Patents

Literature

69results about How to "Enhance the dynamic pressure effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

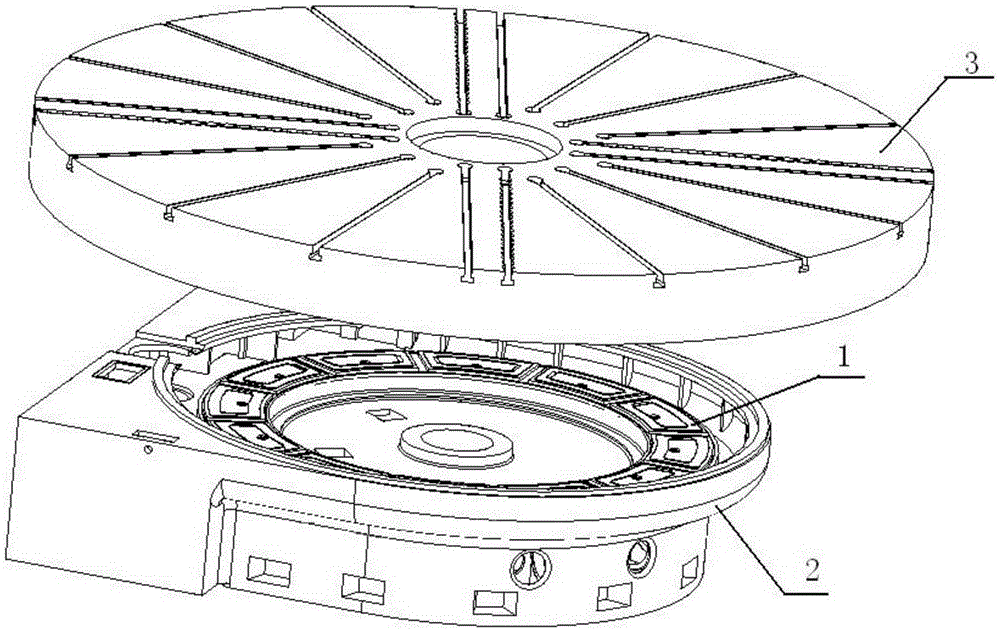

Two-way dynamic-static pressure mixture lubrication thrust bearing

InactiveCN103438097AHigh running precisionImprove running stabilityBearingsGas cushion bearingsThrust bearingEngineering

