Movable five-axis robot

A robot and the fifth technology, applied in the field of movable five-axis robots, can solve the problems of narrowing the working space of the mechanism, small coincidence, and the existence of tooth backlash, etc., to achieve simple and lightweight construction and installation process, high repeatability positioning accuracy, noise The effect of large stroke transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

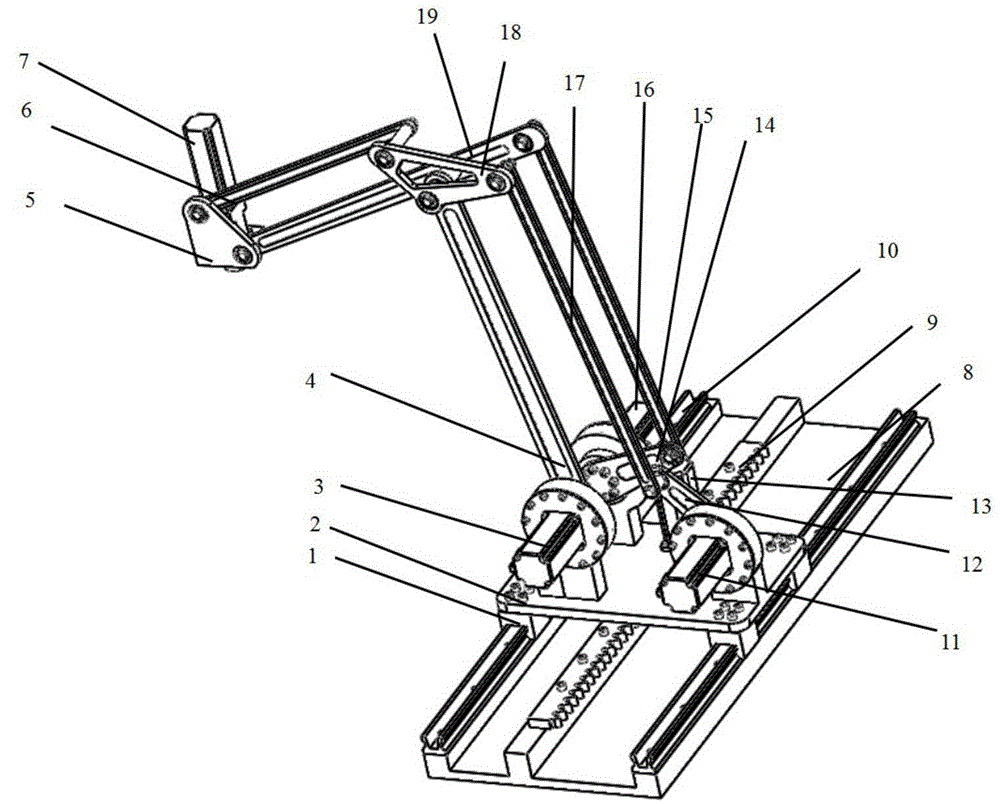

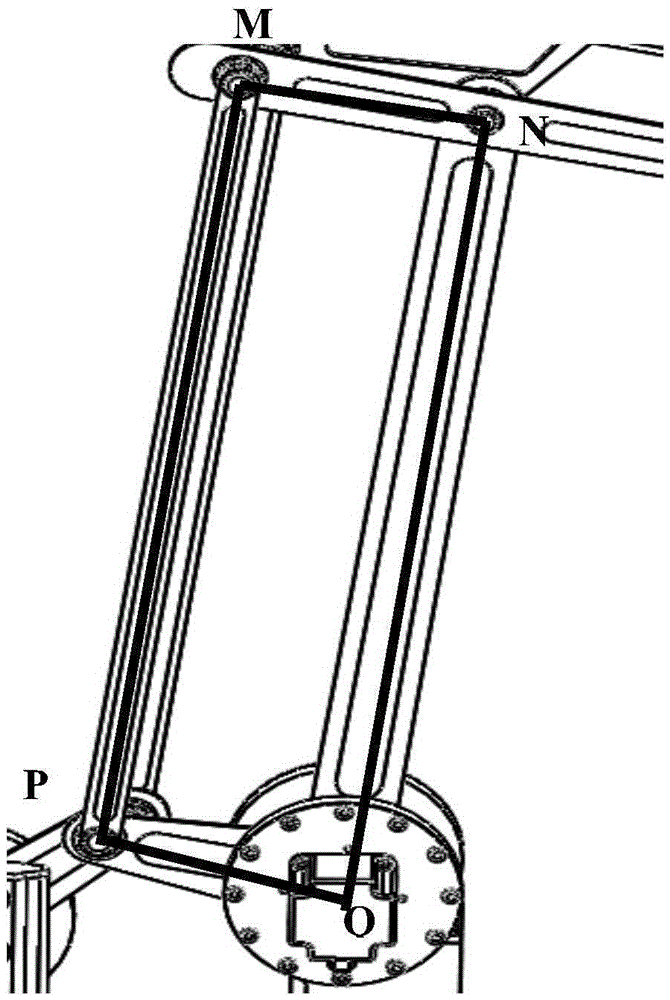

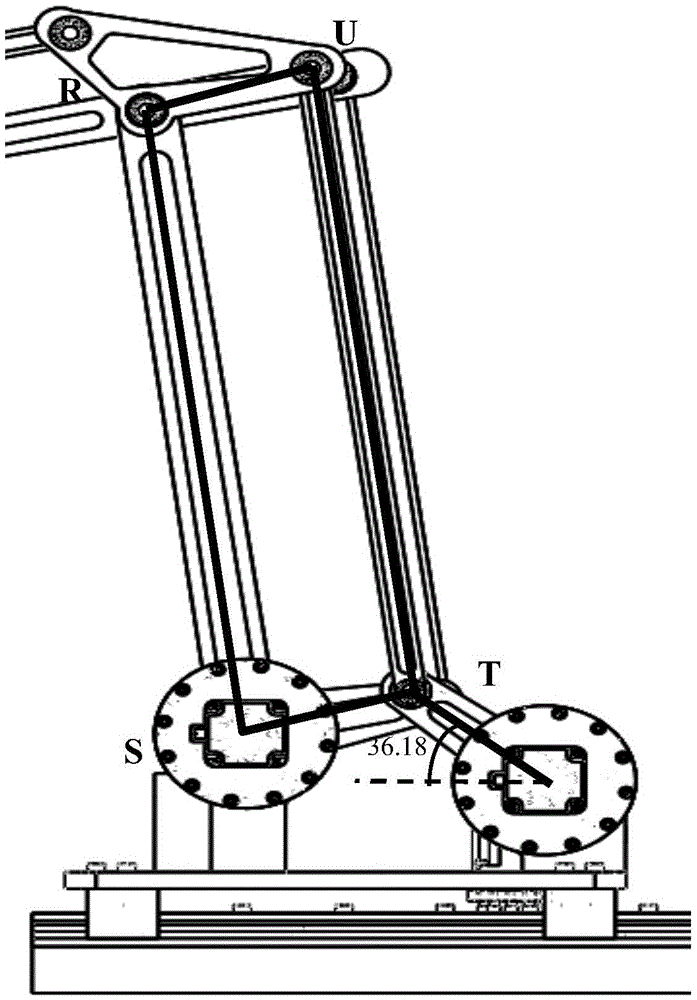

[0022] The present invention will be further explained below in conjunction with the drawings:

[0023] A movable five-axis robot provided by the present invention includes a fixed base 8, a guide rail 10, a slider 1, a trochoid rack 9, a roller 20, a robot mounting base 2, an end mounting base 5, a first driving device 13, The second drive device 3, the third drive device 16, the fourth drive device 11, the fifth drive device 7, the first branch, the second branch, and the third branch; the first branch includes a boom 4, The forearm 19; the second branch chain includes the forearm 14, the forearm rod 15; the third branch chain includes the rear arm 12, the first posture-preserving lever 17, the tripod connecting frame 18, and the second posture-preserving lever 6; The first drive device 13 includes a servo motor 20; the second drive device 3, the third drive device 16, and the fourth drive device 11 are all composed of a servo motor and a harmonic reducer; the fifth drive devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com