Patents

Literature

880results about How to "Achieve discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for energy-saving charging and discharging of cells and system for testing energy-saving charging and discharging of cells

ActiveCN102361101AAchieve recyclingRealize chargingElectrical testingSecondary cells charging/dischargingProcess engineeringBattery energy

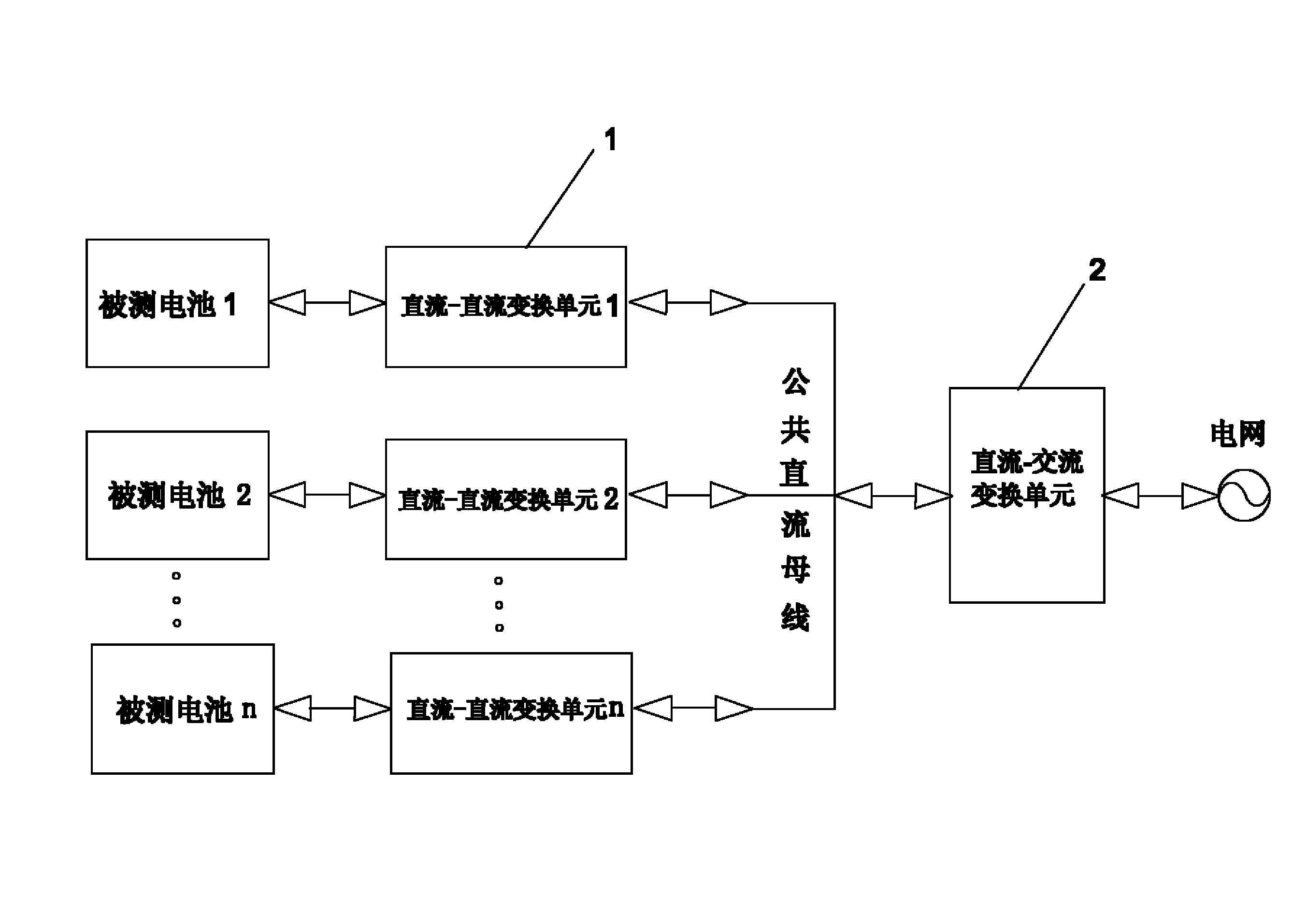

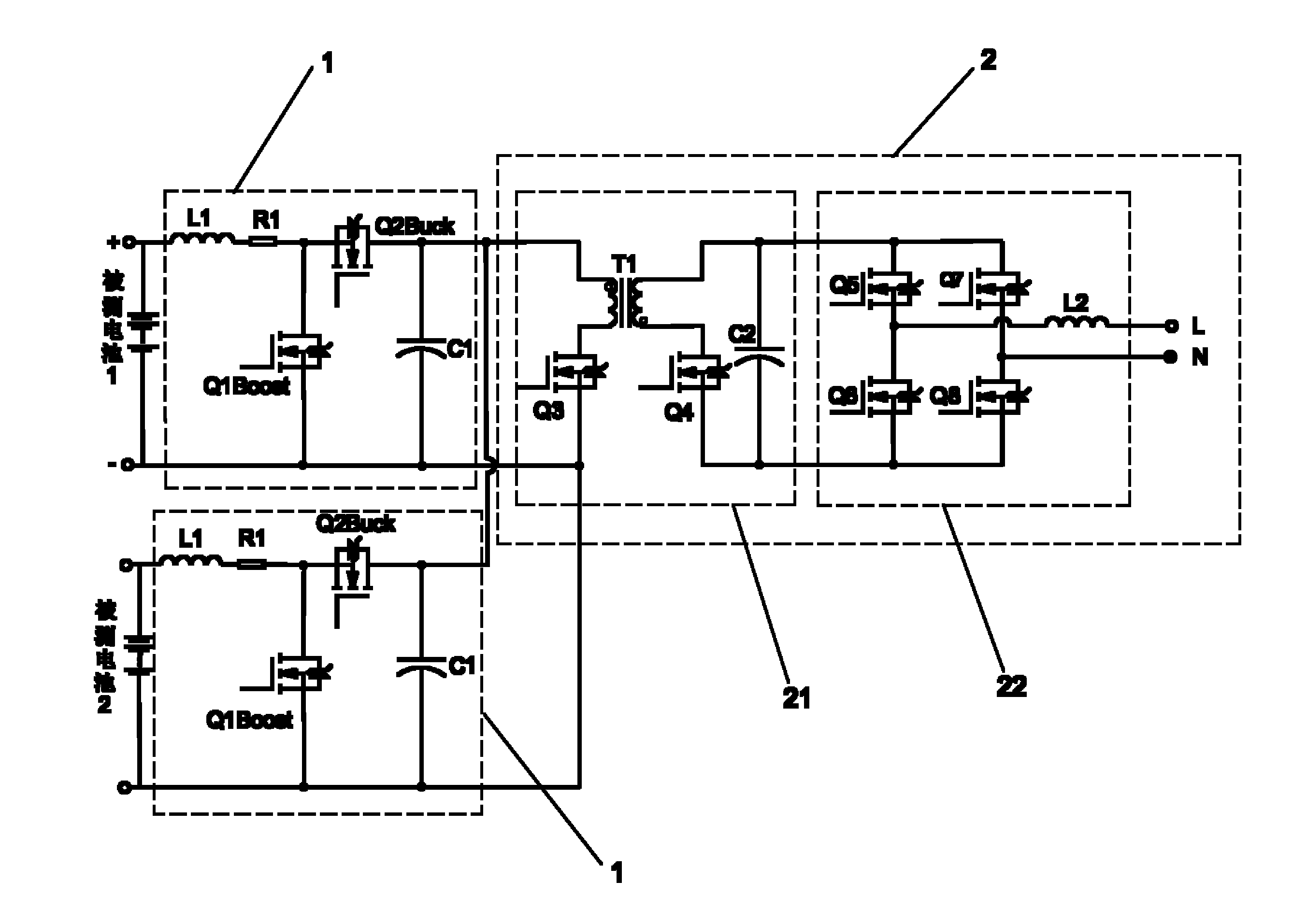

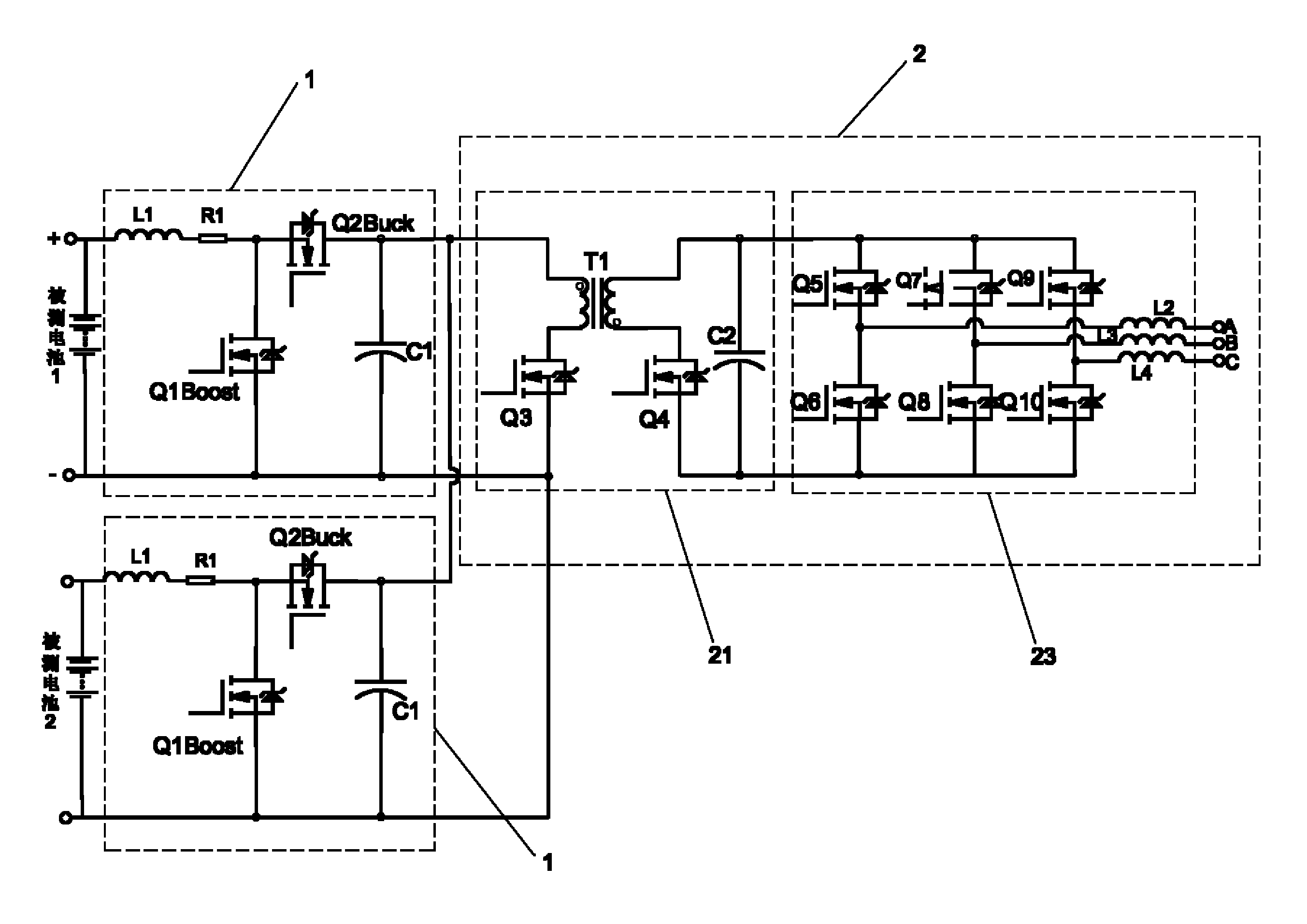

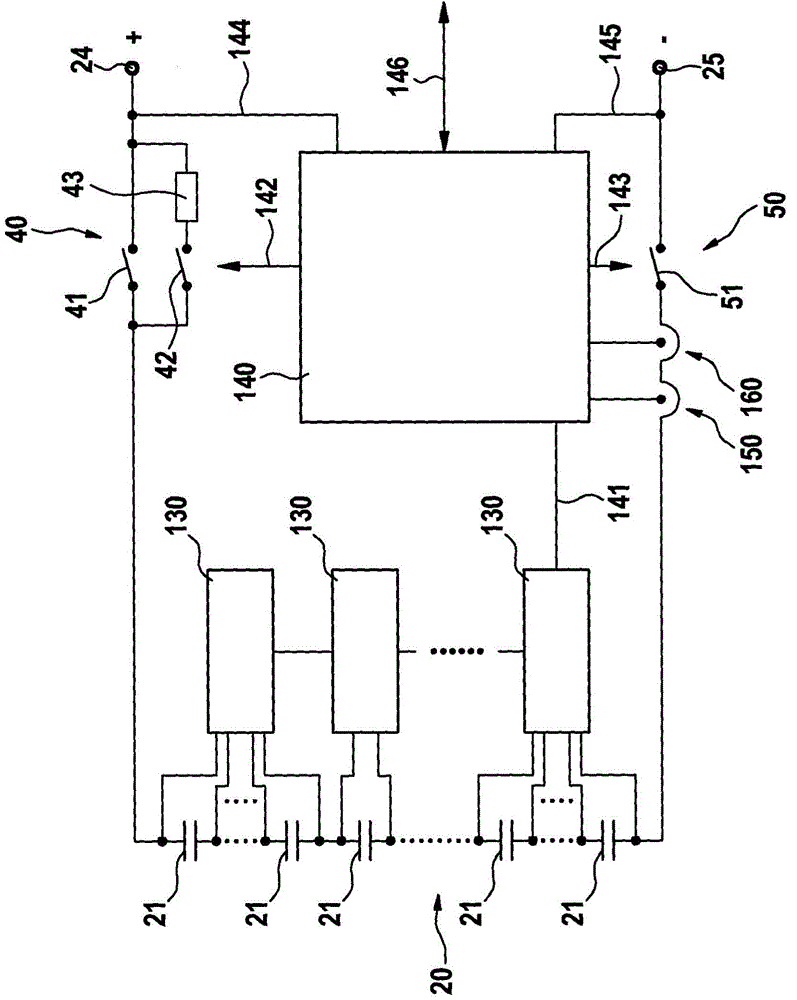

The invention relates to the technical field of an energy-saving charging and discharging test on cells, and specially, relates to a method for energy-saving charging and discharging of cells and a system for testing energy-saving charging and discharging of cells. When all cells are in a charging state, power is sent from an electrical network and orderly passes through a direct current-alternating current transformation unit, a direct current-direct current transformation unit and the cells. When all the cells are in a discharging state, power is sent from the cells and orderly passes through the direct current-direct current transformation unit, the direct current-alternating current transformation unit and the electrical network. When cell charging powder and cell discharging powder are unequal, the powder unbalance is adjusted by the direct current-alternating current transformation unit and the electrical network. In the invention, charging and discharging of cells are realized simultaneously. Powder produced by cell discharging is fed back to an electrical network so that powder cyclic utilization is realized and powder-saving effects are obtained. A part of the cells are in a charging state and the other part of the cells are in a discharging state so that powder can be transmitted between the two parts without passing through the electrical network and thus powder cyclic utilization efficiency is improved; powder consumption is reduced; charging-discharging integration is realized; and operation processes are simple and efficient.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

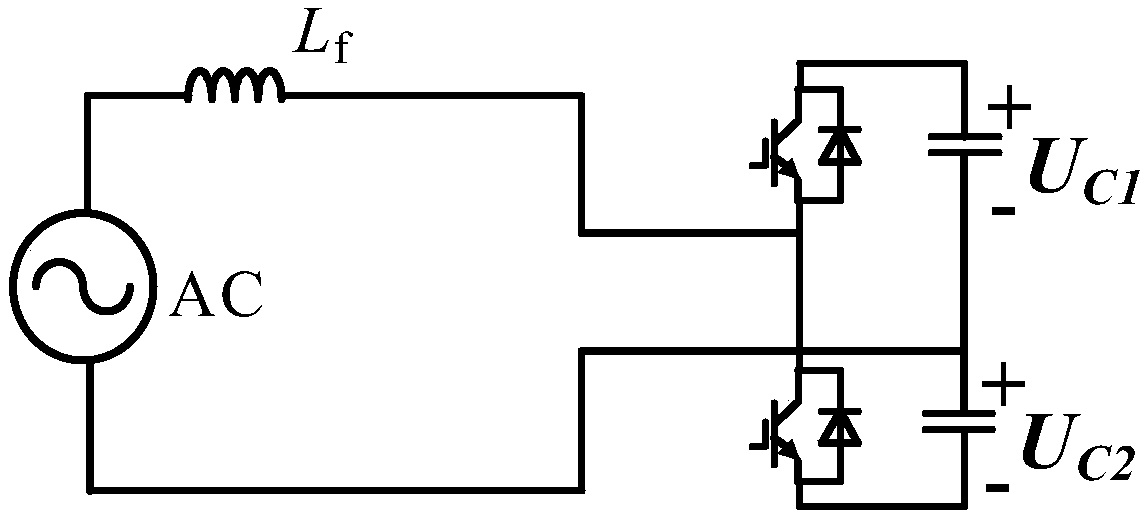

Accumulator multi-unit synchronous charging/discharging device and its method

InactiveCN101145697ASolve the problem of low power factor and high harmonic content causing great pollution to the power gridRealize synchronous chargingBatteries circuit arrangementsSecondary cells charging/dischargingPower factorEngineering

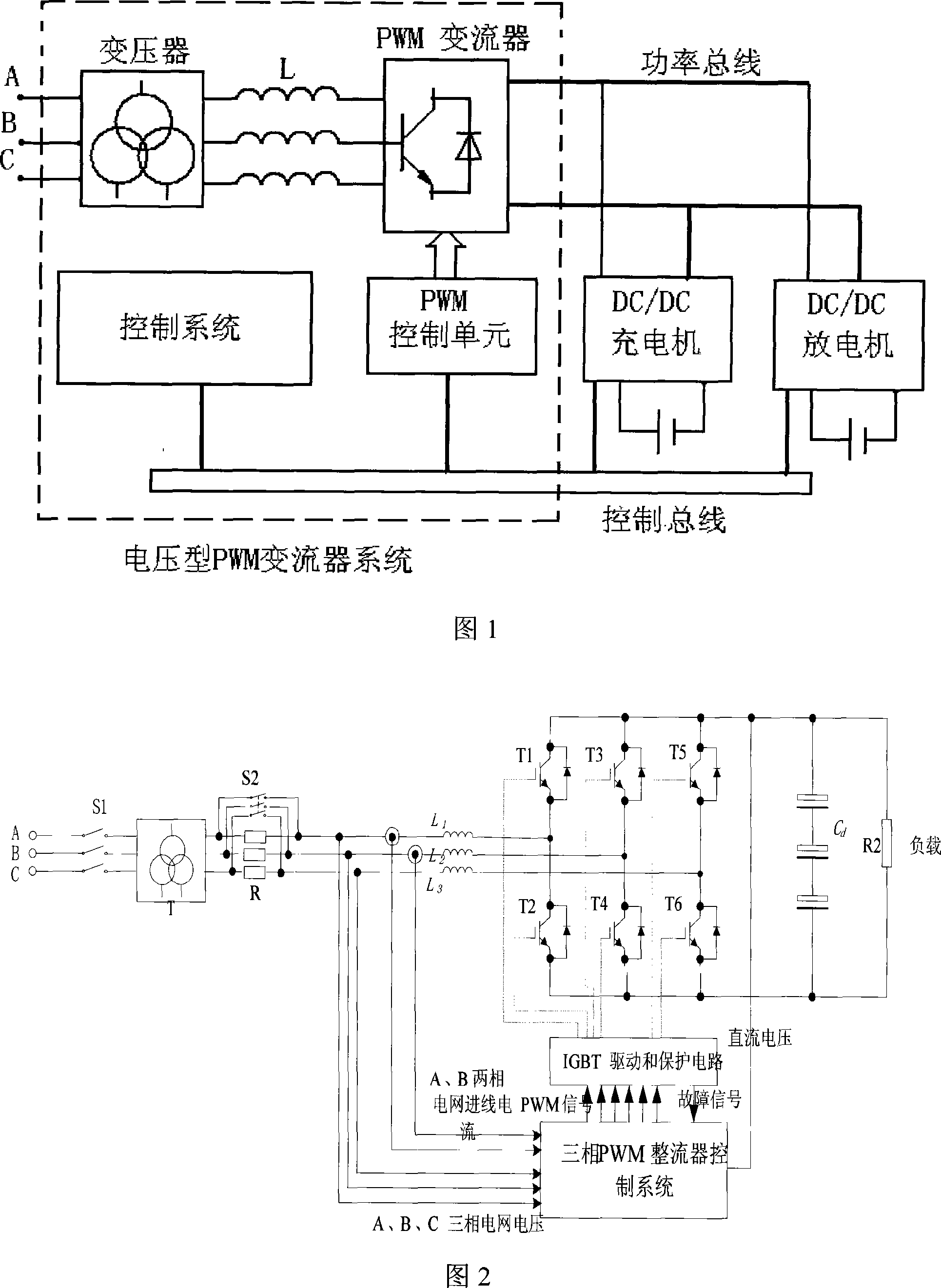

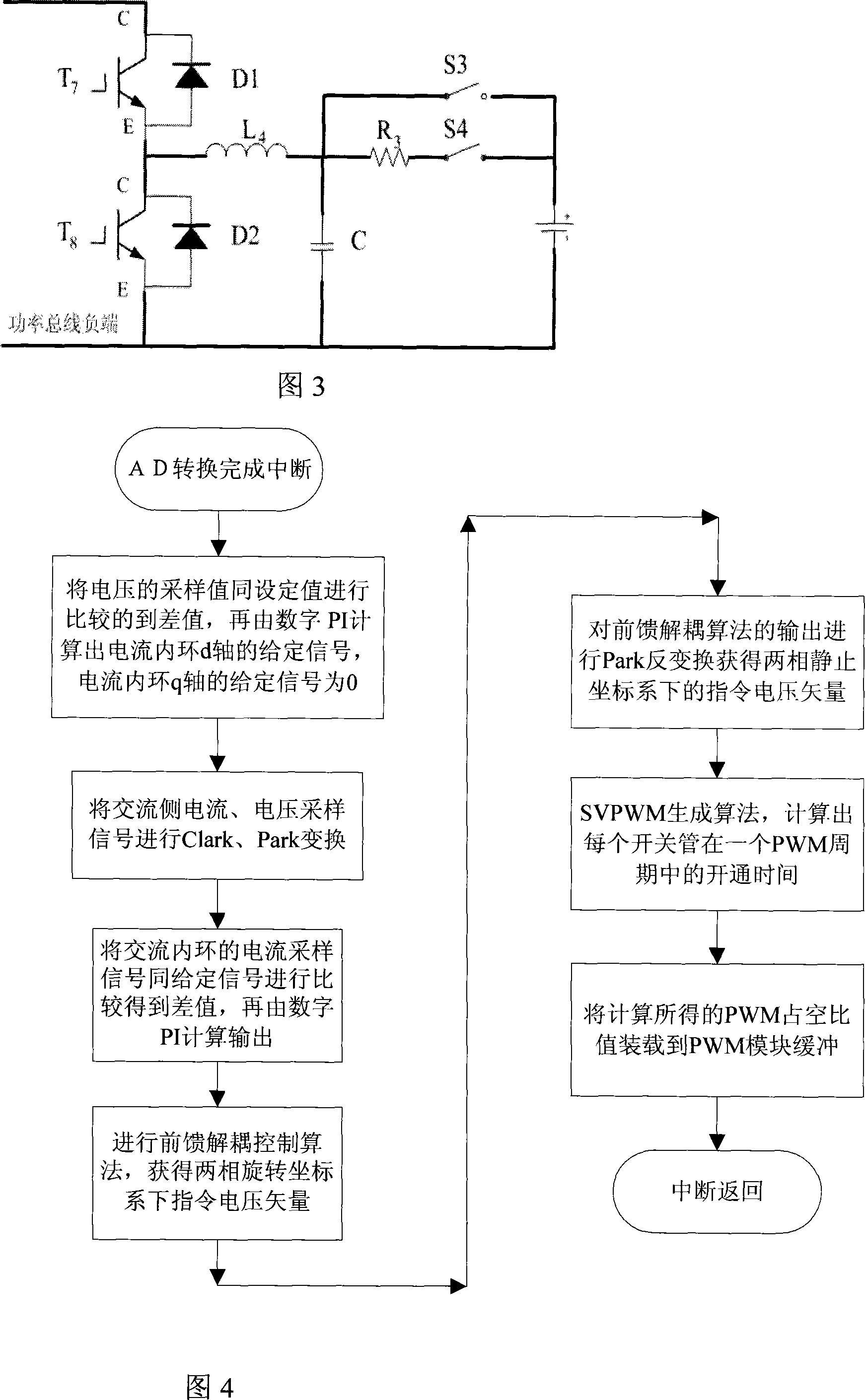

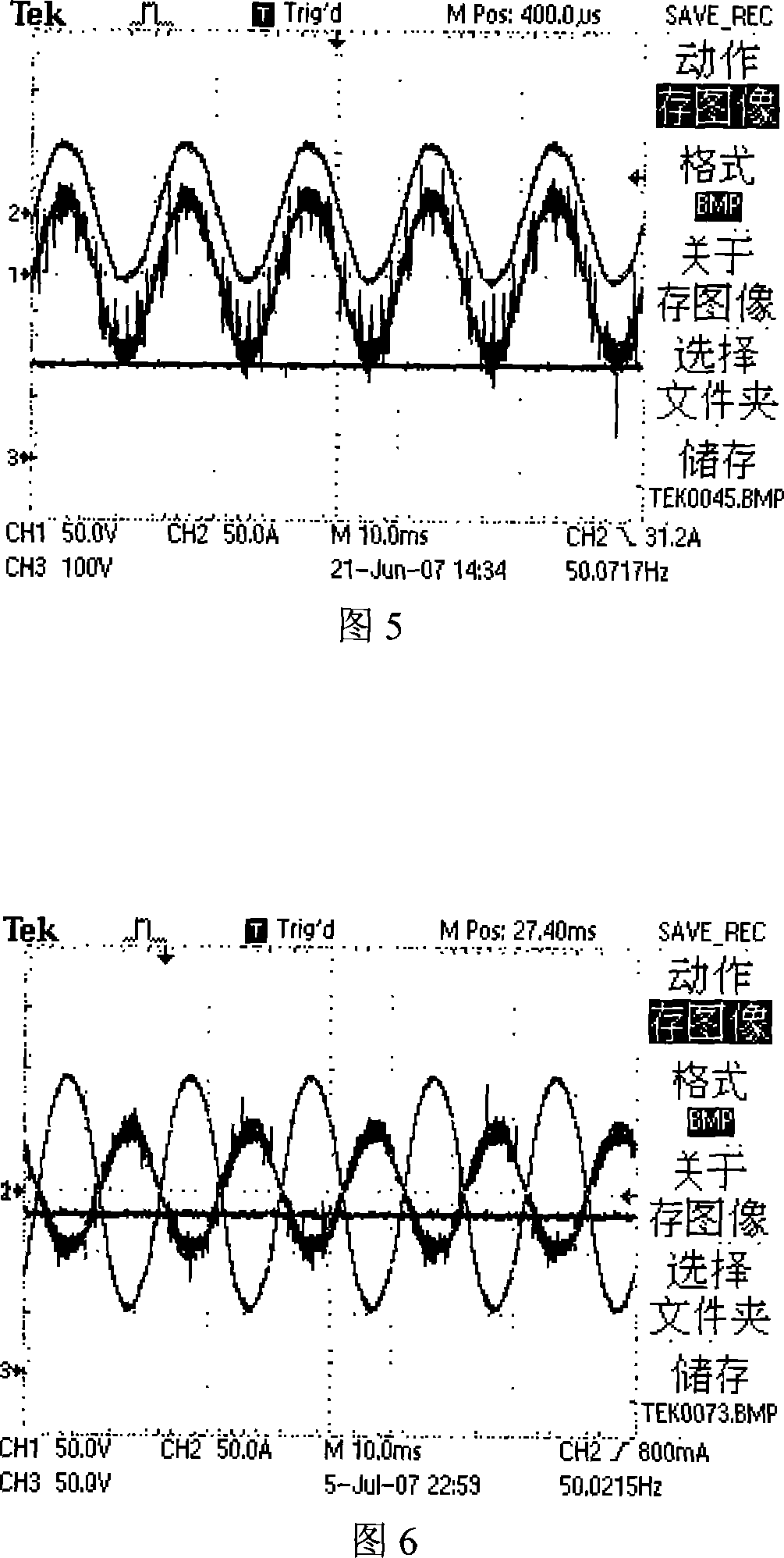

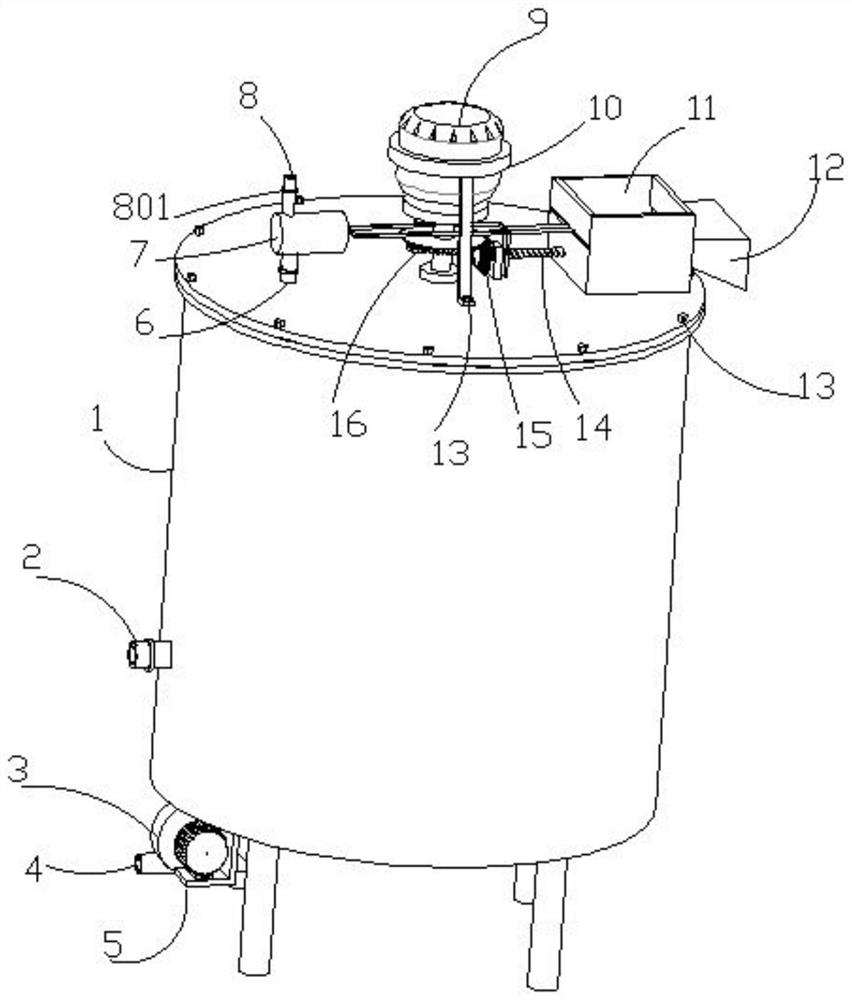

The invention provides a multi-unit device and a method for synchronically charging and discharging an accumulator. A main controller is respectively connected with a rectification (inversion) unit, a DC-DC converter unit, and an upper computer. The main circuit structure of the main controller comprises a front circuit part and a back circuit part. With the space vector pulse width modulation (SVPWM) technique used in the front circuit part of the inventive device, the power factor is approximately 1 in the charging mode and approximately -1 in the discharging mode, so as to improve the energy utilization efficiency, therefore, reducing the capacity requirement of an isolation transformer, and costs of other hardware. Meanwhile, the harmonic wave content is decreased and the pollution to a power grid is reduced. The device is in parallel connected with a plurality of independent two-way DC-DC converters, when a plurality of groups of battery units are synchronically charged or discharged, the residual electricity released by certain batteries can be charged into other batteries without passing through the power grid, so as to improve the service efficiency of the battery residual electricity and save electricity expenditure.

