Patents

Literature

42results about How to "Achieve performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injectable double-crosslinked hyaluronic acid aquagel and preparation method thereof

ActiveCN104910396ARaw materials are easy to getMild reaction conditionsAnimal cellsPharmaceutical non-active ingredientsTissue engineeringPhotoinitiator

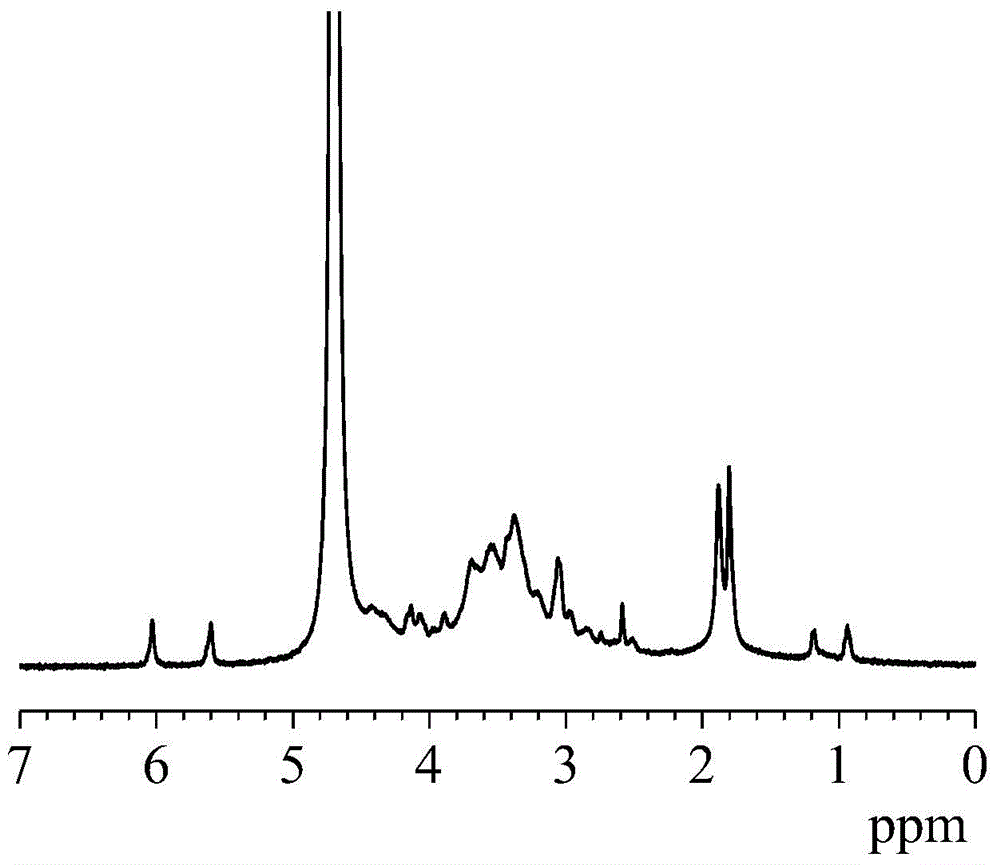

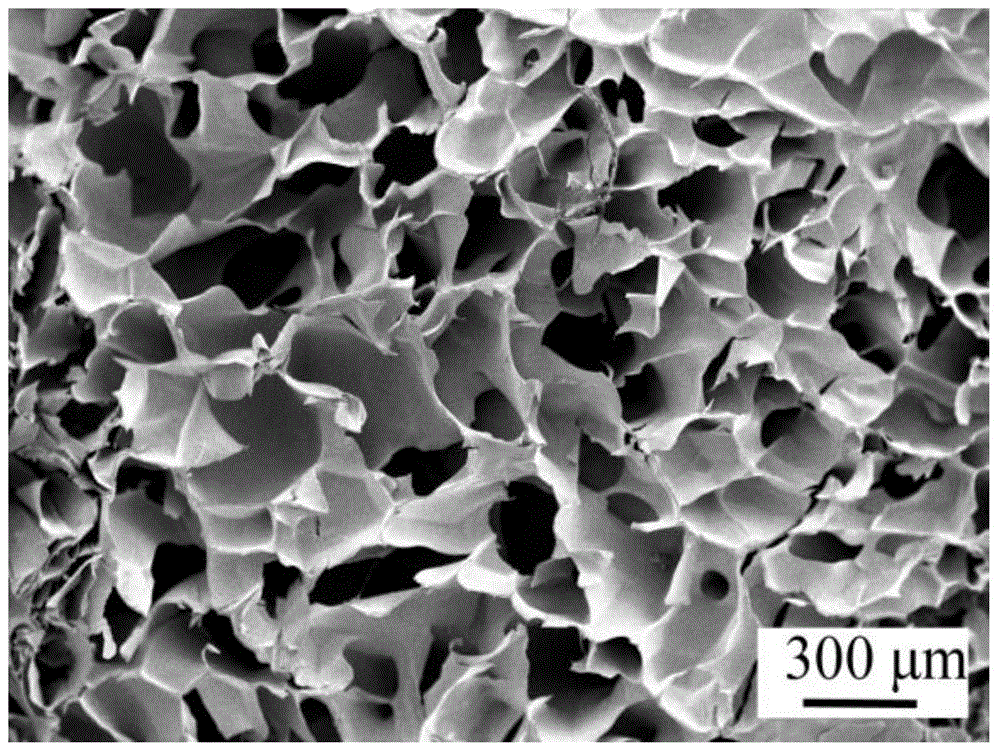

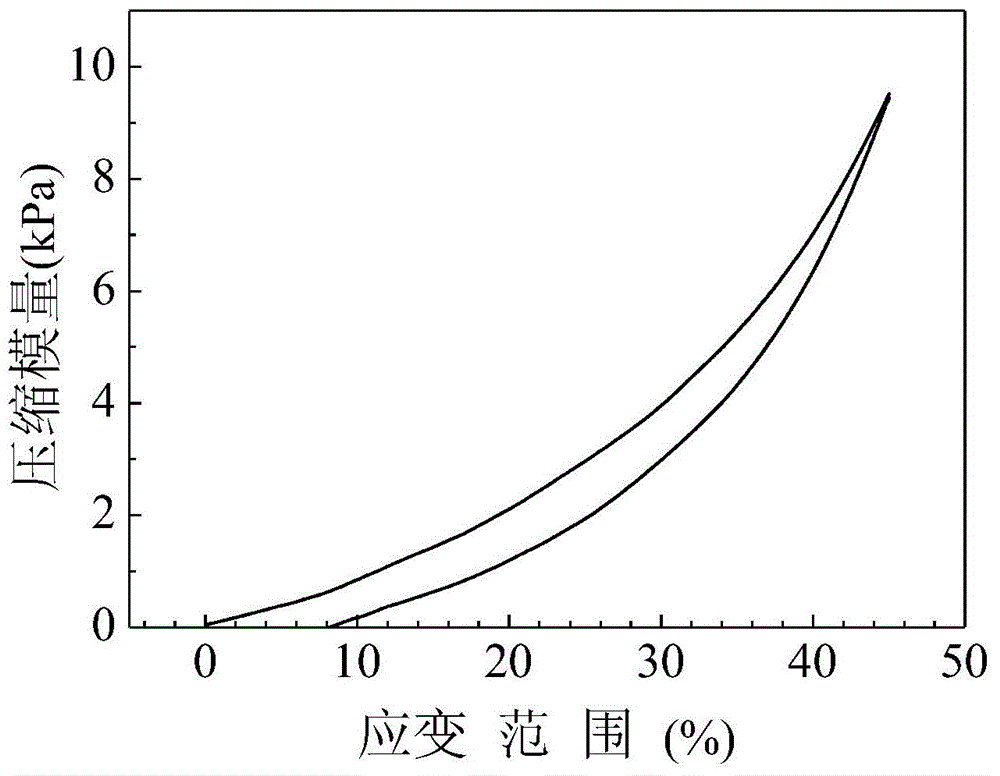

The invention discloses an injectable double-crosslinked hyaluronic acid aquagel and a preparation method thereof. The preparation method comprises the following steps: synthesizing formylated hyaluronic acid and amino / methylacryloyl bifunctional hyaluronic acid containing disulfide bond in the side chain, uniformly mixing the formylated hyaluronic acid and amino / methylacryloyl bifunctional hyaluronic acid containing disulfide bond in the side chain with a water-soluble photoinitiator, and carrying out photochemical polymerization to obtain the injectable double-crosslinked hyaluronic acid aquagel. The method has the advantages of accessible raw materials, mild reaction conditions, short reaction time, simple technique and the like. The prepared aquagel is formed by a Schiff base crosslinking mechanism and a photocrosslinking mechanism, and the two crosslinking networks are connected together. The crosslinking network chain of the aquagel contains the disulfide bond and Schiff base, and thus, the aquagel has dual sensitivities for reduction and pH. The hyaluronic acid aquagel has flexible and adjustable mechanical properties, microstructure, degradation property, swelling capacity and the like, is injectable, and has application prospects in the aspects of cell transfer, tissue engineering, three-dimensional cell culture and the like.

Owner:WUXI JIANGNAN CABLE

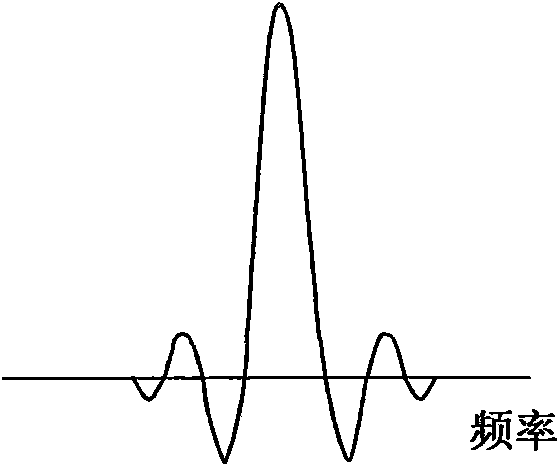

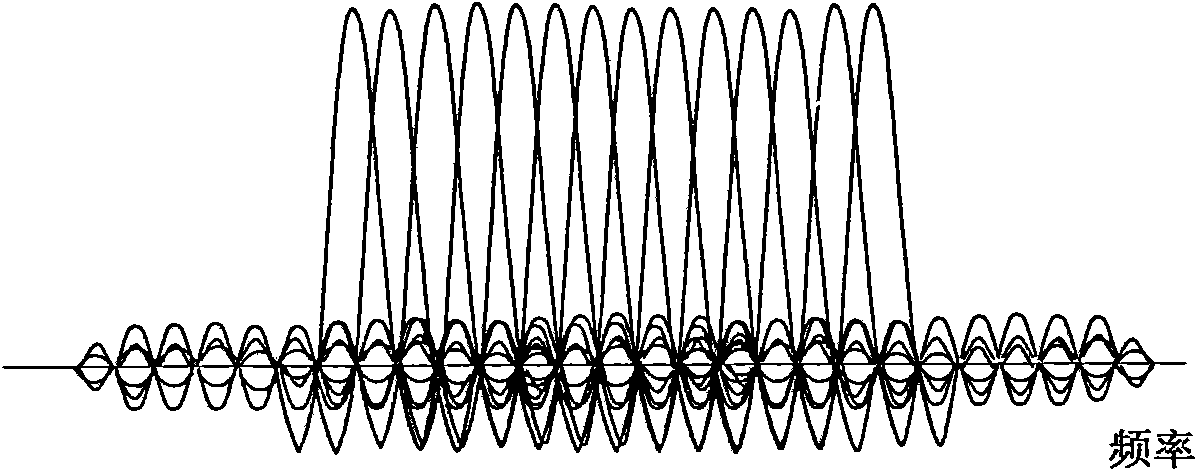

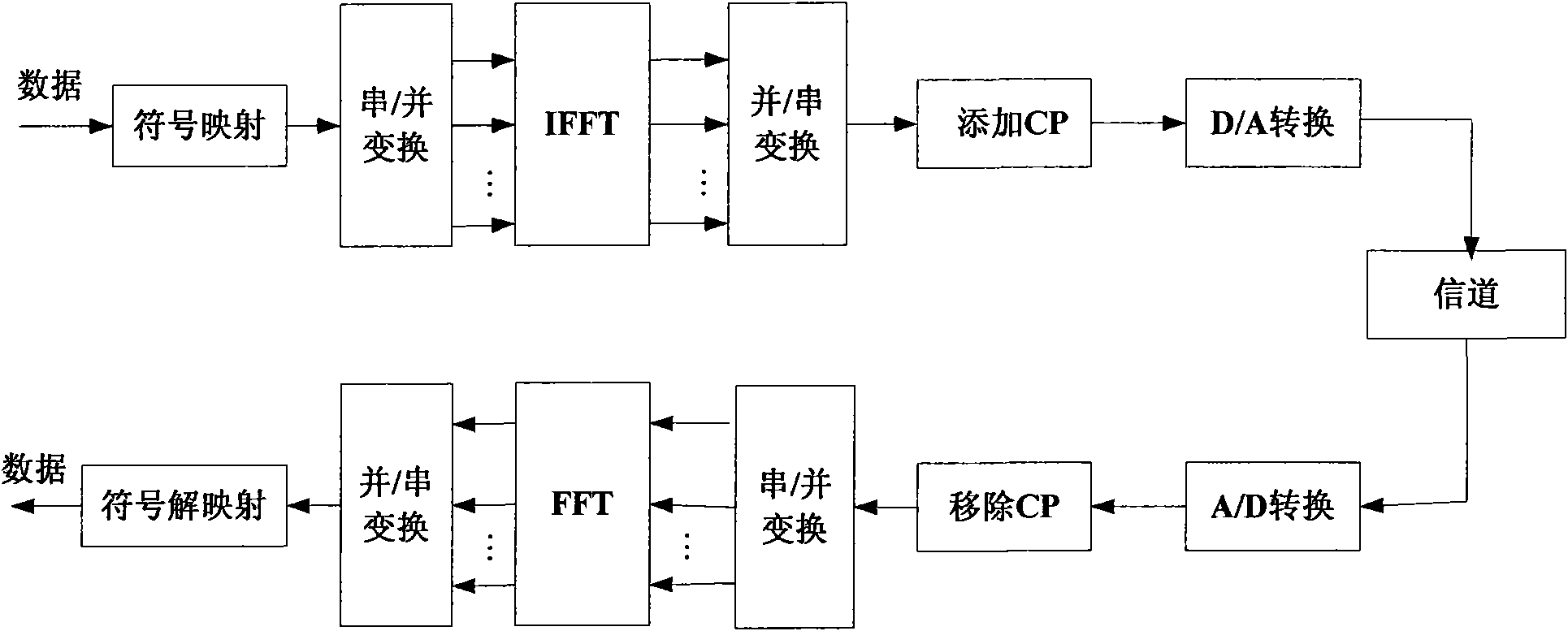

Multi-input and multi-output selectivity OFDM underwater sound communication system and method

InactiveCN101631099AIncrease channel capacityIncrease transfer rateSpatial transmit diversityMulti-frequency code systemsSubcarrierFrequency domain

The invention relates to a multi-input and multi-output selectivity OFDM underwater sound communication system and a method thereof, having the advantages of resisting multi-path interference, resisting frequency selectivity deep fading, improving the transmission rate of information and the like. The transmitter of the system comprises a space multiplexing unit, a plurality of spectrum spreading units, a subcarrier zero setting unit, a plurality of OFDM modulation units, a multiple sonar transmitting unit and a communication channel estimation unit, wherein, the spectrum spreading units are connected between the space multiplexing unit and the subcarrier zero setting unit; the OFDM modulation units are connected between the subcarrier zero setting unit and the multiple sonar transmitting unit. A receiver comprises a multiple sonar receiving unit, a plurality of OFDM demodulation units, a communication channel frequency domain balancing unit, a plurality of dispreading units and space demultiplexing units, the OFDM demodulation units are connected between the multiple sonar receiving unit and the communication channel frequency domain balancing unit, the dispreading units are connected between the communication channel frequency domain balancing unit and the space demultiplexing unit, and the communication channel estimation unit is respectively connected with the subcarrier zero setting unit and the communication channel frequency domain balancing unit.

