Liquid lubricated end face seal structure with cross-scale surface texture characteristic

A technology of end face sealing and liquid lubrication, which is applied to the sealing of engines, liquid fuel engines, and parts of pumping devices for elastic fluids, etc. Improve the sealing lubrication, enhance the pumping effect, and enhance the operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

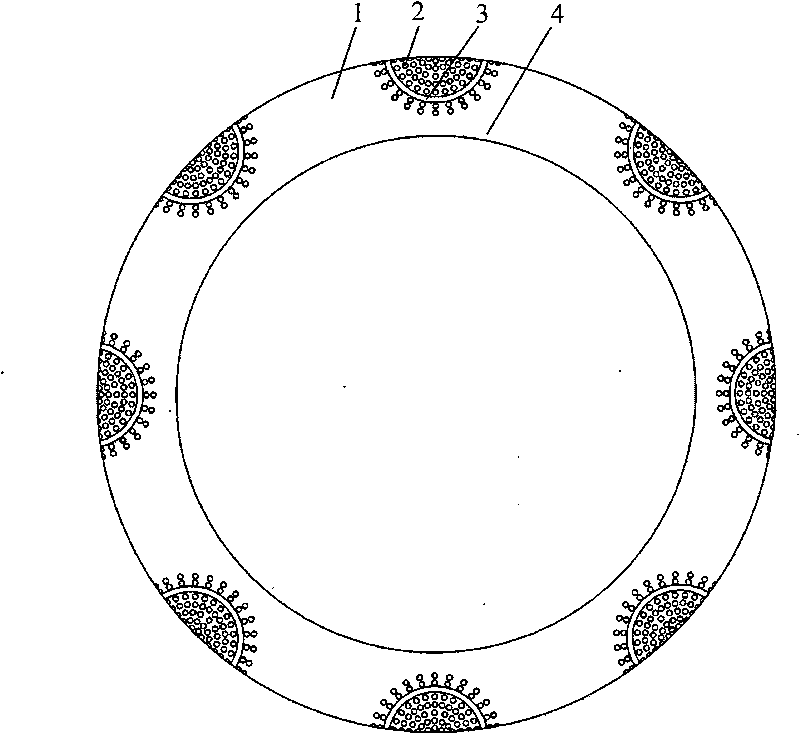

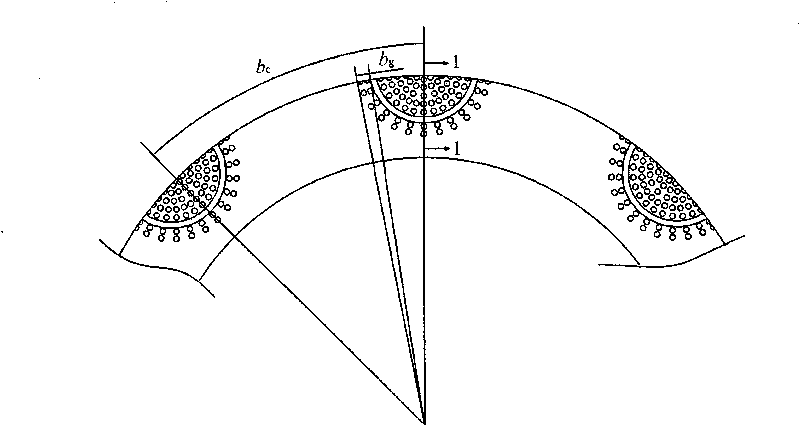

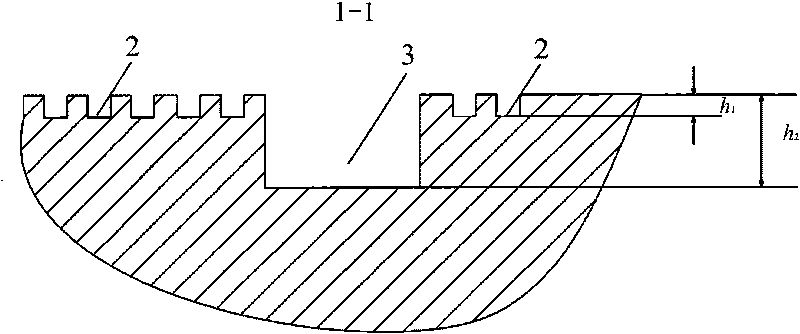

[0026] refer to Figure 1-3 , a liquid lubricated end face seal structure with cross-scale surface texture features, including a dynamic ring and a static ring of a mechanical seal, one side of the end faces of the dynamic ring and the static ring is the high pressure side, that is, the upstream, the dynamic ring and the static ring The other side of the end face of the static ring is the low-pressure side, that is, the downstream side. Several cross-scale textured face grooves are processed on the end face of the moving ring or the static ring of the mechanical seal. The cross-scale textured face grooves are composed of mm-level The deep groove 3 is composed of micron-scale micropores 2, the deep groove 3 is located upstream of the end face, and the micropores 2 are distributed around the deep groove 3; a sealing weir 1 is provided between the cross-scale textured surface grooves, An annular sealing dam 4 of an unopened face groove is arranged downstream of the cross-scale te...

Embodiment 2

[0033] refer to Figure 4 , Figure 5 The difference between this embodiment and the first embodiment is that the deep groove 3 is semicircular, and the bottom surface of the deep groove 3 is processed with microholes 2 . The rest of the structure and implementation are the same as in Embodiment 1. The shape of the deep groove 3 can also be rectangle 31, E shape 32, crescent shape 33, X shape 34, T shape 35, U shape 36, V shape 37, other shapes such as trapezoid 38, refer to Figure 7 .

Embodiment 3

[0035] refer to Figure 4 , Figure 6 The difference between the present embodiment and the second embodiment is that the depth of the microholes 2 on the bottom surface of the deep groove 3 gradually becomes shallower along the radial direction from upstream to downstream, which enhances the pumping effect. The rest of the structures and implementations are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com