Automatic mold gripping method and device for intelligent robot for building component

A technology of intelligent robots and building components, applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve the problems of restricting production efficiency, production safety and product quality, affecting and restricting enterprise production, and high structural load-bearing requirements, so as to reduce the lifting height , The effect of reducing the weight of the equipment and reducing the load requirements of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

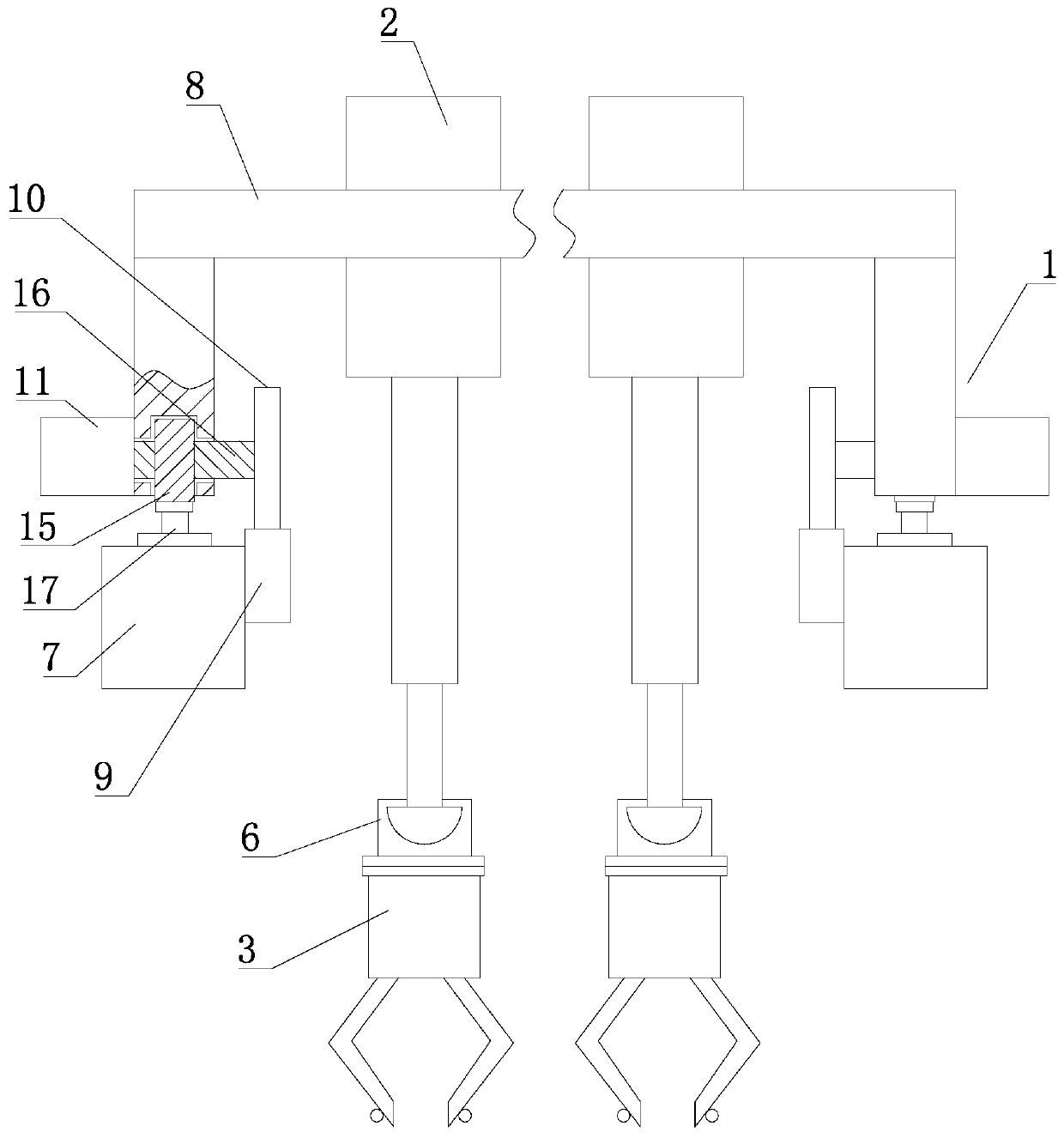

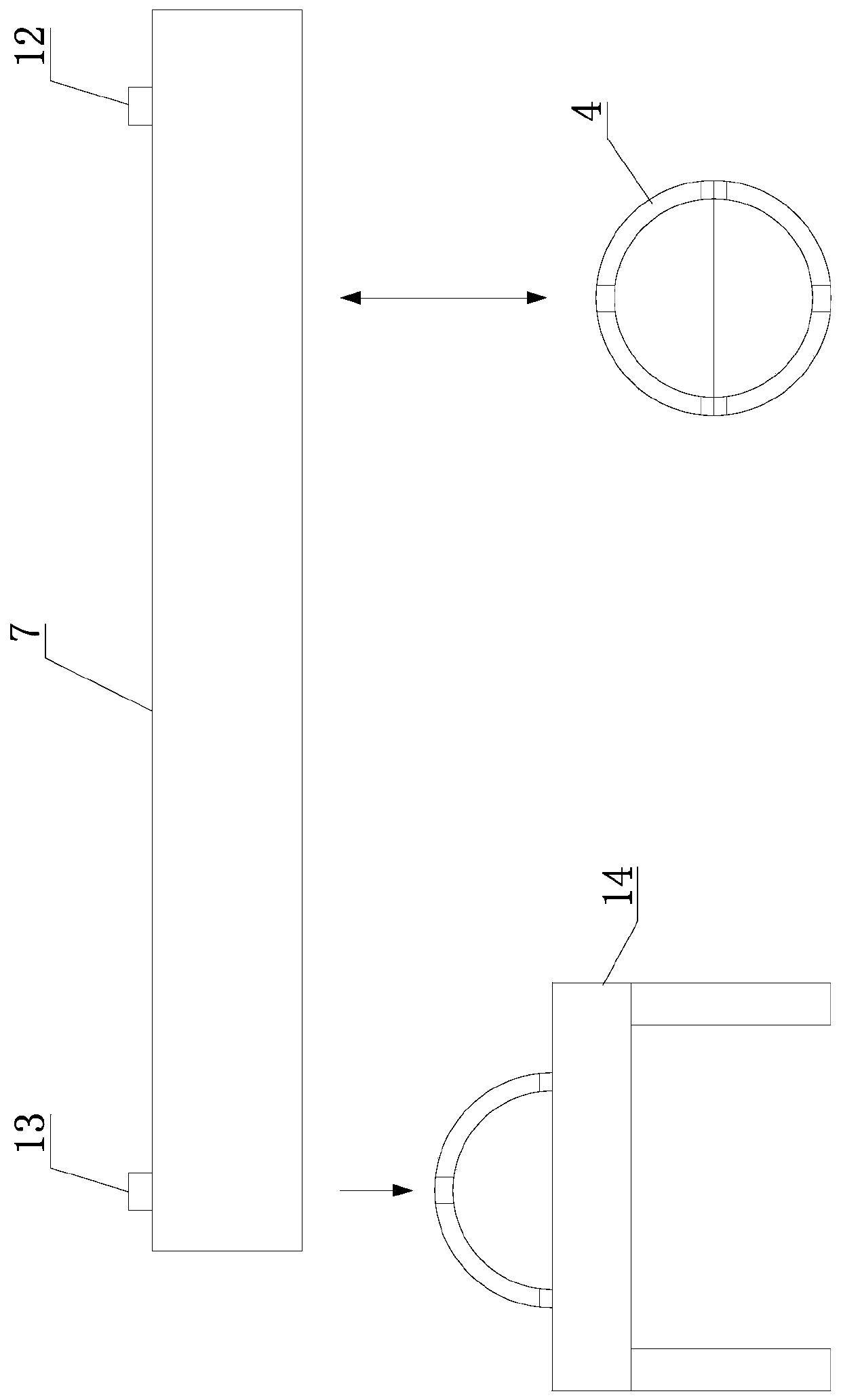

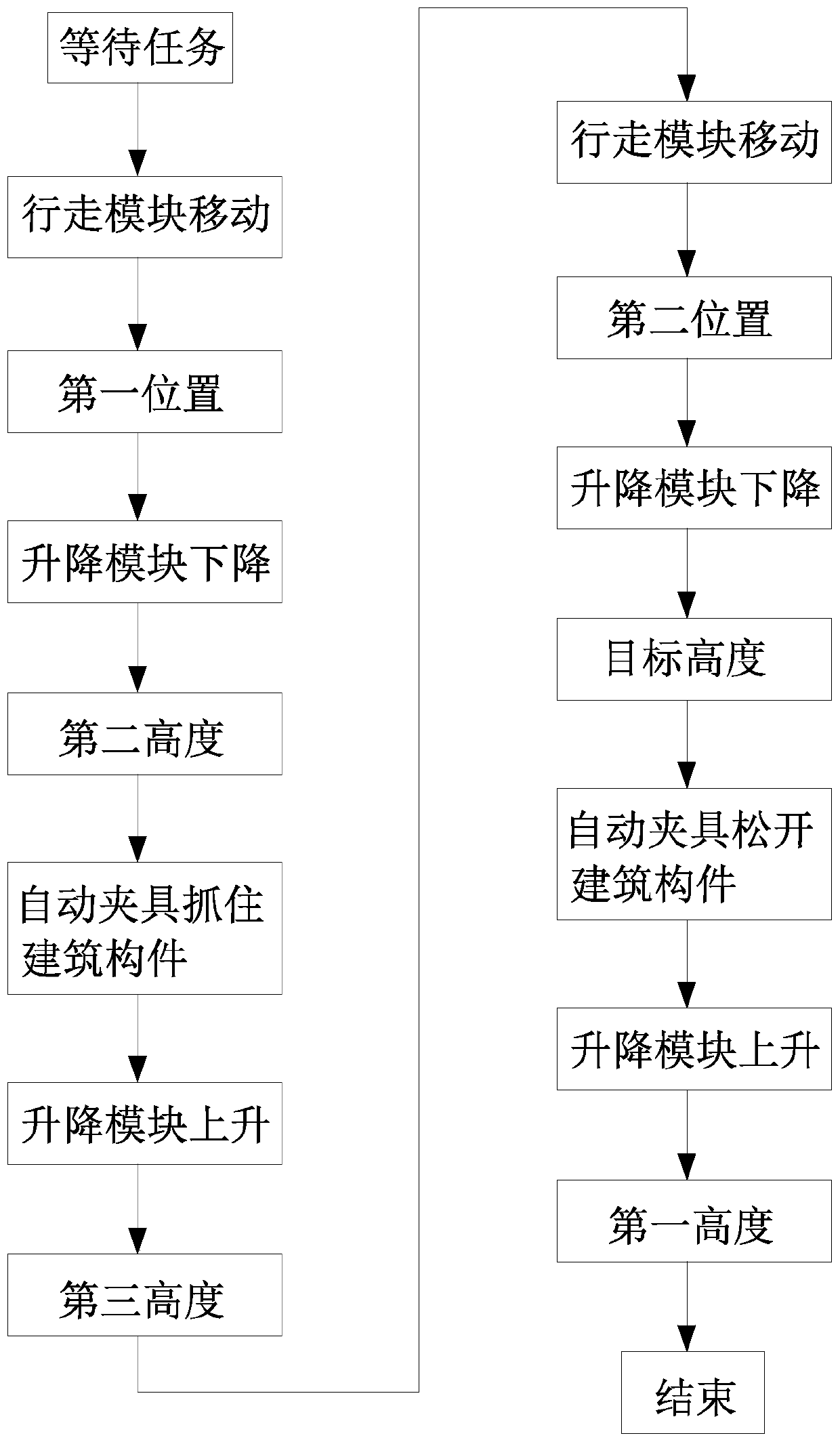

[0028] Such as Figure 1-3 Shown, a kind of intelligent robot automatic mold grasping method of building components, described robot comprises walking module 1, lifting module 2, grasping module 3 and control module, described mold grasping method comprises the following steps:

[0029] S1: the control module sends an instruction to the walking module 1, and the walking module 1 moves to a preset first position along the first direction and then stops;

[0030] S2: The control module sends instructions to the lifting module, and the lifting module 2 drives the grasping module 3 to drop from the initial first height to the second height position where the building component is located, and lifts the module 2 after the grasping module 3 is in place stop; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com