Owner:SOUTH CHINA UNIV OF TECH

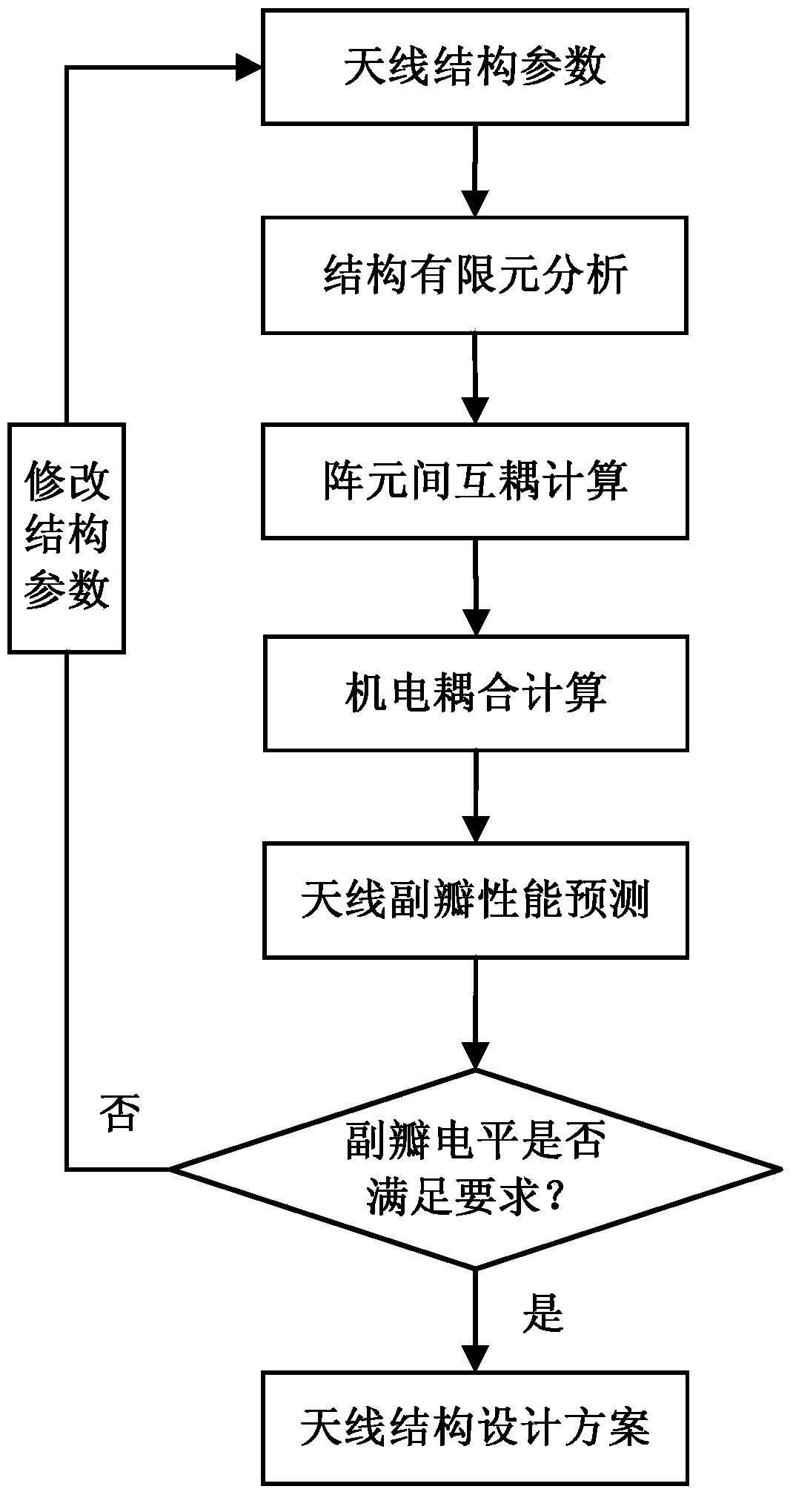

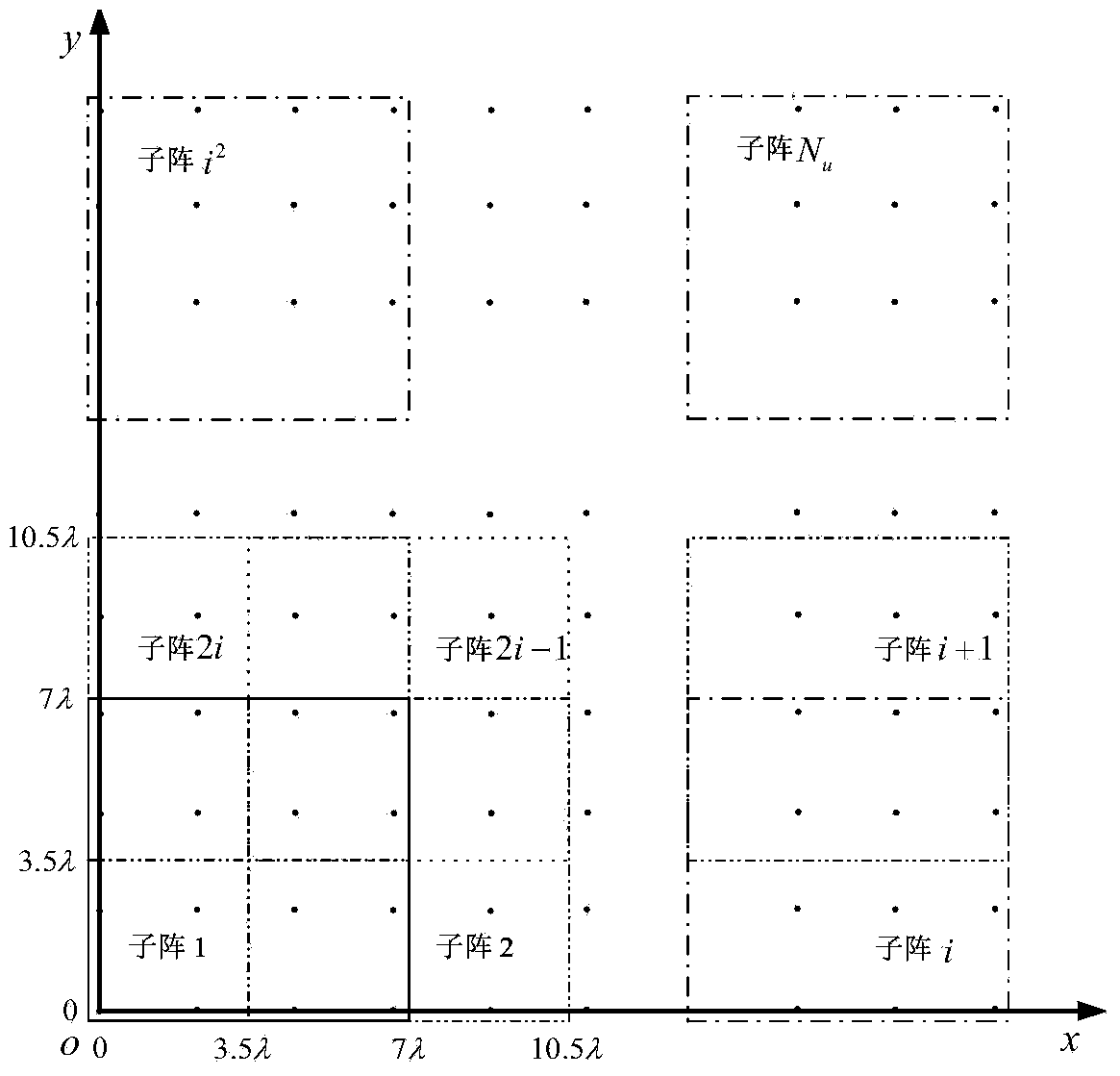

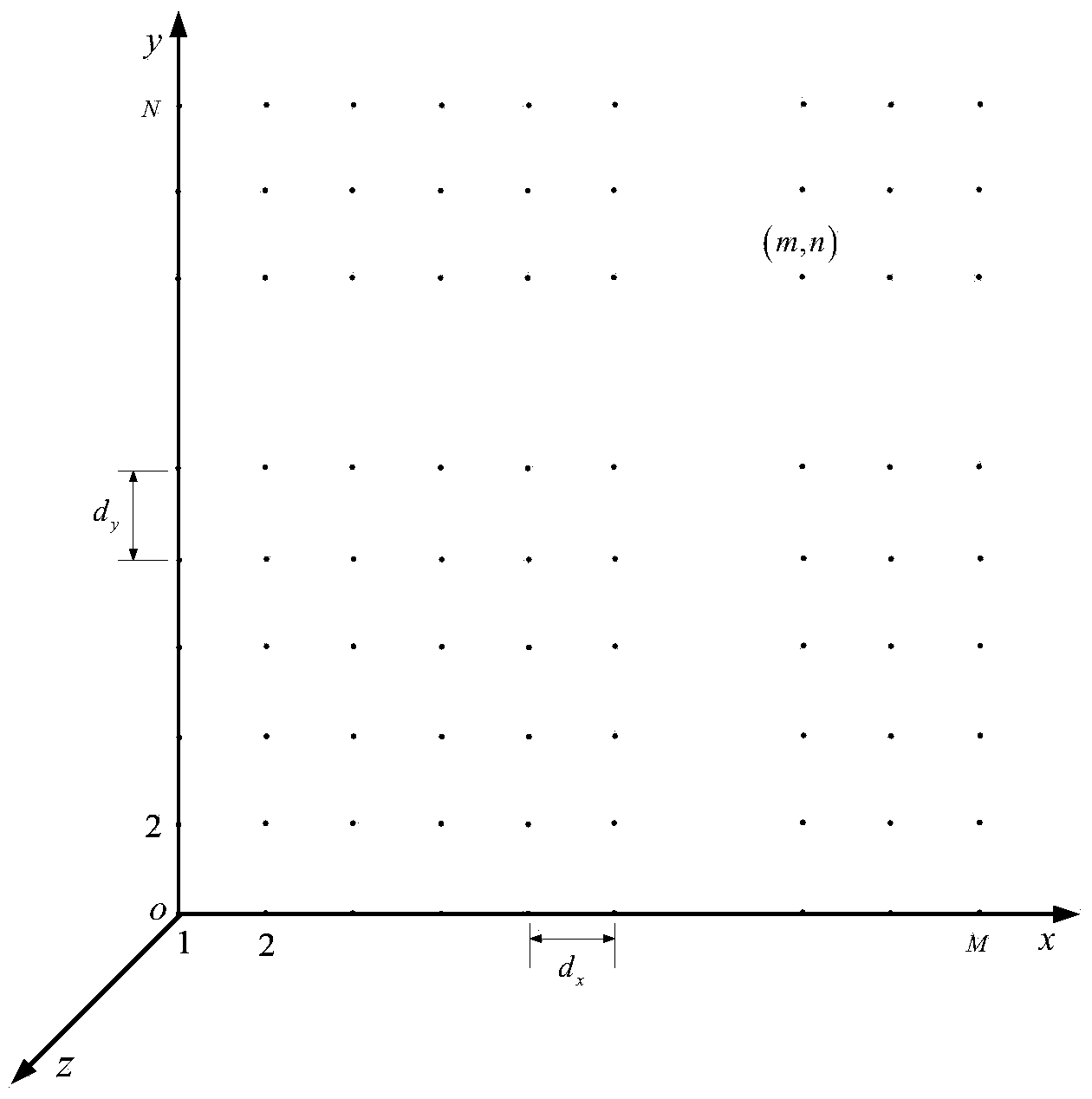

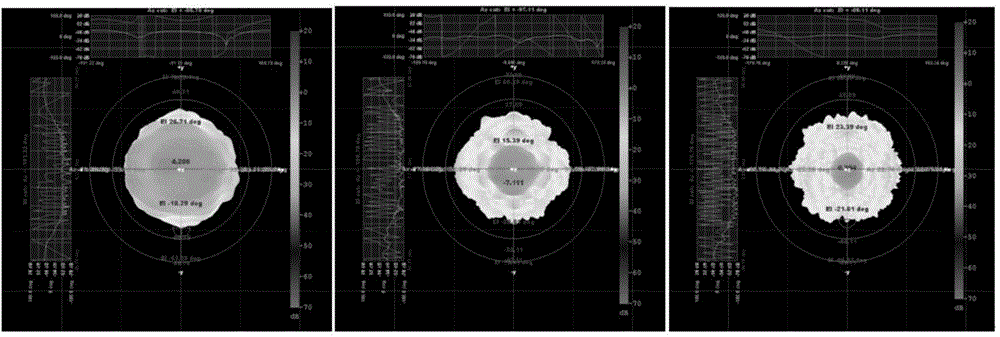

Large deformation array antenna sidelobe performance prediction method based on array element mutual coupling

ActiveCN104036093ARealize Quantitative MappingImprove applicabilitySpecial data processing applicationsElement modelFinite element software

The invention discloses a large deformation array antenna sidelobe performance prediction method based on array element mutual coupling. The method includes determining an array antenna structural finite element model according to structural parameters and material attributes of an array antenna; performing structural finite element analysis through finite element software, acquiring the position offsets of array elements in fronts after the array antenna is deformed, and determining new coordinates of the array elements; dividing the array antenna in to sub arrays in a staggered manner, and establishing the mutual coupling parameter matrix of the entire deformed array antenna through the mutual coupling parameter matrix of the sub arrays; according to the position offsets and mutual coupling parameters of the array elements, and utilizing an array antenna electromechanical coupling module to calculate the antenna far-zone electric field distribution; according to an array antenna far-zone electric field value, establishing a relationship between a power pattern extreme value and an array element amplitude phase, calculating the antenna sidelobe level, and implementing fast prediction of the array antenna sidelobe performance. The method can be applied to antenna structural design guidance and array antenna sidelobe performance analysis and evaluation.

Owner:XIDIAN UNIV

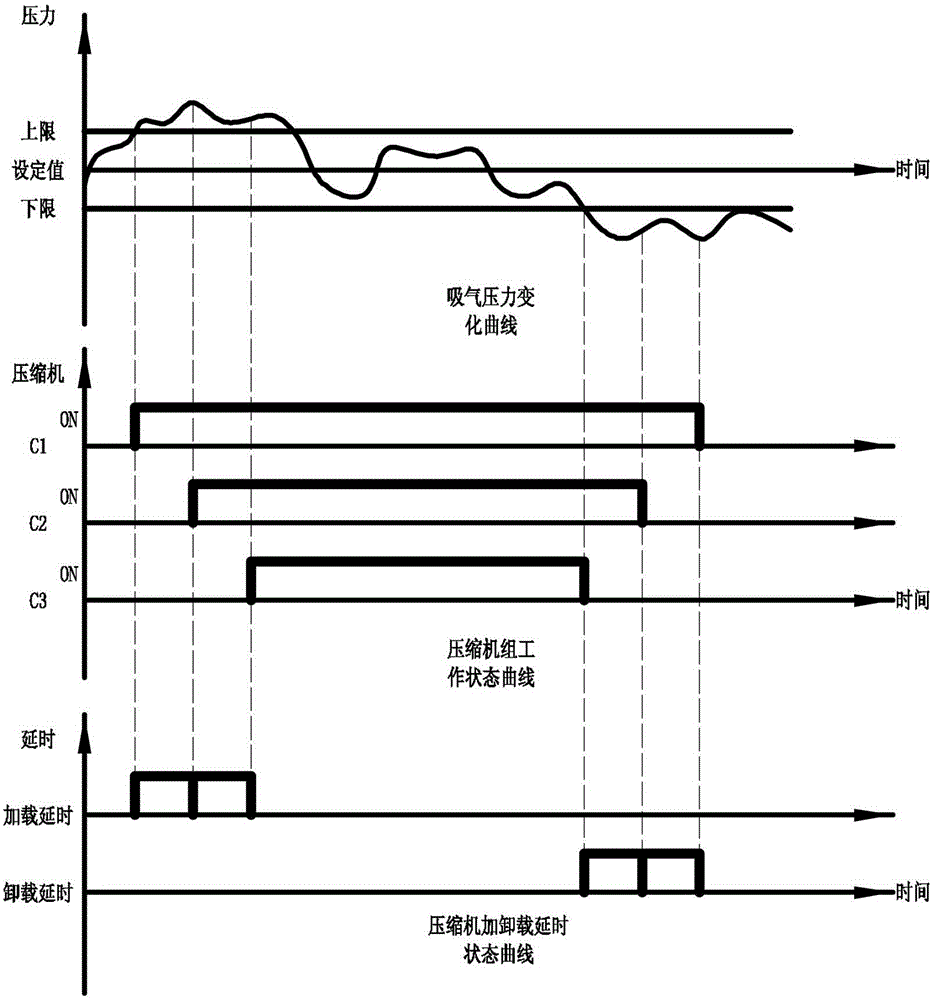

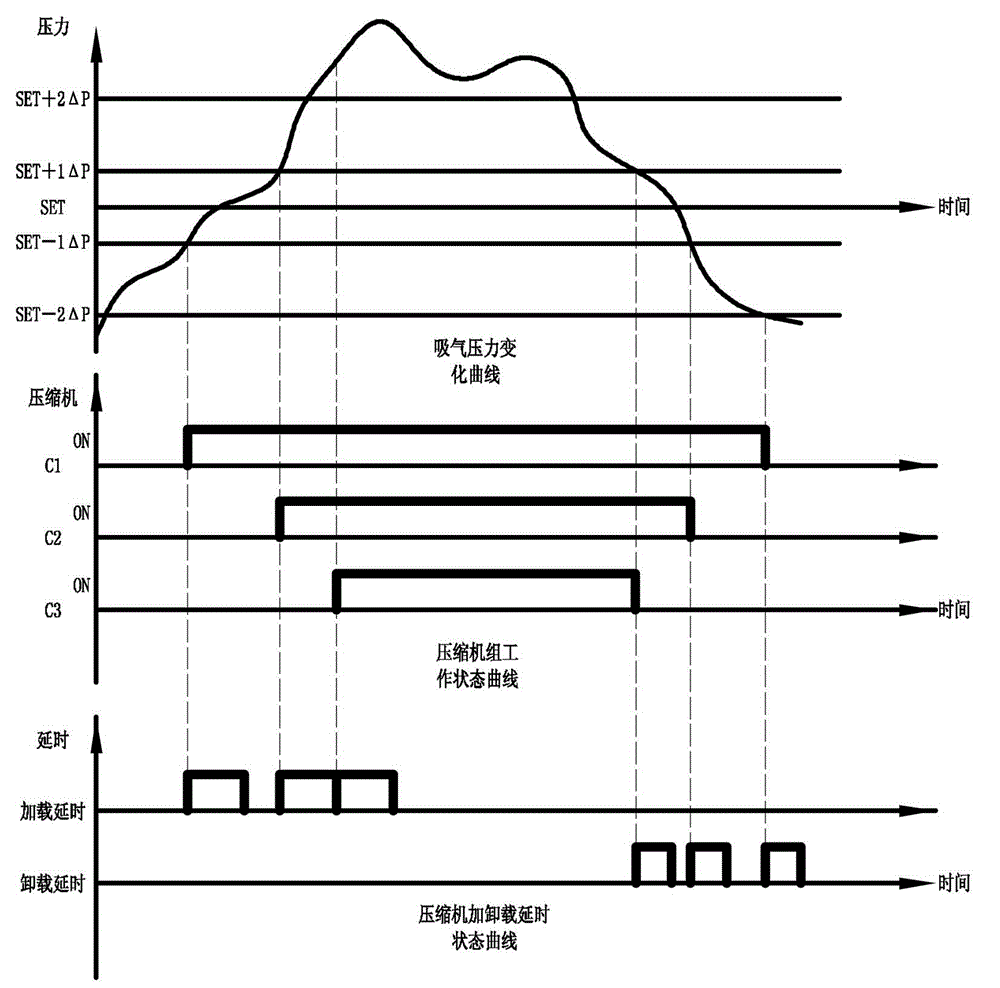

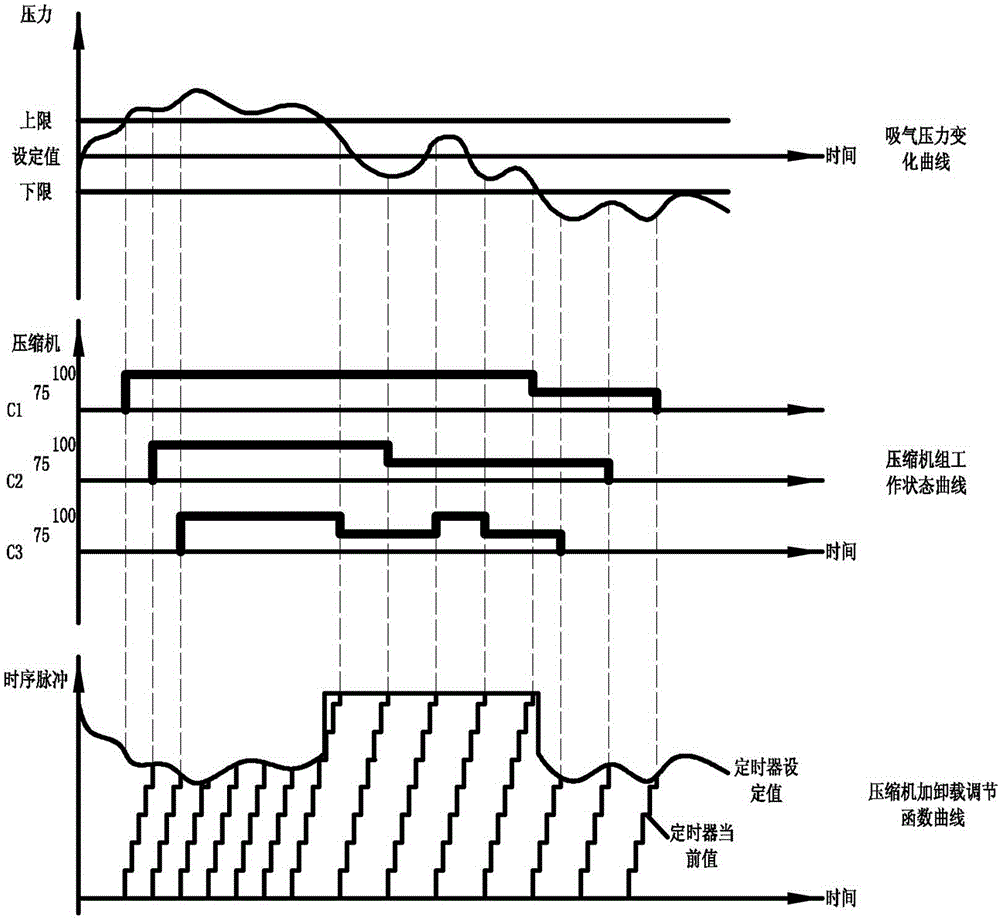

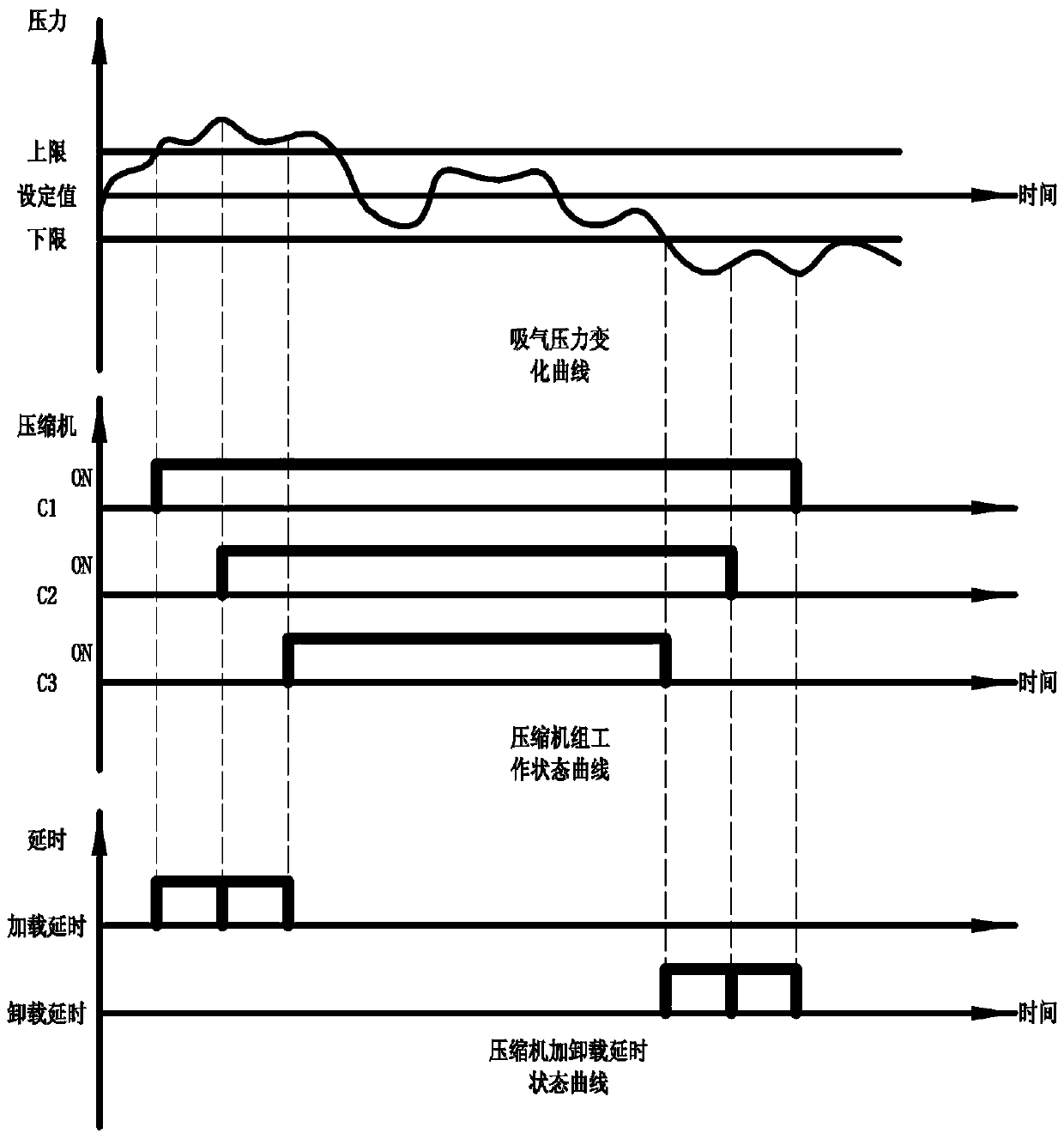

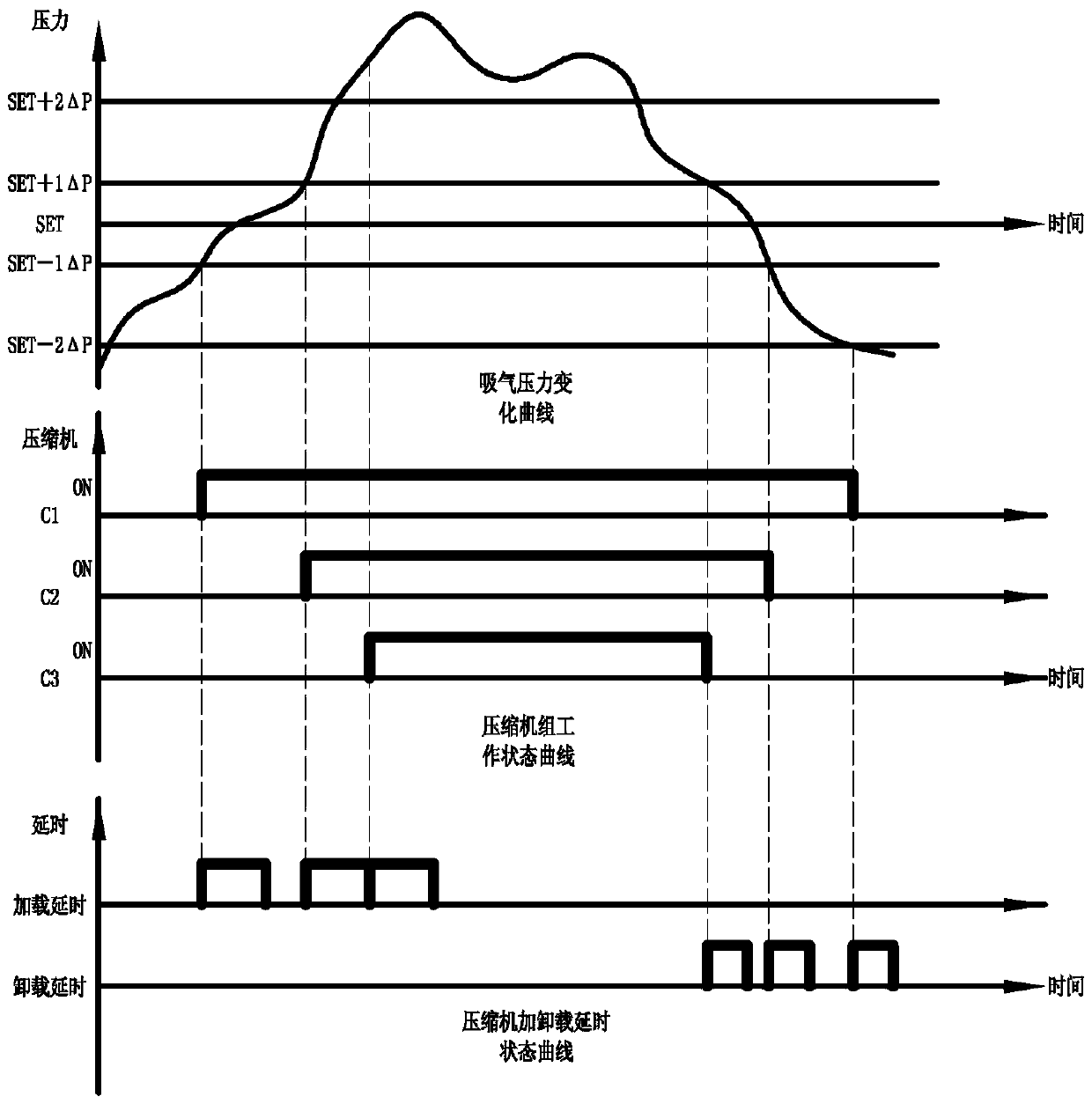

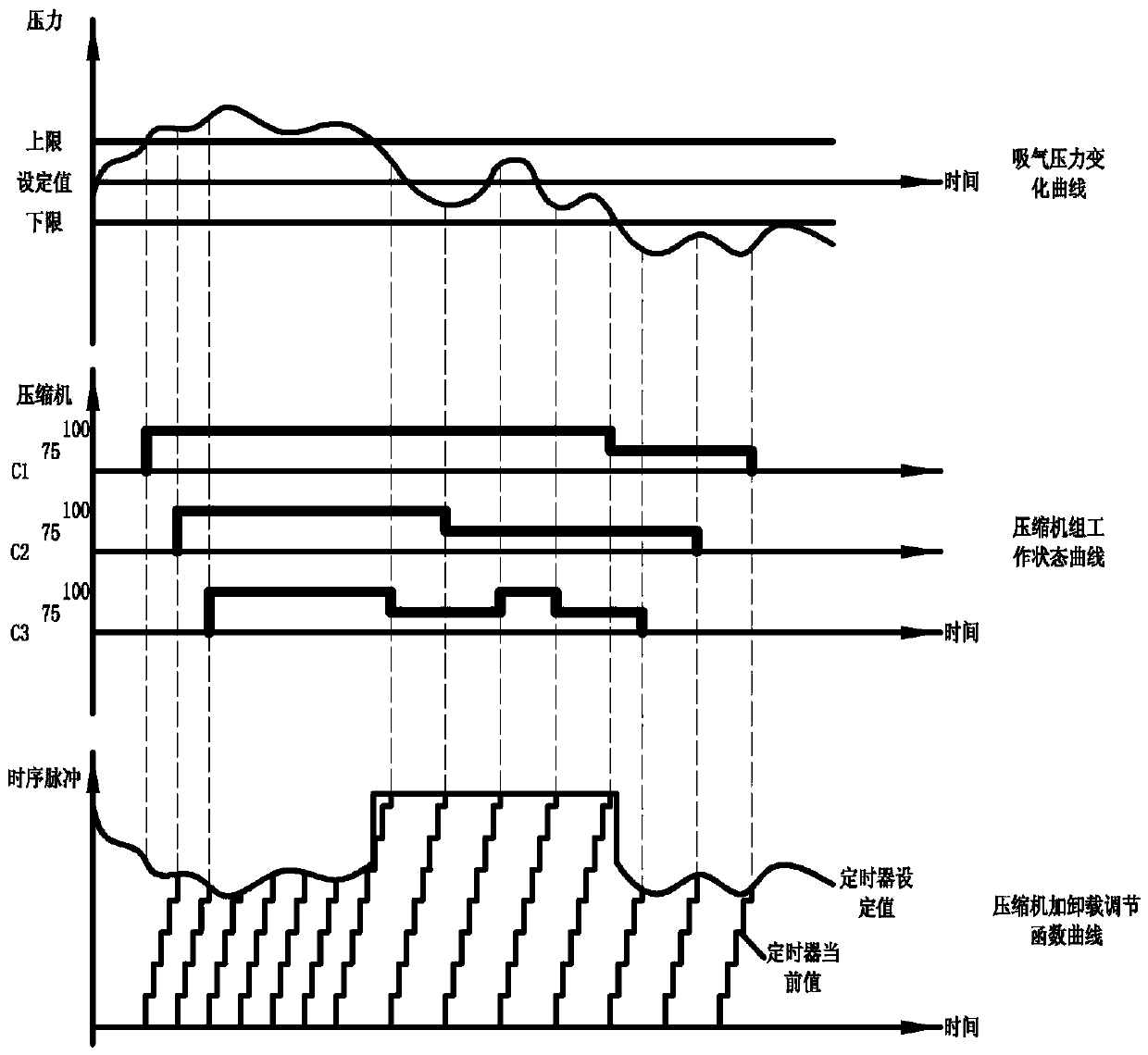

Parallel unit energy saving operation adjusting system and control method thereof

