Rack for tunnel excavation and adit construction method applying rack

A bench and tunnel technology, applied in the field of benches for tunnel excavation, can solve the problems of difficult waste residue cleaning, small operating space, and unsatisfactory use of benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

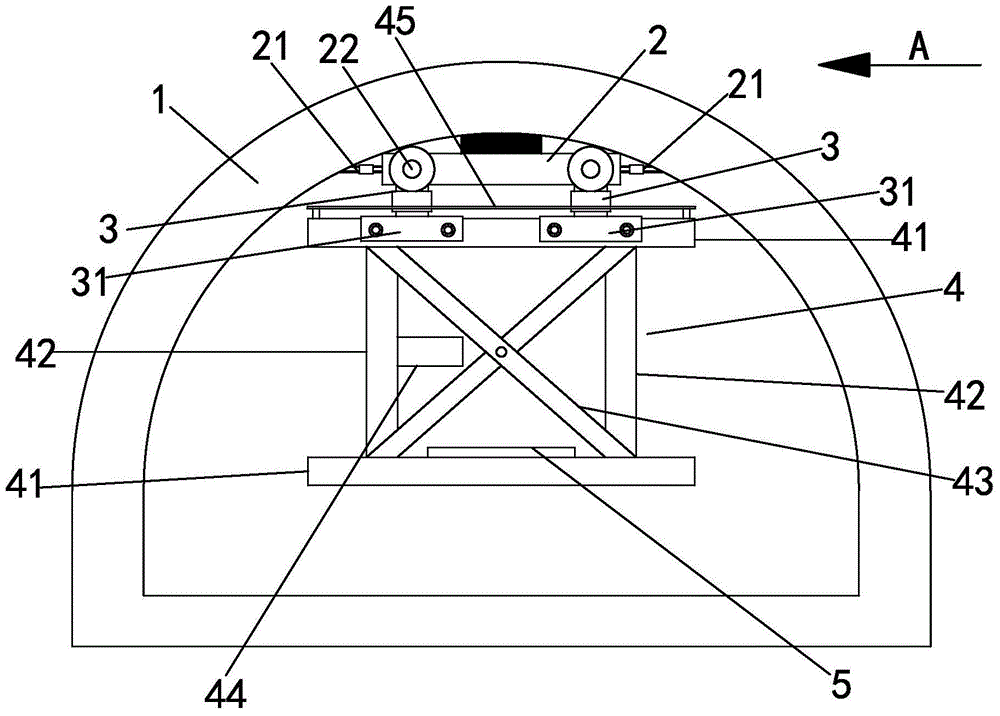

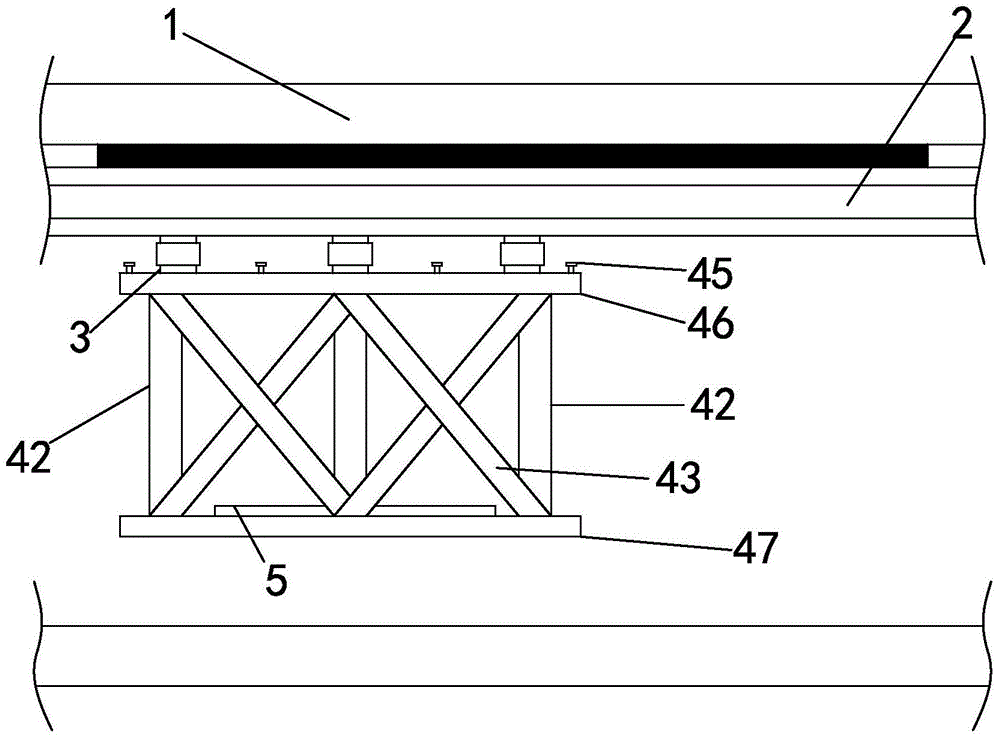

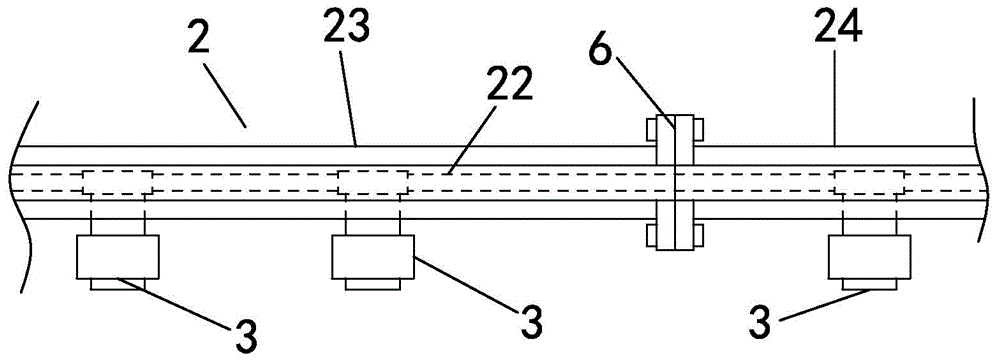

[0084] Such as Figure 1 to Figure 8 As shown, a platform for tunnel excavation includes a flat hole 1 and a platform 4. The platform 4 can accommodate equipment, construction personnel and waste residue, has a certain transportation function, saves time and effort, and significantly speeds up the construction progress. The upper end of the flat hole 1 is fixed with a straight rod, and the lower end of the straight rod is connected with a mobile support 2, and a cable 22 is installed in the mobile support 2, and the cable 22 runs through the mobile support 2. Mobile support 2 comprises first mobile support 23 and second mobile support 24, and first mobile support 23 and second mobile support 24 can be connected by flange 6, can be connected by flange 6 between the second mobile support 24, when construction When the personnel need to change the length of the mobile support 2, they only need to connect an appropriate number of second mobile supports 24 on the first mobile suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com