Owner:BEIJING JIAOTONG UNIV

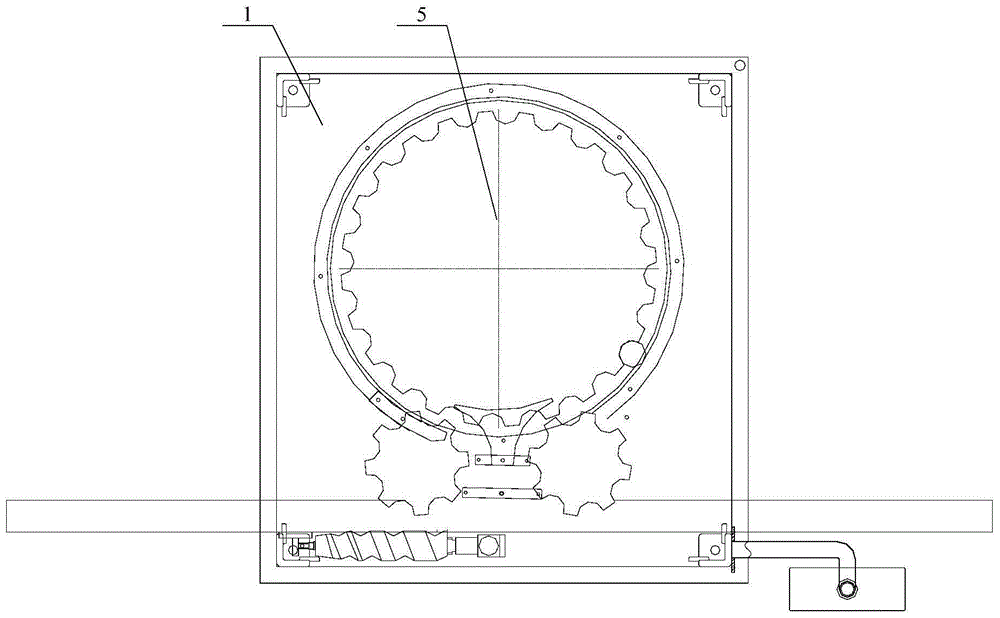

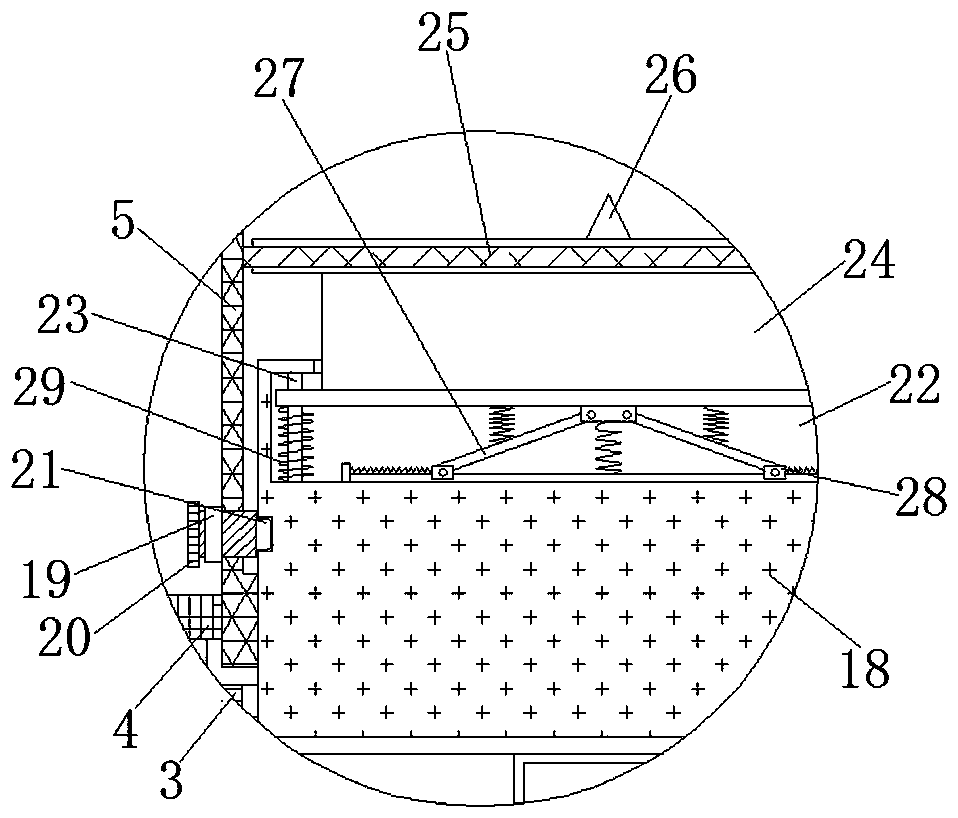

Environment-friendly sewage treatment device and sewage treatment method

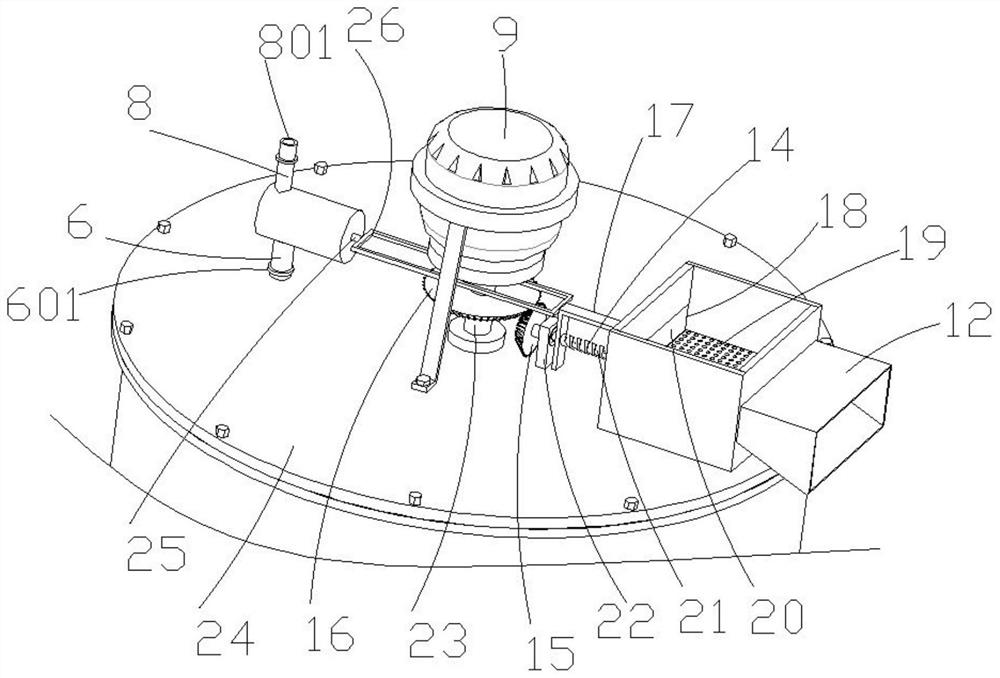

InactiveCN111620471AIncrease the degree of mixingOpposite direction of rotationRotary stirring mixersTransportation and packagingSludgeElectric machine

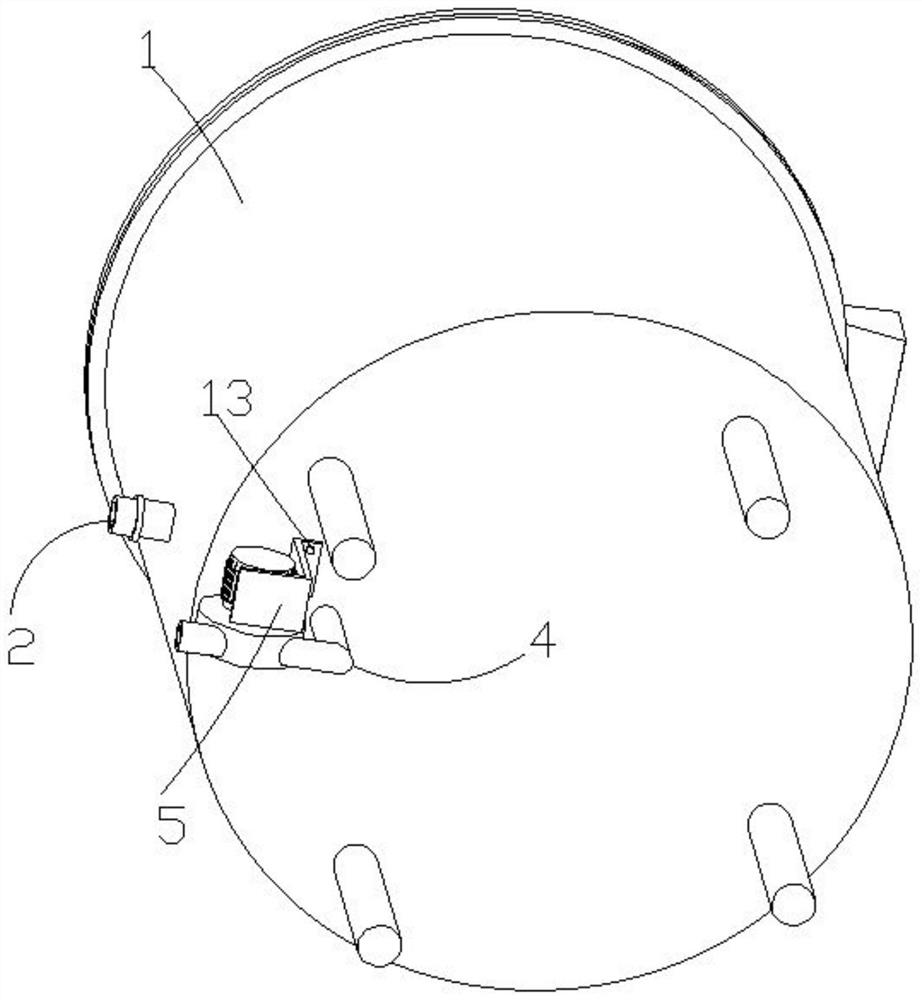

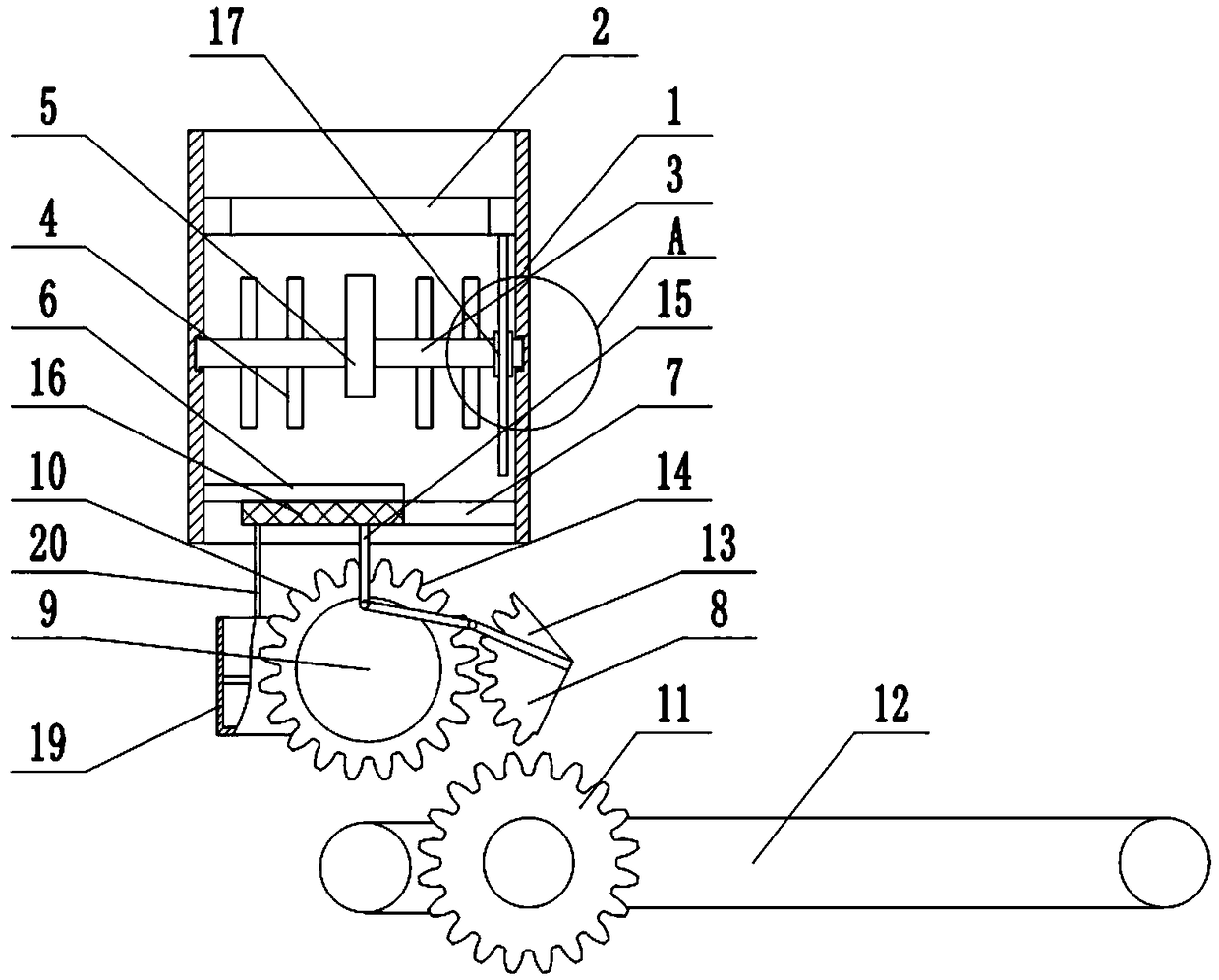

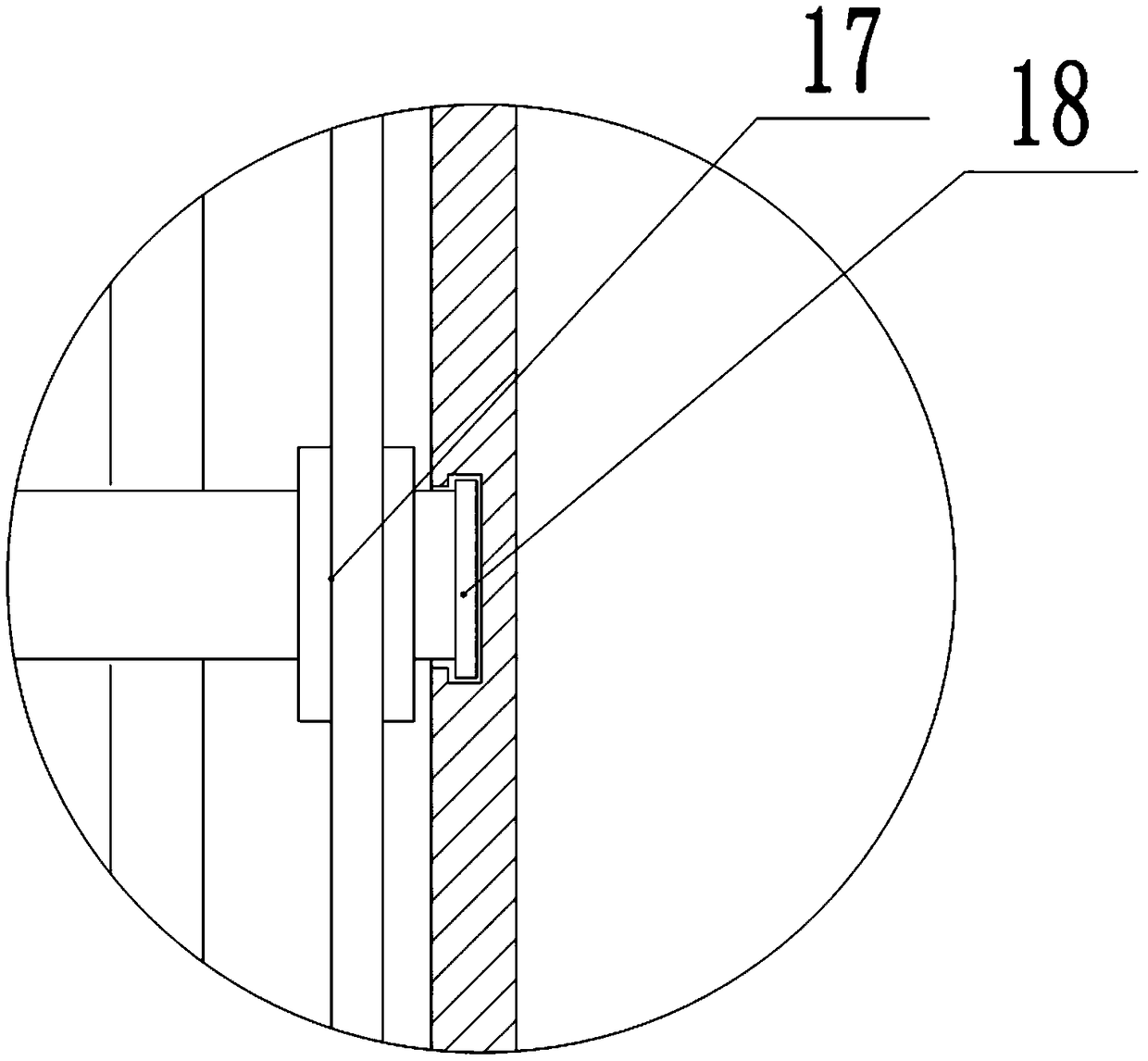

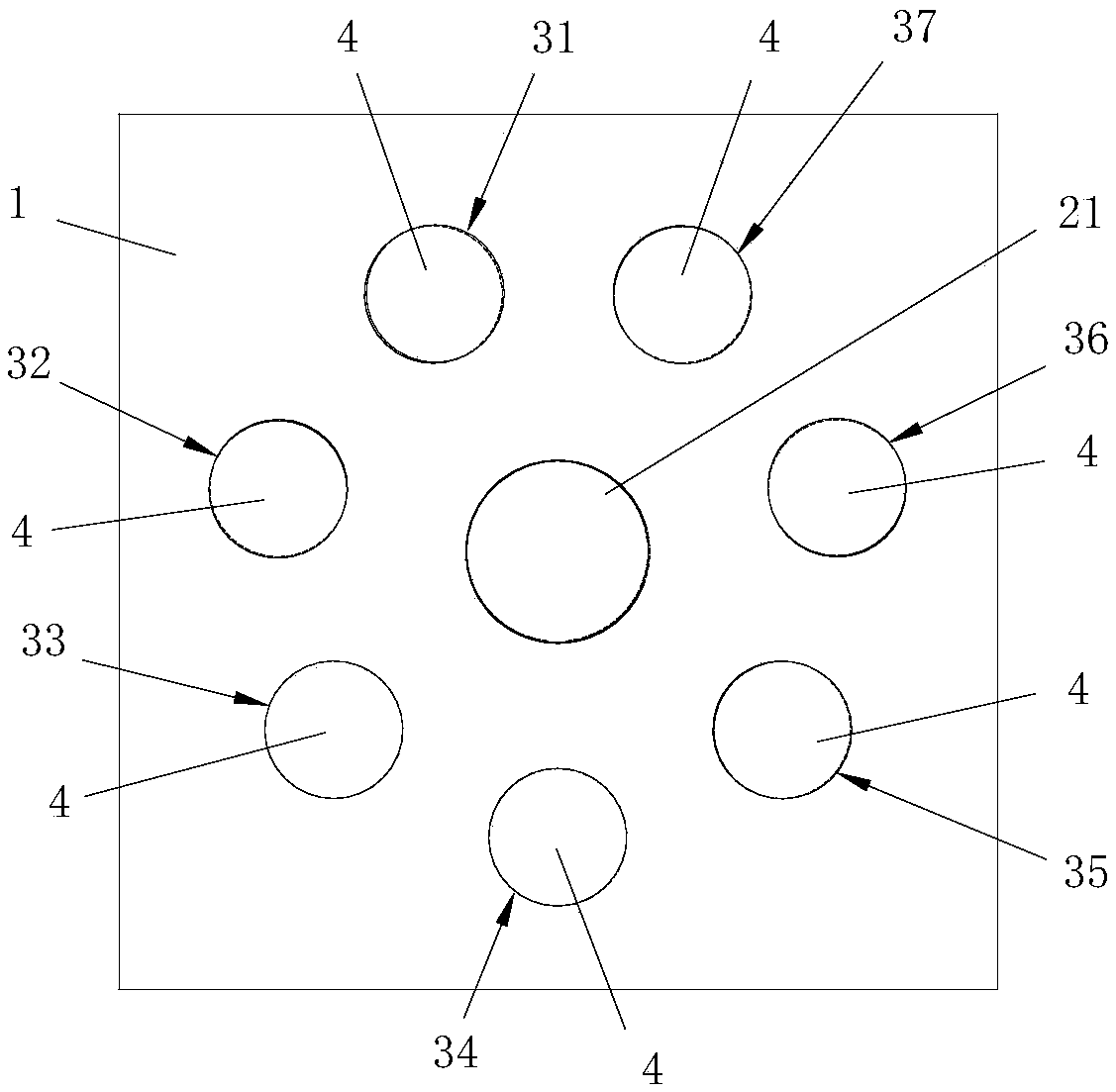

The invention relates to an environment-friendly sewage treatment device and a sewage treatment method in the technical field of sewage treatment. The environment-friendly sewage treatment device comprises a box body, the box body is provided with a cover plate, the cover plate is provided with a mounting frame and a square water inlet cylinder, the water inlet cylinder is provided with a supporting plate, the supporting plate is provided with a filter plate, the mounting frame is provided with a rotating motor, the rotating motor is provided with an upper rotating shaft, the upper rotating shaft is provided with a second bevel gear, and the second bevel gear is provided with a cleaning structure; the cleaning structure is provided with a flocculant uniform spraying structure; the upper rotating shaft is provided with a third bevel gear, the third bevel gear is provided with a fourth bevel gear, the fourth bevel gear is provided with a cross rod, the cross rod is connected with the boxbody, the fourth bevel gear is provided with a fifth bevel gear, the fifth bevel gear is provided with a lower rotating shaft, the lower rotating shaft and the upper rotating shaft are provided withstirring frames, each stirring frame is provided with a straight scraper blade, the straight scraper blade at the lowest end is provided with a transverse scraper blade, the box body is provided witha water outlet pipe with a control valve, and the box body is provided with a sludge pipe, so that the sewage stirring directions in the box body are opposite, the sewage stirring mixing degree is improved, and rapid flocculation treatment is realized.

