Patents

Literature

41 results about "Tubular linear motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tubular linear motor is a type of linear electric motor with a forcer consisting of a series of solenoids wrapped around a cylinder enclosing a movable rod that contains a number of strong cylindrical permanent magnets aligned in alternating and opposing directions. Tubular linear motors are used in applications requiring linear actuators with performance that cannot be met by other forms of linear actuators such as pneumatic cylinders or lead screw linear actuators. Either the forcer (the part containing the coils) or the rod (the part containing the msgnets) may be the moving part, depending on the application.

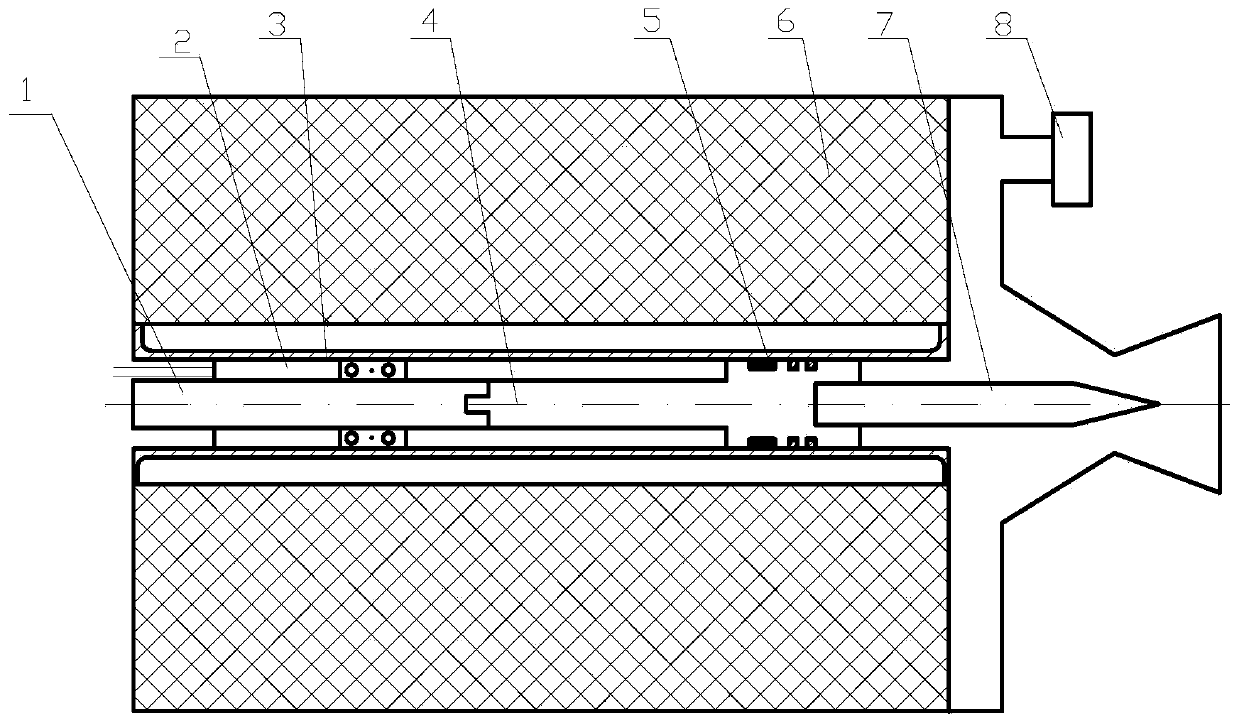

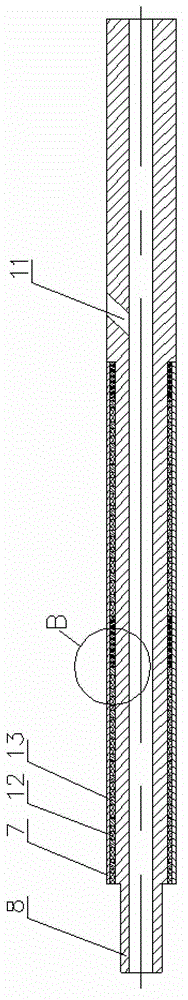

Solid rocket ramjet fuel gas flow regulation device driven by linear motor

InactiveCN103423032AExact random adjustmentNo intermediate transmission errorRocket engine plantsRamjetTubular linear motor

The invention discloses a solid rocket ramjet fuel gas flow regulation device driven by a linear motor. The nozzle throat area of a fuel gas generator is changed through the linear motor driving a cone-shaped valve head, and thus the fuel gas flow of the fuel gas generator is regulated; an inner shell structure is formed in the fuel gas generator, a thermal insulation bushing is mounted in an inner shell, the tubular linear motor is arranged in the thermal insulation bushing, a rotor of the linear motor is fixed in the thermal insulation bushing, a stator of the linear motor is fixedly connected with one end of a valve rod, the other end of the valve rod is fixedly connected with the cone-shaped valve head which stretches into a spray pipe of the solid fuel gas generator, one end, close to the cone-shaped valve head, of the valve rod is matched with an inner hole of the thermal insulation bushing, an annular groove is arranged, a movable sealing piece is arranged in the annular groove, and a pressure sensor is mounted at a rear seal head of the fuel gas generator. According to the solid rocket ramjet fuel gas flow regulation device driven by the linear motor, fuel gas flow can be accurately and randomly regulated, the precision is high, the structure is simple and compact, the size is small, the weight is light, and the sealing effect is reliable.

Owner:NANJING UNIV OF SCI & TECH

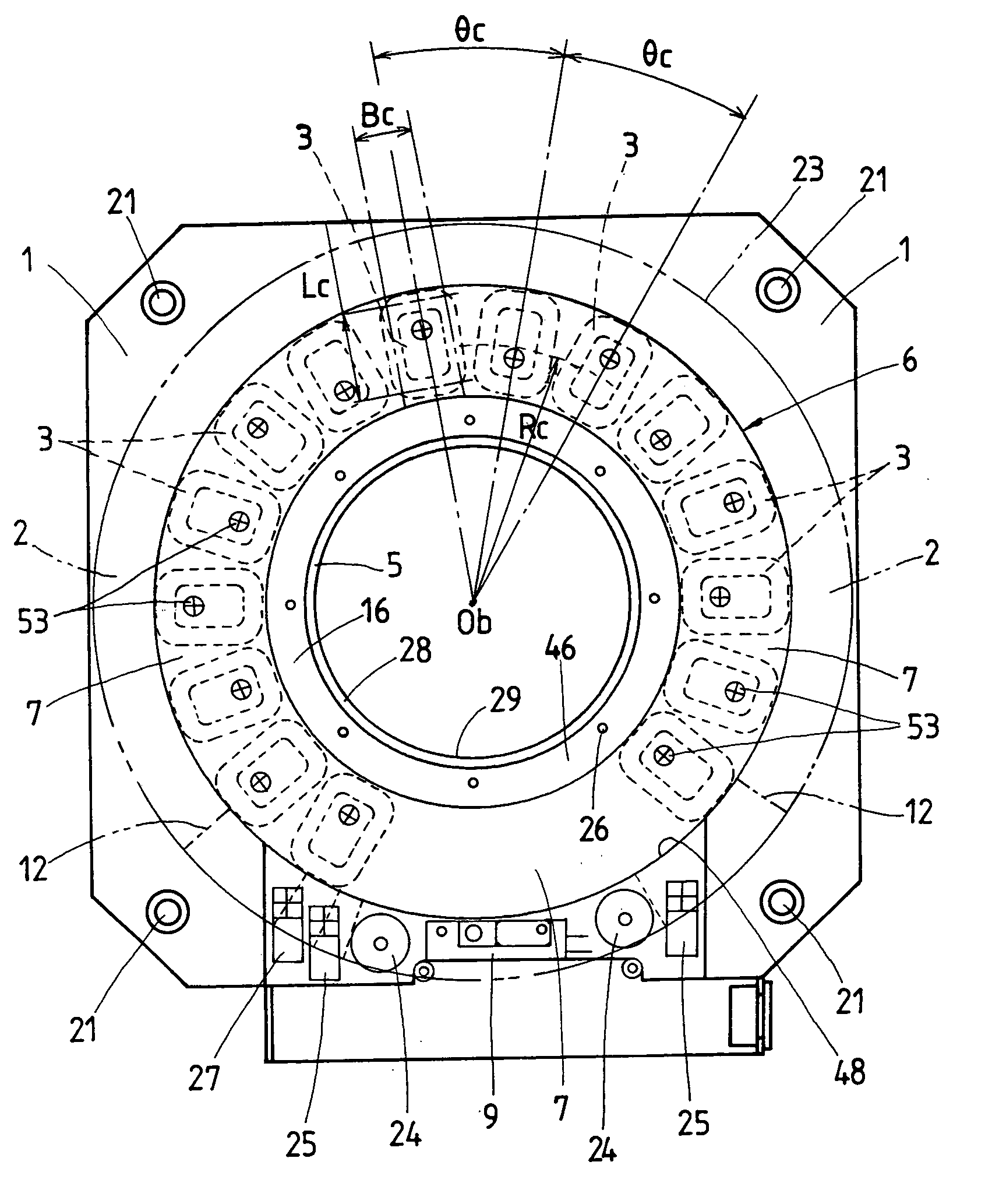

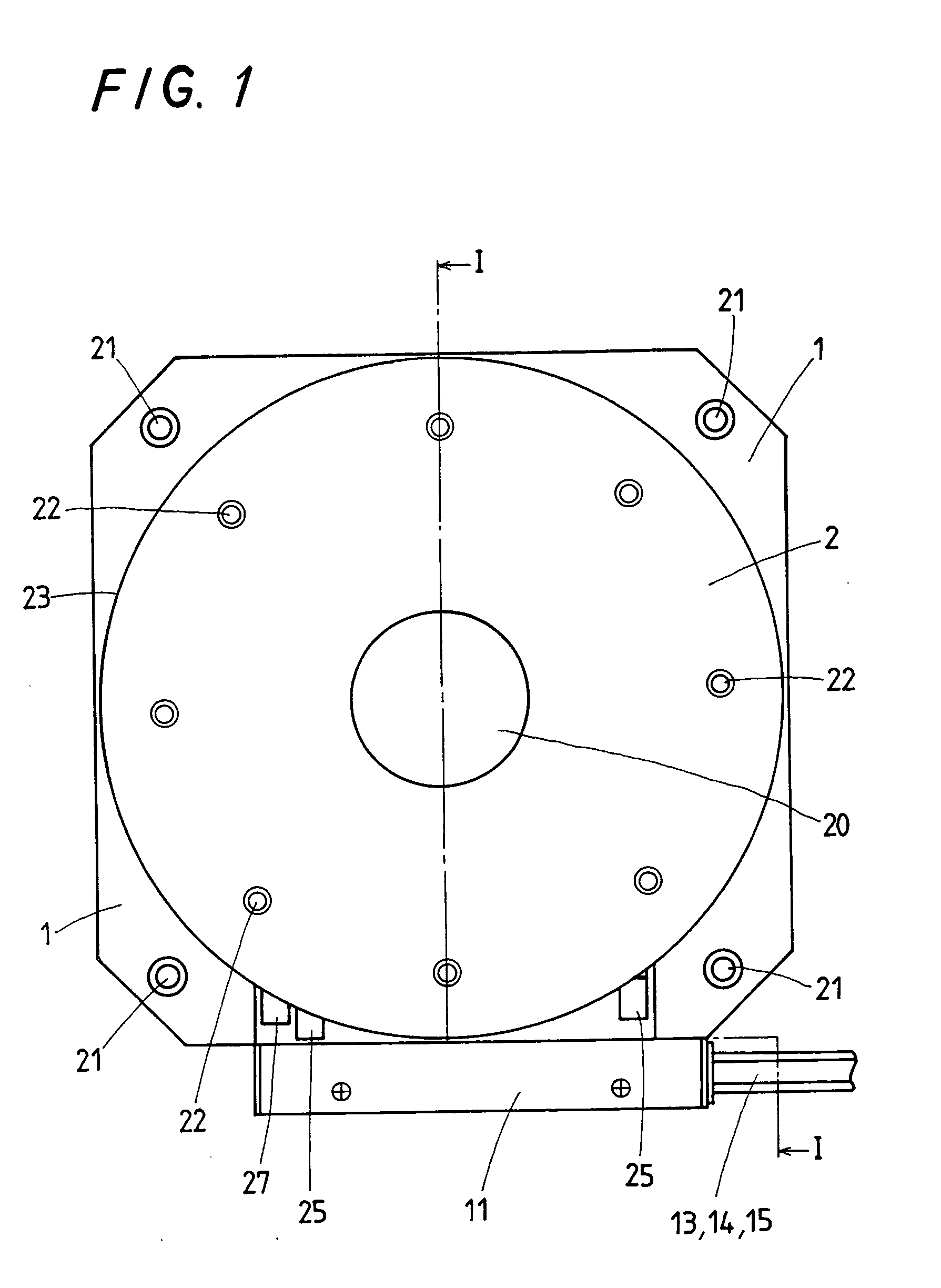

Position-control stage with onboard linear motor

A position-control stage is disclosed which makes it possible to extend largely an angular movement in circular direction for position control, rendering the stage itself compact in construction, allowing to work with high precision in clean environment and further produce the stage with inexpensive cost. The position-control stage has an onboard linear motor composed of armature windings of primary side and field magnets of secondary side. The armature windings are each made in a hollow rectangle where winding turns are wound in the form of flat loop, and are circularly arranged on a disc surface of the bed along a preselected curvature in such a way lying in radial juxtaposition in circumferential direction. The field magnets are made in a flat shape and arranged underneath the turntable in such a pattern lying radially on a disc surface of the preselected curvature in opposition to the armature windings, with their unlike poles alternating in polarity along a circular direction.

Owner:NIPPON THOMPSON

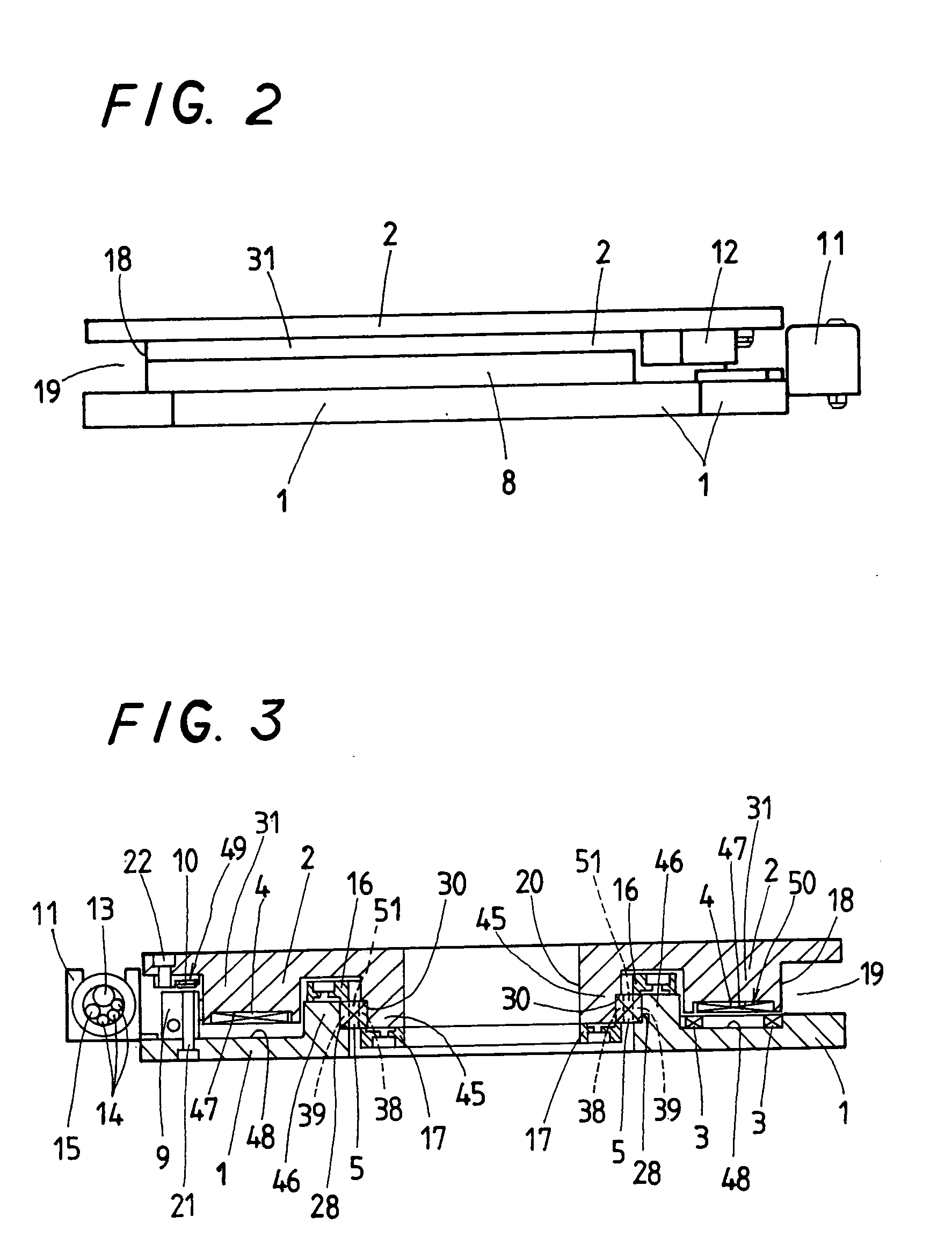

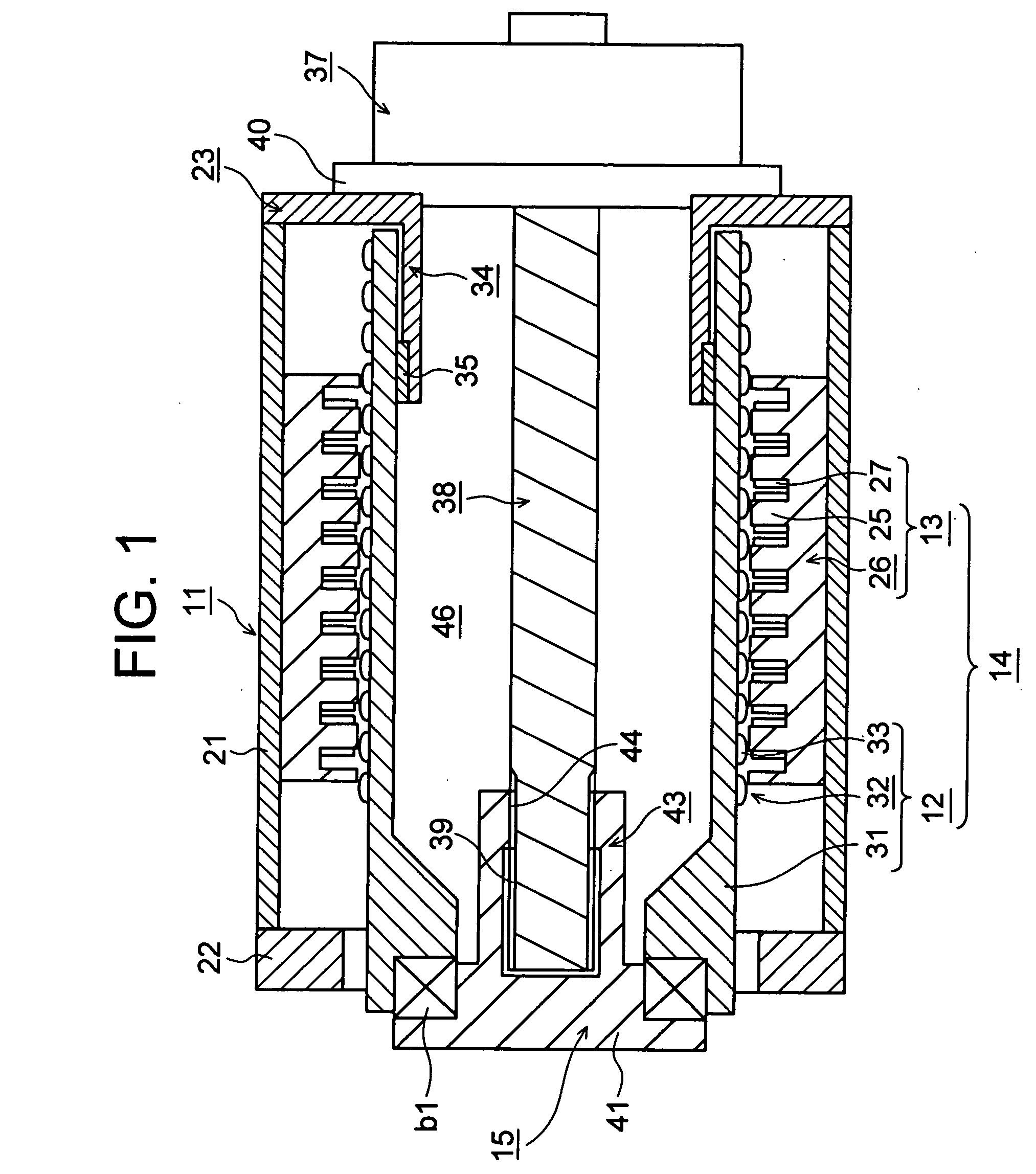

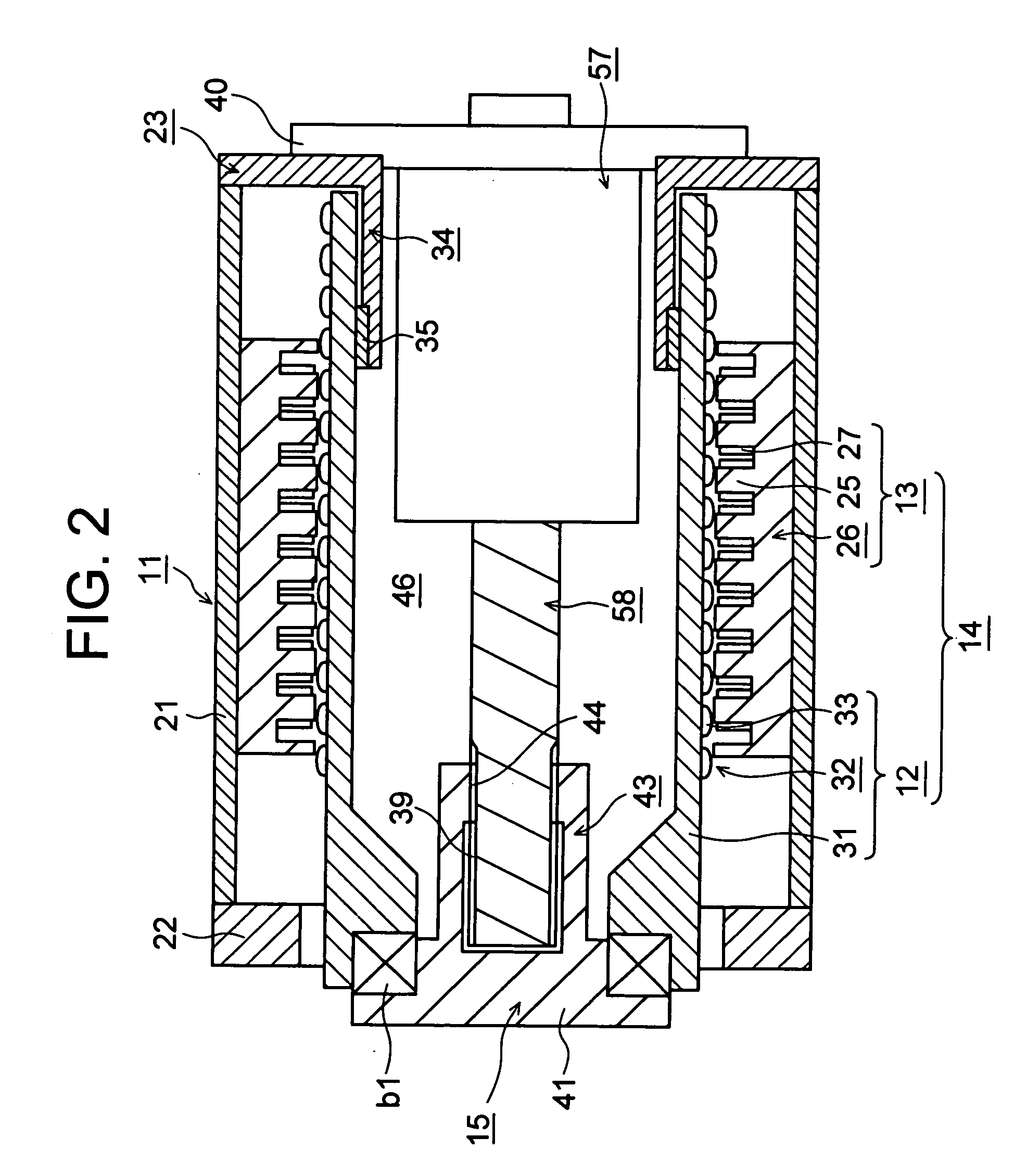

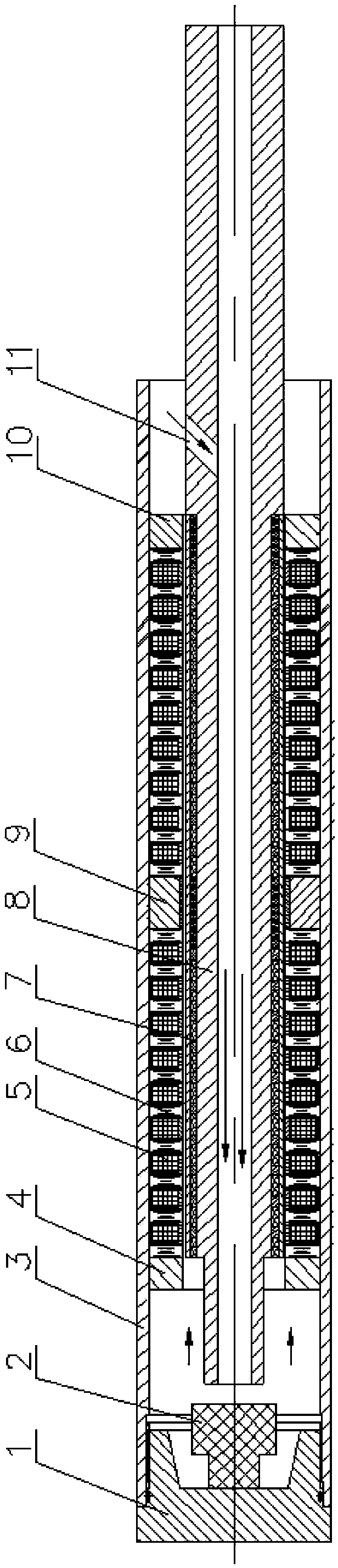

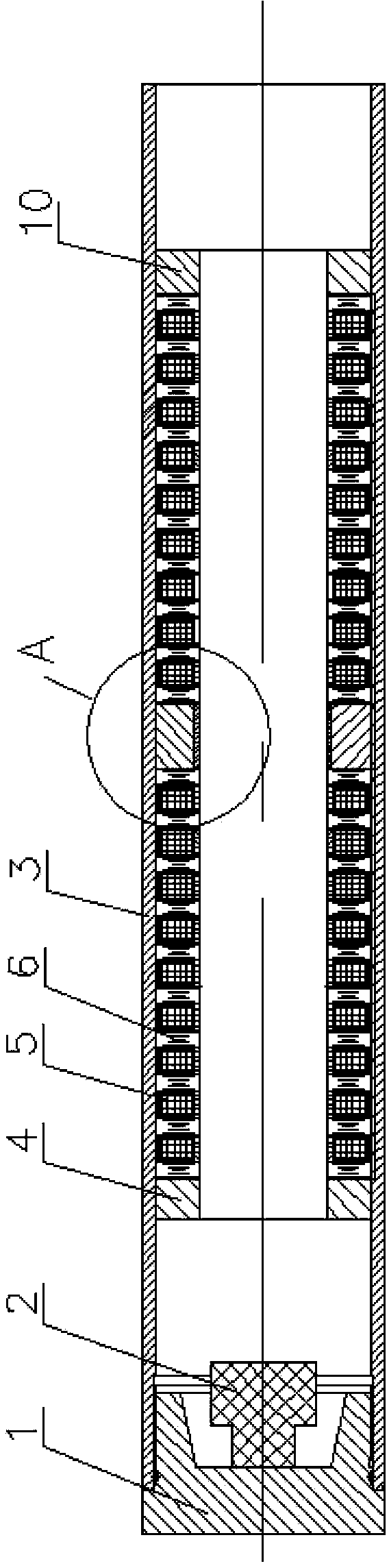

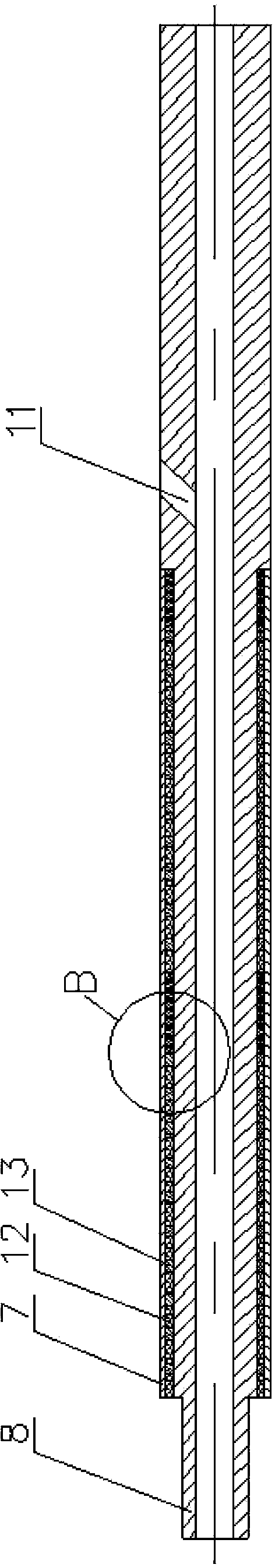

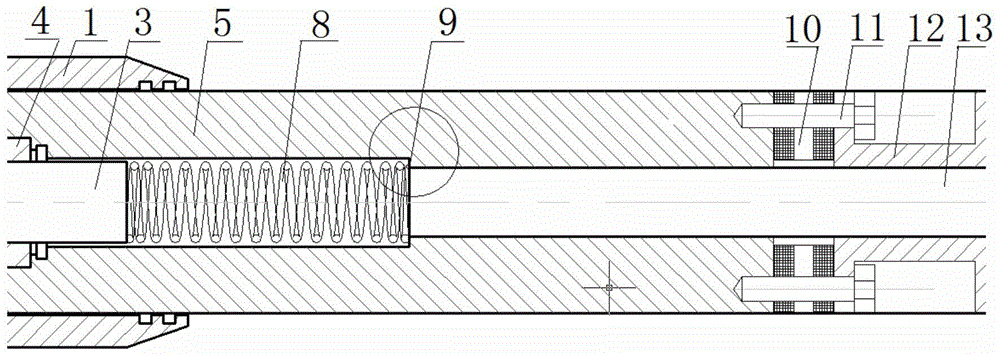

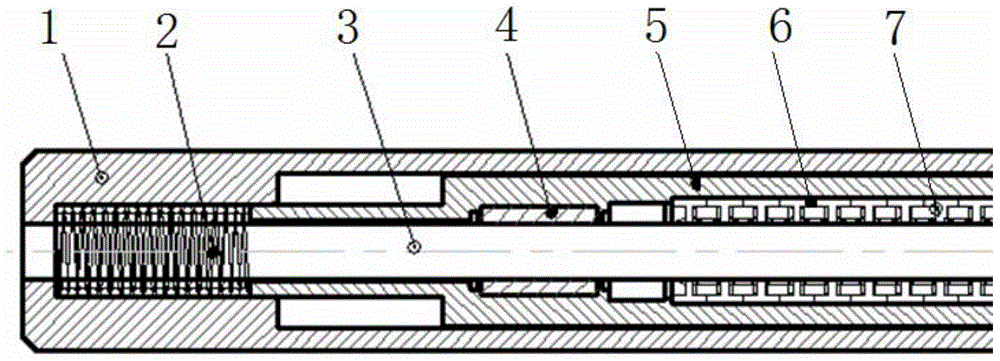

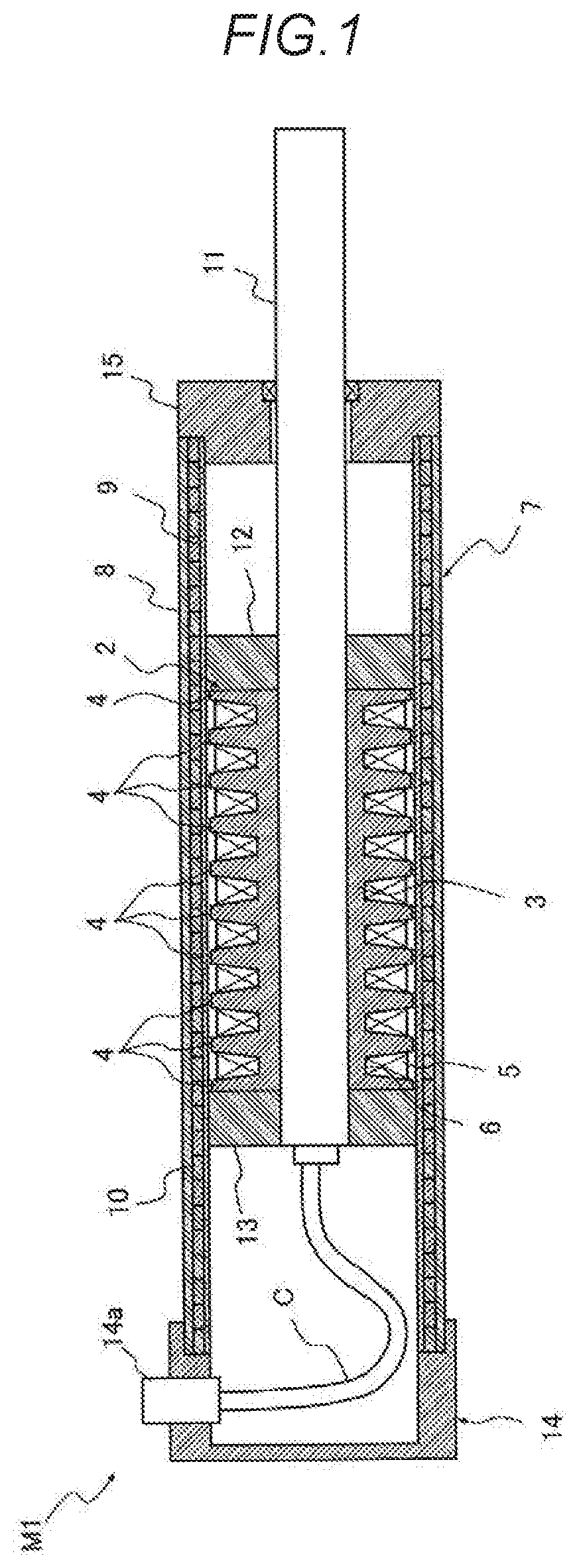

Drive apparatus for injection molding machine, injection apparatus, and mold clamping apparatus

