Patents

Literature

264results about How to "Improve the pumping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

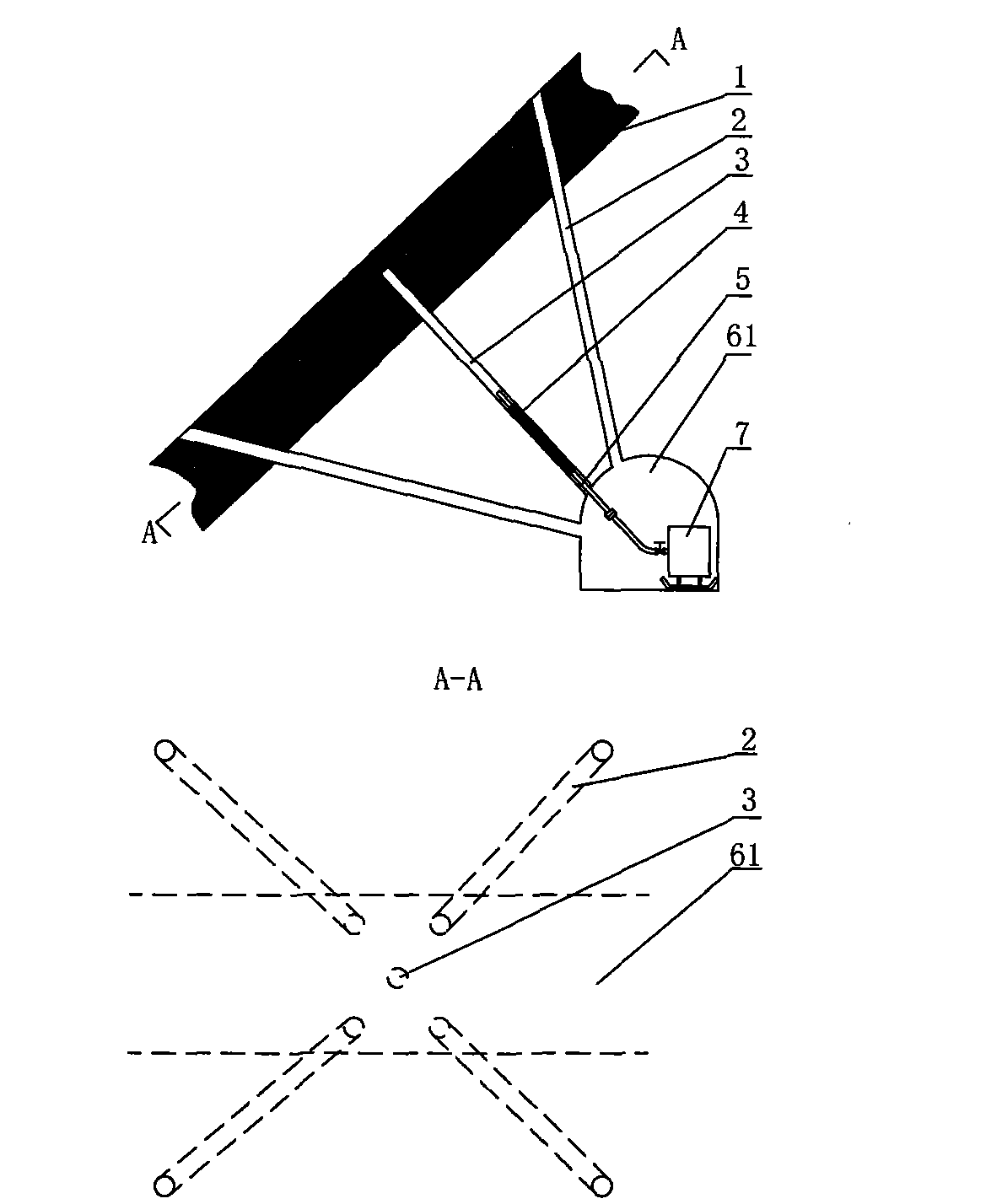

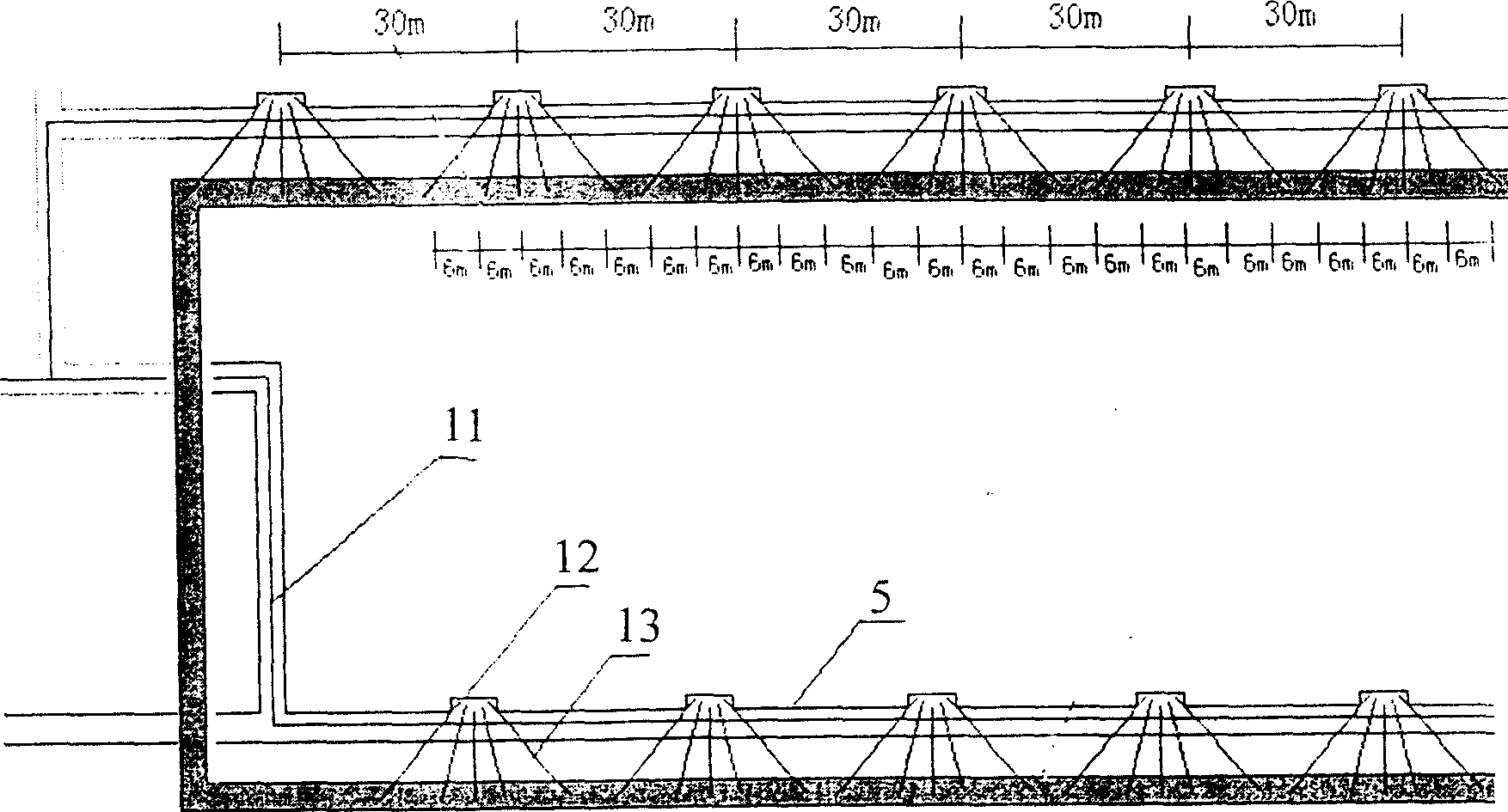

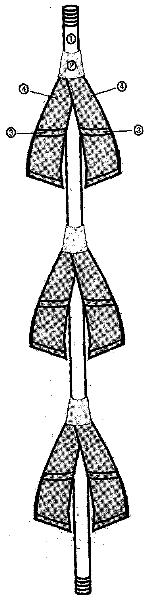

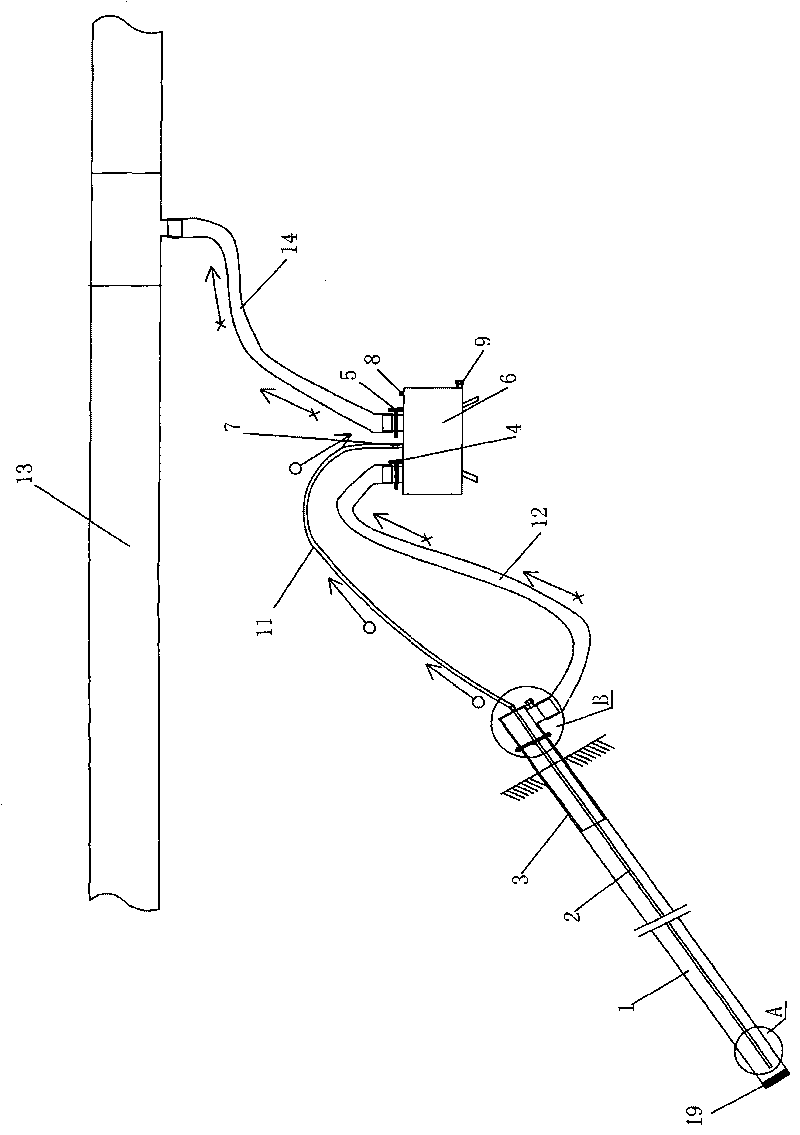

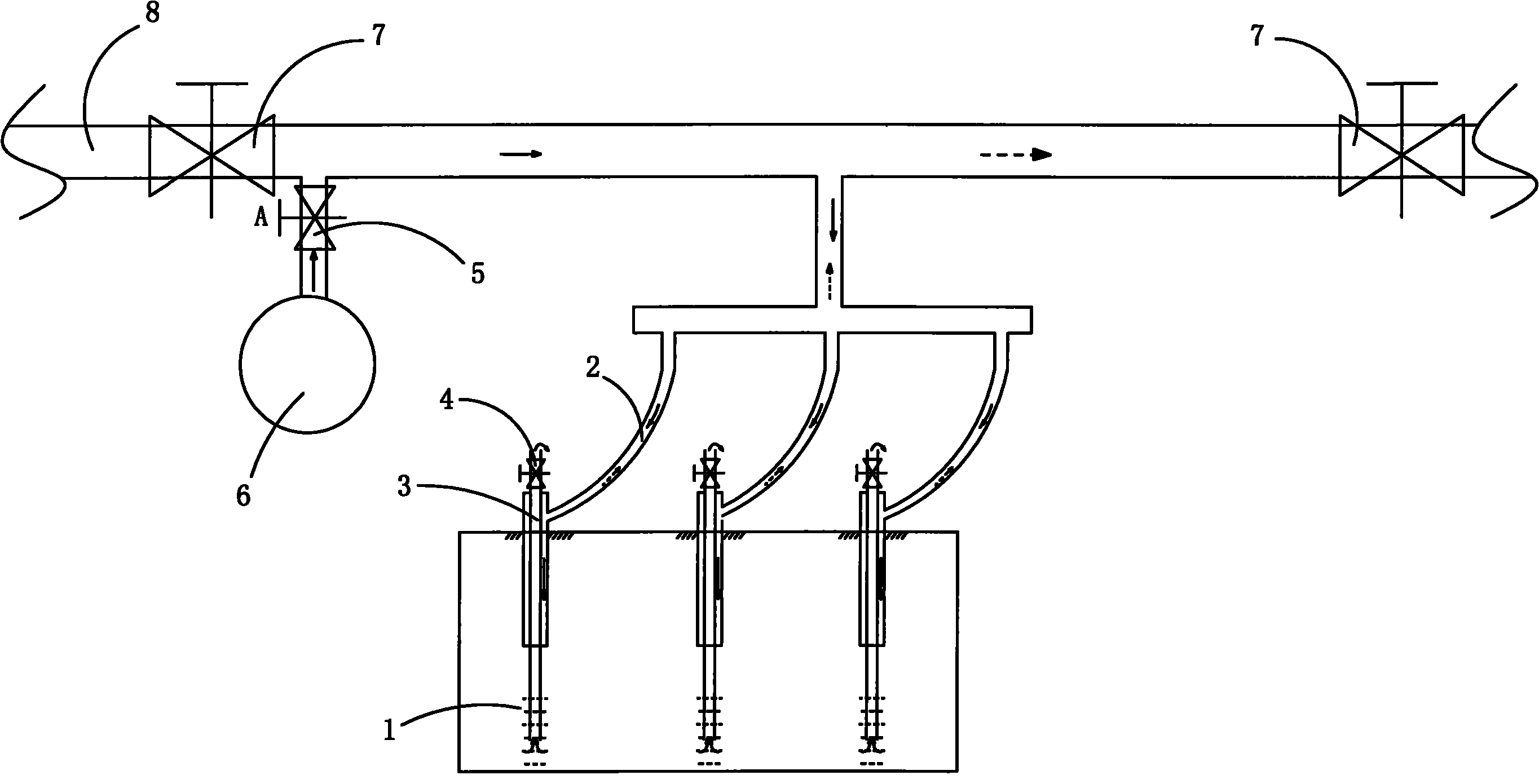

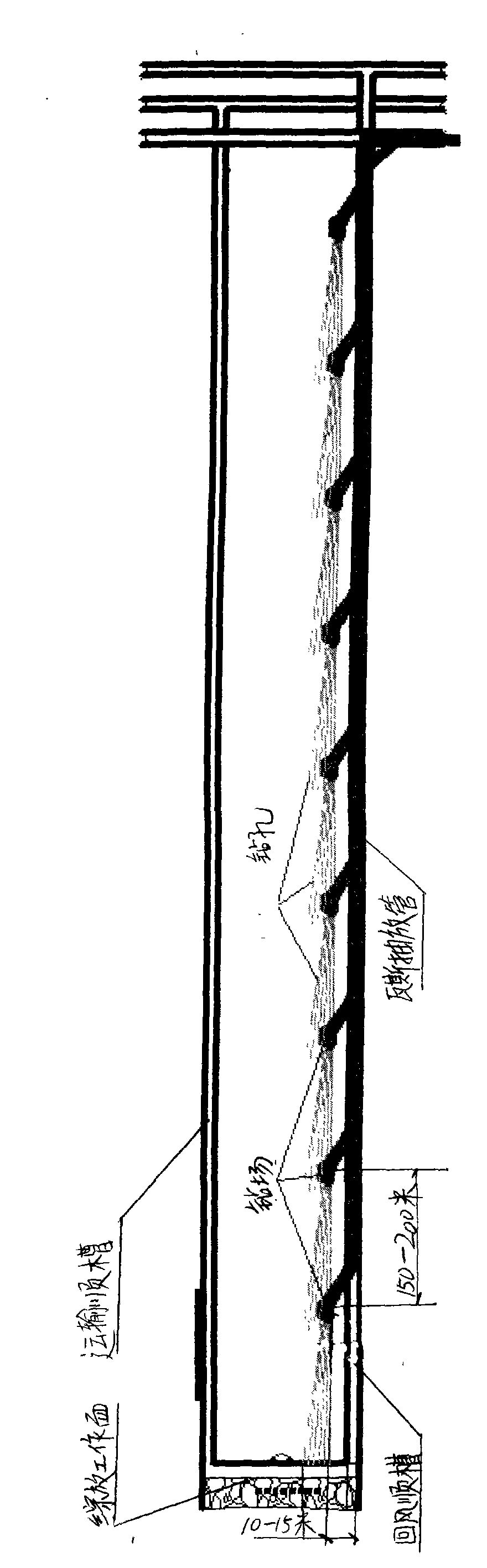

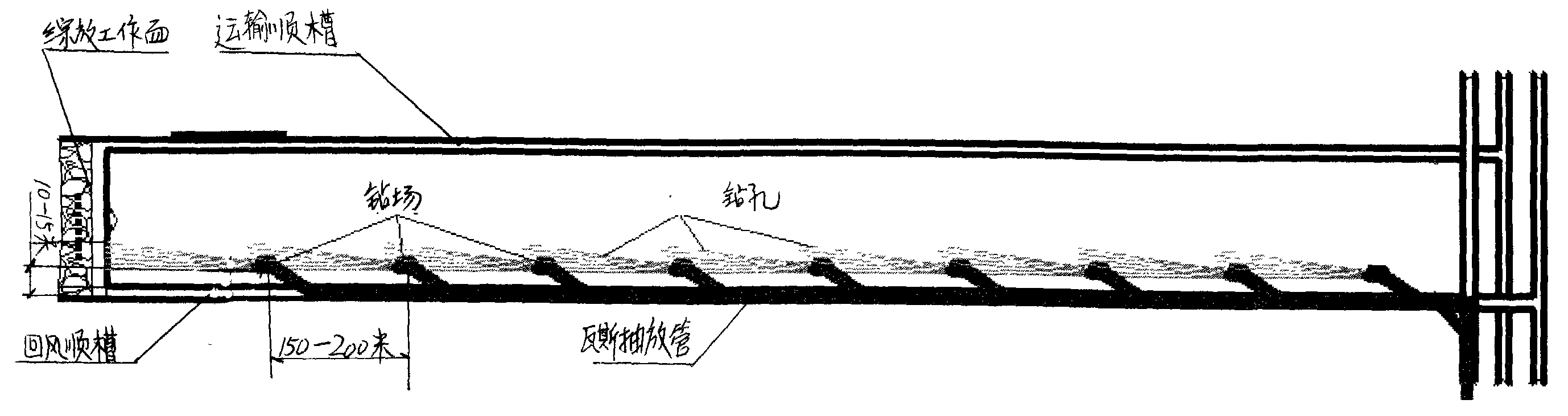

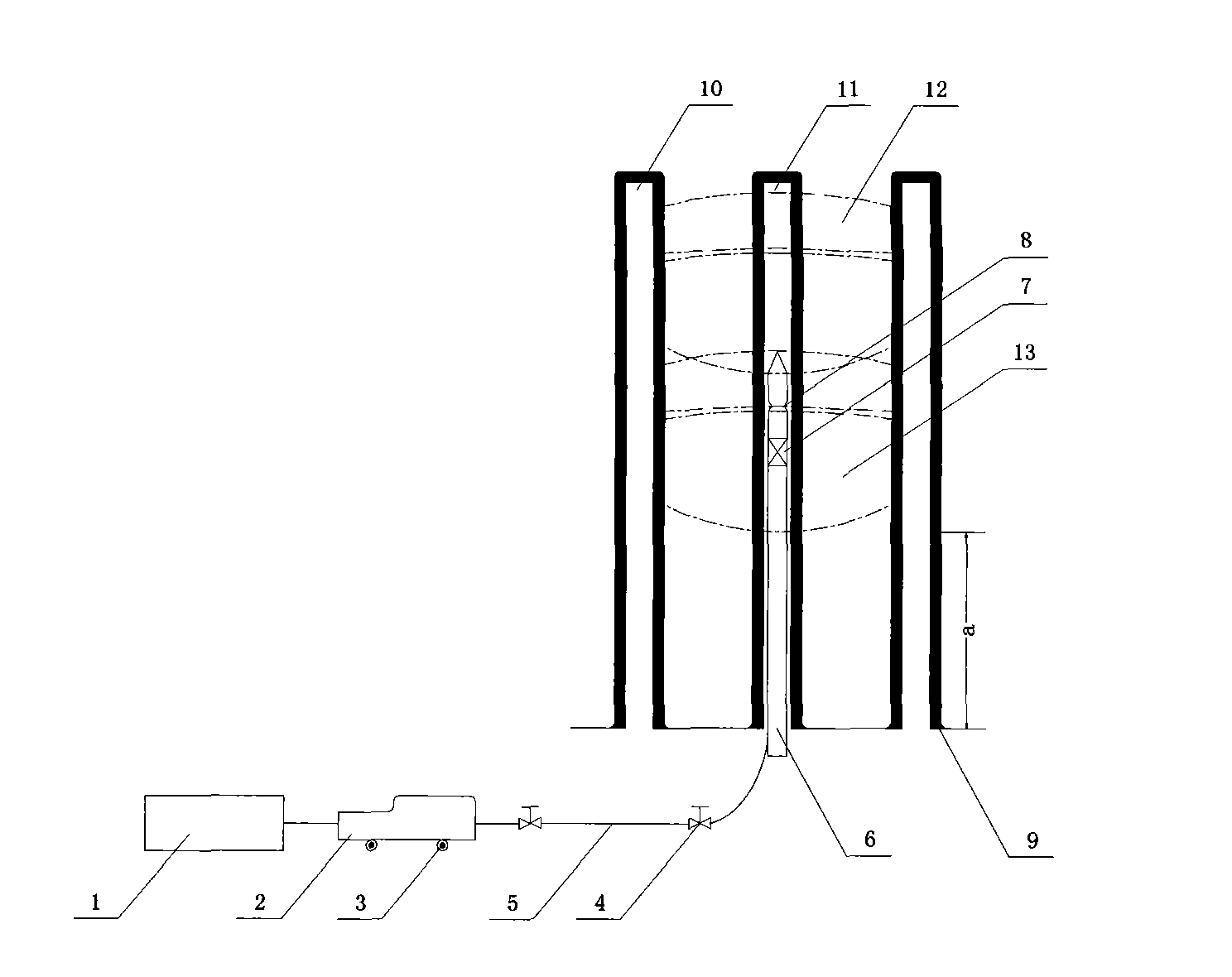

Gas drainage method for loosening coal body through cross layer boring and hydraulic fracture

ActiveCN101581231AImprove the pumping effectReduce ground stressGas removalHydraulic fracturingHigh pressure water

The invention discloses a gas drainage method for loosening a coal body through cross layer boring and hydraulic fracture, which comprises the step of boring a hydraulic fracture borehole to a coal layer in a laneway. The method is characterized in that after a plurality of control boreholes are bored on the periphery of the hydraulic fracture borehole, the hydraulic fracture borehole is subjected to hydraulic fracture, the laneway can be rock lane and also can be coal lane, the length of the hydraulic fracture borehole entering the coal layer is greater than one half of the thickness of the coal layer, and both the hydraulic fracture borehole and the control boreholes can be used as gas pumping boreholes. The method has the beneficial effects that a certain number of control boreholes are bored on the periphery of the hydraulic fracture borehole, the coal body in certain distance of the periphery of the hydraulic fracture borehole generates a compression-resistant weak area when the fracturing range reaches the control boreholes, high-pressure water can press through the coal body between the hydraulic fracture borehole and the control boreholes, and continuously fracture the coal body, and simultaneously the high-pressure water takes out coal slacks from the control boreholes, so the high-pressure water has the function of loosening the coal body at the same time of fracturing so that the ground stress is reduced and the hydraulic fracture and gas pumping effects are improved.

