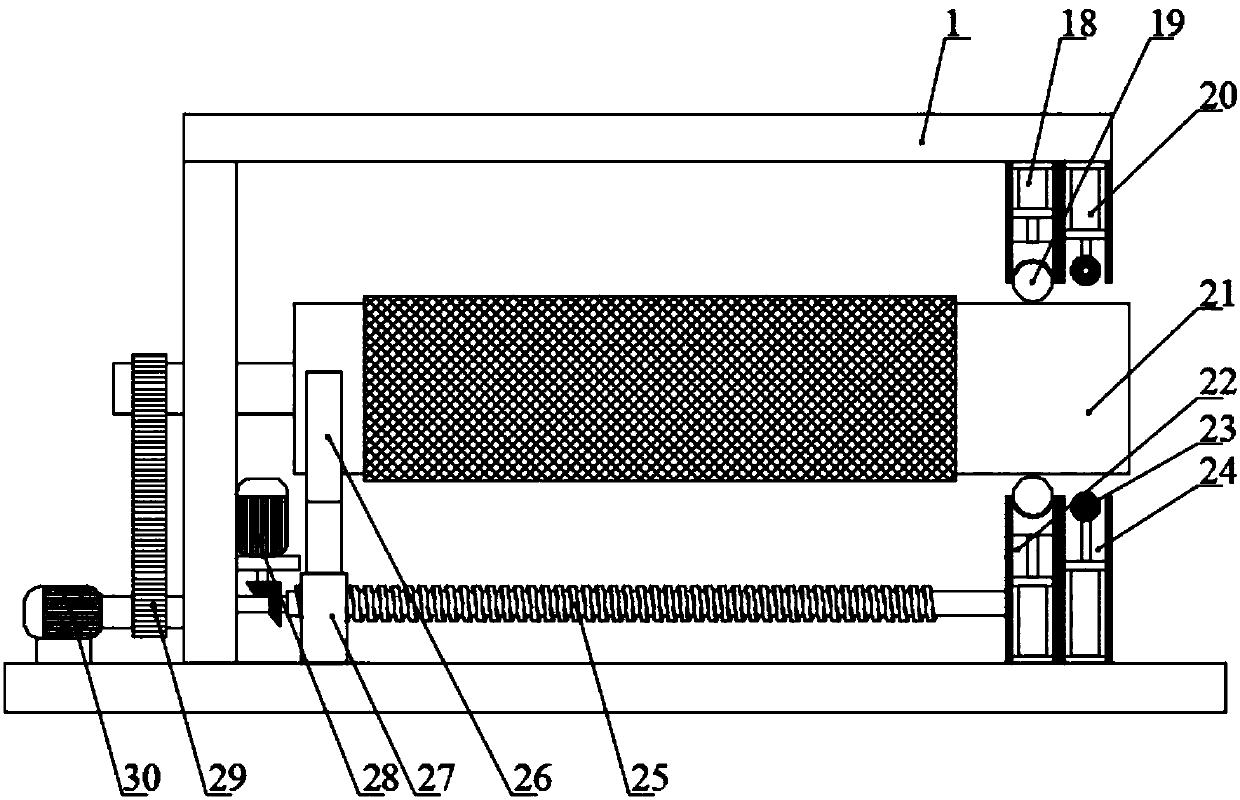

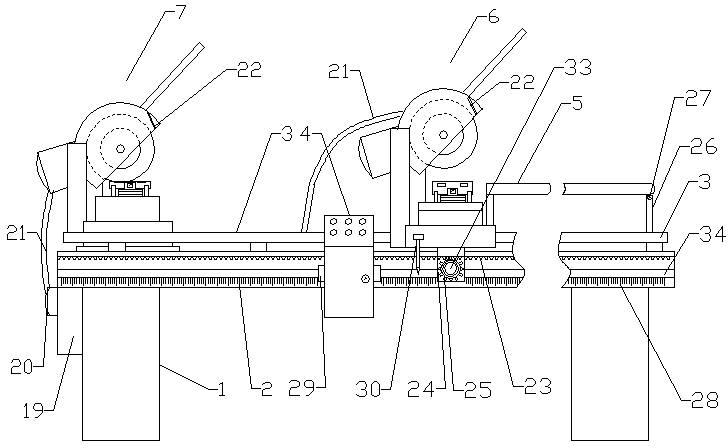

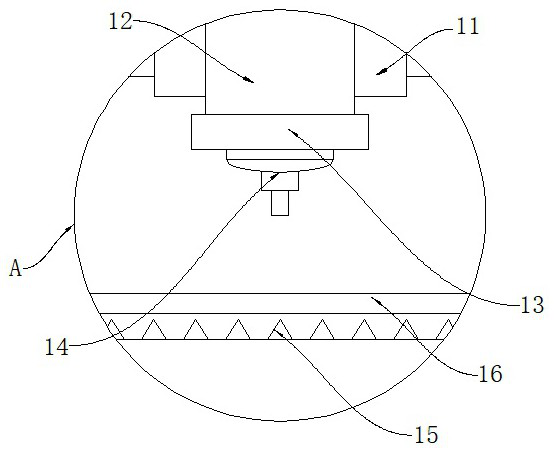

Fully automatic sample-injection mechanism of flow cytometer

ActiveCN104111344ASmooth horizontal movementSimple structureIndividual particle analysisReciprocating motionControl theory

Owner:SUZHOU RIHE TECH

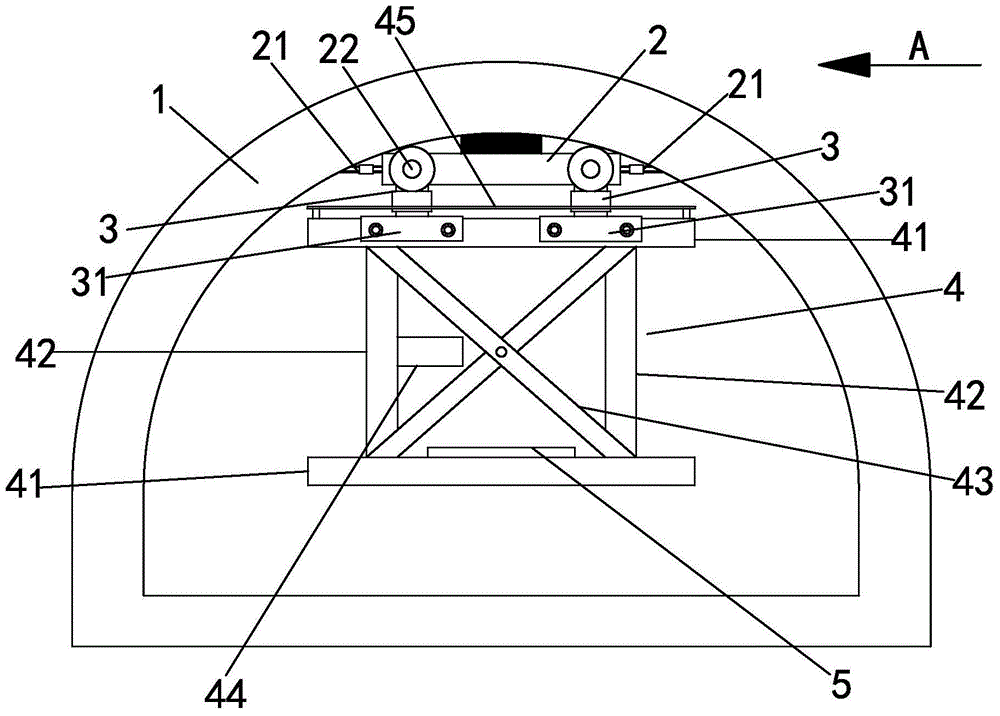

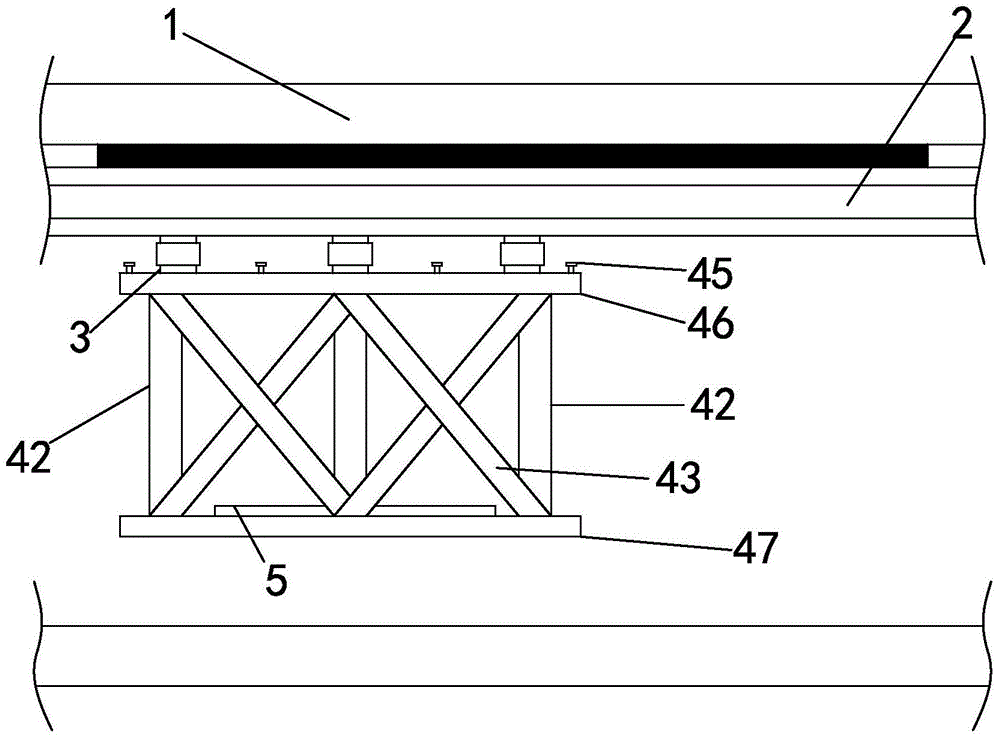

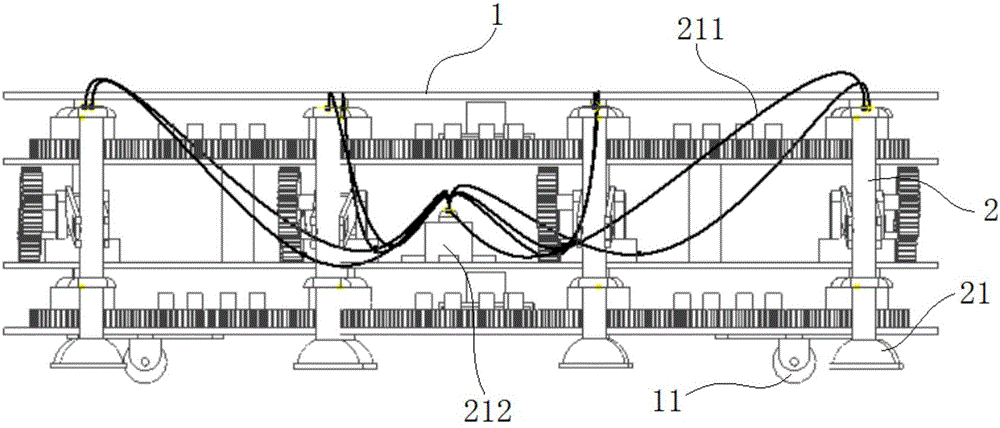

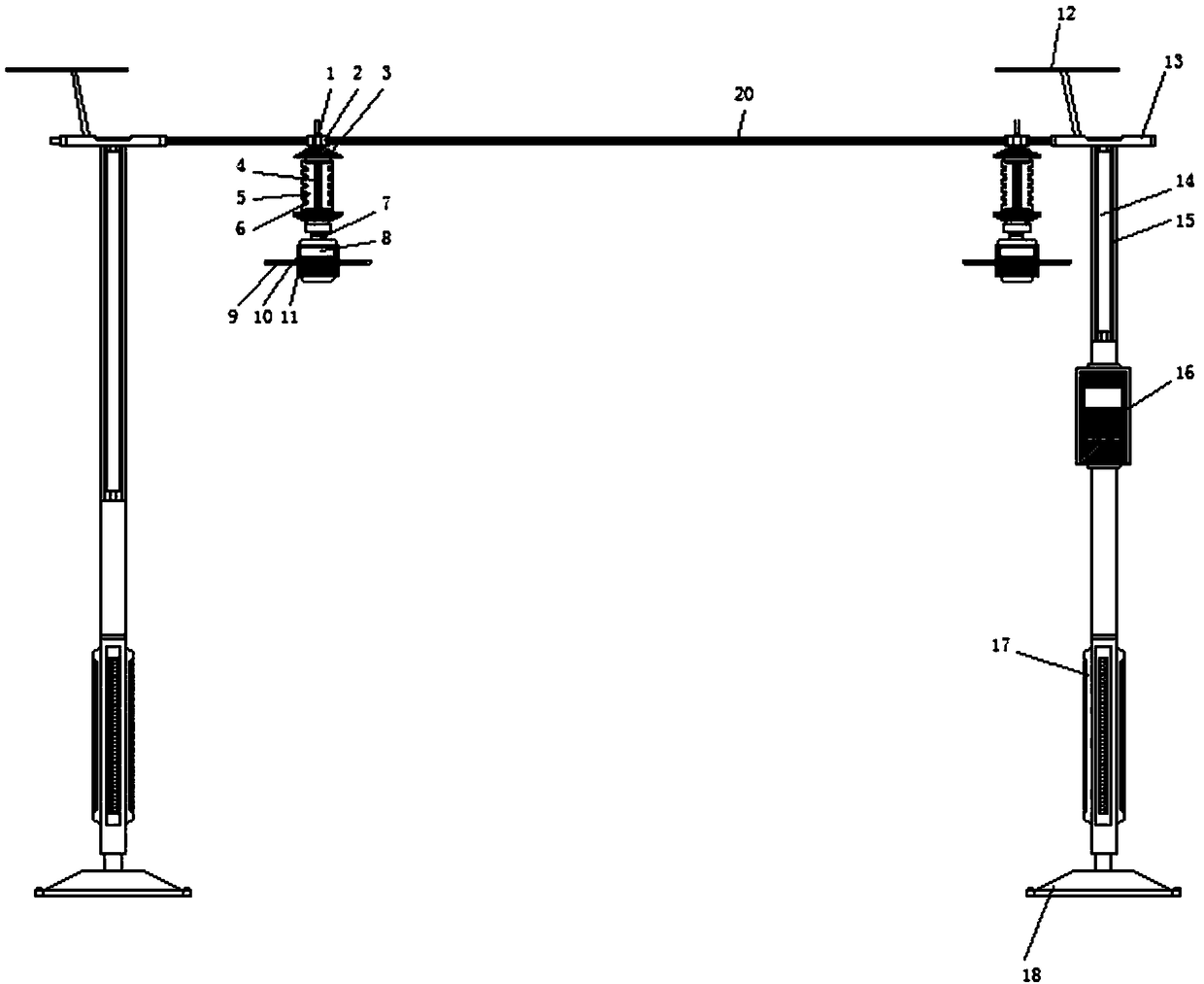

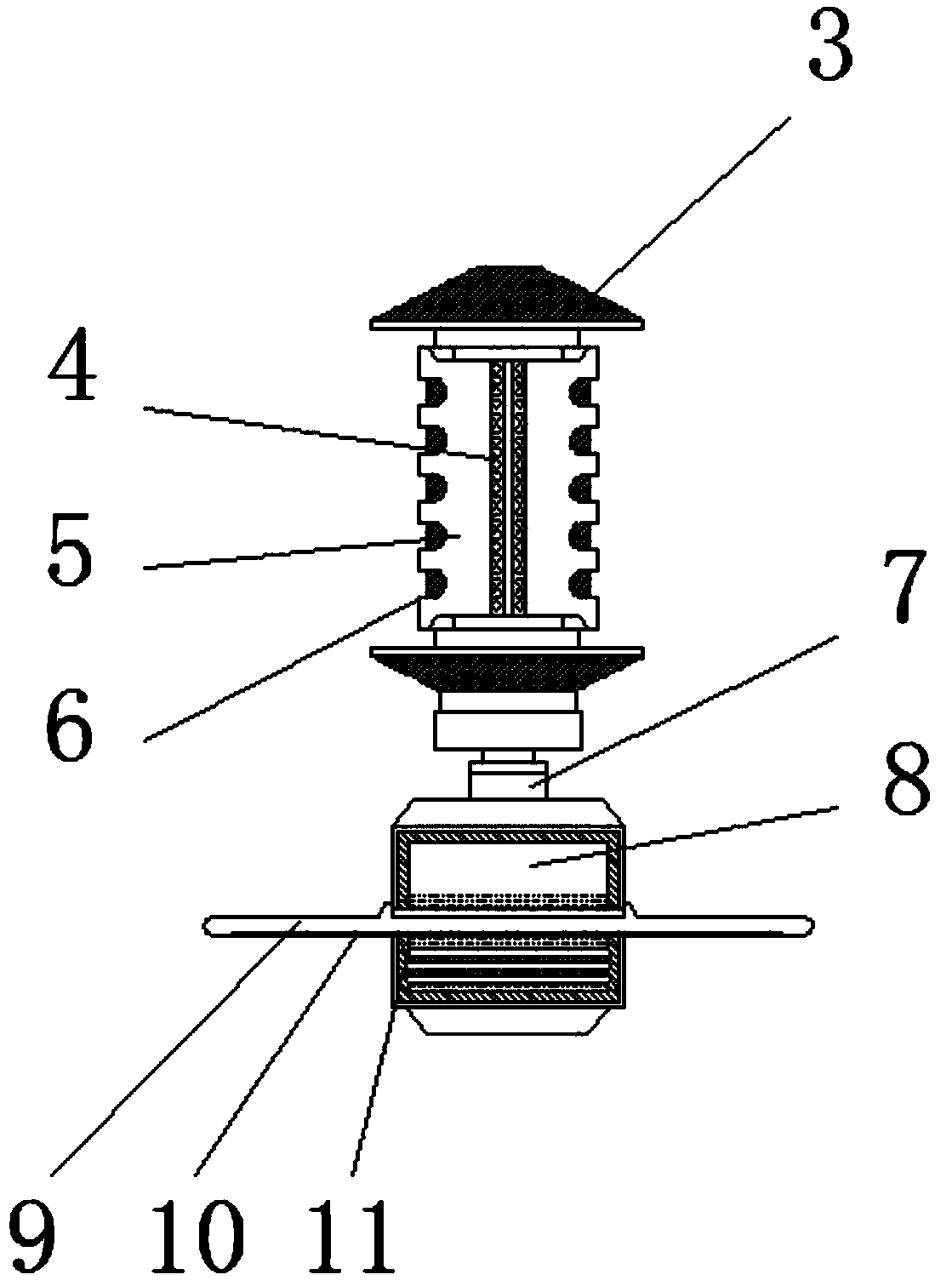

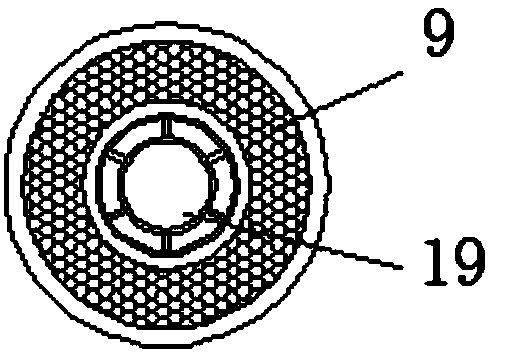

Rack for tunnel excavation and adit construction method applying rack

ActiveCN104533449AEasy to moveImprove work efficiencyUnderground chambersDrainageAditAutomatic control

The invention discloses a rack for tunnel excavation and an adit construction method applying the rack. The rack is automatically controlled through a cable, construction accuracy can be improved, the moving range of the rack can be adjusted, and the rack is very suitable for adit construction. In addition, a device fixing apparatus is added on the rack, movement of a part of machines and tools is facilitated, the machines and tools can be used in the construction process at any time anywhere, and the working efficiency of the adit construction and construction effect can be remarkably improved. The adit construction method applying the rack is characterized by comprising the following steps of (a) construction preparation, (b) opening plane arrangement, (c) spoil area site selection, (d) protection and greening of a spoil area site, (e) opening excavation, (f) main tunnel first-stage construction, (g) rack assembly and (h) main tunnel second-stage construction. The main tunnel construction is performed in a two-stage mode, mutual reference can be achieved in the construction process, and project quality can be improved.

