Patents

Literature

46results about How to "Reduce equipment weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

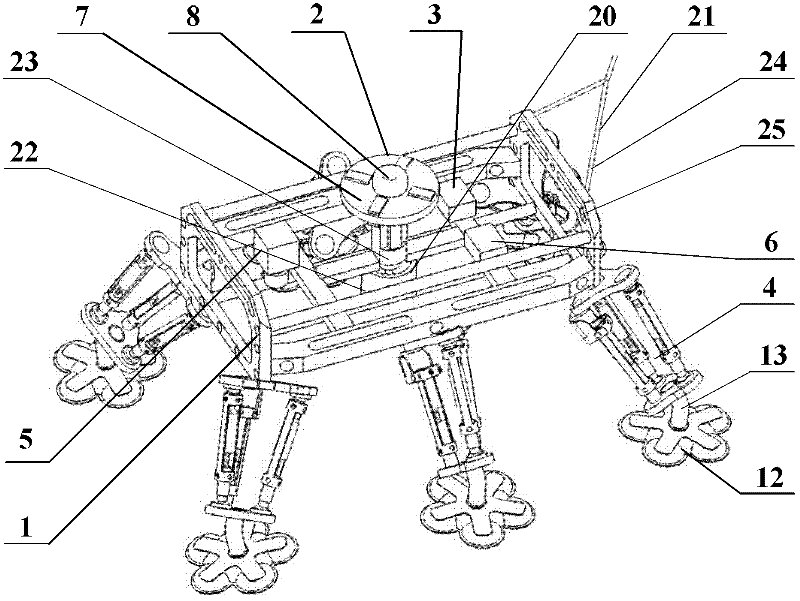

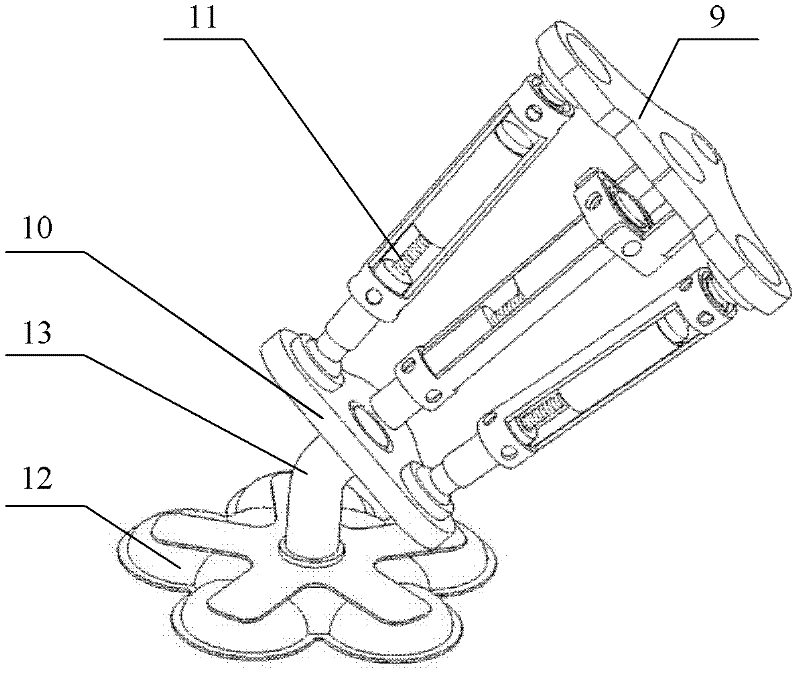

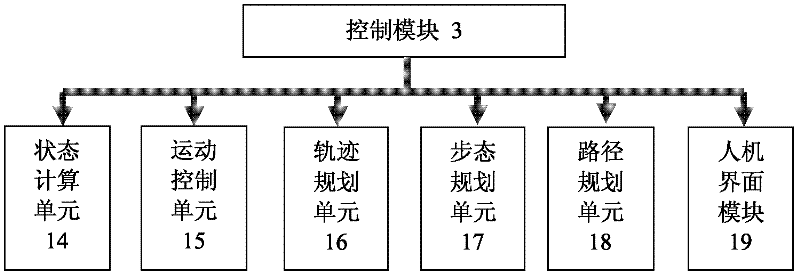

Suction cup integrated robot

InactiveCN102294502AReduce the numberMid section savingsManipulatorVehiclesRobotic systemsComputer module

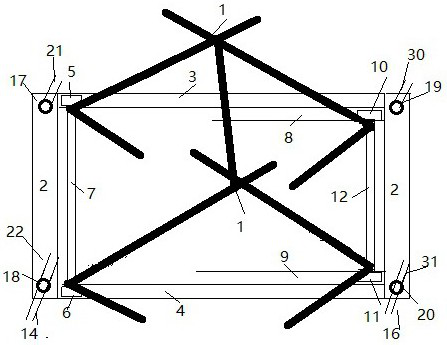

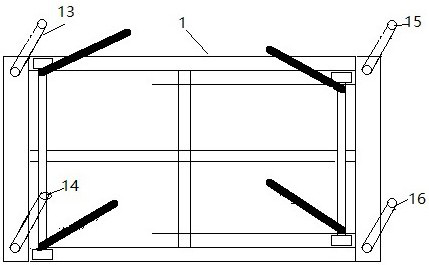

A sucker-type integrated robot in the field of robot technology, comprising: a frame, a hole-making mechanism, a control module and six sets of leg mechanisms, the six leg mechanisms are respectively fixed around the frame and the output ends of the sensing mechanism Connected with the control module to output six-dimensional force sensor data, the hole making mechanism and the control module are fixedly arranged on the frame, and the control end of the hole making mechanism is connected to the output end of the control module to receive control instructions. The present invention adopts the integrated design scheme of walking hole-making operation, which can be used for butt jointing and circular automatic hole making of various sections of the fuselage (such as the docking between the sections of the nose, front fuselage, middle fuselage, middle and rear fuselage), machine Automatic hole making for longitudinal splicing of body wall panels, automatic hole making on the surface of wall panels for airfoil components (such as the connection of wing skin and ribs), etc. The robot system has the advantages of good flexibility, adaptability to various workpieces, short implementation period, low cost, light weight and convenient use.

Owner:SHANGHAI JIAO TONG UNIV

Robot capable of washing outer wall across obstacle and operating method

ActiveCN106725141AReduce equipment weightFlexible operationCarpet cleanersFloor cleanersEngineeringFuture of robotics

The invention relates to a robot capable of washing an outer wall across an obstacle and an operating method. The robot comprises a robot body, and the robot capable of washing the outer wall across the obstacle is a washing robot across the protruded obstacle on a working face; the robot capable of washing the outer wall across the obstacle is provided with a mobile sucker capable of being sucked on the working face, the mobile sucker performs reciprocating movement relative to the robot body in a walking direction of a walking caterpillar, and the sucker further performs reciprocating movement perpendicular to the bottom face of the robot body; the robot body crosses the protruded obstacle through the movement of the sucker. The robot capable of washing the outer wall across the obstacle has the advantages that based on an existing window wiping robot technology, through the adoption of the mobile sucker capable of telescopically moving positions, the protruded obstacle can be crossed, the equipment is light in weight, flexible to operate and convenient to install and operate, and intellectualized and consecutive washing of large-area wall faces of a glass curtain wall and the like is achieved.

Owner:BEIJING JIAYU DOOR WINDOW & CURTAIN WALL JOINT STOCK

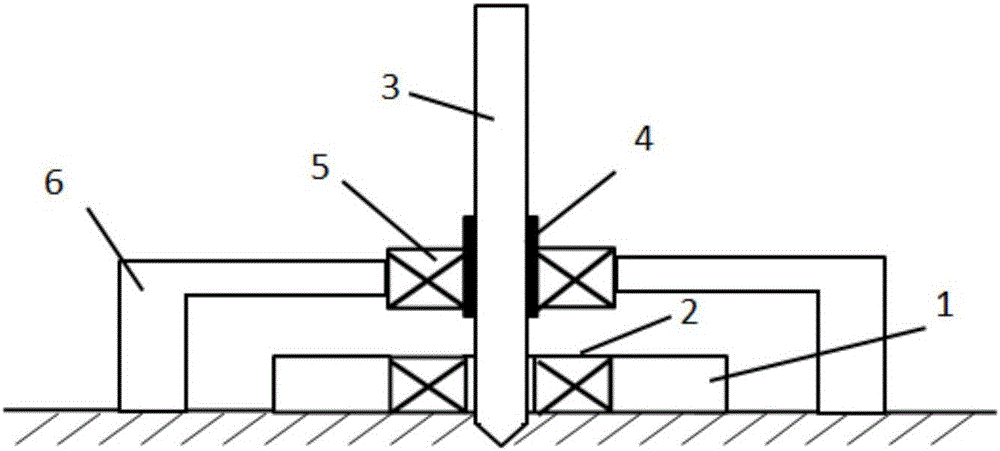

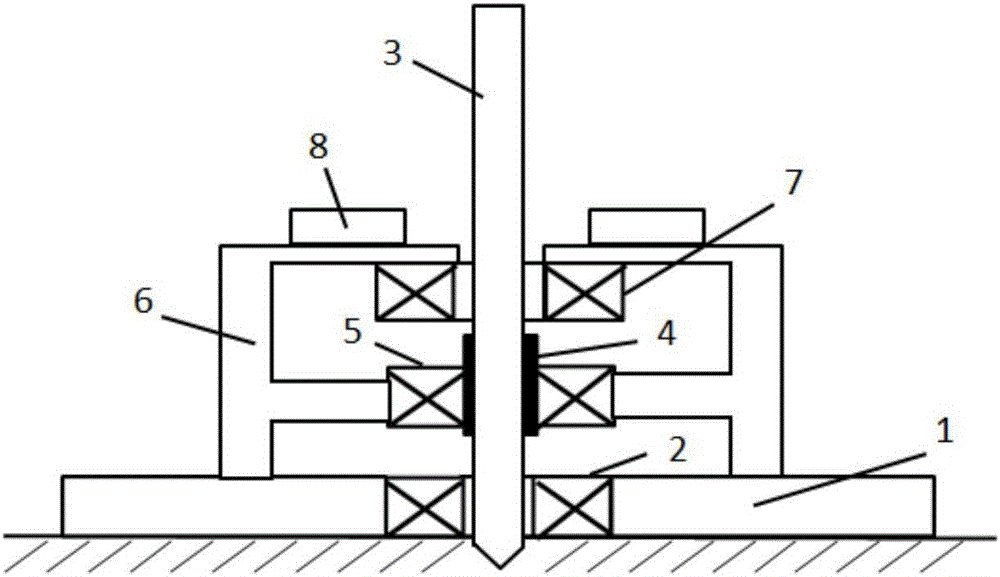

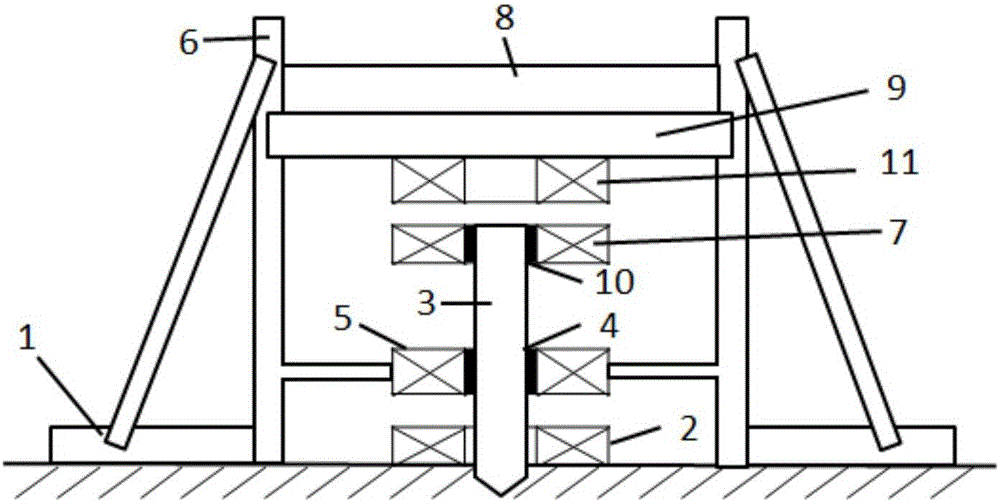

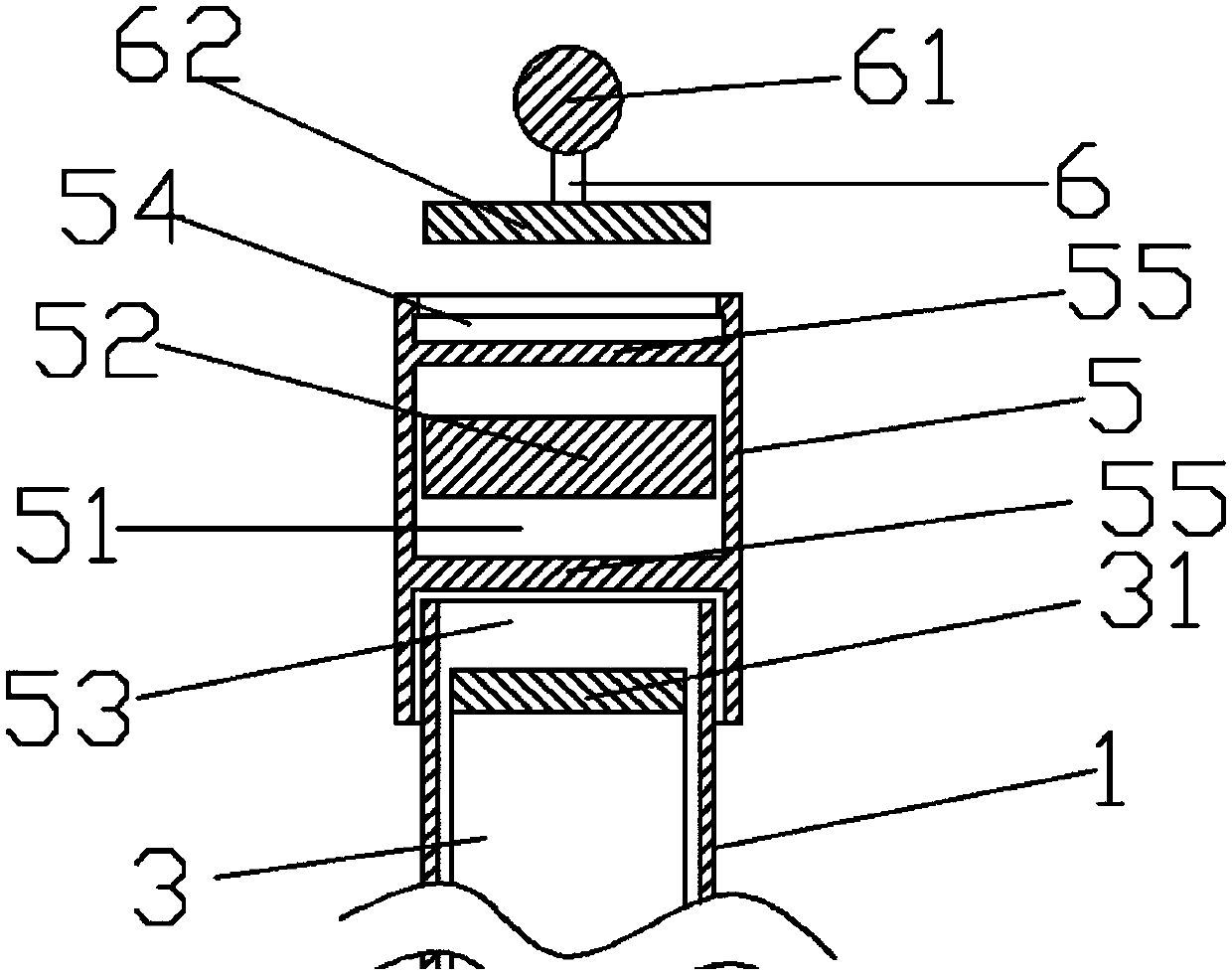

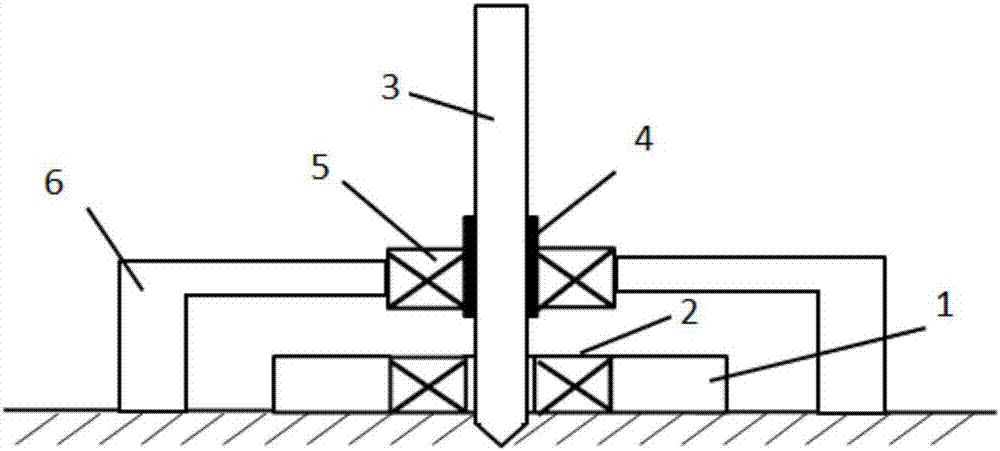

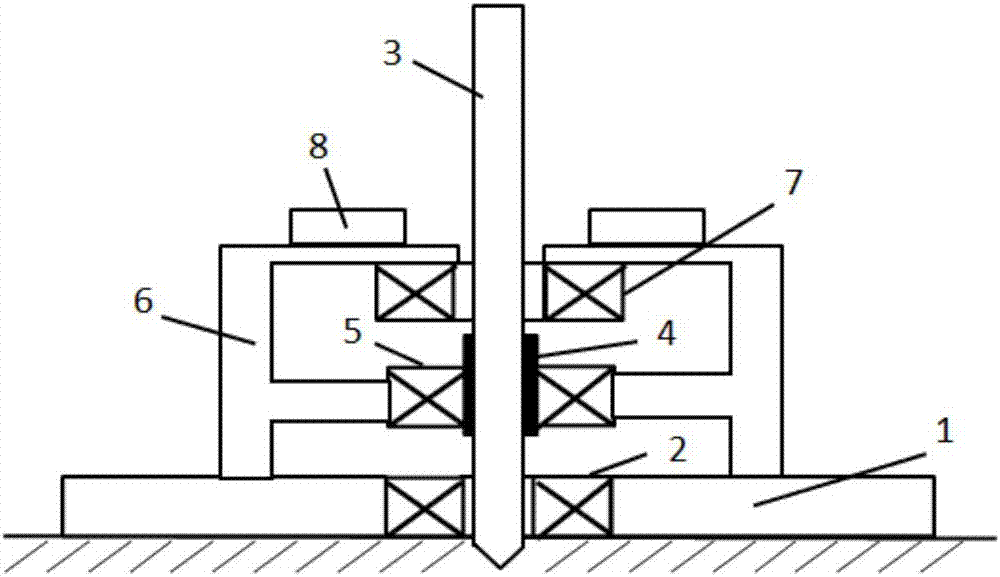

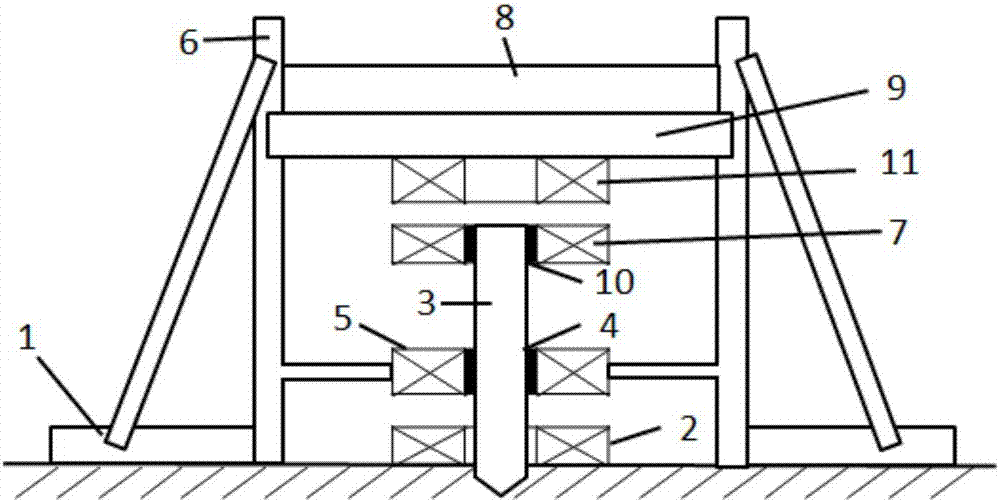

Electromagnetic piling device and electromagnetic piling method

ActiveCN105735314AReduce manufacturing costReduce equipment weightBulkheads/pilesPower flowSoil properties

The invention discloses an electromagnetic piling device and an electromagnetic piling method. The electromagnetic piling device comprises a base, a ground coil assembly, a pile, a pile clamping mechanism and a pile coil assembly. The electromagnetic piling device and the electromagnetic piling method have the advantages that impact force / static pressures which are generated during traditional piling can be completely replaced by electromagnetic repulsive / attractive force generated between the coil assemblies; different current waveforms are designed, accordingly, the electromagnetic piling force can be flexibly controlled, and the optimal piling effects can be realized; the current waveforms can be selected, so that the single piling speed can be increased, the piling efficiency can be enhanced, and the electromagnetic piling device is little in vibration and influence on surrounding soil masses; the electromagnetic piling device and the electromagnetic piling method are provided on the basis; the electromagnetic piling device is free of pollution, low in noise, convenient to mount, easy to construct, high in adaptability, expansibility and safety coefficient, is free of influence of soil properties and pile types and is particularly applicable to municipal construction and night construction requirements, in particular to pile foundation engineering in crowded building places, high-rise buildings and buildings with narrow spaces.

