Patents

Literature

103 results about "Melt and pour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melt and Pour soap crafting is a process often used by soapmakers, both for large scale (commercial) and small scale (domestic, artisanal) manufacture. Small scale artisan soap makers find "melt and pour" production useful when trying out new product lines. The process differs from the cold process or hot process in utilising a pre-manufactured solid soap base which has already undergone saponification, so the soap maker does not need to handle caustic alkali, i.e. lye.

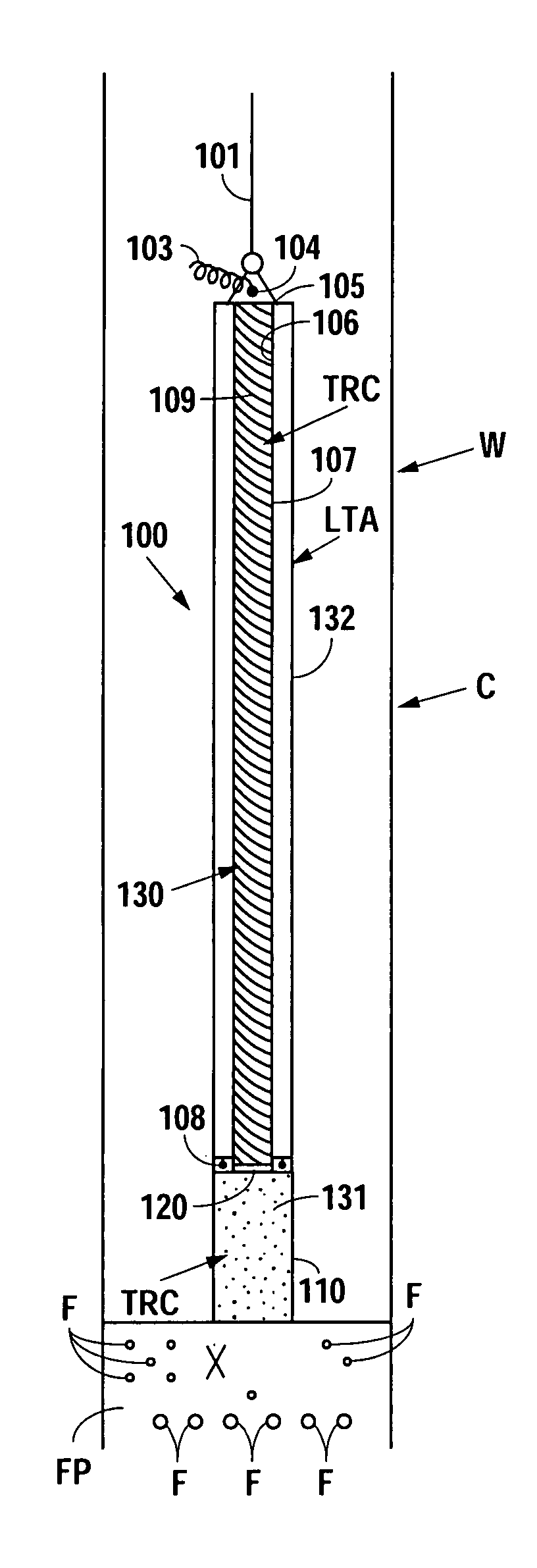

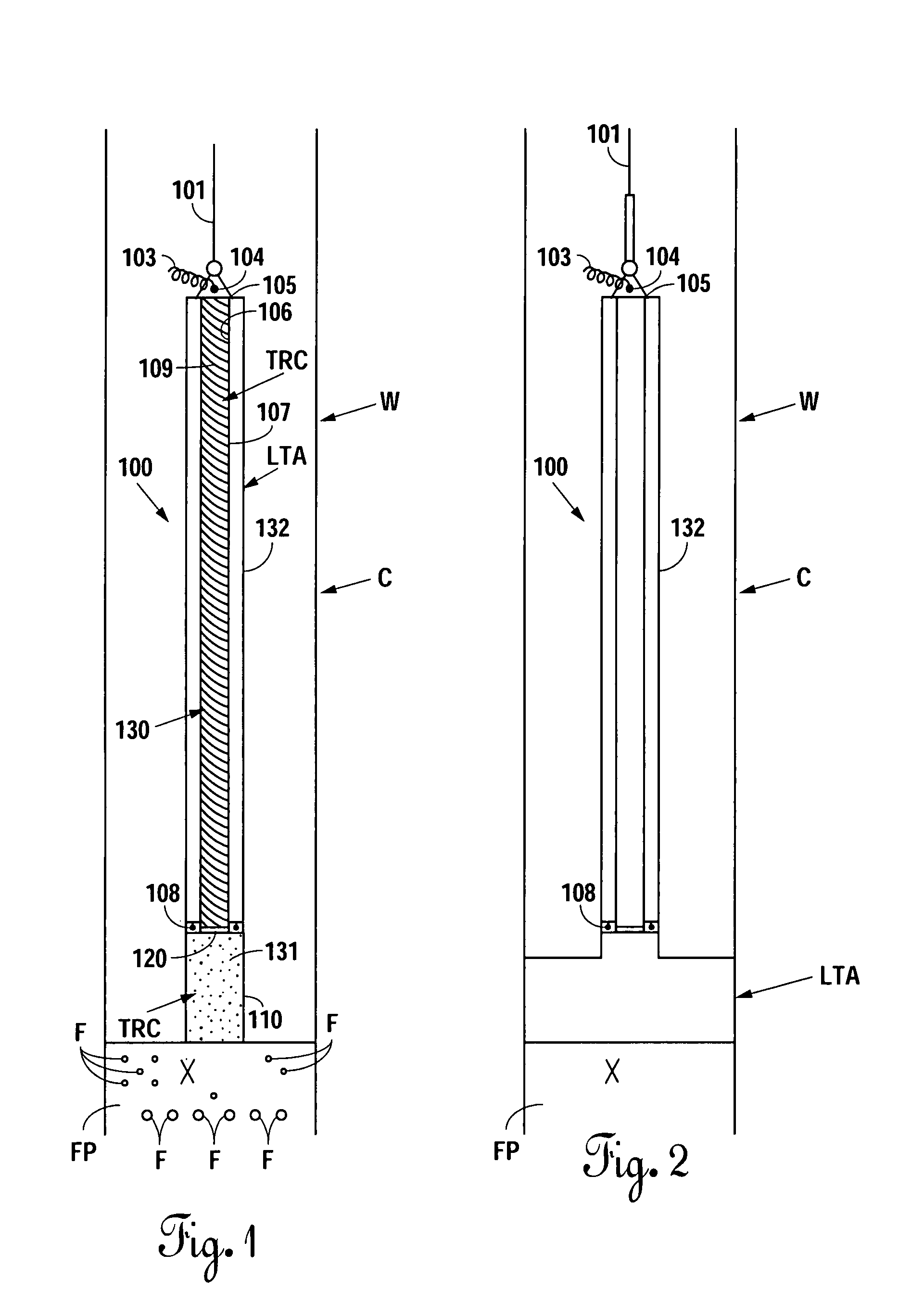

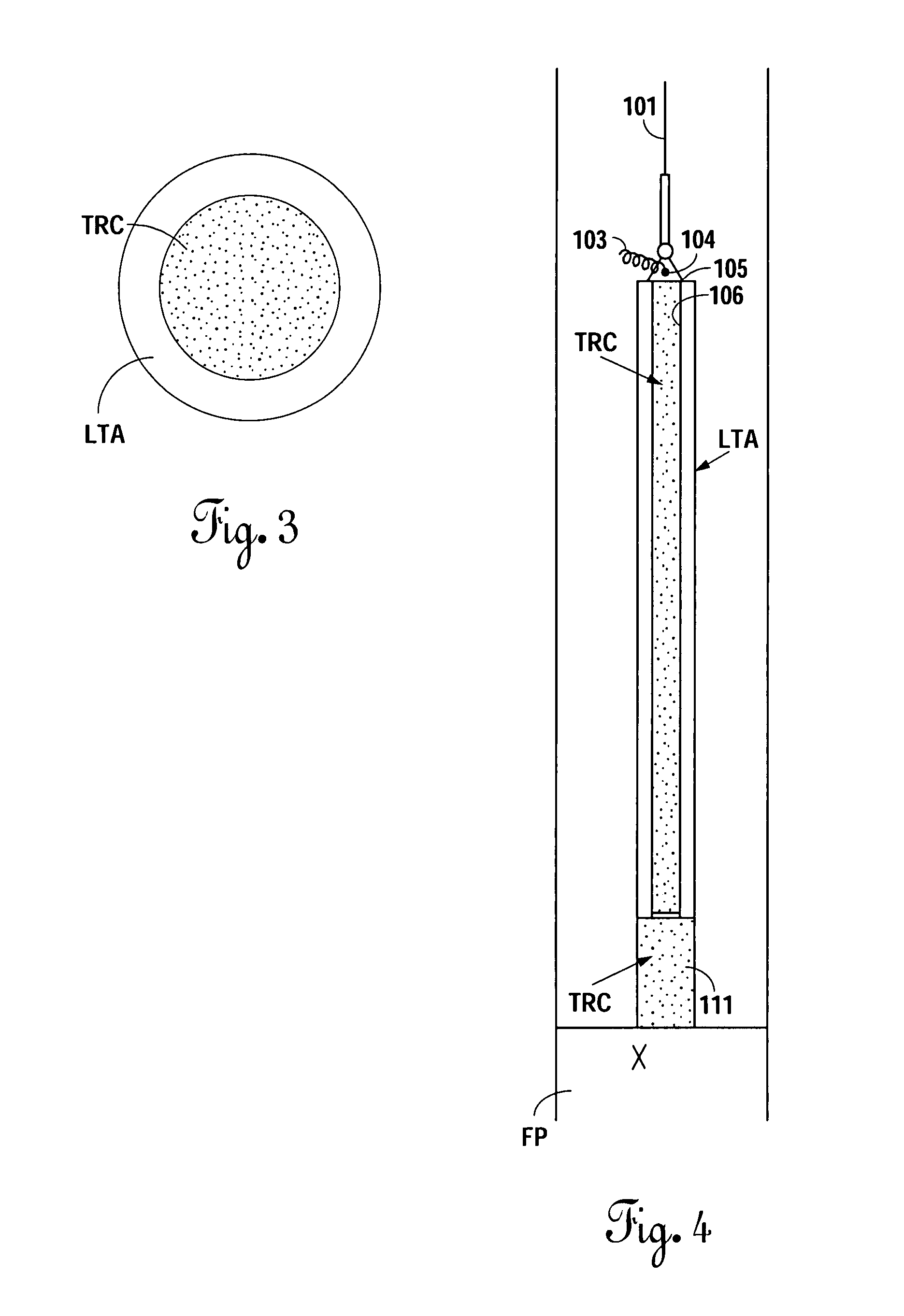

Subterranean well secondary plugging tool for repair of a first plug

A secondary plugging tool is disclosed for use in a subterranean plug, such as in a plugged and / or abandoned well. The repaired plug may be of a cementicious material, or a mechanically, hydraulically or electrically set plug or packer. The plugging tool includes an outer housing containing an eutectic metal alloy. A thermitic reaction charge is contained within chambers within an inner tubular member and a lower housing. The lower end of the outer housing being ported circumferentially there around, the thermitic reaction charge activates the eutectic metal charge such that the eutectic charge melts and pours out of the outer housing and across and upon the initial plug to repair any failure areas therein.

