Cable single twister allowing height and side-direction adjusting

A technology of height adjustment screw and single stranding machine, which is applied in the direction of textile cables, textiles and papermaking, cable/conductor manufacturing, etc. It can solve the problem that the height and side of the stranding mechanism cannot be adjusted, the cable cannot be used, and the work efficiency is low. Problems, to achieve the effect of increasing height adjustment and side adjustment functions, reducing damage, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

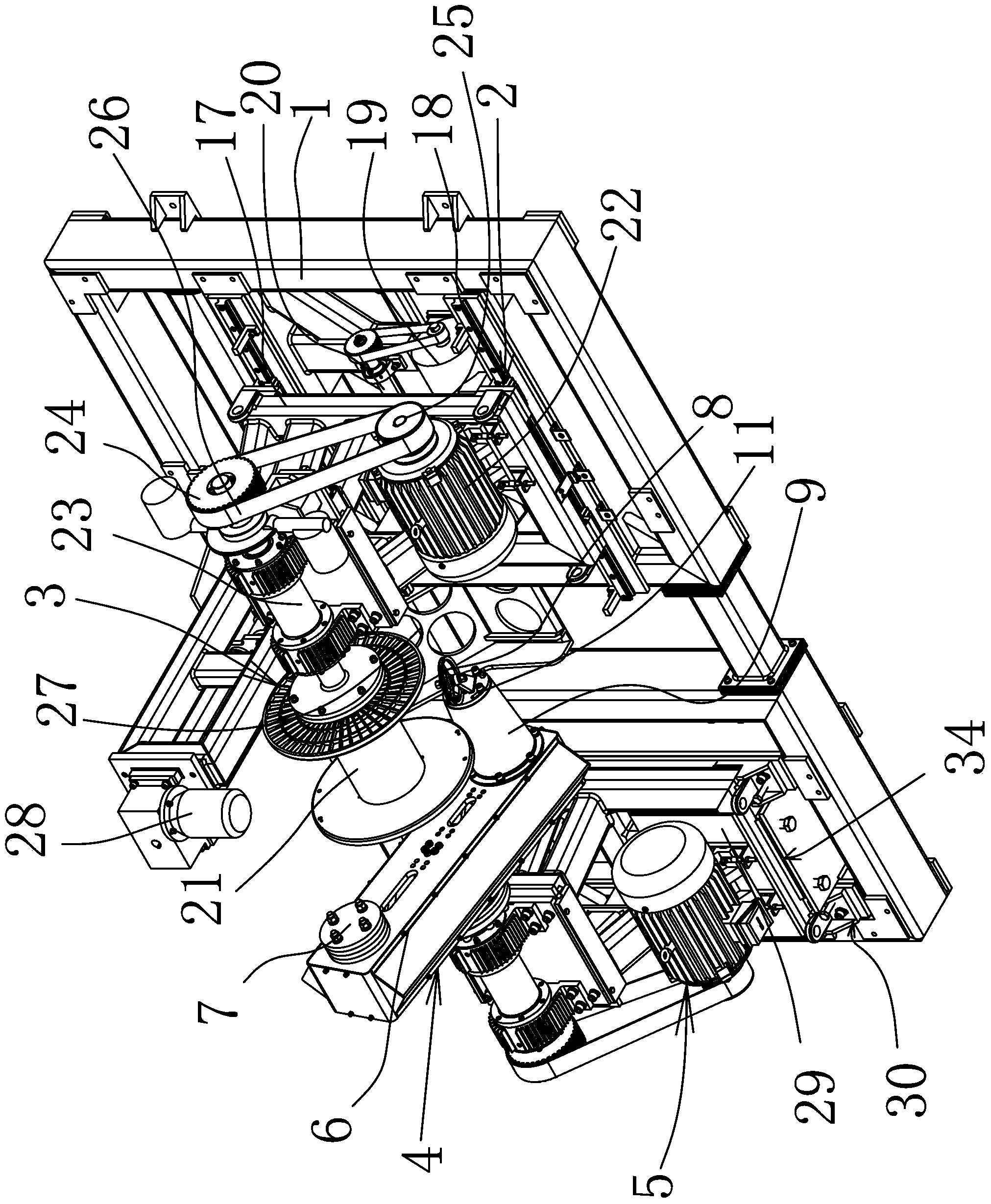

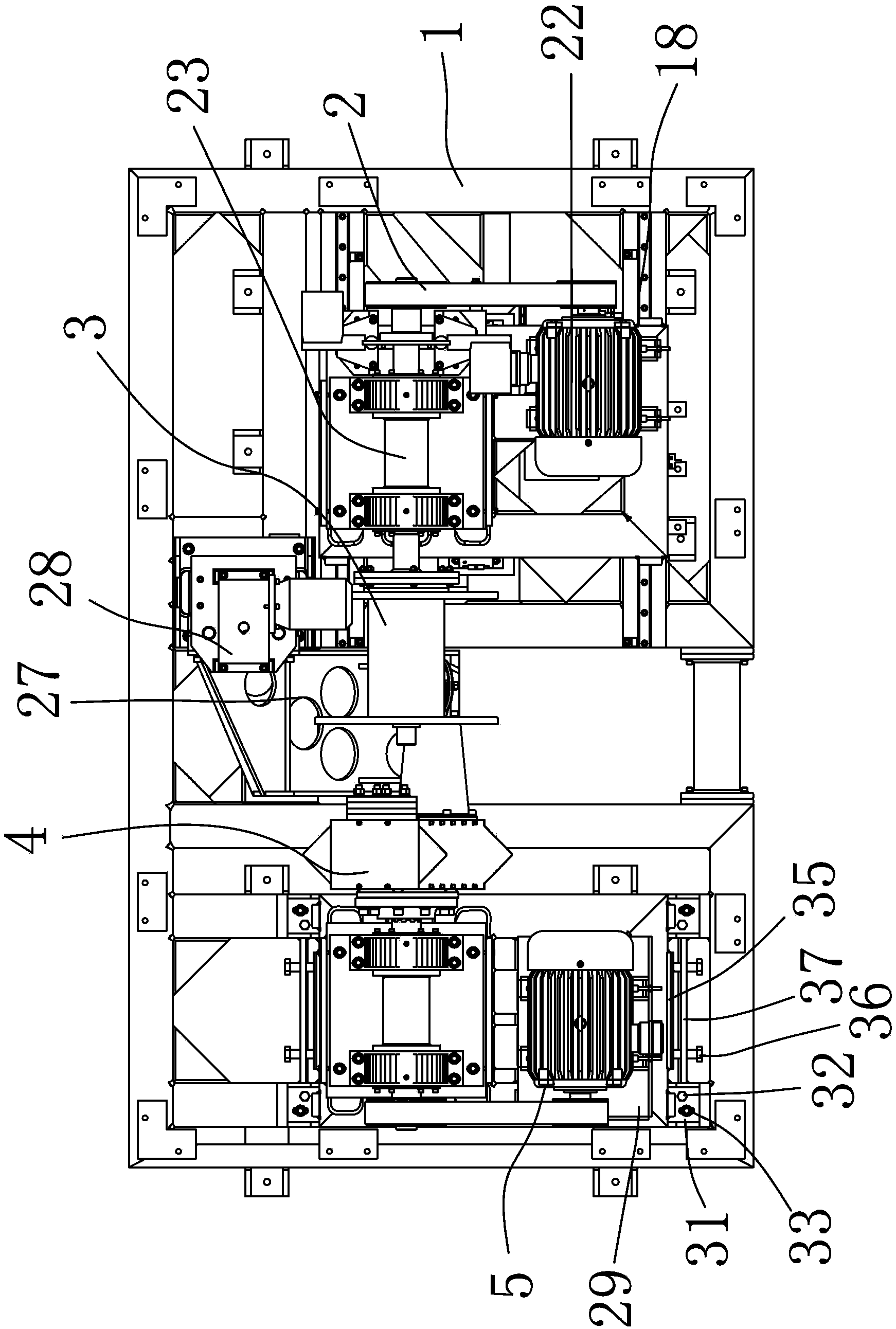

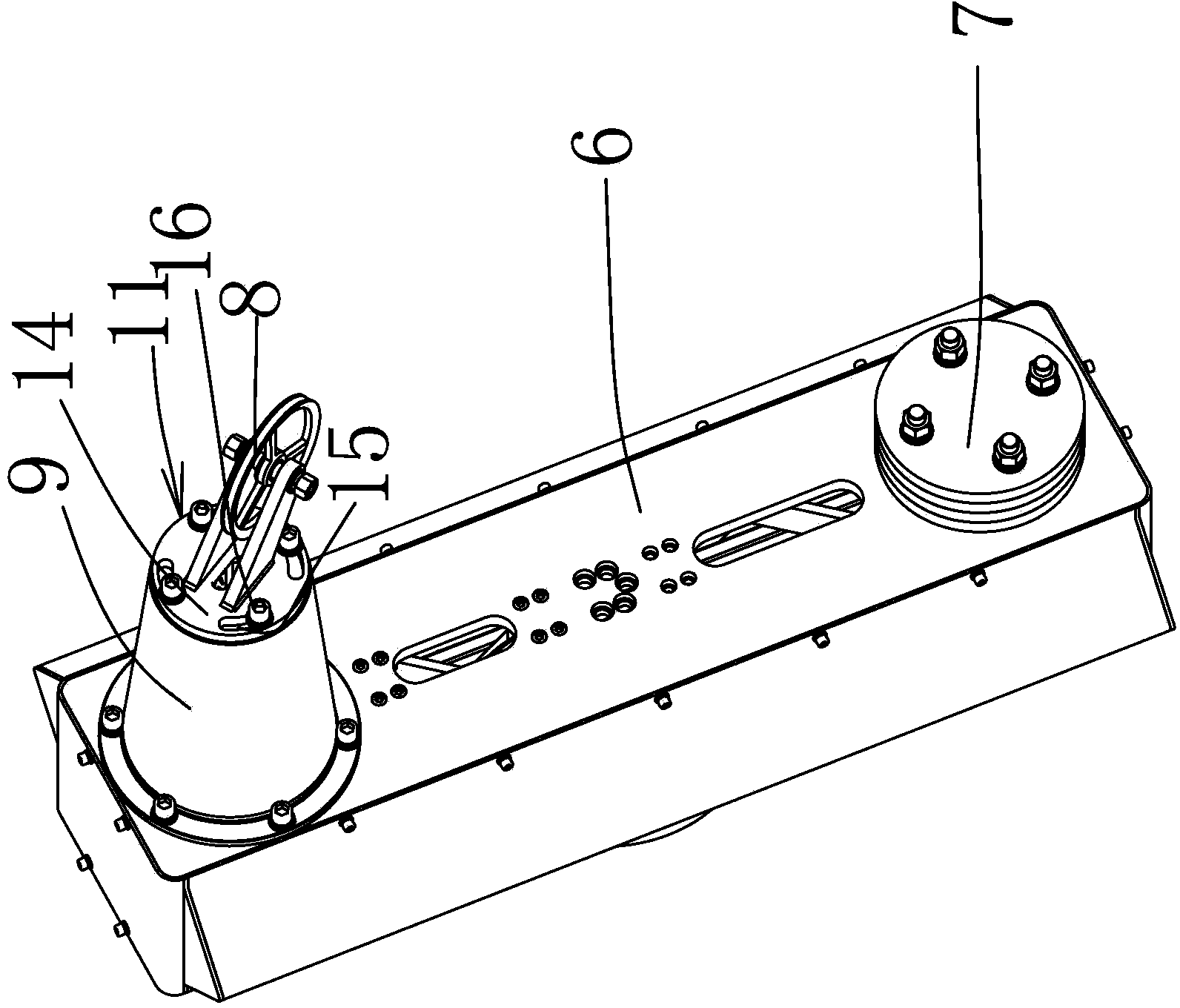

[0021] In the figure, the frame 1; the moving mechanism 2; the take-up mechanism 3; the twisting mechanism 4; the twisting driving mechanism 5; the twisting bow arm 6; the counterweight 7; ; the first guide wheel 12; the second guide wheel 13; adjusting disc body 14; adjusting slot 15; locking member 16; moving frame 17; moving guide rail 18; moving drive motor 19; Take-up drive motor 22; take-up rotating shaft 23; first pulley 24; second pulley 25; synchronous belt 26; rack 27; drive motor 28 for rack; Adjusting sheet 31 ; height adjusting screw 32 ; height locking screw 33 ; lateral distance adjusting part 34 ; top pressure plate 35 ; lateral adjusting screw 36 ; lateral fixing plate 37 .

[0022] Such as figure 1 as w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com