Patents

Literature

43results about How to "High controllability of process parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for refining grains of large medium high alloy steel forgings

InactiveCN102134637AReduce tissue geneticsStrong theoretical basisHeat treatment process controlPearliteDecomposition

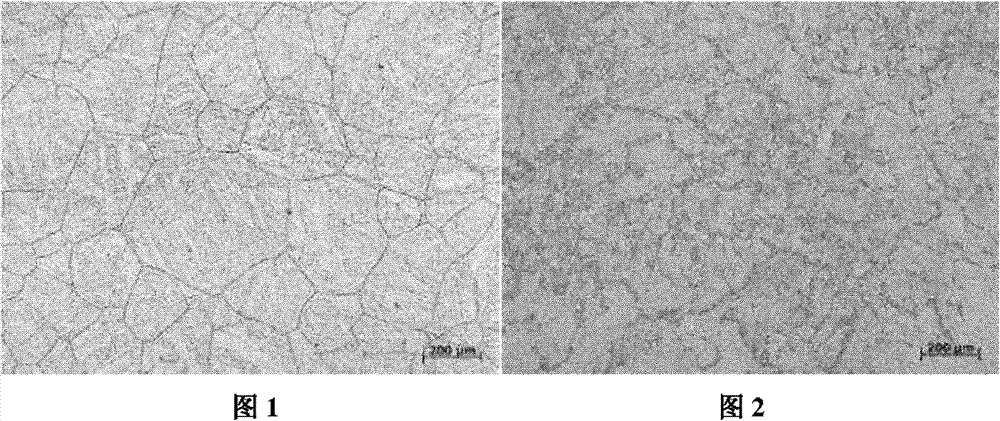

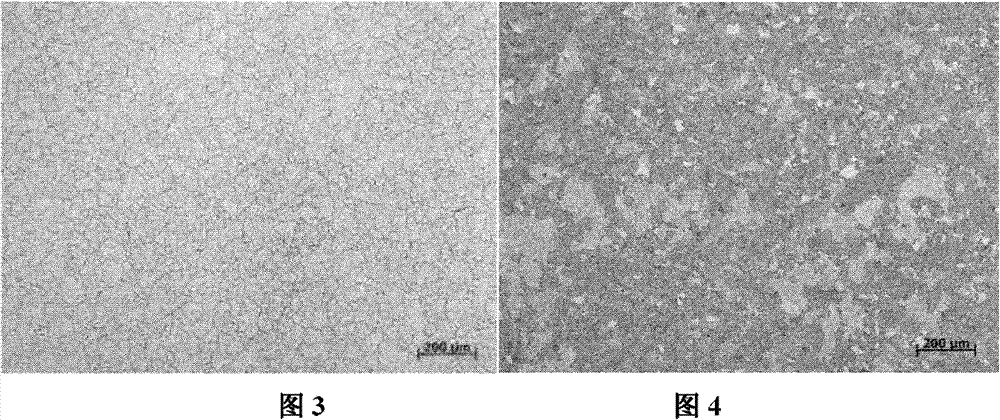

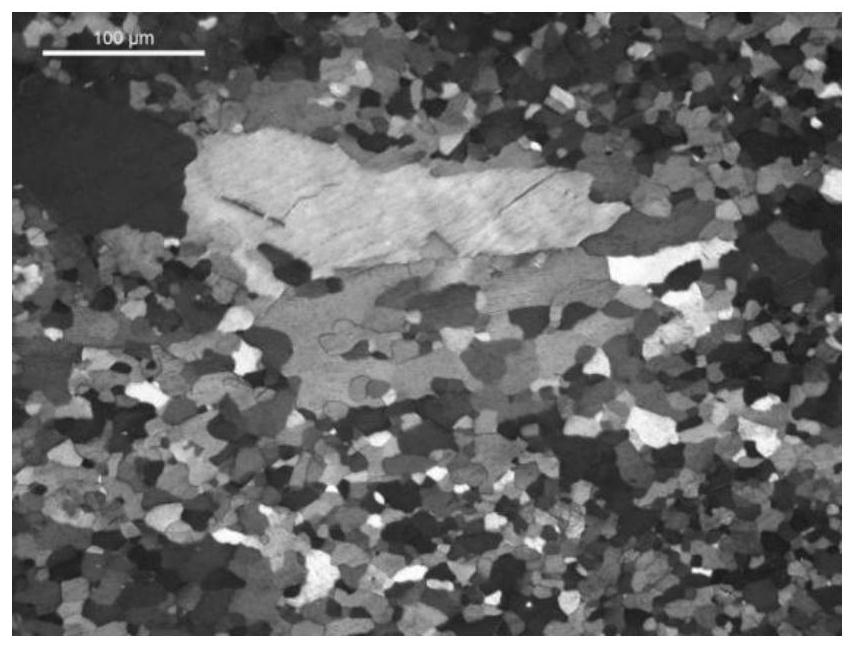

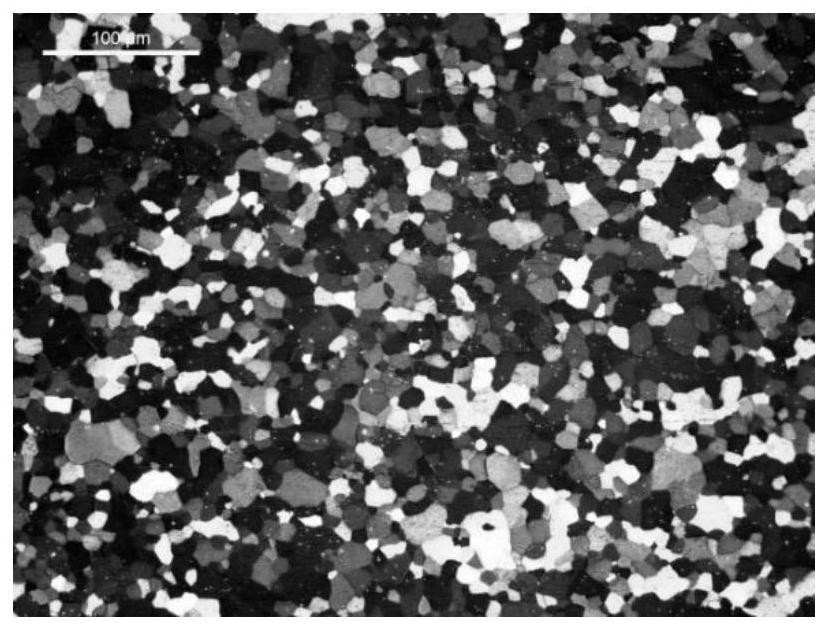

The invention discloses a method for refining grains of large medium high alloy steel forgings in the technical field of metal heat treatment. The method comprises the following steps of: austenitizing the forged forgings, cooling to tip temperature of a perlitic transformation area, and isothermally keeping temperature or fluctuantly keeping temperature to realizing isothermal decomposition of pearlite; and cooling to room temperature, and performing the secondary austenitizing process to realize recrystallization to refine the grains again. The method solves the problem that the traditional multiple normalizing process in actual production has instable effect of refining the grains of the large forgings, and a serious phenomena of coarse grains and mixed grains. By incomplete isothermal balanced decomposition of austenite, structure inheritance is cut off and eliminated, average austenite grain size above ASTM No.5 grade is achieved, the structure state of the large forgings is improved, the ultrasonic inspectability of the large forgings is improved; meanwhile, working hours are greatly shortened, the energy consumption is reduced, and the cost is saved.

Owner:SHANGHAI JIAO TONG UNIV

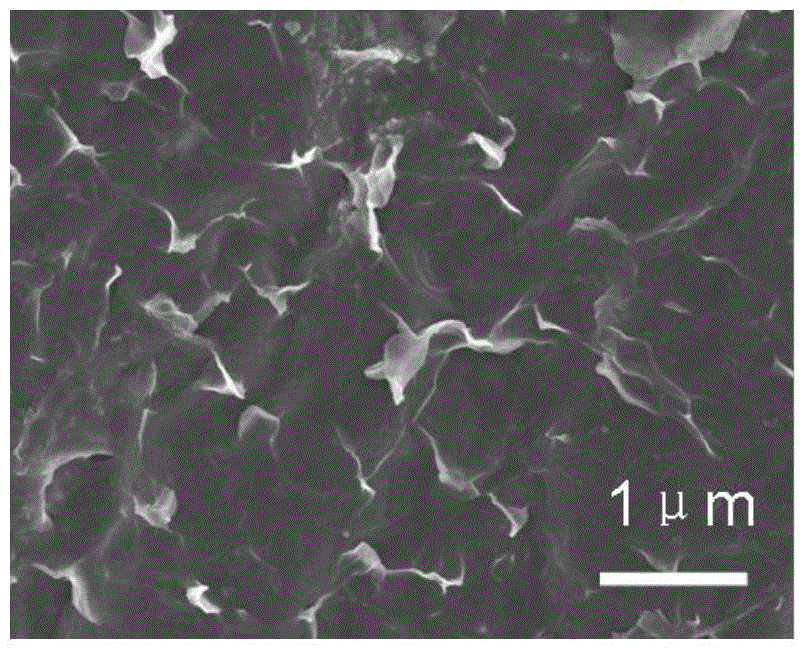

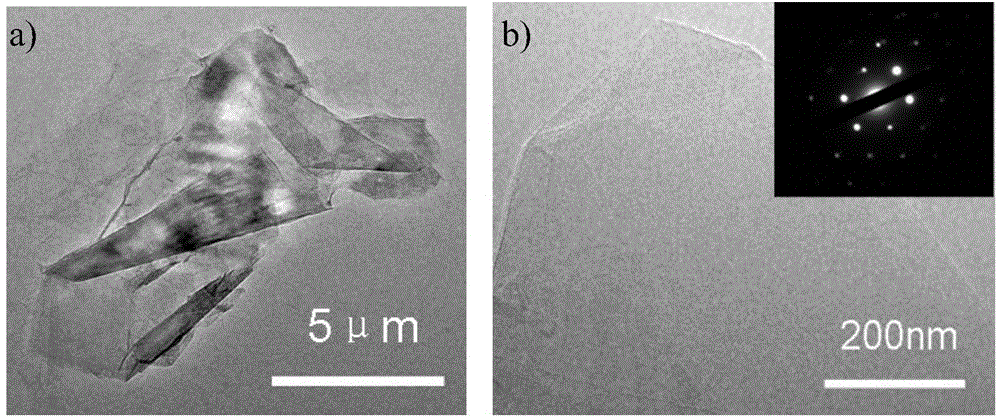

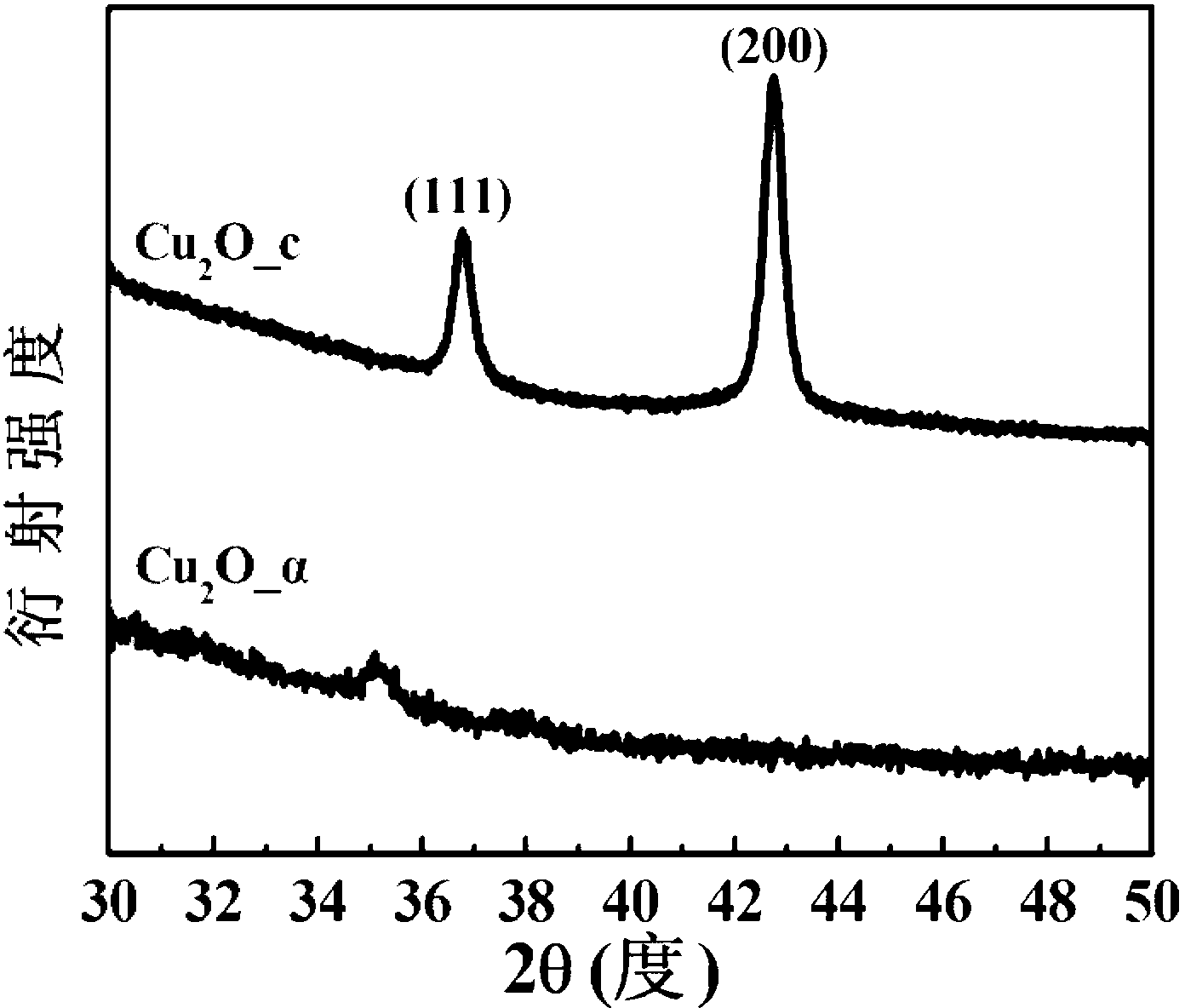

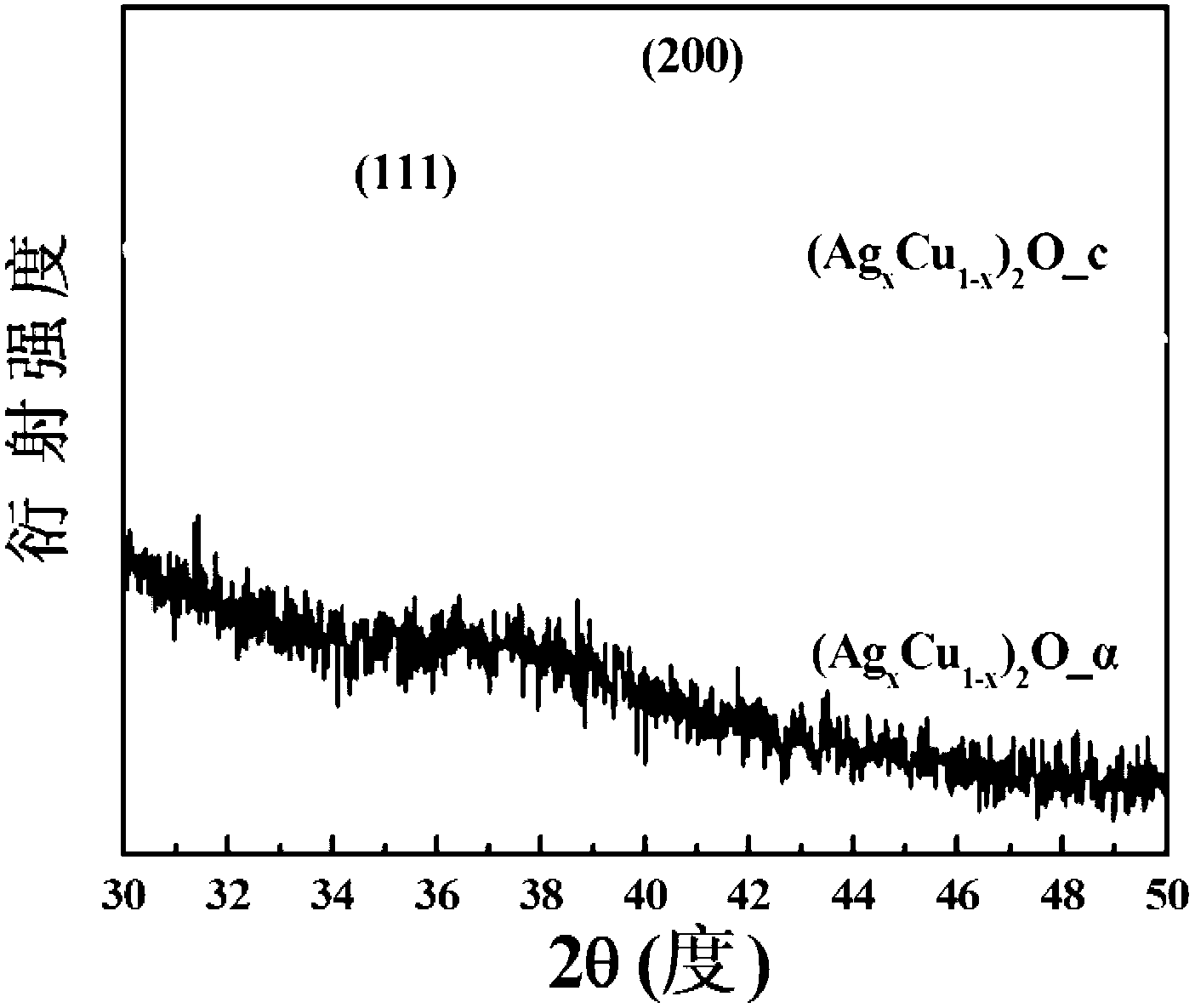

Preparation method of high quality graphene conductive film

Owner:QINGDAO UNIV OF SCI & TECH

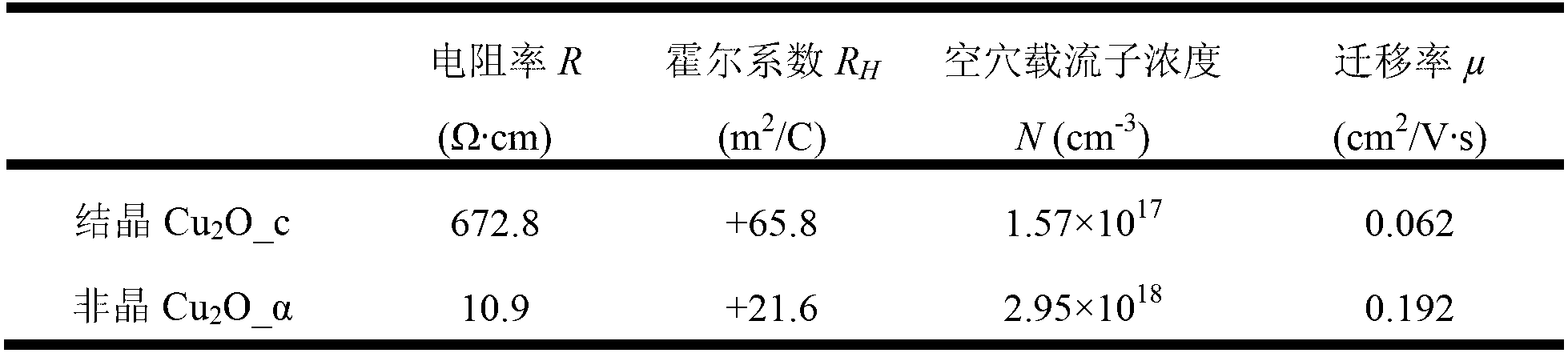

Preparation method of (doped amorphous) p-type transparent conductive oxide films

InactiveCN103173732AThe principle is simpleLow deposition temperatureVacuum evaporation coatingSputtering coatingCrystalline oxideDeposition temperature

The invention discloses a preparation method of films of (doped amorphous) p-type transparent conductive oxide films, and relates to the technical field of semiconductor films. The amorphous films having a higher hole carrier concentration and a higher mobility than crystallized oxide films are prepared through adopting a reaction magnetron sputtering process and controlling technological parameters. The preparation method has the advantages of simple principle, low deposition temperature, strong controllability of the technological parameters, low preparation cost, and huge scale production potential.