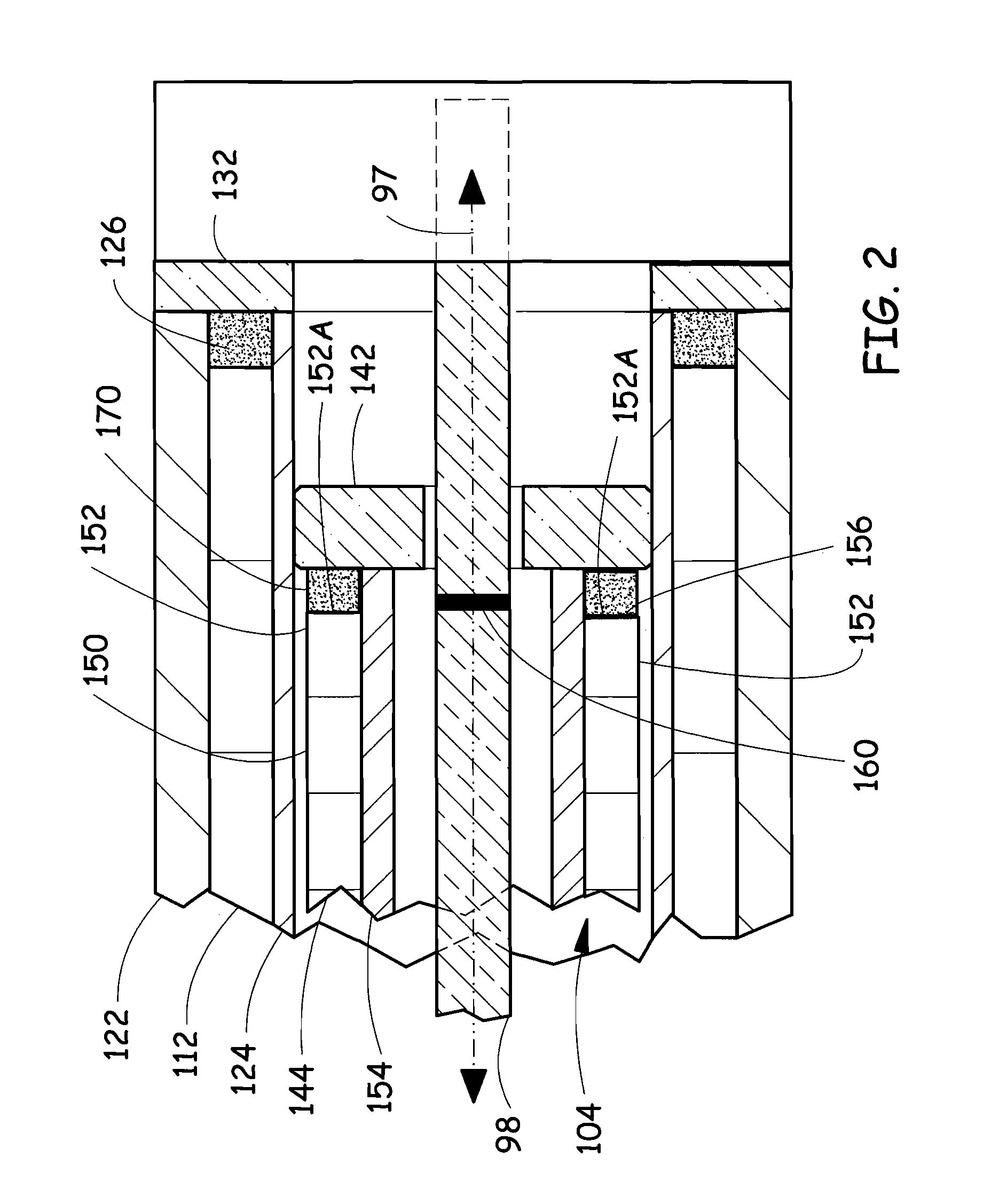

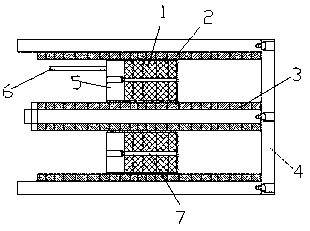

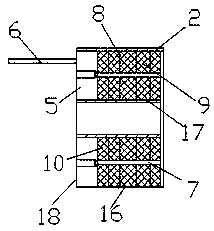

InactiveUS7442022B2Large thrustIncrease capacityMagnetic circuitSynchronous machinesTubular linear motorEngineering

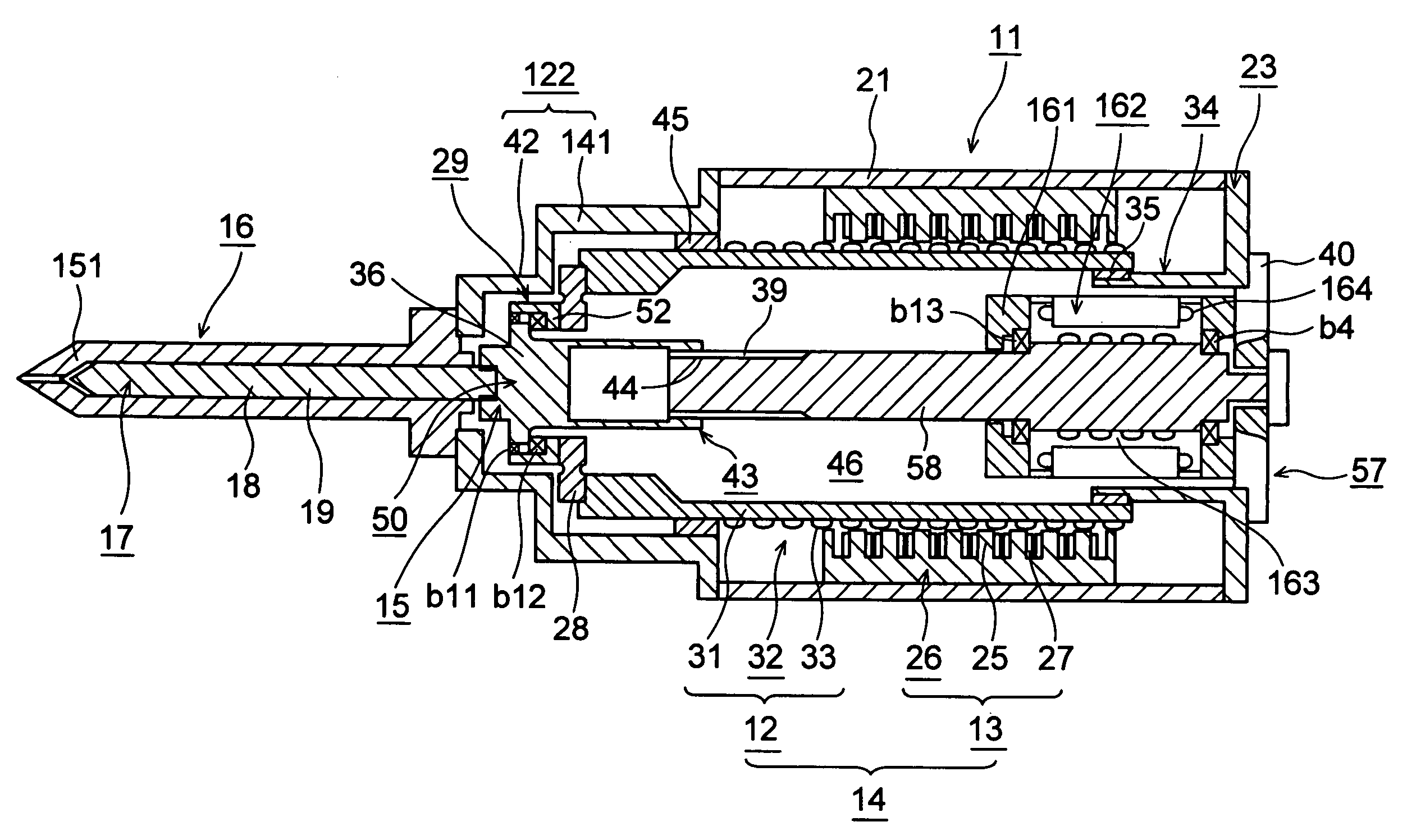

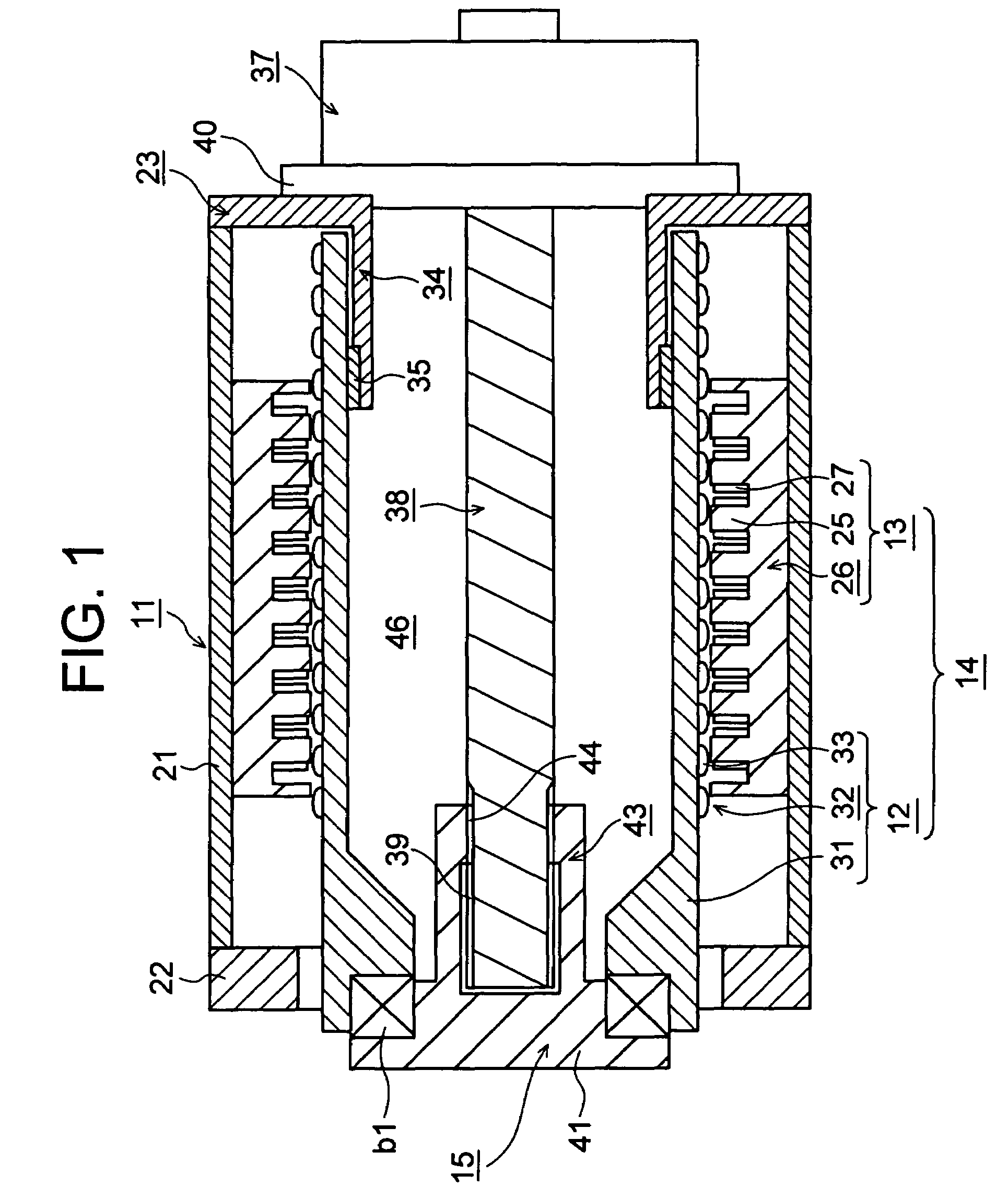

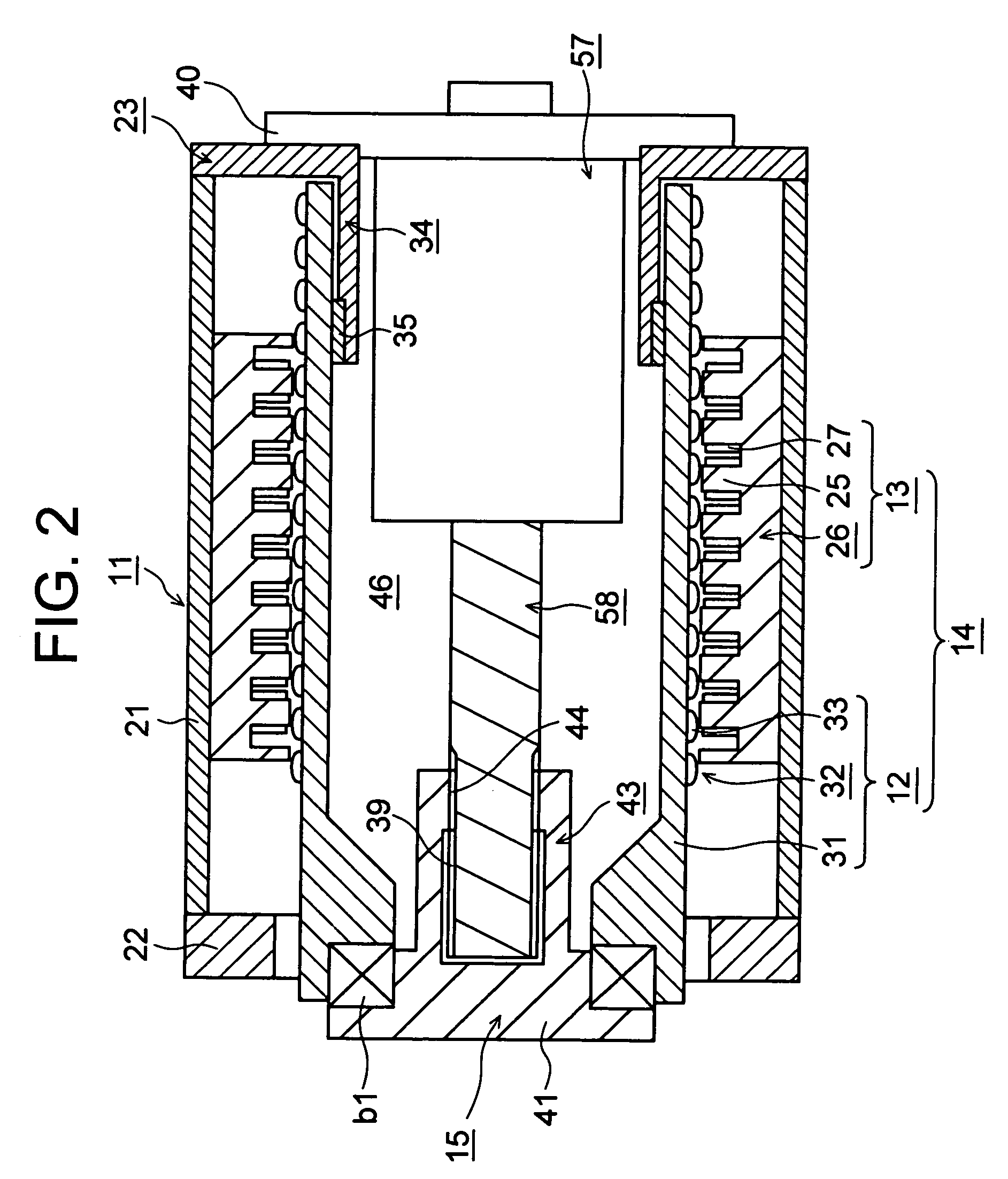

An object is to provide a drive apparatus for an injection molding machine which can generate a large thrust force and can provide short-cycled continuous drive. The drive apparatus includes a housing (11); a tubular linear motor (14) including a movable element (12) disposed within the housing (11) in a manner capable of advancing and retreating, and a stationary element (13) attached to the housing (11), the linear motor (14) serving as a first drive section; a member-to-be-driven (15) caused to advance and retreat together with the movable element (12); and a second drive section attached to the housing (11) and disposed such that at least a portion of the second drive section overlaps the linear motor (14) along the axial direction. By merely a slight increase in a radial dimension, the area of a permanent magnet (23) of the movable element (12) can be sufficiently increased, and the capacity of the linear motor (14) can be increased.

Owner:SUMITOMO HEAVY IND LTD

Injection molding machine driving device, injection device, and mold clamping device

InactiveUS20060147578A1Large thrustIncrease capacityMagnetic circuitSynchronous machinesTubular linear motorInjection molding machine

An object is to provide a drive apparatus for an injection molding machine which can generate a large thrust force and can provide short-cycled continuous drive. The drive apparatus includes a housing (11); a tubular linear motor (14) including a movable element (12) disposed within the housing (11) in a manner capable of advancing and retreating, and a stationary element (13) attached to the housing (11), the linear motor (14) serving as a first drive section; a member-to-be-driven (15) caused to advance and retreat together with the movable element (12); and a second drive section attached to the housing (11) and disposed such that at least a portion of the second drive section overlaps the linear motor (14) along the axial direction. By merely a slight increase in a radial dimension, the area of a permanent magnet (23) of the movable element (12) can be sufficiently increased, and the capacity of the linear motor (14) can be increased.

Owner:SUMITOMO HEAVY IND LTD

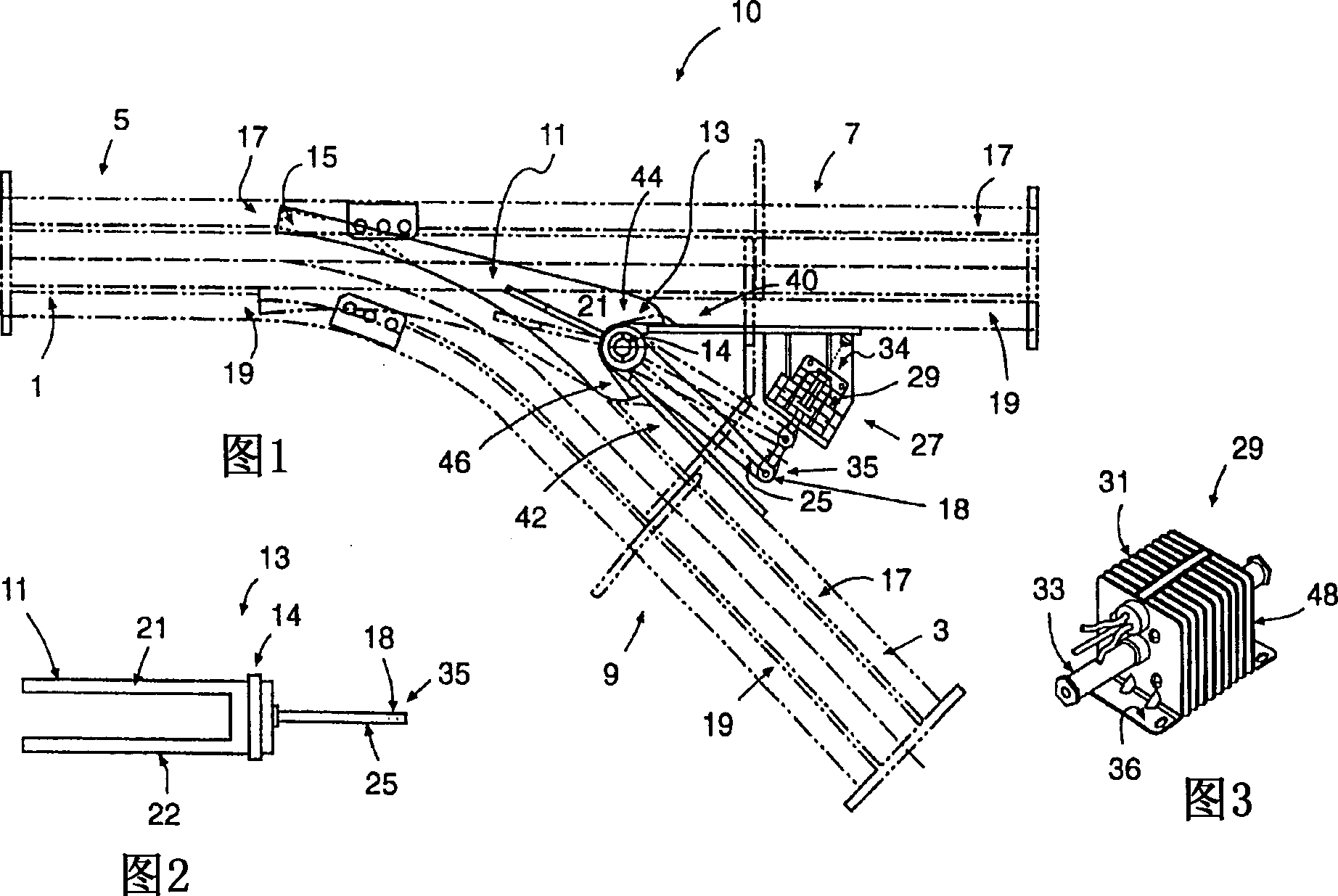

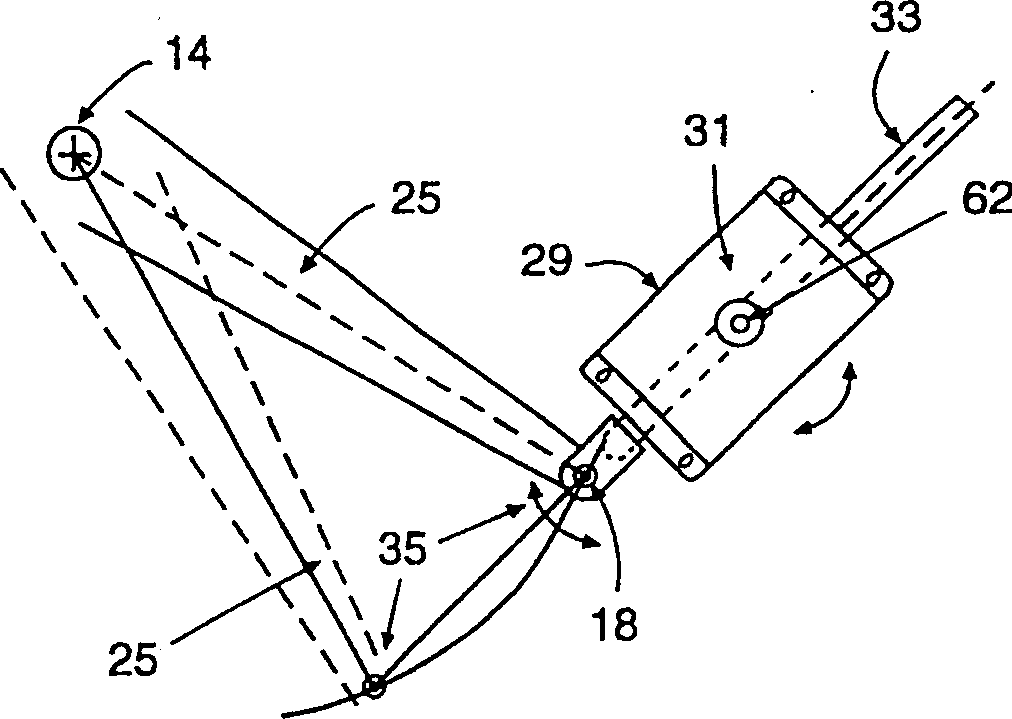

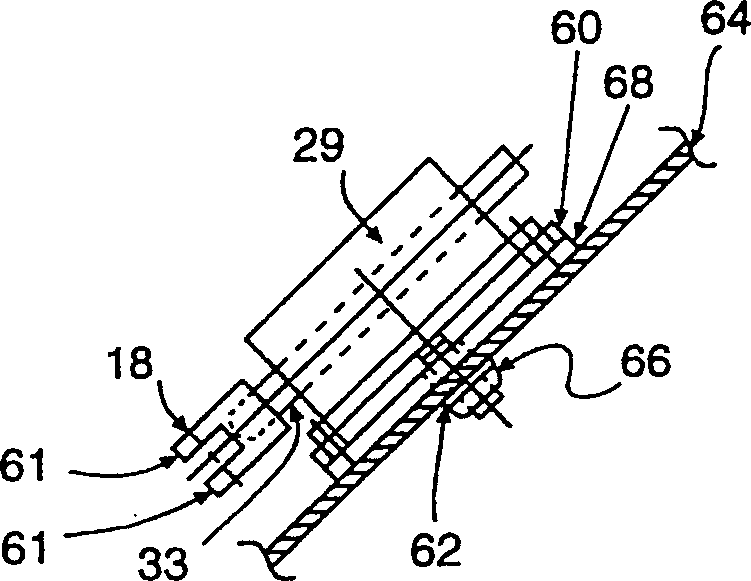

Conveyor system switch using tubular linear induction motor

A conveyor switch for a conveyor track comprising a tubular linear induction motor as the switch drive. A switch tongue is adapted to be pivoted between first and second positions on the conveyor track and has a driving arm extending from one end thereof. The switch drive is operatively connected to the driving arm for driving the switch tongue, wherein the switch tongue is adapted to direct a moving conveyor component between first and second paths of travel on the conveyor track. Various means are provided to account for the linear movement of the switch drive in relation to the arcuate movement of the switch tongue. The switch assembly is especially adapted for switches in power and free conveyor systems.

