Patents

Literature

112results about How to "Running balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

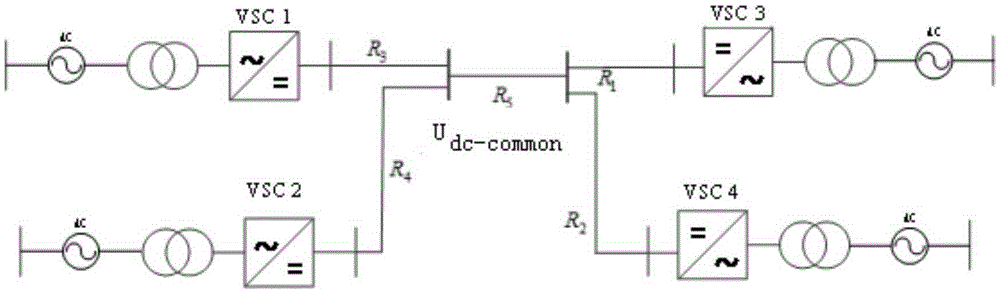

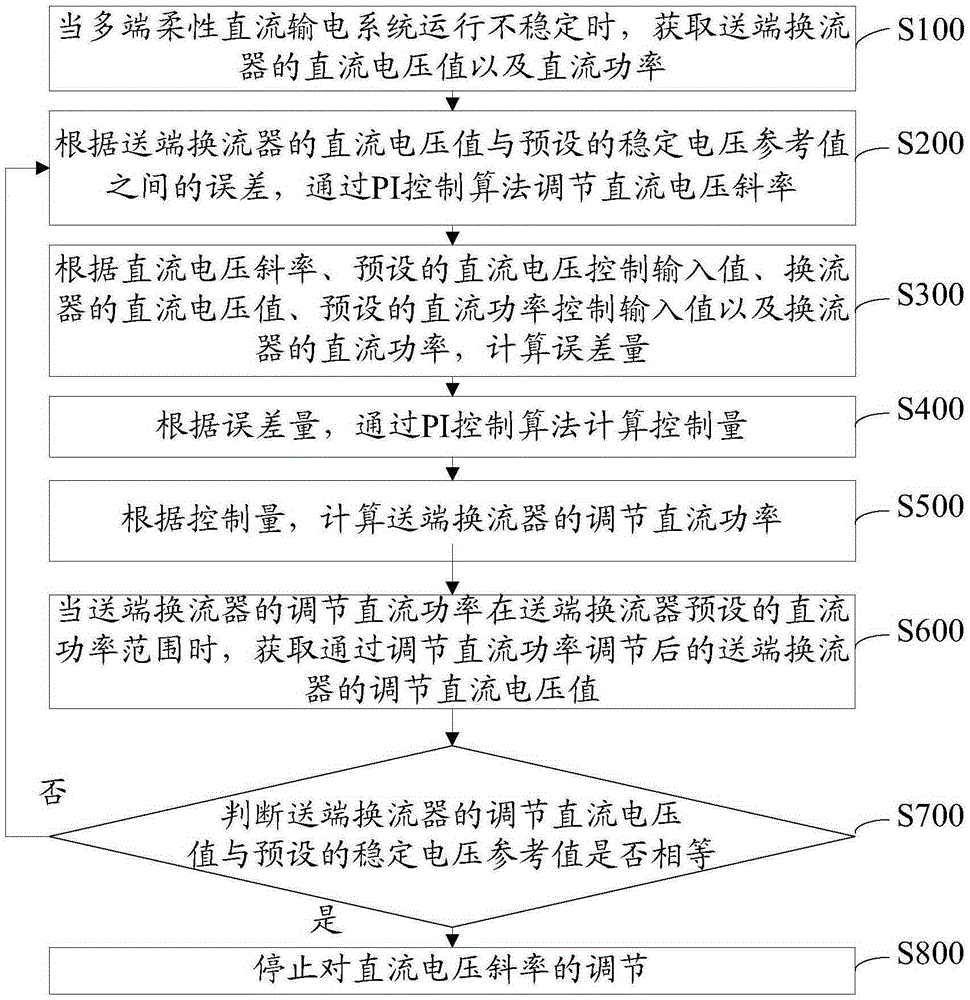

DC voltage slope control method for multiterminal flexible DC power transmission system and system

ActiveCN105244902AAchieve constant controlGuaranteed uptimeElectric power transfer ac networkSelf adaptivePower control

The invention discloses a DC voltage slope control method for multiterminal flexible DC power transmission system and a system. The DC voltage slope control method comprises steps of regulating DC voltage slope through a PI control algorithm according to the error between the DC voltage value and the preset stable voltage reference value, calculating the error amount according to the DC voltage slope, the preset DC voltage control input value, the DC voltage value of a sending terminal converter, the preset DC power control input value and the DC power, calculating at control amount through a PI control algorithm according to the error, and regulating DC power of the sending terminal converter according to the control amount in order to make the DC voltage of the sending terminal converter approximate to a preset stable voltage reference value. Through the fact that the DC voltage slope can perform self-adaption adjustment along the deviation of the DC voltage of the multi-terminal flexible DC power transmission system when the multi-terminal flexible DC power transmission system is disturbed, the invention cannot only regulate the DC power of the current converter to balance the inner power of the DC power transmission system, but also realizes the constant control of the voltage.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

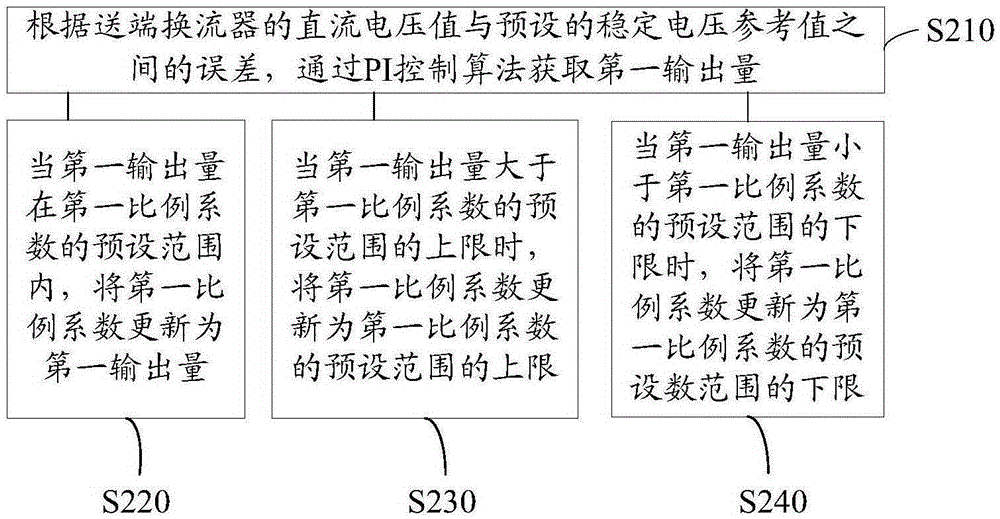

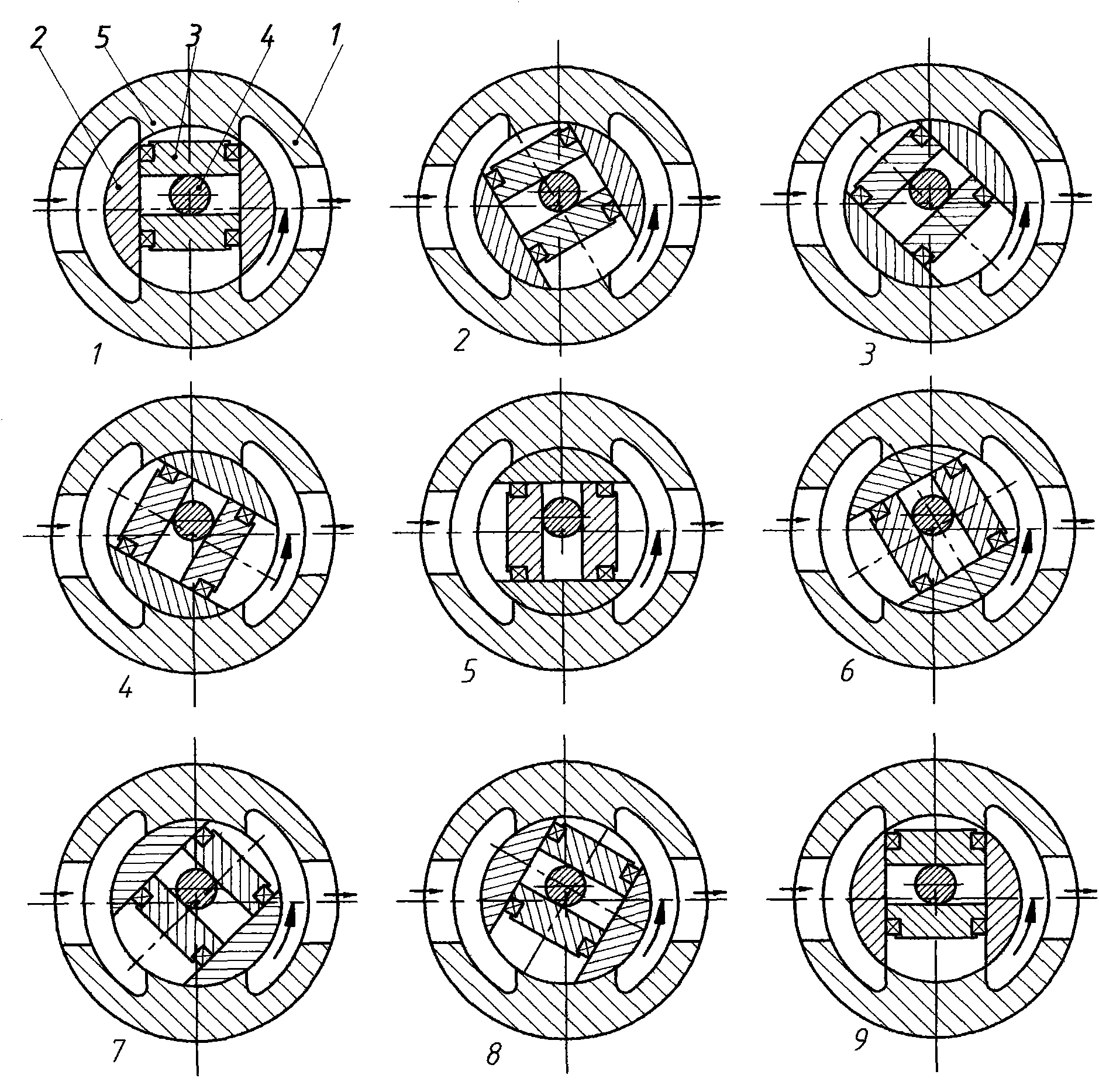

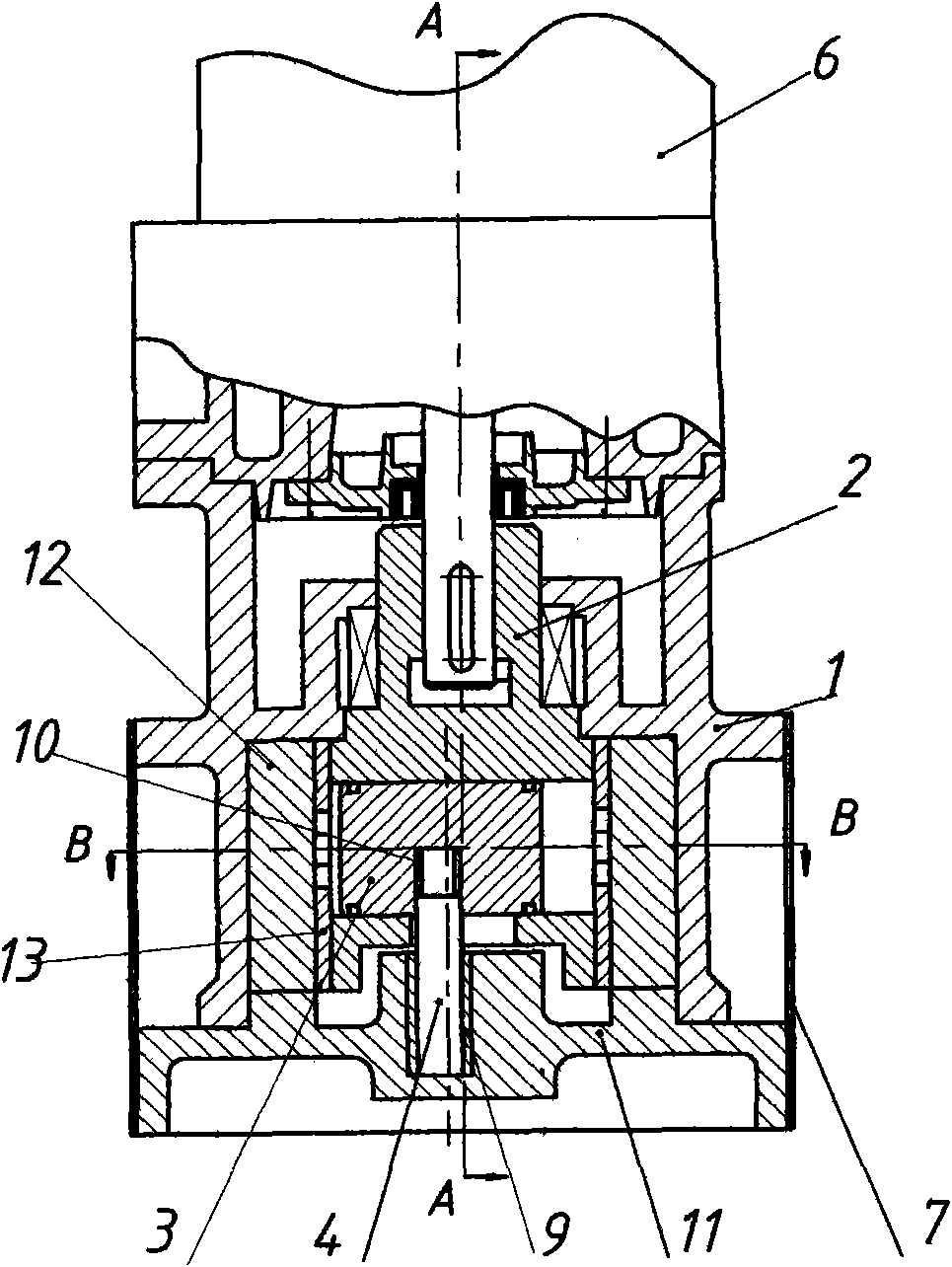

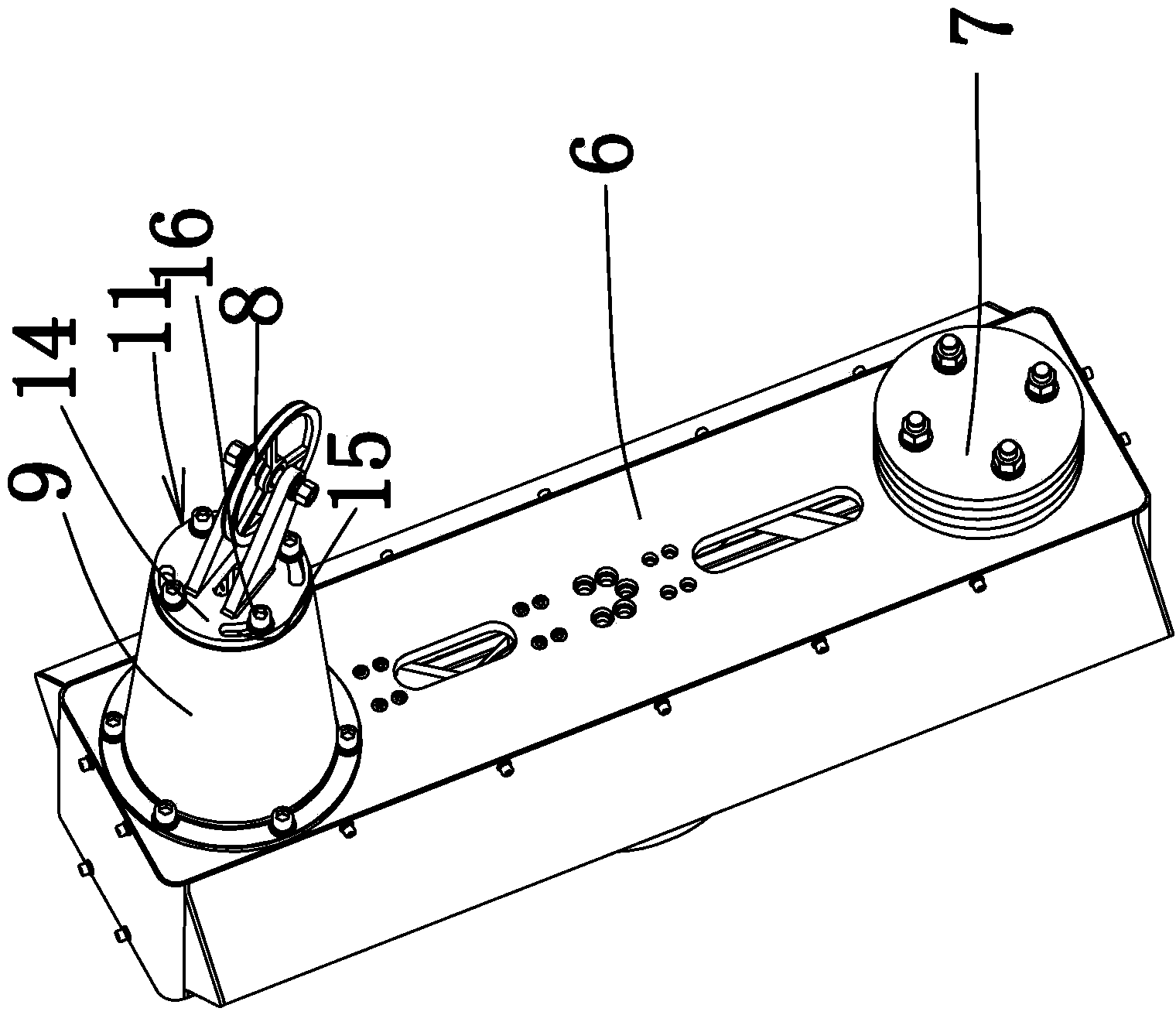

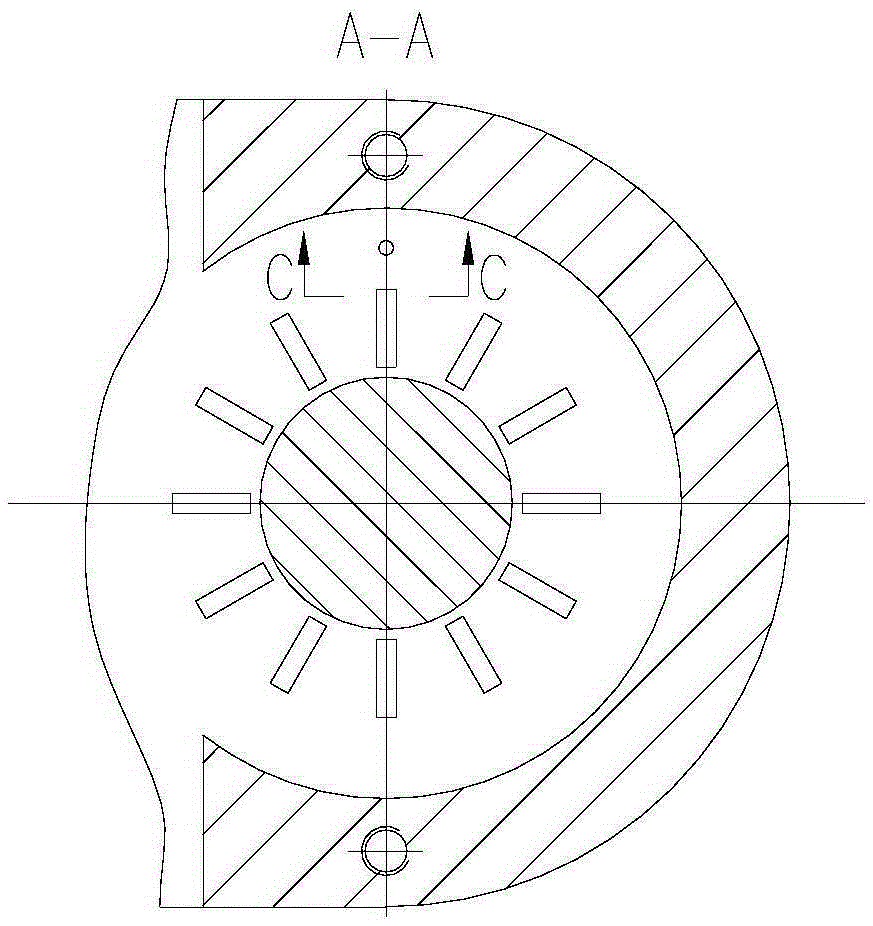

Small rotor-type submersible pump

InactiveCN101871449AGood self-primingWide runnerRotary piston pumpsRotary piston liquid enginesViscous liquidMotor drive

The invention relates to a small rotor-type submersible pump suitable for operation under liquid, which is formed by a pump body, a volute tongue bush, a rotor, a rotor bush, a piston, an eccentric shaft, a pump base, a filter screen and a submersible motor. The invention uses the principle of an eccentric mechanism to realize the reciprocating motion of the piston. When the submersible motor drives the rotor to rotate, the piston rotates around the eccentric shaft while the piston makes reciprocating motion and thereby liquid is drawn in and drained. Under the high-speed rotation, the piston drains liquid two times per turn and thereby the liquid flow output is stable, no pulse is caused, the vibration is low and the noise is low; and moreover, the volume is small, the number of parts is small, the cost is low, the hydraulic loss and the volumetric loss are small, the efficiency is above 70 percent and the pump is a high-efficiency energy-saving product for replacing a centrifugal submersible pump. Moreover, the pump has the good self-absorption performance and the wide runner of a displacement pump and can be used for delivering water liquid and pumping viscous liquid such as petroleum and liquid containing fibrous impurities and particle impurities, and thereby the application scope of the pump is widened.

Owner:余文凌

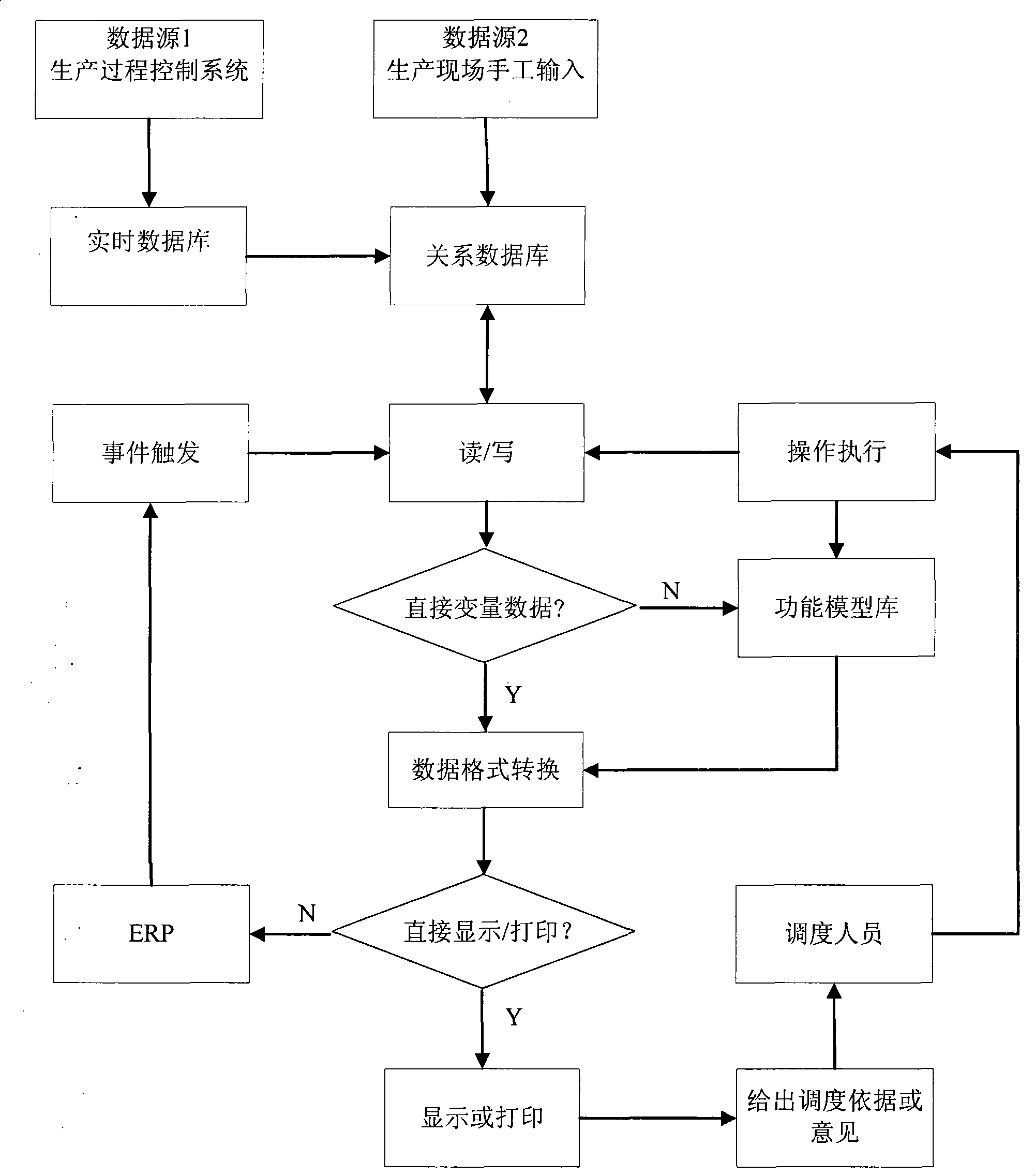

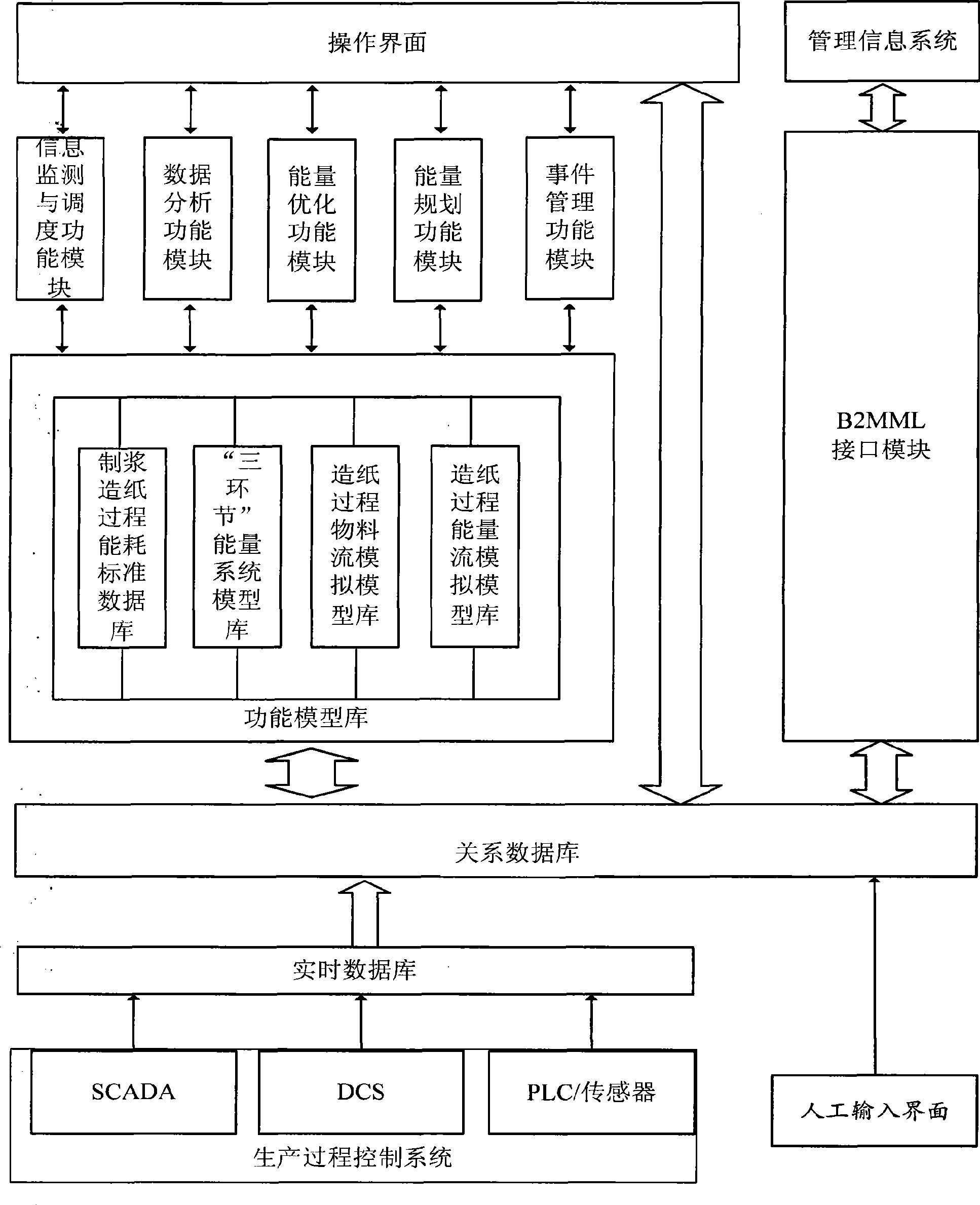

Synthesis optimizing and scheduling method of energy system

InactiveCN101377679AAvoid the Pitfalls of Isolated ResearchImprove labor productivityEnergy industryTotal factory controlScheduling functionRelational database

The method comprises the following steps: firstly, field production energy flow data are input into a relational database through a manual input interface, or a real-time database collects the field production energy flow data transmitted by a production process control system and stores the data into the relational database; secondly, the scheduling personnel operates the information monitoring and scheduling function module, the data analysis function module through an operation interface, or triggers an event management function module through an external event, so as to read and write the relational database, or the scheduling personnel reads and writes the relational database through the operation interface or an management information system, transforms the data format of the read data, transmits the data to the operation interface for displaying or printing or to the management information system; thirdly, the scheduling personnel operates an energy optimizing function module and an energy planning function module to adopt the corresponding optimal scheduling for the production energy system according to the displayed or printed data and advice. The present invention can realize the global optimization of the enterprise energy scheduling.

