Patents

Literature

239results about How to "High acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

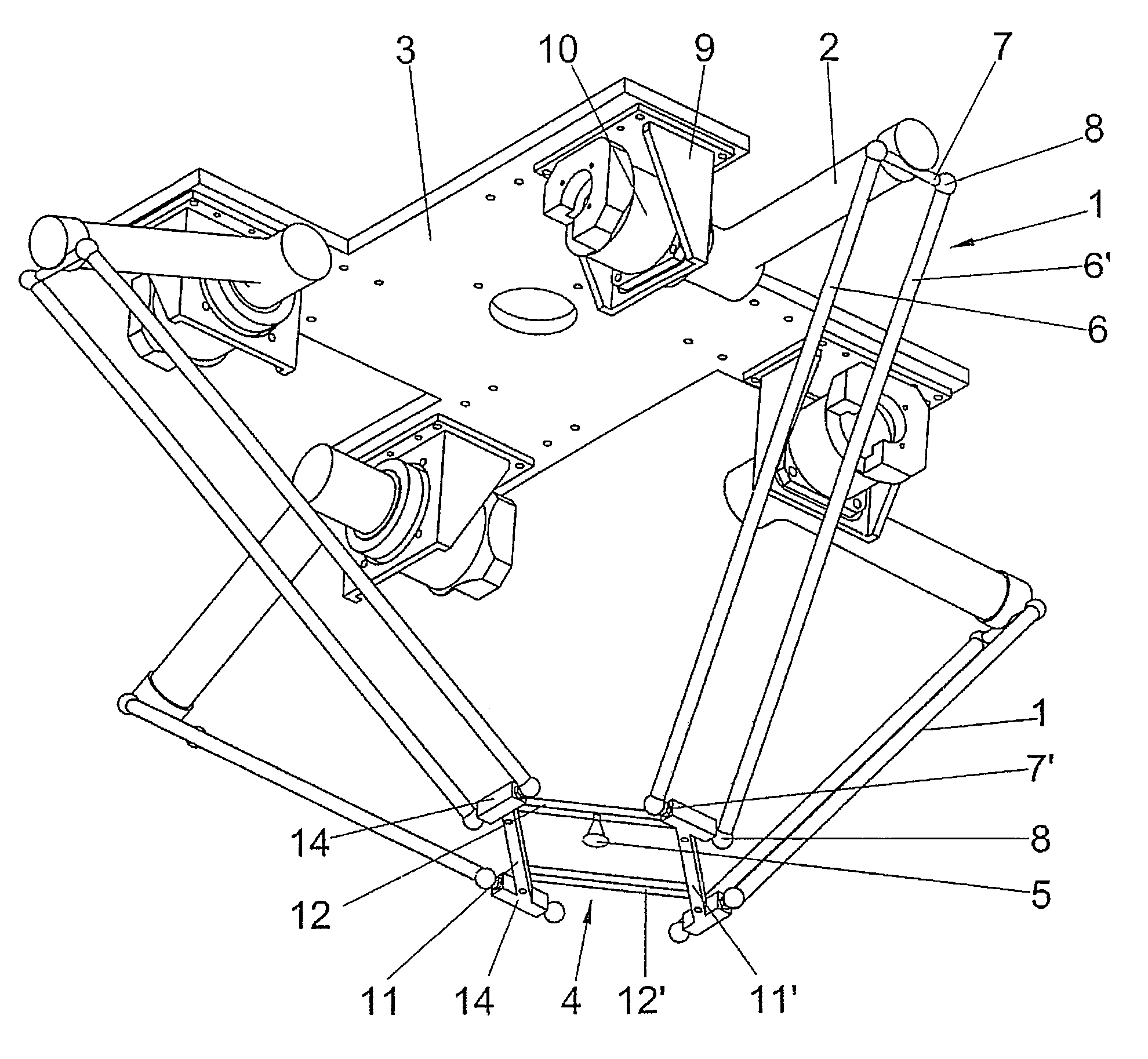

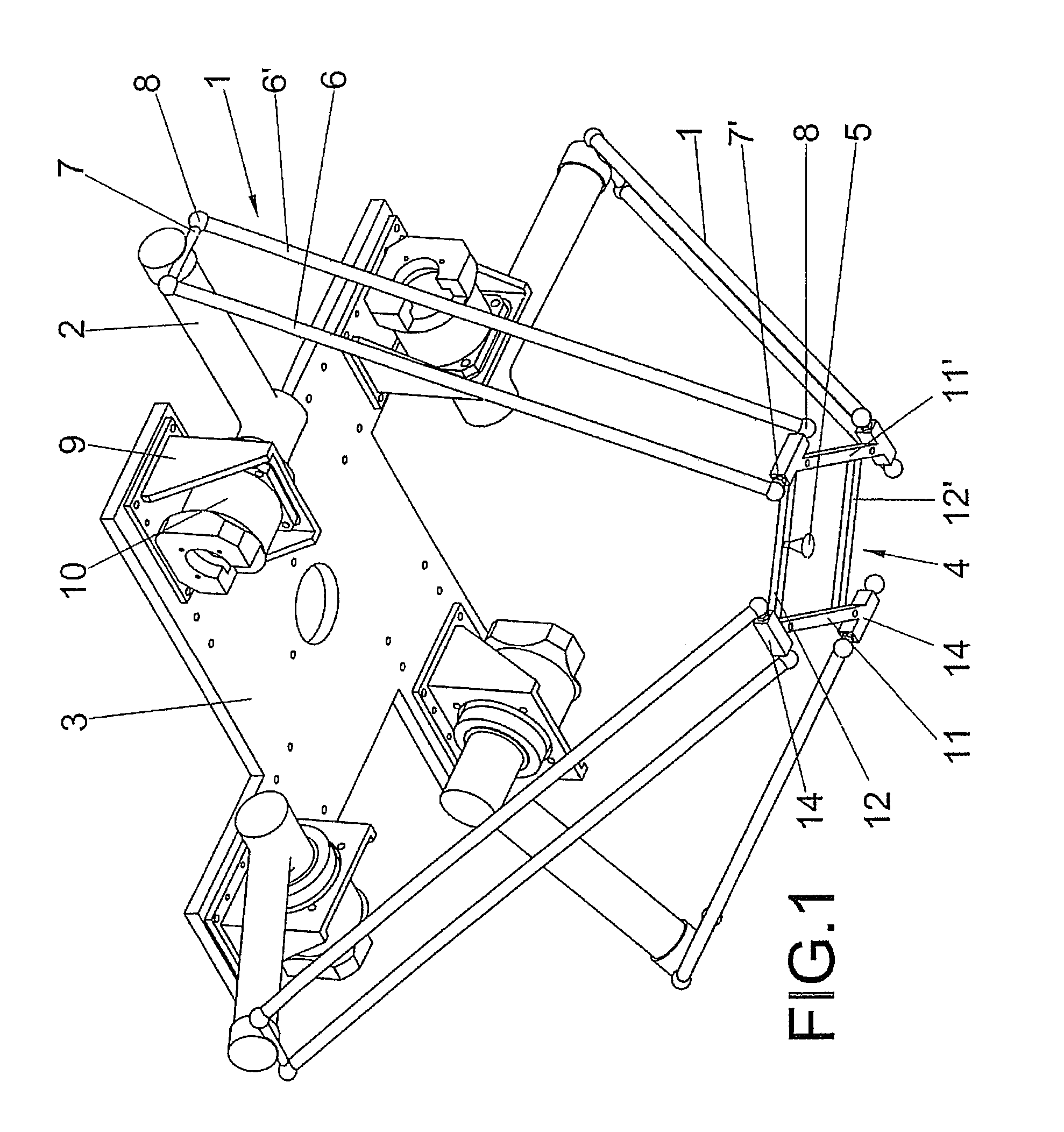

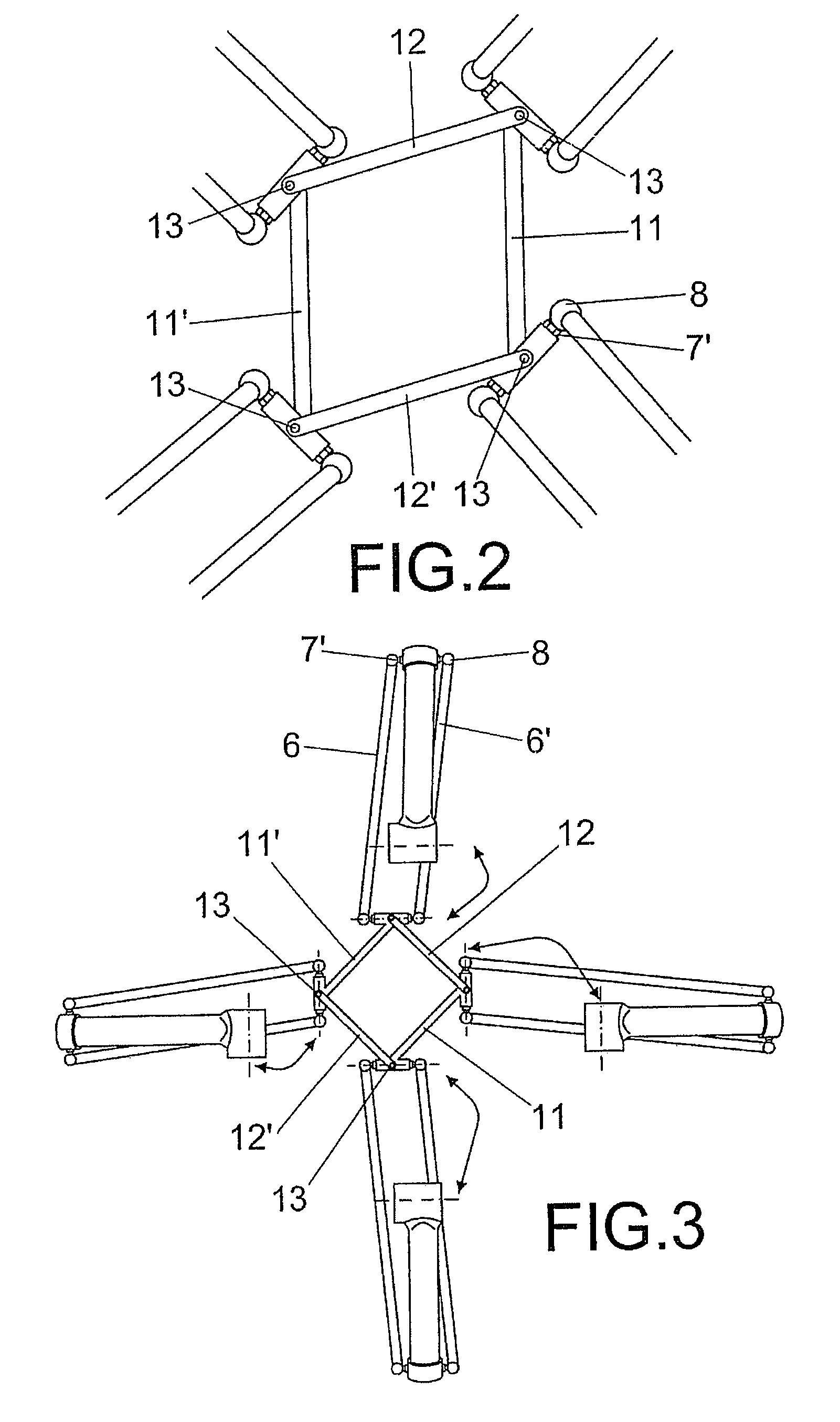

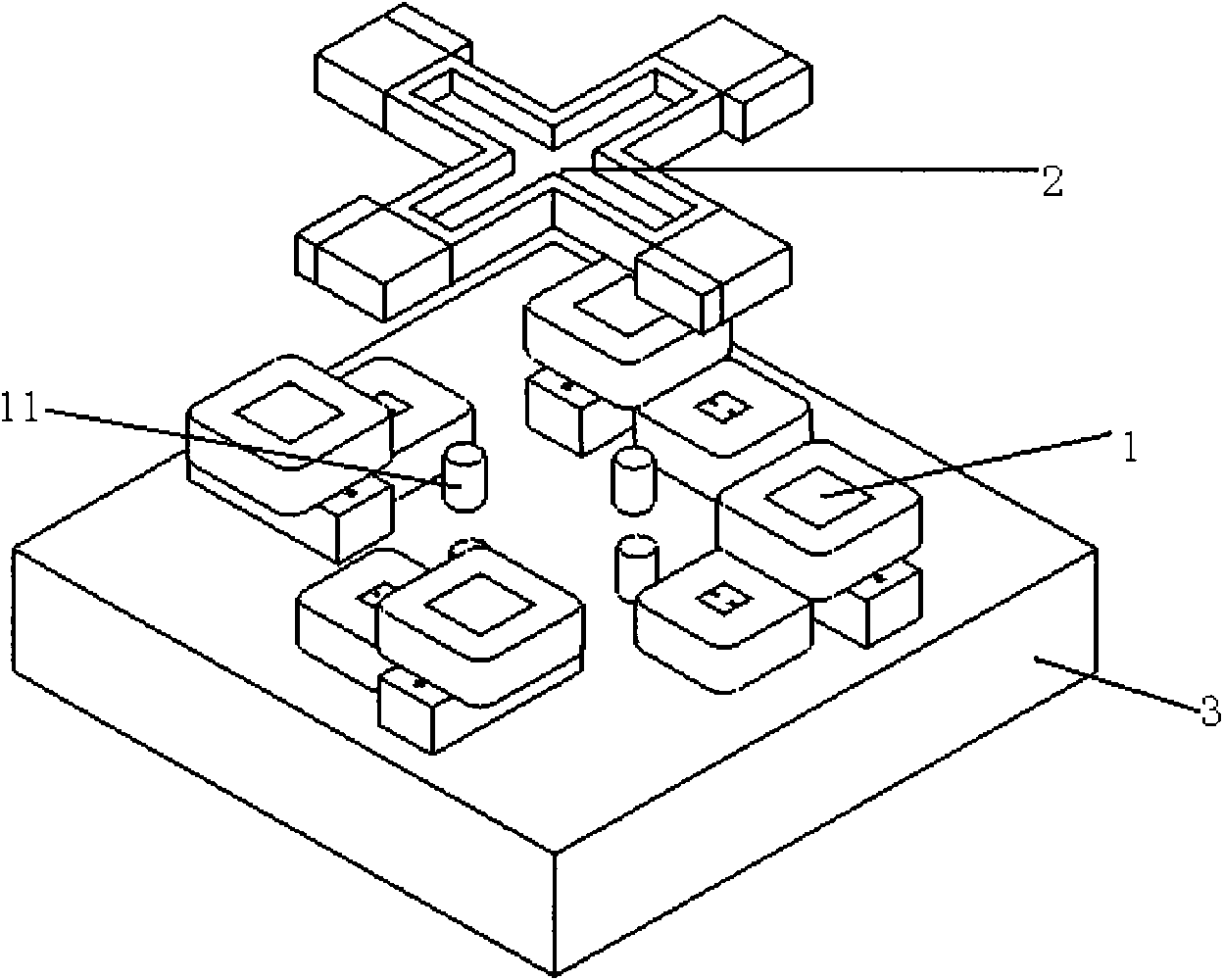

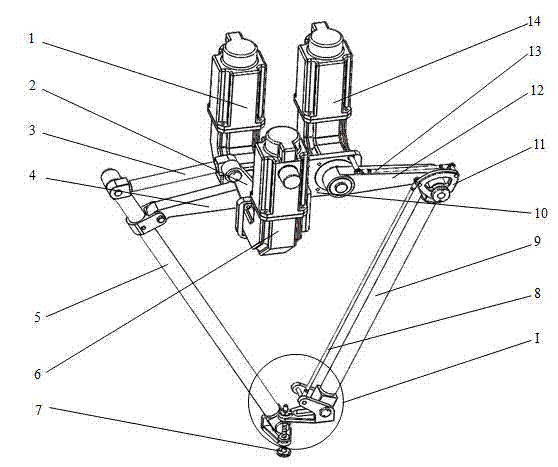

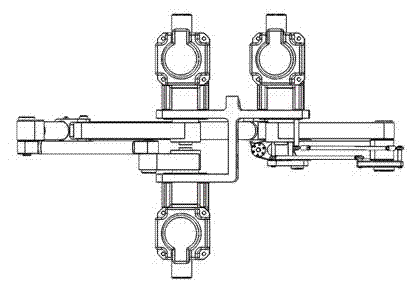

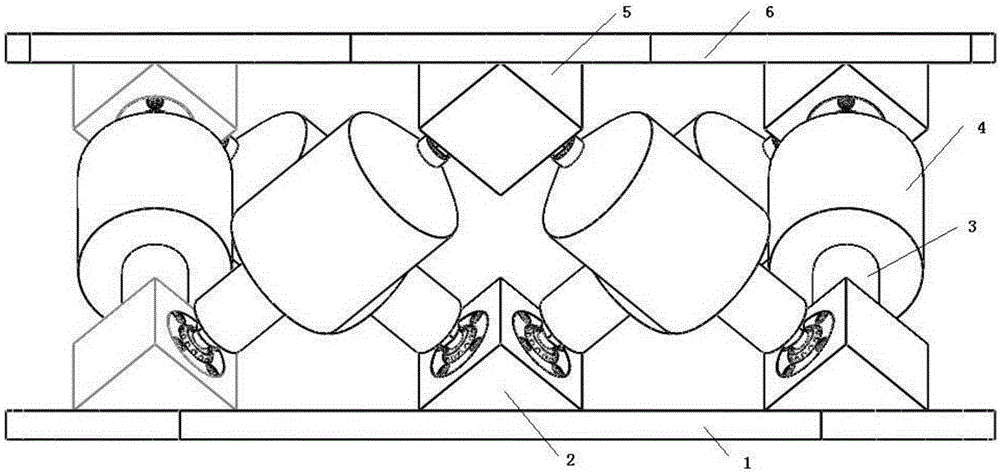

High-speed parallel robot with four degrees of freedom

InactiveUS20090019960A1High accelerationIncrease speedProgramme-controlled manipulatorMechanical apparatusKinematic chainEngineering

The invention relates to a high-speed parallel robot with four degrees of freedom comprising four kinematic chains (1) articulated at one of their ends to a mobile platform (4) carrying the tool (5) and at their other end, through a rotational joint (2), to an actuador integral with a base plate (3). The mobile platform (4) is formed by four members (11), (11′), (12), (12′), linked together by means of articulated linkages (13), at least two of the members being parallel to each other, forming an articulated mobile platform with one degree of freedom in the plane of the mobile platform. The actuators are positioned with any orientation in the base plate (2) and preferably at 45°, 135°, 225° and 315°.

Owner:FUNDACION TECNALIA RES & INNOVATION

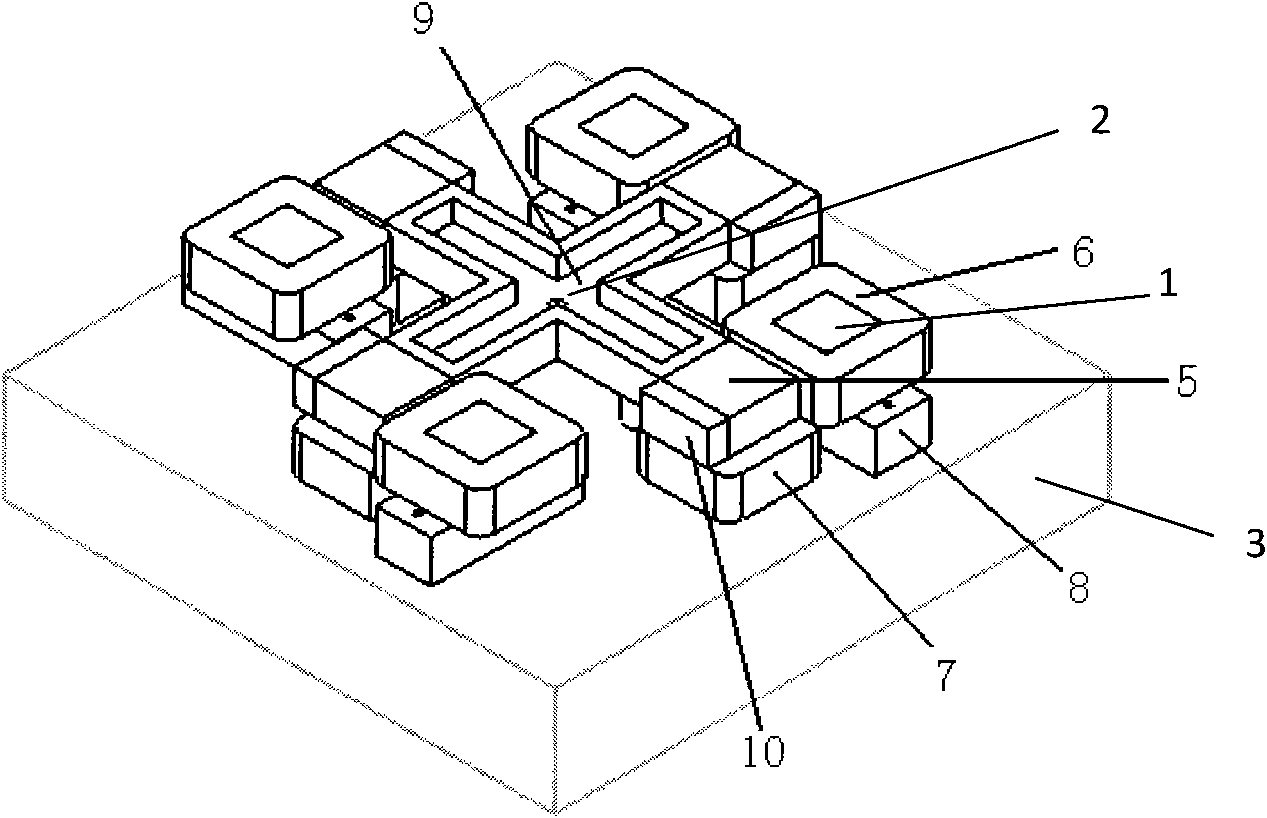

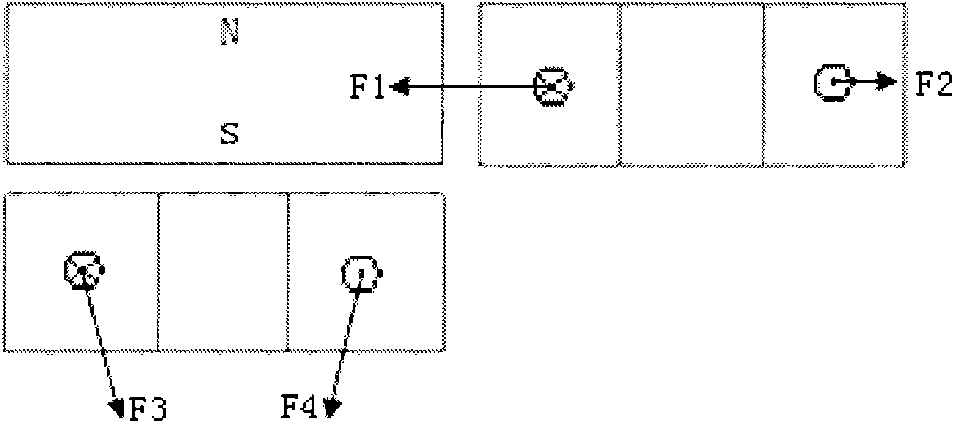

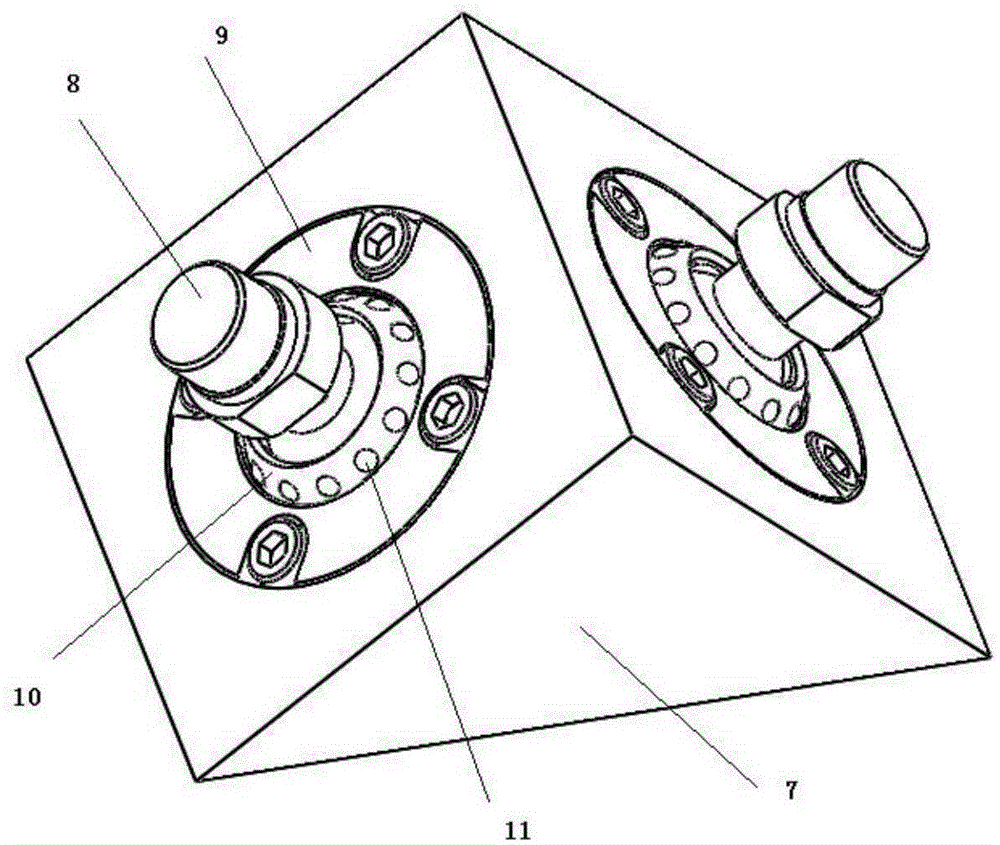

Nano-precision six-freedom-degree magnetic suspension jiggle station and application

ActiveCN101807010ASimple structureGreat driving forcePhotomechanical exposure apparatusMicrolithography exposure apparatusSix degrees of freedomStator

The invention discloses a nano-precision six-freedom-degree magnetic suspension jiggle station and application. The jiggle station is mainly applied to semiconductor photoetching equipment. The jiggle station comprises a cross stand and four two-freedom-degree actuators. Each two-freedom-degree actuator comprises permanent magnets polarized along the vertical direction, a horizontal force coil and a vertical force coil, wherein the permanent magnet is fixed at the tail end of the cross stand, and the horizontal force coil and the vertical force coil are arranged on the lateral surface and the underside of the permanent magnet respectively and keep a clearance with the permanent magnet; the cross stand and four permanent magnets polarized along the vertical direction form a rotor of the jiggle station; the horizontal force coil and the vertical force coil are fixed by a coil framework respectively to form a stator of the jiggle station; and the stator is fixed on a pedestal of the jiggle station. The combination of two jiggle stations and a two-freedom-degree large-stroke linear motor can form a positioning system of a double silicon wafer station of a photoetching machine. The jiggle station has the characteristics of simple structure, large driving force, light mass and no cable disturbance, and easily realizes high-precision and high-acceleration six-freedom-degree jiggle.