Owner:BEIHANG UNIV

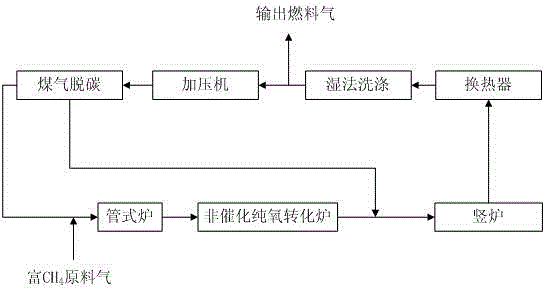

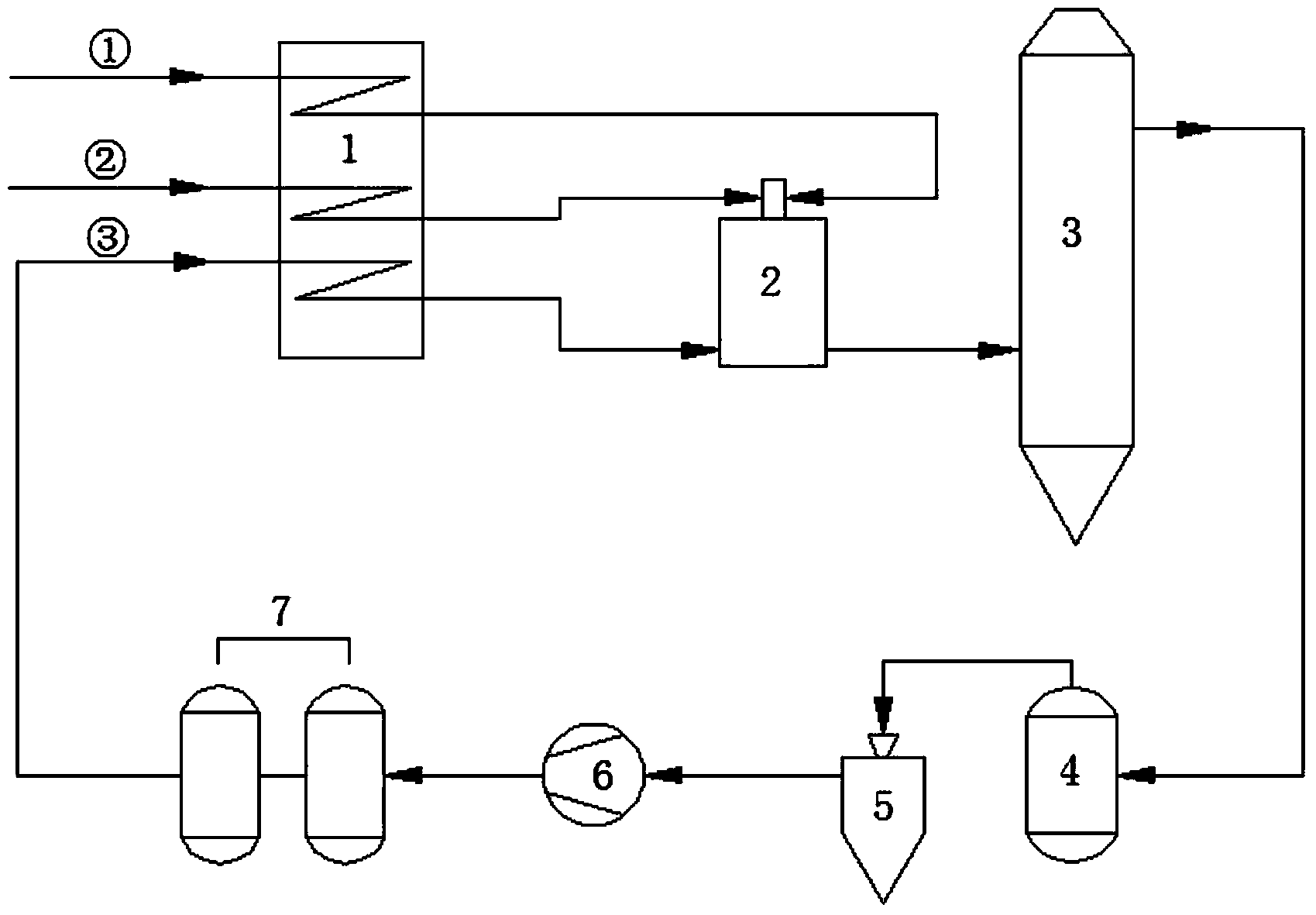

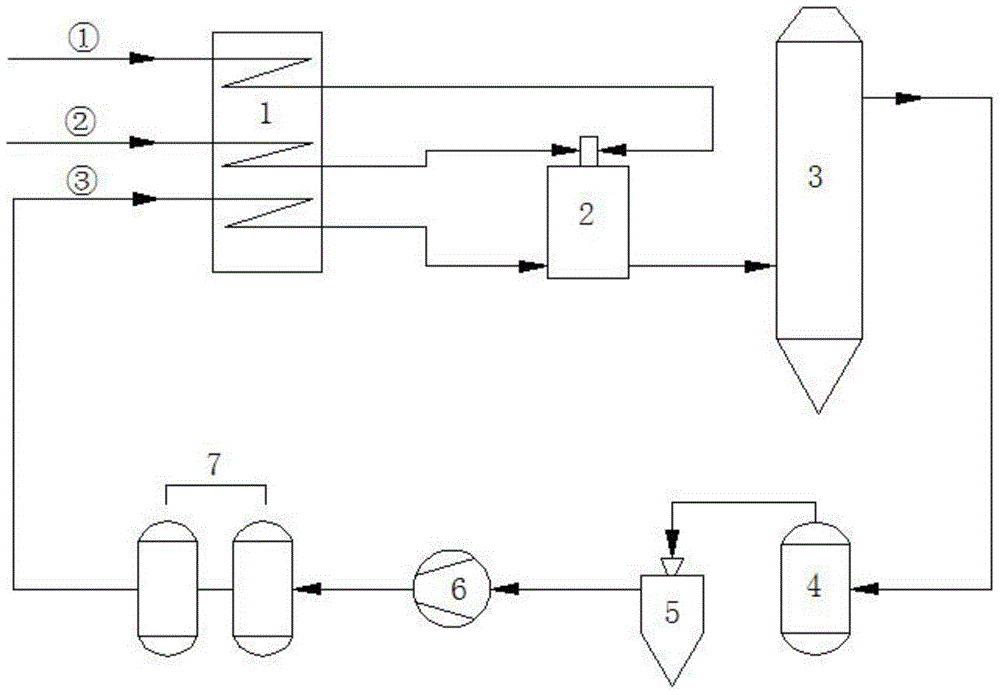

Direct reduction process for sponge iron production implemented by using non-catalytic conversion of CH4

ActiveCN103146866ALower the preheat temperatureLess investmentShaft furnaceGas emission reductionDust controlShaft furnace

The invention discloses a direct reduction process for sponge iron production implemented by using the non-catalytic conversion of CH4, and the direct reduction process comprises the following steps: feeding a feed gas rich in CH4 and subjected to purification and pressure regulation and a stock gas output by a shaft furnace and subjected to cooling, dust removal, pressurization and decarburization into a tube furnace together and preheating; feeding the preheated coal gas into a non-catalytic pure oxygen reforming furnace, performing combustion reaction and heating on the preheated coal gas and oxygen in the non-catalytic pure oxygen reforming furnace, and performing non-catalytic conversion on the CH4 so as to generate CO+H2; after the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace and the stock gas discharged at the front end and subjected to cooling, dust removal, pressurization and decarburization are mixed and cooled, feeding the mixed gas into the shaft furnace and reducing iron ores, thereby producing sponge irons; and after the stock gas discharged from the shaft furnace is subjected to cooling, dust removal, pressurization and decarburization, feeding part of the stock gas and the supplementary feed gas rich in CH4 into the tube furnace and the non-catalytic pure oxygen reforming furnace together, wherein the other part of the stock gas is used as the cold-doped coal gas of the high-temperature coal gas discharged from the non-catalytic pure oxygen reforming furnace. Because the preheating temperature is low, no carbon precipitation occurs, and no strict limitation on the H2S content of the feed gas rich in CH4 exits, so that the bonding of the sponge irons can be prevented.

Owner:CISDI ENG CO LTD

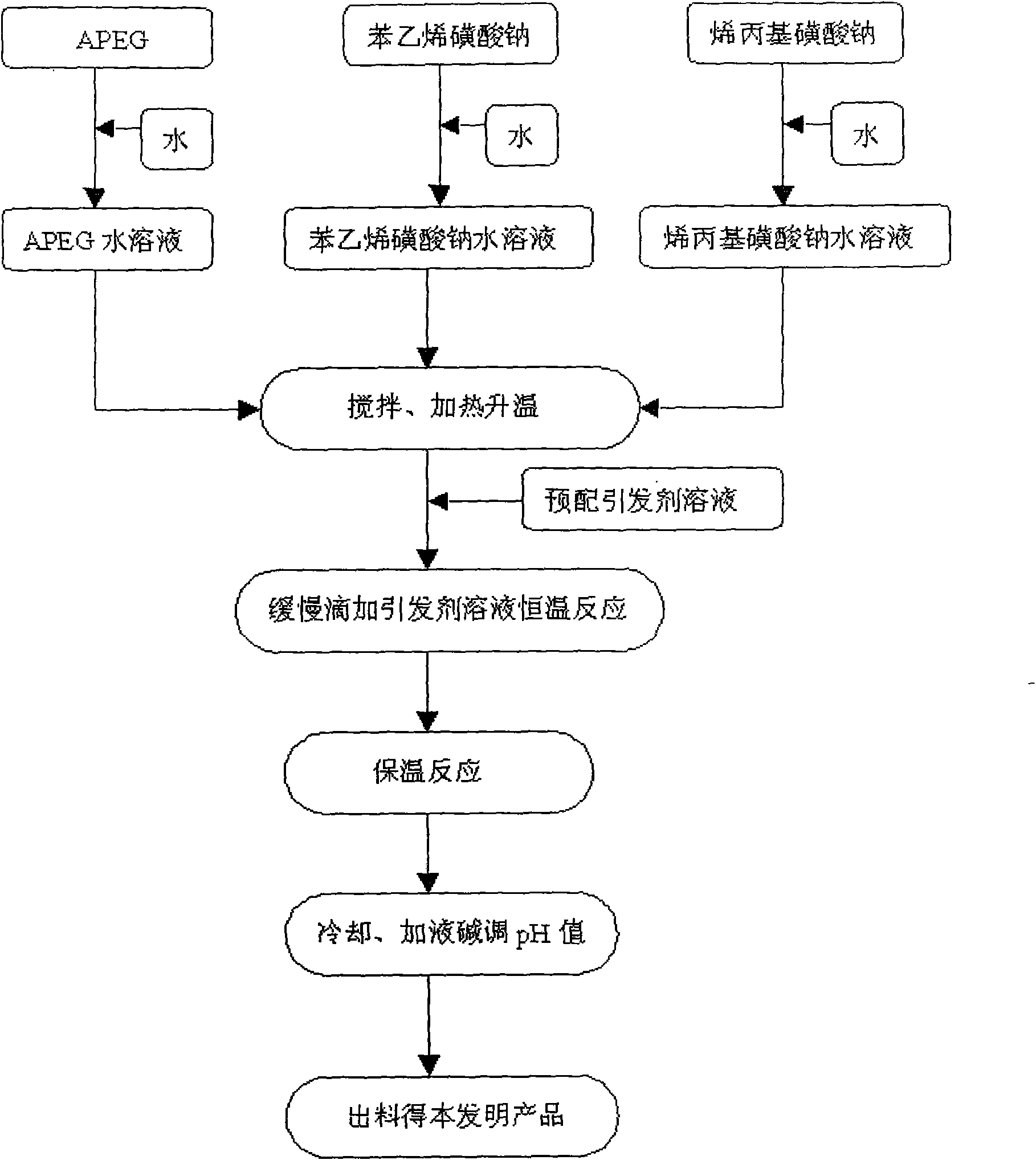

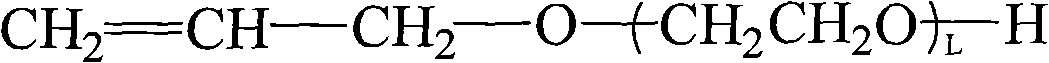

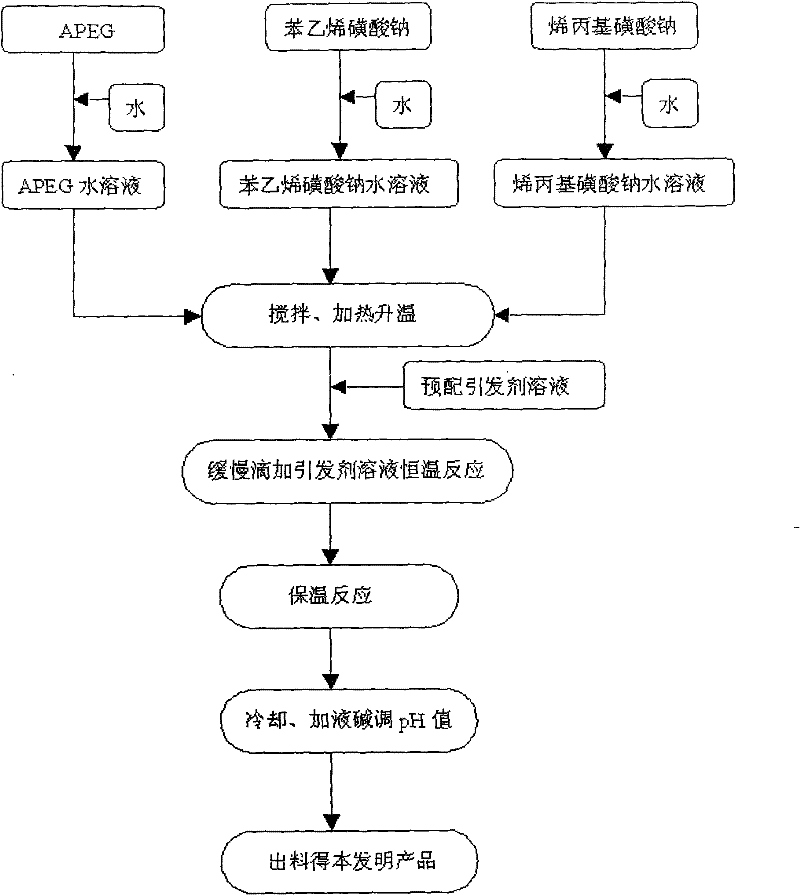

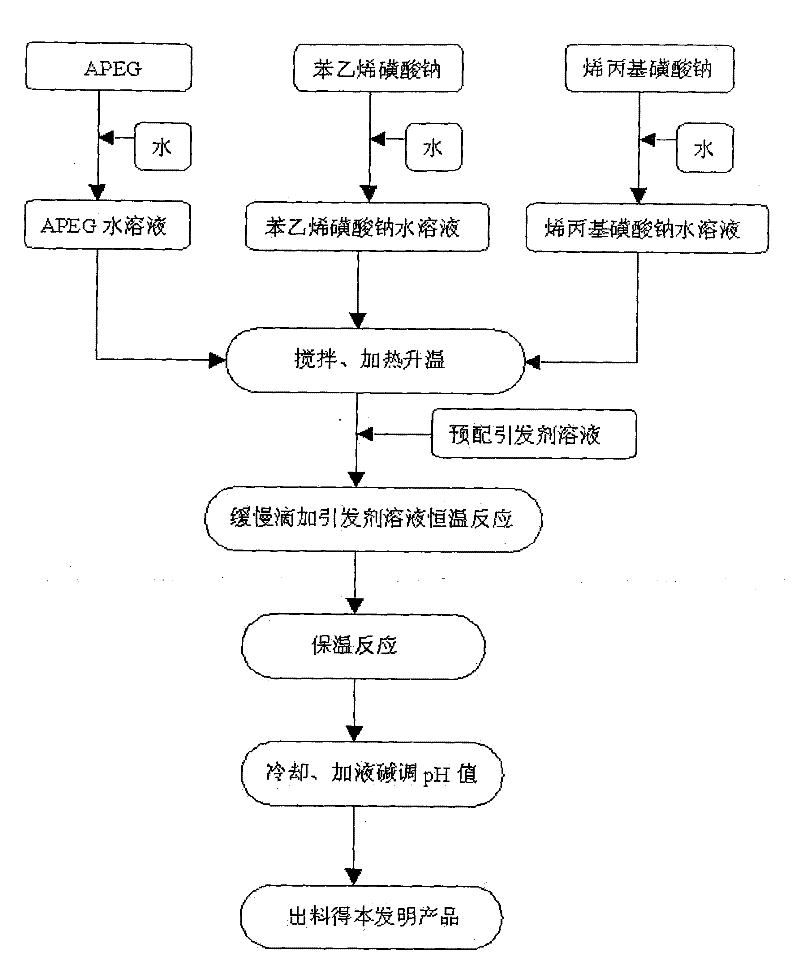

Comb-shaped low-slump concrete plastic-reserving agent with poly-sulphoacid structure

