Patents

Literature

82results about How to "Suck away in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

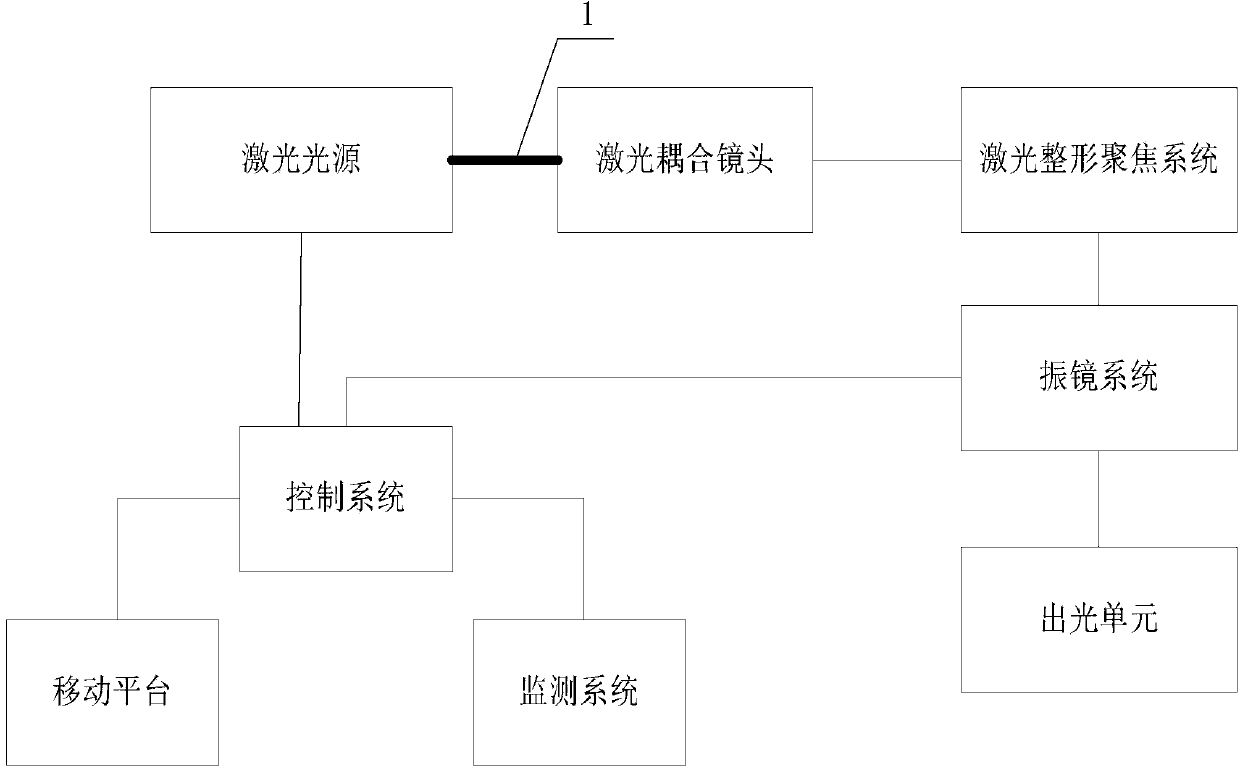

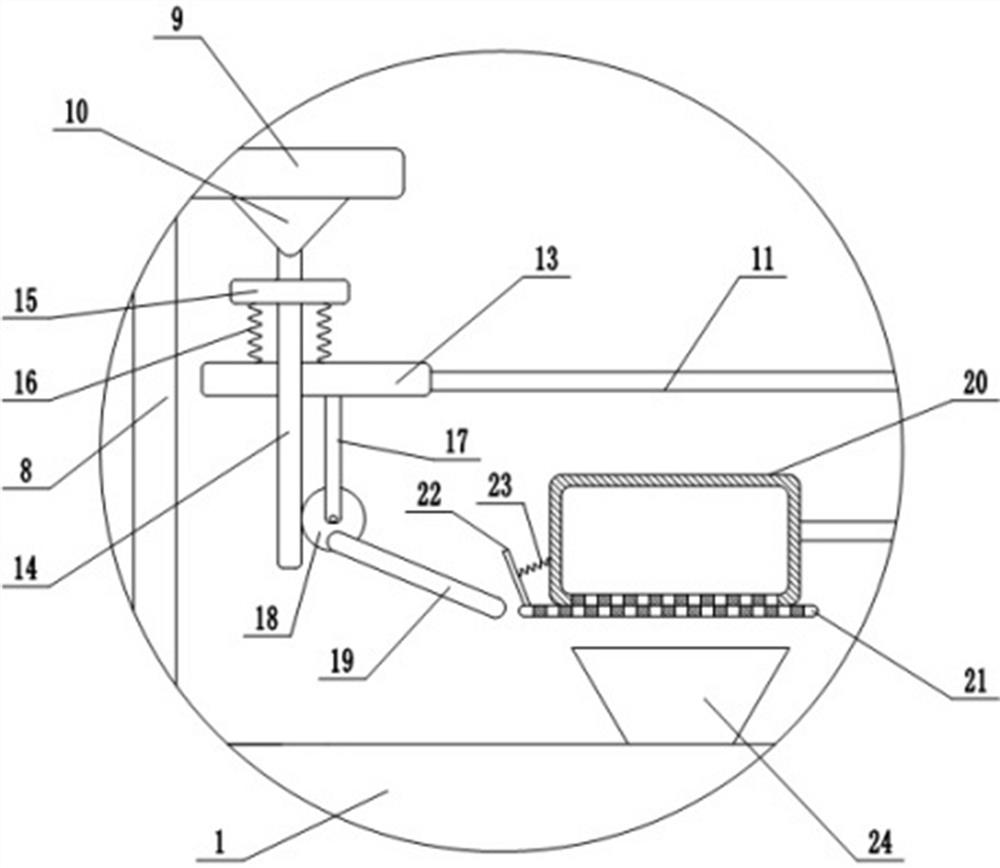

Fiber laser cleaning machine

InactiveCN104259142ACause damageAvoid secondary pollutionCleaning processes and apparatusControl systemMonitoring system

The invention relates to the technical field of laser equipment, in particular to a fiber laser cleaning machine. The fiber laser cleaning machine comprises a laser system, a laser transmission system, a light beam adjusting system, a dust collecting system, a monitoring system, a control system and a mobile platform. The light beam adjusting system, the dust collecting system and the monitoring system are arranged on the mobile platform. The laser system is connected with the laser transmission system; and the light beam adjusting system is arranged at the front end of the laser transmission system. An air port of the dust collecting system is formed in the front side of a workpiece. The monitoring system is connected with the control system; and the control system is connected with the light beam adjusting system, the dust collecting system and the mobile platform. The fiber laser cleaning machine, provided by the invention, has the advantages of good cleaning effect, high efficiency and high automation degree. The fiber laser cleaning machine, provided by the invention, cannot damage the workpiece. In addition, the fiber laser cleaning machine, provided by the invention, is further provided with the dust collecting system, so that impurities generated in the cleaning can be timely absorbed to prevent the cleaned workpiece from generating secondary pollution.

Owner:武汉和骏激光技术有限公司

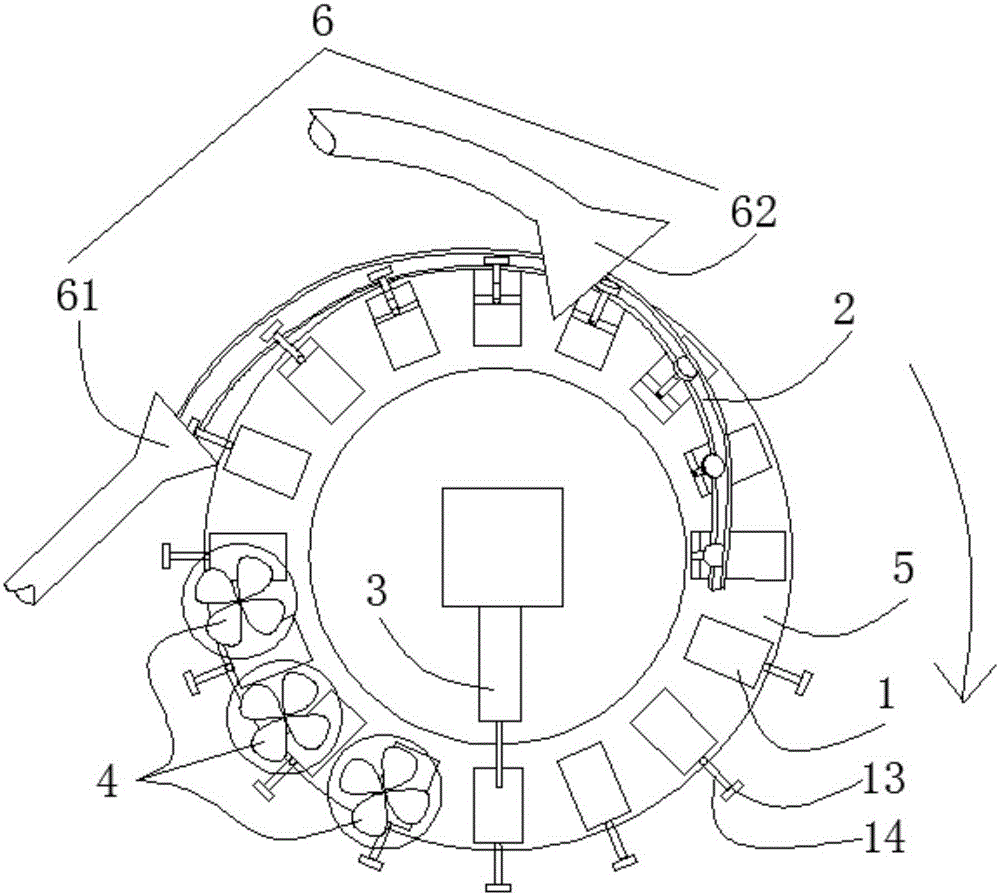

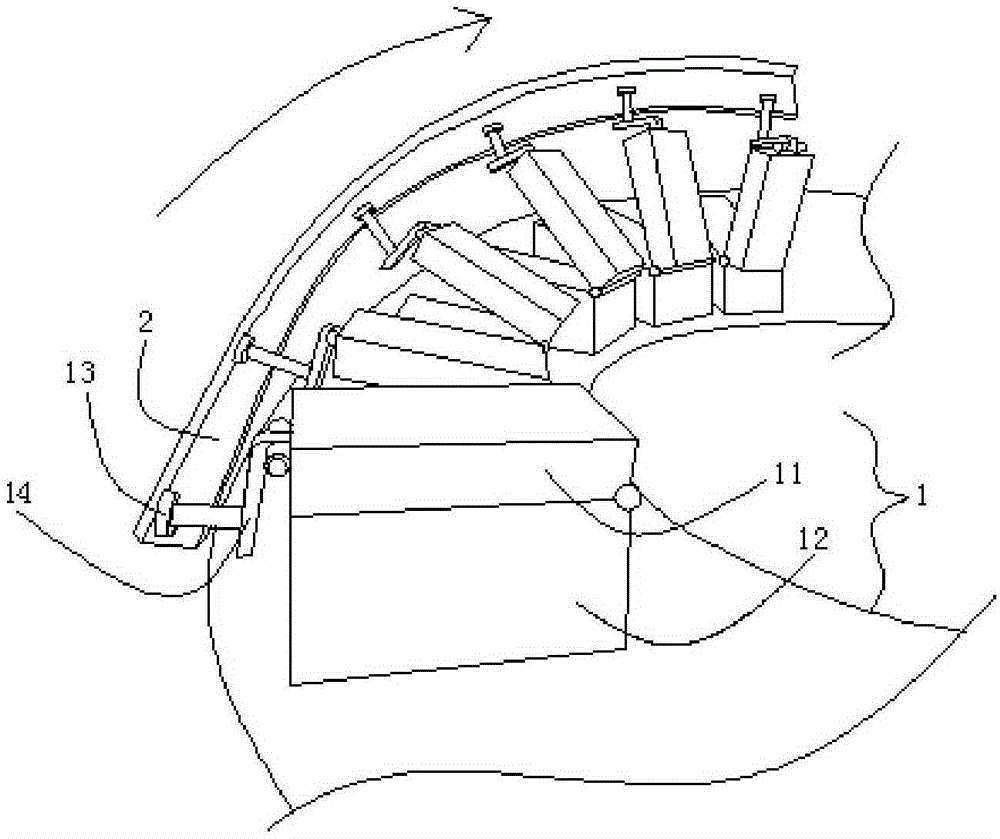

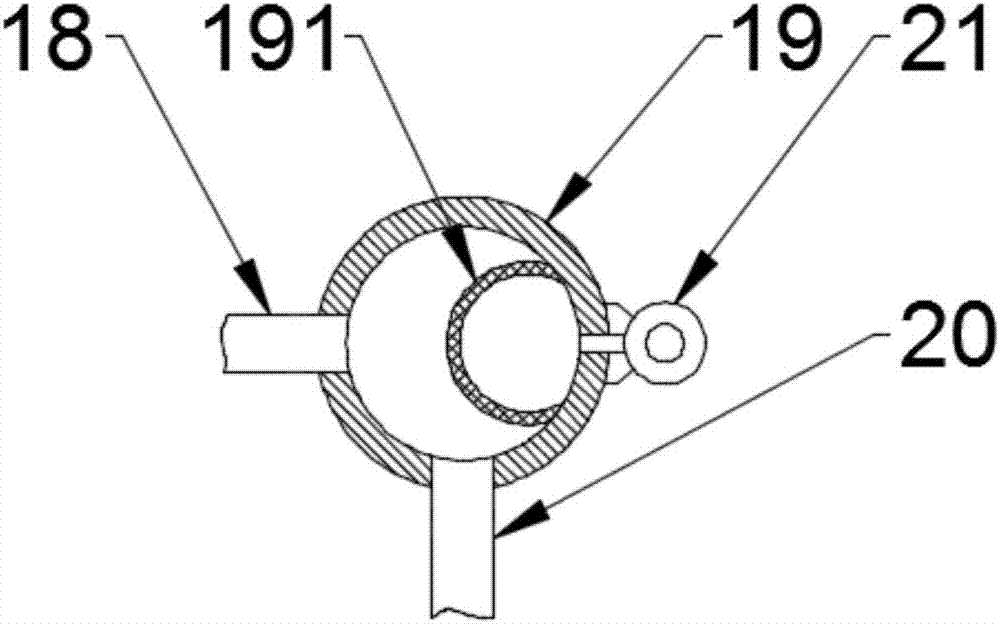

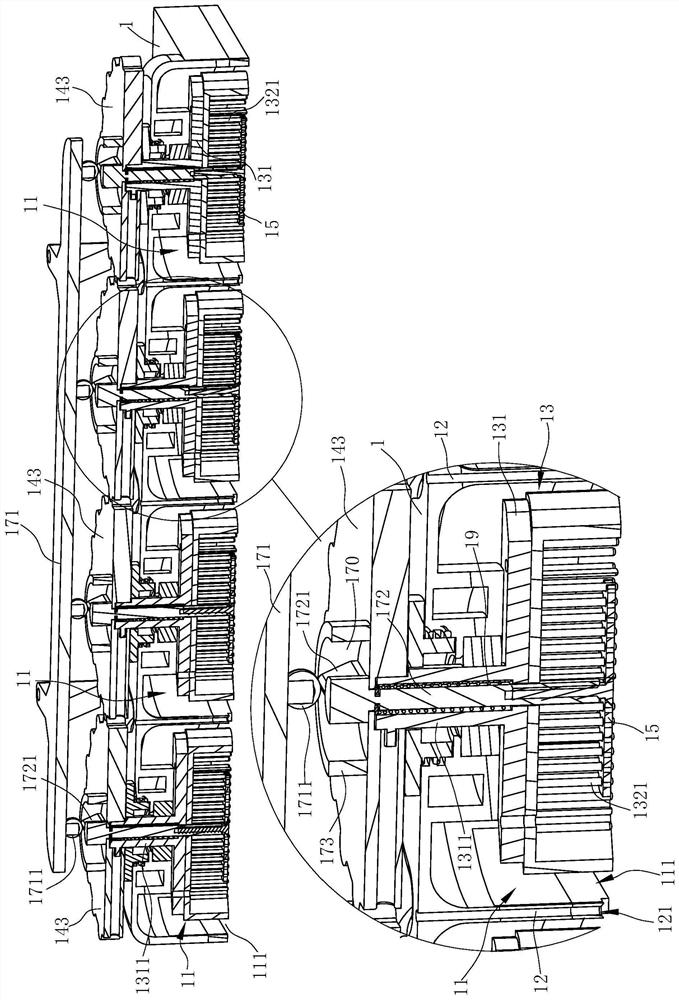

Shoemaking injection molding machine

InactiveCN105216216AReduce CooldownIncrease usageDomestic articlesMultiple injectionInjection molding machine

The invention provides a shoemaking injection molding machine. The injection molding machine comprises injection molds and a rotating working table. The multiple injection molds are annularly arranged on the rotating working table, and each injection mold comprises an upper mold body and a lower mold body; one end of each upper mold body is hinged to one end of the corresponding lower mold body, and the other end of each upper mold body is an open end; the hinge ends face the center of the rotating working table; and the shoemaking injection molding machine further comprises a mold opening mechanism. The mold opening mechanism comprises rotating rollers and an arc-shaped rail; the rotating rollers are arranged at the opening ends of the upper mold bodies; and one end of the arc-shaped rail gradually rises to the other end along the rotating direction of the molds. The middle axis of the arc-shaped rail is coincident with the motion trails of the rotating rollers in the upper mold opening process. When the rotating rollers roll from one end, which is lower in position, of the arc-shaped rail to the other higher end, the rotating rollers are gradually lifted by the arc-shaped rail, and therefore the upper mold bodies are driven to be gradually opened. Compared with the prior art, due to the design of the arc-shaped rail, the arc-shaped rail is perfectly matched with the rotating rollers on the upper mold bodies, and automatic starting work of the molds is completed.

Owner:安徽省泗州鞋业有限公司

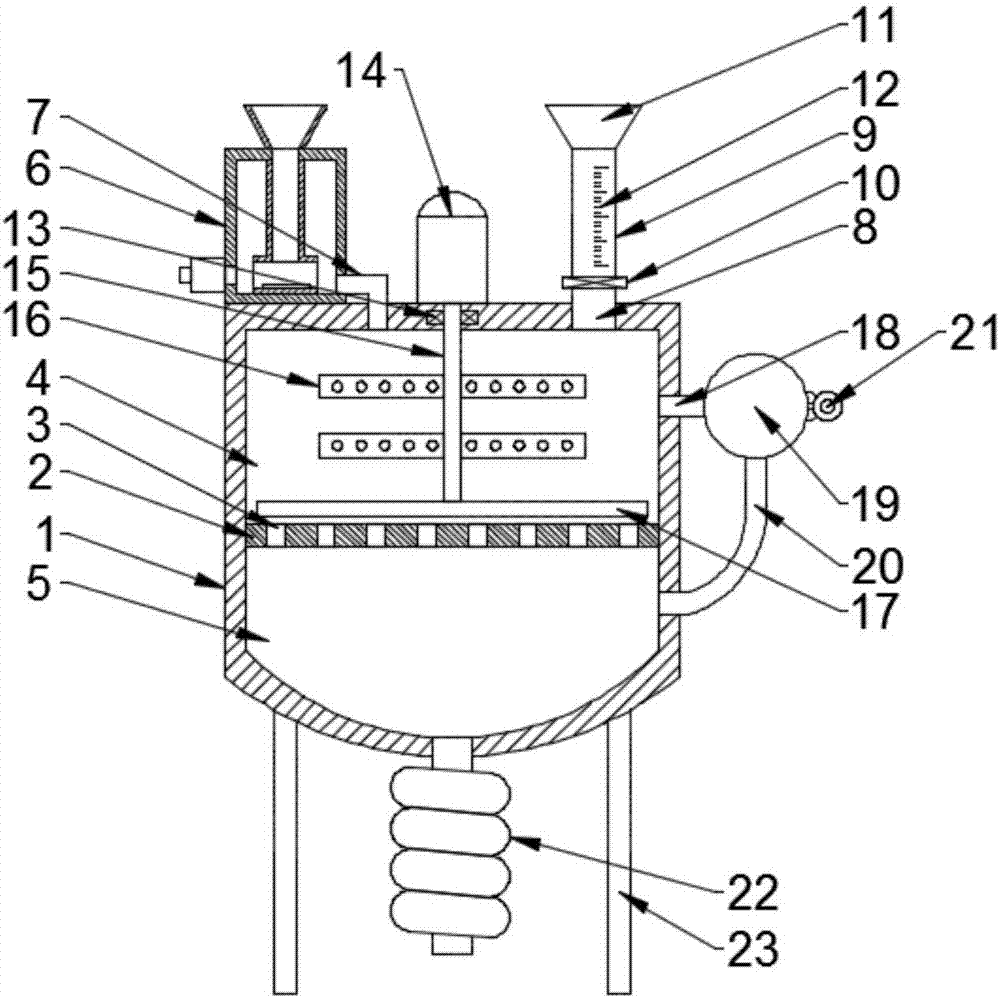

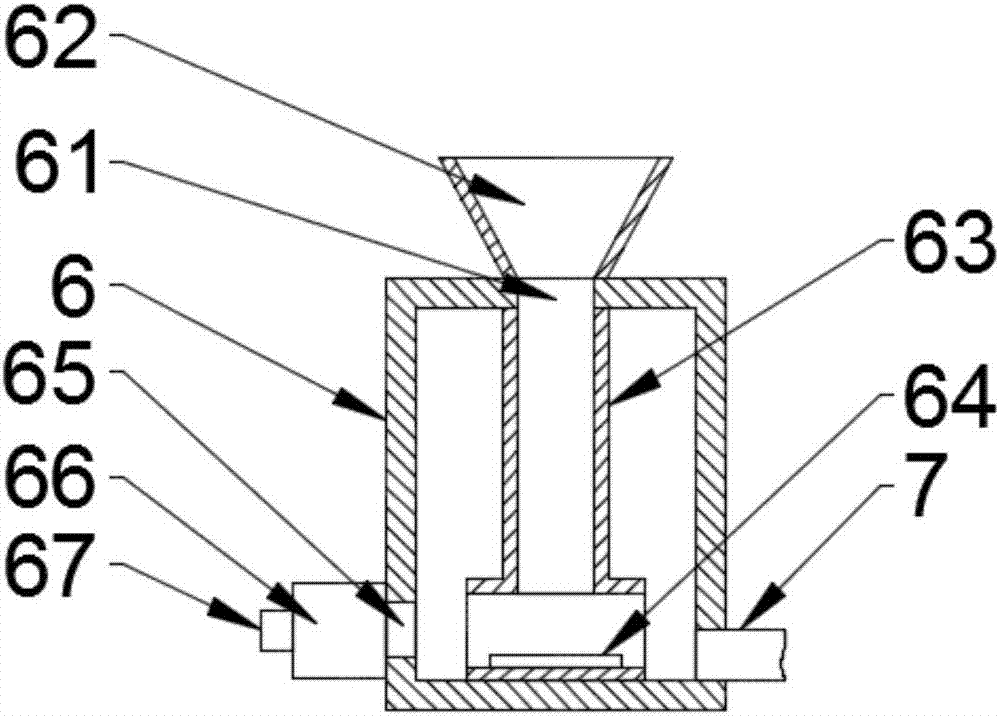

Feed additive dosing device

PendingCN107224933AMeet the needs of useAdd accurateFeeding-stuffRotary stirring mixersEngineeringFeed additive

The invention discloses a feed additive dosing device. The feed additive dosing device comprises a mixing box, a feeding box and a dust collection box, wherein a separating baffle plate is arranged at the middle part of an inner cavity of the mixing box; the separating baffle plate is used for separating the inner cavity of the mixing box into a mixing cavity and a discharging cavity; the mixing cavity is internally provided with a stirring shaft; the top end of the stirring shaft penetrates through the top wall of the mixing box and is fixedly connected to a motor shaft of a motor; the bottom end of the stirring shaft is fixedly connected with a second stirring blade which is matched with the separating baffle plate; a plurality of first stirring blades are uniformly arranged at the middle part of the stirring shaft; a first feeding hole is formed in one side of the top wall of the mixing cavity; the top part of one side wall of the mixing cavity is in through connection with the dust collection box through an air inlet pipe. According to the feed additive dosing device disclosed by the invention, two weighing and dosing modes of the feeding box and a weighing drum are arranged, the using demands of different additives are met, and accurate adding of various additives is ensured; due to the arrangement of the dust collection box, flying dust generated by stirring the additives can be collected, and meanwhile, the collected flying additive smoke dust can return to the discharging cavity again, so that accurate proportioning of all the additives is ensured.