Owner:TSINGHUA UNIV +1

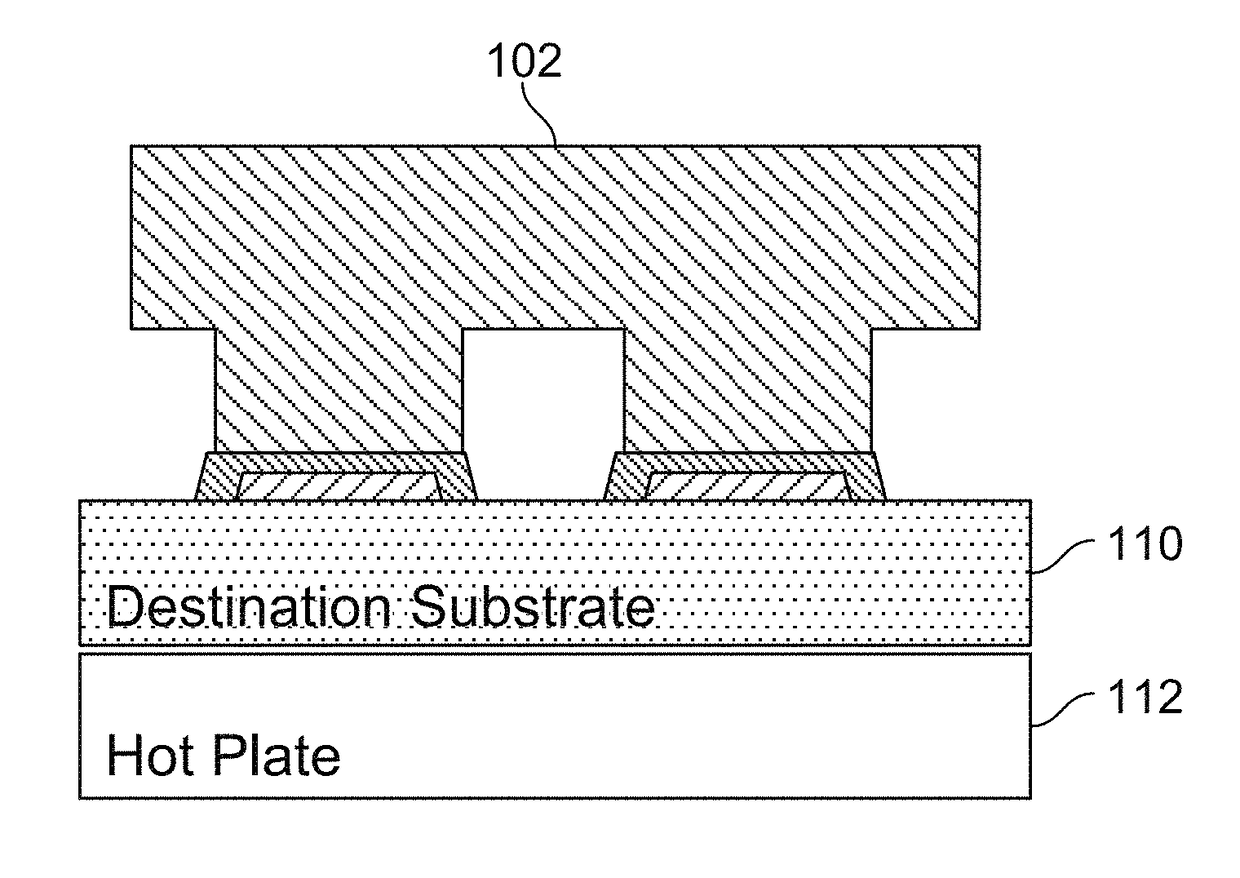

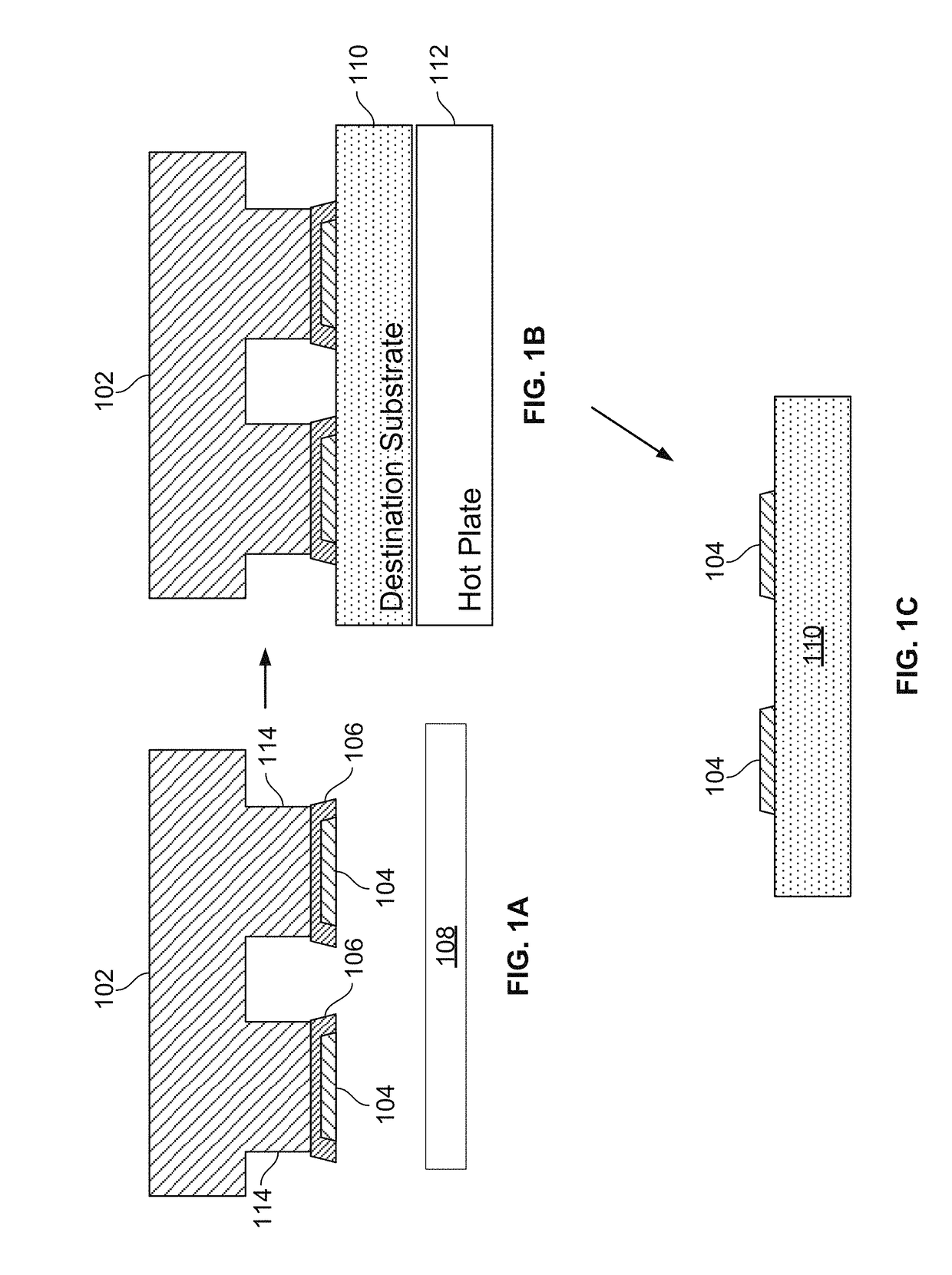

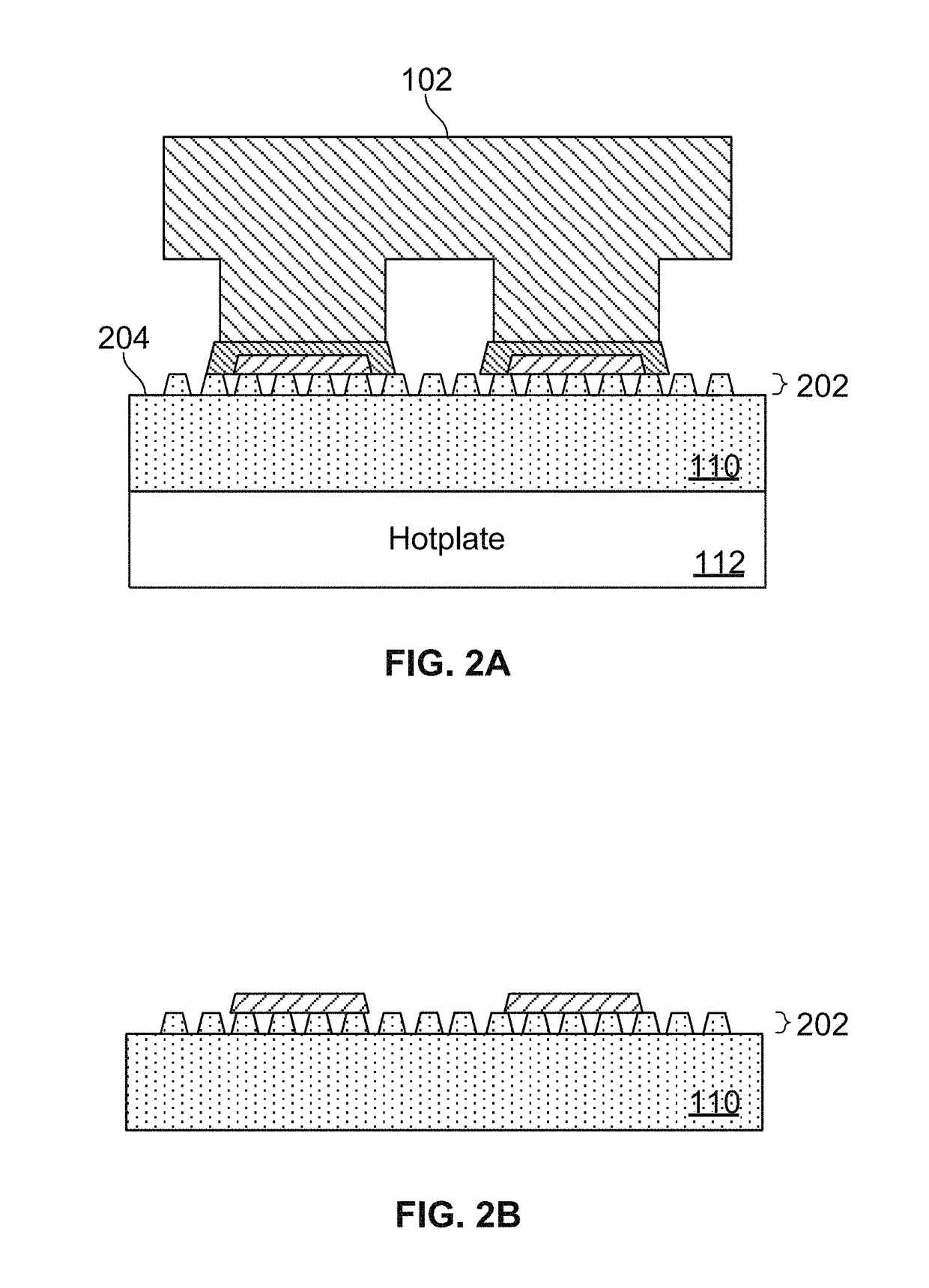

Apparatus and methods for micro-transfer-printing

InactiveUS20170207193A1High velocityHigh accelerationTransfer printingSemiconductor/solid-state device detailsSemiconductorTransfer printing

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed. In yet another aspect, a method and structure for heat-assisted micro-transfer printing is disclosed.

Owner:X DISPLAY CO TECH LTD

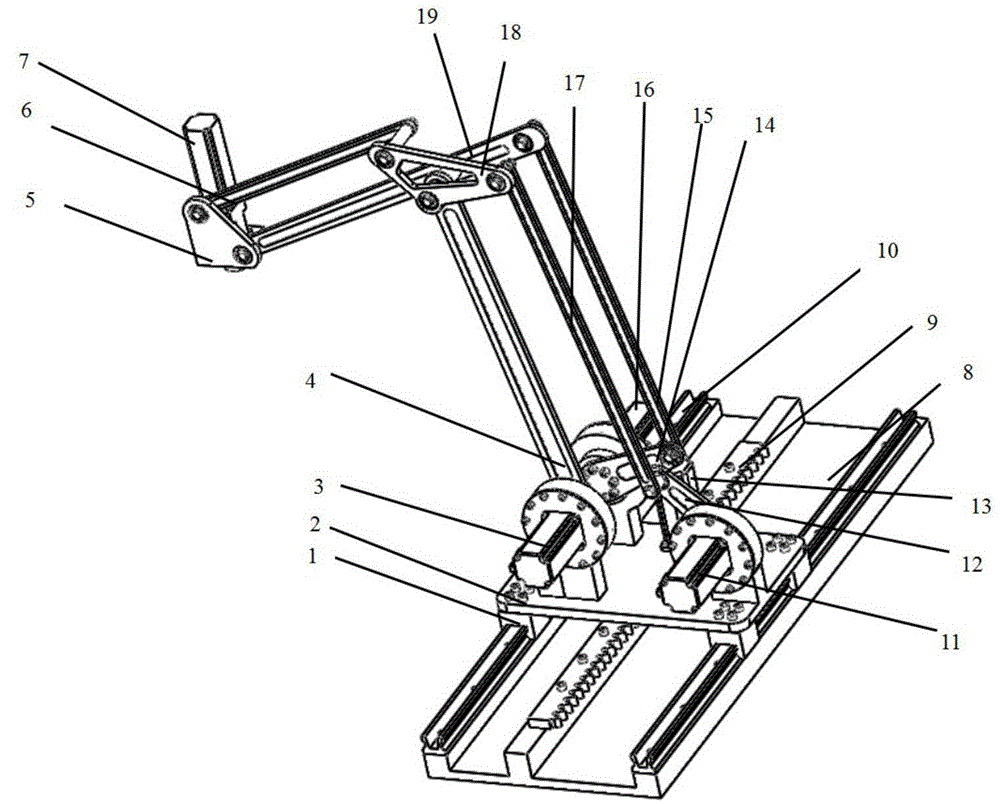

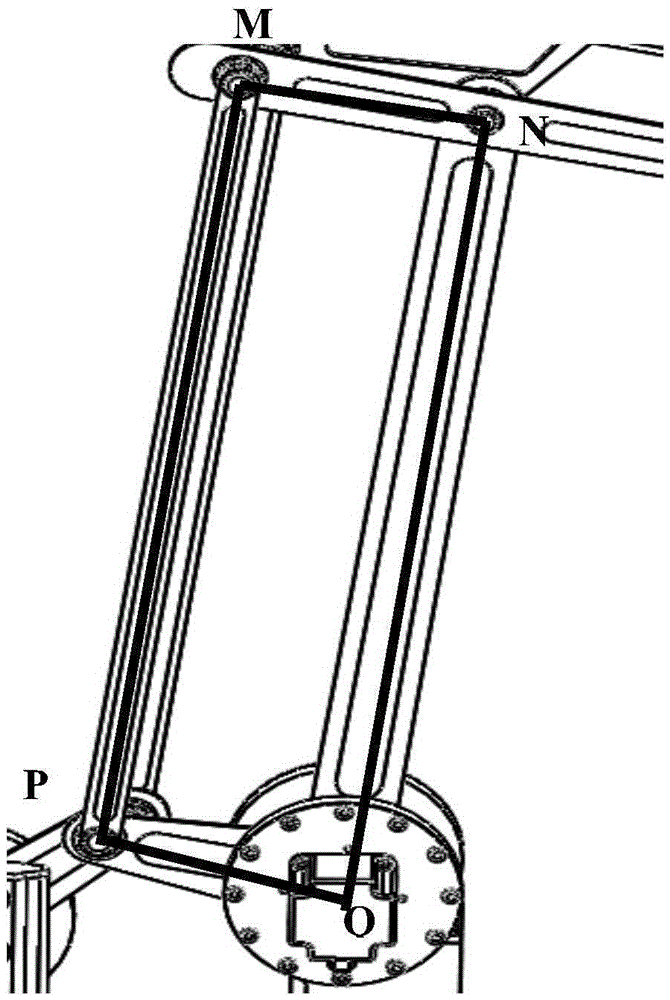

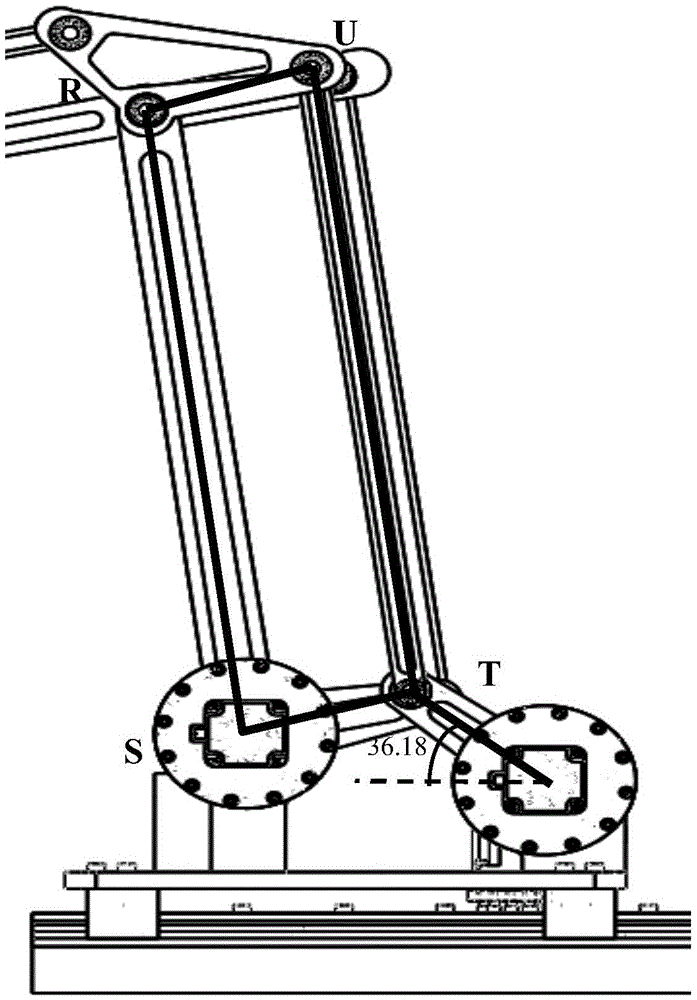

Movable five-axis robot

InactiveCN105459109AHigh precisionReduce noiseProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a movable five-axis robot and belongs to the technical field of application of industrial robots. The robot comprises a fixing base, guide rails, sliding blocks, a trochoidal rack, a roller, a robot mounting base, a tail-end mounting seat, a first driving device, a second driving device, a third driving device, a fourth driving device, a fifth driving device, a first branch chain, a second branch chain and a third branch chain, wherein the first branch chain comprises a large arm and a front arm; the second branch chain comprises a small arm, a small arm pull rod and a front arm; and the third branch chain comprises a rear arm, a first attitude holding rod, a triangular connecting frame and a second attitude holding rod. Through adoption of a transmission device composed of the trochoidal rack and roller pins, the robot is applicable to occasions where the robot is required to move; different types of grippers can be mounted at the tail end of the robot so as to finish gripping of different types of objects; and besides, the robot is simple in structure, high in rigidity and stability, simple to manufacture, convenient to mount and debug and low in mechanism manufacturing cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

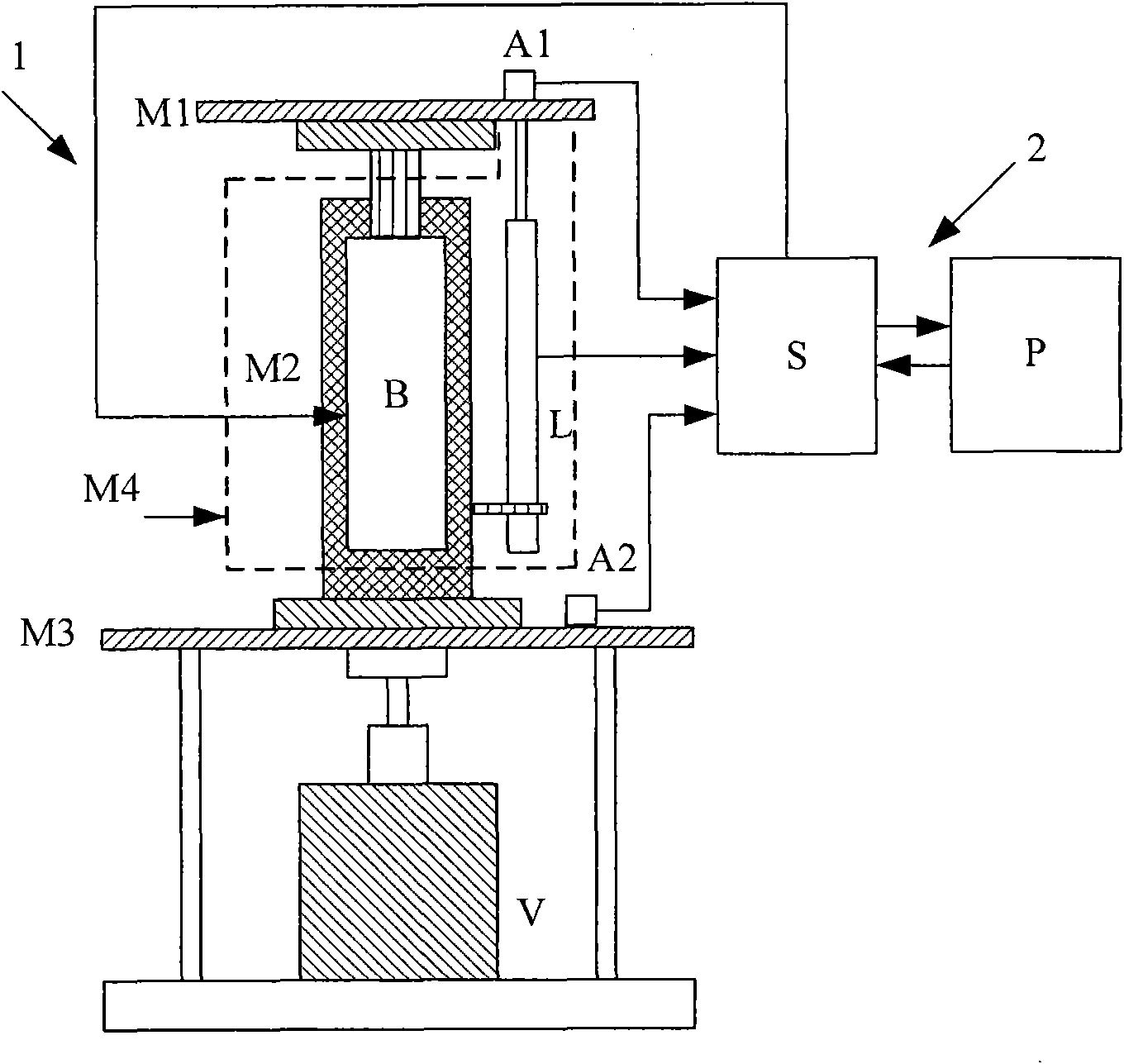

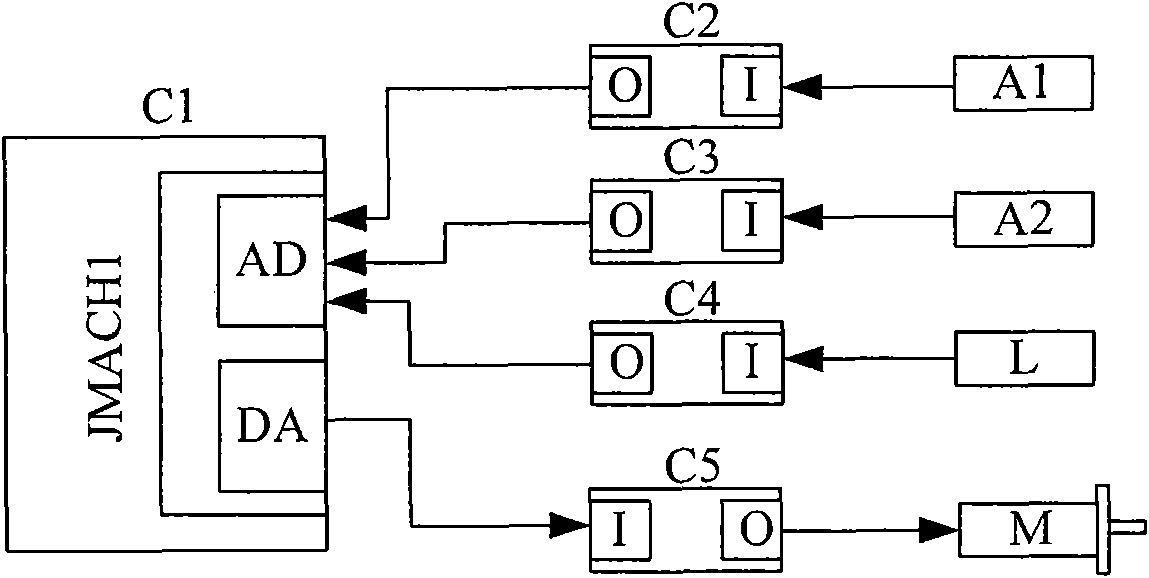

Active vibration isolation control platform

ActiveCN101609341ASimple structureReduce noiseMechanical oscillations controlEnergy industryLinear variable differential transformerExecution control

The invention discloses an active vibration isolation control platform. The active vibration isolation control platform comprises an active vibration isolation device and an active vibration isolation controller; the active vibration isolation device comprises a lower platform, a midbody and an upper platform; a voice coil motor actuator is arranged between the midbody and the lower platform; a linear variable differential transformer type displacement sensor is arranged between the upper platform and the midbody; and two three-freedom-degree acceleration sensors are arranged on the upper platform and the lower platform respectively. The vibration isolation controller is designed according to a master-slave open type control structure and consists of an upper control computer and a lower execution controller, wherein the upper control computer is a mainframe of an embedded type industrial control computer PC / 104; and the lower execution controller is an open-type controller. The active vibration isolation control platform is quite effective on low-frequency vibration isolation and is applicable to precise manufacture, precise measurement, aerospace application and other vibration isolation fields with special requirement on vibration environment.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

