Patents

Literature

566results about How to "High running precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

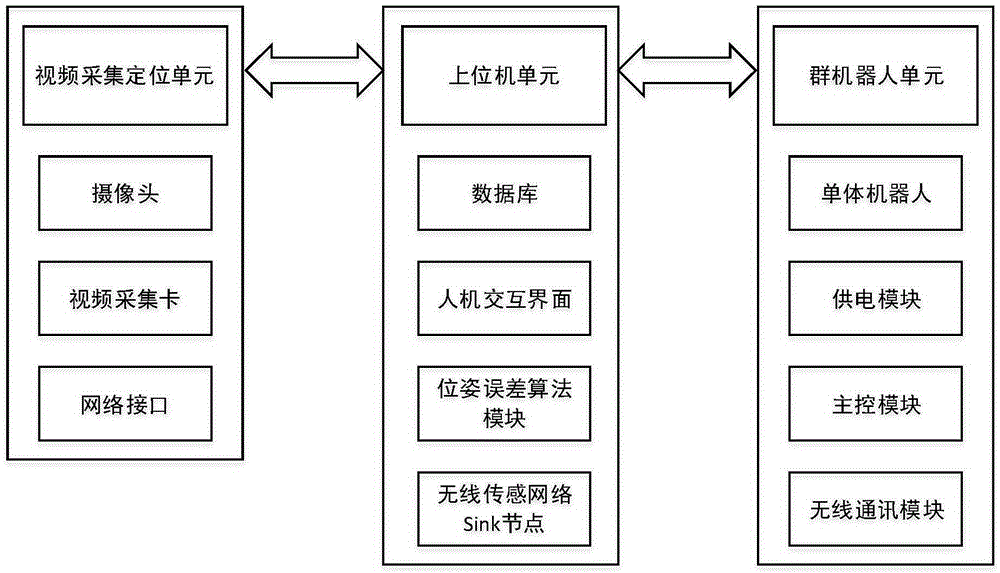

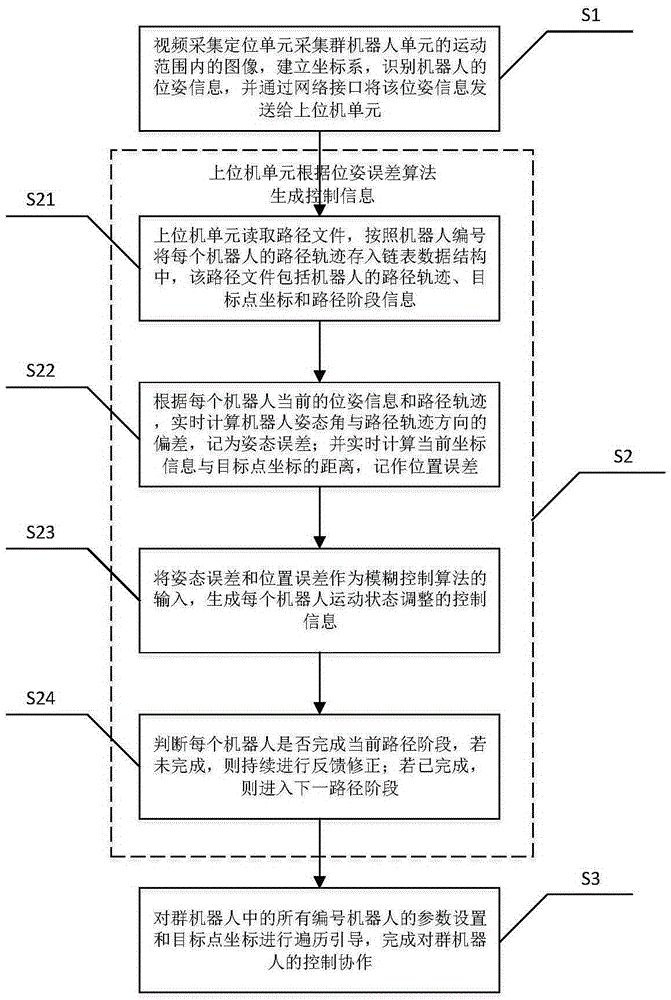

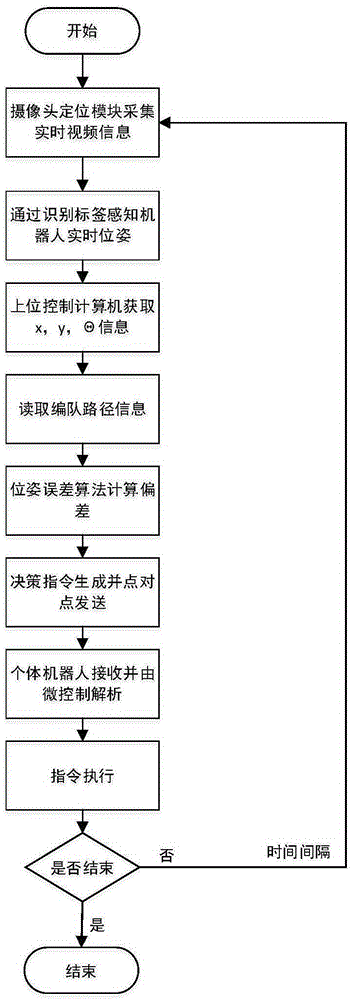

Swarm robot control system and method based on visual positioning

ActiveCN105425791AEnsure collaborative control operationImprove individual work abilityPosition/course control in two dimensionsVehiclesRange of motionEngineering

The invention discloses a swarm robot control system and method based on visual positioning, and the system comprises a video collection positioning unit, an upper computer unit, and a swarm robot unit. The video collection positioning unit is used for collecting an image in a movement range of the swarm robot unit, building a coordinate system, recognizing the pose information of each robot in the swarm robot unit, and transmitting the pose information to the upper computer unit. The upper computer unit is used for generating control information for correcting the movement posture of the robots in real time, and transmitting the control information to the robots through a wireless sensing network. The swarm robot unit consists of a plurality of robots, and is used for receiving and analyzing the control information, adjusting a walking strategy, and completing the following control of a path track and a group dispatching task. The system and method can achieve the accurate coordinative control of the movement states of the swarm robots through the technology of visual positioning, and complete the execution of a single task and a group of tasks simply, conveniently and quickly.

Owner:WUHAN UNIV OF TECH

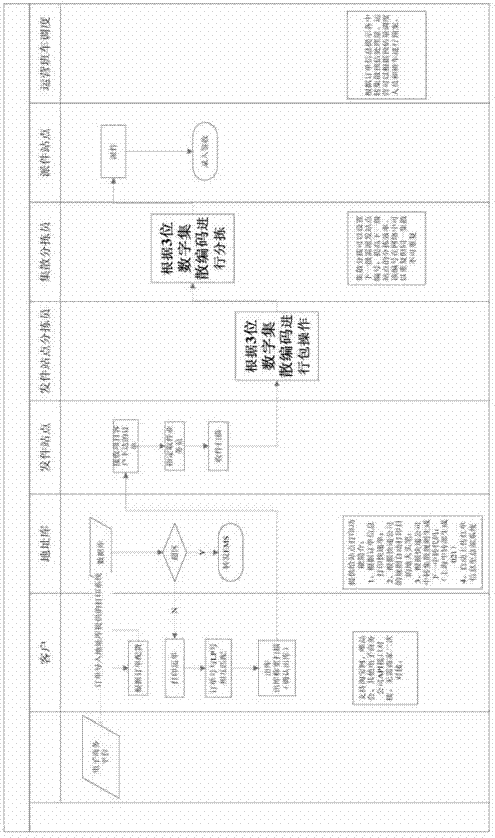

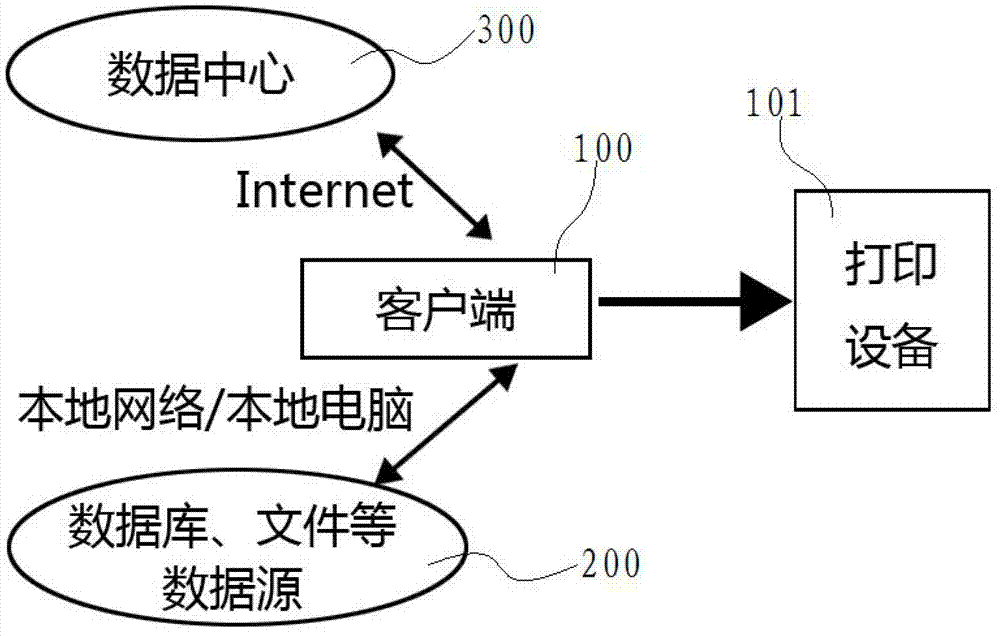

Logistics processing system and logistics processing method in direct connection with e-commerce platform

InactiveCN102880949ARealize manpowerRealize physical resourcesLogisticsData informationUnit operation

The invention discloses a logistic processing system and a logistics processing method in direct connection with an e-commerce platform. According to the logistic processing system and the logistics processing method provided by the invention, a client side is directly connected with the e-commerce platform through a port to acquire confirmed electronic order data information in the e-commerce platform and generate destination codes and next-level transfer codes accordingly; and the client side prints express lists accordingly and transmits duplicate information to a central management unit and a station management unit. The station management unit is used for storing and managing information data of all stations of a logistics company; and the central management unit, which is used for storing and managing data information of the whole logistics processing system, is respectively connected with the client side and data of the station management unit. According to the logistic processing system and the logistics processing method provided by the invention, 40-50% of labour cost in a current logistics express industry can be reduced, unit operation time can be shortened by 2-3hours, work pressure from bottom to up in the current logistics express industry can be relieved, and the whole operating efficiency can be increased by more than one third.

Owner:上海鲲达软件科技有限公司 +2

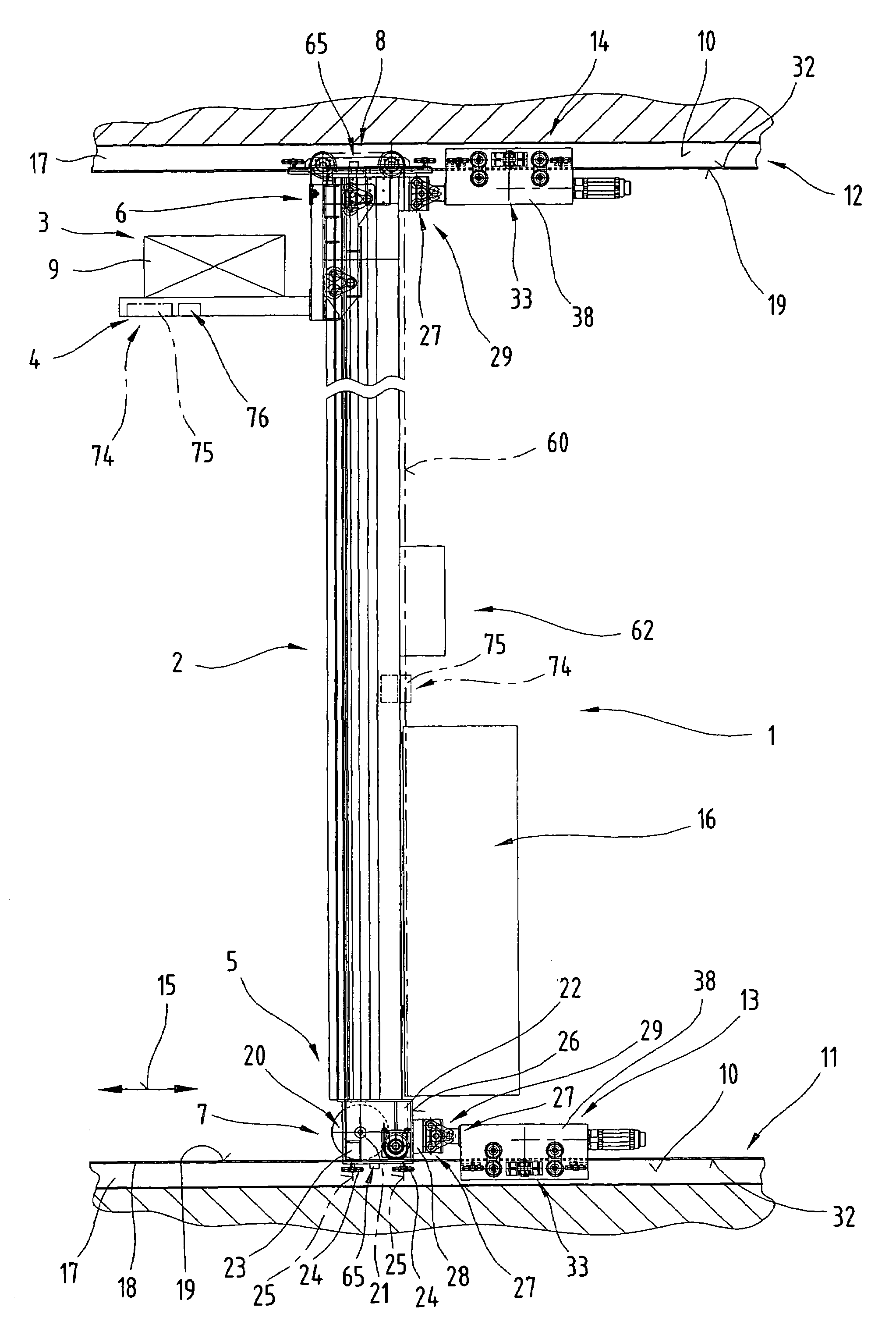

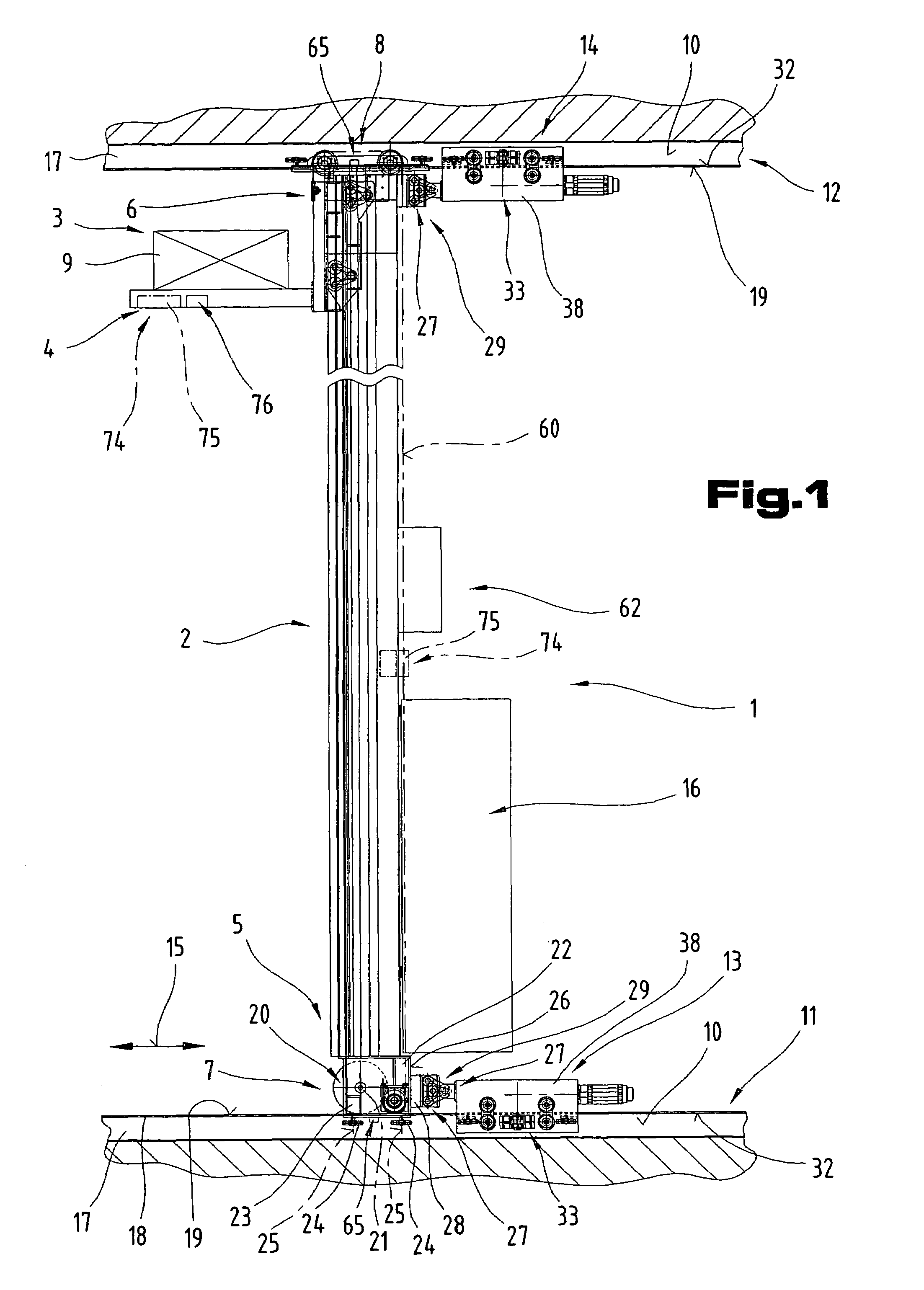

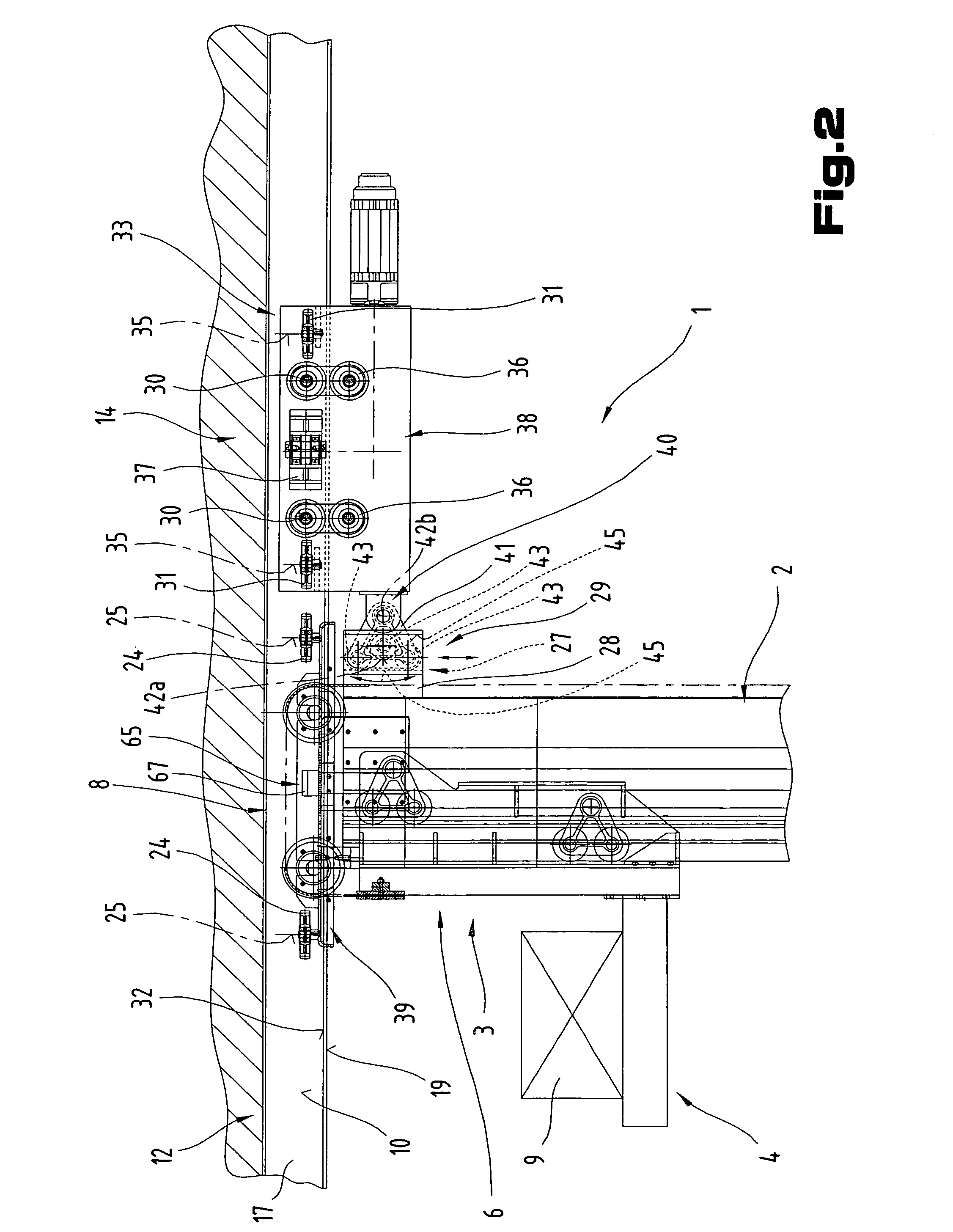

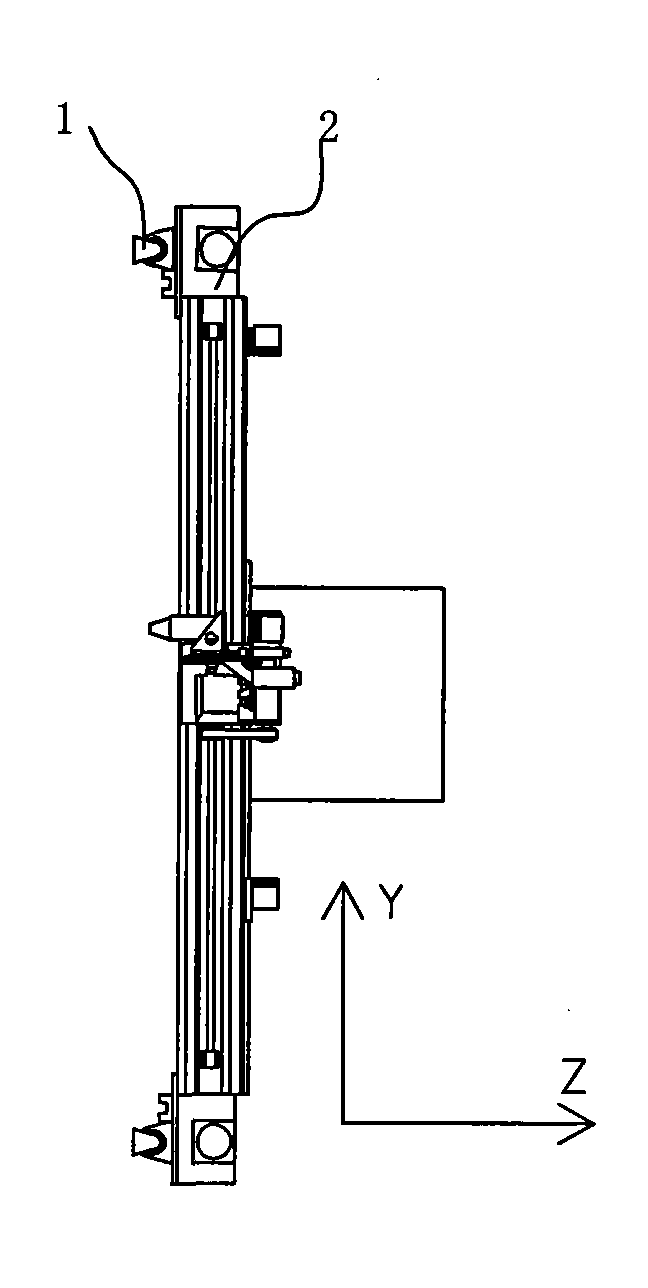

Loading/unloading device for shelving

InactiveUS7281608B2Improve rigidityIncreased load-bearing capacityComputer controlLifting devicesBogieCoupling

The invention relates to a rack serving device (1) with a load-bearing means (4) displaceable in the height direction of a mast (2), the mast (2) being guided by means of bogie assemblies (7, 8) on bottom and top guide tracks and mounted so as to be displaceable along the guide tracks by means of a bottom and top friction-locking displacement drive (13, 14). The bottom and the top adjusting mechanisms are guided by means of height and lateral guide elements on the guide track and are designed to be displaceable relative to the guide tracks by means of a drive system (33). Arranged respectively between the displacement drives (13, 14) and bogie assemblies (7, 8) is a coupling mechanism (29), comprising at least two displaceable coupling parts (28) and, extending between the articulation axes of the coupling parts (28), at least one coupling connection (27) which is pivotable about the articulation axis substantially perpendicular to the longitudinal extension of the guide track relative to a coupling part (28) and, at an end region remote from this articulation axis, mounted so as to be slideable in a longitudinal guide extending substantially parallel with the longitudinal extension of the mast (2).