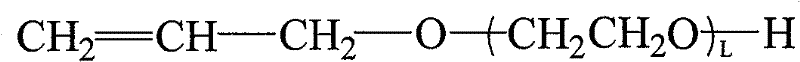

The invention relates to a comb-shaped plastic-reserving agent with a poly-sulphoacid structure particularly suitable for low-slump concrete, which is prepared with allyl polyether, sodium styrene sulfonate and sodium alkyl sulfonate as raw materials. The average molecular weight of the allyl polyether is 400-1500, the feeding amount of the allyl polyether accounts for 50-92 percent of the total molecular weight of the raw materials; and the molar ratio of the sodium styrene sulfonate and the sodium alkyl sulfonate is 1:0.2-1:5. The preparation method comprises the following steps: mixing the aqueous solution of each raw material monomer, heating to 65-98 DEG C, adding an initiator ammonium persulfate solution, completing the dropping within 2-4 hours, maintaining the temperature for 1 hour, cooling until the temperature is below 40 DEG C, adding caustic soda liquid for neutralization, and taking out the product, thereby obtaining the plastic-reserving agent, a comb-shaped polymer with the poly-sulphoacid structure. The structure of the polymer combines the advantages of two water reducing agents, naphthalene and polycarboxylic acid. Therefore, the polymer can realize excellent plastic-reserving property of the low-slump concrete with the slump being 7-9cm. simultaneously; the polymer has good physical and chemical compatibility with the two water reducing agents, naphthalene and polycarboxylic acid.

Owner:NANJING RUIDI HIGH TECH

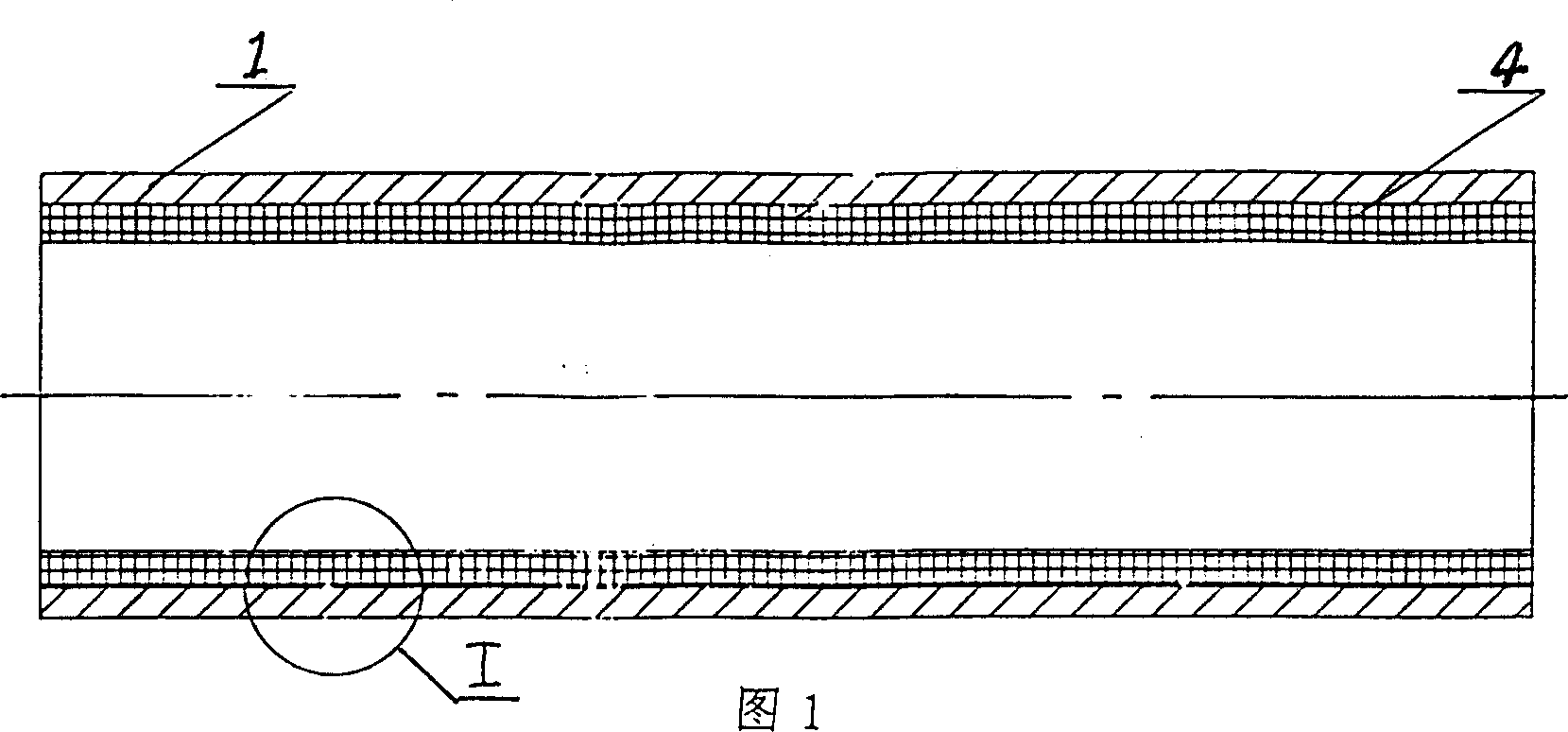

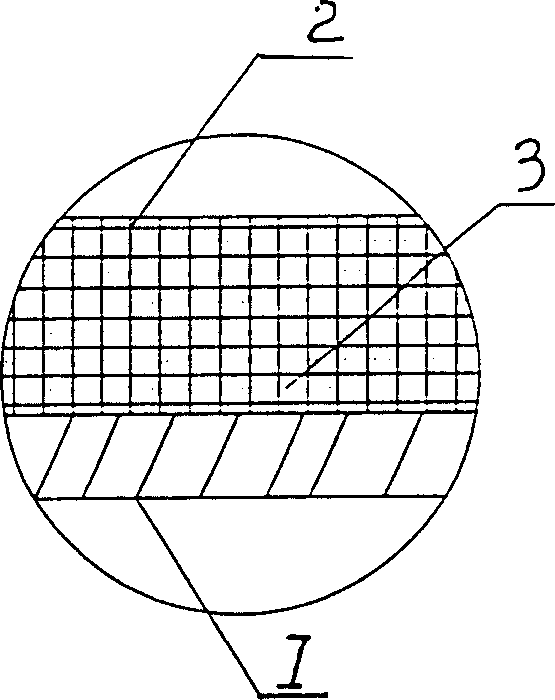

Metallic pipe with nano-structure metal wire screen-ceramic liner and its making technology

InactiveCN1397754AHigh strengthHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationNano structuringMetallurgy

A composite metal pipe is composed of the external sleeve pipe and the composite liner pipe consisting of metallic wire net and antiwear ceramic material. Its advantages are controllable technological parameters, high productivity and quality and long service life.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

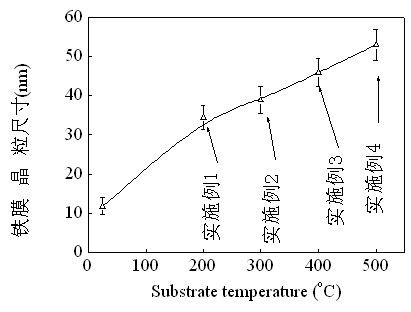

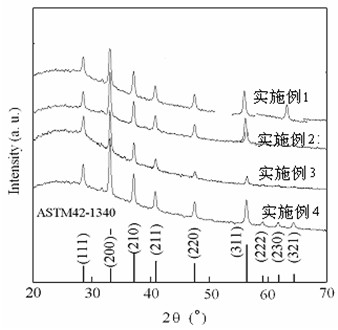

Method used for preparing FeS2 film and capable of controlling precursor grain size

InactiveCN102560374ARefined grain sizeControl grain sizeFinal product manufactureVacuum evaporation coatingAlcoholControl quality

The invention discloses a method used for preparing a FeS2 film and capable of controlling precursor grain size. A coating substrate is boiled in saturation chromic acid solution, washed with deionized water, and washed and dried through ultrasonic oscillation in acetone, absolute ethyl alcohol and deionized water sequentially. A pure Fe film is sputtered, and temperature and thickness of the substrate are controlled. The pure Fe film and sulphur powder are packaged in a glass tube to be processed through sulfidizing. The method can obtain fine and even precursor ferrum film grain size, and the grain size can be controlled conveniently. The method can use optimization of different technology of optimizing precursor film sputtering and following sulfidizing and flexibly controls quality and state of the finally obtained FeS2 film. A control means and a control process are flexible, optimization of preparation technology is facilitated, and more choices for industrial production of the FeS2 film are also provided.

Owner:ZHEJIANG UNIV

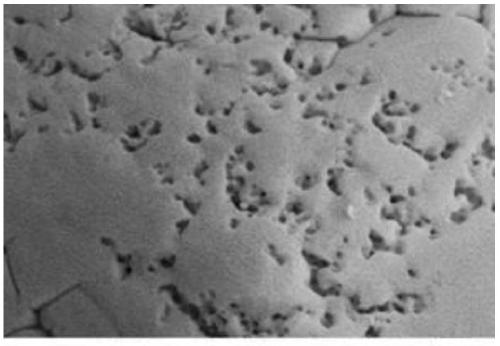

Method for preparing battery-grade iron phosphate by using ferrophosphorus

ActiveCN103086341ASimple processHigh controllability of process parametersPhosphorus compoundsLithium iron phosphateFiltration

The invention discloses a method for preparing battery-grade iron phosphate by using ferrophosphorus. According to the method, ferrophosphorus is grinded into particles with a certain particle size, and is heated and dissolved in a mixed acid solution; the mixture is filtered, such that a filtrate is obtained; the filtrate is subjected to physicochemical methods such as re-crystallization, membrane filtration, carbon absorption, complex concealment, and the like, such that impurity elements are removed; the filtrate is concentrated, and is heated to a temperature of 60-95 DEG C; iron phosphate solution induction is carried out, such that iron phosphate is prepared. Therefore, high-purity spherical battery-grade iron phosphate with micro size is obtained. With the method, prepared iron phosphate has the advantages of low impurity content, and uniform particle size distribution. The iron phosphate is suitable to be used for further preparing battery-type lithium iron phosphate.

Owner:WENGFU (GRP) CO LTD +1

Method for preparing composite abrasion-proof lining board

The invention discloses a method for preparing a composite wear resistant lining plate. The method comprises the following steps: adopting alloy powder core bar materials of which the volume percentage is between 20 and 60 percent of the total volume of the lining plate, filling alloy powder in the core part of the alloy powder core bar materials, preset the alloy powder core bar materials in a lining plate casting mould, selecting base metal to be melted and poured in the lining plate casting mould, and cooling and demoulding the lining plate to obtain the composite wear resistant lining plate consisting of the alloy powder core bar materials and the base metal. The cylindrical hard phase of the composite wear resistant lining plate prepared by the method is generated by compounding in situ in a matrix, thus the composite wear resistant lining plate has the characteristics that segregation is not generated, the organization structure is even, the hard phase is difficult to fall off, the lining plate not only has the intensity and the toughness of the base metal but also has the high hardness and the high wear resistance of the hard phase, the service life is improved by an order of magnitude compared with the prior lining plate, the lining plate can bearing high impact force and strong wear at the same time, the technological parameter controllability of the preparation process is strong, and the price is low. The composite wear resistant lining plate can satisfy the applications under complex working conditions such as various wears, high impact and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

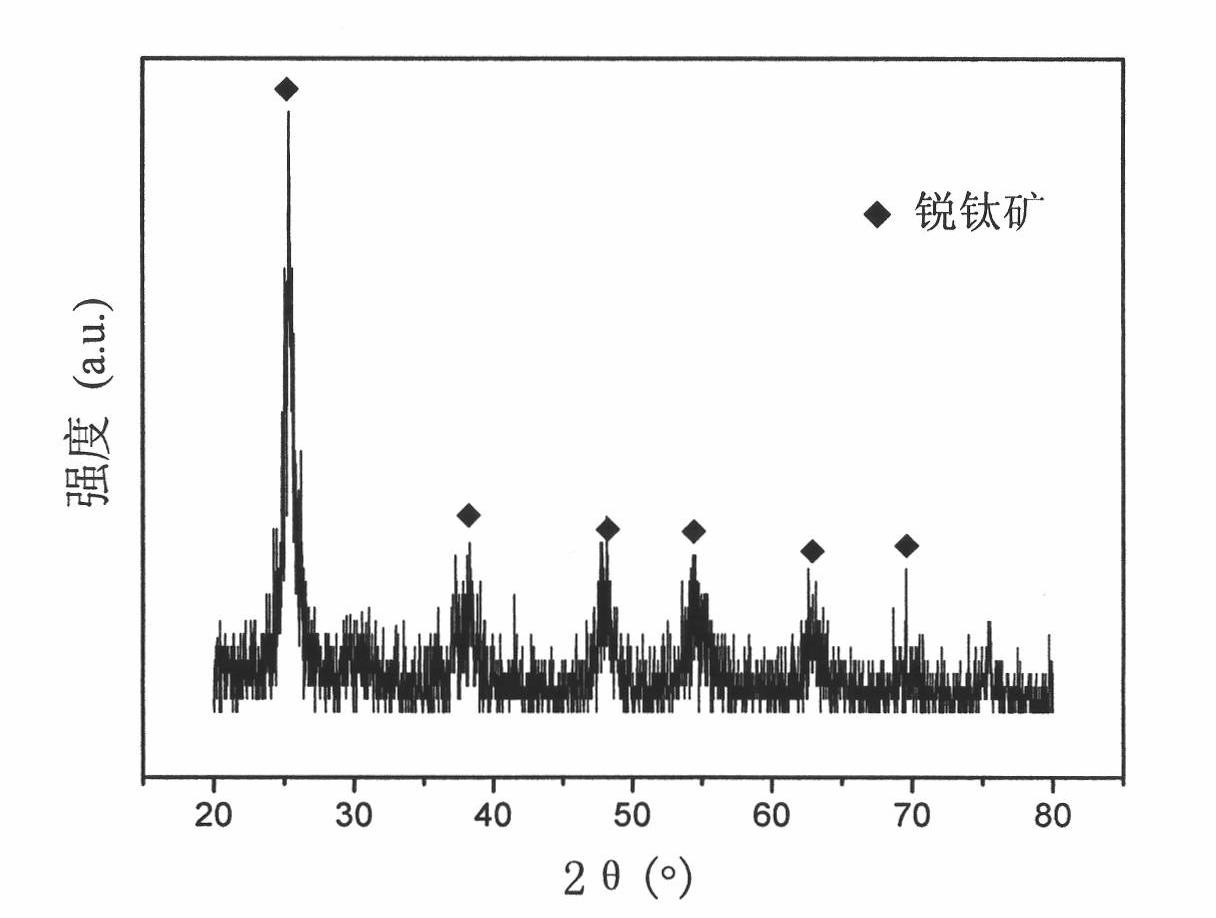

Method for preparing metal ion-doped titanium dioxide target material and target material thereby

The invention relates to a method for preparing a metal ion-doped titanium dioxide target material and a target material thereby. The target material is prepared by adopting the steps of preparing metal ion-doped titanium dioxide powder through a solution reaction and compressing and sintering. The preparation process is simple and is easy to realize uniform doping of one or more metal ions; the doping amount of the ions can be precisely controlled, and the metal ions can enter a titanium dioxide crystal lattice in the preparation process to generate chemical bonding; the average crystal granularity of titanium dioxide in the prepared target material is below 200 nano, and the target material has high density; and the target material can be used for preparing a metal ion-doped titanium dioxide nano film by adopting a magnetron sputtering method.

Owner:INNER MONGOLIA UNIV OF TECH

Method for preparing In2S3 film by chemical bath deposition

InactiveCN102643032AImprove efficiencyImprove photoelectric conversion efficiencyWater bathsChemical vapor deposition

The invention discloses a method for preparing an In2S3 film by chemical bath deposition, which comprises the following steps: after soaking a filming substrate in a chromic acid washing liquid, washing with deionized water; sequentially washing by ultrasonic oscillation in acetone and ethanol for 5-20 minutes; after washing with deionized water, drying at the constant temperature of 120 DEG C for later use; vertically putting the filming substrate in a prepared deposited film water solution; putting the container containing the solution into a thermostatic water bath at 70 DEG C to deposit a film; and after soaking the deposited film in deionized water to remove surface residues, drying in air. Compared with the background technology, the In2S3 film prepared by the chemical bath deposition method has the advantages of stable chemical composition, single structure, strong controllability of technological parameters, simple preparation technique and equipment, and higher efficiency. The invention can provide more options for research of FeS2 film photoelectric conversion material buffer layers.

