Patents

Literature

1619results about How to "Small inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

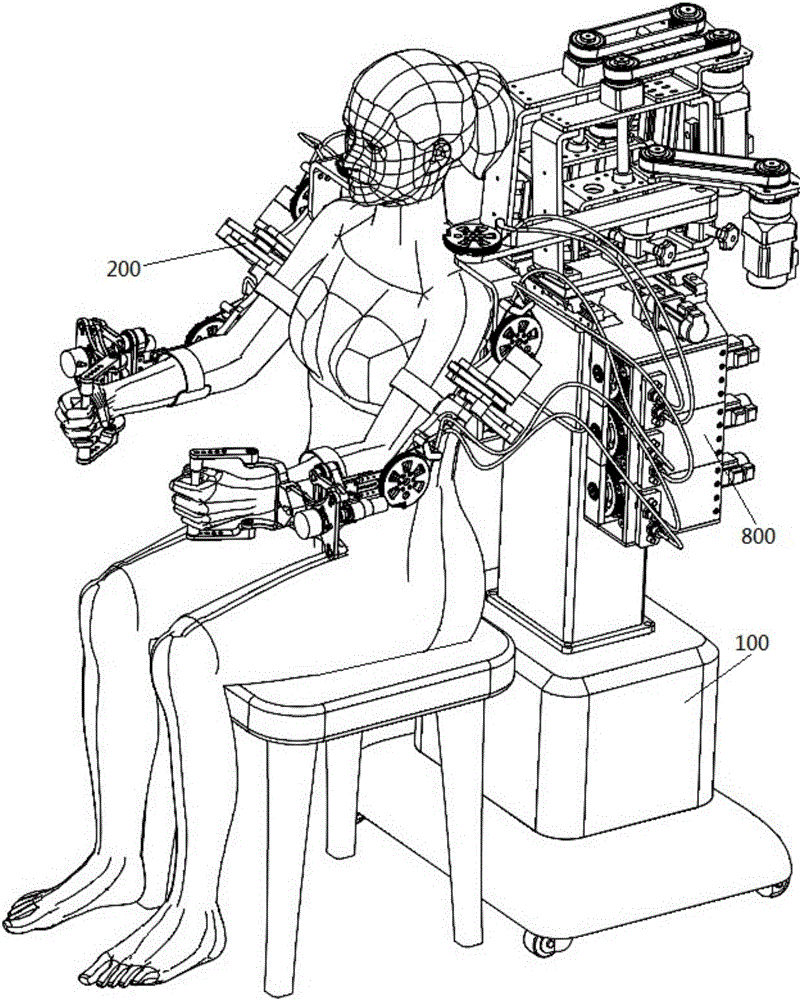

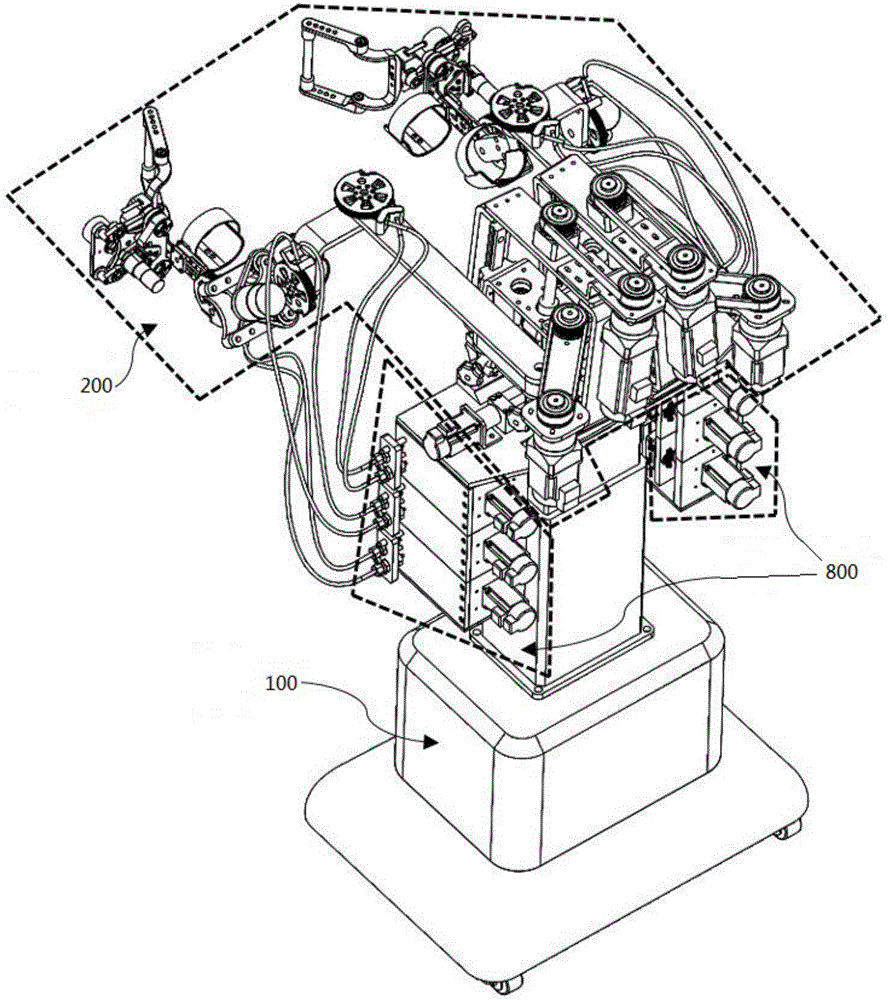

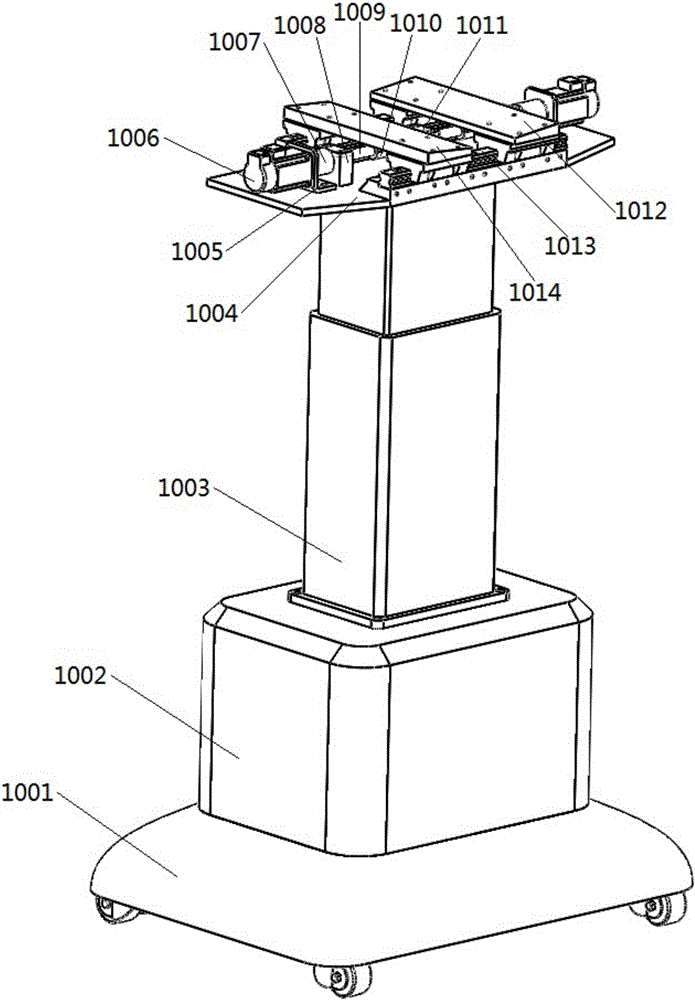

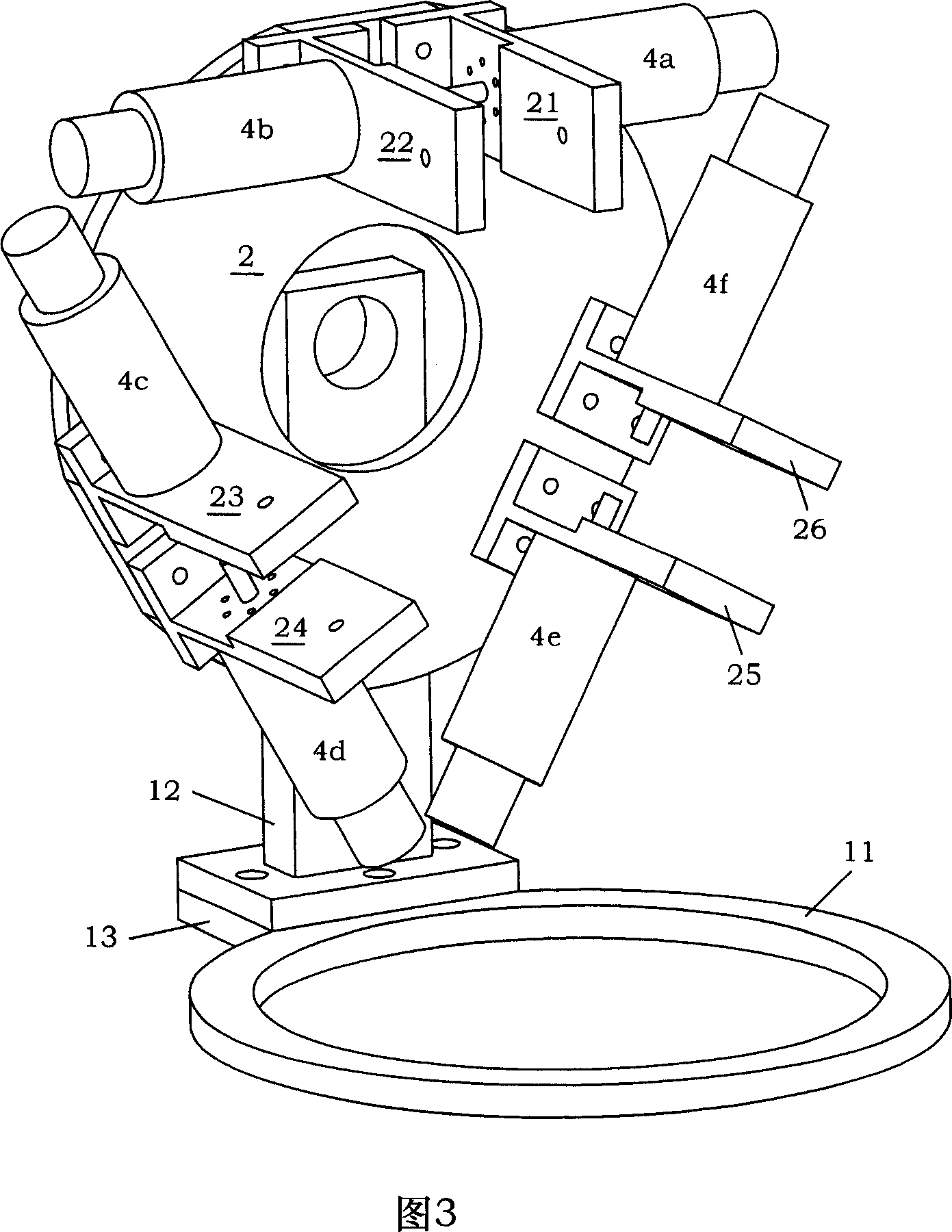

Exoskeletal rehabilitation robot for upper limbs

PendingCN105662782ASolving Mismatch ProblemsWon't hurtProgramme-controlled manipulatorChiropractic devicesEngineeringUpper limb rehabilitation

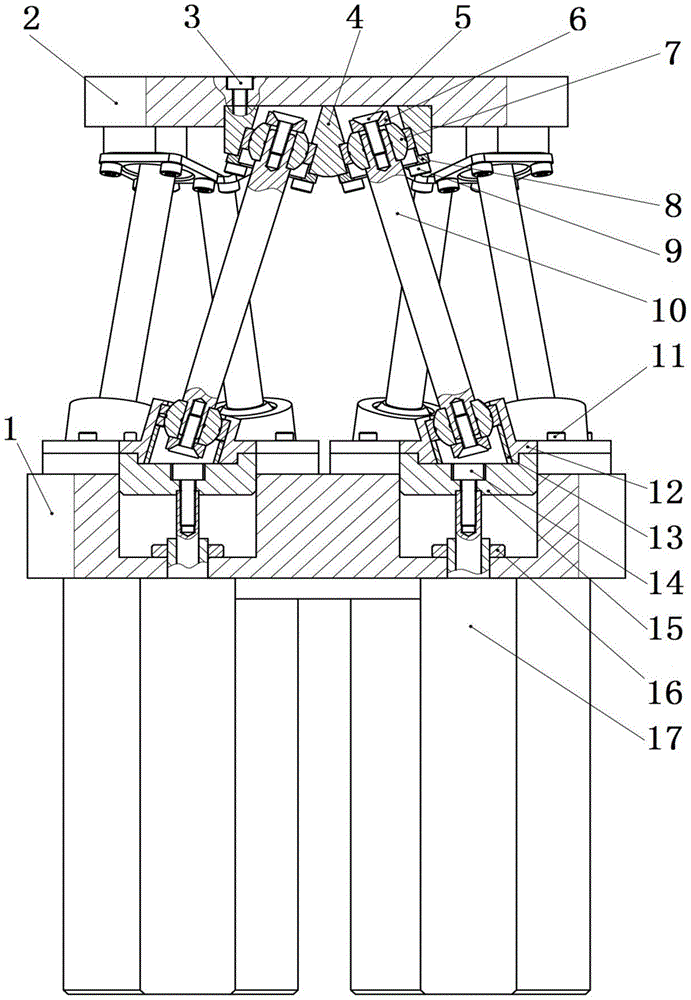

The invention discloses an exoskeletal rehabilitation robot for upper limbs. The exoskeletal rehabilitation robot comprises a base, two mechanical arm assemblies and six motor driving components, wherein the base comprises a moving base, an electrical cabinet, an electric lifting post, a base platform, a motor mounting corner bracket, a base rotating motor, a coupling, a base main bearing block, a base and ball screw nut assembly, a base nut seat, a base shared secondary bearing block, a right support, a base linear guide rail assembly and a left support; the mechanical arm assembly comprises a mechanical shoulder girdle assembly, a mechanical shoulder joint assembly, a mechanical elbow joint assembly, a mechanical front arm assembly, a mechanical wrist joint assembly and a mechanical hand part assembly; each motor driving assembly comprises a motor and speed reducing component, a torque sensor component and a driving component which are respectively arranged on the same motor driving base frame. The exoskeletal rehabilitation robot can be worn on the upper limbs of the human body and can be used for assisting the upper limbs of the human body in moving in a three-dimensional space and performing rehabilitation training.

Owner:SHANGHAI ZHUODAO MEDICAL TECH CO LTD

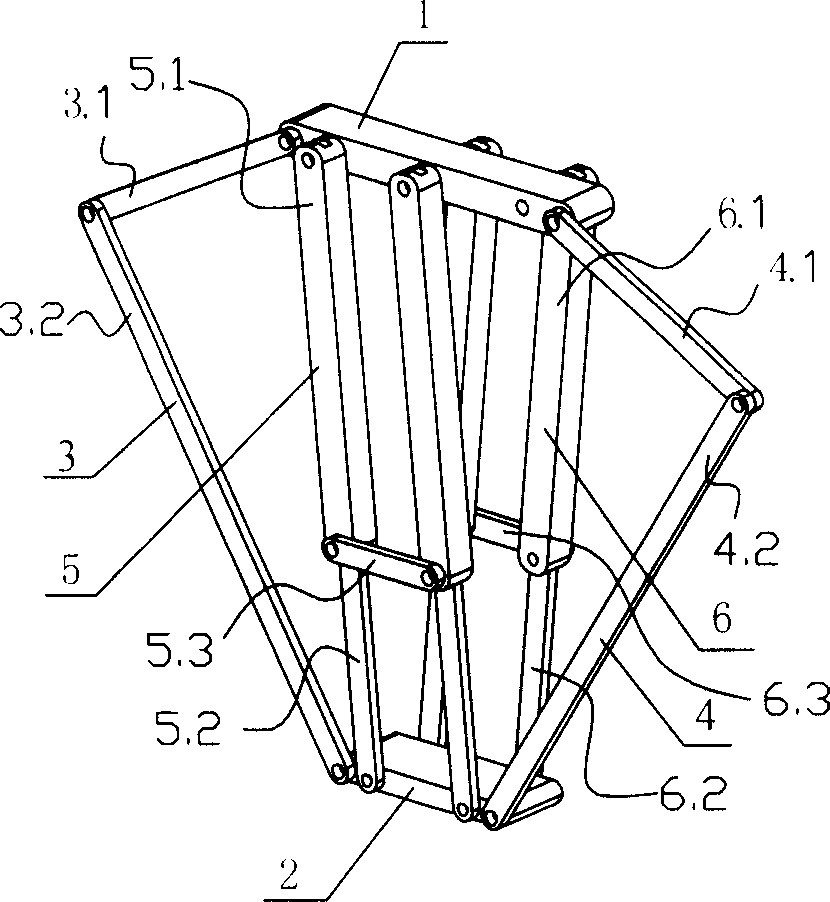

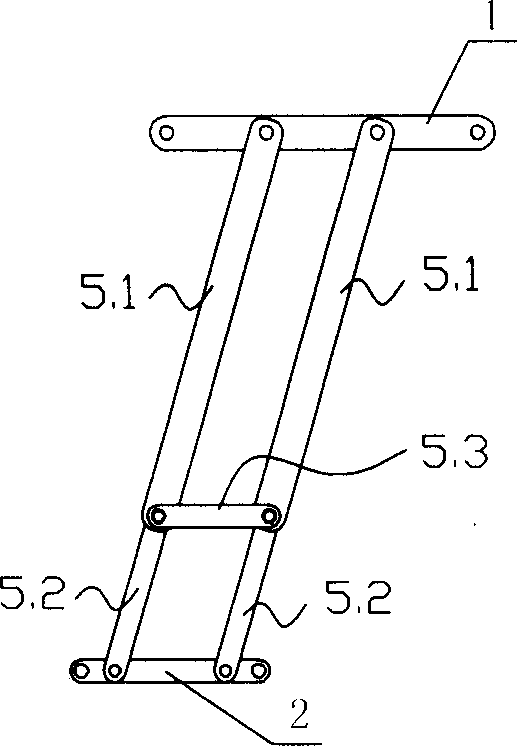

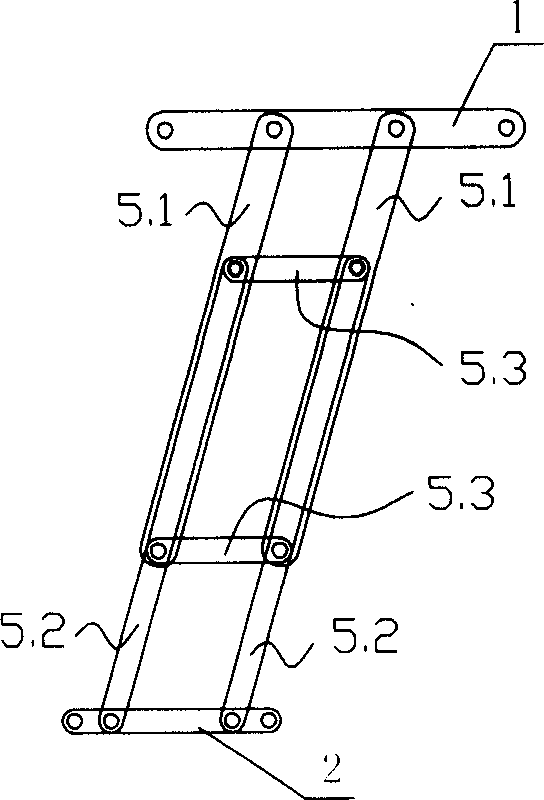

Robot machanism able to achieve two-D movement and of two-freedom plane-parallel type

InactiveCN1903521ASmall inertiaImprove dynamic performanceProgramme-controlled manipulatorControl theoryPlane parallel

A two-freedom robot mechanism with 2D translation and planar parallel connection is composed of a static plat form, a dynamic platform, and 4 branches including 2 active branches and 2 passive branches for linking dynamic platform with static platform. Said active branch consists of a drive arm and a driven arm.

Owner:SOUTH CHINA UNIV OF TECH

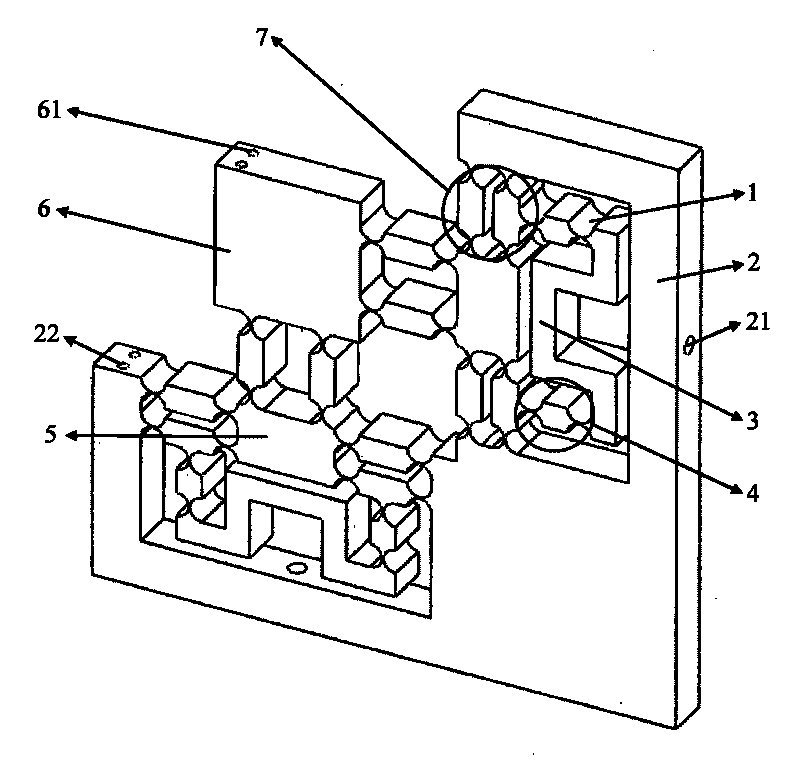

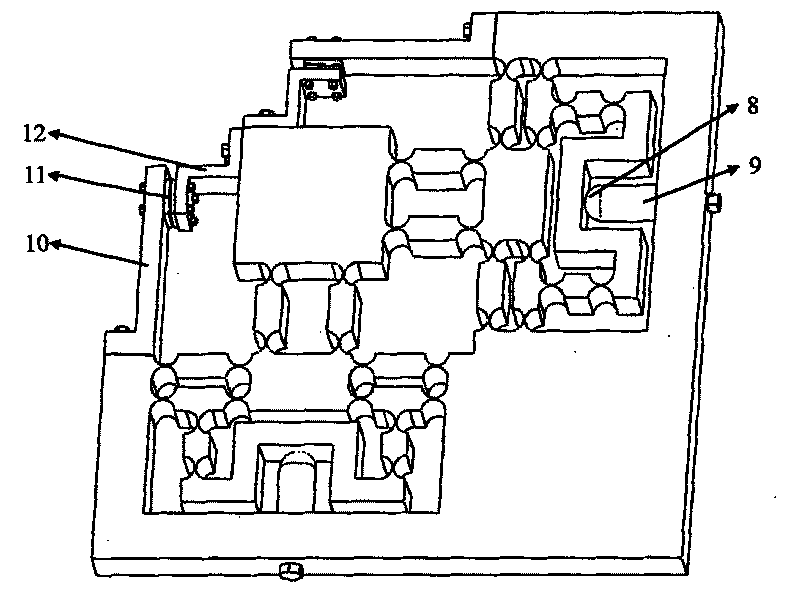

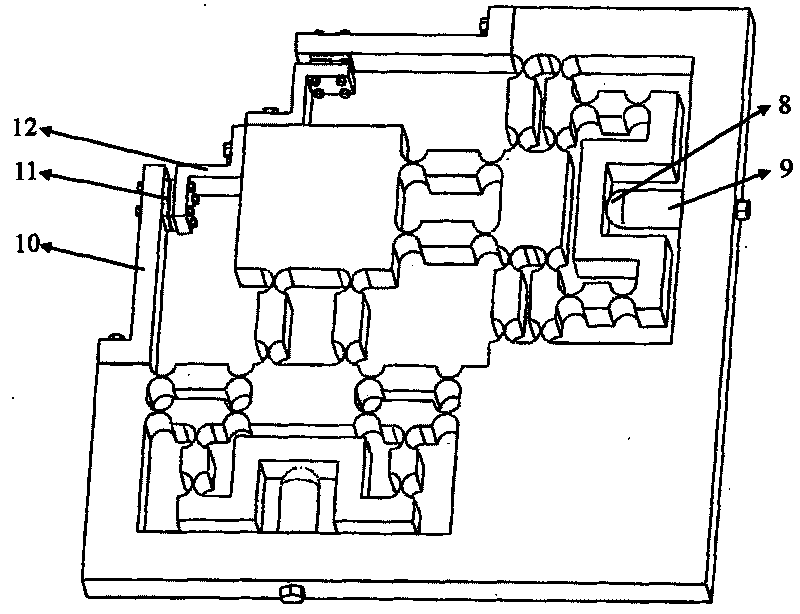

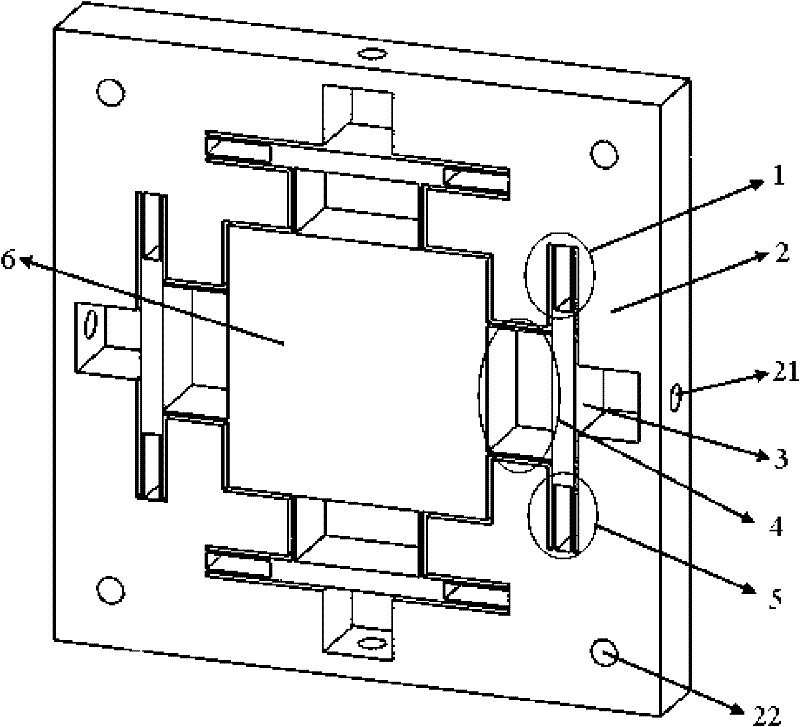

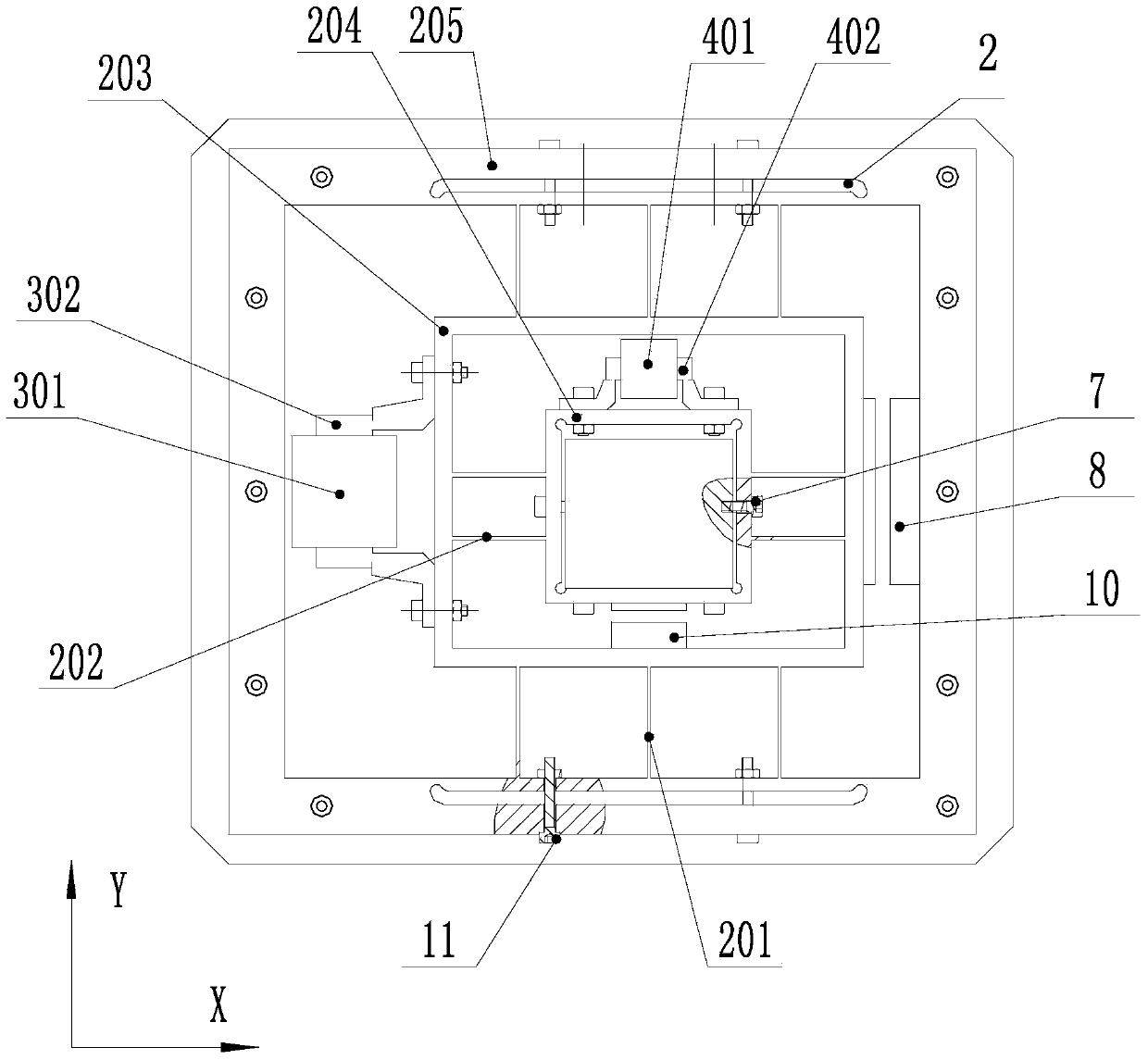

Flexible micro-positioning stage with two degrees of freedom

ActiveCN101738855AAvoid assemblyNo gapPhotomechanical apparatusFlexible MechanismsLithographic artist

The invention discloses a flexible micro-positioning stage with two degrees of freedom, the design of the flexible micro-positioning stage with two degrees of freedom comprises a flexible mechanism and an integral structure, two piezoelectric ceramic drivers are adopted in the structure, the tail part of each driver is connected with a base through a bolt, and the top end of each driver is connected with a spherical joint through a thread, thereby realizing Hertz contact. The flexible mechanism of the positioning stage mainly comprises three parts of the base, flexible branched chains with entirely consistent structures and a supporting movable platform thereof. Two displacement sensors are used for measuring actual output of the movable platform and respectively fixed between the base and the movable platform through an L-shaped support and a Z-shaped support. The flexible micro-positioning stage is characterized by high resolution and fast dynamic response speed, and can be taken as an auxiliary positioning platform of a nano-imprint lithography positioning system for realizing micro-feeding and precise positioning.

