Blade for silk-screen printing on a substrate

A technology of screen printing and blade, applied in the direction of screen printing machine, printing, printing machine, etc., can solve problems such as inability to guarantee, and achieve the effect of avoiding disturbance phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

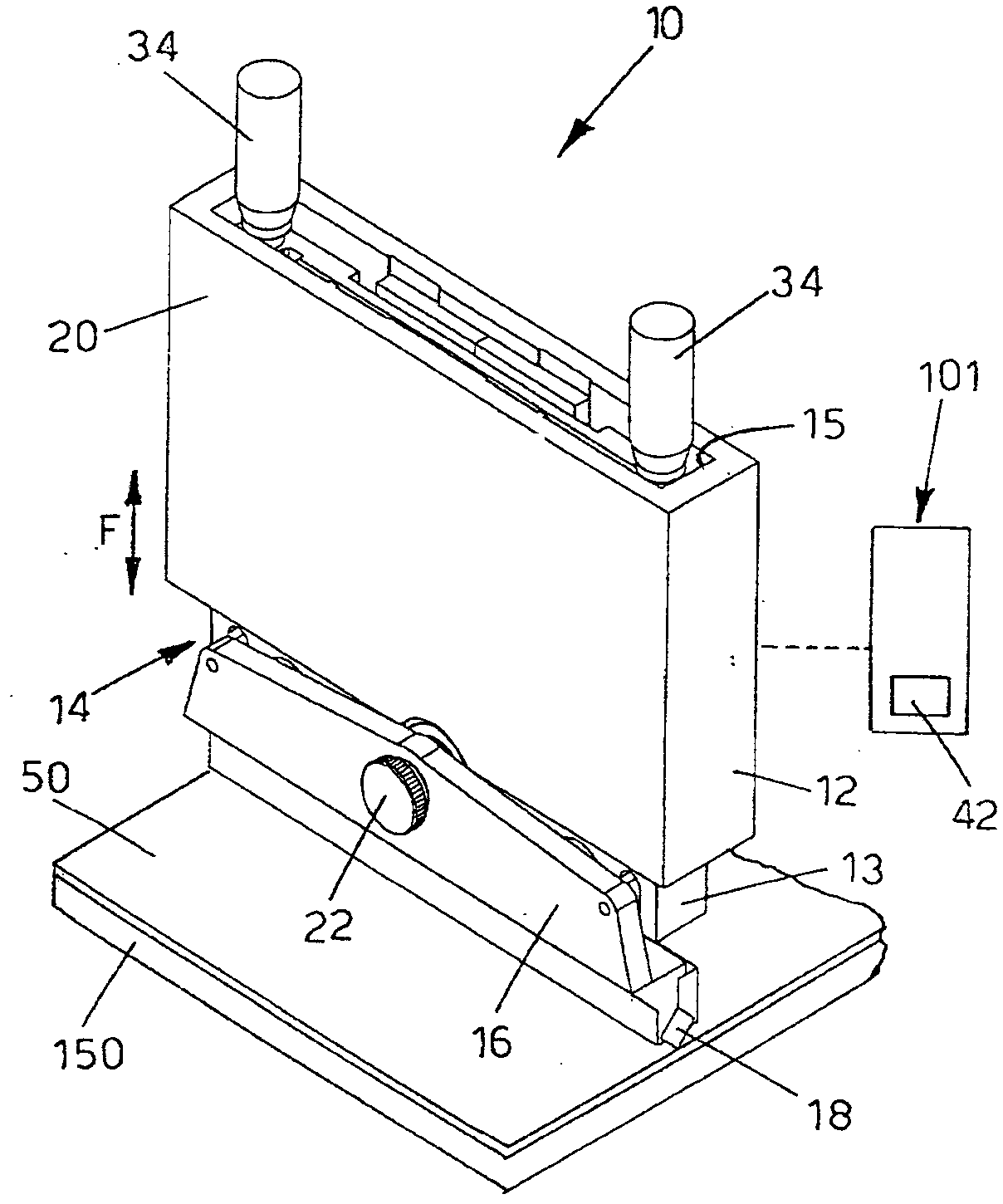

[0048] Referring to the drawings, a blade 10 according to the invention is used in a suitable printing head for screen printing a printing material (in this case a printing paste for screen printing, such as a conductive paste, but not only limited to this) to replicate desired circuits on the substrate, such as conductive circuits, in this example, planar components such as electronic or similar devices are placed below the grid, and these planar components are used, for example, to manufacture Silicon-based wafers for photovoltaic cells.

