High speed and high precision micro stamping drive system based on dual linear motors

A drive system, linear motor technology, applied in circuits, electrical components, microstructure technology and other directions, can solve the problem of inability to meet the microplastic forming of parts, and achieve accurate and controllable speed-displacement, high positioning accuracy, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

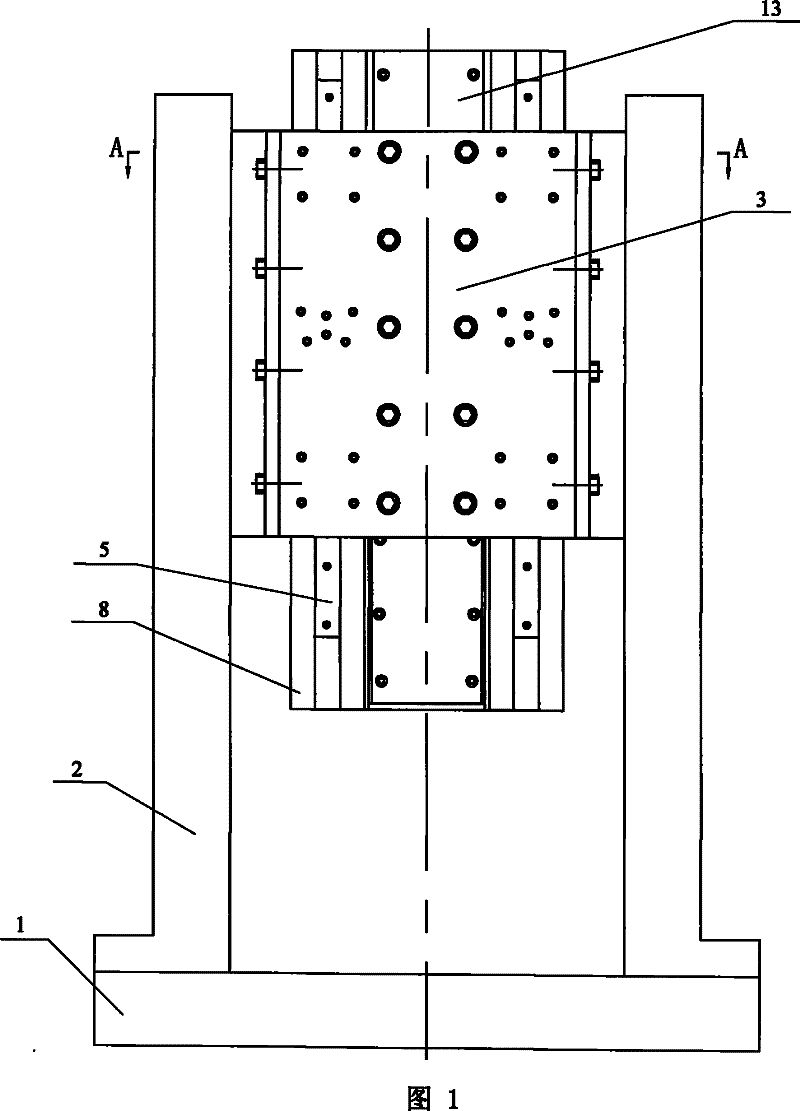

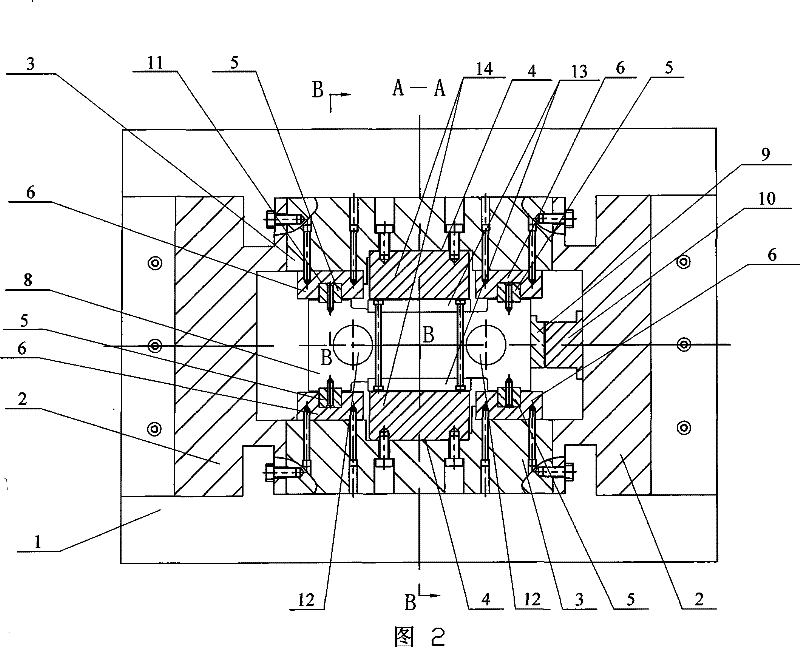

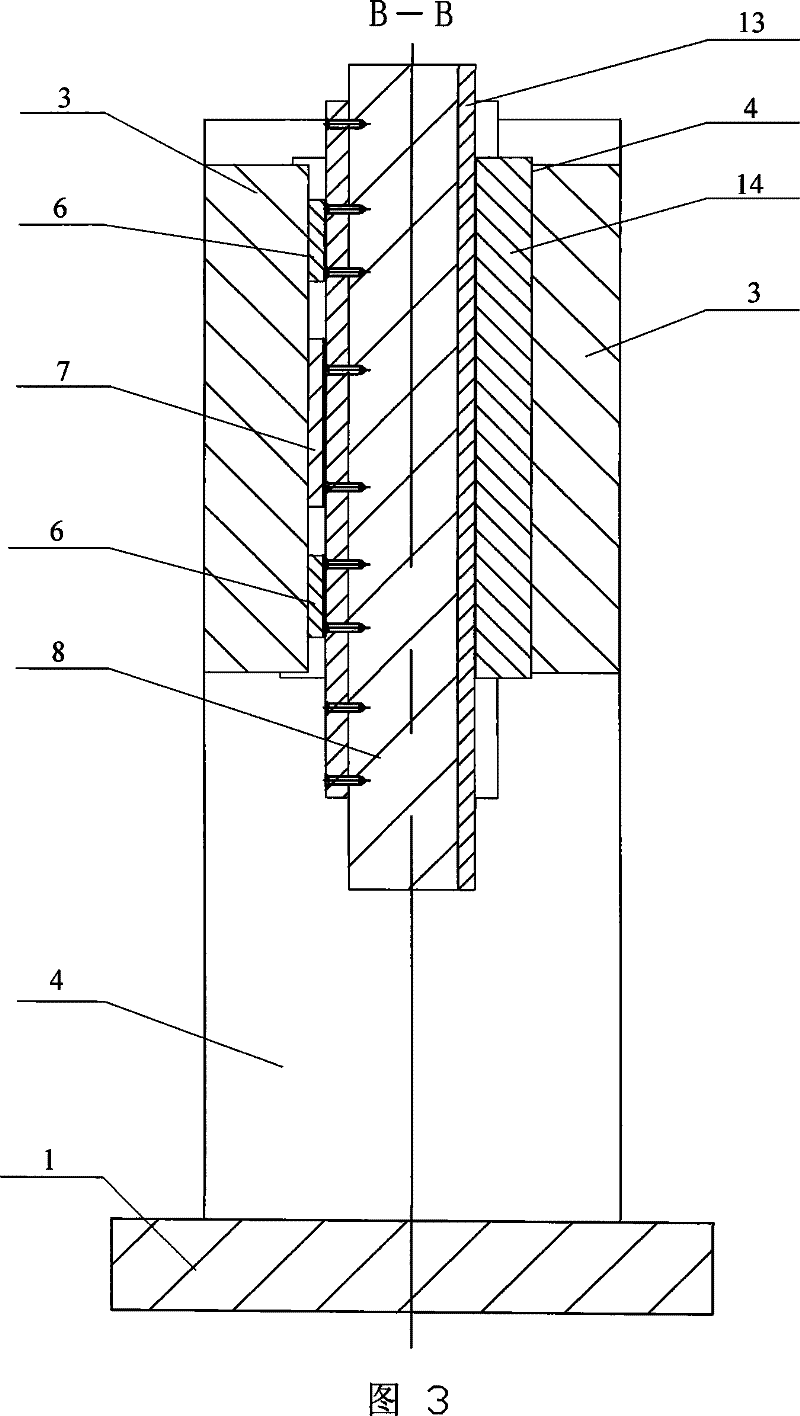

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment consists of base 1, two racks 2, two brackets 3, two linear motors 4, four guide rails 5, eight guide rail sliders 6, four brakes 7 and sliders 8, grating ruler 9 and grating ruler probe 10; the lower ends of the two frames 2 are fixedly connected to the left end and the right end of the upper end surface of the base 1 respectively, and the two brackets 3 are arranged side by side between the two frames 2 front and rear and respectively connected to the The two racks 2 are fixedly connected, and the two brackets 3 are used as supports for the two linear motors 4; the slider 8 is installed between the two brackets 3, and a linear motor is arranged symmetrically at the front end and the rear end of the slider 8 4. It can obtain good acceleration performance and large output load, and can ensure that the center of the output force is consistent with the center of the eq...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 2 To illustrate this embodiment, two longitudinal weight-reducing through holes 12 are provided on the upper end surface of the slider 8 of this embodiment at positions symmetrical to the central axis. With this setting, good acceleration performance can be obtained. Under the same force, the lighter the moving part, the better. Other components and connections are the same as those in the first embodiment.

[0010] The working process of the system of the present invention is: in order to ensure the synchronization of the motion of the two linear motors, the two linear motors are controlled by a set of controllers. According to the specific forming process, the motion trajectory of the linear motor is formulated, that is, the output displacement-time curve of the linear motor, and the linear motor controller controls the motion of the linear motor according to the motion trajectory. At the beginning of the movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com