Sealing ring and sealing unit

A technology of sealing unit and sealing ring, which is applied in the direction of engine sealing, engine components, wind power generation, etc., can solve the problems of deformation, distortion, grease leakage, etc., and achieve the effect of reducing maintenance cost, reducing wear and tear, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

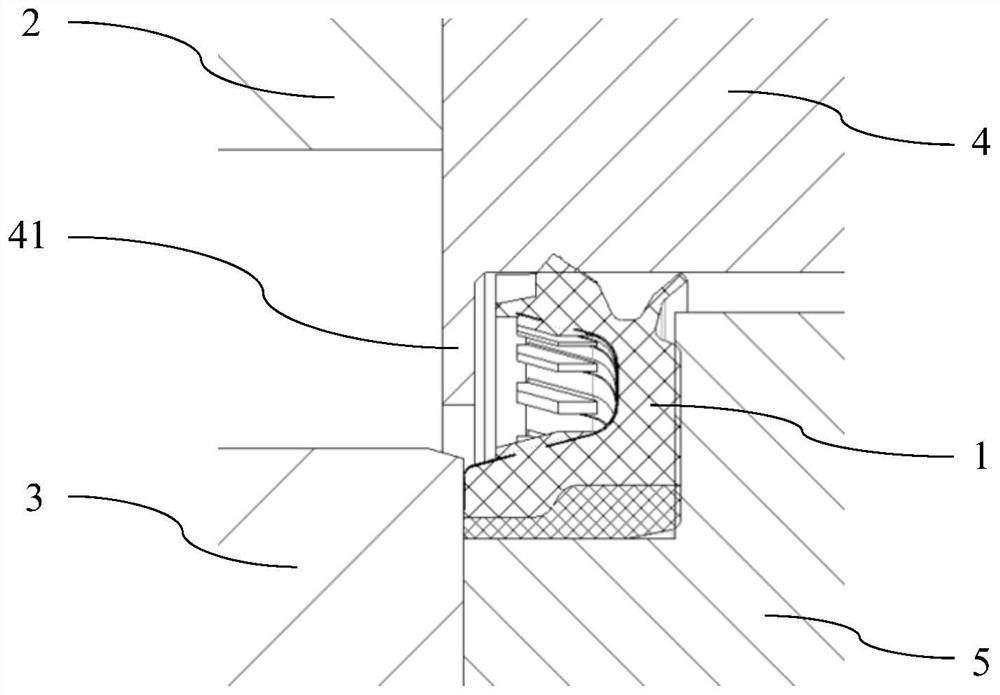

[0034] figure 1 A schematic cross-sectional view of a sealing unit according to a preferred embodiment is shown. Here, sealing units are used to seal large bearings in wind turbines. The bearing includes an outer ring 2 and an inner ring 3 and can perform two-way relative rotation according to the working conditions. The sealing ring 1 of the sealing unit is fixed on the sealing seat of the cover ring 5 by an interference fit at its radial inner side and forms an interference fit with the inner ring 3 of the bearing and the cover ring 5 respectively in the axial direction. The sealing ring 1 forms a dynamic contact seal on the radially outer side with the end cover 4 fixedly connected to the outer ring 2 in order to prevent air-side contamination from entering the bearing and to prevent leakage of the fluid-side, ie, in this case, grease in the bearing.