Owner:HUAZHONG UNIV OF SCI & TECH

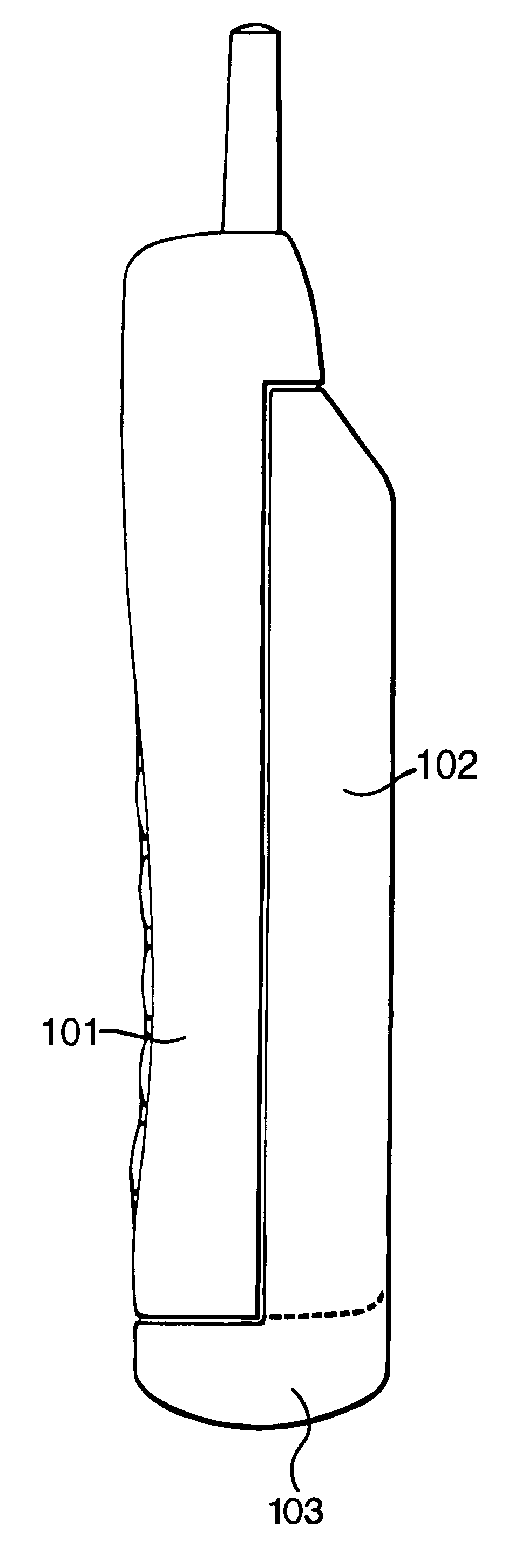

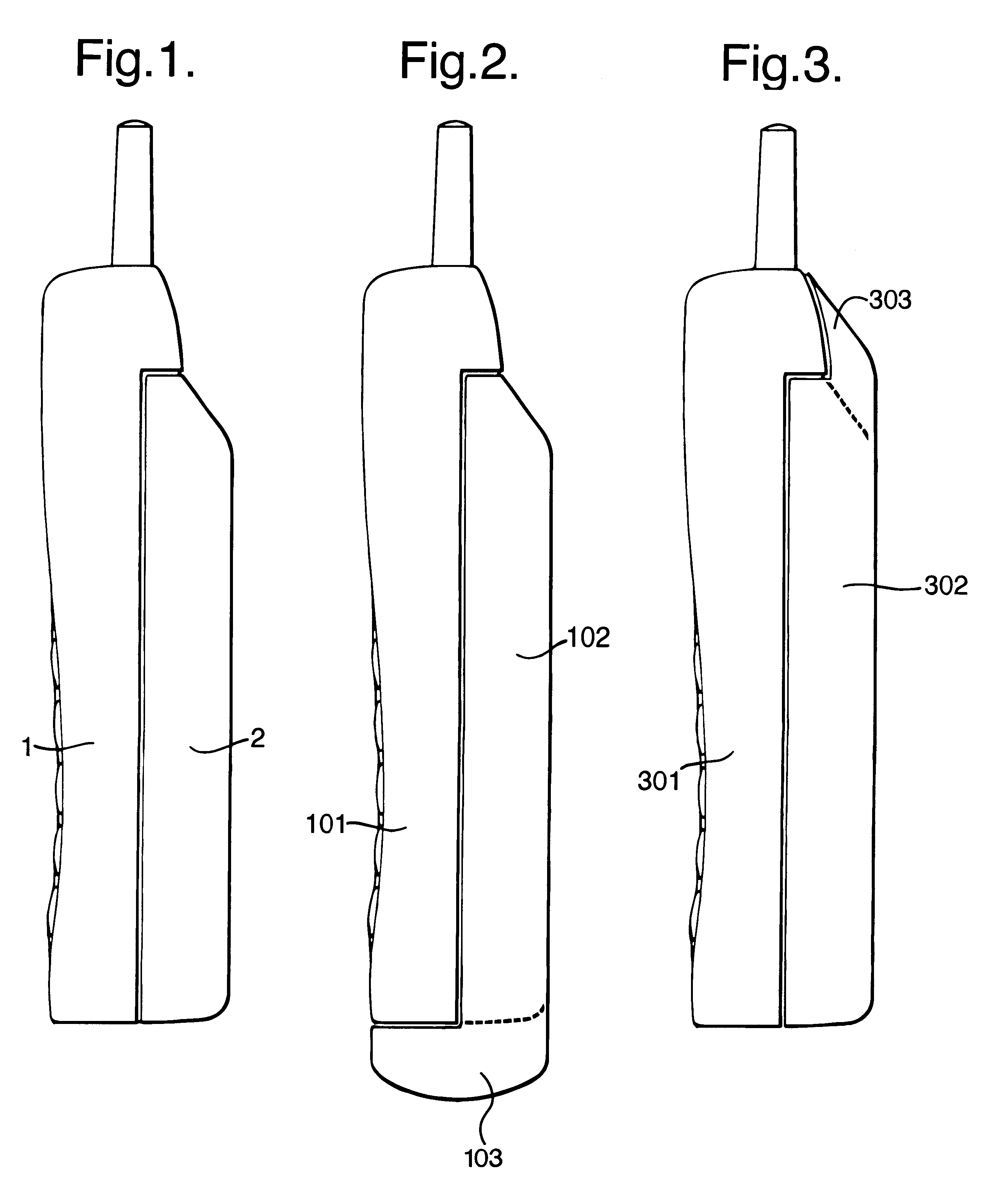

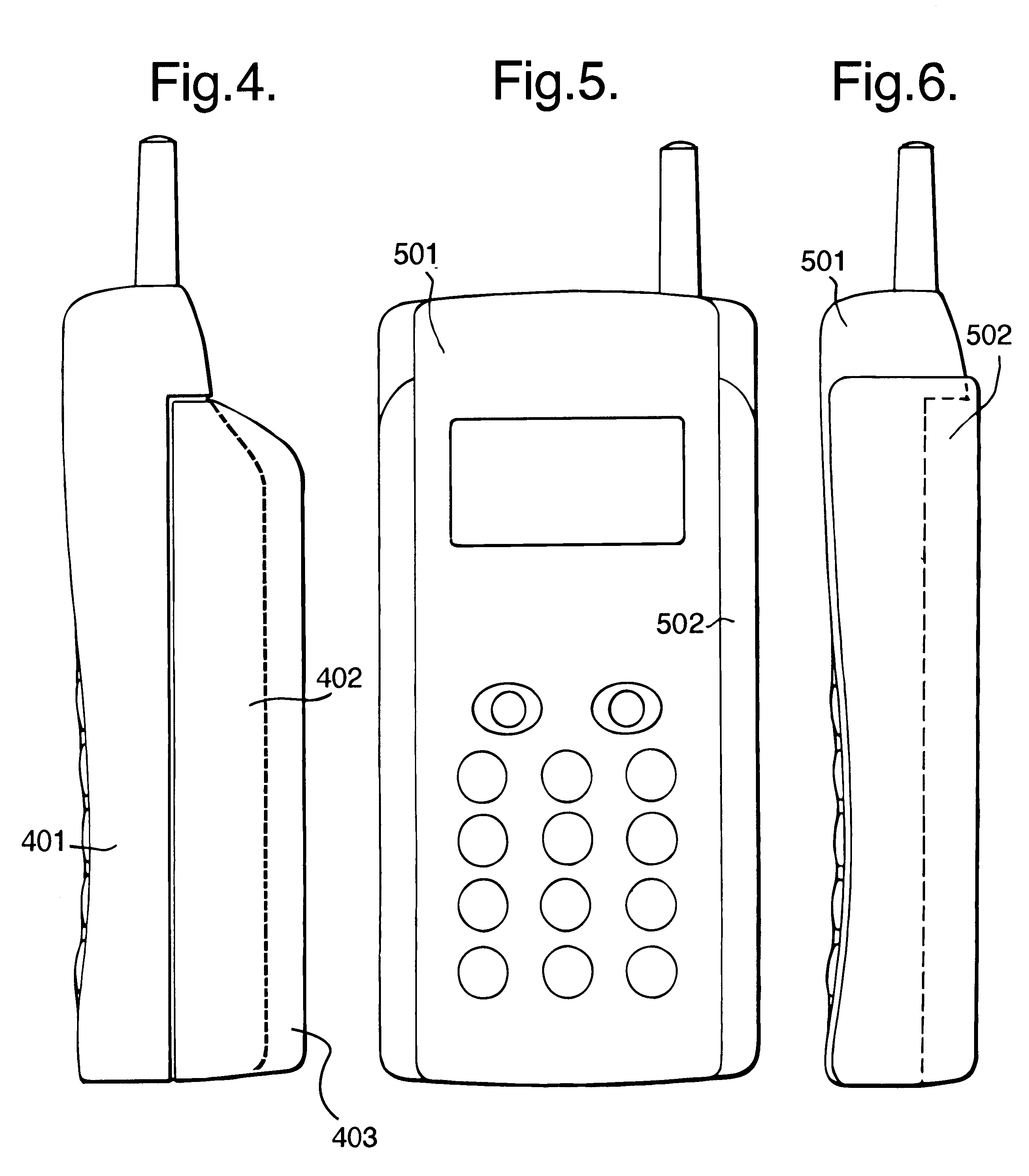

Arrangement in an electric apparatus

InactiveUS6355374B1Optimize volumeReduce weightFinal product manufactureCell component detailsMobile phoneBuoyancy

The present invention relates to an arrangement in a portable device, in particular a mobile telephone powered by batteries, and for the purpose of keeping the mobile telephone floating if it falls into water, it is according to the present invention suggested that the phone comprises a detachably affixed battery pack comprising buoyancy means, for example, a waterproof space or cavity giving buoyancy when the phone with battery housing is in water.

Owner:WIRSCHING SVEN

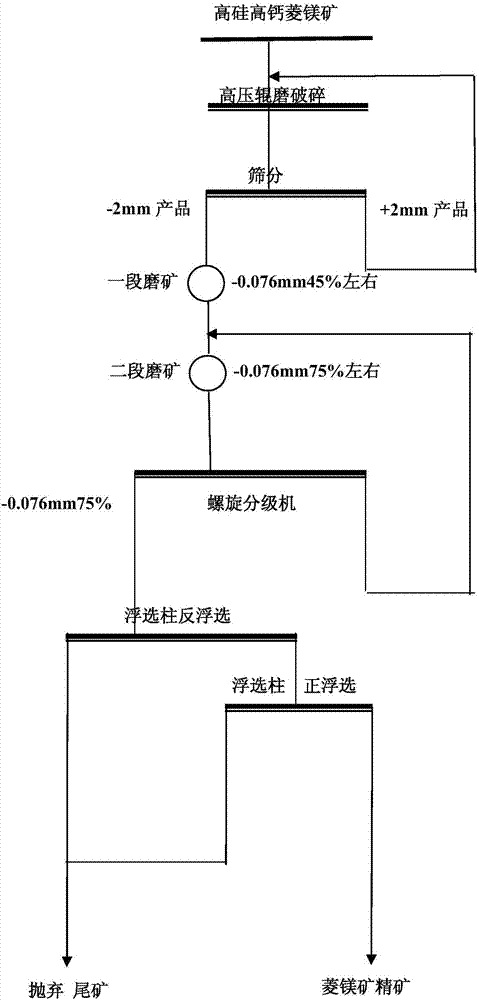

Low-cost mineral processing technology for high-silicon high-calcium magnesite

The invention relates to a low-cost mineral processing technology for high-silicon high-calcium magnesite. The low-cost mineral processing technology comprises the steps of raw material crushing operation, grinding operation and flotation operation. The low-cost mineral processing technology is characterized by comprising the following specific technological steps that raw magnesite is crushed through a medium crusher, grinding operation is conducted through a closed circuit grinding assembly composed of a primary grate ball mill, a secondary grate ball mill and a spiral grading machine, an overflow product with the particle size of 70-80% of the overflow product being -0.076 mm is obtained and subjected to flotation operation adopting primary reverse flotation and primary obverse floatation, the magnesite comprising 46.50-47.00% of magnesium oxide, 0.80-1.50% of silicon dioxide and 0.90-2.00% of calcium oxide is obtained, wherein the concentrate yield is 82.00-90.00%, and the recovery rate is 81.45-85.00%. The low-cost mineral processing technology has the advantages that flotation operation adopting only primary reverse flotation and primary obverse floatation, thus, the grade of the silicon dioxide in the high-silicon high-calcium magnesite can be lowered to 0.5-1.5% from 2%, the content of silicon is lowered by 50% or above, the grade of the calcium oxide is lowered to 1-2% from 3%, and the content of calcium is lowered by 50% or so.

Owner:中冶北方(大连)工程技术有限公司

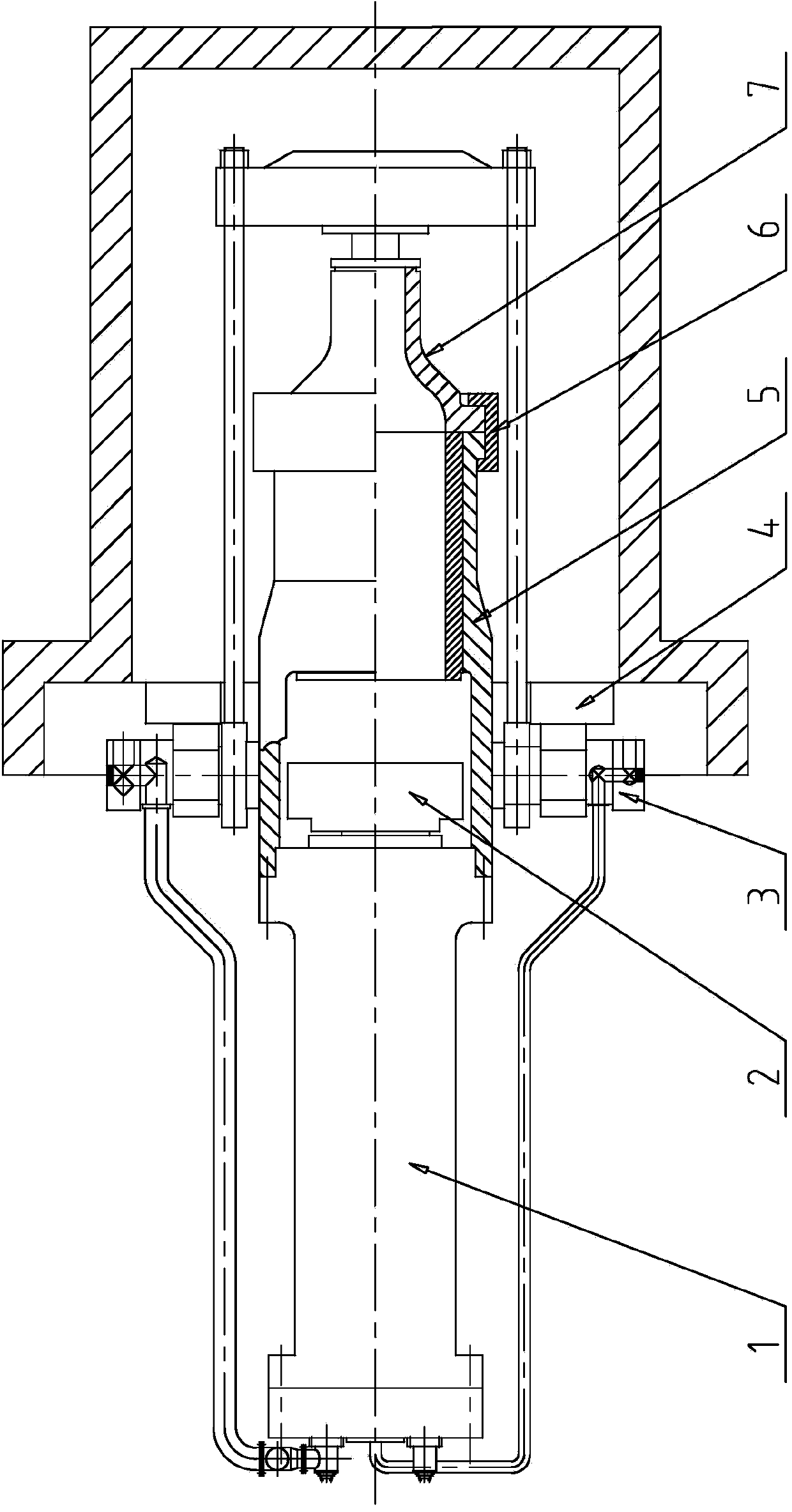

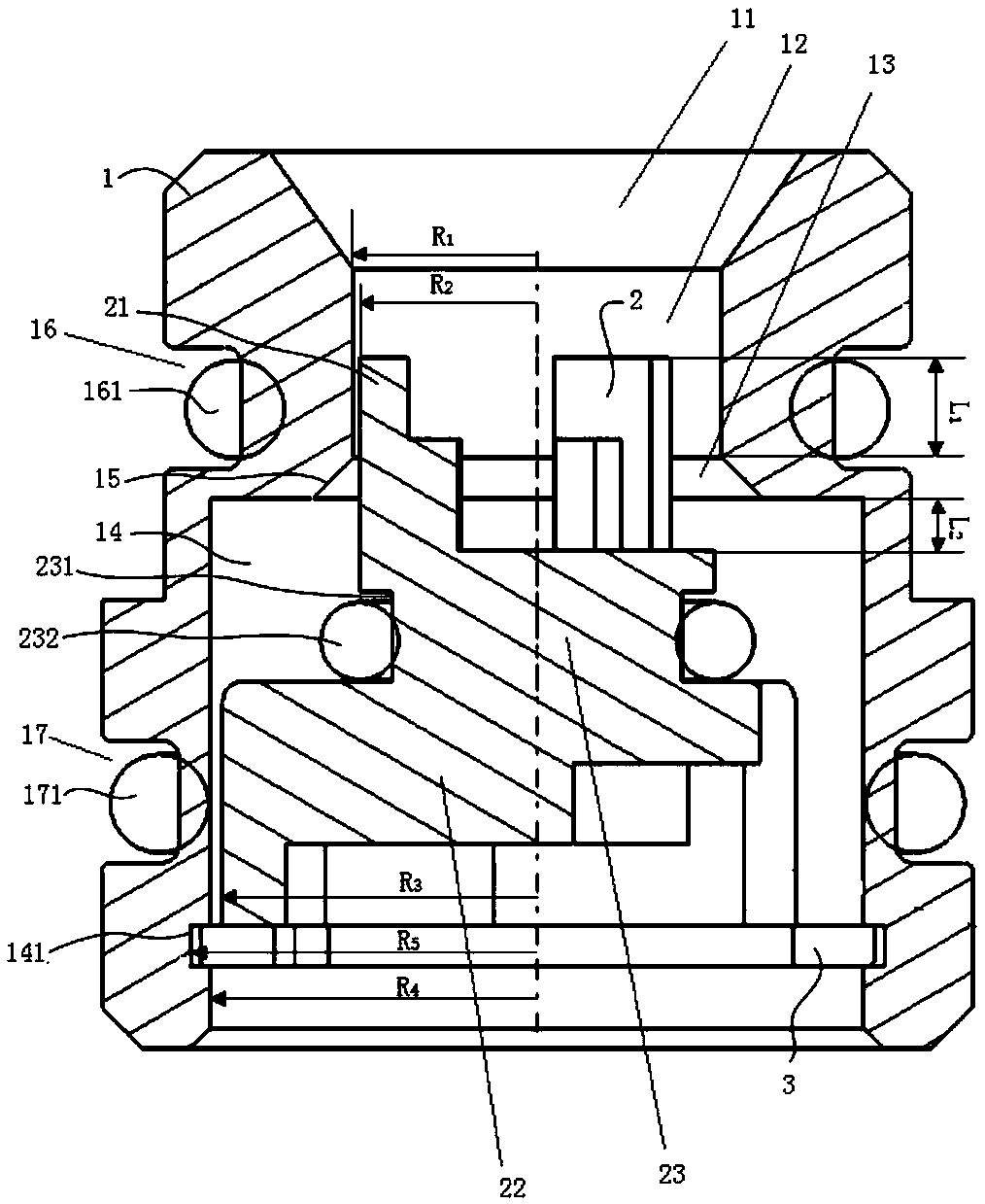

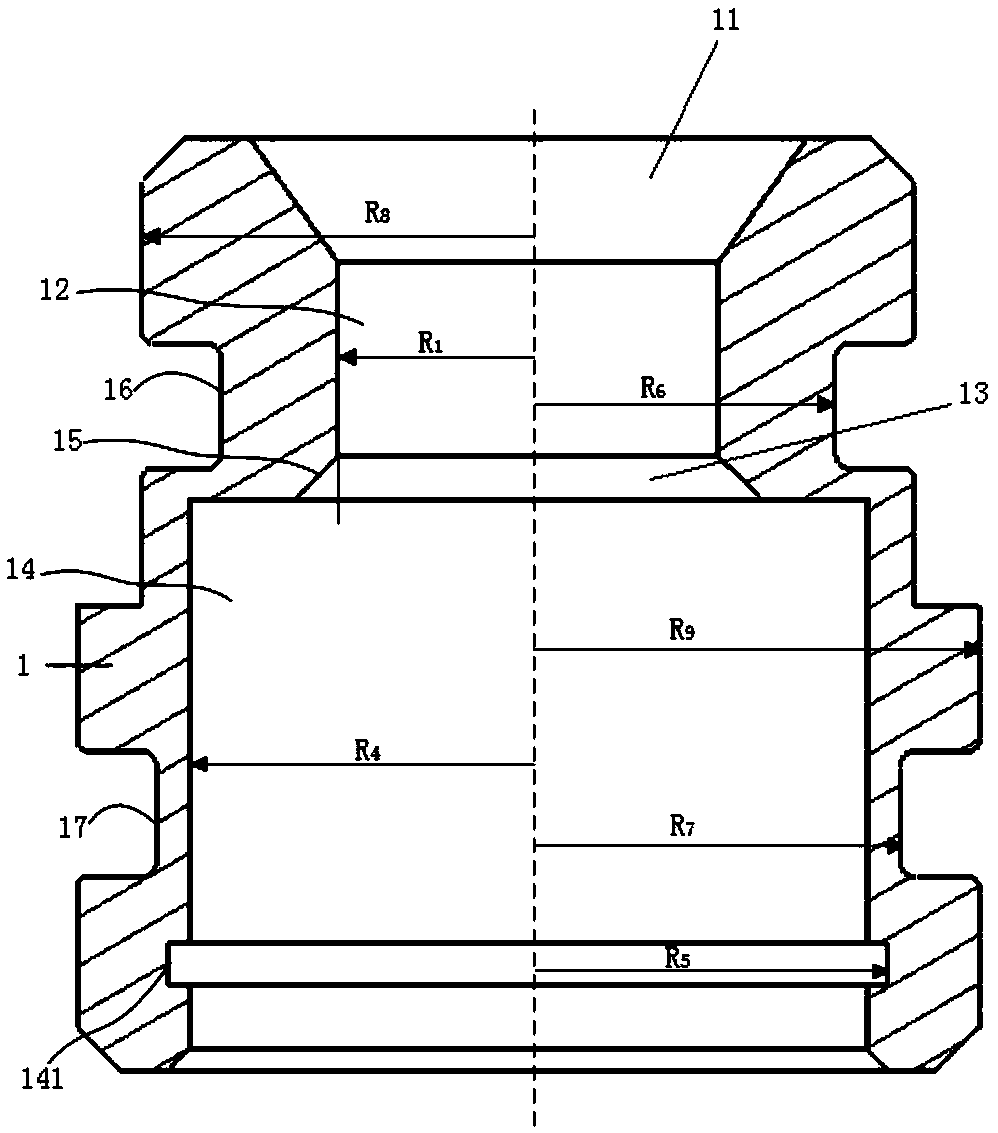

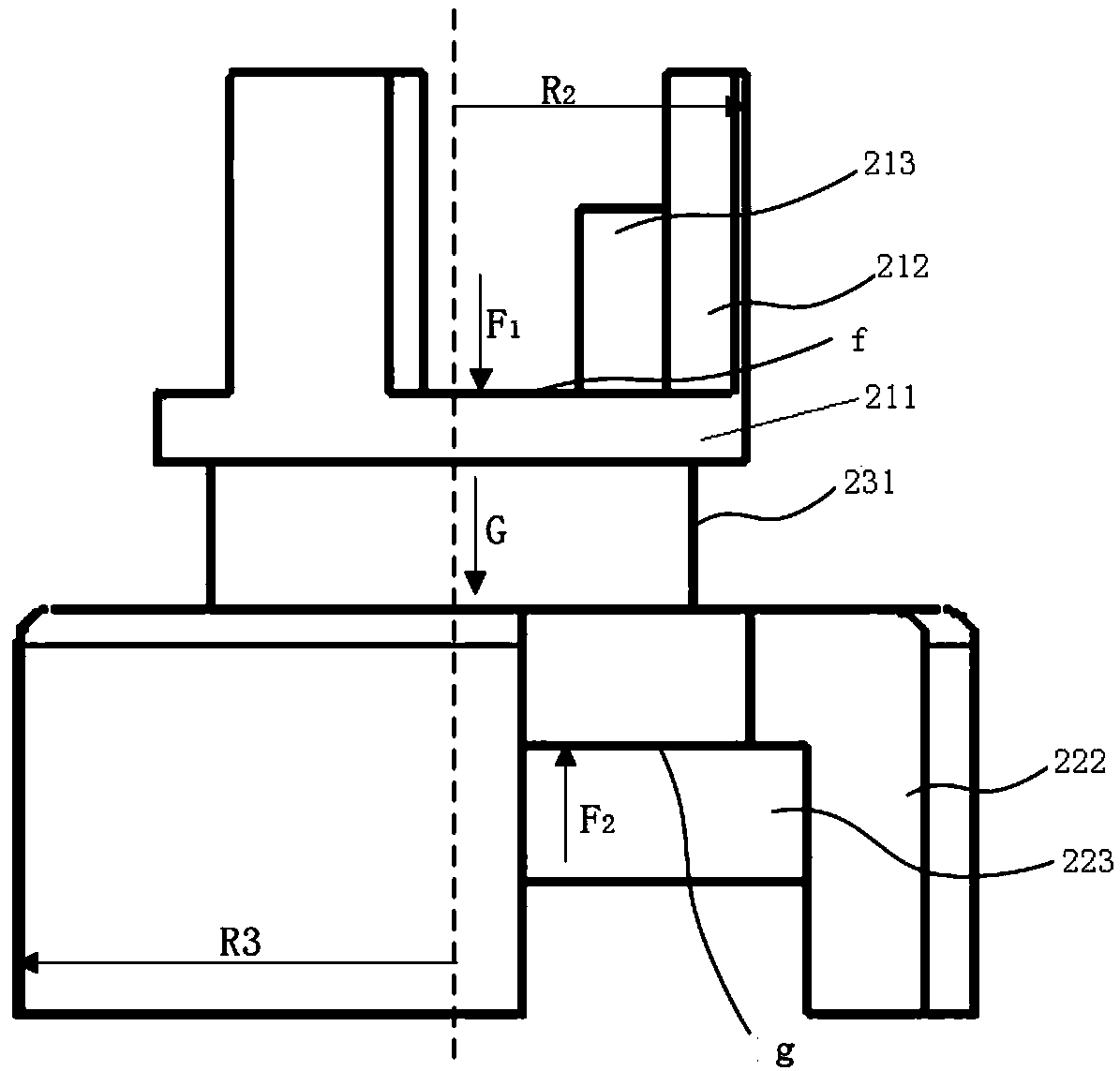

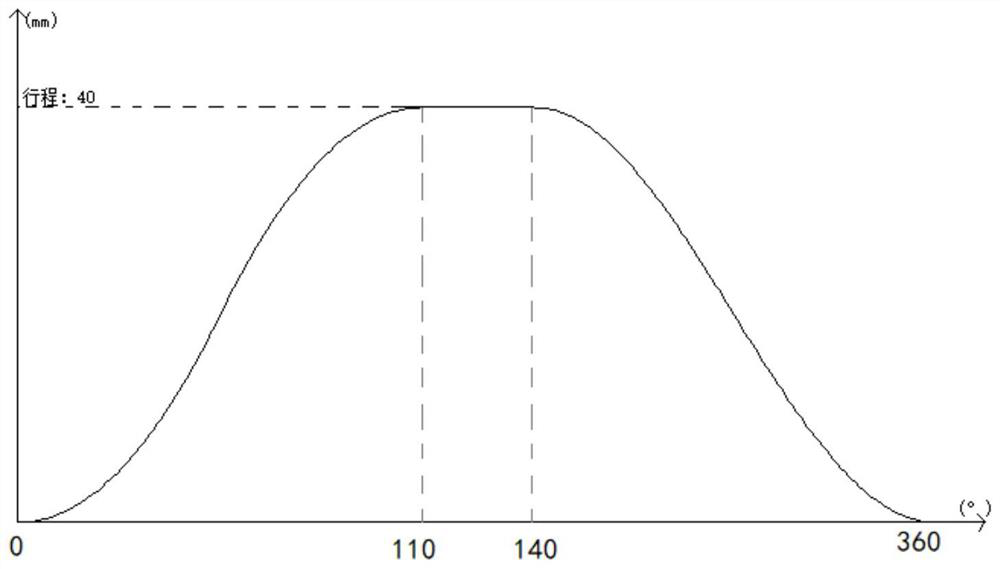

Rotary carbon electrode extruder and extruding method thereof

InactiveCN103737954AReduce equipment weightLow manufacturing costShaping pressPistonWorking pressure

The invention discloses a rotary carbon electrode extruder and an extruding method thereof. The extruder comprises a main working cylinder, supporting seats, a material chamber, a clamp, a mouth, a rotating mechanism, a baffle mechanism, rotating joints and a vacuum system, wherein the material chamber is fallen up on one supporting seat through trunnions, the two rotating joints are respectively connected with the two trunnions of the material chamber, and the vacuum system is connected at one end of the main working cylinder; the baffle mechanism is connected with the trunnions at the two sides of the material chamber through four pull rods, one end of a plunger of a rotating mechanism cylinder is connected with a plug on the outer wall of the material chamber and is provided with a function of rotating the whole extruder at 0-90 degrees. According to the extruder, the whole extruder is fallen up on the two support seats, the whole extruder is dragged to rotate around the material chamber at 90 degrees by the rotating mechanism, so that the equipment weight can be reduced and the manufacture cost can be greatly reduced. The piston of the main working cylinder is large in diameter, the working pressure is high, and the precompression is large and can maximally reach up to 40MN, so that the extruder is beneficial for the promotion of product quality.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

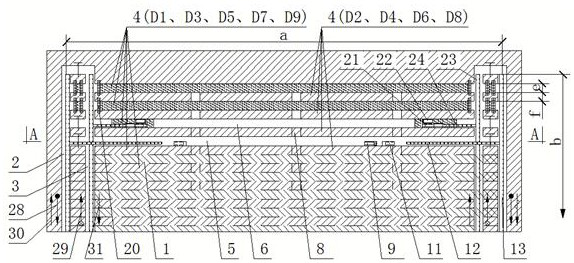

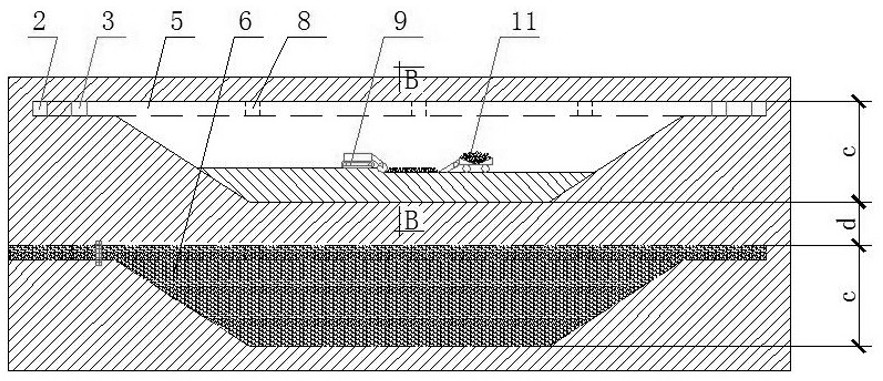

Efficient filling mining method for extra-thick coal seam

ActiveCN111691885AReduce equipment weightReduce coal costMining devicesUnderground miningCoal miningCoal gangue

The invention discloses an efficient filling mining method for an extra-thick coal seam. The method comprises the following steps that mining and filling key technical parameters are determined; a roadway and a mining and filling production system are arranged; a mining and filling connection sequence is determined, milling type coal mining is carried out, a long "ship"-shaped deep groove goaf isconstructed, the goaf is filled, and the goaf is filled close to back; and safe and efficient mining of the extra-thick coal seam, low-cost and efficient filling of coal gangue and the like and effective protection of the ecological environment are achieved. The method can improve the coal mining capacity, reduce the coal mining cost, simplify the mining and filling connection relation, improve the filling capacity, guarantee the mining and filling safety, optimize the filling space structure, achieve full-volume filling of the goaf, simplify the filling process system, reduce the filling cost, expand the filling mining application range, liberate stagnant coal resources, improve the mine recovery rate, efficiently fill the ground and the underground coal gangue at low cost, solve the ecological environmental protection problem, and achieve coal resource development and utilization optimization and ecological environment influence minimization on the whole.