Owner:CRYSTAL WATER & BLUE SKY ENVIRONMENTAL ENG

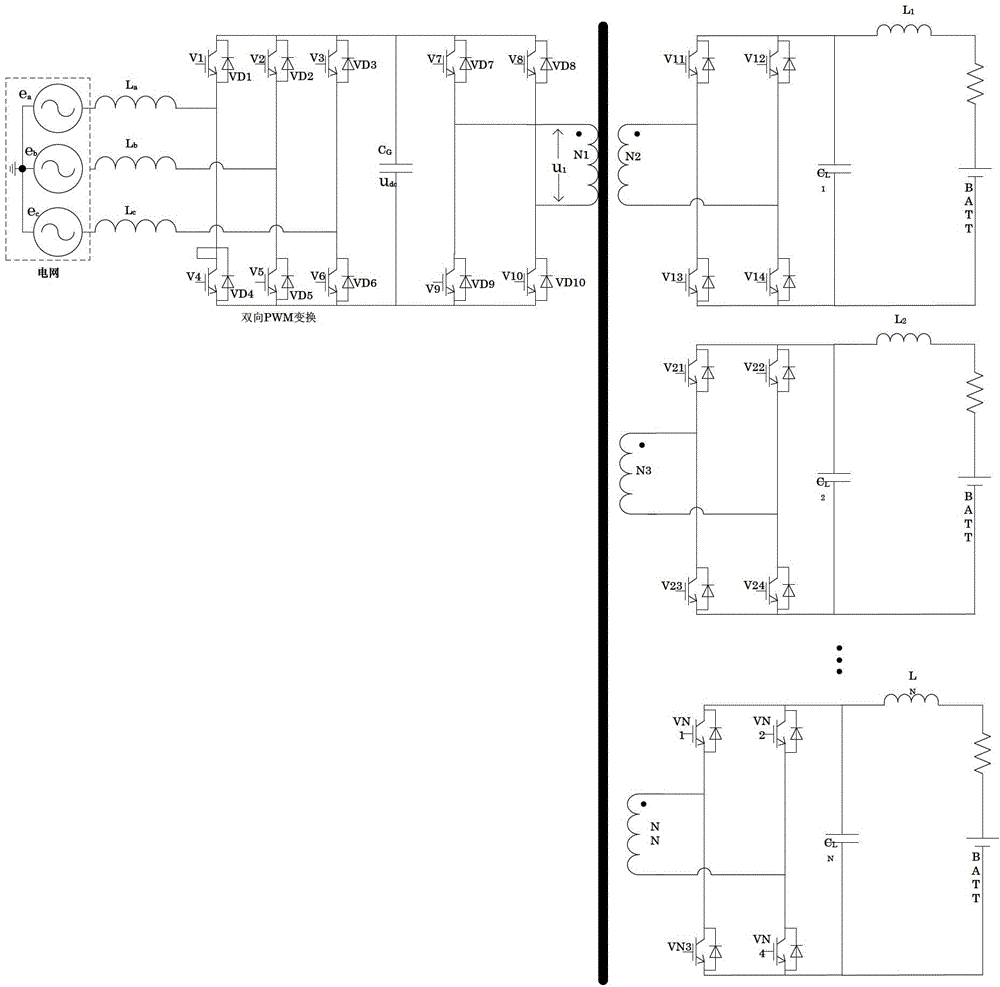

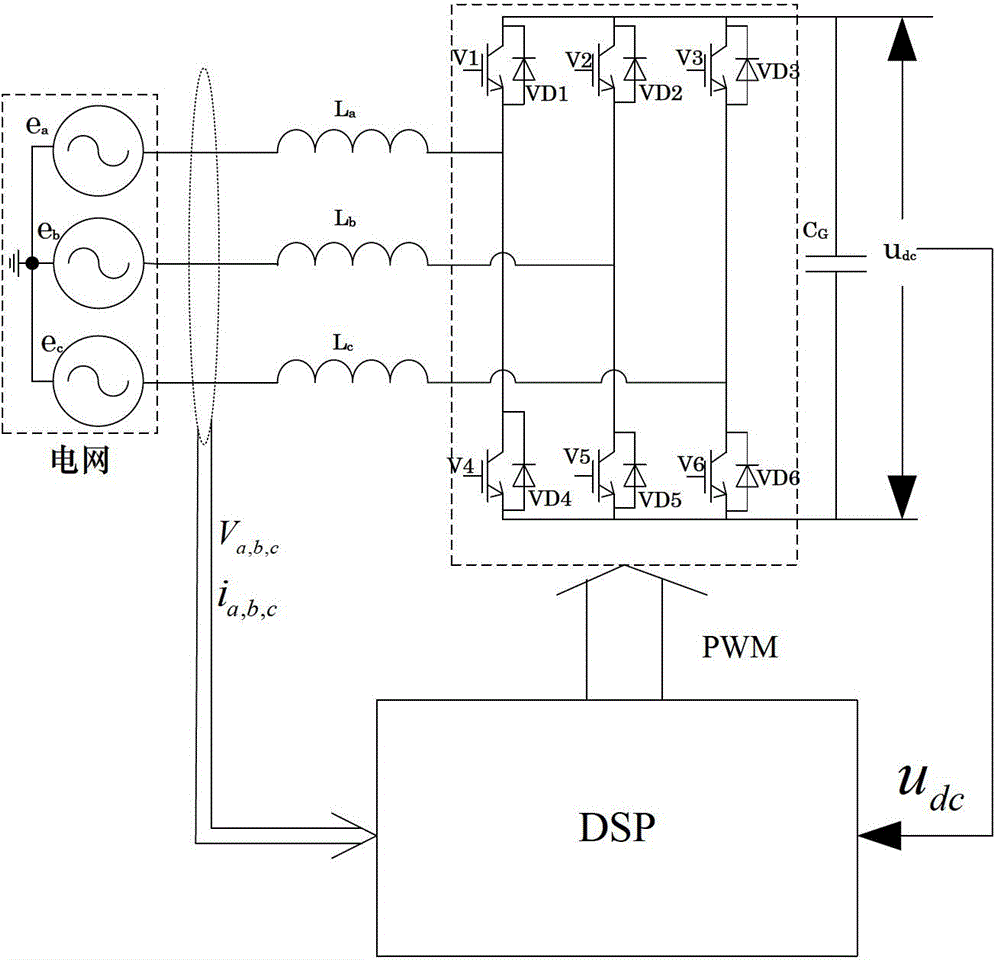

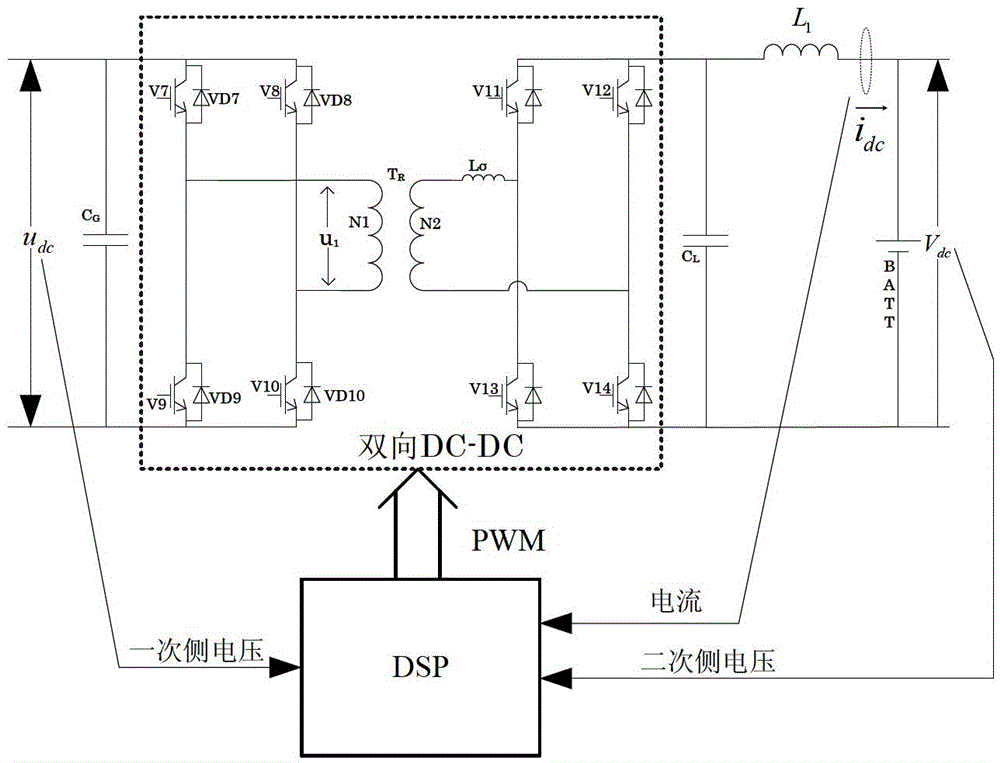

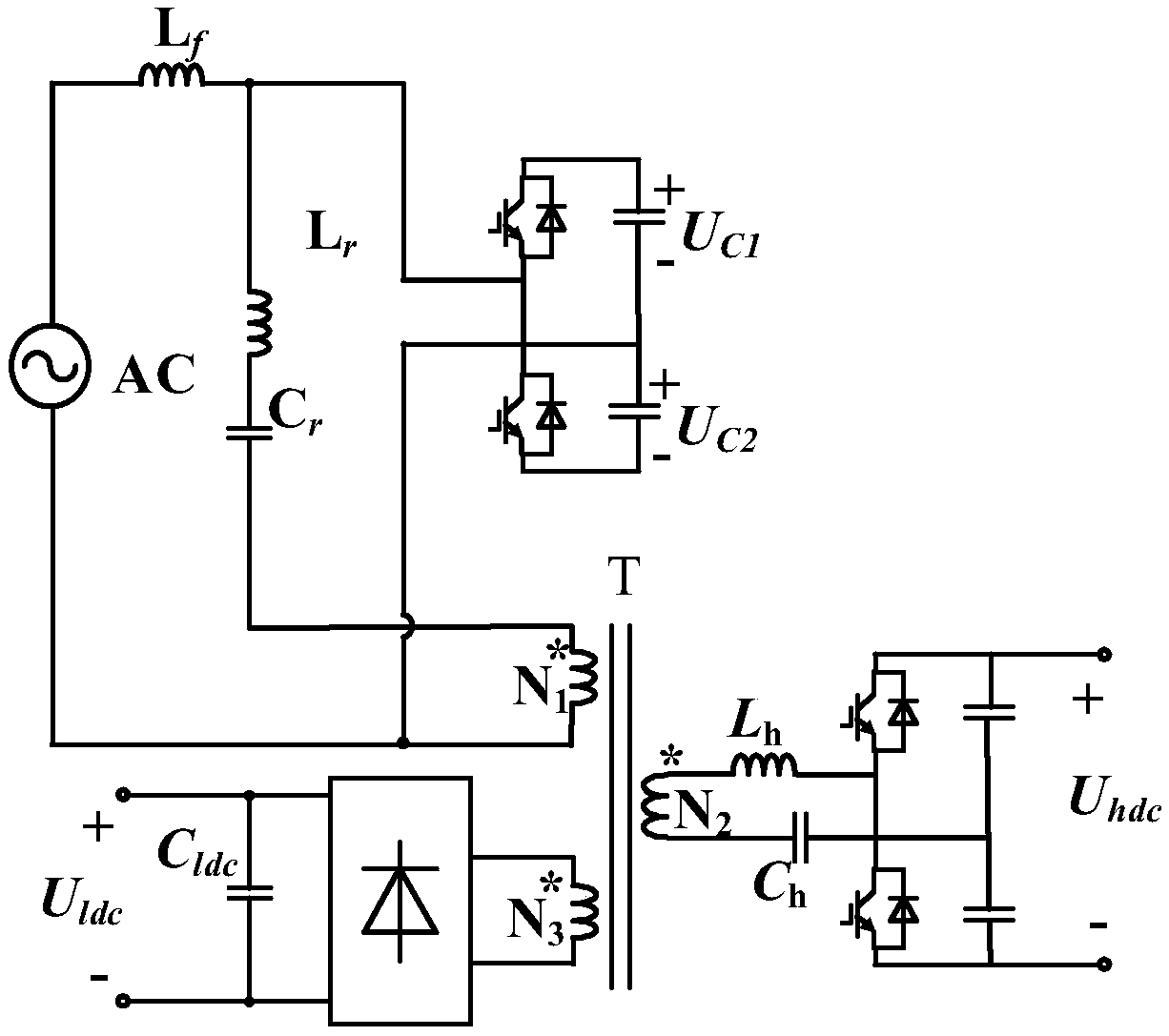

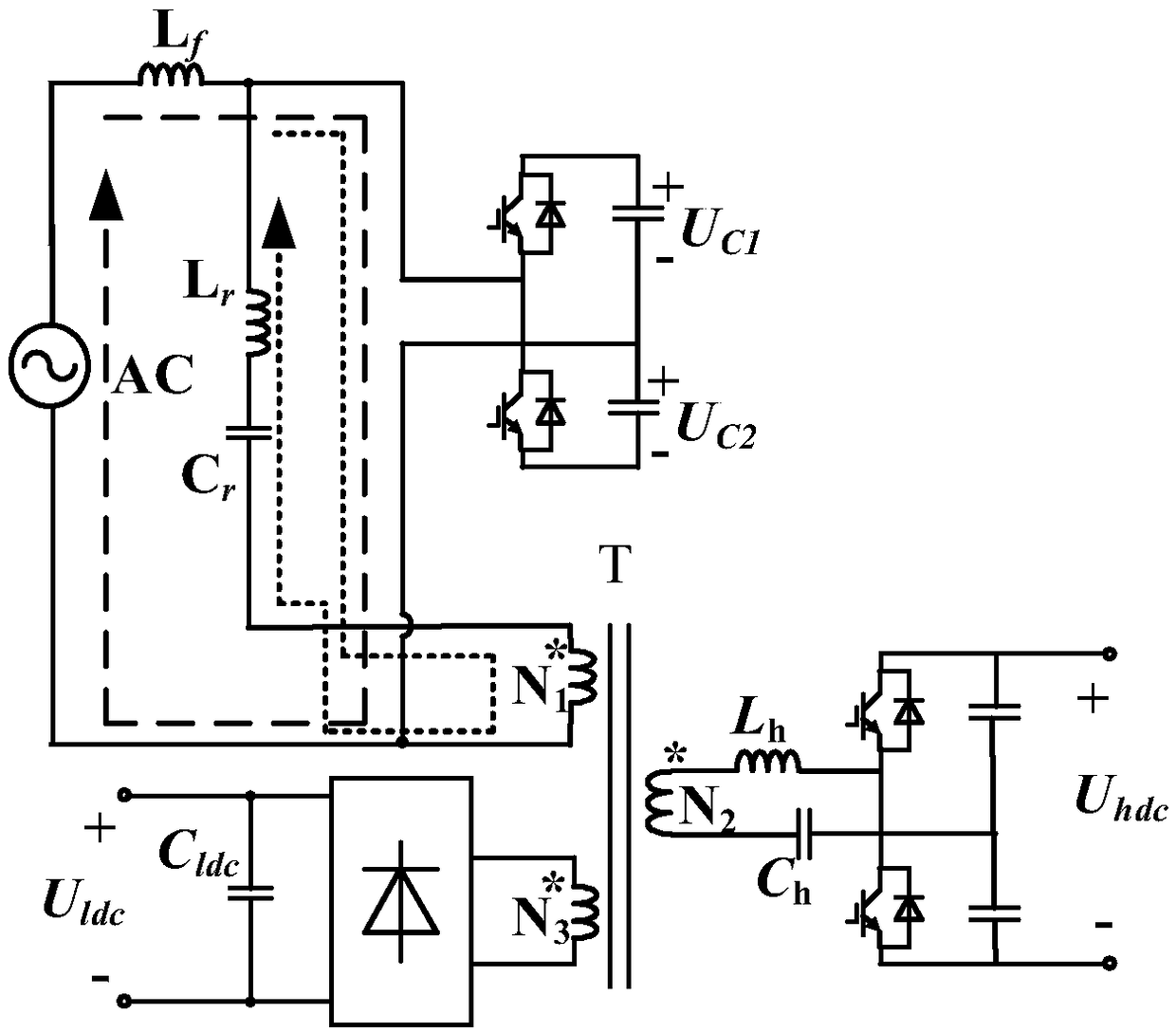

Storage battery charge and discharge circuit topology

ActiveCN102751772AReduce Harmonic PollutionWide output voltage rangeBatteries circuit arrangementsElectric powerPower gridPower flow

The invention relates to storage battery charge and discharge circuit topology which comprises a first stage of circuit, a second stage of circuit and a digital signal processor (DSP) controller; the first stage of circuit comprises three phases of alternating current power grids and an inverter circuit; the inverter circuit is provided with six transistors of a three-phase bridge, and the second stage of circuit comprises a first conversion circuit, a transformer, a second conversion circuit and a battery; and the DSP controller controls the output voltage, the output current and the switching direction of the inverter circuit and two direct current-direct current (DC-DC) conversion circuits so as to control the charge or the discharge of the whole circuit. After the device is adopted, charge and discharge with unit power factor can be realized for a power grid side; the pollution to the power grid is little; through a certain control method, a pulse width modulation (PWM) rectifier can realize a scalable vector graphics (SVG) function; the output of a wide voltage scope can be realized; and the charge and discharge efficiency is higher.

Owner:XIAN ACTIONPOWER ELECTRIC

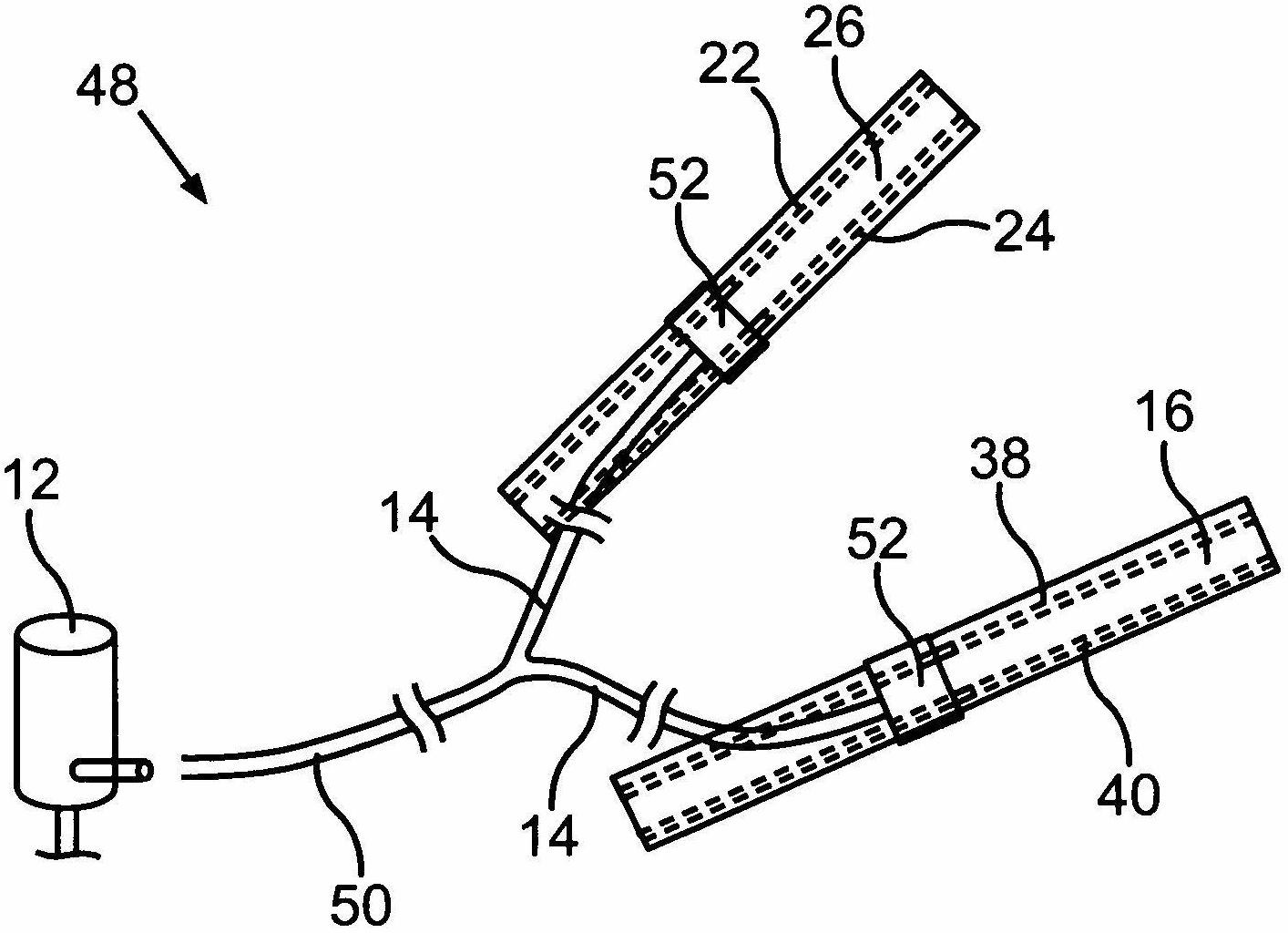

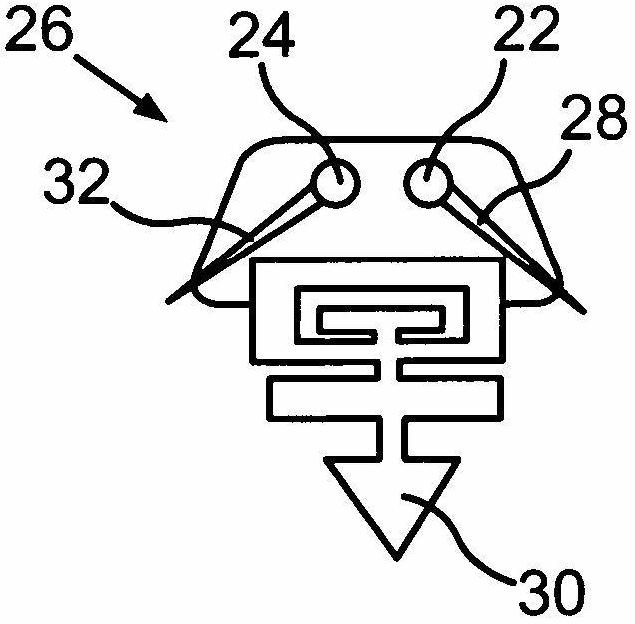

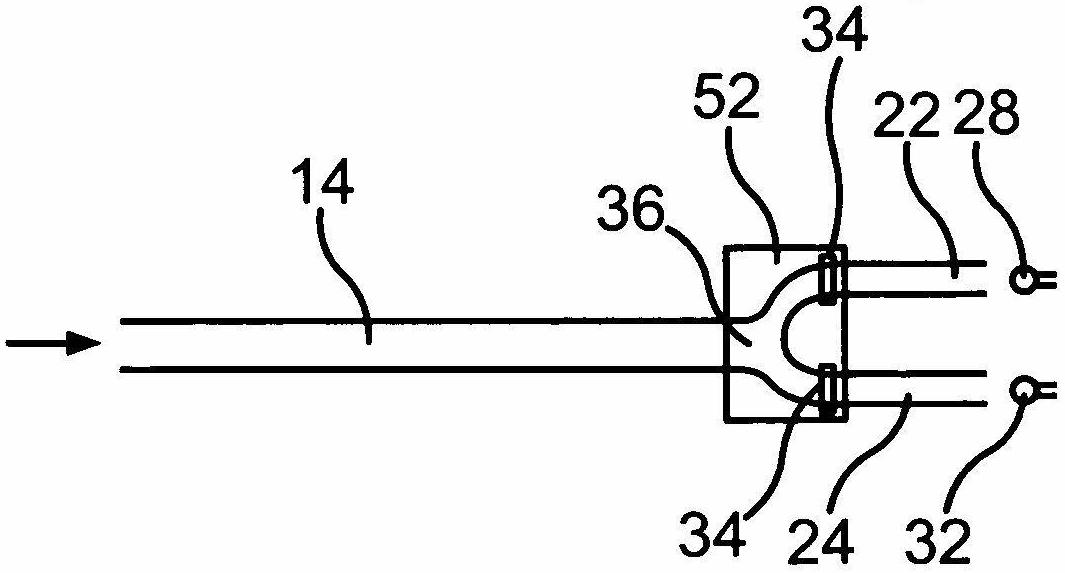

Wiper arrangement and method for operating a wiper arrangement for a motor vehicle

InactiveCN102652083APrevent wrong dischargeShort reaction timeVehicle cleaningEngineeringMechanical engineering

The invention relates to a wiper arrangement (48) with an associated windscreen washing system for a motor vehicle. The windscreen washing system comprises a washing liquid supply pipe (14) leading to outlets. The outlets are preferably arranged on the wiper blade (16, 26) and can consequently be moved together with a corresponding wiper arm of the wiper arrangement (48). A coupling part (52), by means of which the wiper blade (16, 26) is connected to the respective wiper arm, and which moves with the wiper arm as the latter moves, has switching valves. The discharge of washing liquid from the outlets can be controlled by means of the switching valves. Furthermore, the invention relates to a method for operating such wiper arrangement (48).

Owner:DAIMLER AG

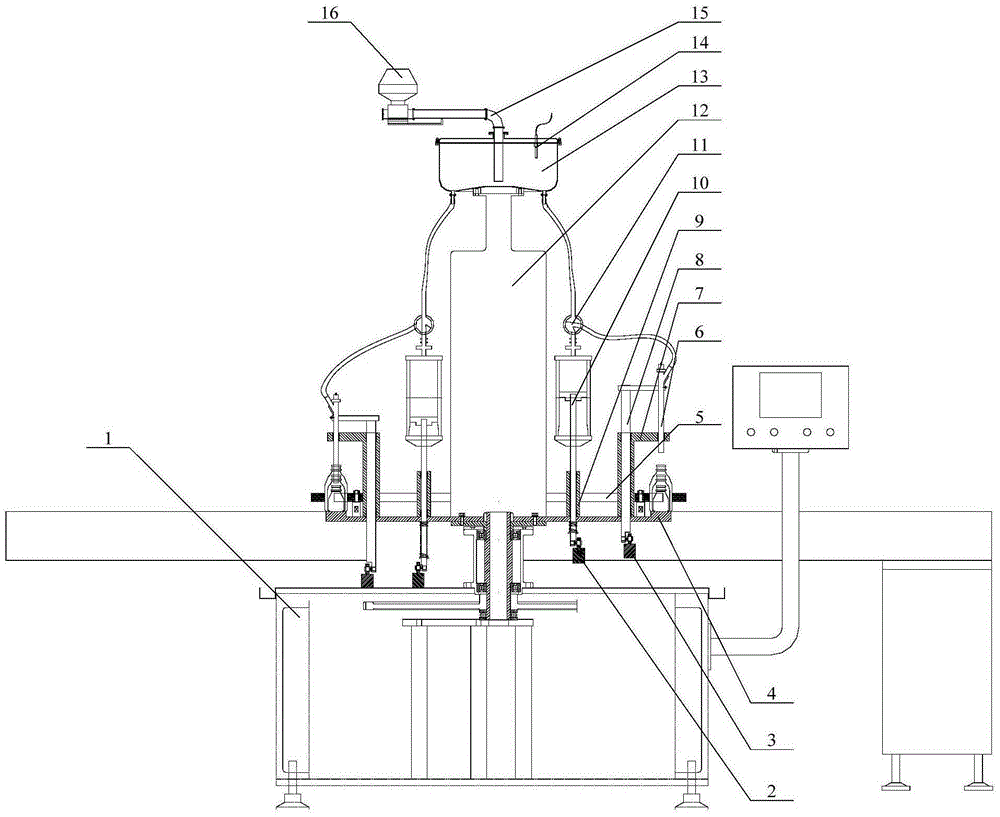

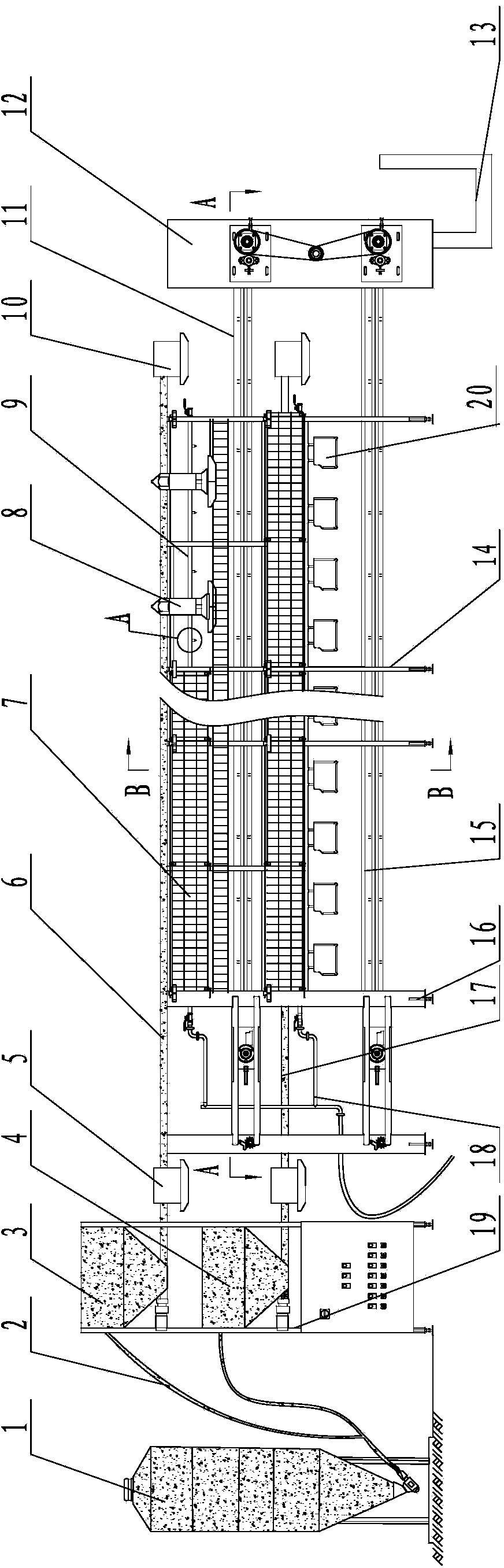

Filling machine

ActiveCN105174169AAchieve dischargeEfficient dischargeFilling using suctionLiquid storage tankEngineering

The invention discloses a filling machine. The filling machine comprises a filling station located on a machine frame. The filling station comprises a plunger pump, a filling device and a pneumatic corner valve, wherein a pump body of the plunger pump is fixed to a rotary base plate, and a piston rod of the plunger pump is connected with a first lifting device; a filling nozzle of the filling device is aligned with a bottle opening of a preparation bottle; the pneumatic corner valve comprises an inlet and two outlets, the inlet is communicated with a high-position liquid storage tank, one outlet is communicated with an opening in the pump body of the plunger pump, and the other outlet is communicated with the filling nozzle. Liquid medicine is sucked in and pressed out through the plunger pump, the requirement for the preparation bottle is not strict, and the filling machine can be adaptive to most preparation bottles; the quantity of liquid medicine sucked in and discharged by the plunger pump can be accurately controlled by adjusting the expansion amount of the piston rod, so that the filling quantity is accurately controlled. By controlling the lifting frequency of the first lifting device, the first lifting device can be matched with other equipment on a production line, the production speed is guaranteed, and production efficiency is improved. Moreover, the filling machine is simple in structure, convenient to disassemble, wash and maintain, and low in manufacturing and using cost.