Owner:SOUTH CHINA UNIV OF TECH

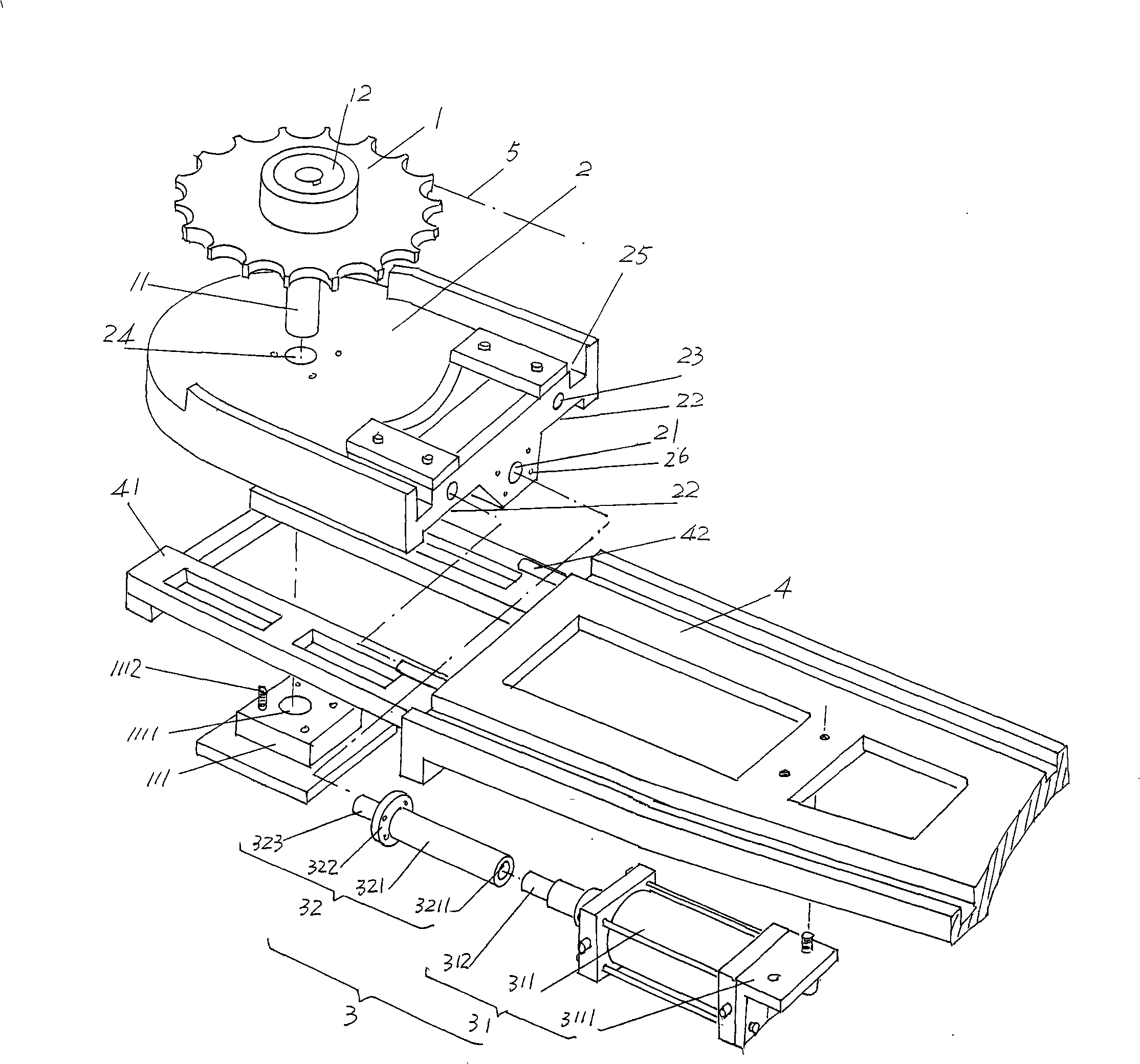

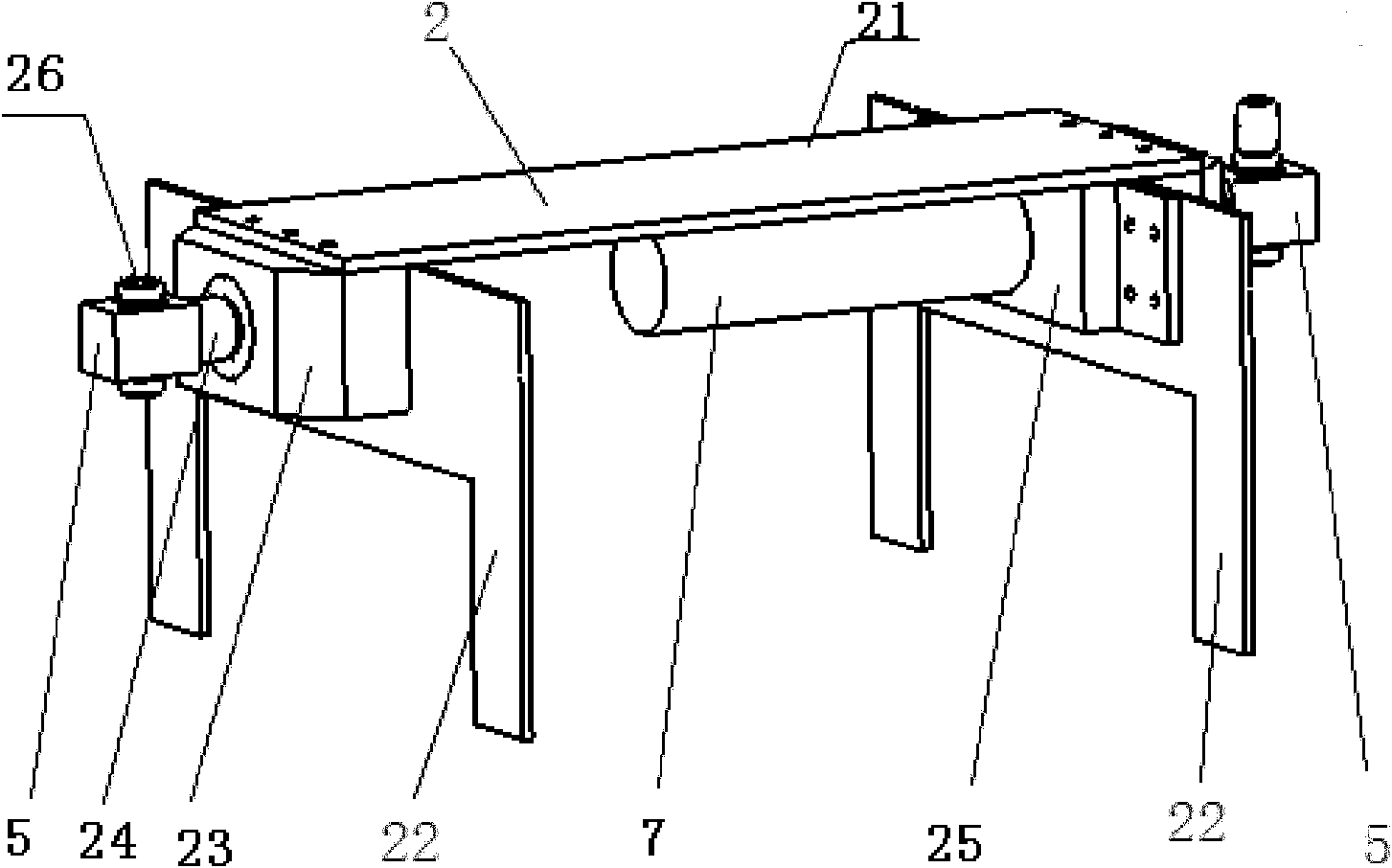

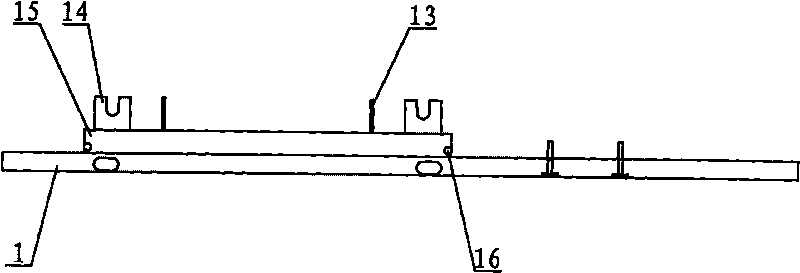

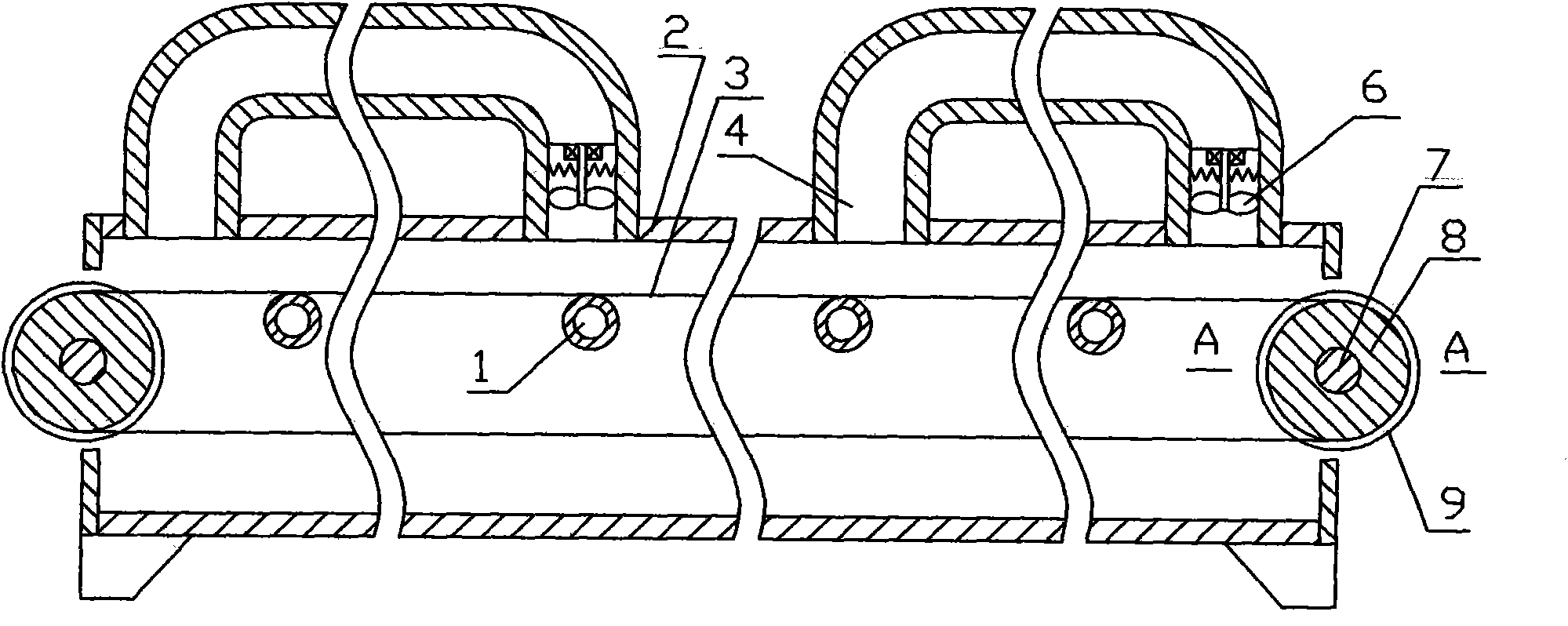

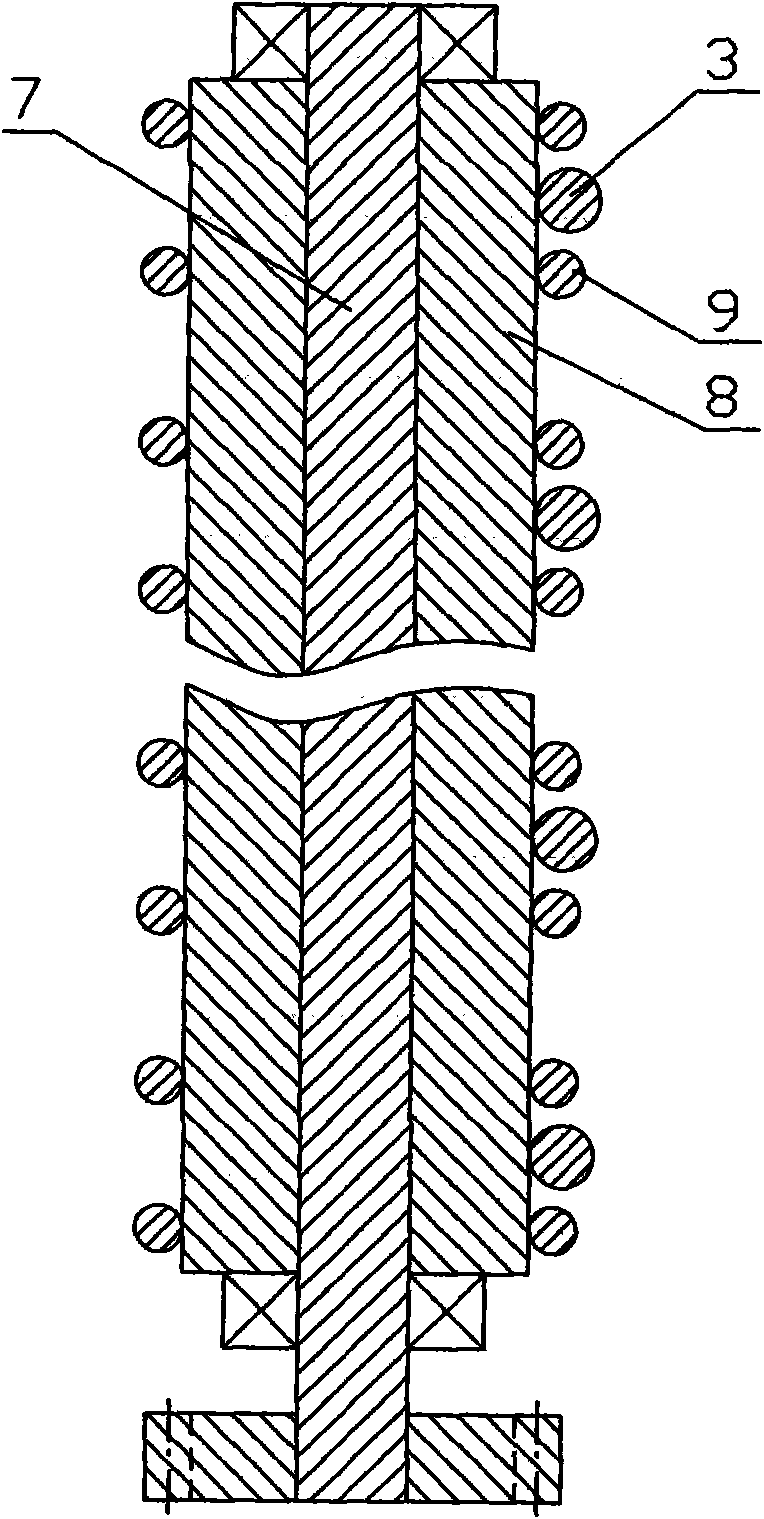

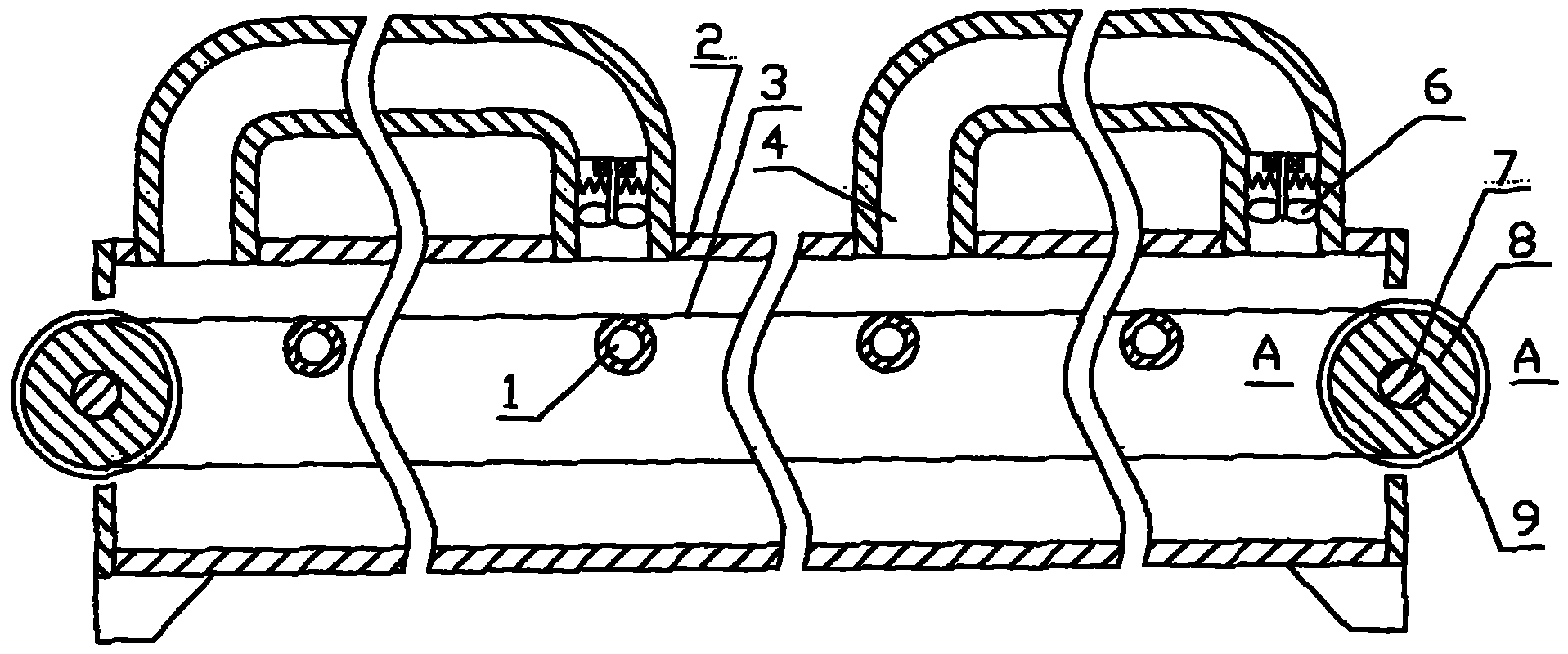

Chain transmission tension regulating mechanism of framing shaping machine

A chain transmission tensioning mechanism of a shaping tenter belongs to the after-finish machinery technology field of non-woven products. The mechanism comprises a chain wheel, a sliding seat and a tensioning, wherein, the chain wheel is rotationally arranged on the sliding seat through a central shaft; the sliding seat is connected with the tensioning device; and the sliding seat and the tensioning device are in sliding fit on a machine head. The mechanism is characterized in that the tensioning device comprises an acting cylinder and an ejector rod; the cylinder body of the action cylinder is fixed on the machine head of the tentering and forming machine; the cylinder column of the acting cylinder is matched with one end of the ejector rod; and the other end of the ejector rod is fixed with the sliding seat. The mechanism has the advantages that the acting cylinder is adopted to realize tension control instead of adopting a spring to realize tension control on the tension device in the prior art, therefore, constant tension control can be realized for chain transmission, so as to allow the chain transmission to be balanced, and ensure that the shaped non-woven fabrics have the consistent shaping effect.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

Biped walking four-bar mechanism

InactiveCN102114879ASolve the function of changing line movementRealize three degrees of freedom movementVehiclesLinear motionUniversal joint

The invention relates to a biped walking four-bar mechanism which comprises two parallel moving feet, two connecting bars, three motors and four universal joints, wherein the two moving feet and the two connecting bars are connected through the four universal joints to form a monocycle closed-type parallel four-bar mechanism; the two moving feet are respectively provided with the motors which areparallel to the moving feet, and when one moving foot steps on the ground, the motor on the moving foot drives the other moving foot to rotate around the moving foot, so that the two moving feet moveup and down alternately to move forward; the motors on the two moving feet work synchronously, and the lifted moving foot can rotate around the rotating axis thereof, so that supporting plates remainin downward positions; and the third motor is perpendicularly arranged at the end of any connecting bar, which is in connection with one moving foot, and the connecting bar is driven by the third motor to rotate by taking the moving foot as an axis, so as to drive the other moving foot to laterally move. Accordingly, the biped walking four-bar mechanism achieves the effect of three-degree-of-freedom motion and the function of adjusting a detection attitude, and solves the problem that the simple four-bar travel mechanism fails to serve the function of non-linear motion.

