Two-way dynamic-static pressure mixture lubrication thrust bearing

A hybrid lubrication and thrust bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low precision and poor operation stability, and achieve a reasonable matching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

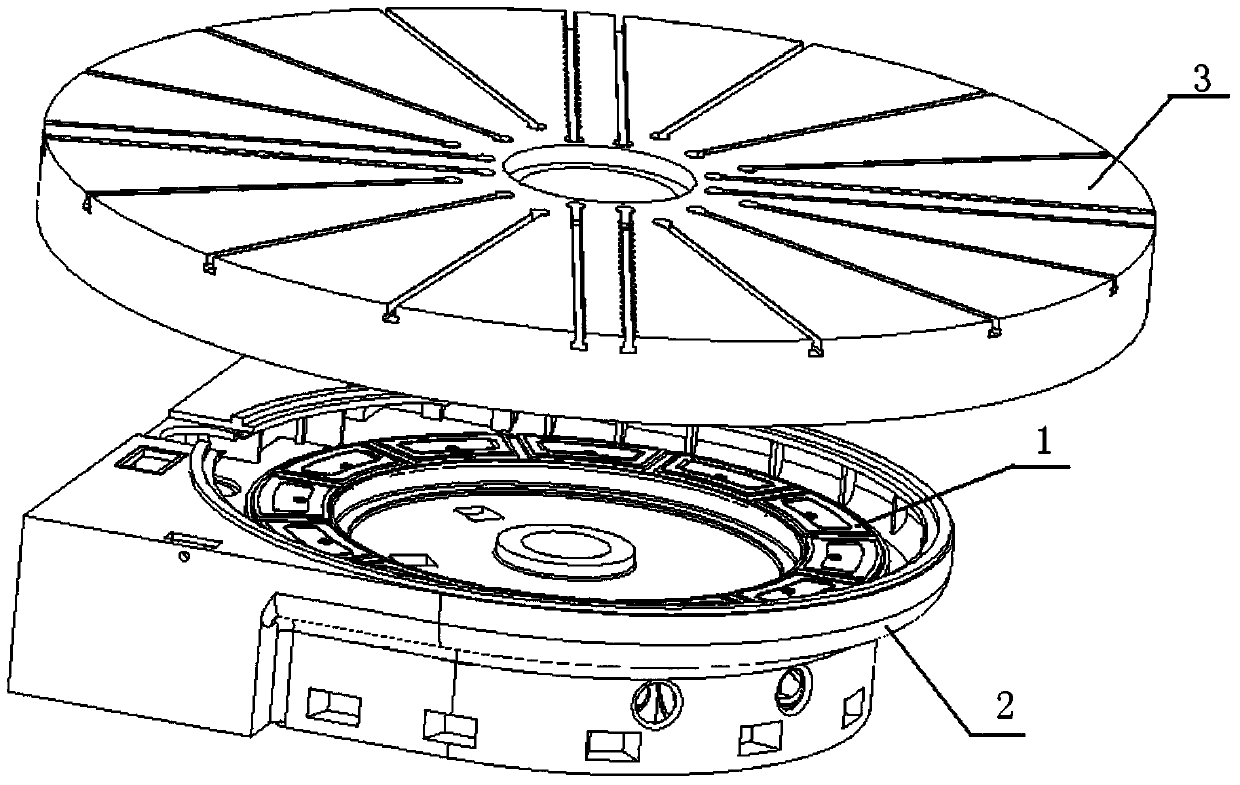

[0030] Embodiment 1: The two-way dynamic and static pressure mixed lubrication thrust bearing of this embodiment includes a dynamic and static pressure oil pad 1, a circular machine tool base 2 and a rotary table 3;

[0031] A rotary table 3 is provided directly above the dynamic and static pressure oil pad 1, and a circular machine tool base 2 is provided directly below the dynamic and static pressure oil pad 1;