ActiveCN105020951AAvoid frequent startupAchieve performance requirementsRefrigeration safety arrangementTemperature controlProcess engineering

The invention aims to solve the problems in a conventional control method that a starting speed cannot satisfy needs, and a compressor is frequently started; the parallel unit energy saving operation adjusting system and control method thereof comprise a refrigeration unit; the refrigeration unit is connected in sequence with a condenser, a throttle, and an evaporator; the evaporator is connected with the refrigeration unit through an air suction pipeline, and arranged in a refrigeration house; the refrigeration unit is connected with a PLC; the PLC is connected with a touch screen; the air suction pipeline is provided with an air suction pressure sensor connected with the PLC. The parallel unit energy saving operation adjusting system and control method thereof can control the air suction pressure, are suitable for a refrigeration house group, can prevent the problem that end temperature control in the refrigeration system is behind parallel unit cooling performance output, thus preventing frequent starting of the compressor.

Owner:河南千年冷冻设备有限公司

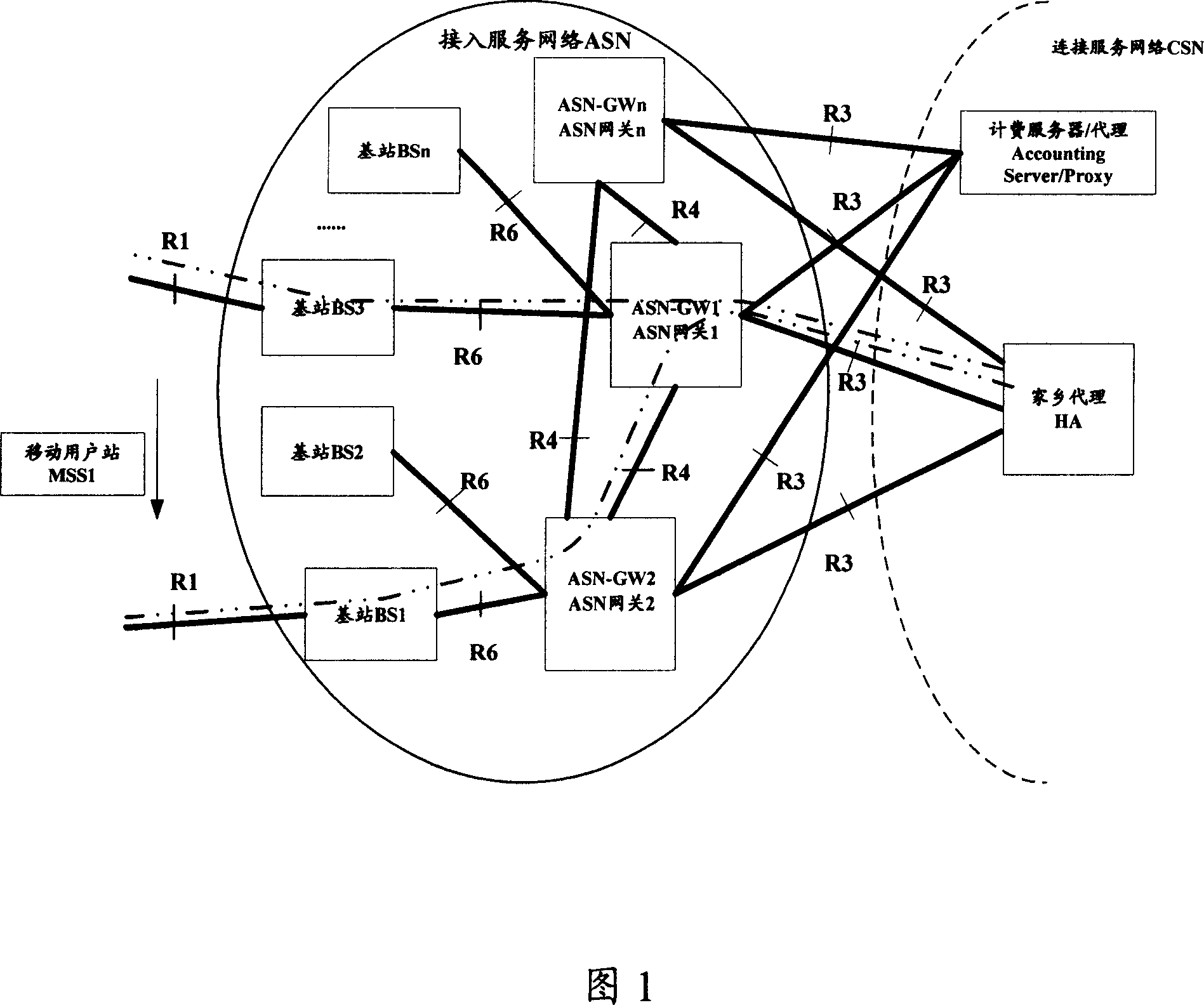

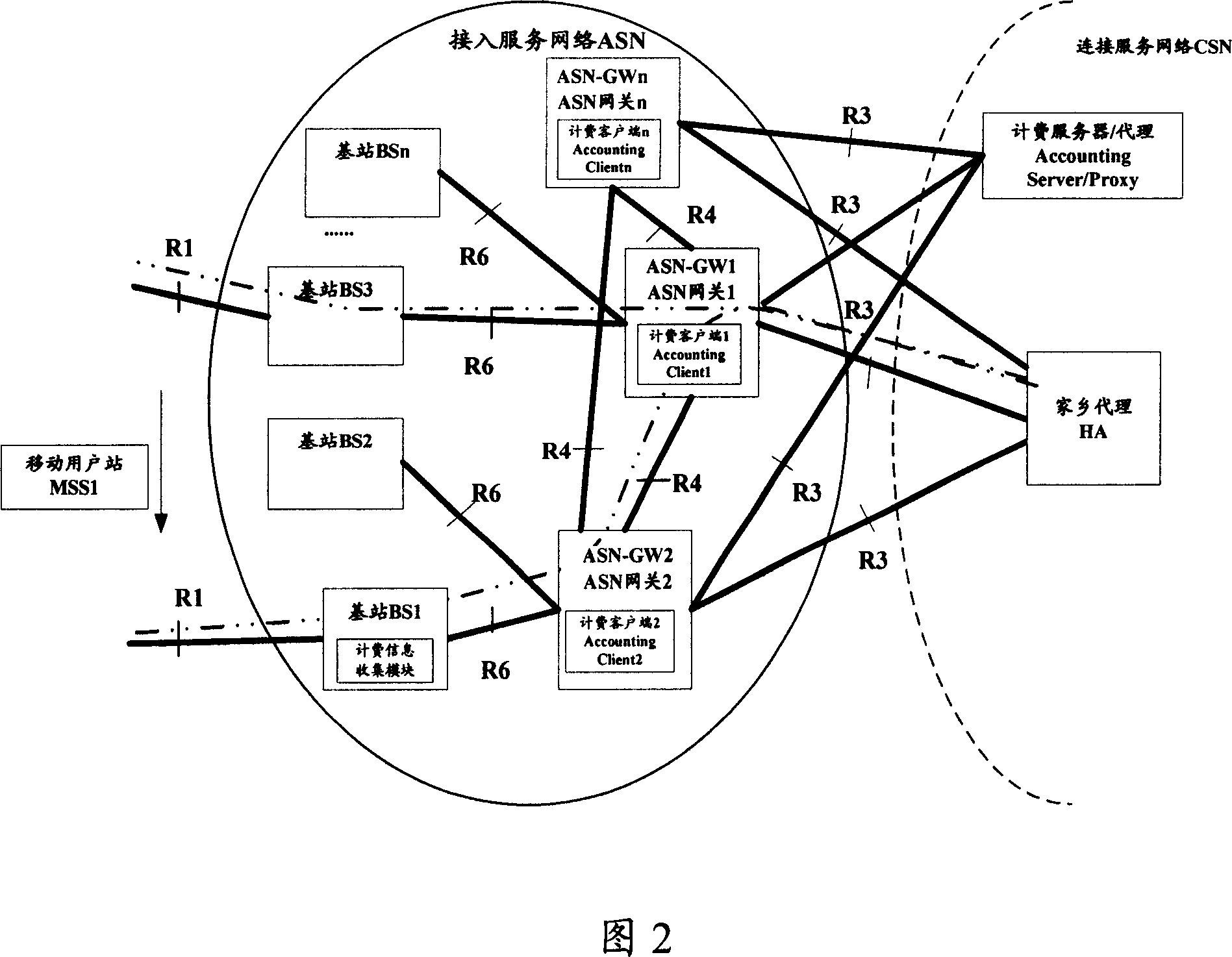

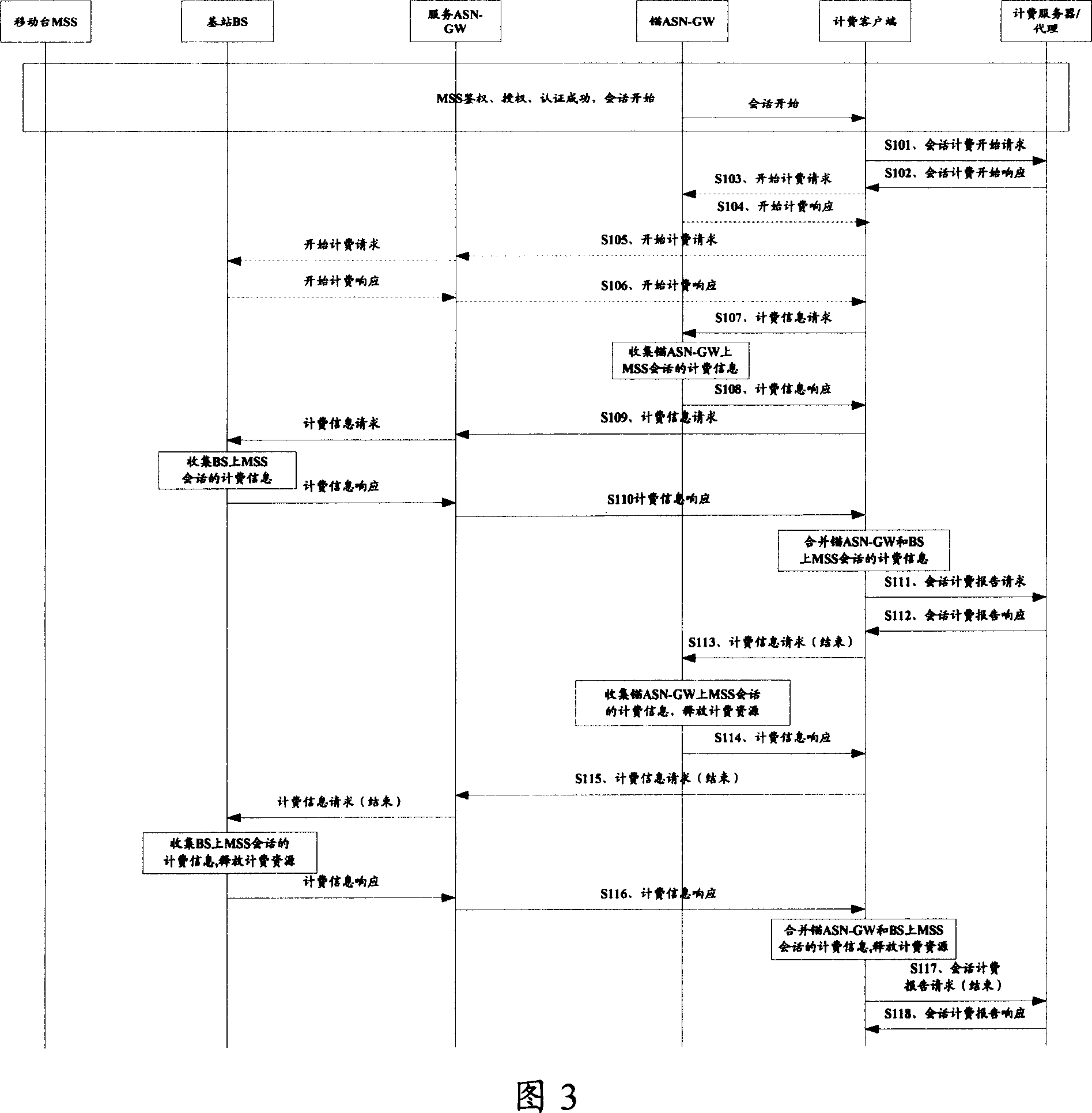

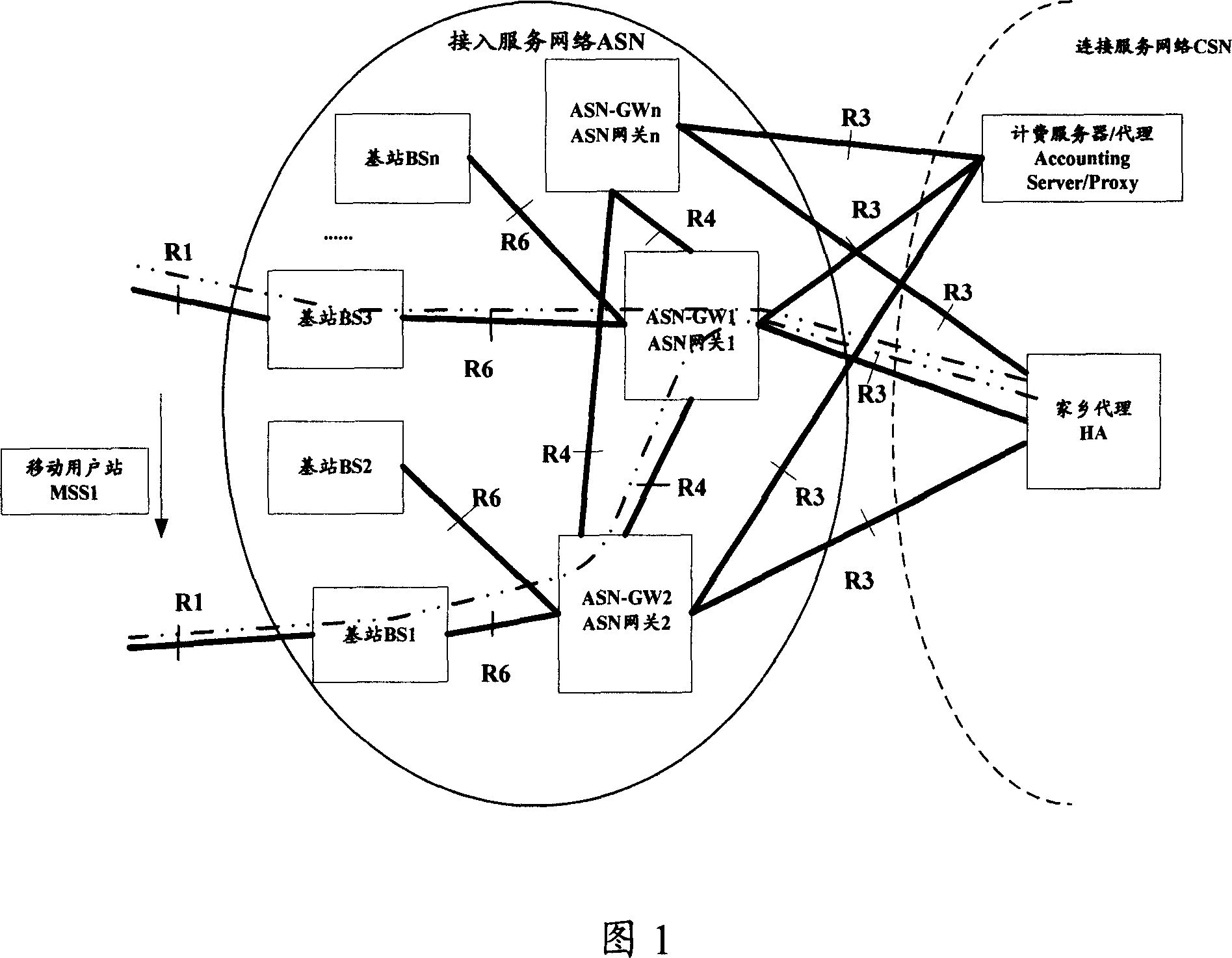

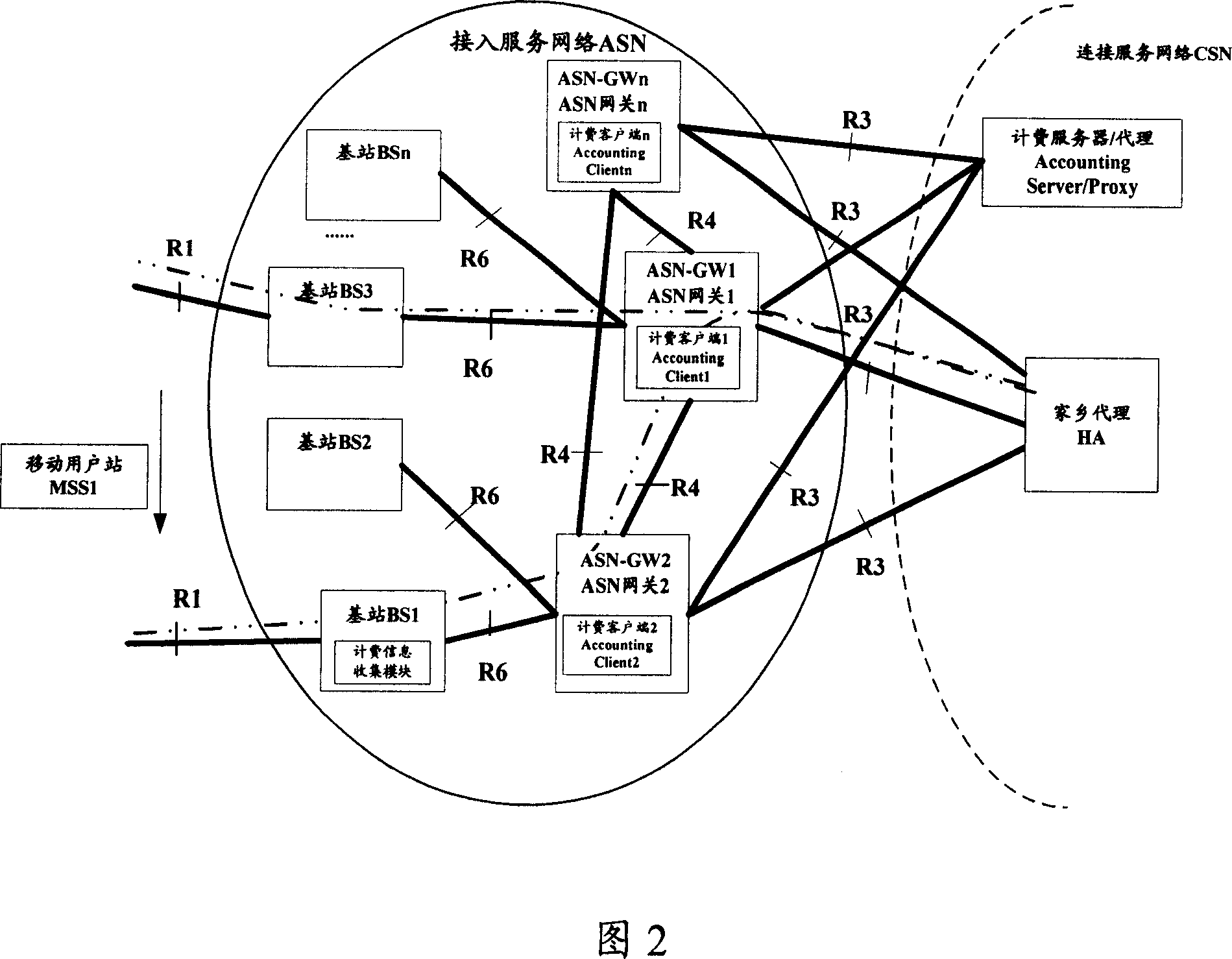

Postpayment charging system and charging information collecting and reporting method

InactiveCN1933525AAccurate collectionReduce deliveryMetering/charging/biilling arrangementsTelephonic communicationPaymentCommunications system

A method for collecting and reporting charge information includes reporting request by gateway and / or base station of access service network according to periodical charge information of client end being charge and then collecting session charge information being reported to said client end, sending received charge information to charging server / agent for carrying out payment treatment by said client end. The charging system of post-payment is also disclosed.

