Multi-purpose electromagnetic induction melting device and method

A technology of electromagnetic induction and electromagnetic induction coil, which is applied in the field of multi-purpose electromagnetic induction smelting equipment, can solve the problems of complex structure, easy to be oxidized, and exposed electromagnetic induction coil, achieve high airtight effect, prevent oxidation or corrosion, and improve pouring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

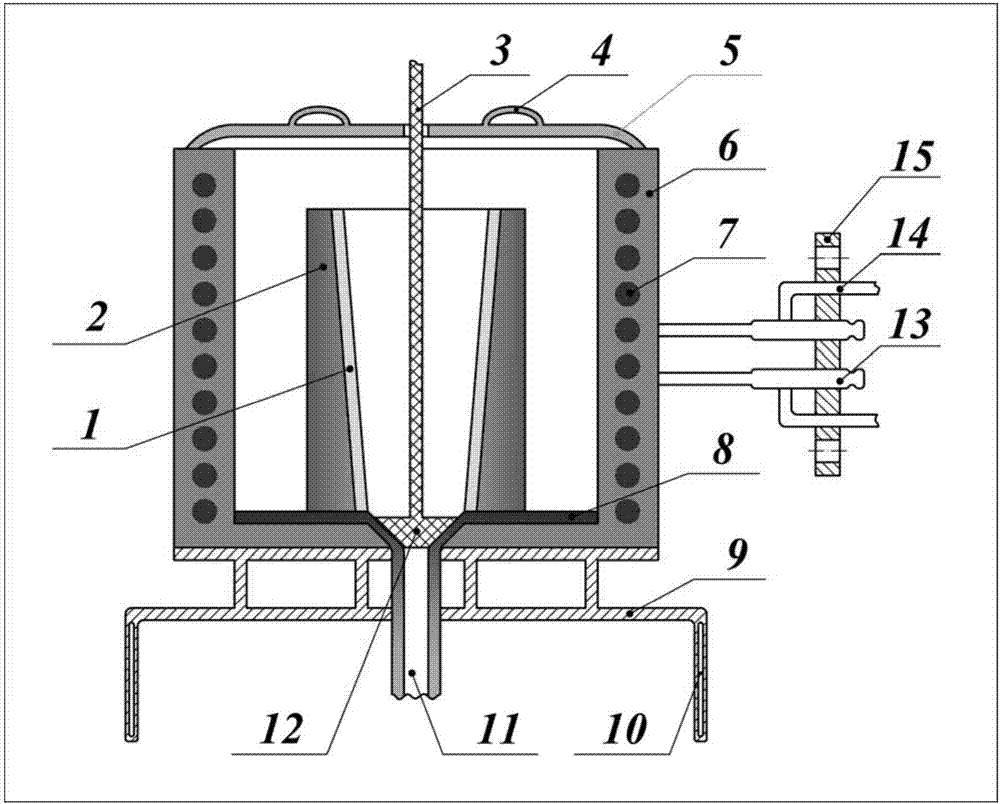

[0027] like figure 1 As shown, the present invention is a multipurpose electromagnetic induction smelting device, said device is based on the principle of electromagnetic induction heating, comprising a zirconia crucible 1, a graphite crucible 2, a ceramic lifting rod 3, a top cover handle 4, a top cover 5, a magnesium oxide crucible Sand knotted body 6 , electromagnetic induction coil 7 , conical funnel 8 , support structure 9 , ceramic draft tube 11 , ceramic plug 12 , and power terminal 13 and cooling pipeline 14 embedded in flange 15 .

[0028] The zirconia crucible 1 is an inverted cone, which is a place for heating and melting materials. It is located in the center of the entire melting device, and its size is determined according to the maximum melting capacity; The geometric structure of the zirconia crucible 1 is turned and milled, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com