Owner:邹铁梅

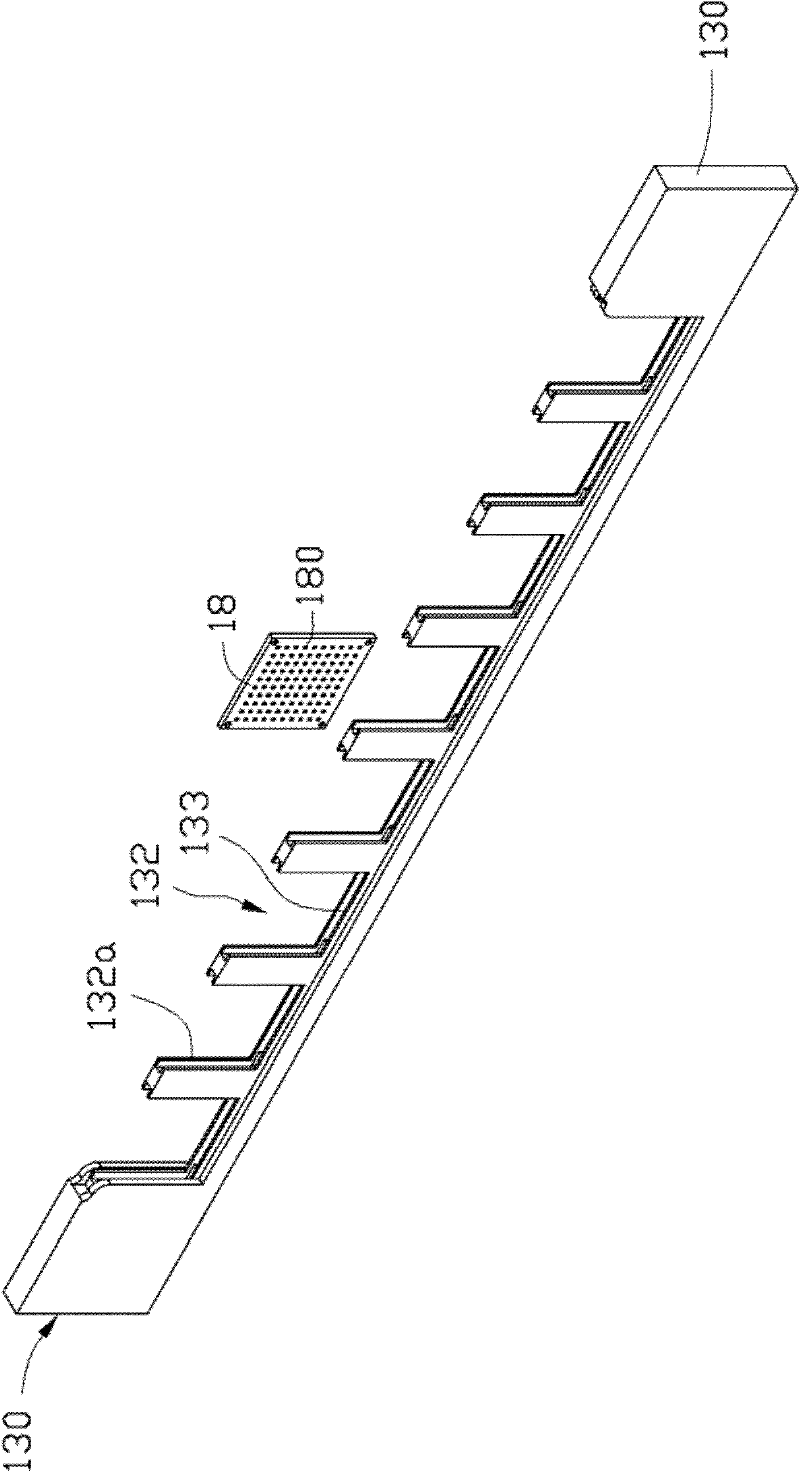

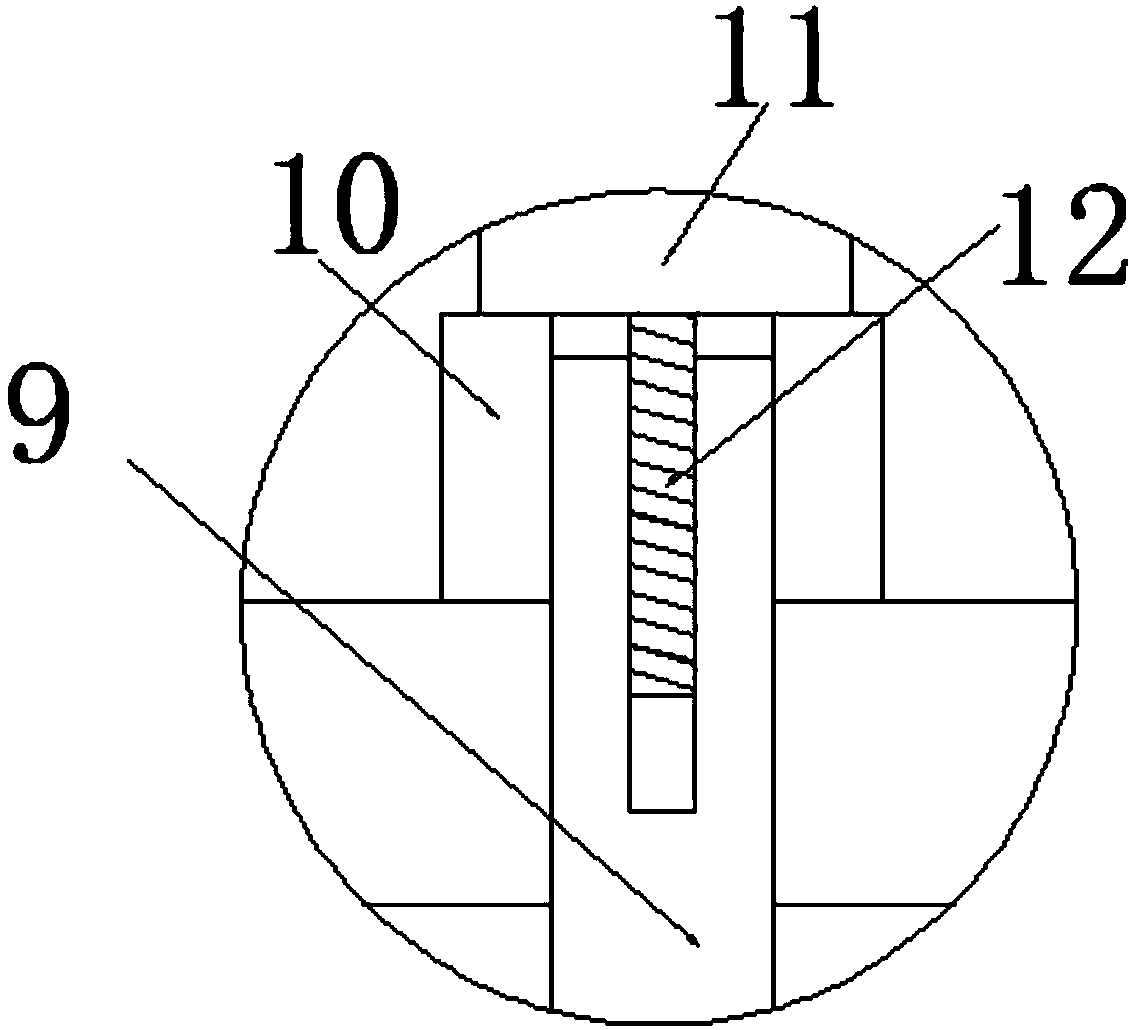

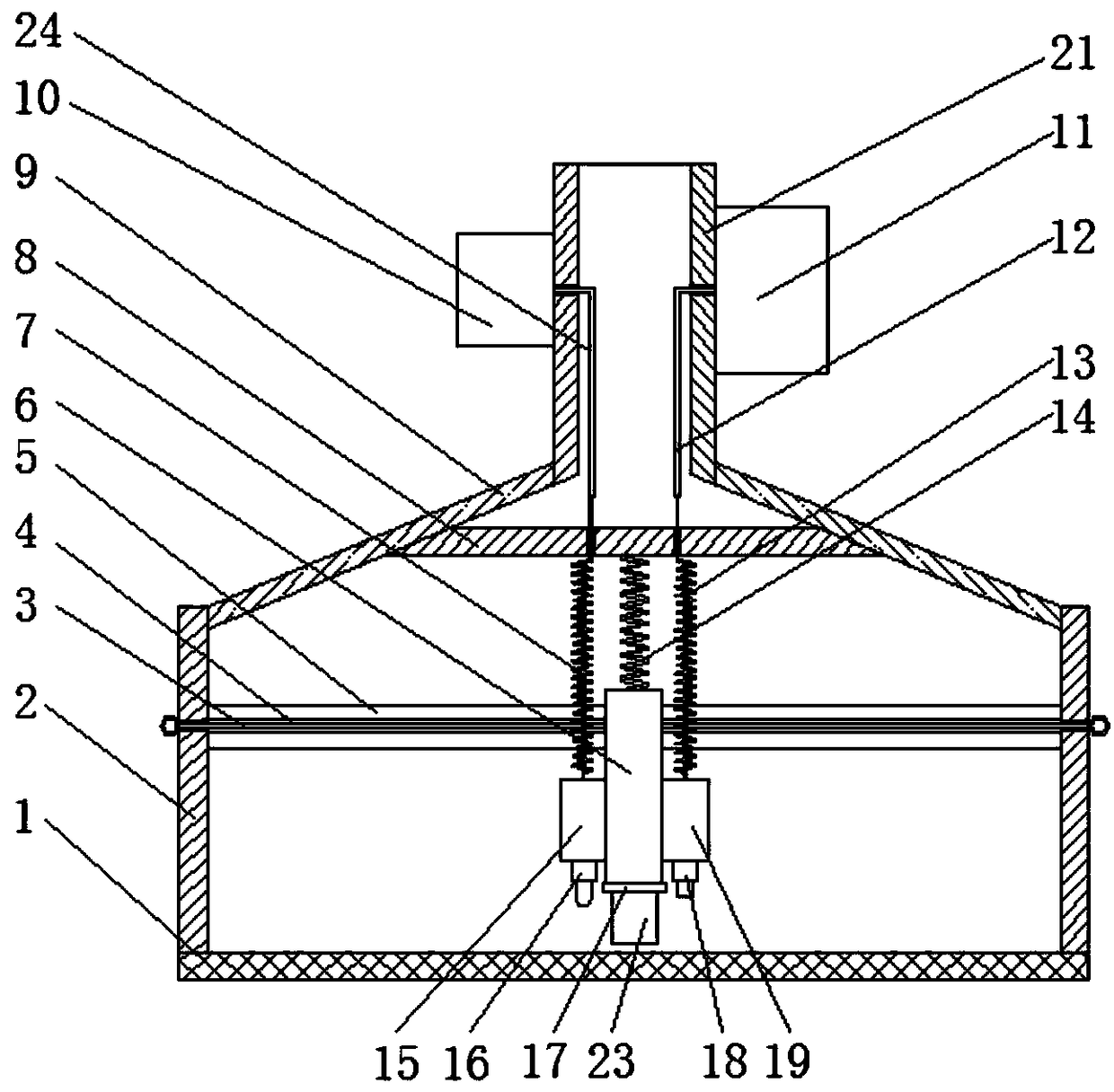

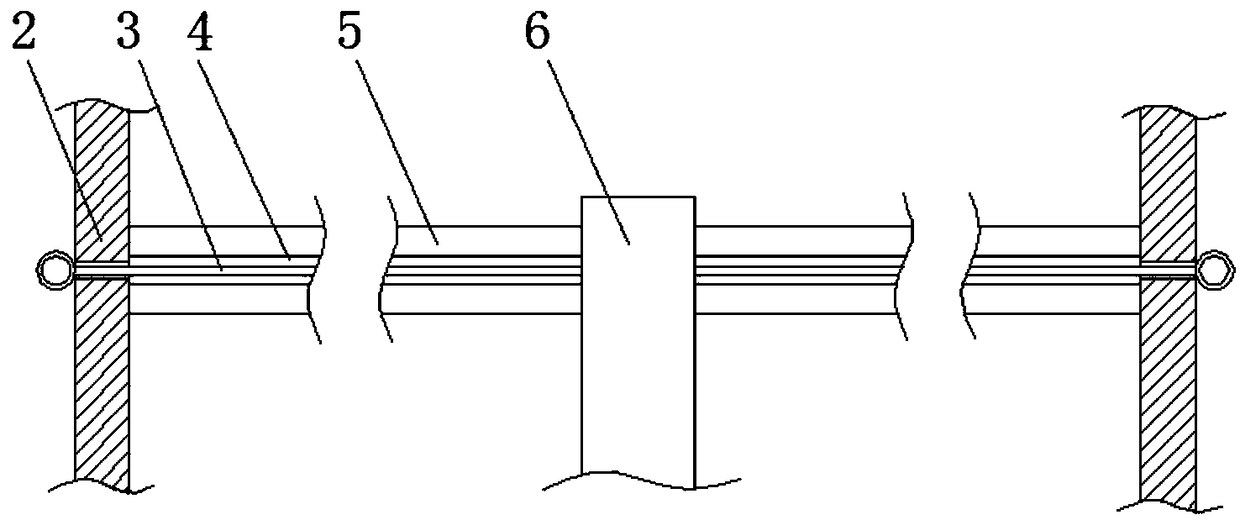

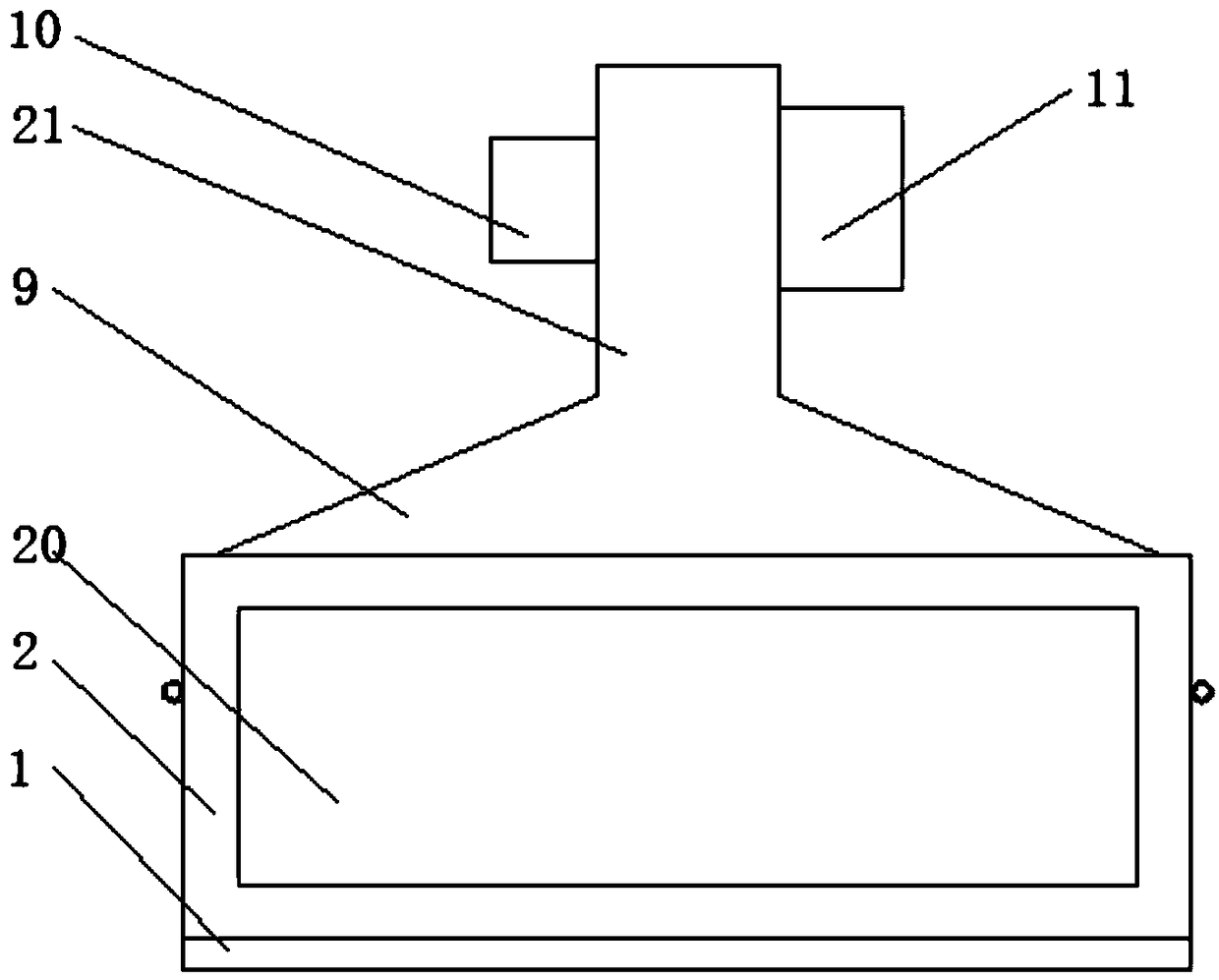

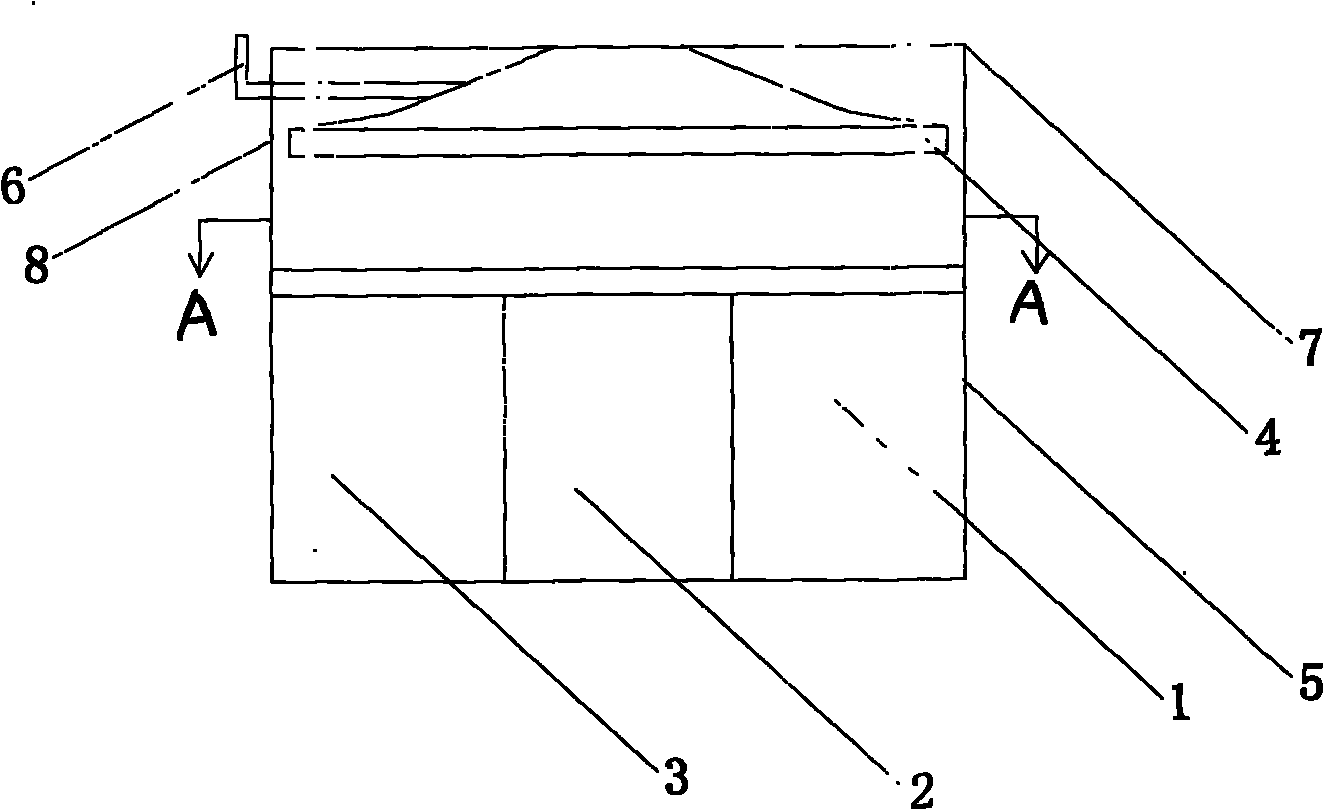

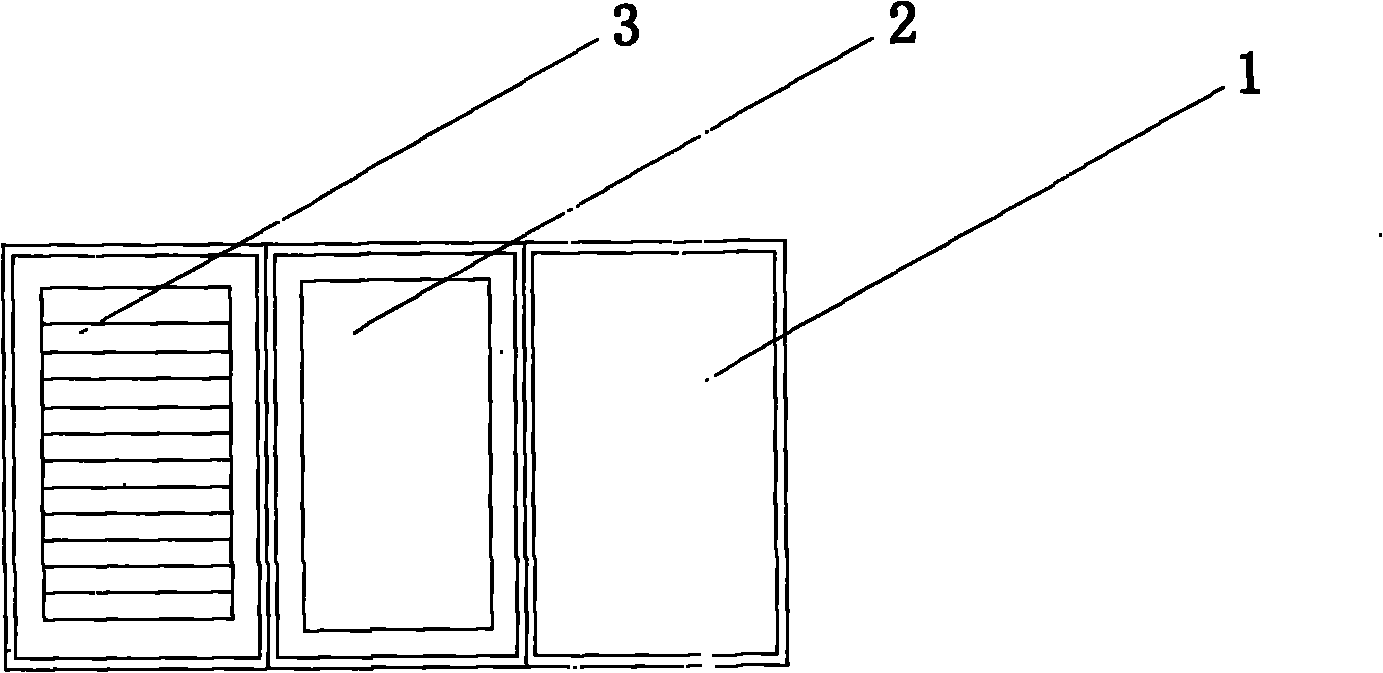

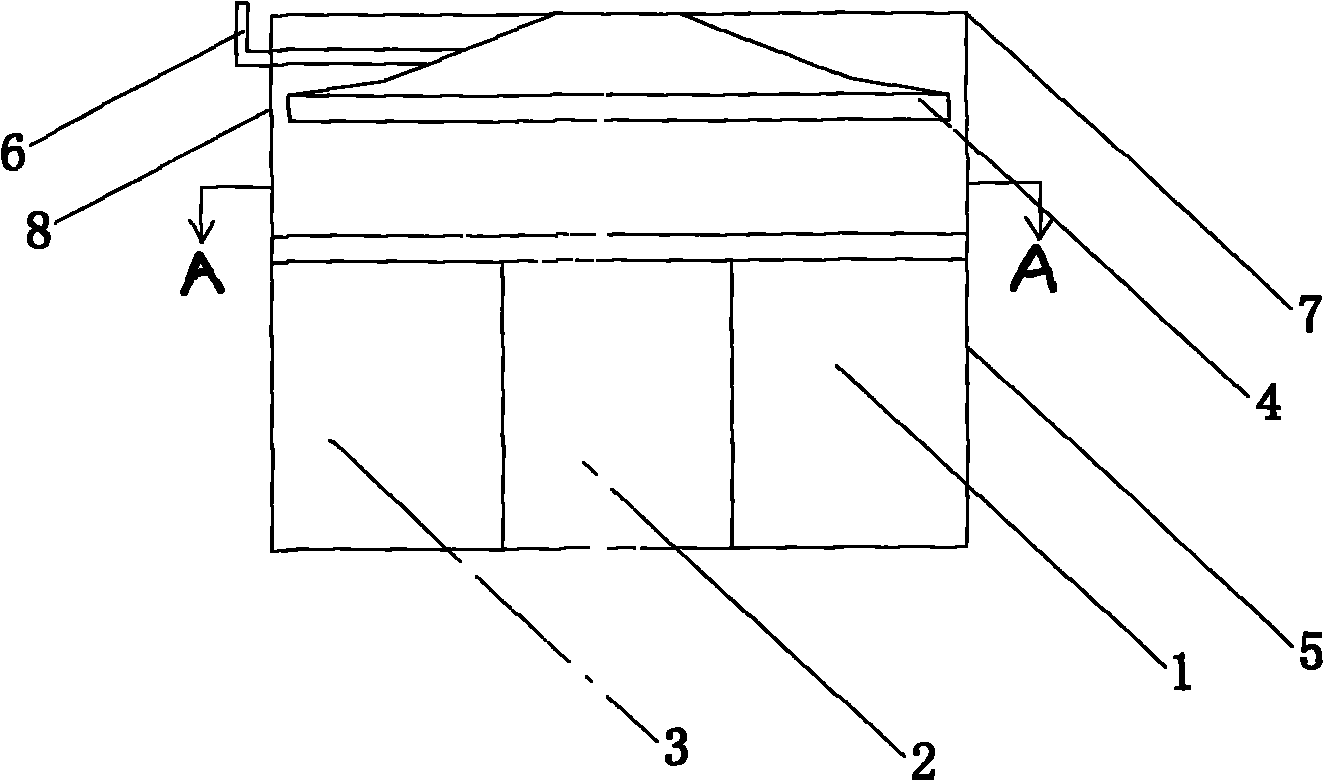

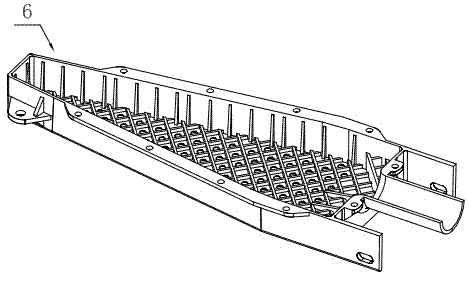

Dedusting device

InactiveCN102233341ASuck away in timeAvoid affecting the dust removal effectCleaning using gasesMechanical engineeringAir blower

The invention provides a dedusting device. The dedusting device comprises a top cover, an accommodation cavity, a bracket, a sliding rail, a dedusting sliding seat, an air extractor, an air blower and a lens bearing disk, wherein the accommodation cavity is provided with an opening; the top cover is used for sealing the opening of the accommodation cavity so as to form a closed accommodation space; two ends of the bracket are respectively fixed in the accommodation cavity; at least one side of the bracket is equipped with the sliding rail parallel to the bracket; the lens bearing disk is fixed on the bracket and used for bearing a lens to be dedusted; the air extractor and the air blower are arranged outside the accommodation cavity; and the dedusting sliding seat is respectively connected with the air extractor and the air blower and slides along the sliding rail so as to blow and suck air for the lens bearing disk fixed on the bracket at the same time, thereby blowing off and sucking out ash on the lens.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

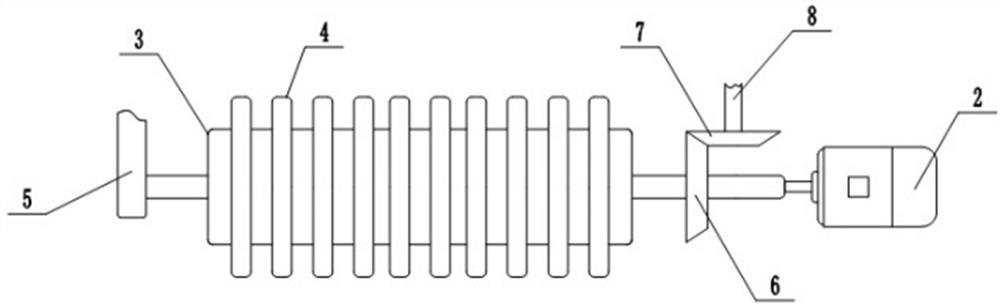

Polishing machine for producing empty capsules

InactiveCN104308714ASuck away in timeAvoid secondary pollutionEdge grinding machinesPolishing machinesDrive shaftSolid structure

A polishing machine for producing empty capsules comprises a polishing barrel, a supporting rack, a motor, a transmission shaft, a transmission connecting device, a dust collector and a dust collection pipe, wherein the polishing barrel is connected with the upper end of the supporting rack through a bolt; the motor is fixed on the right side of the supporting rack; the transmission shaft penetrates in the polishing barrel; the left end of the transmission shaft is connected to the transmission connecting device; the motor is fixed on the right side of the transmission connecting device; the polishing barrel consists of two layers; the inner layer has a net-shaped structure; the outer layer has a solid structure; a gap is formed between the two layers; the polishing barrel is provided with an opening; a pressing frame is arranged on the opening; a chute is formed in the pressing frame; a baffle is arranged in the chute; the dust collection pipe is positioned on the left side of the polishing barrel, wraps the tail end of the right side of the transmission shaft and is connected with the dust collector; and the dust collector is placed on the bottom of the supporting rack. The polishing machine is simple in structure and convenient to operate; damage on the empty capsules is low; the empty capsules are cleaned thoroughly; and secondary pollution on the empty capsules can be avoided effectively.