Owner:长沙汇一制药机械有限公司

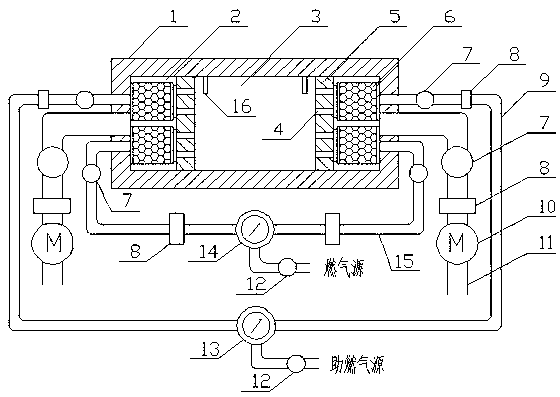

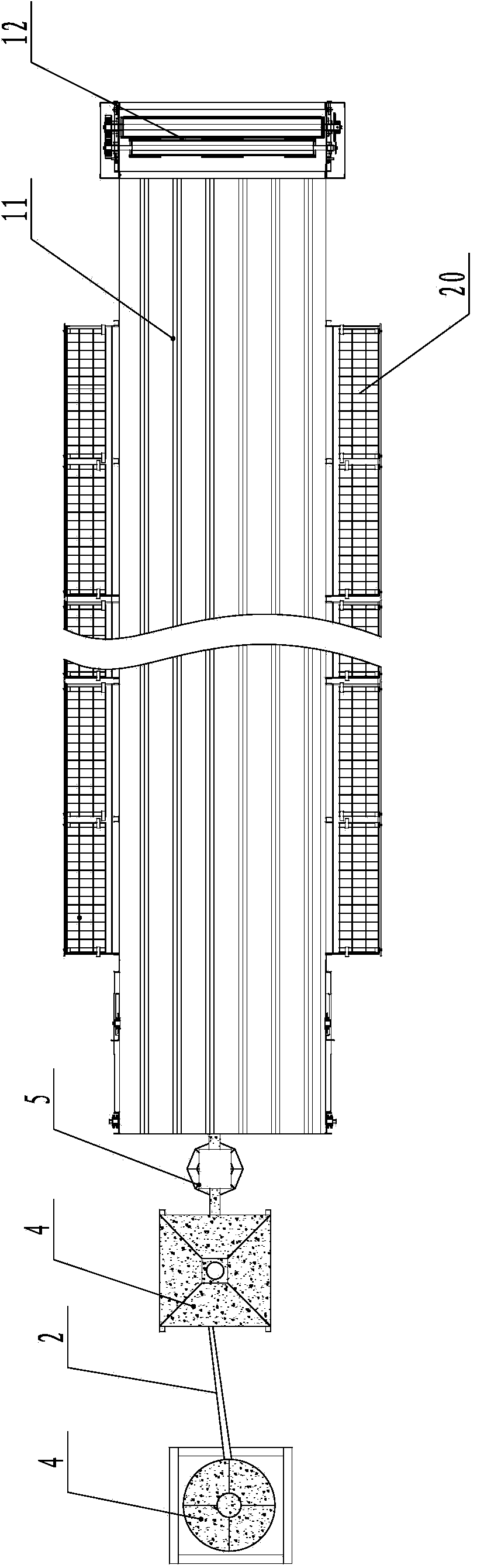

High thermal efficiency regenerative heating furnace

The invention discloses a high thermal efficiency regenerative heating furnace which is used for solving the problem that an existing regenerative heating furnace is low in thermal efficiency. The high thermal efficiency regenerative heating furnace comprises a furnace body, a partition wall divides an inner cavity of the furnace body into a combustion chamber and regenerative chambers arranged at two sides of the combustion chamber, the partition wall is provided with at least one combustion channel used for communicating the regenerative chambers with the combustion chamber. A heat accumulator is arranged inside each regenerative chamber, and is connected with a fuel combustion assisting pipeline and a fuel pipeline, and the fuel combustion assisting pipeline and the fuel pipeline are respectively connected with a combustion assisting gas source and a fuel source. The heat accumulator is further connected with a check valve capable of enabling fuel combustion assisting gas to enter the furnace body. The fuel pipeline is provided with a check valve capable of enabling the fuel to enter the furnace body. The high thermal efficiency regenerative heating furnace is capable of preventing burning smoke from entering the fuel combustion assisting pipeline and the fuel pipeline, and therefore ratio of the fuel and the fuel assisting gas is effectively controlled, and combustion efficiency is improved.

Owner:PANZHIHUA DUOSHI MACHINERY MFG

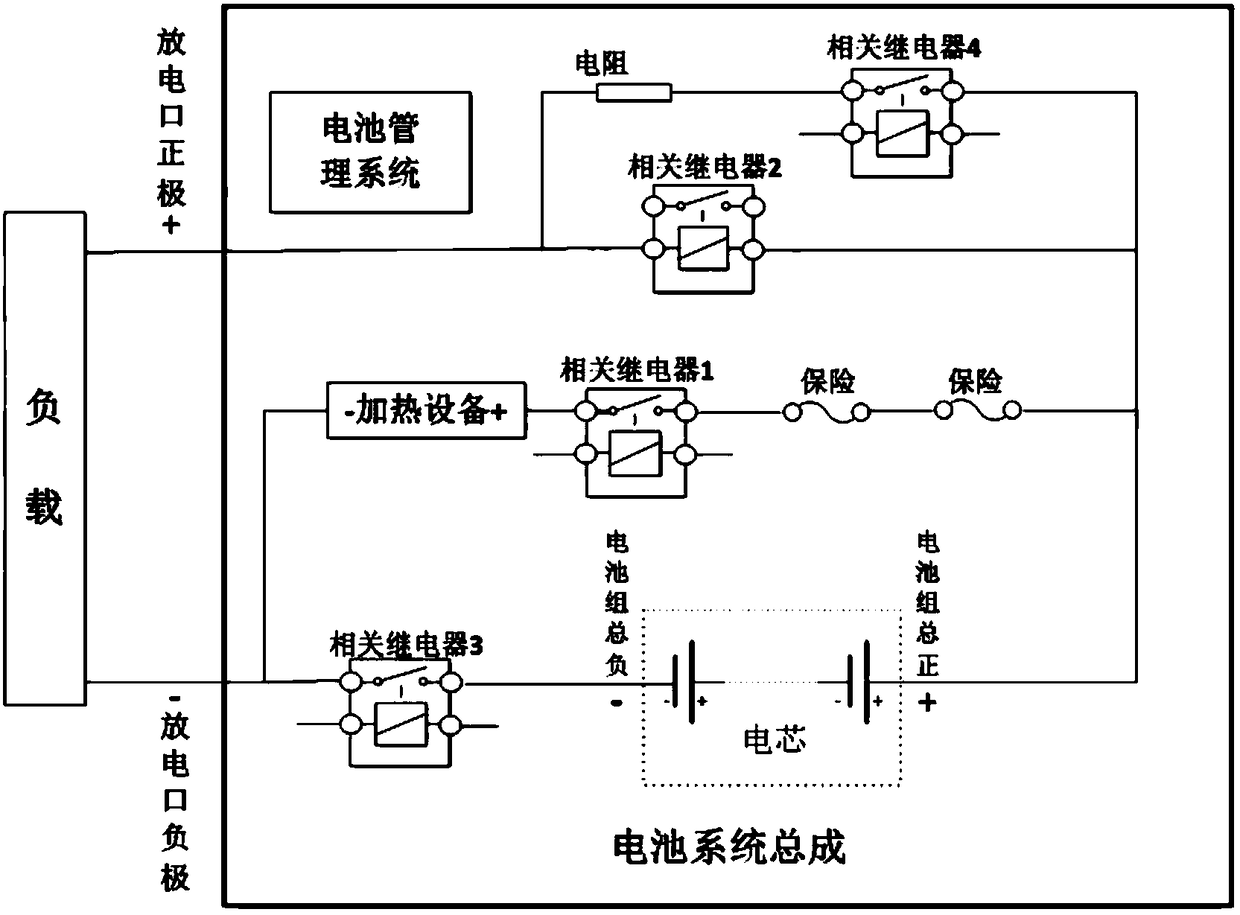

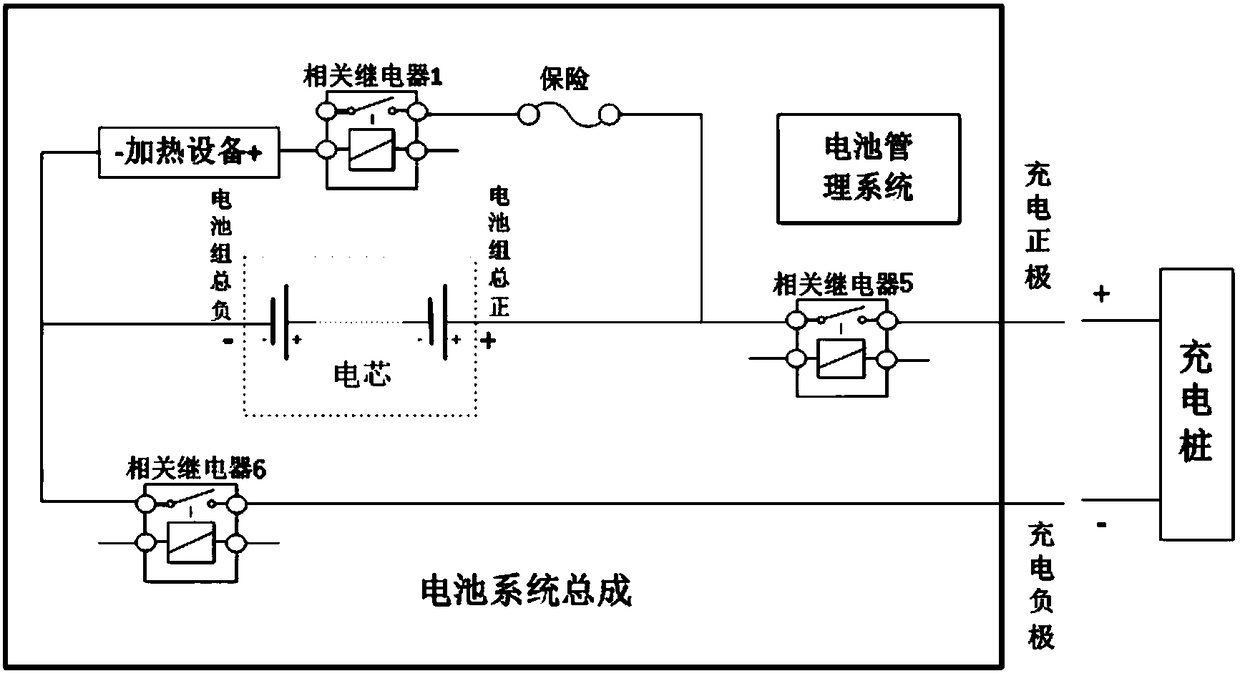

Low-temperature protection system and method for battery of electric automobile

ActiveCN108493517AAchieve dischargeMeet travel needsSecondary cellsVehicular energy storageExtreme ColdAutomotive battery

The invention discloses a low-temperature protection system for a battery of an electric automobile. A temperature sensor for acquiring the temperature of an electric core is arranged in a battery system assembly and outputs a temperature signal to a battery management system; heating equipment for heating the electric core is arranged in the battery system assembly; a total negative line of a battery pack of the electric core is connected with a negative electrode of a discharge port through a related relay 3; a total positive line of the battery pack of the electric core is connected with apositive electrode of the discharge port through a related relay 2 and a related relay 4 which are connected in parallel; after being connected with a related relay 1 in series, the heating equipmentis connected with the two ends of the related relay 3 and the electric core; the battery management system outputs a drive signal to the related relay 1, the related relay 2, the related relay 3 and the related relay 4. The low-temperature protection system disclosed by the invention can realize the aim of normal discharge in an extreme cold environment through low-temperature preheating, better meets the travel needs of a user and is more realistic.

Owner:CHERY AUTOMOBILE CO LTD

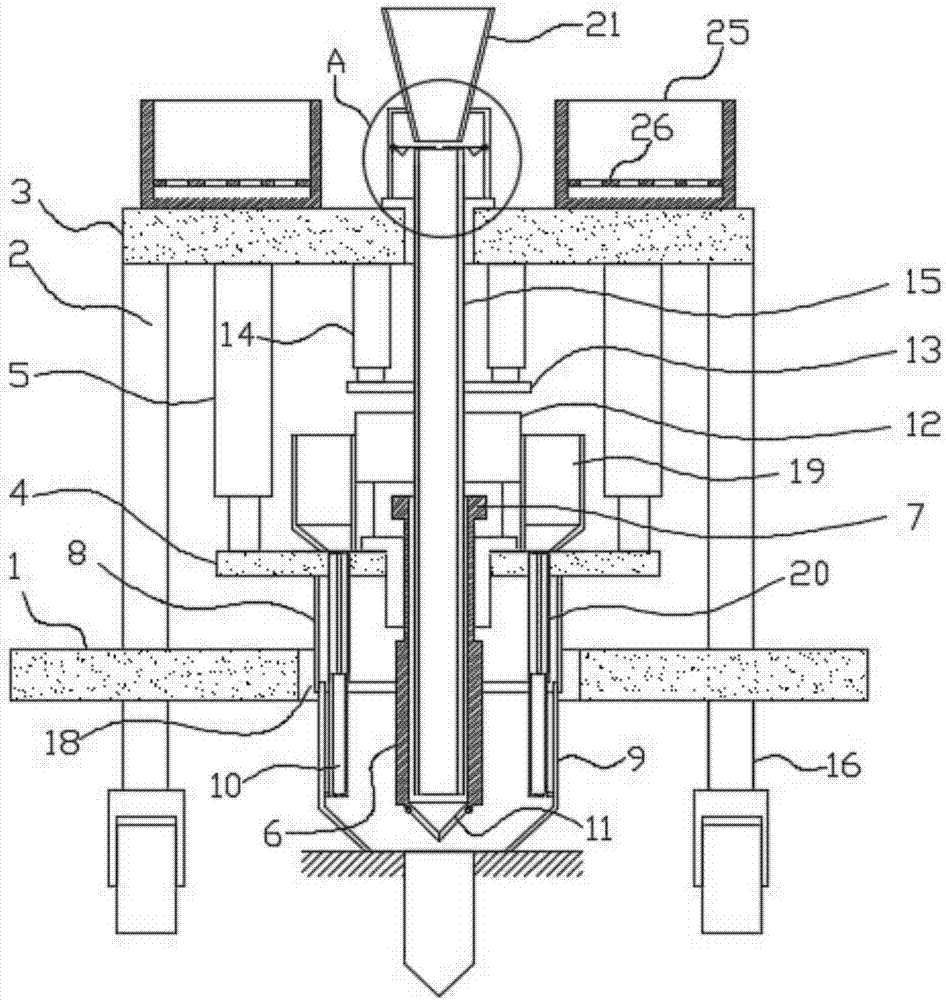

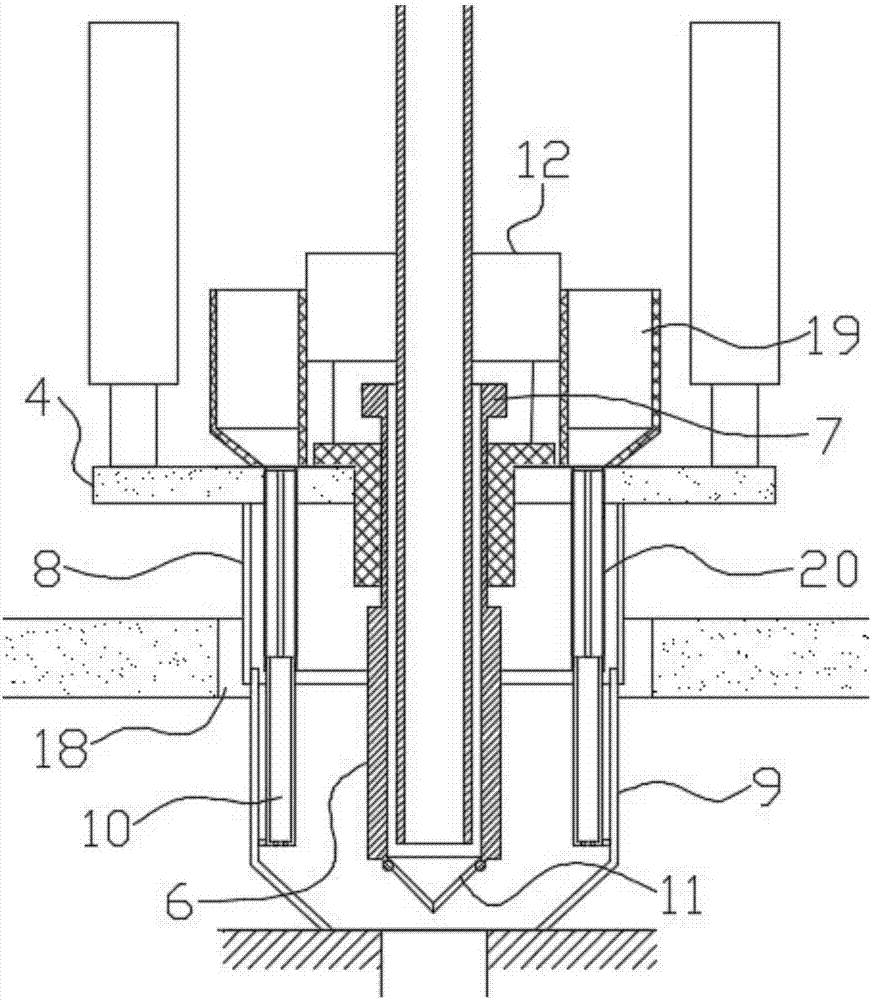

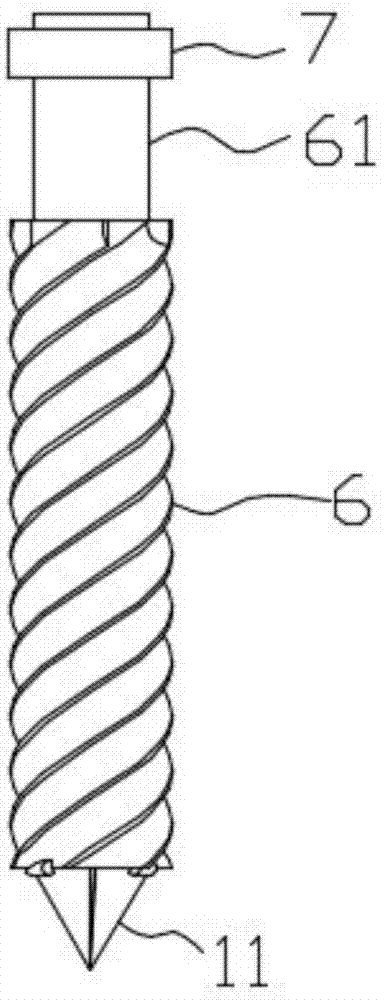

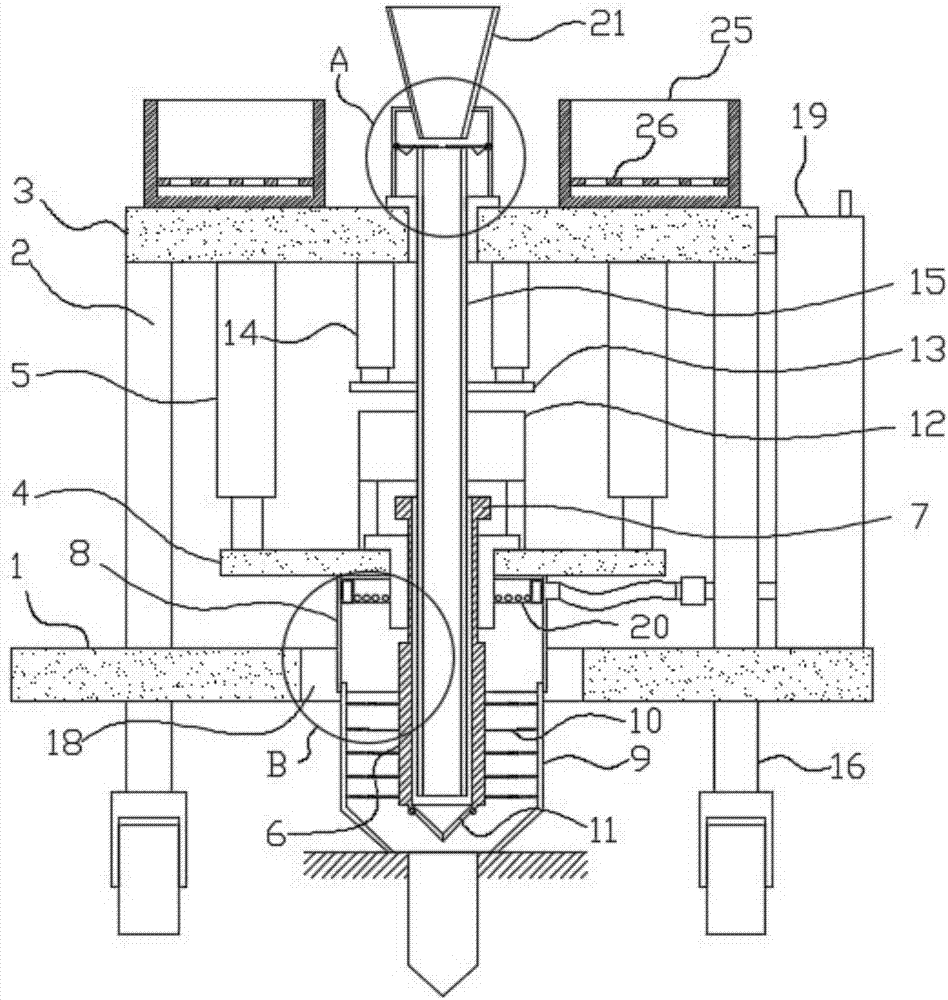

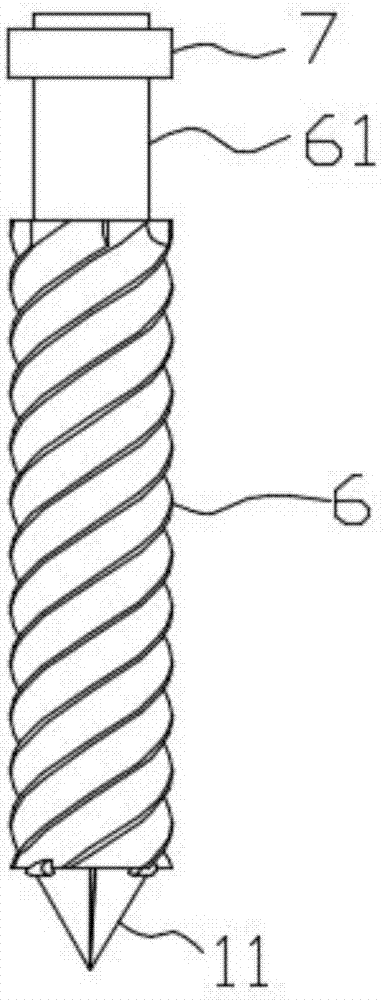

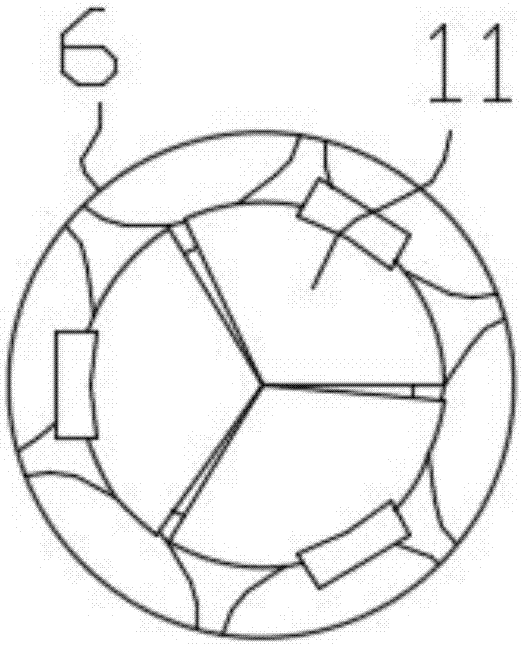

Automatic sapling fertilizing and planting device

PendingCN107333500AImprove planting efficiencyWon't hurtFertiliser distributersTransplantingAgricultural engineeringEngineering

The invention discloses an automatic sapling fertilizing and planting device. An auxiliary oil cylinder is arranged on the bottom surface of an upper seat plate; a lifting plate is arranged on the auxiliary oil cylinder and provided with a drill bit; a fixed cylinder is arranged at the bottom of the lifting plate; a telescopic cylinder is arranged in the fixed cylinder; a telescopic shaft is connected into the drill bit in a sleeving manner; a mounting plate is connected with the upper end of the telescopic shaft and connected with the auxiliary oil cylinder; the auxiliary oil cylinder is arranged is arranged at the bottom of the upper seat plate; an opening and closing head is arranged at the lower end of the drill bit; a sapling accommodating bucket is arranged at the upper end of the upper seat plate; a control cylinder is arranged at the lower end of the sapling accommodating bucket; a blocking plate is hinged into the control cylinder; the telescopic shaft is arranged in the control cylinder; sapling storage boxes are arranged on two sides of the sapling accommodating bucket; a storage box is arranged on the upper end surface of the lifting plate; the lower end port of the storage box is communicated with a guiding sleeve; the guiding sleeve is arranged in the fixed cylinder in a sleeving manner; a scattering box is sleeved with the guiding sleeve; scattering holes are formed in the bottom end and inner side outer wall of the scattering box; the lower end of the scattering box is fixed in the telescopic cylinder. The device has the advantages that automatic hole drilling and sapling planting can be realized, automatic fertilization and earth mulching can be performed, and sapling planting efficiency and quality are greatly improved.