Owner:CCTEG SHENYANG RES INST

'Three-soft' low permeability high gas coal seam rapidly digging method

InactiveCN101382073AImprove parsing speedImprove the pumping effectUnderground miningSurface miningPunchingPressure controlled ventilation

The invention discloses a method for rapidly digging 'three soft' low permeability and high gas coal layer, which comprises the steps of arranging a stone head in a bottom plate rock under the coal layer, and constructing pre-extracted penetrating drill holes of gas in the bottom plate rock layer and pulling the bit back to the bottom plate of the coal layer after the bit penetrates the coal layer, and punching the drill holes by pressure water with the depth of the punching holes being less than or equal to three meters, and the control radius of the punching holes being from two to six meters to realize continuously, draining gas in the holes, and stopping draining while the gas draining amount is at 0.1 cubic meter per hour; injecting water to the coal layer by using the drained gas drill holes, with water injection pressure controlled between ten to fifteen Mpa, and stopping water injection when the water injection effect reaches the demands of construction in coal layer; and draining goaf by the drill holes after extraction in mining face. The digging method increases the resolving speed of the 'three soft' low permeability coal layer gas, improves the gas draining effect and realizes the low gas construction in the high gas coal layer and one hole for three purposes, not only ensures the safety during construction, but also improves the digging speed in the roadway maximally.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

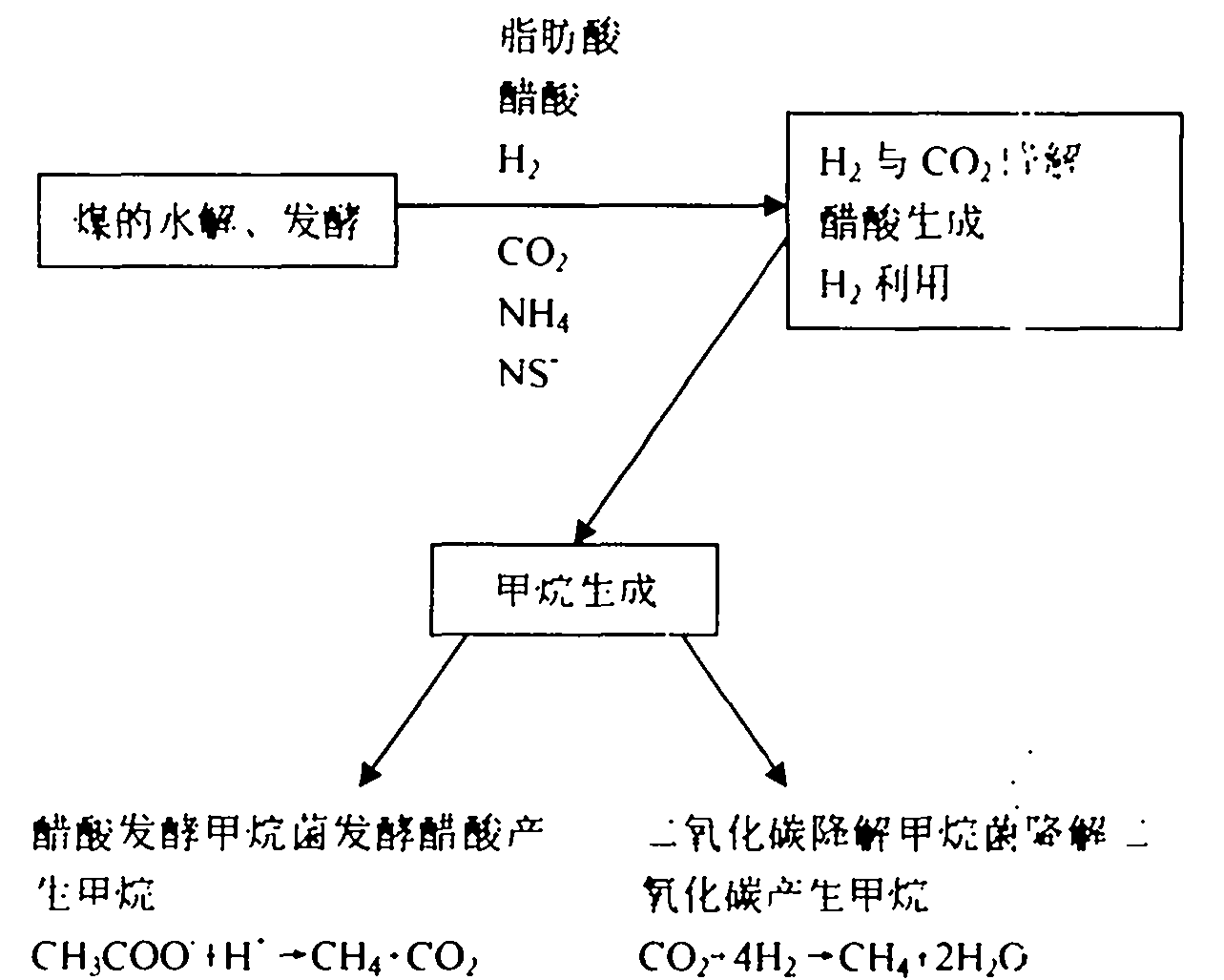

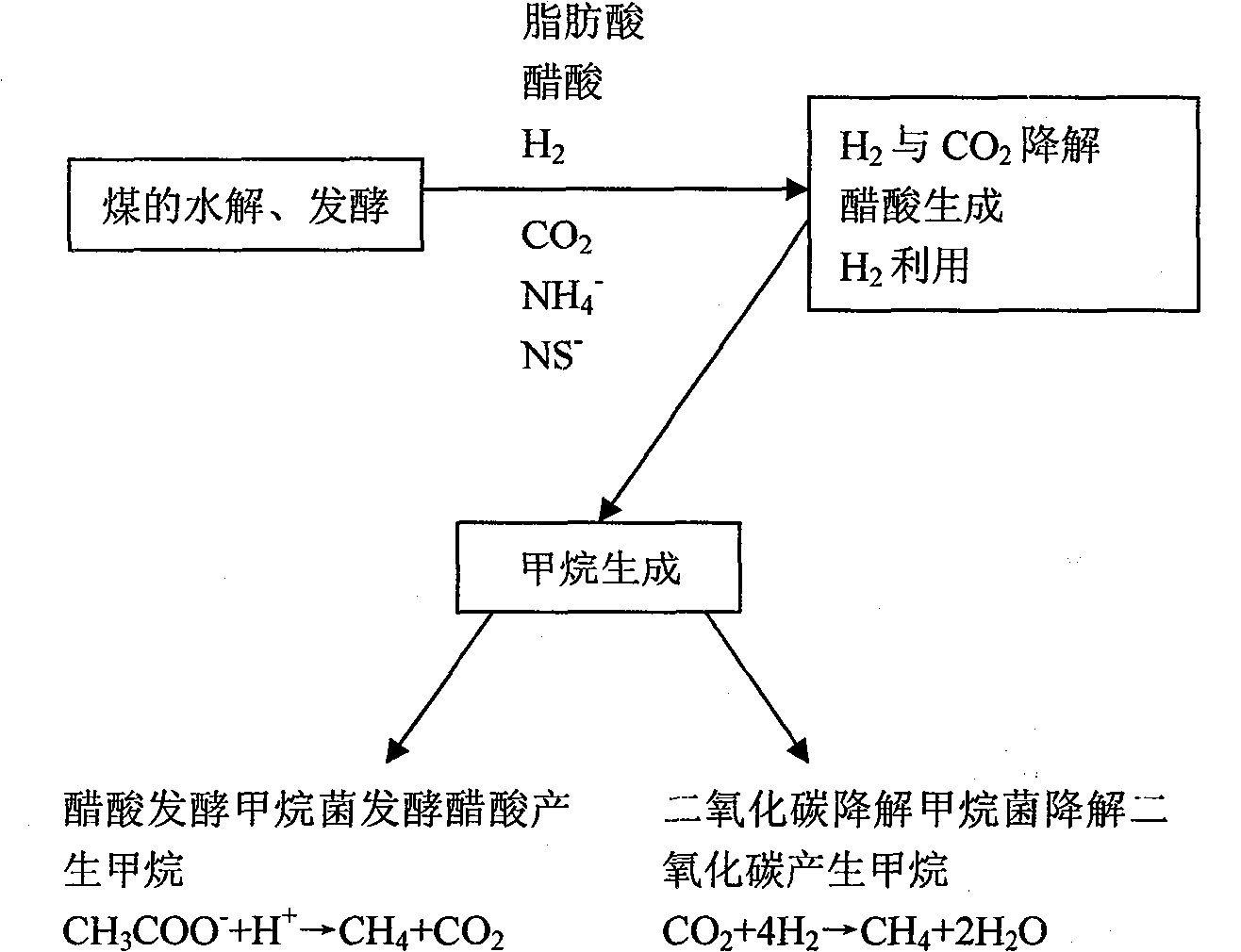

Method for making natural gas by underground coal bed microorganism

InactiveCN101922287AWill not cause pollutionImprove breathabilityConstructionsCoal gasificationProduct gasProcess engineering

The invention discloses a method for making natural gas by underground coal bed microorganism. Mainly, culture solution is utilized to cultivate and activate flora existing in the coal bed to convert underground methane flora into methane gas. The invention not only can convert coal into methane to serve as natural gas but also can improve the air permeability of the coal bed in the gas making process, so that the invention has an important meaning for improving the drainage capability of methane and ensuring upper safe extraction; more importantly, percent conversion is high, and converted coal bed resource can be reused so as to overcome the defects of the existing hot gasification method that percent conversion is low, and coal resource in the gasification area can not be reused after gasification ends.