Owner:南通致远船舶设计有限公司

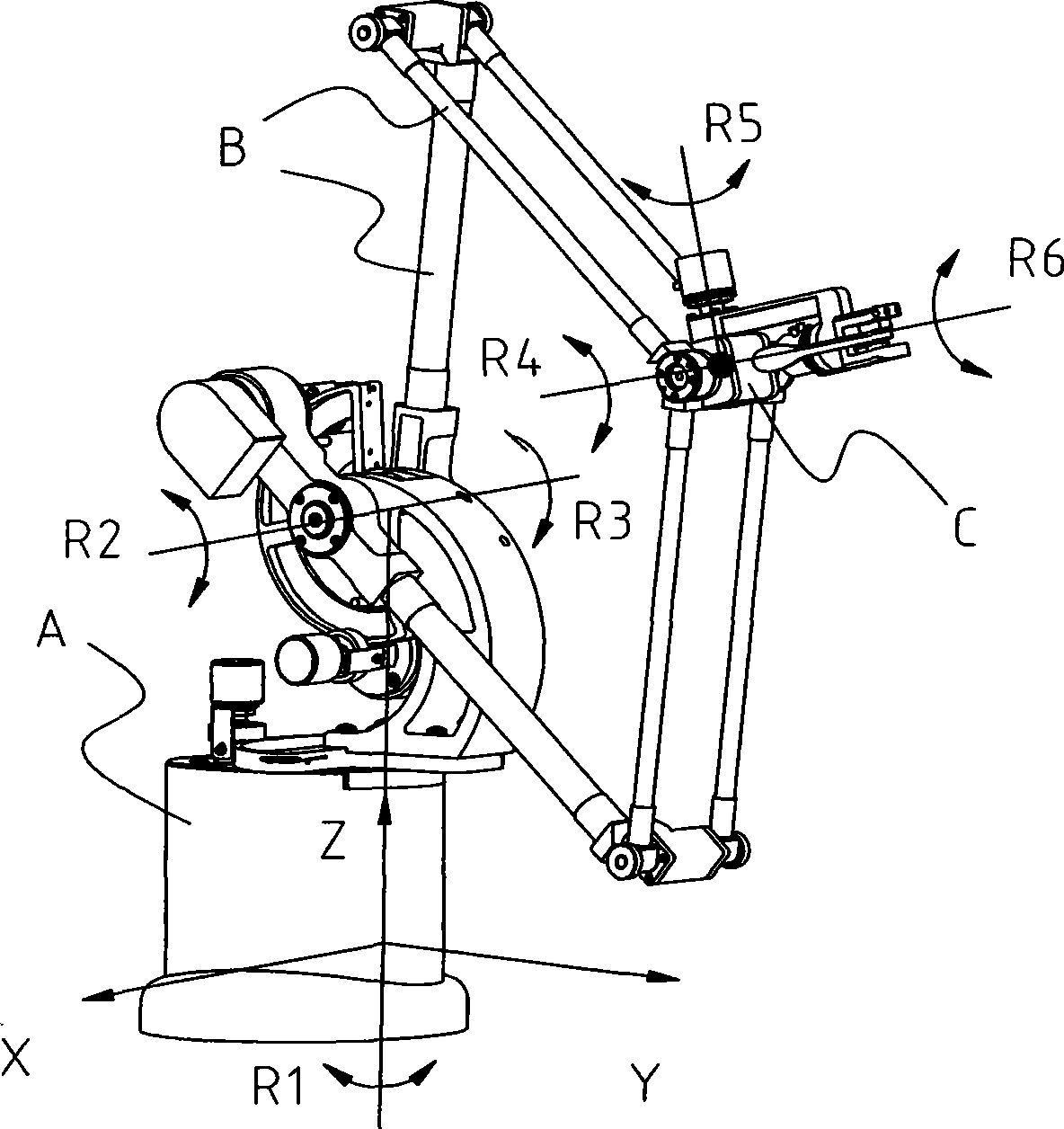

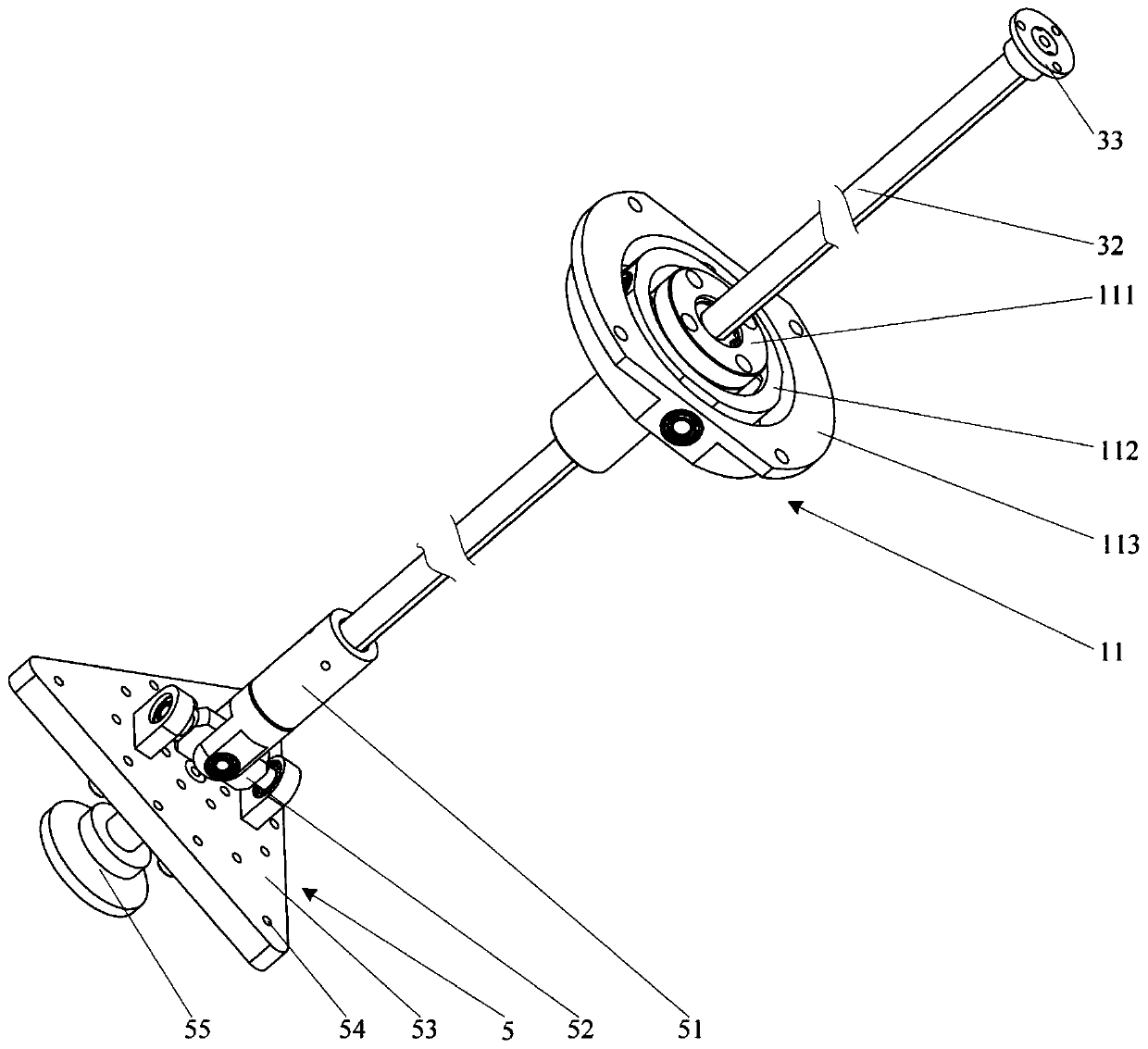

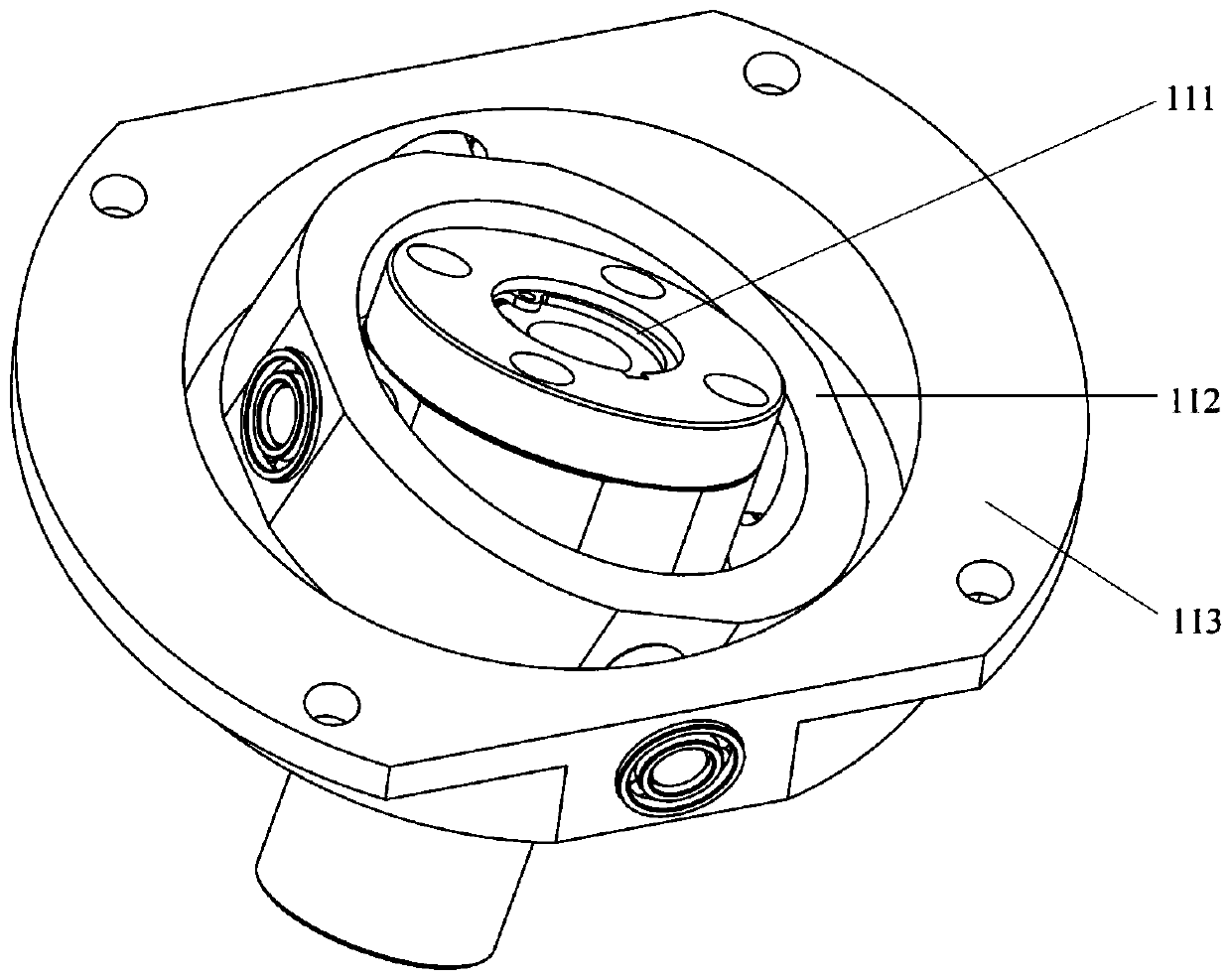

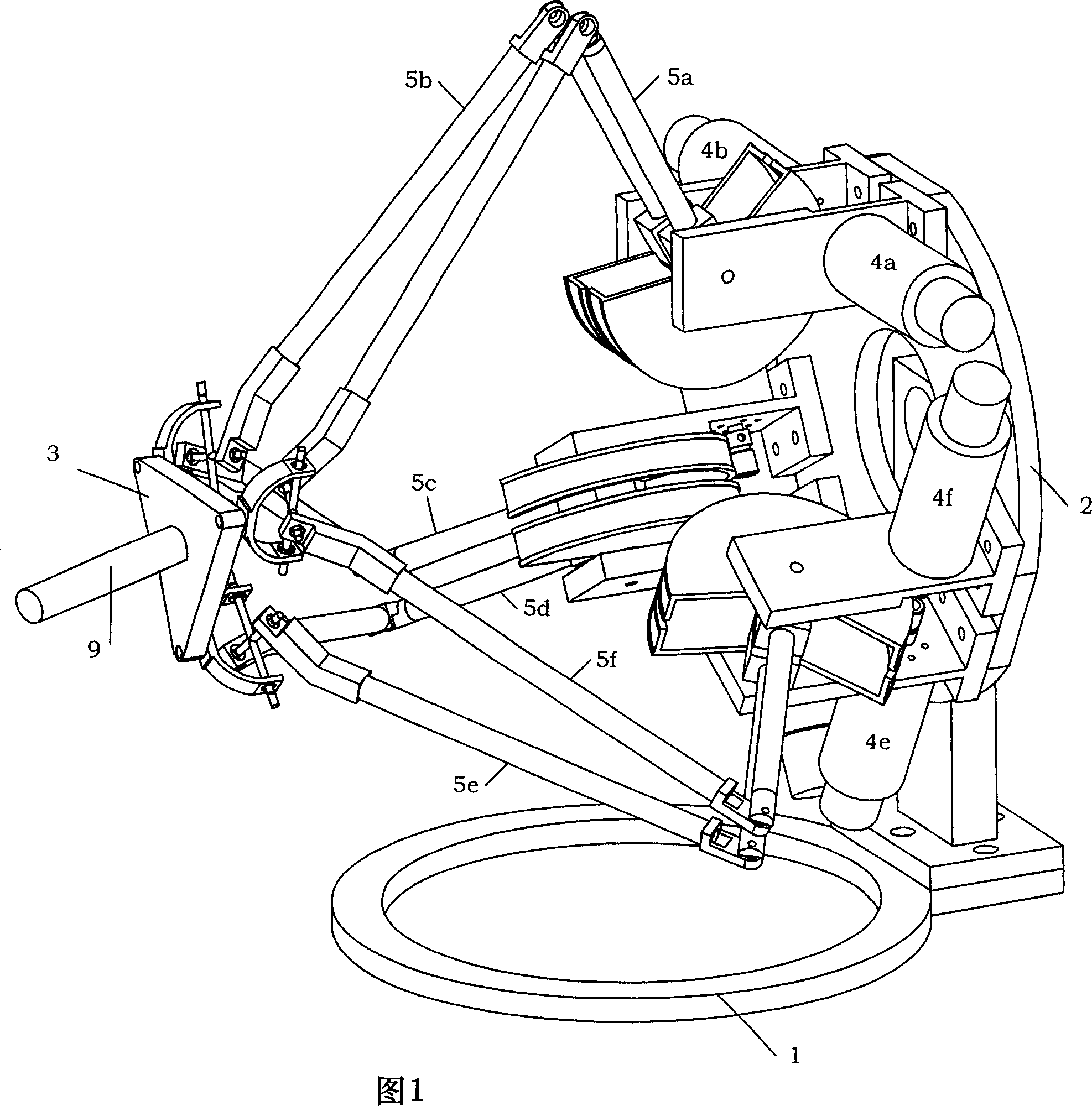

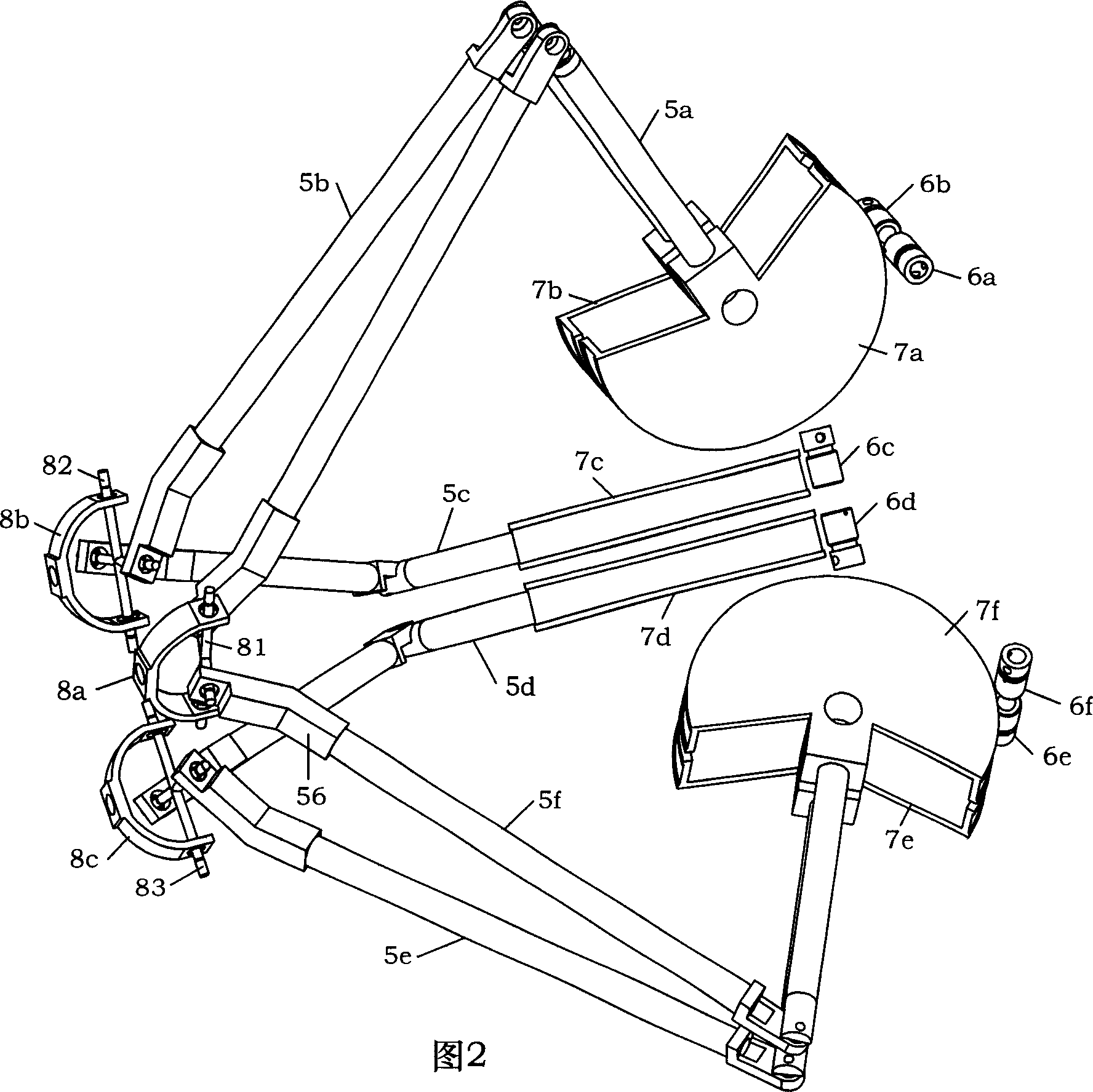

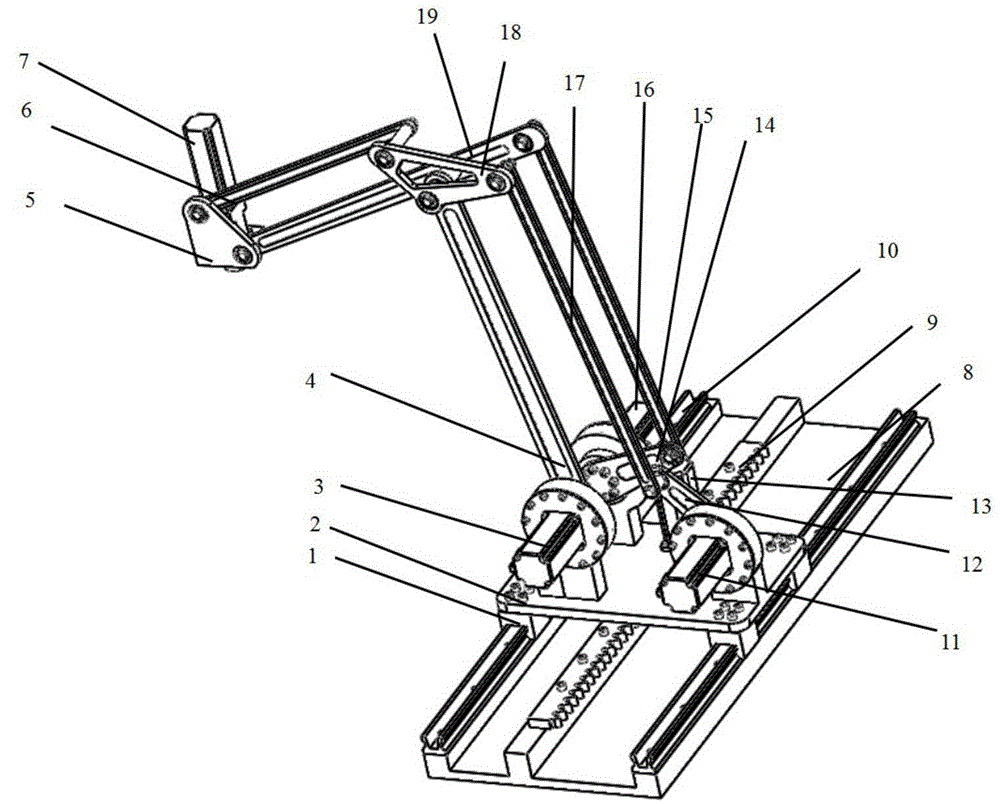

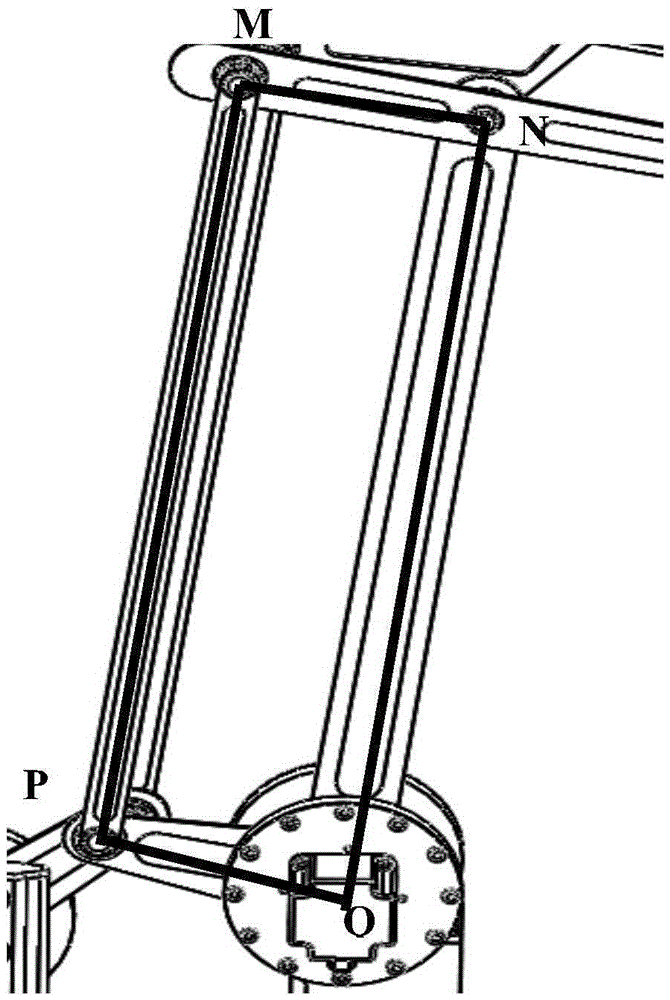

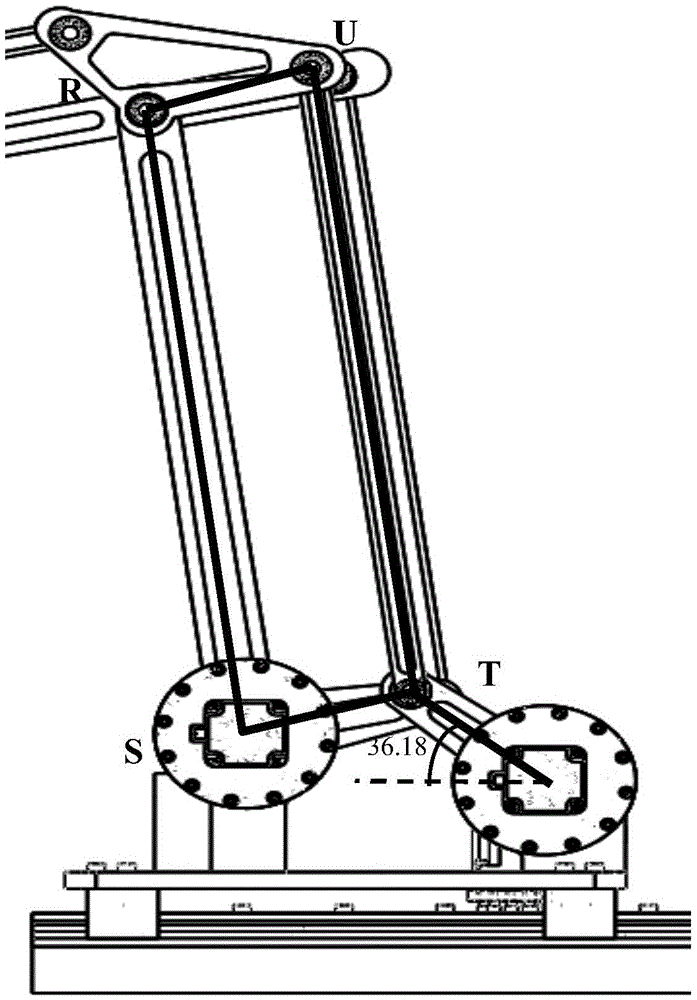

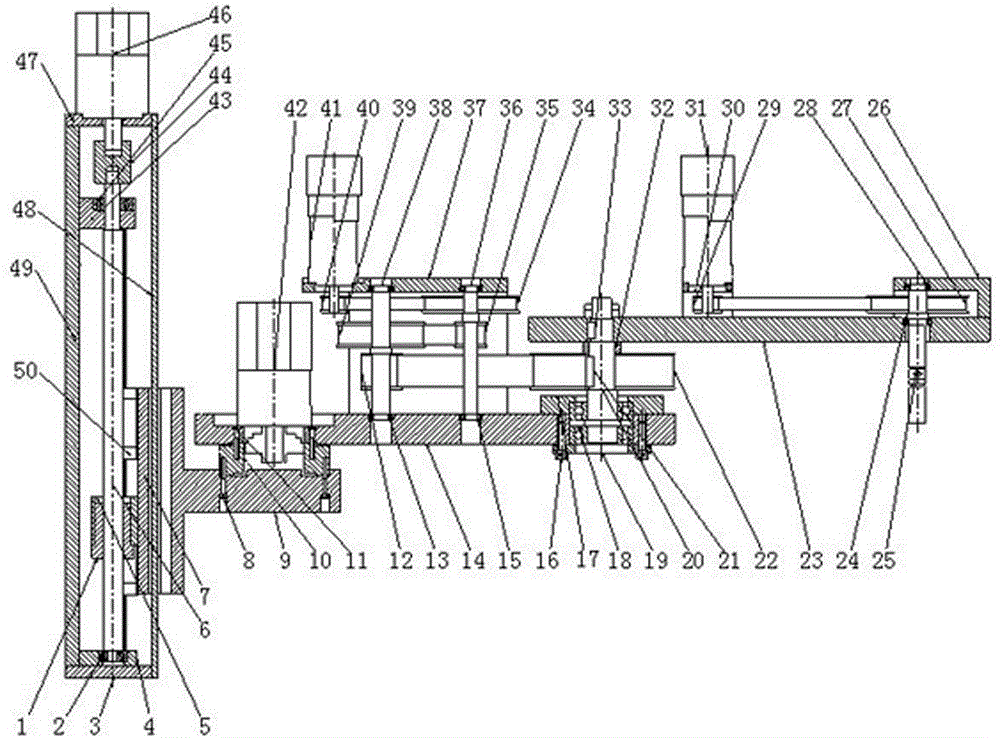

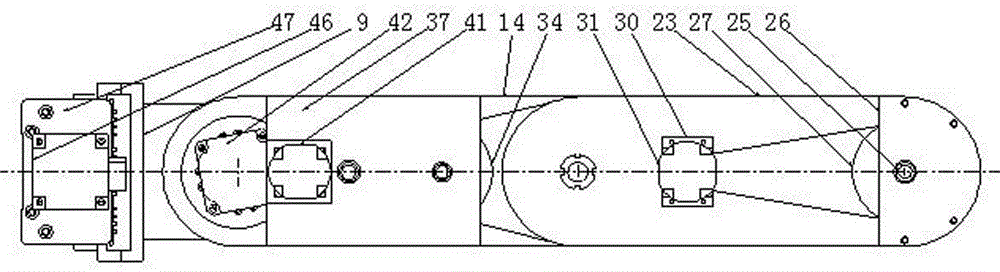

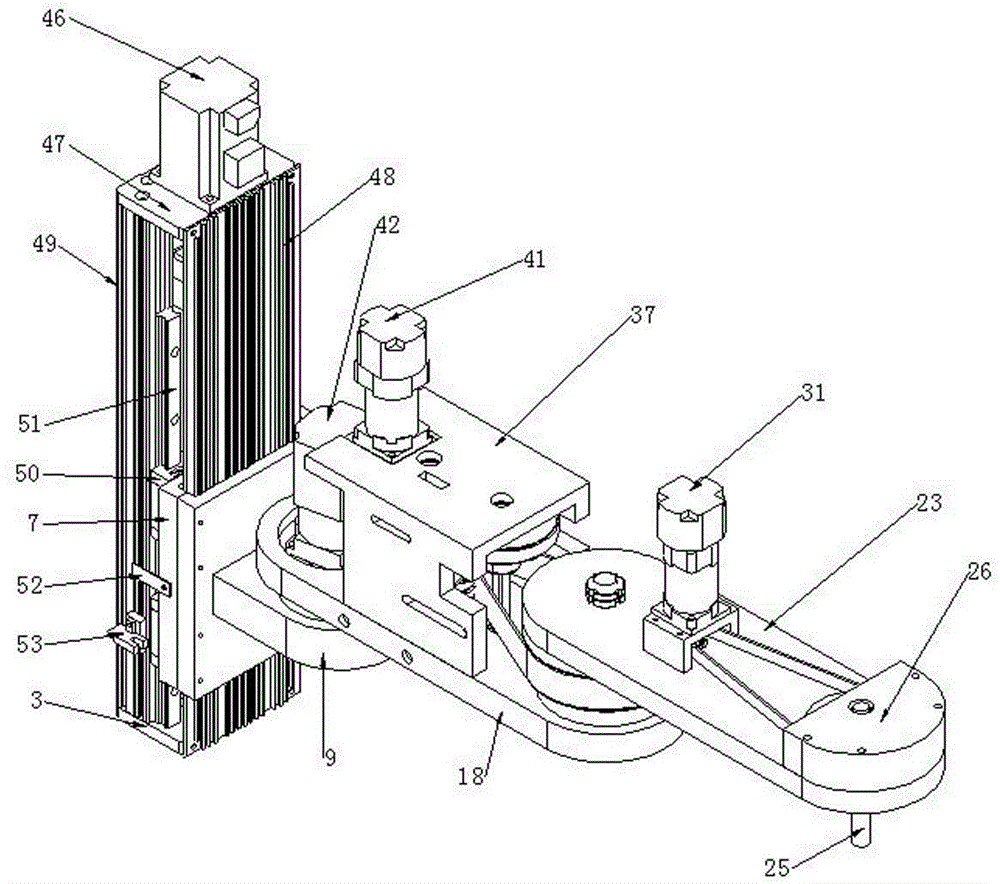

Three dimensional force feedback main operator assisting minimally invasive surgery robot

InactiveCN101444431ASimple structureReduce volumeMicromanipulatorDiagnosticsRotational freedomEngineering

The invention discloses a three dimensional force feedback main operator used for assisting a minimally invasive surgery robot. A base mechanism comprises a base and an upright post, wherein, a fan-shaped bottom plate is arranged on the top surface of the upright post; a four-bar mechanism comprises an arc support arranged on an arc bottom plate and a parallelogram mechanism formed by an upper near rod, a lower near rod, an upper distant rod and a lower distant rod; a wrist mechanism comprises a wrist body, a fifth projecting shaft is arranged at the upper part of the wrist body, one end of a knuckle is sheathed on the fifth projecting shaft, the other end of the knuckle is sheathed on a sixth projecting shaft arranged on a handle base by a bearing; two handle shafts are connected to the handle base by the bearing, the two handle shafts are engaged together by a gear, and a handle is stuck on each handle shaft. In the device of the invention, rotating centres of three rotational freedom of the wrist mechanism intersect at one point, and the working point is arranged at the intersection; the design eliminates pose compensation when the pose is adjusted and can realize six-shaft linkage.