Owner:BEIJING JIAOTONG UNIV

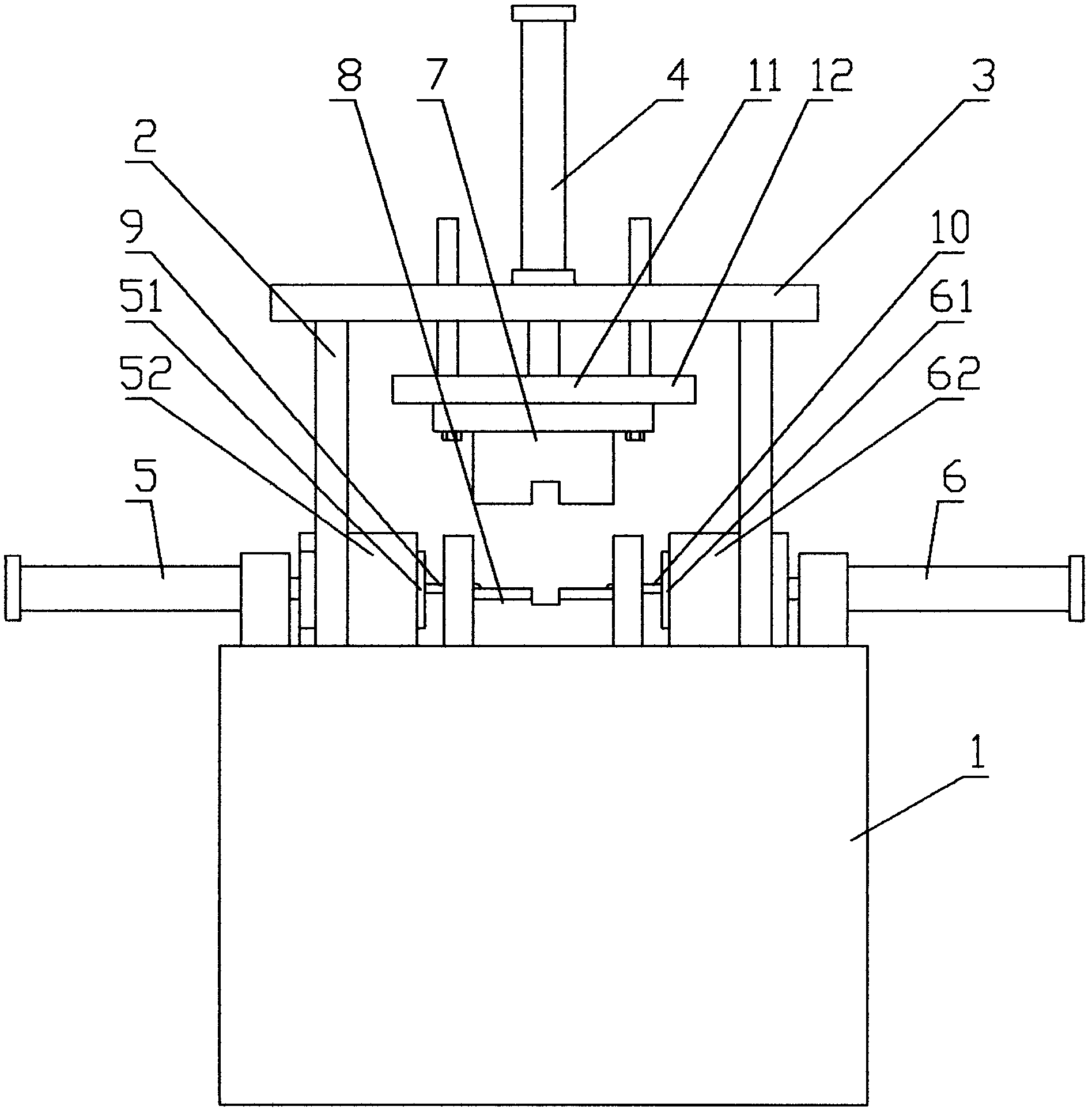

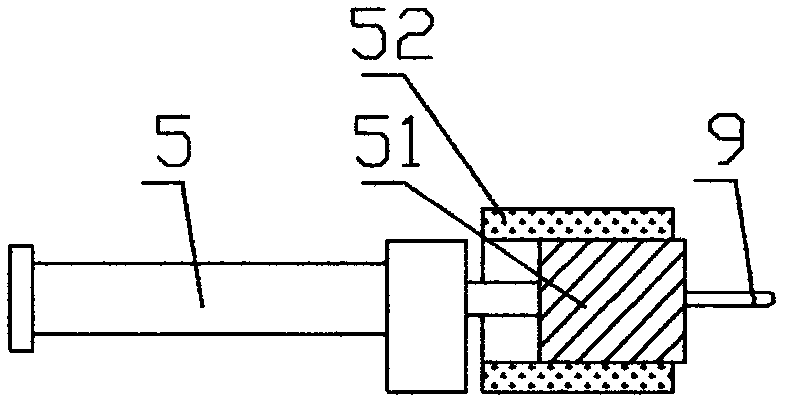

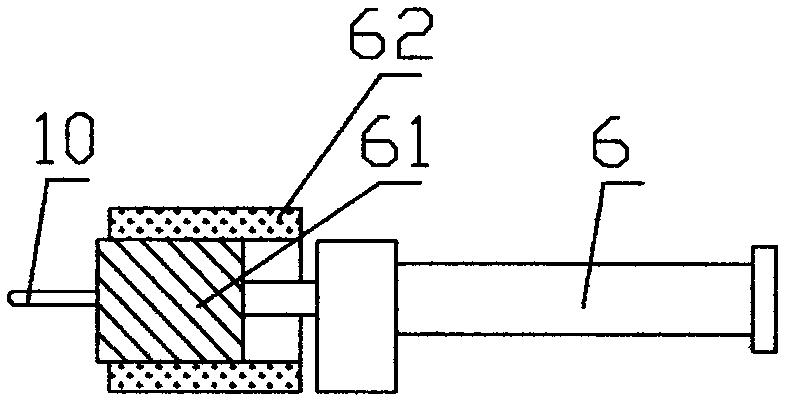

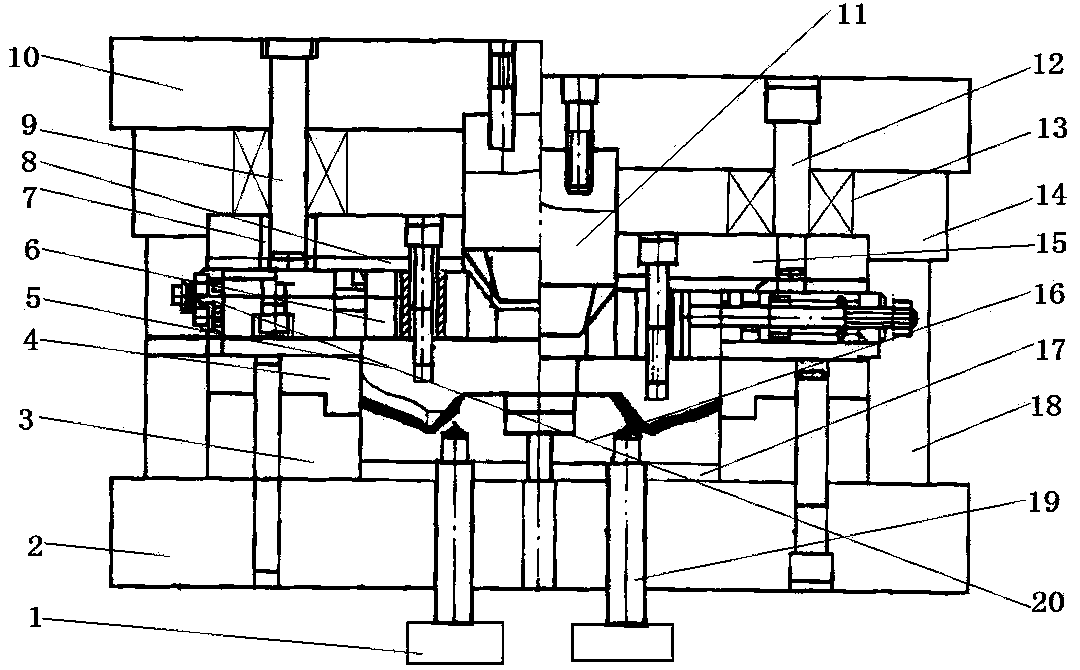

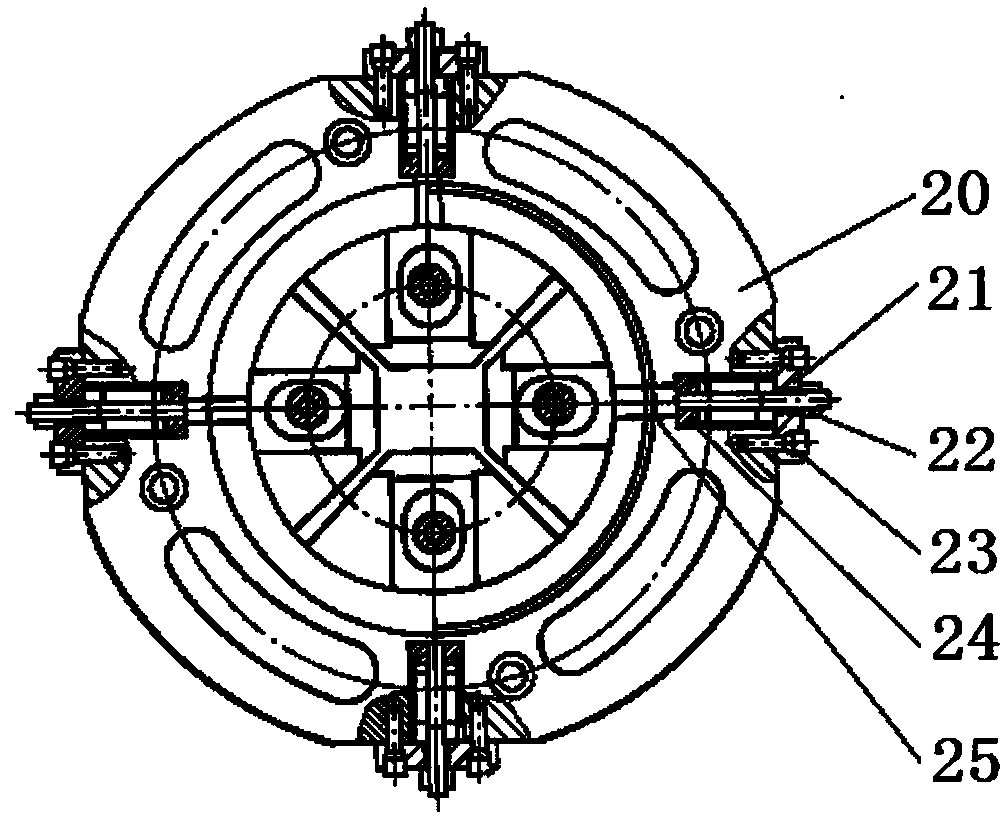

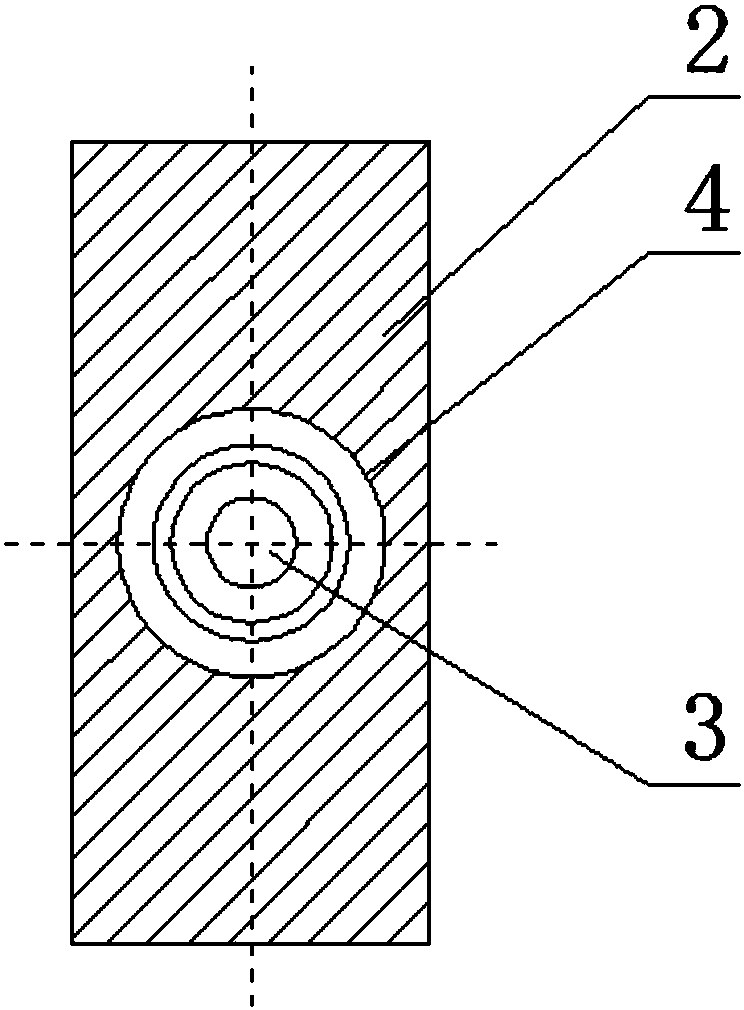

Bilateral special-shaped hole punching machine

The invention discloses a bilateral special-shaped hole puncher. In the bilateral special-shaped hole puncher, a left punch and a right punch are driven by a left hole punching oil cylinder and a right hole punching oil cylinder so as to punch holes on a metal rod piece which is clamped in an upper mould semicircular groove and a lower mould semicircular groove. An upper mould is fixed on an upper mould pressure plate; the upper mould pressure plate is fixed on the piston rod of an upper mould driving oil cylinder; a lower mould is fixed on a working table; the upper mould semicircular groove, an upper mould piece-fetching square groove and a positioning square groove are formed on the upper mould; the lower mould semicircular groove, a lower mould piece-fetching square groove and a step are formed on the lower mould; the upper mould semicircular groove is opposite to the lower mould semicircular groove; the upper mould piece-fetching square groove is opposite to the lower mould piece-fetching square groove; and the positioning square groove is clamped on the step. The holes with different diameters can be punched on the two sides of the metal rod piece at the same time by the bilateral special-shaped hole puncher, a workpiece is convenient to fetch and place, and production efficiency is improved; meanwhile, the moulds of the bilateral special-shaped hole puncher can ensure that the metal rod piece does not deform greatly in the hole punching process, and the yield of products is high.

Owner:东莞市才立金属科技有限公司

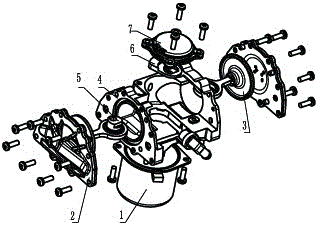

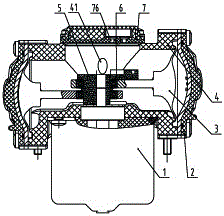

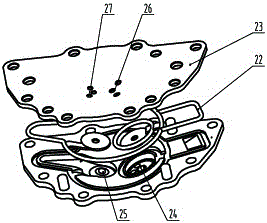

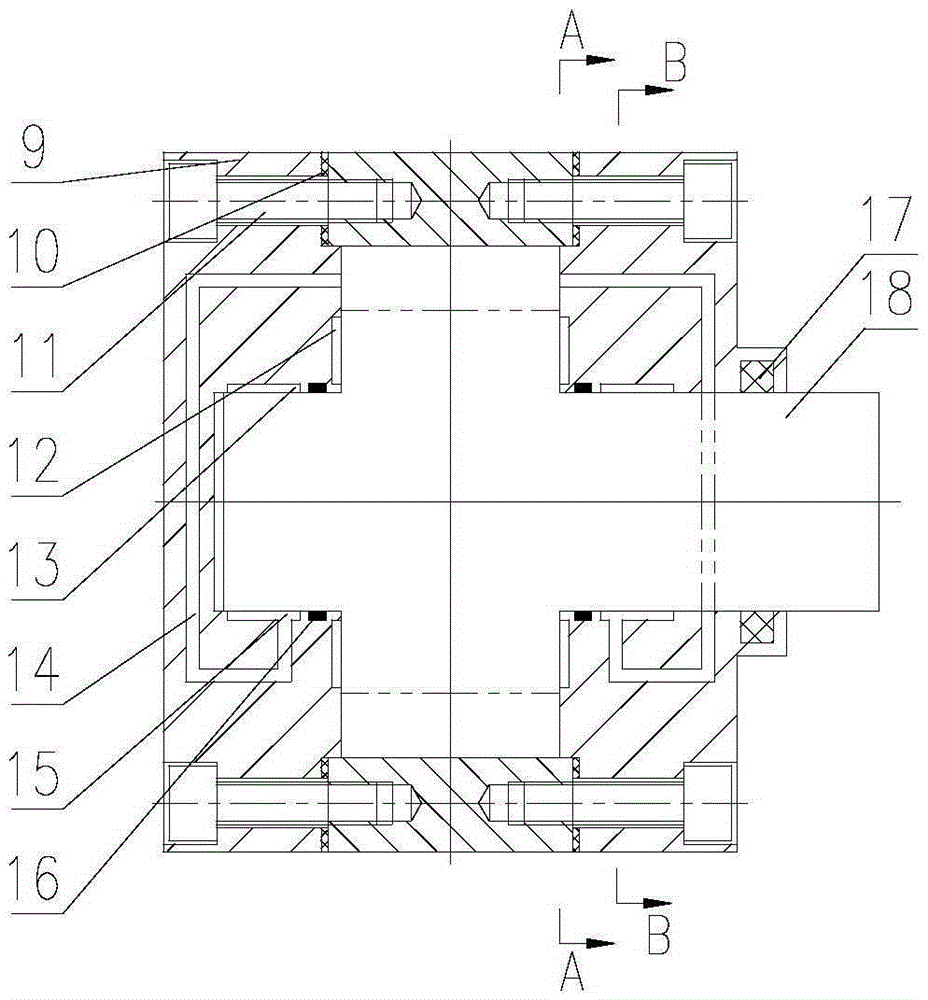

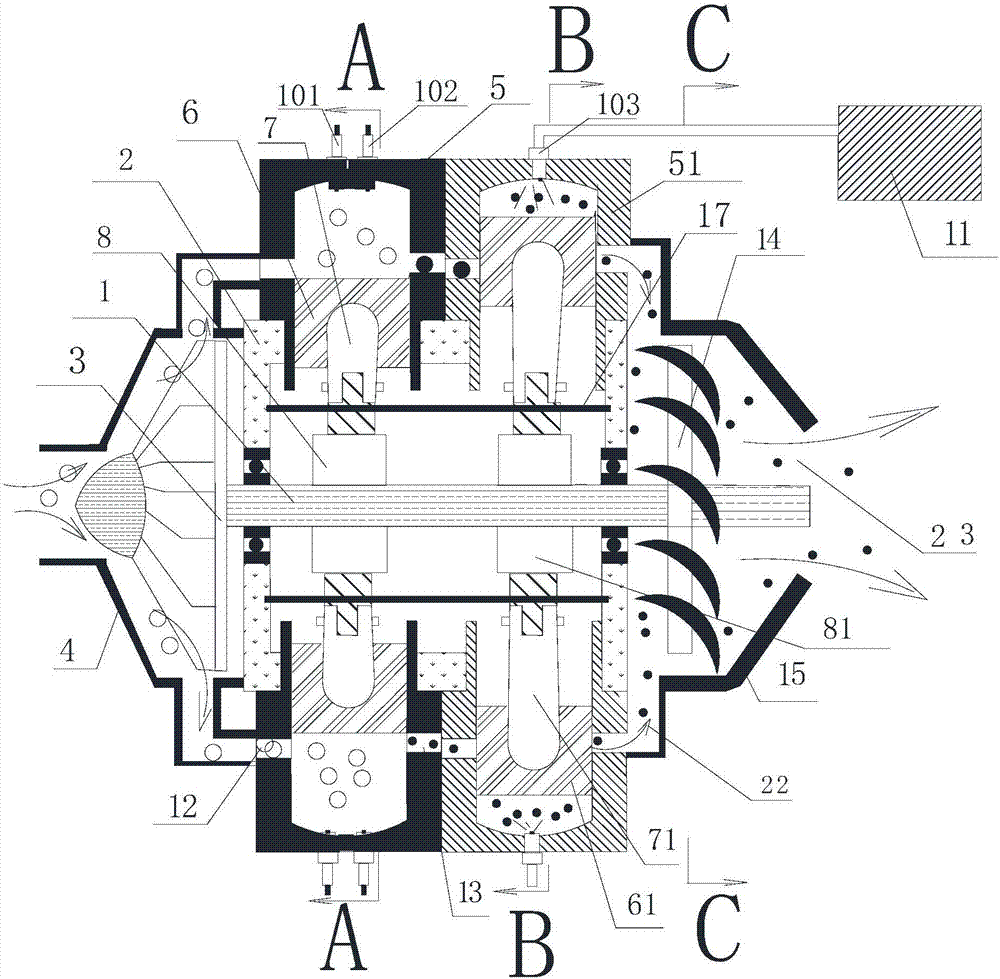

Air entering/draining mechanism for membrane type automobile electric vacuum pump

InactiveCN105889041AReduce energy consumptionRunning balancePositive displacement pump componentsFlexible member pumpsPistonMembrane configuration

The invention belongs to the field of an automobile brake assisting system and particularly relates to an air entering / draining mechanism for a membrane type automobile electric vacuum pump. The air entering / draining mechanism for the membrane type automobile electric vacuum pump disclosed by the invention comprises a motor and a pump body, wherein an air entering / draining channel is arranged on the pump body; left and right end cover components are arranged at the left and right ends of the pump body; when a forming chamber in the membrane is maximal, the air entering / draining mechanism is under air exhaust state; when the forming chamber in the membrane is under negative pressure and generates suction force, and the forming chamber volume at the oppositely arranged piston component is minimal, the air entering / draining mechanism is under the exhausting state; a counterbalance matched with a spindle is arranged on the pump body. The air entering / draining mechanism for the membrane type automobile electric vacuum pump has the beneficial effects of better air exhaust property, higher safe coefficient, longer service life and accumulative work time reaching above 1200 hours.

Owner:HUZHOU ANRUINENG HYDRAULICPNEUMATIC TECH CO LTD

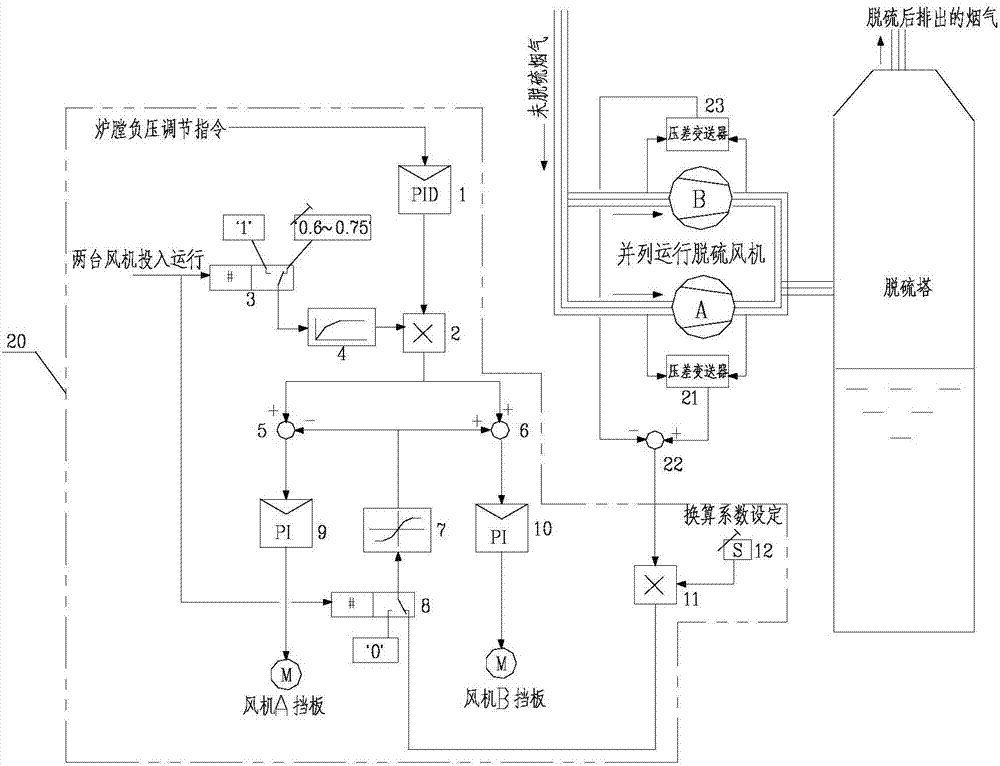

Control method for preventing parallel running fans from tacking phenomenon

InactiveCN106861407ASmooth switching processIncrease resistanceDispersed particle separationPump controlBoiler furnaceSmoke

The invention relates to a control method for preventing parallel running fans from tacking phenomenon. The method comprises the following steps: adopting a pressure difference transmitter for measuring pressure difference at outlet and inlet of each fan; performing subtraction on the measured pressure difference signal values of the two fans; applying an operation result to a regulation control loop for an opening degree of a baffle of each fan; and under the conditions that no correction function is executed when a single fan runs and each pressure difference signal and the smoke volume passing by each fan are in direct proportion to each other when the two fans run, correcting the regulation control loop for the opening degree of the baffle of the fan by the operation result of the pressure difference signal subtraction according to different directions and strengths, maintaining the equal smoke volume passing by each fan as far as possible and balancing the fan running, and meanwhile, receiving a boiler furnace negative pressure regulation instruction by the regulation control loop for the opening degree of the baffle of the fan, thereby synchronously acting according to the boiler furnace negative pressure regulation instruction and reducing the influence on the running safety of the boiler.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

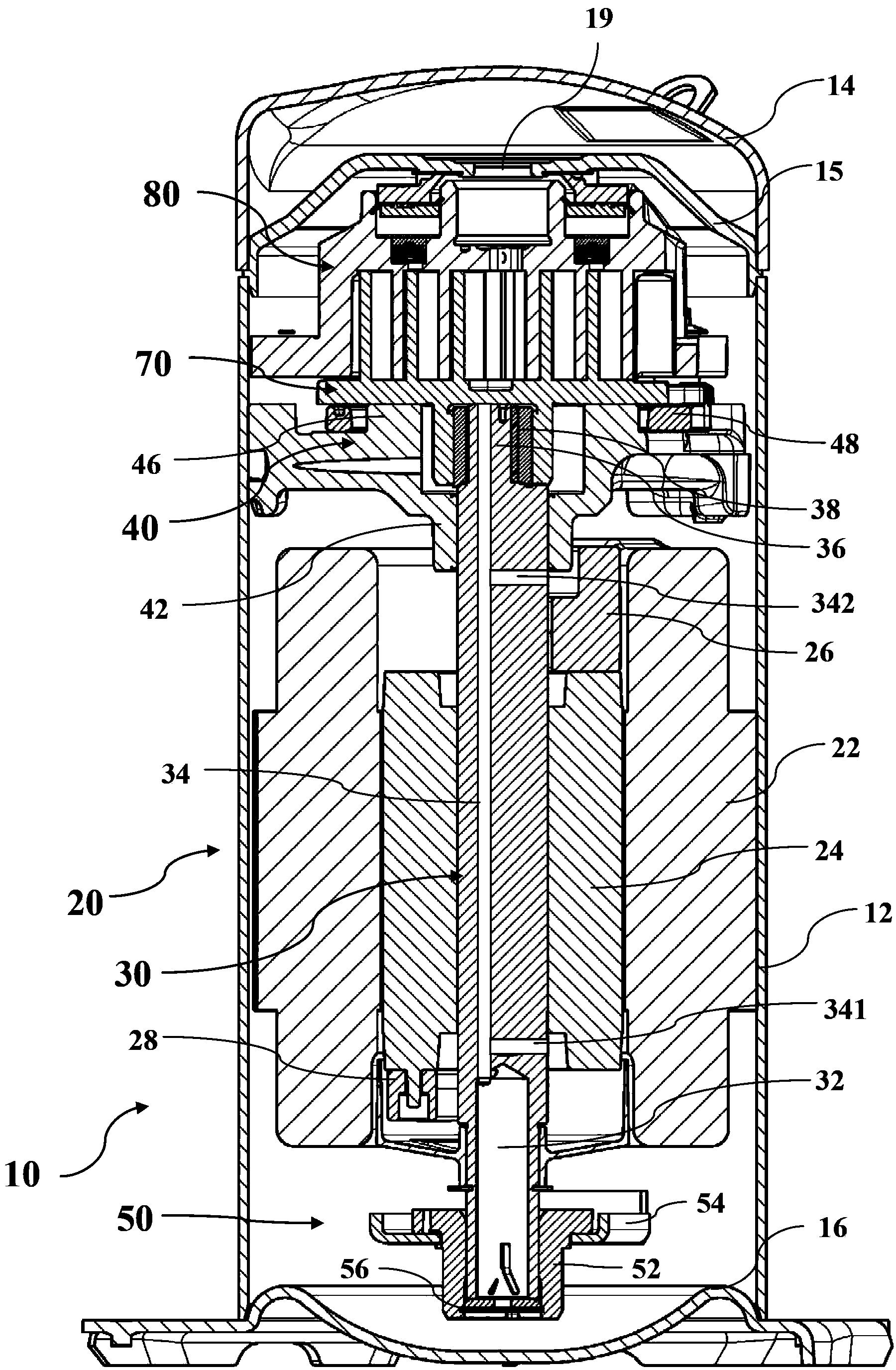

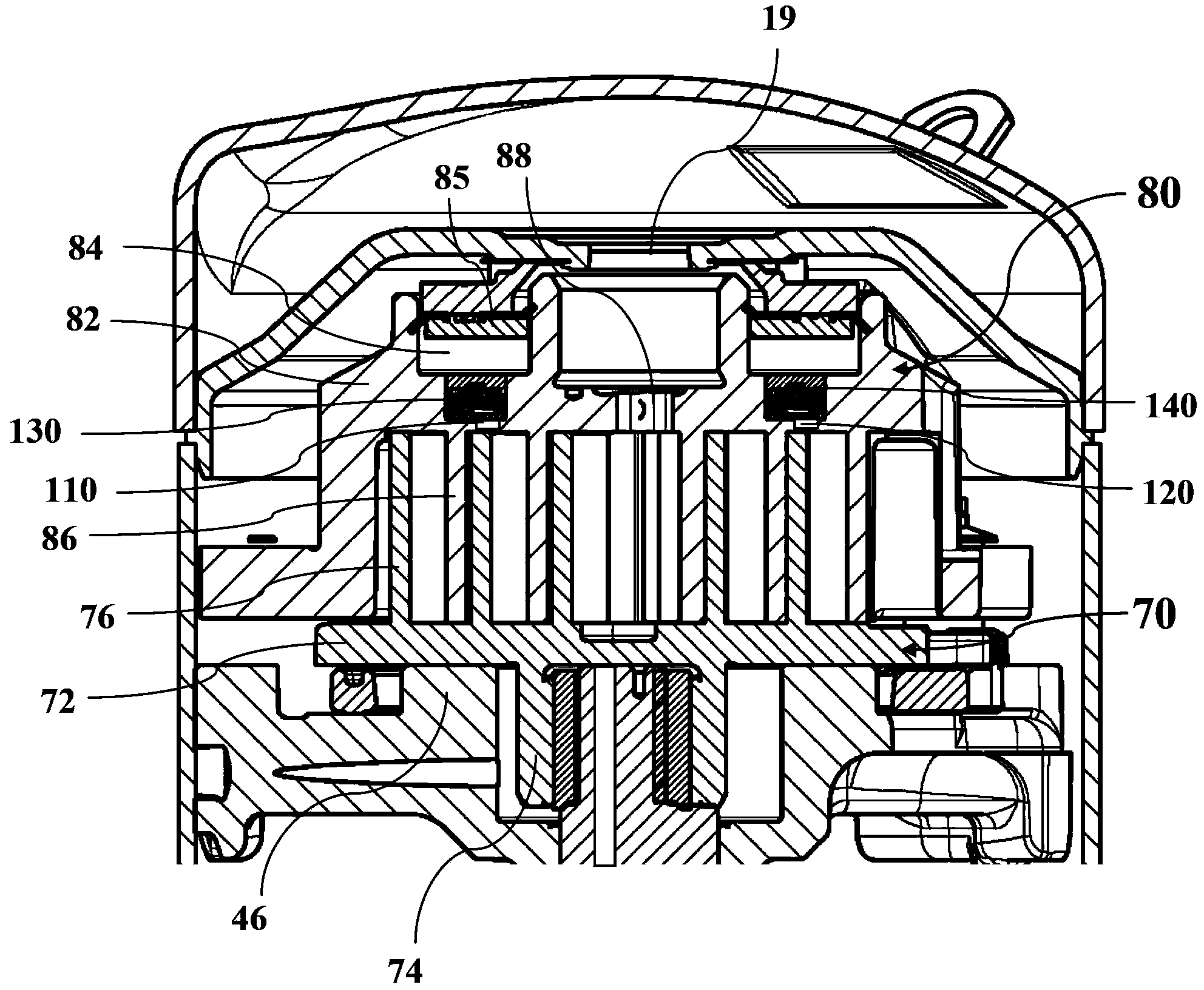

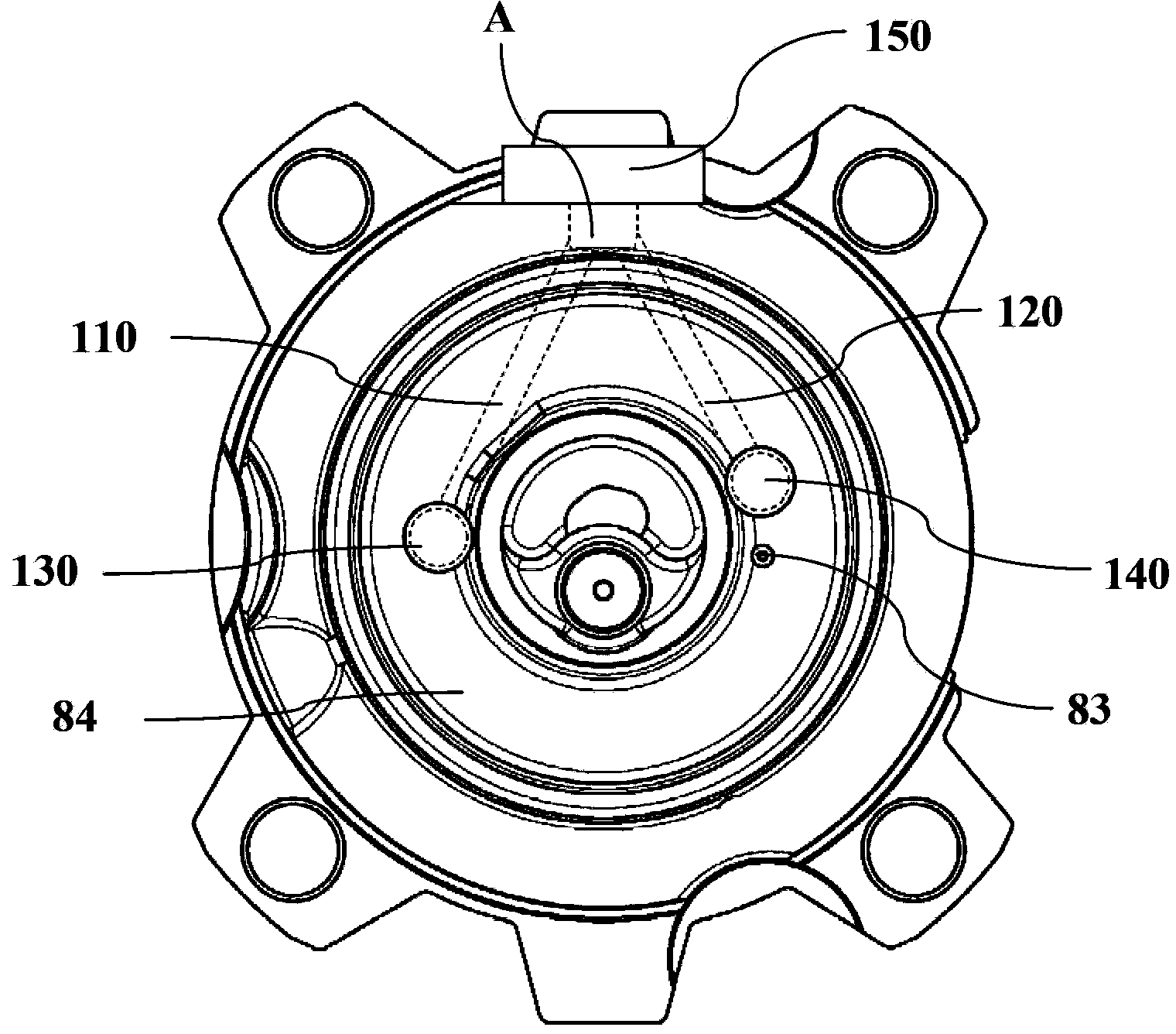

Compressor

ActiveCN103573619ASave design costSave manufacturing costRotary piston pumpsRotary piston liquid enginesControl valvesDischarge pressure

A disclosed compressor (10) comprises: a shell (12) in which an inspiratory pressure zone and an exhaust pressure zone are defined, and a compression mechanism arranged in the shell; and the compression mechanism comprises: a first vortex part (80) comprising a first end plate (82) and a first vortex blade (86), a second vortex part (70) comprising a second end plate (72) and a second vortex blade (76), a first communication channel (110) which is arranged between a first compression chamber (C1) and the inspiratory pressure zone and selectively provides fluid communication, and a first control valve (150). When the first control valve closes the first communication channel, the compressor works with full capacity, and when the first valve opens the first communication channel, the compressor works with reduced capacity. The compressor provided by the invention helps to realize capacity adjusting of compressors by employing a relatively simple manner.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