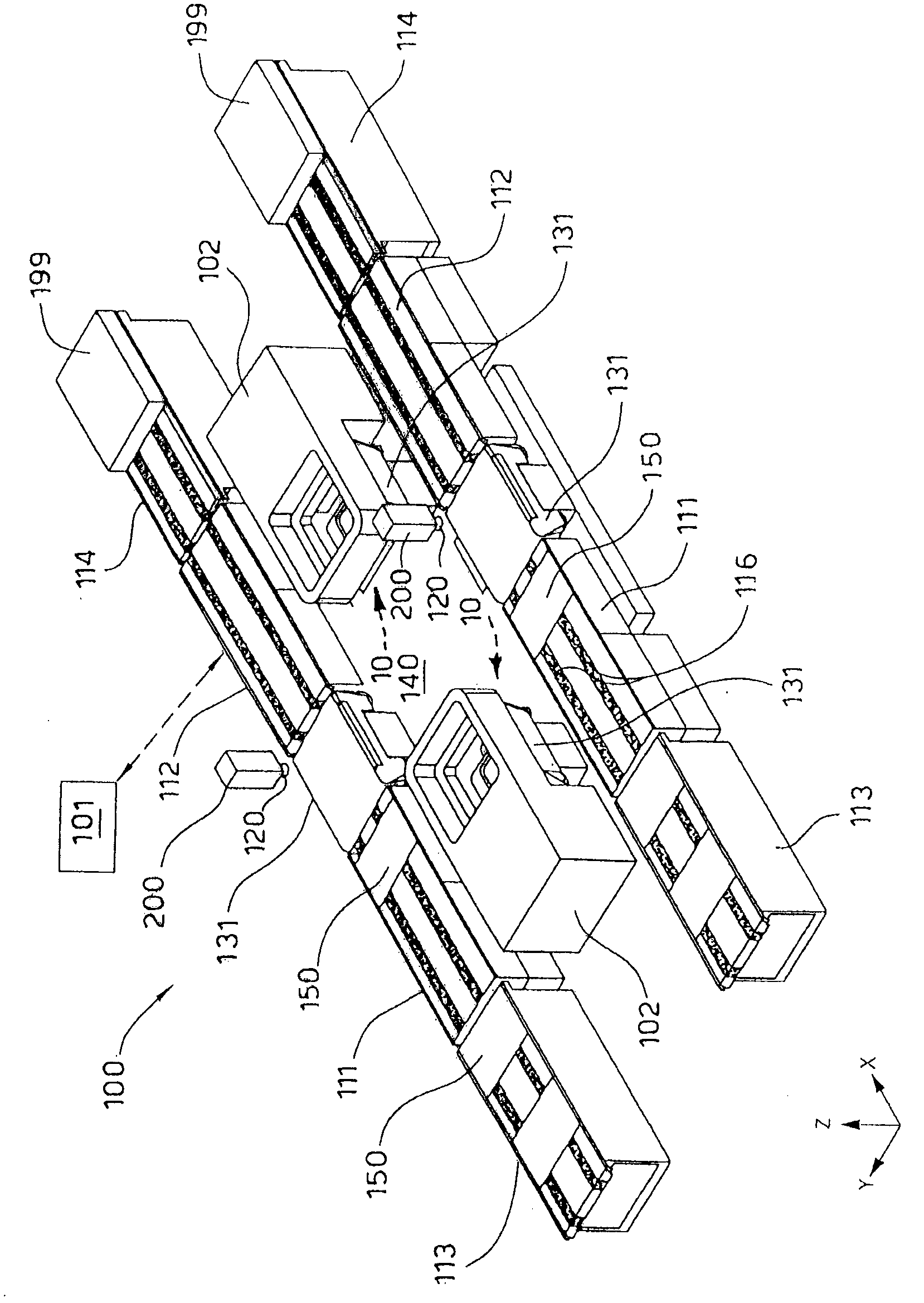

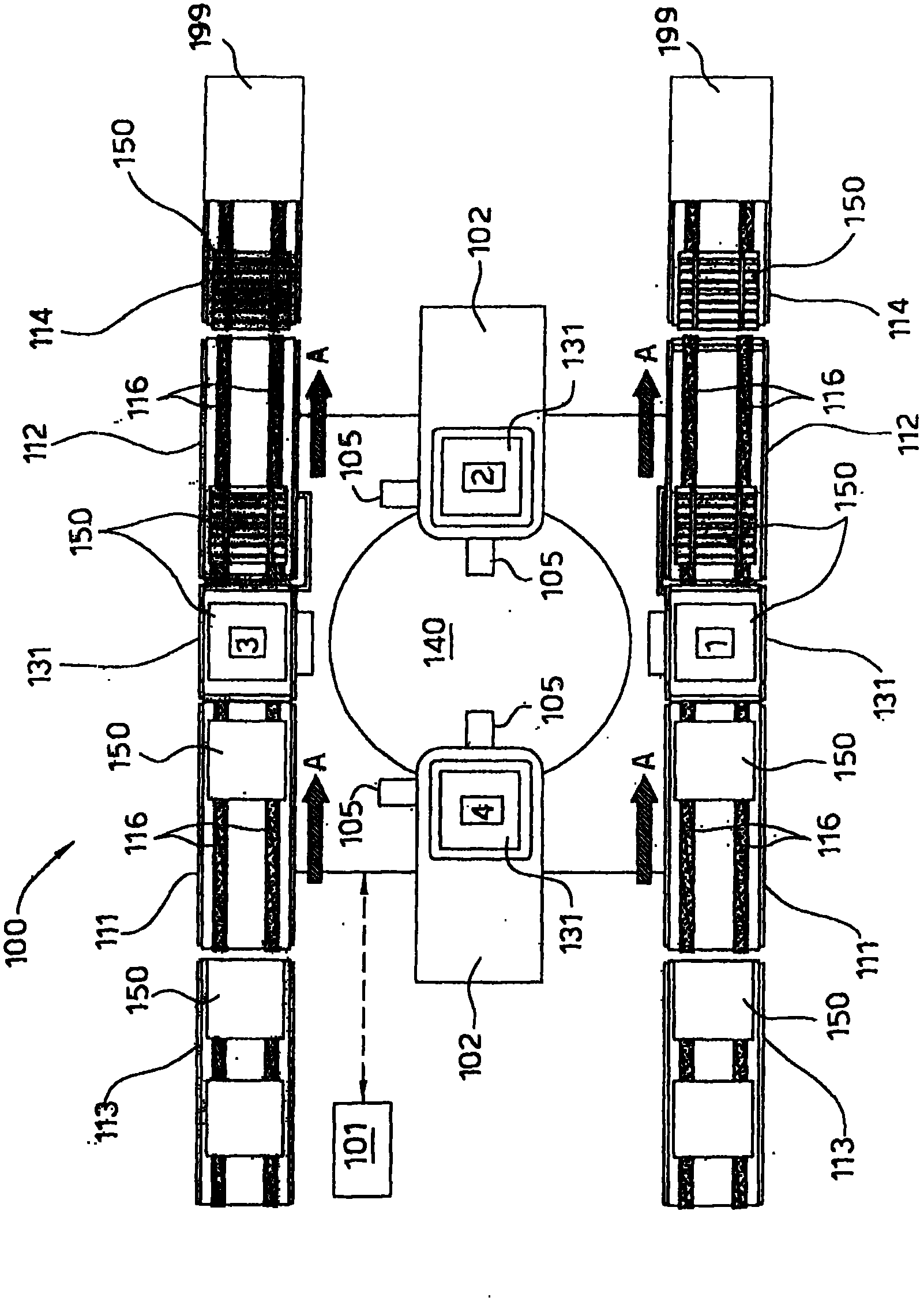

[0049] figure 1 An isometric view of a substrate screen printing processing system or system 100 with screen printing components designed to screen print a patterned layer of material on a substrate 150 . In particular, the system 100 provides a plurality of print heads 102 each having a blade 10 according to the present invention. In one embodiment, the system 100 generally includes two incoming conveyors 111, an actuator assembly 140, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com