Owner:TIANJIN UNIV

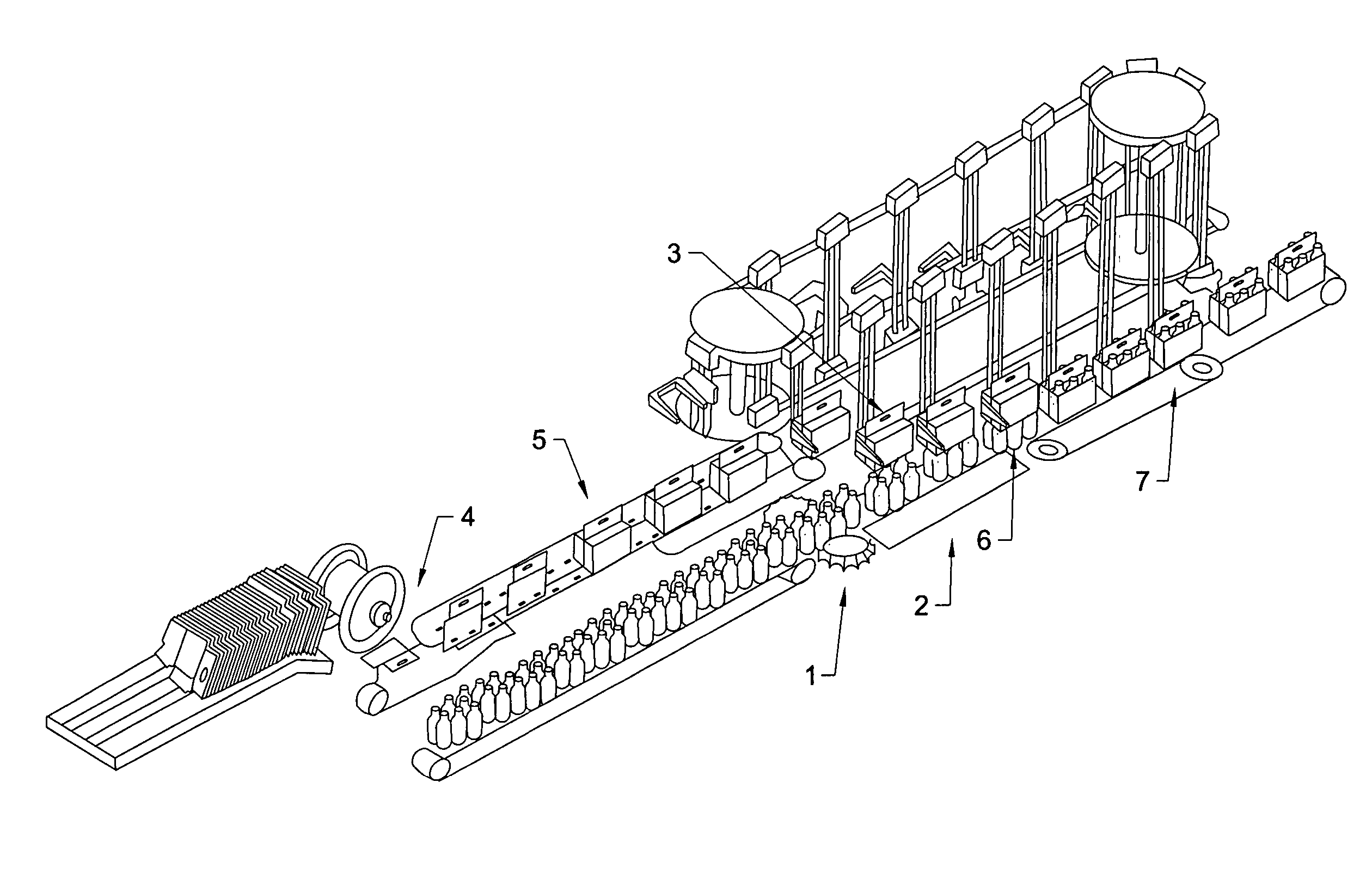

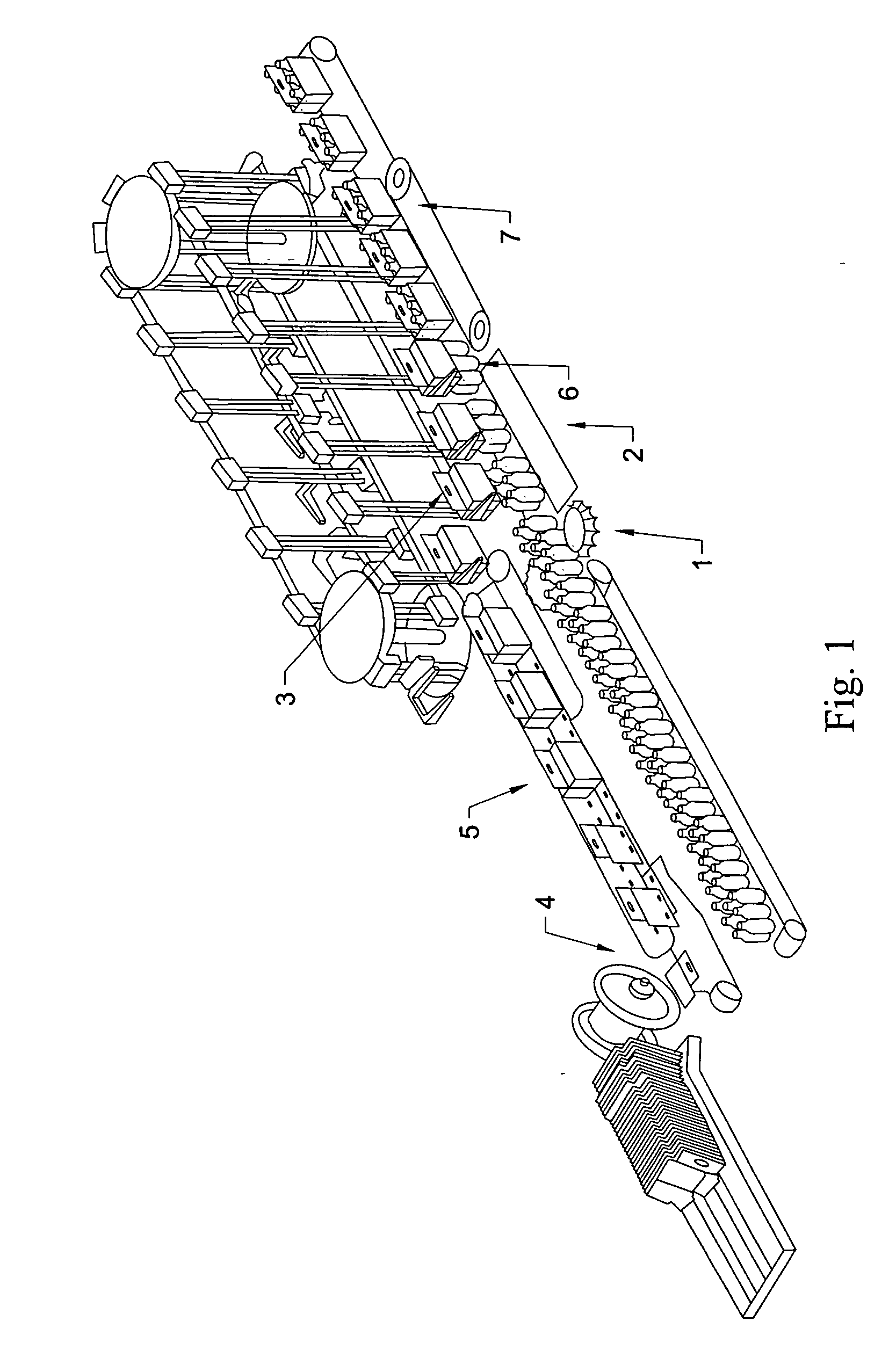

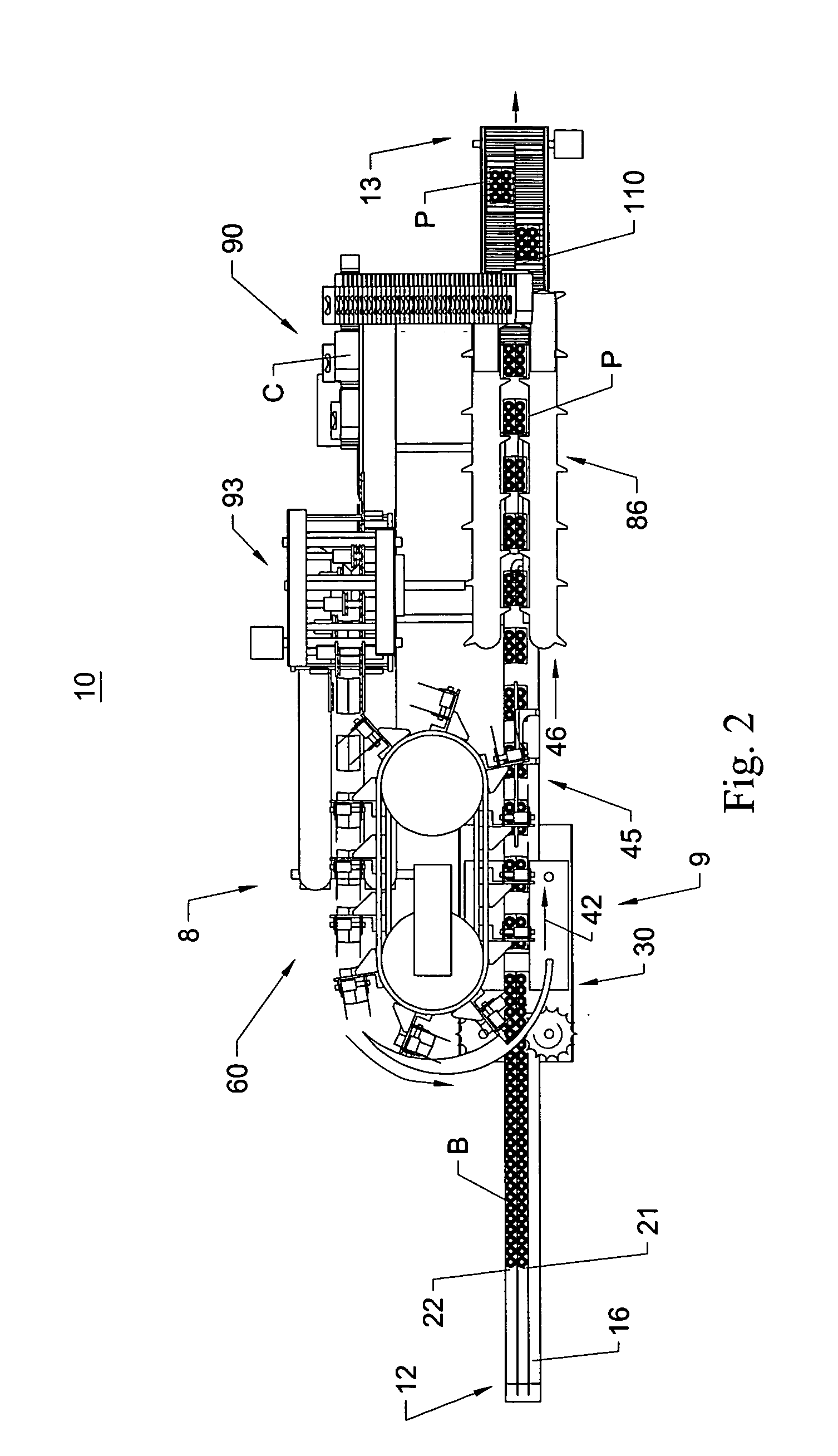

Packaging system having loading carousel

A packaging system utilizes two sides of a loading carousel, which reduces both the height and footprint of the packaging system. Mass and inertia are also reduced, allowing higher operational speeds. The loading carousel receives opened cartons on a first side and lowers them over product groups on a second side.

Owner:GRAPHIC PACKAGING INT

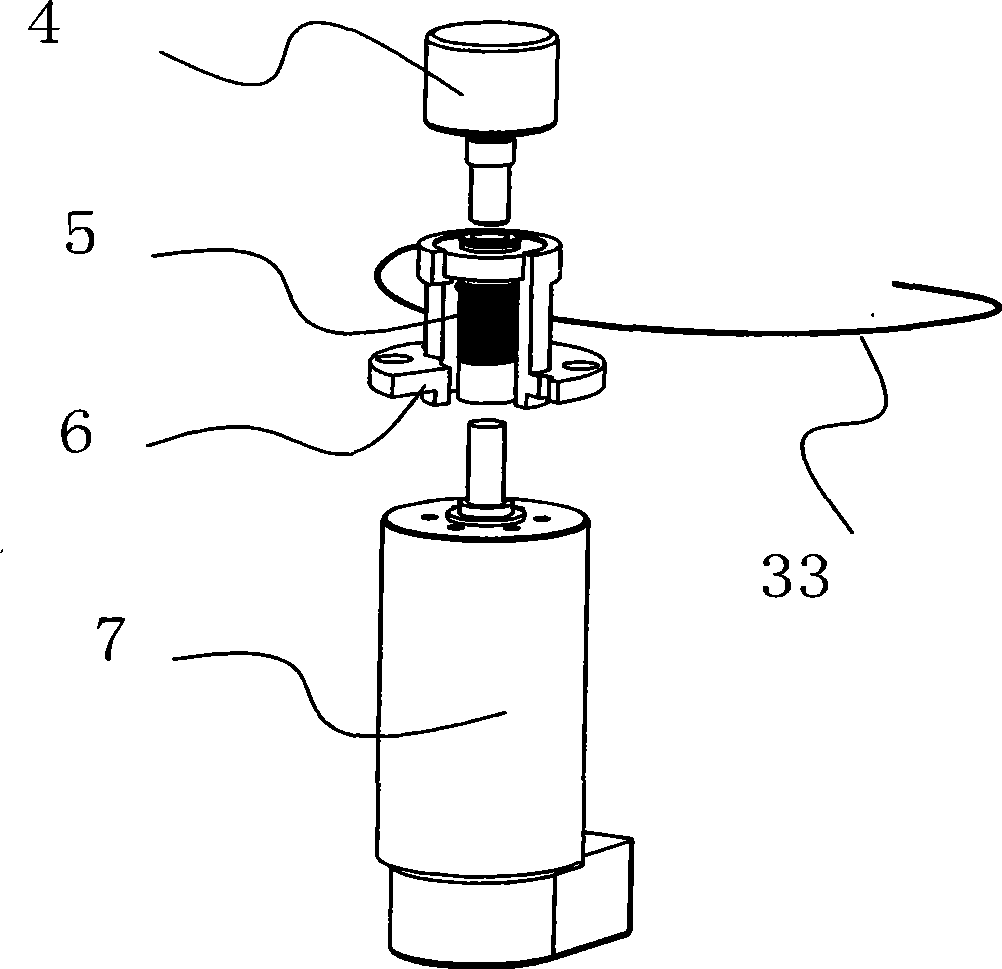

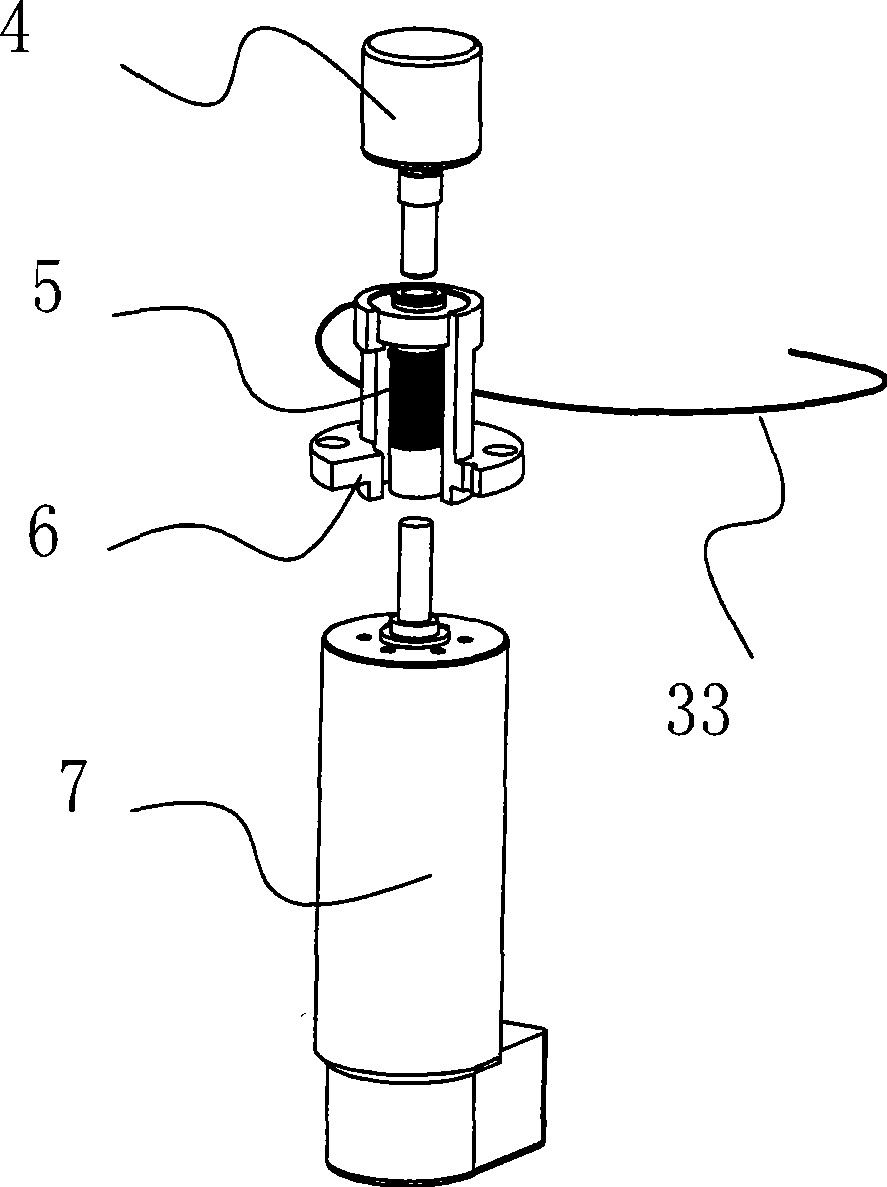

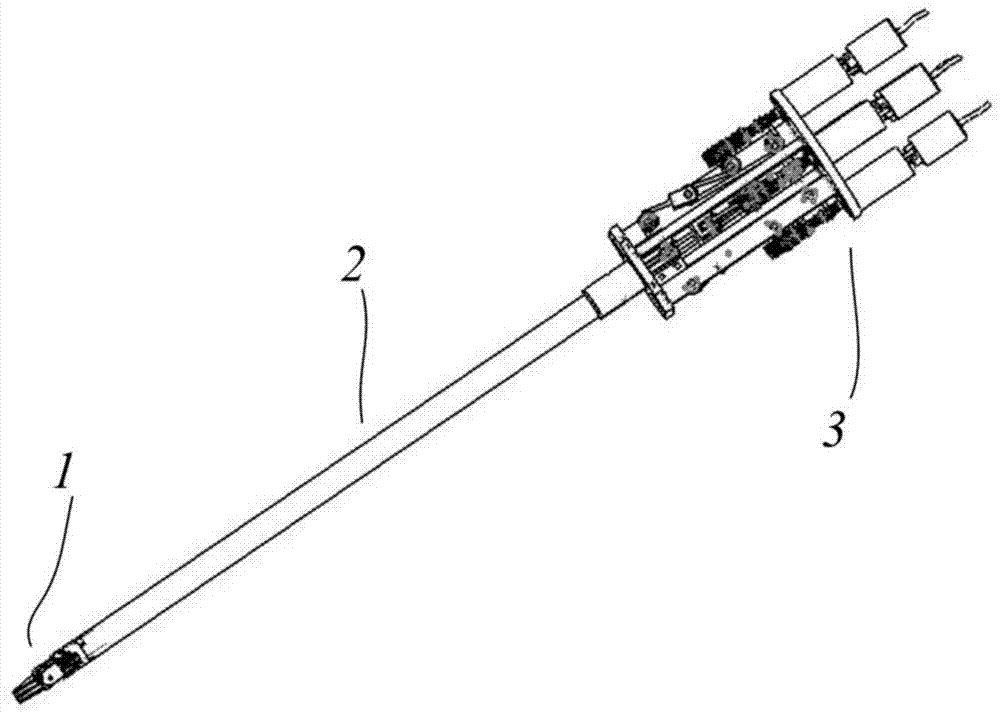

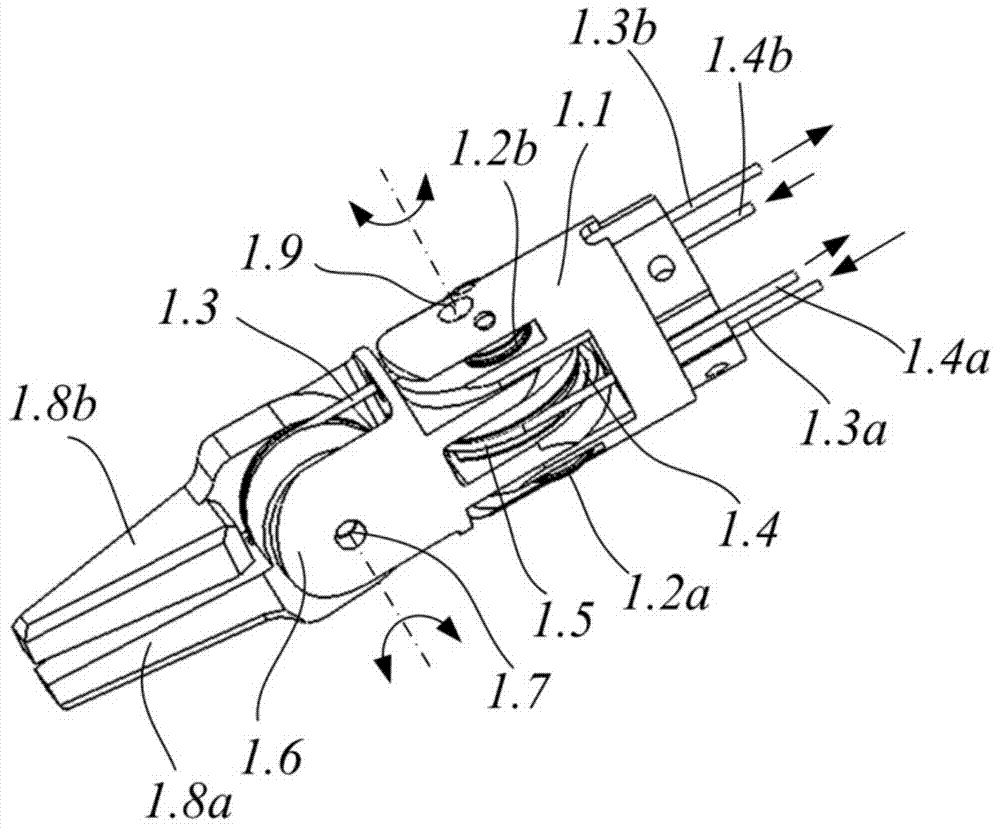

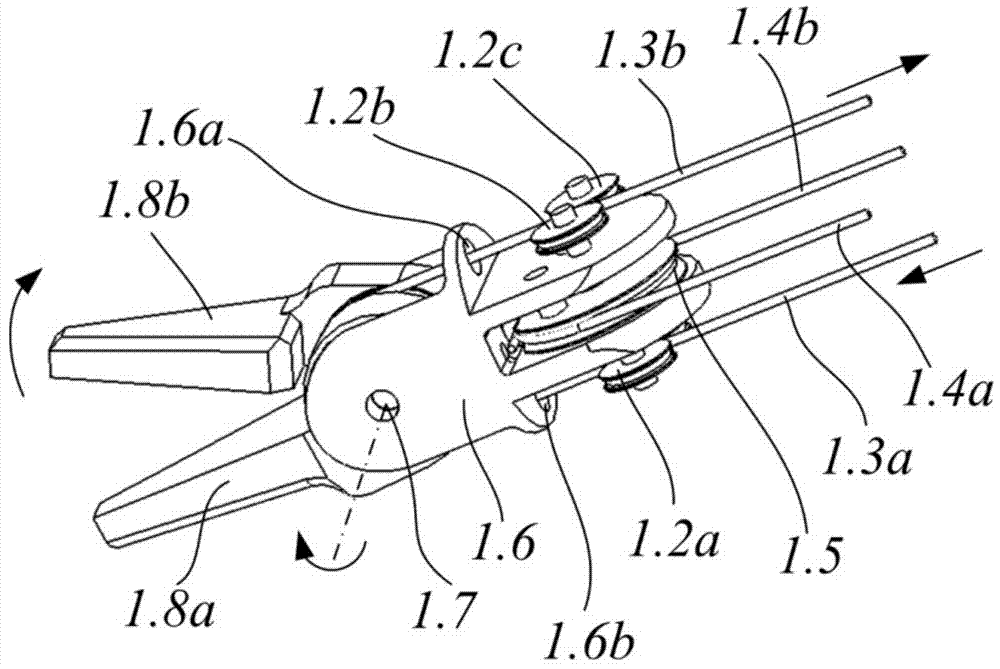

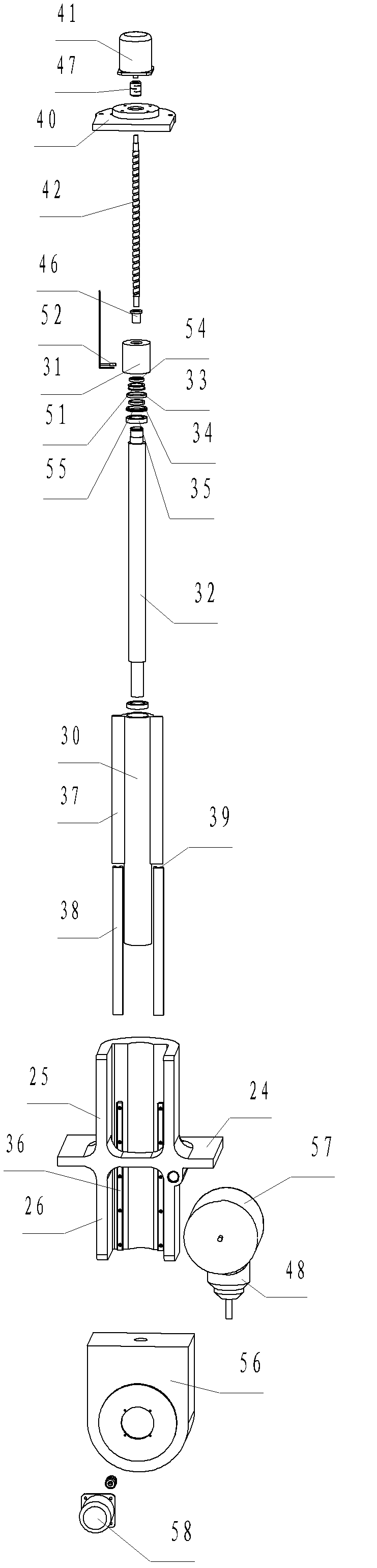

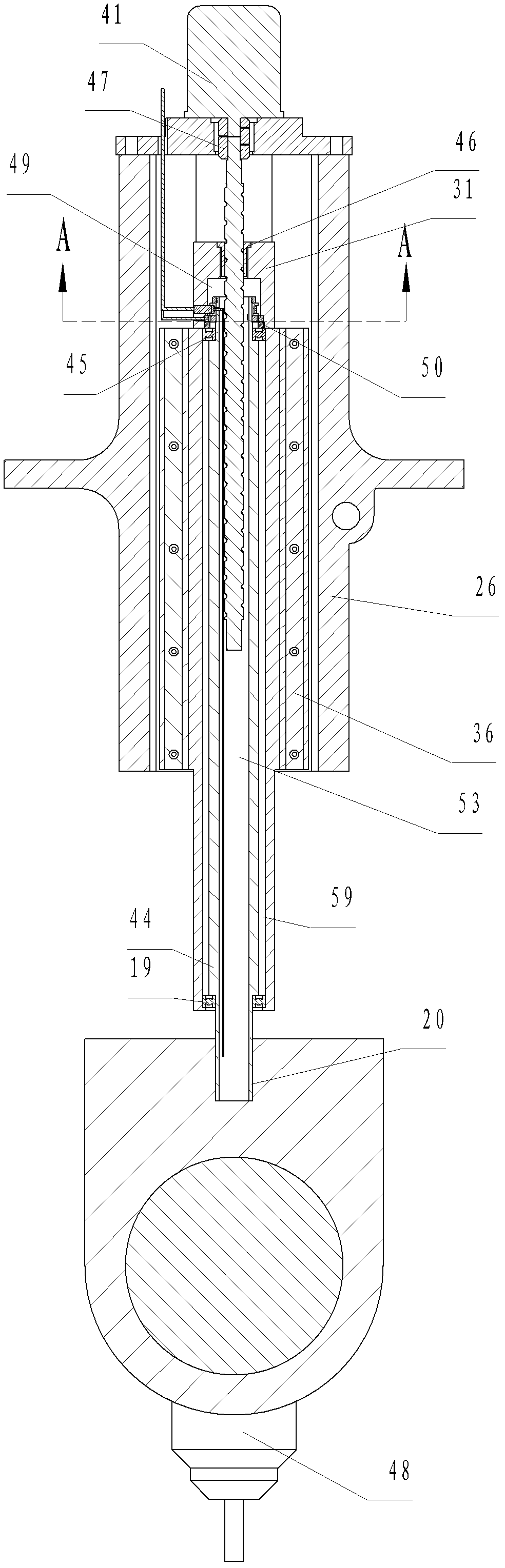

Low-friction low-inertia surgical instrument for minimally invasive surgical robot

ActiveCN104116547AEliminate motion interference problems of traditional joint designReduce usageSurgical forcepsEngineeringActuator

The invention relates to a low-friction low-inertia surgical instrument for a minimally invasive surgical robot. The low-friction low-inertia surgical instrument comprises a power driving portion (3), a main body connecting rod portion (2) and an end effector portion (1), wherein the power driving portion (3), the main body connecting rod portion (2) and the end effector portion (1) are connected with one another in sequence. The end effector portion (1) comprises a finger opening and closing joint and a wrist pitching joint. The power driving portion (3) penetrates through the main body connecting rod portion (2) through a steel wire rope driving structure and then is connected with the finger opening and closing joint and the wrist pitching joint of the end effector portion (1) respectively, so that finger opening and closing motion and wrist pitching motion of an end effector are achieved. Compared with the prior art, the low-friction low-inertia surgical instrument has the advantages that decoupling of end joint motion is achieved, a driver is simple in structure, the inertia of a body of the surgical instrument is effectively lowered, friction force of the driver is reduced, and reverse driving can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

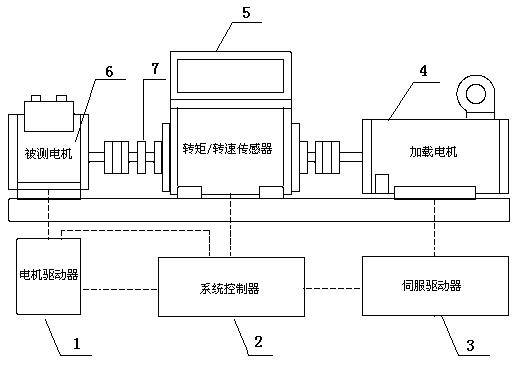

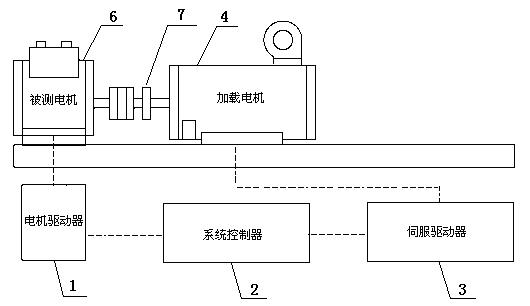

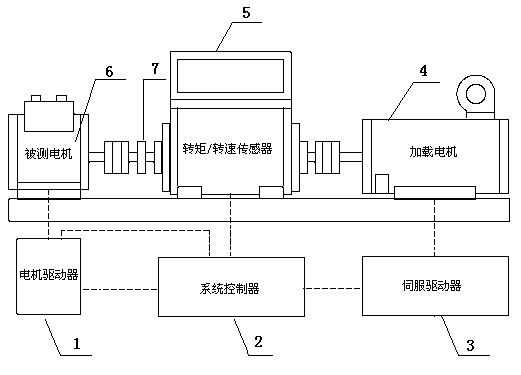

Dynamic loading methods based on servo motor

InactiveCN101793605ARealize dynamic characteristic testSimple structureEngine testingCurrent meterBrake torque

The invention relates to dynamic loading methods based on a servo motor, belonging to the field of motors and solving the problem that the properties of a direct-current motor can not satisfy the requirements of an electric loading system. The first method comprises the following steps of: transmitting a driving torque instruction value and an initial braking torque instruction value by utilizing a system controller according to the given loading spectrum to drive a measured motor to rotate; meanwhile, driving a loading motor to generate a braking torque for loading the measured motor; and then, feeding back the actual output torque value applied to the measured motor by the loading motor through adopting a torque / rotary speed sensor, and regulating the braking torque instruction value by utilizing the system controller according to a deviation so that the actual output torque value applied to the measured motor by the loading motor rapidly tracks the initial braking torque instruction value. The second method of the invention comprises the following steps of: calibrating the input and output torque relation curve of the loading motor by using the torque / rotary speed sensor, and then transmitting the driving torque instruction value and the braking torque instruction by using the system controller according to the given loading spectrum and the relation curve to load the measured motor.