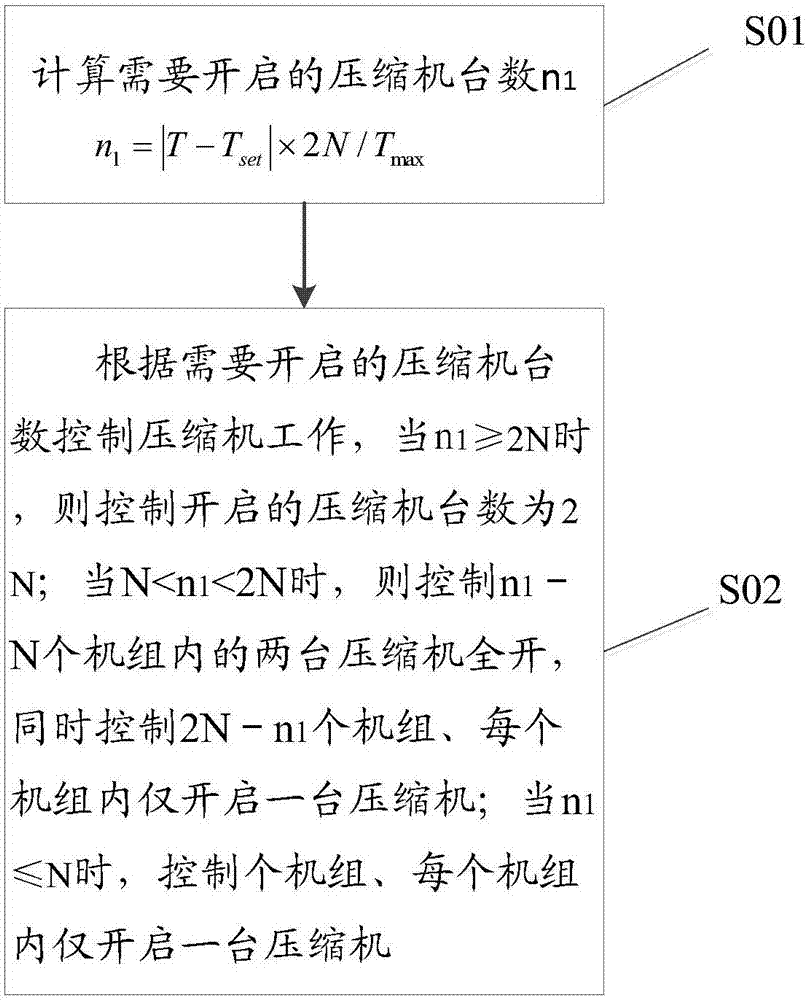

Compressor control method and system of modular water machine

ActiveCN107062554ASolve technical problems such as low energy efficiency ratioRunning balanceMechanical apparatusSpace heating and ventilation safety systemsBusiness efficiencyTemperature difference

The invention discloses a compressor control method and system of a modular water machine. The compressor control method comprises the steps that the number n<1> of compressors needing to be started is calculated through a formula shown in the specification, wherein N is the number of modular water machine units which are in parallel connection in the system, T<max> is the full open temperature difference when the units are started for the first time, T<set> is the set refrigeration or heating temperature, and T is the current environment temperature; the compressors are controlled to work according to the number of the compressors needing to be started, and when n<1> is equal to or larger than 2N, the number of the compressors controlled to be started is 2N; when n<1> is larger than N and smaller than 2N, the two compressors in each of the (n<1>-N) units are controlled to be fully opened, and meanwhile, only one compressor in each of the (2N-n<1>) units is controlled to be started; and when n<1> is smaller than or equal to N, only one compressor in each of the n<1> units is controlled to be started. By adoption of the design, operation of a water machine system can be balanced, the number of the working compressors is determined by referring to actual supply and demand conditions, the situation that only the adaptive number of the compressors are controlled to work can be achieved, compressor working waste or insufficiency is avoided, and the system energy efficiency ratio is increased.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

Horizontal trimming mold

The invention provides a horizontal trimming mold which comprises an upper mold holder and a lower mold holder. The lower mold holder is provided with a female mold body, a female mold fixing base, a base plate and a retainer plate. A wedge central spindle and a supporting plate are installed on the upper mold base. A pressing plate is arranged below the supporting plate. A cutter is arranged between the supporting plate and the pressing plate. The cutter is clamped between the supporting plate and the pressing plate through a limiting sleeve and attached to the slope of the wedge central spindle. A gap adjustment plate is further connected to the supporting plate. Reset mechanisms are arranged in the gap adjustment plate. According to the horizontal trimming mold, the wedge central spindle and the movable cutter are matched with the female mold body to work, trimming work on the periphery of a workpiece can be completed at a time, and the production efficiency is high. Meanwhile, the reset mechanisms and a locating mechanism of the workpiece are further arranged in the horizontal trimming mold, therefore, the horizontal trimming mold is stable on the whole, stable in operating and balanced, the machined workpiece is not prone to being deformed, the quality of the workpiece is high, and the follow-up work requirement can be well met.

Owner:TAICANG WEIGUAN ELECTROMECHANICAL

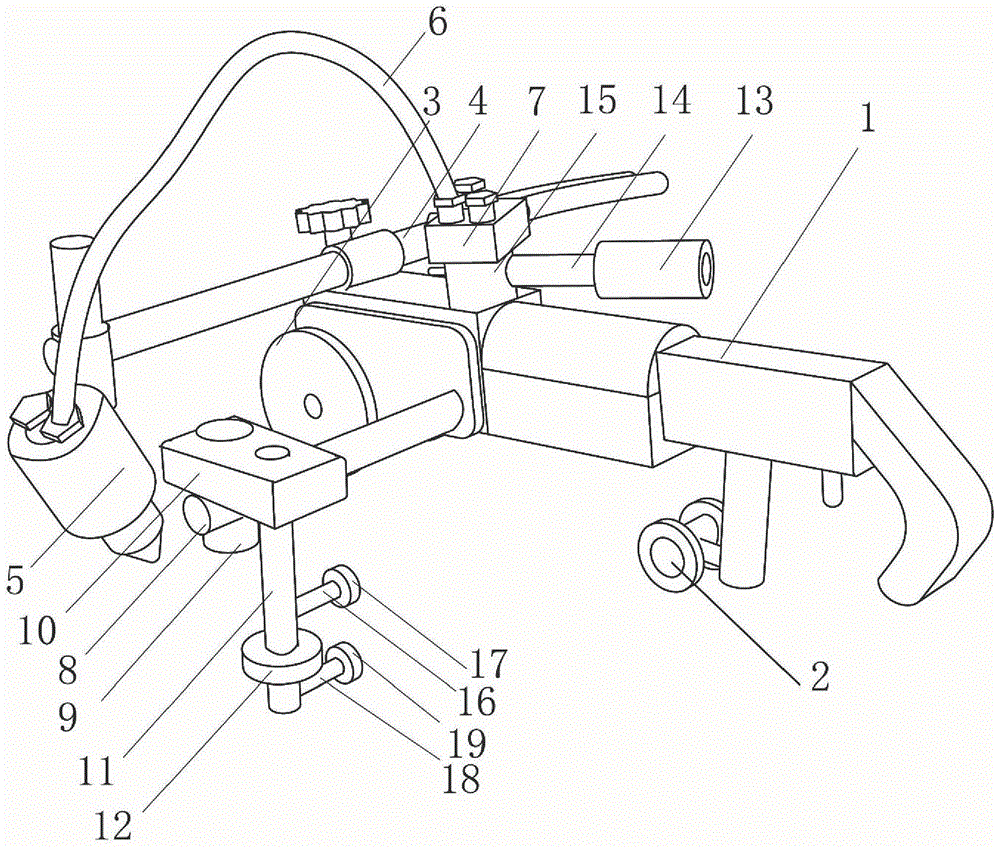

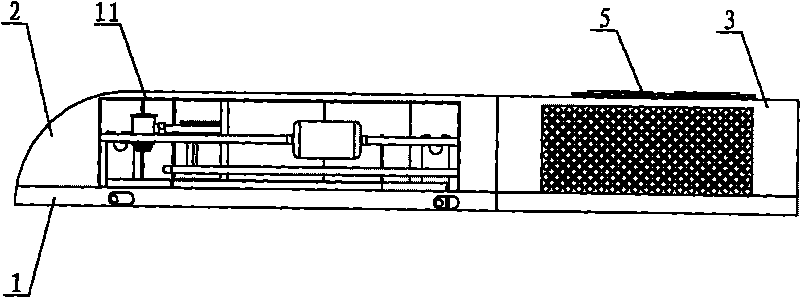

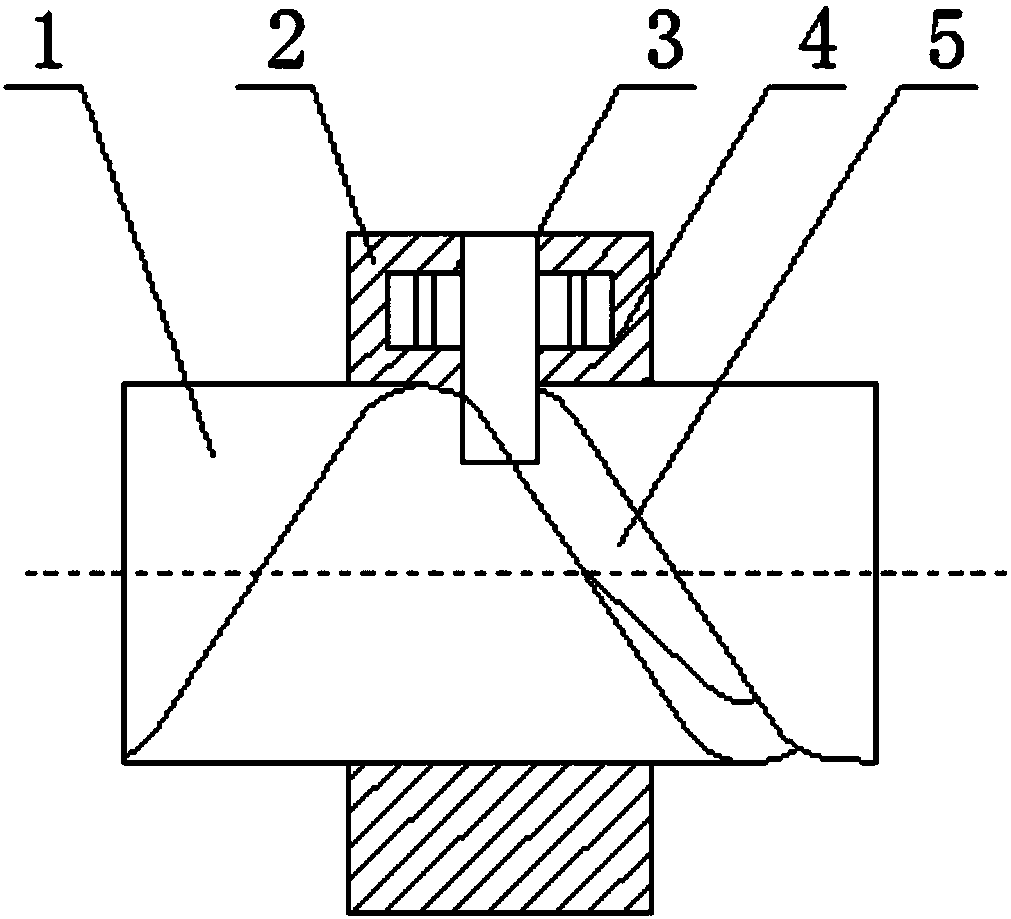

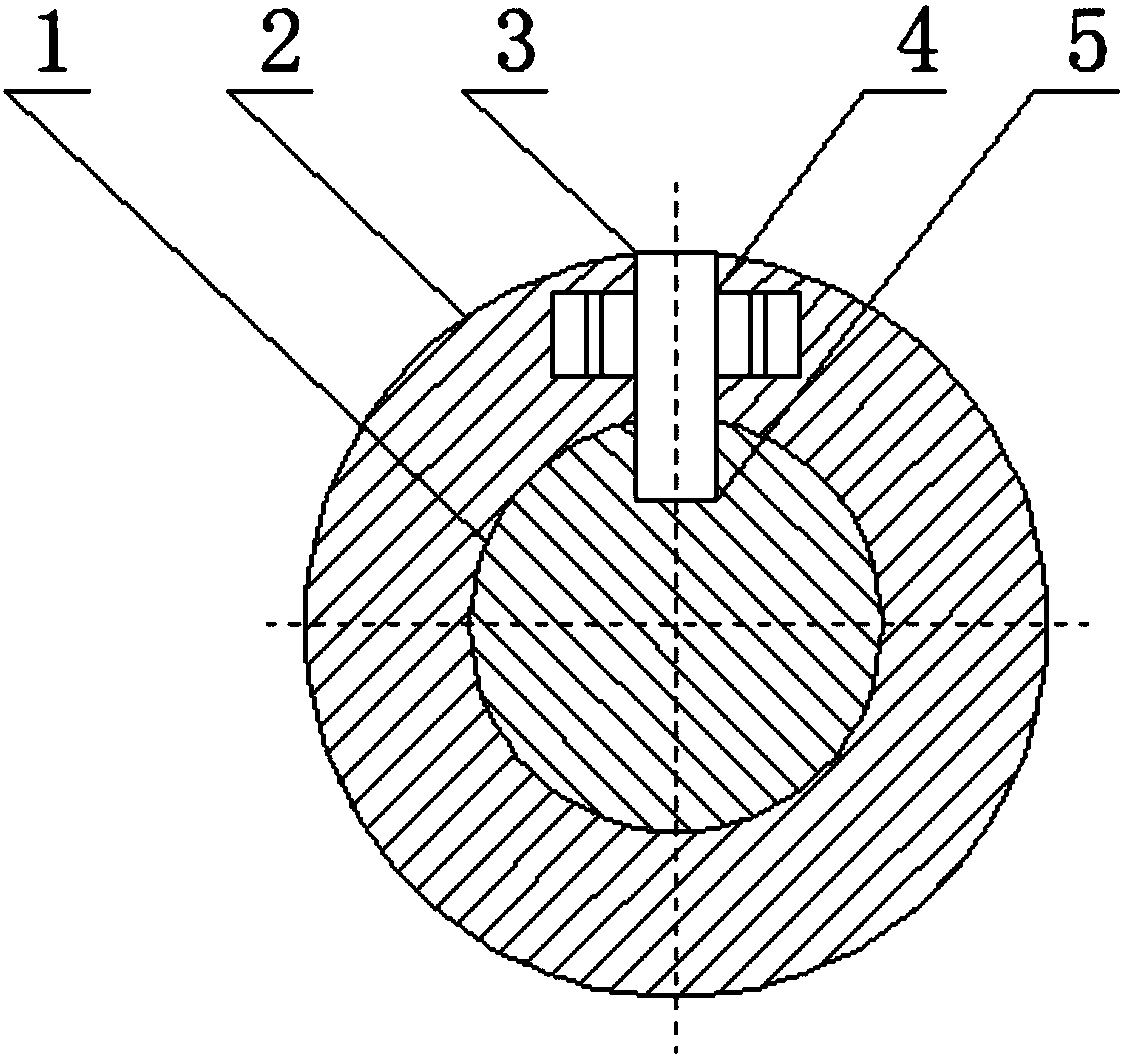

Chamfering and cutting flame trolley

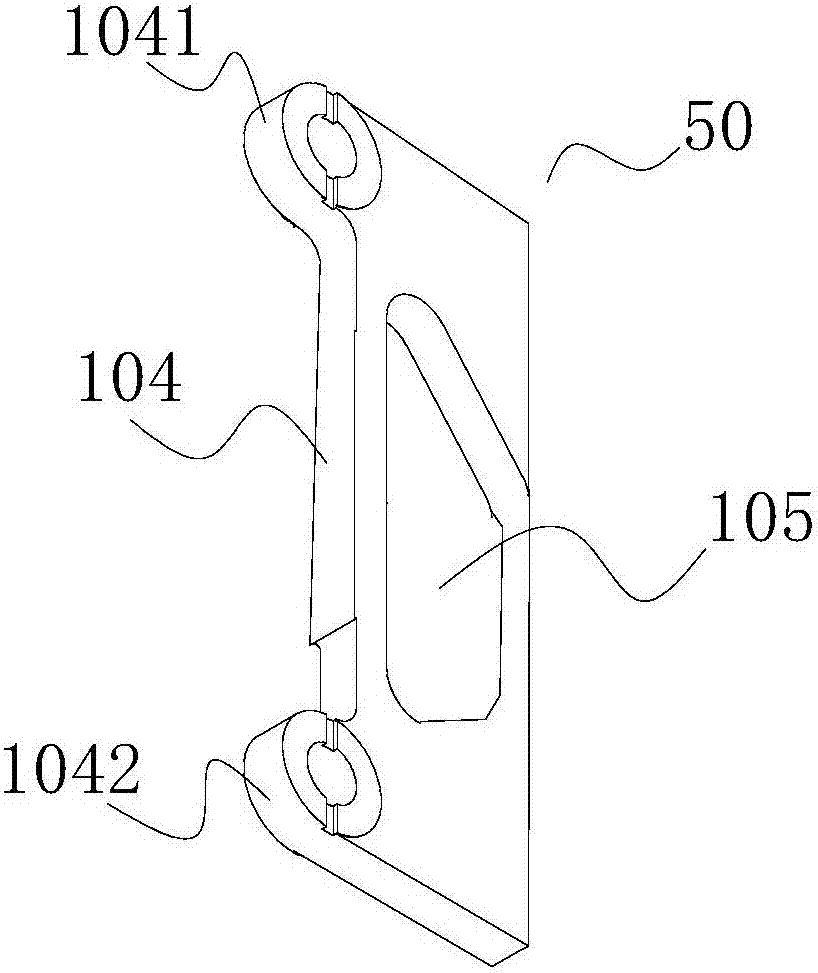

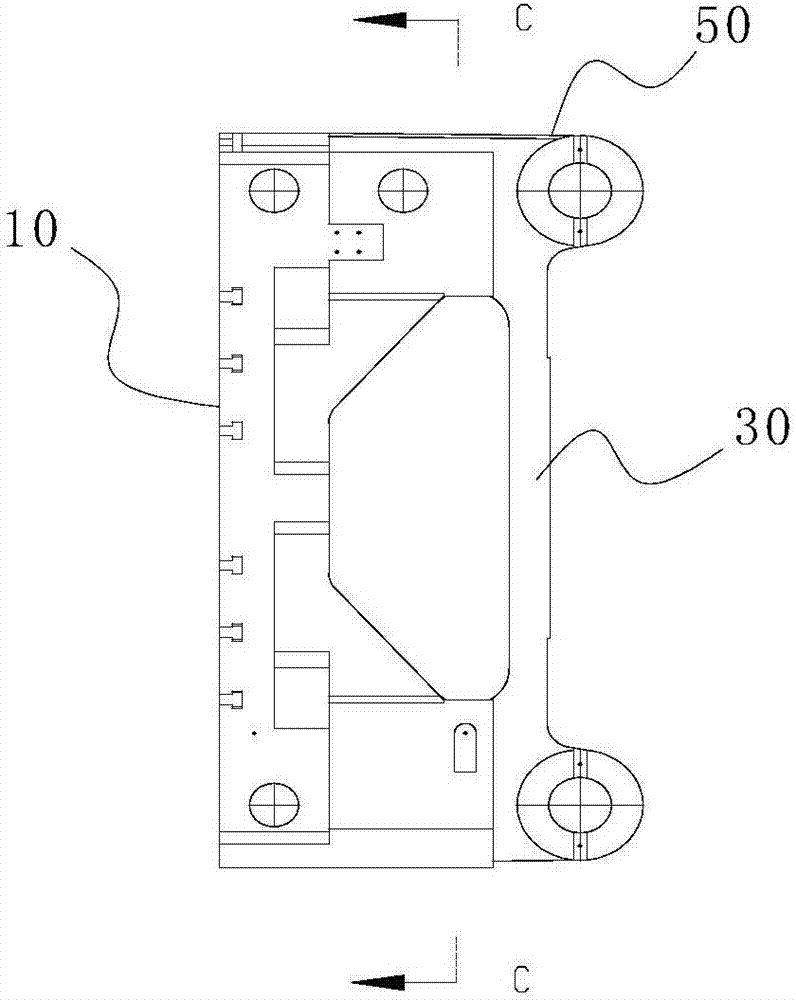

The invention discloses a chamfering and cutting flame trolley, comprising a flame gas cutting machine main body (1), a universal wheel (2), traveling wheels (3), a tail adjusting rod (4) and a flame sprayer (5), wherein the universal wheel (2) and the traveling wheels (3) are respectively mounted on the front part and the rear part of the flame gas cutting machine main body (1); one end of the tail adjusting rod (4) is connected with the flame gas cutting machine main body (1); and the other end of the tail adjusting rod (4) is provided with the flame sprayer (5) which is connected with a gas delivery pump (7) on the flame gas cutting machine main body (1) through a gas delivery pipe (6). The chambering and cutting flame trolley is characterized in that a side connecting rod (8) is fixed on the side, with the flame sprayer (5), of the flame gas cutting machine main body (1); and the side connecting rod (8) is connected with a guide clamping piece (10) through a side lifting rod (9). According to the chamfering and cutting flame trolley, a guide wheel is added on the side part of a flame gas cutting machine, so that the edges of arc-shaped, S-shaped and semi-circular plates can be chambered by the flame trolley.

Owner:中船桂江造船有限公司

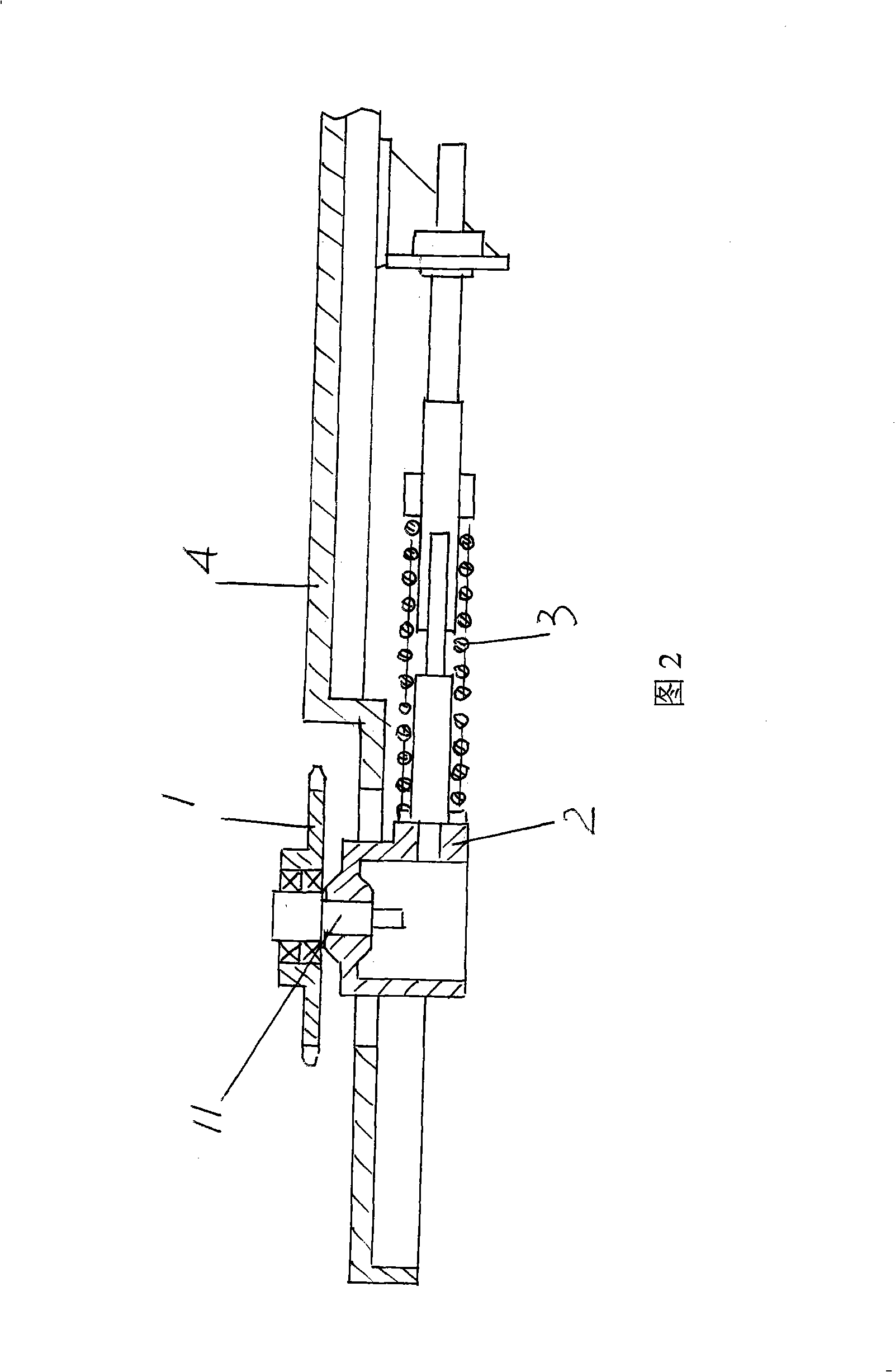

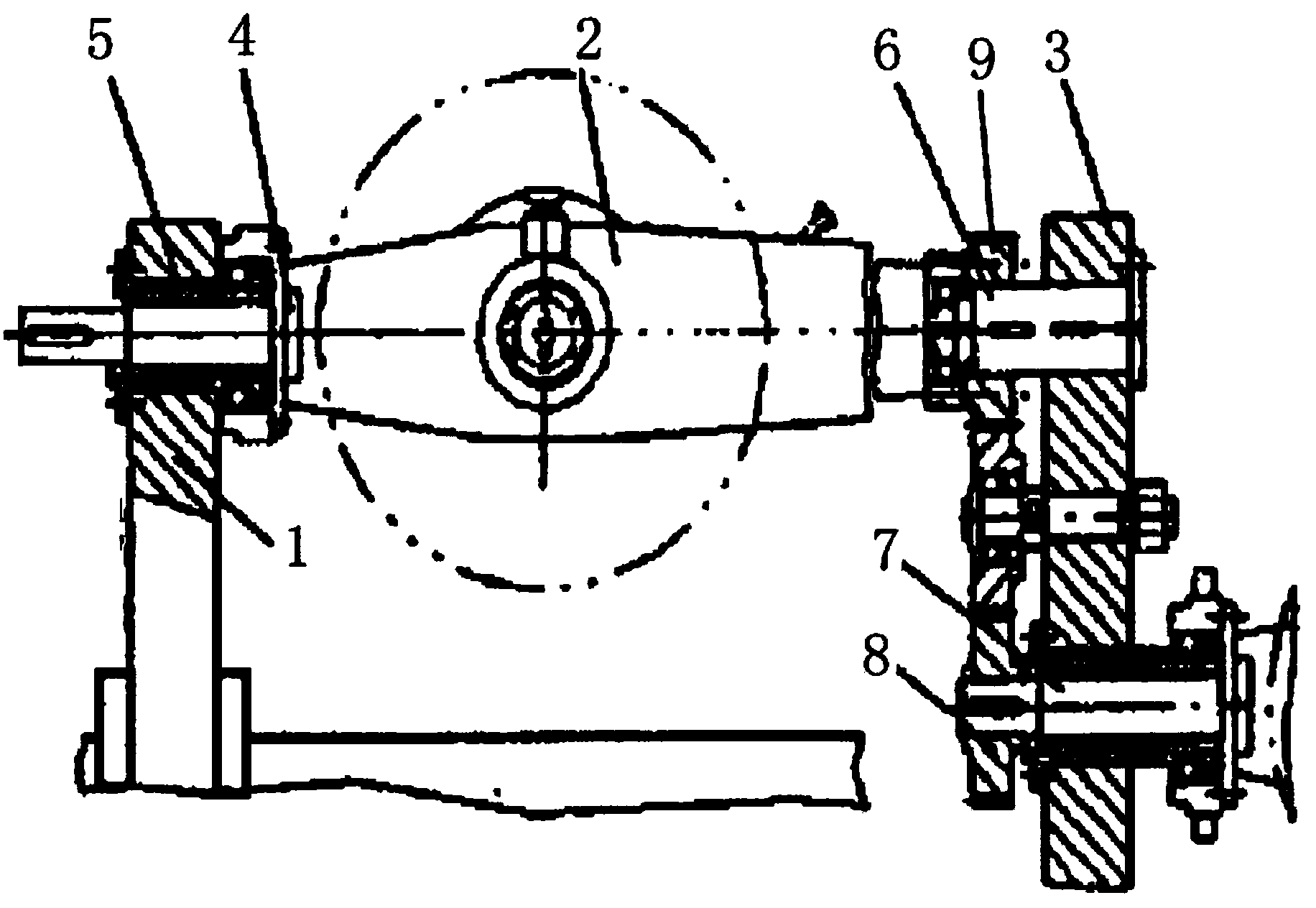

Cable single twister

ActiveCN103366900ACause damageGuaranteed quality and reliabilityCable/conductor manufactureEngineeringMachining process