Owner:湖南尔康正阳药用胶囊有限公司

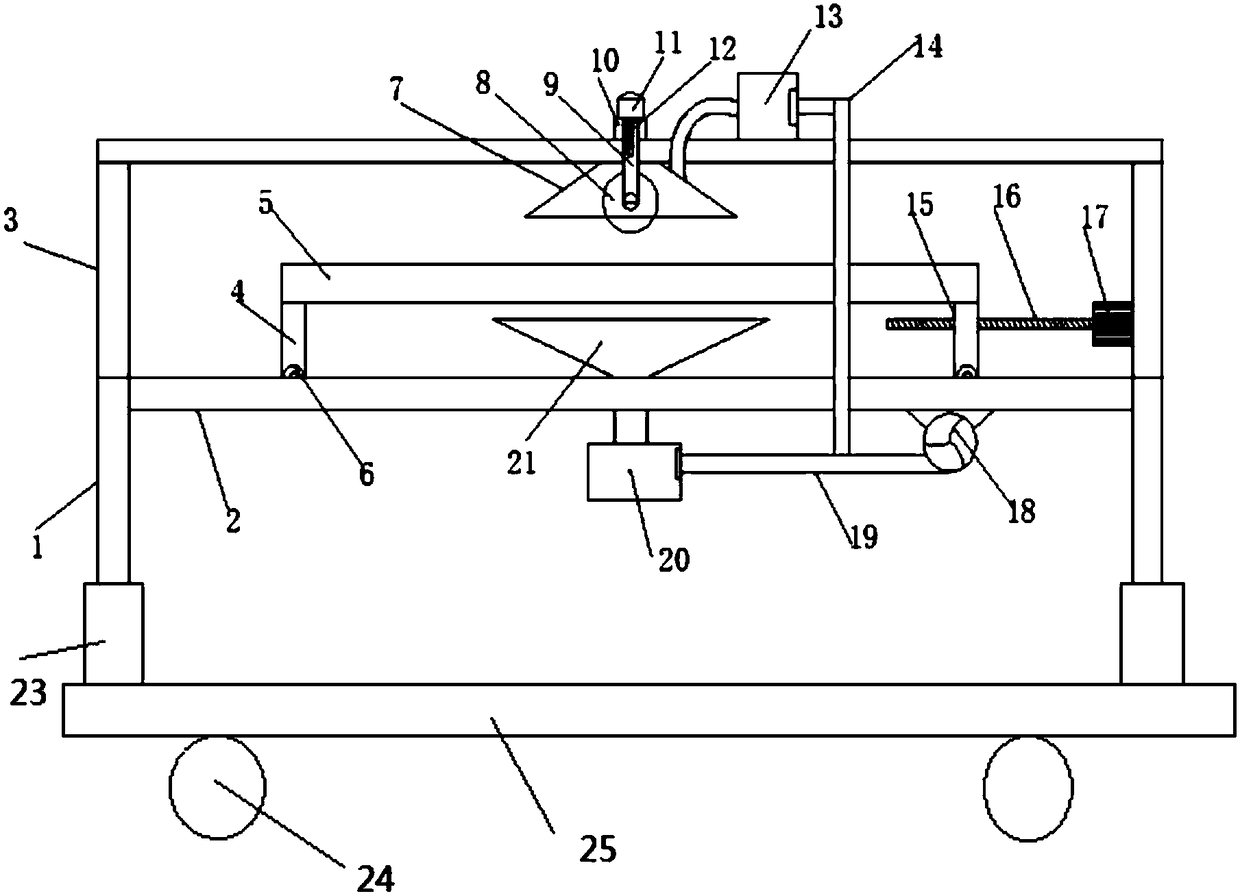

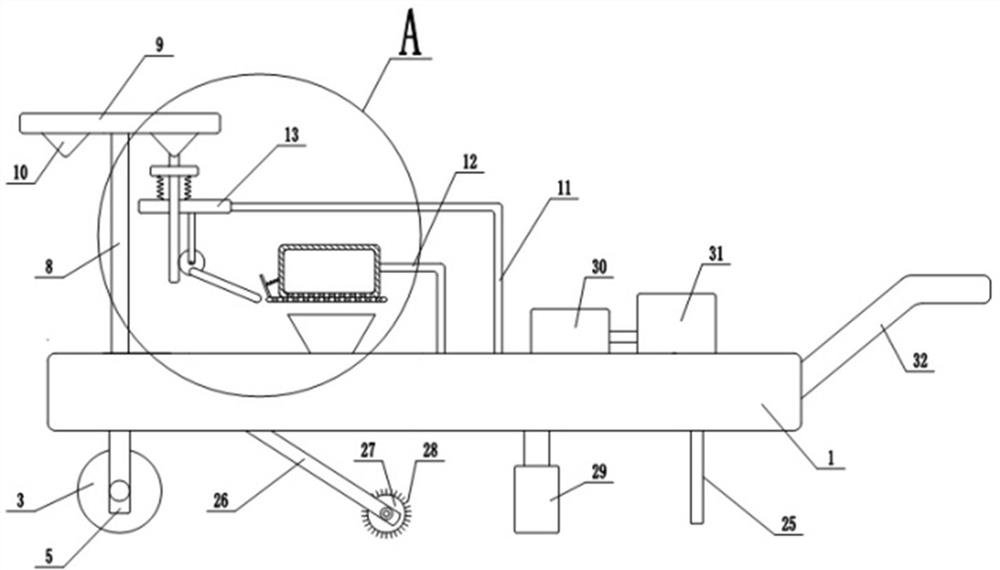

Dust-free board cutting machine for furniture production

InactiveCN108099032ASuck away in timeSimple structureWorking accessoriesStone-like material working toolsEngineeringThreaded rod

The invention discloses a dust-free board cutting machine for furniture production. The dust-free board cutting machine for furniture production comprises supporting legs, an installation plate and afixed rack. The supporting legs are arranged at the two sides of the lower end of the installation plate symmetrically. The fixed rack is arranged at the upper ends of the supporting legs. A board fixing plate is horizontally arranged at the upper end of the installation plate. Sliding legs are symmetrically arranged at the lower end of the board fixing plate. A sliding wheel is arranged at the lower end of each sliding leg. A transmission plate is perpendicularly arranged in the middle of the right lower end of the board fixing plate. A horizontal threaded rod is arranged on the transmissionplate in a penetration manner. The horizontal threaded rod is in thread connection with the transmission plate. The right end of the horizontal threaded rod is connected with the output end of a horizontal motor. A through hole is formed in the middle of the upper end of the fixed rack. A fixing block is arranged at the upper end of the through hole. A lifting hole with the rectangular section isarranged on the fixing block. The lifting hole communicates with the through hole. A lifting column is arranged in the lifting hole in a matched manner. A cutting tool is arranged at the lower end ofthe lifting column. A lifting screw hole is formed in the upper end face of the lifting column. The dust-free board cutting machine for furniture production is simple and reasonable in structure, andthe processing environment is protected because dust-free processing is realized.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

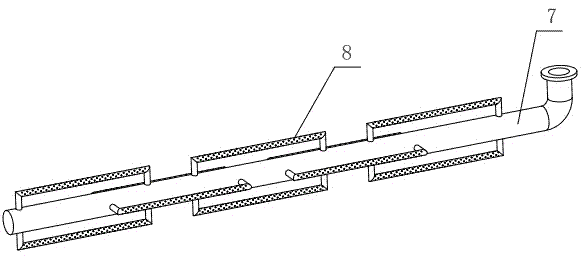

Warm gas isolation device of subway channel

ActiveCN110469938AIsolated entryAvoid churnDrying solid materials without heatFootwear cleanersEngineeringAir blower

The invention discloses a warm gas isolation device of a subway channel. The warm gas isolation device of the subway channel involves the subway channel, the top of one side of the subway channel is provided with an air blower, the air outlet end of the air blower is connected with an air outlet pipe extending along the top of the subway channel, a plurality of air outlets are formed in the lowerend of the air outlet pipe at equal intervals, an electromagnetic valve is installed at the corner of the tail end of the air outlet pipe, fan blades are arranged in the tail end of the air outlet pipe, the fan blades are connected with a connecting shaft, the ground of the subway channel is provided with a drainage groove, the bottom of the drainage groove is connected with a drainage pipe, a notch of the drainage groove is covered with an isolation net, an installation groove is horizontally formed in the inner wall of the drainage groove, the lower end of the connection shaft extends into the installation groove, and the inner wall of the installation groove is rotationally connected with a reciprocating lead screw. The warm gas heat isolation device has the advantages that the structure is reasonable, an air curtain can be formed to isolate the hot gas, the electric energy required by refrigeration of an air conditioner can be reduced, and accumulated water on the isolation net canbe timely sucked away.

Owner:杭州叶蓁科技有限公司

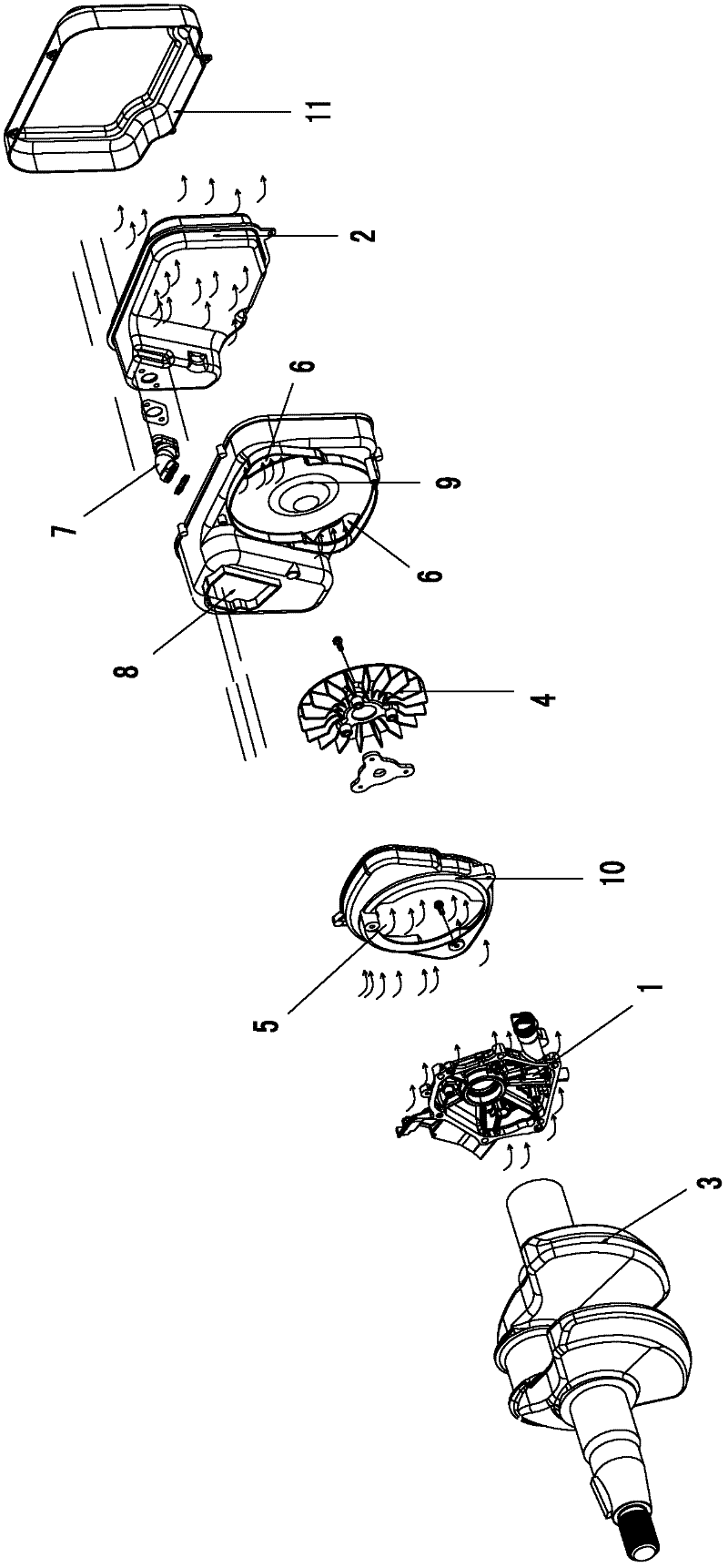

Ventilated cooling device of digital generating set

ActiveCN102242666AGood ventilation and cooling effectFor quick replacementAir coolingExhaust apparatusImpellerCooling effect

The invention discloses a ventilated cooling device of a digital generating set. The ventilated cooling device comprises an engine side cover, a silencer arranged at the outer side of the engine side cover, a crankshaft, and an impeller arranged on the crankshaft and positioned between the engine side cover and the silencer, wherein one end of the crankshaft extends out of the engine side cover. The ventilated cooling device is characterized in that: a volute air guide device is also arranged between the engine side cover and the silencer, the volute air guide device is provided with a main air inlet and a main air outlet along the axial direction of the crankshaft, meanwhile, a volute cavity is formed in the volute air guide device, and the impeller is positioned in the volute cavity. The volute air guide device is arranged between the engine side cover and the silencer, the volute air guide device is combined with the impeller therein to form a 'turbo charging cooling device' together, and the 'turbo charging cooling device' can eliminate hot air circulation in the digital generating set and enhance the cooling effect.

