Surface lubricating texture, compressor parts, compressor and air conditioner

A technology for compressors and parts, applied in the field of tribological characteristics of mechanical parts, can solve the problems of weak dynamic pressure effect of texture texture, insufficient oil in lubrication gap, consumption of lubricating oil, etc., to ensure reliable and stable operation and long life demand, increase the damping effect of the lubricated surface, and improve the effect of the hydrodynamic pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

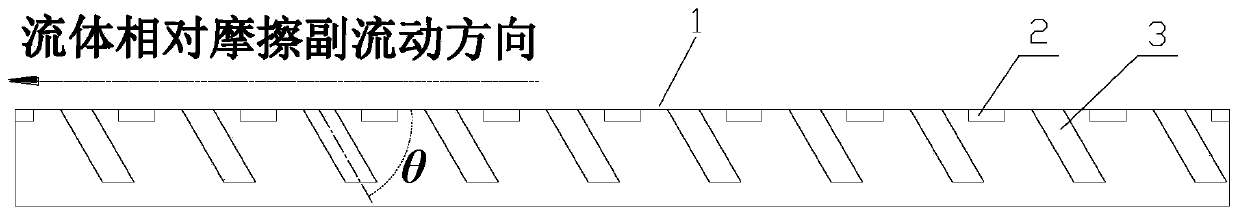

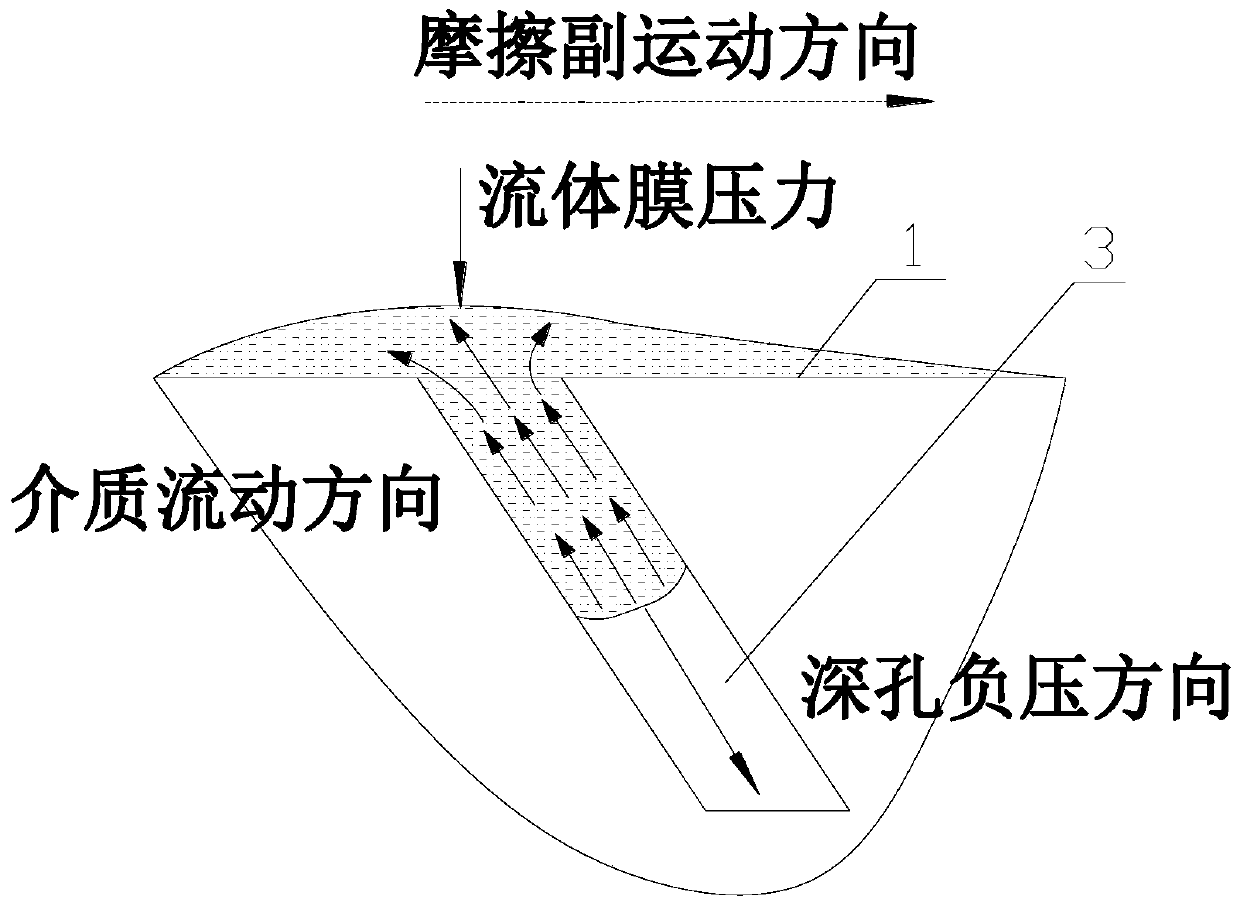

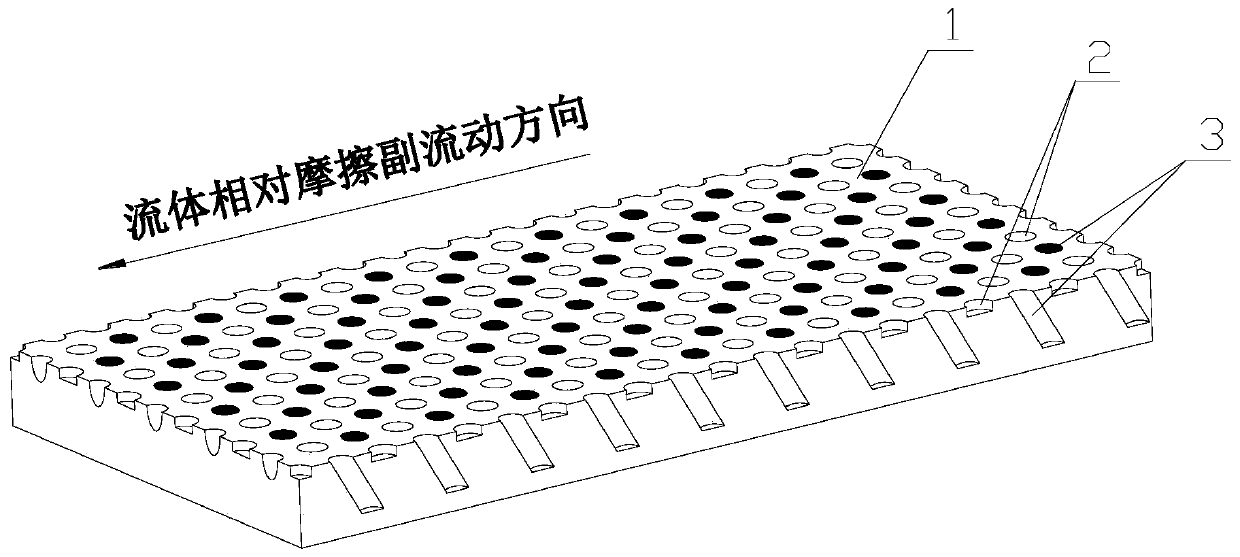

[0039] see in conjunction Figure 1 to Figure 6 As shown, according to the embodiment of the present application, the surface lubrication texture includes a dynamic pressure lubrication surface 1, and a pore structure is arranged on the dynamic pressure lubrication surface 1. The pore structure is arranged along the fluid flow direction, and the pore structure includes a first hole 2 and a second hole. Two holes 3 , the first holes 2 and the second holes 3 are arranged at intervals, and the depth of the first holes 2 is smaller than that of the second holes 3 . The surface lubricating texture is applied to the lubrication between the lubricating surfaces of the friction pairs to improve the lubrication effect between the friction pairs.

[0040] By forming the first hole 2 and the second hole 3 with different depths on the dynamic pressure lubrication surface 1, the first hole 2 with a smaller hole depth can be used to provide sufficient dynamic pressure effect on the dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com