Owner:HARBIN INST OF TECH

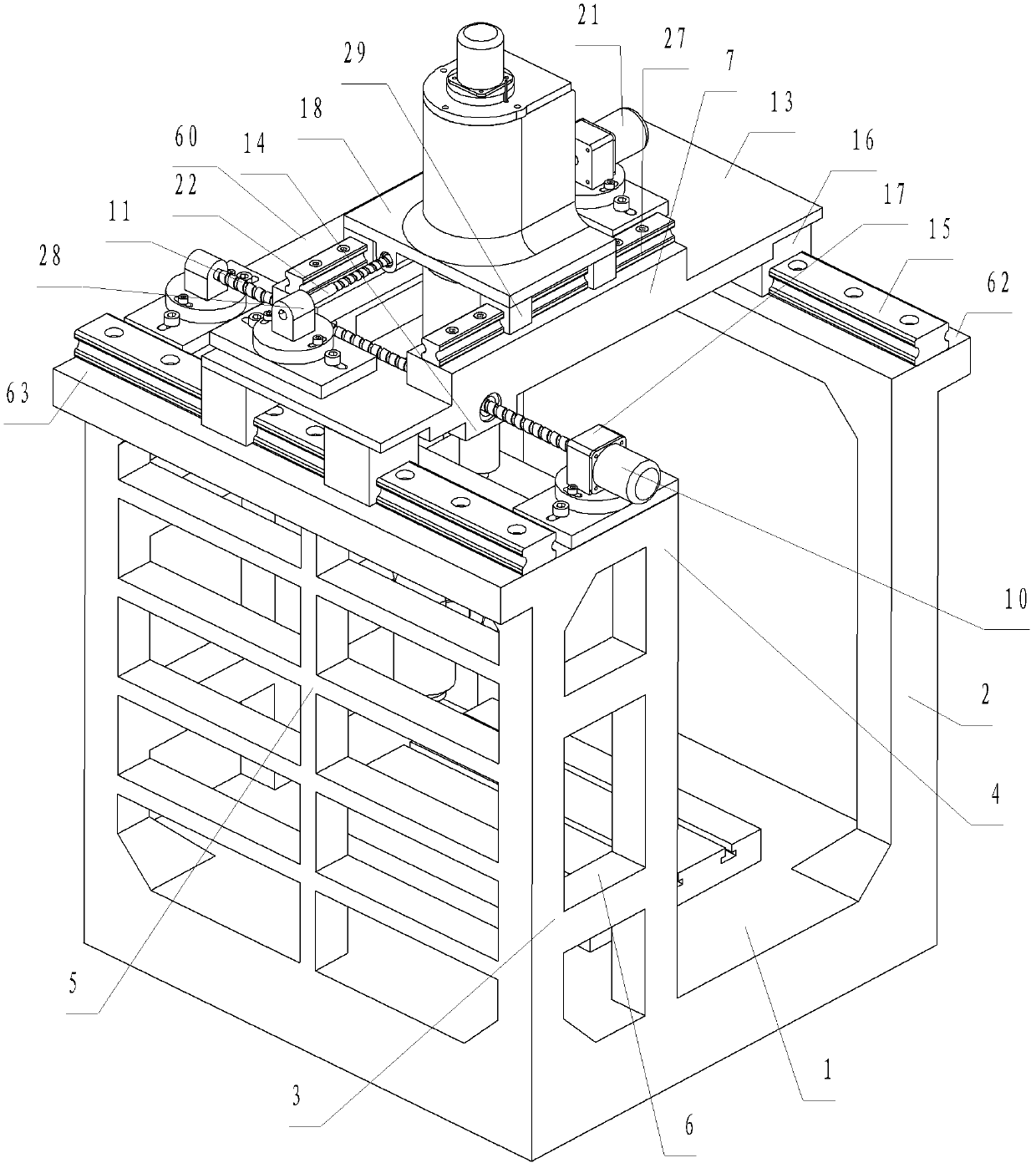

Three-degree of freedom flexible precision positioning workbench

InactiveCN101770182AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistThree degrees of freedom

The invention discloses a three-degree of freedom flexible precision positioning workbench. In a structure of the workbench, six piezoelectric ceramic drivers are adopted, the tail of each driver is connected with a substrate through bolts, and the top end is in threaded connection with a ball joint to realize hertz contact; a flexible structure of the positioning workbench mainly comprises the substrate, six flexible branched chains with identical structures and a movable platform supported by the flexible branched chains; and three position sensors are used for measuring the actual output of the movable platform and are respectively fixed between a rigid support and the movable platform. The precision positioning workbench has the characteristics of high resolution ratio and high speed of dynamic response, and can be used as an assisted positioning platform of a nano-imprint lithography positioning system to realize microscale feeding and precision positioning.

Owner:TIANJIN UNIV

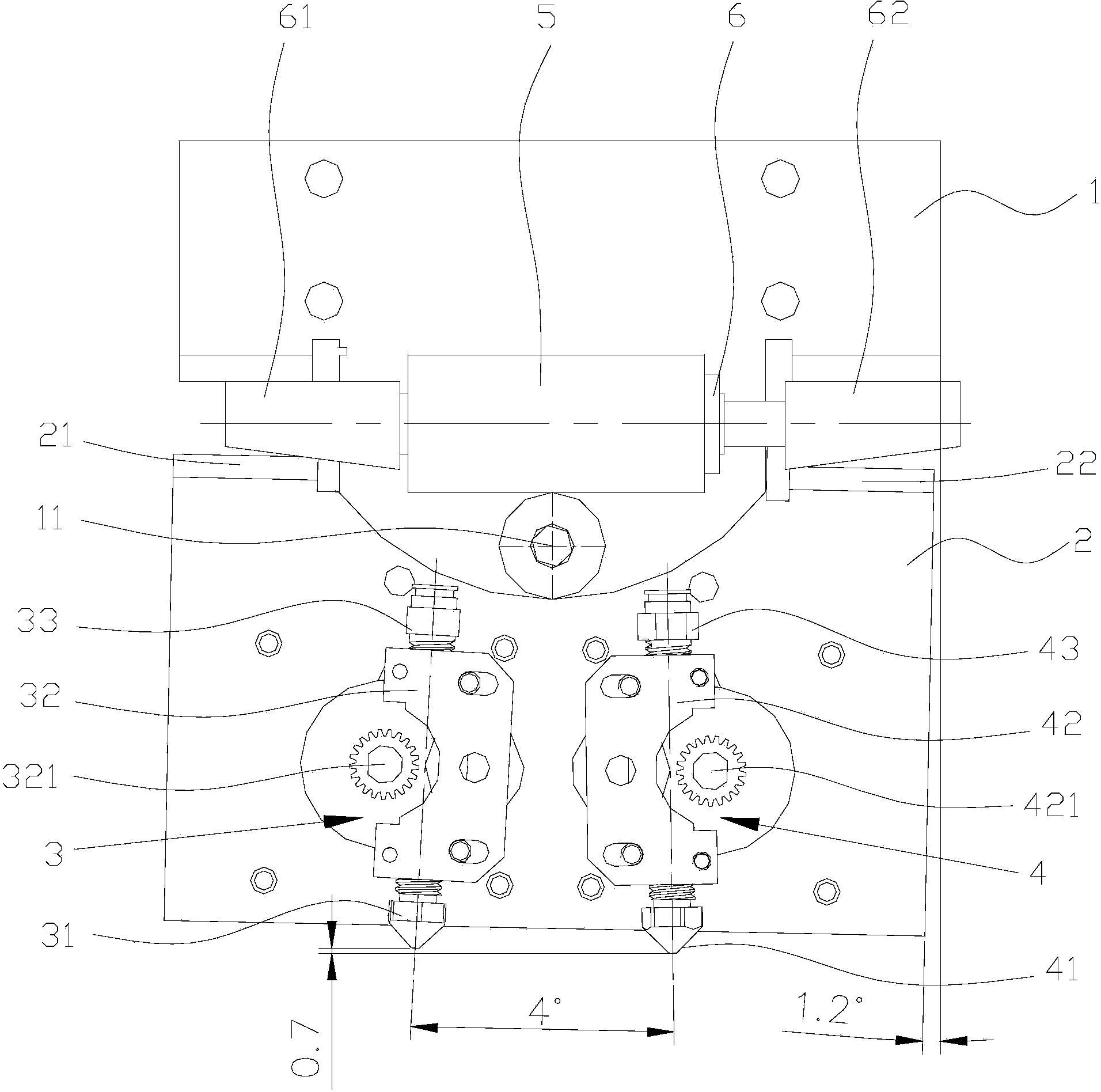

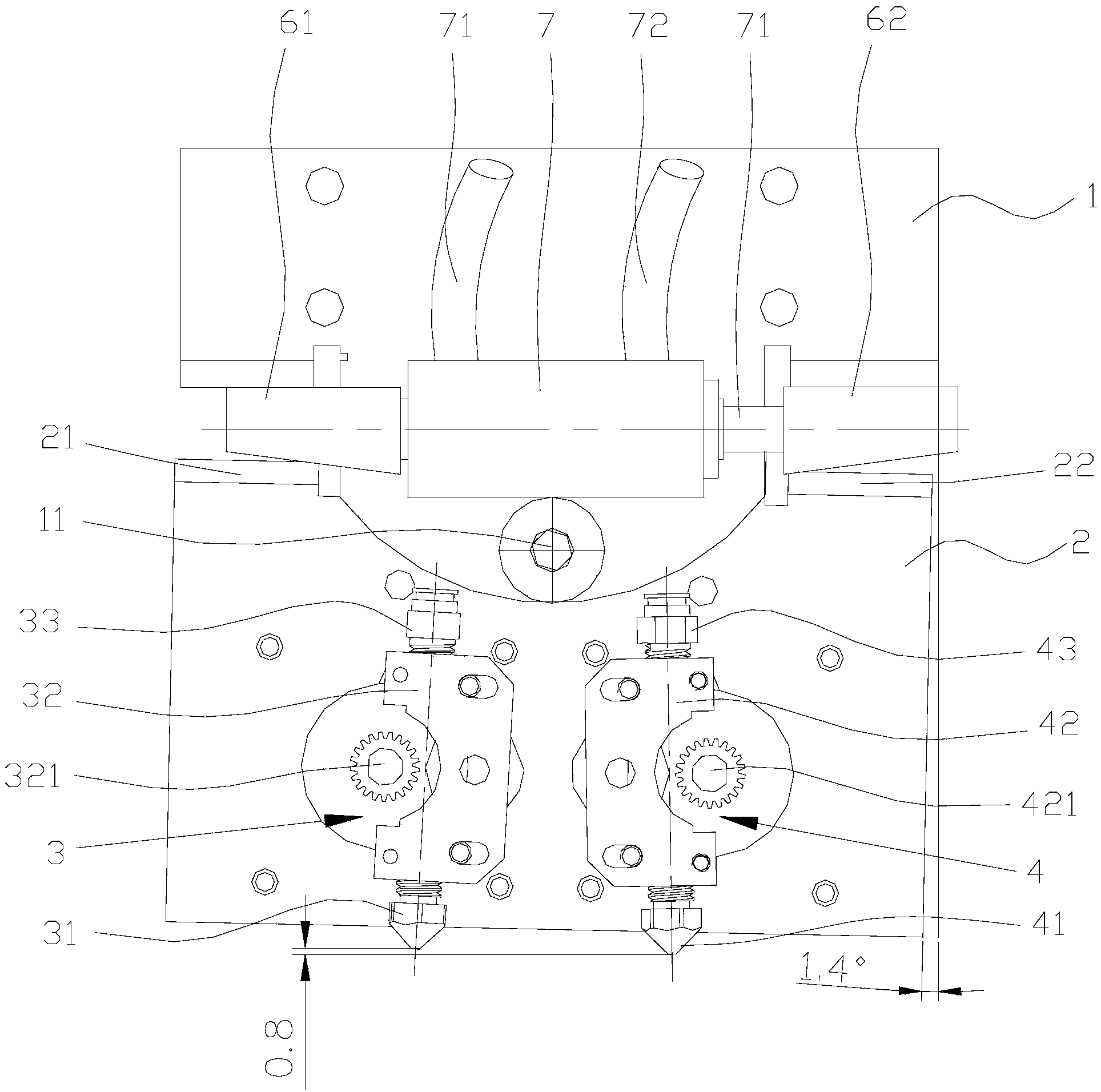

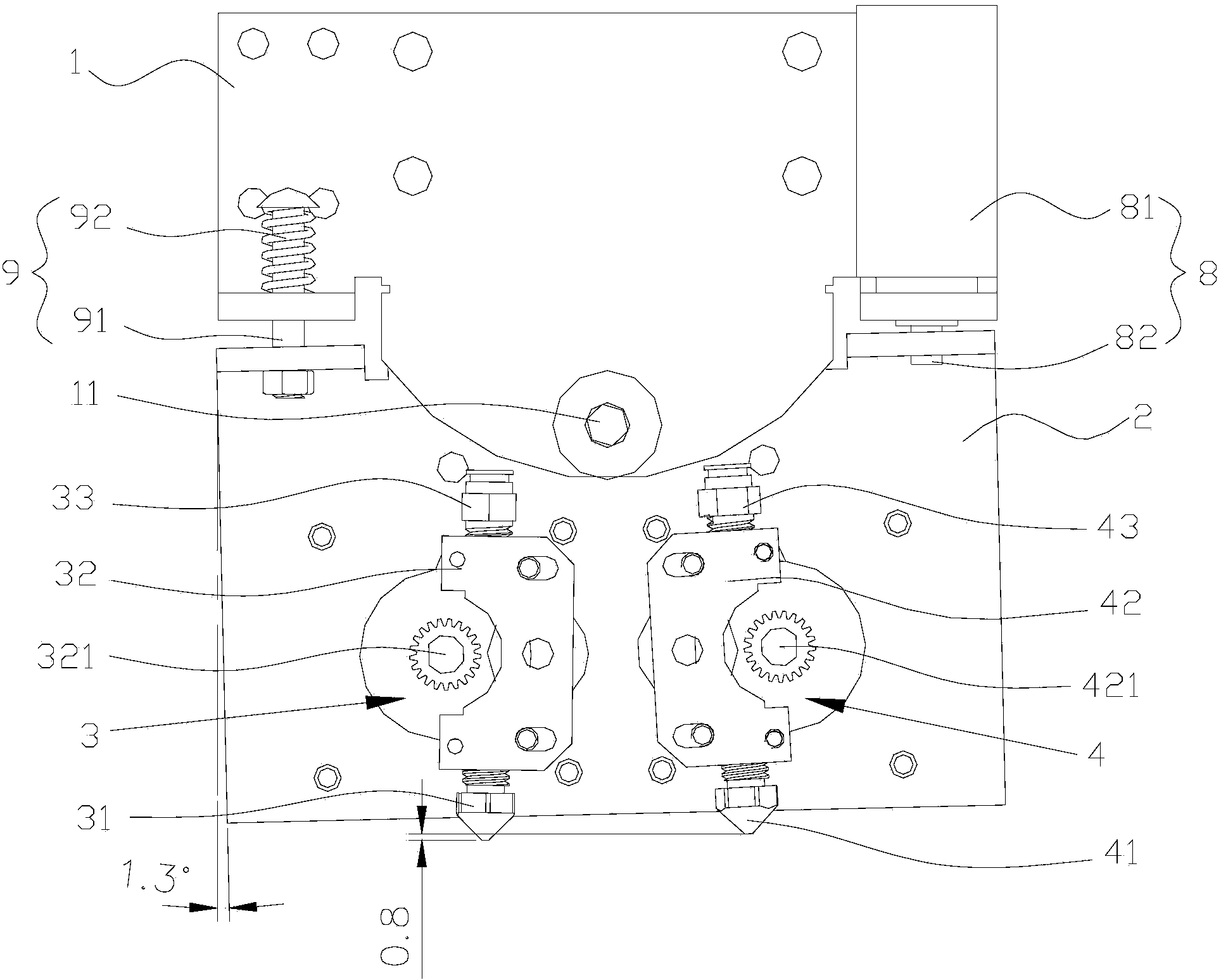

Dual-head 3D printer capable of rotatably switching printing heads

ActiveCN104228069AGuaranteed heightOvercoming problems with being at the same heightEngineering3d printer

Owner:苏州江南嘉捷光机电技术有限公司

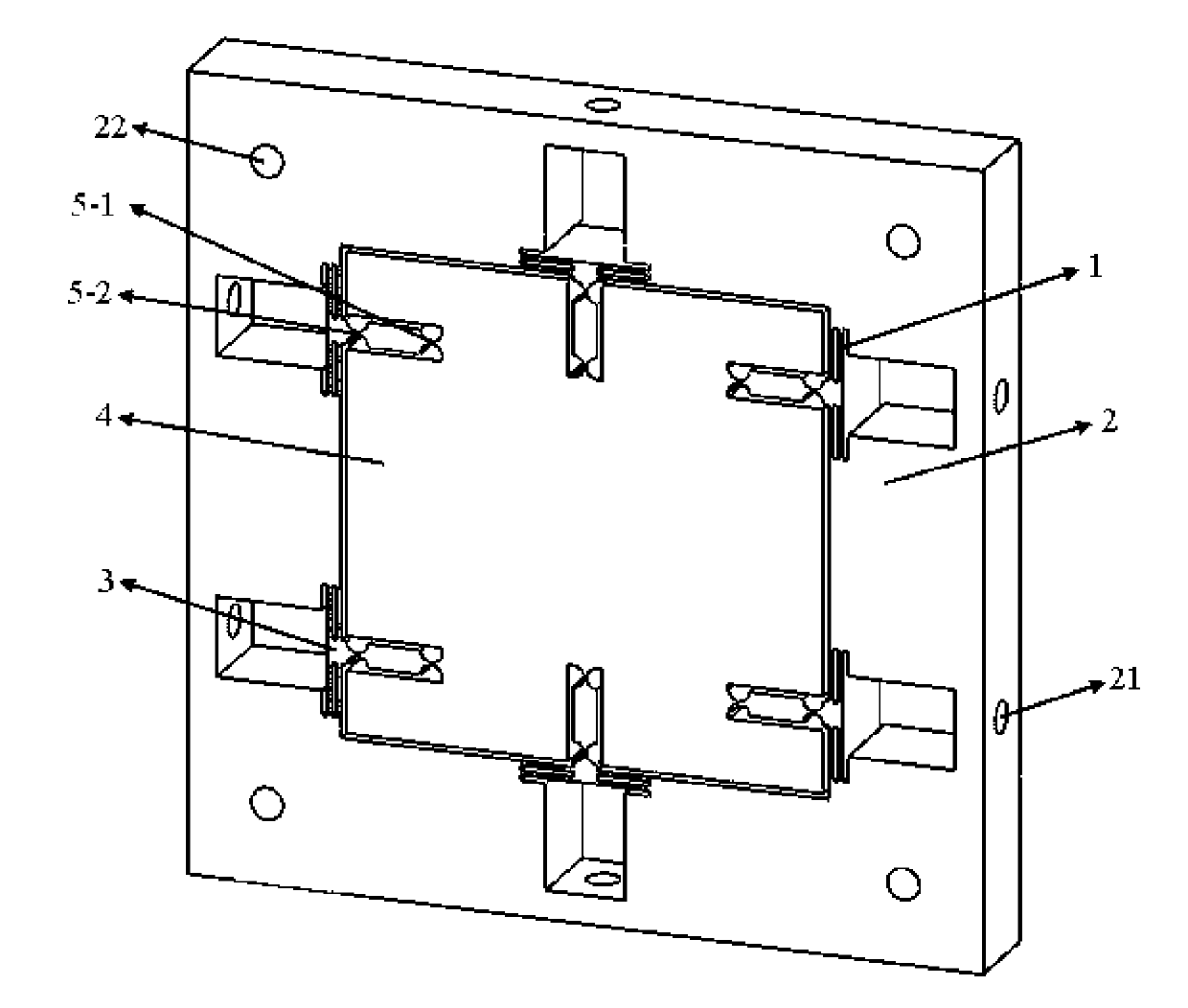

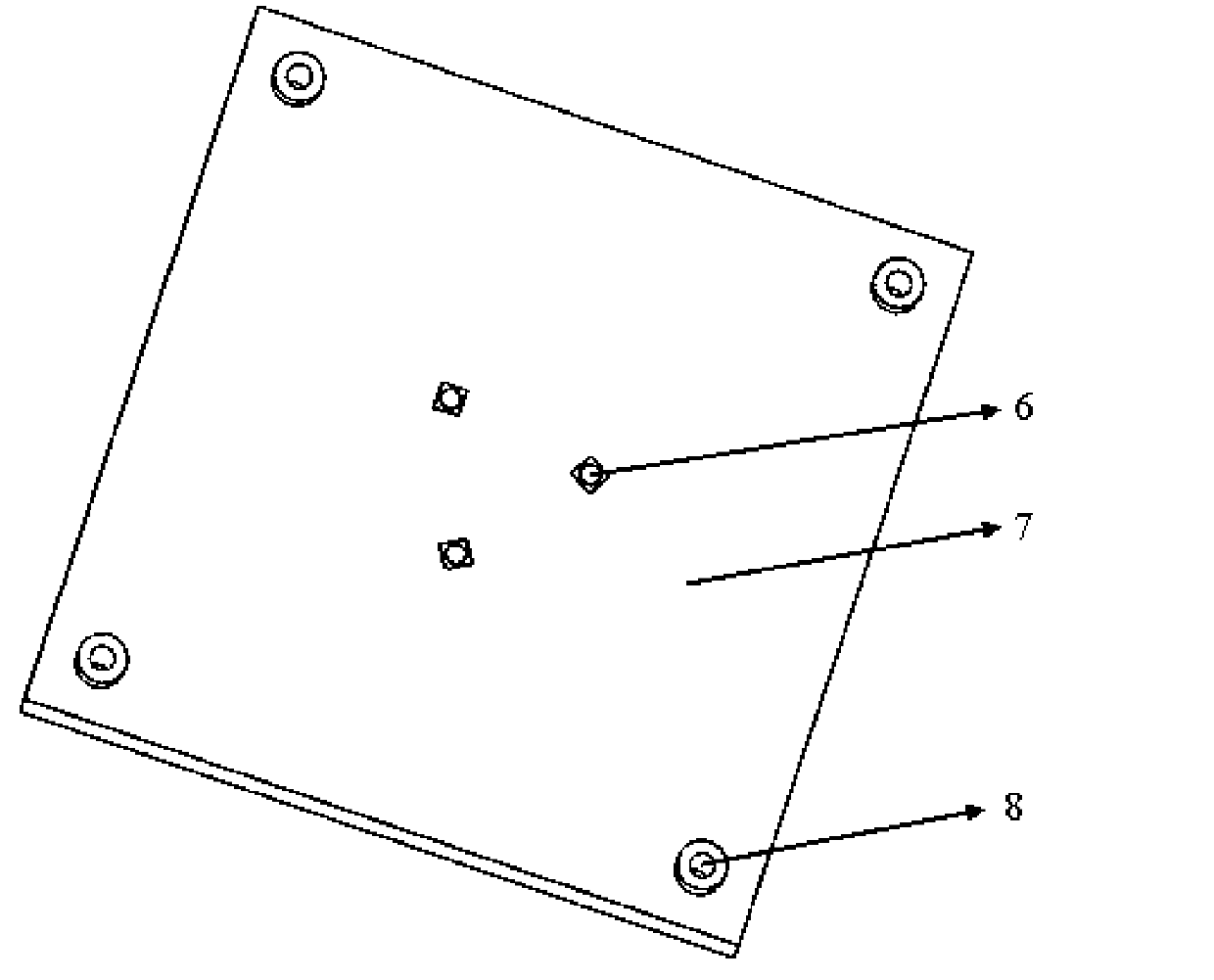

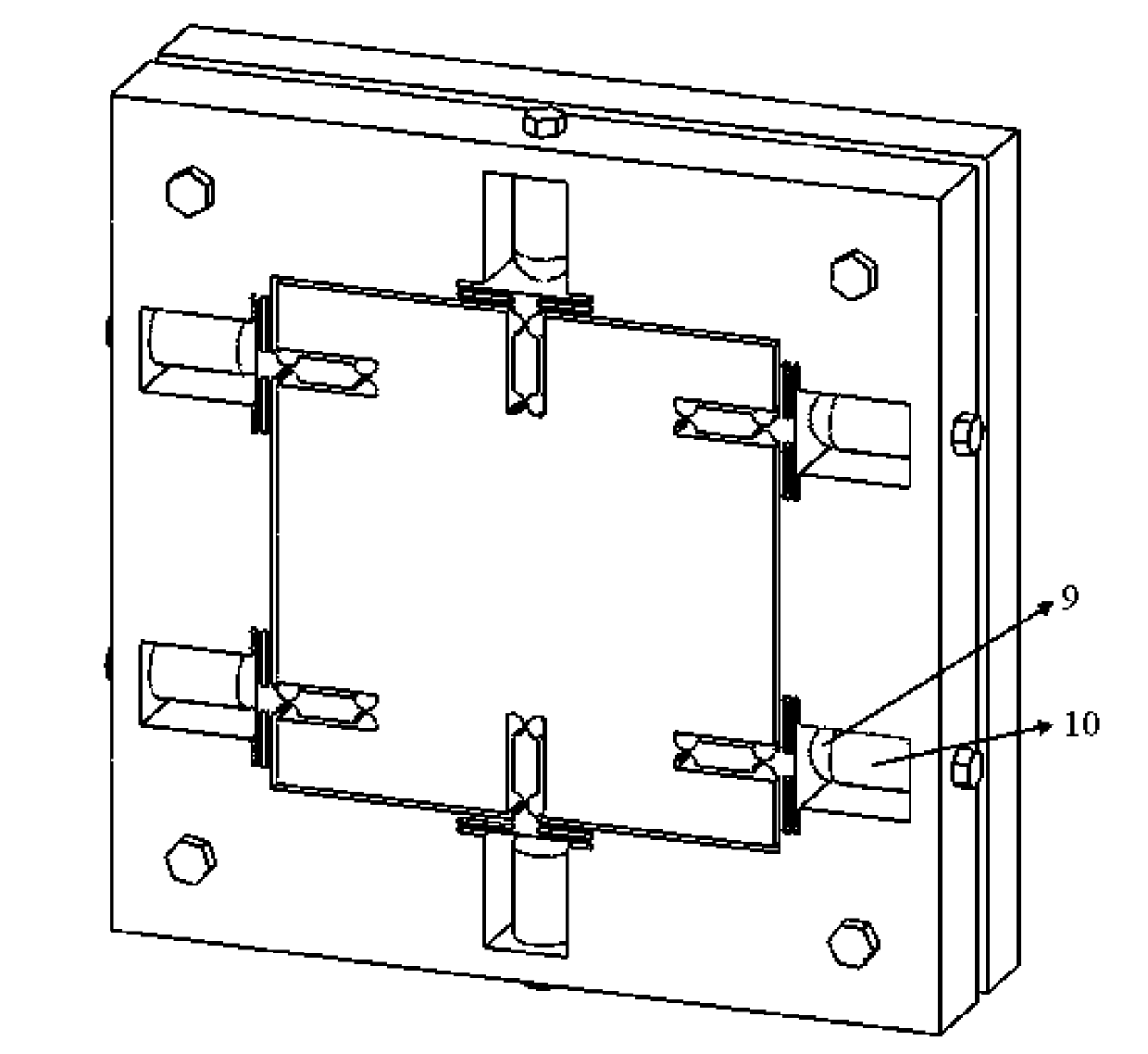

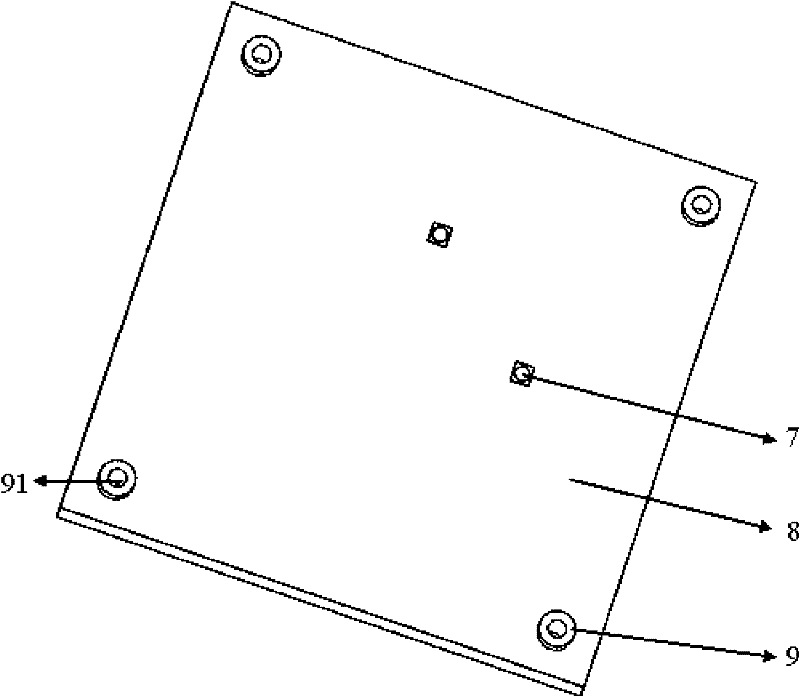

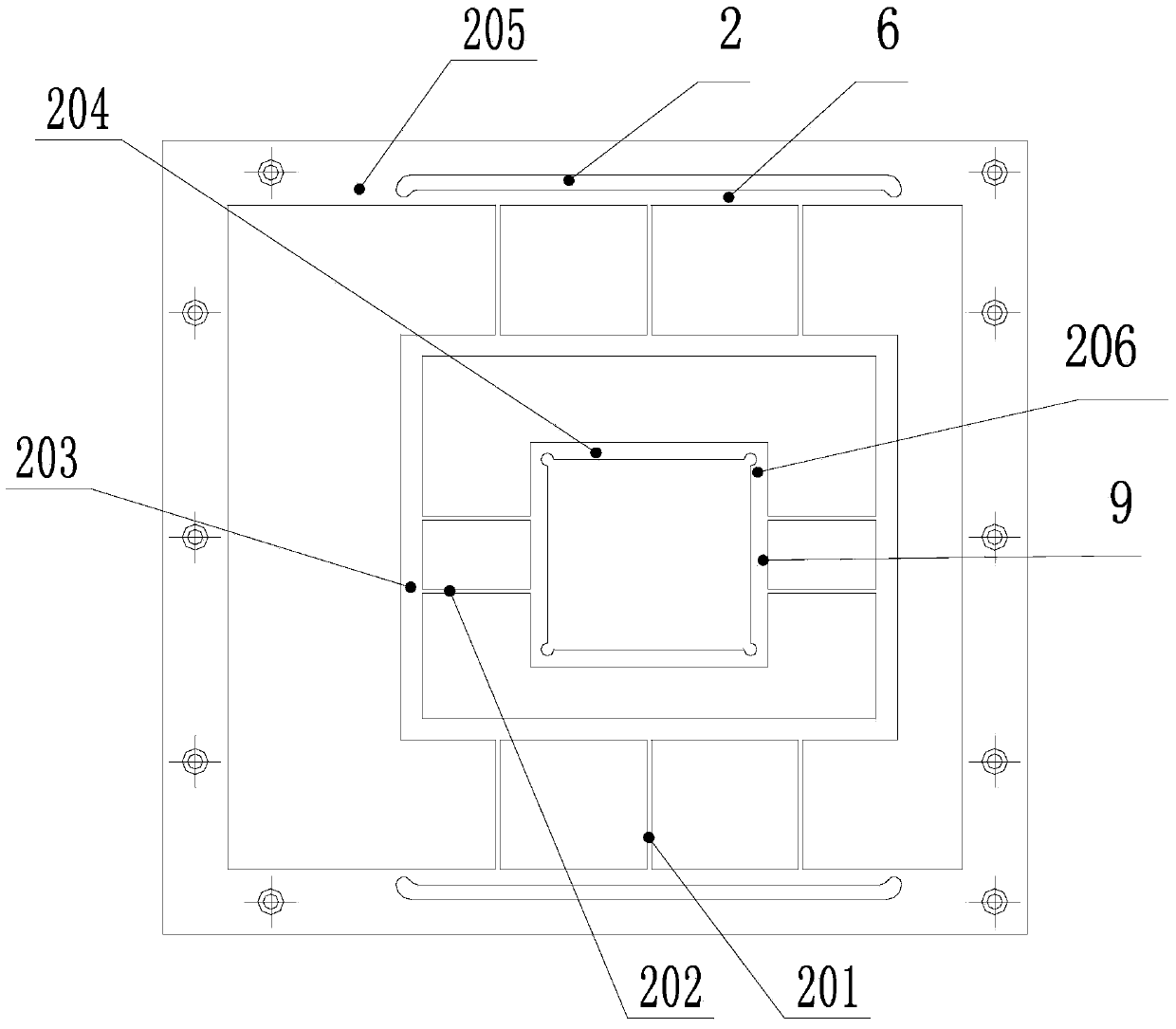

Two-degree of freedom precise positioning work table

The invention discloses a two-degree of freedom precise positioning work table, which comprises a base, a moving platform, a rigid support which is connected with the bottom of the base, and four flexible branched chains which are connected between the moving platform and the base, wherein each flexible branched chain comprises a moving block and three groups of flexible plate spring structures; each flexible plate spring structure consists of two '-'-shaped flexible plate springs; a first group and a second group of the flexible plate spring structures are respectively positioned at the left side and the right side of the moving block; the lower ends of the two '-'-shaped flexible plate springs of a third group of the flexible plate spring structures are connected with the side wall of the upper end of the moving block, and the upper ends thereof are connected with the side wall of the moving platform; four piezoelectric ceramics driving devices are respectively horizontally arranged; a ball-shaped joint of each driving device is supported on the side wall of the lower end of the moving block; and conducting strips of two position sensors are respectively connected with the upper plane of the rigid support and the lower plane of the moving platform. The positioning work table can be taken as an auxiliary positioning platform of a nanometer embossing photoetching positioning system to realize the microscale feeding and the precise positioning.