The invention belongs to the technical field of machinery, and provides a cable single twister. The cable single twister comprises a base, and a moving mechanism, a take-up mechanism and a wire twisting mechanism which are arranged on the base, wherein the take-up mechanism and the moving mechanism are positioned on the right side of the base; the wire twisting mechanism is positioned on the left side of the base; the take-up mechanism is positioned on the moving mechanism; the wire twisting mechanism comprises a twisted wire driving mechanism, a twisted bow arm, a balance weight block and an outgoing line plate wheel; the twisted wire driving mechanism is connected with the twisted bow arm; the lower end of the twisted bow arm is provided with a connecting part; the upper end of the twisted bow arm is provided with the counter weight block; the connecting part is provided with an angle adjusting assembly; the outgoing line plate wheel is connected with the connecting part through the angle adjusting assembly. The cable single twister has the advantages that a strand of two cables can be automatically twisted, and the machining working efficiency is improved; since each component is matched with each other to draw the cables, the transmission stability is good, the cables cannot be damaged during the machining process, and the quality reliability of machined products is ensured.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

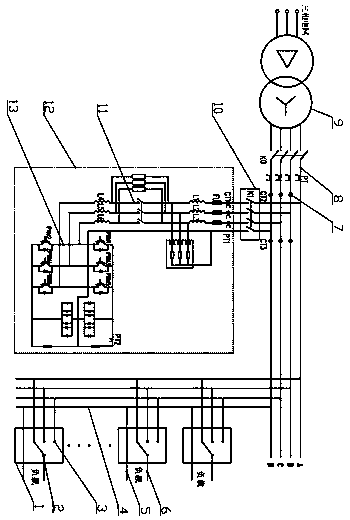

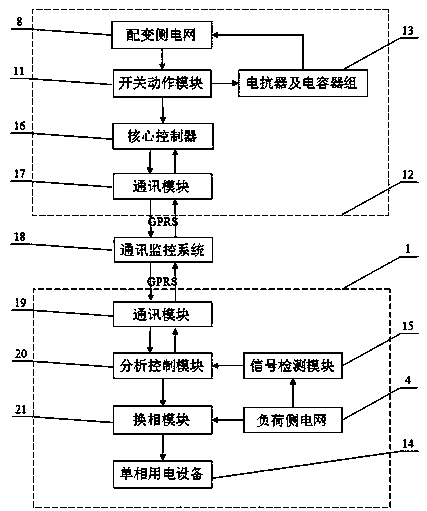

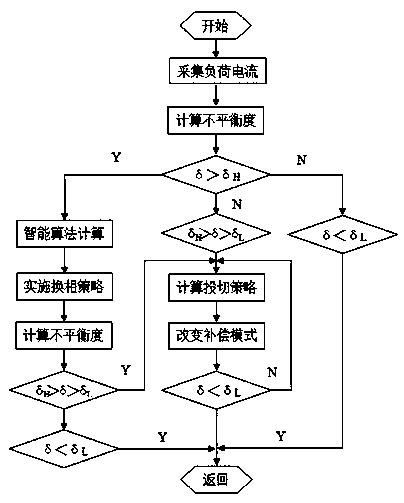

A low-voltage power network three-phase load unbalance control system

InactiveCN109088420ASolve balance problemsRunning balancePolyphase network asymmetry elimination/reductionPolyphase network asymmetry reductionCapacitancePower compensation

The invention discloses a low-voltage power network three-phase load unbalance control system. The low-voltage power network three-phase load unbalance control system is a hierarchical control system,which includes a load-side control system, a distribution-transformer-side control system and a communication monitoring system. After receiving the three-phase current information and calculating the optimal adjustment strategy by an intelligent algorithm, the control system realizes the initial adjustment through the load-side control system, and then realizes the fine adjustment by changing the capacitance compensation quantity and the capacitance compensation way through the distribution-side control system. The hierarchical control system can regulate three-phase unbalance by automatic detection, calculation, automatic real-time switching and power compensation, thereby effectively solving the problem of the current and voltage imbalance in the power grid caused by the three-phase load imbalance, avoiding manual load adjustment and other manual work and safety accidents, and achieving the balanced and stable operation of the power grid.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +2

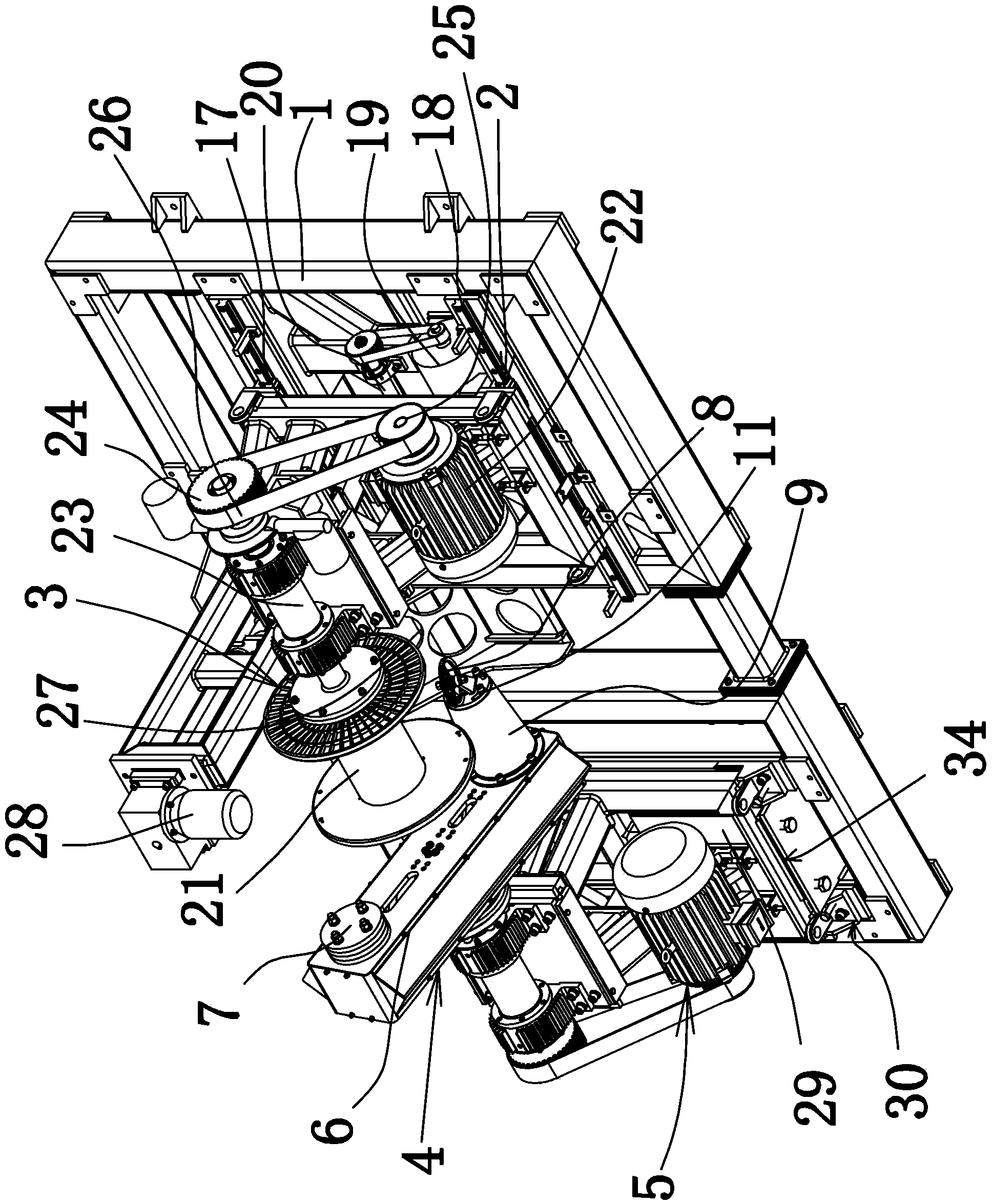

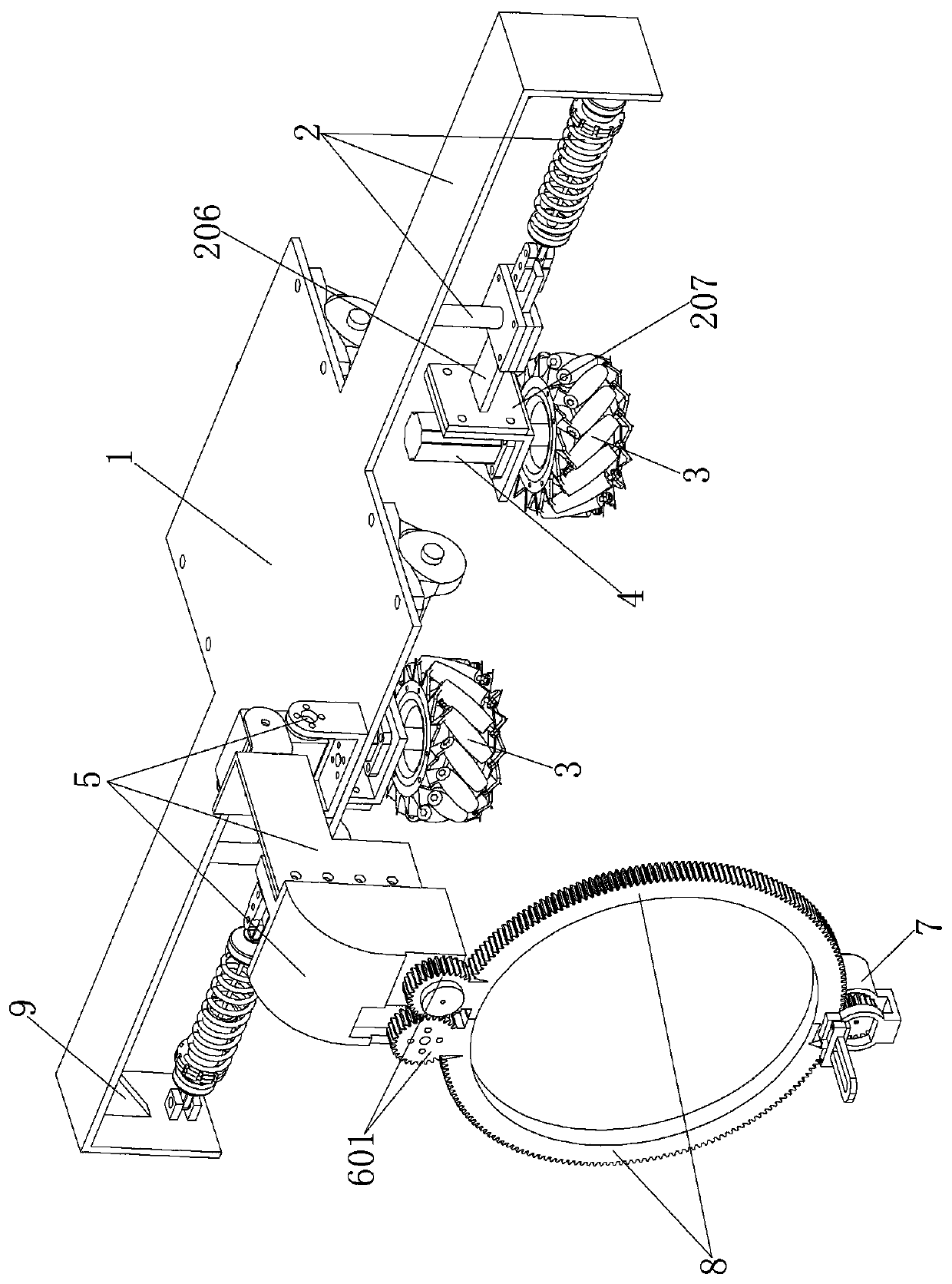

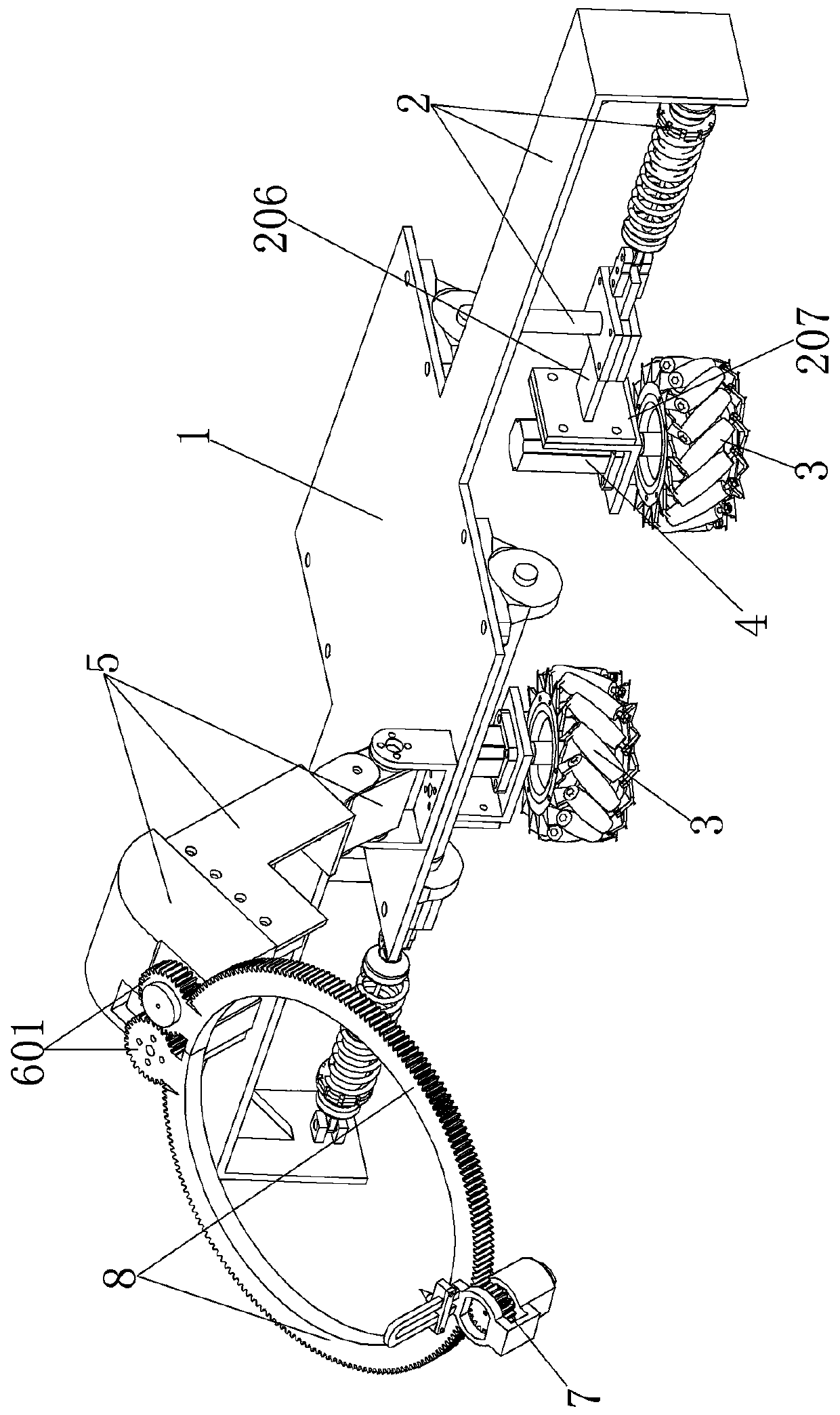

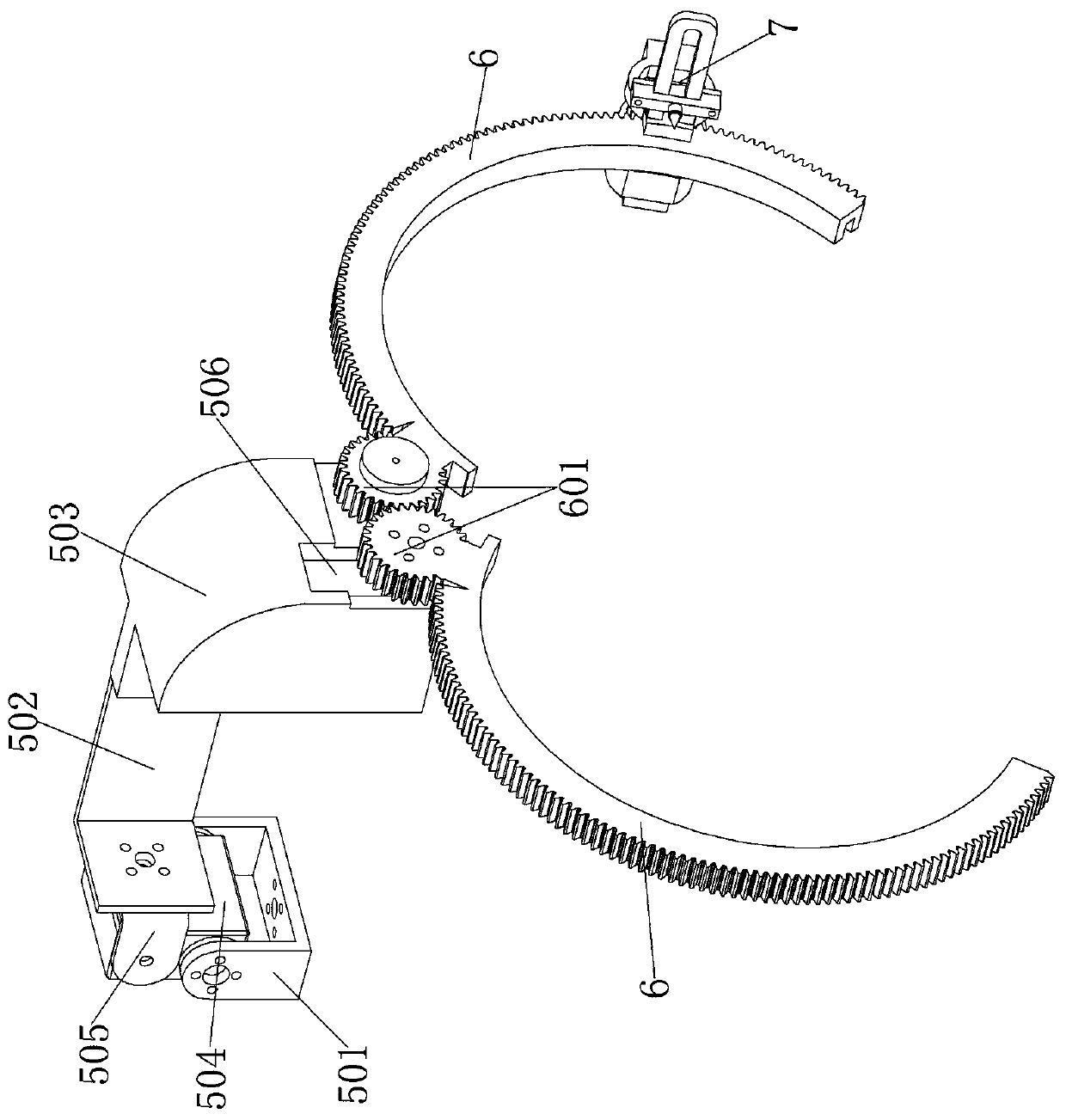

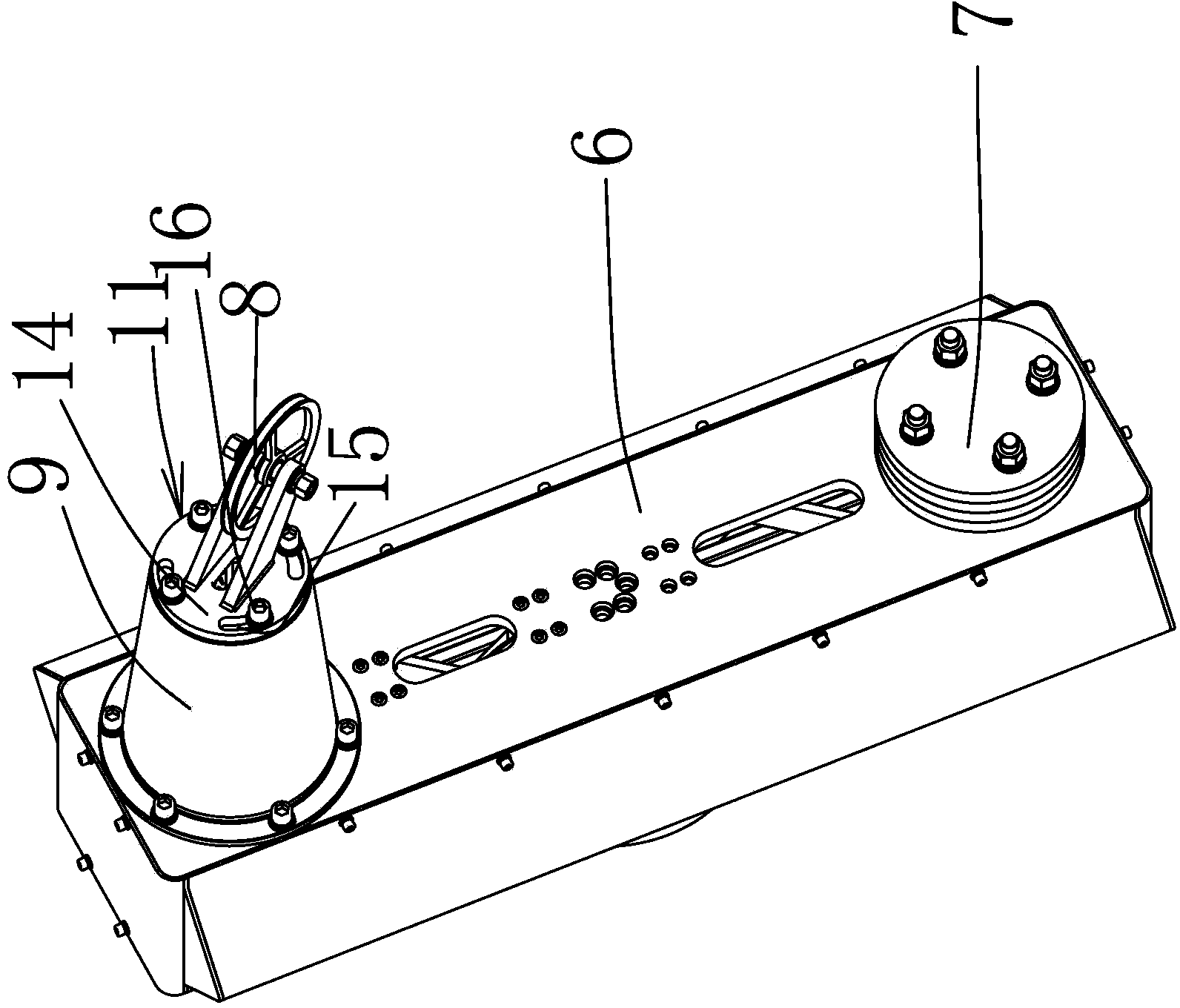

Pipeline crawling welding robot

PendingCN109967833AStrong load capacityRunning balanceArc welding apparatusTubular articlesMecanum wheelEngineering

The invention relates to a pipeline crawling welding robot. The pipeline crawling welding robot includes a traveling mechanism and a welding mechanism, wherein the traveling mechanism adopts a suspension structure with Mecanum wheels, the two symmetrical Mecanum wheels are installed on the end parts of an extensible rod of the inner end of a suspension spring, and are provided with an independentmotor for driving, and thus the two Mecanum wheels can bestride on a pipeline to move back and forth under pressure of the suspension spring; the welding mechanism is fixed to the front end of the traveling mechanism and can be raised and recycled to the upper end of the traveling mechanism without affecting crawling of the robot; and when the welding mechanism descends, two semicircular gear rings can be enclosed to the circumference of the pipeline, and a moving welding machine is controlled to rotate to weld a joint of the pipeline. The welding robot can crawl and turn a corner on the pipeline, meanwhile, the all-direction welding task of the pipeline can be completed, and welding of the pipeline by human in the field can be replaced; and at the same time, the pipeline crawling weldingrobot has the advantages of being high in welding quality, high in welding precision, high in efficiency, and low in cost, and is beneficial to promoting the market.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

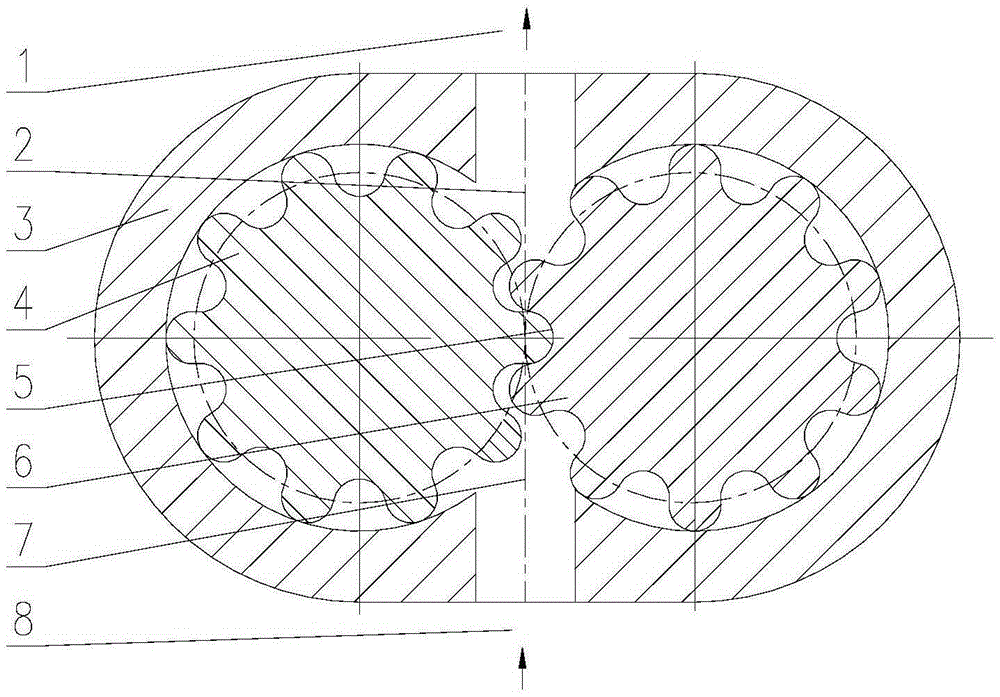

Dynamic and static pressure bearing circular tooth gear oil pump

InactiveCN105298835AExtended service lifeCompact structureRotary piston pumpsLubricating pumpsAxial forceHigh pressure

The invention relates to a dynamic and static pressure bearing circular tooth gear oil pump. A dynamic pressure bearing for bearing a gear shaft of a driving circular arc gear and a gear shaft of a driven circular arc gear is arranged on the inner side of a pump cover. The dynamic pressure bearing comprises a gear shaft hole formed in the inner end face of the pump cover. A plurality of shaft side dynamic pressure grooves extending in the axial direction are formed in the inner wall of the gear shaft hole in the circumferential direction, wherein the shaft side dynamic pressure grooves in one side of a low-pressure cavity form a static pressure balance groove. An oil way is further formed inside the pump cover, one end of the oil way penetrates a high pressure cavity, and the other end of the oil way penetrates the static pressure balance groove. Supporting rings are arranged between the inner wall of the gear shaft hole and shaft shoulders of the gear shafts of the driving circular arc gear and the driven circular arc gear. A plurality of wheel side dynamic pressure grooves extending in the radial direction are formed in the inner end face of the pump cover in the circumferential direction of the outer side of the gear shaft hole. The wheel side dynamic pressure grooves in the two sides of the driving circular arc gear and the driven circular arc gear are symmetric and provide the axial force in the same magnitude and opposite directions.

Owner:CENT RES INST OF TIANJIN BENEFO MECHANICAL EQUIP GRP CO LTD

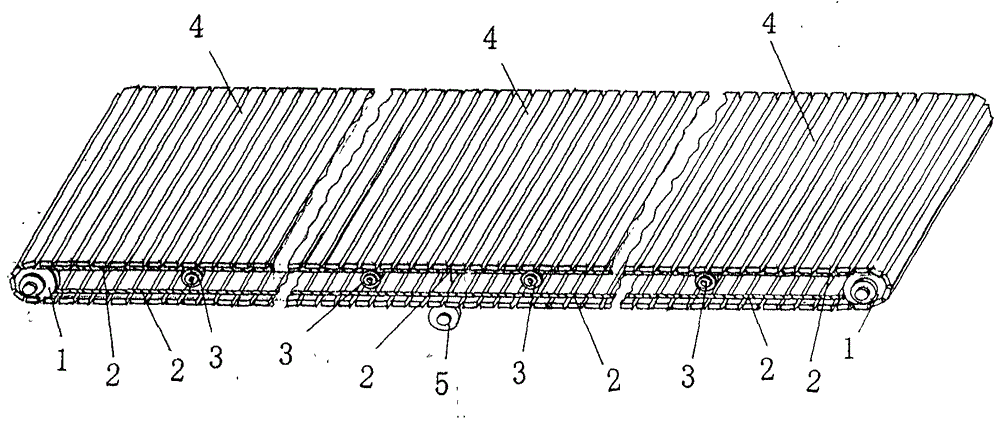

Roller blind type phosphogypsum drying conveyer belt

InactiveCN104925457AHigh temperature resistantSolve many difficult problemsConveyorsPhosphogypsumBatten

The invention provides a roller blind type phosphogypsum drying conveyer belt. Driving grooved wheels are arranged at the two ends on the two sides of the conveyer belt for conveying a material; steel wire ropes rotating circularly are wound between the driving grooved wheels at the two ends on the two sides; a plurality of battens densely distributed are laid on the steel wire ropes; a plurality of support wheels with driving disks are distributed in the steel wire ropes on the two sides; and accordingly, the formed roller blind type conveyer belt is equipped with a tension wheel entirely. When the belt is in use, a motor power machine rotates to allow the steel wire ropes on the two sides to rotate circularly, thereby circularly conveying the material in a conveyer belt manner, and the belt can be used for conveying various materials.