Owner:江苏君东新材料科技发展有限公司

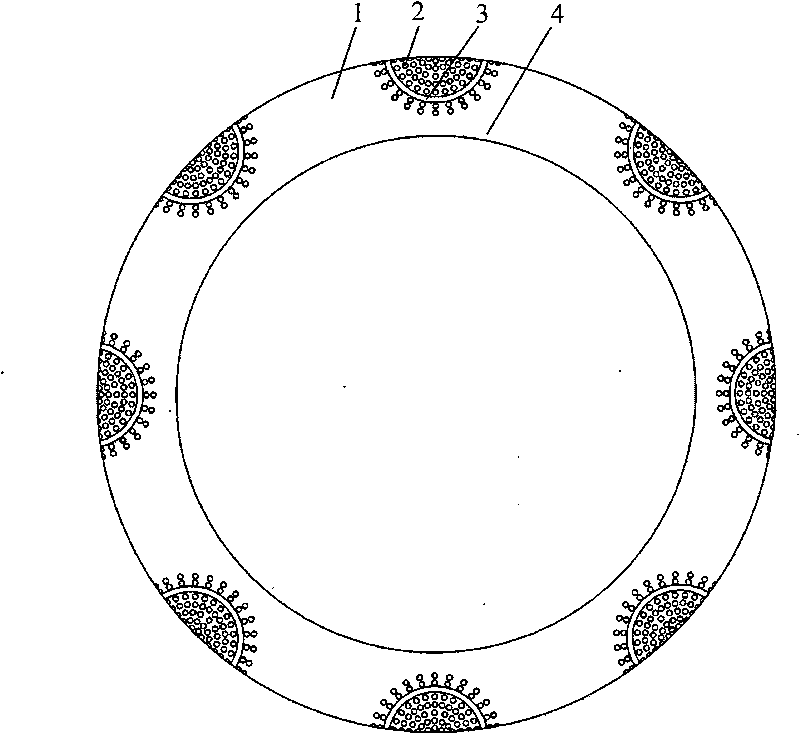

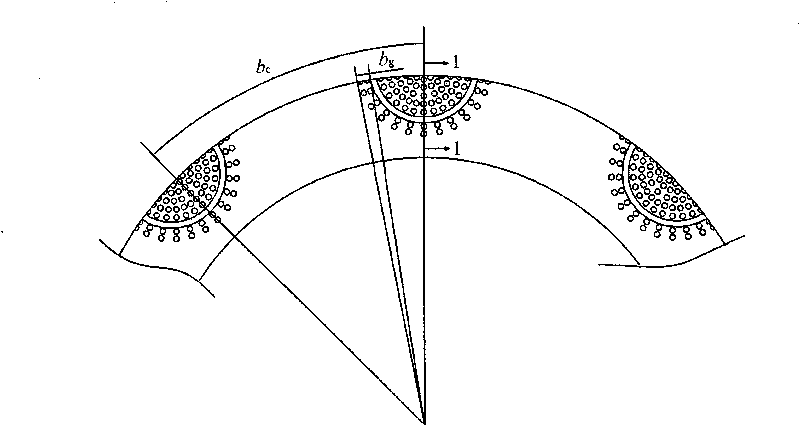

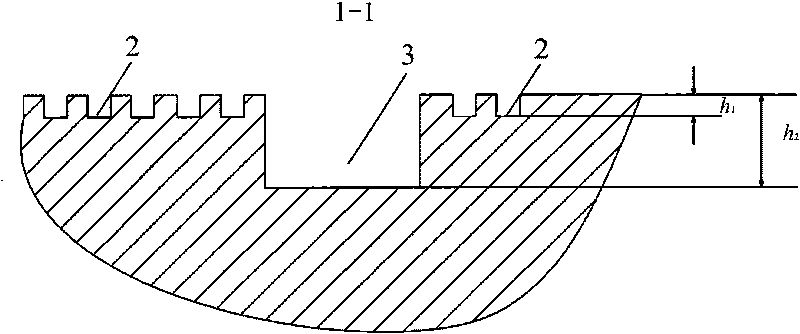

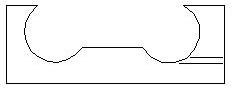

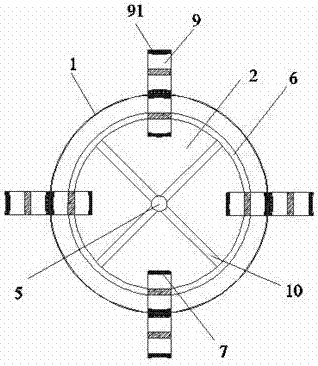

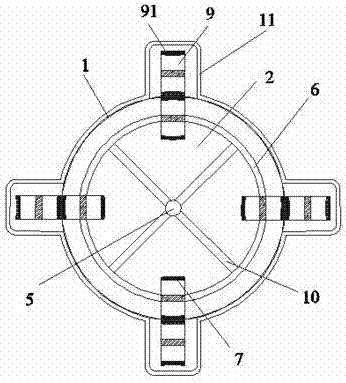

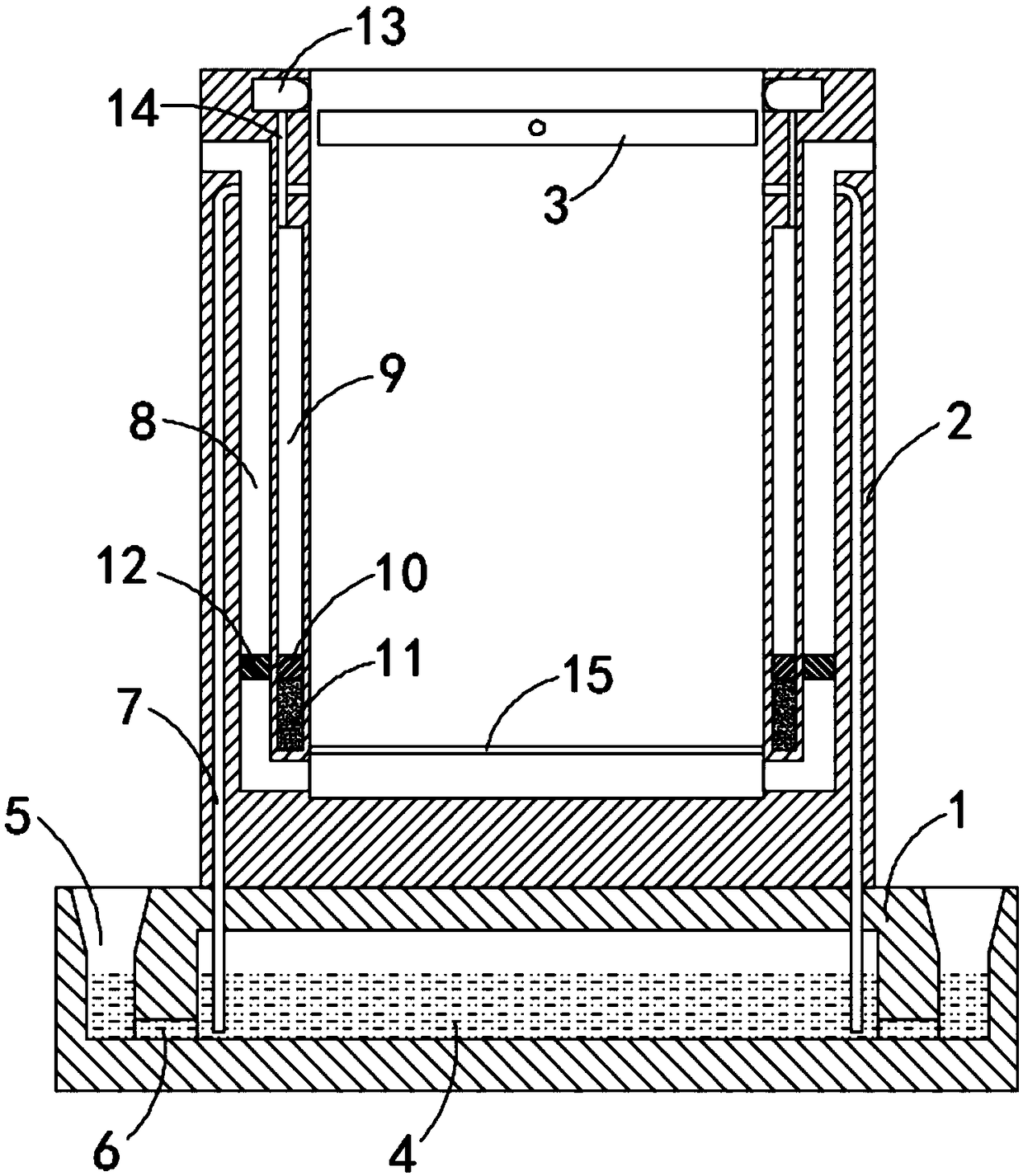

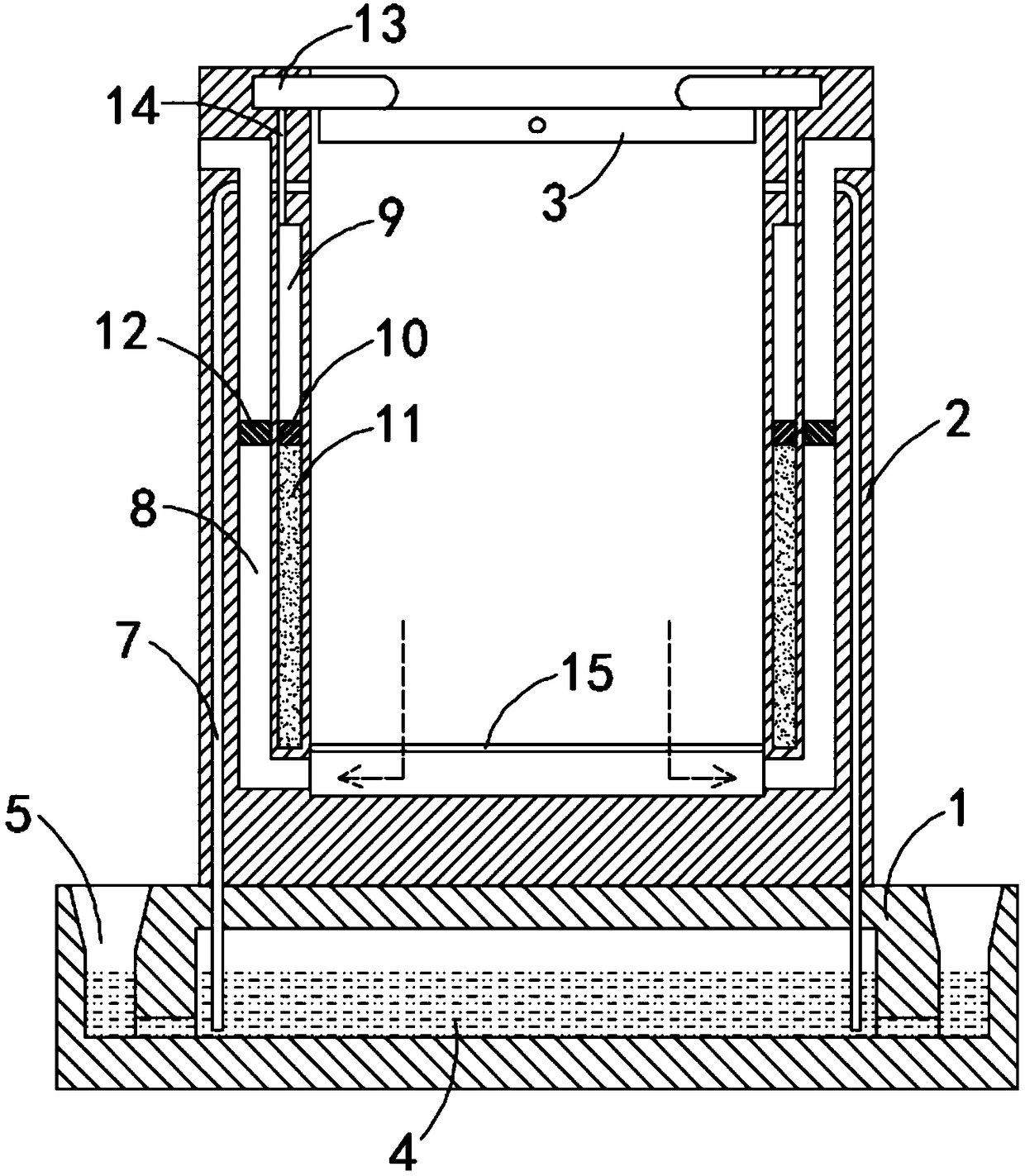

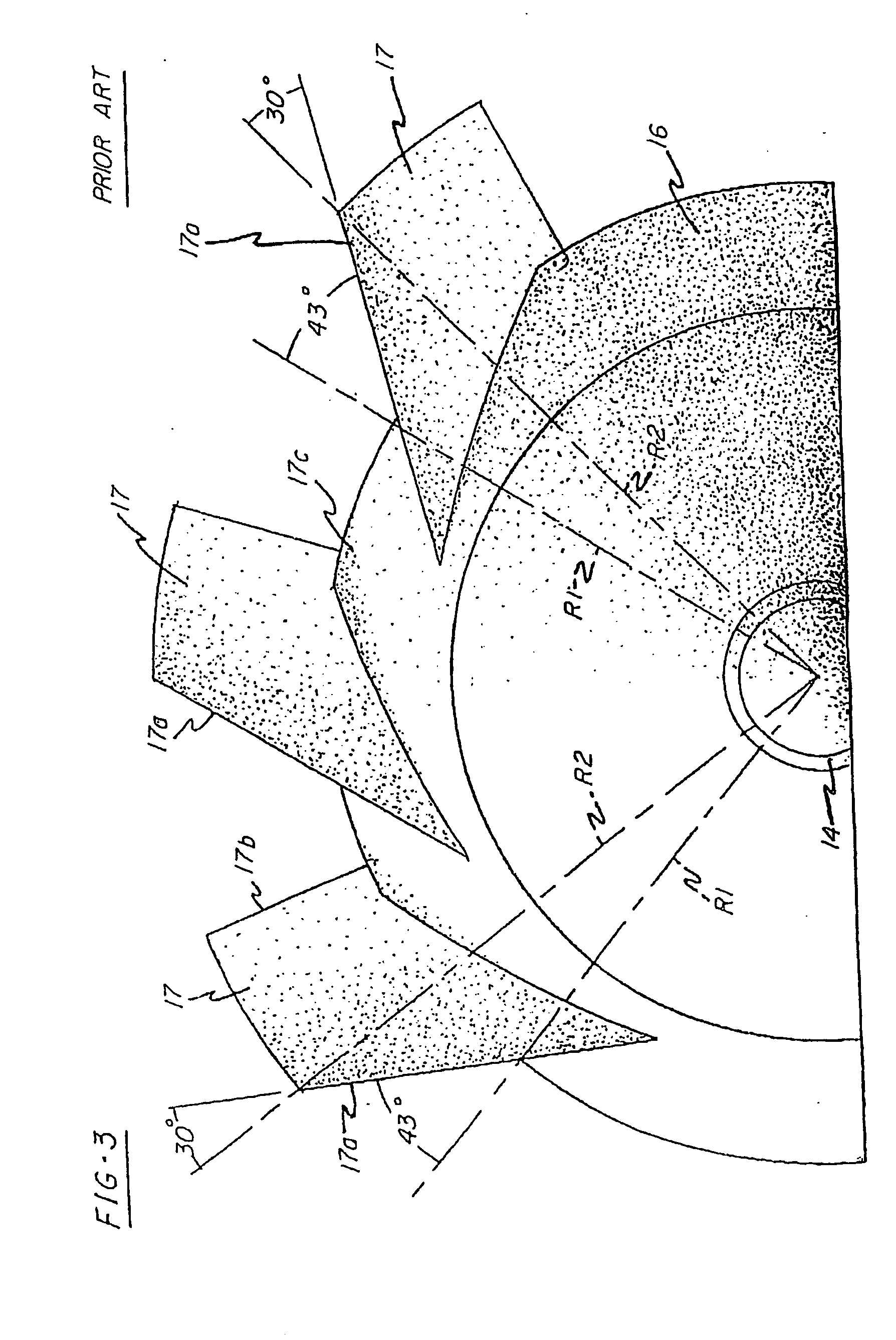

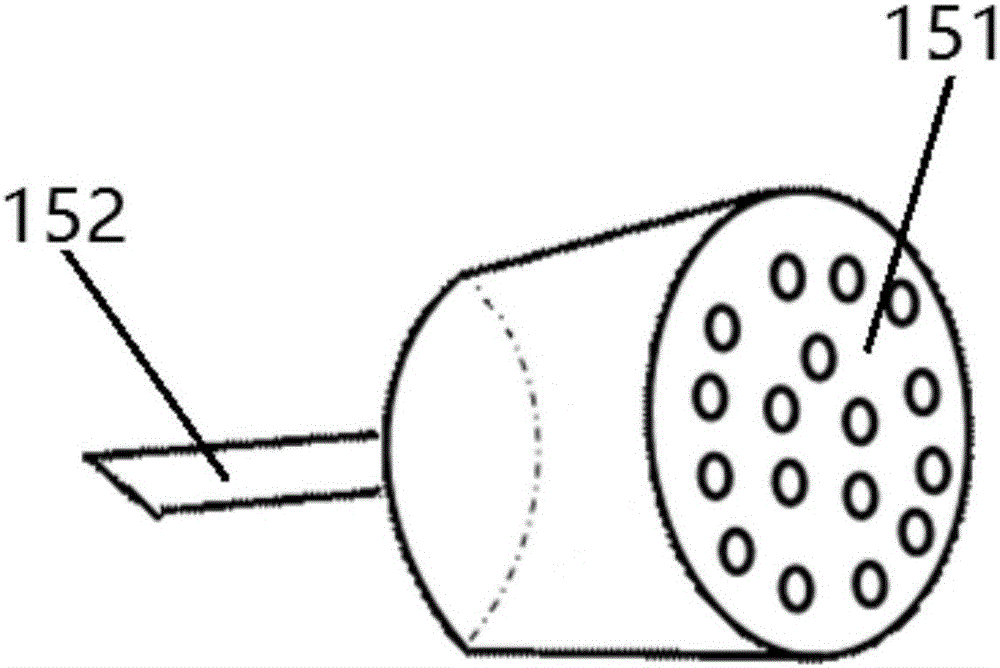

Liquid lubricated end face seal structure with cross-scale surface texture characteristic

ActiveCN101696728AImprove throttling effectEnhanced pumping effectEngine sealsPump componentsLubricationMicrometer

The invention discloses a liquid lubricated end face seal structure with a cross-scale surface texture characteristic, which comprises a moving ring and a static ring of a mechanical seal; and one side of an end face of the moving ring / static ring is a high pressure side, namely an upstream, while the other side is a low pressure side, namely a downstream. The liquid lubricated end face seal structure is characterized in that: a plurality of cross-scale texture face grooves are processed on the end face of the moving ring or the static ring of the mechanical seal; each cross-scale texture face groove consists of a millimeter deep groove and micrometer micropores; the deep groove is positioned at the upstream of the end face; the micropores are distributed on the periphery of the deep groove; seal weirs are arranged between the cross-scale texture face grooves; and a downstream of each cross-scale texture face groove is provided with an annular seal dam of a non-opened face groove. The liquid lubricated end face seal structure has the advantages of improving seal lubrication, improving the rigidity of a fluid film and the pressure and heat resistance of the mechanical seal, greatly strengthening the operational reliability, stability and leak tightness of the seal, and prolonging the service life of the seal.

Owner:ZHEJIANG UNIV OF TECH +1

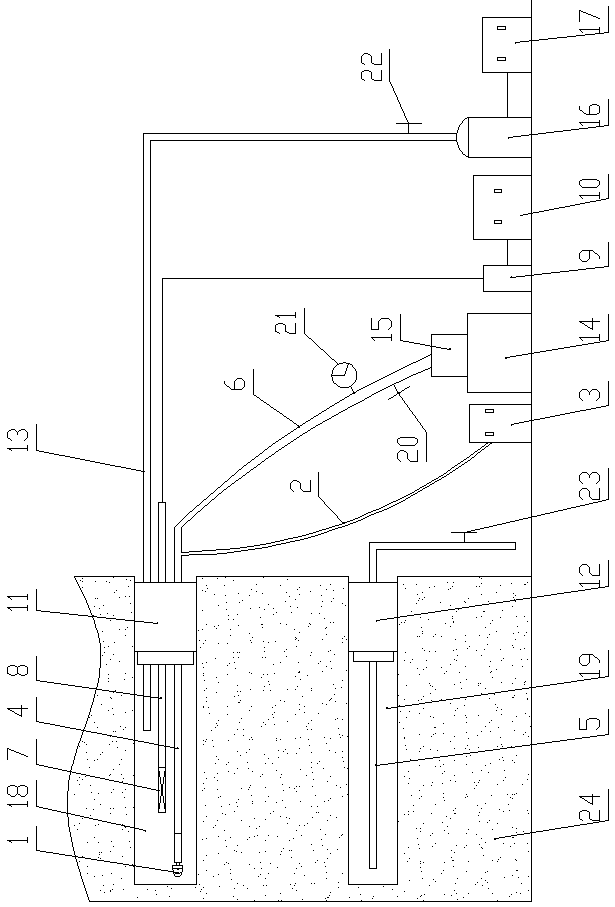

Low permeability coal seam electricity explosion vibration and microwave assisting liquid nitrogen freeze-thawing permeability increasing device and method

PendingCN108361061AIncreased number of riftsEasy to crackFluid removalGas removalFreeze thawingPorosity

The invention provides a low permeability coal seam electricity explosion vibration and microwave assisting liquid nitrogen freeze-thawing permeability increasing device. The low permeability coal seam electricity explosion vibration and microwave assisting liquid nitrogen freeze-thawing permeability increasing device comprises a pulse discharging reactor, a cable, a high voltage pulse generator,a fracturing pipe, a mining pipe, a high pressure rubber pipe, a microwave transmitter, a coaxial waveguide, a microwave converter, a microwave generator, a first hole packer, a second hole packer, anitrogen inflating pipe, a water box, a high pressure water pump, a liquid nitrogen pump and a liquid nitrogen tank. The invention further discloses a low permeability coal seam electricity explosionvibration and microwave assisting liquid nitrogen freeze-thawing permeability increasing method. A hydraulic fracturing technology, an electricity explosion vibration technology, a liquid nitrogen freeze-thawing technology and a microwave technology are harmoniously integrated, the permeability and the porosity of a coal seam are increased to a great extent, coal seam fractures can be increased, the liquid nitrogen freeze-thawing efficiency is improved, circular work is conducted, ice in the fractures is easily molten, the permeability of a low-permeability coal seam is greatly improved, the effect of mining and exhausting methane gas is improved, expected time needed for mining the methane gas is shortened by a large margin, and a superior premise is provided for mining the methane gas ofa mine.

Owner:HENAN POLYTECHNIC UNIV

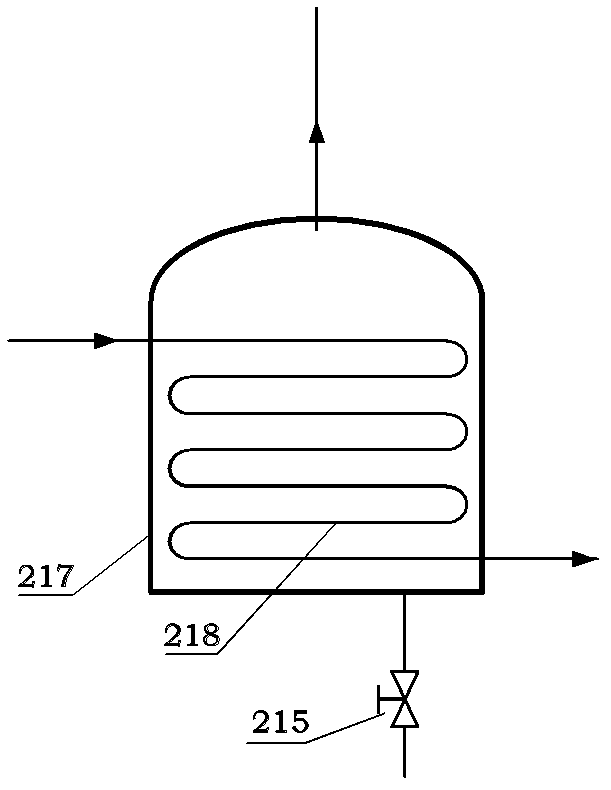

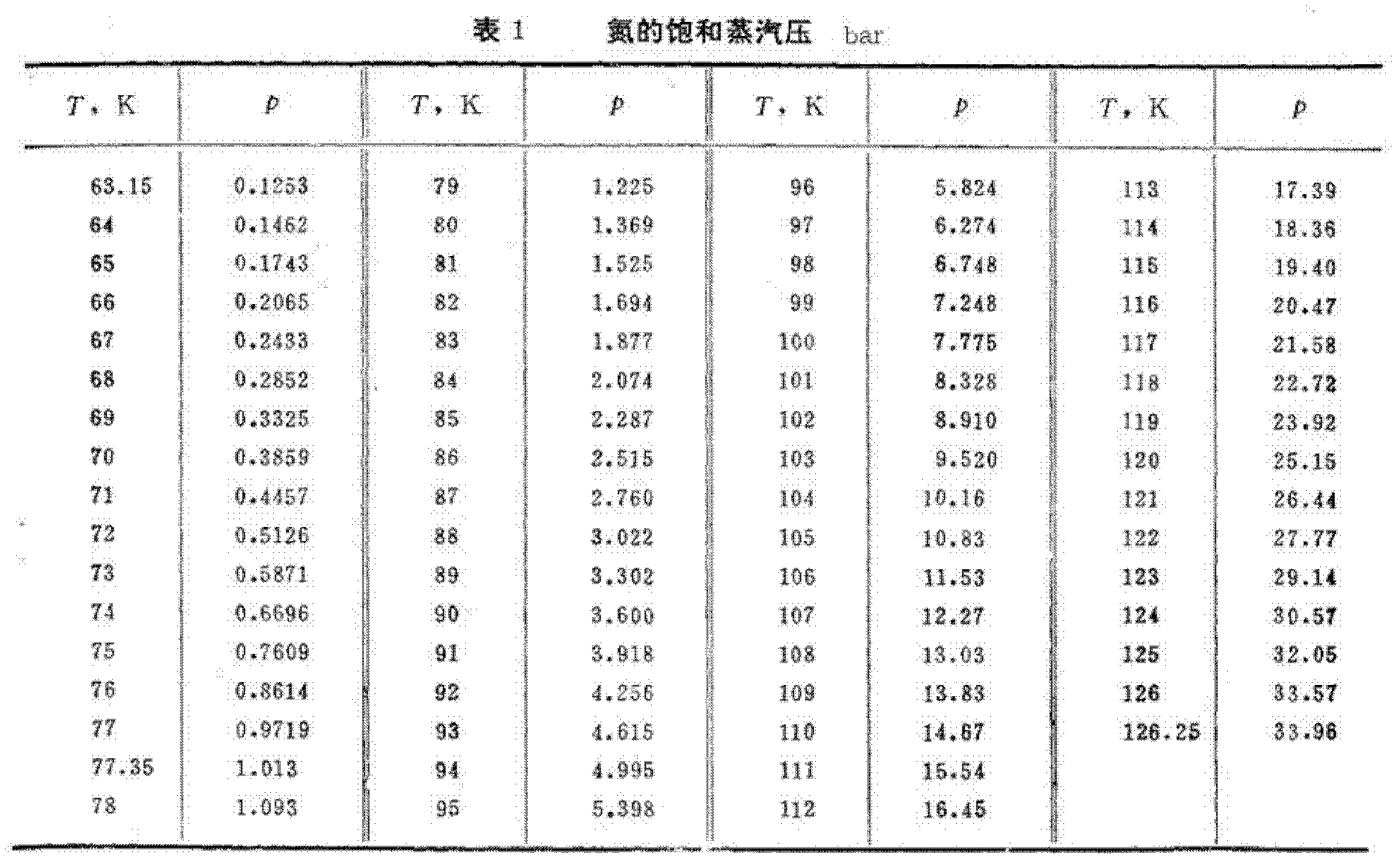

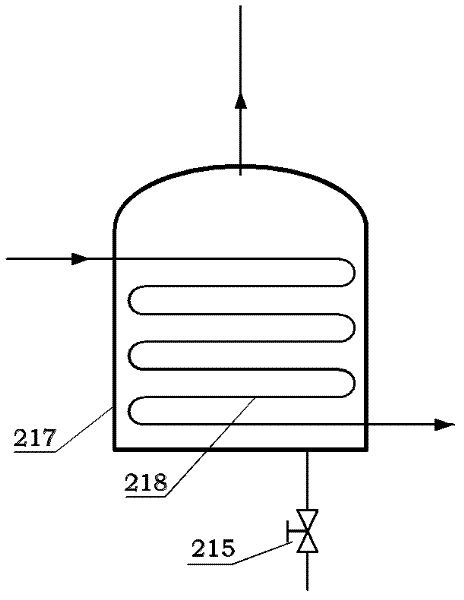

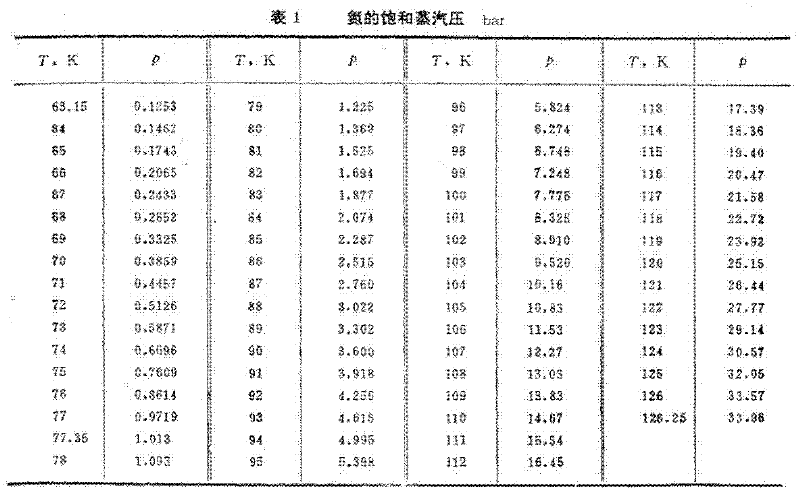

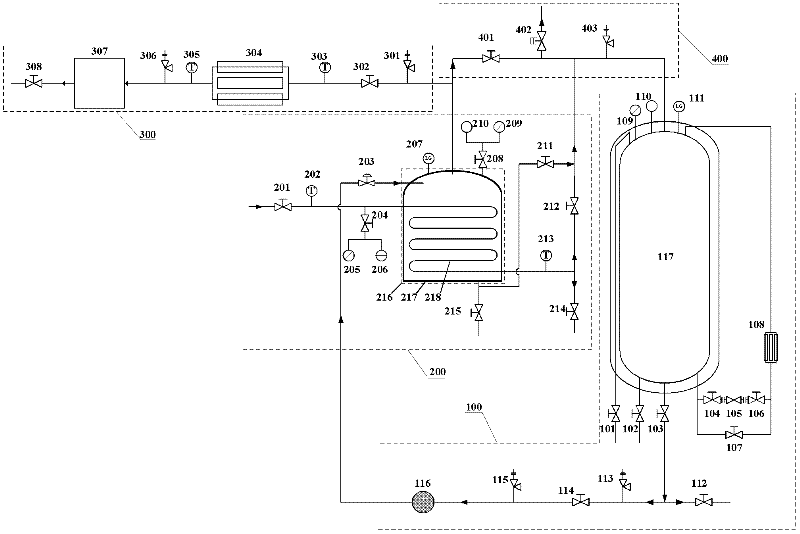

Negative-pressure liquid nitrogen subcooler and method therefore for reducing liquid nitrogen temperature

InactiveCN102374708ALower heat sink temperatureIncreased pumping capacity and efficiencySubcoolersChemistryHeat sink

The invention provides a negative-pressure liquid nitrogen subcooler and a method therefore for reducing liquid nitrogen temperature. The negative-pressure liquid nitrogen subcooler comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhausting system and a discharging system, wherein the liquid nitrogen conveying system is used for supplying liquid nitrogen to the subcooler system; the negative-pressure air exhausting system is used for reducing pressure for the subcooler; and the discharging system is used for discharging gasified nitrogen. In the negative-pressure liquid nitrogen subcooler, an electric heater is adopted to raise the temperature of gaseous nitrogen to 20-30 DEG C, so that the subcooler is not limited to the weathers; a liquid level sensor is adopted to automatically regulating the opening of a pneumatic regulating valve, so that the height of the liquid level is maintained. The method comprises the steps of: firstly, injecting the liquid nitrogen for a liquid nitrogen container and regulating pressure; then injecting the liquid nitrogen for the subcooler, wherein the height of the liquid level of the liquid nitrogen in the subcooler is kept constant; then starting the negative-pressure air exhausting system, and cooling the liquid nitrogen through a heat exchanger; and finally, recovering the liquid nitrogen and discharging the liquid nitrogen. According to the invention, the temperature of a heat sink can be further reduced, the temperature of the heat sink is regulatable within a range of 70-77k, and the advantagesof simple equipment, good effect and low operating cost are achieved.

Owner:BEIHANG UNIV

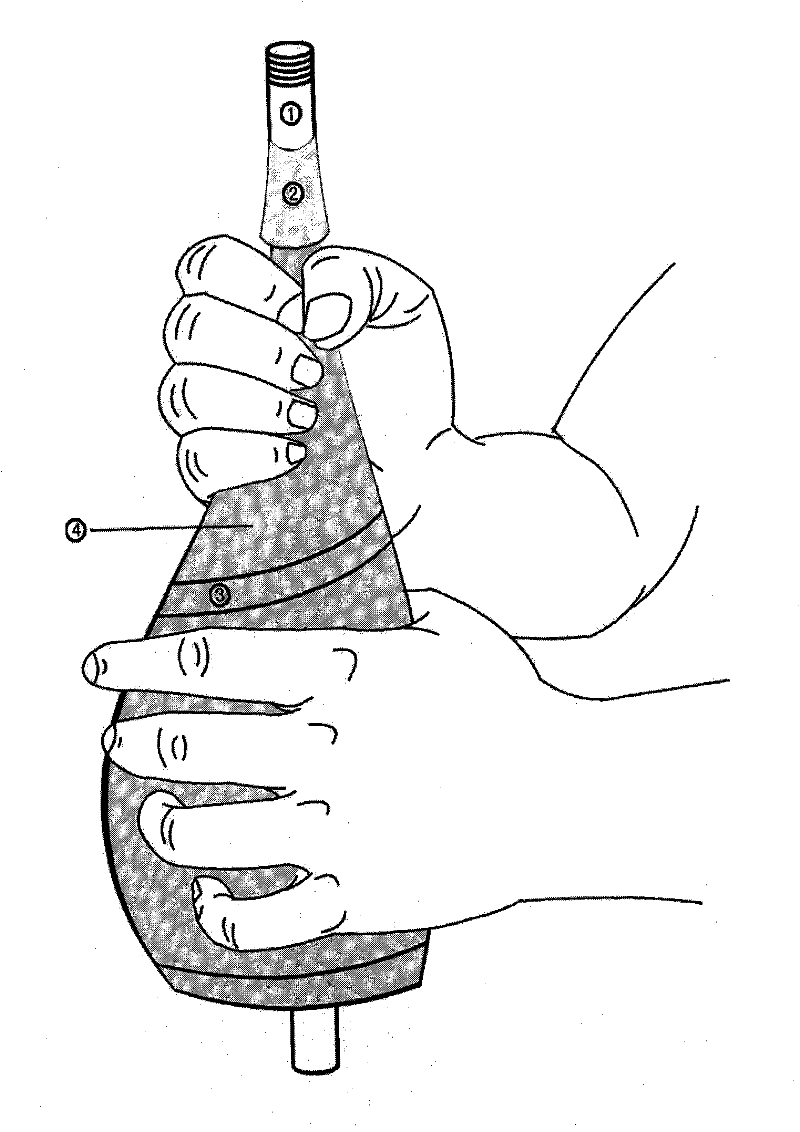

Polyurethane foaming bag blocked gas drainage hole

ActiveCN102052087AImprove the pumping effectDoes not consume energyGas removalSealing/packingCoalEnergy conservation

The invention provides a polyurethane foaming bag blocked gas drainage hole, relating to a method for blocking the gas drainage hole by using a polyurethane foaming bag in coal mine underground operation with the advantages of energy conservation, safety, and capability of further blocking and improving the gas drainage effect. At present, the widely applied method for blocking the gas drainage hole by two-component polyurethane has the defects that: two kinds of materials cannot be sufficiently mixed and waste is caused, while further blocking cannot be performed, so the operation requirement cannot be fulfilled. To overcome the defects, the polyurethane foaming bag is used to block the gas drainage hole. The method comprises the following steps: the polyurethane foaming bag is tied on adrainage pipe vertically with a rubber tape; the isolating middle seal of the foaming bag is opened manually, and the two kinds of materials in the bag are sufficiently mixed by rubbing and grasping;the gas drainage pipe tied with the foaming bag is delivered into the gas drainage hole; and the foaming bag performs 'self destruction', and foams overflow to achieve the effect of blocking.