Owner:HUAWEI TECH CO LTD

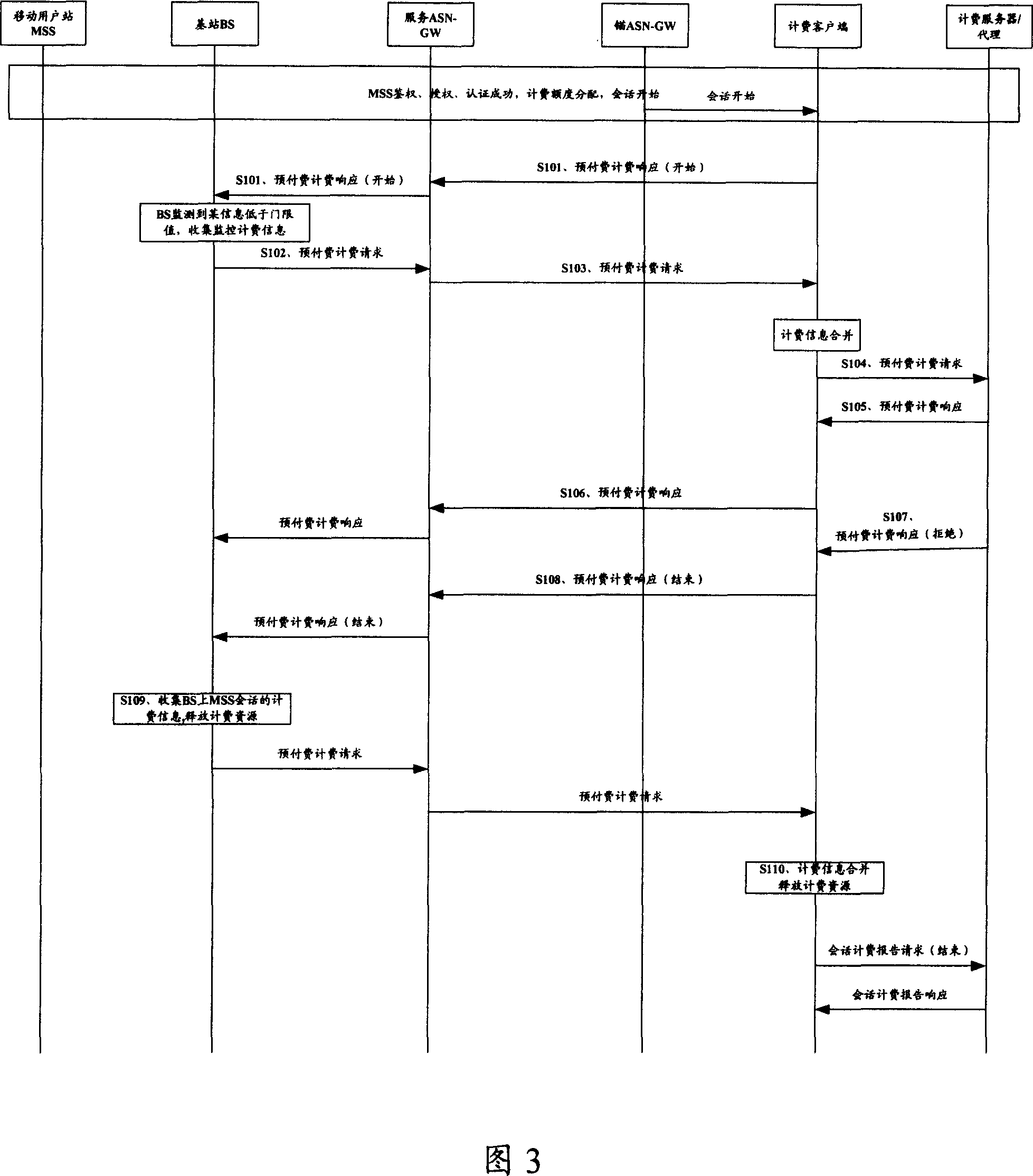

Prepayment charging system and charging information collecting and reporting method

InactiveCN1933526AAvoid passingAccurate collectionRadio/inductive link selection arrangementsPrepayment telephone systemsCommunications systemMobile communication systems

A method for collecting and reporting charge information includes sending session charge quota and threshold value to gateway / base station of access service network by charge server / agent through client end being charge, collecting session charge information and reporting it to said client end when surplus value of said quota is less than said threshold value then sending received session charge information to charge server / agent by said client end, distributing new session charge quota and threshold valve or stopping session service by charge server / agent. The charging system of prepayment is also disclosed.

Owner:HUAWEI TECH CO LTD

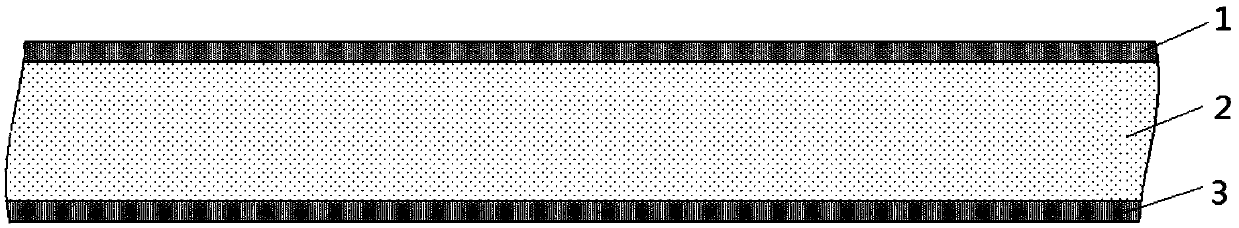

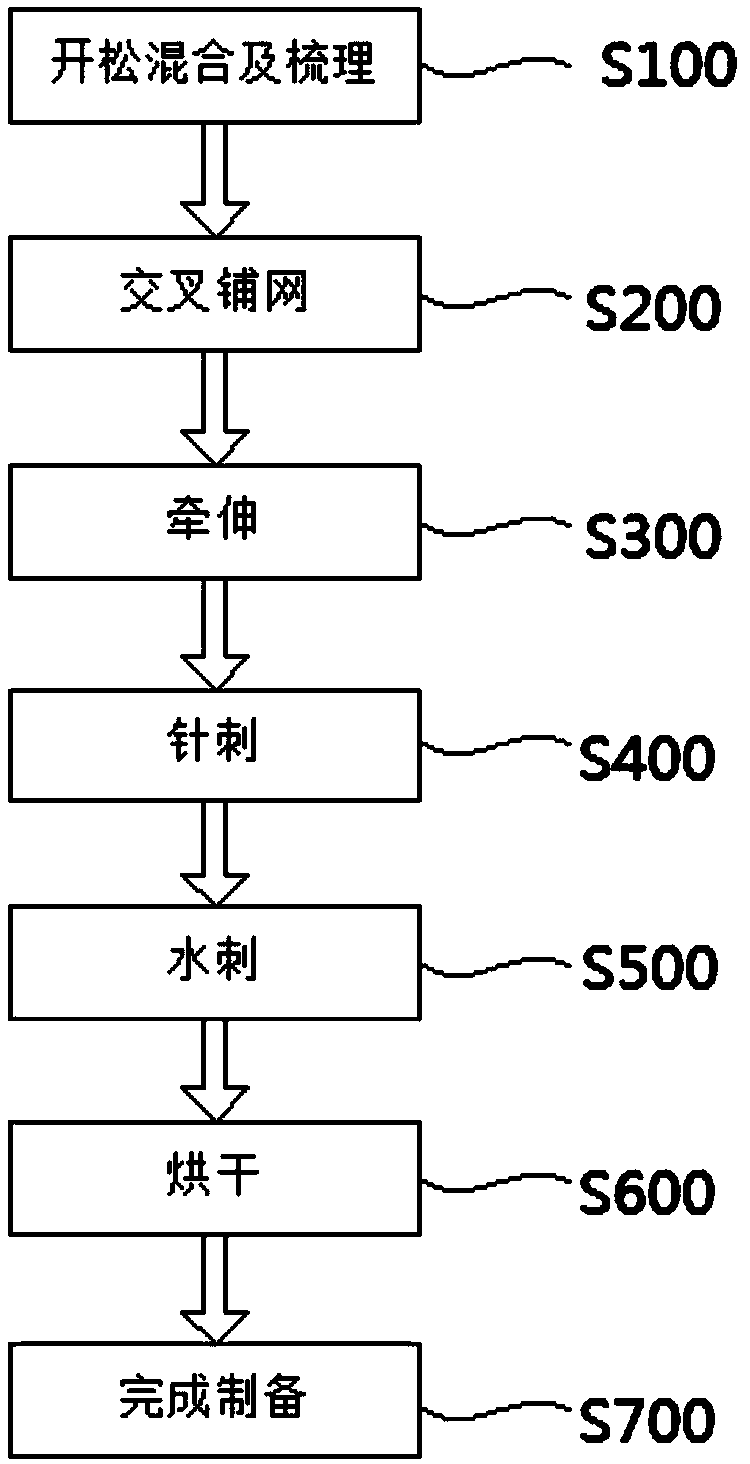

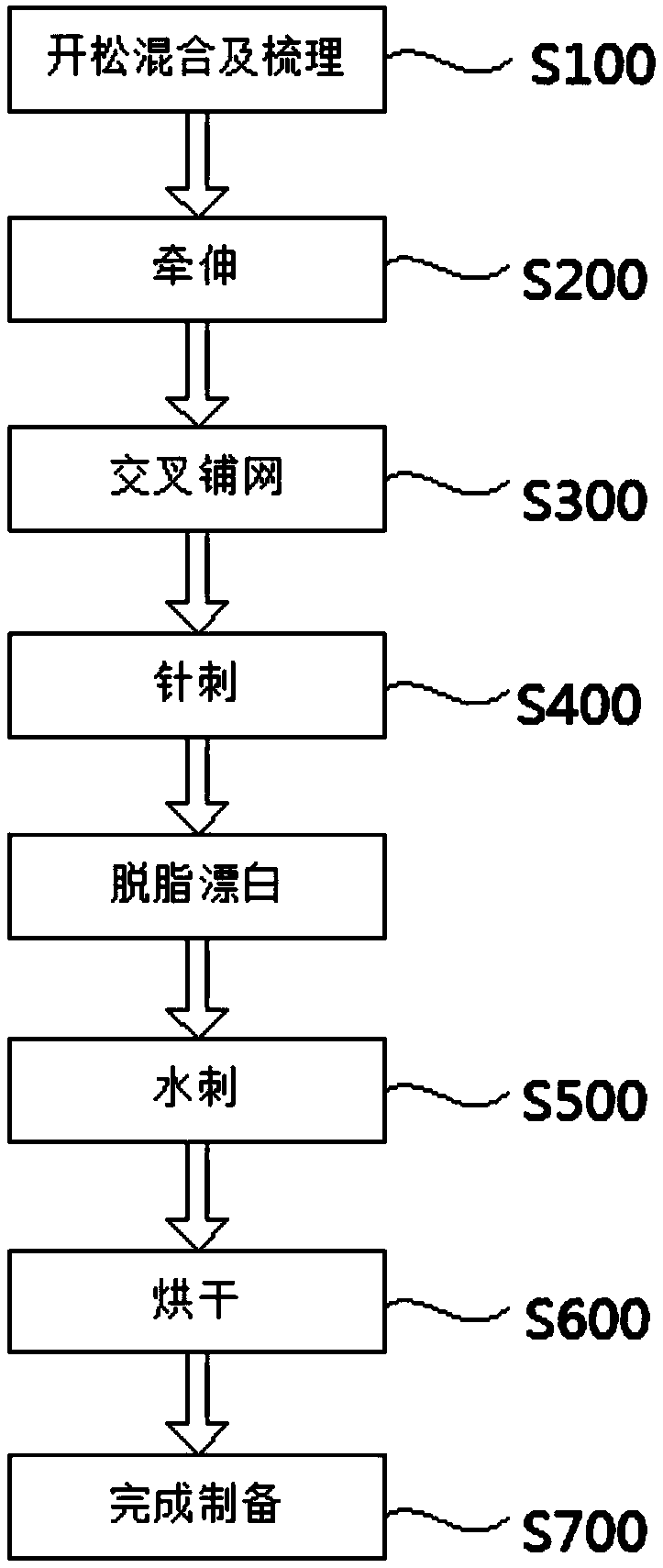

Preparation method for pure cotton non-woven product

The invention discloses a preparation method for a pure cotton non-woven product. The method comprises the following steps that cotton fibers are subjected to loosening and mixing and combing, then cross lapping is conducted, and therefore a cotton web is formed; the cotton web is formed and drafted; after drafting, the cotton web is reinforced by utilizing needling to form a needle-punched cottonweb; then the needle-punched cotton web is subjected to spunlace processing, the surface layer of the needle-punched cotton web is subjected to forward spunlace processing, the bottom layer of the needle-punched cotton web is subjected to reverse spunlace processing, and a spunlace product with the surface layer and the bottom layer being spunlace non-woven fabrics and the middle layer being theneedle-punched cotton web is formed; finally, a flat web drying mode is adopted for drying the spunlace product, and preparation of the non-woven product is completed. By adopting the preparation method, the natural cotton fibers are prepared into an integrally formed 'cloth-web-cloth' structure through a composite technology of needling and spunlace processing, and therefore the spunlace productcan be washable, cannot be deformed easily, and is soft, good in elasticity, higher in comfort and capable of keeping warm in the using process.

Owner:SHENZHEN PURCOTTON TECH +1

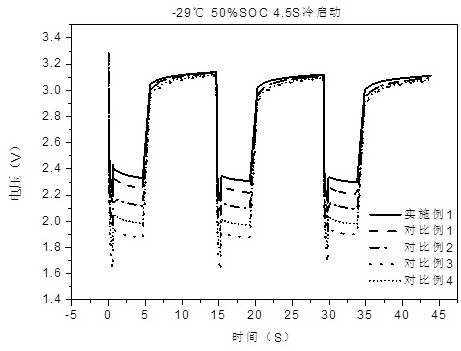

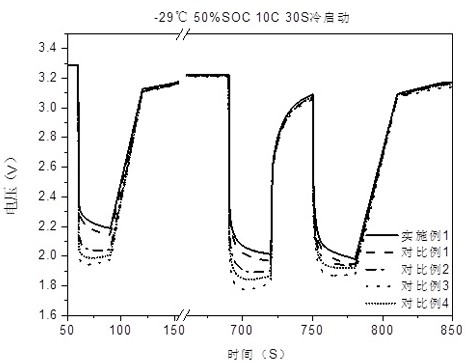

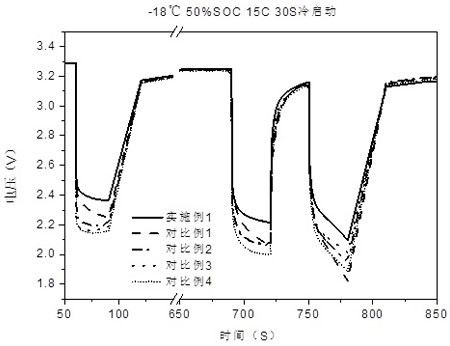

Wide-temperature-band 12V start-stop battery chemical system

InactiveCN111864202AMeet wide temperature requirementsFacilitated DiffusionMaterial nanotechnologyCell electrodesImideLithium iron phosphate

The name of the invention is a wide-temperature-band 12V start-stop battery chemical system. The invention belongs to the technical field of automobile start-stop battery systems. The invention mainlysolves the problems that a lithium battery cannot meet the requirements of cold start power at low temperature and the service life attenuation is fast at high temperature. The system is mainly characterized in that a lithium iron phosphate material is a nano lithium iron phosphate material and is coated with carbon, the graphite is modified artificial graphite doped with soft carbon; an electrolyte further comprises lithium bis(fluorosulfonyl) imide, lithium bis(fluorooxalate) phosphate and vinylene carbonate. According to the invention, the positive electrode impedance is reduced, the contact impedance is reduced, the problem of poor lithium ion diffusion is further improved, the high and low temperature operation performance of the battery is improved, the performance requirements of the start-stop battery are realized, the service life and the weight are superior to those of a lead-acid start-stop battery, the purpose of no replacement of the battery for the lifetime is achieved,and the system is mainly used for 12V start-stop lithium ion batteries.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

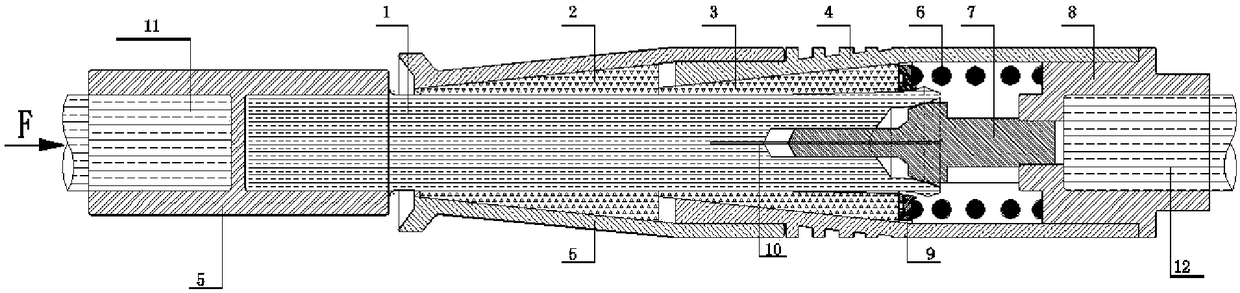

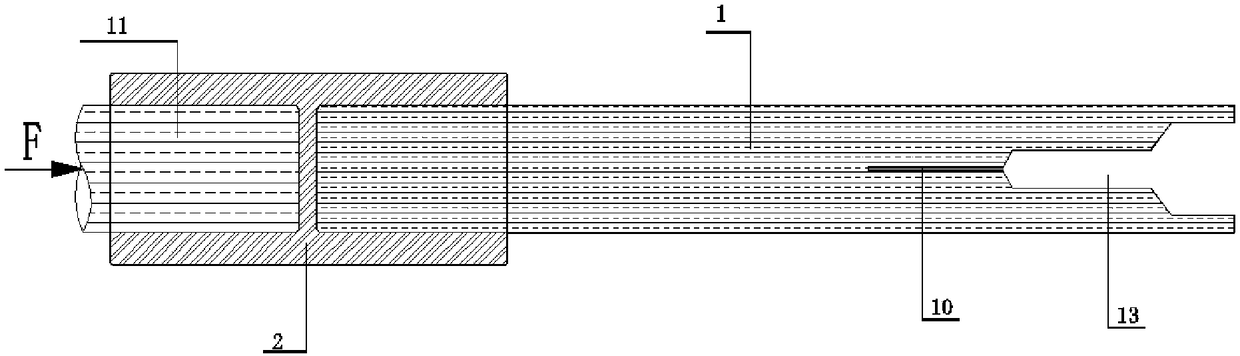

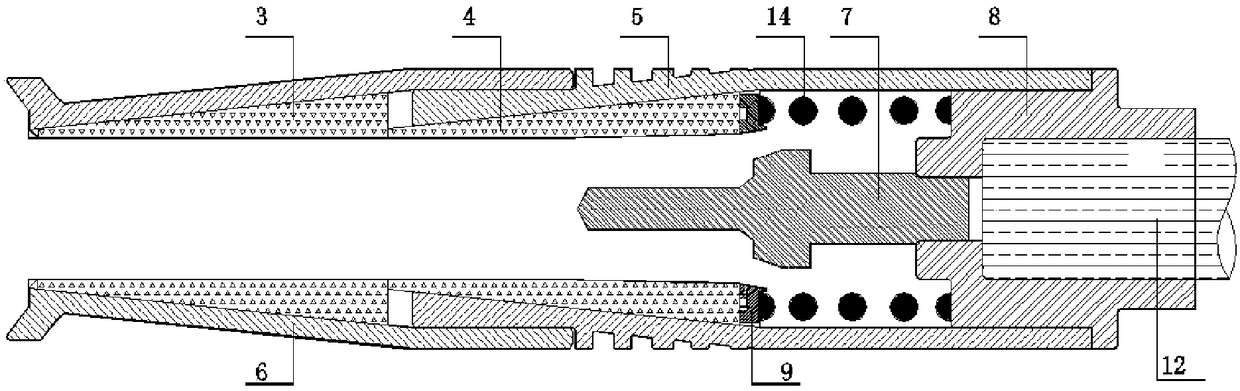

Self-locking mechanical connecting sleeve

The invention discloses a self-locking mechanical connecting sleeve. The self-locking mechanical connecting sleeve comprises a first sleeve pipe part and a second sleeve pipe part, wherein the secondsleeve pipe part comprises a second steel bar connector, a thimble, a first sleeve pipe, a second sleeve pipe, a first clamping piece and a second clamping piece; the thimble is connected to one end of the second steel bar connector, one end portion of the second steel bar connector is sleeved with the first sleeve pipe, and one end portion of the first sleeve pipe is sleeved with the second sleeve pipe; the first clamping piece is arranged on the inner circumferential wall of the second sleeve pipe, and the second clamping piece is arranged on the inner circumferential wall of the first sleeve pipe. The self-locking mechanical connecting sleeve has the beneficial effects that through a self-locking mode, under the action of pressure, the connection of steel bars is realized, the pressurecan be the self-gravity of prefabricated components or the pre-pressure, the use is convenient, compared with a grouting sleeve, the connection performance is no longer determined by the quality and compactness of grouting material, and at the same time the complicated grouting construction process is cancelled.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

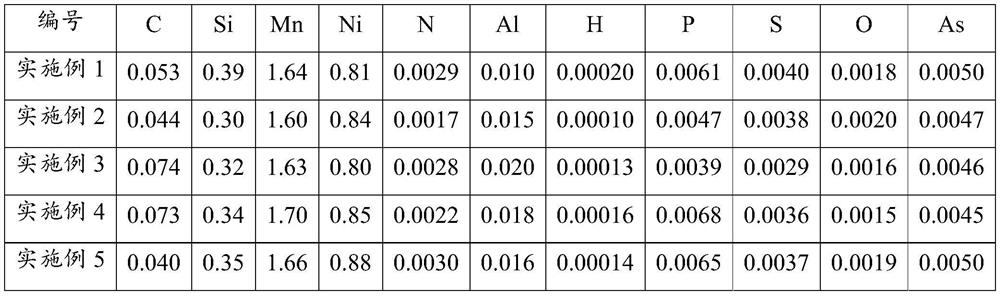

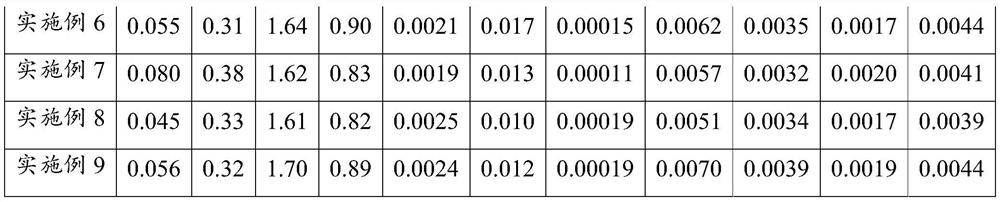

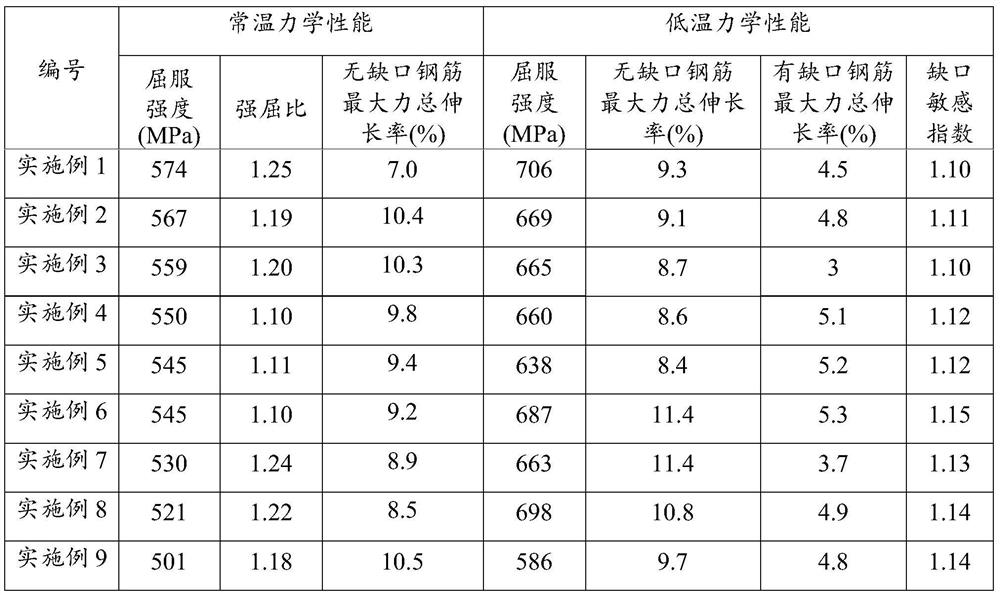

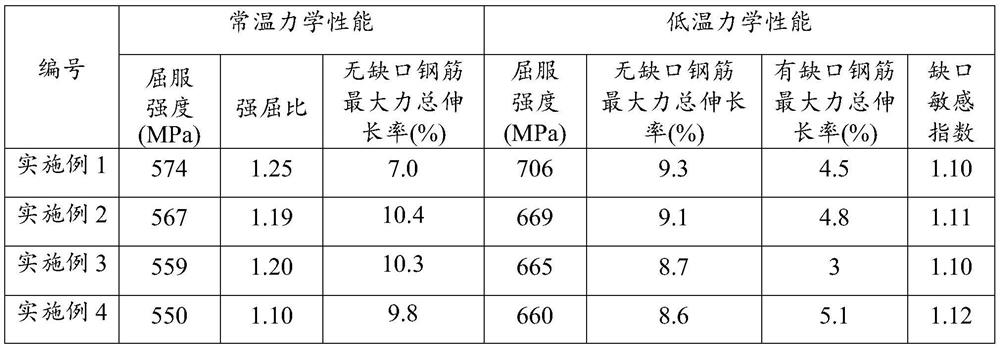

Low-temperature steel bar and production method thereof

ActiveCN113186466AAchieve performance requirementsLow production costProcess efficiency improvementRebarImpurity