Owner:CINARUCO INT CALLE AGUILINO DE LA GUARDIA

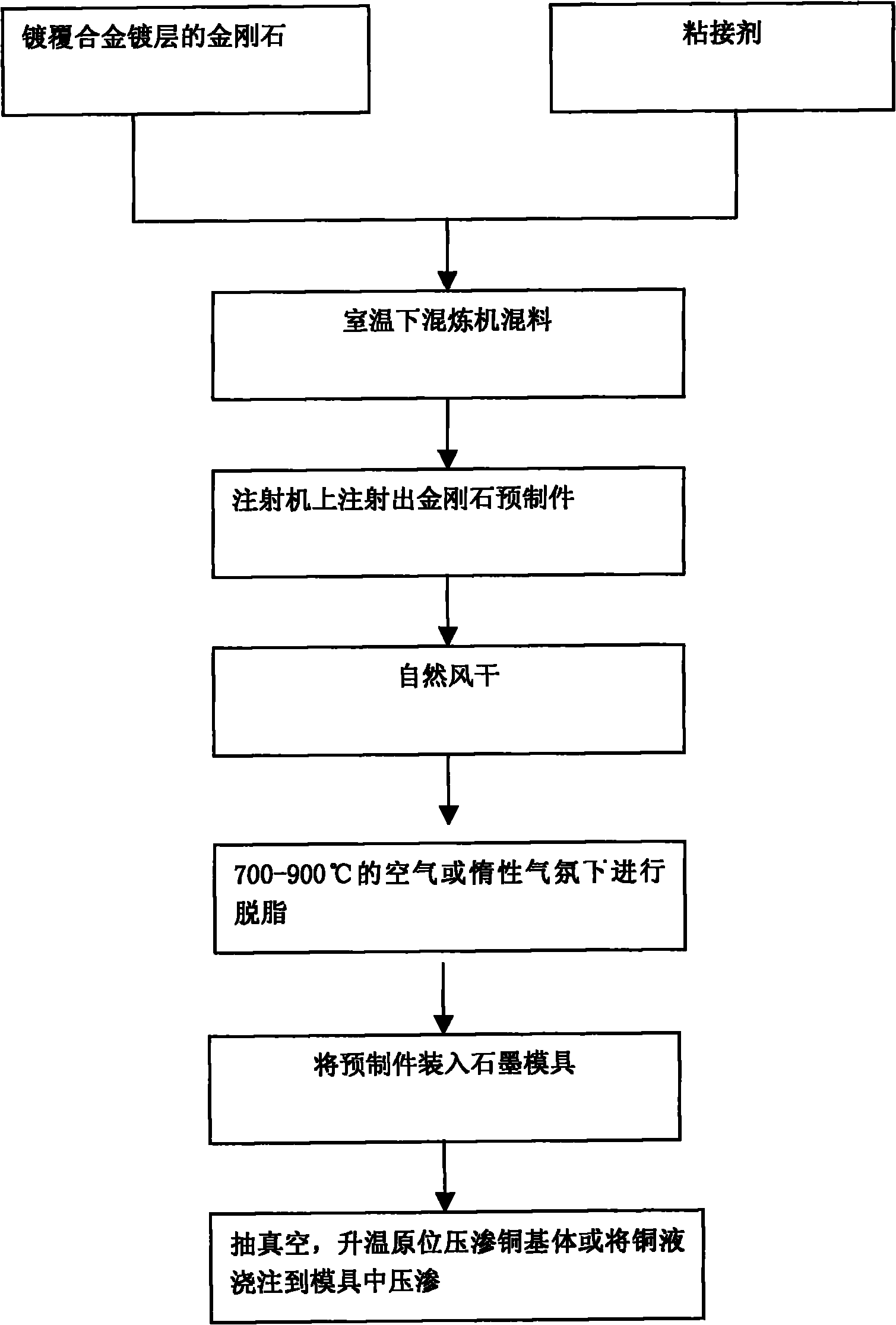

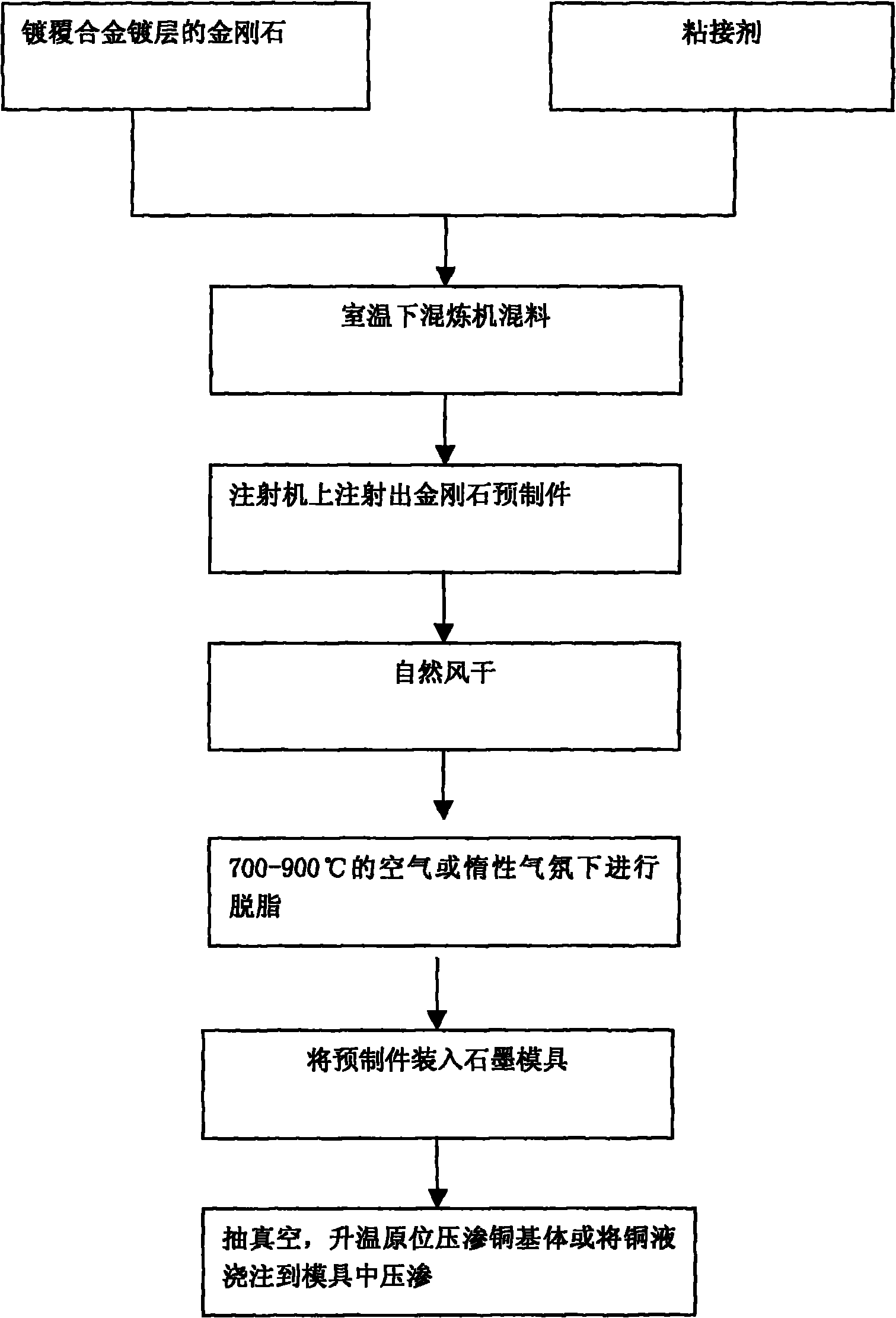

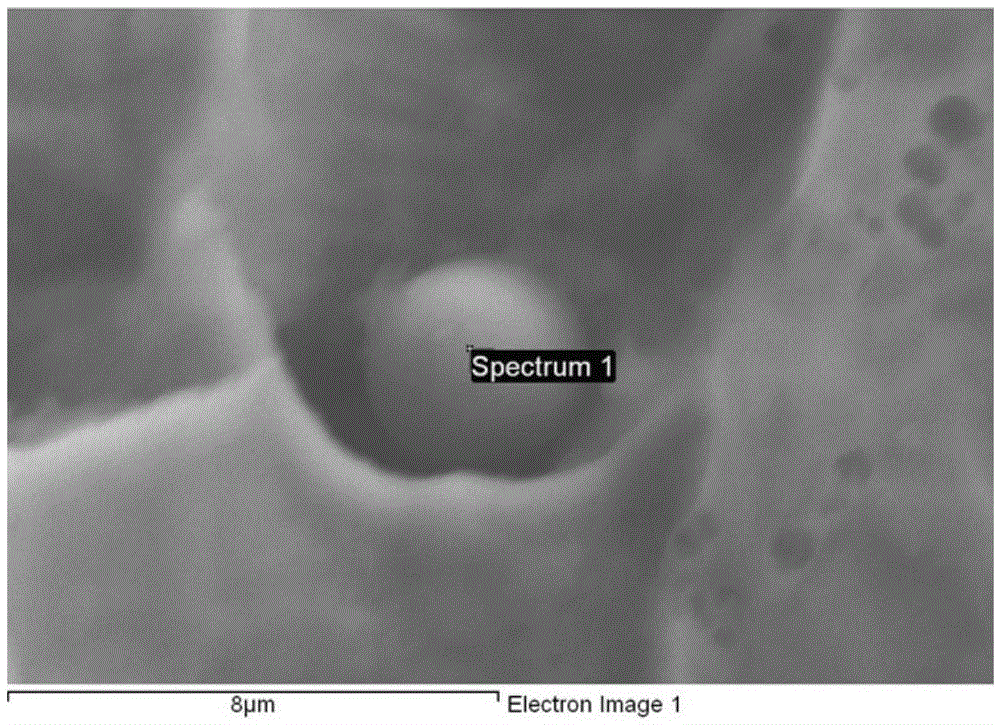

High heat-conducting copper-based composite material and preparation method thereof

InactiveCN101831584ALow densitySmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingInterfacial thermal resistanceThermal expansion

The invention relates to a high heat-conducting copper-based composite material and a preparation method thereof, belonging to the technical field of electronic packaging materials. The copper-based composite material consists of 50-80 percent by volume of electroplated diamond particles and 20-50 percent by volume of copper. The electroplated diamond particles and a caking agent are mixed according to the volume ratio of 1:1-4:1 and are produced into a diamond prefabricated part by using an injection forming process of the prefabricated part; and a copper matrix is directly placed on the diamond prefabricated part or is melt and poured on the diamond prefabricated part to be produced into the high heat-conducting copper-based composite material by using a pressure infiltration process. The copper-based composite material has higher heat conductivity ratio than that of an aluminum-based composite material; by plating the surface of diamond, the interface bonding of the matrix copper and the diamond can be improved and the interface heat resistance can be reduced; in addition, the material has low density and small thermal expansion coefficient and meets the requirement for light quality of packaging materials.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

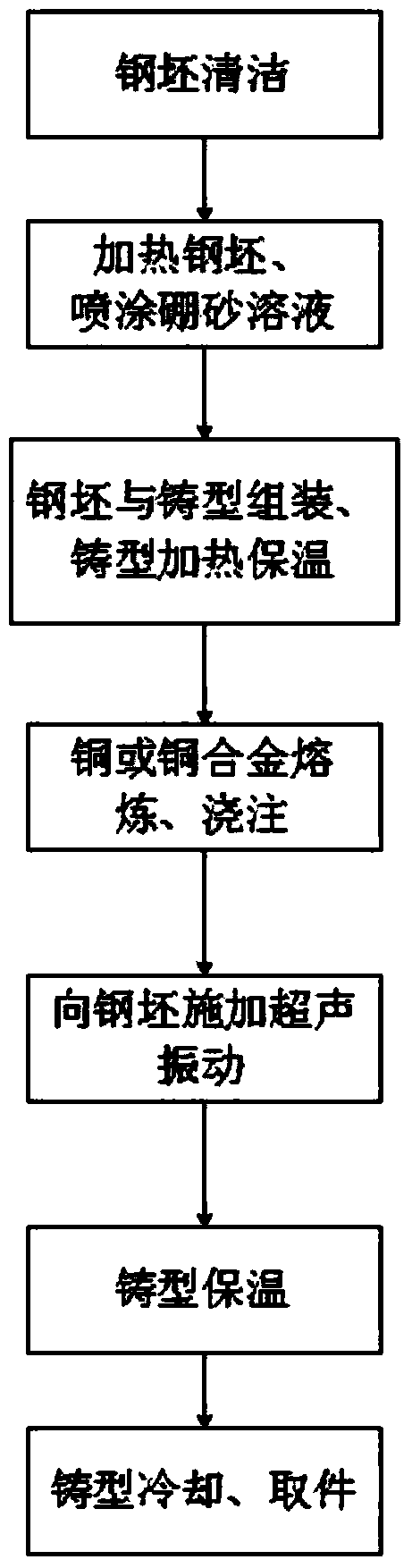

Copper-steel bimetal casting improved technology

The invention provides a copper-steel bimetal casting improved technology. Copper or copper alloy in a certain thickness is directly cast on a steel base body through a static cast type casting method, and the main technical process comprises the steps of: cleaning a steel billet, heating the steel billet and spraying a borax solution on the heated steel billet, combining the cast, heating and keeping the heat, melting and pouring the copper or copper alloy, performing ultrasonic vibration on the steel billet, and keeping the high temperature of the cast. Through the copper-steel bimetal casting improved technology provided by the invention, the ultrasonic vibration and stirring step is added on the basis of the static embedding process technology, a copper or copper alloy layer in a certain thickness and without segregation can be obtained by casting on steel billets in various types and various sizes, and good metallurgical bonding can be realized between the copper or copper alloy layer of the obtained cast and the steel billet.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Method for manufacturing cast magnesium alloy

The invention discloses a method for manufacturing cast magnesium alloy, omprising the steps: 1, batching: calculating the percentage of elements including Gd, Y, Zr, and Mg as balance; calculating the weight and the respective batching weight of elements; 2: smelting: adding in sequence Mg, Mg-Gd, Mg-Y and Mg-Zr with Gd, Y and Zr as intermediate alloy; feeding in SF6 / CO2 protective gas for refining; dredging up dregs at the bottom of a crucible, then reheating the crucible to 780-800 DEG C, standing the crucible for 30 minutes under heat preservation, and cooling the crucible to 730-740 DEG C along with furnace and subsequently removing scum on the surface; 3: pouring: preheating a mould, adjusting the temperature of magnesium alloy melt and pouring; 4: heat treatment, including: solution treatment and aging treatment. Solving the problems of high cost, low elongation percentage, inadequate heat resistance of the manufactured material, environmental pollution and the like, the method obtains the effect of high strength, good heat resistance, small tendency of incompactness, segregation and crack of the manufactured material.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

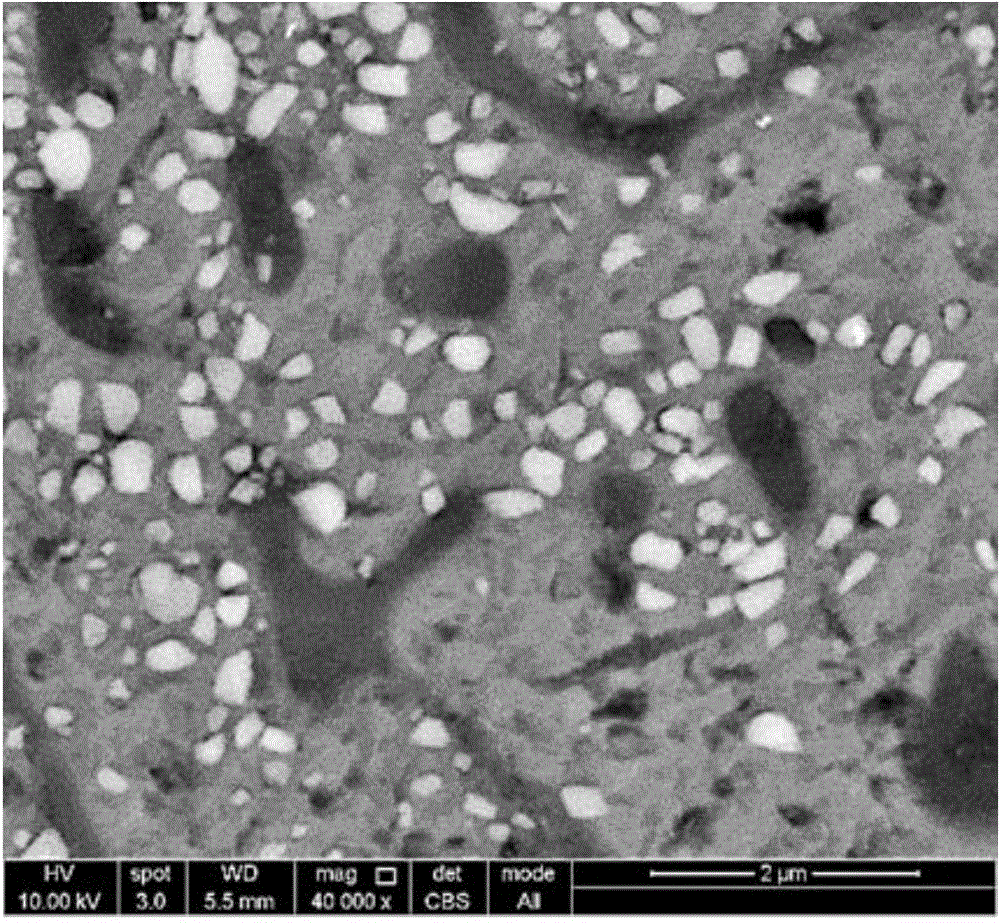

In-situ particle mixed reinforced aluminum-based composite material and preparation method thereof

ActiveCN104911416AGuaranteed lightweight requirementsIncrease volume fractionPhase volumeMaterials science

The invention discloses an in-situ particle mixed reinforced aluminum-based composite material and a preparation method thereof. TiB2 and Mg2Si are taken as particle reinforcements, and are generated by reacting KBF4 and K2TiF6 mixed salts and adding alloy elements, respectively; the volume fractions of the two reinforcements (TiB2 and Mg2Si) in the whole composite material are 1-10% and 2-20%, respectively. The aluminum alloy matrix is an Al-Mg alloy. The preparation method comprises the following steps: pretreatment, namely drying and mixing the alloy accessories and mixed salts; melting the alloy and keeping the temperature at 700-900 DEG C; adding the mixed salts and stirring mechanically; preserving the heat of the melt and synthesizing TiB2; after finishing heat preservation, reducing the temperature to about 700-780 DEG C and removing the reaction salt residue; adding Si in the form of an Al-Si intermediate alloy and adding pure Mg, wherein the atomic ratio of Si to pure Mg is 1: 2; preserving heat at the temperature of 700-780 DEG C and stirring to synthesize Mg2Si; refining and degassing the melt and pouring. The composite material has the advantages of low density, excellent mechanical properties, large reinforcement phase volume fraction range and the like. The aluminum-based composite material with better mechanical properties can be provided while the lightweight requirement is met.