Owner:TGW MECHANICS GMBH

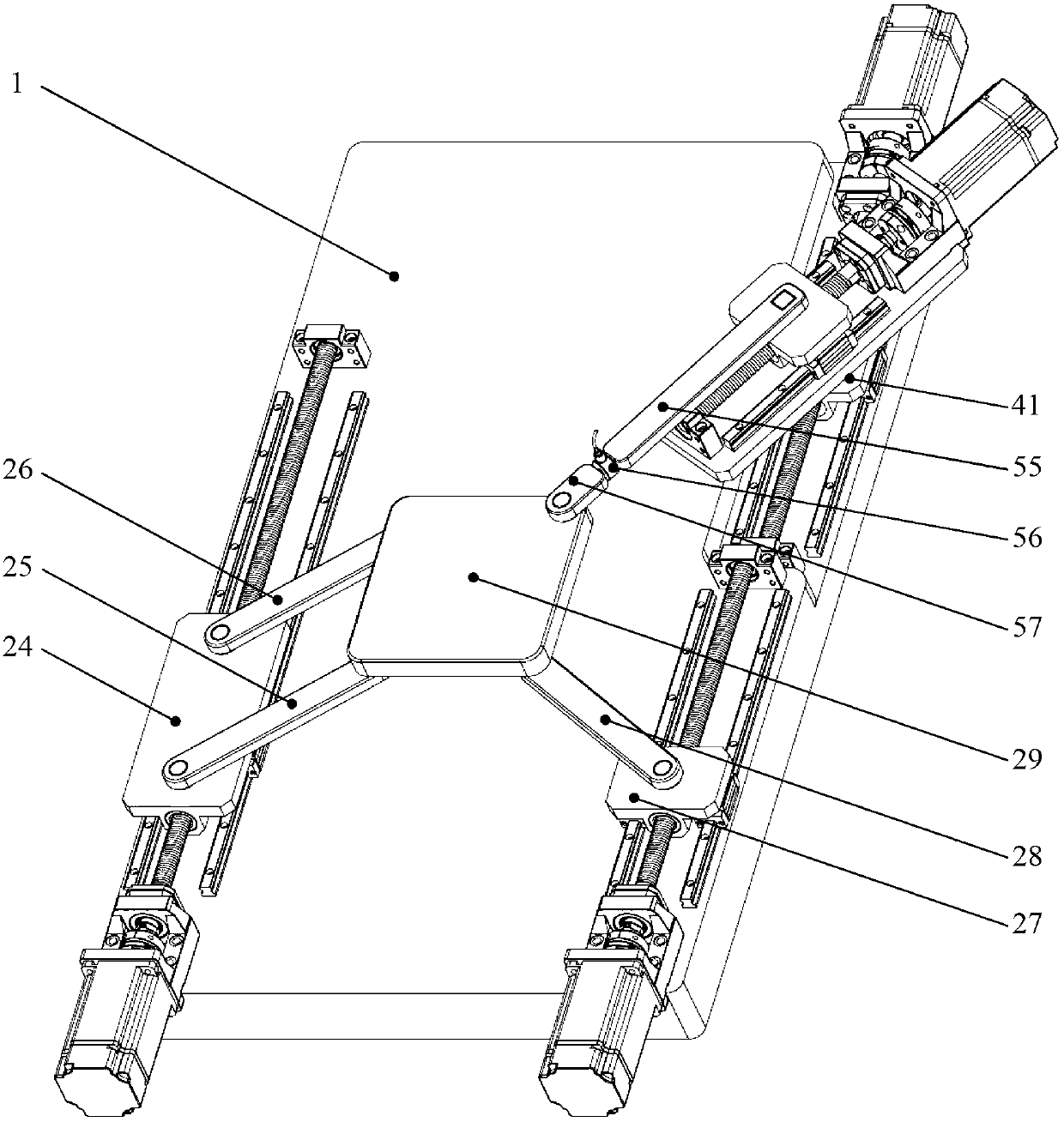

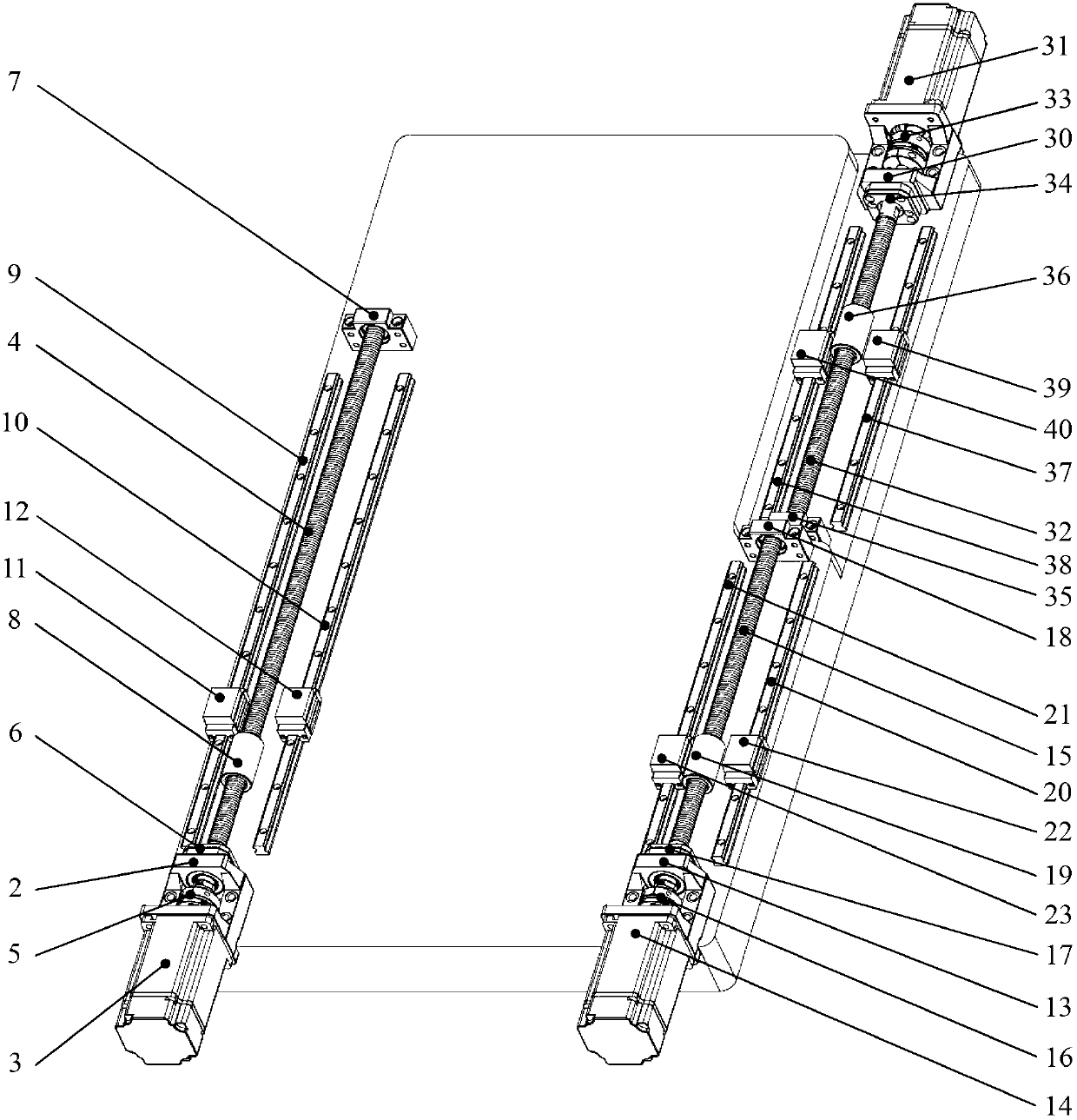

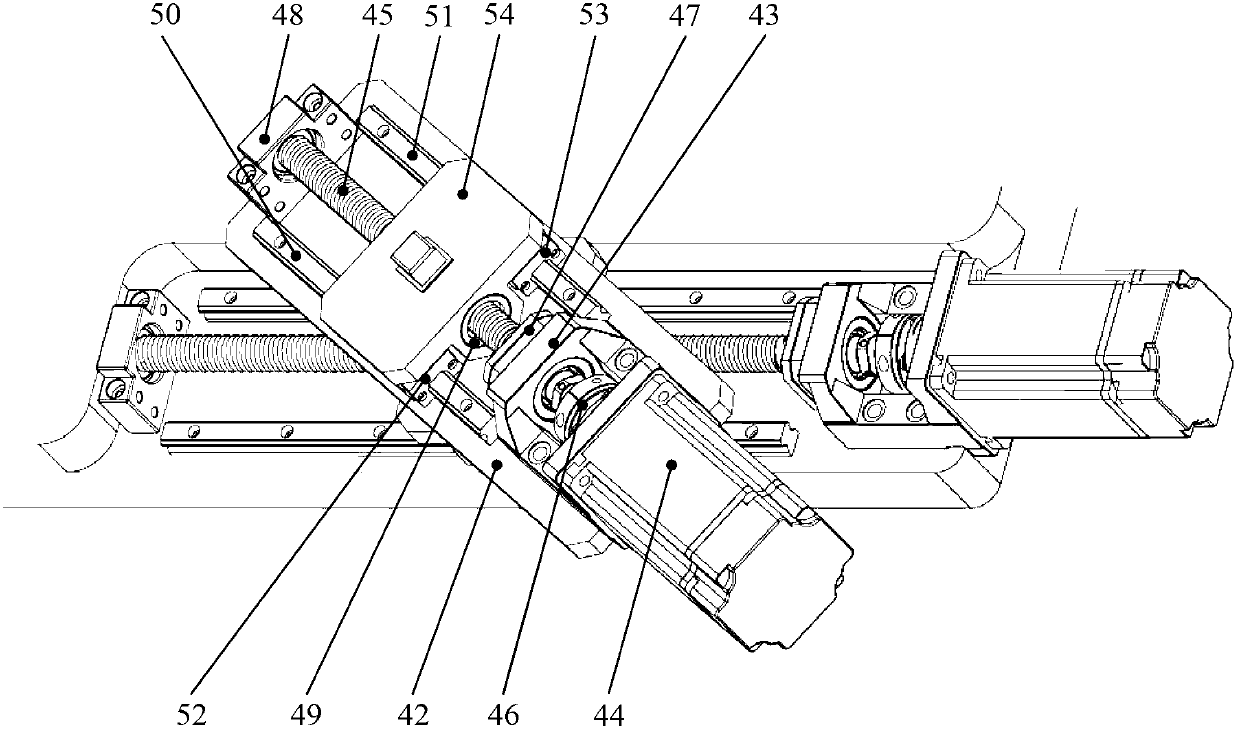

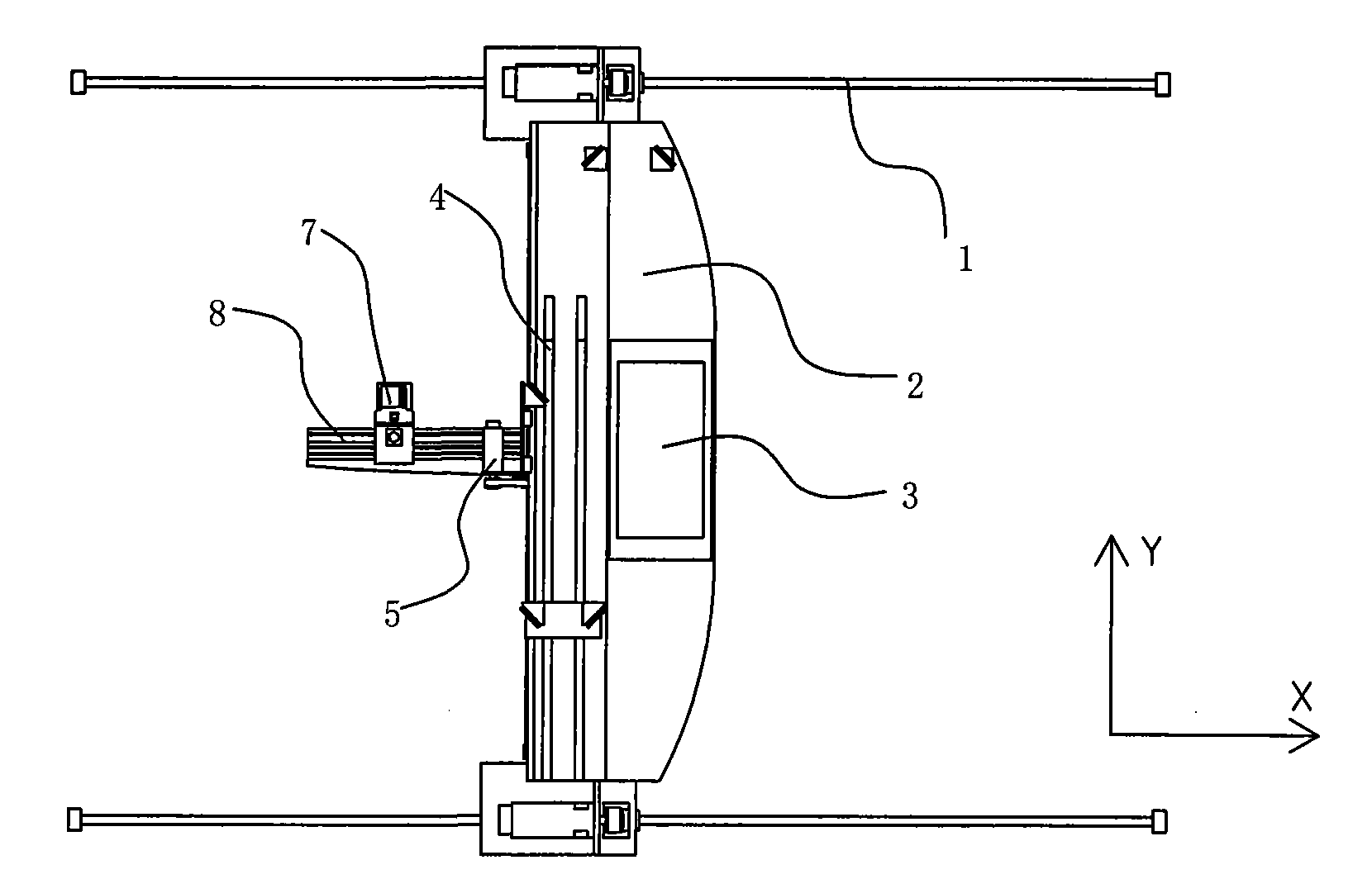

Novel plane two-degree-of-freedom redundant drive parallel moving platform

InactiveCN103101050AIncrease stiffnessImprove dynamic performanceProgramme-controlled manipulatorLoop controlDegrees of freedom

The invention discloses a novel plane two-degree-of-freedom redundant drive parallel moving platform, and belongs to the technical field of mechanical manufacturing. The novel plane two-degree-of-freedom redundant drive parallel moving platform comprises a moving platform, parallel guide rails, three equal-length branch chains, a telescopic branch chain and slide blocks; the positions of the slide blocks on the corresponding guide rails and the lengths of the telescopic branch chains are controlled under driving of a servo motor; and the moving platform has two translation degrees of freedom in the plane. Because a parallel mechanism is adopted, the moving platform has the advantages of high rigidity and good dynamic performance; the telescopic branch chains are taken as the redundant drive branch chains, a pull pressure sensor is installed close to the connection point of the telescopic branch chains and the moving platform, preset pull pressure force can be applied to the moving platform by utilizing the servo motor at the point along the directions of the telescopic branch chains through force enclosed loop control. Through optimizing the size and direction of applied load of the redundant drive branch chains, the rigidity and dynamic performance of the mechanism can be improved further.

Owner:TSINGHUA UNIV

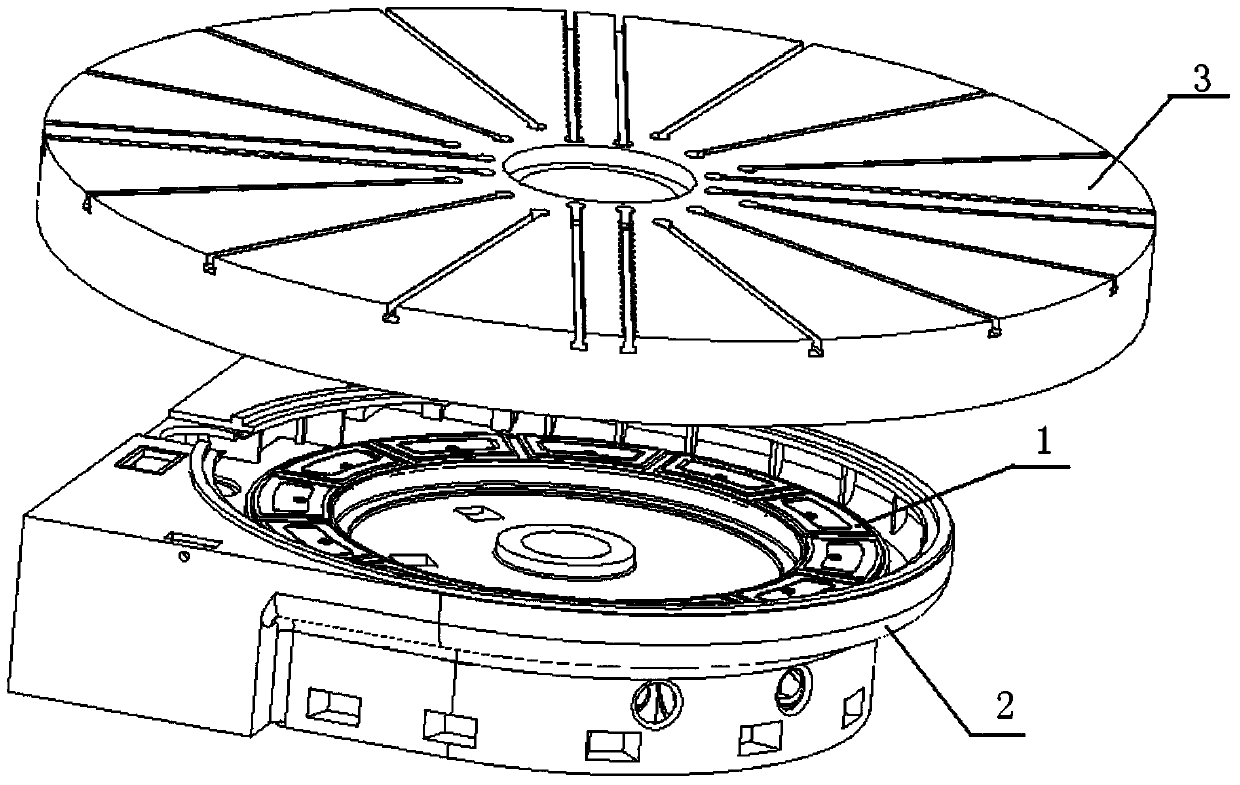

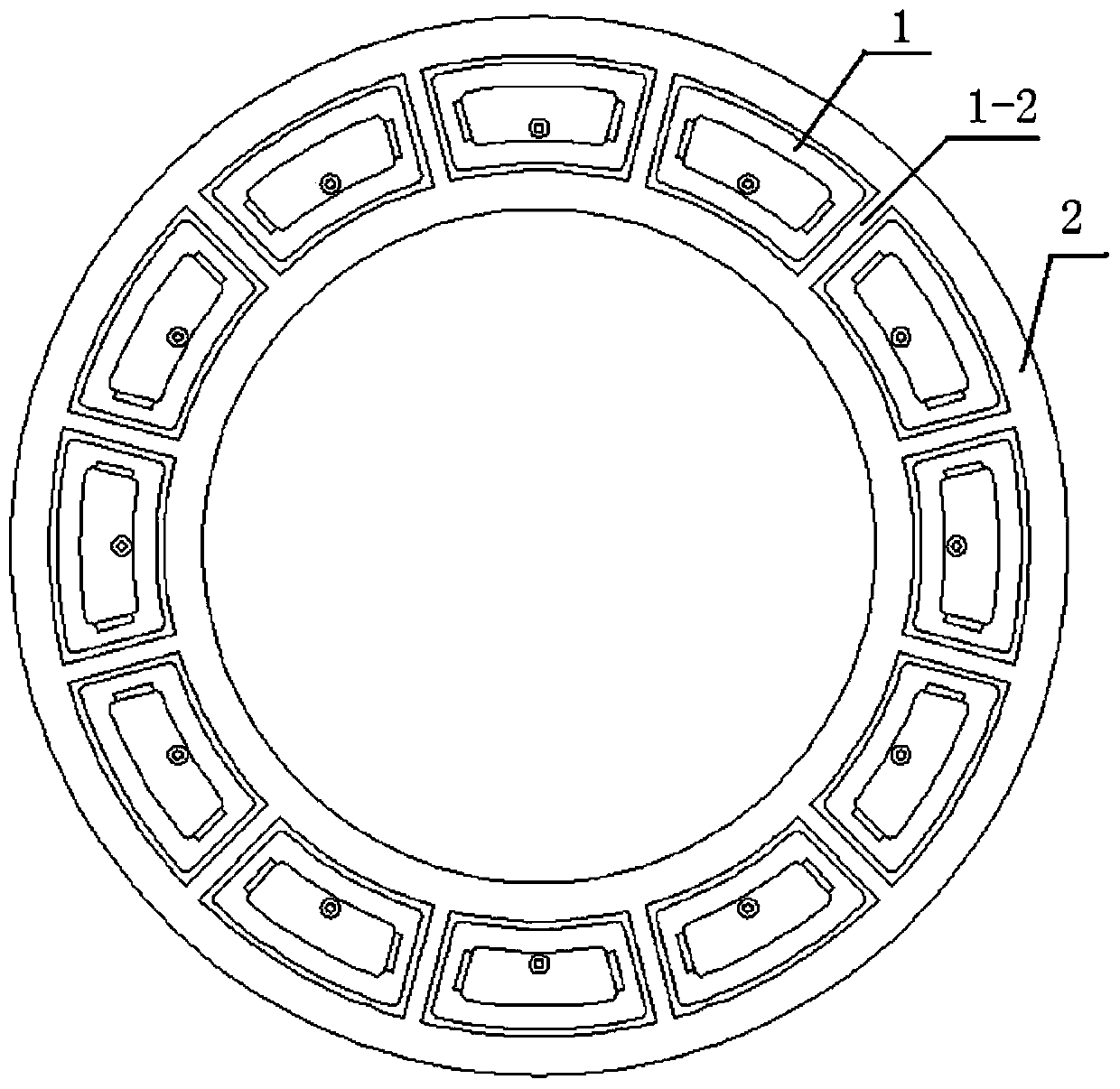

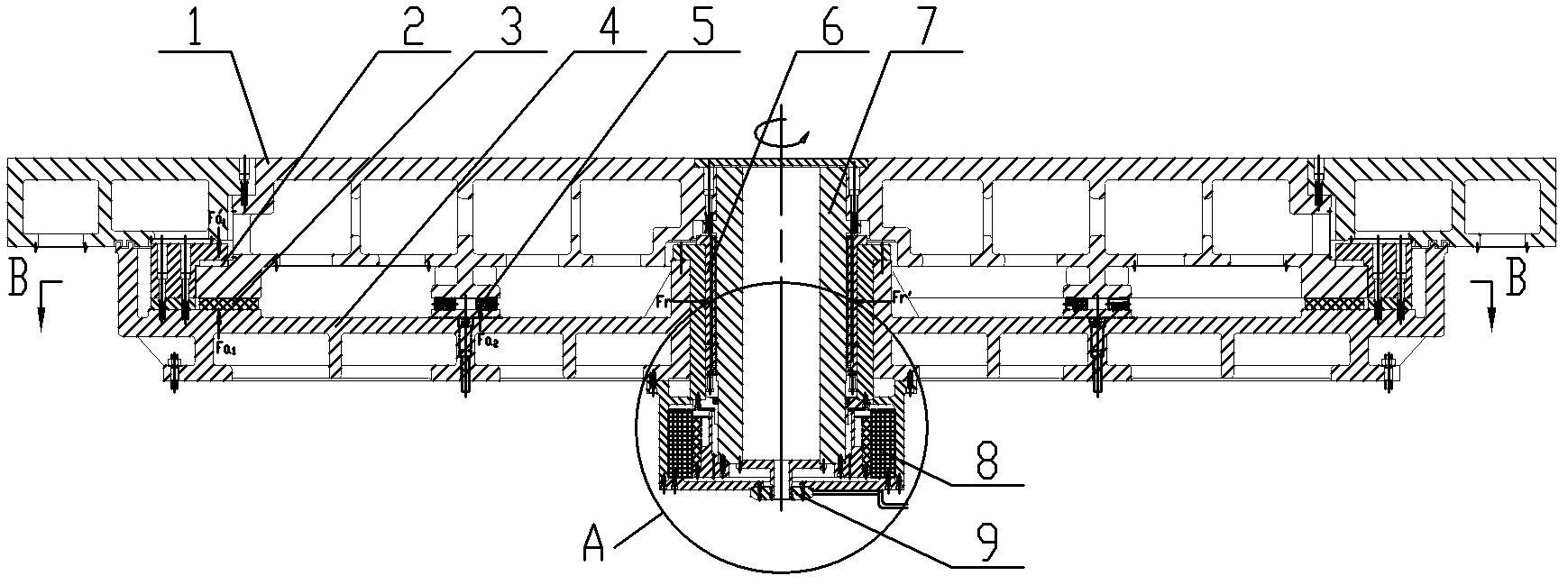

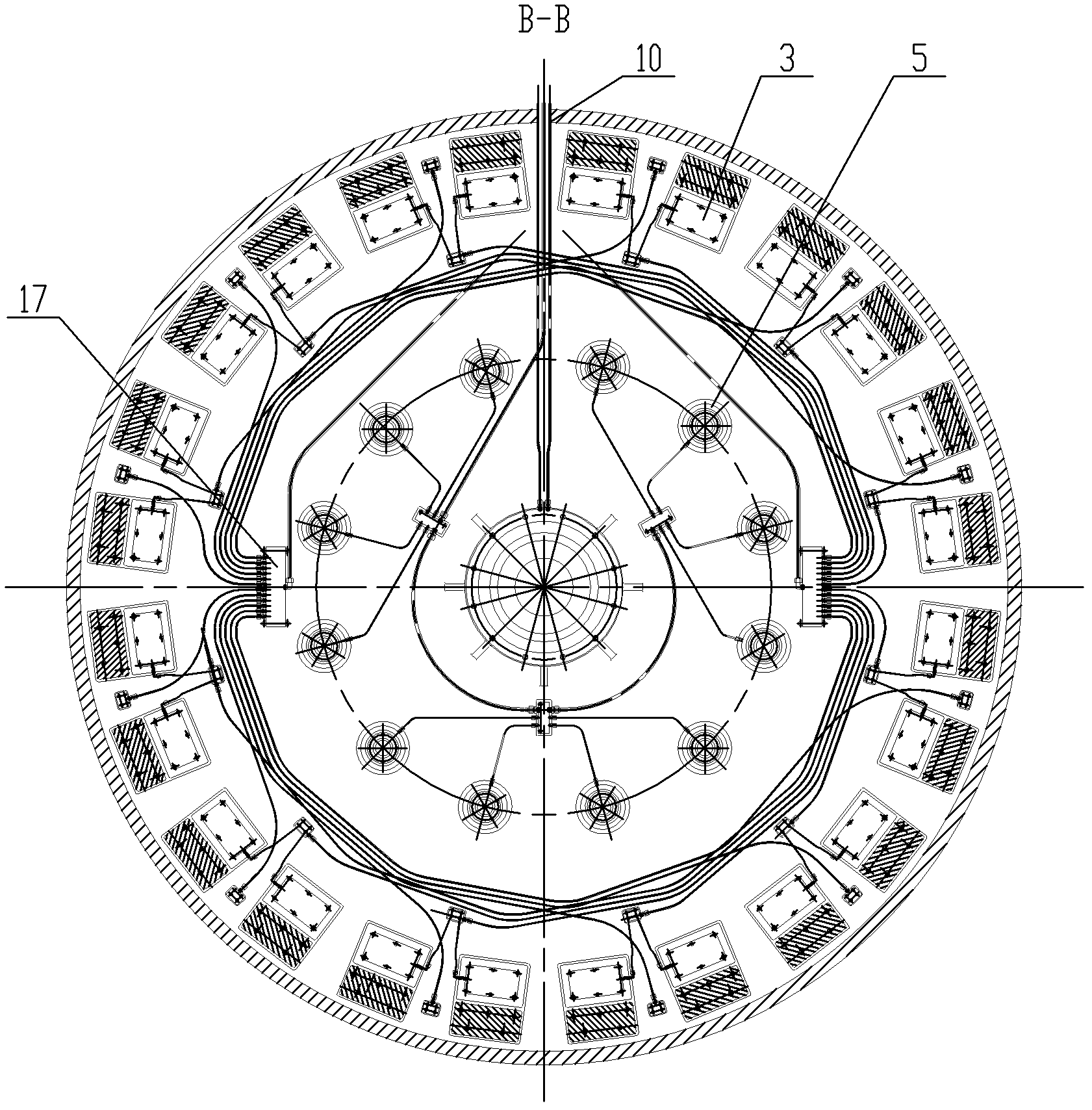

Two-way dynamic-static pressure mixture lubrication thrust bearing

InactiveCN103438097AHigh running precisionImprove running stabilityBearingsGas cushion bearingsThrust bearingEngineering

The invention relates to a two-way dynamic-static pressure mixture lubrication thrust bearing. Aiming to solve the problems of low accuracy and poor operating stability in an existing high-speed and heavy-load extreme working condition, the invention provides the two-way dynamic-static pressure mixture lubrication thrust bearing. The two-way dynamic-static mixture lubrication thrust bearing comprises a dynamic-static pressure oil pad, a circular machine tool base and a rotary workbench, wherein the rotary workbench is arranged right above the dynamic-static pressure oil pad; the circular machine tool base is arranged under the dynamic-static pressure oil pad; wedges are arranged on the dynamic-static pressure oil pad of the two-way dynamic-static pressure mixture lubrication thrust bearing and are arranged in two inner sides of the circumferential direction of an oil sealing edge. The two-way dynamic-static pressure mixture lubrication thrust bearing is applied to the field of high-speed and heavy-load machine tool workbenches.

Owner:HARBIN UNIV OF SCI & TECH

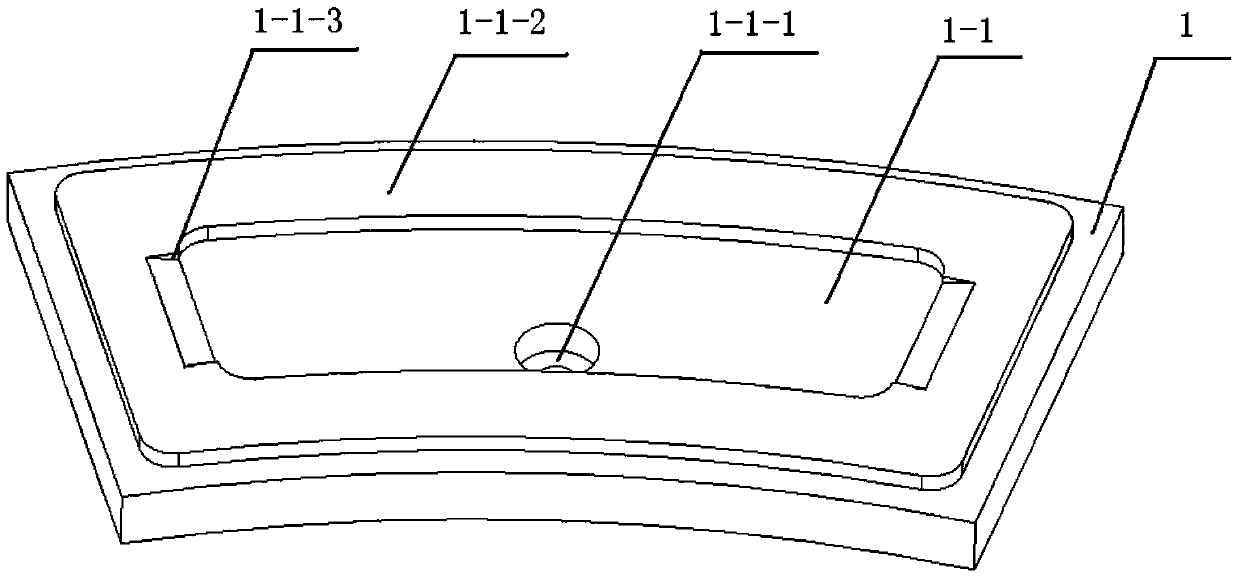

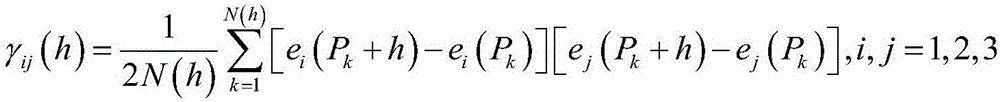

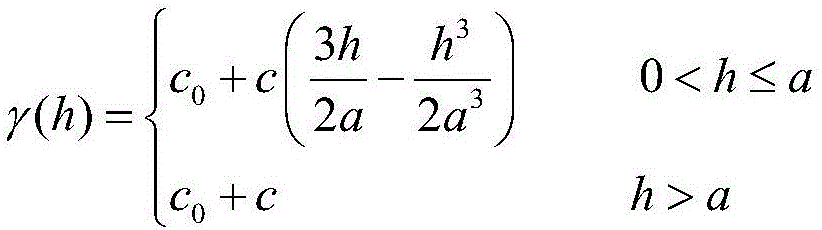

Industrial mechanical arm precision calibrating method based on collaborative Kriging

The invention discloses an industrial mechanical arm precision calibrating method based on collaborative Kriging and belongs to the technical field of robots. A device used for the method is composed of an industrial mechanical arm, a laser tracker and a target ball. The target ball is fixed to the tail end of the industrial mechanical arm and serves as a tool center point. According to the method, actual coordinates of some points are measured through the laser tracker; then position errors of theoretical coordinates and the actual coordinates of the points are obtained; and by building a crossover variation function and adopting a collaborative Kriging interpolation method, the position errors of the points in the movement space of the industrial mechanical arm are estimated. The method is simple, it is not needed to build a kinetic model of the industrial mechanical arm, and the method has the beneficial effects that universality is good, the running precision of the industrial mechanical arm can be improved, and inner parameters of an industrial mechanical arm controller device are not needed to be modified.