Owner:SUZHOU ERMA MECHNICAL & ELECTRICAL

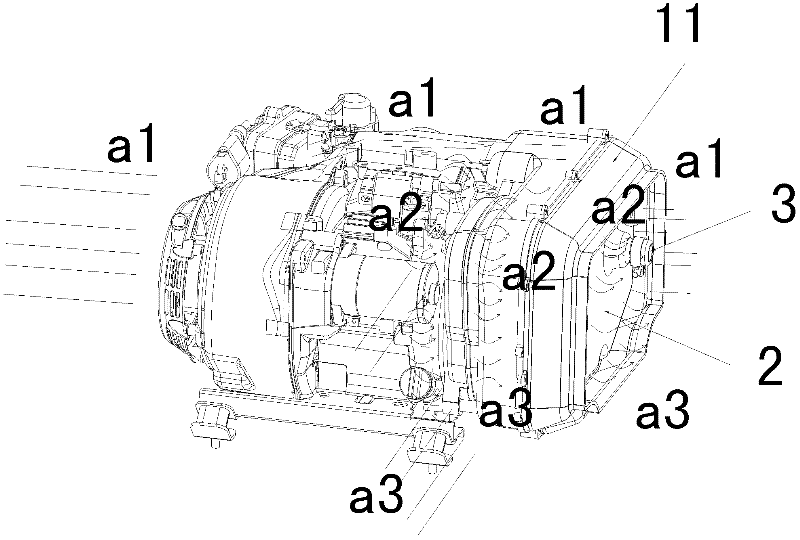

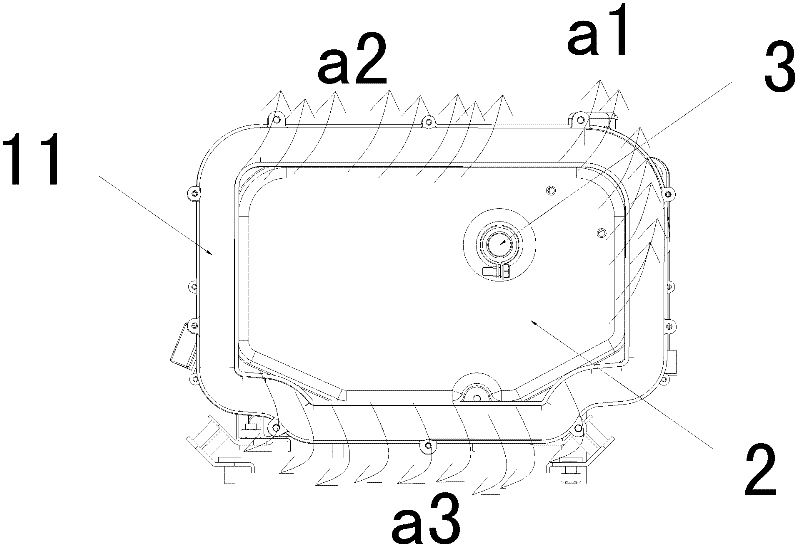

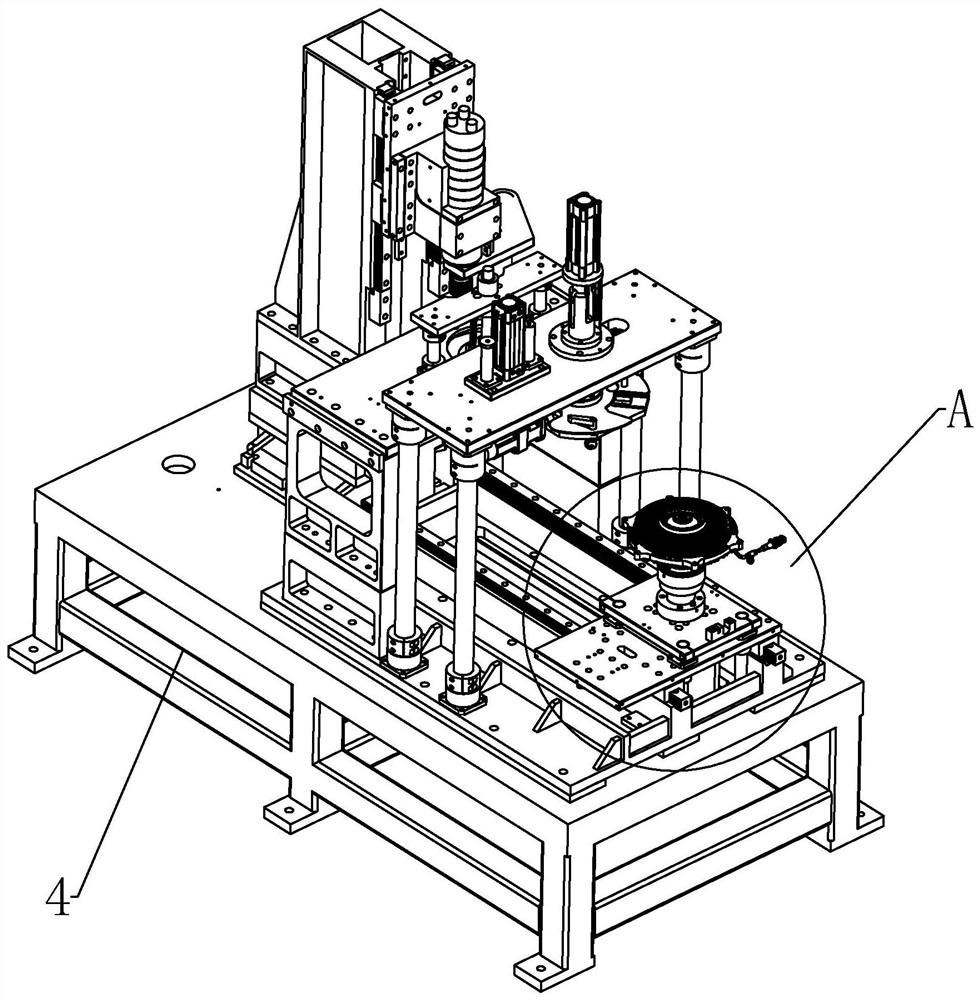

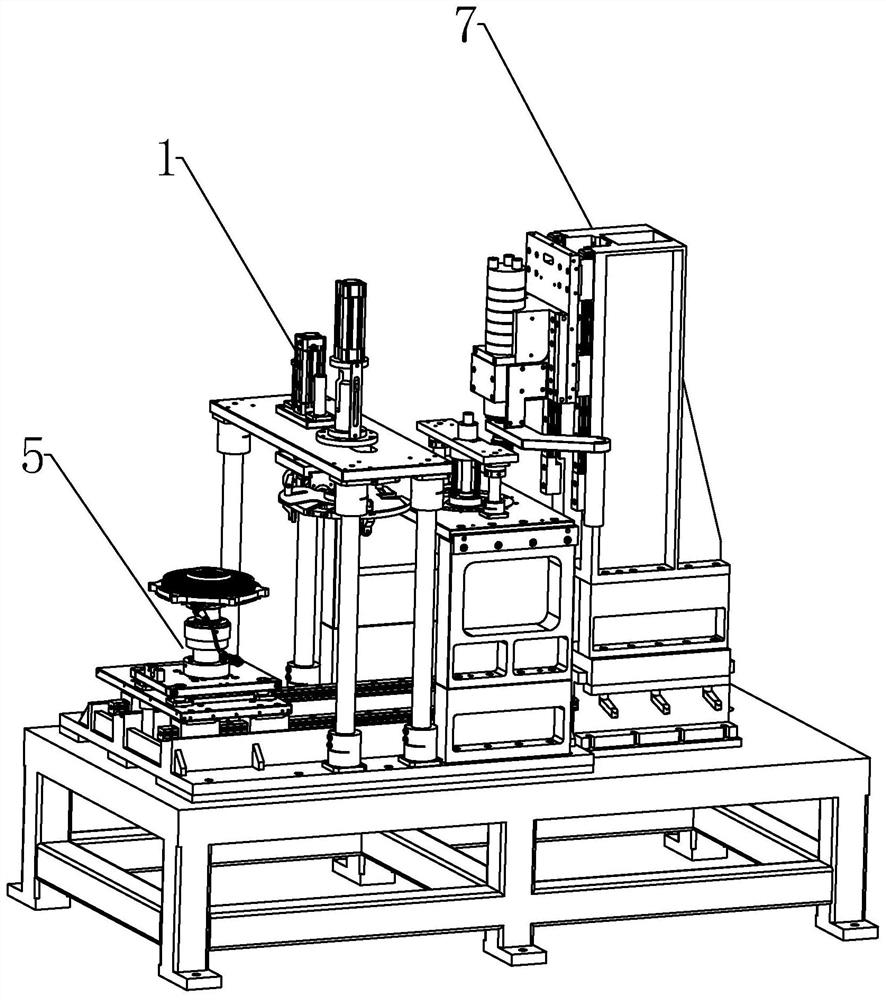

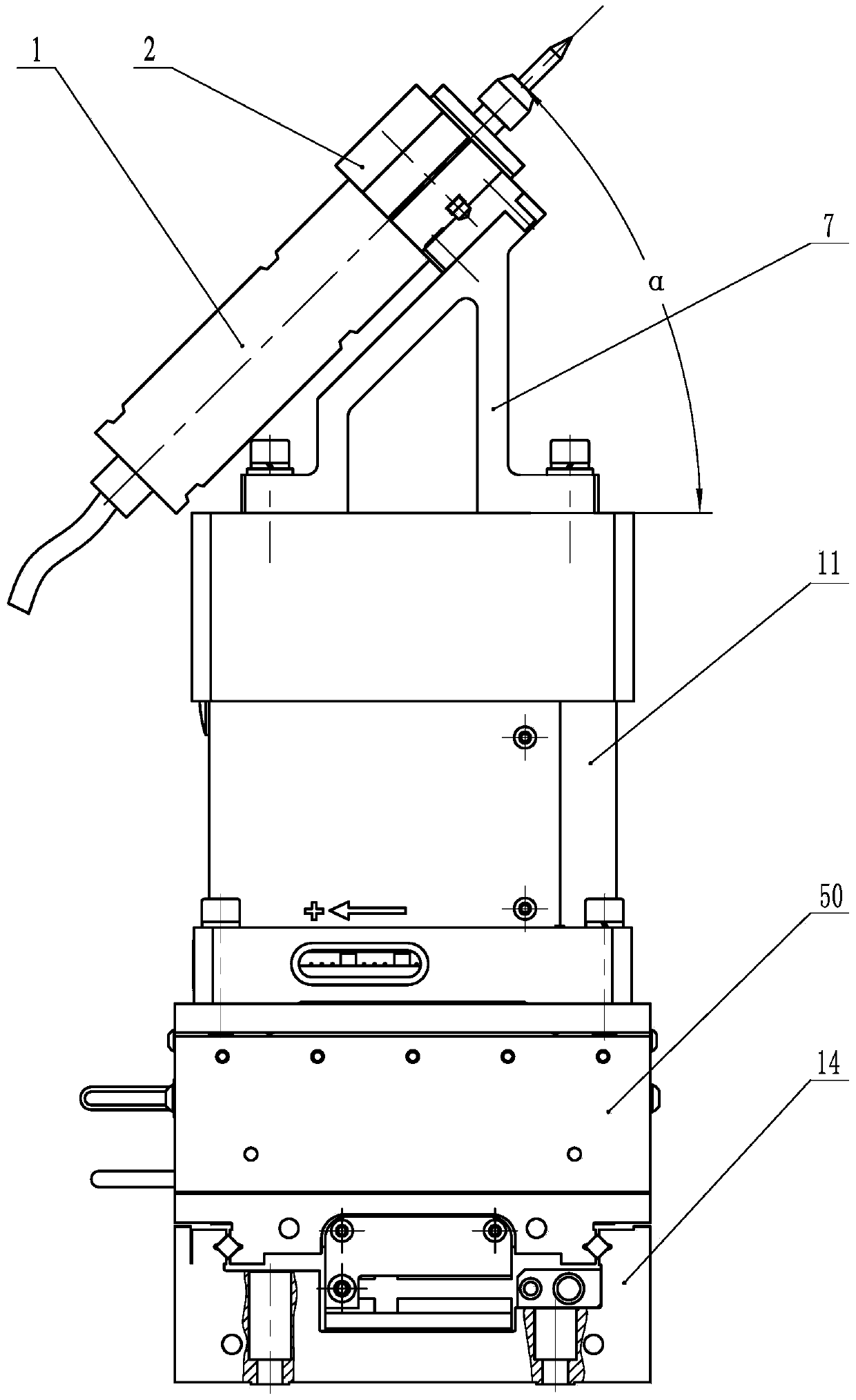

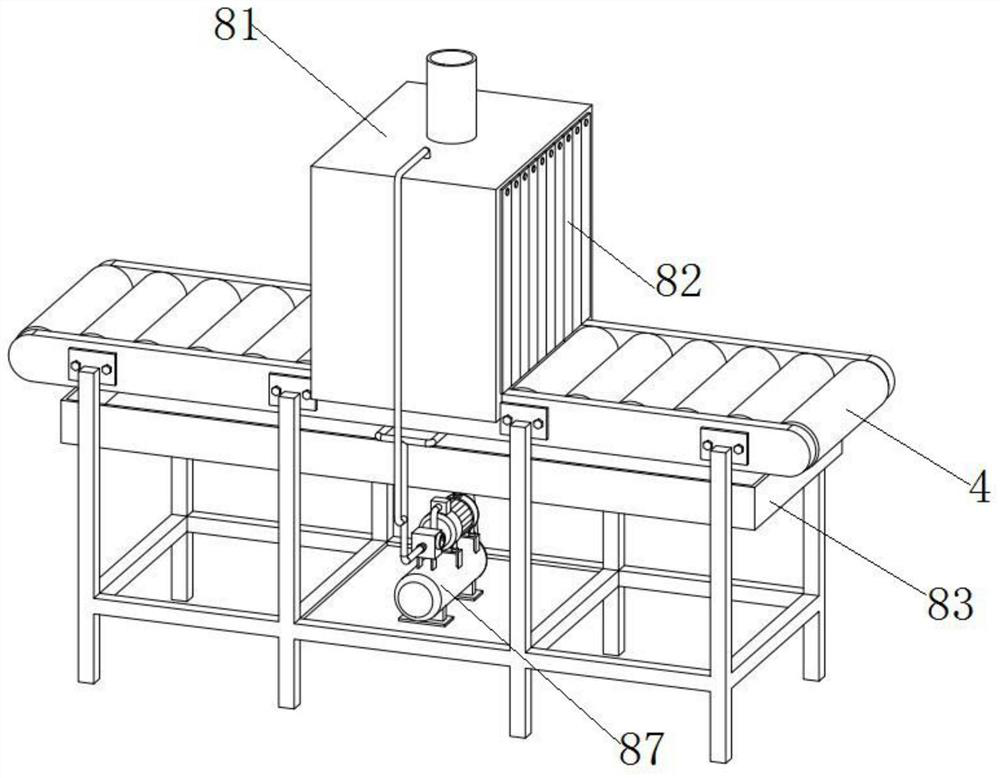

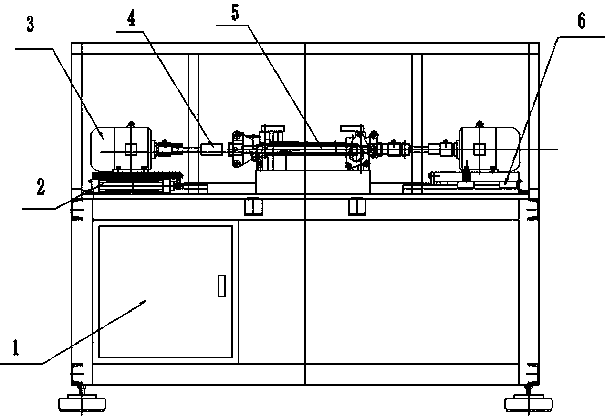

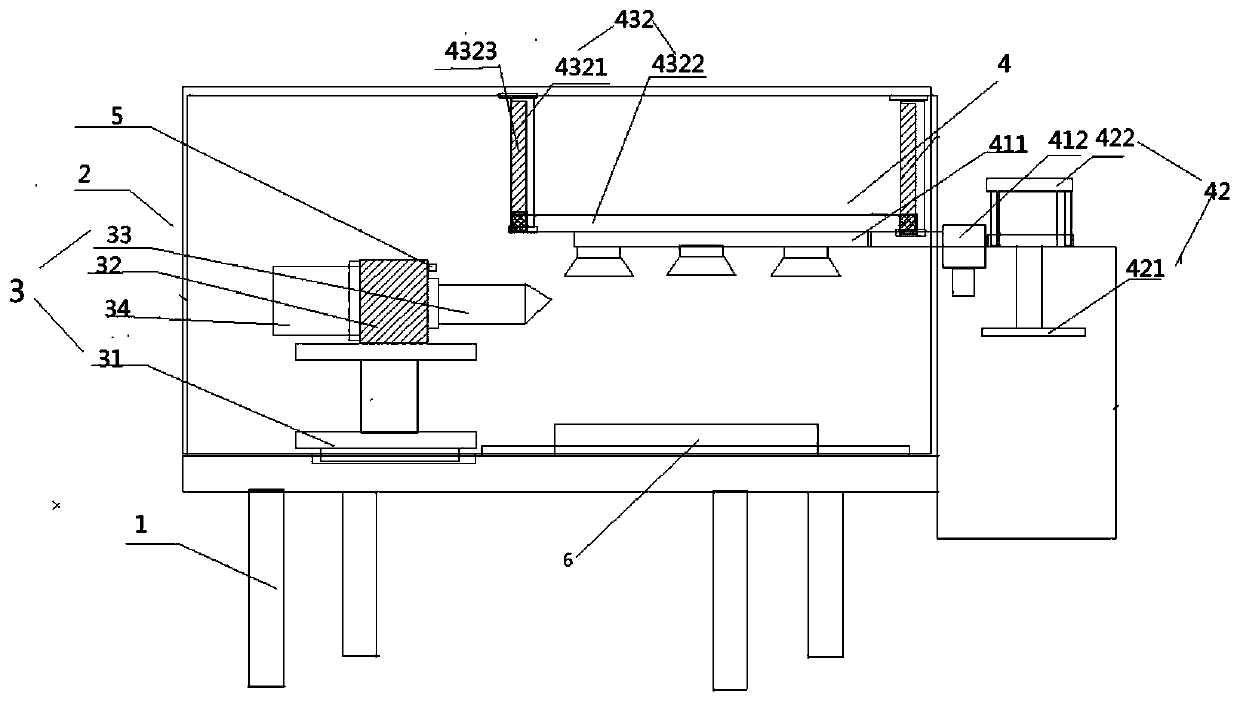

Milling detection equipment

PendingCN112692632ASuck away in timeAvoid compromising milling qualityMeasurement/indication equipmentsMilling equipment detailsElectrical connectionMachine

The invention discloses milling detection equipment which comprises a rack. A feeding mechanism, a detection mechanism, a machining mechanism and a controller are arranged on the rack. The detection mechanism is used for detecting the height difference between a shell and a driving plate of a product; the machining mechanism is used for milling the driving plate of product; the feeding mechanism is used for fixing the product and conveying the product to the detection mechanism and the machining mechanism in sequence for detection and machining; and the controller is electrically connected with the feeding mechanism, the detection mechanism and the machining mechanism. According to the equipment, the detection procedure and the milling procedure are integrated on one machine, the continuity between the two procedures is improved, and the machining quality and the machining efficiency of the product can be improved by adopting the equipment.

Owner:WARNER SHENGLONG NINGBO CO LTD

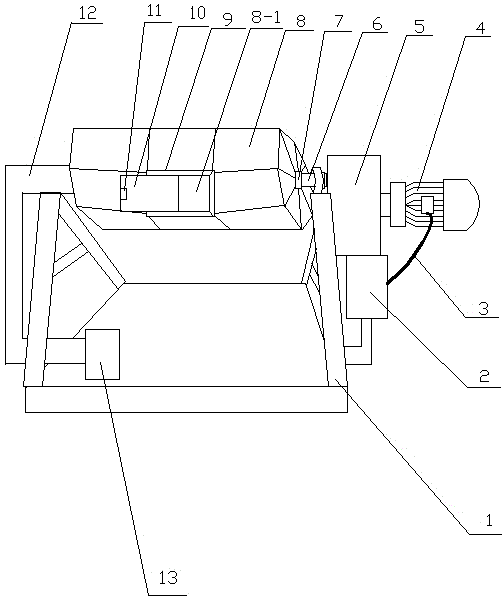

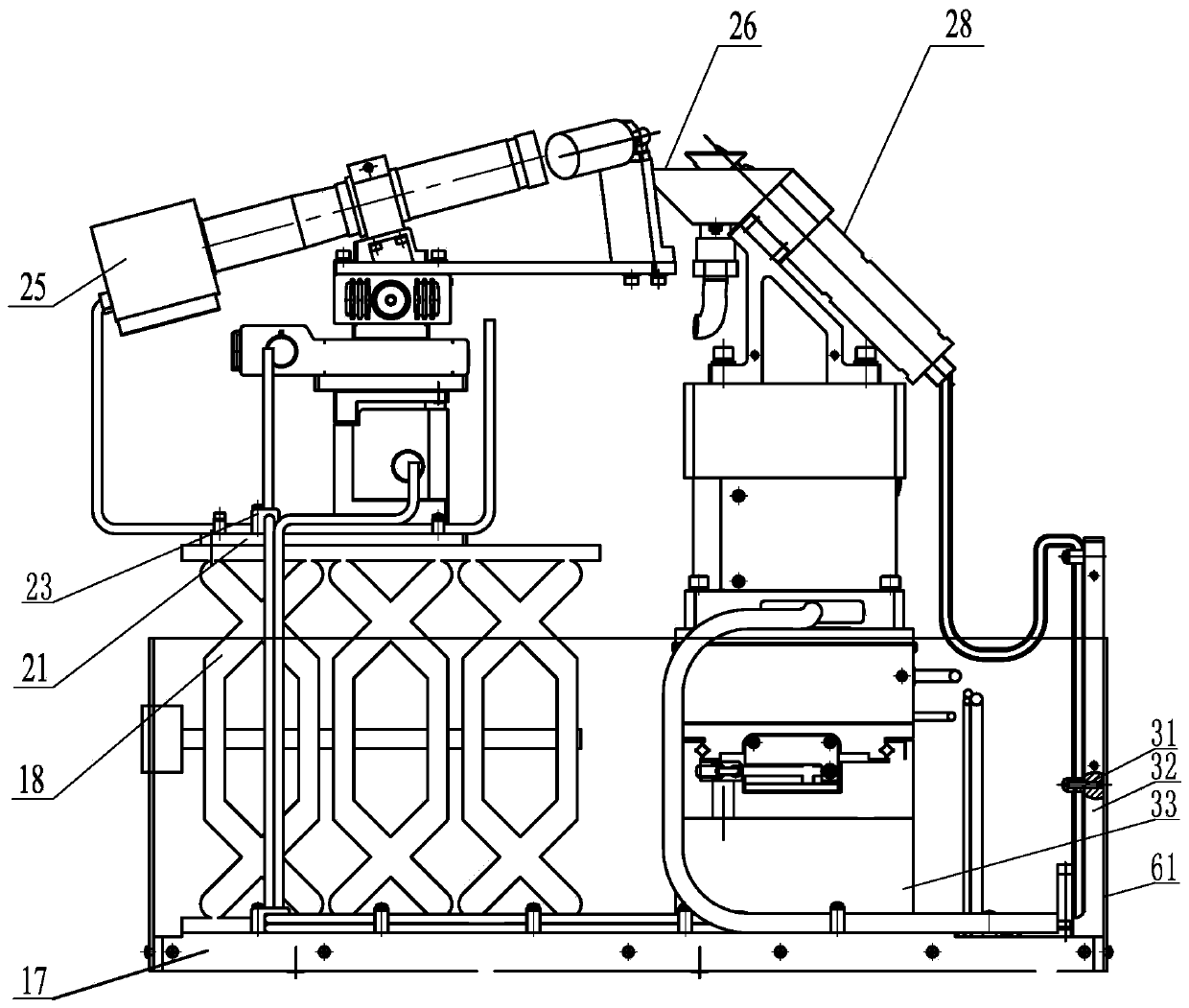

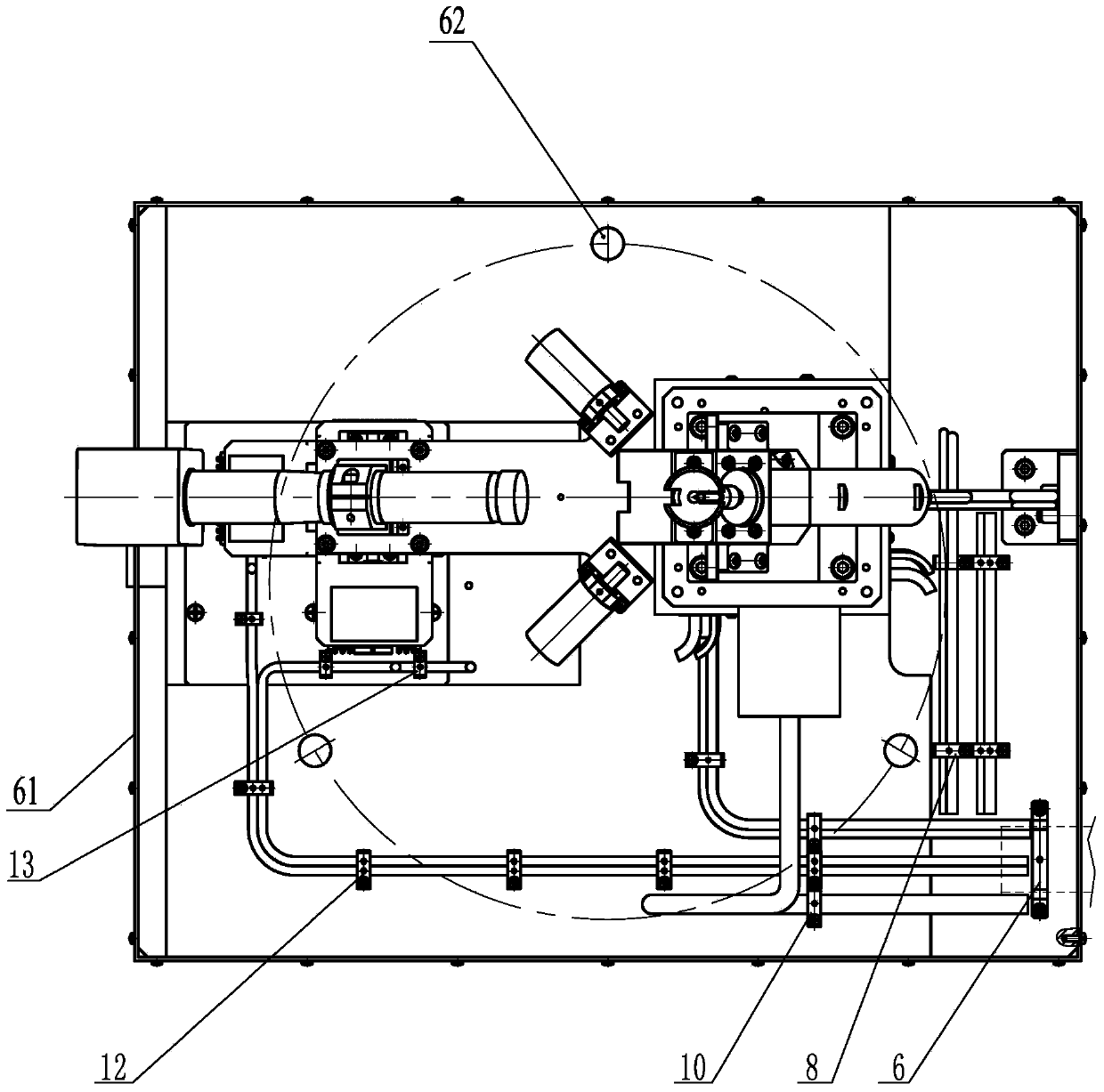

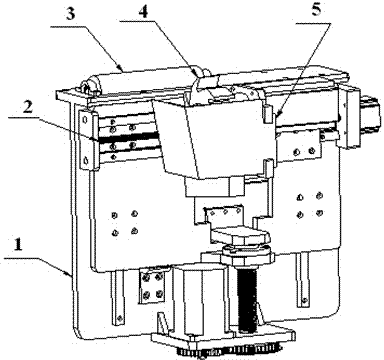

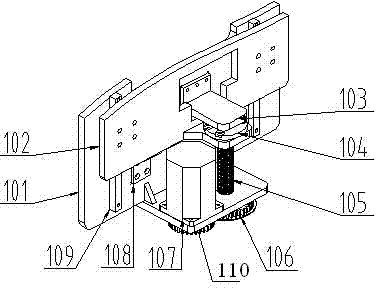

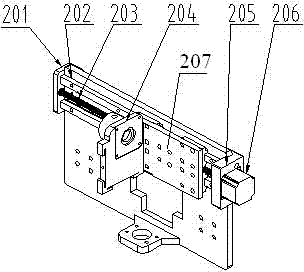

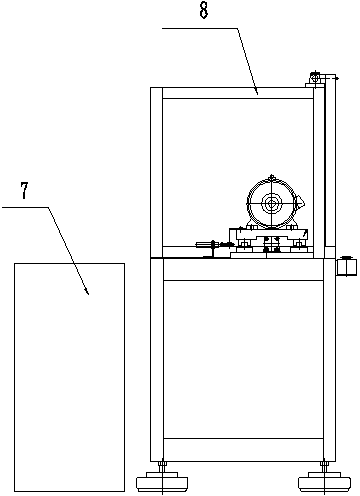

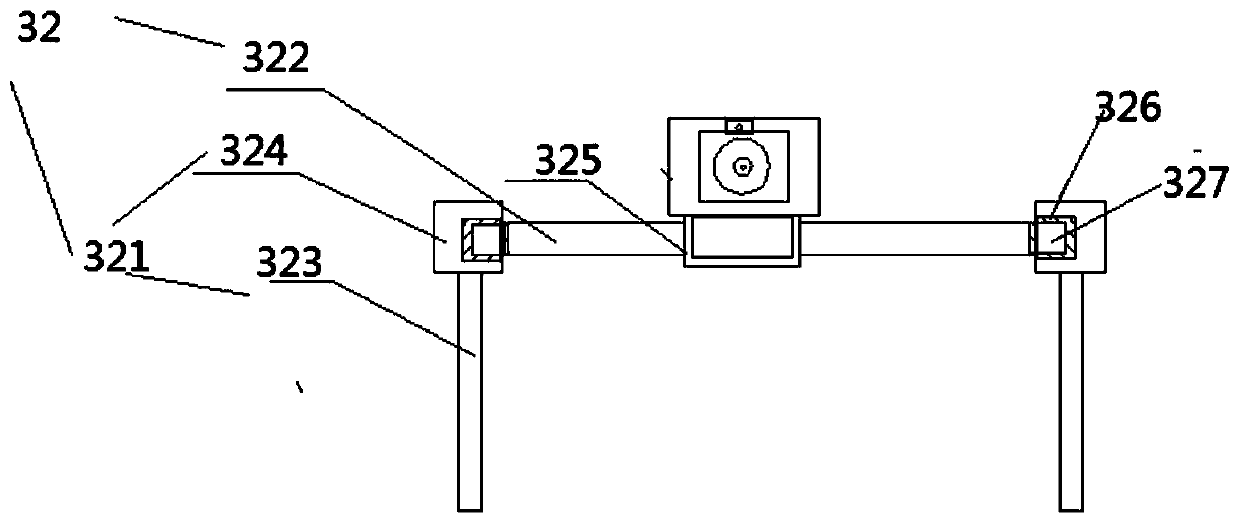

Ultra-precise three-axis association micro-milling device with micro-tool monitoring capacity

The invention provides an ultra-precise three-axis association micro-milling device with micro-tool monitoring capacity, relates to an ultra-precise three-axis association micro-milling device, and aims to solve the problem that in the prior art, no equipment for repairing micro-defects on the surfaces of large-caliber KDP crystal elements exists. A tool moving part wiring board, a tool moving part cushion block and a hand-operated lifting adjustment platform are all fixed to the upper end face of a bottom installation flat board, a tool three-axis association platform is fixed to the tool moving part cushion block, a chip collection assembly is connected with the tool three-axis association platform, a tool microscope moving platform, the hand-operated lifting adjustment platform and a microscope connecting board are sequentially connected from top to bottom, and the microscope connecting plate is connected with the upper end face of the bottom installation flat board. The ultra-precise three-axis association micro-milling device is used for repairing the micro-defects on the surfaces of the large-caliber KDP crystal elements in an ultra-precise mode.