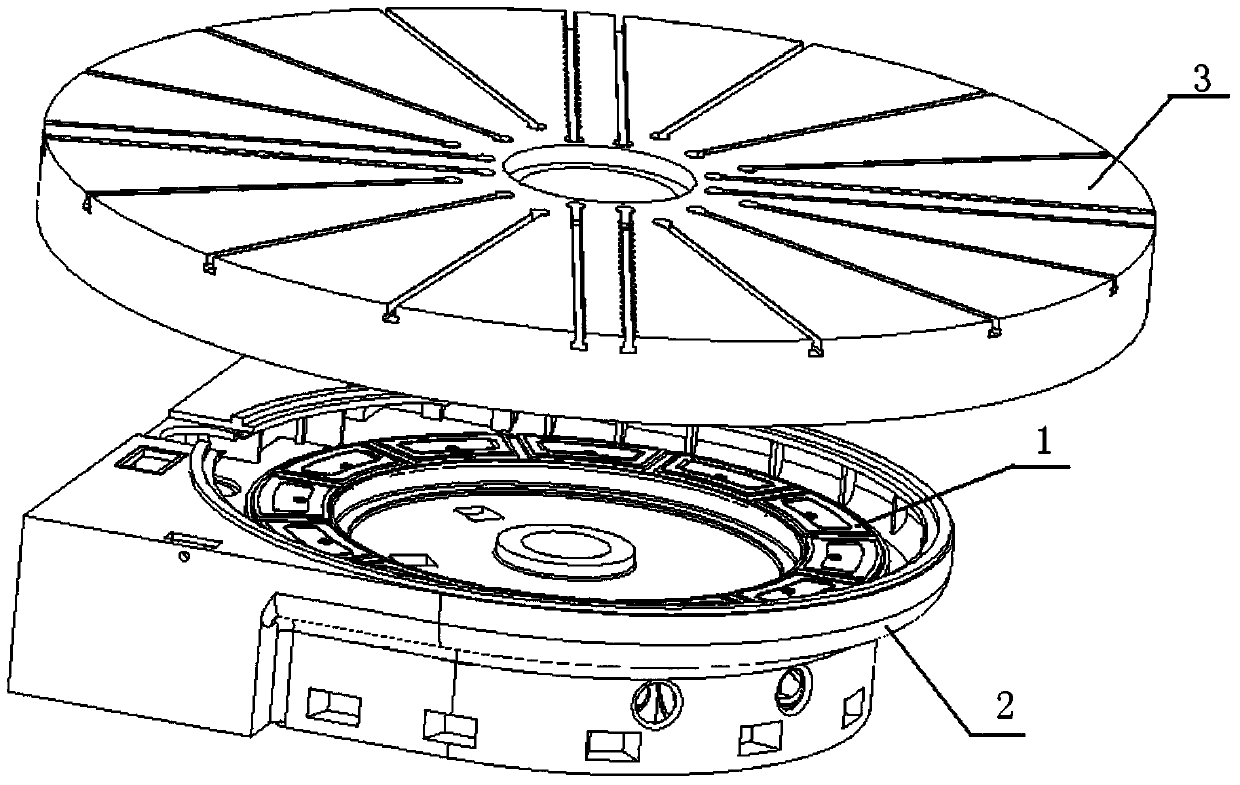

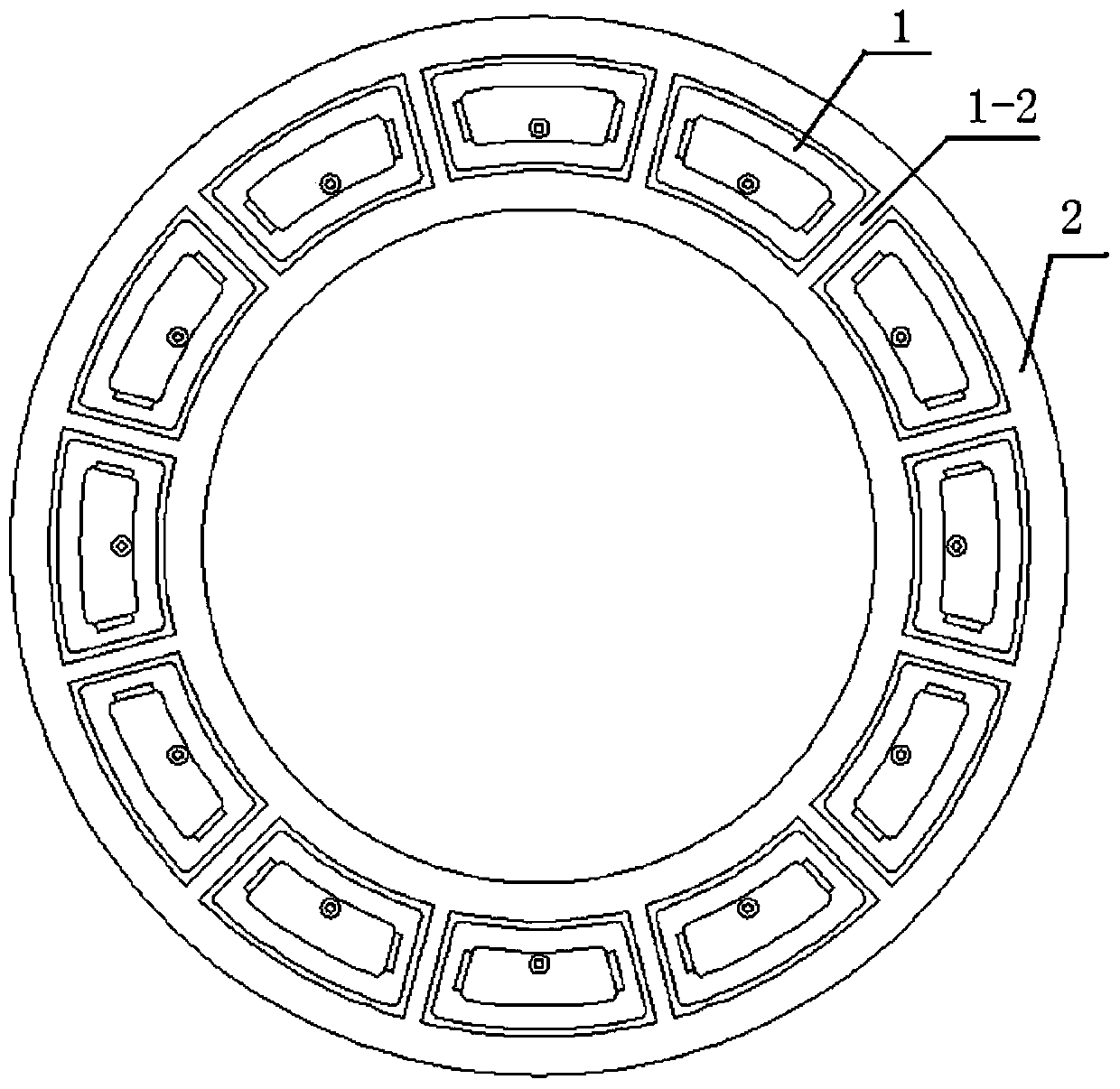

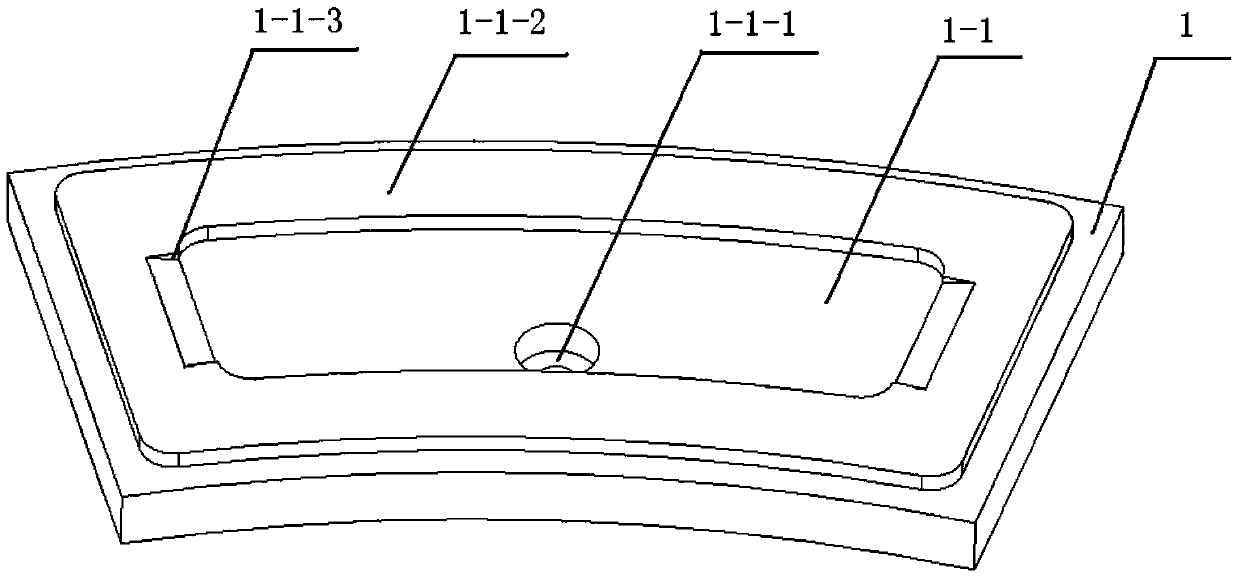

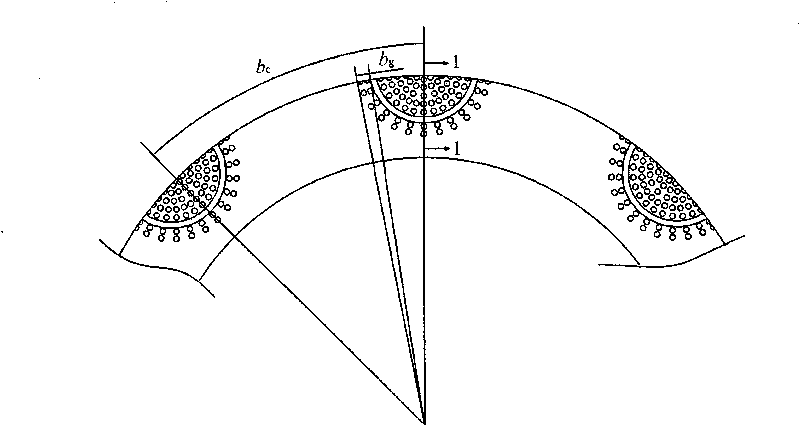

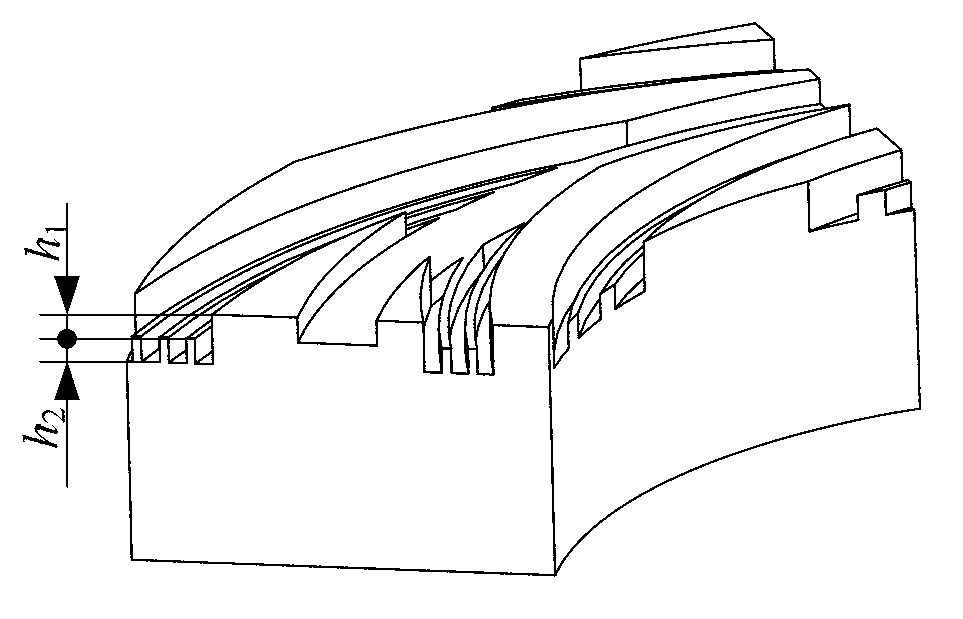

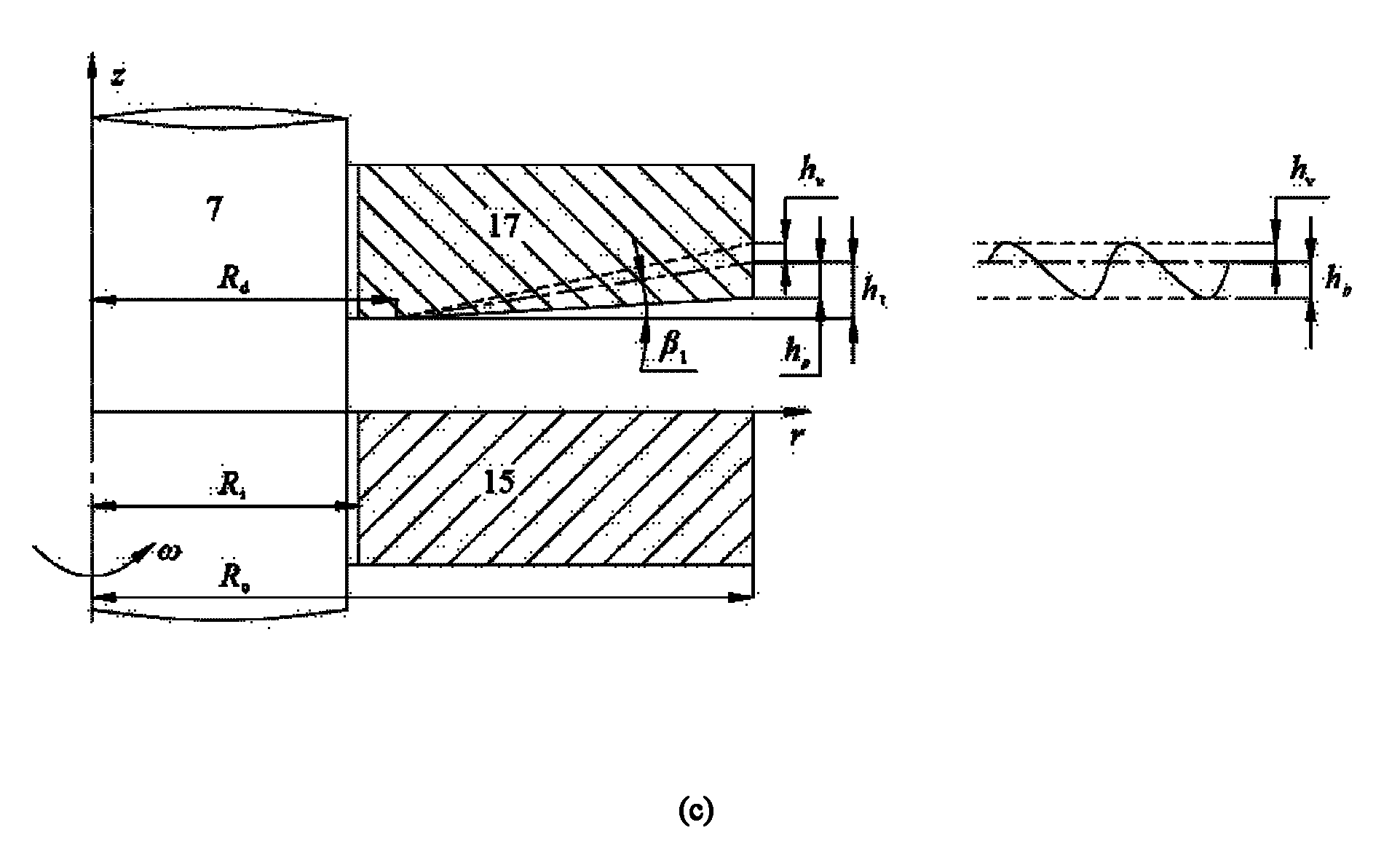

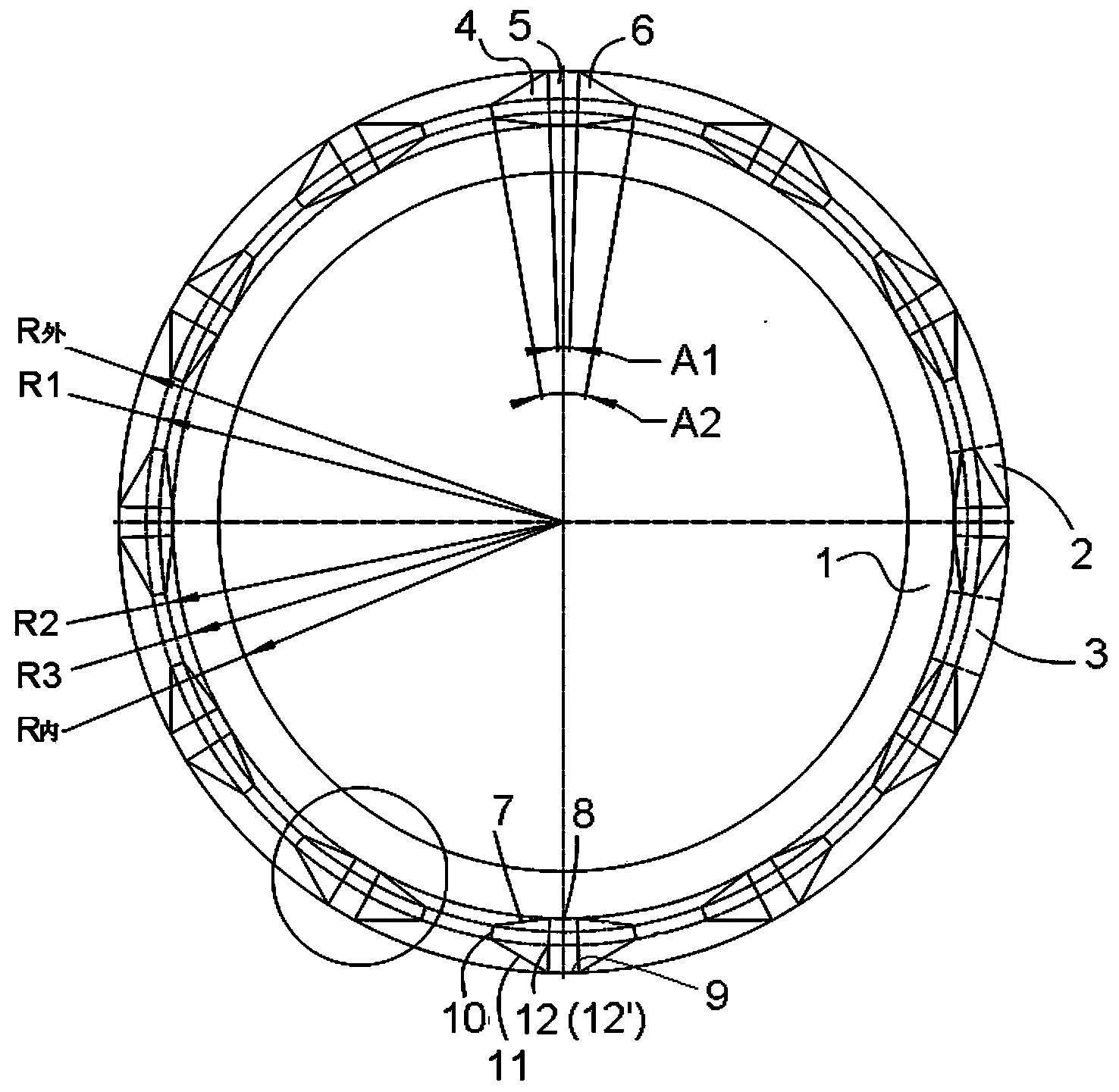

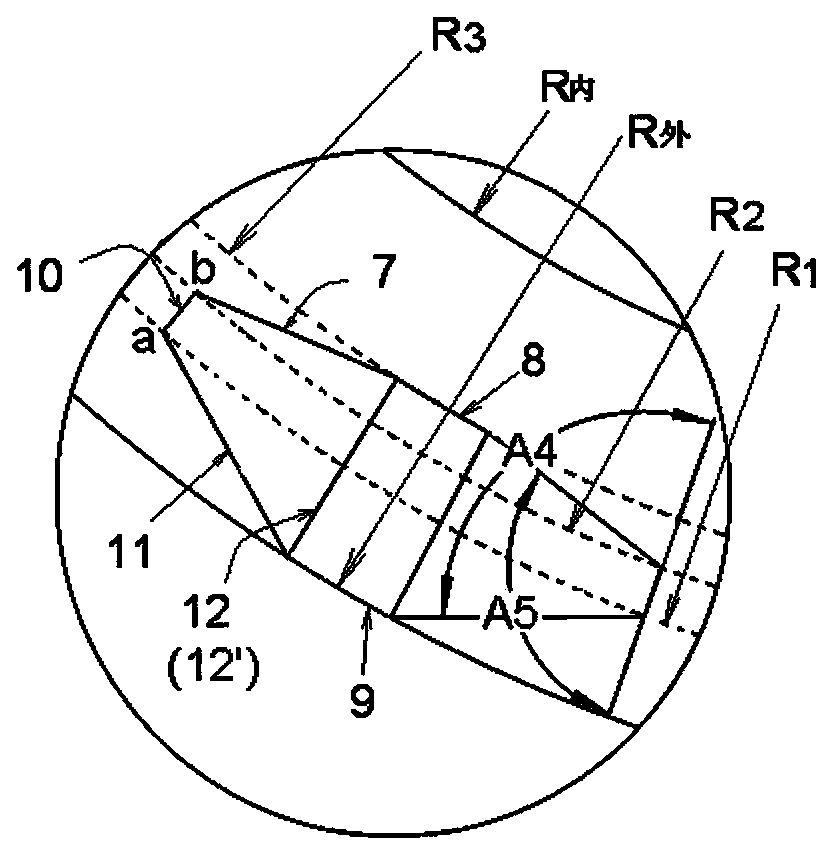

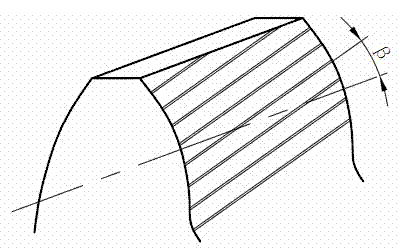

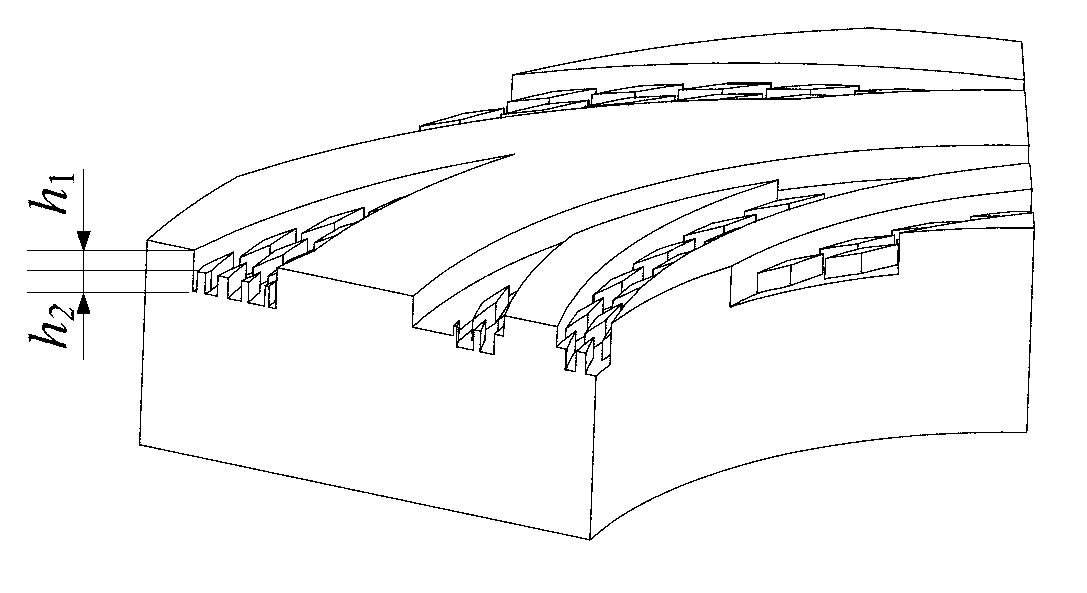

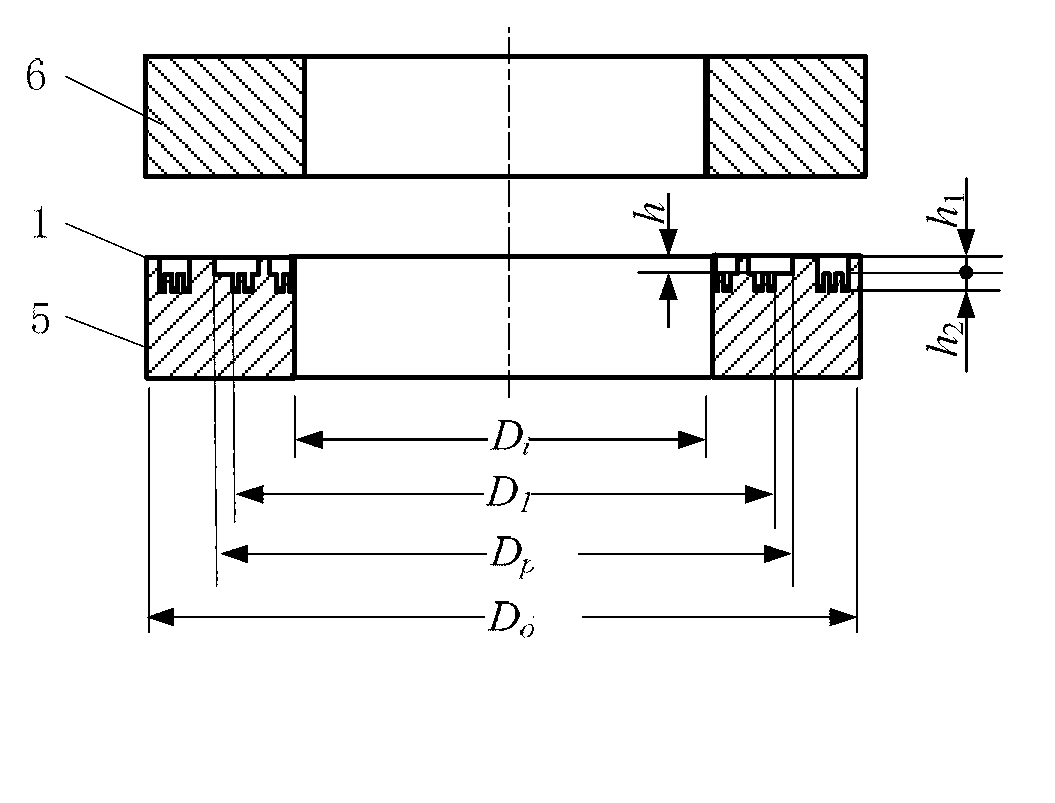

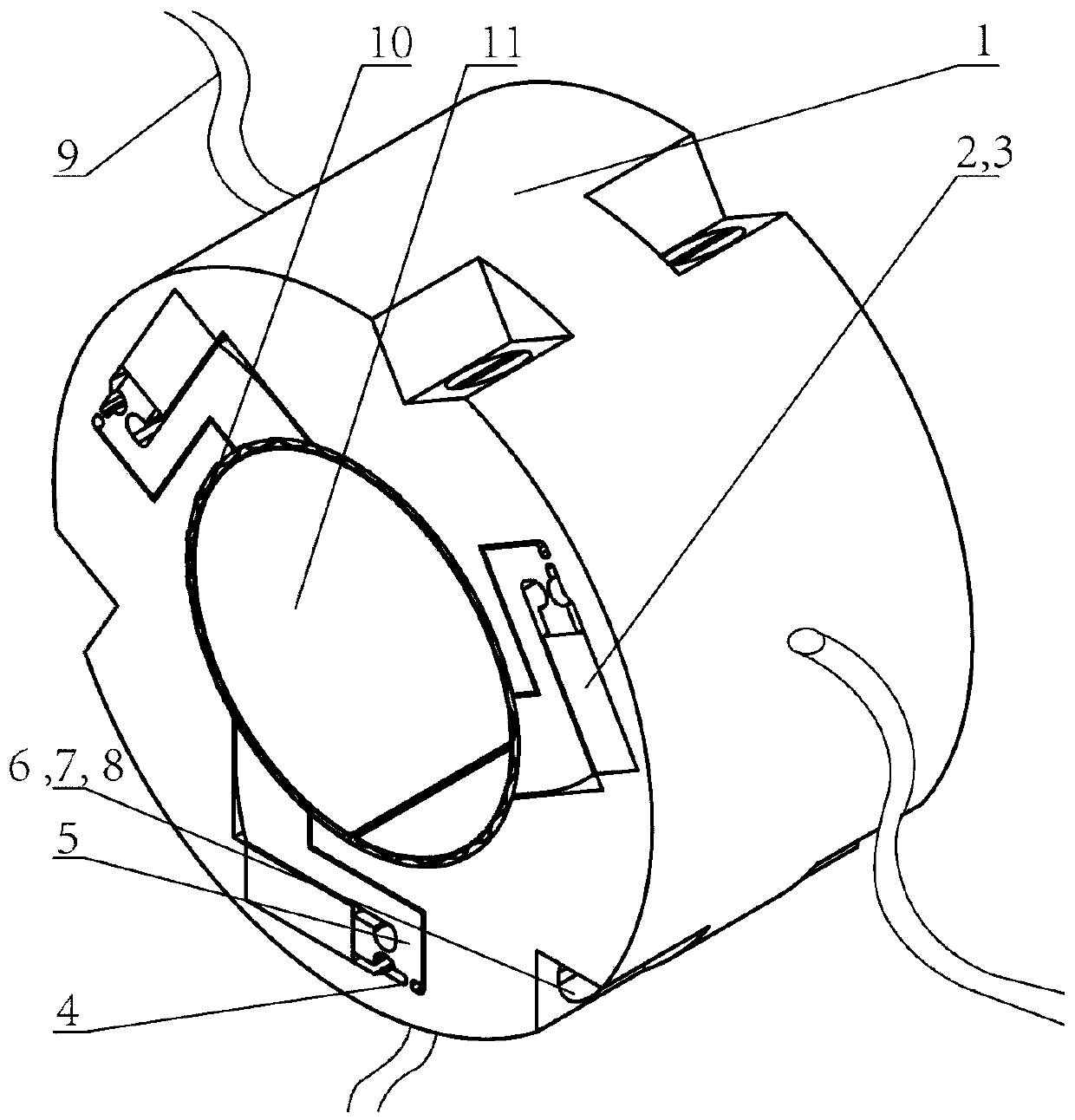

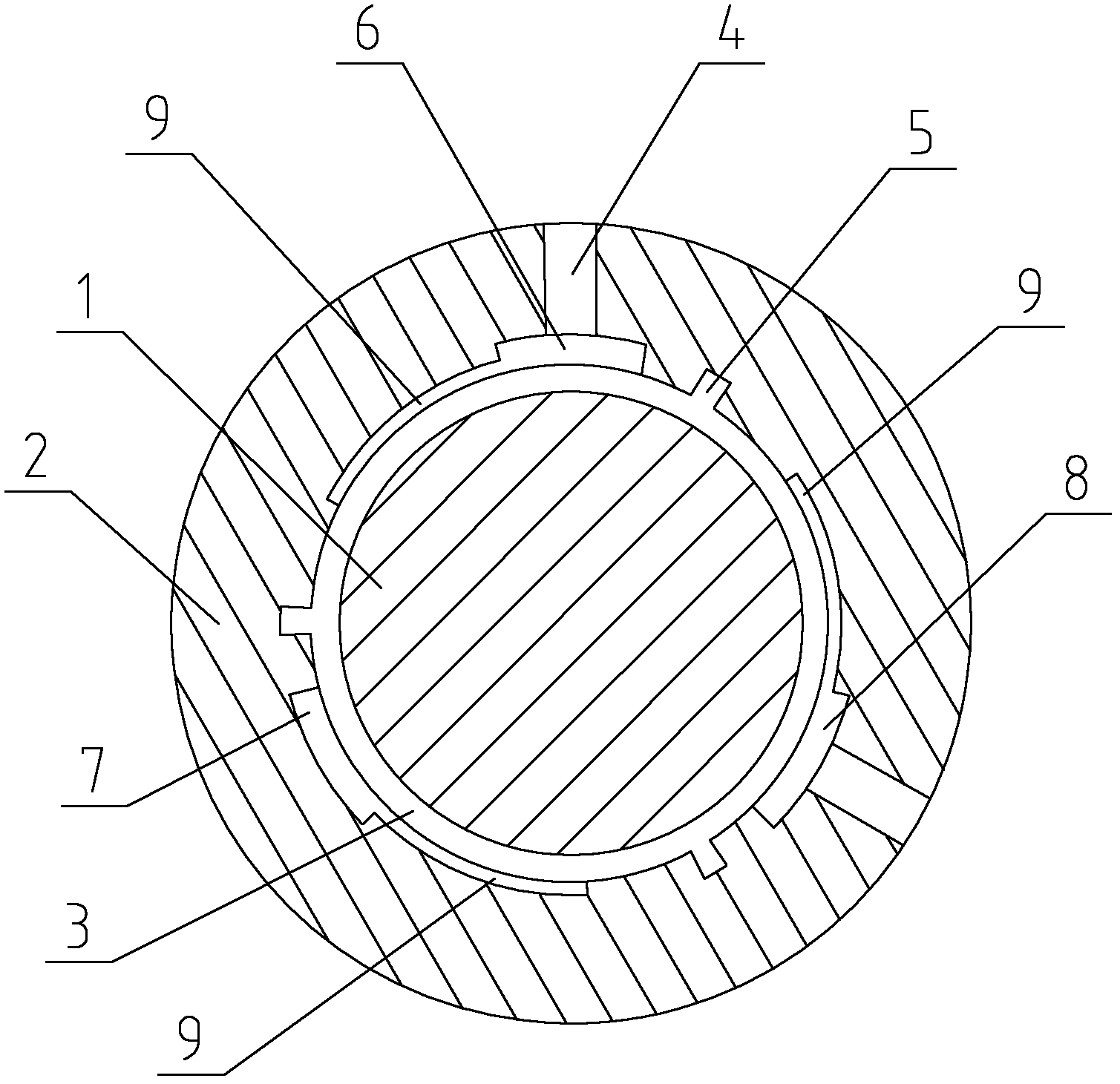

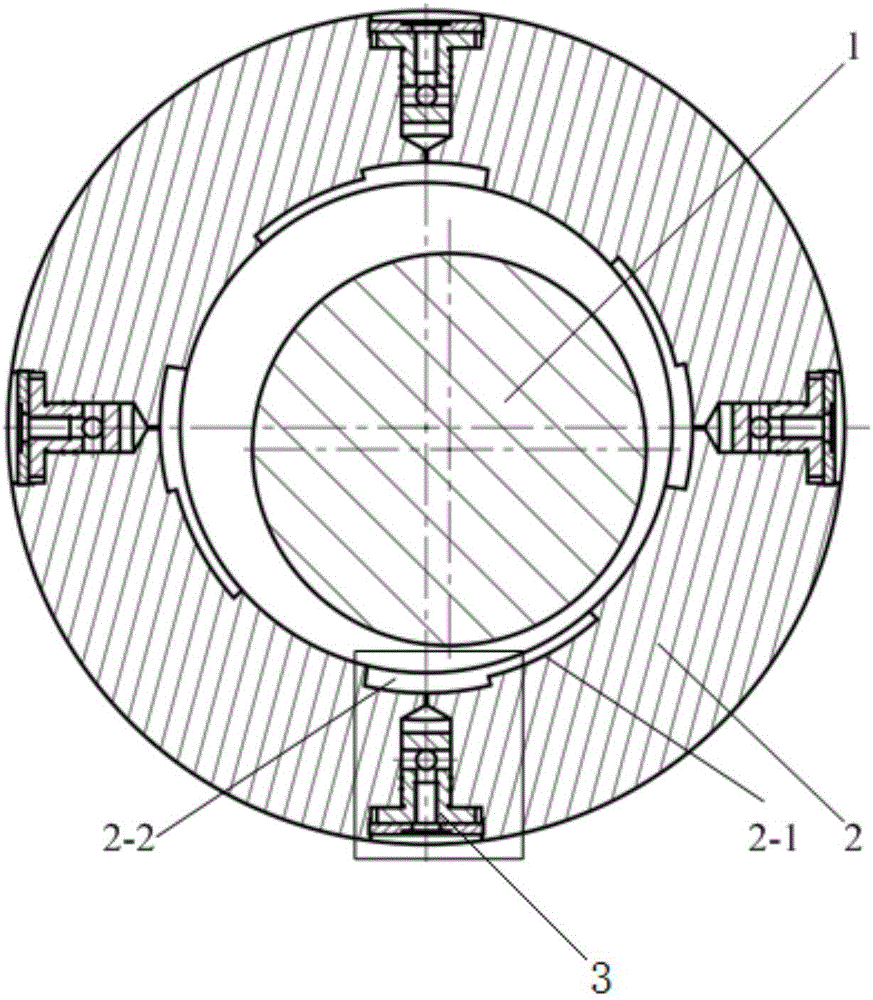

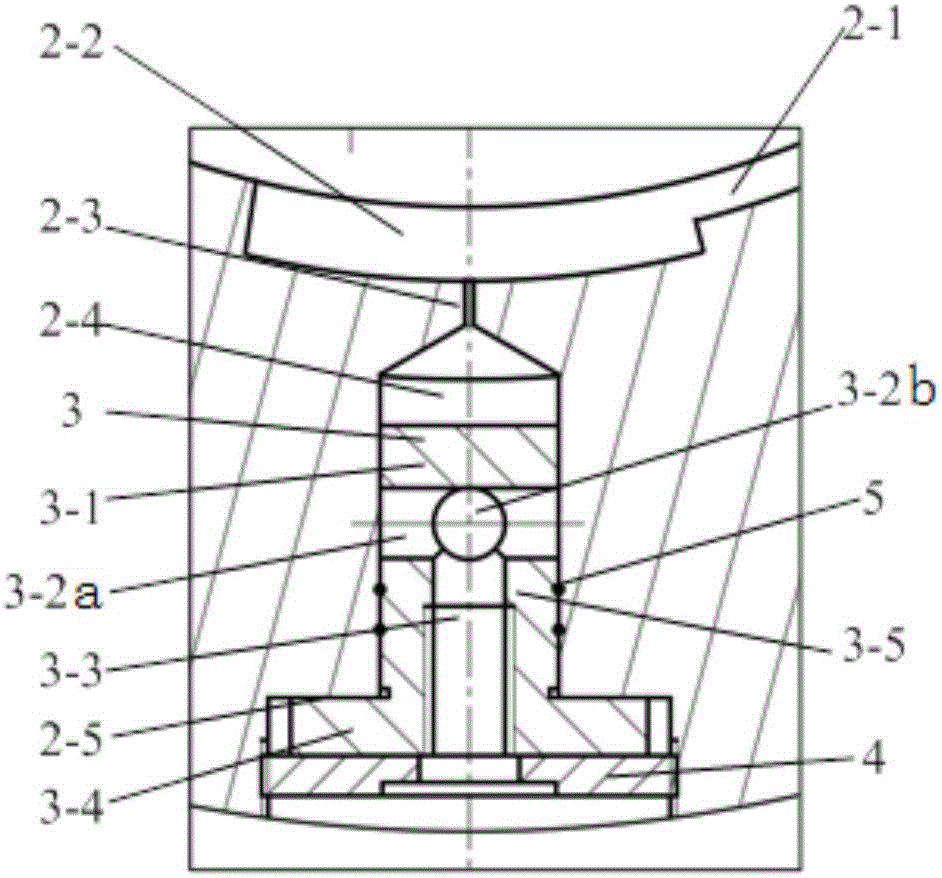

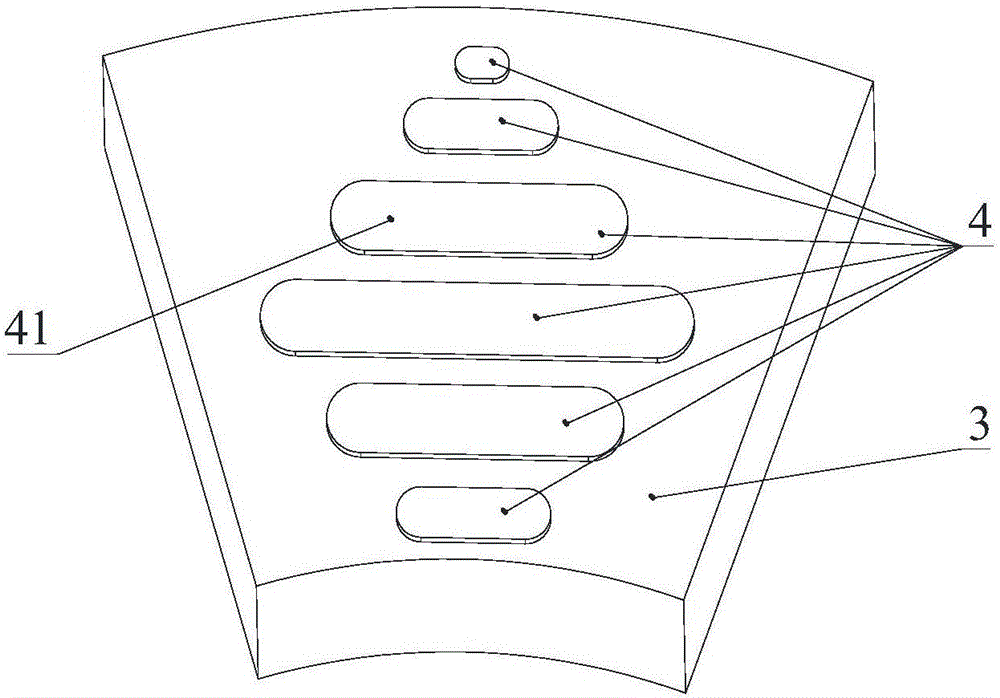

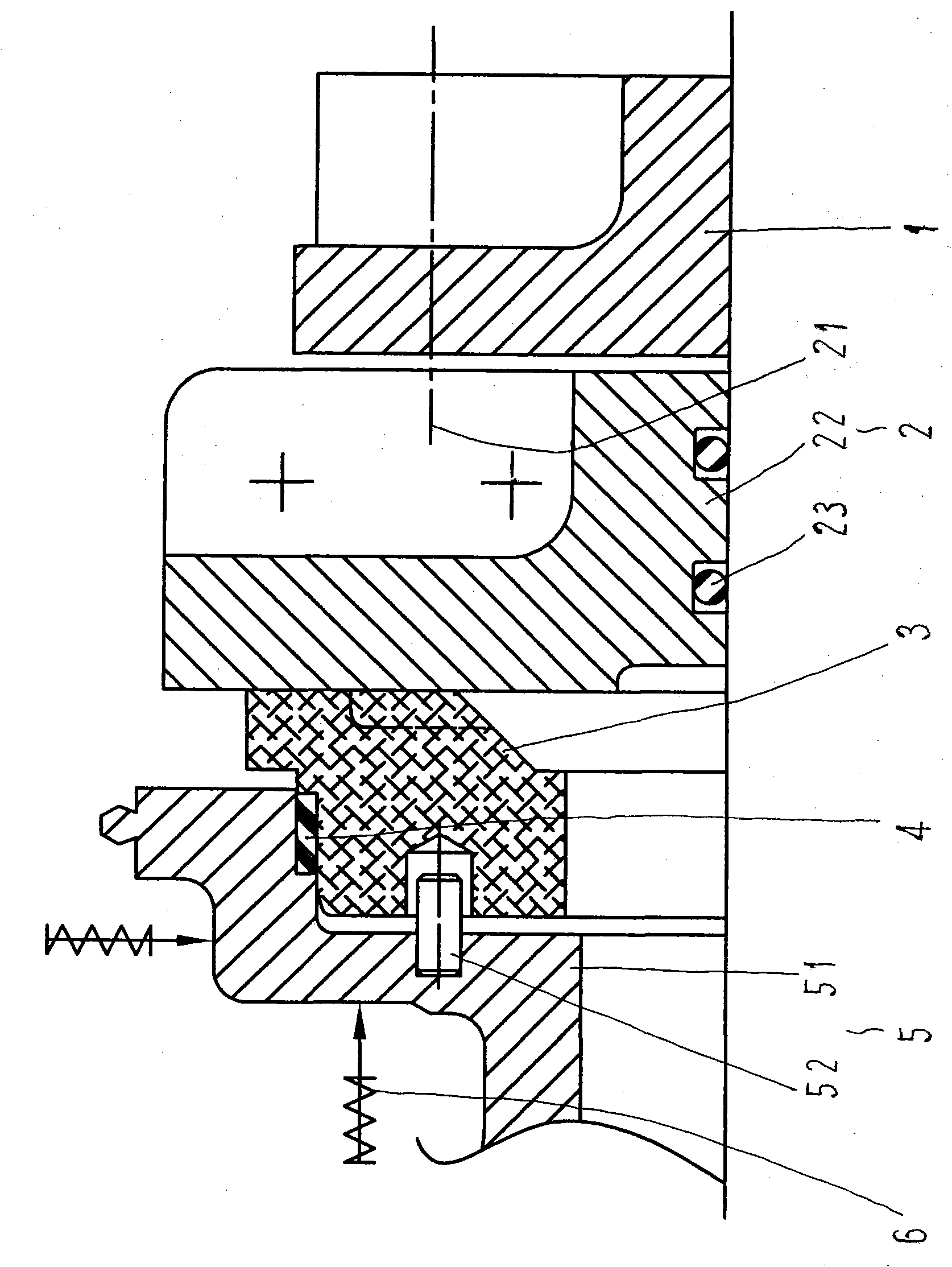

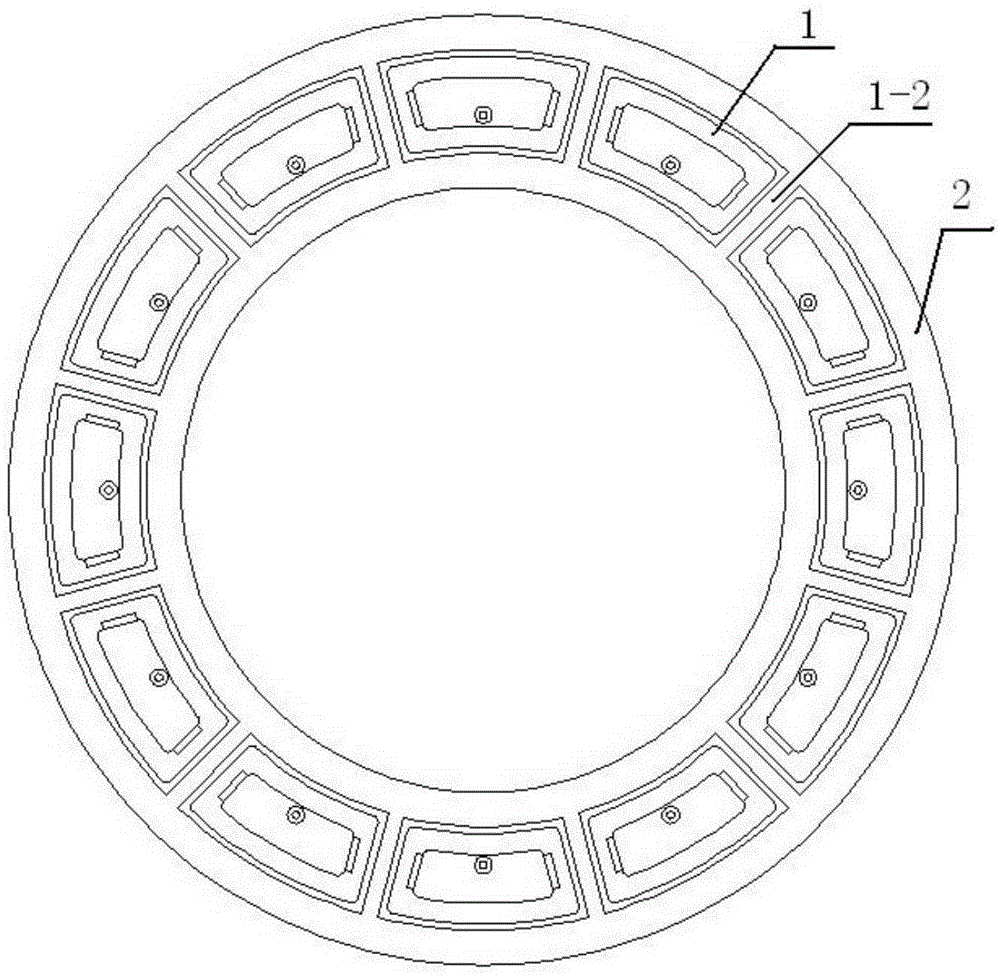

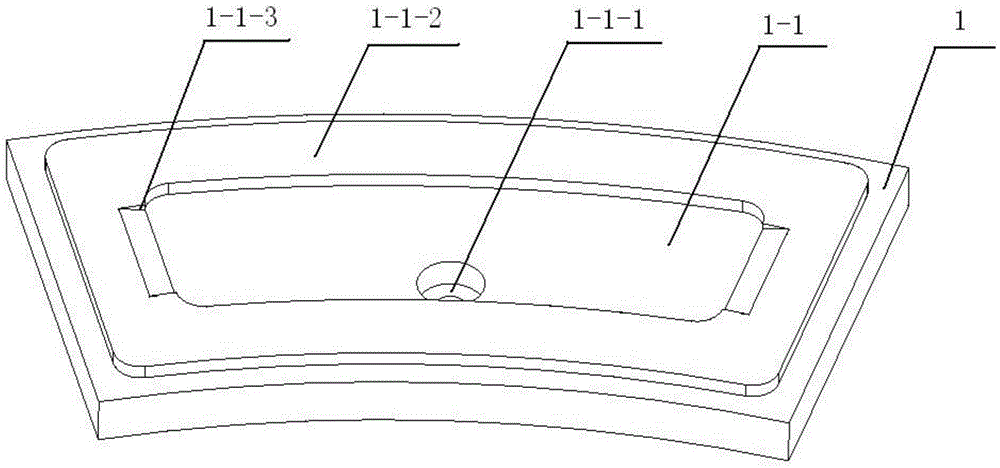

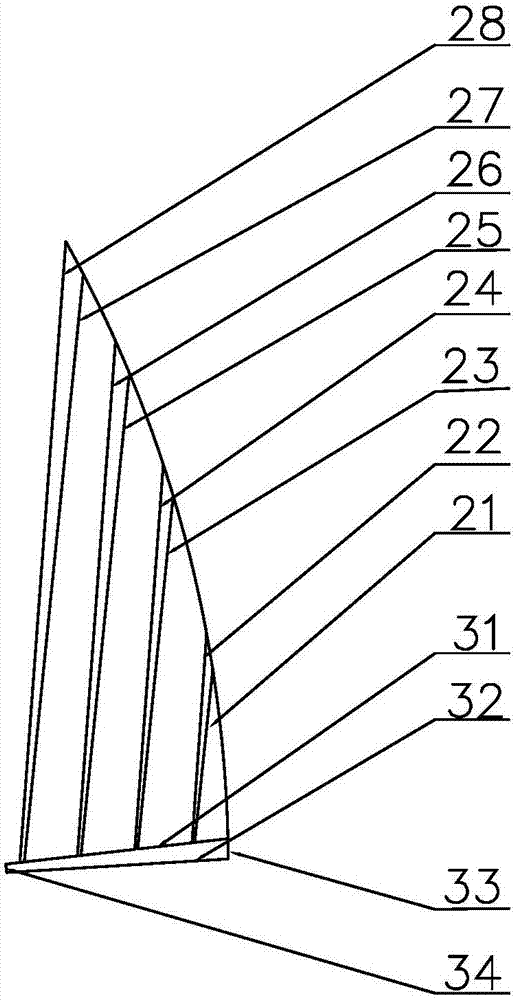

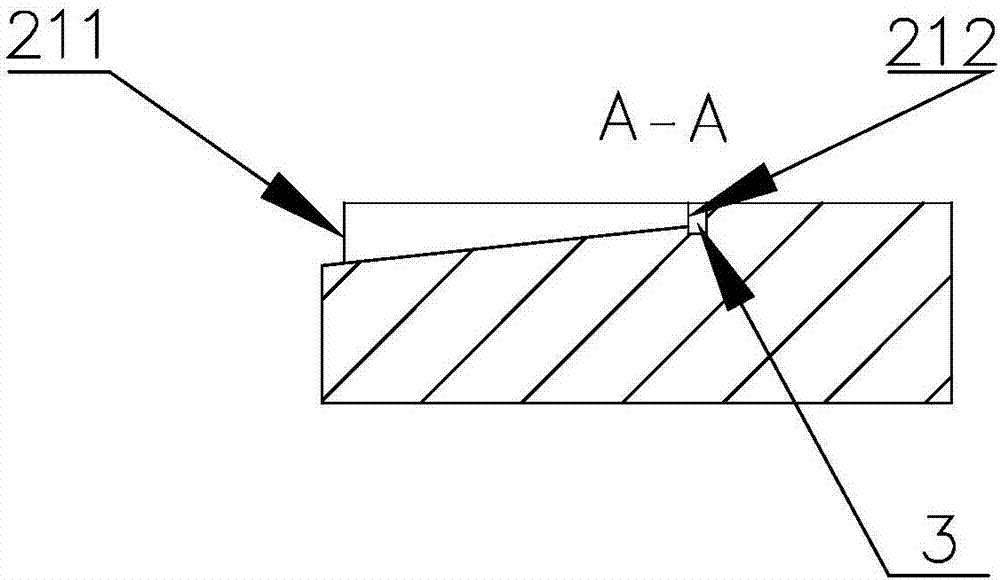

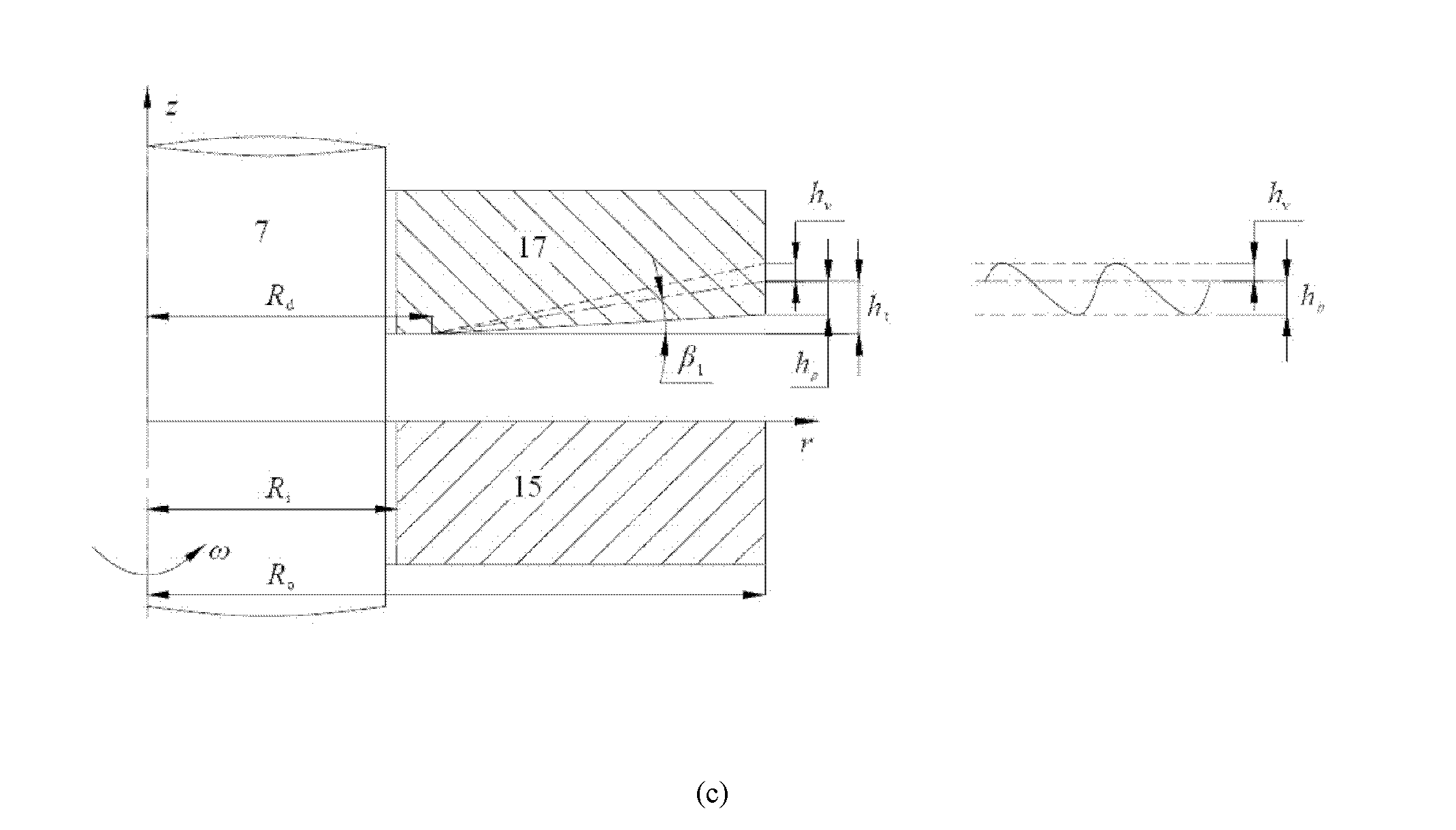

The invention relates to a two-way dynamic-static pressure mixture lubrication thrust bearing. Aiming to solve the problems of low accuracy and poor operating stability in an existing high-speed and heavy-load extreme working condition, the invention provides the two-way dynamic-static pressure mixture lubrication thrust bearing. The two-way dynamic-static mixture lubrication thrust bearing comprises a dynamic-static pressure oil pad, a circular machine tool base and a rotary workbench, wherein the rotary workbench is arranged right above the dynamic-static pressure oil pad; the circular machine tool base is arranged under the dynamic-static pressure oil pad; wedges are arranged on the dynamic-static pressure oil pad of the two-way dynamic-static pressure mixture lubrication thrust bearing and are arranged in two inner sides of the circumferential direction of an oil sealing edge. The two-way dynamic-static pressure mixture lubrication thrust bearing is applied to the field of high-speed and heavy-load machine tool workbenches.