Owner:TAIYUAN UNIV OF TECH

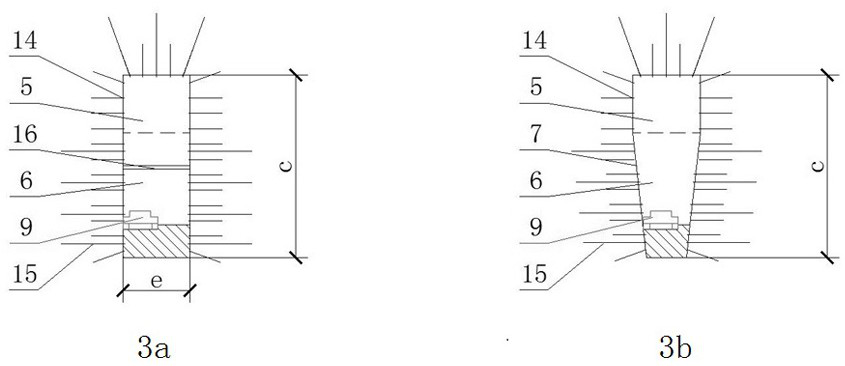

Device with temperature and humidity control capability and adaptive control method thereof

InactiveCN110430722AReduce system sizeReduce equipment weightModifications using gaseous coolantsSelf adaptiveAdaptive control

The invention relates to a device with temperature and humidity control capability and an adaptive control method thereof. The device comprises a fan, a gas-liquid heat exchanger, a semiconductor refrigeration chip, a condenser, a temperature and humidity sensor, a control device and an external liquid supply system. The device can control the start and stop or the rotational speed of the fan according to the air temperature feedback inside the space, can automatically adjust the air side air flow during the heat exchange process and controls the air outlet temperature, thereby controlling thetemperature in the space; according to the humidity feedback in the space, the start and stop of the semiconductor refrigeration chip is controlled to control the humidity in the space at a constantlevel; and in particular, the device combines the gas-liquid heat exchanger and a semiconductor dehumidifier, and the semiconductor dehumidifier adopts a liquid cooling and heat dissipation mode to avoid the defects that the use and the refrigeration of the fan of a traditional dehumidifier are greatly influenced by the ambient temperature; and moreover, the overall condensation caused by the traditional low-temperature water-liquid-liquid heat exchanger is avoided, and the reliability of the device and the environmental adaptability in the conditions without low-temperature water and with thelimited space are greatly improved.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