Owner:BEIHANG UNIV

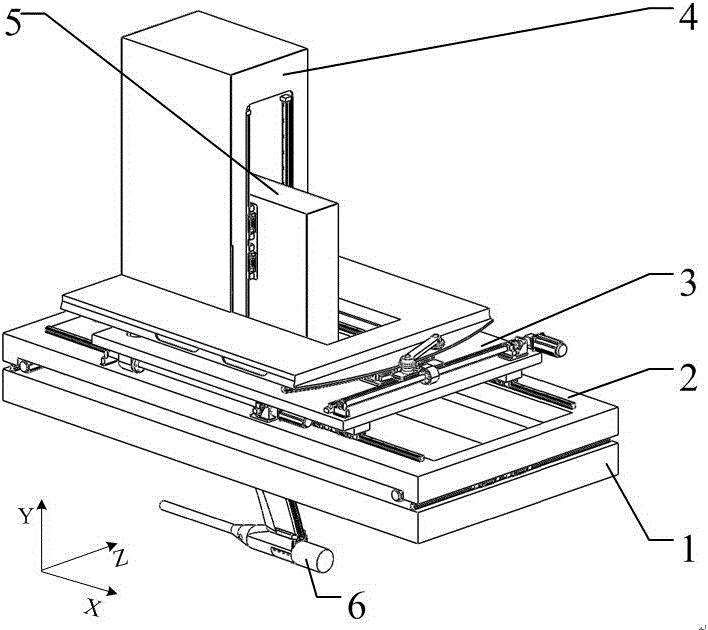

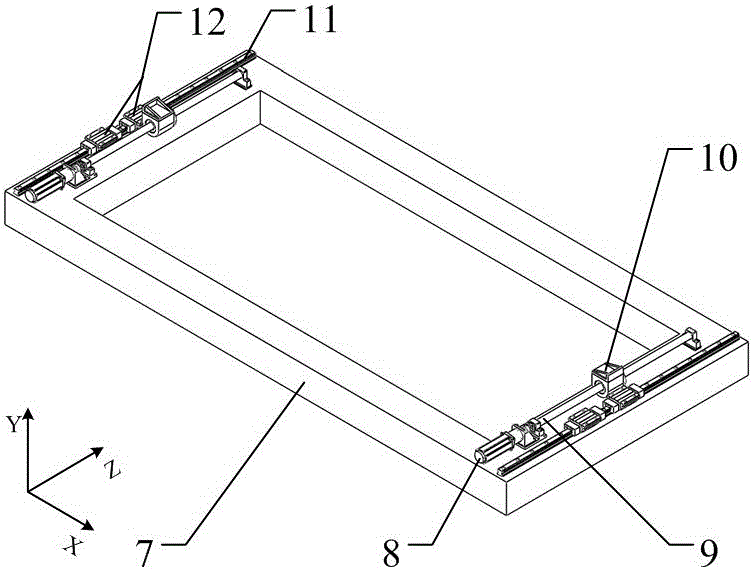

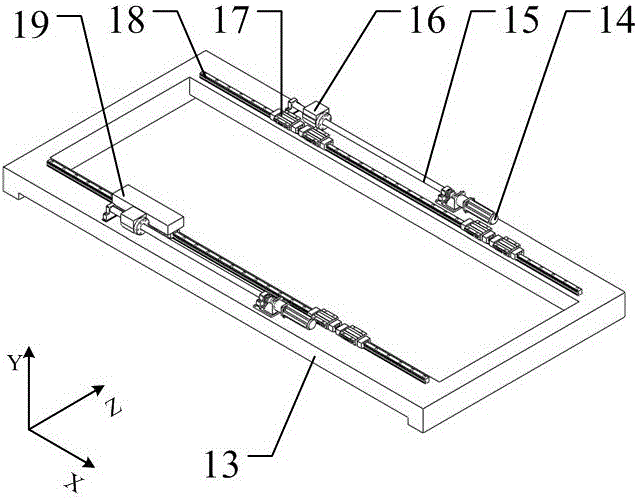

Space six-degrees-of-freedom mechanism used for hypersonic wind tunnel multi-body separation test

ActiveCN106124157ASmall degree of blockageGuaranteed independence movementAerodynamic testingThree degrees of freedomDrive motor

The invention provides a space six-degrees-of-freedom mechanism used for a hypersonic wind tunnel multi-body separation test. The mechanism comprises Z, X and Y three degrees of freedom straight-line motion mechanisms and [beta], [alpha] and [gamma] three degrees of freedom angular displacement motion mechanisms. The six-degrees-of-freedom are realized layer by layer and are connected step by step, and in terms of structure, embedment integration is achieved by a box stacking mode. A Z-direction mechanism, an X-direction mechanism and a [beta] mechanism are sequentially overlapped from bottom to top, and a Y-direction mechanism and a [alpha] mechanism are in embedded connection from outside to inside. A [gamma] mechanism is fixedly connected with the [alpha] mechanism through a bent blade, and is individually arranged in a wind tunnel flow field. Each of the Z-direction mechanism, the X-direction mechanism and the Y-direction mechanism adopts two driving assemblies in symmetric arrangement, so that the power and the size of a driving motor are effectively reduced, and the overall stability of the mechanism is improved. The [beta] mechanism and the [alpha] mechanism adopt line-to-arc mechanisms for implementation, so that overlapping of traditional three degrees of freedom rotation pairs is prevented, and the mechanism cantilever length is shortened. The structure is compact, the rigidity is good, andsix-degrees-of-freedom movement of high speed, high precision and high bearing capacity is achieved.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

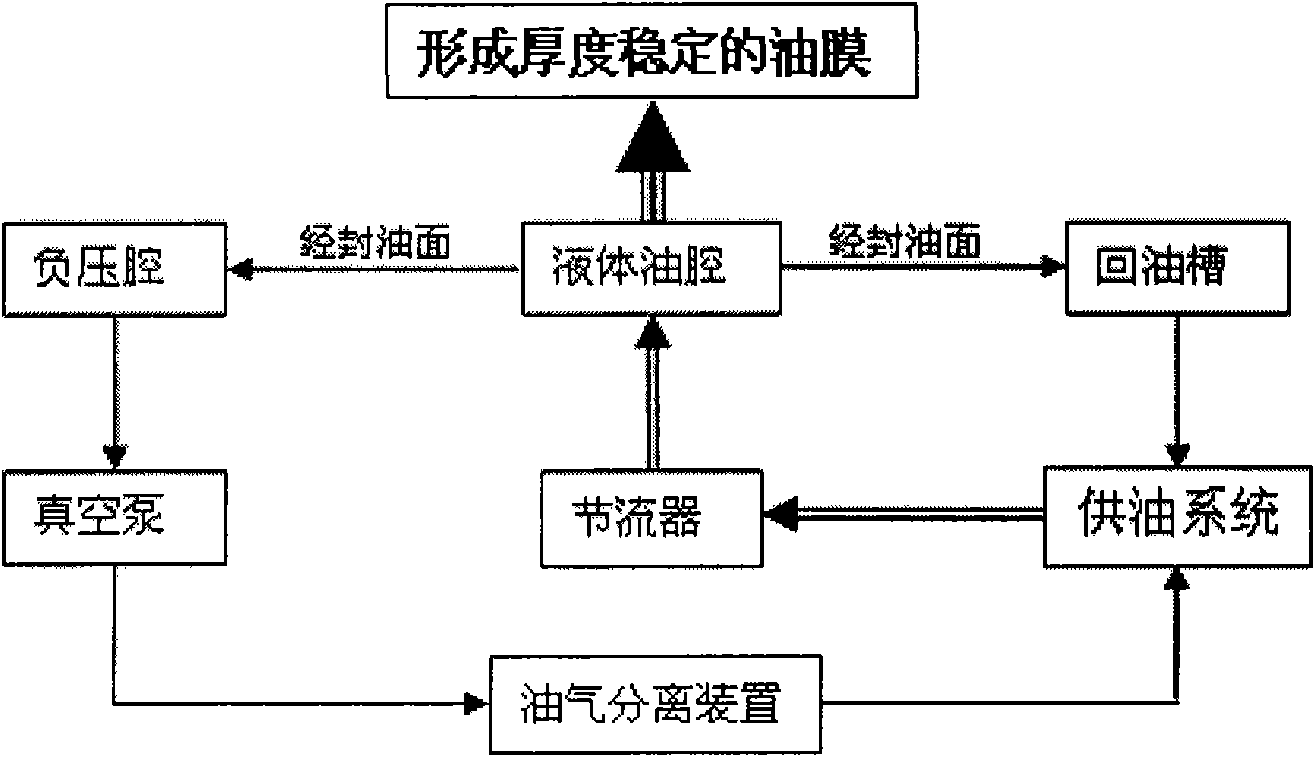

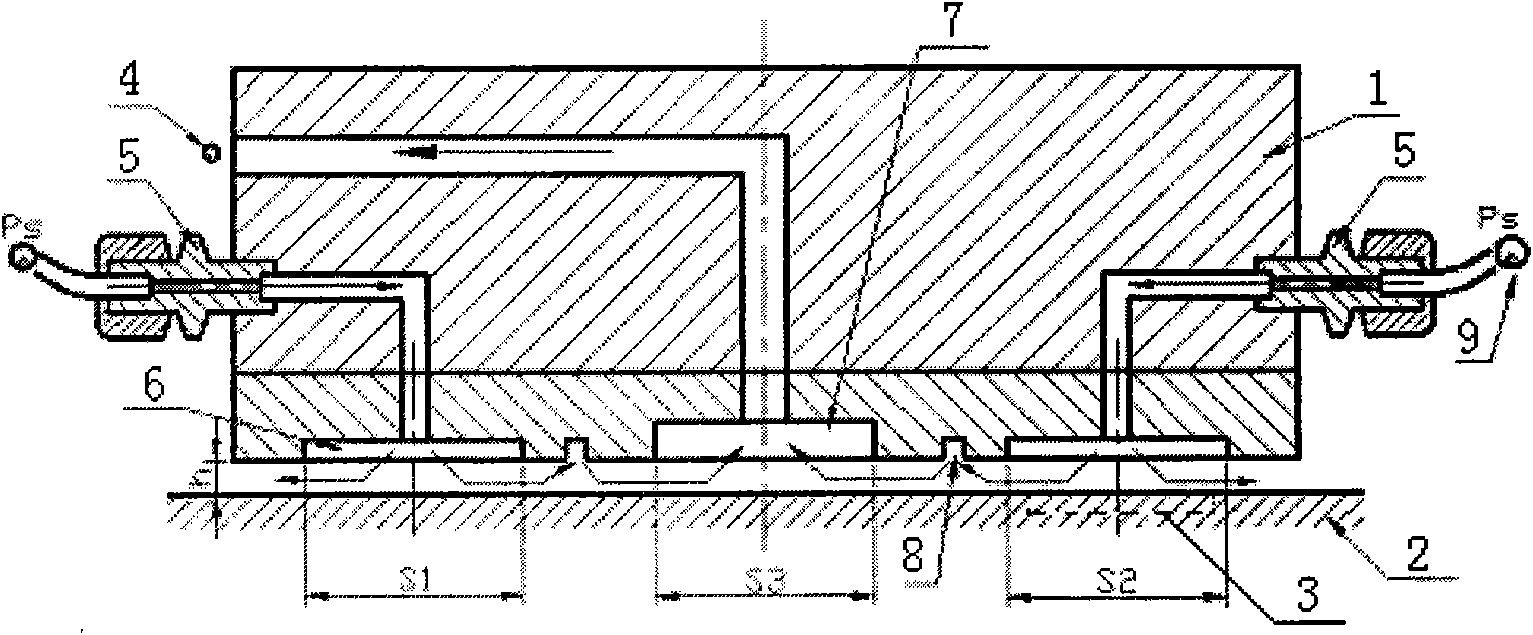

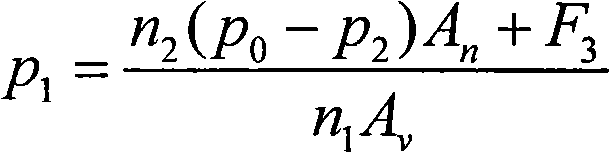

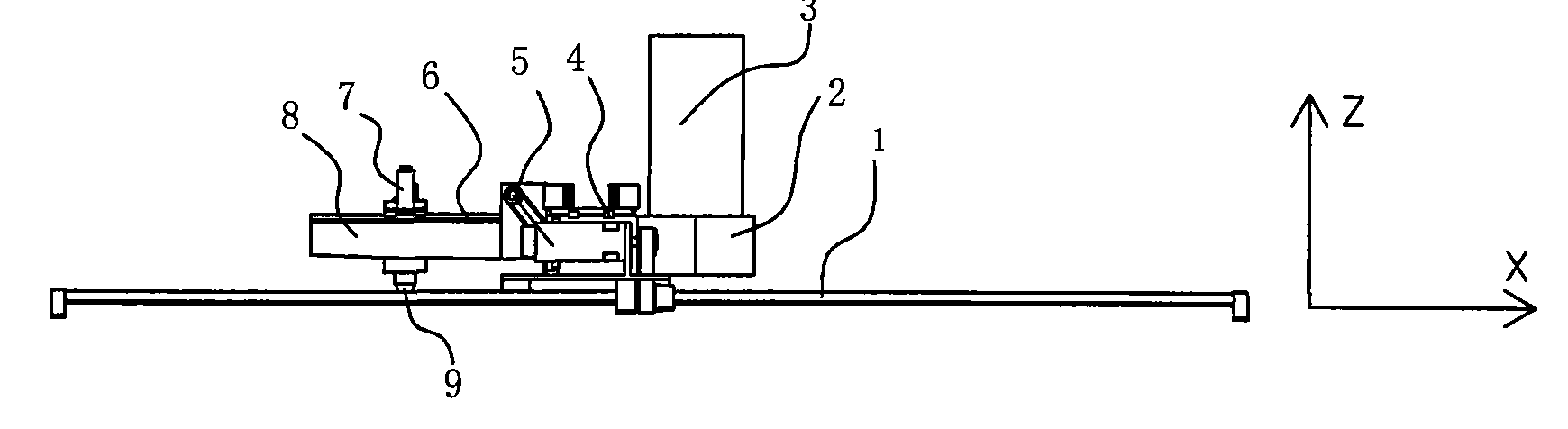

No-drifting high accurate open type static pressure guide rail

The invention relates to a no-drifting high accurate open type static pressure guide rail, which comprises a floating guide rail (1) and a supporting guide rail (2); the floating guide rail (1) is placed on the supporting guide rail (2); a static pressure oil chamber (6) and a negative pressure chamber (7) are formed on the contacting surface of the floating guide rail (1) and the supporting guide rail (2); an oil supply system (9) is connected to the static pressure oil chamber (6) by a restrictor (5); the negative pressure chamber (7) is connected with the vacuum pump (4); the vacuum pump is connected with the fuel supply system (9) by a oil gas separator; and a oil-returning groove connected with the oil supply system (9) is formed between the floating guide rail (1) and the supporting guide rail (2). The invention is simple and practicable, increases oil membrane rigidity, can regulate the oil membrane thickness by the vacuum pump, can be widely applied in open type static pressure guide rails with various structures, especially small and middle low load precision or super-precision machine tools such as precision roll grinding machine and sophisticated planer which are limited by the problem of drifting.

Owner:DONGHUA UNIV

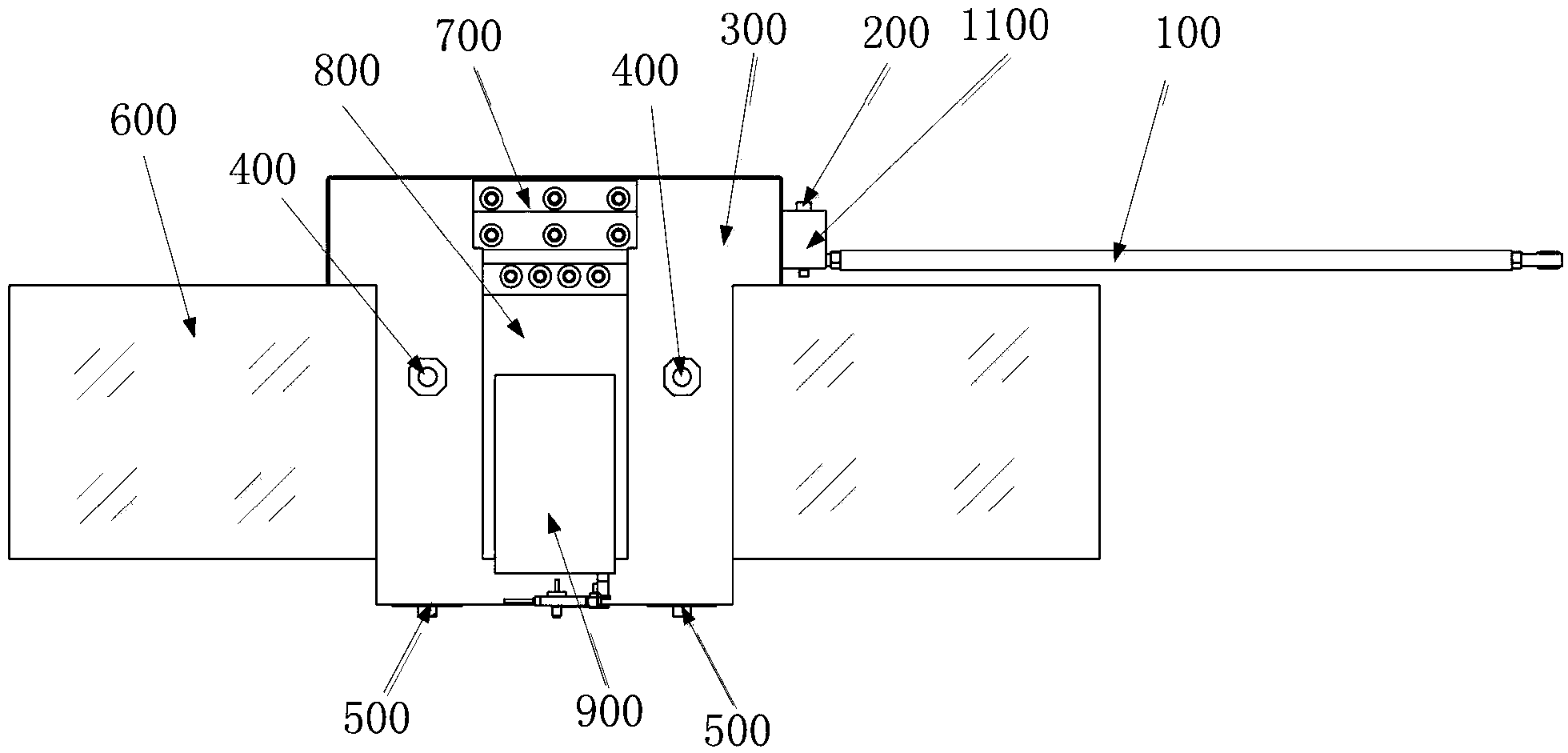

Laser cutting machine and working method thereof

ActiveCN101862909AGuaranteed uniformityHigh running precisionLaser beam welding apparatusLaser cuttingLong axis

The invention relates to a laser cutting machine and a working method thereof. Like a small-breadth laser cutting machine, the laser cutting machine of the invention has high cutting quality, high efficiency and high accuracy, and the consumed power of a driving system in the cutting process is smaller. The laser cutting machine comprises a stand provided with an X lead rail, a main beam provided with a Y lead rail and a laser head seat, wherein the main beam is movably connected with the X lead rail on the stand; the laser cutting machine also comprises a cantilever beam for a laser head to realize short-distance movement in the X direction; the cantilever beam is provided with an X short lead rail; the root of the cantilever beam is movably connected with the Y lead rail on the main beam to enable the cantilever beam to make Y-direction movement; and the laser head seat is movably connected with the X short lead rail. The working method comprises the following steps: 1. installing a buffer area on the short lead rail; 2. according to different processing requirements, calculating by different steps respectively; and 3. starting the laser cutting machine according to the calculating to manufacture. In the invention, a vector control principle is adopted to synthetize VX minor-axis speed, VX long-axis speed and VY speed so as to effectively control the speed in processing to ensure the processing quality.

Owner:扬州蝶湖科技产业发展有限公司

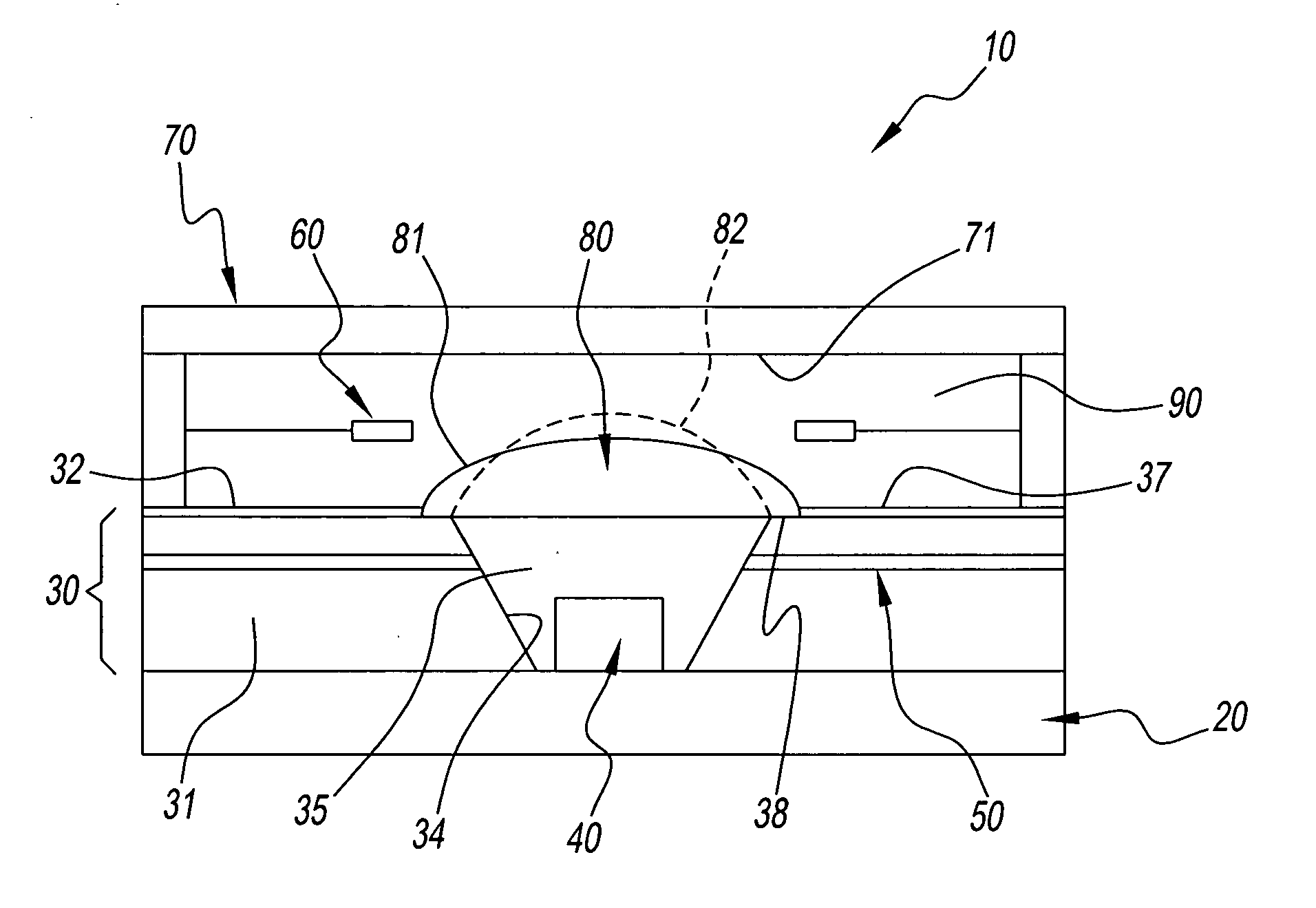

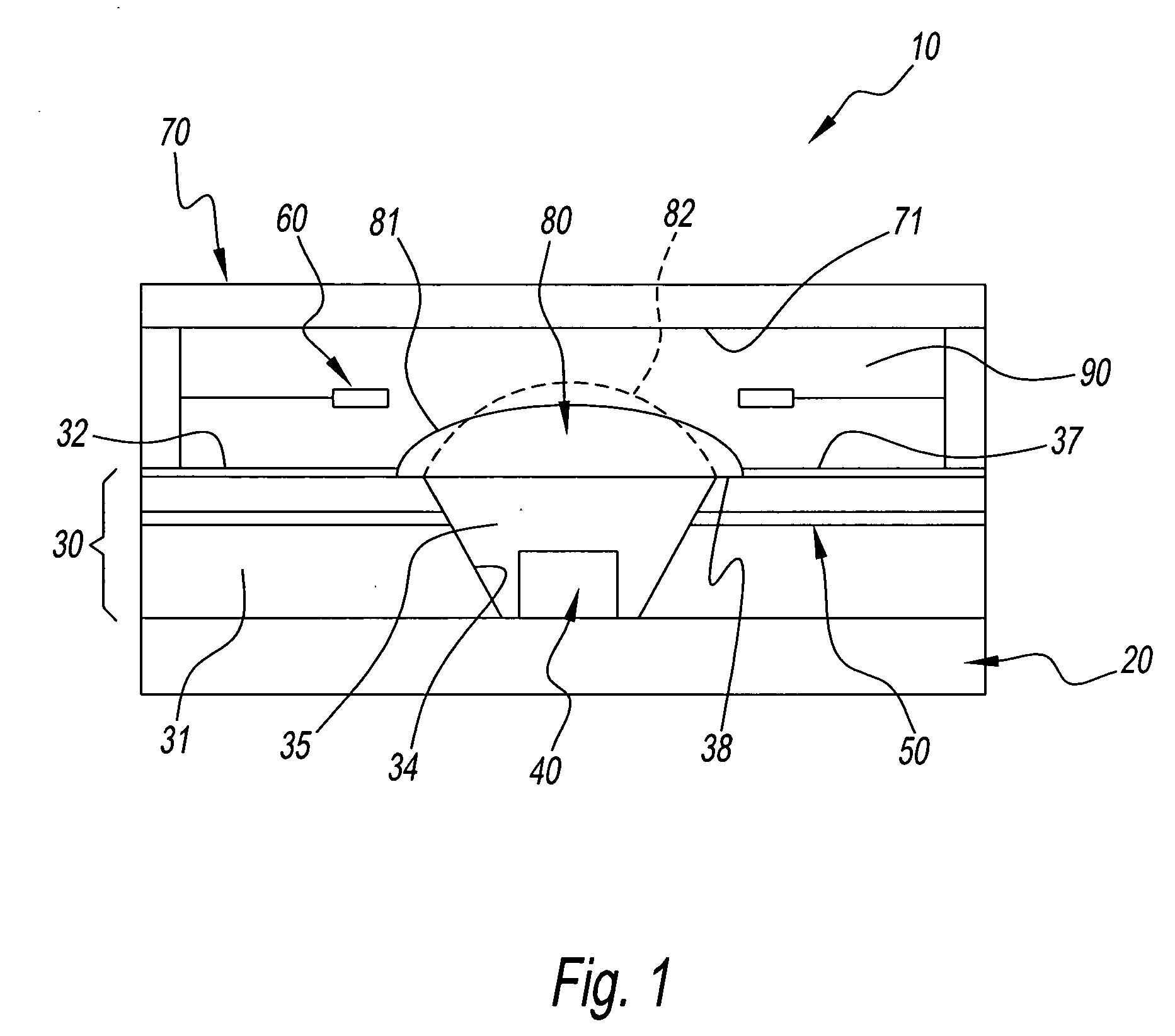

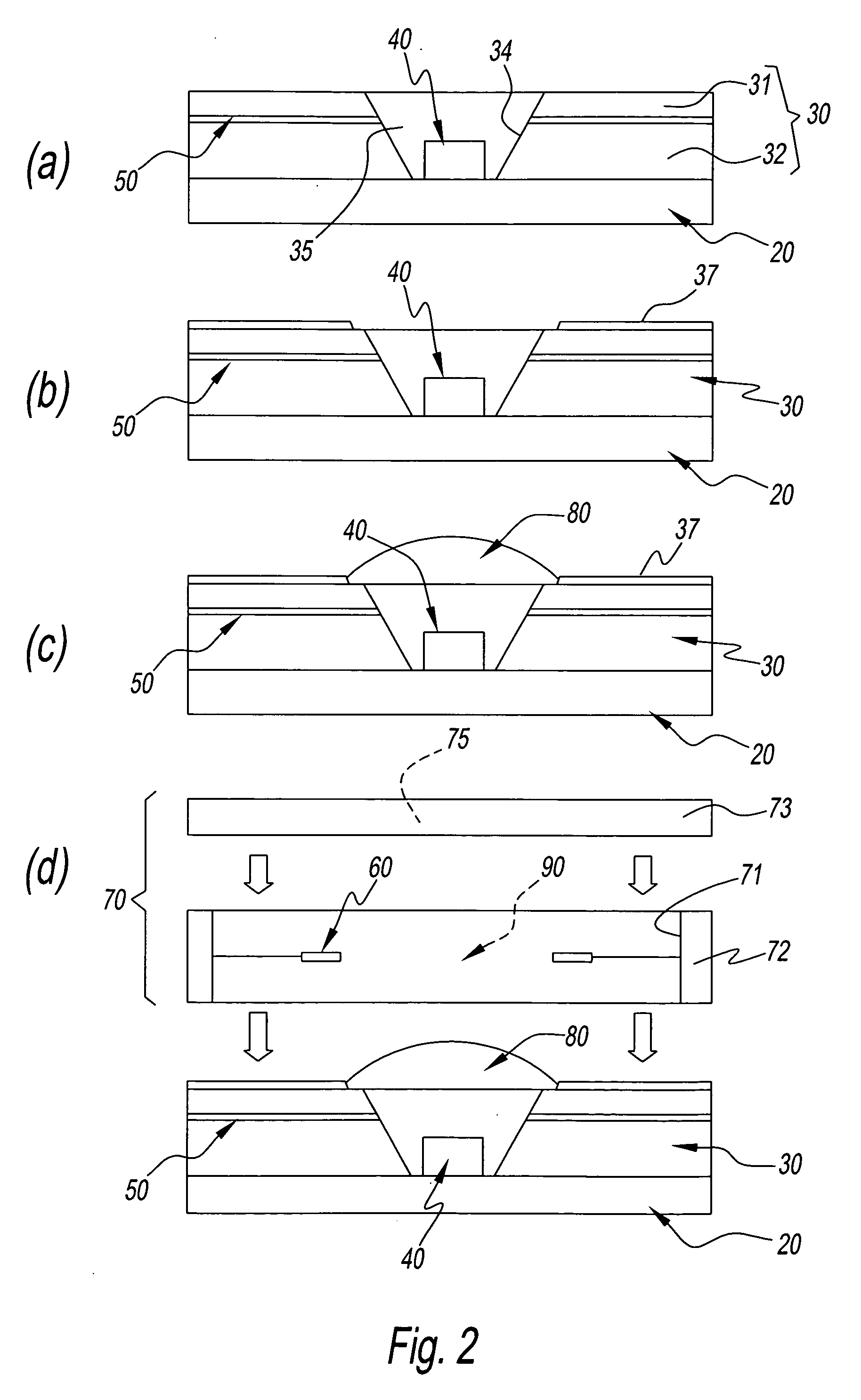

Light-emitting device and method of making same

InactiveUS20060114678A1Easy to handleHigh operating precisionSolid-state devicesGlobesEngineeringVoltage

A light-emitting device which comprises as one unit a semiconductor light-emitting element; a first liquid for condensing the light from the semiconductor light-emitting element; a second liquid that is separate from but contacts the first liquid; an airtight space in which at least first liquid and second liquid are disposed; and first and second electrodes to which voltage is applied so as to change the shape of the interface between first liquid and second liquid and adjust the condensed state of the light from semiconductor light-emitting element.