Owner:JERVIS B WEBB INT CO

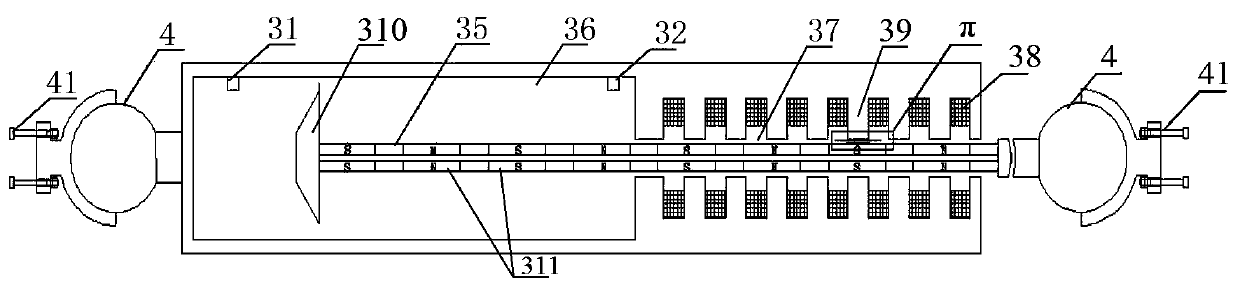

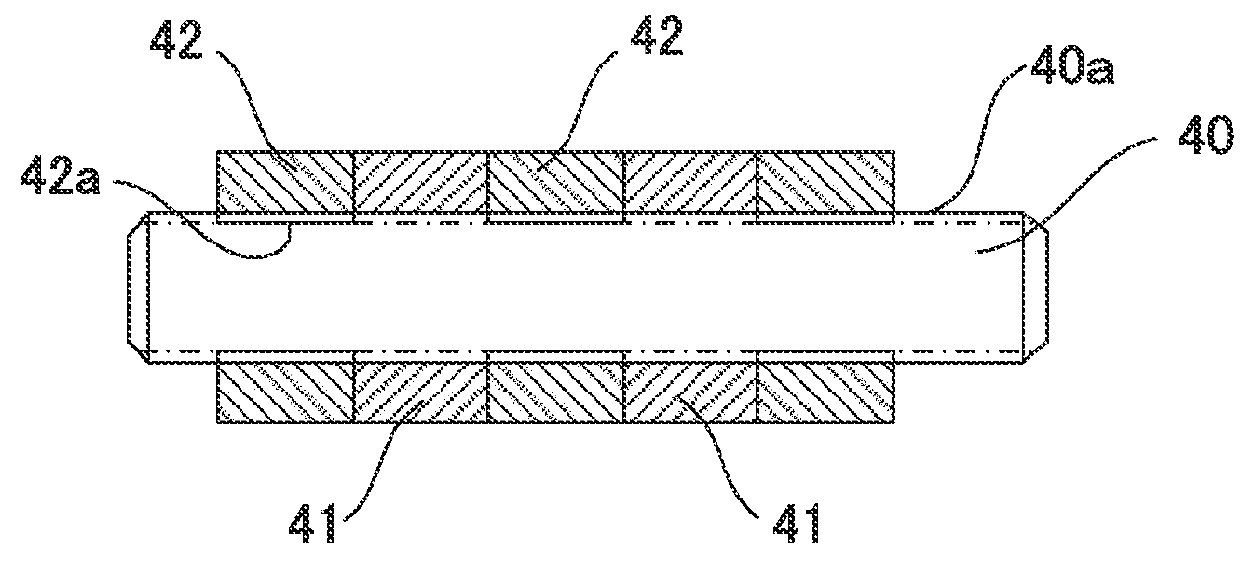

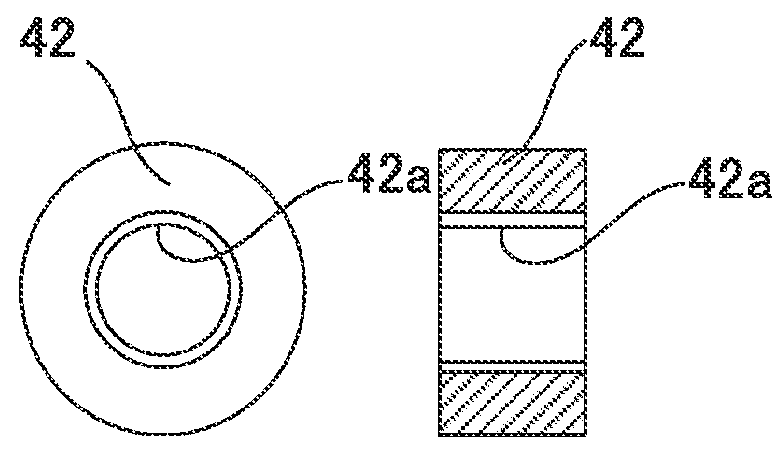

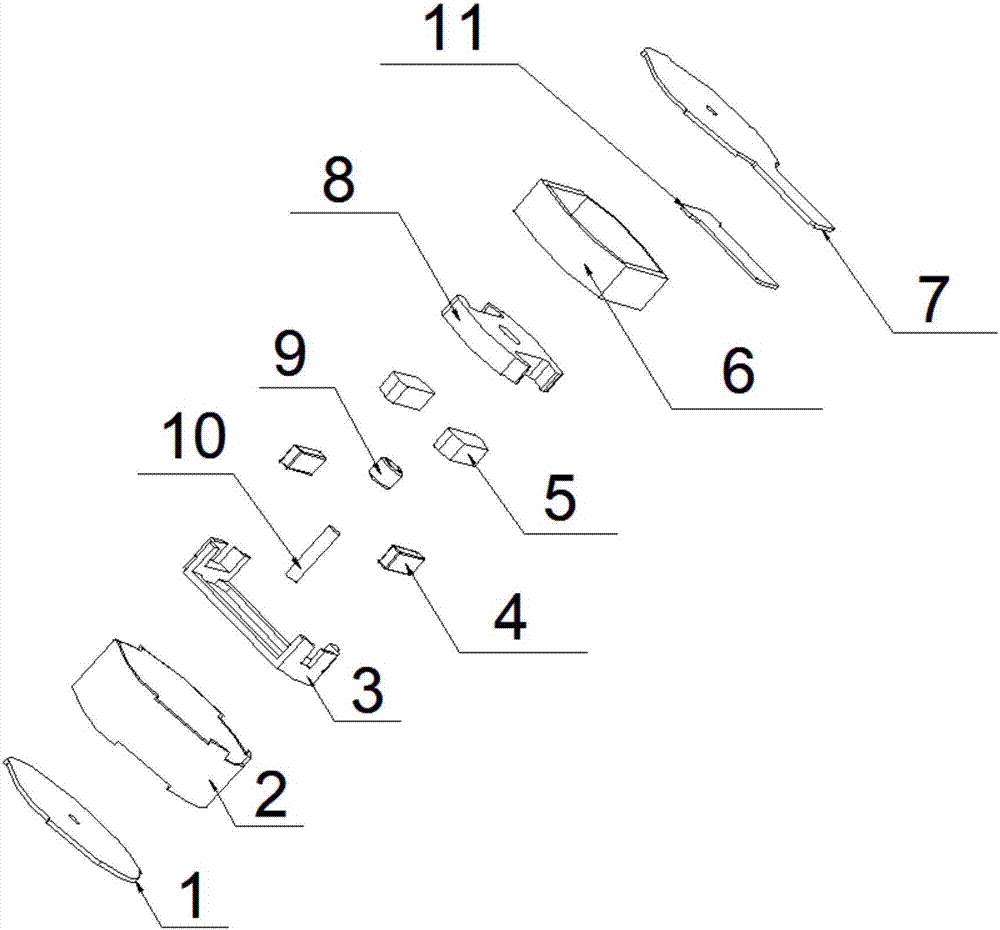

High-thrust tubular linear motor

ActiveCN103427587AStrong resistance to demagnetizationReduce magnetic densityPropulsion systemsTubular linear motorConductor Coil

The invention relates to a high-thrust tubular linear motor which comprises a stator shell, a stator and a rotor. The stator is coaxially and fixedly mounted in the stator shell, the rotor is coaxially and slidably mounted in an inner cavity of the stator, the stator comprises silicon steel sheets and windings which are arranged at intervals and fixedly mounted on the stator shell, the rotor comprises a rotor shaft, permanent magnets and magnetic conduction rings, and the permanent magnets and the magnetic conduction rings are arranged at intervals on the rotor shaft. The high-thrust tubular linear motor is characterized in that the rotor shaft is made of hollow soft magnetic materials, a copper tube is coaxially sleeved outside the rotor, the windings and the silicon steel sheets are fixedly mounted at intervals to form the stator, and the windings and the silicon steel sheets correspond to the permanent magnets and the magnetic conduction rings of the rotor. The high-thrust tubular linear motor is ingenious in design, reasonable in structure, large in starting force, fine in tightness and reliable in operation.

Owner:伟力驱动技术(深圳)有限公司

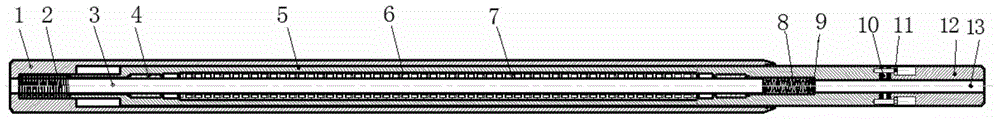

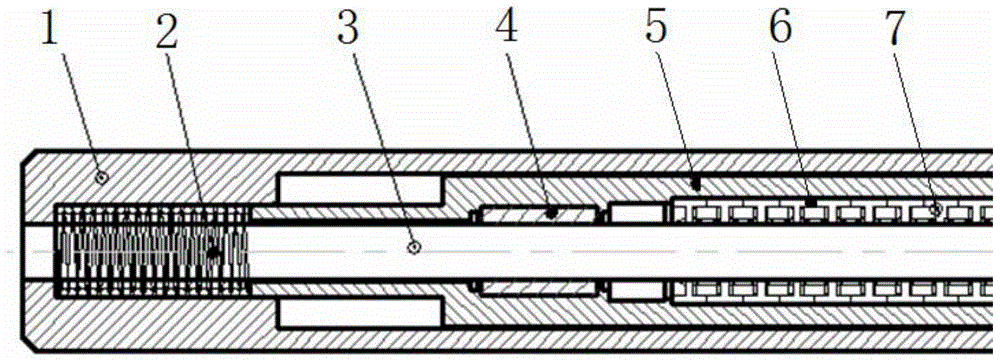

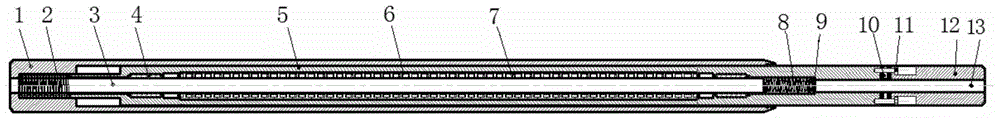

Hole-bottom tubular linear motor electric impactor

InactiveCN104022616AIncrease electromagnetic forceLaunch fastConstructionsReciprocating drilling machinesTubular linear motorBall bearing

The invention relates to a hole-bottom tubular linear motor electric impactor which comprises a motor outer cylinder, a permanent magnet rod, a linear ball bearing, a rotor, rotor silicon steel sheets and a rotor coil. The motor outer cylinder is an outer shell of a linear motor. The permanent magnet rod is fixed to the motor outer cylinder and serves as a stator of the linear motor. The rotor moves relative to the permanent magnet rod through the linear ball bearing. An iron core composed of the rotor silicon steel sheets is inlaid inside the rotor. A groove is formed in the iron core and internally provided with the rotor coil. A three-phase alternating current winding is adopted for the coil, and the three-phase symmetrical alternating current is led into the coil to generate a traveling wave magnetic field coincident with the rotor in the movement direction. Two damping springs are further arranged to be used for buffering shock. According to the hole-bottom tubular linear motor electric impactor, a movable-coil type structure is adopted, namely, the permanent magnet rod and the iron core are fixed, and the coil is movable. Meanwhile, a buffering gasket is designed between the rotor and a base, and the fatigue resistant service life of the hole-bottom tubular linear motor electric impactor is prolonged. The hole-bottom tubular linear motor electric impactor is simple and firm in structure and low in manufacturing and maintenance cost, the impacting stroke speed and the impacting stroke frequency are easy to adjust, and the hole-bottom tubular linear motor electric impactor is high in efficiency and can be used for deep hole drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

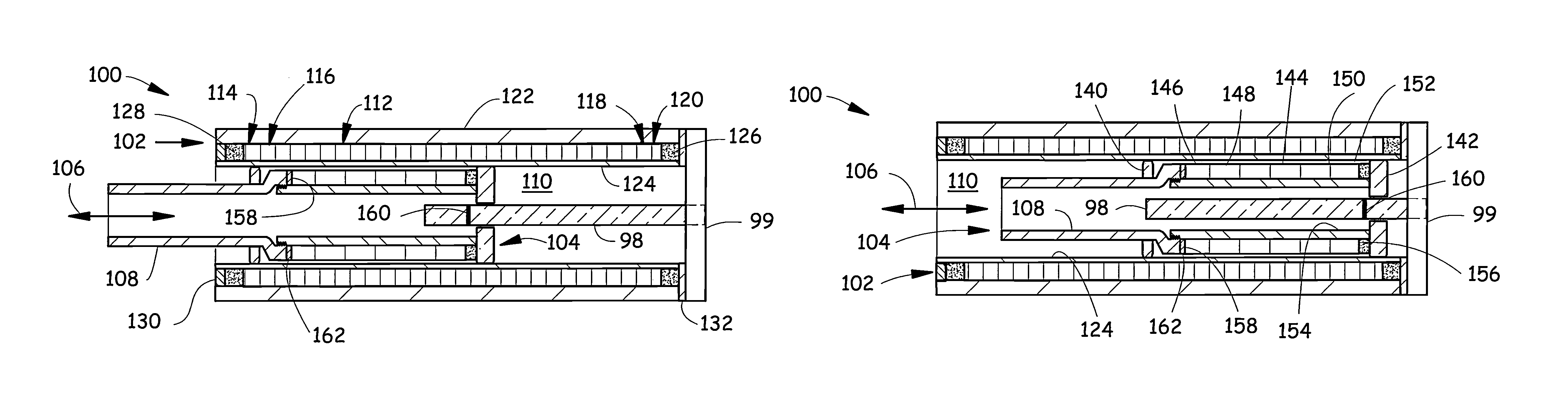

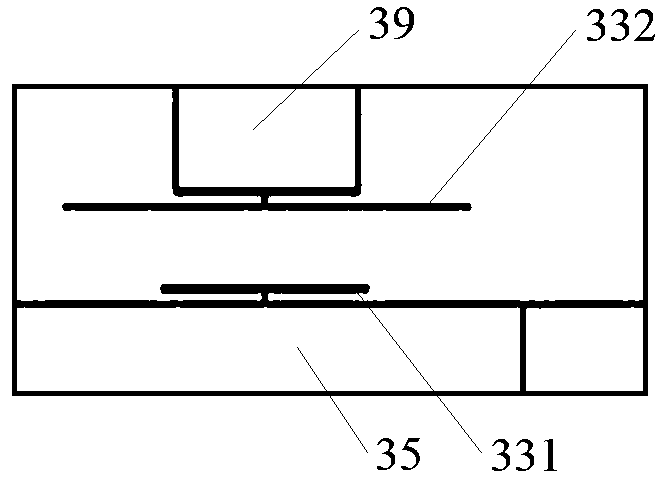

Tubular linear motor with magnetostrictive sensor

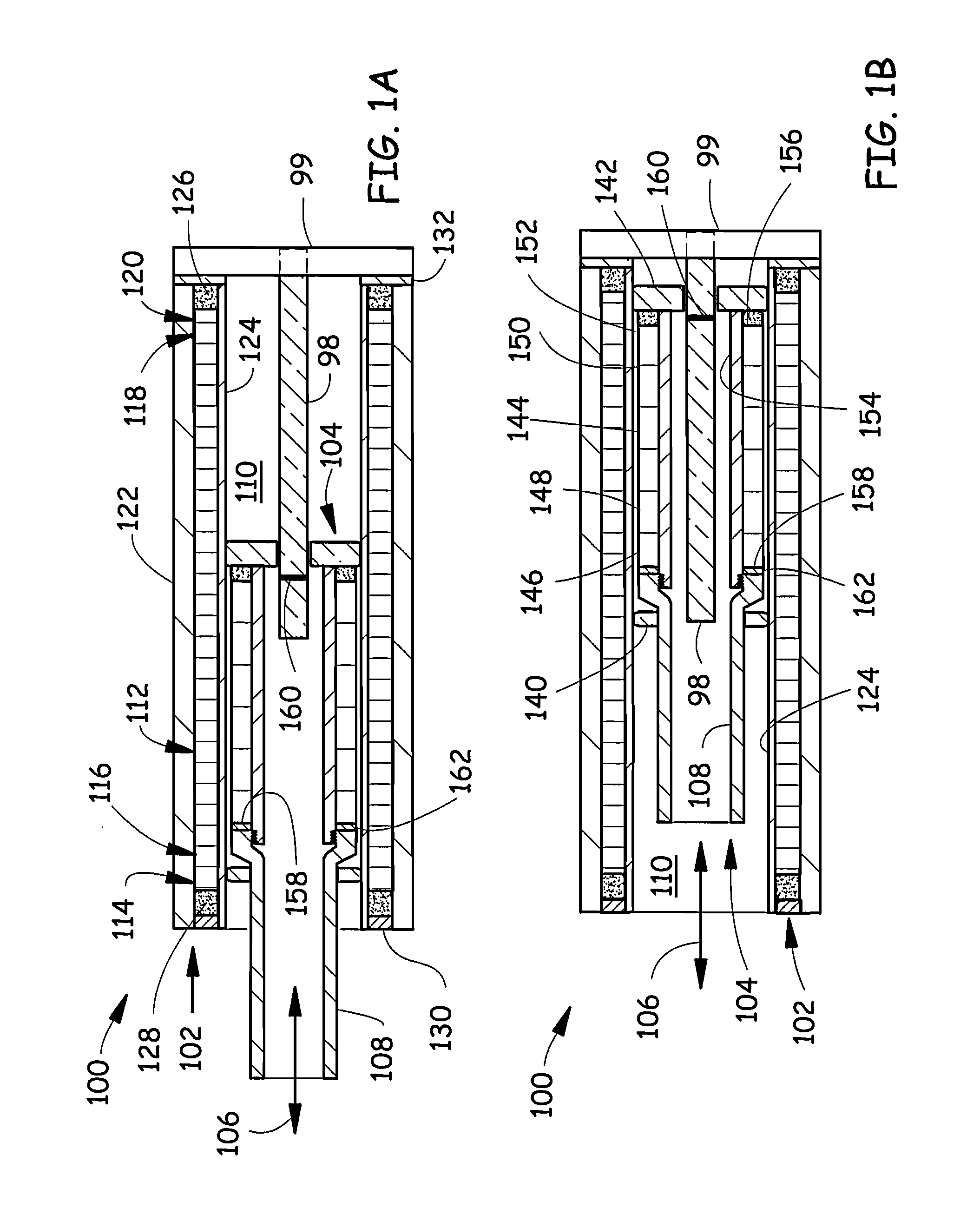

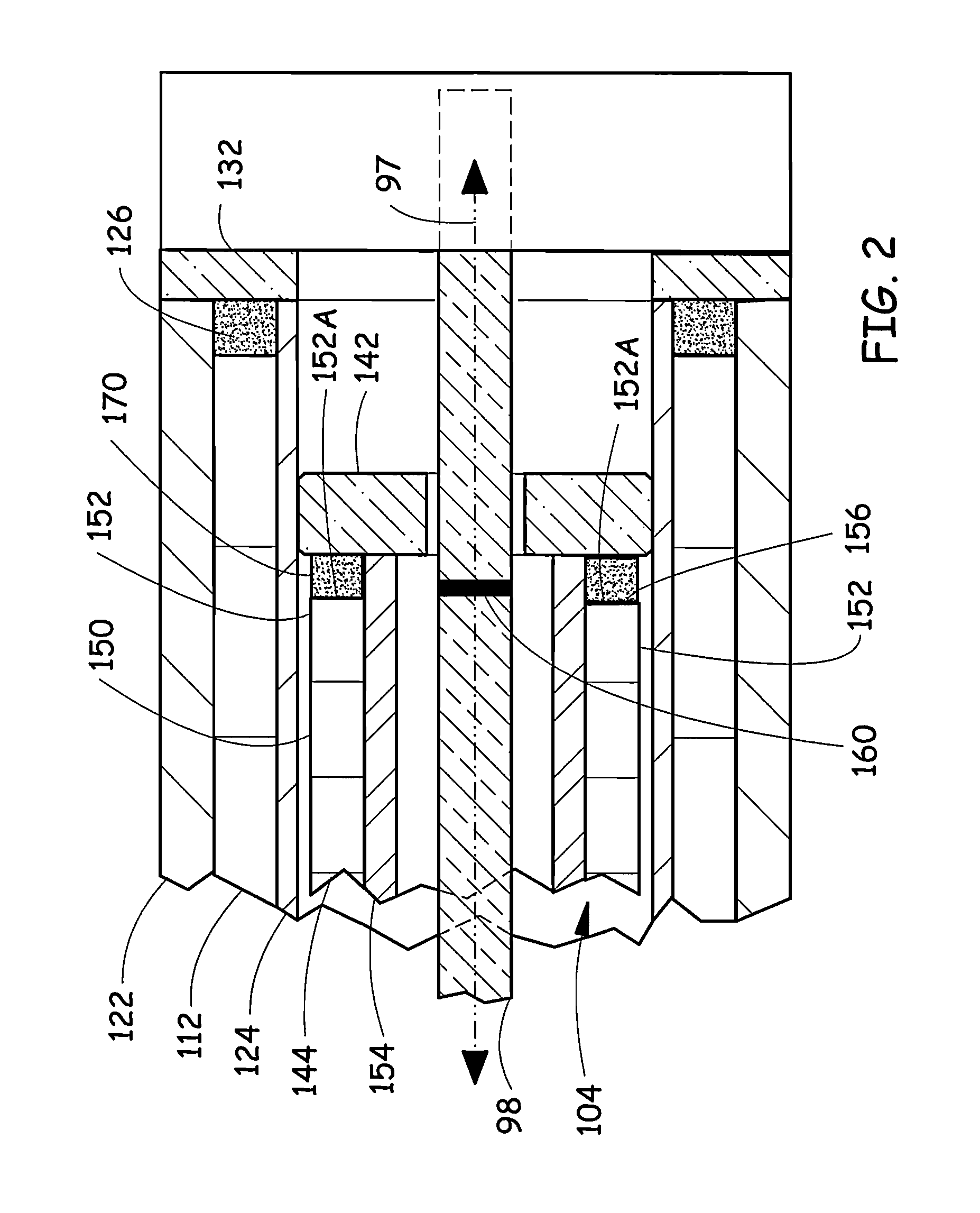

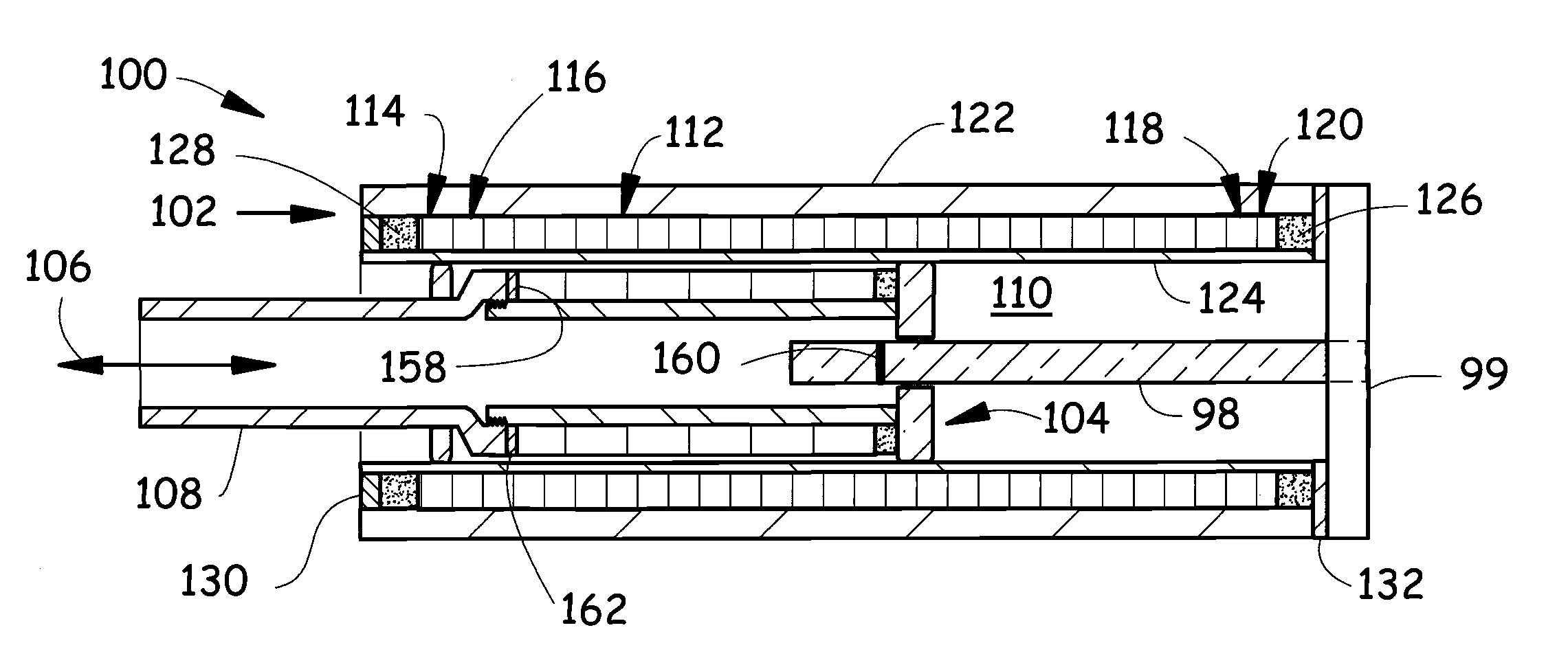

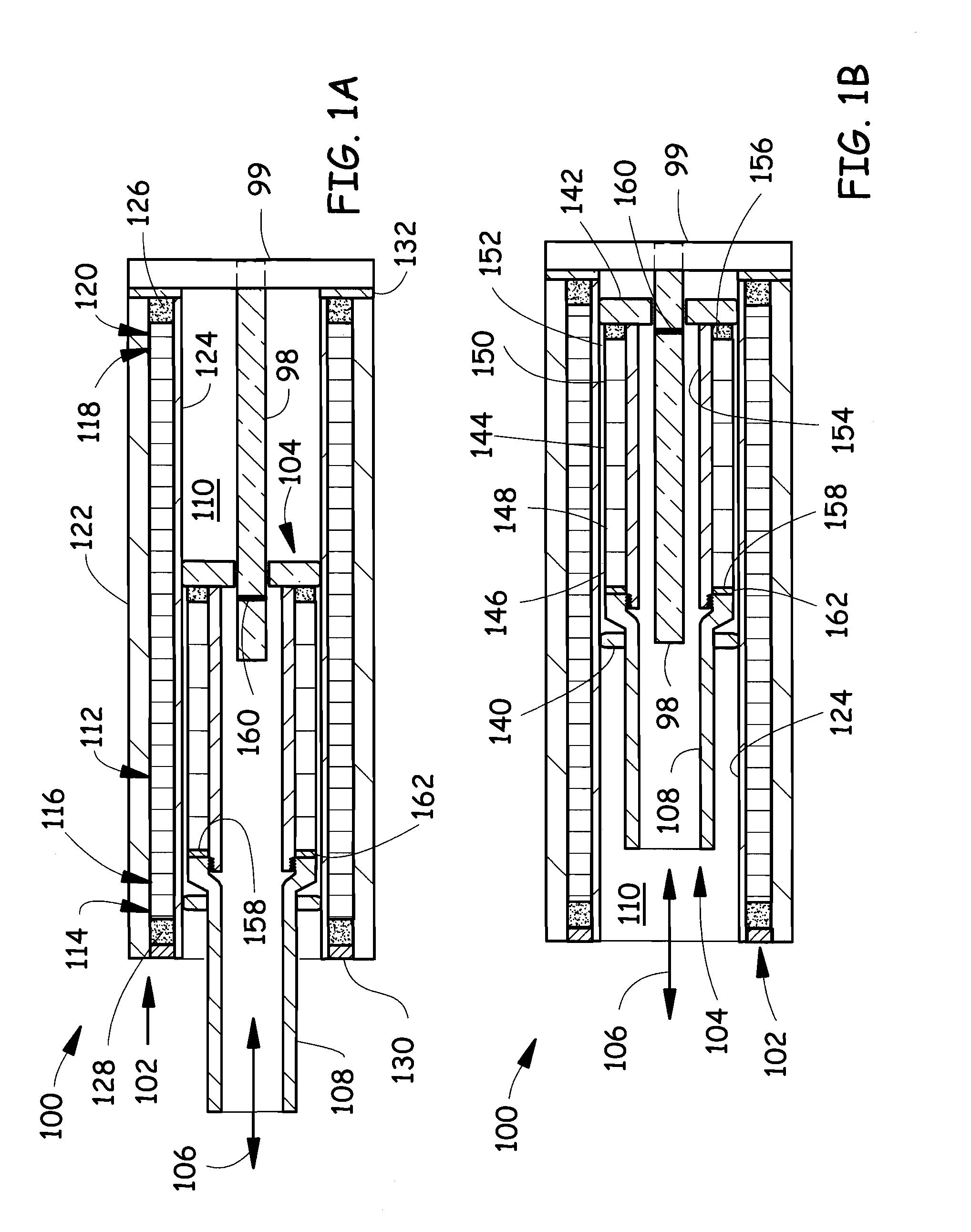

InactiveUS9479031B2Improve permeabilityReducing cost and complexityMagnetic circuit rotating partsConverting sensor ouput using wave/particle radiationTubular linear motorNon magnetic

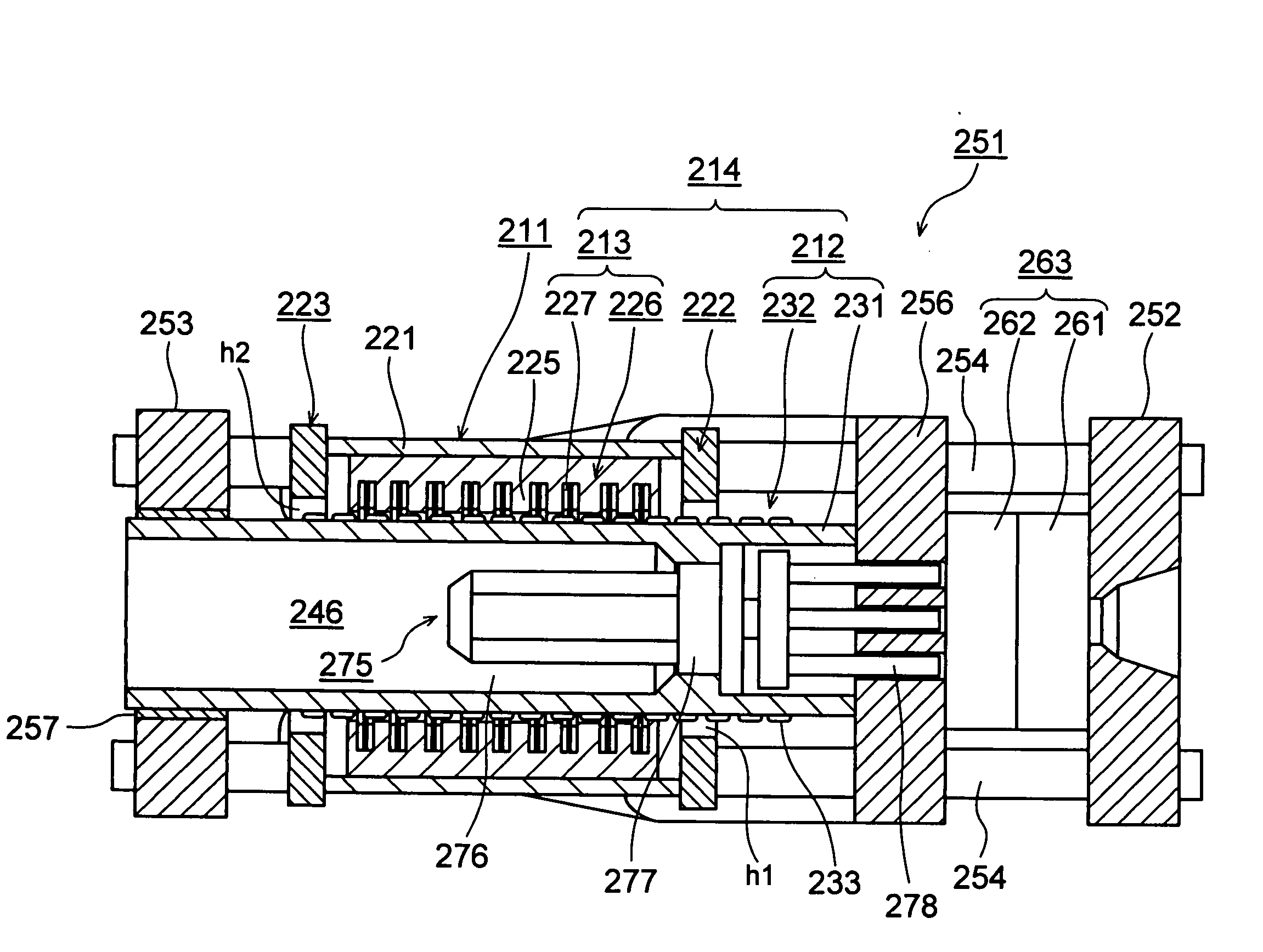

A motor includes a position-sensing magnetostrictive element that extends along a stator bore. A slider slides in the stator bore and includes a stack of motor magnets. The stack includes a first stack end that provides a magnetic field pattern that magnetizes a region of the magnetostrictive element. The motor includes shield elements such as a non-magnetic shield tube and a magnetic flux diverter.