Owner:蒋文

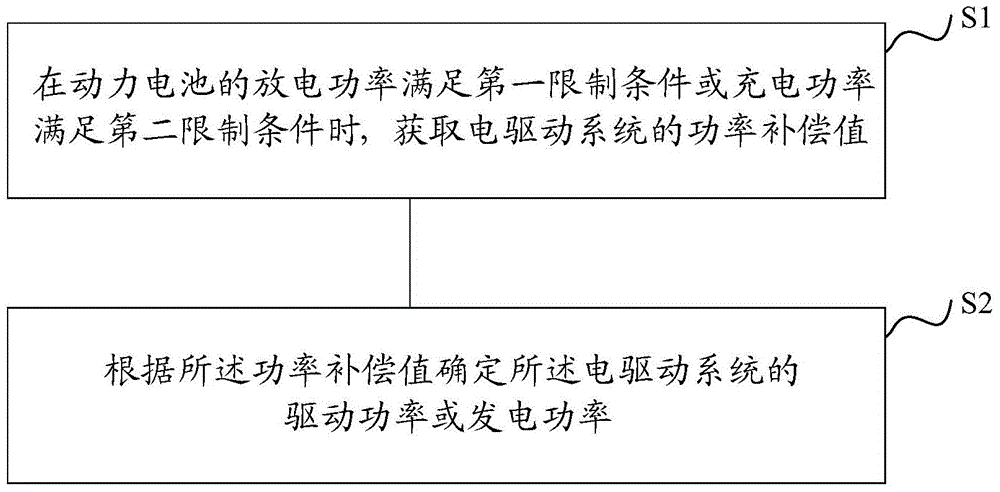

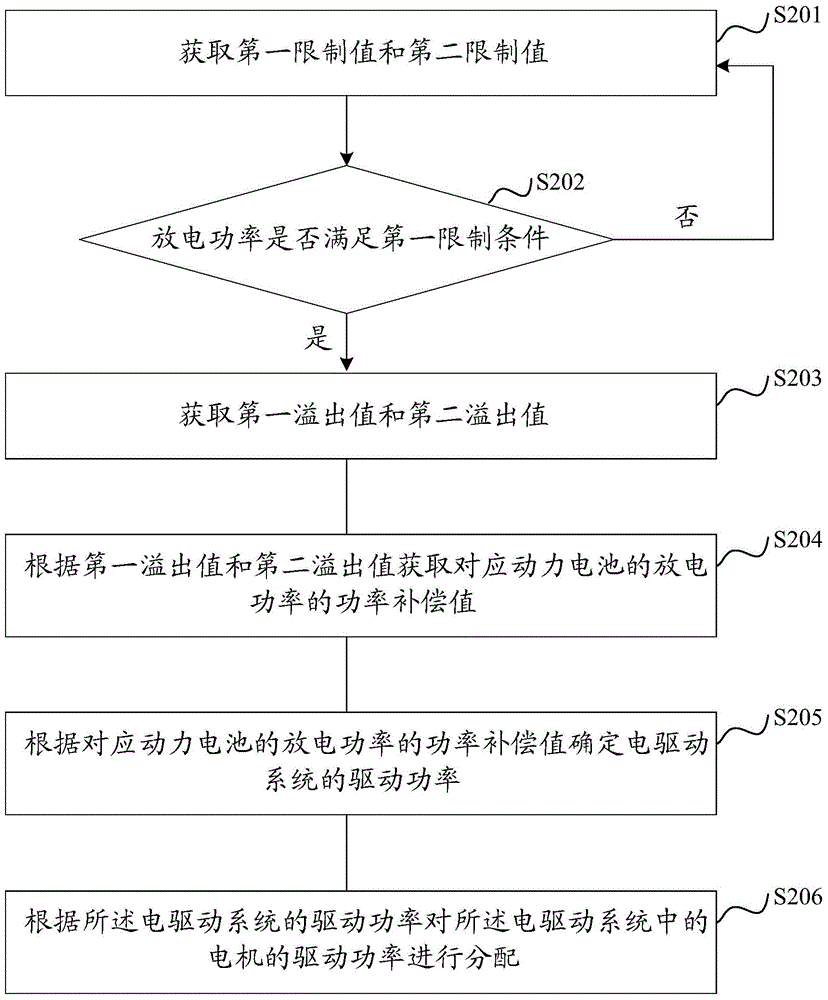

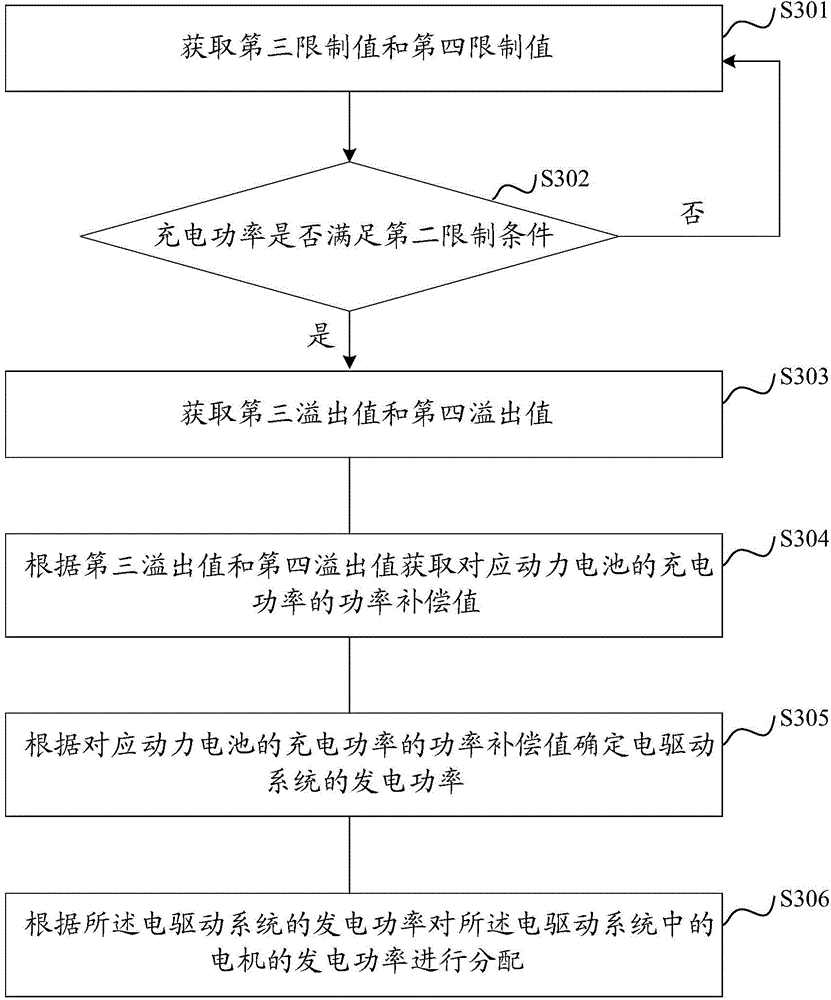

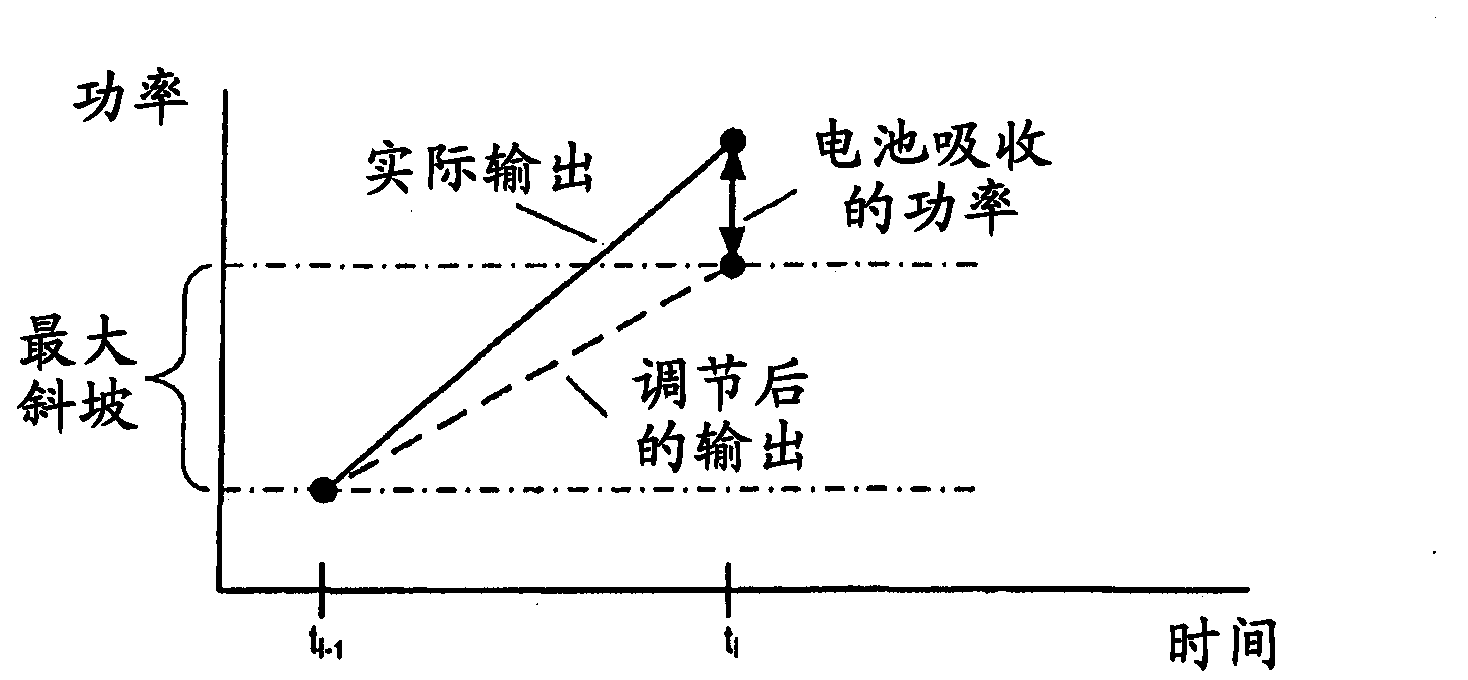

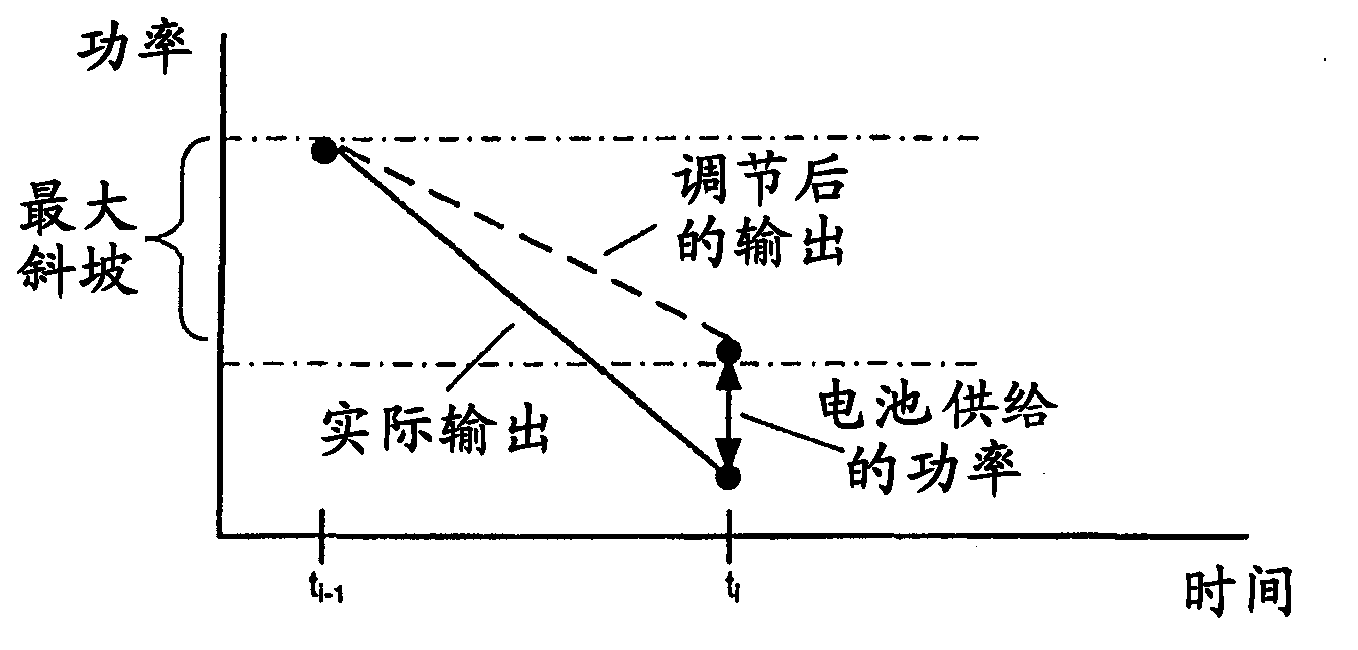

Method and device for controlling power of electric drive system

ActiveCN105667497AExtended service lifeImprove performanceHybrid vehiclesPower compensationElectricity

The invention provides a method and device for controlling power of an electric drive system. The method includes the steps that a power compensation value of the electric drive system is obtained when the discharge power of a power battery meets a first limiting condition or the charge power of the power battery meets a second limiting condition; the first limiting condition associates with the discharge power and a discharge threshold of the power battery, and the second limiting condition associates with the charge power and a charge threshold of the power battery; and the drive power or the generation power of the electric drive system is determined according to the power compensation value. According to the method, during the discharge and charge process of the power battery, the drive power and the generation power of the electric drive system are controlled in real time according to the power compensation value, so that the actual discharge and charge power of the power battery is made to be within a reasonable power range, and the power battery is prevented from being overused; the service life of the power battery can be effectively prolonged, and vehicle performance is improved.

Owner:SAIC MOTOR

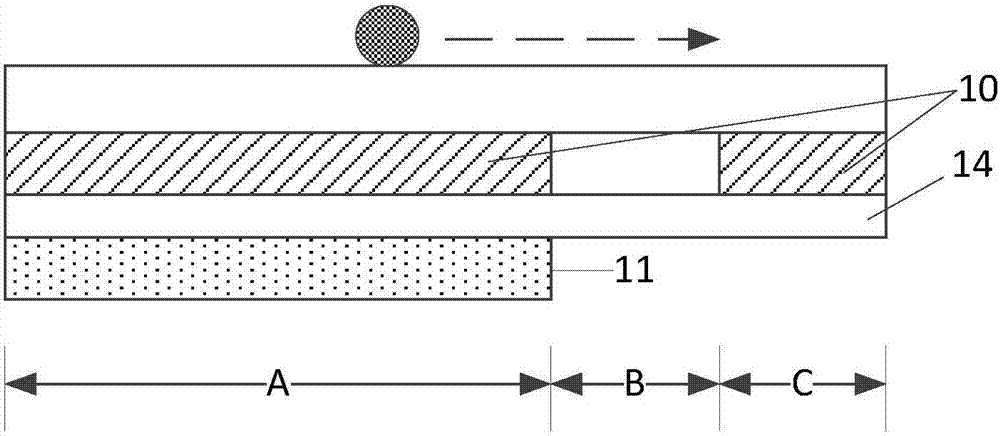

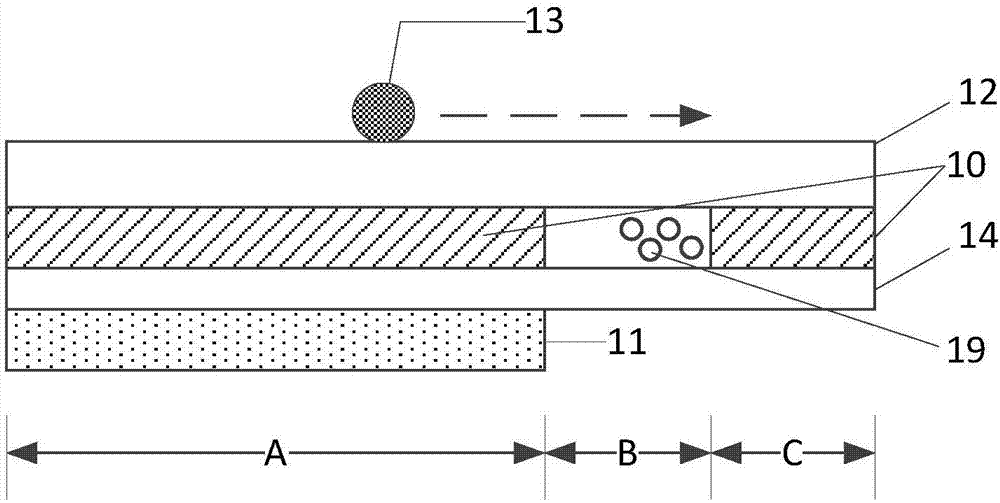

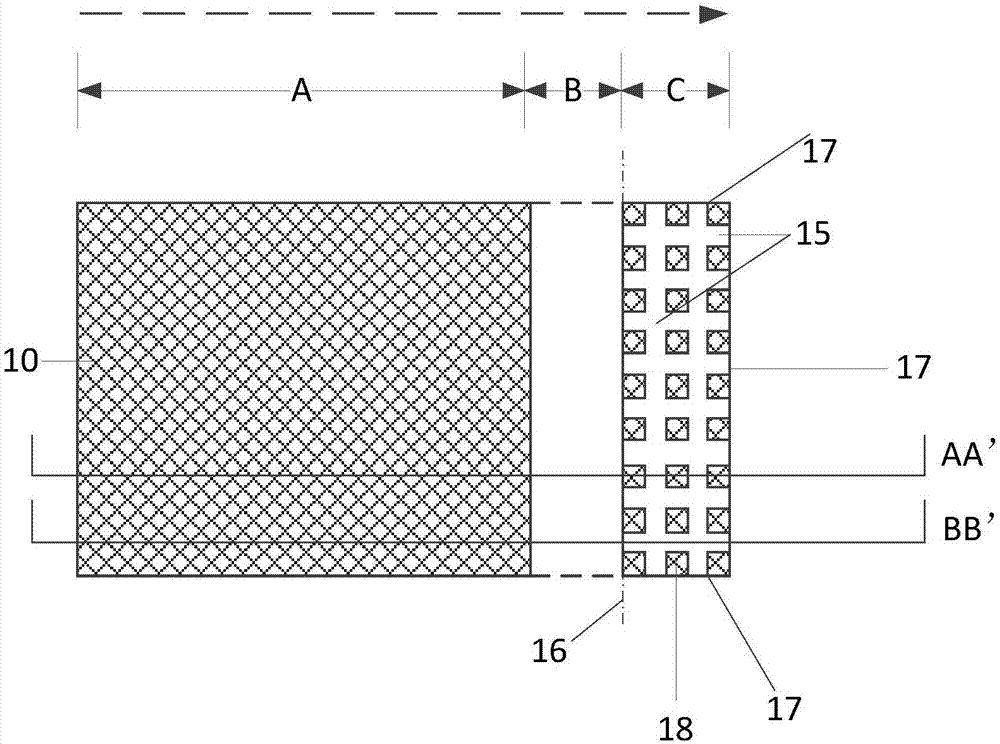

Flexible display panel and display device

ActiveCN107579169AImprove the sticking effectAvoid gatheringSolid-state devicesSemiconductor/solid-state device manufacturingTectorial membraneDisplay device

An embodiment of the invention provides a flexible display panel and a display device. The flexible display panel comprises: a first area, a second area and a third area, the second area included in aplane of the flexible display panel, with the second area arranged between the first area and the third area; a flexible substrate having a first surface and a second surface facing each other, wherein the flexible substrate covers the first area, the second area and the third area; and a first protective film positioned on a first side of the flexible substrate, wherein the first protective filmcovers not the second area but the first area and the third area, one side, far away from the flexible substrate, of the first protective film covering the third area has a groove structure, the groove structure extends from a junction of the second and third areas to a first edge of the third area except for the junction, and the first edge coincides with the edge of the first protective film. The flexible display panel and the display device according to the technical scheme allow bubbles in the second area to be discharged, and attaching effect of the protective film is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

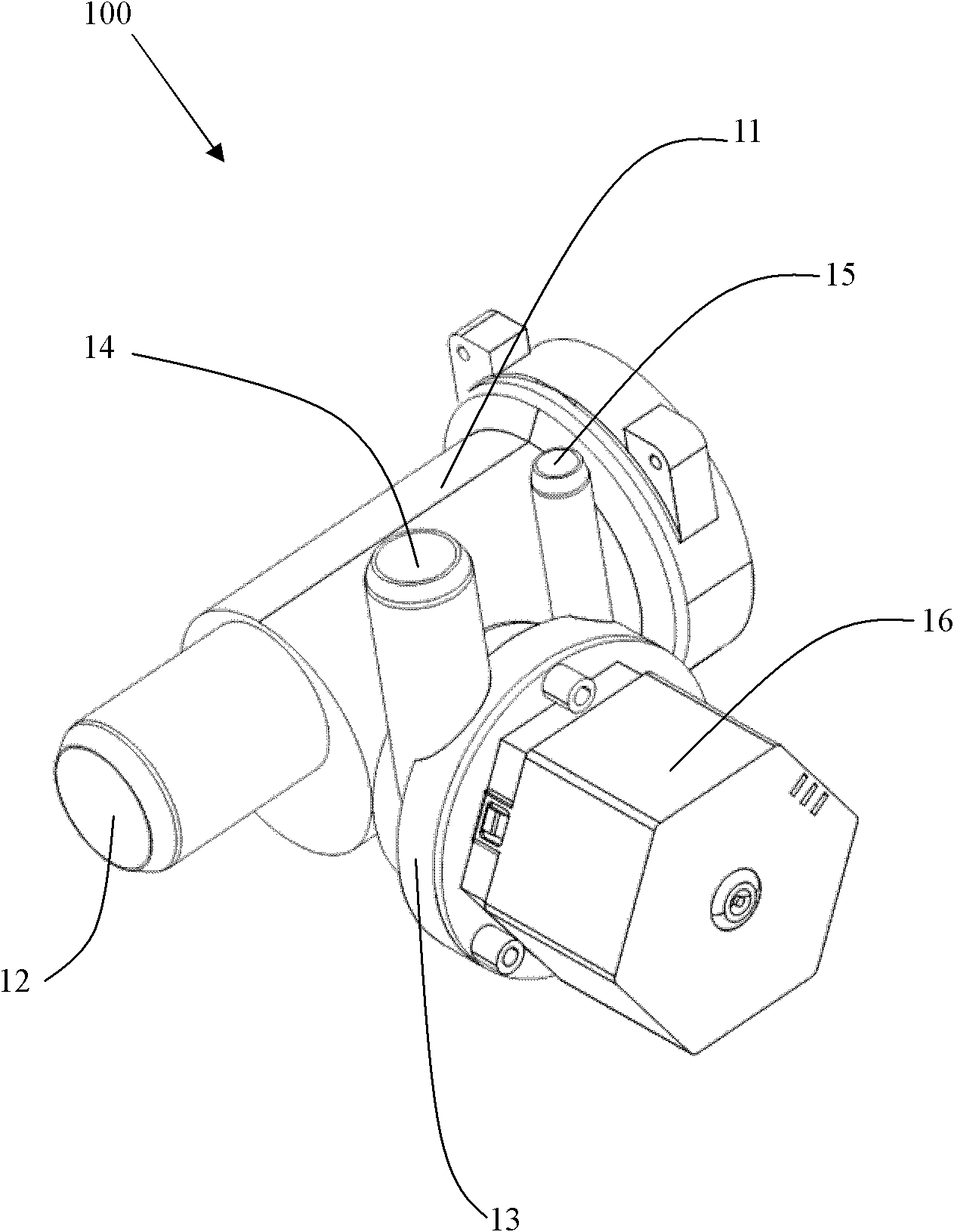

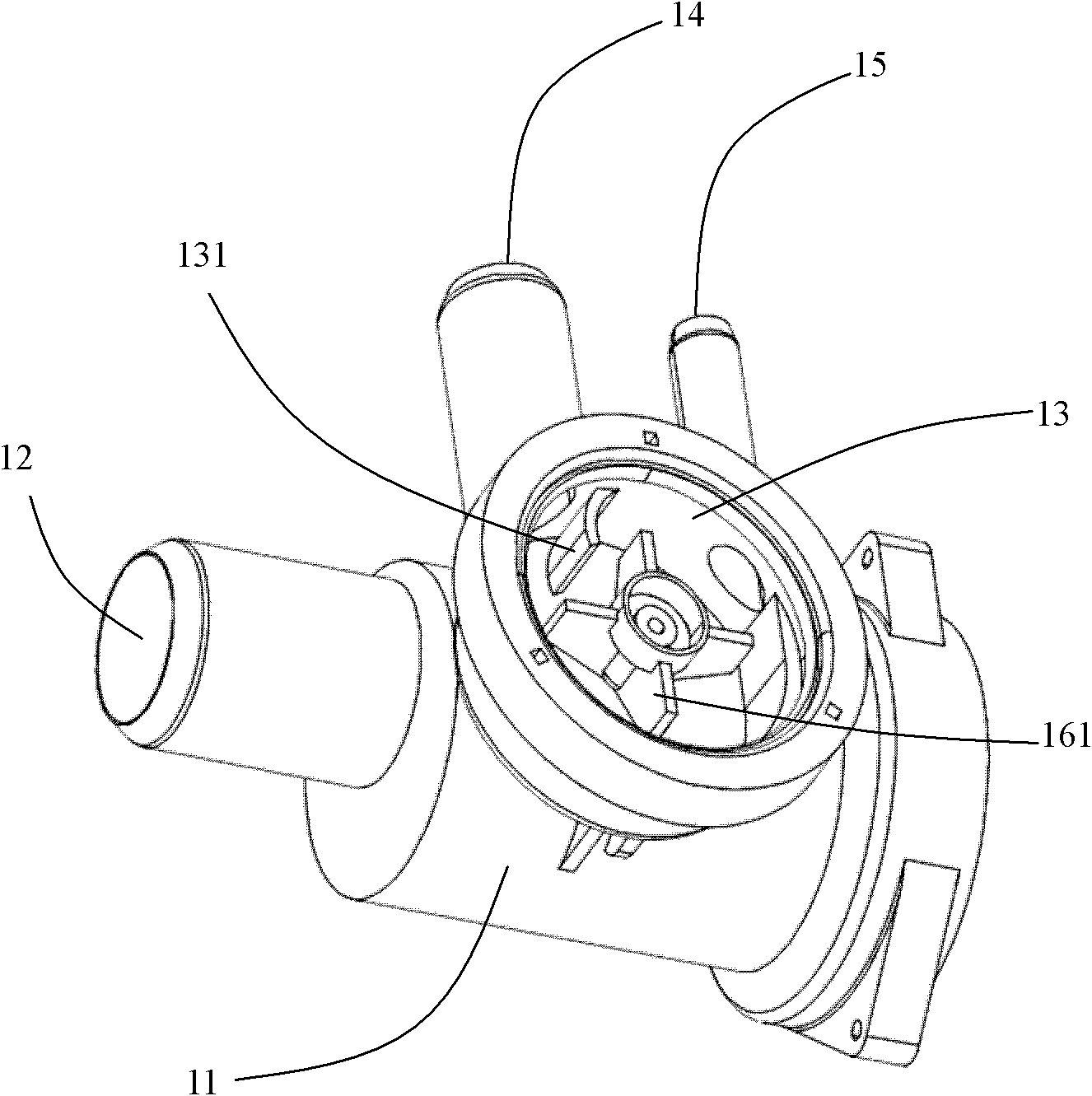

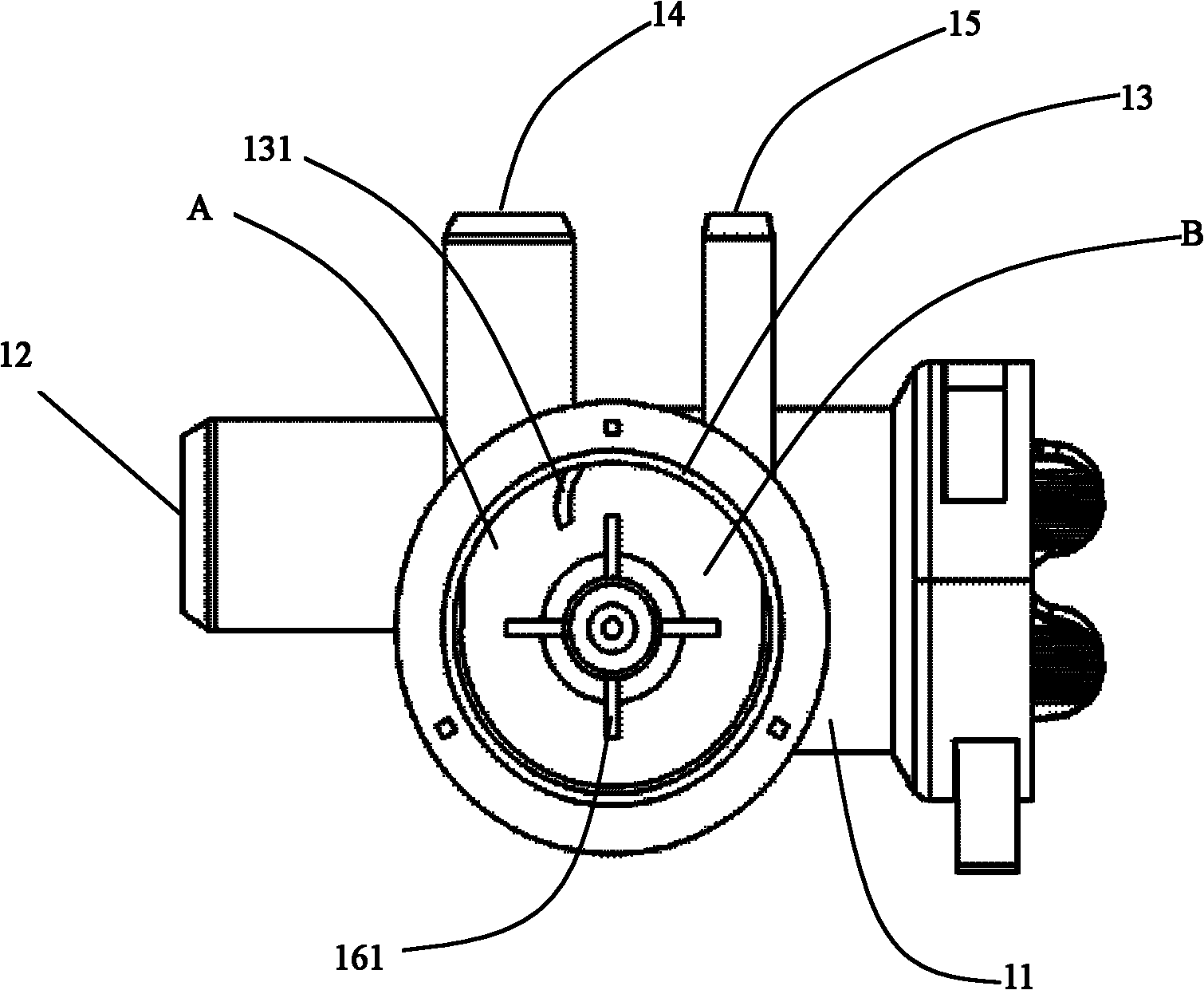

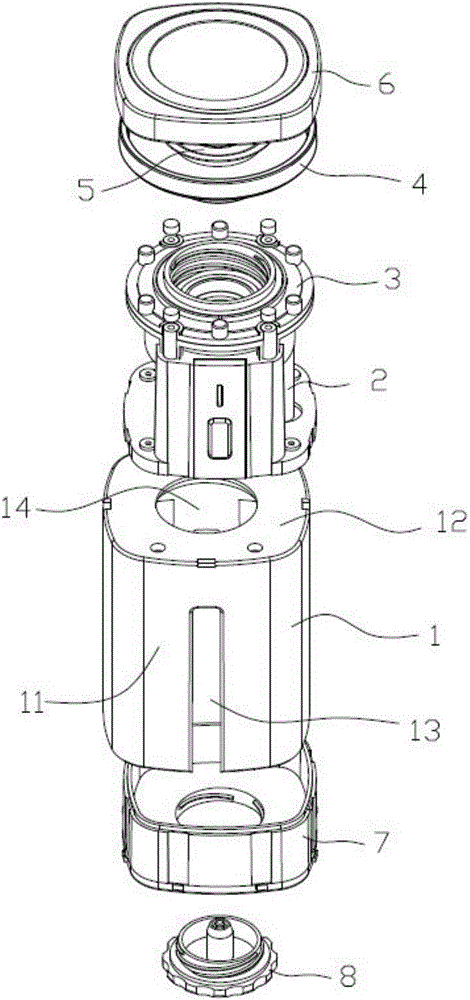

Water pump and washing machine provided with same

InactiveCN102212955AAchieve cycleAchieve dischargePump componentsOther washing machinesImpellerWater discharge

The invention discloses a water pump and a washing machine provided with the same. A drainage channel and a water circulation channel are communicated with a cavity; water in the cavity is discharged through the water circulation channel when an impeller positively rotates and is discharged through the drainage channel when the impeller reversely rotates, so water discharge and water circulation can be realized by controlling the impeller of a motor to positively rotate and reversely rotate to make the water pump miniature and reduce the cost.