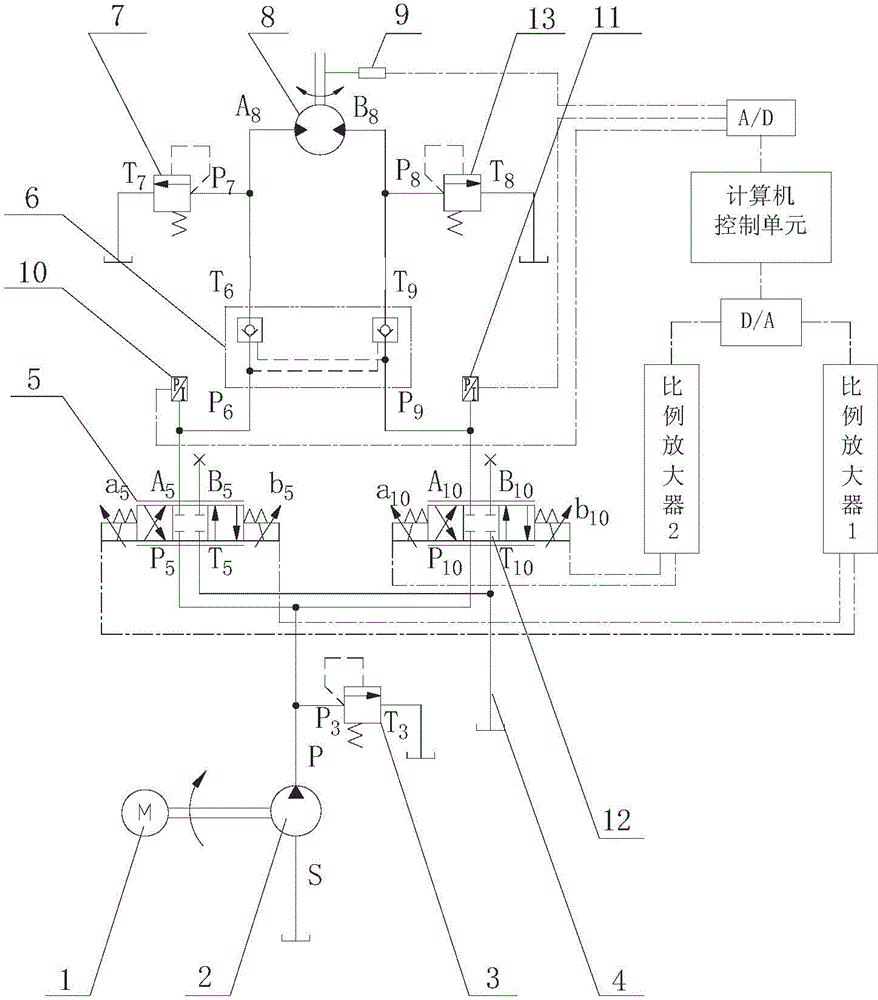

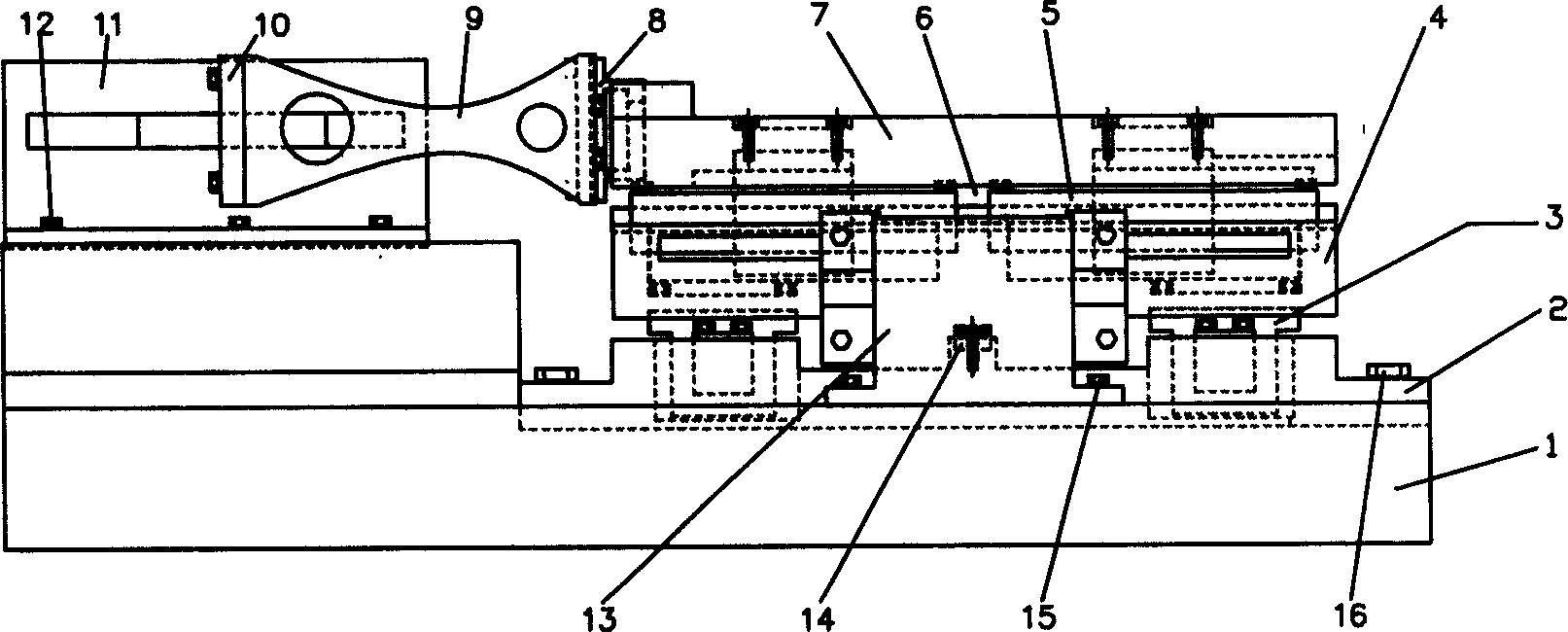

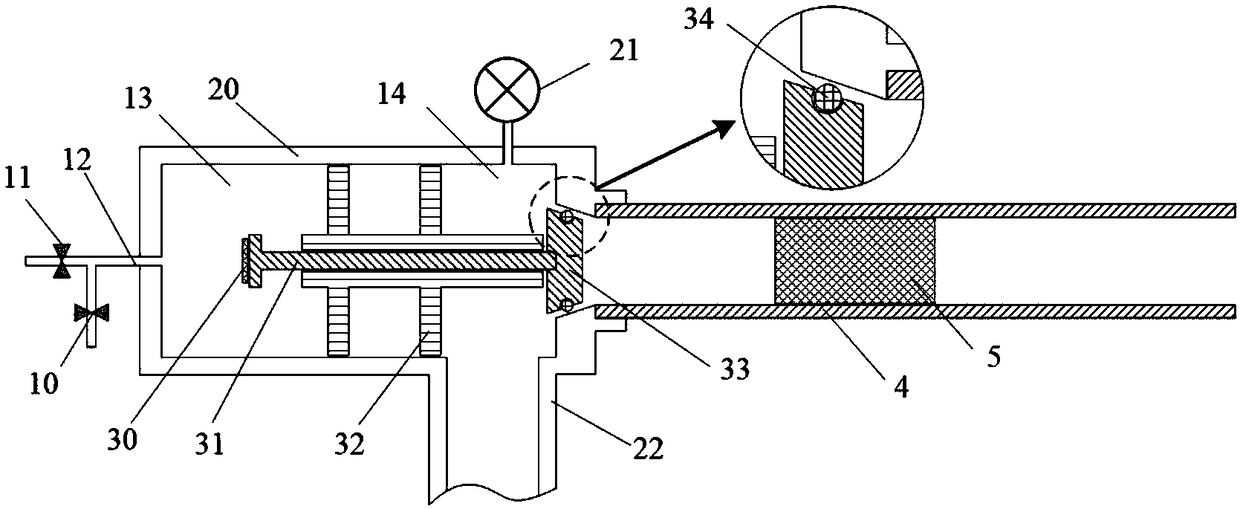

Electrohydraulic control system for rotation motion of pipe splicing machine

InactiveCN104564863AHigh accelerationReduce speed fluctuationUnderground chambersServomotorsBack pressureEnergy consumption

The invention discloses an electrohydraulic control system for rotation motion of a pipe splicing machine. The electrohydraulic control system comprises a motor, a constant displacement pump, three overflow valves, an oil return pipe, two three-position four-way proportional reversing valves, a hydraulic lock, a hydraulic motor, a force moment and rotating speed sensor and two pressure sensors. Since the electrohydraulic control system disclosed by the invention adopts the two three-position four-way proportional reversing valves to carry out independent control on the flow of an oil inlet of the hydraulic motor and the backpressure of an oil return port of the hydraulic motor; by controlling the backpressure of the oil return port of the hydraulic motor during an accelerated motion process, a constant motion process and a decelerated motion process of the rotation motion of the pipe splicing machine, the acceleration during the accelerated motion process of the rotation motion of the pipe splicing machine can be increased, the energy consumption during the constant motion process of the rotation motion of the pipe splicing machine and the speed fluctuation under the action of external load variation interference can be reduced, and the stability and the locating accuracy during the decelerated motion process of the rotation motion of the pipe splicing machine can be increased, so that the dynamic characteristic and the stability accuracy of the electrohydraulic control system for the rotation motion of the pipe splicing machine can be increased.

Owner:DALIAN UNIV OF TECH

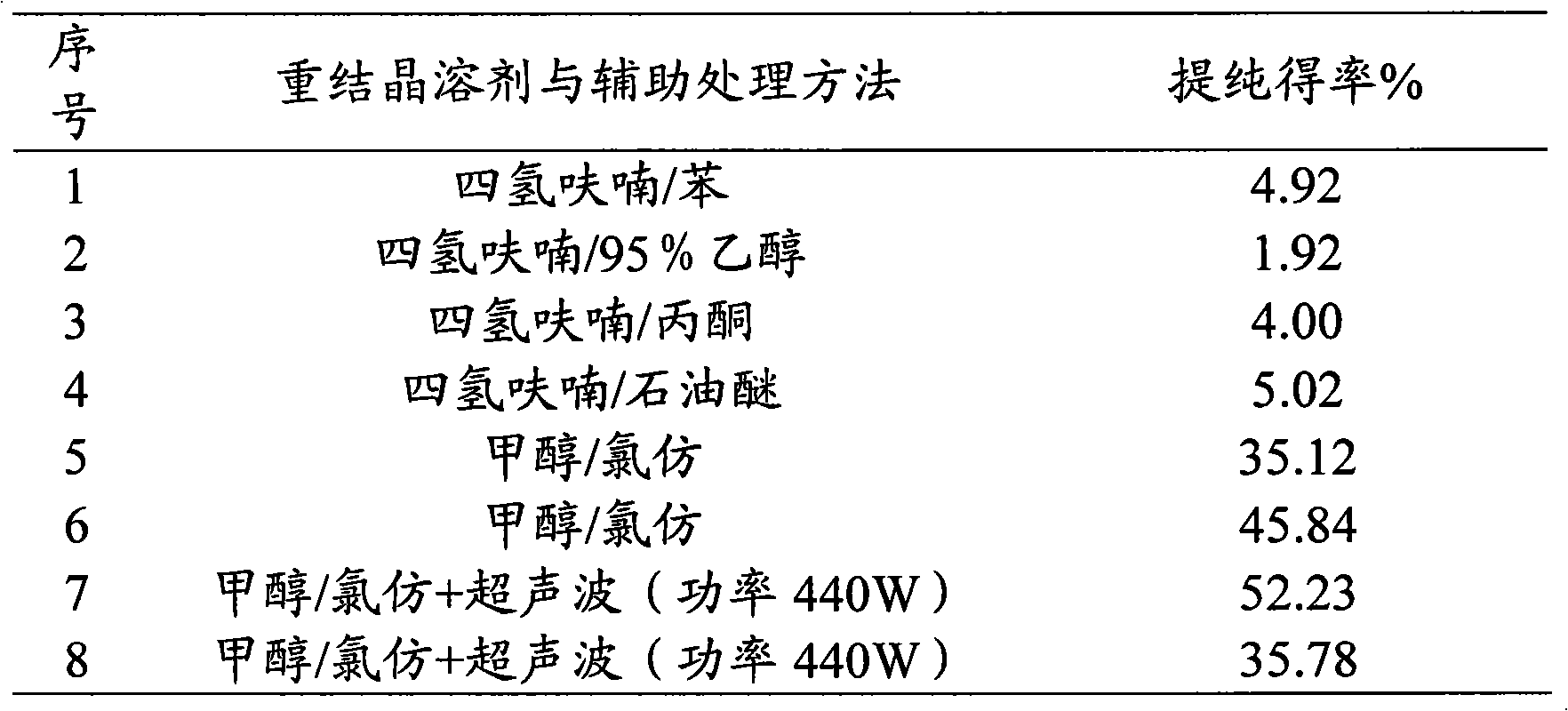

Method for extracting betulin from birch bark

The invention discloses a method for extracting betulin from birch barks, comprising the following steps: firstly, crushed birch barks are added into an ethanol water solution, undergo reflux extraction under auxiliary processing of ultrasonic waves, and then are filtrated for removal of residue, and an extract is obtained; secondly, solid powder is separated out after decompression and concentration of the extract, and then dried to the constant weight so as to obtain betulin coarse products; and thirdly, the betulin coarse products are added into an organic solvent, undergo ultrasonic treatment and then stand, crystals are separated out, and the betulin is obtained after the separated crystals are dried to the constant weight. The method has a simple operation flow, short extraction time, low production cost and high safety, and provides a better method and a better platform for further development and utilization of natural products.

Owner:ZHEJIANG UNIV

Preparation method and use of ginkgo-leaf extract

The invention discloses a preparation method and an application of a ginkgo leaf extract, wherein the method comprises the following steps of: a) washing and then drying ginkgo leaves; b) crashing and sieving; c) soaking by ethanol; d) oscillating by a ultrasonic cell crasher; e) extracting and filtering; and f) condensing in vacuum and drying. The invention has the advantages of adopting an ultrasonic-assisted extraction method, utilizing the functions of strong vibration, extremely high acceleration, strong cultivation effect, even stirring and the like generated by ultrasonic waves, accelerating the entry of the medicament effective constituents into the solvent, simultaneously avoiding the effect of high temperature on extraction constituents and greatly improving the yield of the extract. In the extract, flavonoids accounts for 36 percent, ginkgo terpene lactones account for over 8 percent while the injurant phenolic acid is less than 3PPM, therefore, the product has high safety. The obtained Ginkgo leaf extract of 4 to 6g is added to each kilogram of feeding stuff, therefore, the animal immune anti-inflammatory action and the production property can be raised by more than 10 percent and 2 to 3 percent respectively.

Owner:曹阳春

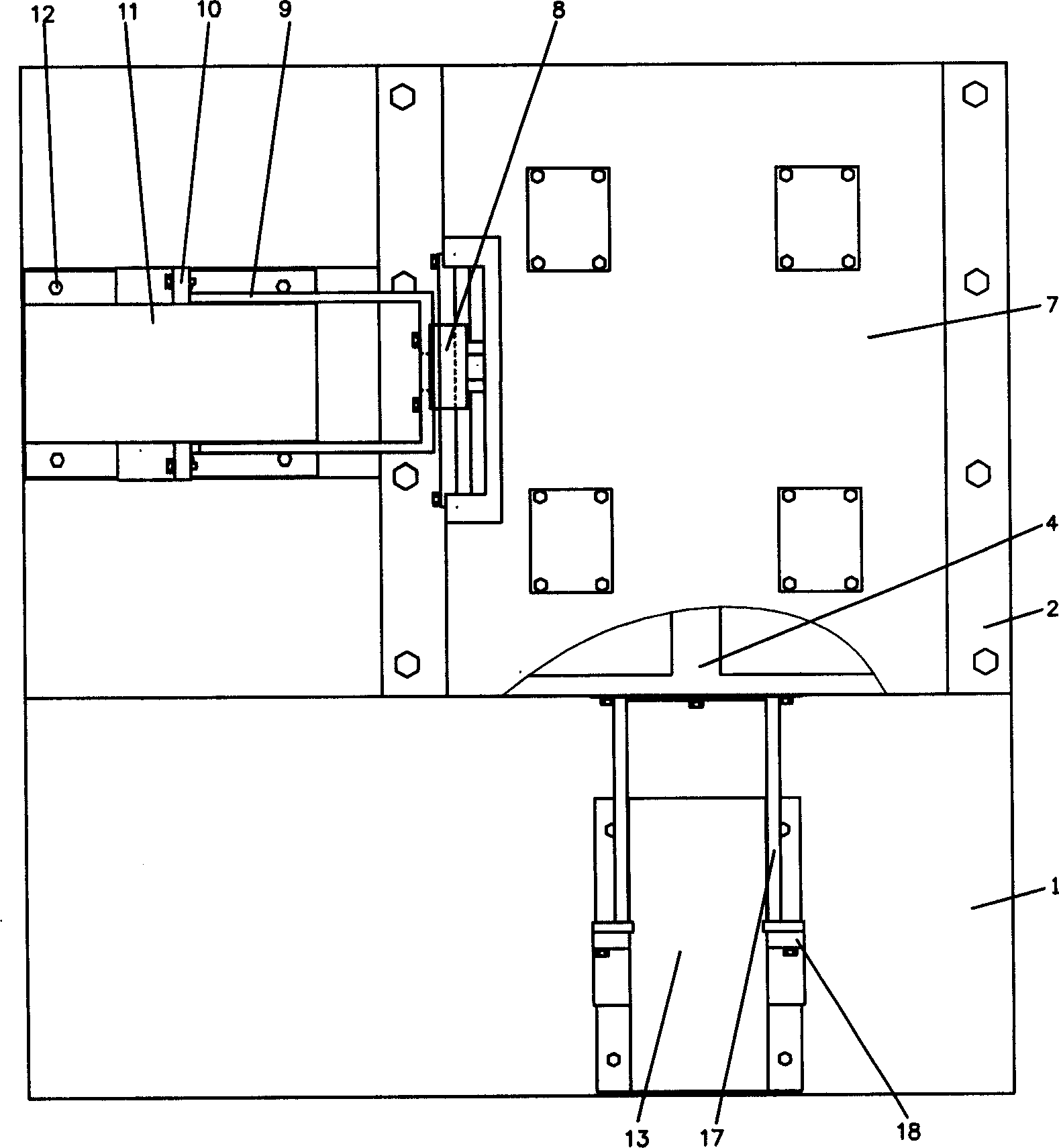

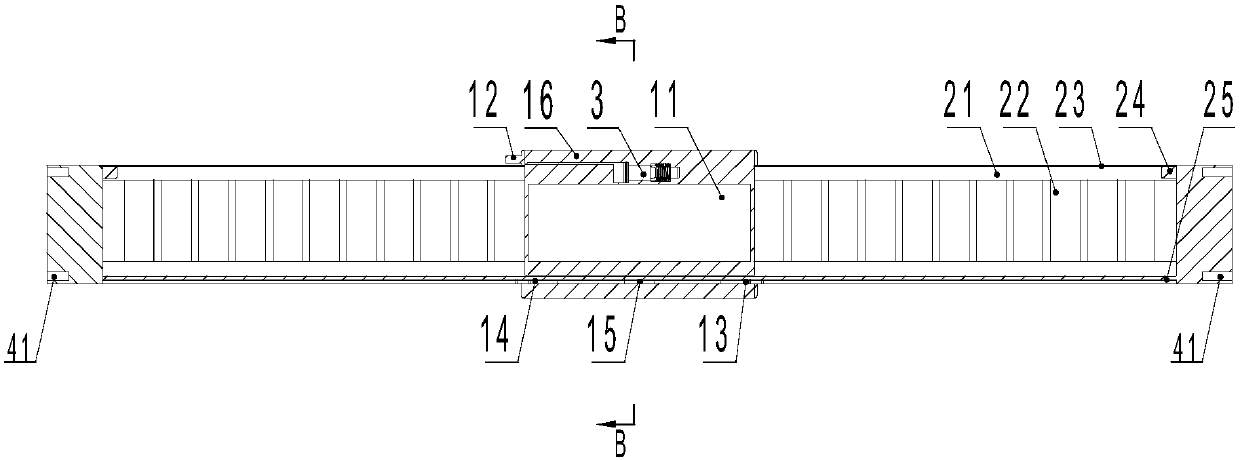

Air floation XY coordinates plane movoment platform

InactiveCN1564317ASmall moment of inertiaImprove structural rigiditySemiconductor/solid-state device manufacturingGratingHigh acceleration

The motion platform is composed of two linear motors perpendicular to each other, three platforms, two groups of position limited optical coupler and initial point optical coupler and two groups of optical grating ruler. Working platform, intermediate platform and lower platform are piled and connected to base. Platforms are connected through air floating guides. Intermediate platform and lower platform are movable in X direction relatively; working platform and intermediate platform are movable in Y direction relatively. Working platform and linear motors are connected through linear motor. Two linear motors drive motions of working platform along X and Y directions respectively. Stators of motor are fixed on base so as to reduce movement inertia. The invention is suitable to working platform in XY coordinate plane at high speed, high acceleration and precision.

Owner:SHANGHAI JIAO TONG UNIV

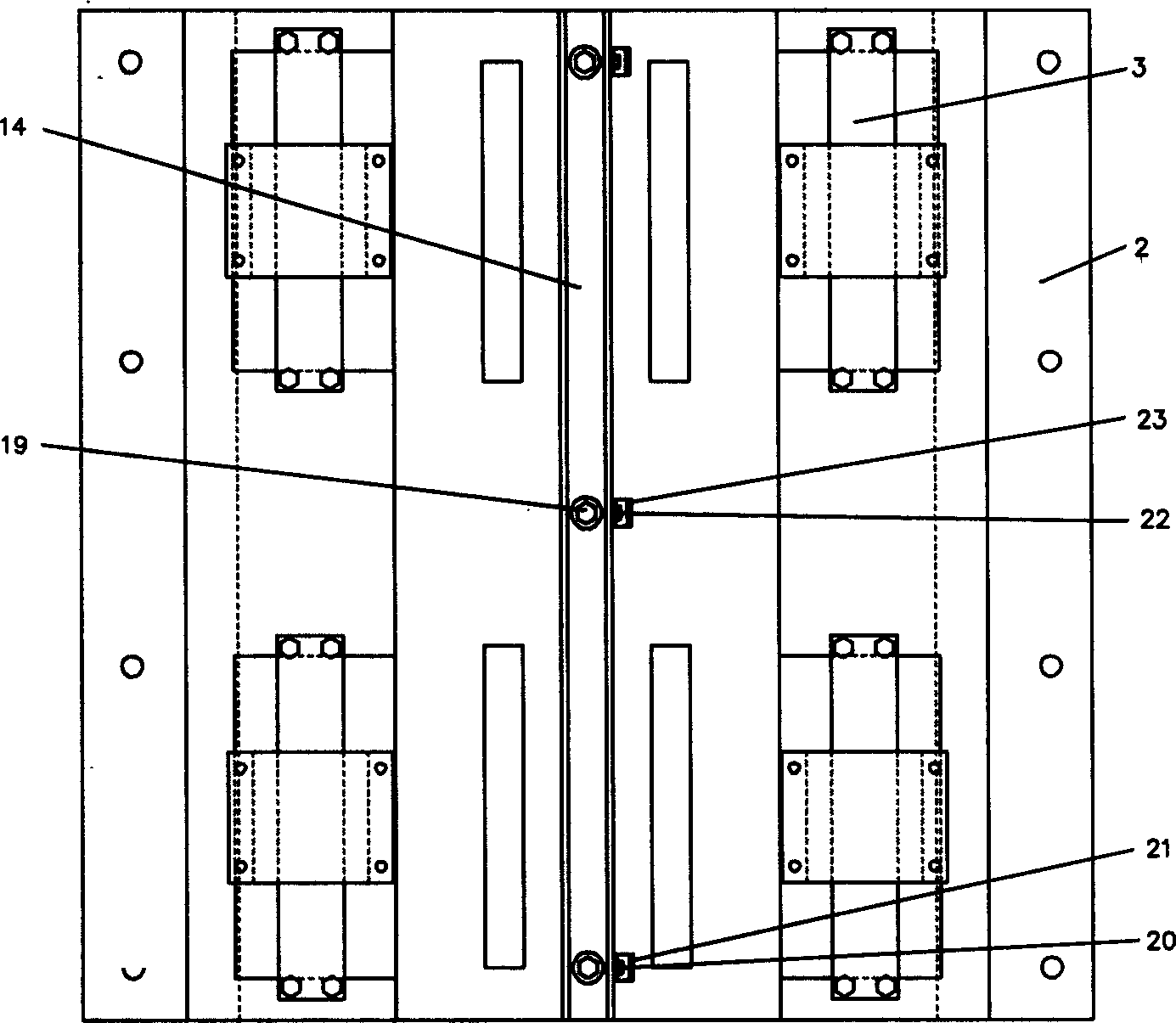

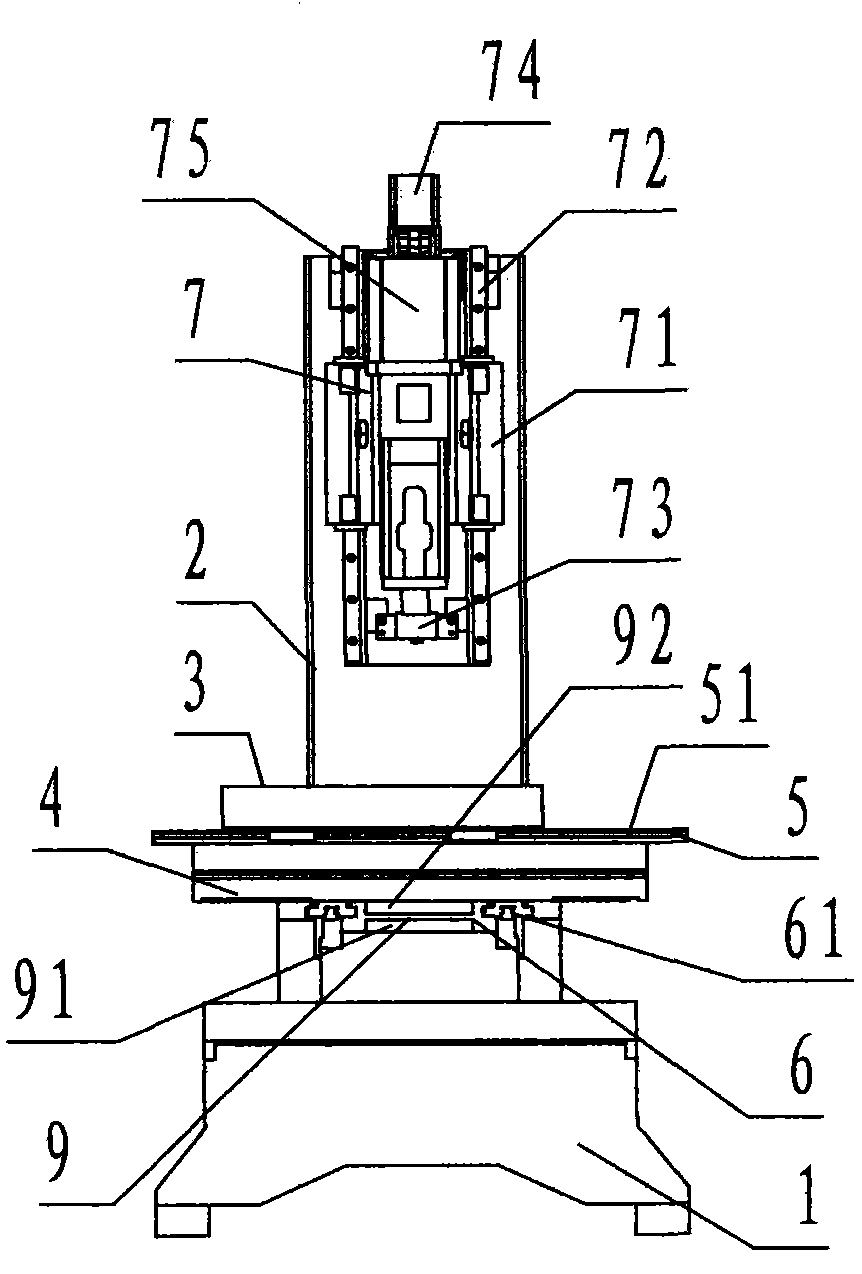

High-efficiency numerical-control drilling-milling machine tool

InactiveCN103862287AStiffness effectDrag fastFeeding apparatusOther manufacturing equipments/toolsUltrasound attenuationNumerical control

The invention discloses a high-efficiency numerical-control drilling-milling machine tool. The high-efficiency numerical-control drilling-milling machine tool comprises a bed (1), a stand column (2), a worktable (3), an orthogonal carriage (4), an X slide seat pair (5), a Y slide seat pair (6), a Z slide seat pair (7), a main shaft motor (75), an X-shaft linear motor (8) and a Y-shaft linear motor (9). An X-shaft slide plate and a Y-shaft slide plate are dragged by the linear motor, a Z-shaft slide plate is dragged by a rotating servo motor and a ball screw assembly to drill and mill a three-dimensional seek, so that the problems and weaknesses of the prior art that the efficiency of the seek is low, the attenuation of the positioning precision is fast, and the working stroke is limited can be overcome; by adopting the characteristics of the linear motor that the dragging speed is high, the acceleration is high, the positioning precision is high, the abrasion attenuation is avoided and the traveling stroke is not limited, the seek efficiency is improved, the attenuation of the positioning precision is eliminated and the traveling length is not limited by adopting the numerical-control drilling-milling machine tool.