The invention discloses a low-temperature steel bar and a production method thereof. The low-temperature steel bar comprises the following chemical components in percentage by mass: 0.8-0.9% of Ni, 1.6-1.7% of Mn, 0.3-0.4% of Si, 0.04-0.08% of C, 0.01-0.02% of Al, less than or equal to 0.007% of P, less than or equal to 0.004% of S, less than or equal to 0.002% of O, less than or equal to 0.003% of N, less than or equal to 0.005% of As, less than or equal to 0.0002% of H and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of KR molten iron pretreatment, converter smelting, LF furnace refining, RH furnace refining, continuous casting and steel rolling. According to the steel bar and the production method thereof, component design and mass production of the low-temperature steel bar are completed at low cost, and the effects of strictly controlling impurity elements, inclusions and surface quality and reducing low-temperature brittleness are achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

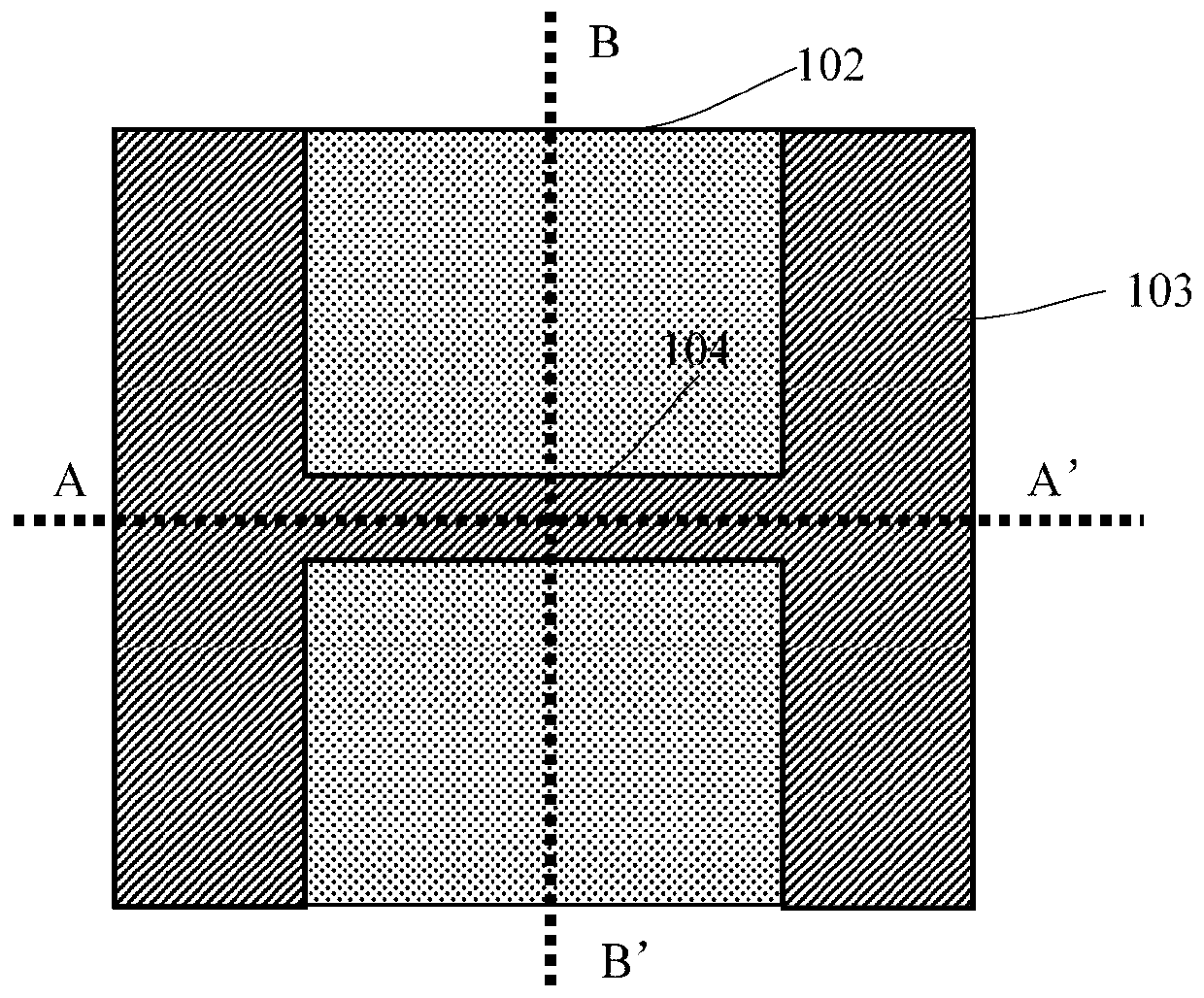

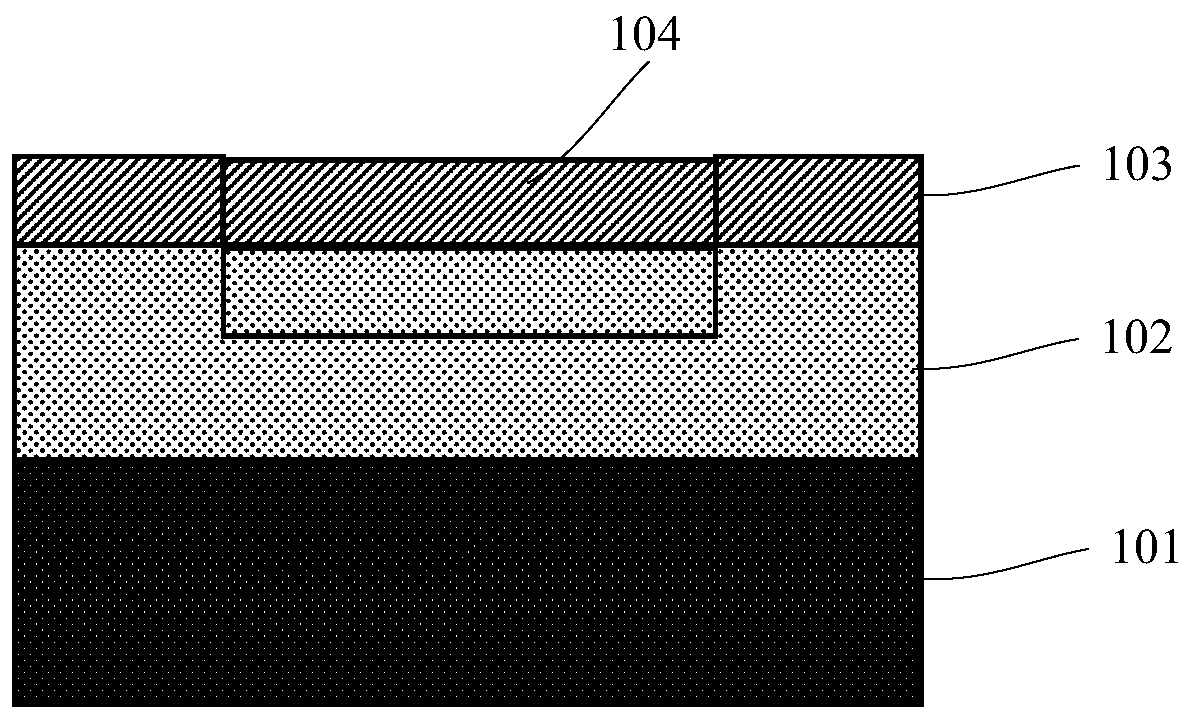

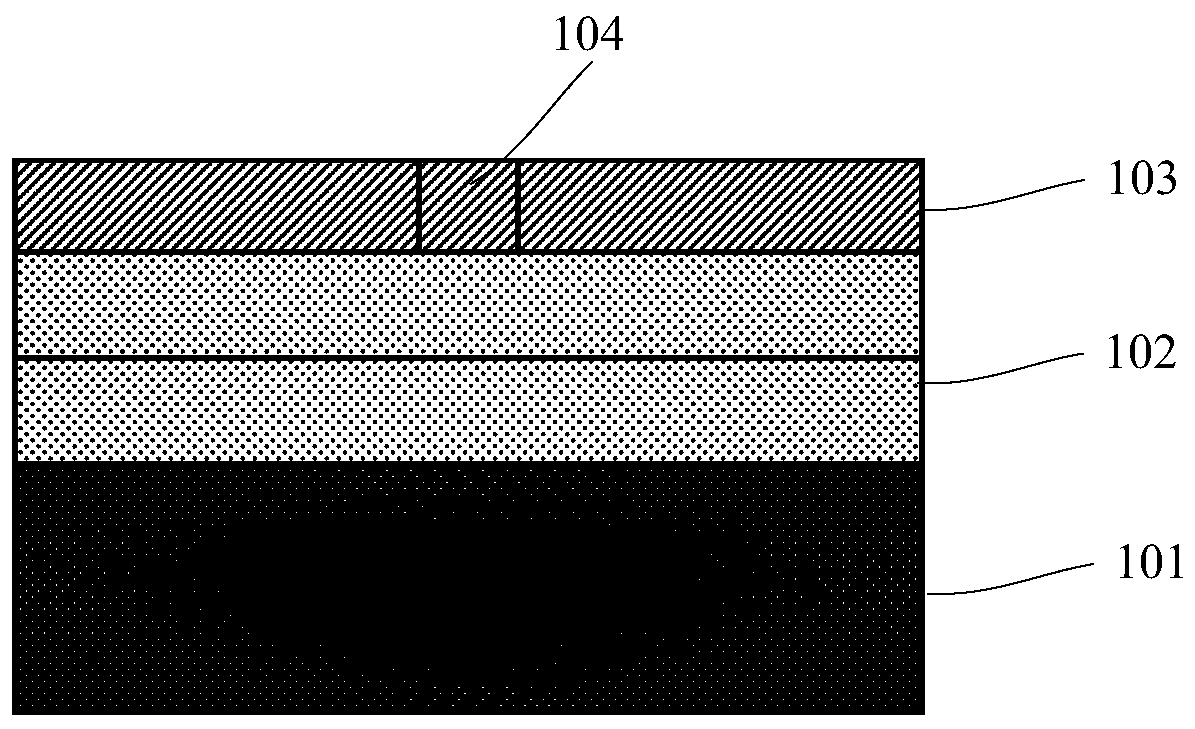

Preparation method of gate-all-around transistor

ActiveCN111435678ABroaden your optionsAchieve performance requirementsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricNanowire

The invention provides a preparation method for a gate-all-around transistor, and the method comprises the steps: 1), providing an SOI substrate, and forming a groove in an insulating layer of the SOIsubstrate; 2) forming a semiconductor nanowire structure which is suspended and stretches across the groove; 3) rounding and thinning the semiconductor nanowire structure; 4) forming an injection barrier layer on the surface of the channel region, wherein the injection barrier layer exposes the preparation regions of the source region and the drain region; 5) performing an ion implantation process to form the source region and the drain region; 6) forming a fully-surrounded gate dielectric layer and a gate electrode layer on the surface of the semiconductor nanowire, and performing patterningto form a gate structure; and 7) forming a source electrode and a drain electrode. The gate-all-around transistor is prepared by adopting a gate-last process, so that the selection range of gate materials can be effectively widened, different device performance requirements are met, isotropic wet etching is not needed when the semiconductor nanowire is prepared, and a concave cavity can be effectively prevented from being generated.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

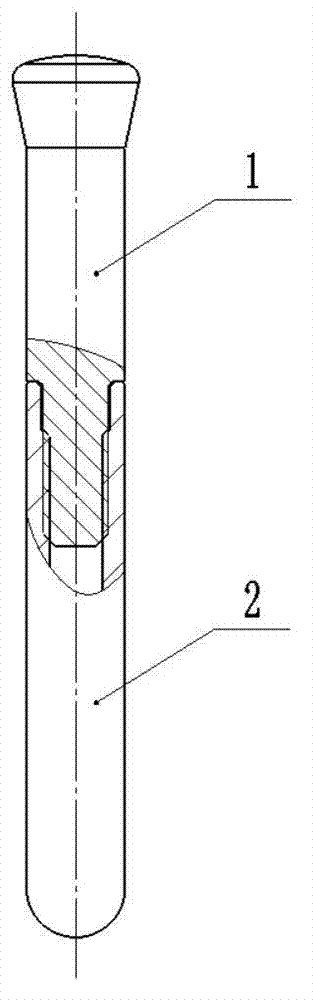

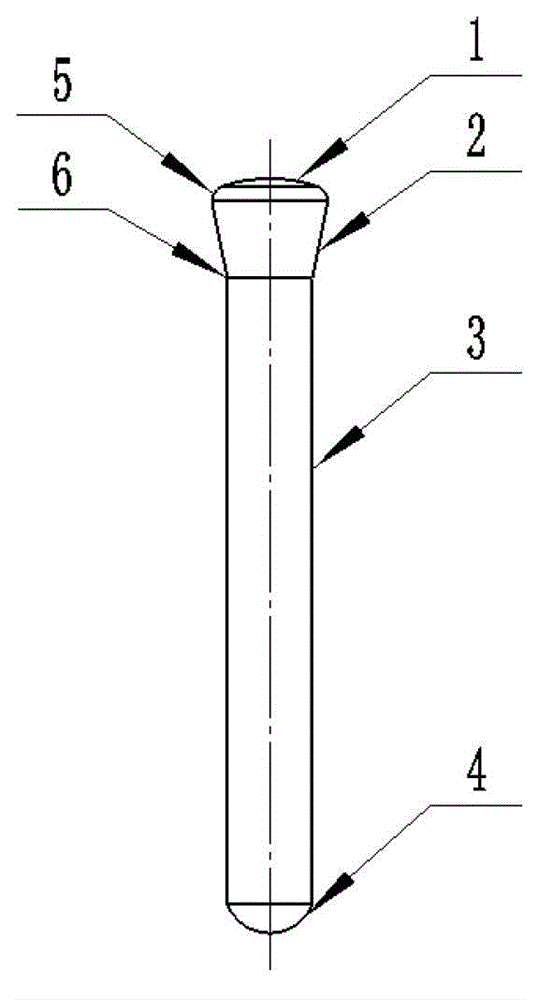

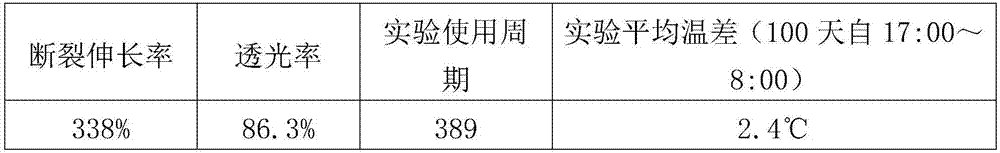

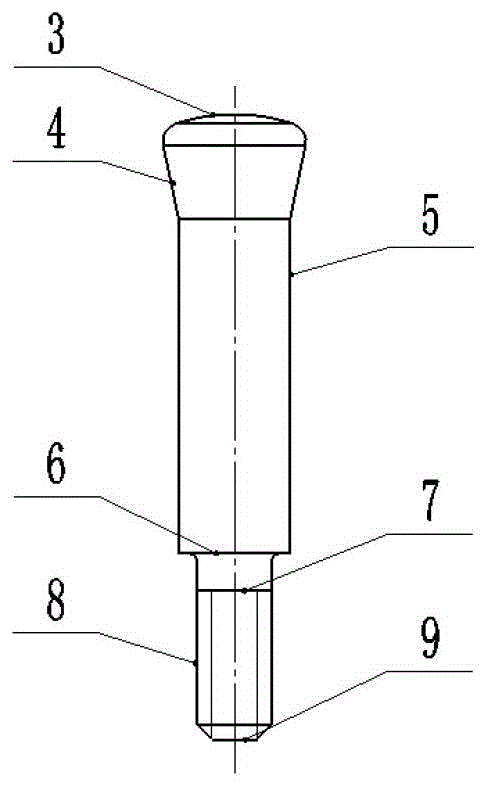

Sectional pin for semiconductor coating equipment

ActiveCN102820250AReduced precision requirementsAchieve performance requirementsSemiconductor/solid-state device manufacturingTransfer procedureScrew thread

The invention relates to a sectional pin for semiconductor coating equipment, which mainly solves the technical problems that the sectional pin for the semiconductor coating equipment in the prior art is complex in structure, high in machining cost and large in installation difficulty. The sectional pin for the semiconductor coating equipment consists of an upper part of a pin and a lower part of the pin. The upper part of the pin is made of ceramic, and an external screw thread is prepared outside the upper part of the pin. The lower part of the pin is made of nickel, and an internal screw thread is prepared inside the lower part of the pin. The upper part and the lower part of the pin are connected through the inner and outer screw threads. The sectional pin at least consists of two sections which are connected by screw threads or pins to form an integral pin. The sectional pin for the semiconductor coating equipment has the beneficial effects that the structure can realize performance requirement in a wafer transmission process of the pin, and the sectional pin for the semiconductor coating equipment is more reasonable compared with the prior art, has less requirement on precision of parts, is simple in structure, is not provided with a complex guiding structure or counter weight structure, and is convenient to machine and install, and the cost is relatively low.

Owner:PIOTECH CO LTD

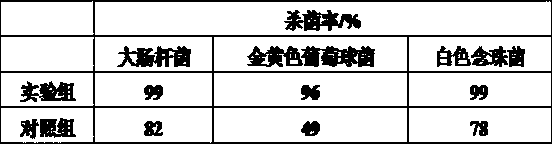

Medical multifunctional haemostatic dressing and preparation method thereof

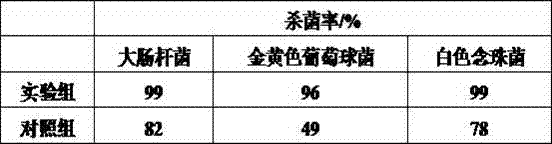

InactiveCN107296976AImprove antibacterial propertiesPlay a synergistic rolePharmaceutical delivery mechanismAbsorbent padsCross-linkWound healing

The invention belongs to the technical field of medical materials, and particularly relates to a medical multifunctional haemostatic wound dressing and a preparation method thereof. According to the invention, the multifunctional haemostatic gel dressing is prepared by using chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone, polyglycolic acid, glutaraldehyde, I-type collagen powder and mesoporous nano hydroxyapatite as raw materials through a cross-linking reaction. The multifunctional haemostatic gel dressing prepared by the invention can take effects of stop bleeding, sterilizing and promoting wound healing, and can meet the requirement of a wound for dressing performance in different healing stages; the chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone is prepared into the gel dressing in a form of the invention, so that an antibacterial effect of the chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone is improved.

Owner:JILIN UNIV FIRST HOSPITAL

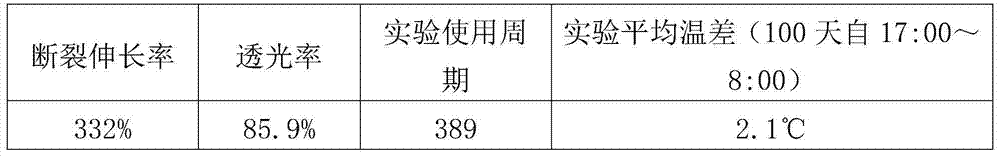

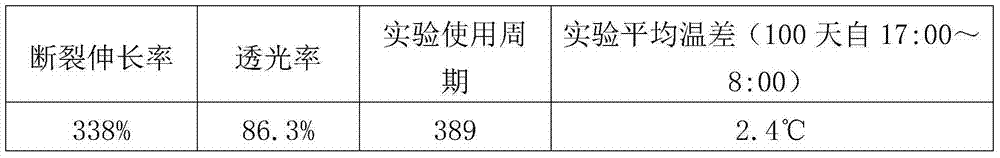

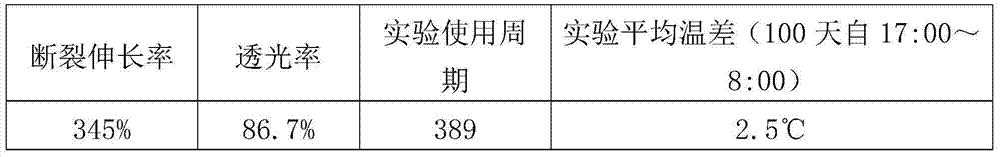

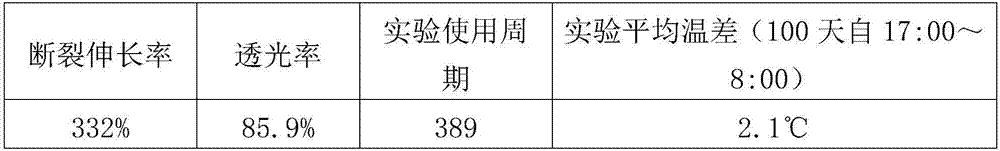

Diatomite and kaolin thermal-insulation film master batch and preparation method thereof

The invention discloses diatomite and kaolin thermal-insulation film master batch and a preparation method thereof. The diatomite and kaolin thermal-insulation film master batch comprises the following components in percentage by mass: 22%-26% of diatomite, 30%-34% of kaolin, 32%-35% of polyethylene, 2%-3% of an aluminate coupling agent, 0.5%-0.8% of stearic acid, 0.3%-0.5% of calaium strarate, 2%-3% of paraffin, 1%-2% of PE (polyethylene) wax and 0.5%-0.8% of an antioxidant. The raw materials are mixed in a high-speed mixer in stages and then are extruded by a same-direction parallel twin-screw extruder to prepare the master batch. According to the diatomite and kaolin thermal-insulation film master batch and the preparation method thereof disclosed by the invention, the diatomite, the kaolin and the polyethylene are mixed and modified, the adding proportion of the diatomite to the kaolin is controlled to be 52%-60% to prepare master batch, the infrared-ray transmission rate of mulching film prepared by 5%-15% of the match batch can be reduced by 31%-34%, and the thermal insulation effects are obvious.