Owner:TIANJIN UNIV

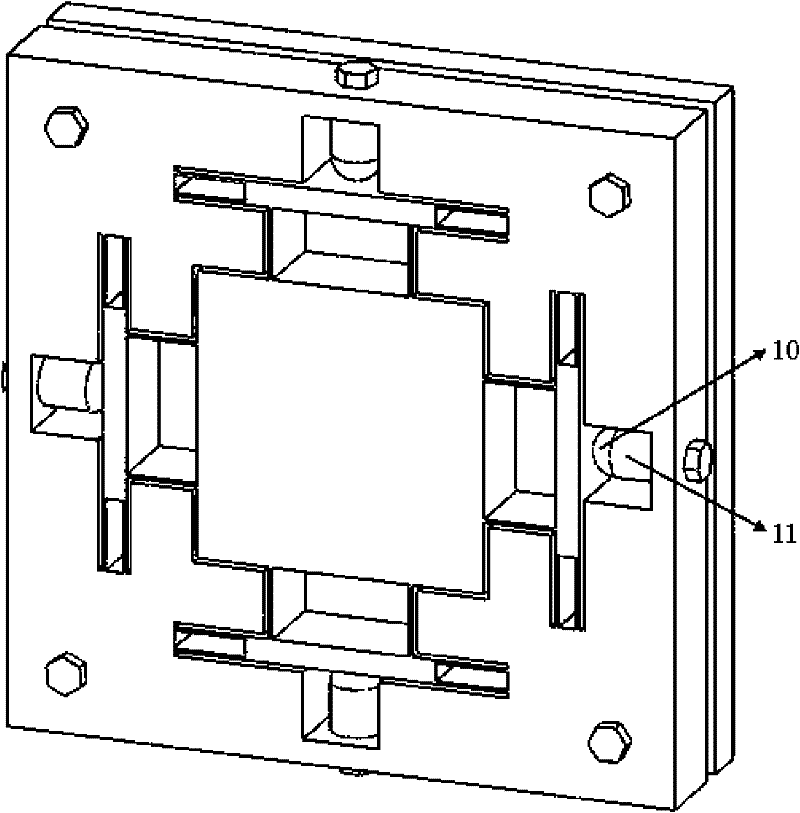

Plane parallel type three-freedom-degree precise positioning work table

InactiveCN103021472ACompact structureFlexible controlInstrumental componentsWork benchesDynamic stiffnessKinematics

A plane parallel type three-freedom-degree precise positioning work table has three flexible branched chains which are total the same in structure and respectively and correspondingly arranged on the inner sides of three equal sides of a base of a triangular structure and a movable platform arranged on the inner sides of the three flexible branch chains and arranged at the center of the base, wherein the base, the three flexible branched chains and the movable platform are integrally formed, the three flexible branched chains are in flexible connection with the base, displacement input ends of the three flexible branched chains respectively correspond to three included angles of the base, the movable platform is in flexible connection with the three flexible branched chains, a groove is formed between the inner side of each included angle of the base and the corresponding flexible branched chain, a piezoelectric ceramic driver is horizontally arranged in the groove, one end of the piezoelectric ceramic driver is in hertz contact with the displacement input ends of the flexible branched chains, and the other end of the piezoelectric ceramic driver is fixedly connected on the base through bolts. The plane parallel type three-freedom-degree precise positioning work table is compact in structure, flexible to control, high in static and dynamic stiffness, high in kinematic accuracy, low in inertia, free of error accumulation, free of friction and heating and fast in responding.

Owner:TIANJIN UNIV

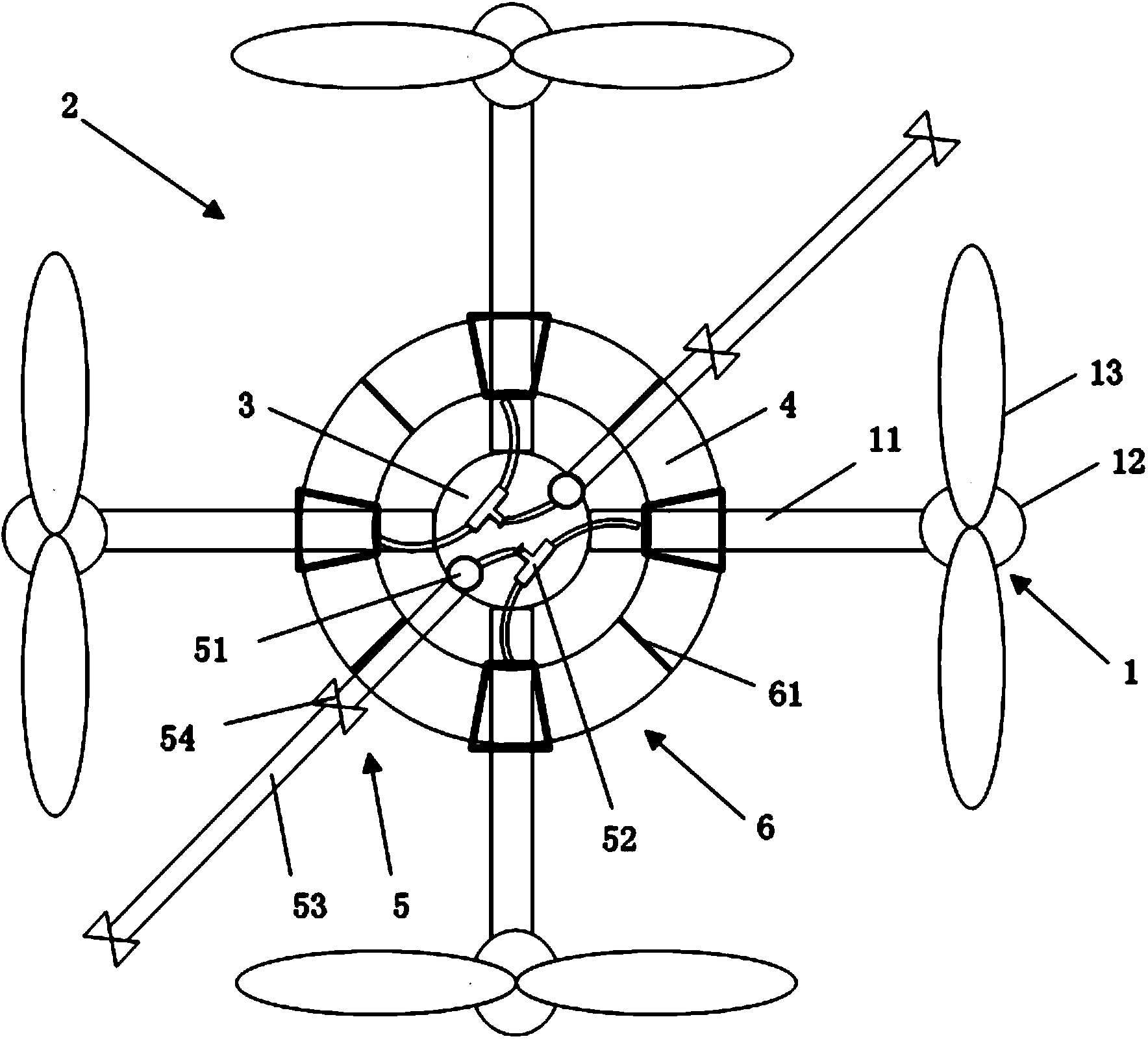

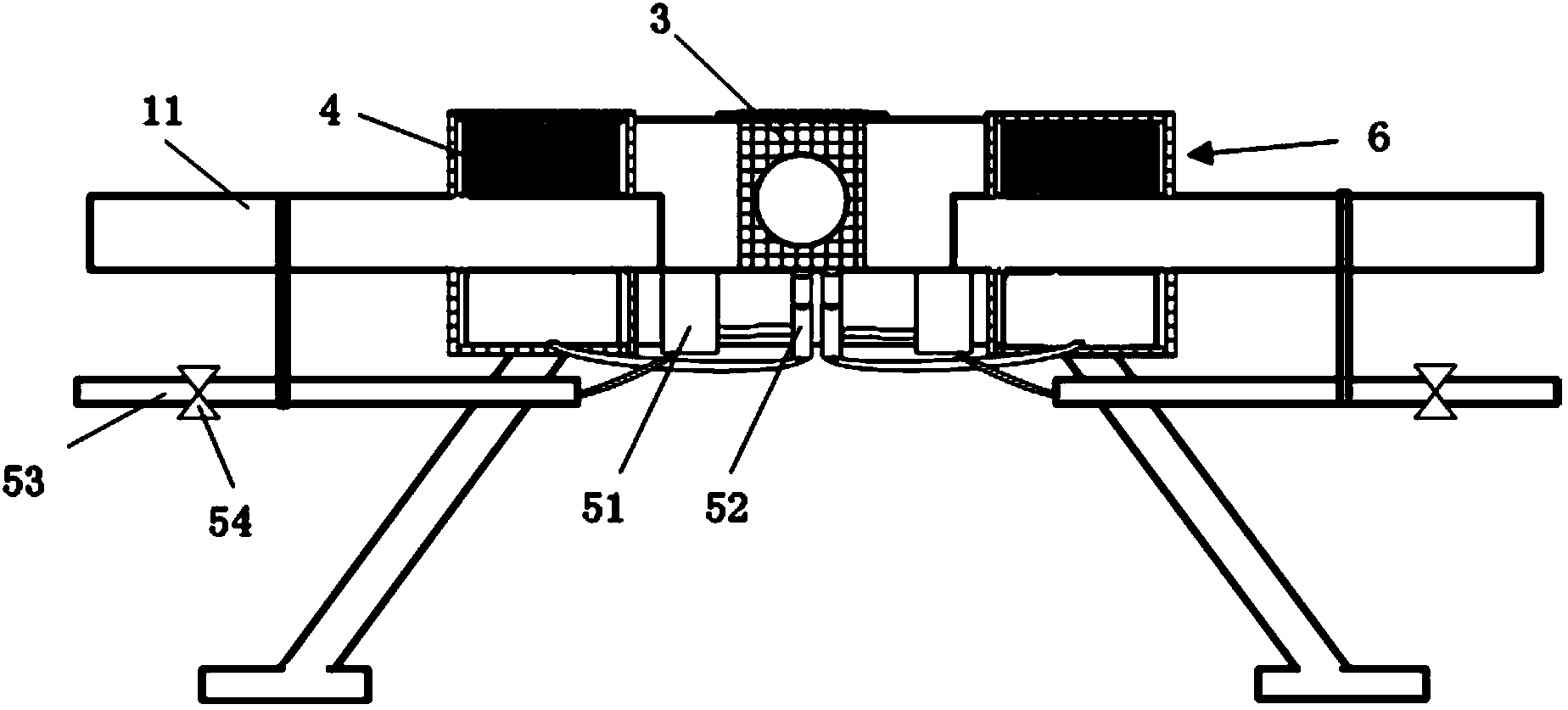

Rotary wing type unmanned aerial vehicle for spraying pesticides

ActiveCN104354864ASmall inertiaStable flightAircraft componentsLaunching weaponsGravity centerEngineering

The invention relates to a rotary wing type unmanned aerial vehicle for spraying pesticides. The rotary wing type unmanned aerial vehicle comprises a vehicle body with a rotary wing component, wherein a plurality of pesticide boxes and a pesticide spraying device connected with the pesticide boxes are further mounted on the vehicle body; all the pesticide boxes are flatly arranged and the whole horizontal gravity center coincides with the horizontal gravity center of the vehicle body. According to the rotary wing type unmanned aerial vehicle for spraying pesticides disclosed by the invention, a large pesticide box is divided into a plurality of small pesticide boxes with the same size, so that the inertia of pesticide liquid inside a single pesticide box can be reduced, the horizontal center-of-gravity shift generated by the liquid inside each pesticide box is relatively small under the condition that the aerial vehicle suddenly stops, the overall horizontal center-of-gravity shift is greatly smaller than that under the condition that the single pesticide box is filled with the pesticide liquid, and thus the problem that flight control cannot correct out-of-control falling caused by too large horizontal center-of-gravity shift and too large dip angle of the vehicle body is avoided.

Owner:ZHEJIANG UNIV

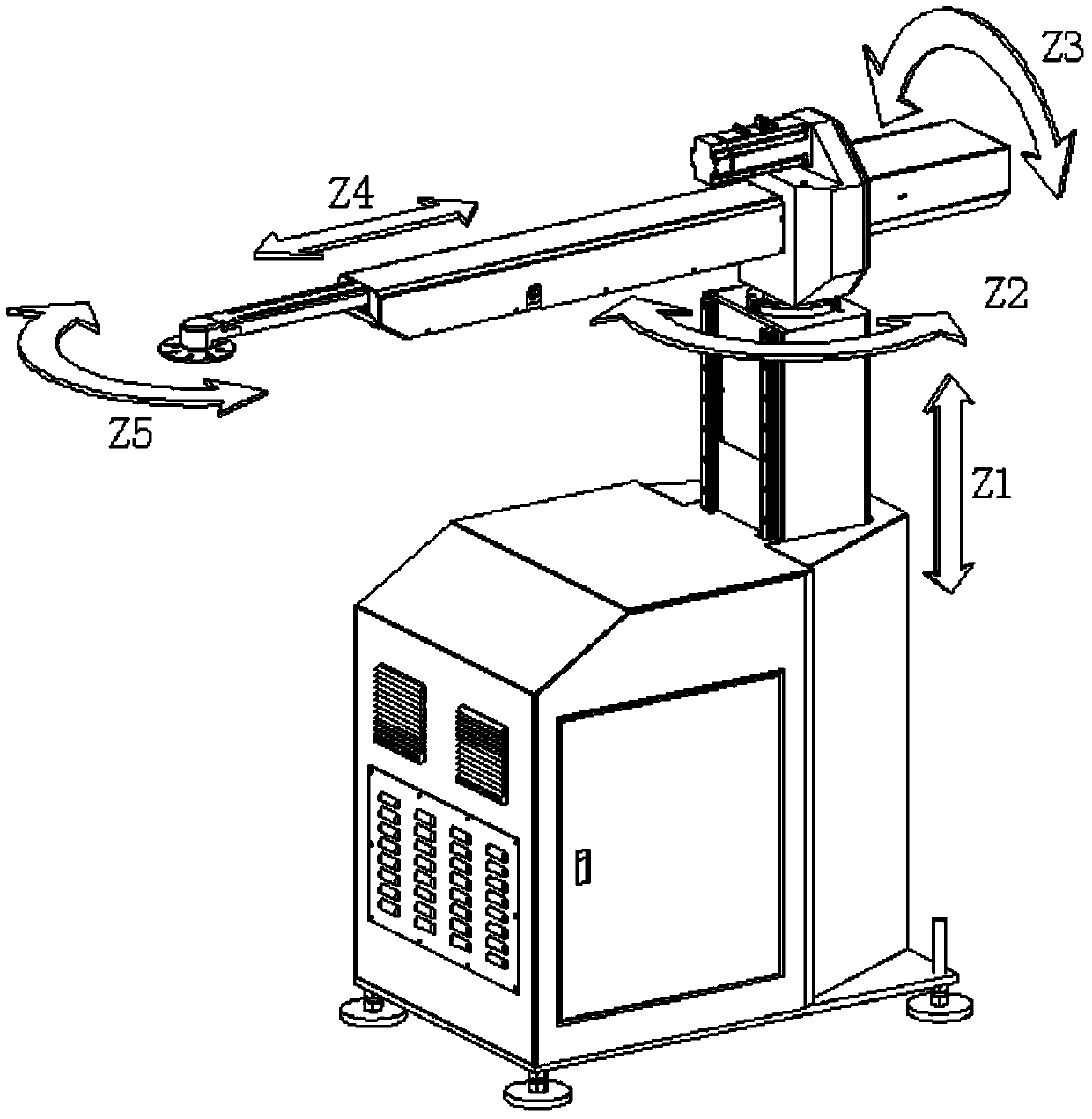

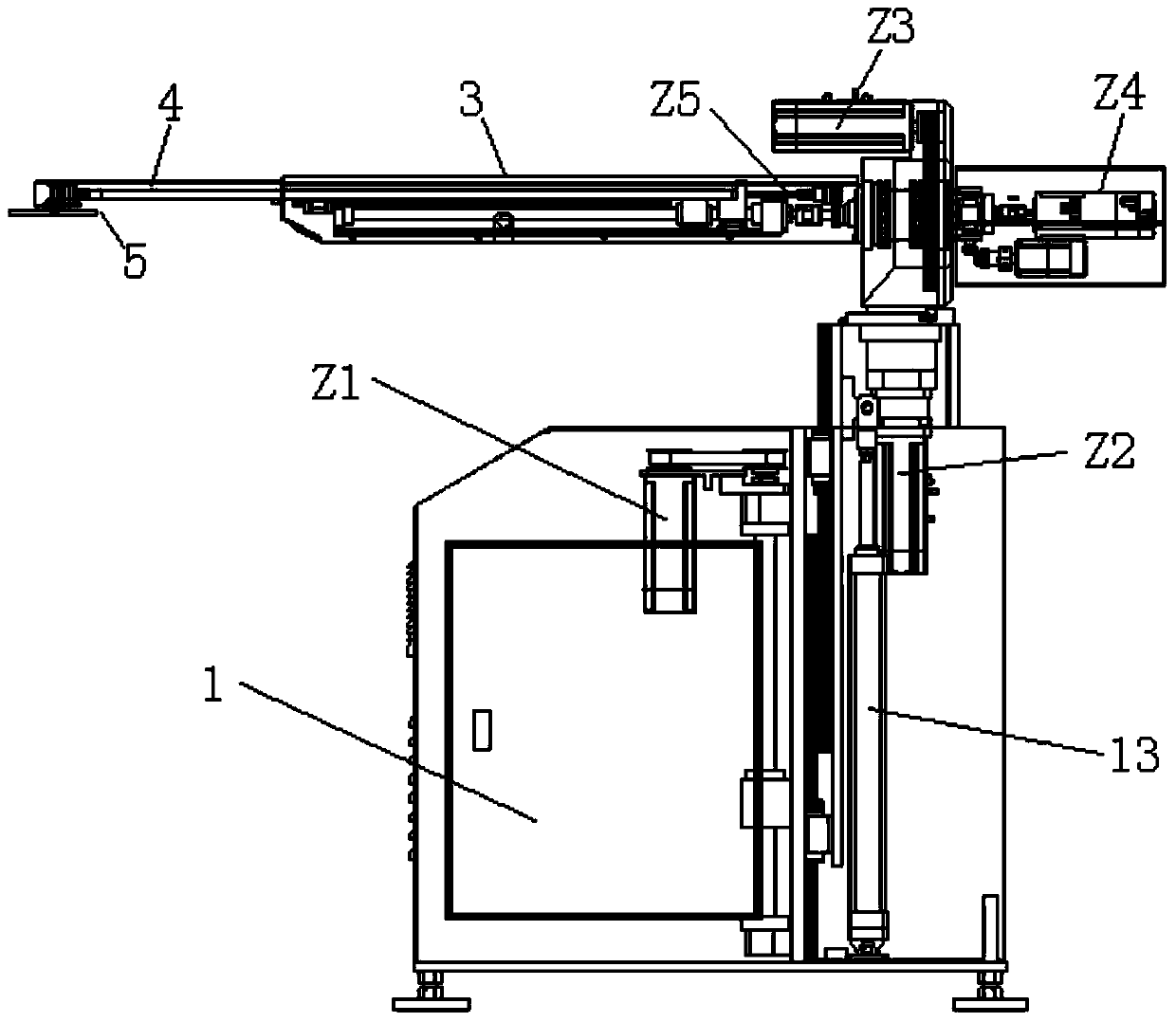

Intelligent five-shaft manipulator

The invention discloses an intelligent five-shaft manipulator. The manipulator comprises a manipulator body and five movement mechanisms, wherein a swing arm movement mechanism is supported on a vertical movement mechanism, and can be driven to realize upper and lower mobile positioning through the vertical movement mechanism; an overturning movement mechanism is supported on the swing arm movement mechanism, and can be driven to rotate by the swing arm movement mechanism; a horizontal movement mechanism and an actuating station rotary movement mechanism are supported on the overturning movement mechanism, and can be driven to rotate together by the overturning movement mechanism, and the horizontal movement mechanism can drive a telescopic arm to move to and fro in the length direction of a main arm; and a flange plate can be driven to revolve around the center of the actuating station rotary movement mechanism through the actuating station rotary movement mechanism; and the mounting positions of the five movement mechanisms are reasonably configured to reduce the bearing capacities of the swing arm movement mechanism and the horizontal movement mechanism, so that the intelligent five-shaft manipulator is not only fast in movement speed, small in inertia and flexible to operate, but is also high in positioning precision, high in stability and good in safety.

Owner:昆山威创自动化科技有限公司

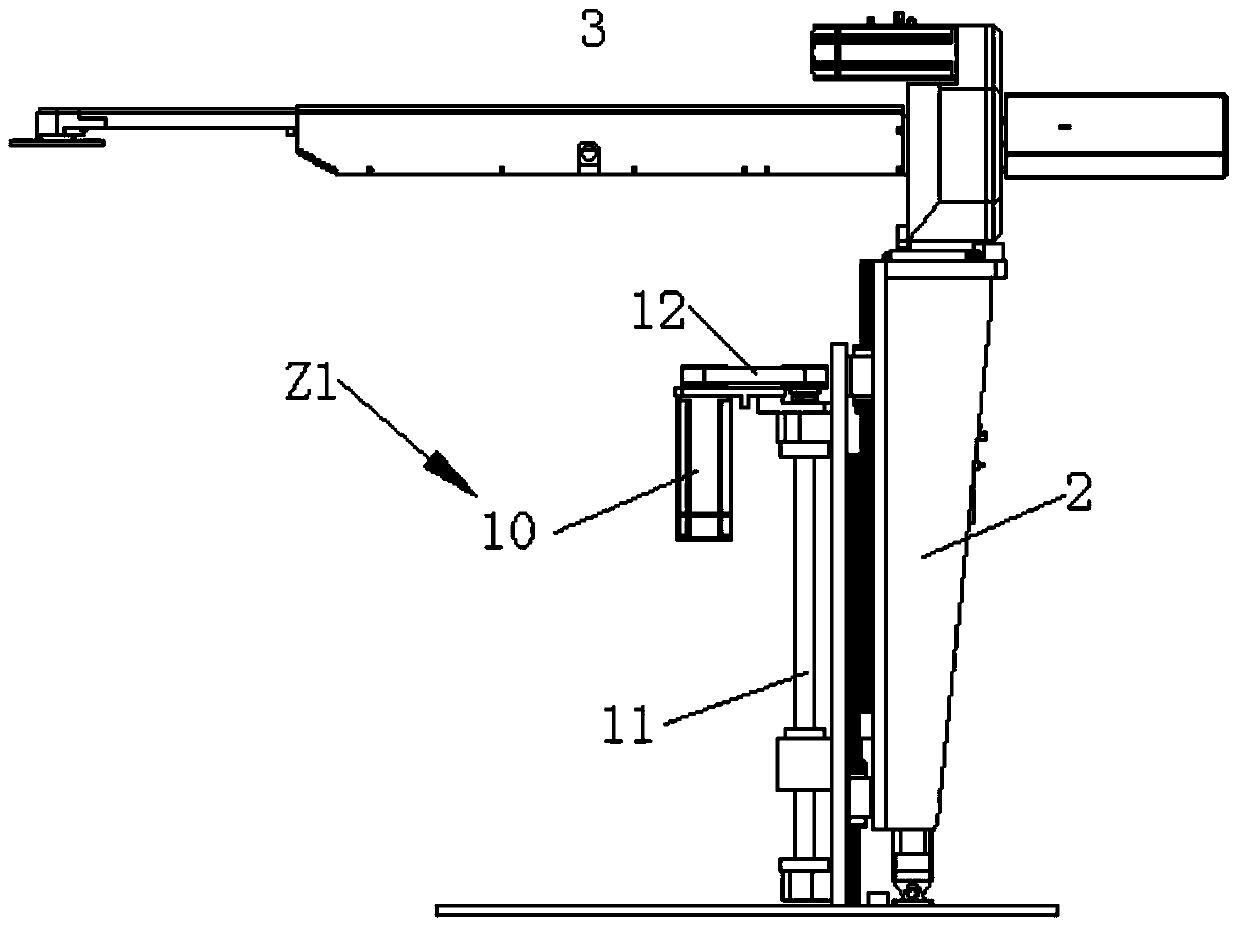

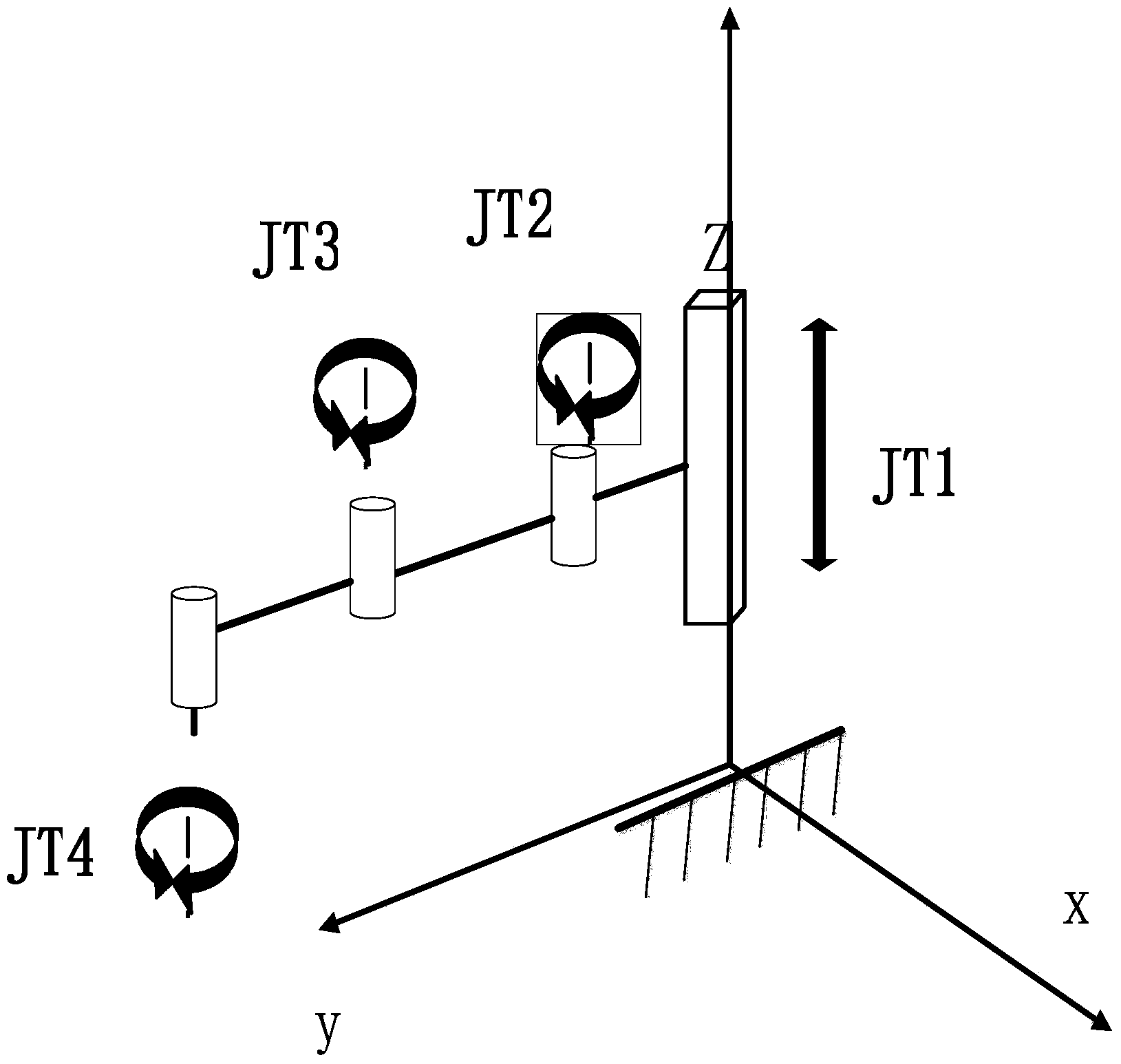

Novel plane articulated robot structure

InactiveCN103640028ACompact structureConvenient ArrangementProgramme-controlled manipulatorJointsCantilevered beamOptical axis

The invention provides a novel plane articulated robot structure which comprises a base, a lifting seat, a first mechanical arm, a second mechanical arm and an operation spindle. The base functions in supporting and reducing vibration; the lifting seat vertically moves along a Z-axis direction under the limiting action of a lead screw and a polished shaft; the first mechanical arm is rotatably mounted on the lifting seat by taking an X axis parallel to a Z axis as a rotating center; the second mechanical arm is rotatably mounted on the first mechanical arm by taking a Y axis parallel to the X axis as a rotating center; the operation spindle is rotatably mounted on the second mechanical arm by taking an R axis parallel to the Y axis as a rotating center. The vertically moving Z axis of a plane articulated robot with four degrees of freedom moves to the base of the robot, so that the inertia of the mechanical arms of the industrial robot can be decreased by the design, stress of the mechanical arms serving as cantilever beams is improved, the running speed and control stability of the robot are effectively improved, and the working space of the industrial robot is enlarged.