Owner:宁波市凯博数控机械有限公司

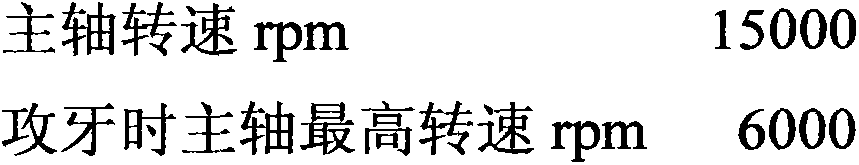

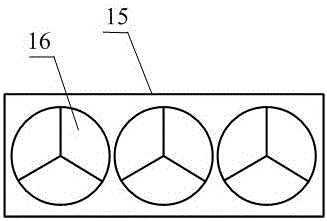

Large-stroke high-scanning frequency optical fiber delay line

PendingCN105891958AReduce coupling effectLow insertion lossCoupling light guidesComputer moduleDrive motor

The invention discloses a large-stroke high-scanning frequency optical fiber delay line. The large-stroke high-scanning frequency optical fiber delay line comprises a mobile reflecting module and a fixed reflecting module which are mutually and oppositely arranged; the mobile reflecting module is connected with a drive motor through a connecting piece; the drive motor is connected to a computer through a driver, and motion control is performed by using upper computer software; each of the mobile reflecting module and the fixed reflecting module comprises a plurality of uniformly-arranged hollow aluminum pyramid reflecting mirrors, and the quantity of the hollow aluminum pyramid reflecting mirrors on the fixed reflecting module is one more than that of the hollow aluminum pyramid reflecting mirrors on the mobile reflecting module. According to the large-stroke high-scanning frequency optical fiber delay line disclosed by the invention, by utilizing the reverse reflection characteristic of the pyramid reflecting mirrors, reflected light can be strictly parallel to incident light, so that the effect of shaking on optical fiber coupling in the scanning process is reduced, and the system insertion loss is reduced; as the N pyramid reflecting mirrors and the N-1 pyramid reflecting mirrors are oppositely arranged, multiple reflections are formed in the two reflecting modules to realize optical path delay; in comparison with single pyramid reflecting mirrors, the delay scope can be improved by N times under the situation that the motor stroke is unchanged.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Efficient anti-oxidative acne-removing handmade soap

InactiveCN107937176ADestructiveImprove antioxidant capacitySurface-active non-soap compounds and soap mixture detergentsDetergent compounding agentsBULK ACTIVE INGREDIENTSOAP

The invention relates to a high-efficiency anti-oxidation and anti-acne handmade soap, which is characterized in that: calculated according to the weight fraction, it includes the following components: 10-15 parts of Chinese medicine extract, 5-10 parts of Phyllostachys pubescens leaf extract, 1-10 parts of Pyracantha fruit extract 3 parts, 1-3 parts of indigo fruit extract, 1-2 parts of mangosteen husk extract, 1-2 parts of Italian Buglossia extract, 2-4 parts of lychee leaf extract, 2-4 parts of bayberry leaf extract, Perilla leaf extract 1‑2 parts, mugwort extract 1‑2 parts, nicotinamide 6‑10 parts, tea saponin 0.3‑1 part, seabuckthorn seed oil 70‑100 parts, natural soap base 250‑350 parts. The handmade soap raw material extract of the present invention is extracted by ultrasonic extraction. This process has high extraction efficiency, and the utilization rate of active ingredients in plant and fruit medicines is extremely high, because the biological transdermal accelerator is derived from plant extracts and has good biophase Capacitive, and will not cause damage to the skin, with safety.

Owner:宁波秋日小城智能科技有限公司

Engine brake detection

InactiveCN101835967AMinimize the effect of large valve forceHigh accelerationElectrical controlInternal combustion piston enginesExhaust valvePiston

The present invention relates to a method for reducing engine vibrations during engine braking with a malfunctioning engine brake, where said engine brake comprising means for altering a timing of at least one exhaust valve and means for varying an exhaust gas back pressure, comprising the steps of: detecting piston acceleration for each cylinder in the engine during the use of said engine brake,comparing said detected piston acceleration with a predetermined reference value, decreasing exhaust gas back pressure during engine braking if at least one piston is detected with a piston acceleration deviating more than a predefined amount from said predetermined reference value so that said piston acceleration will be falling within said predefined amount from said predetermined reference value.

Owner:VOLVO TRUCK CORP

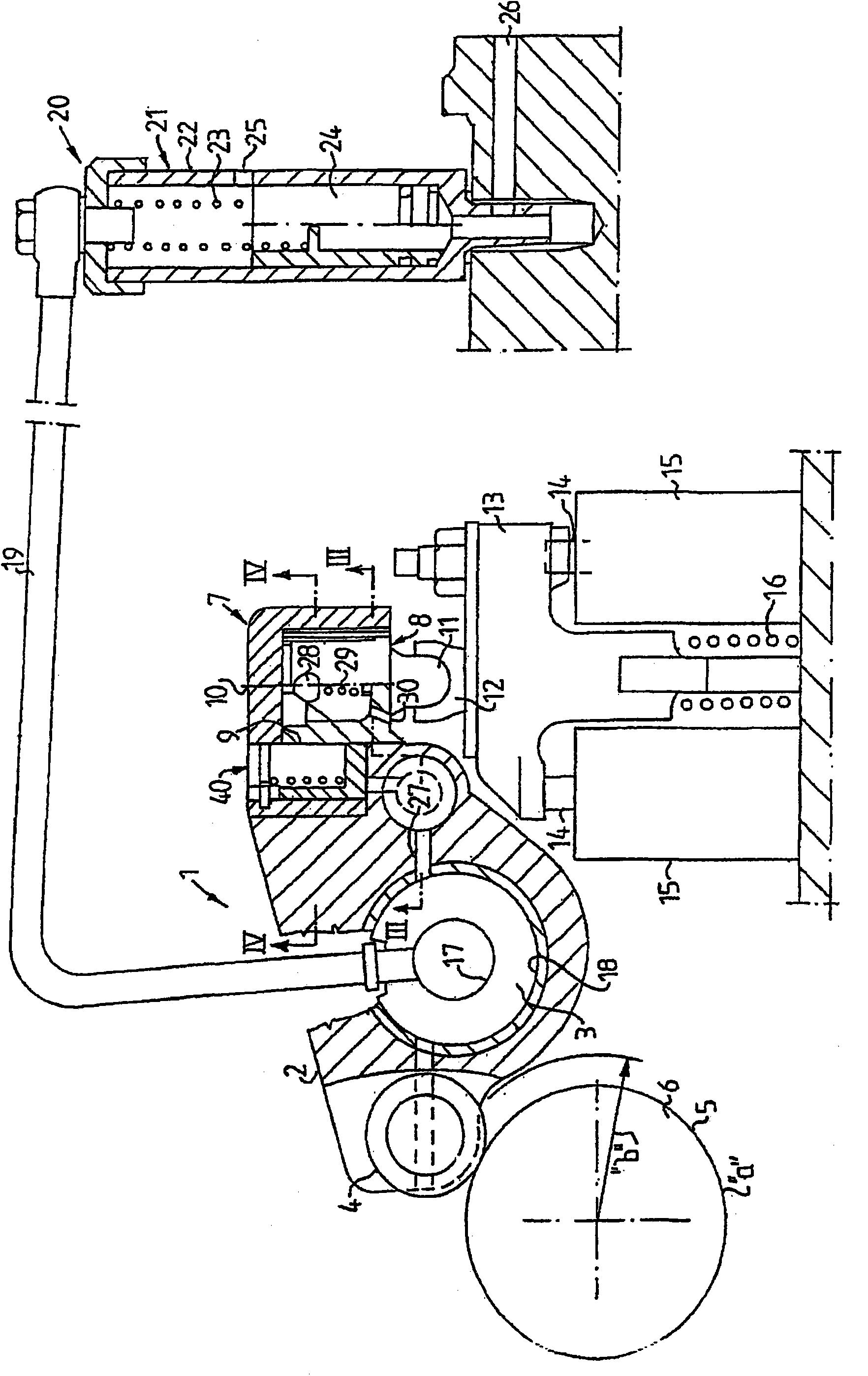

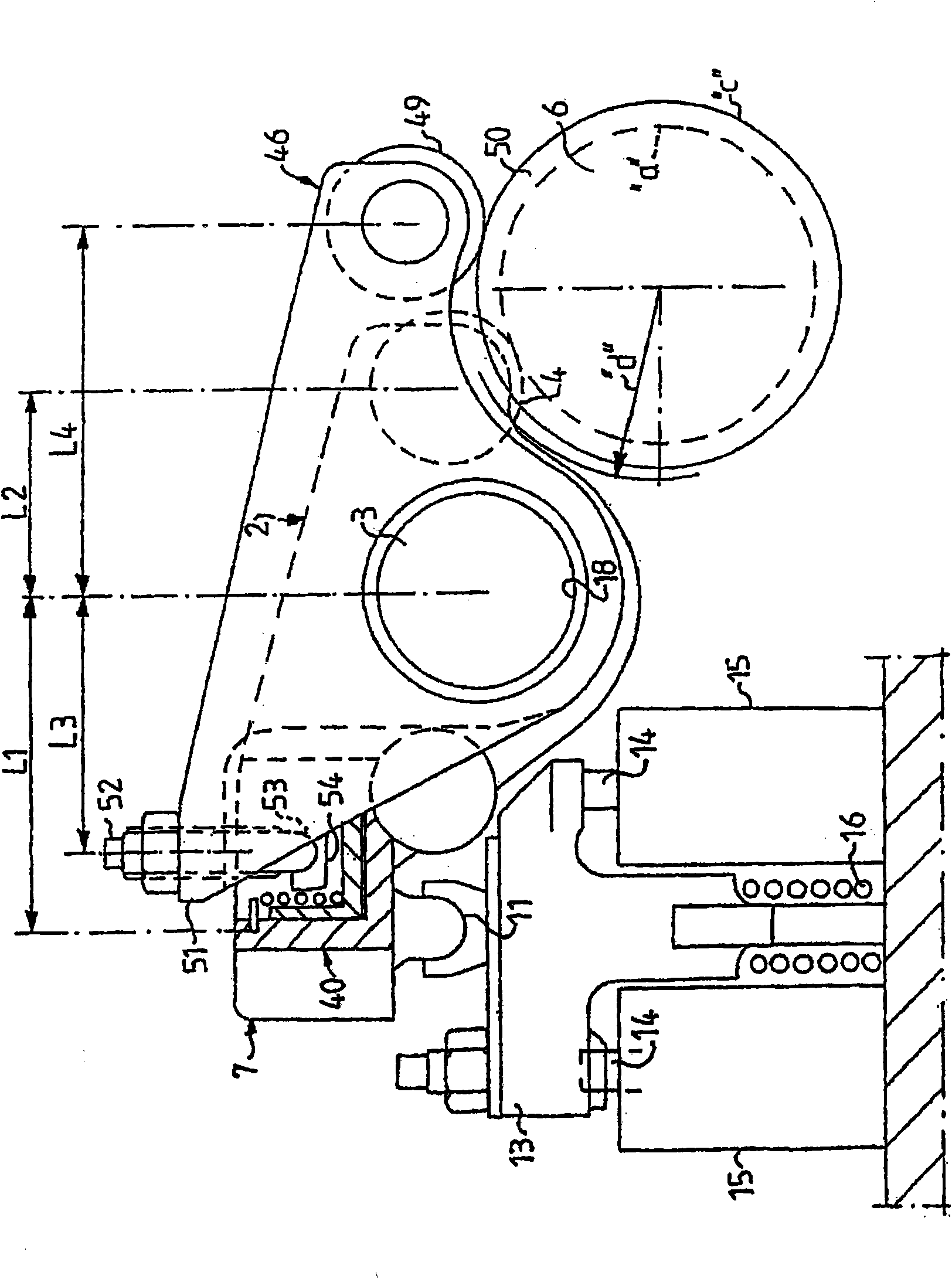

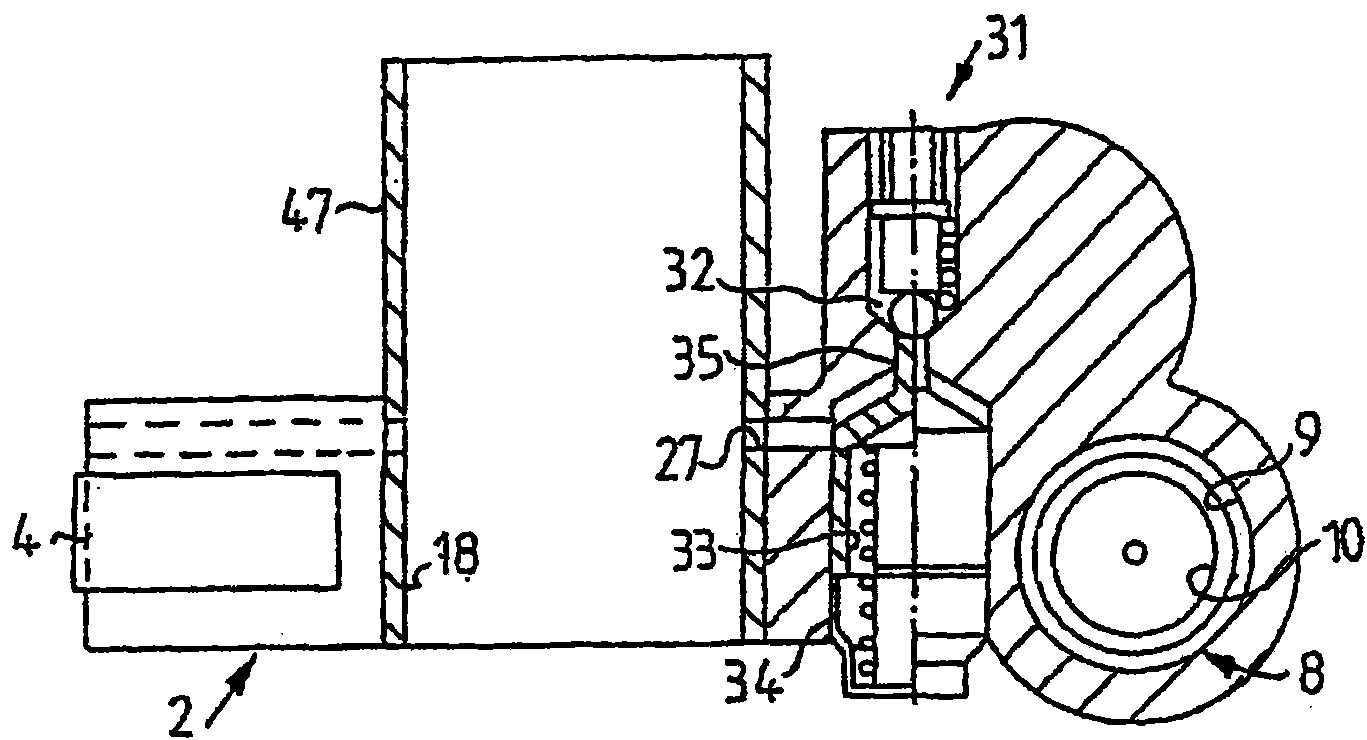

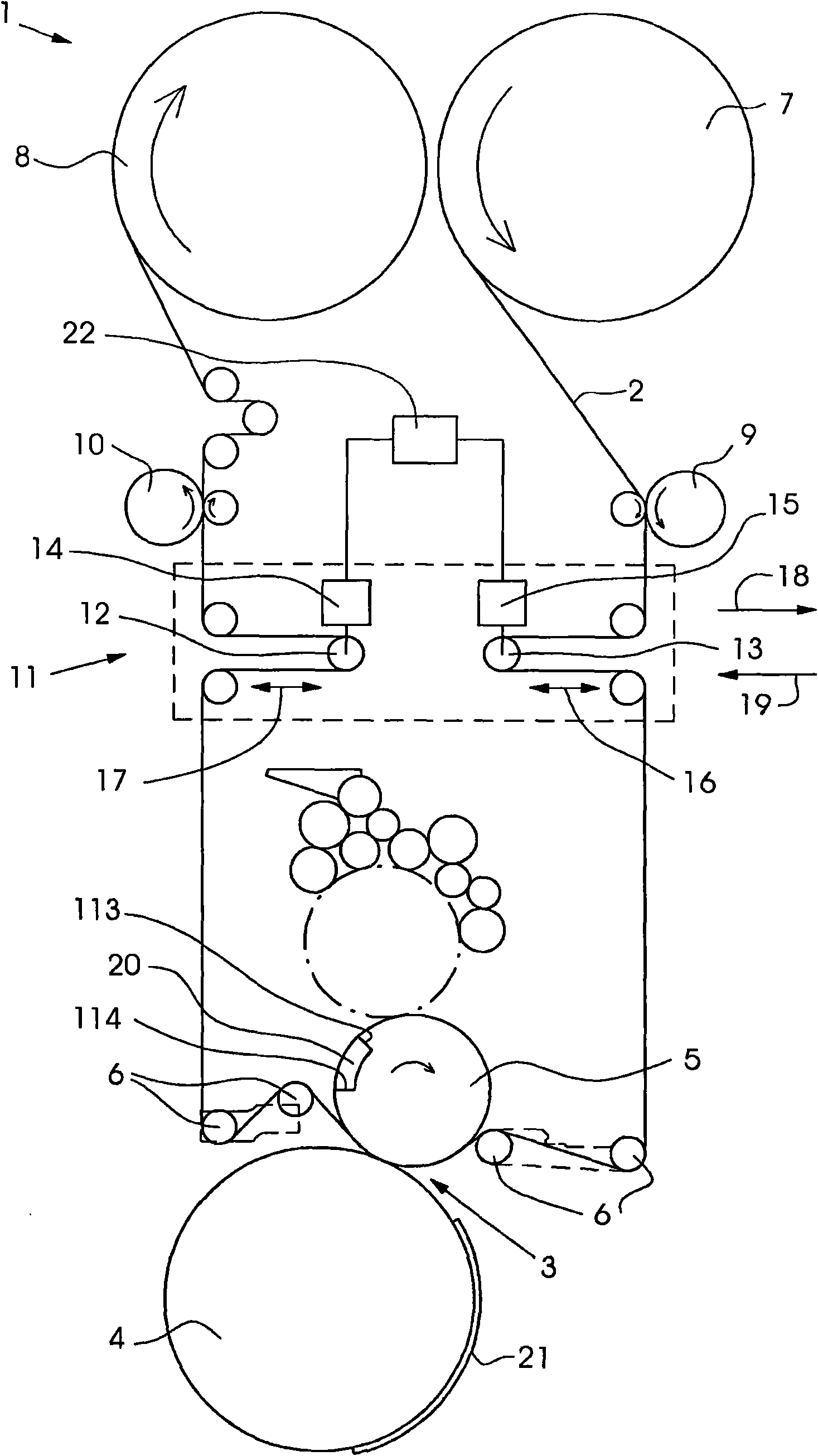

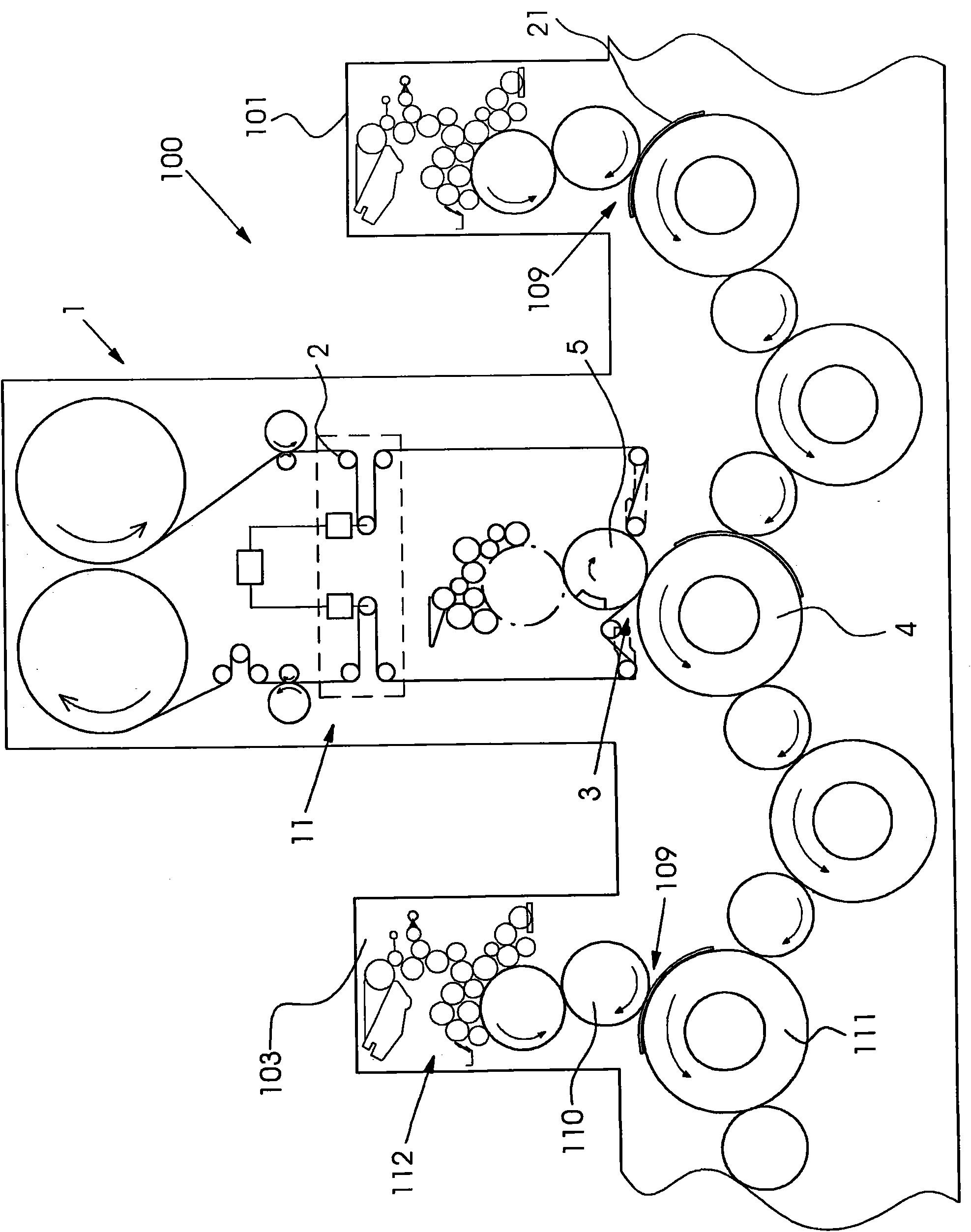

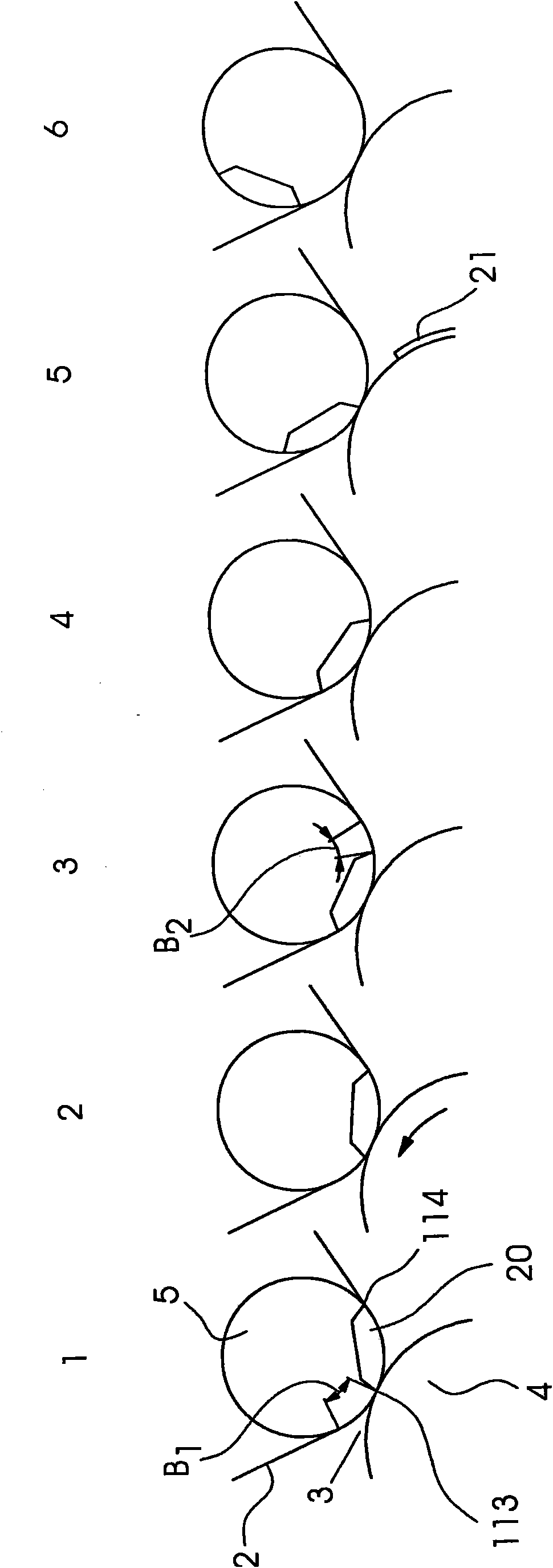

Beating device

ActiveCN101590717AReduced belt tension fluctuationsReduce the overall heightTransfer printingPrinting press partsEngineeringElectrical and Electronics engineering

Owner:海德堡印刷机械知识产权股份两合公司

Three-degree-of-freedom parallel robot mechanism

ActiveCN103203741ALarge working spaceIncrease flexibilityProgramme-controlled manipulatorThree degrees of freedomBall screw

The invention discloses a three-degree-of-freedom parallel robot mechanism and belongs to the technical field of industrial robots. The robot mechanism is a parallel robot mechanism capable of realizing two degrees of freedom of a plane and the rotation degree of freedom of an end-effector in a three-dimensional manner and continuously rotating at three degrees of freedom. The robot mechanism provided by the invention comprises a rack, a moving branch chain, movable platforms, a ball screw and the end-effector. A first driving branch chain drives a first movable platform so as to ensure the position accuracy of the end-effector, and a second driving branch chain drives a second movable platform so as to ensure the attitude accuracy of the end-effector. The robot mechanism is simple in structure, and can be used for realizing the space control over the end-effector, and simplifying the structure of a robot.