Owner:CHENGLONG CONSTR GROUP

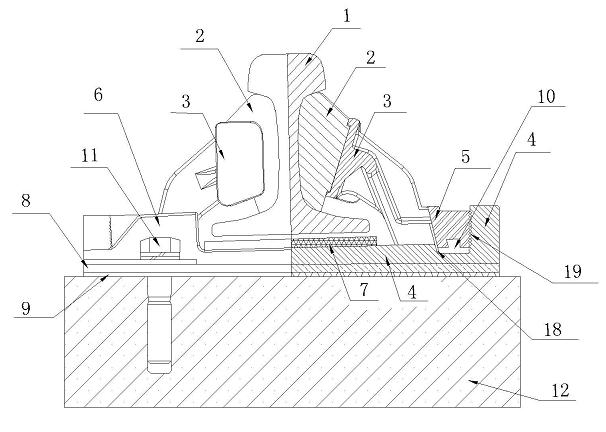

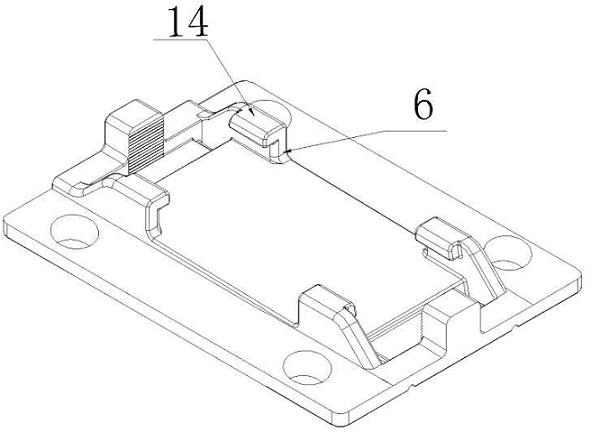

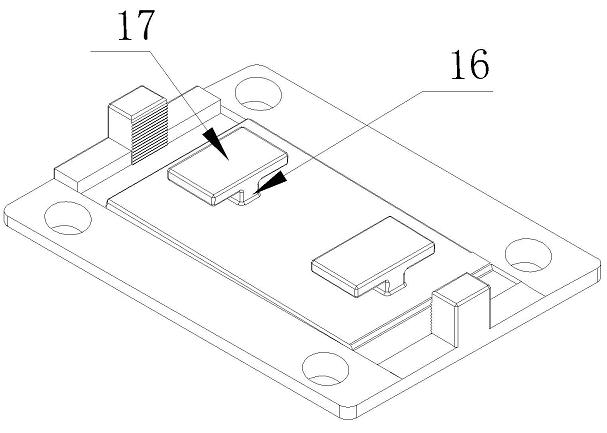

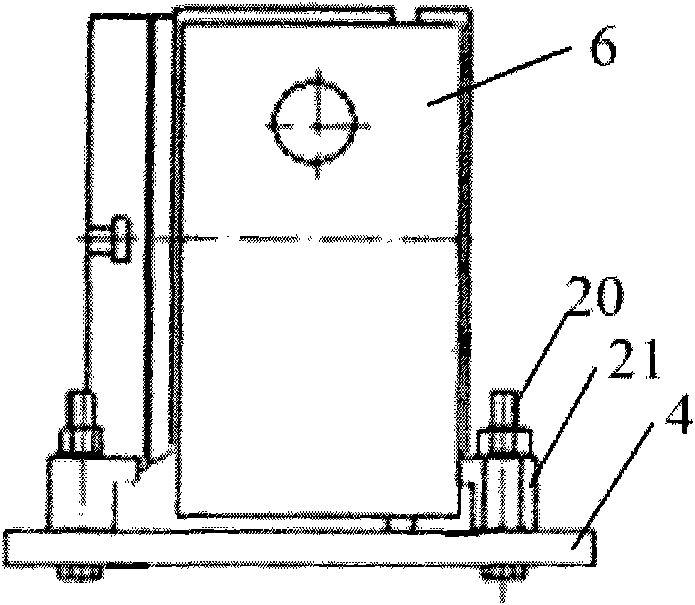

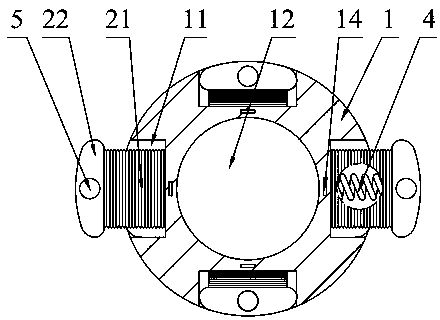

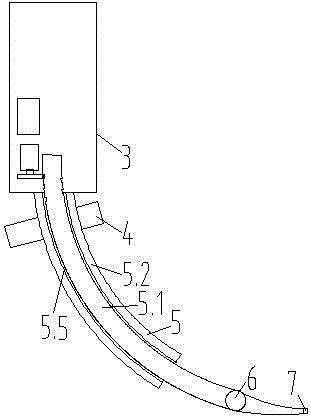

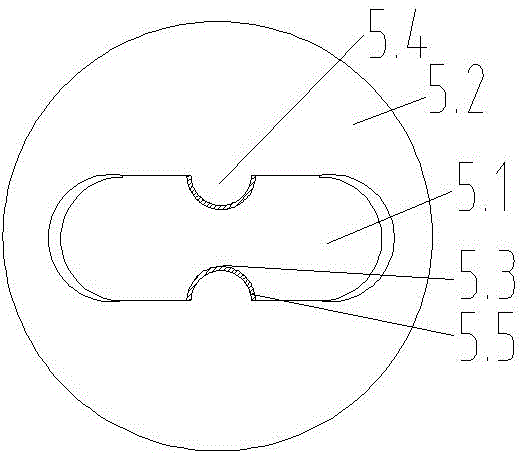

Chute-mounted suspended steel rail vibration reduction fastener

ActiveCN102359036ASmall overall deformationEnsure driving safetyRail fastenersNoise reductionVehicle safety

The invention belongs to the field of rail vibration reduction and noise reduction, and provides a chute-mounted suspended steel rail vibration reduction fastener. A structure for limiting a lateral bracket (3) is arranged at the joint position of a fastener bottom plate (4) and the lateral bracket (3), and the limiting structure is provided with at least one limiting surface I (6) for limiting the lateral bracket (3) to move in the laying direction of a steel rail and at least one limiting surface II (14) for limiting the lateral bracket (3) to move vertically; and a space for allowing the lateral bracket (3) to horizontally move in the direction vertical to the laying direction of the steel rail (1) is formed between the limiting surface I (6) and the limiting surface II (14). Through the fastener, movement of the lateral bracket (3) in the vertical direction and the laying direction of the steel rail (1) can be effectively controlled, torsion of the lateral bracket (3) due to torsion of the steel rail (1) can be effectively controlled, the stability of the lateral bracket (3) structure is effectively enhanced, and the safety of a vehicle is ensured.

Owner:洛阳双瑞橡塑科技有限公司

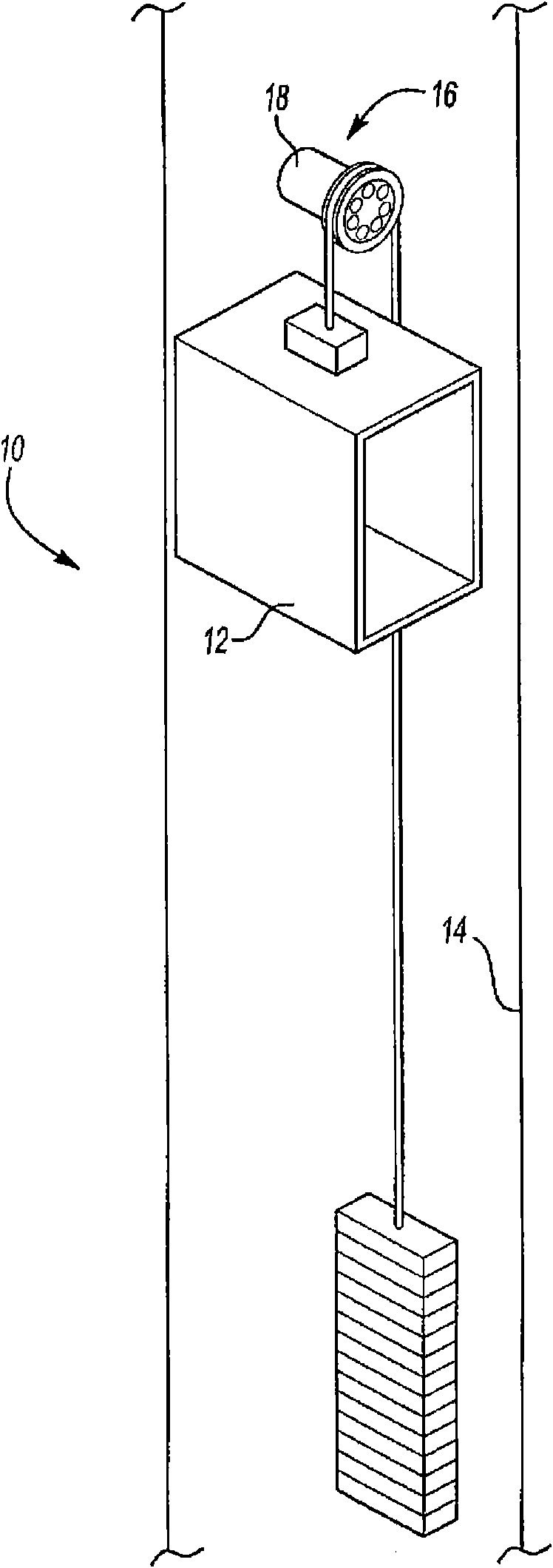

Permanent magnet elevator disk brake

InactiveCN101583511ASmall currentEasy to move and controlBraking action transmissionElectrodynamic brake systemsControl mannerElectrical polarity

Owner:OTIS ELEVATOR CO

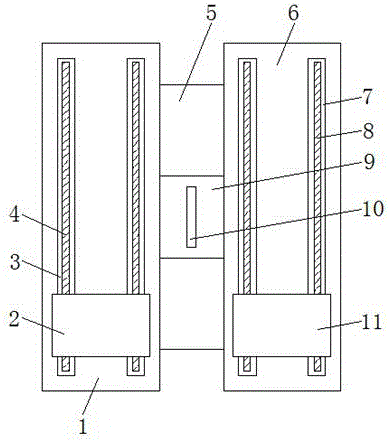

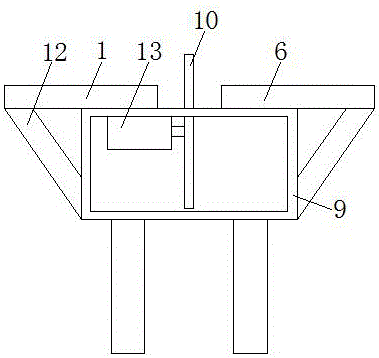

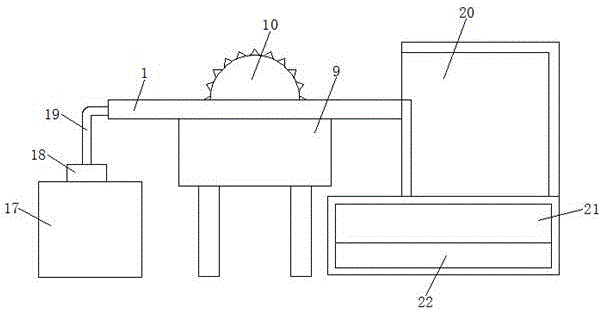

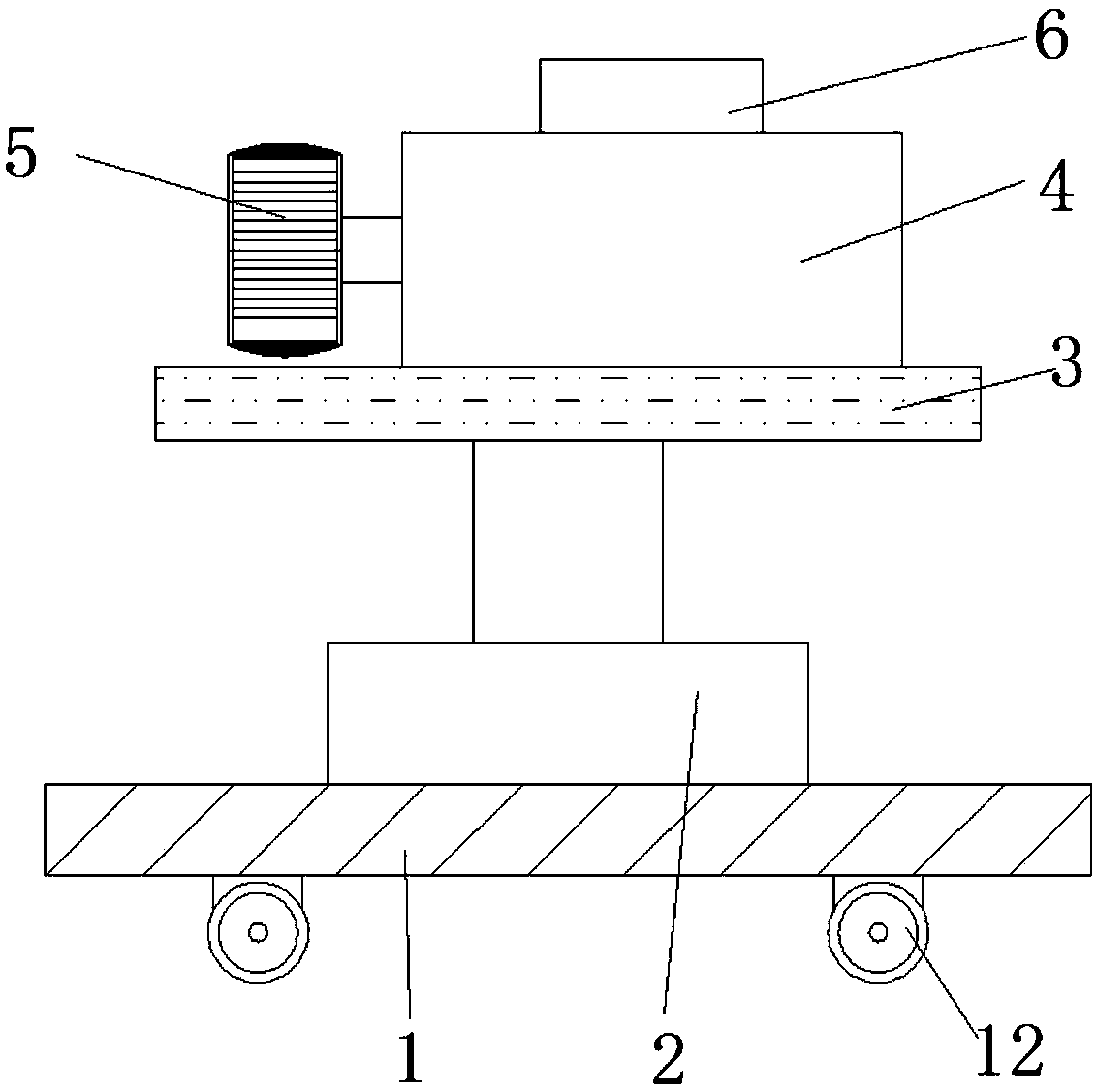

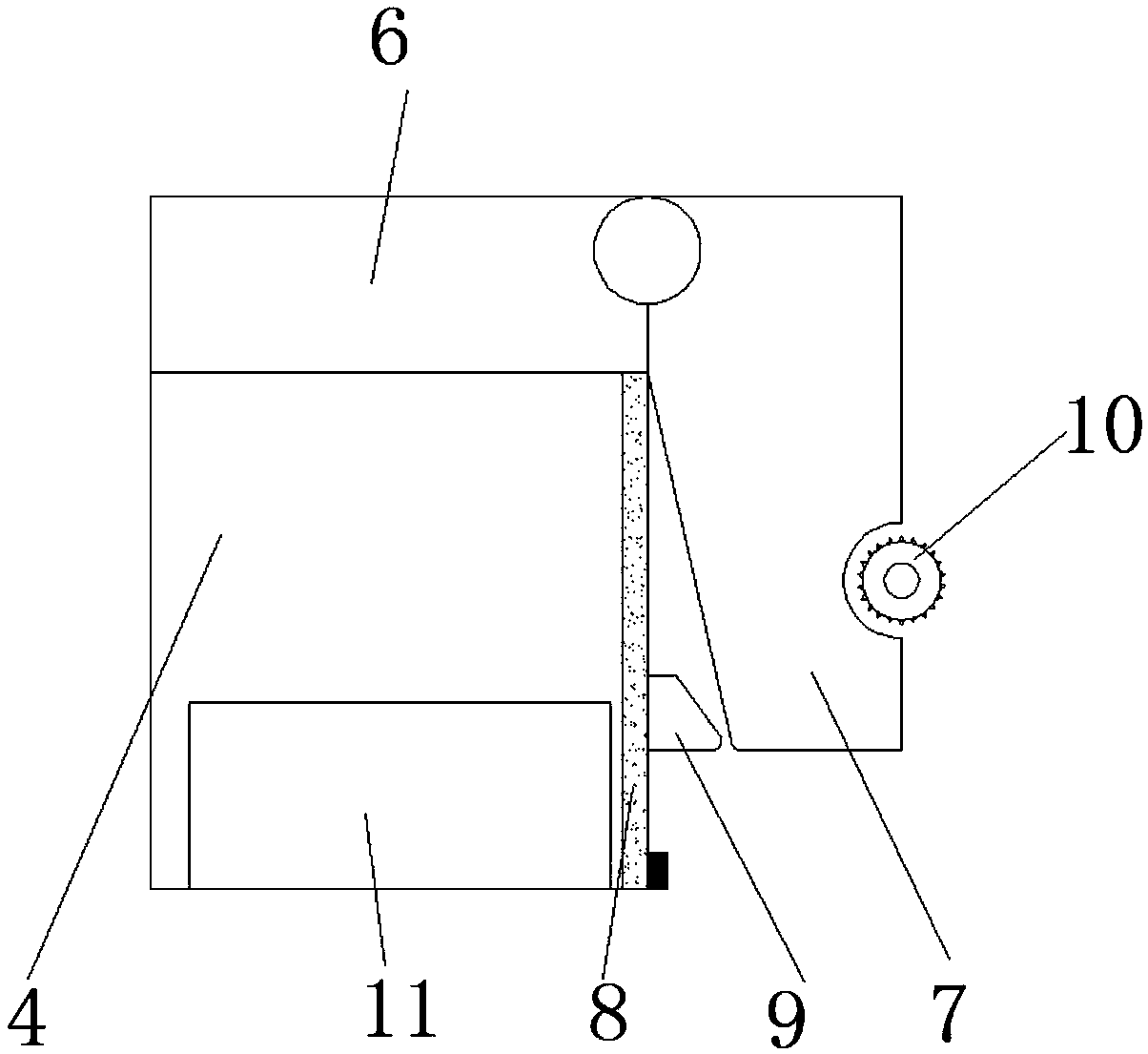

Cutting device used for wood processing

InactiveCN107175727AEasy to moveEasy to move and controlProfiling/shaping machinesBark-zones/chip/dust/waste removalPulp and paper industryWood processing

The invention discloses a cutting device used for wood processing. The cutting device comprises a case. Connecting plates are fixedly mounted at the two ends of the case correspondingly. A first supporting plate and a second supporting plate are fixedly mounted on the left side and the right side of the case correspondingly. The bottom of the first supporting plate and the bottom of the second supporting plate are fixedly connected with the bottom of the case through supporting rods correspondingly. First guide rails are fixedly mounted on the two sides of the upper surface of the first supporting plate correspondingly. A first fixing plate is arranged on the upper sides of the first guide rails. First sliding grooves are formed in the upper surfaces of the two first guide rails correspondingly and slidably connected with the first fixing plate through first sliding blocks arranged in the first sliding grooves correspondingly. Through the cutting device, wood can be fixed in the processing process, the situation that the wood moves and consequently a cutting plate is stuck can be avoided, the wood can be controlled to move conveniently, workload of workers can be lowered, time can be saved, and the working efficiency is improved advantageously.

Owner:赵咪咪

Automobile part soaking and cleaning structure

InactiveCN109226045AImprove immersion cleaning efficiencyEasy to take outDrying solid materials without heatCleaning using liquidsCouplingEngineering

The invention relates to the technical field of automobile parts and discloses an automobile part soaking and cleaning structure. The structure comprises a cleaning box which is of a hollow structurewith an open top, a circular moving plate is arranged in the cleaning box, a cleaning net cylinder is fixedly connected to the upper surface of the moving plate, and openings are formed in both ends of the cleaning net cylinder; the bottom of the cleaning box is fixedly connected with a servo driving motor, an output end of the servo driving motor is connected with a lead screw through a coupler,the other end of the lead screw penetrates through the bottom of the cleaning box and extends to an inner cavity of the cleaning box, and the lead screw is rotatably connected with the bottom of the cleaning box; the lead screw penetrating through the center of the moving plate penetrates through the cleaning net cylinder and is in threaded connection with the moving plate, a first sliding slot isformed in the inner wall of one side of the cleaning box, and a first sliding block matched with the first sliding slot is slidably connected in the first sliding slot. The automobile part soaking and cleaning structure not only improves the efficiency of soaking and cleaning the automobile parts but also provides convenience for taking out the automobile parts after cleaning.

