Permanent magnet elevator disk brake

一种永磁体、电梯的技术,应用在控制机电制动器、制动器、电力制动系统等方向,能够解决有限使用寿命、影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

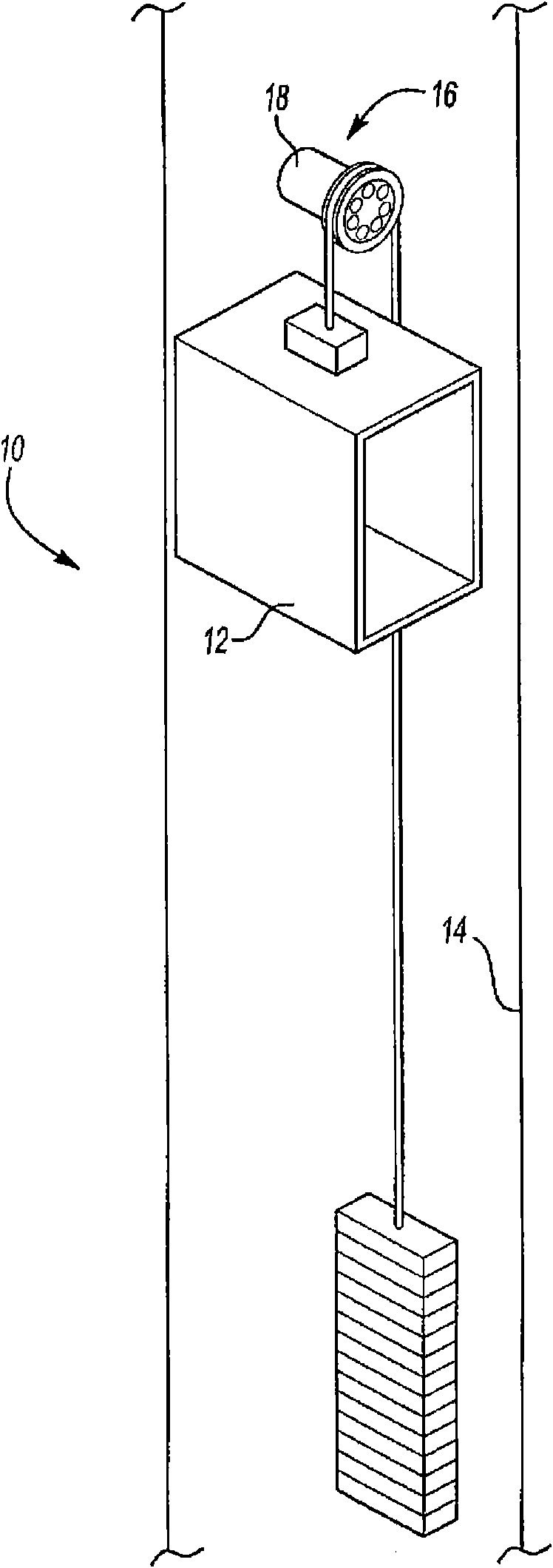

[0020] attached figure 1 An elevator system 10 is shown schematically, comprising an elevator car 12 moving within a hoistway 14, with a motor 16 moving the elevator 12 in a known manner. The brake assembly 18 utilizes permanent magnets combined with electromagnets to work stably. The brake assembly 18 is mounted adjacent to the motor 16 to brake and hold the elevator car 12 in a desired position within the hoistway 14 .