Owner:HUAZHONG UNIV OF SCI & TECH

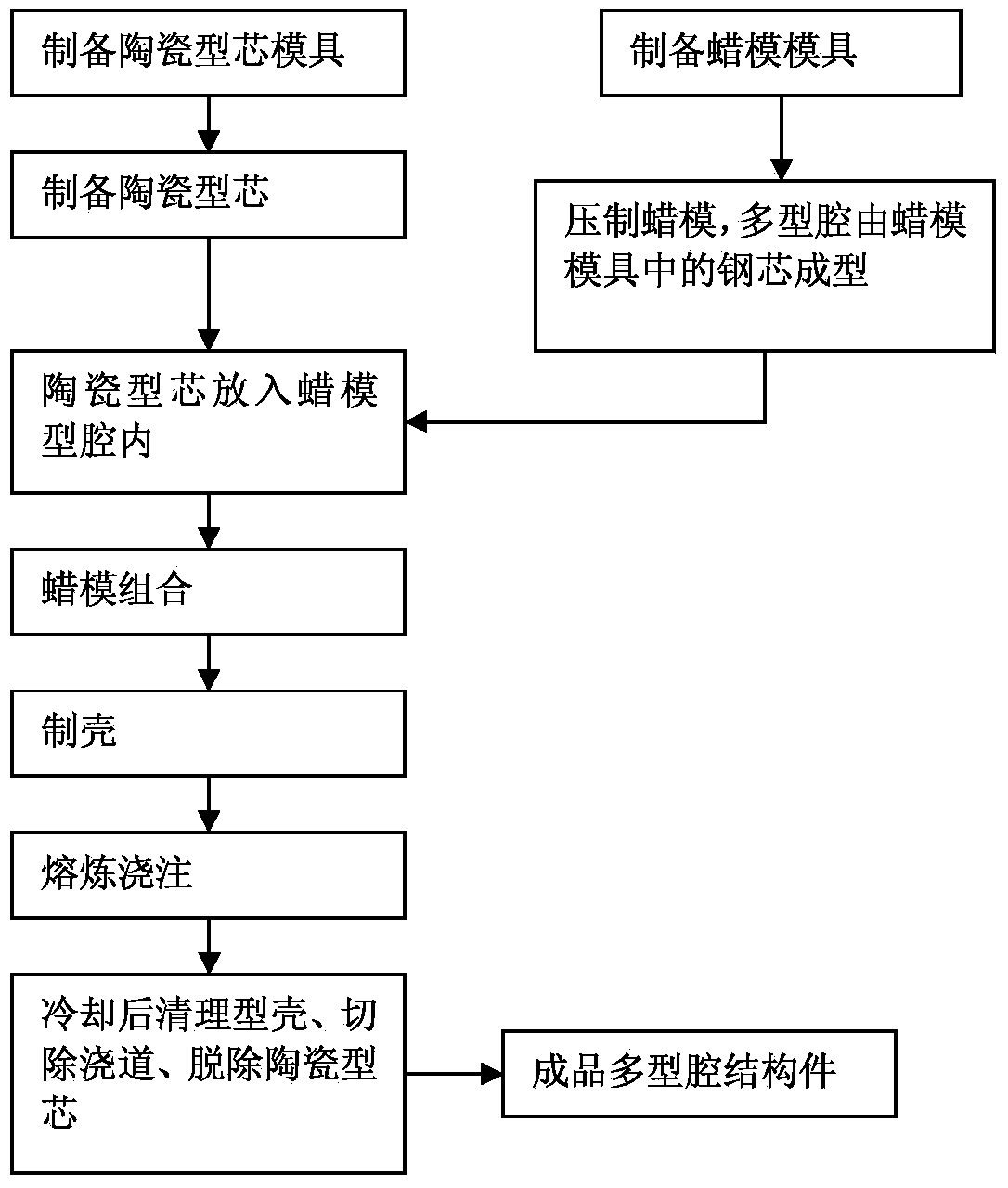

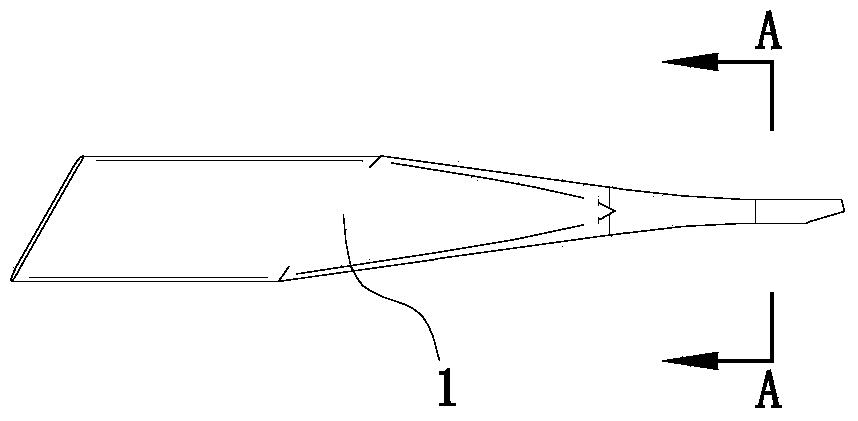

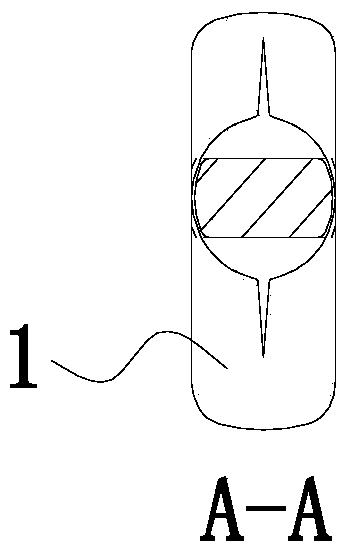

Precision casting method for multi-cavity structural part

ActiveCN103586413AReduced strength requirementsGuaranteed pass rateFoundry mouldsFoundry coresWaxAlloy

The invention discloses a precision casting method for a multi-cavity structural part. The precision casting method for the multi-cavity structural part comprises the following steps: ceramic cores are prepared; multi-cavity structural part wax molds are designed and manufactured, and a plurality of cavities are formed in a manner that steel cores are placed inside each wax mold; the multi-cavity wax molds are obtained through pressing; the pre-prepared ceramic cores are placed inside the cavities of the wax molds, and gaps between the ceramic cores and the wax molds and at the openings of the cavities are sealed through adhesive wax; the wax molds with the ceramic cores are combined into a tree group in a certain manner; the outer surface of the tree group is repeatedly subjected to sizing coating, stuccoing and drying, so as to form a housing which covers the whole outer surfaces of the wax molds and has at least one reserved opening for pouring and / or discharging; the housing is sintered, and the melted wax molds are discharged from the opening, so as to form a hollow housing with the opening; the temperature of the housing is kept, and an alloy material for casting the multi-cavity structural part is melted and poured into the hollow housing until the hollow housing is full of the alloy material; the housing and the ceramic cores are removed after cooling; the multi-cavity structural part is formed.