Owner:AVAGO TECH INT SALES PTE LTD

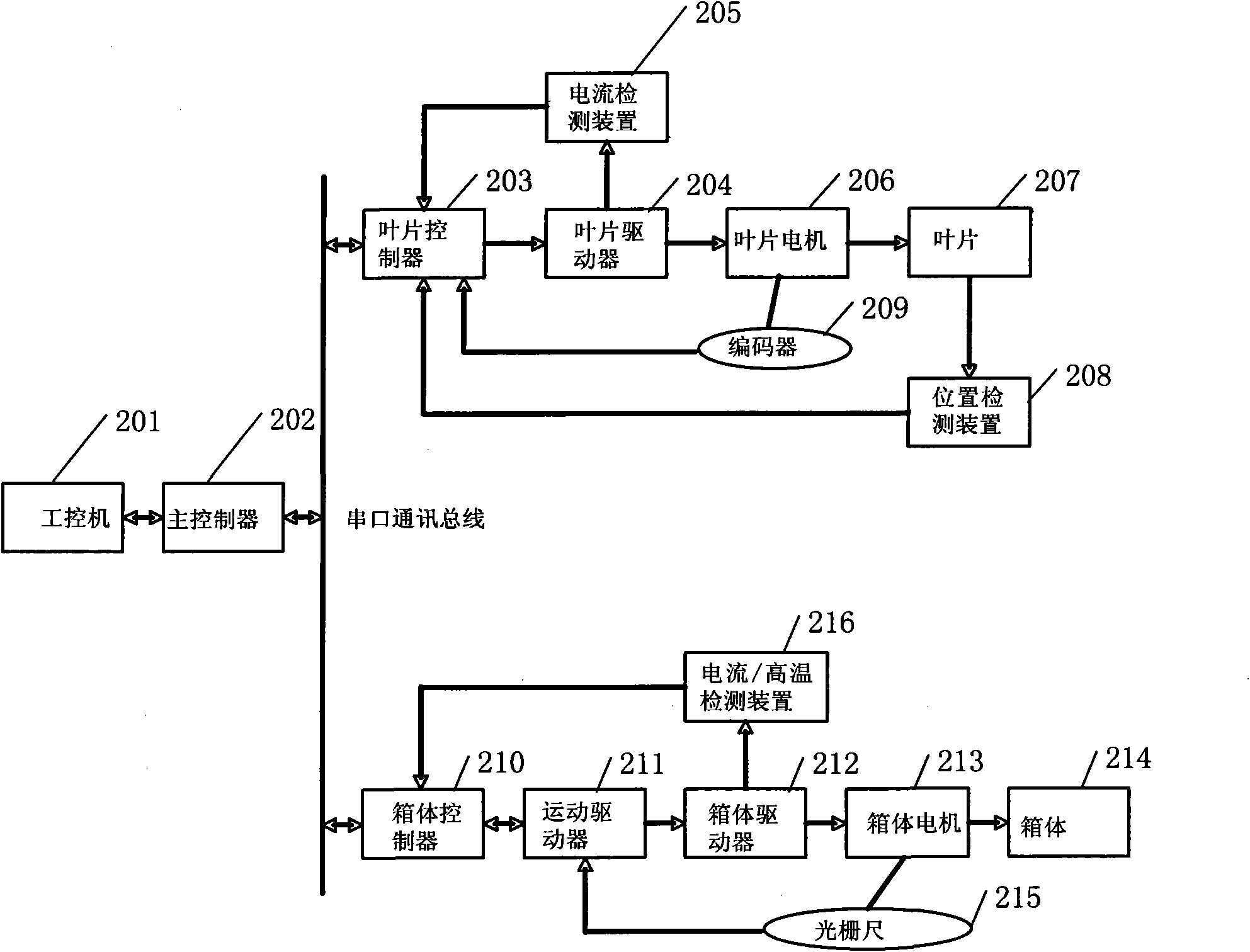

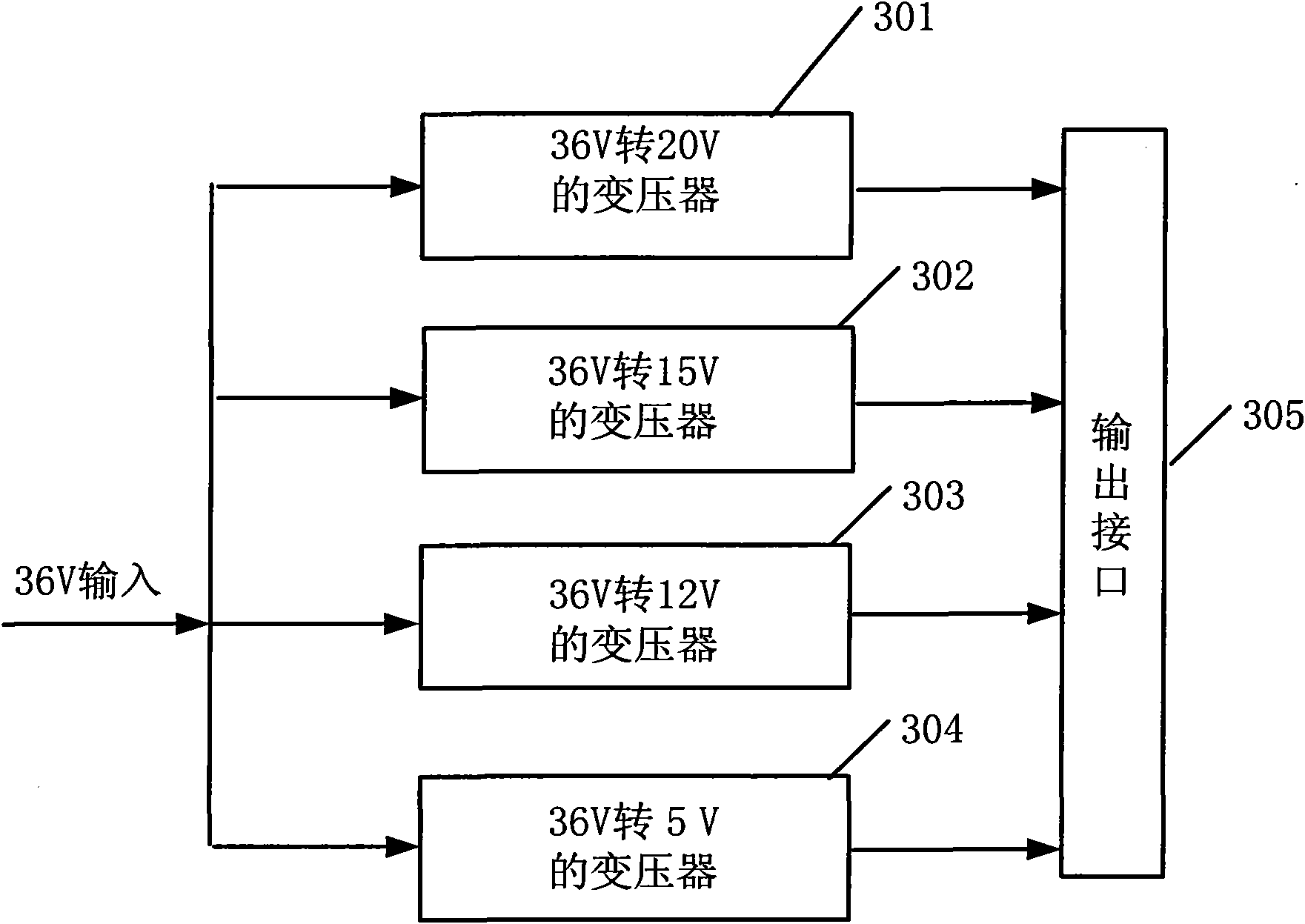

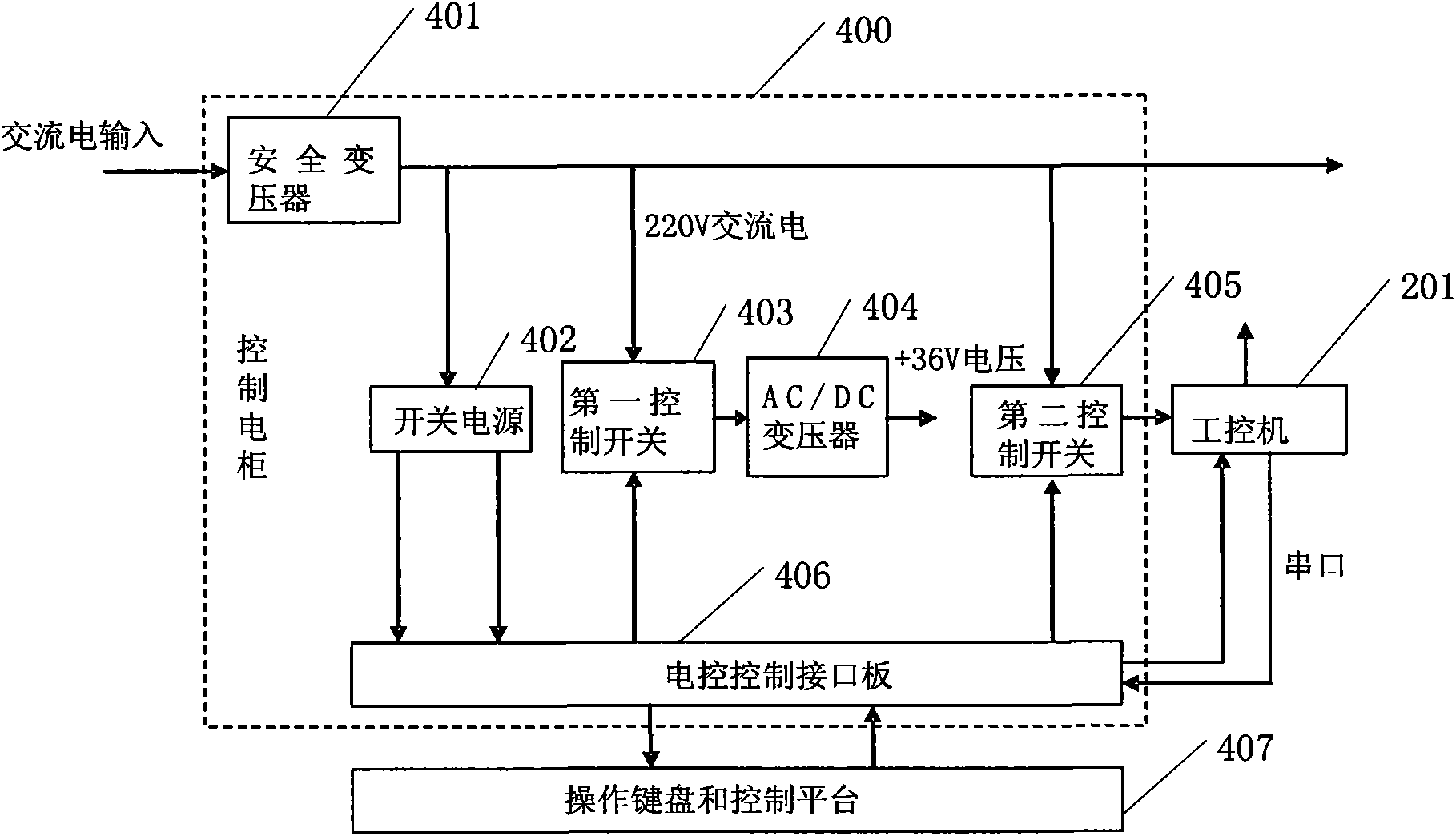

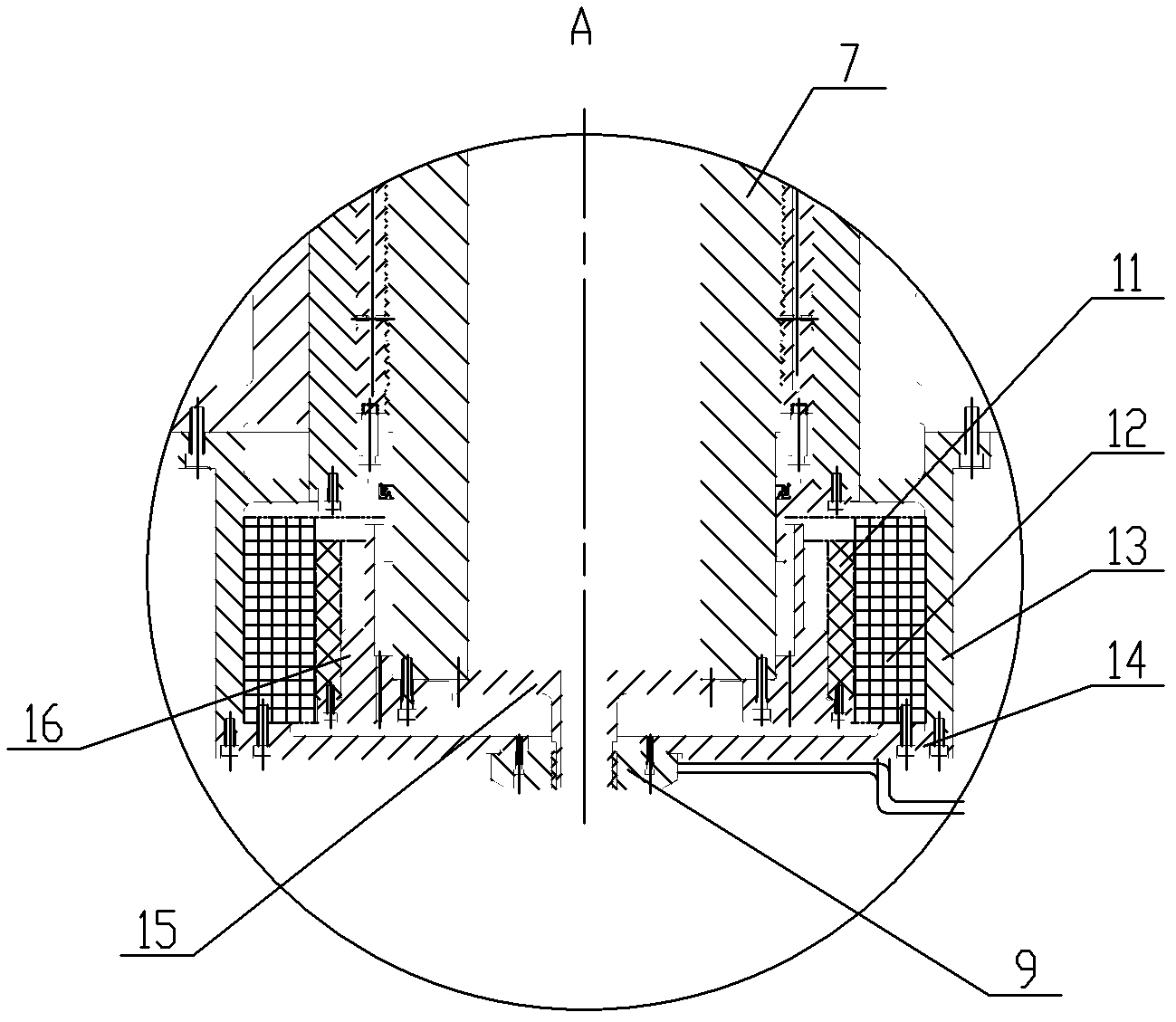

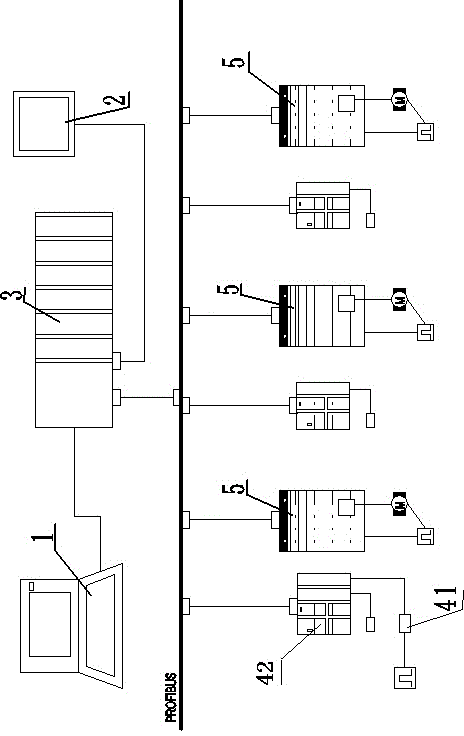

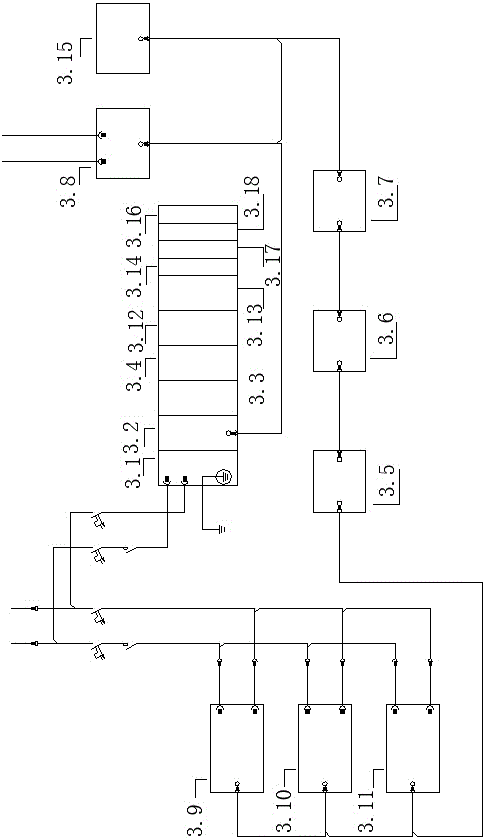

Multi-leaf collimator control system

ActiveCN102117051AHigh running precisionThe control process is stable and reliableProgramme controlComputer controlControl systemClosed loop feedback

The invention relates to a multi-leaf collimator control system, comprising an industrial control computer, and a main controller connected with the industrial control computer, wherein the main controller is connected with a blade and cabinet controller which controls and connects with a blade and cabinet driver; the blade and cabinet driver is in driving connection with a blade and cabinet motor which is in transmission connection with a blade and a cabinet body; the blade and the cabinet body are provided with position detectors which are connected with the blade and cabinet controller to form a feedback loop; and the driver is connected with the blade and cabinet controller by a current detector to form a feedback loop. The multi-leaf collimator control system is controlled by the industrial control computer, realizes the closed-loop feedback adjustment by using an encoder or a linear scale, and improves running precision of the blade and the cabinet body; moreover, the control process is stable, reliable, convenient and rapid.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

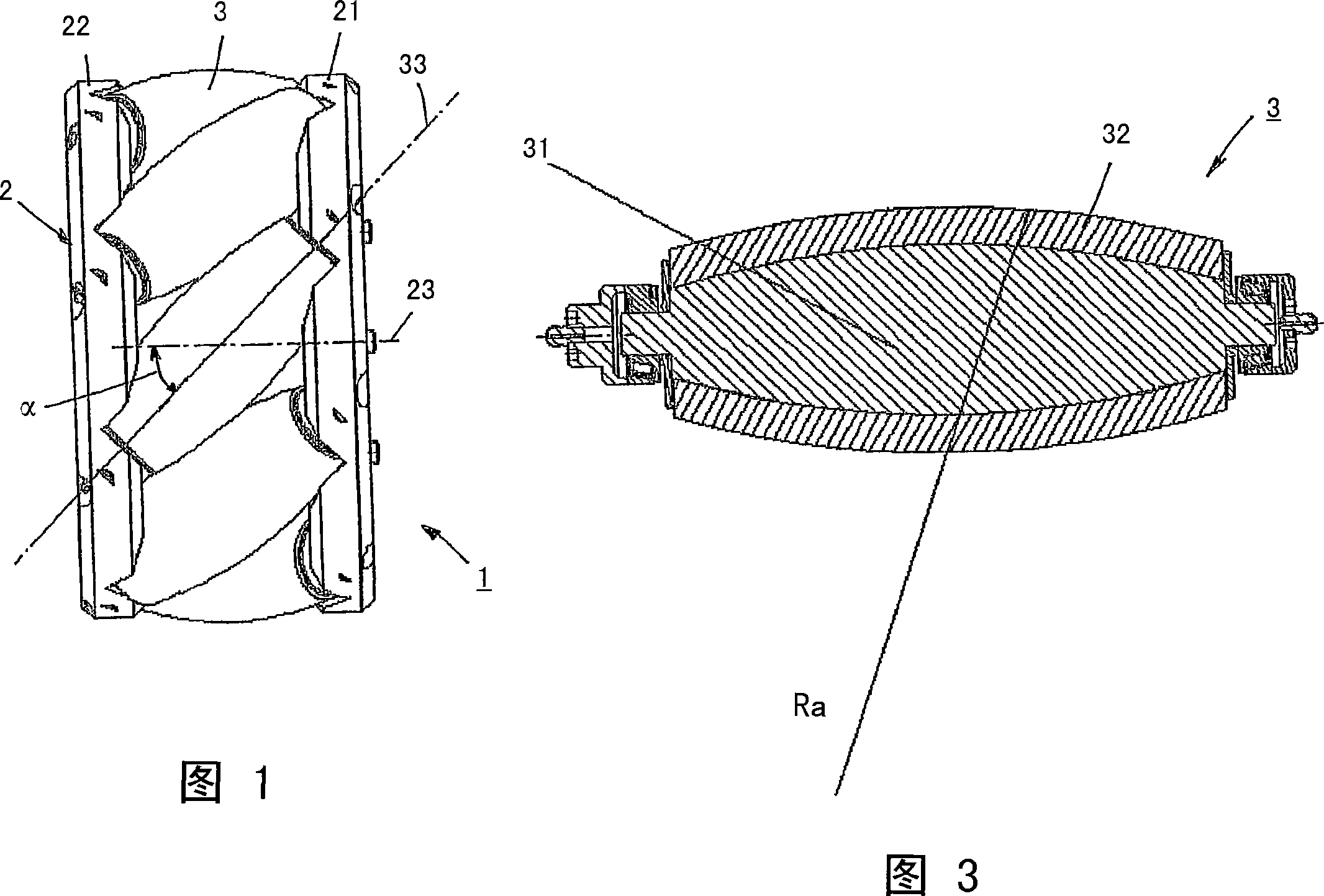

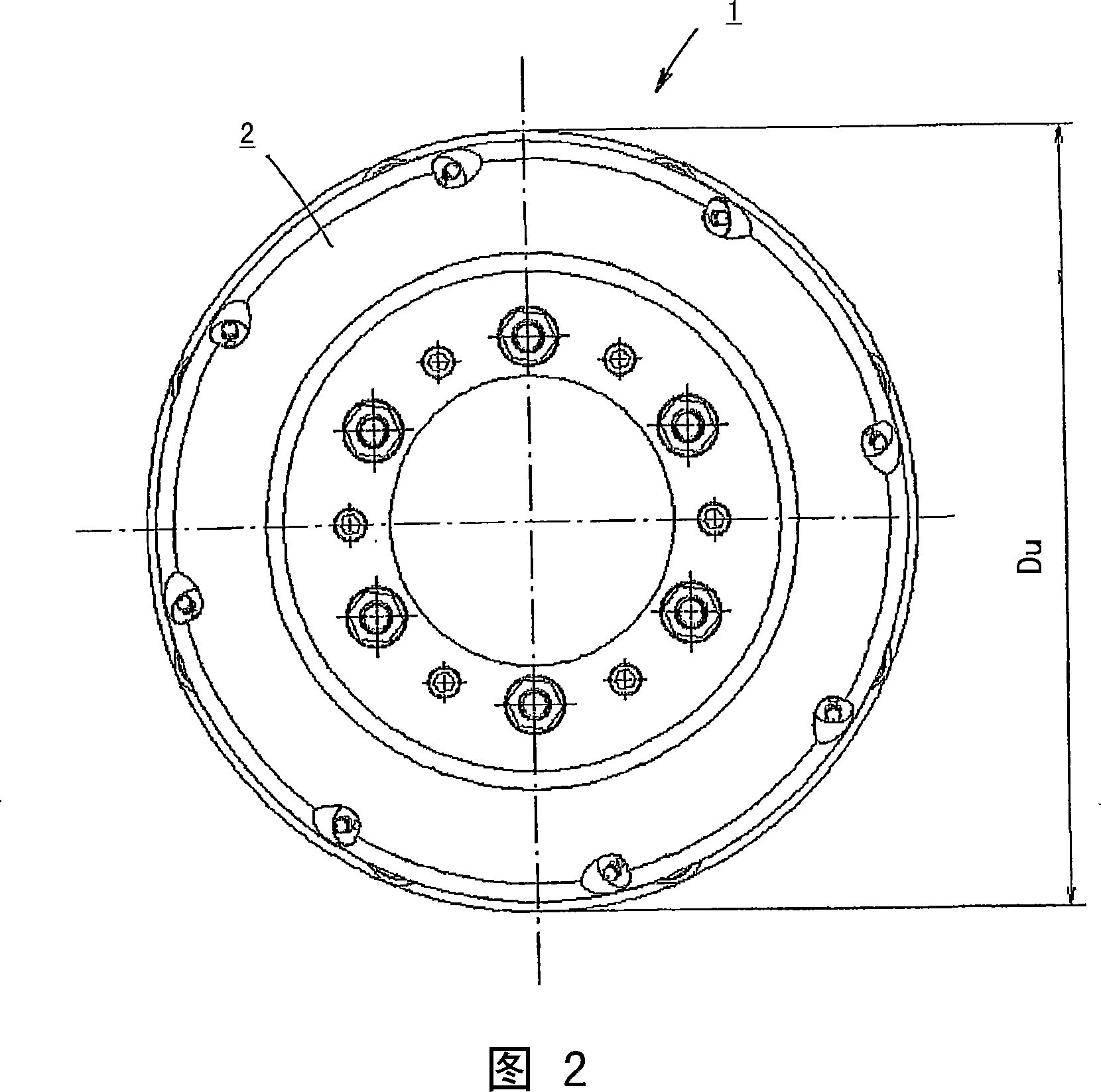

Wheel

The invention relates to a wheel (1) with a driven wheel body (2), comprising two support elements (21, 22), between which a number of roller bodies (3) with a spherical surface are arrange to rotate, which at least partly extend beyond the circumference of the support elements (21, 22) the rotational axes of which are arranged at an angle to the rotational axis (23) of the wheel body (2). The ratio of the outer diameter (Du) of the wheel (1) to the maximum radius (Ra) of the roller body (3) is between 1.08 and 1.13, in particular, between 1.09 and 1.12.

Owner:KUKA ROBOTER

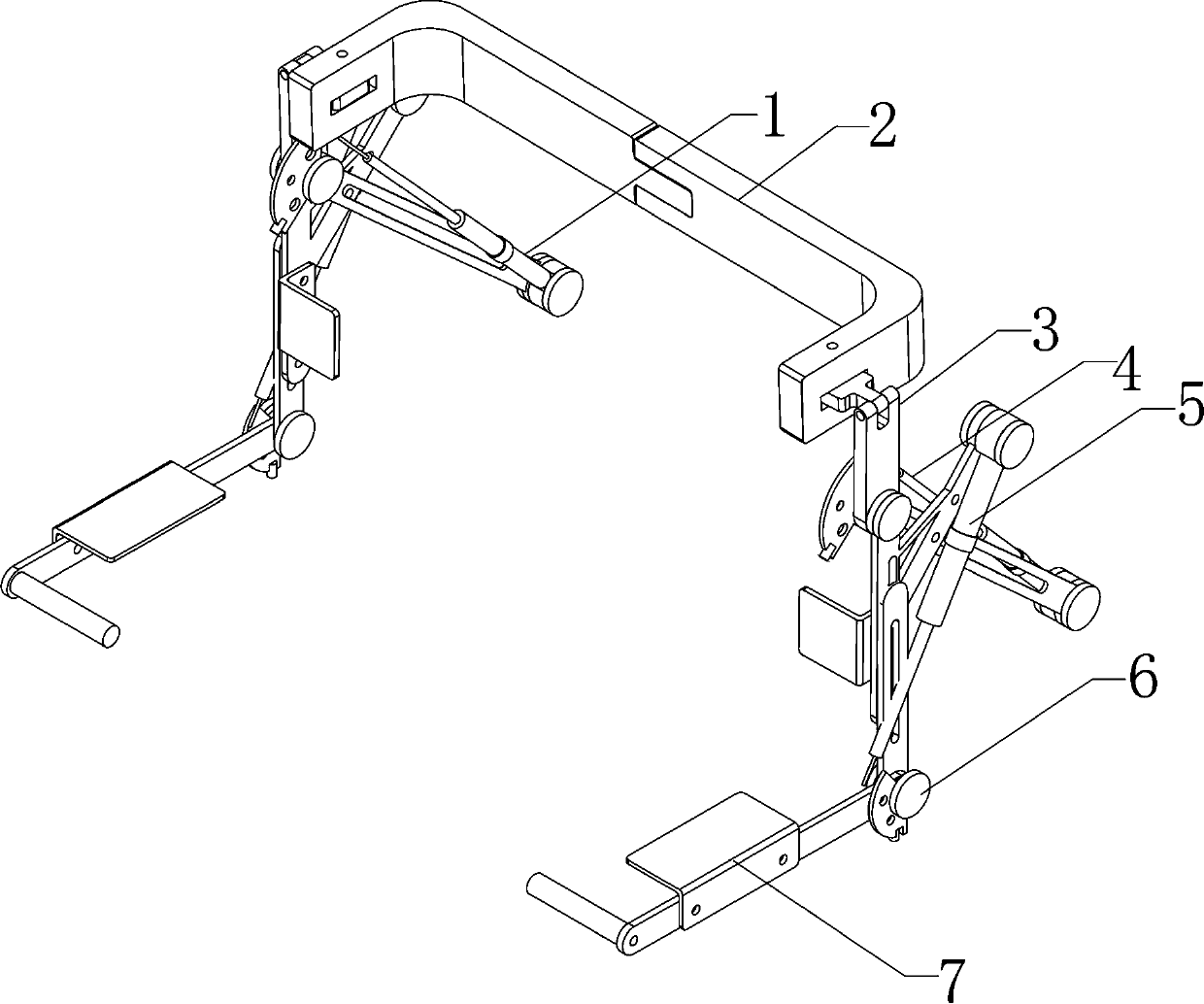

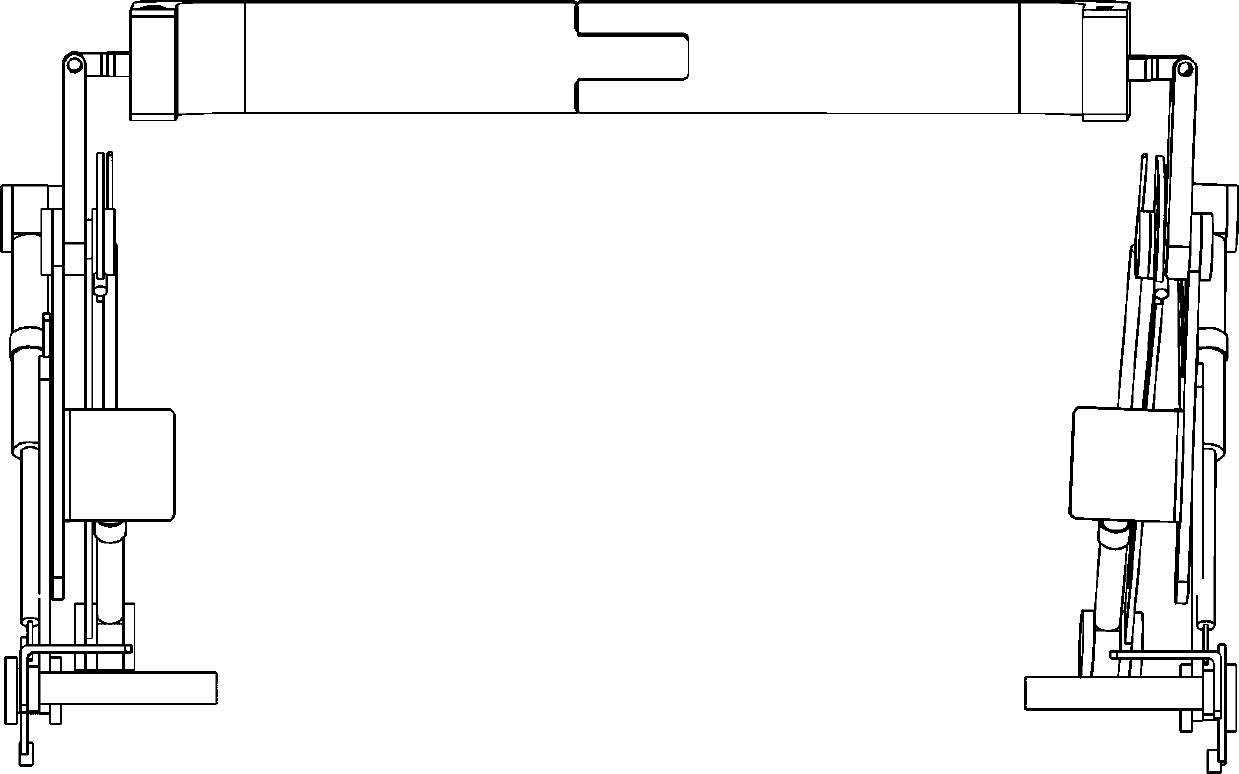

Upper limb powered exoskeleton mechanism system

PendingCN107671848AEnhanced system stiffness and stabilityImprove compliance and running precisionProgramme-controlled manipulatorStructural rigiditySystem structure

The invention provides an upper limb powered exoskeleton driving system. The upper limb powered exoskeleton driving system is composed of an upper arm gas and liquid driving cylinder, a strap, shoulder inner side joints, shoulder front stretching joints, a lower arm gas and liquid driving cylinder, elbow joints and a lower arm supporting frame. According to the upper limb powered exoskeleton driving system, the gas and liquid series connection cylinders serve as a driving executor of the shoulder joints and the elbow joints in an upper limb powered exoskeleton mechanism, on the basis that fastness of an original pneumatic system is retained, the rigidity and stability of the system are enhanced by means of a hydraulic portion, the defects that the pneumatic system is poor in stability, lowin structural rigidity and the like are overcome, and meanwhile the compliant capacity and the running precision of the system are improved. Compared with pneumatic, electric and hydraulic systems, the upper limb powered exoskeleton mechanism system has the beneficial effects of being high in power-to-mass ratio and power-to-volume ratio, high in responding speed, low in cost, clean, free of pollution and the like, the compliance of exoskeletons can be improved, and the total weight of the system is reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