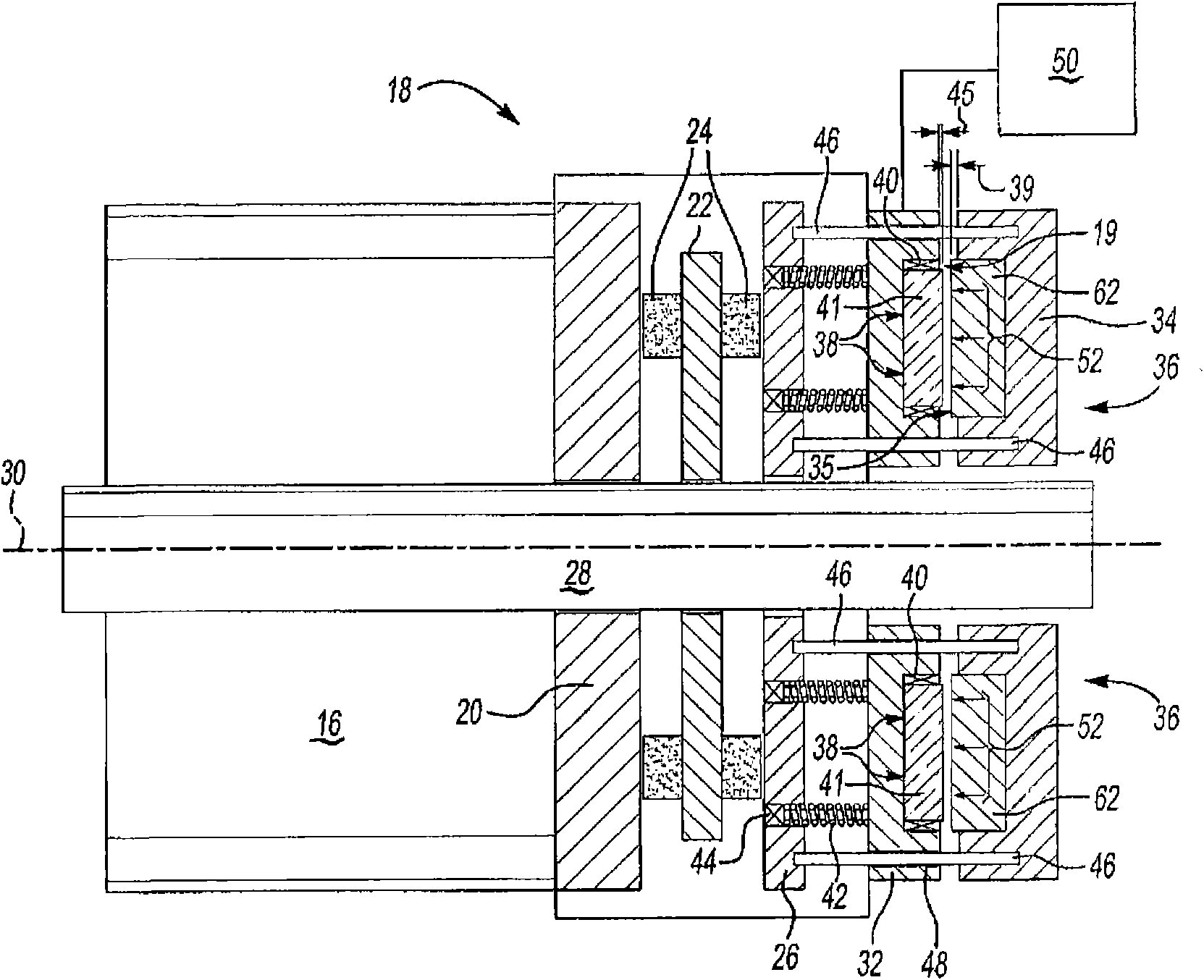

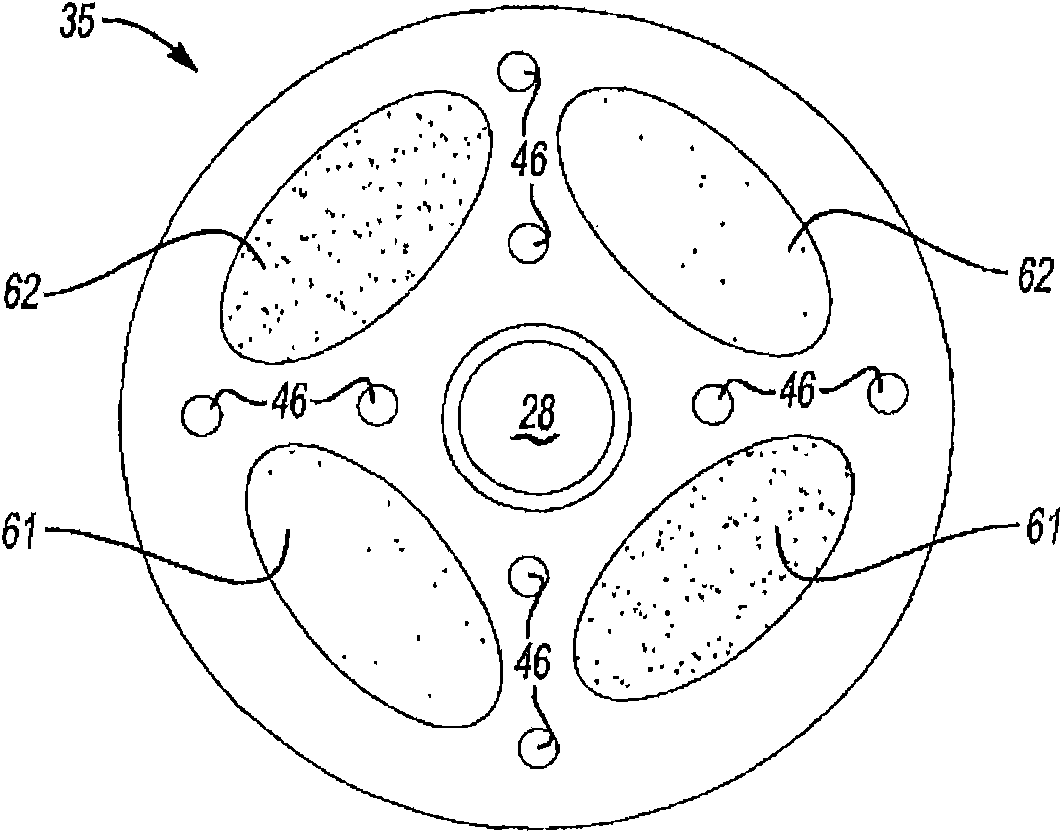

[0021] attached figure 2 An example brake assembly 18 is shown schematically in a braked or lowered position. The motor 16 drives a shaft 28 about an axis 30 that extends from the motor 16 and into the brake assembly 18 . The brake assembly 18 includes a stationary housing 20 , an axially movable disc 22 and an axially movable plate 26 . The disc 22 has a friction material 24 that simultaneously engages the housing 20 and the plate 26 in the lowered position. Furthermore, the disc 22 is keyed to the shaft 28 in a known manner so as to be able to move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com