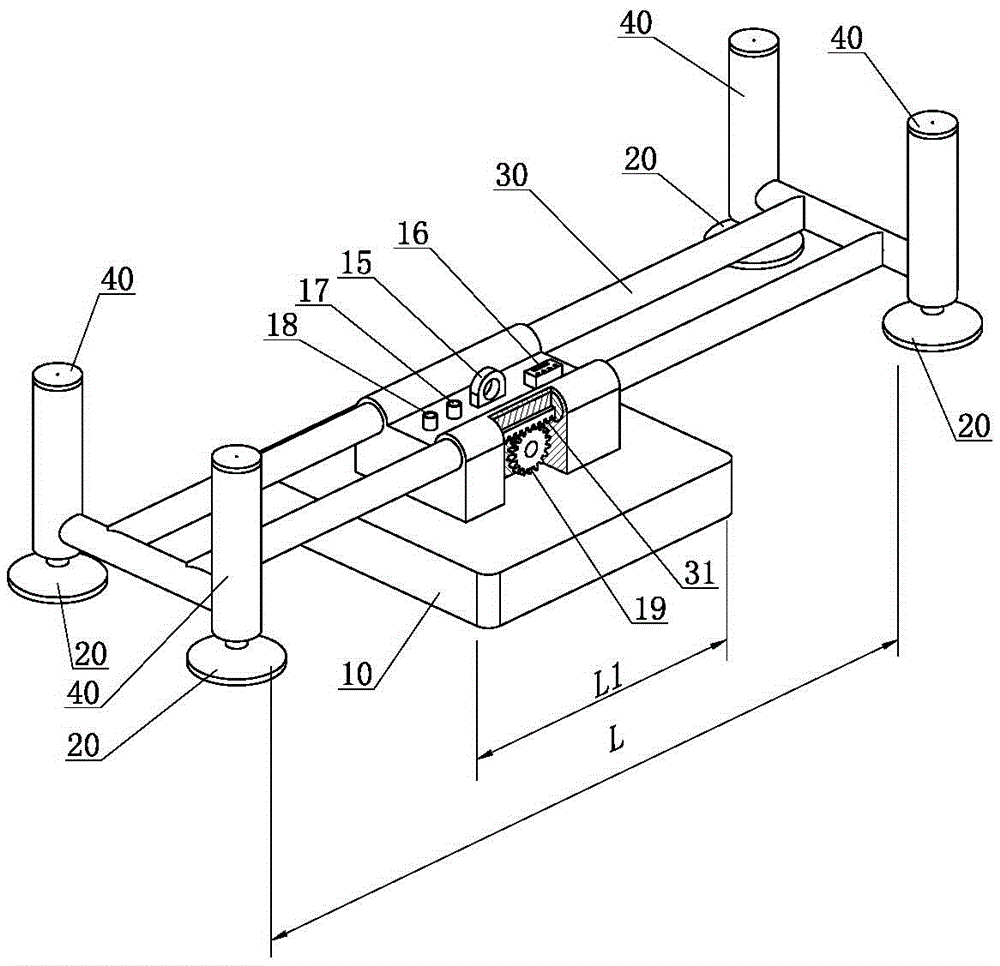

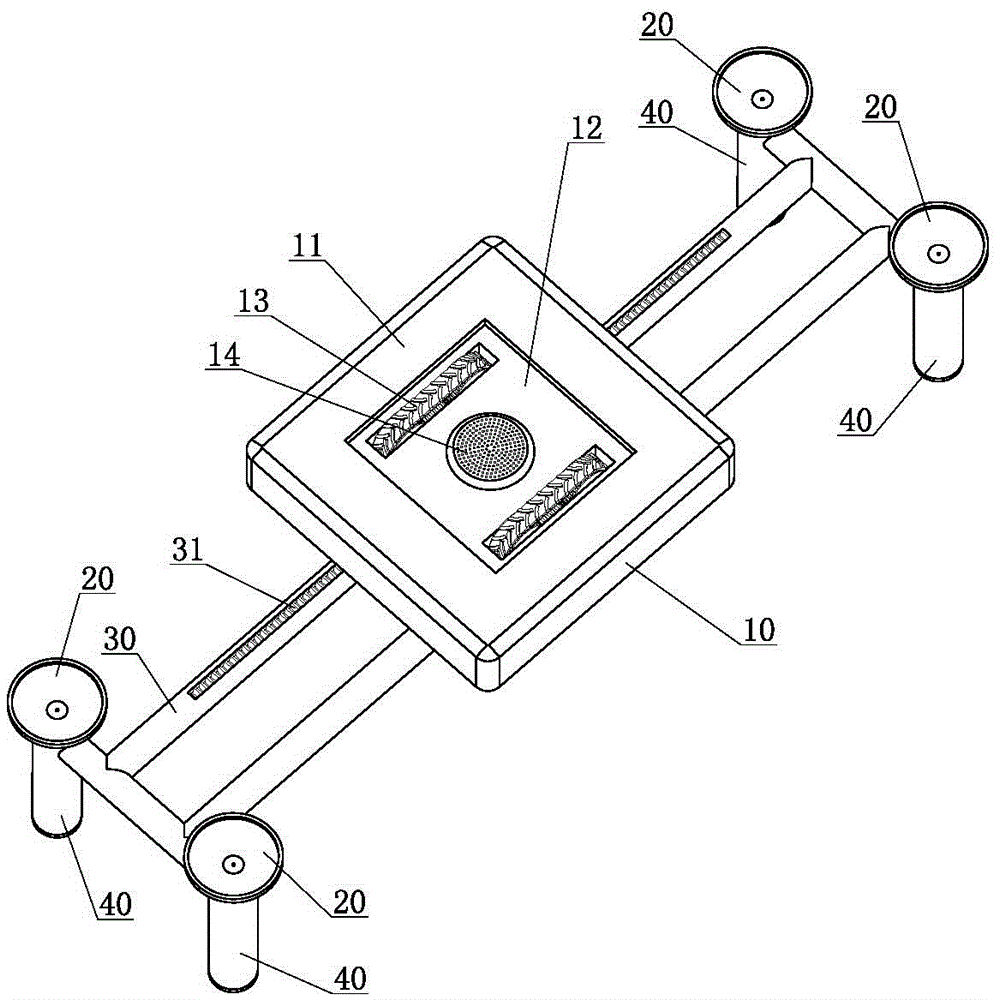

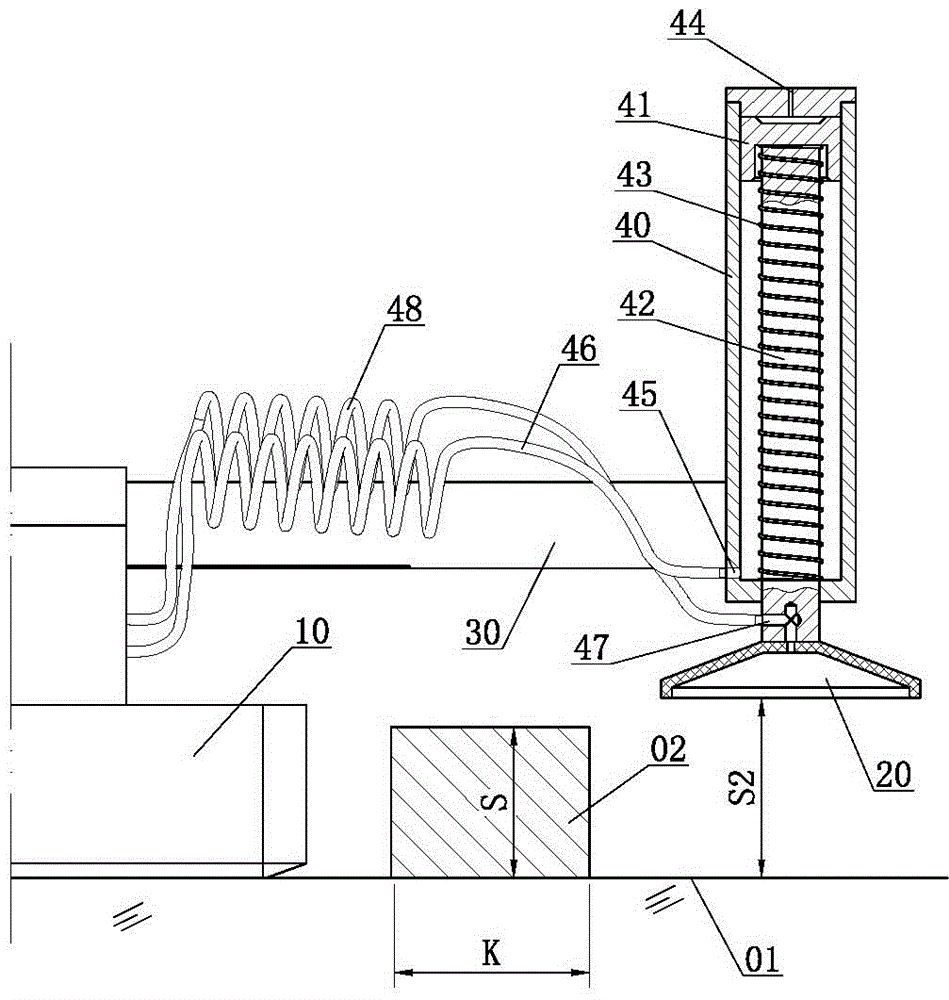

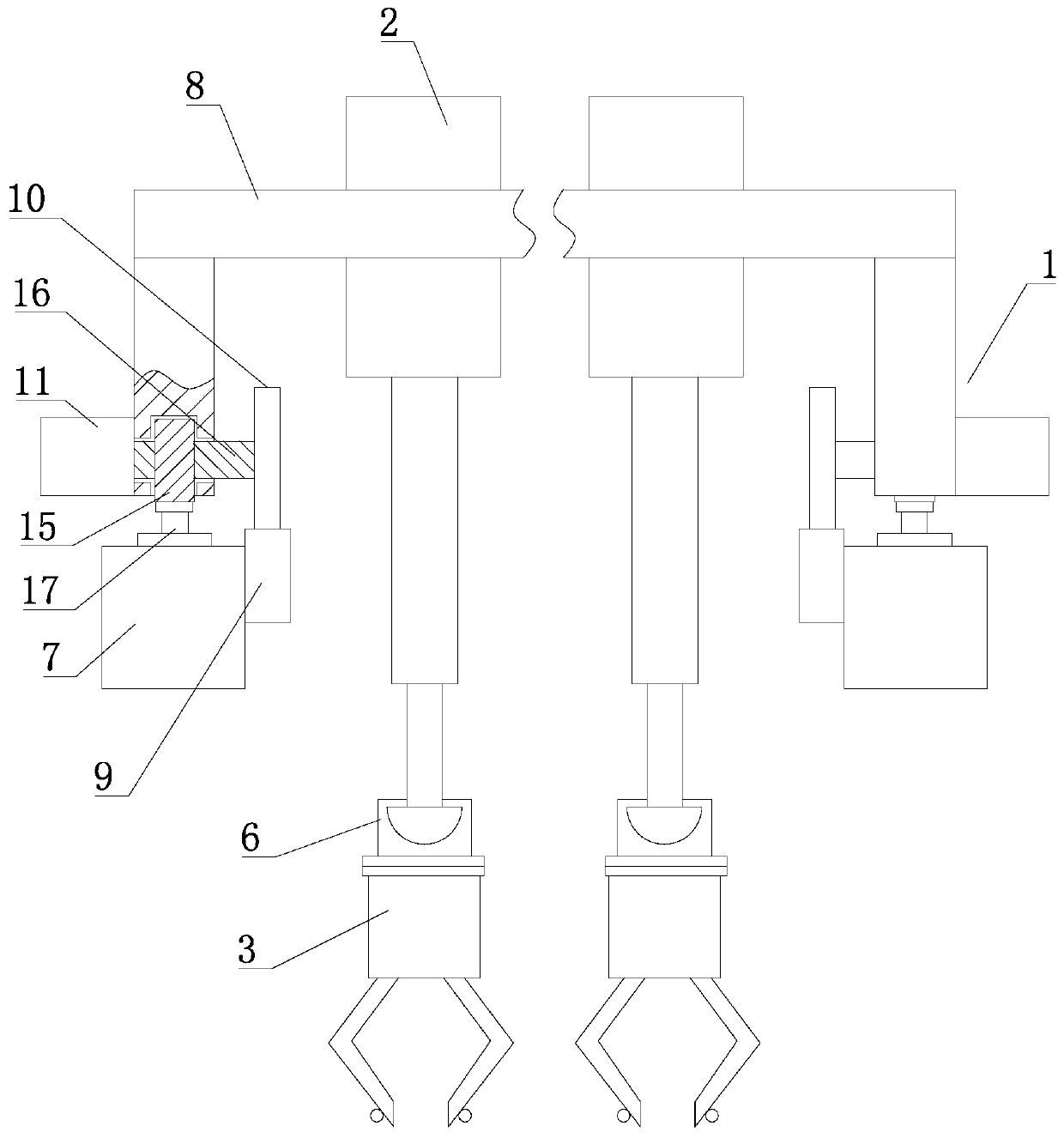

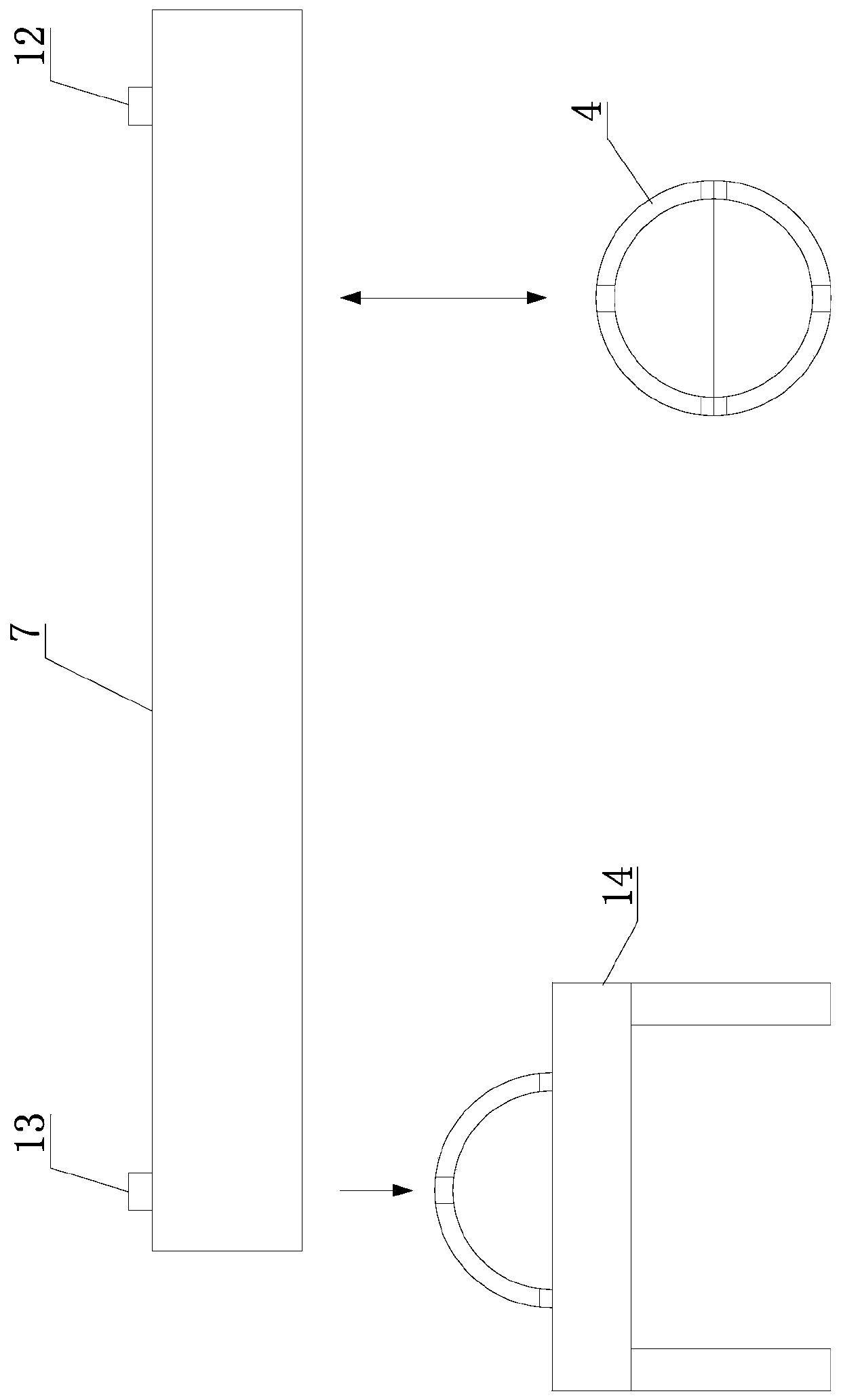

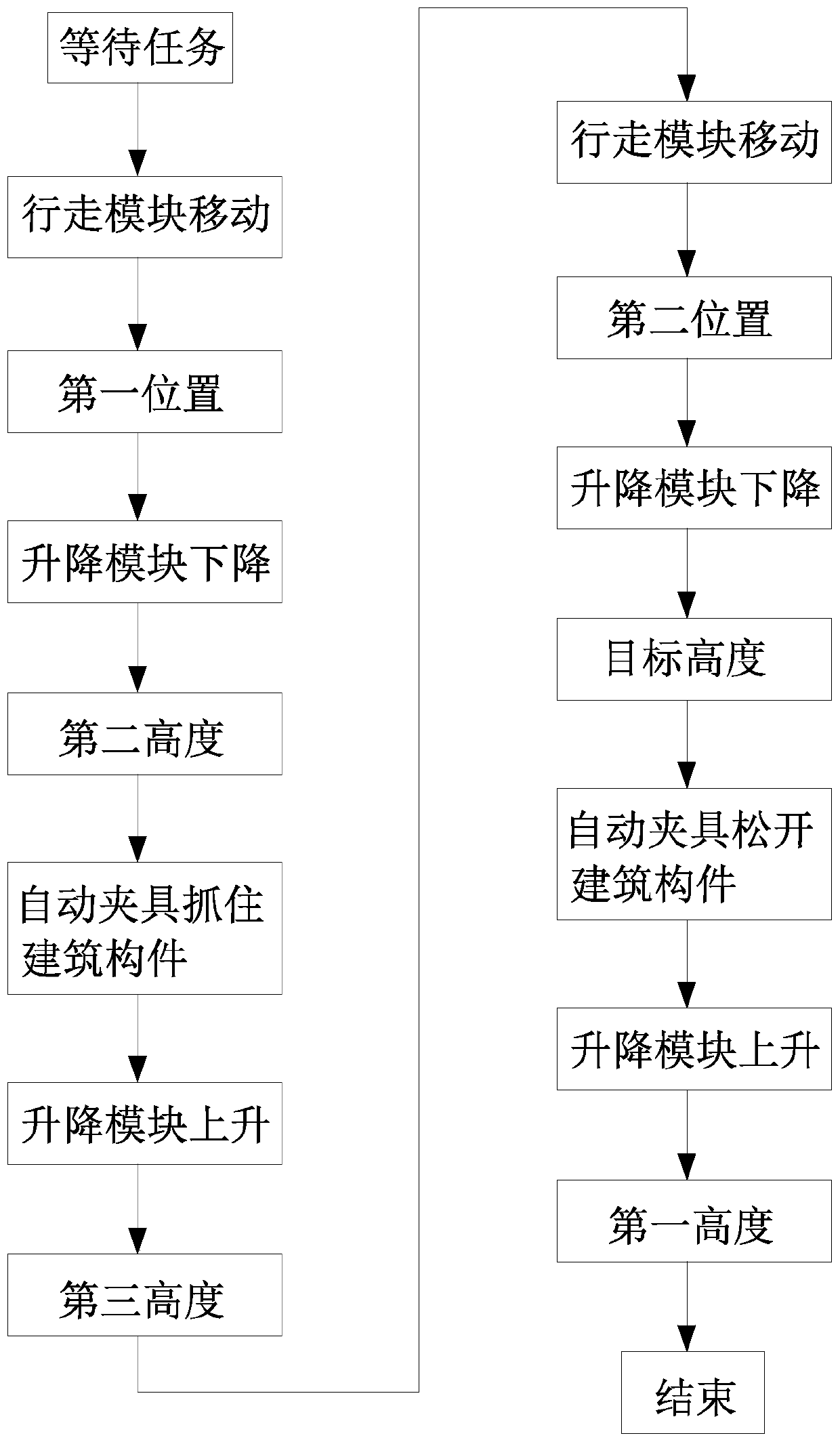

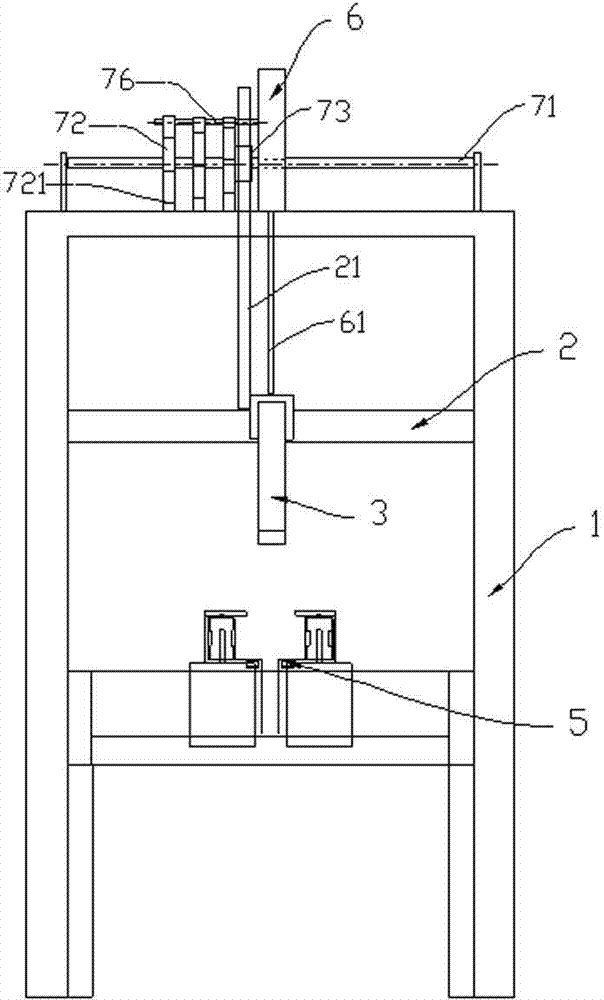

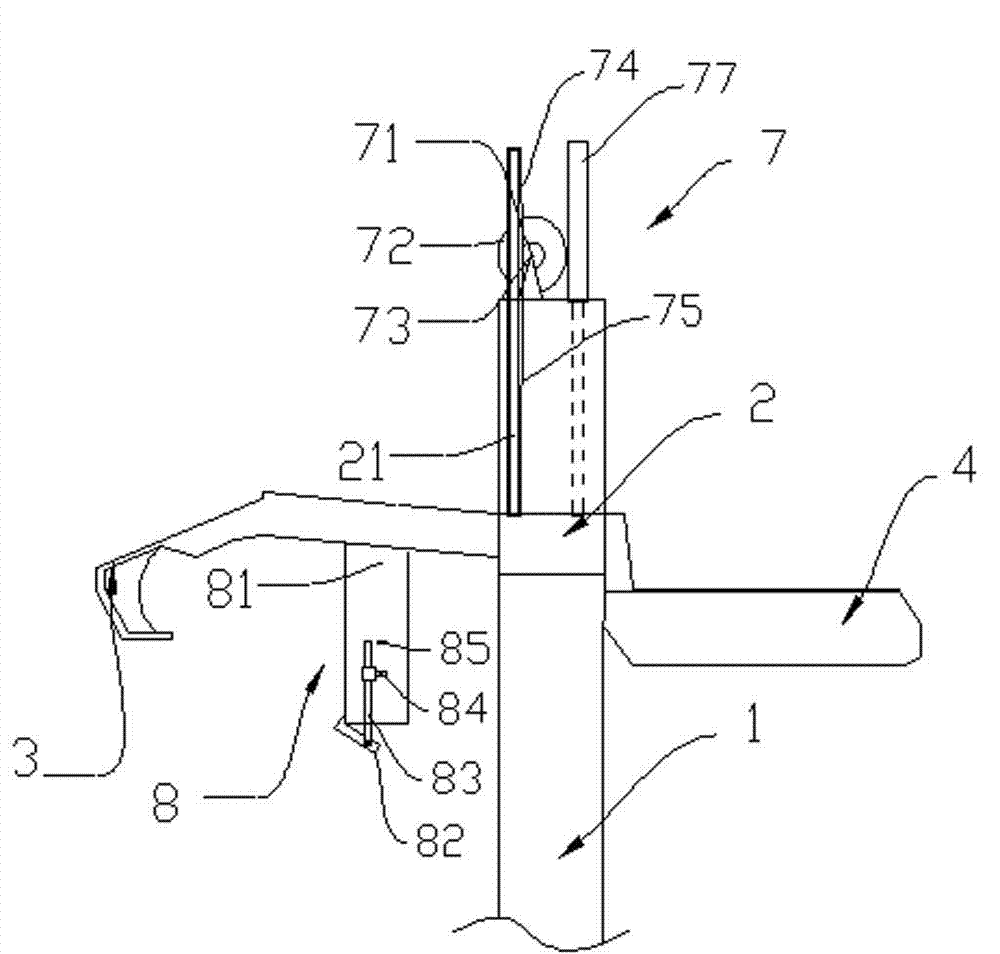

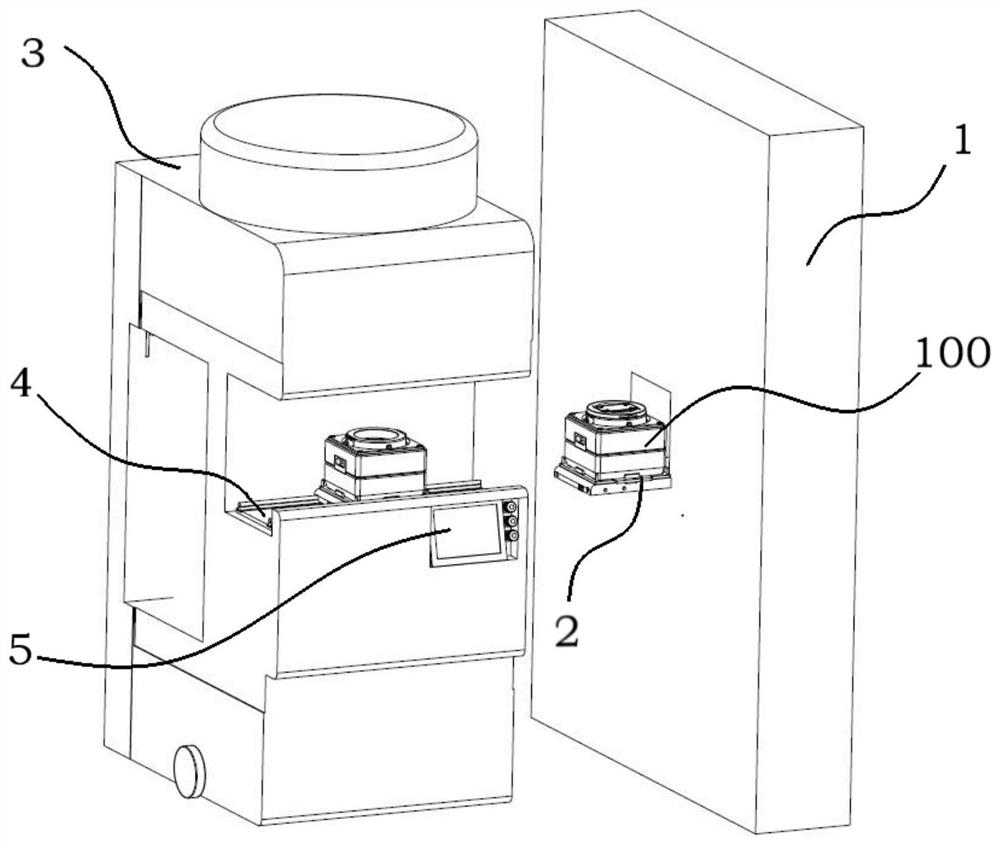

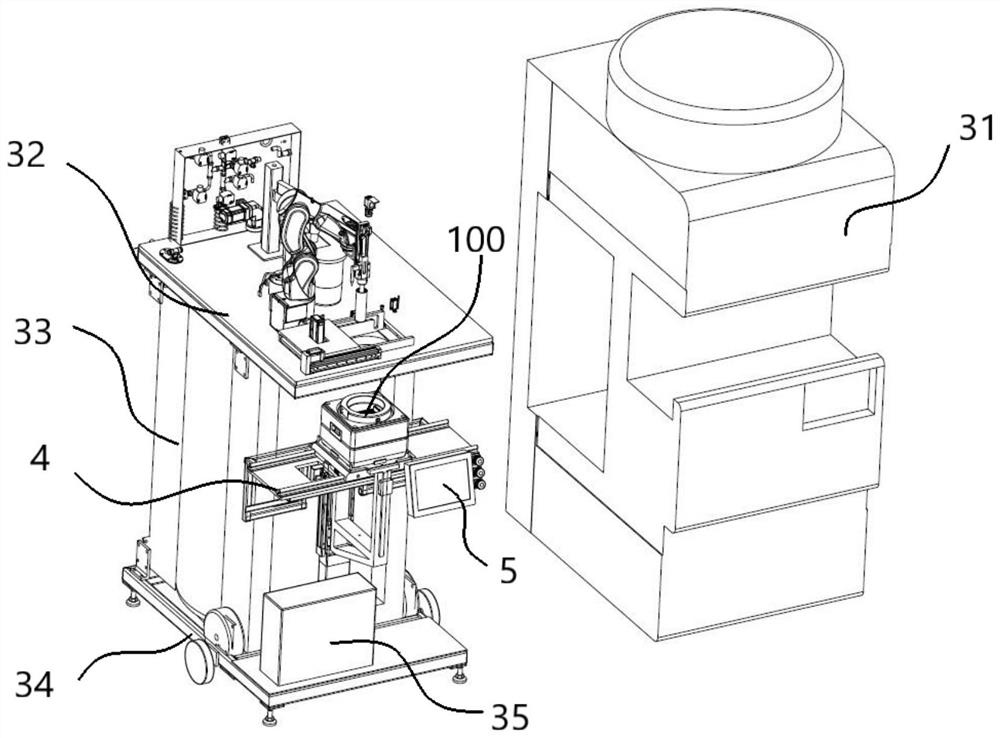

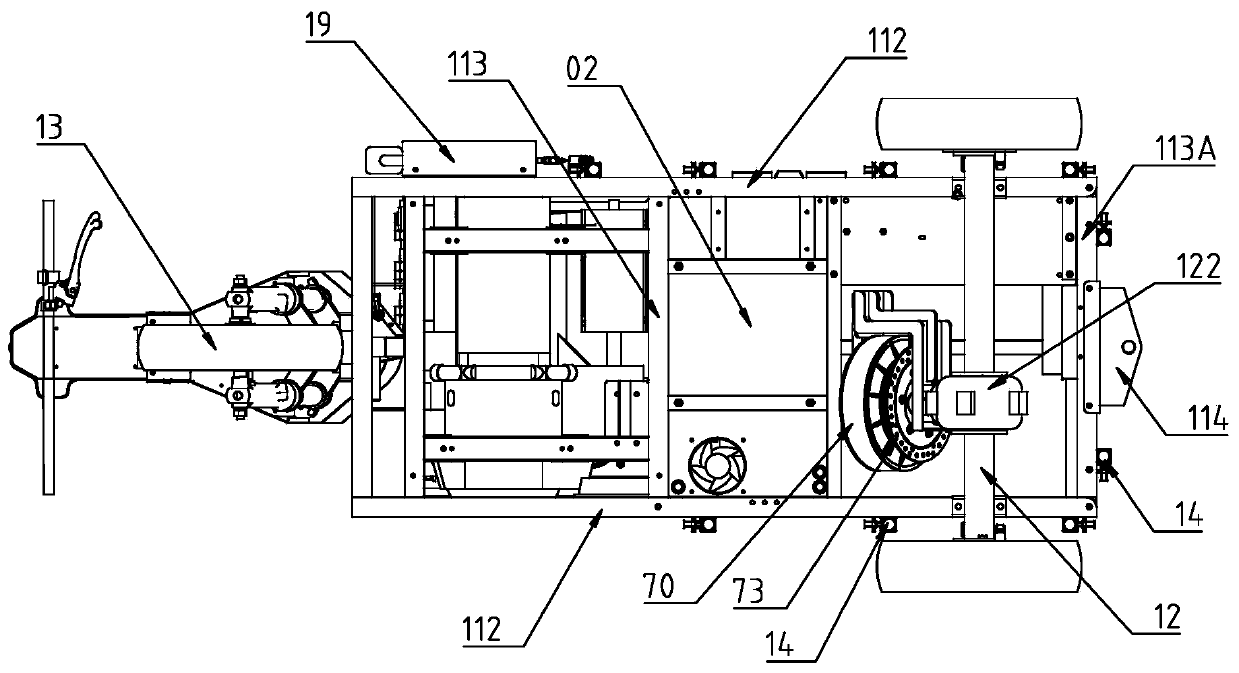

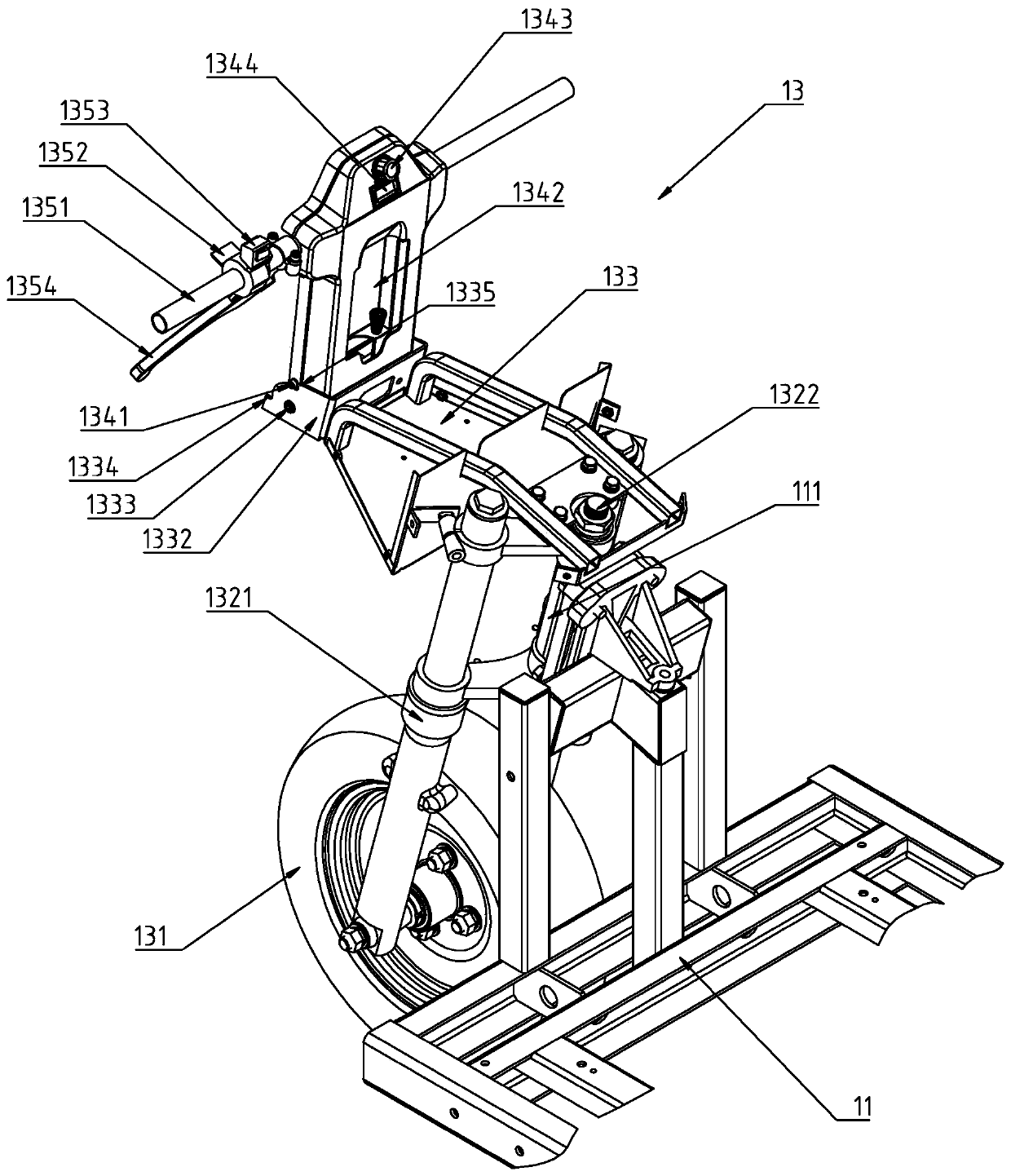

Automatic mold gripping method and device for intelligent robot for building component

PendingCN109823967ASmall inertiaReduce structural load-bearing requirementsTravelling cranesTravelling gearProduction lineAutomatic control

The invention relates to the field of building, in particular to an automatic mold gripping method and device for an intelligent robot for a building component. The robot comprises a walking module, an ascending-and-descending module, a gripping module and a control module. The mold gripping method comprises the following steps that 1, the control module transmits a command to the walking module,and the walking module moves to a preset first position in the vertical direction and then stops; and 2, the control module transmits a command to the ascending-and-descending module, the ascending-and-descending module drives the gripping module to descend from an initial first height to a second height position where the building component is located, and after the gripping module is in the right place, the ascending-and-descending module stops. The automatic mold gripping device is reasonable in structural design; the device is different from a traditional bridge crane in that the device isarranged above a building component production line; compared with the bridge crane, the mounting height and the equipment self weight are greatly lowered; manual driving operation is not needed; a mold on the production line can be automatically gripped; and intelligent automated control over the gripping action, on the production line, of the building component is achieved.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

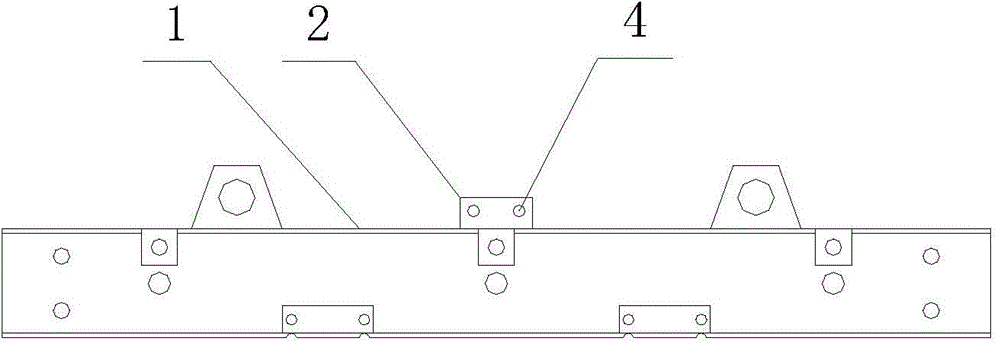

Box sealing machine

The invention relates to a box sealing machine. The box sealing machine comprises a machine base, a machine head arranged on the machine base, a cover folding mechanism, an upper machine core and a conveying rail arranged on the machine base, wherein the cover folding mechanism and the upper machine core are arranged on the machine head, and the machine head can move up and down relative to the machine base so as to adjust the distance between the cover folding mechanism and the conveying rail as well as the distance between the upper machine core and the conveying rail. The box sealing machine further comprises a first air cylinder and a cut-off mechanism, wherein the first air cylinder is installed above the machine head, and a piston rod of the first air cylinder is fixedly connected with the machine head; the cut-off mechanism comprises a rotary shaft rotationally arranged on the machine base, a ratchet wheel, a belt wheel, two belts and a pawl, the ratchet wheel and the belt wheel are fixedly installed on the rotary shaft, the two belts are wound on the belt wheel in the opposite directions, the pawl is rotationally arranged on the machine base, a plurality of notches are formed in the edge of the ratchet wheel and arranged in the circumferential direction of the ratchet wheel, one end of a chain is connected with the machine base through a coiled spring, and the other end of the chain is fixedly connected with the machine head. The box sealing machine is low in cost and safe to use.

Owner:SU ZHOU XUENUO MECHANICAL PROD

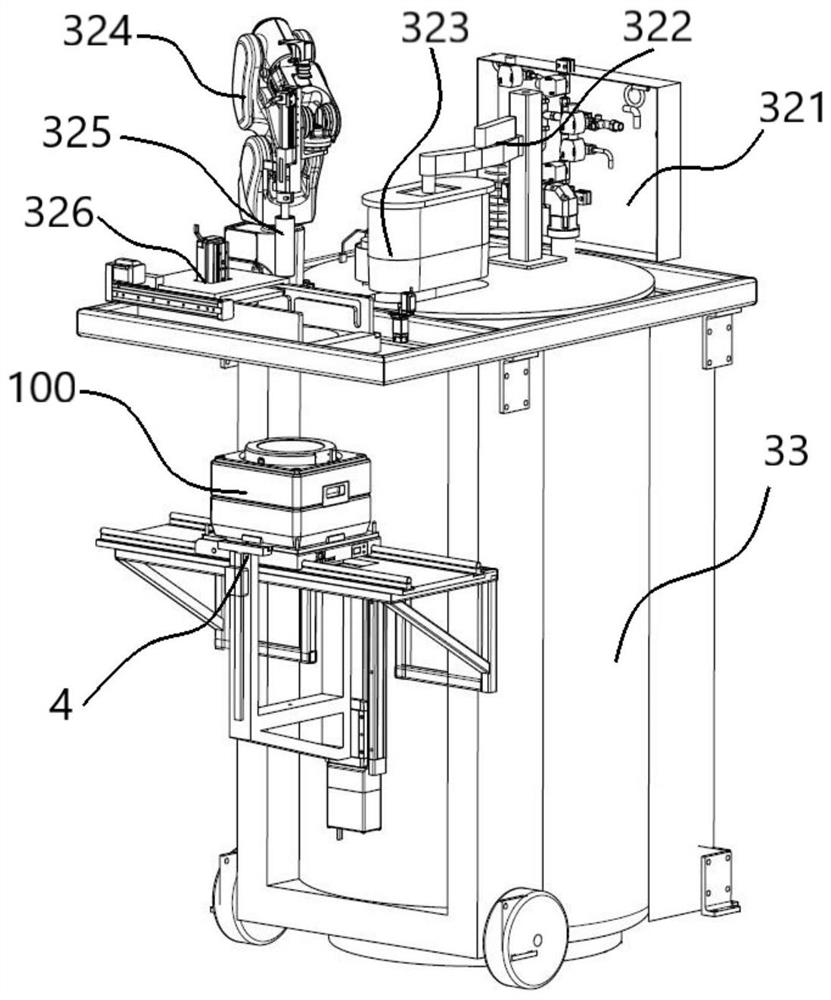

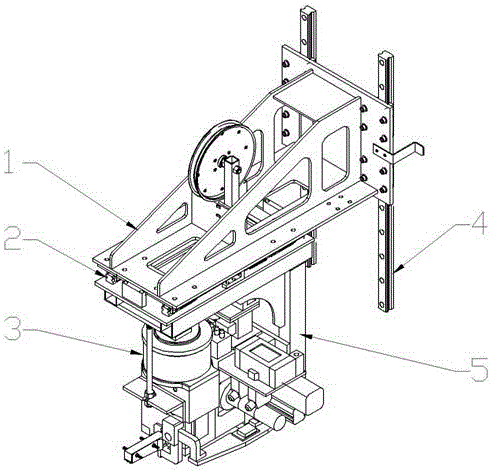

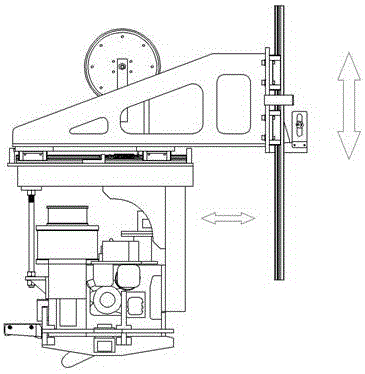

Portable sample storage equipment and storage method

PendingCN113104469AReduce equipment costsReduce equipment weightBottle/container closureCharging stationsEmbedded systemStorage efficiency

The invention discloses portable sample storage equipment and a storage method. The equipment comprises a transportation device, a storage equipment body and a transmitting and docking device, wherein the transportation device is used for bearing a transfer box in which samples are stored, the storage equipment body is used for storing samples, and the transmitting and docking device is used for transmitting the transfer box which is carried by the transportation device and stores the samples and docking the transfer box with the storage equipment body, so that the storage equipment body can store the samples conveniently. The equipment is specially provided with the transmitting and docking device which can achieve rapid butt joint of the transfer box and the storage equipment, and the storage efficiency is improved; a mechanical arm is adopted in the storage equipment body to achieve multi-directional operation, a three-axis coordinate mechanism is replaced, the equipment cost is reduced, and the equipment weight is reduced; and through cooperation between the transfer box, the transportation device and a lifting mechanism in the transmitting and docking device, a many-to-many storage function can be quickly realized, the sample storage efficiency is improved, and the storage management efficiency of a sample library is improved.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

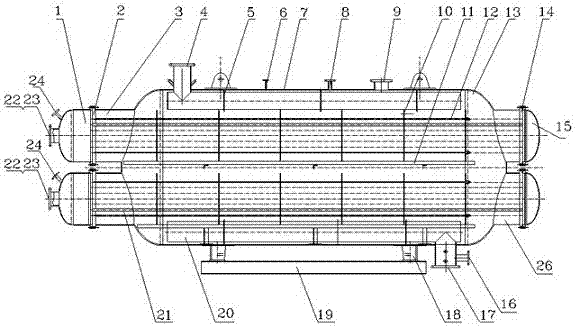

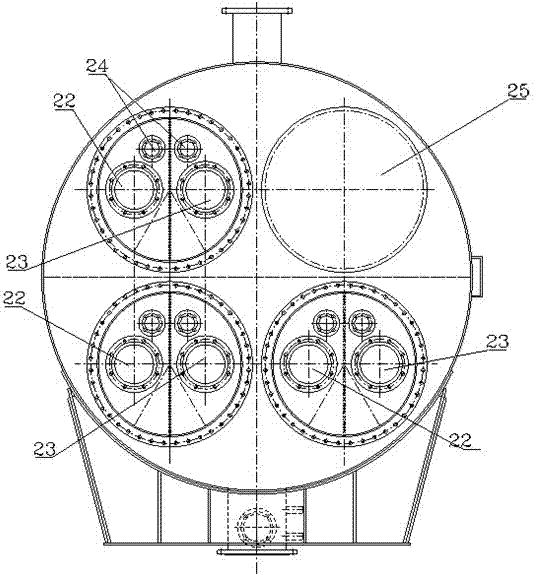

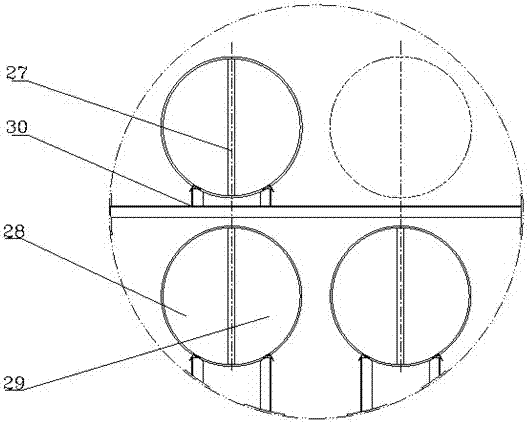

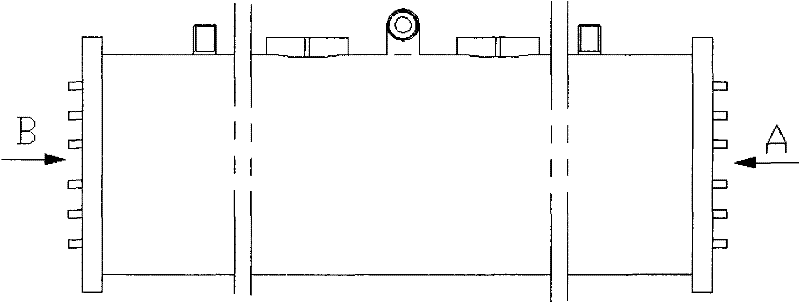

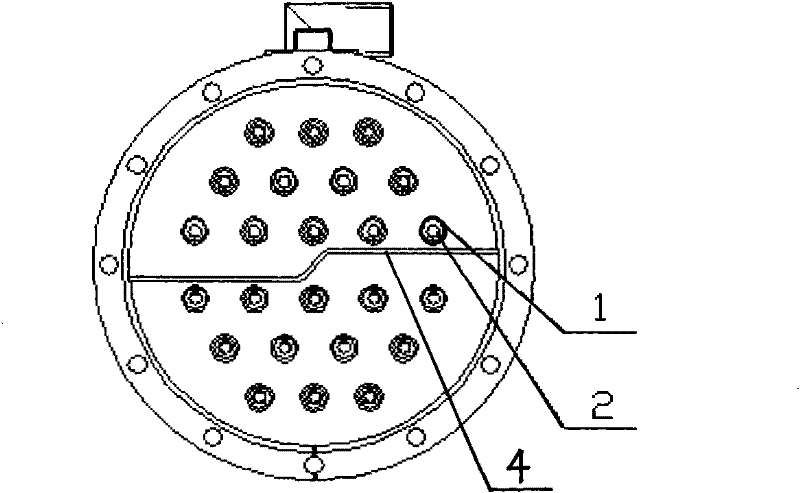

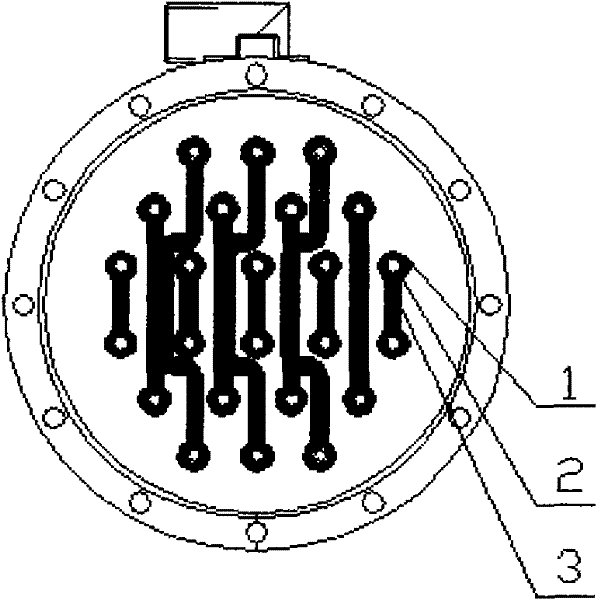

Compound corrugated tube heat exchanger

PendingCN108007243AEquipment manufacturing cost is lowReduce equipment weightStationary tubular conduit assembliesTubular elementsSmall footprintEngineering

The invention discloses a compound corrugated tube heat exchanger. A plurality of left flow guide barrels and right flow guide barrels which are arranged in pairs are arranged at the two ends of a shell-pass barrel body, and the outer end of each left flow guide barrel is connected with a left tube plate and a left tube box; and the outer end of each right flow guide barrel is connected with a right tube plate and a sealing head, a corrugated heat exchange tube is arranged between each left tube plate and the corresponding right tube plate, a pass partition plate is arranged in each left tubebox and divides the left tube box into a tube-pass flow inlet cavity and a tube-pass flow outlet cavity to form an independent tube-pass part, each independent tube-pass part can be applied to a heatmedium fluid, and a plurality of the independent tube-pass parts share one shell-pass part, so that the heat exchanger disclosed by the invention is capable of recycling the waste heat of a pluralityof fluid mediums simultaneously. The equipment is low in manufacturing expense; connection pipelines among tube passes are omitted, so that low installation expense is achieved; after connection pipelines among the heat exchangers are omitted, pipeline resistance is correspondingly reduced, and conveying power consumption is reduced; and the volume of the equipment is further effectively reduced,and the equipment is simple in structure, low in cost and small in floor area.