Owner:ZHEJIANG UNIV

Direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation

ActiveCN104313228ALower the preheat temperatureLess exhaust smokeShaft furnaceGas emission reductionOxygen enrichmentCaking

The invention relates to a direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation. A process route comprises the following steps: preheating a CH4-enriched raw gas and oxygen-enriched air which are subjected to purification and pressure regulation, then introducing the CH4-enriched raw gas and the oxygen-enriched air into a non-catalytic oxygen-enriched transformation furnace for a combustion reaction in the non-catalytic oxygen-enriched transformation furnace, and raising the temperature to transform CH4 therein into CO and H2 to form a high-temperature transformation gas; in the meantime, cooling, dedusting and pressurizing a top gas of a shaft furnace, then introducing the top gas into a hydrogen purification device to prepare purified hydrogen, preheating the purified hydrogen, and then introducing the preheated purified hydrogen into the lower part of the catalyst oxygen-enriched transformation furnace to be mixed with the high-temperature transformation gas generated through the combustion reaction to form a reduced coal gas; and introducing the reduced coal gas into the shaft furnace to reduce iron ores into the sponge iron. The direction reduction process disclosed by the invention not only has the advantages of short process flow, availability for energy saving and emission reduction, long service life of a nozzle and low investment cost, and can be used to prevent the sponge iron from caking and avoid carbon formation.

Owner:CISDI ENG CO LTD

Polyimide fiber mica paper and preparation method thereof

ActiveCN105369672AImprove electrical performanceImprove temperature resistancePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperFiber bundlePhosphoric acid

The invention discloses polyimide fiber mica paper which is formed by causing modified mica and modified polyimide fiber to undergo on-line processing in a paper sheet machine. The invention further discloses a method for preparing the mica paper. The method for preparing the mica paper comprises the steps of preparing modified mica; causing the modified mica to undergo defibering to make mica slurry; making concentrated solution of polyimide into polyimide fiber, and causing the polyimide fiber to undergo fiber bundle removal and then be modified through phosphoric acid; adding PEO into the polyimide fiber to serve as a dispersing agent, adding the polyimide fiber into the mica slurry, and obtaining the polyimide fiber mica paper through on-line forming hot-pressing drying. The paper has more stable dielectric properties and temperature resistance, the quality of an insulating material is improved, the service life of the material is prolonged, the stability of the material is improved, and the electrical industry development is promoted effectively. Besides, the polyimide fiber mica paper is simple in process steps, the controllability of process parameters is high, the raw material source is extensive, raw materials are low in price, the production conditions are mild, and the application prospect is wide.

Owner:SHAANXI UNIV OF SCI & TECH

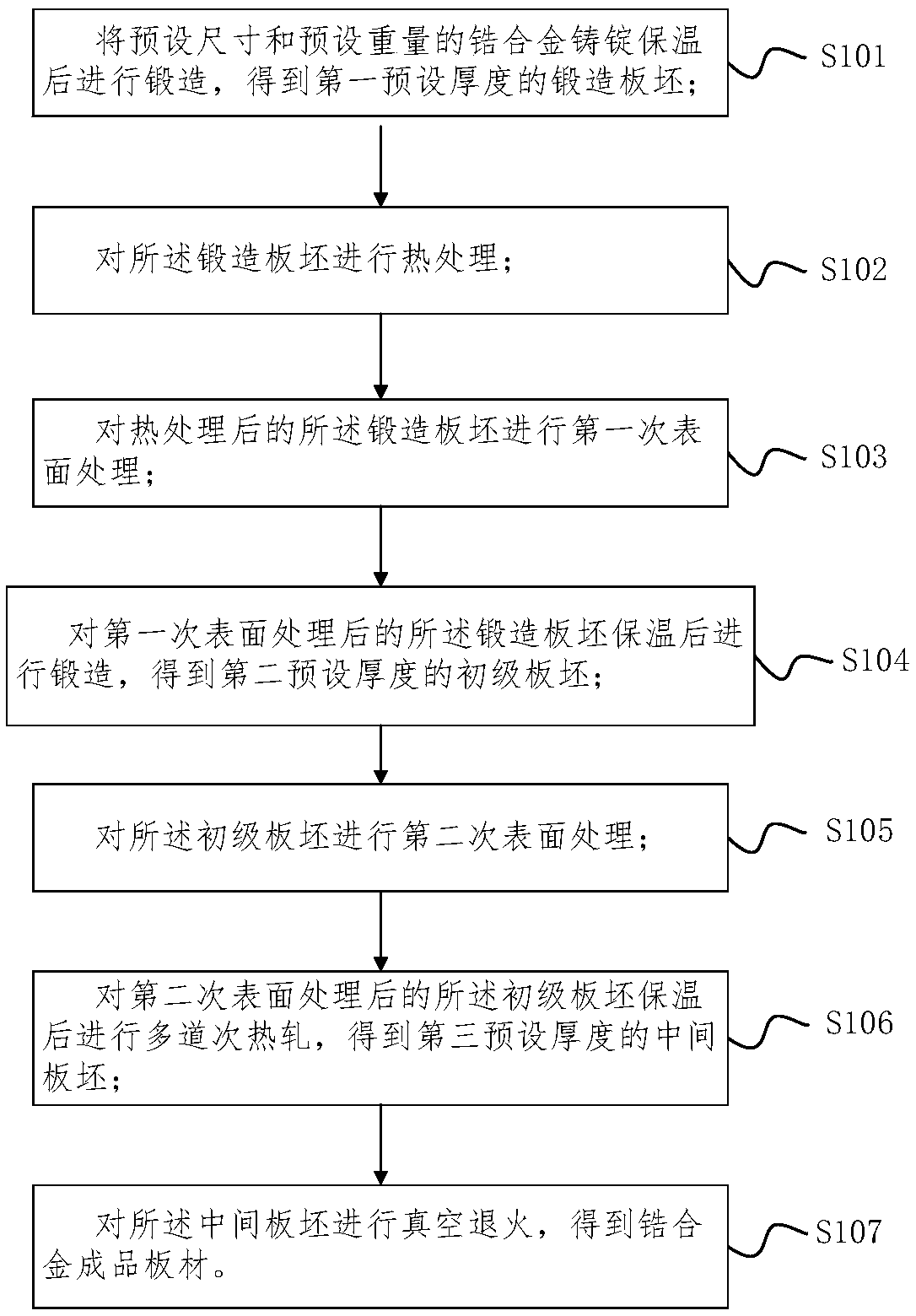

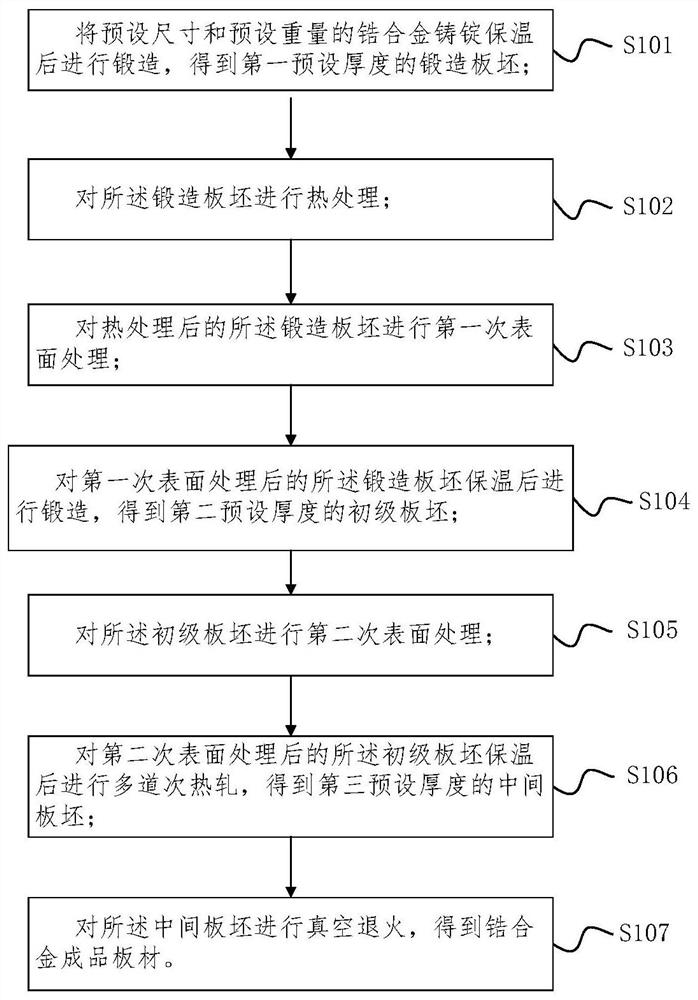

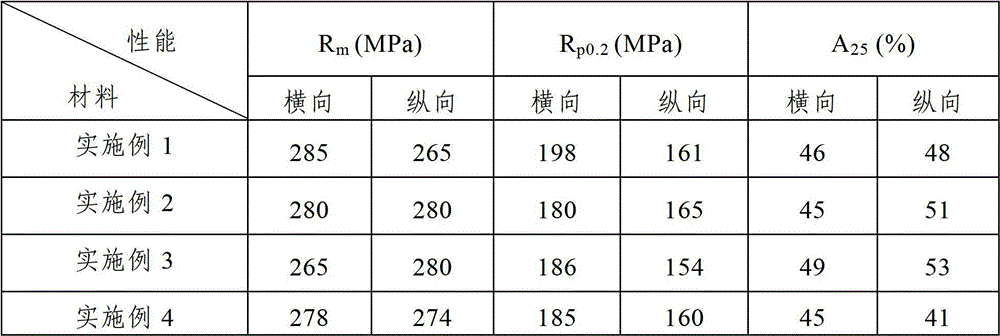

Preparing method of zirconium alloy hot rolled plate

ActiveCN110877050AImprove corrosion resistanceImprove mechanical propertiesTemperature control deviceMetal rolling arrangementsThick plateNuclear reactor

The embodiment of the invention discloses a preparing method of a zirconium alloy hot rolled plate. The method comprises the steps that zirconium alloy casting ingots with the preset size and the preset weight are subjected to heat preservation and then subjected to forging, heat treatment, primary surface treatment, forging after heat preservation, secondary surface treatment, multi-pass hot rolling and vacuum annealing. The manufactured zirconium alloy hot rolled medium and thick plate has the excellent anti-corrosion property and mechanical property, and has the uniform and fine structure,and the plate meets the technical standard requirement of zirconium alloy medium and thick plates for a nuclear reactor. The method is simple in process, flow in preparing flow, and low in productioncost. The situation that domestic high-property zirconium alloy medium and thick plates are dependent on import for a long time can be expected to be changed.

Owner:国核宝钛锆业股份公司

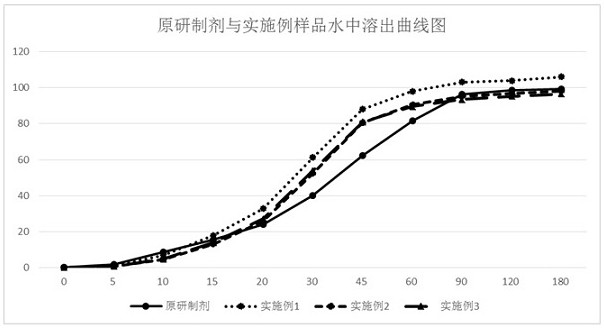

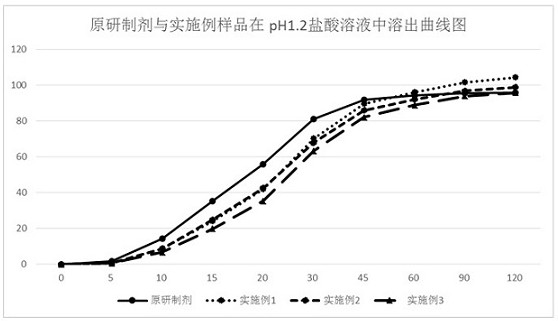

Indapamide capsule preparation method

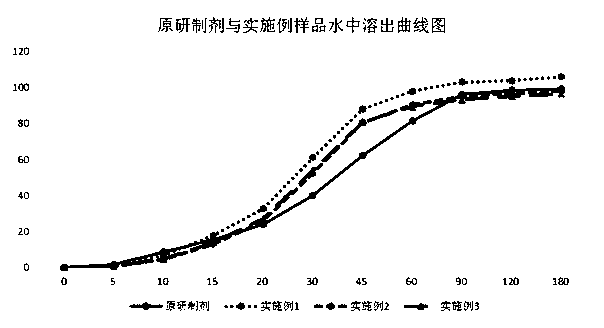

ActiveCN110123775AGood molding effectNot easy to cause pollutionOrganic active ingredientsGranular deliveryHard CapsuleMedicine

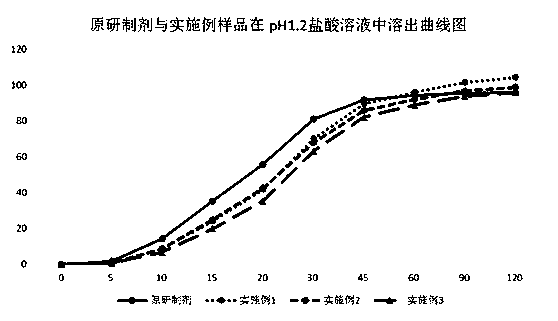

The invention relates to an indapamide capsule preparation method. The method includes steps: preparing granulation liquid, performing top-spraying one-step granulation with a fluidized bed, screeningdried granules, well mixing with a lubricant, and finally filling the granules in hard capsule shells to obtain indapamide capsules. The method has advantages that process steps are reduced, preparation time is shortened, airtight equipment is adopted for preparation in a whole production process, and accordingly pollution to the environment and operating personnel can be avoided, and productionefficiency is remarkably improved; air inlet temperature is 70 DEG C or below, and the method is low in potential safety hazards in production and suitable for industrial production and has advantagesof low energy consumption, high safety production coefficient and the like; problems of poor mixing uniformity and nonuniformity in release in a wet granulation process are solved, high granule formability and high controllability of process parameters in the production process are realized, influences of manual operation are reduced, medicine quality stability is improved, and the problem of content uniformity disqualification or low dissolution rate of products is solved.

Owner:珠海润都制药股份有限公司

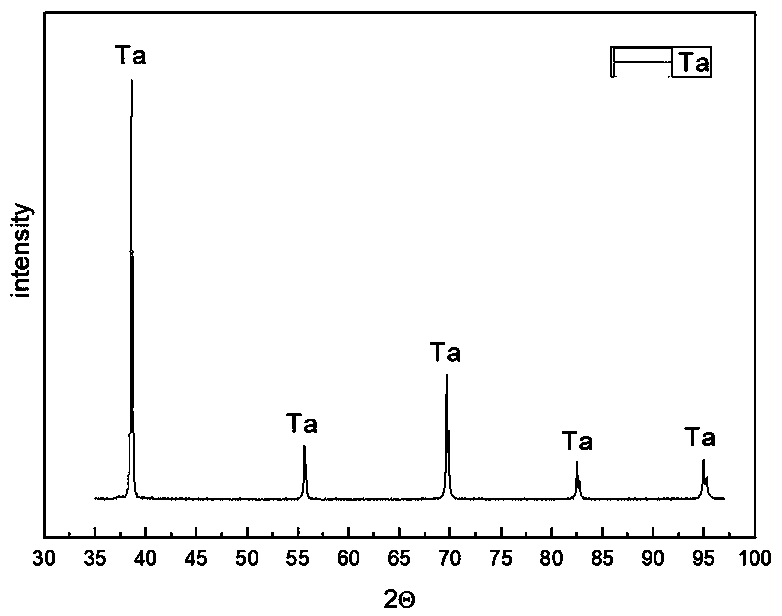

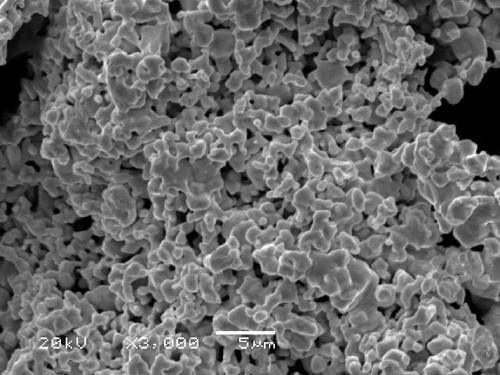

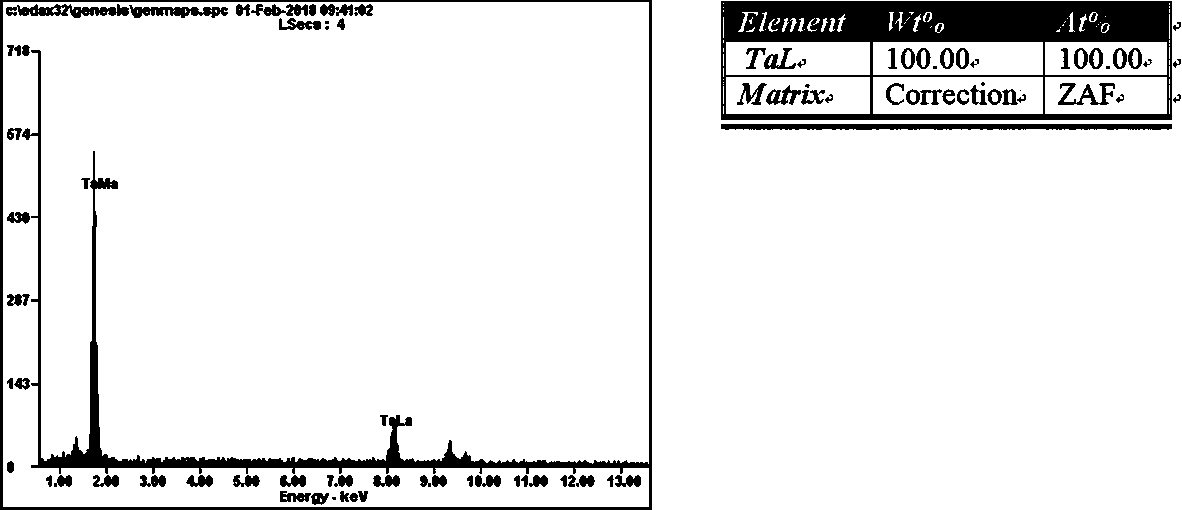

A preparation method of high-purity tantalum target material for electronic materials

ActiveCN108655403BHigh crystallinityAchieve performance requirementsTransportation and packagingVacuum evaporation coatingDevice materialElectronic materials

The invention relates to a method for preparing a high-purity tantalum target for electronic materials, which belongs to the field of powder metallurgy and semiconductor device manufacturing. The preparation method is to pulverize a high-purity tantalum block first, and then ball mill it to a particle size of 5-150 μm. Tantalum powder; after mixing the tantalum powder, install the mold, vibrate and compact; then put the mold into a high-temperature hot-press furnace, and press at 1500-1800°C; after sintering, cool to room temperature and release the furnace to obtain high-purity Green body of tantalum target, density 11.3‑14.5g / cm 3 . According to the requirements of the magnetron sputtering equipment, the green body is cut and processed, and the processed green body is welded to the corresponding back plate according to the user's requirements to obtain a high-purity tantalum target. The high-purity tantalum target prepared by the present invention can significantly reduce the technical difficulty of preparing the target by the traditional casting method, greatly improve the controllability of the process, and contribute to the improvement of the coating performance of later materials.

