Fiber laser cleaning machine

A fiber laser and cleaning machine technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, low degree of automation, poor cleaning effect, etc., to avoid secondary pollution, high degree of automation, Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

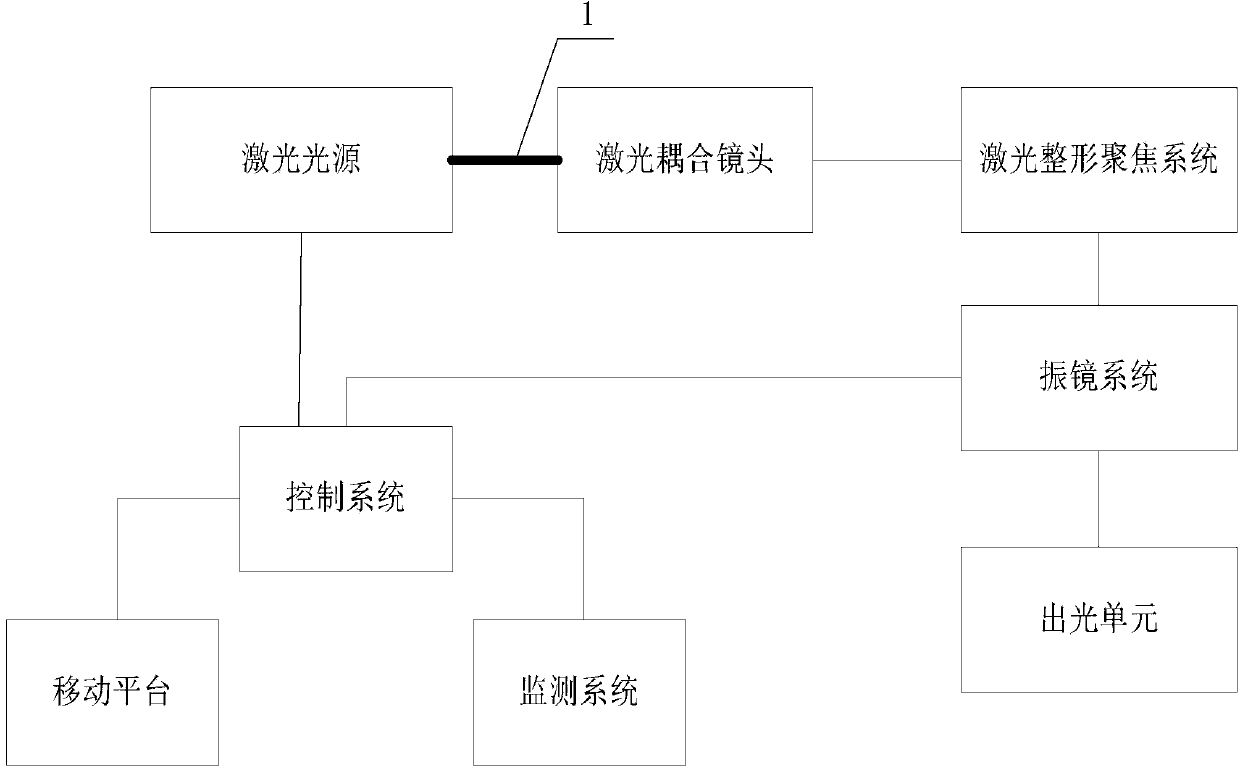

[0015] see figure 1 , the embodiment of the present invention provides an optical fiber laser cleaning machine, including: a laser system (including a laser and a cooling system), a laser transmission system (including a laser energy fiber 1 and a laser coupling lens), a beam adjustment system (including a laser shaping and focusing unit , galvanometer system and light unit), vacuum system, monitoring system, control system, housing, sealing ring, metal hose and mobile platform. The beam adjustment system, dust collection system and monitoring system are set on the mobile platform, and the mobile platform can move on a specially set track to drive the beam adjustment system, dust collection system and monitoring system to different areas, so as to realize the monitoring of different workpieces. cleaning. see figure 1 , the heat dissipation system is arranged near the laser to dissipate heat from the laser. The laser is connected to the laser coupling lens through the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com