Owner:HARBIN UNIV OF SCI & TECH

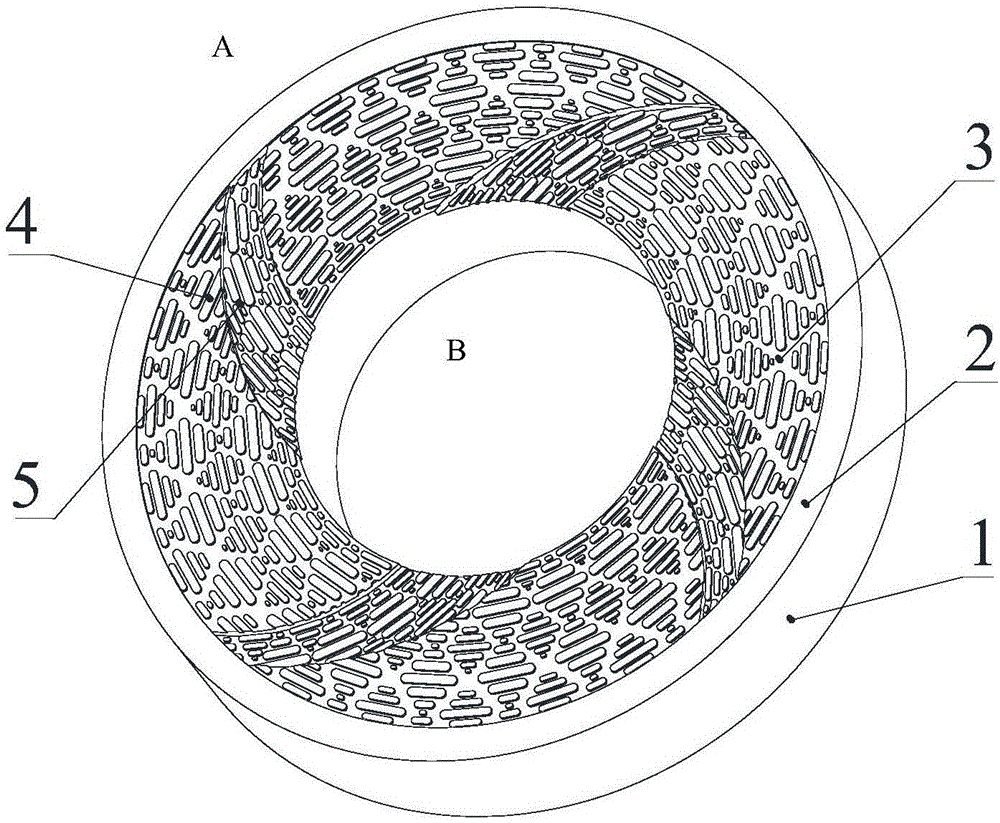

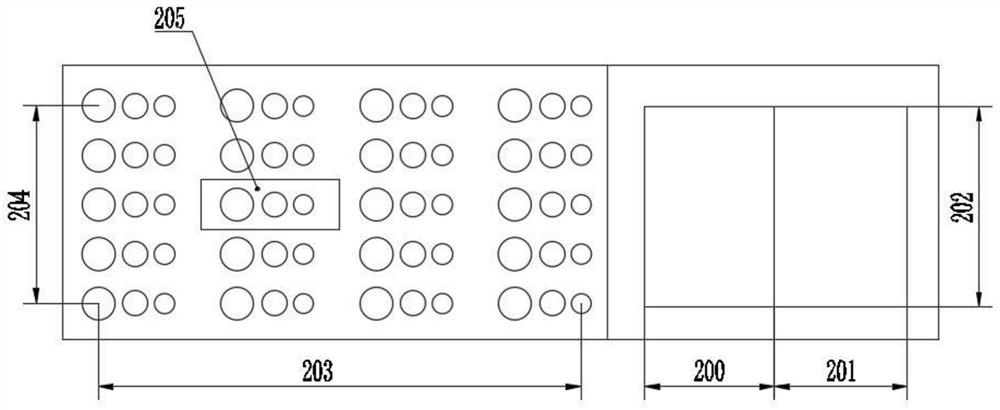

Liquid lubricated end face seal structure with cross-scale surface texture characteristic

ActiveCN101696728AImprove throttling effectEnhanced pumping effectEngine sealsPump componentsLubricationMicrometer

The invention discloses a liquid lubricated end face seal structure with a cross-scale surface texture characteristic, which comprises a moving ring and a static ring of a mechanical seal; and one side of an end face of the moving ring / static ring is a high pressure side, namely an upstream, while the other side is a low pressure side, namely a downstream. The liquid lubricated end face seal structure is characterized in that: a plurality of cross-scale texture face grooves are processed on the end face of the moving ring or the static ring of the mechanical seal; each cross-scale texture face groove consists of a millimeter deep groove and micrometer micropores; the deep groove is positioned at the upstream of the end face; the micropores are distributed on the periphery of the deep groove; seal weirs are arranged between the cross-scale texture face grooves; and a downstream of each cross-scale texture face groove is provided with an annular seal dam of a non-opened face groove. The liquid lubricated end face seal structure has the advantages of improving seal lubrication, improving the rigidity of a fluid film and the pressure and heat resistance of the mechanical seal, greatly strengthening the operational reliability, stability and leak tightness of the seal, and prolonging the service life of the seal.

Owner:ZHEJIANG UNIV OF TECH +1

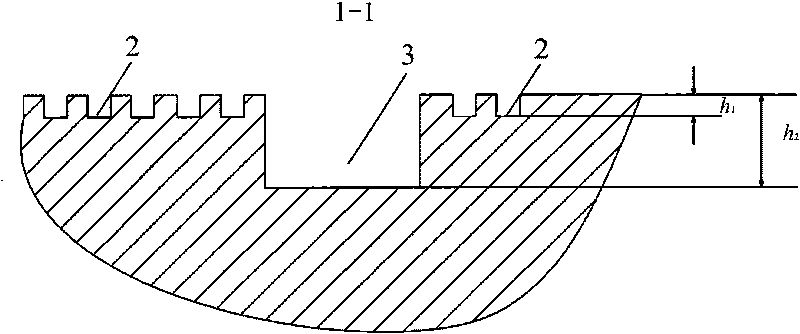

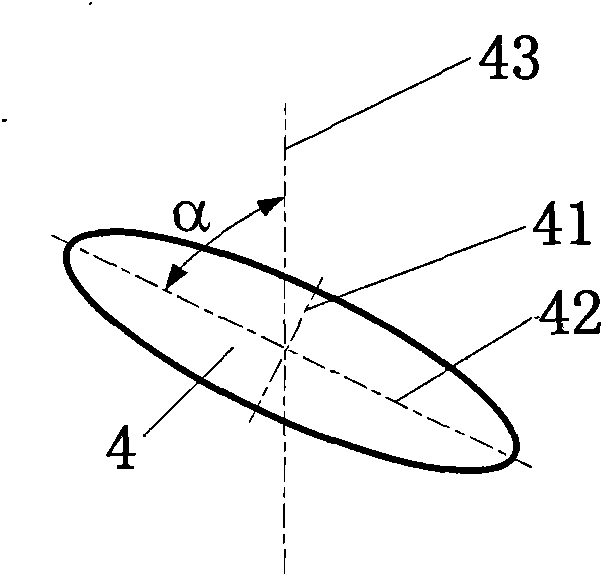

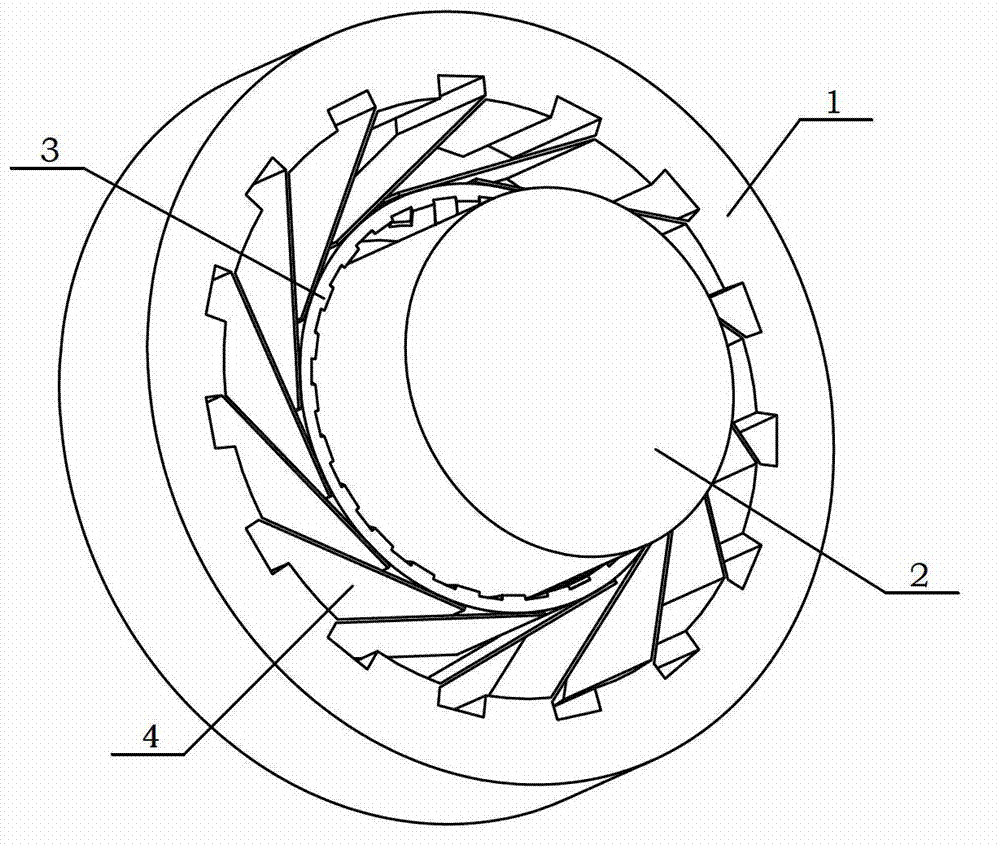

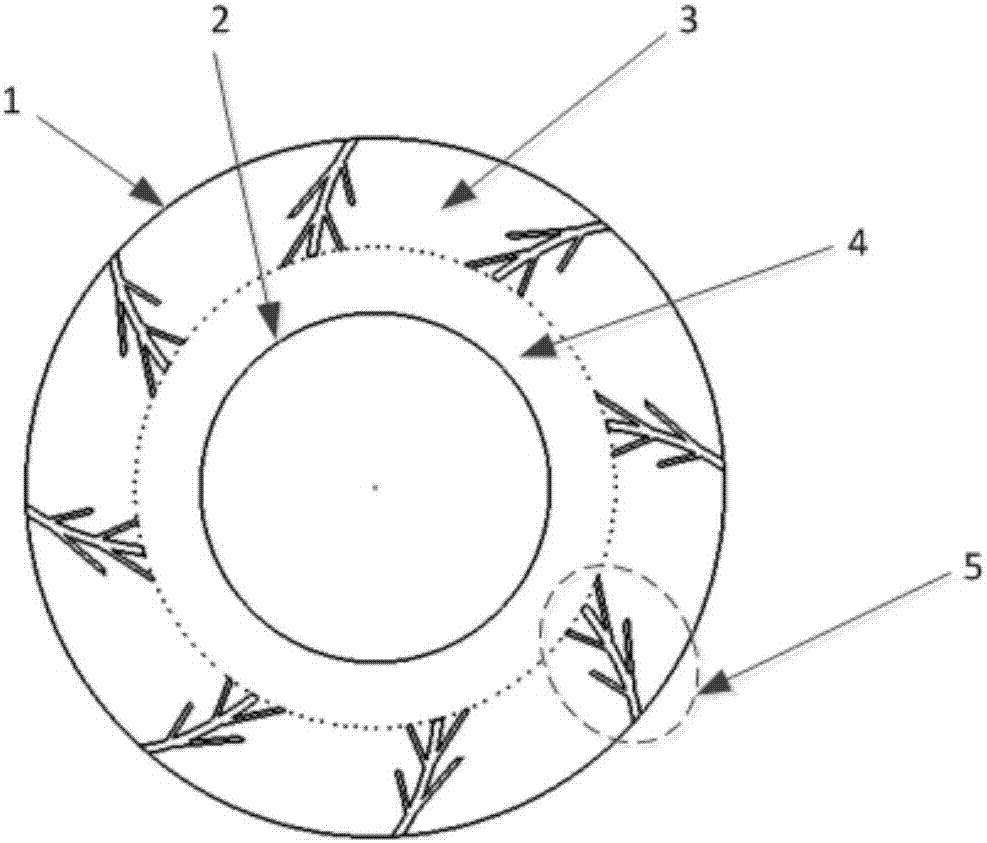

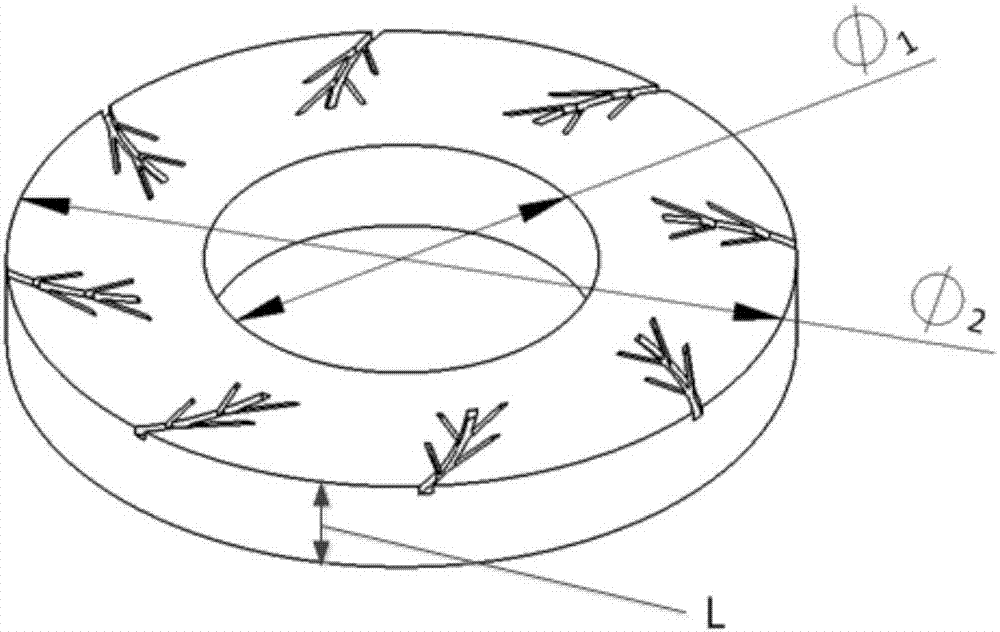

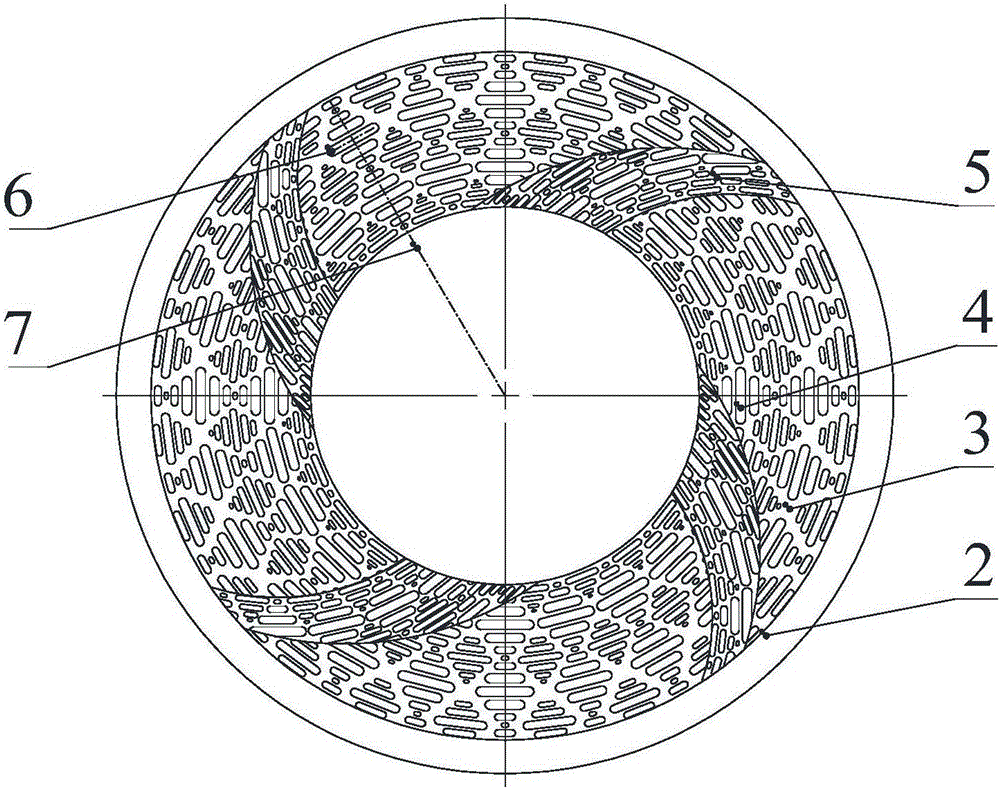

Double-row tilting directional microporous end surface no-leakage mechanical sealing structure

ActiveCN101672364AImproved hydrodynamic effect and tightnessGood start and stop effectEngine sealsDouble rowEngineering

The invention relates to a double-row tilting directional microporous end surface no-leakage mechanical sealing structure, comprising a dynamic ring and a static ring which are sealed mechanically, wherein one side of the end surface of the dynamic ring or the static ring is an high-voltage side, namely an upstream part, and the other side thereof is a low-voltage side, namely an downstream part,the end surface of the dynamic ring or the static ring is provided with an outer microporous ring belt and an inner microporous ring belt; microporous long shafts of the outer microporous ring belt and the inner microporous ring belt are opposite to the direction of a tilting angle of the diameter of the sealing end surface passing through the center of the micropore; the outer microporous ring belt and the inner microporous ring belt are respectively arranged on the upstream part and the downstream part of the end surface; and a continuous ring-shaped sealing dam are respectively arranged between the outer microporous ring belt and the inner microporous ring belt and the downstream part of the inner microporous ring belt. The mechanical sealing structure has the beneficial effects of: realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

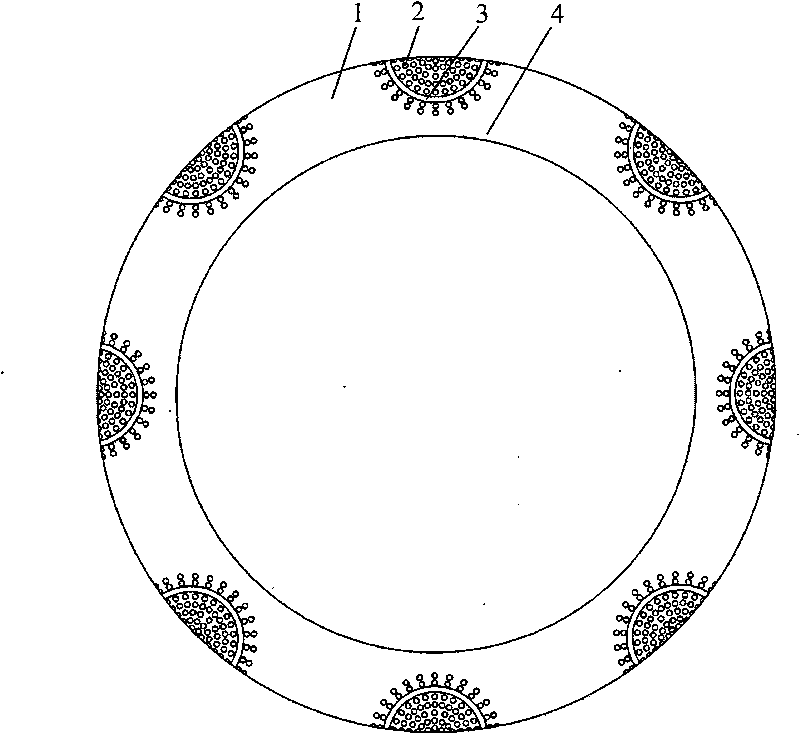

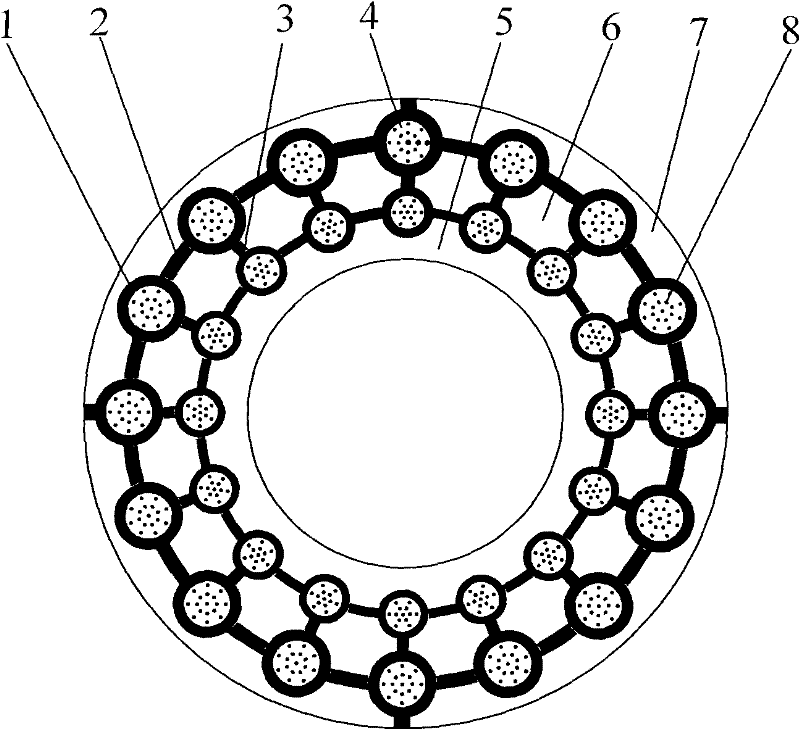

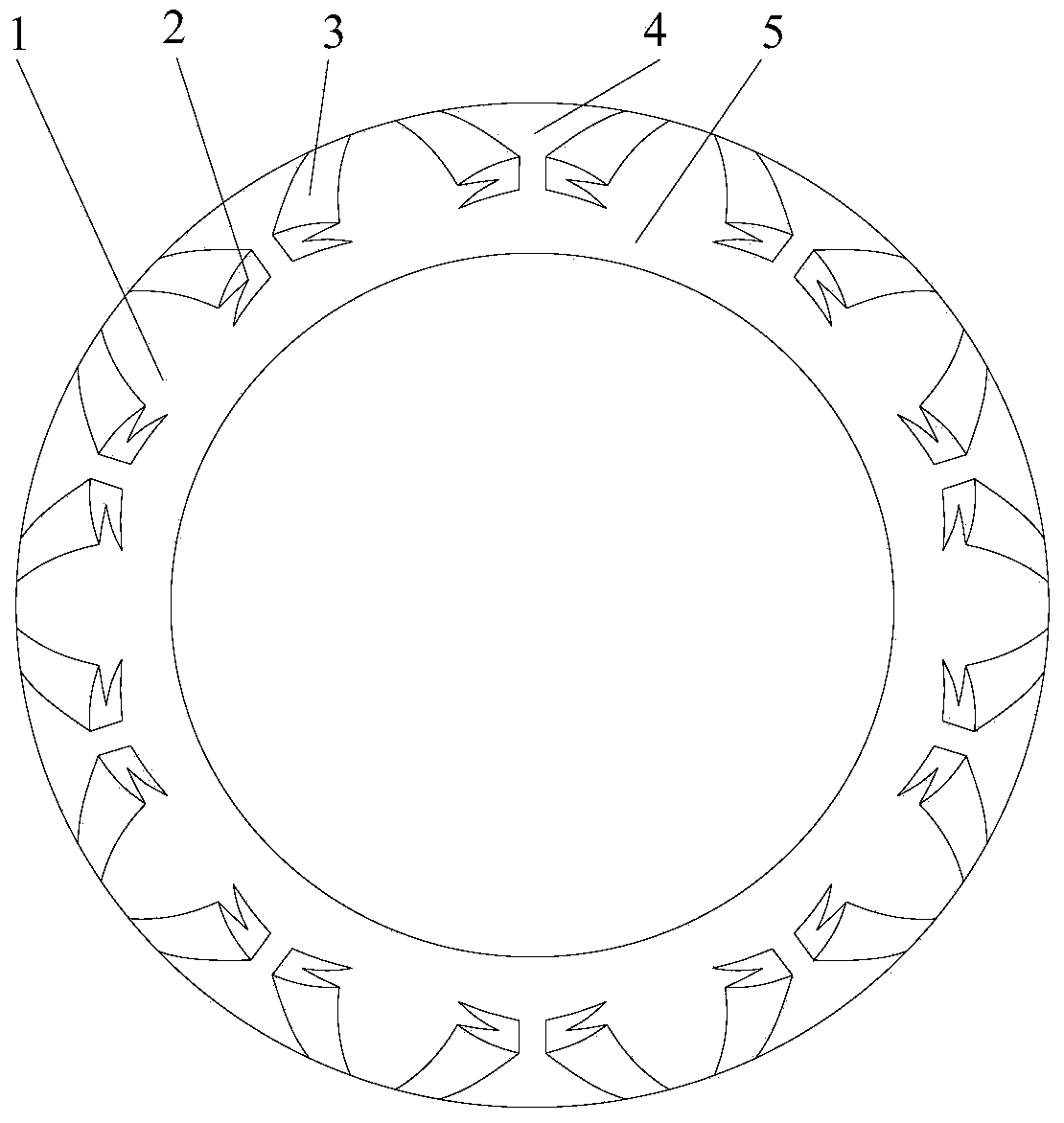

Mechanical sealing structure of pearl-row-like annular groove zoning end face

InactiveCN101749431AEnhance the dynamic pressure effectWide range of applicationsEngine sealsCentre of rotationEnd face mechanical seal

The invention relates to a mechanical sealing structure of a pearl-row-like annular groove zoning end face, comprising mechanically sealed rotating rings and static rings. The end face of at least one of the sealed rotating rings and the static rings is provided with pearl-row-like annular zones, and the pearl-row-like annular zones are composed of a plurality of annular grooves, and are distributed symmetrically to a rotating center, each annular groove is arranged round a circular convex table, annular sealing dams are arranged inside and outside the end face, and the annular grooves on thesame annular zones are communicated through circumferential arc grooves. The mechanical sealing structure of the pearl-row-like annular groove zoning end face has the advantages of good wearing resistance, low-speed low-pressure starting and dynamic pressure, and can be applied to seal common liquid and gases.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