Owner:陈群

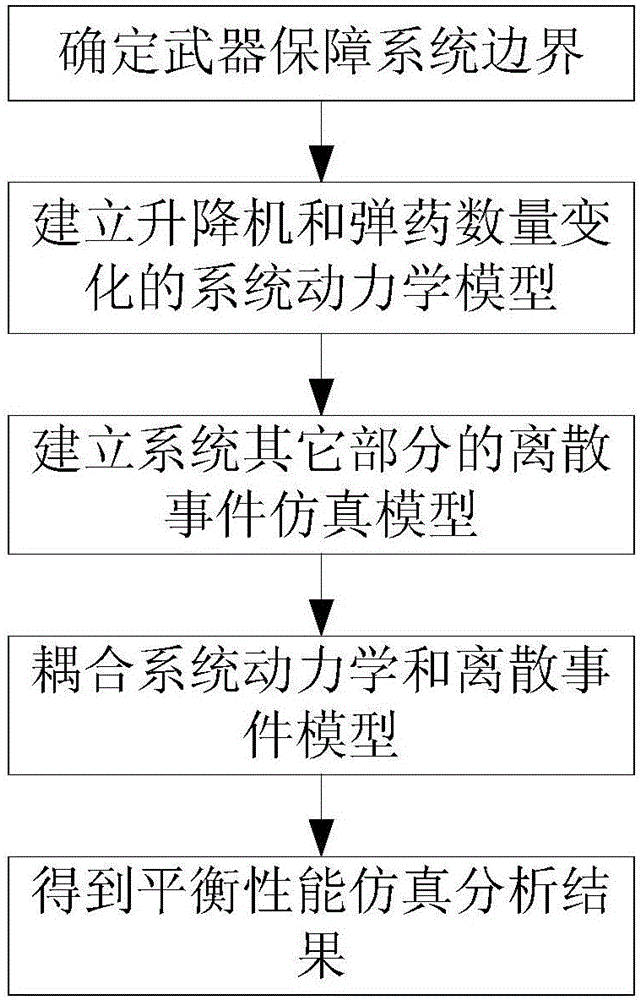

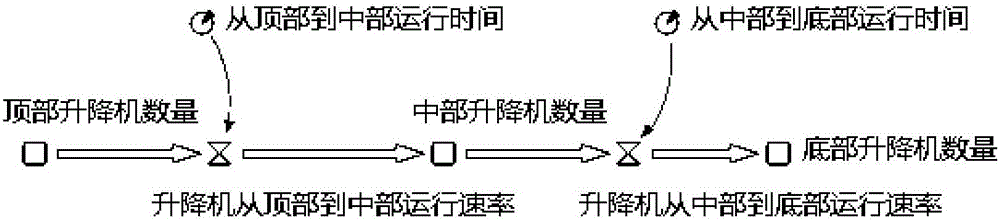

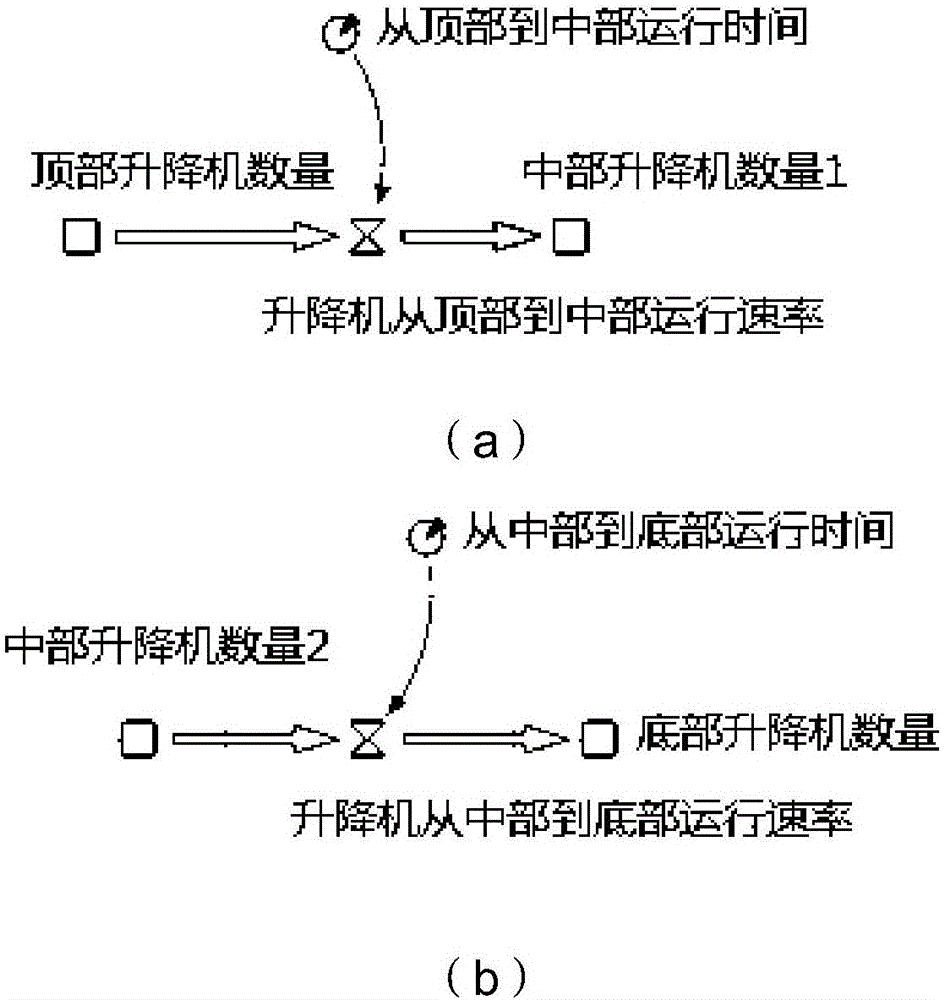

System-dynamics-based balance design method for weapon support system

ActiveCN105824999AImprove transport efficiencyMeet consumptionSpecial data processing applicationsResource utilizationEvent model

A system-dynamics-based balance design method for a weapon support system comprises the following steps: firstly, determining the boundary of the weapon support system, and making clear that system dynamics is used for modeling of a lift and the change of ammunition quantity and discrete event simulation is used for modeling of other parts in the system; then building a system dynamics model of the lift and the change of ammunition quantity, and building a discrete event simulation model of other parts of the system; coupling the system dynamics model and the discrete event model to obtain an integral model of the weapon support system; finally, performing simulation analysis based on the obtained integral model to obtain a balance performance simulation result and to identify probable unbalance points in the weapon support system. The system-dynamics-based balance design method can analyze transport of ammunition and assembly resource utilization ratio in the system, find out bottleneck and unbalanced links in the process and improve the resource utilization efficiency of the system.

Owner:CSSC SYST ENG RES INST

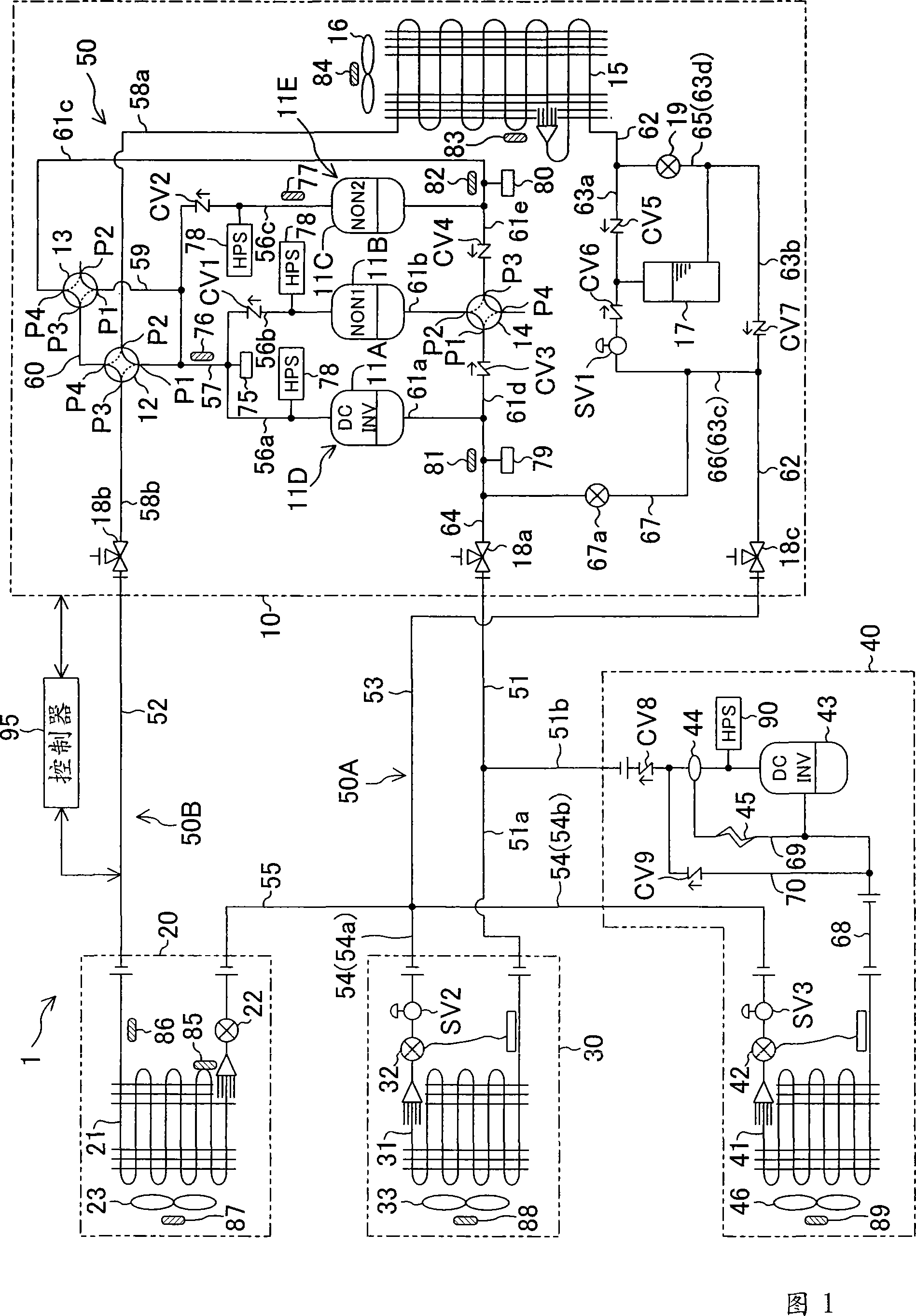

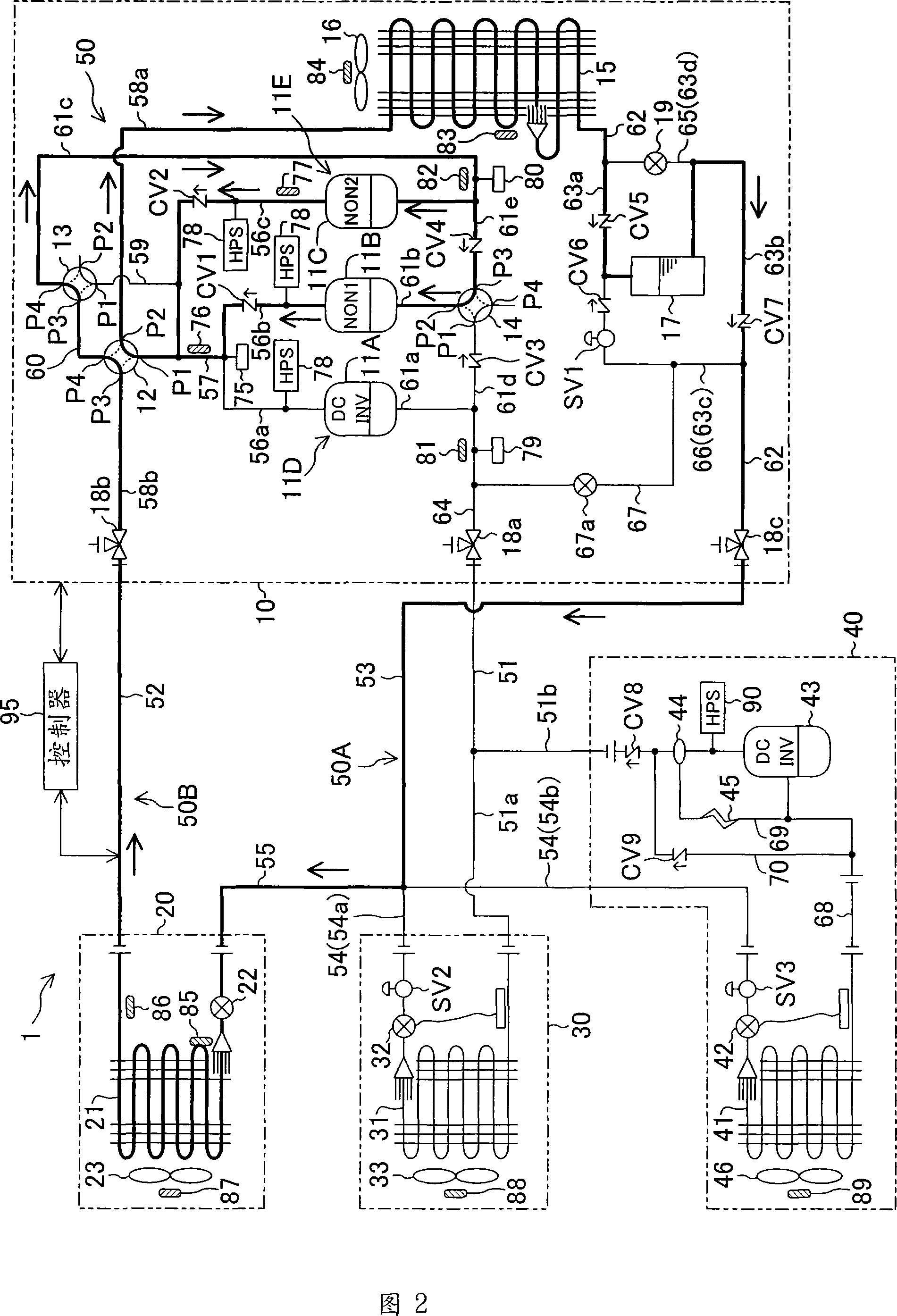

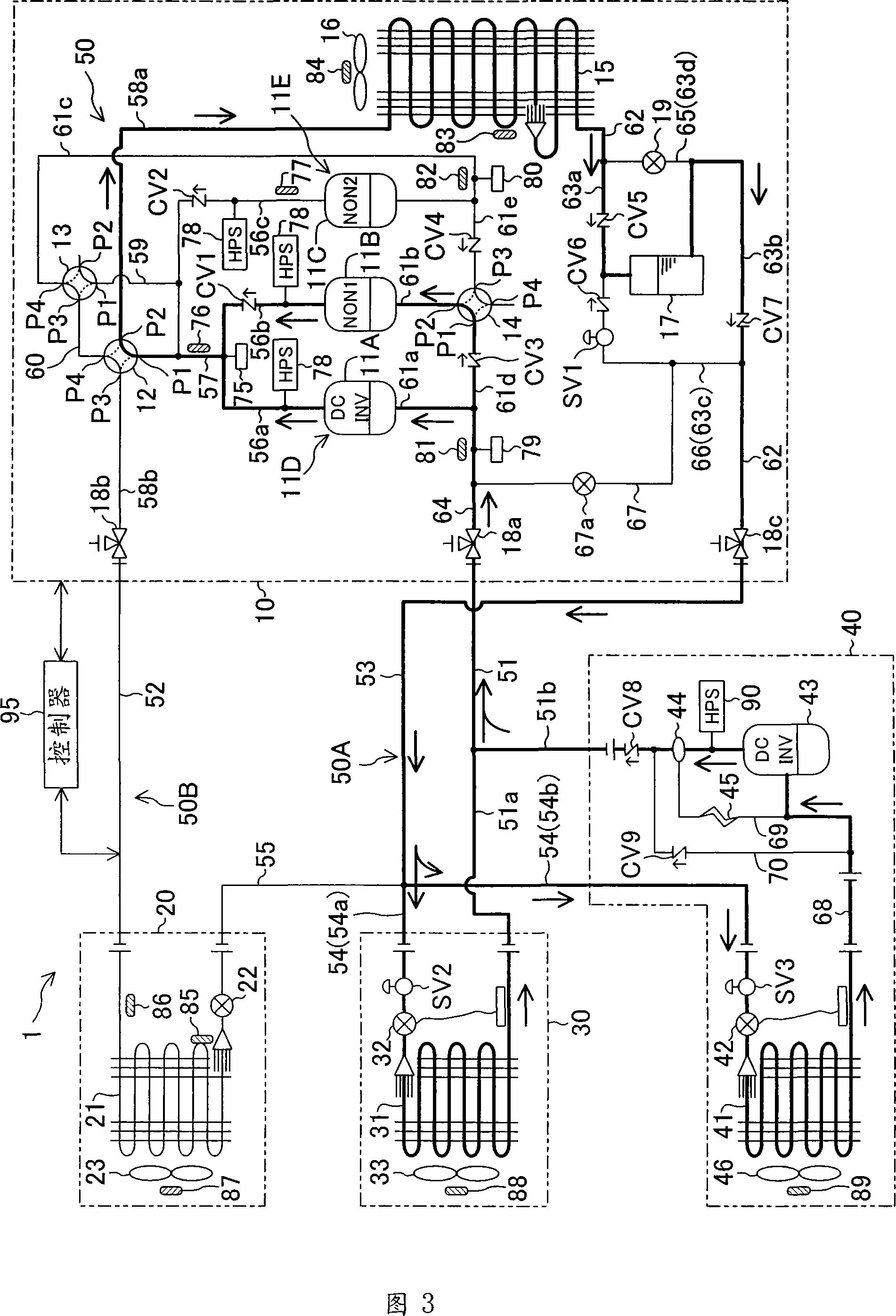

Refrigeration device

InactiveCN101223405ARunning balanceImprove operational capacityMechanical apparatusCompression machines with non-reversible cycleLiquid lineEngineering

In a refrigerating system that has multiple systems of use-side heat exchangers (20, 30, 40) and one liquid-side connecting pipe (53, 54, 55) to connect the liquid pipes of multiple systems, the unused outdoor When the heat exchanger (15) performs heating operation with 100% heat recovery, even when the outdoor air temperature is low, the refrigerant flow in the refrigerant circuit (50) can be stabilized and the refrigeration capacity will not be reduced, and at the same time, it can prevent the malfunction of the device from causing 1 operation is stopped, therefore, the heat source side liquid pipe (62) and liquid receiver (17) of the outdoor unit (10) connected to the liquid side communication piping (53, 54, 55) A liquid refrigerant inflow passage (66) is connected to the inflow port of the liquid refrigerant inflow passage (66), and an on-off valve (SV1) capable of being opened and closed is provided on the liquid refrigerant inflow passage (66).

Owner:DAIKIN IND LTD

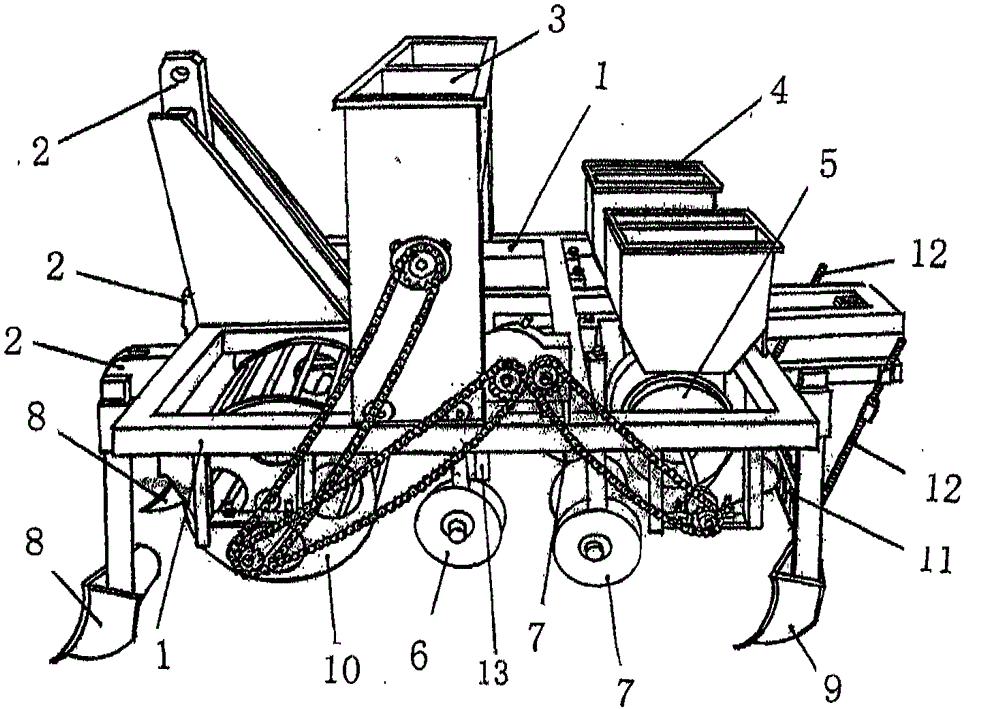

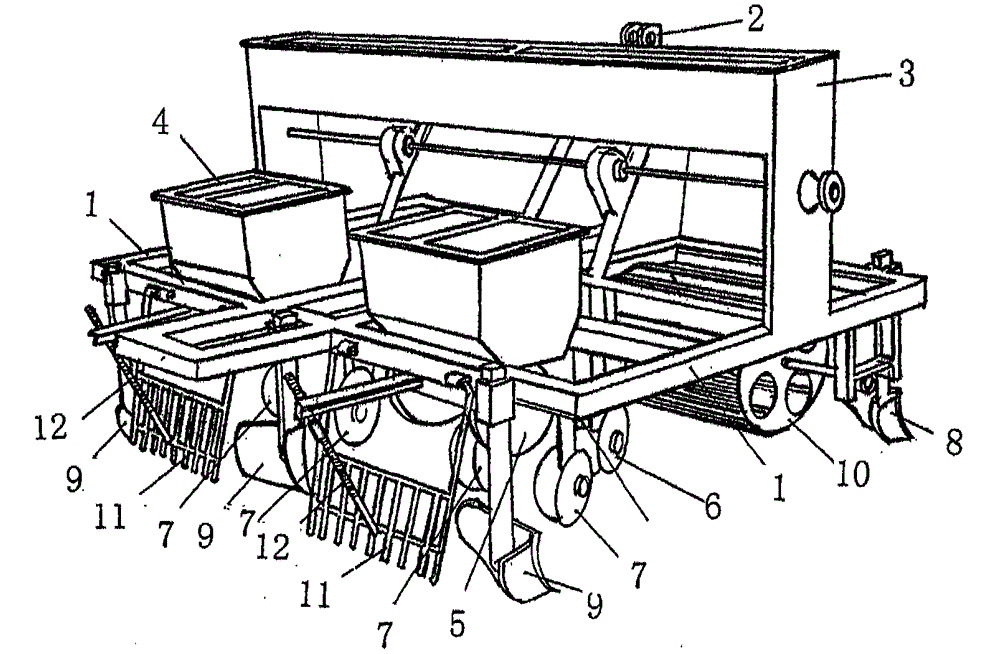

Peanut seeder

InactiveCN104412745AAccelerateEasy to operate and adjustSpadesPloughsAgricultural engineeringFast speed

The invention provides a peanut seeder. The seeder for seeding the peanuts is a parallelly-expanded frame-type rack. The front end of the rack is provided with a traction bracket, a fertilization box and a seeding box are installed above the rack, an elevation-adjustable ridging hiller is installed at the front end under the rack, the back end of the rack is provided with an elevation-adjustable shaping hiller, a fertilization furrow opener is installed under the fertilization box, a seed-metering device is installed under the seeding box, a seeding furrow opener matched with the seed-metering device is located under the front of the seeding box, a press wheel matched with the ridging hiller is installed under the front of the rack, and a soil-lining plate for shaping, hilling and seeding is installed under the back of the rack. The peanut seeder can be driven by the motive power machine so as to automatically achieve a series of peanut seeding operations, such as ribbing shaping, fertilizing, seeding and leveling, and is capable of seeding 8-10 mu of land per hour with fast speed and good effect.

Owner:黄忠兵

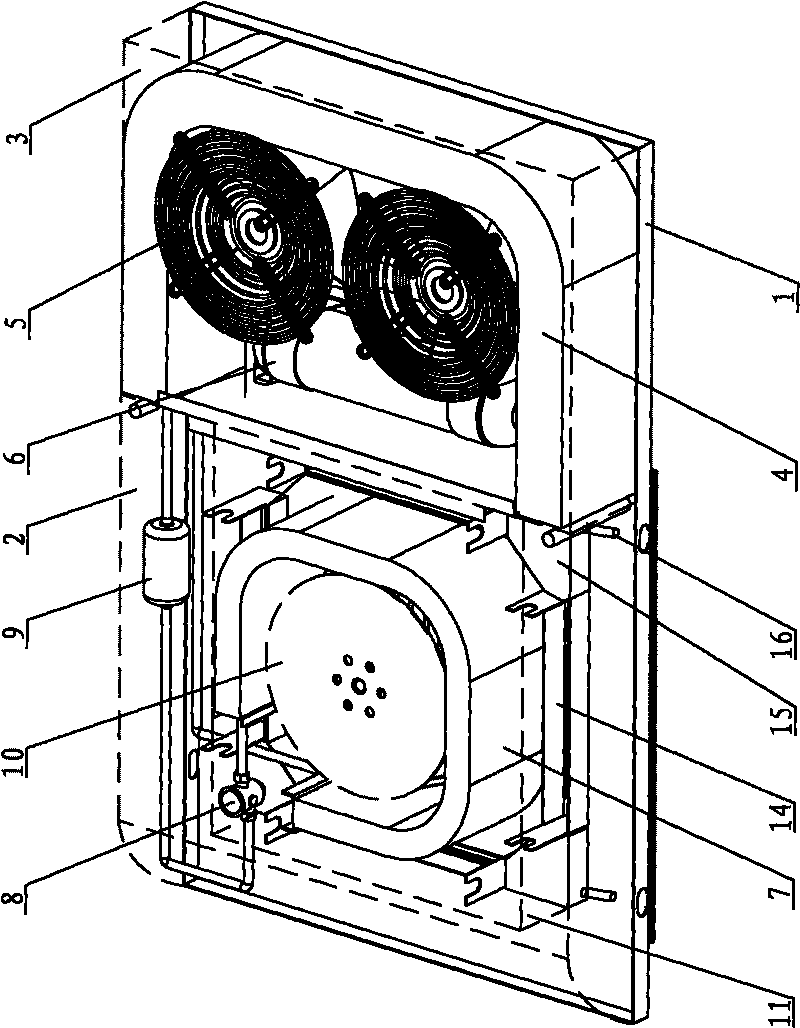

Low-noise type ultrathin overhead type frequency-conversion shelter air conditioner

ActiveCN101761989AReduce working noiseImprove cooling effectCondensate preventionLighting and heating apparatusLow noiseType frequency

The invention relates to a low-noise type ultrathin overhead type frequency-conversion shelter air conditioner which mainly comprises chassises, an outdoor heat exchanger and an indoor heat exchanger, wherein the outdoor heat exchanger comprises two axial flow fans, a condenser and a frequency-conversion compressor, the condenser is installed on a chassis in an outdoor casing, and the vibration center line of the frequency-conversion compressor is superposed with the center line of the width direction of the chassis; and the indoor heat exchanger comprises an evaporator, an expansion valve, a filter, a volute-free centrifugal blower and an evaporator cover, wherein the evaporator is installed in the center of a chassis of the indoor heat exchanger, a chassis of an inner ring of the evaporator is provided with a return air inlet with an air deflector, four air outlets are evenly arranged on a chassis of an outer ring of the evaporator, the evaporator, the return air inlet, the air deflector and the four air outlets are all packaged in the evaporator cover, and the volute-free centrifugal blower is fixed below the evaporator cover and is correspondingly consistent to the center of the return air inlet. The invention has reasonable design, compact structure, balanced running of the air conditioner, low noise, large air output and good refrigeration effect and is suitable for a shelter air conditioner with high requirement to an indoor working environment to use.