Owner:HENAN UNIV OF SCI & TECH

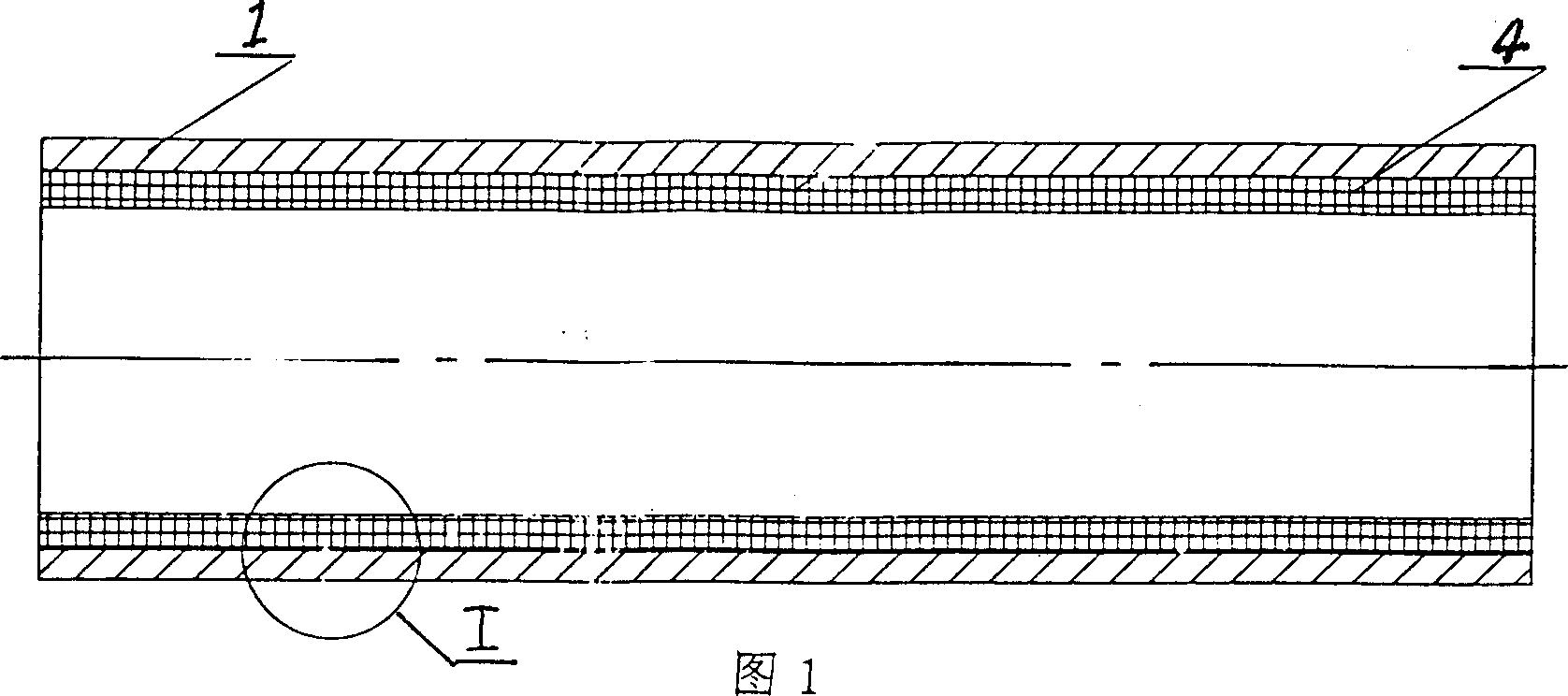

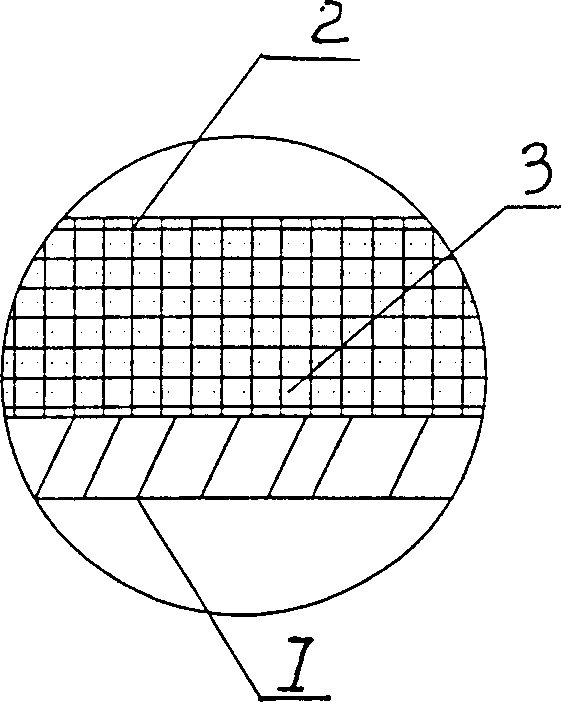

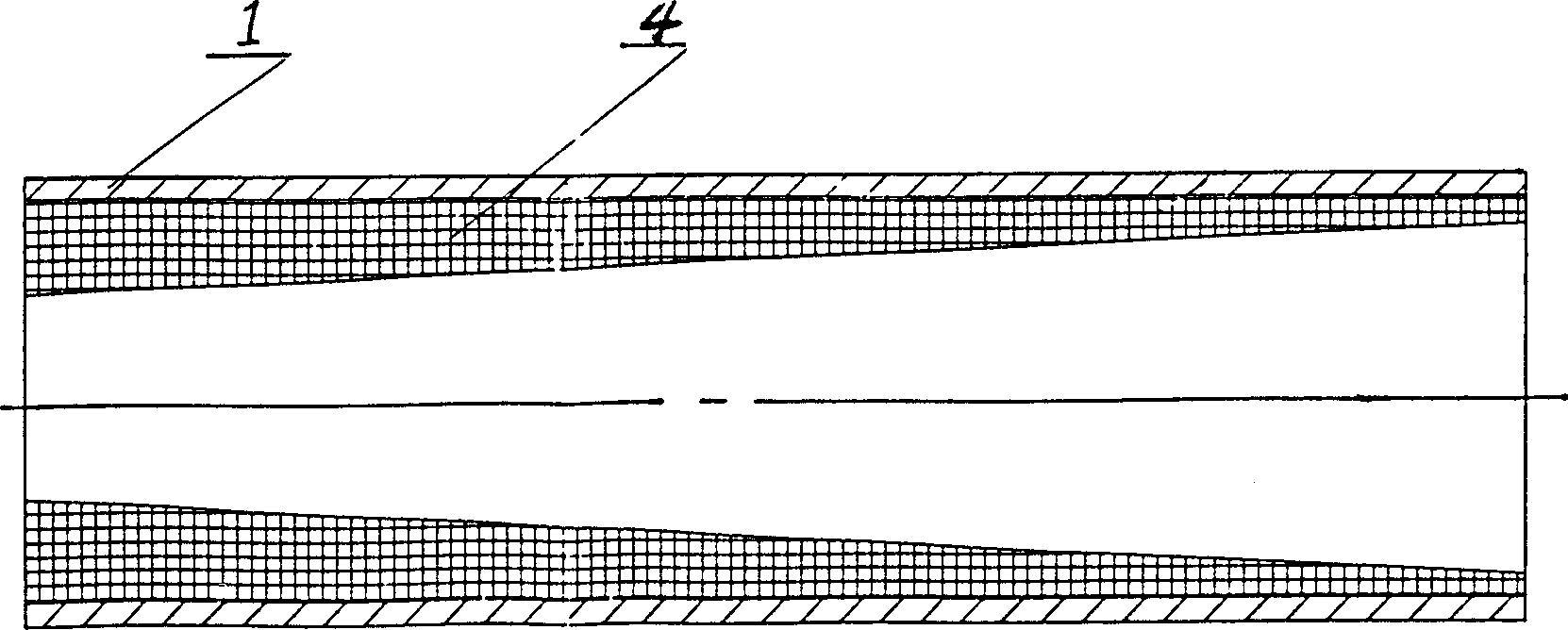

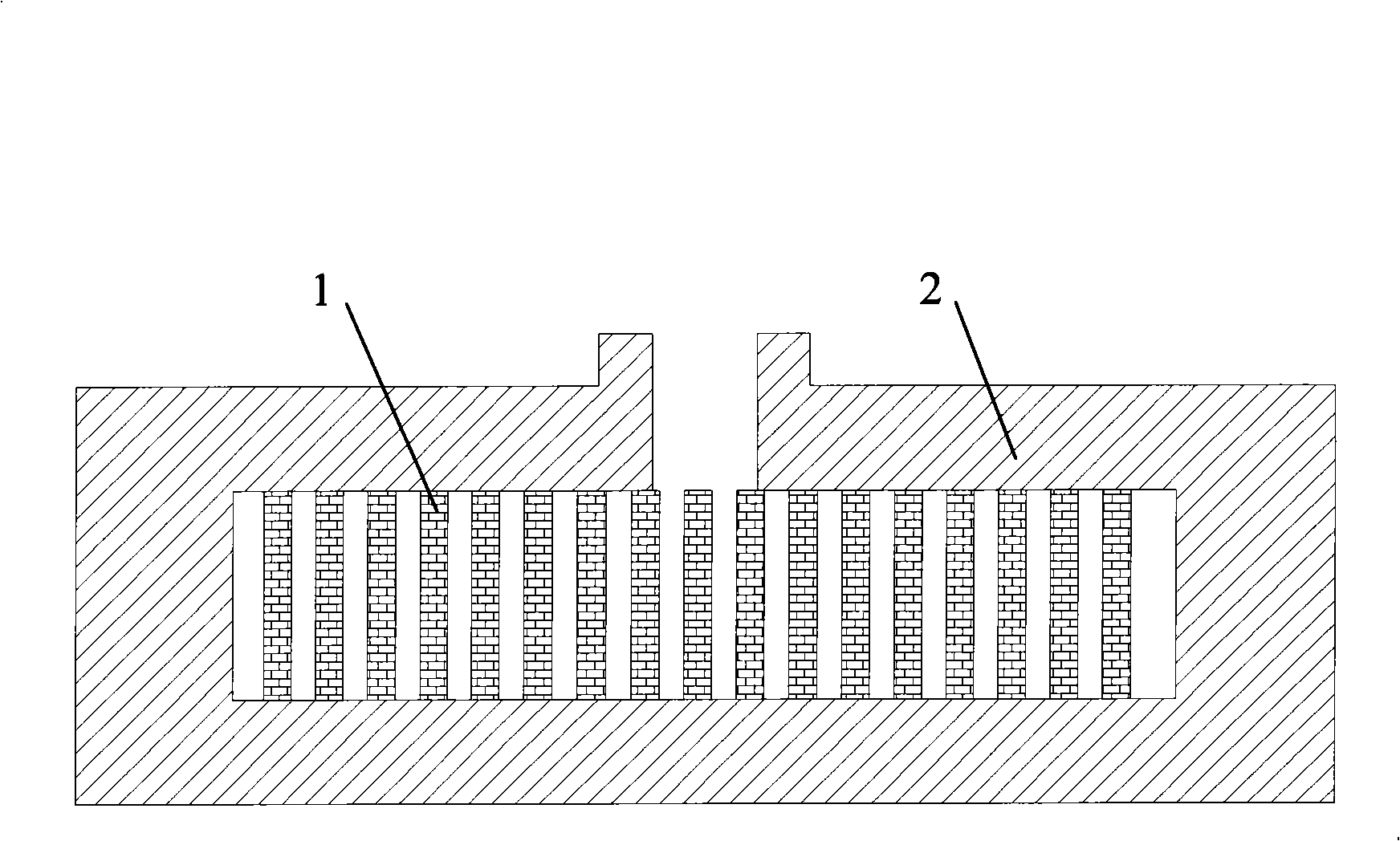

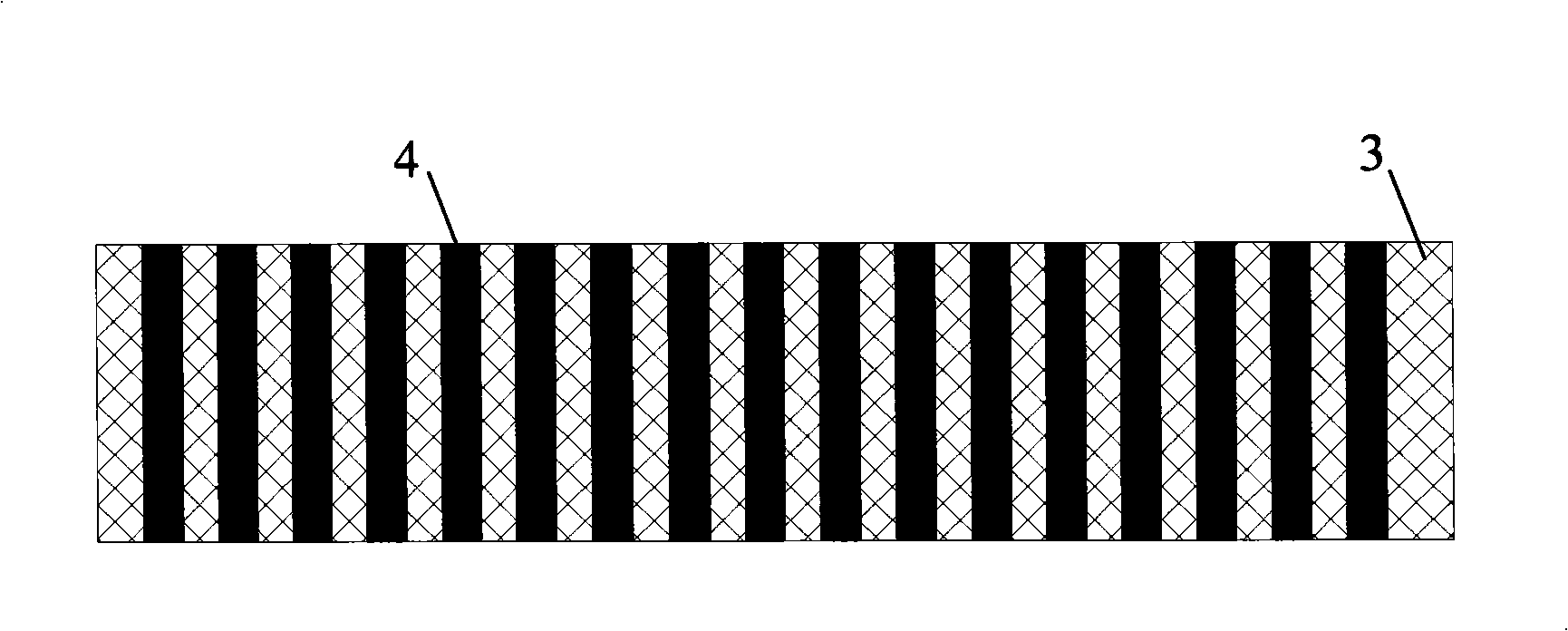

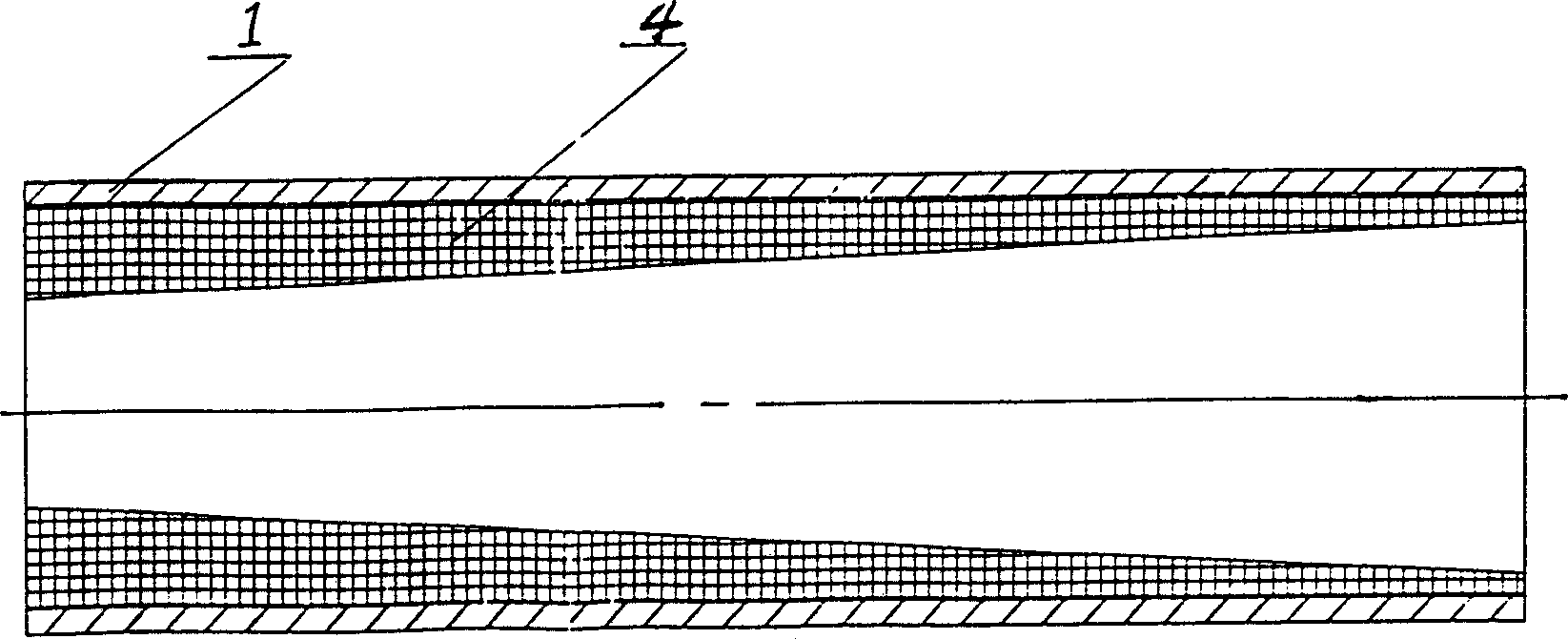

Technology for making metallic pipe with nano-structure metal wire screen-ceramic liner