Owner:MTS SENSOR TECH

Tubular linear motor with magnetostrictive sensor

InactiveUS20140252889A1Accurate measurementAvoid interferenceMagnetic circuit rotating partsStructural associationTubular linear motorNon magnetic

A motor includes a position-sensing magnetostrictive element that extends along a stator bore. A slider slides in the stator bore and includes a stack of motor magnets. The stack includes a first stack end that provides a magnetic field pattern that magnetizes a region of the magnetostrictive element. The motor includes shield elements such as a non-magnetic shield tube and a magnetic flux diverter.

Owner:MTS SENSOR TECH

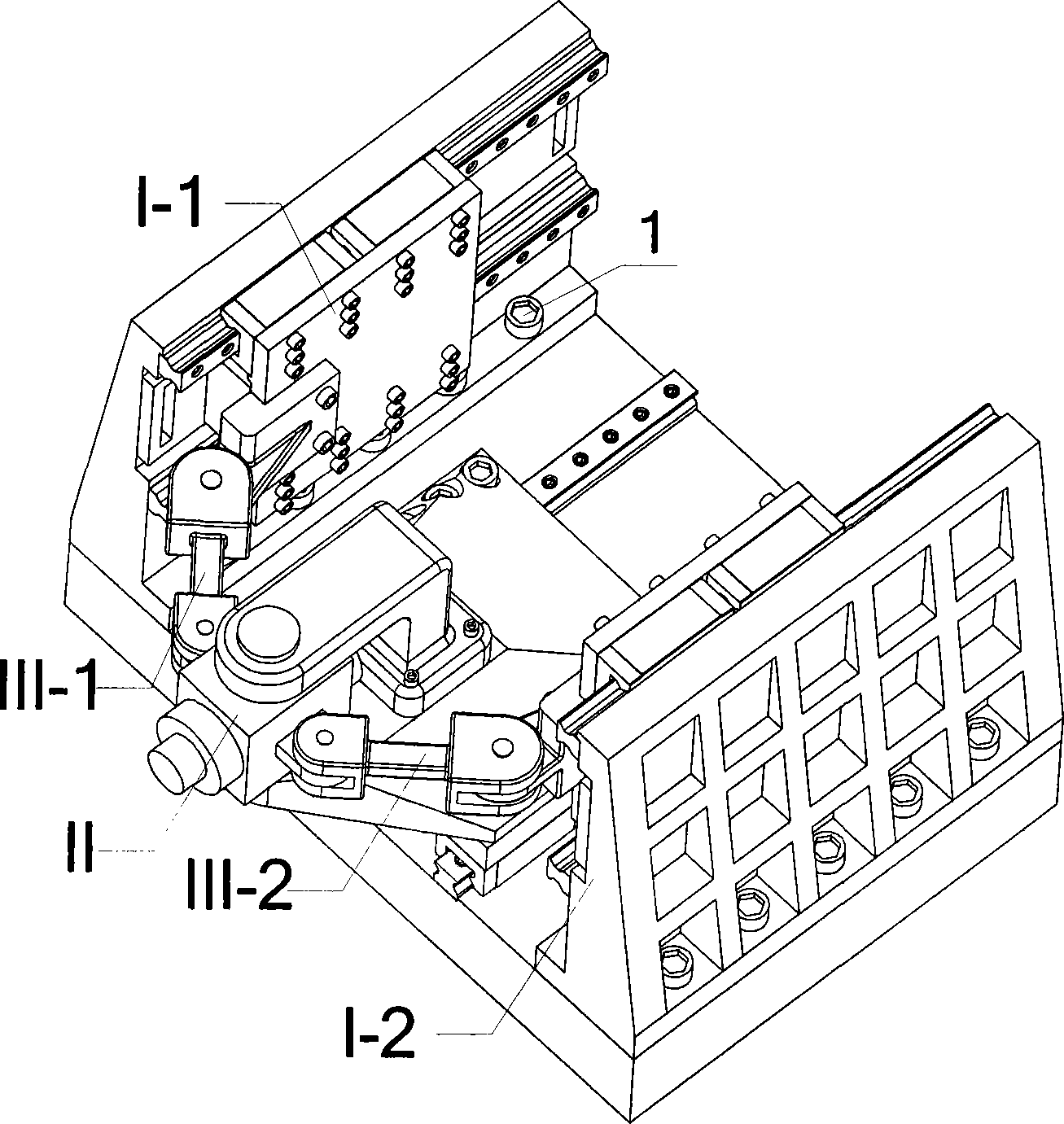

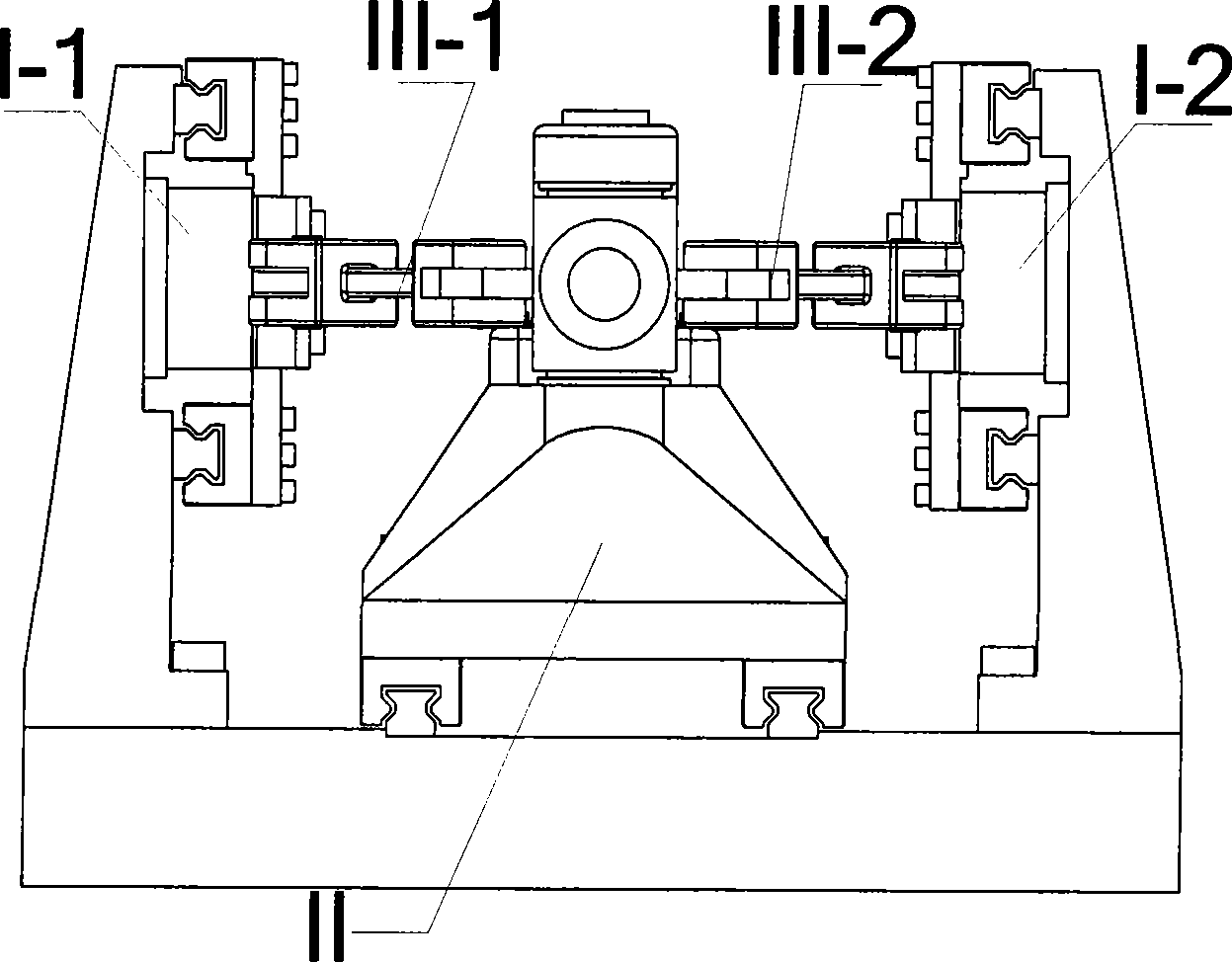

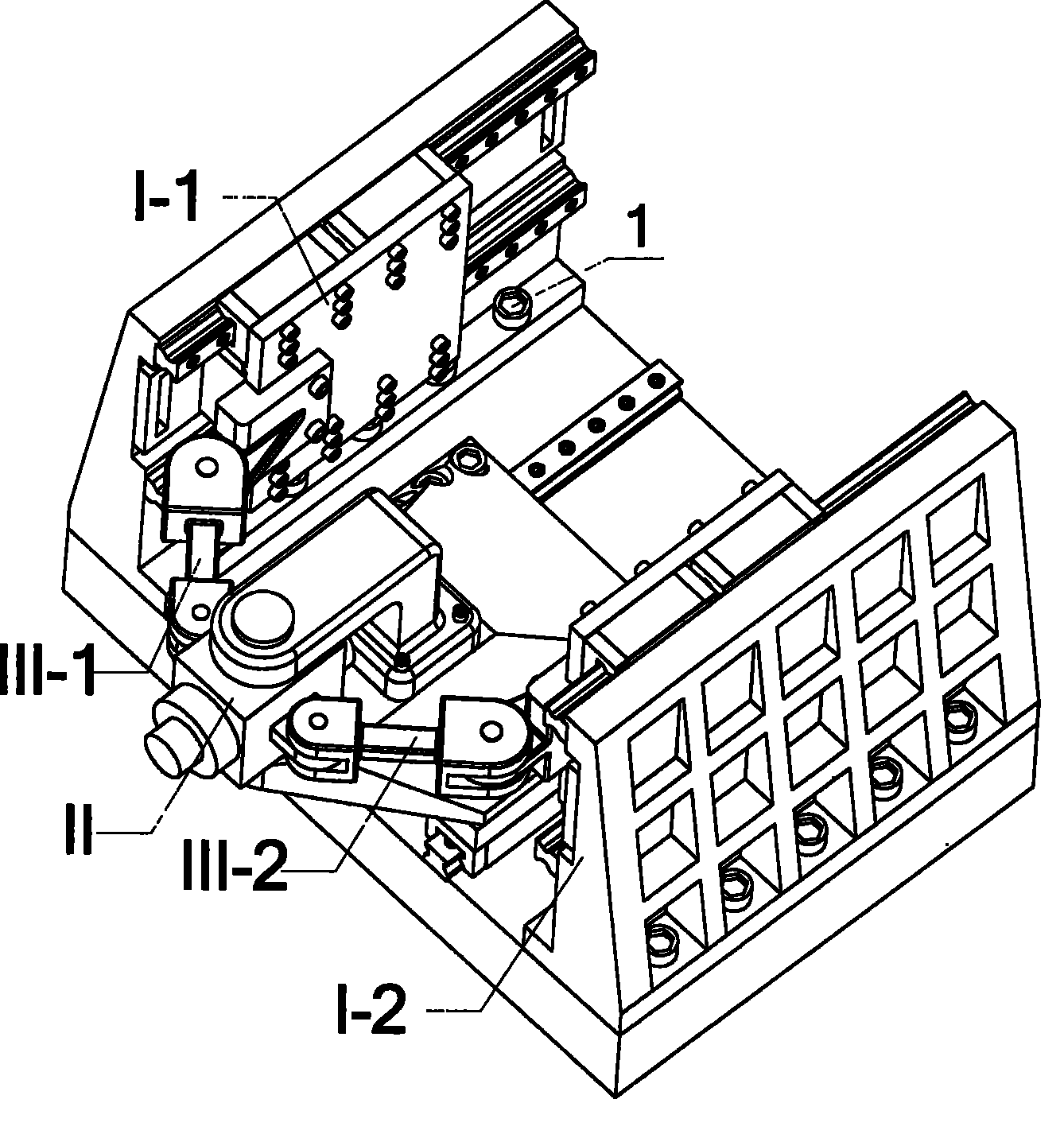

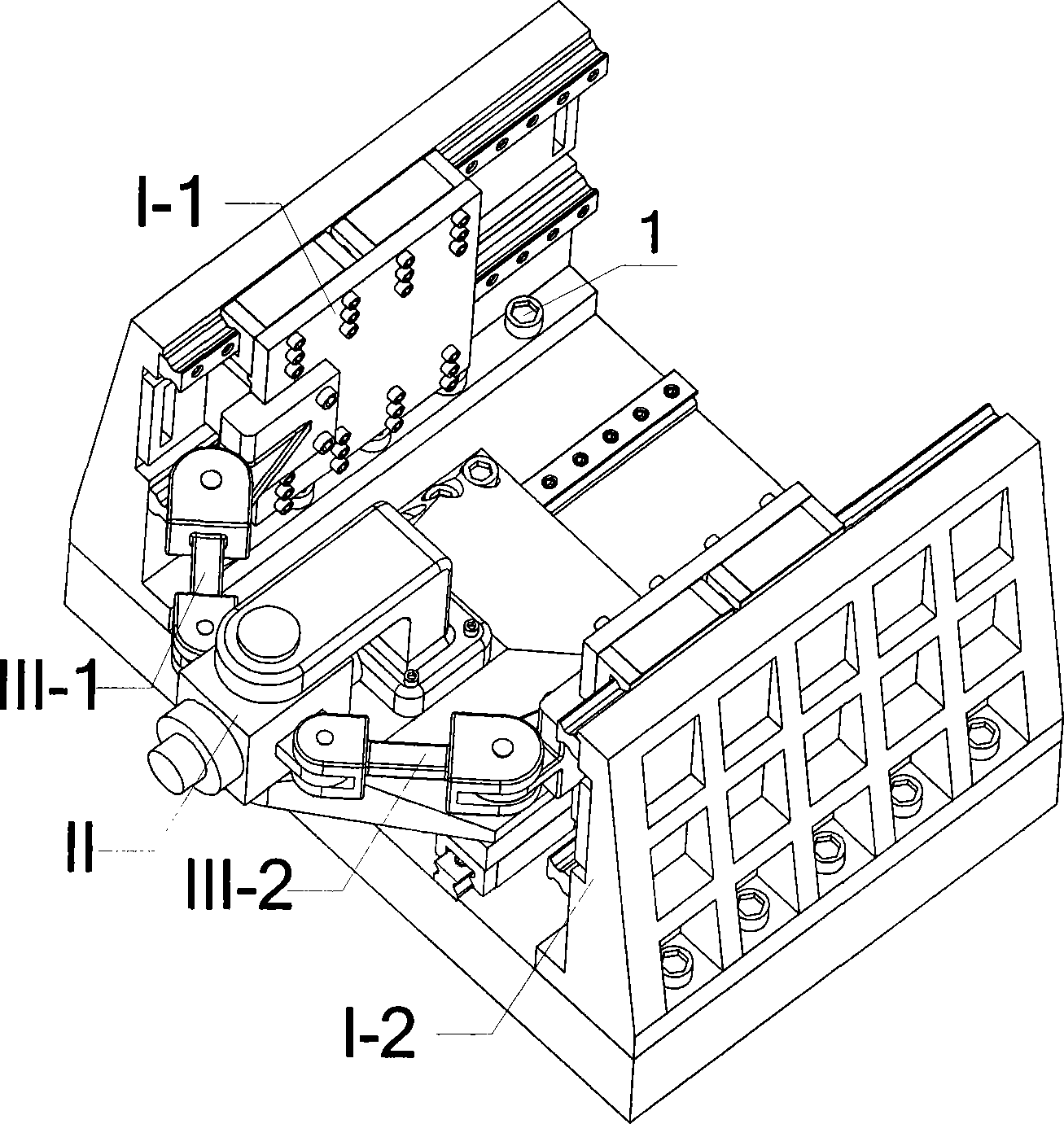

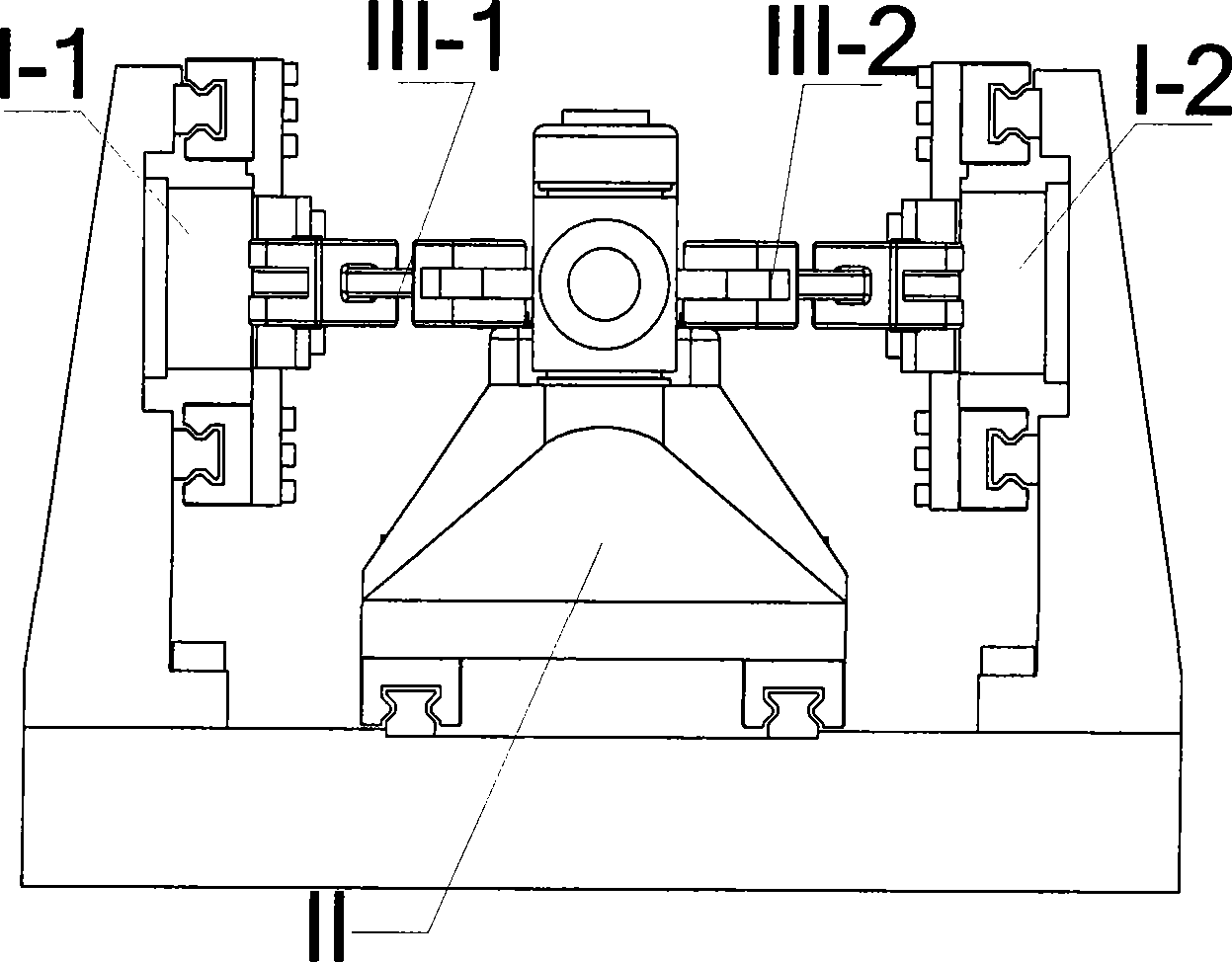

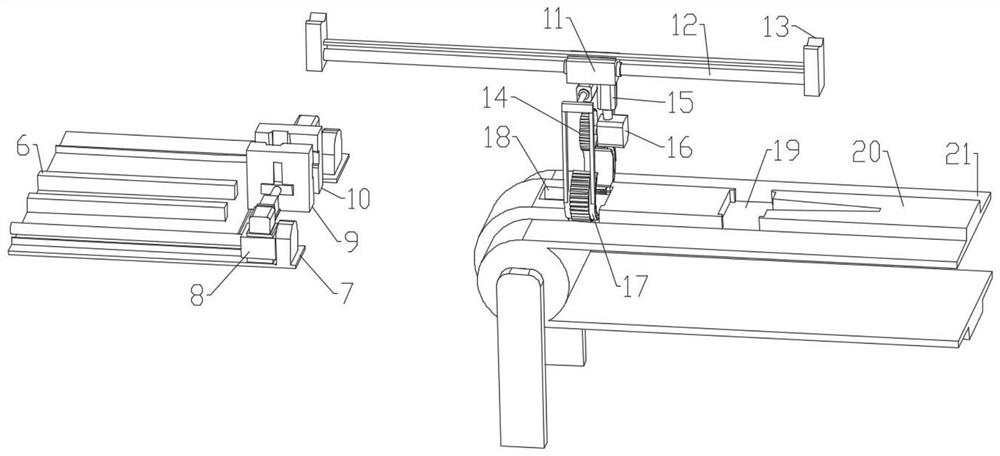

Linear electric motor driven numerical control machine functional module

InactiveCN101244516ARealize linear motionAchieving yaw motionFeeding apparatusDriving apparatusNumerical controlTubular linear motor

The invention relates to a function module of the NC machine tool driven by a linear motor, which is characterized in that: the invention comprises two groups of linear driving modules, a moving module of the cutter platform, two groups of connecting rod parts; the function module is a symmetrical structure of the linear moving axis of the cutter platform; the linear driving modules are respectively arranged at two sides of the moving module of the cutter platform, and are respectively connected with the moving module of the cutter platform by the connecting rod parts; each group of the linear driving module is a linear feeding module driven by the linear motor, and the linear moving axis is in parallel to the linear moving axis of the moving module of the cutter platform. The NC machine tool function module has the advantages of adopting parallel driving of the double linear motor, achieving the linear movement and deflecting movement of the cutter platform, good dynamic performance, small mechanical inertia and big rigidity.

Owner:BEIHANG UNIV

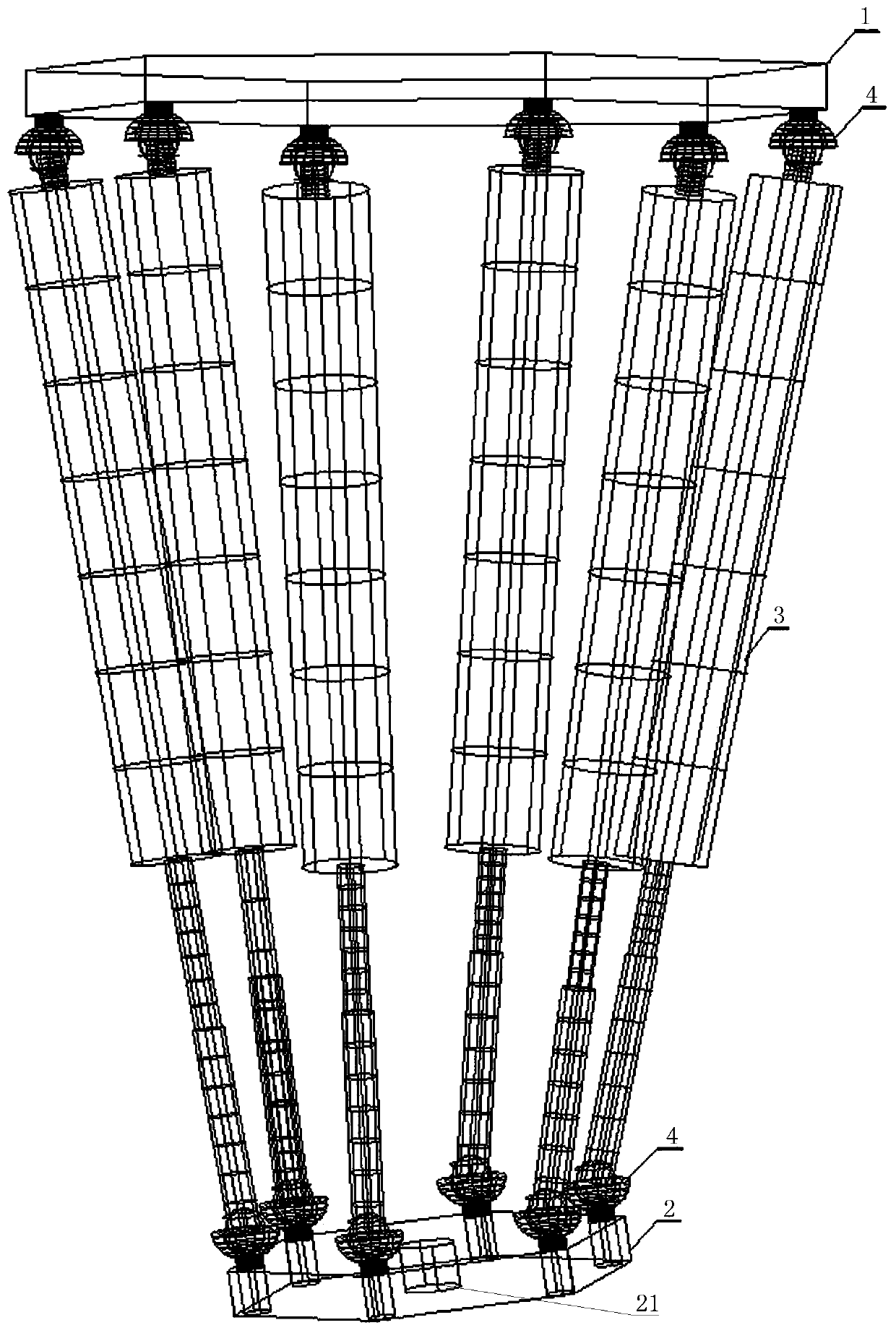

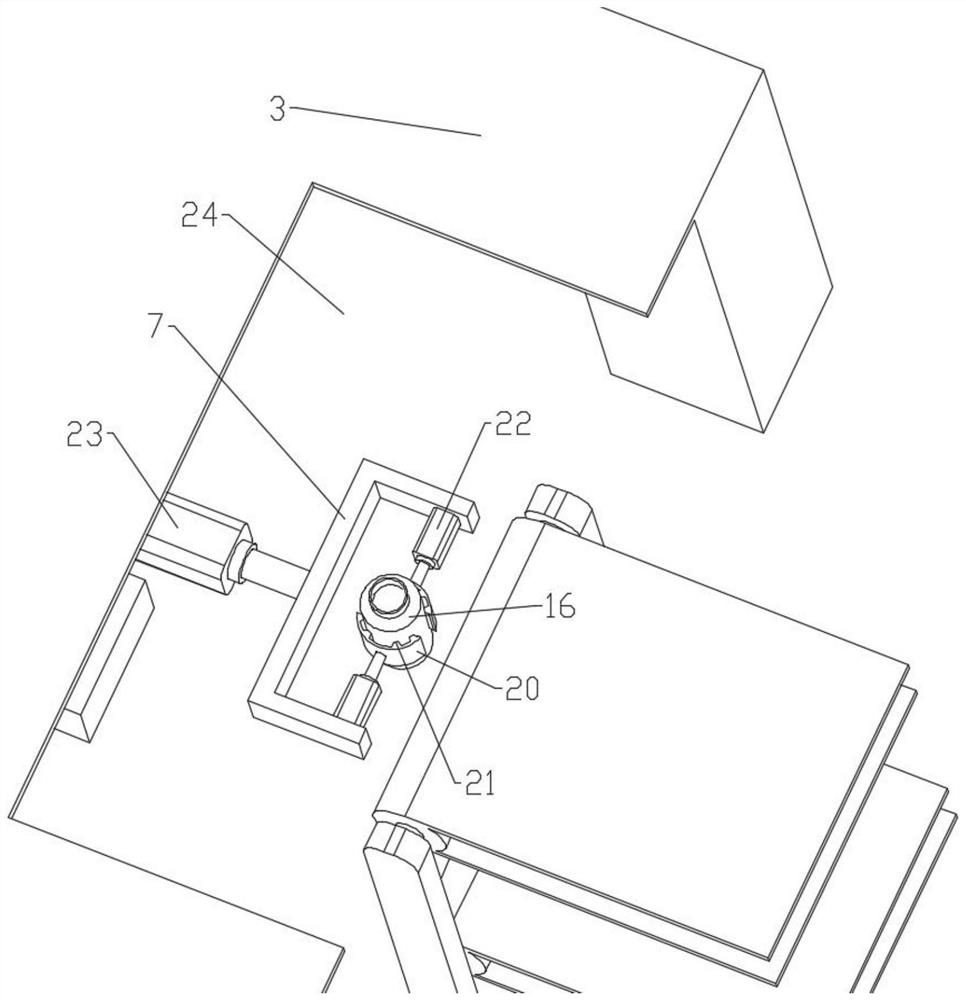

Six-freedom-degree parallel machine arm driven by tubular linear motors and control method of six-freedom-degree parallel machine arm

PendingCN108145699AReduce lossSimple structureProgramme-controlled manipulatorAC motor controlLower limitTubular linear motor

The invention relates to a six-freedom-degree parallel machine arm driven by tubular linear motors and a control method of the six-freedom-degree parallel machine arm. The parallel machine arm comprises a fixed platform, a movable platform, upper limiting photoelectric sensors, lower limiting photoelectric sensors, grating ruler sensors and parallel controllers. The multiple tubular linear motorsare evenly distributed between the fixed platform and the movable platform. Each tubular linear motor comprises an outer circular pipe and a drive shaft, wherein the outer circular pipe is internallyprovided with a motion cavity and a drive cavity which are in communication in the axial direction, the diameter of the motion cavity is larger than that of the drive cavity, the upper end, stretchinginto the motion cavity, of the drive shaft is provided with a limiting block, and the corresponding upper limiting photoelectric sensor and the corresponding lower limiting photoelectric sensor are correspondingly arranged at the two ends of the drive cavity. The grating ruler sensors are arranged between motor stator windings and the drive shafts. The parallel controllers are connected with theupper limiting photoelectric sensors, the lower limiting photoelectric sensors and the grating ruler sensors correspondingly and connected with the motor stator windings through motor drivers. Compared with the prior art, the six-freedom-degree parallel machine arm has the beneficial effects of being small in weight, small in size, high in motion speed and efficiency and the like.