Owner:辽宁兰特科技发展有限公司

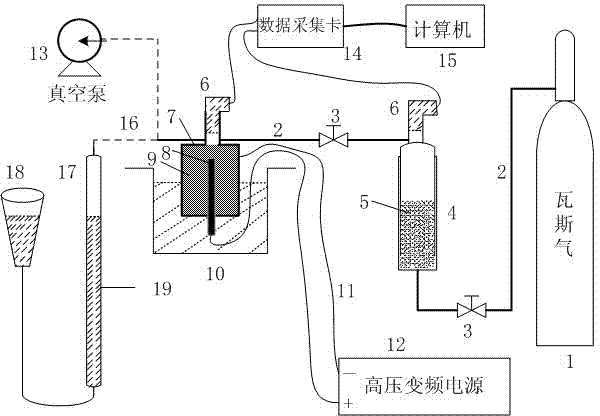

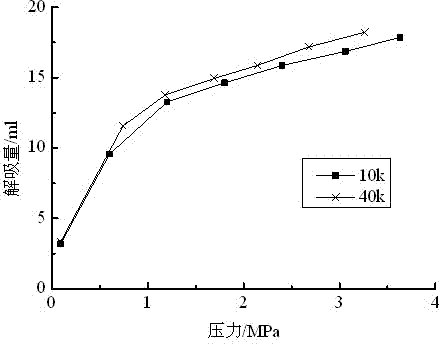

Experimental method for raising gas desorption property

ActiveCN102901801AImprove the desorption effectImprove adsorption capacityFuel testingGas cylinderVacuum pump

The invention discloses an experimental method for raising gas desorption property, characterized by based on the experimental study of gas absorption, desorption and permeability by existing non-mechanical method, using an experimental device which comprises a gas bottle, a pressure-tolerant gas pipe, a valve, a gas storage tank, a drying agent, a pressure sensor, a desorption pot, a positive electrode, a constant temperature water tank, a guide wire, a high-voltage variable-frequency power source, a vacuum pump, a data collection card, a computer, a rubber pipe, a measuring tube, and an Erlenmeyer flask, putting an experimental coal sample in the desorption pot, using the high-voltage variable-frequency electric field to change the physicochemical properties of the coal and allow the moisture in the coal and different charged ions dissolved in the water molecules to directionally move, thus free and adsorbed gas is increased, and the desorption property is raised. According to the invention, compared with the gas desorption property obtained by using a natural coal sample, when the high-voltage variable-frequency power source output voltage is 2kV and the frequency is 40Hz, the desorption is averagely raised by 11.42%.

Owner:SCI & TECH RES OF SHANXICOAL TRANSPORTATION & SALES GROUP +1

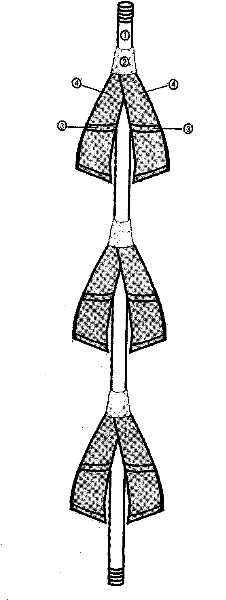

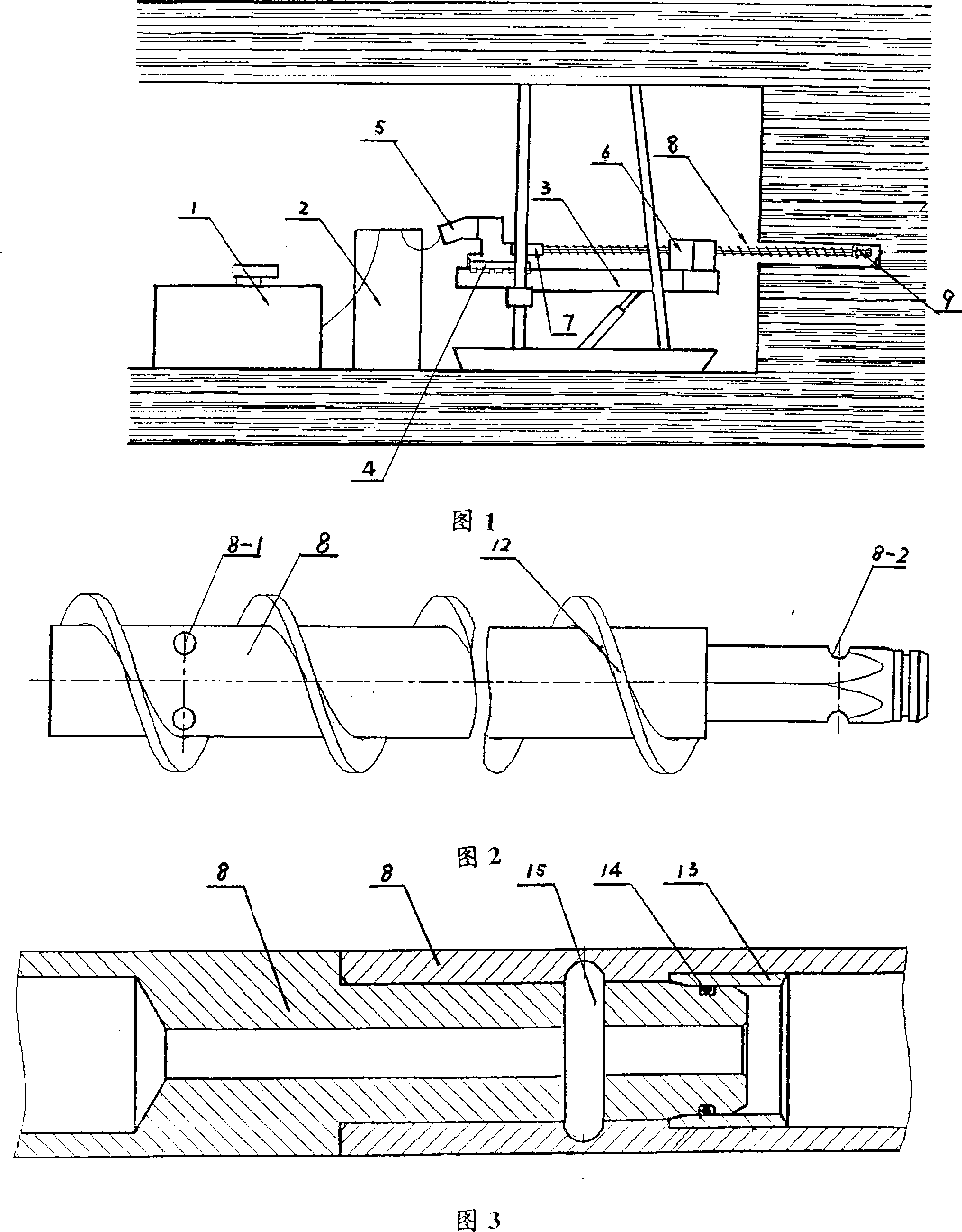

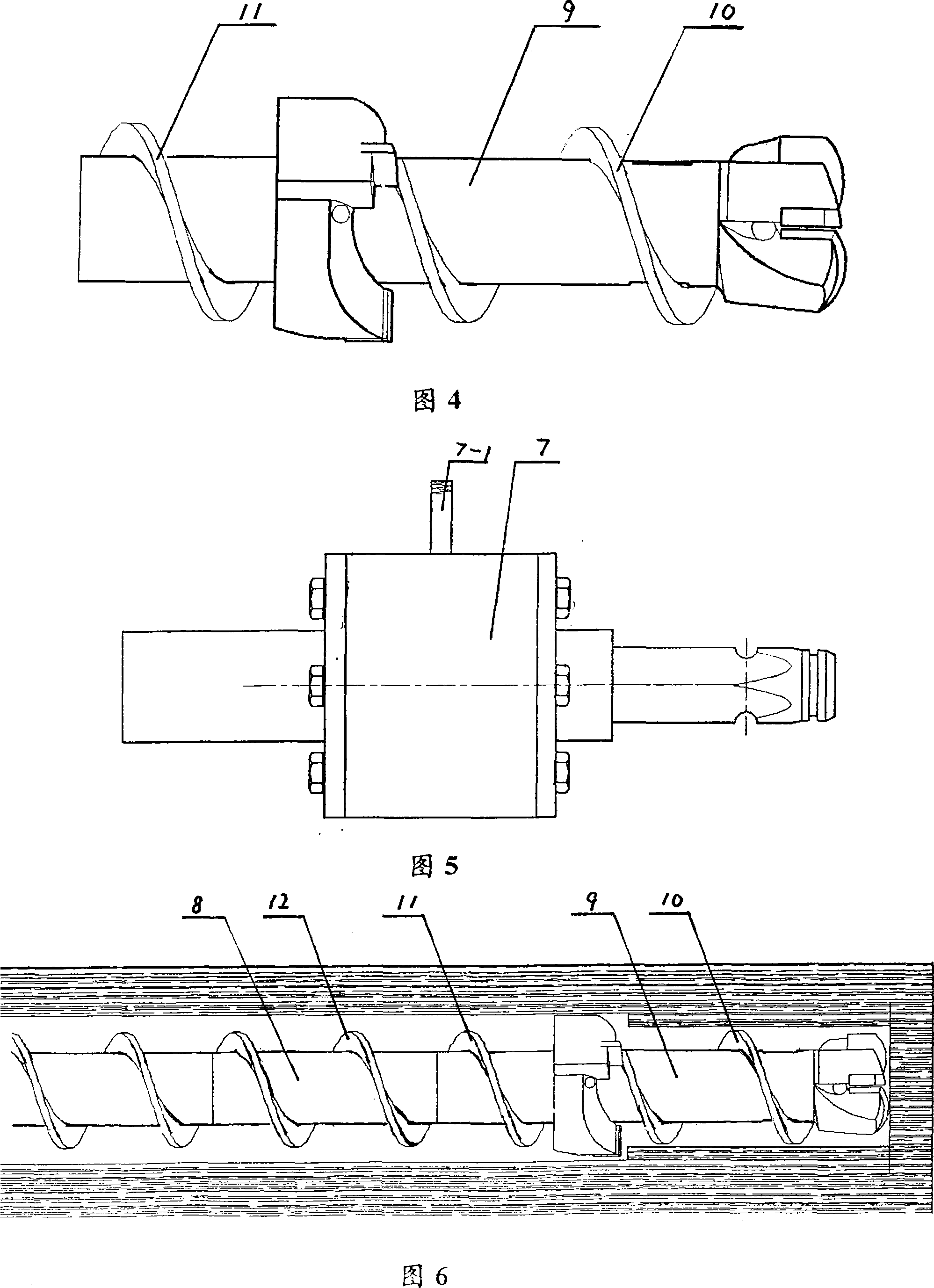

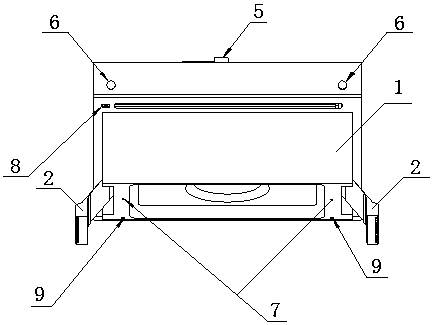

Down-hole coal bed air-pressing helix drilling tools and drilling method using the same

InactiveCN101131091AImprove the pumping effectEnsure safe productionDrill bitsDrilling rodsCoalDrill bit

The present invention relates to compressed air underground coal bed drilling auger, which includes one pump station, one operating console, one machine frame, one traveling unit, and one power head set on the traveling unit. The underground coal bed drilling auger features the air feeding change-over unit with one end fitting to the power head and one compressed air inlet connected the mine air compressing system, the hollow auger stem with one end connected to the air feeding change-over unit and the other end stretched through one gripper, and the two-stage combined drill fitting to the hollow auger stem. The underground coal bed drilling auger has rotation speed of the power head controlled in 180-650 rpm, homogeneous drilling rate controlled in 0.5-1 m / min, and air feeding pressure maintained in 0.2-0.75 MPa. The present invention has great hole forming depth, high hole forming rate, high hole forming rate and high gas exhausting effect.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

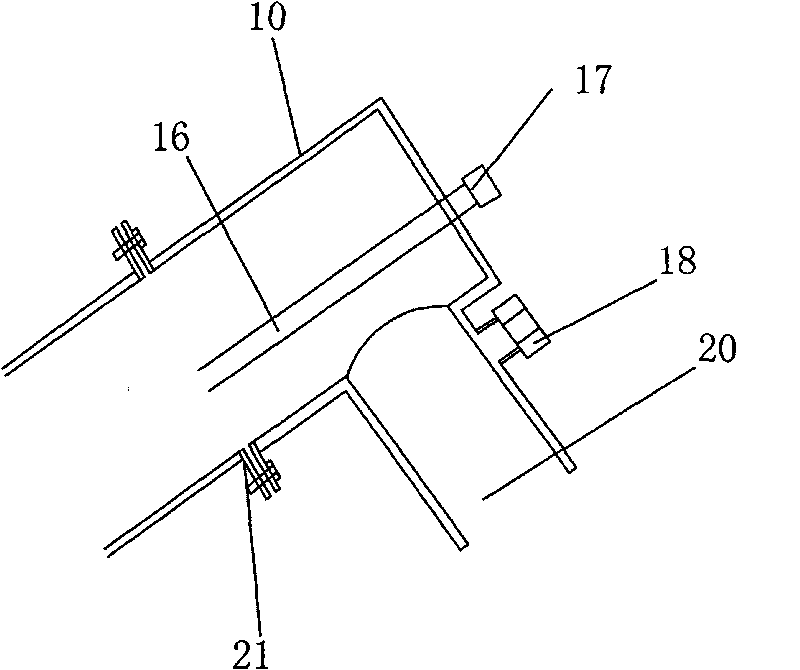

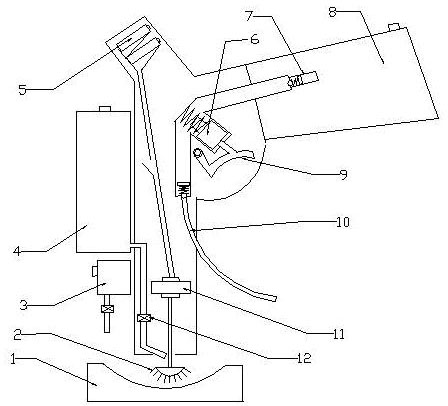

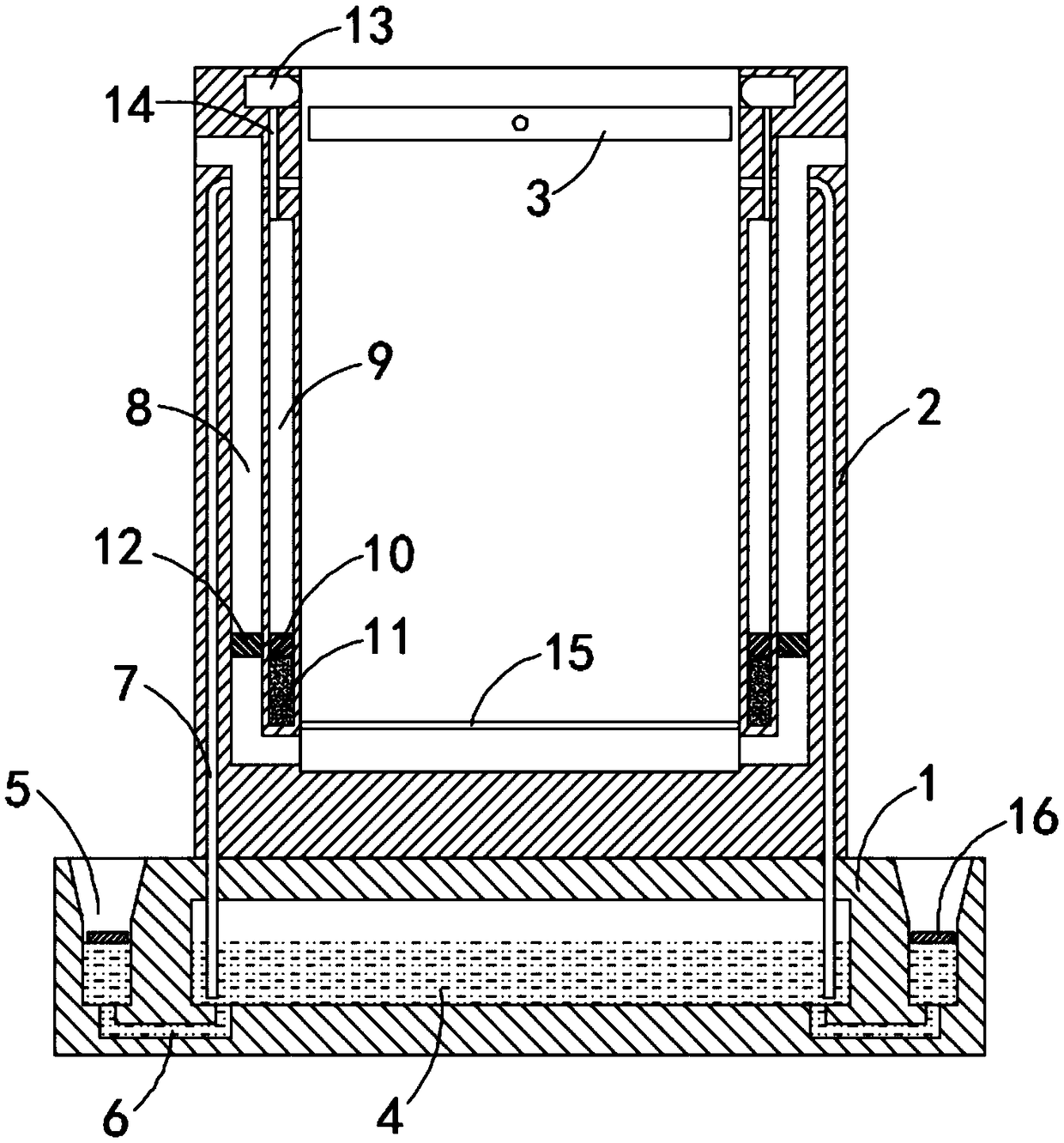

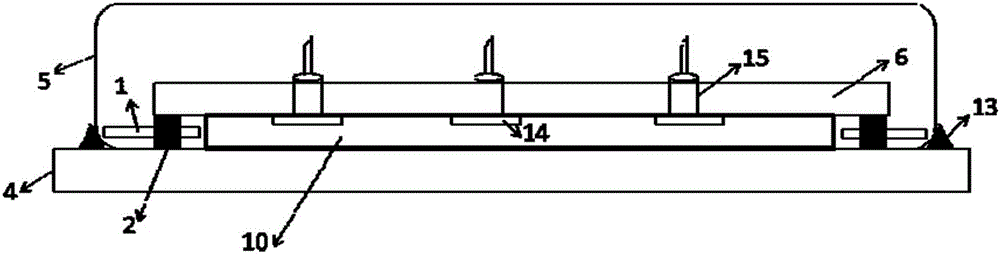

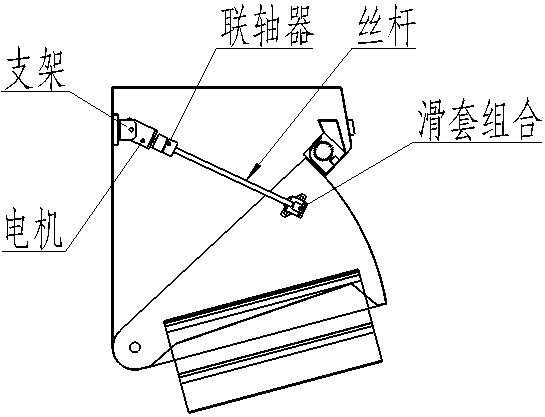

Device for pumping and draining water from downward hole of coal bed

The invention relates to an auxiliary device for a drilling hole for gas drainage, in particular to a device for pumping and draining water from a downward hole of a coal bed, which solves the problems that the accumulated water in the downward hole of the coal bed cannot be drained out in time to influence the effect on gas drainage. The device comprises a liquid draining and pumping pipe, a drilling hole sealing device, and a drainage device provided with a first gate valve and a second gate valve, wherein the upper part of the drainage device is provided with a water inlet and a ventilation bolt of the drainage device, while the lower part is provided with a drainage bolt; the upper end of the drilling hole sealing device is connected with a hole connecting device; the upper end of the liquid draining and pumping pipe is extended in the hole connecting device, and a liquid guiding pipe is connected between the liquid draining and pumping pipe and the water inlet of the drainage device; and one side of the hole connecting device is provided with a first embedded wire pipe, and the second gate valve of the drainage device is connected with a second embedded wire pipe communicated with a gas drainage pipeline. The device can quickly and effectively drain out the accumulated water in the drilling hole to ensure the normal drainage and pumping of the drilling hole, improve the draining and pumping effect of the downward hole (or the drilling hole of a lower adjacent layer) of the coal bed, and reduce the gas content of the coal bed (or the lower adjacent layer) on a working surface; besides, the device has a simple structure and convenient connection and operation.

Owner:SHANXI COKING COAL GROUP

Local washing gun

InactiveCN102071550AEasy spot removalRealize power-free operationBrushing washing machinesOther washing machinesSewageLaundry

The invention relates to a local washing gun, which can conveniently wash spots at parts of clothes, and comprises a battery, a motor, a washing head, a clean water storage tank, a cleaning solution storage tank, a sewage storage tank, a sewage pumping device and a concave laundry sink. The sewage pumping device is of a water pump structure or of a vacuum pump structure. The bottom of the laundry sink can be a raised round platform, or sphere cavity shape with an opening. The local washing gun makes a washed wet part be limited only around the local spot. By adopting the local washing gun, the local spots of the cloths can be conveniently eliminated in a targeted way whatever at home, school, during the journey or outdoors.

Owner:刘之雨

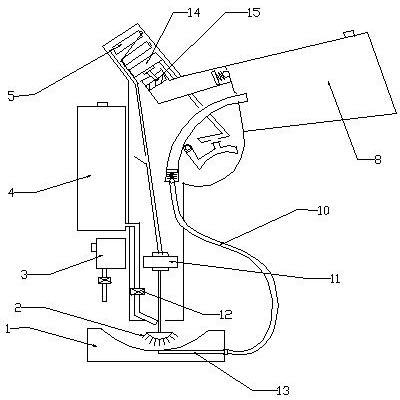

Device for intensively and fast draining water in downward drainage drill hole

The invention discloses a device for intensively and fast draining water in a downward drainage drill hole. The device is characterized in that a three-way hole-sealing sleeve pipe composed of an inner pipe and an outer sleeve pipe is arranged in a drainage drill hole; an annular chamber used as an airflow channel is arranged between the side wall of the inner pipe and the side wall of the outer sleeve pipe, and an external air delivery pipe is communicated with the annular chamber; the inner pipe is used as a draining pipe, a nozzle at the bottom of the draining pipe is connected with a draining hose used for being inserted in the bottom of the drainage hole; the nozzle at the top of the draining pipe is provided with a water draining valve; and one path of the external air delivery pipe is connected with a high-pressure air pipe by an air inlet valve, and the other path is connected with a drainage pipeline by an air discharge valve. The device can effectively drain the accumulated water in the downward drainage hole, and ensure gas drainage effect.