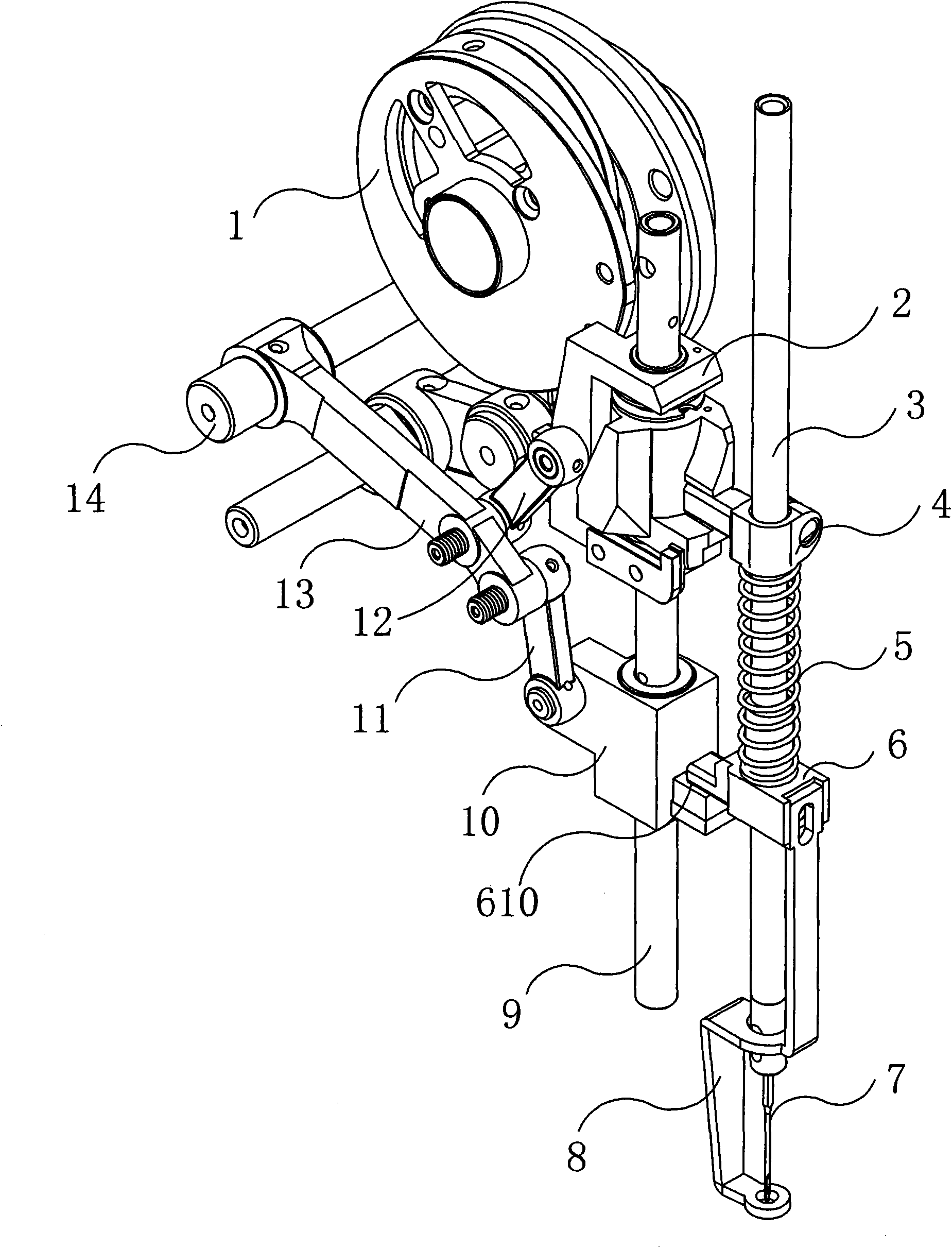

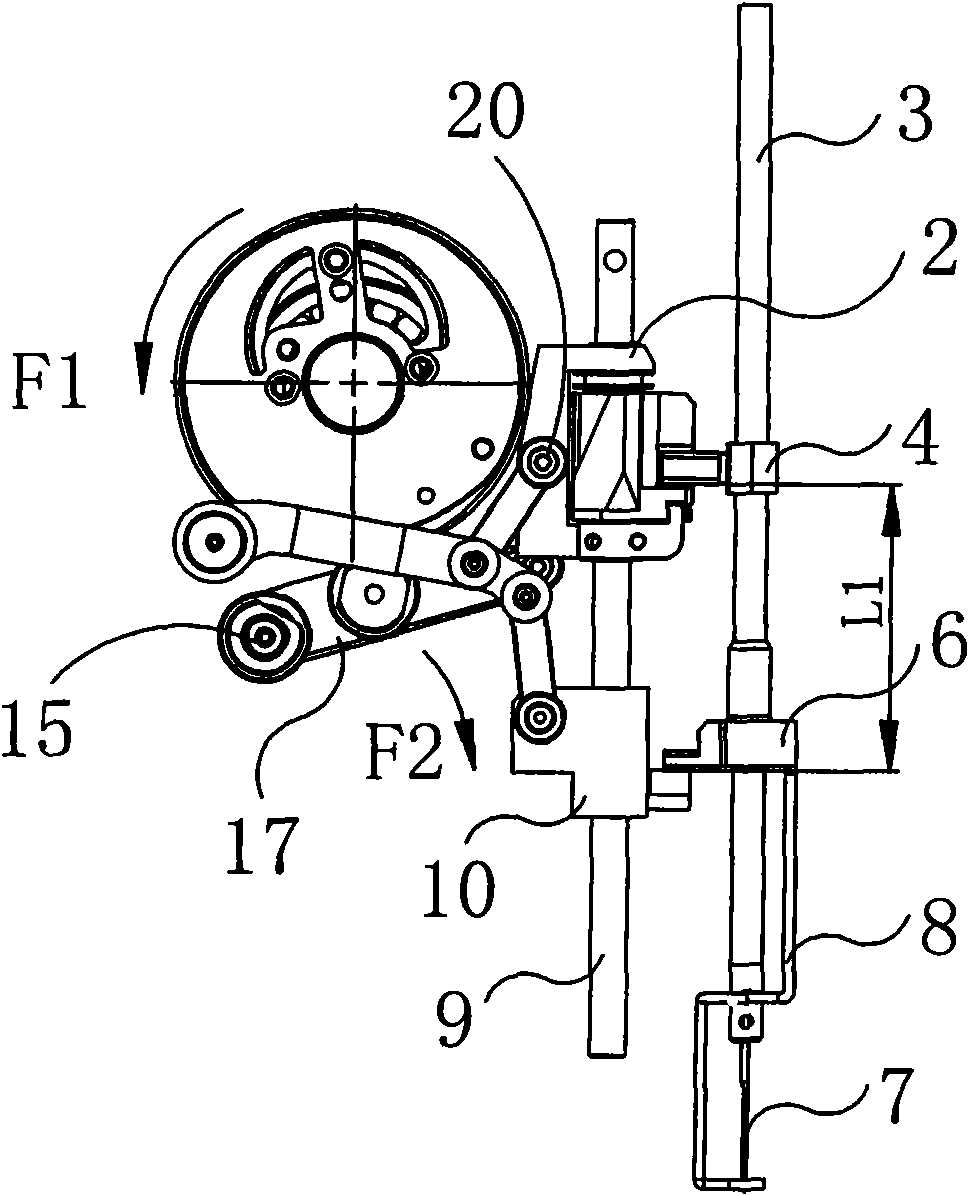

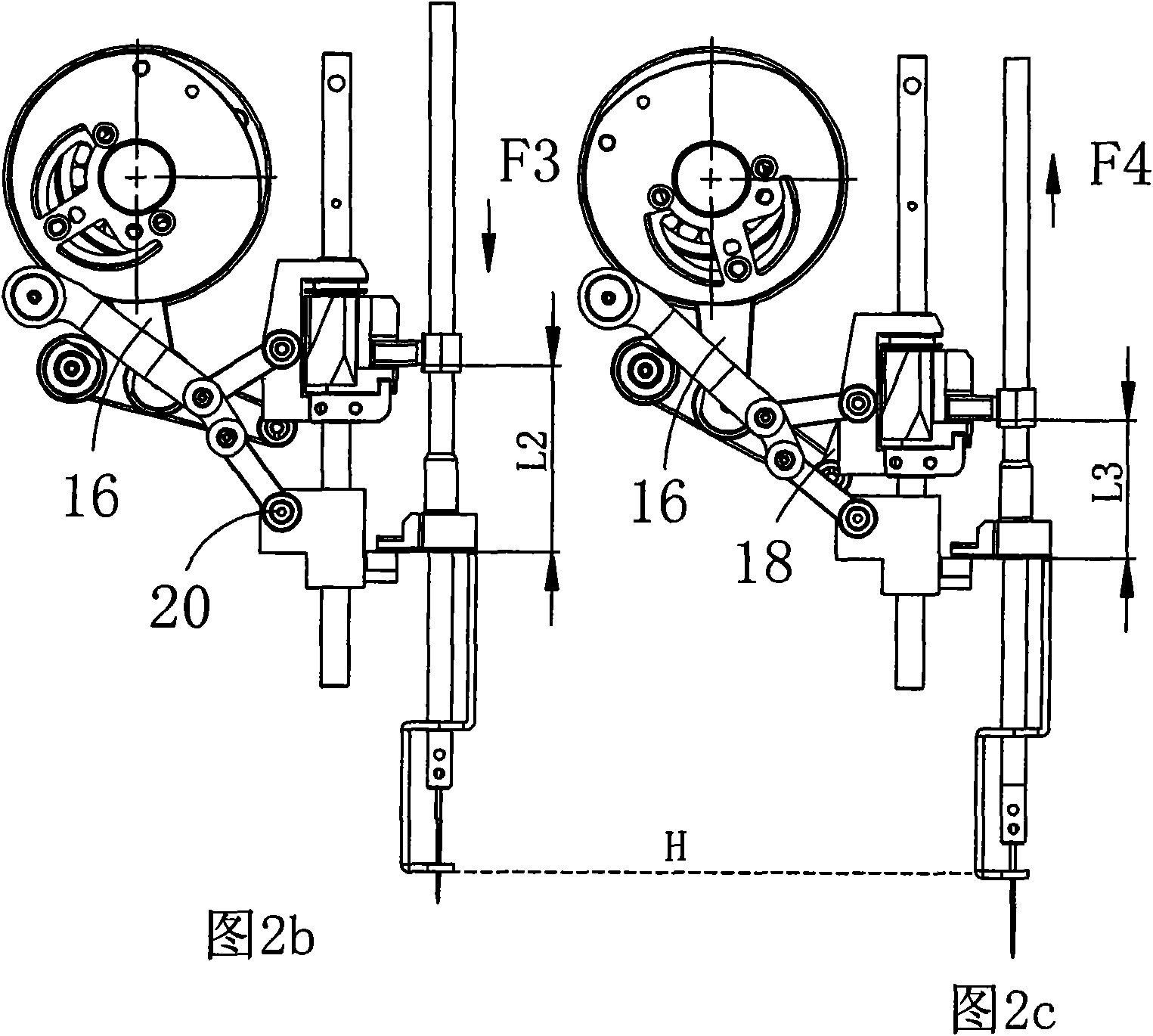

Auxiliary lifting mechanism of presser foot of computerized embroidery machine

InactiveCN101775716AReasonable designSimple structurePressersEmbroidering machines apparatusMechanical engineeringSynchronism

The invention relates to an auxiliary lifting mechanism of a presser foot of a computerized embroidery machine, which is designed aiming at the technical problem of poor structure of the auxiliary lifting mechanism (a cam mechanism) of the presser foot of the computerized embroidery machine. A link mechanism adopting three connecting rods is arranged in the auxiliary lifting mechanism of the presser foot and is in a Y shape, one end of the link mechanism is fixed in a casing of a machine head by a shaft A, and the other two ends are respectively fixed at a slide block A and a slide block B. In a group of link mechanism comprising a three-hole connecting rod A, a two-hole connecting rod B and a two-hole connecting rod C, the three-hole connecting rod A is bent in an arc shape; and a hole C1 of the three-hole connecting rod A is connected with a hole A2 of the two-hole connecting rod B by a pin shaft, and a hole A1 of the three-hole connecting rod A is connected with a hole A3 of the two-hole connecting rod C by a pin shaft. The invention has high running accuracy, small noise, convenient maintenance, assembly and use, good movement matching synchronism and stability, low production cost and extensive application range and is suitable for a high-speed computerized embroidery machine and similar tailoring equipment.

Owner:冯品牛

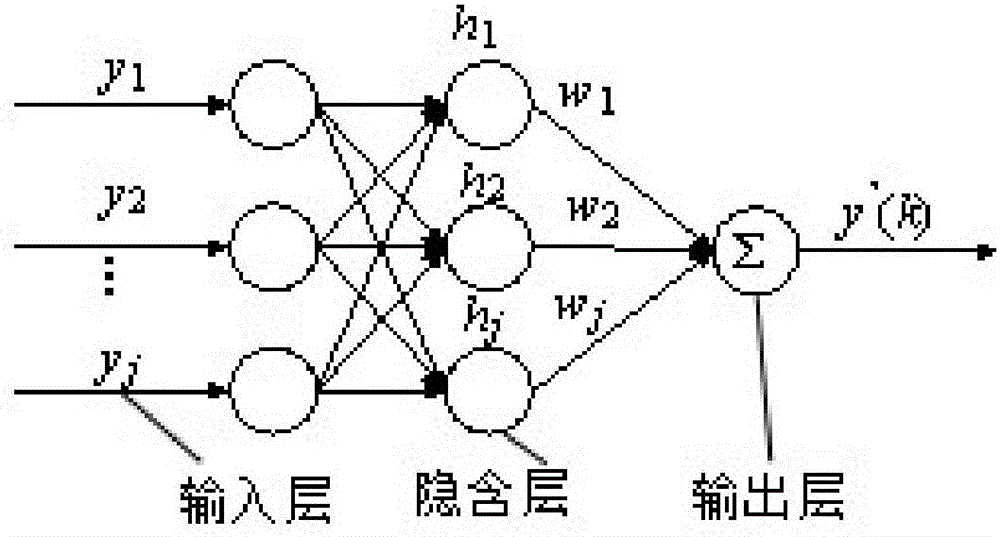

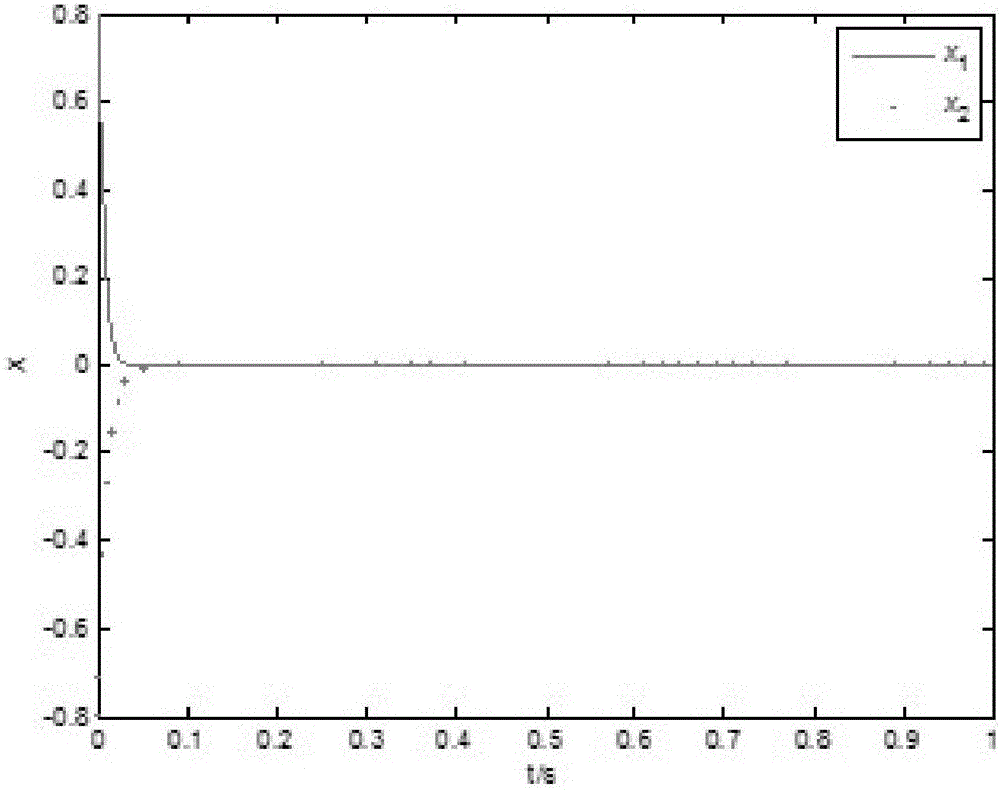

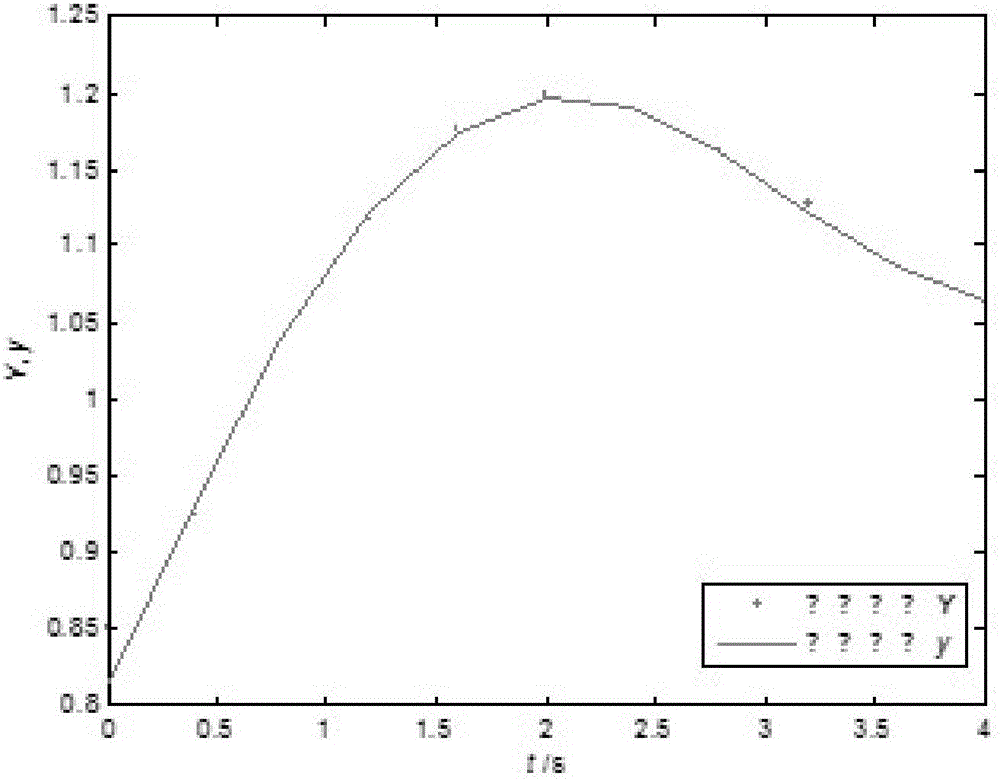

Networked control system fault detection method based on neural network prediction

ActiveCN106249599ASimple compositionSimple calculationAdaptive controlNetworked control systemNeural network system

The invention discloses a networked control system fault detection method based on neural network prediction, which comprises four steps of RBF neural network system building, system fault detection function building, system stability judgment and operation and system fault judgment and operation function building. The system building and operation process is simple, the operation efficiency and the operation precision are relatively high, an improved RBF neural network prediction controller is adopted to effectively predict system output data information, and thus, bad influences on the system by packet loss can be effectively cancelled, errors are smaller and training times are reduced through adjusting learning efficiency on the basis of adopting feedback correction on the obtained predicted output value for correction, and better convergence and quicker prediction speed can be obtained. Meanwhile, when fault happens to the system, happening of the fault can be quickly detected according to a designed fault observer and a judgment criterion.

Owner:HENAN POLYTECHNIC UNIV

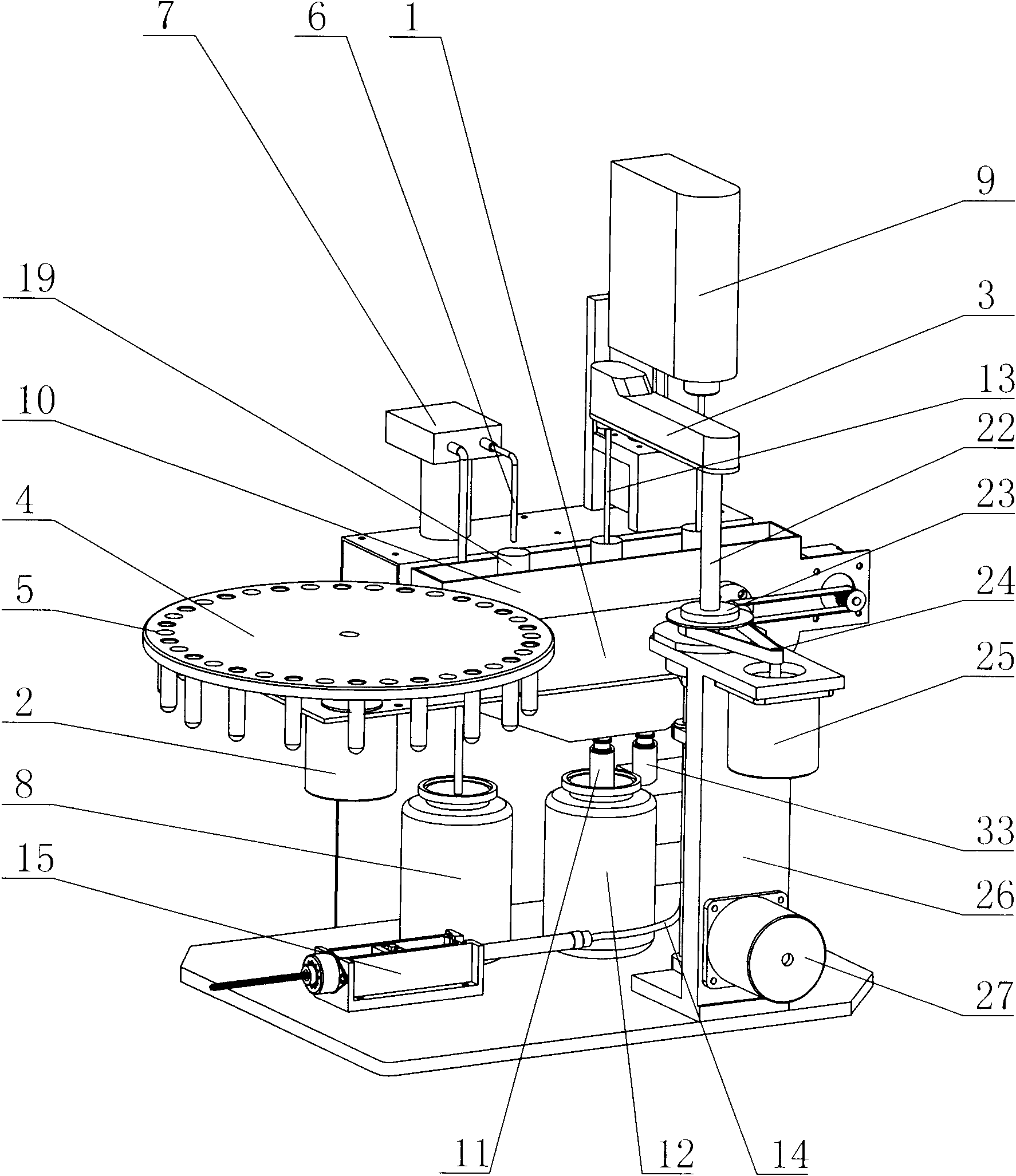

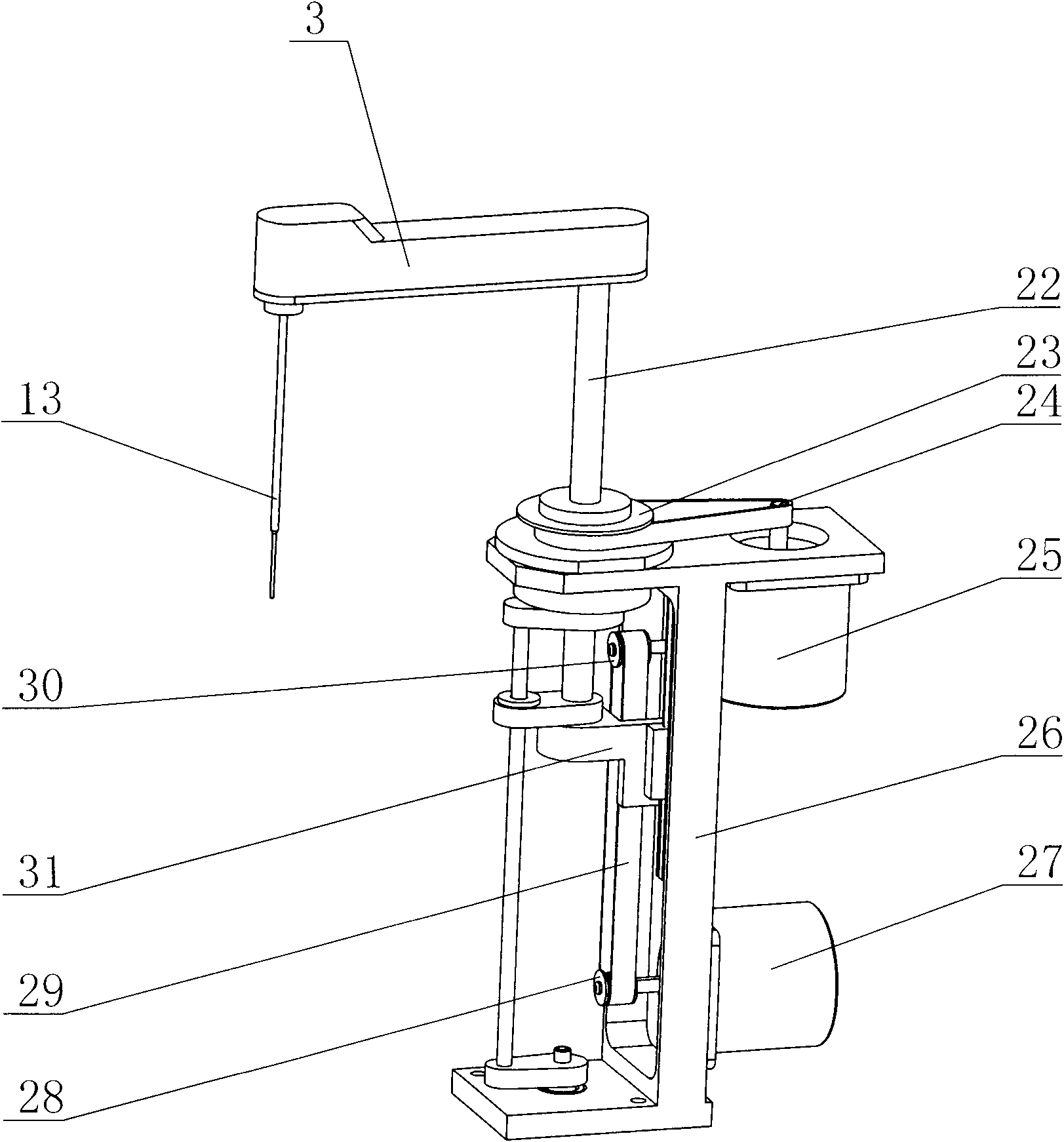

Automatic sampling mechanism of analytical instrument

InactiveCN101982779ANo positional deviationHigh running precisionMaterial analysisPipetteEngineering

The invention provides an automatic sampling mechanism of an analytical instrument, comprising a rack; the rack is provided with a first stepped motor, a pipette drive device and a liquid collecting box, wherein, the output shaft of the first stepped motor is provided with a rotary table; a plurality of test tube fixing holes are evenly arranged on the edge of the rotary table; the pipette drive device is provided with a pipette which is connected with a liquid sucking pump through a conduit; the liquid collecting box is provided with a detection cup transmission device which is provided with a plurality of detection cups; a reagent filling tube and a measuring electrode are arranged above the liquid collecting box; the reagent filling tube is connected with a reagent container through a liquid adding pump; and the bottom of the liquid collecting box is provided with a water outlet which is connected with a waste liquor collecting tank through a pipeline. The automatic sampling mechanism provided by the invention has the advantages of high operation precision, rapid sampling speed, simple structure and low cost.

Owner:济南齐力医疗器械有限公司

Static pressure workbench for extra-large vertical grinder

InactiveCN102398214AIncrease stiffnessHigh precisionGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to a static pressure workbench for an extra-large vertical grinder. The workbench comprises a workbench base and an upper workbench, wherein a rotary centering spindle which extends vertically downwards is fixedly arranged in the center of the upper workbench. The workbench is characterized in that: a spindle static pressure radial support for supporting the rotary centering spindle is arranged at a center hole of the workbench base; a moment servo motor direct drive mechanism is arranged between the workbench base and the rotary centering spindle; and a far end closed axial positioning static pressure system is arranged between the workbench base and the upper workbench. The static pressure system and a drive system are organically unified, so that high rigidity, accuracy and sensitivity are ensured, the operating accuracy and rigidity of the system are improved, and the service life of the system is prolonged.