Owner:MINJIANG UNIV

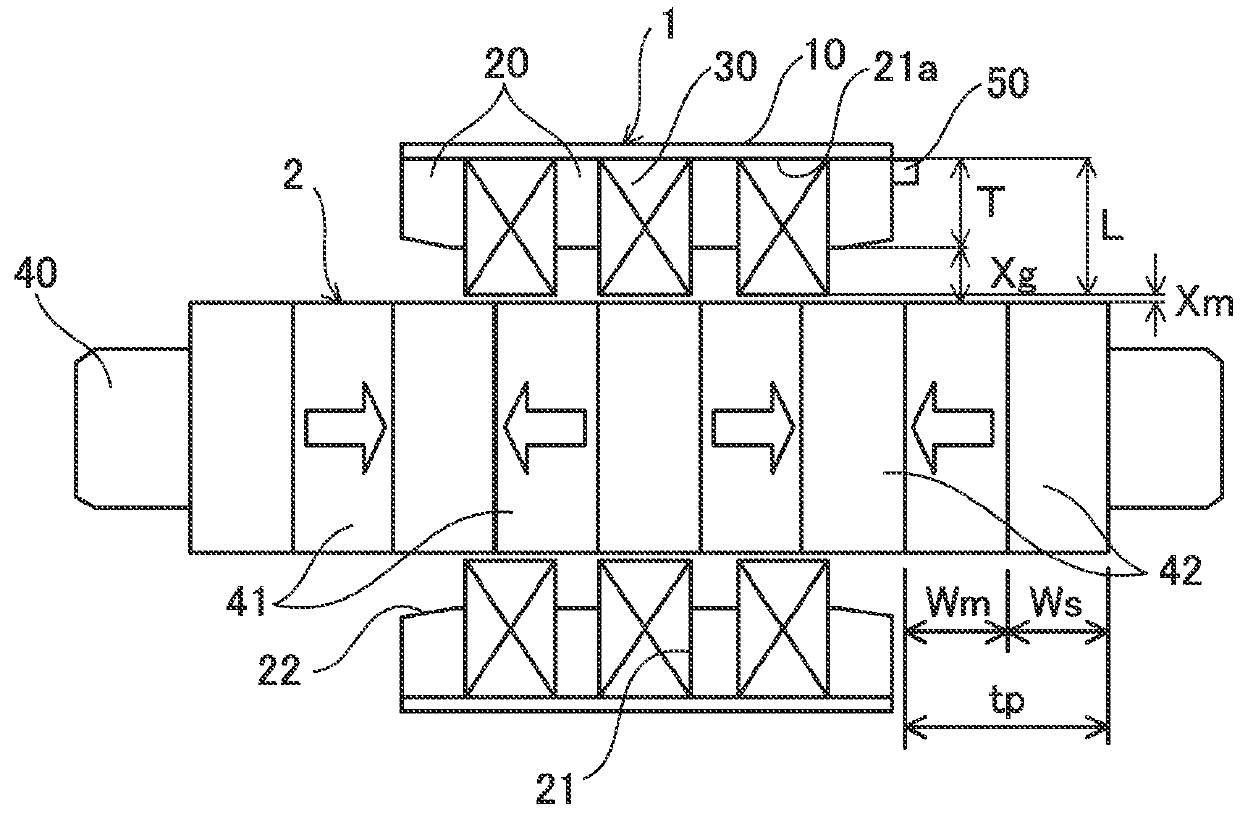

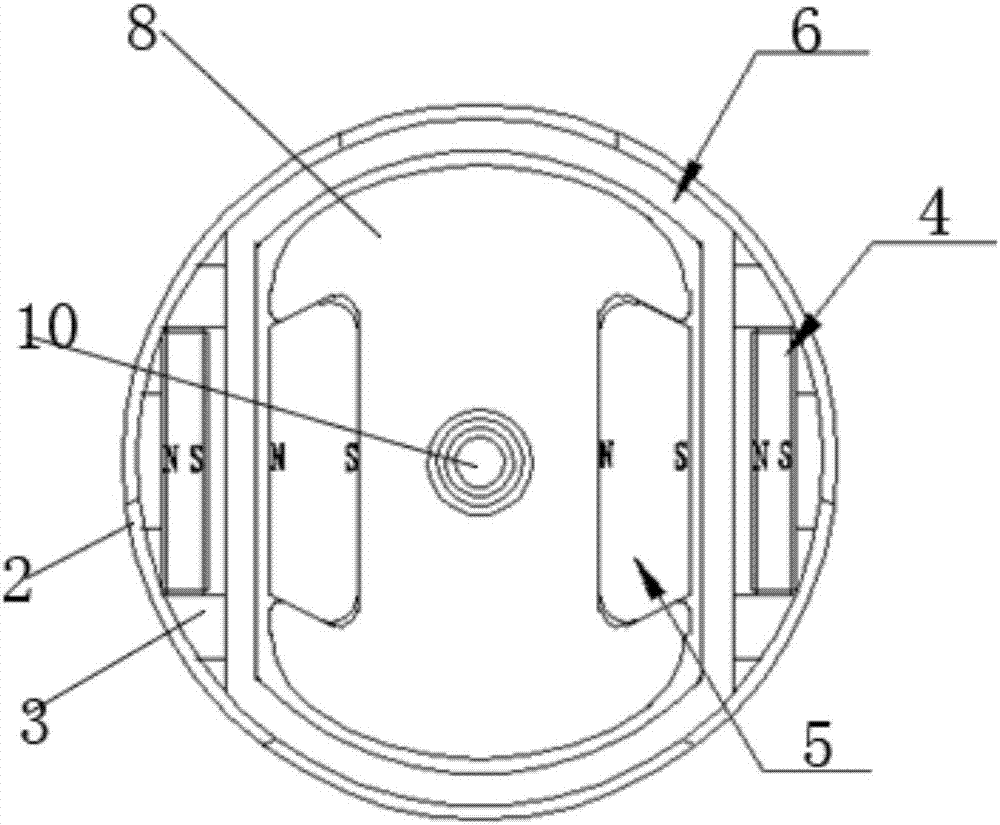

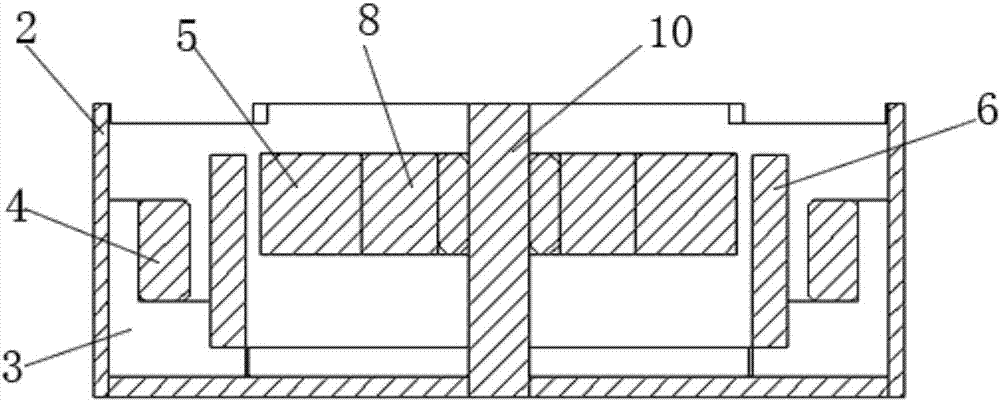

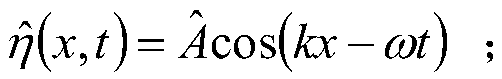

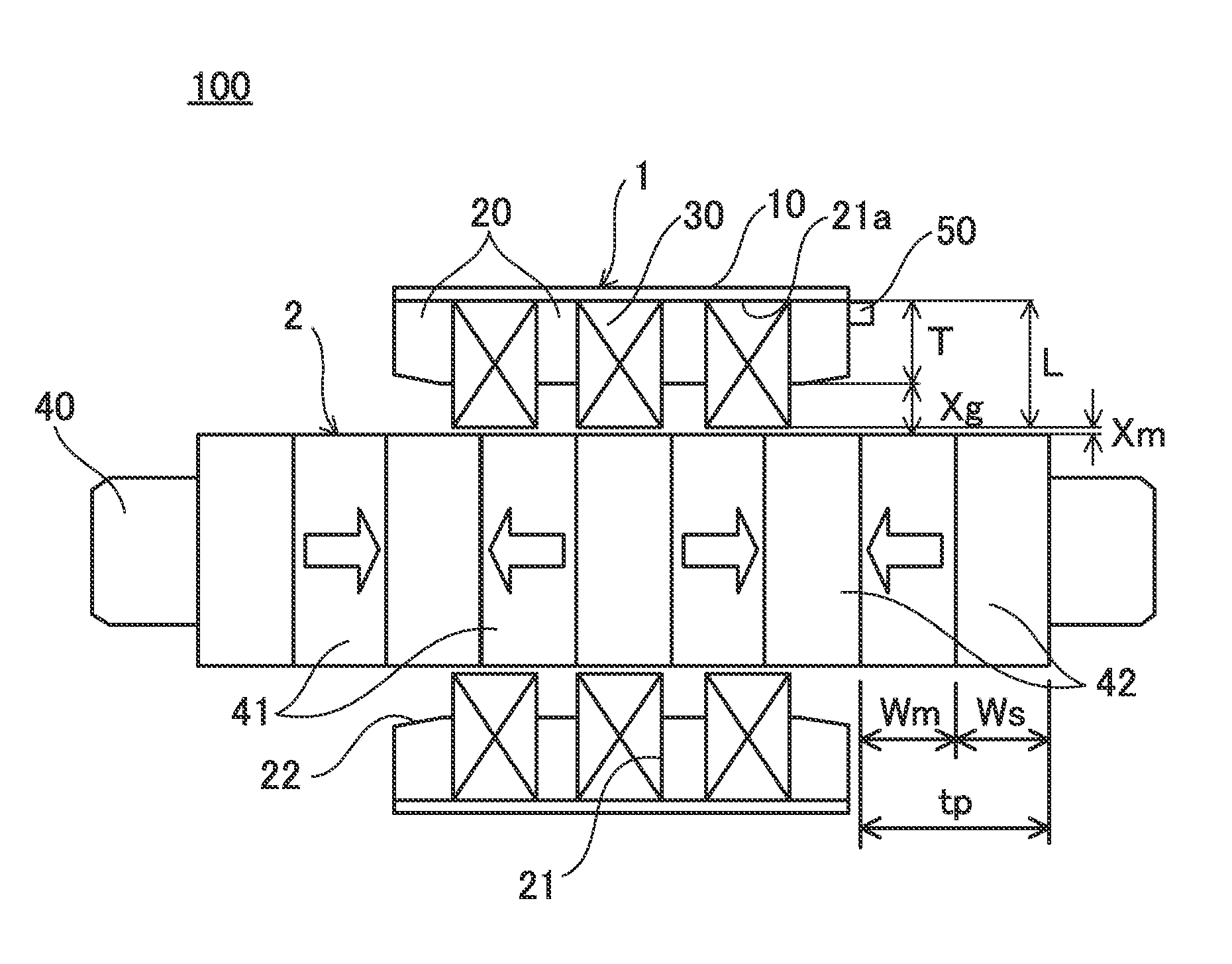

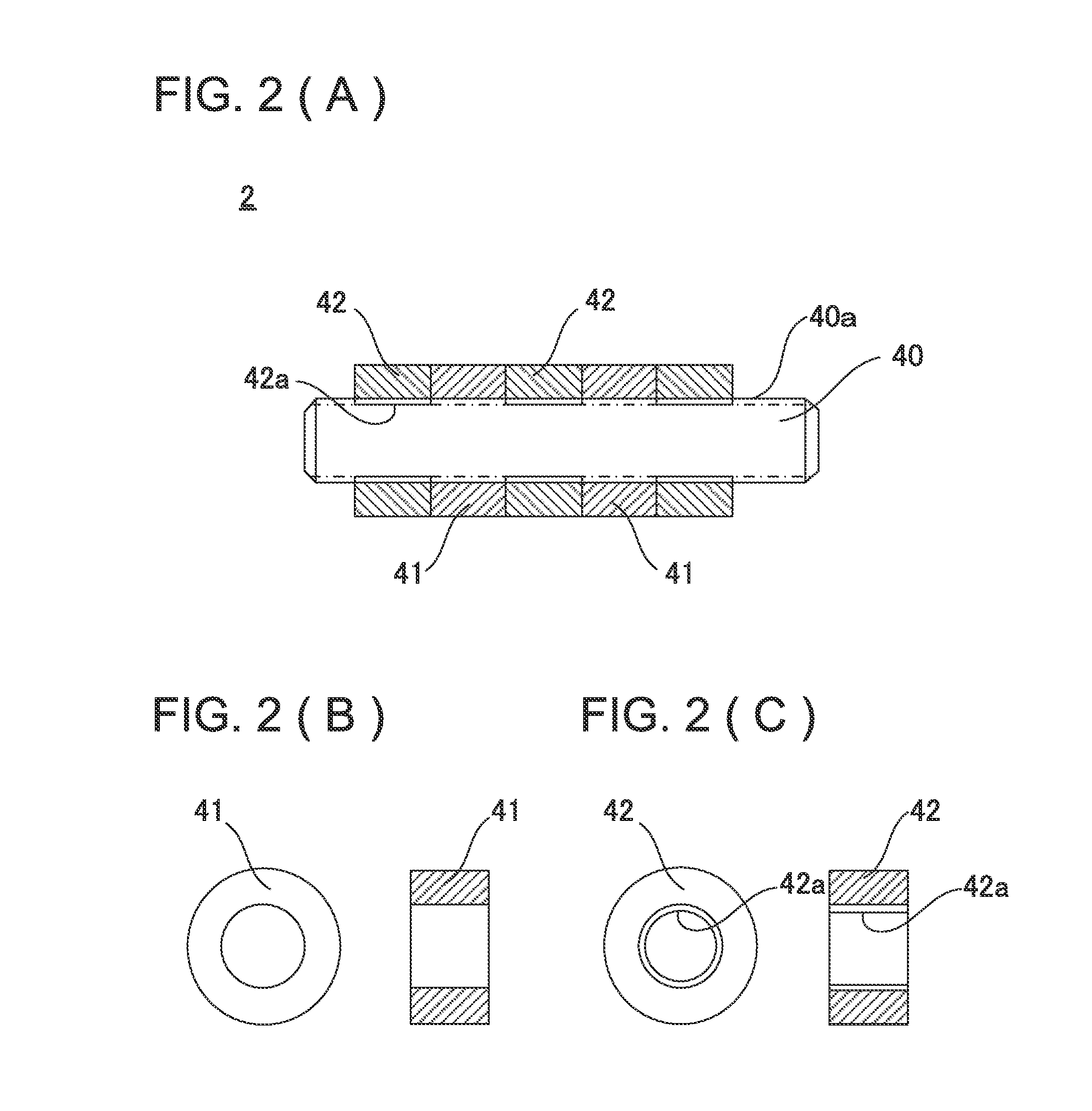

Tubular linear motor

InactiveUS9379599B2Reduce impactIncreasing average magnetic flux density and effective utilization rateWindingsMagnetic circuit rotating partsTubular linear motorMagnetic flux

The tubular linear motor includes an armature having a coil and a magnetic exciter having a permanent magnet provided to face the coil. The armature has a yoke that blocks a magnetic flux, teeth that partition a slot for storing the coil, and the coil that is arranged to extend over the teeth from an inner side of the slot toward the magnetic exciter while a mechanical gap is reserved between the magnetic exciter and the coil. The magnetic exciter has a plurality of permanent magnets by interposing a soft magnetic body.

Owner:SANYO DENKI CO LTD

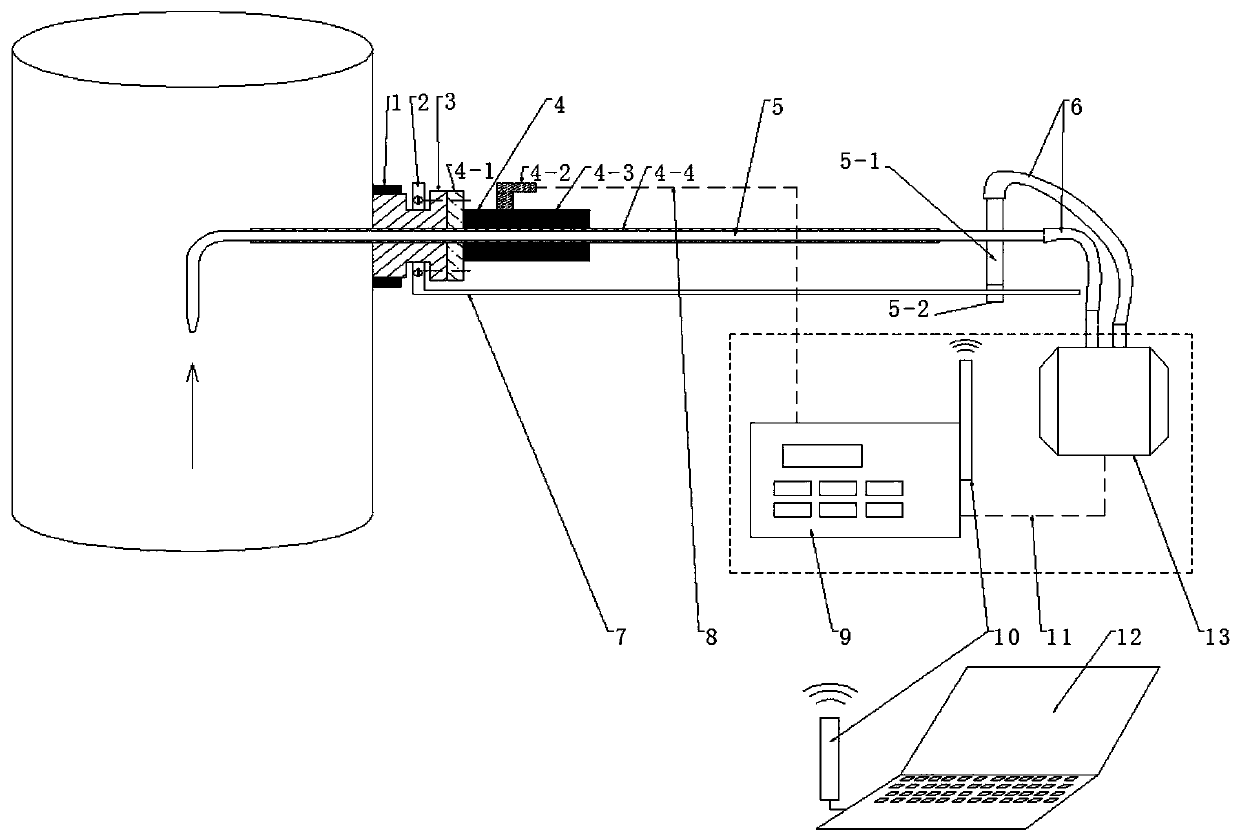

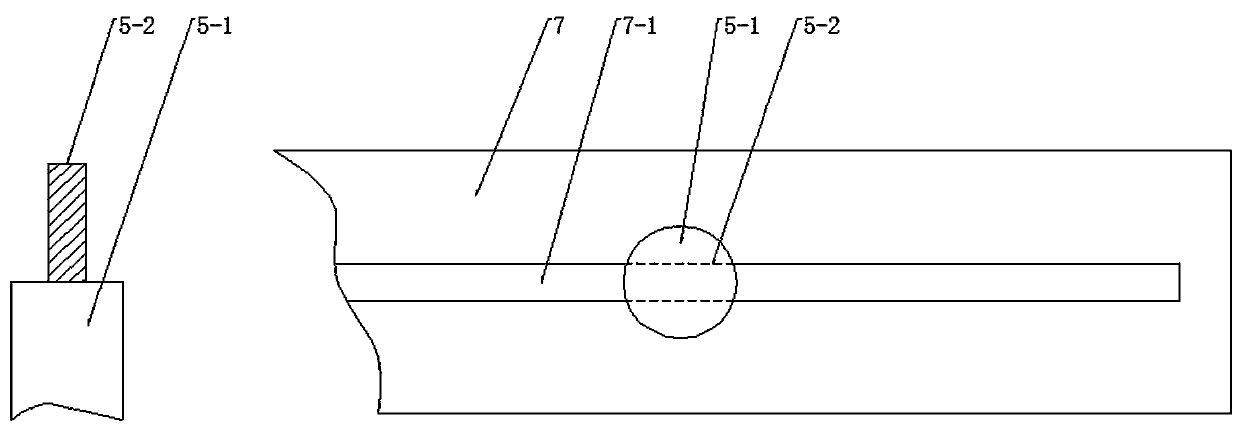

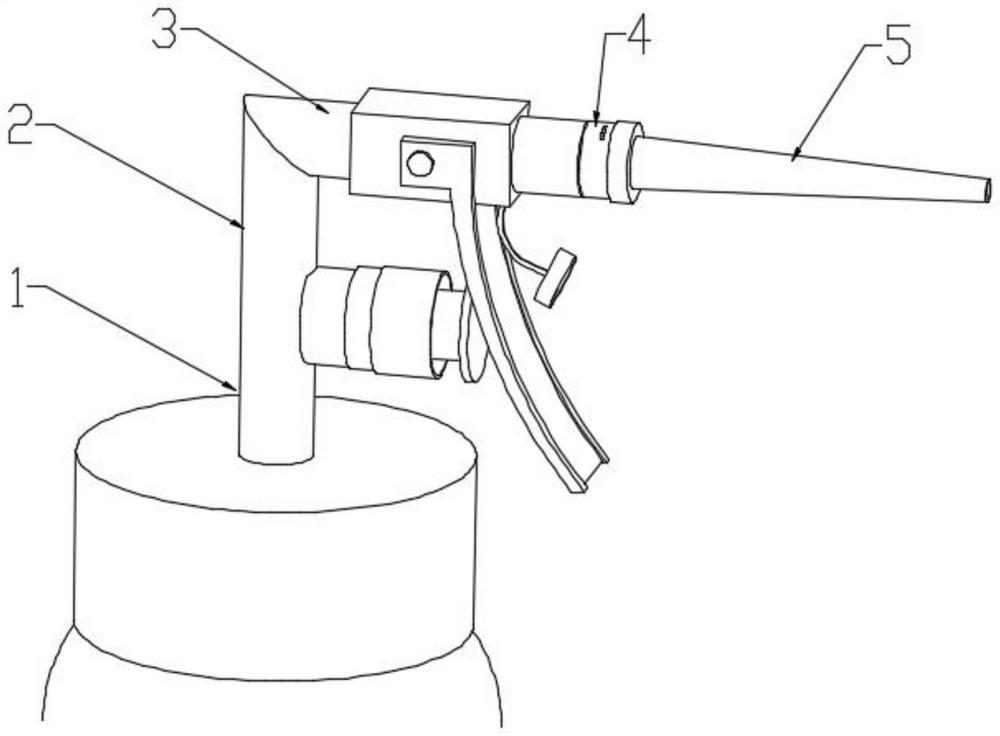

Primary wind speed leveling and automatic measuring device

InactiveCN107817102AReal-time adjustmentReduce work intensityMachine part testingTransmission systemsTubular linear motorDifferential pressure

The invention provides a primary wind speed leveling and automatic measuring device. The device comprises a flue, a pitot tube, a tubular linear motor, an automatic controller and a differential pressure transmitter. According to the primary wind speed leveling and automatic measuring device, the primary wind speed can be automatically and accurately measured, and the workload is greatly reduced.The human error is reduced and the test work can be completed by one person. The work intensity of the test personnel is greatly reduced. An additional positioning ruler is not needed, and the automatic positioning of the pitot tube is achieved through a built-in positioning device of the tubular linear motor. The positioning precision is high, and the human error caused during the measurement ofa handheld ruler is avoided. The measurement accuracy is improved. The wind speed of each primary wind pipe of the same-layer combustor can be measured at the same time, and the measurement time is greatly shortened. The automatic data recording, the wireless data transmission and the control of the primary wind speed leveling test can be realized. The real-time adjustment of the test working condition can be realized.

Owner:SHANDONG ELECTRIC POWER RES INST +2

Flat linear motor

ActiveCN107508446AAvoid mechanical fatigueExtended service lifePropulsion systemsTubular linear motorLinear motor

The invention discloses a flat linear motor, which comprises a housing. The housing is internally provided with a stator, a rotor and a single shaft. The single shaft passes through the center of the rotor. The stator comprises a driving coil, wherein the driving coil is wound around the rotor. At least two pairs of magnets are arranged between the stator and the rotor. Each pair of magnets comprise a drive positioning magnet and a positioning magnet, wherein the drive positioning magnet is arranged on the rotor; the drive positioning magnet is arranged opposite to the positioning magnet; and the positioning magnet is fixed corresponding to the housing. When powered on, the driving coil drives the rotor provided with the drive positioning magnet to be in reciprocating rectilinear movement along the single shaft; and meanwhile, the attraction force between the drive positioning magnet and the positioning magnet enables the rotor to keep horizontal in the same horizontal plane. The drive positioning magnet integrates functions of driving the rotor and keeping balance of the rotor, thereby greatly simplifying overall structure of the linear motor, and facilitating reducing the size of the linear motor.