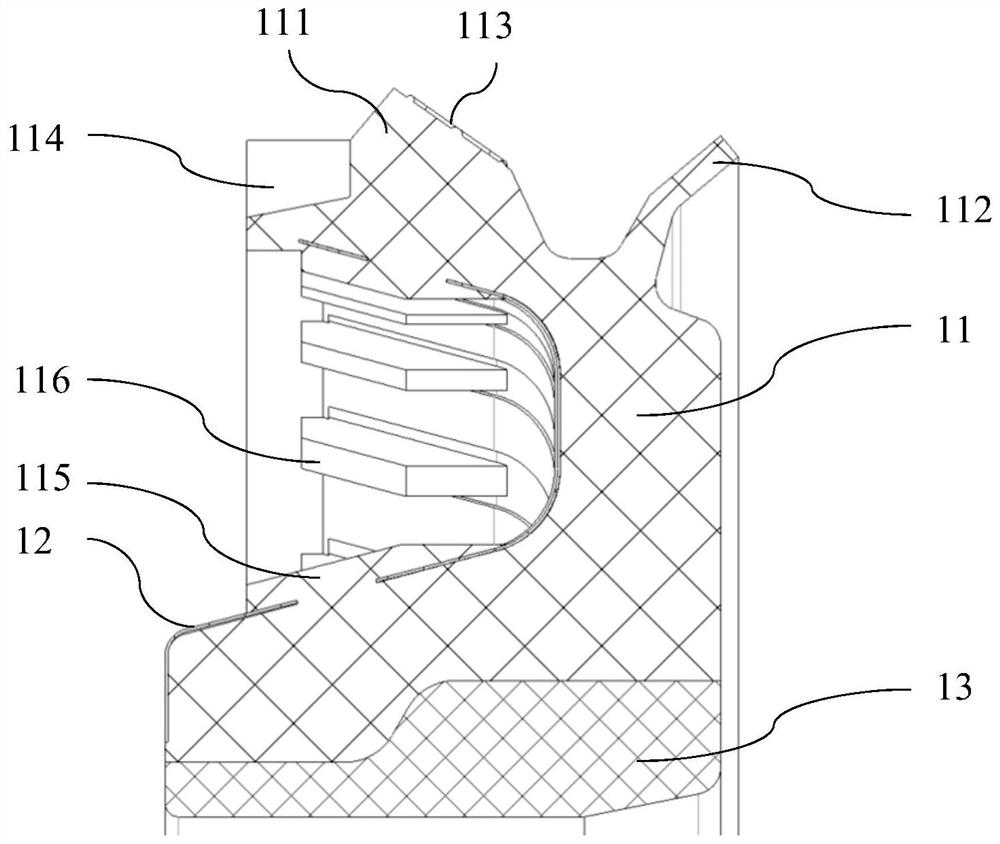

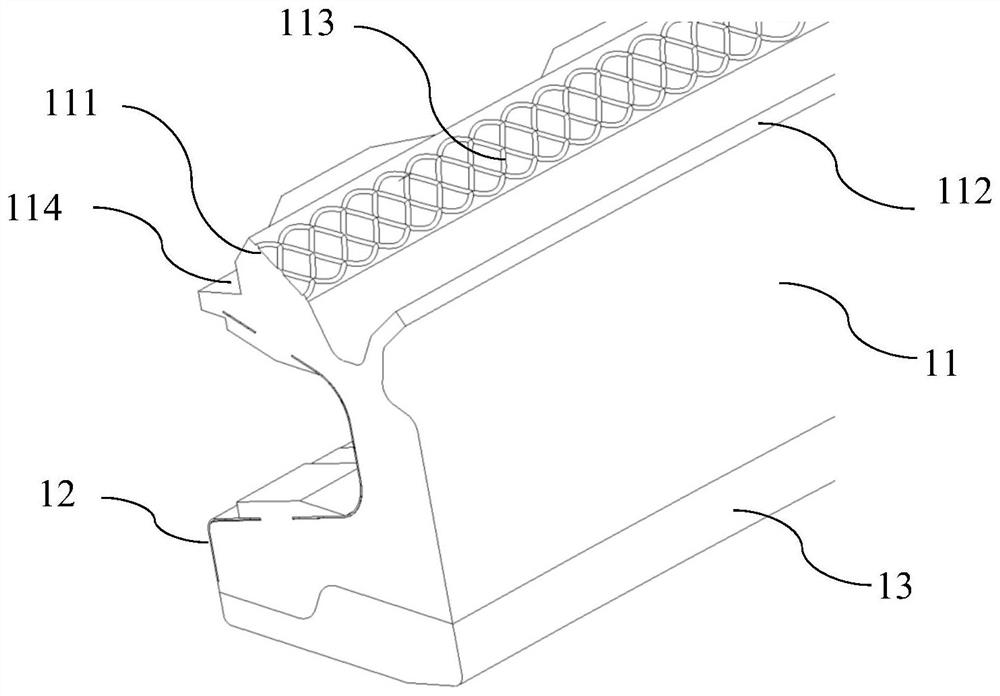

[0035] figure 2 shows according to figure 1 A schematic cross-sectional view of the sealing ring 1 in the sealing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com