Owner:济南市水处理设备厂有限公司

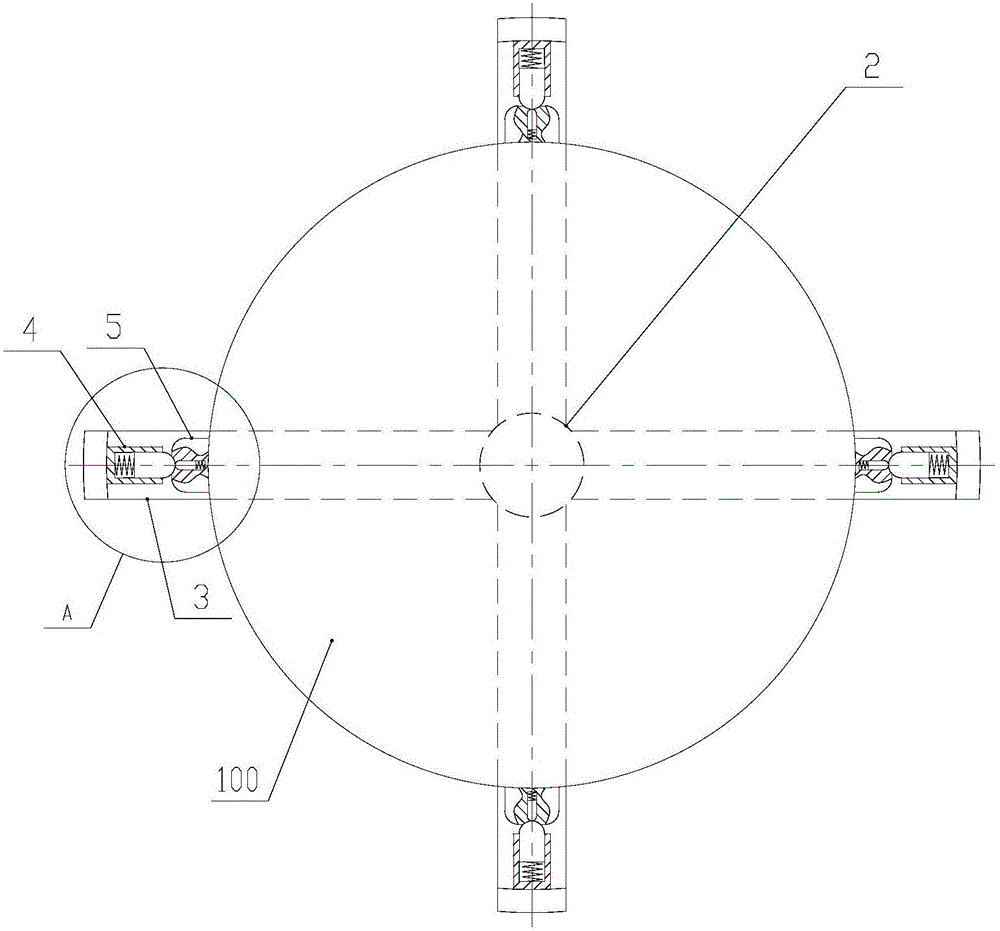

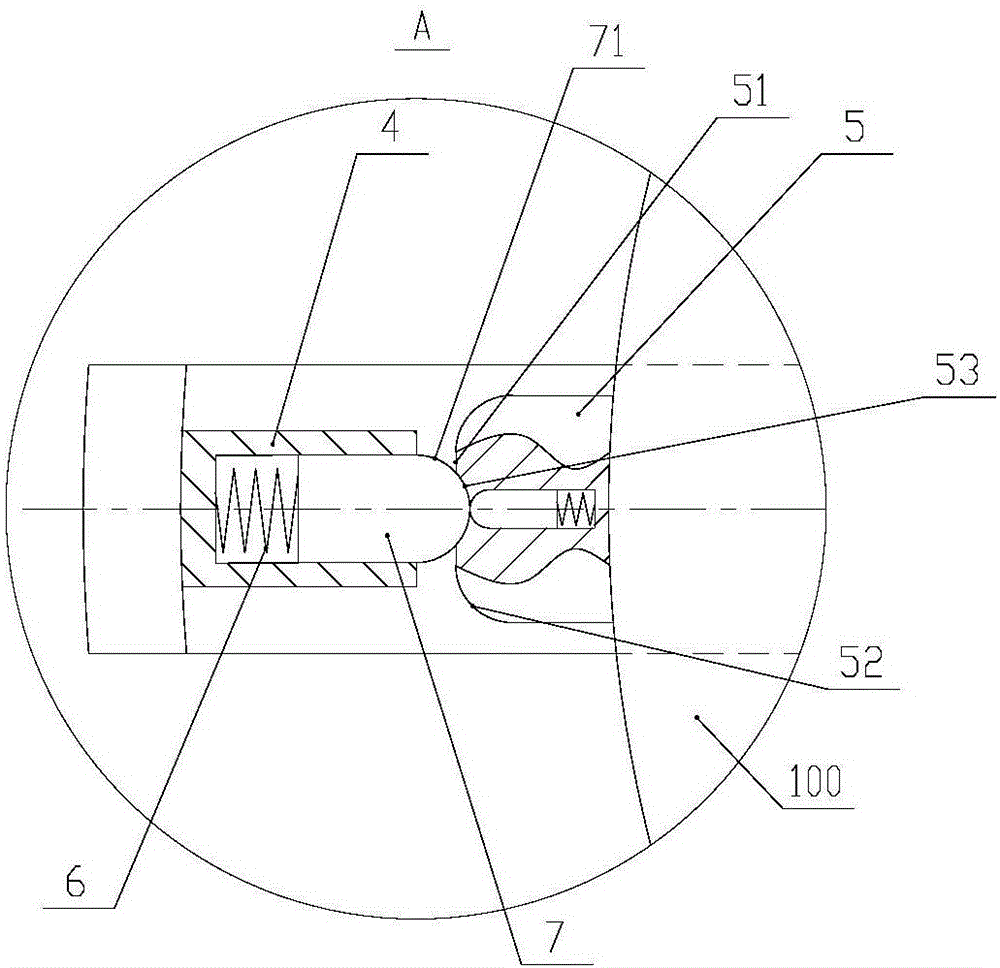

Outer circle clamper

ActiveCN106695364ASimple structureReduce equipment weightWork clamping meansPositioning apparatusEngineeringMachine parts

The invention discloses an outer circle clamper. The outer circle clamper comprises a fixed plate, a rotating plate, supporting arms, pushing blocks and pressing blocks. The rotating plate is rotationally arranged below the fixed plate. The number of the supporting arms is at least one pair. Each pair of supporting arms are symmetrically arranged at the two ends of the radial direction of the rotating plate and extend to the outside of the rotating plate. The pushing blocks, the pressing blocks and the supporting arms are the same in number. The pushing blocks are fixed above the supporting arms. The pressing blocks are located inside the radial direction of the fixed plate relative to sliding blocks and can slide in the radial direction of the fixed plate. When the rotating plate rotates, the pushing blocks can extrude the pressing blocks to move towards the interior of the fixed plate and abut against the outer circle of a machined part on the fixed plate in a pressing mode. According to the outer circle clamper, the machined part is clamped through the pushing blocks on the supporting arms and the pressing blocks on the fixed plate; compared with a three-jaw or four-jaw chuck, the outer circle clamper is simple in structure and light in equipment weight; and especially for large-size machined parts, the outer circle clamper is high in positioning precision.

Owner:浙江宇钻精密元件有限公司

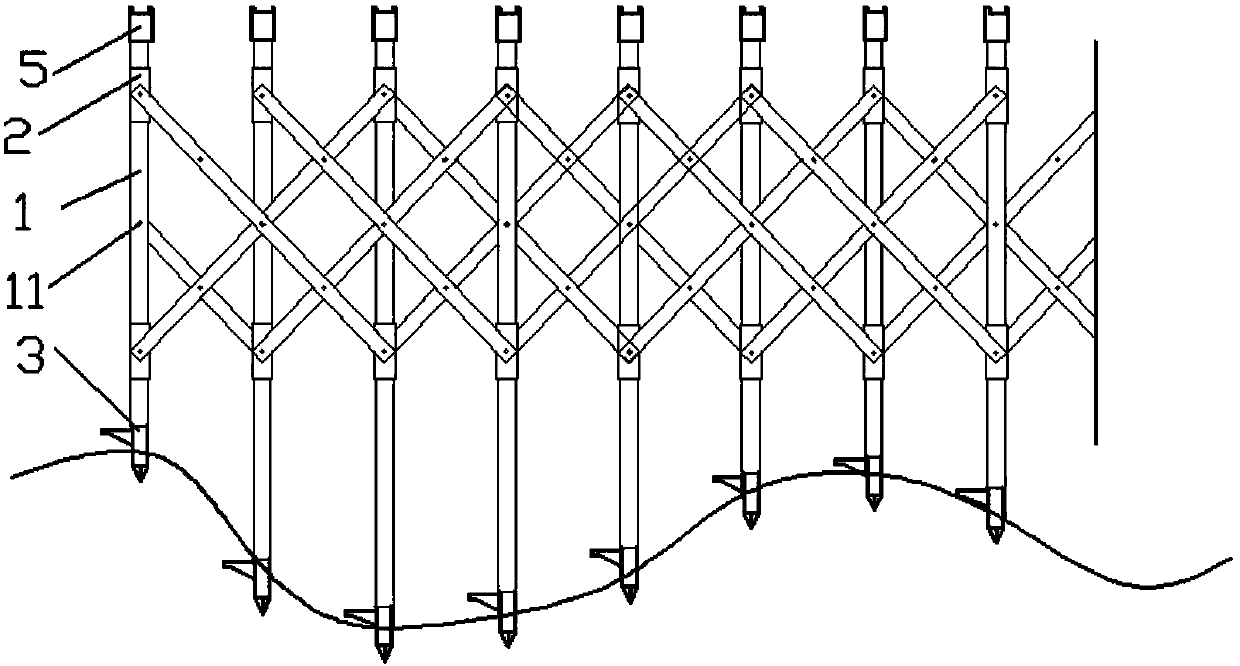

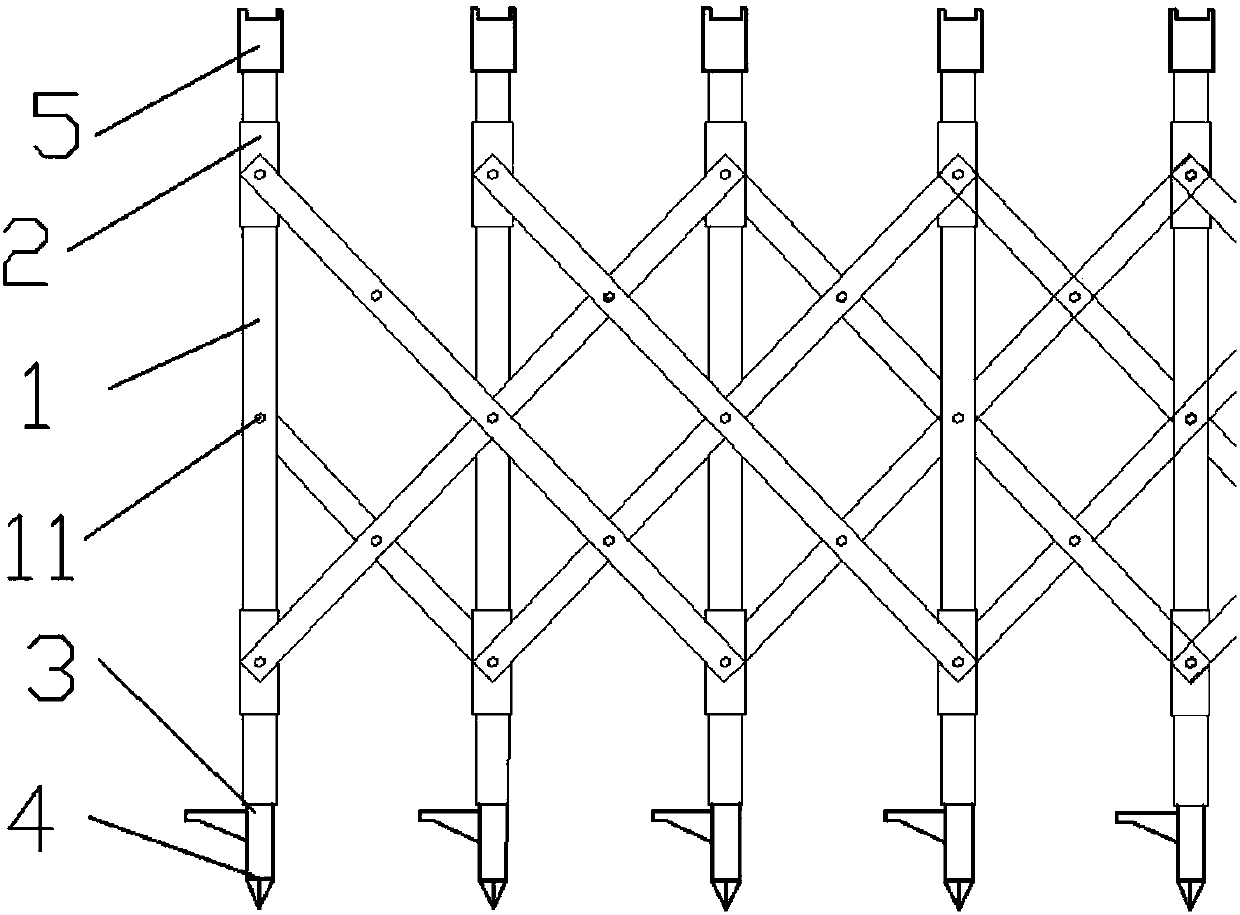

All-terrain telescopic fence

PendingCN110359393AEasy to unfold and stretchReduce equipment weightRoadway safety arrangementsTerrainInstability

The invention belongs to the technical field of protective fences, and particularly relates to an all-terrain telescopic fence. The all-terrain telescopic fence comprises fence rods, main rods, sliding cylinders, grounding rods, top end magnetic locks, wherein the fence rods are crossed with one another and matched in a rotating mode; the sliding cylinders are in nest match with the main rods at the head ends and the tail ends of the main rods, and the fence rods are in rotating match with the sliding cylinders; the fence can fold and stretch, the interiors of the main rods are hollow, and thegrounding rods are arranged inside the main rods; grounding nails and pedals are arranged at the bottom ends of the grounding rods, the ground nails can be inserted into the ground by treading the pedals, so that the grounding rods are fixed; and the top end magnetic locks plays a role in locking the grounding rods, and the grounding rods are stored in the main rods through magnetic blocks insidethe top end magnetic locks. The fence is safe and firm, the problems of instability and easy toppling of a movable fence are effectively solved, the fence is convenient to install and fully fixed, and is suitable for various terrains; the fence is fully contacts with the ground and is suitable for uneven terrains, and gaps are reserved at the bottom of the fence to enable people or other animalsto duck through the fence; and the fence is safe, reliable, good in stability and high in adaptability.

Owner:朱家旺

Electromagnetic piling device and piling method

ActiveCN105735314BReduce manufacturing costReduce equipment weightBulkheads/pilesPower flowSoil properties

The invention discloses an electromagnetic piling device and an electromagnetic piling method. The electromagnetic piling device comprises a base, a ground coil assembly, a pile, a pile clamping mechanism and a pile coil assembly. The electromagnetic piling device and the electromagnetic piling method have the advantages that impact force / static pressures which are generated during traditional piling can be completely replaced by electromagnetic repulsive / attractive force generated between the coil assemblies; different current waveforms are designed, accordingly, the electromagnetic piling force can be flexibly controlled, and the optimal piling effects can be realized; the current waveforms can be selected, so that the single piling speed can be increased, the piling efficiency can be enhanced, and the electromagnetic piling device is little in vibration and influence on surrounding soil masses; the electromagnetic piling device and the electromagnetic piling method are provided on the basis; the electromagnetic piling device is free of pollution, low in noise, convenient to mount, easy to construct, high in adaptability, expansibility and safety coefficient, is free of influence of soil properties and pile types and is particularly applicable to municipal construction and night construction requirements, in particular to pile foundation engineering in crowded building places, high-rise buildings and buildings with narrow spaces.