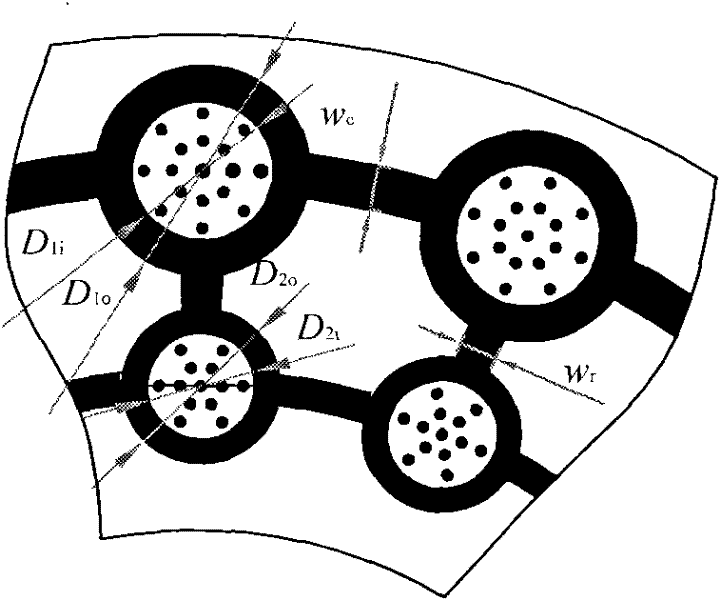

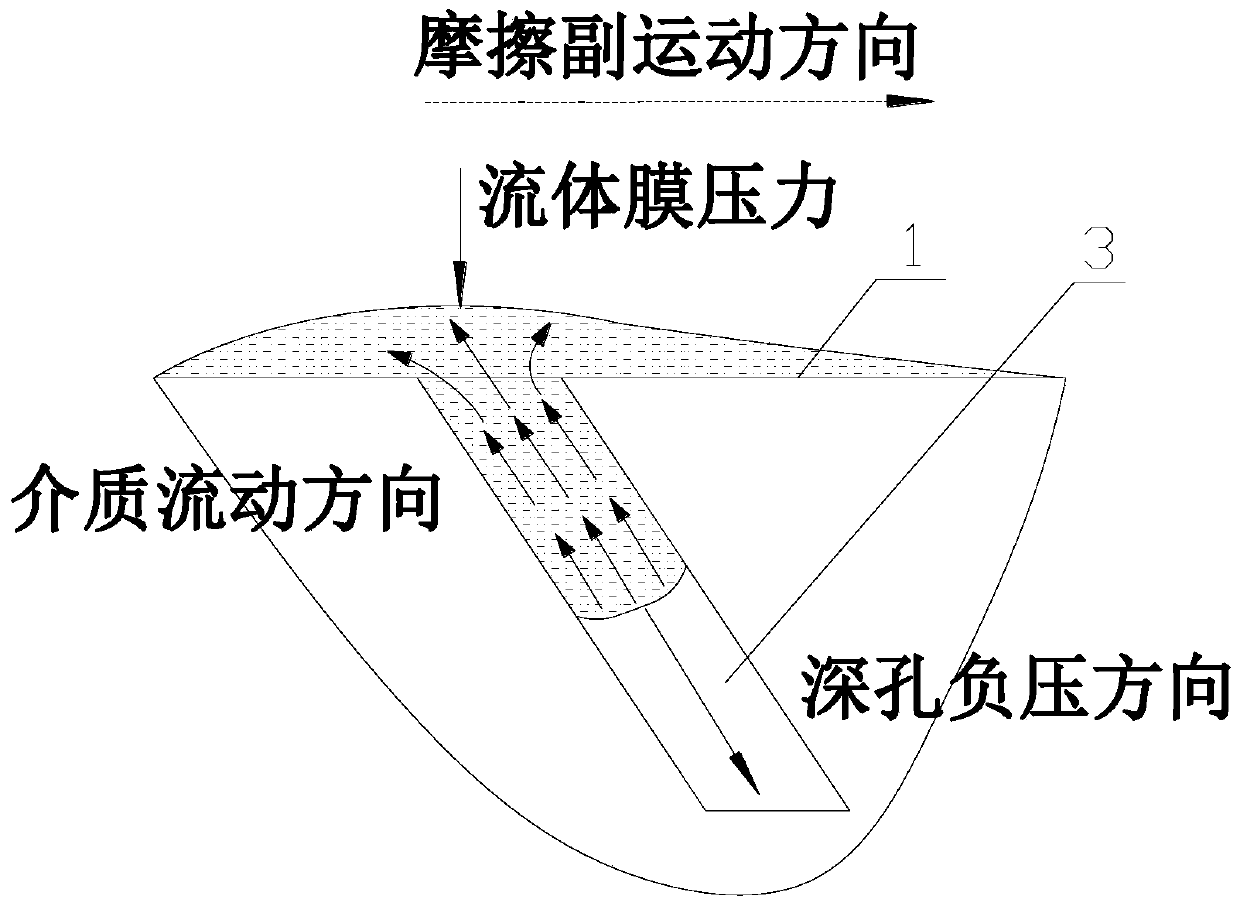

Microgroove double-layer composite groove deep end surface mechanical seal structure

ActiveCN103062411AEnhance the dynamic pressure effectImprove adsorption capacityEngine sealsEngineeringHigh pressure

The invention discloses a microgroove double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a microgroove double-layer composite groove deep dynamical pressure groove, a ring groove and a microgroove double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, the upper layer of the dynamical pressure groove is hollow, and a microgroove shape line on the lower layer of the dynamical pressure groove forms an upstream texture and is same to a dynamical pressure groove shape line on the upper layer; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, the upper layer of the pumping groove is hollow, and a microgroove shape line on the lower layer of the pumping groove forms a downstream texture and is same to a shape line on the upper layer of the pumping groove; the upstream texture and the downstream texture are connected through the ring groove; and the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove.

Owner:山东誉中新材料股份有限公司

Gas cylinder surface sealing device with cantilever support and spiral chute

InactiveCN102758918AAchieving deformation adaptabilityAvoid or reduce contact wearEngine sealsHigh-pressure areaGas cylinder

The invention discloses a gas cylinder surface sealing device with a cantilever support and a spiral chute. The device comprises a sealing retainer, a rotor journal, a floating sealing ring and a cantilever supporting plate, wherein a dynamic pressure cylindrical sealing area is formed between the cylindrical sealing interface of the floating sealing ring and the cylindrical surface of the rotor journal, a high-pressure area and a low-pressure area are respectively arranged on two sides of the floating sealing ring, and the rotor journal and the floating sealing ring rotate relatively; and the floating sealing ring is supported by a plurality of cantilever sheets which are distributed circumferentially, and the cantilever sheets are fixed by the sealing retainer. The cylindrical surface gas film sealing device realizes non-contact and small-leakage sealing while adapting to the deformation in position sealing work process through the flexibility of the support and a dynamic pressure gas film, and is adaptive to the installation space requirement on non-shaft end position sealing through the cylindrical surface structure.

Owner:BEIHANG UNIV

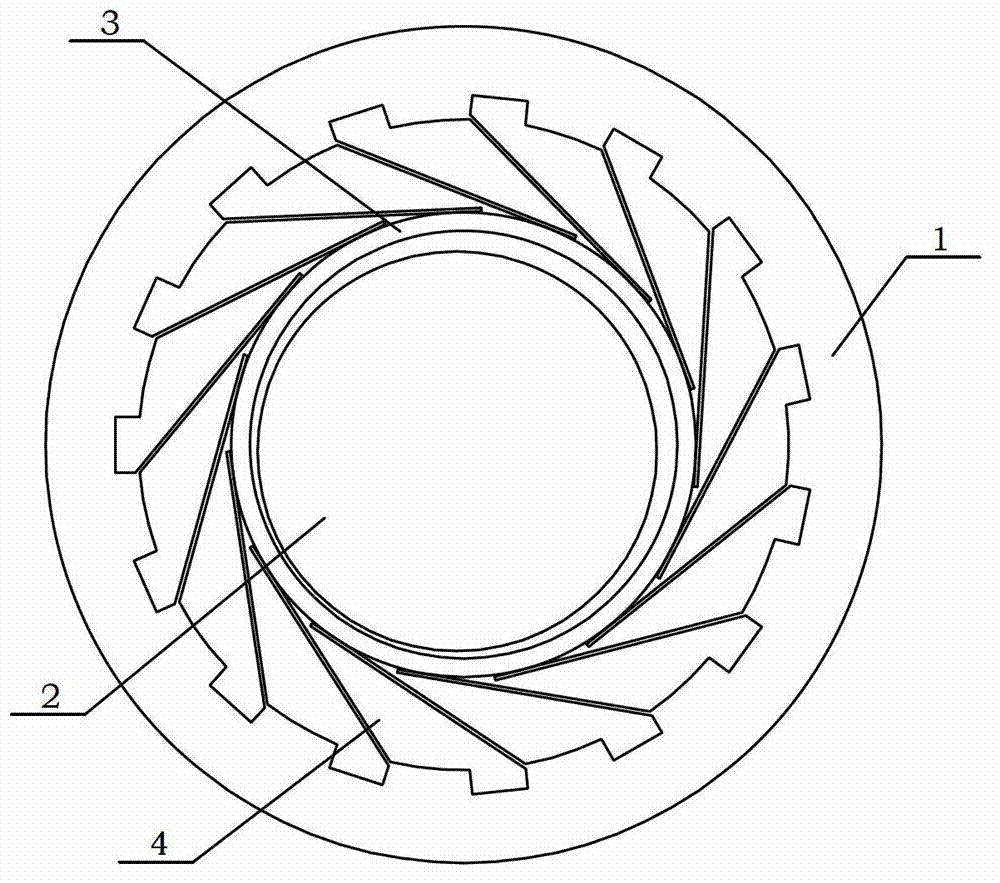

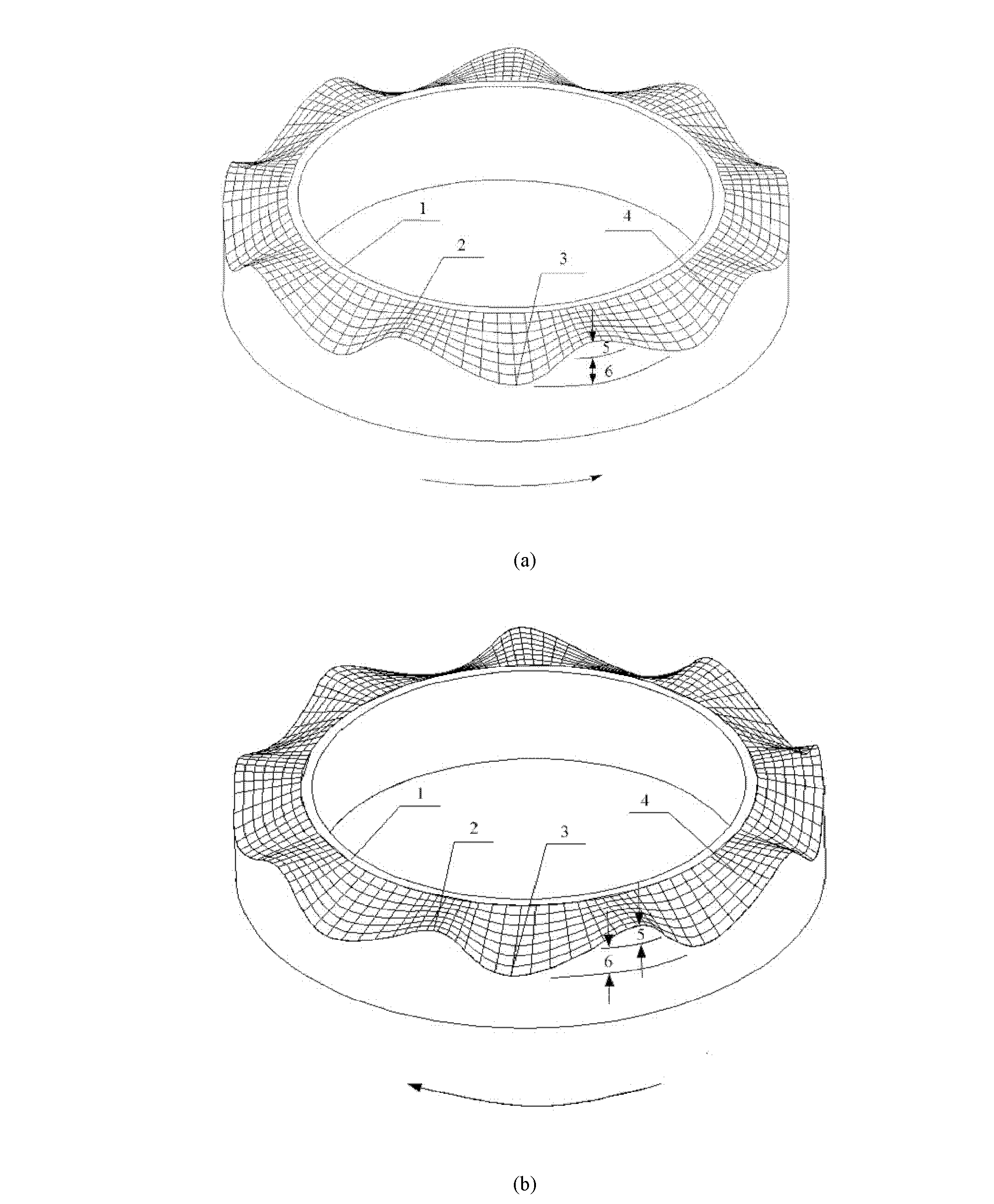

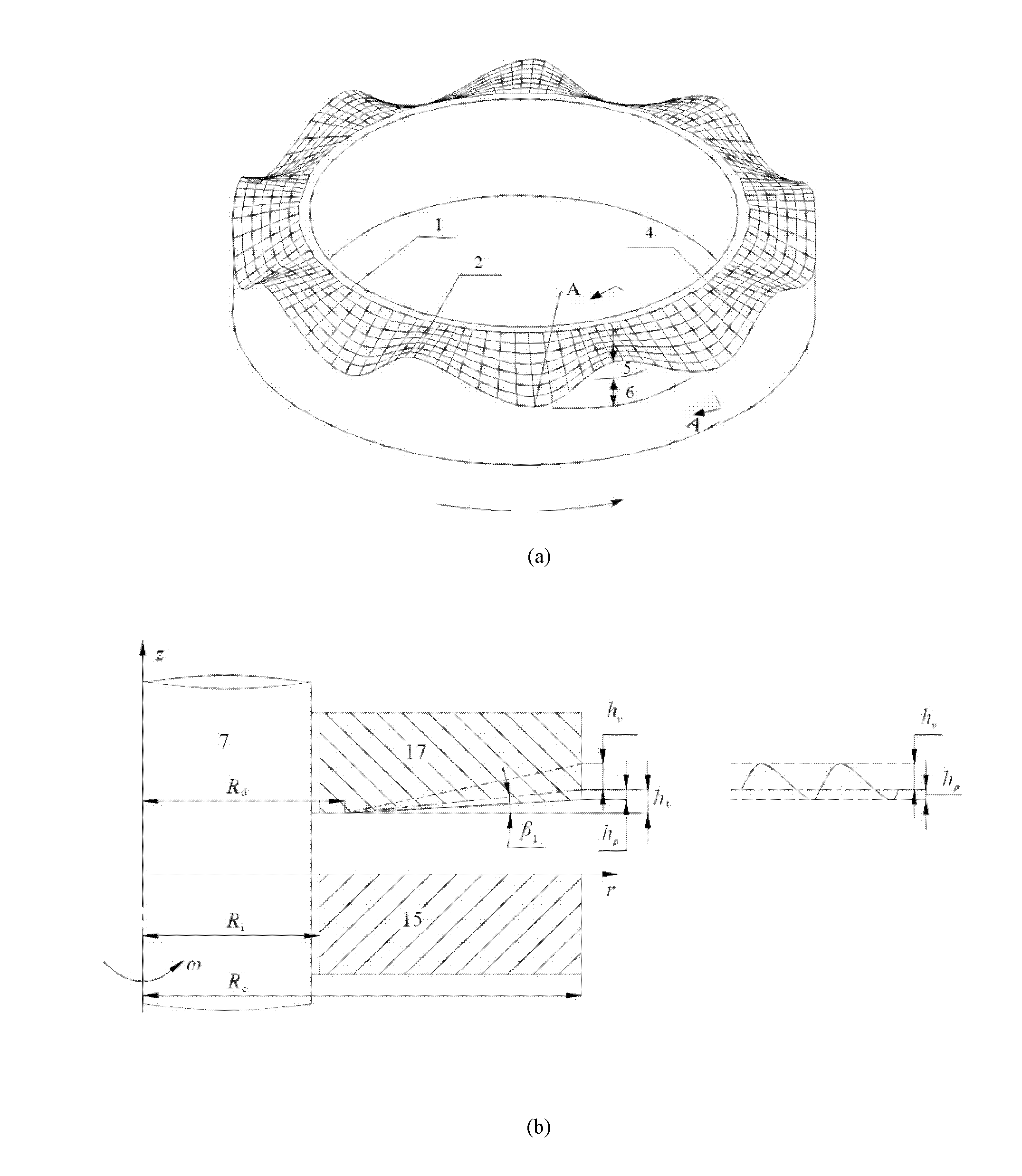

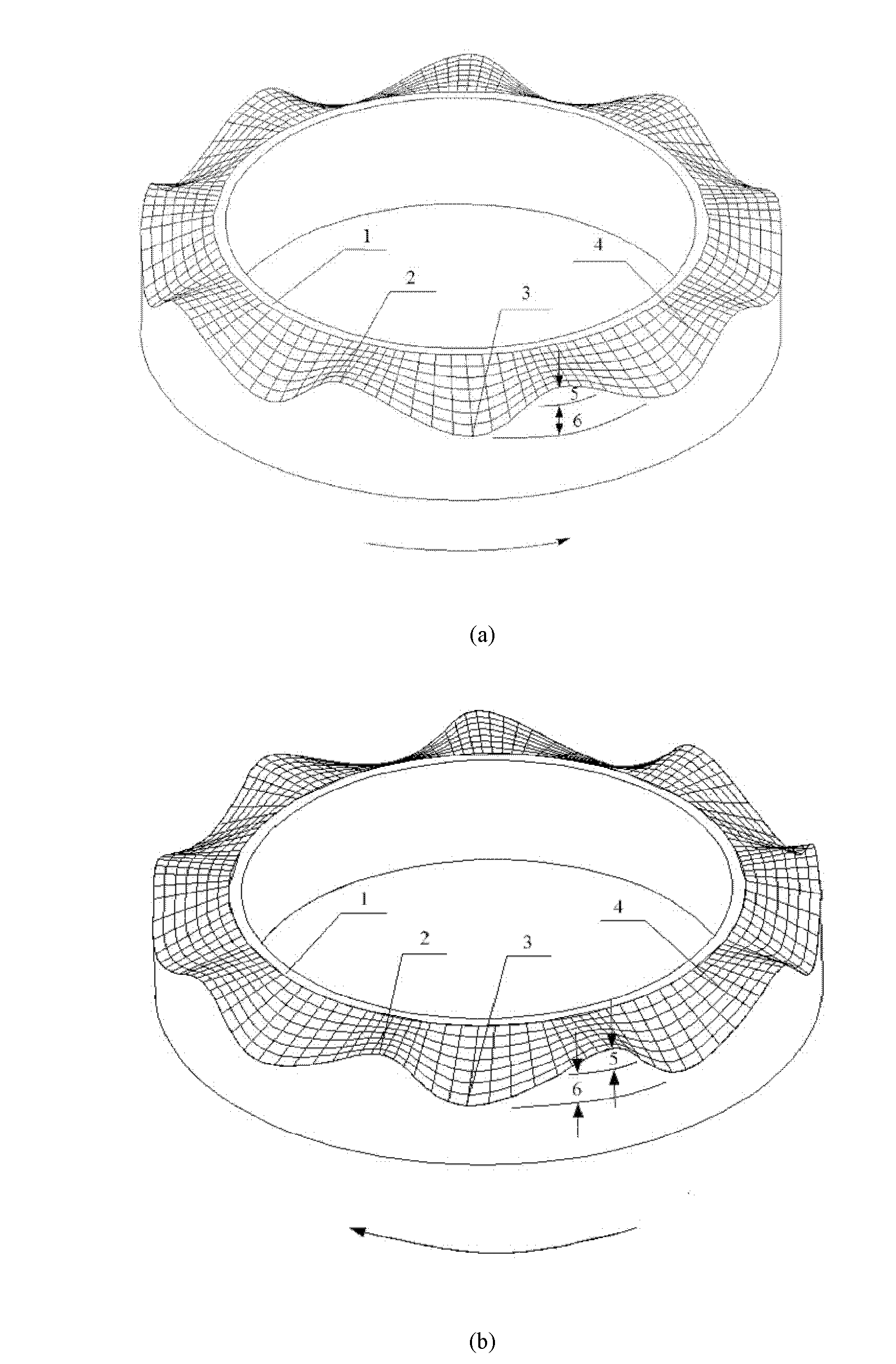

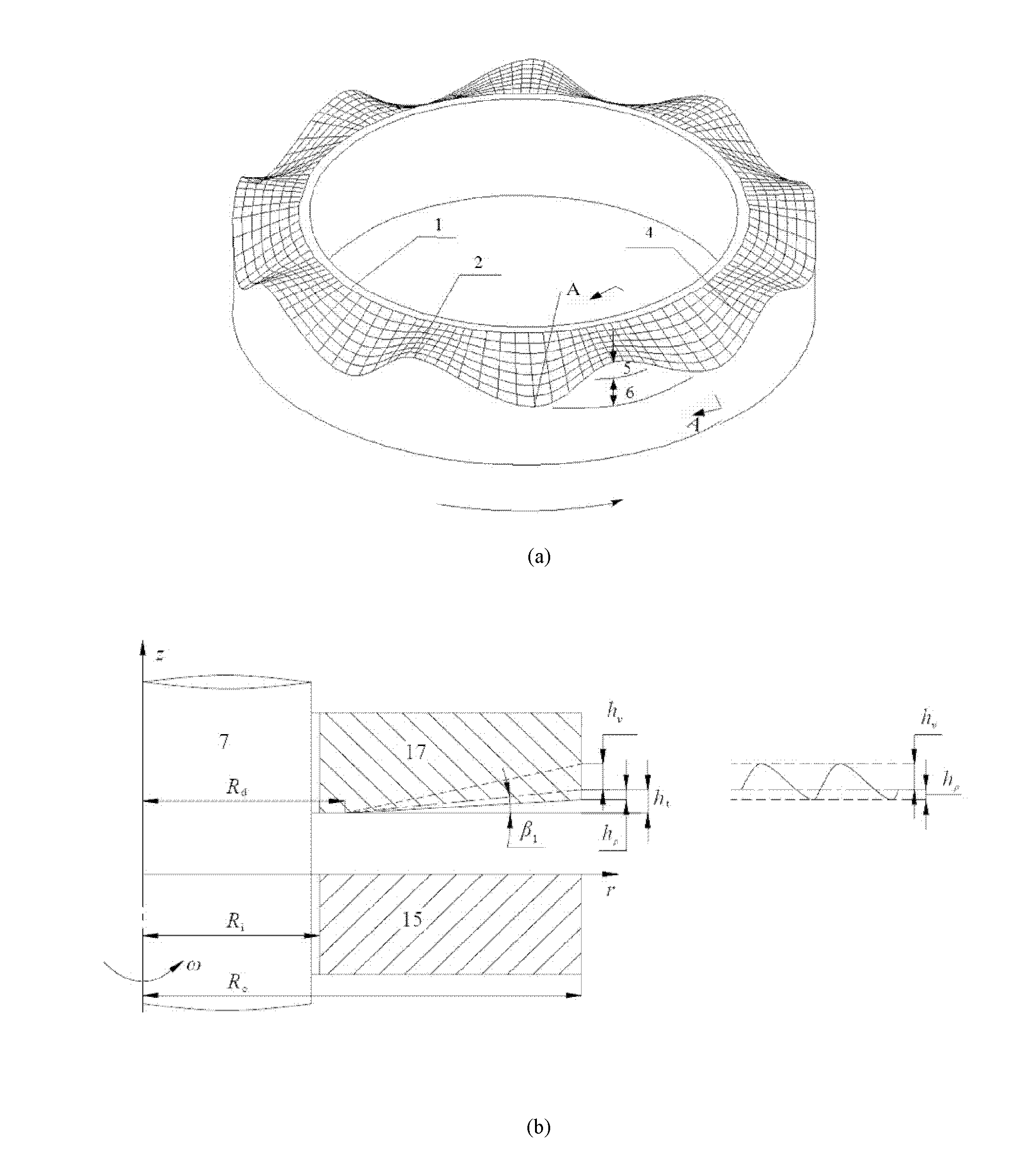

Dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure

ActiveCN102322528AEnhance the dynamic pressure effectImprove work performanceEngine sealsNon symmetricEngineering

The invention provides a dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure. At least one sealing end face on a moving ring and a stationary seal ring is provided with more than two three-dimensional asymmetrical waviness appearances, the asymmetrical waviness is in a periodical arrangement on the at least one sealing end face, the asymmetrical waviness sealing end face comprises a dam area, a conical surface and a wave crest and a wave trough of the asymmetrical waviness, the dam area is a groove-less parallel annular sealing dam arranged at the low-pressure side, the wave crest and the wave trough are connected through the conical surface, the conical surface is a linear convergence cone formed from the high-pressure side to a low-pressure side and is connected with the dam area, the conical surface can realize sealed non-contact static pressure effect; the conical degree combines with the asymmetrical waviness so that the sealing reliability can be improved, an asymmetrical waviness smooth transition curve can prevent the particles in the sealing fluid from being cumulated, and the dam area can realize static sealing when the axle is stationary. The structure provided by the invention has strong pressure resistance and antijamming capability, the leakage rate is lower at the conditions of high parameters, the fluid has good dynamic pressure effect in the process of start and stop and the fluid bearing capacity is sufficient in the normal operation.

Owner:TSINGHUA UNIV

Mechanical sealing structure with end face being provided with vein-shaped grooves

ActiveCN107218396AEnhance the dynamic pressure effectImprove work performanceEngine sealsVeinPressure difference

Owner:BEIHANG UNIV

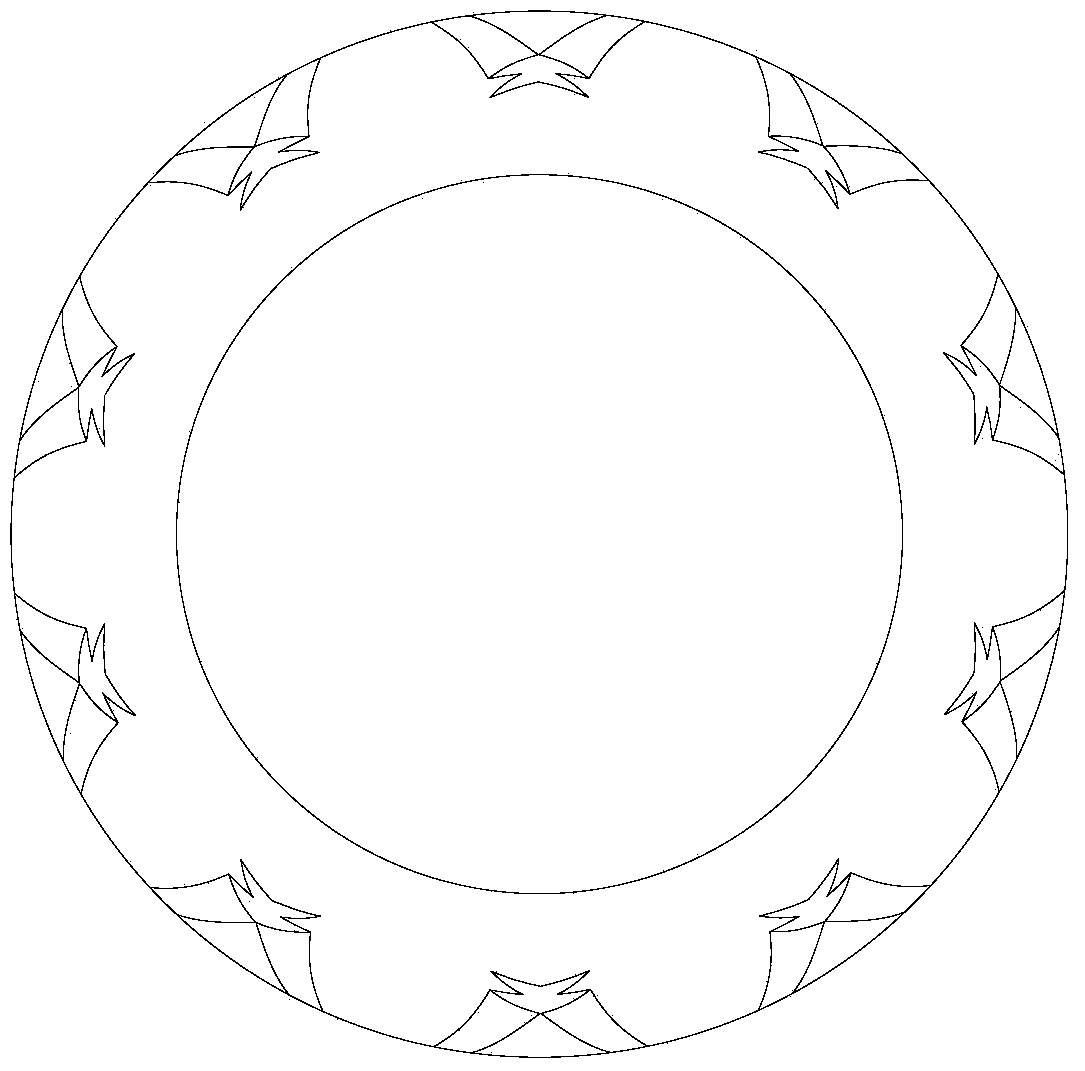

Non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves

ActiveCN103453147AImprove opening forceImprove job stabilityEngine sealsEngineeringMechanical engineering

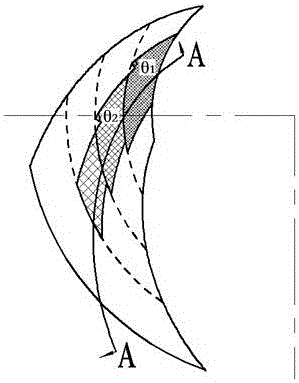

The invention provides a non-contact mechanical seal ring with dual-rotating-direction hydrodynamic grooves. Hydrodynamic groove structure units in same forms are arranged on the outer side of a seal end face circumferentially at equal intervals; the hydrodynamic groove structure unit is in a wing-shaped structure formed by a central groove and same wing grooves which are connected to two sides of the central groove respectively and which extend symmetrically in a converged manner; the central groove and two wall edges thereof are two radial extending segments of the seal end face respectively, the wall edge on the inner side is an arc concentric with the seal end face, and the central groove is formed in the circumferential wall of a seal ring body, long side edges of two sides of the wing grooves and short grooves at the converged-extending ends are two radial extending segments of the seal end face; the long side edges of two sides of the wing grooves fit and are connected with the side wall of the central groove where the same located. By the aid of the hydrodynamic groove structure, seal hydrodynamic effect can be improved, seal end face opening force is increased, thickness and strength of the fluid film between the seal end faces are increased, seal leakage is reduced, groove processing difficulty is reduced, and process requirements on seal parts processing and assembling are lowered.

