Moveable dust collector

A technology of dust collector and mobile device, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problem of limited area and time of action between gas and filter bag, shortening the service life of filter bag, inconvenient movement, etc. To achieve the effect of enhancing the action area and action time, prolonging the service life and improving the injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

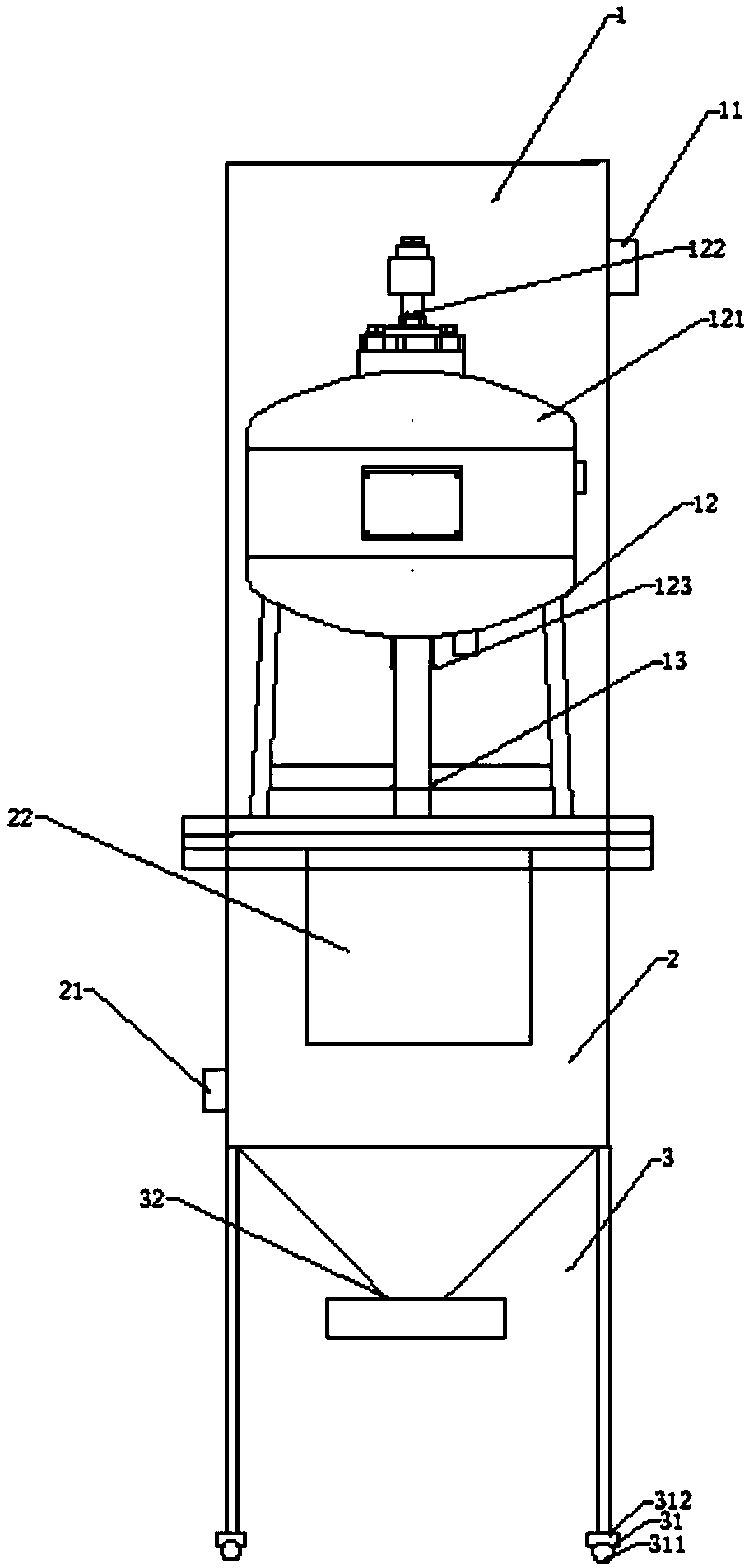

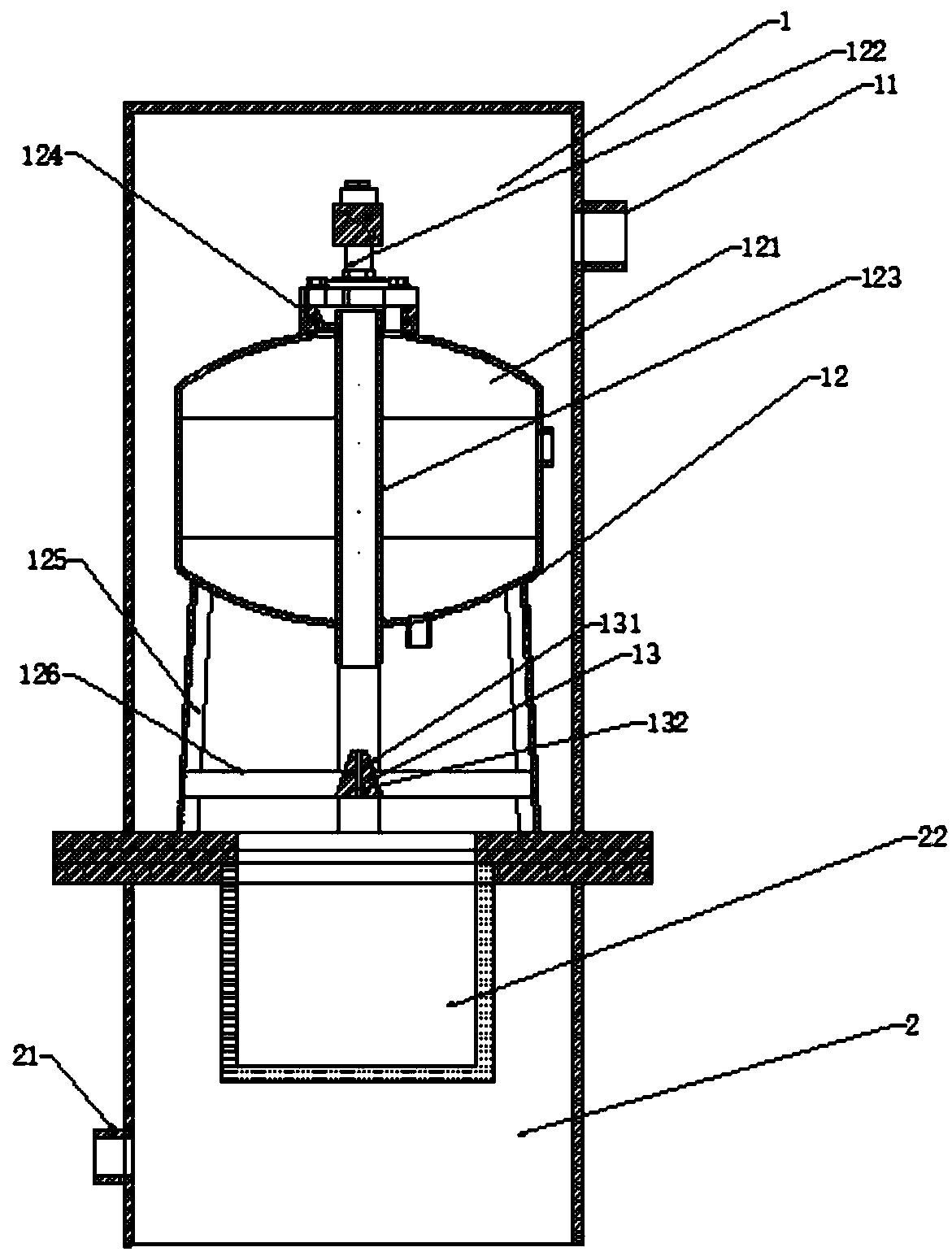

[0026] Please refer to the attached figure 1 And attached figure 2 , a movable dust collector, comprising an upper air purification box 1, a middle dust removal box 2 and a lower dust collection box 3; a movable device 31 is provided at the lower end of the lower dust collection box 3, and a dust collection device 32, the lower dust collection box 3 communicates with the middle dust removal box 2; the side wall of the middle dust removal box 2 is provided with an air inlet pipe 21, and a filter device 22 is arranged inside, and the filter device 22 cleans the upper part. The air box 1 is separated from the middle part dust removal box 2; the side wall of the upper clean air box 1 is provided with an air outlet pipe 11, and the inside is provided with a blowing device 12 and a guide body 13, and the guide body 13 has the The gas ejected from the blowing device 12 scatters into the diversion slope 131 and the diversion hole 132 of the filter device 22 .

[0027] In practical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com