Owner:安徽省皖北煤电集团孟庄煤矿

Novel roller bit sealing ring

ActiveCN102628338AReduced service lifeExtended service lifeConstructionsThermodynamicsMetal framework

The invention discloses a novel roller bit sealing ring, which belongs to the field of bearing sealing. The novel roller bit sealing ring is disposed in a sealing groove between a bearing shaft hole and a tooth palm journal. Both ends of the sealing groove are respectively communicated with an inside lubricating oil channel and an outside drilling fluid channel. The novel roller bit sealing ring comprises a metal framework fixed in the sealing groove, the metal framework separates the sealing groove into a lubricating oil sealing groove communicated with the inside lubricating oil channel and a drilling fluid sealing groove communicated with the outside drilling fluid channel. A lubricating oil sealing part is disposed in the lubricating oil sealing groove and completely seals and separates the inside lubricating oil channel together with the metal framework. A drilling fluid sealing part is disposed in the drilling fluid sealing groove and completely seals and separates the outside drilling fluid channel together with the metal framework. The novel roller bit sealing ring is more suitable for severe environment of drilling work, and capable of more effectively and simultaneously separating lubricating oil and drilling fluid, rock debris and the like. Separation of lubricating oil and separation of drilling fluid do not affect each other, and service life of a sealing device is prolonged.

Owner:CHENGDU SHENGBANG SEALS

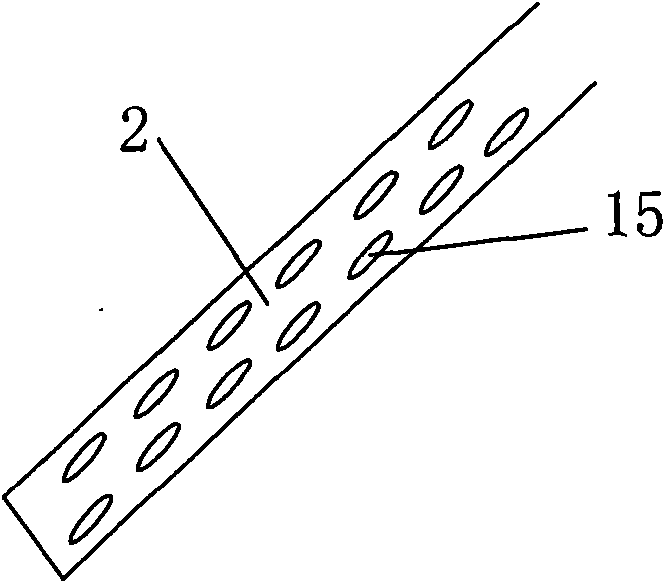

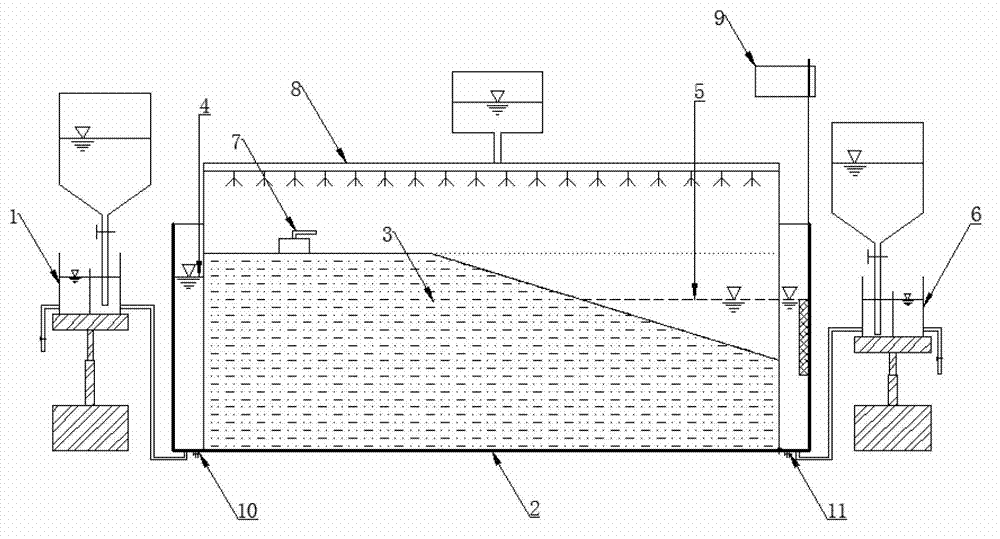

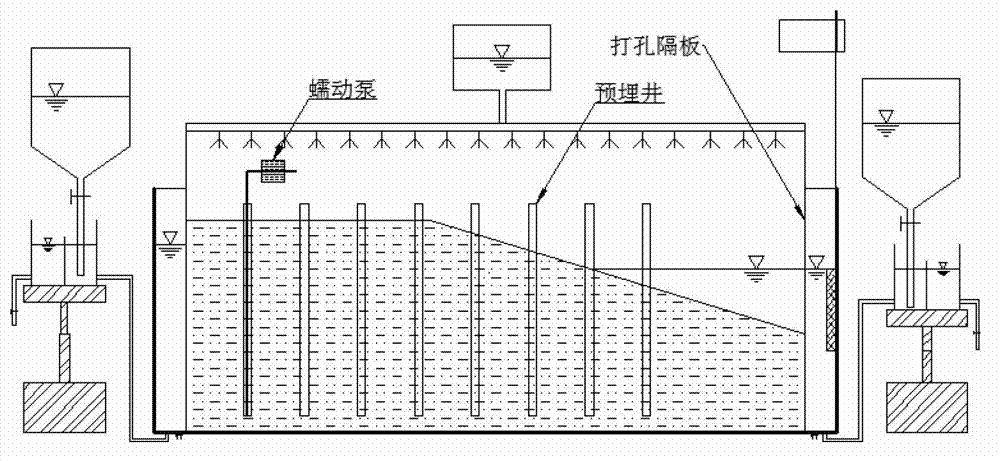

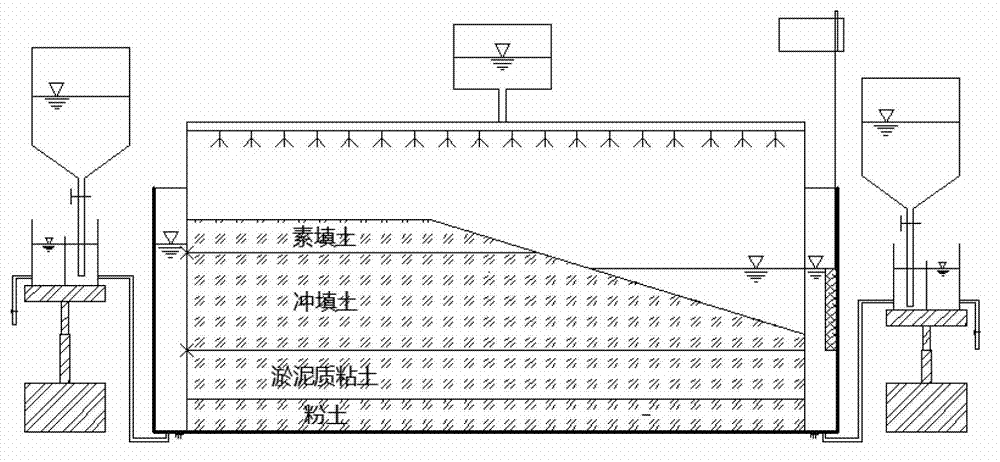

Vertical well pipe for assisting in efficiently extracting groundwater in low permeable aqueous medium in laboratory and usage method of vertical well pipe

InactiveCN103046528AGuaranteed cleanlinessIncrease the pumping rateIn situ soil foundationPorous pipeEnvironmental geology

The invention discloses a vertical well pipe assisting in efficiently extracting groundwater in a low permeable aqueous medium in a laboratory and a usage method of the vertical well pipe. With an ordinary well pipe improved, a rubber plug with two holes are added on a nozzle, and one hole serves as an air inlet and outlet port while the other hole serves as an insertion hole for an pumping hose. The inner portion of a porous pipe part positioned on the lower portion of the well pipe is of the structure of double layers, and washing cotton is used for filling the inner portion of a cylindrical ring while macroporous membrane is used for being stuck on an inner ring. The outer portion of the porous pipe is distributed with pores unevenly and asymmetrically. When the well pipe is vertically arranged, owing to symmetric distribution, water flow is fast due to the effect of groundwater flow; owing to the asymmetric distribution, cumulative amount in pumping can be increased, flow rate can be reduced, area of the water contact surface is expanded, pressure is increased, and therefore the siphon effect of the hose is improved.

Owner:TIANJIN UNIV

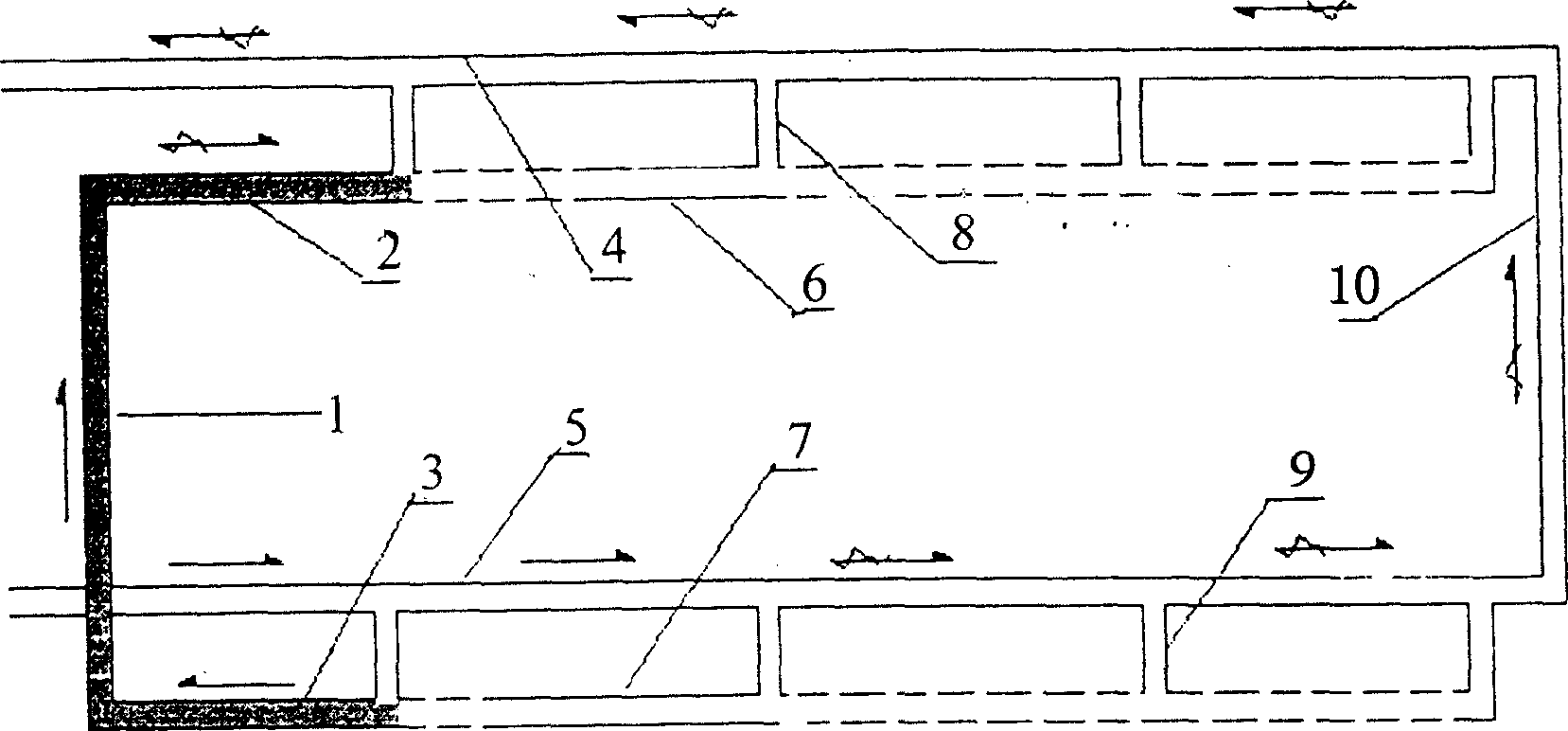

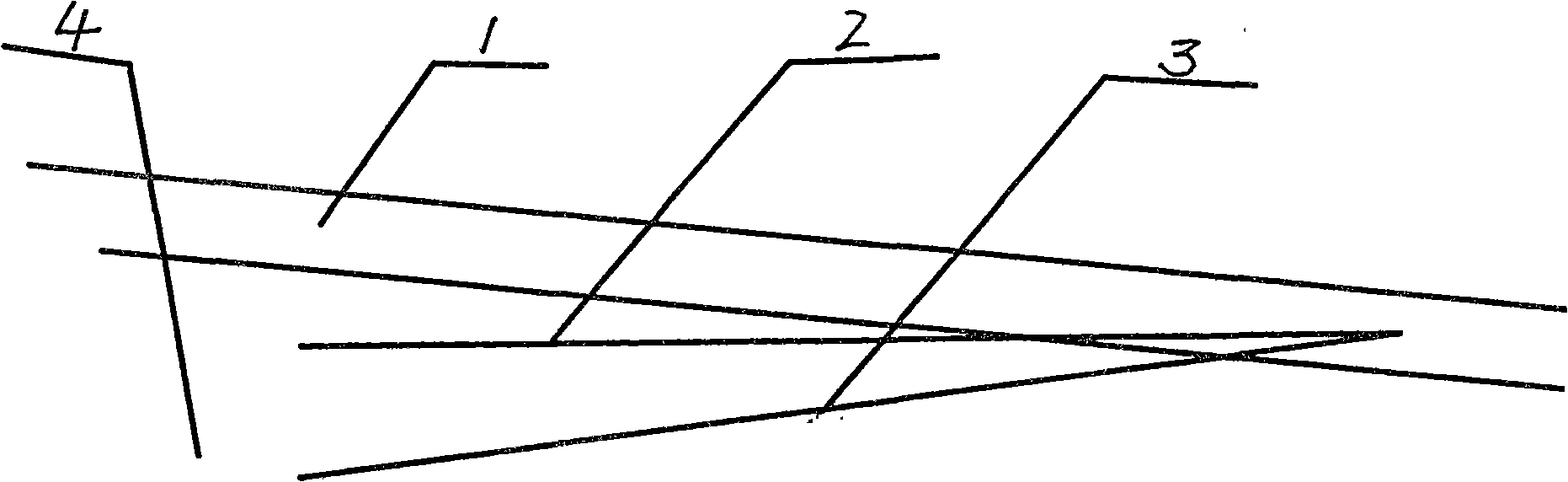

Arrangement method for gas drainage drill sites of highly-gassy fully-mechanized top-coal caving surface

InactiveCN102162367APlay the role of blocking gasTimely supplementDirectional drillingGas removalDrill siteCoal

The invention discloses an arrangement method for gas drainage drill sites of a highly-gassy fully-mechanized top-coal caving surface, which comprises the following steps of: constructing the drill sites above a roof of a coal seam of an air return roadway of the fully-mechanized top-coal caving surface; constructing six drill holes in the drill sites, and drilling the drill holes by using a centralizer according to the design direction, wherein the coverage range of the drainage drill hole in the latter drill site on the previous drill site is more than or equal to 50 meters; and after constructing the drill holes, pre-burying an end pipe by using a polyurethane material, and arranging a gas drainage pipe in the end pipe to drain gas. The arrangement method has the advantage that after top coal of the caving surface is discharged, the effused gas rises to a fissure zone and enters the drill holes constructed to the inside of the fissure zone, and is drained by the gas drainage pipe without entering air turn corners again, so the high-position drill holes plays the role of blocking and intercepting the gas.

Owner:BIN COUNTY WATER CURTAIN CAVE COAL

Negative-pressure liquid nitrogen subcooler and method for liquid nitrogen temperature reduction

InactiveCN102393107AImprove the pumping effectImprove efficiencySubcoolersLiquid nitrogen containerNitrogen

The invention relates to a negative-pressure liquid nitrogen subcooler and a method for liquid nitrogen temperature reduction. The negative-pressure liquid nitrogen subcooler is applied to the field of motor vacuum science and technology and comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhaust system and a discharge system. Wherein the liquid nitrogen conveying system is used for providing liquid nitrogen for the subcooler system, the negative-pressure air exhaust system is provided with an air temperature type vaporizer which is used for reducing the pressure of the subcooler, gas and nitrogen are discharged by the discharge system, in the subcooler system, a pneumatic control valve is adjusted manually in a long-distance manner, so that liquid level of the liquid nitrogen in the subcooler is kept constant. The method comprises the following steps that: firstly, the liquid nitrogen is filled into a liquid nitrogen container, pressure is adjusted, the liquid nitrogen is filled into the subcooler, and the liquid level of the liquid nitrogen in the subcooler is kept constant; then, the negative-pressure air exhaust system is started, and the liquid nitrogen is cooled through a heat exchanger; at last, the liquid nitrogen is recycled and residual liquid is discharged. In the negative-pressure liquid nitrogen subcooler, defect that a constant-pressure liquid nitrogen subcooler only can provide the liquid nitrogen with the minimum temperature of 77 DEG C can be overcome, heat sink temperature can be further reduced, adjustable heat sink temperature between 70 DEG C and 77 DEG C can be achieved, equipment is simple, effect is good and cost is low.

Owner:BEIHANG UNIV

Multipurpose pumping-exhaust flue dust processor of serially-connected gas-washing pools

InactiveCN102784533AImprove the pumping effectRemove completelyUsing liquid separation agentFlueExhaust fumes

The invention discloses a multipurpose pumping-exhaust flue dust processor of serially-connected gas-washing pools, which is characterized in that flue dust is collected by a gas-collecting hood and is forcedly blown into the bottoms of the gas washing pools by an exhaust fan, and gas bubbles are generated by the pumping force of a vacuum pump. The gas bubbles are cut and dispersed into small gas bubbles by a gas bubble dispersing screen mesh when floating upward, and thus the contact area with a washing solution is increased. The washing solution mainly comprises surfactants such as soap liquid and the like, and thus the solubility of harmful gas and the wetability of the dust are improved. Meanwhile, according to the characteristics of harmful gas, proper solutions can be filled into the serially-connected gas-washing pools. The processed tail gas is pumped away by the vacuum pump. After such processing, harmful gas in the flue gas and the dust are removed thoroughly. The invention is applicable to chimney tops, exhaust gas discharge ports of workshops generating toxic / peculiar smell gas, oil smoke discharge ports for cooking, smoke dust discharge ports of smoking rooms at public places, and even air exits of smoke ventilators for household, and has very important significance for air quality improvement.

Owner:徐自升 +1

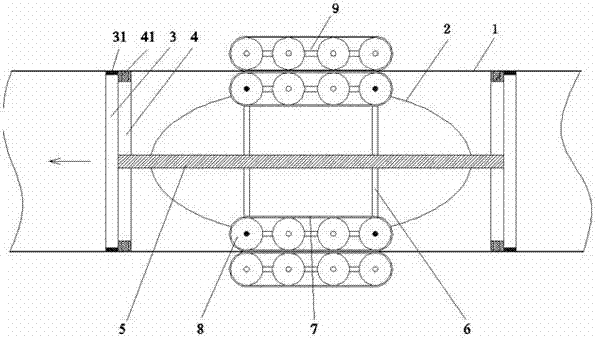

Pipeline transportation vacuum forming method and device adopting piston-type vehicle push and press air exhaust

ActiveCN107161160AAvoid the problem of low exhaust efficiencyLow costRailway tunnelsExhaust valveDrive wheel

The invention discloses a pipeline transportation vacuum forming method adopting piston-type vehicle push and press air exhaust and a pipeline transportation vacuum forming device adopting piston-type vehicle push and press air exhaust. The pipeline transportation vacuum forming method comprises the following specific steps that (1) a piston-type vehicle a and a piston-type vehicle b enter air brake stations correspondingly; (2) inner side isolation doors of the air brake stations are closed, a transportation pipeline between the air brake stations forms a closed pipeline; (3) piston rings on the piston-type vehicles are adjusted to seal the piston-type vehicles and the pipeline; (4) the piston-type vehicle a and the piston-type vehicle b travel opposite to each other, so that air is discharged from air exhaust valves; (5) when the piston-type vehicle a and the piston-type vehicle b operate to the middle of the pipeline, the exhaust valves are closed, and the air exhaust process is completed; and (6) the piston-type vehicle a and the piston-type vehicle b travel back to the starting points, namely the air brake station A and the air brake station B of the piston-type vehicle a and the piston-type vehicle b. The pipeline transportation vacuum forming device comprises the pipeline, the piston-type vehicles, pistons, auxiliary pistons, longitudinal beams, connecting rods, magnetic caterpillar bands, driving wheel air exhaust valves and air exhaust devices. According to the pipeline transportation vacuum forming method and device adopting piston-type vehicle push and press air exhaust, pipeline transportation vacuumizing efficiency can be improved, and the construction and operating cost is reduced.

Owner:BEIJING JIUZHOU ARTERY TUNNEL TECH CO LTD

Water collecting type inflaming retarding garbage can

ActiveCN109132285AImprove the sealing effectImprove pumping effectRefuse receptaclesEngineeringSanitation

The invention belongs to the field of environment sanitation facilities, and particularly relates to a water collecting type inflaming retarding garbage can. The water collecting type inflaming retarding garbage can comprises a base, the upper end of the base is fixedly connected with a can body, a can cover is rotatably connected into the can body, a water storage cavity is formed in the base, anannular water collecting groove is formed in the upper end of the base, and communicates with the water storage cavity through multiple water conveying channels, multiple water sucking pipes are arranged on the side wall of the can body in a penetrating manner, the input ends of the water suction pipes are attached to the bottom face of the water storage cavity, the output ends of the water suction pipes are arranged on the inner side wall of the can body, multiple Z-shaped air exhaust channels are formed in the inner side wall of the can body, two ends of the Z-shaped air exhaust channels are arranged on the inner and outer side walls of the can body, an annular cavity is formed in the inner side wall of the can body, a piston ring is in sliding seal connection into the annular cavity, and the interior of seal space formed by the lower side wall of the piston ring and the annular cavity is filled with evaporation liquid. Collected rainwater is used for achieving fire extinguishing ofthe garbage can, and the garbage can is energy-saving, environment-friendly, high in speed and capable of avoiding large danger.