Owner:SICHUAN SUNNY SEAL

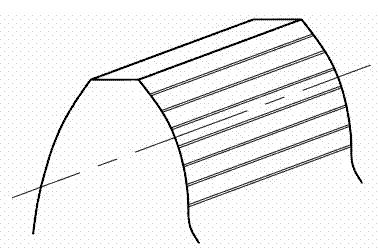

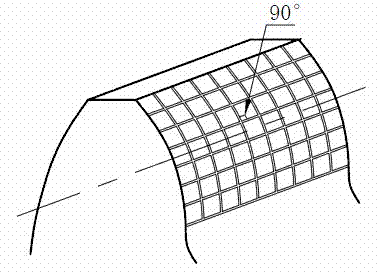

Gear with surface texture tooth surfaces

InactiveCN102889362AReduce abrasive wearAvoid Three-Body FrictionGear lubrication/coolingPortable liftingMachined surfaceLubrication theory

The invention discloses a gear with surface texture tooth surfaces. Uniformly arranged surface texture mark forms are arranged on each tooth surface of the gear. The surface texture mark forms are strip-type convex mark forms or strip-type concave mark forms which are parallel to gear engagement lines. Or, the surface texture mark forms are provided with grid-like convex mark forms or grid-like concave mark forms which are parallel and vertical to gear engagement lines. A surface texture is machined on a tooth surface, so that the gear with surface texture tooth surfaces can accommodate abrasive particles, and reduce the abrasive particle abrasion between the tooth surfaces; the gear with the surface texture tooth surfaces can store lubricating oil, take away friction heat generated between the tooth surfaces, reduce the tooth surface temperature, and prevent tooth surface agglutination from invalidation; and according to a partial film elastic fluid lubrication theory, the gear with surface texture tooth surfaces is favorable for forming an elastic fluid hydrodynamic lubricating oil film to improve the lubrication state. By the surface texture tooth surfaces, the wearing resistance of the gear can be improved, and the service life of the gear can be prolonged.

Owner:ZHEJIANG UNIV +1

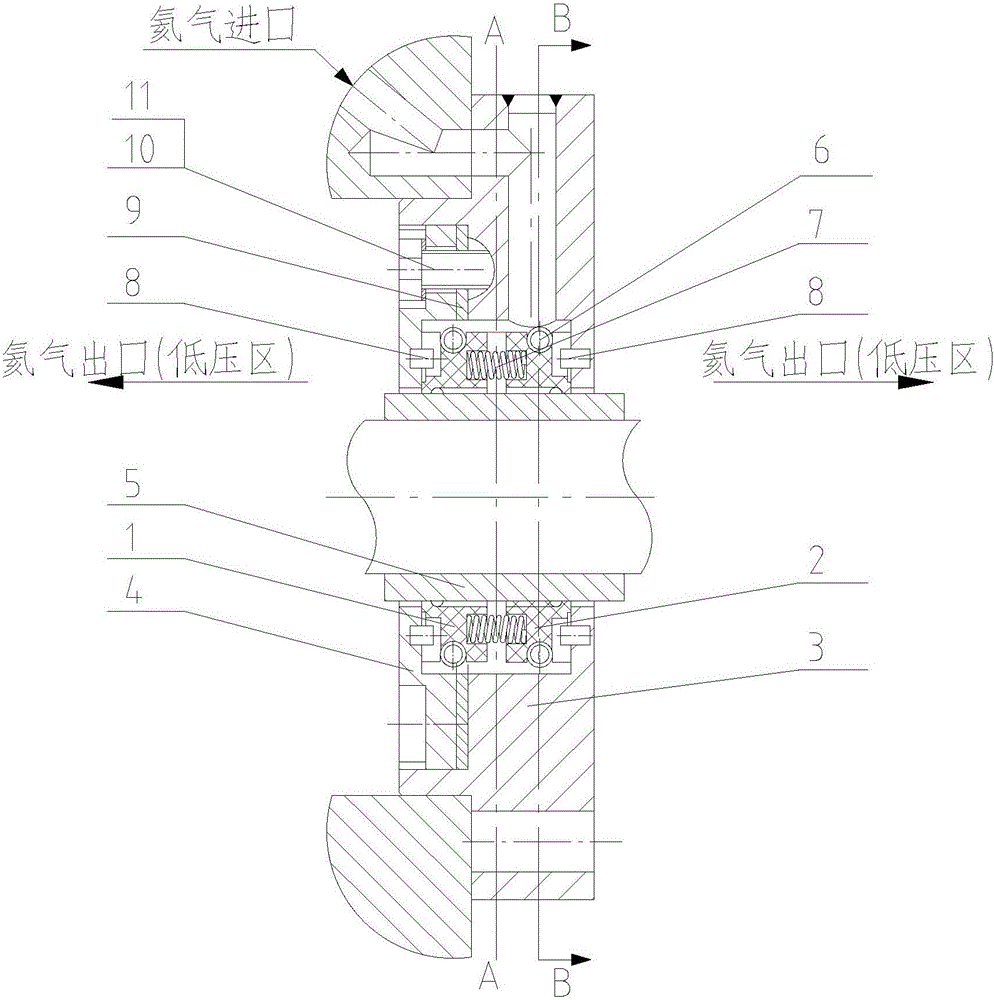

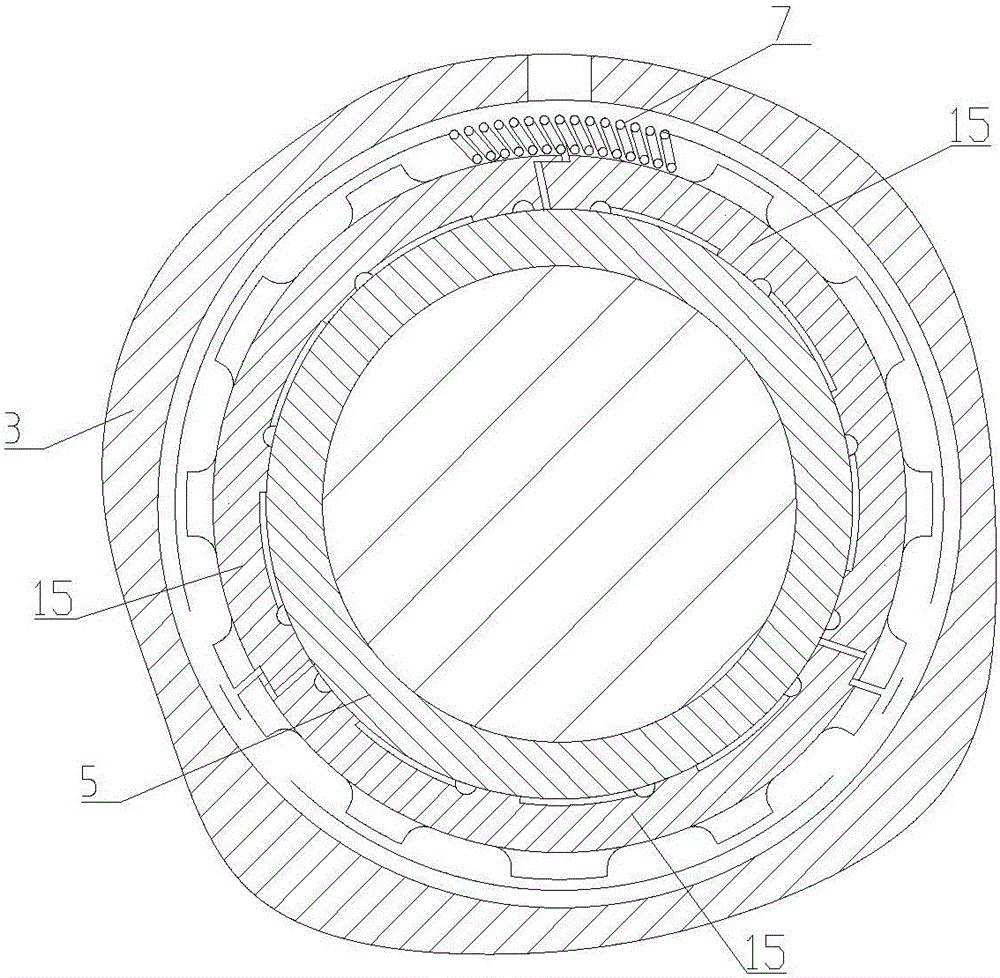

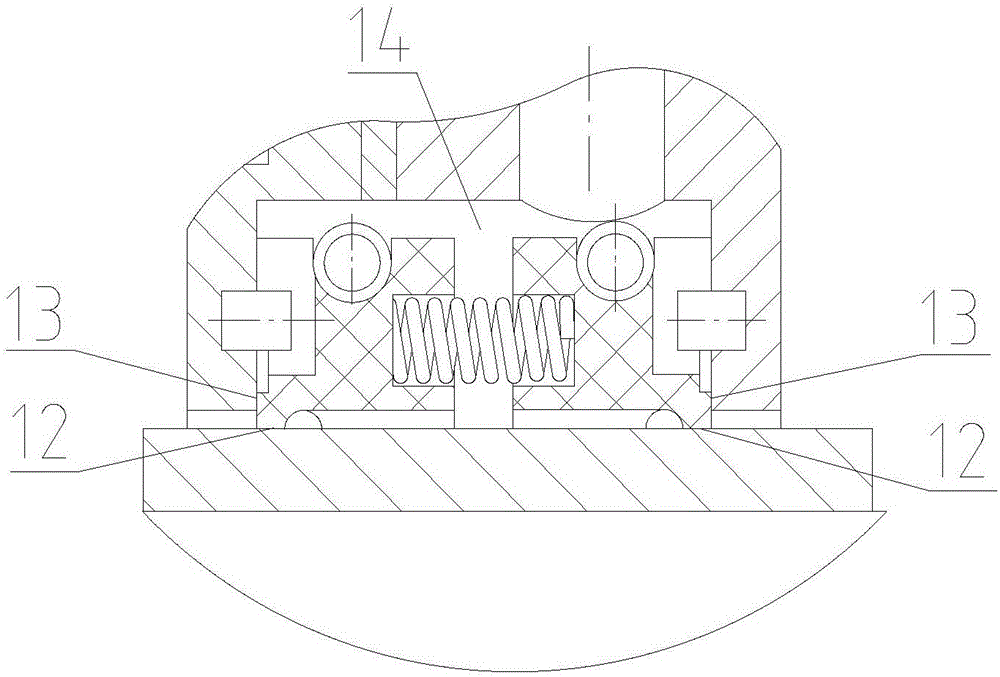

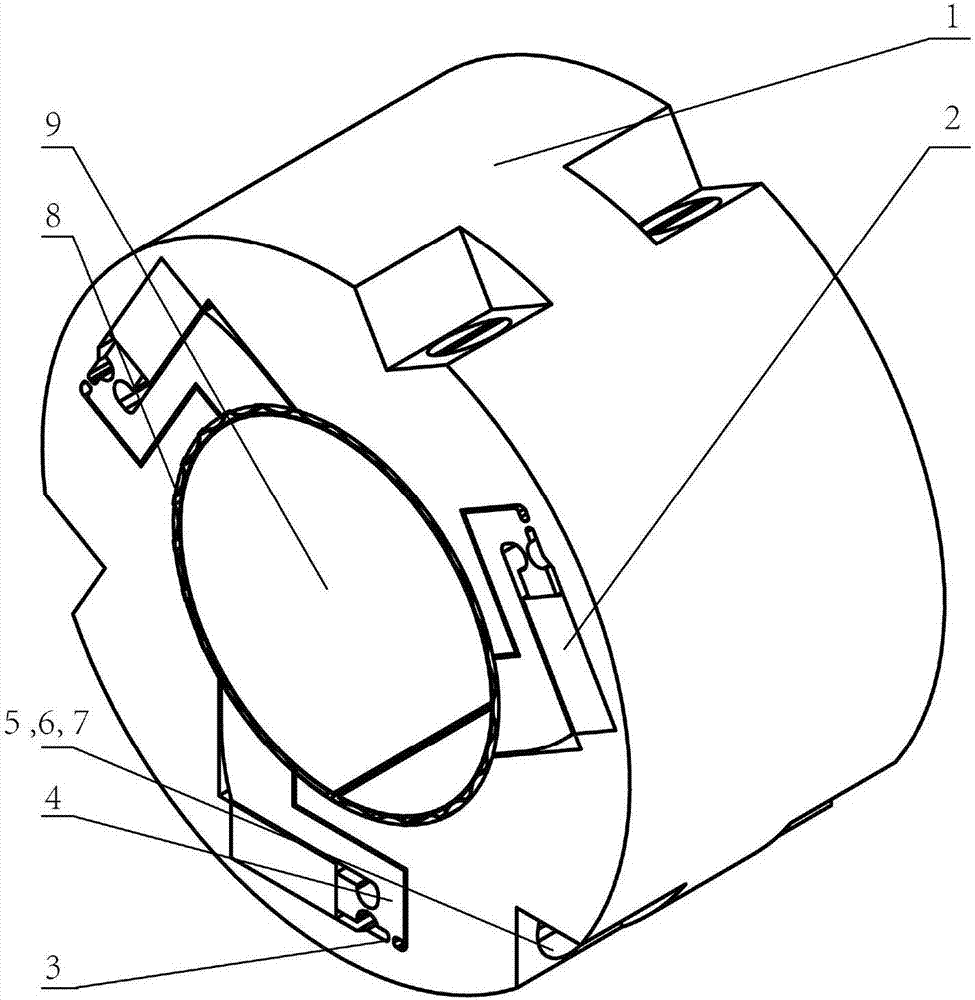

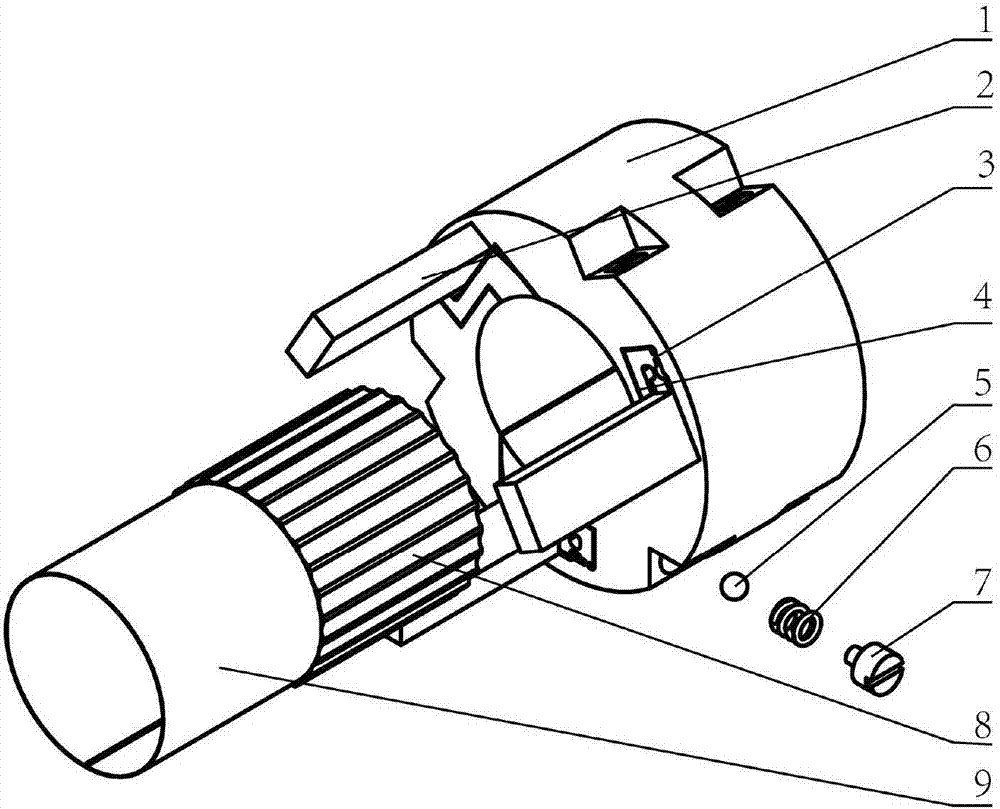

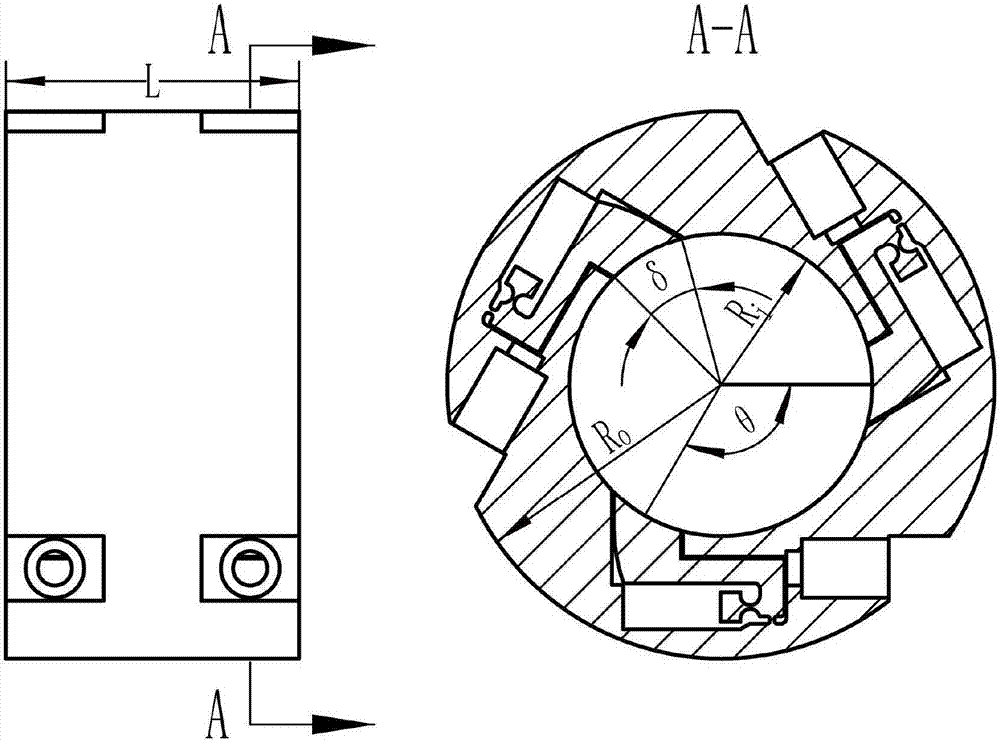

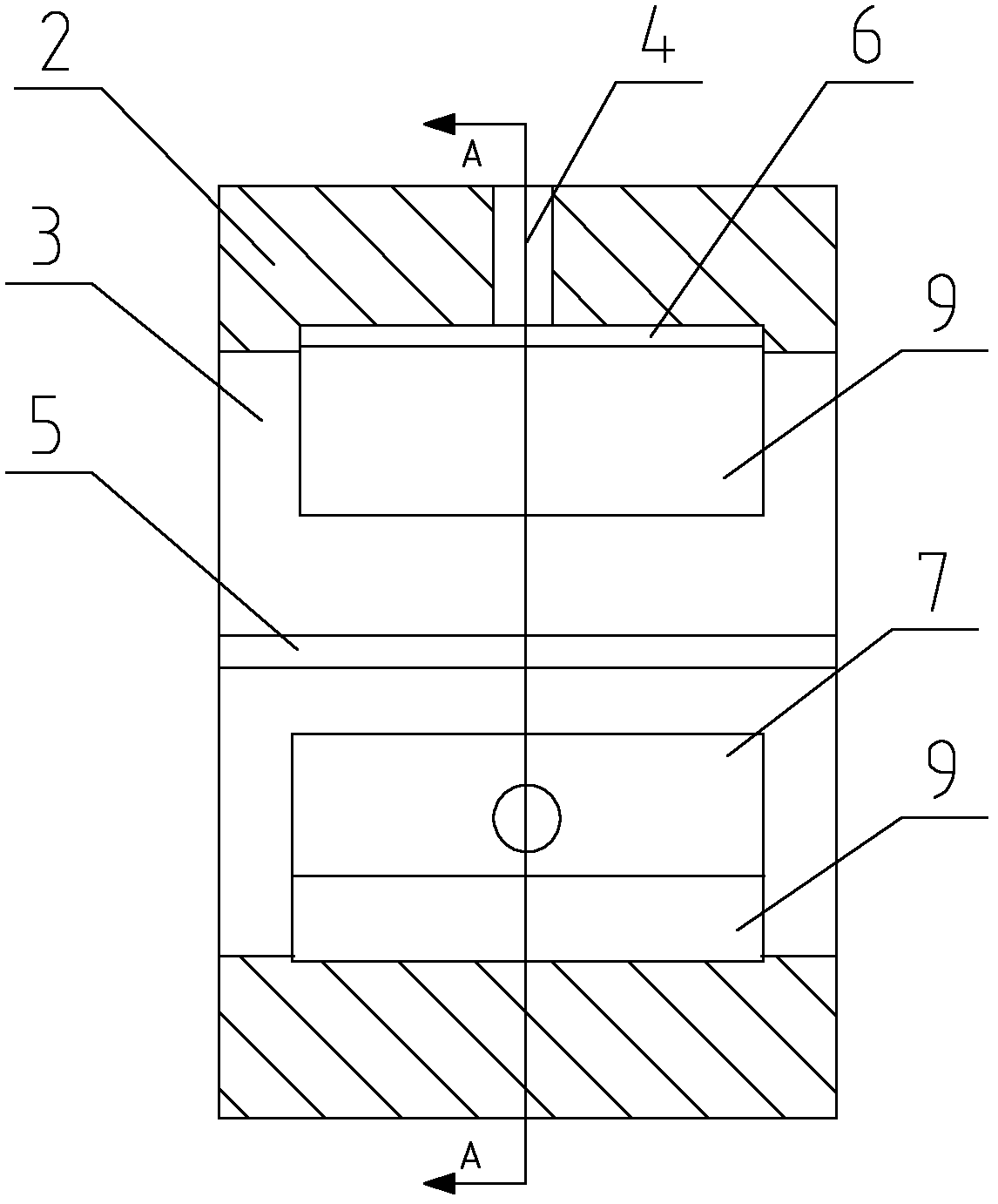

Circumferential sectioned helium sealing device for oxygen turbine pump of hydrogen oxygen engine

The invention discloses a circumferential sectioned helium sealing device for an oxygen turbine pump of a hydrogen oxygen engine. According to the circumferential sectioned helium sealing device, a circumferential sectioned sealing ring I and a circumferential sectioned sealing ring II are placed in a cavity formed by a cover plate and a sealing shell; sealing shaft sleeves are placed in rings of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II; the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II are oppositely placed and pre-tensioned by virtue of pre-tensioning springs; and each of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II is formed by connecting a plurality of fan-shaped arc sections with the same structure end to end, and constrained on an excircle surface through garter springs. According to the circumferential sectioned helium sealing device, each sealing ring is composed of the plurality of fan-shaped arc sections, a hydrodynamic groove structure is introduced, and a hydrodynamic effect of a sealing clearance fluid is adequately utilized, thus the helium sealing device reliably works under an extremely small clearance, and a low leakage amount is maintained.

Owner:BEIJING AEROSPACE PROPULSION INST

Micro-bulge double-layer composite groove deep end surface mechanical seal structure

The invention discloses a micro-bulge double-layer composite groove deep end surface mechanical seal structure which comprises a movable ring and a static ring. The movable ring and the static ring are mechanically sealed, a mutual contact surface of the movable ring and the static ring is an end surface, and a micro-bulge double-layer composite groove deep dynamical pressure groove, a sealing dam, a ring groove and a micro-bulge double-layer composite groove deep pumping groove which are symmetrically distributed along a rotation center are sequentially arranged on the end surface of the movable ring or the static ring from a high pressure side to a low pressure side; the dynamical pressure groove is arranged on the upstream (the high pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the dynamical pressure groove; the pumping groove is arranged on the downstream ( the lower pressure side) of the end surface, and a micro-bulge body texture is processed on the lower layer of the pumping groove; the inclining direction of the pumping groove is opposite to that of the dynamical pressure groove; the sealing dam is an unprocessed smooth plane; and the ring groove is communicated with the pumping groove and arranged on the upstream of the pumping groove.

Owner:JINTUO PETROLEUM MACHINERY MANUFACTRING CO LTD

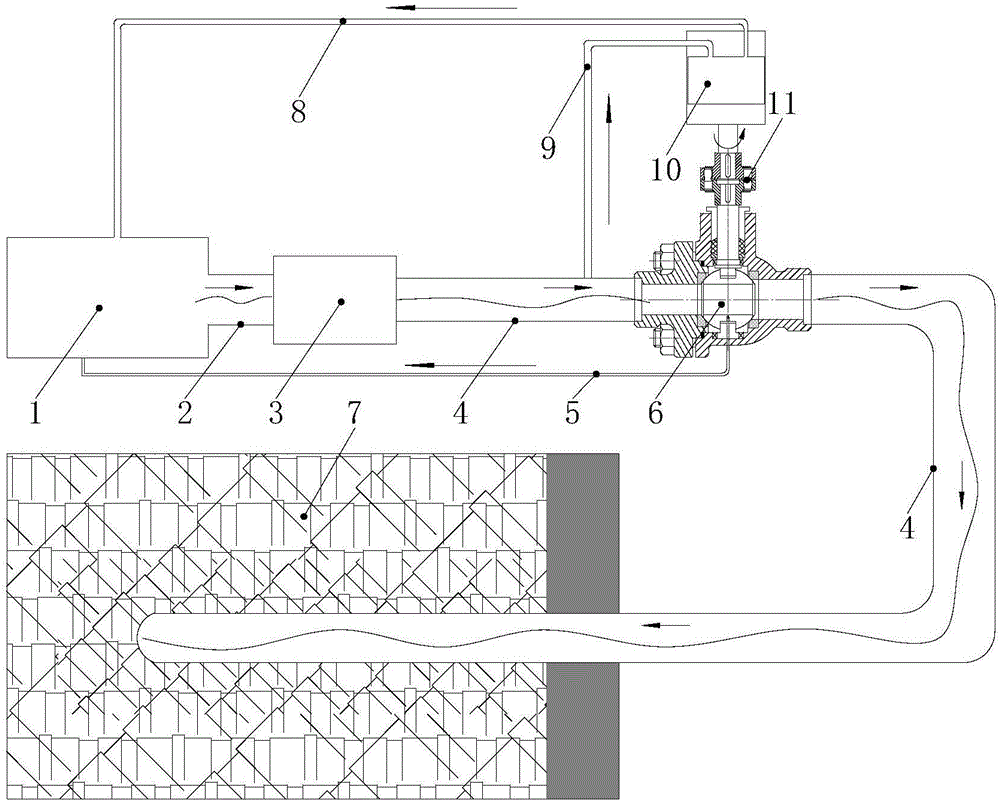

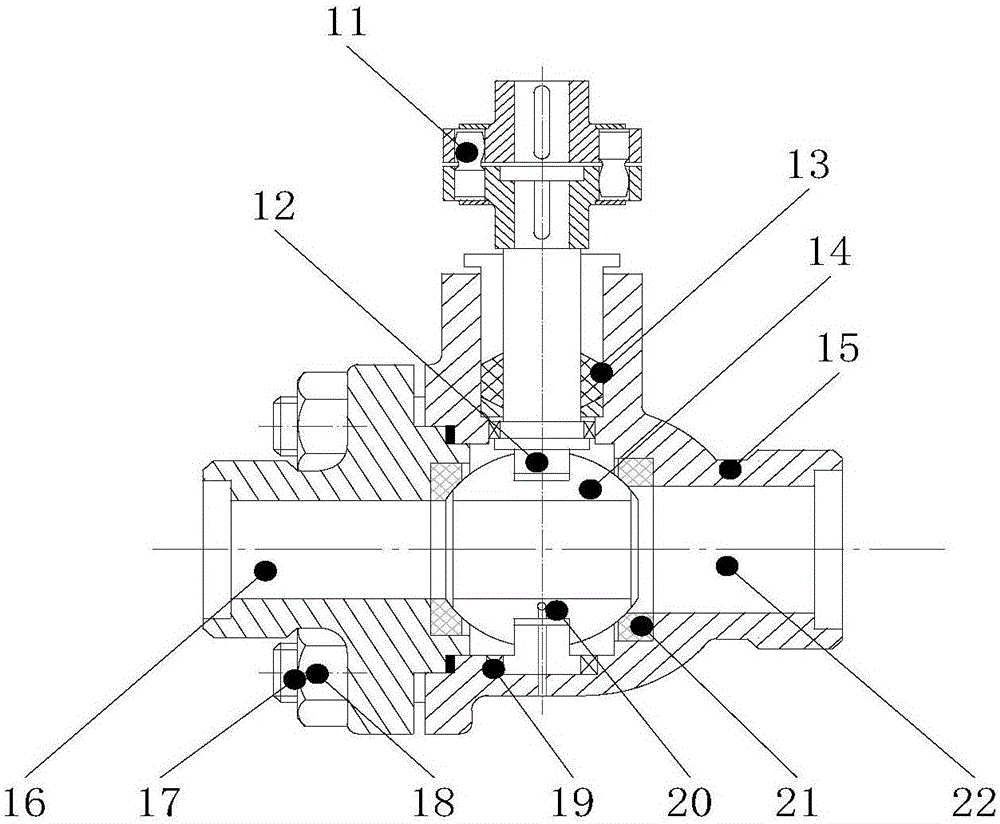

Pulse hydraulic fracturing device and method based on continuous rotary valve

InactiveCN106523023AImprove fracturing effectEnhance the dynamic pressure effectPlug valvesFluid removalVibration amplitudeHydraulic motor

The invention provides a pulse hydraulic fracturing device and method based on a continuous rotary valve. The pulse hydraulic fracturing device based on the continuous rotary valve is composed of a water tank, a water injection pipeline, a water pump, a pressure relief pipeline, the continuous rotary ball valve, a hydraulic motor and the like. According to the pulse hydraulic fracturing method based on the continuous rotary valve, stable pulse water pressure is generated in the water injection pipeline through periodical opening and closing of the continuous rotary ball valve, and a novel technical approach is provided for dynamic hydraulic fracturing of coal rocks. After the continuous rotary ball valve is connected into the water injection pipeline, a valve element of the continuous rotary ball valve is driven by the hydraulic motor to rotate, the valve is opened and closed continuously and stably, the periodical water hammer effect is formed in a water path injected into a coal rock body, and the pulse water pressure is generated; and the continuous rotary ball valve is improved, when the improved continuous rotary ball valve is closed, high-pressure water in the coal rock body can decrease the pressure actively, the vibration amplitude of the pulse water pressure is increased, and the technical effect of hydraulic fracturing is improved.