Owner:ANHUI TIANYI HEAVY IND

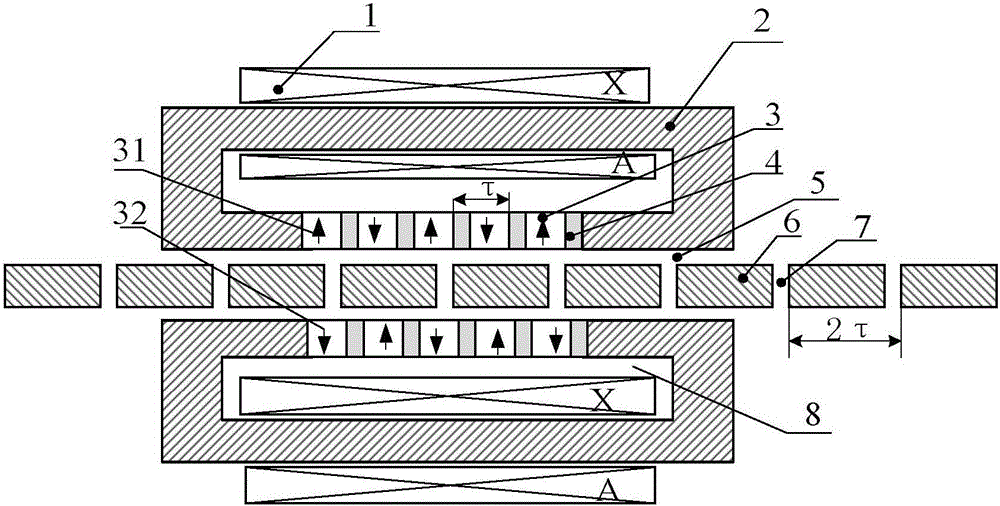

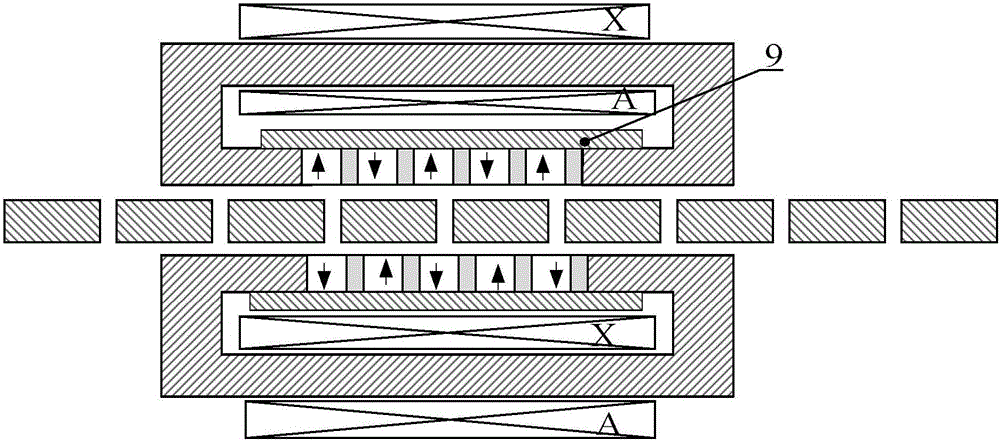

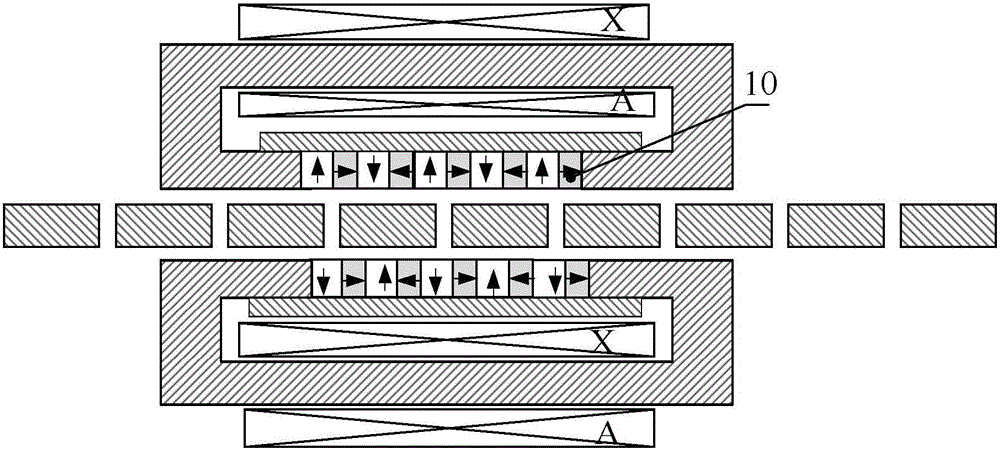

Independent-winding double-side plate permanent magnet linear motor

ActiveCN106100283ASimple winding processEasy to achieve coolingPropulsion systemsModular compositionElectricity

The invention discloses an independent-winding double-side plate permanent magnet linear motor, which comprises primary sides, a secondary side and air gaps. Each primary side comprises an armature winding, a primary magnetic-conductive iron core and a permanent magnet array. The two primary side assemblies are arranged at the two sides of the secondary side respectively to form a double-side structure. The primary magnetic-conductive iron core forms a big open slot structure, and the permanent magnet array is arranged in the slot mouth. One side, opposite to the corresponding open slot, of each primary magnetic-conductive iron core is provided with the armature winding; and the armature windings of the two primary sides at the two sides of the secondary side are same-phase windings, but electrical angle difference is 180 degrees. The secondary side is formed by magnetic-conductive iron cores having a salient pole structure, and gaps. The two air gaps are formed between the two primary sides and the secondary side respectively. The motor is a single-phase motor or a multi-phase motor, wherein the multi-phase motor is modular combination of the single-phase motors. Permanent magnets and the armature windings of the permanent magnet linear motor are arranged at the primary sides; through the big open slot structure design, winding heat dissipation is realized helpfully, and through the design of a large electrical load, thrust is improved; and meanwhile, the secondary side is simple in structure and light in weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

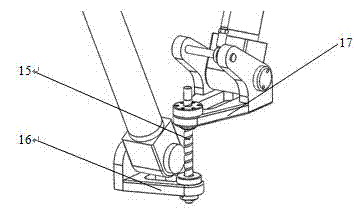

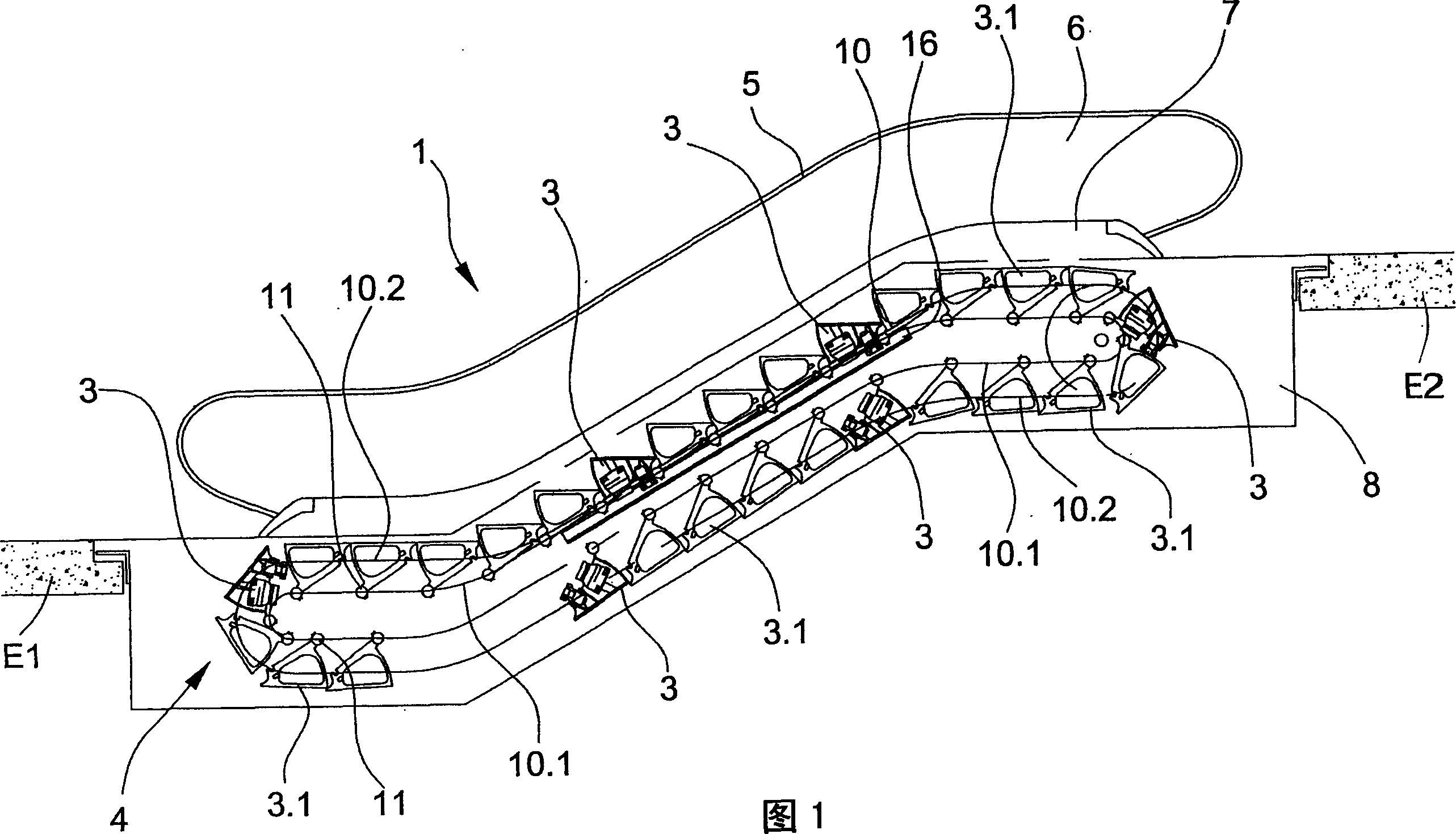

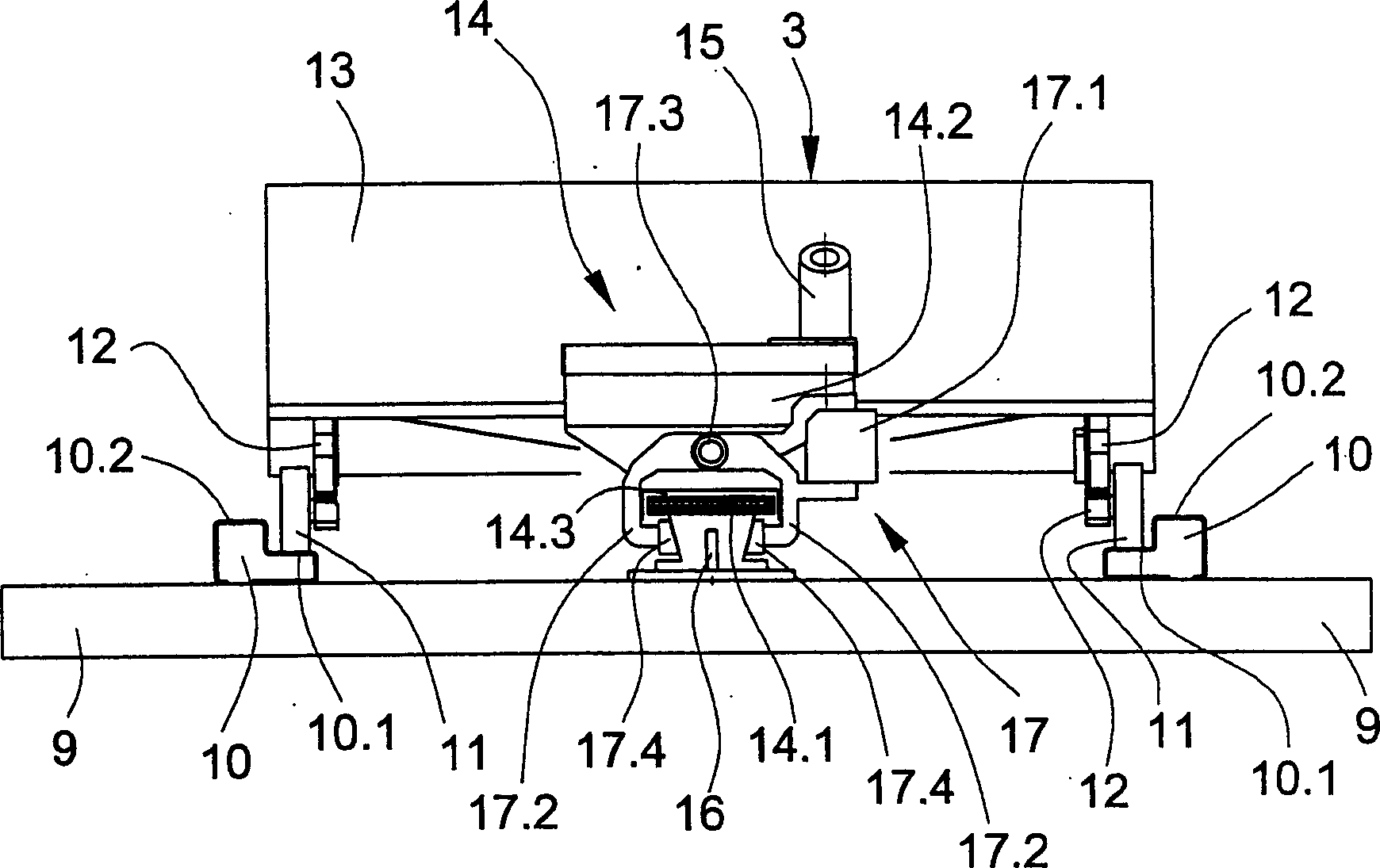

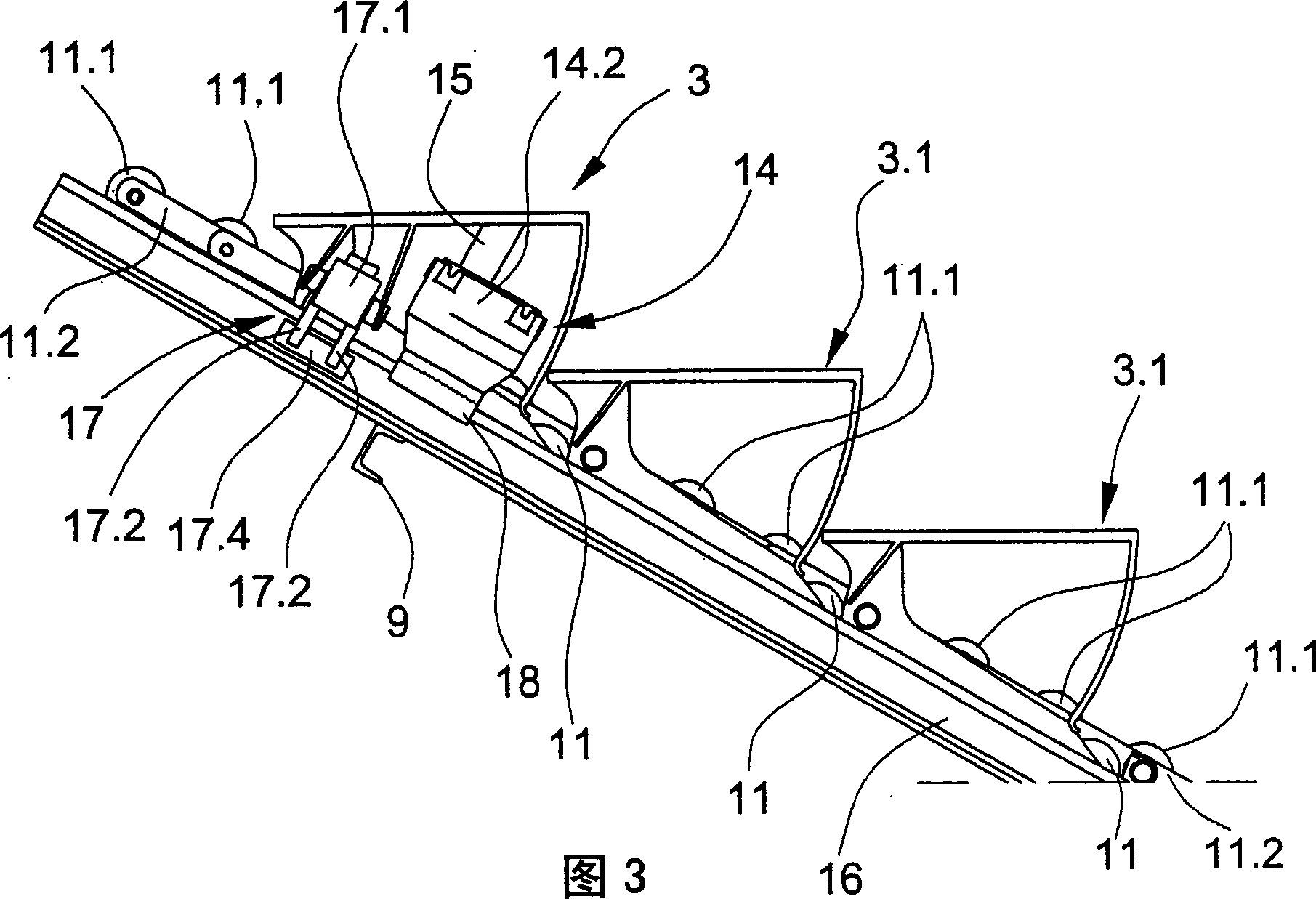

Drive equipment for escalator step or moving walkway plate

In the case of this escalator the step belt consists of motor-driven steps ( 3) and of free-running steps. Running rails (10) are arranged at transverse means (9) of the support construction and each have a respective running surface (10.1) for the step rollers (11) and a running surface (10.2) for the chain rollers. The step rollers (11) ar e connected with the step body (13) by means of arms (12). The secondary part (14.2) of a linear motor (14) is connected with the step body (13) by means of step pins (15). A guid e rail (16) serving for guidance and drive of the step (3) is provided along the forward running part or return running part of the escalator centrally at the beams (9), wherein the primary part (14.1) of the linear motor (14) is integrated in the guide rail (16). Each motor step (3) is provided with a brake (17) which acts on the guide rail (16).

Owner:INVENTIO AG

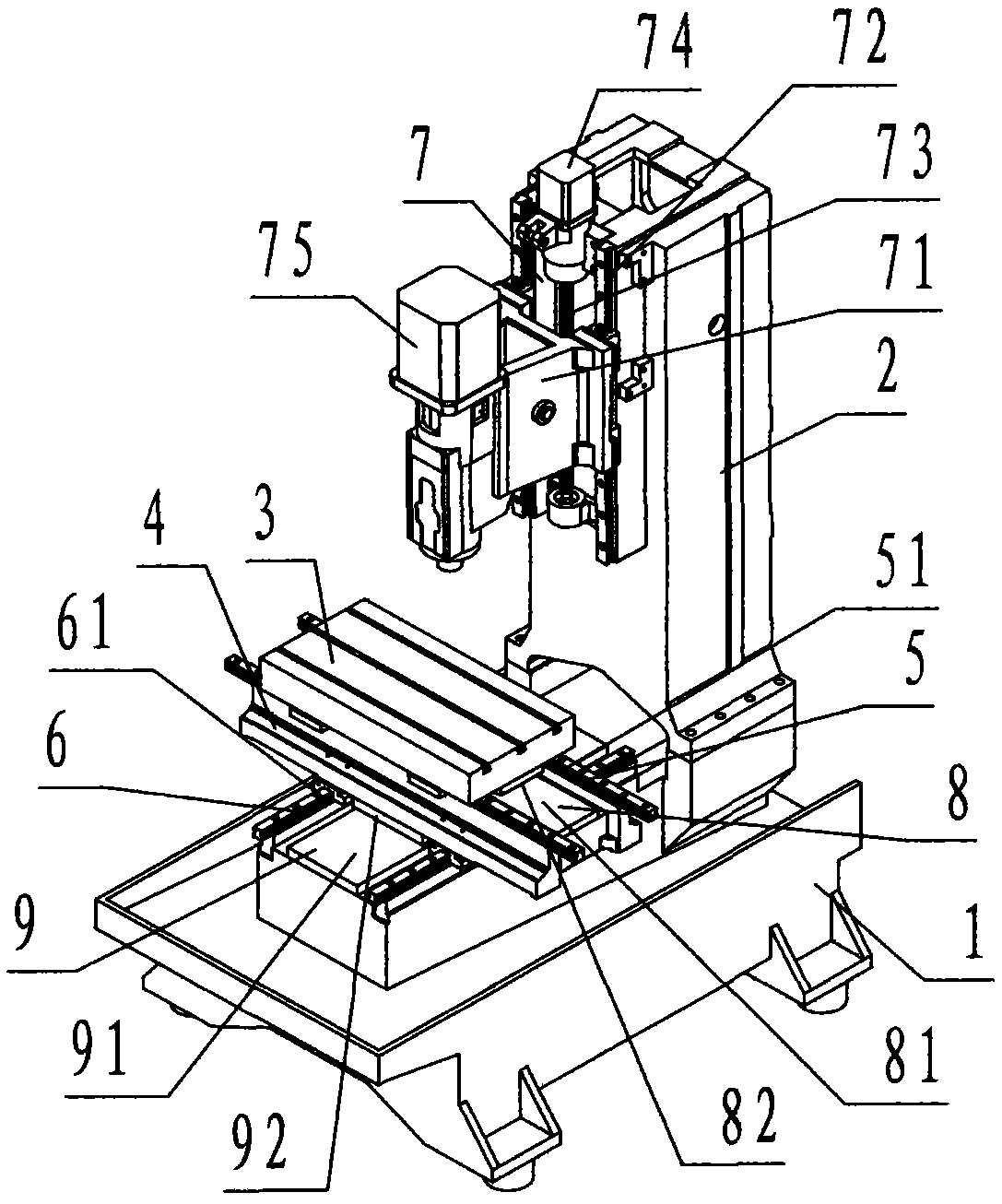

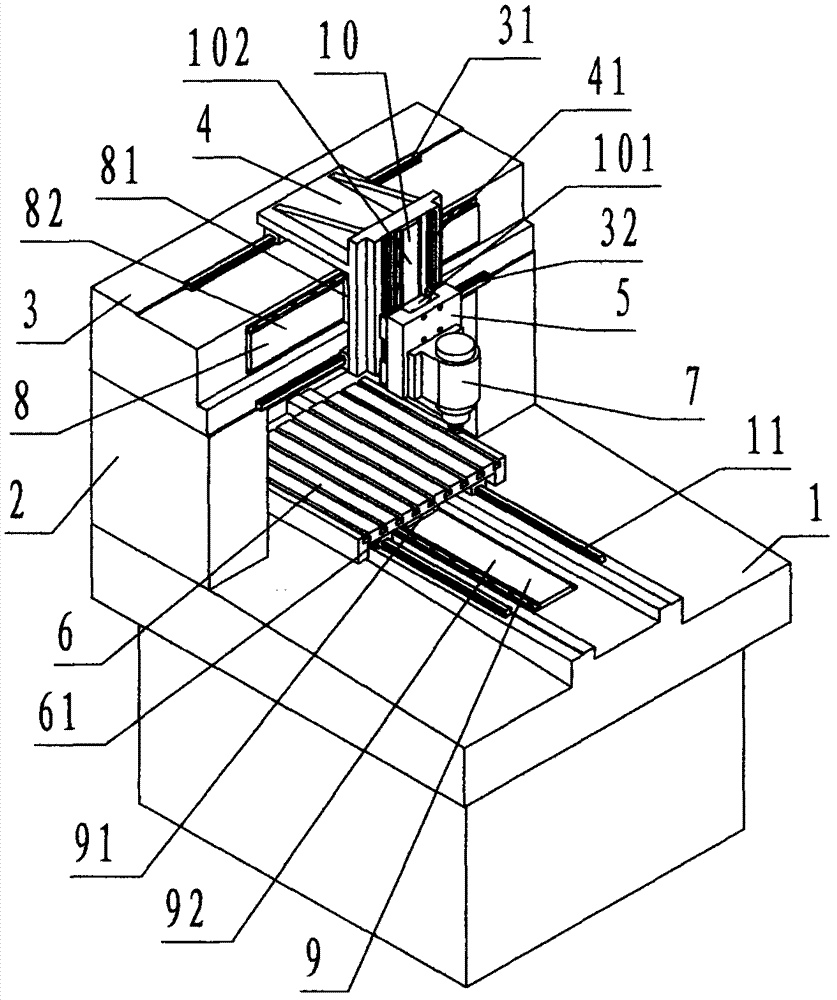

Numerical control engraving and milling machine tool with linear motors

InactiveCN102729099AAccelerateHigh positioning accuracyFeeding apparatusLarge fixed membersMachine toolLinear motor

The invention discloses a numerical control engraving and milling machine tool with linear motors, comprising a tool body (1), a vertical column (2), a cross beam (3), an X-axis sliding plate (4), a Z-axis sliding plate (5), a working platform (6), a main shaft motor (7), an X-axis linear motor (8), a Y-axis linear motor (9) and a Z-axis linear motor (10). The numerical control engraving and milling machine tool disclosed by the invention has the advantages that the technical scheme that the linear motors are used for dragging the X-axis sliding plate, the Y-axis sliding plate and the Z-axis sliding plate to carry out three-dimensional target-seeking engraving-milling cutting and machining is adopted, and the characteristics of the linear motors that the dragging speed is fast, the acceleration is high, the positioning accuracy is high, no wear attenuation is generated, no stroke length limitation exists are utilized, so that the defects that the dragging is realized by rotating a servo motor and adding a ball screw assembly is avoided, and the purposes of improving the target-seeking machining efficiency, alleviating the positioning accuracy attenuation and no limitation on the stroke length are achieved.