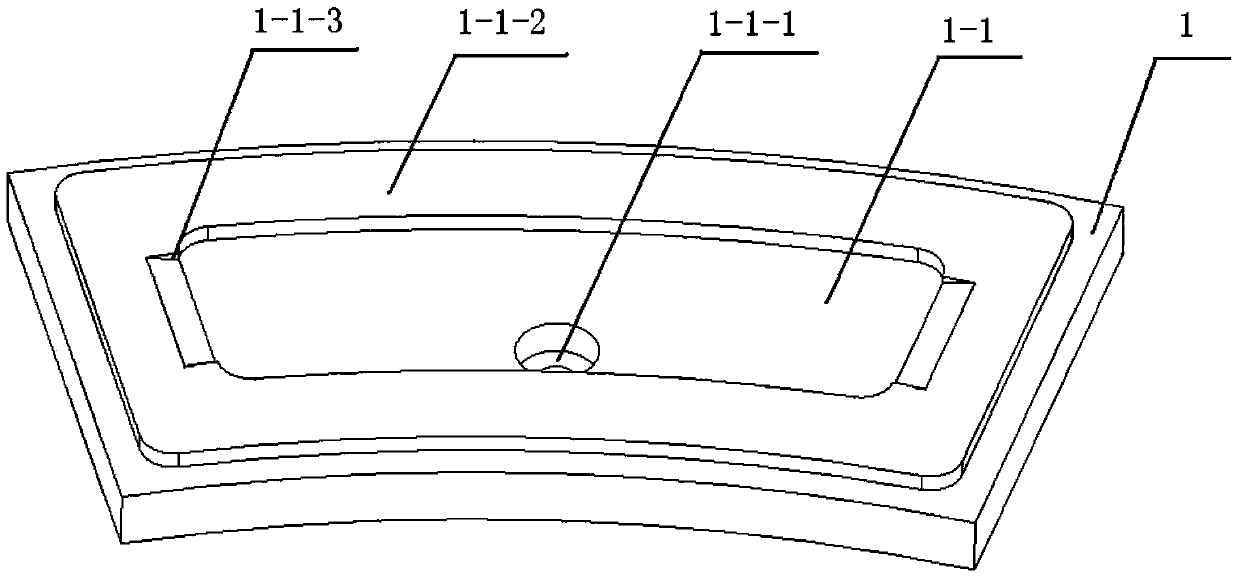

[0032] The upper end surface of the dynamic and static pressure oil pad 1 is provided with an oil chamber 1-1, an oil inlet hole 1-1-1 is opened in the middle of the oil chamber 1-1, and an oil seal is provided on the outer periphery of the oil chamber 1-1. The side 1-1-2 is characterized in that the dynamic and static pressure oil pad 1 of the two-way dynamic and static pressure mixed lubrication thrust bearing also includes a wedge 1-1-3;

[0033] The wedge 1-1-3 is arranged on the inner side of both circumferential sides of the oil sealing edge 1-1-2.

[0034] w...

specific Embodiment approach 2

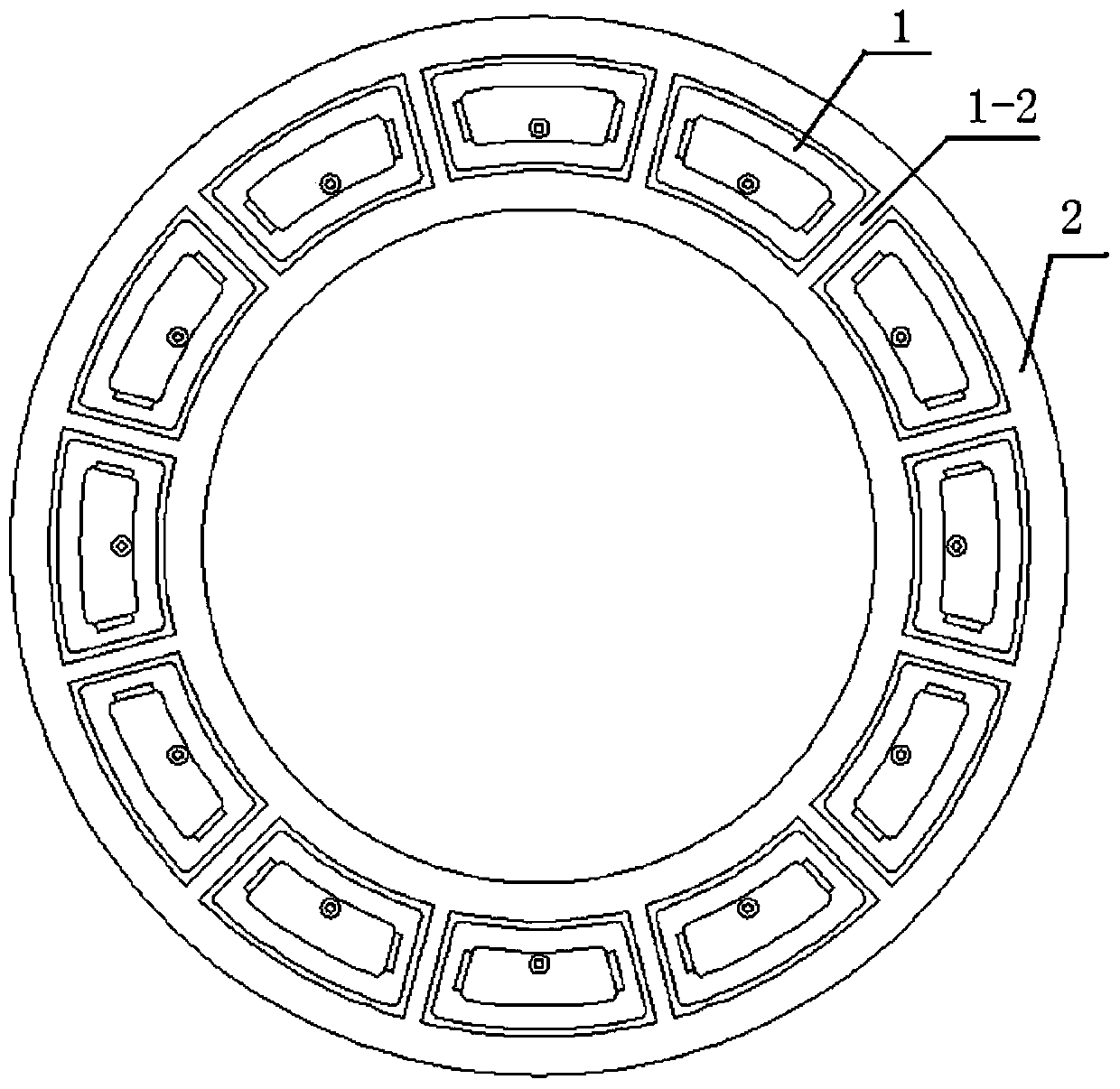

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that: there are 12 hydrodynamic and static pressure oil pads 1 . Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0051]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the dynamic and static pressure oil pads 1 are fan-shaped, and the dynamic and static pressure oil pads 1 are evenly distributed in the circumferential direction of the circular machine tool base 2 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com