Owner:杭州杉芽科技有限公司

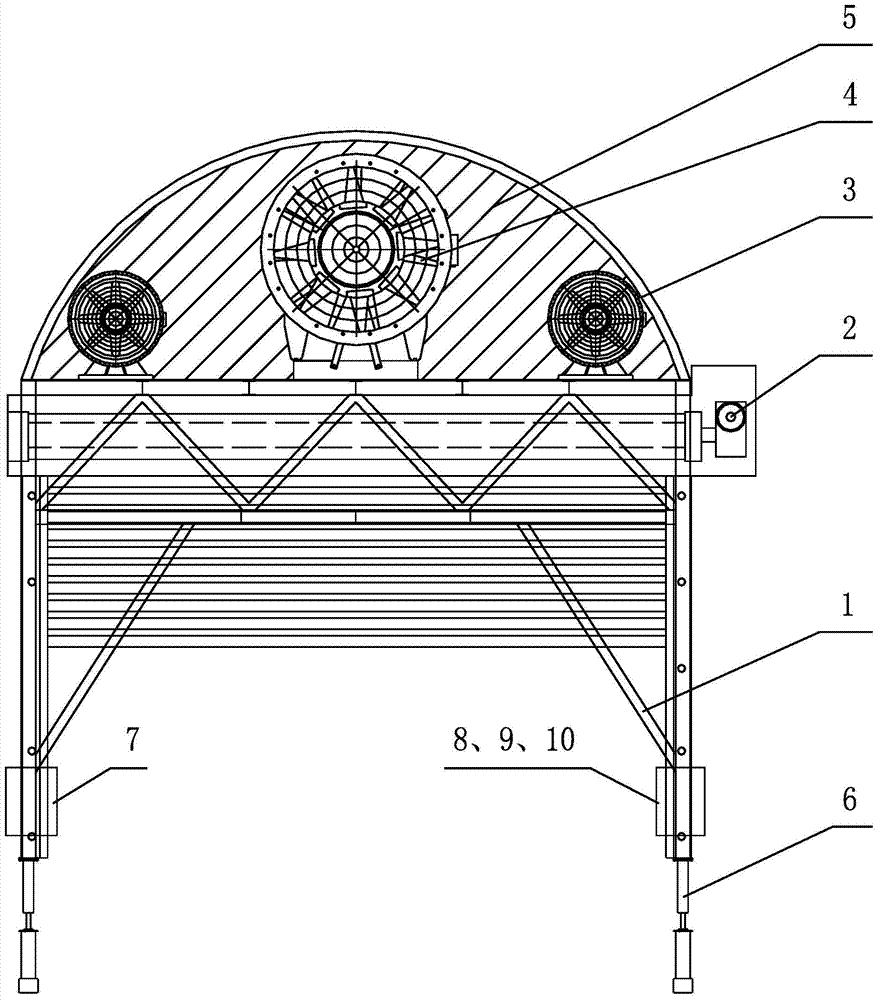

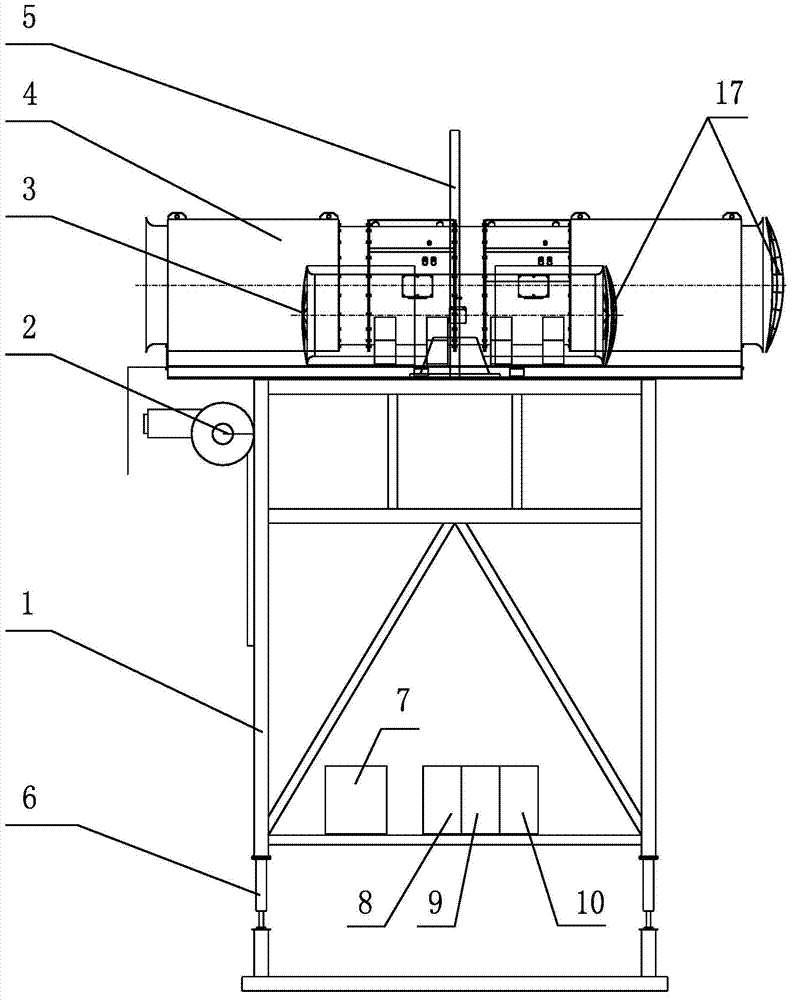

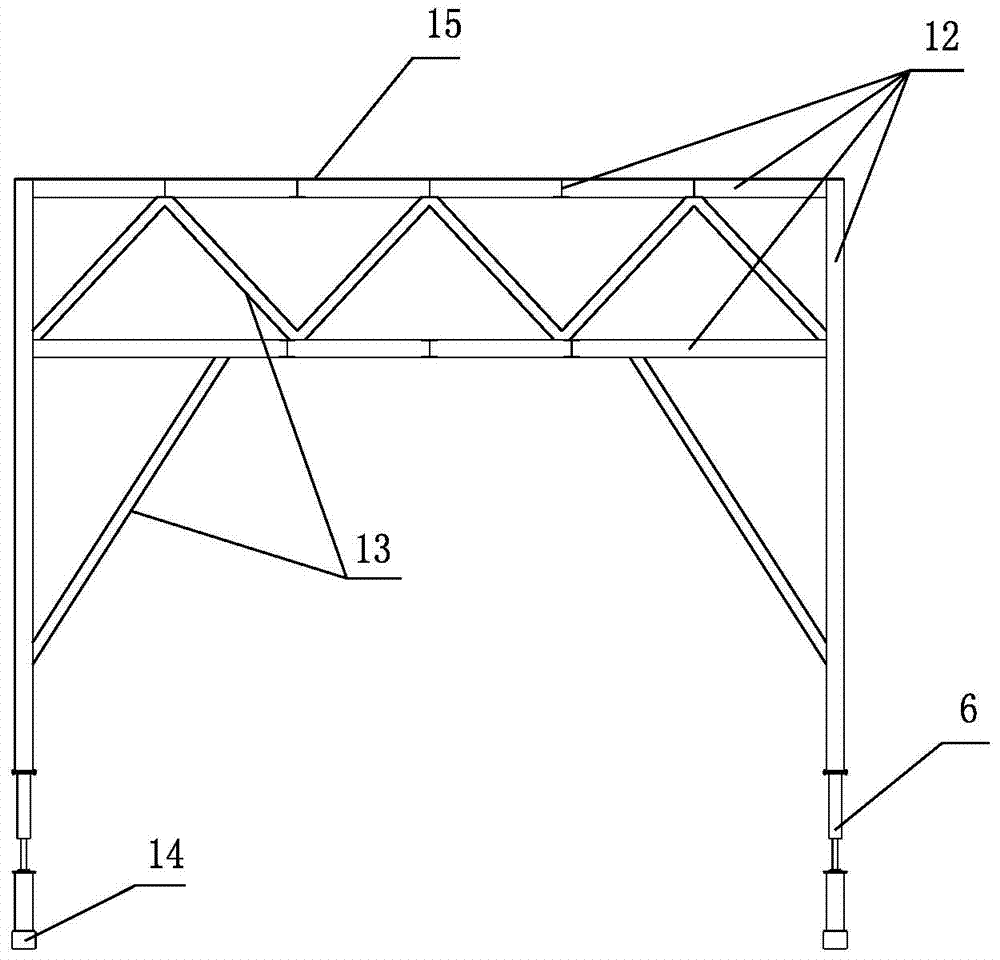

Rapid ventilation and smoke exhausting device and method for construction period of long-distance tunnel

ActiveCN104500123AGuaranteed structural strengthEasy to operateDust removalFire preventionElectric machineryPollutant

The invention provides a rapid ventilation and smoke exhausting device for a construction period of a long-distance tunnel. The rapid ventilation and smoke exhausting device comprises a gantry bracket, a fixed wind door and a movable wind door, an axial flow ventilator and a jet flow draught fan, and a motor control system, wherein the fixed wind door is arranged at the upper end of the gantry bracket and the movable wind door is arranged on one side of the gantry bracket; the axial flow ventilator and the jet flow draught fan penetrate through the fixed wind door; the fixed wind door is matched with the unfolded movable wind door so that the axial wind flow in the tunnel is separated; a wind inlet of the axial flow ventilator and a wind outlet of the jet flow draught fan are formed in one side, which is close to a working surface, of the fixed wind door; the wind outlet of the axial flow ventilator is connected with a flexible wind barrel; the wind outlet of the flexible wind barrel extends to the outer part of the tunnel. According to a ventilation and smoke exhausting method provided by the invention, the wind doors for separating the axial wind flow are arranged in the tunnel; a safe space and a closed polluted space are formed on the two sides of the wind doors respectively, and pollutants in the polluted space can be discharged out of a hole along an airflow through a closed exhausting channel by using ventilation equipment; blasting equipment is used for blasting wind into the polluted space from the safe space so that the pollutants rapidly flows towards the inlet of the ventilation equipment.

Owner:中国葛洲坝集团第三工程有限公司

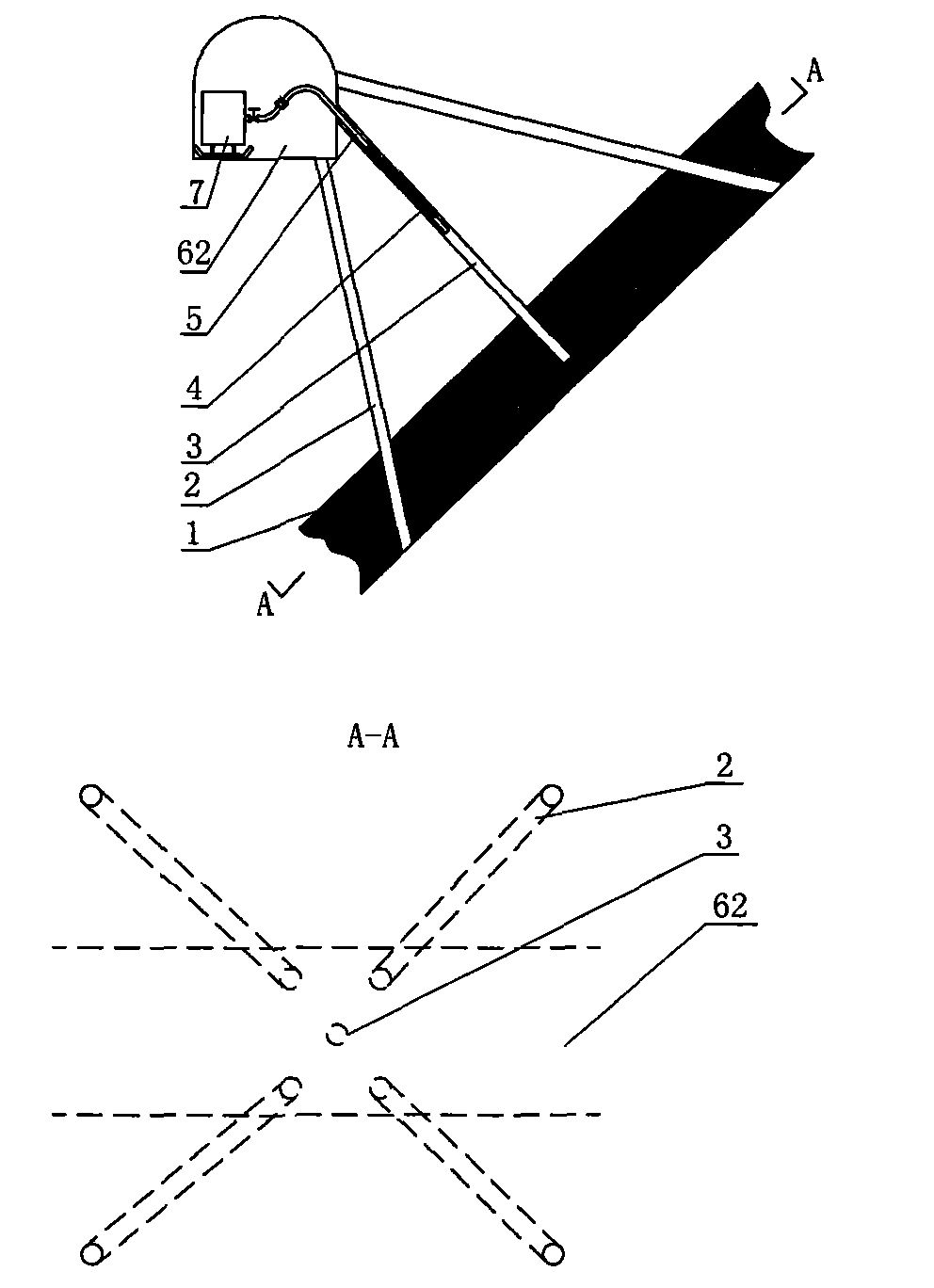

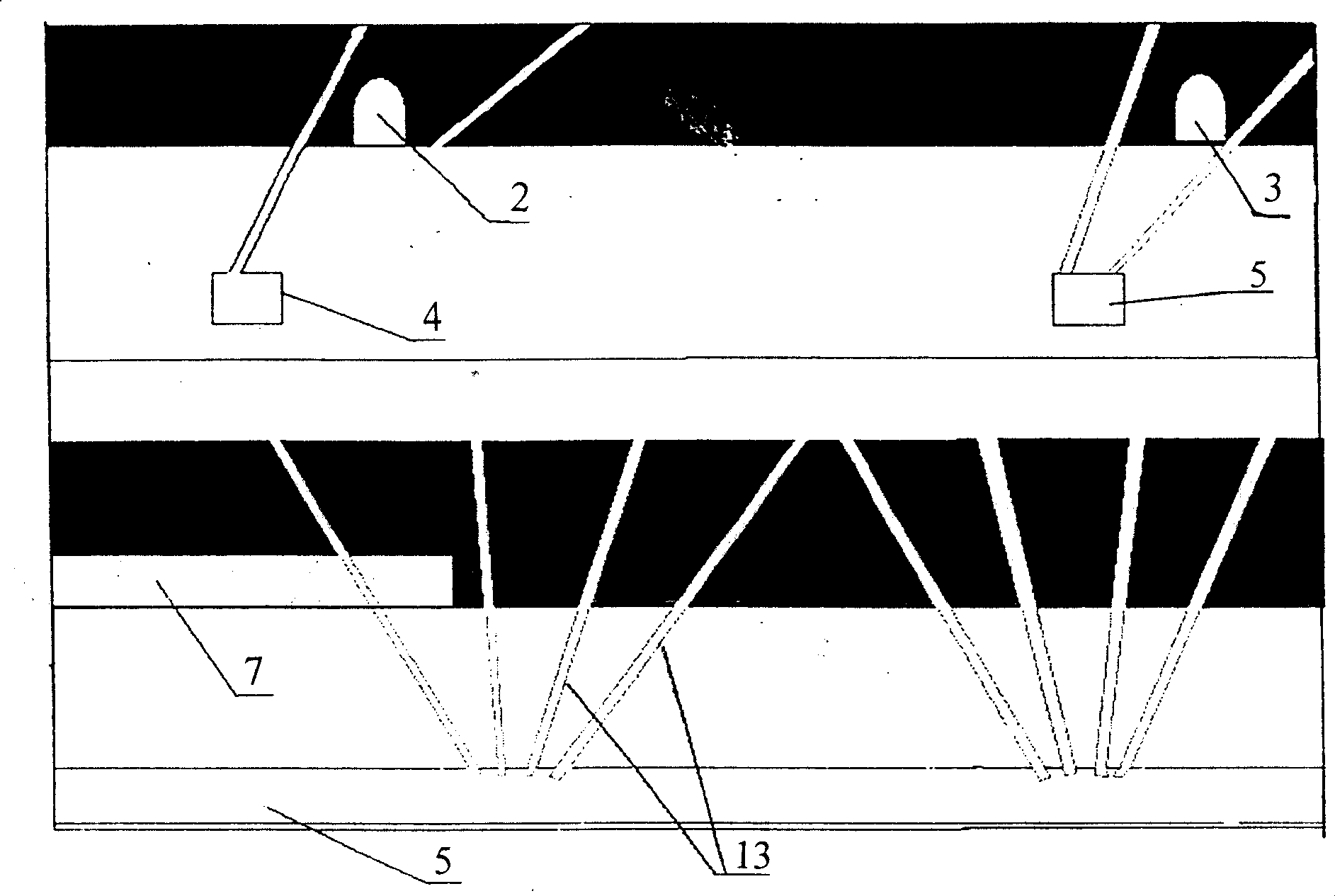

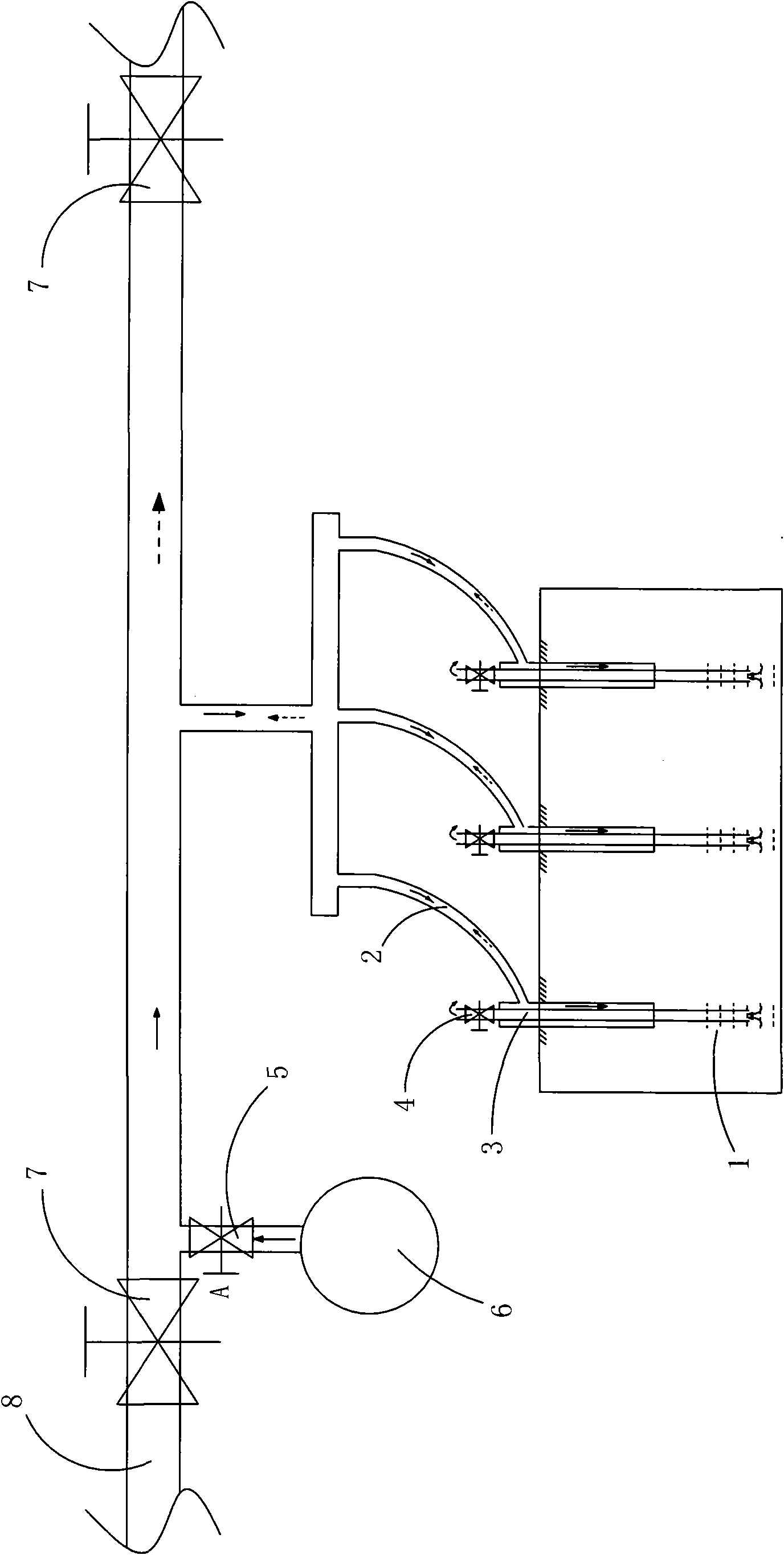

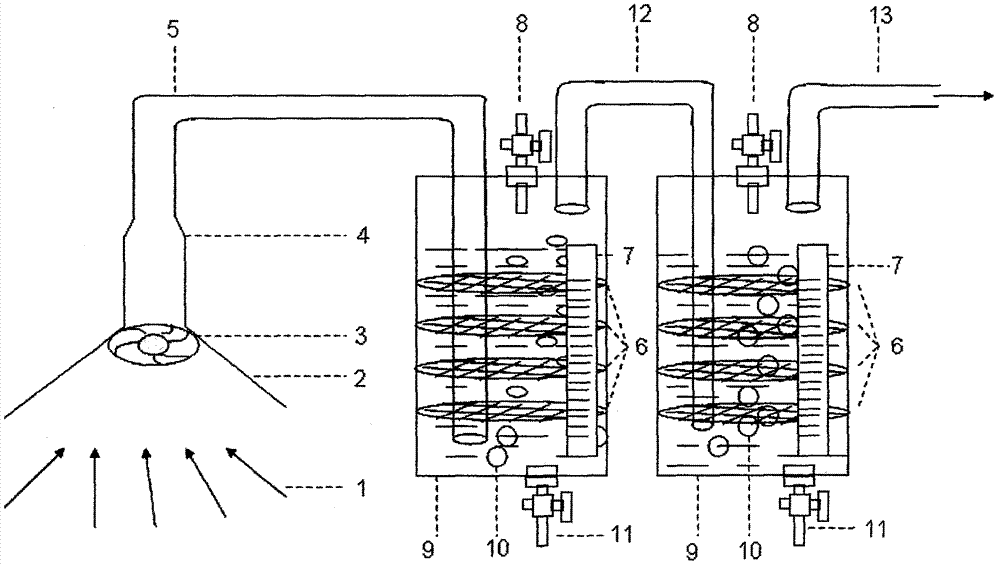

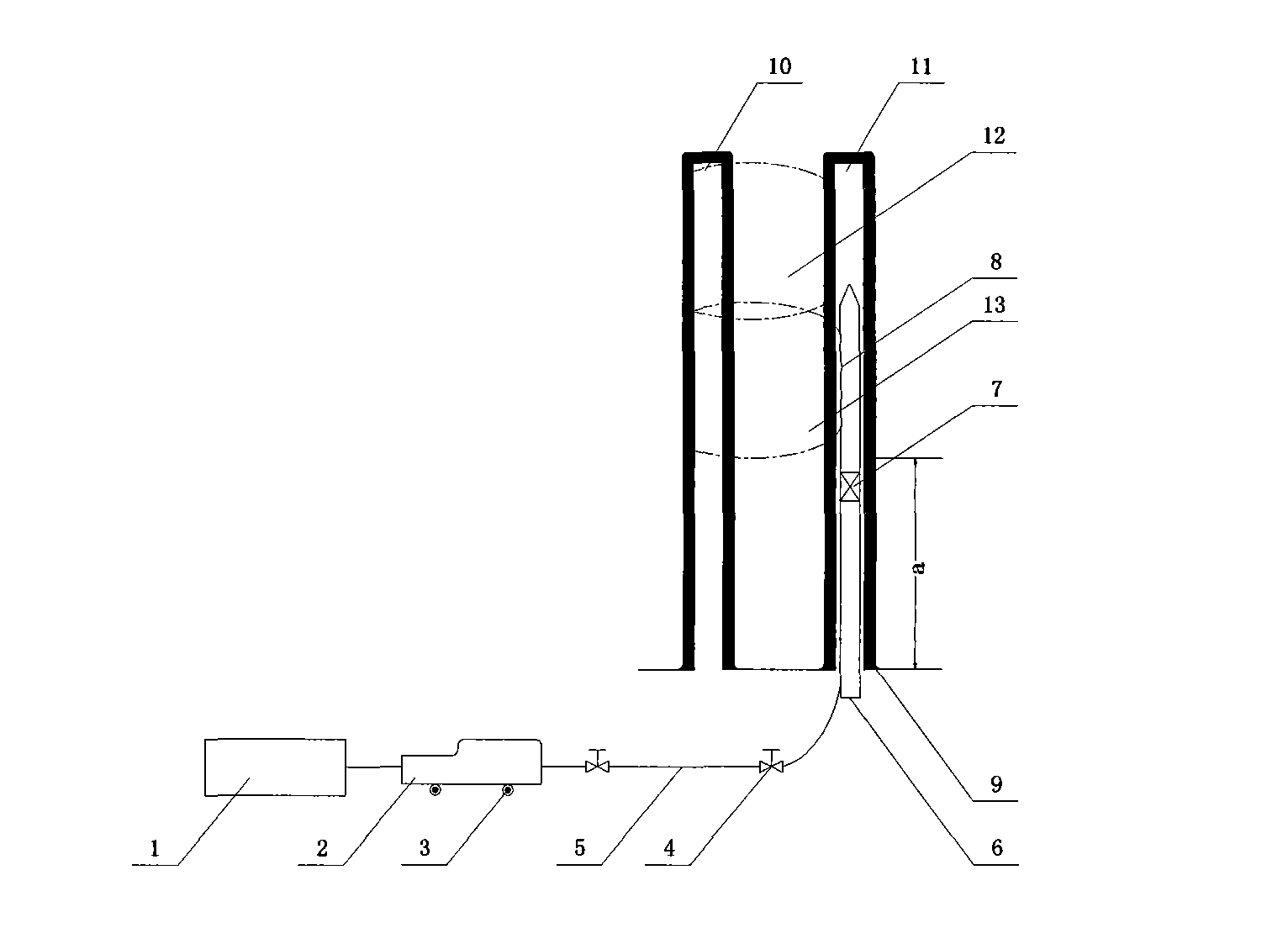

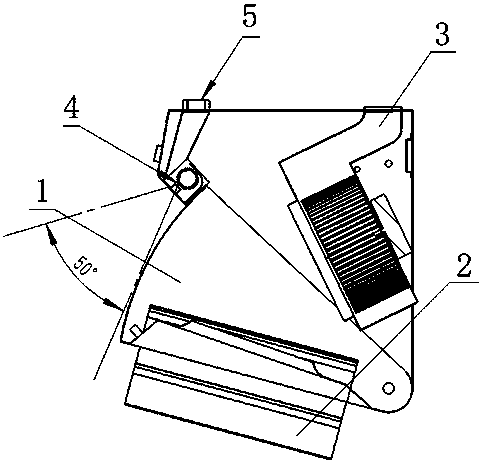

Method and device for pre-pumping coal body gas by concussion fracture of high-pressure gas