Owner:宁波市凯博数控机械有限公司

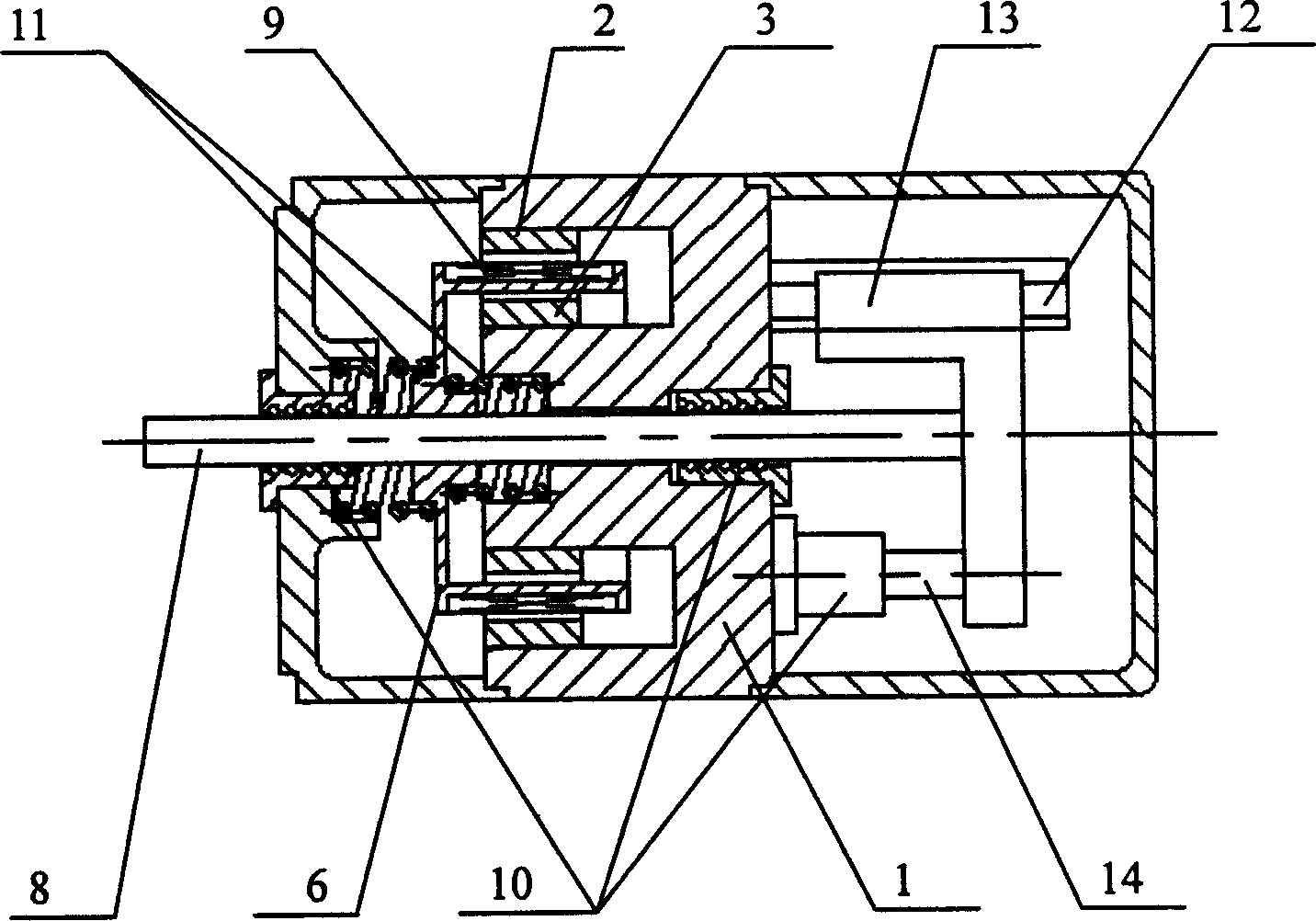

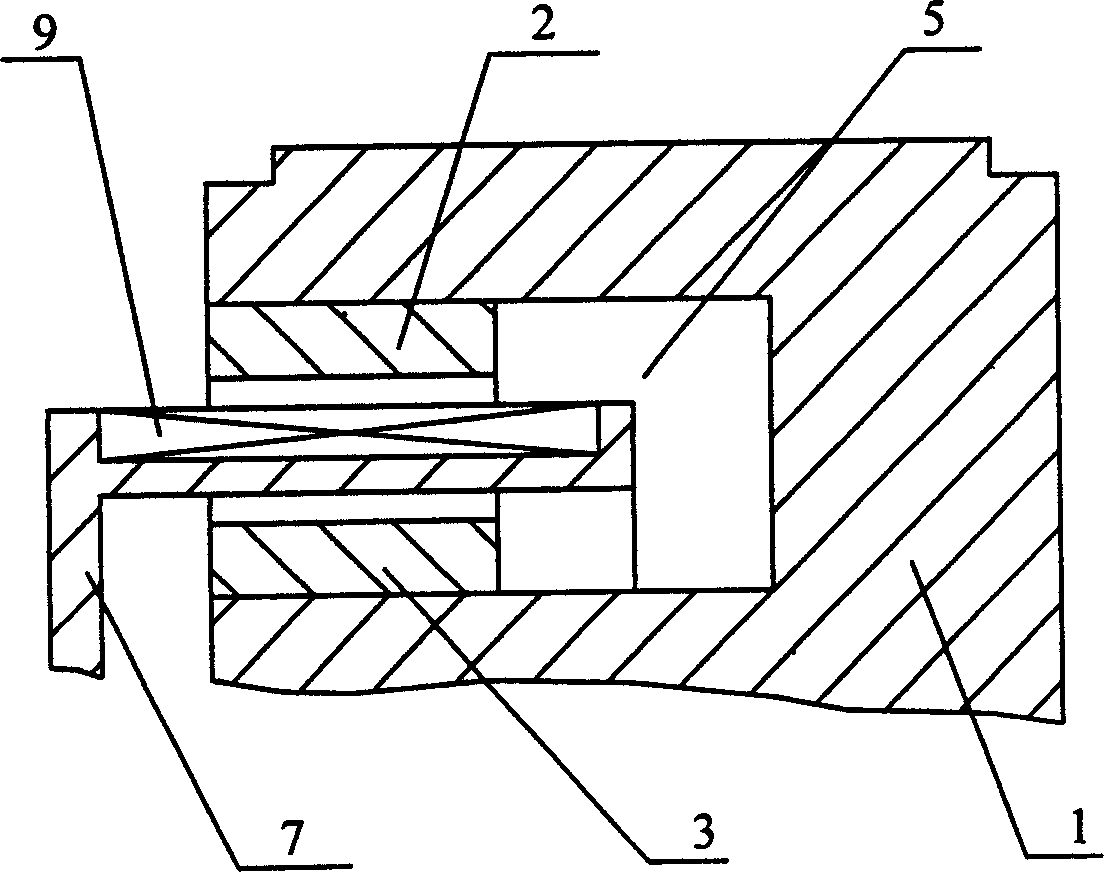

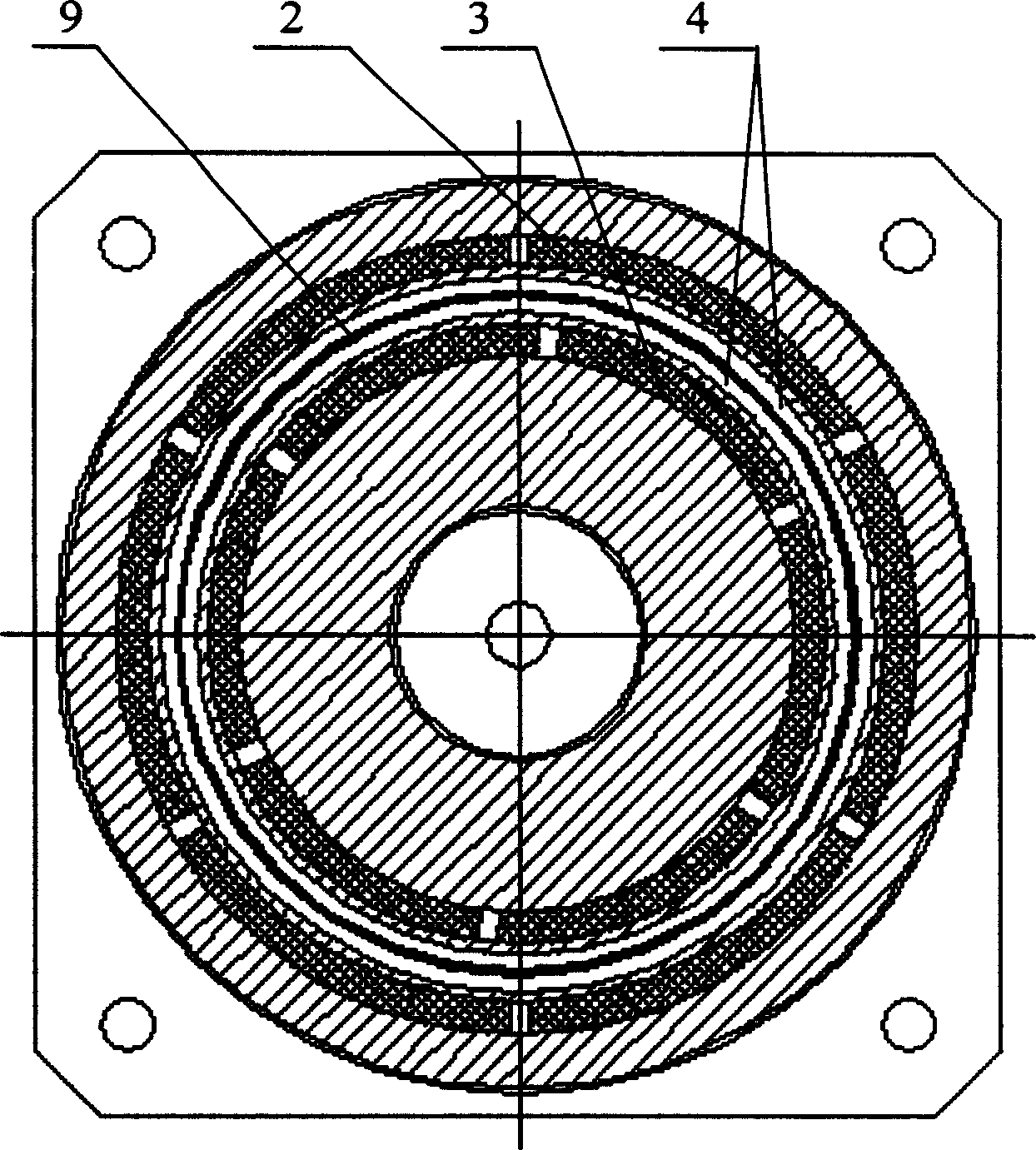

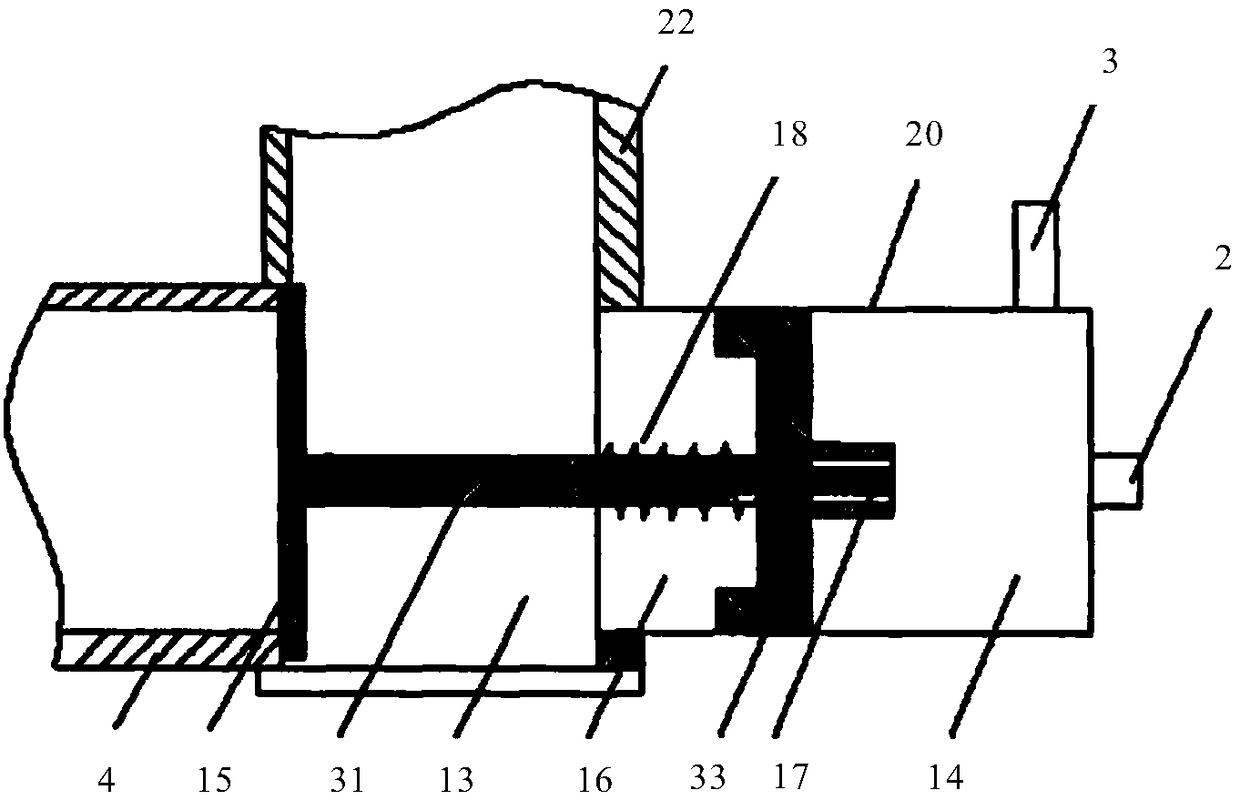

Short journey high responding linear motor

InactiveCN1595774AGuaranteed zero point positioningGuaranteed linearizationPropulsion systemsElectric machineHigh acceleration

The invention is a short-travel high-response straight-line electric machine, including a stator and a rotor, where the stator is of a permanent magnet steel internally-embedded annular structure and the rotor is composed of coil framework, connection shaft and coil and makes straight-line motion to and fro under the control of a servo driver; the connection shafts are both supported on a end cover and the stator through straight-line bearing; the connection shafts on two sides of the rotor are coated with a spring, respectively, and the ends of the two springs supports against the end cover and rotor, respectively. For improving push and speed indexes, it reduces rotor mass and size of electric machine; adopts an electric machine position detection-control integrative technique; shows high speed, high acceleration, high precision and high dynamic property and can be applied to high-speed to-and-fro small-displacement three-dimensional vibrating mirror dynamically focusing system, noncircular processing, high-speed grinder, and other places.

Owner:HUAZHONG UNIV OF SCI & TECH

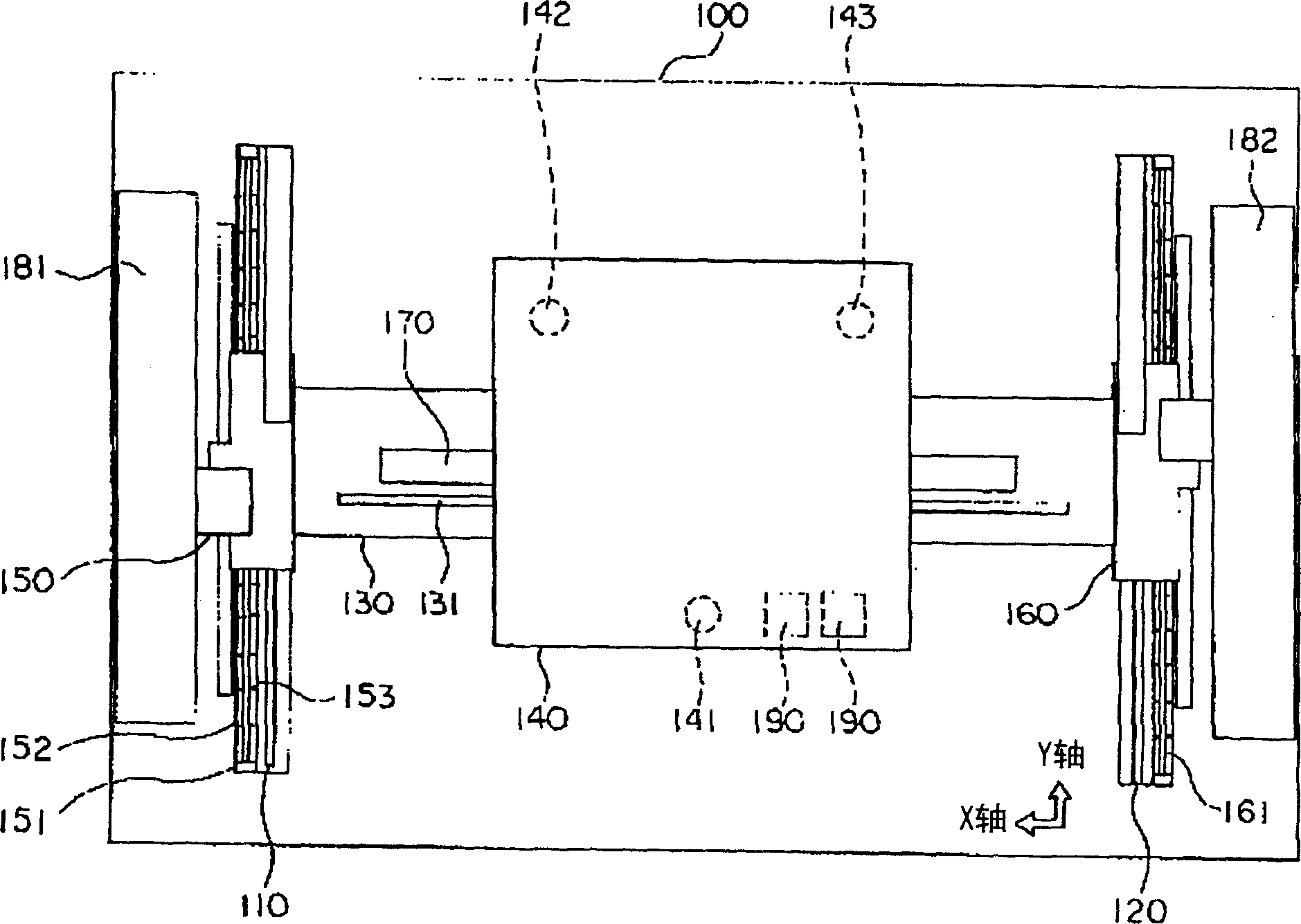

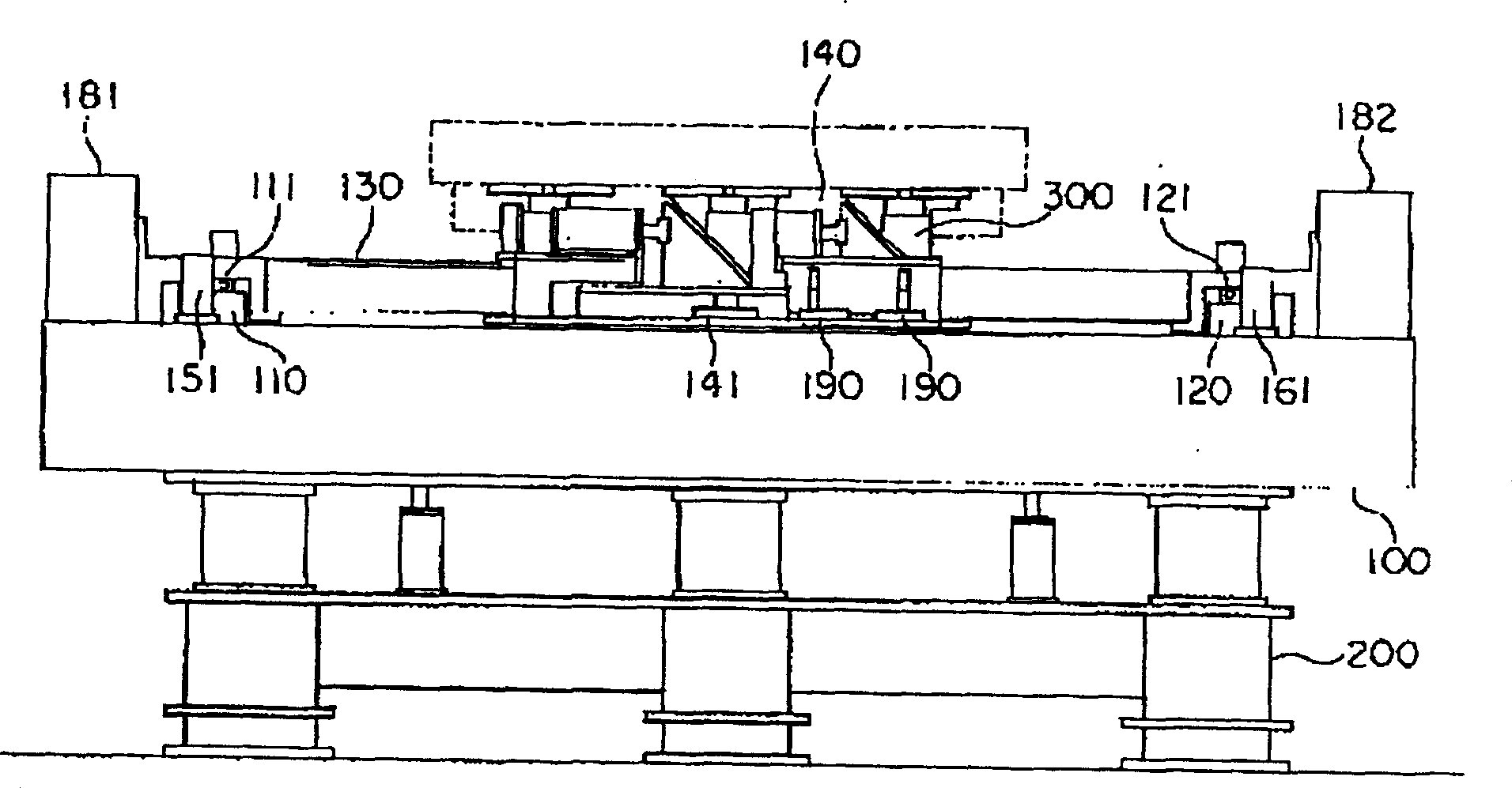

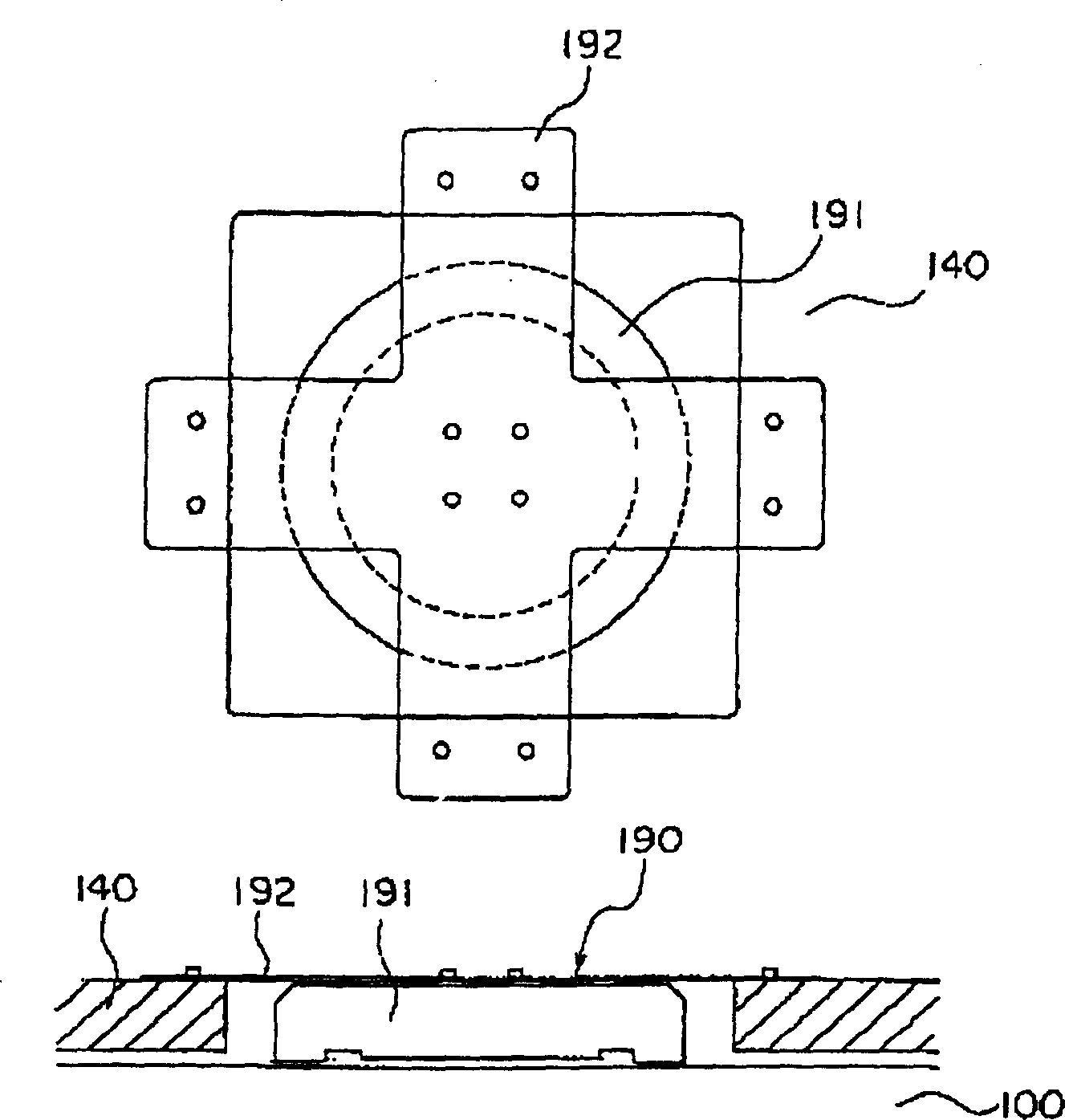

X-Y objective talbe

InactiveCN1534688AHigh mobile flatnessHigh stopping accuracyInstrumental componentsFeeding apparatusEngineeringMechanical engineering

An x-y stage device is provided to obtain the high stop accuracy while reducing expensive components. Two guide rails(110,120) are fixed on a base(100). An Y slider(130) moves through the guide rails by combining with the guide rails. An X slider(140) is combined with the Y slider to move through the Y slider in perpendicularly. The Y slider is moved with separating from the surface of the base by supporting in the guide rails with rolling bearings. The X slider is moved by including the rolling bearing between the Y slider and moved with floating from the surface of the base by including plural static pressure bearings(141143). The stop accuracy is improved by a brake device(190).