Owner:HARBIN INST OF TECH

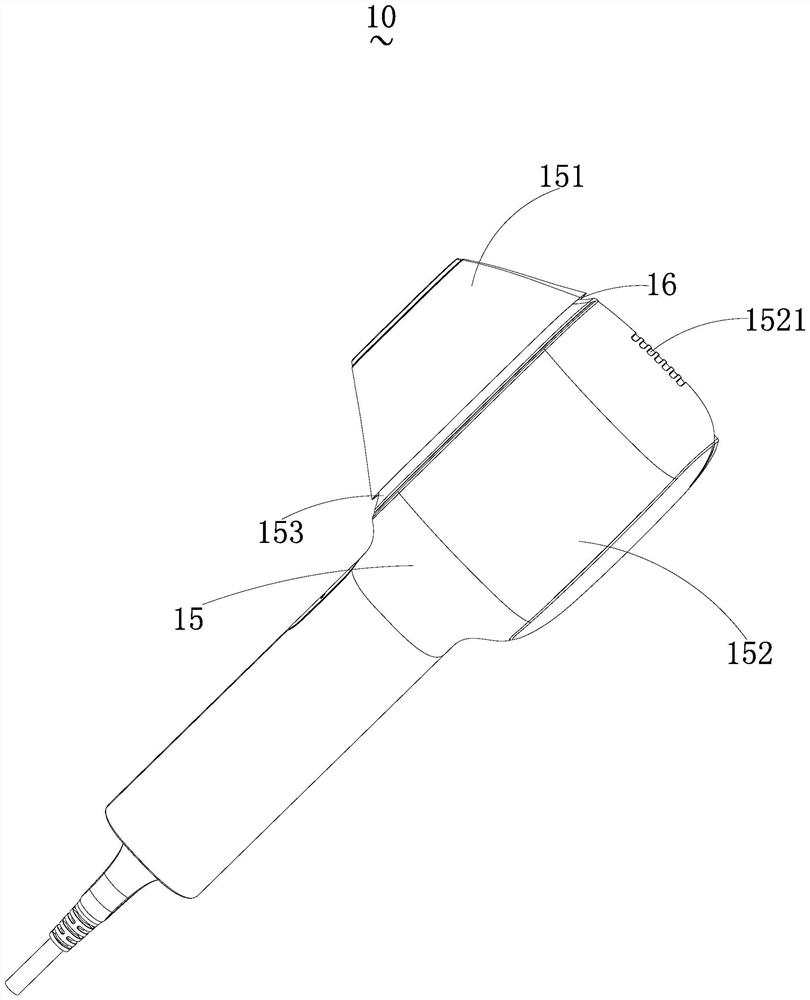

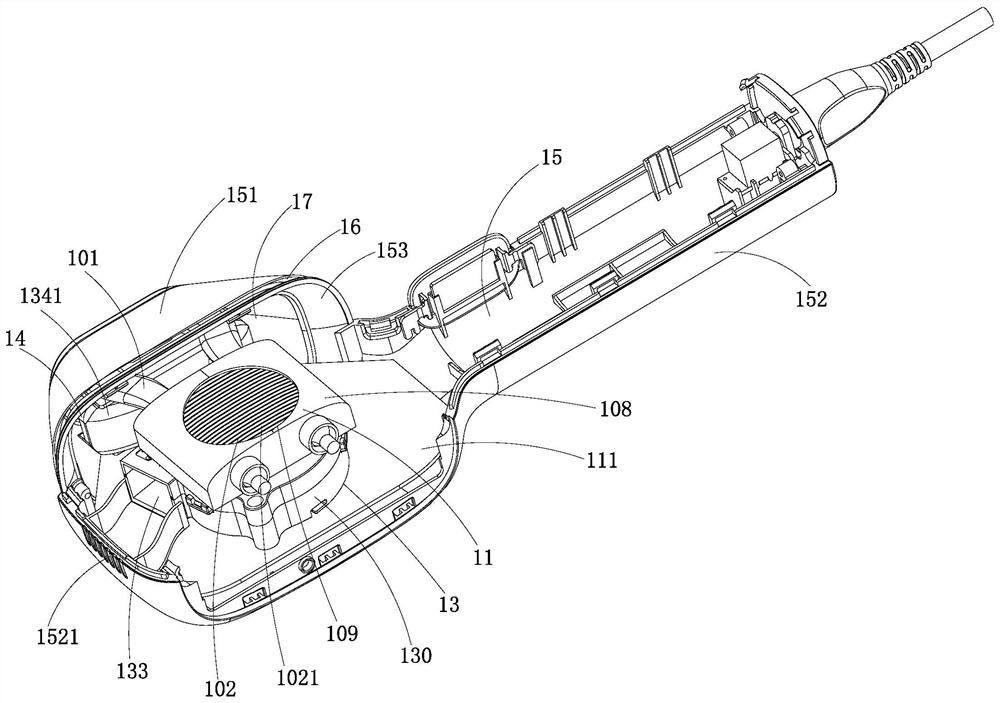

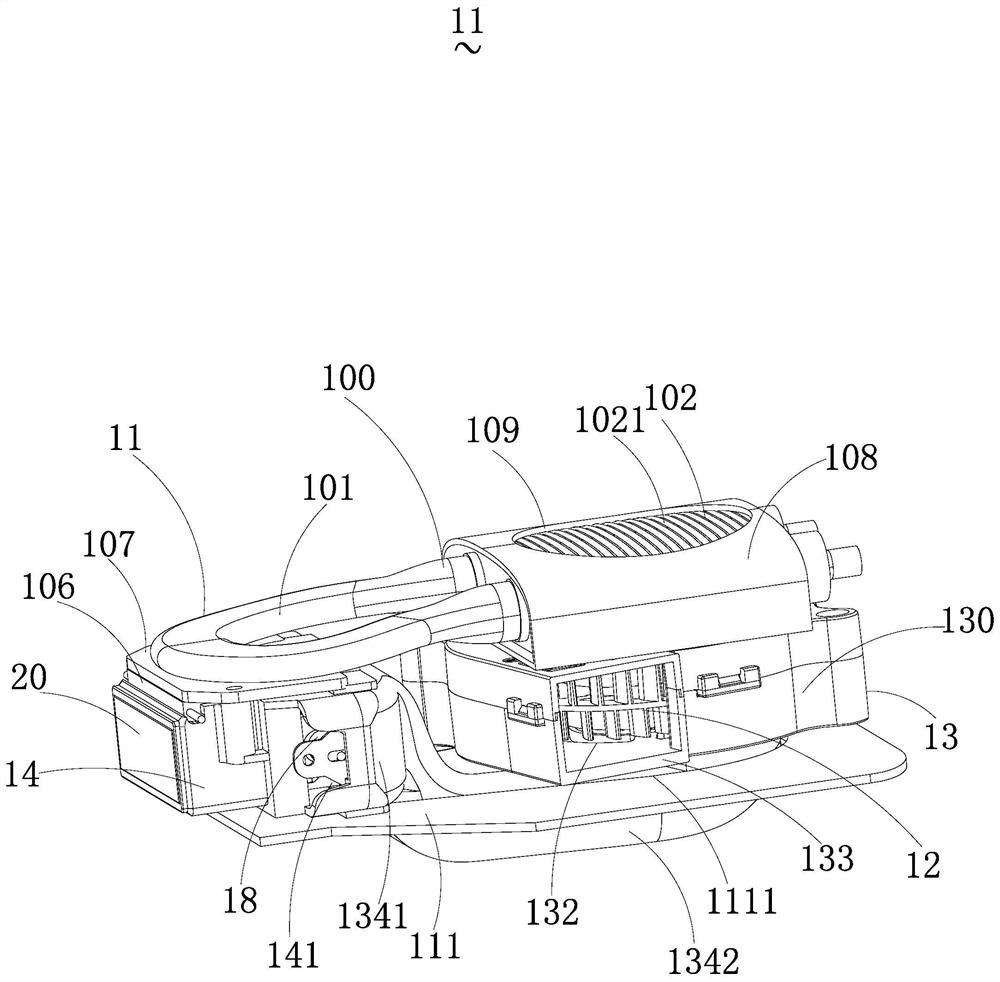

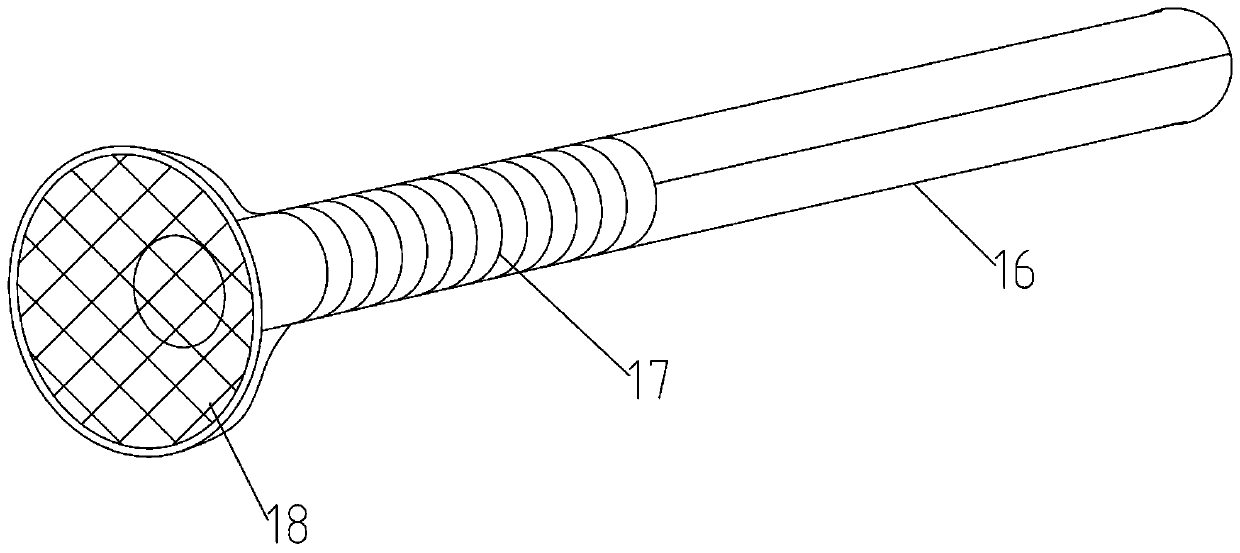

Unhairing instrument

PendingCN113144436AImprove cooling effectIncreased durabilitySurgical instruments for heatingLight therapyMechanical engineeringPhysics

Owner:SHENZHEN YANGWO ELECTRONICS

Wood floor hand-scraped grain machining device

InactiveCN104772790AEasy to disassembleImprove performanceProfiling/shaping machinesBark-zones/chip/dust/waste removalProduction rateMaterial resources

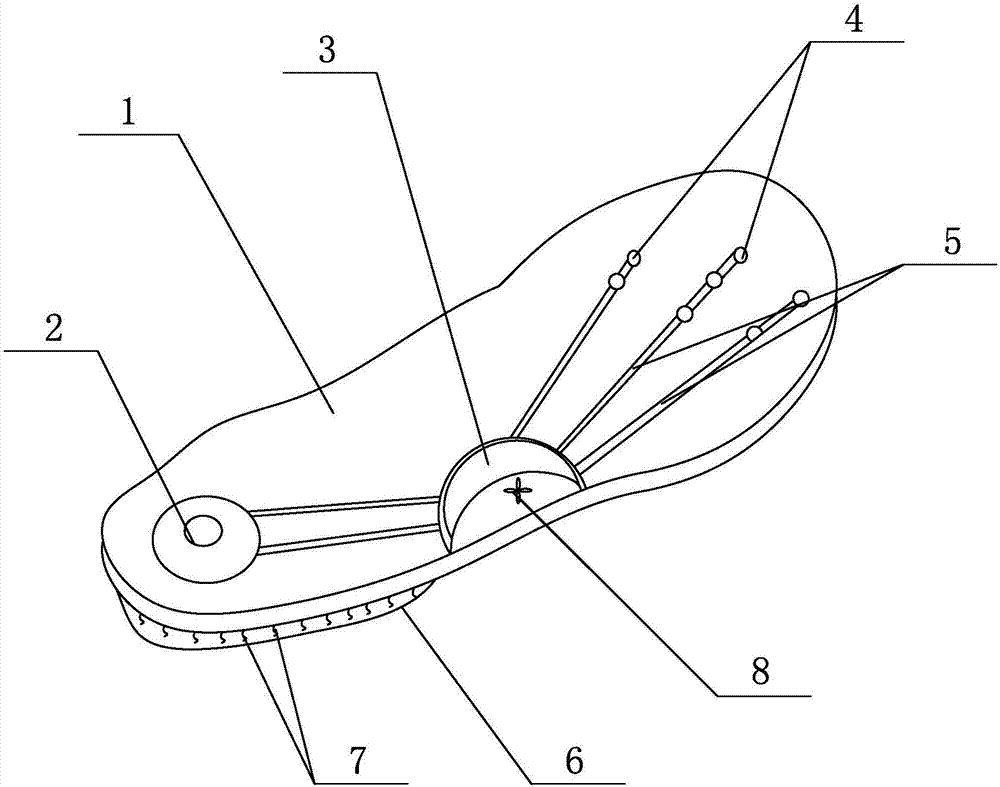

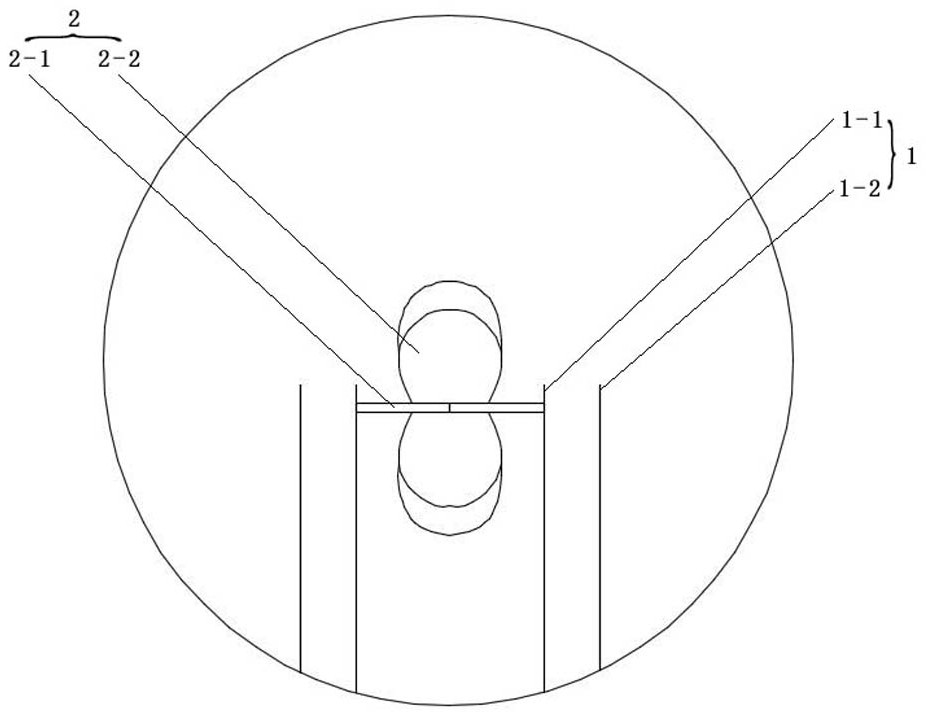

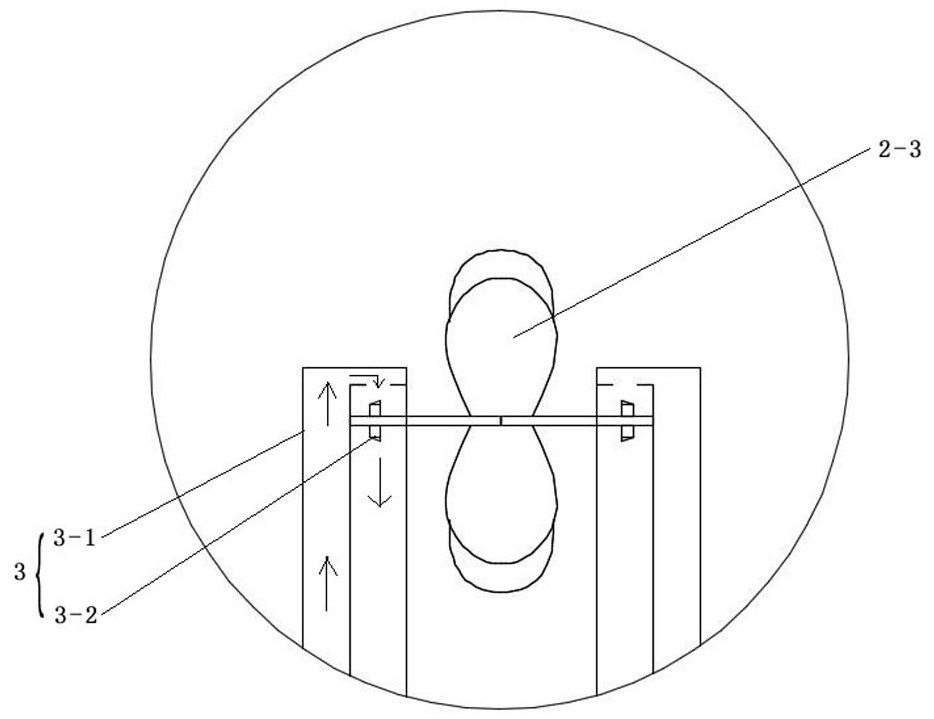

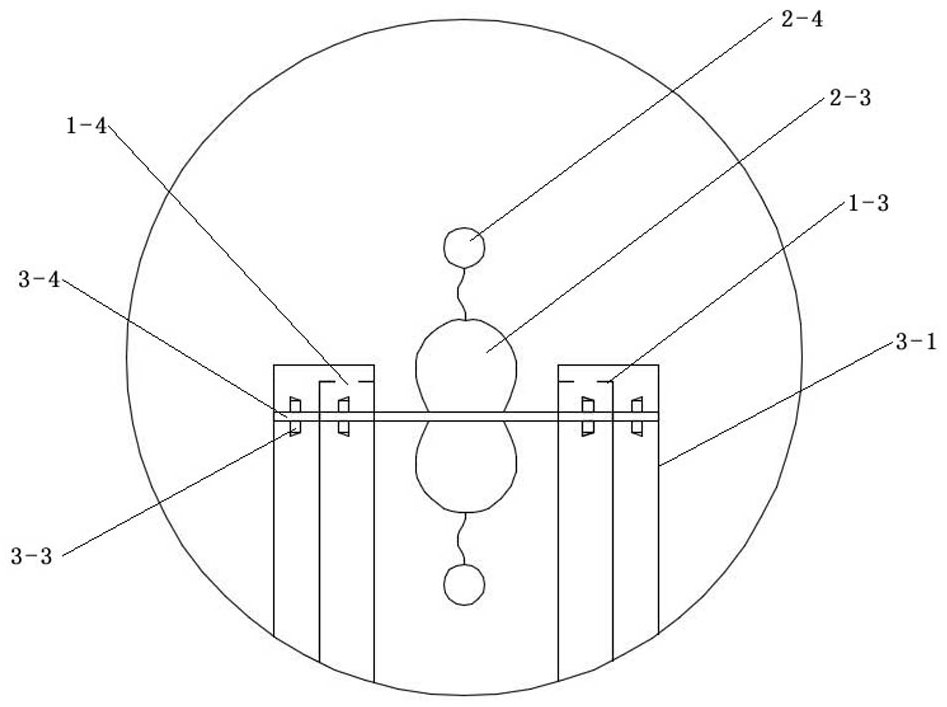

The invention discloses a wood floor hand-scraped grain machining device. The machining device comprises a lifting mechanism (1), a swing mechanism (2), a material floating mechanism (3), a cutting mechanism (4) and a dust suction device (5), wherein the swing mechanism (2) and the material floating mechanism (3) are installed on the lifting mechanism (1), the cutting mechanism (4) is installed on the swing mechanism (2), and the dust suction device (5) is installed on the cutting mechanism (4). The wood floor hand-scraped grain machining device is reasonable in structural design, convenient to operate, high in intelligentization and automation degree, capable of saving manpower and material resources greatly, high in production efficiency, low in production cost, capable of machining archaistic wood floor through groove type scraped grain and segment type scraped grain and high in practicability and has the function of adjusting the length and the depth of the segment scraped grain.

