Automatic-positioning vibration sampler

An automatic positioning and sampling machine technology, which is applied in the field of sampling machines, can solve the problems of poor mixing effect, large space occupation, and high cost, and achieve the effects of improving sampling accuracy, reducing equipment weight, and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

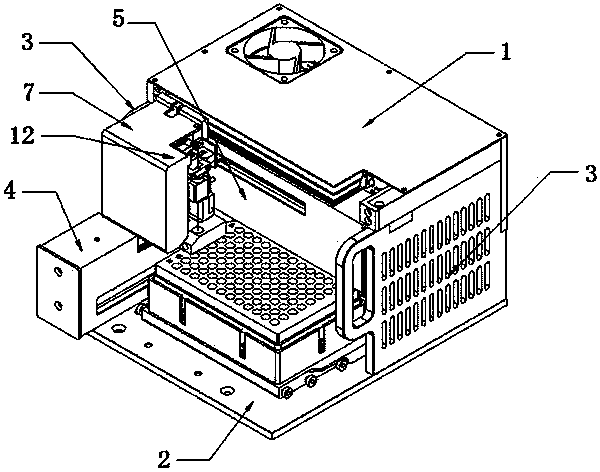

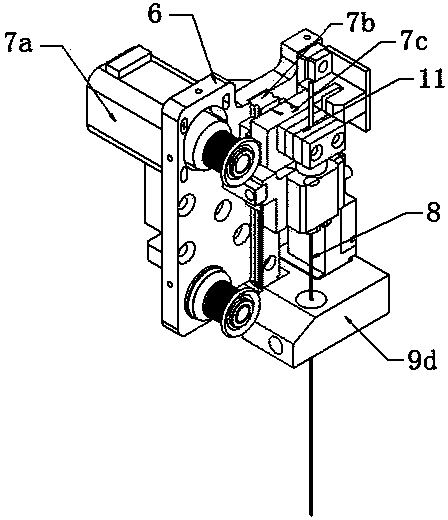

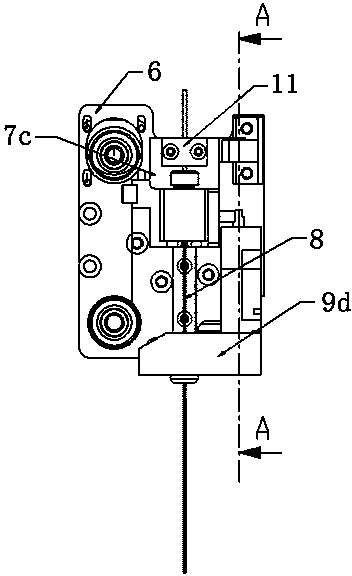

[0026] Example: refer to Figures 1 to 6 As shown, an automatic positioning vibrating sampling machine includes upper and lower fixing plates 1, 2, a support plate 3 that is used to connect and fix and is vertically arranged with the upper and lower fixing plates 1, 2, and is located on the lower fixing plate 2. X-direction drive mechanism 4, Y-direction drive mechanism 5 connected with X-direction drive mechanism 4, Z-direction drive mechanism 7 connected with Y-direction drive mechanism 5 through longitudinal fixing seat 6, sampling needle 8 connected with Z-direction drive mechanism 7 , and the sampling needle vibration mechanism, the sampling needle vibration mechanism includes a vibration motor 9a fixed on the longitudinal fixed seat 6, an eccentric wheel device 9b connected to the output end of the vibration motor 9a, and a vibration device connected to the eccentric wheel device 9b through a connector 9c plate 9d, one end of the sampling needle 8 passes through the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com