Engine brake detection

A technology of engine braking and engine, applied in the direction of engine control, engine components, combustion engine, etc., which can solve the problems of fuel no longer available, damage to engine cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

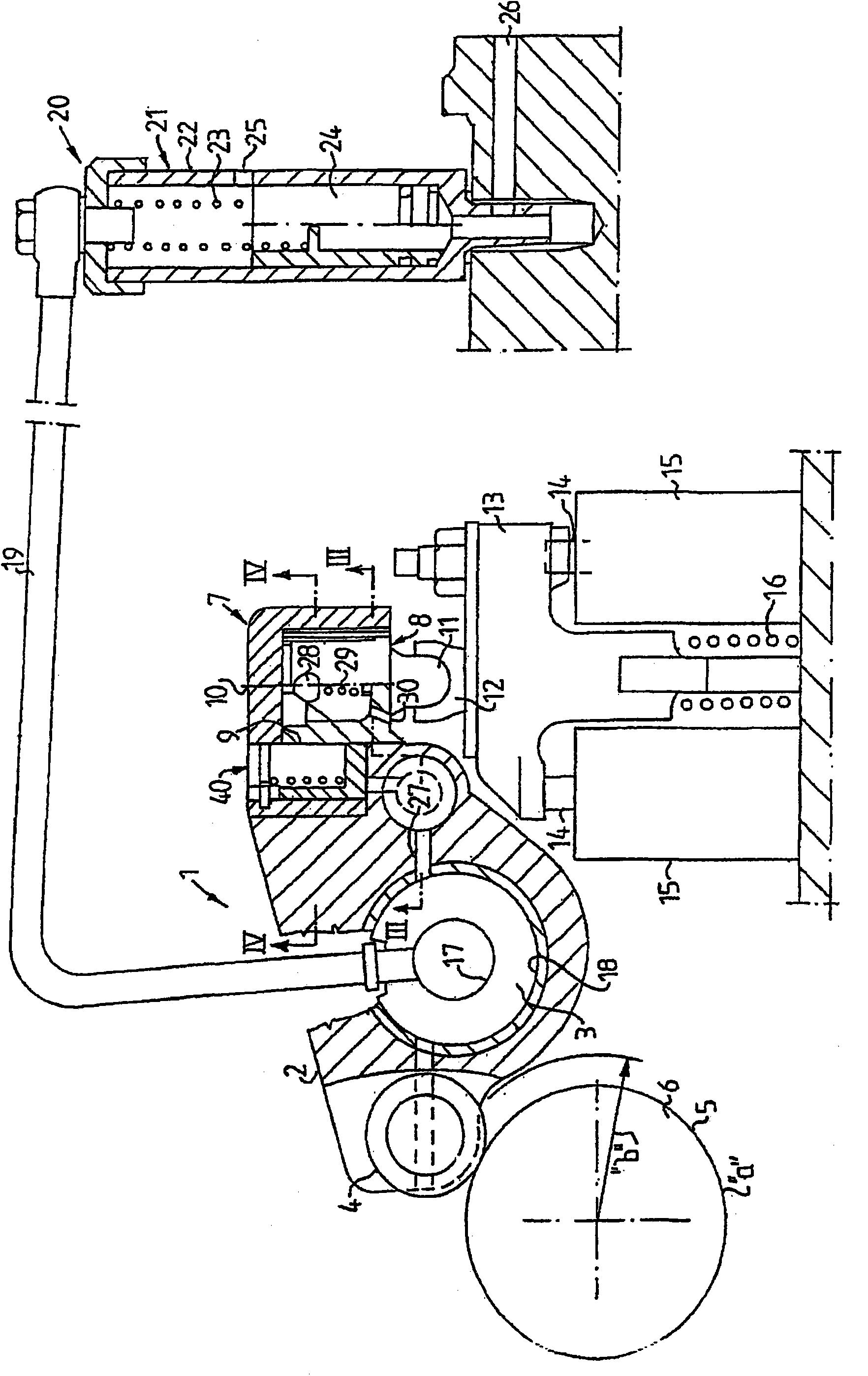

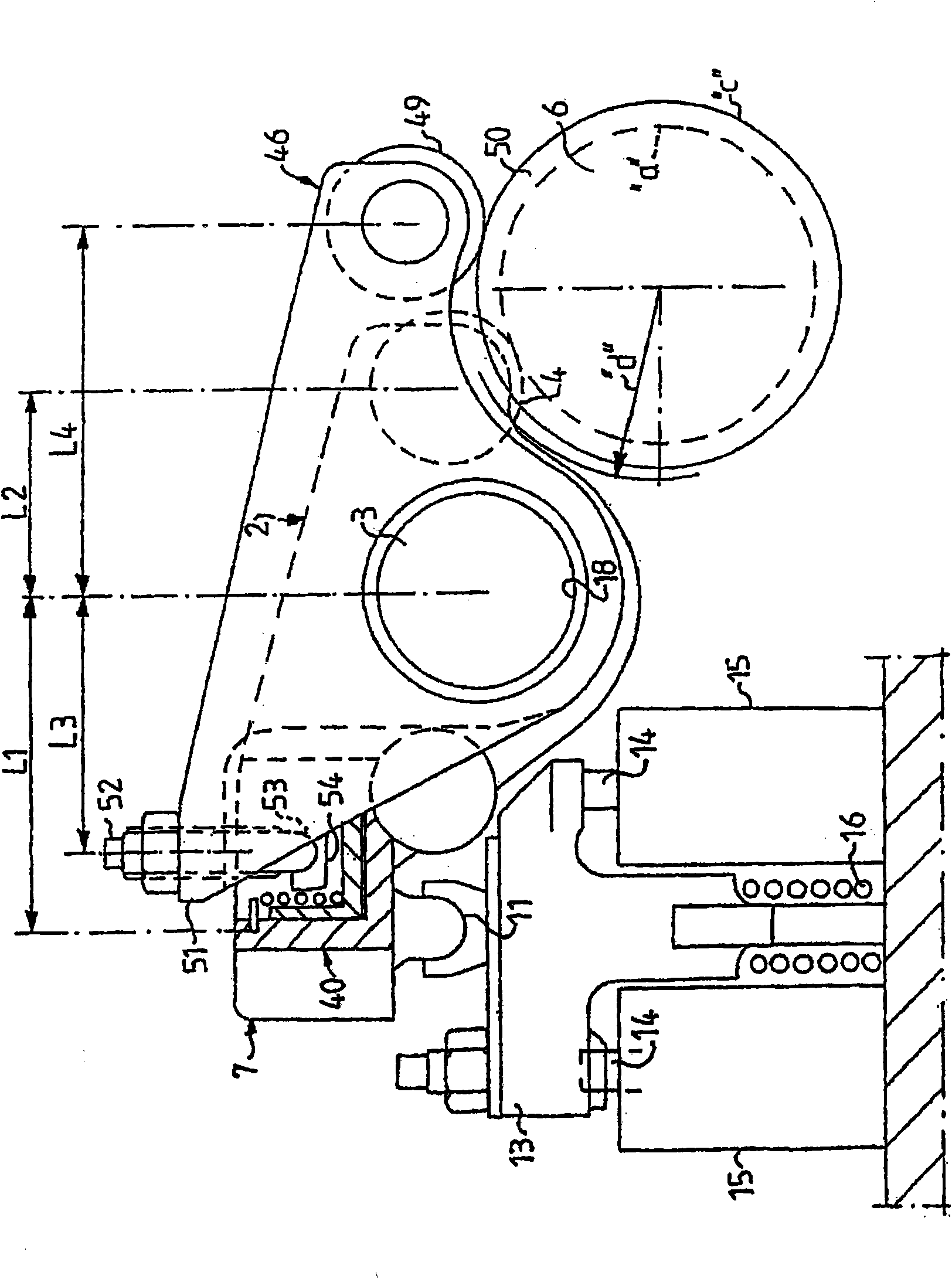

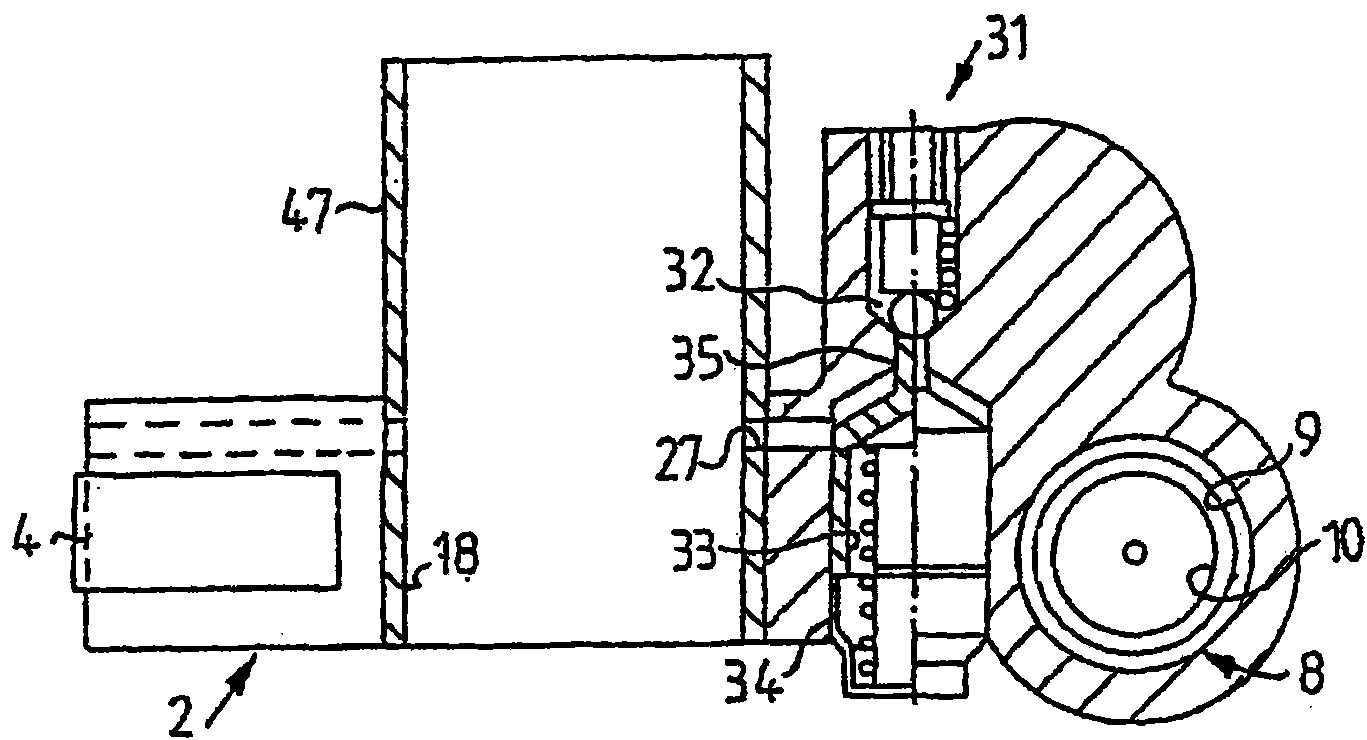

[0042] An exhaust pressure regulator for adjusting the exhaust back pressure may be located in the exhaust system after the exhaust manifold but before the tailpipe. The exhaust pressure regulator may be a butterfly regulator, that is, the butterfly regulator is placed in the exhaust system and adjusted by an electric or hydraulic engine so that the opening of the exhaust system can be increased or decreased as required. Opening may be any position between fully open and fully closed, including fully open and fully closed positions. Another restriction within the exhaust system may be the pistons that move in and out of the exhaust system. The open area within the exhaust system is at a maximum when the piston is in its fully external position and may be partially or completely closed when the piston is in its fully internal position. Any position between fully closed and fully open can be selected as desired. Another possible variable restriction means could be a plate inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com