Owner:JIANGSU ZHONGTIAN DEFENSE EQUIP CO LTD

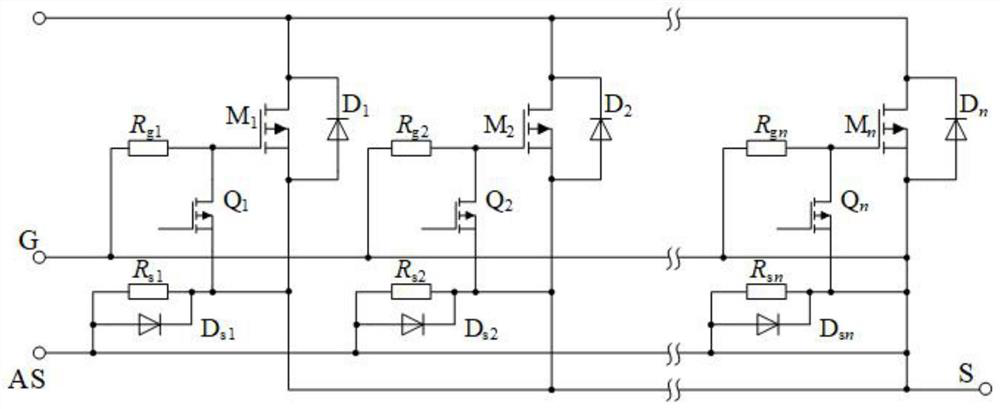

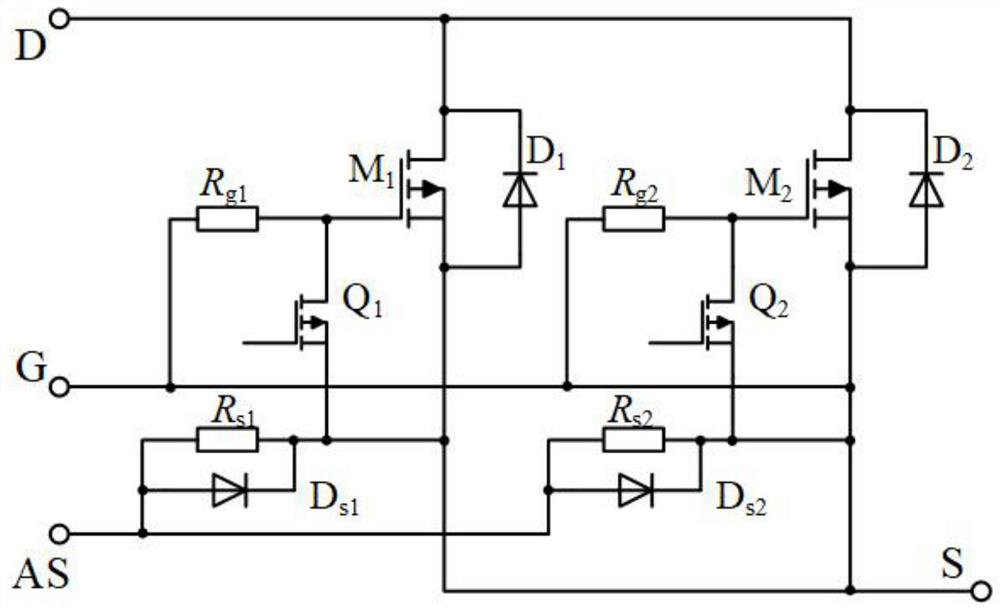

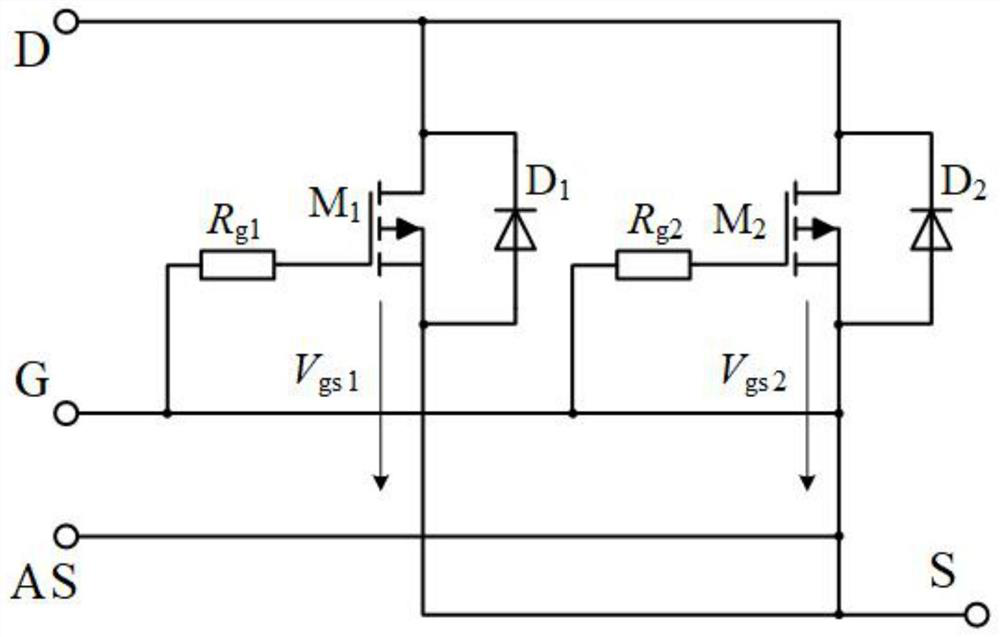

Drive circuit suitable for parallel connection of SiC MOSFET

InactiveCN111697800AReduce switching speedFast switching speedEfficient power electronics conversionPower conversion systemsMOSFETStray inductance

The invention discloses a drive circuit suitable for parallel connection of SiC MOSFETs. The drive circuit comprises a gate resistor Rgx; anauxiliary source electrode resistor Rsx which is provided with a Schottky diode Dsx in parallel connection; and a common low-voltage Si MOSFET tube Qx arranged between the grid electrode and the source electrode. According to the universal parallel SiC MOSFETdriving circuit structure,the number of SiC MOSFETs which can be connected in parallel is not limited. One end of the grid resistor Rgx is connected with the grid electrode of the SiC MOSFET Mx; the drain electrode of the common low-voltage Si MOSFET Qx is connected to the grid electrode of the SiC MOSFET, and the source electrode of the common low-voltage Si MOSFET Qx is connected to the two endsof the source electrode of the SiC MOSFET; one end of the source resistor Rsx is connected with the source of the SiC MOSFET Mx; drain electrodes of all the SiC MOSFETs are connected together to forma common drain electrode end D; and the other end of the gate resistor Rgx is connected to form a common gate terminal G. According to the invention, the problems of unbalanced switching speed of theSiC MOSFETs connected in parallel, non-uniform gate threshold voltage and parallel circulation caused by stray inductance are solved, and the SiC MOSFETs can be effectively protected.

Owner:NANTONG UNIVERSITY

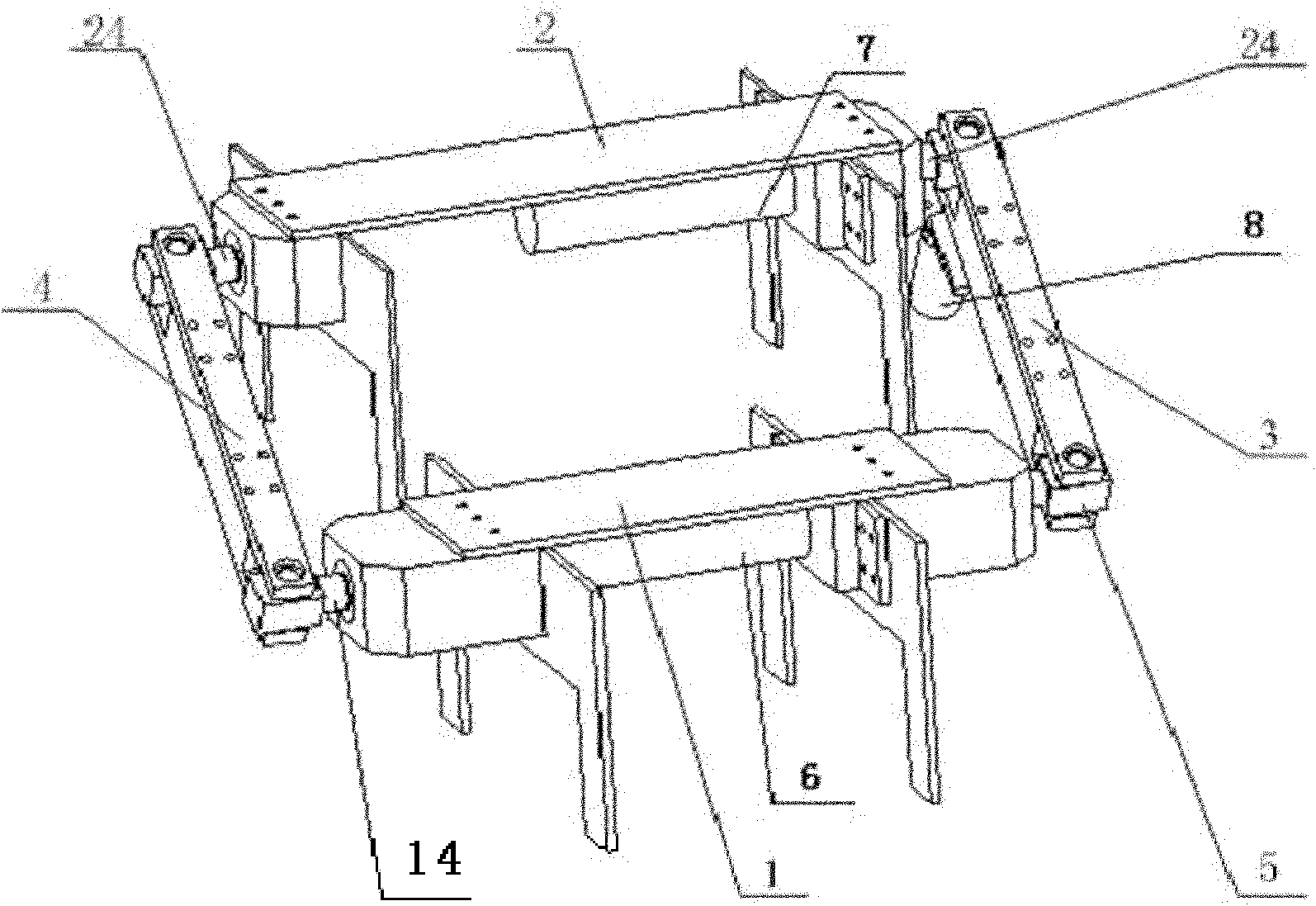

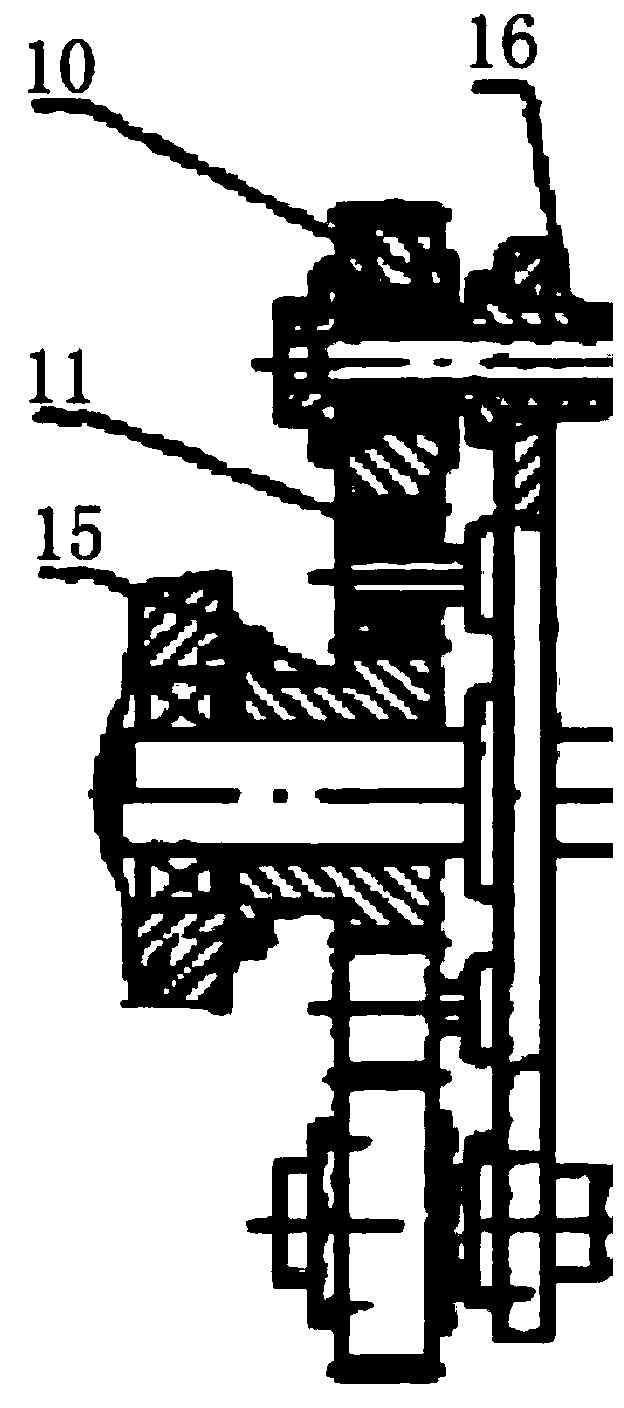

Cable single twister allowing height and side-direction adjusting

ActiveCN103383882ACause damageGuaranteed quality and reliabilityCable/conductor manufactureTextile cablesEngineeringMechanical engineering

The invention belongs to the technical field of machines and provides a cable single twister allowing height and side-direction adjusting. The single twister comprises a machine base and a moving mechanism, a taking-up mechanism and a twisting mechanism which are arranged on the machine base, the taking-up mechanism and the moving mechanism are located on the right side of the machine base, the twisting mechanism is located on the left side of the machine base, the taking-up mechanism is located on the moving mechanism, the twisting mechanism comprises a twisting driving mechanism, a fixed plate is arranged on the lower portion of the twisting driving mechanism and on the machine base on the left side, the twisting driving mechanism is installed on the fixed plate, upper and lower height adjusting components are arranged between four corners of the fixed plate and the machine base, and side-direction distance adjusting components are arranged on upper and lower side portions of the fixed plate. The single twister has the advantages that height adjusting and side portion adjusting functions are added, so that the twisting mechanism and the taking-up mechanism are located on the same horizontal plane in all directions, the whole machine is stable and balanced during operation, and the performance of twisted lines is stable.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

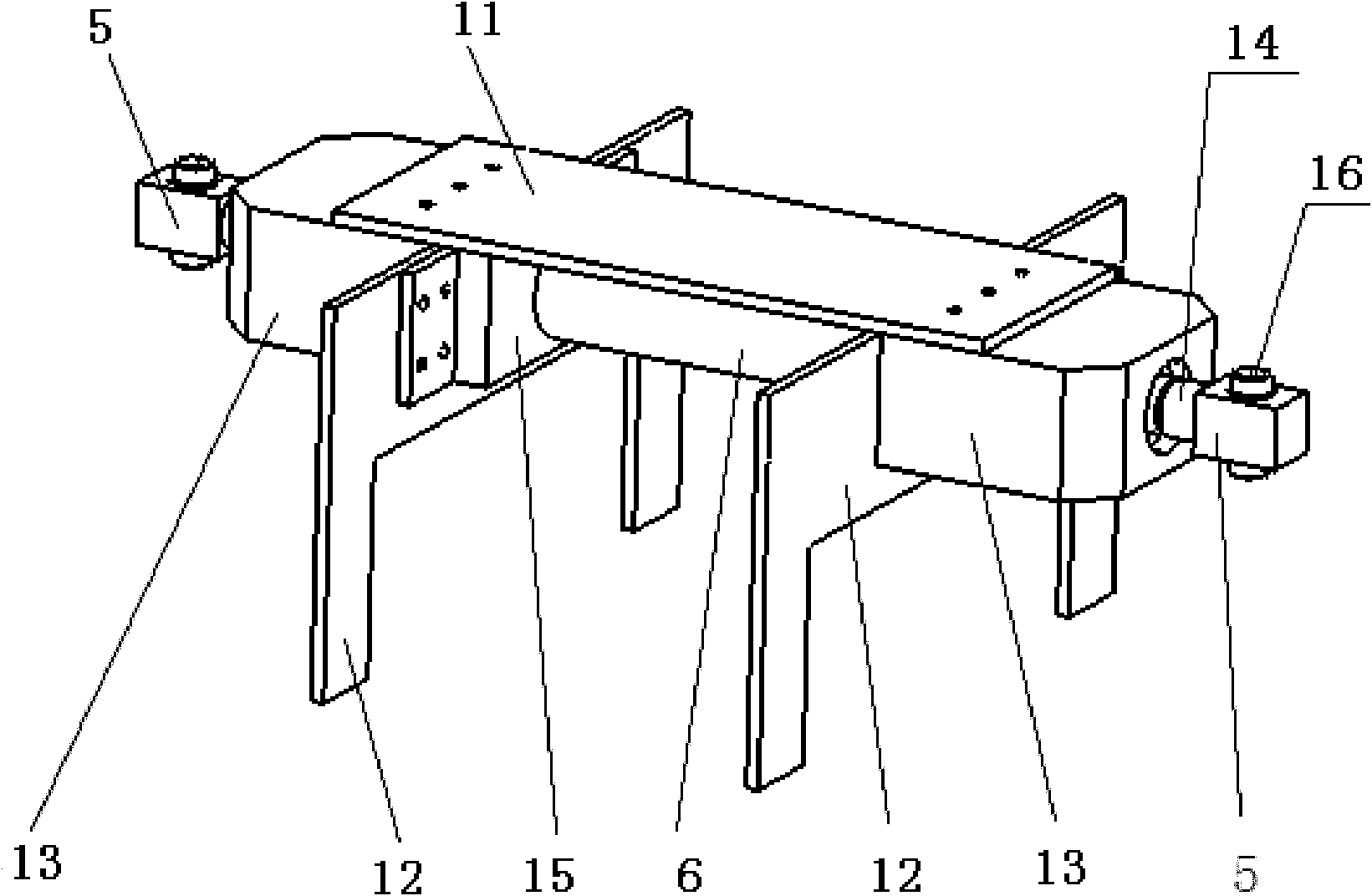

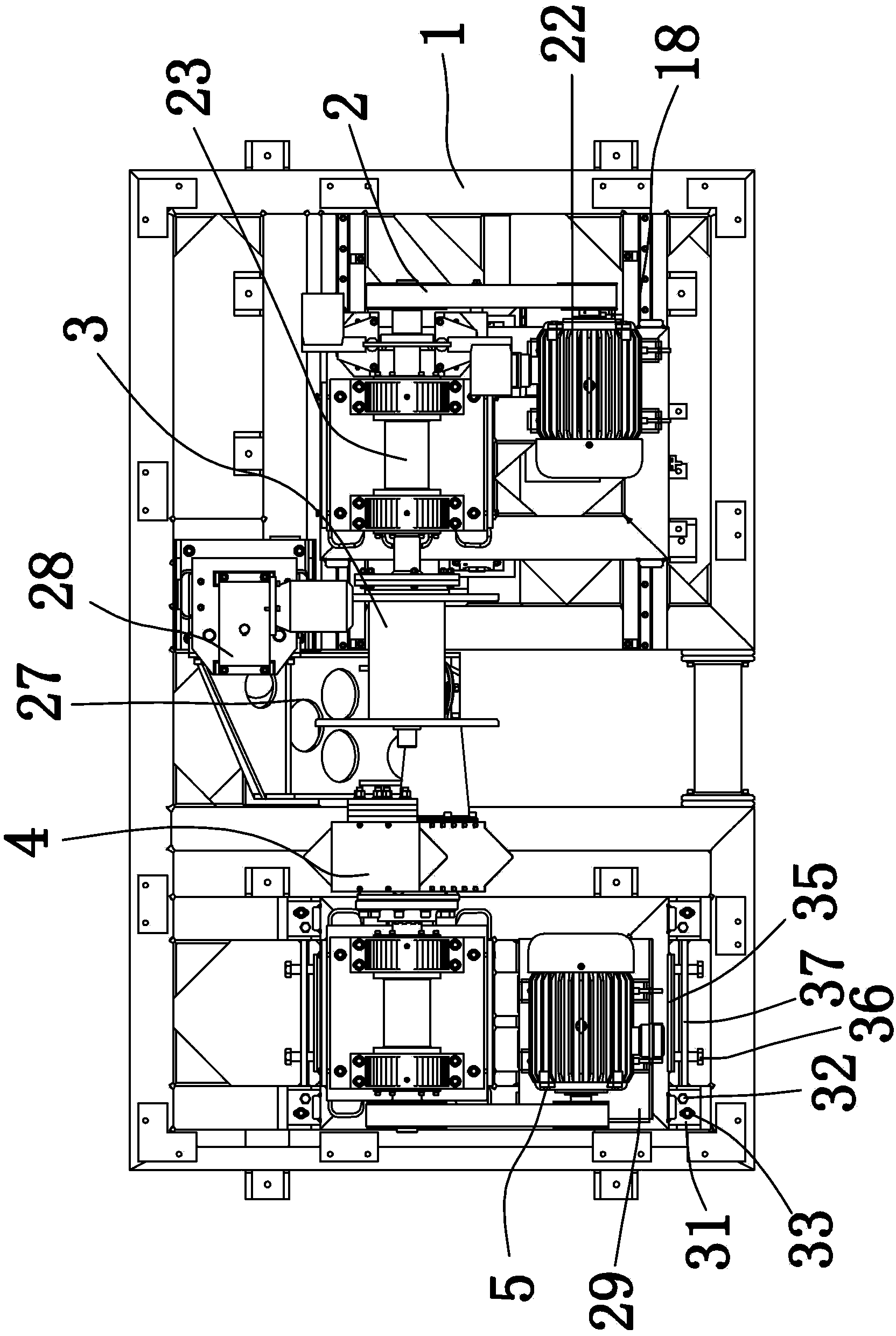

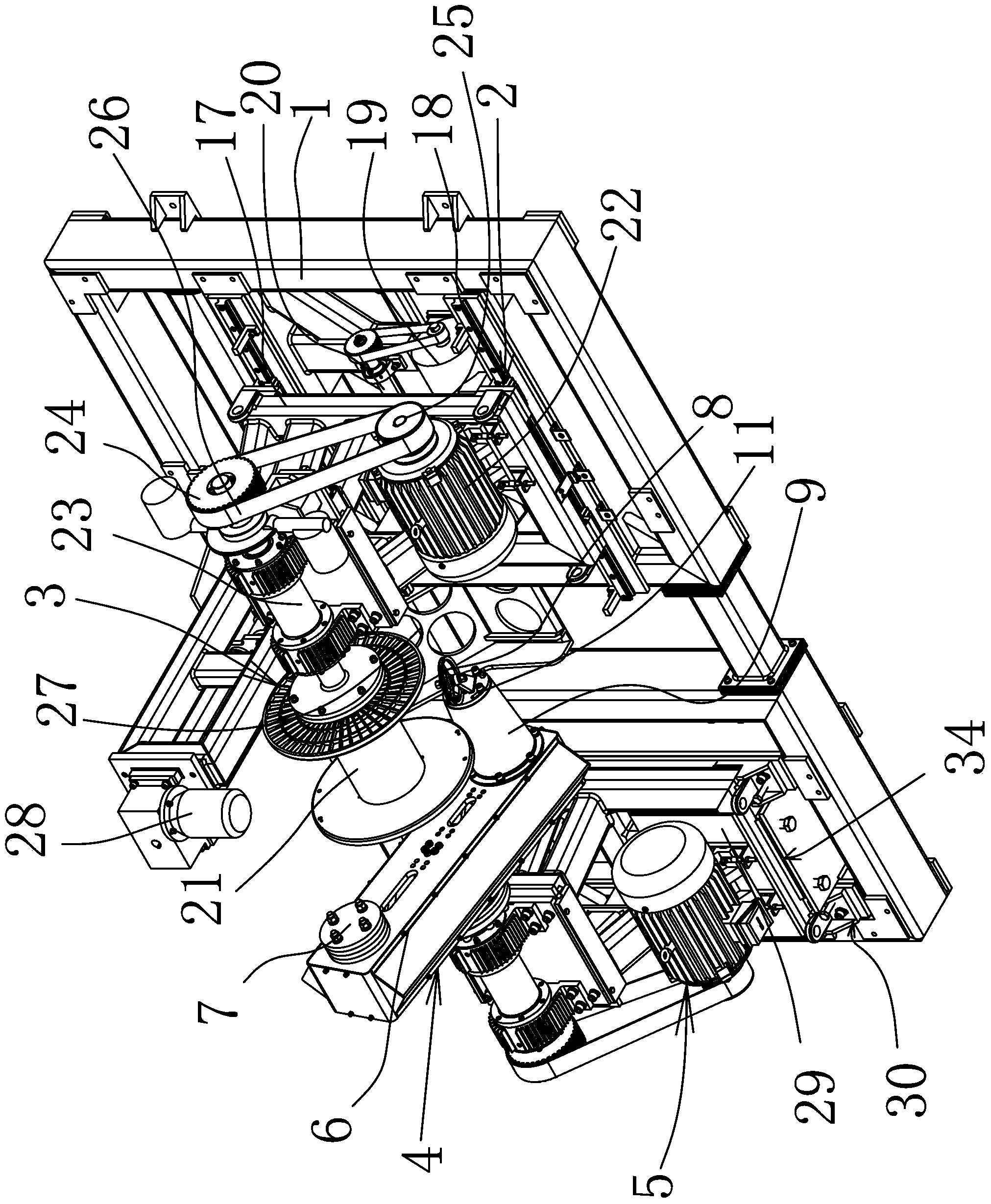

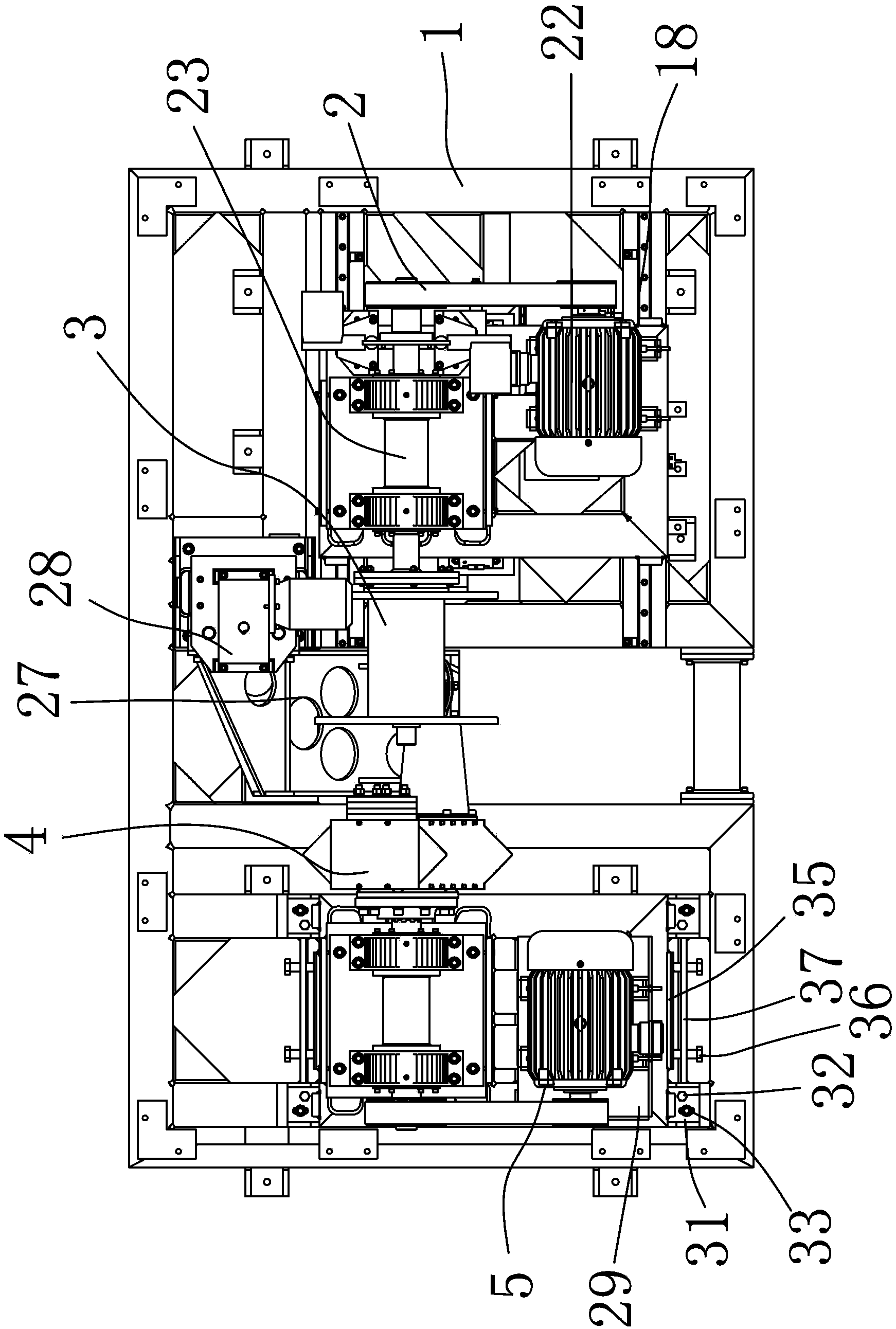

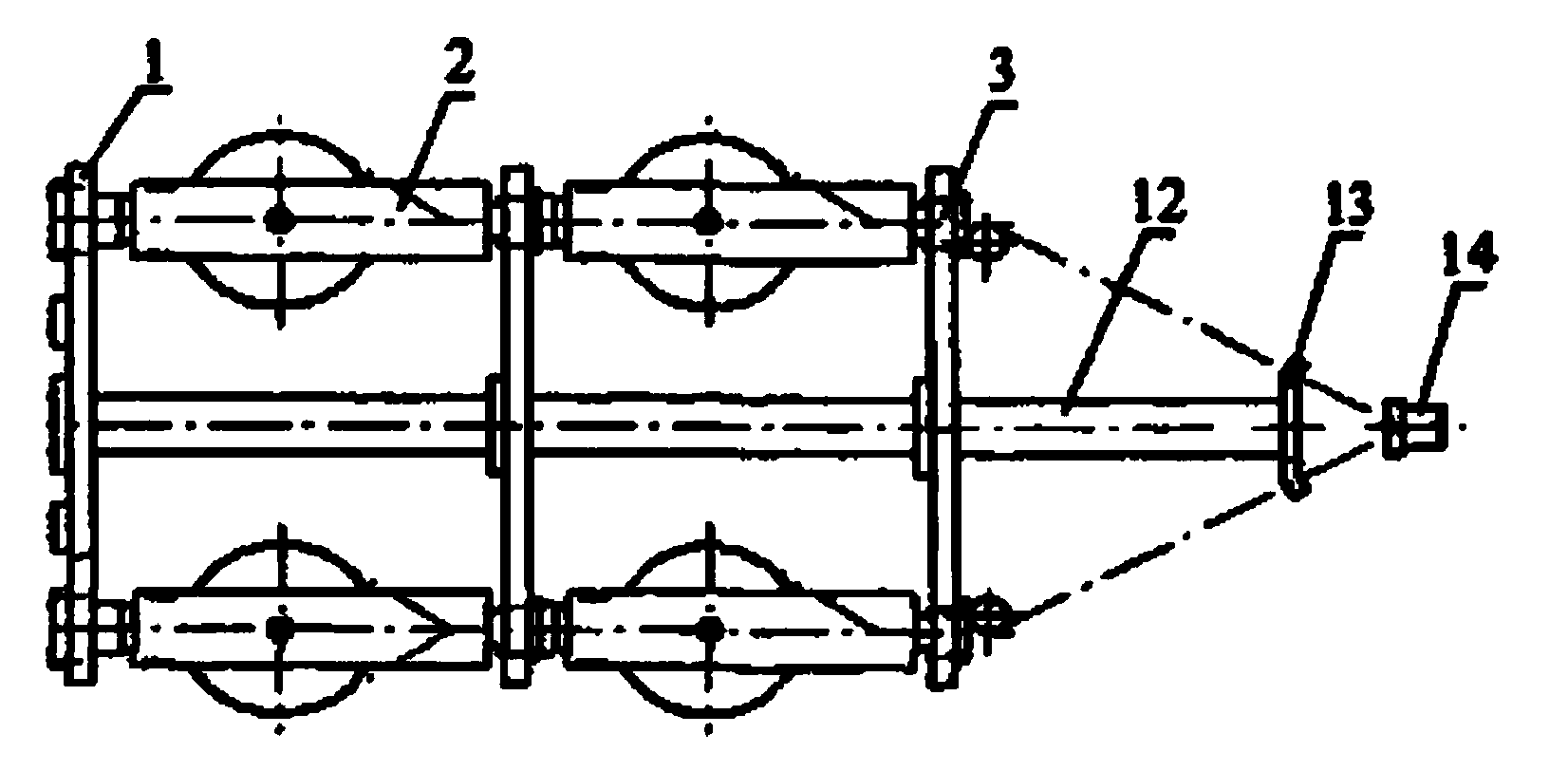

Stranding machine for producing power supply cable of hydraulic pump station

InactiveCN104240852AReduce deformationRunning balanceCable/conductor manufactureGear wheelHydraulic pump

The invention discloses a stranding machine for producing a power supply cable of a hydraulic pump station and relates to a pay-off rack supporting mechanism of a cage type stranding machine. The stranding machine comprises a stranding cage, the stranding cage comprises a first winch, pay-off racks, a second winch, a spindle, a wire distributor plate and a wire doubling mold, wherein the spindle is sleeved with the first winch, the second winch, the wire distributor plate and the wire doubling mold in sequence at intervals, the two sets of pay-off racks are placed between the first winch and the second winch with one set of pay-off rack above the other set of pay-off rack, a wire coil and a tension device are placed on each set of pay-off rack, the left end of each set of pay-off rack is connected with a first half shaft which is connected with a first spigot shaft through a shaft sleeve, each first half shaft is sleeved with the corresponding first spigot shaft, the first spigot shafts are fixedly connected with the first winch, a back-twist mechanism is connected to the tail end of each first spigot shaft, the right end of each set of rack-off rack is connected with a second spigot shaft which is arranged in a through hole in the right end of the pay-off rack in a sleeved mode and fixedly connected with the second winch, back-twist gear sets are connected to the second winch through second half shafts, the second spigot shafts are sleeved with gears, and the gears are meshed with the back-twist gear sets.