Owner:NANJING LG PANDA APPLIANCES

Automatic planting and watering device for saplings

ActiveCN107396808AImprove planting efficiencyWon't hurtPlantingWatering devicesEngineeringKnife blades

The invention discloses an automatic planting and watering device for saplings. The bottom of a base is provided with supporting rods, the bottom of each supporting rod is provided with a wheel; the upper end of the base is connected with upper base boards; the bottom surface of each upper base board is provided with an auxiliary oil cylinder; the auxiliary oil cylinders are connected with a lift board; the lift board is provided with a drill head; the bottom of the lift board is provided with a fixed cylinder; the interior of the fixed cylinder is provided with a telescopic cylinder; the interior of the drill head is provided with a casing pipe shaft; the casing pipe shaft is connected with the auxiliary oil cylinders; the lower end of the drill heads is provided with an opening-closing head; a sapling placing hopper is arranged above the upper base boards; the lower end of the sapling placing hopper is provided with a control cylinder; material blocking boards are symmetrically arranged in the control cylinder in a hinged manner; the material blocking boards are located on the casing pipe shaft; two sides of the sapling placing hopper are provided with sapling storage boxes; the interior of each sapling storage box is provided with a partition board; each partition board is provided with limit holes; the upper end of the inner wall of each fixed cylinder is provided with an annular spray head; the annular spray heads are connected with a water box, and the internal wall of each telescopic cylinder is provided with an annular blade array along with an axial direction. According to the invention, holes are automatically dug for planting the saplings, soil smashing and covering can be realized, automatic watering is realized, and efficiency and quality of sapling planting are greatly improved.

Owner:常宁市天堂山云雾茶开发有限公司

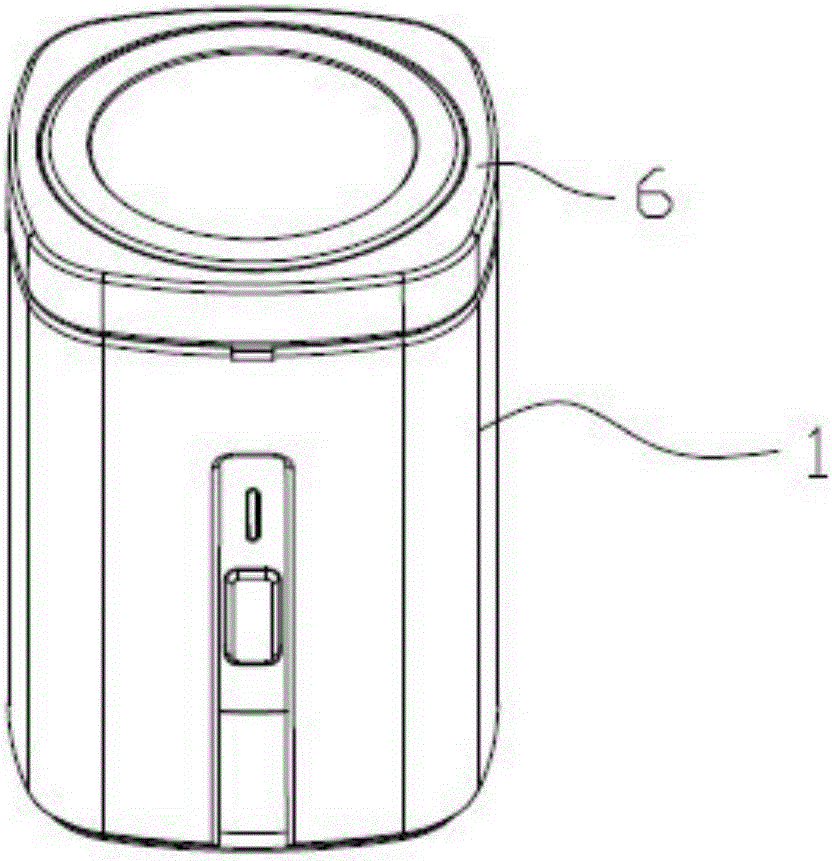

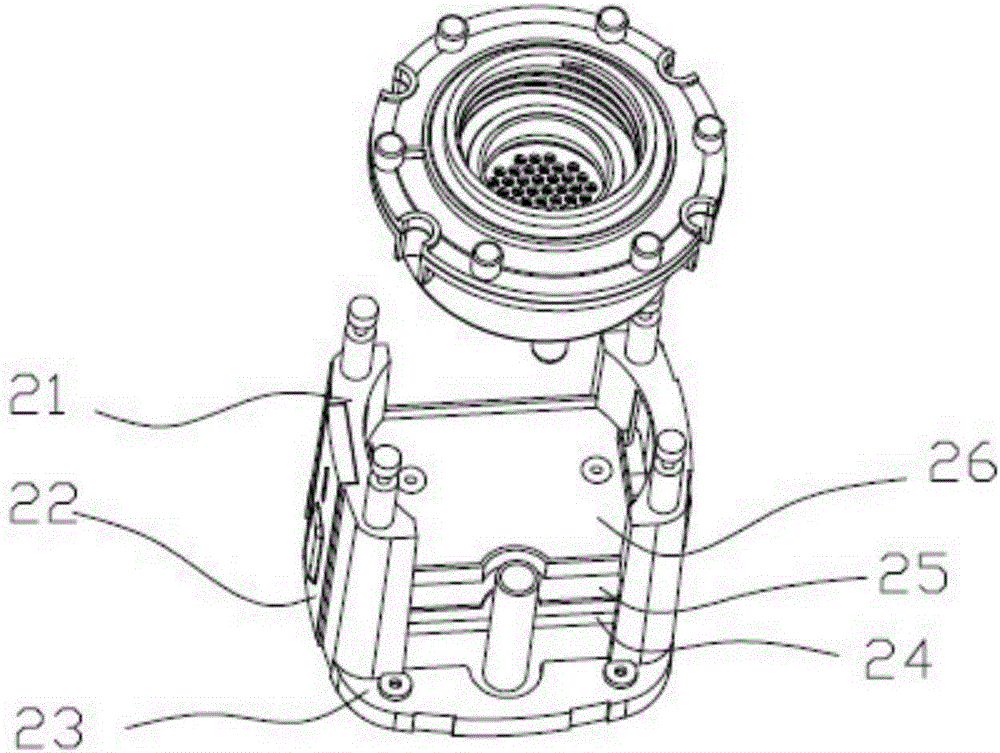

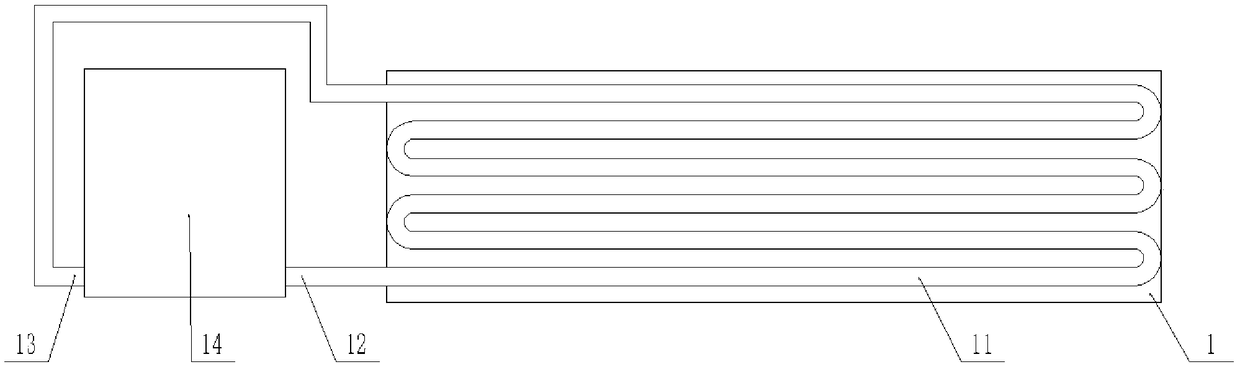

Portable hydrogen-rich water generating device

ActiveCN105220173AAchieve dischargeHigh efficiency in producing hydrogenElectrolysis componentsFiberHydrogen

The invention provides a portable hydrogen-rich water generating device. The portable hydrogen-rich water generating device comprises a middle shell, a suport, a generator, an adapter, a rubber cover, an upper cover, a bottom cover and a movable switch. A grid solid phase extraction (SPE) membrane structure in the generator comprises an ionic membrane and a fixed net. The fixed net is fixed to the ionic membrane. The ionic membrane is provided with a sulfoacid layer and a carboxylic acid layer sequentially from bottom to top, and reinforced fibers and chlorine are arranegd in the sulfoacid layer. A battery, a circuit board and a support plate are arranegd in the support in three layers. Through the adsorption function of washable cotton in the generator, waste gas and waste liquor enter a second duct through a containing cavity of the generator, pass a rubber pipe to enter a first duct, and then enter the bottom cover. The movable switch is operated so that the waste gas and the waste liquor can be discharged. The efficiency of producing hydrogen is high. In addition, the device is convenient to carry, low in cost, small in size and low in weight, and is an indispensable article in home life.

Owner:深圳市智慧水科技有限公司

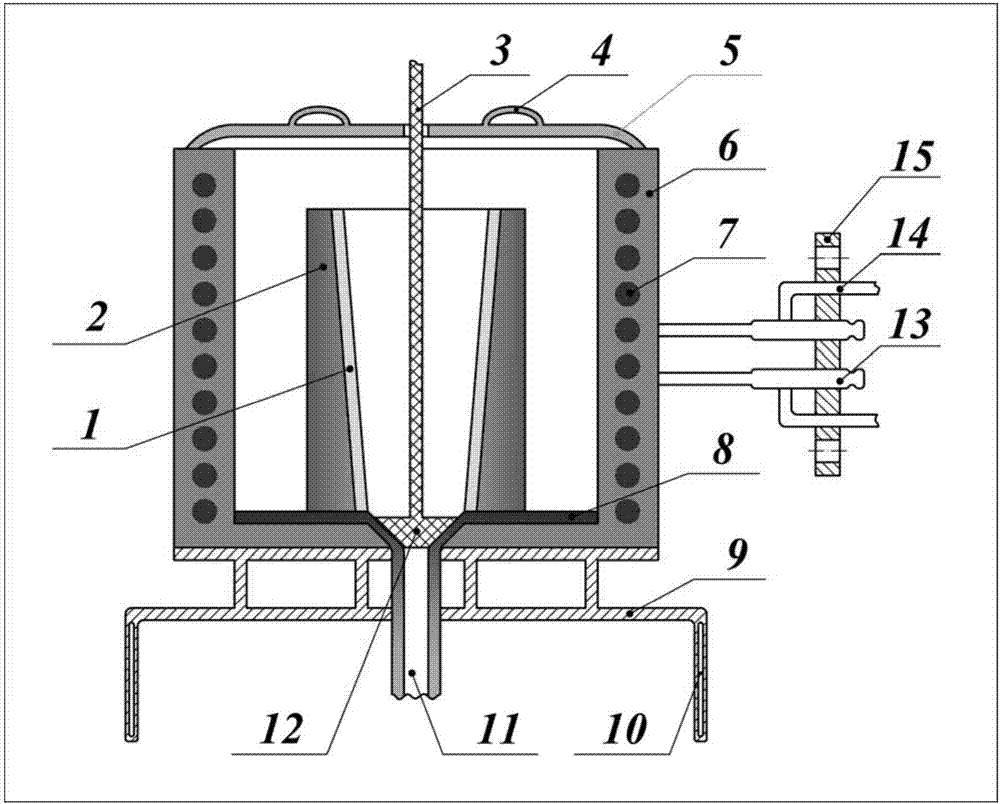

Multi-purpose electromagnetic induction melting device and method

InactiveCN107388823AAvoid pollutionPrevent oxidationCharge treatment typeCrucible furnacesEddy currentElectromagnetic induction

A multi-purpose electromagnetic induction melting device and a method are disclosed. The multi-purpose electromagnetic induction melting device comprises a zirconia crucible, a graphite crucible, an electromagnetic induction coil, a upper-portion top cover, a conical funnel, a ceramic flow guide pipe, a ceramic plug, a supporting mechanism, power-line terminals and cooling pipelines; the zirconia crucible is arranged in the graphite crucible and serves as a place for material melting, and the graphite crucible has magnetic conductivity and emits heat under the effect of eddy currents; the electromagnetic induction coil is placed at the outer portion of a double-layer crucible and subjected to sintering protection by adopting magnesite, and can be used in a corrosion environment; the power-line terminals and the cooling pipelines of the electromagnetic induction coil are all welded to a flange plate, and seamless connection with a sealed container can be achieved; the zirconia crucible is connected with the ceramic flow guide pipe through the conical funnel at the bottom and cooperates with the ceramic plug to control opening and closing of a crucible bottom hole; and the whole device is fixedly connected with a base or the inner wall of a container through the supporting structure at the bottom of the device. The multi-purpose electromagnetic induction melting device can be used in severe environments such as the corrosion environment, and electromagnetic induction melting and casting of materials are achieved.

Owner:XI AN JIAOTONG UNIV

Rabbit hutch for automatic breeding

ActiveCN103503784ARealize automatic feedingAchieve dischargeAnimal housingAnimal breedingWater drinking

The invention belongs to the field of animal breeding, and particularly relates to a rabbit hutch for automatic breeding. The rabbit hutch comprises a frame body, breeding cages are distributed on the frame body, a material conveying device is arranged above the breeding cages, a water drinking device penetrates through the interior of the breeding cages, an excrement discharging device is arranged below the breeding cages, one end of the material conveying device is connected with an automatic feeding device, and the two sides of the lower portion of each breeding cage are provided with breeding boxes. The rabbit hutch is simple and compact in structure, automatic breeding and excrement discharging of large-scale rabbit breeding can be achieved through the material conveying device, the water drinking device, the excrement discharging device and the automatic feeding device, working efficiency is improved, the work environment of workers and the live environment of rabbits are improved, and breeding quality can be improved.

Owner:SHINVA MEDICAL INSTR CO LTD

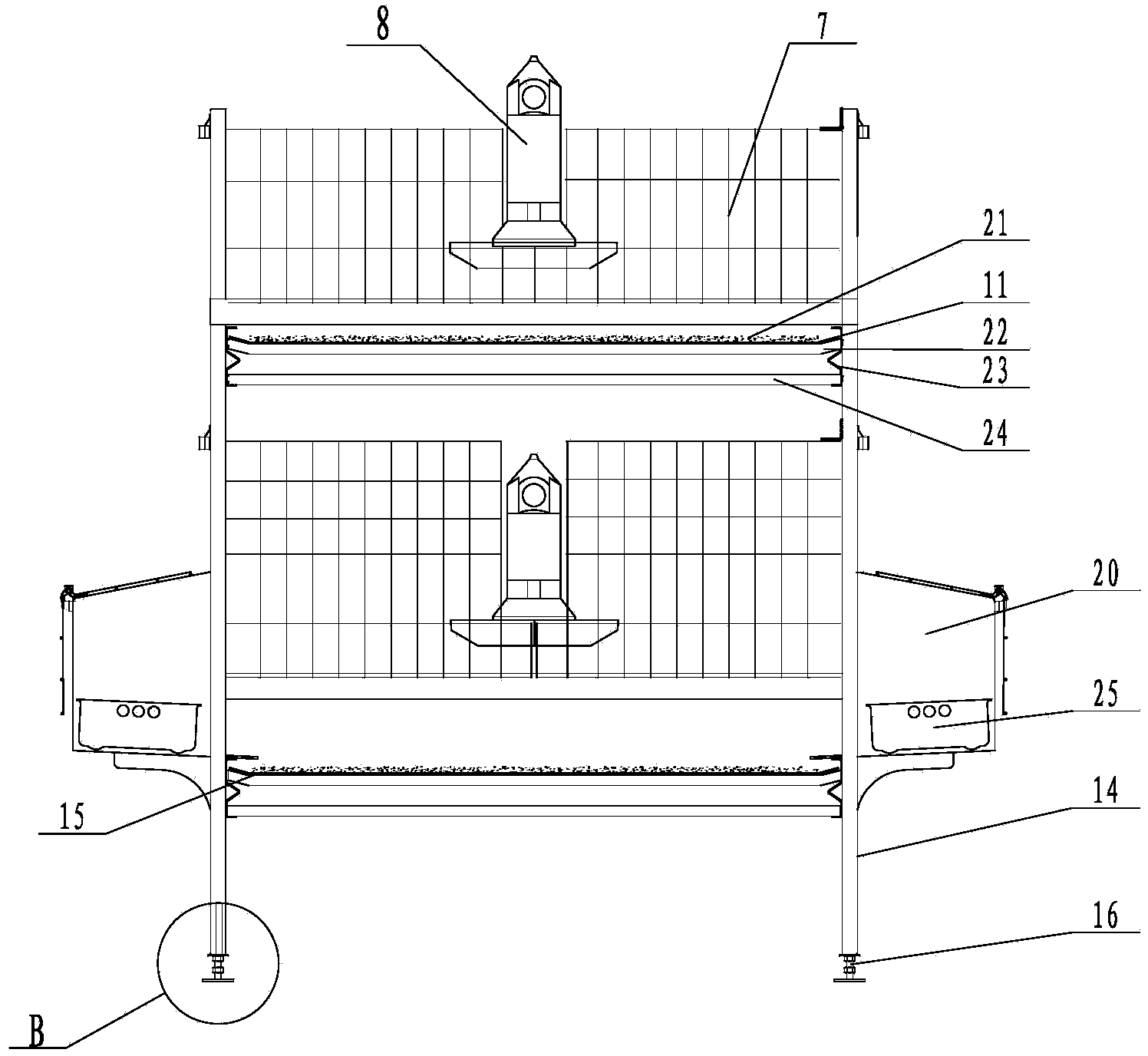

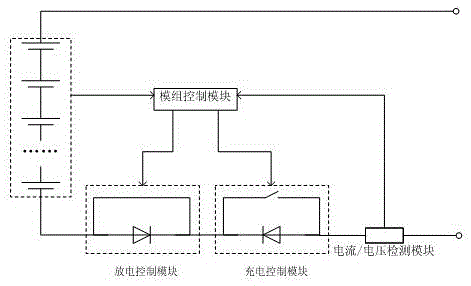

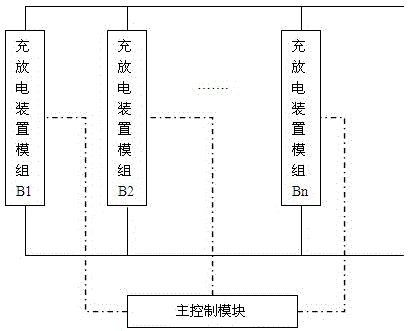

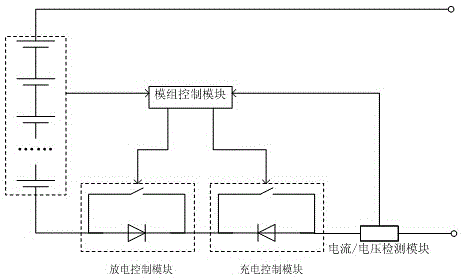

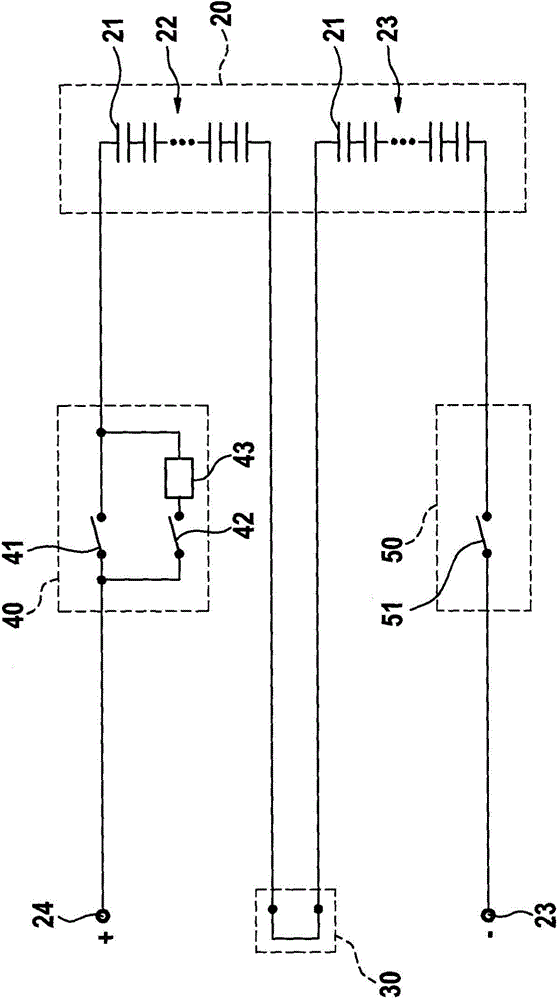

Full-cycle control system for supporting arbitrary parallel connection of different types of charging-discharging devices and control method thereof

ActiveCN105048574ASolve the problem of mutual charging and dischargingRealize chargingBatteries circuit arrangementsElectric powerCyclic processControl system

The invention discloses a full-cycle control system for supporting arbitrary parallel connection of different types of charging-discharging devices and a control method thereof. The system comprises two or more than two parallel-connected charging / discharging device sets and a main control module, wherein the charging / discharging device sets are connected in parallel with a direct current bus via a positive-negative port for charging or discharging; each charging / discharging device set comprises a charging / discharging device, a charging control module, a discharging control module, a current / current detection module and a set control module; the charging / discharging device, the charging control module and the discharging control module are connected in series onto a loop; and the current / voltage detection module is used for detecting the current of the loop or the voltage of a detection bus. By the full-cycle control system, the problem of mutual charging and discharging caused by mutual parallel connection of a plurality of charging-discharging device sets with different types of voltage classes is solved, the full-cycle process of charging and discharging of each charging-discharging module set is achieved.