Owner:无锡市明鑫数控磨床有限公司

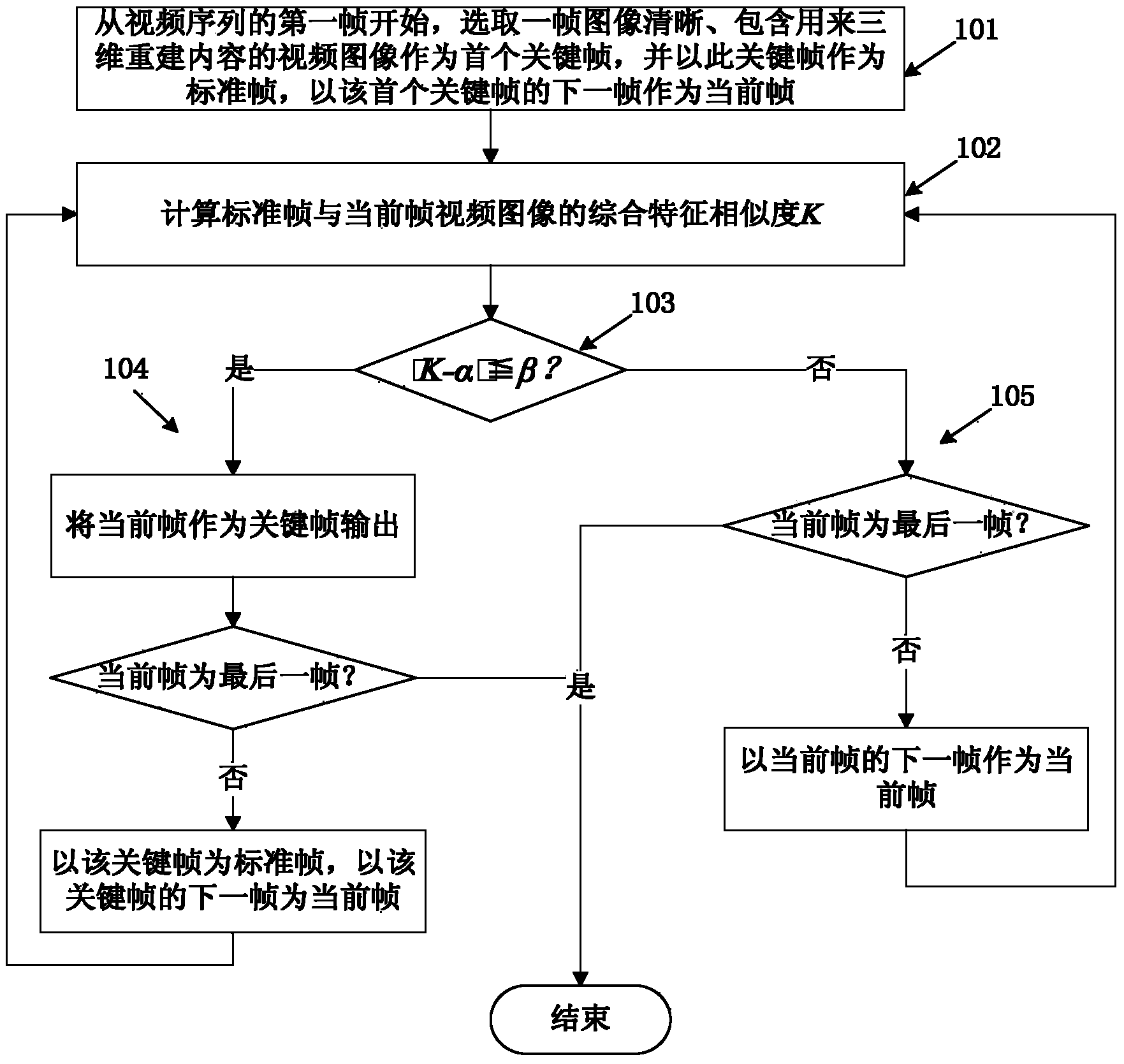

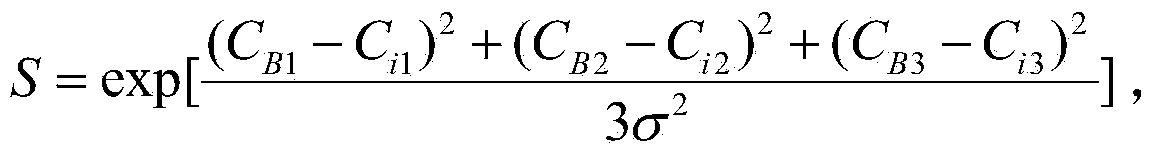

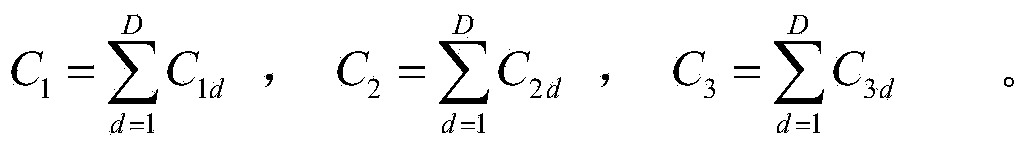

Method for extracting video sequence key frame in three-dimensional reconstruction

InactiveCN103761738AExtended run timeHigh running precisionImage analysis3D modellingKey frameVideo sequence

The invention discloses a method for extracting a video sequence key frame in three-dimensional reconstruction. The method is used for extracting the key frame from a video sequence used for conducting three-dimensional reconstruction. According to the method, starting from a first frame of the video sequence, a frame of video image which is clear and comprises the content for three-dimensional reconstruction is selected to be used as a first key frame which is used as a standard frame, the comprehensive feature similarity of the standard frame and current frames of vide images is compared one by one, the video image with small redundant information is extracted to be used as the key frame according to the comparison result, and the newly extracted key frame is used as the standard frame to continuously conduct comparing until the last frame in the video sequence is compared. According to the method for extracting the video sequence key frame in three-dimensional reconstruction, the key frame can be effectively extracted, a large amount of redundant information can be removed, the operation time for three-dimensional reconstruction is shortened, and the precision of the three-dimensional reconstruction is improved.

Owner:HANGZHOU KUANGLUN TECH CO LTD

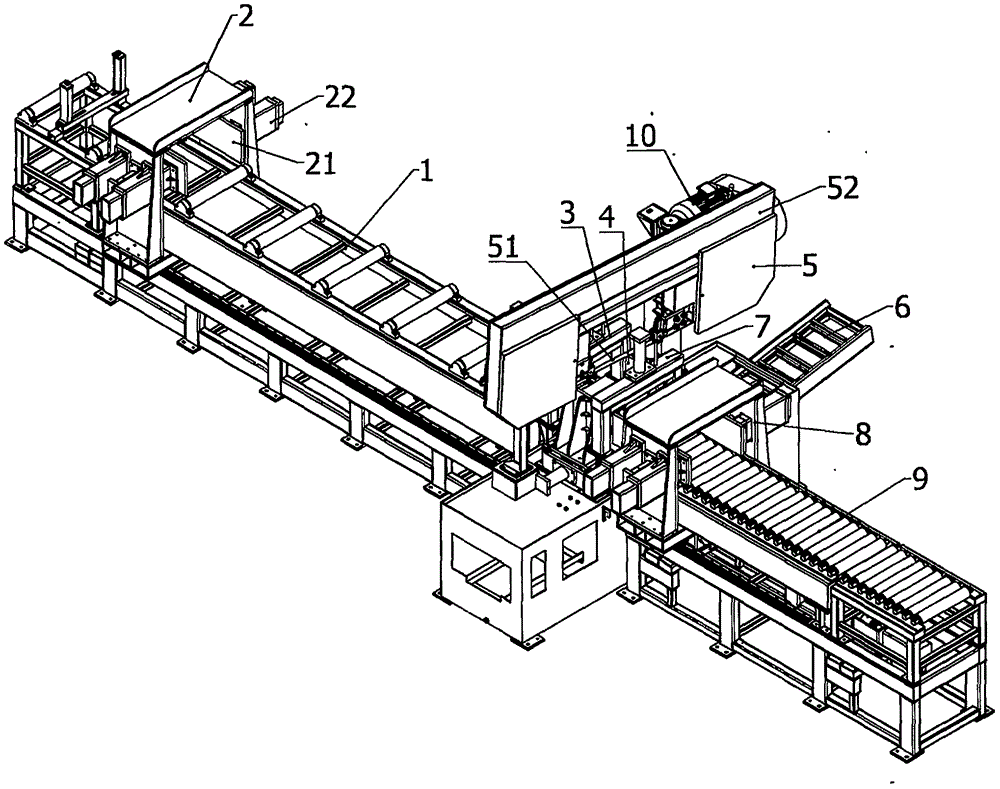

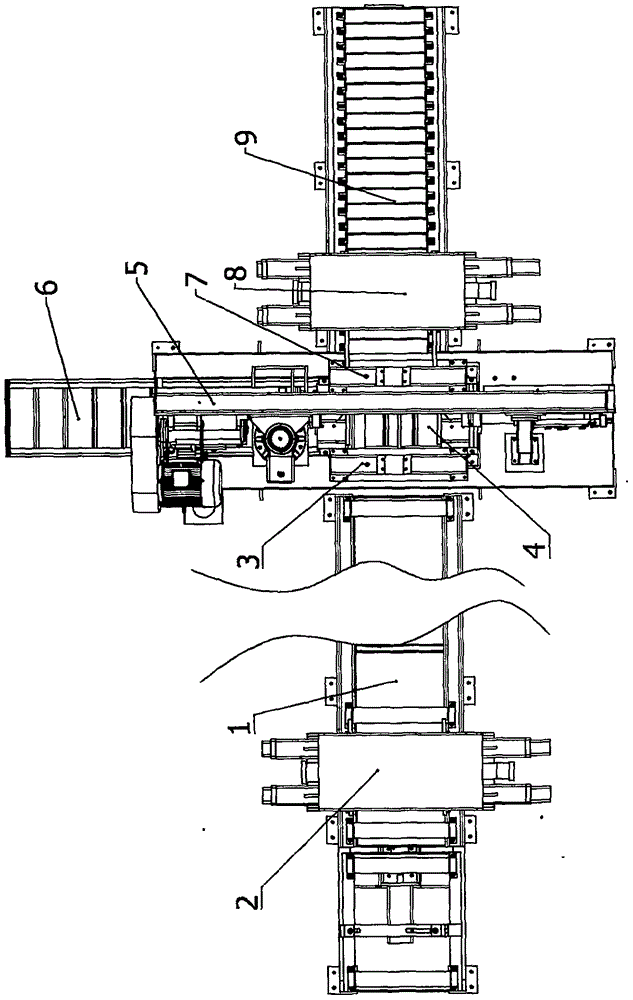

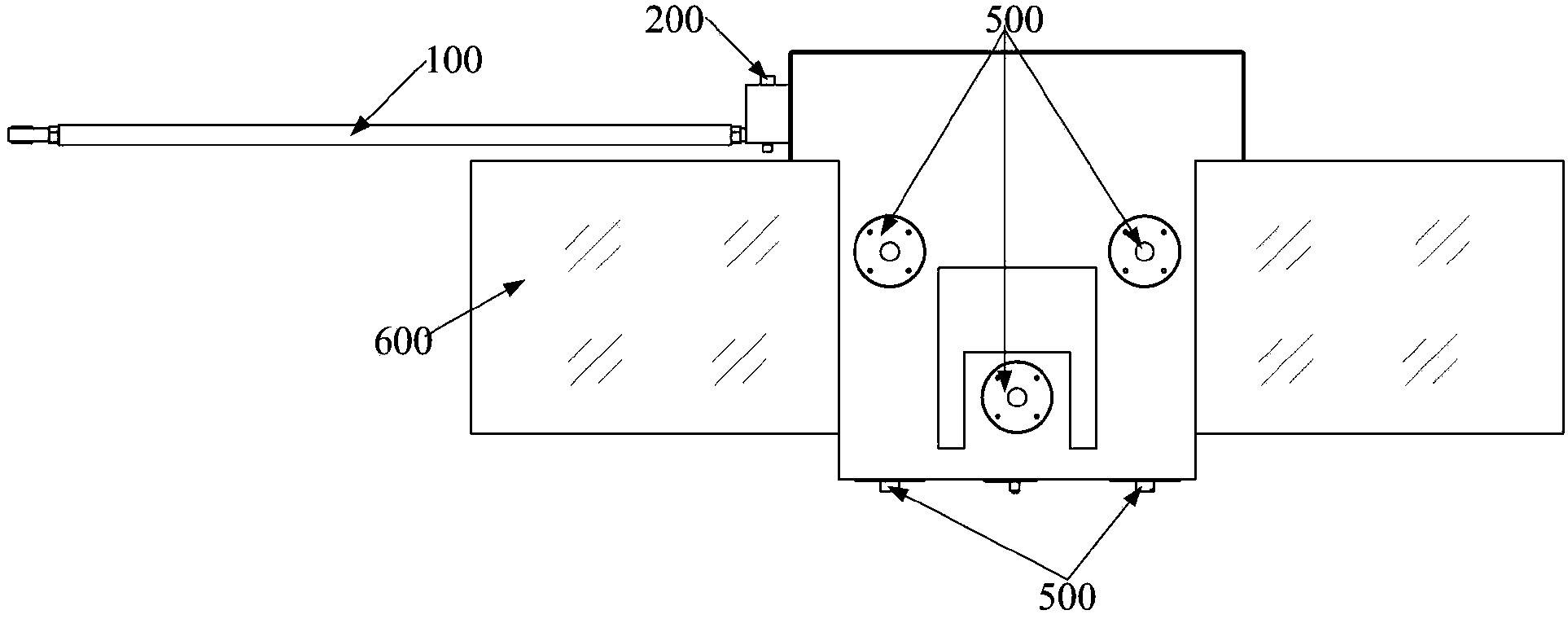

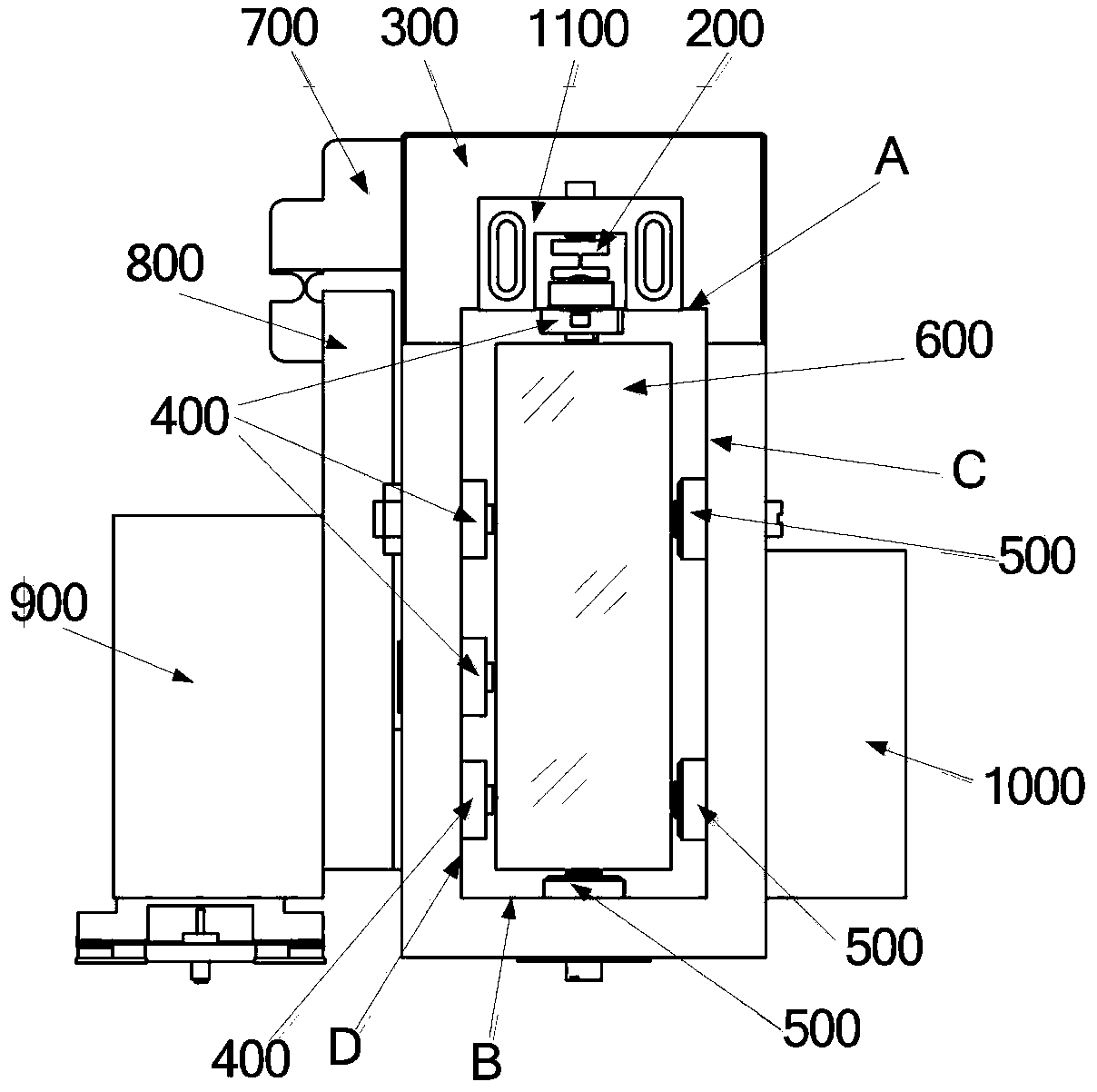

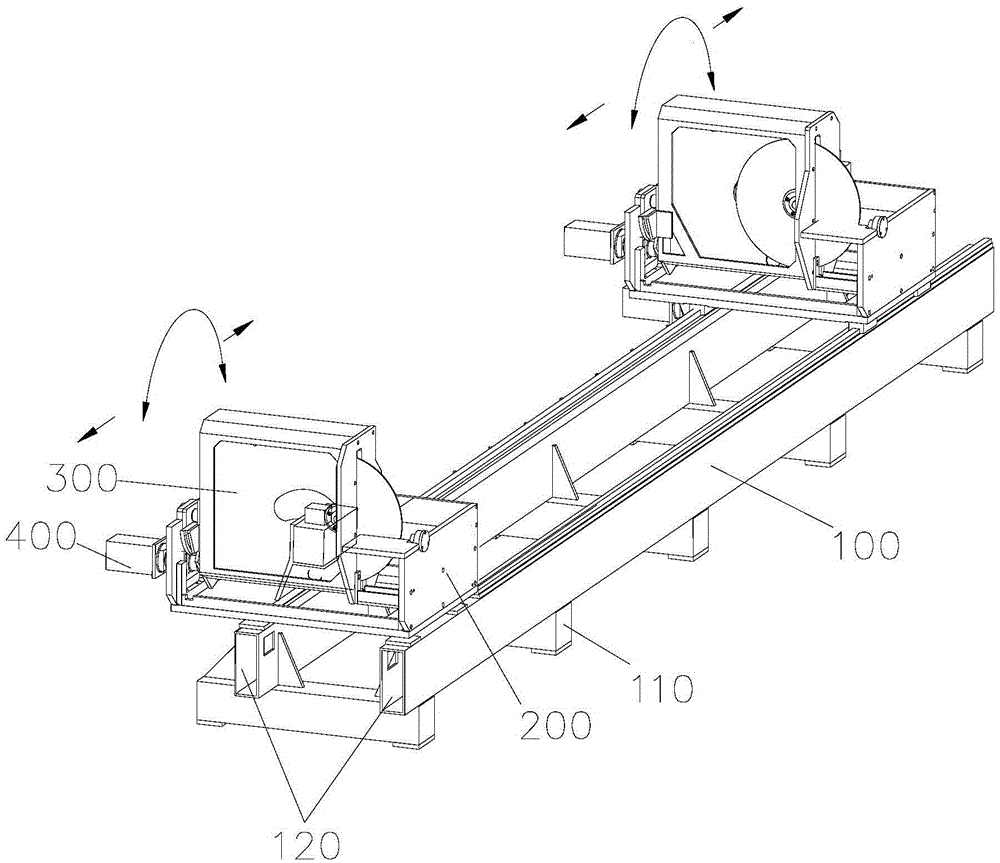

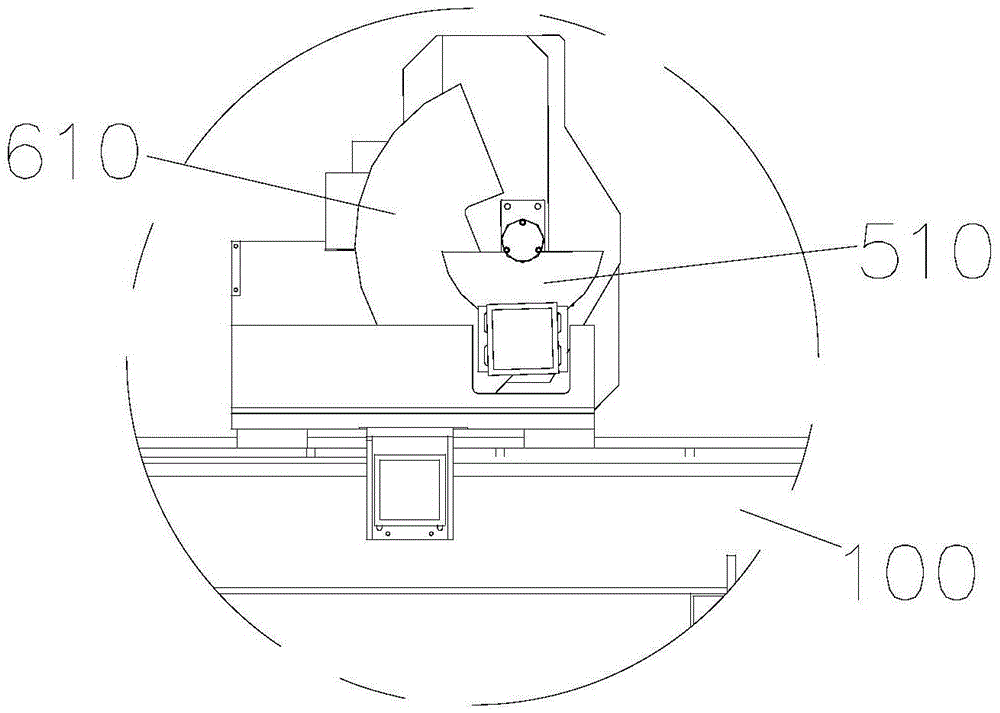

Full-automatic feeding type sawing machine

ActiveCN105772856APrecisely control the running processHigh running precisionMetal sawing devicesEngineeringProcessing accuracy

The invention provides a full-automatic feeding type sawing machine. The full-automatic feeding type sawing machine comprises a sawing machine body. The sawing machine body comprises a feeding clamping part, a sawing machine main clamp, a saw belt motor, a waste discharging mechanism, a saw belt feeding device, a discharging clamping part and a photoelectric switch used for sensing materials. The saw belt feeding device comprises a saw belt and a feeding rack. The full-automatic feeding type sawing machine is characterized by further comprising a conveying rack arranged on the front section of the feeding clamping part; a conveying moving clamp reciprocating on the conveying rack and a discharging rack located on the rear section of the discharging clamping part are arranged on the conveying rack; a discharging moving clamp reciprocating on the discharging rack is arranged on the discharging rack; the conveying rack is of a track structure used for sending the materials to the position under the saw belt; and the full-automatic feeding type sawing machine further comprises a PLC. The full-automatic feeding type sawing machine can achieve full-automatic feeding of the materials and has the advantages of being intelligent, efficient and high in processing accuracy.

Owner:WENZHOU UNIVERSITY

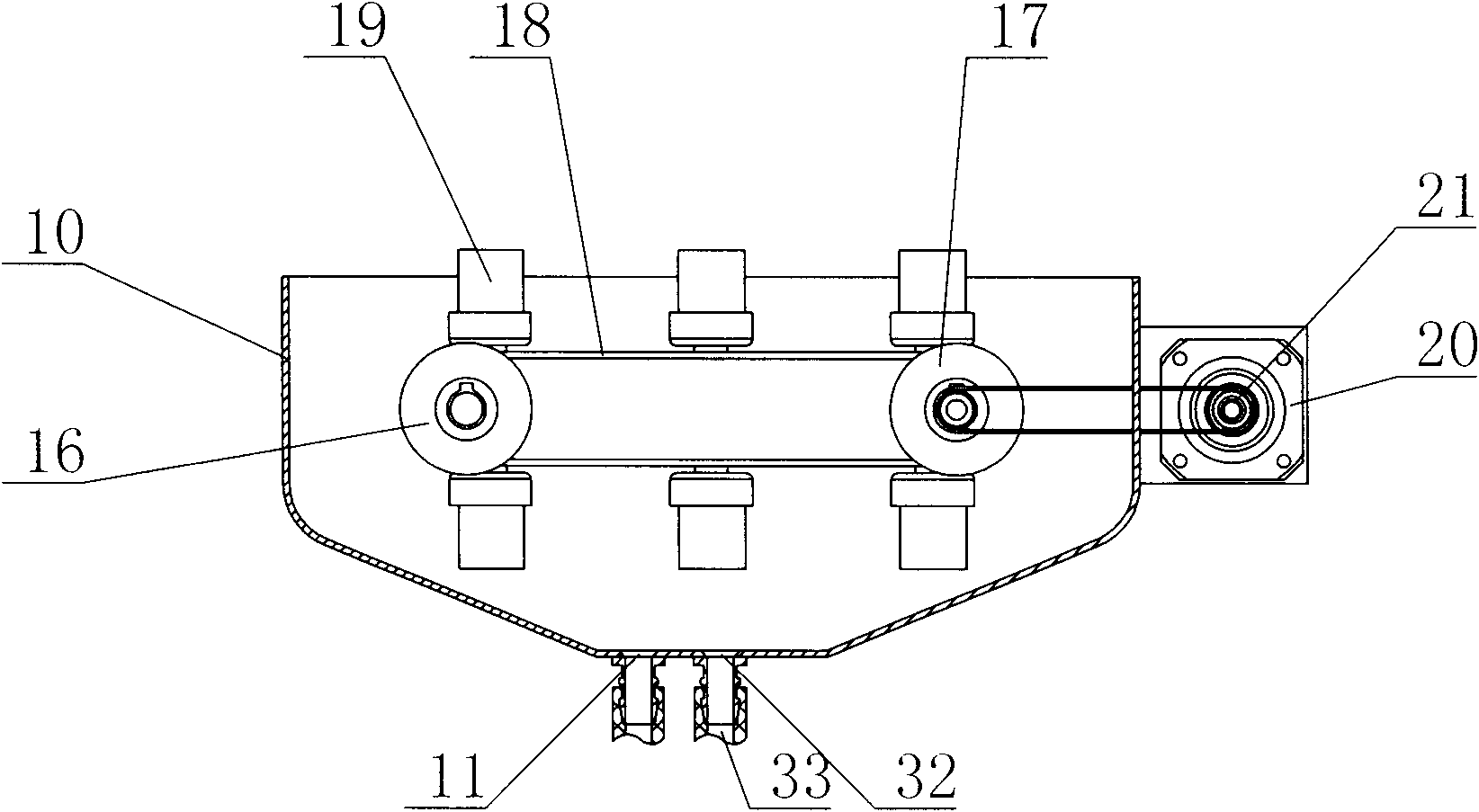

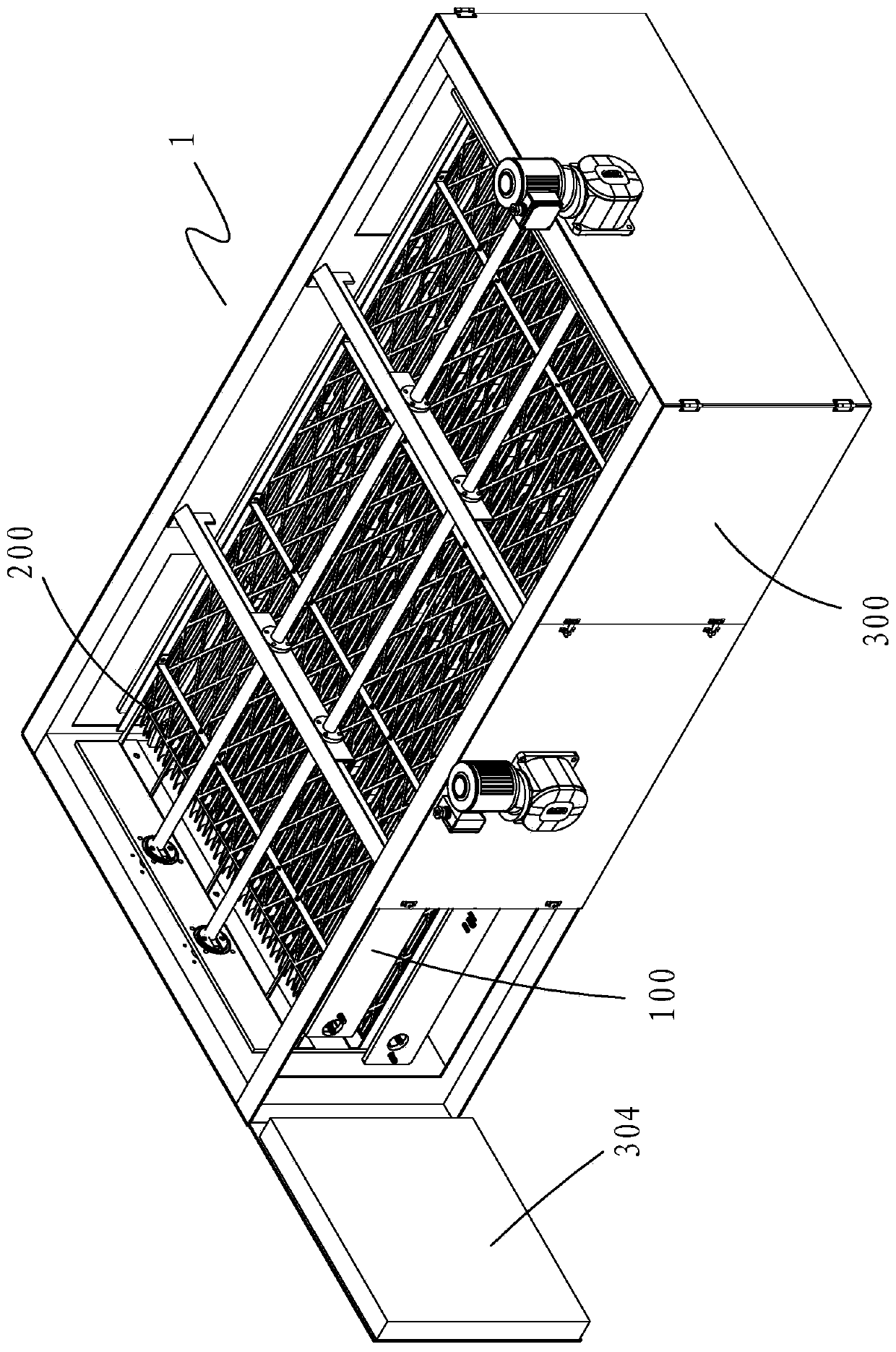

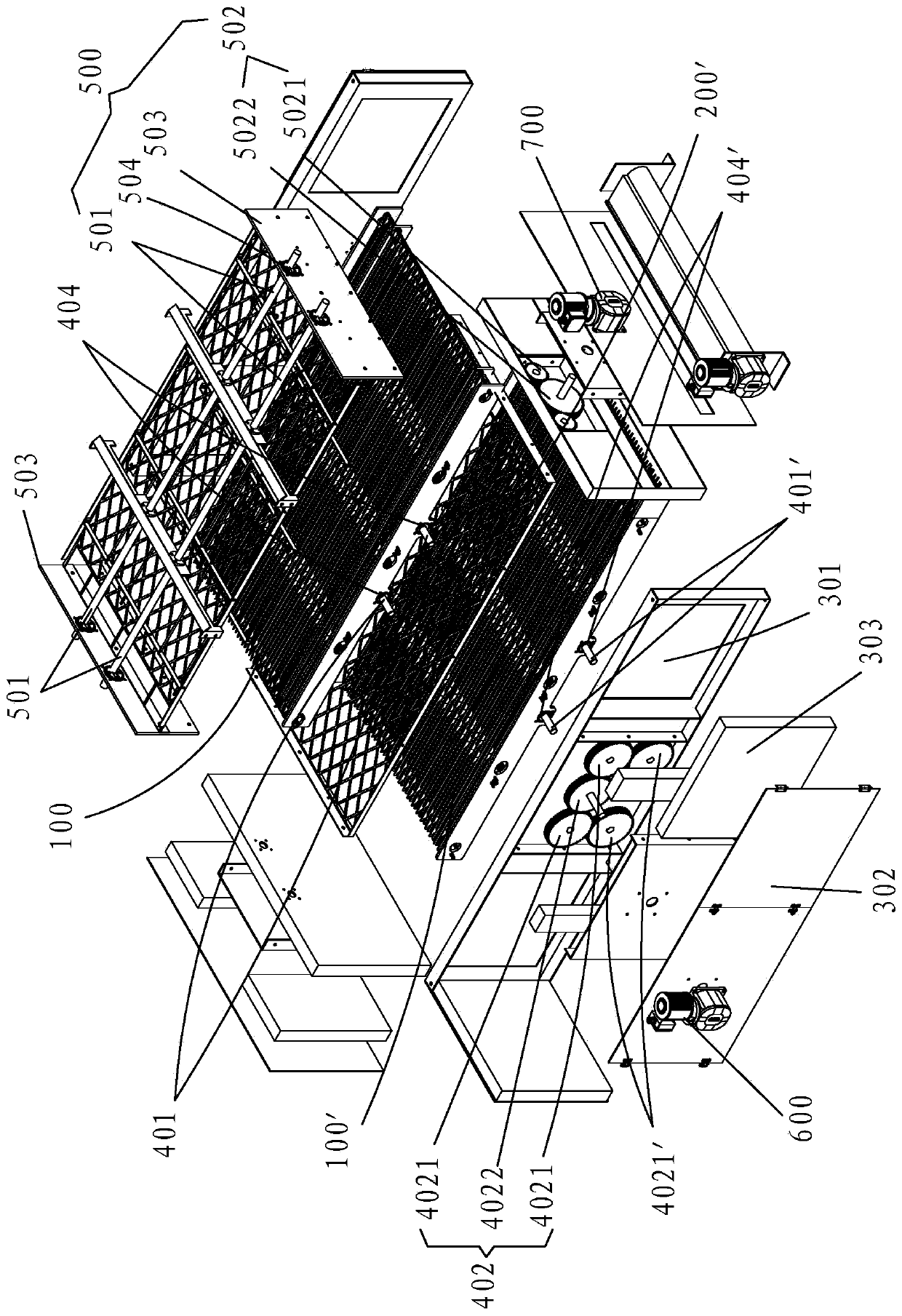

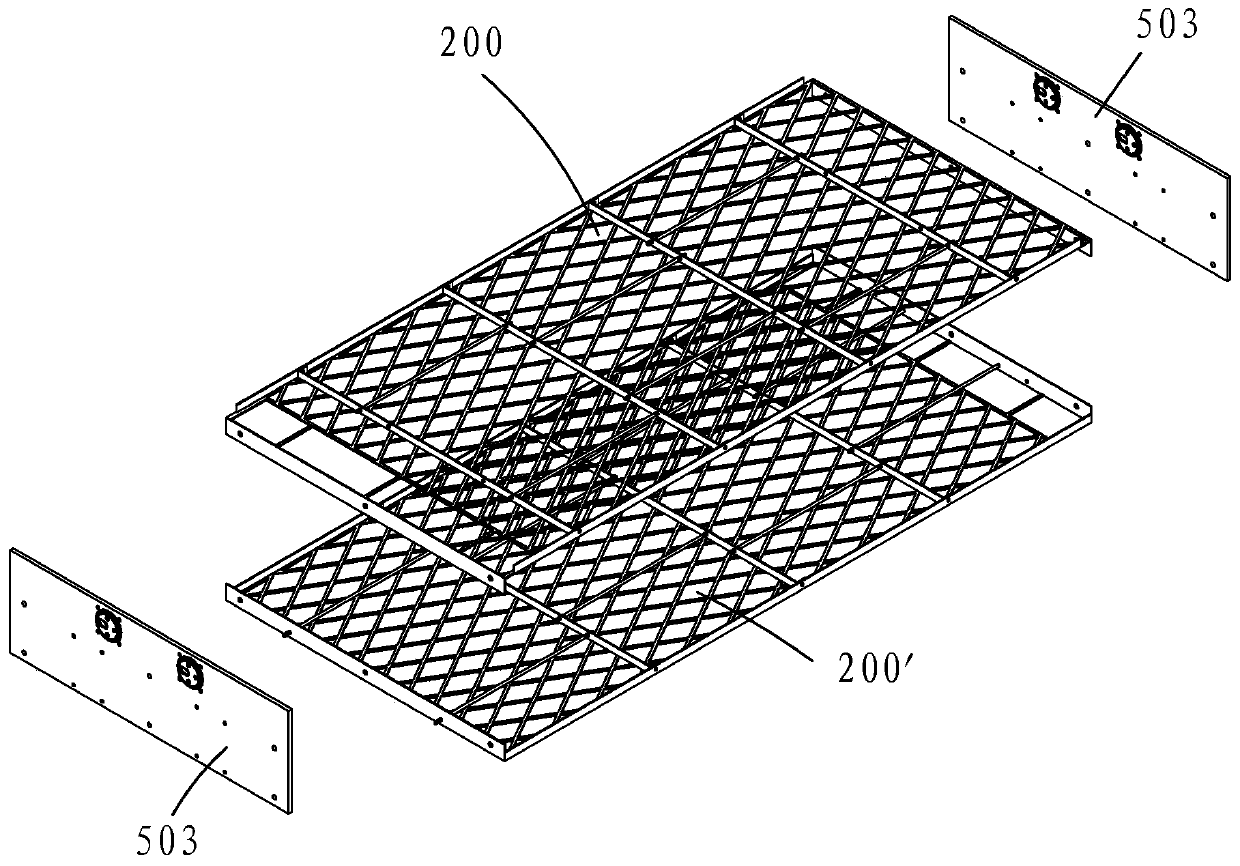

Material grinding and conveying module and drying chamber thereof

PendingCN111377588AFully rolledEvenly distributedSludge treatment by de-watering/drying/thickeningElectric machineEngineering