Owner:YINGKOU XIAOJIAZU IND +1

Low-cobalt high-strength hard alloy and preparation method thereof

The invention relates to the technical field of hard alloys, and particularly discloses a low-cobalt high-strength hard alloy, which comprises the following raw materials in parts by weight: 93.5-94.2 parts of a composite hard phase; 5.8 to 6.5 parts of a bonding phase; the bonding phase is cobalt; and the composite hard phase comprises tungsten carbide A with a Fisher particle size of 3.10 [mu] m to 3.60 [mu] m. The preparation method specifically comprises the following steps: material preparation: putting the composite hard phase and the bonding phase in parts by weight into a ball milling barrel; performing ball milling: adding hexane or alcohol, paraffin and stearic acid into the ball milling barrel, covering the ball milling barrel, starting a ball mill, and performing ball milling for 24-60 hours; preparing mixed granules, namely filtering and discharging slurry, and performing spray drying and granulation on the slurry through a spray tower to obtain the mixed granules required by pressing; pressing, specifically, the mixed granules are pressed and formed through a mold and a press machine, and a needed hard alloy semi-finished product blank is prepared; sintering: putting the hard alloy semi-finished product blank into a pressure sintering furnace for high-temperature sintering; and finishing preparation. The low-cobalt high-strength hard alloy provided by the invention has high bending strength and toughness.

Owner:ZIGONG CEMENTED CARBIDE CORP

A parallel unit energy-saving operation adjustment system and its control method

ActiveCN105020951BAvoid frequent startupAchieve performance requirementsRefrigeration safety arrangementTemperature controlProcess engineering

The technical problem to be solved by the present invention is that in the existing control method, the start-up speed cannot meet the requirements, and the problem of frequent start-up of the compressor is prone to occur. Refrigeration unit, the refrigeration unit is connected to the condenser, throttle valve, and evaporator in turn, the evaporator is connected to the refrigeration unit through the suction pipe, the evaporator is set in the cold storage, the refrigeration unit is connected to the PLC, the PLC is connected to the touch screen, and the suction pipe An air suction pressure sensor is arranged on the top, and the air suction pressure sensor is connected with the PLC. The invention adopts the suction pressure as the control object, can be applied to the cold storage group, and also avoids that the terminal temperature control in the refrigeration system lags behind the cooling capacity output of the parallel unit, and avoids frequent startup of the compressor.

Owner:河南千年冷冻设备有限公司

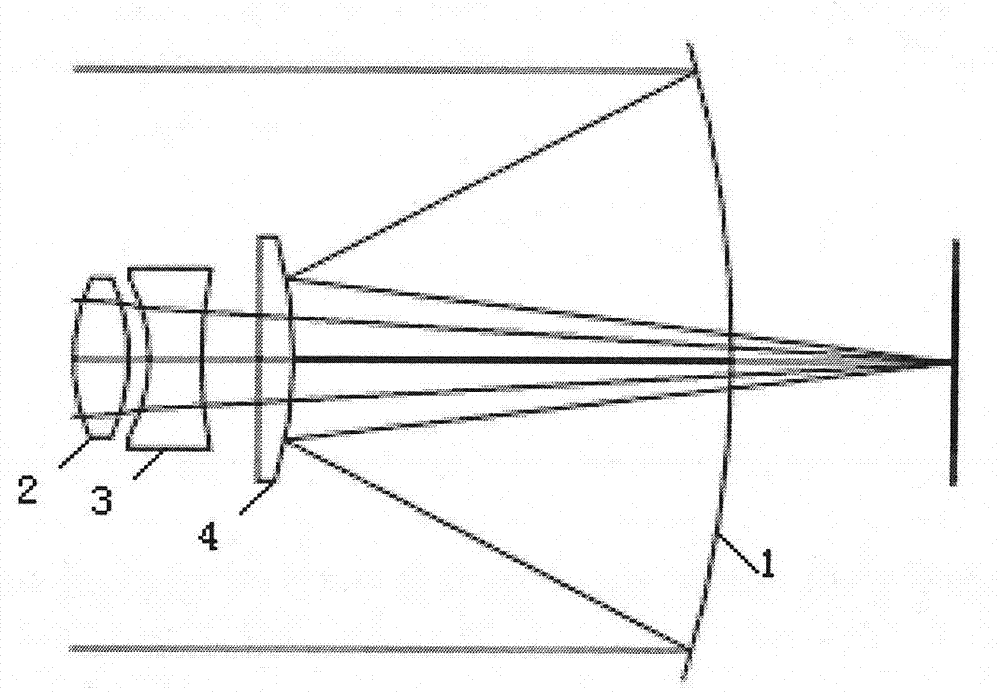

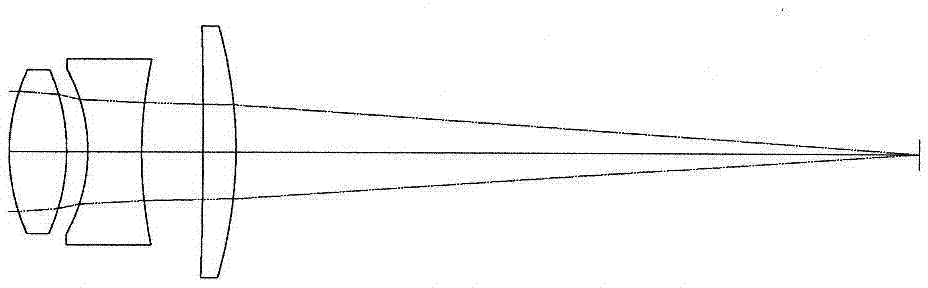

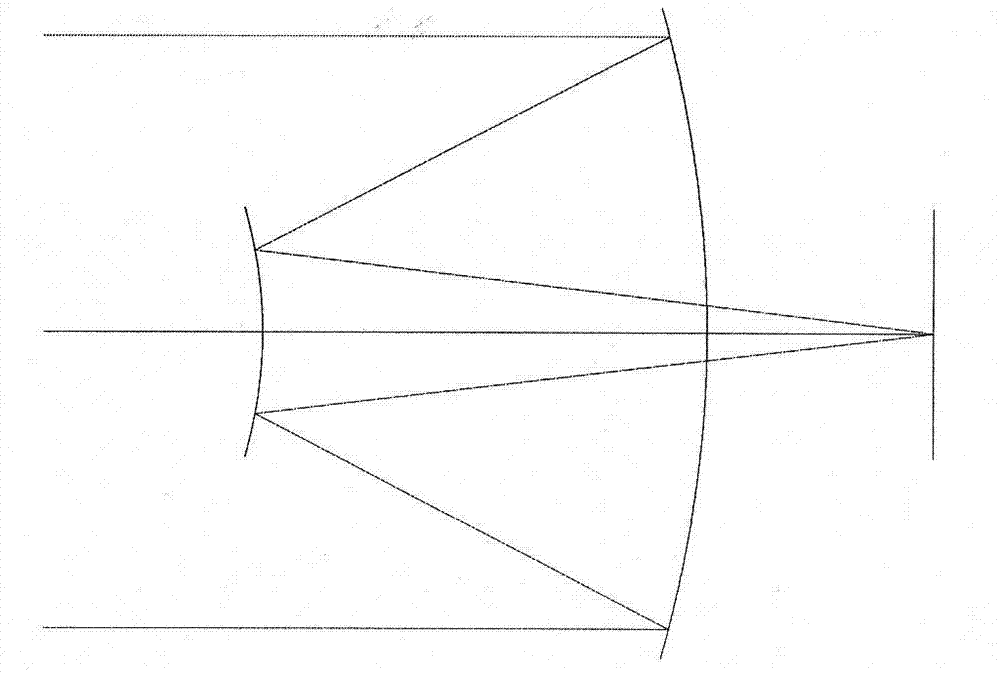

Compound imaging simulation optical system

ActiveCN104503082AReduce overall sizeMeet overall requirementsCoatingsOptical elementsCompound imagingLarge aperture

The invention provides a compound imaging simulation optical system which is mainly composed of a reflection-type infrared optical system and a transmission-type visible light and laser optical system. The compound imaging simulation optical system sequentially comprises a large-aperture reflecting mirror, a first lens, a second lens, and a third lens. By combining the reflection-type optical system and the transmission-type optical system and reasonably matching parameters of the lenses such as material, radius, distance and thickness, the imaging quality requirement (+ / -0.5 degrees) of the infrared optical system and the observation range requirement (+ / -5.5 degrees) of the visible light and laser optical system can be satisfied, and the performance demand of a three-in-one common-aperture optical system is ultimately achieved. The overall size of the whole system device is minimized, and the overall requirement of the whole system device is met.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

Preparation method of controllably degradable component gradient magnesium-based implant material

The invention discloses a preparation method of a controllably degradable component gradient magnesium-based implant material, and the method comprises the following steps of: (1) taking pure magnesium, pure zinc, silicon particles and Mg-Gd alloy as raw materials, removing oxidation films on the surfaces of the raw materials, and performing drying for later use; (2) smelting the raw materials to obtain an Mg-Zn-Si-Gd magnesium-based implant material; (3) carrying out homogenization heat treatment on the Mg-Zn-Si-Gd, and cooling the Mg-Zn-Si-Gd; (4) cutting the Mg-Zn-Si-Gd wire to obtain an Mg-Zn-Si-Gd plate, and cleaning and polishing the Mg-Zn-Si-Gd plate; (5) disposing a blind hole in the Mg-Zn-Si-Gd plate, filling the blind hole with HAP, and conducting compaction; (6) carrying out stirring friction processing on the Mg-Zn-Si-Gd plate filled with HAP to prepare a component gradient magnesium-based implant material; (7) carrying out heat treatment on the component gradient magnesium-based implant material; and (8) rolling the component gradient magnesium-based implant material. The preparation method is simple, fine-particle HAP with a bone repair function is adopted, the magnesium-based implant material with high biological activity and hydroxyapatite gradient distribution is obtained, the biocompatibility and the safety are good, and rapid formation of new tissues can be promoted after the magnesium-based implant material is implanted into a human body.

Owner:JIANGSU UNIV OF TECH +1

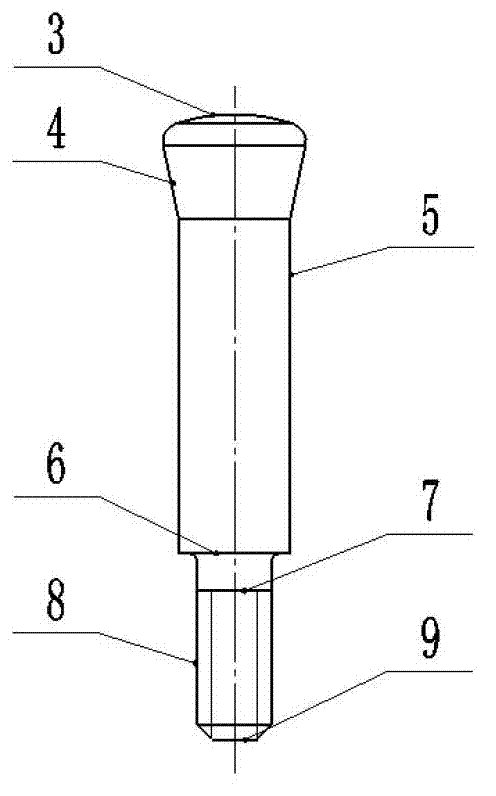

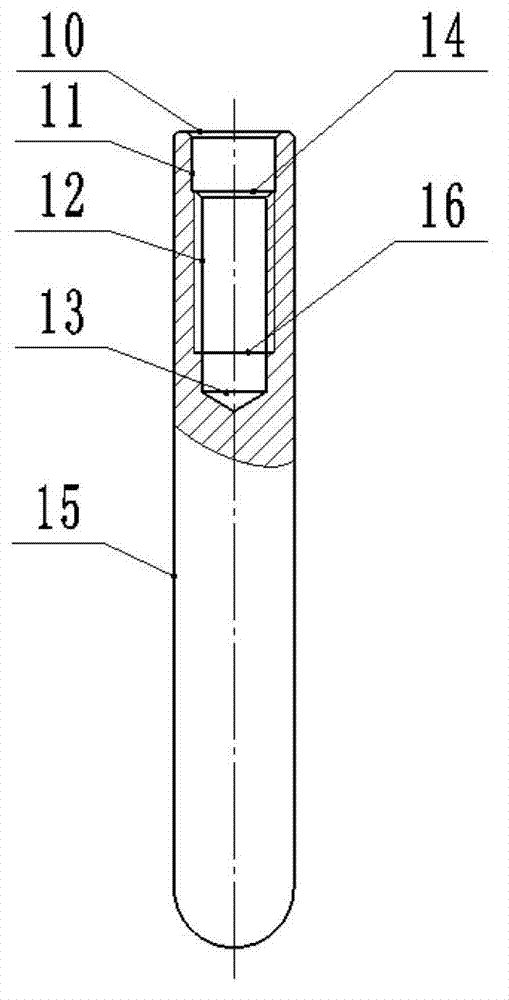

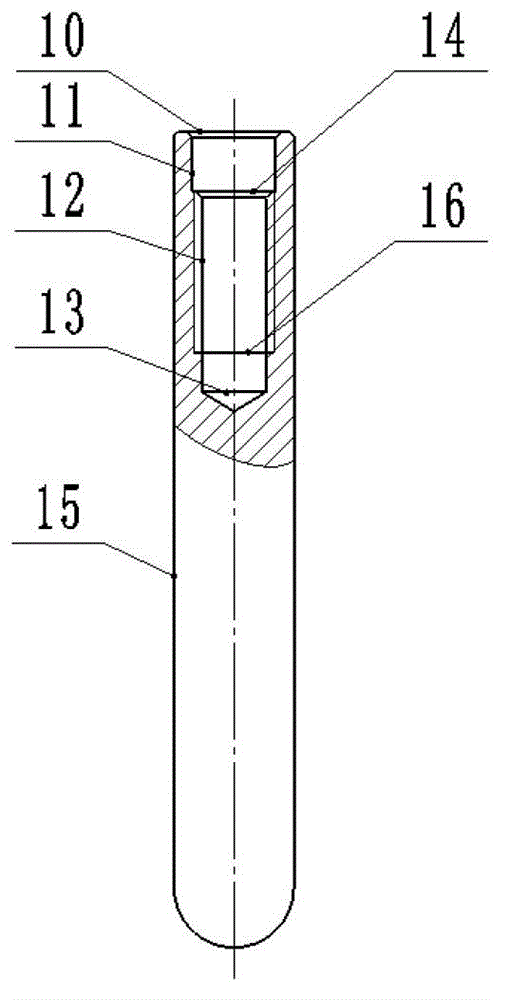

Pins with different heights for semiconductor coating device and use method thereof

ActiveCN103337472AAchieve performance requirementsAchieve horizontal supportSemiconductor/solid-state device manufacturingHeight differenceSupport point

The invention discloses pins with different heights for a semiconductor coating device and a use method thereof, and mainly aims to solve the problem in the prior art that heights of pins at different supporting points are inconsistent. The plurality of pins with same structures but different heights are arranged at the supporting points to achieve the same height of the pins at the supporting points. In the invention, through switching among the pins with the different heights, the pins are enabled to be consistent in the height at the supporting points to ensure normal transmission of a wafer. An upper end portion of a pin main body is a cone structure, an upper end surface of the pin main body is a spherical structure; a transition zone is arranged between the upper end surface of the pin main body and the upper end portion of the pin main body; the transition zone and a joint section between an upper end of the transition zone and the pin main body are rounded structures; and a lower end surface of the pin main body is a hemispherical structure. In the method, in accordance with a pin height reference value, two height differences are respectively arranged over the pin height reference value and under the pin height reference value, i.e., the pins with five different heights can meet use requirements of devices. Compared with the prior art, the pins with the different heights of the invention is more reasonable, simple in structure and requires relatively low-precision parts.

Owner:PIOTECH CO LTD

A kind of medical multifunctional hemostatic dressing and preparation method thereof

InactiveCN107296976BImprove antibacterial propertiesPlay a synergistic rolePharmaceutical delivery mechanismAbsorbent padsCross-linkWound dressing

The invention belongs to the technical field of medical materials, and particularly relates to a medical multifunctional haemostatic wound dressing and a preparation method thereof. According to the invention, the multifunctional haemostatic gel dressing is prepared by using chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone, polyglycolic acid, glutaraldehyde, I-type collagen powder and mesoporous nano hydroxyapatite as raw materials through a cross-linking reaction. The multifunctional haemostatic gel dressing prepared by the invention can take effects of stop bleeding, sterilizing and promoting wound healing, and can meet the requirement of a wound for dressing performance in different healing stages; the chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone is prepared into the gel dressing in a form of the invention, so that an antibacterial effect of the chitosan-g-N-carboxymethyl-2-sulfo-4,5-2H imidazolinone is improved.