Owner:嘉兴万顺精密机械有限公司

Oil and gas transmission pipeline laying and mounting construction method

ActiveCN110375114ALabor intensiveDecrease productivityPipe laying and repairGas transmissionUltimate tensile strength

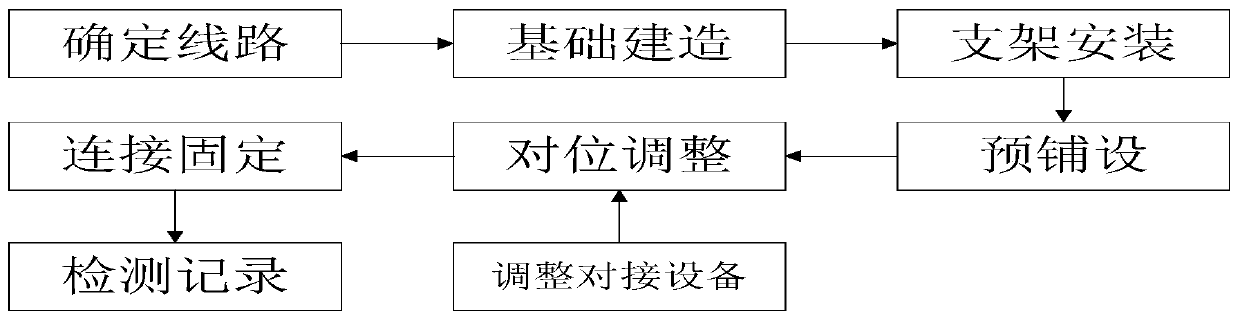

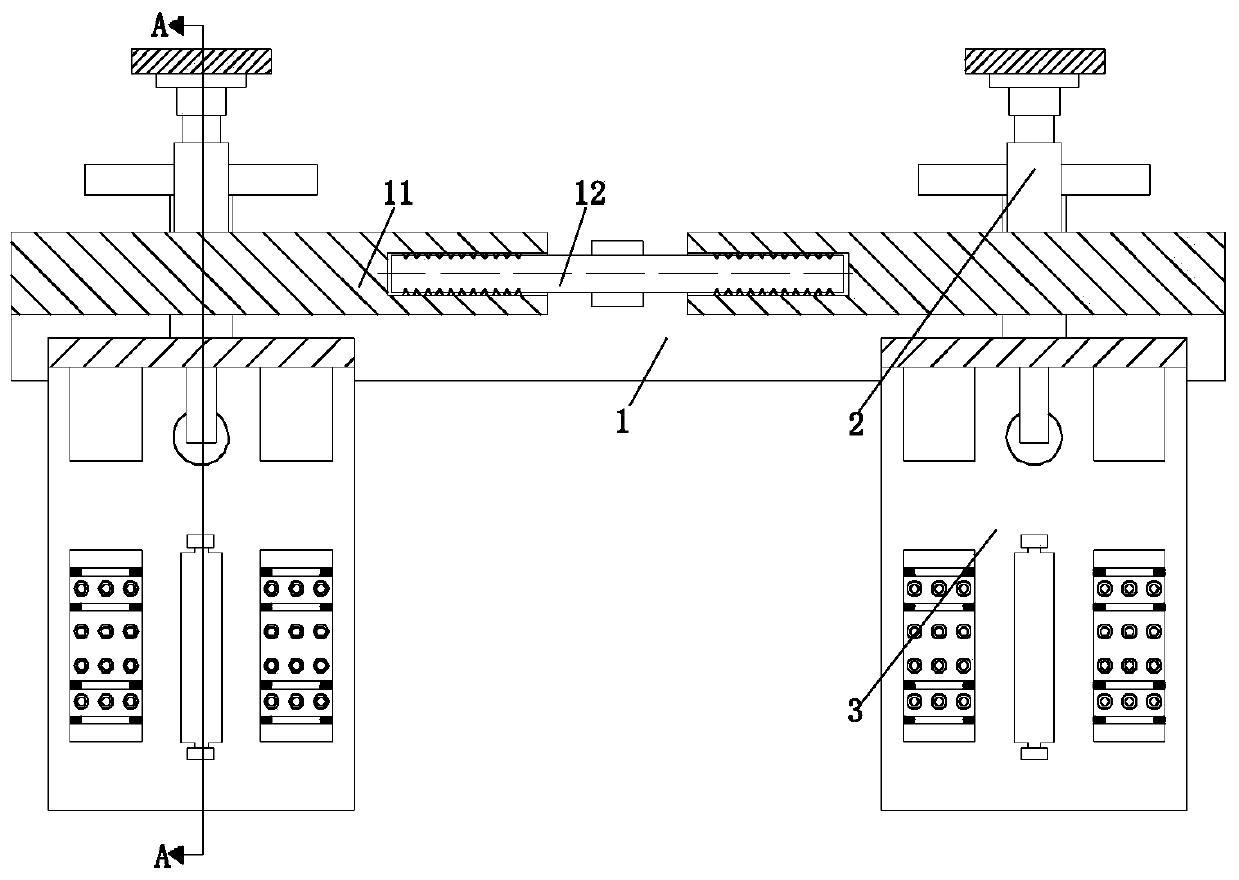

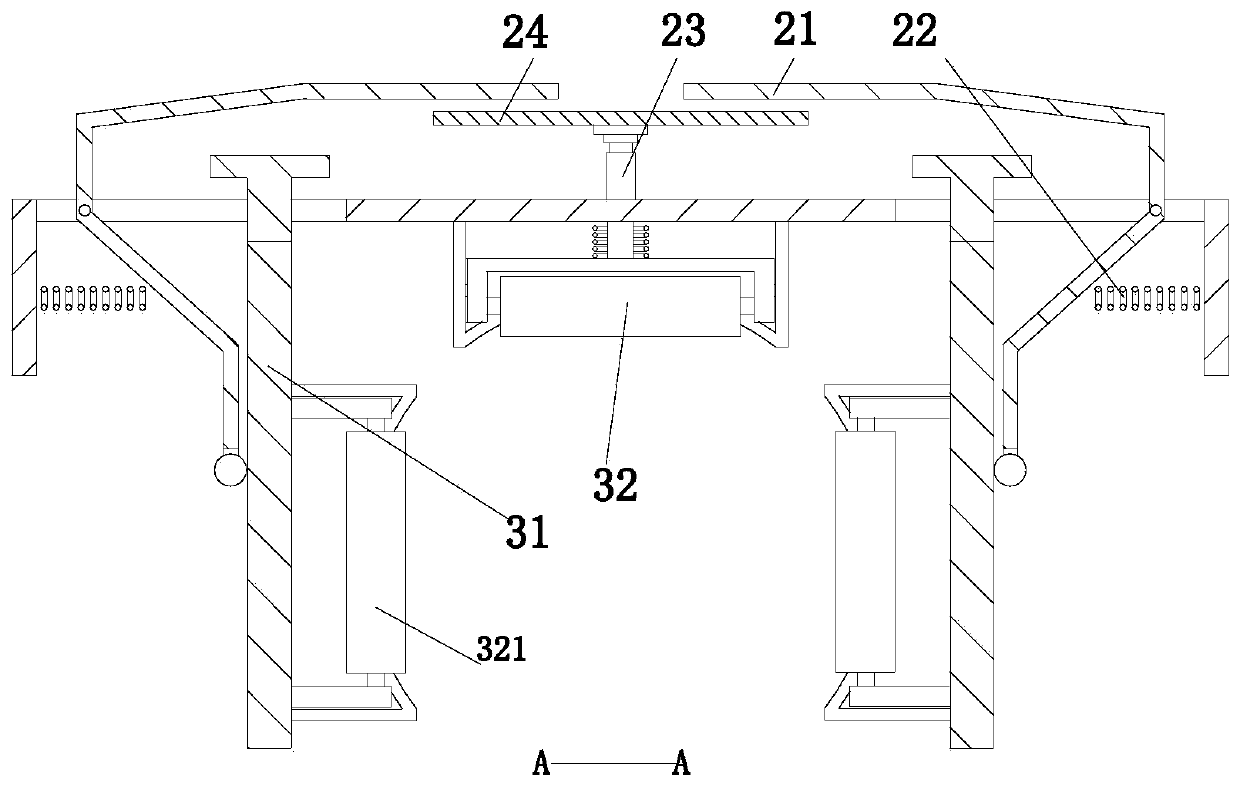

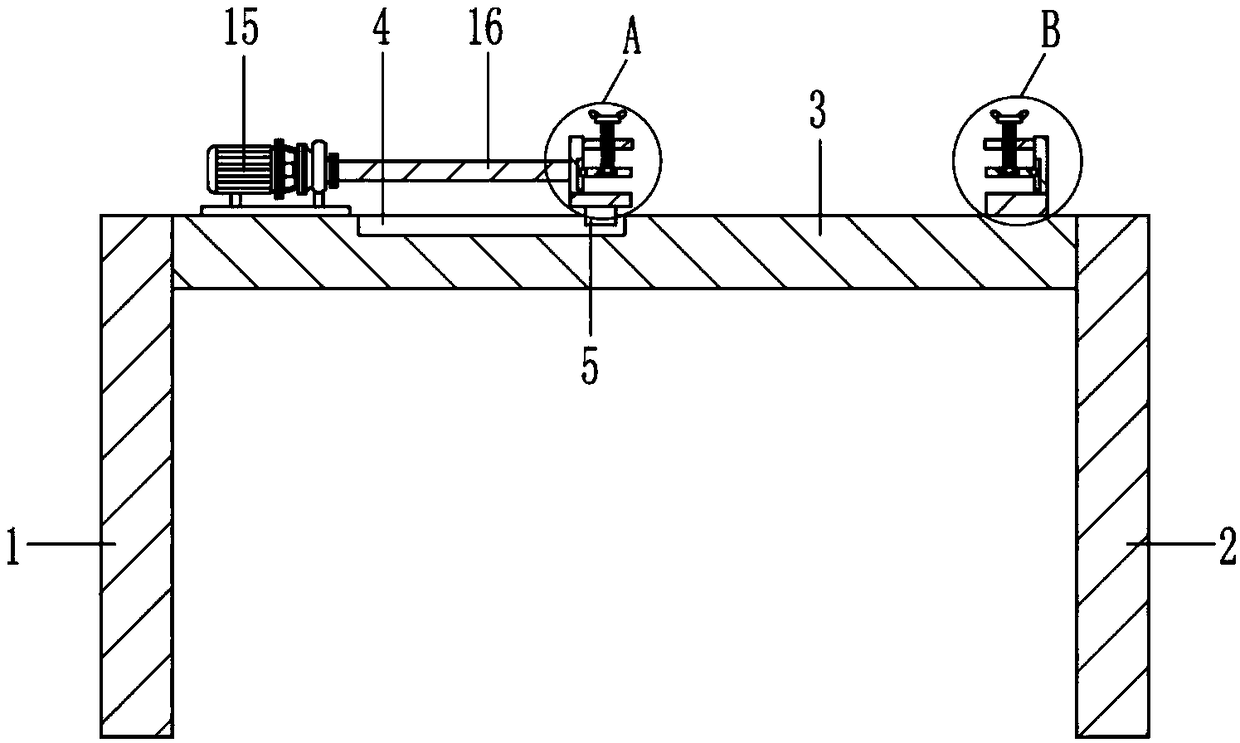

The invention relates to an oil and gas transmission pipeline laying and mounting construction method. The oil and gas transmission pipeline laying and mounting construction method comprises the following steps: line determination, base construction, bracket mounting, pre-laying, aligned adjustment, connection and fixation, detection and recording and the like. Adjusting and docking equipment usedin the aligned adjustment step comprises a mounting bed frame, auxiliary mechanisms are symmetrically arranged at the left and right ends of the mounting bed frame, and a locking mechanism is arranged on each auxiliary mechanism. The oil and gas transmission pipeline laying and mounting construction method can solve the problems in an existing line pipeline laying process: a, the pipeline dockinglabor intensity by manual control is great, and the follow-up welding effect of the pipelines is affected as the uniformity of gaps in connecting parts of pipelines cannot be guaranteed; and b, it iscomplex to operate by controlling the pipelines to dock mechanically, corresponding machinery is selected for pipelines of different specifications, and the labor intensity is great and the work efficiency is low as pipeline docking machinery needs to be carried according to a mounting line.

Owner:HANGZHOU SANWO INTELLIGENT TECH CO LTD

Leather detection device for leather processing

The invention relates to a detection device, and particularly relates to a leather detection device for leather processing. The technical problem to be solved by the invention is to provide a leatherdetection device for leather processing, which has various detecting capabilities. The leather detection device for leather processing comprises: a first supporting plate, a second supporting plate, amounting plate, a first sliding block, a first connecting plate, a first fixing rod, a second sliding block, a first fixing plate, a first clamping plate and the like; the other end is installed on one side part of the second supporting plate; and a first sliding slot is formed in the top of the mounting plate, the first connecting plate is slidably connected with the first sliding slot through the first sliding block, the first fixing rod is fixedly connected to the top of the first connecting plate, and a second sliding slot is formed in one side part of the first fixing rod. The leather detection device for leather processing provided by the invention achieves the effect of having various detection capabilities.