Owner:SICHUAN DINGRUI HYDRAULIC EQUIP MFR

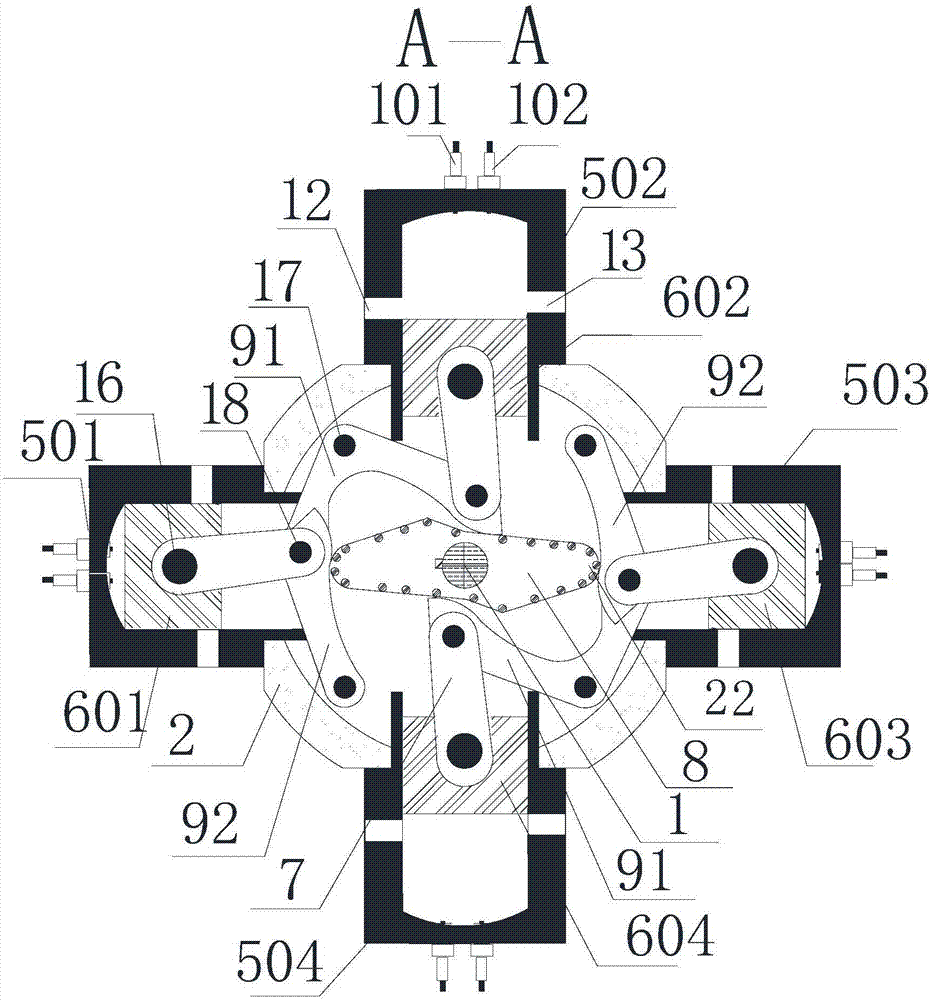

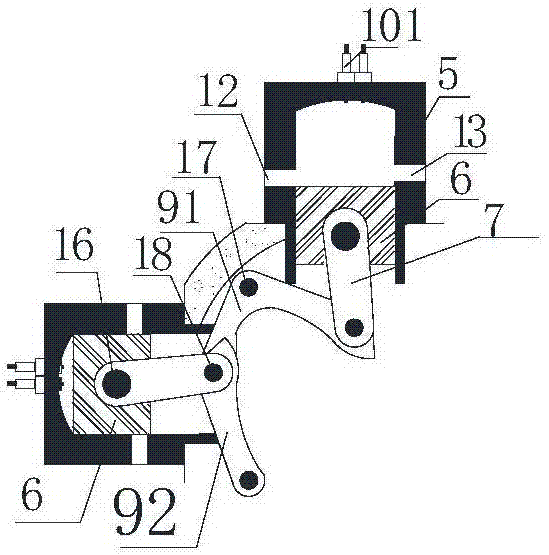

Tumbler and piston type engine

InactiveCN106968789AIncrease the number ofReduce volumeCombustion process measuresMachines/enginesReciprocating motionDrive shaft

The invention discloses a tumbler and piston type engine. The engine comprises a cylindrical block, a transmission shaft, a fuel air cylinder group and a first linkage assembly; an accommodating cavity is formed in the cylindrical block; the transmission shaft is rotationally arranged on the axis of the cylindrical block; a first flat cam is fixed on the transmission shaft; a driving surface and a stressed surface which are centrosymmetric are arranged at each of two ends of the first flat cam; the fuel air cylinder group comprises a first fuel air cylinder, a second fuel air cylinder, a third fuel air cylinder, a fourth fuel air cylinder and piston-connecting rod assemblies arranged in the four fuel air cylinders; the first fuel air cylinder, the second fuel air cylinder, the third fuel air cylinder and the fourth fuel air cylinder are arranged sequentially; an air inlet and an air exhaust port are formed in two sides of the middle of the cylinder block part of each fuel air cylinder; the first linkage assembly comprises two strip-shaped tumblers and two V-shaped tumblers; and the reciprocating movement of pistons in the four fuel air cylinders drives the transmission shaft to rotate through extrusion of the driving surfaces and the stressed surfaces by the aid of the inner side surfaces of the two strip-shaped tumblers and the two V-shaped tumblers. The engine is high in energy conversion efficiency and simple and reasonable in structure.

Owner:黄荣嵘

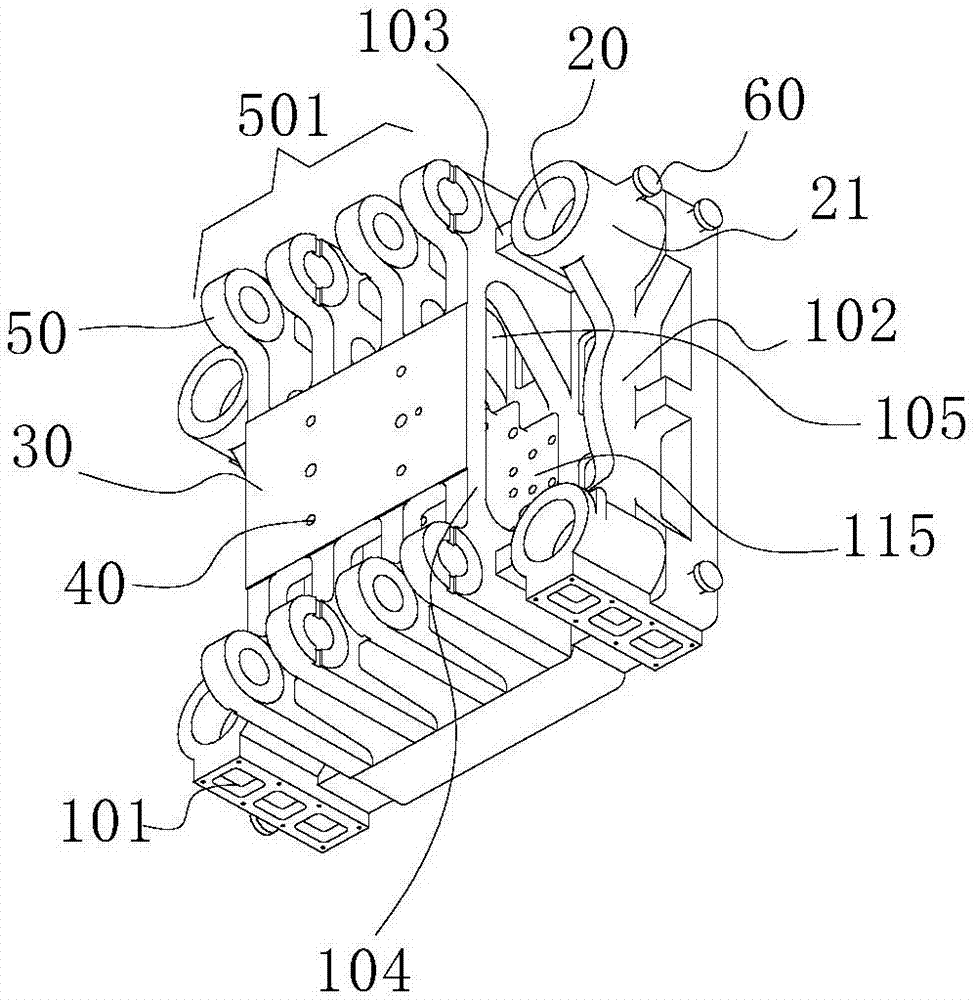

Moving die plate of injection molding machine and injection molding machine

The invention discloses a moving die plate of an injection molding machine and the injection molding machine. The moving die plate of the injection molding machine comprises a die block base body, a guide cylinder provided with a guide column hole, an ejecting mechanism mounting plate and mechanically reamed connecting bases, wherein the guide cylinder and the mechanically reamed connecting bases are separately arranged on the die block base body, the mechanically reamed connecting bases are arranged in pairs, and a first reinforcing rib plate is connected between each pair of mechanically reamed connecting bases; the ejecting mechanism mounting plate is arranged on the first reinforcing rib plates; and the mechanically reamed connecting bases are directly connected to the die block base body, and no gaps are arranged between the mechanically reamed connecting bases and the die block base body, so that the mechanically reamed connecting bases cannot easily deform or crack when subjected to tensile force or pressure. Therefore, the strength and the rigidity of the mechanically reamed connecting bases can be increased; and at the same time, by adopting reasonable mechanism design, used materials are reduced, and the weight of the moving die plate is reduced, so that the moving die plate is more flexible in running and more convenient to machine.

Owner:广东佳明机器有限公司

Carbon removing device for reducing carbon deposits in automobile cylinder and purifying tail gas emission and method thereof

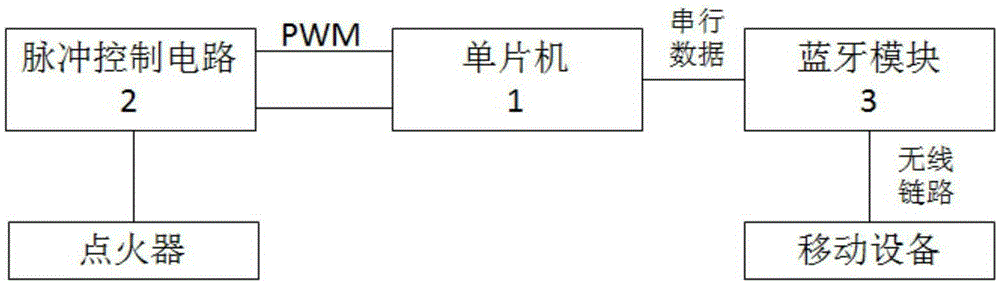

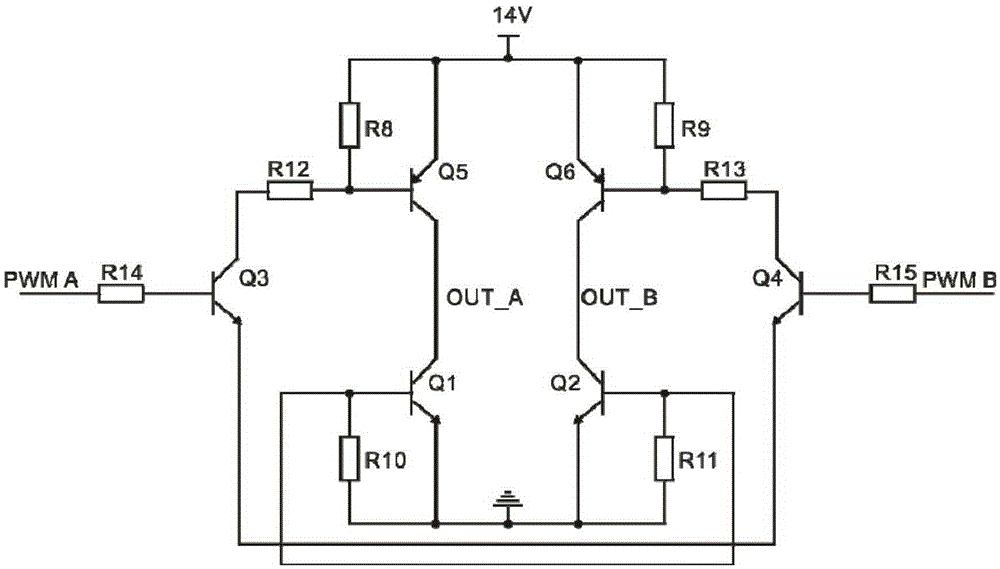

ActiveCN105386898AObserve workReduce carbon depositionCombustion-air/fuel-air treatmentMachines/enginesMicrocontrollerIgnition coil

The invention discloses a carbon removing device for reducing carbon deposits in an automobile cylinder and purifying tail gas emission and a method thereof. The device is composed of a single-chip microcomputer, a pulse control circuit and a Bluetooth module. A vehicle-mounted direct current source provides a power source for the system. The pulse control circuit generates a pulse current, and the two output ends of the pulse control circuit are connected with an ignition coil of an igniter. After an automobile is started, the carbon removing device begins to work; after the automobile flames out, the carbon removing device stops working. When an igniter is connected for ignition in a secondary mode, an alternating pulse current is input into the ignition coil for generating an alternating magnetic field, and thus fuel oil atomization is accelerated, and the combustion efficiency is improved. Eddy currents are further generated on the inner wall of the cylinder through the alternating magnetic field, and burning of the carbon deposits is accelerated under the action of a skin effect. According to the carbon removing device, it is beneficial to improving the anti-interference capability, operating of a vehicle is stable, the combustion efficiency is improved, and the carbon deposits in the cylinder and harmful gas components in the tail gas emission are significantly reduced.

Owner:杭州圣马汽车用品有限公司

Bamboo veneer semi-finished product dryer

InactiveCN102012151ASimple structureRunning balanceDrying machines with progressive movementsHeat sinkWork in process

The invention discloses a bamboo veneer semi-finished product dryer, and relates to a drying device. The structure of the bamboo veneer semi-finished product dryer consists of a motor, a drive mechanism, a delivery mechanism, a box-shaped sealed cover body and a radiating fin, and is characterized in that: holes are reserved on the upper surface of the sealed cover body for fixing a plurality of axial flow fans; an exhaust tube is fixed in front of each axial-flow fan; the air outlet of the exhaust tube is communicated with the air inlet of each axial-flow fan through a pipeline; a rotating drum is respectively sleeved on a drive shaft and a driven shaft of the delivery mechanism fixedly; a plurality of pairs of spacing steel rings are fixedly welded on the outer circle of each rotating drum; a steel rope ring circles in the spacing space of the steel rope rings corresponding to the outer circles of each pair of drive and driven rotating drums; and a plurality of transverse pipe brackets are uniformly arranged on an inner rack of the delivery mechanism fixedly. The bamboo veneer semi-finished product dryer has the advantages that: the internal circulation of waste heat air is fully utilized by the combination of the exhaust tubes and the axial flow fans; and the temperature differences of each section are relatively uniform. The structure is simplified by taking a steel rope instead of a chain crawler type screen plate as a delivery belt; and the operation is balance.

Owner:福建新立丰竹业集团有限公司

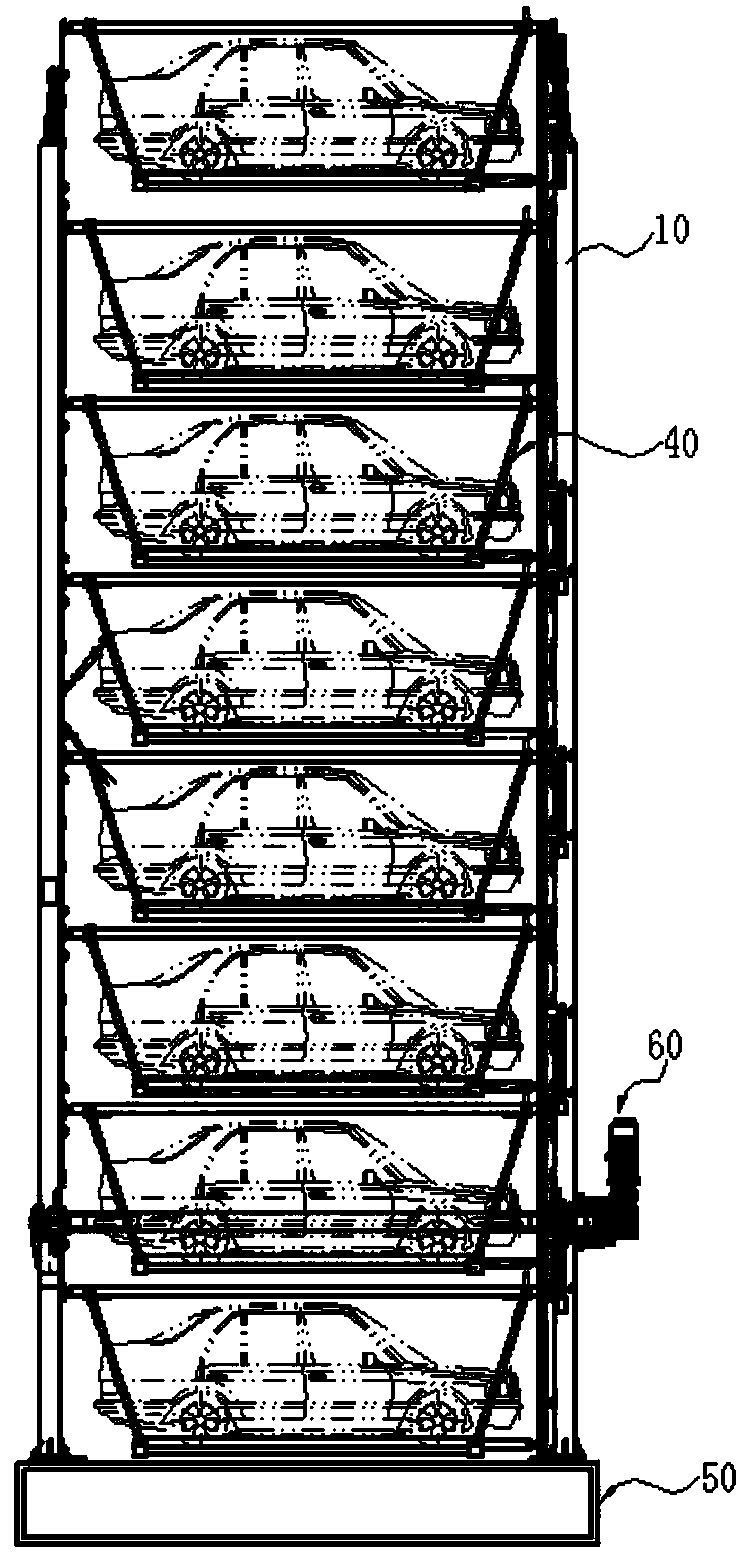

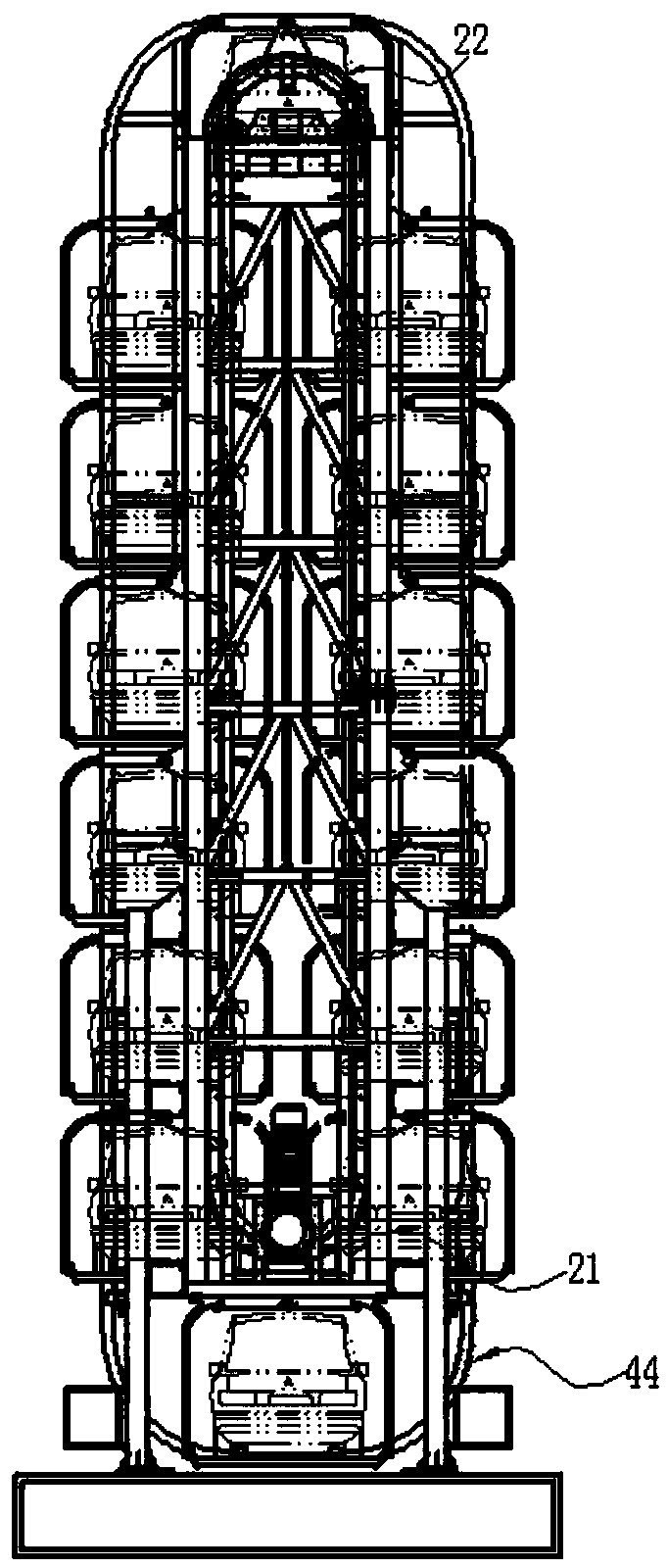

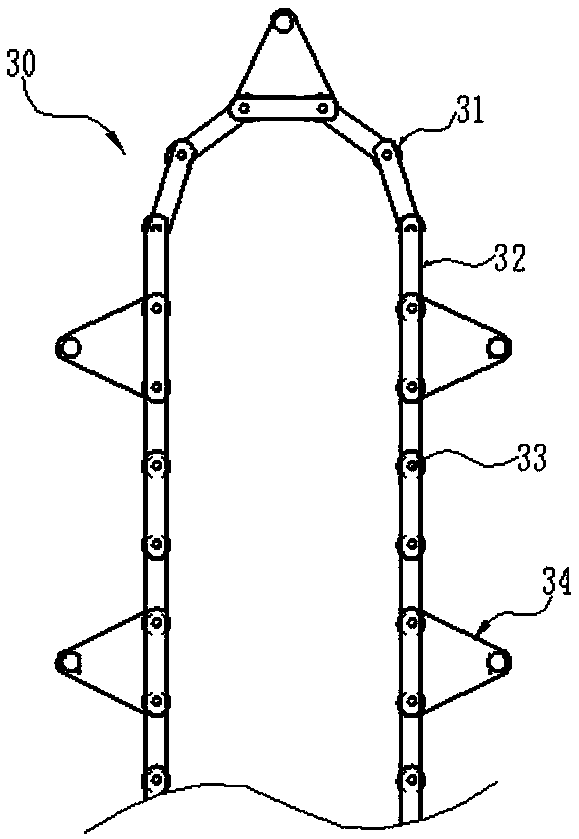

Mixed type vertical circulation ITG (intelligent three-dimensional garage)

The invention relates to the technical field of garages, in particular to a mixed type vertical circulation ITG (intelligent three-dimensional garage). The mixed type vertical circulation ITG comprises a frame assembly and a drive assembly, wherein the frame assembly comprises two frame plates which are in opposite vertical distribution, drive wheels are rotationally distributed at the two ends ofthe frame plates respectively, lifting chains are distributed on the drive wheels under driving of the drive assembly, and vehicle-carrying hanging baskets for vehicle placement are distributed on the drive chains at intervals. Therefore, when the ITG operates, pulleys on each vehicle-carrying hanging basket operate in guide grooves, a connecting cross beam at the lower part is provided with cushion supports to flatten and align drag plates tightly close to the upper parts of the cushion supports, the vehicle-carrying hanging baskets at linear segments of the guide grooves are overlapped andcorrected mutually, vehicles are more balanced and more stable during traveling, and the problem of certain potential safety hazard caused by the fact that the vehicle-carrying hanging baskets are prone to shaking during using of the three-dimensional garage in the prior art is solved.

Owner:蚌埠市行星工程机械有限公司

Electromagnetic force balance-based high-life variable-pitch screw mechanism

ActiveCN108488343ARunning balanceExtended service lifeGearingFastening meansEngineeringMechanical engineering

A high-life variable-pitch screw mechanism based on an electromagnetic force balance includes a lead screw, a nut, a pin roller, and an electromagnet, a variable-pitch helical groove is arranged in the outer wall of a body of the lead screw, the two ends of the lead screw are respectively secured to a base of a load-bearing drive mechanism of a subway door, the nut sleeves the lead screw to form ascrew pair, the pin roller and the electromagnet are both disposed within the nut, the pin roller includes a roller and a pin, the roller is rotatably connected to one end of the pin, the other end of the pin is fixedly connected with the annular inner wall of the nut, the electromagnet includes concentrically disposed first and second electromagnetic rings, the second electromagnetic ring sleeves the pin, the second electromagnetic ring is in transitional engagement with the pin, the first electromagnetic ring sleeves the second electromagnetic ring, the nut is fixedly connected with the subway door via the screw pair. The present invention takes advantage of the electromagnetic forces generated by the electromagnet to balance the force of the rollers against the helical groove and the force of the pin by the nut, such that the operation of the entire variable-pitch screw mechanism is balanced, and the service life is improved.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com