Owner:新疆四美新能源有限公司

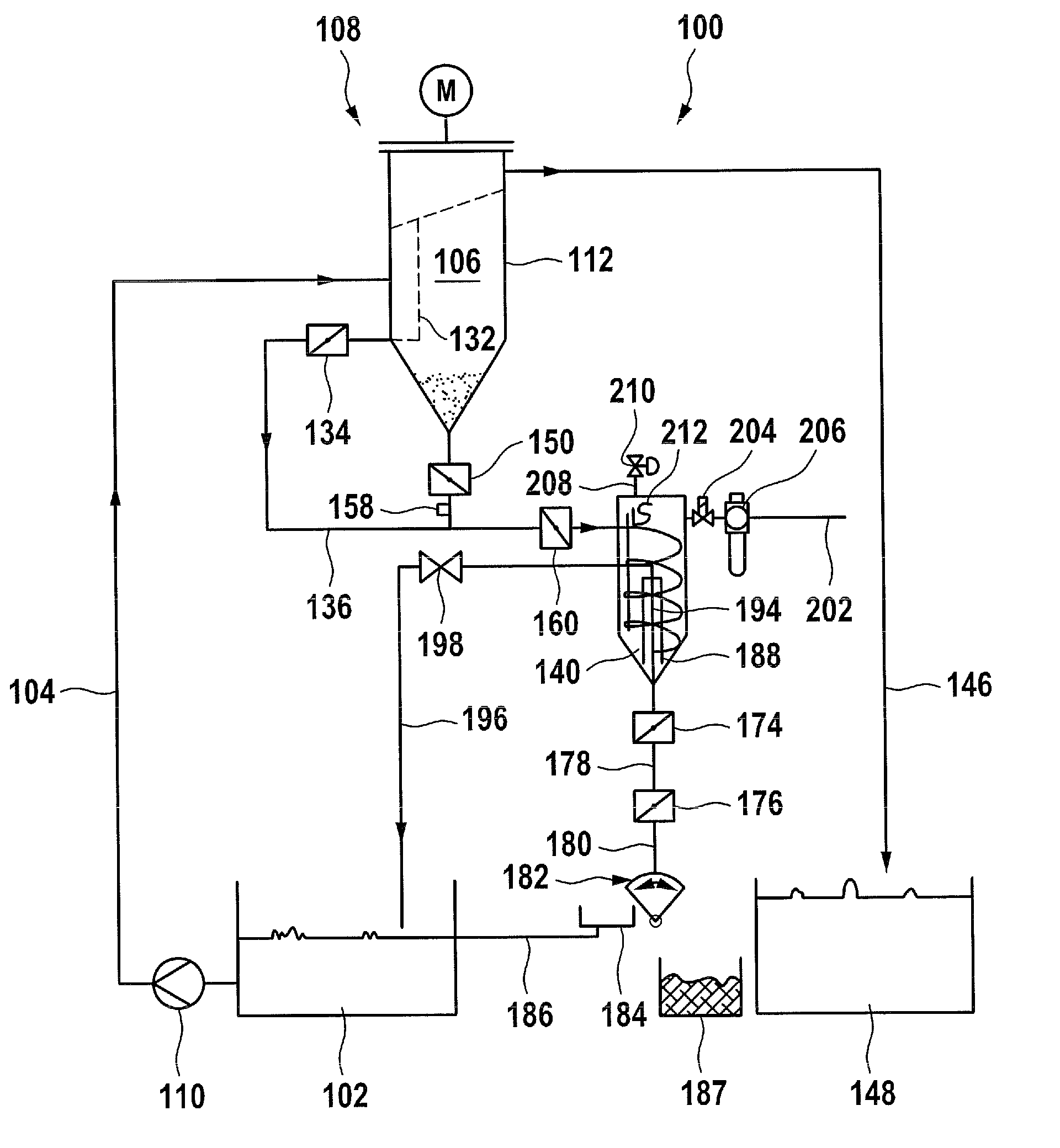

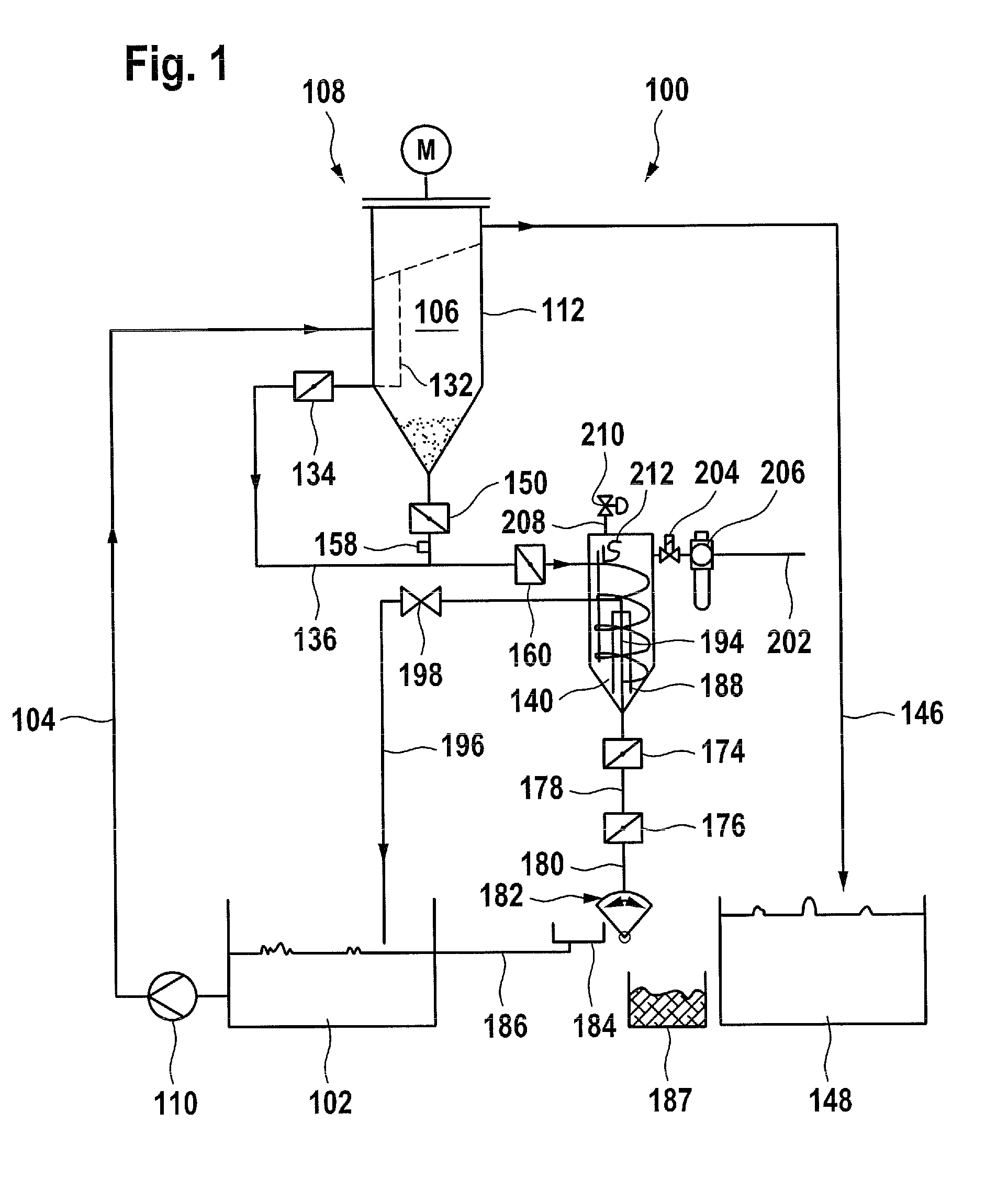

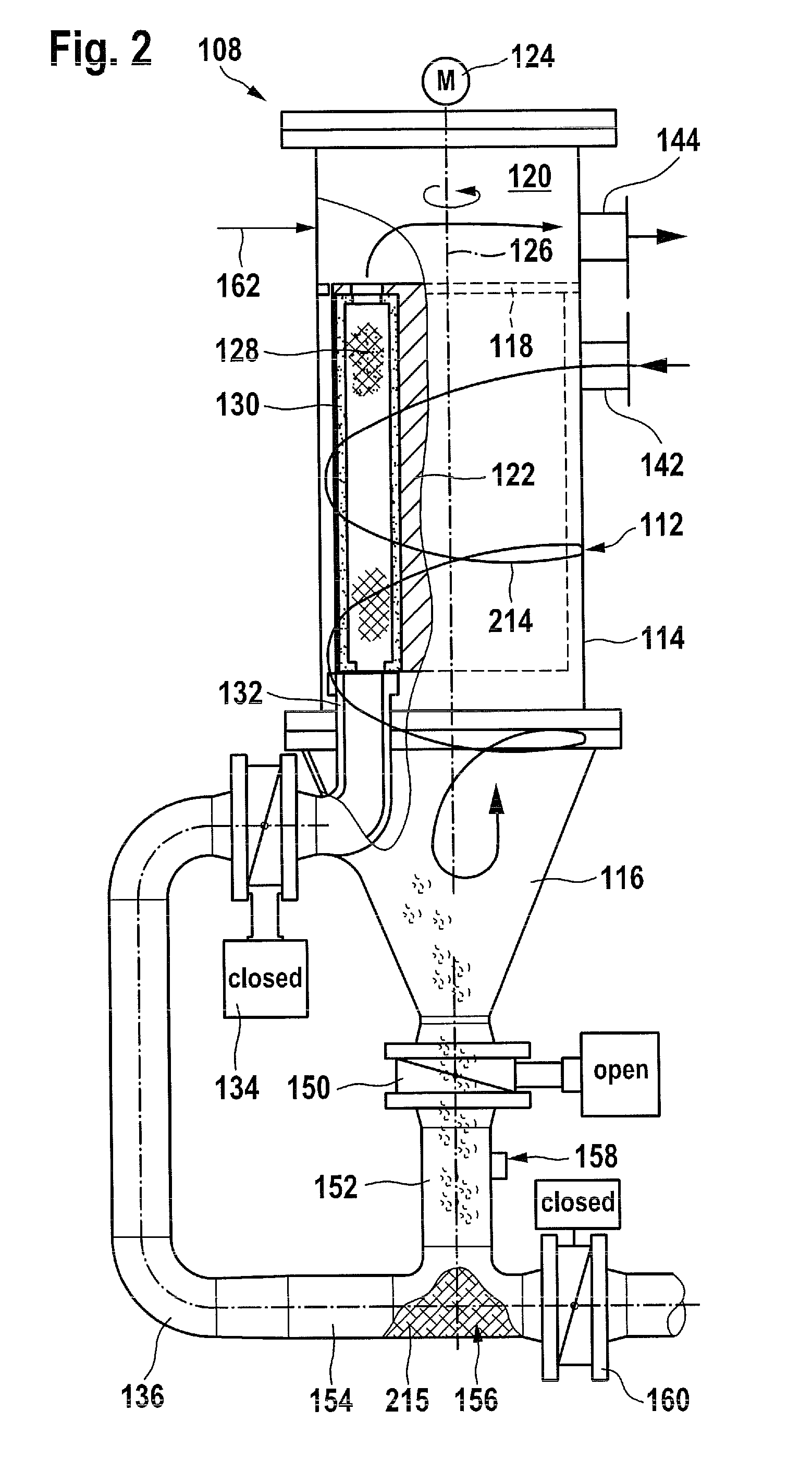

Device and method for processing backflushed fluid

InactiveUS20090050581A1Residual amountAchieve dischargeLiquid displacementLoose filtering material filtersSedimentSedimentation

In order to provide a device for processing backflushed fluid from a backflushing filter containing solids, comprising a sedimentation device for separating solids from the backflushed fluid by sedimentation in a sediment collecting region, which device allows a discharge of solids without auxiliary filter agents, and has a fluid loss which is as low as possible, it is proposed that the sedimentation device should comprise a sluice mechanism, by means of which the sediment collecting region can be connected to a sedimentation container during a sedimentation phase and can be separated from the sedimentation container during a discharge phase and can be emptied.

Owner:BLANCO GMBH & CO KG +1

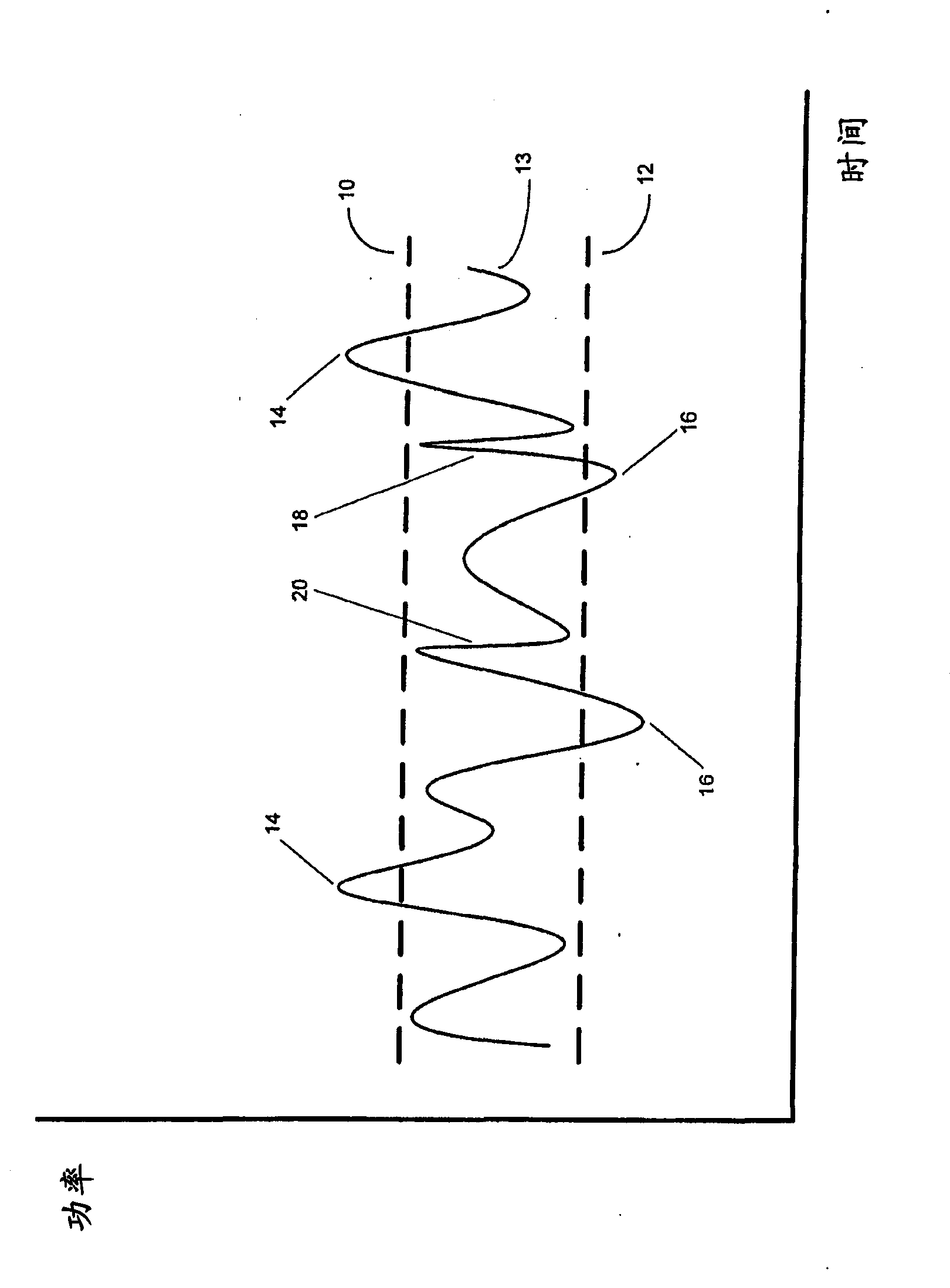

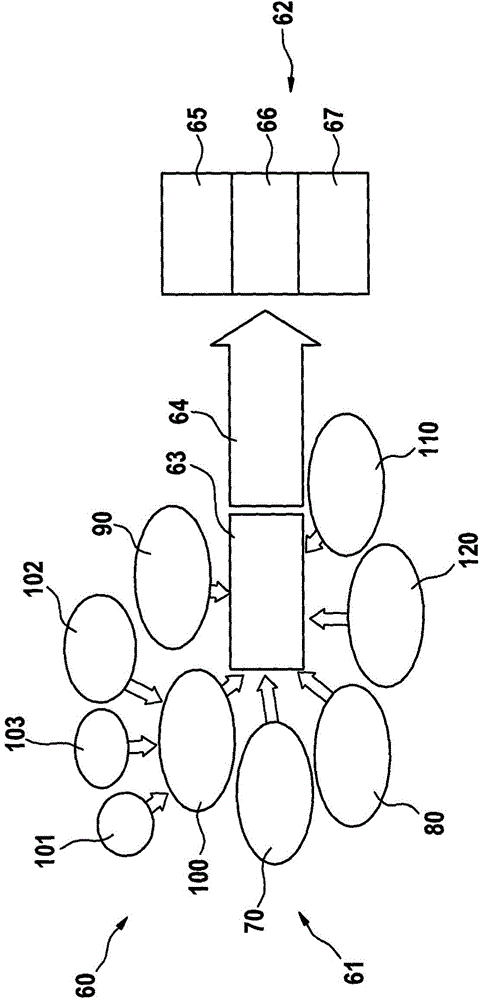

Regulation of contribution of secondary energy sources to power grid

ActiveCN103081290AHigh outputReduce outputBatteries circuit arrangementsAc network load balancingElectricityStored energy

An energy storage medium is combined with a secondary energy source that supplies power to an electricity distribution grid. The charge and discharge behavior of the energy storage medium is controlled so that rapid increases in the output of a secondary source of energy are absorbed by the storage system, whereas rapid decreases in the output of the secondary source are compensated by discharging stored energy onto the grid. The combined contributions of the secondary source and the energy storage system ensures a rate of change that does not exceed a defined level. Maximum and minimum output power levels for the secondary source can be established to define a normal operating range. The charging or discharging of the energy storage system is also performed when the secondary output power level exceeds or falls below the limits of the defined range.

Owner:FLUENCE ENERGY LLC

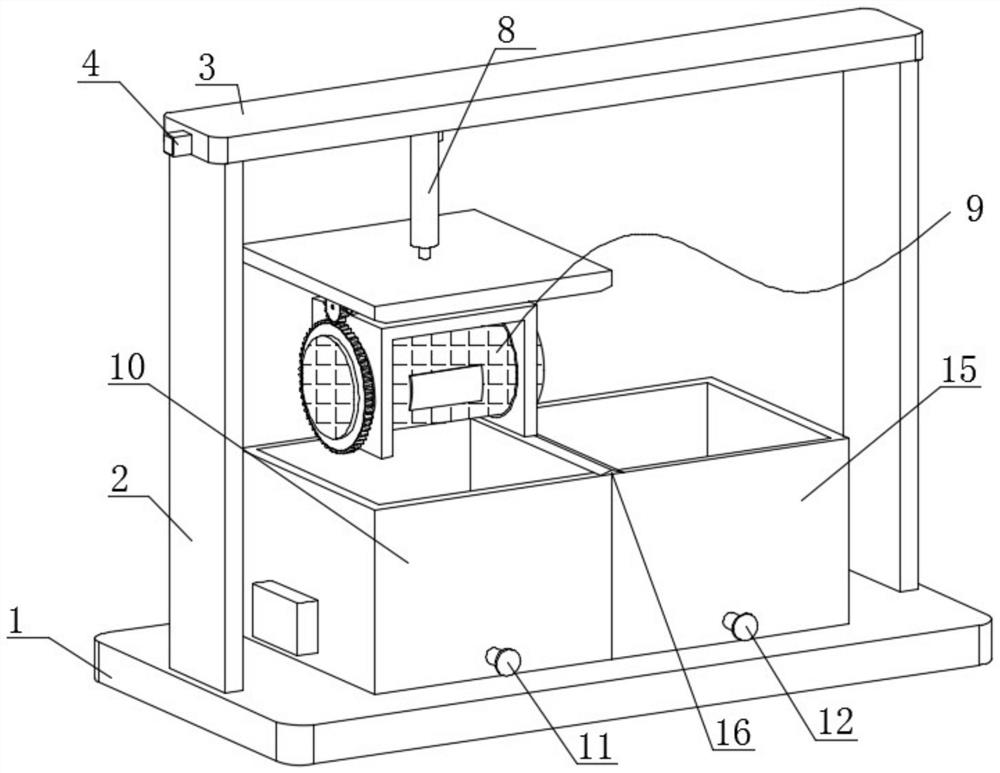

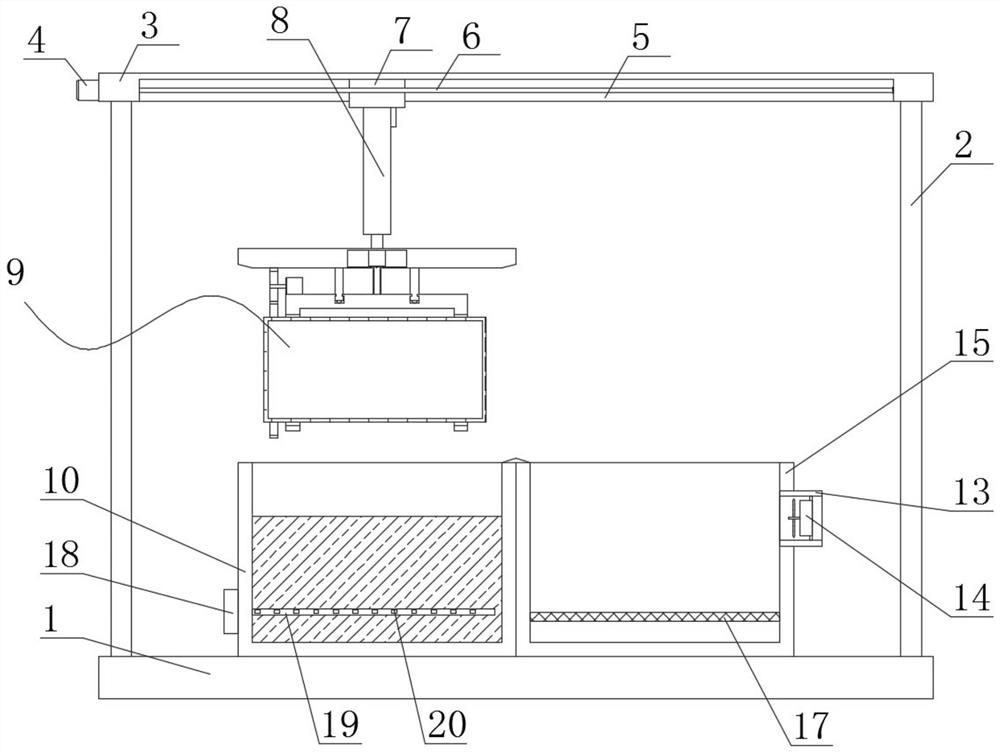

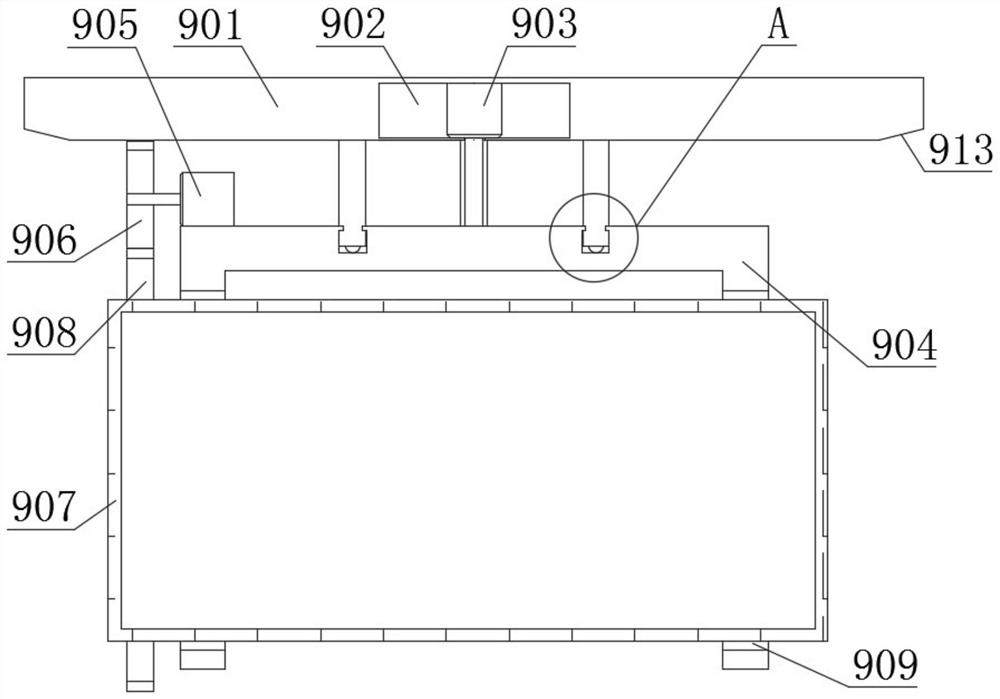

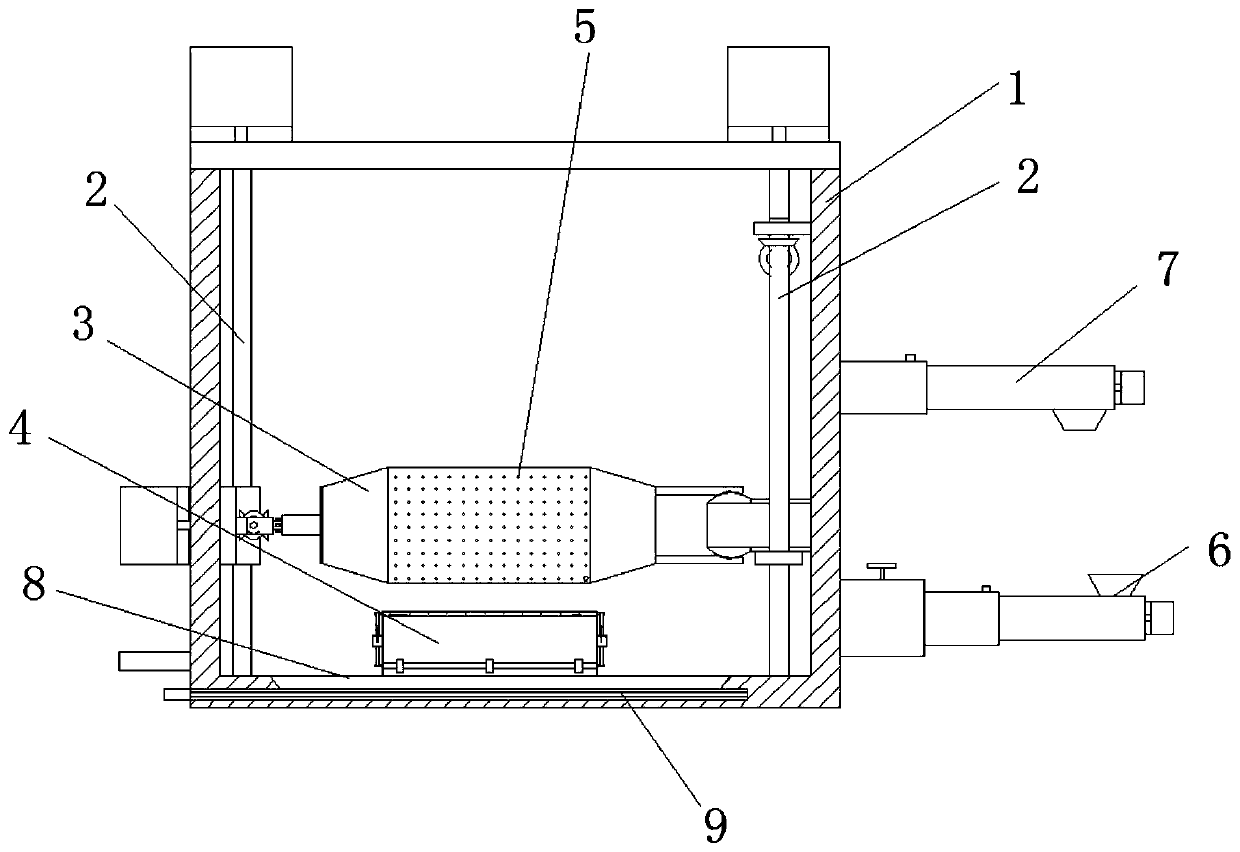

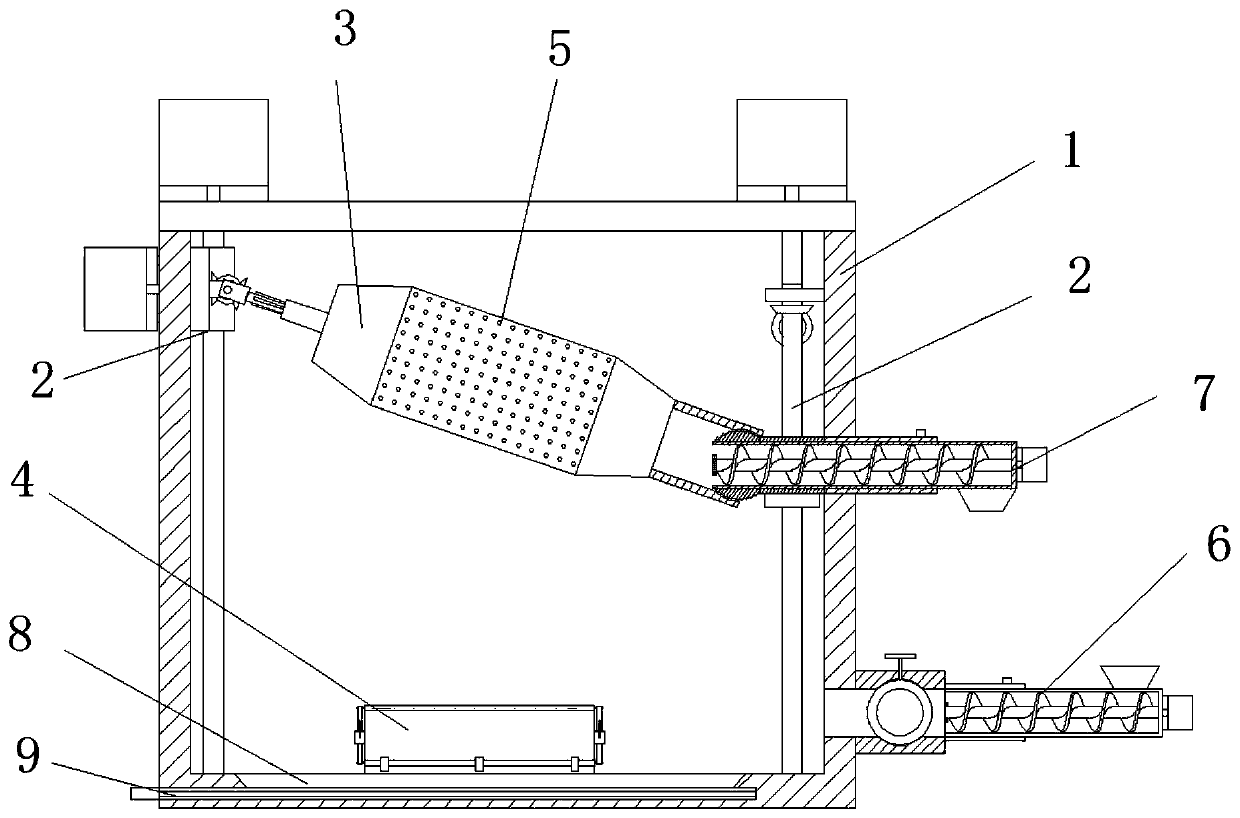

Automatic oil immersion equipment for rust prevention of hardware machined parts and use method

InactiveCN112871555AAchieve dischargeGuaranteed oil immersion anti-rust effectLiquid surface applicatorsCoatingsOil canMachine parts

The invention discloses automatic oil immersion equipment for rust prevention of hardware machined parts and a use method, and belongs to the technical field of machined part rust prevention treatment. The automatic oil immersion equipment comprises a bottom plate, vertical rods are fixedly connected to the two ends of the upper surface of the bottom plate, a top plate is arranged above the bottom plate, and the two ends of the bottom face of the top plate are fixedly connected with the upper surfaces of the two vertical rods correspondingly; and the left side face of the top plate is fixedly connected with a first motor, and a sliding groove is formed in the bottom face of the top plate. According to the automatic oil immersion equipment, through the arrangement of an oil immersion mechanism, namely the cooperative arrangement of a second motor, a concave block, a third motor, a first gear, a steel wire cage, a second gear and a bearing, rust-proof oil can be completely smeared on the outer surfaces of the machined parts, and the oil immersion rust-proof effect on the machined parts is guaranteed; and through cooperative arrangement of a filter screen, a collecting box, a filter screen, an air pipe, a controller, a transverse electromagnet and an electromagnetic rod, the anti-rust oil can be recycled, waste of the anti-rust oil is reduced, and the machining cost of a factory is reduced.

Owner:东阳市君泽钓具有限公司

Adjusting method of blocking component

ActiveCN109954665AAchieve tilt adjustmentGuaranteed water expansionSievingScreeningScreening effectEngineering

The invention relates to the technical field of soybean machining, in particular to an adjusting method of a blocking component. An arc plate, arc connecting strips, limiting pieces, a roller shaft, arc rods, limiting balls, pressure springs and elastic cloth are included; the arc plate is arranged on the bottom of the inner wall of a seal box, the arc connecting strips are symmetrically arrangedon the outer side wall of the arc plate, a strip groove is formed in the position, above the arc connecting strips, of the arc plate, the four limiting pieces are symmetrically arranged on the side wall of the arc plate, through holes are formed in the limiting pieces, the roller shaft is movably arranged in the strip groove, and is arranged on the upper end of the side wall of the arc plate through symmetric rotating rods, the limiting balls are arranged at one ends of the arc rods, the other ends of the arc rods penetrate through the through holes and the pressure springs to be connected with the rotating rods, and the elastic cloth is arranged on the upper end of the arc plate. The problem that existing screening is not thorough, dead soybeans in the soybeans are hard to treat, and soybean water absorbing expansion is not uniform is solved, the screening effect is thorough, and the soybean water absorbing expansion is more uniform.