Owner:HUAZHONG UNIV OF SCI & TECH

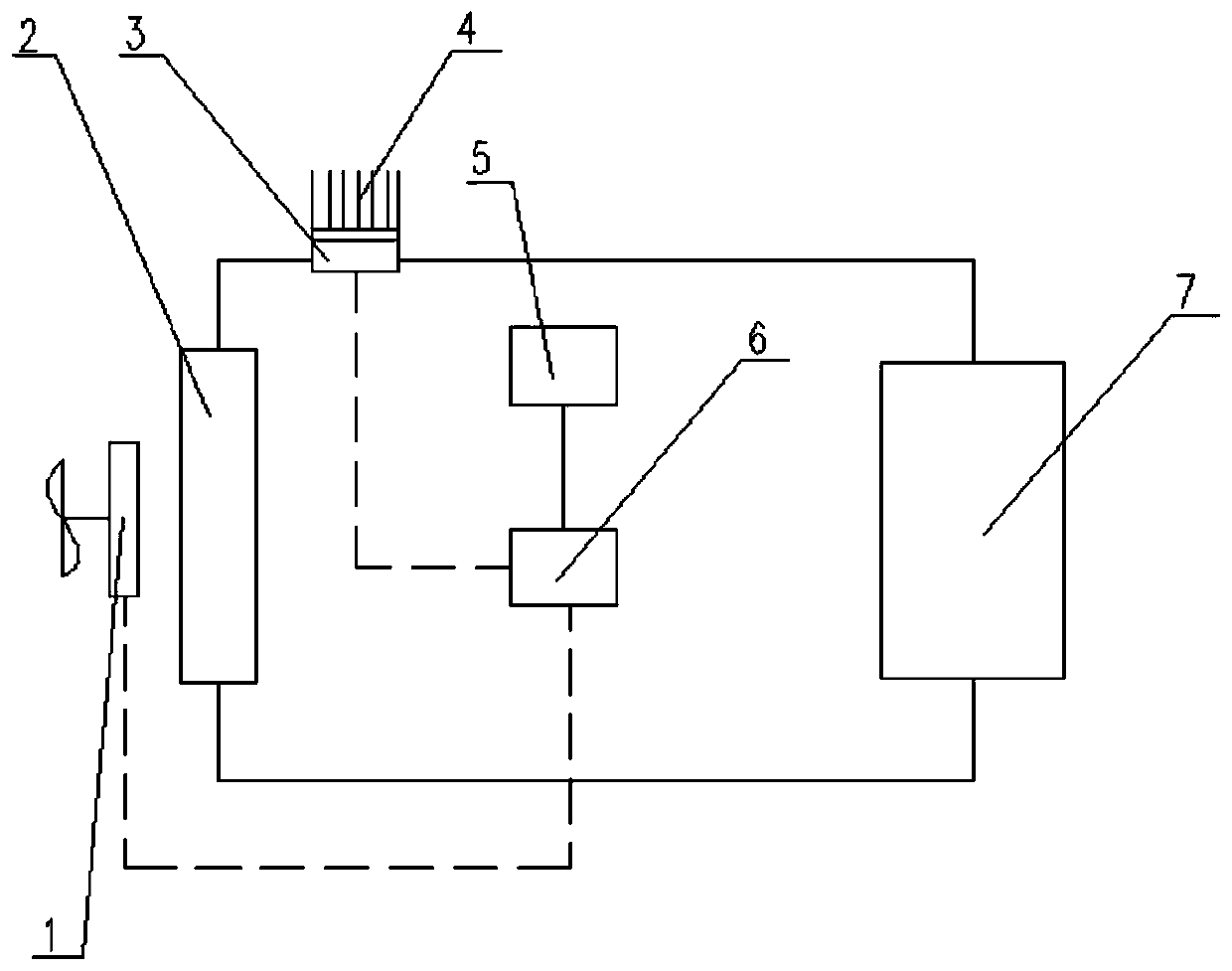

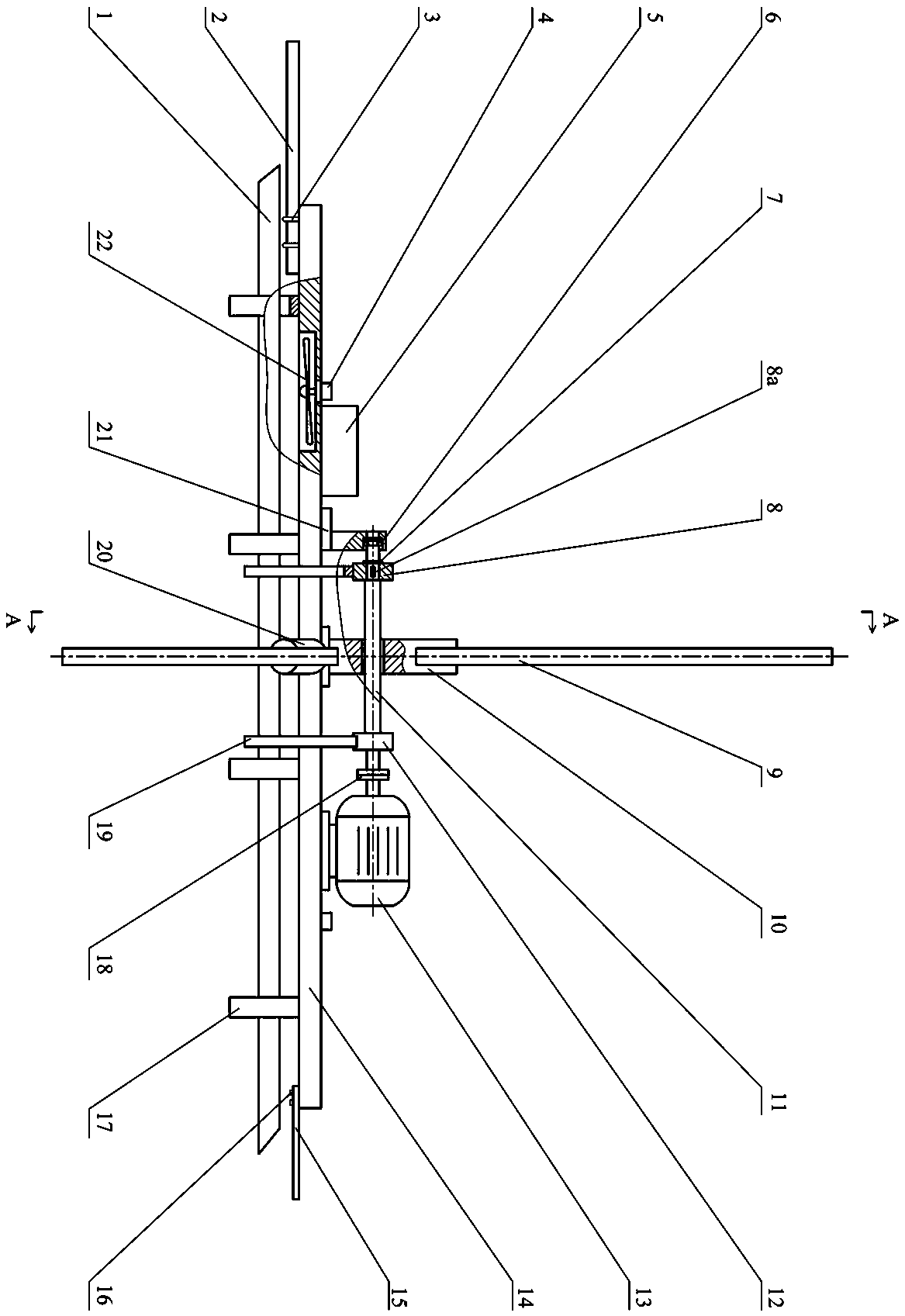

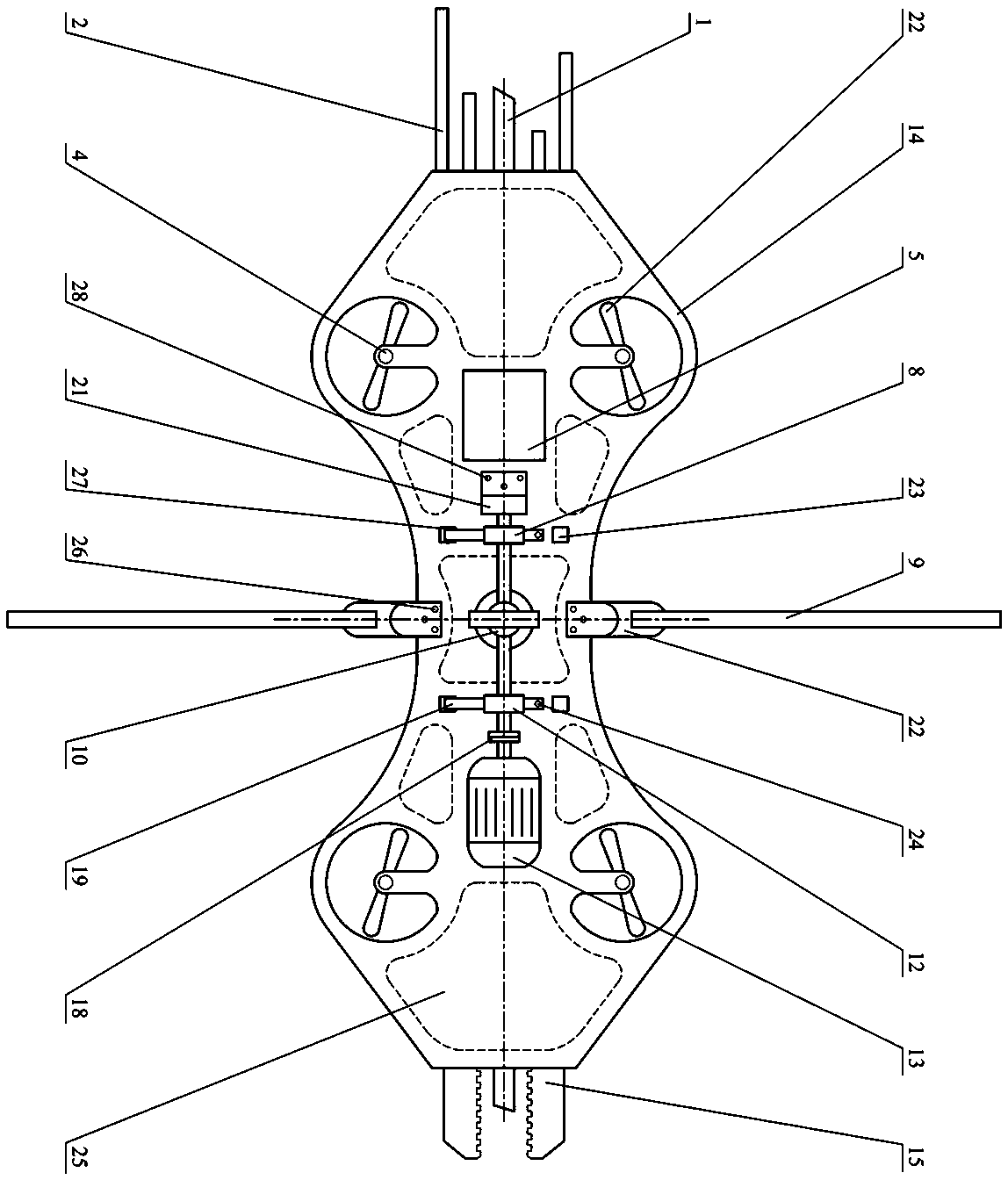

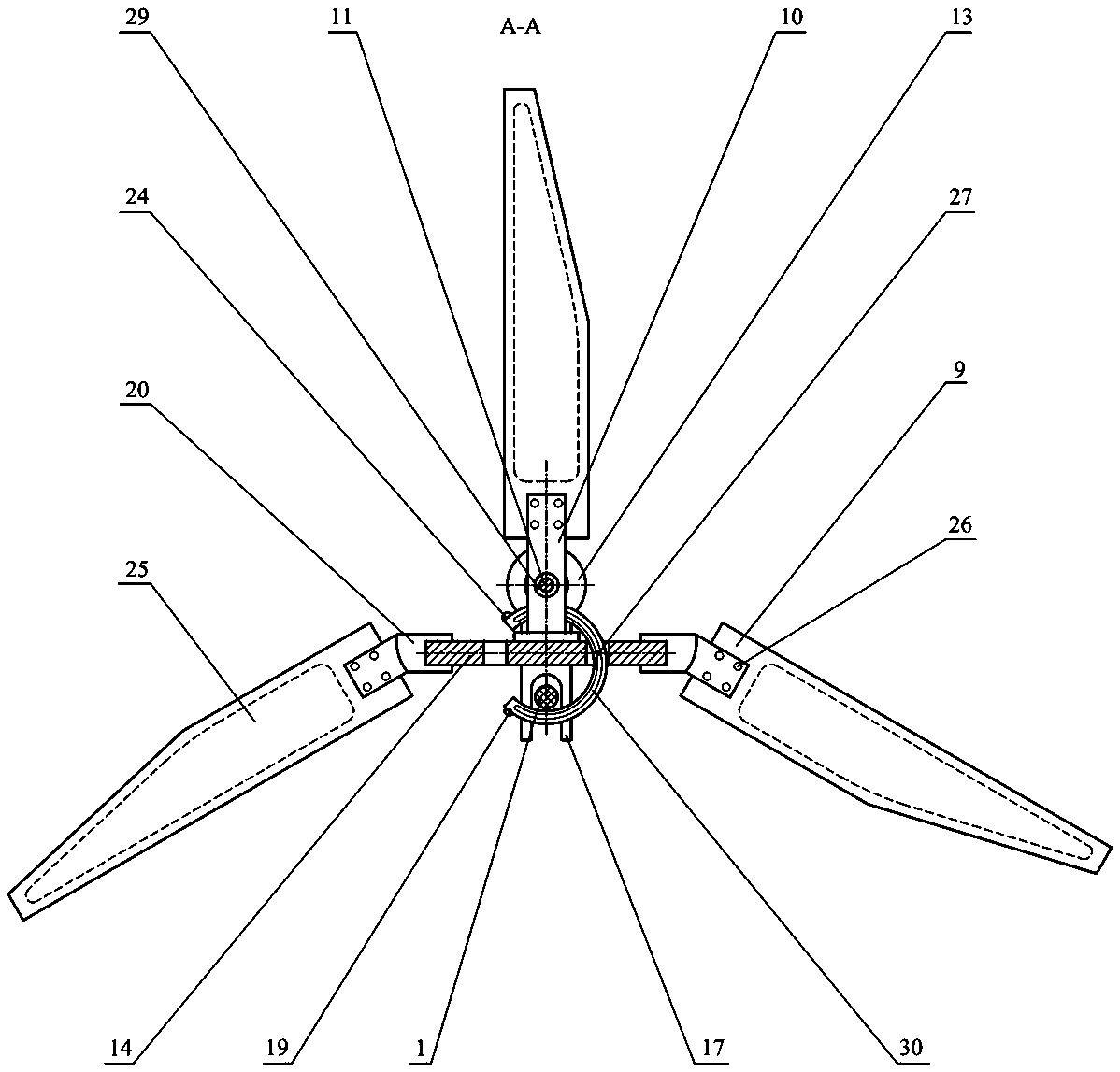

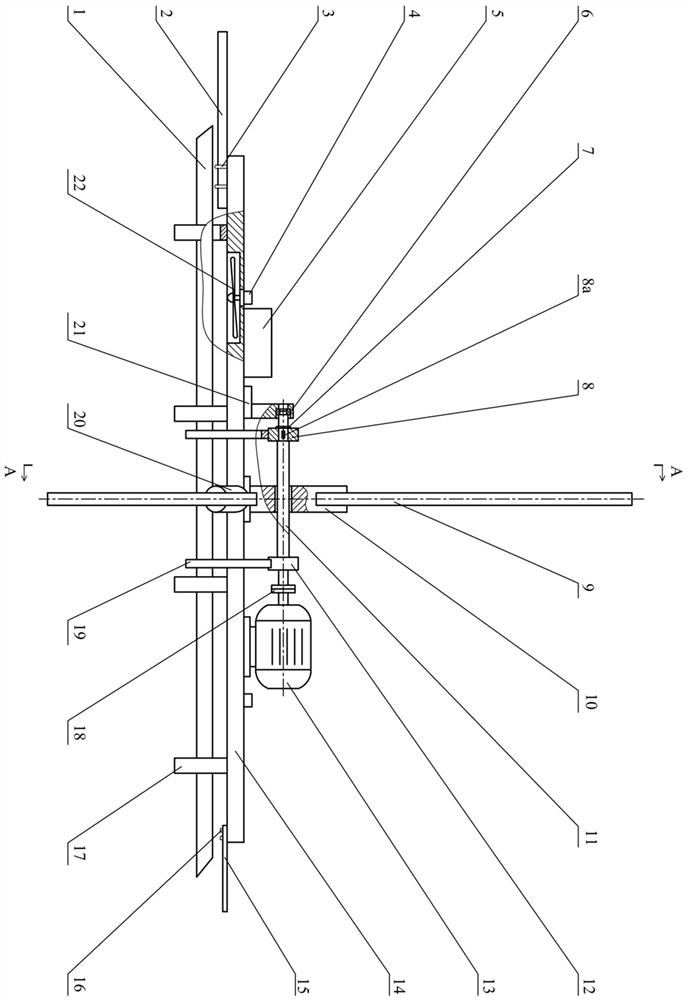

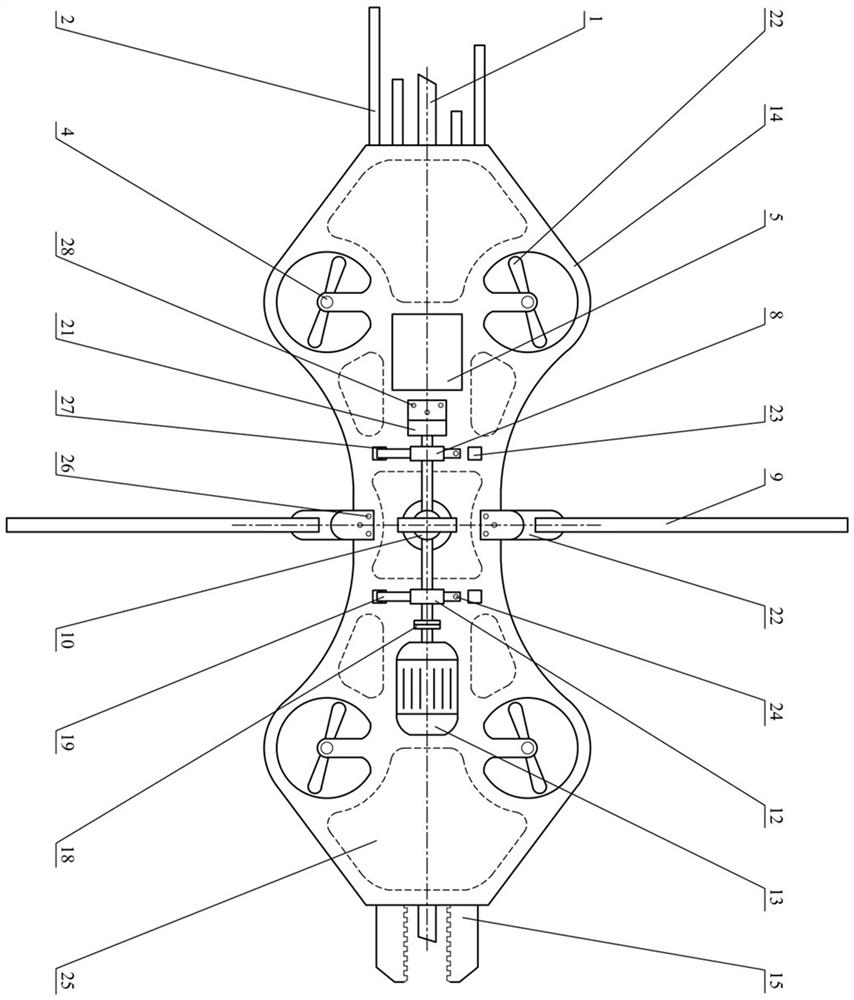

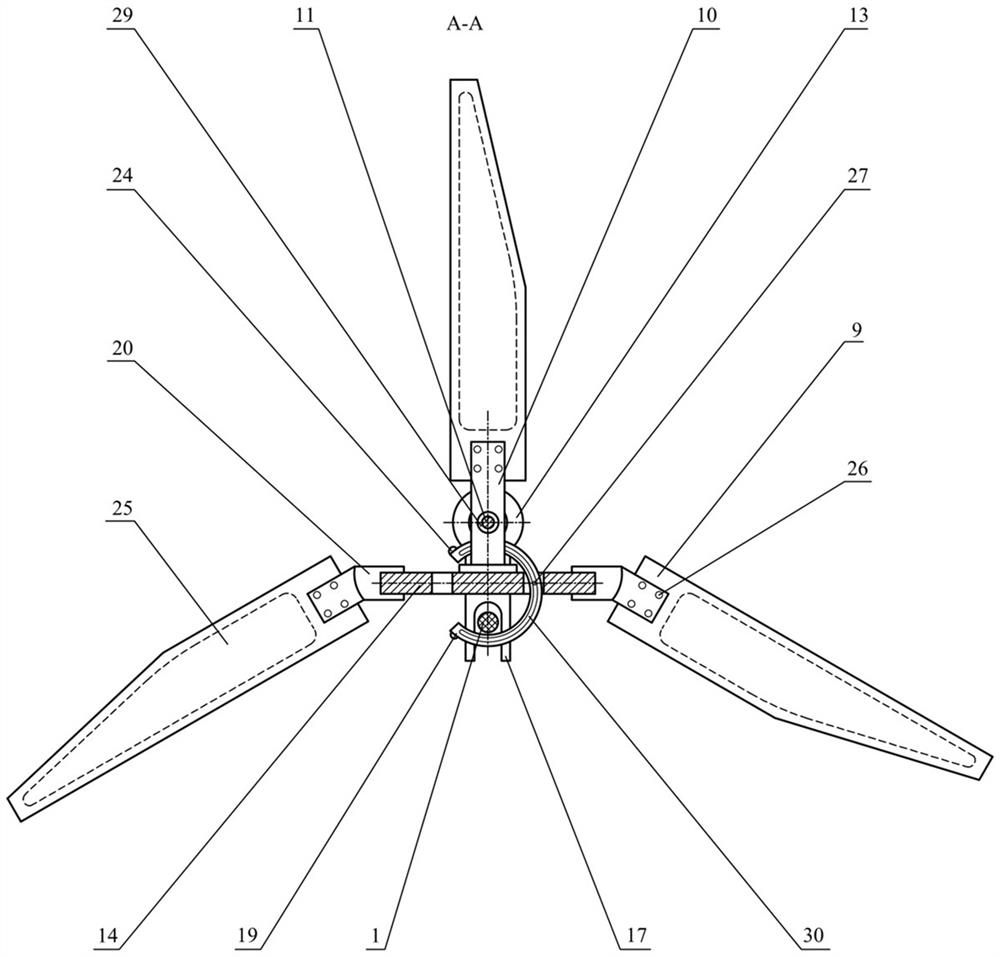

Four-wing three-paddle type wind-solar hybrid power transmission line deicing device

InactiveCN110611285ALow costReduce equipment weightOverhead installationBatteries circuit arrangementsFiberCarbon fibers

The invention relates to four-wing three-paddle type wind-solar hybrid power transmission line deicing device. Four fans 22 and three blades 9 mounted on a butterfly-shaped panel 14 can realize vertical lifting and horizontal overturning; four crushing rods 2 and a pair of serrated knives 15 can remove covered ice; solar film cells 25 adhered to the surfaces of the panel 14 and the blades 9 can charge a battery 5 so as to supply power to the fans 22; a motor 13, a gear shaft 11, a gear ring 19 and a saddle plate 17 are matched, so that the device can be reliably encircled ona cable 1; the panel 14 and the paddles 9 are made of carbon fibers; the crushing rods 2, steel clamps (3) and the serrated knives 15 are made of stainless steel; and the components are made of aluminum alloy. The device has the advantages of continuous power, energy conservation, high efficiency, reliability in installation, low cost, light weight, easiness in operation and the like.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

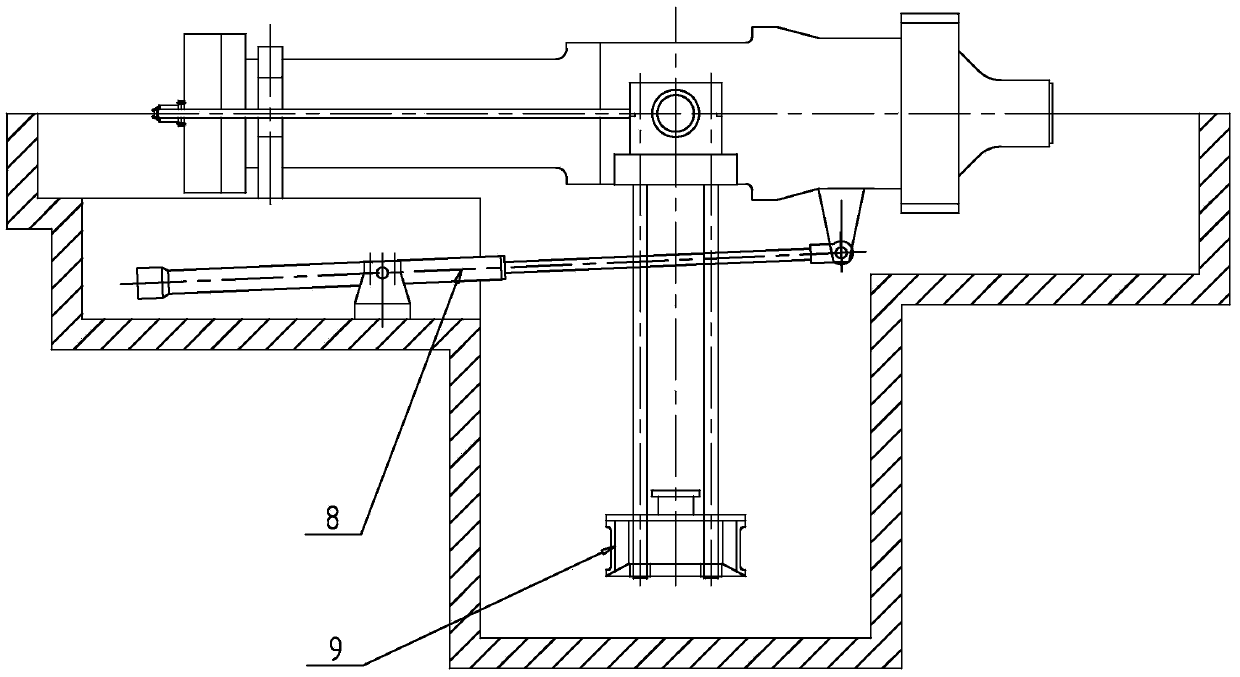

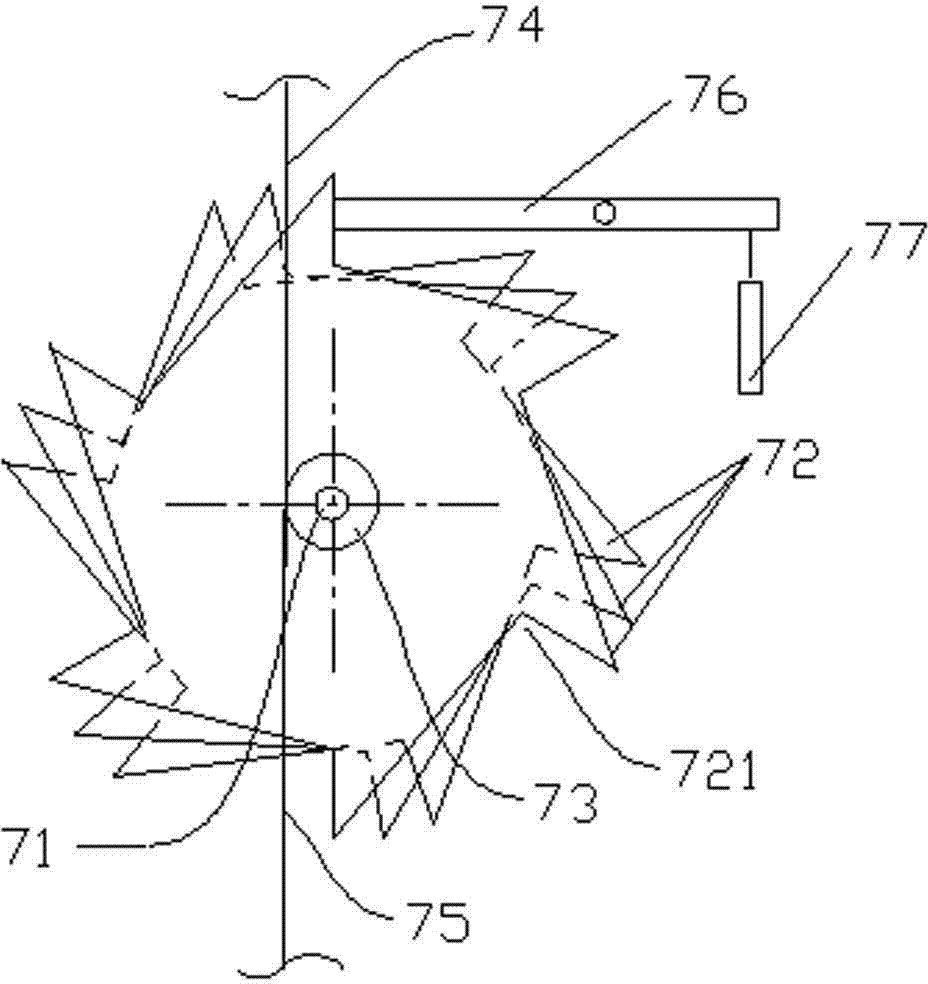

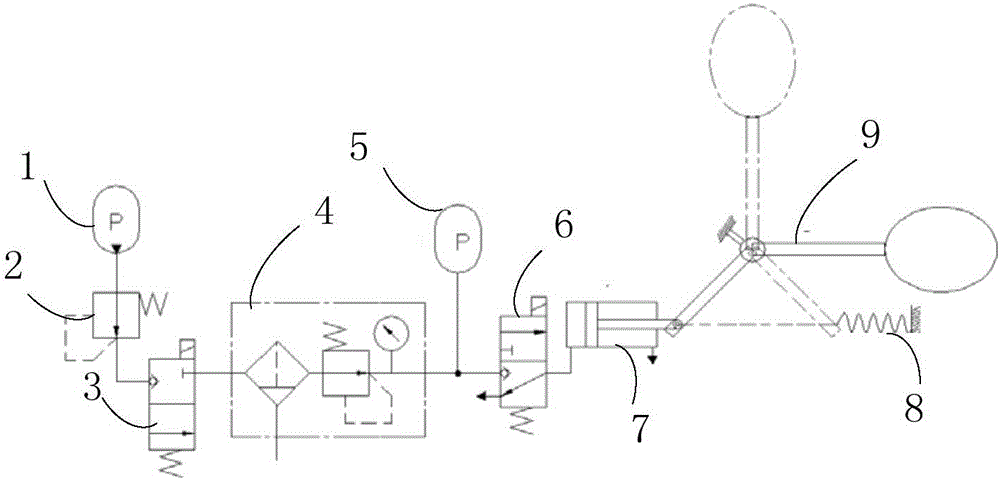

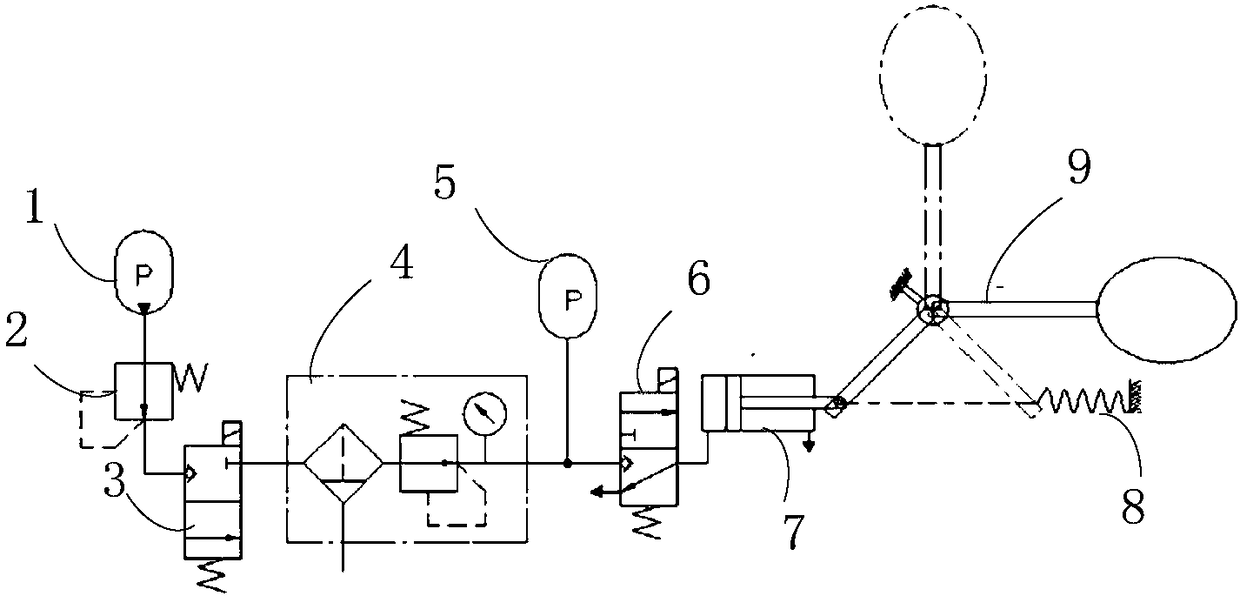

Pneumatic target resetting and falling control system

ActiveCN106704277AHigh power weightReduce volumeAccumulator installationsServomotorsControl systemEngineering

The invention discloses a pneumatic target resetting and falling control system which comprises a high-pressure air storage tank, a stop valve, a low-pressure air storage tank, a solenoid directional control valve, an actuating air cylinder, a spring buffer device and a target resetting and falling control mechanism, wherein the high-pressure air storage tank fills the low-pressure air storage tank with air through the stop valve, and the stop valve is closed when the low-pressure air storage tank reaches a working pressure value; the low-pressure air storage tank is connected with the actuating air cylinder through the solenoid directional control valve; the low-pressure air storage tank provides power when the target resetting and falling control mechanism resets a target, plays a buffering role when the target resetting and falling control mechanism brings the target down, and recycles and stores energy produced when the target resetting and falling control mechanism brings the target down for next target resetting; a push rod end of the actuating air cylinder is connected with one end of the target resetting and falling control mechanism; the spring buffer device is arranged at the other end of the target resetting and falling control mechanism; and the spring buffer device plays a buffering role when the target resetting and falling control mechanism resets the target, provides power when the target resetting and falling control mechanism brings the target down, and stores elastic potential energy into a hydraulic energy storage device. Compared with a conventional target resetting and falling control device, the pneumatic target resetting and falling control system is simple in design, smaller in size and lighter in weight, fully utilizes energy and saves more energy.