Owner:JILIN UNIV FIRST HOSPITAL

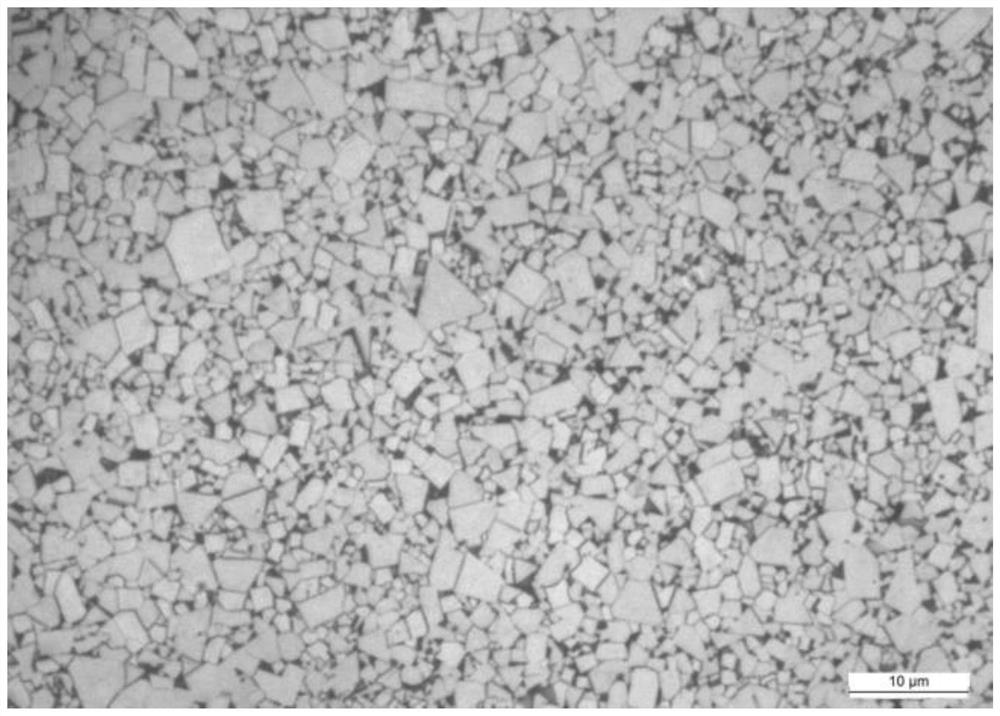

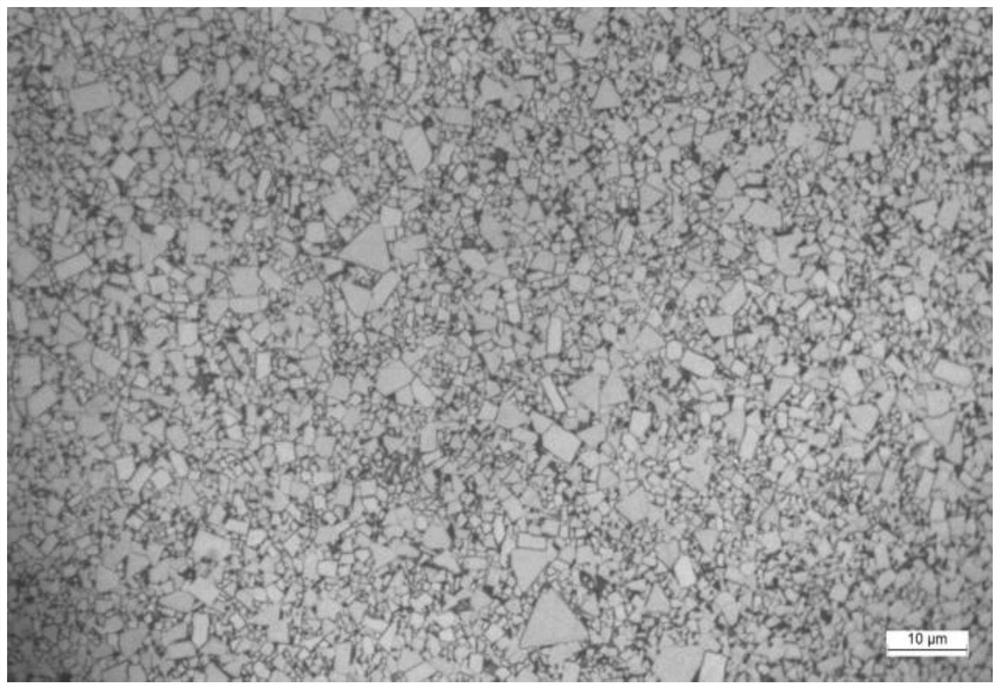

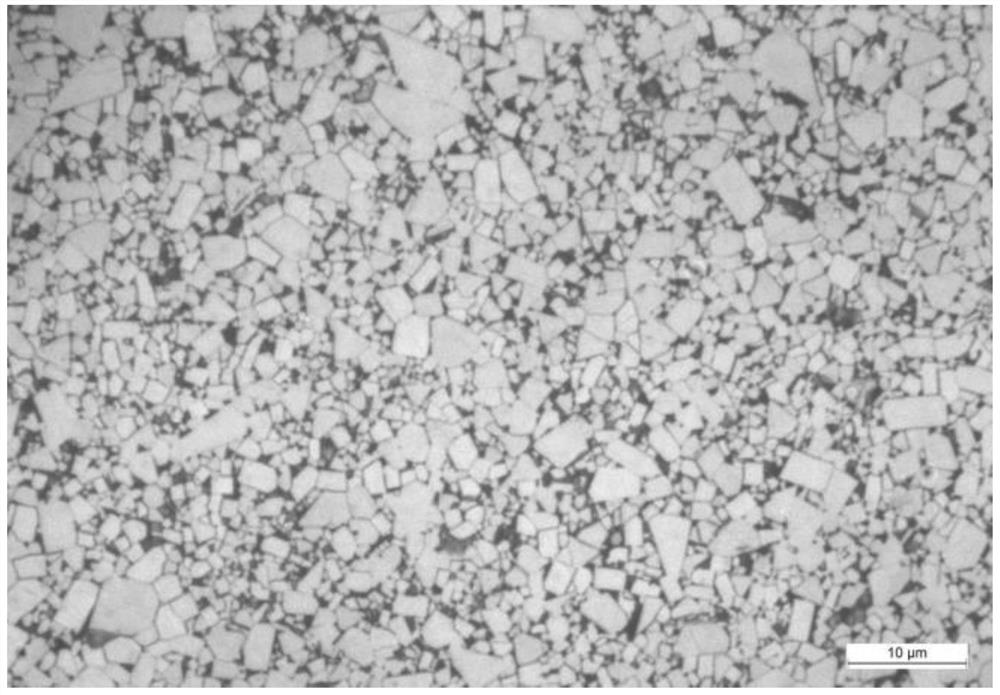

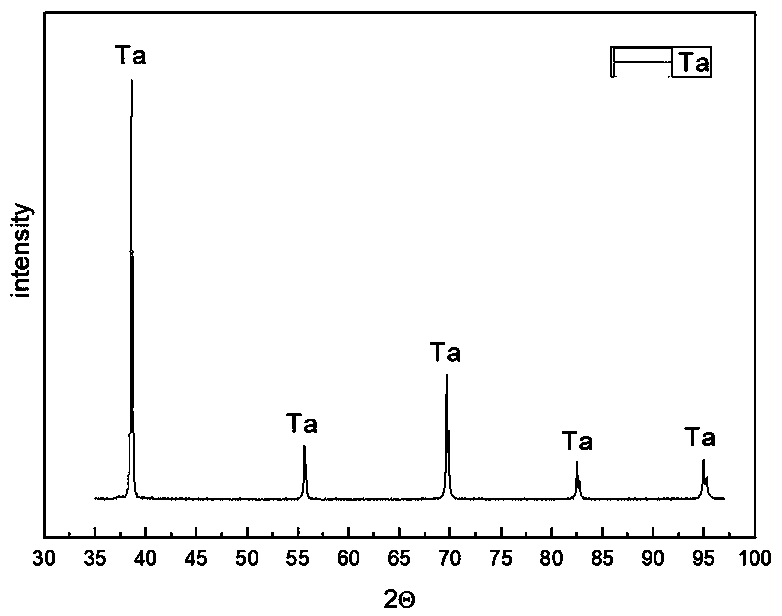

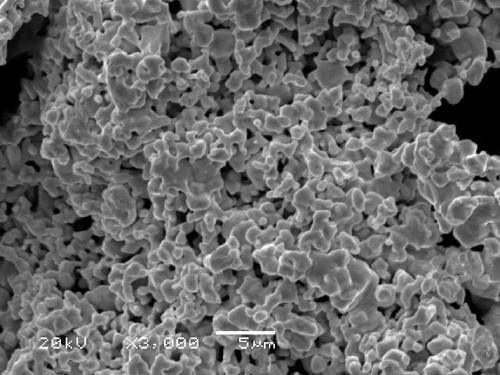

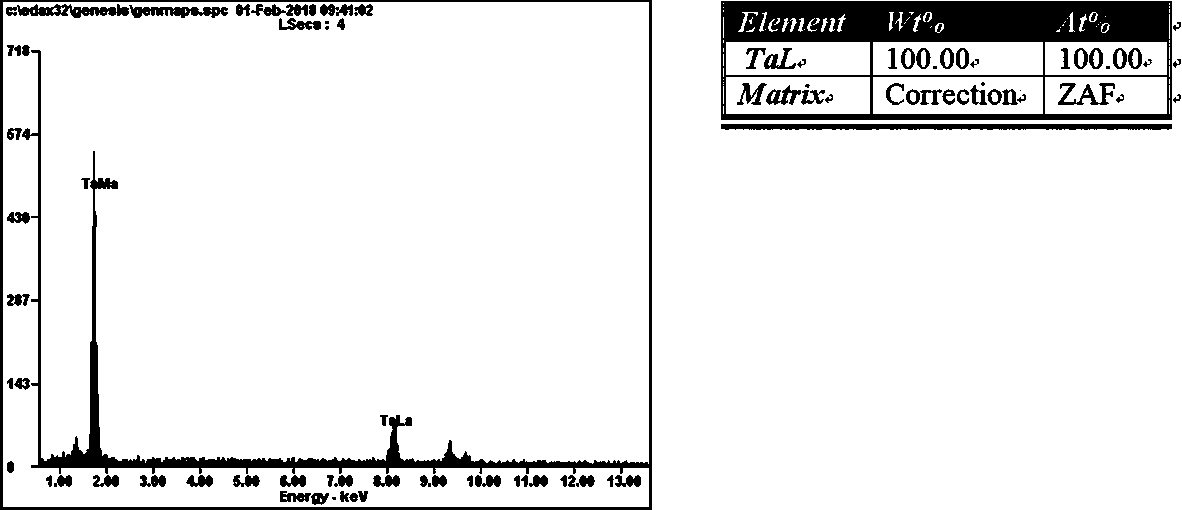

A preparation method of high-purity tantalum target material for electronic materials

ActiveCN108655403BHigh crystallinityAchieve performance requirementsTransportation and packagingVacuum evaporation coatingDevice materialElectronic materials

The invention relates to a method for preparing a high-purity tantalum target for electronic materials, which belongs to the field of powder metallurgy and semiconductor device manufacturing. The preparation method is to pulverize a high-purity tantalum block first, and then ball mill it to a particle size of 5-150 μm. Tantalum powder; after mixing the tantalum powder, install the mold, vibrate and compact; then put the mold into a high-temperature hot-press furnace, and press at 1500-1800°C; after sintering, cool to room temperature and release the furnace to obtain high-purity Green body of tantalum target, density 11.3‑14.5g / cm 3 . According to the requirements of the magnetron sputtering equipment, the green body is cut and processed, and the processed green body is welded to the corresponding back plate according to the user's requirements to obtain a high-purity tantalum target. The high-purity tantalum target prepared by the present invention can significantly reduce the technical difficulty of preparing the target by the traditional casting method, greatly improve the controllability of the process, and contribute to the improvement of the coating performance of later materials.

Owner:HENAN UNIV OF SCI & TECH

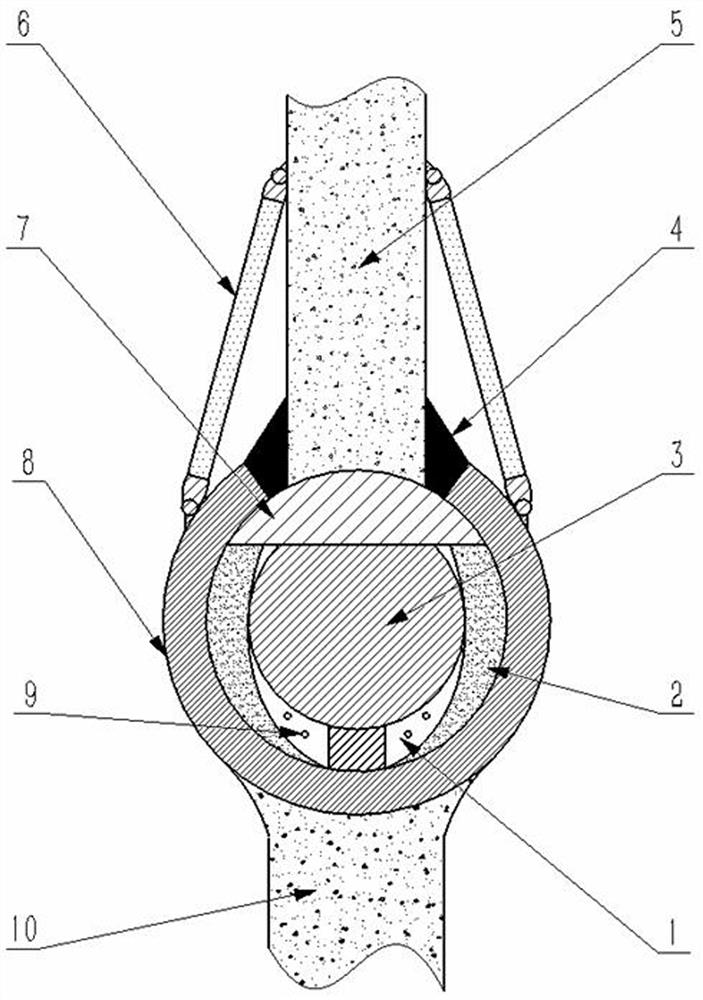

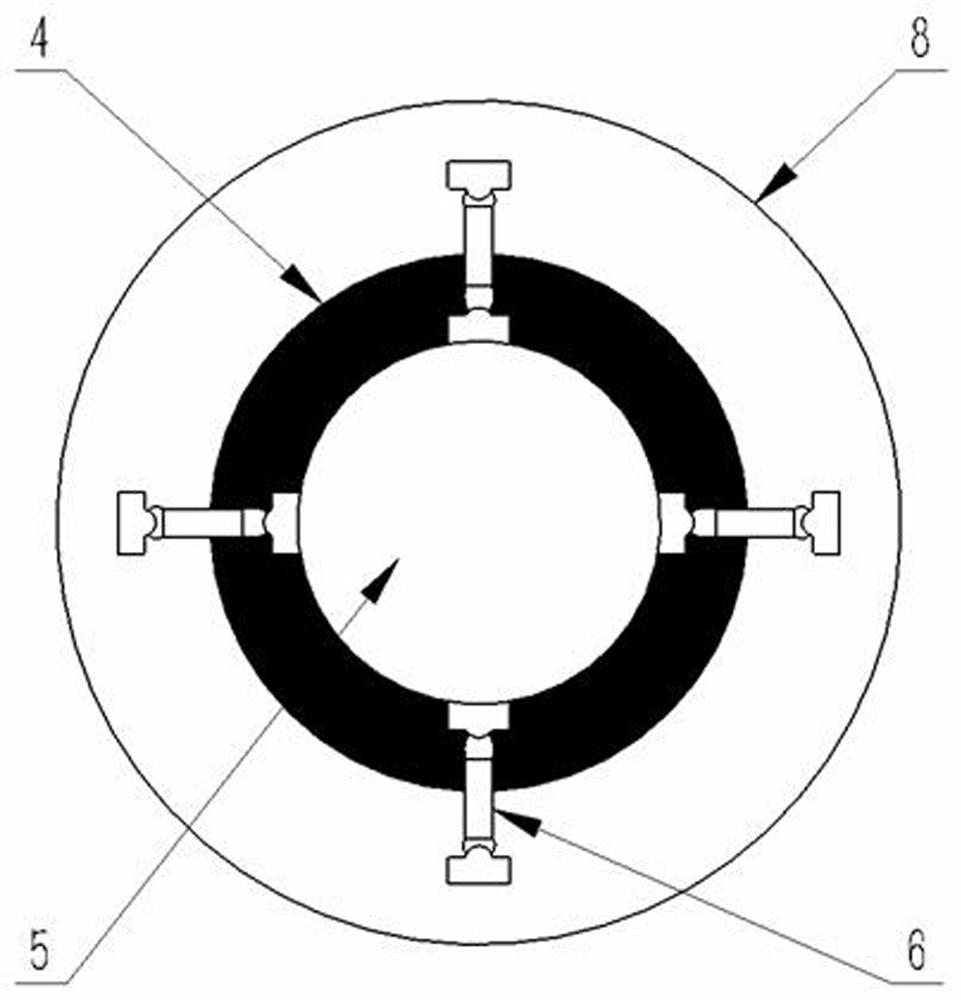

A bionic joint with pneumatic muscles based on magnetorheological fluid

ActiveCN108890690BApplicable to the needs of different working conditionsLarge range of motionJointsMagnetorheological fluidEngineering

The invention discloses a pneumatic muscle bionic joint based on magnetorheological fluid, which comprises a bionic motion bone rod, a bionic joint support member with a hollow ball structure with a tapered hole at the top, and a bionic driven bone rod; the bionic motion bone rod The side wall and the side wall of the bionic joint support are connected by pneumatic artificial muscles, and the bionic driven bone is connected to the lower end of the bionic joint support; the bionic joint support is equipped with a spherical body, a cross arc damping block, a movable block, and a cross arc The shape damping block divides the interior of the bionic joint support into four spaces, which are filled with magnetorheological fluid; the lower end of the bionic motion bone rod passes through the conical hole and connects with the spherical body through the movable block, and connects the bionic joint support with the A rubber sealing ring is sleeved between the tapered circular holes. The invention realizes the motion regulation and control of the bionic joint through air pressure control; the magnetorheological fluid realizes the motion regulation and control of the bionic joint through electromagnetic control, and has the advantages of compact structure, similar shape, stable driving, and excellent performance.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

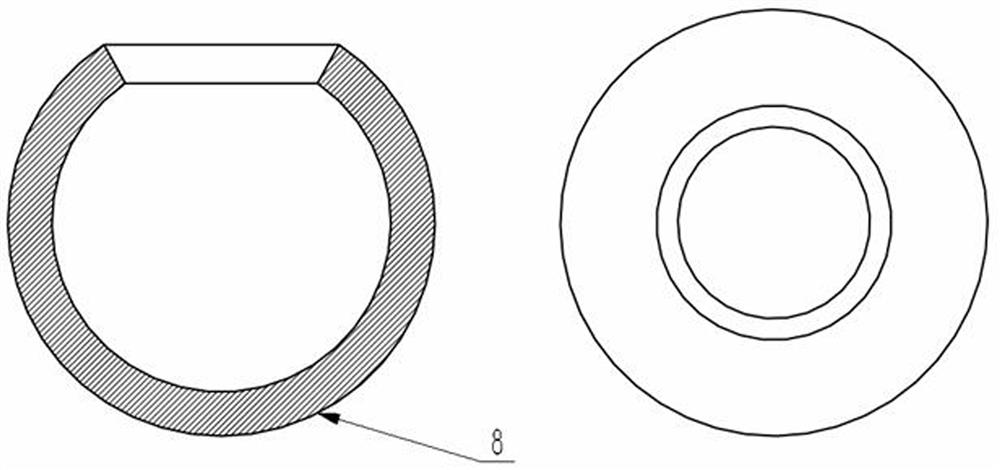

A surface treatment method for an anti-wear ring of a cylinder liner

ActiveCN107586921BGuaranteed sizeGuaranteed roughness requirementsFurnace typesMetallic material coating processesCombustion chamberMaterials science

The invention discloses a surface treatment method of an anti-wear ring of a cylinder sleeve. The surface treatment method comprises steps as follows: 1) a formed anti-wear ring of the cylinder sleeveis pretreated, and pretreatment means phosphorization processing; 2) the pretreated anti-wear ring of the cylinder sleeve is subjected laser surface strengthening, wherein the treatment parts comprise an inner hole and a cutting edge of the anti-wear ring; 3) the treated anti-wear ring of the cylinder sleeve is polished; 4) checking and packaging are performed. By means of the surface treatment method, the problems of wear resistance, corrosion resistance, hardness and the like of the anti-wear ring of the cylinder sleeve can be effectively solved, the anti-wear ring of the cylinder sleeve can be used for a long time, and high-frequency replacement and unnecessary waste are avoided; besides, wear of the cylinder sleeve can also be reduced, engine oil is prevented from moving upwards intoa combustion chamber, consumption of the engine oil is reduced, fuel gas leakage is reduced, granularity emission is reduced, the sealing property is improved, and power of an engine is increased.

Owner:ZHONGYUAN HUAGONG LASER ENG HENAN PROV

Low-temperature steel bar and its production method

ActiveCN113186466BAchieve performance requirementsLow production costProcess efficiency improvementChemical compositionRebar

The invention discloses a low-temperature steel bar and a production method thereof, the chemical composition of which is calculated by mass percentage: Ni 0.8-0.9%, Mn 1.6-1.7%, Si 0.3-0.4%, C 0.04-0.08%, Al 0.01-0.02 %, P≤0.007%, S≤0.004%, O≤0.002%, N≤0.003%, As≤0.005%, H≤0.0002%, and the rest are Fe and unavoidable impurities. The production methods include KR molten iron pretreatment, Converter smelting, LF furnace refining, RH furnace refining, continuous casting and rolling. The invention completes the composition design and mass production of the low-temperature steel bar at a relatively low cost, and achieves the effects of strictly controlling impurity elements, inclusions and surface quality, and reducing low-temperature brittleness.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