Owner:CHINA HANGFA SOUTH IND CO LTD

Method for reclamation of precious metals from circuit board scrap

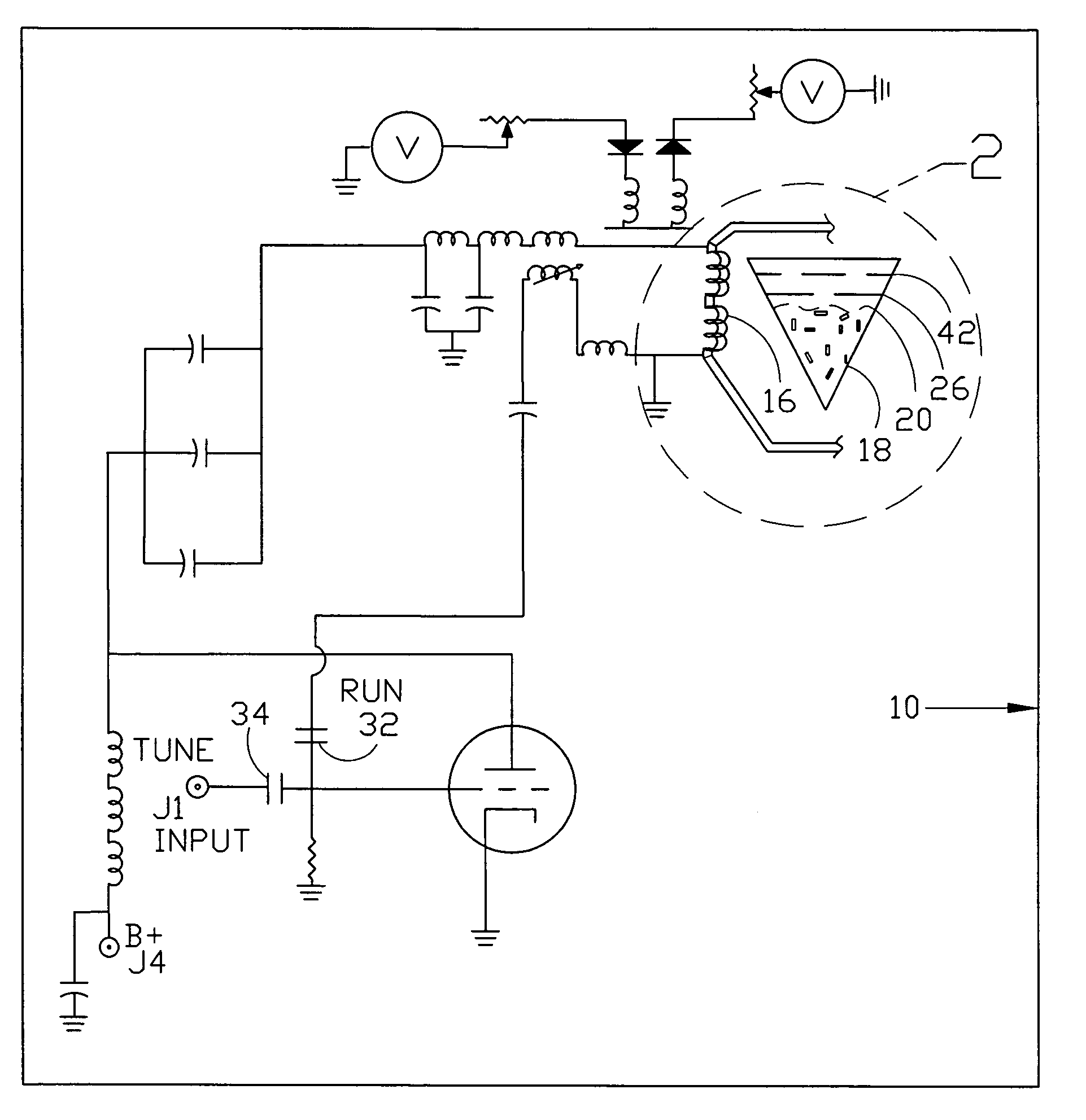

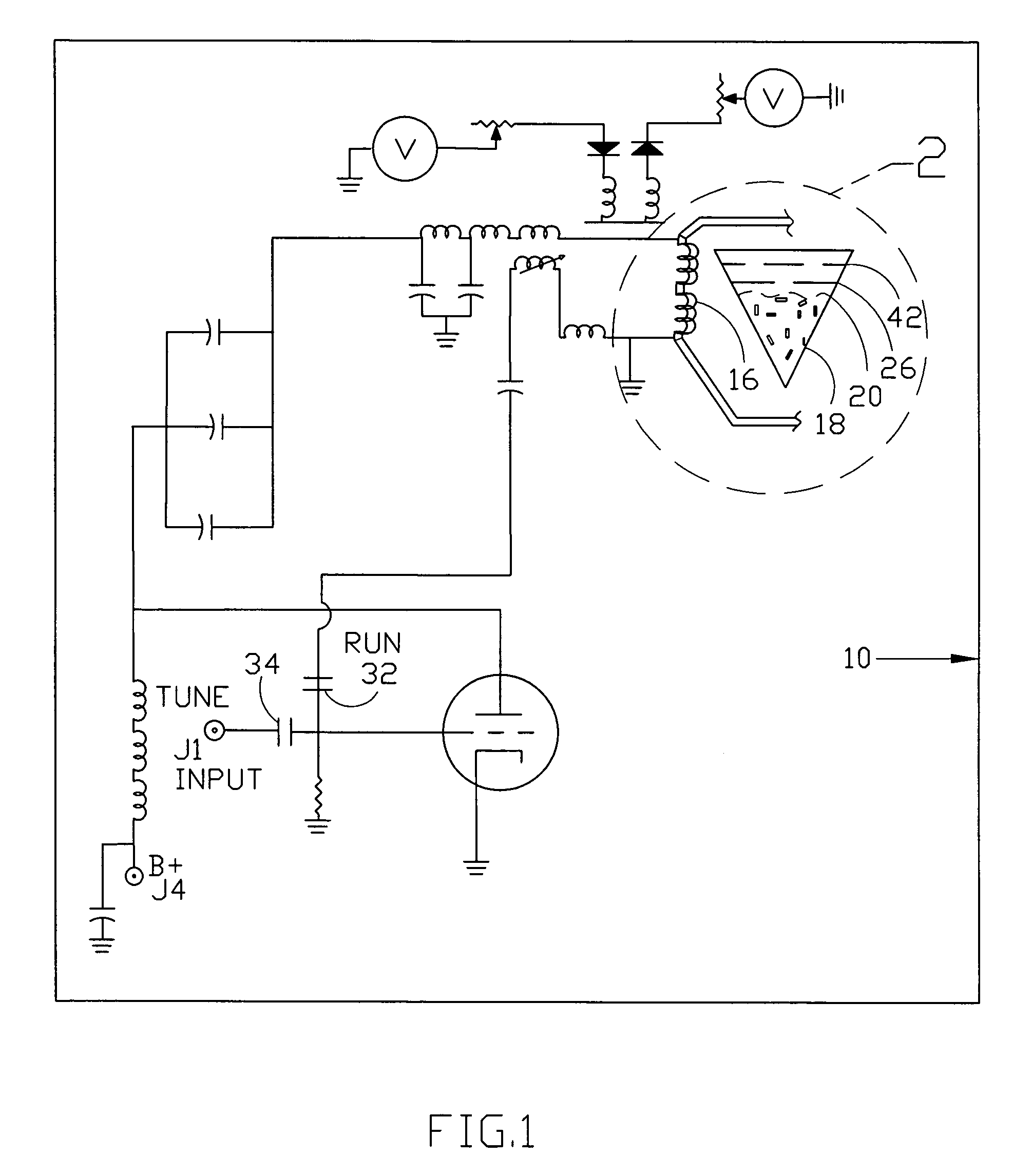

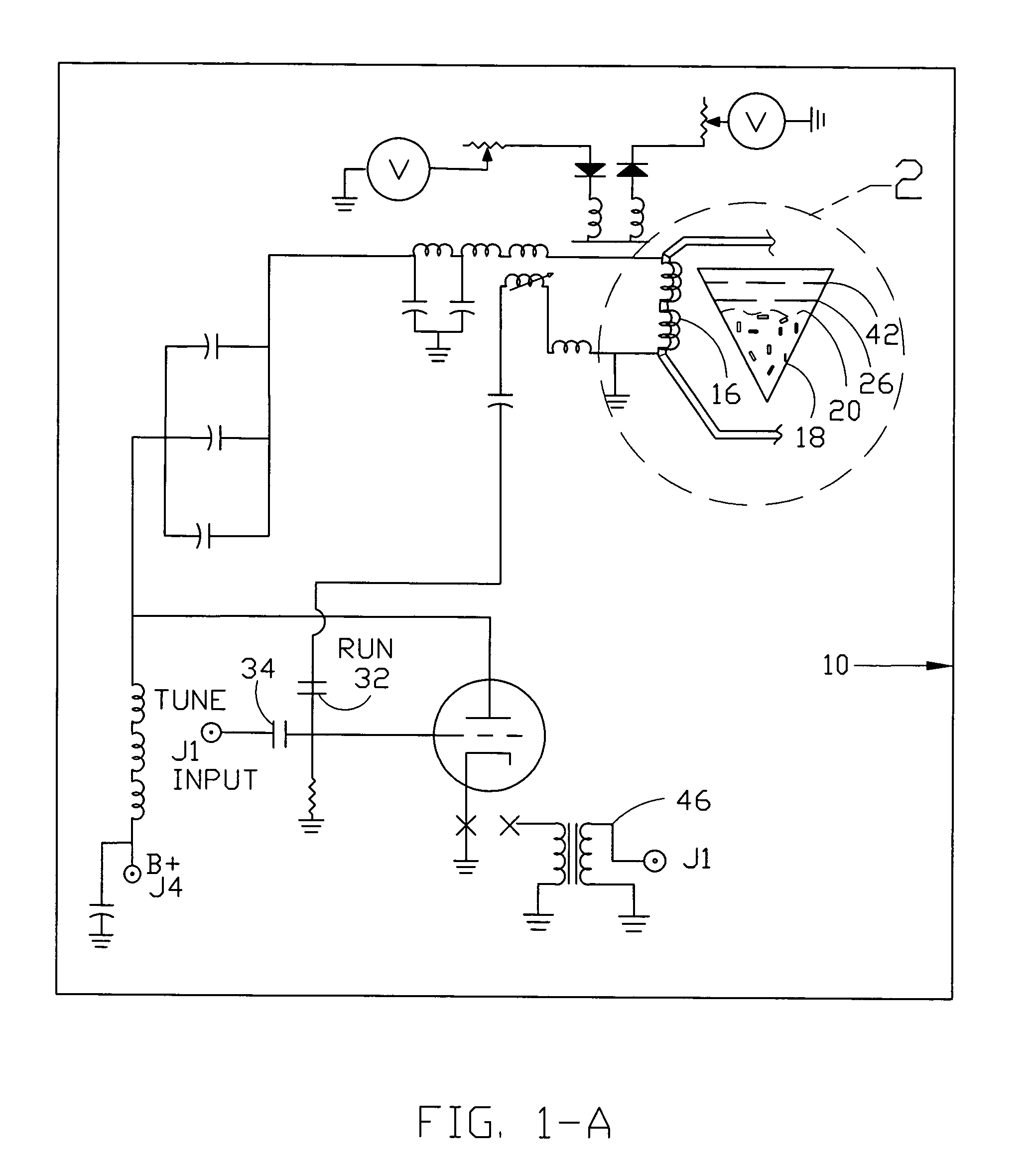

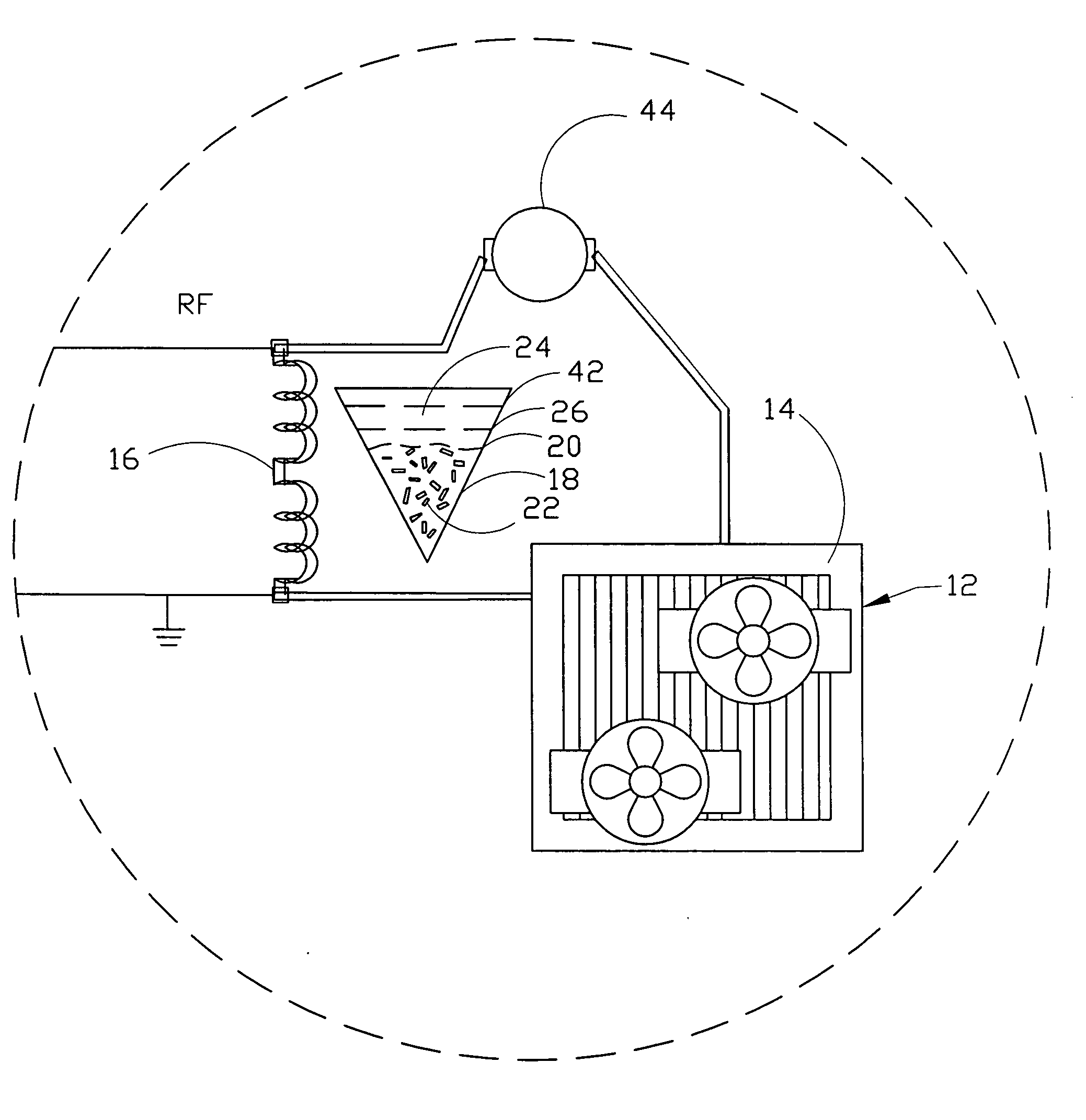

InactiveUS6986192B2Small footprintInexpensiveElectrostatic separationLayered productsDenatured alcoholHigh rate

The present invention springs from the discovery that mild acids could be utilized to shear undesired metals away from desired precious metals that have been plated onto circuit board runners or contacts. This shearing action occurs at a high rate when metal scrap segments are immersed in mild acid and excited by application of an electromagnetic field at specific frequencies and power levels. These frequencies and power levels are based on the end metal desired and the metals contained in the scrap and the acid utilized. When mild acid saturated with copper sulfate and loaded with scrap metals is subjected to an electromagnetic field at the appropriate frequency and power levels copper and nickel molecules are sheared rapidly and absorbed into solution, leaving only the desired metal, such as gold, in a 99.5% pure flake which can be skimmed off the surface of the solution or filtered from the solution. The captured metal flake is then rinsed in water and denatured alcohol, compressed, melted and poured into bars or nuggets for further use or sale.

Owner:FITCH MICHAEL K

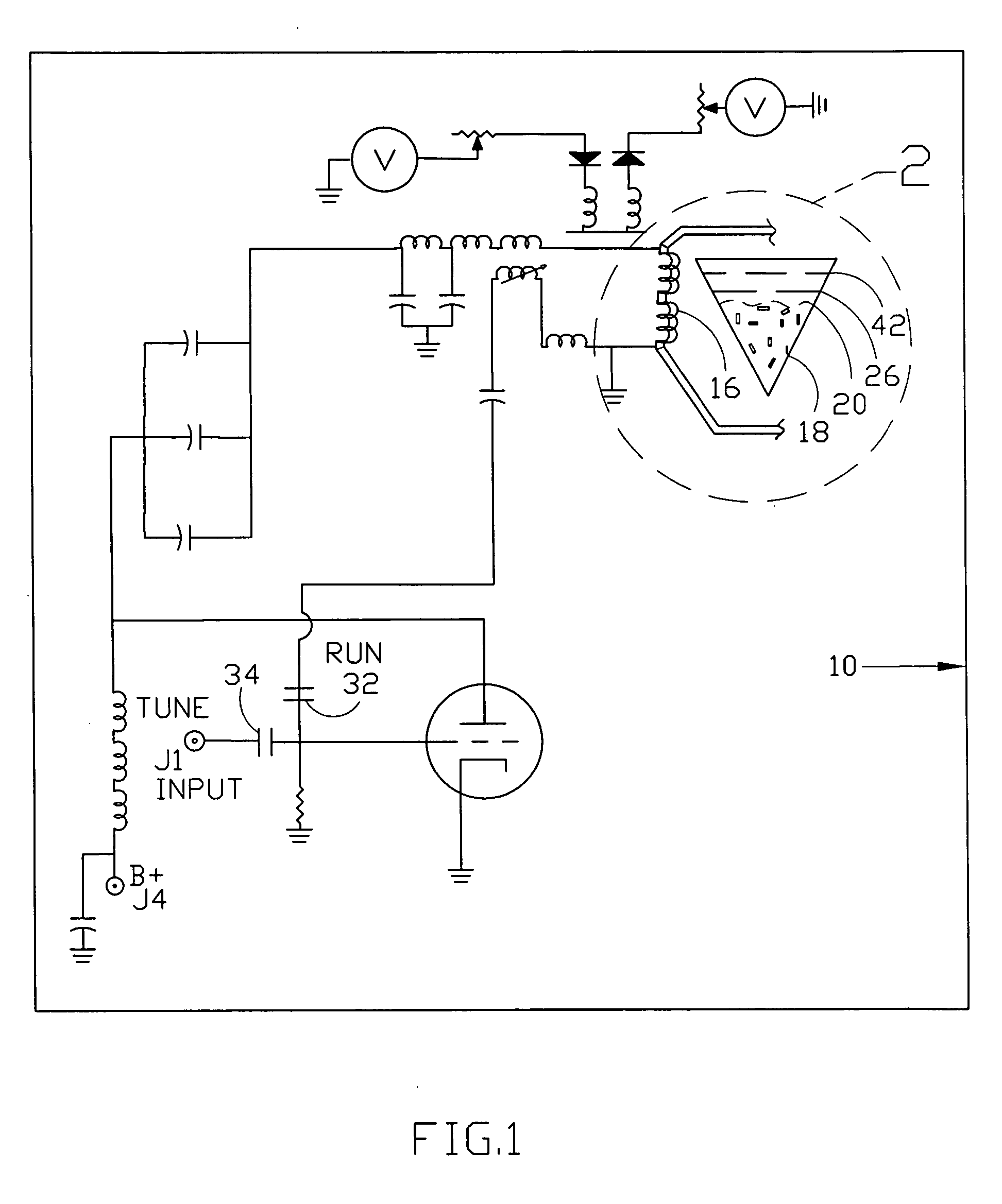

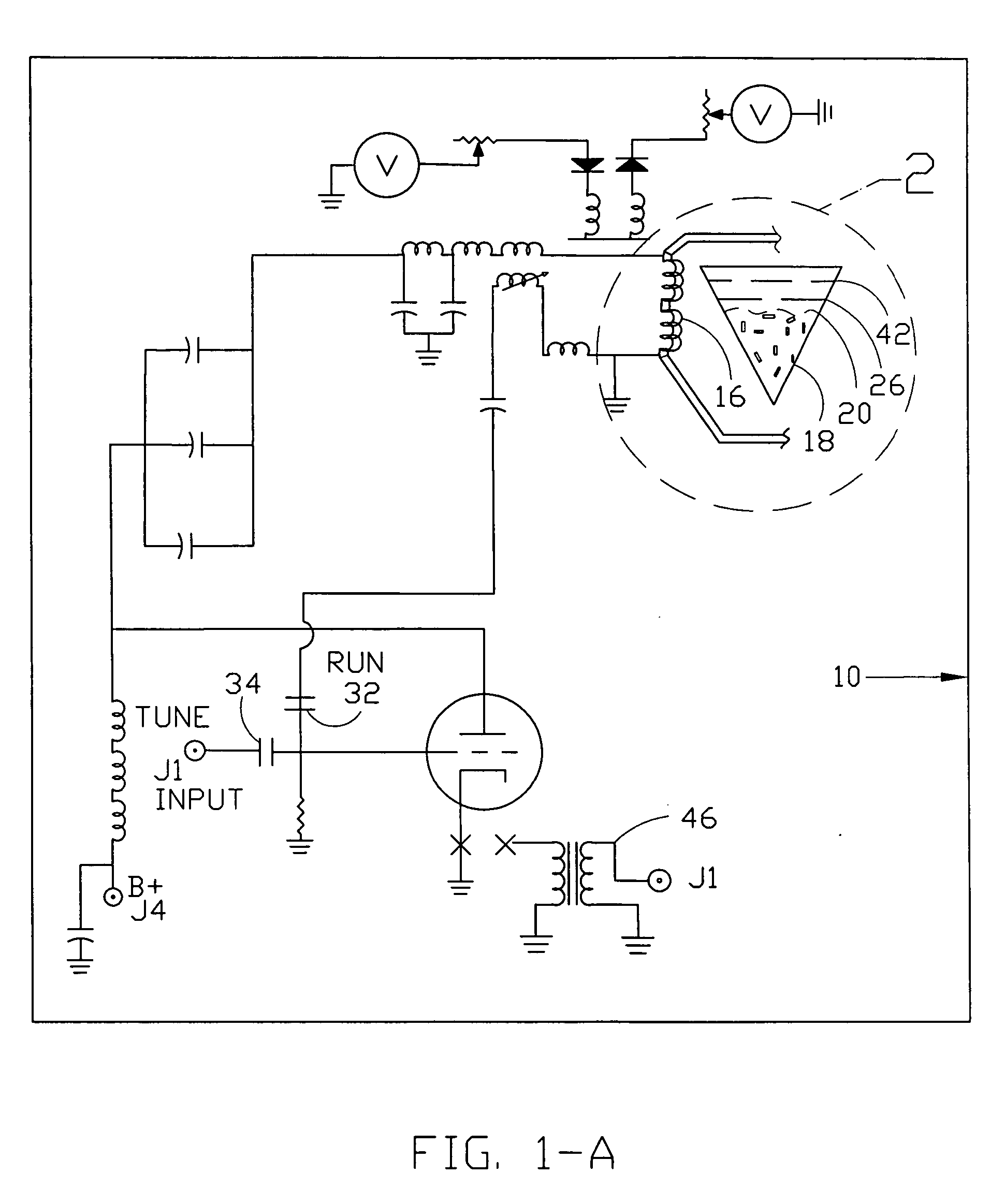

Apparatus for reclamation of precious metals from circuit board scrap

Owner:FITCH MICHAEL K

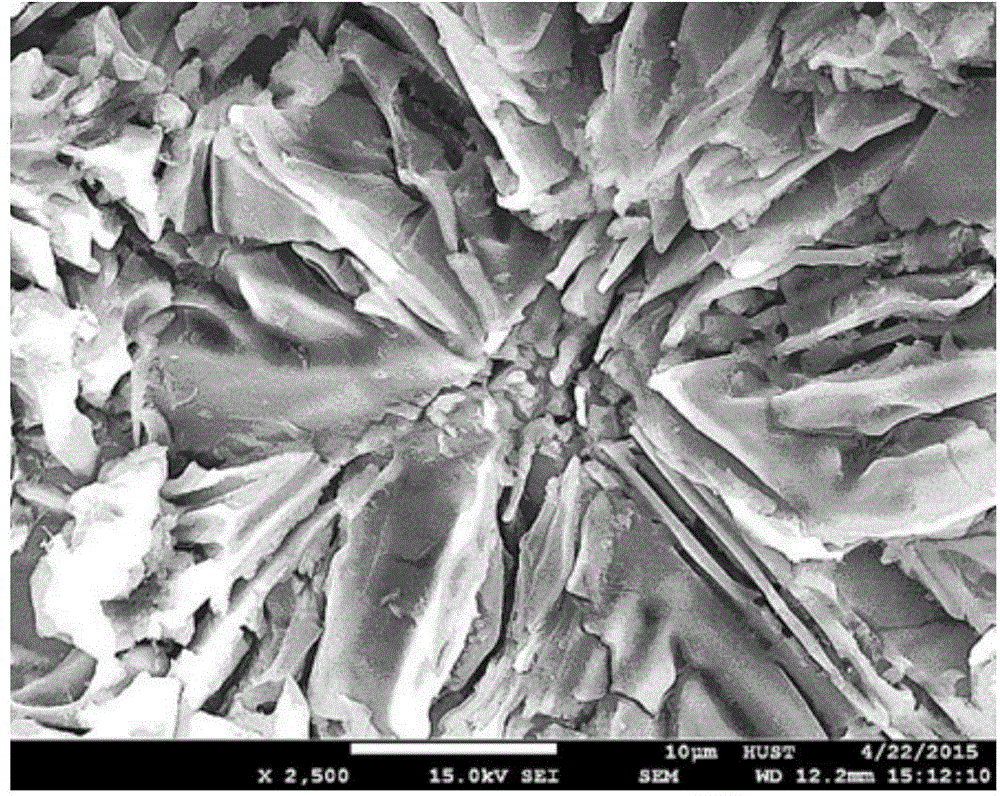

Boron-containing casting die steel and preparation method thereof

InactiveCN101260499AImprove wear resistanceReduce manufacturing costProcess efficiency improvementChemical compositionHigh intensity

The invention relates to boracic cast die steel and a preparation method thereof, which belongs to the die technical field. The boracic cast die steel comprises the following chemical compositions in percentage by weight (wt percent): 0.85 to 1.00 percent of C, 6.0 to 8.0 percent of Cr, 0.6 to 1.0 percent of Si, 0.8 to 1.5 percent of Mn, 2.2 to 2.8 percent of B, 0.25 to 0.5 percent of Al, 1.2 to 1.5 percent of Ti, 0.08 to 0.15 percent of N, 0.05 to 0.08 percent of Mg, 0.08 to 0.12 percent of RE, less than 0.04 percent of S, less than 0.04 percent of P, the balance being Fe. In the invention, molten steel is melted and poured and cast to a die, then kept between 950 DEG C and 1000 DEG C for 2h to 5h and treated by oil quenching and drawing temper between 180 DEG C and 250 DEG C for 6h to 8h, thereby making the boracic cast die steel. Compared with the prior art, the boracic cast die steel has the advantages of high intensity and rigidity, good toughness and wear resistance, low cost, etc.