Owner:CHINA UNIV OF MINING & TECH

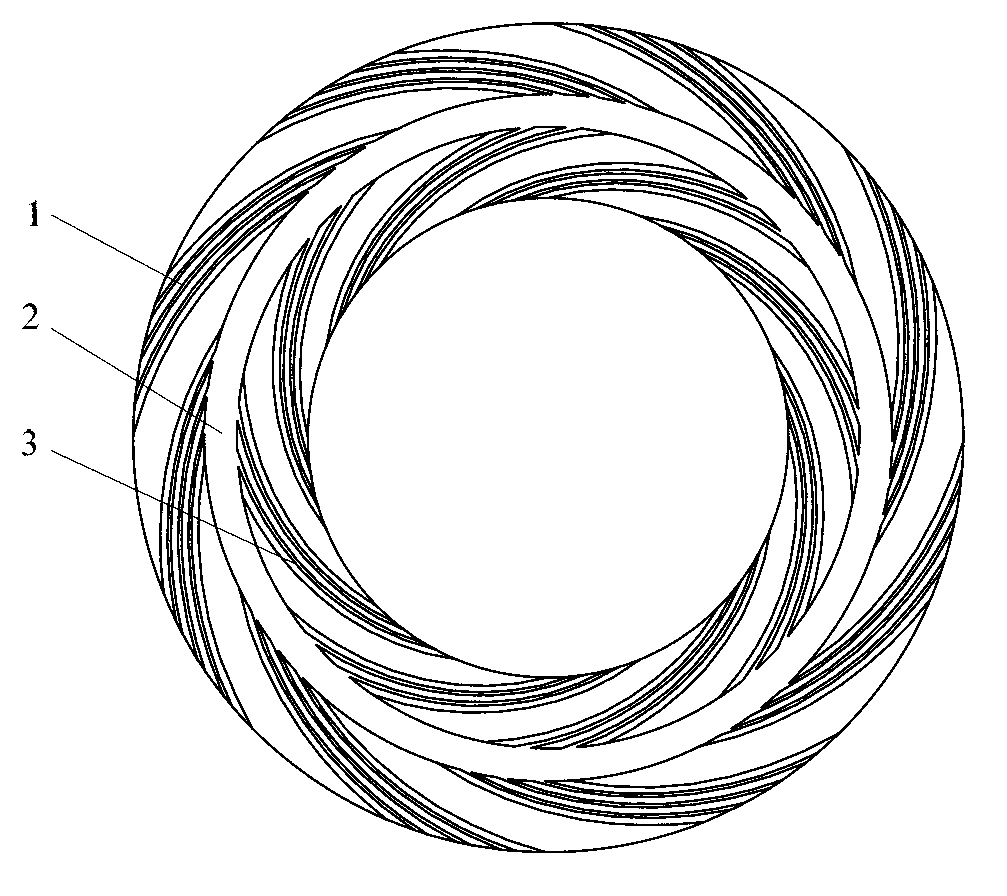

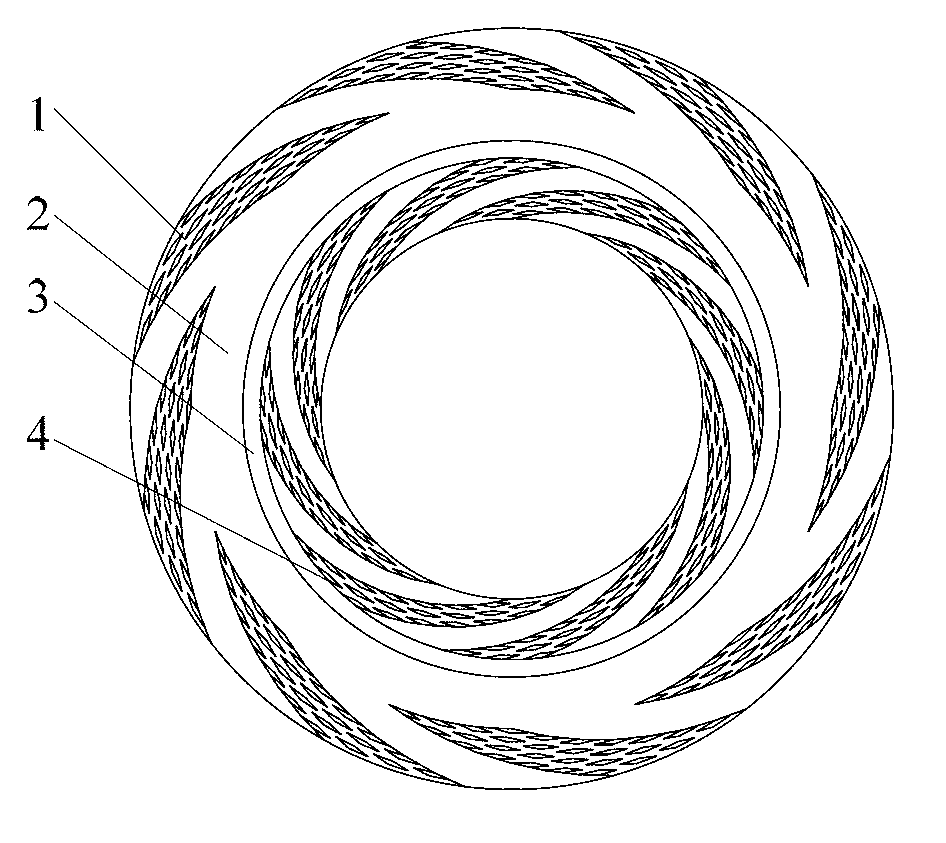

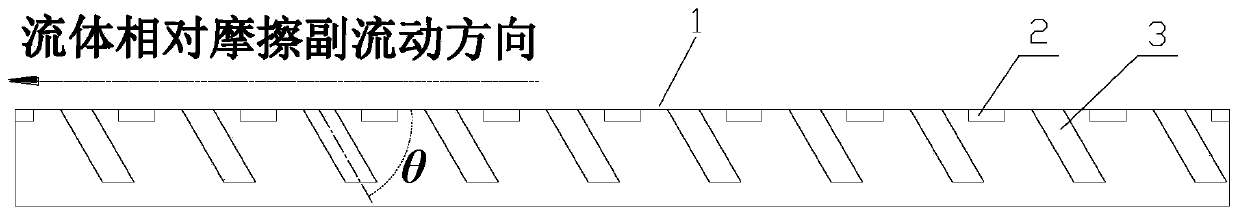

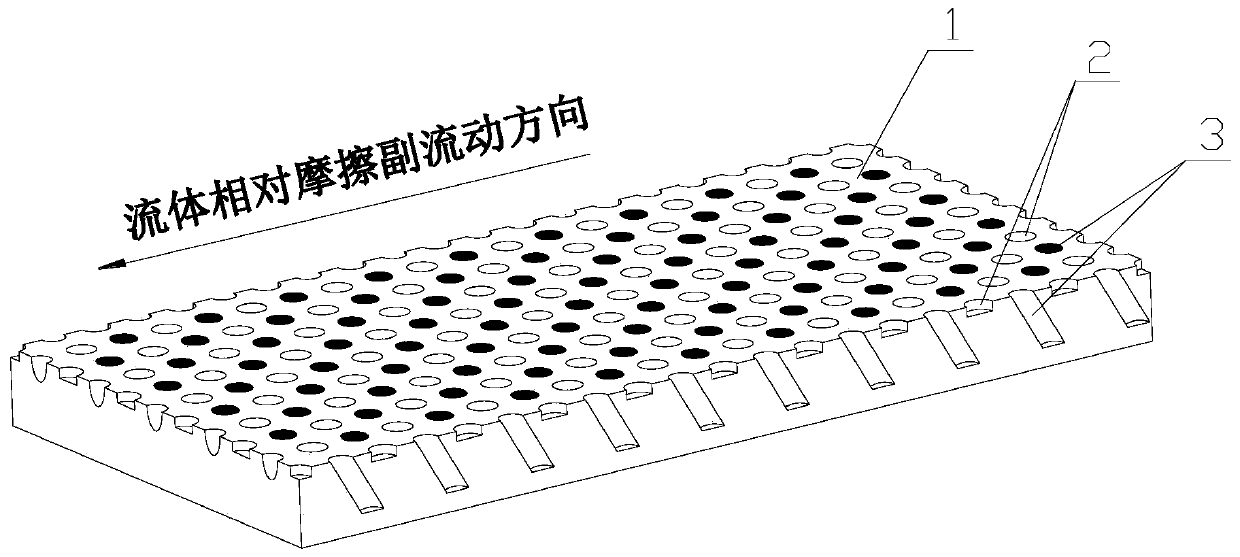

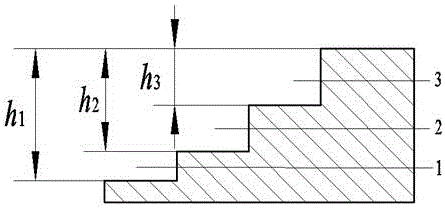

Surface lubricating texture, compressor parts, compressor and air conditioner

ActiveCN110145466AImprove carrying capacityIncreased damping effect of lubricated surfacesPositive displacement pump componentsPositive-displacement liquid enginesReturn functionEngineering

The invention provides a surface lubricating texture, compressor parts, a compressor and an air conditioner. The surface lubricating texture comprises a dynamic pressure lubricating surface (1), a hole structure is arranged one the dynamic pressure lubricating surface (1), and the hole structure is arranged in a flowing direction of fluid; the hole structure comprises first hole (2) and second hole (3); the first holes (2) and the second holes (3) are arranged at intervals, and the hole depth of the first holes (2) is smaller than the hole depth of the second hole (3). According to the surfacelubricating texture provided by the invention, long-term oil storage and oil returning functions are met while sufficient fluid dynamic pressure effect can be provided, the reliable and stable operation and long-service-life requirements of a friction pair are effectively ensured.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

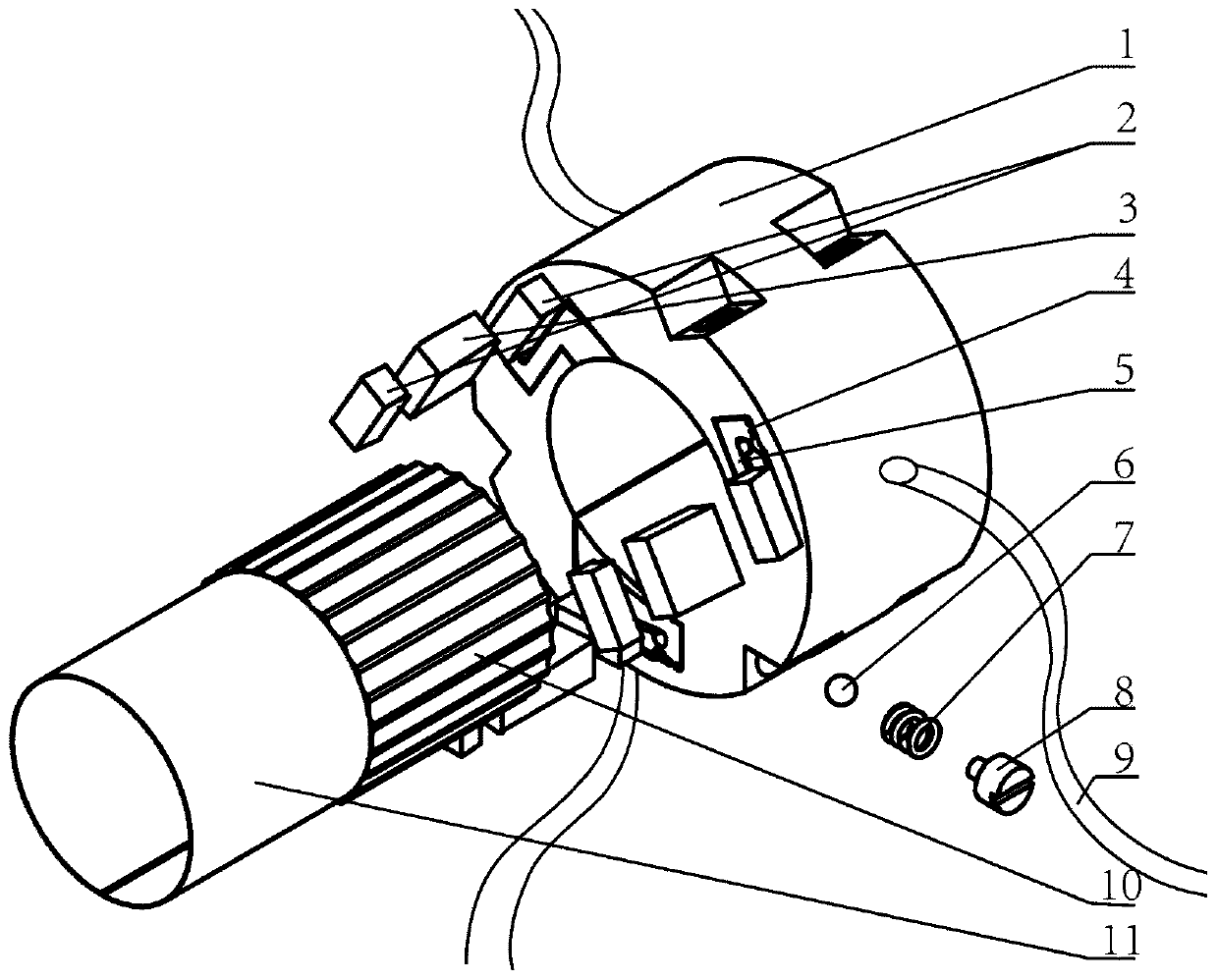

Novel active air foil bearing based on PZT and SMA

InactiveCN111457007AStable jobEnhance the dynamic pressure effectBearing componentsSliding contact bearingsEngineeringMechanical engineering

The invention discloses a novel active air foil bearing based on PZT and SMA. The novel active air foil bearing comprises a shaft sleeve, piezoelectric ceramics (PZT), a memory alloy wire mesh block (SMA block), flexible hinges, a rigid push rod, pre-pressure applying devices, a cooling pipe, a wave foil and a top foil; the PZT and the SMA block are installed in pre-machined through grooves, the corresponding pre-pressure applying devices are designed for the PZT and SMA block, the wave foil is formed by pressing an elastic material, one end of the wave foil is welded, and the other end of thewave foil is free. The top foil overlies the wave foil. Power supply signals of the PZT are controlled, the flexible hinges are coupled, PZT deformation is amplified, the wave foil is supported by the rigid push rod, the wedge-shaped space is enlarged, therefore, the crossed coupling effect is weakened, the dynamic pressure effect of the bearing is enhanced, and the rigidity characteristic of thebearing is improved; by controlling the temperature of the SMA block, the SMA block expands and contracts to generate larger structural damping, and the damping characteristic of the bearing is improved; and finally, the rigidity and damping characteristics of the bearing are actively controlled, and the stability of the system is improved.

Owner:HUNAN UNIV

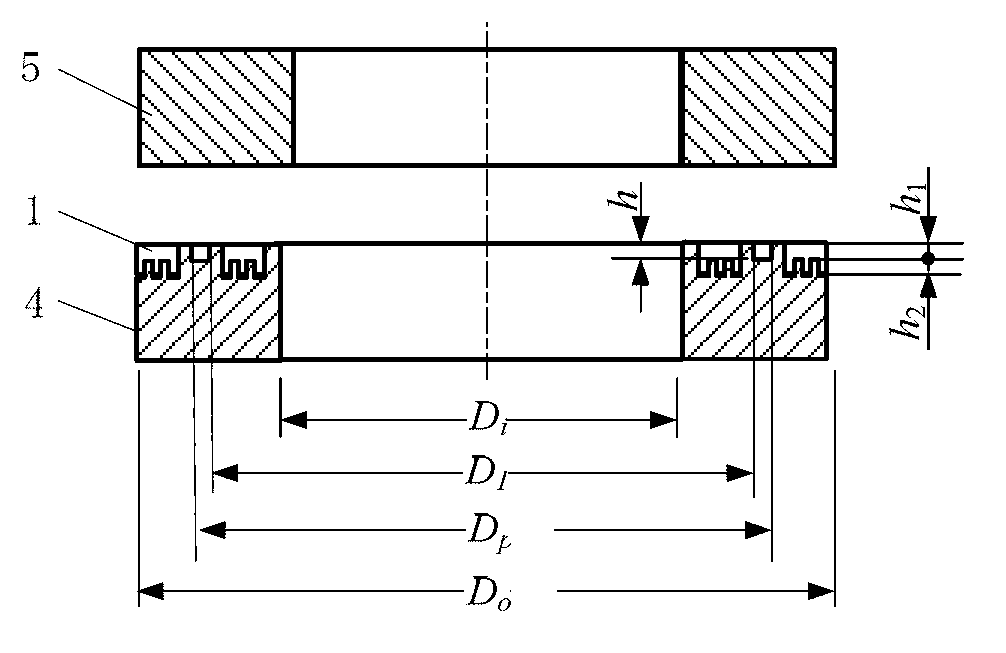

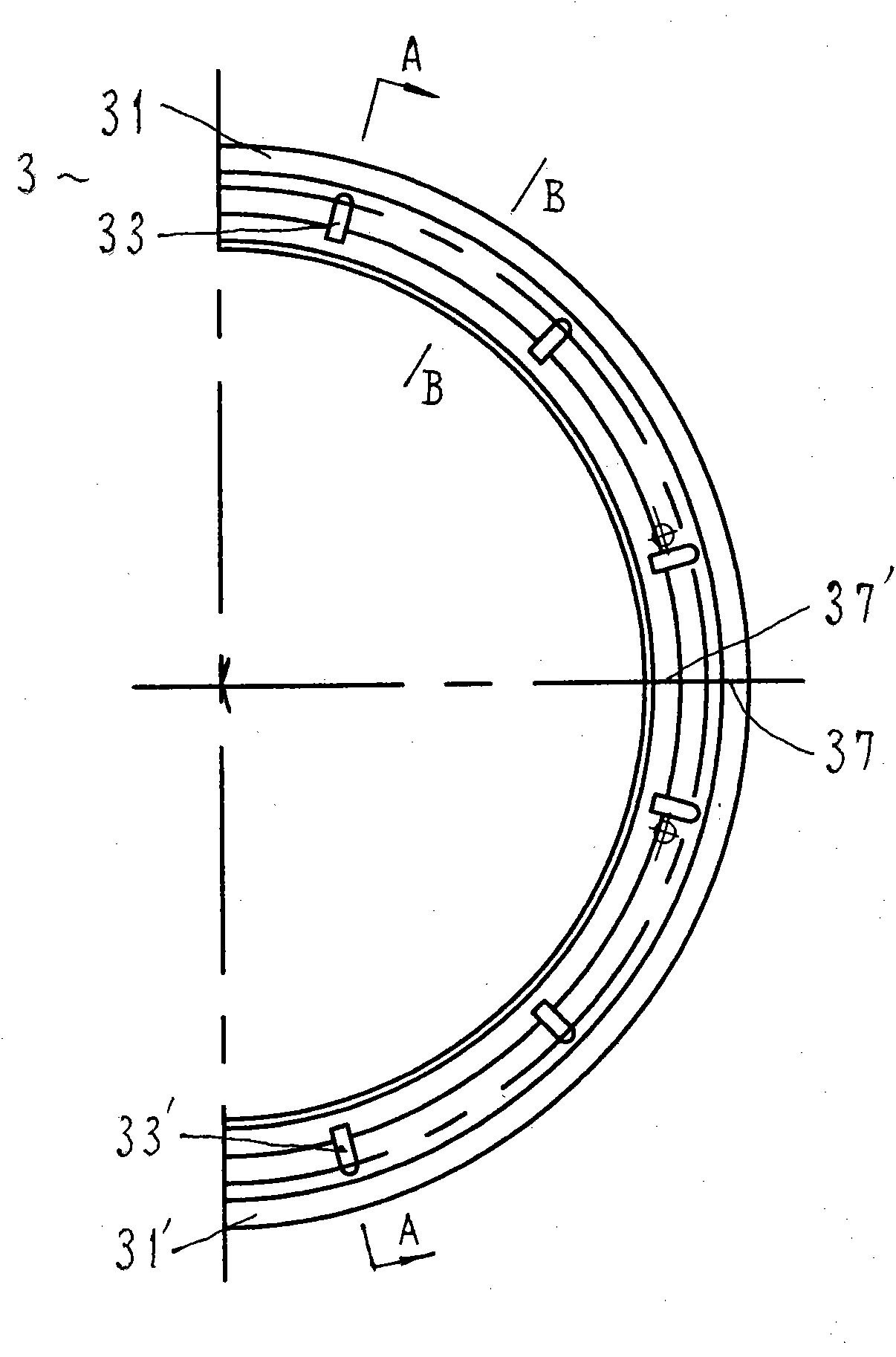

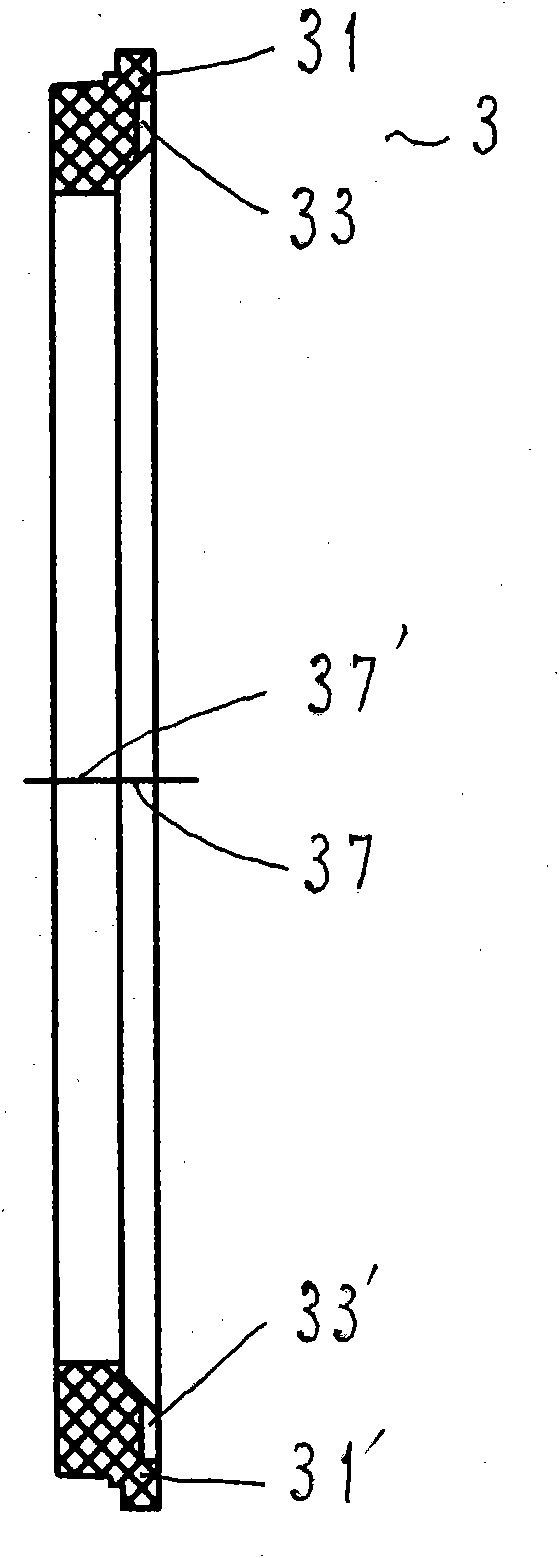

Upstream pumping machinery sealing ring with multiple stages of helical grooves

ActiveCN106763778AAids in compression boostContribute to local pressurizationEngine sealsEngineeringHigh pressure

The invention relates to an upstream pumping machinery sealing ring with multiple stages of helical grooves. The multiple stages of helical grooves uniformly distributed along the circumference of the end surface are formed in the end surface; openings of the multiple stages of helical grooves are formed in the low pressure side of the end surface; the circumferential width and the depth of each stage of helical groove are gradually decreased from the low pressure side to the high pressure side, thus overall forming convergent gaps and greatly enhancing the hydrodynamic pressure effect of the end surface; and therefore, the friction resistance of a machinery seal in an operation process is reduced, and the service life is greatly prolonged.