Owner:广东艾斯瑞仪器科技有限公司

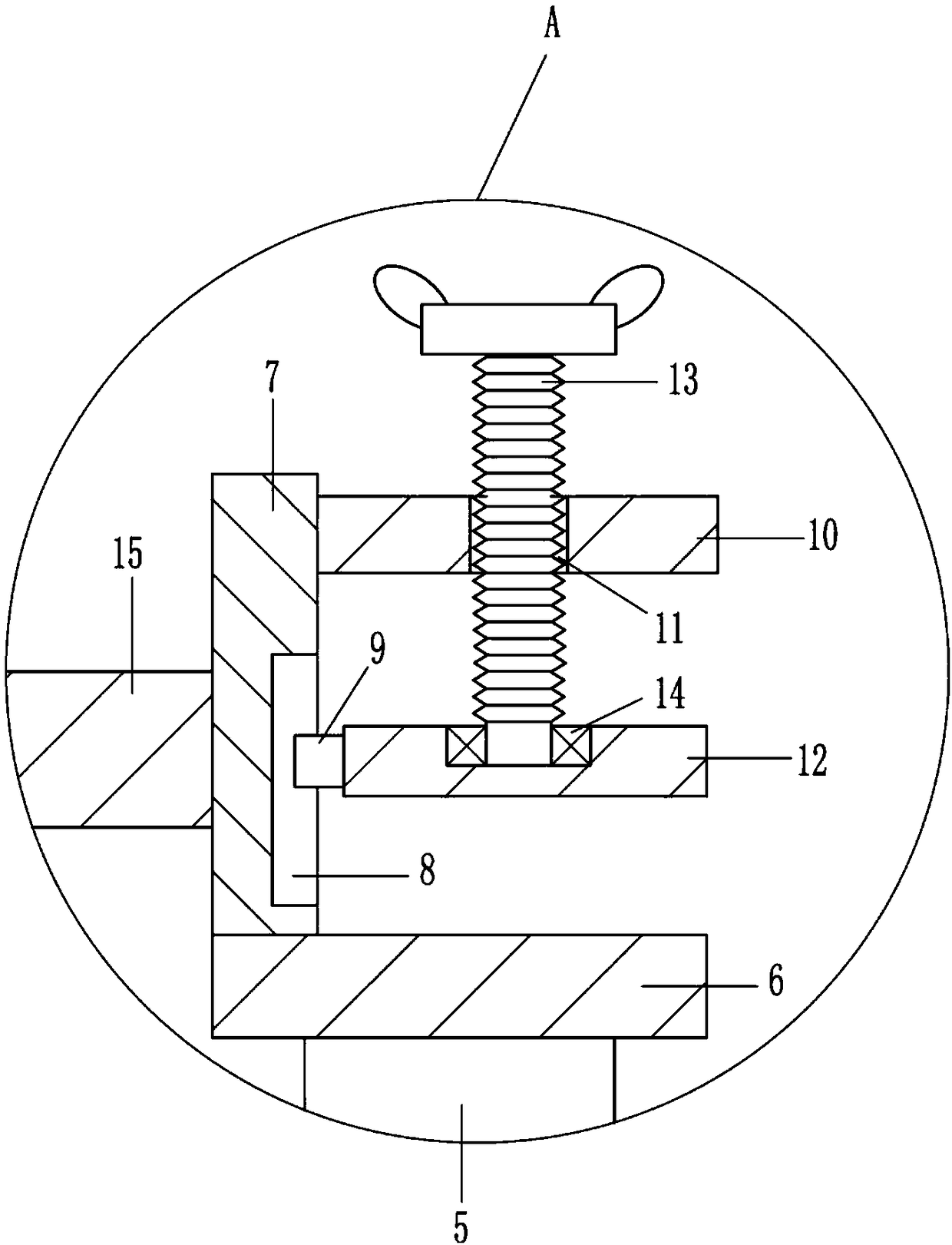

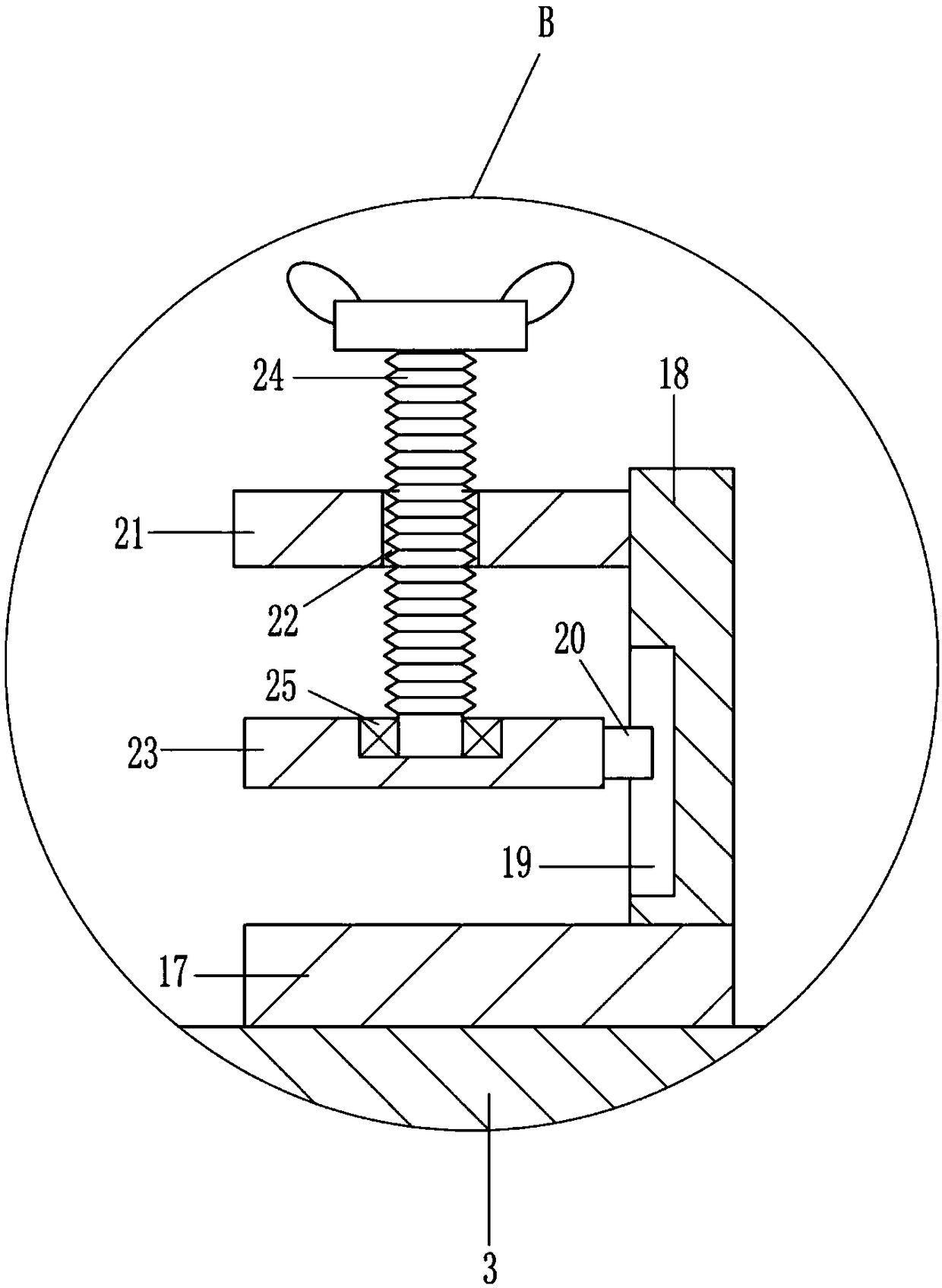

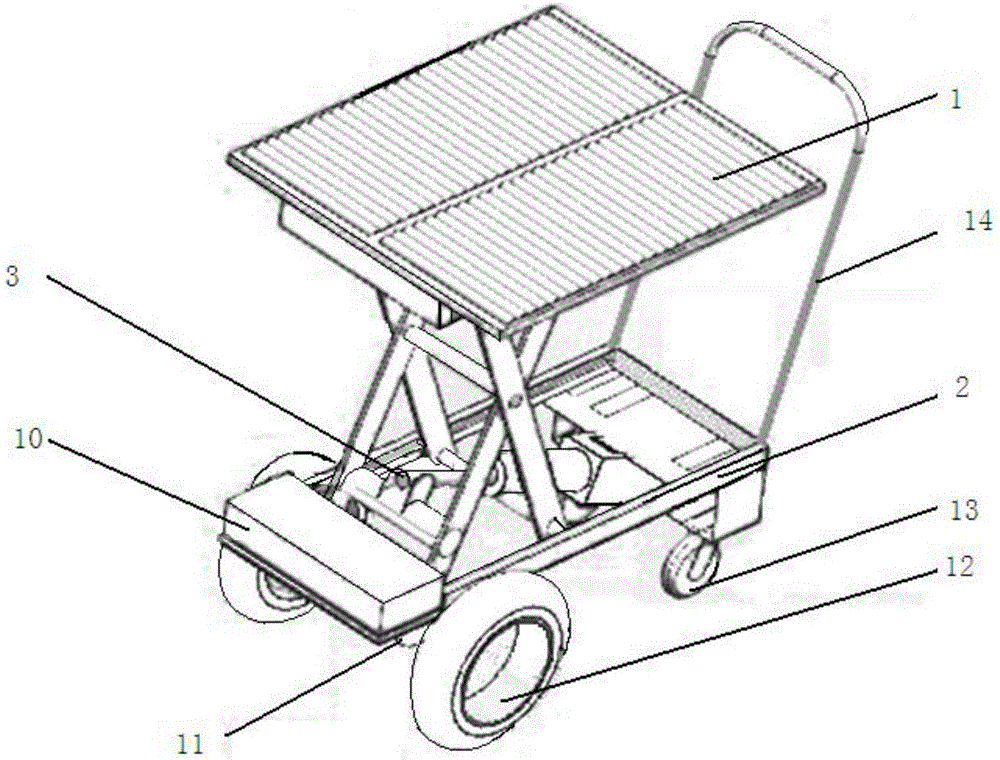

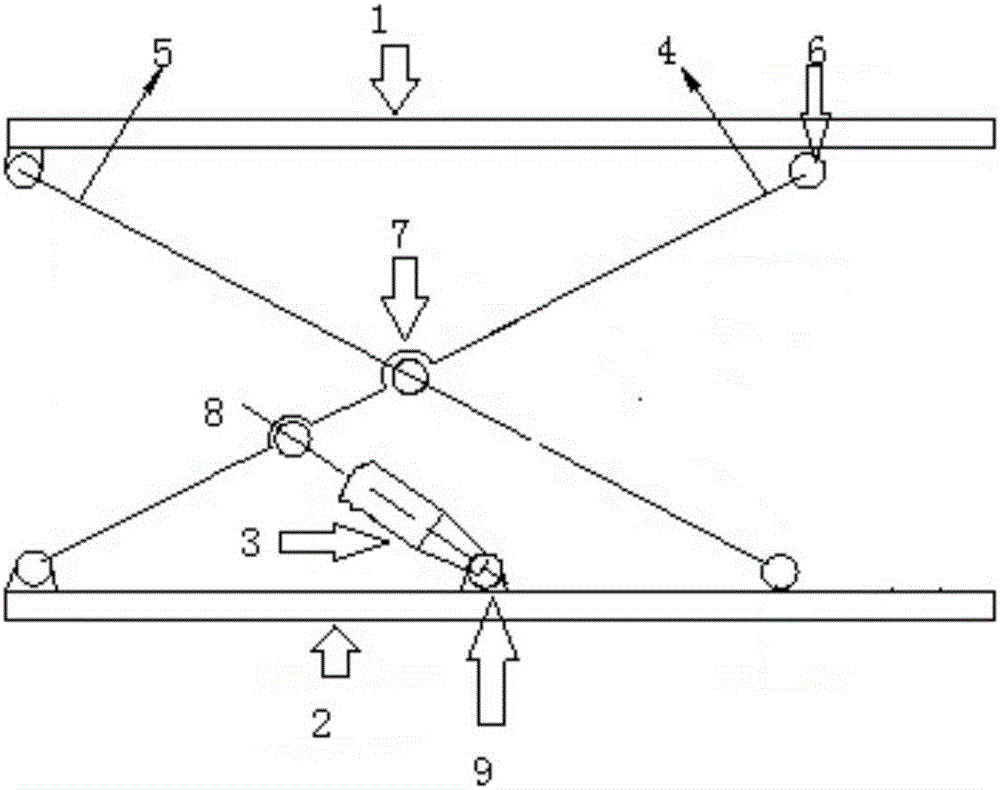

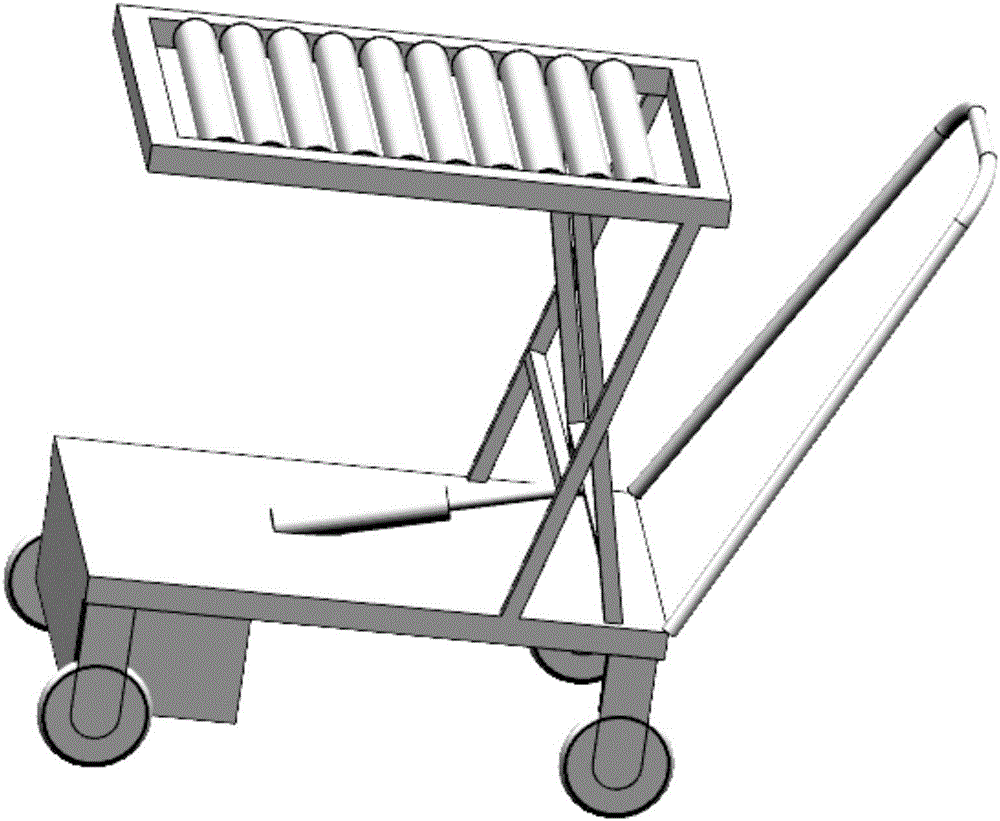

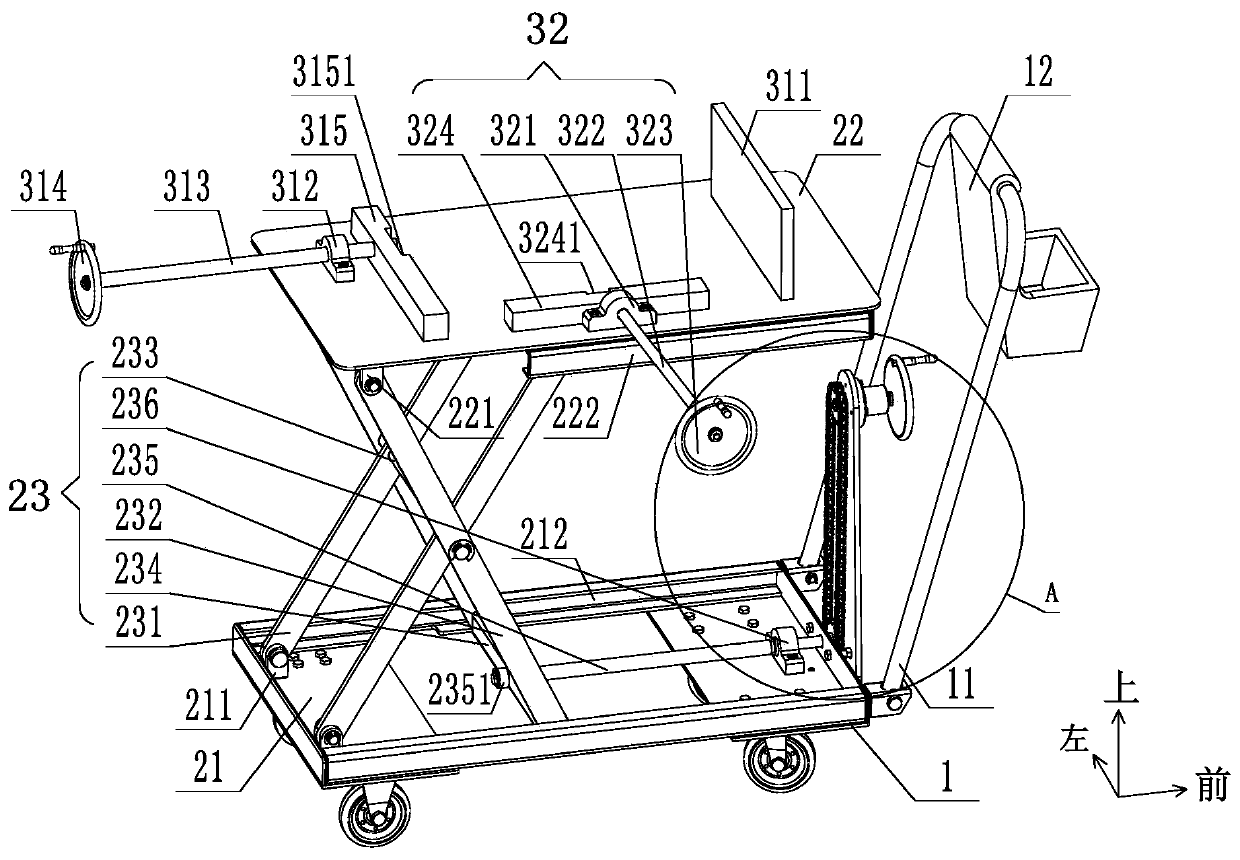

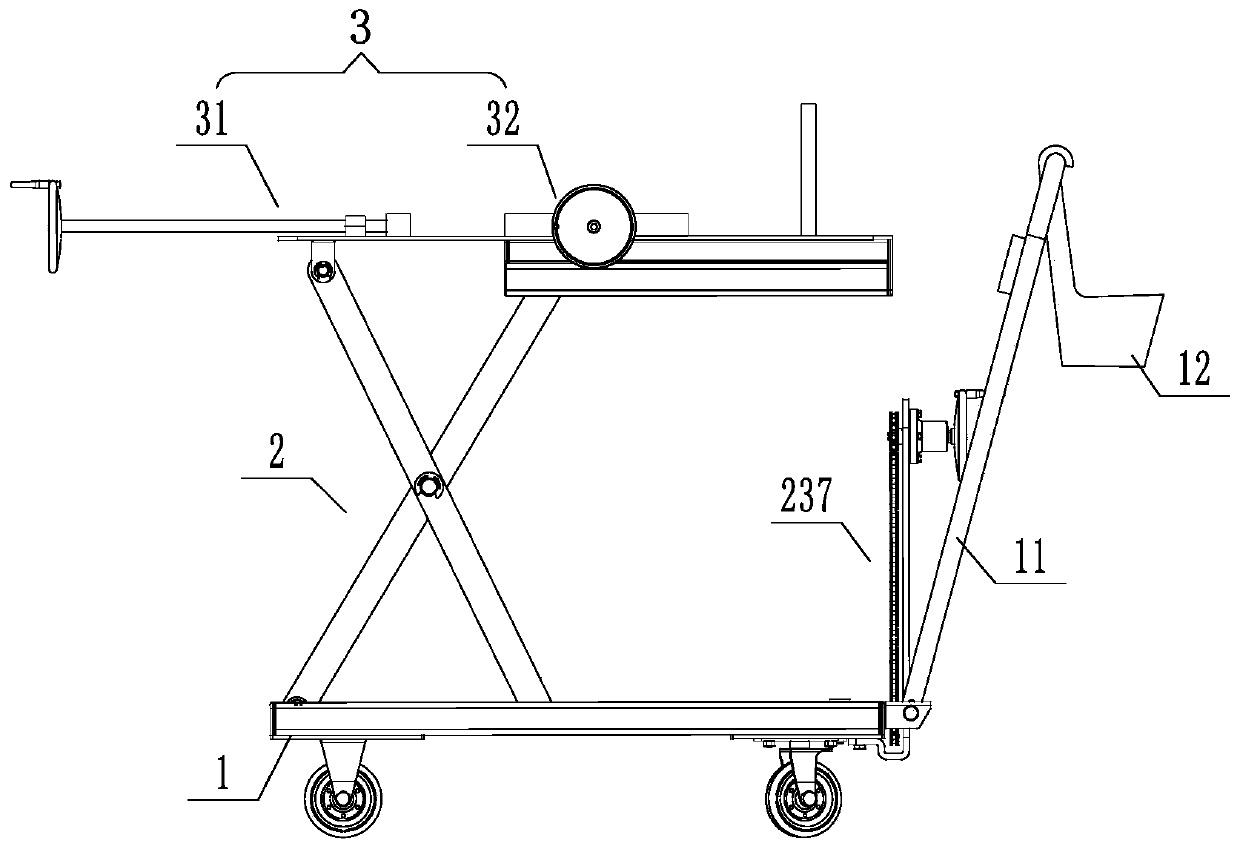

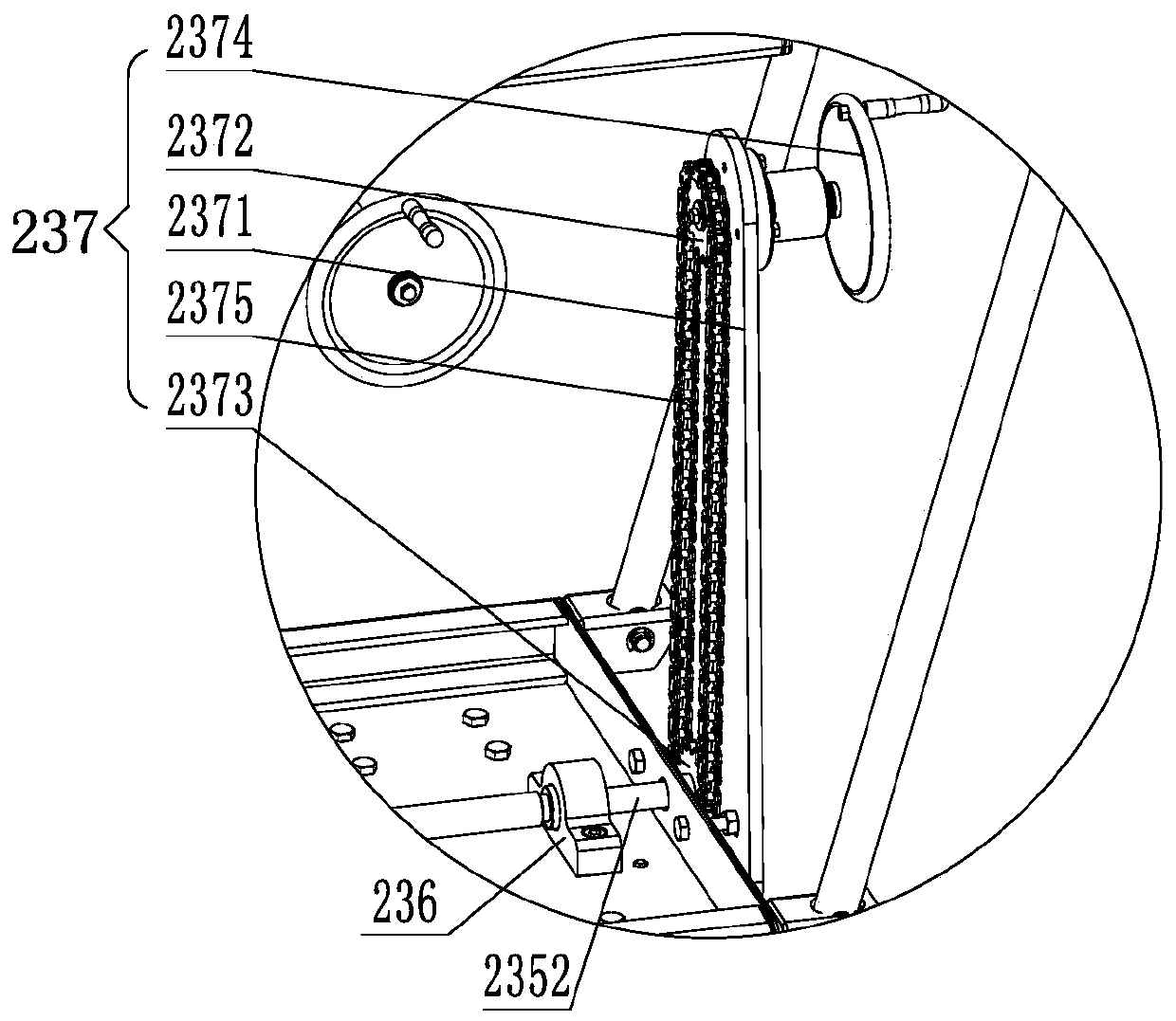

Small hydraulic lifting electric truck

InactiveCN106744483AImprove carrying capacitySimplify the body structureLifting framesHand carts with multiple axesCartElectric drive

The invention discloses a small hydraulic lifting electric truck. The small hydraulic lifting electric truck comprises a working platform, a frame type base, hydraulic lifting mechanisms, a hydraulic cylinder, an idler wheel mechanism and an electric driving mechanism; the working platform comprises a base frame, a panel and a rolling tube platform, the hydraulic lifting mechanisms are a plurality of X-shaped mechanisms, and X-shaped mechanisms comprise first rods and second rods which are symmetrically installed and are hinged; the hydraulic cylinder is installed on the frame type base to push the X-shaped mechanisms to move, two opposite channel steel are adopted by the frame type base and serve as longitudinal beams, and a slide inverted trough is formed in each channel steel; and an integral type truck bridge is adopted between driving wheels of the idler wheel mechanism and is internally provided with a differential mechanism. The bearing capacity of the truck is high, and a whole truck body is simple in structure; through arrangement of the idler wheel mechanism, while the conditions that the labor strength in the carrying process is relieved, and safety is improved are achieved, the structure of the truck is simplified; and the rolling tube rolling platform is beneficial for translating a heavy object, so that the labor strength for heavy object carrying is effectively relieved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