InactiveCN1203272CHigh strengthHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationCeramic compositeNano structuring

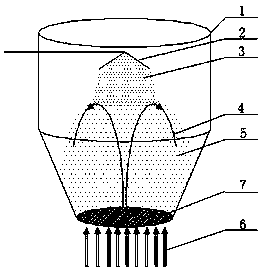

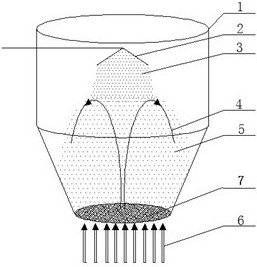

The invention discloses a preparation process of a nano-structure wire mesh-ceramic composite lining metal pipe. It is composed of an outer casing (1) and a composite lining pipe (4), and the composite lining pipe (4) is composed of a wire mesh (2) and a ceramic wear-resistant material (3). Preparation process: Weaving wire mesh (2), cutting, preparing ceramic wear-resistant material (3), evenly coating on the wire mesh (2) and inserting ceramic particles into the gaps of the wire mesh (2), placing The composite plate body of the lining pipe is rolled and placed in the outer casing (1), and the composite lining pipe (4) and the outer casing (1) are rolled and cured by heating, so that the composite lining pipe (4) is closely attached Inside the outer sleeve (1). The invention has the advantages of strong controllability of process parameters, high yield, stable quality and high production efficiency. The product has a long service life, and its wear resistance is 8 to 10 times that of ordinary steel, and 4 to 6 times that of rare earth steel. This process is suitable for the production of pipe products of any shape and size, and has a wide range of applications, and the composite thickness can be adjusted.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Comb-shaped low-slump concrete plastic-reserving agent with poly-sulphoacid structure

The invention relates to a comb-shaped plastic-reserving agent with a poly-sulphoacid structure particularly suitable for low-slump concrete, which is prepared with allyl polyether, sodium styrene sulfonate and sodium alkyl sulfonate as raw materials. The average molecular weight of the allyl polyether is 400-1500, the feeding amount of the allyl polyether accounts for 50-92 percent of the total molecular weight of the raw materials; and the molar ratio of the sodium styrene sulfonate and the sodium alkyl sulfonate is 1:0.2-1:5. The preparation method comprises the following steps: mixing theaqueous solution of each raw material monomer, heating to 65-98 DEG C, adding an initiator ammonium persulfate solution, completing the dropping within 2-4 hours, maintaining the temperature for 1 hour, cooling until the temperature is below 40 DEG C, adding caustic soda liquid for neutralization, and taking out the product, thereby obtaining the plastic-reserving agent, a comb-shaped polymer with the poly-sulphoacid structure. The structure of the polymer combines the advantages of two water reducing agents, naphthalene and polycarboxylic acid. Therefore, the polymer can realize excellent plastic-reserving property of the low-slump concrete with the slump being 7-9cm. simultaneously; the polymer has good physical and chemical compatibility with the two water reducing agents, naphthalene and polycarboxylic acid.

Owner:NANJING RUIDI HIGH TECH

Method for refining grains of large medium high alloy steel forgings

InactiveCN102134637BGenetic reductionReduce consumptionHeat treatment process controlDecompositionMaterials science

Owner:SHANGHAI JIAOTONG UNIV

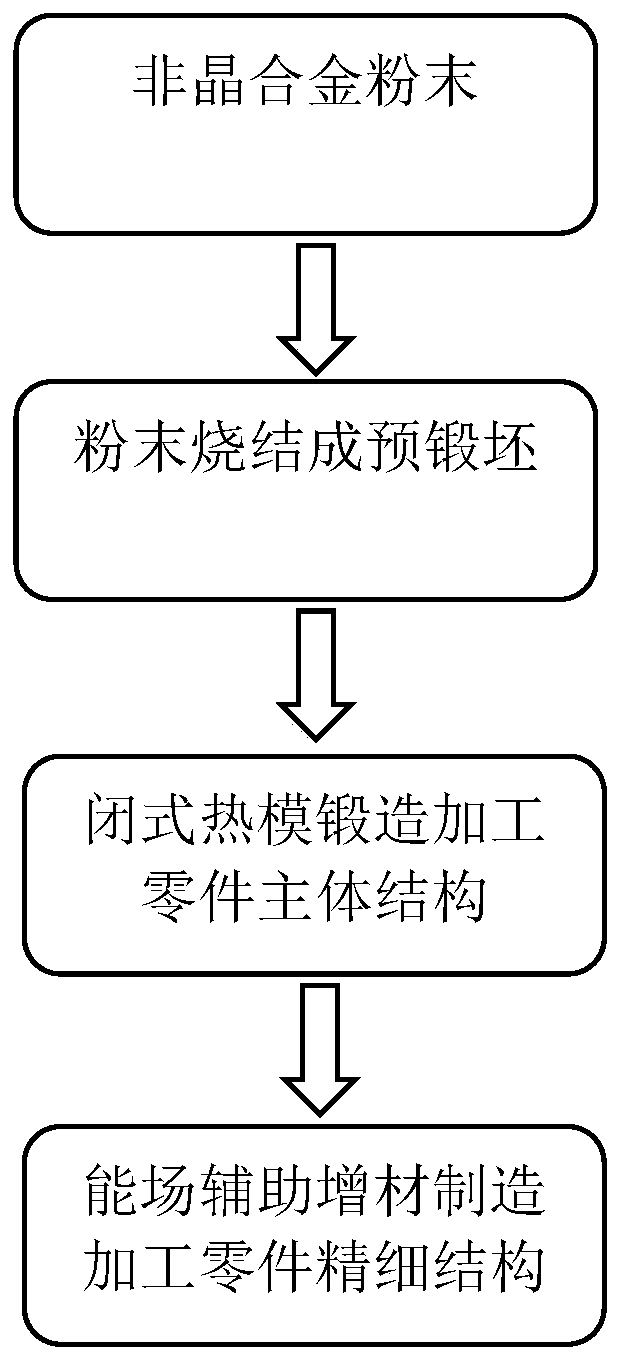

A method for forging/additive composite manufacturing of amorphous alloy parts

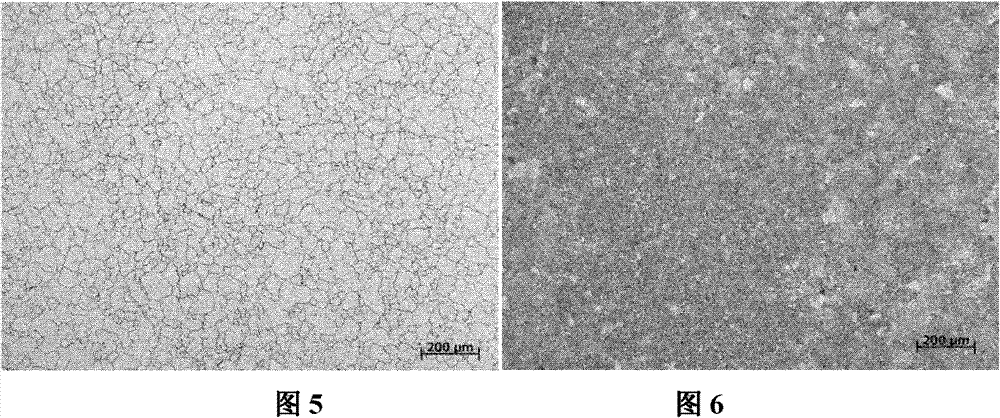

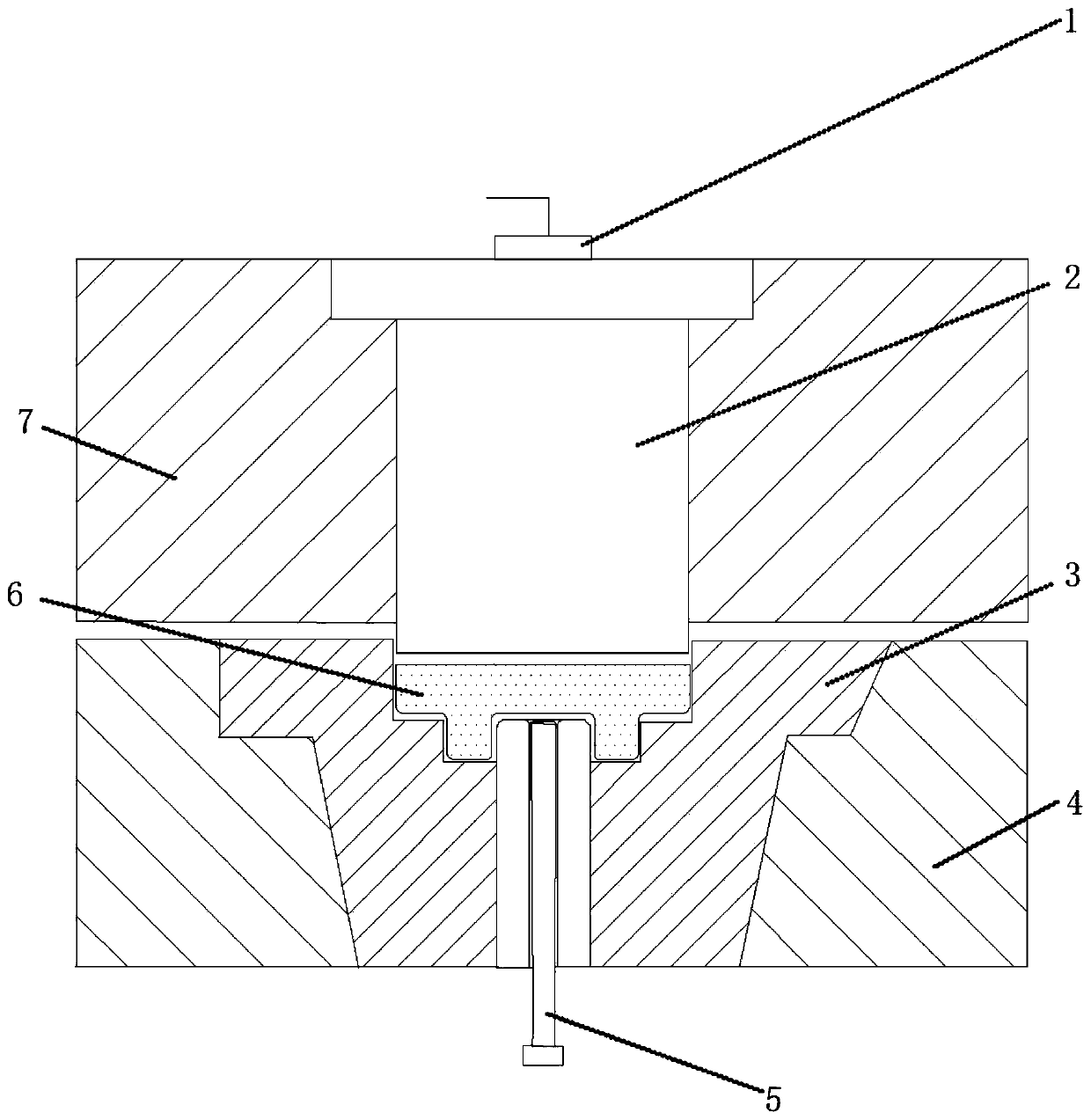

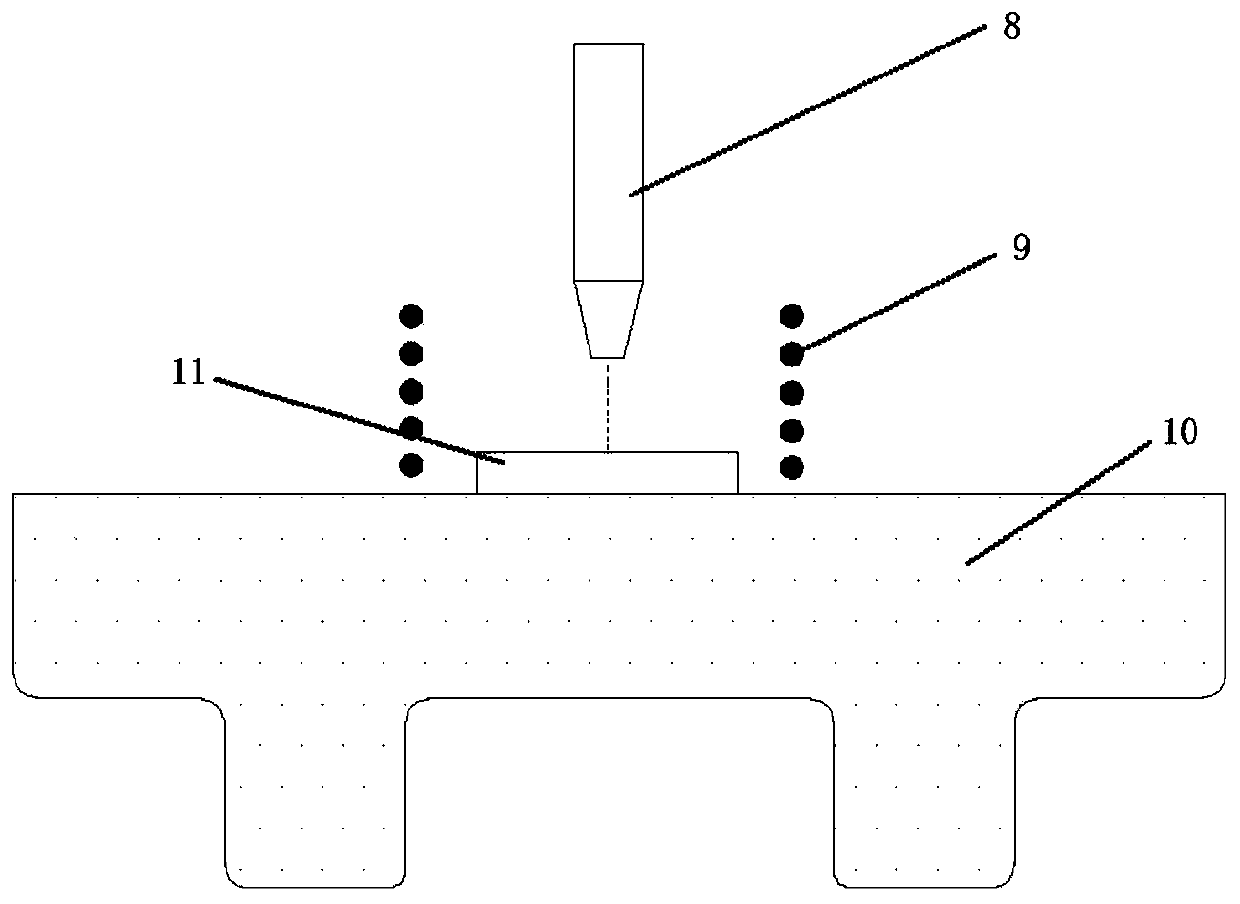

ActiveCN109465442BIrreplaceableHas a complex fine structureAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyAlloy

The invention belongs to the technical field of thermoplastic forming and additive manufacturing of amorphous alloys, and specifically relates to a forging / additive composite manufacturing method of amorphous alloy parts, which first uses powder sintering technology to make amorphous alloy powder materials into pre-forged billets, Then place the pre-forged blank in a closed forging die for closed hot die forging to obtain the main structure of the amorphous alloy part. Finally, the energy field-assisted additive manufacturing technology is used on the main structure to process fine parts with relatively small sizes. structure, or some structures that cannot be formed by forging, such as thin-walled ribs, hollow shells, conformal cooling channels, etc. Correspondingly, a forging / additive composite manufacturing method for large-scale and complex amorphous alloy parts is obtained, especially the interface connection performance between the main structure of the amorphous alloy and the local fine structure is strengthened and improved.