Owner:BEIJING UNIV OF TECH

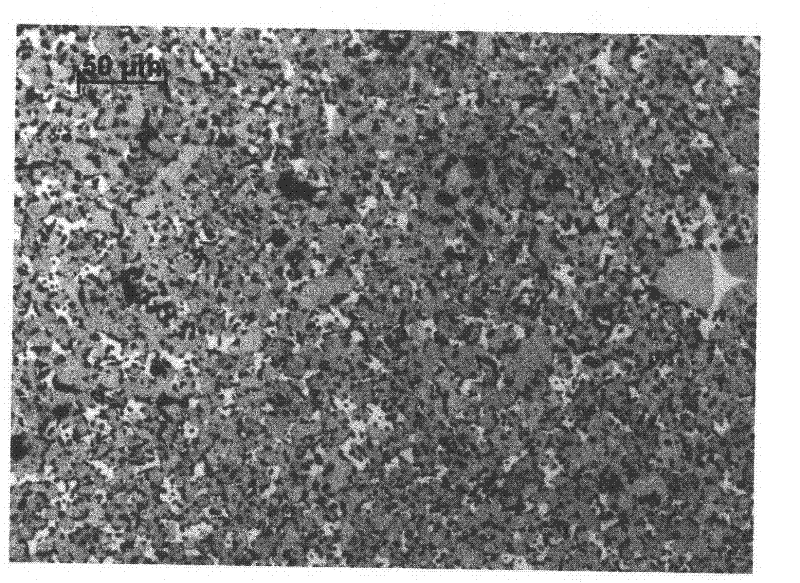

Casting method of SiO2-reinforced nodular cast iron-based brake disc

InactiveCN102367536AWon't wear outReduce hardnessBraking discsFriction liningDuctile ironWear resistance

The invention discloses a casting method of a SiO2-reinforced nodular cast iron-based brake disc. The casting method comprises five steps of SiO2 particle selection, nodular cast iron selection, sand mold preparation, melting and pouring, and cooling and cleaning. The casting method has the advantages that the SiO2-reinforced nodular cast iron-based brake disc obtained by the casting method does not wear brake blocks; SiO2 particles adopted by the casting method are combined according to different particle sizes, are uniformly distributed in a nodular cast iron matrix in a way that large particles and small particles are arranged alternately and have a certain support effect on the nodular cast iron matrix, and thus brake disc wear resistance is greatly improved and a brake disc service life is prolonged; and the casting method is simple and is easy.

Owner:陈均

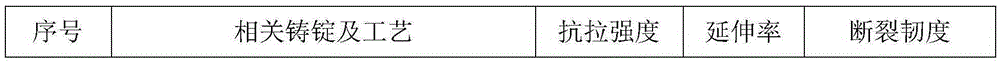

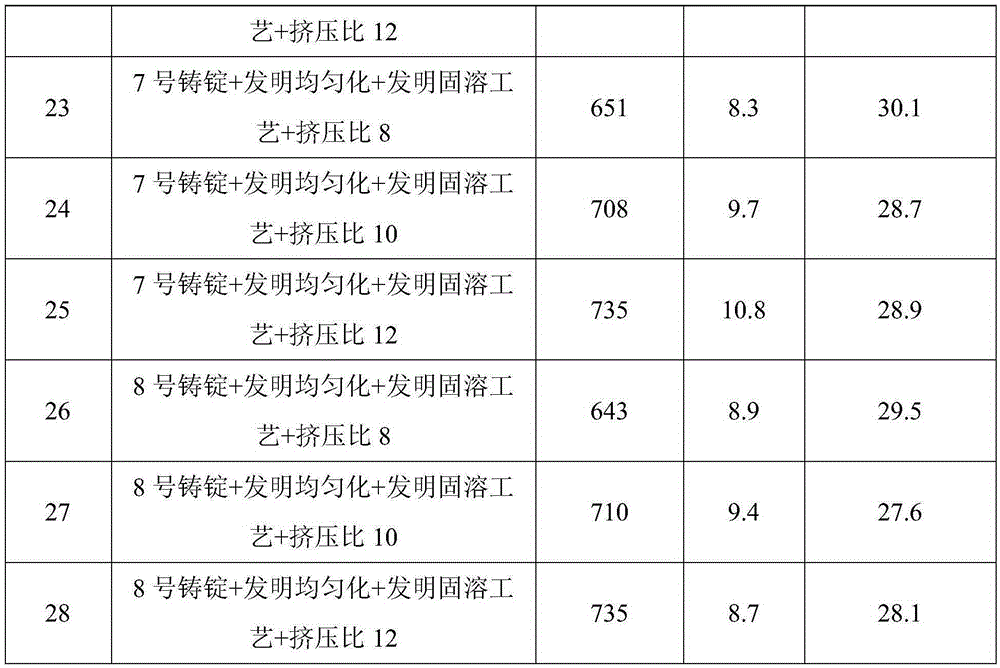

Aluminum alloy extruded sectional material at grade of 700 MPa

The invention provides an aluminum alloy extruded sectional material at the grade of 700 MPa. The sectional material is composed of, by weight, 7.8%-10.3% of Zn, 1.3%-2.0% of Mg, 1.3%-2.0% of Cu, 0.08%-0.15% of Zr, 0-0.15% of Si, 0-0.15% of Fe, 0-0.05% of other single impurities, 0-0.15% of other impurities, and the balance Al. The alloy components are subjected to burdening. The raw materials are melted and poured to form alloy ingots with required specifications after furnace refining and standing. The alloy ingots are subjected to an optimal extrusion technique to be formed after optimized three-grade homogenization, and the alloy ingots can be used for machining parts after heat treatment. The novel aluminum alloy extruded sectional material is even in microscopic structure and stable in performance; the ultimate tensile strength can be over 700 MPa, and meanwhile the elongation rate is higher than 8% and the fracture toughness is up to 26 MPa.m<1 / 2>, so that the requirement for aerospace material selection at present is met, and the aluminum alloy extruded sectional material can be widely applied to the fields of nuclear industry, transportation, weapons and the like at the same time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

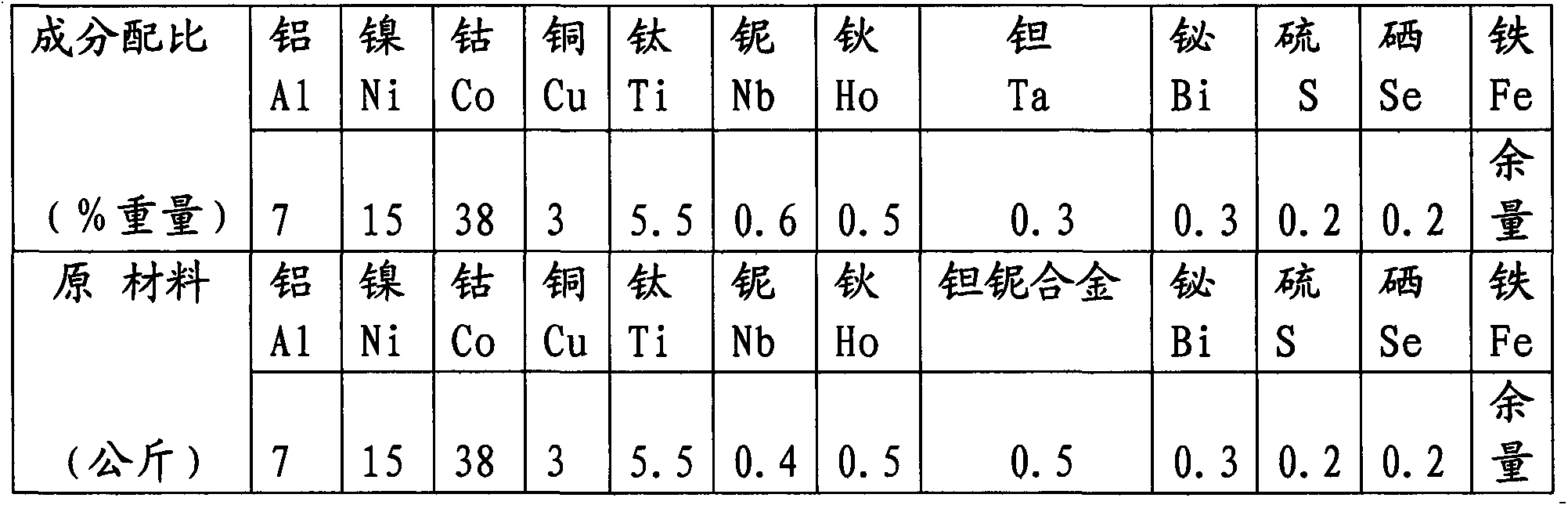

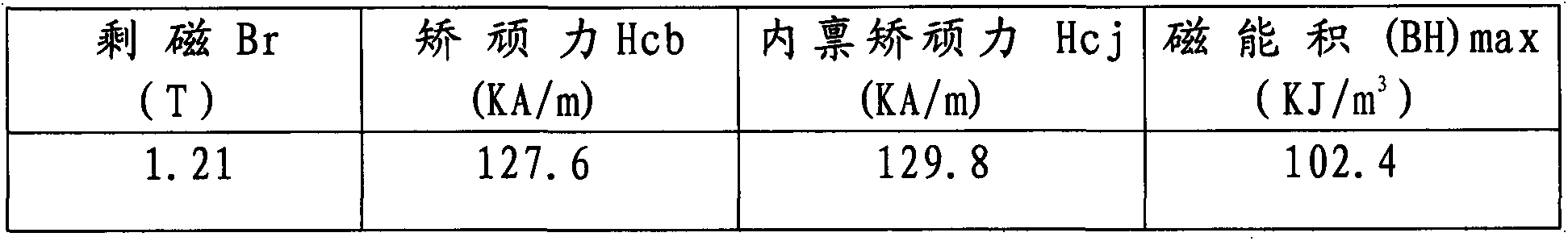

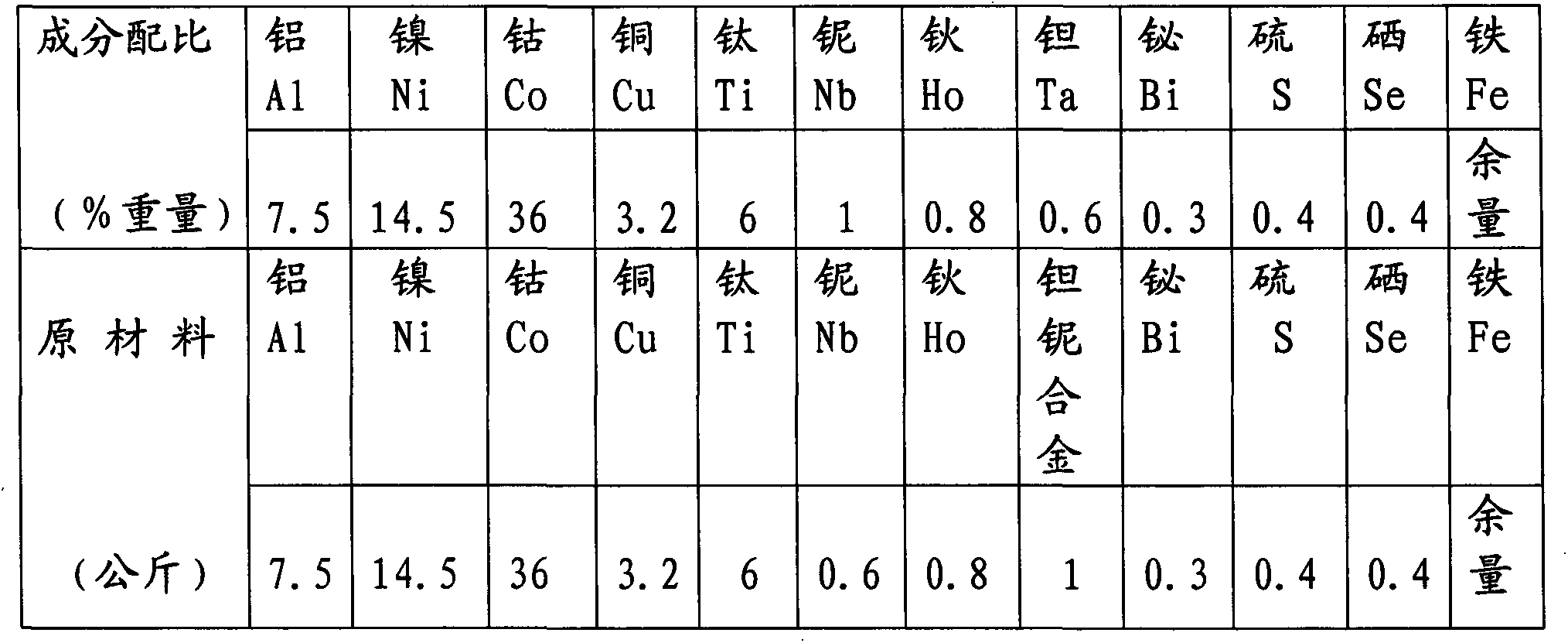

Manufacturing method of columnar crystal Al-Ni-Co-Ti permanent magnetic alloy

Owner:SHENZHEN YINGZU TECH CO LTD

Method for precision casting of titanium alloy

InactiveCN102366819AAchieve precision castingImprove performanceFoundry mouldsFoundry coresMicrowaveTitanium alloy

The invention discloses a method for precision casting of a titanium alloy. The method comprises the five steps of: wax mould preparation, mould shell coating, microwave dewaxing, melting and pouring, and hot isostatic pressing. By integrating advanced rapid prototyping wax mould preparation technology, microwave dewaxing technology, and hot isostatic pressing technology, the invention makes fully use of the advantages of the advanced technologies and realizes precision casting of a Ti-Al-Sn-Zr-Mo-Si high-temperature titanium alloy. The method of the invention can prepare parts with complicated shapes, and guarantees the dimensional precision of casting as well as excellent high-temperature titanium alloy performances.

Owner:刘群联

Preparation method of engine component

InactiveCN105537518AReduce usageReduce porosity defectsFoundry mouldsFoundry coresFiberEnvironmental resistance

The invention discloses a preparation method of an engine component. The preparation method comprises the steps of mold shell preparing, alloy burdening, melting and pouring, cooling, posttreatment and the like. A TiAl-based titanium aluminum compound is adopted as a component material, and therefore the engine component can continuously work for a long time at high temperature, performance is improved, and the service life is prolonged; wood bits and crop straw fibers are adopted as shell manufacturing materials, the usage amount of refractory matter is lowered, and environment friendliness is facilitated; a reasonable ratio is adopted, and air permeability is increased on the premise of guaranteeing the strength of a shell; a porous material, attapulgite, is adopted, air exhaust is facilitated, blowhole defects of the component are reduced, and the yield is increased; and meanwhile the weight of the mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