A material grinding and conveying module comprises a conveying platform composed of grid bar assemblies, a grinding device arranged above the conveying platform and a supporting frame. A first motor drives a first driving mechanism to drive the conveying platform to do reciprocating synchronous circular motion to bear and propel materials to advance; the grinding device comprises a grinding platform and a second driving mechanism; a second motor drives the second driving mechanism to drive the grinding platform to do reciprocating type synchronous circular motion perpendicular to the pushing direction of the materials to grind and scrape the materials; the second motor alternately performs forward rotation and reverse rotation, and the forward rotation time is equal to the reverse rotationtime. A drying chamber comprises a material grinding and conveying module, and the number of the material grinding and conveying module is one or more than one which are stacked. The grinding platform conducts grinding in the forward direction and the reverse direction, materials can be more evenly distributed on the conveying platform, the evaporation area is increased, and the drying efficiencyis improved.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

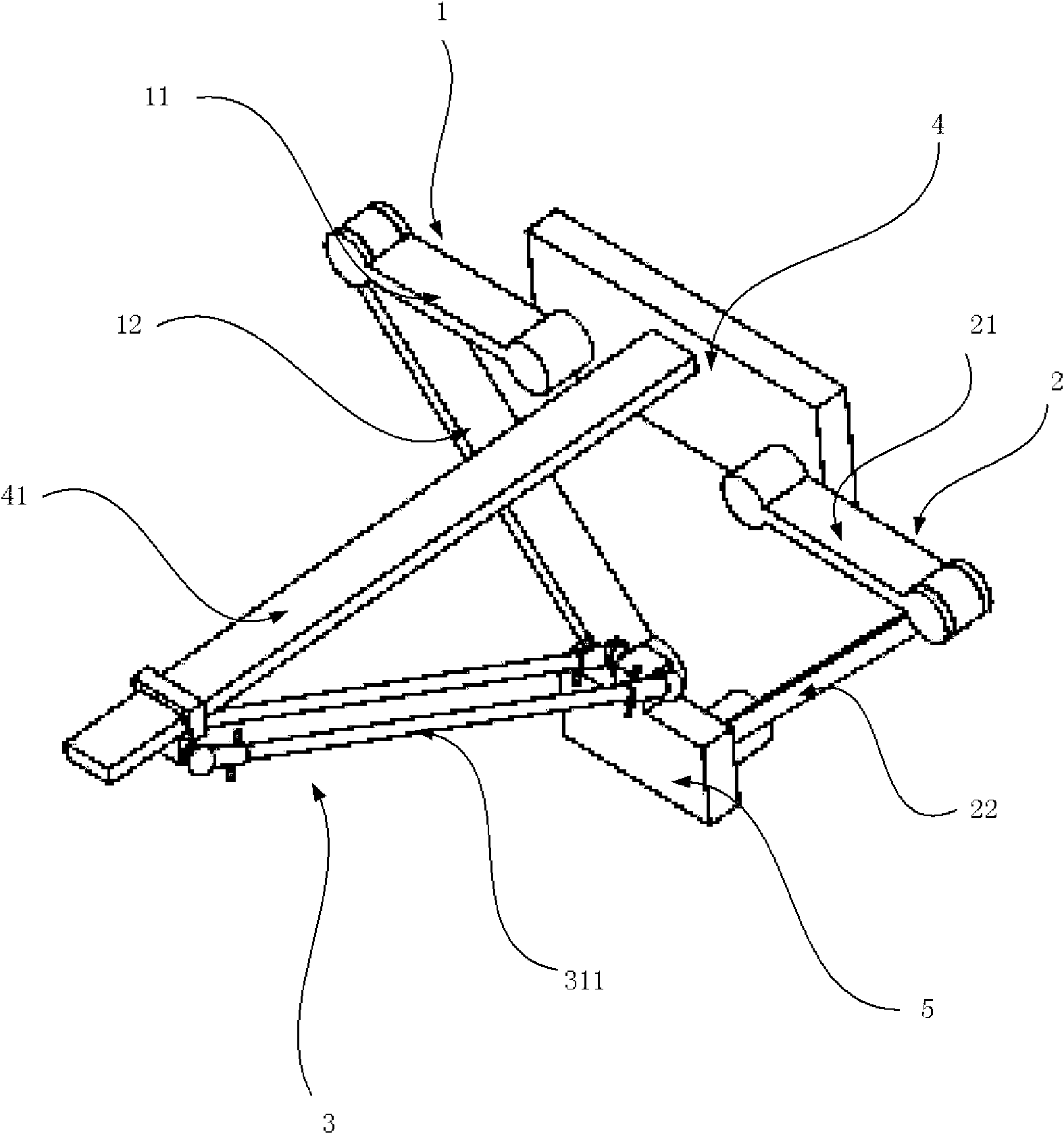

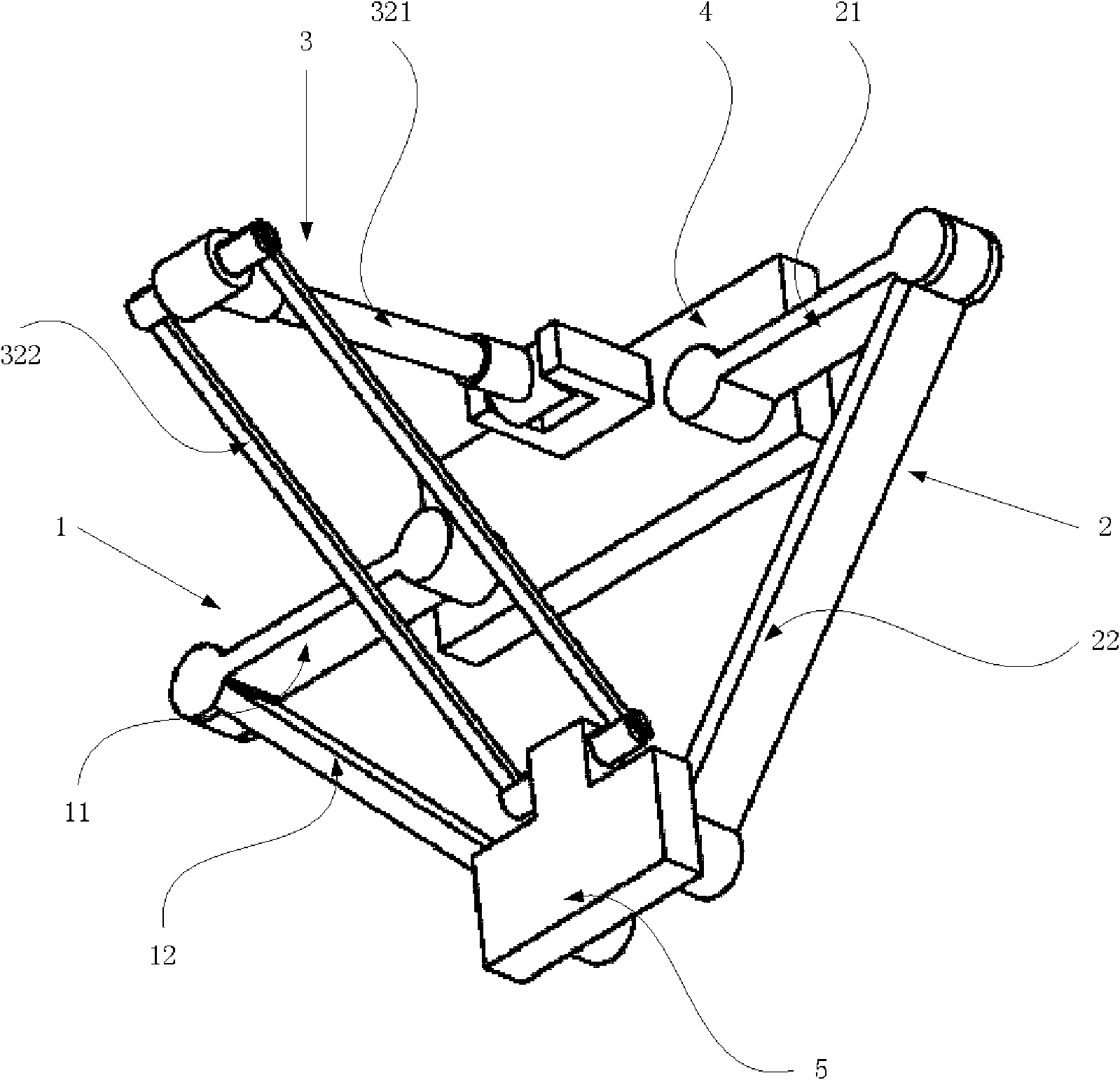

Two-degrees-of-freedom translation parallel robot mechanism

The invention provides a two-degrees-of-freedom translation parallel robot mechanism, comprising a substrate, a movable platform and a branched chain which is connected with the substrate and the platform respectively. The branched chain comprises a first active branched chain, a second active branched chain and a third passive branched chain, wherein a movable plane of the second active branchedchain and a movable plane of the first active branched chain are of the same plane or two parallel planes; and a movable plane of the third passive branched chain is crossed with a movable plane of the first active branched chain. The robot mechanism has the advantages that the third passive branched chain is adopted to connect the substrate and the movable platform to improve the attitude duration of the movable platform, and enables the robot mechanism to realize higher operation accuracy; the third passive branched chain is adopted, so that the first active branched chain and the second active branched chain have the same structure, simple design and symmetric kinematics and dynamic properties; and the first active branched chain and the second active branched chain respectively use a first master arm and a second master arm as dynamic input, thus the operation velocity of the robot mechanism is further improved.

Owner:SHENZHEN POLYTECHNIC

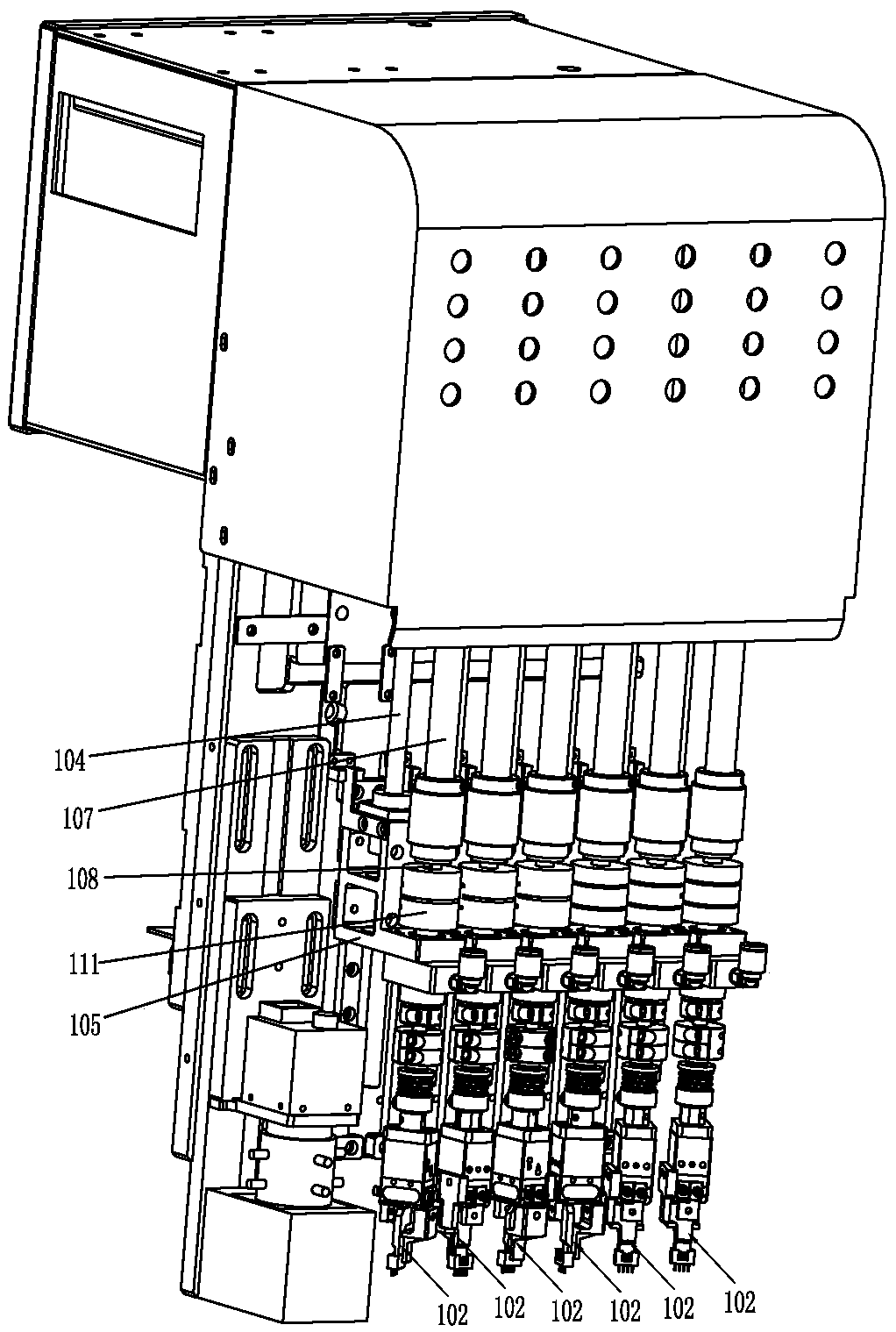

Large-area grating ruling cutter frame system

ActiveCN103645531AHigh running precisionReduce positioning errorsDiffraction gratingsPush and pullGrating

The invention discloses a large-area grating ruling cutter frame system, relates to the technical field of grating ruling, and solves a problem that the long-term operation stability of a cutter is difficult to be ensured because connection between a sliding block and a cutter frame mounting plate is of a hinge structure and an axial gap error exists between a rotating shaft and a shaft sleeve of the hinge structure. The large-area grating ruling cutter frame system comprises a glass guide rail, a sliding block, a connecting rod, a ruling cutter frame and a cutter frame mounting frame, wherein the sliding block slides along the glass guide rail, the sliding block is of an all-closed hollow shape, sleeved on the glass guide rail and provided with guide sliding feet and elastic sliding feet, and the guide sliding feet and the elastic sliding feet are all contacted with the external surface of the glass guide rail; the connecting rod is connected with an external driving mechanism and the sliding block, and the driving mechanism pushes and pulls the connecting rod so as to drive the sliding block to slide along the glass guide rail; and the cutter mounting plate is used for mounting a cutter frame, the upper end of the cutter frame mounting plate is fixedly connected with the sliding block, and the lower end of the cutter frame mounting plate is provided with the guide sliding feet. The large-area grating ruling cutter frame system is conducive to reducing the scribed line position error during grating ruling and improving the large-area grating ruling precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

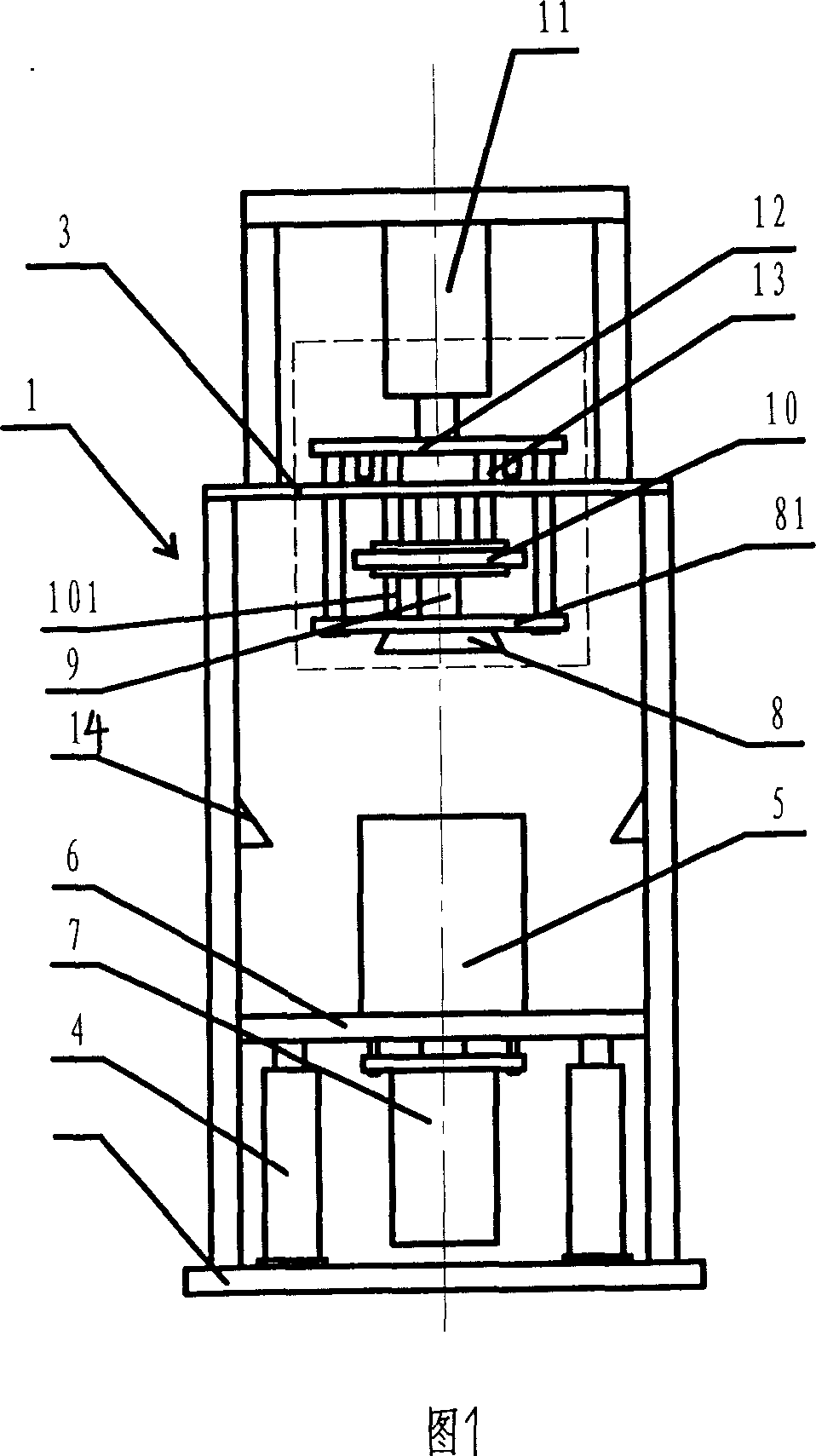

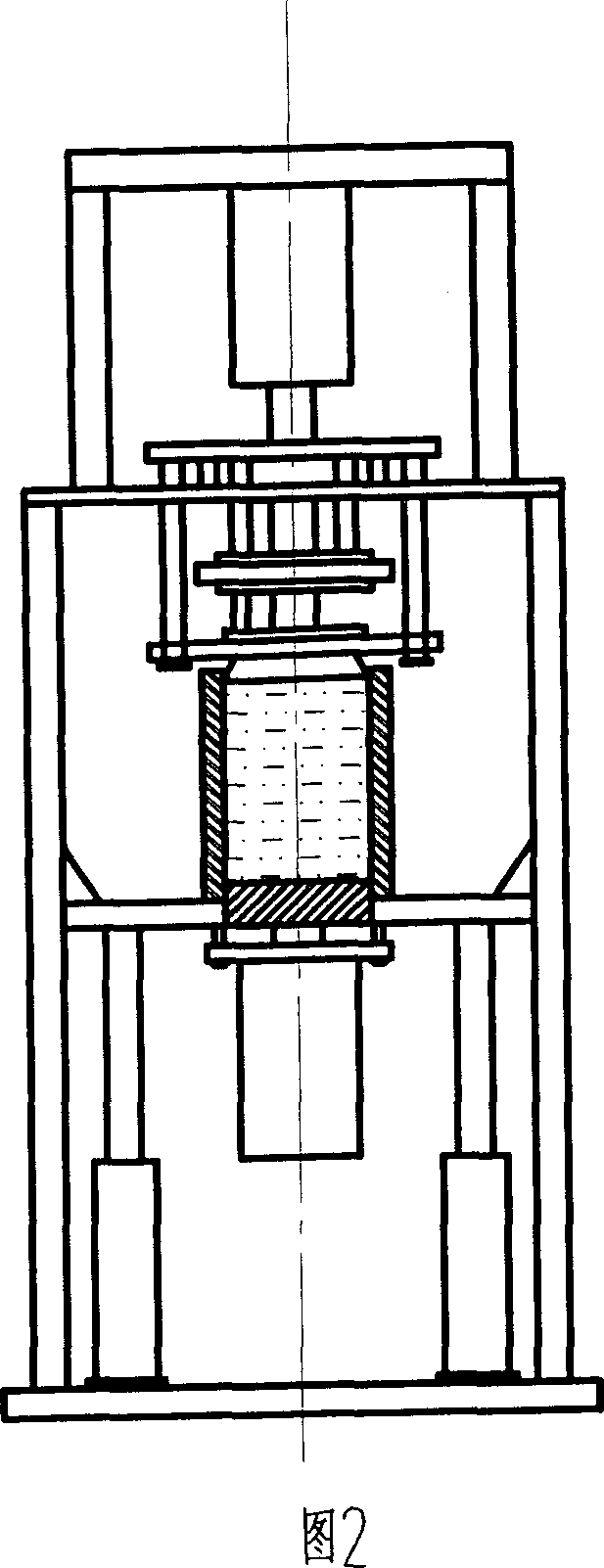

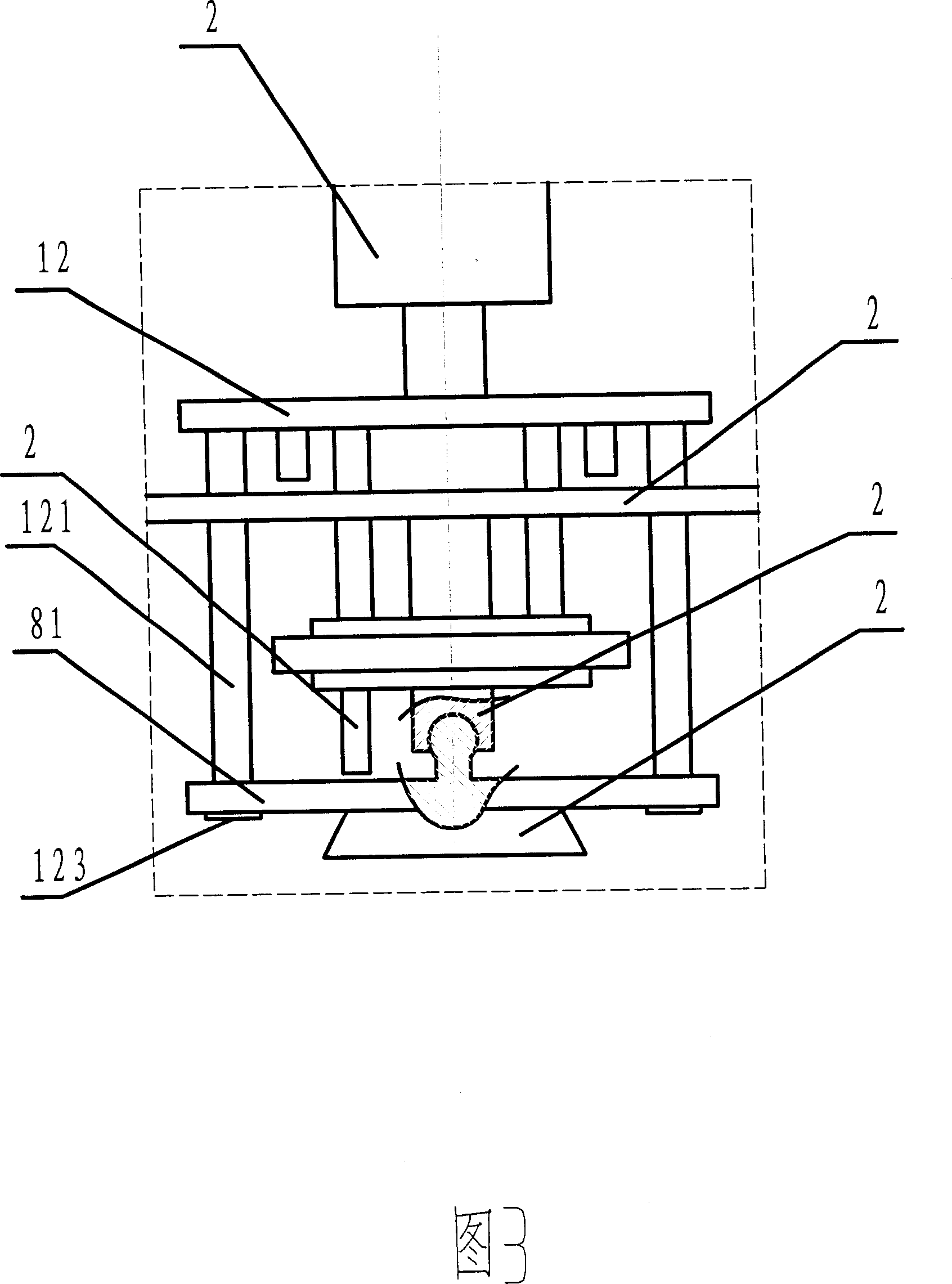

Rotary compactor

InactiveCN1945323ASimple structureWork reliablyMaterial testing goodsStrength propertiesRoad surfacePetroleum engineering

The rotary compacting instrument includes frame, bottom plate, top plate, elevating oil cylinder on the bottom plate, fixed testing drum with backup board connected to the output shaft of the elevating oil cylinder, compacting oil cylinder on the backup board, pressing head in the upper part of the frame, pressing head oil cylinder on the top plate, pressing disc fixed to the output shaft of the pressing head oil cylinder, and downward extending pressing rod in the lower part of the pressing disc, with the top plate having hole corresponding to the pressing rod. The present invention has rotary compacting to simulate the practical condition for wheel to roll the road surface and can obtain practical experiment data.