Owner:SOUTH CHINA UNIV OF TECH +1

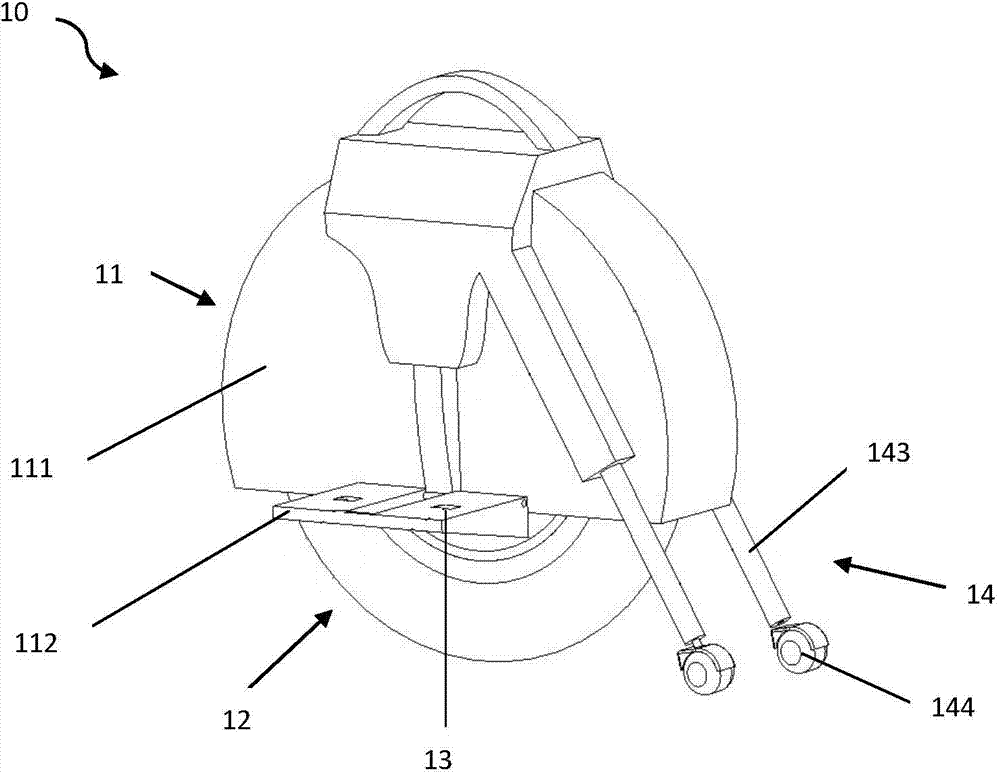

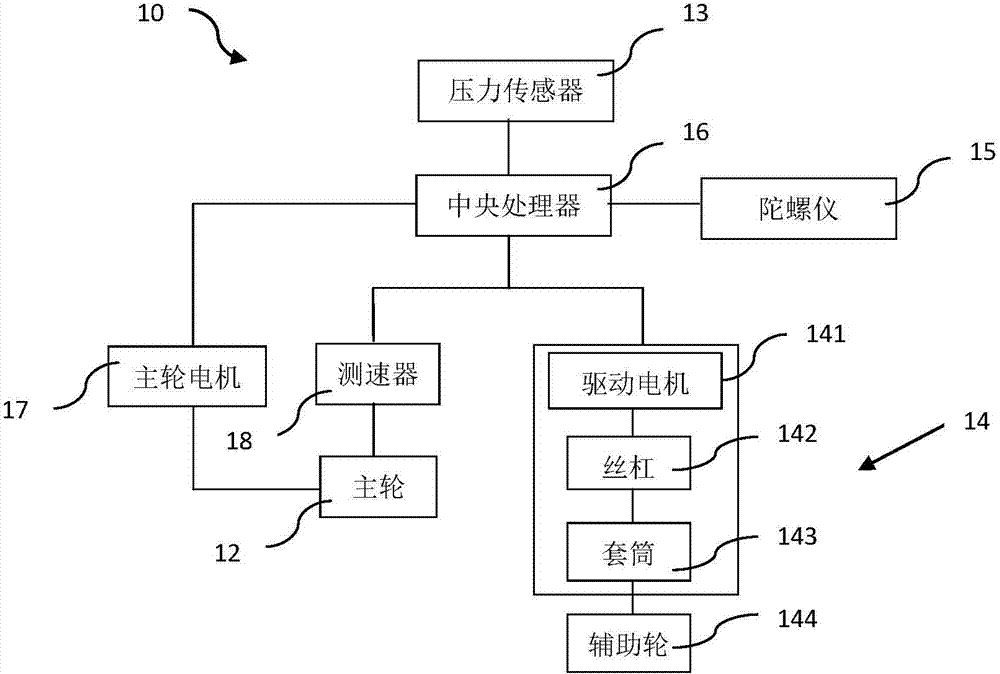

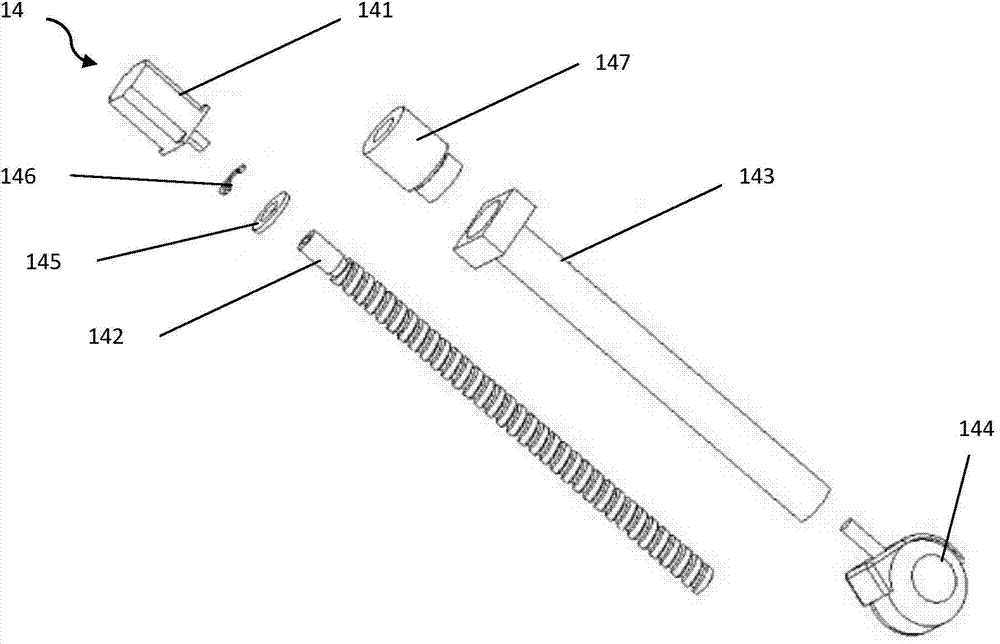

Electric monocycle

InactiveCN104760644AImprove safety performanceAdaptable to road conditionsUnicyclesBicyclesVehicle frameEngineering

The invention provides an electric monocycle which is provided with a frame, a main wheel, a pressure sensor, a gyroscope and a central processing unit. The electric monocycle is characterized in that a speedometer and two sets of balancing devices are further included, and the speedometer is connected with the main wheel and the central processing unit and used for detecting monocycle speed information and transmitting the monocycle speed information to the central processing unit; the balancing devices are symmetrically arranged on the two sides of the frame, and comprise telescopic components and auxiliary wheels, the telescopic components are connected with the central processing unit and can be lengthened or shortened, the auxiliary wheels are connected with one ends of the telescopic components, and when the central processing unit judges that the monocycle speed is larger than a high monocycle speed threshold value, the central processing unit sends a shortening instruction to the telescopic components, the telescopic components are shortened to the minimum according to the shortening instruction, and the auxiliary wheels are made to be away from the ground; when the central processing unit judges that the monocycle speed is smaller than a low monocycle speed threshold value, the central processing unit sends a lengthening instruction to the telescopic components, the telescopic components are lengthened, and the auxiliary wheels and the main wheel are on the ground. According to the technical scheme, the electric monocycle is high safety performance, high in adaptability to road conditions, not likely to fall off and suitable for being used by various people.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

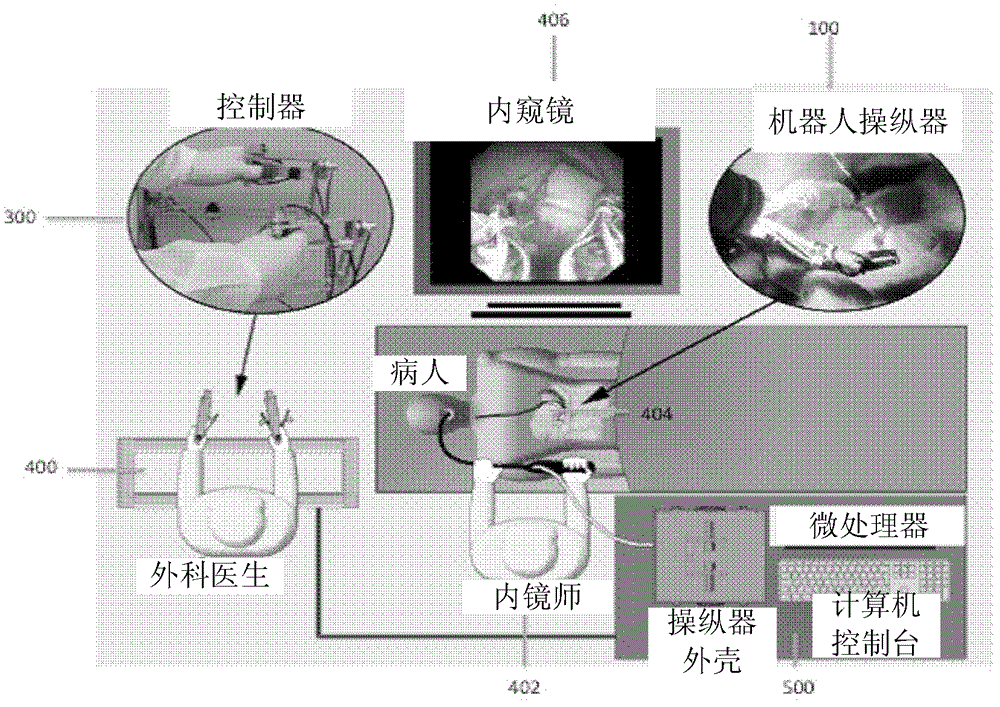

Robotic system for flexible endoscopy

ActiveCN102802551ASmall inertiaEndoscopesSurgical instruments for heatingFlexible endoscopyRobotic systems

A robotic manipulator (100), controller (300) and system for use in flexible endoscopy, the manipulator (100) comprising a flexible member configured to be coupled to an endoscope, and an arm connected to and movable by the flexible member, wherein the flexible member has a first end connected to the arm and a second end connectable to the controller (300) to allow a physical movement of the arm to be controllable by a physical movement of the controller (300).

Owner:NANYANG TECH UNIV +1

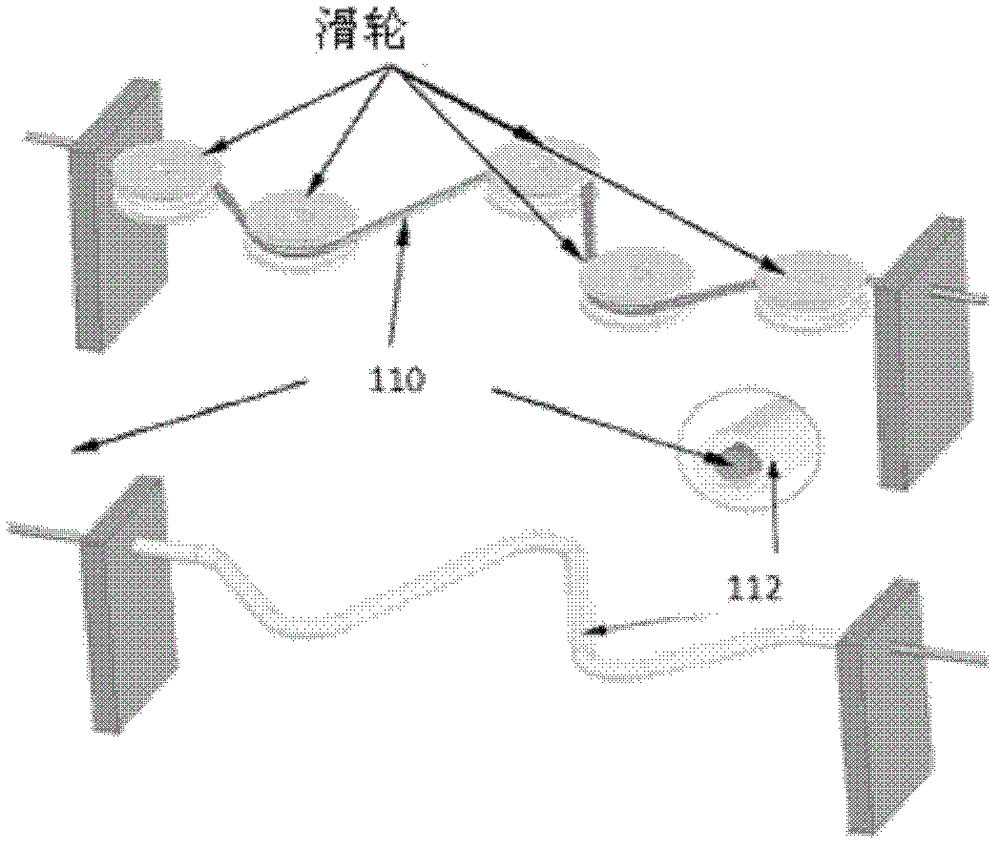

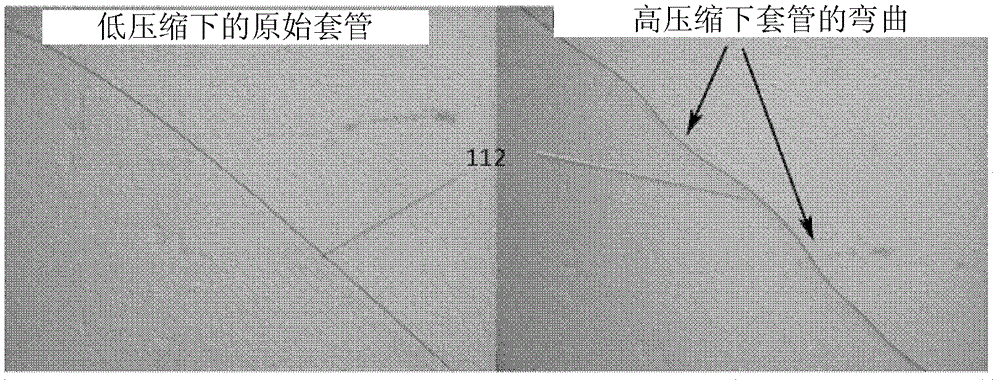

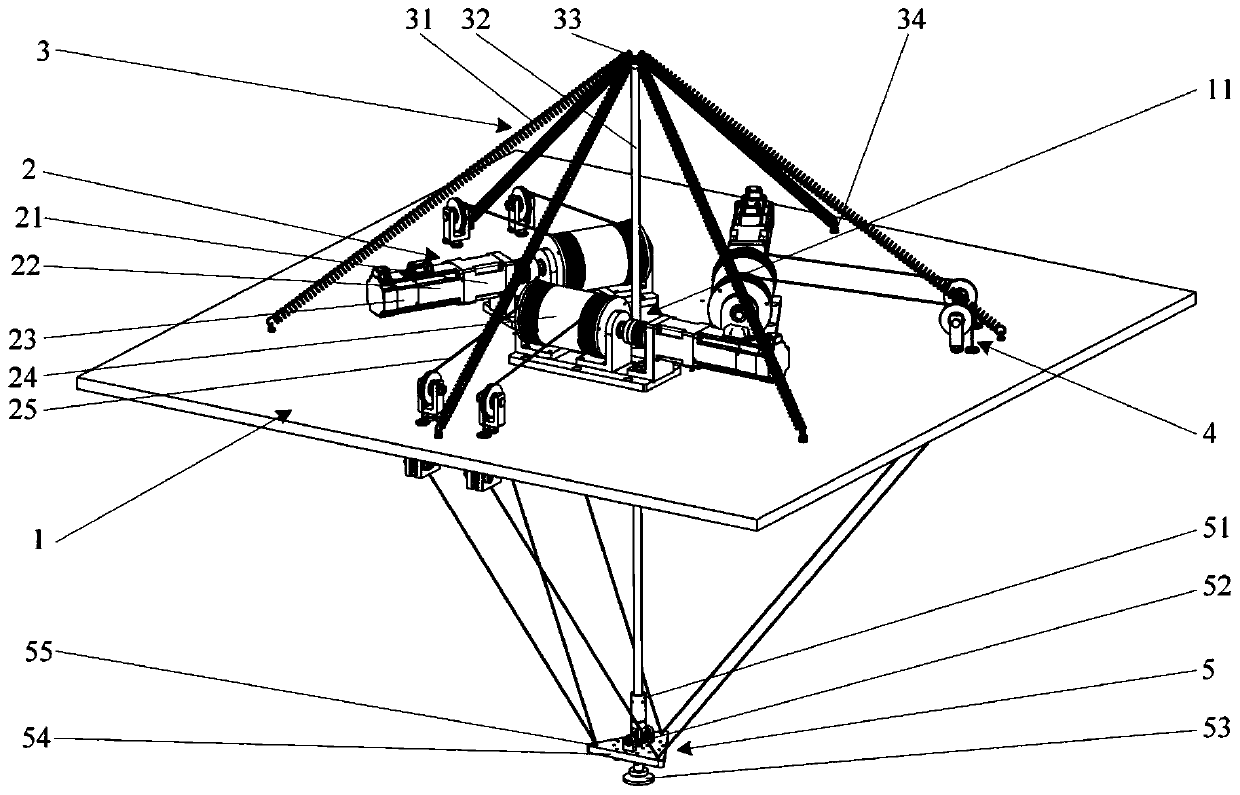

Parallel sorting robot driven by ropes tensioned through driven springs

ActiveCN110315511AImprove carrying capacitySmall inertiaProgramme-controlled manipulatorDrive motorEngineering

The invention discloses a parallel sorting robot driven by ropes tensioned through driven springs. The robot comprises a static platform, driving assemblies, a tensioning assembly, pulley assemblies and a movable platform assembly, wherein the static platform is used for erection of a framework of the whole device and providing part mounting positions; each driving assembly comprises a drive motor, a speed reducer, an encoder and drive ropes and used for driving and feedback control of terminal motion; the pulley assemblies play a role in direction guiding for ropes; the tensioning assembly guarantees tensioning of the ropes through the driven stretched springs and rigid rods; a movable platform is a terminal motion part, and an actuator such as a suction cup is mounted on the movable platform to carry out movement and operation. Three-degrees-of-freedom translational motion of the terminal is achieved under driving of the parallel ropes; meanwhile, the ropes are tensioned through thedriven springs and the rigid rods, three drivers drive the terminal to carry out the three-degrees-of-freedom motion, the driven springs guarantee tensioning of the ropes, redundant drive is avoided,the rigidity of the system can be adjusted, and large-range rapid sorting operation can be achieved at low cost.

Owner:TSINGHUA UNIV

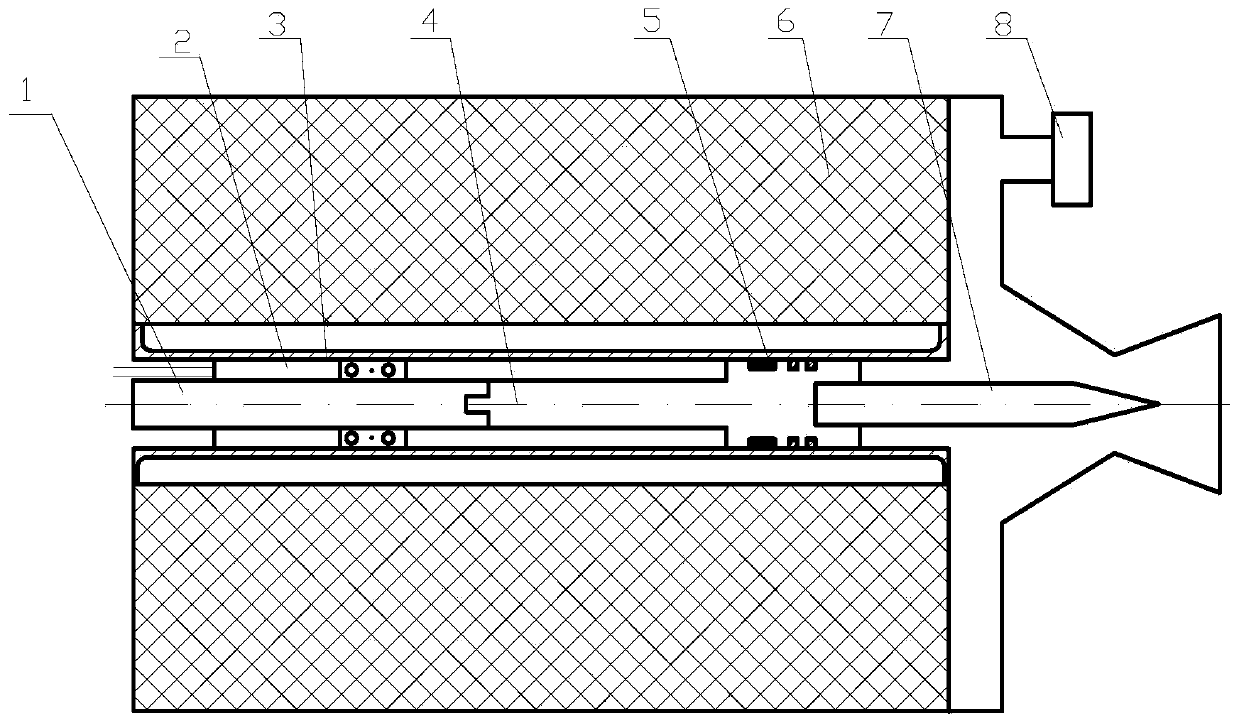

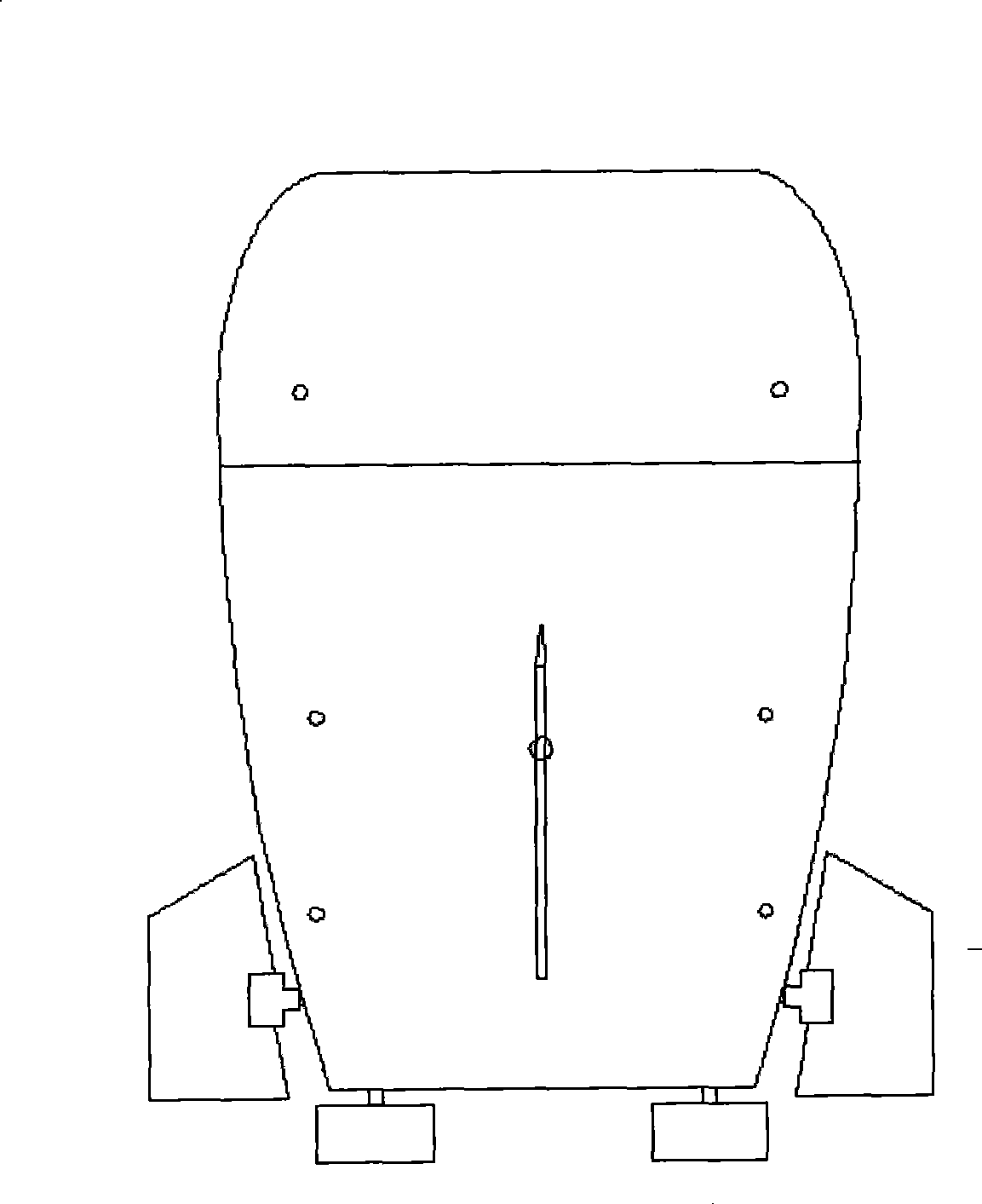

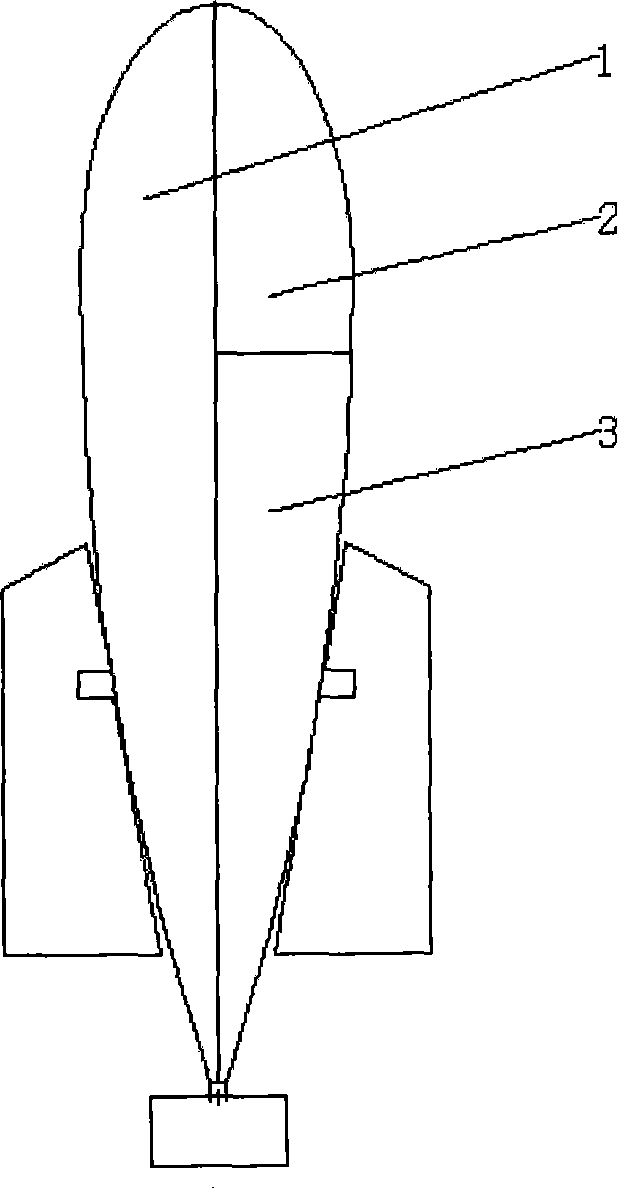

Solid rocket ramjet fuel gas flow regulation device driven by linear motor

InactiveCN103423032AExact random adjustmentNo intermediate transmission errorRocket engine plantsRamjetTubular linear motor

The invention discloses a solid rocket ramjet fuel gas flow regulation device driven by a linear motor. The nozzle throat area of a fuel gas generator is changed through the linear motor driving a cone-shaped valve head, and thus the fuel gas flow of the fuel gas generator is regulated; an inner shell structure is formed in the fuel gas generator, a thermal insulation bushing is mounted in an inner shell, the tubular linear motor is arranged in the thermal insulation bushing, a rotor of the linear motor is fixed in the thermal insulation bushing, a stator of the linear motor is fixedly connected with one end of a valve rod, the other end of the valve rod is fixedly connected with the cone-shaped valve head which stretches into a spray pipe of the solid fuel gas generator, one end, close to the cone-shaped valve head, of the valve rod is matched with an inner hole of the thermal insulation bushing, an annular groove is arranged, a movable sealing piece is arranged in the annular groove, and a pressure sensor is mounted at a rear seal head of the fuel gas generator. According to the solid rocket ramjet fuel gas flow regulation device driven by the linear motor, fuel gas flow can be accurately and randomly regulated, the precision is high, the structure is simple and compact, the size is small, the weight is light, and the sealing effect is reliable.

Owner:NANJING UNIV OF SCI & TECH

Numerical control equipment

InactiveCN102699768AGuaranteed shape and position accuracyAchieve rigid fixationFeeding apparatusLarge fixed membersNumerical controlEngineering

Numerical control equipment comprises a main frame and a workpiece clamping device. The main frame consists of a base, a first main support portion and a second main support portion, and the first main support portion and the second main support portion are arranged on two opposite sides of the base and are mounted with the base. The numerical control equipment is characterized in that the first main support portion and the second main support portion consist of separate first sides on the middle upper portions, a first driving device and a first driving device mounting portion, the first driving device drives an X-direction sliding seat to reciprocate, the first driving device mounting portion is connected with the first main support portion or the second support portion and is placed between an X-direction front guide rail and an X-direction rear guide rail, and the first driving device consists of an X-direction lead screw or a group of X-direction linear motors which drives the X-direction sliding seat to reciprocate and is parallel to the X-direction front guide rail and the X-direction rear guide rail. The X-direction lead screw penetrates through the X-direction sliding seat, and two ends of the X-direction lead screw are protruded out of a worktable and mounted on the first driving device mounting portion; or two ends of a stator of each X-direction linear motor are protruded out of the worktable and are fixed to the first driving device mounting portion. The numerical control equipment has the advantage that a workpiece is convenient to hoist.

Owner:杨东佐

Redundant controlled microminiature underwater robot, and method for failure diagnosis and fault tolerant control

InactiveCN101462587AWith fault diagnosisWith fault-tolerant control capabilityUnderwater vesselsUnderwater equipmentImpellerDoppler velocity

The invention provides a redundant controlled micro underwater robot and a fault diagnosis and fault-tolerant control method. A shell has a streamline shape spliced by a lower shell, an upper front shell and an upper back shell; an inclination compass cabin, a depth gauge, a battery tank, a Doppler speed meter, an electronic cabin, horizontal propeller impellers and a turning rise-sink control actuator are arranged inside the shell from the front to the back; and the depth gauge, the battery tank and the Doppler speed meter are arranged in parallel and positioned at the back of the inclination compass cabin together, the turning rise-sink control actuator is positioned in the middle of two horizontal propeller impellers, and the two horizontal propeller impellers and the turning rise-sink control actuator are arranged transversely in parallel and positioned at the tail of the underwater robot together. The robot and the method have the characteristics of high intellectualization degree, strong fault-tolerant capability, good safety, flexile motion, and convenient structural adjustment.

Owner:如皋市生产力促进中心

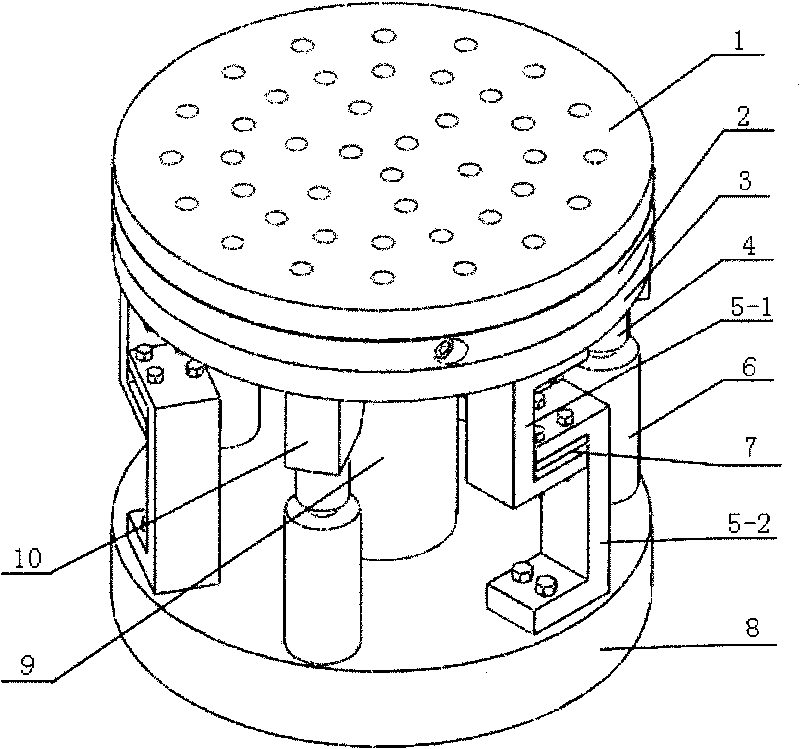

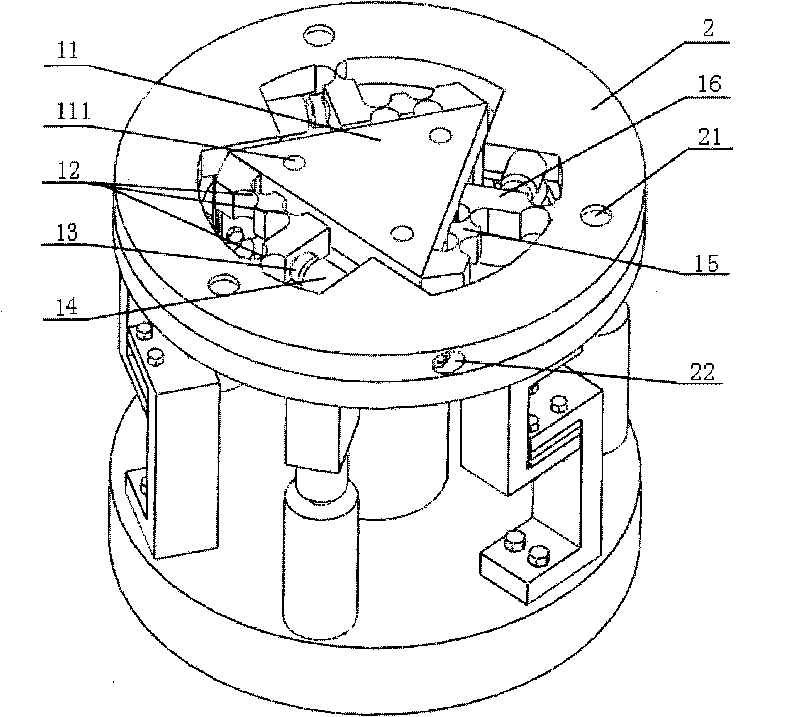

Force sense man-machine interaction device with six degrees of freedom

InactiveCN101003133ALarge attitude corner rangeSmall inertiaManipulatorMan machineHuman–computer interaction

A 6-freedom man-machine interactive mechanism with force feeling is composed of a base, a static platform, a dynamic platform, 6 branches driven by 6 DC motors, a drive unit with a speed reducing mechanism in steel cable driving mode, and several composite ball sets. The 6 freedoms of dynamic platform can be realized by 3 composite ball set not on a same line for outputting 3D force and 3D force moment.