Owner:马强

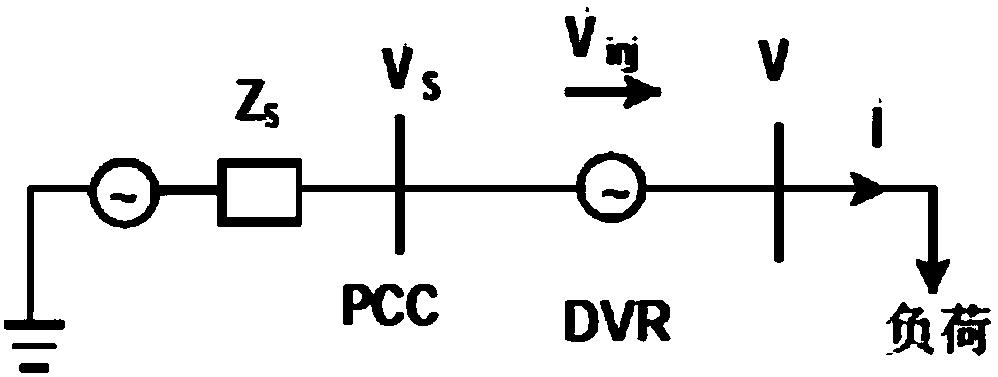

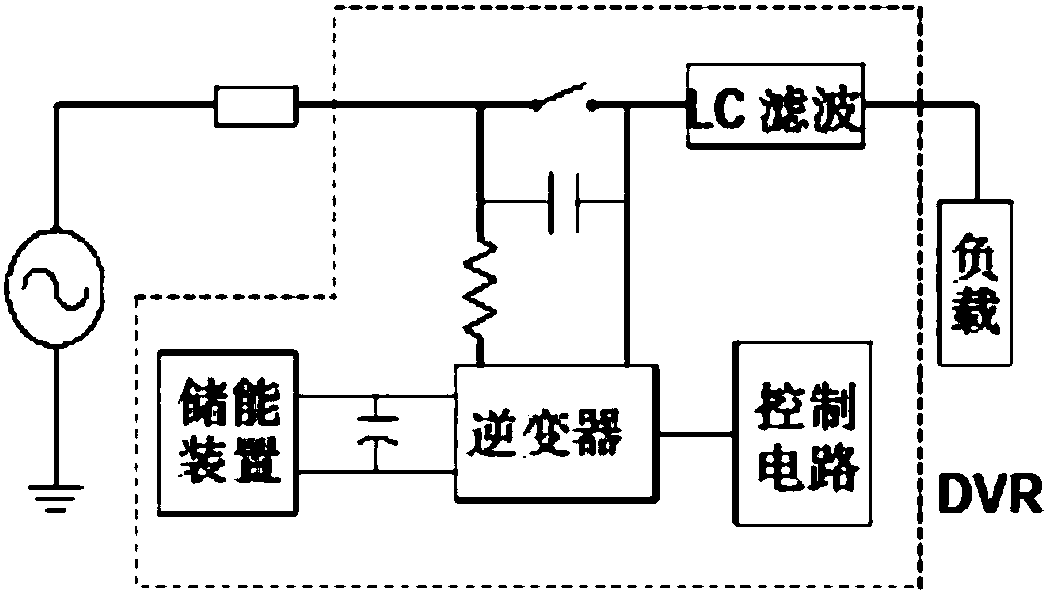

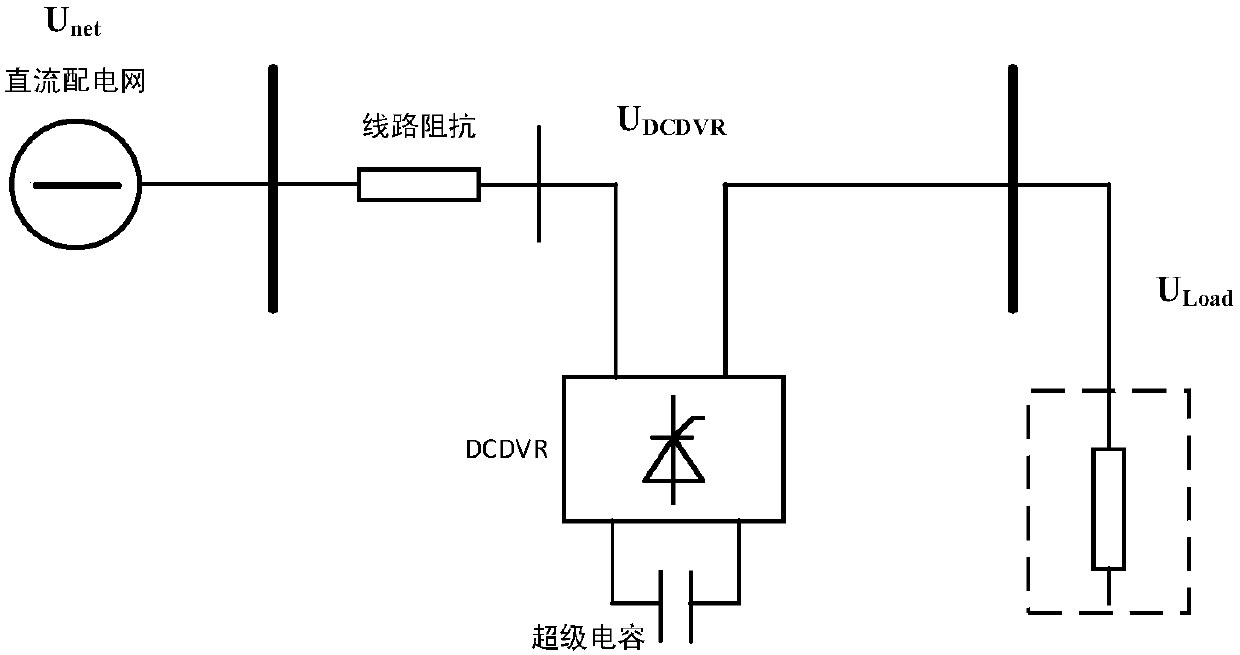

DC system dynamic voltage recovery device based on energy storage

ActiveCN107732893AQuick compensationContinuous loadDc source parallel operationVoltage dropVoltage compensation

The invention relates to a DC system dynamic voltage recovery device based on energy storage. The DC system dynamic voltage recovery device based on energy storage is applicable to a DC power distribution network system and can realize voltage compensation of a DC system through a charging circuit which is connected to a DC bus in parallel and a voltage compensation circuit which is connected to the DC bus in series. When voltage drop does not occur on the DC bus, a charging circuit is utilized to charge an energy storage module. When voltage drop occurs on the DC bus, the energy storage module can compensate the voltage drop on the DC bus through the voltage compensation circuit. As a result, the DC system dynamic voltage recovery device based on energy storage can perform fast compensation on voltage and can guarantee that a load can continuously and stably operate.

Owner:XJ ELECTRIC +3

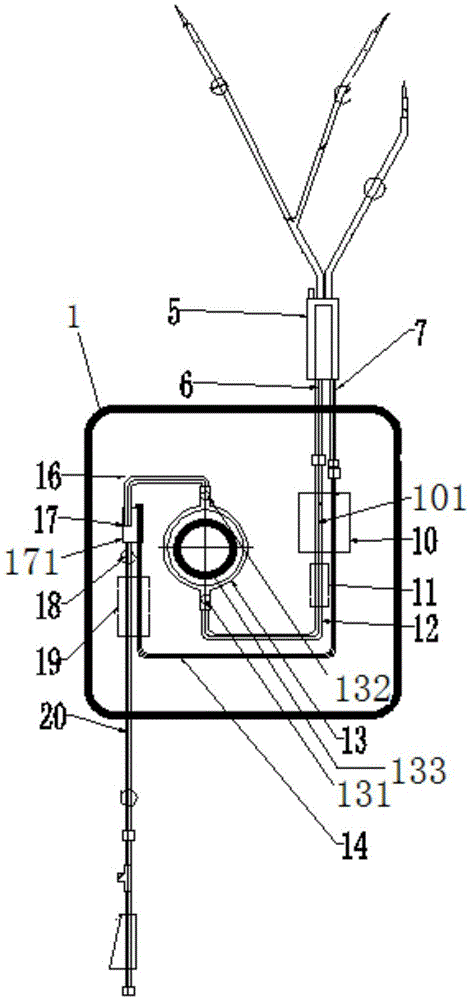

Rapid infusion equipment capable of achieving induction heating and using method of rapid infusion equipment

InactiveCN105521533AHeating safetyHeating evenlyMedical devicesPressure infusionLiquid temperatureControl valves

The invention belongs to the technical field of a medical apparatus, and in particular relates to rapid infusion equipment capable of achieving induction heating and a using method of the rapid infusion equipment. The rapid infusion equipment comprises a casing, a controller, a locating rack, a directional control valve, a pressure measurement device, an air detection sensor and a liquid running-out detection sensor 101, wherein an electromagnetic induction heater, which is used for heating an infusion apparatus, and an infrared temperature sensor, which is used for detecting the temperature of infusion liquid on the inlet and the outlet of the heat exchange ring, are arranged on the casing; the directional control valve, the pressure measurement device, the air detection sensor, the electromagnetic induction heater and the infrared temperature sensor are connected to the controller; and the controller is additionally connected to an infusion pump on the infusion apparatus. The rapid infusion equipment not only can meet the requirements on existing infusion functions but also can keep liquid temperature within a constant value, so that infusion is performed nearby human body temperature; therefore, the purpose of rapid constant-temperature infusion in emergency is effectively achieved.

Owner:XIAN LIBANG MEDICAL ELECTRONICS

Self-cleaning keyboard

ActiveCN108446028AAvoid accumulationAchieve cleaningInput/output for user-computer interactionDirt cleaningInjection airElectrical and Electronics engineering

The invention belongs to an input device with a manual operation switch, and specifically discloses a self-cleaning keyboard. The self-cleaning keyboard comprises a shell, a keycap and a circuit board; an opening for up-down movement of the keycap is formed in the shell; a dust removal mechanism and a collection mechanism for collecting dust are arranged in the shell; the dust removal mechanism comprises a separation plate which extends from the edge of the opening to the interior of the shell; the separation plate surrounds the keycap; an air injection mechanism is fixed on the circuit boardbelow the keycap; the air injection mechanism is driven by the keycap; the air injection mechanism is used for blowing dust and applying pressure on the circuit board; the collection mechanism comprises a guiding channel and a collection pipe; the collection pipe is fixed on the lower end face of the shell; the guiding channel penetrates through the circuit board and the shell; one end of the guiding channel is communicated with one side, close to the air injection mechanism, of the separation plate and the other end of the guiding channel is communicated with the side wall of the collection pipe; and two ends of the collection pipe are communicated with the external world. The invention aims at solving the problem that dust enters gaps between existing keyboards and keyboard shells so asto enter the keyboards and then be stacked on circuit boards.

Owner:赫比(苏州)通讯科技有限公司

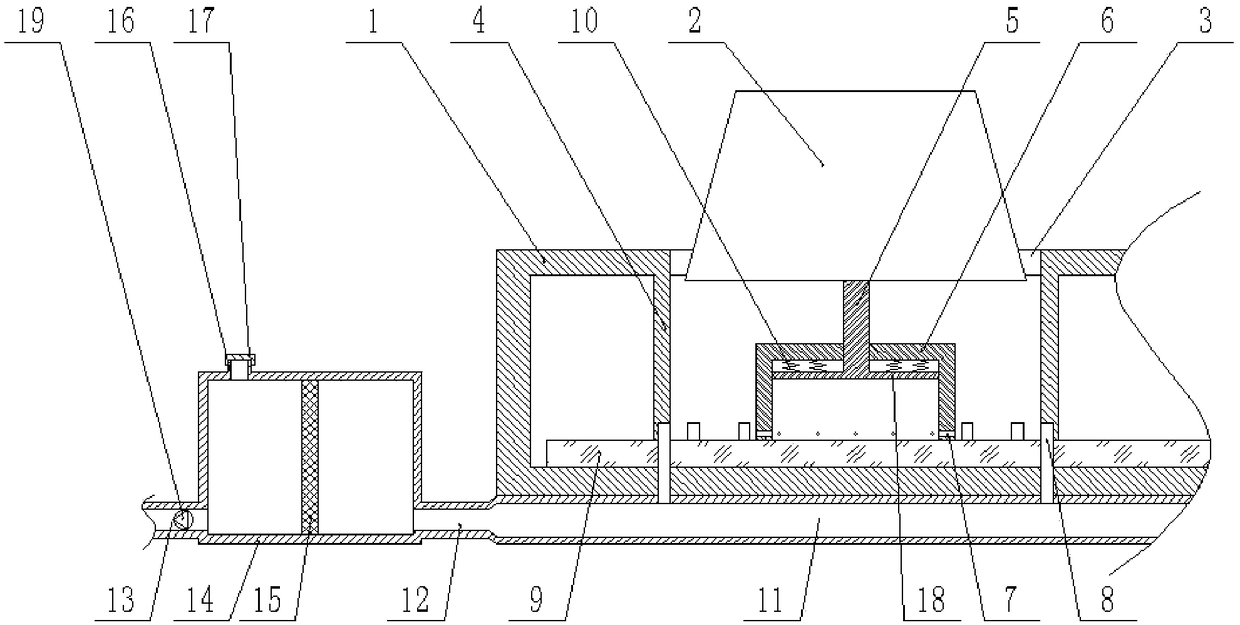

Novel vehicle-mounted electric automobile battery charger and control method thereof

InactiveCN108736552AImprove charging efficiencyLow costBatteries circuit arrangementsAc network load balancingSoft switchingLow voltage

The invention discloses a novel electric automobile charging circuit and a control method thereof. The circuit comprises a control unit and a main circuit, wherein the main circuit comprises a high frequency circuit and a power frequency circuit; the power frequency circuit comprises a charging input end, a half-bridge PWM rectifier and an energy storage capacitor which are connected in sequence;the input end of the half-bridge PWM rectifier is connected to a resonance circuit, a high frequency isolation transformer, a high voltage rectifier filter circuit, a low voltage rectifier filter circuit, a low voltage output end and a charging output end to form the high frequency circuit; and the control unit is used for controlling the operation of the half-bridge PWM rectifier and the operation of the rectifier filter circuit according to obtained voltage and current information. Power factor correction and the soft-switching technology of a high voltage rectifier bridge are realized, thequantity of switching devices required for a battery charger can be reduced effectively, the volume of the transformer is reduced, the quantity of transformers can be reduced due to the application ofa three-winding transformer, the efficiency of power transmission is improved, and the volume and cost of the system are reduced.

Owner:SOUTHEAST UNIV

Battery module and method for monitoring battery module

InactiveCN104052102AAchieve dischargeTimely dischargeBatteries circuit arrangementsElectric devicesMonitoring and controlBattery cell

The invention discloses a battery module (221). The battery module (221) has a battery cell circuitry (226) that is provided with several battery cells (21), and a monitoring and control unit (230) which is used for monitoring the functional state of the battery module (221). The battery module (221) comprises a couple unit and a discharge circuit (270). The couple unit is connected with power semiconductors (241,242) in half bridge arrangement, for coupling the battery cell circuitry (226) to output terminals (224,225). The discharge circuit (270) is coupled with the battery cell circuitry, for enabling the fast discharge of the battery module. The couple unit and the discharge circuit are controlled by the monitoring and control unit (230).

Owner:ROBERT BOSCH GMBH +1

Method for separating valuable components of monazite slags

ActiveCN102925681ARealize closed loop recyclingEasy to separateProcess efficiency improvementDecompositionSlag

The invention discloses a method for separating valuable components of monazite slags, and particularly relates to a method for separating valuable components of monazite slags into a liquid phase (a solution containing uranium, thorium and rare earth) and a solid phase (a filter residue containing useful minerals such as monazite, zirconite and rutile). The method is characterized by comprising the following steps of acid leaching, filter pressing and water scrubbing. According to the invention, monazite slags are subjected to low-acid and low-temperature leaching, and a liquid phase and a solid phase are separated easily; after secondary slags are subjected to mineral processing and alkaline decomposition by using a mineral processing process, the closed cycle collection of uranium, thorium and rare earths can be realized; meanwhile, an extract residue waste acid can be subjected to cyclic utilization, thereby reducing the wastewater discharge, reducing the consumption of sulfuric acids and new water and the wastewater treatment cost, and reducing the production cost; and the recovery rates of valuable elements such as uranium, thorium and rare earths can be greater than 97%, therefore, an effect of no radioactive wastewater and waste residue discharge in the whole process can be achieved.

Owner:YIYANG HONGYUAN RARE EARTH

Tea packaging device

The invention belongs to the field of tea processing, and particularly discloses a tea packaging device. The tea packaging device comprises a rack. The rack is provided with a stirring unit, a vibration unit and a packaging unit from top to bottom in sequence. The stirring unit comprises a stirring barrel fixed to the rack, an end face gear arranged on the inner wall of the stirring barrel and a first rotary shaft located below the end face gear. The end of the first rotary shaft is fixedly connected with a first gear engaged with the end face gear. The vibration unit comprises a first vibration plate and a second vibration plate. The first vibration plate and the second vibration plate are hinged to the two sides of the bottom of the stirring barrel respectively. Both the first vibrationplate and the second vibration plate are electric heating plates. The rack is rotationally connected with a sector gear. The end, away from a first connecting rod, of a second connecting rod is fixedto the end face of the sector gear. The packaging unit comprises a second rotary shaft rotationally connected to the rack. The packaging unit further comprises a conveyer belt used for transferring packaging boxes. By adopting the tea packaging device of the scheme, the problem that tea is not evenly heated when being dried is solved.

Owner:务川自治县鑫隆缘茶业有限责任公司

Microfluidic PCR chip and operation method thereof

ActiveCN109536364AImplement extractionAchieve hybridBioreactor/fermenter combinationsHeating or cooling apparatusPcr chipFluid control

The invention provides a microfluidic PCR chip and an operation method thereof. The microfluidic PCR chip comprises a matrix; a fluid control structure consisting of a cavity and a control body is arranged on the matrix. The microfluidic PCR chip also comprises a plurality of cavities constructed on the matrix, the top ends of all the cavities are provided with openings, the cavities are correspondingly connected with channels in the fluid control structure one by one respectively, and each cavity at least comprises a lysate tank loaded with a lysate, a washing buffer solution tank loaded witha washing buffer solution, an eluent tank loaded with an eluent, and a DNase-free water tank loaded with DNase-free water. On the basis of realizing the functions of fluid extraction, mixing and discharge, the microfluidic PCR chip saves the trouble of setting a separated storage or mixing cavity, reduces the operation steps, reduces the complexity of the chip, does not need externally-connectionlarge-scale equipment, reduces the cost of the chip, makes the chip suitable for being used as a disposable microfluidic chip, and has good practicability.

Owner:SHENZHEN SHINEWAY HI TECH CO LTD

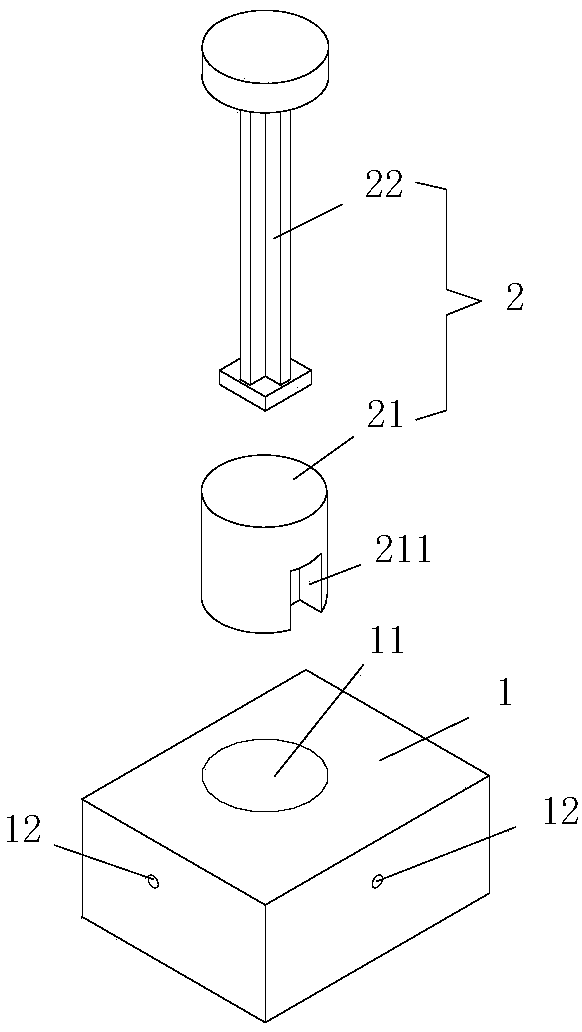

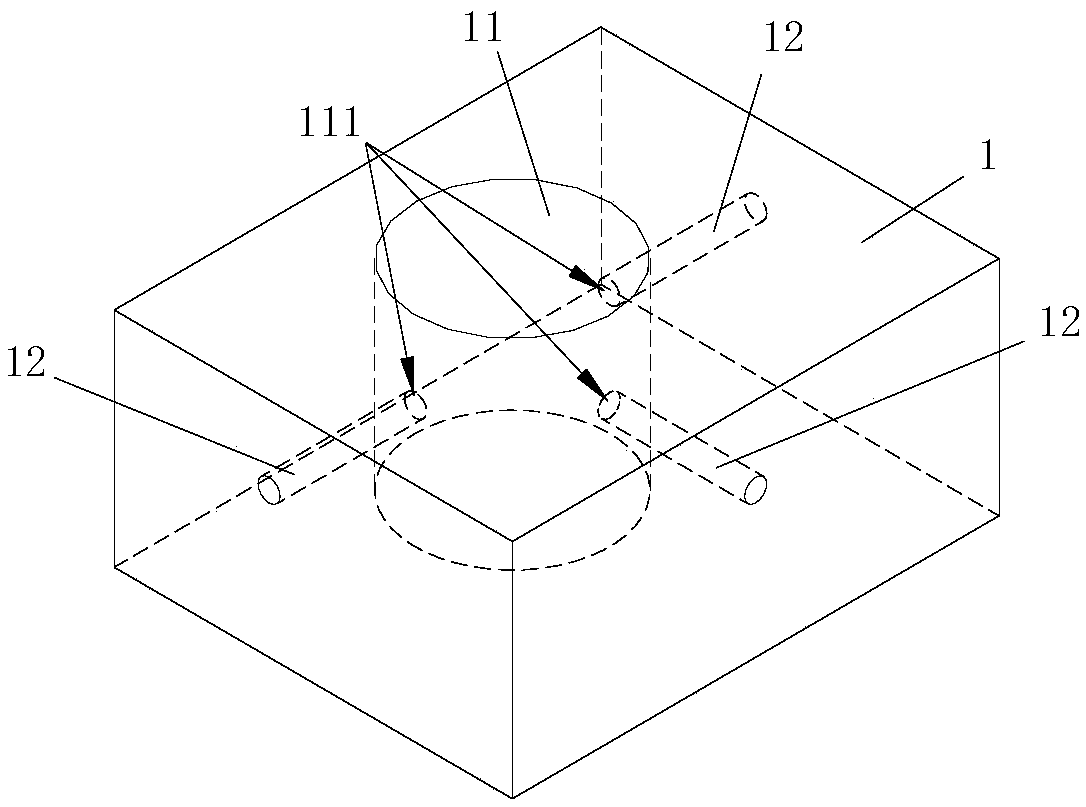

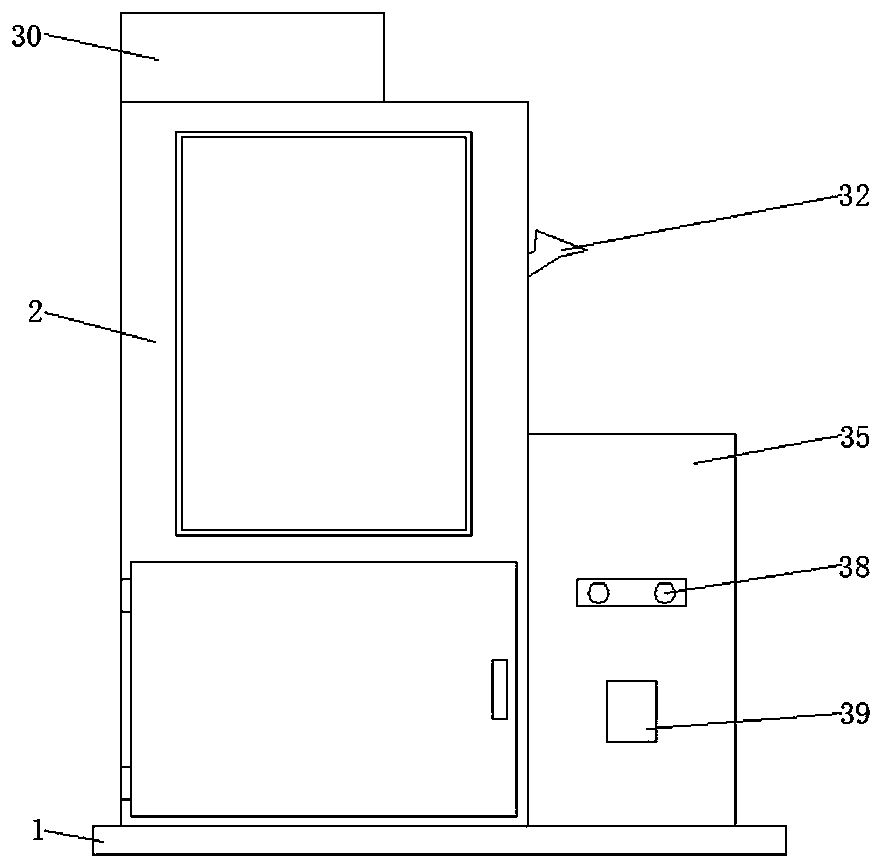

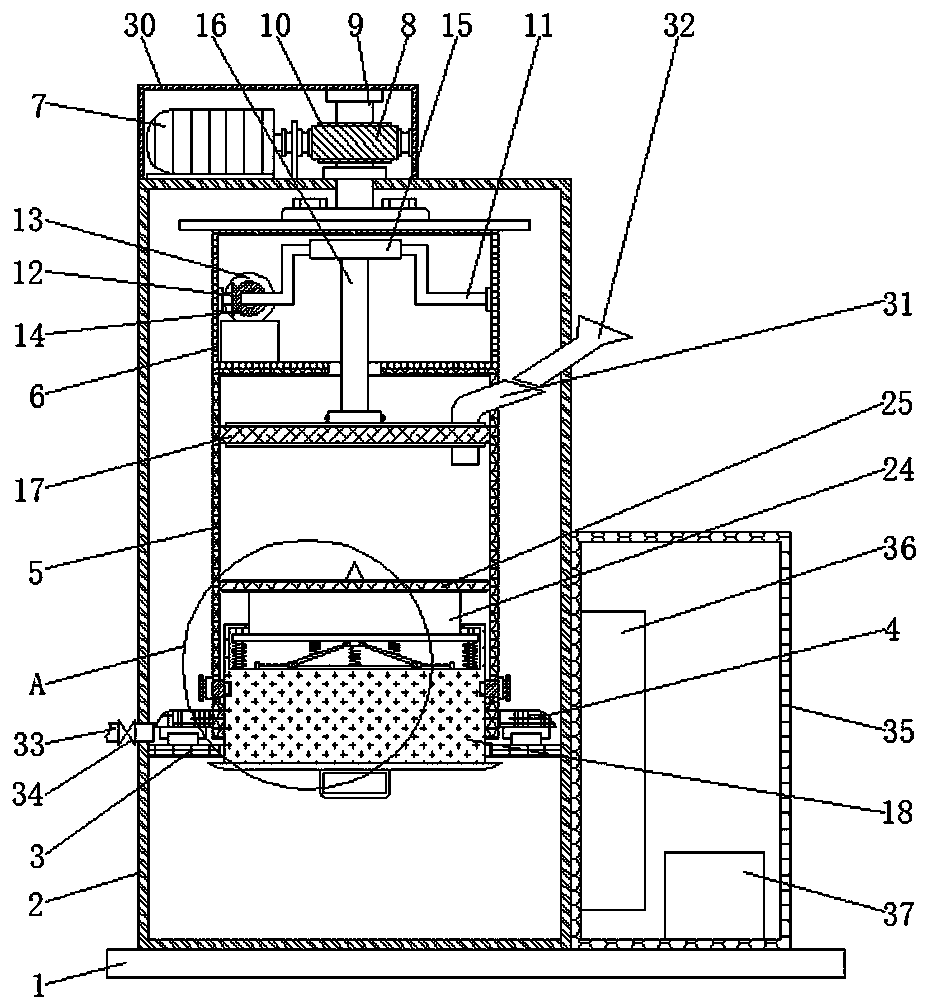

Sludge treatment system and sludge treatment method

ActiveCN108423965AFast spinQuick squeeze dehydrationSludge treatment by de-watering/drying/thickeningMoving filtering element filtersSludgeCoupling

The invention discloses a sludge treatment system. The sludge treatment system comprises a bottom plate; the top of the bottom plate is fixedly connected with a treatment box; a partition plate is fixedly connected with the part between the two sides of the inner wall of the treatment box; the top of the partition plate is rotatably connected with a turnplate through a round sliding rail; the interior of the turnplate is fixedly connected with a filtering cylinder; the top of the filtering cylinder is fixedly connected with an extruding box; the top of the treatment box is fixedly connected with a rotary motor through a connecting block; one end of an output shaft of the rotary motor is fixedly connected with a worm through a shaft coupler. The invention relates to the technical field of sludge treatment. According to the sewage treatment system and the sewage treatment method, the dehydration effect is greatly enhanced, the dehydration efficiency is improved well, people do not need to take a large amount of time to dehydrate the sludge mixed material, the work burden of people is greatly reduced, the working efficiency of people is improved, and rapid and efficient dehydration treatment on the sludge mixed mater is realized.

Owner:福建省海洲建材实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com