Owner:SUMITOMO HEAVY IND LTD

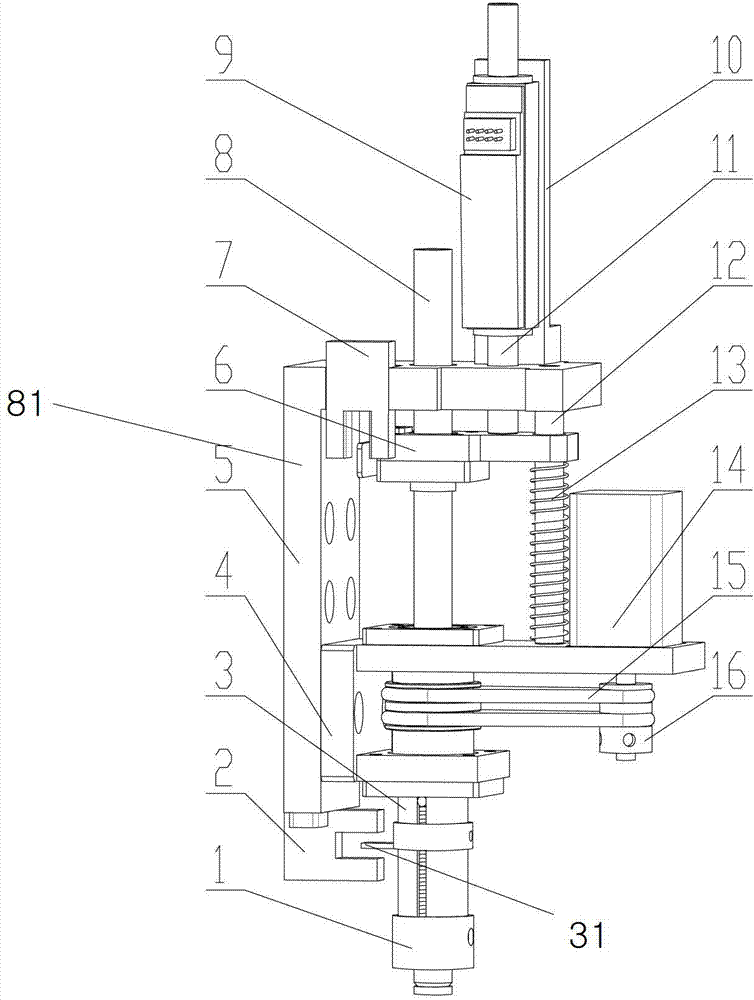

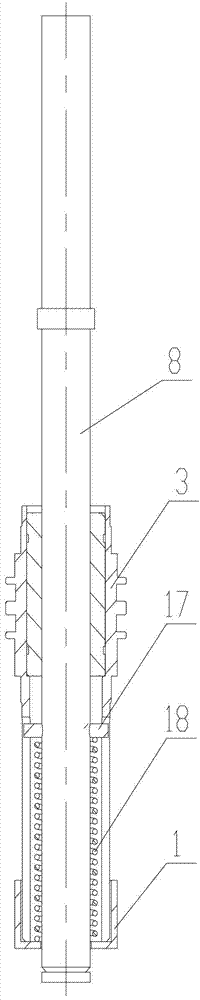

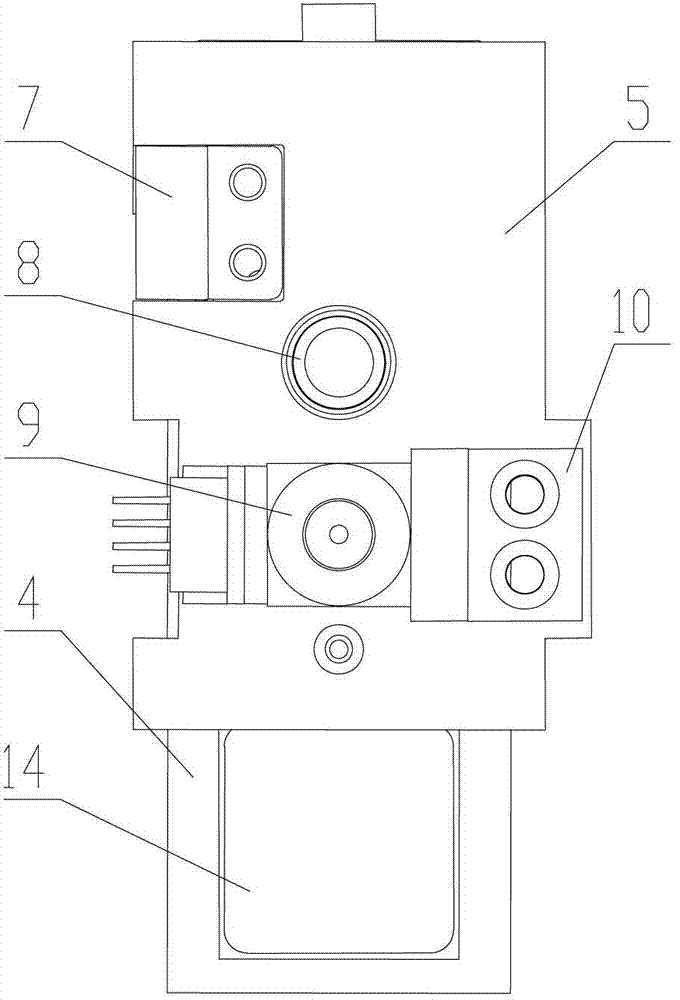

Module type high-speed mounting head for chip mounter

ActiveCN102869201ASimple structureCompact structurePrinted circuit assemblingElectric machineSurface mounting

The invention discloses a module type high-speed sticking head for a chip mounter and relates to the field of chip mounters of electronic surface mount, aiming at providing a module type high-speed sticking head which is simple in overall structure, small in size, light in weight, high in mounting efficiency, good in precision, flexible to integrate, easy to control and convenient to maintain. The module type high-speed sticking head comprises a mounting head fixing bracket, a belt wheel bracket, a mounting main shaft, an elevating mechanism and a rotating mechanism, wherein the belt wheel bracket, the mounting main shaft, the elevating mechanism and the rotating mechanism are connected with the mounting head fixing bracket; the elevating mechanism comprises a servo linear motor, a linear motor push rod and a pressing block, wherein the servo linear motor is installed on the mounting head fixing bracket; the pressing block is connected with the linear motor push rod; and the rotating mechanism comprises a stepper motor, a small belt wheel, an O-shaped belt and a belt wheel shaft, wherein the stepper motor is installed on the belt wheel bracket; and the belt wheel shaft is elastically connected with the mounting main shaft longitudinally.

Owner:JIANGSU NANJIXING TECH +1

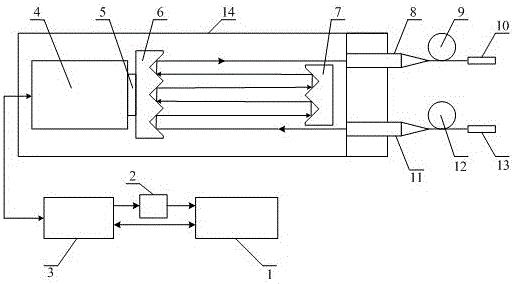

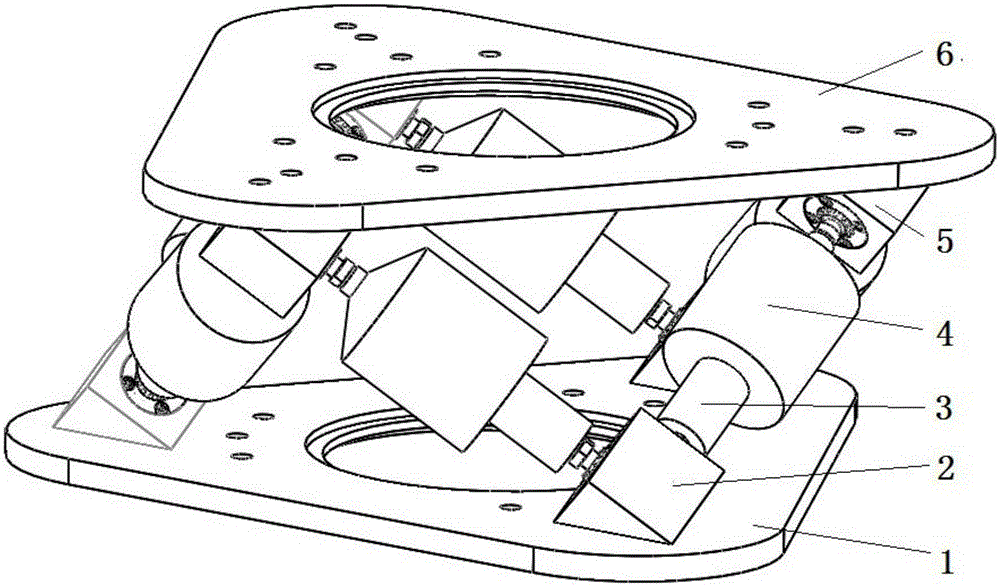

Stewart active and passive integrated vibration isolation platform adopting electromagnetic drive

InactiveCN105204543AAchieve decouplingGuaranteed pose adjustment functionMechanical oscillations controlMedium frequencyEngineering

The invention provides a Stewart active and passive integrated vibration isolation platform adopting electromagnetic drive. The vibration isolation platform comprises a foundation platform, three lower connecting blocks, six supporting legs, three upper connecting blocks and a load platform, wherein the foundation platform, the three lower connecting blocks, the six supporting legs, the three upper connecting blocks and the load platform are connected in sequence. The vibration isolation platform is characterized in that the supporting legs comprise force sensors and voice coil actuators; one ends of the force sensors are connected with the lower connecting blocks, the other ends of the force sensors are connected with the voice coil actuators, and the force sensors are used for detecting acting force on the supporting legs; one ends of the voice coil actuators are connected with the upper connecting blocks, the other ends of the of the voice coil actuators are connected with the force sensors, and the voice coil actuators are used for generating different displacement elongations according to external vibration source disturbance, so that system vibration is actively controlled. The vibration isolation platform is mainly used for passively isolating high frequency and actively isolating low and medium frequency; the posture of an upper platform is controlled through displacement generated by the voice coil actuators, so that micro vibration is actively controlled and isolated; the vibration isolation platform has the advantage that ultra-low frequency control can be achieved by adopting electromagnetic drive.

Owner:SHANGHAI JIAO TONG UNIV

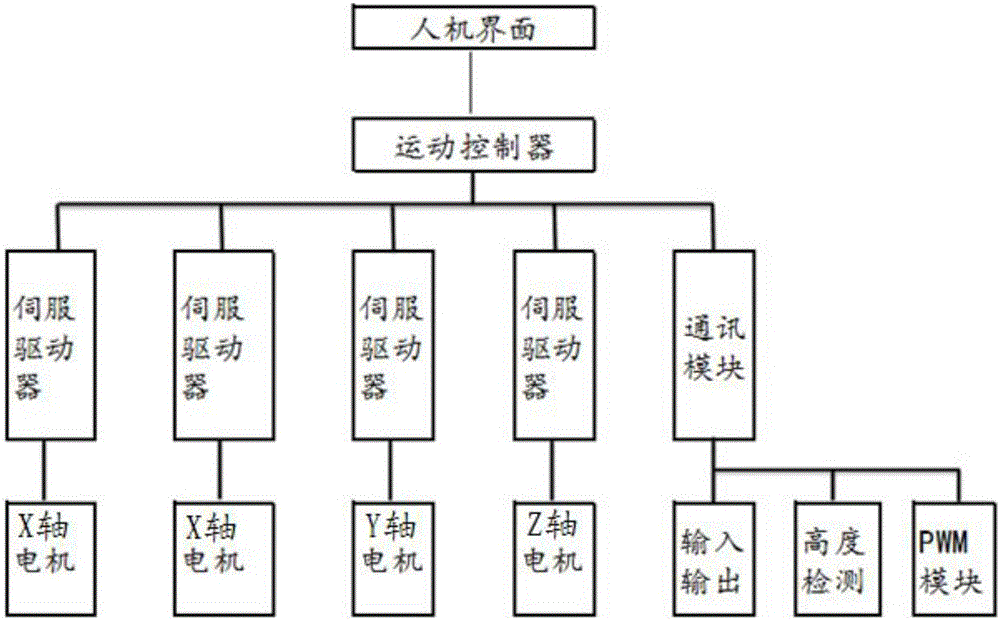

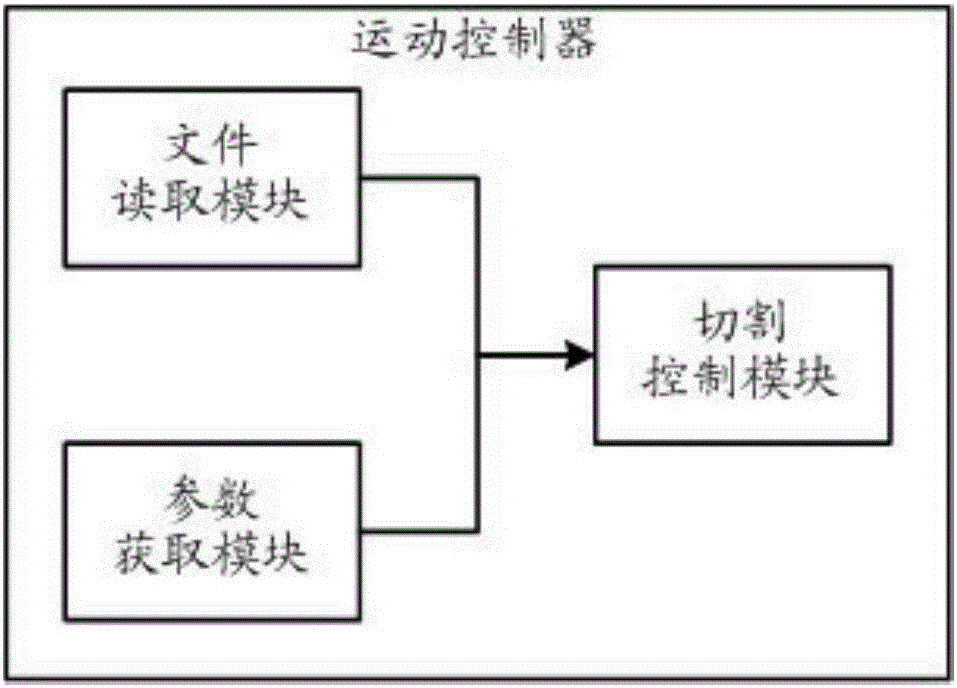

Bi-axial synchronous laser cutting machine control system

ActiveCN105834578AReduce wearGuaranteed uptimeLaser beam welding apparatusMachine controlControl system

The invention relates to a bi-axial synchronous laser cutting machine control system. The bi-axial synchronous laser cutting machine control system comprises a movement controller, a plurality of servo drivers and a plurality of motors. The bi-axial synchronous laser cutting machine control system is characterized in that the movement controller is connected with the servo drivers and the motors through a bus; the movement controller is also connected with a pulse width modulation (PWM) module through a communication module, and the PWM module is used for controlling the power and frequency of a laser device; the movement controller comprises a file reading unit, a parameter acquisition unit and a cutting control unit; the file reading unit is used for reading a cutting program file; the parameter acquisition unit is used for acquiring cutting parameters; and the cutting control unit is used for forming a control command according to the cutting program file and the cutting parameters and controls the laser device driven by the servo drives and the motors to achieve cutting of complex shapes according to the control command. By the adoption of the bi-axial synchronous laser cutting machine control system, higher-precision and higher-speed movement can be achieved.

Owner:PHASE MOTION CONTROL SOLUTION WUHAN CO LTD

Method for separating and extracting composite amino acid from hibiscus syriacus leaf

ActiveCN103642862AMild conditions for enzymatic actionPlay a role in breaking the wallOrganic compounds purification/separation/stabilisationFermentationBiotechnologyActivated carbon

The invention relates to a separation and purification method of composite amino acid, and particularly relates to a method for separating and extracting the composite amino acid from hibiscus syriacus leaves. The method comprises the following steps of: (1) pretreating; (2) ultrasonically treating; (3) decoloring; (4) removing impurities; (5) purifying; (6) dissolving a crystal, adding active carbon, stirring, filtering, placing into a refrigerator for filtration, precipitating an amino acid, and drying to obtain a composite amino acid crystal. The method disclosed by the invention can be used for extracting the composite amino acid from the hibiscus syriacus leaves by jointly acting on the hibiscus syriacus leaves through a complex enzyme and an ultrasonic wave, is moderate in enzyme acting condition and plays a wall-breaking role, namely a role of enabling the amino acid contained in the hibiscus syriacus leaves to be thoroughly dissolved. According to the invention, an ultrasonic wave extracting process is a physical process, no chemical change is generated in the extracting process, and a leached biological active substance is kept unchanged within a short time, so that the crushing time is shortened.

Owner:BEIJING EURO & AMERICAN INST OF SCI & TECH

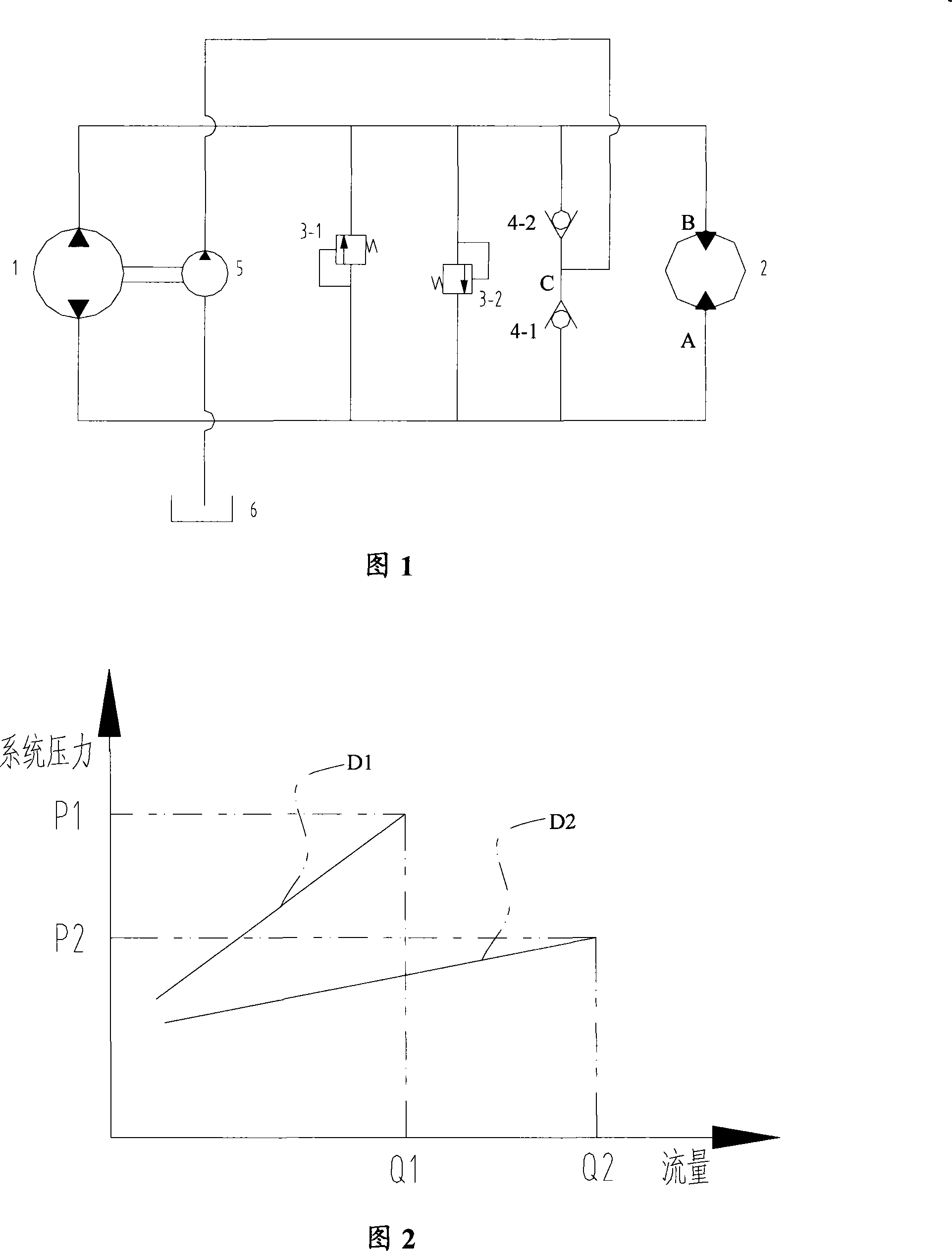

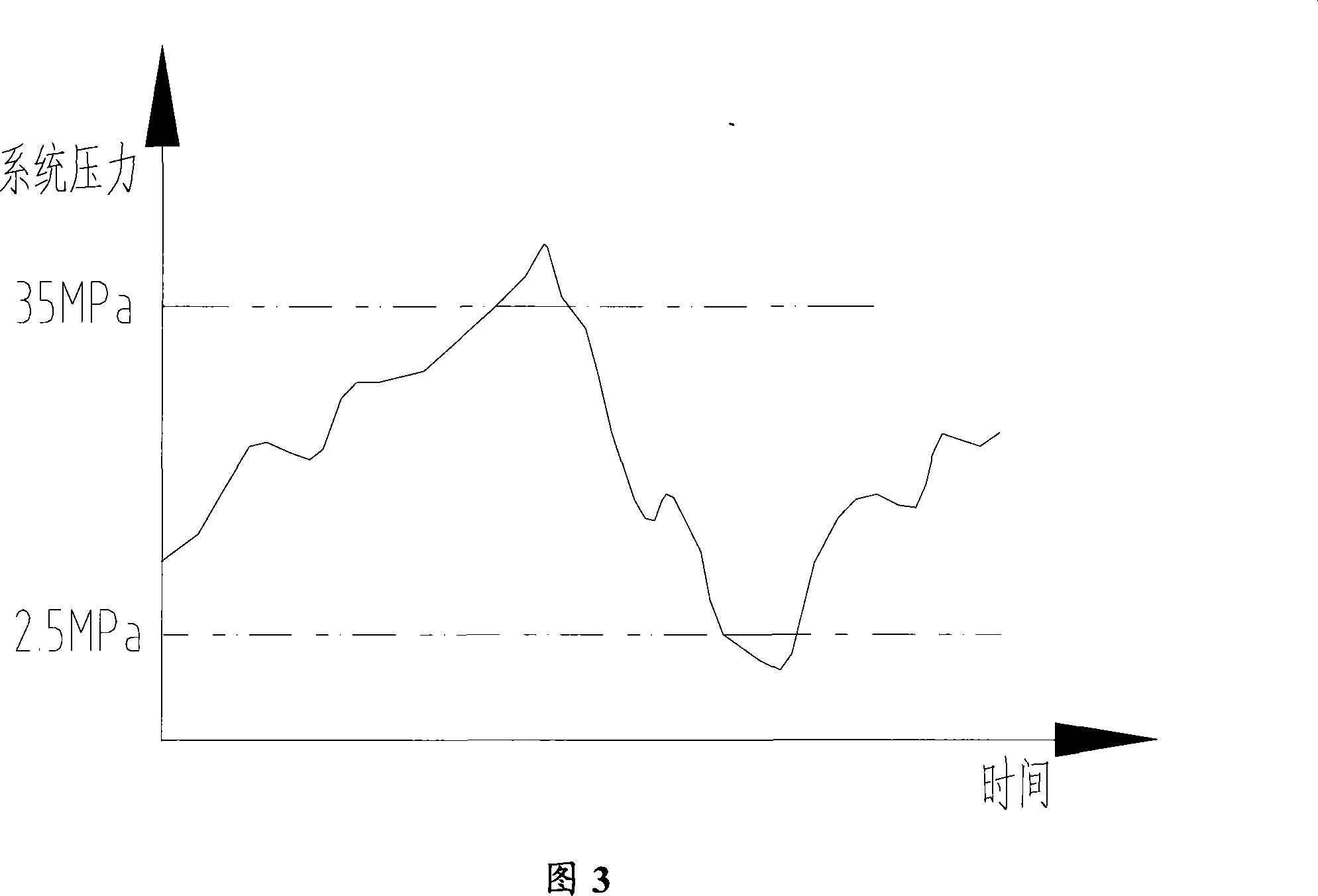

Engineering vehicle walking driving hydraulic system

InactiveCN101178083AMeet job requirementsHigh maximum drive capacityServomotorsHydraulic motorWorking pressure

The invention discloses an engineering vehicle walking driving hydraulic system, comprising a bidirectional hydraulic pump and a bidirectional hydraulic motor. Two oil nozzles of the bidirectional hydraulic pump are respectively connected with the driving chamber oil nozzle and the backing chamber oil nozzle of the bidirectional hydraulic motor by connecting pipelines. By the connecting pipelines, the bidirectional hydraulic pump supplies oil for the bidirectional hydraulic motor; a driving chamber overflow valve and a backing chamber overflow valve with reverse overflow directions are arranged in parallelism between the two pipelines which connect the bidirectional hydraulic pump with the bidirectional hydraulic motor; wherein, the driving chamber overflow valve provides overflow loop for the bidirectional hydraulic motor driving chamber; the backing chamber overflow valve provides overflow loop for the bidirectional hydraulic motor; furthermore, the overflow pressure valve value of the driving chamber overflow valve is higher than that of the backing chamber overflow valve. Compared with the prior art, when the engineering vehicle walking driving hydraulic system provided by the invention carries out a backing operation, the highest stable working pressure is low, which leads the highest acceleration is low and the driving characteristic is flexible when the vehicle backs.

