Method for preparing composite abrasion-proof lining board

A composite wear-resistant liner and liner technology, which is applied in the production of parts of mechanical equipment and the preparation of composite wear-resistant liners, can solve the problems of inability to be composited as a whole, difficulty in hard alloy prefabrication, and low bonding strength. , to achieve the effects of strong controllability of process parameters, convenience for large-scale production, and uniform organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

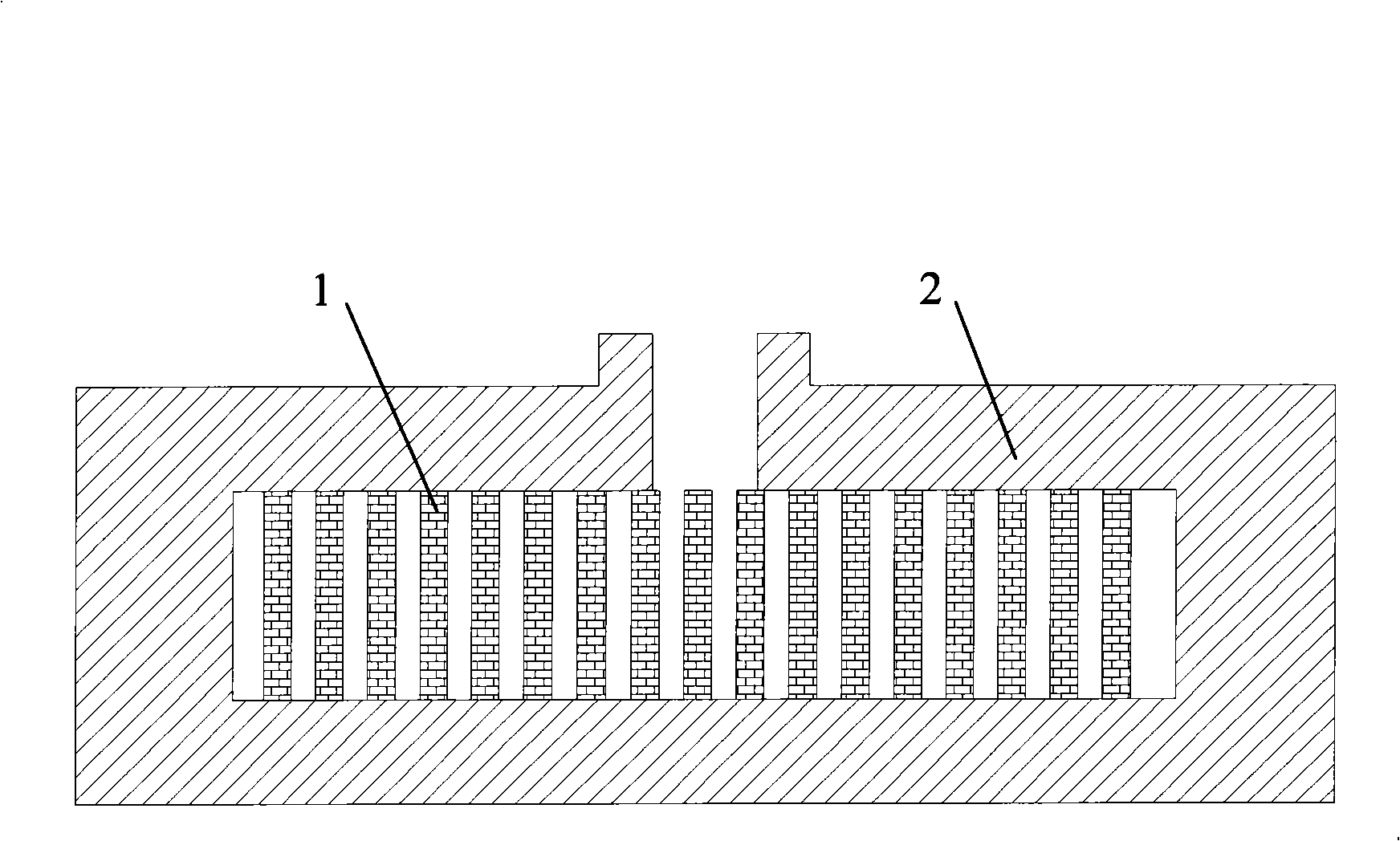

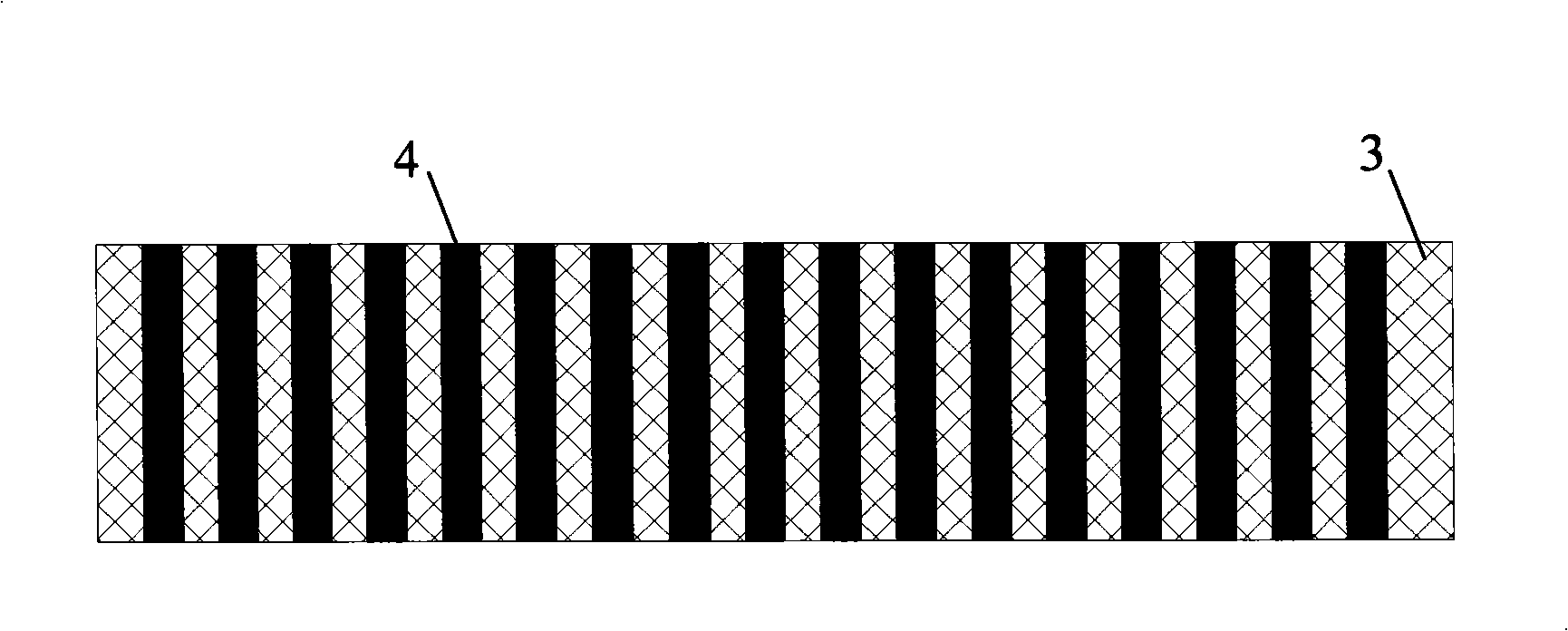

[0016] Example 1: Preparation of rod-shaped composite wear-resistant lining plate with high chromium alloy as hard phase and A3 steel as matrix

[0017] This embodiment proceeds according to the following steps:

[0018] 1. Select the alloy powder core rod 1 with a diameter of 5mm, the wall thickness is 0.5mm, the alloy powder is high-carbon ferrochrome powder, the particle size is 100-150 mesh, and it is cut to the same length as the thickness of the liner;

[0019] 2. Use resin sand to make mold 2 according to the casting process requirements;

[0020] 3. The alloy powder core rod 1 is preset in the cavity of the casting mold 2 according to the volume ratio of 50% of the lining plate;

[0021] 4. Select A3 steel as the base metal 3. After the A3 steel is smelted and melted in an intermediate frequency furnace, it reaches 1600°C and is released from the furnace. The A3 molten steel is poured into the cavity of the mold 2 until it is full;

[0022] 5. The casting mold 2 is c...

Embodiment 2

[0024] The difference between this embodiment and Example 1 is that the diameter of the alloy powder mandrel rod 1 is selected as 10mm, and the wall thickness is 1mm. Powder=85:15), its particle size is 100~200 orders, selects 45 steels as matrix metal 3 for use, all the other are the same as embodiment 1.

Embodiment 3

[0026] The difference between this embodiment and Example 1 is that the diameter of the alloy powder mandrel rod 1 is 2mm, and the wall thickness is 0.1mm, and the alloy powder is made of high-carbon ferrochromium powder and molybdenum Iron powder=85:15), its particle size is 50~100 orders, selects T10 steel as matrix metal 3 for use, and the rest is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com