Owner:BEIHANG UNIV

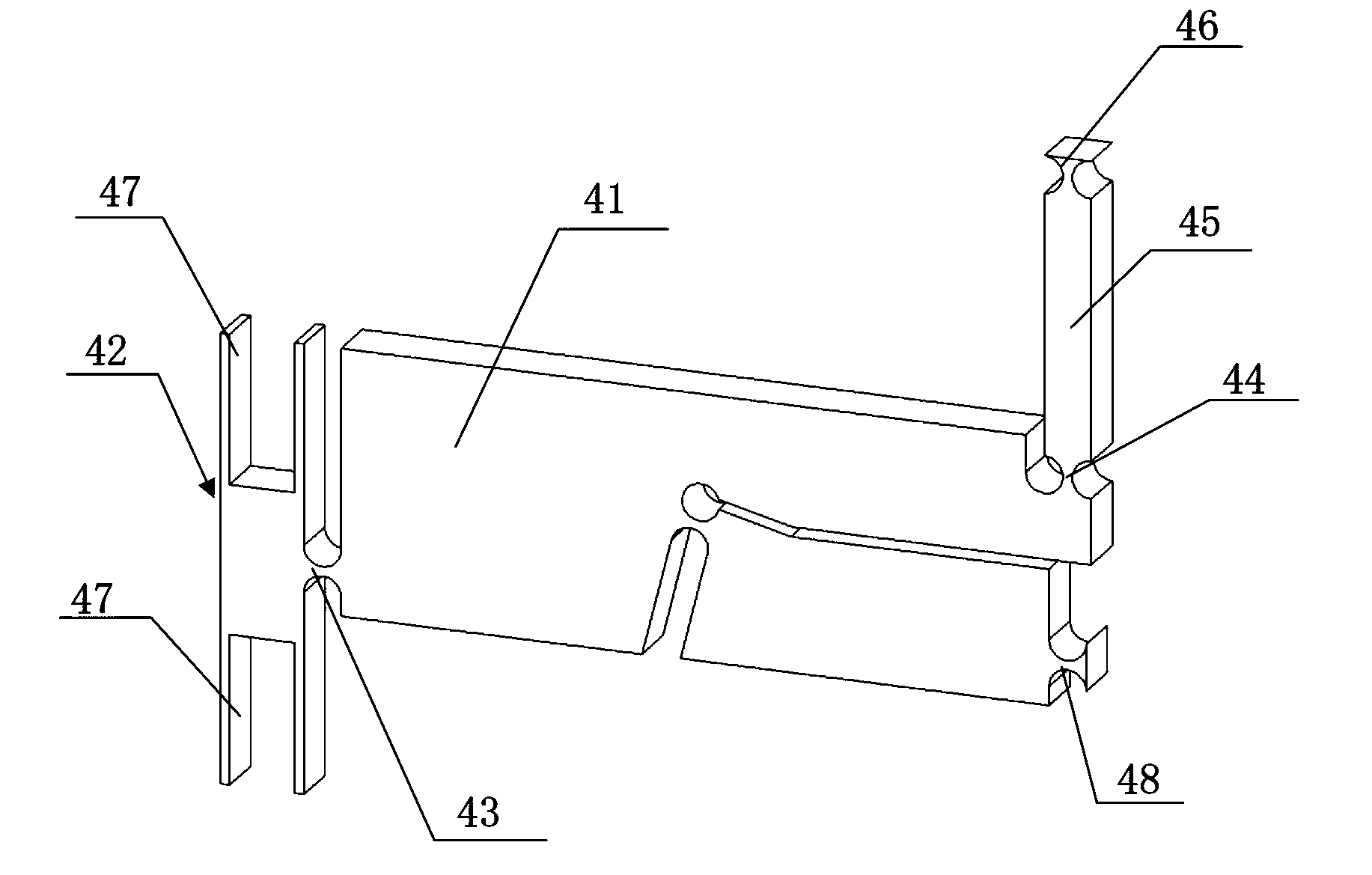

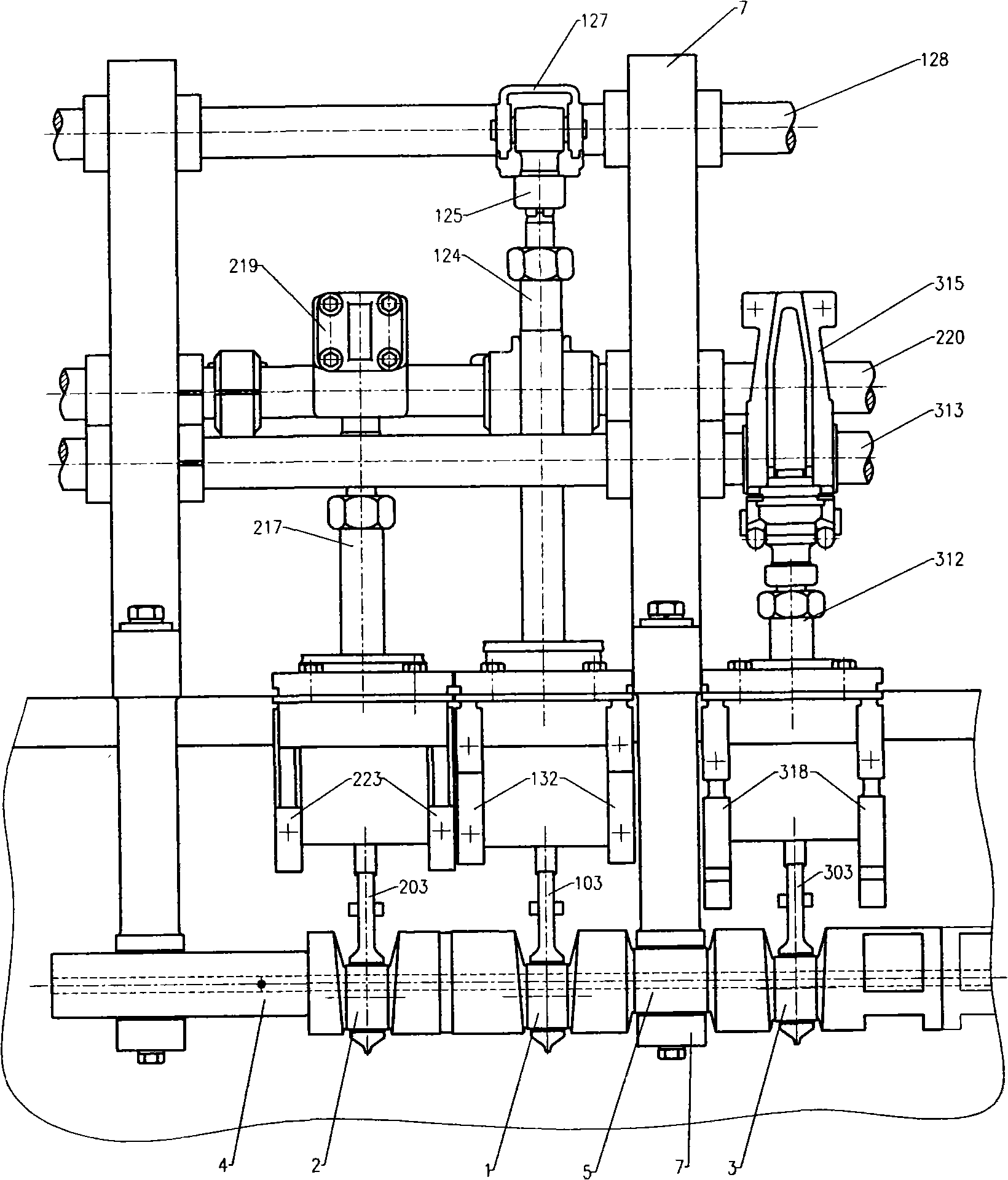

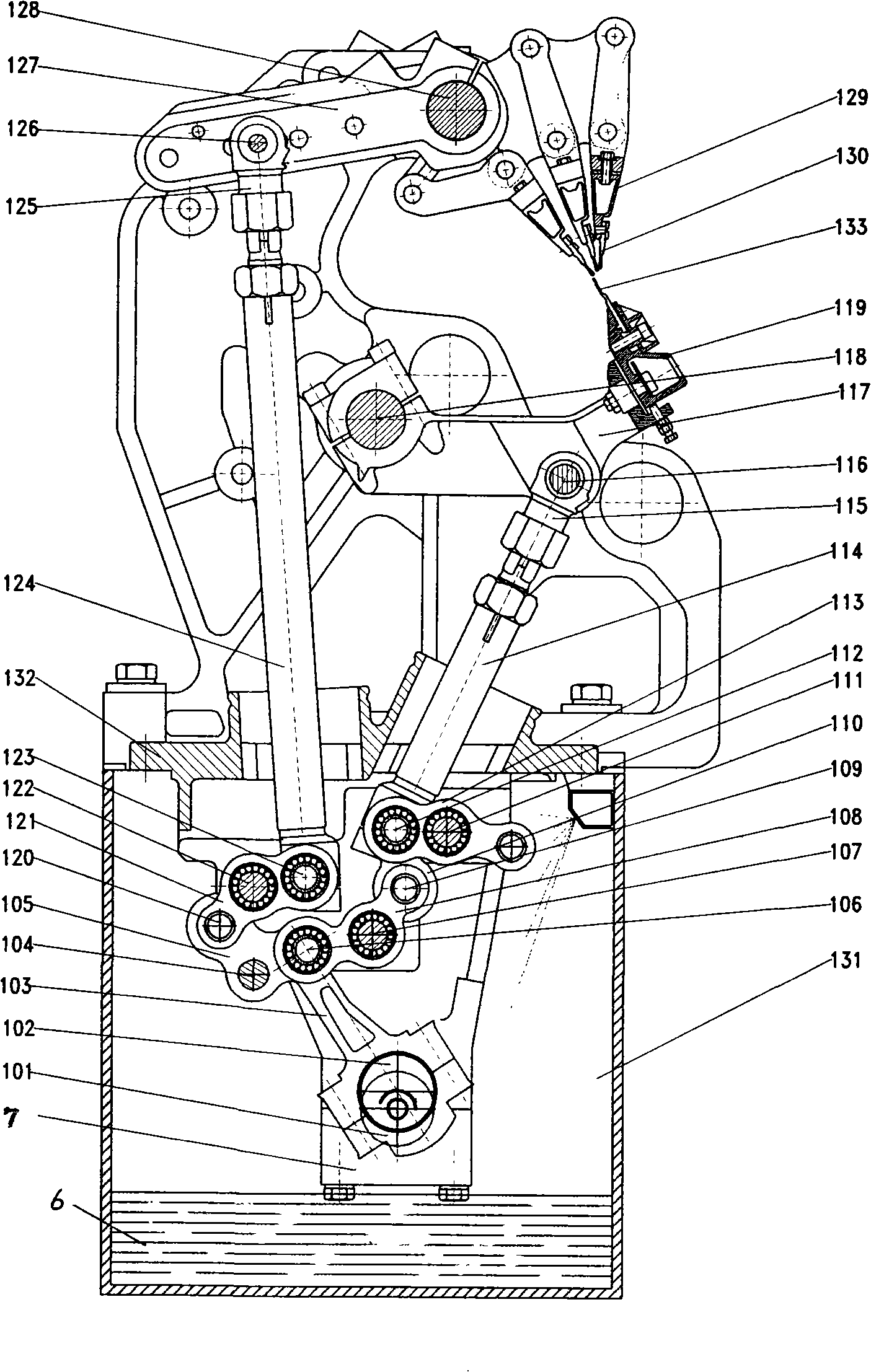

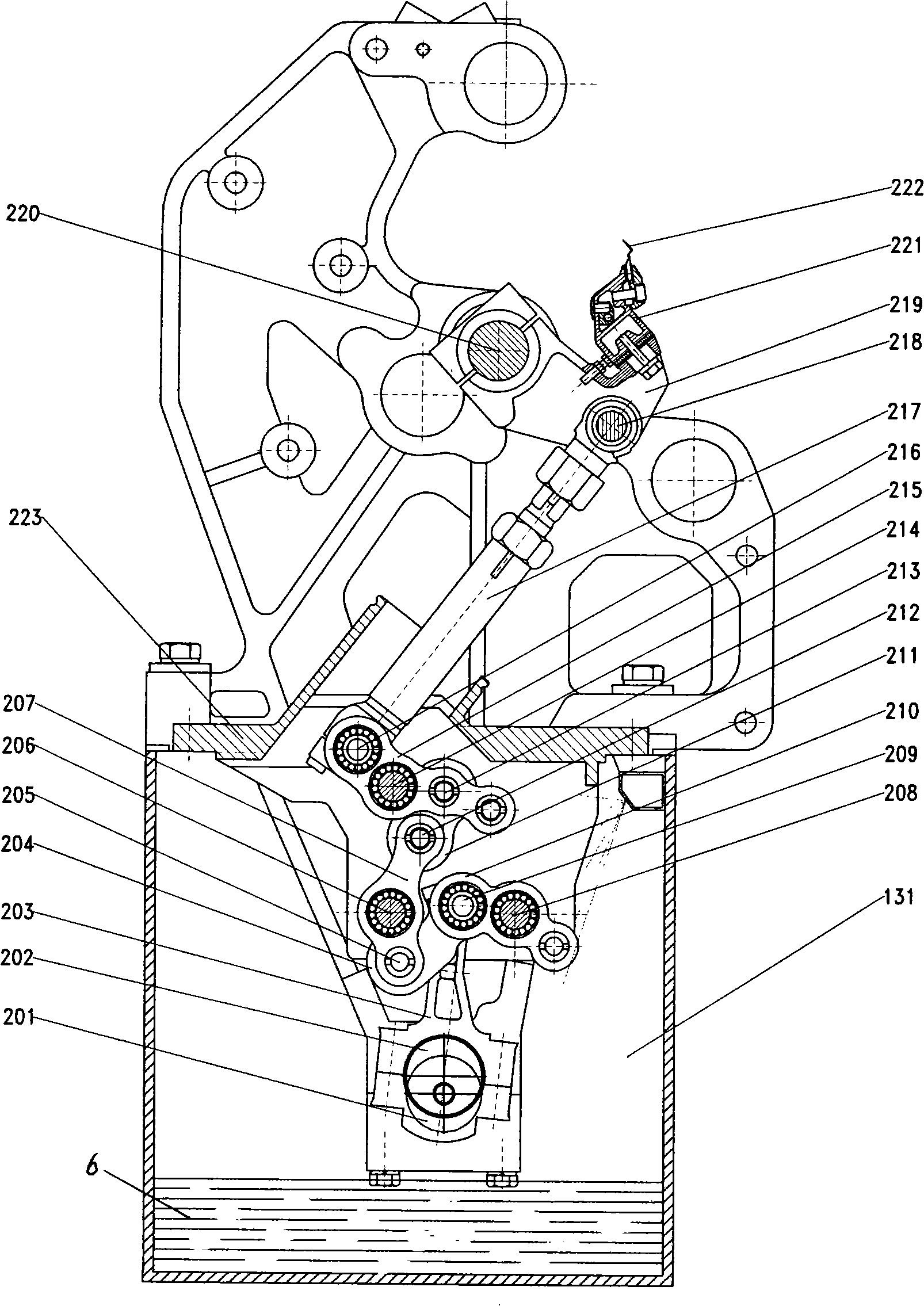

Short tranverse crankshaft connecting rod device of warp knitting machine

The invention discloses a short-stroke crankshaft connecting rod device for a tricot machine. The invention comprises eccentric shafts, a first shaft journal (4), a second shaft journal (5), a central wall plate (7), a grooved needle bed connected with a first eccentric shaft (1), a yarn guide needle bed crankshaft connecting rod mechanism, a stylet bed crankshaft connecting rod mechanism connected with a second eccentric shaft (2), and a sinker bed crankshaft connecting rod mechanism connected with a third eccentric shaft (3). The first shaft journal (4) and the second shaft journal (5) are respectively and fixedly connected with the end parts of the second eccentric shaft (2) and the third eccentric shaft (3). The second eccentric shaft (2), the first eccentric shaft (1) and the third eccentric shaft (3) are connected with each other in turn and are rotated around the first and second shaft journals (4, 5). The short-stroke crankshaft connecting rod device effectively shortens the motion stroke of weaving elements; the grooved needle travel is between 8 and 12 millimeters; the moving time of yarn guide needles is between 1.5 and 1.8 microseconds; the engine speed is improved to be 2500 to 3000 turns per minute; the noise is less than or equal to 85 decibels; the vibration is small; the energy consumption is low; the device is suitable for high-speed rotation; the power is small; and the productivity is obviously improved.

Owner:NEWTRY COMPOSITE

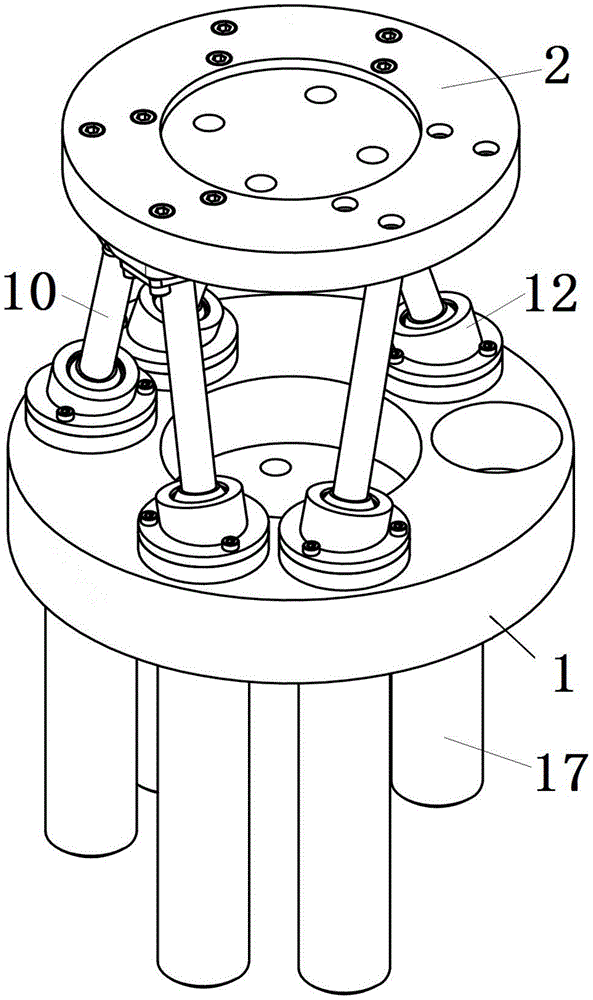

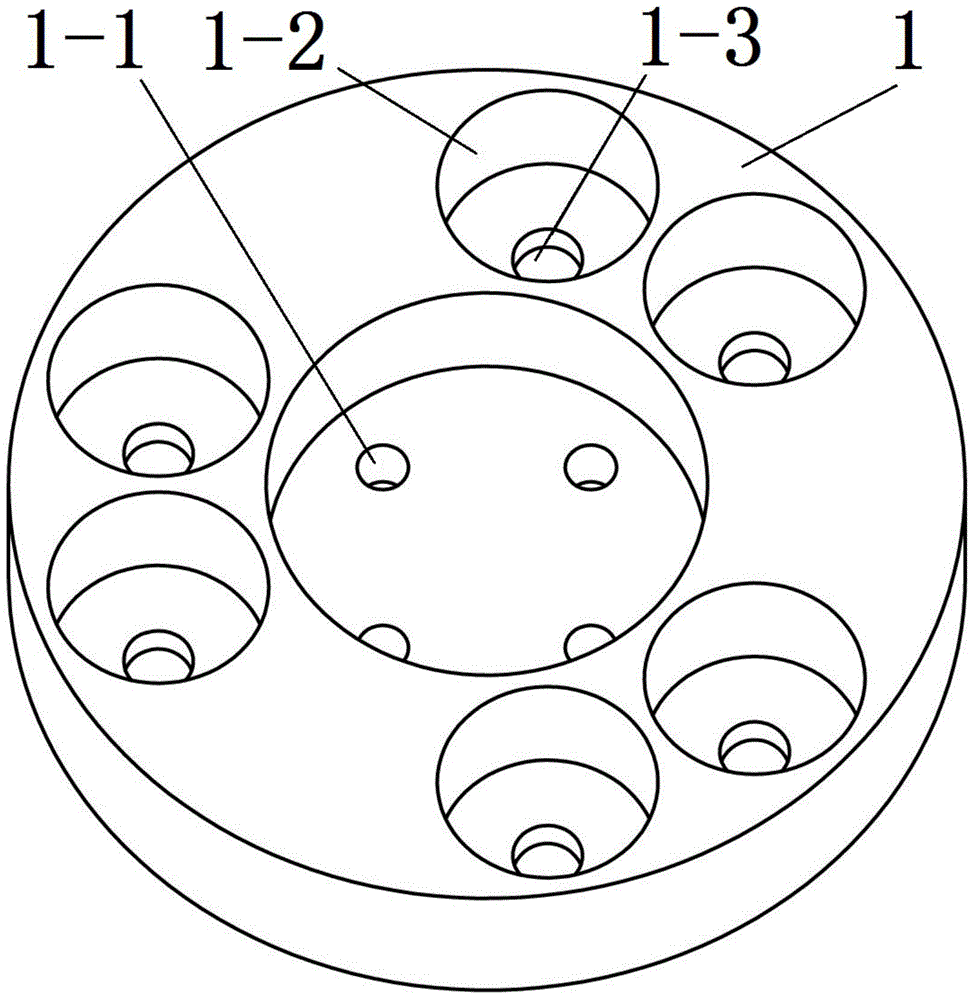

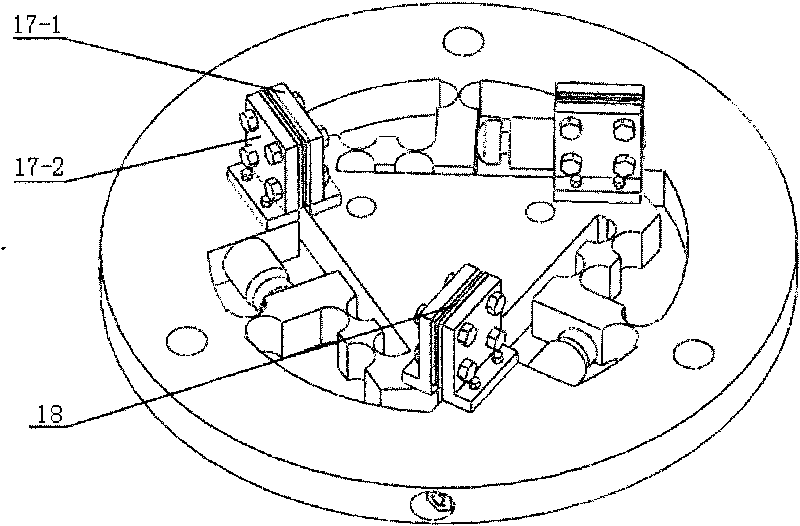

Six-degree-of-freedom parallel micro platform

InactiveCN104002299ASolve sizeSolve the accuracy problemProgramme-controlled manipulatorFixed bearingActuator

The invention discloses a six-degree-of-freedom parallel micro platform which comprises a fixed platform body and a movable platform body. The lower surface of the movable platform body is evenly provided with three sets of fixing bearing bases, and each fixing bearing base is connected with the fixed platform body downwards in a transmission mode through two branch chains, namely, the three sets of the bearing bases and six branch chains are arranged between the fixed platform body and the movable platform body. According to the six-degree-of-freedom parallel micro platform, the fixed platform body is fixed to the installation end face at the tail end of a macro robot through a micro platform installation hole, a tail end actuator is fixed to the movable platform body through a gripper installation hole in the movable platform body, the size is small, the weight is low, rigidity and precision are high, six-degree-of-freedom precise trimming of space postures of a workpiece in the assembly process is achieved, and the aim of precise assembly is achieved.

Owner:XIAN UNIV OF TECH

Six-freedom-degree precision positioning table for nano-imprint lithography system

ActiveCN101726997ACompact structureIncrease stiffnessPhotomechanical apparatusWork benchesElectricityImage resolution

The invention discloses a six-freedom-degree precision positioning table for a nano-imprint lithography system, wherein a spatial flexibility mechanism comprises a pre-tightening mechanism, three first displacement sensor and three first piezoelectric ceramic drivers, the pre-tightening mechanism comprises an elastic pre-tightening ring connected with a rigid ring, a base, a vertical column, three bottom elastic hinges and a first displacement sensor, the piezoelectric ceramic drivers are pushed on the elastic hinges; a plane flexibility mechanism comprises a rigid ring, a rigid supporting table, three flexible branched chains and three second piezoelectric ceramic drivers, each flexible branched chain comprises three top part elastic gemels, three second elastic gemels are connected by a driving connecting rod and a middle connecting rod, two second elastic gemels are respectively connected with the rigid ring and the rigid supporting table, the second piezoelectric ceramic drivers are pushed against on the driving connecting rod, three pairs of the supports are arranged, and each pair of the supports are connected with a second displacement sensor, and the rigid supporting table is connected with a movable platform; the working table has high resolution ratio and rapid dynamic response speed.

Owner:南通致远船舶设计有限公司

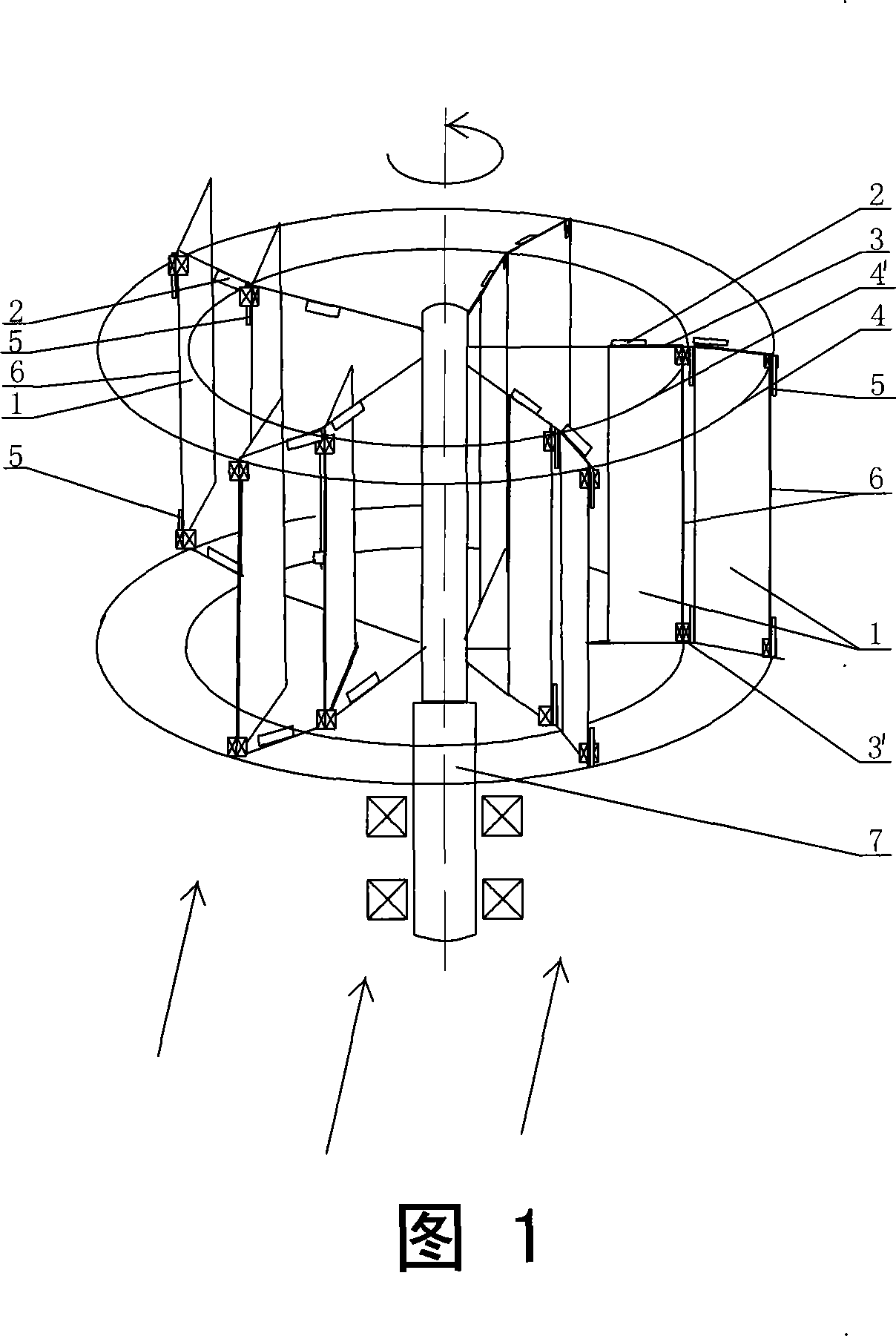

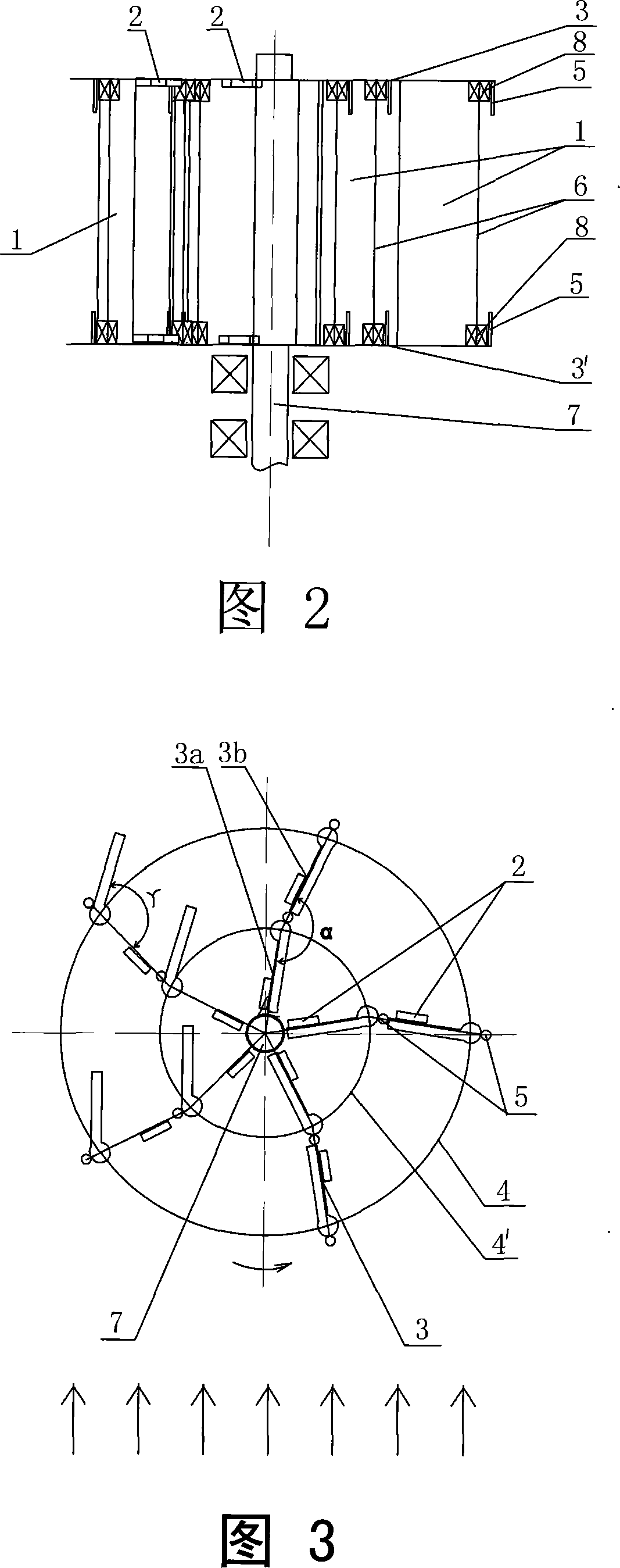

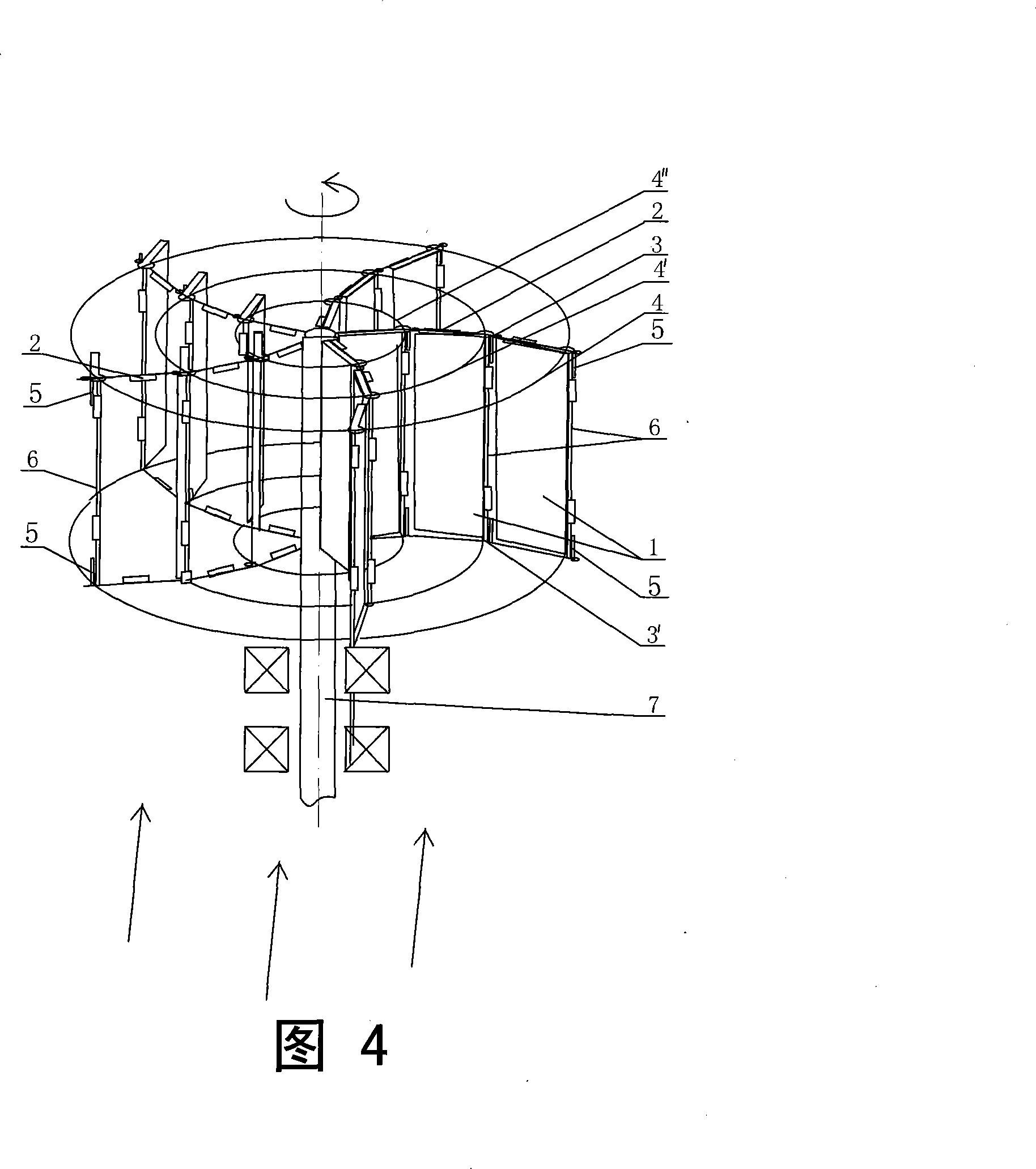

One-arm multi-leaf vertical axis wind mill

InactiveCN101230837AImprove efficiencyEasy to manufactureMachines/enginesRenewable energy generationEngineeringCantilever

The invention discloses a vertical-shaft windmill with one arm and a plurality of vanes, and the windmill comprises wind vanes, a wind vane rotary shaft, a windmill rotary shaft, a vane arm and a wind vane swing spacing mechanism, wherein, the wind vane swing spacing mechanism is composed of a chock block and a swing angle spacing block; one end of the vane arm is connected to the windmill rotary shaft, and the other end extends outwards by suspending the arm radially with the windmill rotary shaft as the center of a circle; each vane arm is provided with two or more wind vanes; each wind vane is hinged on the vane arm by the wind vane rotary shaft vertically connected to the vane arm, and the swing angel of each wind vane is limited by the wind vane swing spacing mechanism. The windmill of the invention uses a plurality of small-sized wind vanes to substitute a large-size wind vane with one arm and single vane, can utilize wind energy better, and can improve the efficiency of the windmill.