Owner:浙江史笛威电子有限公司

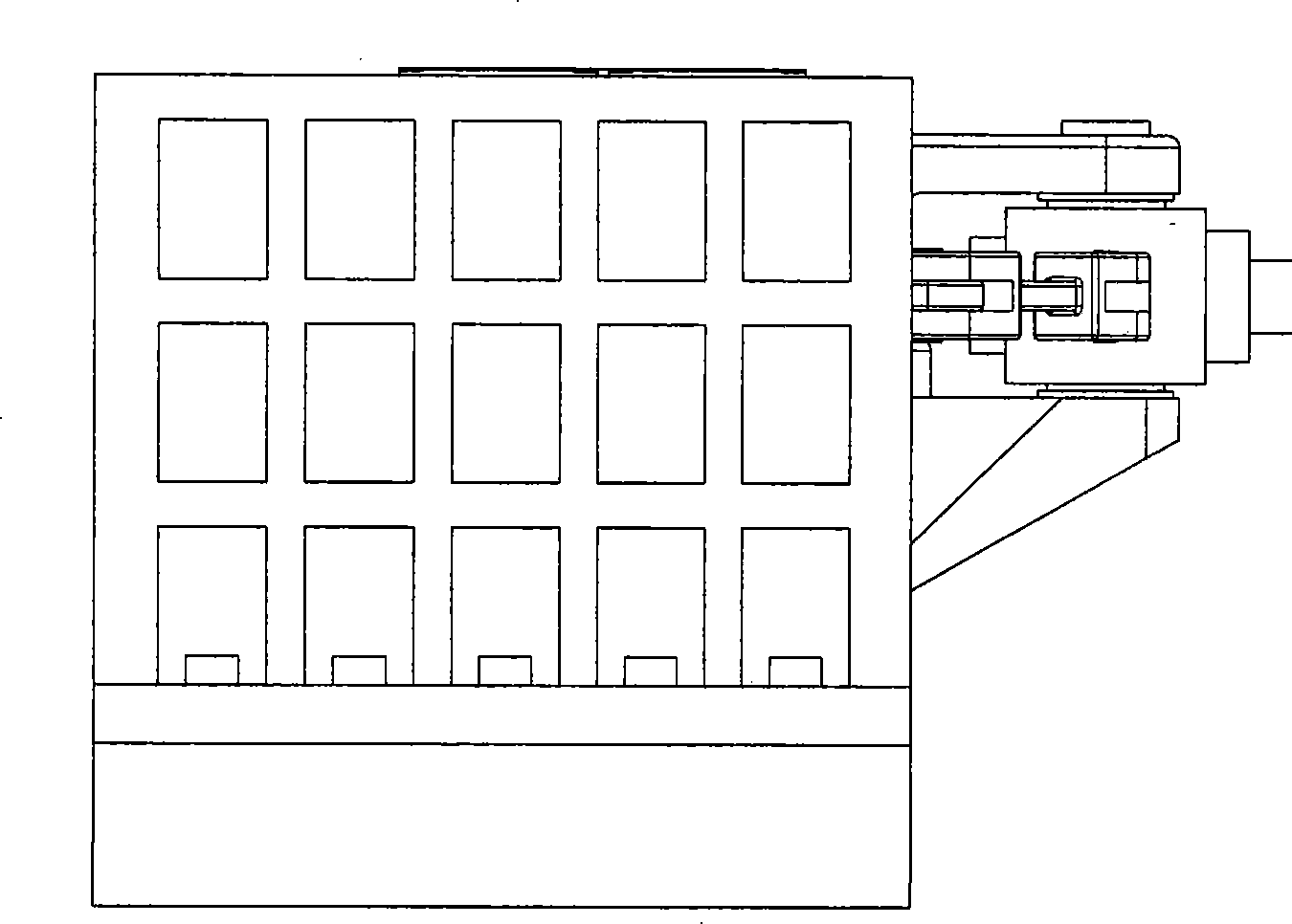

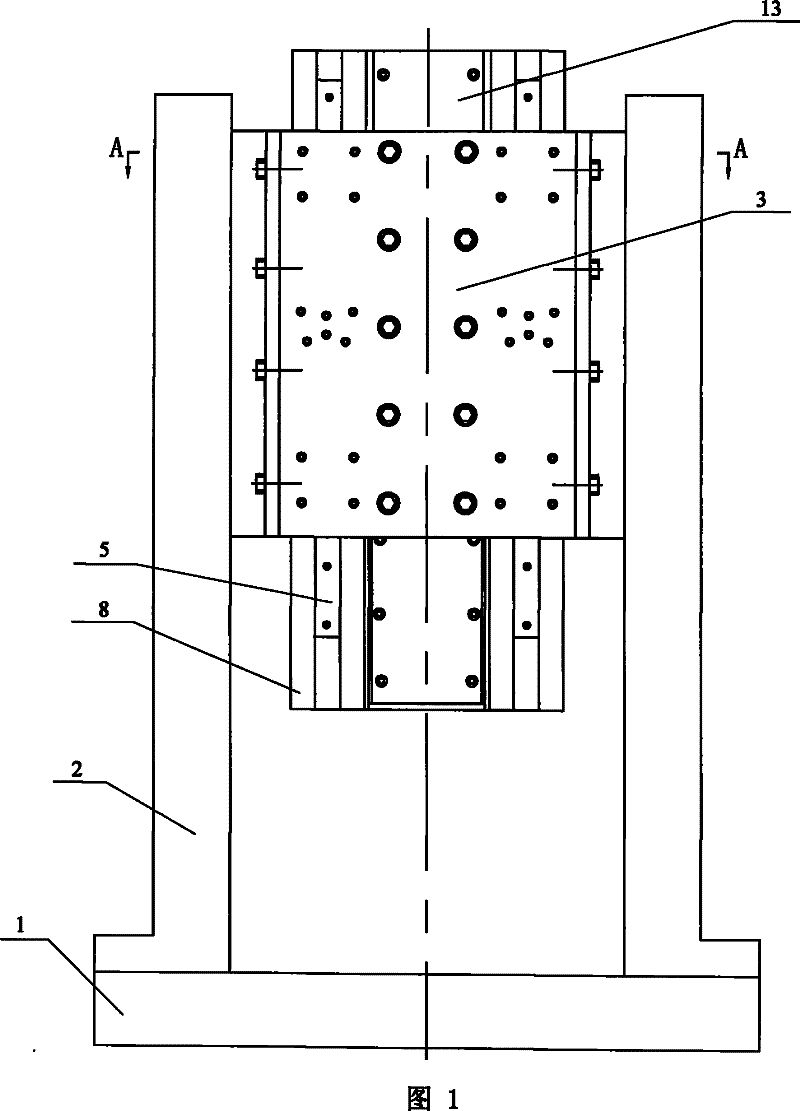

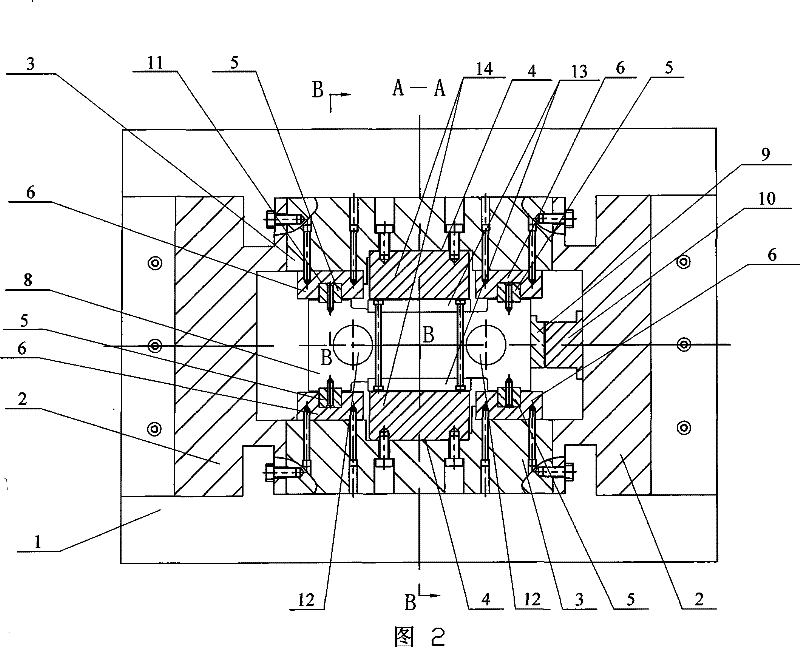

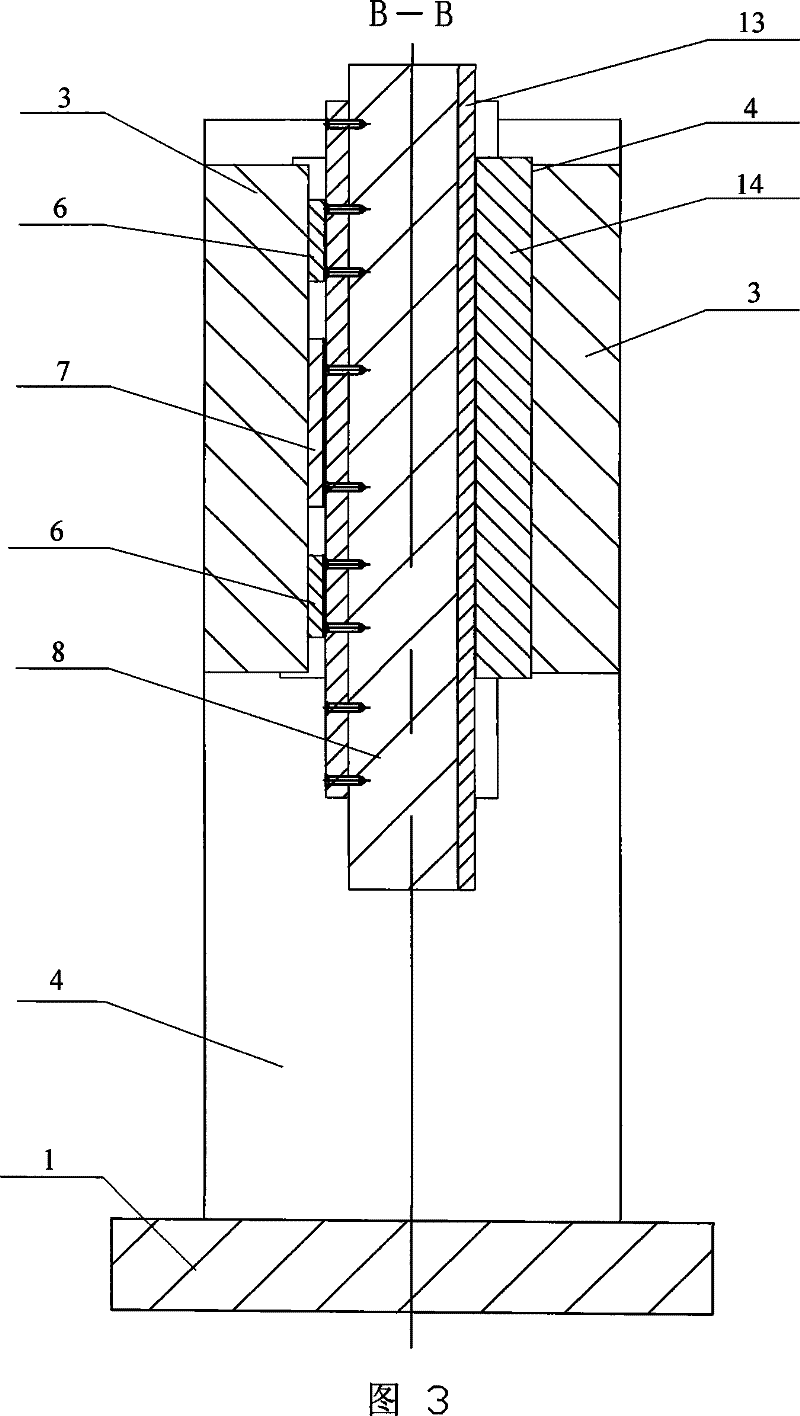

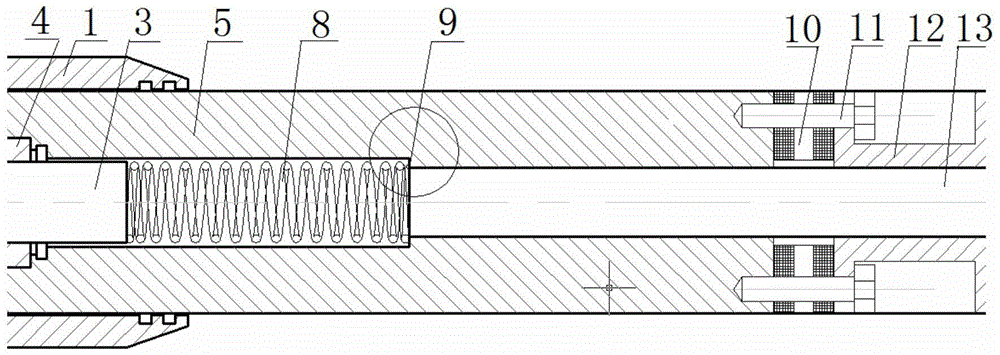

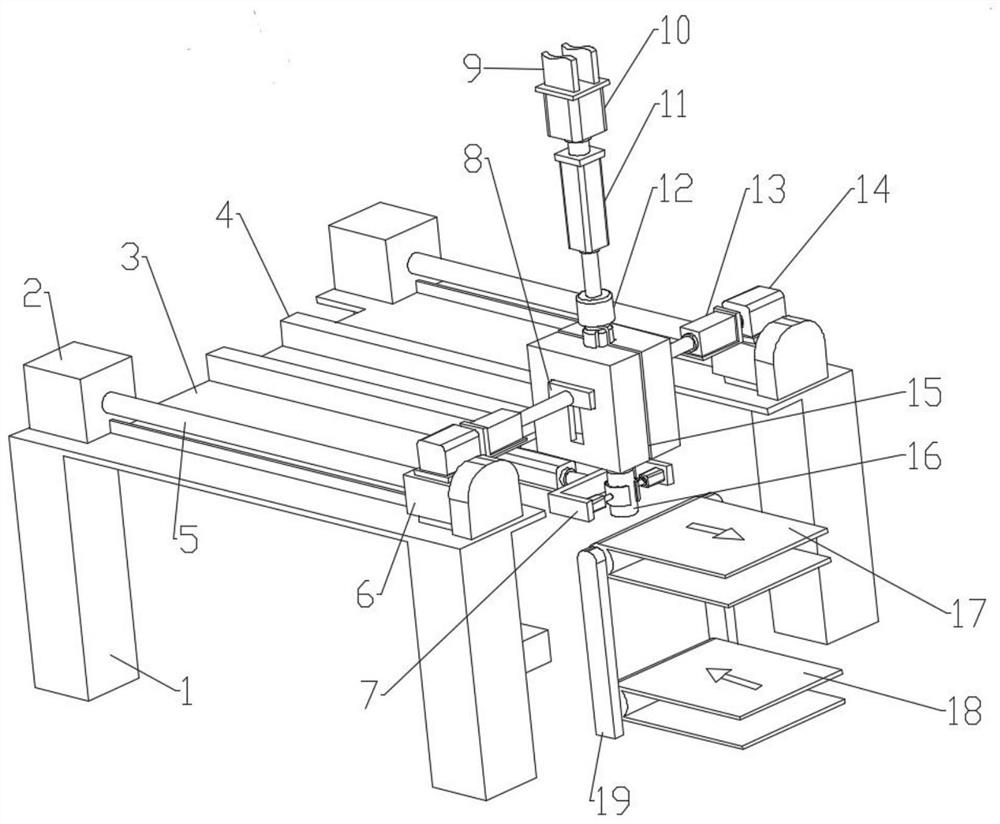

High speed and high precision micro stamping drive system based on dual linear motors

ActiveCN101206481BAchieve precision microplastic formingAccurate and controllable speed-displacementSemi-permeable membranesControl using feedbackTubular linear motorGrating

The invention relates to a high-speed and high-precision micro-punching drive system based on double linear motors, which relates to a high-speed and high-precision micro-punching forming drive device for micro parts. The invention can solve the problem that the driving device of the traditional forming equipment cannot satisfy the microplastic forming of parts. The two frames (2) are fixedly connected to the left and right ends of the base (1), the two brackets (3) are fixedly connected to the two frames (2), and the slider (8) is installed between the two brackets (3). Between, the front and rear ends of the slider (8) are symmetrically provided with a linear motor (4), the primary (14) of the linear motor (4) is fixedly connected with the support (3), and the secondary (13) of the linear motor (4) Fixedly connected with the slide block (8), four guide rails (5) are fixedly installed on the slide block (8), and the guide rail (5) slides and cooperates with the guide rail chute (11) of the guide rail slider (6), and the guide rail slide block (6 ) is fixedly connected with the bracket (3), the air brake (7) fixedly connected with the bracket (3) is arranged directly above the four guide rails (5), the grating scale (9) is fixedly mounted on the slide block (8), and the grating scale The probe (10) is set close to the grating ruler (9) and fixed on the frame (2). The invention can realize low-cost, large-volume microplastic parts forming.

Owner:HARBIN INST OF TECH

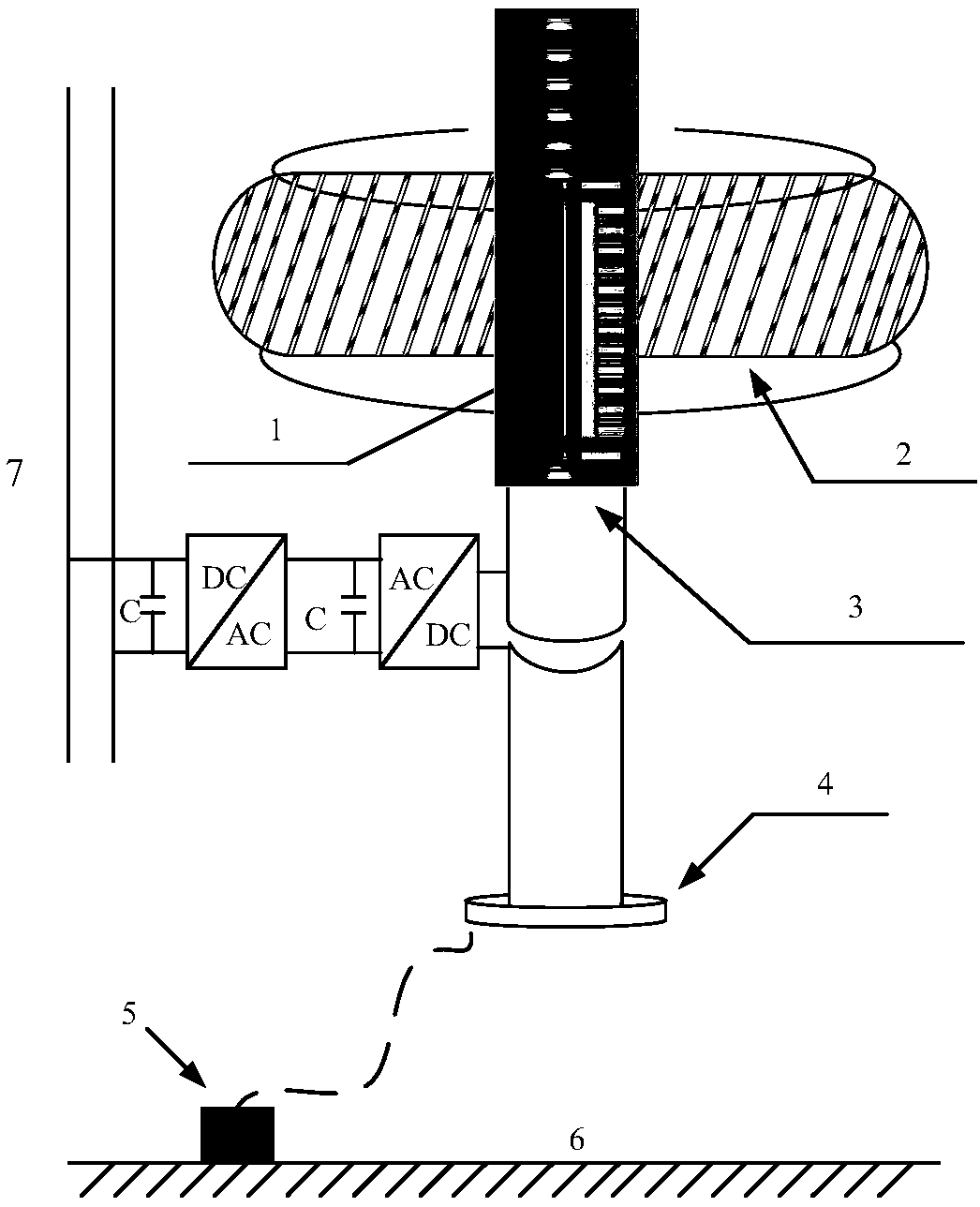

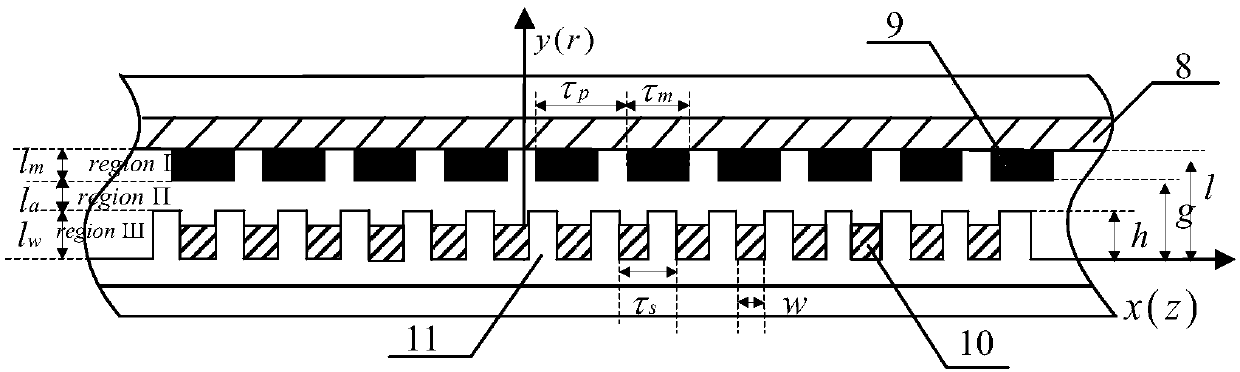

Wave power generation system based on magnetic gear speedup effect and designing method of wave power generation system

ActiveCN108678885ANo pollutionReduce labor costsGeometric CADEngine fuctionsTubular linear motorWave power generation

The invention discloses a wave power generation system based on the magnetic gear speedup effect and a designing method of the wave power generation system. The wave power generation system comprisesa tubular linear motor, an outer float buoy and an inner float buoy; the tubular linear motor comprises a primary part and a secondary part, and a gas gap is formed between the primary part and the secondary part; the outer float buoy is connected outside the primary part in a sleeving mode, and the inner float buoy is arranged above the secondary part and is rigidly connected with the secondary part; by adjusting the counterweight of the outer float buoy, the vibration frequency and moving speed of the outer float buoy are close to or equal to the vibration frequency and moving speed of the ocean wave; and by adjusting the draught depth of the inner float buoy, the oscillation period of the inner float buoy is kept away from the oscillation period of the ocean wave. The wave power generation system has the beneficial effects that the tubular linear motor based on the magnetic gear speedup effect is combined with the wave power generation system, the shortcomings of low efficiency of wave power generation and low power generation cost performance are effectively overcome, and an efficient and accurate analytical calculation method is provided for the design of the systems.

Owner:SOUTHEAST UNIV

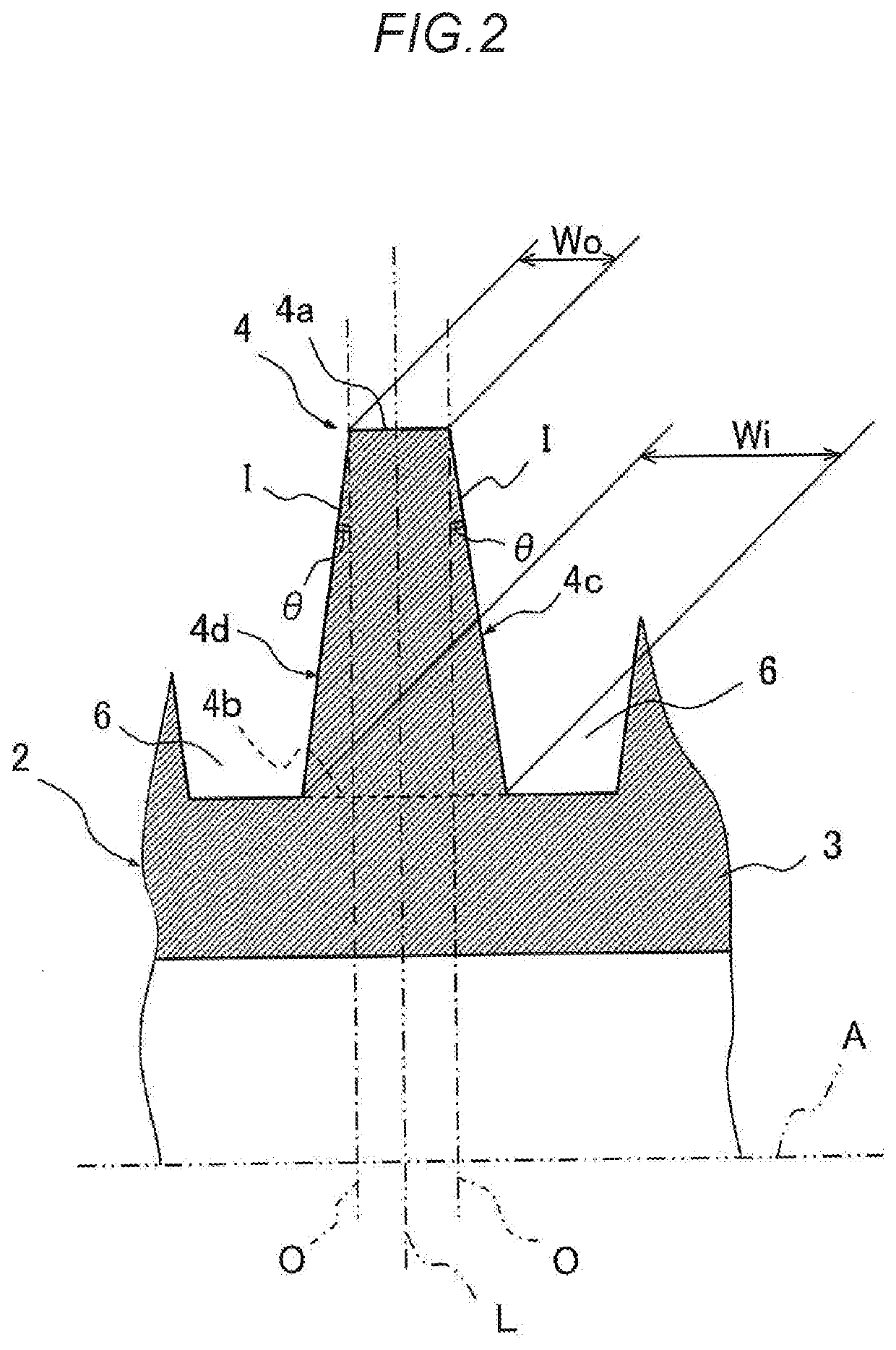

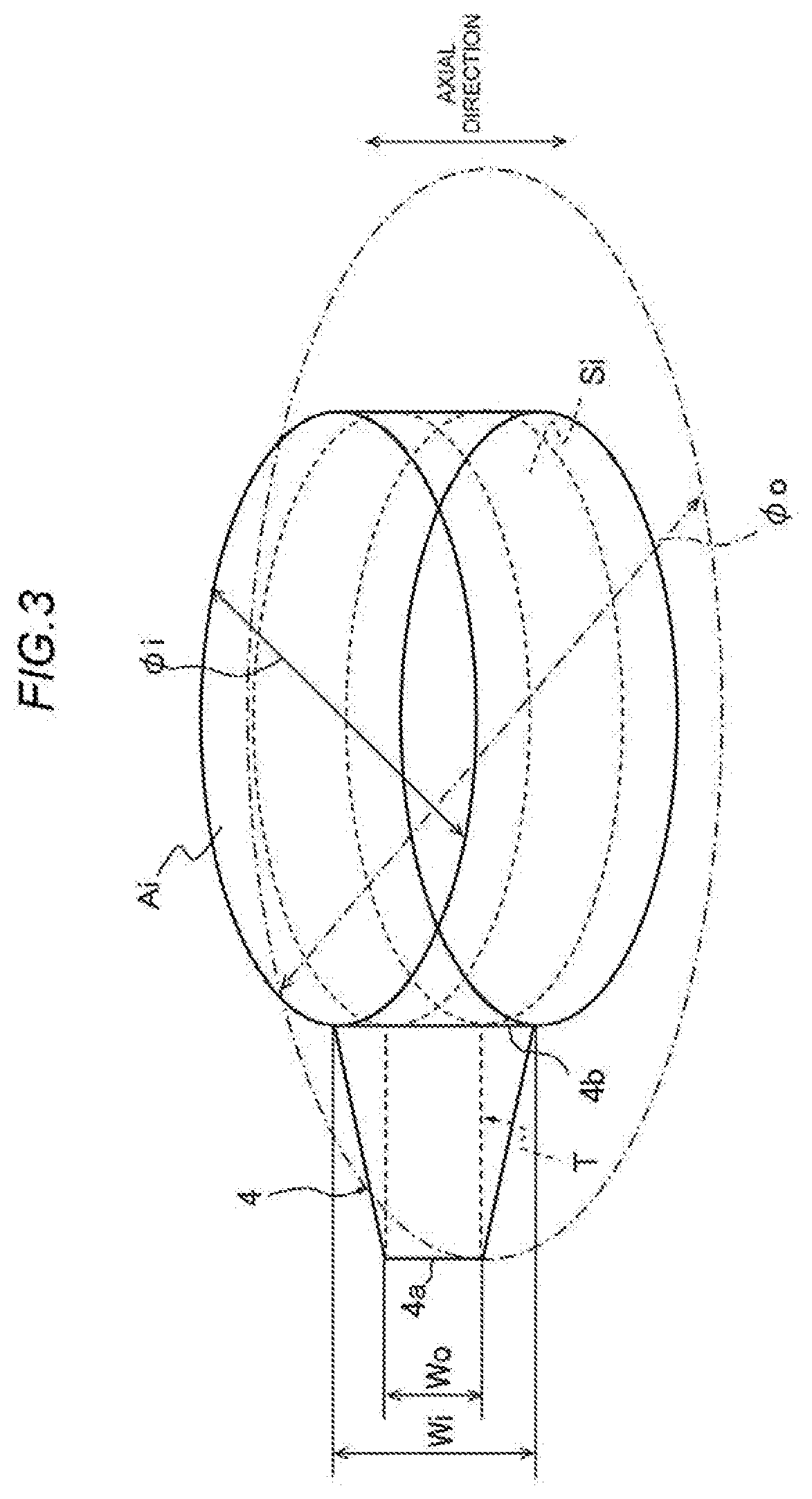

Tubular linear motor

InactiveUS20130257180A1Increase the number of coilsIncrease of thrust forceWindingsMagnetic circuitTubular linear motorMagnetic flux

The tubular linear motor includes an armature having a coil and a magnetic exciter having a permanent magnet provided to face the coil. The armature has a yoke that blocks a magnetic flux, teeth that partition a slot for storing the coil, and the coil that is arranged to extend over the teeth from an inner side of the slot toward the magnetic exciter while a mechanical gap is reserved between the magnetic exciter and the coil. The magnetic exciter has a plurality of permanent magnets by interposing a soft magnetic body.