Owner:盐城鼎恒机械有限公司

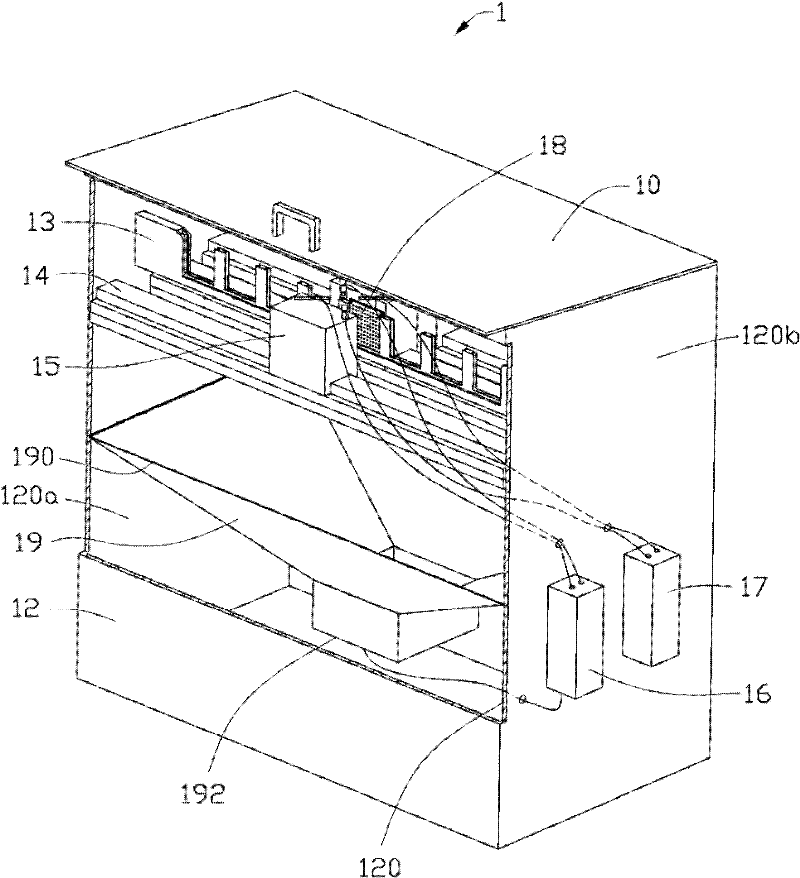

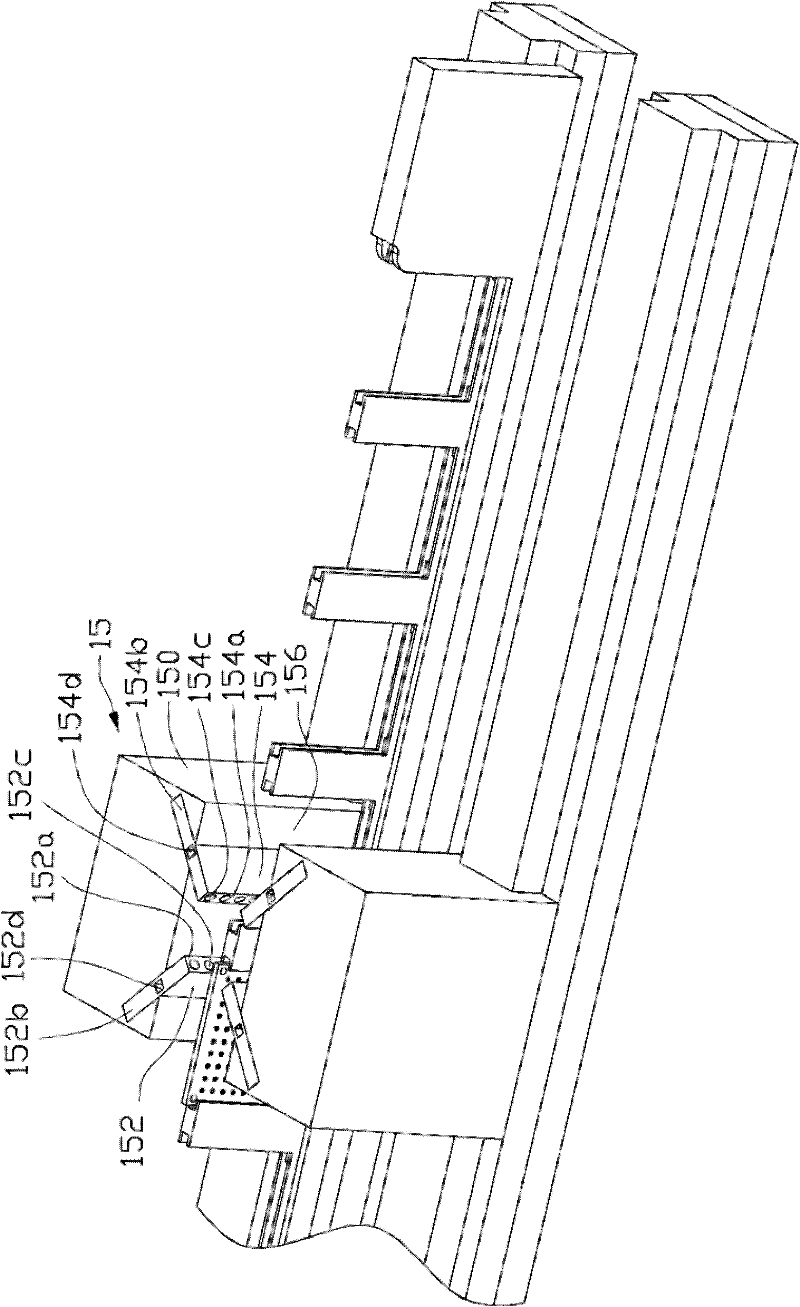

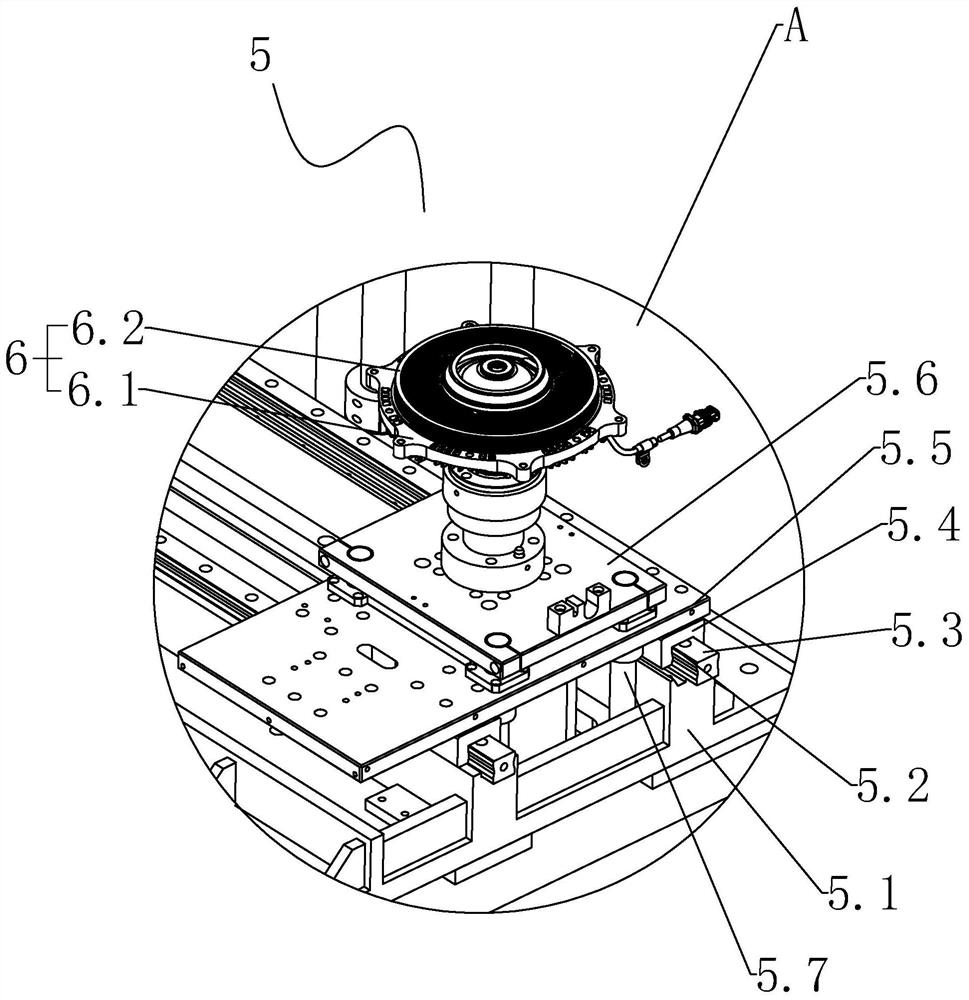

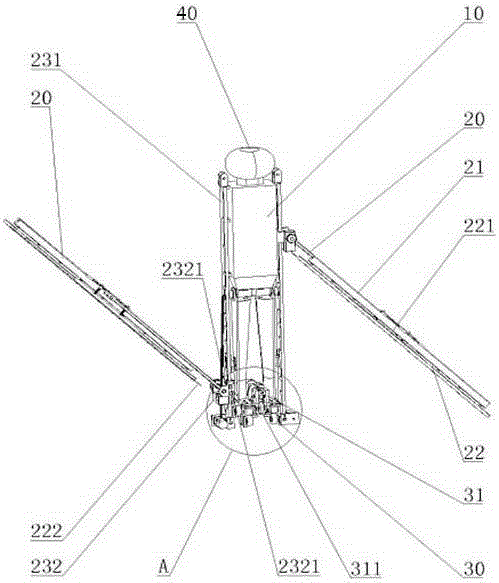

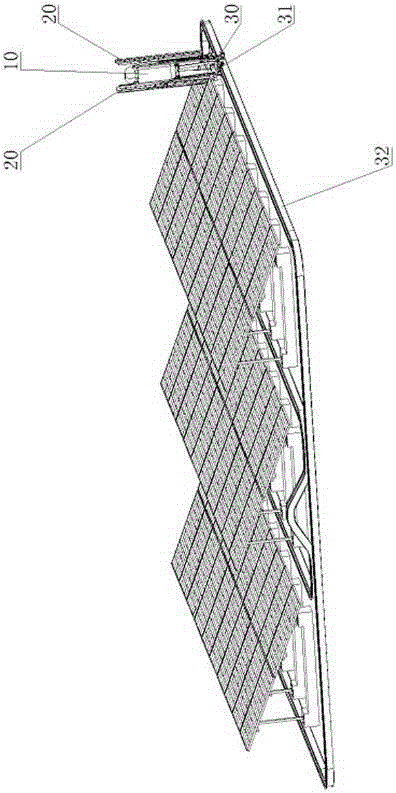

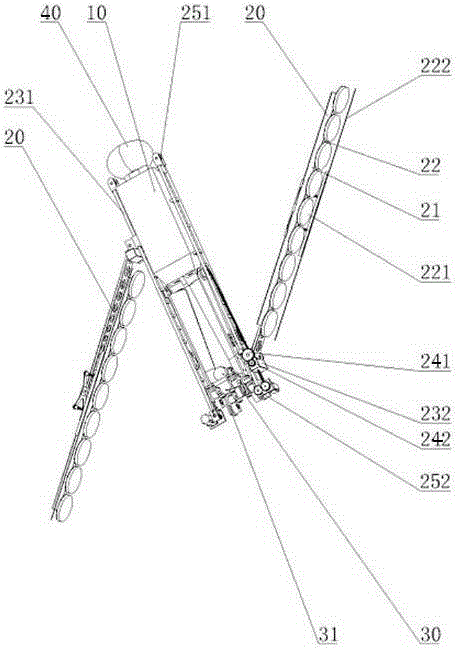

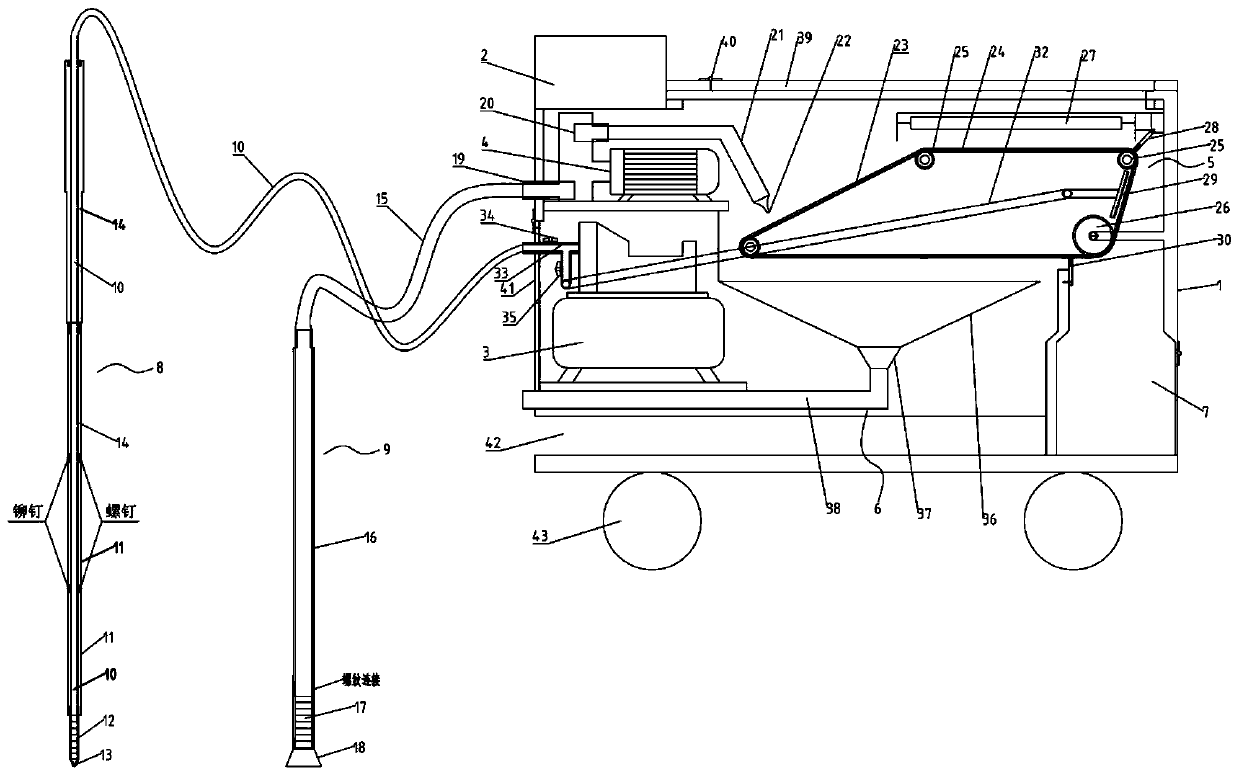

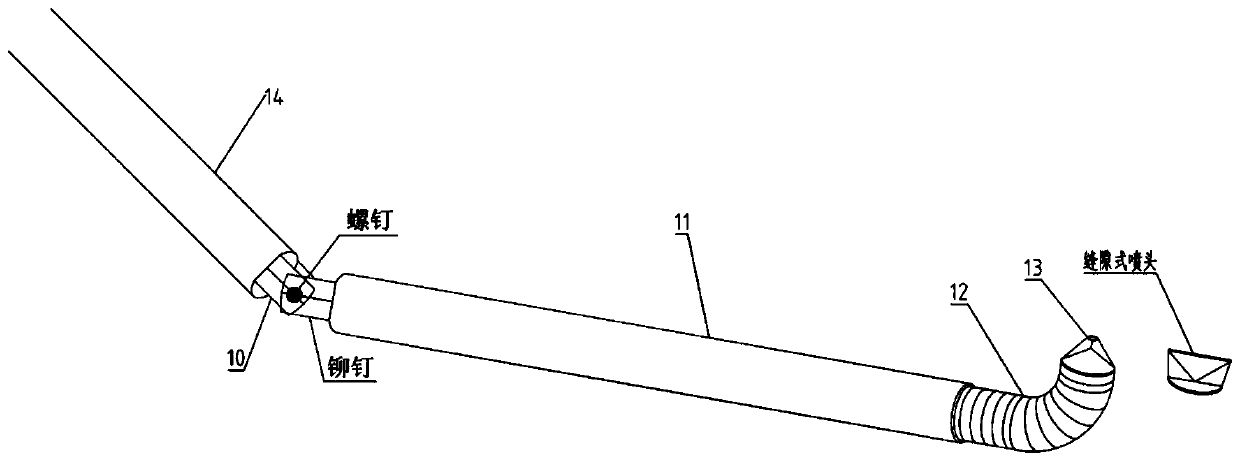

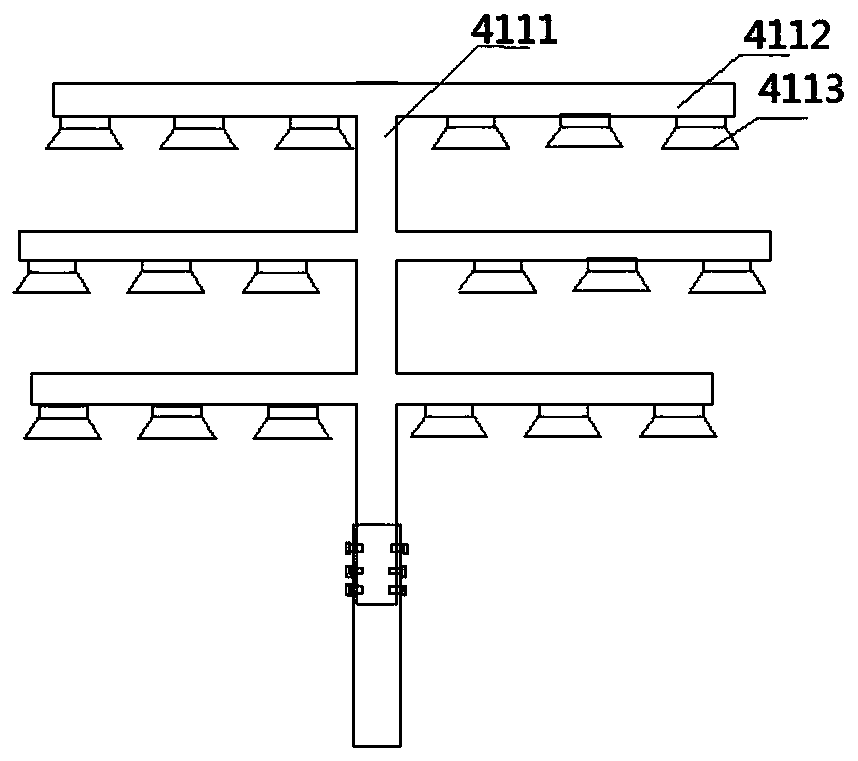

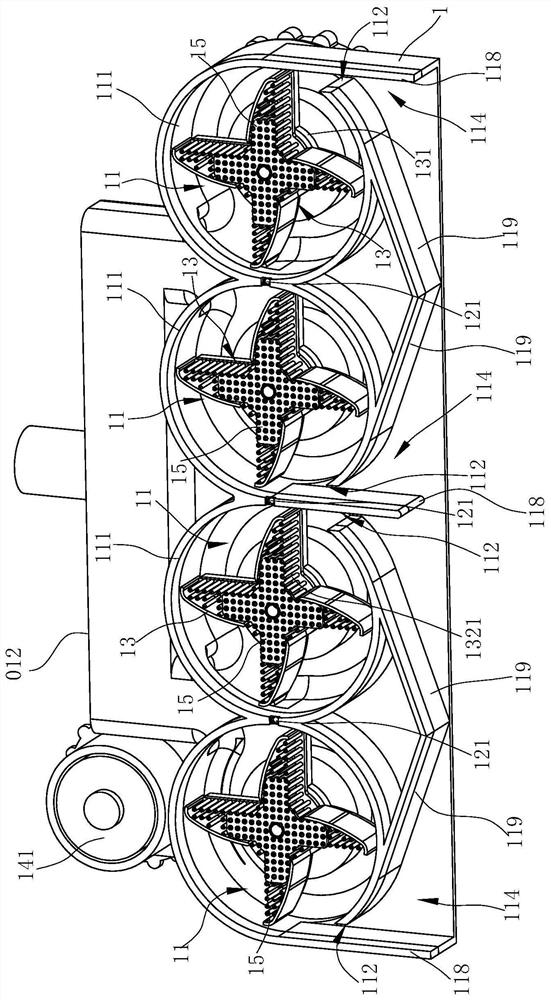

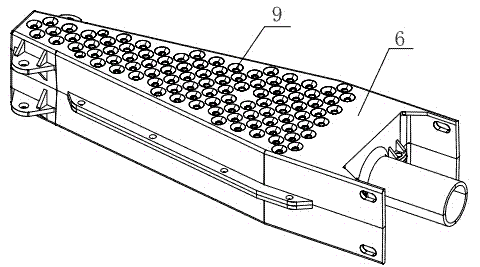

Cleaning mechanism and solar power station cleaning robot employing cleaning mechanism

ActiveCN106391622ASuck away in timeEasy to cleanDirt cleaningFlexible article cleaningPhotovoltaic power stationEngineering

The invention discloses a cleaning mechanism. The cleaning mechanism comprises a walking main body and support arms installed on the walking main body. The support arms can go up or down relative to the walking main body, each support arm can rotate around the lower end of the support arm, each support arm is provided with a cleaning module, the cleaning module comprises a plurality of rotating brush discs which are sequentially arranged from top to bottom along the support arm, and the rotating brush discs are driven by a rotating power unit to rotate. The cleaning mechanism can clean solar cell panels which are arranged on different positions. The invention discloses a solar power station cleaning robot employing the above cleaning mechanism at the same time. The solar power station cleaning robot comprises a moving device which is arranged under the walking main body and provides displacement for the walking main body. When the walking main body moves, the cleaning mechanism is arranged at one side of the walking track of the walking main body. The solar power station cleaning robot being of the above structure can clean solar cell panels efficiently, and therefore the generating efficiency of the photovoltaic power station is greatly improved.

Owner:SHENZHEN QIANHAI ZHENGXI NEW ENERGY TECH DEV ENG CO LTD

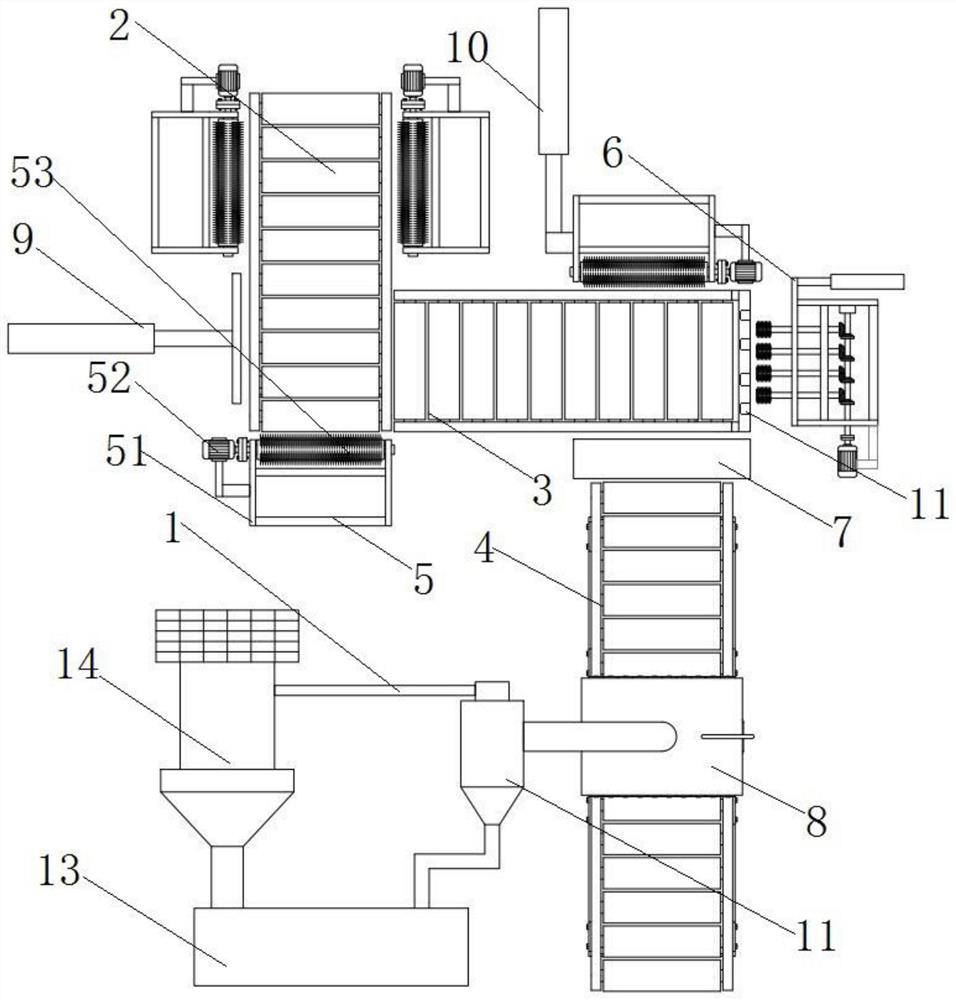

Environment-friendly cleaning equipment for prebaked anode carbon bowls for aluminum

PendingCN112775059AQuick clean upSuck away in timeCombination devicesCleaning using toolsDust controlProcess engineering

The invention discloses environment-friendly cleaning equipment for a prebaked anode carbon bowl for aluminum. The environment-friendly cleaning equipment comprises a conveying device, a cleaning device and a dust removal device, wherein the cleaning device and the dust removal device are installed on the conveying device. The conveying device comprises a first carrier roller conveyor, a second carrier roller conveyor and a third carrier roller conveyor. The cleaning device comprises a side face cleaning mechanism, a carbon bowl cleaning mechanism, a scraper mechanism and a high-pressure airflow cleaning mechanism. According to the environment-friendly cleaning equipment for the prebaked anode carbon bowl for aluminum, online cleaning of prebaked anode carbon blocks can be completely achieved, manual operation can be replaced, automatic production is achieved, the equipment integrates electric operation and hydraulic operation, the working efficiency can be improved, and the production cost can be reduced. The carbon bowl can be rapidly cleaned, and automatic cleaning is achieved. Due to the fact that the dust removal device is arranged in the equipment, cleaned powder can be sucked away in time and does not fly, and therefore environment pollution can be reduced.

Owner:SUNSTONE DEV

Pavement embossing device

InactiveCN111733668AGuaranteed flatnessSmooth and continuous coloring processDirt cleaningRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of building construction, in particular to a pavement embossing device which comprises a bottom plate and a marking roller, a plurality of annular protrusions are evenly and fixedly connected to the surface of the marking roller, the marking roller is rotationally connected to the bottom plate and comprises a pigment coloring mechanism and a residue suction mechanism, the pigment coloring mechanism comprises a material storage box, an intermittent driving mechanism used for driving a discharging plate to transversely slide is further arranged on thedischarging plate, and a transmission mechanism is connected between the intermittent driving mechanism and the marking roller. A material guide plate is arranged on the bottom plate, material guideopenings corresponding to the protrusions in a one-to-one mode are formed in the material guide plate, when the marking roller operates, the residue suction mechanism is used for sucking residues, pigment in the material storage box flows into the material guide plate, and the material guide plate colors anti-skid lines. By arranging the marking roller, a cleaning barrel, a dust collection barreland a dust collector, anti-skid lines can be embossed on the surface of a road, residues can be sucked away in time, the flatness of the surface of the road can be guaranteed, and meanwhile subsequentpigment coloring is not affected.

Owner:王光林

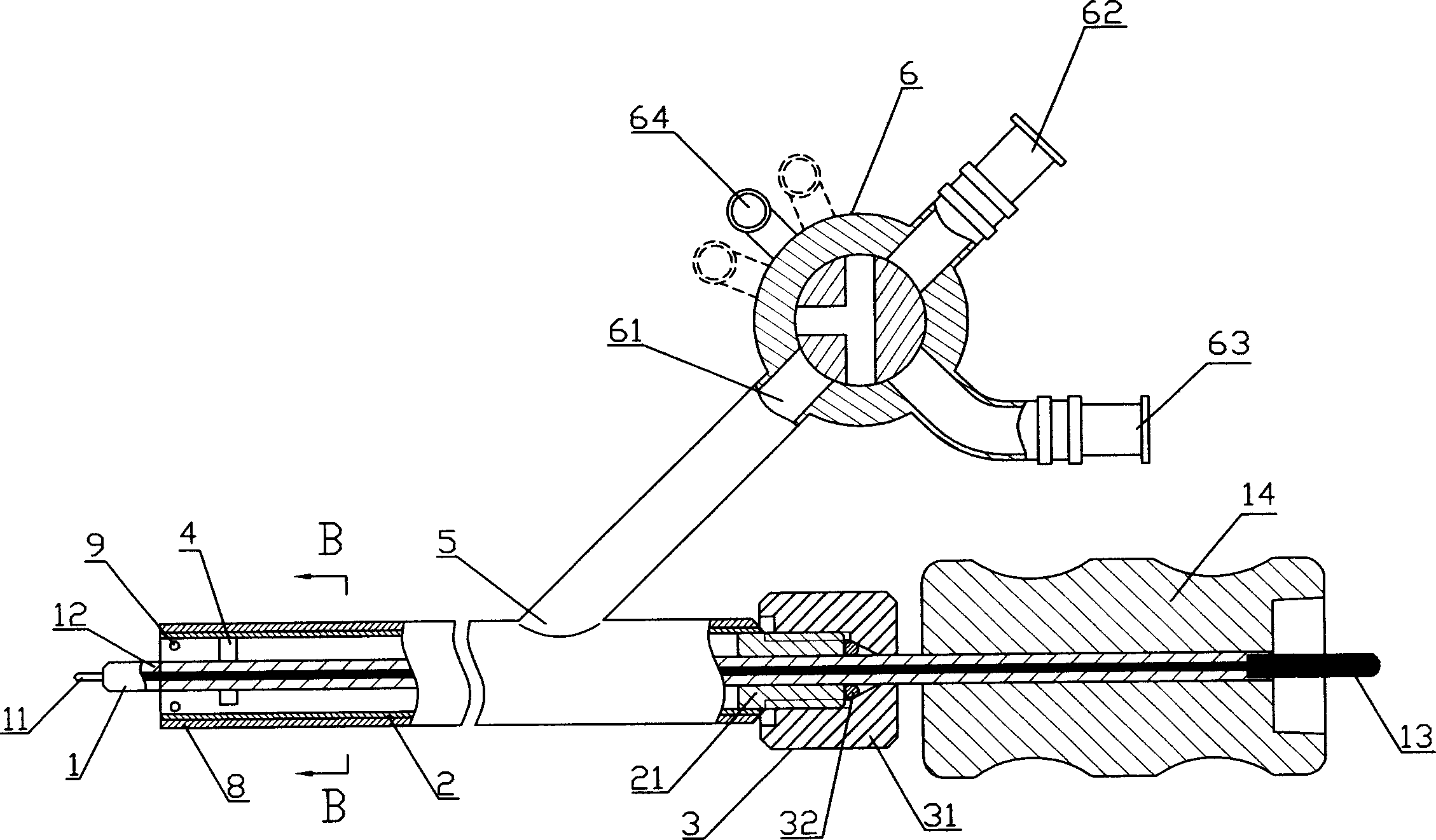

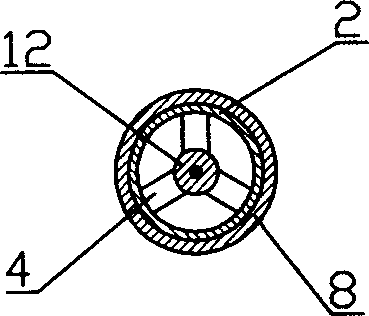

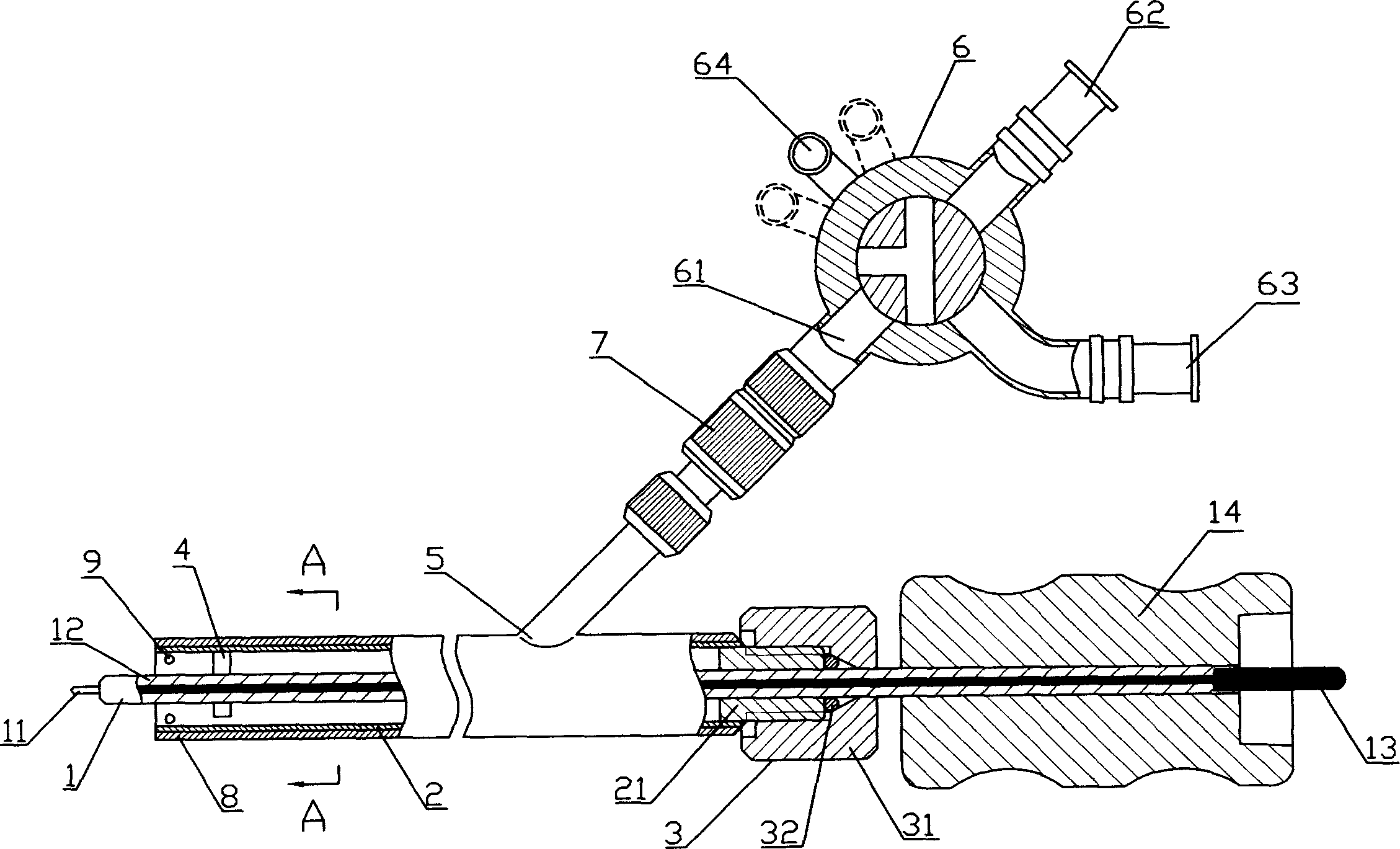

Electric needle capable of flushing and sucking

InactiveCN1586421AQuick suckQuick and timely suctionSurgical instruments for heatingElectricityClean wounds

The flushing and sucking electric needle includes one electric needle body comprising electric needle coated with insulator and power source joint in the tail of the electric needle; and one hollow suction device jacketing the electric needle body and connected to the electric needle body detachably and hermetically via tail connecting part. The suction device has one set of separated blocks in the inner wall at the other end to support the electric needle body in the center of the suction device. One T-valve has one end connected to the outlet in the side wall of the suction device, the other end connected to negative pressure sucking pipe and the third end connected to washing liquid pipe, and can make the space between the suction device and the electric needle body communicated with the negative pressure sucking pipe or the washing liquid pipe. The electric needle can eliminate mist and excessive liquid timely to provide clear operation environment and clean wound.