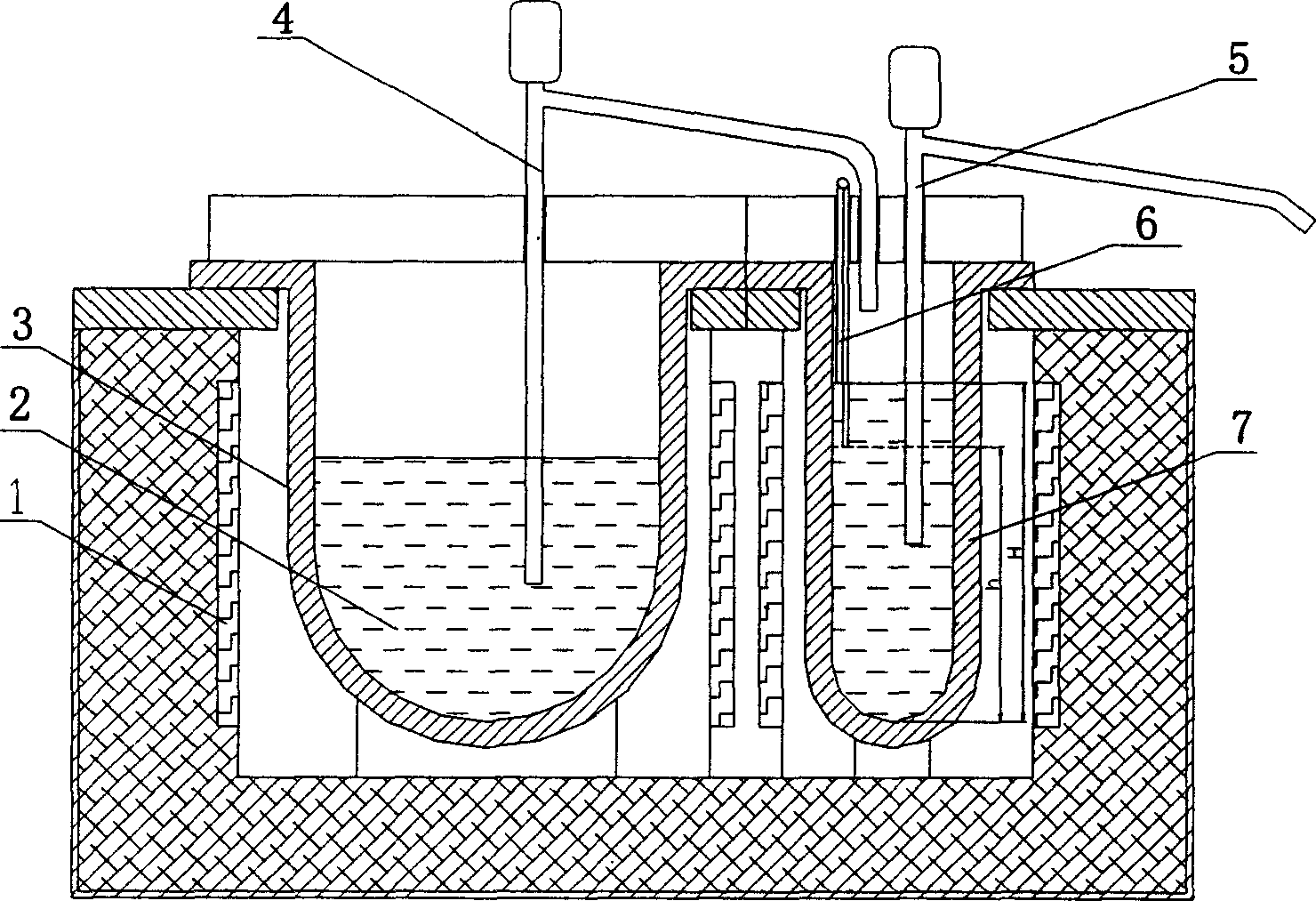

Melting dosing method in two curcibles utilized in procedure of melting and pouring nonferrous alloy

InactiveCN1562530AGuarantee the quantitative accuracy of feedingEasy to controlMolten metal supplying equipmentsCrucible furnacesCrucibleNon-ferrous metal

A dual-crucible smelting and quantitative feeding method for smelting and casting the non-ferrous alloy features that a large-diameter crucible and a small-diameter crucible are respectively used for smelting and temp holding, when the level height in small crucible is lower than the height setting the molten alloy is pumped from the large crucible into small one, and the molten alloy is them pumped in mould.

Owner:TSINGHUA UNIV

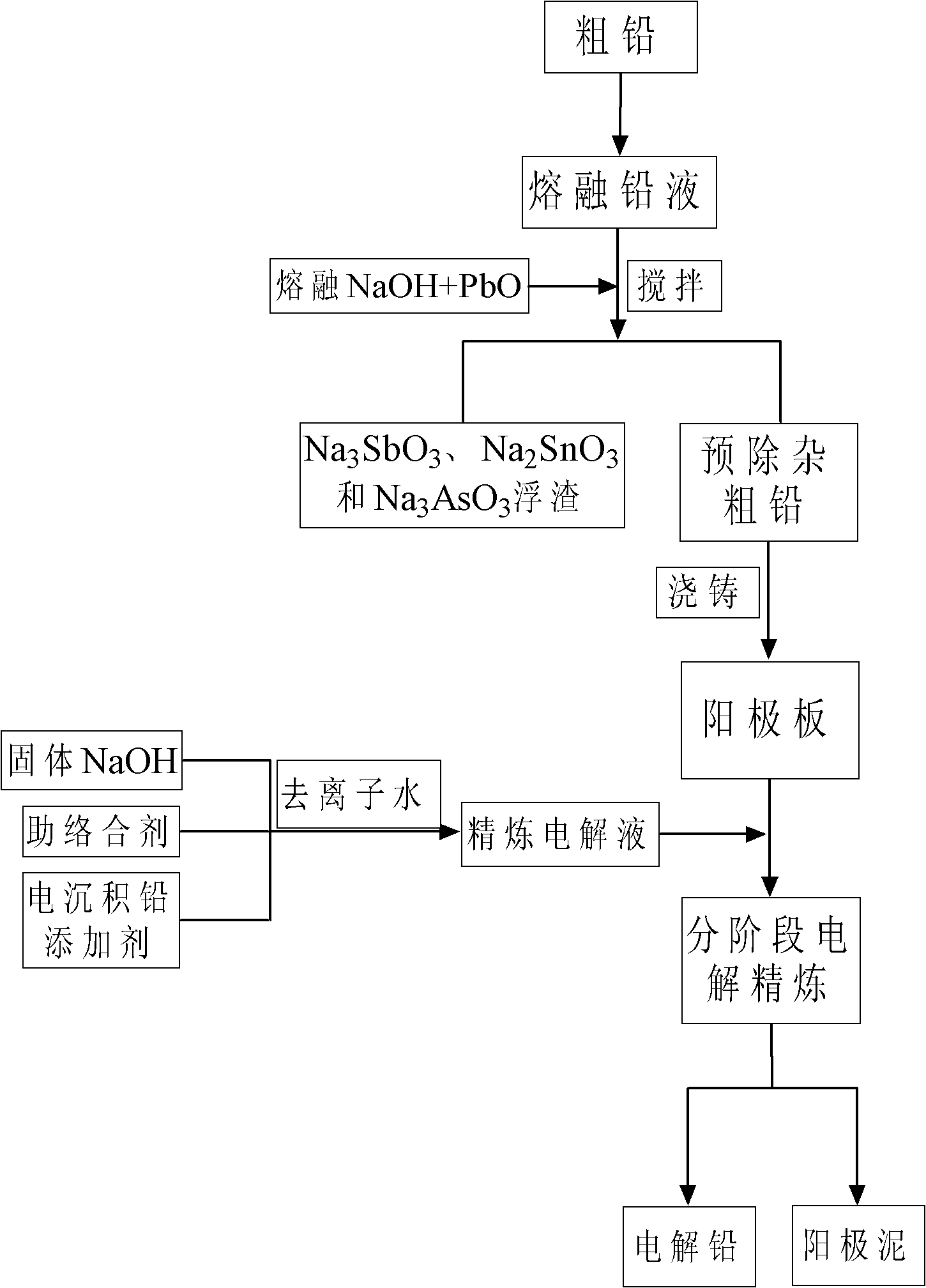

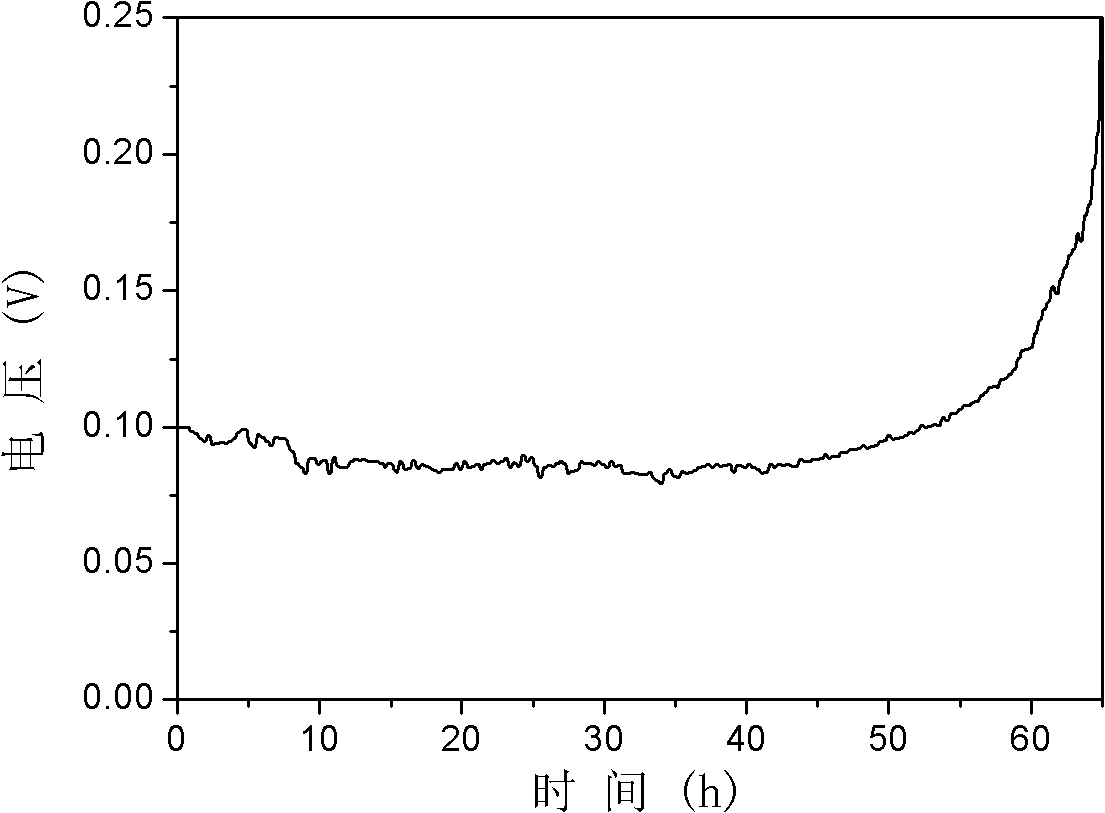

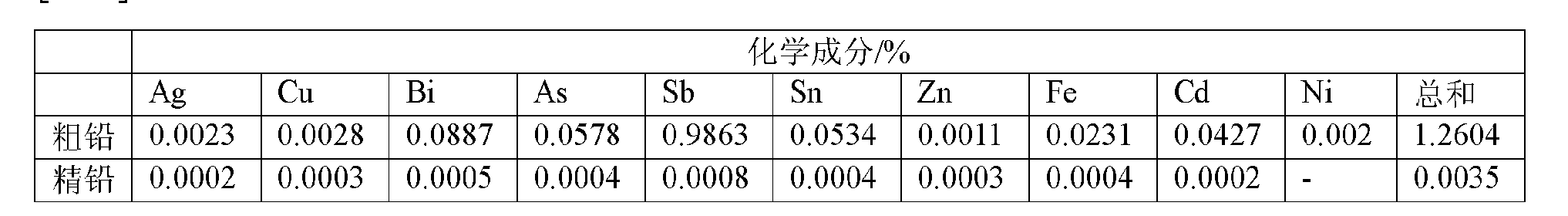

Method for refining crude lead

ActiveCN102534661AImprove solubilityHigh purityPhotography auxillary processesMolten stateEnergy consumption

The invention relates to a method for refining crude lead, which belongs to the technical field of lead refining. Firstly, crude lead that is obtained through smelting or reducing lead reacts with NaOH containing PbO under a molten state so as to pre-remove As and Sb; then crude lead to be purified is processed through electrolytic refining in NaOH solution containing PbO, auxiliary complexing agents and electrodeposition lead additives so as to obtain electroanalysis lead and anode slime; and finally, electroanalysis lead is melted and poured. The method adopts a nontoxic and non-volatile alkaline medium, and adopts NaOH electrolyte with high conductivity, so that compact and smooth electroanalysis lead can be obtained; in addition, lower electrolytic cell pressure is adopted during the electrolytic process, so that electrolysis energy consumption is reduced, and the electrolysis energy conservation effect is obvious.

Owner:BEIJING UNIV OF CHEM TECH

Large ship propeller casting technology

InactiveCN105195681AImprove profile accuracyQuality improvementFoundry mouldsFoundry coresWrinkle skinMedium frequency

The invention discloses a large ship propeller casting technology. The technology includes the first step of sand mold manufacturing, the second step of riser and chilling block arrangement, the third step of melting and pouring, the fourth step of cast drying and cooling and the fifth step of cleaning and riser gas cutting. In the step of riser and chilling block arrangement, two round open risers are arranged at the upper end of a sand mold, and an outer chilling block is placed on the portion, close to the thick and large part of a propeller hub, at the lower end of the sand mold. In the step of melting and pouring, a large double-furnace-body medium-frequency electric furnace is adopted so that a cast alloy ingot can be melted into cast alloy melt, then the cast alloy melt is poured in a bottom injection type pouring mode, and a large ship propeller casting is manufactured after pouring is completed. In the step of cast drying and cooling, after pouring is completed, the large ship propeller casting is dried through an electric hot air furnace, and then heat preservation, cooling and demolding are carried out. In the way, the technology is simple and easy to control, the blade outline precision and the surface quality of a propeller can be improved, the defect that pores, wrinkles and the like occur in the surface of the propeller is avoided, and accordingly the finished product yield of the large ship propeller is effectively increased.

Owner:SUZHOU JINYE MARINE MACHINERY PLANT

Production technology of high-strength rare earth aluminum alloy applied to automotive pedal

ActiveCN103205587AImproved hot workabilityImprove plastic processing performanceAnodisationRare-earth elementPolyester

The invention discloses a production technology of high-strength preparing the components of the aluminum alloy including, based on the mass percentage, 0.508% of Si, 0.886% of Mg , 0.157% of Cr, 0.289 of Cu, 0.192 of Fe, 0.2% of RE , 0.1% of the rest impurities and the balance of Al; S2, melting and pouring at the temperature of 720 DEG C-730 DEG C for 1 minute; S3: extrusion molding; S4: on-line quenching; S5: artificial aging, that is heat preservation for 2.5-3.5h at a temperature of 190-210 DEG C; S6, anode oxidation; S7, spray coating with polyester powder. According to the invention,the contents of Mg and Al are controlled strictly to improve the hot-working property of the alloy; and an appropriate amount of rare earth element is added in the melting and pouring process to improve the plastic processing property and mechanical property.

Owner:CHENGDU SUNSHINE ALUMINUM

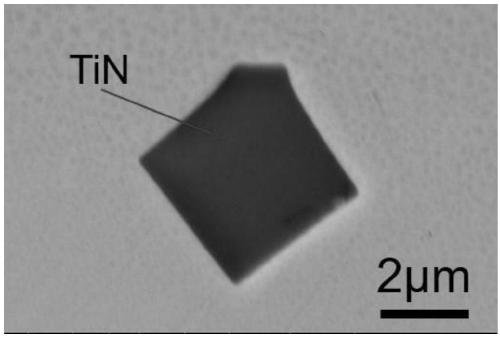

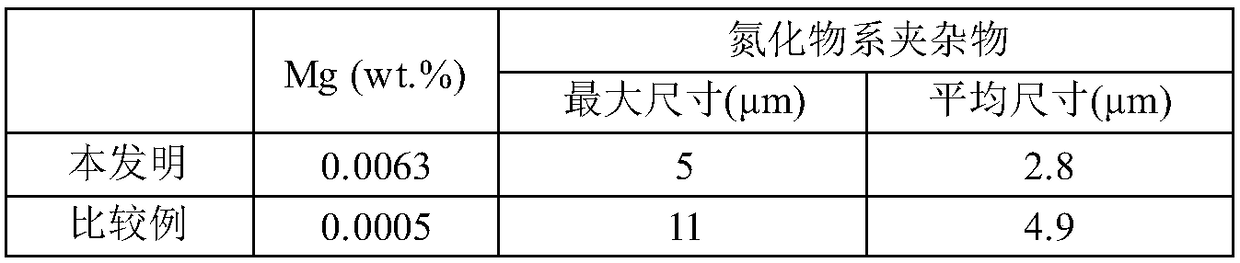

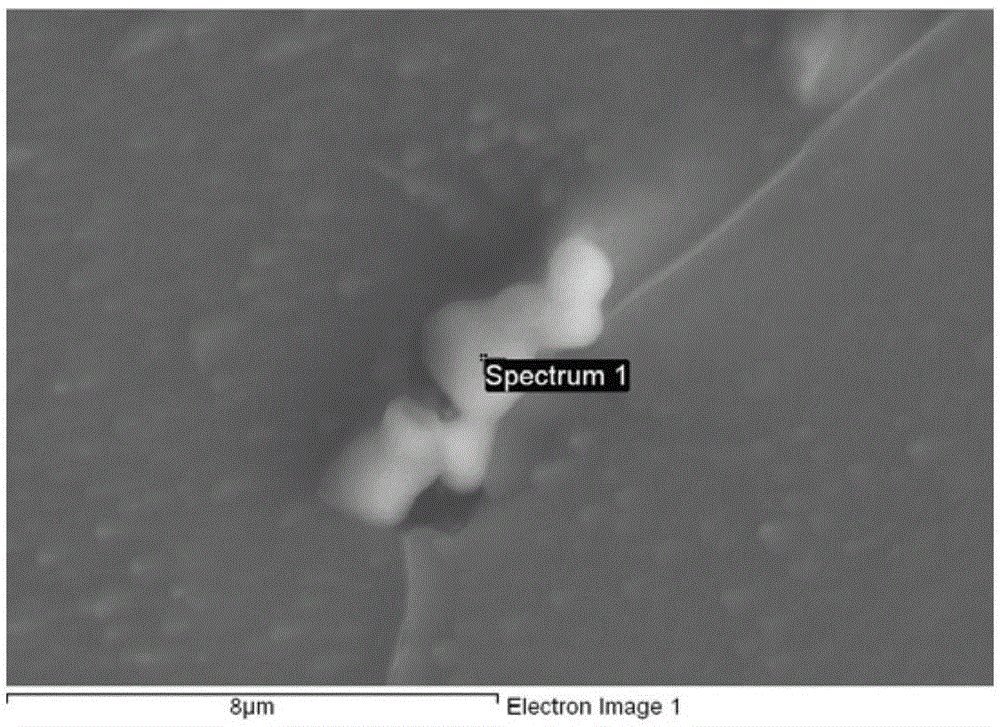

Method for refining nitride inclusions in nickel base deformation high temperature alloy