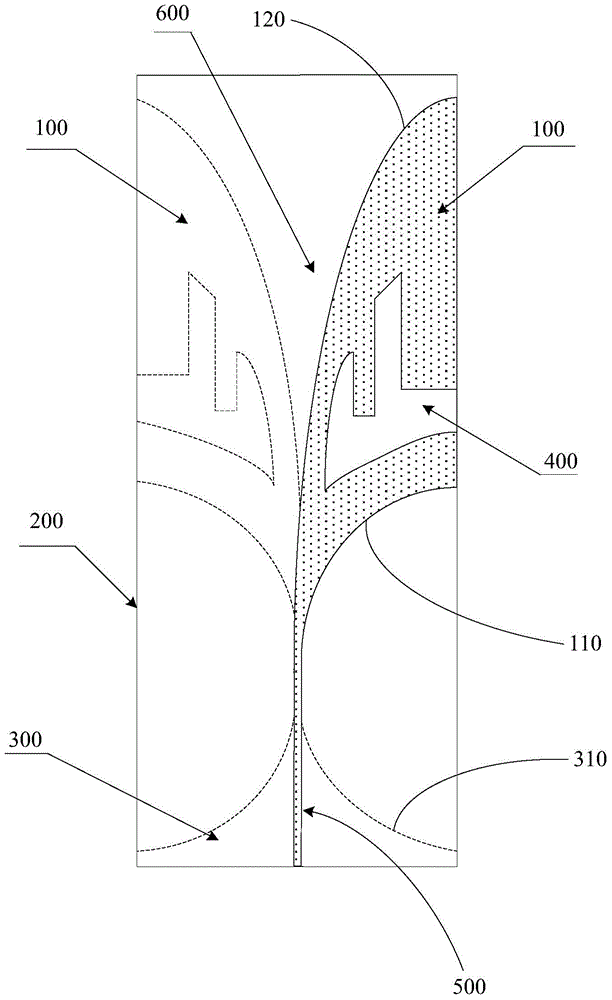

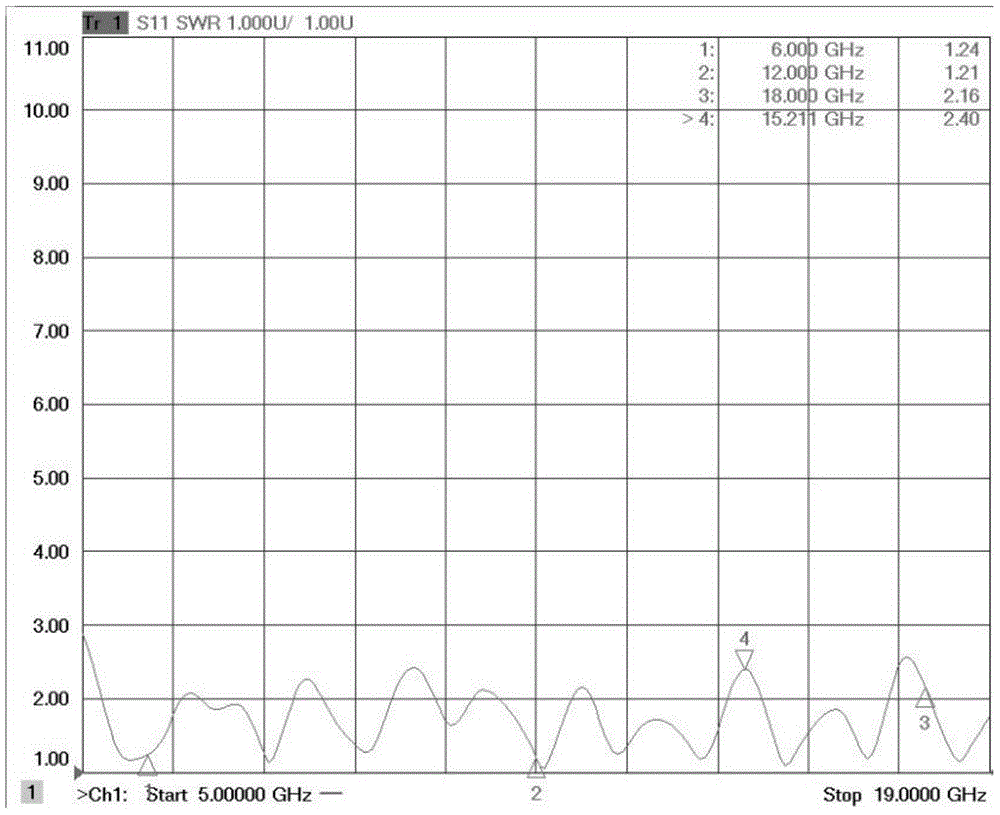

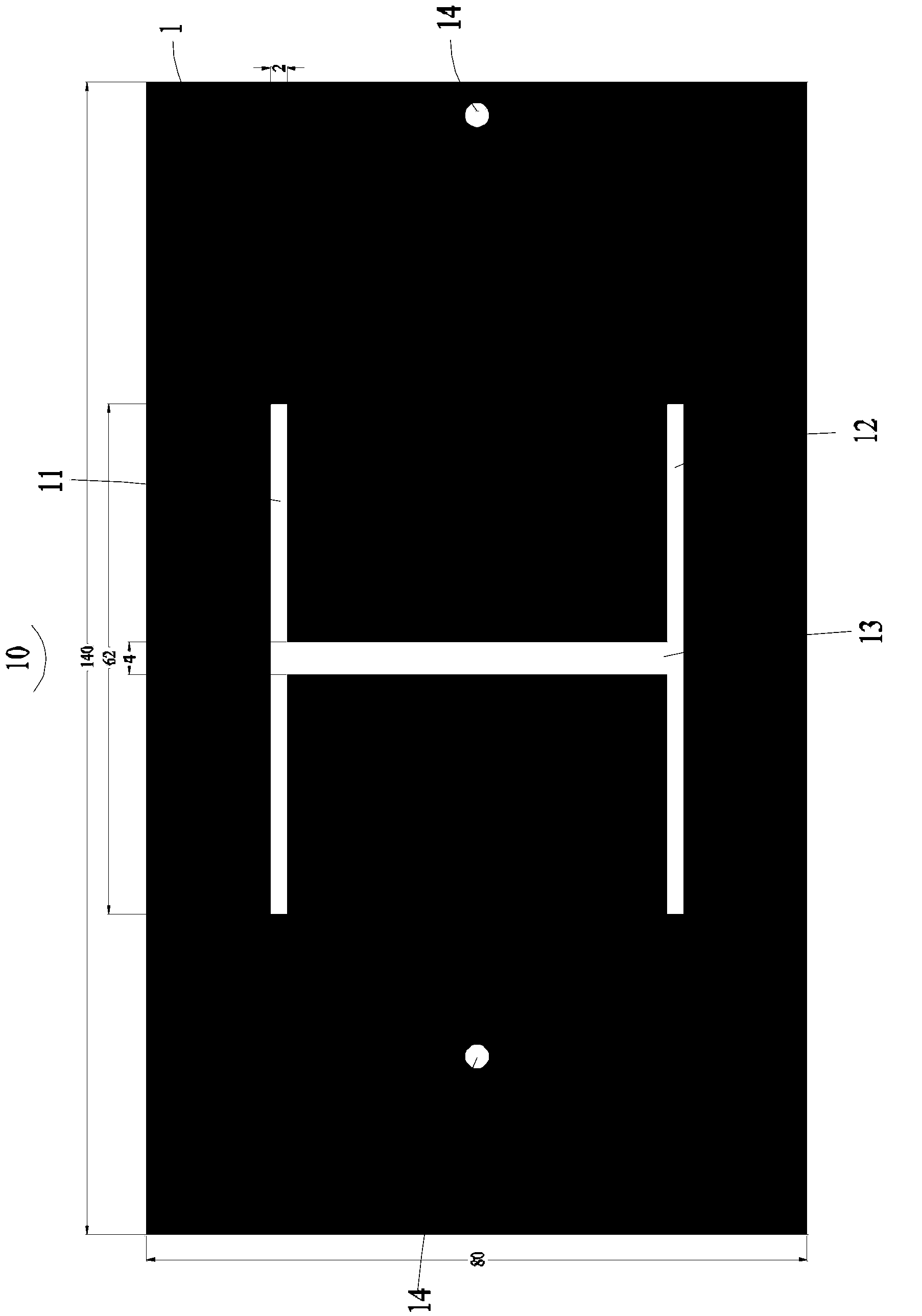

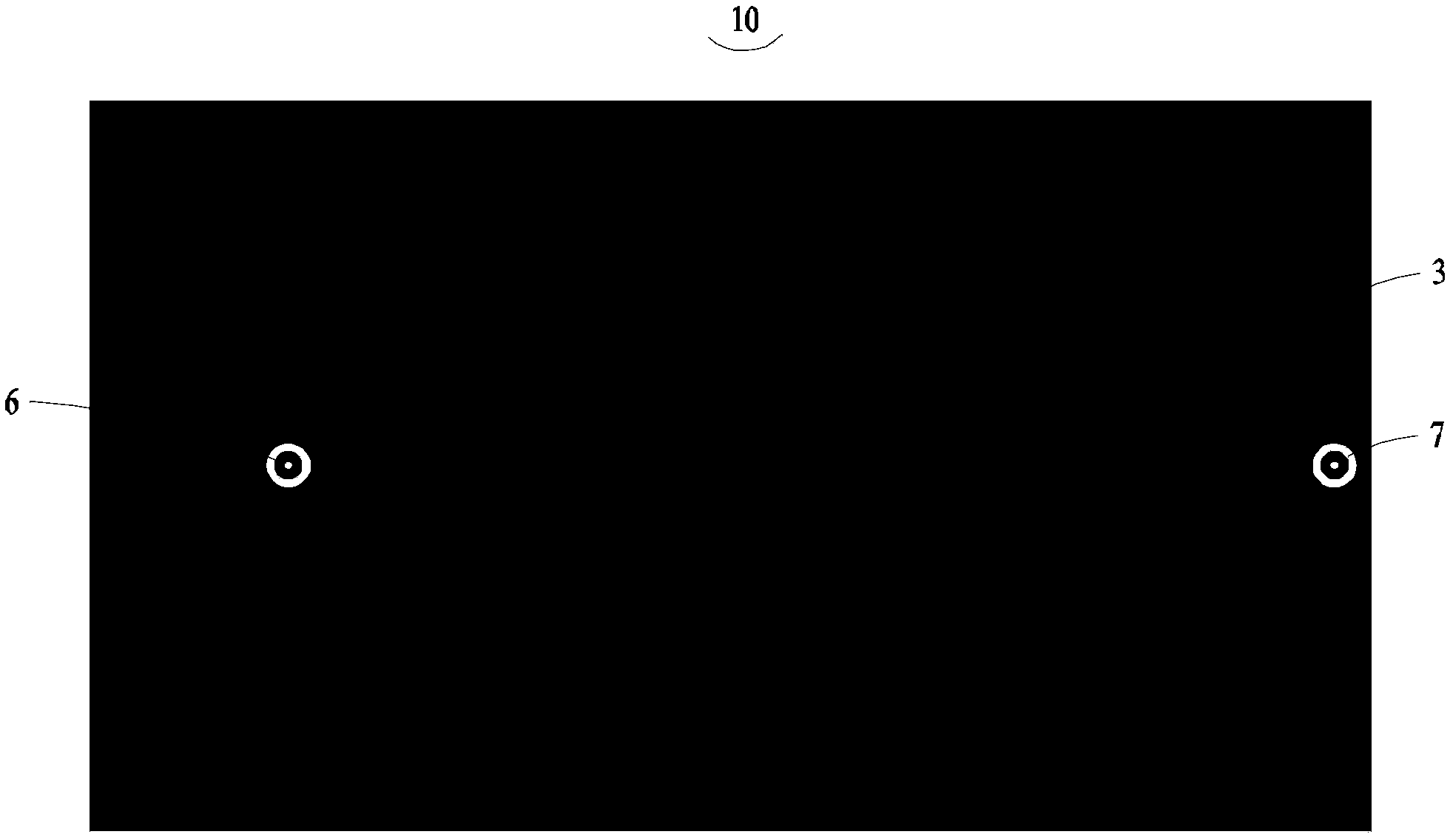

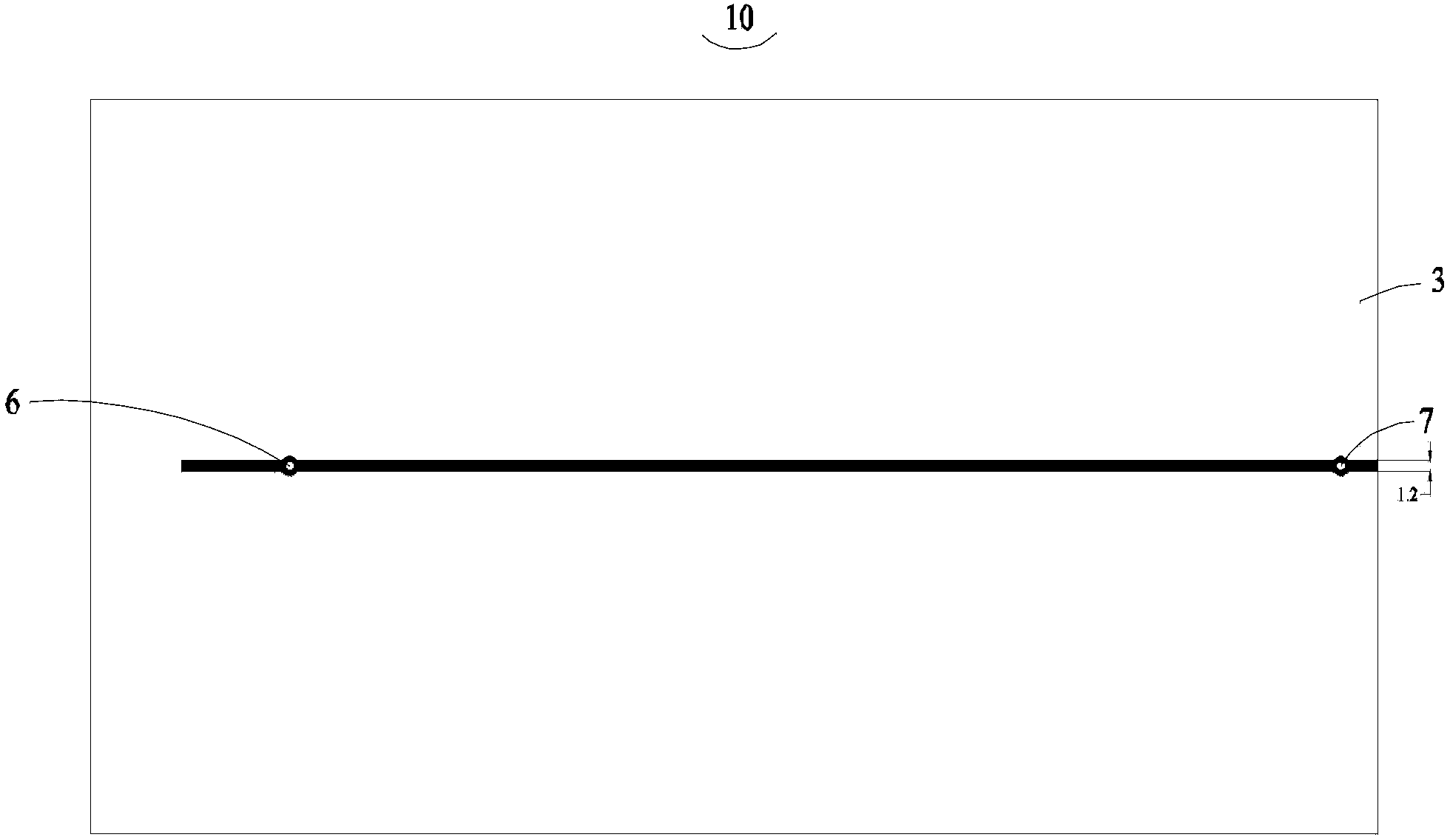

Antenna

PendingCN106299635AImprove performanceWith ultra-wideband performanceRadiating elements structural formsMiniaturizationBroadband

The invention relates to an antenna. The antenna includes radiation fins and a base plate. There are two radiation fins which are arranged on a first surface and a second surface of the base plate, wherein the second surface is opposite to the first surface. Gaps are arranged on the two radiation fins. The antenna possesses the two radiation fins. Through the gaps with the same structure on the two radiation fins, a broadband of the antenna is increased. Through testing, the antenna possesses good performance between 5GHz to 20GHz, ultra wide band performance and a good radiation property. The ultra wide band performance is realized and a performance requirement to the antenna is satisfied. A problem that antenna performance can not meet the requirement is solved, simultaneously the size of the antenna with the structure can be small, miniaturization of the antenna is realized, a requirement to the antenna size is satisfied and application and promotion of the antenna are greatly promoted.

Owner:KUANG CHI INST OF ADVANCED TECH +1

CMMB antenna and mobile multimedia broadcaster

ActiveCN102694248BAchieve performance requirementsRadiating elements structural formsAntennas earthing switches associationCopper coatingDielectric substrate

The invention provides a CMMB antenna. The CMMB antenna comprises a radiation unit. The radiation unit comprises a dielectric substrate, a first copper coating and a second copper coating respectively covering the dielectric substrate, a copper strip in the dielectric substrate, and a plurality of plated-through holes in the edge of the dielectric substrate and distributed at the two sides of the copper strip. A plurality of micro groove structures are arranged on the first copper coating. One end of the copper strip is provided with a feeding interface penetrating the dielectric substrate. The first copper layer and the second copper layer are electrically connected through the plated-through holes. The invention further provides a multimedia mobile broadcaster in which the CMMB antenna is applied. The CMMB antenna of the invention uses the microstrip transmission principle. The performance requirement of the CMMB antenna is realized through a simple structure. Combined with the utilized low-loss antenna dielectric substrate, the CMMB antenna arranged in the mobile multimedia broadcaster has an effect basically same with the effect of the existing external CMMB antenna.

Owner:江苏慧煦电子科技有限公司

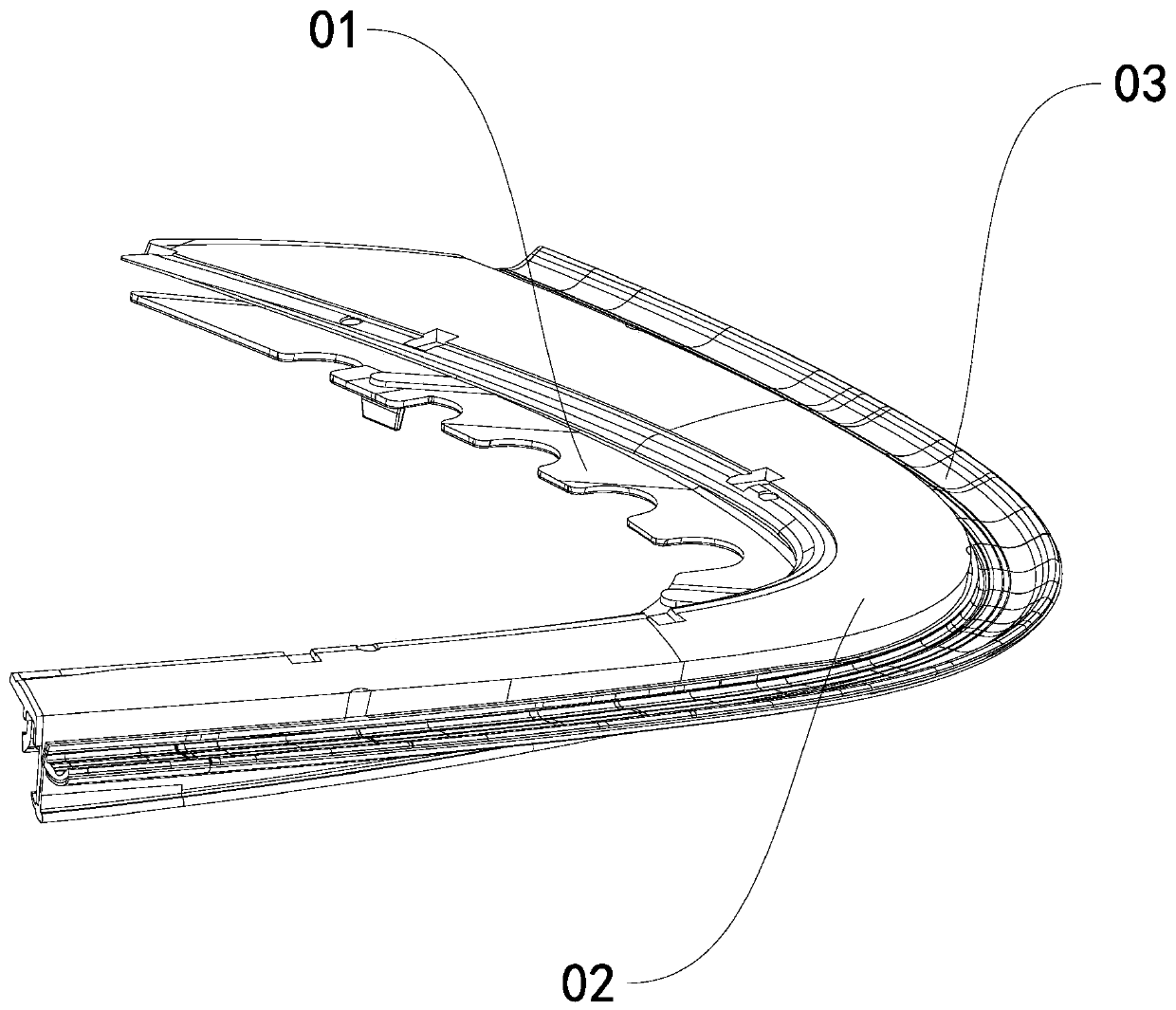

Forming method of automobile rear door triangular window covered edge

PendingCN111055437AAchieve performance requirementsCannot meet performance requirementsDomestic articlesManufacturing engineeringBack door

Owner:宁波本祥汽车零部件有限公司

A kind of diatomite, kaolin thermal insulation film masterbatch and preparation method thereof

The invention discloses diatomite and kaolin thermal-insulation film master batch and a preparation method thereof. The diatomite and kaolin thermal-insulation film master batch comprises the following components in percentage by mass: 22%-26% of diatomite, 30%-34% of kaolin, 32%-35% of polyethylene, 2%-3% of an aluminate coupling agent, 0.5%-0.8% of stearic acid, 0.3%-0.5% of calaium strarate, 2%-3% of paraffin, 1%-2% of PE (polyethylene) wax and 0.5%-0.8% of an antioxidant. The raw materials are mixed in a high-speed mixer in stages and then are extruded by a same-direction parallel twin-screw extruder to prepare the master batch. According to the diatomite and kaolin thermal-insulation film master batch and the preparation method thereof disclosed by the invention, the diatomite, the kaolin and the polyethylene are mixed and modified, the adding proportion of the diatomite to the kaolin is controlled to be 52%-60% to prepare master batch, the infrared-ray transmission rate of mulching film prepared by 5%-15% of the match batch can be reduced by 31%-34%, and the thermal insulation effects are obvious.

Owner:YINGKOU XIAOJIAZU IND +1

Sectional pin for semiconductor coating equipment

ActiveCN102820250BReduced precision requirementsAchieve performance requirementsSemiconductor/solid-state device manufacturingTransfer procedureScrew thread

The invention relates to a sectional pin for semiconductor coating equipment, which mainly solves the technical problems that the sectional pin for the semiconductor coating equipment in the prior art is complex in structure, high in machining cost and large in installation difficulty. The sectional pin for the semiconductor coating equipment consists of an upper part of a pin and a lower part of the pin. The upper part of the pin is made of ceramic, and an external screw thread is prepared outside the upper part of the pin. The lower part of the pin is made of nickel, and an internal screw thread is prepared inside the lower part of the pin. The upper part and the lower part of the pin are connected through the inner and outer screw threads. The sectional pin at least consists of two sections which are connected by screw threads or pins to form an integral pin. The sectional pin for the semiconductor coating equipment has the beneficial effects that the structure can realize performance requirement in a wafer transmission process of the pin, and the sectional pin for the semiconductor coating equipment is more reasonable compared with the prior art, has less requirement on precision of parts, is simple in structure, is not provided with a complex guiding structure or counter weight structure, and is convenient to machine and install, and the cost is relatively low.

Owner:PIOTECH CO LTD

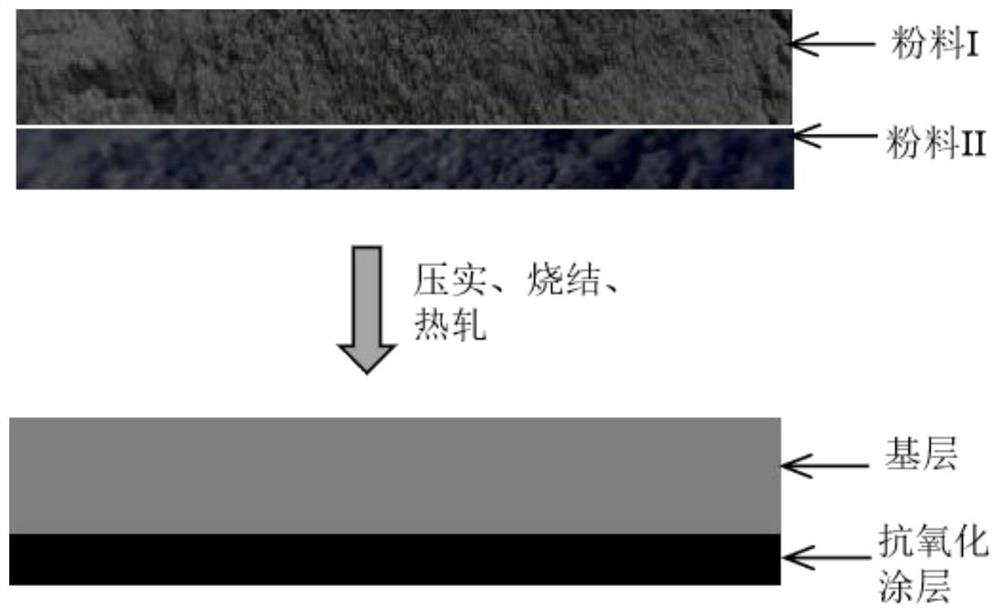

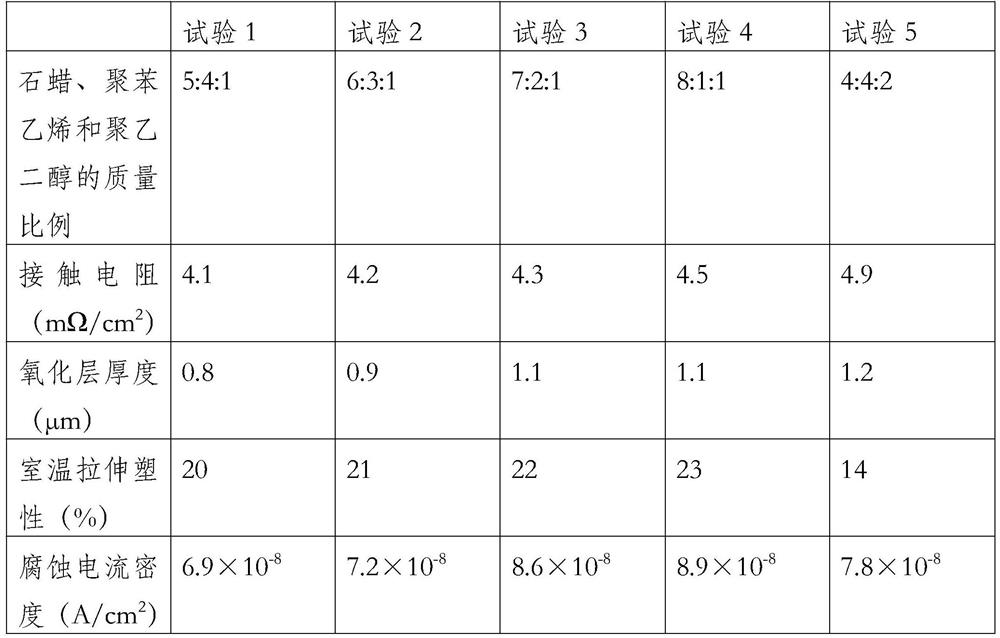

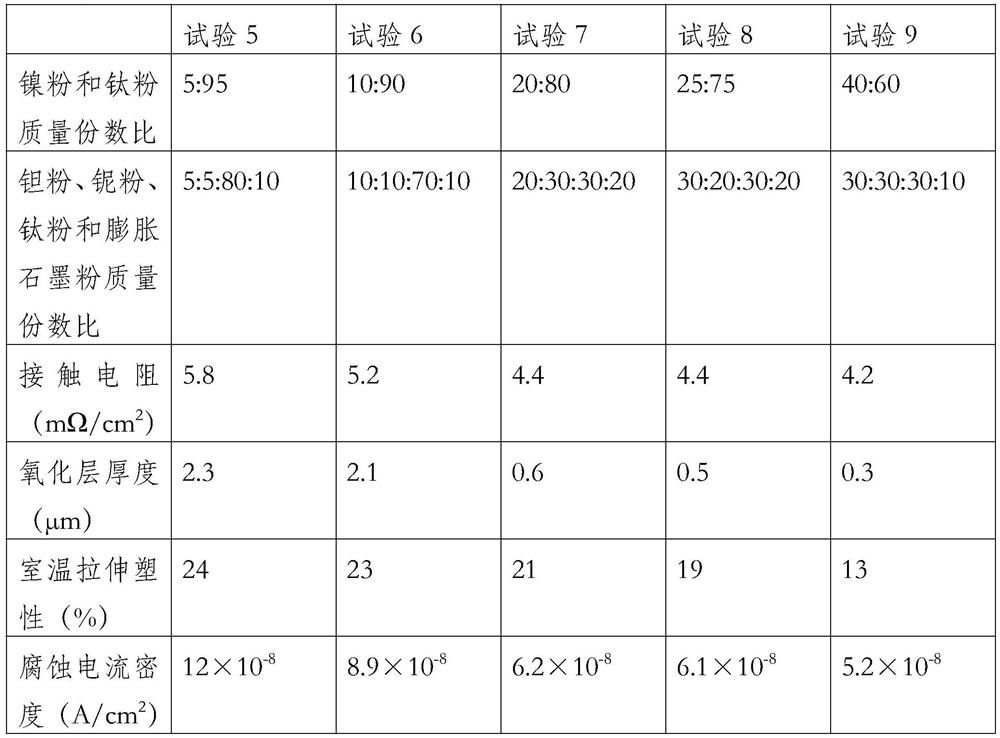

PEM hydrolysis hydrogen production titanium metal bipolar plate and preparation method thereof

PendingCN114653943AAchieve performance requirementsStrong corrosion resistanceNon-noble metal oxide coatingsTransportation and packagingTitanium metalNiobium

The invention discloses a PEM hydrolysis hydrogen production titanium metal bipolar plate and a preparation method thereof, and the bipolar plate is prepared by weighing nickel powder, cobalt powder, pure titanium powder, metal tantalum-niobium powder I and metal tantalum-niobium powder II according to a certain mass ratio, and performing compaction, sintering and hot rolling on the nickel powder, the cobalt powder, the pure titanium powder, the metal tantalum-niobium powder I and the metal tantalum-niobium powder II. The bipolar plate disclosed by the invention has the comprehensive properties of oxidation resistance, high corrosion resistance, high surface conductivity, high corrosion resistance, high strength, easiness in stamping deformation, low cost and the like. The contact resistance of the bipolar plate is lower than 5 m omega / cm < 2 >, the corrosion current density in an anode environment is lower than 9 * 10 <-8 > A / cm < 2 >, the room-temperature tensile elongation is larger than 15%, the thickness of an oxide layer is lower than 1 micron after the bipolar plate operates for 24 h under the cell voltage of 1.6-1.8 v, and the area fraction is smaller than 3%.

Owner:宁波福至新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com