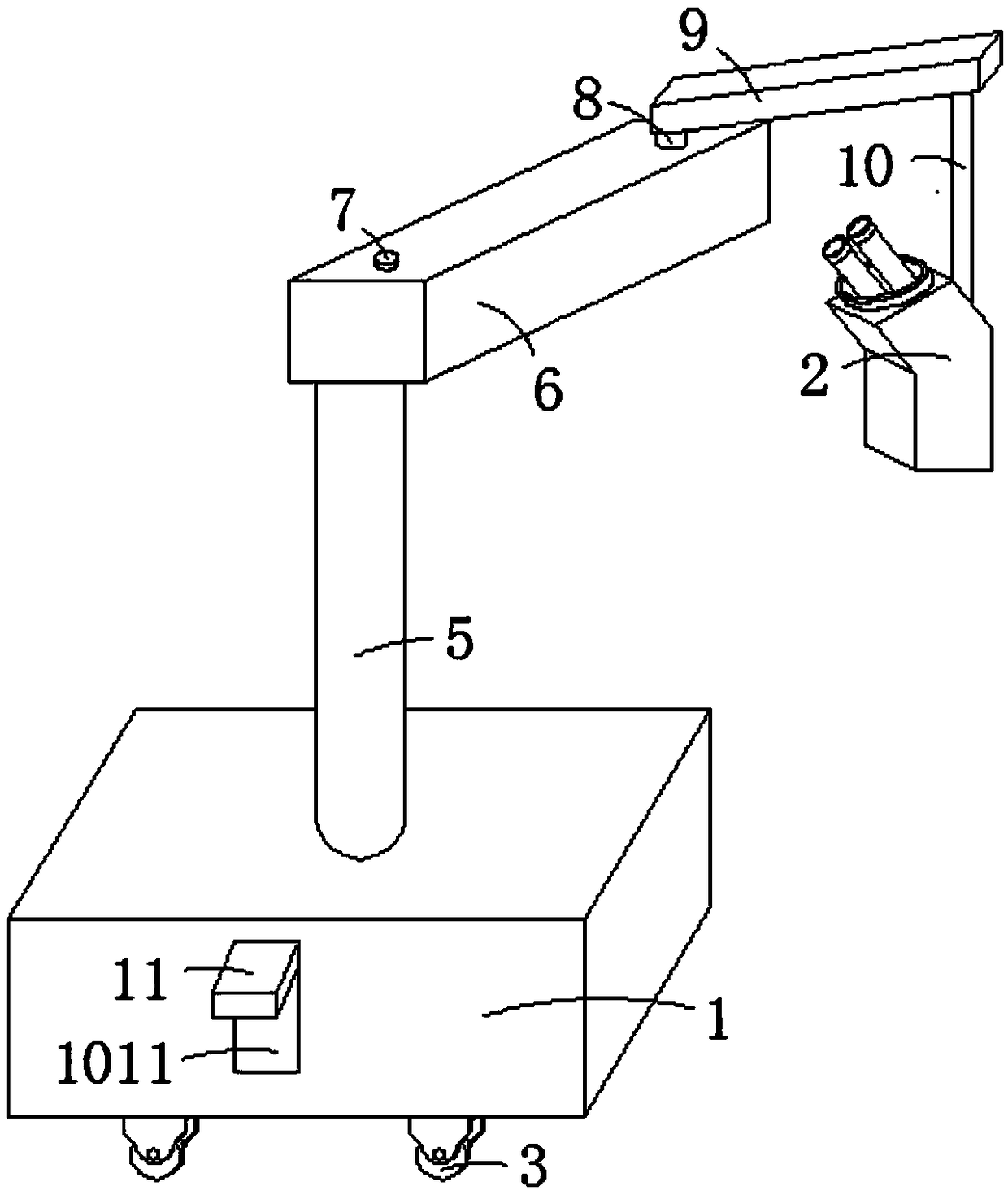

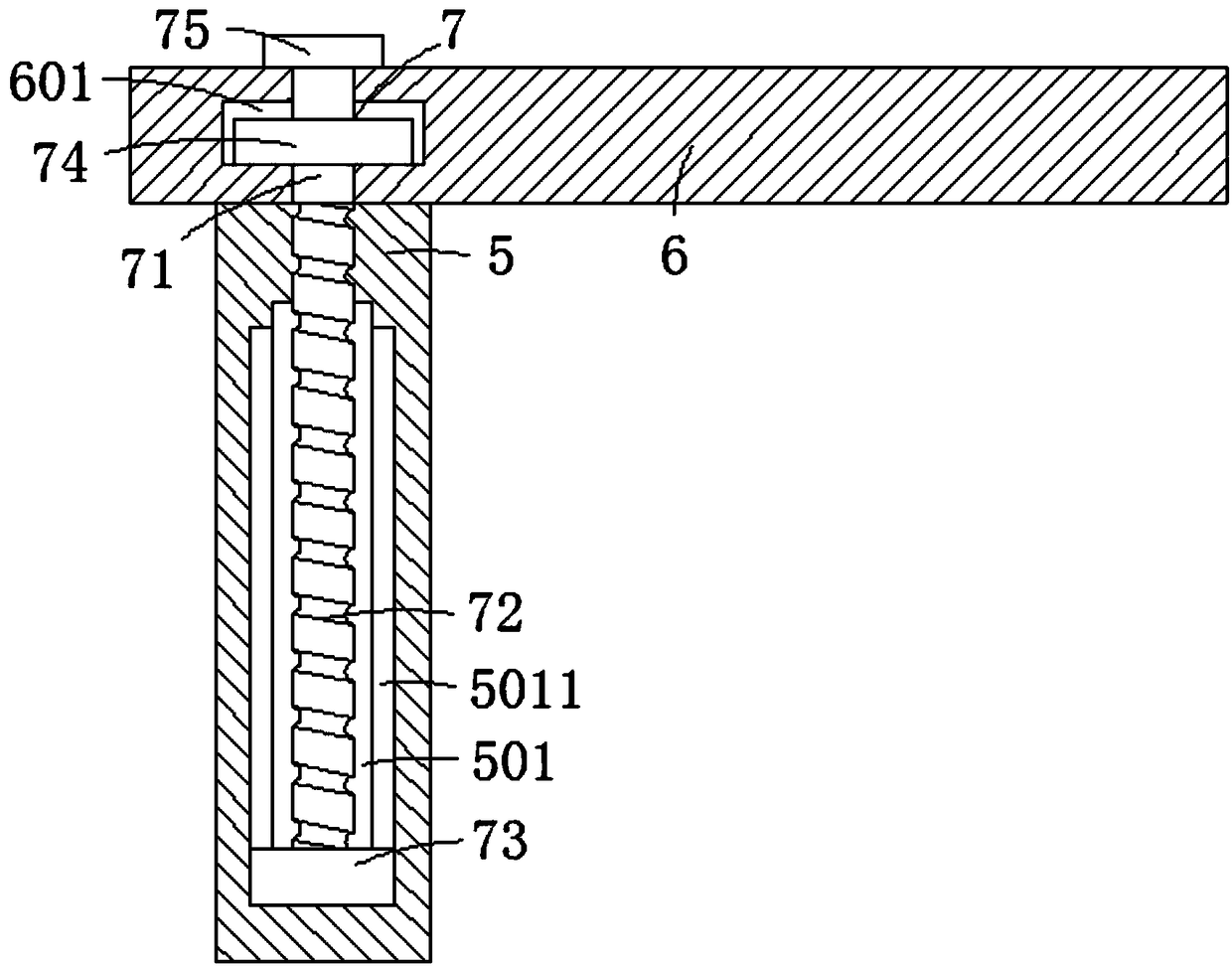

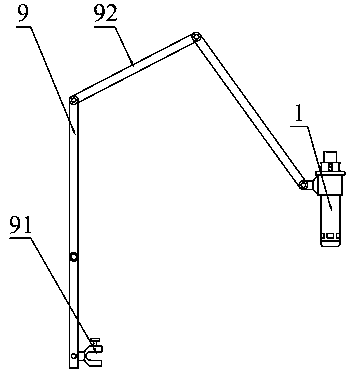

Microscope supporting arm for oral cavity and otolaryngology departments

InactiveCN109143564ASmooth rotationEasy to control rotationMicroscopesSurgical microscopesEngineeringENT surgeon

The present invention discloses a microscope supporting arm for oral cavity and otolaryngology departments. The microscope supporting arm comprises a pedestal and a microscope, four rollers are rotationally connected with four corners at the lower surface of the pedestal, the pedestal is internally provided with a cavity, a spacing mechanism configured to restrict rolling of the rollers is fixedlyconnected at the side wall of the cavity, the upper surface of the pedestal is fixedly connected with a support rod, the upper end face of the support rod is in horizontal contact with a first support plate, the support rod is internally provided with a control cavity, the side wall of the control cavity is rotationally connected with a lifting mechanism configured to lift the first support plate, and the upper end face of the first support plate is rotationally connected with a second support plate through a rotation shaft. The microscope supporting arm for oral cavity and otolaryngology departments can regulate the demand of the support arm as required, and can control a brake devices on the rollers by feet so as to prevent medical workers' hands from touching dust on the ground or thepedestal, guarantee the patients' health on some extent and bring convenience for the medical workers.

Owner:ZHENJIANG XINTIAN MEDICAL DEVICES

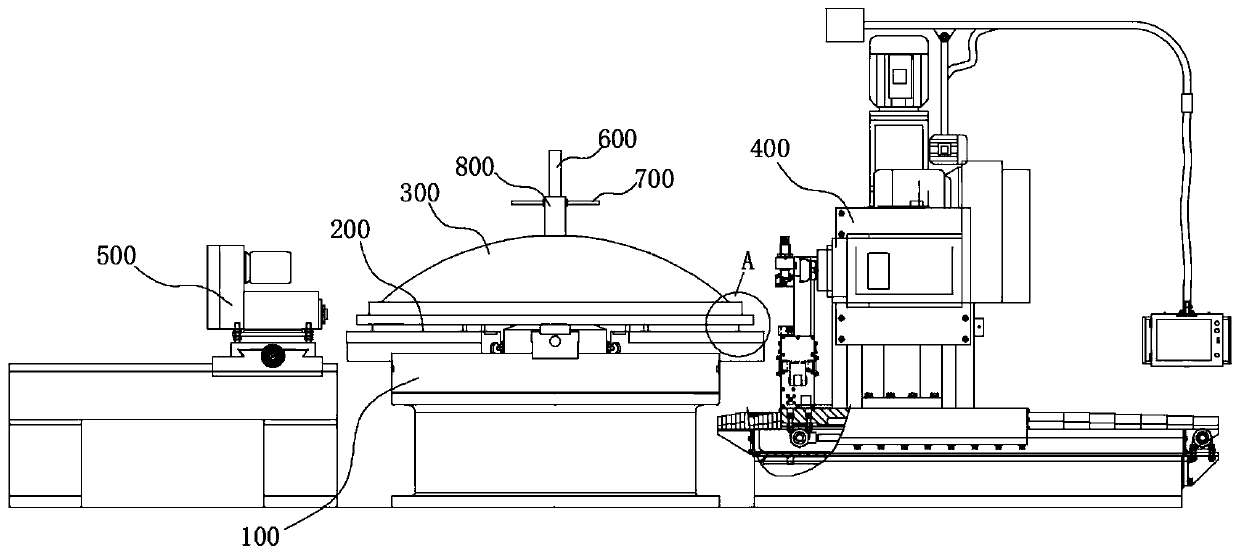

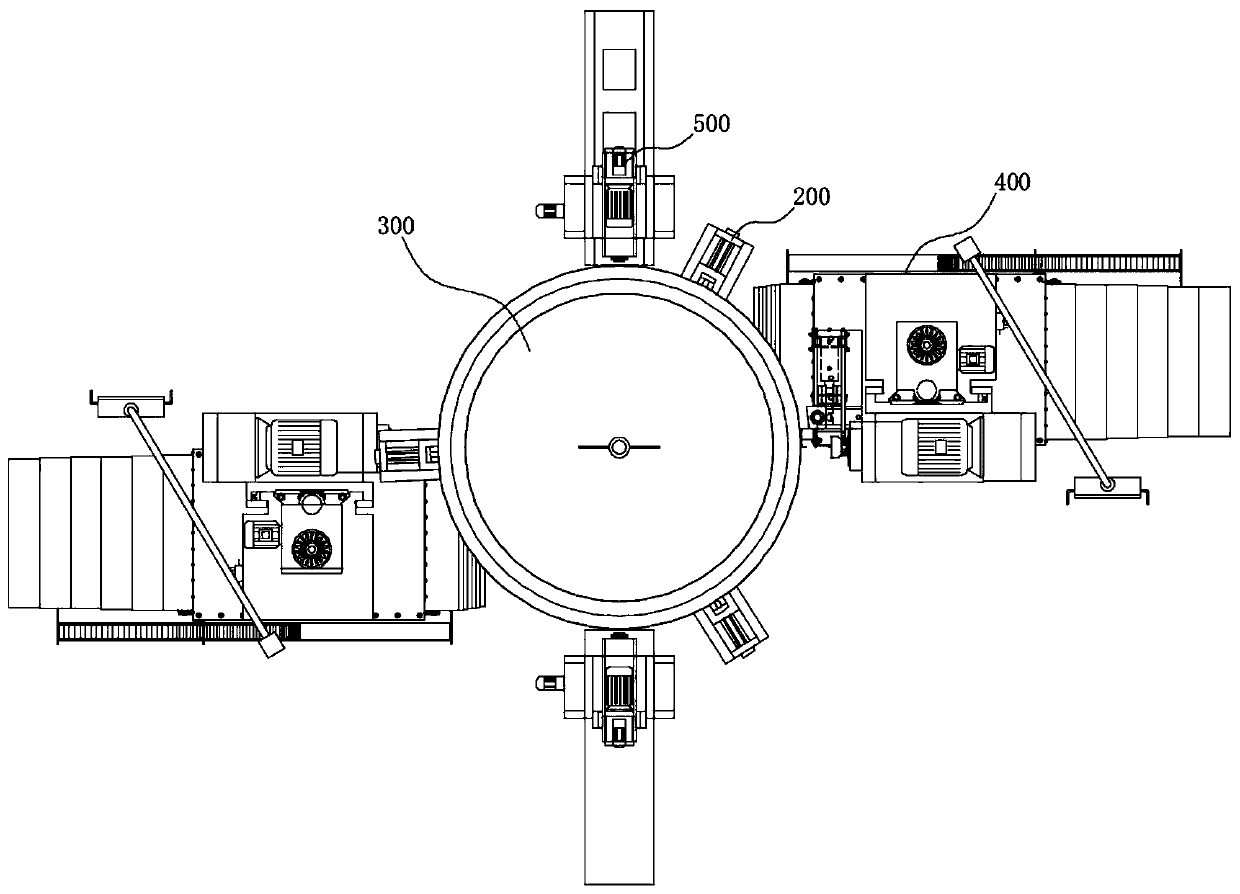

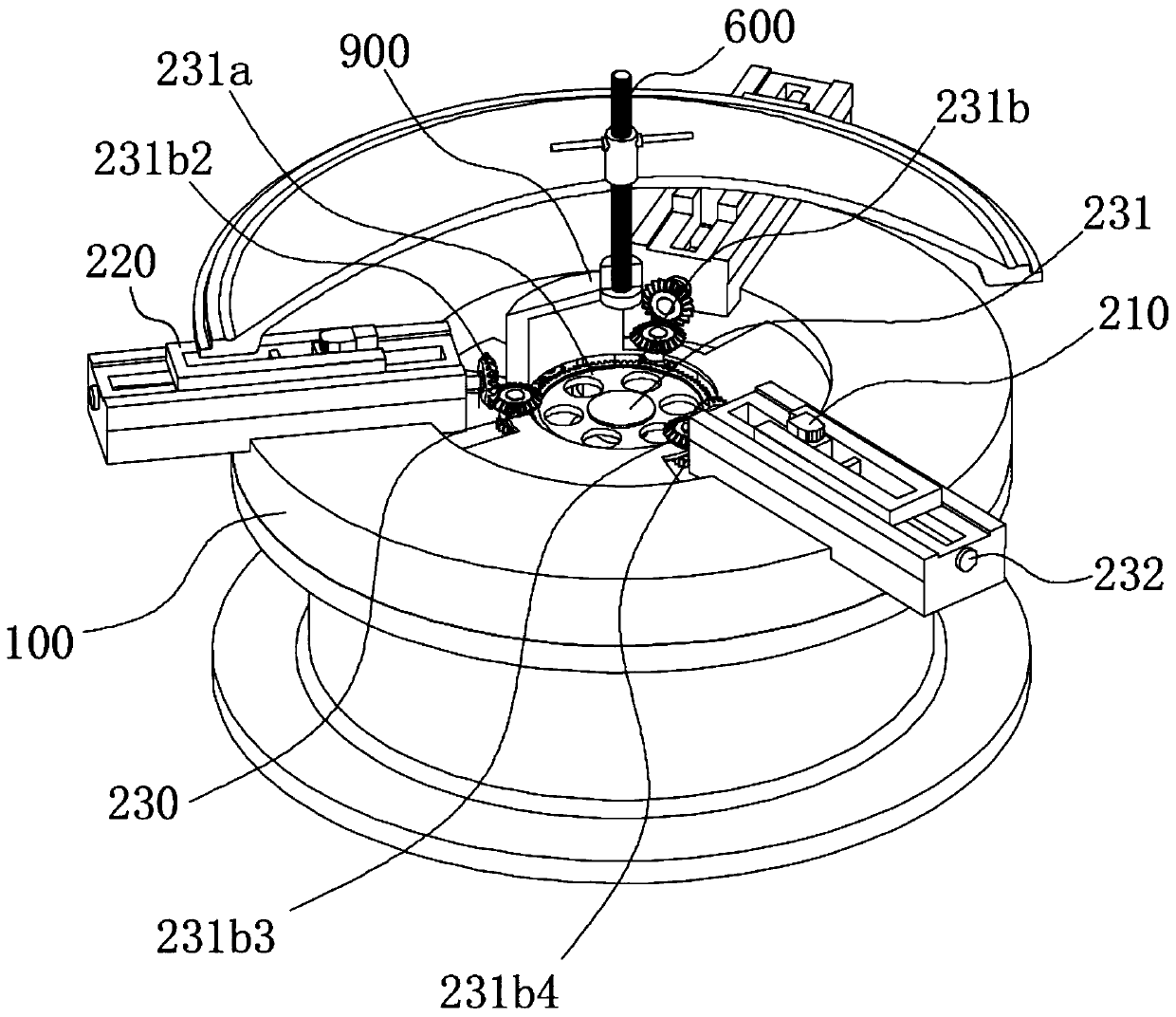

Outer tooth milling machine

ActiveCN110788409AStable processingThere will be no problem of interference with milling gear machiningOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention relates to an outer tooth milling machine. The outer tooth milling machine comprises a machine frame. A rotary table is installed on the machine frame. A tooth milling device and an exhaust groove machining device are arranged around the rotary table. Clamping devices are arranged on the rotary table and are used for clamping and positioning corresponding workpieces to make the to-be-machined outer ring walls of the workpieces in a machined state. The outer tooth milling machine is reasonable in layout, stable in structure, capable of automatically positioning and clamping workpieces with different sizes and making the outer ring walls of the workpieces with the different sizes in the machined state, and high in applicability, and meets existing using requirements.

Owner:安徽金马热能设备有限公司

Feet-type robot

The invention discloses a feet-type robot. The feet-type robot comprises a robot body, feet, translation swinging rods, a first power mechanism, a foot lifting swinging rods and a second power mechanism, wherein wheels are arranged at the bottom of the robot body; the feet are shaped like hollow rods; vacuum suckers are arranged at the lower ends of the feet; the upper ends of the feet are connected with an air pump through hoses; the four pairs of feet are arranged on the robot body in sequence from front to back; each foot movably sleeves the outer end of each translation swinging rod; each translation swinging rod is arranged on the robot body through a front-and-back swinging mechanism; the first power mechanism is used for providing power to the front-and-back swinging mechanism; a first sliding slot is formed in the outer end of each foot lifting swinging rod; a sliding block is arranged on each foot; The feet are movably embedded in the first sliding slots of the foot lifting swinging rods through the sliding blocks; each foot lifting swinging rod is arranged on the robot body through a up-and-down swinging mechanism; and the second power mechanism is used for providing power to the up-and-down swinging mechanisms. According to the feet-type robot disclosed by the invention, it is easy to drive the feet to do translation and foot lifting actions so that the robot is conveniently controlled to move.