Owner:云南流体规划研究院有限公司

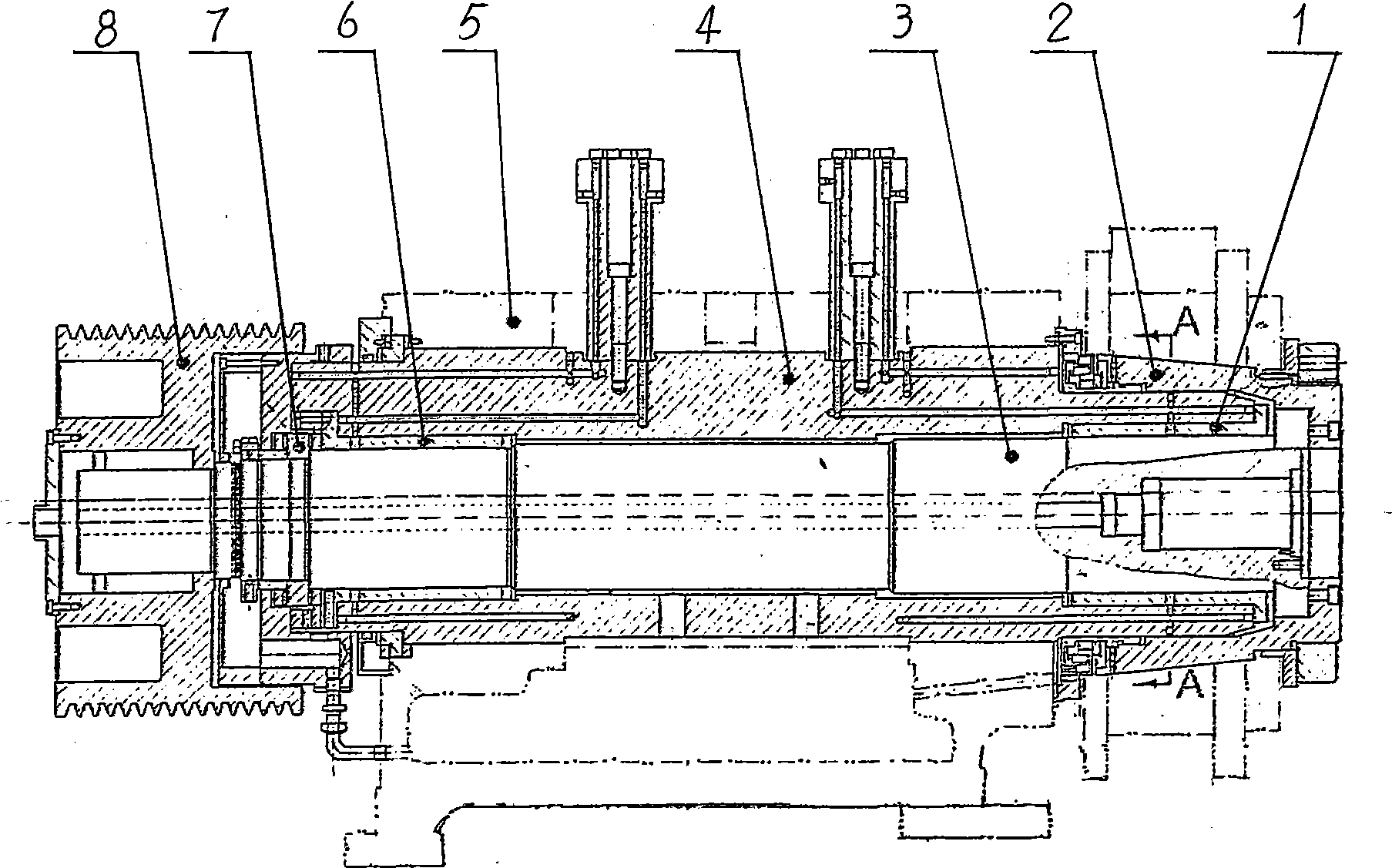

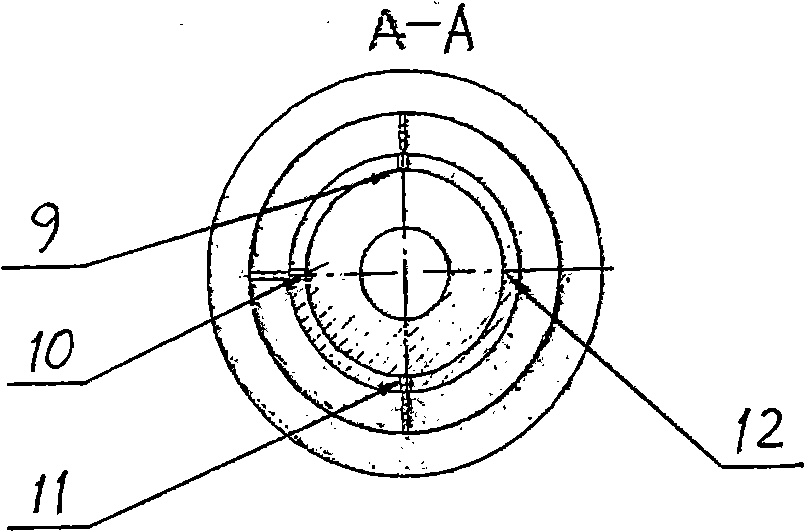

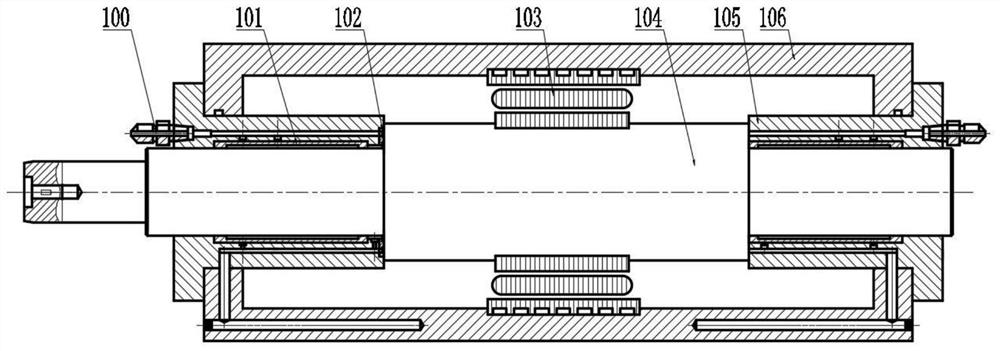

Power high efficiency grinding head

InactiveCN101530977AIncrease pressureEnhance the dynamic pressure effectRevolution surface grinding machinesEngineeringMechanical engineering

A power high efficiency grinding head belongs to an excircle grinding head. A main shaft (3) is mounted in an eccentric sleeve (4); a dynamic and static pressure front bearing (1) is mounted at the front end between the eccentric sleeve and the main shaft; the rear end is equipped with a dynamic and static pressure rear bearing (6) and a roll push bearing (7). All the components are mounted in a grinding rack housing (5). The front end of the eccentric sleeve (4) is equipped with a taper sleeve. The rear end of the main shaft (3) is equipped with a belt wheel (8). The structure format of the dynamic and static pressure beating oil chamber is that an upper chamber (9) is the static pressure, a lower chamber (11) is the static pressure, a front chamber (10) is the static pressure and a rear chamber (12) is the dynamic pressure. This invention improving the own rigid and the interference rejection of the grinding head is suitable for the power grinding so as to improve the grinding efficiency of the roller and the surface macroscopic quality of the roller, and to realize the grinding effect of machining-less of the middle and high rollers with the surface roughness concentration of Ra 0.03, and it is suitable for the excircle surface of the grinding roller.

Owner:险峰机床厂

Novel active air foil bearing based on PZTs and flexible hinges

ActiveCN106884870AStable jobImproved stiffness propertiesSliding contact bearingsWire cuttingRound face

The invention discloses a novel active air foil bearing. The bearing comprises a shaft sleeve, the PZTs, the flexible hinges, rigid push rods, precompression exertion devices, wave foil and top foil; the shaft sleeve is machined through wire cutting, three PZT mounting through grooves circumferentially and evenly distributed, the corresponding flexible hinges and the corresponding rigid push rods are obtained, the top ends of the rigid push rods are flush with the inner cylindrical face of the shaft sleeve, the PZTs are mounted in the through grooves, the corresponding precompression exertion devices are designed for the PZTs, the wave foil is formed by pressing of elastic materials, and is arranged on the shaft sleeve and the inner cylindrical faces of the rigid push rods, one end of the wave foil is welded to the inner round face of the shaft sleeve, and the other end of the wave foil is free. The top foil is arranged on the wave foil in a covering manner. Through control over power supply signals of the PZTs, the PZTs mechanically deform, the flexible hinges are enlarged to deform, and are supported through the rigid push rods to be attached to the wave foil on the push rods and the inner wall of the shaft sleeve, a gap between a bearing and a supporting rotor is changed, the wedge space is increased, the crossed coupling effect is weakened, the bearing dynamic pressure effect is enhanced, the rigid characteristic of the bearing is improved, and finally the aims of actively controlling the rigidity characteristics of the bearing and improving the stability of the bearing are achieved.

Owner:HUNAN UNIV

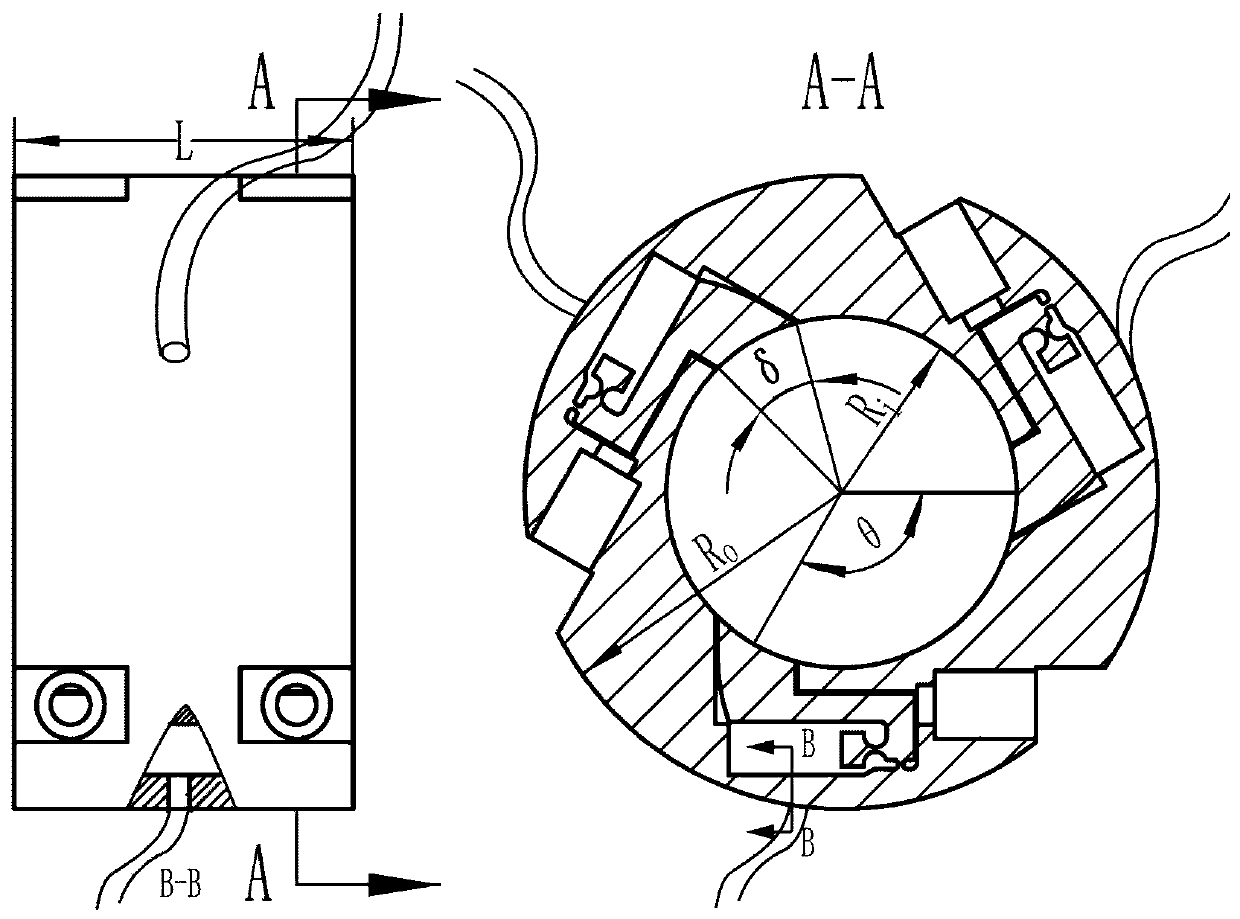

Dynamic static pressure mixing main shaft device

InactiveCN103185071AAvoid contact wearEnhance the dynamic pressure effectBearingsDynamic pressurePetroleum engineering

The invention discloses a dynamic static pressure mixing main shaft device which comprises a main shaft and a bearing disposed correspondingly with the main shaft; a dynamic pressure chamber is disposed between the main shaft and the bearing; an oil inlet and an axial oil return groove are disposed on the bearing; a static pressure oil chamber is disposed on a surface of the bearing opposite to the main shaft; the static pressure oil chamber comprises an upper static pressure oil chamber, a lower static pressure oil chamber, and a front static pressure oil chamber with a 120-degree included angle between each other. The dynamic static pressure mixing main shaft device provided by the invention prevents contact abrasion between the main shaft and the bearing, improves dynamic pressure effect, and is suitable for situations of alternating loads.

Owner:周小明

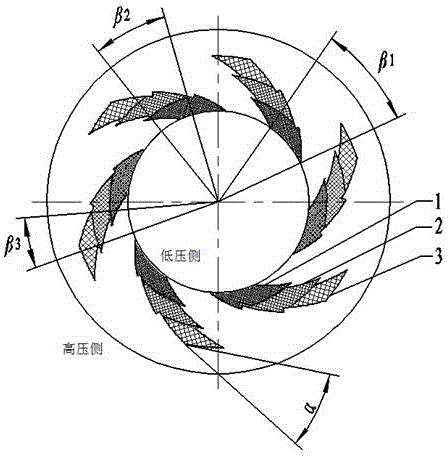

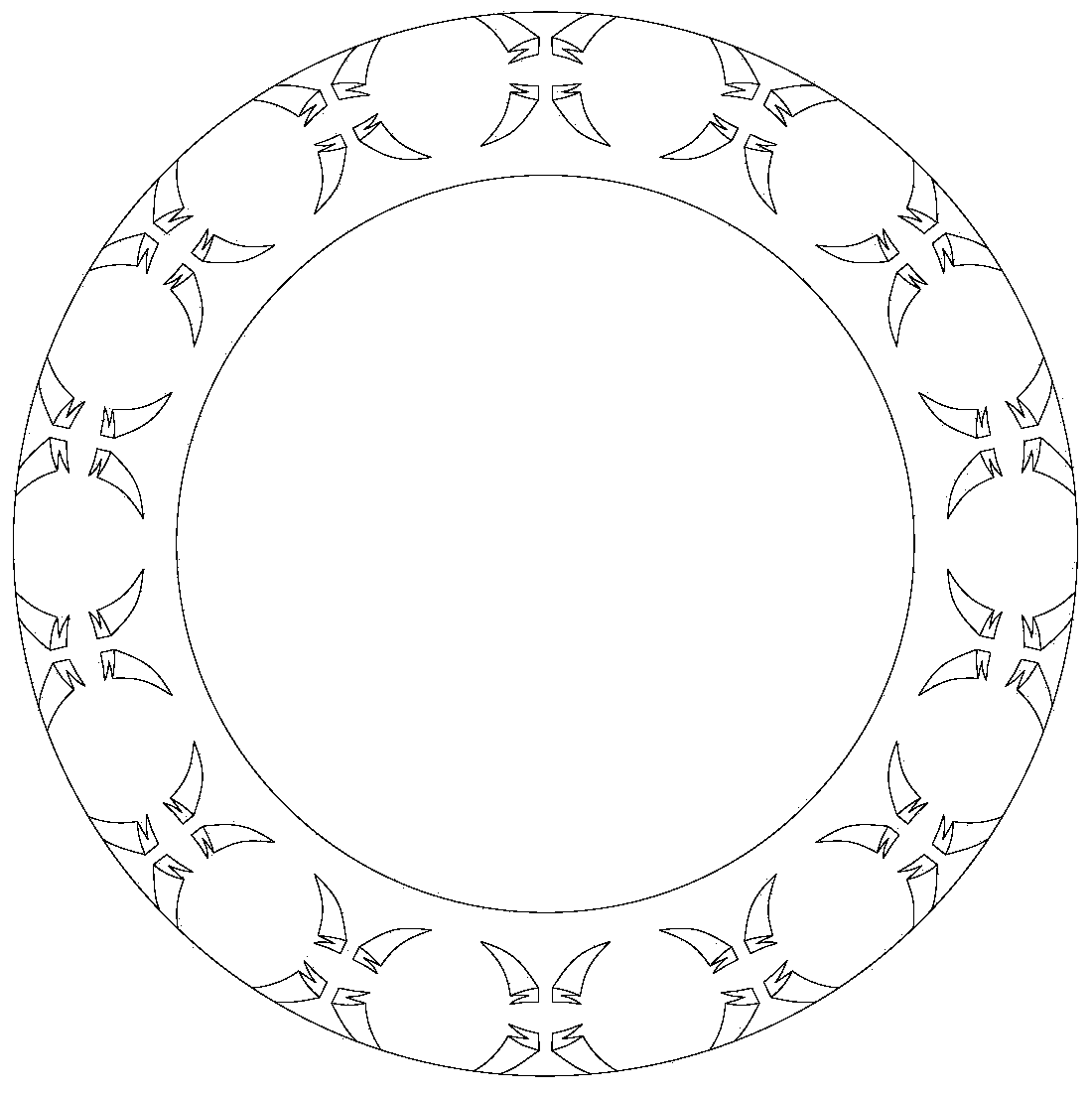

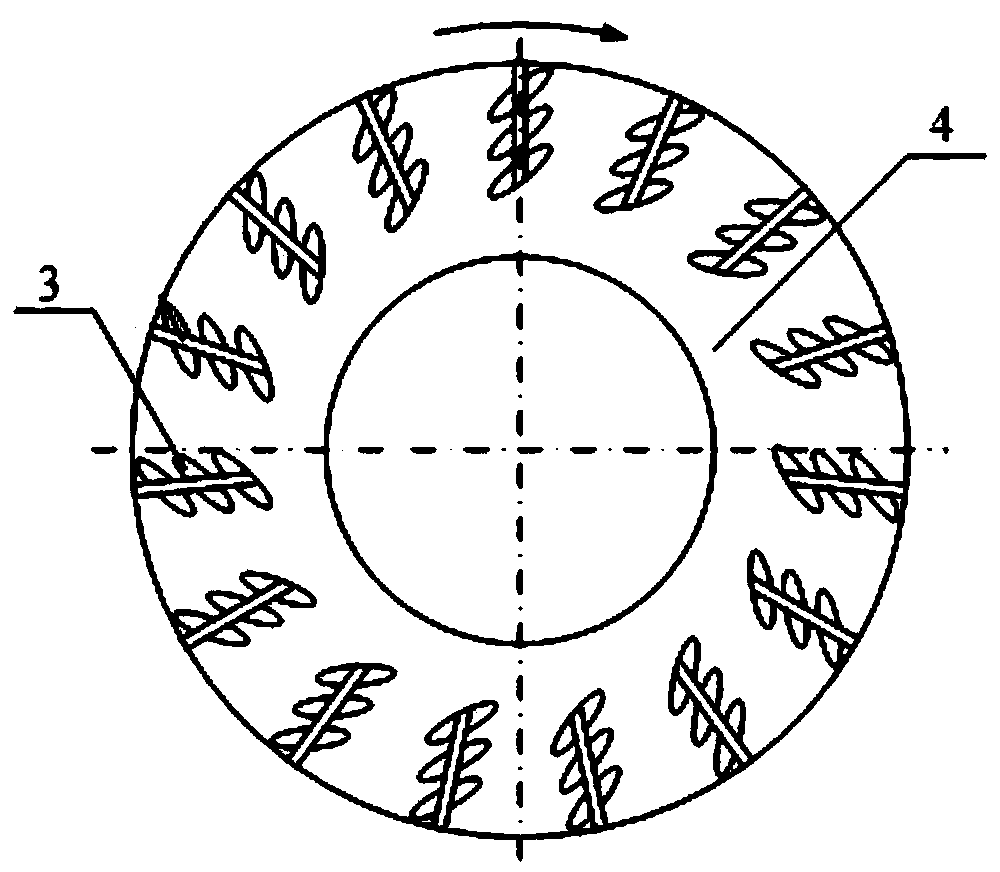

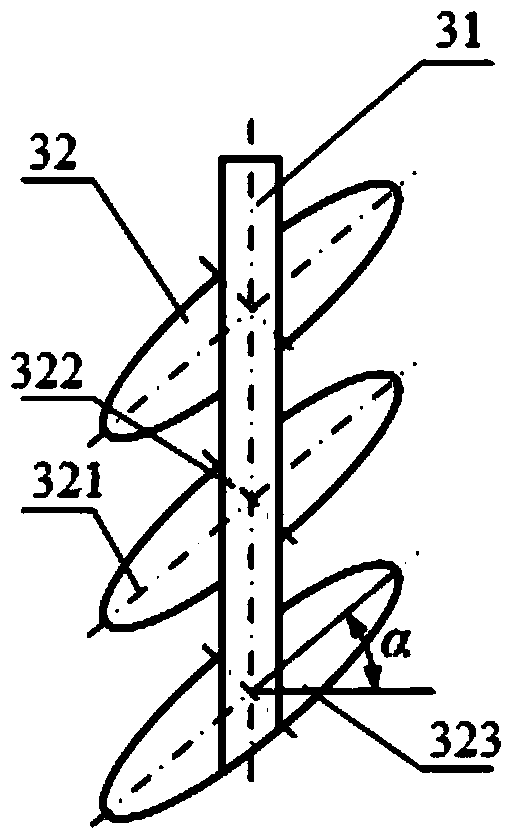

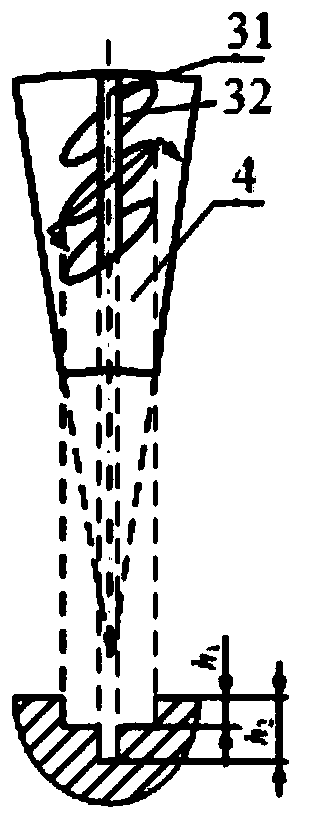

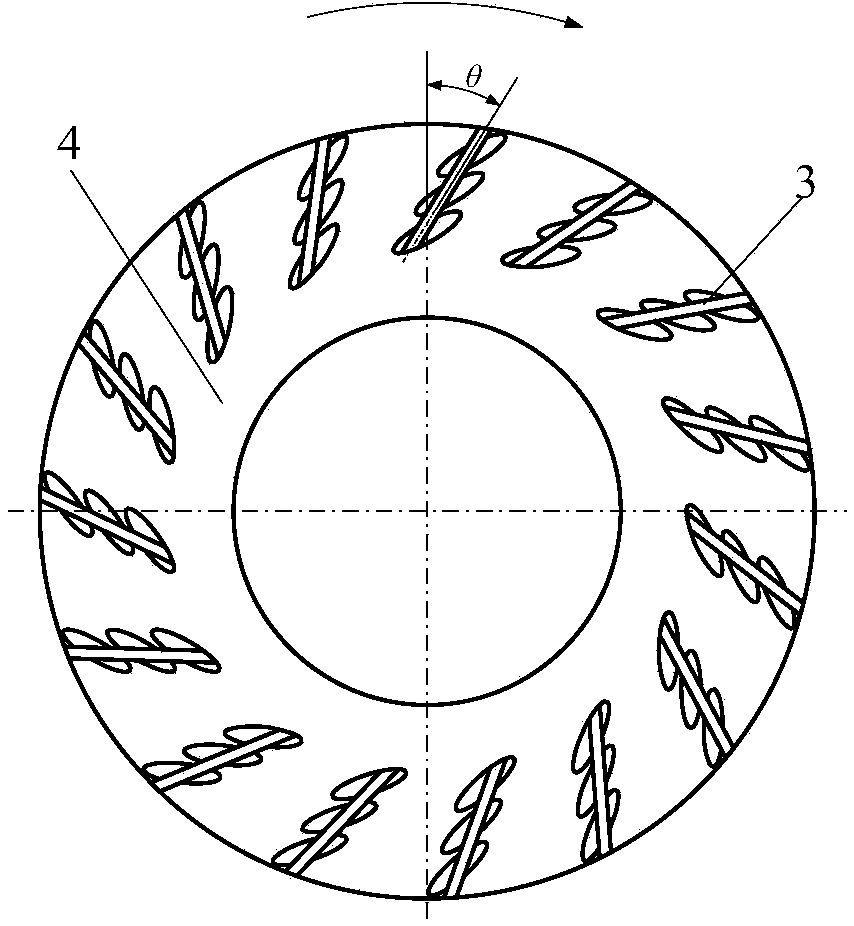

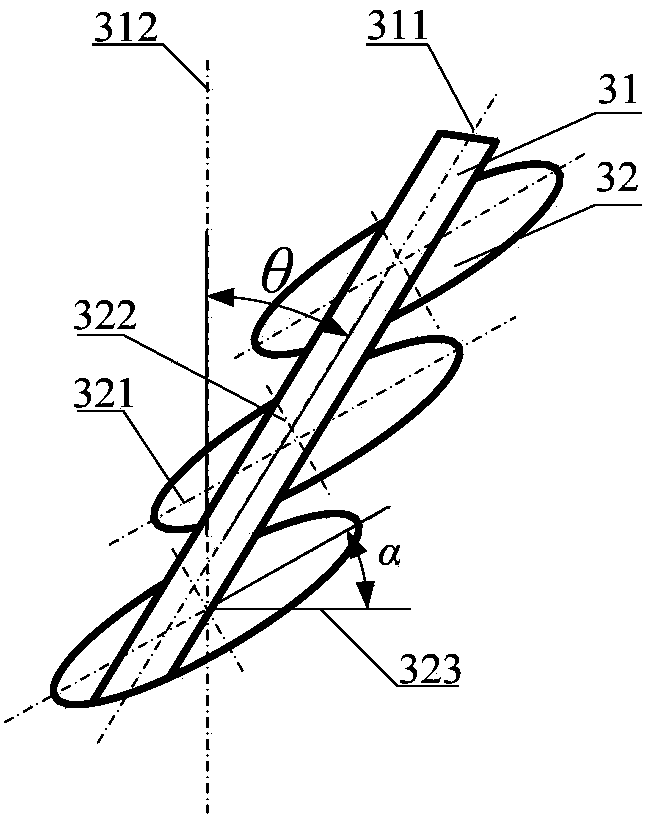

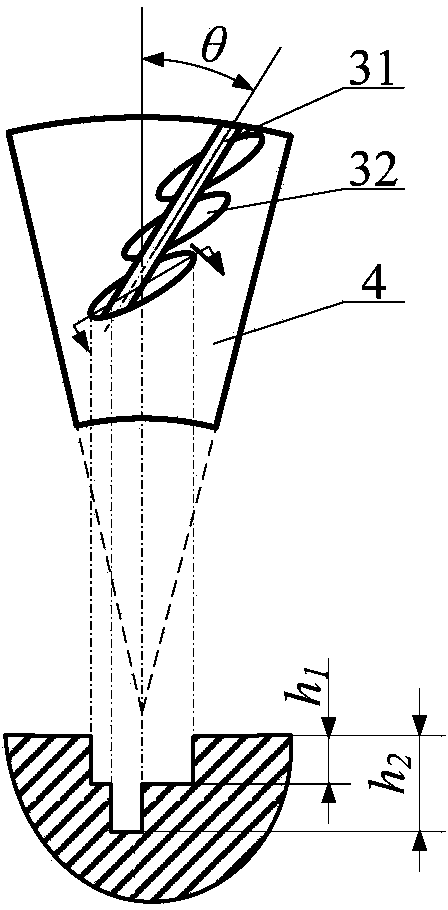

Gas-lubricated bird-wing-shaped groove end face seal structure

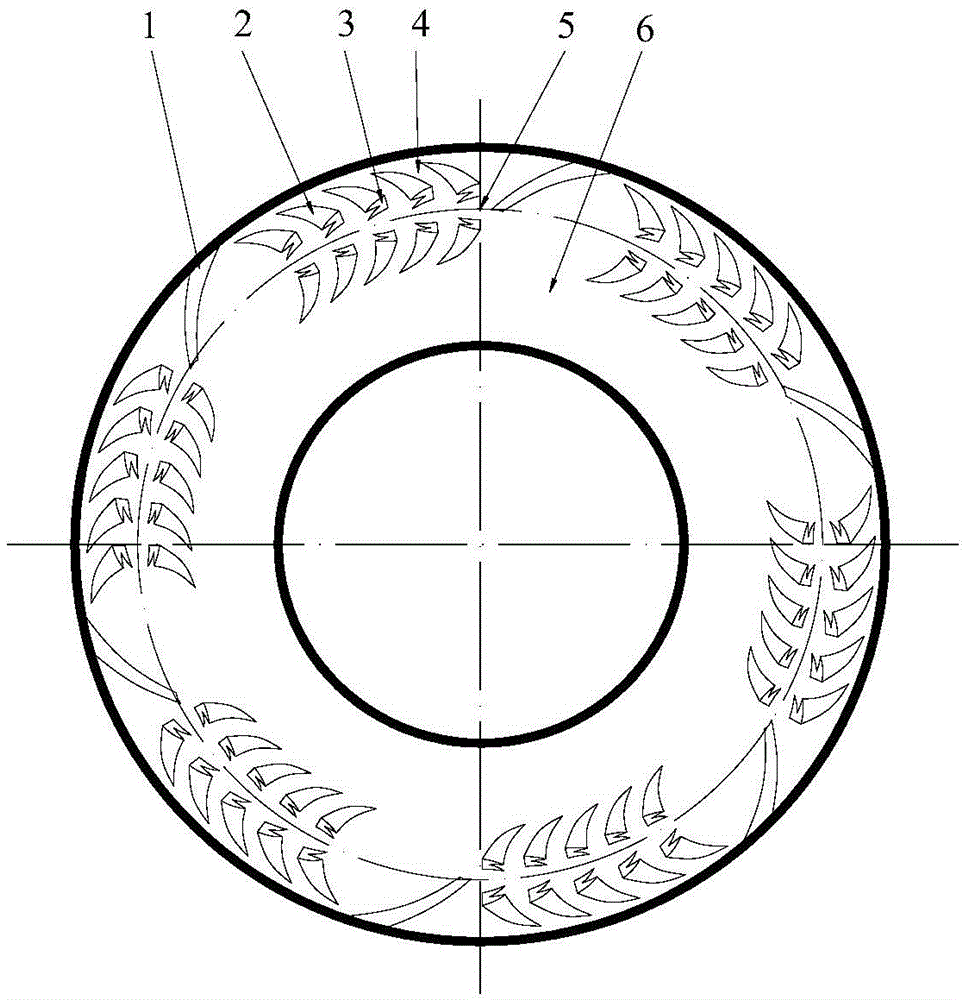

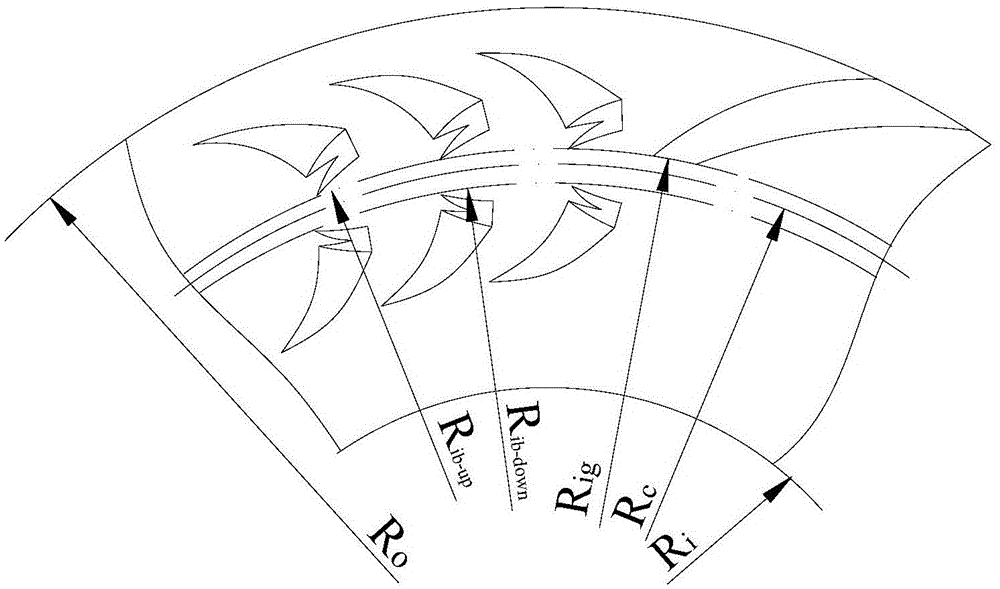

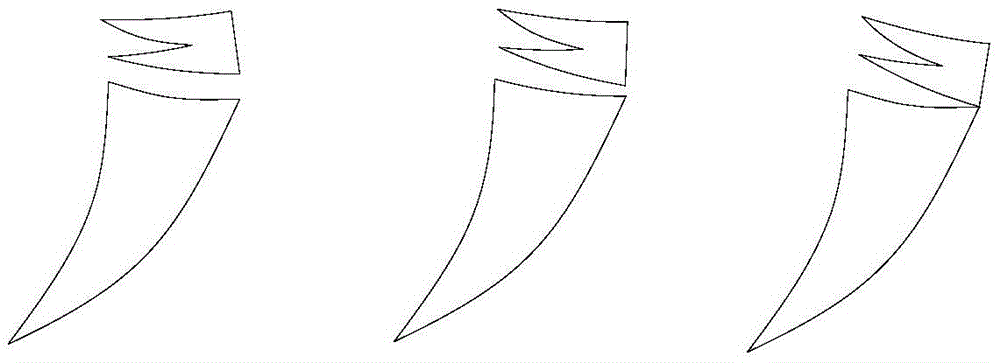

ActiveCN104265906BEnhance the dynamic pressure effectGood opening performanceEngine sealsGas lubricationMicrometer scale

A gas lubrication bird-wing-shape-imitation v groove end face sealing structure comprises two sealing rings with sealed end faces; the two sealing rings comprise a movable ring and a static ring; the end face of at least one of the movable ring and the static ring is provided with a plurality of bird-wing-shape-imitation v grooves; each bird-wing-shape-imitation v groove is composed of a tail-feather-shape-imitation v groove body and a flight-feather-shape-imitation v groove body; the tail-feather-shape-imitation v groove bodies are provided with swallow-tail-shaped furcal tails; the flight-feather-shape-imitation v groove bodies are roughly in a bull horn shape with the thick ends and the tail tip ends; the tail-feather-shape-imitation v groove bodies are transversely arranged at the thick ends of the flight-feather-shape-imitation v groove bodies; the thick segments of the flight-feather-shape-imitation v groove bodies and the thick ends of the tail-feather-shape-imitation v groove bodies are toward airflow; the bird-wing-shape-imitation v grooves are arranged to be bird-wing-shape-imitation v groove annular belts; secondary annular sealing dams are arranged between the bird-wing-shape-imitation v groove annular belts; annular main sealing dams are arranged on the low-pressure sides of the end faces; drainage grooves are arranged on the high-pressure sides of the end faces; the drainage grooves and the bird-wing-shape-imitation v grooves are shallow grooves of the micrometer scale; the depths of the flight-feather-shape-imitation v groove bodies are gradually decreased in the airflow direction. The sealing structure has the advantages of being good in stability and long in service life, and resisting abrasion.