Owner:霍家文 +1

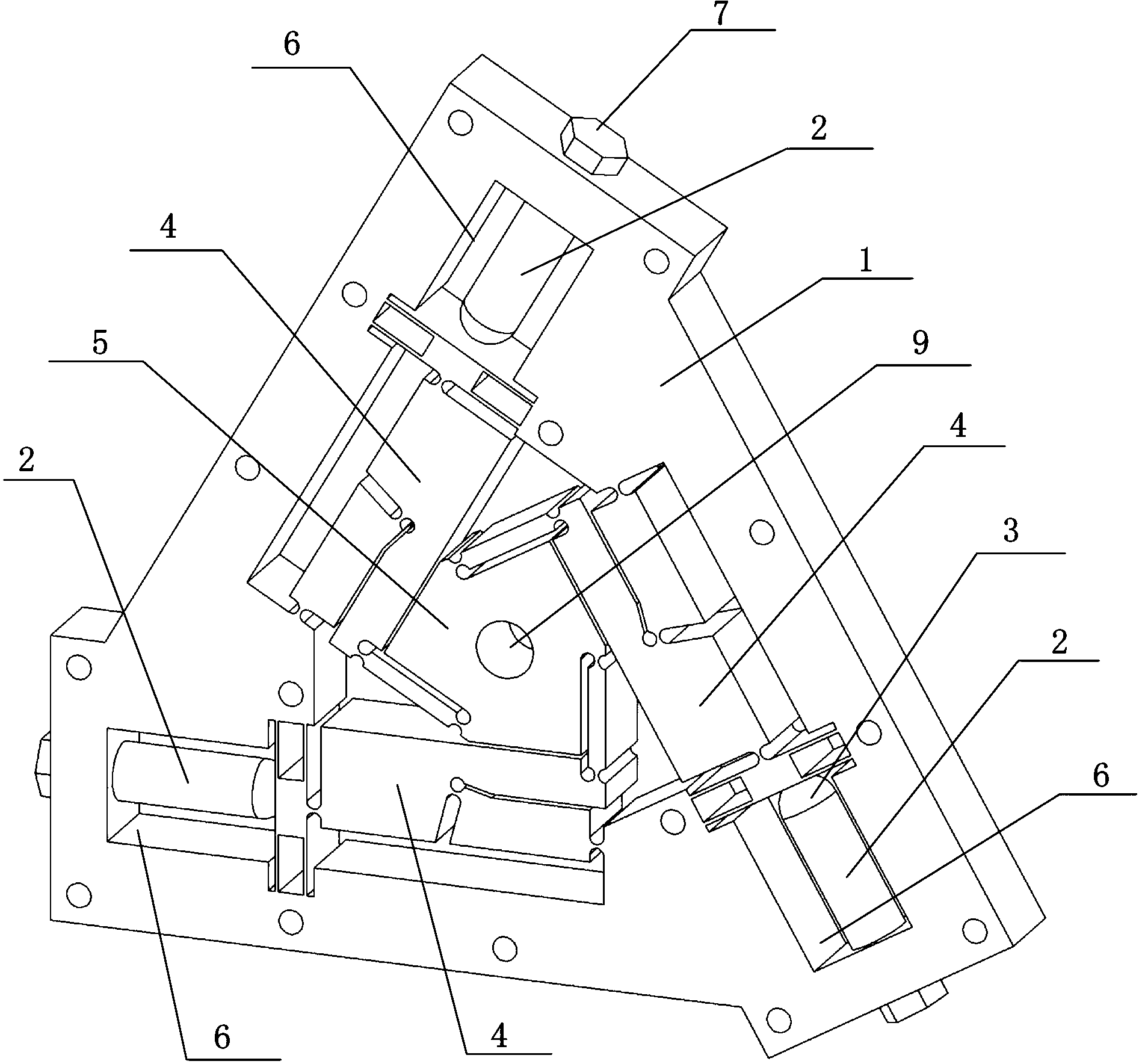

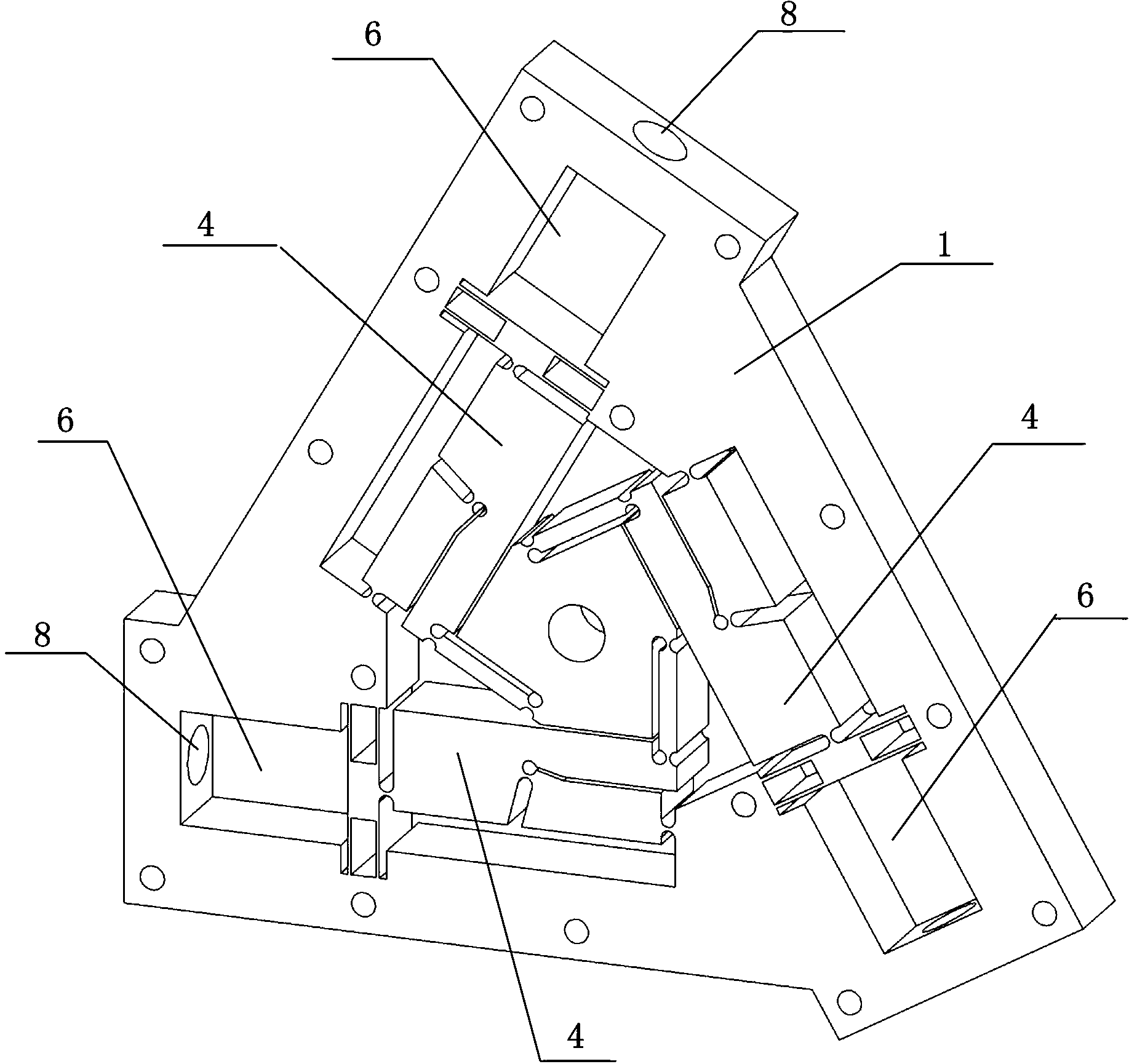

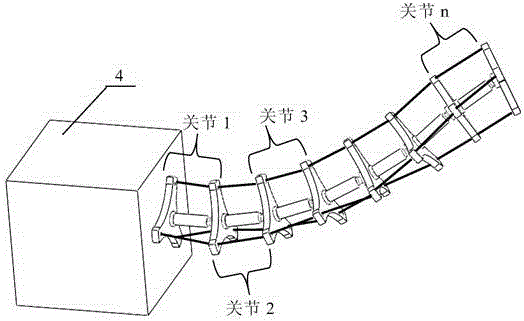

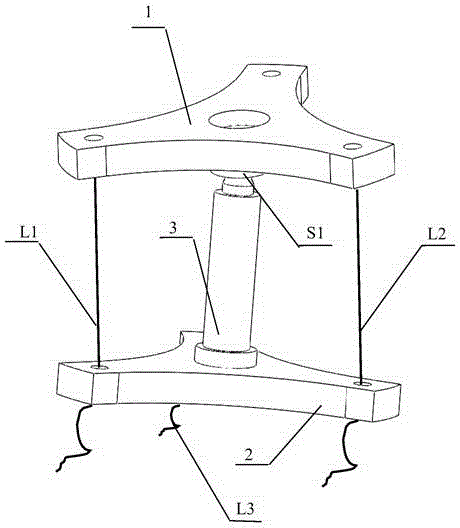

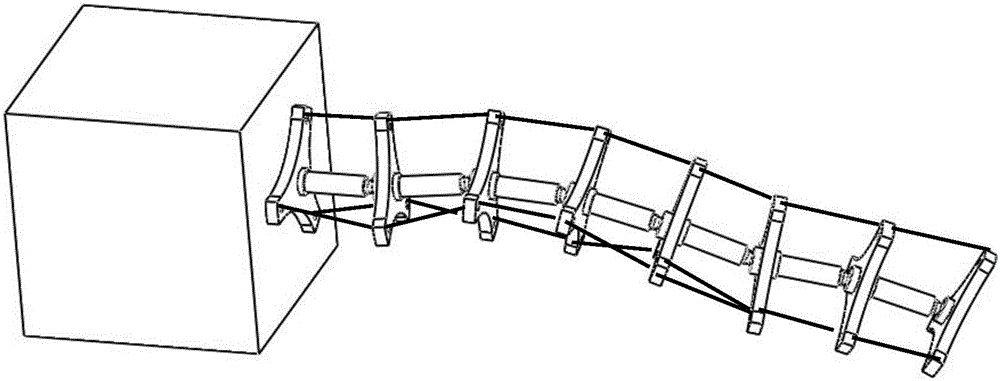

Rigid-flexible coupled trunk-shaped continuous robot

InactiveCN105729458AAchieve continuous motion outputSmall inertiaProgramme-controlled manipulatorReducerEngineering

The invention discloses a rigid-flexible coupled trunk-shaped continuous robot, and relates to the technical fields of robots and advanced manufacturing. The robot comprises a control box and a group of joints which are mounted on one side of the control box, have completely the same structure and are connected end to end, wherein each joint comprises a movable platform, a fixed platform, and a supporting rod and three driving ropes which connect the movable platform and the fixed platform; one end of the supporting rod is fixedly connected with the fixed platform vertically, and the other end of the supporting rod is connected with the movable platform through a ball pair; one ends of the three driving ropes are fixedly connected with three endpoints of the movable platform respectively, and the other ends of the three driving ropes penetrate through three endpoints of the fixed platform to be connected with the ropes in the control box; and the ropes are connected with a motor through a speed reducer. According to the rigid-flexible coupled trunk-shaped continuous robot, working platforms of each joint can achieve motion output of three-dimensional rotation under a cartesian coordinate system; and the motion output of each movable platform is achieved through transmission of the rigid supporting rod and the three driving ropes, so that the rigid-flexible coupled motion characteristic is achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

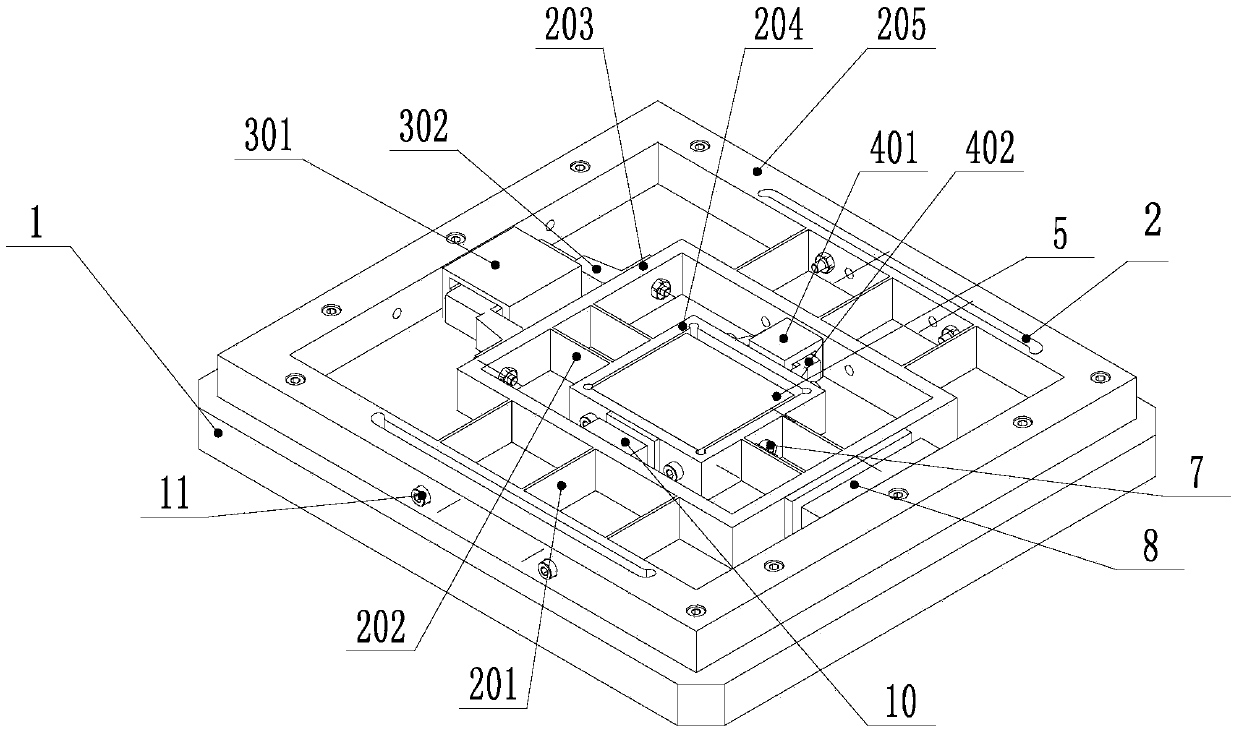

Stiffness frequency adjustable two-dimensional micro-motion platform based on stress stiffening principle

ActiveCN103990998AImprove performanceSmall inertiaMachine tool componentsFeeding apparatusEngineeringMechanical engineering

The invention relates to a precise two-dimensional motion occasion, can be used for precise displacement compensation of a general X-Y motion platform and particularly relates to a stiffness frequency adjustable two-dimensional micro-motion platform based on a stress stiffening principle. The stiffness frequency adjustable two-dimensional micro-motion platform based on the stress stiffening principle comprises X-direction and Y-direction motion sub-platforms, corresponding drivers and a micro-motion working platform, utilizes a film group for adjusting tensile force through screws as a flexible chain and achieves independent adjustment of vibrating frequency. By adopting the structure, the stiffness frequency adjustable two-dimensional micro-motion platform is based on prestress films, is adjustable in frequency and can adjust the inherent frequency of the micro-motion platform according to different working conditions and driving frequencies before working or in the working process, two feeding motion directions are orthogonal, and coupling of the micro-motion working table during two-dimensional motion is avoided.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

Movable five-axis robot

InactiveCN105459109AHigh precisionReduce noiseProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a movable five-axis robot and belongs to the technical field of application of industrial robots. The robot comprises a fixing base, guide rails, sliding blocks, a trochoidal rack, a roller, a robot mounting base, a tail-end mounting seat, a first driving device, a second driving device, a third driving device, a fourth driving device, a fifth driving device, a first branch chain, a second branch chain and a third branch chain, wherein the first branch chain comprises a large arm and a front arm; the second branch chain comprises a small arm, a small arm pull rod and a front arm; and the third branch chain comprises a rear arm, a first attitude holding rod, a triangular connecting frame and a second attitude holding rod. Through adoption of a transmission device composed of the trochoidal rack and roller pins, the robot is applicable to occasions where the robot is required to move; different types of grippers can be mounted at the tail end of the robot so as to finish gripping of different types of objects; and besides, the robot is simple in structure, high in rigidity and stability, simple to manufacture, convenient to mount and debug and low in mechanism manufacturing cost.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

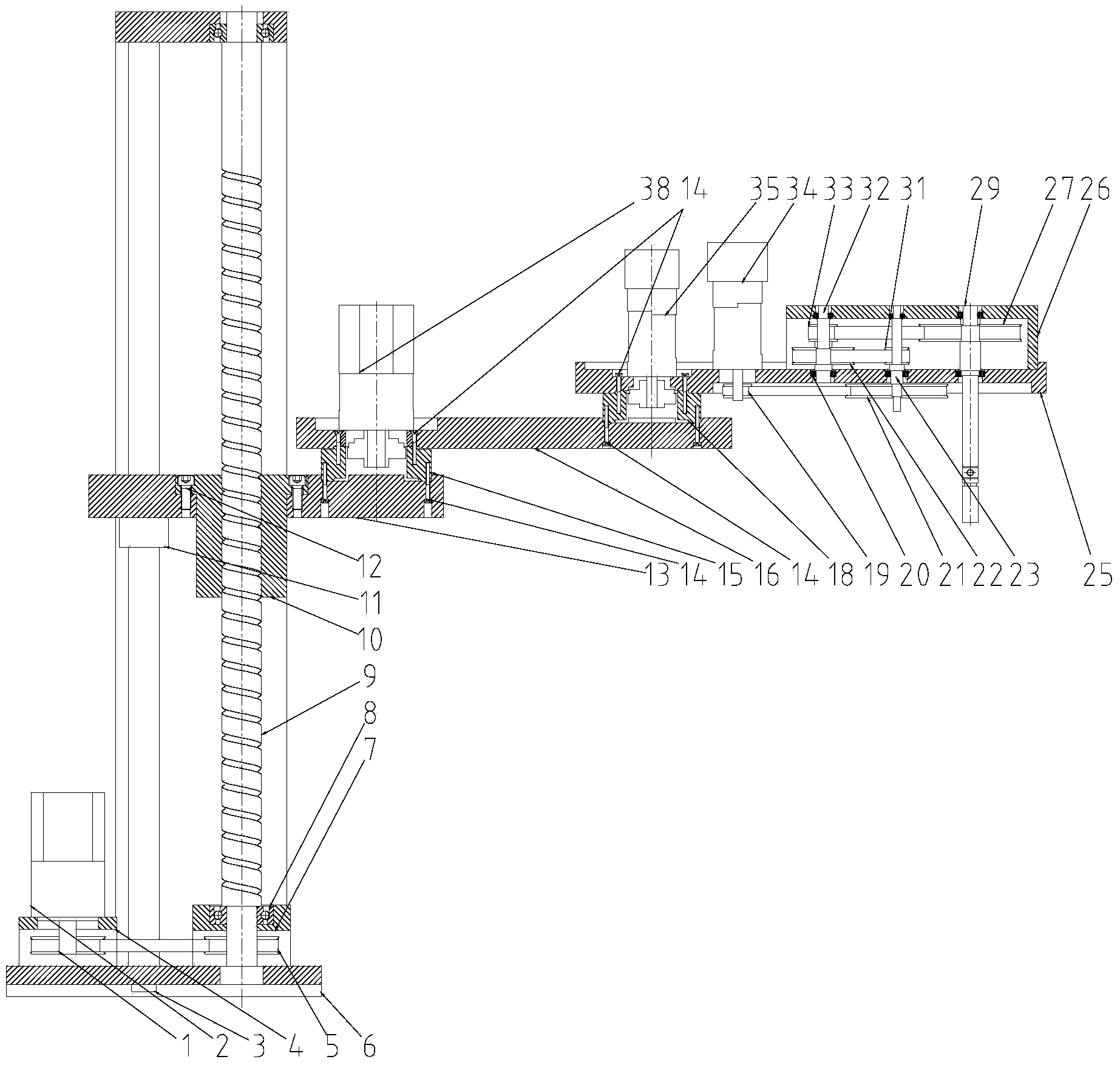

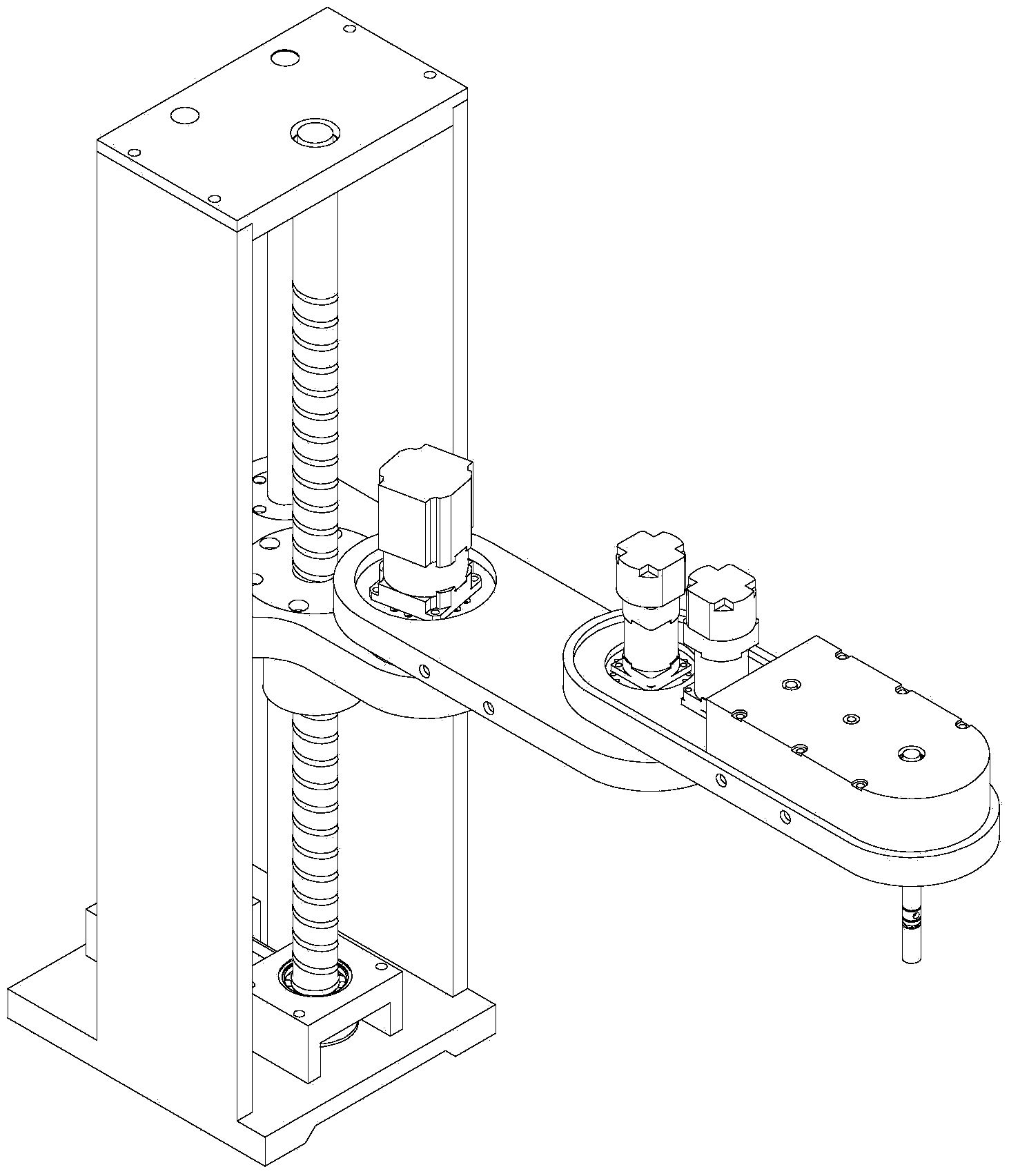

Novel four-degree-of-freedom articulated robot structure

ActiveCN104385260ACompact structureConvenient ArrangementProgramme-controlled manipulatorJointsDegrees of freedomEngineering

The invention discloses a novel four-degree-of-freedom articulated robot structure. The novel four-degree-of-freedom articulated robot structure comprises a base, a lifting seat, a first mechanical arm, a Y-axis cover, a second mechanical arm, and an operation main shaft, wherein the lifting seat vertically moves in the direction of a Z-axis under the limiting actions of a lead screw, a lead screw, and a guide rail pair, the first mechanical arm can rotate around an X-axis parallel to the Z-axis to be installed on the lifting seat, the Y-axis cover is installed on the first mechanical arm, bears a first Y-axis speed reduction device shaft and a second Y-axis speed reduction device shaft, and is provided with through holes for a Y-axis servo motor shaft, the first Y-axis speed reduction device shaft and the second Y-axis speed reduction device shaft to penetrate, the second mechanical arm can rotate around the Y-axis parallel to the X-axis to be installed on the first mechanical arm, and the operation main shaft can rotate around an R-axis parallel to the Y-axis to be installed on the second mechanical arm. The novel four-degree-of-freedom articulated robot structure is simple in structure, low in cost, large in operation space, and high in operation accuracy.

Owner:SOUTH CHINA UNIV OF TECH

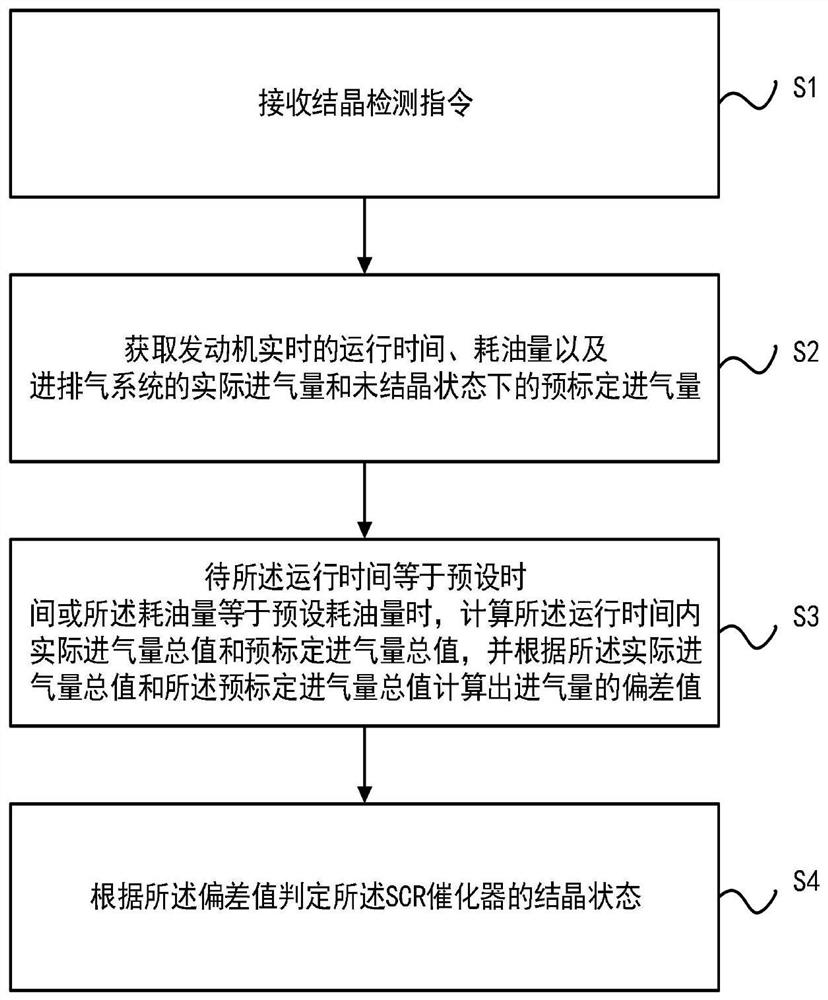

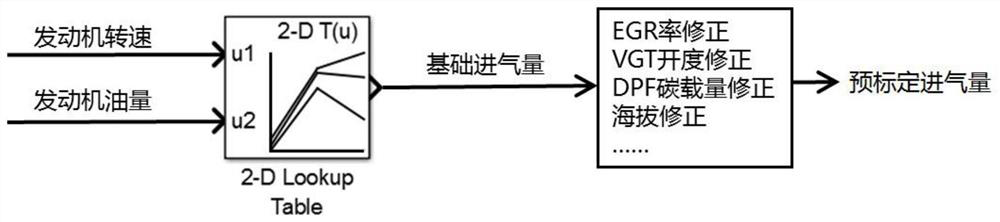

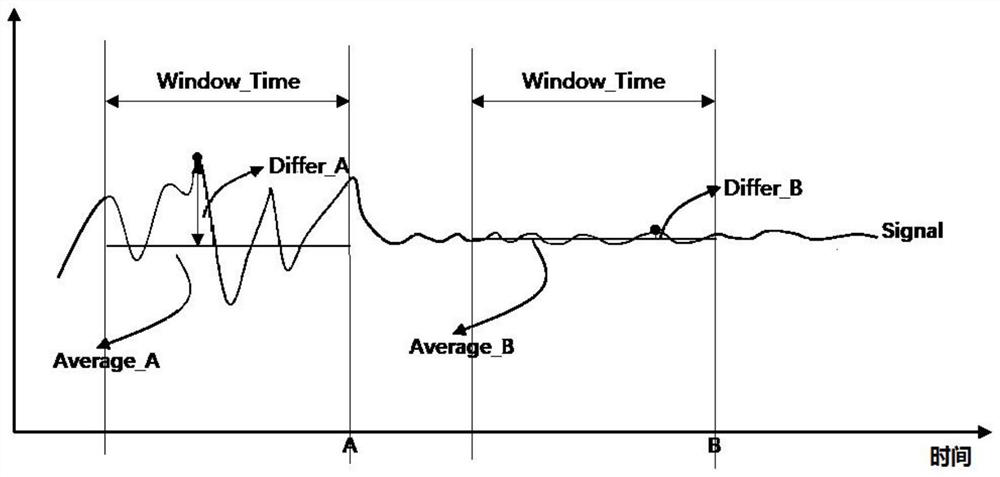

SCR catalyst crystallization detection method, detection device and clearing device

ActiveCN112282906AEffective identification of crystallization failuresReduce active regeneration timesInternal combustion piston enginesExhaust treatment electric controlAir volumeProcess engineering

The invention relates to an SCR catalyst crystallization detection method, a detection device and a clearing device, and relates to the technical field of engine after-treatment control. Real-time acquisition and accumulation of the actual intake air volume of an intake and exhaust system and the pre-calibrated intake air volume in an uncrystallized state are carried out, the crystallization stateof an SCR catalyst can be recognized according to an intake air volume deviation value calculated according to the actual intake air volume total value and the pre-calibrated intake air volume totalvalue, and when it is detected that the SCR catalyst has a light crystallization fault, an exhaust temperature management unit can be used for adjusting own control parameters of an engine to roughlyremove crystals, and when it is detected that the SCR catalyst has the severe crystallization fault, the crystals can be thoroughly removed through a DPF active regeneration unit, so that the crystallization fault in the SCR catalyst can be effectively recognized, and different removing measures can be taken for crystallization states of different degrees to prevent the SCR catalyst from being subjected to severe influence caused by crystallization.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com