Owner:罗中明

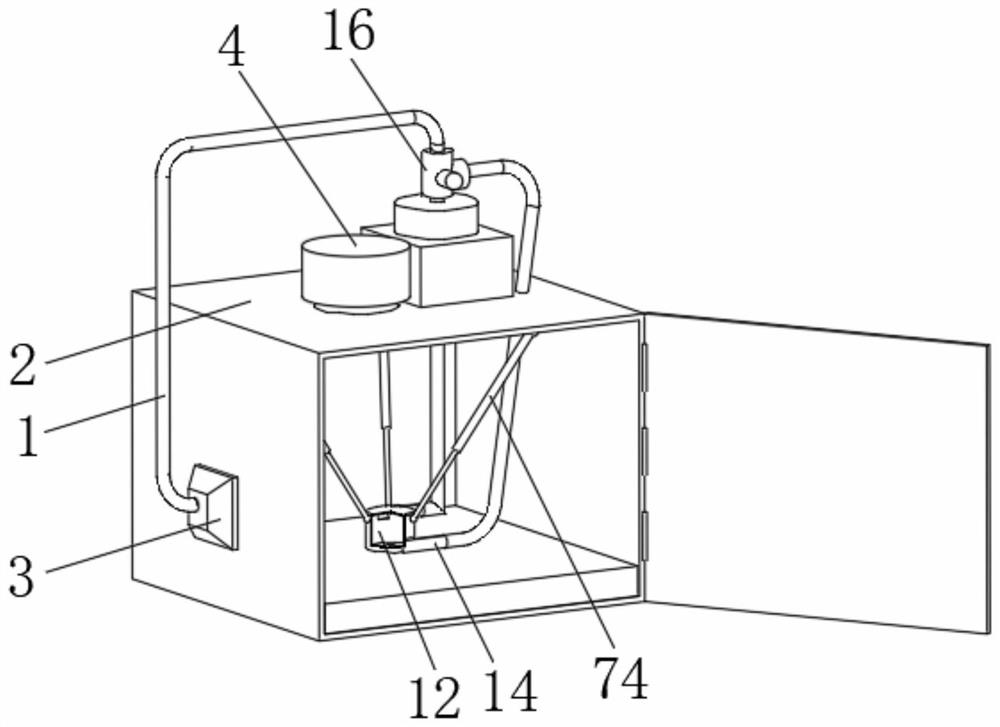

Landscape pool cleaning and water filtering and purifying device

InactiveCN109723133AAny angle adjustmentImprove diffusion abilitySewerage structuresMoving filtering element filtersEnvironmental engineeringAir compressor

The invention discloses a landscape pool cleaning and water filtering and purifying device. The landscape pool cleaning and water filtering and purifying device comprises a case, and an air compressor, a self-priming water pump, a filtering assembly for filtering water drained by the self-priming water pump, a backflow assembly for draining the filtered water generated by the filtering assembly back to a pool, and a filter residue collecting box for collecting filter residues generated by the filtering assembly are arranged in the case. A power source and an equipment control box are arrangedon the case, a high-pressure air sweeping gun and a dirt suction gun which can move freely are arranged outside the case, the high-pressure air sweeping gun is connected whit the air compressor, and the dirt suction gun is connected with the self-priming water pump. The device can clean the pool wall, the pool bottom, stand columns, pipelines, stone cracks, internal corners, dark corners and otherdark corners of the pool, polluted water in the pool can be filtered and purified, tiny attachements, suspended solids and other debris in the water are removed, the purified water is drained into the pool, energy saving and environmental friendliness are achieve, and the pool cleaning effect is good.

Owner:HUAYUAN LANDSCAPE ARCHITECTURE CO LTD

Deburring device

The invention relates to a deburring device. The deburring device comprises a rack, a fixture used for clamping a workpiece is arranged on the rack, and hole brushes are arranged at two ends of the workpiece, driven by a power unit to rotate and can do front and back motion in the horizontal direction. The deburring device has the advantages that the rotatable hole brushes driven by the drive unit can move into the workpiece and achieve rotating motion relative to the workpiece, burrs can be removed quickly and efficiently by means of the friction formed between the hole brushes and the inner wall of a hole of the workpiece; the deburring device is further provided with a dust sucking device, the dust sucking device can suck out the burrs which are cleaned out timely to keep the whole device clean and the workpiece will not be abraded by the burrs cleaned out; in addition, the follow-up cleaning workload is reduced, the labor intensity of operators is relieved, and the continuity of removing and cleaning is truly achieved.

Owner:YANGZHOU RONGTAI IND DEV

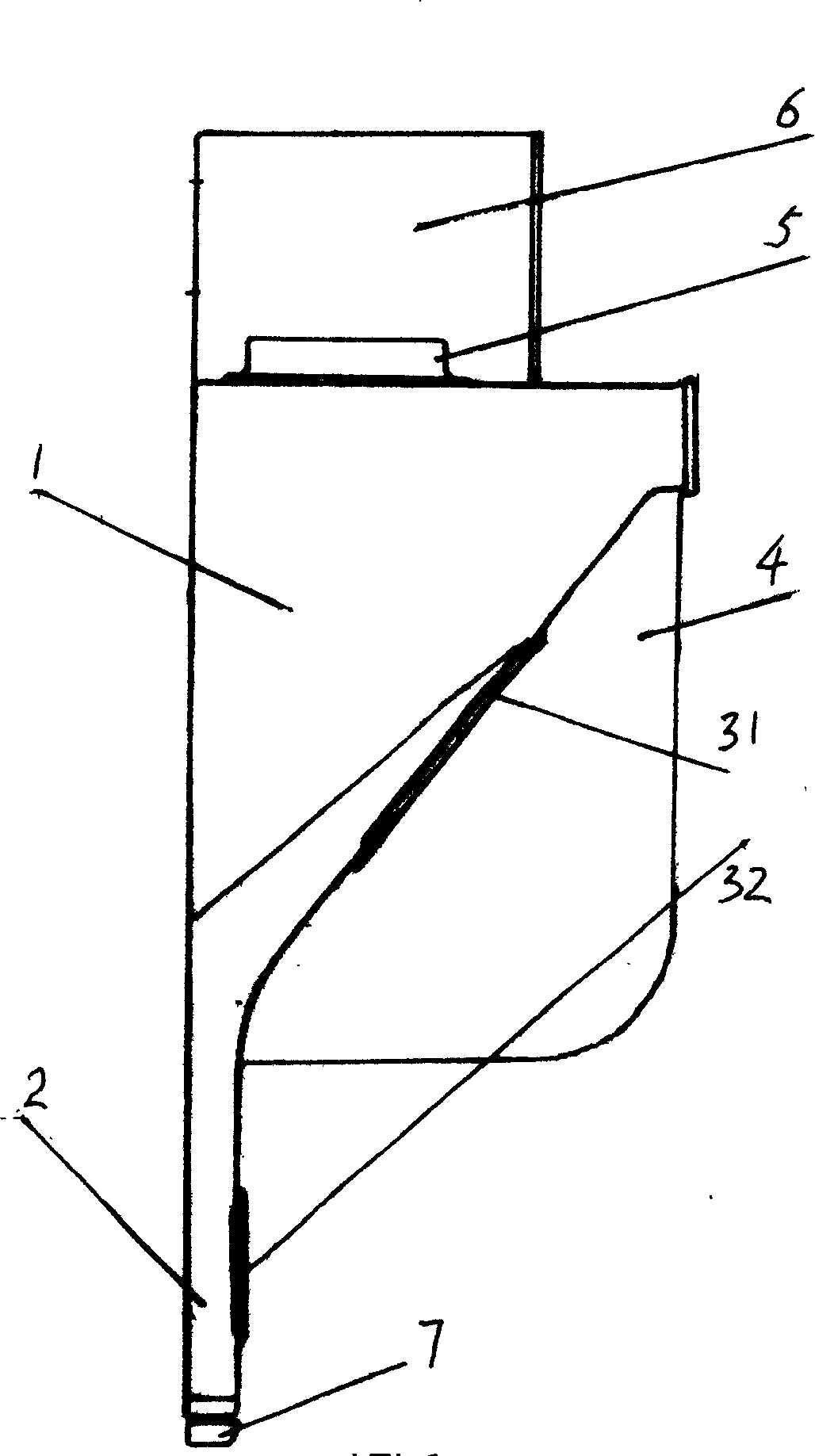

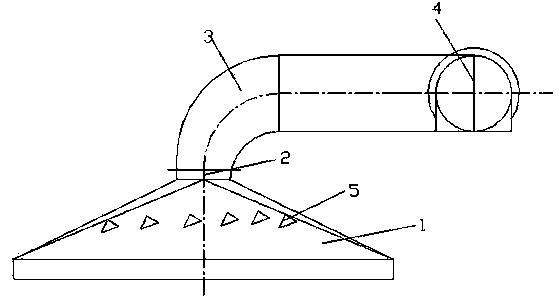

Plate-type fume exhauster

InactiveCN101225975AGood effectSuck away in timeDomestic stoves or rangesLighting and heating apparatusFlueEngineering

The invention relates to a plate type oil fume exhaust device, comprising a fan and a smoke flue communicated with the fan, which is characterized in that: the smoke flue is a wall corner type box body, the box body also comprises a channel extending downward, the box body comprises an outlet communicated with the fan and a smoke absorption port of the box body is positioned on inclined plane of the box body and in front of the channel which extends downward. Thus, the box body which is also the smoke flue can be conveniently arranged on wall surface of lateral side of the cooking range; the smoke absorption port arranged in front of the channel can be extended downward to lateral side of the cooking range, able to absorb the newly effused oil fume; the smoke absorption port arranged on inclined plane of the box body can further absorb and exclude the rising oil fume.

Owner:于勇

High-hardness alloy processing device and working method thereof

ActiveCN110666203AAvoid deformationTimely processingMeasurement/indication equipmentsLarge fixed membersTransmission beltWaste collection

The invention discloses a high hardness alloy processing device. The high hardness alloy processing device comprises a drilling machine, wherein the drilling machine is provided with a worktable, a housing, at least one processing center with adjustable position and a waste recycling device, the housing is arranged on the outer side of the worktable, a transmission belt is arranged on the worktable, the processing center with adjustable position is installed on the worktable, the processing center is equipped with a detection mechanism for detecting the processing position of workpieces, the waste recycling device is equipped with a waste absorption mechanism and a waste collection mechanism, the waste absorption mechanism is connected with the housing through a mounting frame, and the waste collection mechanism is arranged on one side of the drilling machine and connected with the waste absorption mechanism. According to the high hardness alloy processing device and a working method thereof, the detection mechanism is arranged in the processing center so that the processing accuracy of the high hardness alloy processing device can be ensured; and the processing station is providedwith a deformation-resistant clamp so that the occurrence of the workpiece deformation in the processing process can be effectively prevented, further, the product quality can be effectively improvedand the production efficiency can be improved.

Owner:驰逸自动化科技(苏州)有限公司

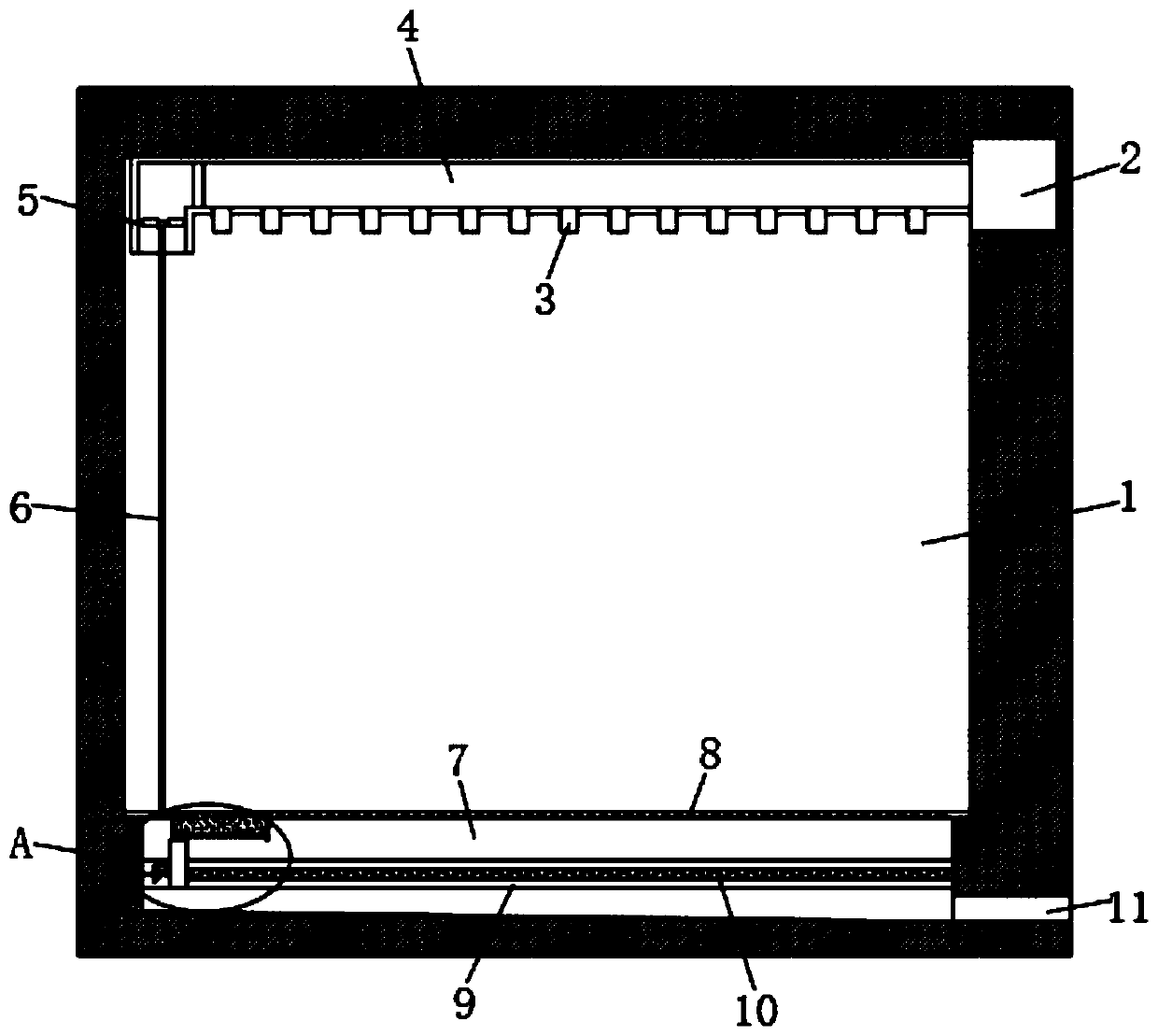

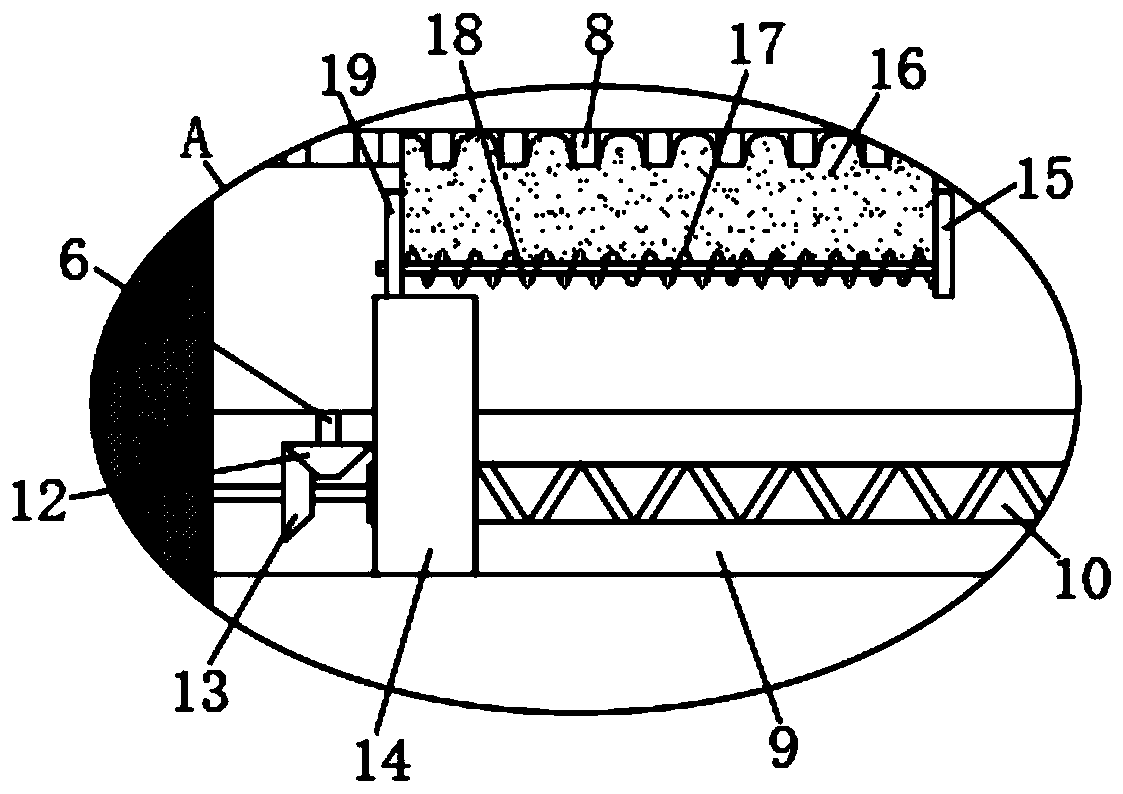

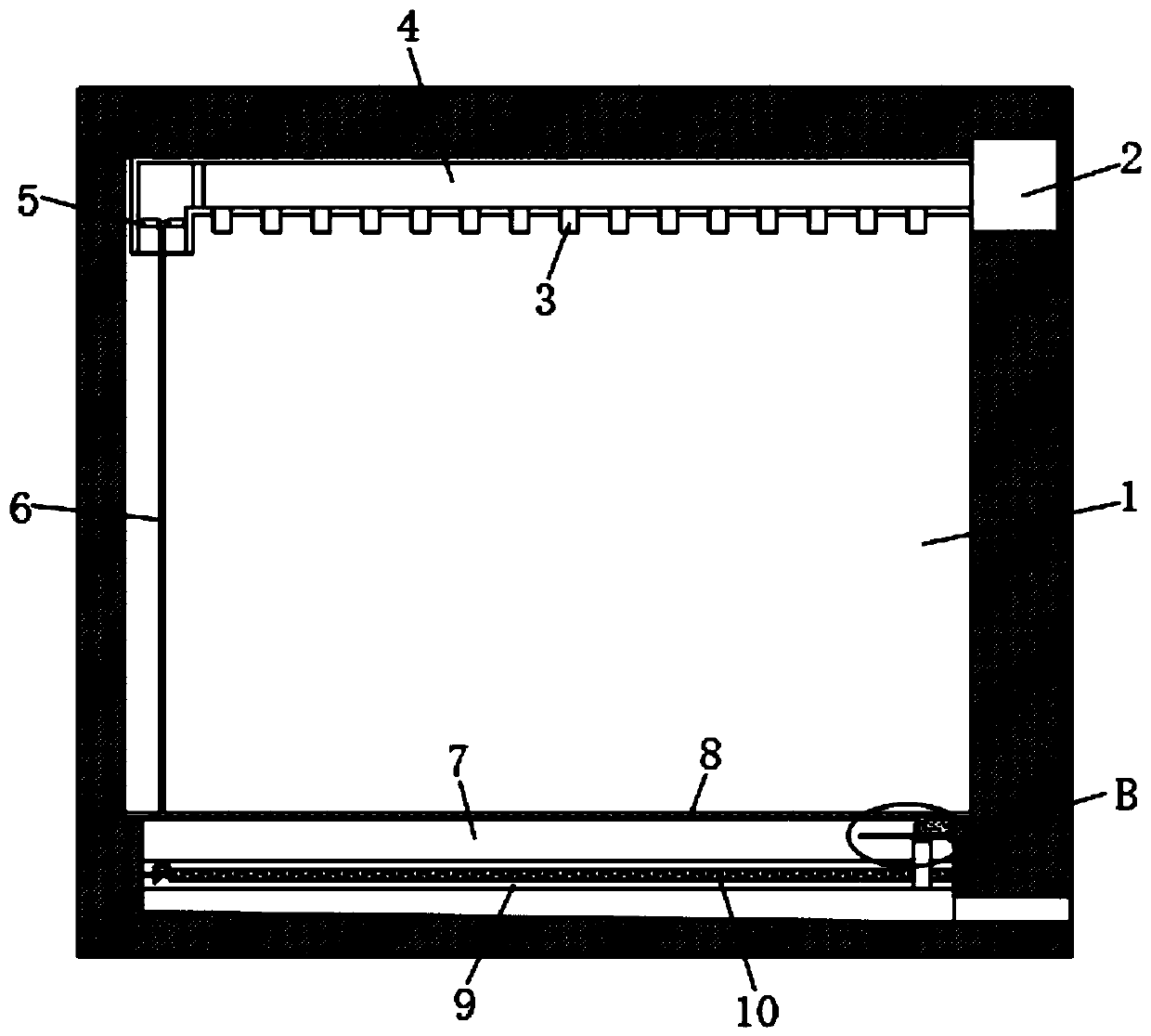

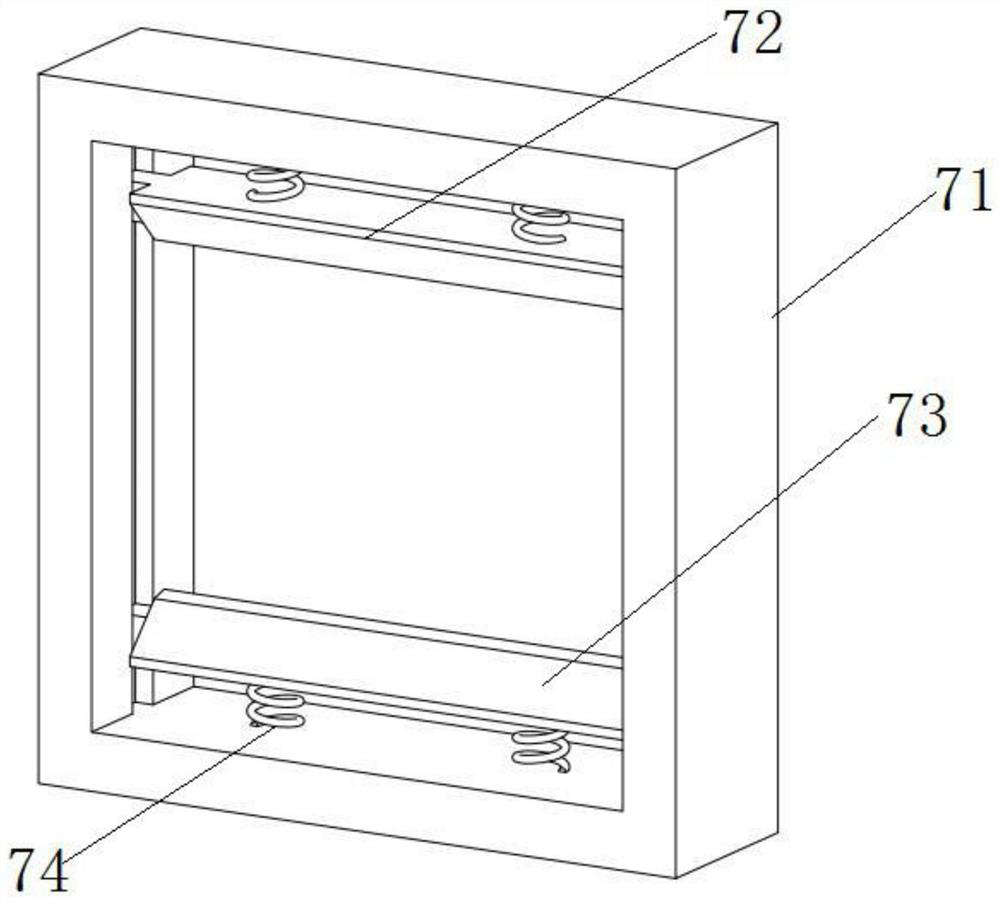

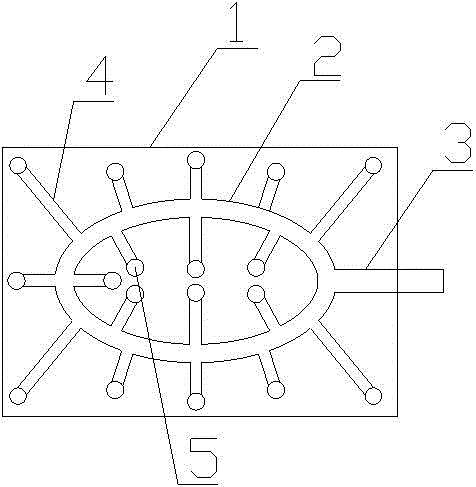

Dust removal device for micro-electronic component

ActiveCN109174819ASuck away in timeSimple structureDirt cleaningCleaning using toolsEngineeringElectronic component

The invention discloses a dust removal device for a micro-electronic component. The dust removal device for the micro-electronic component comprises a rectangular box, wherein a same cone box is welded to the top of the inner walls of the two sides of the rectangular box, and a hollow cylinder is welded to the inner wall of the cone box; an ion generator and a dust collector are correspondingly fixedly installed on the two sides of the hollow cylinder, and a circular plate is welded to the inner wall of the cone box; and a same transverse plate is welded to the inner wall of the two sides of the rectangular box. The dust removal device for the micro-electronic component has simple structure, the ion generator can generate ionic wind, and the ionic wind is blown to the surface of the micro-electronic component through a ionic wind gun, a fur brush can brush away dust which cannot be blown off by the ionic wind, meanwhile, the dust collector can suck away the dust through a dust collection head and a dust collection box, so that the ionic wind gun can focus on and blow the ionic wind to the surface of the micro-electronics component at a close range, the effect of electrostatic eliminating is good, and the dust collection head can suck away the dust which is removed from the micro-electronics component by the fur brush and the ionic wind gun at a close range, the dust can be sucked away in time, secondary pollution is avoided, and the use is convenient.