Owner:HUAZHONG UNIV OF SCI & TECH

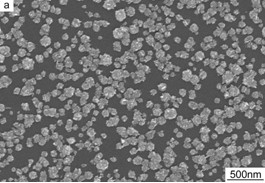

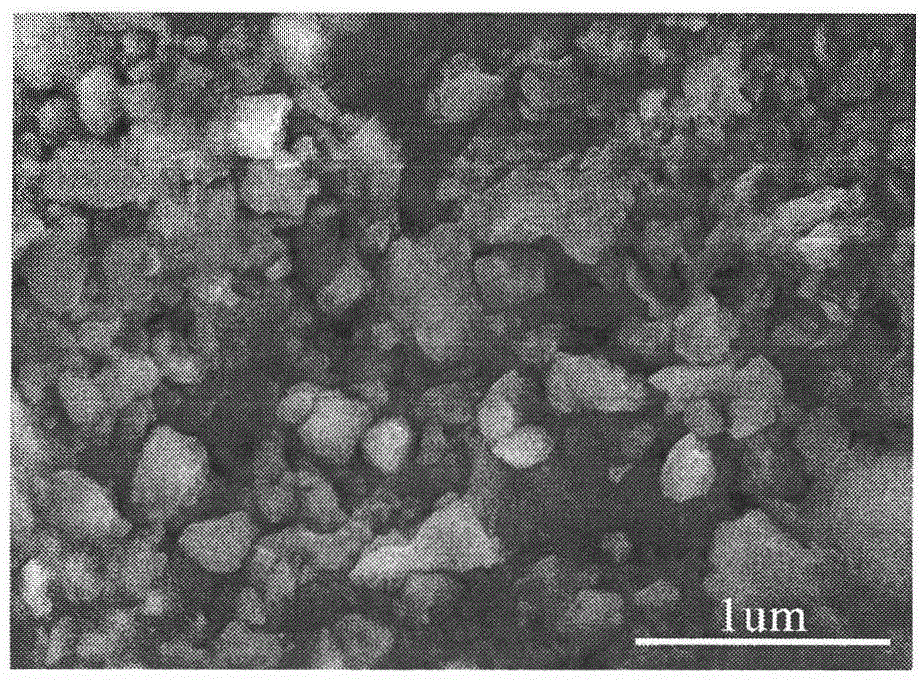

Sol method for preparing electronic-grade ferric phosphate

InactiveCN102476793BSimple processHigh controllability of process parametersPhosphorus compoundsHydrogenLithium iron phosphate

The invention discloses a sol method for preparing electronic-grade ferric phosphate. The method comprises the steps of: preparing a mixed solution from a solution of one or more of phosphoric acid, monohydric phosphate or dihydric phosphate and a ferric salt at a molar ratio of P to Fe being (1:1)-(6:1), and stirring and heating at the temperature of 20-100 DEG C for 0.5-10 hours to form a buffer solution; then adding ferric phosphate sol to the buffer solution, thus changing the pH value and micro chemical environment of the system and promoting the separation of precipitate; and washing the precipitate, filtering and drying to prepare ultramicro fine powder ferric phosphate with D50 being 1-3 mu m. The method disclosed by the invention has the advantages that: the process is simple, the controllability of the process parameters is strong, the use raw materials are fewer, and the method is suitable for scaled industrial production; and ferric phosphate prepared by the method has low impurity content and uniform particle size distribution, and is suitable for being used for further preparing electronic-grade ferric phosphate lithium.

Owner:GUIZHOU UNIV

A kind of preparation method of indapamide capsule

ActiveCN110123775BGood molding effectNot easy to cause pollutionOrganic active ingredientsCapsule deliveryHard CapsuleFluidized bed

The preparation method of a kind of indapamide capsule of the present invention comprises preparation granulation liquid, adopts fluidized bed top spray one-step granulation, then sieves dry granule and mixes with lubricant evenly, finally granule is filled in hard capsule shell Indapamide capsules were prepared. The method reduces the process steps and shortens the preparation time, and the whole production process is prepared by airtight equipment, which is not easy to cause pollution to the environment and operators, and can greatly improve production efficiency; the inlet air temperature is below 70°C, and the production safety hazard is small, which is suitable for industrialization It has the advantages of low energy consumption and high safety production coefficient; it solves the problems of poor mixing uniformity and uneven release in the wet granulation process, good granule formability, high controllability of process parameters in the production process, reducing the influence of manual operations, and improving The quality stability of the drug can solve the problem of unqualified content uniformity of the product or low dissolution rate of the product.

Owner:珠海润都制药股份有限公司

A kind of preparation method of zirconium alloy hot-rolled plate

ActiveCN110877050BUniform tissueImprove corrosion resistanceTemperature control deviceHeating/cooling devicesNuclear reactorThick plate

The embodiment of the present invention discloses a method for preparing a zirconium alloy hot-rolled plate, including: forging a zirconium alloy ingot with a preset size and a preset weight after heat preservation, heat treatment, first surface treatment, forging after heat preservation, The second surface treatment, multi-pass hot rolling and vacuum annealing. The zirconium alloy hot-rolled medium-thick plate produced in the embodiment of the present invention has excellent corrosion resistance and mechanical properties, and has a uniform and fine structure, which meets the technical standard requirements for the zirconium alloy medium-thick plate used in nuclear reactors. The invention has simple process, short preparation process and low production cost, and is expected to change the long-term dependence on imports of domestic high-performance zirconium alloy medium-thick plates.

Owner:国核宝钛锆业股份公司

Method for preparing metal ion-doped titanium dioxide target material and target material thereby

The invention relates to a method for preparing a metal ion-doped titanium dioxide target material and a target material thereby. The target material is prepared by adopting the steps of preparing metal ion-doped titanium dioxide powder through a solution reaction and compressing and sintering. The preparation process is simple and is easy to realize uniform doping of one or more metal ions; the doping amount of the ions can be precisely controlled, and the metal ions can enter a titanium dioxide crystal lattice in the preparation process to generate chemical bonding; the average crystal granularity of titanium dioxide in the prepared target material is below 200 nano, and the target material has high density; and the target material can be used for preparing a metal ion-doped titanium dioxide nano film by adopting a magnetron sputtering method.

Owner:INNER MONGOLIA UNIV OF TECH

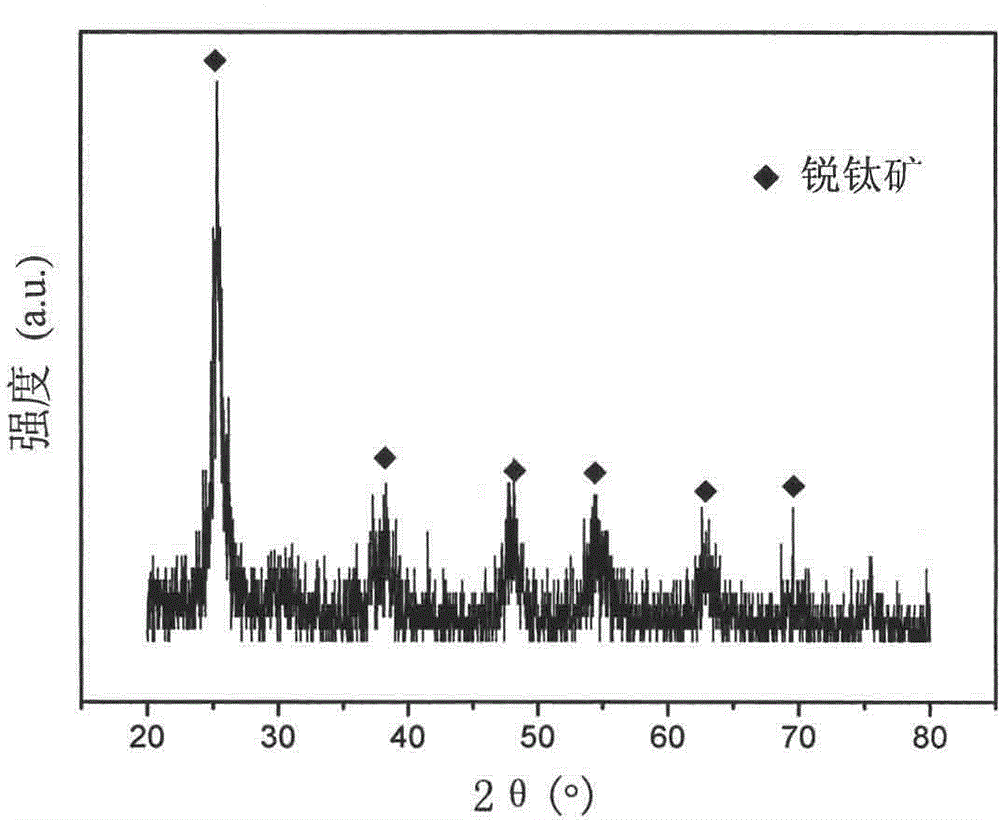

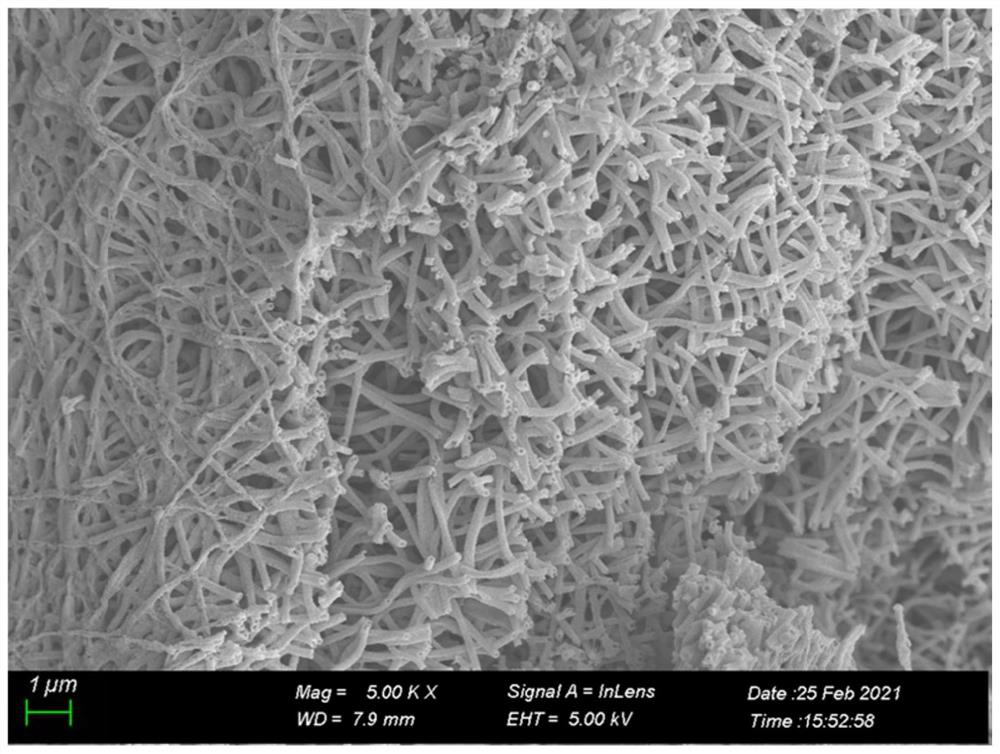

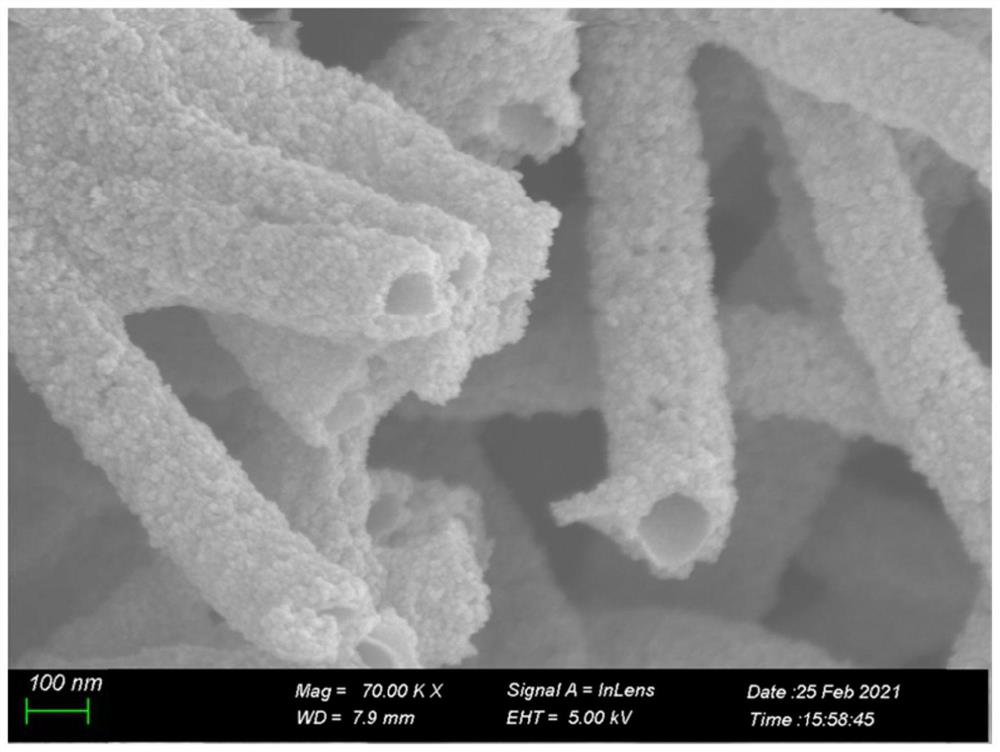

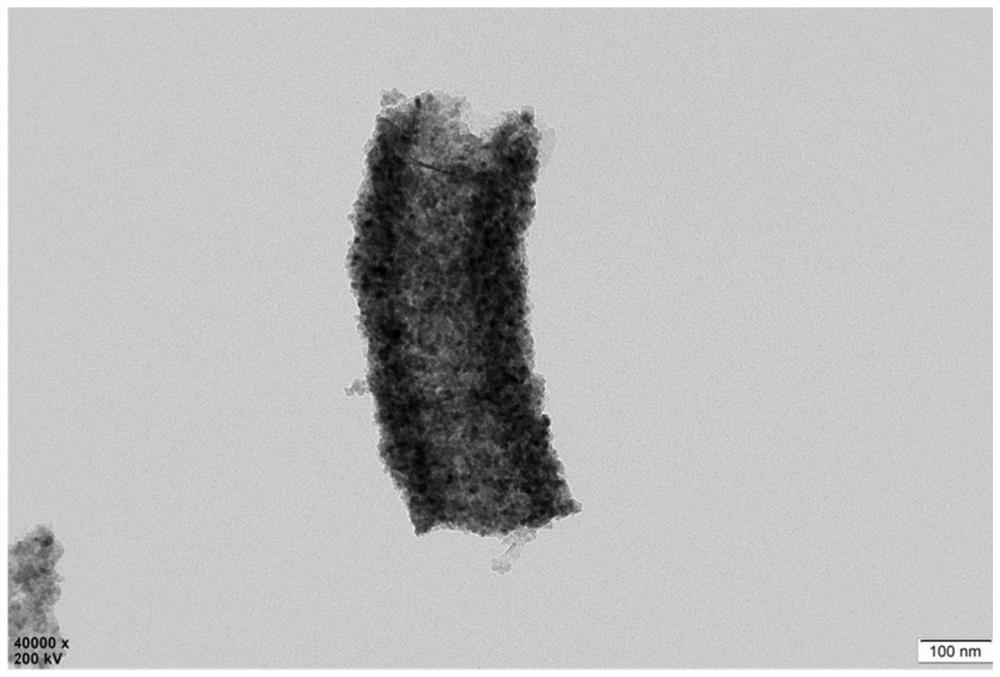

Preparation method of carbon nanotube-loaded titanium oxide photocatalyst

ActiveCN113289667AImprove cycle stabilityLower bandgapPhysical/chemical process catalystsWater/sewage treatment by irradiationSpinningPtru catalyst

The invention relates to a preparation method of a carbon nanotube-loaded titanium oxide photocatalyst, belonging to the technical field of preparation and application of photocatalytic materials. The titanium oxide photocatalyst is in the shape of a nanotube in appearance, and is formed by nitrogen-and-fluorine co-doped anoxic titanium oxide loaded with a fluorine-doped carbon nanotube; and the titanium oxide material can be directly used for simulating photocatalytic degradation of pollutants under sunlight, and is a photocatalyst with excellent performance. The method comprises the following steps: firstly, with polyacrylonitrile as a raw material, adding ammonium fluoride, and preparing polyacrylonitrile nanofibers containing ammonium fluoride through an electrostatic spinning technology; then with tetrabutyl titanate as a titanium source, adding glacial acetic acid, and preparing a polyacrylonitrile fiber-loaded titanium oxide sample through a solvothermal method; and finally, performing high-temperature heat treatment in a vacuum tube furnace in an inert atmosphere to obtain the titanium oxide photocatalyst. The method has the advantages of easily available raw materials, high product yield, low cost and simple and safe production process, and is suitable for large-scale production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

a use of ch 4 A direct reduction process for the production of sponge iron by non-catalytic oxygen-enriched conversion

ActiveCN104313228BLower the preheat temperatureLess investmentShaft furnaceGas emission reductionHydrogenShaft furnace

The invention relates to a direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation. A process route comprises the following steps: preheating a CH4-enriched raw gas and oxygen-enriched air which are subjected to purification and pressure regulation, then introducing the CH4-enriched raw gas and the oxygen-enriched air into a non-catalytic oxygen-enriched transformation furnace for a combustion reaction in the non-catalytic oxygen-enriched transformation furnace, and raising the temperature to transform CH4 therein into CO and H2 to form a high-temperature transformation gas; in the meantime, cooling, dedusting and pressurizing a top gas of a shaft furnace, then introducing the top gas into a hydrogen purification device to prepare purified hydrogen, preheating the purified hydrogen, and then introducing the preheated purified hydrogen into the lower part of the catalyst oxygen-enriched transformation furnace to be mixed with the high-temperature transformation gas generated through the combustion reaction to form a reduced coal gas; and introducing the reduced coal gas into the shaft furnace to reduce iron ores into the sponge iron. The direction reduction process disclosed by the invention not only has the advantages of short process flow, availability for energy saving and emission reduction, long service life of a nozzle and low investment cost, and can be used to prevent the sponge iron from caking and avoid carbon formation.