Owner:GUANGXI UNIV

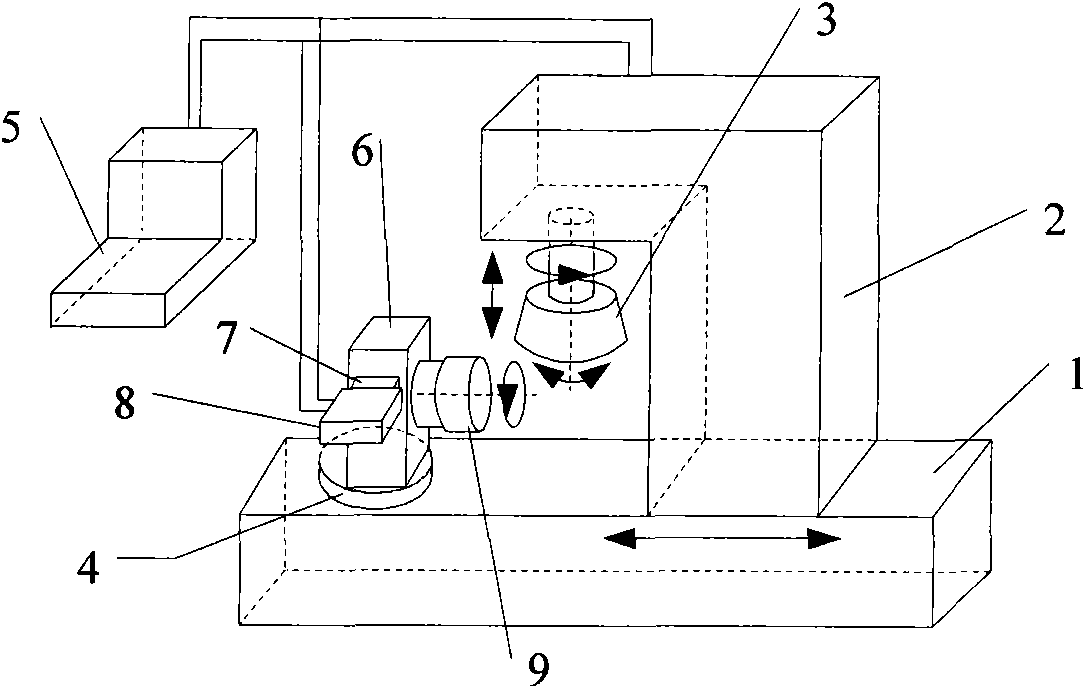

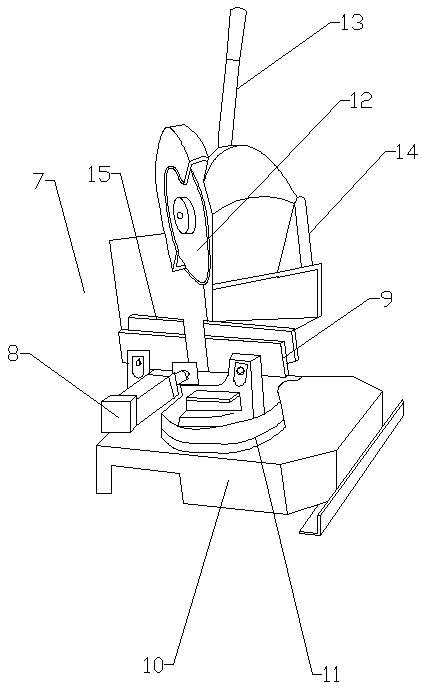

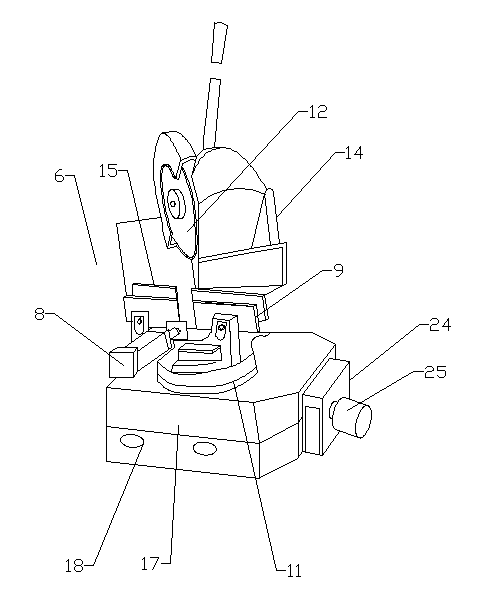

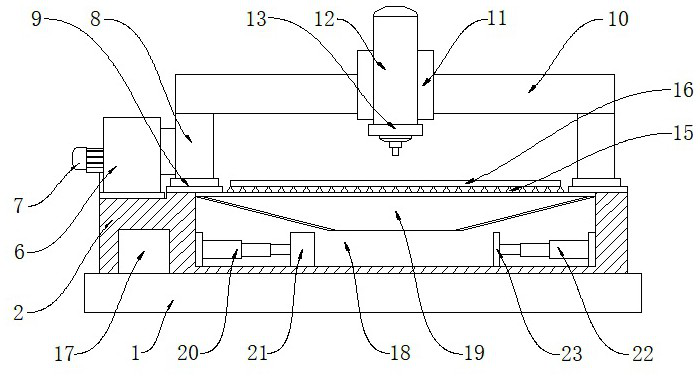

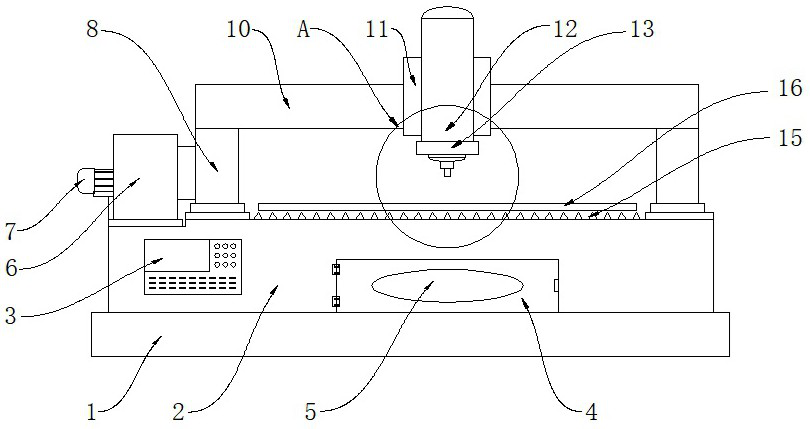

Face gear numerical control machining device and machining method

InactiveCN101979202AEasy to move and controlReduce processing timeGear-cutting machinesGear teethGear wheelEngineering

The invention discloses a face gear numerical control machining device and a face gear numerical control machining method. The face gear numerical control machining device comprises a numerical control gear shaper, a numerical control working turntable, a transition transmission mechanism and a face gear workpiece; the numerical control gear shaper comprises a tool base, a tool body, a gear shaper cutter, a numerical control gear shaper revolution working turntable, a numerical control system and a motor; the tool body is connected with the tool base; the gear shaper cutter is connected with the tool body; a numerical control gear shaper revolution workbench is connected with the base; the numerical control working turntable is fixed on the gear shaper revolution workbench; the motor is connected with the numerical control working turntable through the transition transmission mechanism; the face gear workpiece is fixed on the numerical control working turntable; and the numerical control system is respectively connected with the tool base and the motor. When the face gear numerical control machining device works, the tool body moves on the tool base to realize feed movement of face gear shaping machining; the gear shaper cutter and the face gear workpiece rotate around axes of the gear shaper cutter and the face gear workpiece to realize the generating movement of face gear machining; the gear shaper cutter swings to realize the cutter relieving movement of the face gear shaping machining; and the gear shaper cutter reciprocates up and down to realize the main cutting movement of the face gear shaping machining. The face gear numerical control machining device can realize high-efficiency and high-precision machining of the face gear.

Owner:BEIHANG UNIV

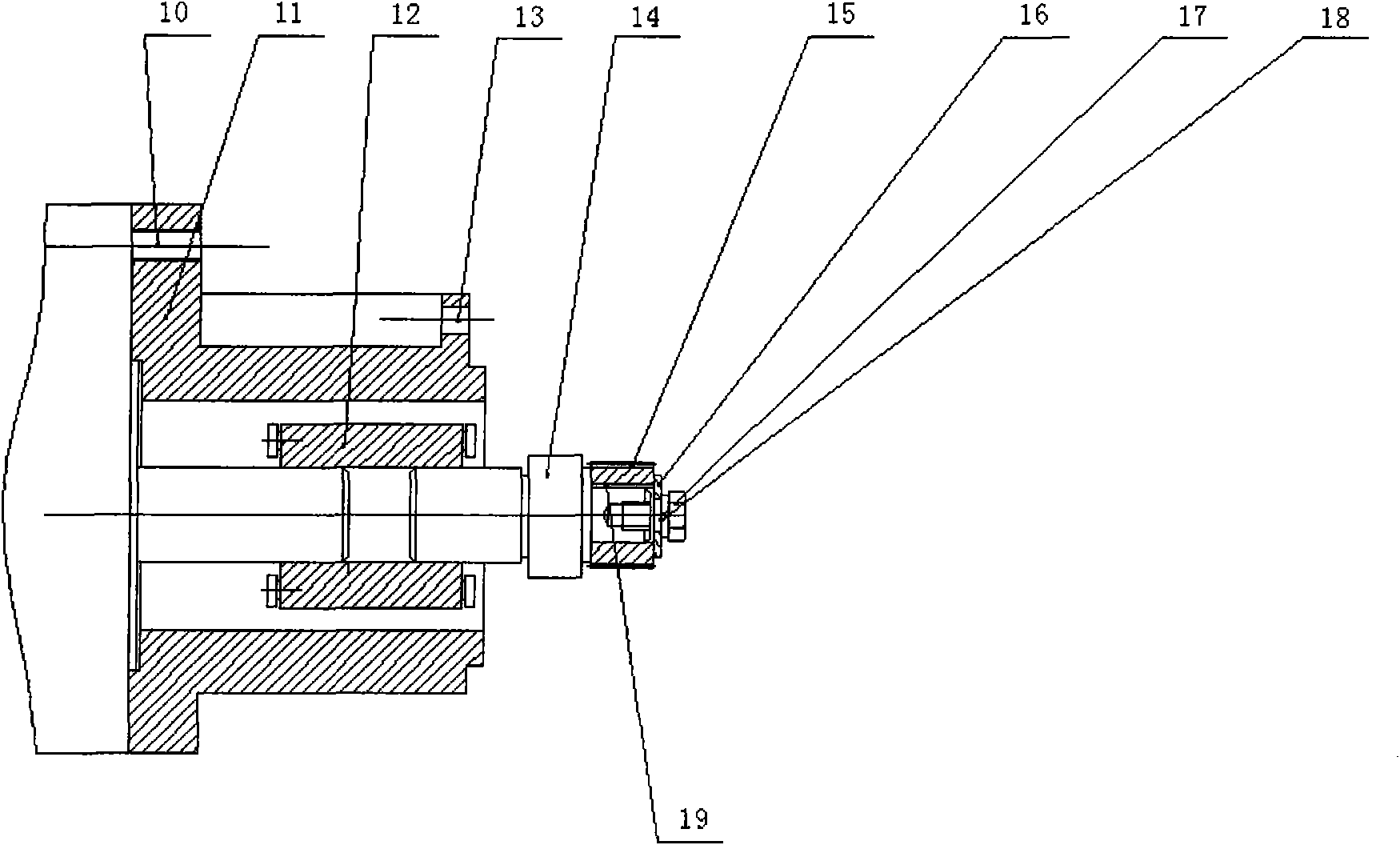

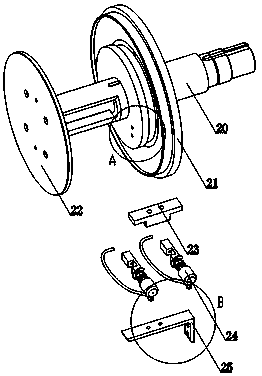

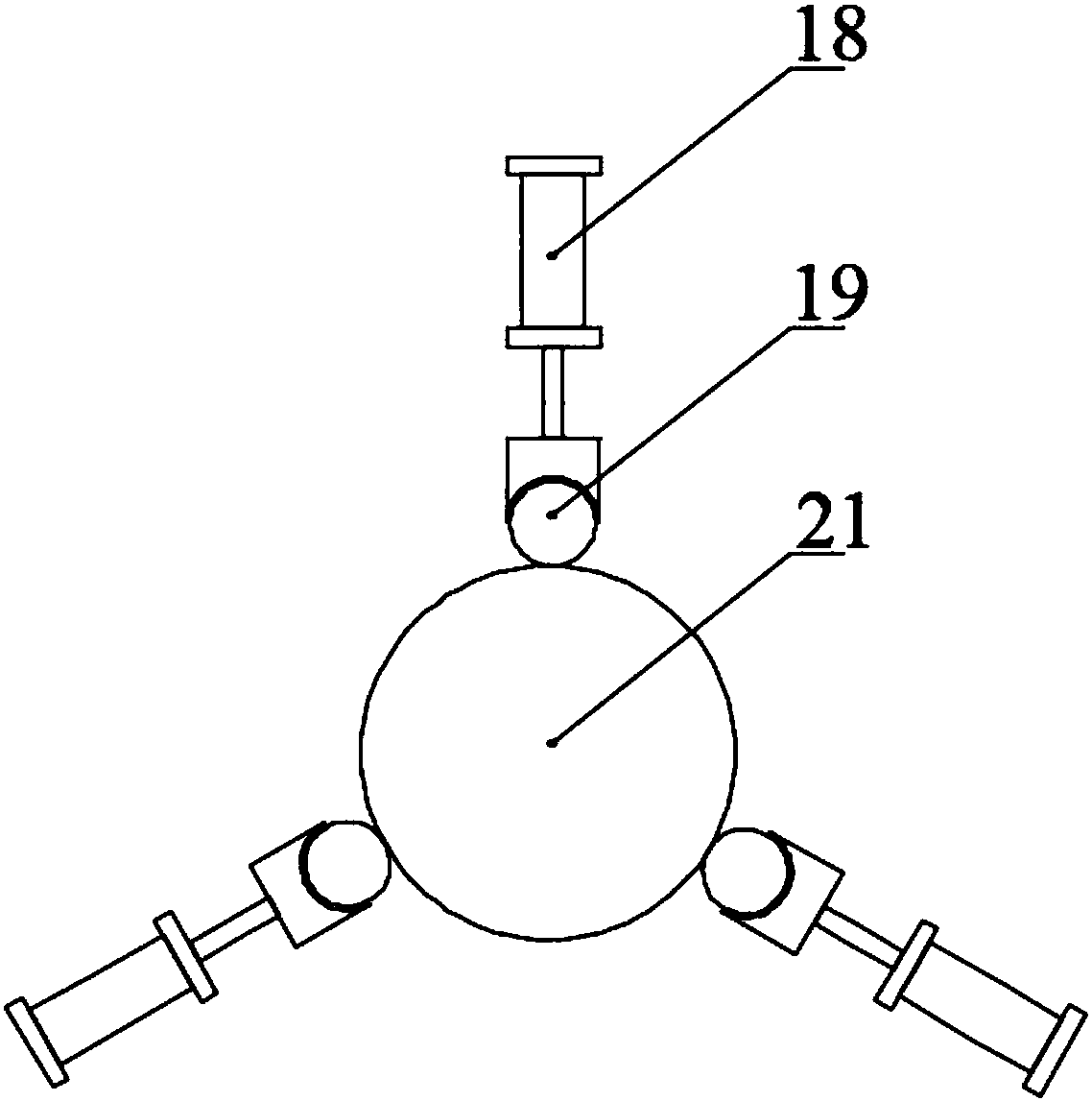

Revolving-extrusion sealing device for pipe sealing machines

The invention discloses a revolving-extrusion sealing device for pipe sealing machines. The device is characterized by comprising a main shaft, a cutter head, a sealing cutter, a sealing cutter guide mechanism and a cutter moving mechanism, wherein the cutter head is arranged at the front end of the main shaft, and the sealing cutter is arranged on the cutter head; the main shaft is driven to rotate by a main shaft driving mechanism; under the guidance of the sealing cutter guide mechanism, the sealing cutter slides along the direction perpendicular to the axis of the main shaft so as to moveclose to or far away from the axis of the main shaft; and the cutter moving mechanism drives the sealing cutter to slide along the sealing cutter guide mechanism. The revolving-extrusion sealing device disclosed by the invention has the advantages that 1, the main shaft driving mechanism drives the main shaft to drive the cutter head to rotate, so that the sealing cutter rotates circumferentiallyalong the main shaft; meanwhile, the cutter moving mechanism drives the sealing cutter to slide along the sealing cutter guide mechanism, so that the sealing cutter slides along the direction perpendicular to the axis of the main shaft so as to move close to or far away from the axis of the main shaft, therefore, the revolving-extrusion sealing processing on an open end of a pipe to be processed can be realized, and finally, a sealing wall perpendicular to the side wall of the pipe to be processed is formed, the thickness of the sealing wall is consistent, and the end sealing effect is good; and 2, the whole revolving-extrusion sealing device is simple and compact in structure, and convenient to control.

Owner:OMS MASCH CO LTD

Abdominal wall supporting device for gasless laparoscopic surgery

InactiveCN108670325AReduce surgical riskAvoid crushing internal organsDiagnosticsSurgeryLaparoscopic surgeryMoving speed

The invention relates to the field of medical devices, and in particular to an abdominal wall supporting device for a gasless laparoscopic surgery. The device comprises a rod-shaped body that cooperates with a cavity mirror puncture, wherein the rod-shaped body is provided with a through hole that cooperates with a laparoscope, the rod-shaped body is provided with at least one supporting mechanism, and the supporting mechanism comprises a telescopic tube and a slider which are detachably connected to each other, the slider is made of silicone material, and the telescopic tube is detachably connected with a gas supply device, the gas supply device controls the amount of gas in the telescopic tube, changes the distance between the slider and the rod-shaped body, and the telescopic tube is ina contracted state when the rod-shaped body is placed in the abdominal cavity in order to prevent the supporting mechanism from causing damage to the cavity mirror puncture, during the extension of the telescopic tube, the slider made of silicone material does not cause damage to the organ, at the same time, the gas supply device is used to control the moving speed of the slider, so as to avoid the crushing injury caused by the slider moving too fast, the abdominal wall and the internal organs can separate safely to form a surgical space for laparoscopic surgery in the abdominal cavity.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

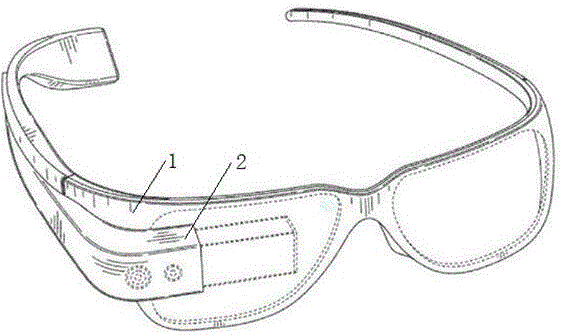

Movable efficient laryngoscope

ActiveCN106419814AImprove inspection efficiencyEasy to observe and operate laryngoscopeBronchoscopesLaryngoscopesWireless dataLaryngoscopes

The invention discloses a movable efficient laryngoscope. The movable efficient laryngoscope comprises a wearing observer, a wireless data transmitter and a movable laryngoscope body, wherein the wearing observer is respectively connected with the movable laryngoscope body and the wireless data transmitter wirelessly; the wireless data transmitter is mounted on a computer and is used for receiving data signals of the wearing observer and transmitting the data signals to the computer; the wearing observer comprises a wearing rack and an observing device which is detachably arranged on the wearing rack; the wearing rack comprises a cross beam and legs; two nose pads are arranged in the middle of the cross beam; the legs are arranged on two sides of the cross beam; and the cross beam and the legs are integrated. The invention aims to provide the laryngoscope which can examine movably, can wirelessly transmit examination data to the computer, and accurately observes laryngoscope detection images through the wearing observer. By the movable laryngoscope with the wearing function, detection time can be greatly shortened, examination of medical workers to patients is facilitated, and a diseased region can be observed clearly.

Owner:成都测迪森生物科技有限公司

Veneer rotary-cutting device for wood-plastic composite plate

InactiveCN108527481AQuick peel processingEasy to move and controlMetal working apparatusSingle plateSlide plate

The invention discloses a veneer rotary-cutting device for a wood-plastic composite plate. The veneer rotary-cutting device for the wood-plastic composite plate comprises a bottom plate, wherein sideseats are arranged on two sides of the bottom plate; a first fixing plate is arranged between one ends of the side seats; a second fixing plate is arranged between the other ends of the side seats; guide rails are arranged on two sides of the bottom plate; slide seats are arranged on the guide rails; a slide plate is arranged between the slide seats; a positioning seat is arranged on the slide plate; reinforcing plates are arranged between the positioning seat and the slide plate; a drive motor is arranged on the top part of the positioning seat; a drive gear is arranged in front of the drivemotor; a driven gear is arranged in the front surface of the positioning seat and meshes with the drive motor; a rotary pipe is arranged at an axial position of the driven gear; a positioning cylinderis arranged in the front surface of the positioning seat and is coaxial to the rotary pipe; the rotary pipe is arranged in the positioning cylinder; and a rotary-cutting mechanism is arranged on theend part of the rotary pipe. According to the veneer rotary-cutting device for the wood-plastic composite plate provided by the invention, the drive motor and the rotary-cutting mechanism can be conveniently moved and controlled, and an operator can conveniently and quickly rotary-cut the wood-plastic composite plate through the rotary-cutting mechanism.