ActiveCN101581232AGood cracking effectImprove the pumping effectGas removalIntrinsic safetyElectricity

The invention discloses a method for pre-pumping coal body gas by concussion fracture of high-pressure gas, which comprises the step of boring a concussion fracture borehole in a coallayer. The method is characterized in that after a plurality of control boreholes are bored on the periphery of the concussion fracture borehole, the concussion fracture borehole is subjected to coal body concussion fracture, wherein the control boreholes can serve as gas drainage boreholes. The method and the device have the advantages that the periphery of the concussion fracture borehole is provided with the control boreholes, the coal body fracture effect is improved during the concussion fracture of the coal body, the ventilation property of the fractured coal body is enhanced, and the gas pumping effect is improved.

Owner:CCTEG SHENYANG RES INST

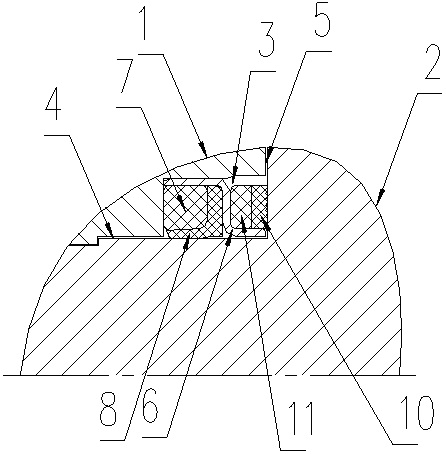

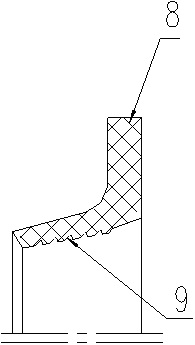

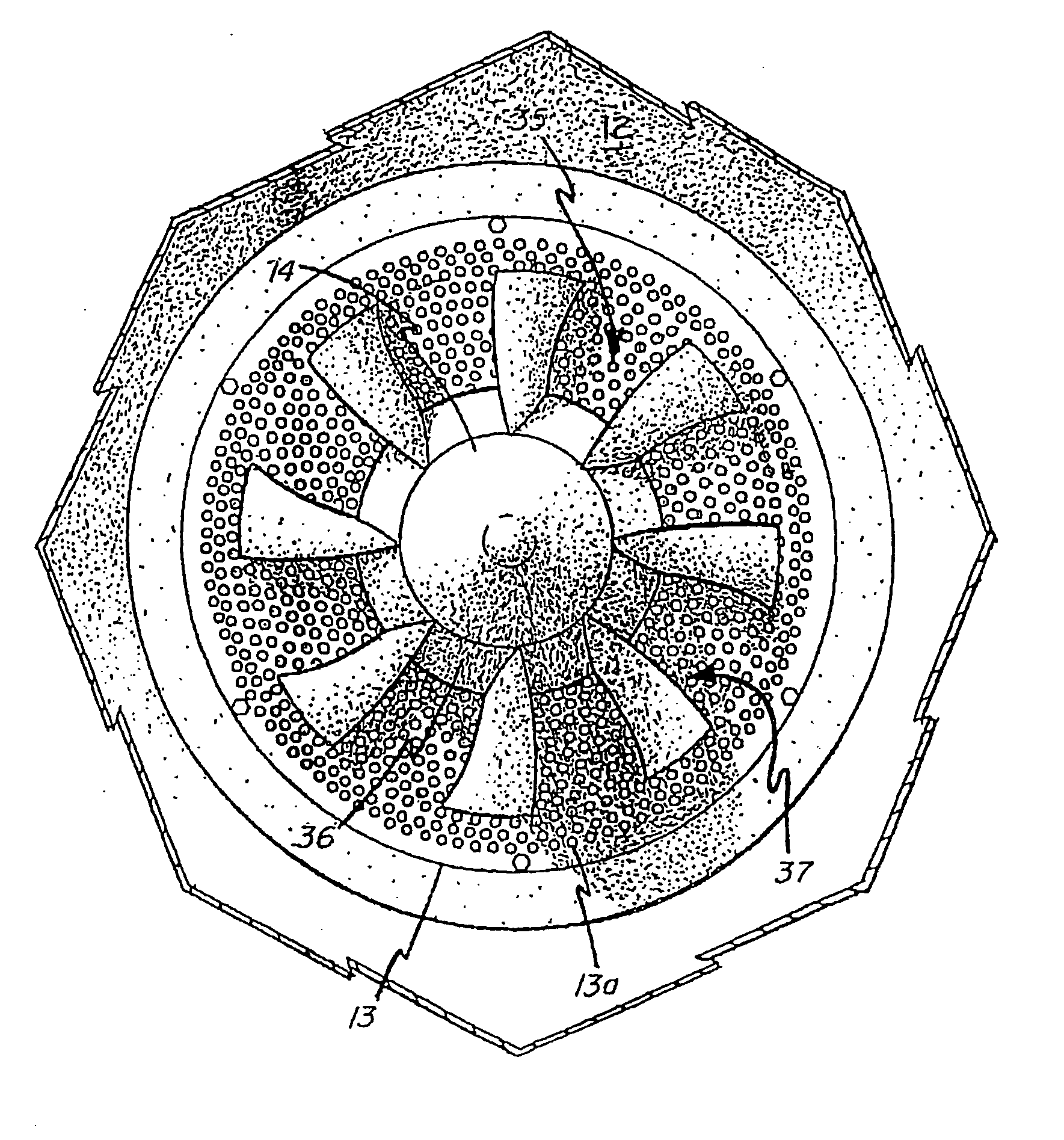

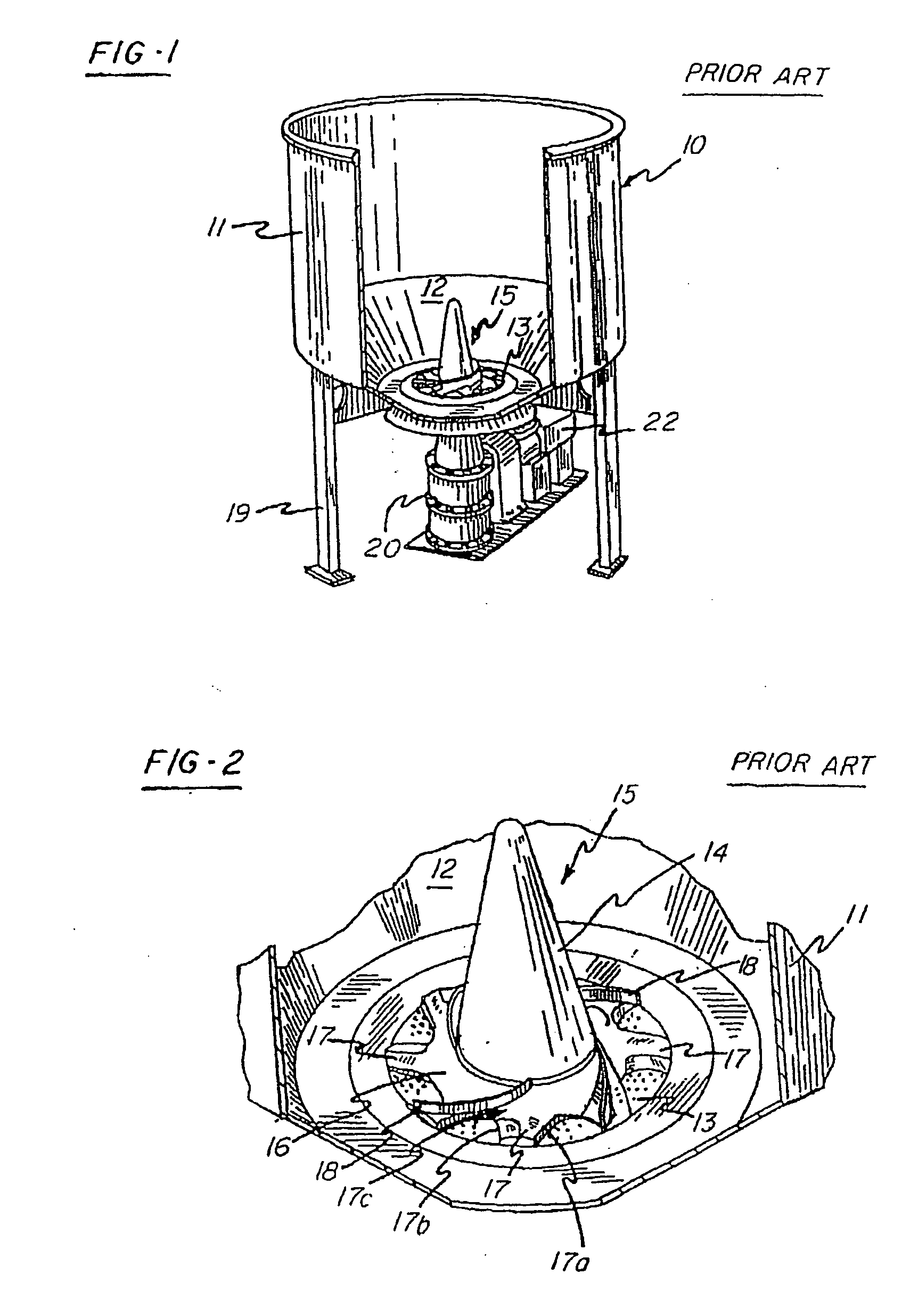

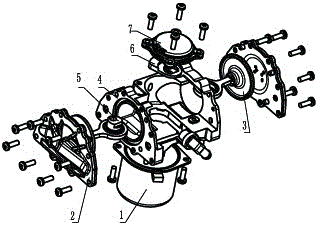

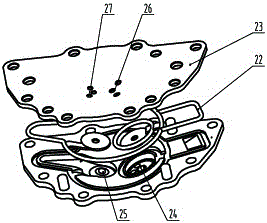

Pulper rotor and assembly

InactiveUS20050224610A1Promote circulationImprove the pumping effectGas current separationGrain millingTrailing edgeWear resistant

An improved pulper, mixer or defibering, rotor having a spar ring attached to a hub of the rotor with a series of curved vanes projecting from the spar ring. The curved vanes have a vane face and a trailing edge. The trailing edge may be unitary and integral with the vane, or may be segmented in combination with trailing edge portion provided on an underlying spar stub to which the vanes are attached. The hydrodynamic suction created by the trailing edge is enhanced by the addition of a dam at the vane tip end of the trailing edge zone. The vanes have a constant vane face angle relative to radians extending outward from the hub of the rotor. As a result of the constant vane face angle the pulp, or other materials, mixed by the vanes during rotation of the rotor are more consistently in contact with the vanes during rotation of the rotor. The vanes are also streamlined to reduce hydrodynamic drag especially at the vane tips where speed and therefore drag potential are at their highest levels. As a result, increased circulation and pumping effects with minimal power requirements are achieved. The vanes may be made of high wear resistant materials and are easily accessible for maintenance, repair or replacement.

Owner:THERMO BLACK CLAWSON

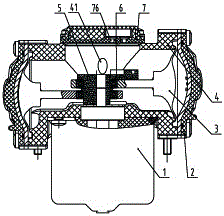

Air entering/draining mechanism for membrane type automobile electric vacuum pump

InactiveCN105889041AReduce energy consumptionRunning balancePositive displacement pump componentsFlexible member pumpsPistonMembrane configuration

The invention belongs to the field of an automobile brake assisting system and particularly relates to an air entering / draining mechanism for a membrane type automobile electric vacuum pump. The air entering / draining mechanism for the membrane type automobile electric vacuum pump disclosed by the invention comprises a motor and a pump body, wherein an air entering / draining channel is arranged on the pump body; left and right end cover components are arranged at the left and right ends of the pump body; when a forming chamber in the membrane is maximal, the air entering / draining mechanism is under air exhaust state; when the forming chamber in the membrane is under negative pressure and generates suction force, and the forming chamber volume at the oppositely arranged piston component is minimal, the air entering / draining mechanism is under the exhausting state; a counterbalance matched with a spindle is arranged on the pump body. The air entering / draining mechanism for the membrane type automobile electric vacuum pump has the beneficial effects of better air exhaust property, higher safe coefficient, longer service life and accumulative work time reaching above 1200 hours.