Owner:CISDI ENG CO LTD

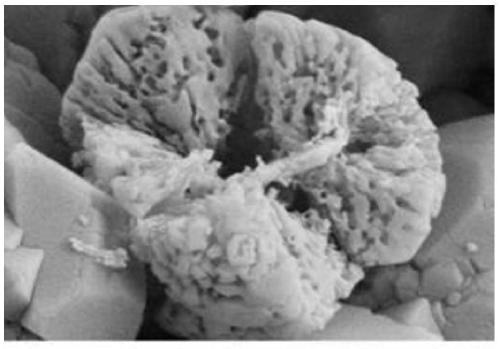

A kind of preparation method of battery grade microporous spherical iron phosphate

ActiveCN106744774BReduce typesWide variety of sourcesPhosphorus compoundsHydrofluoric acidLithium iron phosphate

The invention provides a preparation method of battery level microporous spherical iron phosphate. The preparation method comprises the following steps: mixing and heating a phosphoric acid solution and ferric iron salt, and reacting to form a concentrated solution; adding a 1-3 mol / L nitric acid solution, nano silicon dioxide of which the mass percent is 0.01-0.1% and deionized water into the concentrate at 75-85 DEG C to induce iron phosphate crystals to precipitate out by using the nano silicon dioxide as a crystal nucleus, filtering, washing, and drying to prepare a battery level iron phosphate material; and soaking the iron phosphate prepared in the previous step in hydrofluoric acid for 20-60 minutes, washing, and drying to finally prepare the microporous spherical iron phosphate material, wherein the iron phosphate product prepared in the previous step is etched due to the reaction of the hydrofluoric acid and the nano silicon dioxide. Thus, the electric conductivity and charging / discharging properties of subsequently prepared lithium iron phosphate can be further improved. The invention belongs to the technical field of iron phosphate preparation.

Owner:GUIZHOU UNIV

Manufacturing method for large tantalum plate

ActiveCN102873093BSimple processHigh controllability of process parametersTemperature control deviceMetal rolling arrangementsControllabilityMechanical property

The invention provides a manufacturing method for a large tantalum plate, which comprises the following steps: 1, performing multi-pass cogging and rolling to a tantalum plate mold; 2, grinding and repairing the surface; 3, destressing and annealing; 4, performing multi-pass finished product rolling; and 5, performing annealing treatment to a finished product, and finally obtaining the large tantalum plate with the thickness of 0.5-2 mm, the width of 1000 mm-1300 mm, and the length of 1400 mm-2100 mm. The manufacturing method has the advantages of simple technological process, strong processing parameter controllability and easiness in industrialized mass production. The invention adopts the processing technique of first cogging rolling and then finished product rolling, controls and optimizes the rolling technique and the annealing schedule, finally obtains the large tantalum plate with good surface quality, high planeness and excellent mechanical property, solves the technical bottleneck that the present technique can not manufacture large tantalum plates continuously and stably, and really promotes the development of tantalum plates.

Owner:西安诺博尔稀贵金属材料股份有限公司

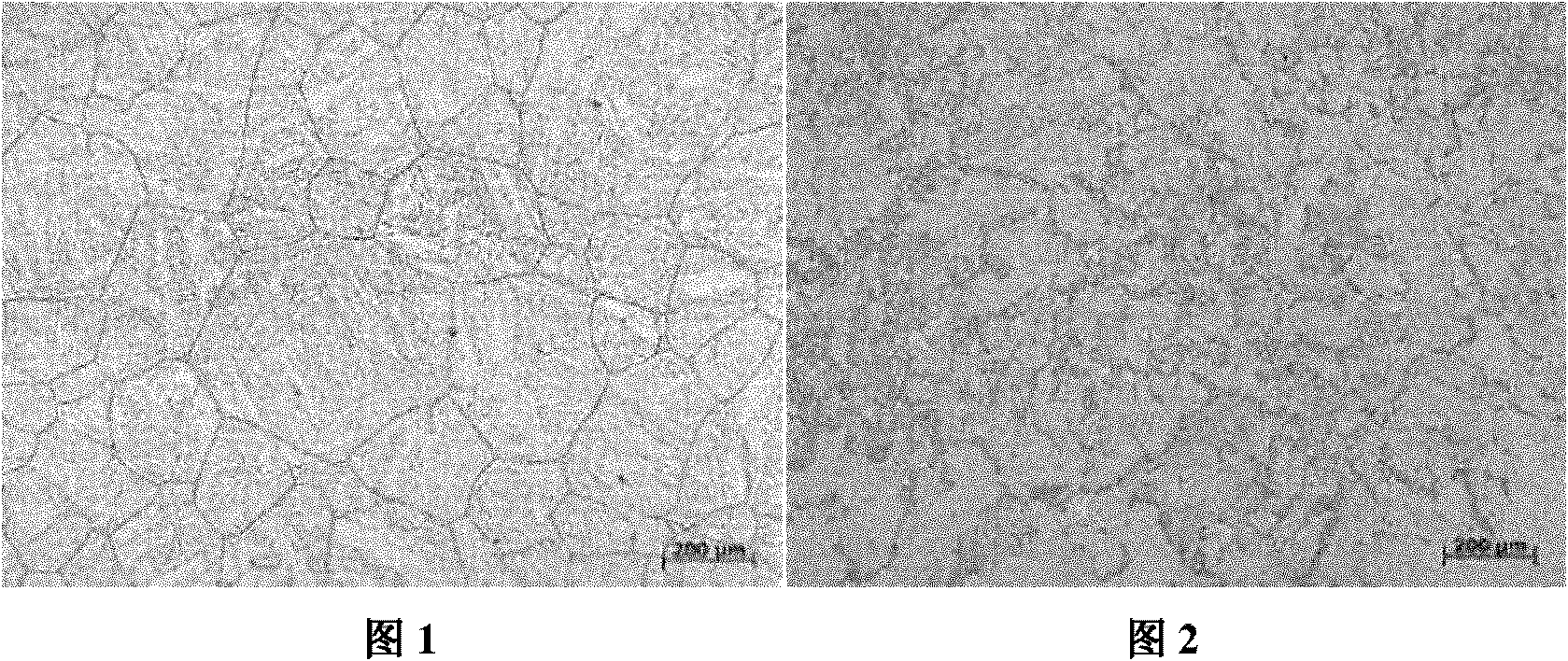

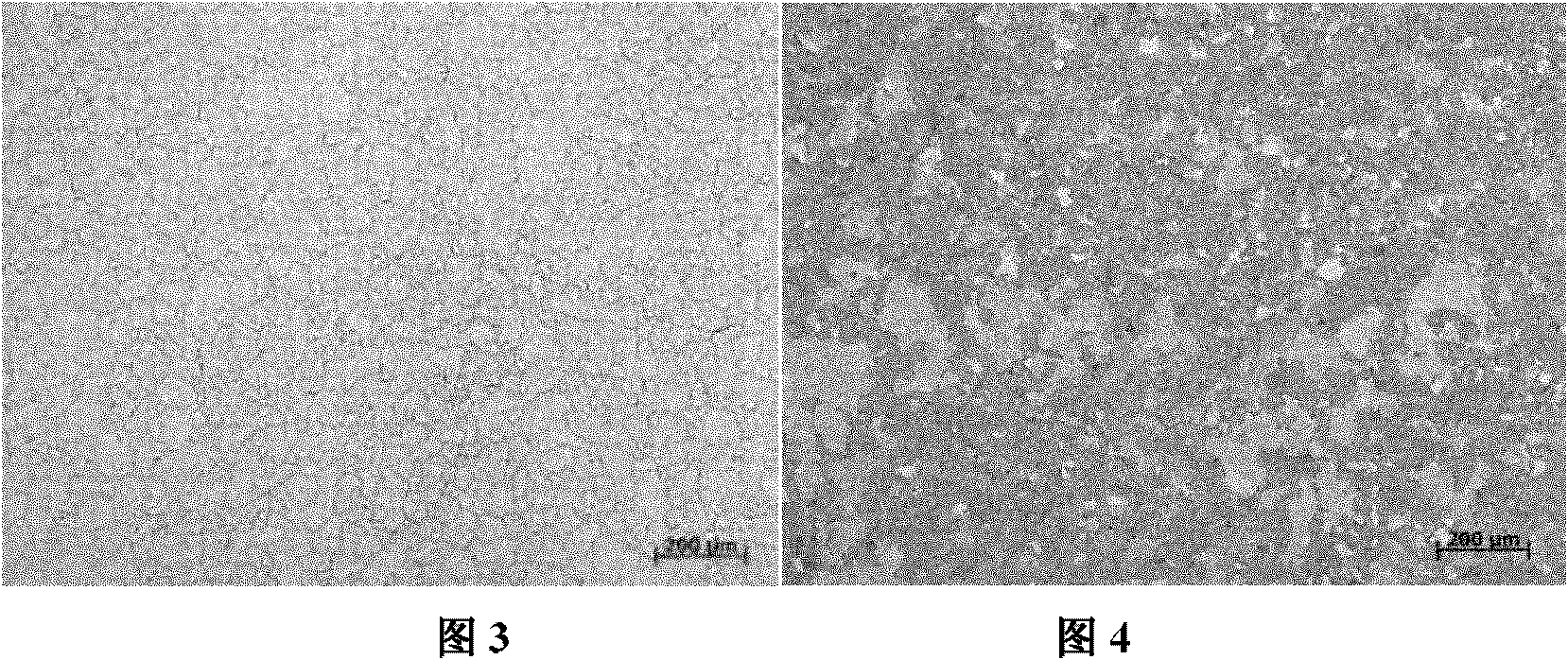

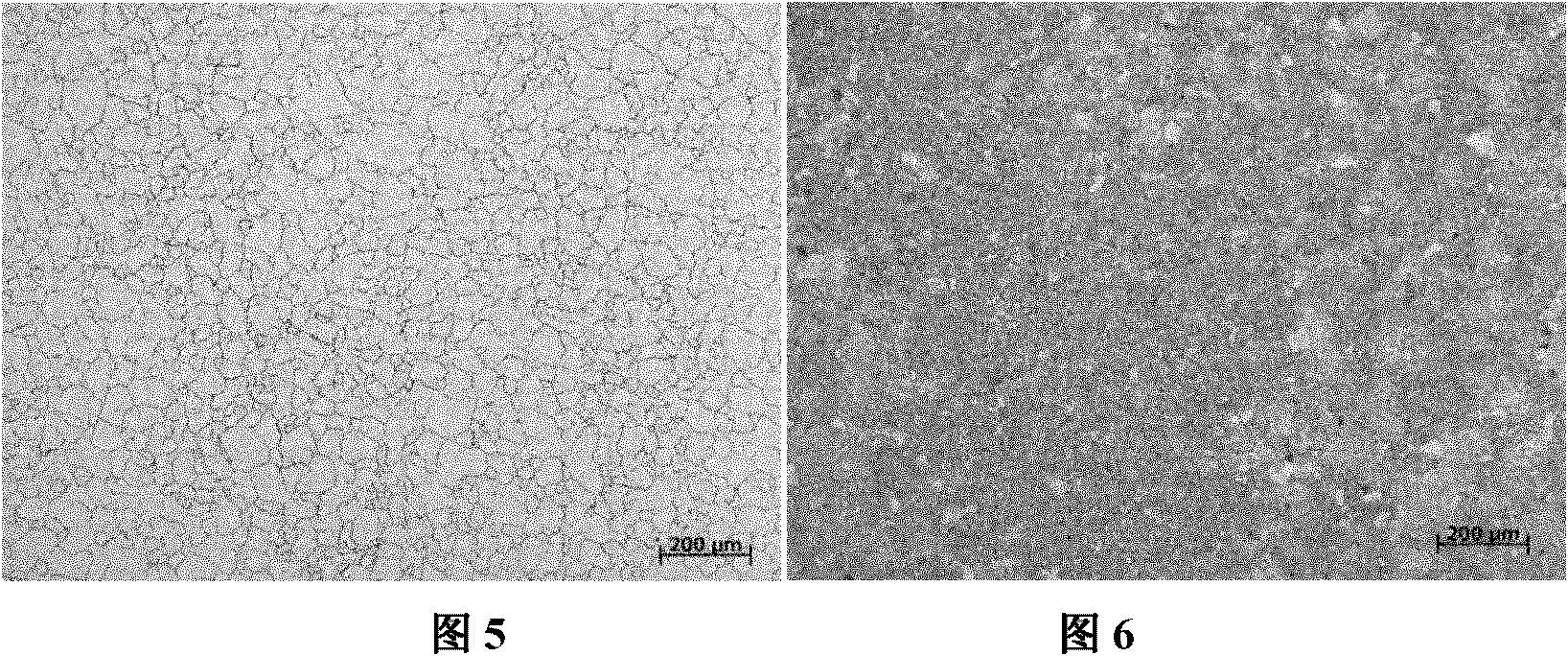

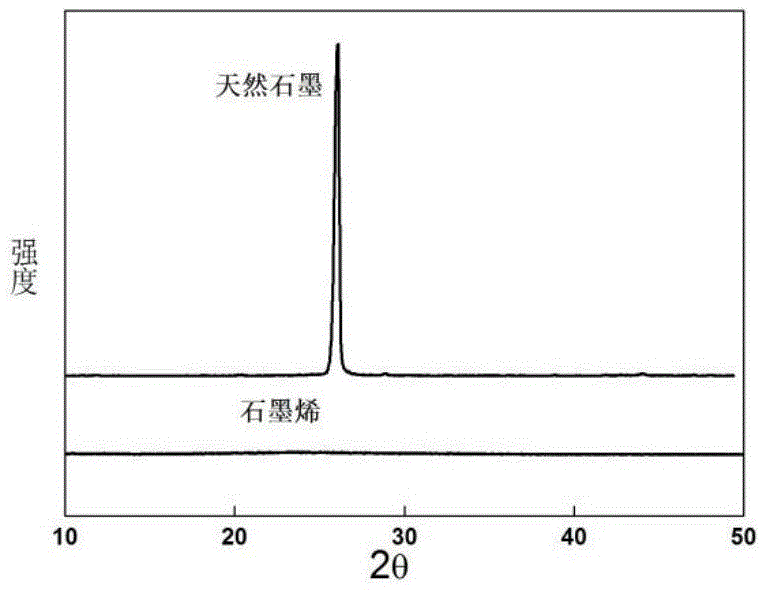

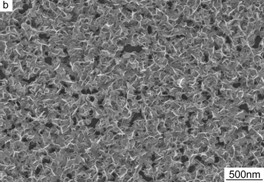

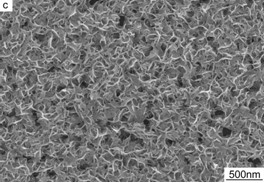

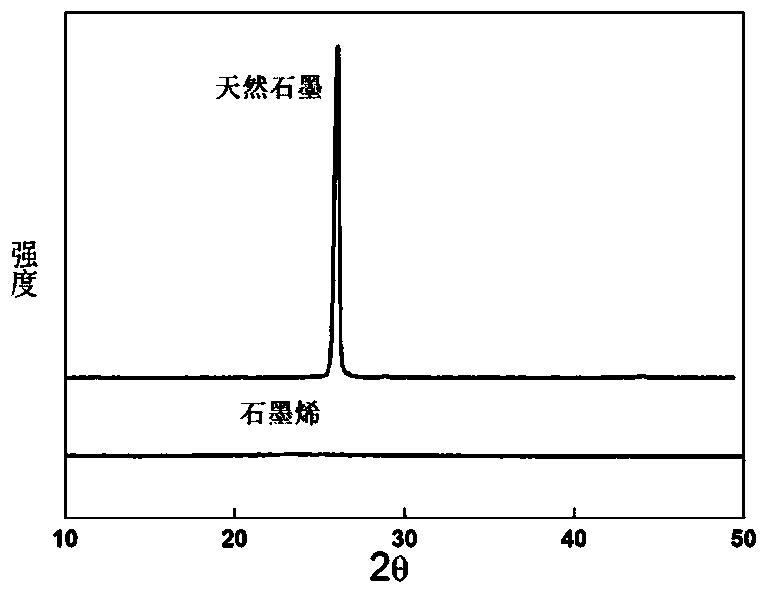

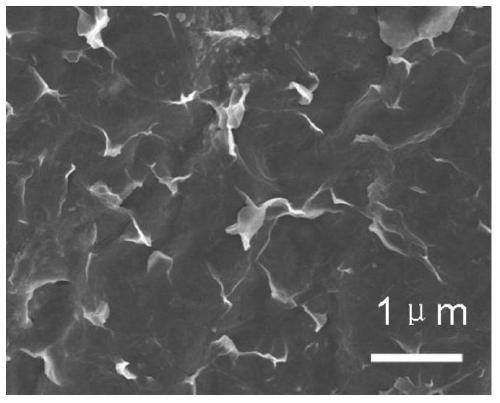

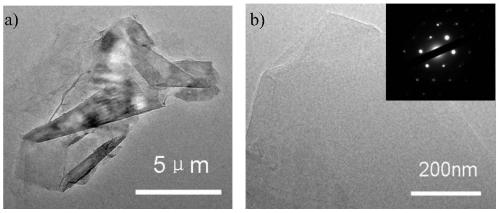

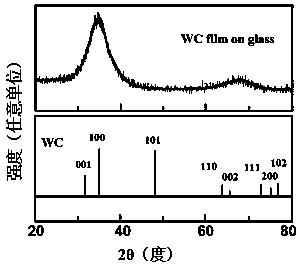

A kind of preparation method of high-quality graphene conductive film

The invention belongs to the technical field of graphene materials and relates to a preparation method of a high quality graphene conductive film. The preparation method comprises the following steps: uniformly mixing natural flake graphite with mixed acid in a reactor, then adding an intercalator and stirring to react, and filtering, washing and drying to obtain layered graphite; then after microwave treatment of the layered graphite, dispersing the layered graphite in water for ultrasonic exfoliation to form a graphene aqueous liquid, and dispersing the centrifugalized graphene aqueous liquid in a solvent to obtain a graphene dispersion liquid; and then after ultrasonic treatment of the graphene dispersion liquid, forming a graphene thin film by virtue of dispensing or filtration of a cellulose filter membrane and polishing the surface of the graphene thin film, and furthermore, transferring the substrate and heating the graphene thin film to prepare the graphene conductive film. The preparation method is simple and convenient to operate, the controllability of process parameters is high and the production cost is low, and moreover, strong oxidants and toxic reducers are avoided, and the preparation method is environment-friendly.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com