Owner:SANYO DENKI CO LTD

A hole bottom tubular linear motor electric impactor

InactiveCN104022616BIncrease electromagnetic forceLaunch fastReciprocating drilling machinesConstructionsTubular linear motorBall bearing

The invention relates to a hole bottom tubular linear motor electric impactor, which comprises a motor outer cylinder, a permanent magnet rod, a linear ball bearing, a mover, a mover silicon steel sheet, and a mover coil. The outer cylinder of the motor is the shell of the linear motor, the permanent magnet rod is fixed on the outer cylinder of the motor, and the permanent magnet rod is used as the stator of the linear motor; the mover moves relative to the permanent magnet rod through the linear ball bearing; The iron core is composed of silicon steel sheets. There are slots in the iron core, and mover coils in the slots; the coils use three-phase AC windings, which are used to connect to three-phase symmetrical alternating current, and generate a traveling wave magnetic field that is consistent with the moving direction of the mover; There are two shock absorbing springs for shock absorption. The impactor adopts a moving coil structure, that is, the permanent magnet rod and the iron core are fixed, and the coil moves. At the same time, a buffer gasket is designed between the mover and the base to improve the anti-fatigue life of the impactor. The impactor has a simple and firm structure, low manufacturing and maintenance costs, easy adjustment of impact stroke speed and frequency, high efficiency, and can be used for deep hole drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

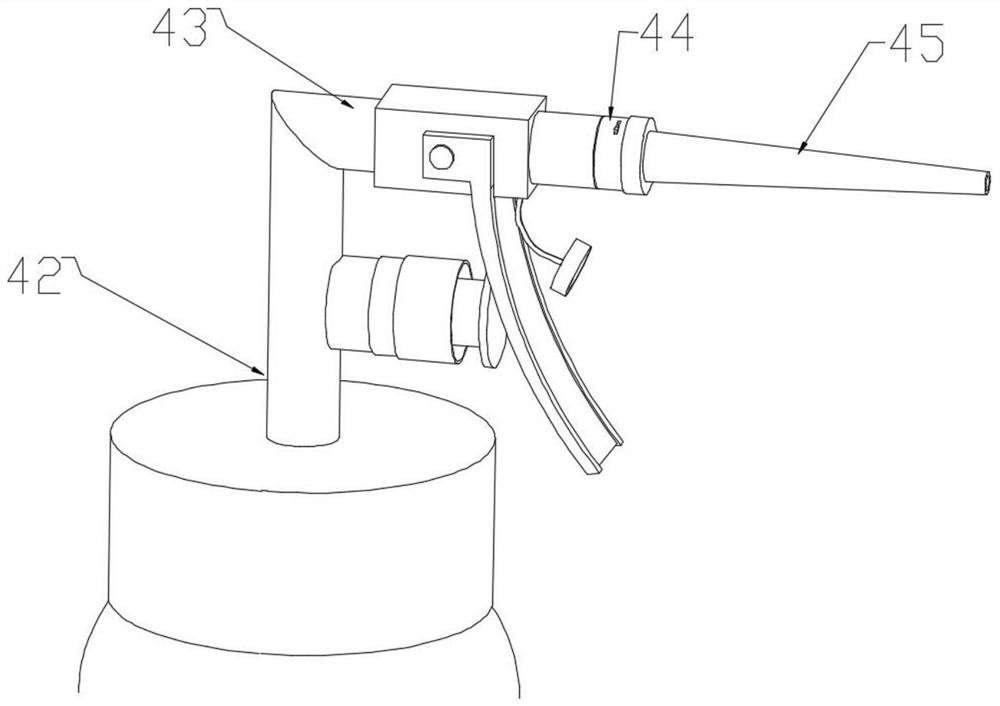

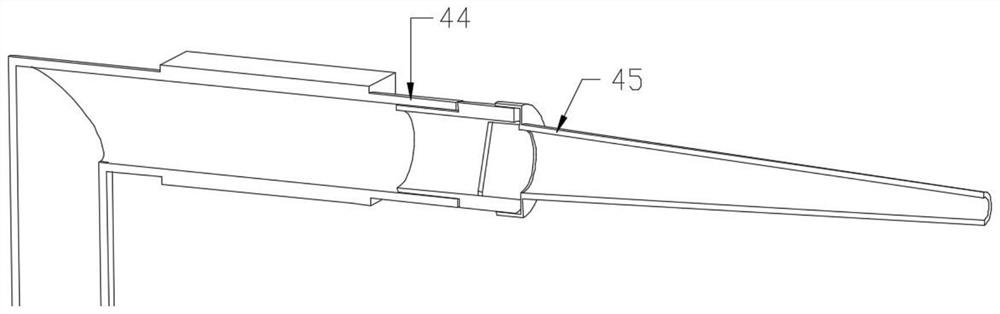

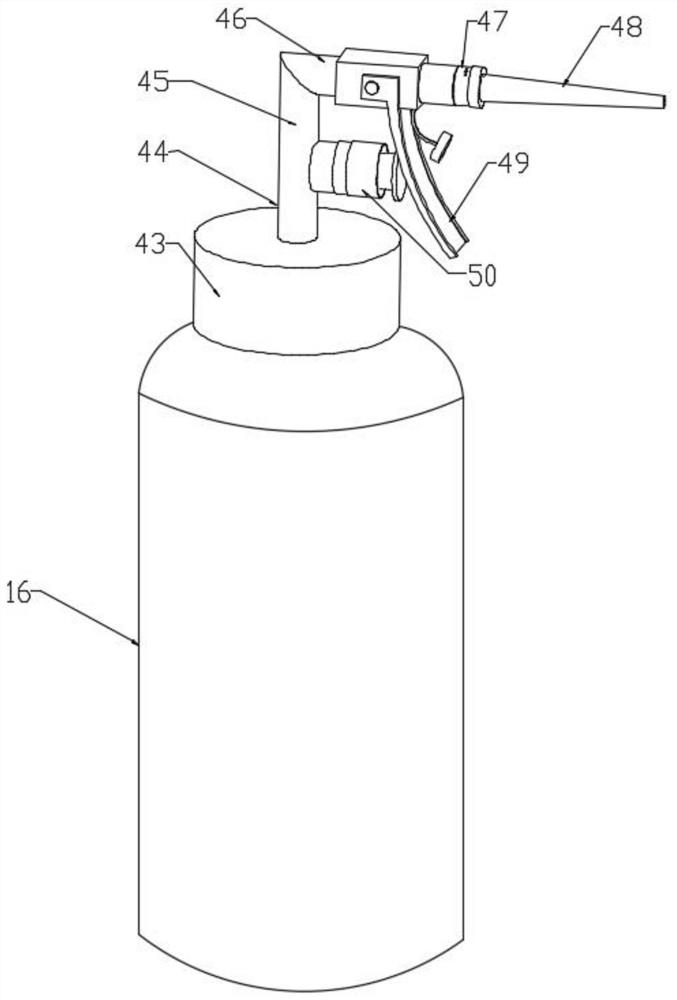

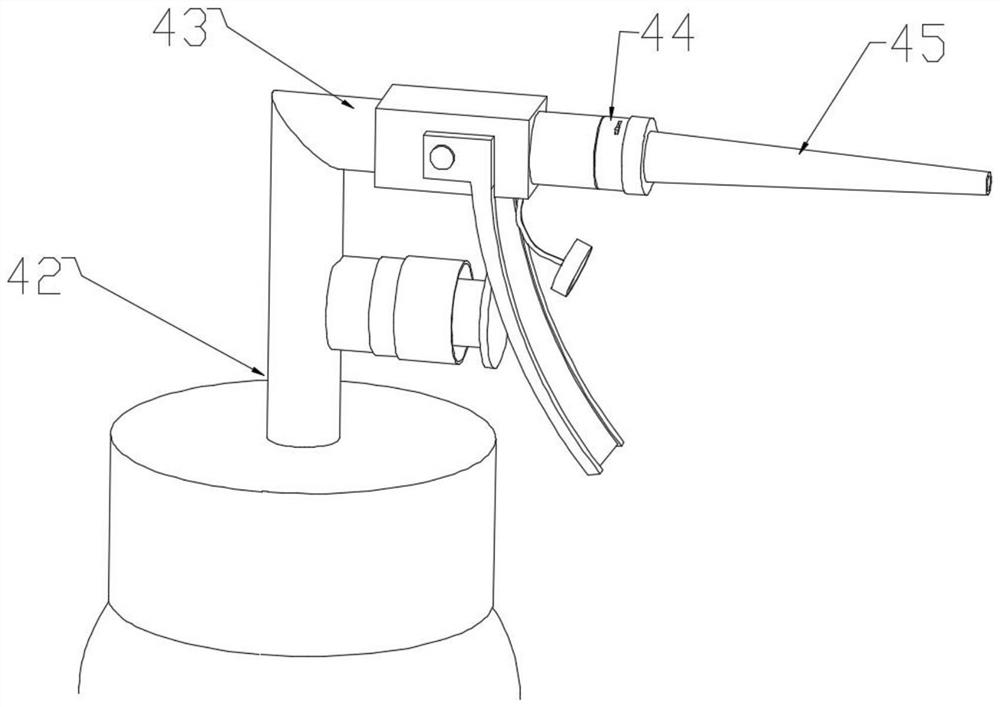

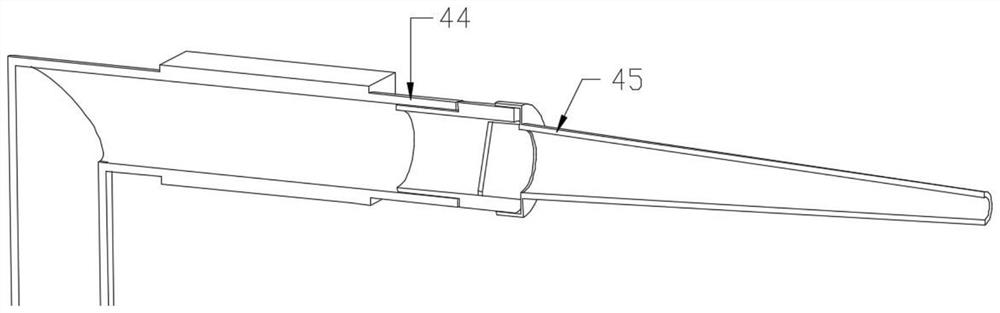

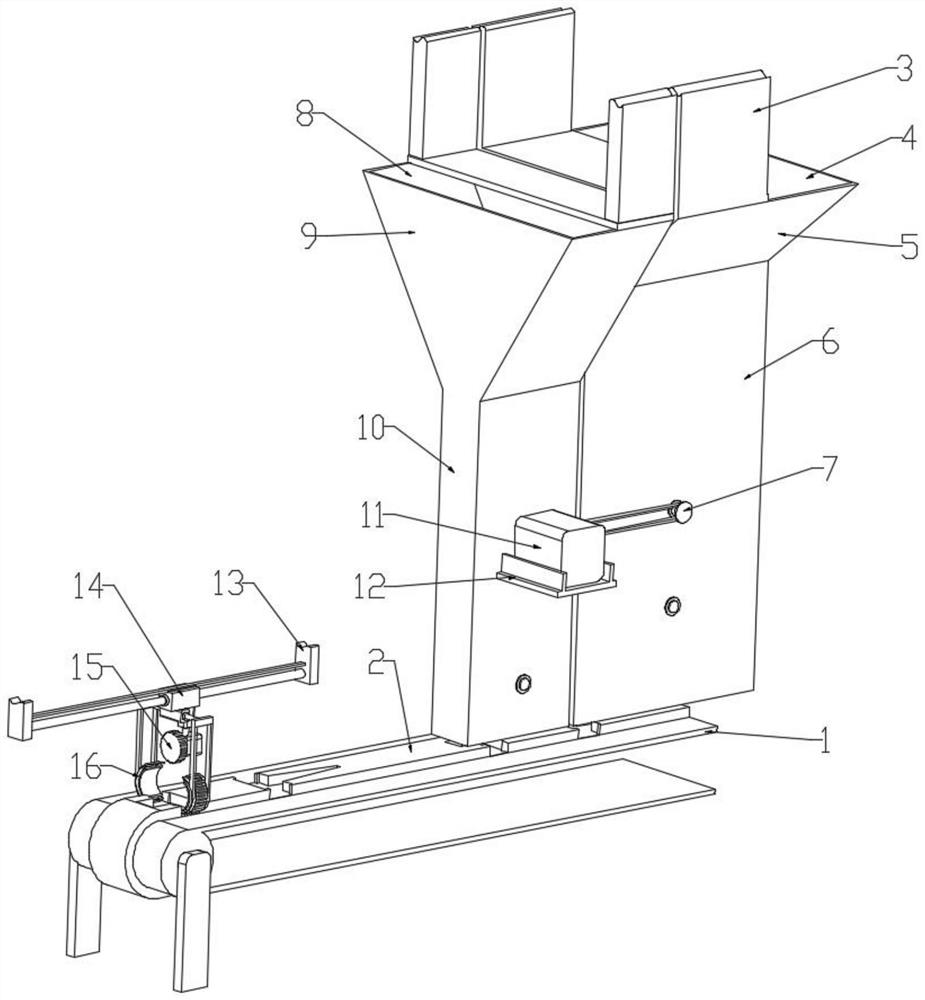

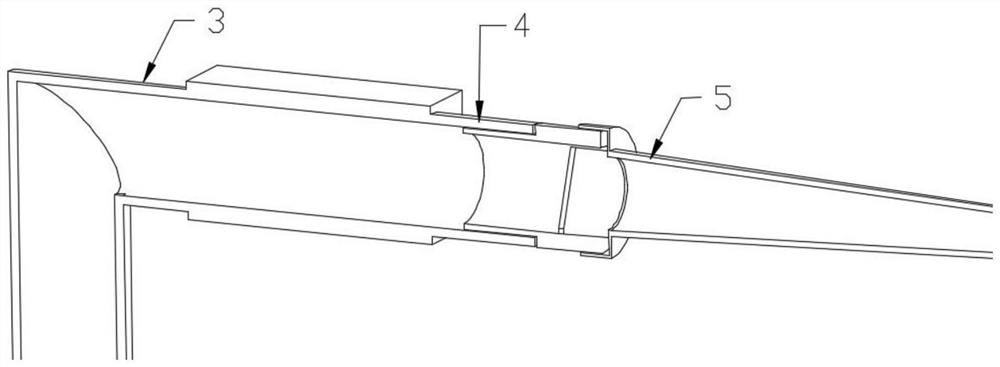

Sprayer assembly taking and clamping device for irrigator production

InactiveCN113233179AAchieve transshipmentRealize opening and closing movementConveyorsConveyor partsTubular linear motorSprayer

The invention discloses a sprayer assembly taking and clamping device for irrigator production, and belongs to the technical field of irrigator machining. The sprayer assembly taking and clamping device comprises a conveying belt, and a nozzle discharging device, a connecting base discharging device and a tubular linear motor are sequentially arranged above the conveying belt. A clamping device is connected to a rotor of the tubular linear motor. A protruding limiting belt is arranged on the surface of the conveying belt, and paired nozzle limiting grooves and connecting base limiting grooves are formed in the surface of the limiting belt in an array mode. The nozzle discharging device comprises a nozzle storage box, a nozzle feeding port is formed in the top of the nozzle storage box, a nozzle discharging channel with an opening in the bottom end is formed in the lower portion of the nozzle storage box, and a first discharging conveying belt is arranged in the nozzle discharging channel. The connecting base discharging device comprises a connecting base storage box, a connecting base feeding port is formed in the top of the connecting base storage box, a connecting base discharging channel with an opening in the bottom end is formed in the lower portion of the connecting base storage box, and a second discharging conveying belt is arranged in the connecting base discharging channel. The clamping device comprises a driving gear, and a rotatable clamp is arranged below the driving gear.

Owner:岳阳职业技术学院

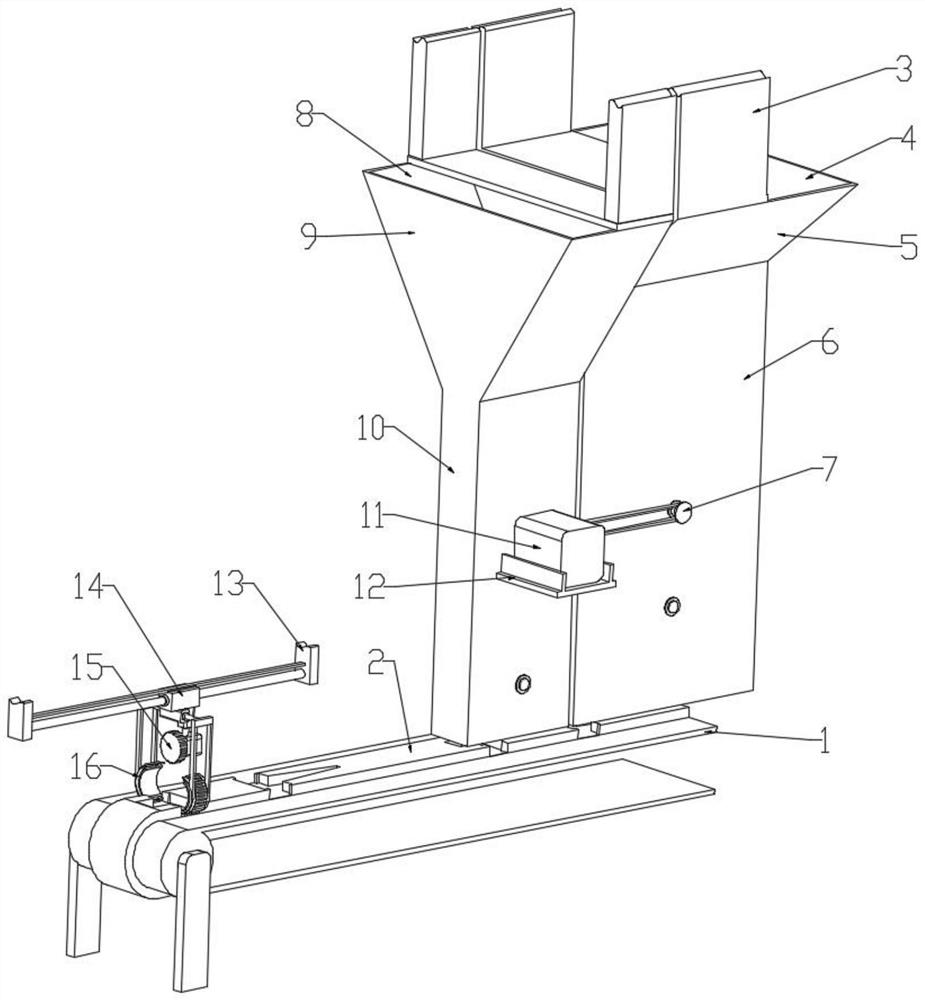

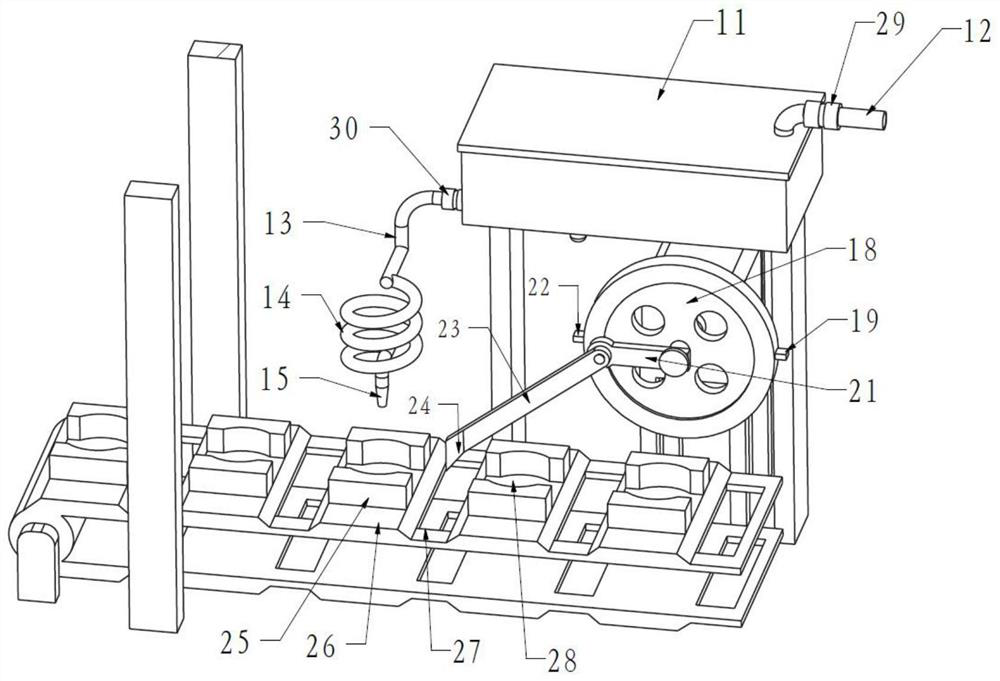

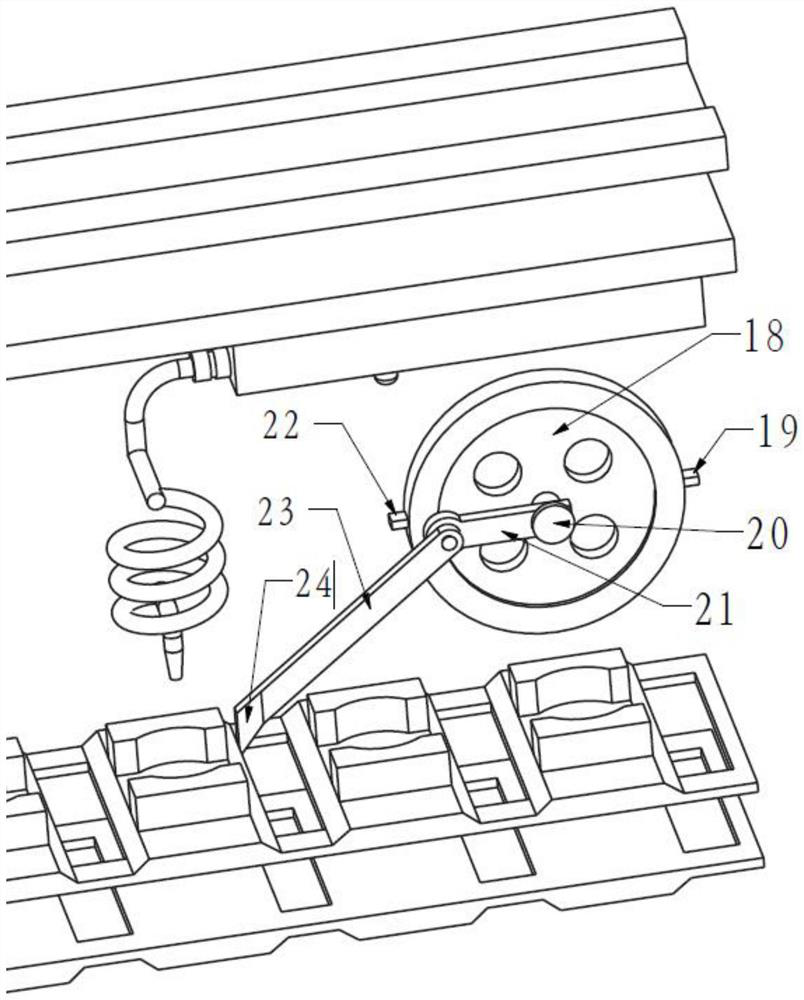

Filling system for preassembled module type flusher

InactiveCN113942672ARealize the collectionReduce occupancyConveyorsPackaging automatic controlTubular linear motorElectric machine

The invention discloses a filling system for a preassembled module type flusher, and belongs to the technical field of flusher processing. The system comprises a feeding conveying belt and a discharging conveying belt, wherein the feeding conveying belt is positioned below the discharging conveying belt, a vertically arranged tubular linear motor is arranged beside the feeding conveying belt and the discharging conveying belt, a bottle clamping mechanism is connected to a rotor of the tubular linear motor, bottle limiting portions are arranged on the feeding conveying belt in an array mode, and slotted holes are formed in the positions, between the bottle limiting portions, of the feeding conveying belt; an interval pushing device is arranged above one side of the feeding conveying belt, the interval pushing device comprises a rotating disc, and a rotating shaft of the rotating disc is connected to a swing rod pushing mechanism to match the slotted holes to push the feeding conveying belt at intervals; a liquid storage tank is arranged above the feeding conveying belt, one end of the liquid storage tank is connected to a liquid inlet pipe, the other end thereof is provided with a liquid outlet pipe, and a liquid inlet valve and a liquid outlet valve are arranged on the liquid inlet pipe and the liquid outlet pipe respectively; and the bottle clamping mechanism comprises bottle clamping members which are symmetrically arranged.

Owner:岳阳职业技术学院

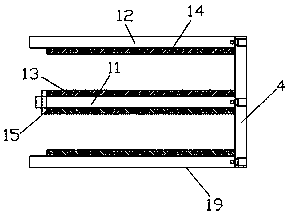

Double-layer conjugate bar-type linear motor structure

InactiveCN109361305AImprove efficiencyThe structure is simple and convenient to manufacturePropulsion systemsTubular linear motorEngineering

The invention discloses a double-layer conjugate bar-type linear motor structure which comprises a movable coil, a magnetic track and a stator yoke. The movable coil comprises a coil body, a framework, an end cover, a rotor yoke and a cable, the coil includes an inner coil and an outer coil, the framework includes an inner framework and an outer framework, the magnetic track comprises a first permanent magnet, a second permanent magnet, a first rotor yoke, a second rotor yoke and a magnetic track supporting frame, partition pads are arranged in the inner coil and the outer coil, the magnetic track supporting frame is arranged at the right end of the first rotor yoke, and a nut is arranged at the left end of the first rotor yoke. Output of the motor is 1.5 times or more that of a common single-layer tubular linear motor, the structure is simpler, iron loss is basically 0W, the efficiency of the motor is greatly improved, product cost is greatly saved, and positioning accuracy and repeated accuracy of a workpiece are improved.