The invention relates to a method for refining nitride inclusions in a nickel base deformation high temperature alloy. The method includes the following steps that (1), surface pretreatment of metal raw materials is carried out; (2), vacuum induction melting is carried out, specifically, Ni, Cr, Co, W, Mo and so on are put into a crucible and vacuumized, C, Nb, Ti and Al are added after melting, agon is filled, B and Zr are added, then the product is completely melted and poured into a steel mold, and a high temperature alloy electrode is obtained; and (3), vacuum electroslag remelting is carried out, specifically, slag charges containing 0.01-0.5 wt.% of MgO are used, vacuumed to 0.01-100 Pa and then filled the high purity agon to 0.01-0.06 MPa, and slugging and refining are carried out.According to the method for refining the nitride inclusions in the nickel base deformation high temperature alloy, fine even distributed MgO inclusions are formed through a metallurgical reaction of slag and alloy liquid during electroslag remelting, and the core for subsequent formation of the nitride inclusions is provided; the size of the nitride inclusions is decreased, and distribution is more uniform; vacuum electroslag remelting can reduce the number of the nitride inclusions; and by controlling the MgO content in electroslag and technological parameters of electroslag remelting, the content of Mg and the quantity and size of Mg oxide inclusions in the alloy can be precisely controlled, the process is stable, and costs are low.

Owner:UNIV OF SCI & TECH BEIJING

Environment-friendly preparation method for automobile engine shell

InactiveCN105618676AReduce usageReduce porosity defectsFoundry mouldsMetallic material coating processesFiberRefractory

The invention discloses an environment-friendly preparation method for an automobile engine shell. The environment-friendly preparation method includes the steps of mold shell preparation, alloy burdening, melting and pouring, cooling, aftertreatment and the like. According to the environment-friendly preparation method, a TiAl-based titanium aluminum compound serves as a shell material, long-time continuous work can be done at a high temperature, the performance is improved, and the service life is prolonged; fine wood bits and crop straw fibers serve as shell manufacturing materials, so that the using amount of refractory matter is reduced, and environmental protection is facilitated; reasonable matching is adopted, so that the breathability is increased on the premise that the shell strength is guaranteed; and cellular material attapulgite is adopted, so that exhausting is facilitated, the defect of air holes in the shell is reduced, the rate of finished products is increased, and meanwhile the weight of the mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

Method for preparing metal material with controllable long and deep through holes

The invention belongs to the field of material preparation and processing, and relates to a method for preparing a metal material with controllable long and deep through holes. The preparation method comprises the steps of selecting fibers, preparing a preform, and melting and pouring the metal material. The method has the advantage of solving the problems of incontrollable hole diameter, hole depth and distribution of the material with long and deep through holes, and can be used for preparing the metal material with controllable position, porosity, diameter and ratio of depth to diameter of long and deep through holes; the diameter of the long and deep through holes of the prepared material is 0.01-10mm, and the ratio of depth to diameter is 1-500. The preparation of the metal material with the long and deep through holes is simple in process and low in cost, and is easy for industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

High-toughness casting Fe-Cr-Mo-based high-damping alloy and preparation method thereof

The invention provides high-toughness casting Fe-Cr-Mo-based high-damping alloy. The alloy contains 0.05-0.8% of Zr in percentage by mass. Preferably, the alloy comprises the following components in percentage by mass: 13-17% of Cr, 1-4% of Mo, 0.3-1.5% of Si, 0.3-1.0% of Mn, 0-2.0% of Ni, 0.05-0.8% of Zr and the balance of Fe. The preparation method of the high-toughness casting Fe-Cr-Mo-based high-damping alloy comprises the following steps: weighing raw materials according to the components and the component ratio of the high-toughness casting Fe-Cr-Mo-based high-damping alloy; carrying out vacuum induction melting and pouring to obtain an alloy casting; and carrying out damping heat treatment on the alloy casting to obtain the high-toughness casting Fe-Cr-Mo-based high-damping alloy. During vacuum induction melting, a Zr source is added in the later stage of refining under the condition of vacuum. On the premise of not reducing damping property, the toughness of the Fe-Cr-Mo-based damping alloy can be greatly improved.

Owner:SICHUAN UNIV

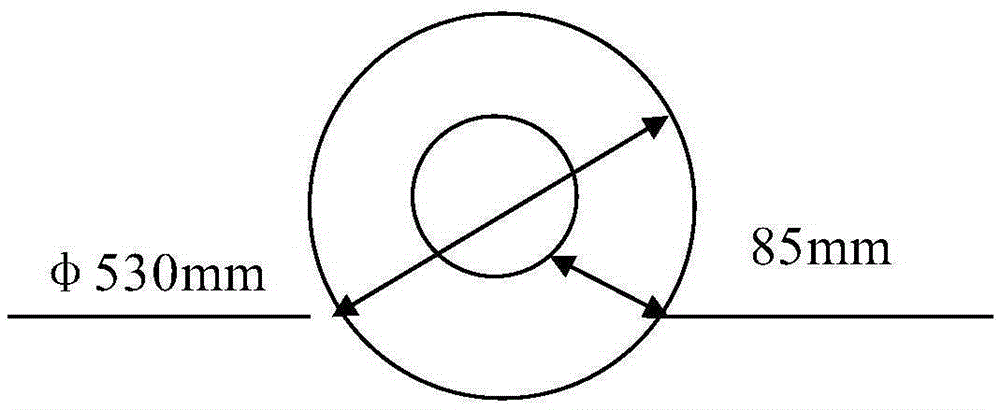

Manufacturing method of ultrahigh cylindrical parts

ActiveCN105290282AShort mass production cycleHigh yieldMetal rolling arrangementsDiameter ratioMelt and pour

Owner:DAYE SPECIAL STEEL CO LTD

A kind of preparation method of oxide dispersion strengthened nickel base alloy

A method for preparing an oxide dispersion-strengthened nickel-based alloy, characterized in that: the specific process of the preparation method for the oxide-based dispersion-strengthened nickel-based alloy is as follows: the first step: first prepare a part of the nickel-based alloy component metal and Composite powder composed of metal oxides, and then the composite powder is molded, the green body is sintered in a reducing atmosphere, and then cooled to room temperature and taken out to obtain a metal oxide master alloy; the second step: according to the composition ratio, the metal The oxide master alloy and the master alloy can be smelted and poured in a furnace. Compared with the prior art, the oxide dispersion-strengthened nickel-based alloy prepared by the present invention can be used as an irreplaceable high-temperature component of aero-engine and gas turbine (for example: turbine blades, guide vanes, turbine discs and combustion chambers) key structural materials. At the same time, the process of the invention is relatively simple, and the technical effect is obviously better than that of the prior art.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

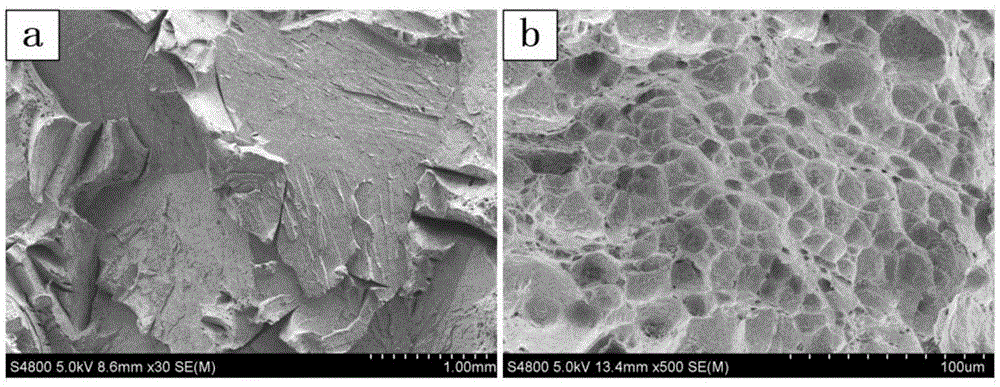

Method for preparing composite abrasion-proof lining board

The invention discloses a method for preparing a composite wear resistant lining plate. The method comprises the following steps: adopting alloy powder core bar materials of which the volume percentage is between 20 and 60 percent of the total volume of the lining plate, filling alloy powder in the core part of the alloy powder core bar materials, preset the alloy powder core bar materials in a lining plate casting mould, selecting base metal to be melted and poured in the lining plate casting mould, and cooling and demoulding the lining plate to obtain the composite wear resistant lining plate consisting of the alloy powder core bar materials and the base metal. The cylindrical hard phase of the composite wear resistant lining plate prepared by the method is generated by compounding in situ in a matrix, thus the composite wear resistant lining plate has the characteristics that segregation is not generated, the organization structure is even, the hard phase is difficult to fall off, the lining plate not only has the intensity and the toughness of the base metal but also has the high hardness and the high wear resistance of the hard phase, the service life is improved by an order of magnitude compared with the prior lining plate, the lining plate can bearing high impact force and strong wear at the same time, the technological parameter controllability of the preparation process is strong, and the price is low. The composite wear resistant lining plate can satisfy the applications under complex working conditions such as various wears, high impact and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

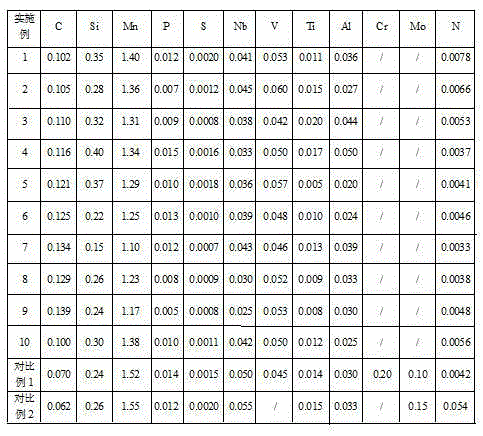

Economical X65 petroleum and gas pipeline steel and production method thereof

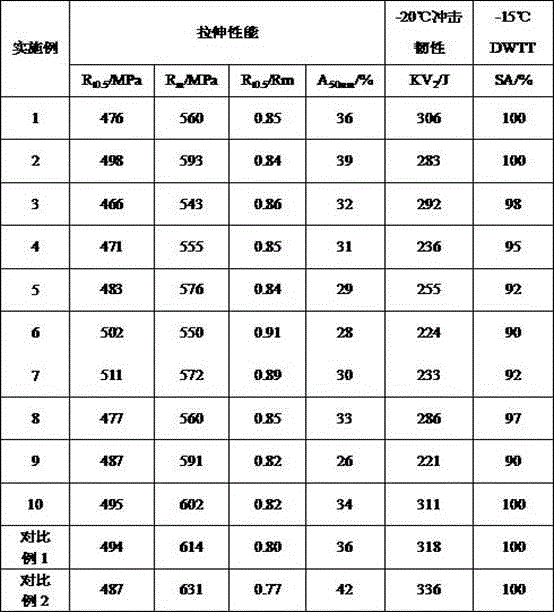

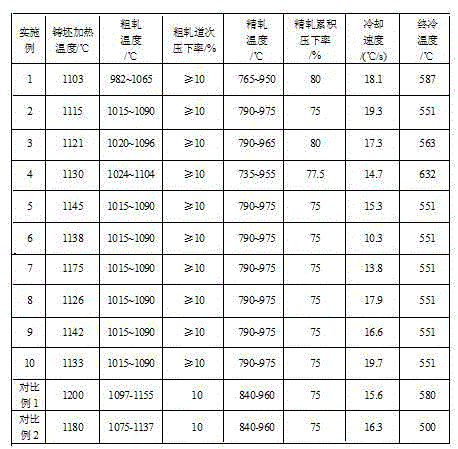

The invention discloses economical X65 petroleum and gas pipeline steel. The economical X65 petroleum and gas pipeline steel comprises, by weight, 0.10-0.14% of C, 0.15-0.40% of Si, 1.10-1.40% of Mn, less than or equal to 0.015% of P, less than or equal to 0.0020% of S, 0.025-0.045% of Nb, 0.041-0.060% of V, 0.005-0.020% of Ti, 0.020-0.050% of Al, and less than or equal to 0.008% of N. The production method comprises the following steps of carrying out melting and pouring blank-molding, heating the casting blank, carrying out rough rolling by a wide-heavy plate mill, carrying out two-stage finish rolling by the wide-heavy plate mill, carrying out cooling and carrying out straightening. The economical X65 petroleum and gas pipeline steel has a price reduced by greater than or equal to 5%, and has steel plate yield strength (R<t 0.5>) greater than or equal to 450MPa, tensile strength (Rm) greater than or equal to 535MPa, yield ratio (R<t 0.5> / Rm) less than or equal to 0.91, elongation percentage (A50mm) greater than or equal to 24%, -20 DEG C KV<2> greater than or equal to 200J and -15 DEG C DWTT SA greater than or equal to 85%.

Owner:武汉钢铁有限公司

Preparation method for precision-investment casting mold shell of easily-oxidized metals

ActiveCN107159869ASimple configurationHigh strengthFoundry mouldsFoundry coresPrecision castingCoating

The invention provides a precision-investment casting method for easily-oxidized metals. The precision-investment casting method comprises the following steps of (1) preparation of a surface layer of a mold shell, specifically, a refractory powder is added into a binder and evenly mixed, a wetting agent and an antiforming agent are further added, and even mixing is conducted to prepare surface layer coating; and the coating is smeared on a wax patter, and after drying, the above operations are repeated for many times to form a surface layer mold shell; (2) preparation of a reinforcement layer of the mold shell, specifically, a bauxite powder is added into a silica sol binder and evenly mixed, bauxite sand is adopted to conduct stuccoing, and after drying, the above operations are repeated for many times to form a reinforcement layer mold shell; (3) mold shell dewaxing and roasting, specifically, an infrared dewaxing technology is adopted; and (4) melting and pouring, a vacuum consumable kish melting method is adopted to conduct melting, and a centrifugal pouring technology is adopted to conduct pouring. According to the precision-investment casting method for easily-oxidized metals, a casting produced by adopting the method is precise in size, the minimum wall thickness is small than or equal to 1.0 mm, the surface roughness is smaller than or equal to 6.3 mu m, the surface reaction layer is smaller than or equal to 0.03 mm, and the surface is free of the defects of cold shut, flow marks, microcracks and the like; and moreover the production cost is reduced, the production cycle is shortened, and the method is suitable for volume production.