Owner:彭翠芳

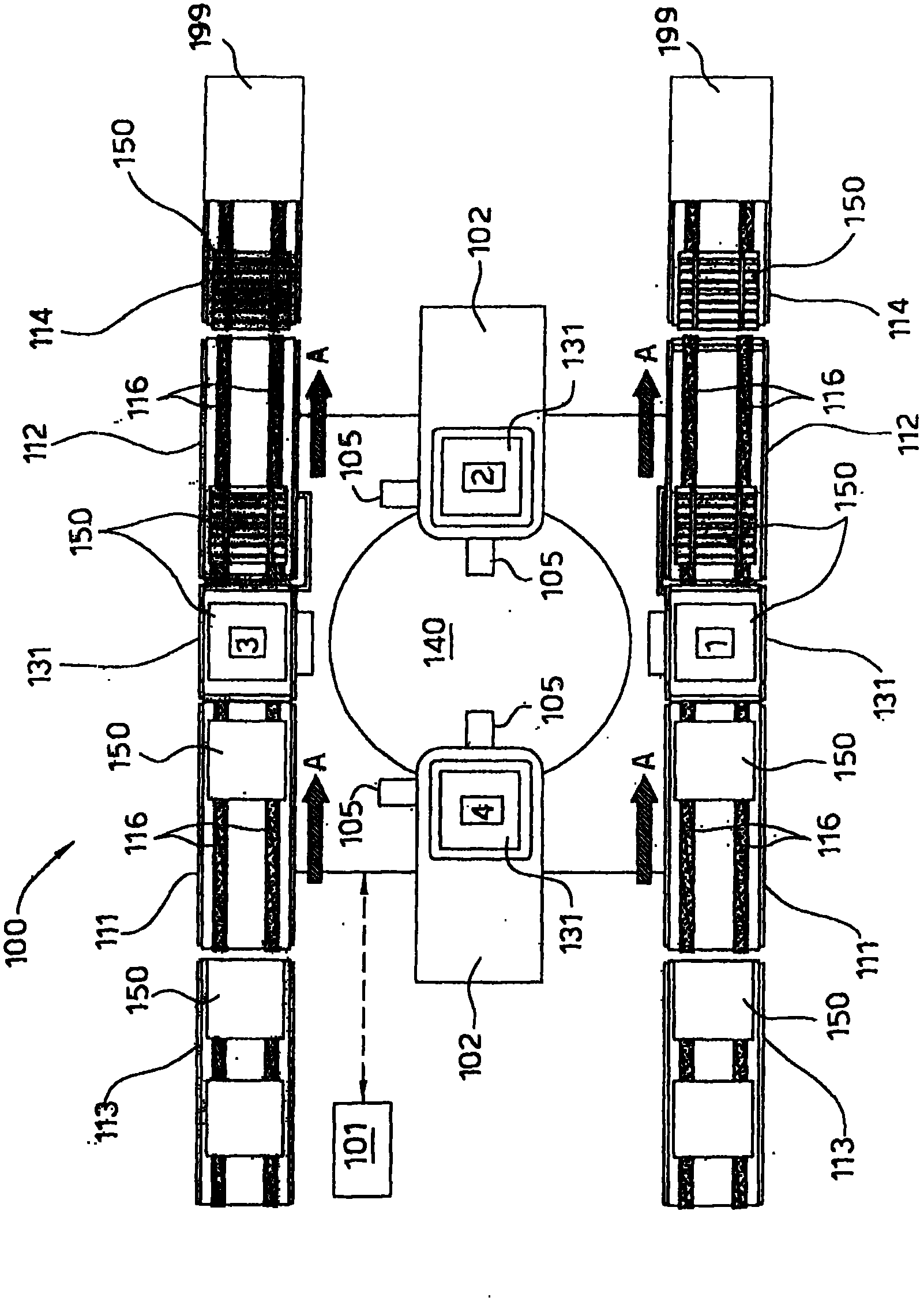

Blade for silk-screen printing on a substrate

InactiveCN102481777AEasy to move and controlPrecise and reliable control of movementScreen printersPrinted circuit manufactureScreen printingEngineering

Blade (10) for the silk-screen printing of one or more print tracks on substrates (150) by means of a print material deposited on a print substrate (150) by means of a silk-screen printing net (50). The blade (10) comprises a print extremity (18) and a supporting structure able to support the print extremity (18). The supporting structure comprises a support frame (12) fixed to a slider (14) mobile with respect to the support frame (12), which slider positions the print extremity (18) at least with respect to the net (50) below. Actuation members are provided to determine the movement of the slider (14) with respect to the support frame (12). The actuation members comprise a linear actuator of the voice coil type.

Owner:APPLIED MATERIALS INC

Automatic-positioning vibration sampler

ActiveCN104111180AImprove sampling accuracyReduce equipment costsWithdrawing sample devicesPreparing sample for investigationPhysicsElectric machinery

The invention discloses an automatic-positioning vibration sampler. The automatic-positioning vibration sampler comprises an upper fixing plate, a lower fixing plate, a support plate which is used for connection fixing and is perpendicular to the upper fixing plate and the lower fixing plate, a X-direction driving mechanism arranged on the lower fixing plate, a Y-direction driving mechanism connected to the X-direction driving mechanism, a Z-direction driving mechanism connected to the Y-direction driving mechanism by a longitudinal fixing base and a sampling pin connected to the Z-direction driving mechanism. The automatic-positioning vibration sampler also comprises a sampling pin vibrating mechanism. The sampling pin vibrating mechanism comprises a vibrating motor fixed to the longitudinal fixing base, an eccentric wheel device connected to an output end of the vibrating motor and a vibrating plate connected to the eccentric wheel device by a connection member. One end of the sampling pin goes through the vibrating plate. The eccentric wheel device in the sampling pin vibrating mechanism drives the vibrating plate to carry out eccentric motion so that the sampling pin is further driven to carry out eccentric motion to stir a liquid to be detected in a test tube and thus compared with the existing sampler, the automatic-positioning vibration sampler improves stirring effects and a sampling precision.

Owner:SUZHOU RIHE TECH

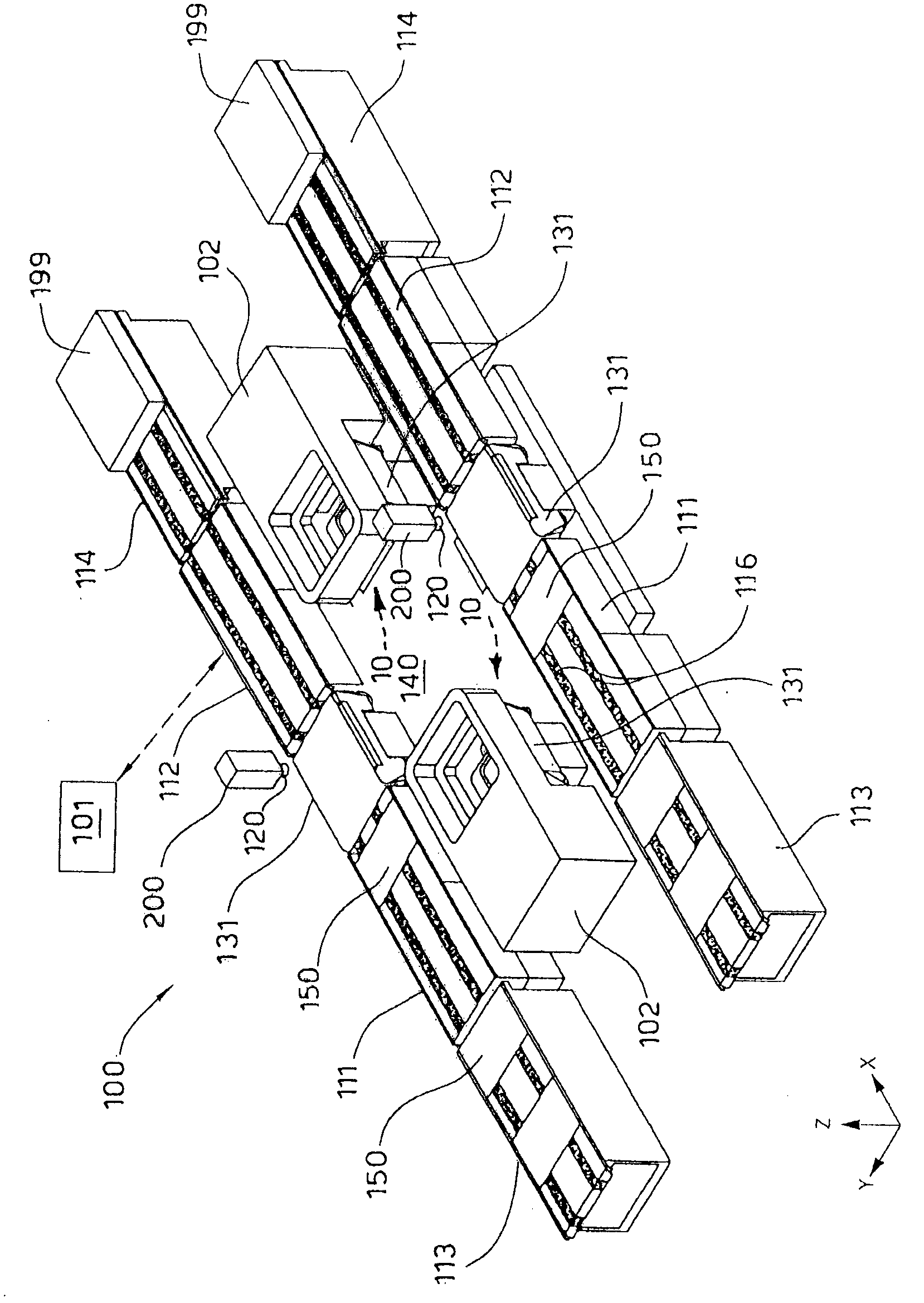

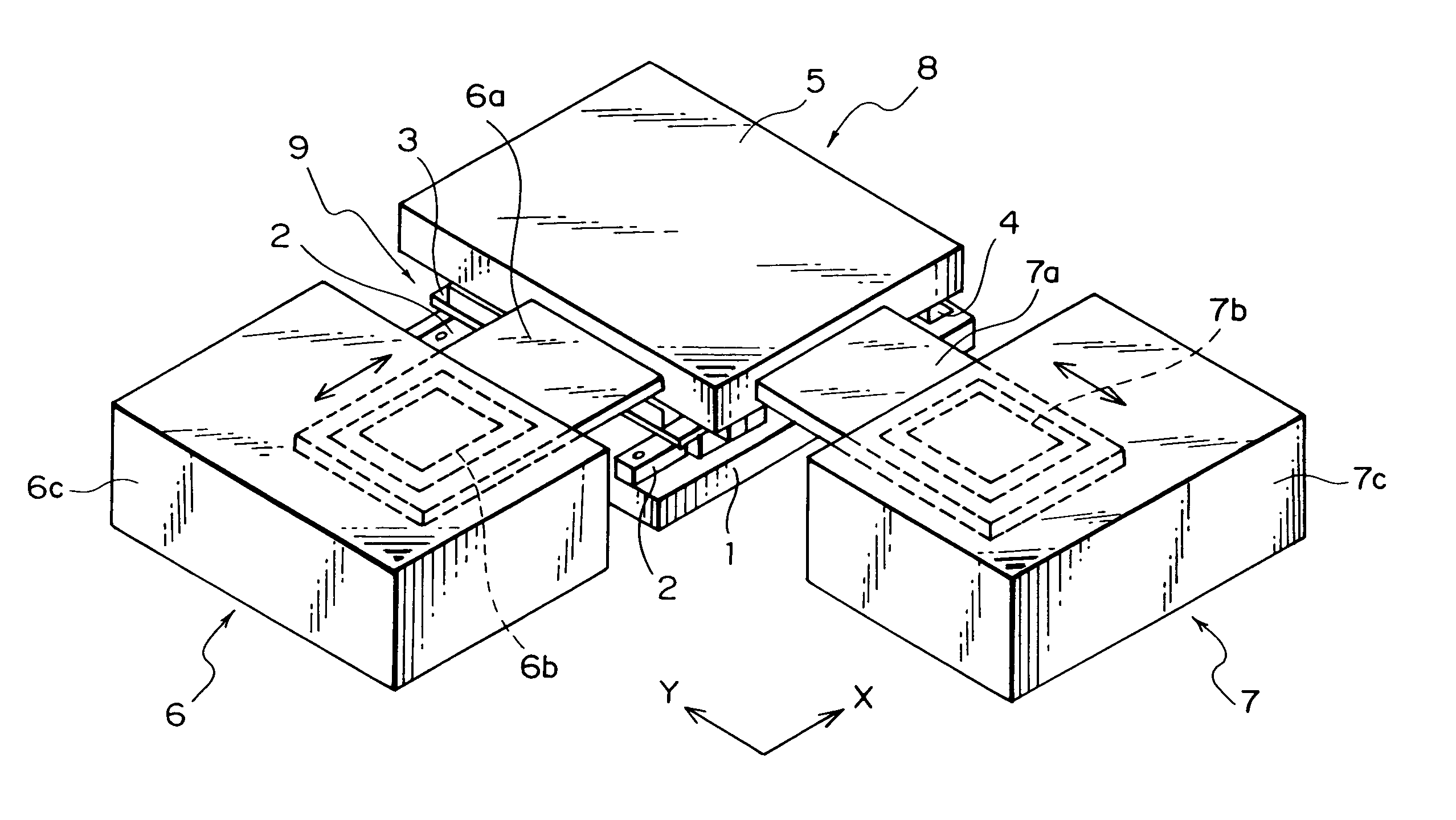

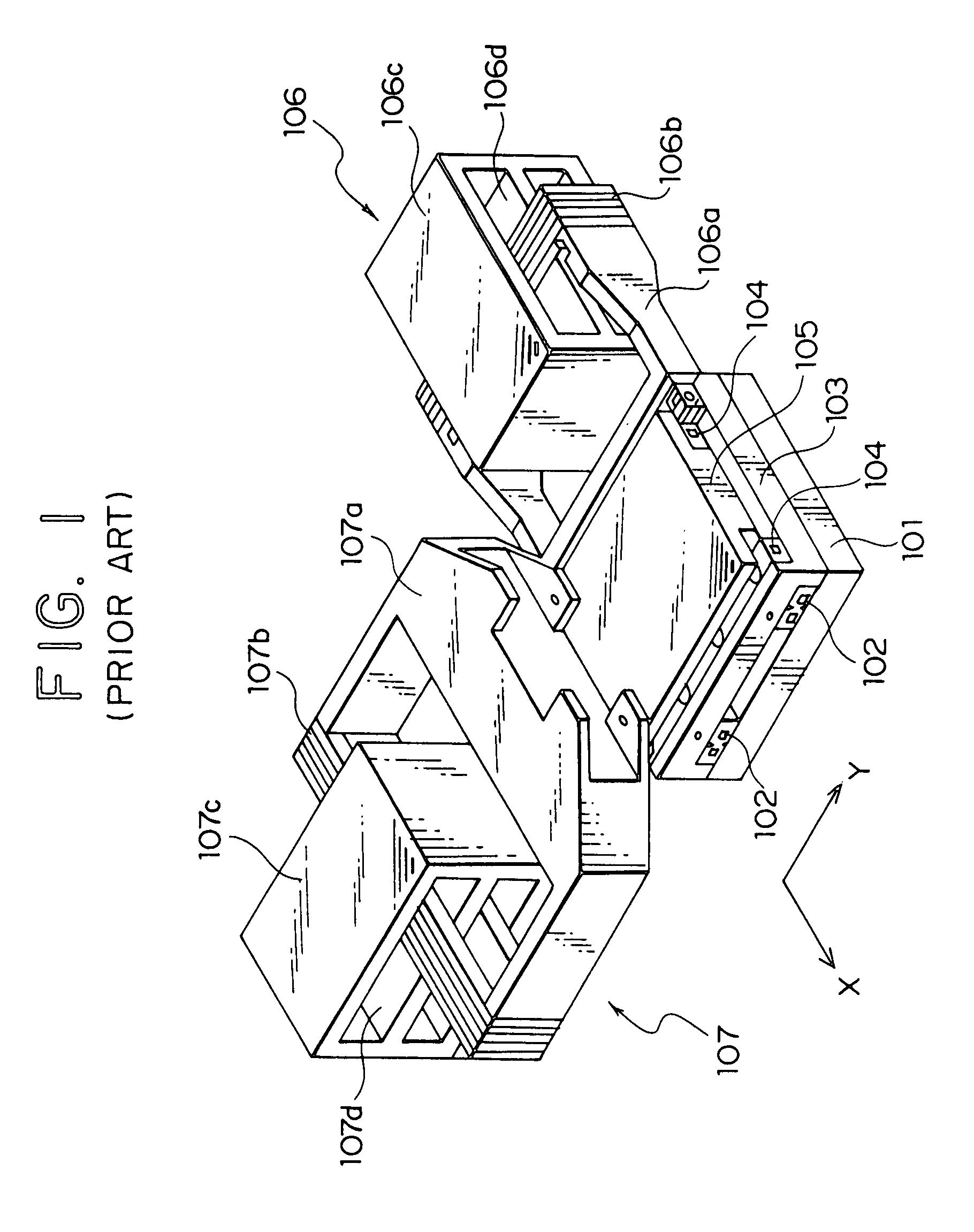

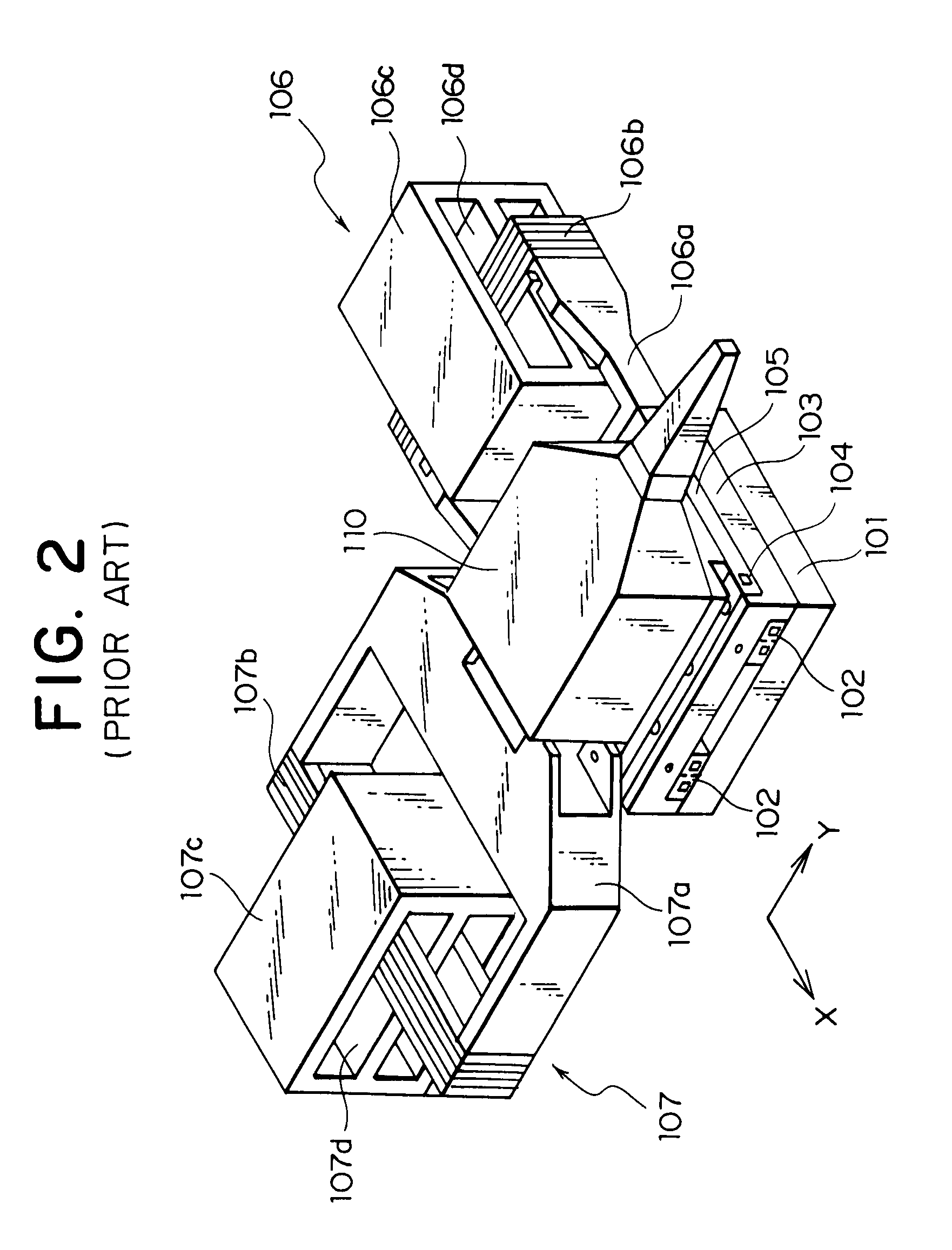

XY stage

InactiveUS7654207B1Sufficiently suppressEasy to move and controlAutomatic control devicesSolid-state devicesLinear motorGravitation

An XY stage comprises a base, a movable table which is disposed on the base so as to be movable in an X direction and a Y direction in an X-Y plane, and a work member which is provided on the movable table. The XY stage further comprises: a first linear motor for giving a driving force in the X direction to the movable table at the same height as the center of gravity of a movable section composed of the movable table and the work member; and a second linear motor for giving a driving force in the Y direction to the movable table at the same height as the center of gravity of the movable section.