Owner:宋局

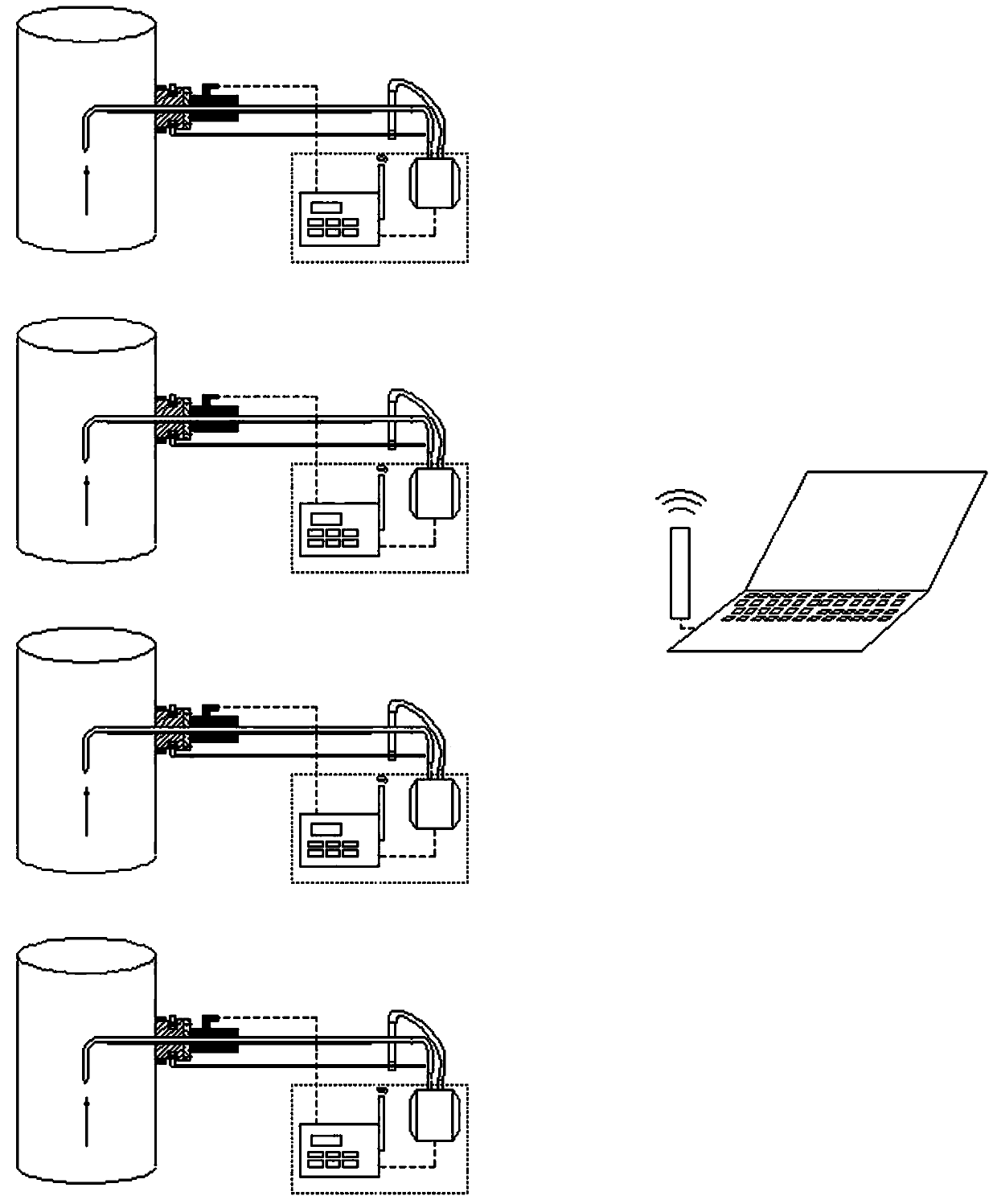

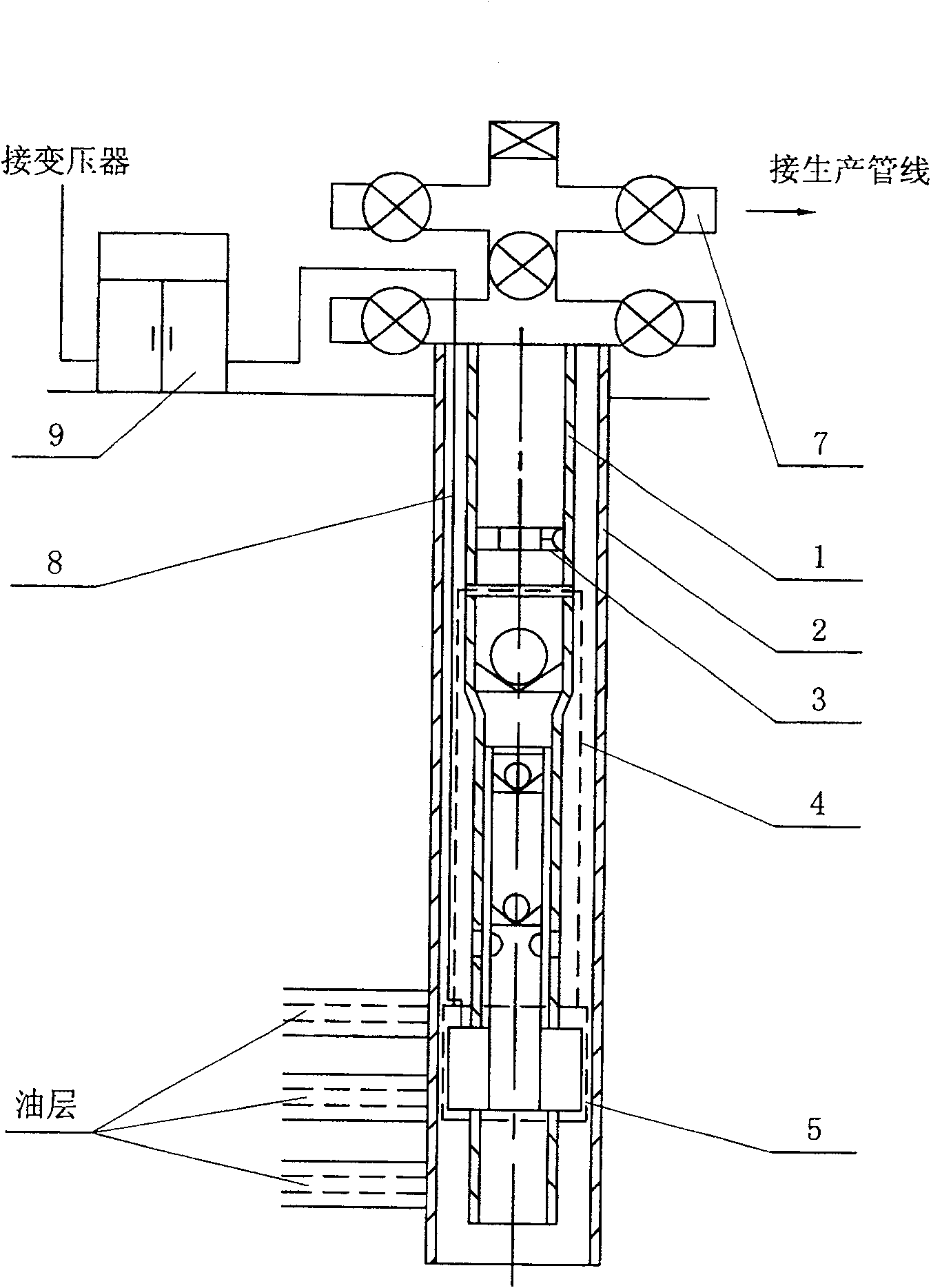

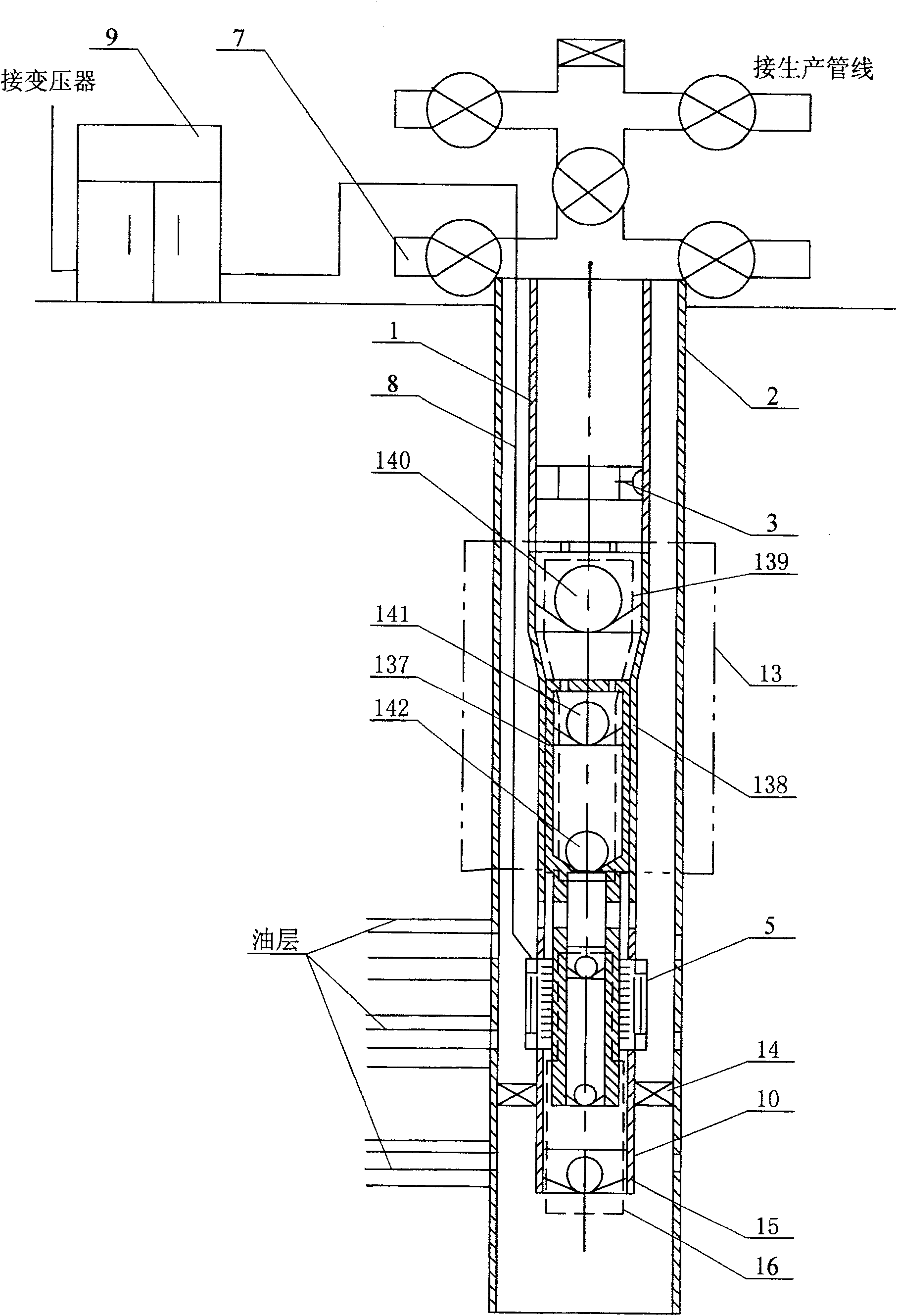

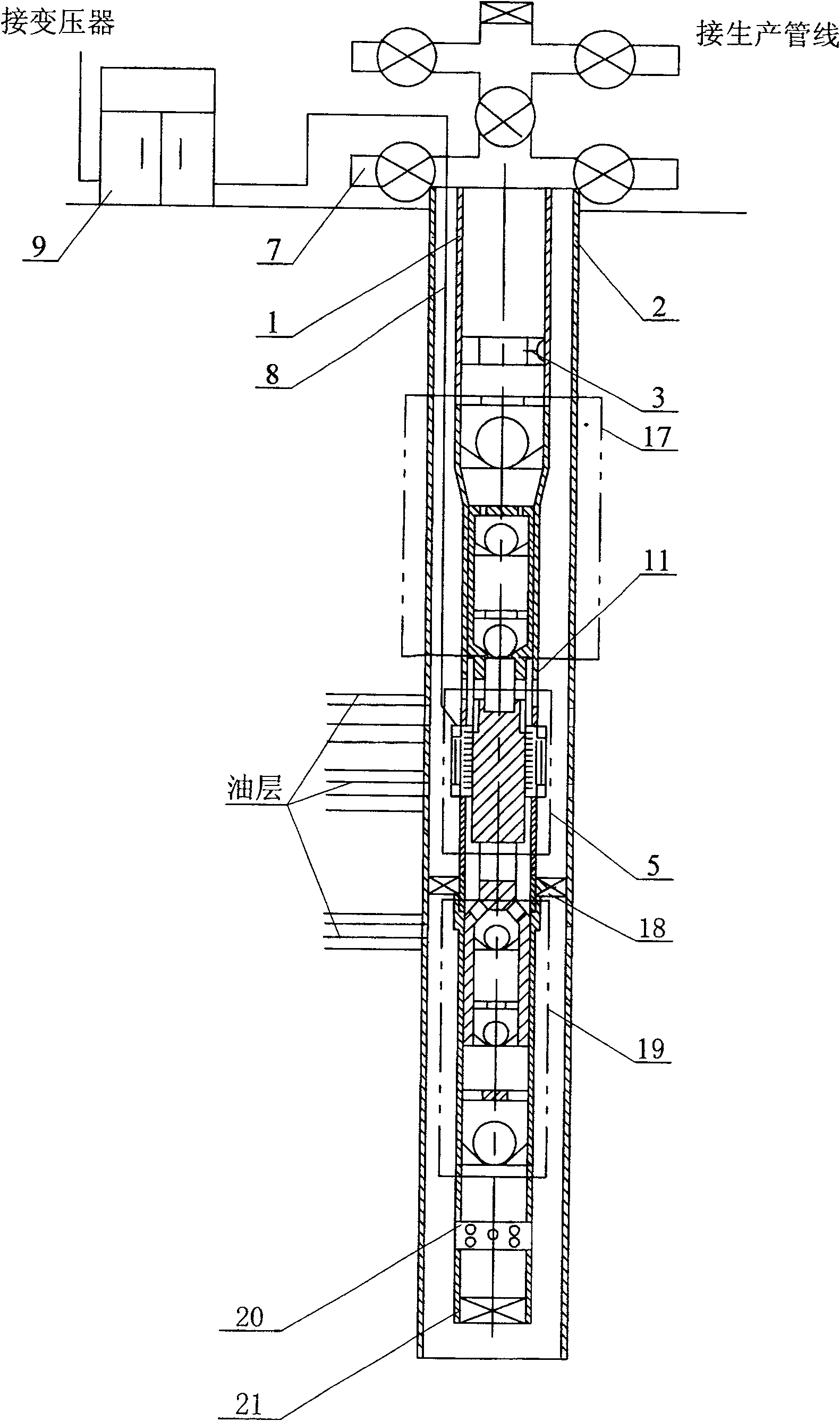

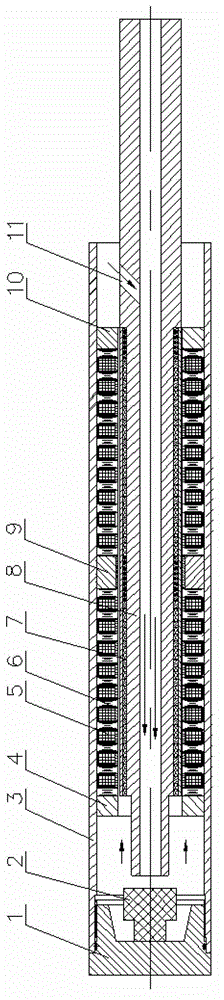

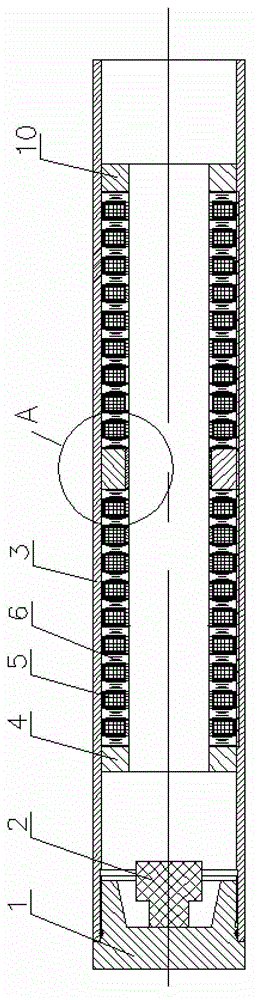

Oil production system of reciprocating submersible electric pump driven by sand-proof linear motor

InactiveCN100567700CWork normally for a long timeTo achieve the purpose of anti-cardFlexible member pumpsFluid removalTubular linear motorElectric machine

A reciprocating electric submersible pump oil production system driven by a sand control linear motor relates to a submersible electric pump oil production system driven by a linear motor. For the reciprocating submersible electric pump oil production system driven by linear motors, since the linear motors used do not have sand control functions, the sand in the well fluid is easy to enter the gap between the mover and stator of the linear motors, affecting the reciprocating submersible electric pumps. Problems with the normal operation of the pump oil production system. The oil pipe is equipped with a drainer, the two ends of the reciprocating plunger pump are fixedly connected with the oil pipe and the linear motor respectively, and the two ends of the cable are respectively connected with the linear motor and the frequency conversion speed control device; the reciprocating plunger pump is a reciprocating split It is one of the plunger pump for stratified mining, reciprocating double pumping plunger pump for stratified mining or reciprocating double-acting plunger pump. The linear motor is a sand control linear motor. The oil production and sand prevention linear motor of the present invention drives the reciprocating electric submersible pump to work, thereby achieving the purpose of preventing the linear motor from jamming and ensuring the normal operation of the reciprocating electric submersible pump oil production system.

Owner:DAQING OILFIELD CO LTD

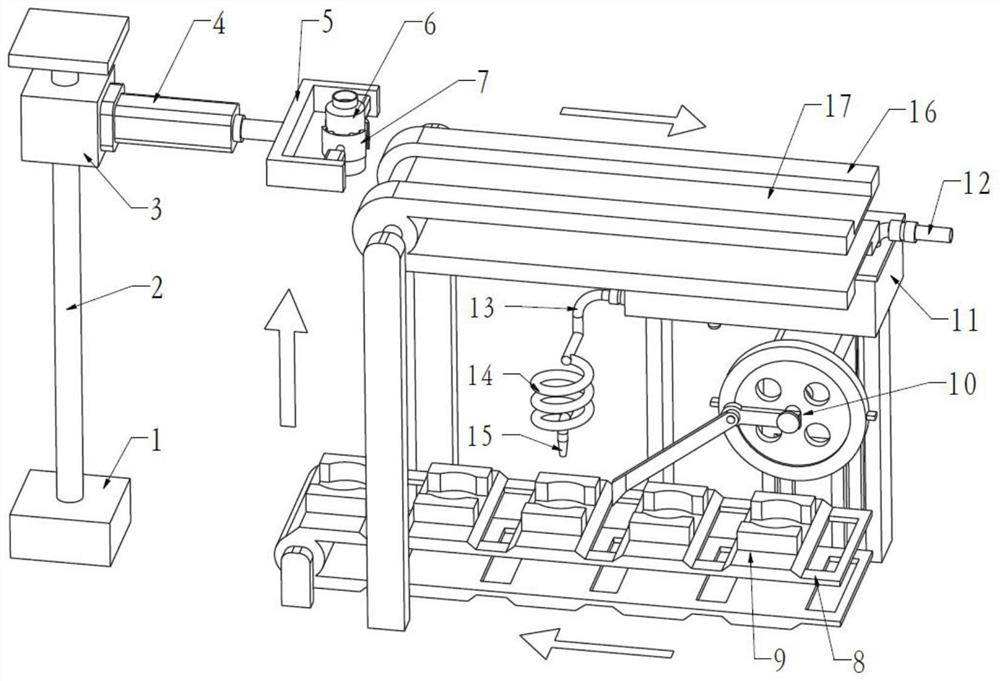

Pressing seat assembly assembling device for automatic production of flusher

InactiveCN113399999ACompact structureSave spaceAssembly machinesTubular linear motorElectric machinery

The invention discloses a pressing seat assembly assembling device for flusher automatic production, and belongs to the technical field of flusher machining. The pressing seat assembly assembling device comprises a supporting table supported by a first supporting column, wherein a pressing seat clamp is movably arranged on the supporting table, first tubular linear motors are symmetrically arranged on the supporting table to drive the pressing seat clamp to translate, a liftable bottle body clamp is arranged below the supporting table, the bottle body clamp is driven by a vertically arranged second tubular linear motor to ascend and descend, a feeding conveying belt and a discharging conveying belt are arranged at the tail end of the supporting table, the discharging conveying belt is located above the feeding conveying belt, and the discharging conveying belt and the feeding conveying belt are supported by second supporting columns; the pressing seat clamp comprises a mold closing clamp; the mold closing clamp is driven by first tubular linear motors on two sides to translate; a notch is formed in the tail end of the supporting table, a clamping piece capable of ascending, descending and rotating is arranged above the notch, and the clamping piece clamps the mold closing clamp and then descends and rotates to screw a bottle cap of the flusher to a bottle body.

Owner:岳阳职业技术学院

Tubular linear motor

ActiveUS20200212787A1Suppress saturationIncrease thrustMagnetic circuitPropulsion systemsTubular linear motorElectric machine

To achieve the foregoing object, a tubular linear motor of the present invention includes a core that has a tubular yoke and a plurality of teeth which are annular and provided at intervals in an axial direction on an outer periphery of the yoke; a winding mounted in a slot between the teeth; and a field magnet that is tubular, into which the core is movably inserted in the axial direction, and having N poles and S poles alternately arranged in the axial direction. An axial width W of a yoke-side inner peripheral edge of the teeth is larger than an axial width of an outer peripheral edge of the teeth.

Owner:KYB CORP

A Large Thrust Cylindrical Linear Motor

ActiveCN103427587BStrong resistance to demagnetizationReduce magnetic densityPropulsion systemsTubular linear motorLinear motor

The invention relates to a high-thrust tubular linear motor which comprises a stator shell, a stator and a rotor. The stator is coaxially and fixedly mounted in the stator shell, the rotor is coaxially and slidably mounted in an inner cavity of the stator, the stator comprises silicon steel sheets and windings which are arranged at intervals and fixedly mounted on the stator shell, the rotor comprises a rotor shaft, permanent magnets and magnetic conduction rings, and the permanent magnets and the magnetic conduction rings are arranged at intervals on the rotor shaft. The high-thrust tubular linear motor is characterized in that the rotor shaft is made of hollow soft magnetic materials, a copper tube is coaxially sleeved outside the rotor, the windings and the silicon steel sheets are fixedly mounted at intervals to form the stator, and the windings and the silicon steel sheets correspond to the permanent magnets and the magnetic conduction rings of the rotor. The high-thrust tubular linear motor is ingenious in design, reasonable in structure, large in starting force, fine in tightness and reliable in operation.

Owner:伟力驱动技术(深圳)有限公司

Linear electric motor driven numerical control machine functional module

InactiveCN101244516BRealize linear motionImprove dynamic performanceFeeding apparatusDriving apparatusNumerical controlTubular linear motor

The invention relates to a function module of the NC machine tool driven by a linear motor, which is characterized in that: the invention comprises two groups of linear driving modules, a moving module of the cutter platform, two groups of connecting rod parts; the function module is a symmetrical structure of the linear moving axis of the cutter platform; the linear driving modules are respectively arranged at two sides of the moving module of the cutter platform, and are respectively connected with the moving module of the cutter platform by the connecting rod parts; each group of the linear driving module is a linear feeding module driven by the linear motor, and the linear moving axis is in parallel to the linear moving axis of the moving module of the cutter platform. The NC machine tool function module has the advantages of adopting parallel driving of the double linear motor, achieving the linear movement and deflecting movement of the cutter platform, good dynamic performance,small mechanical inertia and big rigidity.

Owner:BEIHANG UNIV

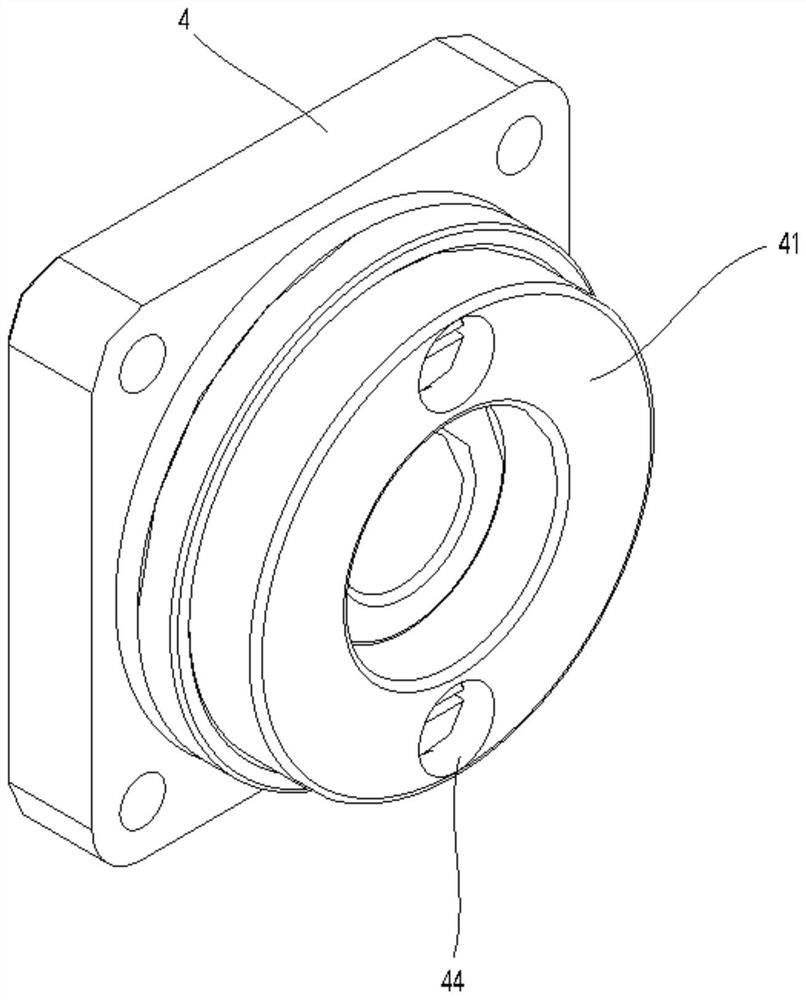

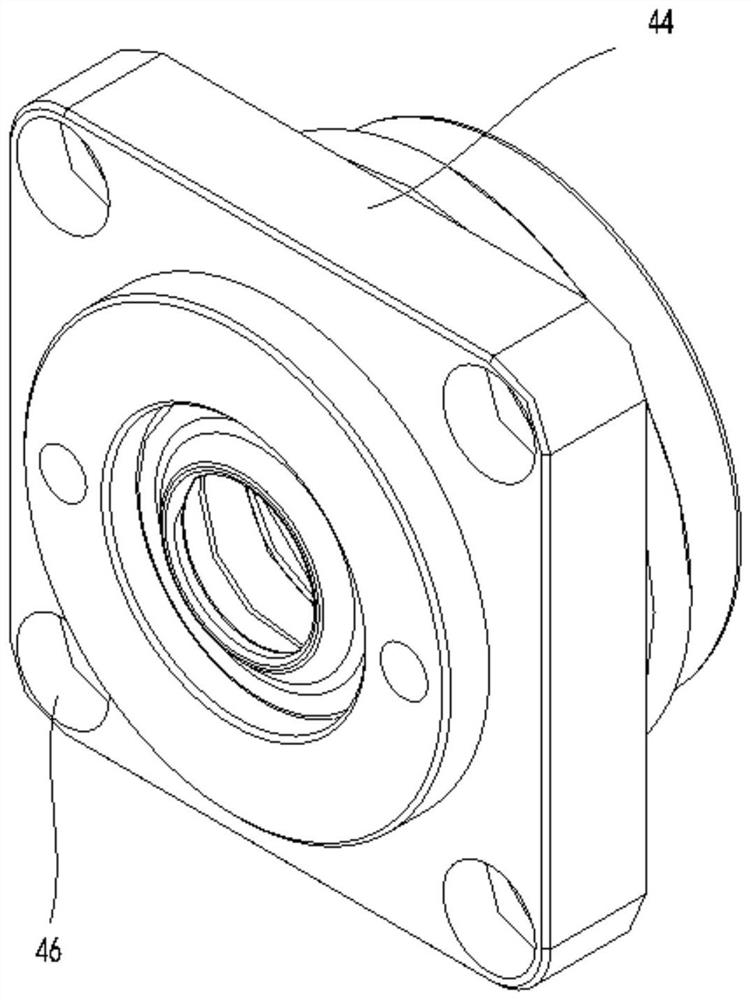

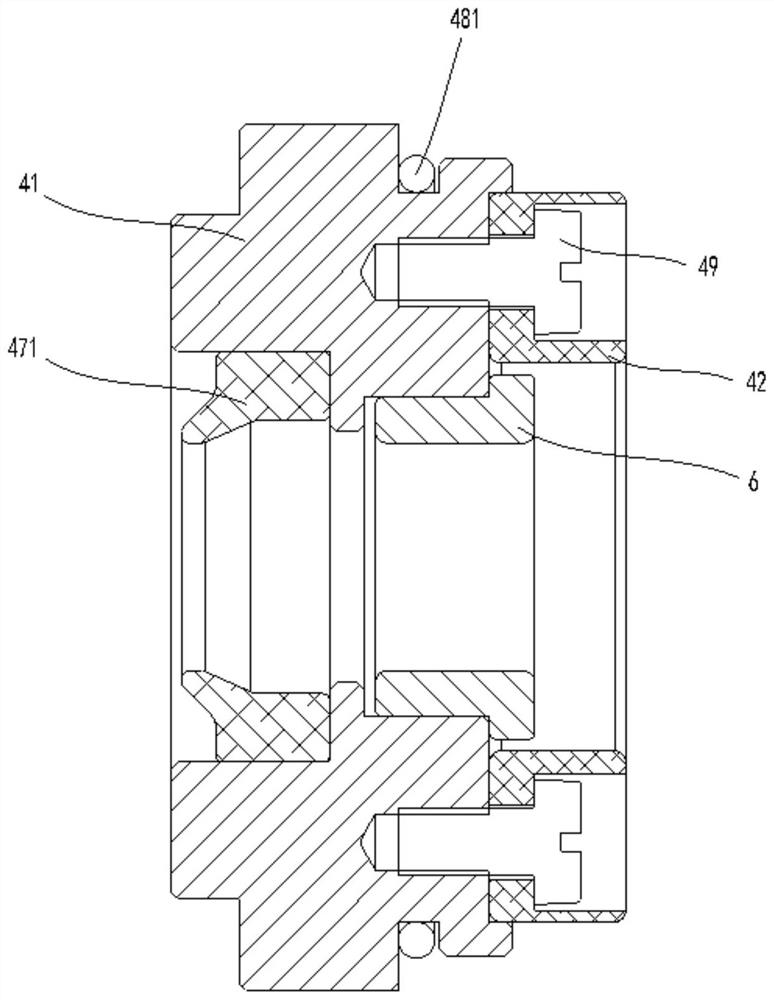

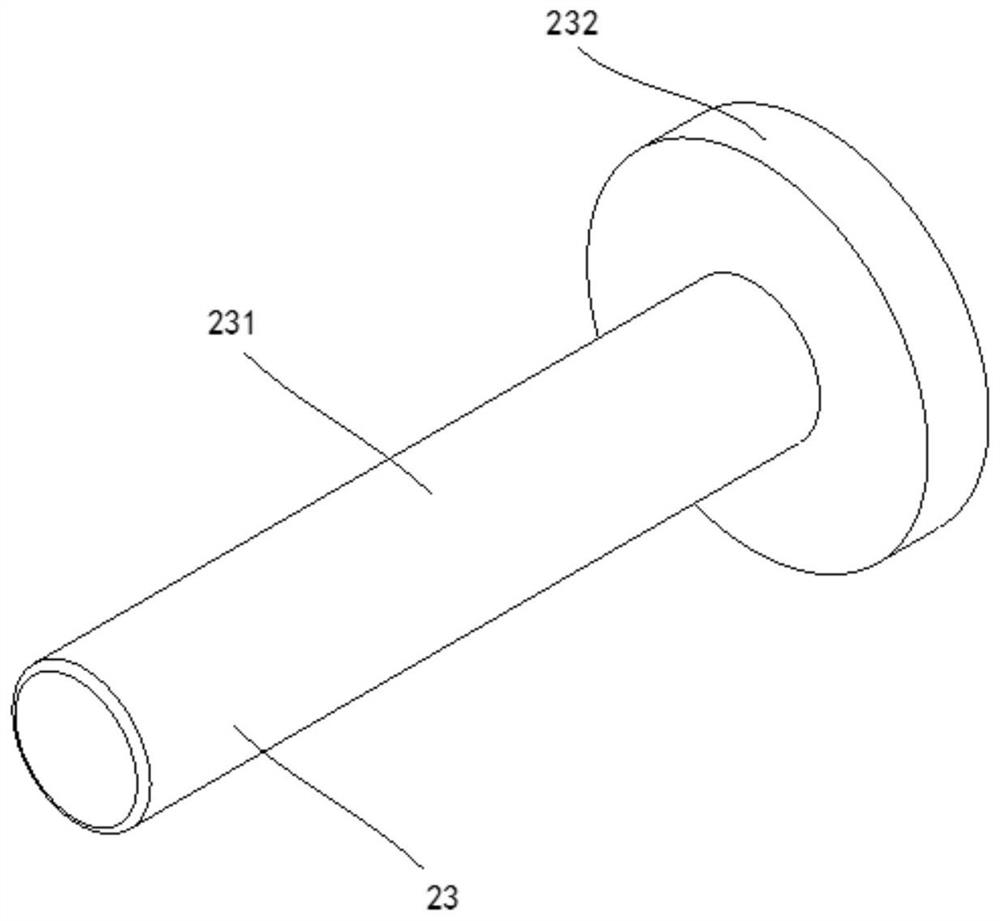

Combined linear motor end cover

ActiveCN112217367AReduce volumeLow costPropulsion systemsSupports/enclosures/casingsTubular linear motorElectric machinery

The embodiment of the invention belongs to the technical field of motors, and relates to a combined linear motor end cover. According to the technical scheme, the end cover comprises an end cover body, a sliding sleeve and a limiting ring; wherein the sliding sleeve is arranged in the end cover body, the sliding sleeve is slidably connected with a rotor and supports the rotor, the limiting ring isarranged on the side, close to the motor body, of the end cover body and used for limiting the stroke of the rotor, the dustproof and protection effects are achieved, the sliding sleeve is arranged to allow the rotor to slide, and operation of the rotor is supported. And the limiting ring can limit the rotor, so that the overall structure of the tubular linear motor can be simplified, the size ofthe linear motor can be reduced, the space occupied by the internal structure of the linear motor is well reduced, the internal structure of the motor is greatly optimized, the cost of the motor is reduced, and the manufacturing and maintenance are simpler and more convenient.

Owner:HANS LASER TECH IND GRP CO LTD +1

Material taking device for sprayer assembly of flusher

InactiveCN114261746AAchieve transshipmentRealize opening and closing movementConveyorsConveyor partsTubular linear motorElectric machine

The invention discloses a material taking device for a sprayer assembly of a flusher, and belongs to the technical field of flusher machining, the material taking device comprises a conveying belt, a nozzle blanking device, a connecting seat blanking device and a tubular linear motor are sequentially arranged above the conveying belt, a clamping device is connected to a rotor of the tubular linear motor, and a protruding limiting belt is arranged on the surface of the conveying belt. Paired nozzle limiting grooves and connecting seat limiting grooves are formed in the surface of the limiting belt in an array manner; the nozzle discharging device comprises a nozzle storage box, a nozzle feeding port is formed in the top of the nozzle storage box, the lower portion of the nozzle storage box is a nozzle discharging channel with an opening in the bottom end, and a first discharging conveying belt is arranged in the nozzle discharging channel. The connecting base discharging device comprises a connecting base storage box, a connecting base feeding port is formed in the top of the connecting base storage box, a connecting base discharging channel with an opening in the bottom end is formed in the lower portion of the connecting base storage box, and a second discharging conveying belt is arranged in the connecting base discharging channel. The clamping device comprises a driving gear, and a rotatable clamp is arranged below the driving gear.

Owner:岳阳职业技术学院

Efficient assembling equipment for sprayer assembly of flusher

InactiveCN114260701AAchieve transshipmentRealize opening and closing movementAssembly machinesMetal working apparatusTubular linear motorElectric machine

Owner:岳阳职业技术学院

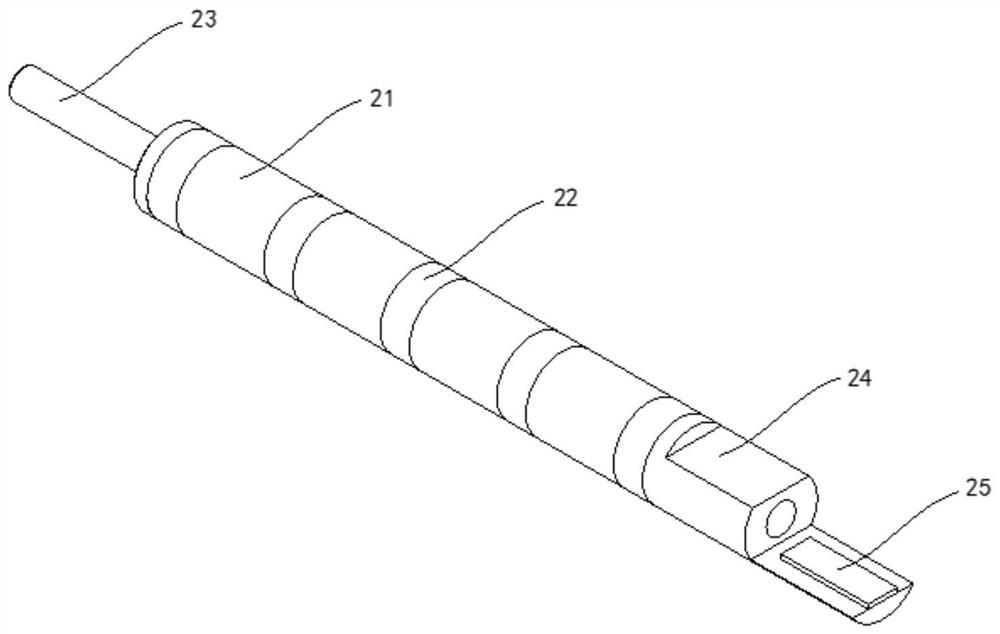

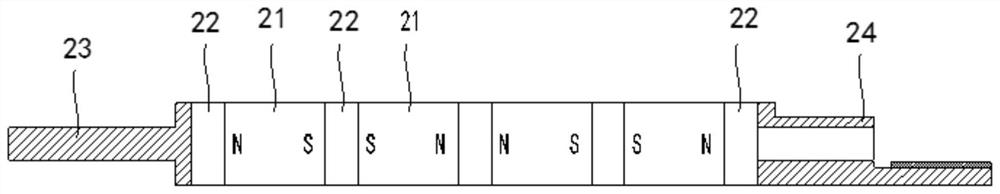

A tubular linear motor mover

ActiveCN112217370BReasonable structureReduce volumePropulsion systemsTubular linear motorElectric machine

The embodiments of the present application belong to the technical field of electric motors, and relate to a tubular linear motor mover. The technical solution provided by this application includes permanent magnets, iron cores and mandrels; the iron cores and the permanent magnets are arranged in a staggered manner, so that the permanent magnets are arranged between the iron cores, and the magnetic poles of the two adjacent permanent magnets are opposite to each other. , the mandrel is arranged on the side of the iron core at both ends away from the permanent magnet, and the mandrel is slidably connected with the sliding sleeve arranged on the stator. The sliding structure between them does not need to occupy additional space, and the volume of the linear motor can be reduced, so that the linear motor can be applied to the occasions with stricter requirements on the volume of the motor. Therefore, the space occupied by the internal structure of the linear motor is better reduced, the internal structure of the motor is greatly optimized, the cost of the motor is reduced, and the manufacture and maintenance are easier.

Owner:HANS LASER TECH IND GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com