Circular sawing machine with dual cutting corners

A circular saw machine and angle cutting technology, which is applied in metal processing and other directions, can solve the problems of low production efficiency, not suitable for large-scale production, and can not cut plastic steel, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

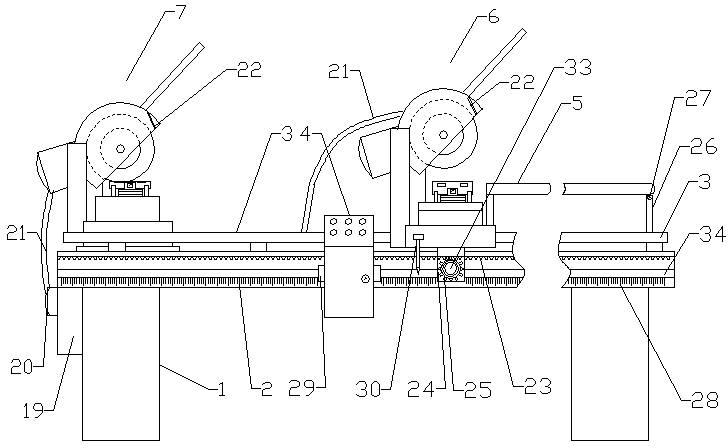

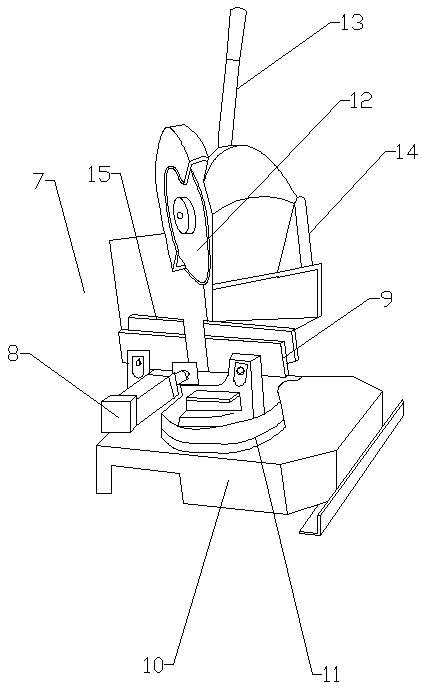

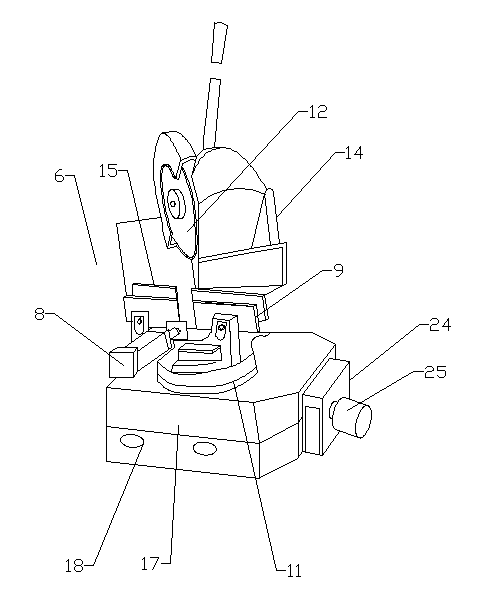

[0028] Examples such as figure 1 And attached figure 2 As shown, a double-angle cutting circular saw machine includes a fuselage 2, a base 1 is provided at the bottom of the fuselage 2, a fixed cutting device 7 and a sliding cutting device 6 are arranged on the fuselage 2; guide rails are provided on the fuselage 2 3. The sliding cutting device 6 is arranged on the guide rail 3, and the guide rail 3 is provided with a plastic steel frame 5, and the sliding cutting device 6 is fixedly connected with the plastic steel frame 5; the fuselage 2 is provided with an electrical control box 4; The end is fixed with a fixed bracket 26, and the fixed bracket 26 is provided with a roller 27; the fuselage 2 is provided with a scale 28, and the sliding cutting device 6 is fixedly provided with a pointer 30; Case sliding guide rail 34, control box sliding guide rail 34 overcoats are connected with control box sliding seat 29, and electrical control box 4 is arranged on the control box sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com