Grating groove bending automatic control and correcting method

A correction method, grating engraving technology, applied in the direction of diffraction grating, metal processing, etc., can solve the problems of poor correction effect of reticle bending, low efficiency, complicated design process, etc., to reduce grating reticle bending, improve quality, and improve operation Effects on precision and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

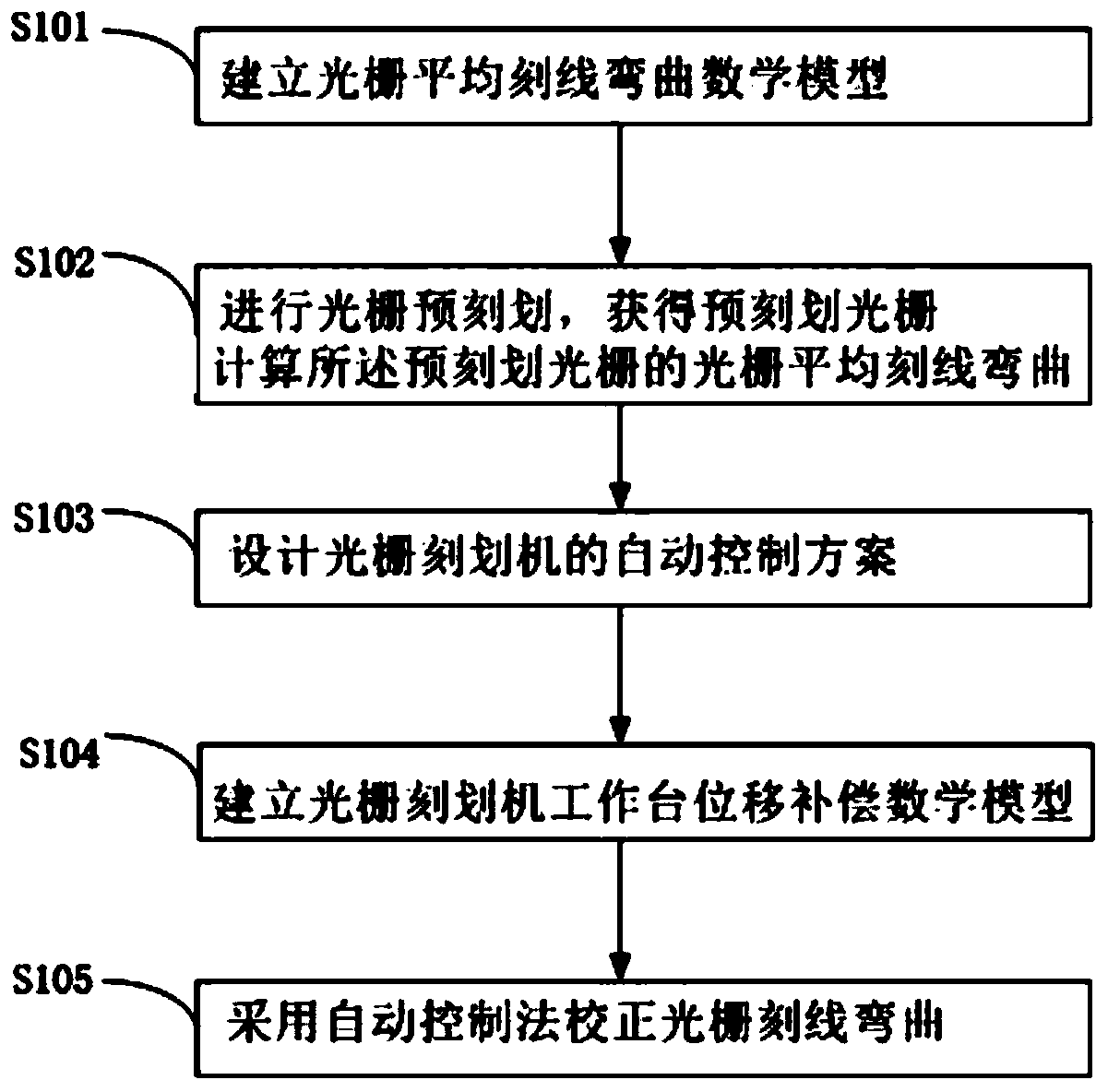

[0033] see figure 1 , the present embodiment provides a method for automatically controlling and correcting grating reticle curvature, which includes the following steps:

[0034] S101. Establish a mathematical model of grating mean line curvature.

[0035] Further includes:

[0036] S1011. Deriving mathematical expressions between grating line errors, grating base surface shape errors, and grating diffraction wavefronts under grating cone diffraction.

[0037] S1012. Deleting the grating swing angle and the overall position error of the grating rule from the grating rule error to obtain a relational expression between the grating average rule bend and the grating rule error.