Owner:安徽星宇生产力促进中心有限公司

Massage health care type insole capable of removing odor

InactiveCN106983228AKeep freshAchieve dischargeInsolesDevices for pressing relfex pointsPhysical medicine and rehabilitationMassage

The invention discloses a massage health care type insole capable of removing odor. The insole comprises an insole body. The insole body comprises a front palm region, an arch region and a heel region. The heel region is provided with an elastic pressing piece; a first hollow cavity is formed between the elastic pressing piece and the insole body; the arch region is located at the edge of the insole body and provided with an arch support shrapnel; a second hollow cavity is formed between the support shrapnel and the insole body; the front palm region is provided with a plurality of rows of ventilation holes; a plurality of breathable passages are arranged in the insole body; a layer of a damping cushion body is bonded below the heel region, and a damping spring is arranged between the damping cushion body and the insole body; a plurality of damping cavity bodies are arranged in the insole body, and the damping spring and a massage magnet are arranged in the damping cavity bodies. According to the breathable insole, by squeezing the hollow cavity arranged on the insole, thus the air in the insole can be discharged out and the fresh air is absorbed; the moisture can be discharged in time, thereby keeping the insole refreshing; and through the damping insole, the impact received by foot can be buffered well, and the protection of users' feet is improved.

Owner:重庆慧高科技有限公司

In-throat emetic head and emetic device with emetic head for emergency internal medicine

ActiveCN112515828AAvoid discomfortSuck away in timeCavity massageNon-surgical orthopedic devicesThroatTonsil

The invention relates to an in-throat emetic head and an emetic device with the emetic head for emergency internal medicine. The in-throat emetic head comprises an in-throat pipe and a stimulation contact assembly, the in-throat pipe comprises an inner pipe and an outer pipe, and the stimulation contact assembly comprises a rotating shaft and a contact; and the contact comprises a blade and a stimulation part arranged on the outer edge of the blade, and the emetic device comprises an in-vitro terminal, a negative pressure generation source, a vomit collection bottle and the in-throat emetic head. The emetic head is provided with a rotary stimulation contact which can be driven by negative-pressure airflow, the blade of the stimulation contact is driven to rotate under the action of the negative-pressure airflow, and the stimulation part is driven to perform contact stimulation on tonsil of a patient in the rotating process of the blade, so that the patient is induced to vomit, on one hand, the negative-pressure airflow plays a role in driving the stimulation contact to act, on the other hand, vomit of a patient can further be sucked away in time, and discomfort of the patient due to the fact that the vomit cannot be discharged in time is prevented.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Smokeless multifunctional food selling vehicle

The invention relates to a smokeless multifunctional food selling vehicle. The vehicle comprises a vehicle body (5), wherein the vehicle body (5) is partitioned into a frying pan area (1), a saucepan area (2) and a barbecue area (3); a roof (7) is fixed at the top end of the vehicle body (5) through four brackets (8); and the roof (6) is provided with a range hood (4) which is communicated with a chimney (6) and provides a power source through a micro generator. By partitioning the vehicle body of the smokeless multifunctional food selling vehicle into the frying pan area, the saucepan area and the barbecue area, the vehicle has the advantages of complete function, simple structure and convenient production and use. The vehicle can suck away the oil smoke to reduce the harm of the oil smoke to human body. The roof is provided with a lighting device, so that a seller can conveniently provide sale a service at night. The roof is fixed at the top end of the vehicle body through the four brackets, so that the effect of avoiding light can be achieved and advertisements can be made on the edge of the roof to attract customers at the same time.

Owner:张弘

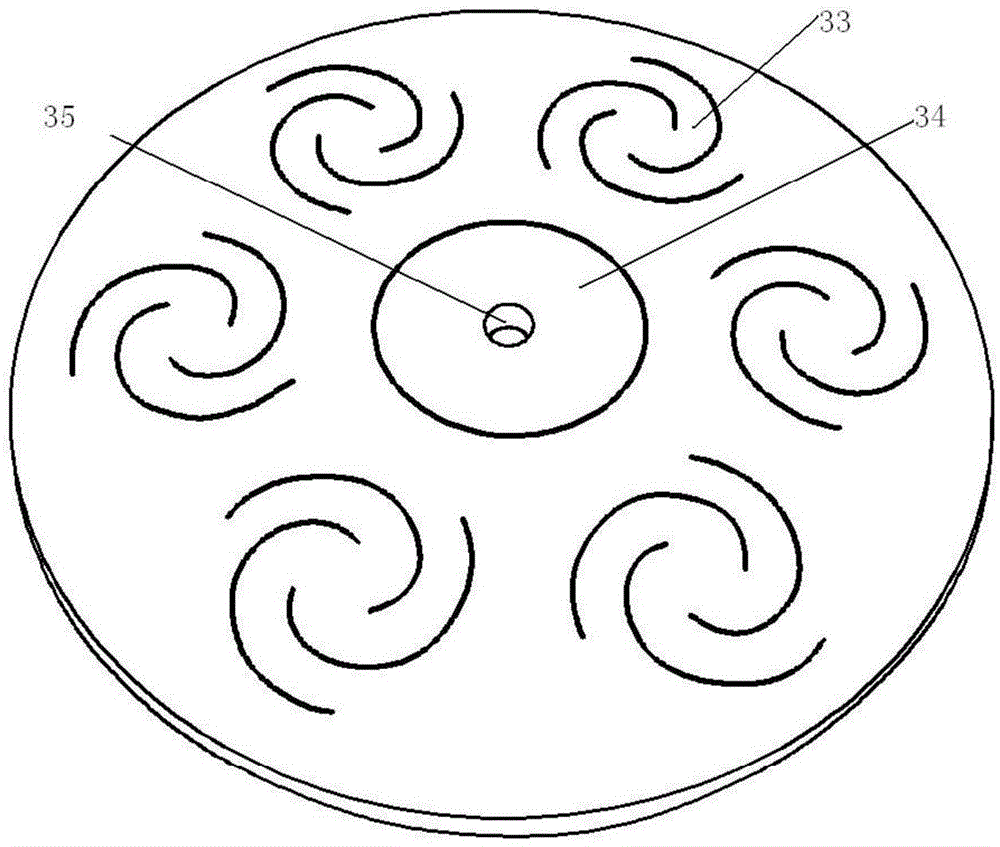

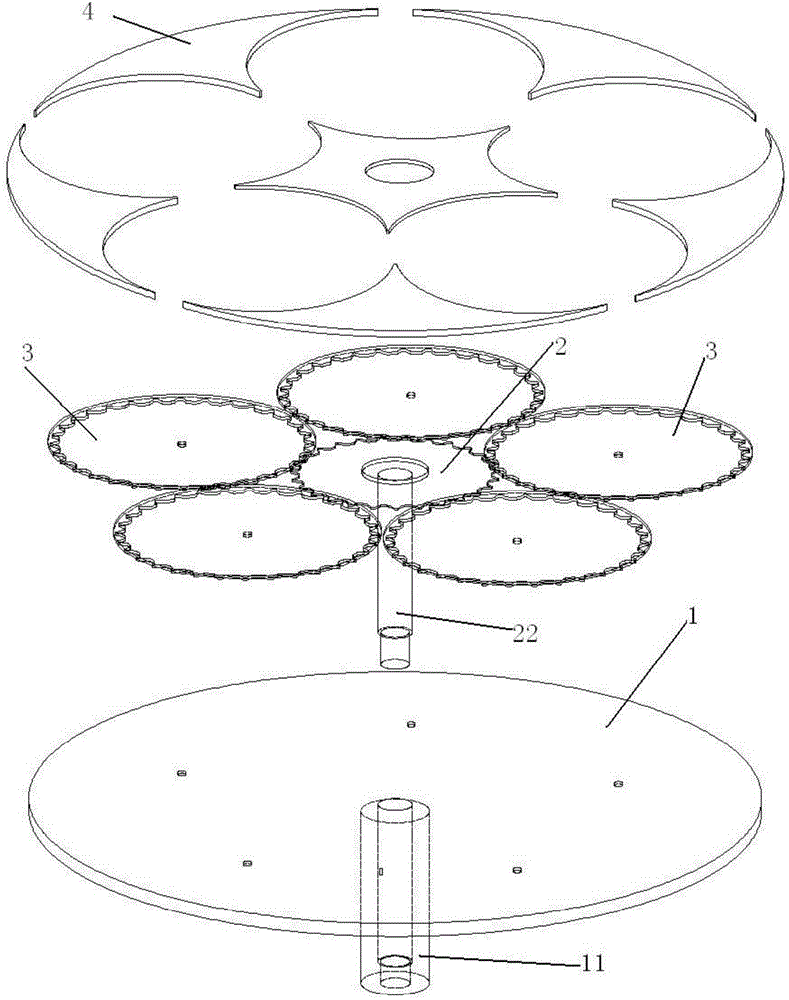

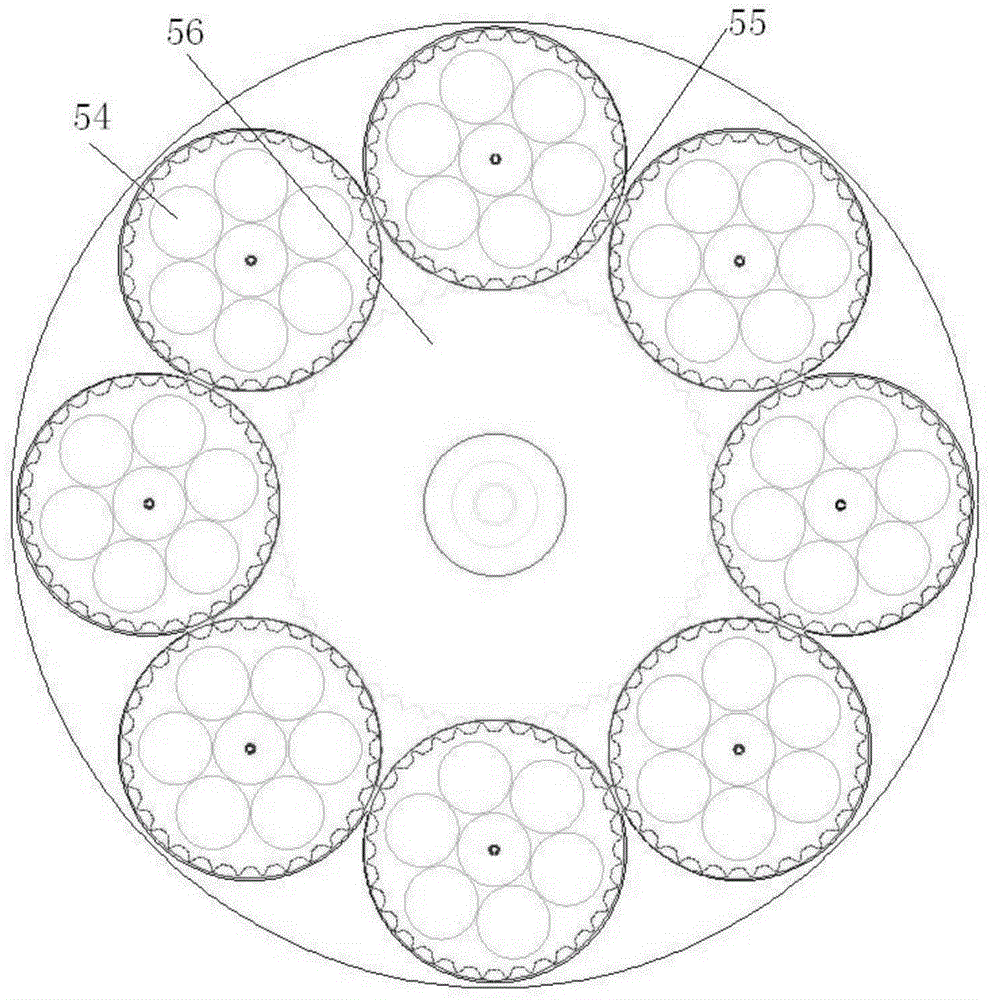

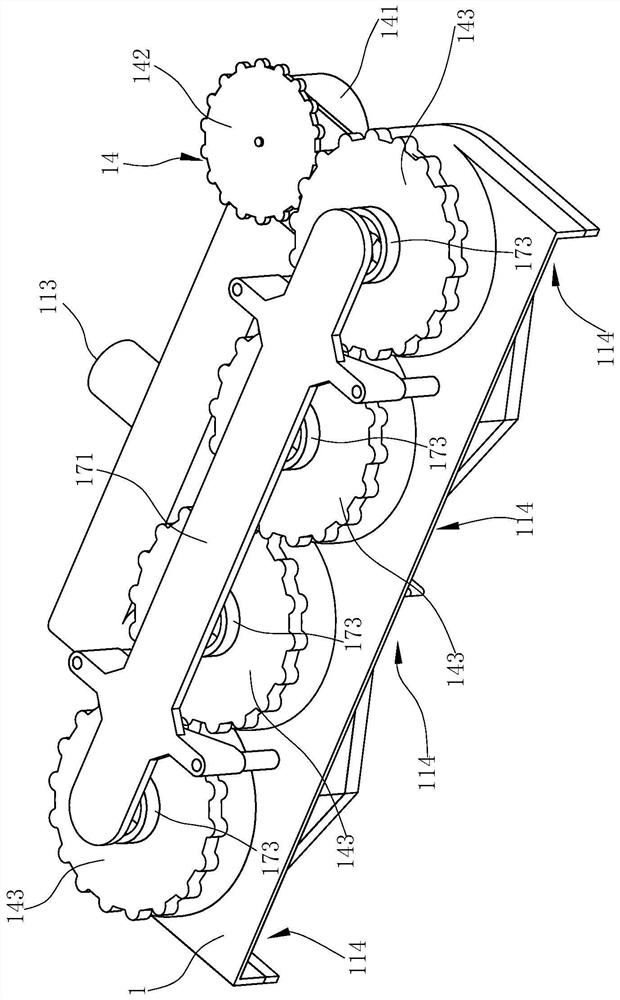

Mechanical autorotating MOCVD (metalorganic chemical vapor deposition) accessory substrate tray

InactiveCN103556130ASuck away in timeDoes not affect growth qualityChemical vapor deposition coatingGear driveGas phase

The invention discloses a mechanical autorotating MOCVD (metalorganic chemical vapor deposition) accessory substrate tray which comprises a substrate placed plate, a substrate gear and a first drive mechanism, wherein a substrate to be subjected to vapor deposition is placed on the substrate placed plate; the substrate gear is fixedly connected below the substrate placed plate; the first drive mechanism drives the substrate gear to rotate along a first direction, and the substrate gear drives the substrate placed plate to rotate. The mechanical autorotating MOCVD accessory substrate tray disclosed by the invention breaks a prejudice of thinking that the substrate placed plate can not be driven by a gear, but can be driven by an air flow in the prior art. According to the invention, the substrate placed plate is running more smoothly under the driving of the gear, so that the effect of vapor deposition is better.

Owner:北京希睿思科技有限公司

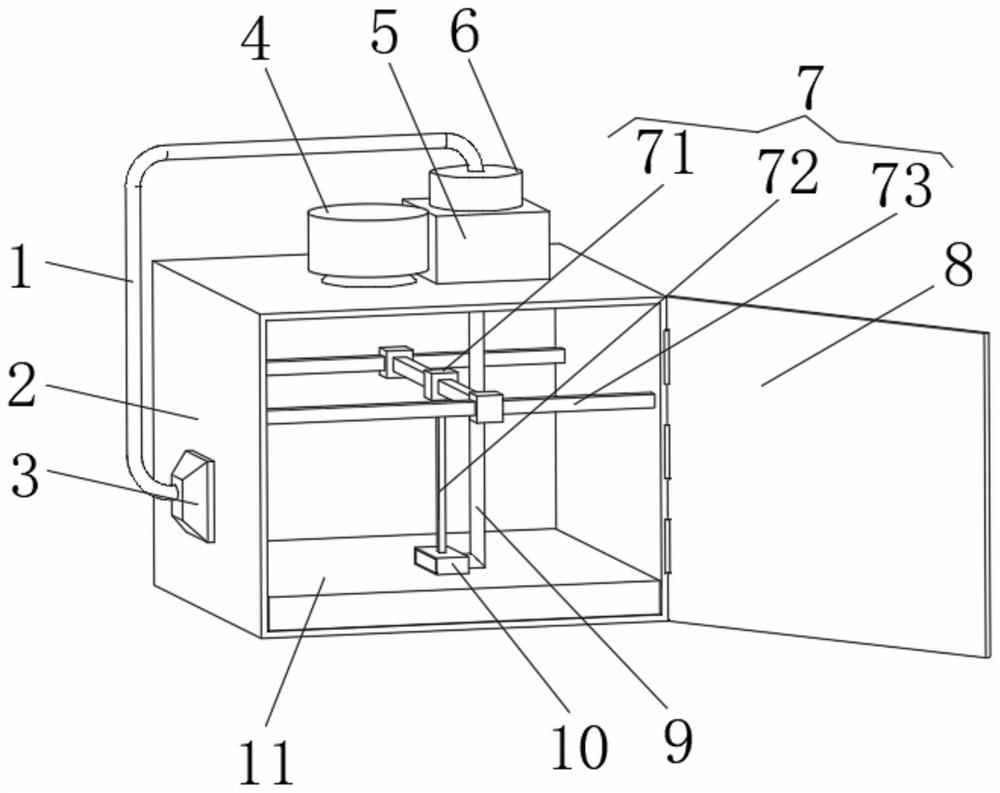

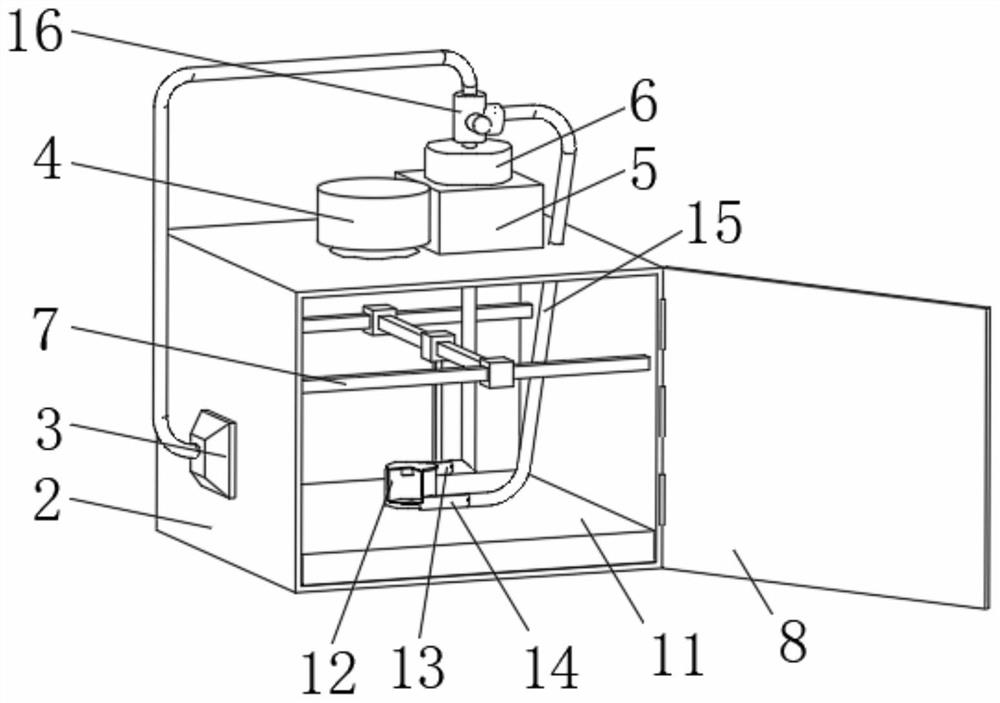

Dust removal structure in sealed cabin for additive manufacturing

InactiveCN112475317ASuck away in timeProcessing does not affectAdditive manufacturing apparatusDispersed particle filtrationParticulatesDust control

The invention discloses a dust removal structure in a sealed cabin for additive manufacturing. The dust removal structure comprises a box body with the hollow interior and a movable supporting piece,an operation opening communicating with the interior and the exterior of the box body is formed in the front side of the box body, a box door capable of being opened and closed is installed on the operation opening, and a machining forming platform is arranged on the bottom side of an inner cavity of the box body; an air inlet cover is installed in an inner cavity of the box body through the movable supporting piece, an air suction port communicating with the interior and the exterior of the air inlet cover is formed in the air inlet cover, an installation hole is formed in the upper side of the box body, a laser generator is installed in the installation hole, and an air purification box and a draught fan are installed on the upper side of the box body; and a through hole for communicating the interior and the exterior of the air inlet cover is formed in the air inlet cover. According to the dust removal structure in the sealed cabin for additive manufacturing, a dust suction device can track and approach a heat source action area in real time and is close enough to the heat source action area, smoke dust particles generated in the additive machining process are sucked away in time through the proper air pressure difference generated by the draught fan, and meanwhile raw material metal powder is not affected.

Owner:广州弦领智创科技有限公司

Annular water guide device for box type non-negative-pressure secondary water supply tank

ActiveCN104878805AWide range of water absorptionEasy to installWater supply tanksWater qualityEngineering

The invention relates to an annular water guide device for a box type non-negative-pressure secondary water supply tank. The annular water guide device comprises the water tank, an annular main pipe, a water outlet pipe, branch pipes and water suction balls. The annular main pipe is arranged in the water tank and communicated with the water outlet pipe. The branch pipes are further arranged on the annular main pipe. Each water suction ball is arranged at one end of the corresponding branch pipe. The annular water guide device for the secondary water supply tank is wide in water suction range and convenient to install. All pipelines are made of food-grade stainless steel smooth materials and are firmly welded. The annular water guide device is wide in water suction range, water in the water tank can be sucked away in time and fully circulated, a dead water zone and a stagnant water layer are avoided, bacteria are not prone to breeding, water quality is well guaranteed, and users can drink healthy water.

Owner:HANGZHOU ATT PUMP IND LIMITED

Brush head module for cleaning machine and cleaning machine

The invention relates to a brush head module used for a cleaning machine and the cleaning machine, the brush head module used for the cleaning machine comprises a shell, an air guide channel is arranged in the shell, and the air guide channel is provided with a dust suction port with a downward opening and an air outlet; the brush head is rotatably arranged in the air guide channel and comprises a connecting plate and a plurality of brush columns which are arranged on the connecting plate and extend along the rotating axis of the brush head; the hair combing device is characterized in that the hair combing device further comprises a hair combing plate which is arranged on the connecting plate and rotates along with the connecting plate, and the hair combing plate is provided with a through opening allowing the corresponding brush column to penetrate through; the power input end of the transmission assembly is in transmission connection with the brush head, and the power output end of the transmission assembly is in driving connection with the combing plate, so that the combing plate is driven to move back and forth along the rotating axis of the brush head relative to the connecting plate. The hair on the brush column can be combed, and the combed hair can be sucked into the air guide channel.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Mud removing device for fully-submerged rotary disk filter

InactiveCN102228756AGuaranteed suctionAvoid suction lossMoving filtering element filtersBubble curtainEngineering

The invention relates to a mud removing device for a fully-submerged rotary disk filter. The mud removing device comprises an aeration device arranged in a central rotating drum of the rotary disk filter and a mud pump arranged outside a rotary disk. A main pipe of the aeration device is fixed on a central axis of the central rotating drum; the input end of the main pipe is connected with an external air pump; the main pipe is provided with a plurality of uniformly distributed branch pipes; and air holes are densely distributed on the branch pipes. During work, the air pump is started to pump normal pressure air into the aeration device, the air passes through the main pipe and enters the branch pipes, and aeration is realized through the micropores uniformly distributed on the branch pipes; in the multi-stage air channel system, air is effectively depressurized and forms uniform small bubble curtains, and the bubble curtains float and raise to pass through rotary disk filter cloth from interior to exterior, so that the sludge deposited on the outer surface of the rotary disk filer cloth is effectively washed away from the filer cloth; and at the moment, the mud pump is started for suction, the sludge and impurities separated from the surface of the filter cloth can be effectively sucked away, so that the sludge is efficiently removed and the filter function of the rotary disk is restored.

Owner:JIANGSU GUOZHEN ENVIRONMENTAL PROTECTION TECH

Packaging table dust collecting cover

InactiveCN103769404ANo pollution in the processSuck away in timeDirt cleaningSolid materialEngineeringStructural engineering

The invention discloses a packaging table dust collecting cover. The packaging table dust collecting cover is characterized by comprising an umbrella-shaped cover body; a communicating pipe is arranged at the top of the cover body; an outlet of the communicating pipe is connected with a dust collecting pipeline; a dust collecting pump is connected to the exterior of the dust collecting pipeline; a spraying device is arranged inside the cover body; the gradient of an inclined surface of the umbrella-shaped cover body is from 25 to 35 degrees. The packaging table dust collecting cover has the advantages of enabling the environment of packaging powder to be free of pollution and collecting unnecessary powder in time due to the dust collecting pump; cleaning the cover body inner wall and the packaging table due to the fact that the spraying device is opened; accordingly being reasonable in structure.

Owner:NANJING HENGAN RESIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com