Owner:SHANDONG LUDA TEST INSTR

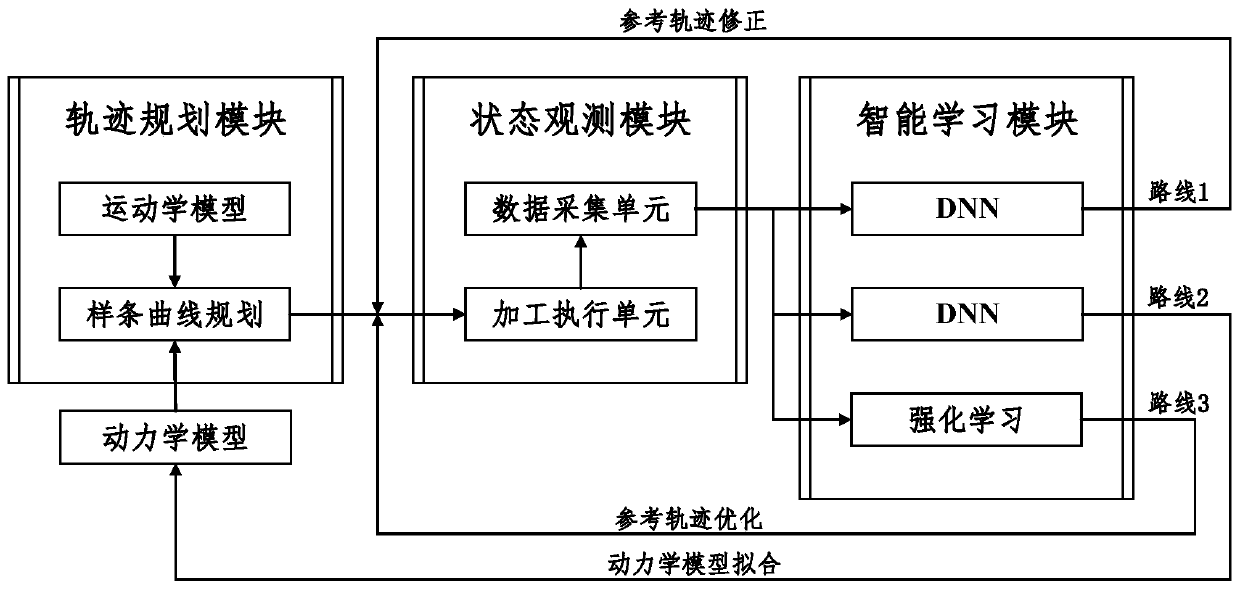

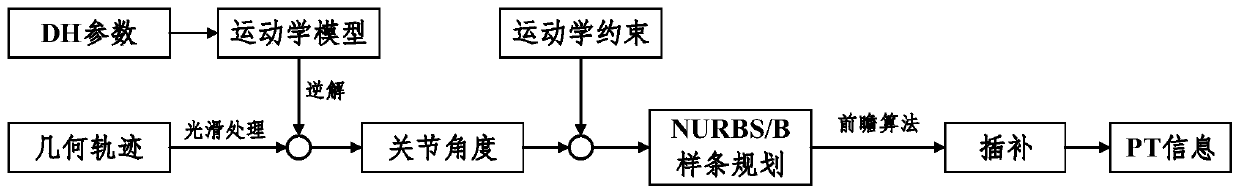

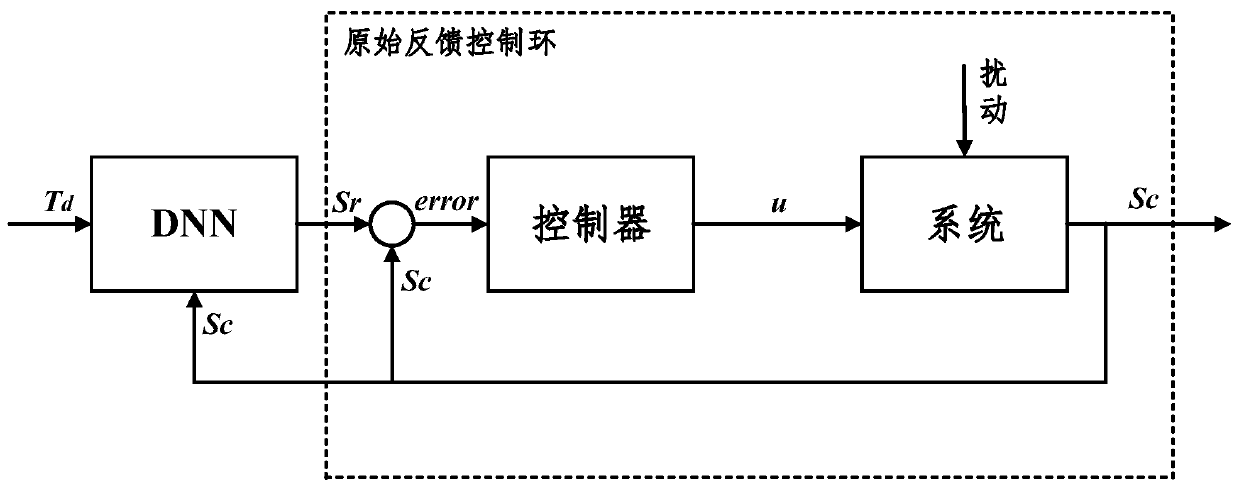

Robot trajectory planning method based on deep learning

ActiveCN110083160AHigh running precisionImprove stabilityPosition/course control in two dimensionsTime informationDynamic models

The invention discloses a robot trajectory planning method based on deep learning, which comprises the following steps: firstly, establishing a kinematics model of a robot, providing a basic planningtrajectory for the robot, moving the robot, acquiring real-time information of the robot, including information such as position and moment, establishing a dynamics model of the robot, and then obtaining an optimal planning trajectory by utilizing Q-learning reinforcement learning; and the modeling and learning are carried out based on actual acquired data, and modeling under an ideal environmentis avoided. The robot trajectory planning method based on deep learning can be applied to industrial robots in various complex environments because the industrial robots have the capabilities of parameter self-learning and self-adjusting. Under the condition that the consistency of the robots is good, the models learned by the robots can be shared with the robot platforms of the same type. The robot trajectory planning method based on deep learning has wide application prospect in industrial production.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Control system of nuclear fuel loading and unloading machine

InactiveCN104575642AReduce volumeImprove comfortNuclear energy generationReactor fuel elementsData displayVideo monitoring

The invention relates to a control system of a nuclear fuel loading and unloading machine, which is integrated and intelligently driven and controlled by a PLC. The control system comprises an operation console, a PLC touch screen, a PLC, a video monitor, a weighing system and a gripping apparatus system, wherein the PLC is applied to data acquisition, logic control, interlock protection, motion calculation and servo driving communication and control; operation buttons, display signal lamps and a data display instrument on the operation console are connected with the PLC; the PLC touch screen comprises a logic control unit and is connected with the PLC by virtue of a PROFIBUS; a video system is used for providing visual images of the position of fixed points; the weighing system is used for monitoring weight signals in real time and providing relatively complete weightlessness, overweight and scratch protection; the gripping apparatus system is used for lifting and releasing nuclear fuel; all the protection of systems is realized in the PLC and text type promoting alarms are provided. An overweight and weightlessness trend data analysis module is additionally arranged, so that error alarms and false alarms of the overweight and the weightlessness can be reduced.

Owner:SHANGHAI YIFENG M&E EQUIP

Double-end saw structure with any tilt angle

ActiveCN105478891AReasonable structureCompact structureMetal sawing devicesFriction reductionGear wheel

The invention discloses a double-end saw structure with any tilt angle. The double-end saw structure comprises a base, supporting seats, cutter box structures arranged in the supporting seats, rotating shafts arranged on the supporting seats through bearing pedestals and rotating power devices. The cutter box structures are arranged on the rotating shafts, and the rotating shafts and the rotating power devices are in transmission connection through fan-shaped rotating mechanisms. Fan-shaped rotating gears are arranged to be used for driving cutters to precisely rotate, the rotating precision of the cutters can reache 0.1phi according to the different moduli of fan-shaped gears, and the rotating precision of the cutters is improved. Brake mechanisms for the fan-shaped transmission gears are arranged, so that residual buffer force is prevented from influencing the angle division precision of the cutters. Linear rails are adopted, so that moving stability of the whole structure is improved, friction is reduced, and noise is lowered. The whole bottom beam structure is reinforced through a span beam manner and cross sleepers, the moving precision and the running speed are improved, and machining scraps can be removed conveniently. The tilt tooth transmission structure is adopted, so that the running torsional moment and the running precision are improved, and the speed is improved.

Owner:广东欧亚特机械设备有限公司

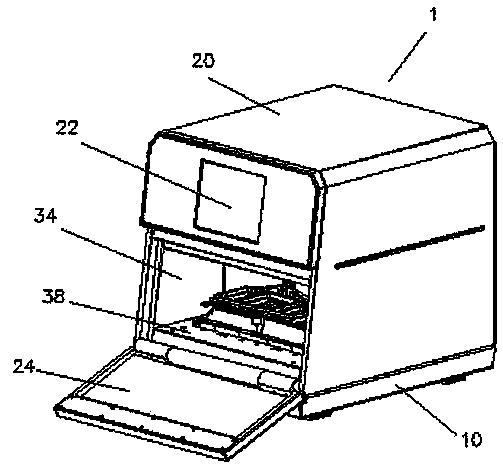

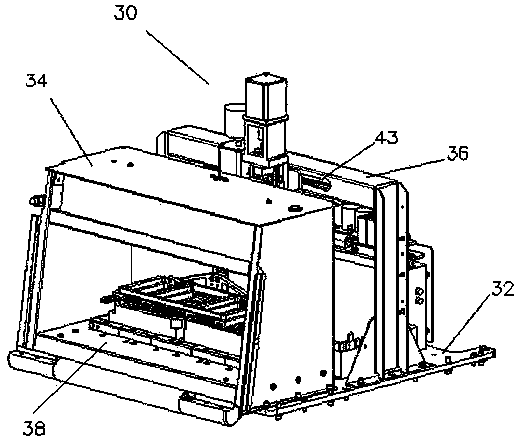

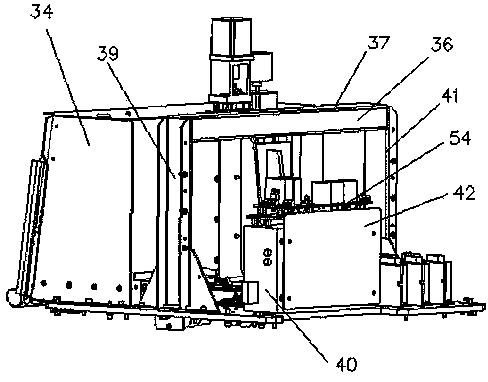

Nucleic acid extractor, and nucleic acid extractor heater and heating method

ActiveCN103881892AImprove extraction efficiencyHigh running precisionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityEngineering

The invention provides a nucleic acid extractor which comprises a base, an outer shell connected with the base, and a main body which is positioned inside the outer shell and installed to the base, wherein the main body comprises a first motor set, a second motor set, a third motor set and an operating console fixed to the base; the first motor is fixed to the base; the second and third motor sets are driven by the first motor set and can move relative to the base; and the operating console comprises a clamp for automatically fixing a deep-hole plate and a heater for heating the deep-hole plate. The nucleic acid extractor has the advantages of high nucleic acid extraction efficiency, high operation precision and high stability.

Owner:ACON BIOTECH (HANGZHOU) CO LTD

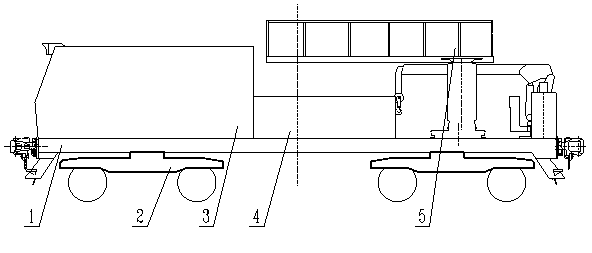

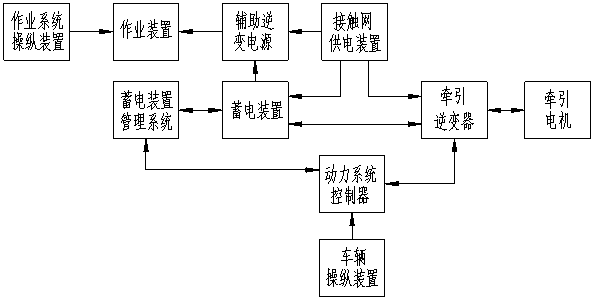

Rail double-power working vehicle

InactiveCN103213584AHigh running precisionImprove vehicle efficiencyElectric locomotivesElectric energy managementBogieElectric power transmission

A rail double-power working vehicle, comprises a vehicle body, a bogie, a machine room and a working system, wherein a traction motor is installed on the bogie, and the traction motor is connected with a vehicle shaft gear case fixed on a bogie wheel pair, to drive the wheel pair by the gear case for walking; a power transmission system is composed of the traction motor, an electrical storage device, an electrical storage device management system, an overhead line system power supply device, an auxiliary invertion power supply, a traction inverter, a vehicle operating device and a power system controller; the electrical storage device, the electrical storage device management system, the overhead line system power supply device, the auxiliary invertion power supply and the traction inverter are fixed on the vehicle body; and the vehicle operating device and the power system controller are installed in a driver's cab, and the driver adjusts the power system controller by the vehicle operating device, thereby controlling the whole vehicle. The rail double-power working vehicle of the invention can individually run when supplied with power by the overhead line system power supply device, and can also individually run when supplied with power by the electrical storage device. Electricity of the electrical storage device can satisfy a daily working demand of the working vehicle, can reduce noise and discharge, can protect environment, and can save energy.

Owner:GEMAC ENG MACHINERY

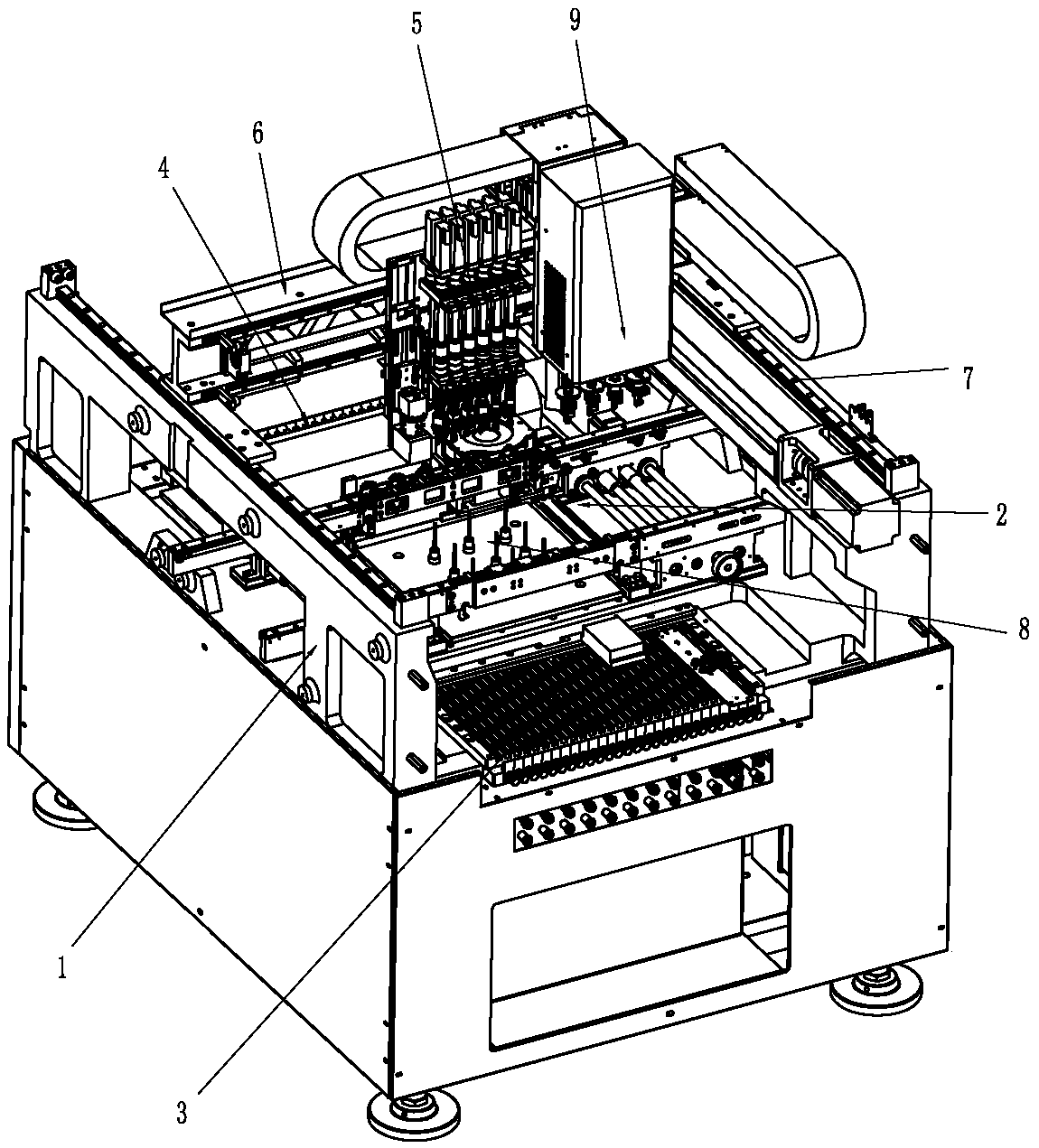

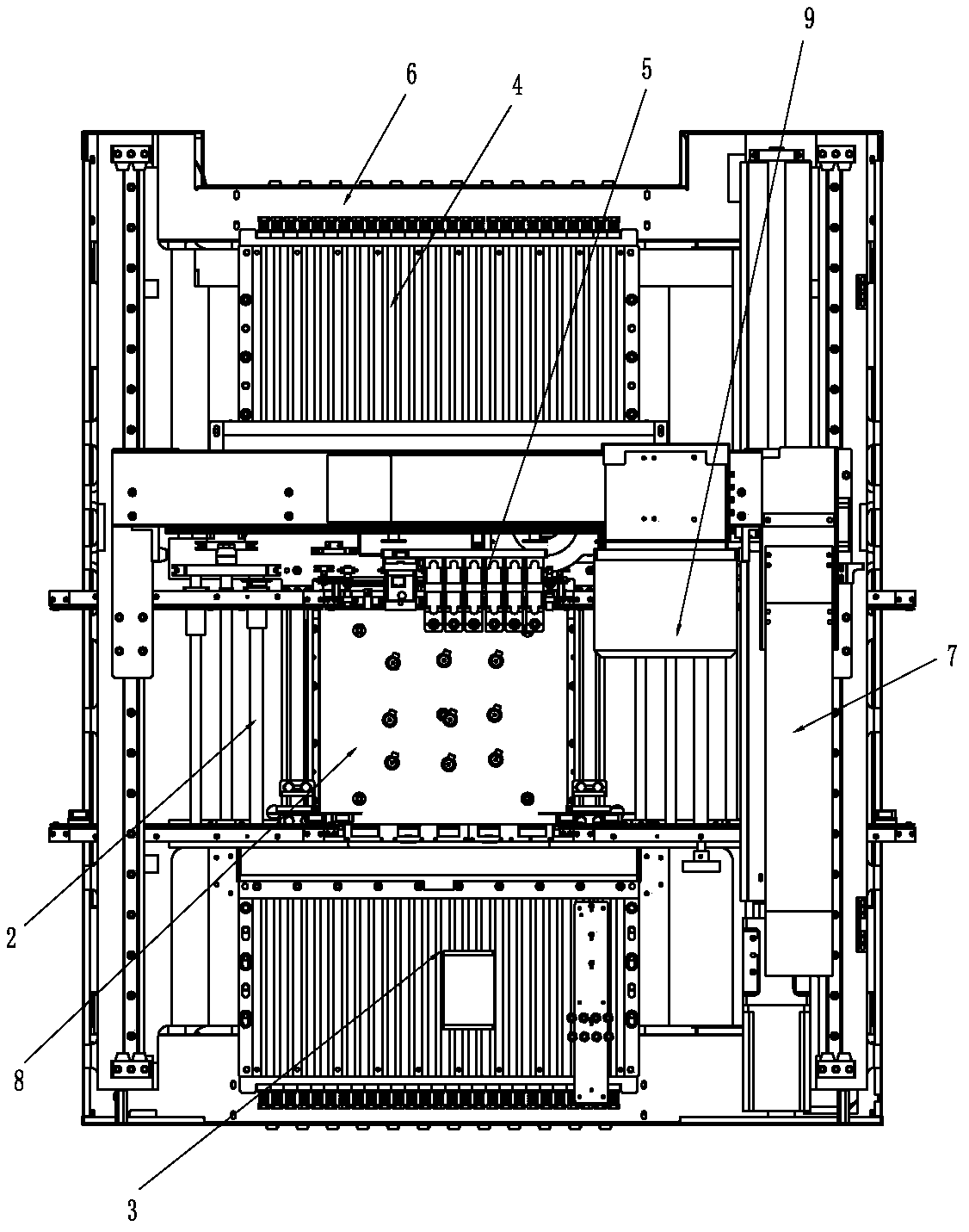

Efficient and accurate automatic component insertion machine

PendingCN109462976AHigh running precisionPrecise positioningElectrical componentsEngineeringInsertion - action

The invention discloses an efficient and accurate automatic component insertion machine. The component insertion machine comprises a rack assembly, and a PCB conveying track, a feeding device, a discharging device and a component insertion machine head which are arranged on the rack assembly; the feeding device and the discharging device are arranged on the two sides of the PCB conveying track respectively; the component insertion machine head is movably arranged above the PCB conveying track; the PCB conveying track comprises a fixed track assembly and a movable track assembly which are arranged oppositely; an adjustable conveying track is formed between the fixed track assembly and the movable track assembly, and can be applied to the component insertion machining of PCBs with various width specifications, so that the universality of equipment is improved; the component insertion machine head comprises a machine head base and a plurality of component insertion mechanical arms mountedon the machine head base; each component insertion mechanical arm is independently connected with a driving assembly; and each driving assembly comprises a lifting motor, a lifting screw rod, a sliding seat, a rotary motor, a spline shaft sleeve and a spline shaft. Therefore, the running precision of the automatic component insertion machine is higher, the precision of a component insertion action is higher, and the action is quicker and more efficient.

Owner:东莞市南部佳永电子有限公司

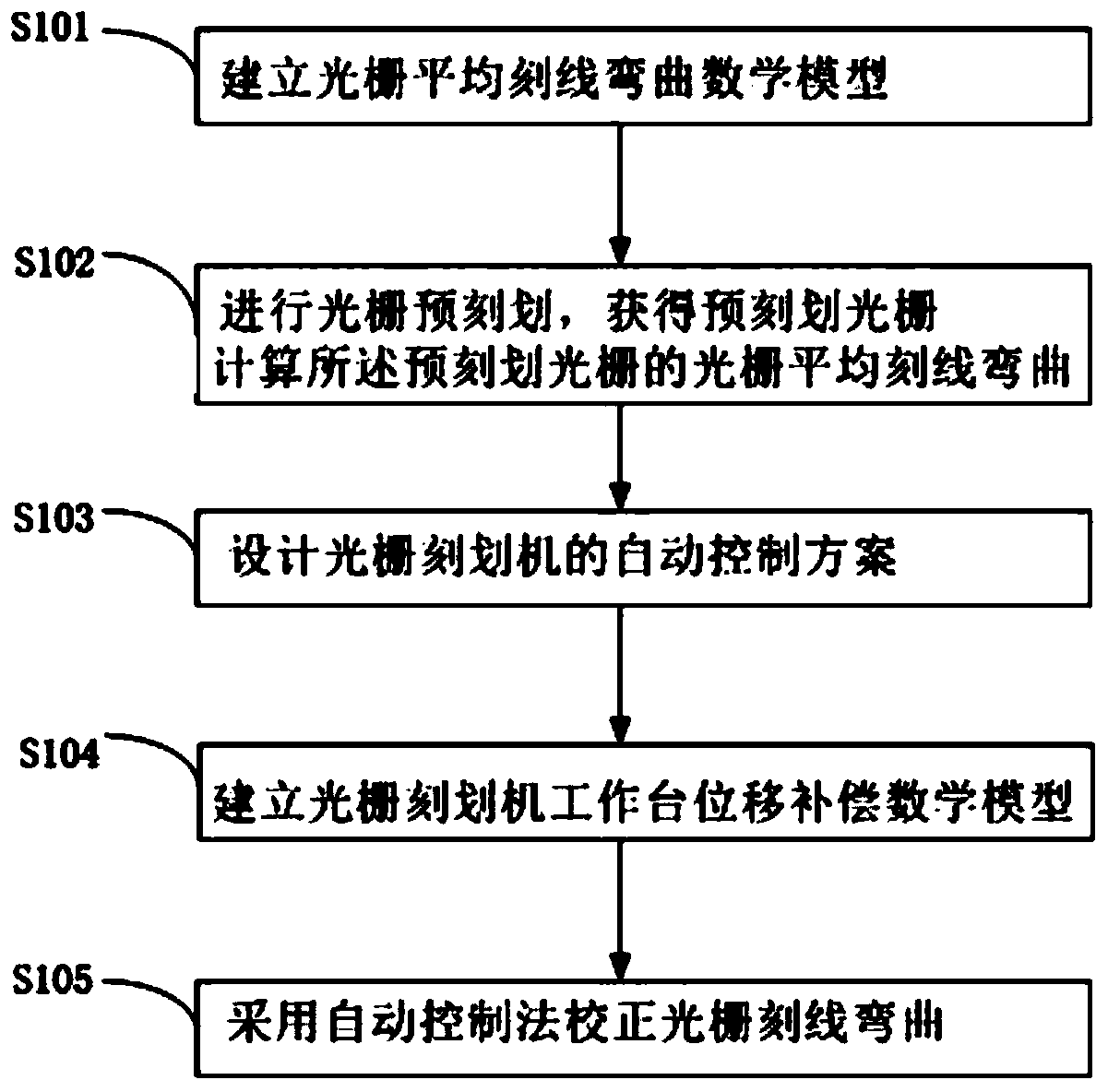

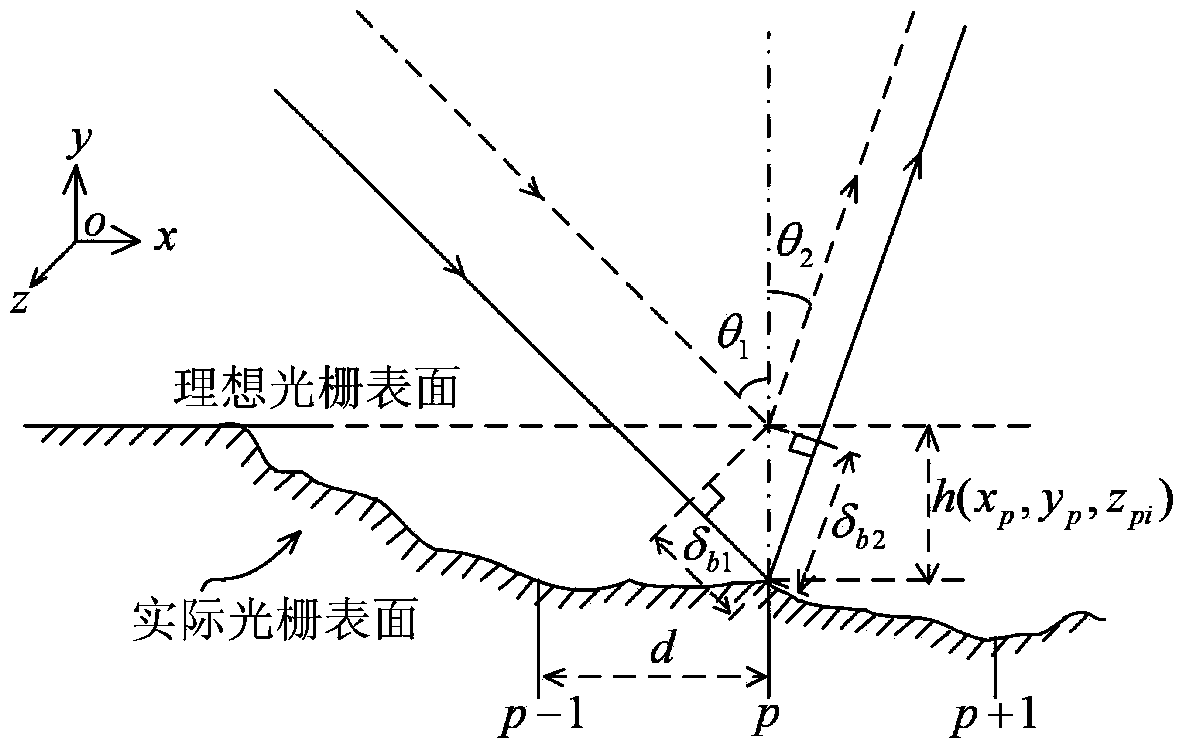

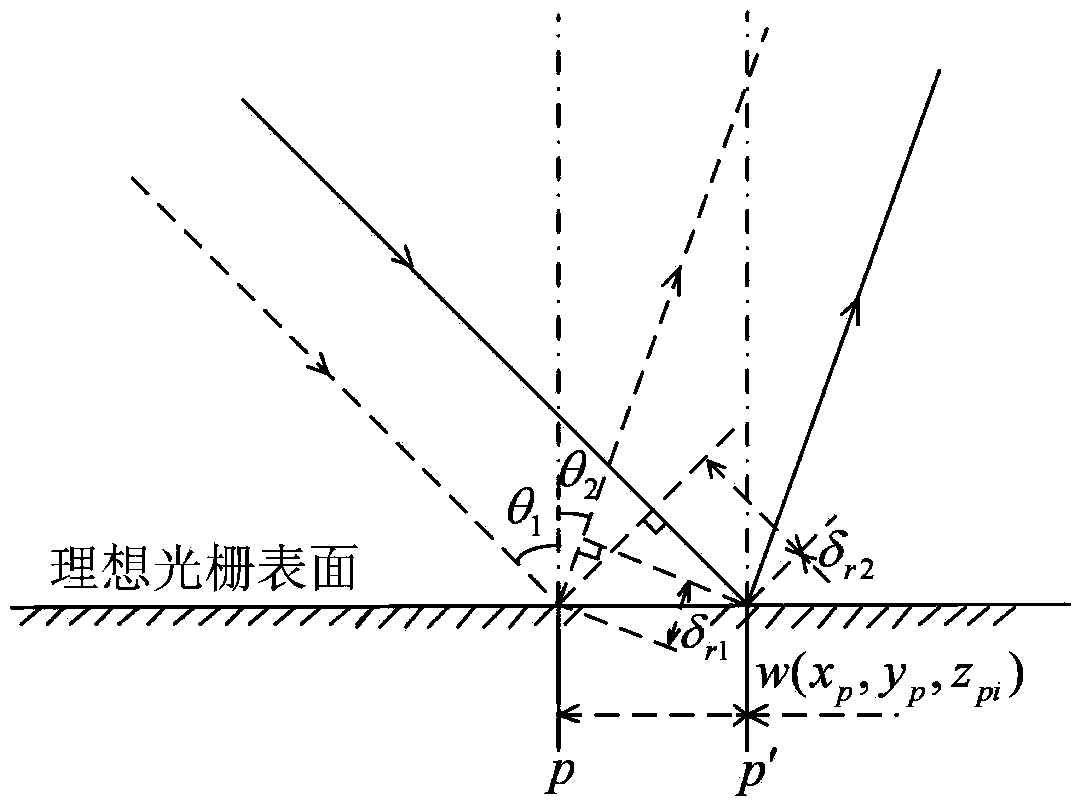

Grating groove bending automatic control and correcting method

ActiveCN104237987ALess bendingQuality improvementDiffraction gratingsMetal working apparatusWavefrontAutomatic control

The invention provides a grating groove bending automatic control and correcting method and relates to the technical field of grating ruling. The automatic control and correcting method solves the problems that improvement design and installation debugging need to be repeatedly carried out on the mechanical structure of a grating ruling machine in a mechanical design method in the existing grating groove bending correction technique, the design process is complex, efficiency is low and the groove bending correction effect is poor. The method includes the steps of (S101) building a grating average groove bending mathematical model, (S102) conducting grating pre-ruling to obtain a pre-ruling grating, and calculating grating average groove bending of the pre-ruling grating, (S103) designing an automatic control scheme of the grating ruling machine, (S104) building a work table displacement compensation mathematical model of the grating ruling machine, and (S105) correcting grating groove bending in an automatic control method. By means of the grating groove bending automatic control and correcting method, grating groove bending can be effectively reduced, grating diffraction wavefront quality is improved, and operation precision and work efficiency of the grating ruling machine are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com