Owner:HUZHOU ANRUINENG HYDRAULICPNEUMATIC TECH CO LTD

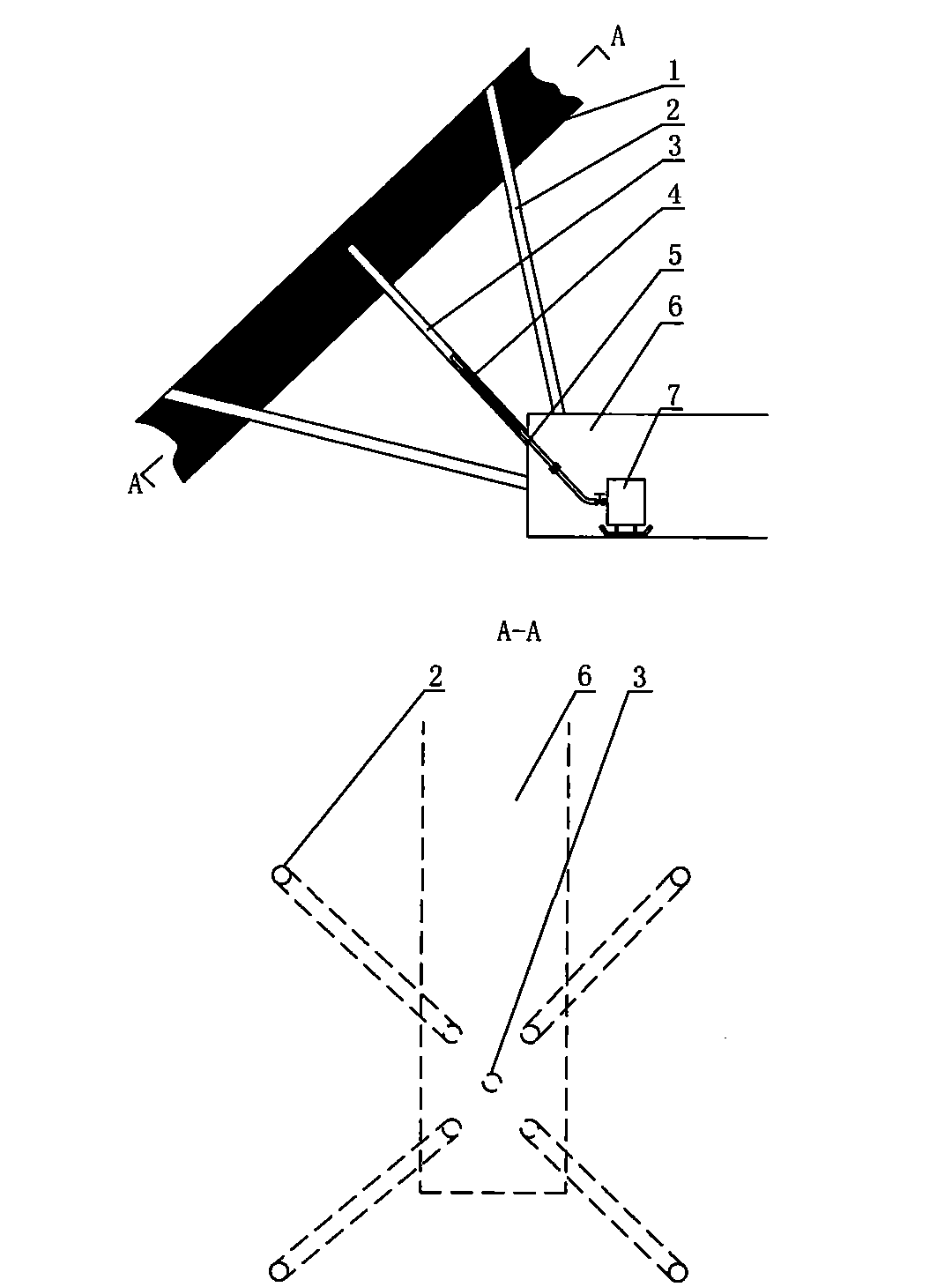

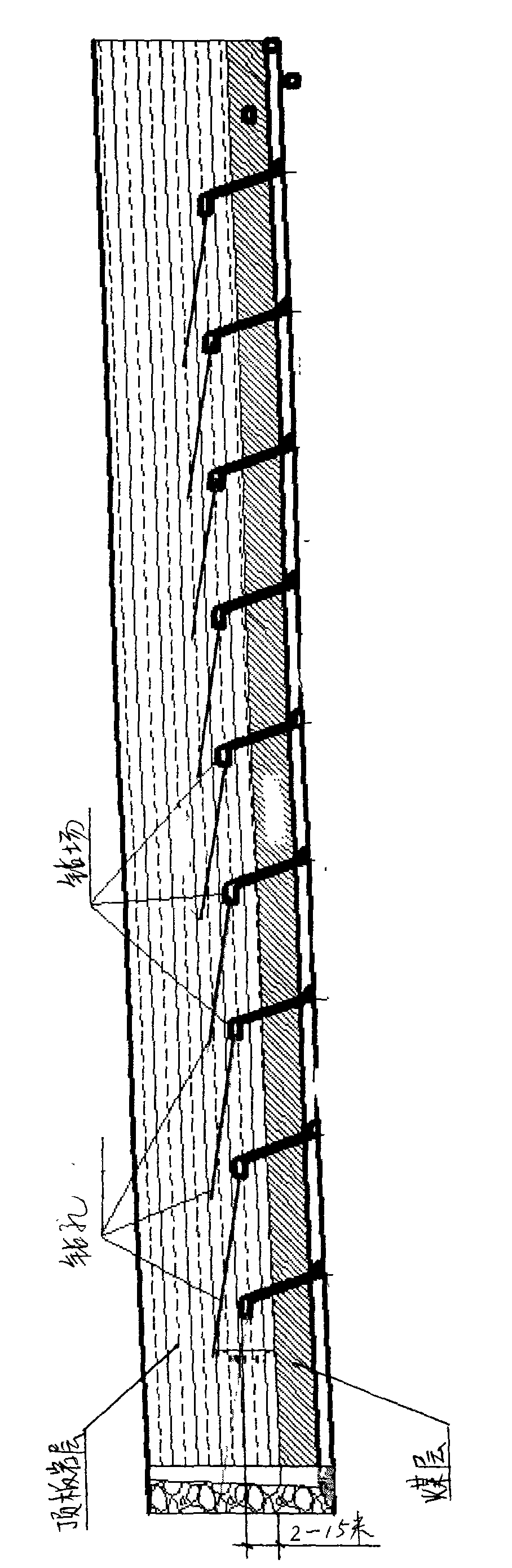

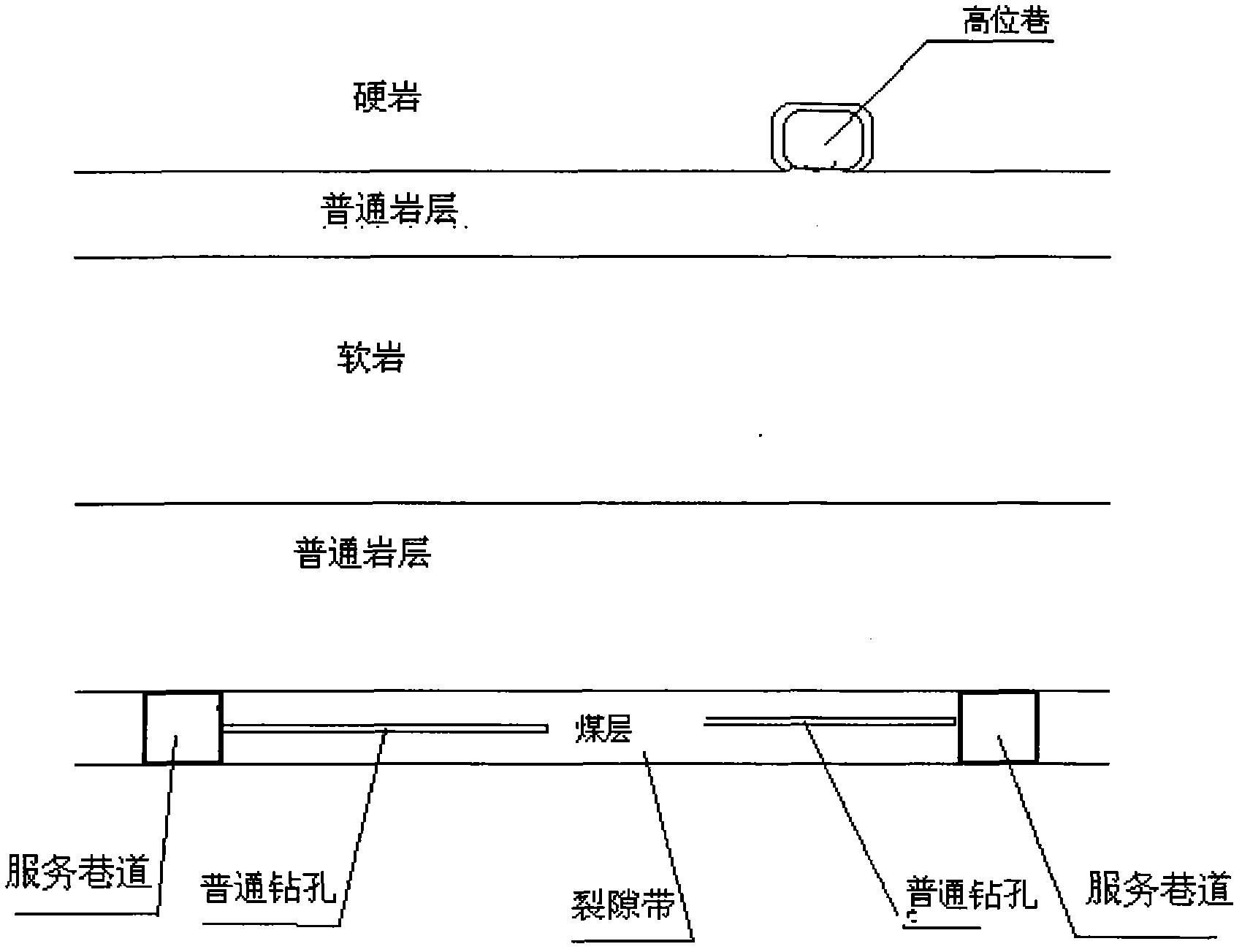

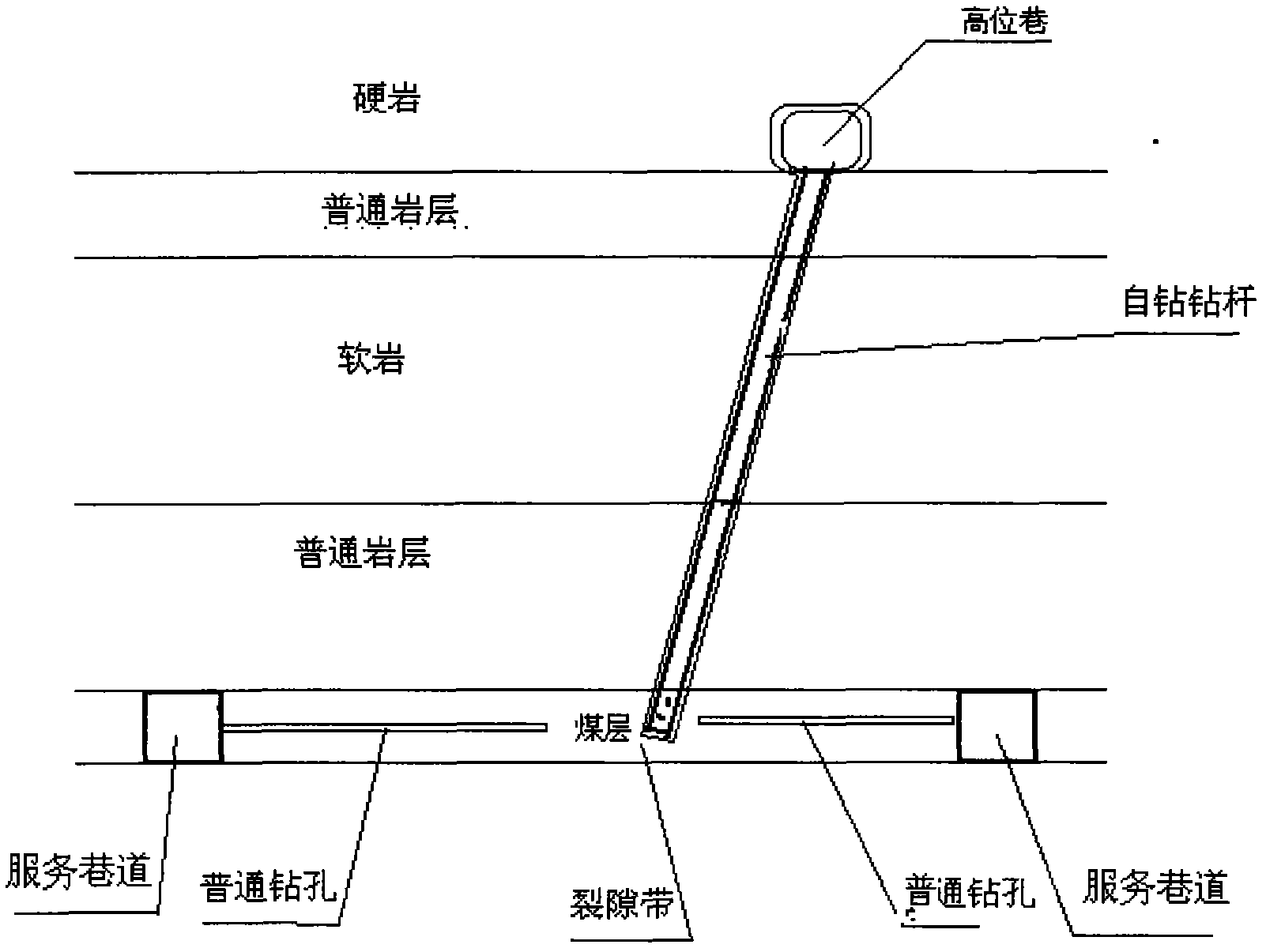

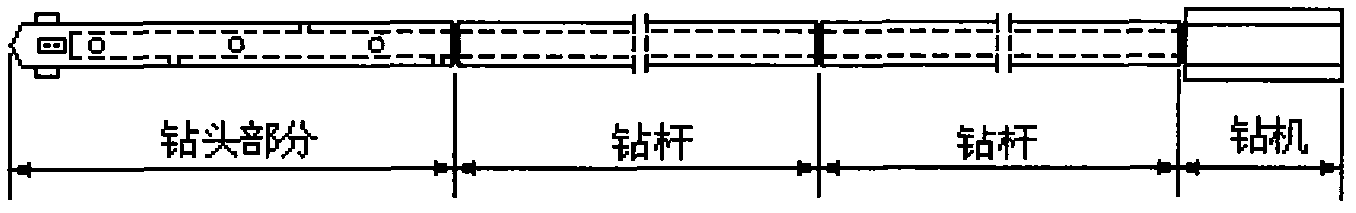

Method for gas drainage from high-position roadway coal seam containing shielded soft rock

The invention discloses a method for gas drainage from a high-position roadway coal seam containing shielded soft rock. According to the method, before the coal seam is mined, a roadway is developed in a hard rock formation of the coal seam roof and is called a high-position roadway for short as being designed at the coal seam roof part. The well-developed roadway can be used for ensuring the stability of surrounding rock and enhancing the temporary support; then during the working surface mining, holes are drilled in the coal seam in the roadway of a working surface, and preliminary gas drainage is carried out; and finally, at the same time of the preliminary gas drainage, holes are drilled in the coal seam in the high-position roadway, self-drilling drill rods with a hollow structure are adopted in the drilling, small holes are processed in the sections where the self-drilling drill rods enter the coal seam, the self-drilling drill rods are kept in the drilling holes of the coal seam after drilling in the coal seam, and the gas drainage can be continuously carried out through the self-drilling drill rods. According to the method, the drainage is carried out in the high-position roadway, the characteristic of upward flow of gas is fit, and thus the drainage is convenient to realize. The hollow drill rods with holes are used for the drainage, the drilling holes can be prevented from being sealed by the shielded soft rock and further a good drainage effect is realized.

Owner:SHANDONG UNIV OF SCI & TECH

Goaf gas drainage method of stope working surface of coal mines

The invention discloses a coal mine stope face goaf gas drainage method which comprises the following steps: first, drill holes are arranged on the upper air channel of the stope face; the drop bottoms of the drill holes are arranged on the top plate of the coal seam of the stope face; when the coal mine is stoped to the drop bottoms of the drill holes, because the top plate of the coal seam naturally caves, the gas of the goaf moves up, is drained by the preset drill holes, enters into the upper air channel and exhausted. The method is an effective method for controlling the gas of the stope face goaf with the gas going out of a mineshaft.

Owner:郭国政

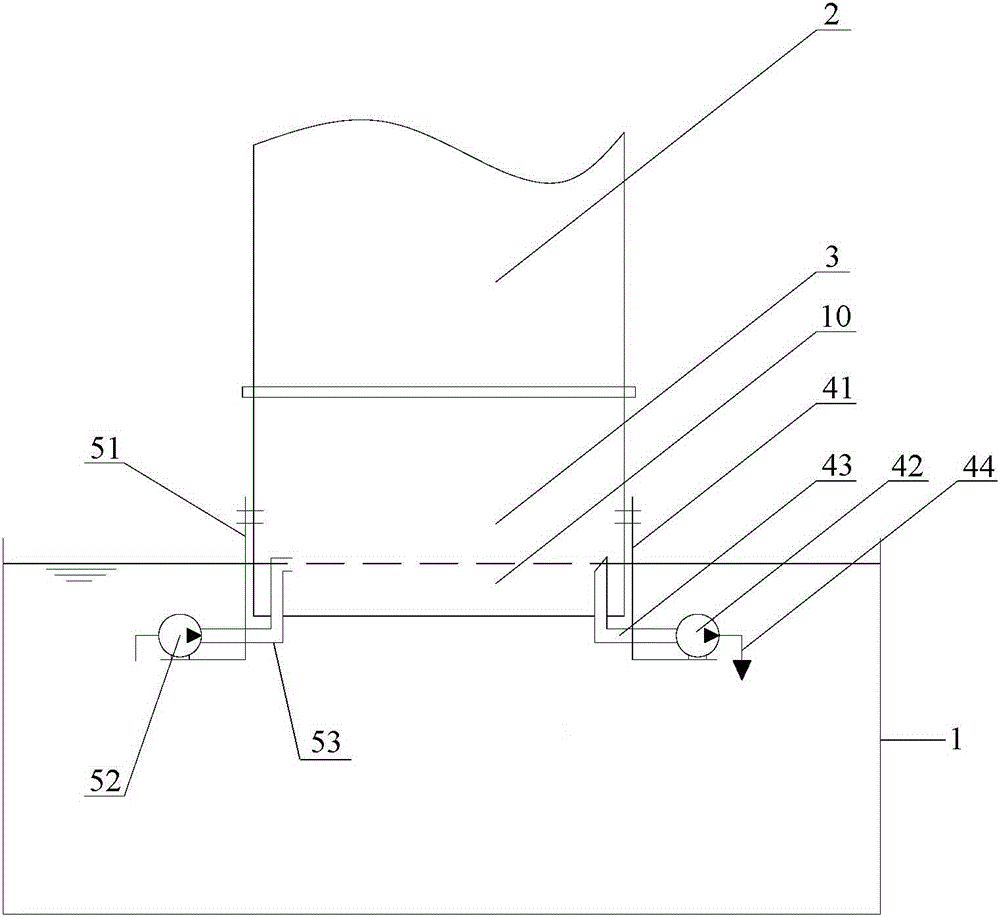

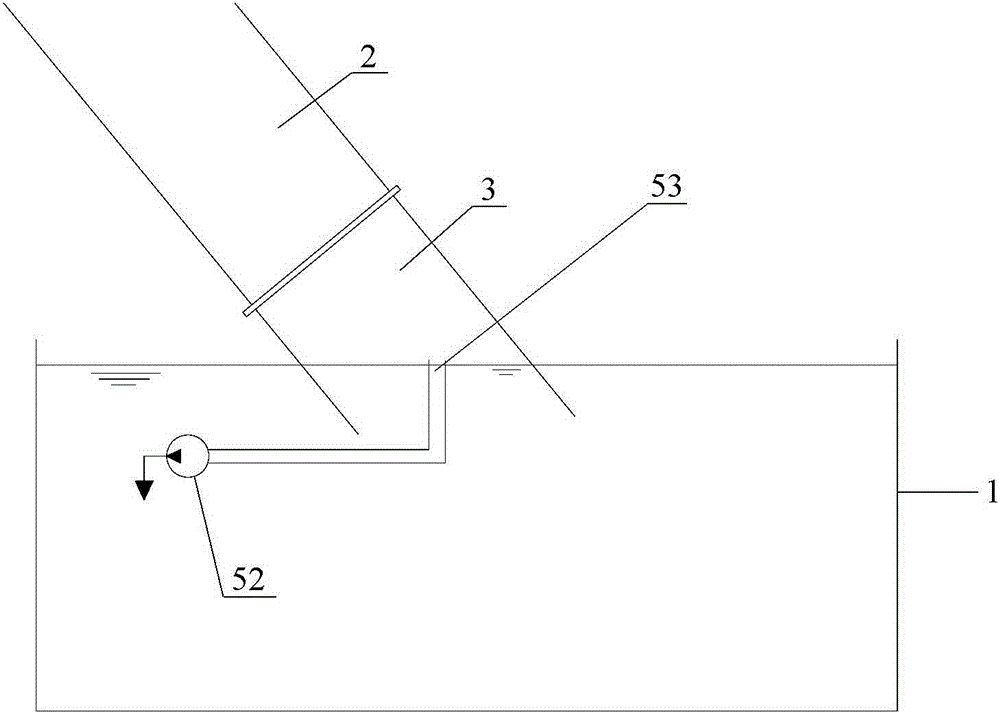

Furnace nose with slag blowing and discharging structure for hot galvanizing belts and use method thereof

The invention relates to the field of the hot-dip galvanizing alloy technology and adopted equipment, in particular to a furnace nose with a slag blowing and discharging structure for hot galvanizing belts and a use method thereof. The furnace nose with the slag blowing and discharging structure for the hot galvanizing belts comprises a zinc pot (1), an annealing furnace chute (2) and a furnace nose body (3) and is characterized by further comprising a molten zinc drawing pump base (41), a molten zinc drawing pump (42), a suction pipe (43), a discharging pipe (44), a molten zinc blowing pump base (51), a molten zinc blowing pump (52) and a blowing pipe (53), wherein the molten zinc drawing pump base (41) and the molten zinc blowing pump base (51) are fixed to the outer side surface of the bottom of the furnace nose body (3). The use method of the furnace nose with the slag blowing and discharging structure for the hot galvanizing belts is characterized by sequentially including the steps of arranging, liquid blowing and slag removing. The furnace nose and the use method thereof have the advantages that the slag removal effect is good, the galvanization quality is high, the operation is convenient, and the manpower and the labor hour are saved.

Owner:SHANGHAI DONGXIN METALLURGY TECH ENG

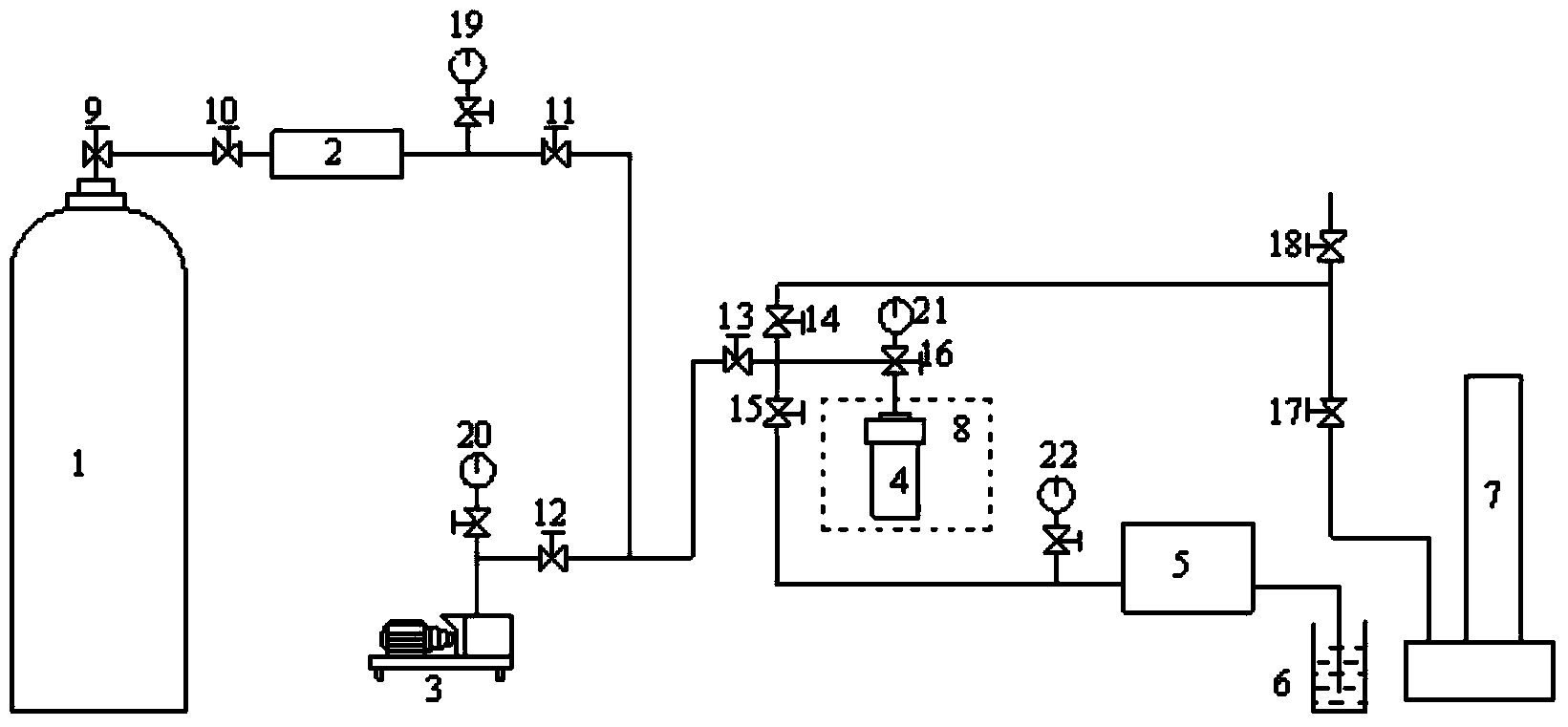

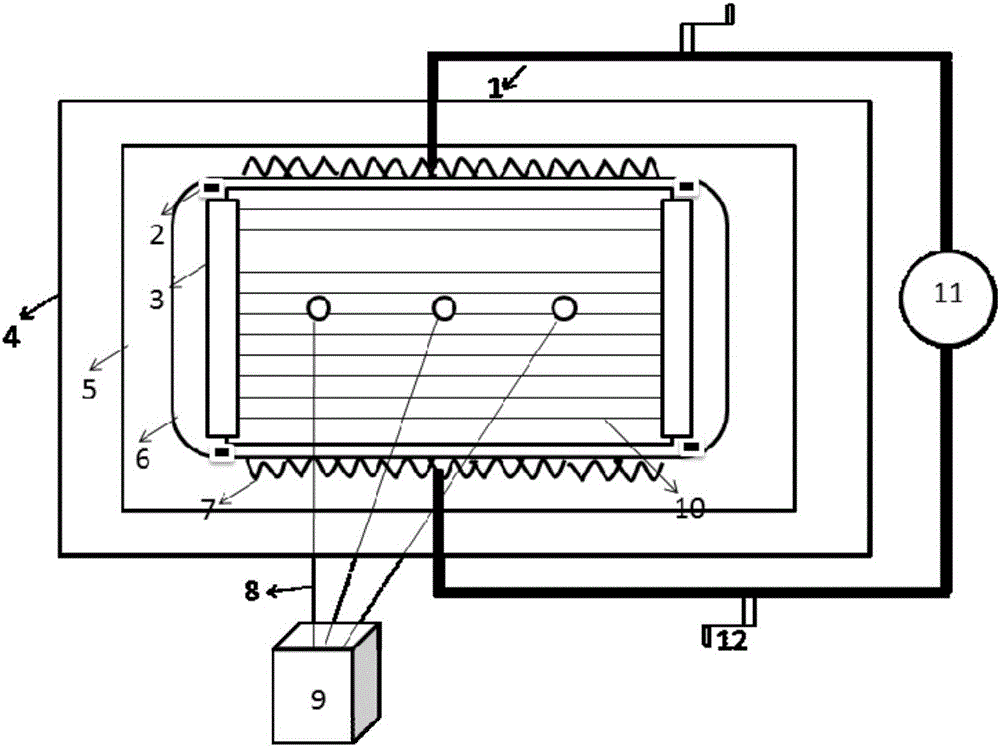

Experiment device for detecting influence of moisture on methane desorption rule

InactiveCN103558357AIncrease the pumping rateImprove the pumping effectFuel testingTemperature UnitEnvironmental geology

The invention relates to an experiment device for detecting the influence of moisture on the methane desorption rule. The experiment device is composed of five systems of vacuum degassing, constant temperature, adsorption balance, coal sample water injection and desorption determination, namely a vacuum degassing unit (1), a constant temperature unit (2), an adsorption balance unit (3), a coal sample water injection unit(4) and a desorption measurement control unit (5). The experiment device provided by the invention is widely applied to the aspects of improving coal gas drawing rate and drawing effect and the like in high gassy mines and coal and gas outburst mines.

Owner:HENAN POLYTECHNIC UNIV

Preparation device for composite board sample used for tests and method

The invention relates to a device for preparing a composite panel smooth in surface, uniform in thickness and used for tests through a vacuum perfusion process, and a method. Auxiliary materials such as diversion nets need to be abandoned for preparation of glass panels smooth in surface, and due to the method, the perfusion speed of resin is low, the flow velocity change of the resin is large and the prepared panels are poor in thickness uniformity. By means of the device and the method, the pore forming manner of multi-hole pressing plates and the perfusion manner of the resin are optimized, and therefore it is ensured that the resin infiltrates enhancement materials at the same speed within a short period of time and the panels uniform in thickness are prepared. Gaskets of the required thickness are placed between a test platform and a perforated plate, and the resin perfusion speed and amount are controlled through a resin flow regulator, and therefore the content stability of fiber in products and the thickness adjustability of the panels are ensured. Compared with the prior art, the standardability of test samples is greatly improved, and the test result has higher reference value.

Owner:湖南中科宇能科技有限公司

Range hood with automatic smoke hood adjustment function

InactiveCN108488866AGood pumping effectImprove cooking environmentDomestic stoves or rangesLighting and heating apparatusMicrocomputerAuto regulation

The invention provides a range hood with an automatic smoke hood adjustment function. The range hood structurally comprises a range hood top hood, an exhaust fan, a rotatable smoke hood, protective wings, an oil smoke pipeline, a fresh air exchange axial flow fan, a fresh air exchange pipeline and connecting rods, wherein the exhaust fan is fixed to the inner side wall of the range hood top hood,the exhaust fan is connected with an oil smoke outlet in the top of the range hood top hood by virtue of the oil smoke pipeline, the fresh air exchange axial flow fan is arranged in the range hood tophood and is connected with a fresh air exchange port in the top of the range hood top hood by virtue of the fresh air exchange pipeline, the rotatable smoke hood is connected with the range hood tophood by virtue of the connecting rods on both sides, the two protective wings are symmetrically arranged on the left and right sides of the bottom surface respectively, and motors which are used for controlling the protective wings to extend and side exhaust fans are arranged in the protective wings. The range hood has the advantages that (1) an automatic microcomputer technique is adopted to realize automatic control, so that the efficiency is improved; (2) a fresh air exchange system is adopted, so that the cooking environment is improved; and (3) an automatic smoke hood exhaust adjustment system is adopted, so that the maximum exhaust efficiency is guaranteed.

Owner:杨文旌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com