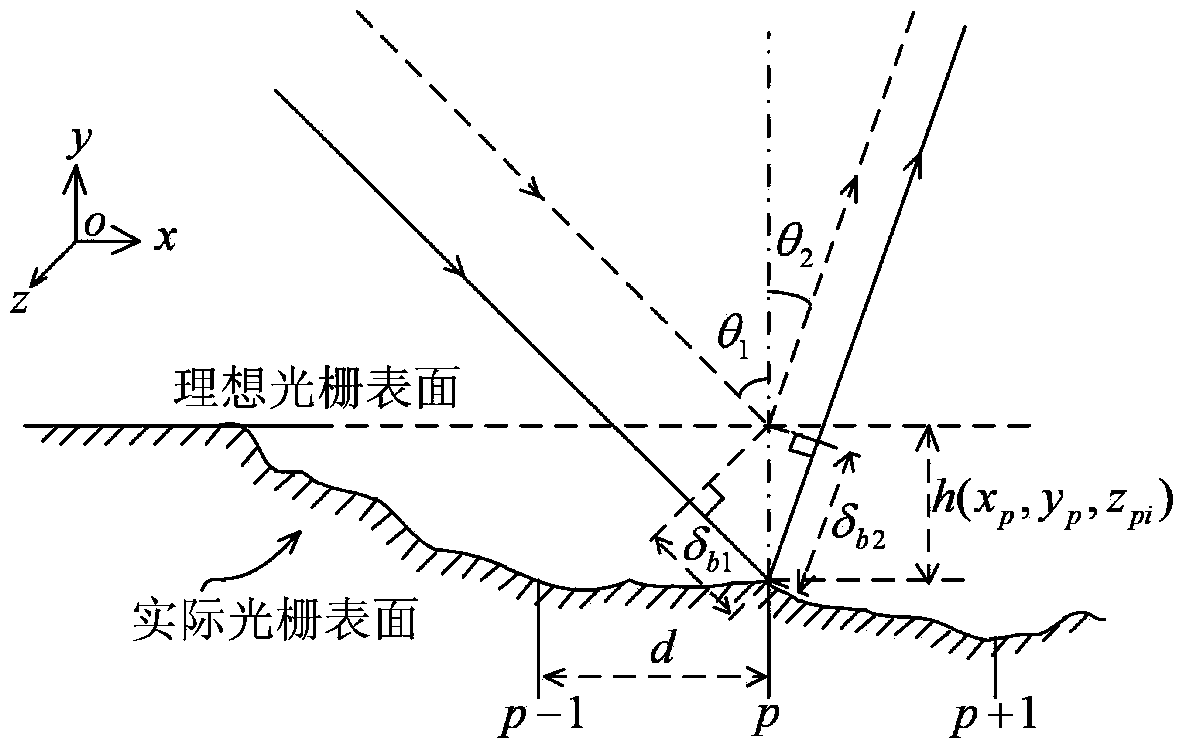

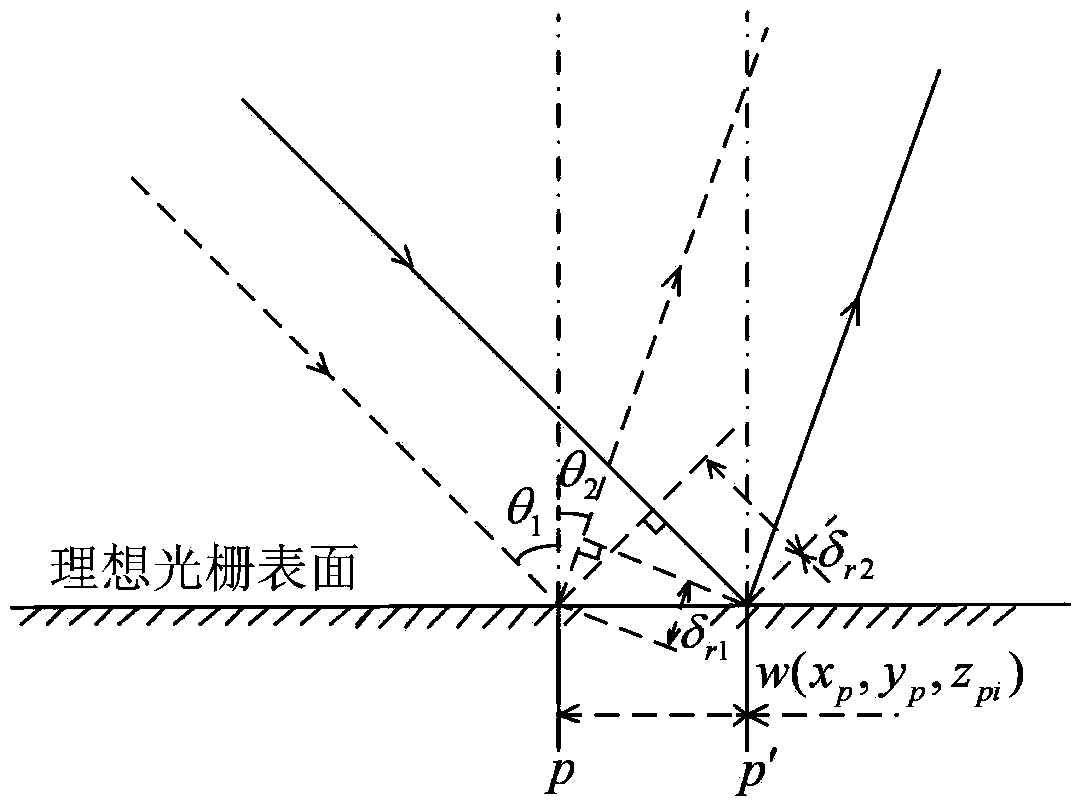

[0038] Specifically, in this embodiment, the geometrical optics method is used to derive the relational expression between the grating rule error, the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com