Owner:杭州富凌科技有限公司

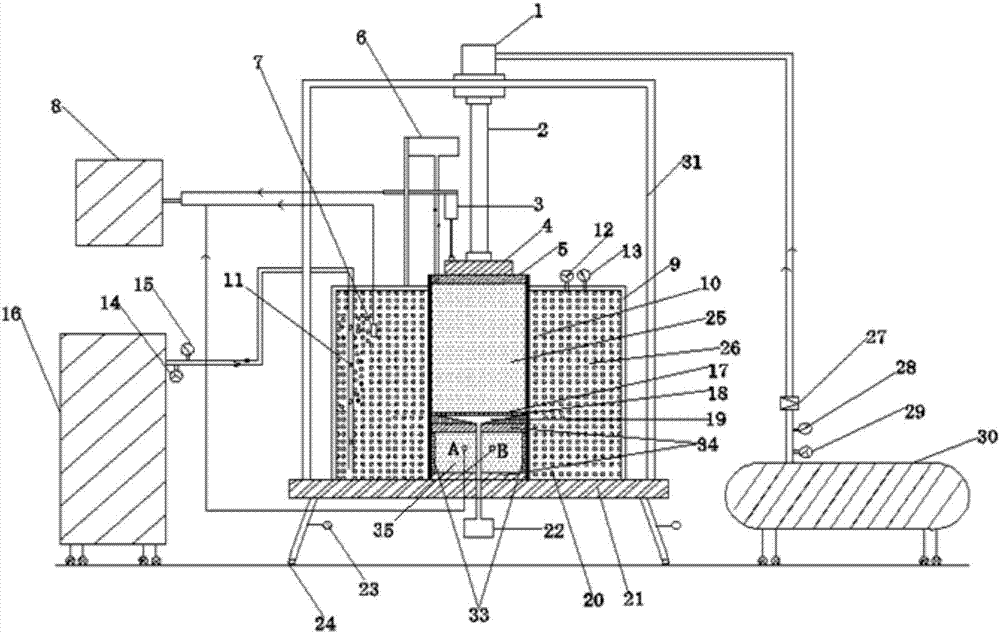

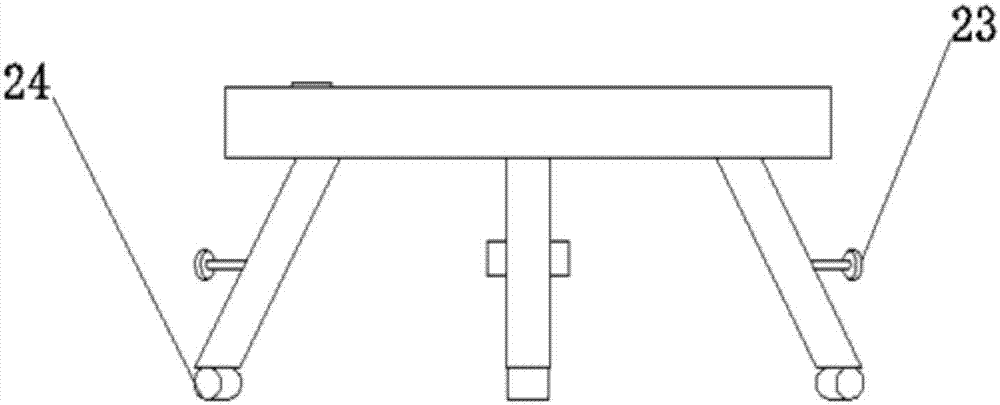

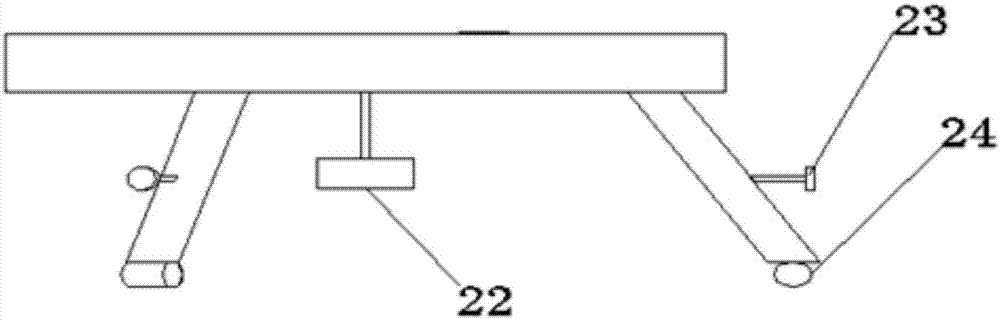

Multifunctional compression and consolidation instrument for municipal domestic waste soil and use method

PendingCN107024374AEvenly heatedReduce equipment weightPreparing sample for investigationLayered structureSteam temperature

The invention discloses a multifunctional compression and consolidation instrument for municipal domestic waste soil and a use method. The multifunctional compression and consolidation instrument comprises a waste soil sample filling system, a constant-temperature steam temperature control system, a pressurizing system and a temperature displacement display system, wherein a waste soil sample can be heated uniformly at an initial period, and the equipment deadweight is lowered by the constant-temperature steam temperature control system. In the multifunctional compression and consolidation instrument, an organic glass barrel is designed with a two-layer structure, namely, a sample room and a temperature monitoring room from top to bottom in sequence; when the temperature monitored by two first temperature sensors in the temperature monitoring room is consistent with the temperature monitored by a second temperature sensor outside the organic glass barrel, a loading test can be performed, so that the defect that the conventional instrument cannot monitor whether the temperature of the sample in the barrel is consistent with the temperature of water outside the barrel or not at an initial loading period is overcome.

Owner:WEIFANG UNIVERSITY

Pneumatic lifting and falling target system

ActiveCN106704277BHigh power weightReduce volumeAccumulator installationsServomotorsControl systemEngineering

The invention discloses a pneumatic target resetting and falling control system which comprises a high-pressure air storage tank, a stop valve, a low-pressure air storage tank, a solenoid directional control valve, an actuating air cylinder, a spring buffer device and a target resetting and falling control mechanism, wherein the high-pressure air storage tank fills the low-pressure air storage tank with air through the stop valve, and the stop valve is closed when the low-pressure air storage tank reaches a working pressure value; the low-pressure air storage tank is connected with the actuating air cylinder through the solenoid directional control valve; the low-pressure air storage tank provides power when the target resetting and falling control mechanism resets a target, plays a buffering role when the target resetting and falling control mechanism brings the target down, and recycles and stores energy produced when the target resetting and falling control mechanism brings the target down for next target resetting; a push rod end of the actuating air cylinder is connected with one end of the target resetting and falling control mechanism; the spring buffer device is arranged at the other end of the target resetting and falling control mechanism; and the spring buffer device plays a buffering role when the target resetting and falling control mechanism resets the target, provides power when the target resetting and falling control mechanism brings the target down, and stores elastic potential energy into a hydraulic energy storage device. Compared with a conventional target resetting and falling control device, the pneumatic target resetting and falling control system is simple in design, smaller in size and lighter in weight, fully utilizes energy and saves more energy.

Owner:杭州富凌科技有限公司

Internal one-way valve

PendingCN108799567ASave equipment spaceReduce equipment weightCheck valvesValve members for absorbing fluid energyEngineeringFluid pressure

The invention provides an internal one-way valve. The internal one-way valve comprises a valve body, a valve element and a clamp spring. An inlet channel, a neck channel, a throat channel and an outlet channel which are sequentially connected are arranged in the valve body. The inner wall, corresponding to the throat channel, of the valve body is an oblique conical face. The inlet channel, the neck channel, the throat channel and the outlet channel are concentric. The valve element comprises a valve element head, a valve element tail and a middle connection section. An annular internal seal groove is formed in the middle connection section. An annular clamp spring clamping groove is formed in the inner wall of the tail end of the outlet channel. The clamp spring is arranged in the clamp spring clamping groove. An inlet fluid pressure-bearing face is arranged on the valve element head, and an outlet fluid pressure-bearing face is arranged on the valve element tail. The internal one-wayvalve can be independently mounted and can also be mounted in a connecting piece body, so that the equipment space is saved, and the equipment weight is reduced; and the internal one-way valve can reciprocate and slightly deflect in the flowing direction of fluid in the channels and can also rotate, so that the resistance of the fluid is greatly reduced; and the noise is low, and the structural strength is high.

Owner:上海银轮热交换系统有限公司

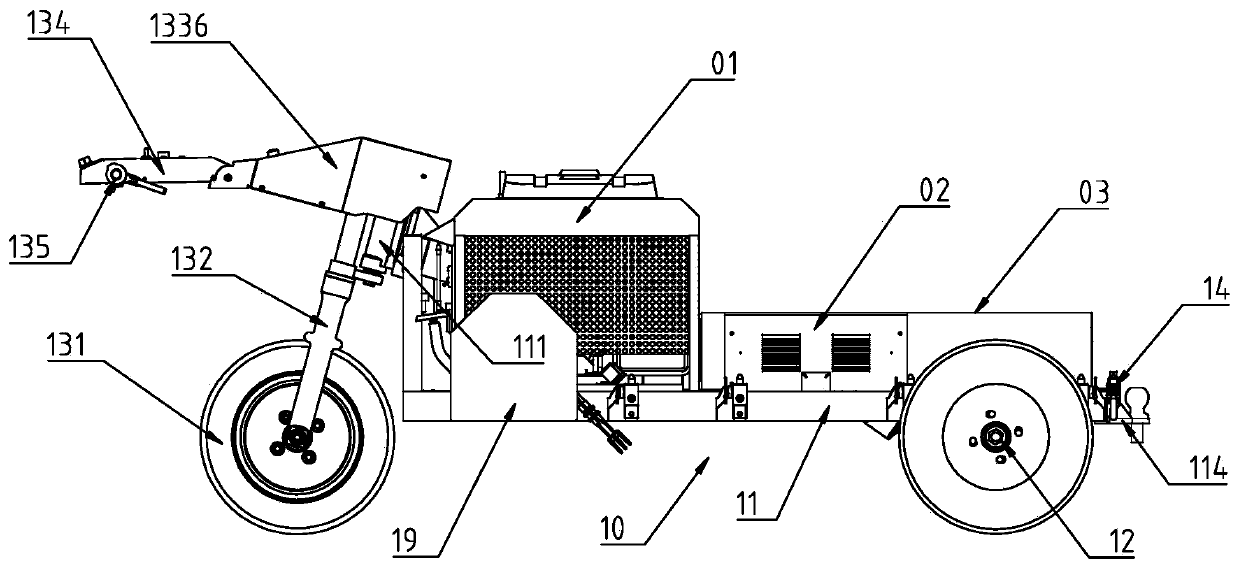

Operating vehicle for orchard

PendingCN111247892ASimple structureReduce equipment weightPlantingPlant waste comminutingElectric generatorOrchard

The invention discloses an operating vehicle for an orchard. The operating vehicle for the orchard comprises a wheel type power chassis, a power device, an electric cabinet and an operating device, wherein the wheel type power chassis comprises a frame and a driving axle serving as a rear axle; the wheel type power chassis is an electric vehicle chassis; the driving axle is driven by a motor; thepower device is a gasoline engine generator or a storage battery; a power output end of the power device is connected with the electric cabinet; the motor of the electric vehicle chassis is powered bythe electric cabinet; the electric cabinet comprises a power supply interface of the operating device; the power device and the electric cabinet are borne by the electric vehicle chassis; the operating device comprises an air duct type spraying device and a lifting platform; and the air duct type spraying device or the lifting platform is selectively mounted on the rear of the frame through a rapid connecting mechanism. The rear axle and the operating device are driven electrically, the structure is simple, the equipment is light in weight, and the passage capacity of the operating vehicle inthe orchard is good.

Owner:SHENZHEN LONGRAY TECH

Cantilever type floating steel strip bundling device

The invention discloses a cantilever type floating steel strip bundling device comprising a cantilever rack. First linear sliding rails are fixedly connected to the lower side of the cantilever rack. Second linear sliding rails are connected to the side edge of the cantilever rack and fixedly connected with a main frame. The first linear sliding rails are connected with a small unit head frame. A bundling unit head is fixedly connected to the small unit head frame. A balance pull rod is fixedly connected to one side of the small unit head frame. A reset tension spring is connected between the small unit head frame and the cantilever rack. Through the floating design of the steel strip bundling unit head, the bundling tightening tension of steel strips is increased, and thus the packing requirement of part of industries requiring the high tension can be met. The cantilever type floating steel strip bundling device can be widely applied to automatic packing of multiple goods of steel ingots, aluminum ingots, zinc ingots and the like in the steel field.

Owner:CHIZHOU SINCHEEN PACKAGING TECH CO LTD

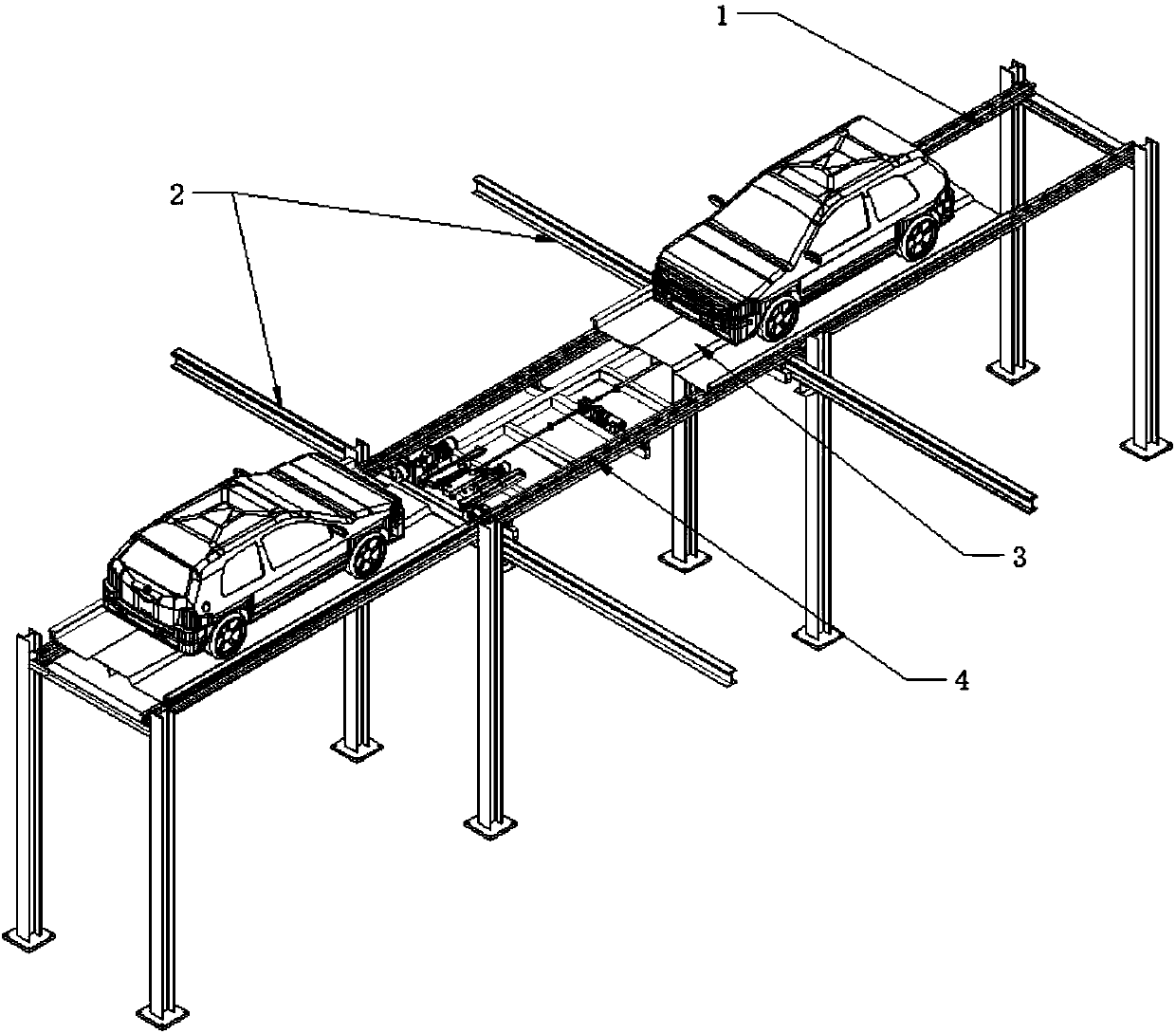

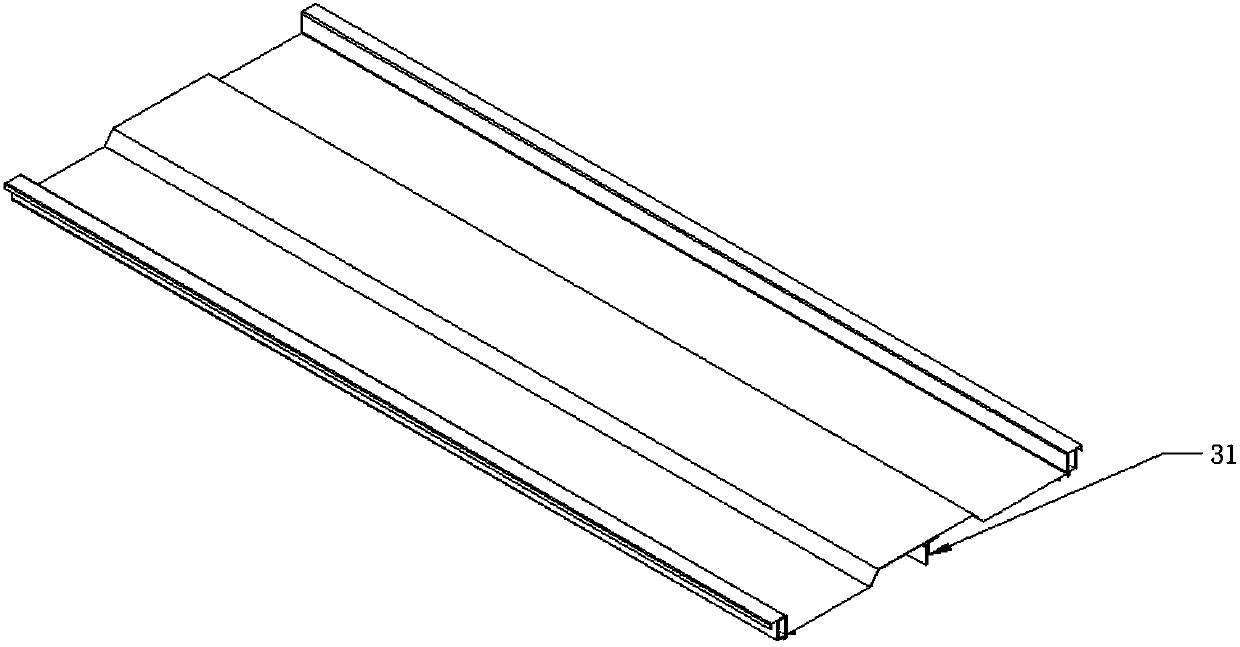

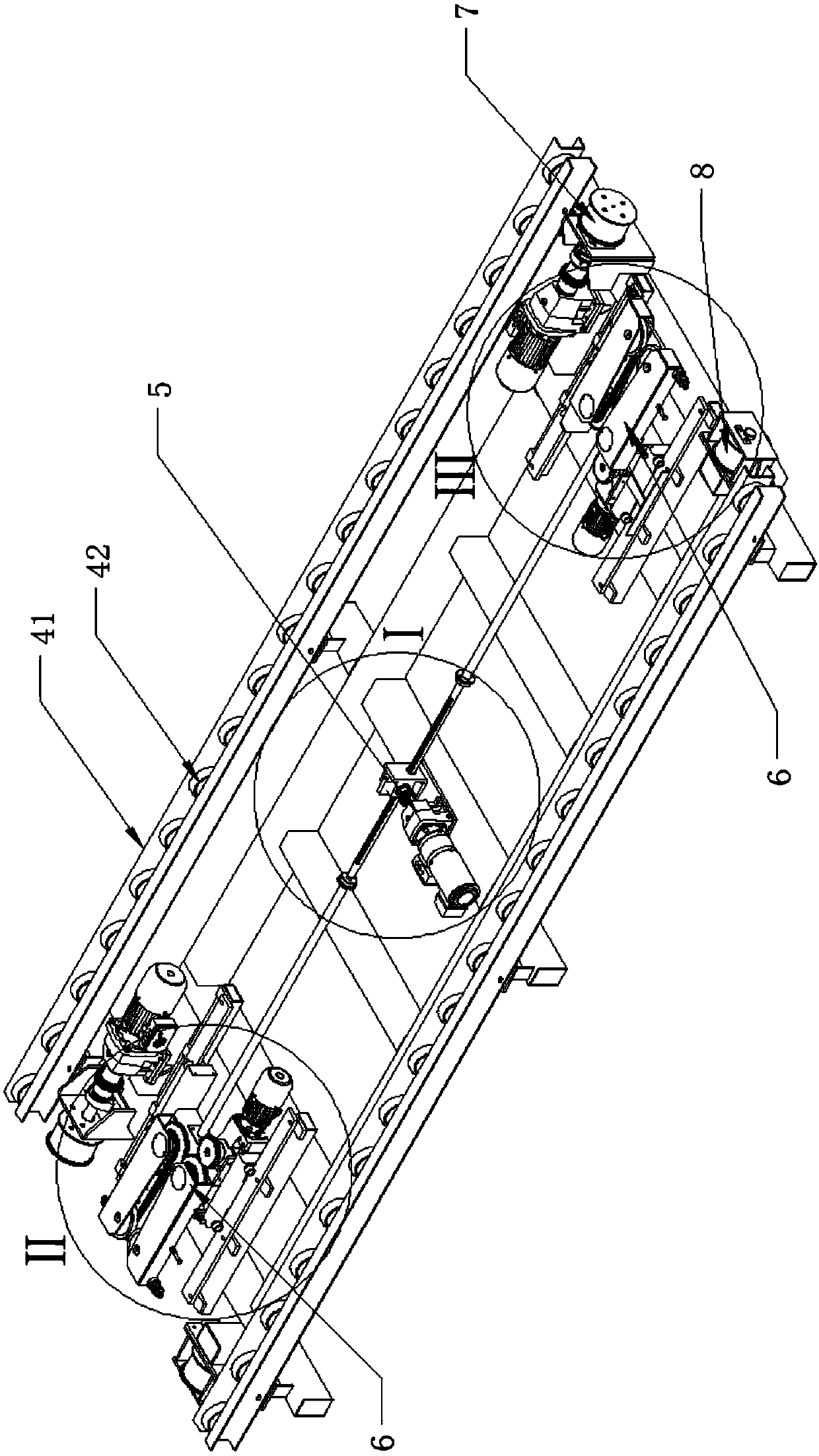

Stereoscopic garage vehicle storing and taking exchanging device

The invention relates to the technical field of parking equipment, aims at solving the problem that an existing vehicle storing and taking exchanging device is complex in structure, and provides a stereoscopic garage vehicle storing and taking exchanging device which is simple in structure, steady in storing and taking process and safe. The stereoscopic garage vehicle storing and taking exchangingdevice comprises an exchanging trolley and vehicle loading plates; in the moving direction of the vehicle loading plates, a connection plate perpendicular to the upper surface of each vehicle loadingplate is arranged at the bottom of the vehicle loading plate; the exchanging trolley is provided with clamping devices and a conveying driving device; the conveying driving device is fixedly installed on the exchanging trolley, and by means of the conveying driving device, the clamping devices can move in the movement direction of the vehicle loading plates; each clamping device comprises a driving device, a clamping wheel and an elastic assembly; by means of the elastic assemblies, the clamping wheels and the connection plates can be in close contact; and the driving devices are used for driving the clamping wheels to rotate.

Owner:SHAANXI LONGXIANG PARKING EQUIP GRP CO LTD

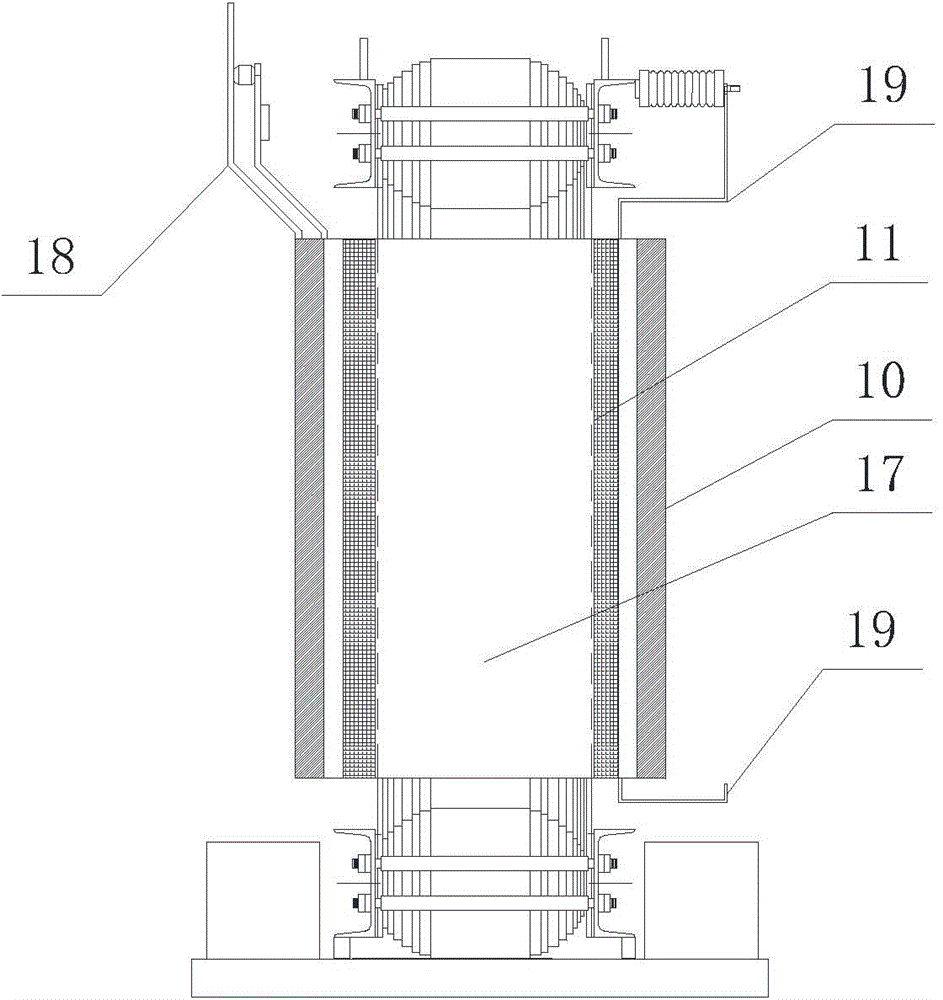

Light and steady high voltage transformer

InactiveCN105719810ALow costReduce equipment weightTransformers/inductances coolingTransformers/inductances coils/windings/connectionsEngineeringSmall hole

The invention provides a light and steady high voltage transformer. The light and steady high voltage transformer comprises an iron core, a low voltage coil, a high voltage coil, clamp channel steel and a PVC tube. A wire outlet copper bar positioning device is arranged on the low voltage coil; the transformer also comprises clamps for clamping the coils and a connection component between the two clamps; the high voltage coil and the low voltage coil sleeve the iron core; the high voltage coil is arranged inside; the low voltage coil is arranged outside; bending plates for mounting the PVC tube are welded and fixed on the tail end of the channel steel; two small holes convenient for binding the PVC tube through ribbons are arranged on each bending plate; the connection component comprises a pull plate base which is fixedly arranged on the middle part of each clamp, and a pull plate which is arranged between the two pull plate bases and in matched connection with the pull plate bases; and the length of the pull plate is less than the distance between the two pull plate bases.

Owner:成都亿科康德电气有限公司

A four-wing and three-blade wind-solar complementary transmission line deicing equipment

InactiveCN110611285BLow costReduce equipment weightOverhead installationBatteries circuit arrangementsFiberCarbon fibers

The invention relates to four-wing three-paddle type wind-solar hybrid power transmission line deicing device. Four fans 22 and three blades 9 mounted on a butterfly-shaped panel 14 can realize vertical lifting and horizontal overturning; four crushing rods 2 and a pair of serrated knives 15 can remove covered ice; solar film cells 25 adhered to the surfaces of the panel 14 and the blades 9 can charge a battery 5 so as to supply power to the fans 22; a motor 13, a gear shaft 11, a gear ring 19 and a saddle plate 17 are matched, so that the device can be reliably encircled ona cable 1; the panel 14 and the paddles 9 are made of carbon fibers; the crushing rods 2, steel clamps (3) and the serrated knives 15 are made of stainless steel; and the components are made of aluminum alloy. The device has the advantages of continuous power, energy conservation, high efficiency, reliability in installation, low cost, light weight, easiness in operation and the like.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

Shell and tube type heat exchanger

ActiveCN101865616BSolve problems that can be exploited simultaneouslyReduce equipment weightStationary tubular conduit assembliesTubular elementsEngineeringTubes types

The invention relates to a shell and tube type heat exchanger. A heat exchanger tube consists of an inner tube and an outer tube, wherein the inner tube is sleeved inside the outer tube, and the length of the inner tube is greater than that of the outer tube. One end of the outer tube is closed, and the closed end of the outer tube is provided with through holes on the tube wall, and two through holes of the outer tube are communicated through a connecting tube. The inner tube is a low finned tube, the outer tube is a finned tube, and a partition board for dividing a plurality of heat exchanger tubes into two parts and is arranged in a shell body. The invention provides the shell and tube type heat exchanger which can solve the problem that a cold or heat source is not available on a vehicle at the same time and has compact structure and good heat exchange effect.

