Parallel unit energy saving operation adjusting system and control method thereof

A technology for regulating control and regulating systems, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of frequent compressor startup and startup speed that cannot meet the requirements, and achieve the effect of energy-saving performance and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

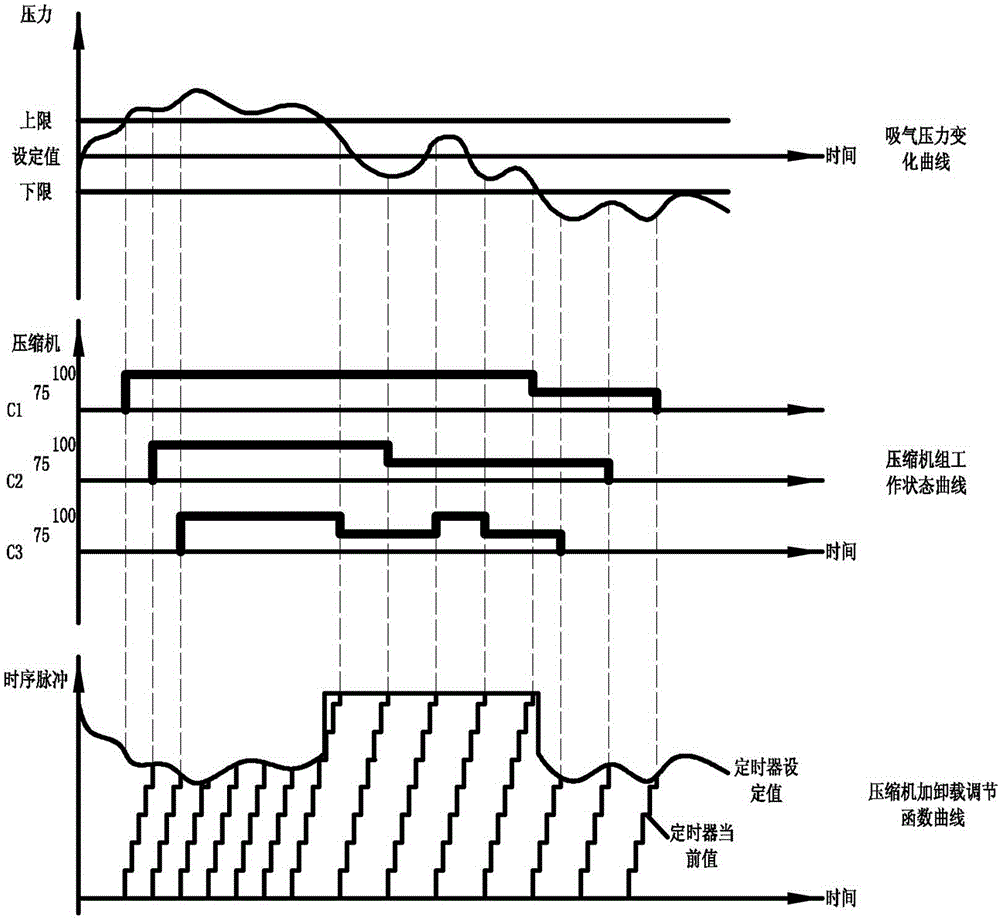

[0040] Such as Figure 5 , an energy-saving operation adjustment system for parallel units, the 601 refrigeration unit is connected to the 602 condenser through the pipeline, the 602 condenser is connected to the 603 throttle valve through the pipeline, and the 603 throttle valve is connected to the 604 evaporator through the pipeline (the evaporator is placed on In the cold storage), the 604 evaporator is connected to the 601 refrigeration unit through pipelines; the PLC605 is connected to the unit suction pressure sensor 606 through a cable, and is connected to the touch screen 607 through a cable. After the refrigerant is compressed by the compressor in the 601 refrigeration unit, it becomes a high-temperature and high-pressure superheated steam. After entering the 602 condenser and condensing, it becomes a low-temperature and high-pressure liquid. After entering the 603 throttle valve, it becomes a low-temperature and low-pressure vapor-liquid. The mixture, after bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com