Owner:SANY HEAVY IND CO LTD (CN)

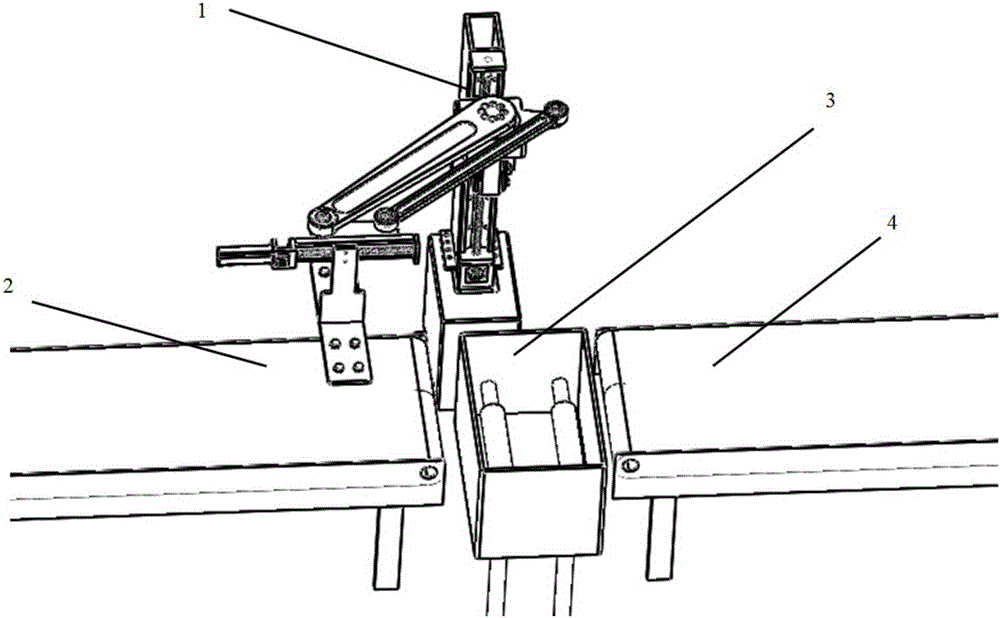

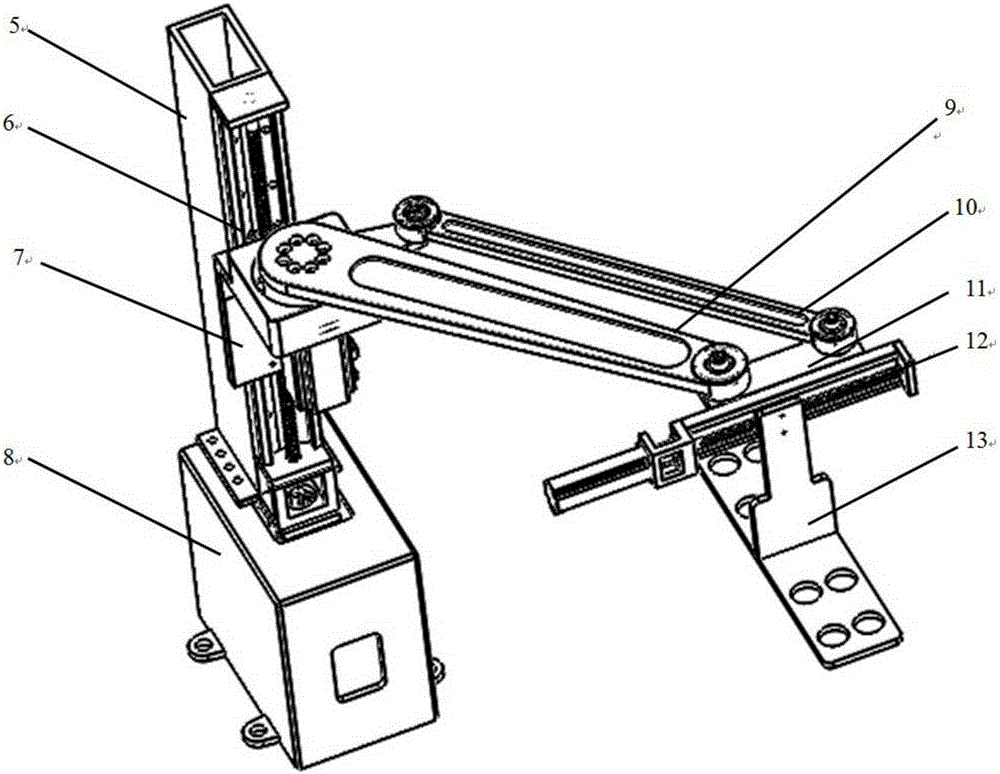

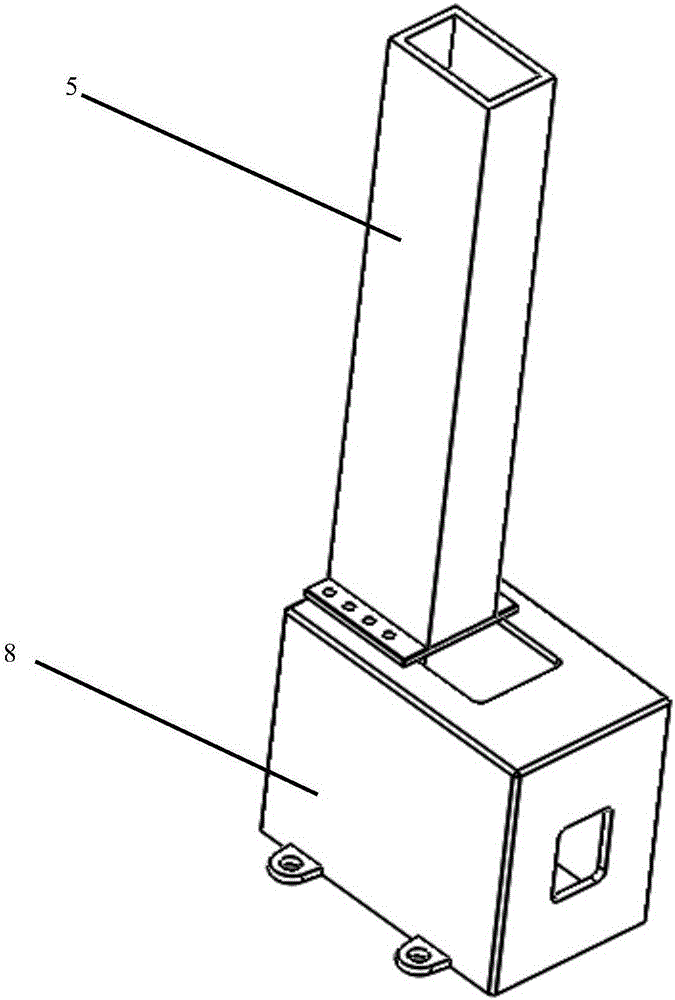

Grabbing and placing device for deburring

InactiveCN105196165ASmall inertiaIncrease freedomGrinding feedersThree degrees of freedomEngineering

The invention discloses a grabbing and placing device for deburring, which belongs to the technical field of industrial robot application. The grabbing and placing device comprises an input conveyor belt, a brush machine, an output conveyor belt and a moving support three-degree-of-freedom transfer robot, wherein the input conveyor belt is horizontally arranged; the brush machine is positioned under a sucking disc mounting plate when an active arm of an arm conveying device of the moving support three-degree-of-freedom transfer robot is positioned at the middle position; the output conveyor belt and the input conveyor belt are symmetrically arranged relative to the brush machine. The grabbing and placing device disclosed by the invention has the advantages of high production efficiency, high automatic degree and capabilities of realizing full-automatic collection, conveying and grabbing operations.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

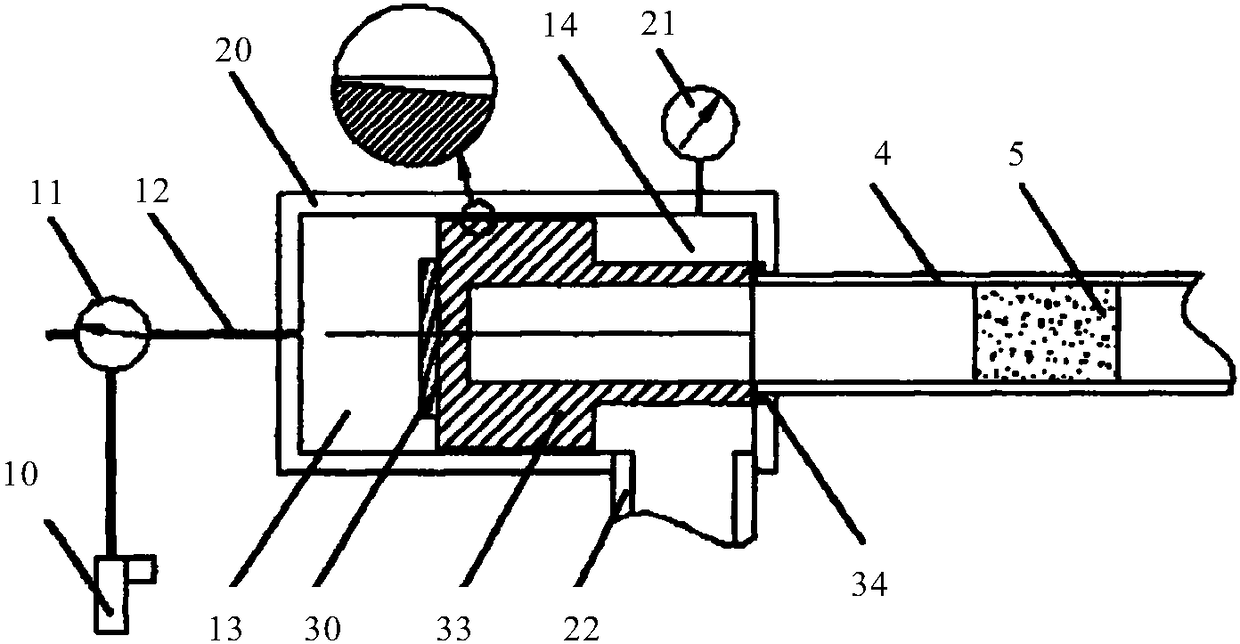

Launching device

ActiveCN108362169AHigh accelerationAvoid movement resistanceLaunching weaponsEngineeringHigh pressure

The embodiment of the invention provides a launching device. By adoption of the launching device, the problem that in the prior art, high-pressure air enters a gun barrel unstably and the shot acceleration is relatively slow can be solved. The launching device comprises an air chamber, an air control device, a launching mechanism and the gun barrel, wherein the air control device and the launchingmechanism are positioned inside the air chamber; and the gun barrel and the air chamber are connected. According to the launching device provided by the embodiment of the invention, an impact hammeris pushed through pressure on two sides of the impact hammer to impact a piston rod at high speed, so that the high-pressure air can instantly enter the gun barrel at the maximum flow rate to push a shot body or a birdshot for being launched; the motion of a piston is achieved when the piston is impacted by the impact hammer through the air floating effect, so that the operation can be flexible, the reliability can be high, and the problem about the resistance to the motion of the piston can be solved; furthermore, the motion speed of the piston is higher, so that the air inlet section where the high-pressure air enters air cavities can instantly reach the maximum, and then the high-pressure air can instantly enter the gun barrel at the maximum flow rate; and accordingly, the constant-pressure and constant-acceleration process that the high-pressure air enters the gun barrel to push the shot body or the birdshot can be guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

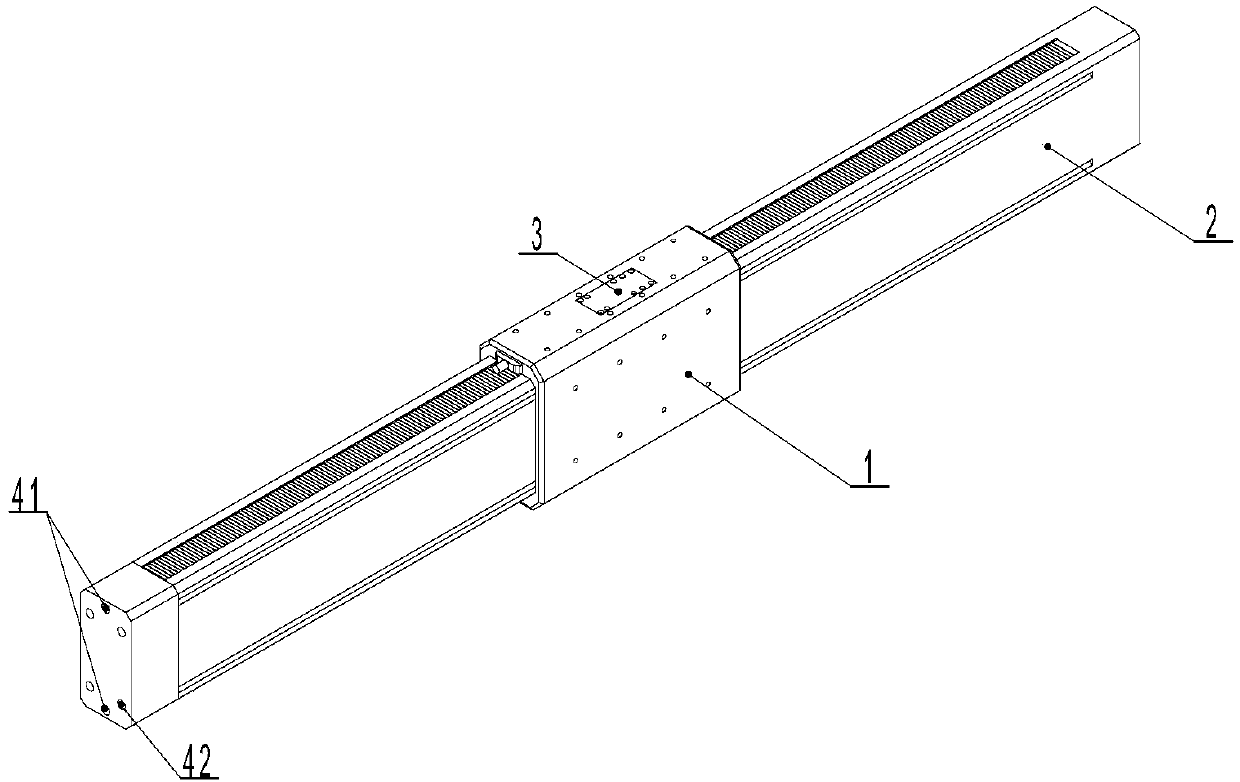

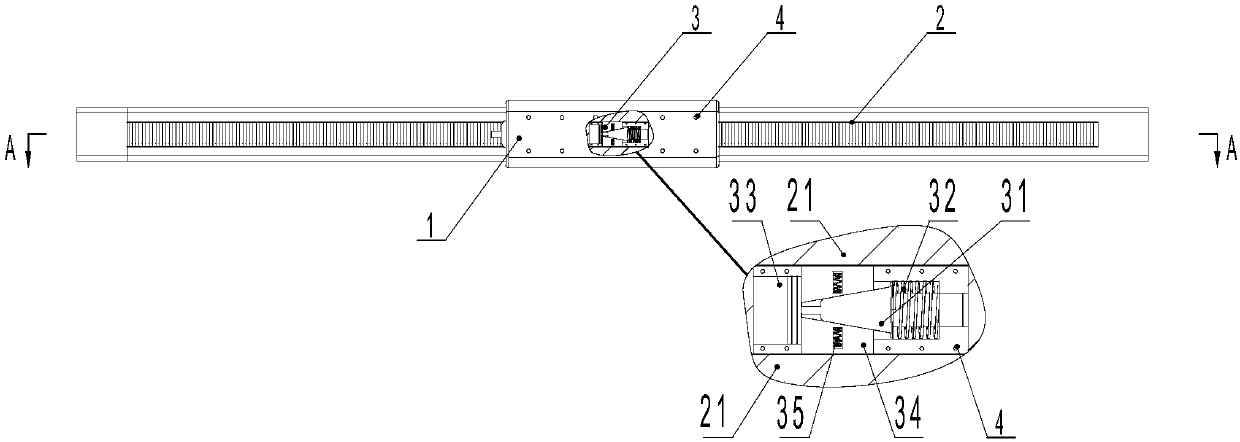

Linear motor module for robot splicing

PendingCN107733204ACompact structureReduce power lossProgramme-controlled manipulatorMechanical energy handlingElectric machineControl engineering

The invention relates to a linear motor module for robot splicing. The linear motor module comprises a rotor assembly, a stator assembly, a brake and a controller, wherein the brake is connected to the rotor assembly, the rotor assembly sleeves the stator assembly, connection holes are formed in both of the rotor assembly and the stator assembly, the rotor assembly comprises a shell, a coil, a connector, a grating reading head, a first limit switch and a second limit switch, the stator assembly comprises a stator body, a permanent magnet and a grating, the brake comprises a wedge-shaped block,a braking spring, a piston, a braking block and an extrusion spring, and the grating reading head, the first limit switch, the second limit switch and the piston all are electrically connected with the controller.

Owner:GSK CNC EQUIP

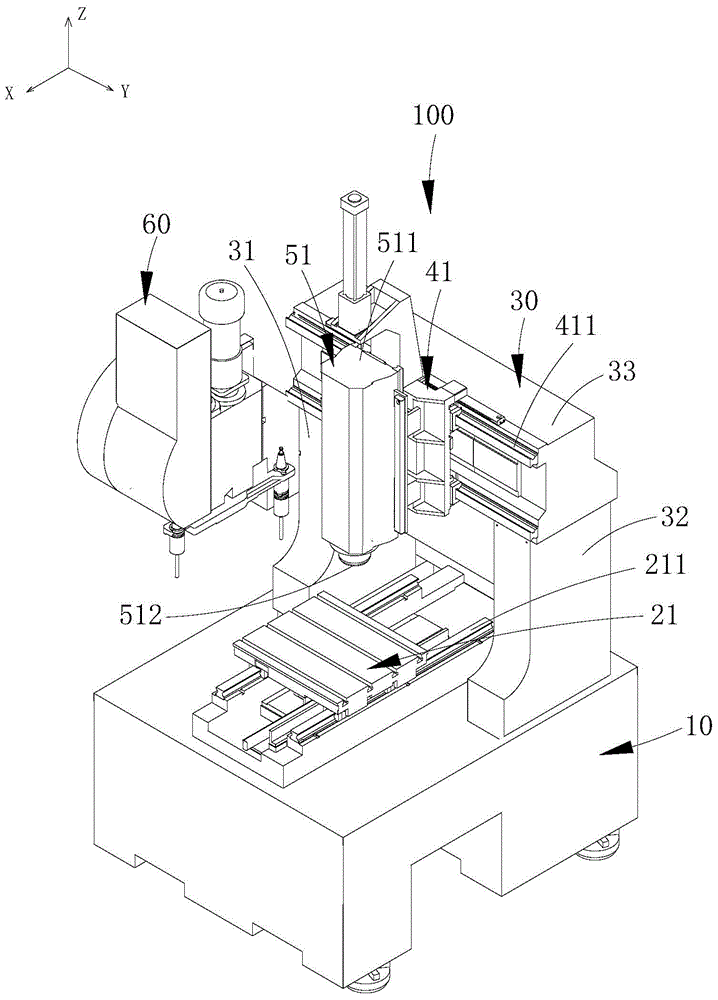

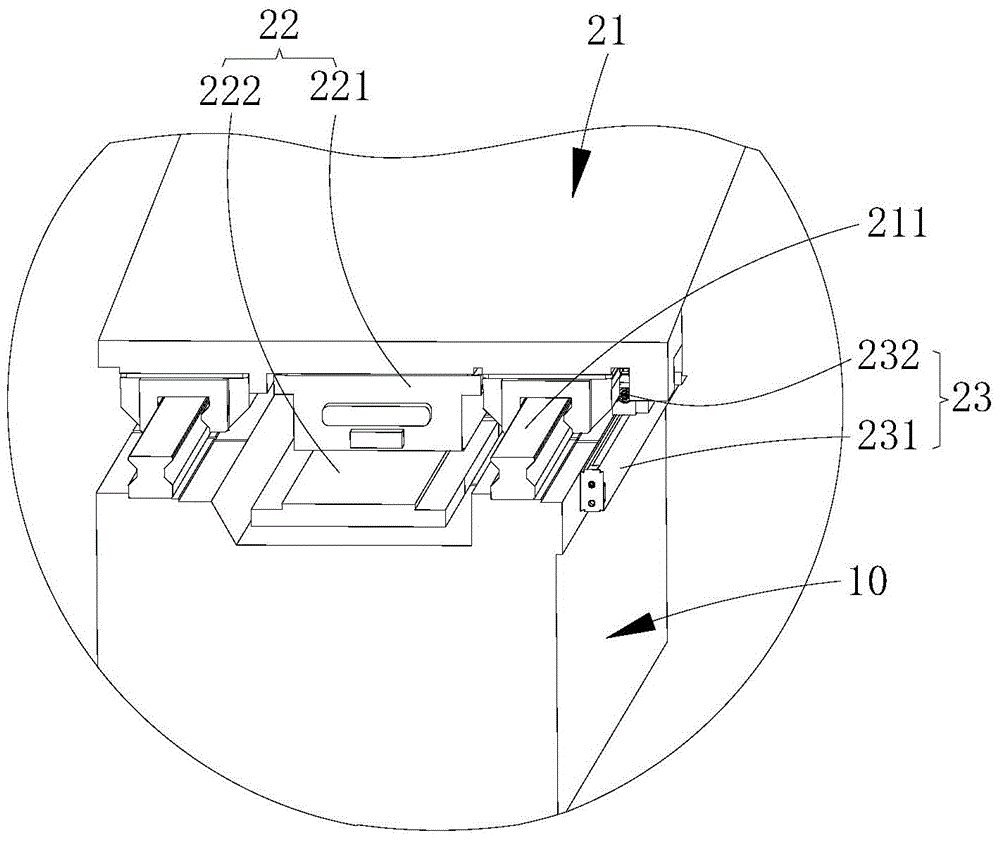

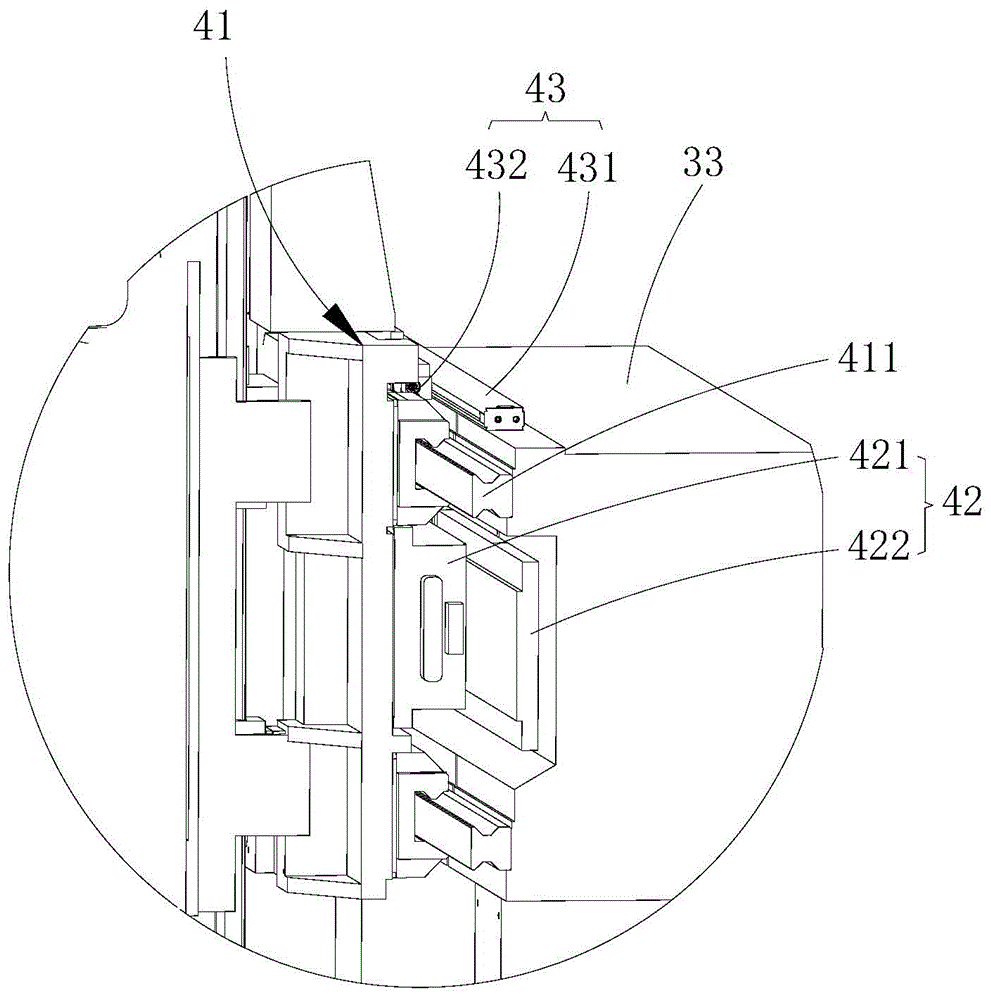

Processing equipment

InactiveCN105619181AGuaranteed accuracyGuaranteed processing efficiencyMeasurement/indication equipmentsLarge fixed membersControl systemLinear motor

The invention discloses processing equipment. The processing equipment comprises a base, an X axis work platform, a first linear motor, a first metering device, a bracket, a Y axis sliding carriage, a second linear motor, a second metering device, a Z axis spindle box, a third linear motor, a third metering device, a tool changer and a control system, wherein through the arrangement of the first linear motor and the first metering device, the sliding precision of the X axis work platform is effectively ensured; through the arrangement of the second linear motor and the second metering device, the sliding precision of the Y axis sliding carriage is effectively ensured; through the arrangement of the third linear motor and the third metering device, the sliding precision of the Z axis spindle box is effectively ensured; and in this way, when a spindle of the Z axis spindle box processes a workpiece, higher workpiece processing precision can be obtained, and at the same time, the processing efficiency of the whole machine is ensured. Due to the adoption of linear motor driving, the processing equipment adopting the transmission mode is high in acceleration speed, compact in structure, free of transmission clearance and free of wear, and the reliability improvement of the whole machine is facilitated.

Owner:深圳市万嘉科技有限公司 +1

Method for extracting pectin from shaddock peel through enzymolysis and ultrasonic waves

InactiveCN106349405AThe role of complete dissolutionMild conditions for enzymatic actionAdditive ingredientChemical change

The invention discloses a method for extracting pectin from shaddock peel through enzymolysis and ultrasonic waves. The method includes the specific steps of (1) pretreatment of the shaddock peel serving as a raw material, (2), enzymolysis and ultrasonic treatment, (3), decoloration and (4), drying so as to obtain the pectin. The method for extracting the pectin from the shaddock peel through the enzymolysis and the ultrasonic waves has the advantages that a compound enzyme and the ultrasonic waves act on the shaddock peel jointly to extract the pectin from the shaddock peel; the enzyme is mild in action condition and plays a role in wall breaking, so that the pectin in the shaddock peel dissolves out thoroughly; an ultrasonic wave extraction process is a physical process without chemical change and is high in extraction rate and capable of protecting functional ingredients of extract effectively, breaking time is shortened, and the pectin yield of the shaddock peel is higher than 25% which is increased by more than 30% than that of a traditional acid extraction method; with the shaddock peel as the raw material, the method is simple, high in yield and high in extracted pectin quality and achieves the purpose of turning waste into wealth.

Owner:安徽旺润生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com