Owner:合肥天鹅制冷科技有限公司

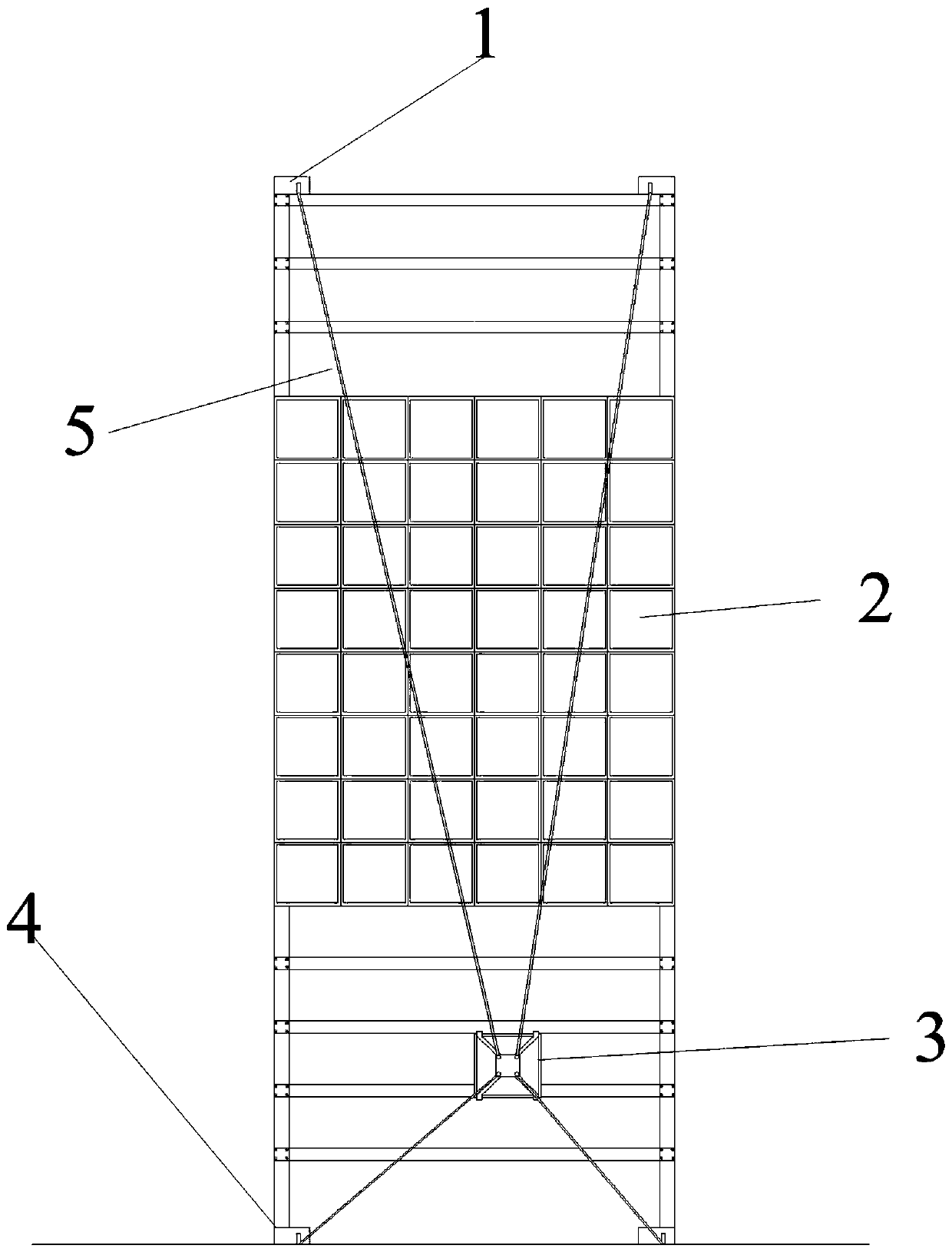

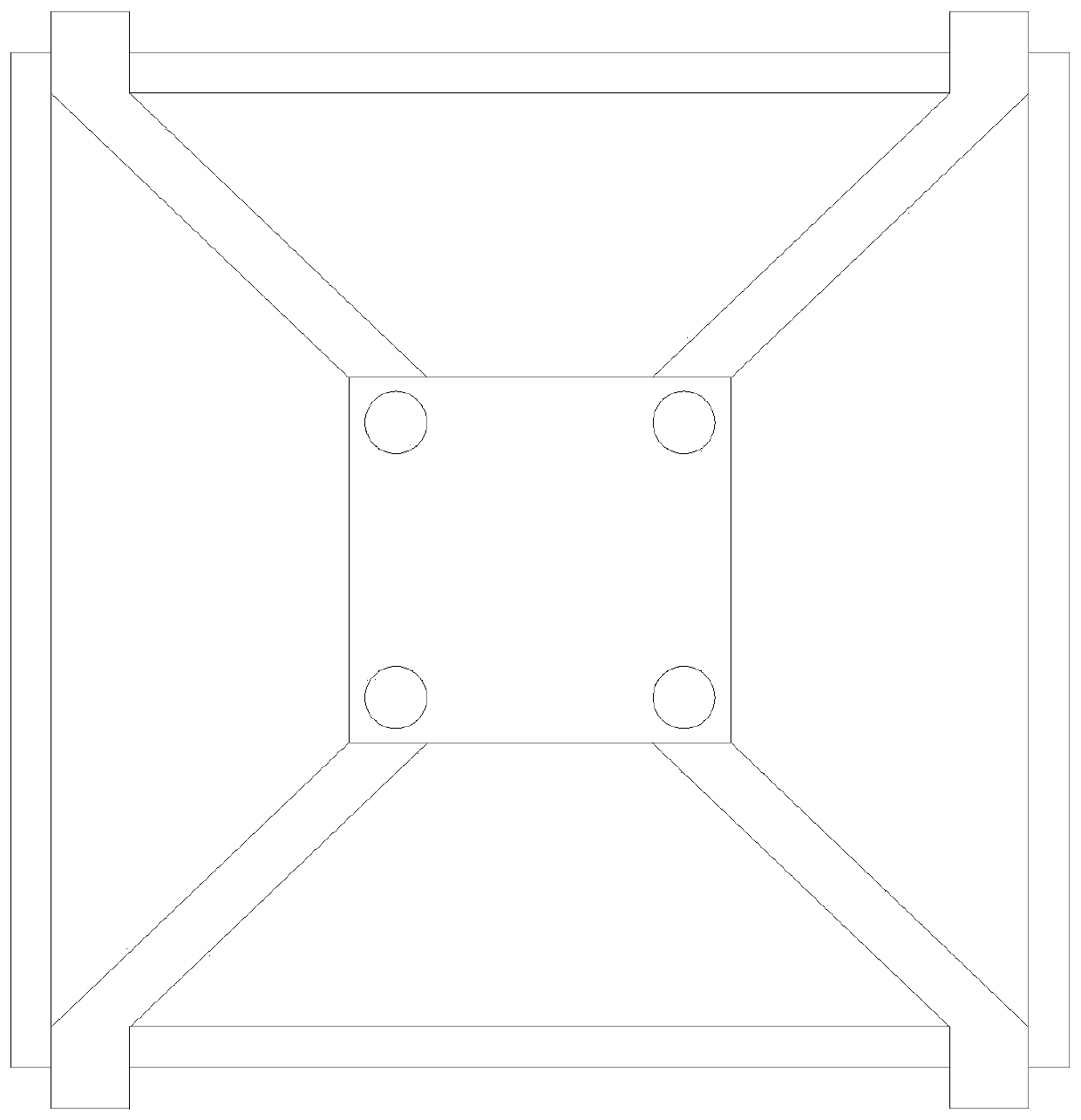

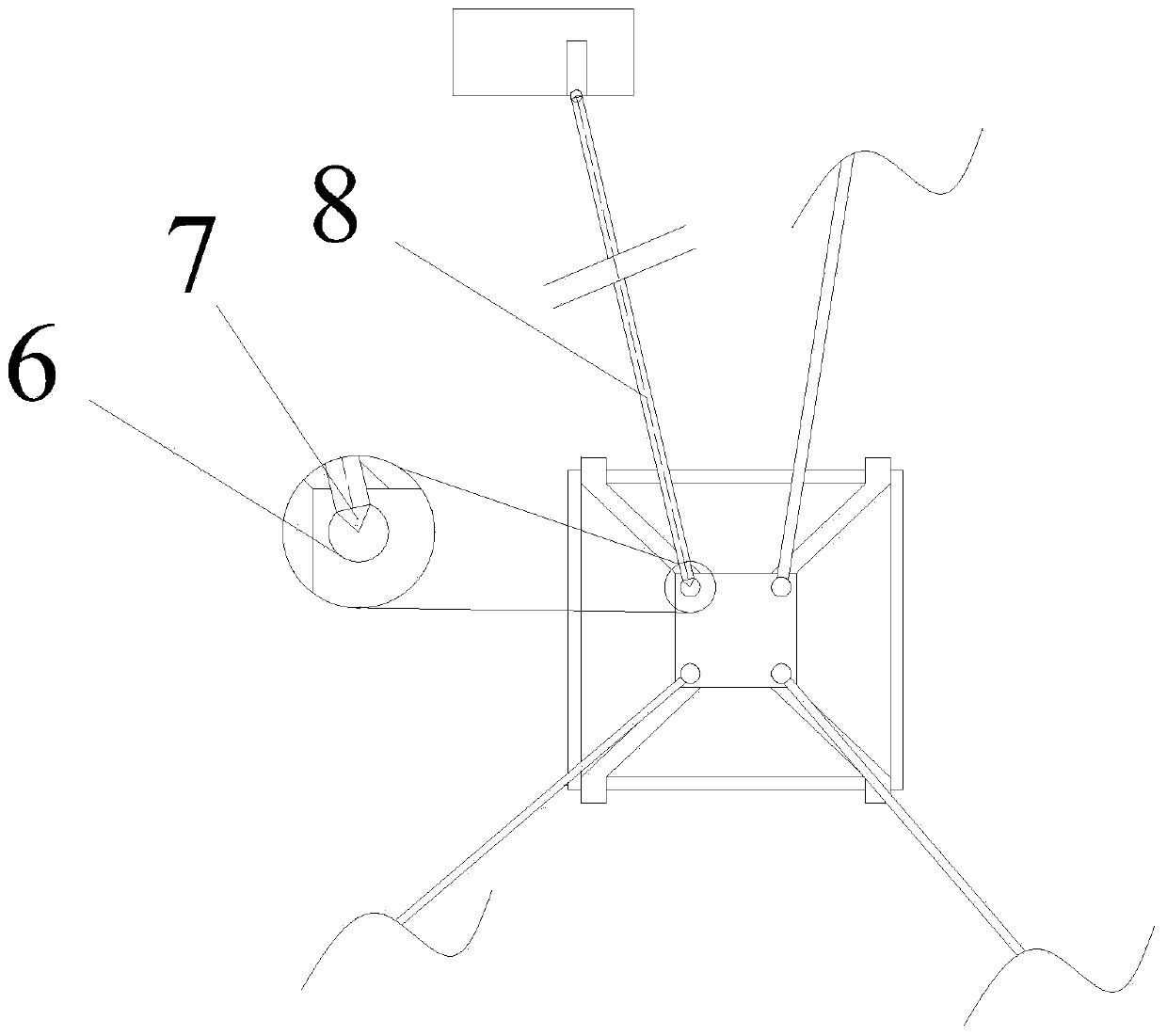

Building curtain wall three-dimensional transporting system

InactiveCN110242056AFlexible layoutReduce equipment weightBuilding material handlingTension controlControl system

The invention discloses a building curtain wall three-dimensional transporting system. The building curtain wall three-dimensional transporting system comprises a curtain wall hanging-bearing system, upper anchor point bases and lower anchor point bases, wherein the curtain wall hanging-bearing system is fixed to the back face of a curtain wall, the upper anchor point bases and the lower anchor point bases are fixed to the four corners of the external facade of a building, and the curtain wall hanging-bearing system is connected with two winches through two upper steel cables, wherein the two winches are mounted on the upper anchor point bases; and the curtain wall hanging-bearing system is connected with two tension control systems through two lower steel cables, wherein the two tension control systems are mounted on lower anchor point bases, and the tension control systems stabilize swinging of the curtain wall in air by maintaining tension on the steel cables. The curtain wall three-dimensional transporting system is arranged on the four vertexes of the external facade of the building, assembling and disassembling are rapid, the curtain wall can be moved rapidly and conveniently, and the mounting efficiency and safety of the curtain wall are improved.

Owner:CHINA MCC17 GRP

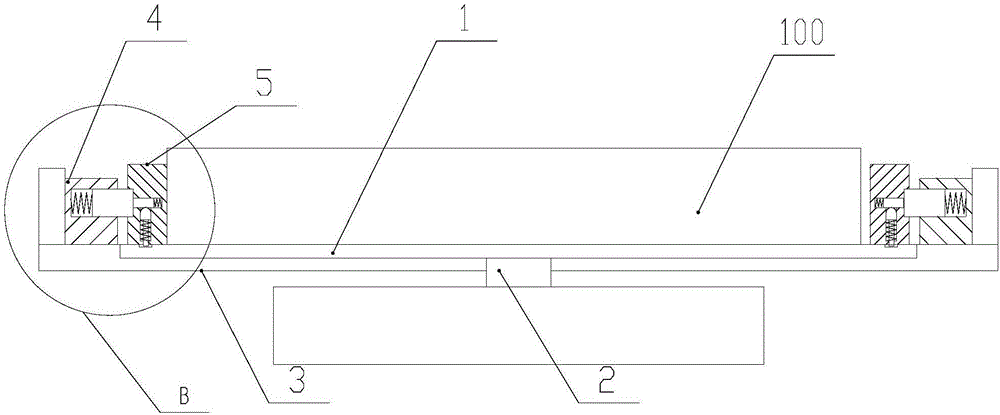

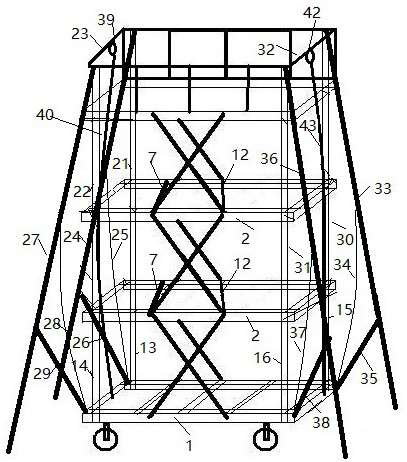

Lifting platform with supporting rod

PendingCN113603029AReduce shakingReduce equipment weightSafety devices for lifting equipmentsSelf weightManufacturing engineering

The invention discloses a lifting platform with a supporting rod. The lifting platform comprises a scissor lifting platform 1, a connecting mechanism, a supporting rod mechanism and a safety mechanism. On the premise of ensuring safe operation of equipment, the bearing capacity of the lifting platform is reduced through the supporting rod mechanism and a prevention mechanism, the self weight of the equipment can be greatly reduced under the condition that the bearing capacity of a traditional lifting platform is not changed, the product becomes light and flexible from heavy, the use environment and the use range of the product are expanded, and meanwhile, the manufacturing cost of the product is effectively reduced.

Owner:张传生

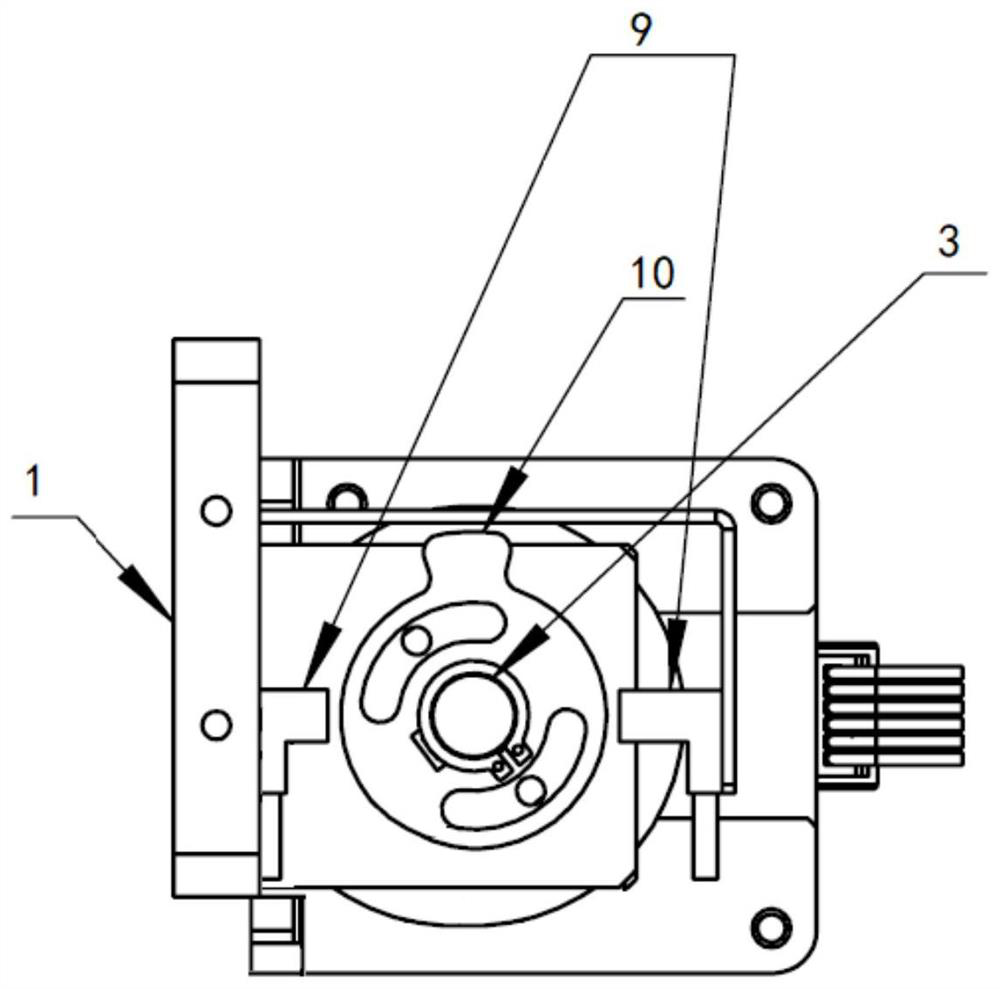

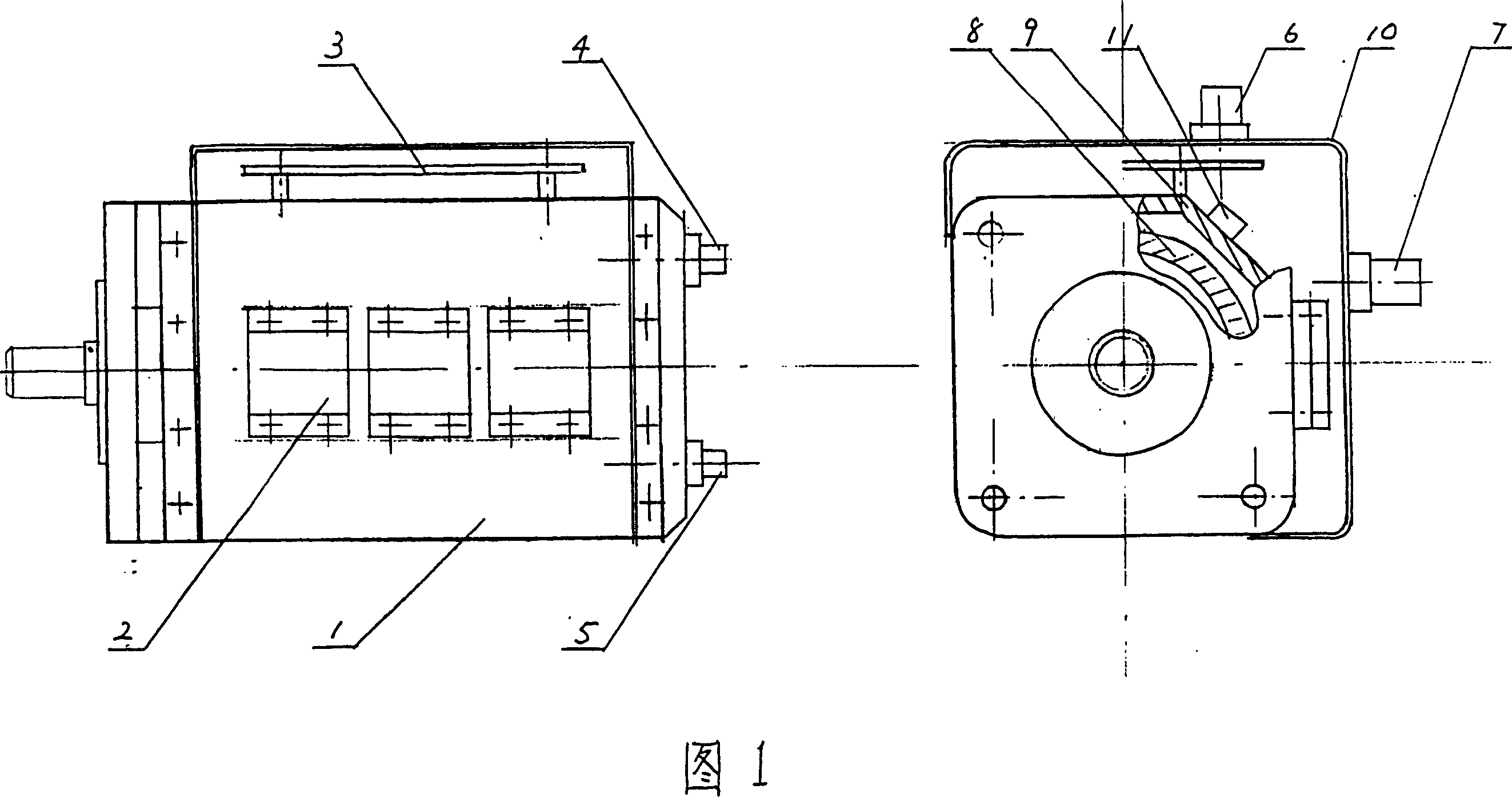

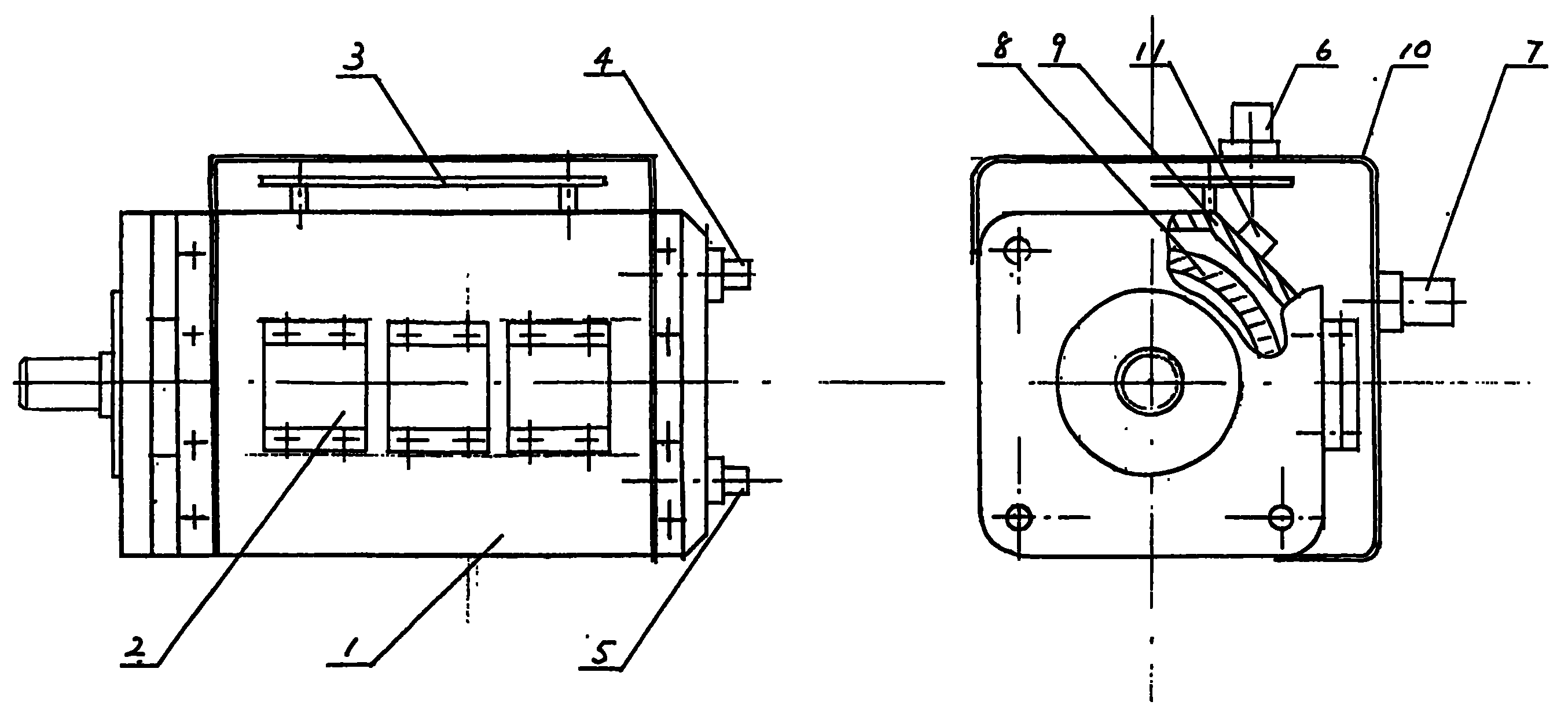

Transmission, double linkage and anti-sway anti-fall device, crane system and wafer handling method

ActiveCN113719595BReduce in quantityPrevent overshootGearingSemiconductor/solid-state device manufacturingRotational axisAutomatic control

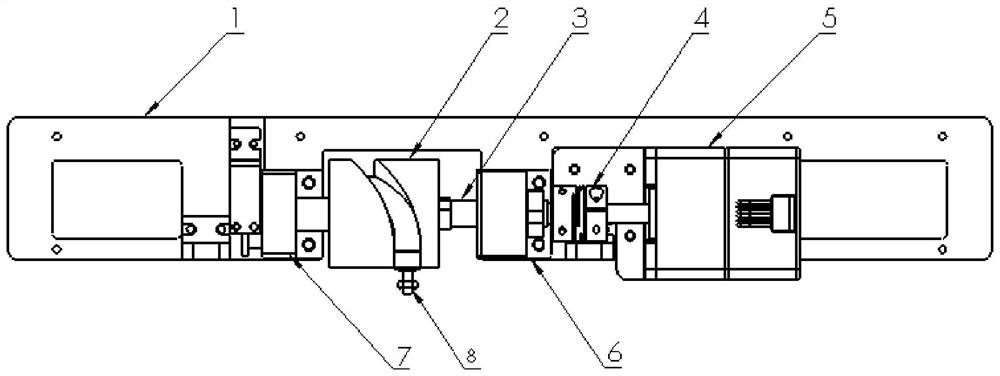

The invention provides a transmission, double linkage and anti-sway anti-falling device, a crane system and a wafer transportation method, which are applied in the field of automatic control technology, and more specifically relate to semiconductor manufacturing technology. The transmission device includes a mounting plate, a motor, The first bearing seat, the second bearing seat, the coupling, the rotating shaft, the cam and the cam follower. The motor, the first bearing seat and the second bearing seat are installed on the mounting plate. The rotating shaft is supported on the first bearing seat and the second bearing seat. Between the two bearing seats, a cam is set on the rotating shaft, and a cam groove is provided on the cam to install a cam follower. The output shaft of the motor drives the rotating shaft through a coupling, and one end of the cam follower is connected to the linkage mechanism. Under the driving of the motor, one end of the cam follower connected to the linkage mechanism is limited to move in the same plane to drive the linkage mechanism. Driven by a single motor, it has a simple mechanism, small size and light weight, and can be flexibly used in wafer handling scenarios in semiconductor manufacturing.

Owner:MEETFUTURE TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com