Owner:SHENYANG RES INST OF FOUNDRY

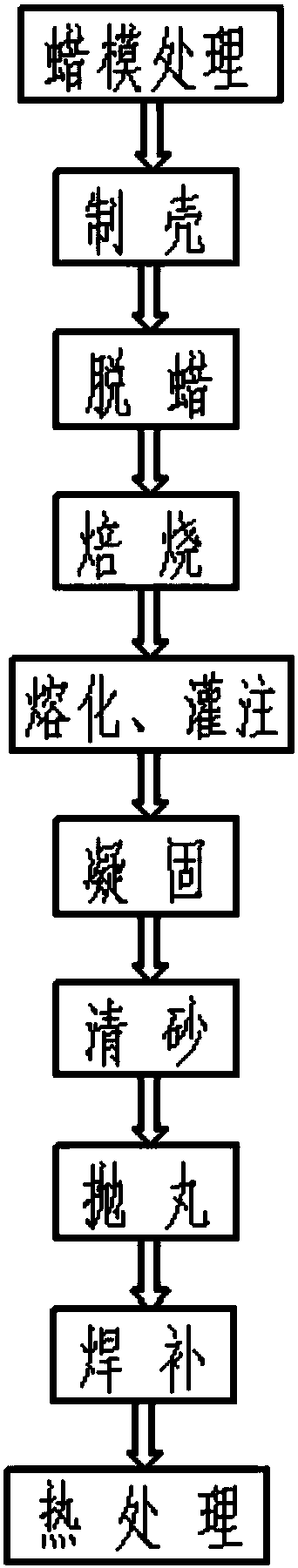

Valve precision casting environment-friendly technology process

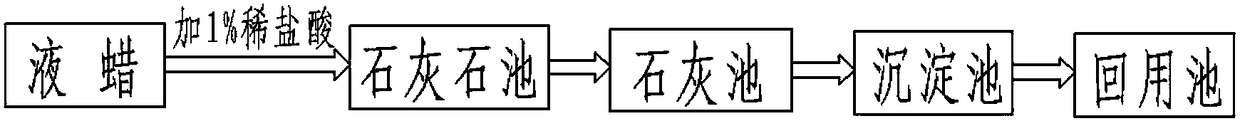

InactiveCN108356224ALow costReduce energy consumptionFoundry mouldsFoundry coresEnvironmental resistanceWax

The invention discloses a valve precision casting environment-friendly technology process. The valve precision casting environment-friendly technological process comprises the following steps of wax mould molding, shell making, dewaxing, roasting, melting and pouring, solidification, cleaning, shot blasting, welding repair and heat treatment. The valve precision casting environment-friendly technology is low in cost, low in rejection rate, simple in process and environmentally friendly. Wax blocks adopted by a casting model and wax materials recovered by the dewaxing are low in melting point,and a manufactured wax mould is low in cost, low in energy dissipation and energy-saving and environmental protection; liquid wax formed by the dewaxing can be recycled and used, waste water is not discharged, and energy conservation and environmental protection are achieved; a precision casting model is easy to be formed and dressed and with high precision and high yield; shells have high hardness, fire resistance and high impact resistance, the manufactured precision castings are non-clay; and during solidification and cooling, the castings do not produce shrinkage cavities and cracks.

Owner:浙江立大阀门有限公司

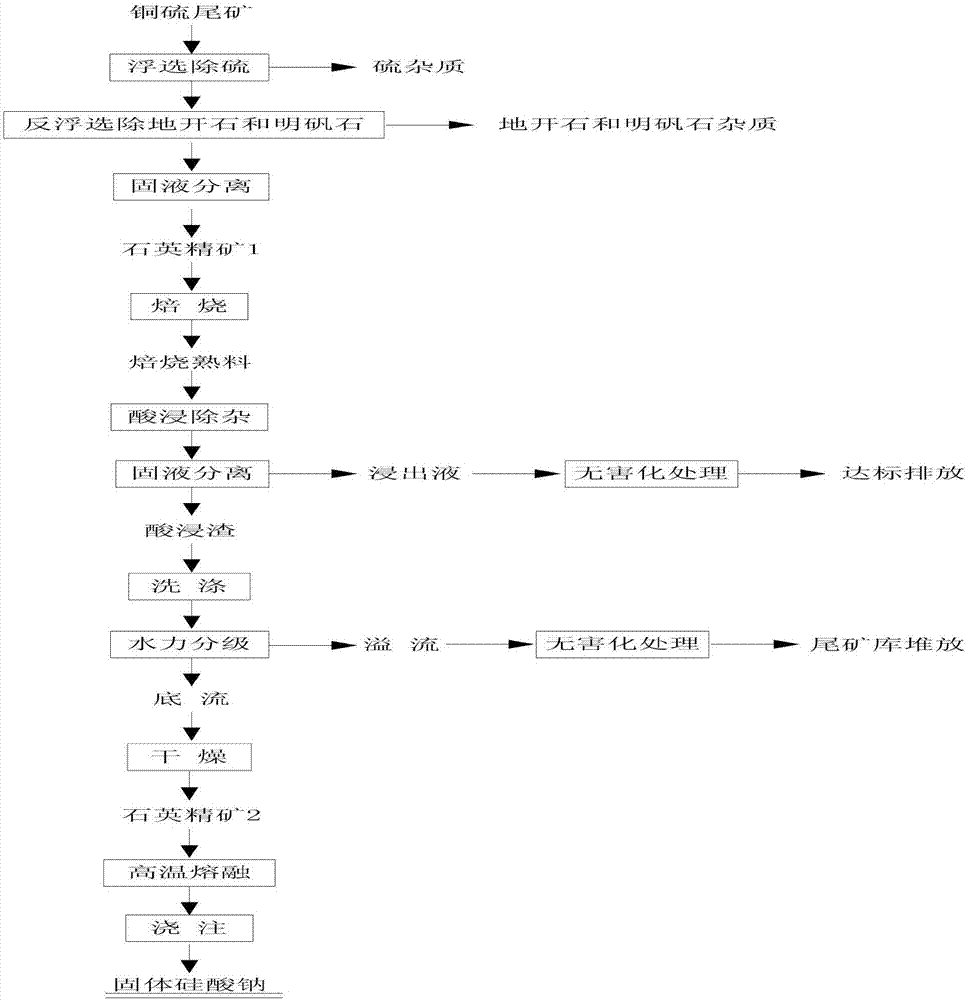

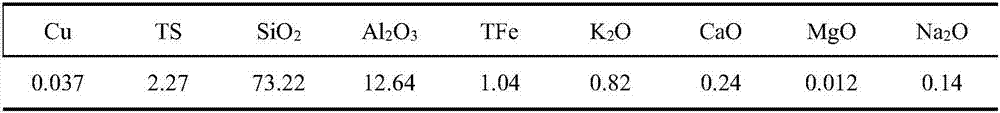

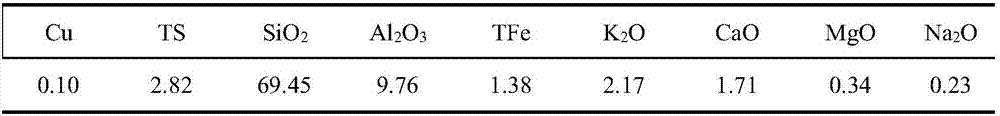

Method for preparing industrial sodium silicate by using waste copper sulfur tailings

The invention relates to a method for preparing industrial sodium silicate by using waste copper sulfur tailings. The method is conducted according to the following step procedures and conditions: performing flotation to remove impurities: adjusting the PH value of copper tailing slurry, adding ammonium dibutyl dithiophosphate, stirring, adding second oil, performing flotation to remove impurities to obtain tailing slurry 1, adding lauryl amine and sodium oleate, stirring, performing reverse flotation to remove impurities such as dickite and alunite to obtain tailing slurry 2, and performing solid liquid separation to obtain quartz concentrate 1; roasting: adding a carbon powder and sodium chloride, mixing uniformly and roasting to obtain roasting clinker; performing acid leaching to remove impurities: feeding the roasting clinker into an acid leaching system, enabling copper, iron and the like in the roasting clinker to leach out, performing solid liquid separation to obtain a leaching liquid and acid leach residue, grading the acid leaching residue to obtain overflow and underflow, and performing solid liquid separation and drying on the underflow to obtain quartz concentrate 2; melting at a high temperature: adding the quartz concentrate 2 into sodium carbonate, mixing uniformly, melting and pouring to obtain a solid sodium silicate product. The method has the advantages of simplicity in process operation, high in practicability, environmental friendliness, easiness in industrialization and the like, and is suitable for comprehensive utilization of mineral resources.

Owner:ZIJIN MINING GROUP

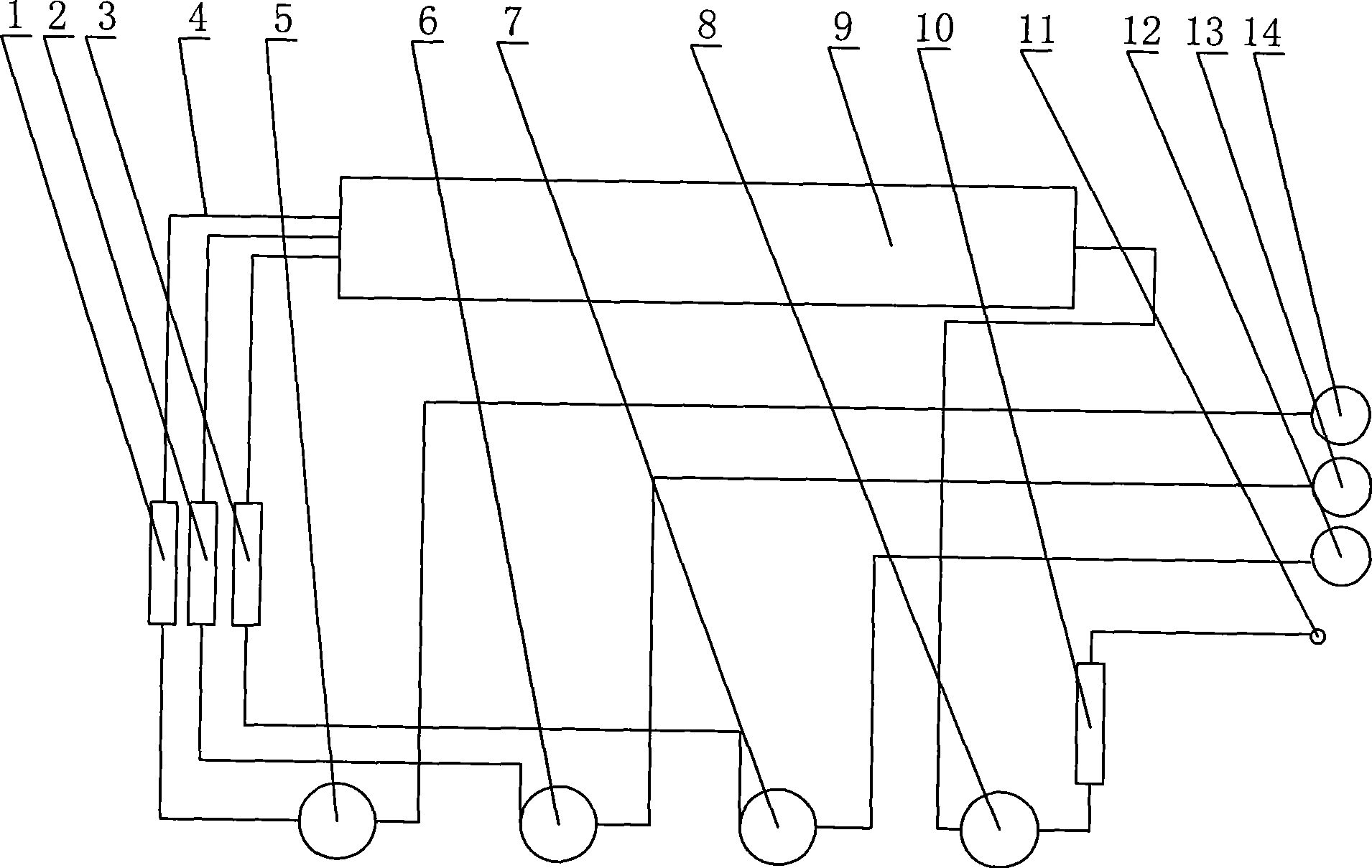

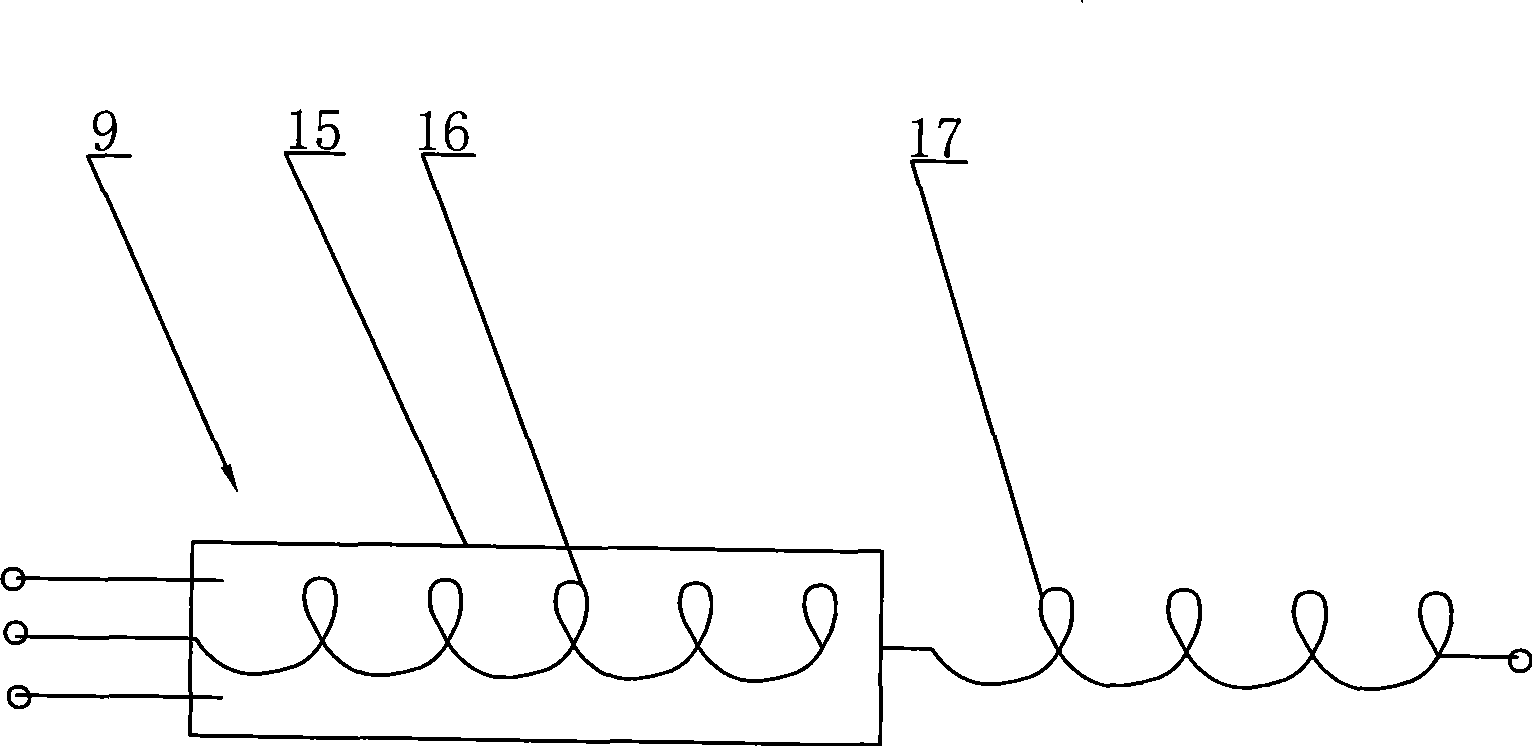

Gas atmosphere shielding device of smelting and pouring magnesium alloy

InactiveCN101412106APrecise Proportion MixingEasy to operateMaintainance of heating chambersGas cylinderEngineering

The invention relates to a protective atmosphere device for melting and pouring a magnesium alloy, which comprises a pipeline, a gas cylinder connected with a plurality of paths of gas inlets, a mixer, and a mixed gas outlet. The device is characterized in that an inlet gas pressure detecting and regulating device and an inlet gas flow detecting and regulating device are arranged between each path of the gas inlet and the inlet of the mixer, and an outlet gas pressure detecting and regulating device and an outlet gas flow detecting and regulating device are arranged between the outlet of the mixer and the mixed gas outlet. The protective atmosphere device for melting and pouring the magnesium alloys mixes gases in a pure mechanical mode, adopts the plurality of the paths to introduce the gases, adopts gas inlet passages with different flow rates, can regulate the pressure and the flow rate according to different requirements, and can mix two or three gases, thus the device is applicable to industrial application and experiment research and development. The device has the characteristics of precisely-proportioned mixing, simple operation, and low cost.

Owner:嘉兴中科亚美合金技术有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com