Owner:ZHEJIANG UNIV OF TECH

Intelligent hybrid bearing based on negative-poisson-ratio structure

InactiveCN106763190AReduce vibrationReduce eccentricityBearingsBearing vibrationMechanical engineering

The invention discloses an intelligent hybric bearing based on a negative-poisson-ratio structure. The intelligent hybric bearing comprises a main shaft, a bearing body and an oil inlet device. The bearing body is arranged on the main shaft in a sleeving manner. An installation hole is formed in the bearing body. The oil inlet device is installed in the installation hole. A first static pressure cavity and a second static pressure cavity which communicate with each other are formed in a bearing face of the bearing body. The oil inlet device is connected with the second static pressure cavity through an oil inlet formed in the bottom of the installation hole. The negative-poisson-ratio structure is adopted in the oil inlet device for achieving oil supply adjustment. According to the intelligent hybric bearing based on the negative-poisson-ratio structure, a specific stretching effect of the negative-poisson-ratio structure is utilized, bearing vibration and eccentricity can be effectively reduced, and therefore the movement precision is improved; and meanwhile, the dependency on bearing clearances under the high-speed work condition is lowered, and the problems that a traditional high-precision hybrid bearing is difficult to machine and likely to be blocked are solved.

Owner:洛阳神实轴承科技有限公司

End-surface mechanical seal structure with sharkskin-imitated surface three-dimensional shape

ActiveCN106838323APrevent adhesionTo achieve the effect of enhanced heat dissipationEngine sealsThree dimensional shapeEngineering

The invention discloses an end-surface mechanical seal structure with a sharkskin-imitated surface three-dimensional shape. The end-surface mechanical seal structure comprises a moving ring or a fixed ring as mechanical seal, wherein the outer ends of the seal end surfaces of the moving ring and the fixed ring are taken as high-pressure sides, namely upstream parts, and the inner ends of the seal end surfaces are taken as low-pressure sides, namely downstream parts; a circle of closed seal dam is arranged at the upstream high-pressure side of at least one seal end surface in the moving ring or the fixed ring, a plurality of upstream pump grooves are uniformly arranged on the circumference of the surface of the seal end surface, a first end of each upstream pump groove extends to the high-pressure side of the seal end surface, and a second end extends to the low-pressure side of the seal end surface; an area between two adjacent upstream pump grooves is a seal weir; micro convex body clusters with the sharkskin-imitated surface shape are processed on the bottoms of the grooves and the surfaces of the seal weirs; the micro convex body clusters are arranged in a staggered manner until the micro convex body clusters uniformly bestrew the whole seal weirs and the bottoms of the upstream pump grooves; and the micro convex body clusters are formed by a plurality of parallel micro convex body units. The end-surface mechanical seal structure has the beneficial effects that attachment, drag reduction, wear resistance and enhanced heat dissipation of marine fouling organisms are prevented through the sharkskin-imitated surface three-dimensional shape.

Owner:ZHEJIANG UNIV OF TECH

Novel static-ring structure of mechanical sealing device

InactiveCN102141151AExtended service lifeImprove reliabilityEngine sealsEngine lubricationEngineeringStatics

The invention relates to a novel static-ring structure of a mechanical sealing device, which mainly solves the technical problems of improving lubricant conditions of primary and secondary seals and the like. The adopted technical scheme is that upper and lower working surfaces of upper and lower static-ring bodies of a split static-ring comprise upper and lower planes and upper and lower inclined planes; the upper and the lower planes are located at outer edges of the upper and the lower inclined planes; a group of upper and lower U-shaped flumes are arranged at the upper and the lower static-ring bodies along the circumferential direction; and the upper and the lower U-shaped flumes are located on the upper and the lower working surfaces and located at inner sides of the upper and the lower planes. The structure provided by the invention is suitable for the sealing of various marine stern tubes.

Owner:704TH RES INST OF CHINA SHIPBUILDING IND CORP

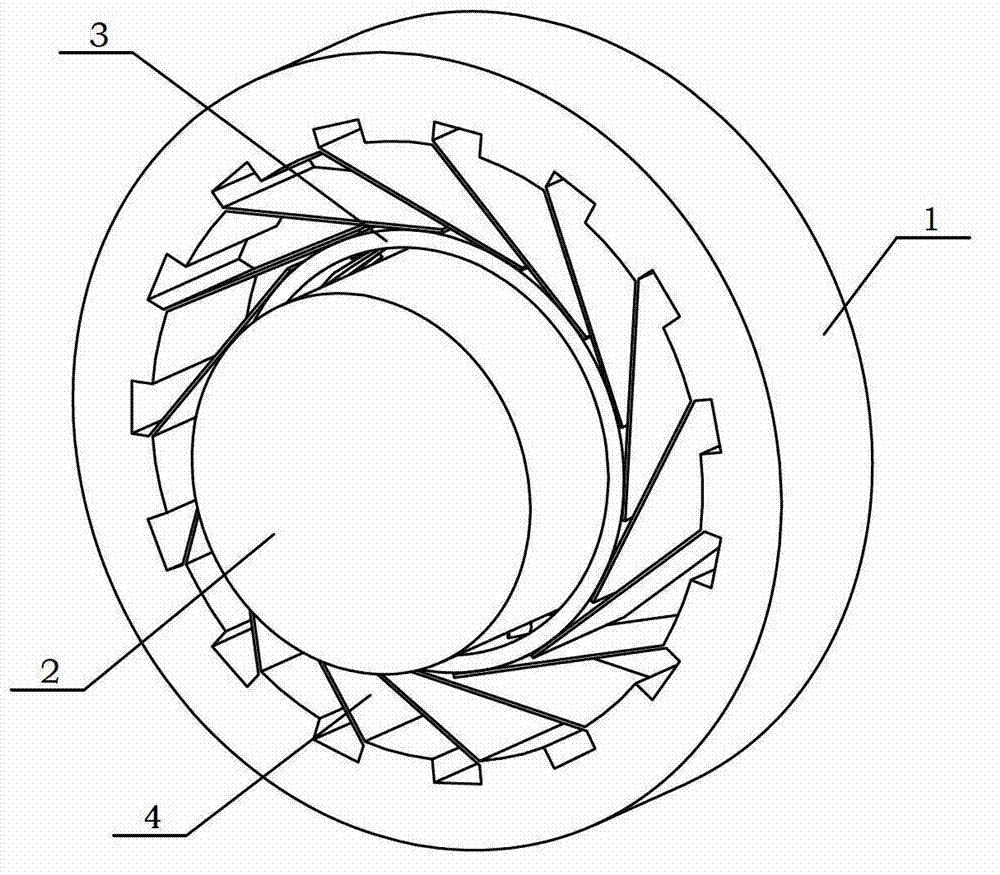

Two-way rotating gas dynamic/static pressure mechanical seal type bird wing-shaped groove structure

ActiveCN104265900AEnhance the dynamic pressure effectStable on and runningEngine sealsMicrometer scaleStructure of the Earth

The invention discloses a two-way rotating gas dynamic / static pressure mechanical seal type bird wing-shaped groove structure. The structure comprises two mechanically sealed sealing rings-a dynamic ring and a static ring. The structure is characterized in that a plurality of bird wing-shaped grooves are formed in the end surface of at least one sealing ring of the dynamic ring and the static ring; the bird wing-shaped grooves are shallow grooves in micrometer scale, and consist of tail feather-shaped grooves and flight feather-shaped grooves; the tail feather-shaped grooves have swallow tail-shaped furcal tails; the flight feather-shaped grooves substantially take the shape of ox horns with thick ends and tail tip ends; the tail feather-shaped grooves are transversely arranged at the thick ends of the flight feather-shaped grooves; every two bird wing-shaped grooves form groove pairs in a splayed shape; multiple groove pairs are evenly arranged peripherally to form a bird wing-shaped groove ring belt; the bird wing-shaped groove ring belt is arranged at the high-pressure side of the end surface; and the depths of the flight feather-shaped grooves are gradually decreased in the airflow direction. The structure has the characteristics of two-way rotation, excellent opening character, good stability, wear resistance and long service life.

Owner:ZHEJIANG UNIV OF TECH

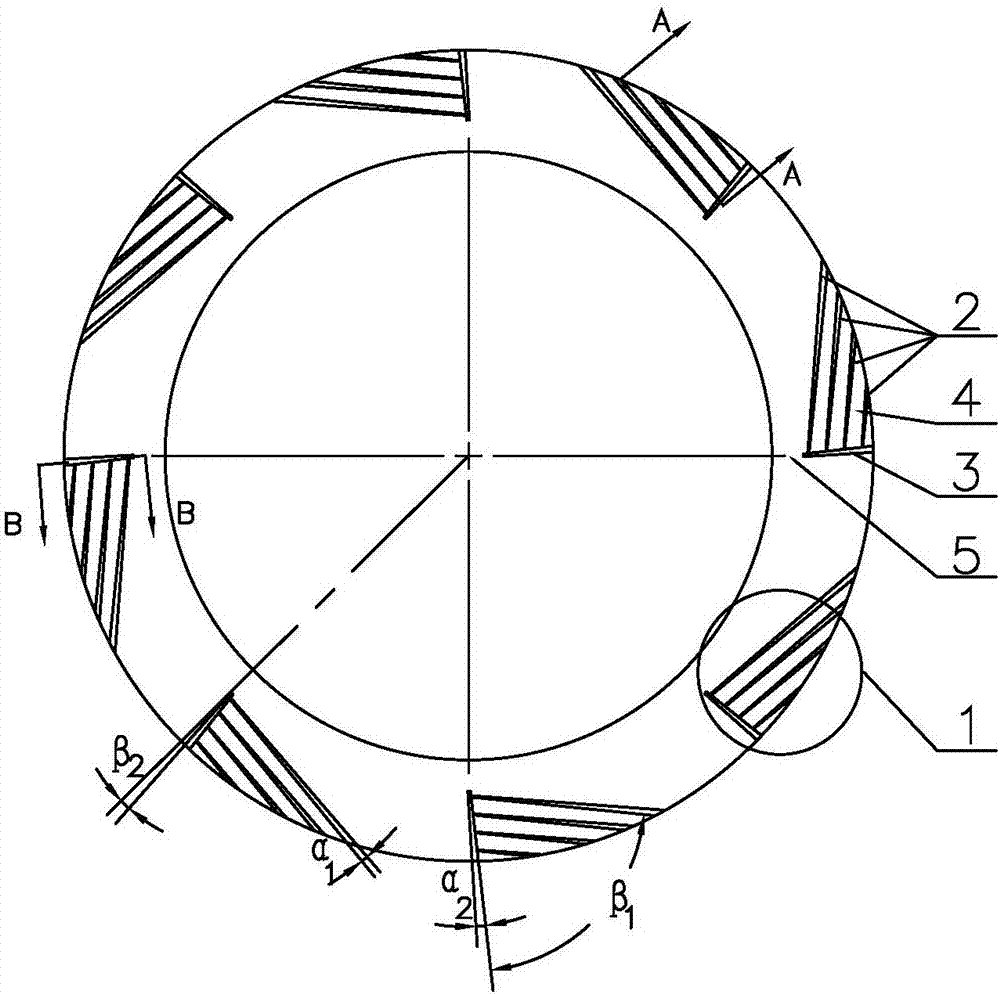

Two-way dynamic and static pressure mixed lubrication thrust bearing

InactiveCN103438097BHigh running precisionImprove running stabilityGas cushion bearingsSliding contact bearingsThermodynamicsThrust bearing

Bidirectional dynamic and static pressure mixed lubrication thrust bearing. The invention relates to a bidirectional dynamic and static pressure mixed lubrication thrust bearing. The present invention is to solve the current problems of low precision and poor operating stability under high-speed and heavy-load extreme working conditions, and provides a two-way dynamic and static pressure hybrid lubricated thrust bearing. A two-way dynamic and static pressure mixed lubrication thrust bearing includes a dynamic and static pressure oil pad, a circular machine tool base and a rotating worktable; a rotating worktable is located directly above the dynamic and static pressure oil pad, and a circular machine tool is located directly below the dynamic and static pressure oil pad. The base; the dynamic and static pressure oil pad of the two-way dynamic and static pressure mixed lubrication thrust bearing also includes a wedge shape; the wedge shape is arranged on the inside of both circumferential sides of the oil sealing edge. The invention is applied in the field of high-speed and heavy-load machine tool worktables.

Owner:HARBIN UNIV OF SCI & TECH

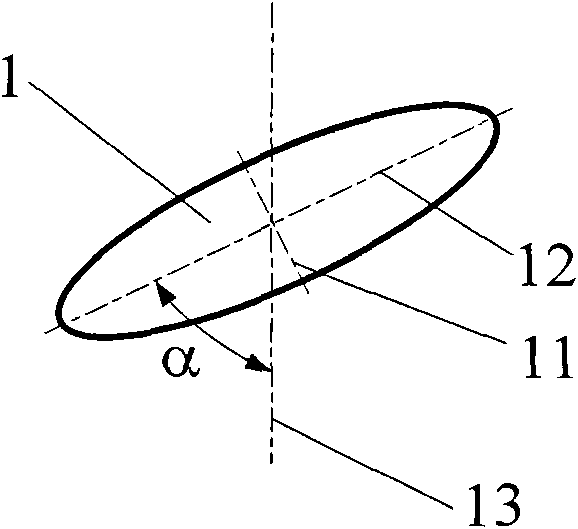

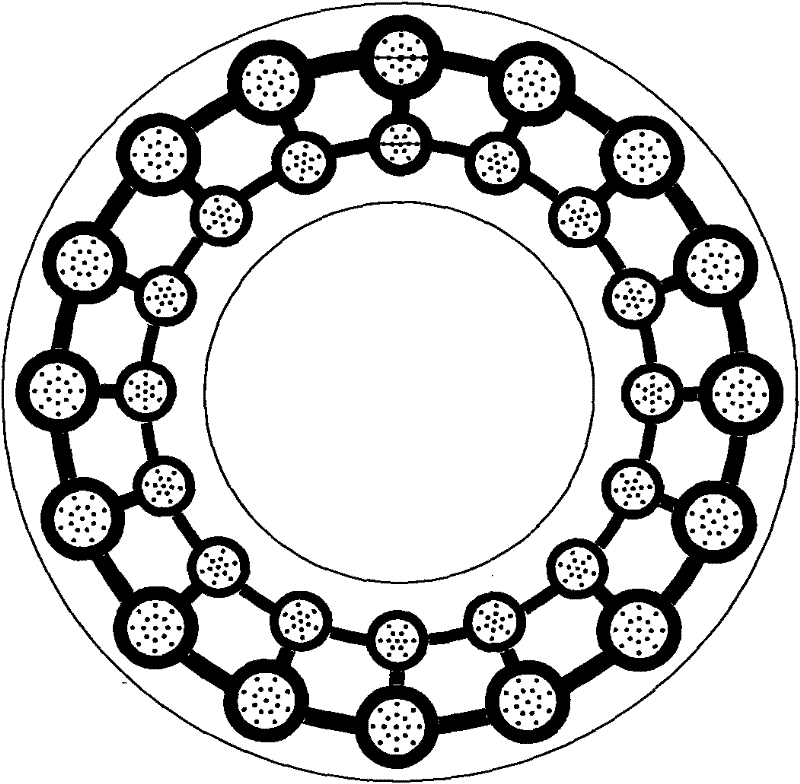

Micro-hole end face mechanical seal structure with air inlet grooves

A micro-hole end face mechanical seal structure with air inlet grooves comprises two end faces for mechanical sealing, namely a moving ring and a stationary ring, wherein one end face is sequentially provided with micro-hole groups and annular sealing dams which are symmetrically distributed relative to the rotation center from the high-pressure side to the low-pressure side. Multiple rows of micro-hole groups are distributed on the high-pressure side of the end face and comprise the linear air inlet grooves and multiple elliptic micro-holes, the centers of the micro-holes are located on the air inlet grooves, included angles formed by long shafts of the micro-holes and the air inlet grooves are identical, and one end of each micro-hole facing air flows is located on the high-pressure side of the end face. A straight line where the air inlet grooves are located is located on the radius of the end face. The low-pressure side of the end face is provided with the annular sealing dams with smooth faces. The micro-hole end face mechanical seal structure has the advantages that the opening performance under the high-pressure frequent start-stop condition is improved; the problem of poor hydrodynamic effect of the end faces caused by the air negative pressure effect is solved; the solid particle preventing capacity and the advantages of the micro-holes are fully played; the hydrodynamic effect and the disturbance-resisting performance are enhanced, the service life is prolonged, and the stability of the end faces is improved.

Owner:ZHEJIANG UNIV OF TECH

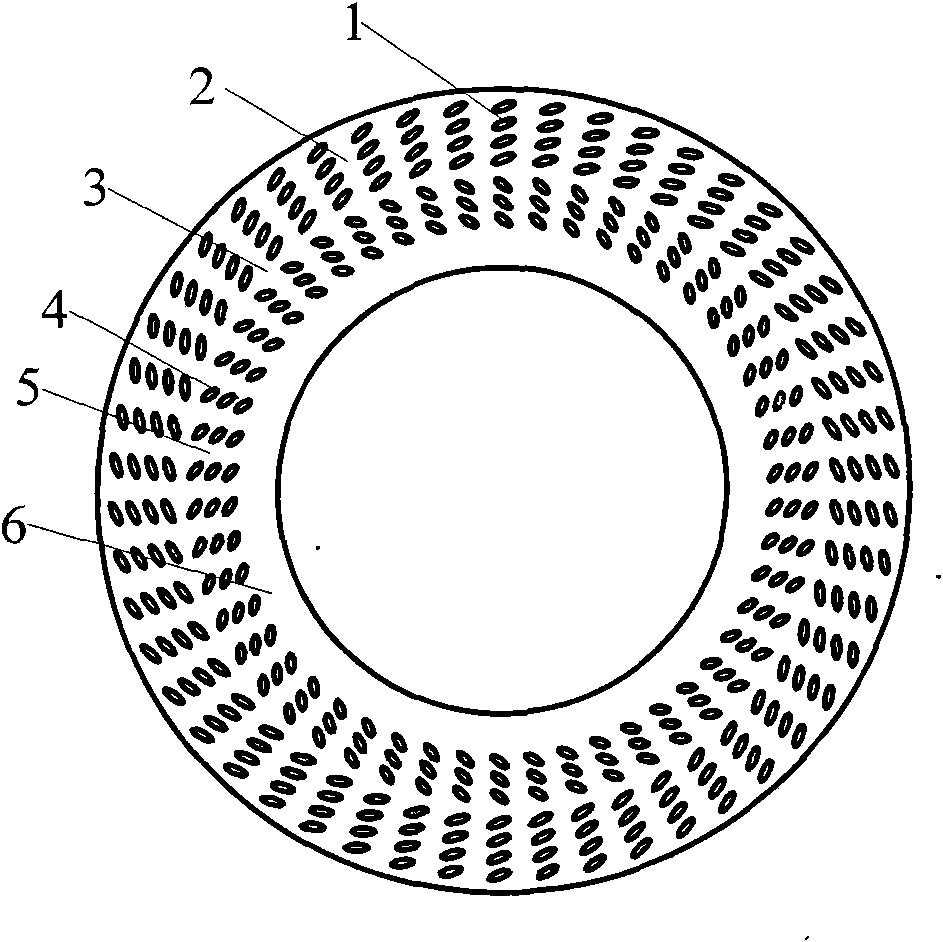

End face mechanical seal structure with air inlet grooves and micropores

InactiveCN103470771AImprove stabilityGood opening performanceEngine sealsLong axisCentre of rotation

An end face mechanical seal structure with air inlet grooves and micropores comprises two end faces for mechanical seal. The two end faces are a moving ring and a static ring. Micropore groups in symmetrical distribution according to the rotation center and a ring-shaped seal dam are sequentially arranged on one end face from the high-pressure side to the low-pressure side; a plurality of micropore groups are distributed on the high-pressure side of the end face, every micropore group comprises a straight-line-shaped air inlet groove and a plurality of oval micropores, wherein the centers of the micropores are located on the air inlet groove, included angles of the long axis of every micropore and the air inlet groove are identical, and one end of every micropore facing to air flow is located on the high-pressure side of the end face. Straight lines where the air inlet grooves are located are obliquely crossed with the radius of the end face, and the shiny side ring-shaped seal dam is arranged on the low-pressure side of the end face. The end face mechanical seal structure has the advantages that starting performance under high-pressure frequent starting and shutdown working conditions is improved; the problem that the end face dynamic pressure effect is weak due to gas negative pressure effect is solved; the capability and the advantages of the micropore in stopping solid particles are brought into full play; the dynamic pressure effect and disturbance resistance are enhanced, the service life is prolonged, and end face stability is improved.

Owner:ZHEJIANG UNIV OF TECH

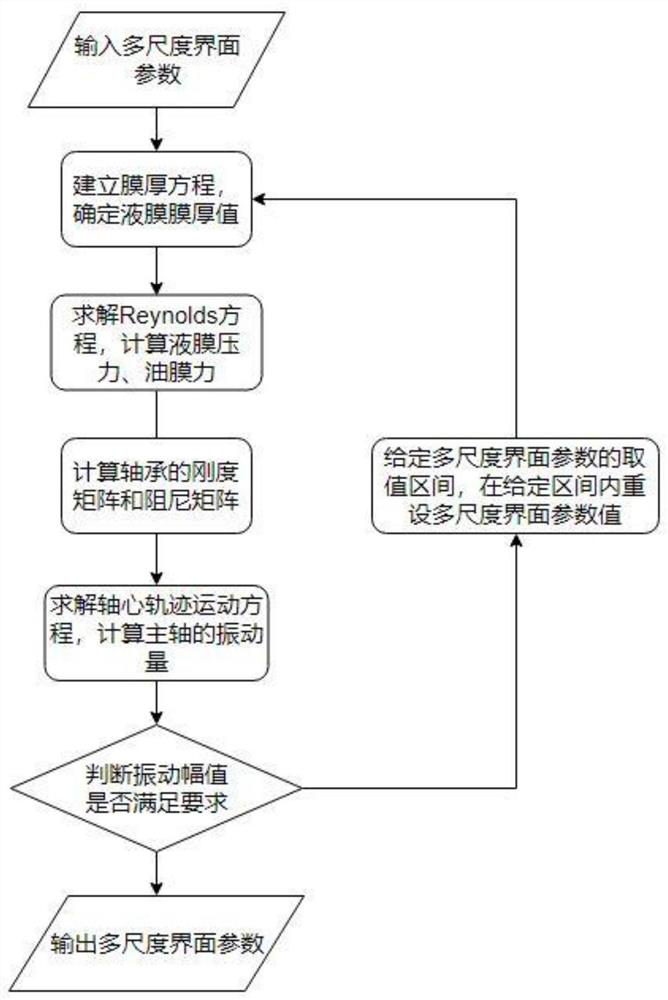

Transcritical main shaft system design method based on multi-scale interface regulation and control

ActiveCN113051684AEnhance the dynamic pressure effectImprove carrying capacityGeometric CADSpecial data processing applicationsSystems designEngineering

Owner:TIANJIN UNIV

Mechanical seal end face structure of imitated grinding disc texture

A mechanical seal end face structure of imitated grinding disc texture comprises a movable ring and a fixed ring which are in mechanical seal; one side of each of the movable ring and the fixed ring serves as the high-pressure side, that is the upstream side, the other side of each of the movable ring and the fixed ring is the low-pressure side, that is the downstream side, multiple streamline grooves of the imitated grinding disc surface texture are evenly distributed in the end face of at least one seal ring of each of the movable ring and the fixed ring in the circumferential direction, composed of foundation movable pressure grooves and flow guide grooves, and gradually narrowed from upstream to downstream and become shallow in depth; the foundation movable pressure groove are arranged in parallel in a multi-row manner, and the grooves are partitioned by sealing weirs with the equal depth; the flow guide grooves penetrates the foundation movable pressure grooves, and seal dams are arranged on the downstream portions of the streamline grooves; through the convergent structure of the imitated grinding disc texture, the higher flow guide effect is achieved, and leakage is reduced while the end fluid movable pressure effect is improved.

Owner:ZHEJIANG UNIV OF TECH

Dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure

ActiveCN102322528BEnhance the dynamic pressure effectImprove work performanceEngine sealsNon symmetricEngineering

The invention provides a dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure. At least one sealing end face on a moving ring and a stationary seal ring is provided with more than two three-dimensional asymmetrical waviness appearances, the asymmetrical waviness is in a periodical arrangement on the at least one sealing end face, the asymmetrical waviness sealing end face comprises a dam area, a conical surface and a wave crest and a wave trough of the asymmetrical waviness, the dam area is a groove-less parallel annular sealing dam arranged at the low-pressure side, the wave crest and the wave trough are connected through the conical surface, the conical surface is a linear convergence cone formed from the high-pressure side to a low-pressure side and is connected with the dam area, the conical surface can realize sealed non-contact static pressure effect; the conical degree combines with the asymmetrical waviness so that the sealing reliability can be improved, an asymmetrical waviness smooth transition curve can prevent the particles in the sealing fluid from being cumulated, and the dam area can realize static sealing when the axle is stationary. The structure provided by the invention has strong pressure resistance and antijamming capability, the leakage rate is lower at the conditions of high parameters, the fluid has good dynamic pressure effect in the process of start and stop and the fluid bearing capacity is sufficient in the normal operation.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com