Owner:NEC CORP

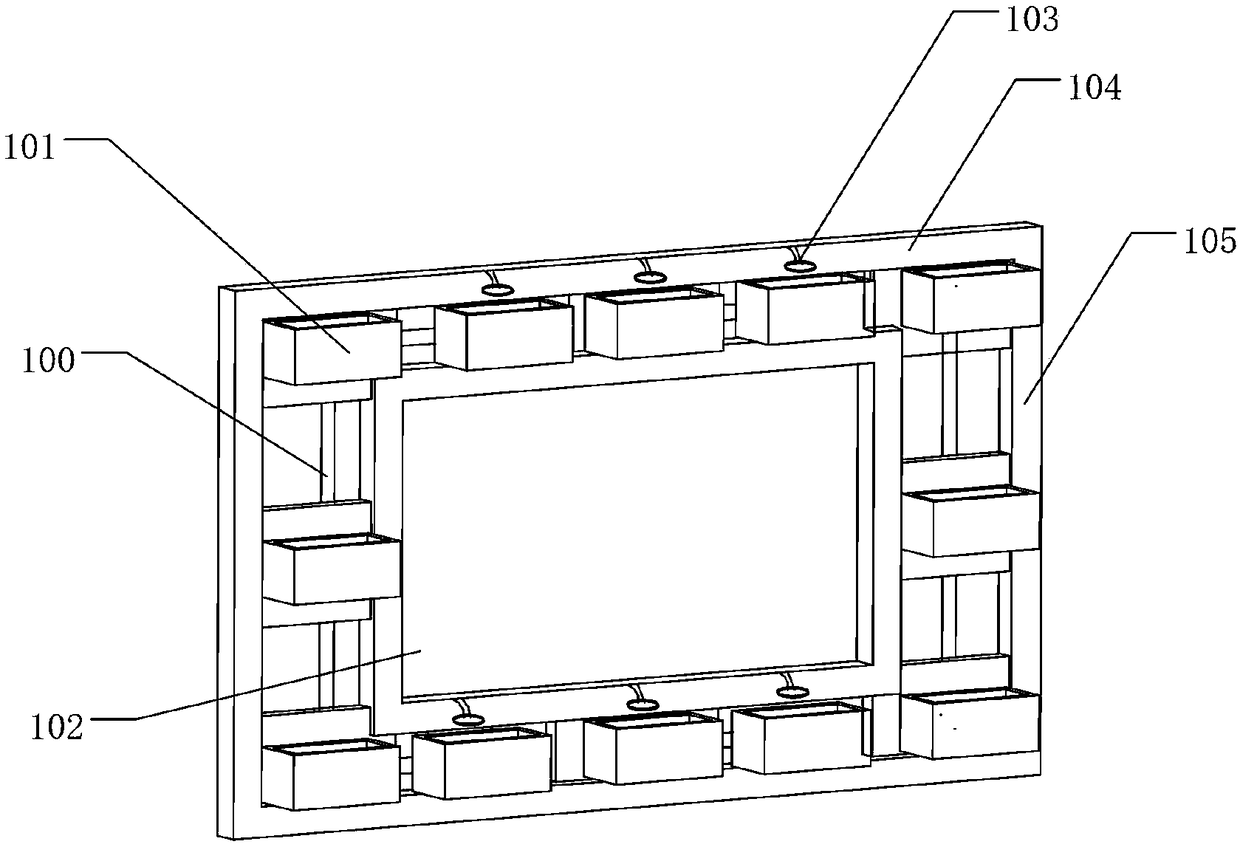

Winding type circular template and production device of winding type circular template

PendingCN108044728AImprove structural stabilityReduce consumptionOther plywood/veneer working apparatusBelt grinding machinesWood veneerEnvironment effect

The invention relates to a winding type circular template and a production device of the winding type circular template. The winding type circular template is of a cylindrical structure with a plurality of layers of wood veneers winding, and the multi-layer wood veneers are in composite bonding; each layer of wood veneer comprises a transverse grain wood veneer and a longitudinal grain wood veneer; the transverse grain wood veneers and the longitudinal grain wood veneers are in composite bonding, and the wood veneer seams at the joints of the transverse grain wood veneers and the longitudinalgrain wood veneers are uniformly distributed in the circumferential direction of the template; and compared with a semicircular template in the prior art, the circular template with the multi-layer cylindrical structure has the advantages of being reasonable in structure and high in stability, and the problems that for the semicircular template, the inner stress is not sufficiently released, the template is hard to store for a long time, and can be greatly influenced by the external environment, and the rejection rate remains high are solved. The circular template with the multi-layer cylindrical structure has the advantages of being not prone to deformation, easy to store, free of deformation and the like; and the qualified rate of finished products is improved, the processing cost is reduced, the yield is improved, the energy loss is reduced by adopting a natural drying and sizing method, and the economic benefits are greatly improved.

Owner:杨月君

Multi-function wall skin shoveling machine for decoration

The invention discloses a multi-function wall skin shoveling machine for decoration. The multi-function wall skin shoveling machine comprises a base, a hydraulic tank is arranged at the top of the base, a hydraulic push rod is led out of the top of the hydraulic tank, the hydraulic push rod vertically extends upwards, an adjusting seat is installed at the top of the hydraulic push rod, and an installation seat is installed on the adjusting seat through a bolt. A fixing support is installed at the top of the installation seat through a bolt, an electric sliding rail is arranged on one side of the installation seat, a sliding block is arranged in the electric sliding rail, and the electric sliding rail is slidably matched with the sliding block. An adjusting support is hinged to the side face of the fixing support, a wall skin shoveling roller is installed on one side, away from the fixing support, of the adjusting support, the wall skin shoveling roller is connected to the output end ofa motor through a rotating shaft, and four groups of universal wheels are installed at the bottom of the base. The multi-function wall skin shoveling machine for the decoration is simple in structure, improves the convenience of shoveling the wall skin during decoration, facilitates the operation, can adjust the depth of the wall skin shoveling in real time according to actual needs, and is practical.

Owner:临清市宏顺国际贸易有限公司

Auxiliary device for installation of distribution box

The invention discloses an auxiliary device for installation of a distribution box. The auxiliary device comprises a flat car, and further comprises a lift platform and a holding-down assembly; the lift platform is arranged on the flat car; the holding-down assembly is arranged on the lift platform, and is used for holding down the distribution box to be installed. The flat car is convenient to move, and the flat car is provided with the lift platform, and thus, the distribution box which needs to be installed can convenient to rise and fall according to the height requirement; by installing the holding-down assembly, the distribution box can be held down onto a wall surface, and thereby, the installation work of the distribution box can be completed by one man only, so that time and laborare saved, and the installation efficiency of the distribution box is increased; and meanwhile, the auxiliary device can also be used for transporting the distribution box, is of a pure mechanical structure from the overall structure, does not need electric energy and is wide in use range and low in manufacturing cost.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

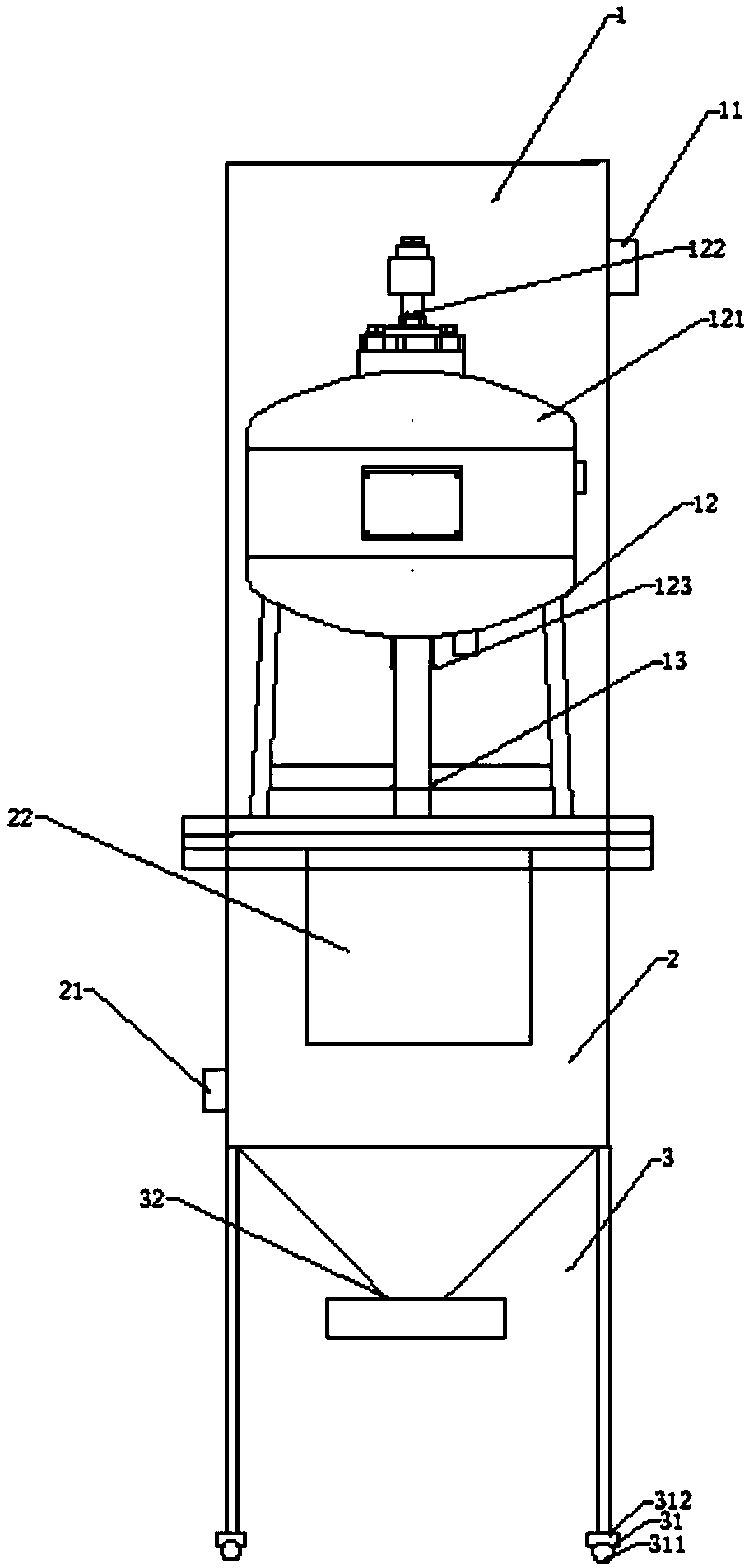

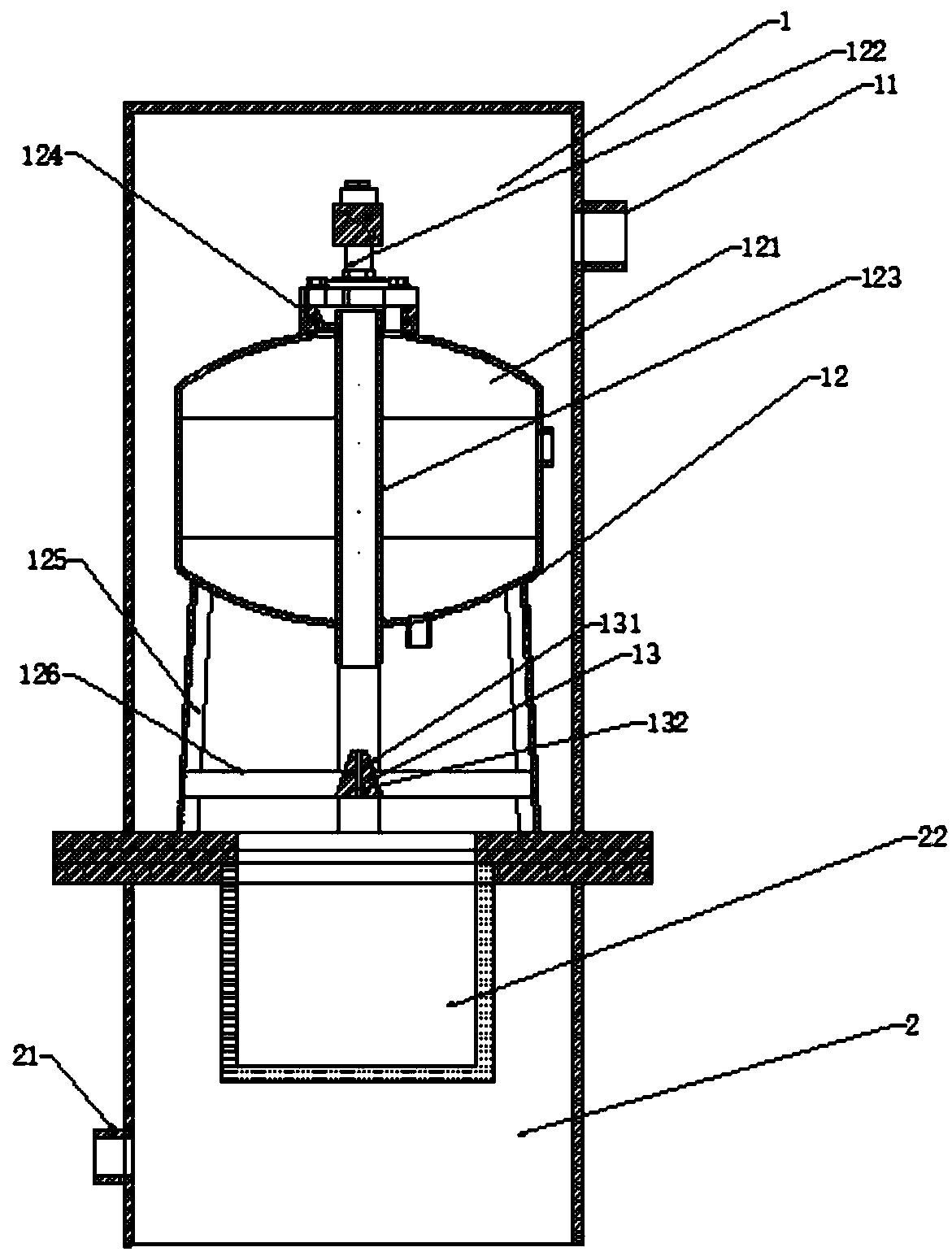

Moveable dust collector

PendingCN109224659AEnhanced area of action and action timeImprove blowing efficiencyDispersed particle filtrationAir cleaningDust collector

The invention relates to the technical field of air cleaning and specifically relates to a moveable dust collector. The moveable dust collector comprises an upper air cleaning box, a middle dust removing box and a lower dust collecting box; a moveable device is arranged on the lower end of the lower dust collecting box; a dust collecting device is arranged in the lower dust collecting box; the lower dust collecting box is connected with the middle dust removing box; an air feeding pipe is arranged on a side wall of the middle dust removing box; a filtering device is arranged in the middle dustremoving box; the upper air cleaning box and the middle dust removing box are separated by the filtering device; an air exhaust pipe is arranged on the side wall of the upper air cleaning box; an injection device and a baffle are arranged in the upper air cleaning box; the baffle is equipped with a flow deflecting slope and a flow deflecting hole used for scattering air injected from the injection device into the filtering device.

Owner:广州碧空环保产品有限公司

Circular sawing machine with dual cutting corners

ActiveCN103341875AEasy to move and controlIncrease productivityMetal working apparatusCircular sawElectrical equipment

The invention discloses a circular sawing machine with dual cutting corners. The circular sawing machine with the dual cutting corners comprises a machine body. The circular sawing machine with the dual cutting corners is characterized in that a fixed cutting device and a sliding cutting device are arranged on the machine body; a guide rail is arranged on the machine body, and the sliding cutting device is arranged on the guide rail; a plastic steel frame is arranged on the guide rail, and the sliding cutting device is fixedly connected with the plastic steel frame; an electric device control box is arranged on the machine body. According to the circular sawing machine with the dual cutting corners, two end faces of plastic steel can be machined simply through one-time feeding, and thus production efficiency is high. Due to the fact that the electric device control box is arranged, cutting power can be controlled, the sliding cutting device can be controlled to move, and automation of working is achieved.

Owner:山东玉景智能家居有限公司

Circulating high-rise outer wall environment-friendly greening system based on big data

ActiveCN108702974AEasy to move and controlConvenient to control whether to moveSelf-acting watering devicesCultivating equipmentsWater storage tankSprayer

The invention discloses a circulating high-rise outer wall environment-friendly greening system based on big data. The system comprises a fixing mechanism, shells, a watering mechanism and a drive mechanism and is characterized in that the fixing mechanism comprises a guide rail and hinges, the guide rail is annularly arranged outside a window outer frame, and the hinges are arranged along the guide rail and can move along the guide rail; each shell is a hollow box with an upper-end opening, the box is divided into an upper box body and a lower box body through a partition, the partition is provided with water seepage holes, and the inner lateral walls of the shells are rotatably movably connected with the hinges through fasteners; the watering mechanism comprises a water storage tank, a pump and sprayers, the water storage tank is fixed on one side of the window outer frame, the pump is arranged in the water storage tank, and the output end of the pump is connected with the sprayers through a water outlet pipe penetrating the a water outlet; the drive mechanism comprises a power mechanism and a transmission mechanism, and the power mechanism drives the hinges to move along the guide rail through the transmission mechanism. The high-rise outer wall environment-friendly greening system based on big data has the advantages that an environment-friendly greening function is achieved by sufficiently utilizing the outer wall space of a building, the shells can rotate around the window to facilitate observation, management and maintenance, green plants on the outer wall can be watered, and great convenience is achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Laser cutting device with scrap collecting function

InactiveCN111604600AGuaranteed cutting effectEasy to cutLaser beam welding apparatusPhysicsElectric machinery

The invention discloses a laser cutting device with a scrap collecting function. The laser cutting device with the scrap collecting function comprises a machining base, wherein a laser cutting table is fixedly connected to the upper surface of the machining base, a control panel is arranged on the front surface of the laser cutting table, an opening and closing door is fixedly connected to the front surface of the laser cutting table through a hinge, an observation window is arranged on the front surface of the opening and closing door, a main frame transmission belt is arranged on the upper surface of the laser cutting table, and a rotating motor is arranged on the left side surface of the main frame transmission belt. According to the laser cutting device with the scrap collecting function for metal casting machining, through the arrangement of a scrap treatment cabin, a collecting hopper, a first extendable push rod, a second extendable push rod, a pusher and a material baffle, scraps generated after laser cuts metal castings can fall off from the collecting hopper and be gathered into the scrap treatment cabin, and the metal scraps falling into the scrap treatment cabin are extruded into blocks to be treated, so that the cutting effect is ensured.

Owner:宋海香

Agricultural pest management device based on internet

ActiveCN108575960AEasy to move and controlEasy to useInsect catchers and killersAutomatic controlControl signal

The invention discloses an agricultural pest management device based on internet. The agricultural pest management device comprises a support rod, wherein a base is mounted at the bottom end of the support rod; an infrared scanner is mounted at the lower part of the support rod; a control panel is mounted in the middle of the support rod; a sprayer is mounted on a pesticide liquid storage box; a spray port is formed in the bottom of the sprayer; a mounting port is formed in the middle of the sprayer. A solar panel is mounted above a connecting sleeve and can convert optical energy into electrical energy, a slide bar is mounted on the connecting sleeve, a pest capture box is mounted on the slide bar through a slide sleeve and is conveniently controlled to move by means of the slide sleeve,a control signal receiving rod is mounted on the slide sleeve and connected with the control panel through a local area network, automatic control can be realized by the control signal receiving rod,and the device is convenient to use.

Owner:六安荣耀创新智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com